Patents

Literature

110results about How to "Does not affect gloss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallic super-toughened PMMA (polymethyl methacrylate) composite material and preparation method thereof

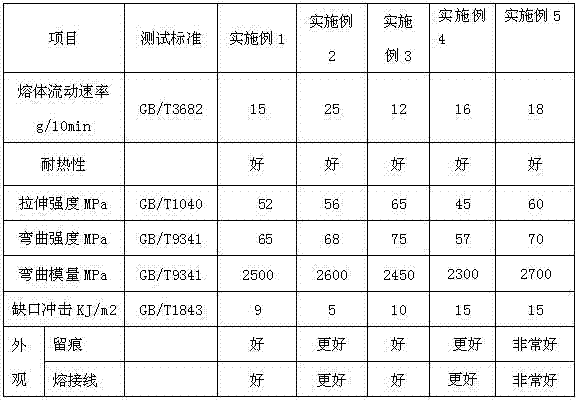

The invention discloses a metallic super-toughened PMMA (polymethyl methacrylate) composite material which consists of PMMA, AS (acrylonitrile) resin, a compatilizer, a flexibilizer, an antioxidant, a lubricant, a reinforcing agent and metal powder. The invention also discloses a preparation method of the metallic super-toughened PMMA composite material. The metallic composite material disclosed by the invention has excellent chemical stability and weather resistance, has a strong mechanical performance and has the advantages of high gloss, high surface hardness, resistance to alcohol corrosion, good scraping resistance and the like; and the appearance of the metallic super-toughened PMMA composite material has the same aesthetic effect with that formed by metal spraying.

Owner:ORINKO NEW MATERIAL CO LTD

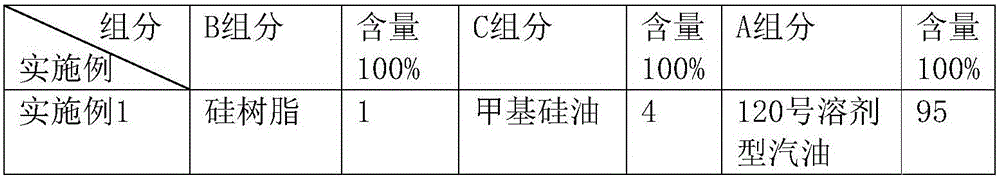

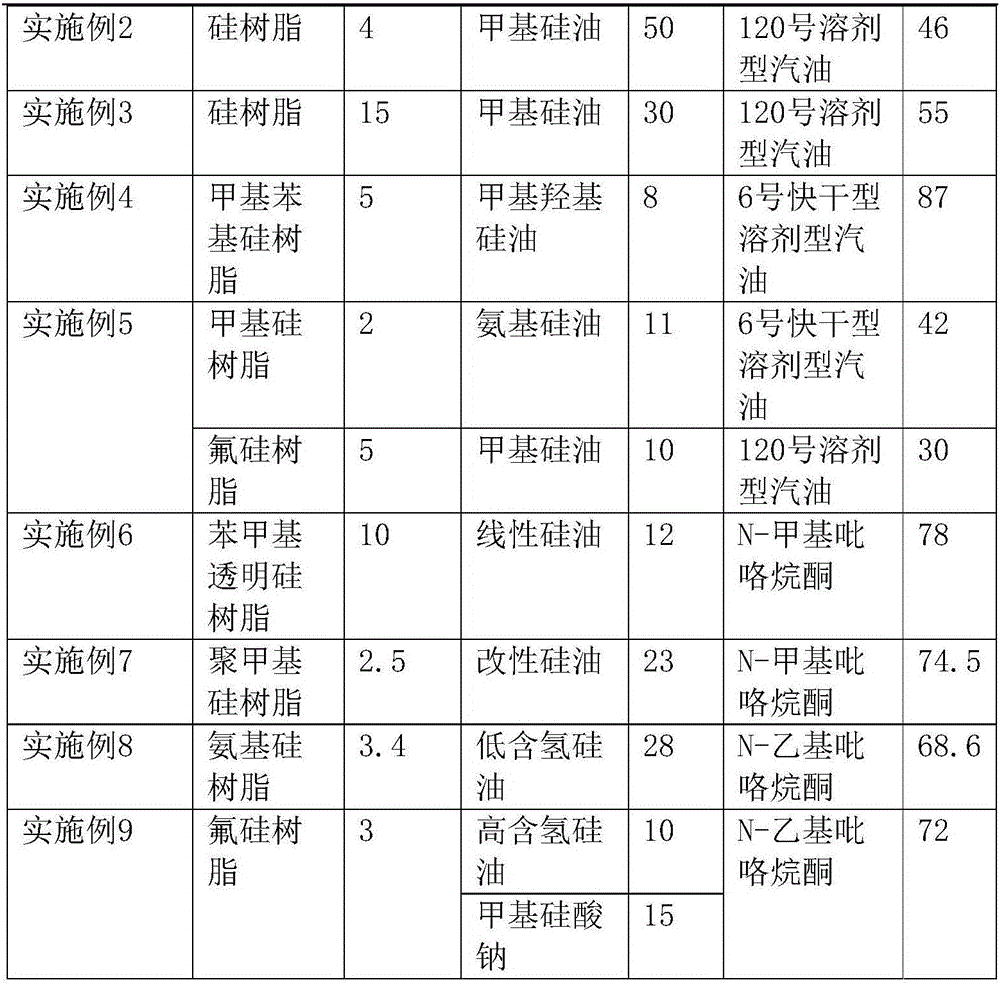

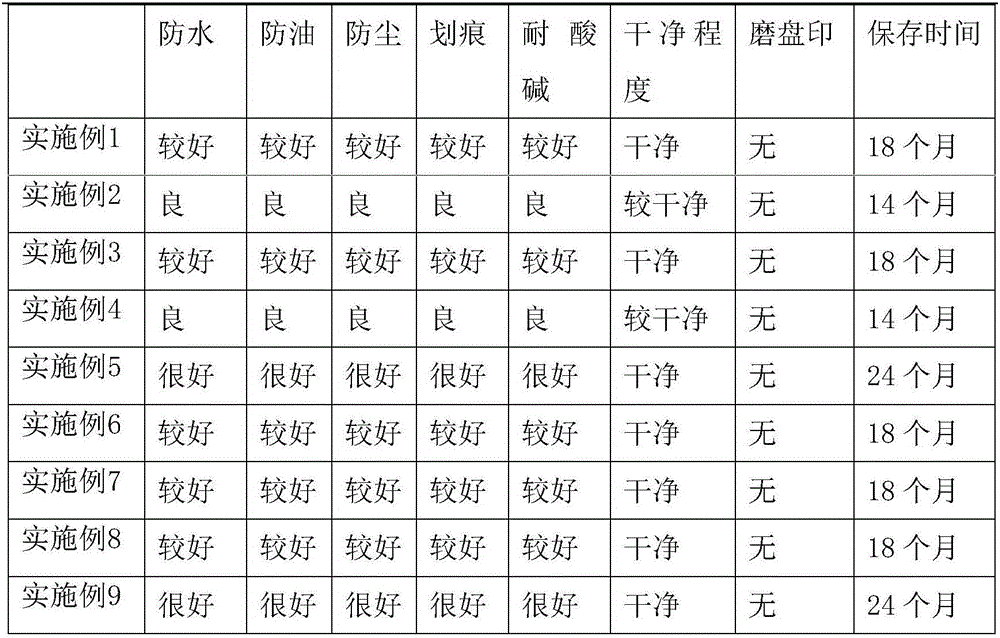

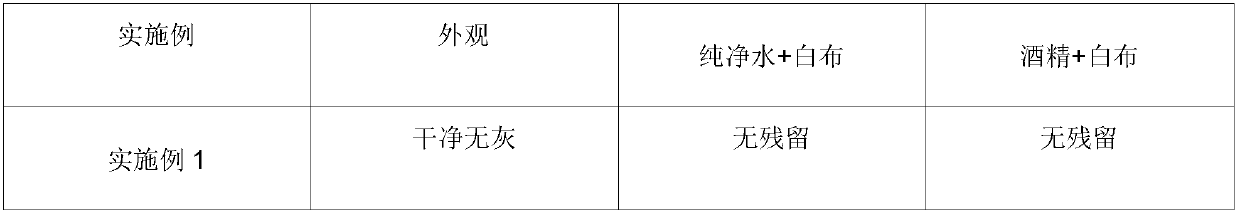

Matte brick stain-proofing agent and preparation method thereof

ActiveCN105860831AAntifoulingExtended service lifeAntifouling/underwater paintsPaints with biocidesOrganic solventBrick

The invention discloses a matte brick stain-proofing agent. The matte brick stain-proofing agent is prepared from a component A, a component B and a component C, wherein the component A is an organic solvent, the component B is silicon resin, and the component C is at least one of silicone oil and organosiloxane monomers. The invention further provides a preparation method of the matte brick stain-proofing agent. By compounding the components, the matte brick stain-proofing agent can achieve a good stain-proofing effect when used for performing stain-proofing treatment on the surfaces of matte bricks in follow-up application; besides, the matte brick stain-proofing agent has a very long shelf life and service life; moreover, the preparation technology is simple and easy to implement and can be conveniently applied to industrial production.

Owner:GUANGDONG NADE NEW MATERIALS CO LTD

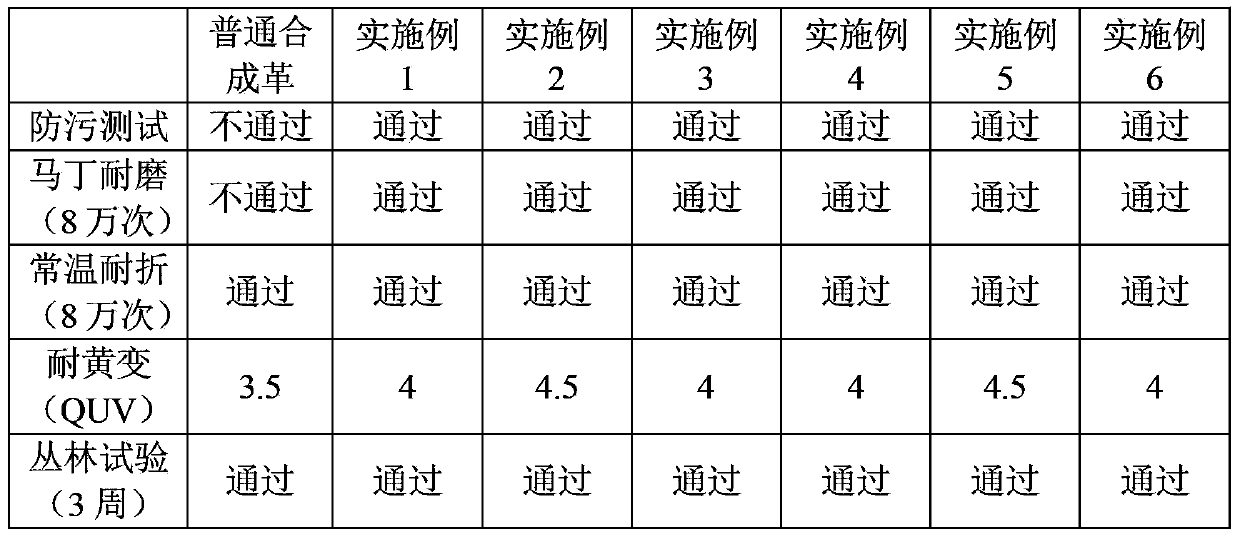

Manufacturing method for antifouling and doodle-preventing polyurethane (PU) synthetic leather

InactiveCN103361989ALower surface energyImprove wear resistanceSynthetic resin layered productsLaminationWork in processSlurry

The invention relates to a manufacturing method for antifouling and doodle-preventing polyurethane (PU) synthetic leather. The manufacturing method comprises the steps of (a) preparing a synthetic leather semi-product and unwinding the semi-product; (b) coating a layer of antifouling and doodle-preventing polyurethane work slurry on the surface of the semi-product by a post-finishing coating process; (c) drying the work slurry at a temperature of 130 DEG C-160 DEG C, wherein a drying and curing time is 1 min-5 min; and (d) cooling and winding to get the high antifouling and doodle-preventing polyurethane synthetic leather. By using a reactive organic fluorinated polyurethane resin or organic silicone polyurethane resin and curing and clinking at a high temperature after the post-finishing process, extremely low surface energy is given to the PU synthetic leather, so that the PU synthetic leather has excellent antifouling property and doodle-preventing property, and particularly can endure doodles by oil-based ink. The manufacturing method is simple in implementation process, and a finished product has excellent physical properties and hand feel.

