Patents

Literature

47results about How to "Automatically adjust the gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

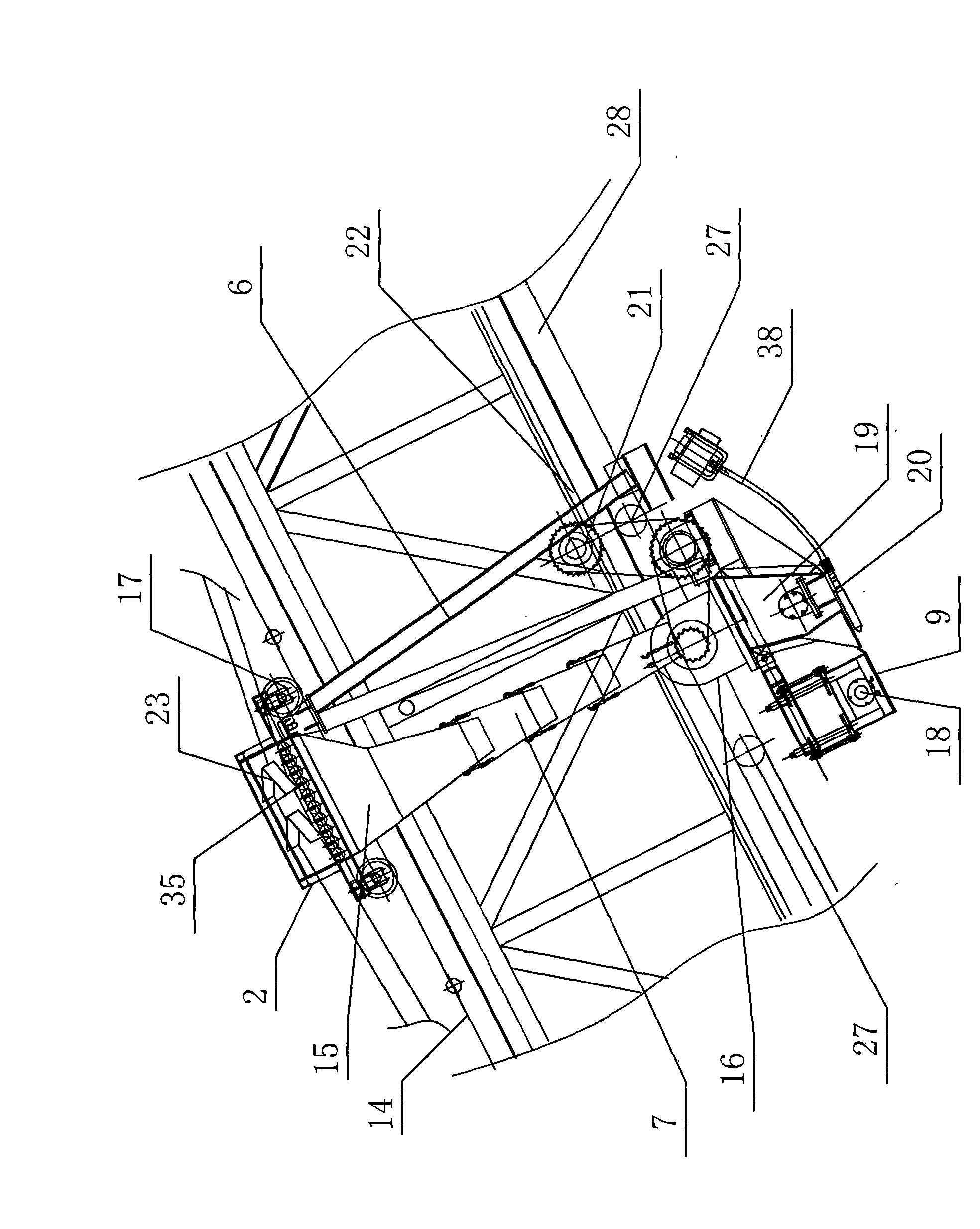

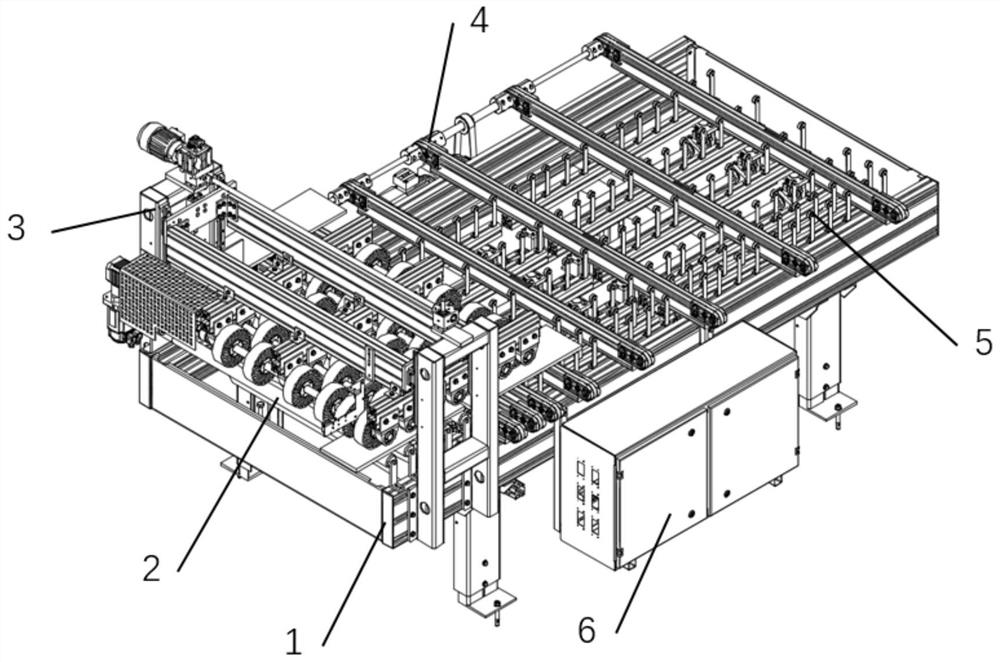

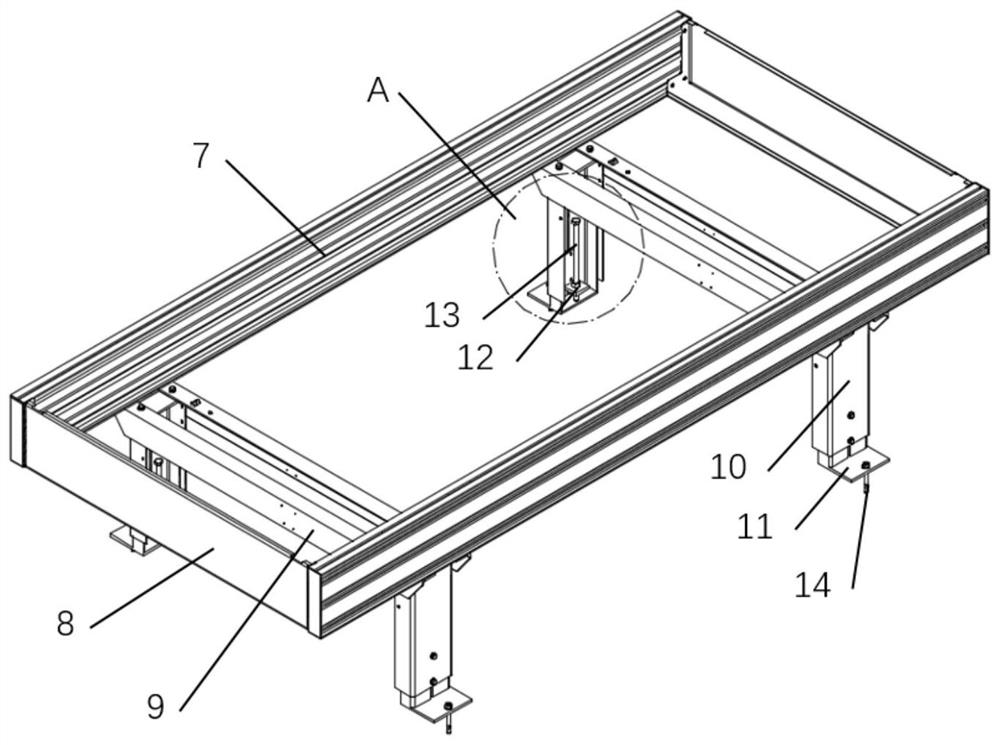

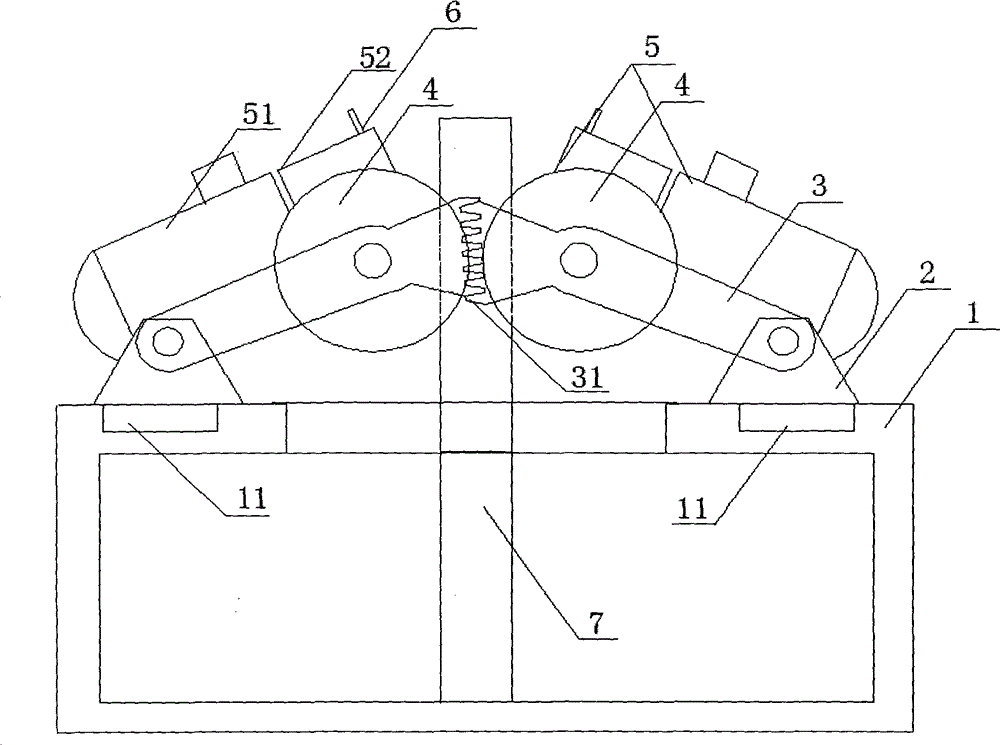

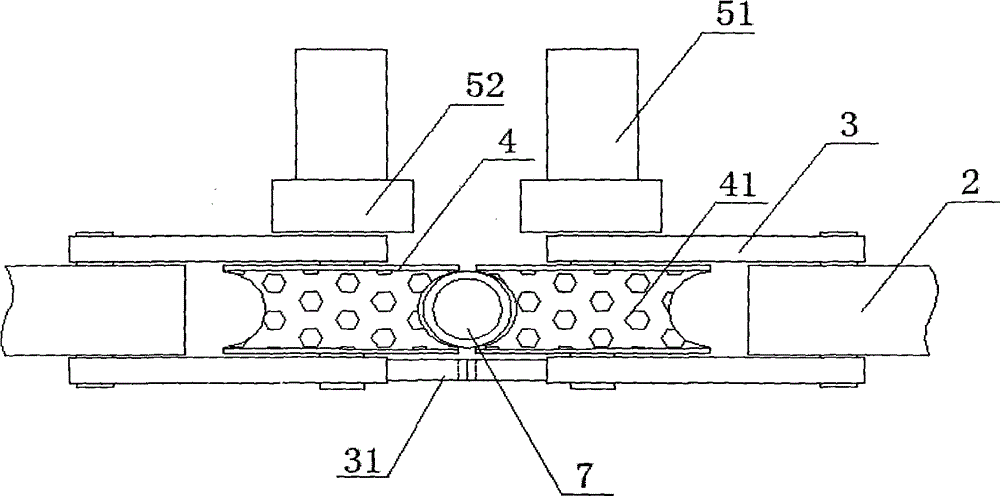

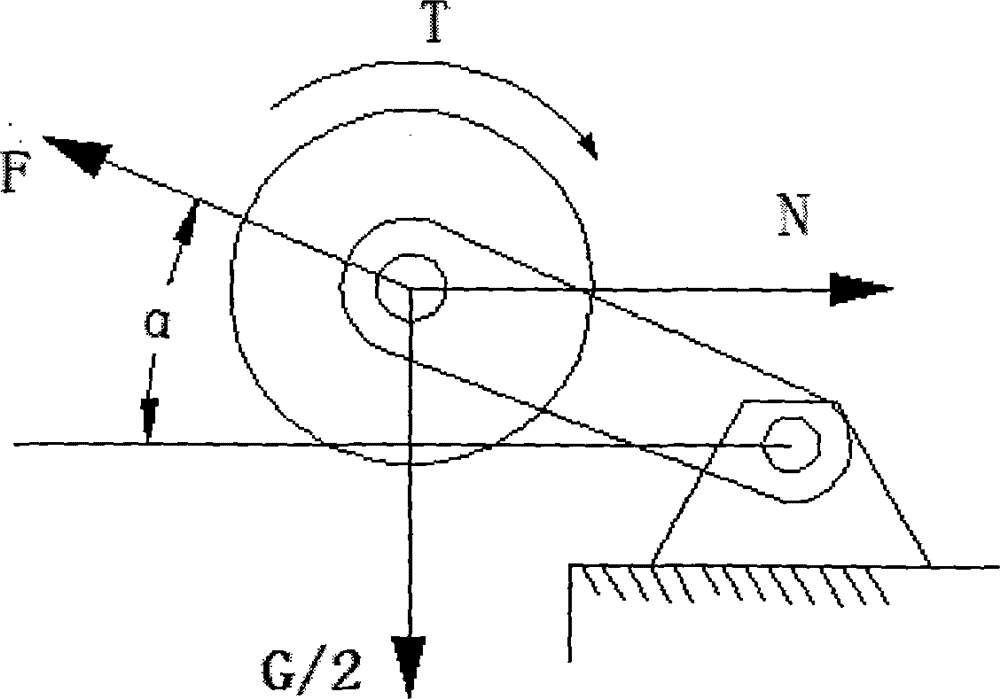

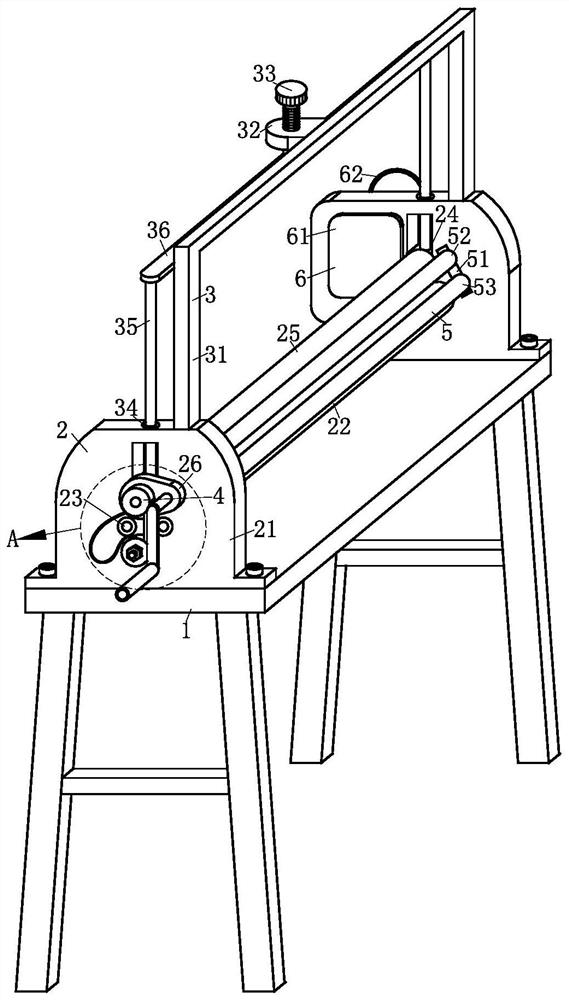

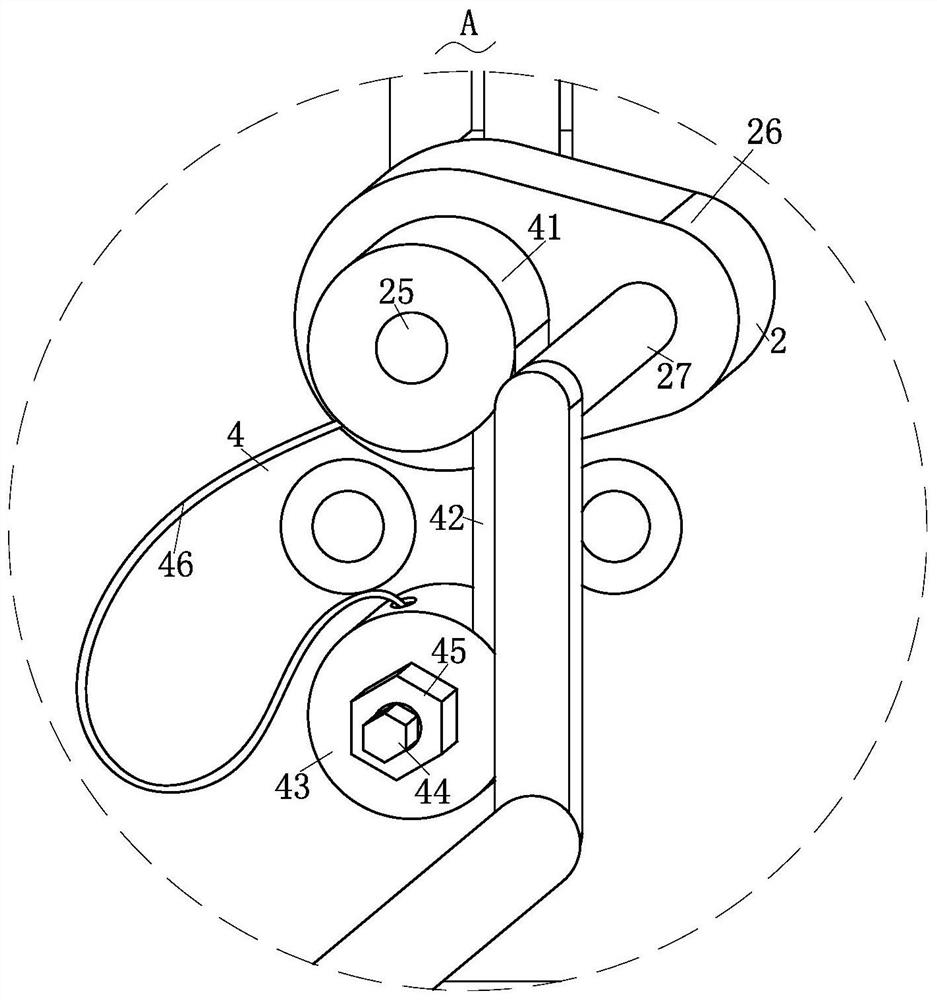

Continuous tube drawing device

InactiveCN103266610AAutomatically adjust the gapWon't hurtBulkheads/pilesTube drawingElectric machinery

