Patents

Literature

869 results about "Polysilazane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

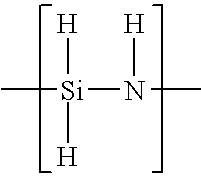

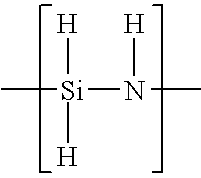

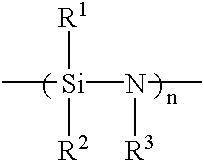

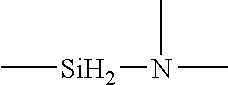

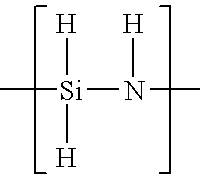

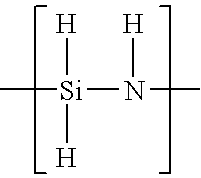

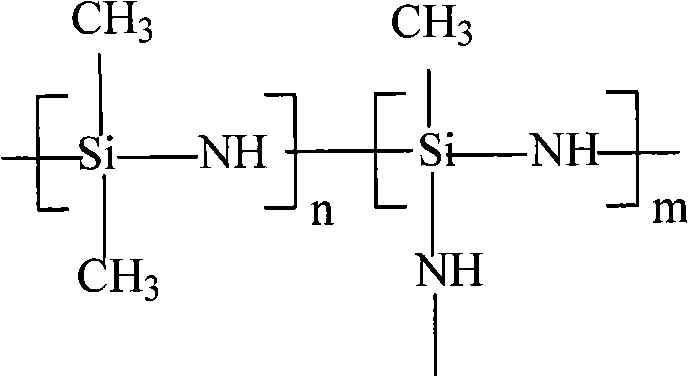

Polysilazanes are polymers in which silicon and nitrogen atoms alternate to form the basic backbone. Since each silicon atom is bound to two separate nitrogen atoms and each nitrogen atom to two silicon atoms, both chains and rings of the formula [R¹R²Si-NR³]ₙ occur. R¹-R³ can be hydrogen atoms or organic substituents. If all substituents R are H atoms, the polymer is designated as Perhydropolysilazane, Polyperhydridosilazane, or Inorganic Polysilazane ([H₂Si–NH]ₙ).