Owner:慈文传媒股份有限公司

High-gloss PTFE (polytetrafluoroethylene) anti-drop agent and preparation method thereof

The invention relates to a high-gloss PTFE (polytetrafluoroethylene) anti-drop agent and a preparation method thereof. The preparation method includes: 1), adding a small amount of an emulsified monomer A solution to a PTFE emulsion and performing irradiation treatment on the PTFE emulsion in high energy ray, and grafting a small number of monomers on the surface of PTFE particles; 2), in the absence of oxygen, initiating monomer B to perform polymerization reaction in the treated PTFE emulsion by the aid of an initiator and adding a cross-linking agent at a later stage to form nuclear-shell nano PTFE composite particles with PTFE particles as nuclears and a polymer as a shell; 3), filtering the modified PTFE emulsion and subjecting a filtrate to spray drying to obtain the high-gloss PTFE anti-drop agent. With the method, under the condition that no dispersants or compatibility agents are added, the anti-drop agent can be well-dispersed in thermoplastic resin with good compatibility, and light transmission, glossiness and the like of matrix resin are unaffected by the anti-drop agent dispersed in engineering plastics of PA, PC and the like.

Owner:安徽申嘉聚合物科技有限公司

Dyeing method of mulberry silk cheese

InactiveCN101838941AAvoid deformationDegumming evenly and fullyDyeing processLiquid/gas/vapor textile treatmentFiberEngineering

The invention provides a dyeing method of a mulberry silk cheese, comprising the following procedures: slack-spooling, pre-processing, dehydrating, drying, dyeing, postprocessing, dehydrating and drying. The dyeing method is characterized in that the constant weight of the cheese for slack-spooling is 0.55-0.6kg / pcs, the density is 0.35-0.4g / cu.cm., and the cheese is wrapped by an elastic fiber sleeve and then is subjected to the pre-processing procedure; and secondary slack-spooling is carried out on the cheese after the procedures of pre-processing, dehydrating and drying, the constant weight of the cheese is still 0.55-0.6kg / pcs, the density is 0.35-0.4g / cu.cm., and the cheese performed with secondary slack-spooling is wrapped by the elastic fiber sleeve and then is subjected tp the dyeing procedure. In the invention, slack-spooling and secondary slack-spooling can effectively overcome various adverse factors affecting the density and the shape of the cheese in the procedures; and situations of uneven dyeing and great inner-outer color difference owing to overlarge density do not occur, and cheese collapse owing to too small density does not occur, thus ensuring the dyeing quality of the cheese. The dyeing method has the outstanding advantage of effectively solving unstable dyeing quality of the mulberry silk cheese.

Owner:TIANJIN TIANGE TEXTILE

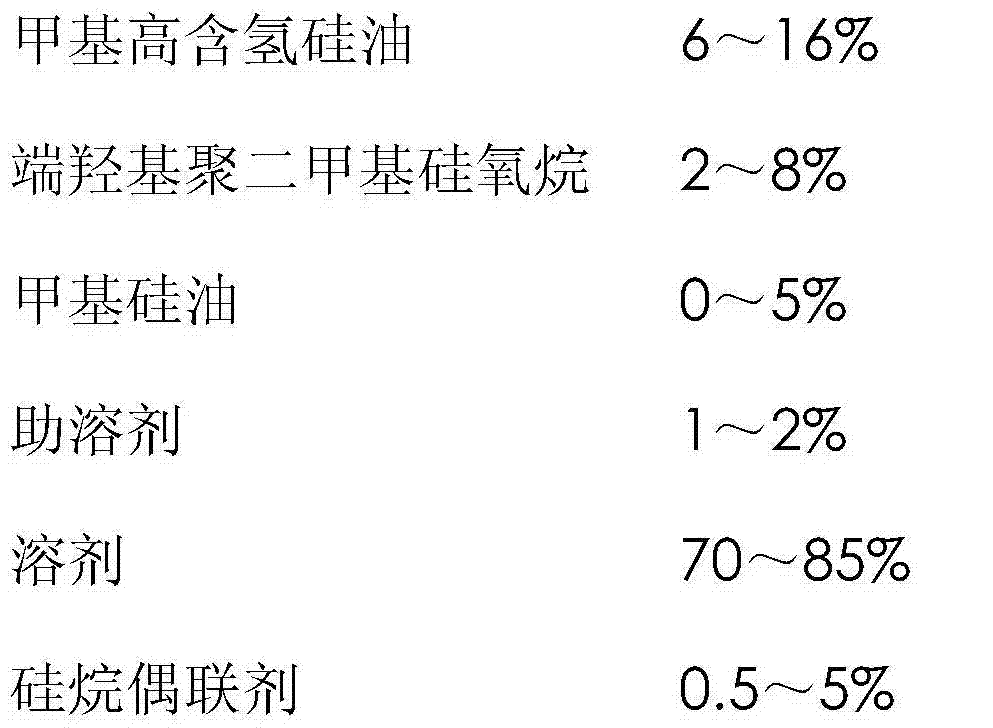

Quartz stone anti-fouling agent and preparation method and application thereof

ActiveCN104497869AVolatile fastGood chemical stabilityAntifouling/underwater paintsPaints with biocidesFoaming agentHydrogen

The invention discloses a quartz stone anti-fouling agent and a preparation method and application thereof. The quartz stone anti-fouling agent comprises the following raw materials in percentage by mass: 6-16% of methyl hydrosilicone oil, 2-8% of hydroxyl-terminated polydimethylsiloxane, 0-5% of methyl silicone oil, 1-2% of cosolvent, 0.5-5% of silane coupling agent and 70-85% of solvent. The quartz stone anti-fouling agent is specially developed for coarse and porous quartz stone which is vulnerable to fouling; and by simply smearing the anti-fouling agent on the surface of the quartz stone, the quartz stone can be effectively protected from oil pens, ink, coffee, tea and other pollutants. The quartz stone anti-fouling agent disclosed by the invention is simple in preparation process, good in anti-fouling property and favorable in scrub resistance and durability, can not influence the surface gloss of the quartz stone, and is non-toxic and non-corrosive, thus not only being applicable to the quartz stone, but also being applicable to agglomerated stone, marble, matt tiles and the like.

Owner:FOSHAN SITECH CHEM TECH

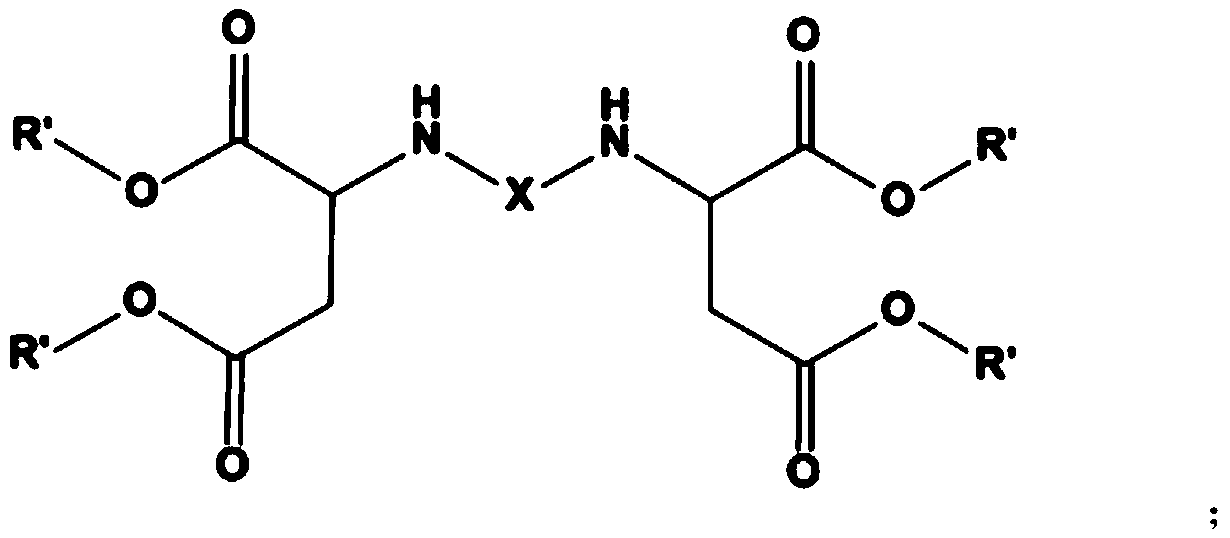

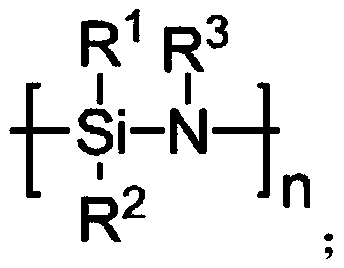

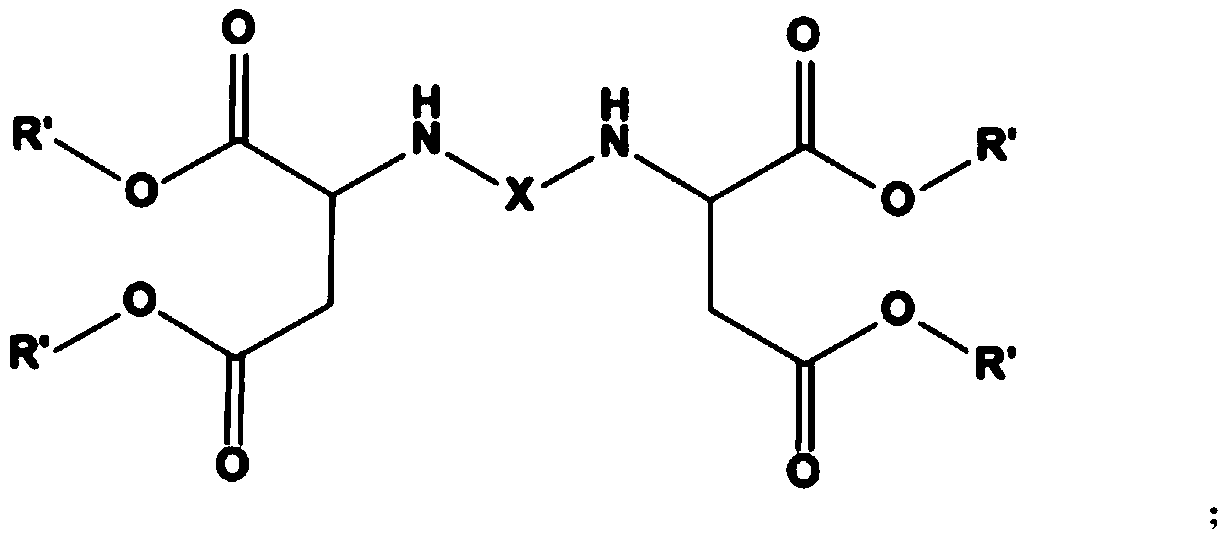

Modified polyaspartate polyurea coating as well as preparation method and application thereof