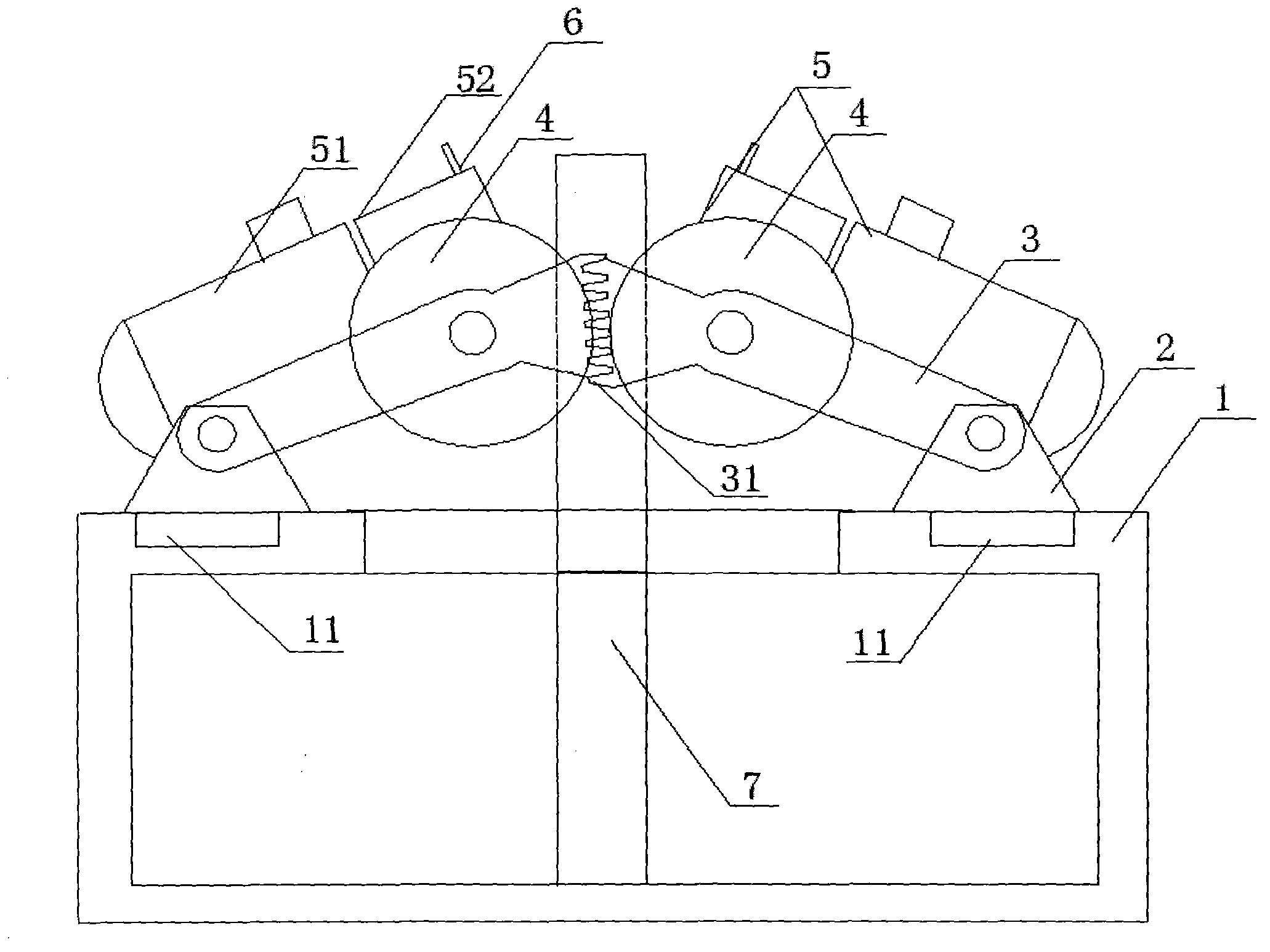

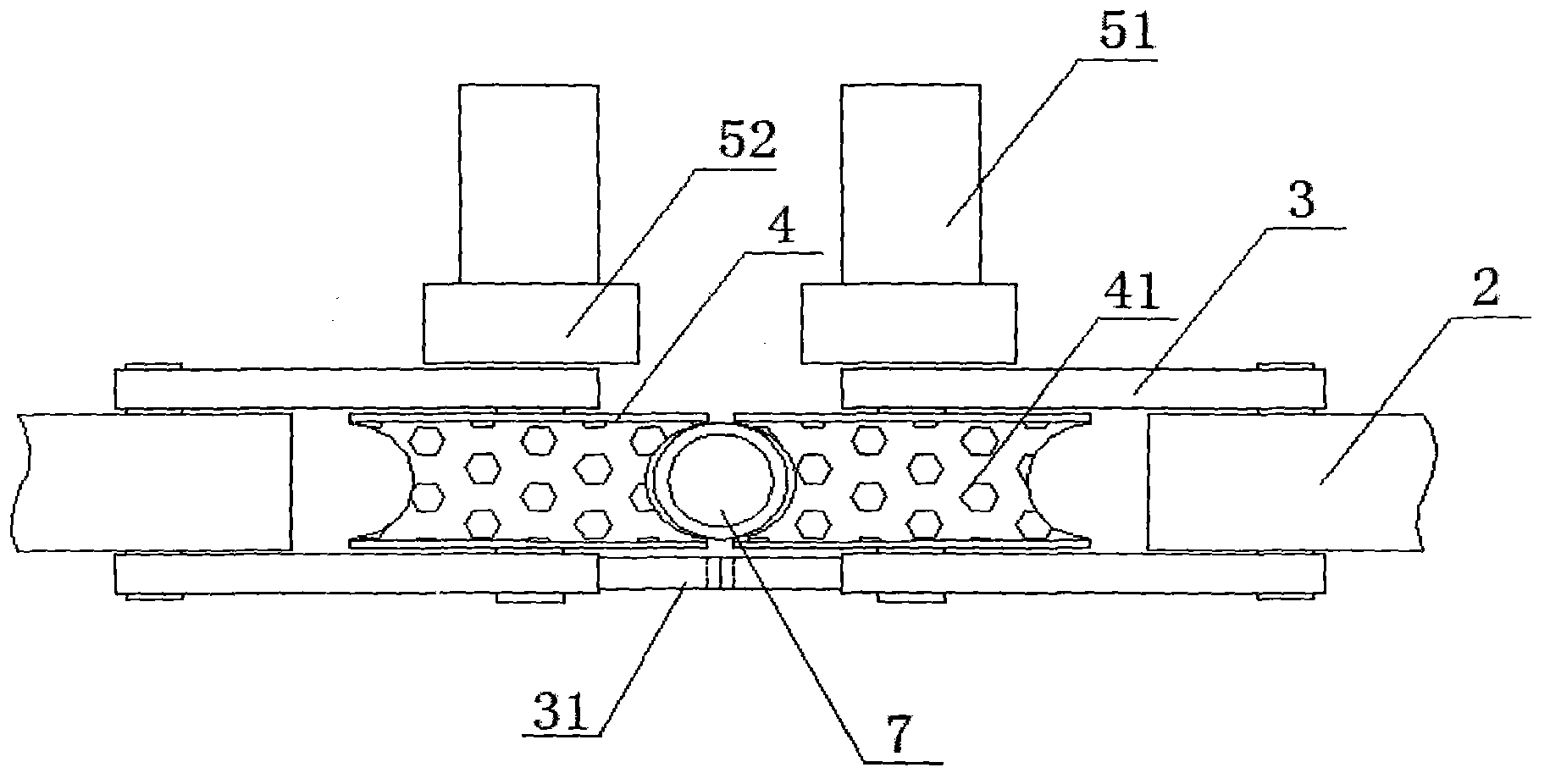

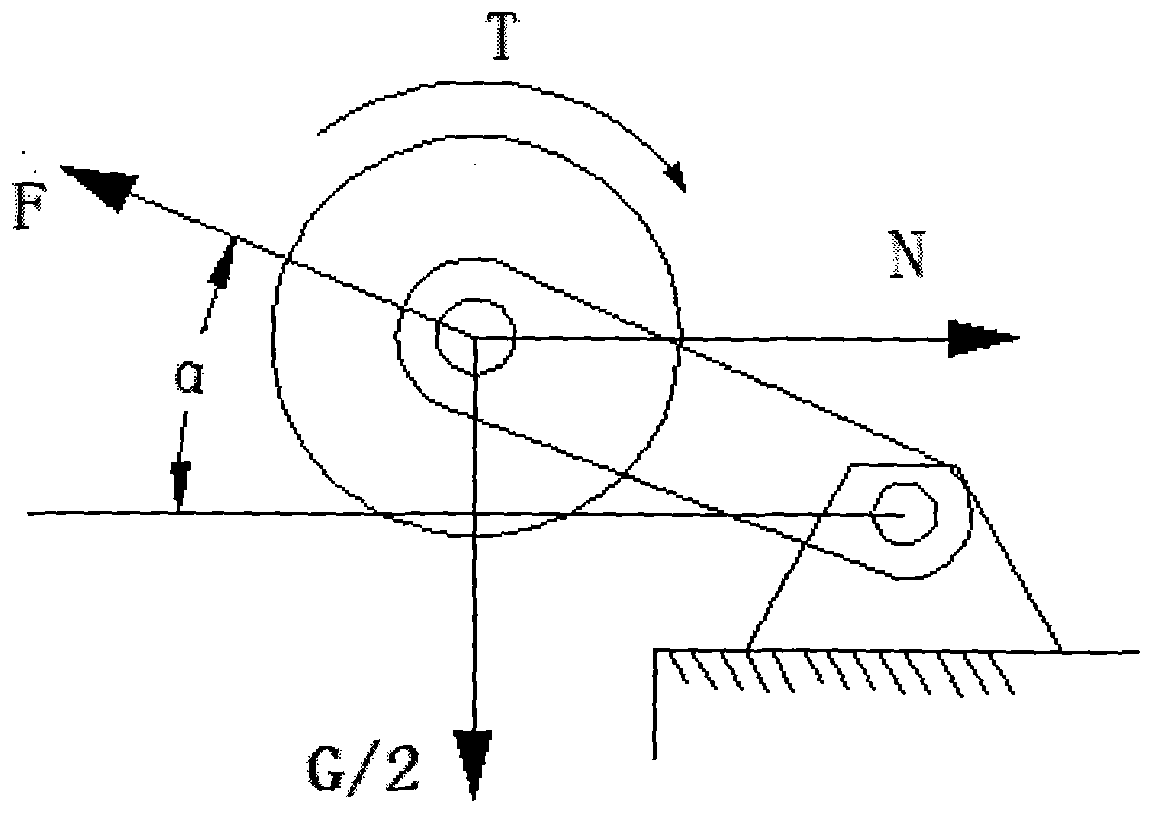

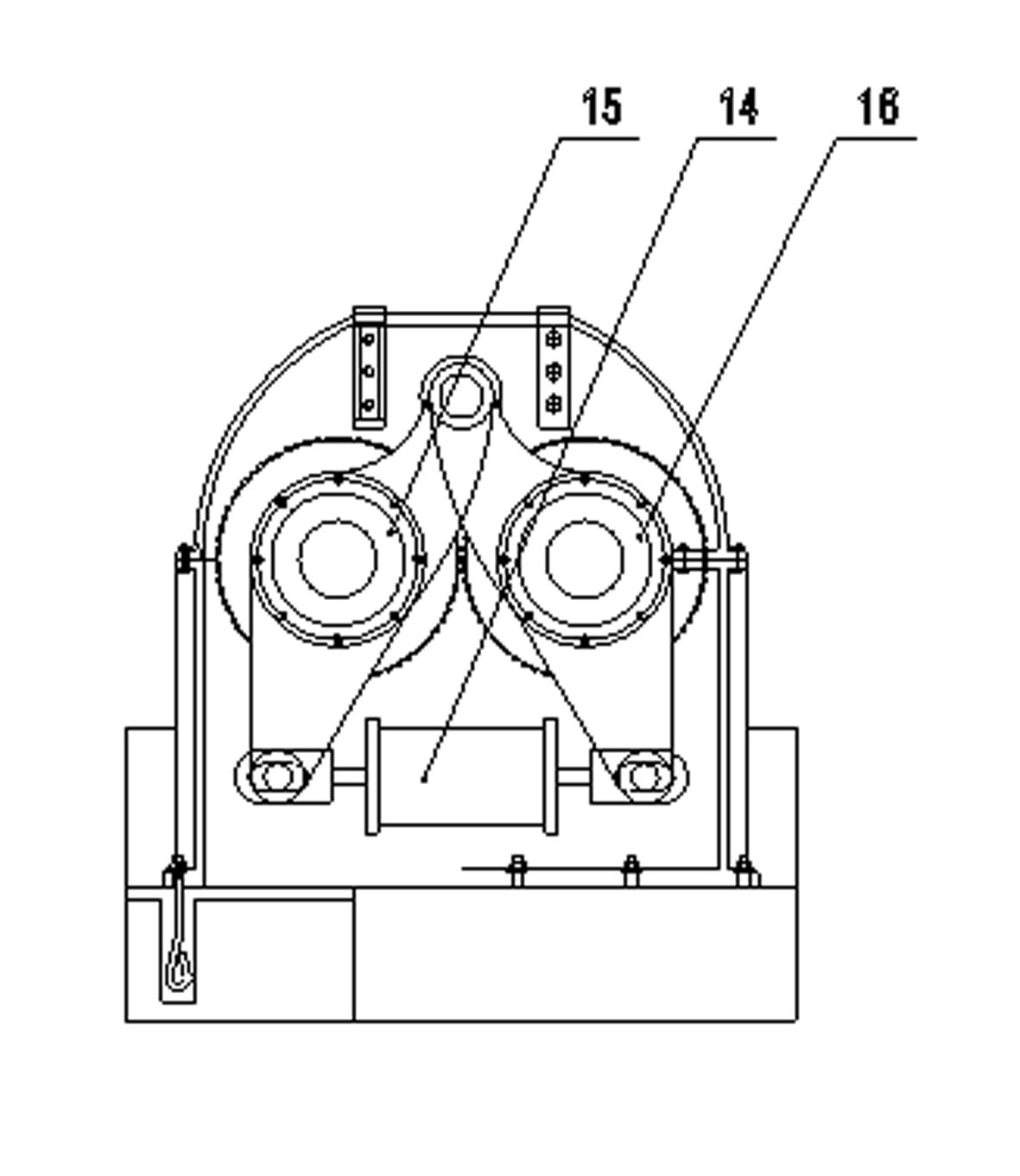

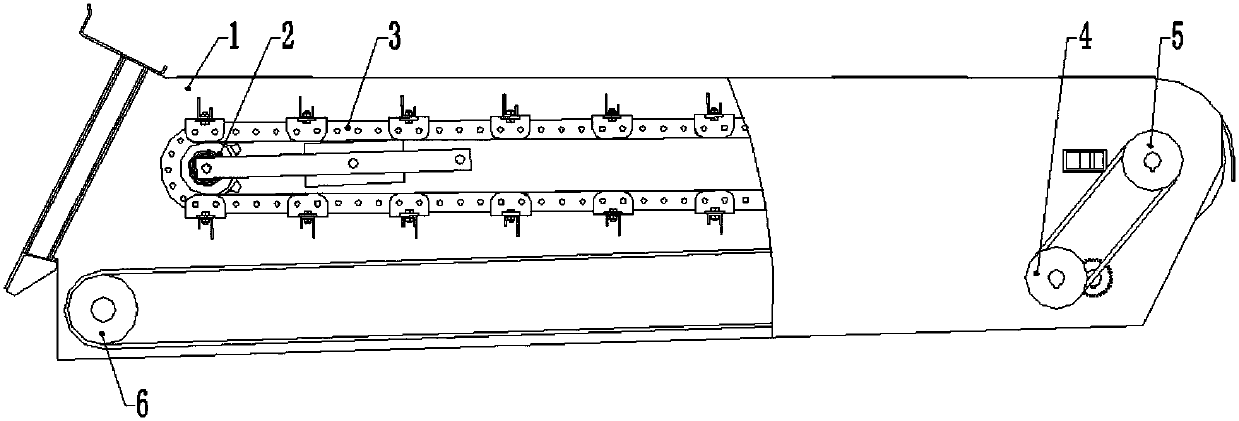

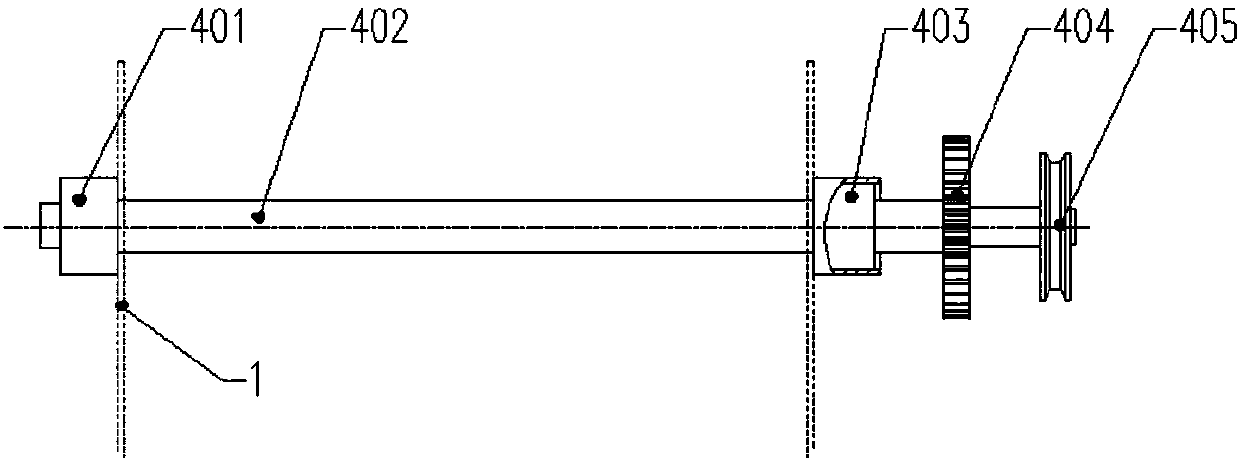

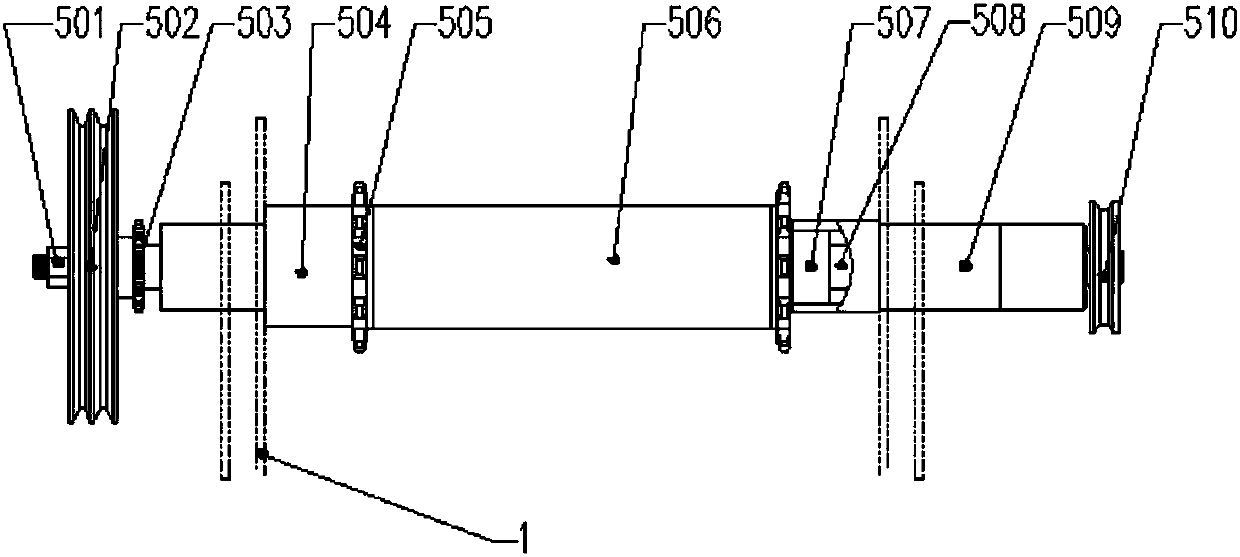

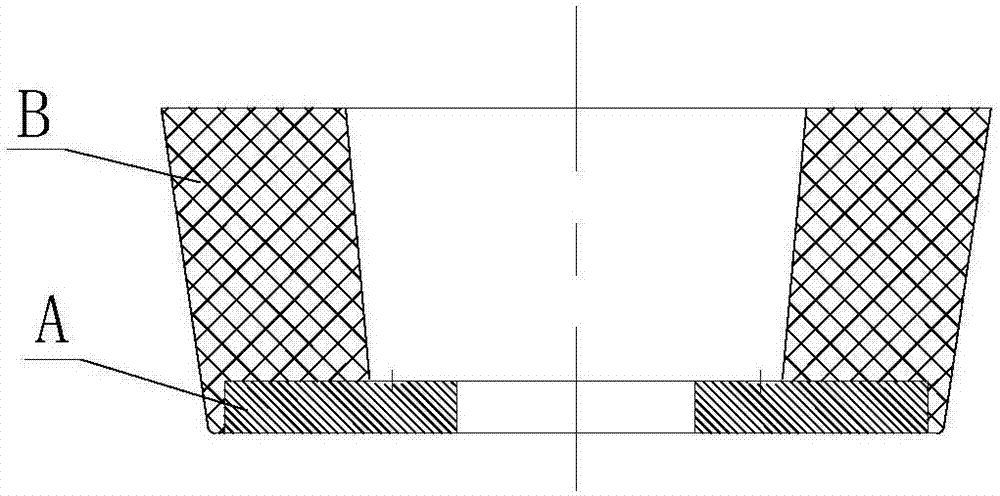

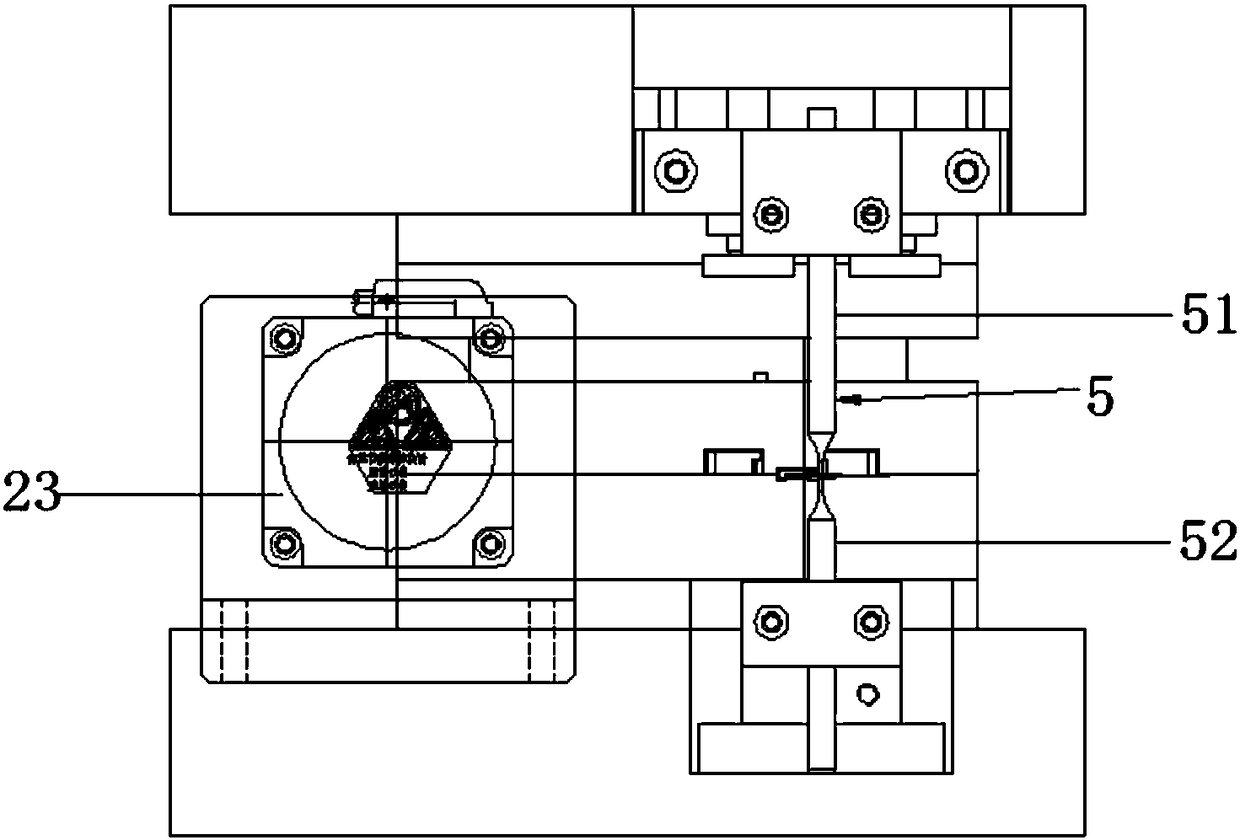

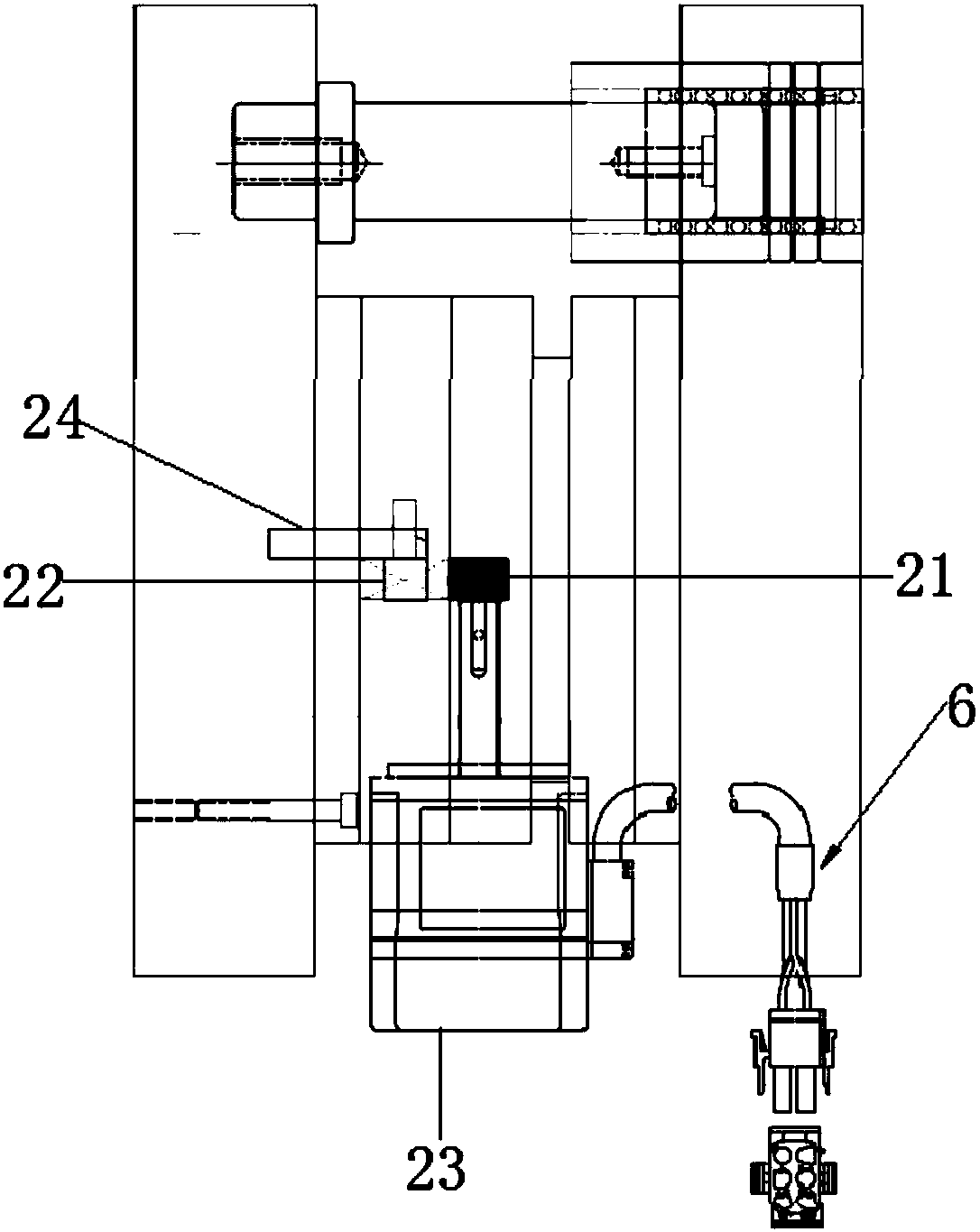

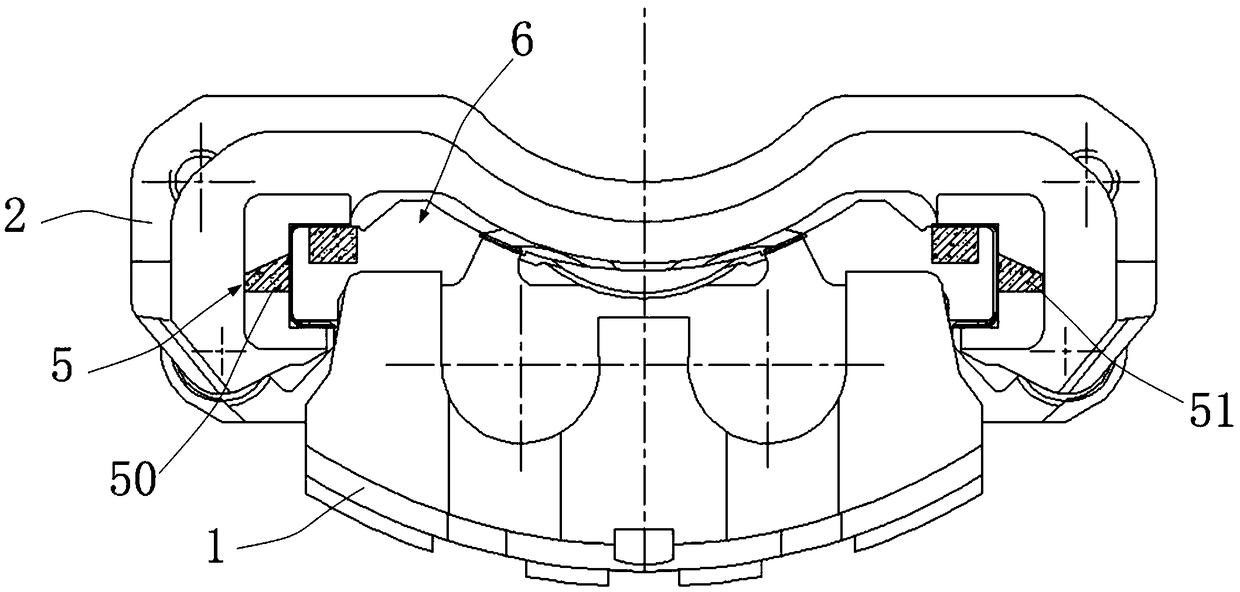

The invention discloses a continuous tube drawing device. The continuous tube drawing device comprises a rack (1), support bases (2) arranged on the rack (1), idler wheels (4), power systems (5) connected with the idler wheels (4) and support arms (3), wherein one end of each support arm (3) is connected with each support base (2) through a movable shaft, and the other end of each support arm (3) is connected with each idler wheel (4) through a movable shaft. The support bases (2), the support arms (3), the idler wheels (4) and the power systems (5) are all set to be two sets and are arranged symmetrically with the rack (1). The power systems (5) comprise transmission motors (51) and speed changers (52), wherein the output shafts of the transmission motors (51) are connected with the speed changers (52), and the idler wheels (4) are arranged on the output shafts of the speed changers (52). The continuous tube drawing device is stable in power output, a tube diameter is adjusted automatically, stress borne by tube materials is adjusted automatically, the tube materials and a transmission system can not be damaged by continuous tube drawing, and using is safer and more reliable.