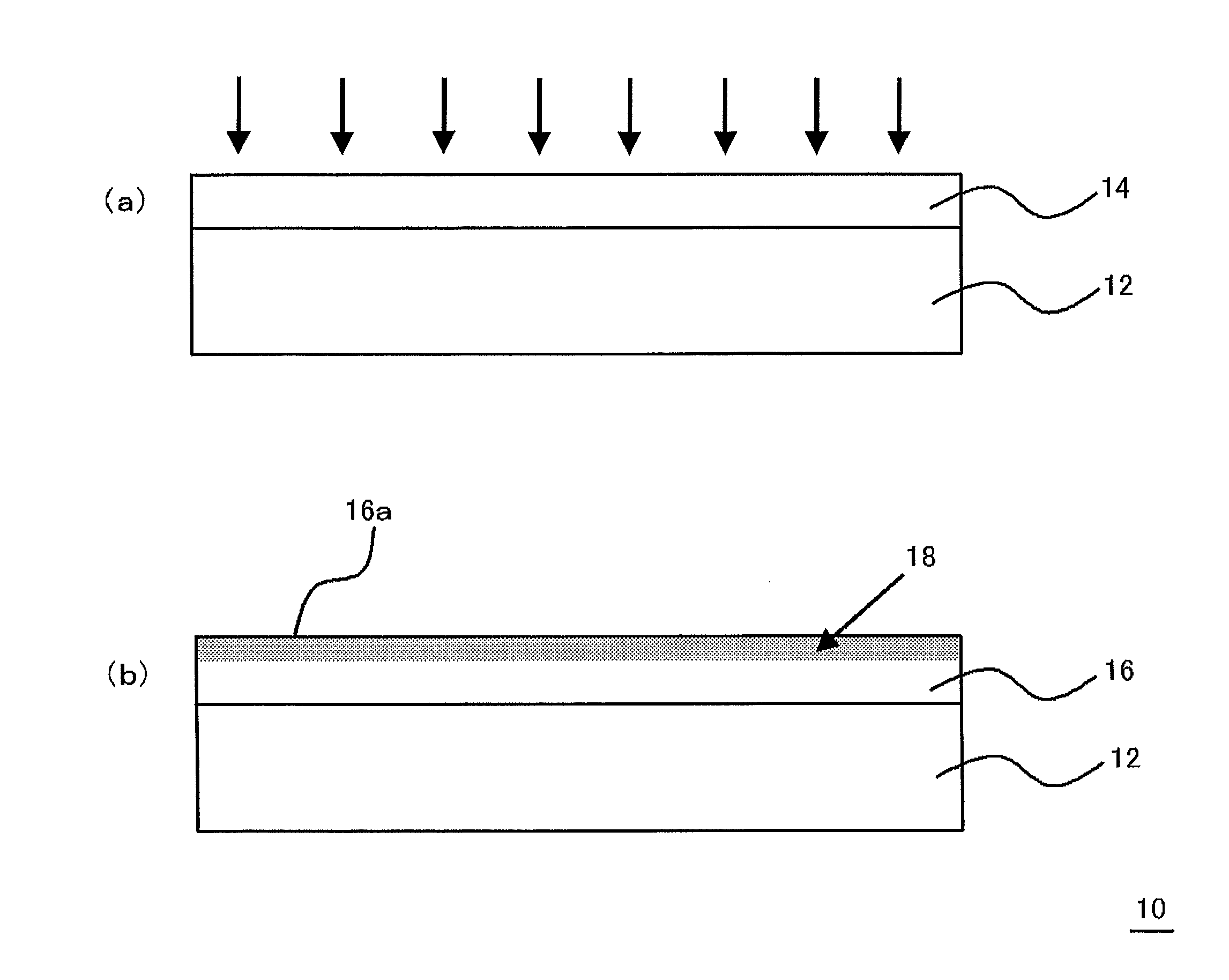

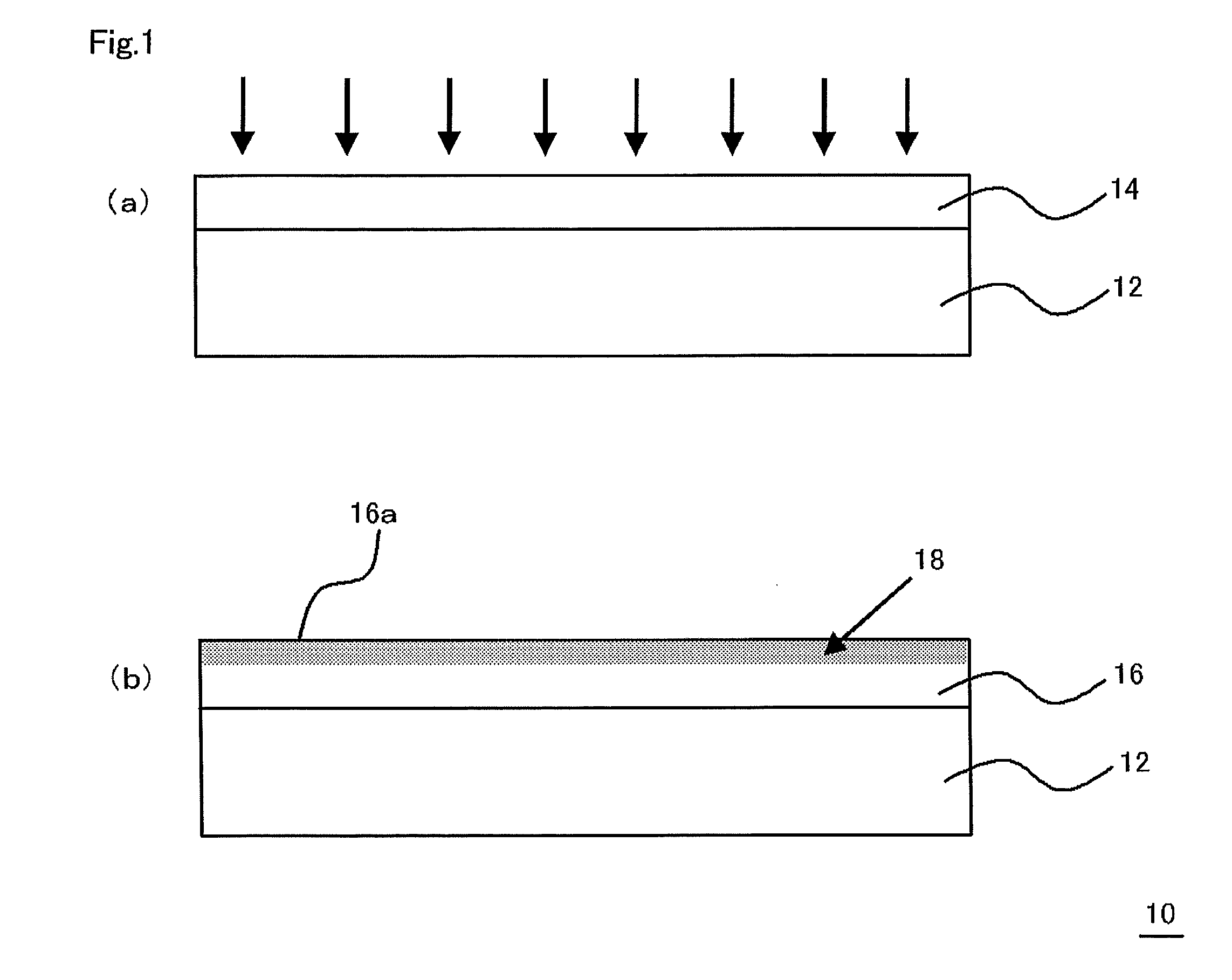

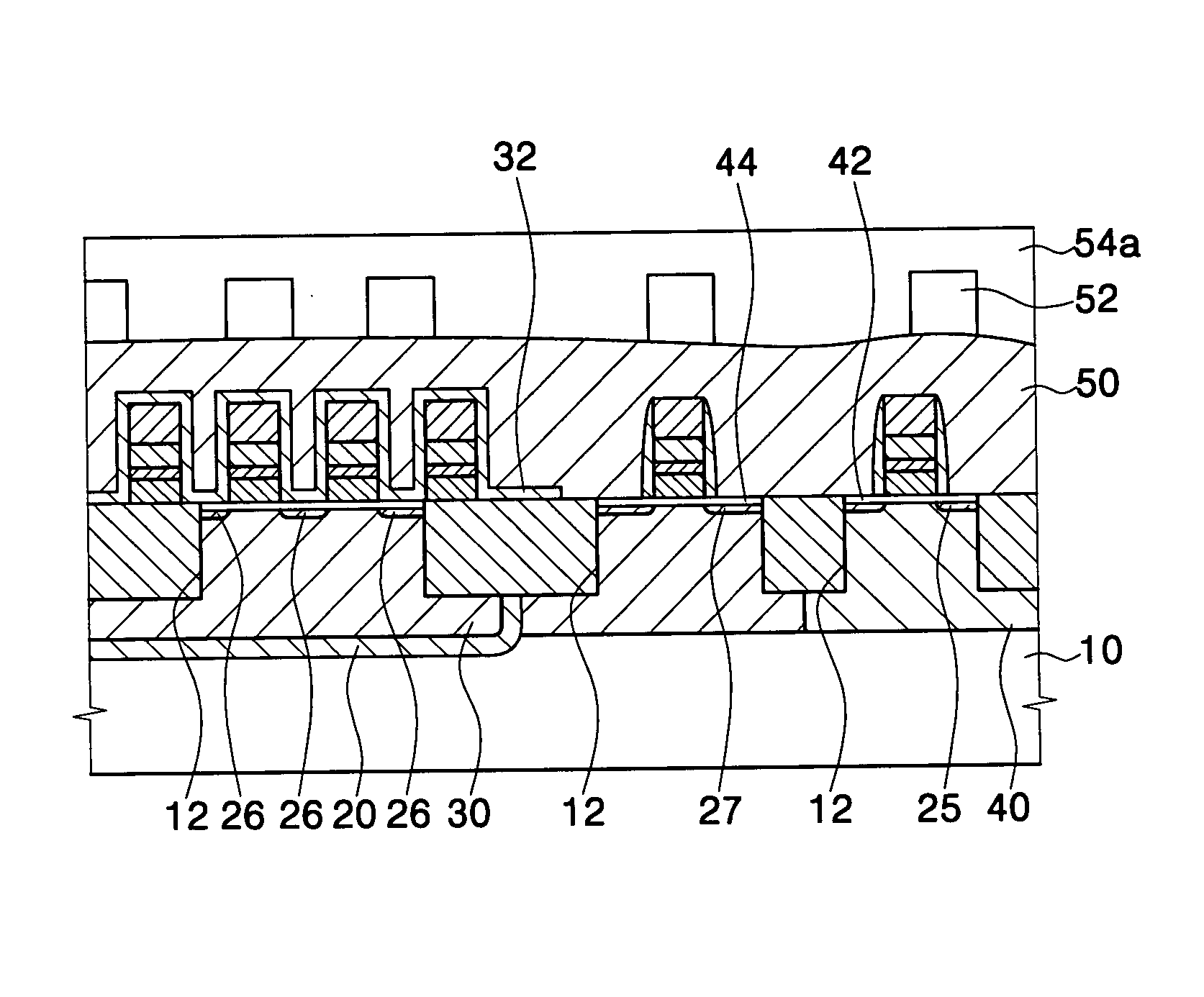

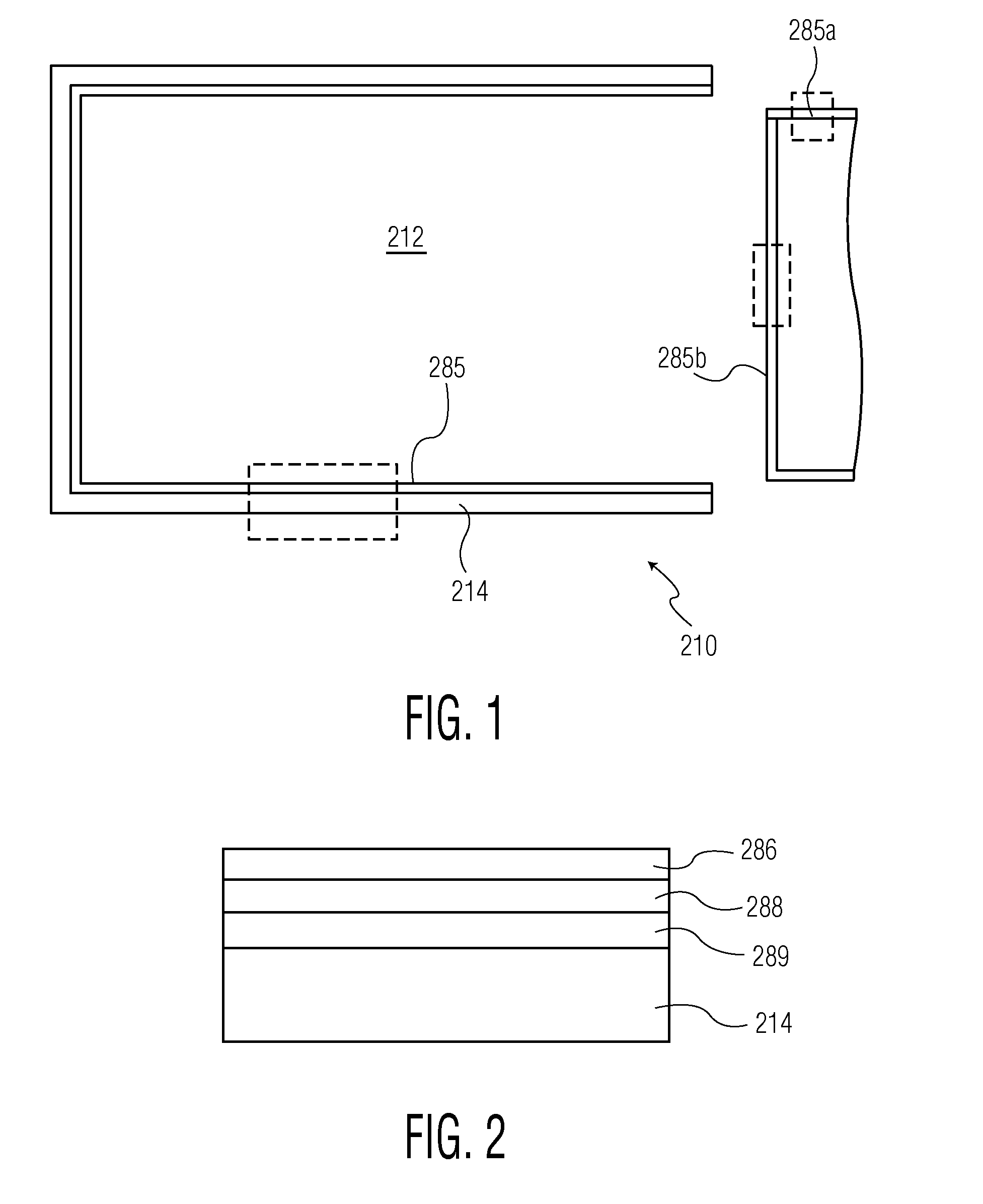

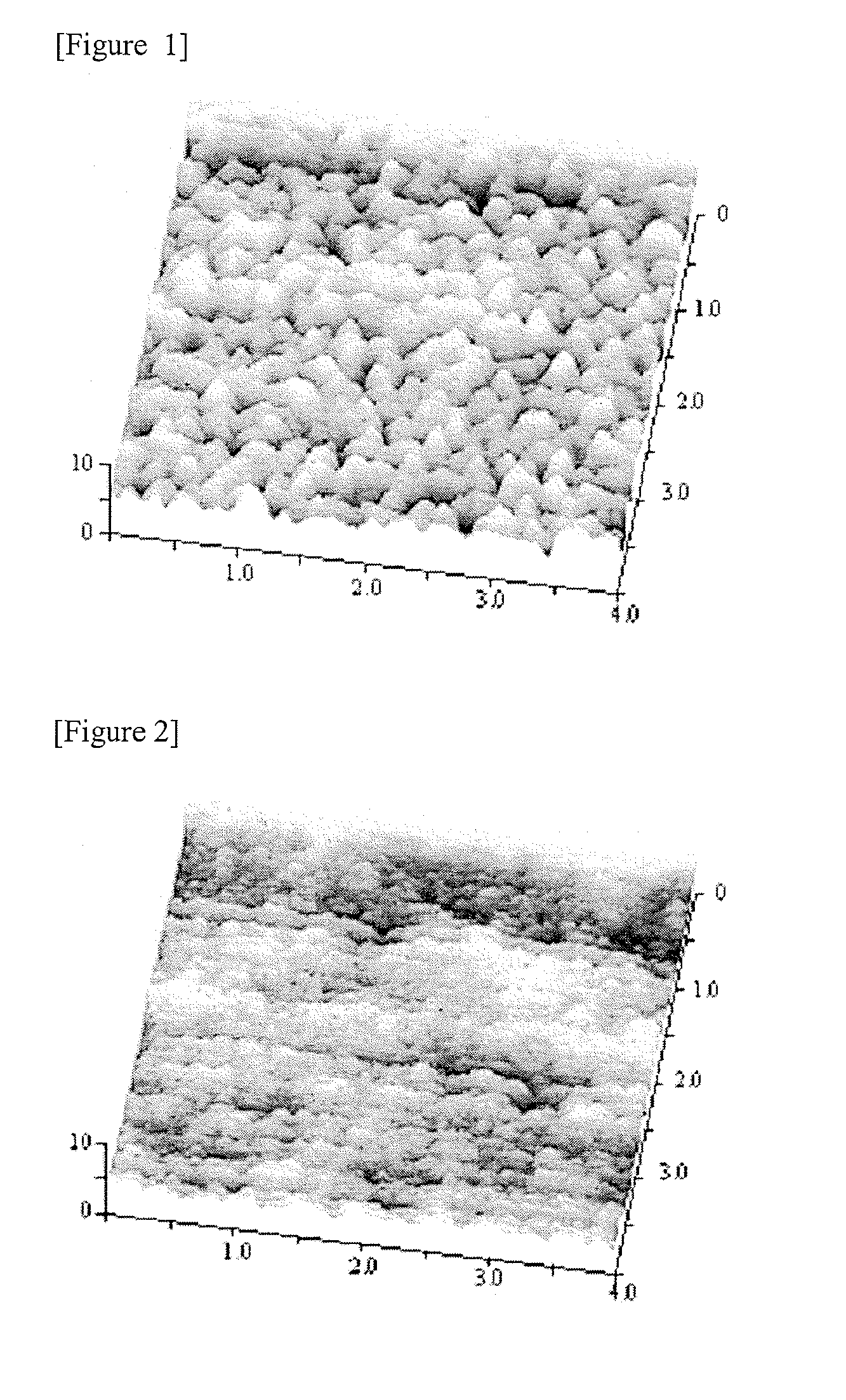

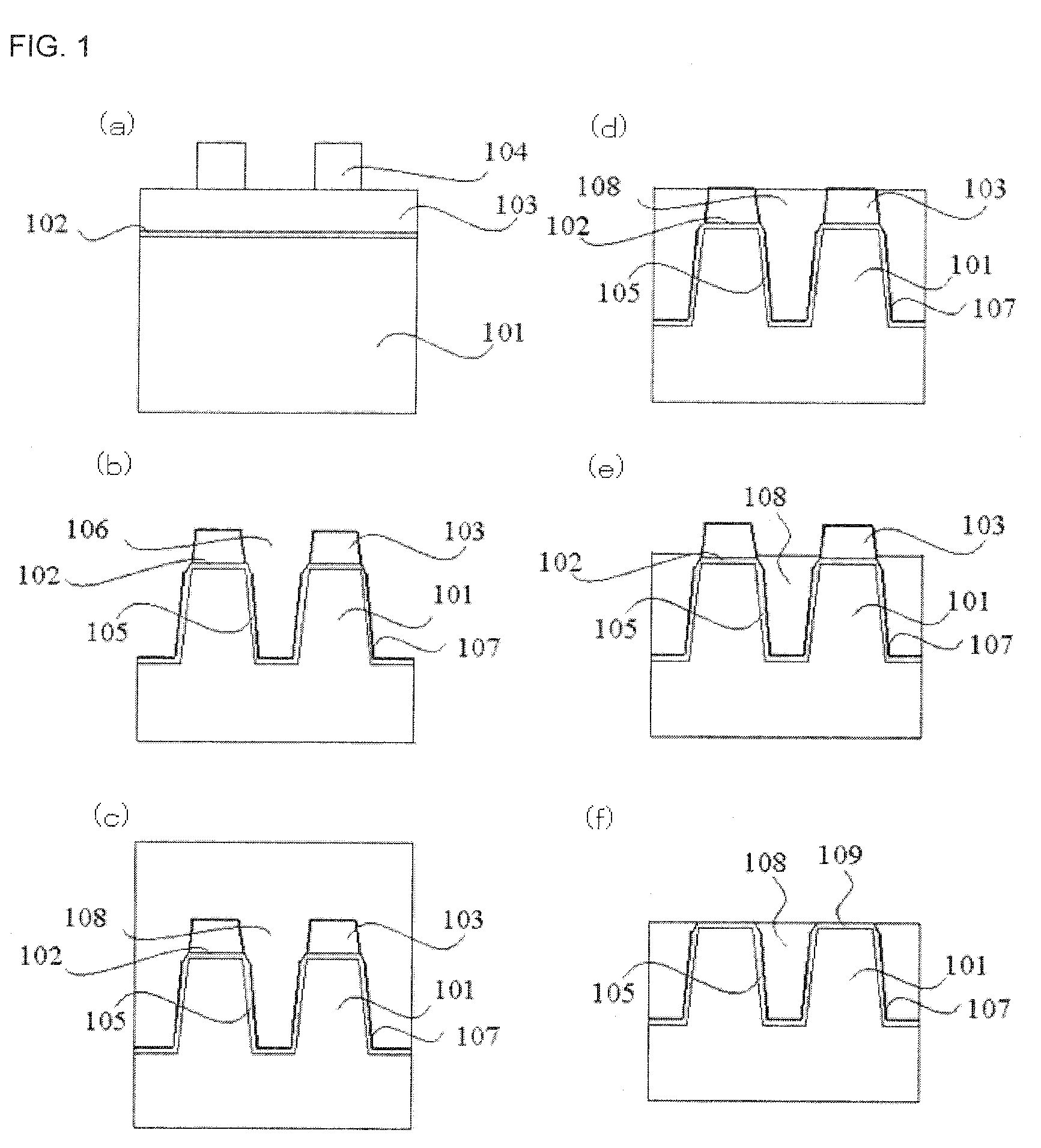

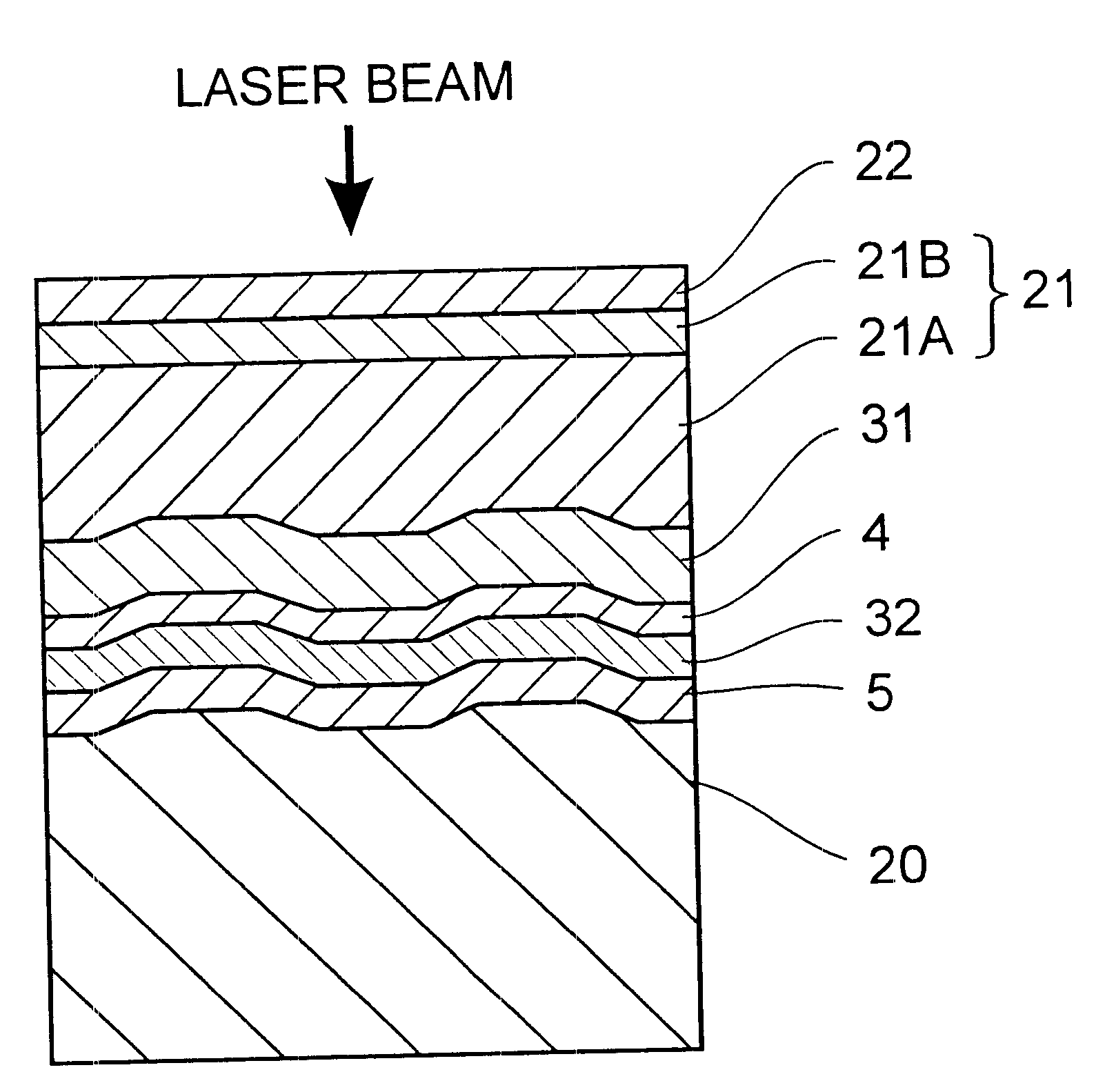

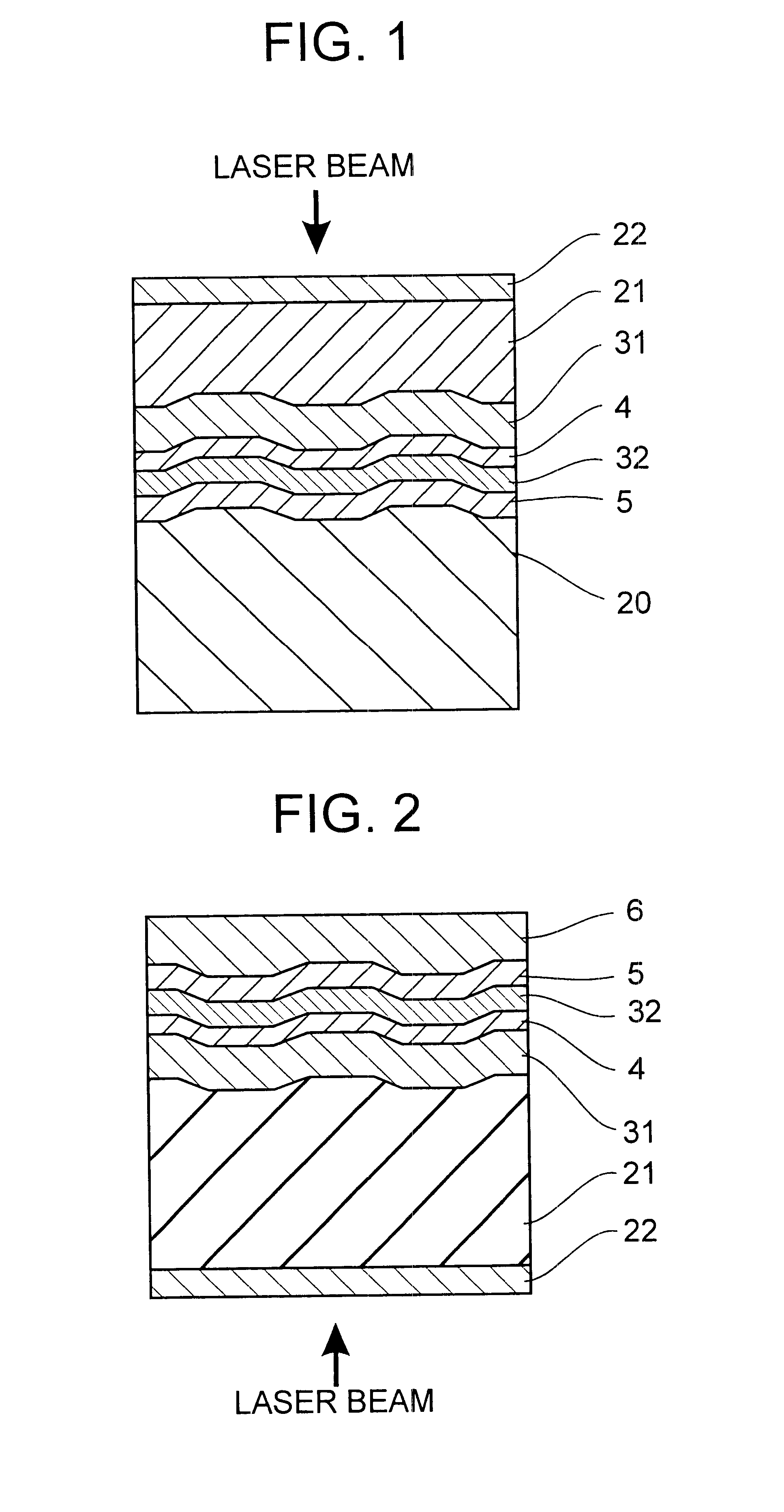

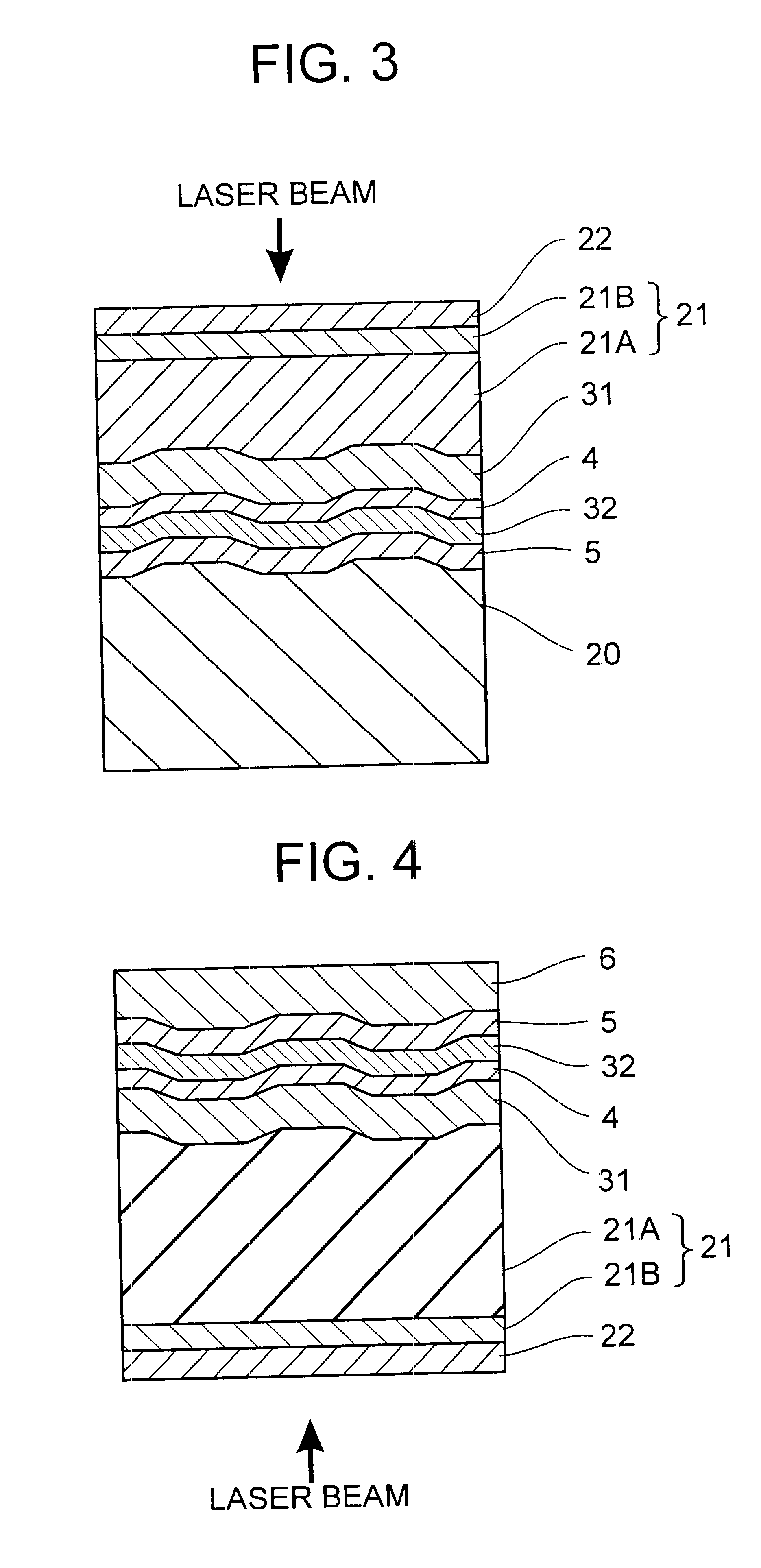

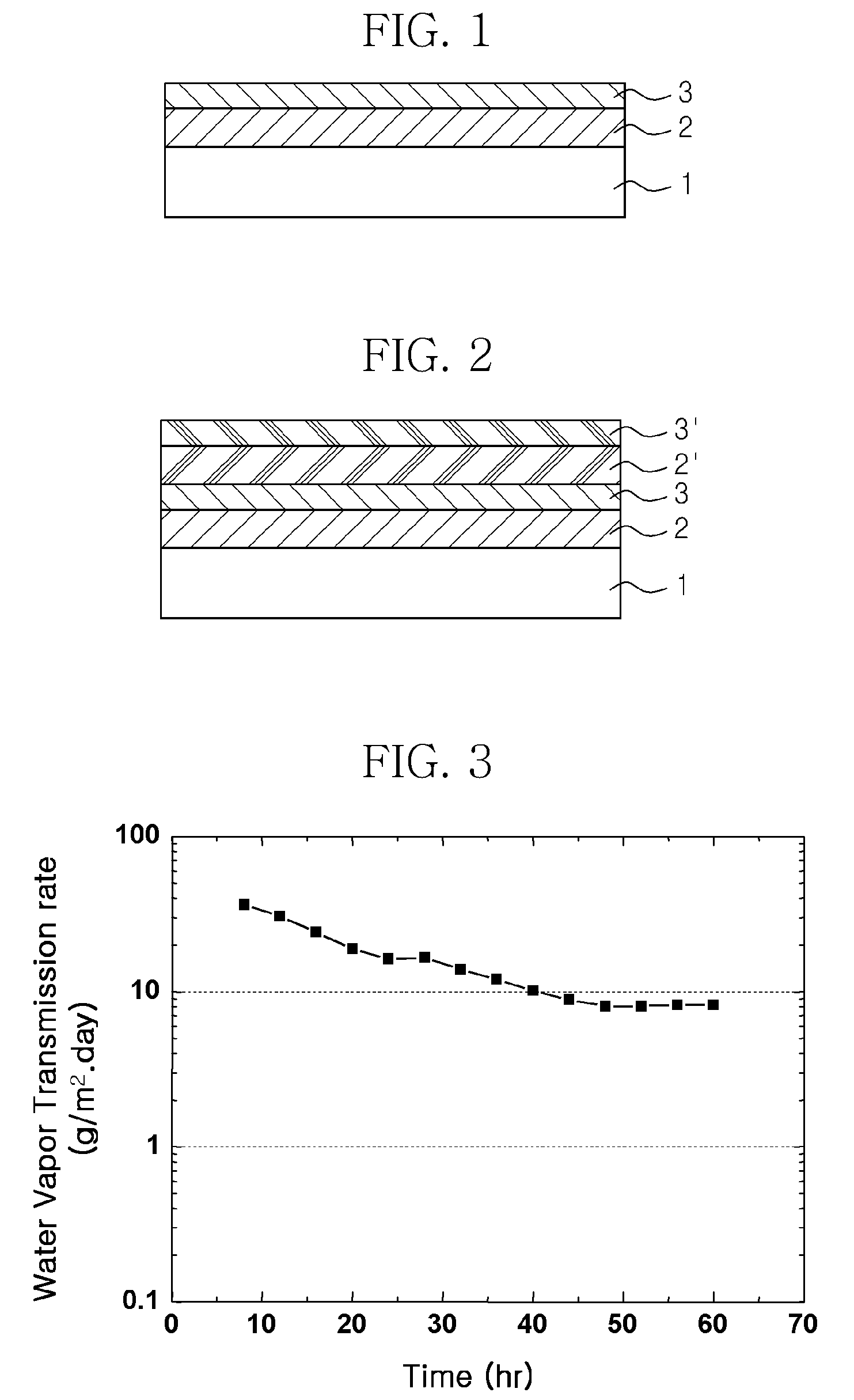

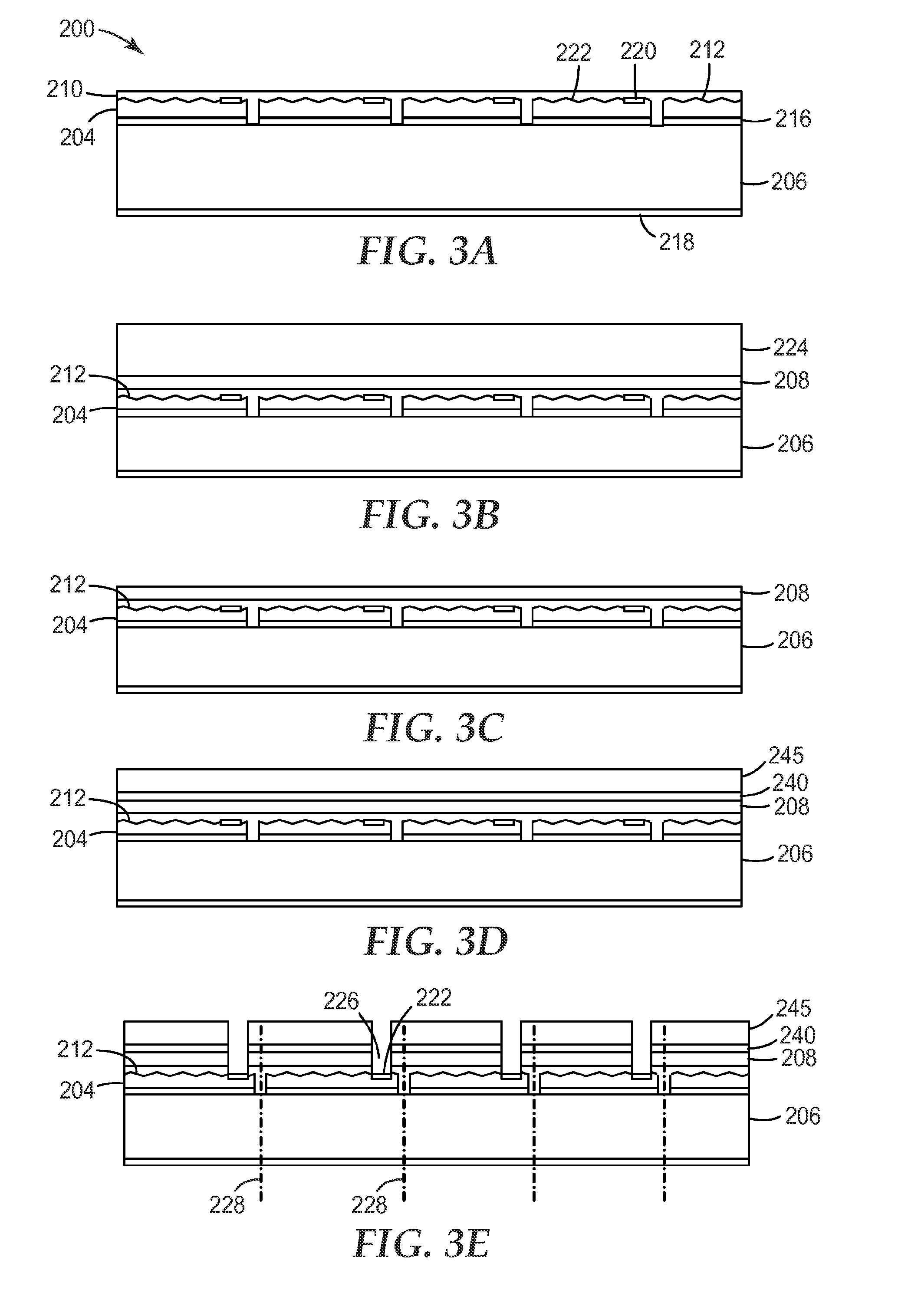

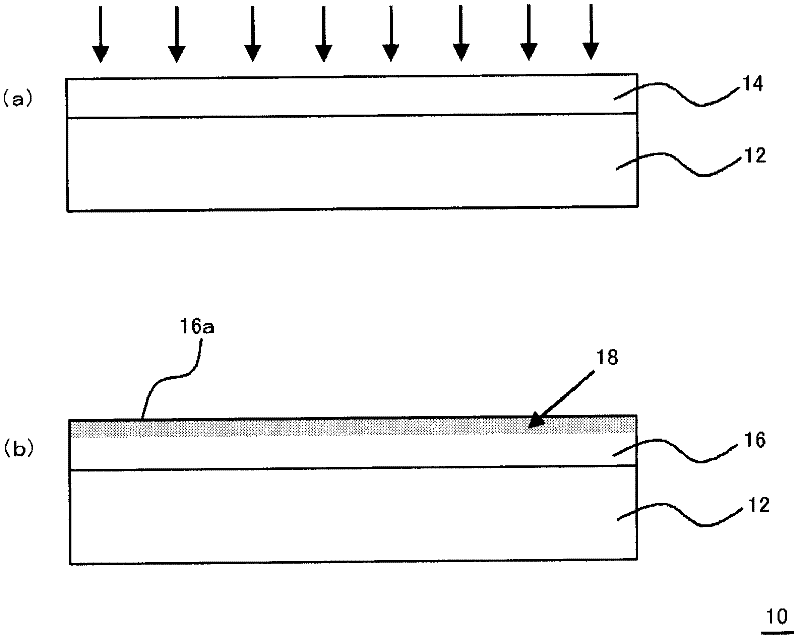

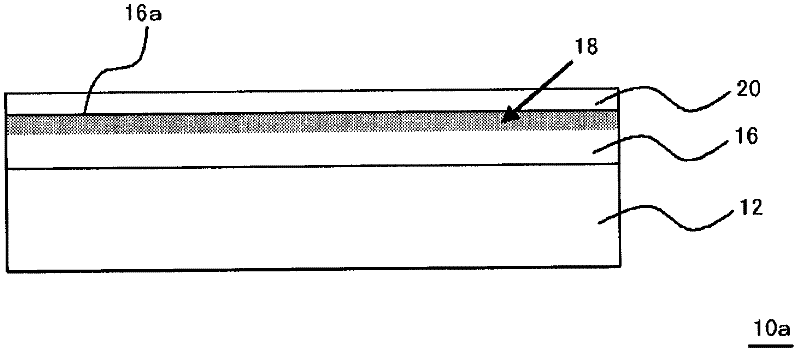

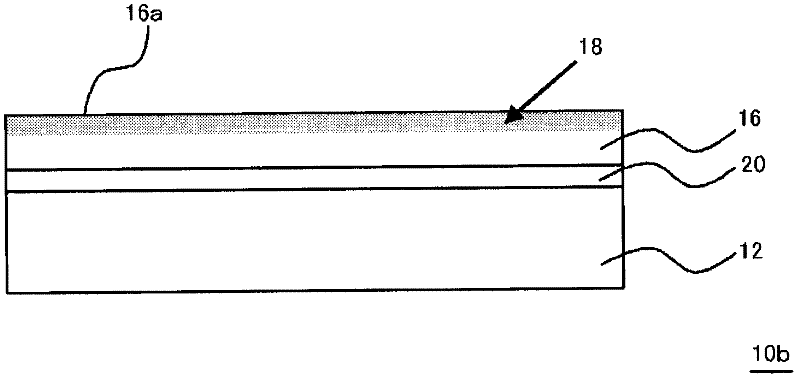

Multilayered material and method of producing the same

InactiveUS20120107607A1Reduce the impactIncrease production capacityRadiation applicationsPretreated surfacesWater vaporPolysilazane

A multilayered material is provided which includes a substrate and a silicon-containing film formed on the substrate, wherein the silicon-containing film has a nitrogen-rich area including silicon atoms and nitrogen