InactiveCN110373099ASimple preparation processEasy to operatePretreated surfacesPolyurea/polyurethane coatingsPolymer sciencePolysilazane

The invention provides a modified polyaspartate polyurea coating as well as a preparation method and application thereof and relates to the technical field of novel coatings. The modified polyaspartate polyurea coating is mainly prepared from polyaspartate, a modifier and a curing agent, wherein the modifier comprises polysilazane, and the curing agent comprises isocyanate and / or a polymer of theisocyanate. According to the modified polyaspartate polyurea coating, a certain quantity of polysilazane and polyaspartate are bridged together by a tripolymer of isocyanate, so that the mechanical properties such as solvent resistance and hardness of a coating are effectively improved. Polysilazane has excellent mechanical properties, and therefore, polyurea resin with improved mechanical properties can be obtained after polysilazane is bridged on polyaspartate. The coating prepared from the polyurea coating has higher hardness, higher surface drying speed and excellent performances such as chemical resistance and wear resistance.

Owner:GUANGZHOU WINHIGH CHEM TECH CO LTD

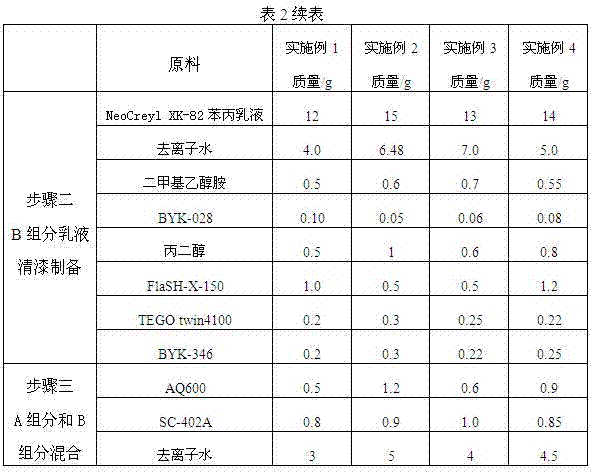

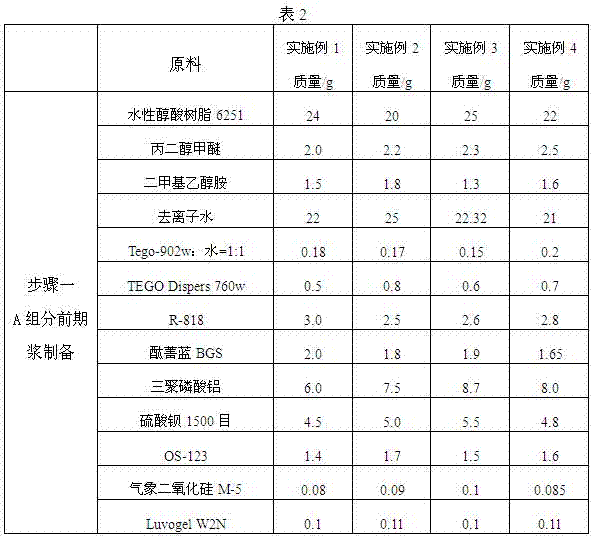

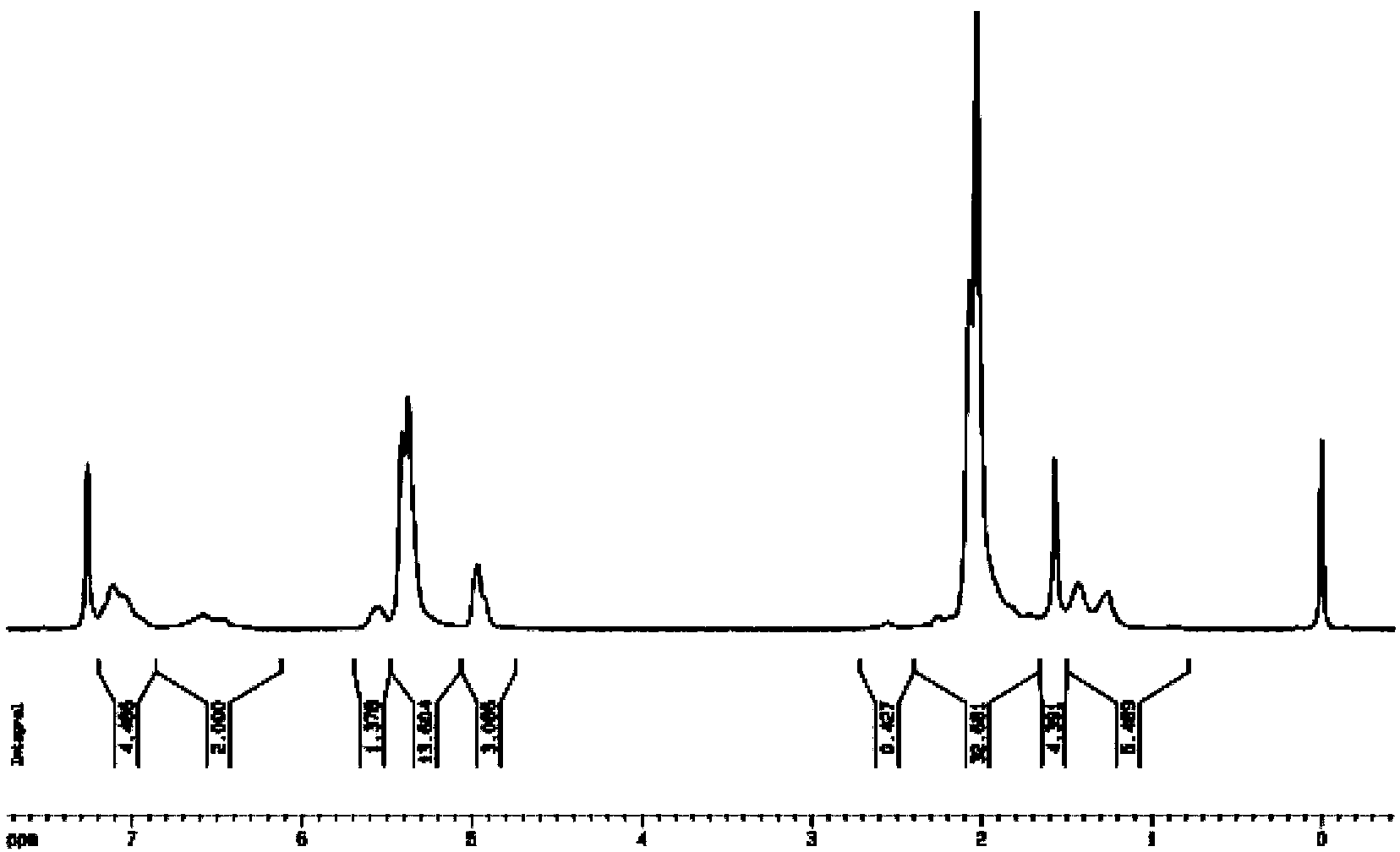

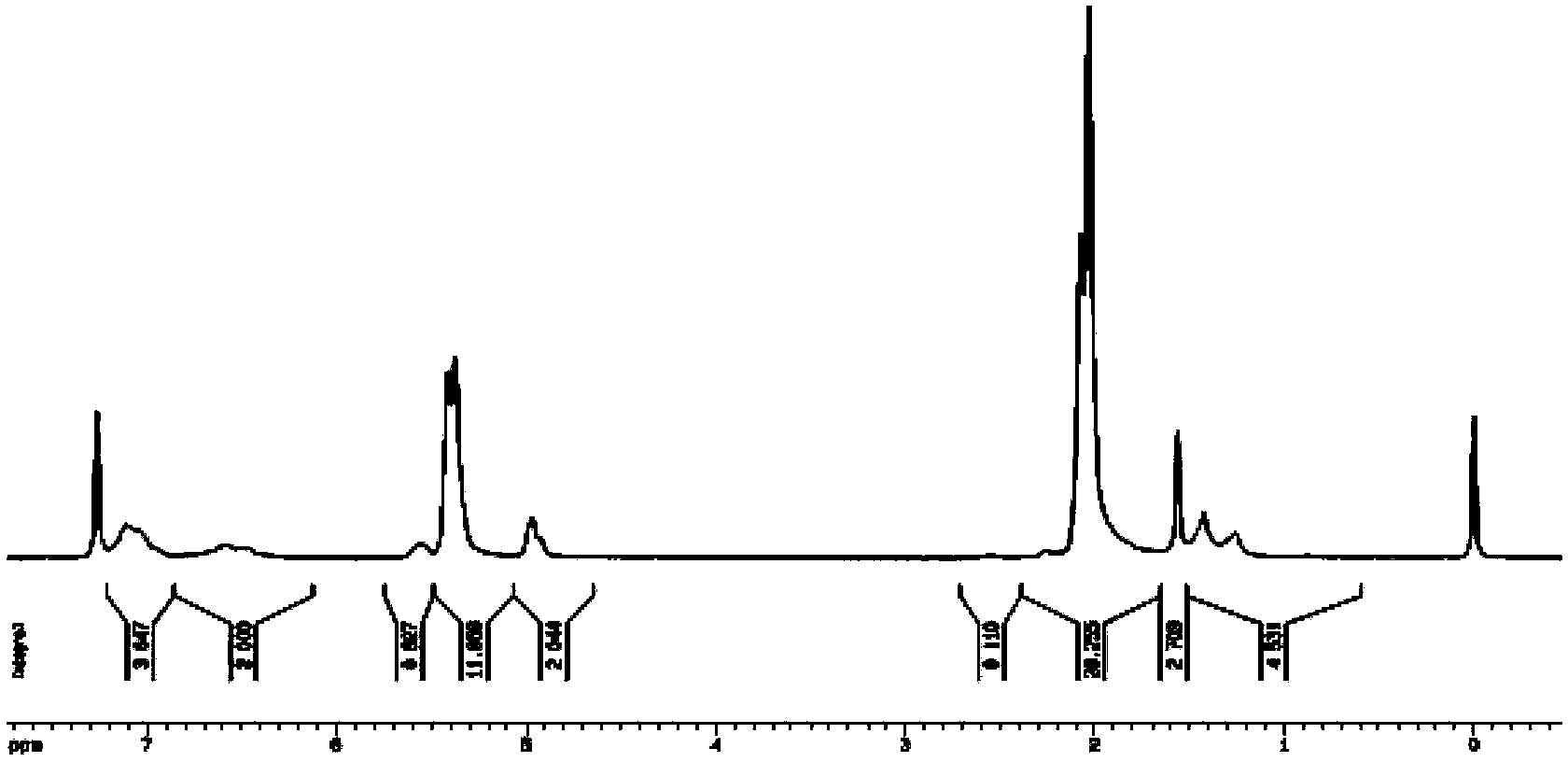

Organosilicon epoxy acrylic acid modified waterborne alkyd resin emulsion and coating thereof