Owner:CHINA COAL SPECIAL DRILLING ENG

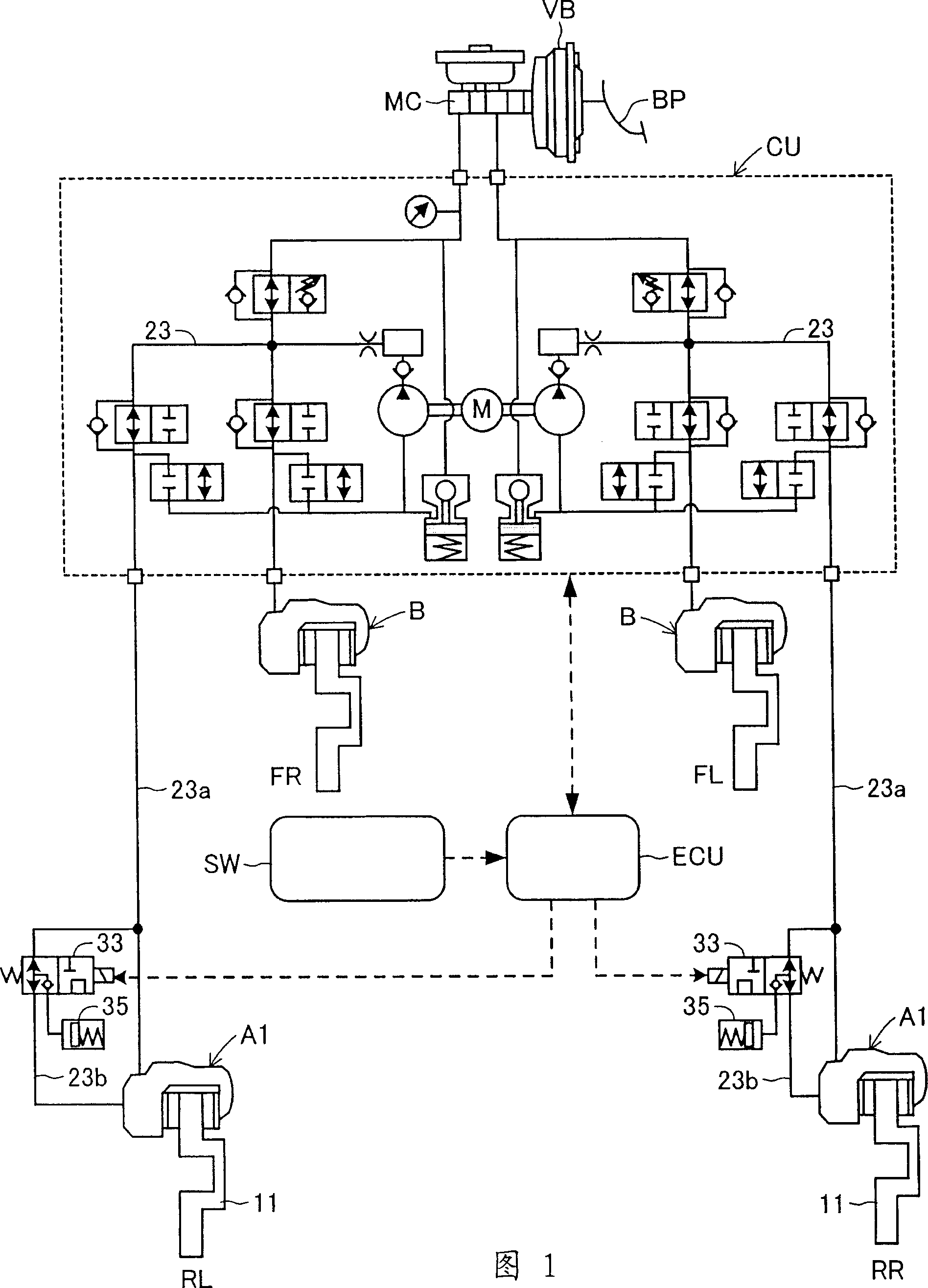

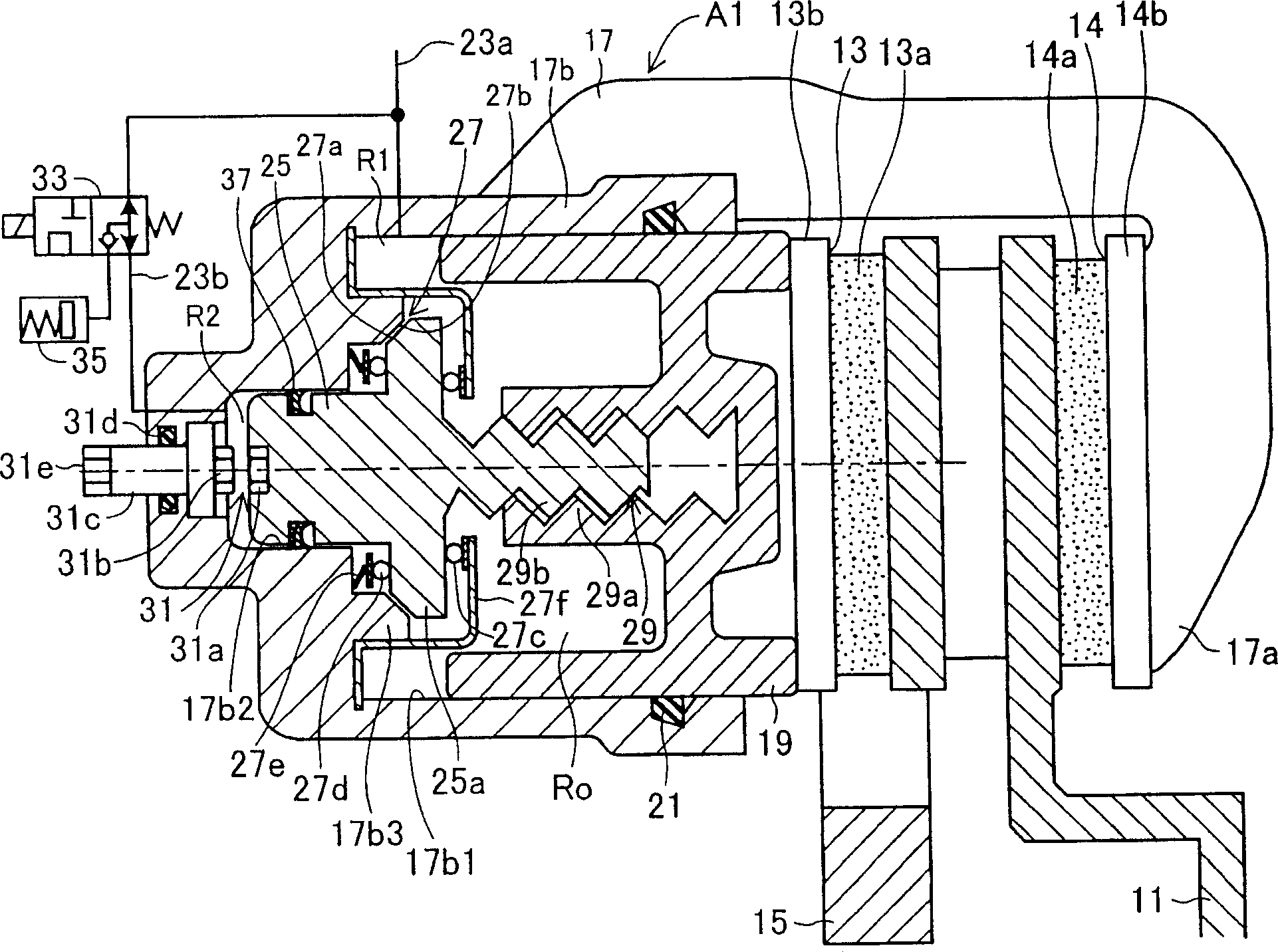

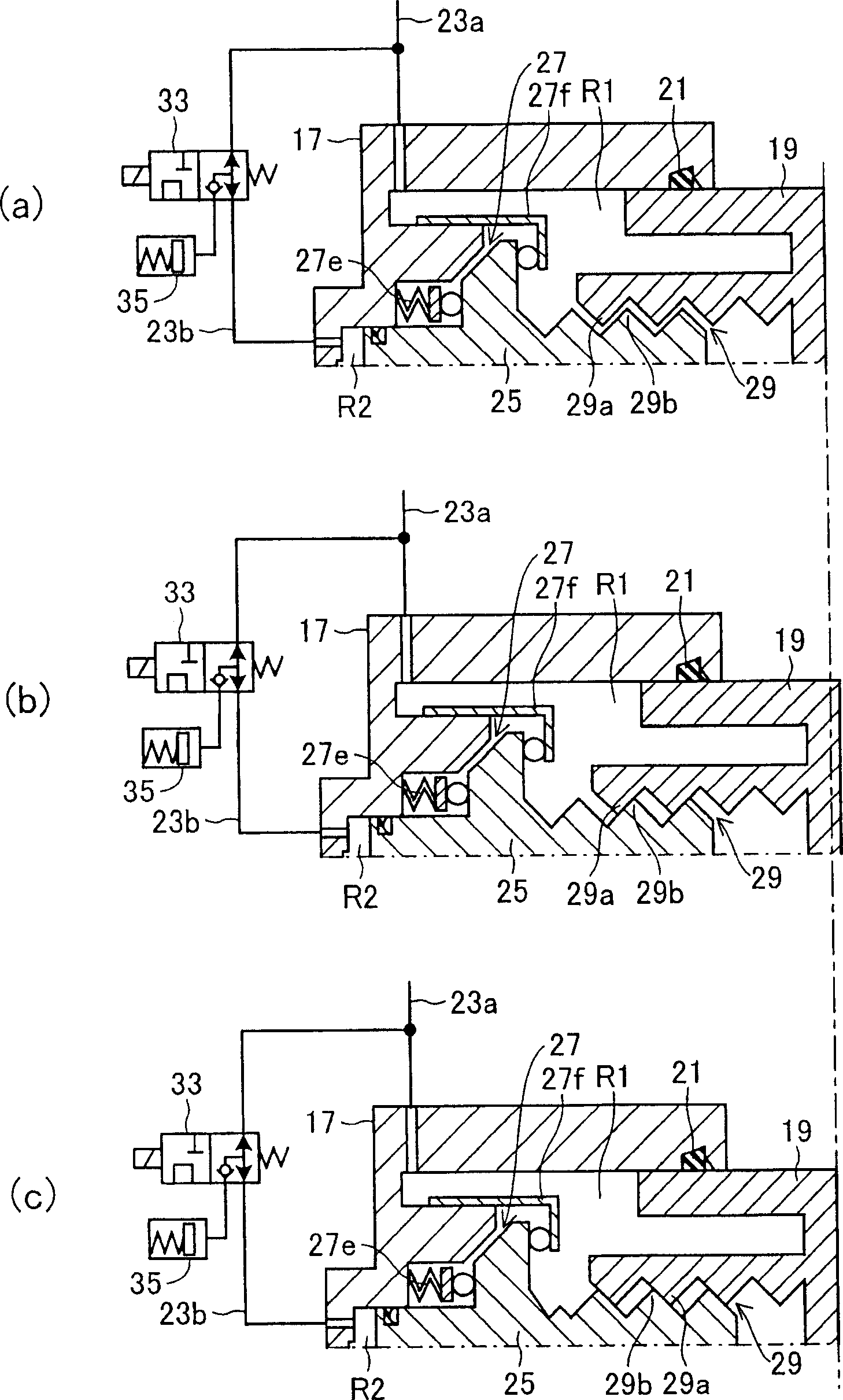

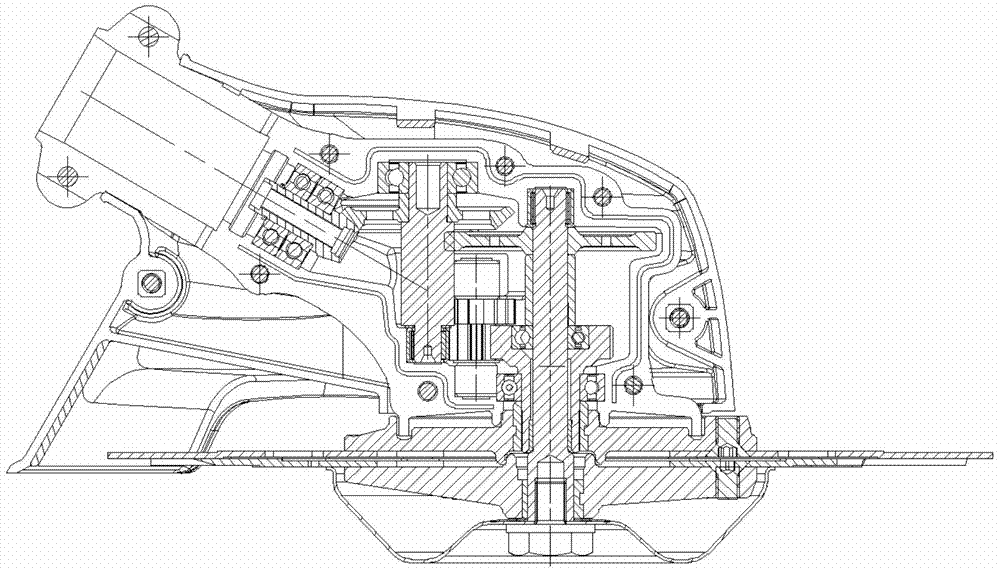

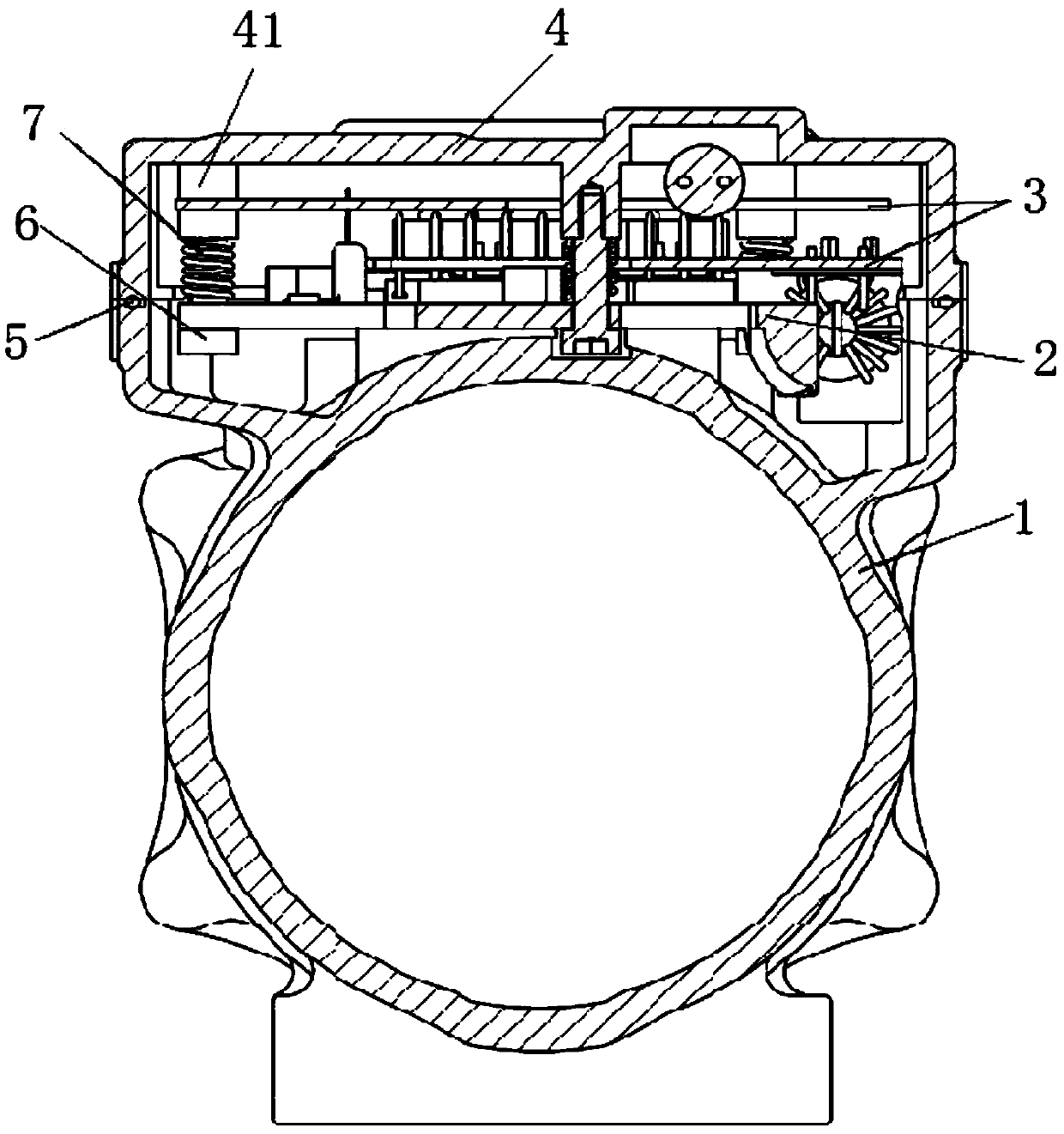

Combined service and parking brake apparatus

InactiveCN1755158AAutomatically adjust operation timingCompact configurationBrake actuating mechanismsSlack adjustersBrake liningParking brake

A combined service and parking brake apparatus includes a piston which forms a hydraulic chamber within a cylinder portion; a brake lining which, when pressed by the piston, brakes rotation of a disc rotor; a second piston which divides the hydraulic changer into a first hydraulic chamber and a second hydraulic chamber; a friction clutch which allows rotation of the second piston when the second piston is held at its home position and which disables rotation of the second piston when the second piston moves by a predetermined distance toward the second hydraulic chamber; an adjuster including an internal-thread portion and an external-thread portion and adapted to adjust the clearance between the pistons in accordance with the amount of wear of the brake lining; and a changeover valve for establishing and shutting off the communication between the first hydraulic chamber and the second hydraulic chamber.

Owner:ADVICS CO LTD

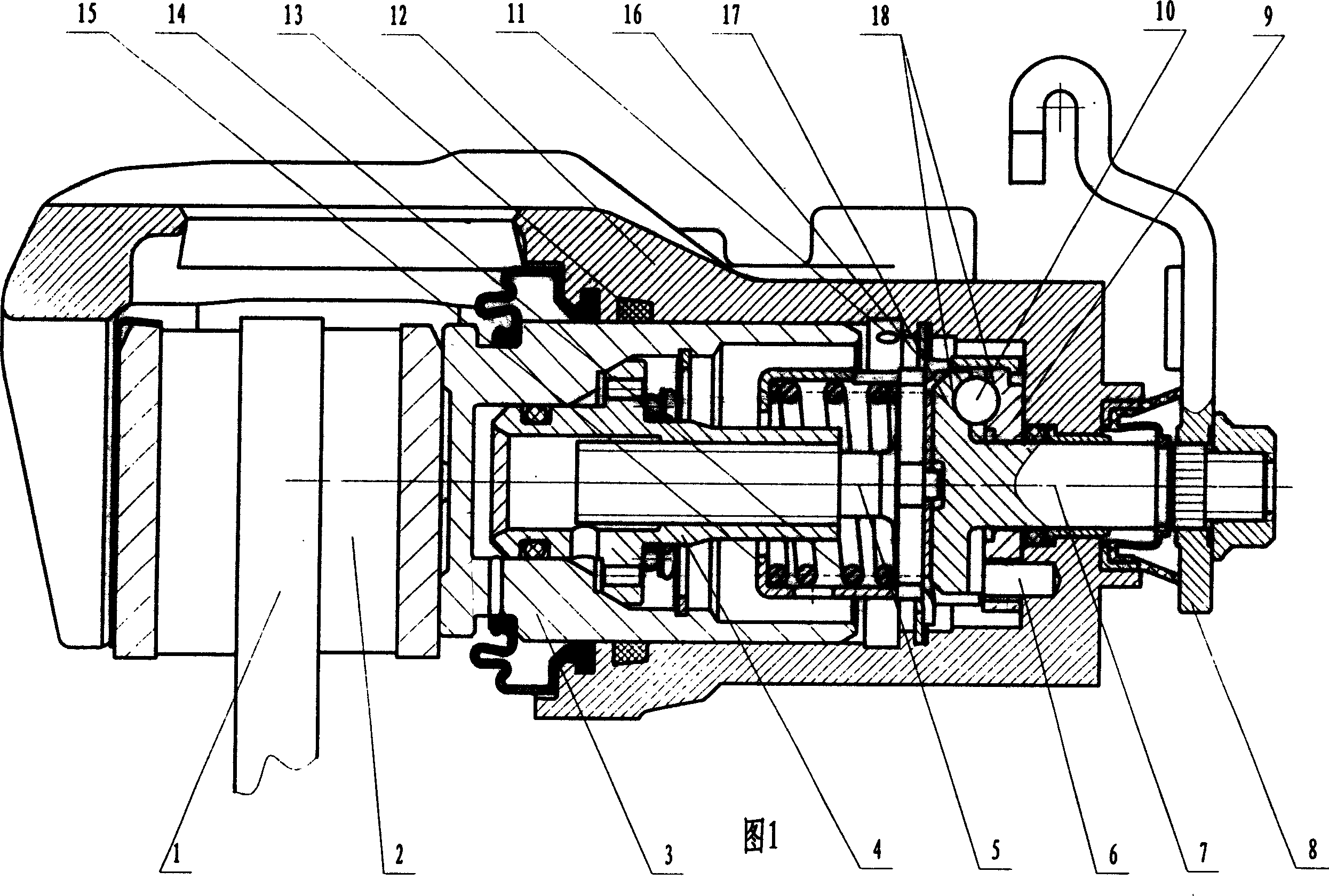

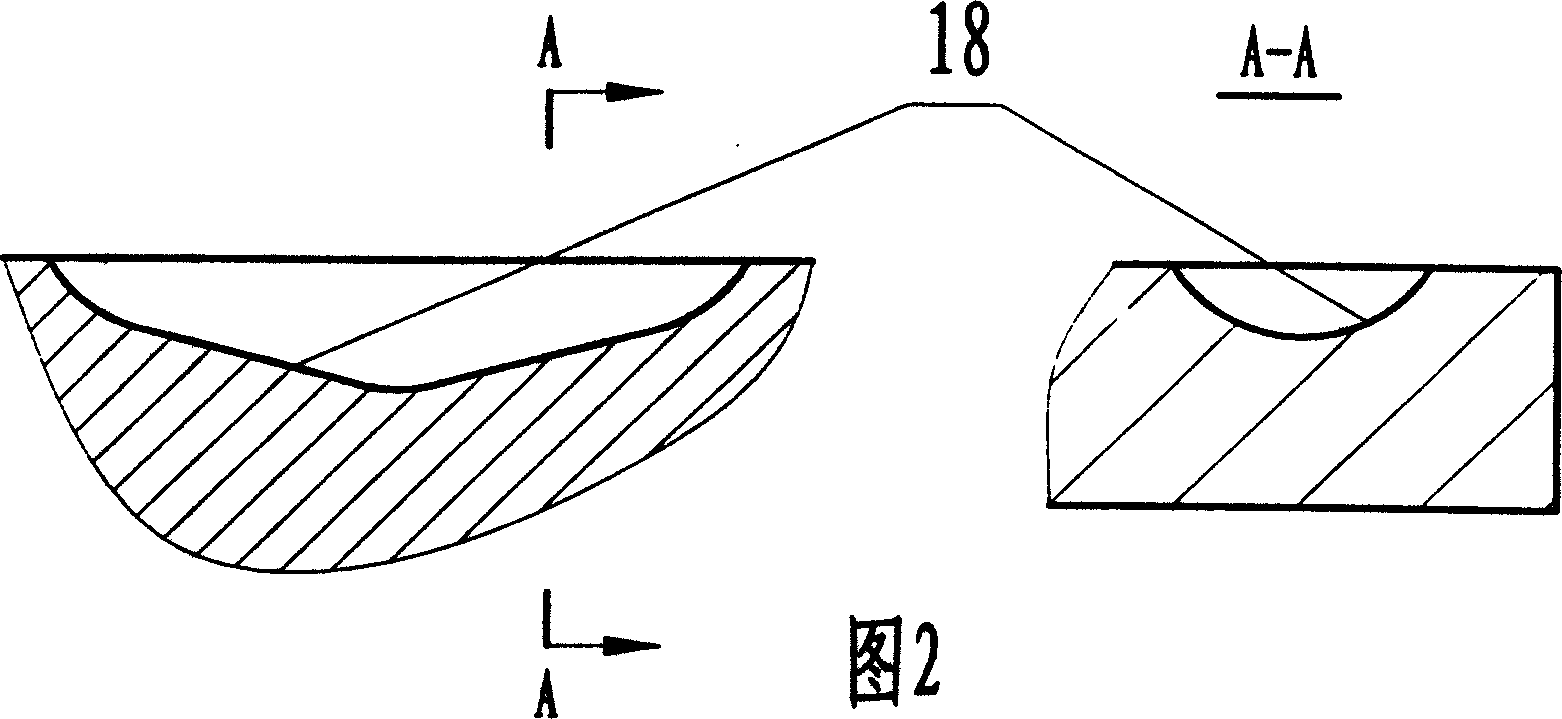

Brake tongs with brake for stationed vehicle

InactiveCN1600609AReduce manufacturing costCompact structureHand actuated initiationsEngineeringSteel ball

A bracking pincers for stopping a car comprises cylinder, piston, oil inlet hole, seal gascket and bracking block. It features having hand bracking arm, steel ball seat, multihead screw, multihead screw casing, top rod, returning spring and spring seat in the cylinder; placing steel ball disc at top rod left end; making the rolling channel on disc and seat; setting axial gap between screw tooth and screw groove bigger than gap between piston and bracking block in thread connection.

Owner:重庆红宇精密工业集团有限公司

Ceramic ball valve

ActiveCN102313040AReduce contact seamsGuaranteed sealing effectSpindle sealingsPlug valvesBall valveMetallurgy

The invention discloses a ceramic ball valve, which consists of a shell, a valve rod, a ceramic ball, a left ceramic valve seat, a right ceramic valve seat, a ceramic middle body, a ceramic flange inner lining, a flange inner lining metal ring and a positioning metal ring, wherein the outer side face of the left ceramic valve seat is in close contact with the inner side face of the shell; the outer side face of the right ceramic valve seat is in close contact with the inner side face of the ceramic middle body; the other end of the ceramic middle body is in close contact with the interior of the left ceramic valve seat; a disc spring pressing ring is arranged between the right vertical surface of the right ceramic valve seat and the ceramic flange inner lining; and a disc spring is arranged between the disc spring pressing ring and the right vertical surface of the right ceramic valve seat. The ceramic ball valve has the characteristics of automatically adjusting a gap of the ceramic ball and the ceramic valve seat, along with good sealing effect on a valve rod part, long service life and good sealing effect.

Owner:步志俊

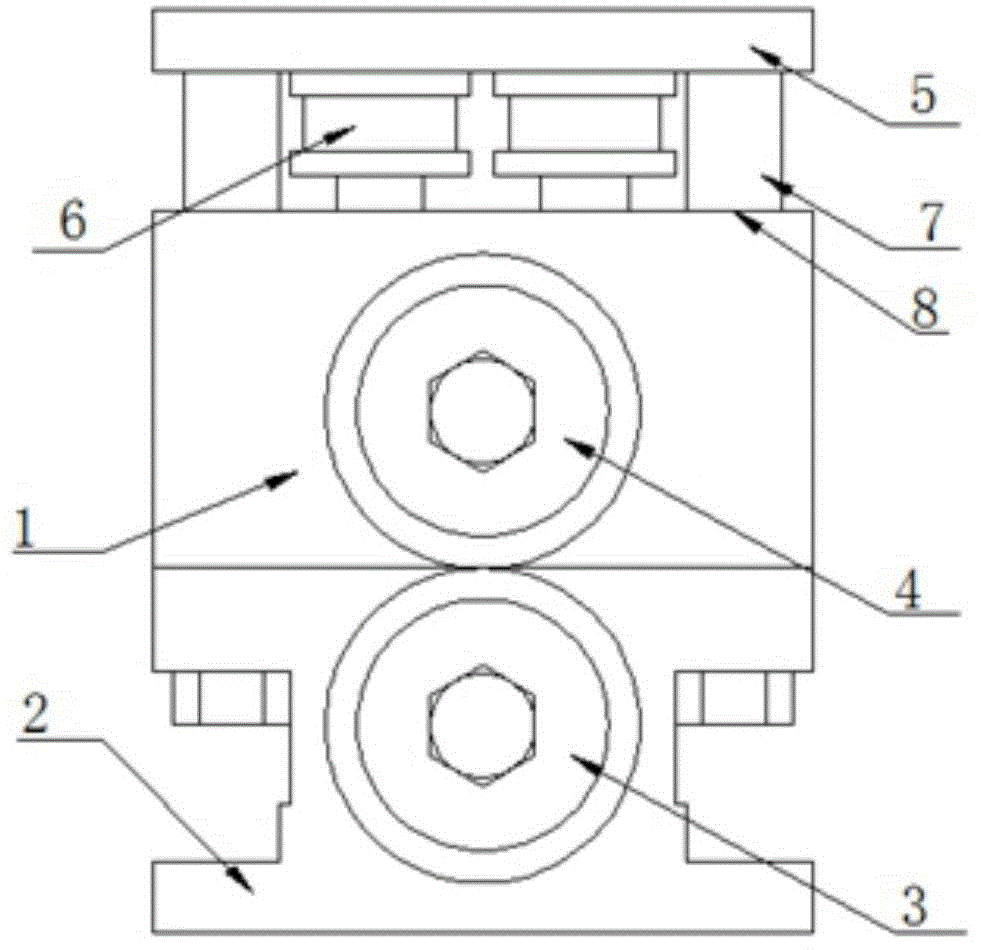

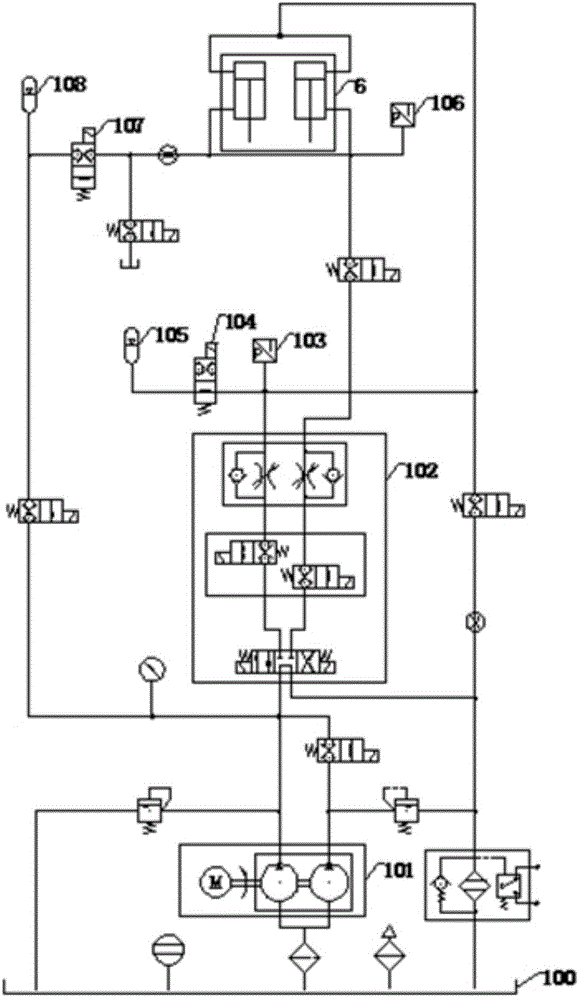

Extrusion device for dry type granulator

ActiveCN104383849AGuaranteed pressure balanceAutomatically adjust the gapGranulation by material expressionGranulation by pressingFuel tankHydraulic pump

The invention relates to an extrusion device for a dry type granulator. The extrusion device comprises an upper tank body, a lower tank body, an extrusion wheel 1, an extrusion wheel 2, a hydraulic cylinder block, a hydraulic cylinder and a hydraulic control system, wherein the hydraulic cylinder block is assembled above the lower tank body; the upper tank body is arranged between the lower tank body and the hydraulic cylinder block; the extrusion wheel 1 is assembled on the lower tank body; the extrusion wheel 2 is assembled on the upper tank body; one end of the hydraulic cylinder is assembled on the hydraulic cylinder block; the other end of the hydraulic cylinder is connected with the upper tank body; the hydraulic cylinder is provided with an oil inlet end 1 and an oil inlet end 2; the hydraulic control system comprises an oil tank, a hydraulic pump and a direction valve, which are sequentially connected in series; the direction valve is connected with the oil inlet end 1 and the oil inlet end 2; a branch circuit composed of a pressure transmitter, a control valve and an energy accumulator is connected between the hydraulic cylinder and the direction valve in parallel; the pressure transmitter is used for collecting the pressure of the hydraulic cylinder and feeding the pressure back to the control valve; and the control valve is used for controlling opening and closing of the energy accumulator to supplement or release the pressure of hydraulic oil, thus automatic pressure supplement and automatic clearance adjustment of the extrusion device are achieved; and the extruded material is relatively uniform in thickness and compactness.

Owner:CHANGZHOU YIBU DRYING EQUIP

Over thick wood chip crusher

InactiveCN101880978AAvoid cloggingThe speed is steplessly adjustableRaw material divisionHydraulic cylinderStub axle

The invention discloses an over thick wood chip crusher provided with a machine shell and rotative compression rollers. The over thick wood chip crusher is characterized in that the machine shell is in a fixed box type structure and can be divided into an upper part and a lower part which can be detachable; two ends of the machine shell are provided with short supporting shafts; the machine shell is internally provided with an upper compression roller and a lower compression roller which do opposite retative motion; grooves and convex teeth regularly spread over the surface of each compression roller; the compression rollers are parallel mutually, arranged on the short supporting shafts through a rocker bearing block, and combined into two movable compression rollers which can relatively swing within a certain range; and a hydraulic cylinder is arranged between the two compression rollers. The invention has the advantages of no blockage, low crushed damage rate and favorable recrushing effect.