atoms, or silicon atoms, nitrogen atoms, and an oxygen atoms and the nitrogen-rich area is formed by irradiating a polysilazane film formed on the substrate with an energy beam in an atmosphere not substantially including oxygen or water vapor and denaturing at least a part of the polysilazane film. A method of producing the multilayered material is also provided.

Owner:MITSUI CHEM INC

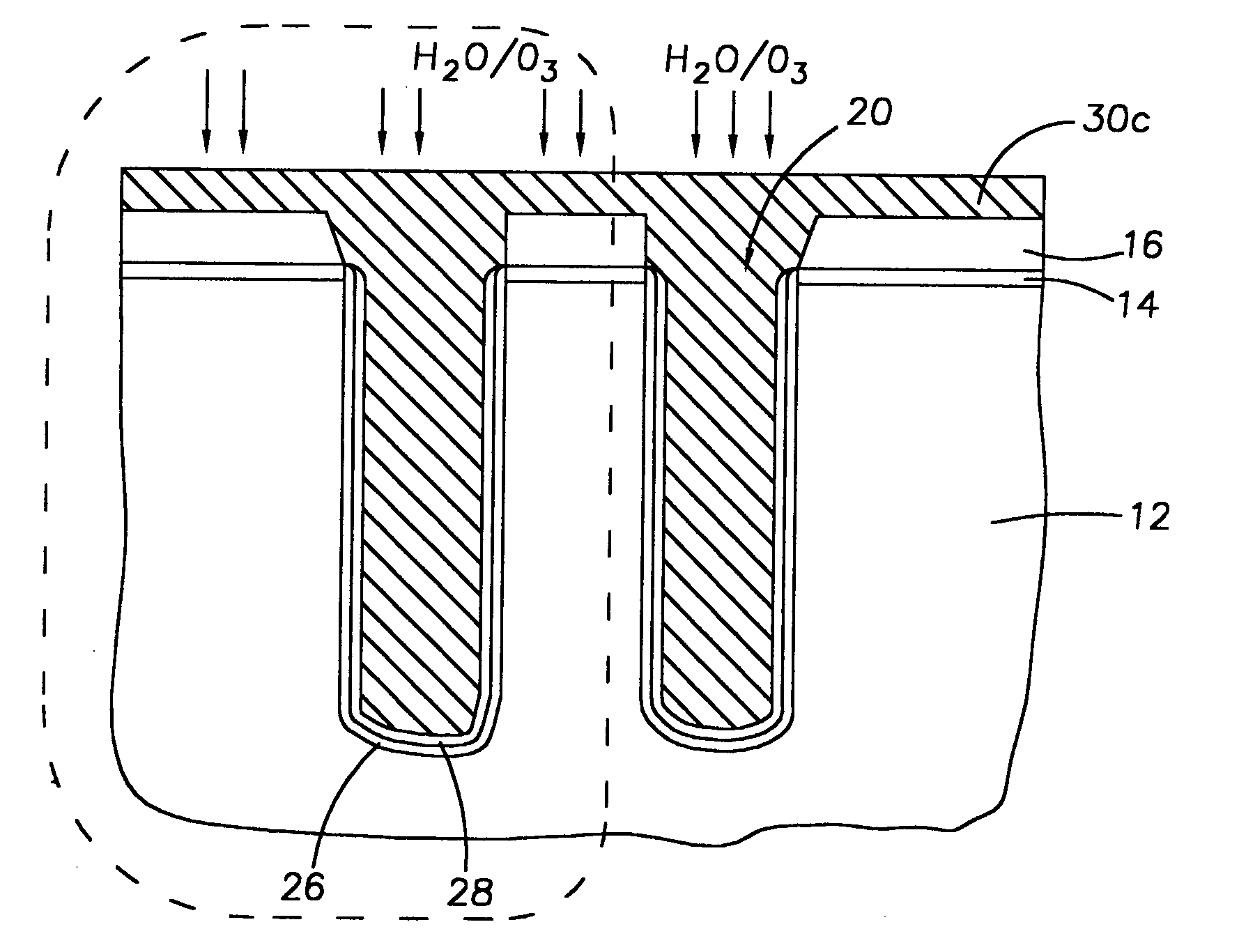

Method for forming a silicon oxide layer using spin-on glass

A method is provided for forming silicon oxide layers during the processing of semiconductor devices by applying a SOG layer including polysilazane to a substrate and then substantially converting the SOG layer to a silicon oxide layer using an oxidant solution. The oxidant solution may include one or more oxidants including, for example, ozone, peroxides, permanganates, hypochlorites, chlorites, chlorates, perchlorates, hypobromites, bromites, bromates, hypoiodites, iodites, iodates and strong acids.