InactiveCN105131263AImprove weather resistanceImprove hydrolysis resistancePolyester coatingsEmulsionOrganosilicon

The invention provides an organosilicon epoxy acrylic acid modified waterborne alkyd resin and a coating thereof; the formula of the coating comprises the components in parts by mass: 40-50 parts of an organosilicon epoxy acrylic acid modified waterborne alkyd resin emulsion comprising the components of 45-65 parts of tung oil, castor oil or linseed oil, 25-45 parts of phthalic anhydride, trimellitic anhydride or trimellitic anhydride, 3-10 parts of xylene, 5-10 parts of epoxy ester and 5-10 parts of organosilicon ester; 3-4 parts of a pigment; 6-26 parts of a packing; 10-20 parts of deionized water; 0.05-0.5 part of a dispersant; 0.1-0.3 part of a defoaming agent; and 0.9-2.5 parts of a drier. The preparation method of the emulsion comprises the steps: heating oil, glycerol, pentaerythritol and trimethylolpropane with nitrogen protection, adding an alcoholysis catalyst, heating up, keeping a reaction until the ethanol tolerance degree reaches 2.0-5.0 ml / 100 ml, and cooling; adding anhydride and xylene; adding organosilicon ester and epoxy ester, and modifying; and adding acrylate, and modifying; and cooling, and dispersing the mixture for two times. The coating has the advantages that easily-volatile organic compounds are reduced with water as a diluent.

Owner:盘锦辽河油田金宇生态环境有限公司

High gloss flame retardant anti-bacterial and weatherproof polypropylene composite material and preparation method thereof

InactiveCN107603007AHigh glossImprove flame retardant performanceEnvironmental resistancePolymer science

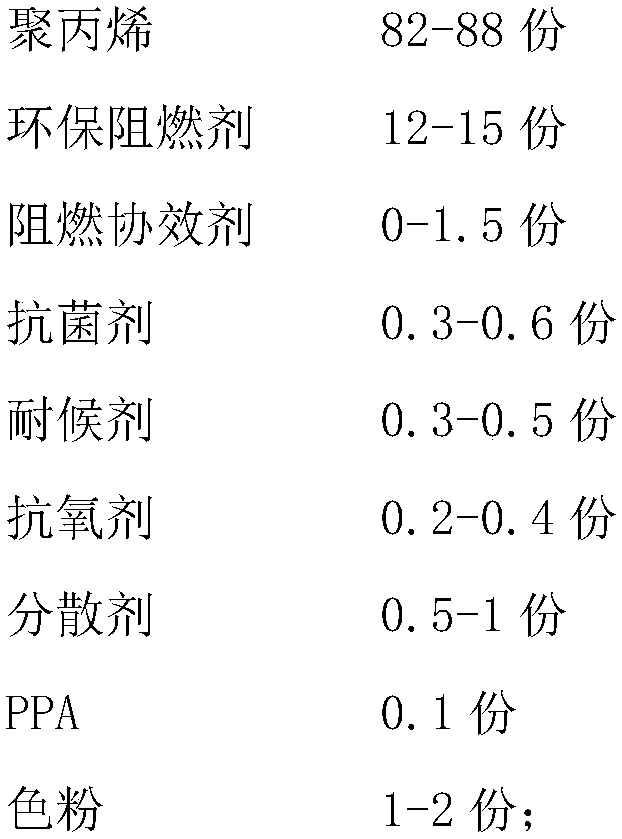

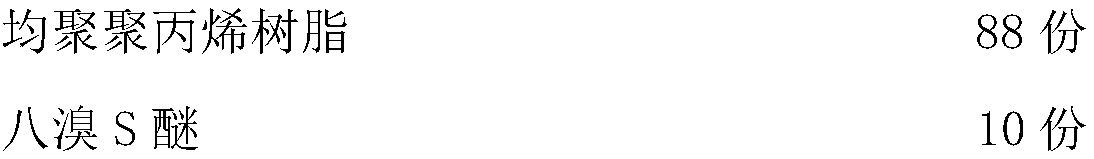

The invention provides a high gloss flame retardant anti-bacterial and weatherproof polypropylene composite material and a preparation method thereof. The high gloss flame retardant anti-bacterial andweatherproof polypropylene composite material is composed of the following components by weight: 82-88 parts of P resin, 12-15 parts of an environment-friendly flame retardant, 0-1.5 parts of a flameretardant synergist, 0.3-0.6 part of an antibacterial agent, 0.3-0.5 part of a weather resistant agent, 0.2-0.4 part of an antioxidant, 0.5-1 part of a dispersant, 0.1 part of a fluoropolymer processing aid, and 1-2 parts of toner. The high gloss flame retardant anti-bacterial and weatherproof polypropylene composite material prepared by the method provided by the invention has gloss (at an angleof 60 degrees) up to more than 85, the flame retardant grade UL-94 up to V-0, an antibacterial rate up to 99% or more, xenon lamp 200h weathering test deltaE of less than or equal to 1.5. The material meets the provisions of the EU ROHS and REACH regulations, and the antibacterial agent accords with the relevant standards of Japan SIAA. The material can be used for intelligent closestool parts, and can effectively prevent fire hazards caused by ignition of electrical contact parts in closestools and the like. Closestools with SIAA logo can effectively inhibit the generation of bacteria and make people's life healthier.