Owner:湖南骏泰新材料科技有限责任公司

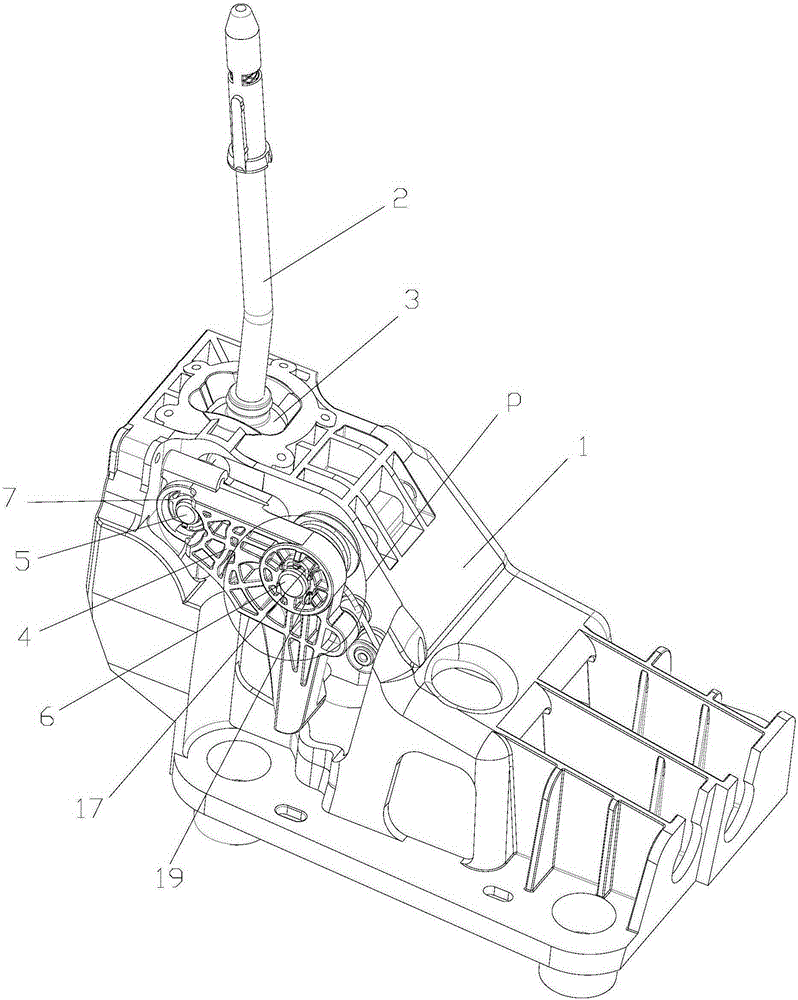

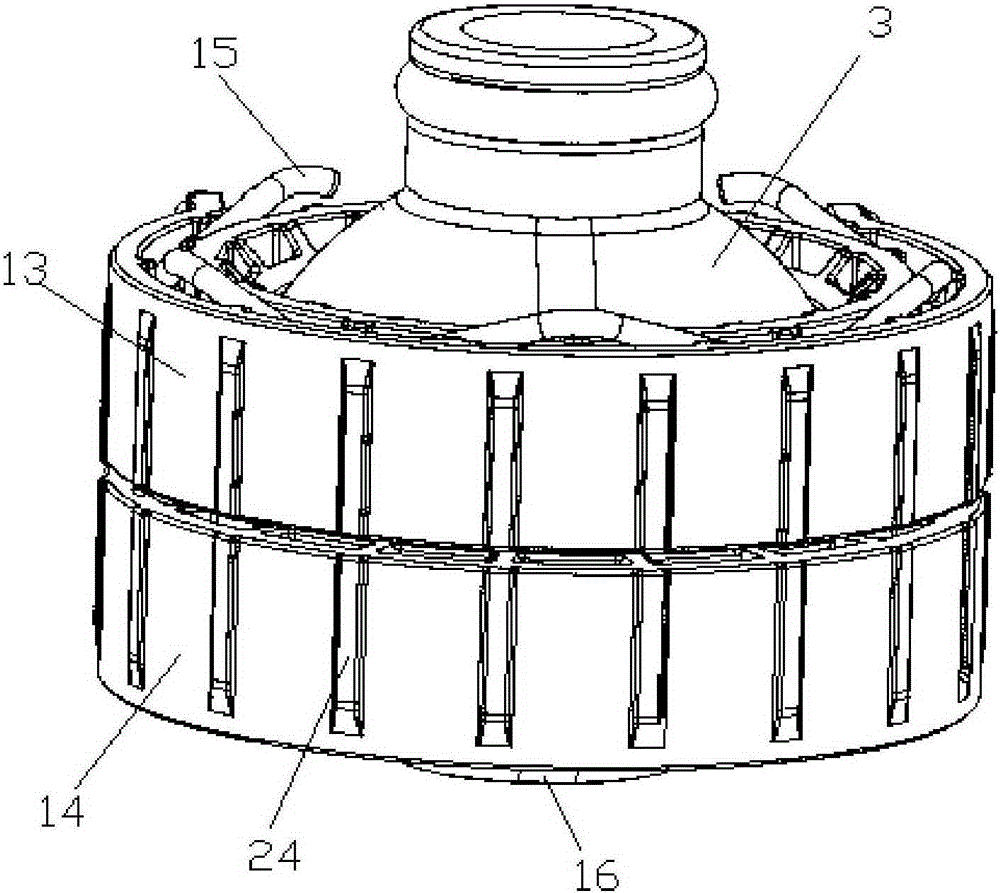

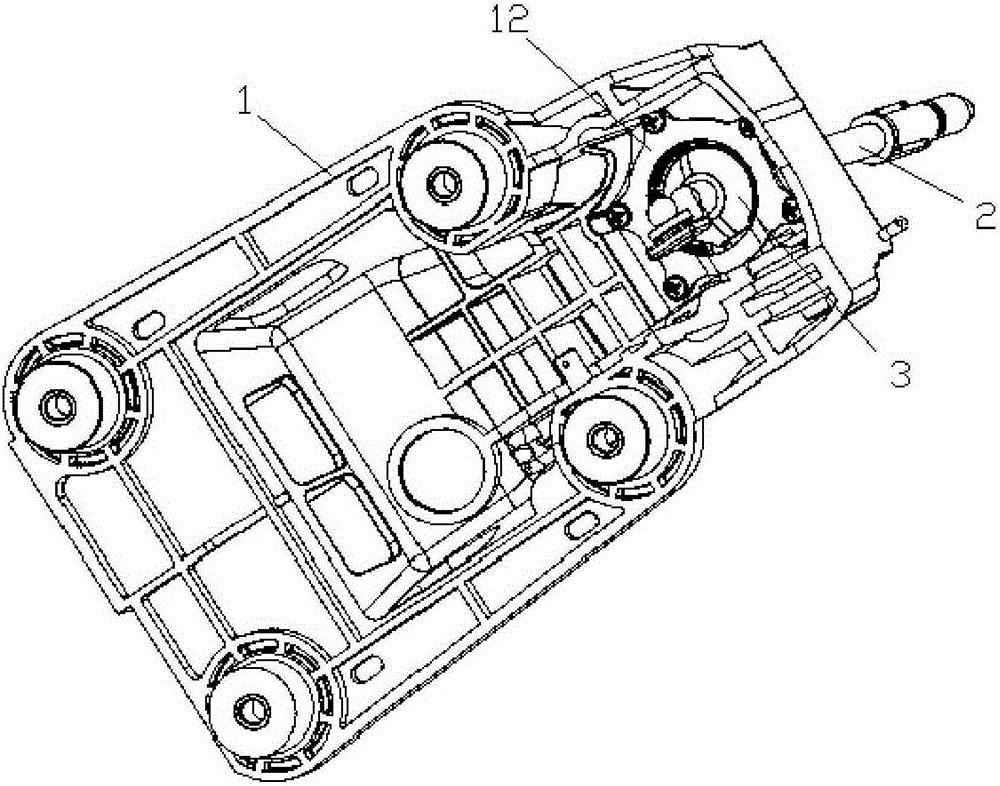

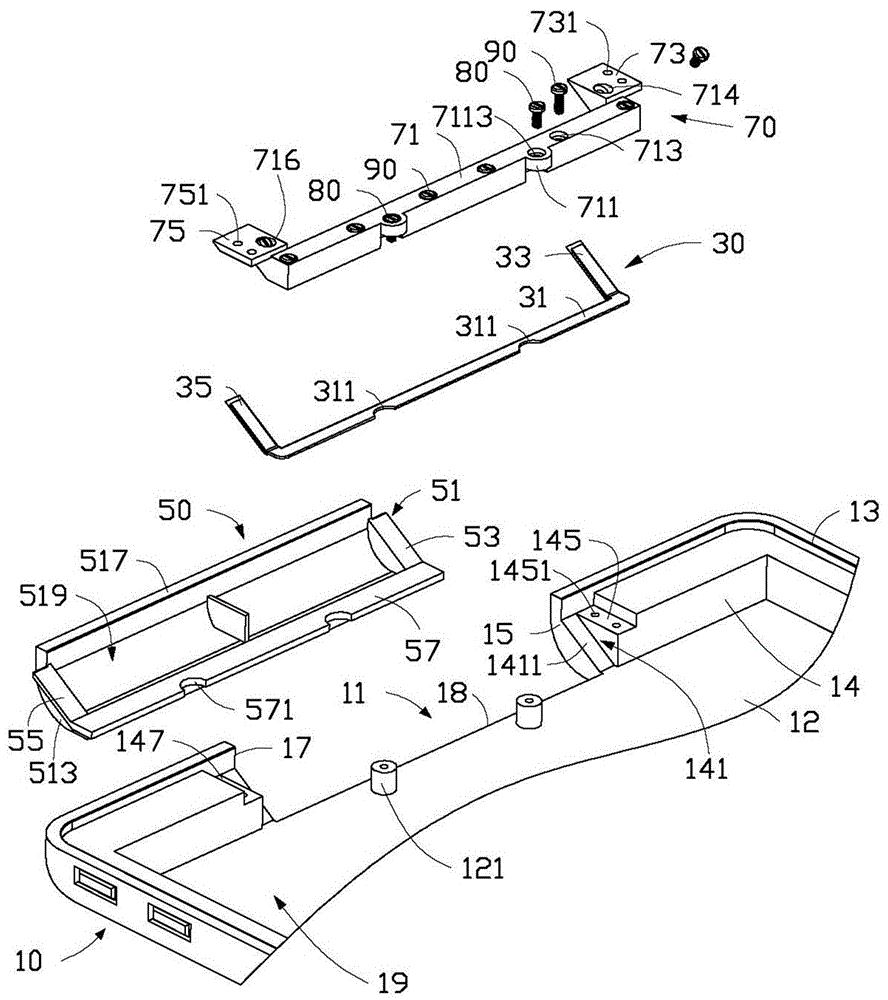

Automotive manual gear shifter convenient and fast to assemble and capable of adjusting clearance automatically

InactiveCN105299206AExtended service lifeEliminates the problem of increased gapsGearing controlAuto regulationJoystick

The invention discloses an automotive manual gear shifter convenient and fast to assemble and capable of adjusting a clearance automatically. The automotive manual gear shifter comprises a base, a joystick, a ball head, a gear selection arm, a connection rod and a pin shaft. The gear selection arm is connected with the connection rod through a spherical bearing. Arc elastic pieces are arranged on the outer circle face of the spherical bearing. A seam adjusting mechanism is arranged between the base and the ball head. A U-shaped elastic clamp is arranged at the end of the pin shaft. A U-shaped positioning groove and limiting stop blocks are arranged on the end face of the gear selection arm. When friction wear exists between the match faces of the arc elastic pieces and the gear selection arm in use, the arc elastic pieces can compensate for the abrasion loss of the match faces automatically; when friction wear exists between the match face of the ball head and the match faces of an upper ring seat and a lower ring seat, an upper spring and a lower spring can push the upper ring seat and the lower ring seat to move, so that the clearance between the ring seats and the ball head is reduced automatically, and the failure rate can be lowered greatly; and no special tool is needed in the U-shaped elastic clamp assembling process, assembling is convenient and fast, and working efficiency is high.

Owner:CHONGQING YUJIE AUTO PARTS

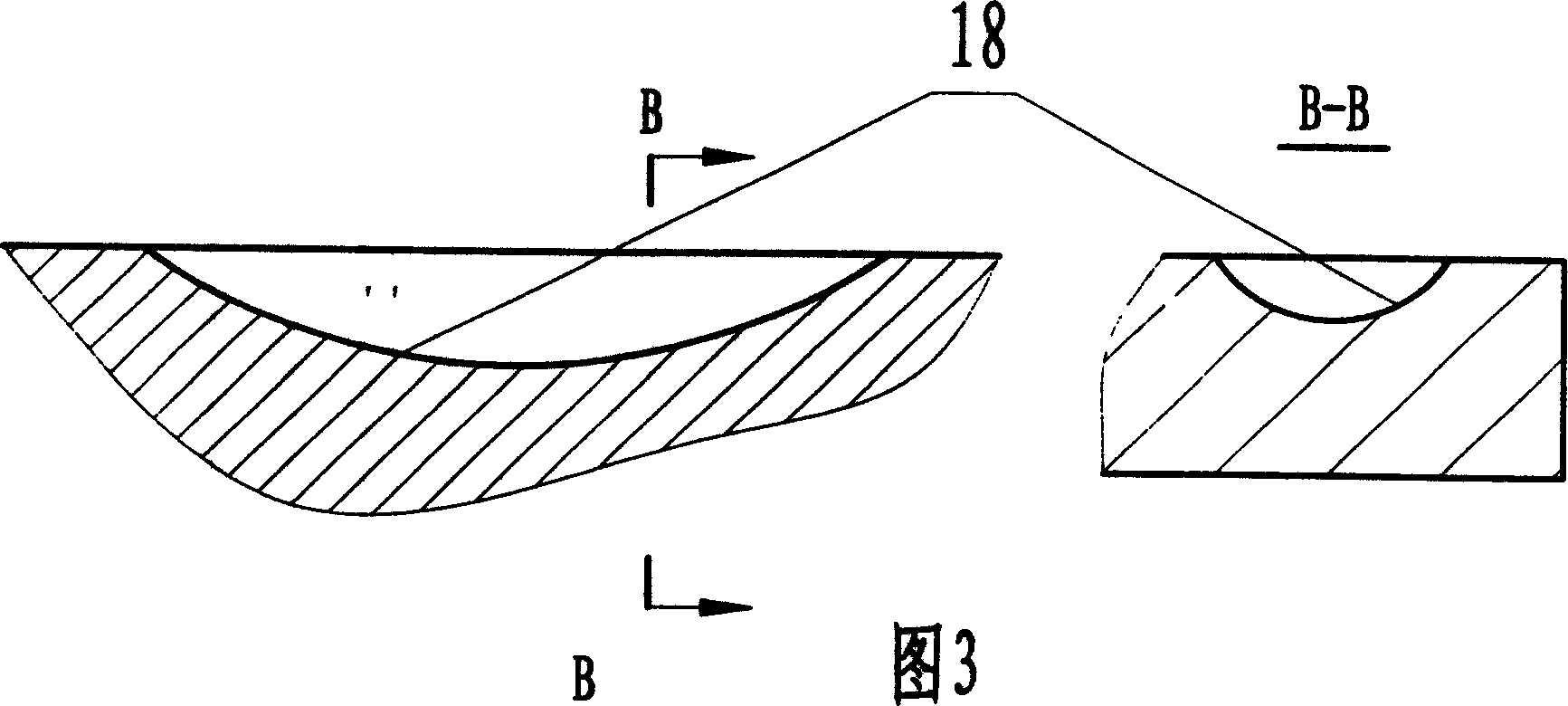

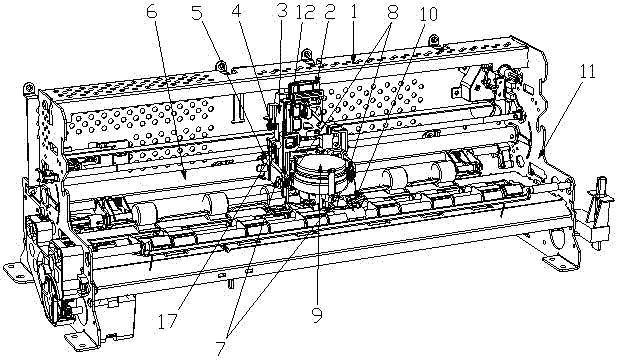

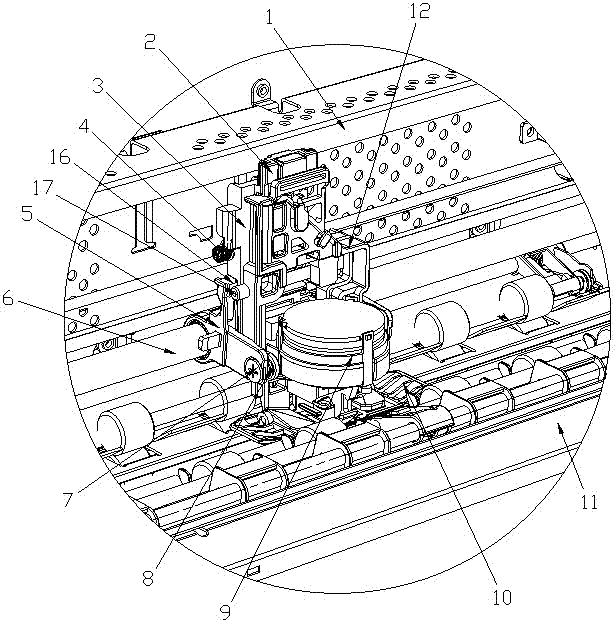

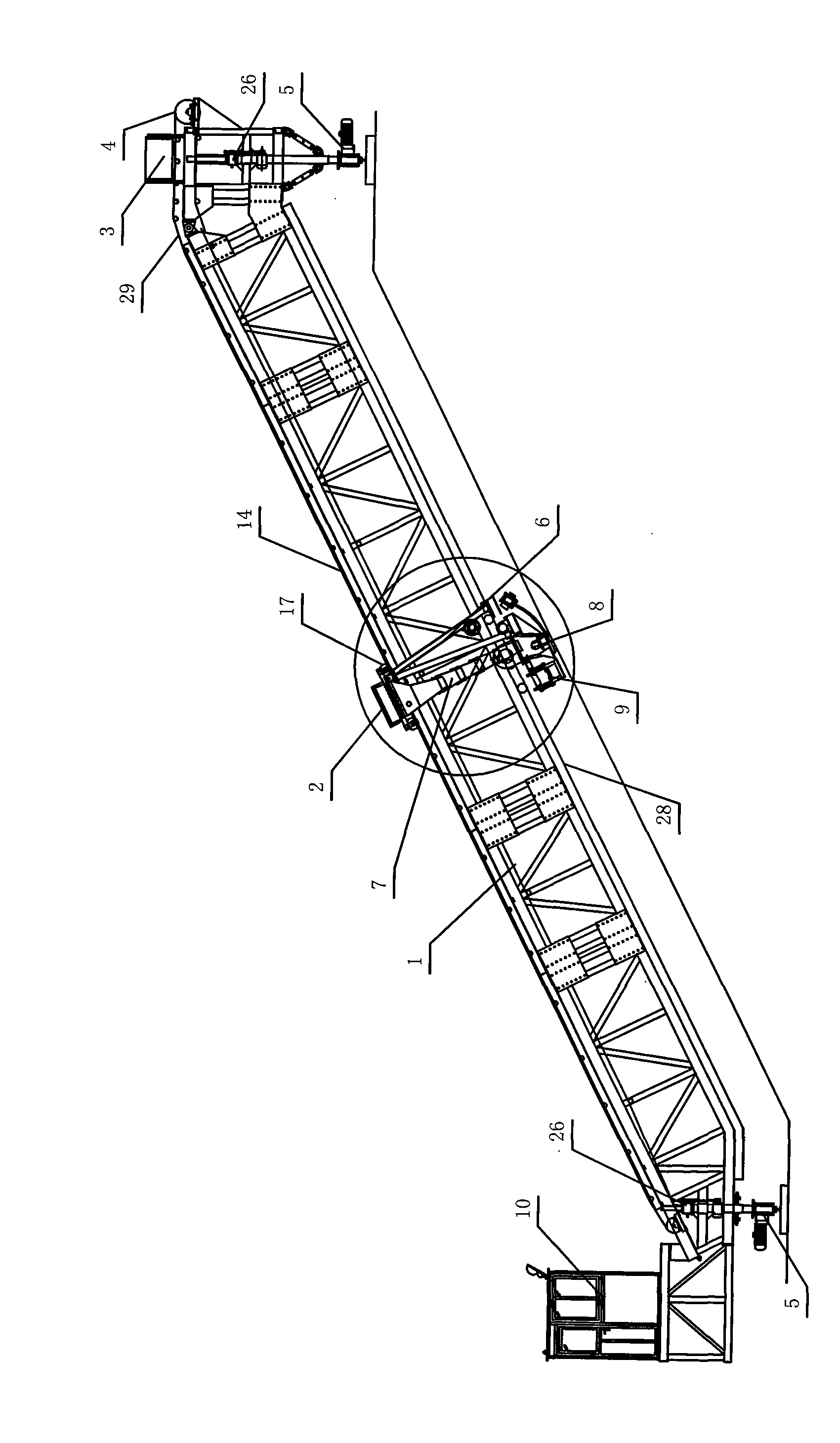

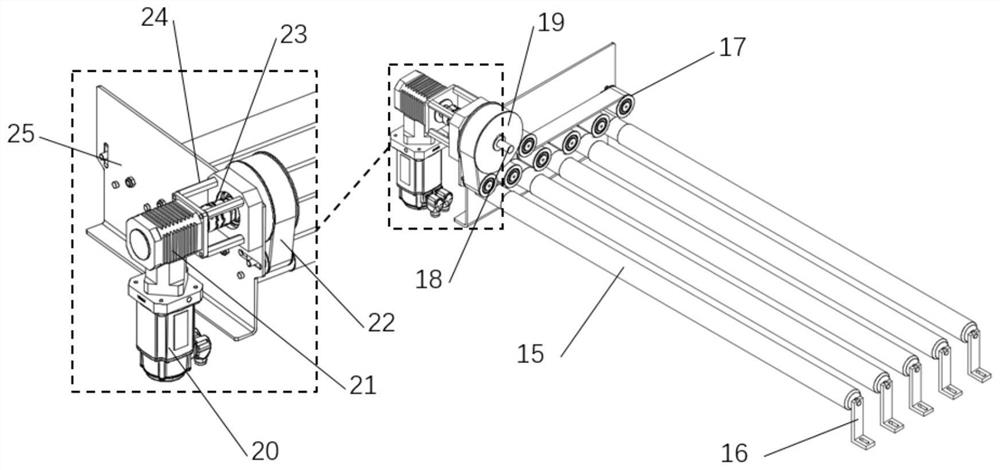

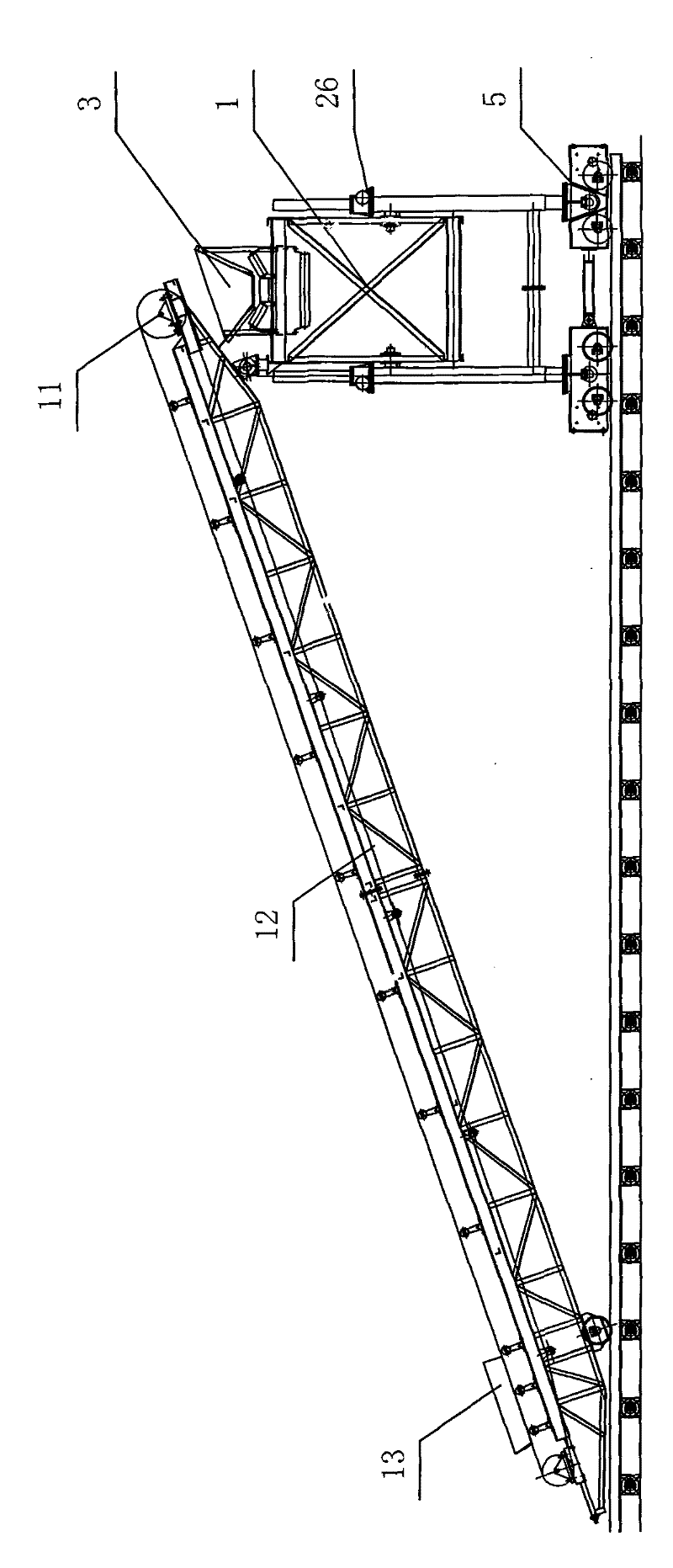

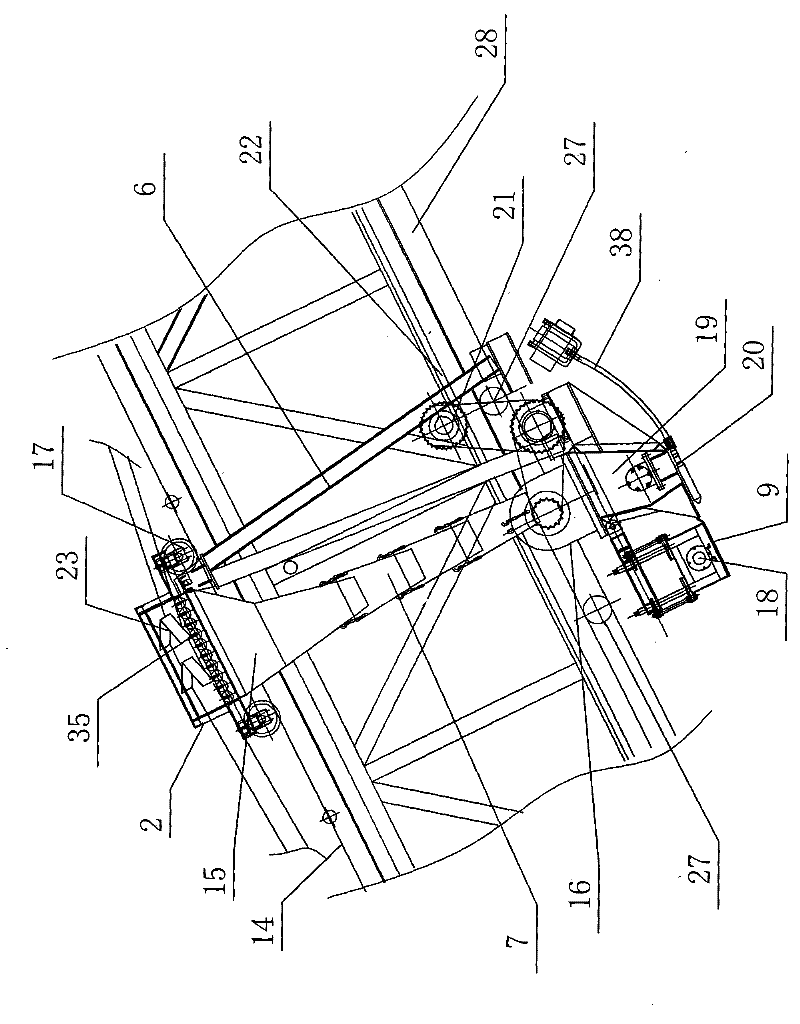

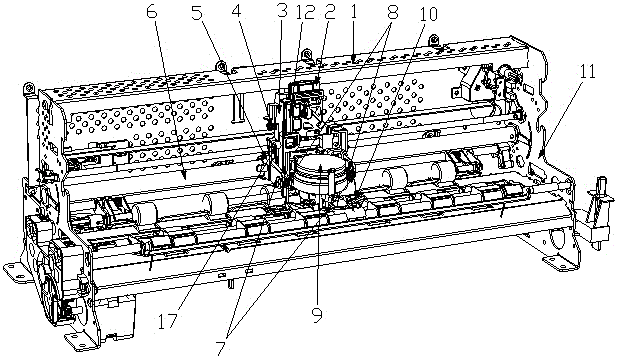

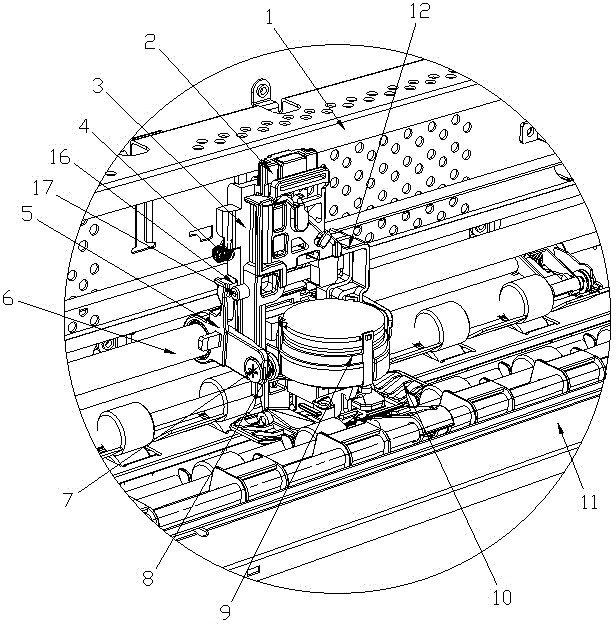

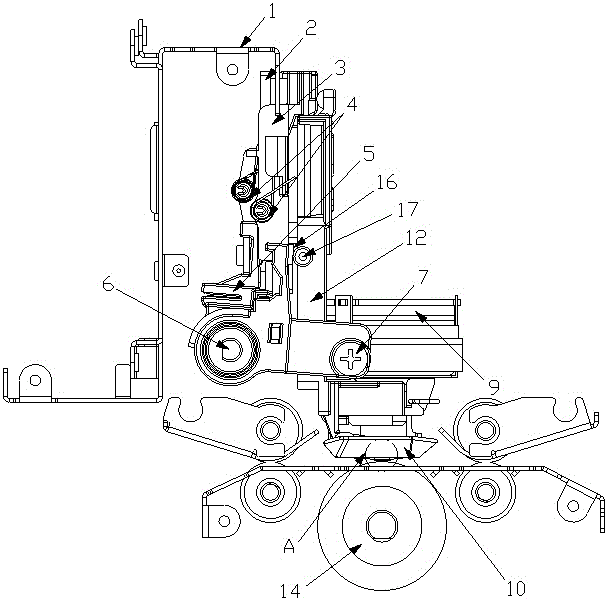

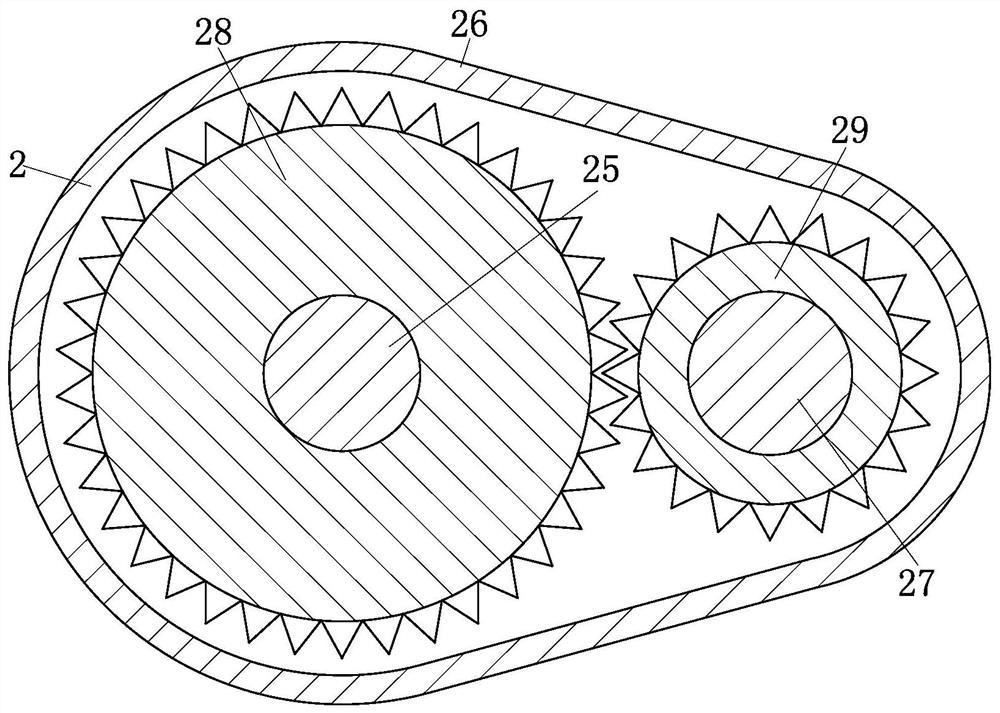

Floating blockage-proof energy-saving low-noise intermediate conveying device

The invention provides a floating blockage-proof energy-saving low-noise intermediate conveying device. The device comprises a frame, a transmission shaft system, a chain, an auxiliary driving shaft system, a driving shaft system and a lower conveyor belt system; the transmission shaft system is installed at the left end of the frame, and the driving shaft system is installed at the right end of the frame; the auxiliary driving shaft system is installed on the lower left of the driving shaft system, belt transmission is adopted between the auxiliary driving shaft system and the driving shaft system, the lower conveyor belt system is installed below the driving shaft system and the transmission shaft system, and gear transmission is conducted between the lower conveyor belt system and an auxiliary driving shaft. Through belt transmission and external gear meshing, the rotation direction of the lower conveyor belt system and the rotation direction of the driving shaft system are opposite, so that the lower surface of the chain and the upper surfaces of conveyor belts move upwards simultaneously, the linear speeds of moving are the same, and then noise and power consumption are reduced; a lower conveyor belt shaft slides around an upper conveyor belt shaft in a bearing base and is connected with the frame through a spring, so that floating connection between the conveyor belts isachieved, and blockage is prevented.