Owner:SAMSUNG ELECTRONICS CO LTD

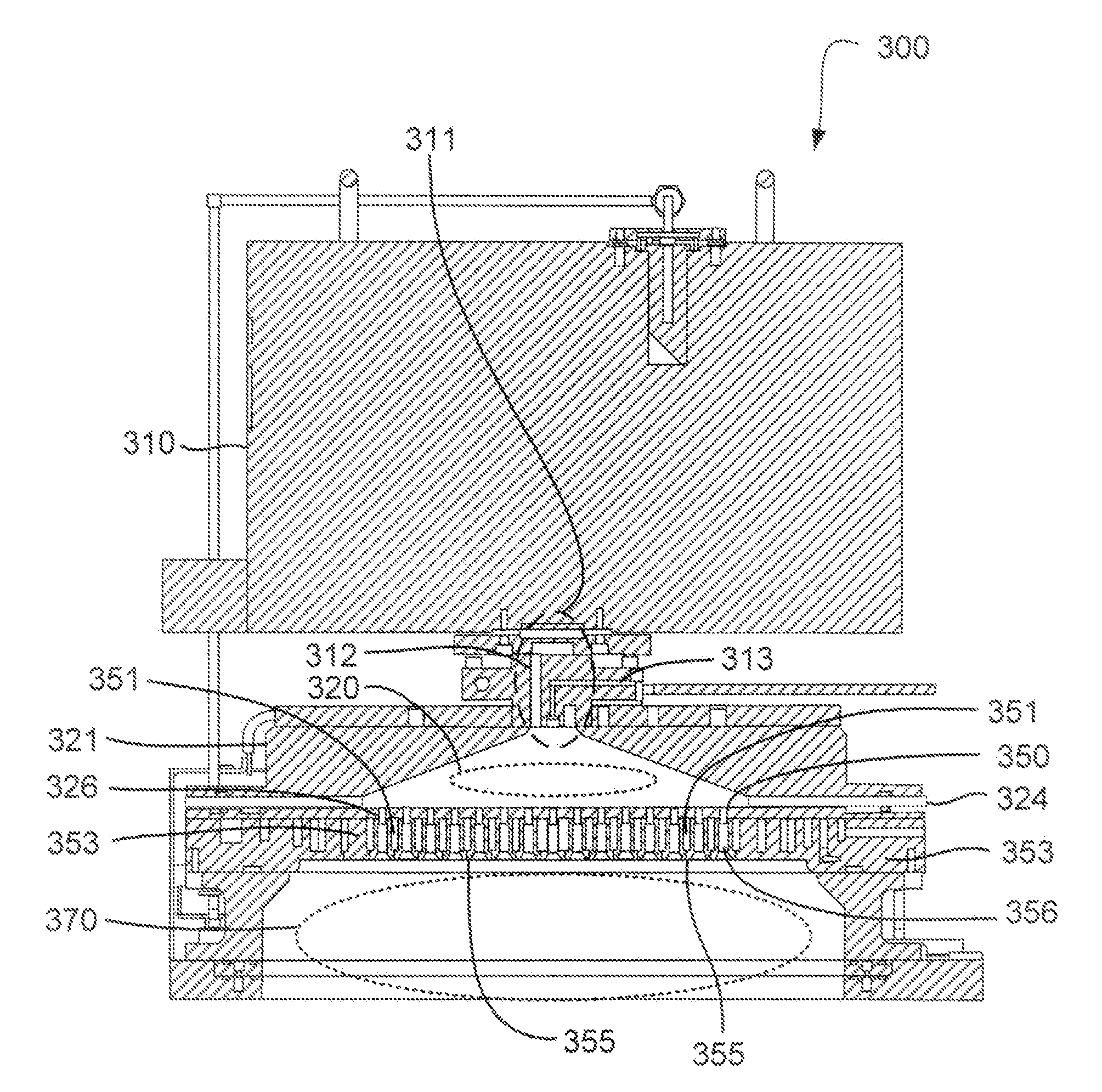

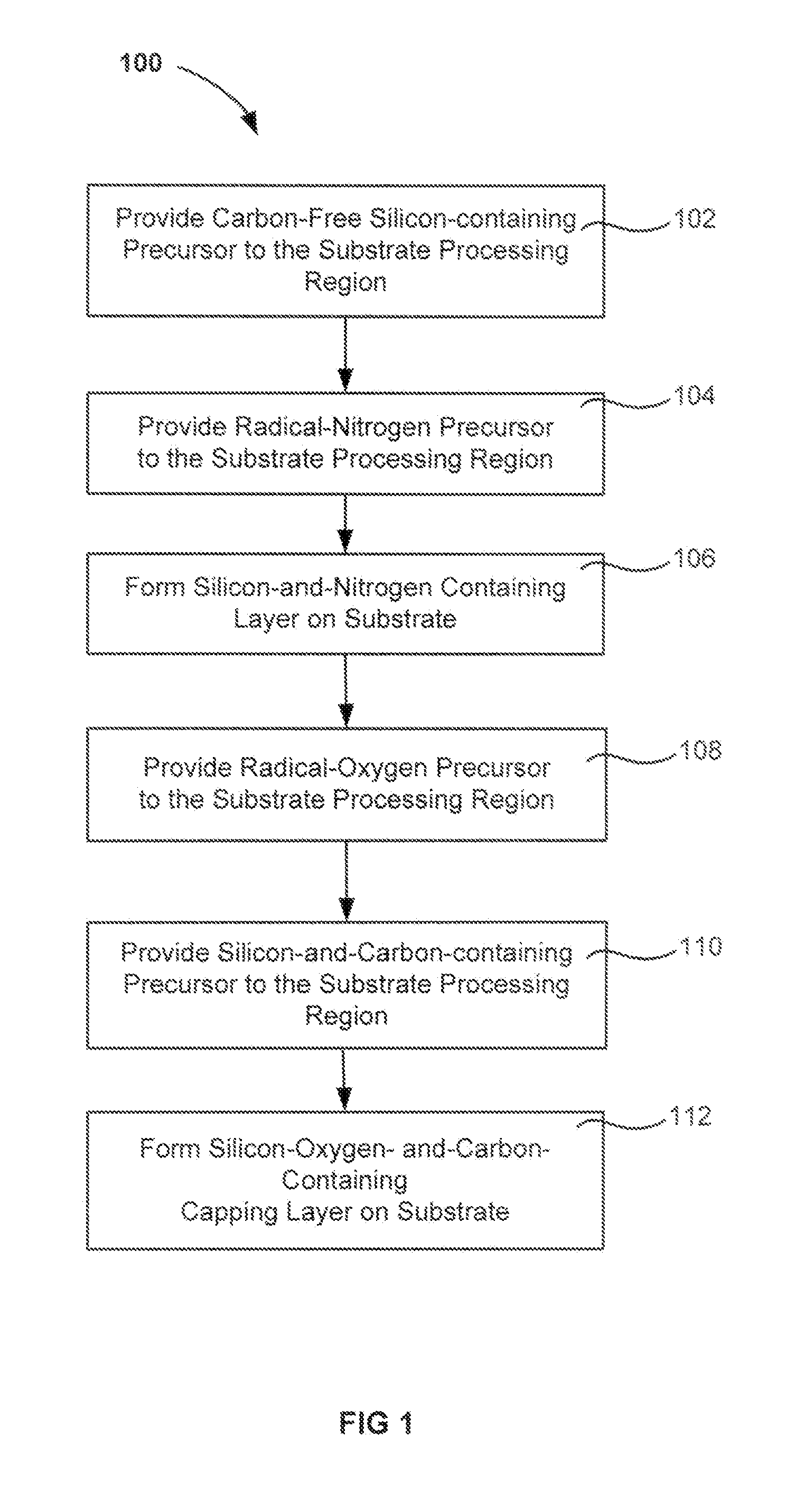

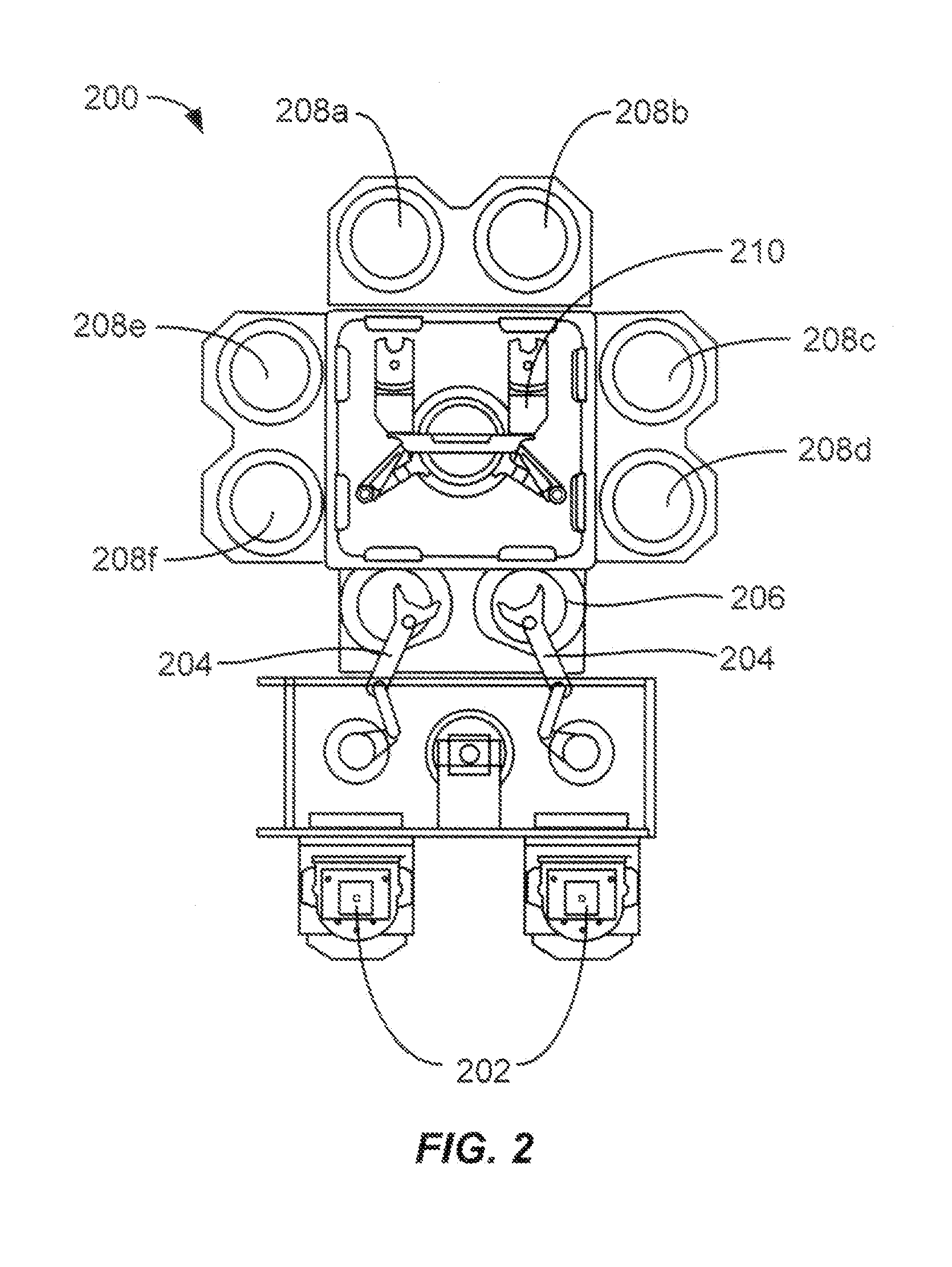

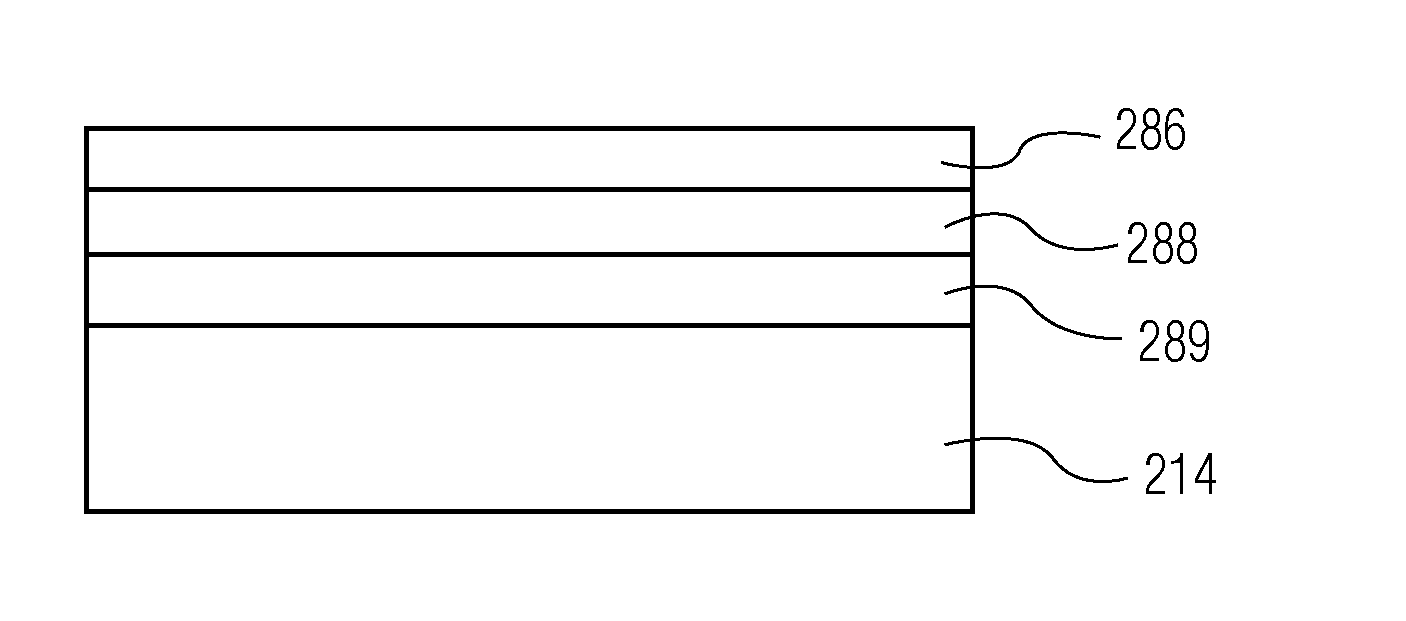

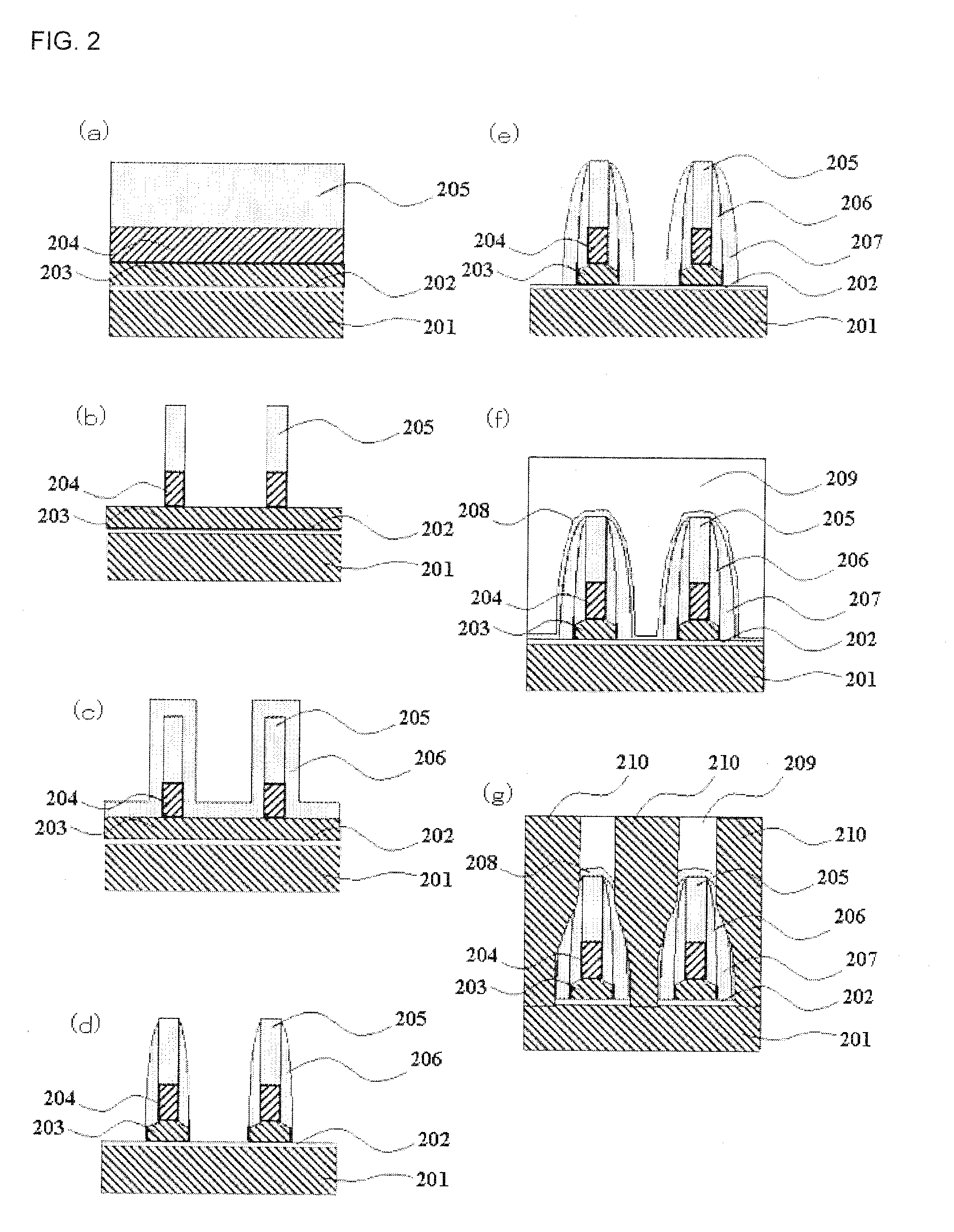

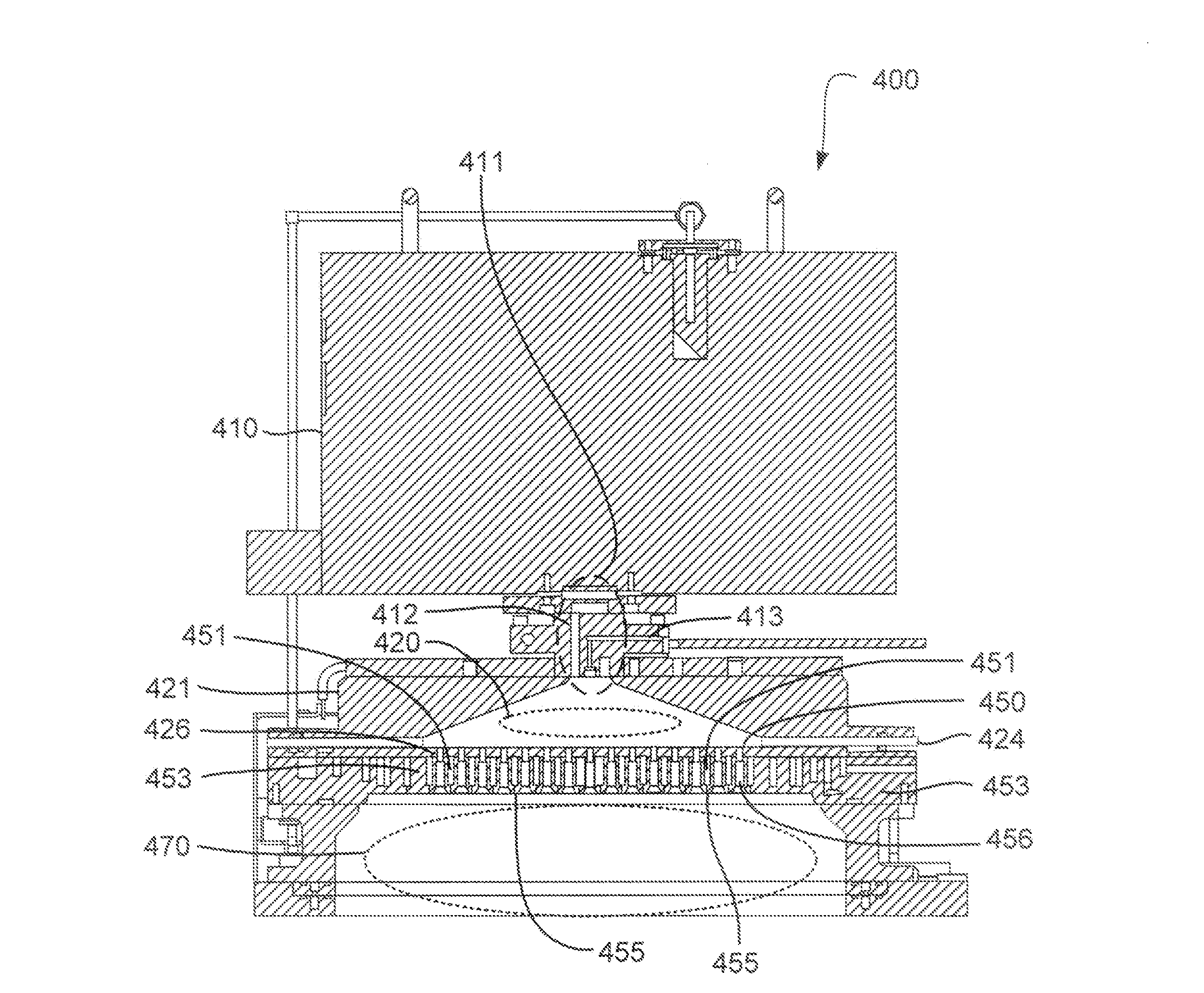

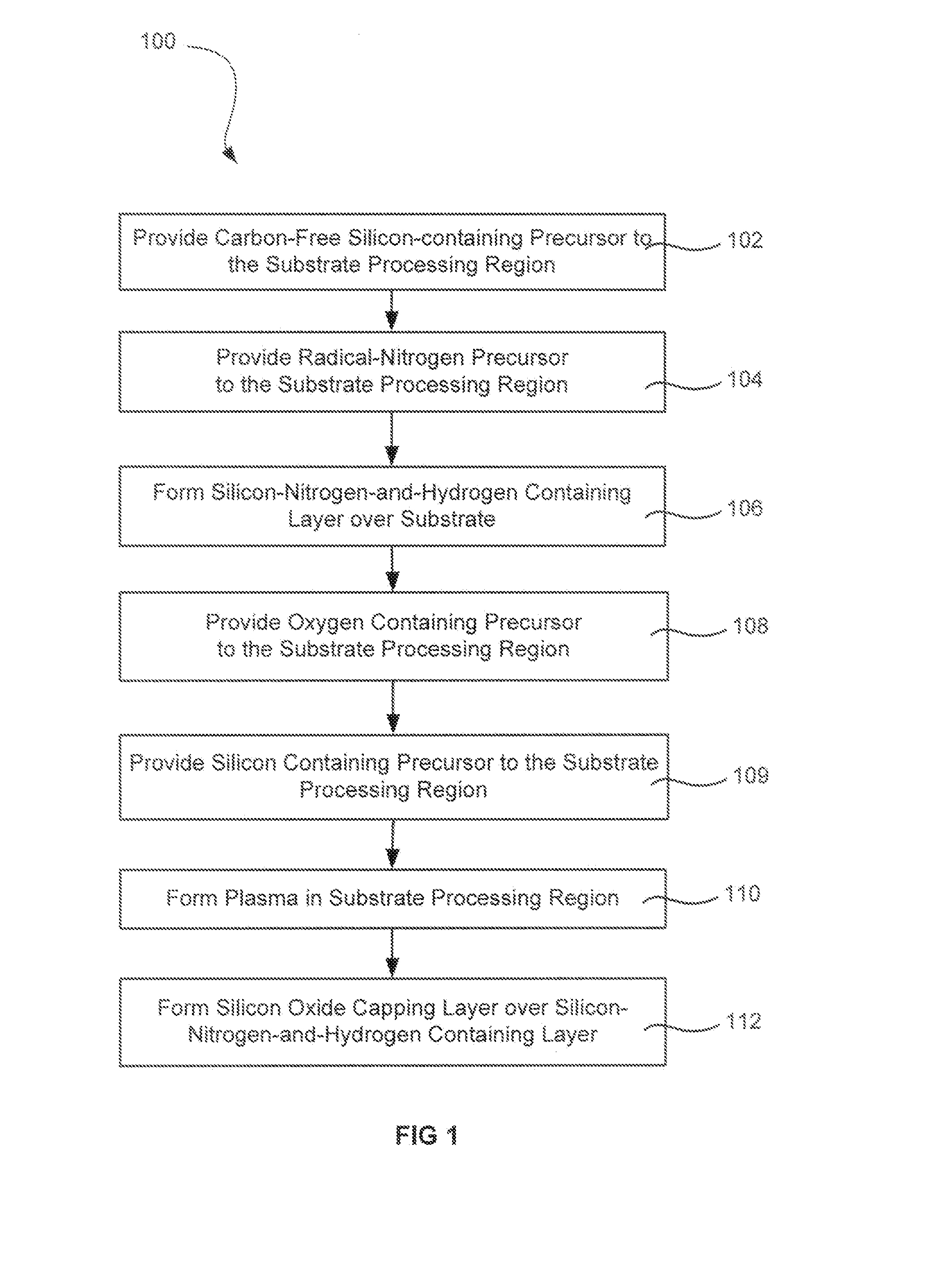

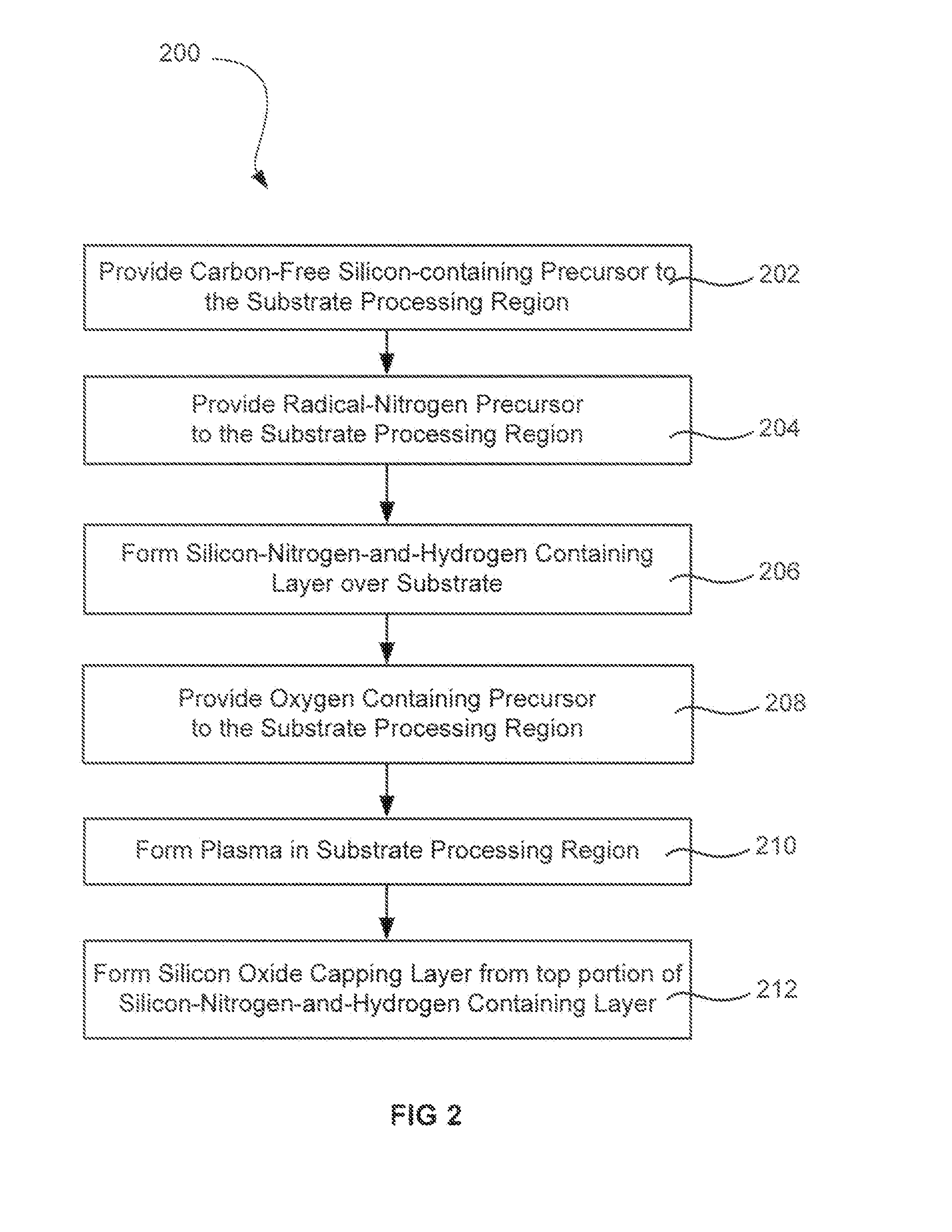

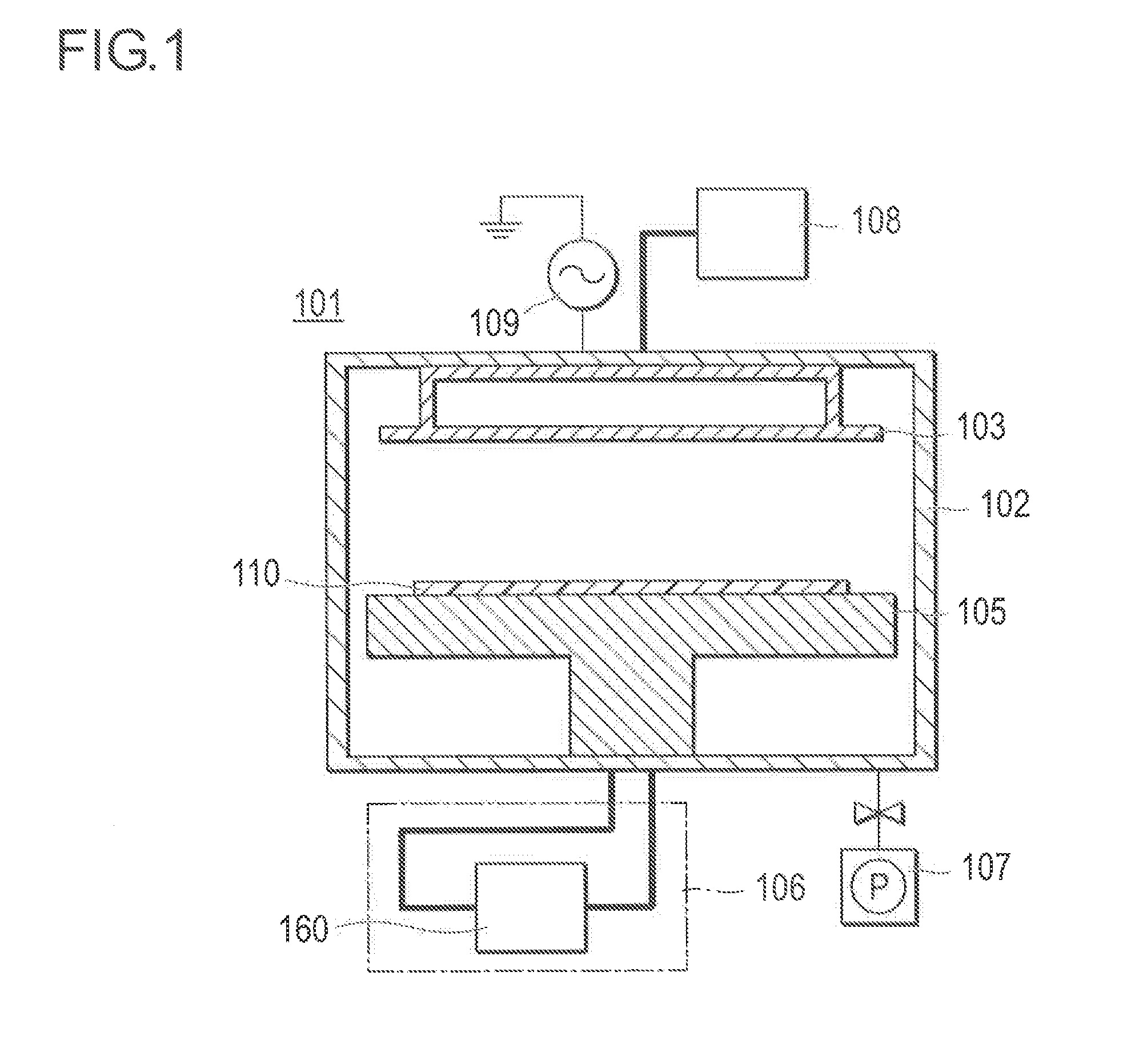

Capping layer for reduced outgassing

InactiveUS8466073B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaHydrogen

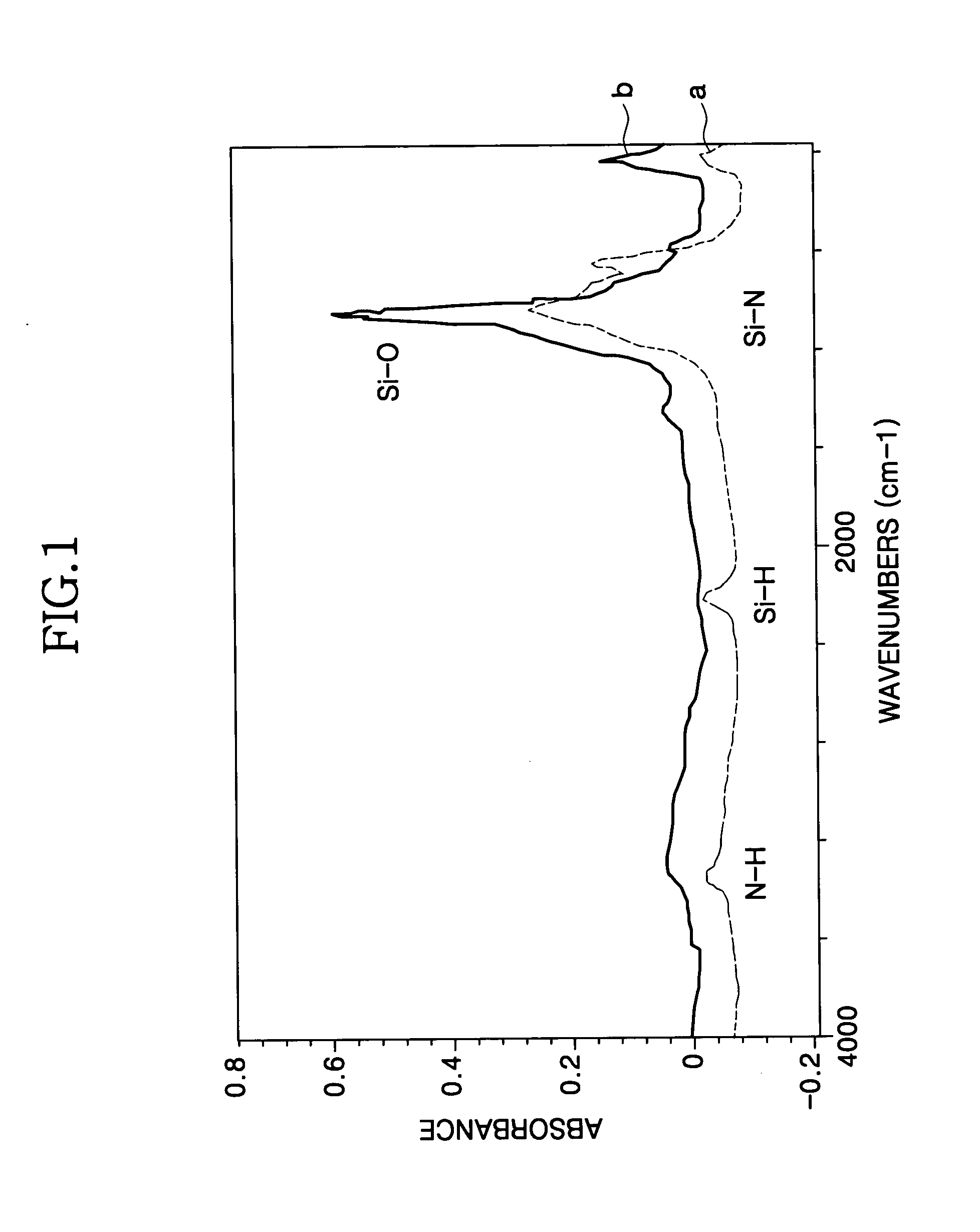

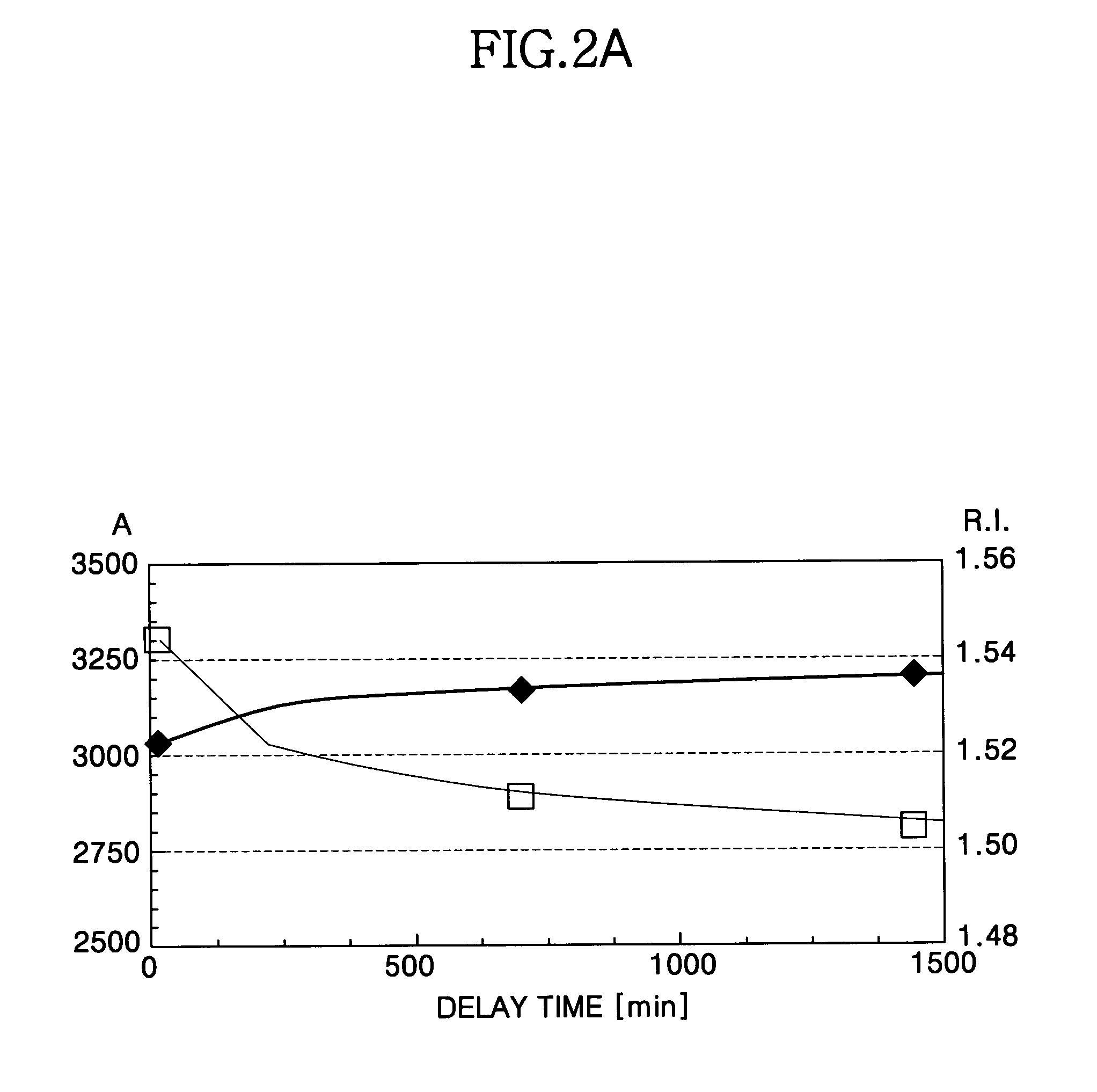

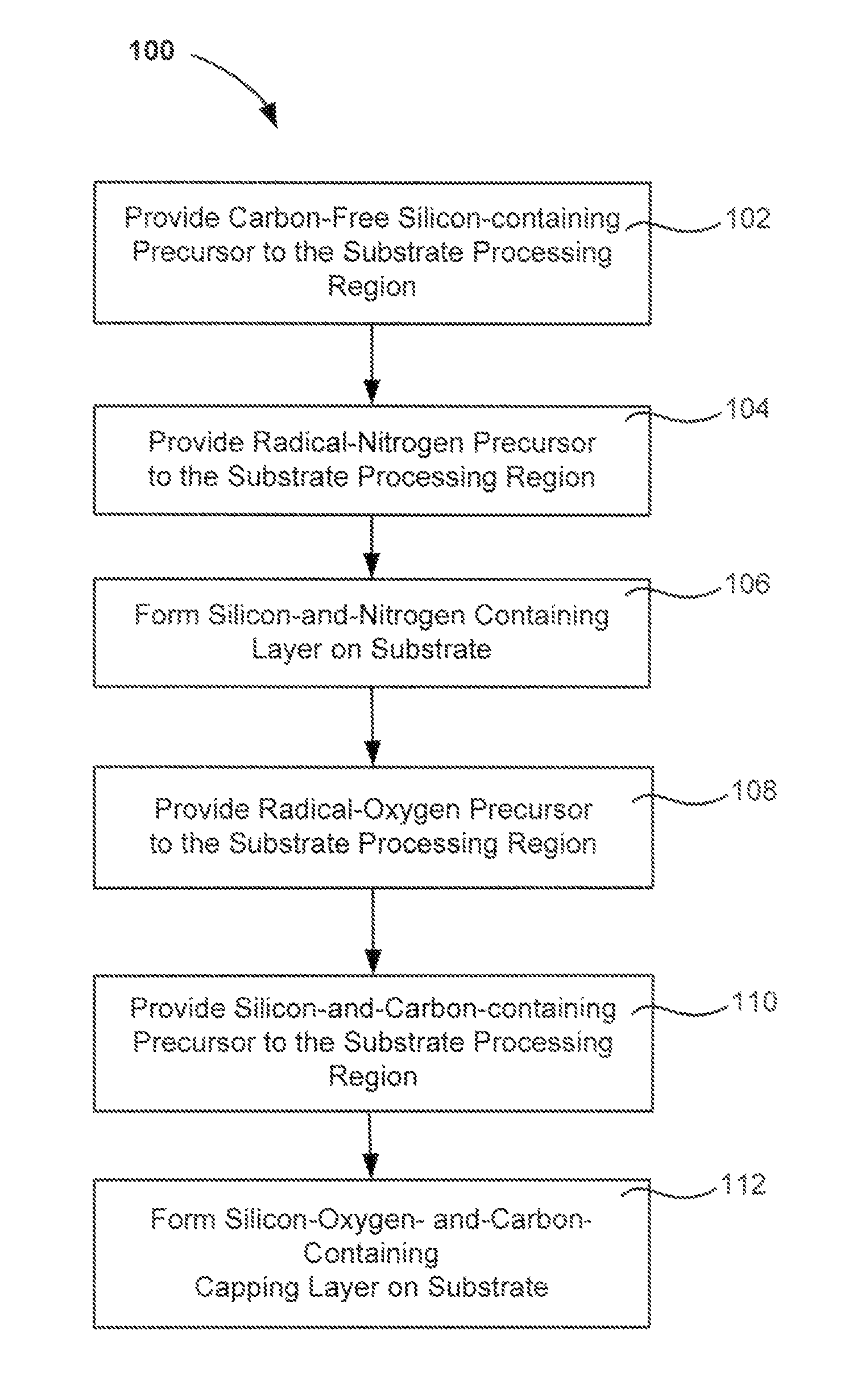

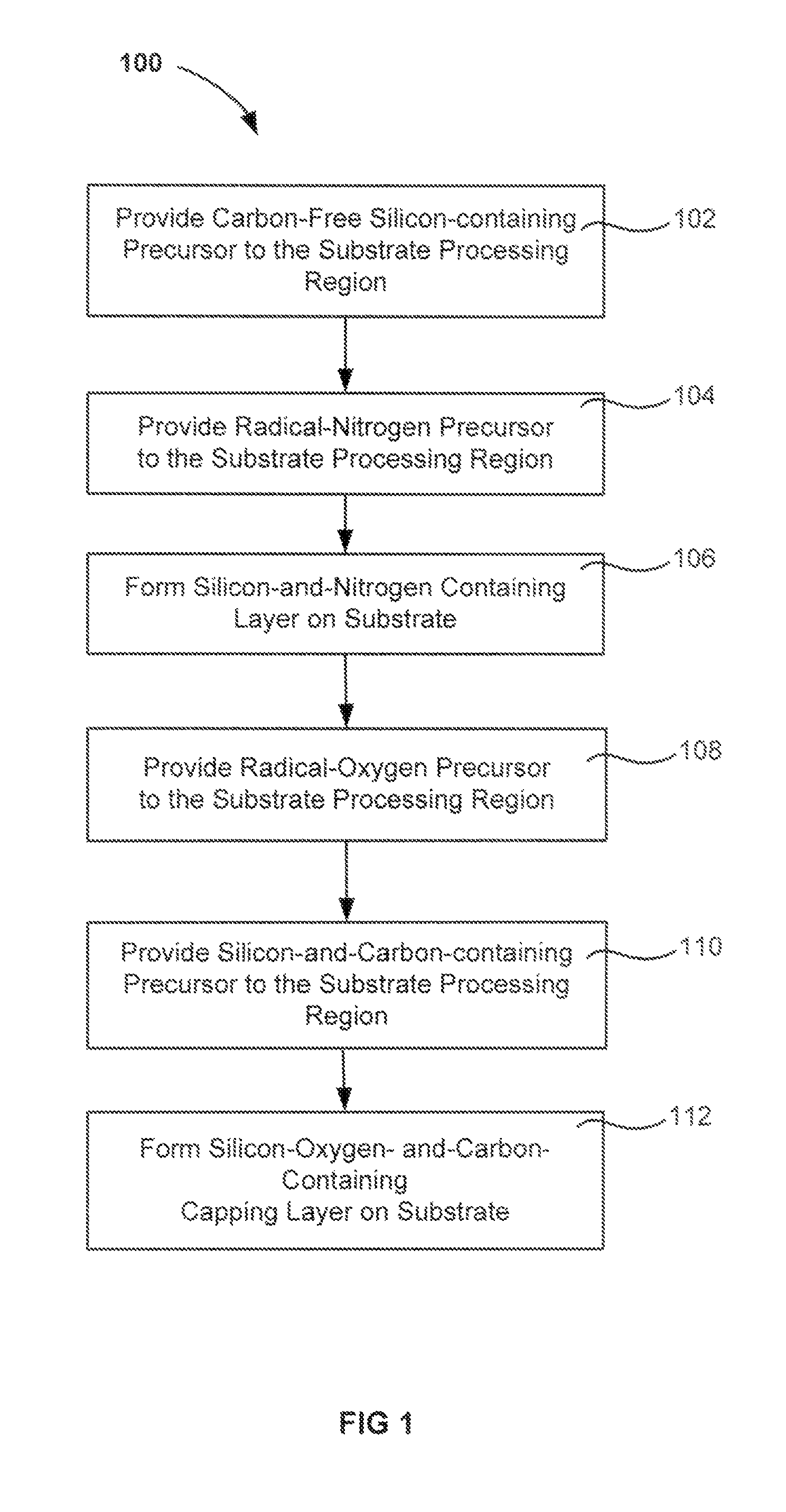

A method of forming a silicon oxide layer is described. The method first deposits a silicon-nitrogen-and-hydrogen-containing (polysilazane) film by radical-component chemical vapor deposition (CVD). The silicon-nitrogen-and-hydrogen-containing film is formed by combining a radical precursor (excited in a remote plasma) with an unexcited carbon-free silicon precursor. A capping layer is formed over the silicon-nitrogen-and-hydrogen-containing film to avoid time-evolution of underlying film properties prior to conversion into silicon oxide. The capping layer is formed by combining a radical oxygen precursor (excited in a remote plasma) with an unexcited silicon-and-carbon-containing-precursor. The films are converted to silicon oxide by exposure to oxygen-containing environments. The two films may be deposited within the same substrate processing chamber and may be deposited without breaking vacuum.