Owner:ORINKO NEW MATERIAL CO LTD

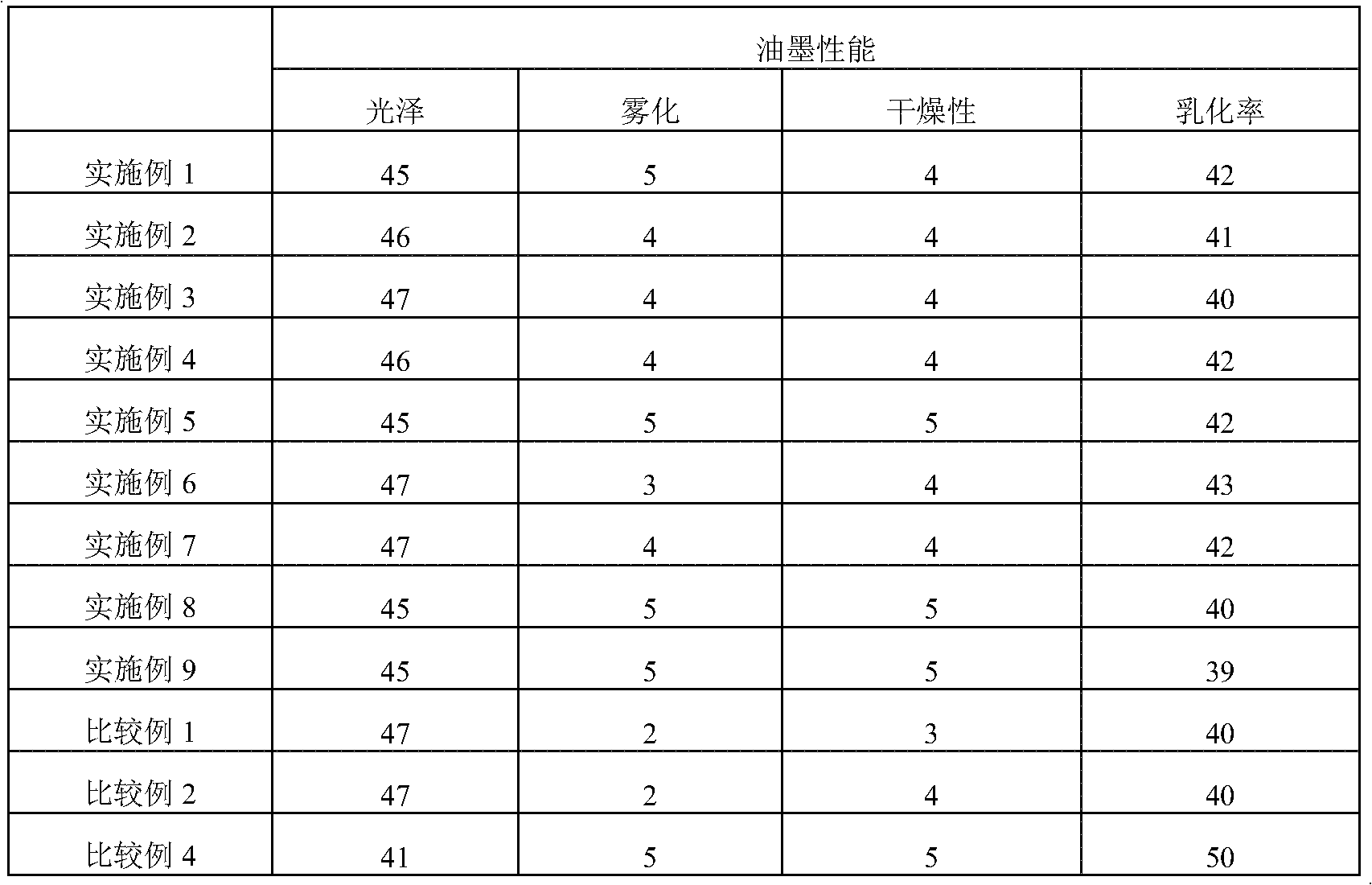

Rosin-modified phenol resin, manufacturing method thereof, and printing ink

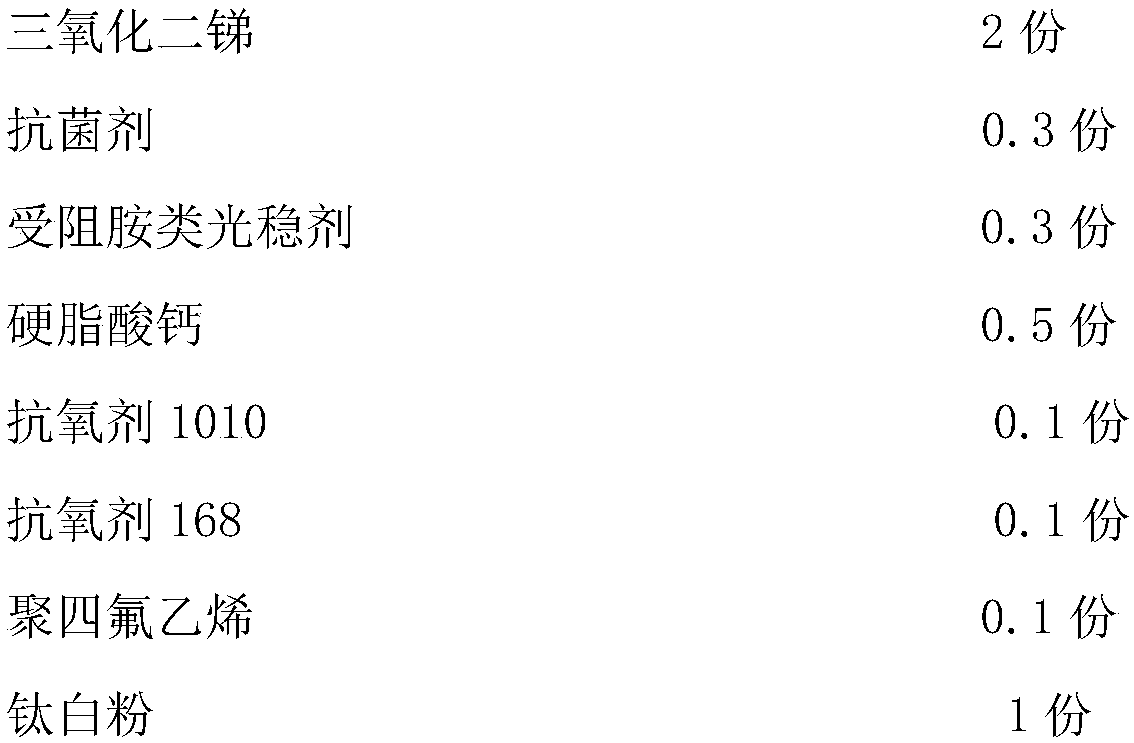

A rosin-modified phenol resin is obtained by reacting (a) rosins containing 0.4-10% of dihydroagathic acid, (b) a condensation product of phenols and formaldehyde, and (c) a polyol. The rosin-modified phenol resin is suitable for printing ink applications, and the amount of printing ink mist can be reduced without the luster of the printed material being diminished while maintaining various ink capabilities (drying properties, emulsifying properties, etc.).

Owner:ARAKAWA CHEM IND LTD

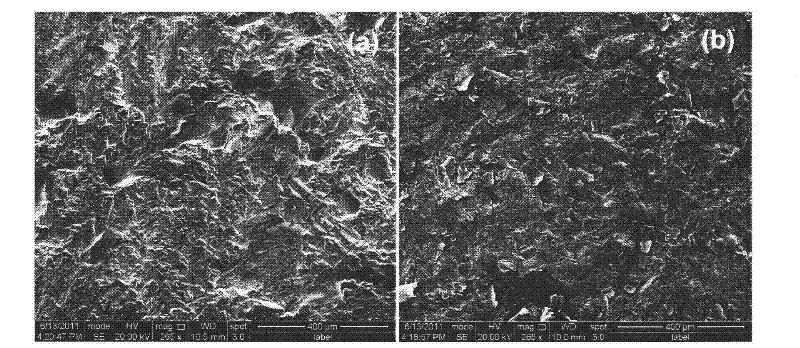

Calcium carbonate biomineralization reinforcing method for calcium carbonate type stone cultural relics

The present invention discloses a calcium carbonate biological mineralizing and strengthening method for calcium carbonate stone cultural relic. The technical process of the present invention is that: the solvent is first used for cleaning the surface of the stone cultural relic; and then the present invention uses a compound solution with biological amphipathic function as a organic molding board to pretreat the surface of the stone cultural relic and to make the surface of the stone add with a functional group unit; the supersaturation solution of calcium carbonate is used for making with infiltration treatment; under the control of the functional group unit, the calcium carbonate is inducted to grow into core directional crystal; the rocked and incompact grain can be connected so as to make the strengthened protection for the surface of the stone material. The present invention has the advantages of similar property between the protective material and the base material, much better compatibility; the present invention does not change the appearance, color and hand feeling of the protected stone cultural relic; and the compression strength, water resistance, acidity resistance and soiling resistance are improved and enhanced greatly.

Owner:ZHEJIANG UNIV

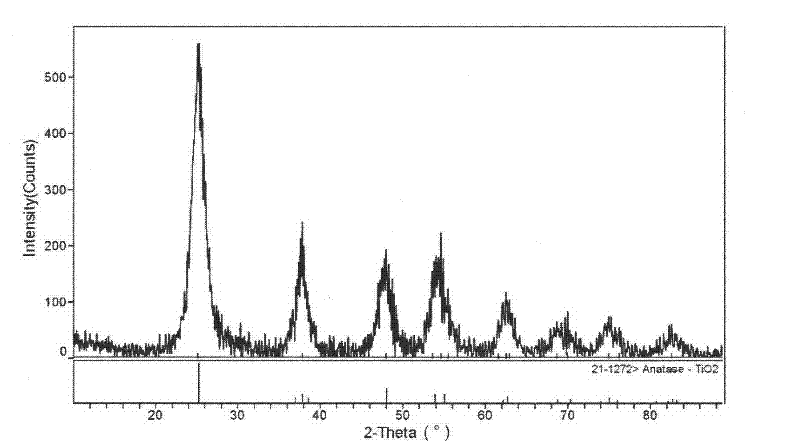

Nanometer photocatalysis surface protection material for stones and stone cultural relic and preparation method of same

InactiveCN102491781ALong-term protection engravingLong-term protective structureTitaniumSoil resistance

The invention relates to the field of protection of stones and stone cultural relic and provides a nanometer photocatalysis surface protection material for stones and stone cultural relic and a preparation method of the material. According to the invention, titanium alcoholate is taken as the main raw material; the titanium alcoholate, solvent, chelating agent, catalyst and the like are mixed, and are stirred fully under the condition of normal pressure and below the temperature of 100 DEG C to react, so as to obtain anatase titanium dioxide collosol surface protection liquid for stones and stone cultural relic; and a surface protection film made of anatase titanium dioxide photocatalysis material is formed on the surface of a stone, which is cleaned with solvent, through the method of brushing, soaking or the like. The nanometer photocatalysis surface protection material has the advantages that the reversibility is good; the compatibility with stones is good; the acid resistance is strong; the alkaline resistance is strong; the weatherability and the soil resistance are good; the self-cleaning capability is strong; the fungus resistance is good; and the appearance, the color and the hand feeling of the original stone are not affected.

Owner:YUNNAN UNIV

Ash removing agent for neutralization treatment of aluminum alloy and preparation method thereof

The invention relates to an ash removing agent for neutralization treatment of aluminum alloy and a preparation method thereof. The ash removing agent is applied to the neutralization treatment afterthe pretreatment of the aluminum alloy and comprises the following components according to parts by weight: 50-200 parts of sulfuric acid, 2-100 parts of hexavalent iron salt, 5-50 parts of ferric iron salt, 10-50 parts of hydrogen peroxide and 5-50 parts of corrosion inhibitor. The ash removing agent for the neutralization treatment of the aluminum alloy is used for removing ash in the neutralization treatment process after the pretreatment of the aluminum alloy, has little corrosion to the aluminum alloy, does not affect the glossiness of an aluminum alloy substrate, has a good ash removal treatment effect and fast ash removal speed, and is low in cost and environmentally-friendly without dead angles and residues; the ash removing agent does not generate toxic and harmful gases in the ash removal process, is environmentally-friendly, has no threat to the health of operators, and solves the problems that as ash cannot be removed completely by a traditional process, the ash can only bewiped by a wet towel after the follow-up anodic oxidation sealing and is difficult to completely wipe. The preparation technology of the ash removing agent is simple, high-efficiency, energy-saving and environmentally-friendly.

Owner:广东双成金属表面科技有限公司

Surface bionic protection method of stone material and lithical cultural relic

The present invention discloses surface bionic protection method of stone material and lithical cultural relic. The protection method includes cleaning the surface with detergent comprising deionized water or organic solvent, treating the surface with biological amphibpatic functional pre-treating liquid, and crystallizing supersaturated calcium oxalate solution on the surface to form fine and compact surface protecting calcium oxalate film. The present invention has the advantages of wide applicable range, excellent compatibility to stone material, high weather resistance, raised corrosion resistance, improved hydrophobicity, firm combination with base stone material and no influence on the outer appearance, color and hand feeling of original stone material.

Owner:ZHEJIANG UNIV

A ceramic polymer composite material and a preparing method thereof

A ceramic polymer composite material is disclosed. The composite material comprises following components by mass: 47-85% of 3Y-ZrO2, 0-8% of polyethylene, 0-8% of polypropylene, 3-15% of paraffin, 0-10% of microcrystalline wax, 0.3-4% of a dispersant, 0-5% of a plasticizer, and 5-25% of graphite particles with the particle size of the graphite particles ranging from 1 [mu]m to 1 mm. The 3Y-ZrO2, the polyethylene, the polypropylene, the paraffin, the microcrystalline wax, the dispersant, the plasticizer and the graphite particles are sintered at a high temperature to obtain a ceramic material with a spongy porous crosslinking structure. The ceramic composite material with light weight and good toughness is formed by injecting the ceramic material with the spongy porous crosslinking structure into a polymer resin material. A preparing method of the ceramic polymer composite material is also disclosed.