Owner:JIANGSU UNIV

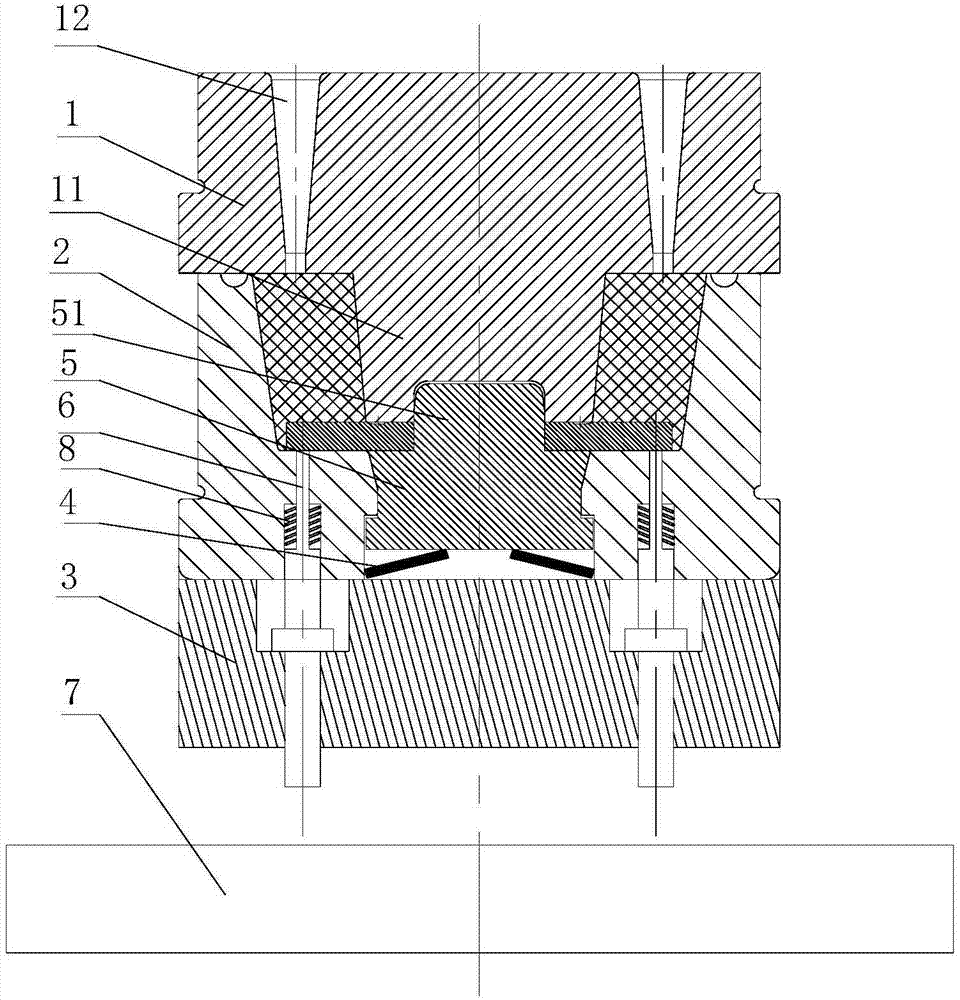

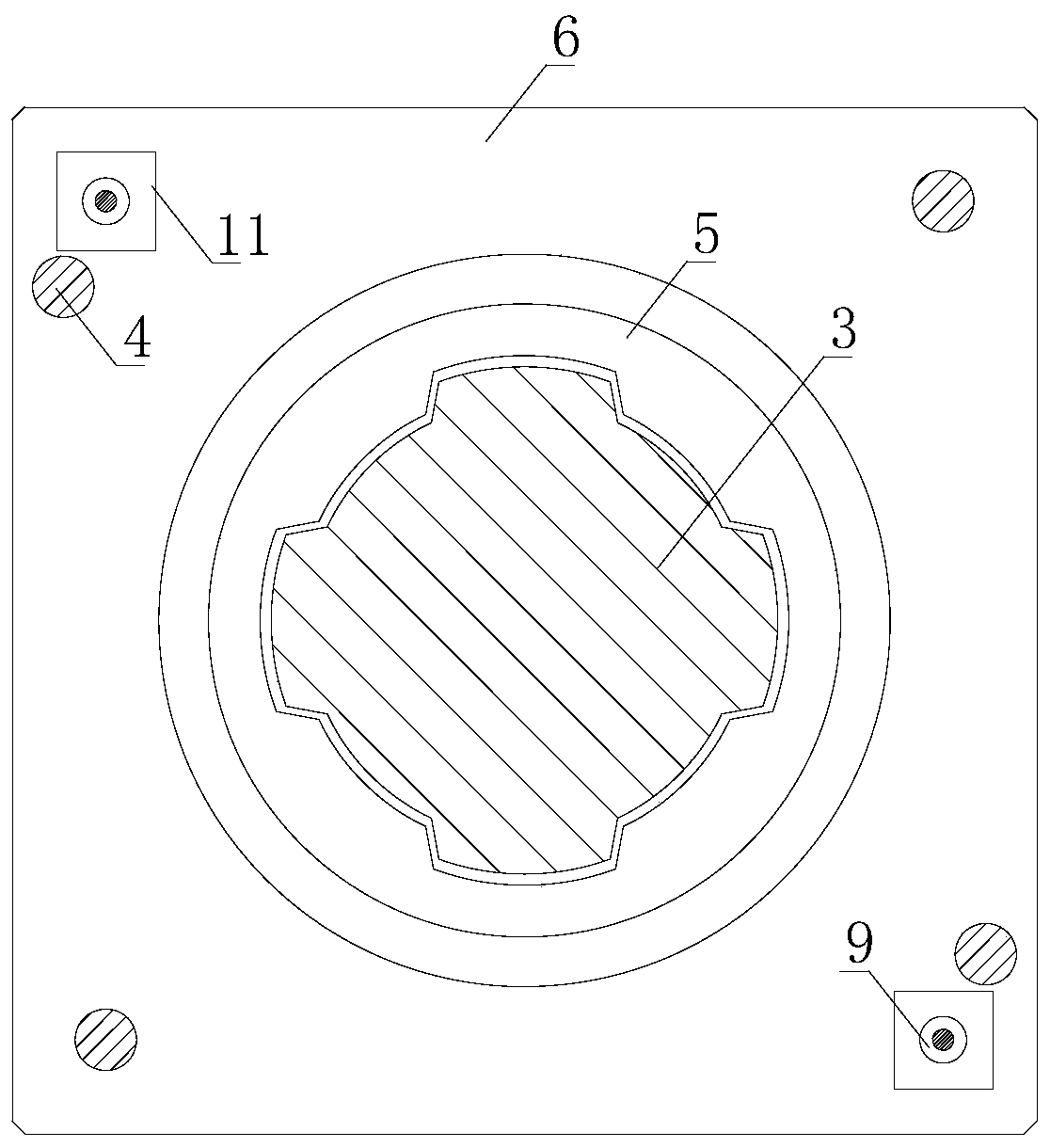

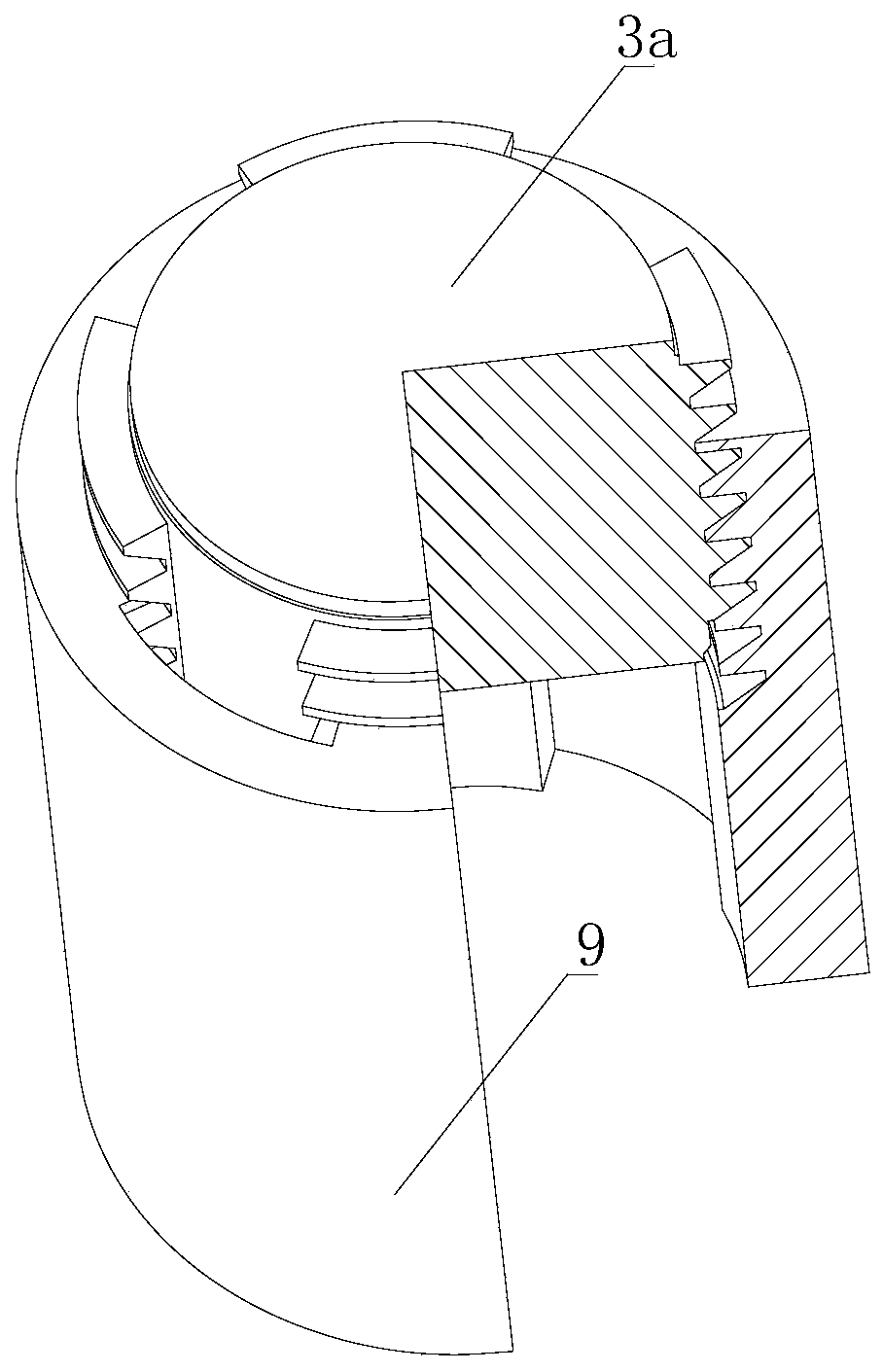

Automatic disc spring sealing compound ejection die

The invention discloses an automatic disc spring sealing compound ejection die. The automatic disc spring sealing compound ejection die comprises an upper die, a middle die, a lower die plate and an ejection mechanism. The upper die is located above the middle die, and is provided with a compound injection opening penetrating the upper end face and the lower end face of the upper die, the end, close to the middle die, of the upper die is provided with a first protrusion part, and a groove is formed in the end of the first protrusion part; the middle die is located above the lower die plate and fixedly installed on the lower die plate, the middle die is provided with a die cavity, a disc spring is arranged at the bottom of the die cavity, and a movable die core is arranged in the die cavity; the upper surface of the movable die core is provided with a second protruding part for a frame inner hole to penetrate, the lower surface of the movable die core abuts against the disc spring, in the die assembly state, a second protrusion part extends into the groove in the end of the first protrusion part, molding cavities are formed on the peripheries of the second protrusion part and the first protrusion part, and the compound injection opening is communicated with the molding cavities; and the ejection mechanism is used for ejecting out materials in the molding cavities. The automatic disc spring sealing compound ejection die is simple and reliable in operation, the manual cost and the labor intensity are reduced, and very high competitive force is achieved on the market.

Owner:宣城安安橡塑有限责任公司

Automatic printing interval adjusting lettering method and device

ActiveCN104760429ASimple structureReduce manufacturing costPower drive mechanismsLetteringElectrical and Electronics engineering

The invention relates to an automatic printing interval adjusting lettering method and device. When a printing medium enters a printing area, if the thickness of the printing medium is smaller than or equal to an interval between a paper pressing block and a printing drum, at the moment, a printing head is located at the lowest position, deformation of a torsional spring on a carriage unit split body B is minimum, and generated torsion is used for adjusting counter-acting force generated when the printing head works; if the thickness of the printing medium is larger than the interval between the paper pressing block and the printing drum, the paper pressing block makes contact with the printing medium, the printing medium pushes a carriage unit split body C to move upwards along the carriage unit split body B, the carriage unit split body C drives the carriage unit split body B to rotate around a carriage unit guide shaft, at the moment, the deformation of the torsional spring on the carriage unit split body B begins to be increased, and the generated torsion enables the paper pressing block to press the printing medium. The device is novel in design and simple in structure, the printing head does not incline, the service life of the printing head is long, the printing medium thickness application range is large, and the device has high practical value and a wide application prospect.

Owner:FUJIAN SHIDA COMP EQUIP

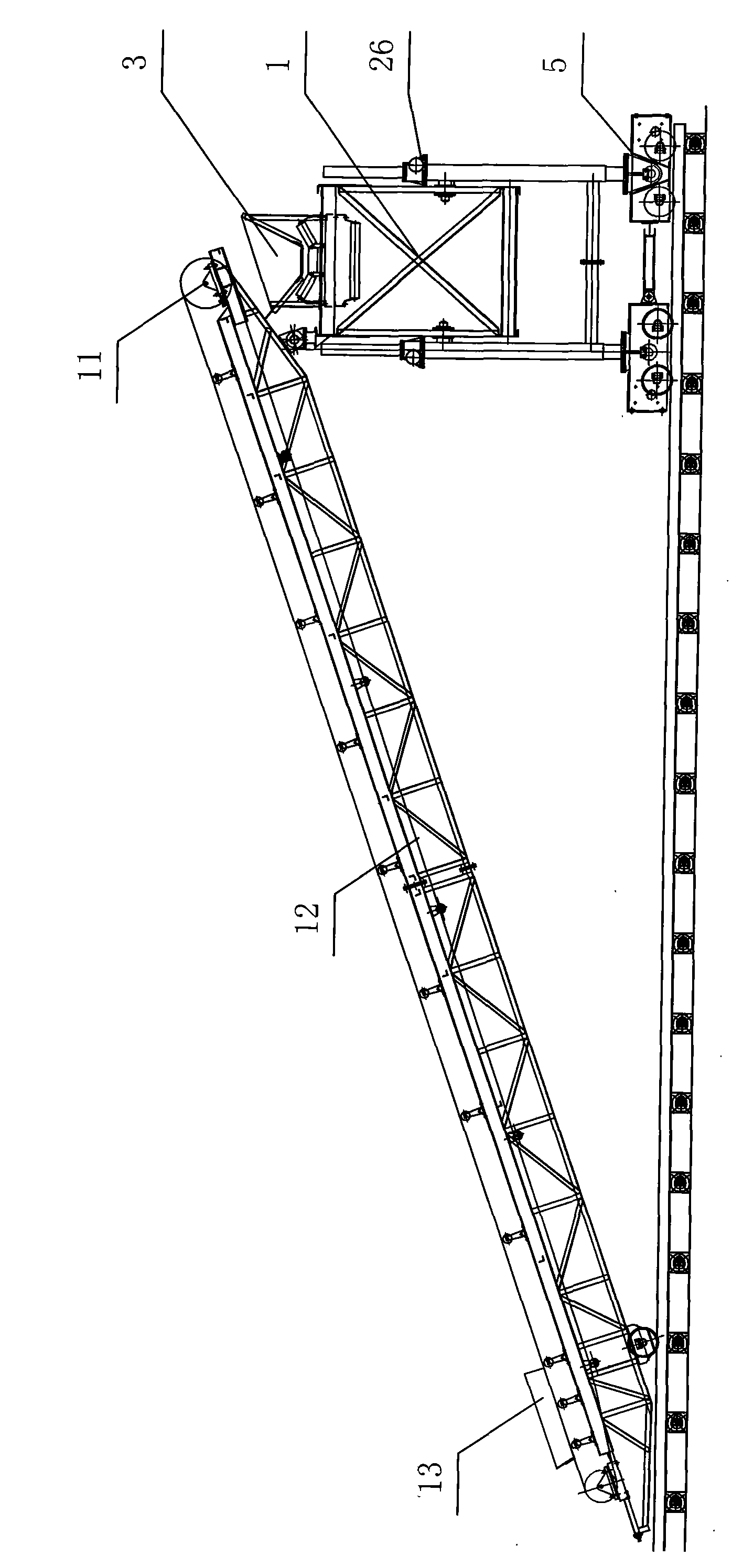

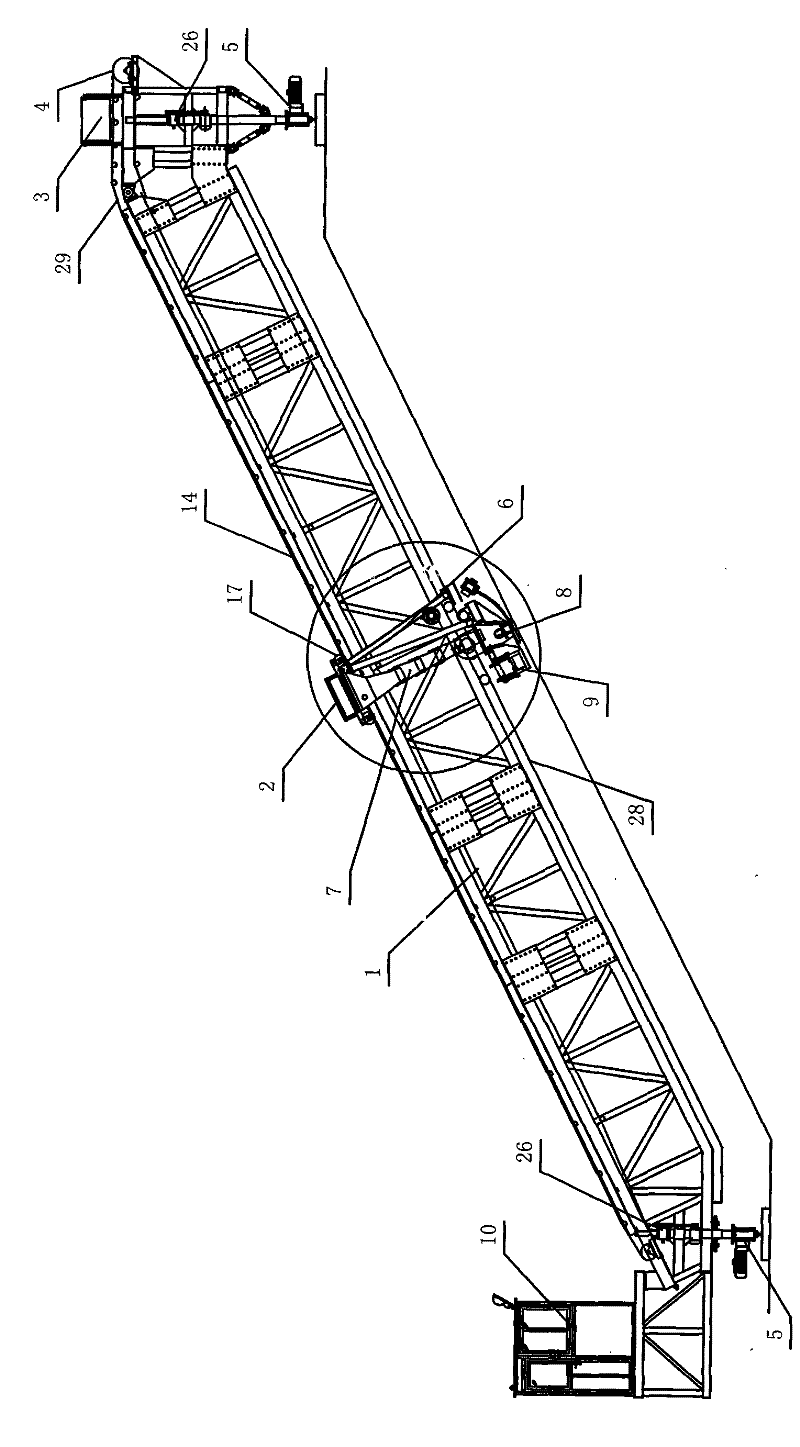

Large-span multifunctional concrete slope masonry machine

InactiveCN101638896AAdjust pressureAutomatically adjust the gapFoundation engineeringSlurryEngineering

The invention relates to a large-span multifunctional concrete slope masonry machine, comprising a main truss, traveling mechanisms arranged at the two ends of the main truss, a main material-receiving hopper, a main belt machine, material-conveying systems arranged on an upper discharging vehicle and a lower discharging vehicle and a forming system arranged on the lower discharging vehicle; and the material-conveying system comprises the main belt machine and a conveying belt arranged on the main truss, a material-dividing slurry scraping device which is arranged on the upper discharging vehicle and is positioned at the upper end of the conveying belt, lower hoppers arranged at the two sides of the lower end of the material-dividing slurry-scraping device, serial drums communicated with the lower hoppers and a material bin on the lower discharging vehicle and a horizontal hinged cage arranged in the material bin. The large-span multifunctional concrete slope masonry machine realizes one-time forming of distributing materials, vibrating and leveling, solves the problems that other types of machines carry out material distributing and vibrating by two steps, the concrete is not easily vibrated to be dense in hot and dry weather if the time interval is excessively long, and the slurry discharging effect of the surface is not good.

Owner:河北省水利工程局集团有限公司

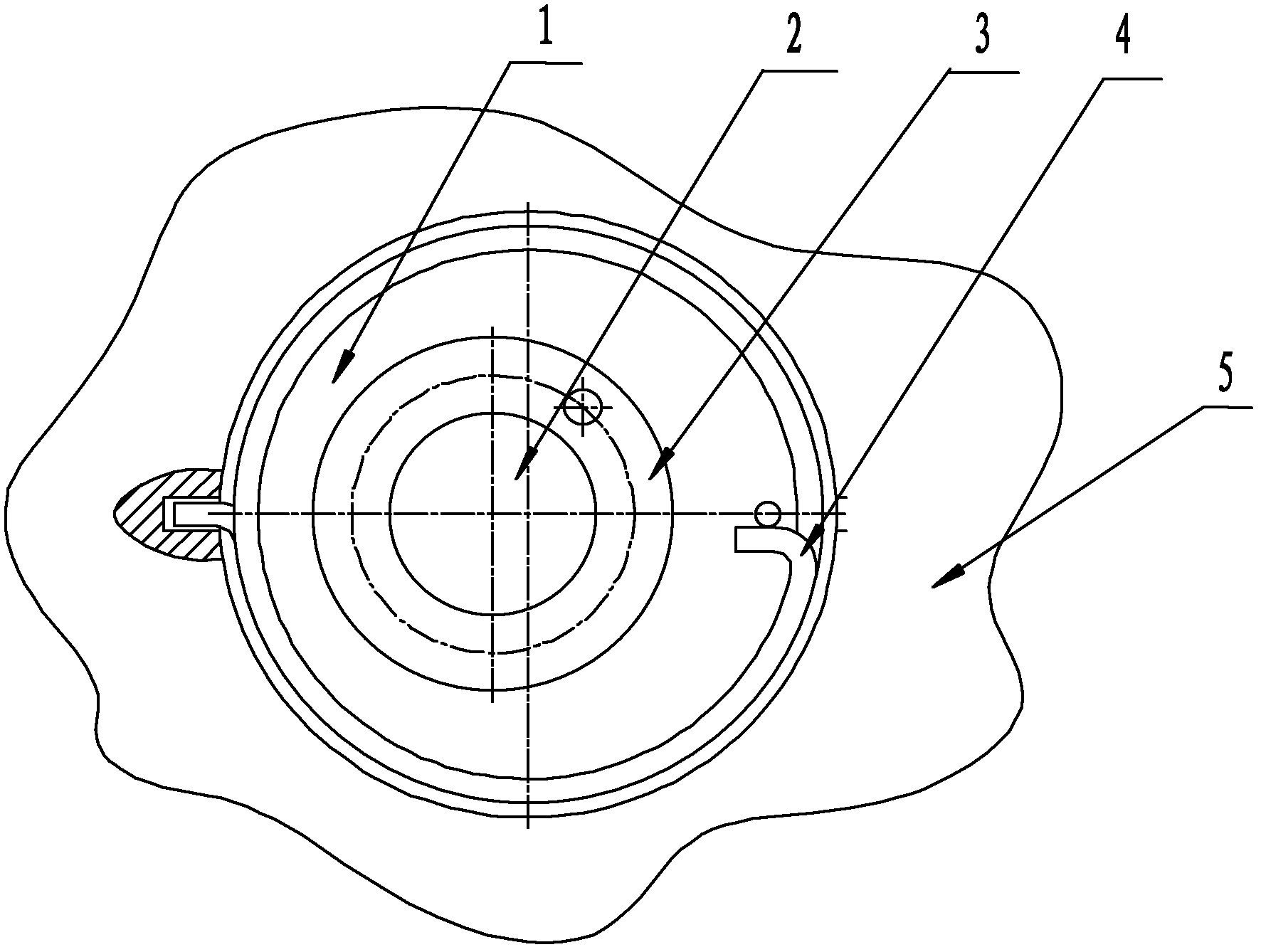

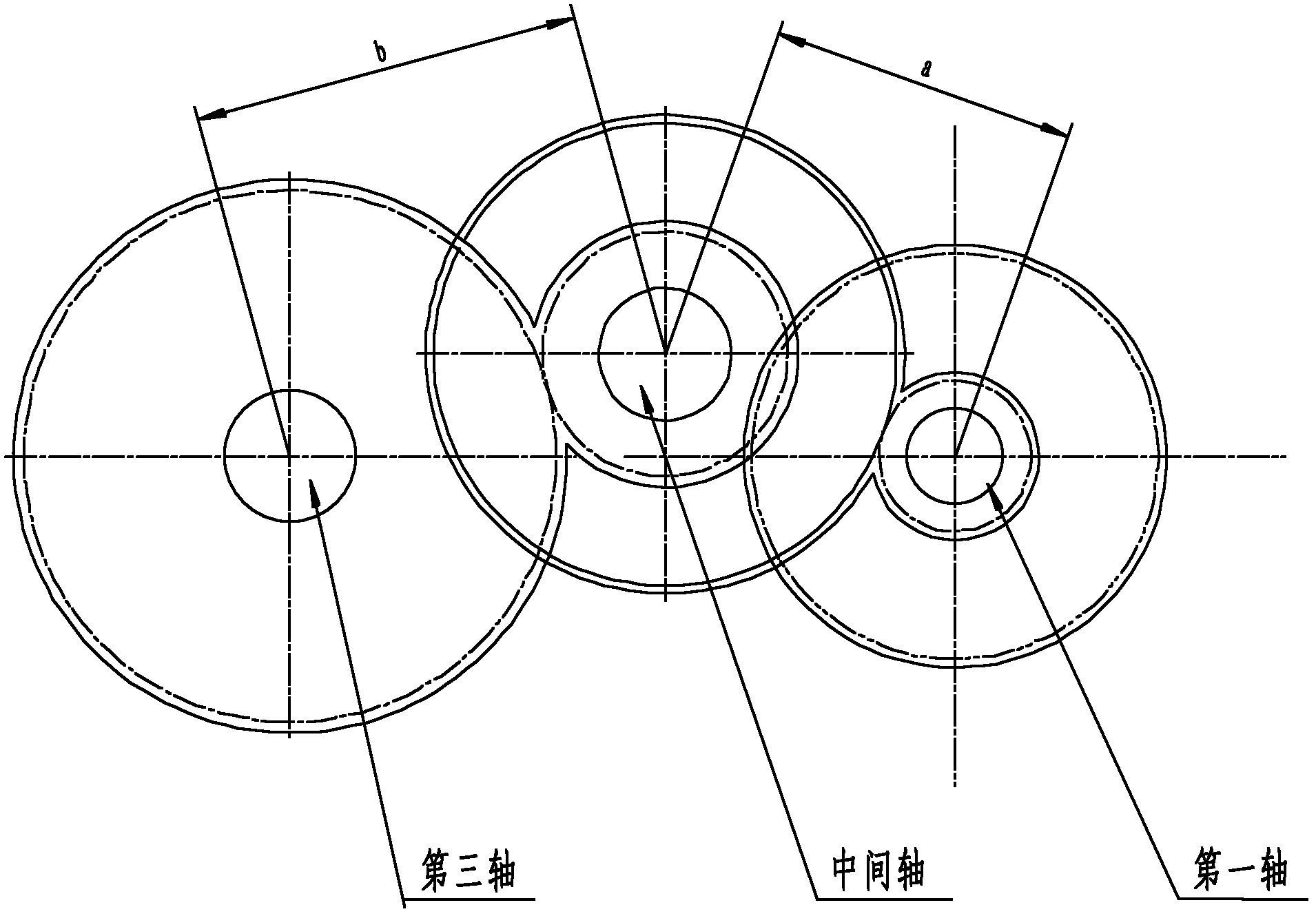

Speed changing box capable of automatically adjusting gear meshing clearance

InactiveCN103104691AReduce or even eliminate drive mesh backlashAutomatically adjust the wheelbaseGearing detailsMedial axisGear wheel

The invention provides a speed changing box capable of automatically adjusting a gear meshing clearance. Main parts of a sample mechanism of the speed changing box mainly comprise a first shaft, a third shaft, a middle shaft 2, a bearing 3, an eccentric bushing 1, a torsional spring 4 and a box body 5. when a gear is abraded to form a clearance, the torsional spring drives the eccentric bushing to rotate in an anticlockwise mode, the position of the middle shaft is enabled to move downwards, the shaft distance a between the middle shaft 2 and the first shaft and the shaft distance b between the middle shaft 2 and the third shaft are reduced, and therefore goals of reduction of the meshing clearance and even elimination of the meshing clearance are achieved.