Owner:APPLIED MATERIALS INC

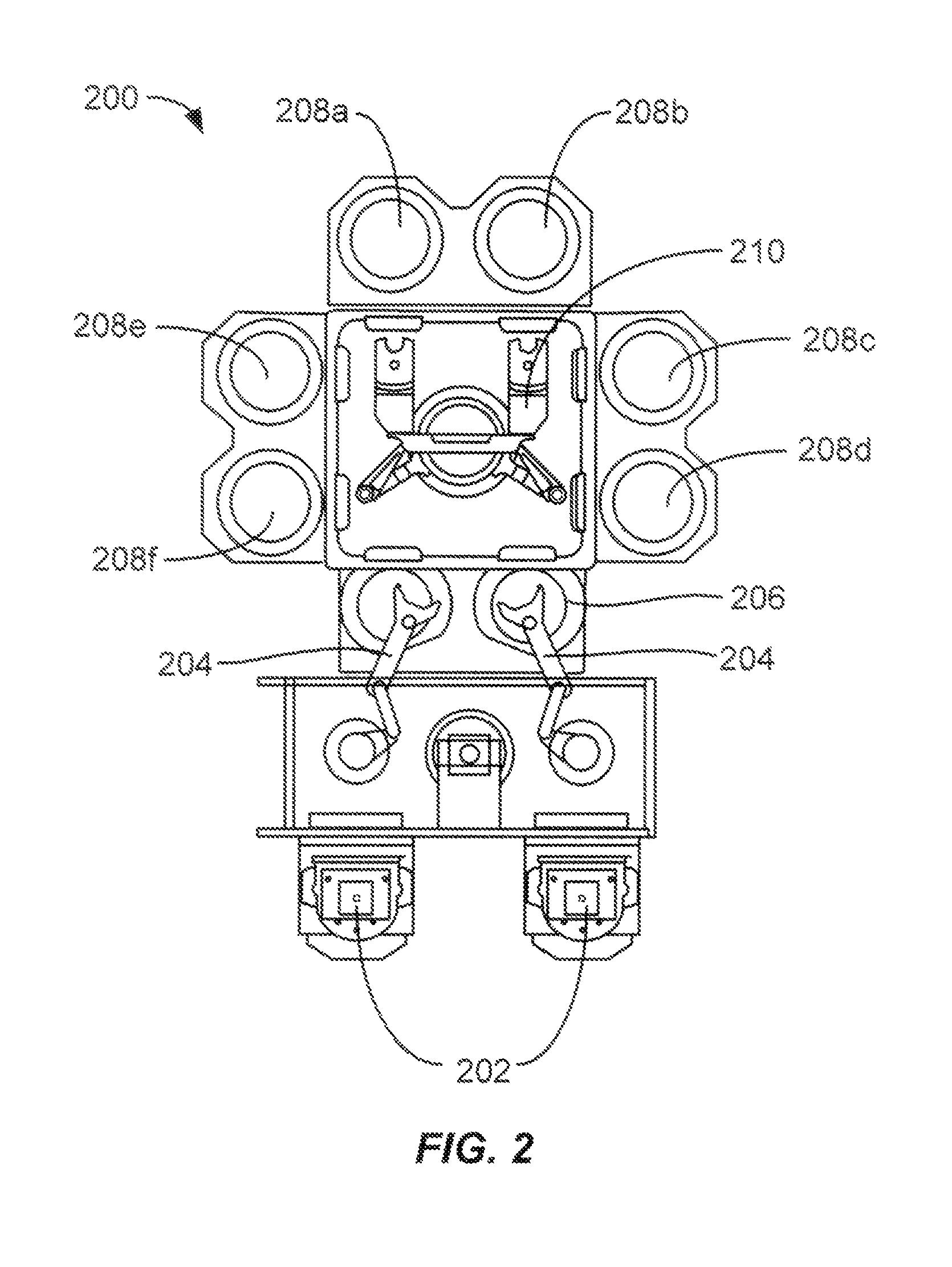

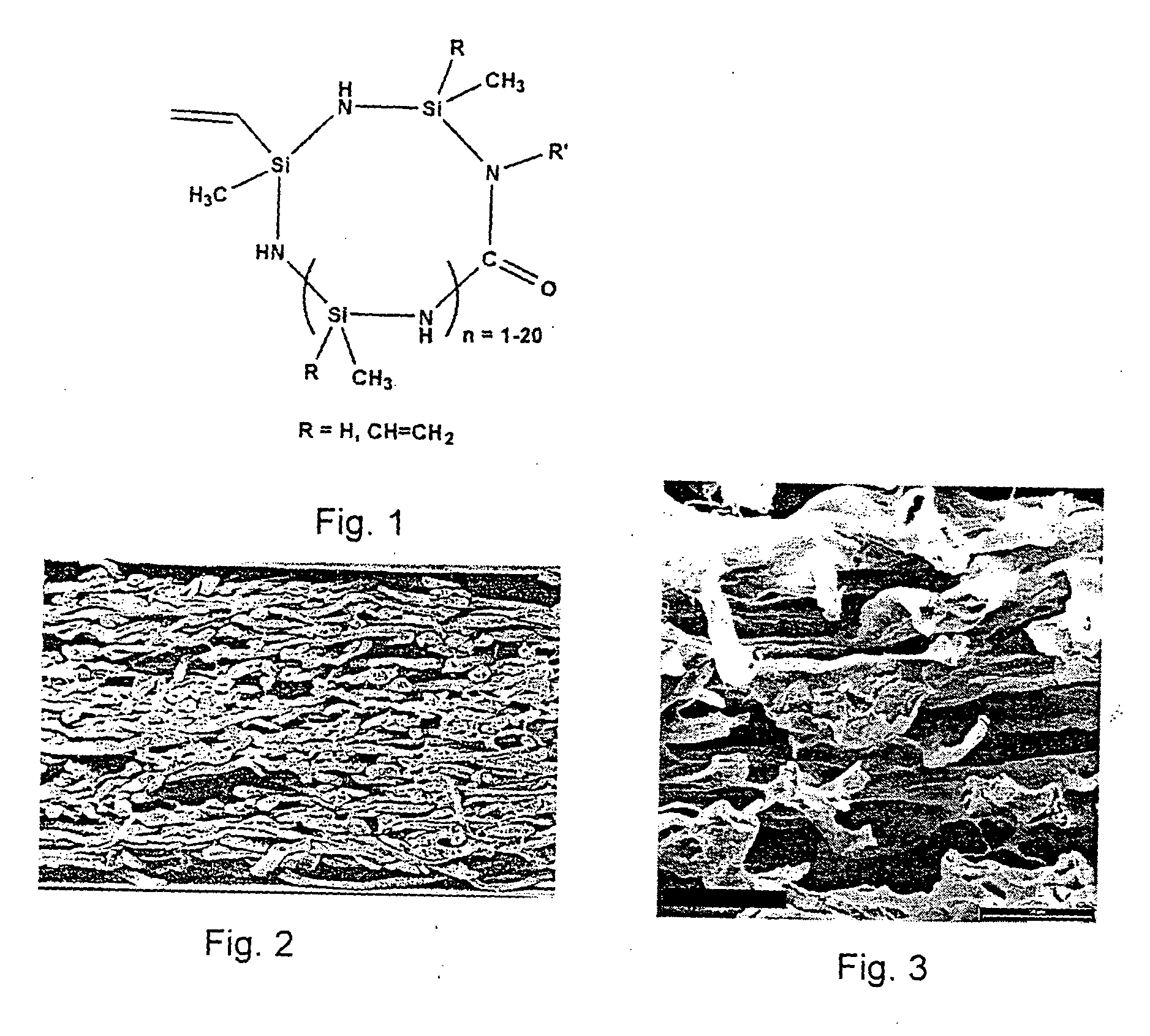

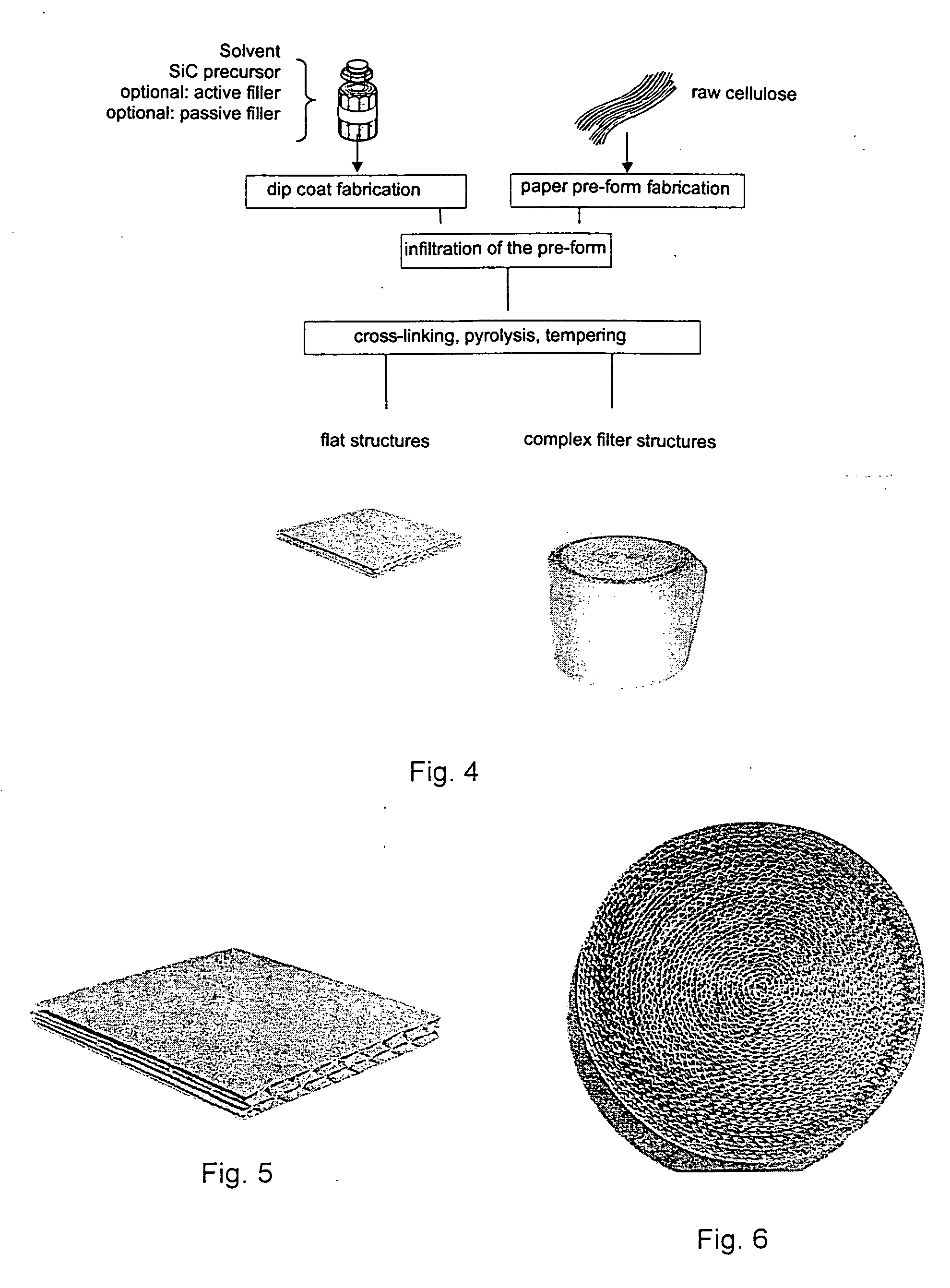

Porous SiC-bodies with micro-channels and process for their fabrication

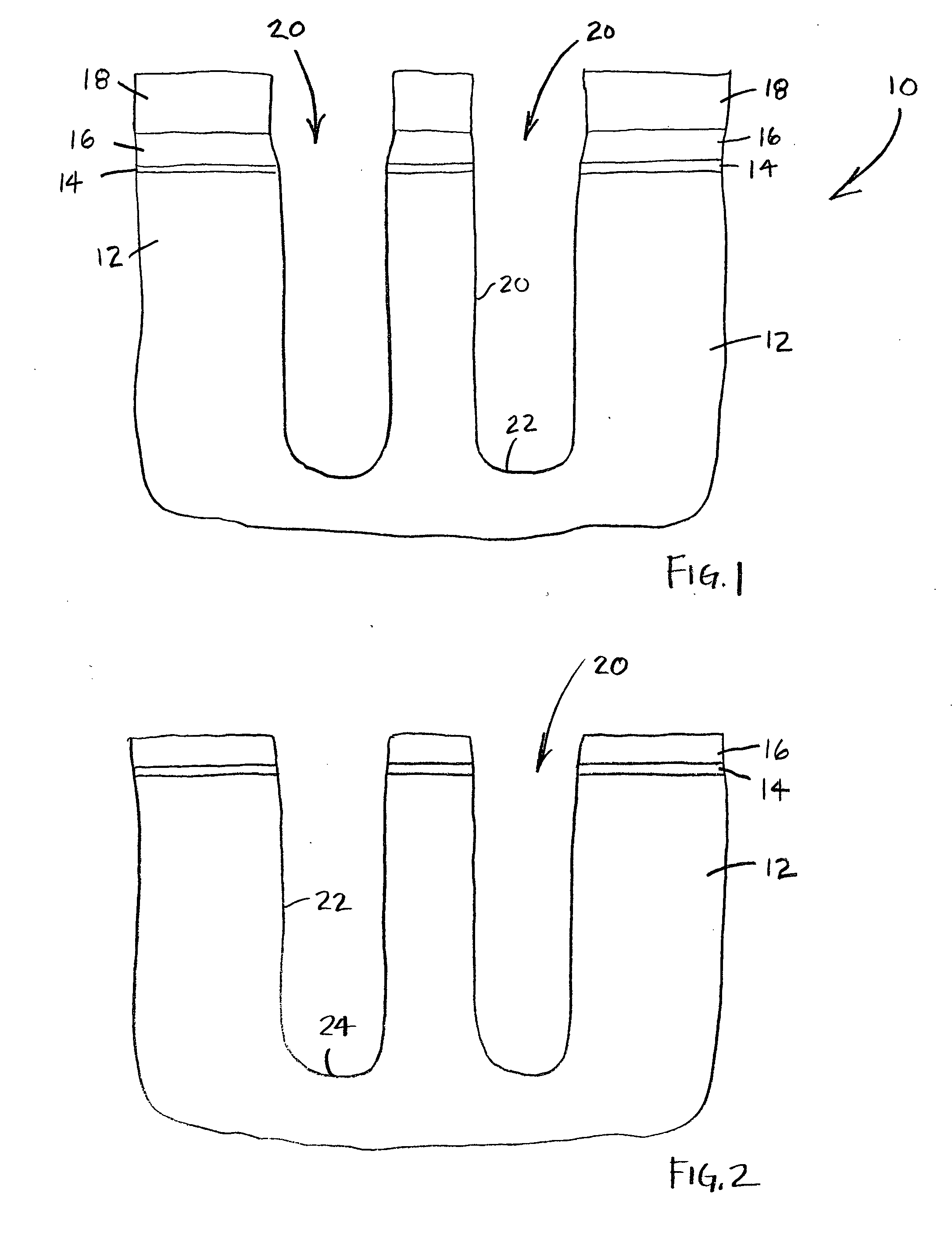

InactiveUS20060121266A1Large effective internal surface areaImprove filtering effectInternal combustion piston enginesLayered productsParticulatesCellulose

Process for the fabrication of porous bodies mainly constituted by SiC containing ceramic with a microstructure which is interfused with micro-channels which consists of the process steps a) Provision of a pre-body made from cellulose or pulp b) Fabrication of an infiltration solution or a slurry consisting of (A) solvent, polysilazane, polysilane and / or polycarbosilane or (B) solvent, polysilazane and / or polysilane as well as active metallic fillers and / or passive ceramic fillers. c) Infiltrating the body with infiltration solution or slurry d) Cross-linking of the polysilazane, polycarbosilane and / or polysilane while generating a solid green body e) Ceramization through pyrolysis of the green body in an inert-gas atmosphere. f) Removal of residual carbon with an oxidizing thermal process, thereof producible catalyst carriers or carbon particulate filters as well as Porous ceramic which is made from at least 80% SiC in which the porous ceramic features a microstructure with micro-channels consisting mainly of SiC coated micro-channels featuring an average diameter between 1 and 25 μm and webs of SiC located between the micro-channels as well as additional ceramic materials with a content below 20 wt %.

Owner:DAIMLER AG

Capping layer for reduced outgassing

InactiveUS20120309205A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaHydrogen

Owner:APPLIED MATERIALS INC

Low temperature process for polysilazane oxidation/densification

ActiveUS20060003596A1Easy to processHigh oxygen contentPretreated surfacesSemiconductor/solid-state device manufacturingPolysilazaneSilicon oxide

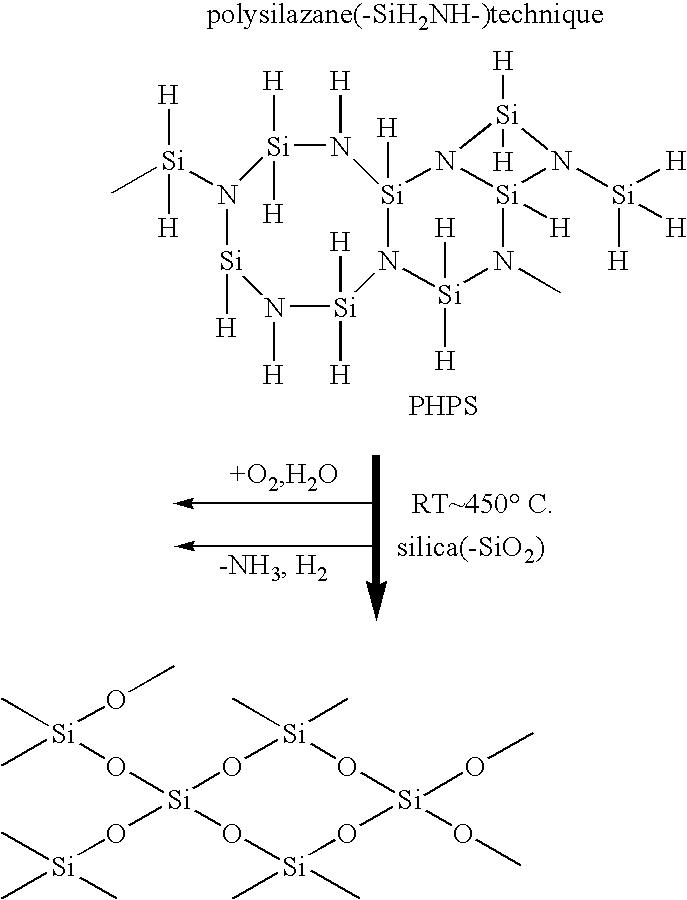

Semiconductor devices, structures and systems that utilize a polysilazane-based silicon oxide layer or fill, and methods of making the oxide layer are disclosed. In one embodiment, a polysilazane solution is deposited on a substrate and processed with ozone in a wet oxidation at low temperature to chemically modify the polysilazane material to a silicon oxide layer.