Owner:湖北国瓷科技有限公司

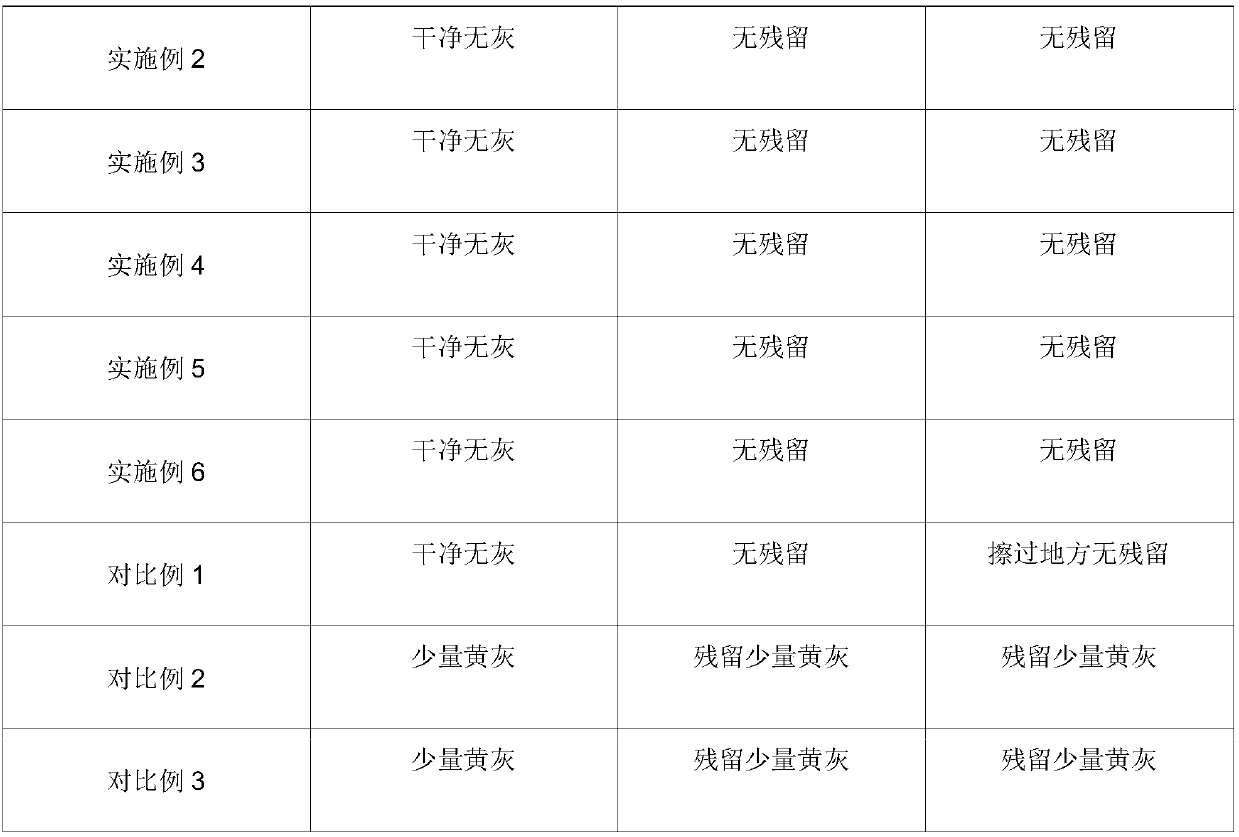

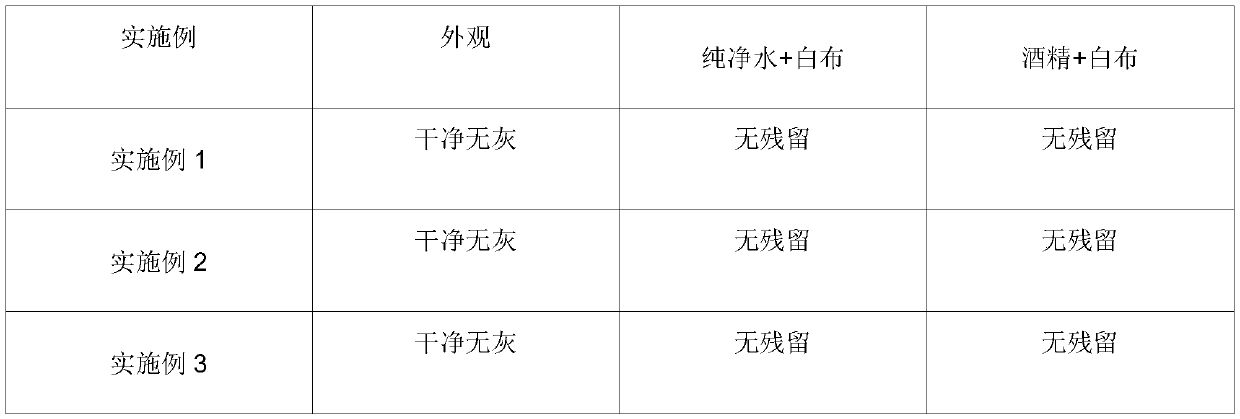

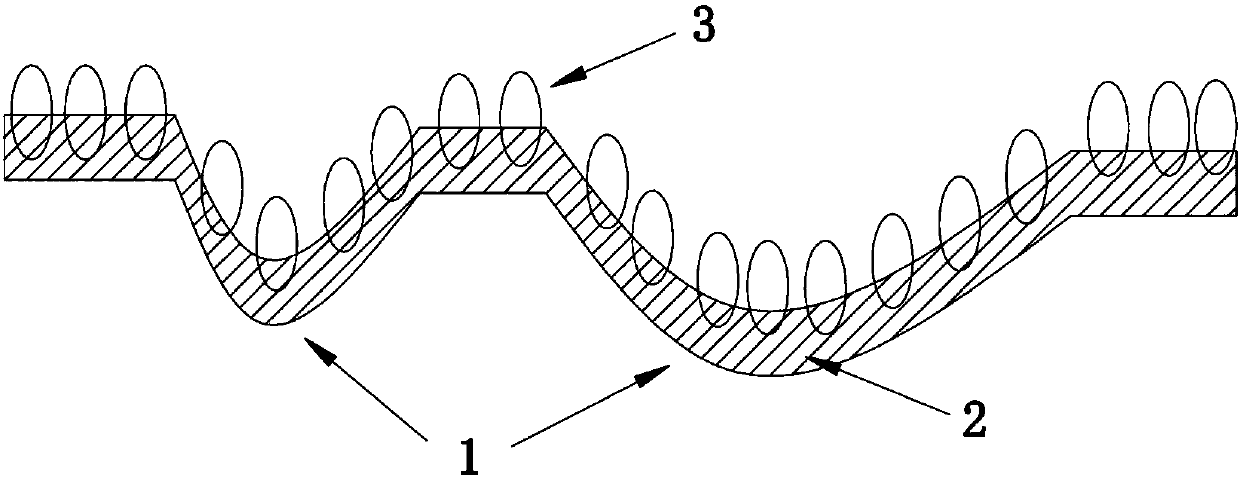

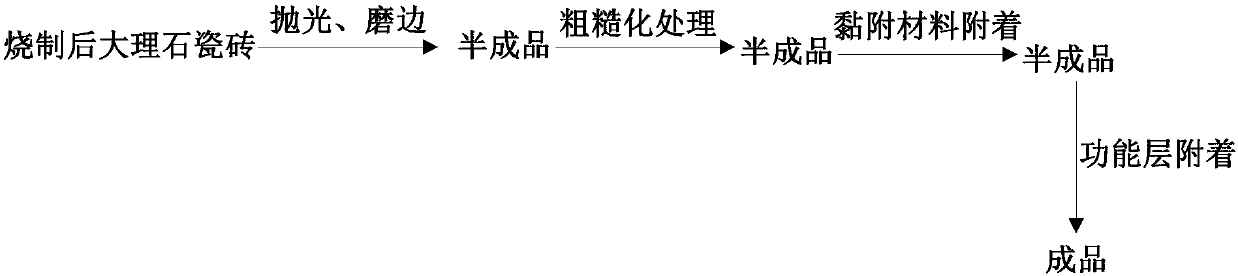

Marble tile capable of degrading formaldehyde and its preparation method

InactiveCN107675850AImprove stabilityNot easy to wearCovering/liningsCeramic shaping apparatusProduction lineAdhesive materials

The invention discloses a marble tile capable of degrading formaldehyde. The marble tile includes a marble tile base layer, a middle adhesive layer and a formaldehyde removing functional layer, wherein the middle adhesive layer is solidified on the upper surface of marble tile base layer, and the formaldehyde removing functional layer is bonded with the upper surface of the middle adhesive layer.According to the marble tile capable of degrading formaldehyde, the formaldehyde removing functional layer not only has the firm attaching effect of adhesive materials, but also has micro pore structures, formed by roughening, on the surface, the formaldehyde removing functional layer is not easy to wear, the service life is greatly improved, and original glossiness, color and luster and other technical indicators of the marble tile are not affected. Meanwhile, the invention discloses a preparation method of the marble tile, the process is simple, operation can be conducted on the original marble tile production line, and industrial application is easily achieved.

Owner:FOSHAN CITY GANI CERAMICS CO LTD +1

Alkyd paint for ship cabin and its production process

InactiveCN1810902AImprove temperature resistanceImprove moisture and water resistanceAntifouling/underwater paintsPaints with biocidesSolventResin modified

The present invention discloses one kind of paint for steel structure surface of ship and its production process. The paint has the main components including organic silicon resin modified alkyd resin, phenolic resin modified alkyd resin, pigment, nanometer zinc oxide, superfine aluminum hydroxide, superfine barium sulfate, nanometer silica, paint drier, No. 200 solvent gasoline and methyl ethyl ketoxime. The production process includes dispersing all the materials except paint drier and methyl ethyl ketoxime in a cylinder for 15 min, sand grinding to fineness superior to 40 microns, regulating with resin and paint drier to acid value not greater than 11 mgKOH / g and viscosity of 200-400 sec at 25 deg.c, filtering, packing while adding methyl ethyl ketoxime. The present invention solves the problem of paint film to release fume and toxic matter and has high safety performance and heat resistance.

