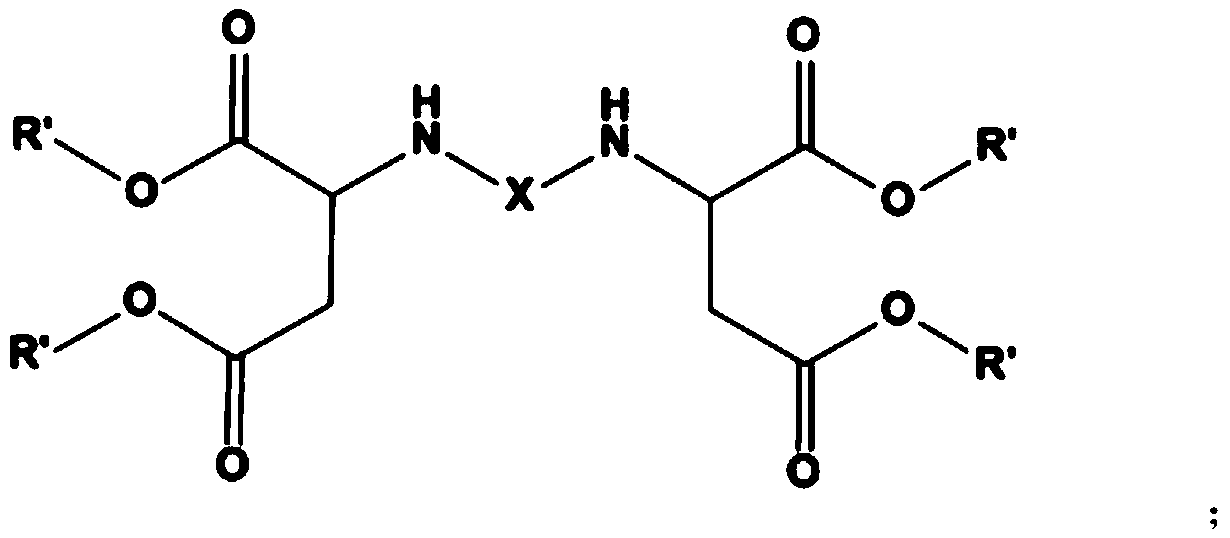

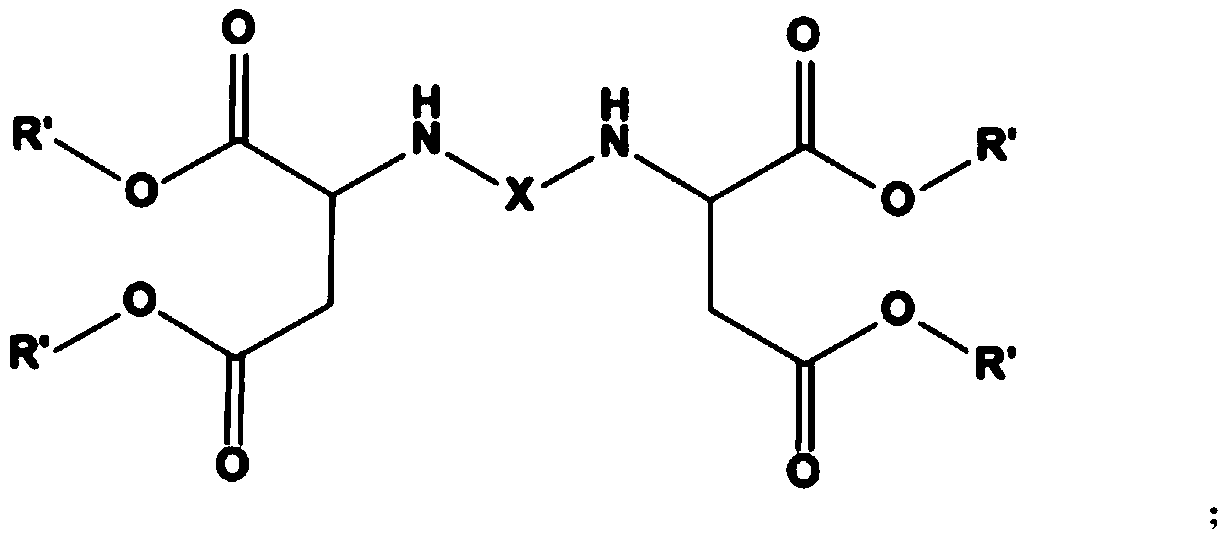

Modified polyaspartate polyurea coating as well as preparation method and application thereof