Owner:MICRON TECH INC

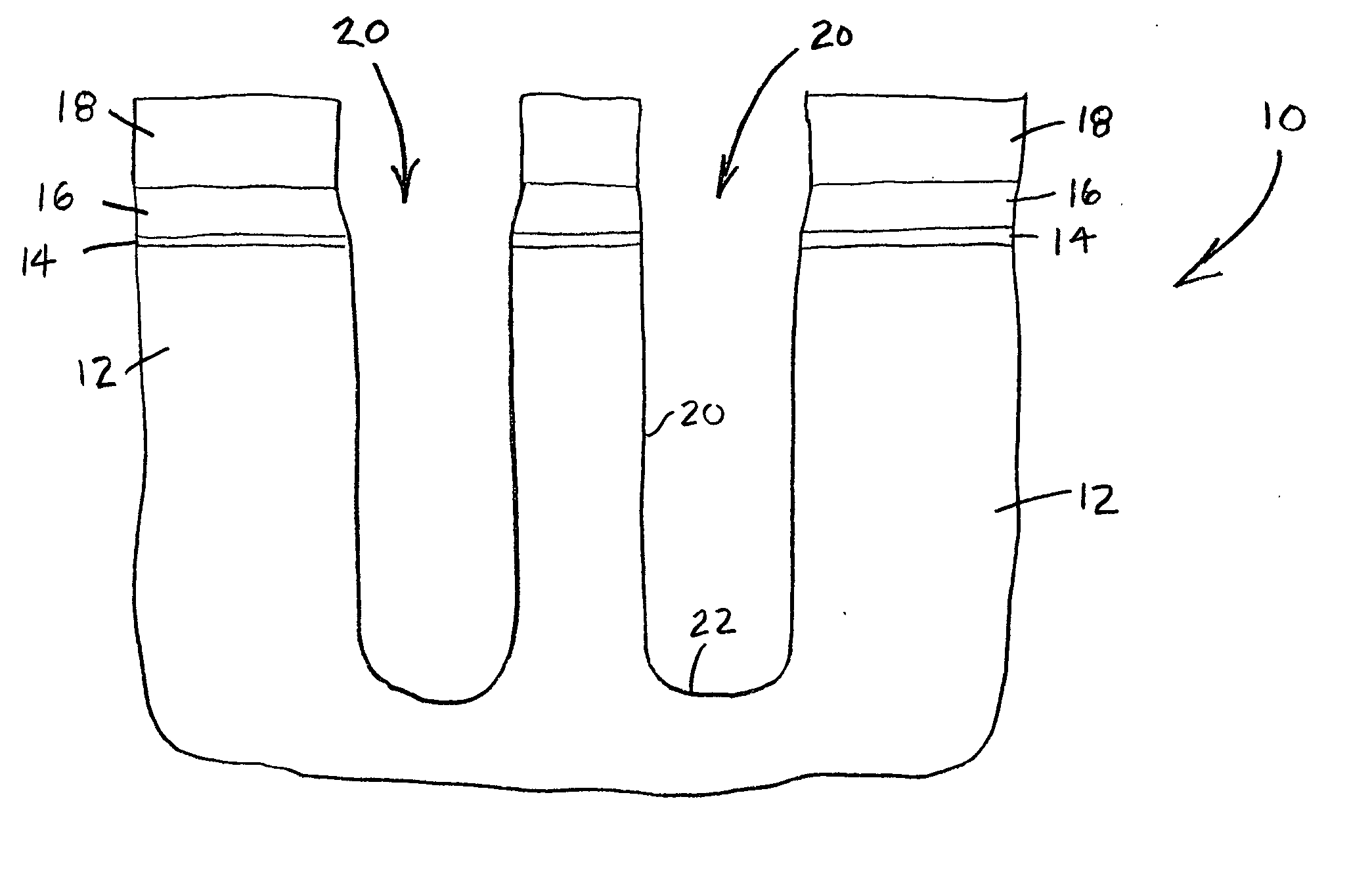

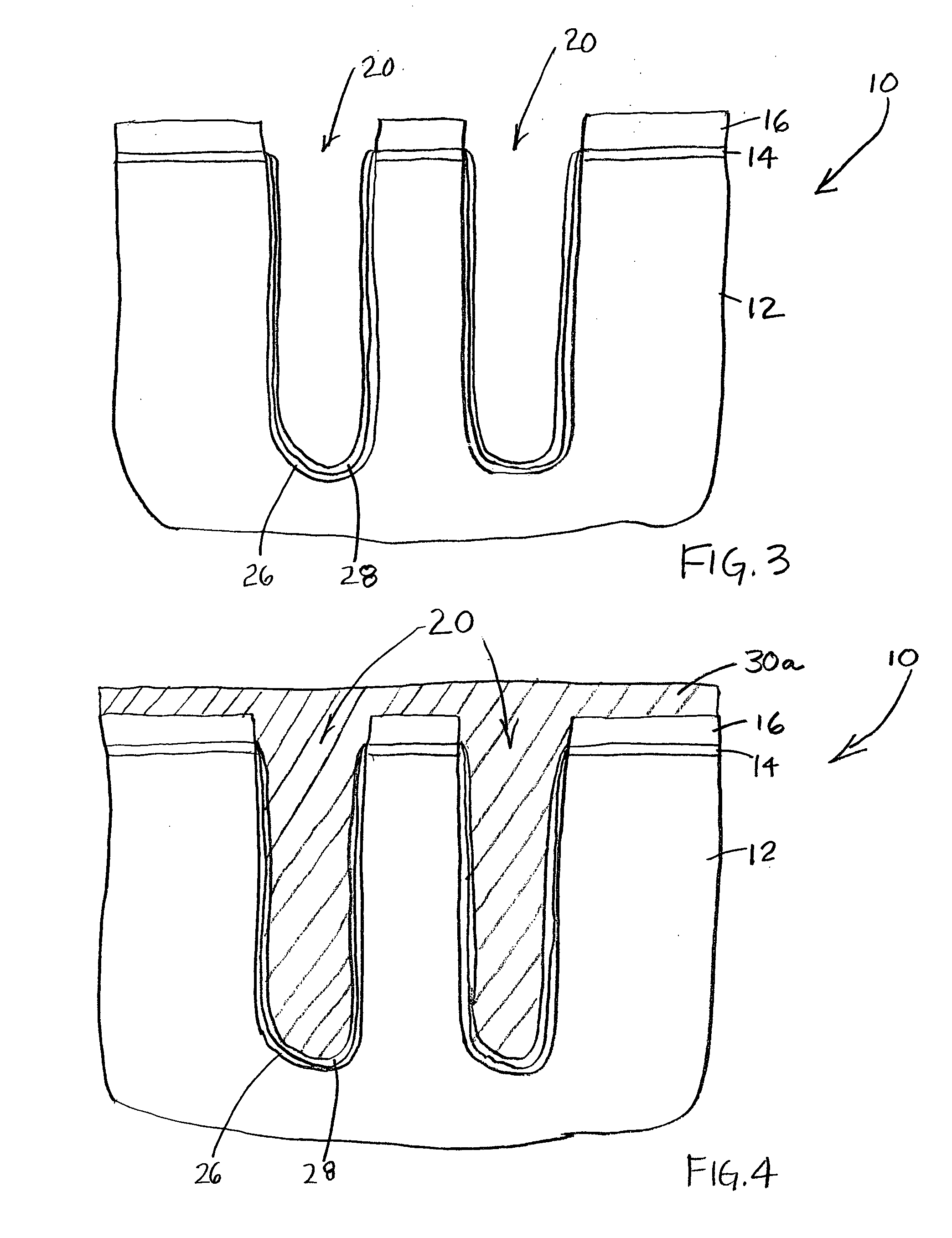

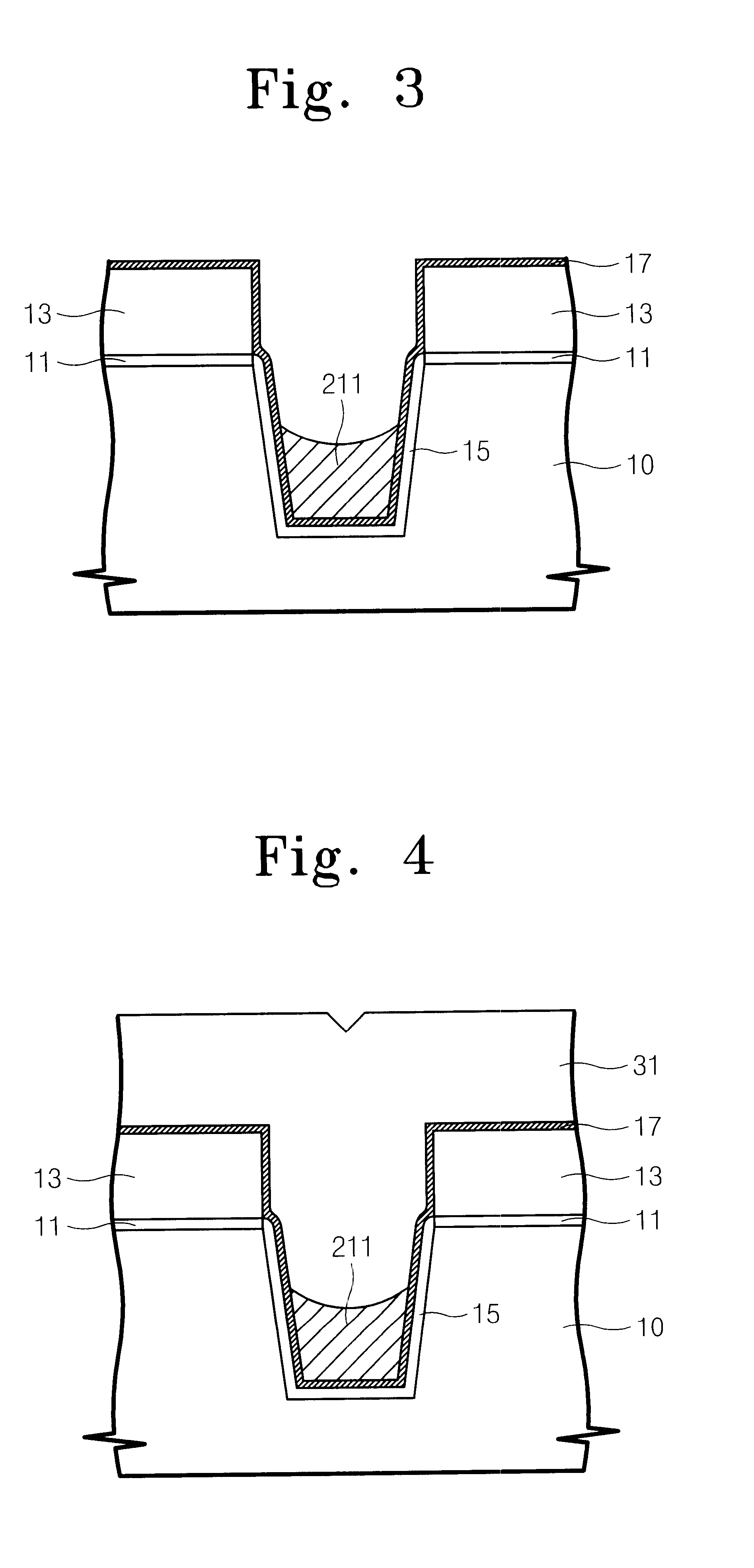

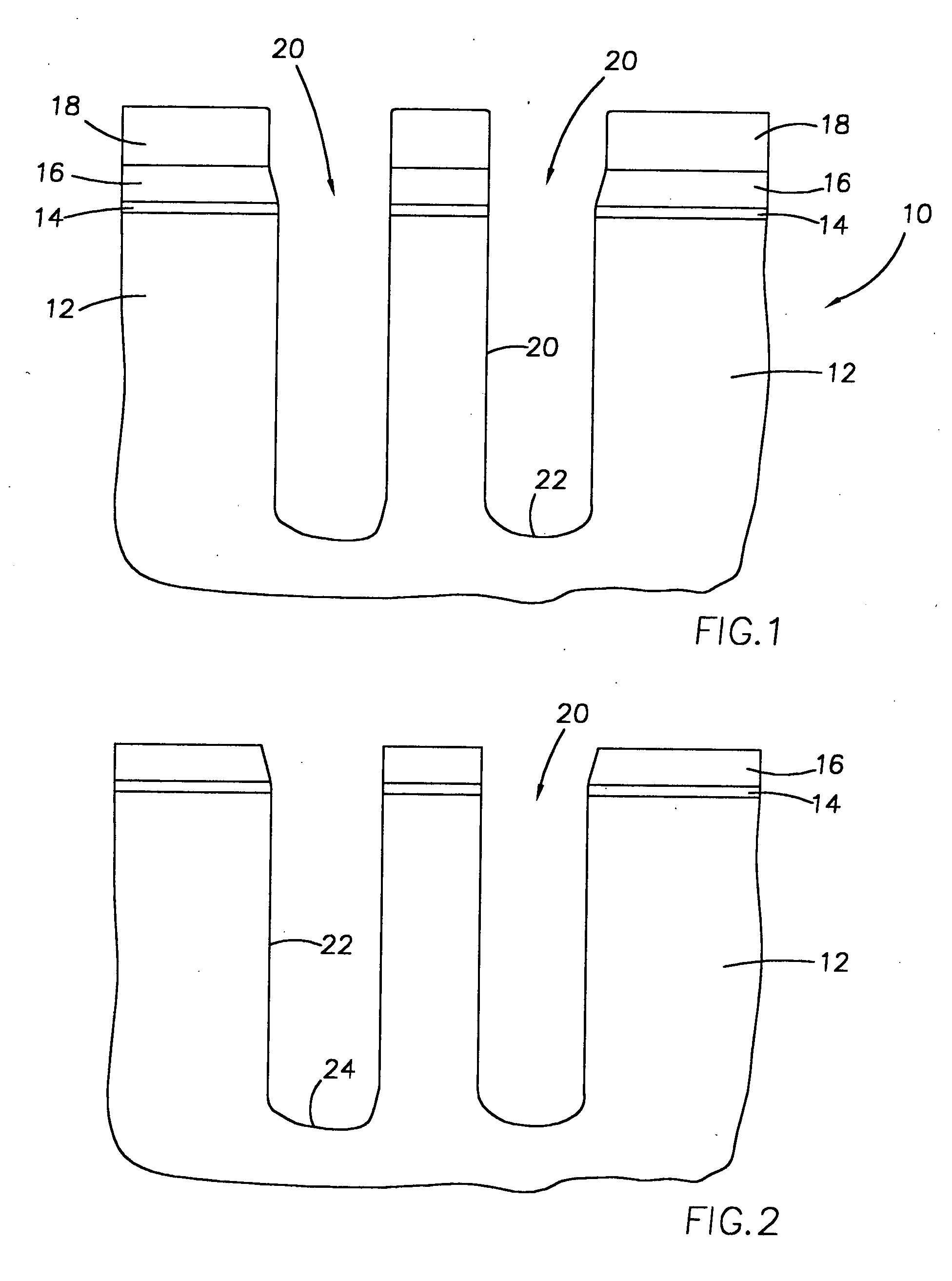

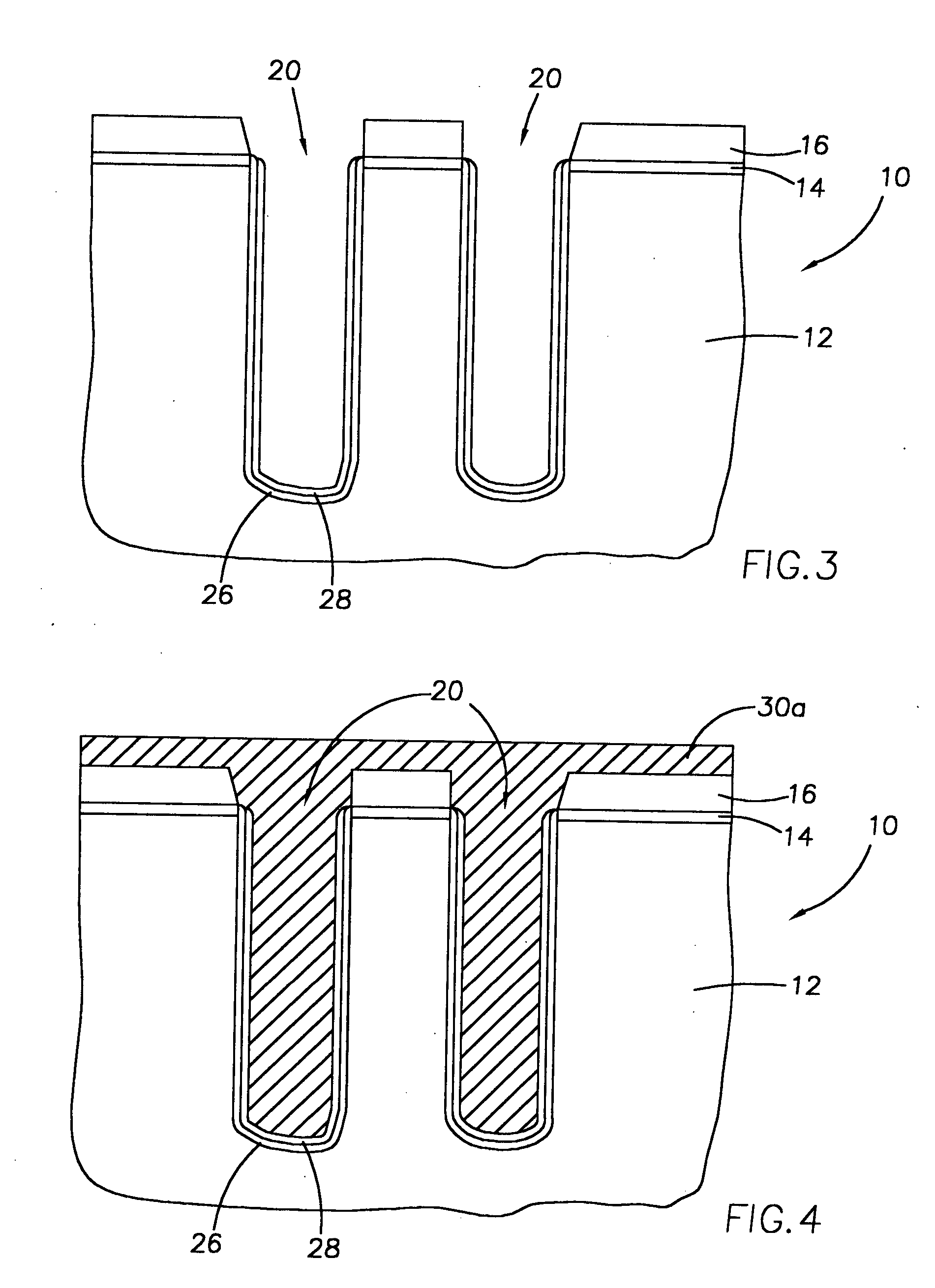

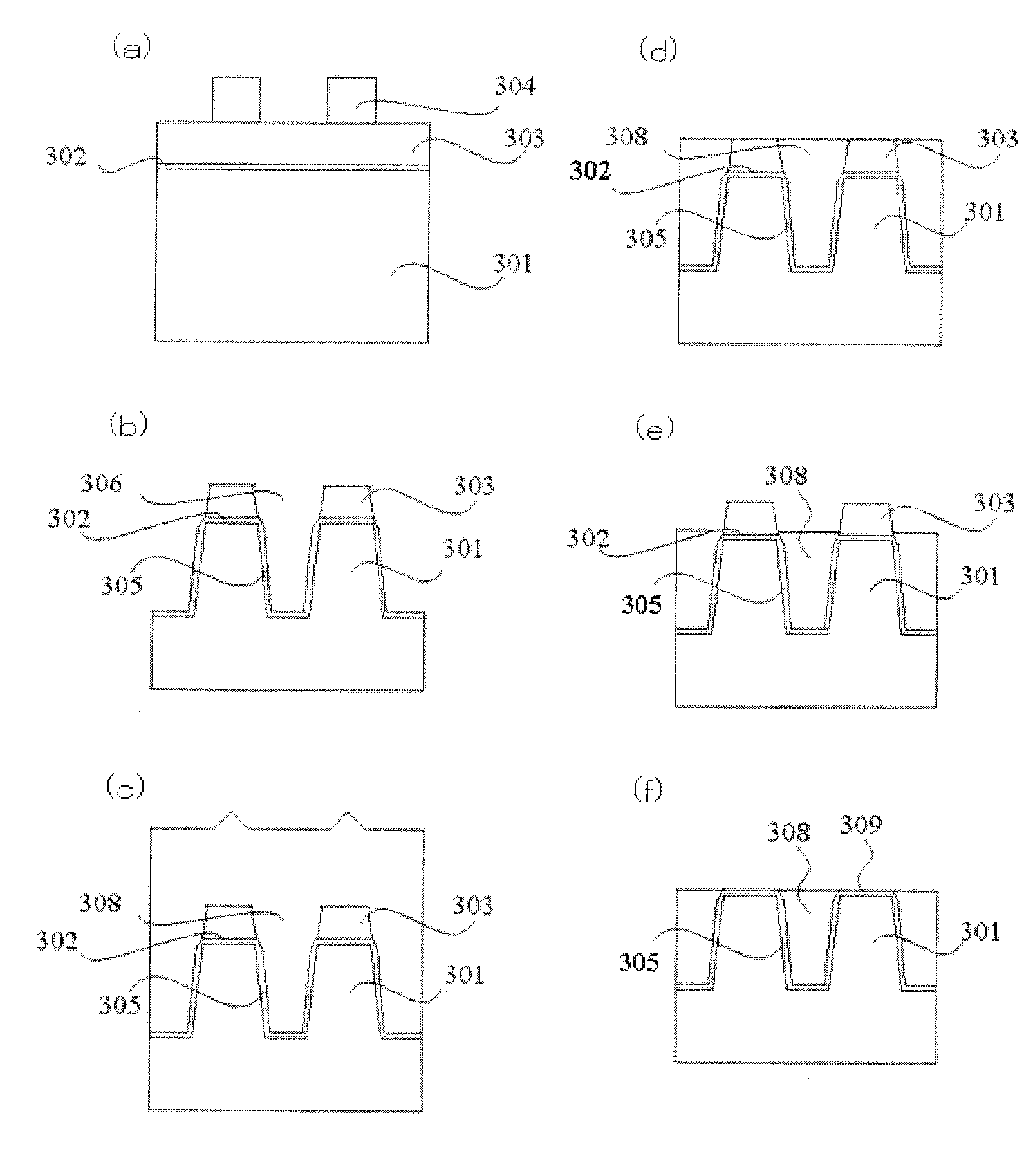

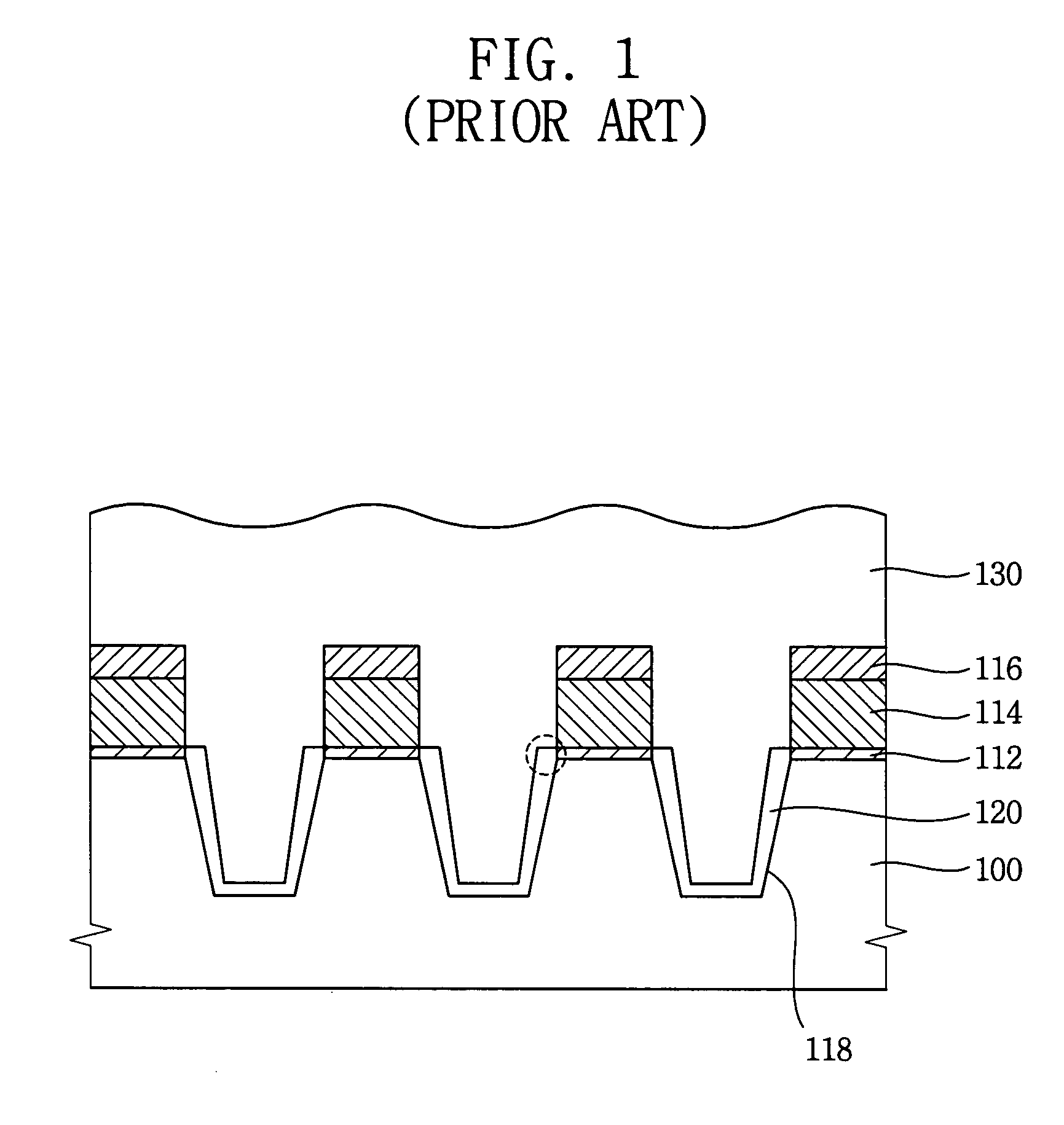

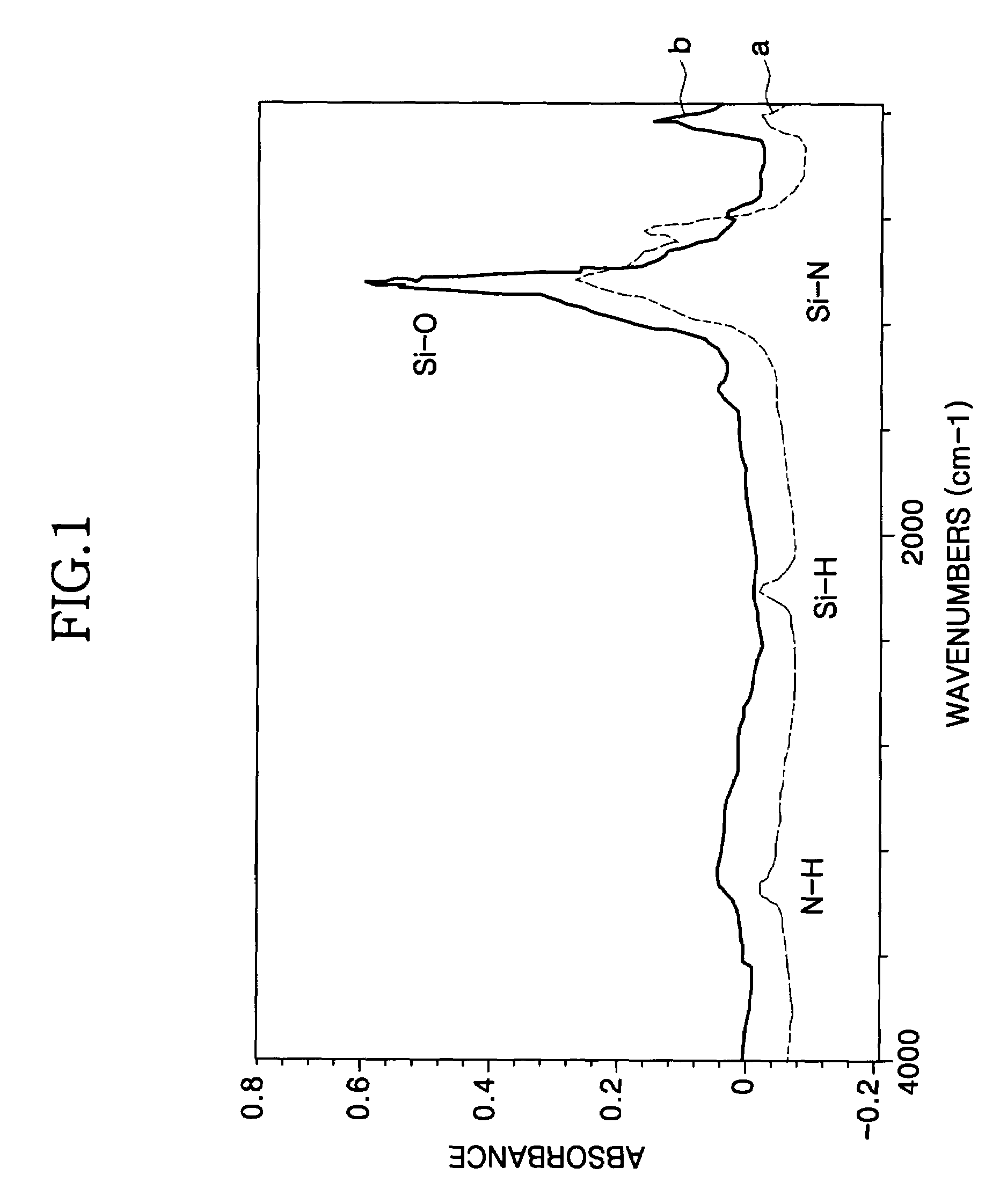

Method of forming an insulating layer in a trench isolation type semiconductor device

InactiveUS6566229B2Good shape retentionEasy annealingSemiconductor/solid-state device manufacturingDevice materialPolysilazane

A method of forming a trench-type device isolation layer in which a trench is filled through two steps, wherein a polysilazane solution is coated on a semiconductor substrate, in which a trench for device isolation layer is formed, in a spin on glass (SOG) manner to form an SOG layer filling a predetermined portion of the trench. In order to maintain a conformal coating thickness without overfilling the trench, the polysilazane solution preferably has a solid-state perhydro polysilazane ([SiH2NH]n) of between about 5 to about 15 percent by weight. Following formation of the SOG layer, a subsequent annealing process is carried out. The SOG layer is etched to make a top surface of the remaining SOG layer recessed down to a degree of about 1000 Å from an inlet of the trench, and a remaining space of the trench is filled with an ozone TEOS USG layer or an HDP CVD layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Polysilane-containing coating solution

InactiveUS20050279255A1Easy-to-clean propertyLow shrinkageFireproof paintsImpression capsBrickSolvent

A coating solution comprising 0.1 to 35% by weight of an inorganic or organic polysilazane having repeating units represented by the general formula below and soluble in a solvent and 0.1 to 10% by weight of catalyst such as 4,4′-trimethylenebis(1-methylpiperidine) based on a pure polysilazane content. By applying the coating solution onto the surface of base materials such as metals, plastics, glass, ceramic, wood, cement, mortar, bricks, etc., a silica coating strongly adhered to the base materials can be formed excellent in corrosion resistance and anti-scratch properties and simultaneously excellent in characteristics such as abrasion resistant, long-lasting anti-fouling properties, wetting properties to water, sealing properties, chemical resistance, oxidation resistance, physical barrier effect, heat resistance, fire resistance and antistatic properties.