Owner:梁新方

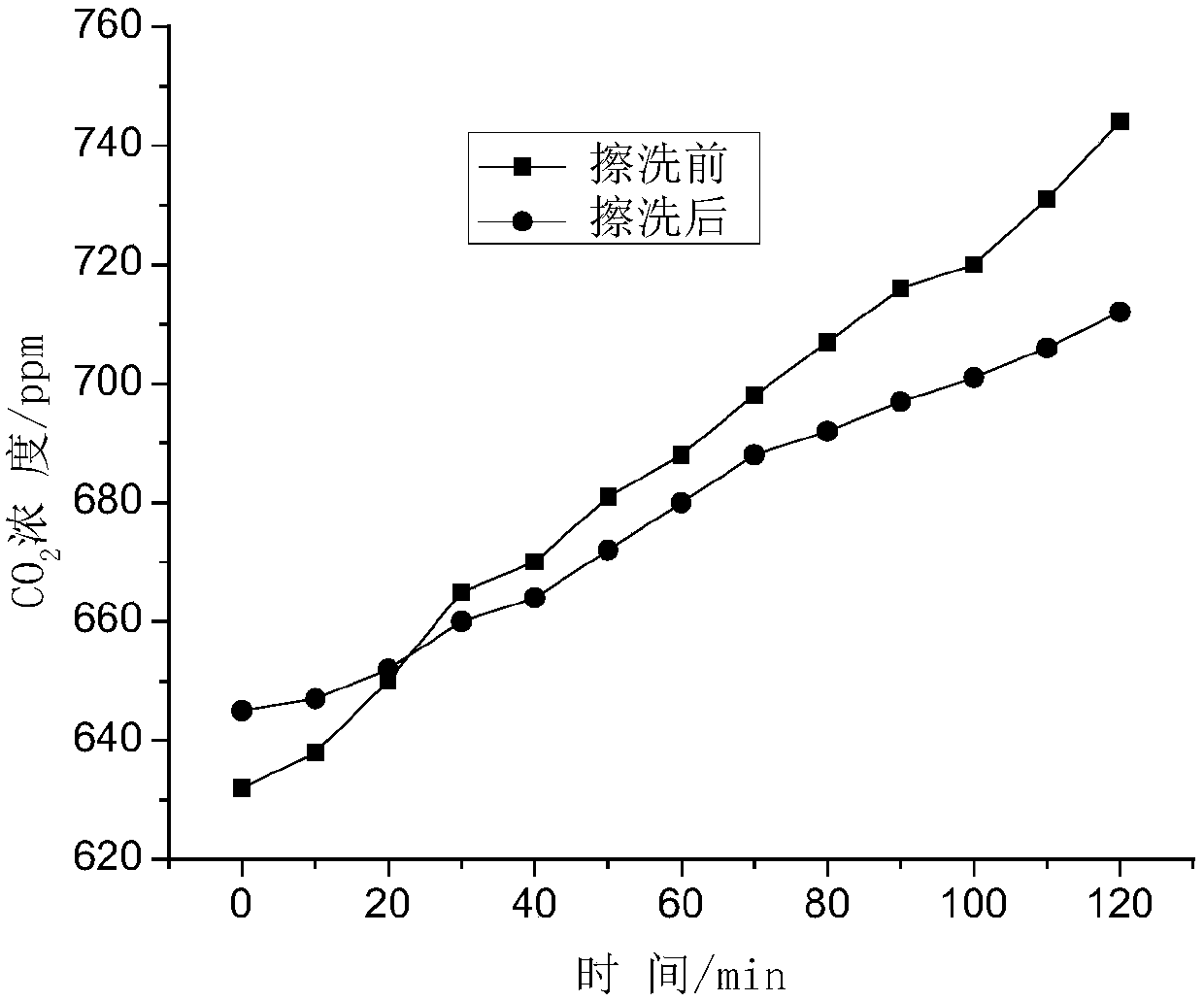

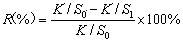

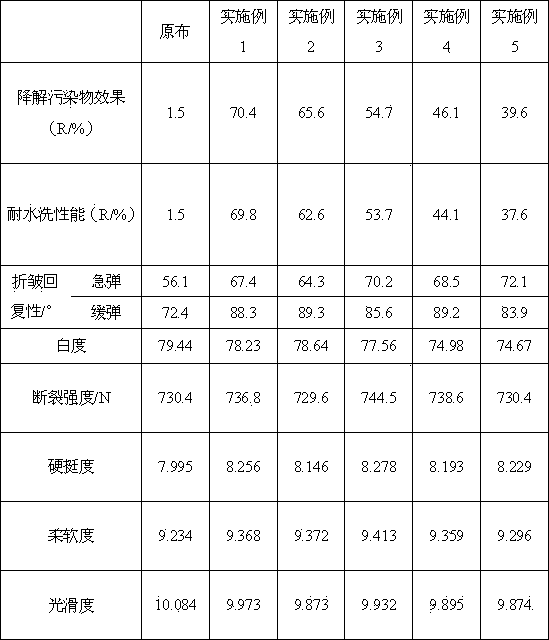

Preparation method of self-cleaning cotton fabric based on light-induced polymer free radicals for degrading pollutants

InactiveCN103410001AImprove mechanical propertiesImprove heat resistanceVegetal fibresCross-linkPolymer science

The invention discloses a manufacturing method of cotton fabric based on light-induced polymer free radicals for degrading pollutants, which belongs to the technical field of functional textiles. According to the manufacturing method, an appropriate H donor agent and a crosslinking agent are selected by utilizing the characteristic that sulfonated polyether ether ketone has high activities to H atoms in organic substances under light induction, so as to cross-link and form a film on the cotton fabric rich in hydroxyl to prepare the self-cleaning fabric which can generate the polymer free radicals by lighting and has an elimination effect on the pollutants. The manufacturing method mainly comprises the following steps: (1) preparing a composite finishing liquid of light-induced free-radical polymer, wherein the finishing liquid contains the sulfonated polyether ether ketone, H donor polymer, the crosslinking agent, HCL (hydrogen chloride) and the like; and (2) padding and baking the cotton fabric in the finishing liquid. The cotton fabric which is prepared by using the preparation method and has a function of degrading the pollutants by the light induction has the effects of antibiosis, pesticide degradation, pigment degradation and the like, can be used for common clothing, medical fabric, household fabric and the like, and has a wide application prospect.

Owner:ZHEJIANG SCI-TECH UNIV

Environment-friendly water-based paint for living container and preparation method thereof

ActiveCN106883739AGood environmental friendlinessProtect physical and mental healthAnti-corrosive paintsPolyester coatingsSolventChemistry

The invention discloses environment-friendly water-based paint for a living container and a preparation method thereof, and relates to the technical field of water-based paint. The environment-friendly water-based paint is prepared from the following raw materials in parts by weight: 20 to 25 parts of waterborne alkyd resin, 12 to 15 parts of waterborne styrene-acrylic emulsion, 28 to 37 parts of deionized water, 2 to 2.5 parts of environment-friendly cosolvents, 1.8 to 2.5 parts of neutralizers, 0.2 to 0.3 part of antifoaming agents, 0.2 to 0.3 parts of flatting agents, 0.2 to 0.3 part of substrate wetting agents, 0.8 to 1.0 part of adhesion promoters, 0.5 to 1 part of coalescing agents, 1.4 to 1.7 parts of waterborne driers, 0.5 to 1.2 parts of flash-rust inhibitors, 0.5 to 1.2 parts of rheological agents, 0.18 to 0.2 part of anti-settling agents, 0.5 to 0.8 part of dispersing agents, 1.65 to 2.0 parts of phthalocyanine blue, 2.5 to 3.0 parts of rutile titanium dioxide, 6 to 8.7 parts of aluminum triphosphate and 4.5 to 5.5 parts of barium sulfate. The environment-friendly water-based paint has the advantages that the environment is protected; the impact resistant, water resistant, weather resistant and salt spray resistant effects are achieved; the indexes such as the adhesive force meet the national standard requirements.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Composition of waterproof agents for leather

The invention provides a composition of waterproof agents for leather. The composition of the waterproof agents for the leather is made of the following raw materials according to the following weight percentage: 10-20 of sodium sulfate, 10-15 of hydrochloric acid, 5-10 of sodium hydroxide, 70-80 of ethanol, 50-60 of stearic acid, 40-50 of chromium trichloride, 2-8 of sodium carbonate and 15-30 of water. In a preparation process, the stearic acid, the chromium trichloride and the ethanol are added into a ceramic reaction kettle to obtain a mixture I, the mixture I is stirred and heated until the temperature of the mixture I rises to 70 DEG C, then the rest raw materials are added into the ceramic reaction kettle for reactions to obtain a mixture II, after the temperature of the mixture II is maintained for 1-2 hours, the mixture II is subjected to cooling, still standing and filtering to obtain a filtrate, and the filtrate is the composition of the waterproof agents for the leather. The composition of the waterproof agents for the leather is reasonable in design, enables the leather to have a waterproof function, cannot affect luster of the leather and can improve the quality of the leather at the same time.

Owner:王超

Hot stamping technique

InactiveCN107399192ADoes not affect glossAvoid affecting the spraying effectDecorative surface effectsHot stampingUV curing

The invention discloses a hot stamping technique, and belongs to the technical field of printing. The hot stamping technique comprises the following steps that (1) proper electric aluminum foil is selected according to the material of a printed article; (2) in a vacuum environment, a gloss oil pattern is sprayed on the printed article, and UV curing is conducted; (3) a hot stamping plate is mounted on a honeycomb plate; (4) the honeycomb plate and the hot stamping plate are mounted at corresponding positions of a hot stamping machine; (5) the electric aluminum foil is mounted; (6) hot stamping technological parameters are set and the honeycomb plate is preheated to the temperature of 110 DEG C firstly, and then hot stamping is conducted on the printed article obtained in the step (2); (7) trial stamping is conducted, and the parameters are adjusted according to a hot stamping result till a product is qualified; (8) sample signing is conducted; and (9) normal hot stamping is conducted. By adoption of the hot stamping technique, dust in air can be prevented from adhering to gloss oil in the gloss oil spraying process and the gloss oil drying process, so that the surface of dried gloss oil is smooth, and the situation that since the pattern is irregular, gloss oil is accumulated in pits of the pattern or small gloss oil particles are formed on the edges of the pattern in the gloss oil spraying process, and the spraying effect is affected is avoided.

Owner:郑州华美彩印纸品有限公司

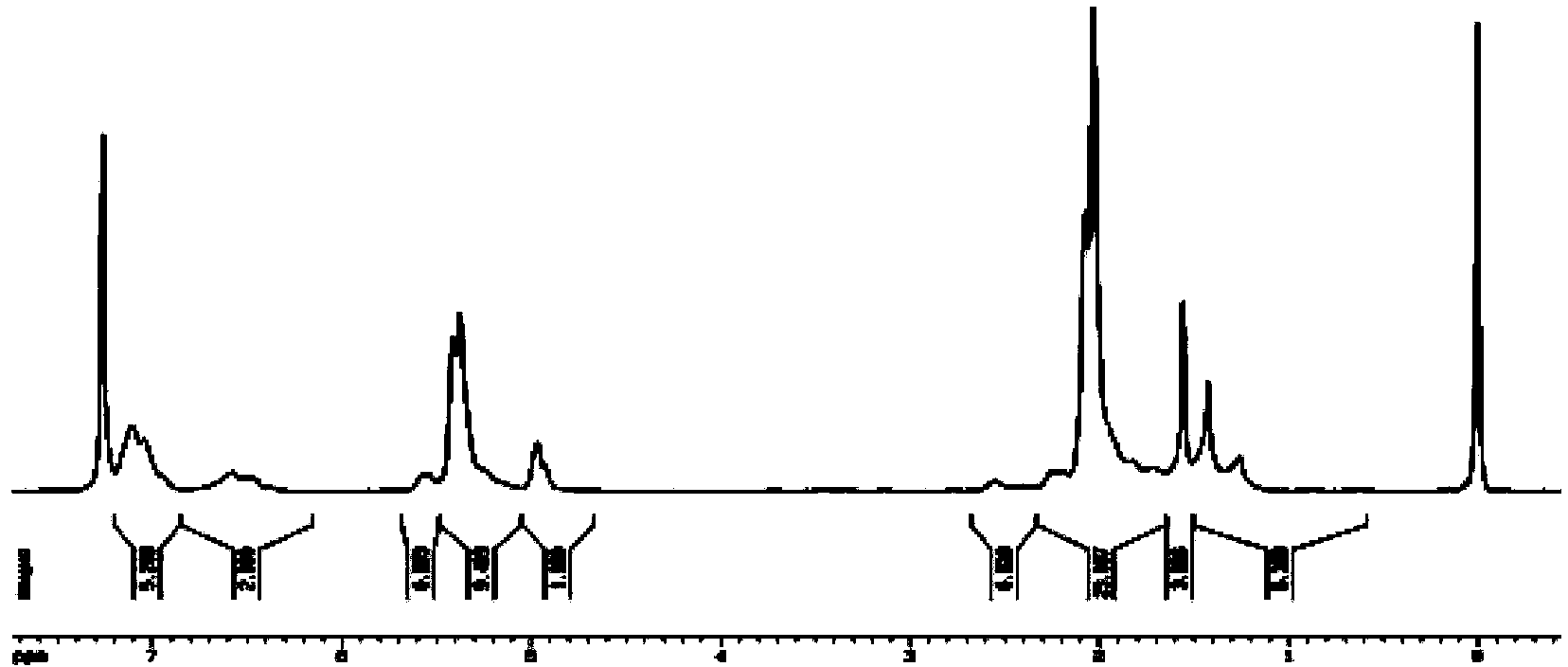

Two-stage material-feeding random gradually-varied butylbenzene co-polymer and preparation method thereof

The invention discloses a two-stage material-feeding random gradually-varied butylbenzene co-polymer and a preparation method thereof. The co-polymer includes a butylbenzene random gradually-varied co-copolymerized segment and a polystyrene homo-polymerized segment. The preparation method includes following steps: controlling temperature of a reactor being filled with a non-polar hydrocarbon solvent, an activity regulating agent and an initiator; adding a mixed monomer including styrene and butadiene; carrying out a first-stage random polymerization reaction; adding styrene for carrying a further reaction; and adding a terminator for stopping the reactor after the reacting completed. The preparation method is simple in process, is easy to carry out and is mild in reaction conditions. The random gradually-varied butylbenzene co-polymer, when being used for modifying ABS resin, has an excellent toughening effect, a good mechanical performance and an excellent glossiness.