A modification technology of aspartic acid ester, applied in polyurea/polyurethane coatings, coatings, devices for coating liquid on the surface, etc., can solve the problems of high reactivity, poor storage stability of polyurea resins, and solvent-resistant wiping , hardness and other poor performance problems, to achieve the effect of simple preparation process, realize industrial scale production, and be conducive to industrial scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

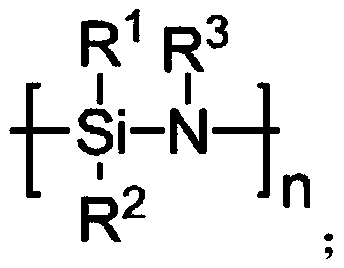

[0113] In a preferred embodiment, the preparation method comprises the following steps:

[0114] (a) dissolving isocyanate and its multimer curing agent in polyaspartic acid ester according to the formula quantity, stirring and reacting for 5-30min at room temperature to obtain an intermediate;

[0115] (b) mix the intermediate and polysilazane obtained in step (a) uniformly according to a certain ratio, add a certain amount of solvent, react at room temperature for 5-10min, add a certain amount of auxiliary agent, and obtain the modified Polyaspartate polyurea coating;

[0116] It should be noted that the present invention is not strict about the reaction temperature of step (a) and step (b), they all need to be reacted at room temperature, for example, each independently can be 10-60°C, or 18-38°C °C, it can also be 20-35 °C, it can also be 22-32 °C, etc.

[0117] The above preparation method has mild reaction conditions, can react at room temperature, has short reaction t...

Embodiment 1

[0142] 1. Modified polyaspartate polyurea coating

[0143] It is mainly prepared from the following raw materials: 6.29g HDI type isocyanate Desmodur N75, 2.77g polyaspartate F420, 2.5g xylene, 1.60g organopolysilazane 1500RC, 0.3g defoamer BYK-104 and 0.1g Leveling agent CAB381-0.1.

[0144] 2. Preparation of modified polyaspartate polyurea coating

[0145] Including the following steps: dissolving 6.29g of isocyanate curing agent Desmodur N75 into 2.77g of polyaspartic acid ester F420, reacting at room temperature for 10min; then adding 2.5g of xylene and 1.60g of organopolysilazane 1500RC, After reacting at room temperature for 5 minutes, 0.3 g of defoamer BYK-104 and 0.1 g of leveling agent CAB381-0.1 were added to obtain a modified polyaspartic ester polyurea coating.

[0146] 3. Application of modified polyaspartate polyurea coating

[0147] The application of this embodiment in hardening and improving the overall performance of the coating:

[0148] The modified pol...

Embodiment 2

[0150] 1. Modified polyaspartate polyurea coating

[0151] It is mainly prepared from the following raw materials: 6.29g IPDI type isocyanate Desmodur 340, 2.91g polyaspartate F520, 2.5g butyl acetate, 1.60g vinyl silicone oil modified polysilazane, 0.3g defoamer BYK -141 and 0.15g leveling agent CAB552-0.2.

[0152] 2. Preparation of modified polyaspartate polyurea coating

[0153] Including the following steps: dissolving 6.29g of IPDI-type isocyanate Desmodur 340 into 2.91g of polyaspartic acid ester F520, reacting at room temperature for 15min; then adding 2.5g of butyl acetate and 1.60g of vinyl silicone oil modified poly Silazane, react at room temperature for 5 minutes, add 0.3g of defoamer BYK-141 and 0.15g of leveling agent CAB552-0.2 to obtain modified polyaspartate polyurea coating.

[0154] 3. Application of modified polyaspartate polyurea coating

[0155] The application of this embodiment in hardening and improving the overall performance of the coating:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com