Owner:徐红旗 +3

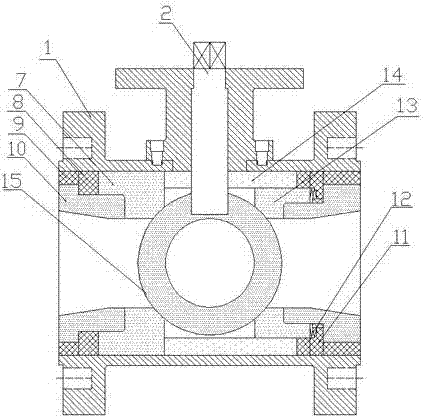

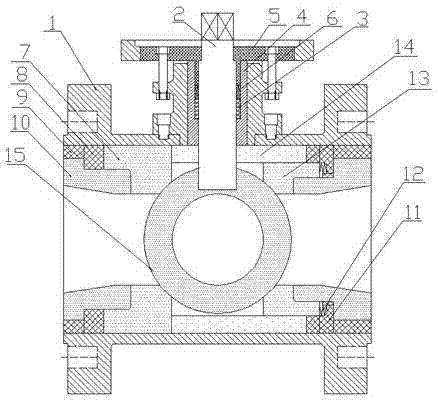

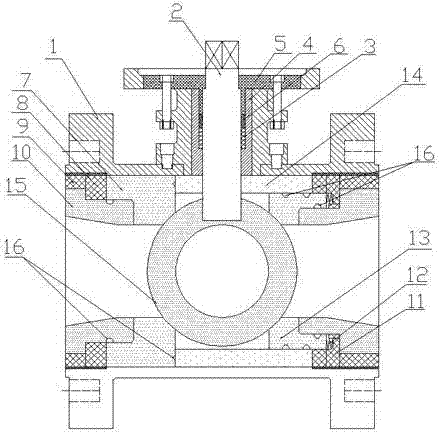

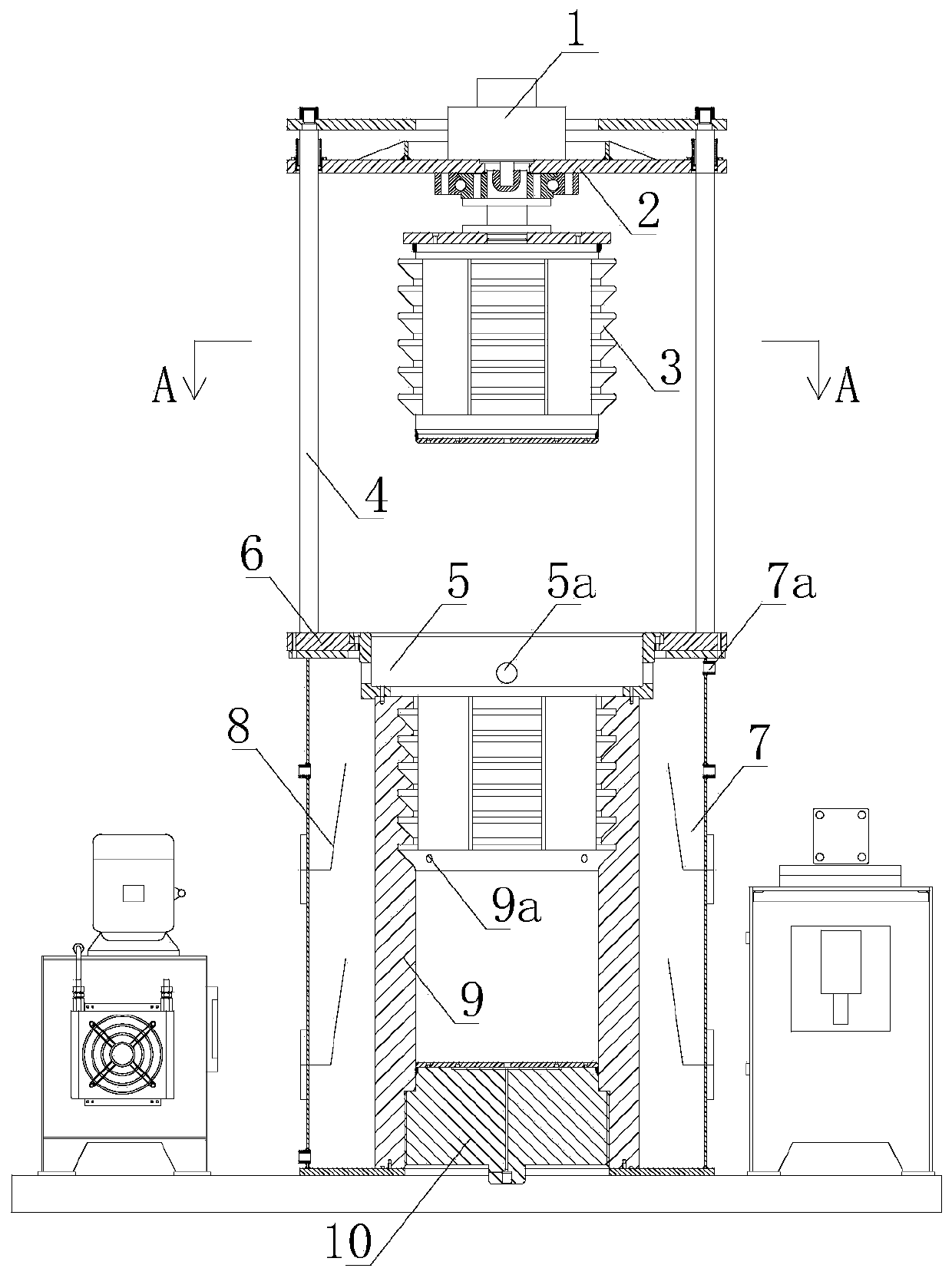

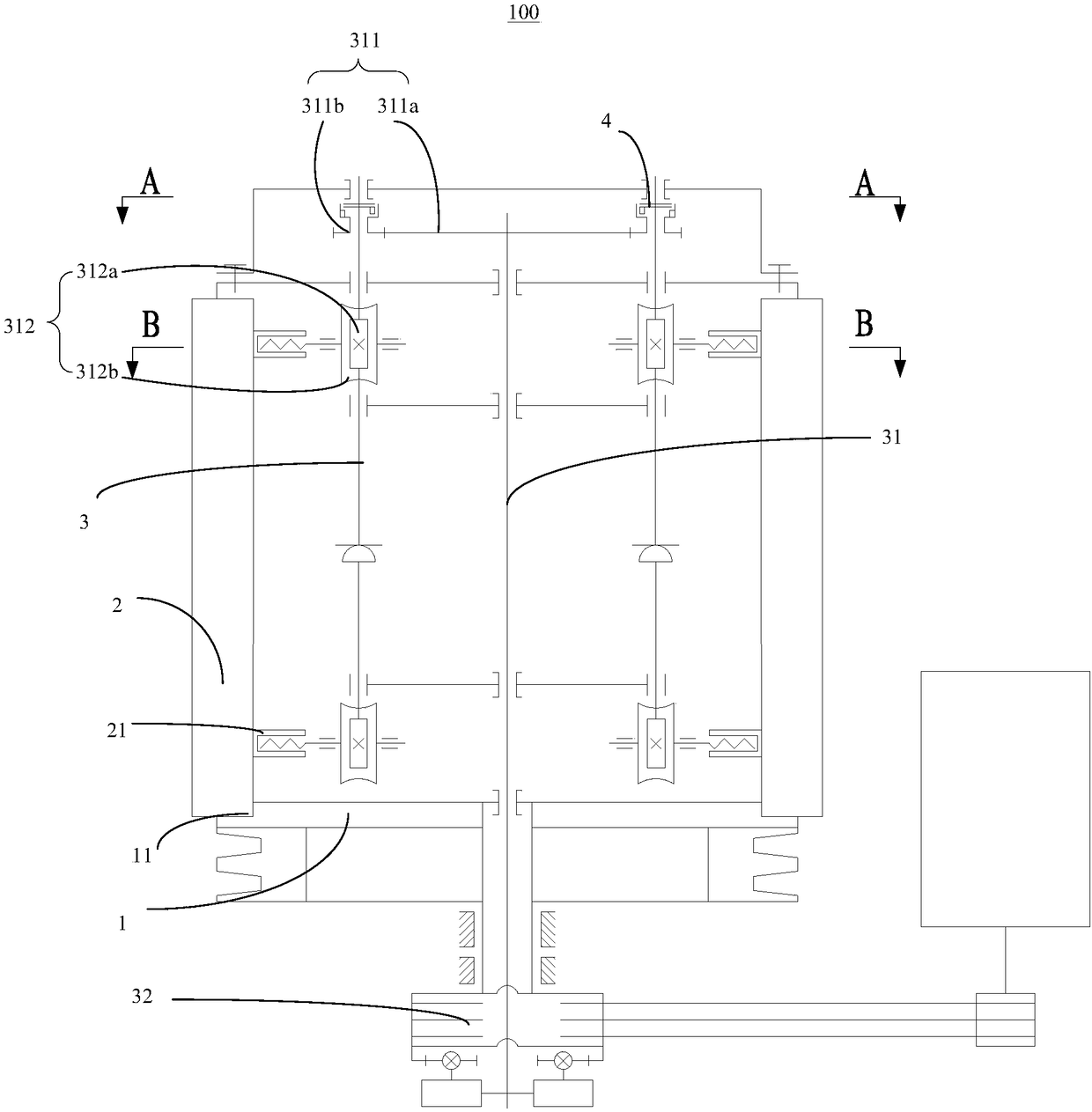

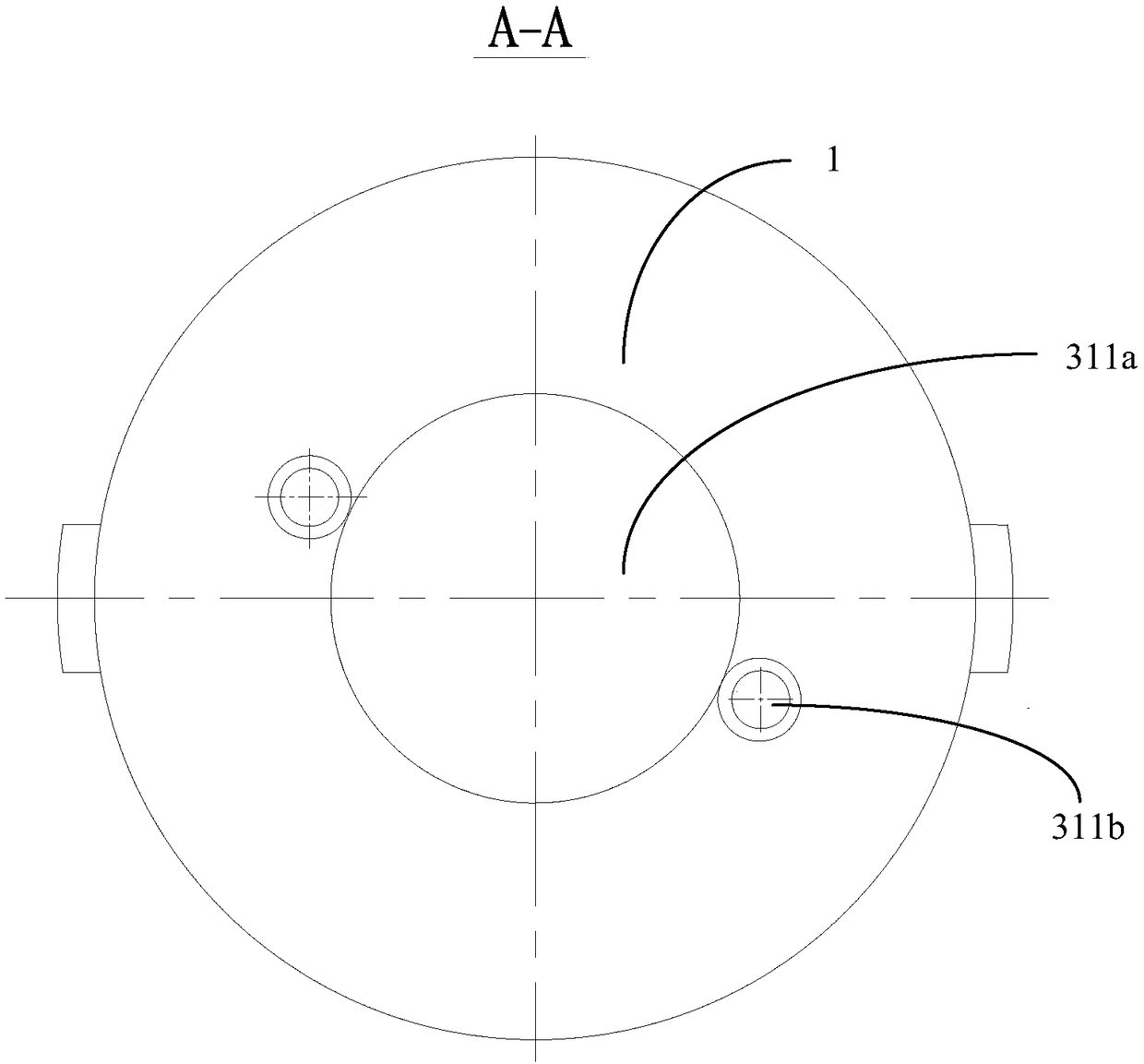

A warm isostatic press

ActiveCN108656620BEasy to assemble and disassembleAvoid damagePressesShaping pressEngineeringCylinder block

The invention belongs to the technical field of isostatic pressing processing equipment and discloses a temperature isostatic pressing machine which keeps temperature constancy of a pressure transfermedium in a cylinder. The temperature isostatic pressing machine comprises a heating charging and discharging system, a working cylinder and an insulating box. The heating charging and discharging system is separately provided with an inlet and an outlet, and the inlet of the heating charging and discharging system is connected to a water tank; the working cylinder comprises a cylinder and an upper end cover assembly and a lower end cover assembly which are hermetically arranged at two ends of the cylinder, separately; a drain hole is formed in the inner wall of the cylinder body, and an outlet communicating to heating charging and discharging system and a hollow channel of the cylinder body are arranged in the lower end cover assembly; the insulating box is arranged between the outer sideof the cylinder body and the inner side of the cylinder body in a sleeved manner and has a gap, and the gap between the insulating box and the cylinder body communicates to the hollow part of the cylinder body through the drain hole; a transitional cover is inserted onto the top end of the insulating box; a positioning spigot for positioning the cylinder body is arranged at the bottom end of thetransitional cover, and a through hole is formed in the inner wall of the transitional cover; and when the upper end cover assembly does not block the cylinder body, and an inner hole of the transitional cover communicates to the hollow part of the cylinder body.

Owner:四川力能超高压设备有限公司

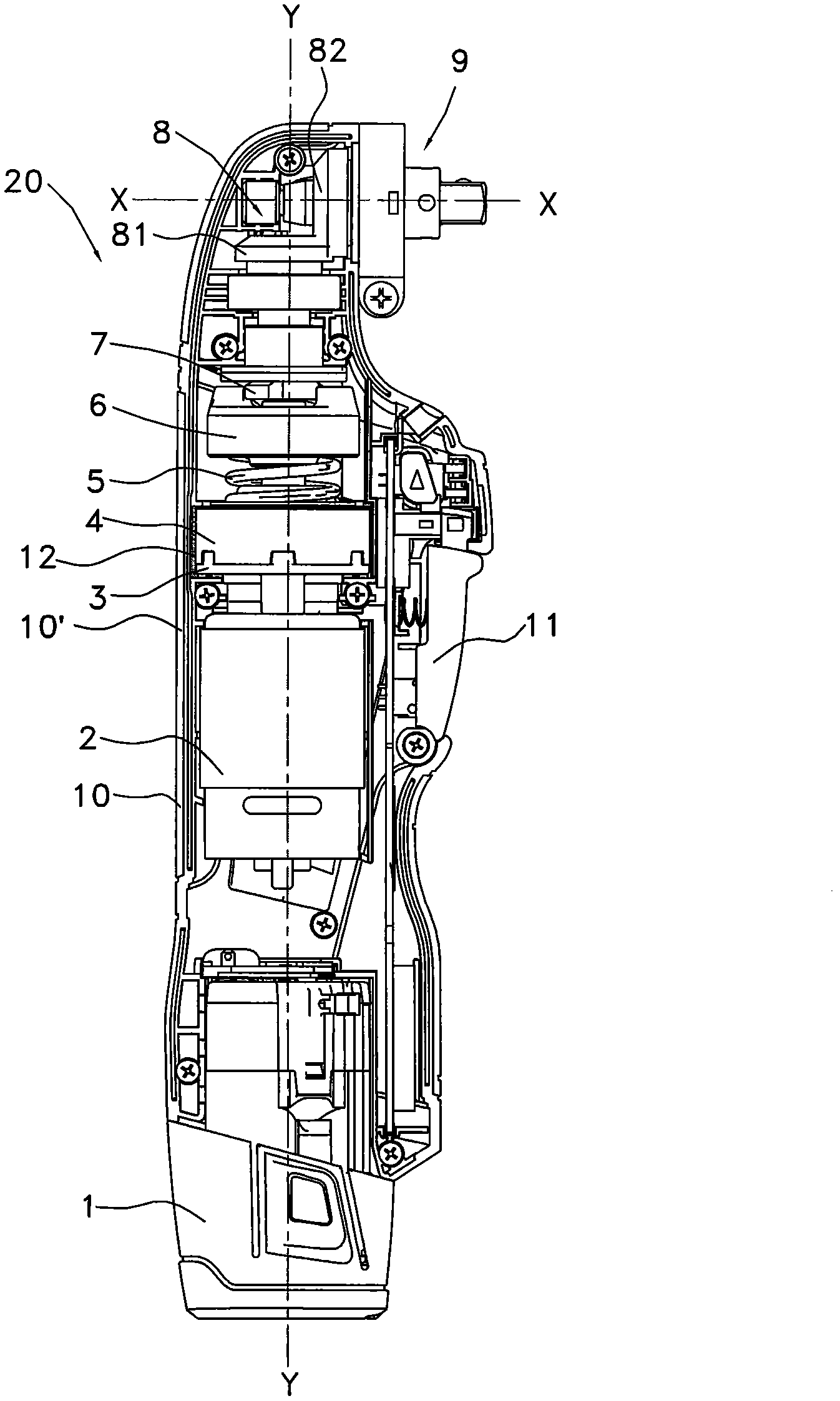

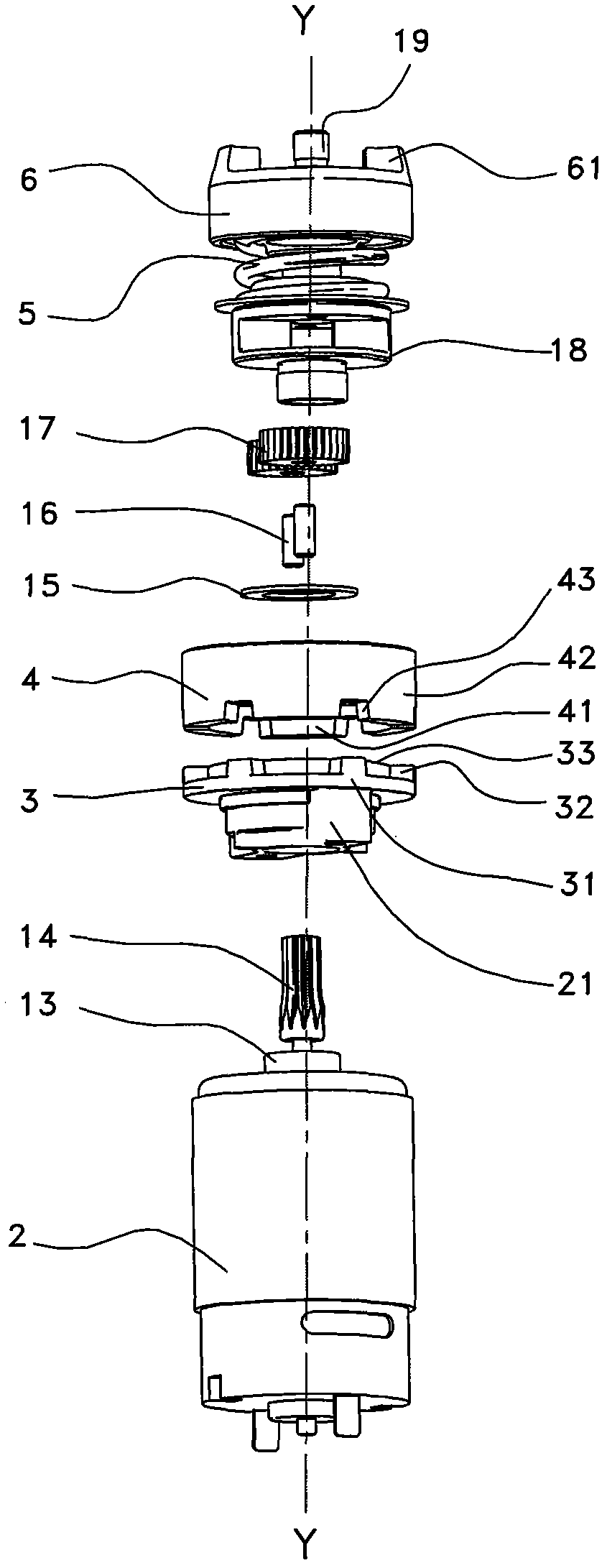

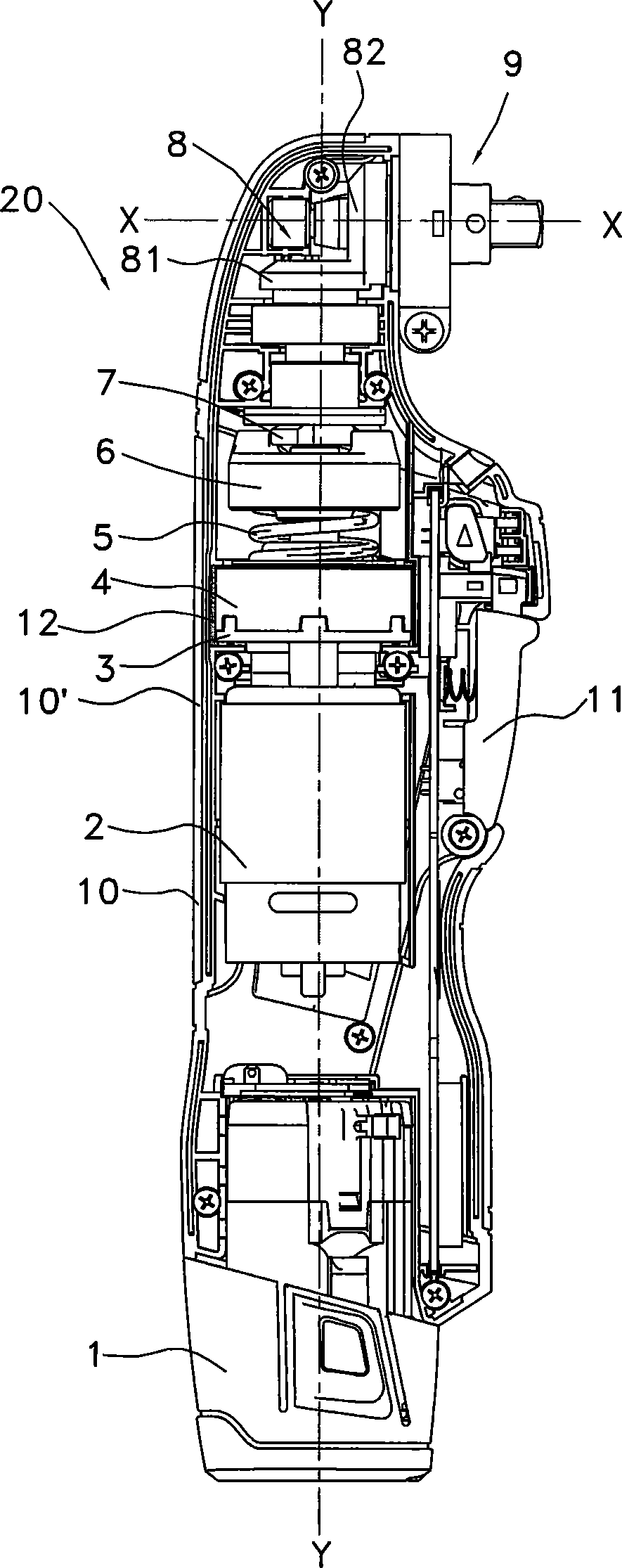

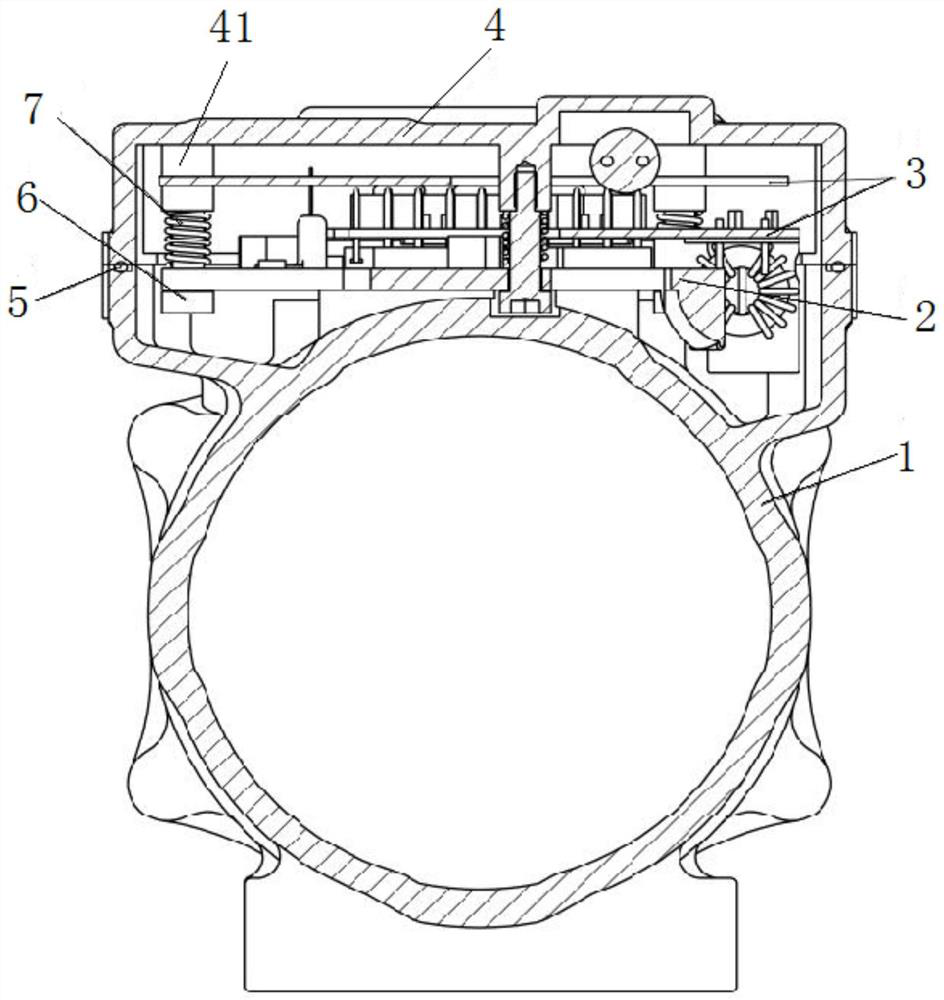

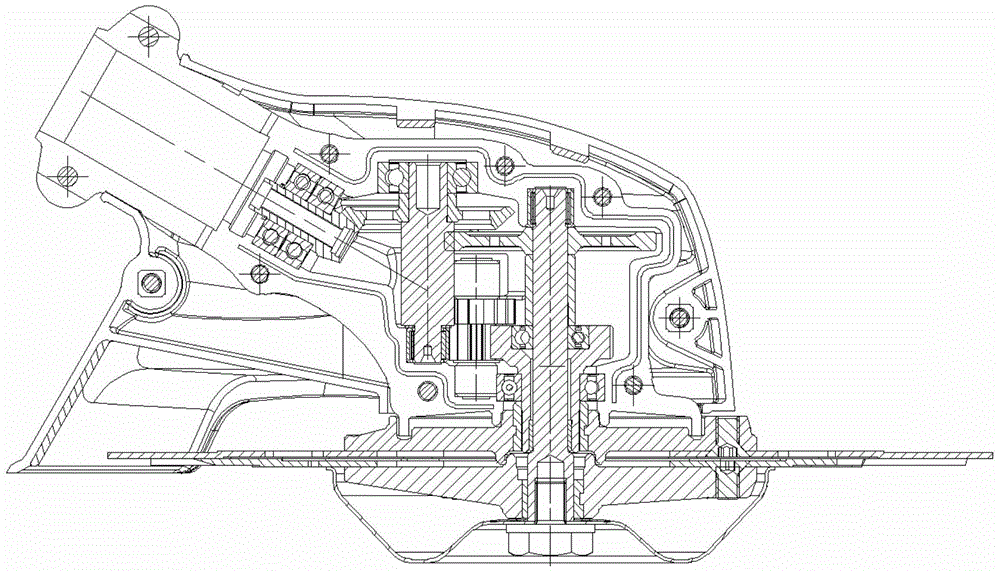

Electric tool

InactiveCN102632483ASavings on gearbox housingsLow costPortable percussive toolsPortable power-driven toolsPower toolElectric machinery

The invention provides an electric tool. The electric tool comprises a shell, a motor placed in the shell and a planet speed reducing mechanism, wherein the planet speed reducing mechanism is provided with a center wheel, a planetary wheel, a planet carrier and a gear ring; and the planet speed reducing mechanism is provided with a gearbox shell in a gapless manner so as to be directly placed in the enclosure. The electric tool can be used for remarkably reducing the radial dimension of a holding part and strengthening the holding comfort feeling of a manipulator, and better accords with man-machine engineering; the traditional gear case shell is omitted, the cost of a part is saved, the structure is simplified, the assembly is convenient, and the production efficiency is improved; and the size and weight of a complete machine are reduced, and the electric tool is more beneficial to operation and carry.

