Large-span multifunctional concrete slope masonry machine

A multi-functional concrete technology, which is applied in construction and infrastructure engineering, etc., can solve the problems that concrete is not easy to vibrate and compact, the follow-up workload is large, and the difficulty of disassembly and assembly is large, so as to achieve continuous and compact feeding and distribution process, and the distribution position Accurate and stable control, reducing the effect of aggregate separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

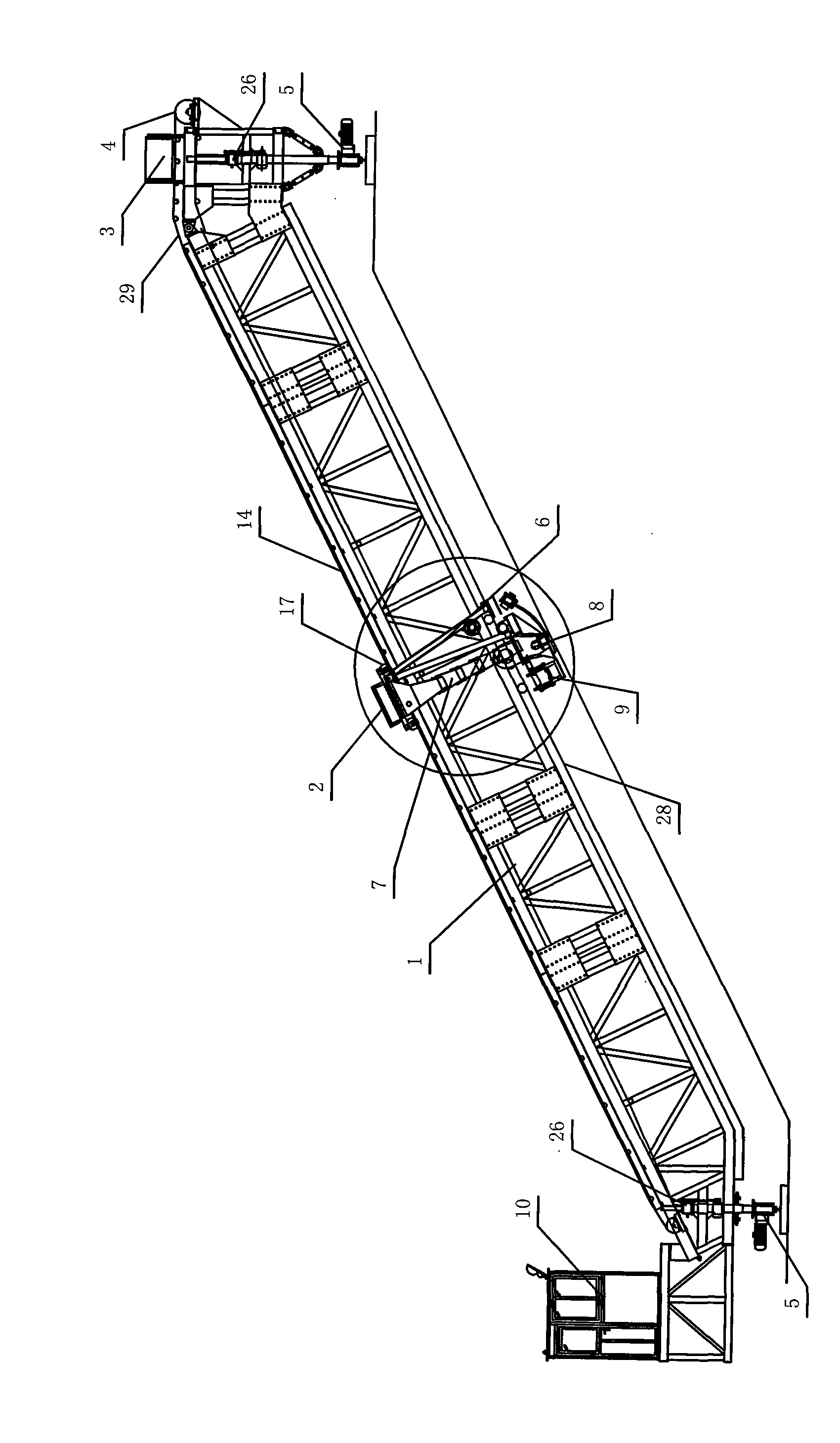

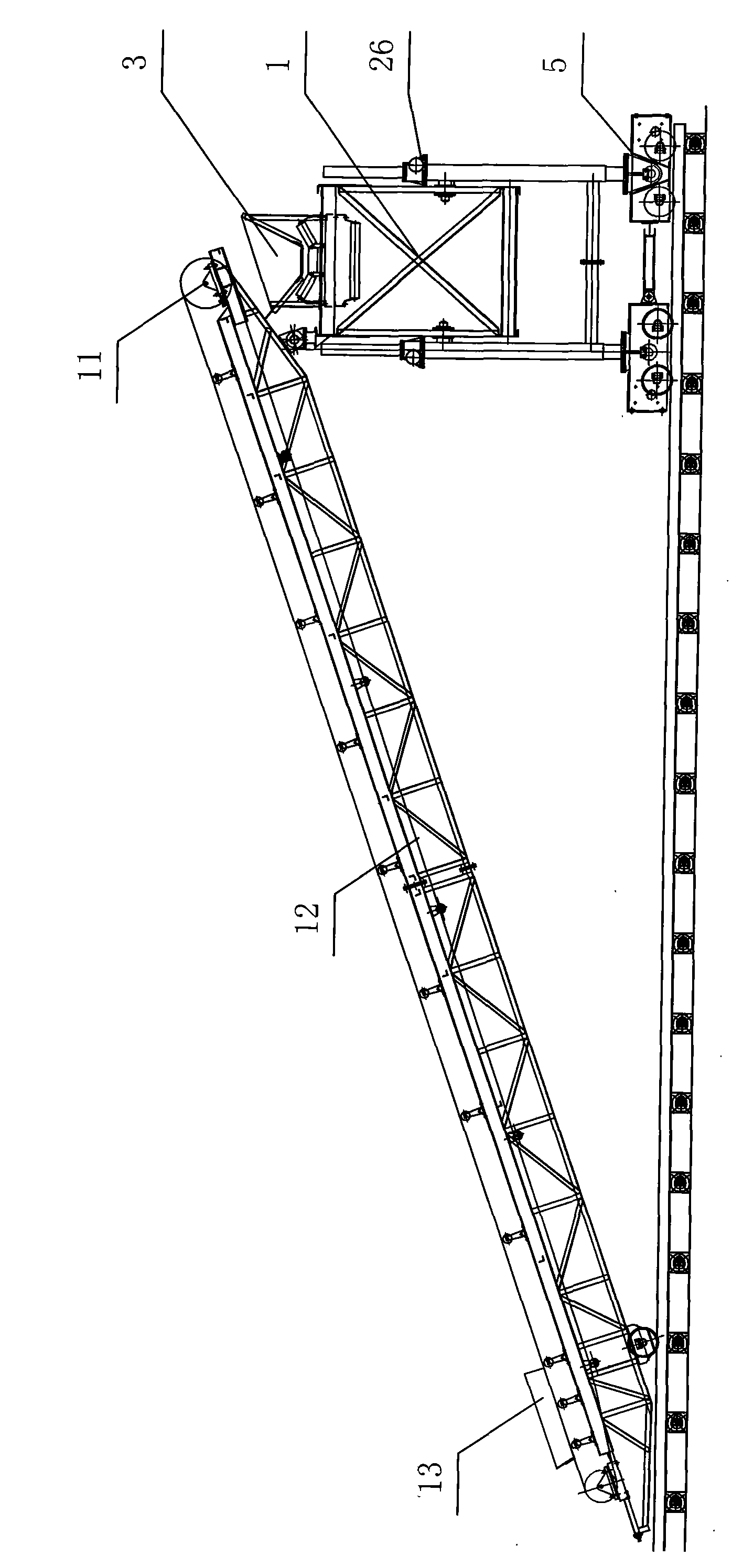

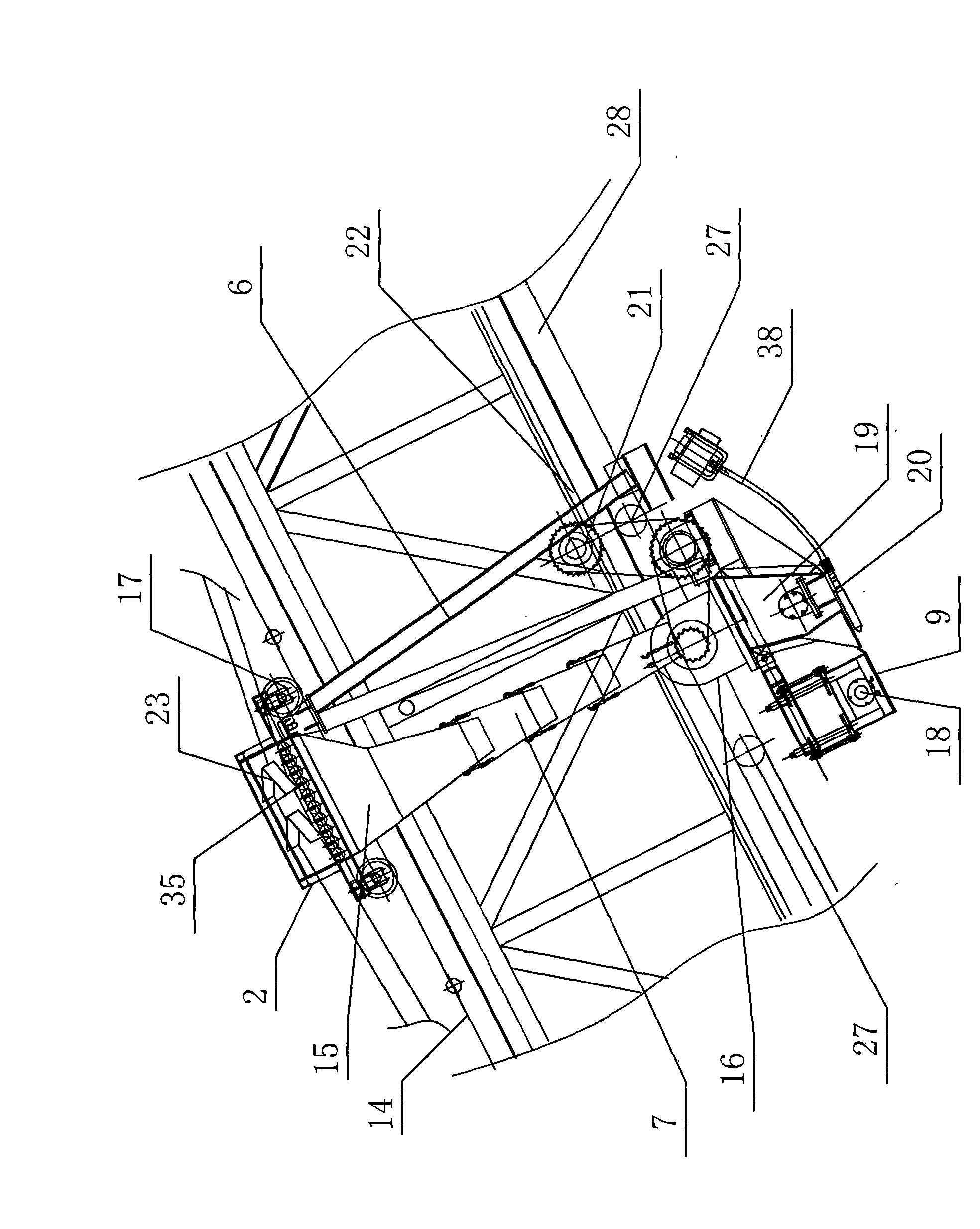

[0047] The present invention will be described in detail below in conjunction with embodiment, as appended figure 1 As shown, the present invention includes a main truss 1, a traveling mechanism 5 arranged at both ends of the main truss, a main receiving hopper 3 arranged at the top of the main truss 1, an electrical operation room 10 arranged at the bottom of the main truss 1, and a The main belt conveyor 4 and the conveying belt 29, the upper unloading vehicle 2 and the lower unloading vehicle 8 arranged on the main truss 1, the conveying system arranged on the upper unloading vehicle 2 and the lower unloading vehicle 8, The molding system on the feeding cart 8, as attached image 3 , 4 , 7, 12, 13, 14, 15, and 16, the conveying system includes the main belt conveyor 4 and the conveying belt 29 arranged on the main truss 1, the conveying belt arranged on the upper unloading car 2 29, the material distribution scraping device 23 at the upper end, the lower hopper 15 arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com