Owner:CHINA PETROLEUM & CHEM CORP

Water emulsification process of alkyd resin coating

The invention discloses a water emulsification process of an alkyd resin coating. The coating is generated by proportionally mixing and stirring four or more substances in alkyd resins (high viscosity), an emulsifying agent, distilled water, sulfates, 200# solvent oil, n-butanol and isobutanol according to the following steps: throwing the distilled water and the sulfates into a head tank with stirring according to the proportion and stirring and dissolving the substances for later use; throwing the alkyd resins and the emulsifying agent into an emulsifying kettle, dropwise adding water solution from the head tank when the stirring linear speed is more than 6m / s and controlling the dropwise adding time between 30 minutes and 90 minutes; and stirring and emulsifying the substances for 40-80 minutes at high speed after dropwise adding and using the solvent oil and / or an alcohol solvent to adjust the viscosity. The process has the following characteristics that the water emulsion replaces part of organic solvents and has stable properties, thus reducing the VOC (volatile organic compounds) of the alkyd resin coating, without affecting the properties of the coating; the VOC can be reduced by 10-30% at most and the product reaches the national standard; and the needed equipment investment is low and the water-in-oil alkyd resin emulsion has good stability.

Owner:CHONGQING SANXIA PAINTS CO LTD

Anti-mildew photocurable waterborne stone protective agent for stone surface and preparation method of anti-mildew photocurable waterborne stone protective agent

ActiveCN108203559AImprove film forming speedImprove the protective effectAntifouling/underwater paintsPaints with biocidesHigh humiditySolvent

The invention discloses an anti-mildew photocurable waterborne stone protective agent for a stone surface and a preparation method of the anti-mildew photocurable waterborne stone protective agent. The protective agent comprises the following components: UV-curable film forming resin, a photoinitiator, a polyphosphoric acid dispersant, an organic silicon defoaming agent, a film forming auxiliary,a slow-release broad-spectrum anti-mildew bactericide and solvent water. Due to a synergistic effect of a light-curable resin technology and a nano-adsorbent carrier slow release technology, the filmforming speed and protective effect of the waterborne stone protective agent are greatly improved, and the curing effect exerting time is greatly shortened while the original advantage of a waterborneprotective agent is retained, so that the construction efficiency can be remarkably increased; and meanwhile, the protective construction operation can also be realized under a low-temperature or high-humidity environment, so that the adaptability of the waterborne stone protective agent in the prior art is widened, and the antibacterial and anti-mildew properties of the waterborne stone protective agent are remarkably improved while the color, glossiness and light transmitting property of a coating are not affected.

Owner:云浮华云创新设计有限公司

Dry mix sub-light powder paint

InactiveCN101368061ASatisfy matting effectDoes not affect glossPowdery paintsPolyester coatingsMetallurgyImpurity

The invention discloses dry mixed matt powder paint, which comprises component A and component B. The component A comprises the following materials by weight portion: 25 to 28 portions of vibrin A; 2 to 5 portions of TGIC; 5 to 7 portions of BaSO4; 2 to 5 portions of CaCO3; and 1.5 to 2.5 portions of TiO2. The component B comprises the following materials by weight portion: 25 to 28 portions of vibrin B; 2 to 5 portions of TGIC; 4.5 to 6.5 portions of BaSO4; 2.5 to 4 portions of CaCO3; and 0.8 to 1.0 portion of TiO2. By comparing the invention with the prior art, the dry mixed matt powder paint contains little impurity, and has excellent scratch resistance and impact resistance as well as comfortable luster, which is solventless thermoset high strength decorative antifriction material and can eliminate light when the powder is cured.

Owner:ANHUI MEIJIA NEW MATERIAL

Gold-based conductive paste for silk-screen printing and preparation method of gold-based conductive paste

InactiveCN108053915AImprove reliabilityTroubleshoot short circuitsNon-conductive material with dispersed conductive materialCable/conductor manufactureOptoelectronicsCopper

The invention relates to gold-based conductive paste for silk-screen printing and a preparation method of the gold-based conductive paste. The conductive paste comprises gold powder particles, glass powder and an organic carrier, wherein a copper element is contained in the organic carrier, and the copper element in the organic carrier exists in a form of organic copper. The gold-based conductivepaste for silk-screen printing, provided by the invention, has the following advantages that (1) the reliability of an electronic component and a wiring substrate is improved; 2) the bonding performance of a gold wire after sintering is obviously improved; and 3) the sintering smoothness of a surface of the gold-based conductor paste is improved.

Owner:西安宏星电子浆料科技股份有限公司

Wax solvent used for soaking and cleaning aluminum cosmetic cap

The invention discloses a wax solvent used for soaking and cleaning an aluminum cosmetic cap. The wax solvent comprises triethanolamine oleic soap, a wetting agent, a non-ionic surface active agent, ethyl alcohol, mildew preventive, an organic silicon defoamer and water. 1 / 3 pure water is added into a reaction still, then the triethanolamine oleic soap is added and automatically stirred for 10 min, the wetting agent and the non-ionic surface active agent are added and automatically stirred for 20 min, finally the ethyl alcohol, the mildew preventive and the organic silicon defoamer are added, and water is added for constant-capacity even mixing, so that the wax solvent is prepared. The wax solvent is used for wax removing treatment of the aluminum cosmetic cap, hardly corrodes the aluminum cosmetic cap and does not influence the glossiness of the aluminum cosmetic cap. The wax removing treatment speed is high, the cost is low, environmental friendliness is achieved, the wax residual amount is smaller than 1%, the brightness change is within 10 gld, and the problems that the wax residual amount is large, energy consumption is large, time is long, the temperature is high, environmental friendliness is not achieved, aluminum cosmetic cap substrates are corroded, and the glossiness of aluminum cosmetic caps is influenced when traditional wax solvents are used for wax removing treatment of the aluminum cosmetic caps are solved.

Owner:广东双成金属表面科技有限公司

Waterborne bronze powder pigment for printing ink and preparation method thereof

InactiveCN104327590AGood compatibilityImprove the level ofInksPigment treatment with macromolecular organic compoundsWater basedDispersity

The invention discloses a waterborne bronze powder pigment for printing ink. The waterborne bronze powder pigment for printing ink is characterized by comprising the following components in parts by weight: 40-60 parts of flaky bronze powder, 8-10 parts of tetraethyl orthosilicate, 0.1-0.3 part of a silane coupling agent A-151, 0.1-0.2 part of sodium benzoate, 3-5 parts of polyethylene glycol, 0.1-0.2 part of palm oil, 0.2-0.4 part of sorbitol, 0.5-1 part of poloxamer, 0.05-0.1 part of bamboo leaf flavonoid, 0.05-0.1 part of myristic acid, 0.05-0.1 part of coconut oil fatty acid diethanolamide, 0.1-0.2 part of polydimethylsiloxane and 0.5-1 part of compound auxiliaries. The waterborne bronze powder pigment has high dispersity in a water-based medium, is stable in property, high in brightness and good in metallic sense and can be applied to the fields of printing ink and screen printing ink which are of an aqueous system.

Owner:HEFEI SUNRISE PIGMENTS

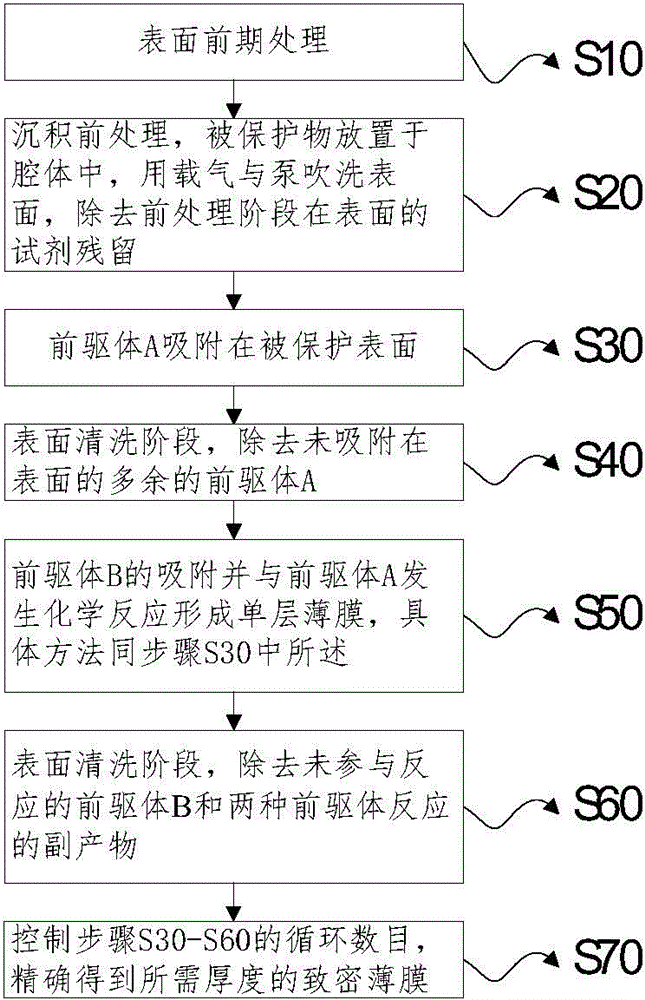

Metal product surface protection method

ActiveCN104060239AHigh strengthImprove wear resistanceChemical vapor deposition coatingChemical reactionReaction temperature

The invention discloses a metal product surface protection method which comprises the following steps: pretreatment: carrying out clearing, degreasing, cleaning and restoration on the metal product surface to be protected; treatment before deposition: putting the pretreated metal product in an atomic layer deposition device, purging the surface with carrier gas, and meanwhile, evacuating the atomic layer deposition device by using a vacuum pump; deposition: alternately introducing multiple precursors at proper reaction temperature under proper pressure to respectively adsorb the precursors to the surface to be protected, and initiating chemical reaction among the precursors to form a single-layer film; and repeating the deposition step to generate a compact film on the surface to be protected, thereby implementing water-barrier oxygen-barrier protection on the metal product surface. The method can solve the problems of insufficient compactness, nonuniform thickness, short service life, high tendency to generating gloss and the like in the existing protective film on the metal product surface.

Owner:HUAZHONG UNIV OF SCI & TECH

Adhesive for PET-PVC composite film

InactiveCN106221628AImprove adhesionAvoid phenomena such as edge explosionStarch derivtive adhesivesGraft polymer adhesivesEpoxyComposite film

The invention discloses an adhesive for a PET-PVC composite film. The adhesive is prepared by matching epoxy resin-acrylate polymer emulsion prepared according to a core-shell polymerization method with a curing agent and other ingredients. The adhesive is good in adhesive effect, and the PVC and PET films can be firmly adhered under the condition that the adhesive layer is thin, so that the phenomena that the composite film cracks during cutting and the like are avoided. Moreover, the adhesive is high in transparency and does not influence the permeability and glossiness of the composite film, and the composite film prepared by using the adhesive is high in aesthetic property.

Owner:深圳市上悦标签有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com