Owner:NANJING CHERVON IND

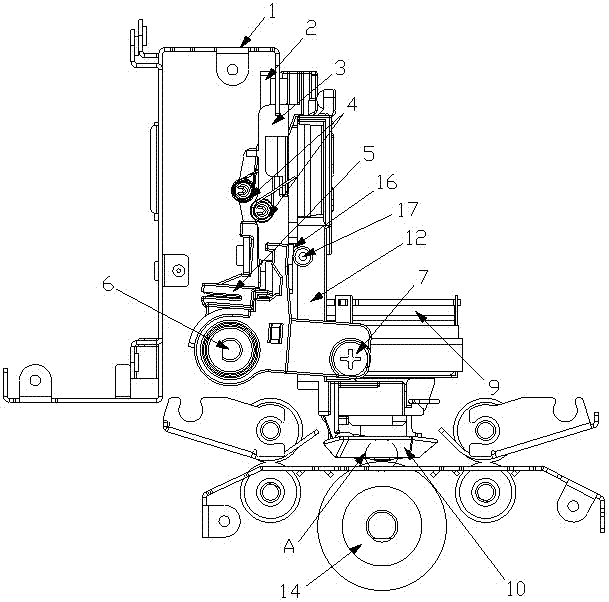

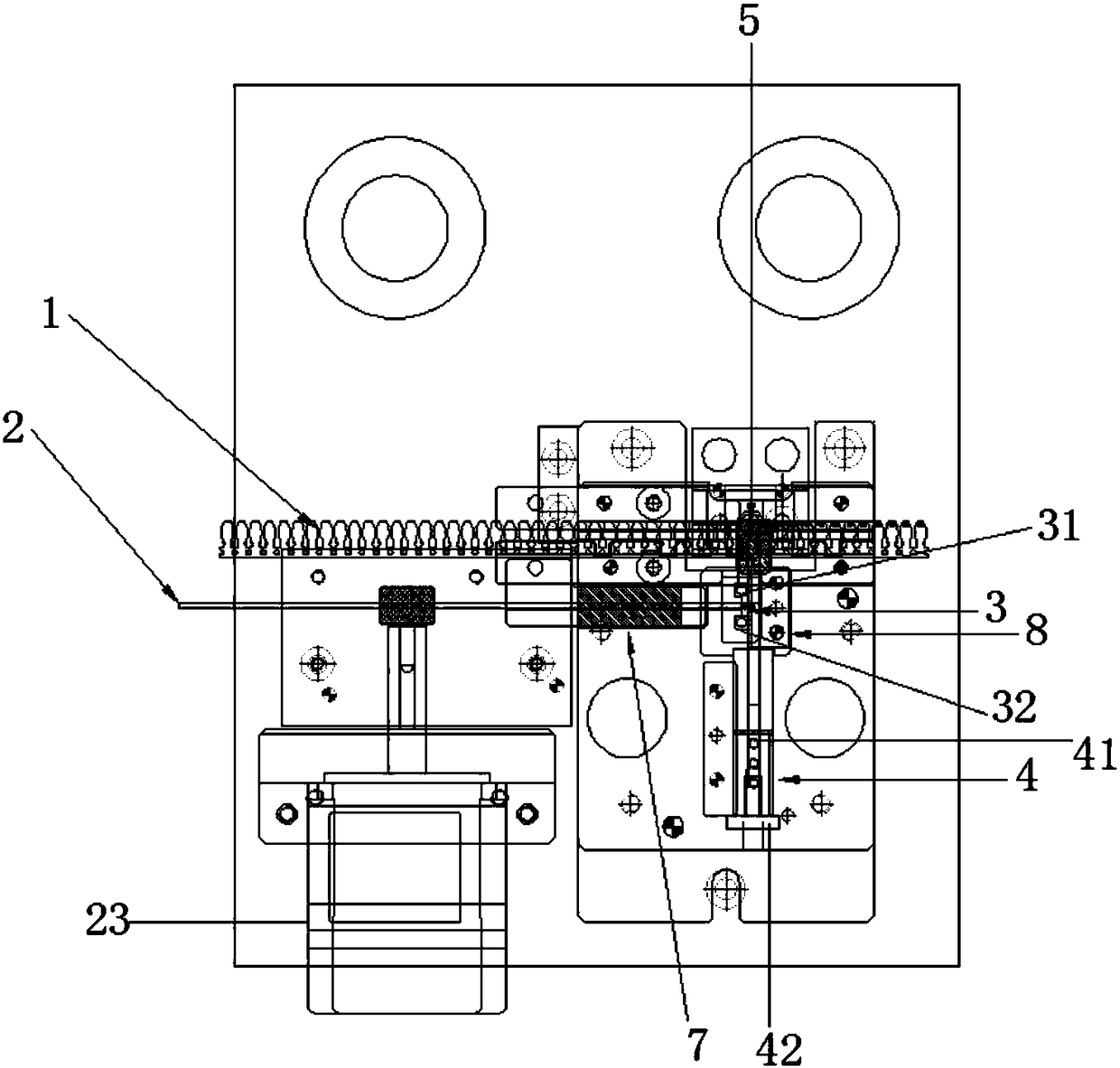

Automatic silver point welding equipment for bimetal sheet of thermal protector

PendingCN108067718ARunning speed is stableThere will be no material jamsWelding/soldering/cutting articlesMetal working apparatusFailure rateDrive wheel

The invention discloses automatic silver point welding equipment for a bimetal sheet of a thermal protector. The automatic silver point welding equipment comprises a bimetal sheet feeding mechanism, asilver belt feeding mechanism, a material cutting mechanism, a material pushing mechanism and a welding mechanism. The bimetal sheet feeding mechanism, the silver belt feeding mechanism, the materialcutting mechanism, the material pushing mechanism and the welding mechanism are respectively fixed on a worktable. The silver belt feeding mechanism includes a conveyor belt, a driving wheel, a driven wheel and a first motor for driving the driving wheel to rotate. The material cutting mechanism includes an upper blade and a lower blade disposed opposite to the upper blade and arranged in dislocation with upper blade. The material pushing mechanism includes a push rod and a cylinder for driving the push rod to move. The welding mechanism includes a positive electrode welding pin and a negative electrode welding pin which are arranged oppositely. According to the equipment, the silver belt feeding mechanism can smoothly convey silver belts to the material cutting mechanism for cutting intosquare silver points to be welded on bimetal sheets, the overall operation speed of the equipment is stable, the phenomenon of material blocking is reduced, the failure rate of equipment operation isreduced, and production efficiency is improved.

Owner:苏州聚生精密冲件有限公司

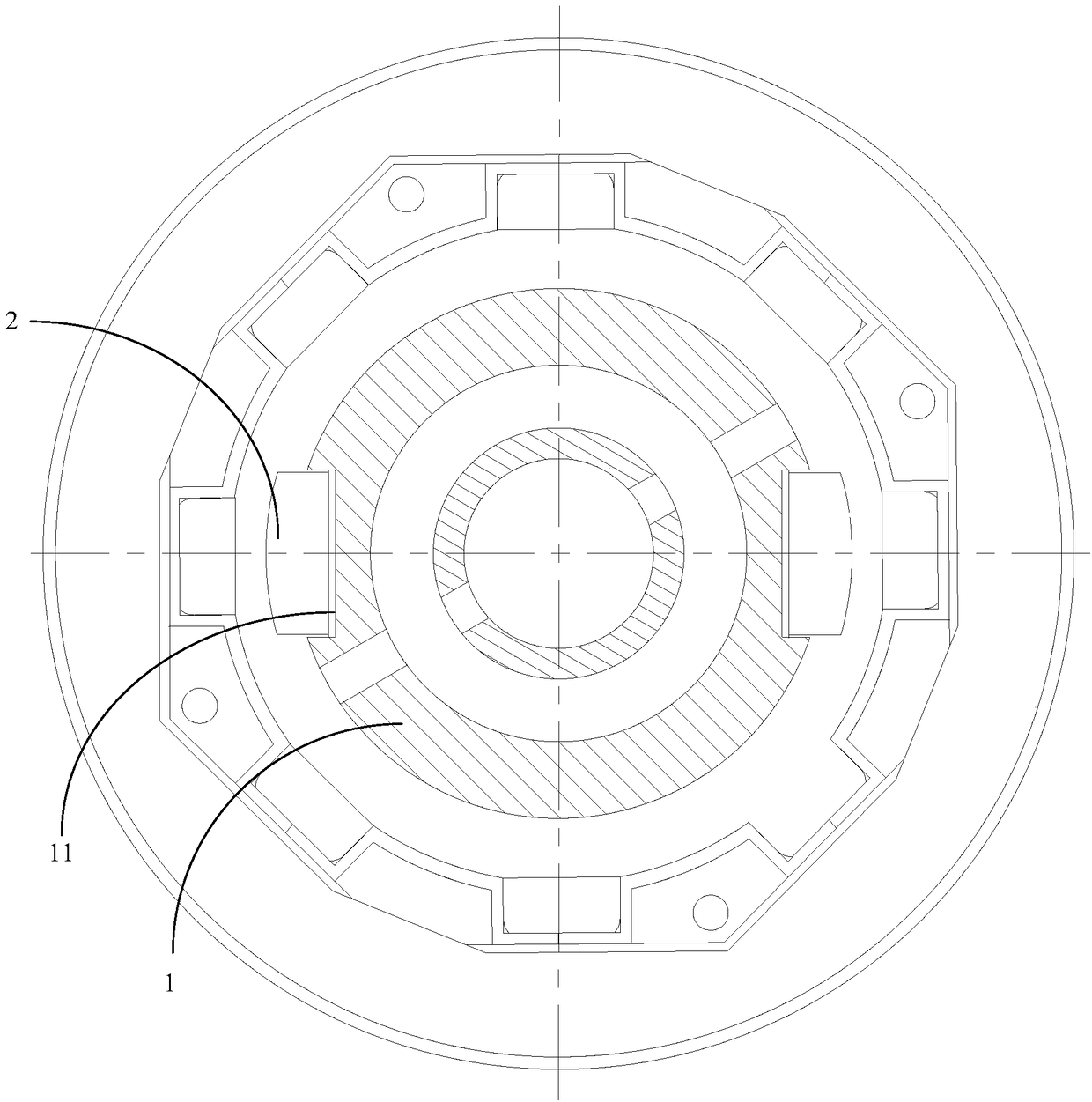

Automatic adjusting device of screw pair of single-screw pump

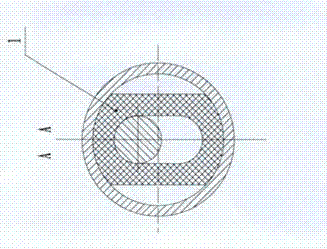

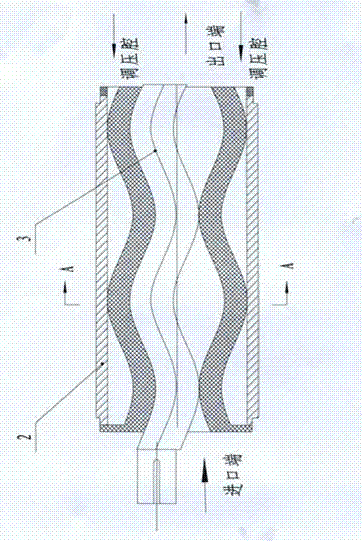

InactiveCN102788015AAutomatically adjust the gapIncrease pressureRotary piston pumpsRotary piston liquid enginesClassical mechanicsEngineering

The invention relates to an automatic adjusting device of a screw pair of a single-screw pump. The automatic adjusting device comprises a stator 1, a stator steel hoop 2 and screws 3. The stator 1 is fixed into the stator steel hoop 2, and a pressure adjusting cavity extending along threaded helixes of the stator 1 and the stator steel hoop 2 is formed between the stator 1 and the stator steel hoop 2. The automatic adjusting device has the advantages that a gap of the screw pair can be adjusted automatically according to the pressure at an outlet end, pressure on the screw pair is increased, leakage is reduced, volumetric efficiency is enhanced, and 1.2MPa pressure can be generated by the one-level single screw pair.

Owner:重庆明珠机电有限公司

a rice mill

ActiveCN107552126BAutomatically adjust the gapAvoid precisionGrain huskingGrain polishingAgricultural engineering

The invention discloses a rice milling machine. The rice milling machine comprises a milling roller, a milling sharpener, a feeding device and a controller, wherein the milling sharpener is movably mounted on the milling roller in the radial direction of the milling roller; the feeding device comprises a transmission mechanism and a driving device; the transmission mechanism is connected with themilling sharpener; the driving device is connected with the transmission mechanism and is used for driving the transmission mechanism to enable the milling sharpener to be moved in the radial direction of the milling roller; and the controller is electrically connected with the driving device. According to the rice milling machine disclosed by the invention, the problems that the milling sharpenerneeds to be manually adjusted and the efficiency is low in the prior art are solved.

Owner:湖北永捷粮油机械股份有限公司

Engineering plate high-efficiency corner transmission equipment with wide adaptability

ActiveCN112607304AWide range of sizesFast deliveryConveyorsControl devices for conveyorsControl engineeringControl theory

The invention discloses engineering plate high-efficiency corner transmission equipment with wide adaptability. The equipment comprises a feeding roller conveying device which is used for conveying material parts according to a first direction, a corner belt conveying device which is arranged at an outlet of the feeding roller conveying device and conveys the material parts in the second direction, and a plurality of unpowered wheel sets; the second direction is perpendicular to the first direction; each unpowered wheel set comprises a plurality of unpowered wheel bodies, and the unpowered wheel bodies are arranged in the first direction, so that the material parts borne on the unpowered wheel bodies can move in the first direction under inertia, and the unpowered wheel sets are arranged at the discharging position of the feeding roller conveying device; and the unpowered wheel sets can ascend and descend, and the bearing faces of the unpowered wheel sets can stay at least at the first height and the second height.

Owner:豪德机械(上海)有限公司

Bearing supporting mechanism for double-edge bidirectional rotating mowing machine

The invention relates to a bearing supporting mechanism for a double-edge bidirectional rotating mowing machine. The bearing supporting mechanism comprises a lower blade, a bottom hood and an output shaft. A center hole of the lower blade is installed on the output shaft. A disc spring and the bottom hood are arranged below the bottom end of the lower blade. The top of the disc spring is in contact with the outer circle of the bottom end of the lower blade to enable the lower blade to be isolated from the end part of the outer side of the bottom hood. The bottom of the disc spring is arranged at the upper end of a bearing. The disc spring is supported by the bearing and is tightly pressed on the bottom end of the lower blade. The left end and the right end of the bearing are respectively fastened on the output shaft and the inner side shell of the bottom hood. The bearing is tightened at the end of the output shaft through a bolt. The bearing supporting mechanism for the double-edge bidirectional rotating mowing machine has the advantages that since the bottom hood and the blade are separated from each other through the disc spring and the bottom hood and the output shaft are separated from each other through the bearing, the effect that the bottom hood does not rotate is realized, the collision between the bottom hood and the bottom and hard objects such as stones due to contact is eliminated, and the phenomenon that the bottom hood is cracked or seriously worn is avoided.

Owner:NINGBO LIHAO MACHINERY

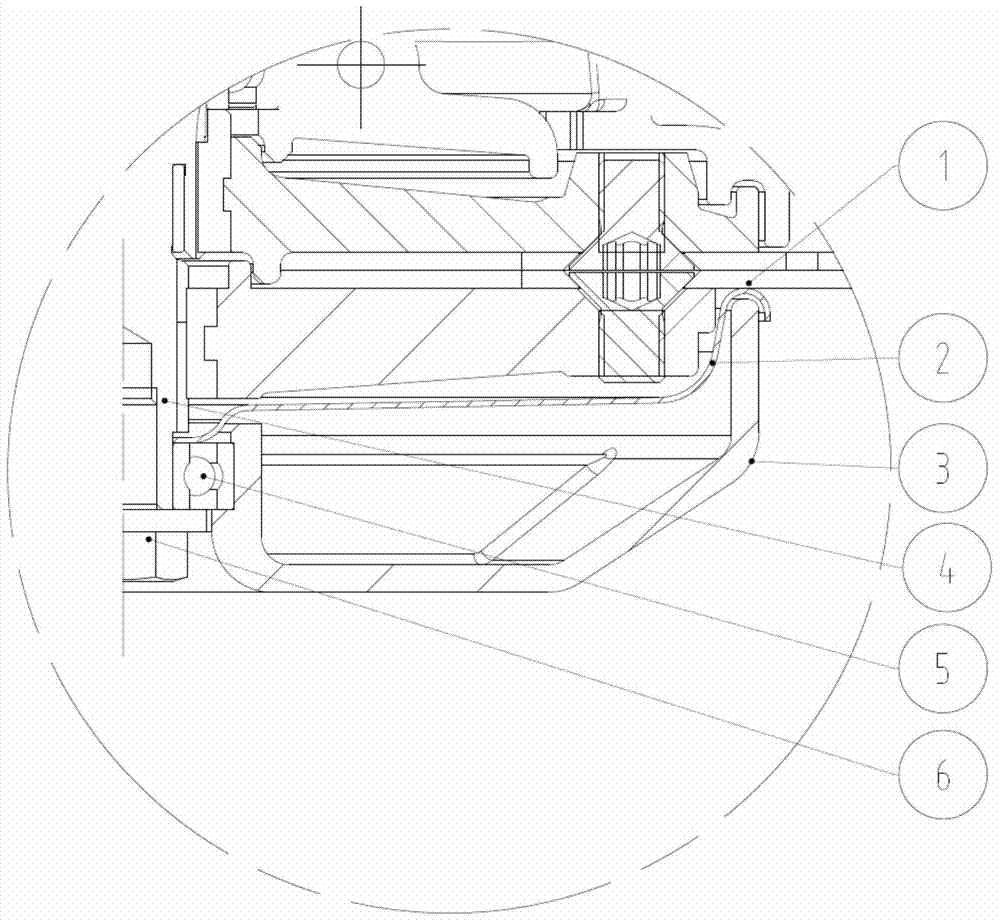

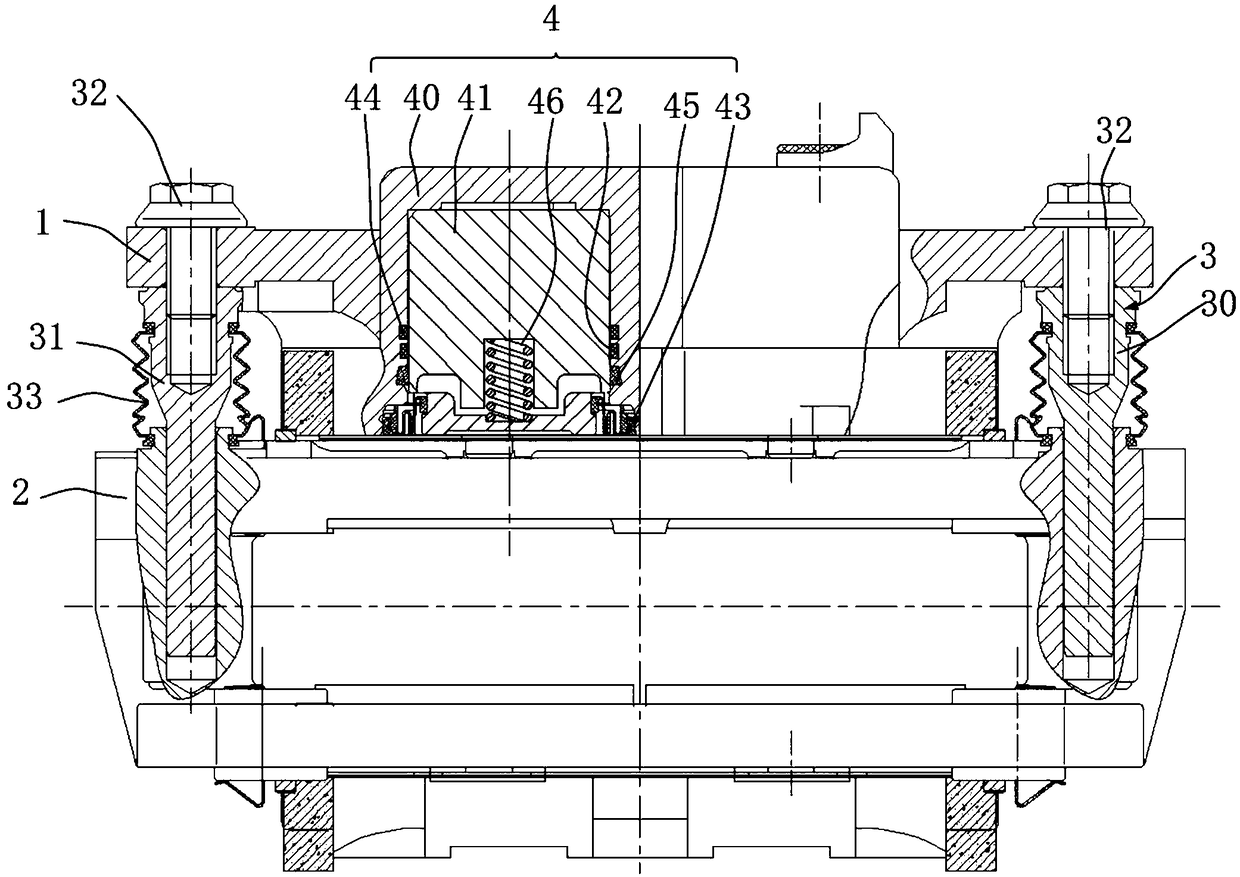

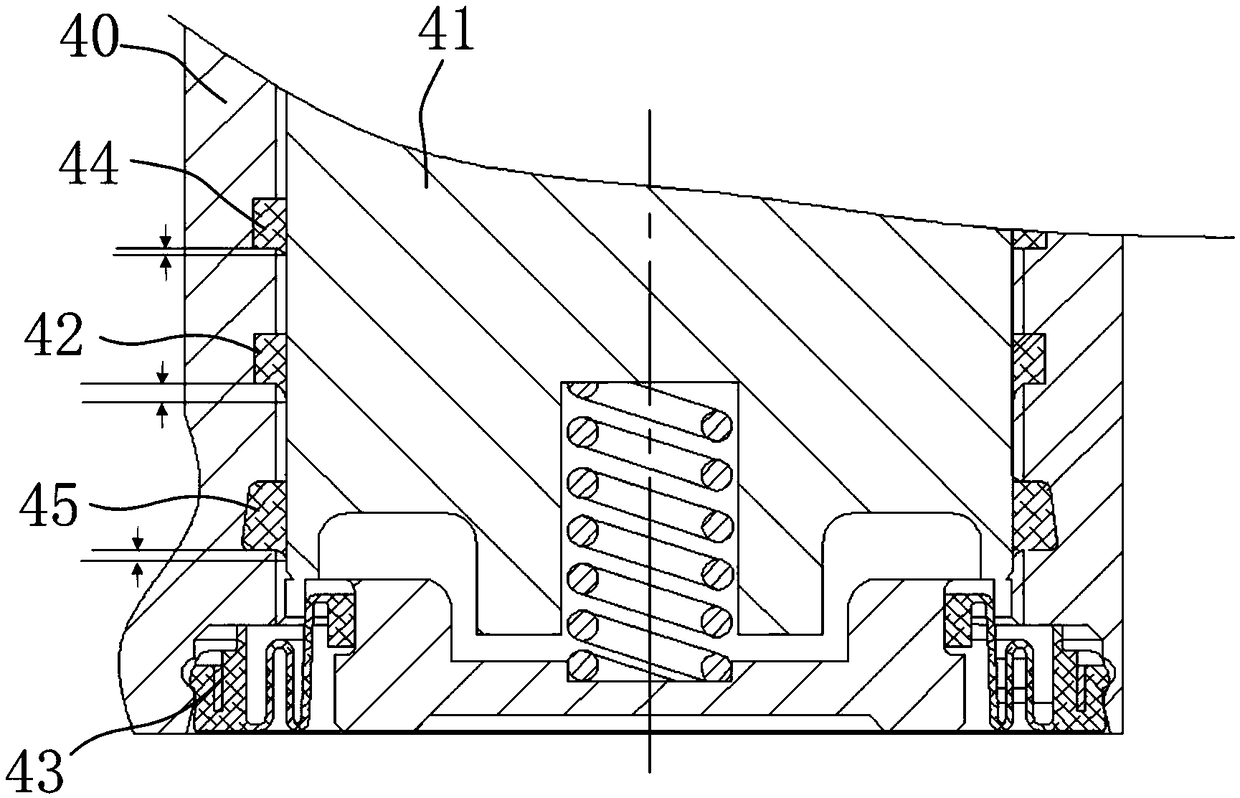

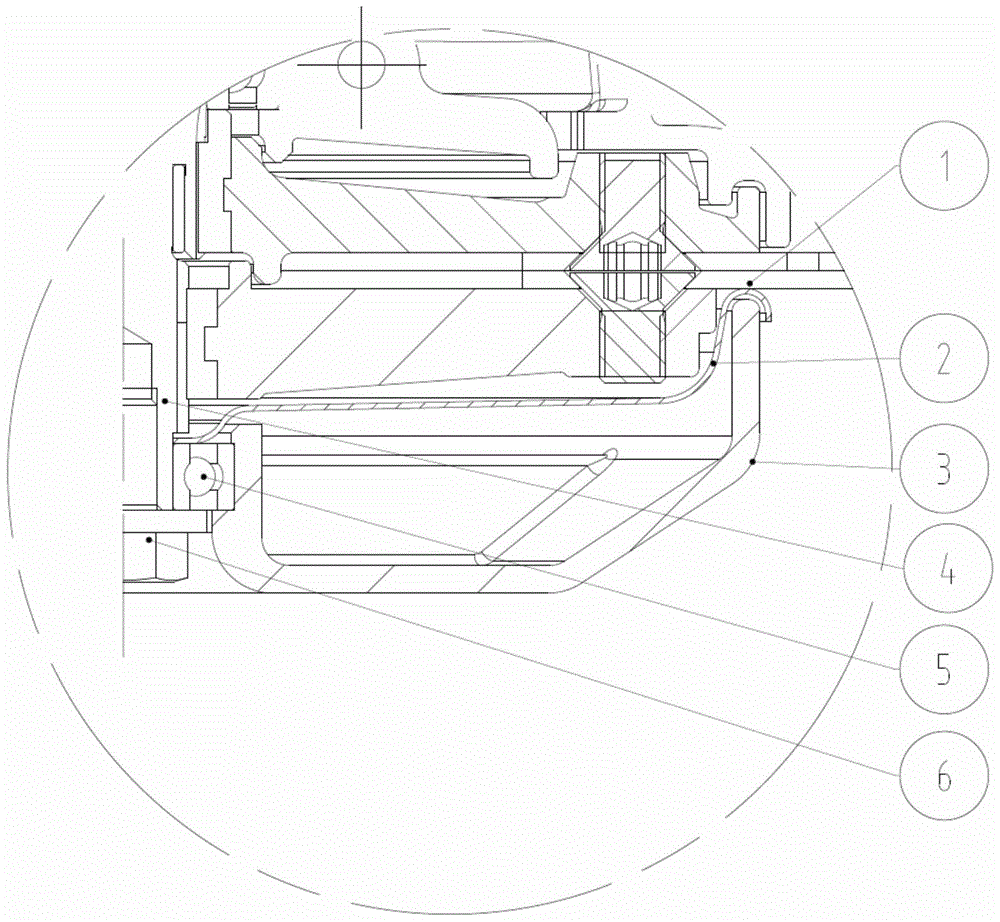

Disc brake caliper

InactiveCN109296679AStay flexibleGuaranteed wear resistanceBrake actuating mechanismsActuatorsHydraulic cylinderEngineering

The invention relates to a disc brake caliper, and belongsto the field of a vehicle brake system. The disc brake caliper ischaracterized bycomprising a brake caliper (1), a brake caliper bracket (2),a sliding shaft (3), a main sliding shaft (30), an auxiliary sliding shaft (31), a sliding shaft bolt (32), a sliding shaft dustproof cover (33) and a hydraulic cylinder (4); the hydraulic cylinder (4) comprises a hydraulic cylinder body (40), a piston (21), a piston sealing ring (42), a piston dustproof ring (43), a guide ring (44), a wearing ring (45), a return spring (46), a stop spring (5) anda friction block assembly (6). The disc brake caliper provided by the invention adopts a structure that the piston sealing ring is combined with the guide ring and the wearing ring, so that the guidefunction is additionally achieved, and the service life of the piston sealing ring is prolonged; meanwhile, the accurate returning of the piston can be ensured by adopting the piston with the structure of the wearing ring and the guide ring; and then the gap can be adjusted automatically.

Owner:HUNAN YUNDA MACHINERY MFG

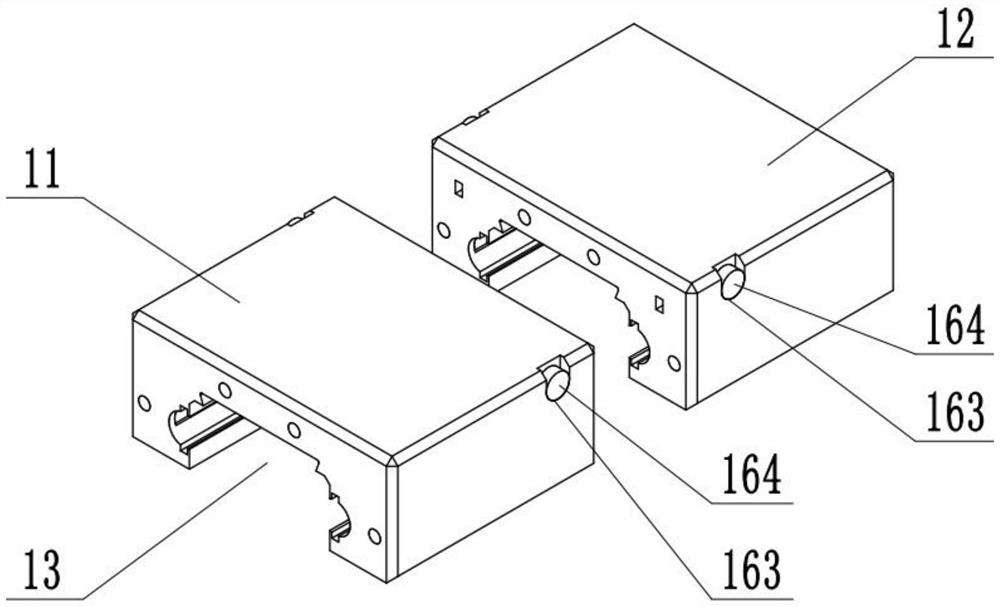

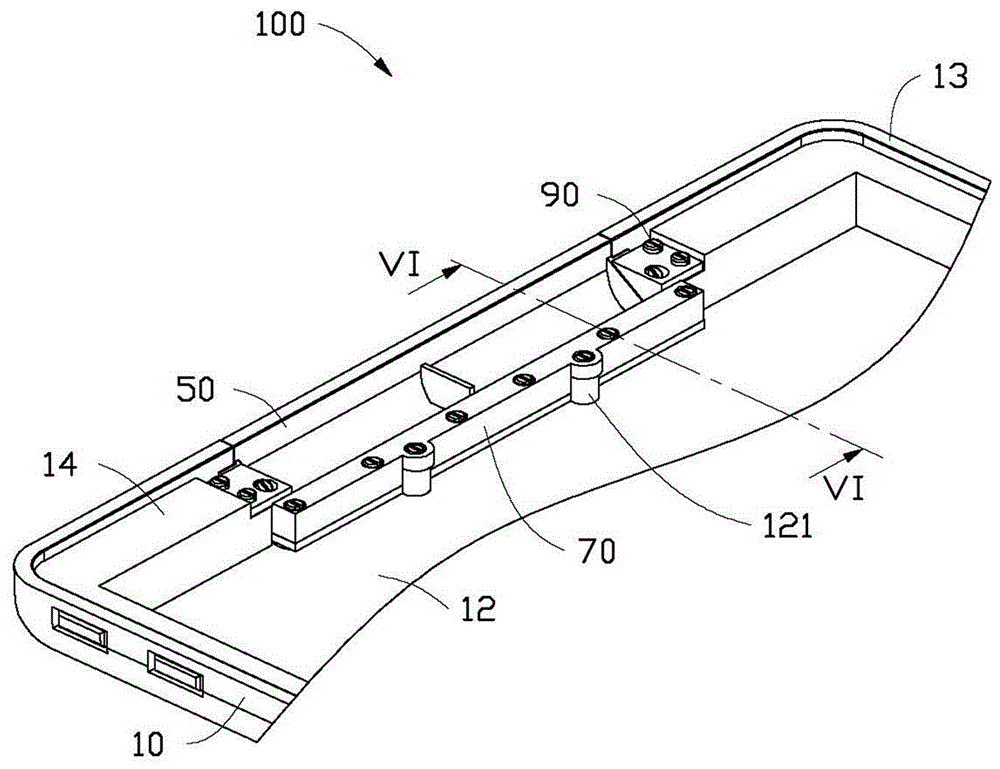

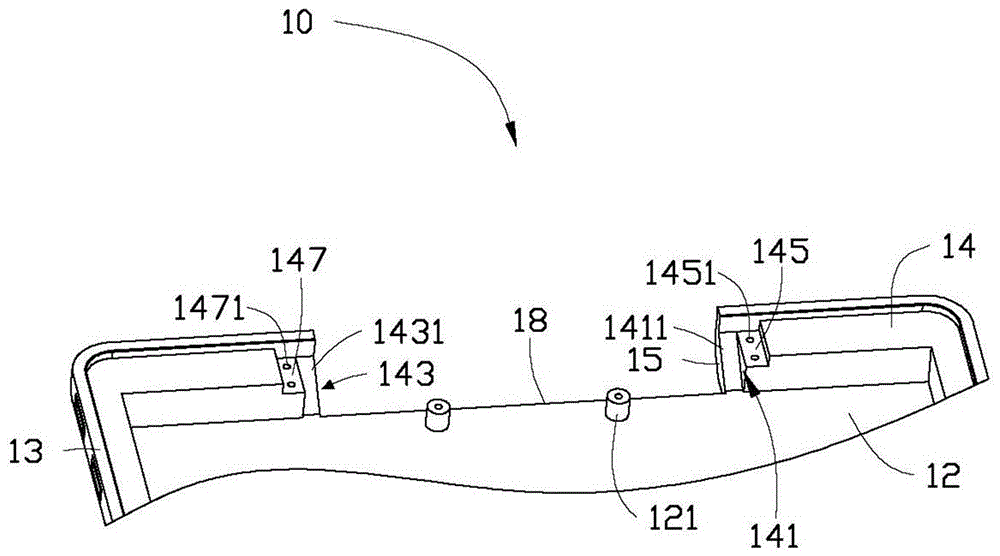

Installation structure of the controller for the scroll compressor of the automobile electric air conditioner

ActiveCN109552003BEffectively fixedAutomatically adjust parallelismAir-treating devicesVehicle heating/cooling devicesControl theoryMechanical engineering

The invention discloses a controller installation structure for a scroll compressor of an electric power air conditioner of an automobile. The structure comprises a compressor mother body, a bracket, a controller integrated circuit, an upper cover, a plug screw and a spring, and is characterized in that: the A cavity is formed on the outer side of the compressor body and the upper cover, the inner top of the upper cover is provided with a threaded mounting hole, the mounting hole is fixedly connected with a plug screw, and the plug screw is provided with a bracket , a controller integrated circuit is fixed on the bracket, and a spring is sleeved on the plug screw between the bracket and the threaded mounting hole. Compared with the prior art, the mounting bracket of the controller has the function of automatically adjusting the height, which can make the bracket and the compressor mother body fit completely, greatly improve the heat dissipation efficiency, and greatly reduce the probability of damage to the controller integrated circuit.

Owner:江西悦轮科技有限公司

A bearing support structure applied to a double-blade bidirectional rotary lawn mower

Owner:NINGBO LIHAO MACHINERY

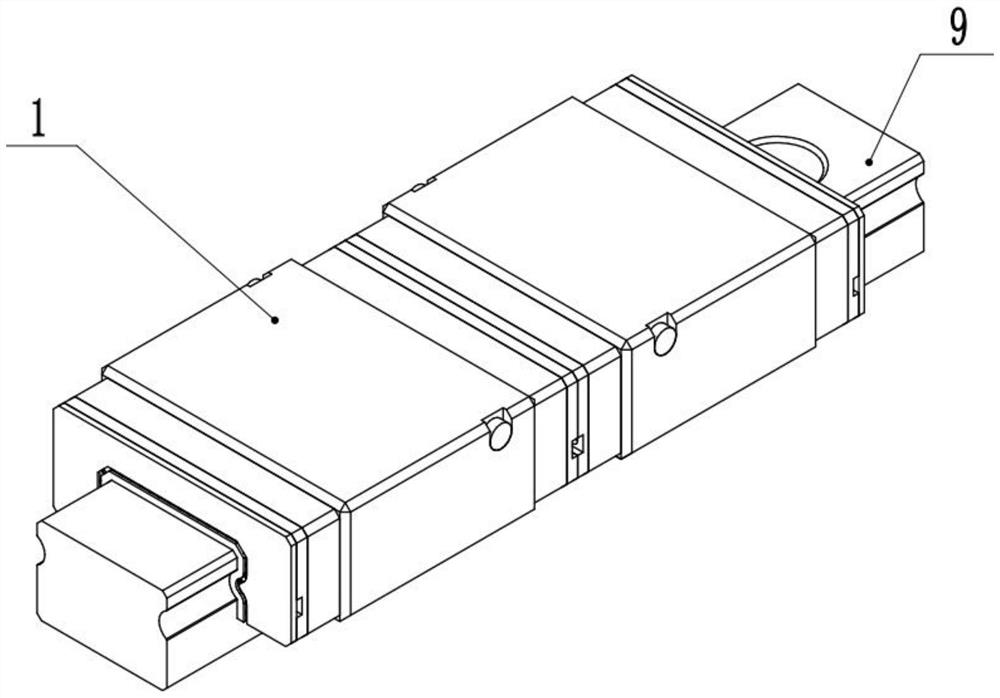

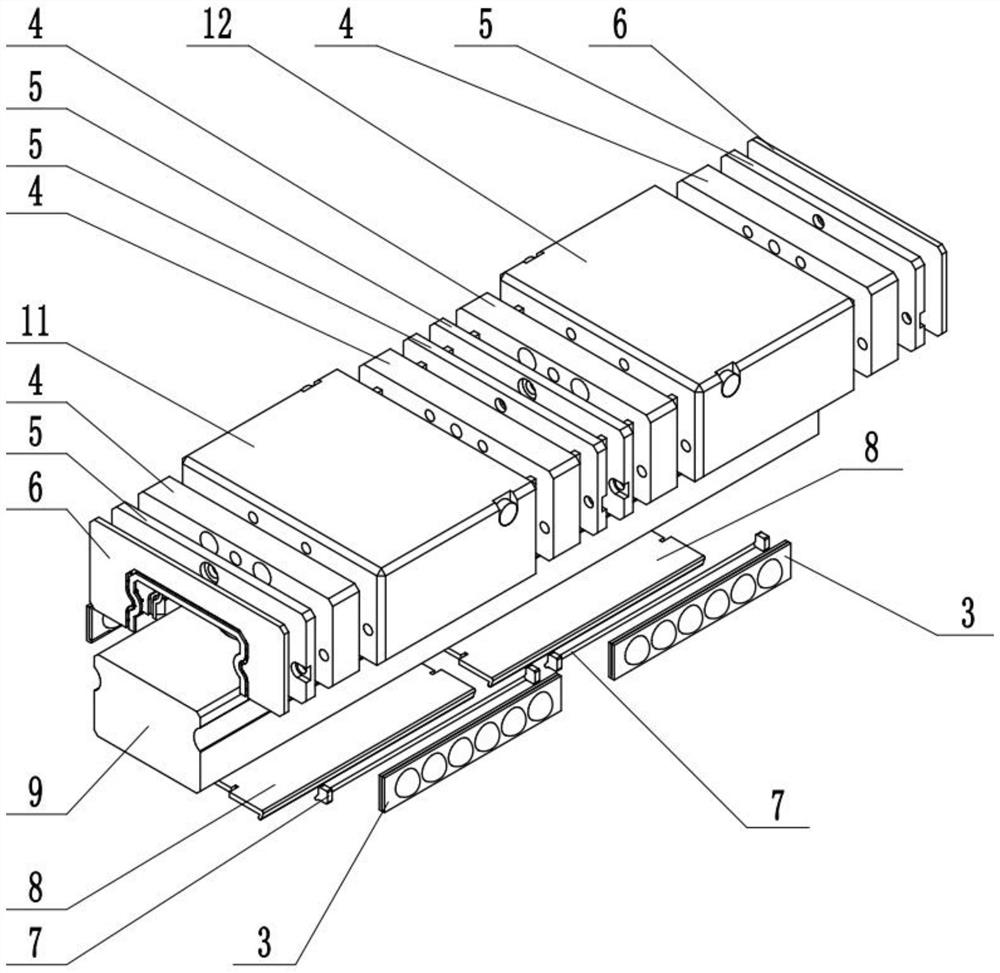

Combined telescopic sliding block

PendingCN113618975AMeet the needs of different lengthsWear effectControl theoryMechanical engineering

Owner:浙江健壮传动科技有限公司

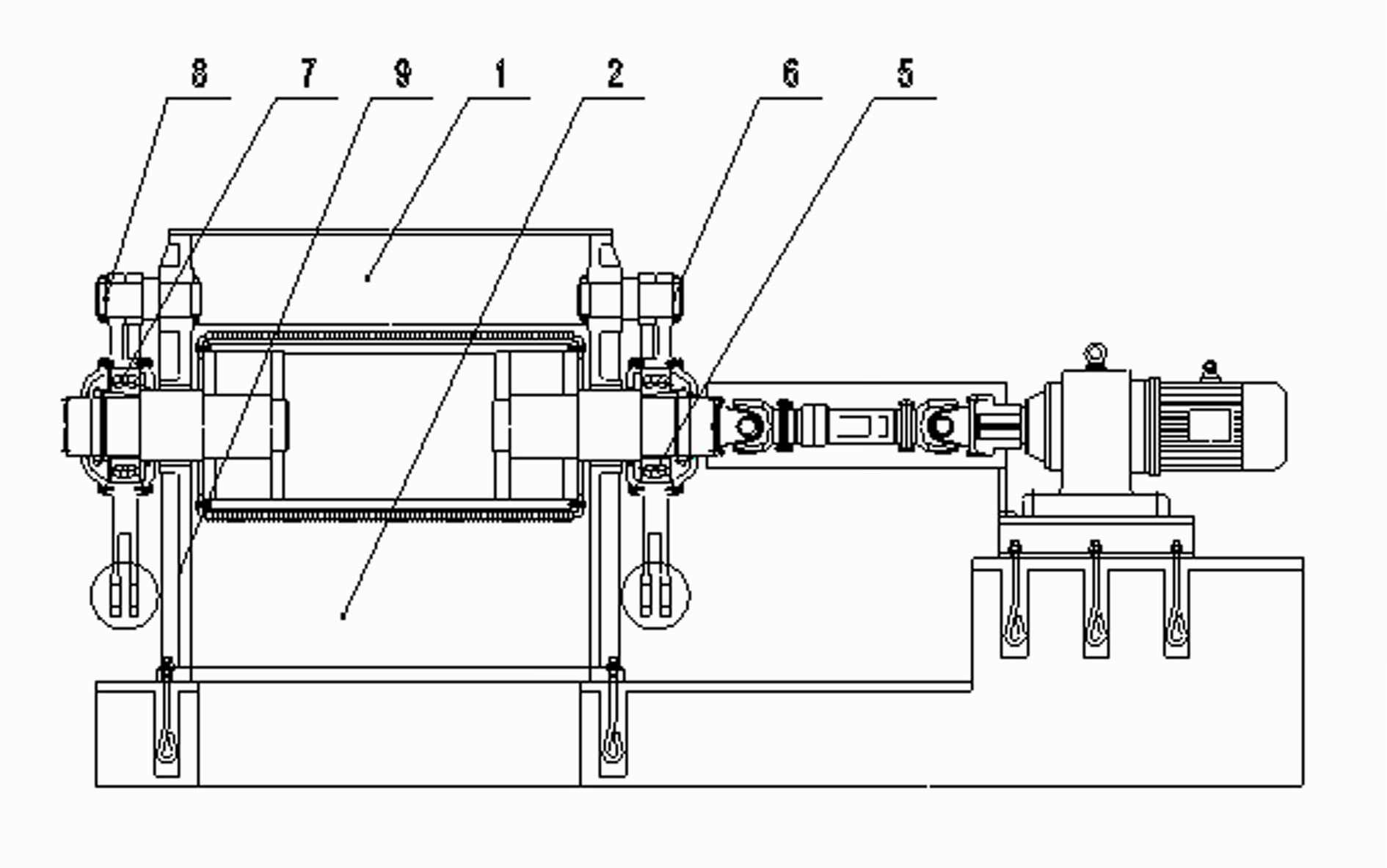

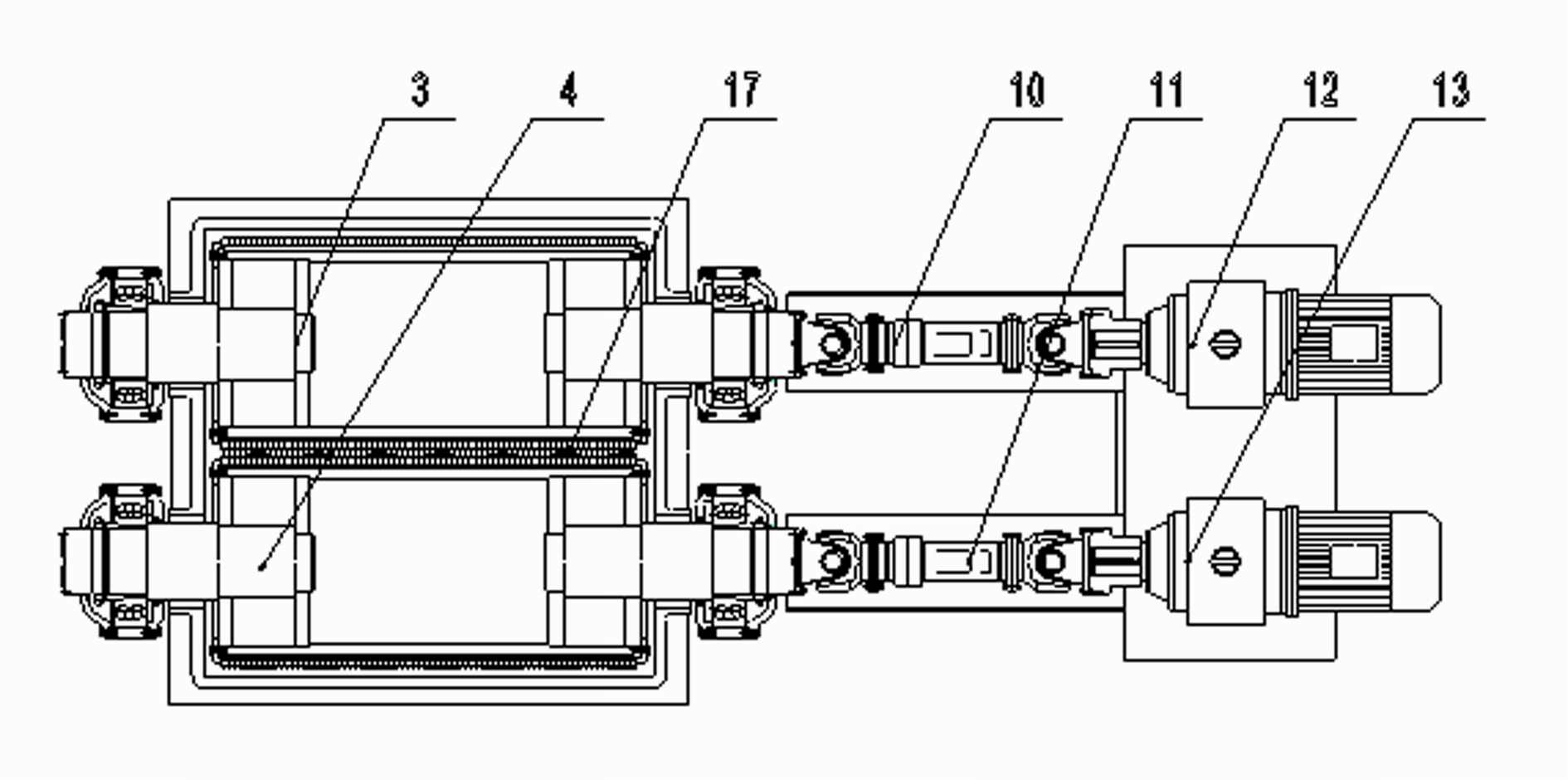

Continuous tube drawing device

InactiveCN103266610BAutomatically adjust the gapWon't hurtBulkheads/pilesTube drawingElectric machinery

The invention discloses a continuous tube drawing device. The continuous tube drawing device comprises a rack (1), support bases (2) arranged on the rack (1), idler wheels (4), power systems (5) connected with the idler wheels (4) and support arms (3), wherein one end of each support arm (3) is connected with each support base (2) through a movable shaft, and the other end of each support arm (3) is connected with each idler wheel (4) through a movable shaft. The support bases (2), the support arms (3), the idler wheels (4) and the power systems (5) are all set to be two sets and are arranged symmetrically with the rack (1). The power systems (5) comprise transmission motors (51) and speed changers (52), wherein the output shafts of the transmission motors (51) are connected with the speed changers (52), and the idler wheels (4) are arranged on the output shafts of the speed changers (52). The continuous tube drawing device is stable in power output, a tube diameter is adjusted automatically, stress borne by tube materials is adjusted automatically, the tube materials and a transmission system can not be damaged by continuous tube drawing, and using is safer and more reliable.

Owner:CHINA COAL SPECIAL DRILLING ENG

Controller mounting structure for automobile electric power air conditioner scroll compressor

ActiveCN109552003AWith automatic height adjustment functionReduce the chance of damageAir-treating devicesVehicle heating/cooling devicesControl theoryElectric power

The invention discloses a controller mounting structure for an automobile electric power air conditioner scroll compressor. The controller mounting structure comprises a compressor body, a bracket, acontroller integrated circuit, an upper cover, a stop screw and a spring, and is characterized in that the outer side of the compressor body and the upper cover form a cavity; the inner top of the upper cover is provided with a threaded mounting hole; the mounting hole is in threaded and fixed connection with the stop screw; the stop screw is provided with the bracket; the controller integrated circuit is fixed to the bracket; and the spring is disposed on the stop screw and between the bracket and the thread mounting hole. Compared with the prior art, the mounting bracket of the controller has a function of automatically adjusting the height, so that the bracket and the compressor body are completely attached to each other, the heat dissipation efficiency is greatly improved, and the damage probability of the controller integrated circuit is greatly reduced.

Owner:江西悦轮科技有限公司

Slope masonry machine with modes of discharging, vibrating and sliding

The invention relates to a slope masonry machine with modes of discharging, vibrating and sliding, comprising a main truss, traveling mechanisms arranged at the two ends of the main truss, a main material-receiving hopper arranged on the top end of the main truss, an electric operating room arranged at the bottom part of the main truss, a main belt machine and a conveying belt which are arranged on the main truss, an upper discharging vehicle and a lower discharging vehicle which are arranged on the main truss, material-conveying systems arranged on the upper discharging vehicle and the lowerdischarging vehicle, and a forming system arranged on the lower discharging vehicle. The slope masonry machine can meet conveying, paving, vibrating and leveling of the concrete, surface forming and preservation of expansion joints in the slope concrete masonry construction of large channels and can operate continuously and effectively improve the slope concrete masonry quality of large channels.

Owner:河北省水利工程局集团有限公司

A printing method and device for automatically adjusting the printing gap

ActiveCN104760429BSimple structureReduce manufacturing costPower drive mechanismsMechanical engineeringLettering

The invention relates to an automatic printing interval adjusting lettering method and device. When a printing medium enters a printing area, if the thickness of the printing medium is smaller than or equal to an interval between a paper pressing block and a printing drum, at the moment, a printing head is located at the lowest position, deformation of a torsional spring on a carriage unit split body B is minimum, and generated torsion is used for adjusting counter-acting force generated when the printing head works; if the thickness of the printing medium is larger than the interval between the paper pressing block and the printing drum, the paper pressing block makes contact with the printing medium, the printing medium pushes a carriage unit split body C to move upwards along the carriage unit split body B, the carriage unit split body C drives the carriage unit split body B to rotate around a carriage unit guide shaft, at the moment, the deformation of the torsional spring on the carriage unit split body B begins to be increased, and the generated torsion enables the paper pressing block to press the printing medium. The device is novel in design and simple in structure, the printing head does not incline, the service life of the printing head is long, the printing medium thickness application range is large, and the device has high practical value and a wide application prospect.

Owner:FUJIAN SHIDA COMP EQUIP

housing for electronic devices

ActiveCN103732018BGood lookingAutomatically adjust the gapElectrical apparatus casings/cabinets/drawersEngineeringFastener

Owner:嘉善罗星创业投资有限公司

A heating ring correction mold for pipeline production and processing

ActiveCN110814109BCurl implementationQuality improvementMetal-working feeding devicesCleaning using toolsDust controlEngineering

The invention relates to the technical field of pipeline production and processing, in particular to a heating ring correction mold for pipeline production and processing, comprising a base, a correction structure, an adjustment structure, a braking structure, a dust removal structure and a limit structure; The combined use of the structure can be used to curl the specific arc of the heating coil, that is, when the arc of a certain arc needs to be curled, it is only necessary to adjust the length of the steel rope in advance according to the length of the certain arc that needs to be curled. One end of the limiting block fixes the first cover, and one end of the first cover fixes the second cover through a connecting rod, and because a third pressing roller is rotated and connected inside the first cover, the second cover is fixed at one end of the first cover. There is a rotating rod inside, and because the third pressure roller and the outside of the rotating rod are both wrapped with steel ropes, and one end of the steel rope is fixed on the third pressure roller, the other end is fixed on the rotating rod, and is fixed on the third pressure roller. The steel wire on the roll can be wound and unwinded with the rotation of the third pressure roll.

Owner:陈方玲

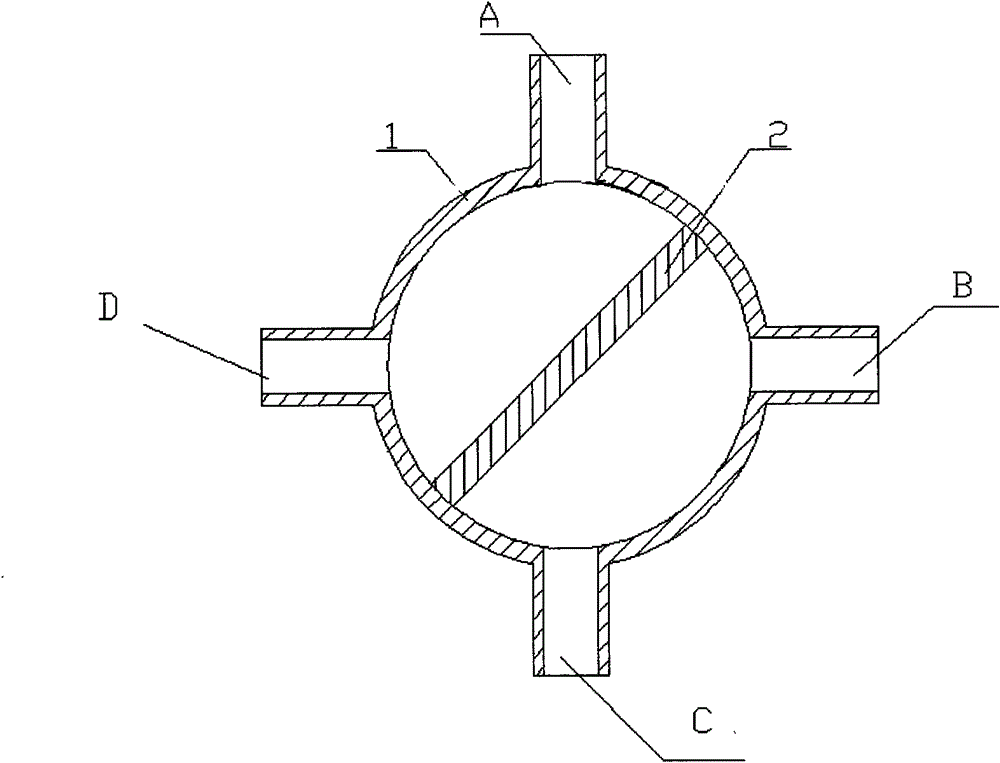

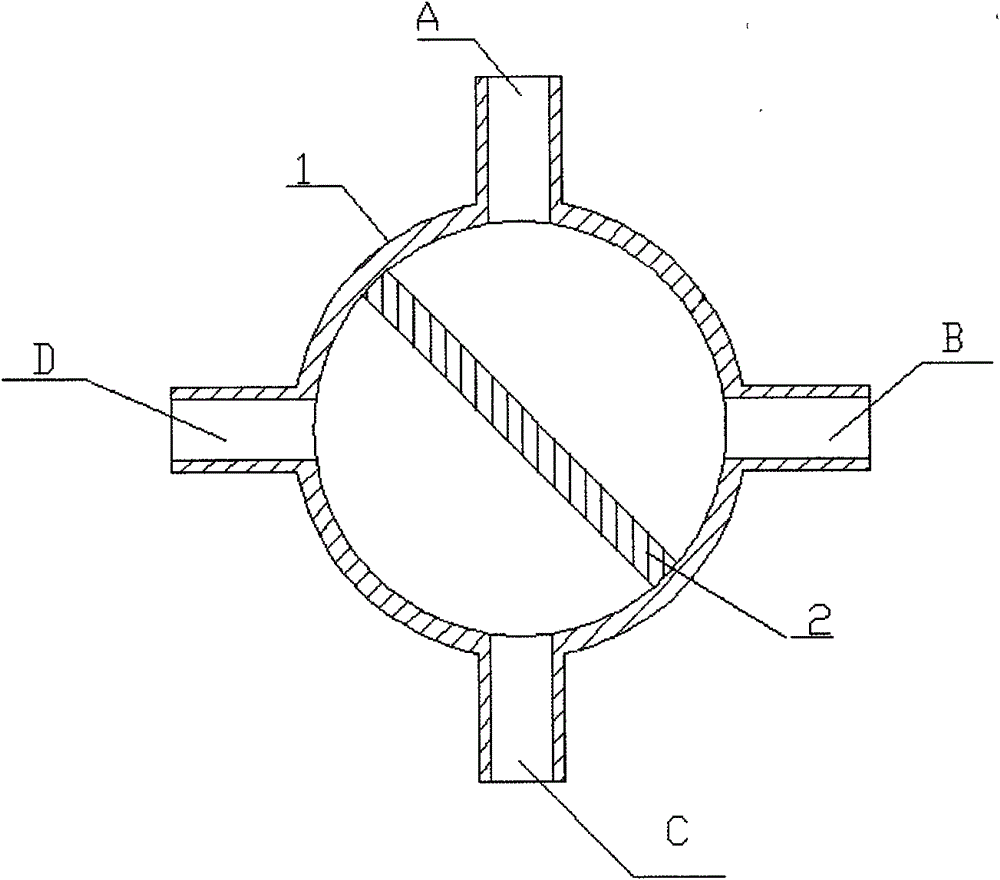

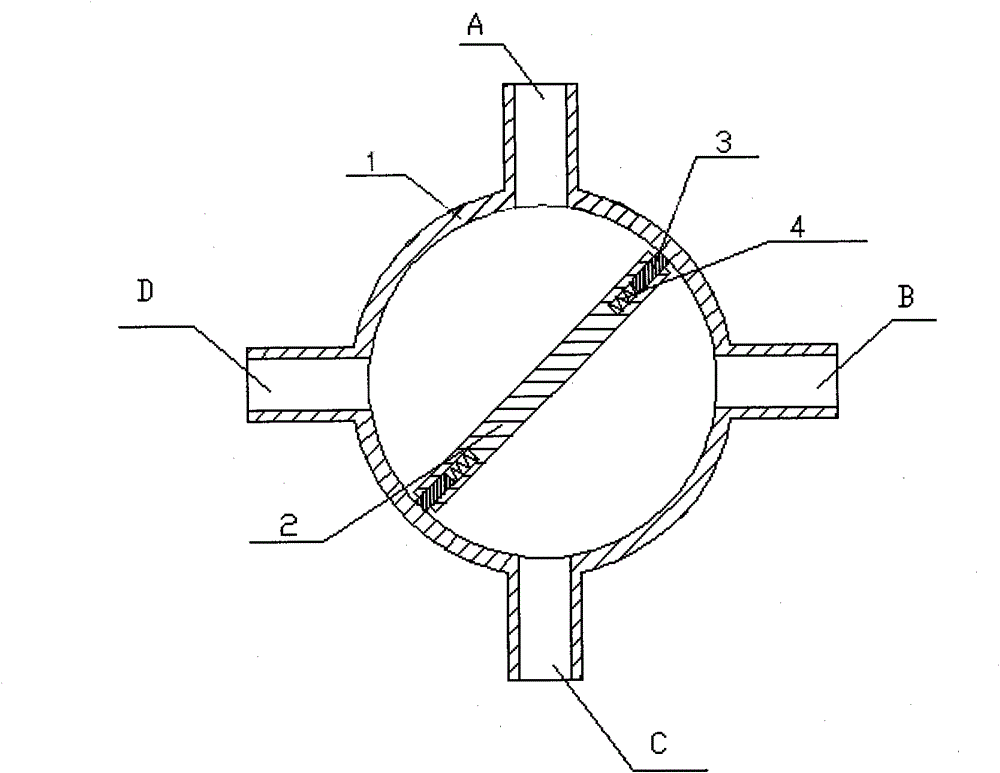

Improved structure of fiberboard production line modulated glue four-way valve

ActiveCN102235520BAutomatically adjust the gapGuaranteed accuracyMultiple way valvesProduction lineFailure rate

The invention relates to an improved structure of a fiberboard production line modulated glue four-way valve, and the improved structure comprises a valve body (1), a valve core (2), and a through hole arranged on the valve body. The improved structure is characterized in that a movable valve block (3) is installed on the end, facing to the valve body (1), of the valve core (2); and the movable valve block is connected in a groove arranged at the end, facing to the valve body, of the valve core faced the valve body through a spring piece, or the movable valve block is a sheet which is installed on the end of the valve core. The improved structure provided by the invention has the advantages that the valve core is designed to be in a mobile structure so as to automatically control the sizeof a valve body gap; the valve core is tightly adhered to the valve body in normal operation, so that the gap between the valve body and the valve core is the smallest, the metering accuracy can be ensured, when solid particles clamp the valve core, the valve core performs automatic regulation so as to increase the gap, the particle can pass through the increased gap, the clamping stagnation is avoided, the work efficiency is improved, and the failure rate is reduced.

Owner:DARE WOOD BASED PANEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com