Owner:CLARIANT INT LTD

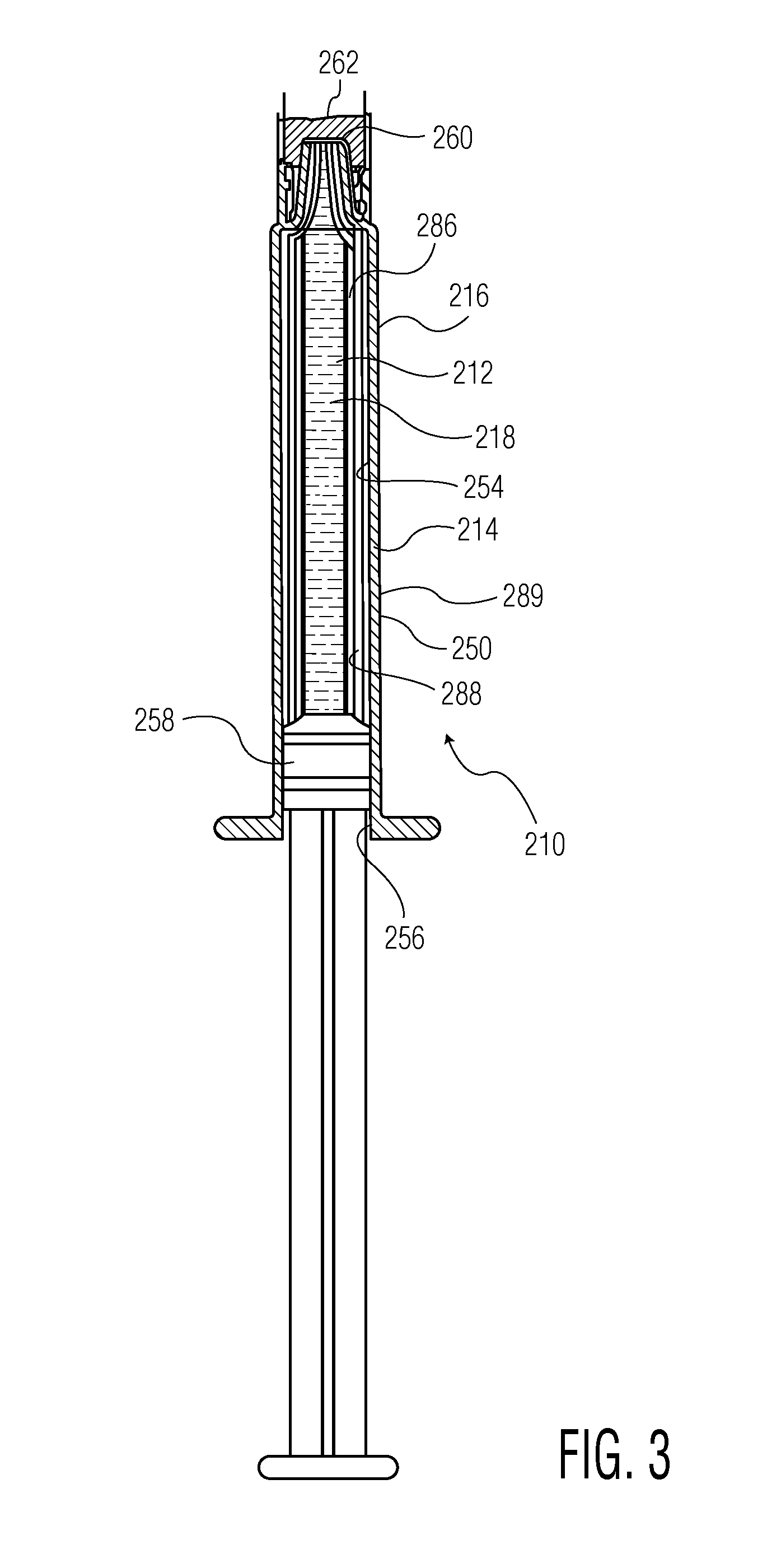

Trilayer coated pharmaceutical packaging

ActiveUS20140251859A1Reduce decreaseSurgeryMaterial analysis by electric/magnetic meansPolymer sciencePolysilazane

An article is described including an article surface and a coating set comprising a tie coating or layer of SiOxCy or Si(NH)xCy applied to the article surface, a barrier coating or layer of Six, and a pH protective layer of SiOxCy or Si(NH)xCy. The respective coatings or layers can be applied by chemical vapor deposition of a polysiloxane or polysilazane precursor in the presence of oxygen. Examples of such an article are a prefilled thermoplastic syringe or thermoplastic pharmaceutical vial with a coated interior portion containing a pharmaceutical preparation or other fluid with a pH of 4 to 8, alternatively 5 to 9. The barrier coating or layer prevents oxygen from penetrating into the thermoplastic syringe or vial, and the tie coating or layer and pH protective coating or layer together protect the barrier layer from the contents of the syringe or vial.

Owner:SI02 MEDICAL PRODS

Low temperature process for polysilazane oxidation/densification

InactiveUS20060102977A1Easy to processIncrease contentSemiconductor/solid-state device manufacturingSemiconductor devicesPolysilazaneSilicon oxide

Semiconductor devices, structures and systems that utilize a polysilazane-based silicon oxide layer or fill, and methods of making the oxide layer are disclosed. In one embodiment, a polysilazane solution is deposited on a substrate and processed with ozone in a wet oxidation at low temperature to chemically modify the polysilazane material to a silicon oxide layer.

Owner:MICRON TECH INC

Light emitting device

InactiveUS6781148B2Electroluminescent light sourcesSolid-state devicesUltravioletMoisture absorption

The invention aims to provide a light emitting device comprising a base material or protective member which has improved light transmittance, heat resistance, passivation (gas barrier, oligomer release prevention and minimized outgassing), anti-water or moisture-absorption, stability against chemical degradation, dimensional and shape stability, anti-surface-reflection, electrical insulation, UV degradation resistance, and weather resistance, and is highly productive due to possible film formation under atmospheric pressure, and hence, a light emitting device featuring high reliability, ease of manufacture and low cost. The object is attained by a light emitting device comprising a base material (1) having flexibility, light transparency and heat resistance, a lower electrode (4) having light transmittance, a light emitting layer (4), and an upper electrode (4) formed on the base material, the device further comprising a silica film and / or a siliceous film (3) which is formed on the substrate side as viewed from the light emitting layer (4) or on opposite sides of the substrate by applying polysilazane and subjecting it to oxidative treatment.

Owner:FUTABA CORPORATION

Organic polysilazane/inorganic nano-material super-hydrophobic coating and preparation method thereof

ActiveCN106189832AHigh hardnessImprove scratch resistanceFireproof paintsLiquid surface applicatorsMetallic materialsChemical stability

The invention discloses an organic polysilazane / inorganic nano-material super-hydrophobic coating and a preparation method thereof. According to the preparation method, firstly, an organic polysilazane solution is prepared, a silane coupling agent containing hydrophobic units is used for carrying out hydrophobization on an inorganic nano-material, and dispersion liquid of the hydrophobic inorganic nano-material is prepared; then, an organic material or an inorganic material or a metal material serves as a base material, and an organic polysilazane and the hydrophobic inorganic nano-material alternatively deposit on the surface of the base material in sequence through a deposition method; finally, appropriate heat treatment is carried out on the surface which is subjected to multiple times of alternative deposition. The obtained coating shows good super-hydrophobic performance, the contact angles of water drops on the surface of the coating are larger than 150 degrees, the rolling angles are smaller than 10 degrees, and the coating has good mechanical and chemical stability and has wide application prospect in the field of waterproof clothes, exterior wall coating, oil-water separation, biomedicine and the like. According to the method, the preparation process is simple, and large hydrophobic coatings can be established on various base material surfaces.

Owner:SOUTH CHINA UNIV OF TECH

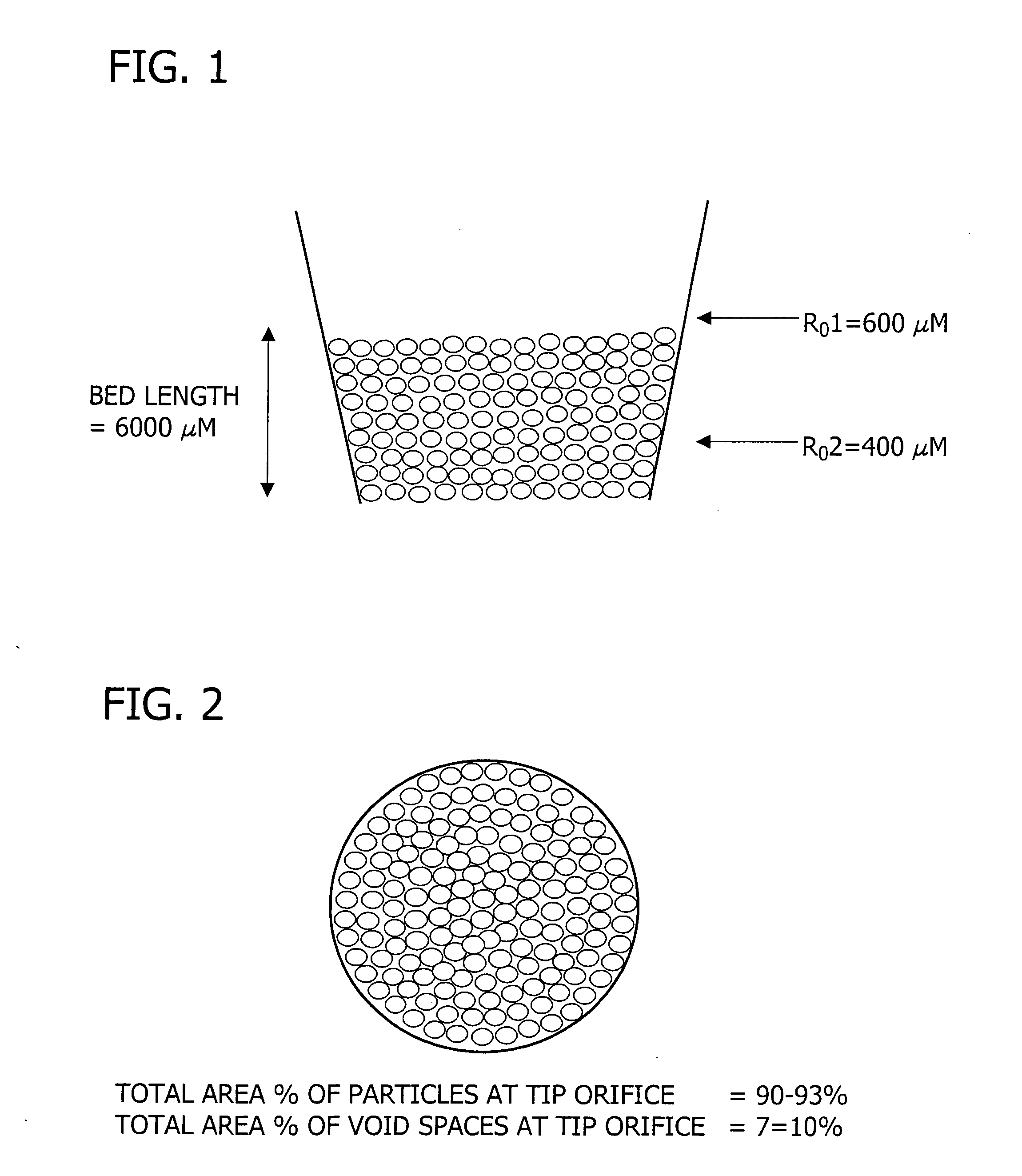

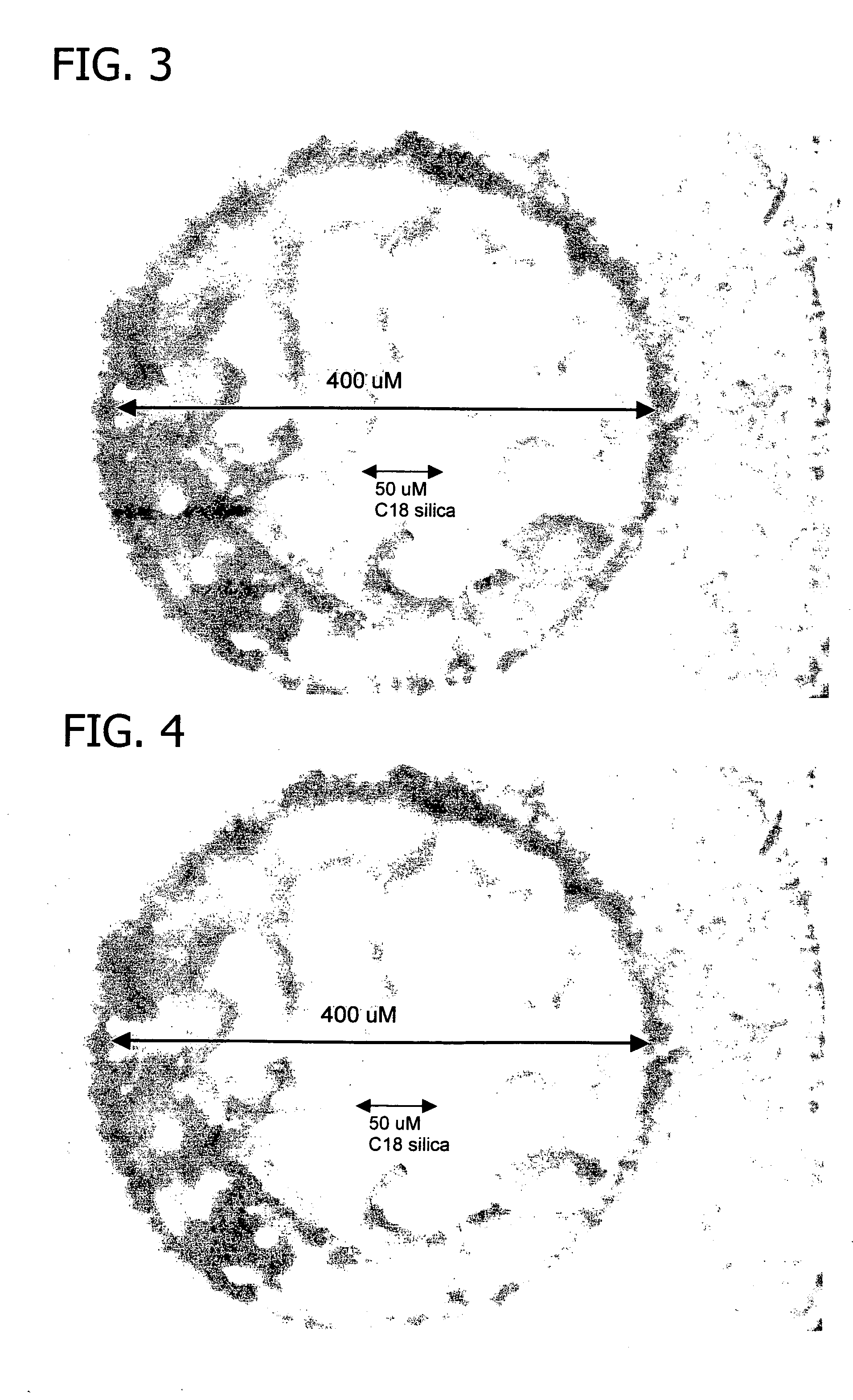

Polysilazane thermosetting polymers for use in chromatographic systems and applications

Owner:SIGMA ALDRICH CO LLC

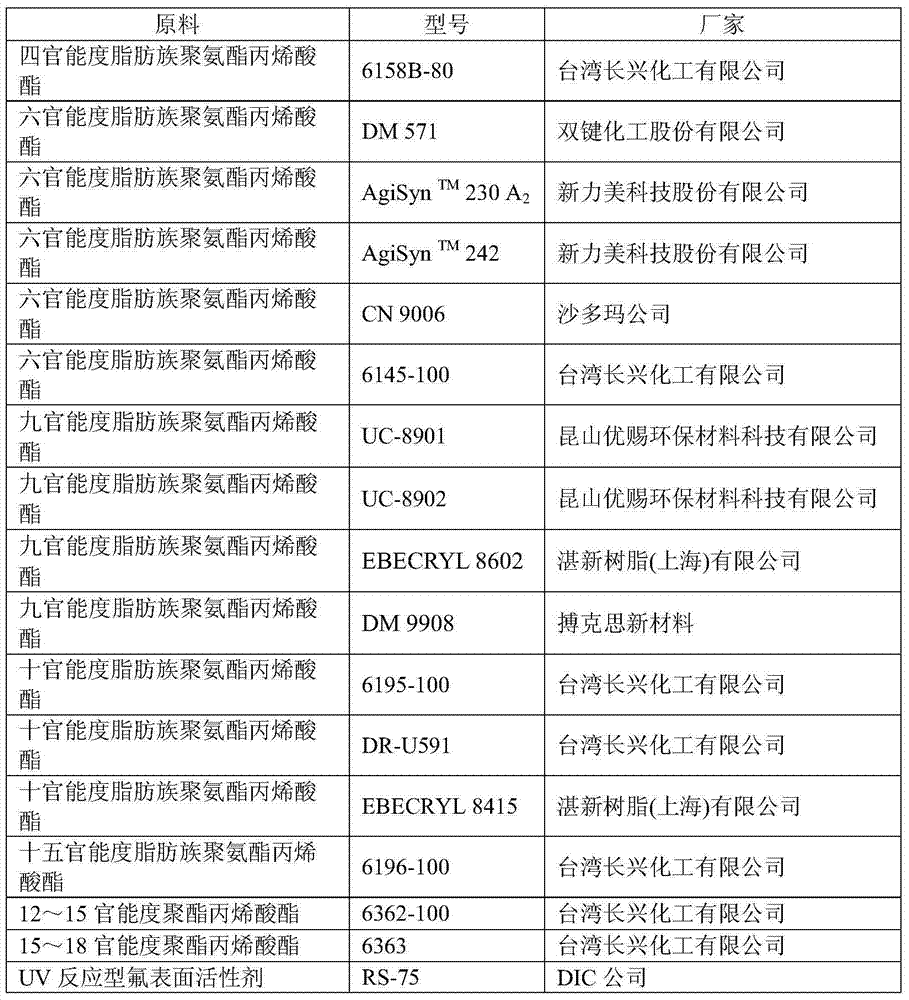

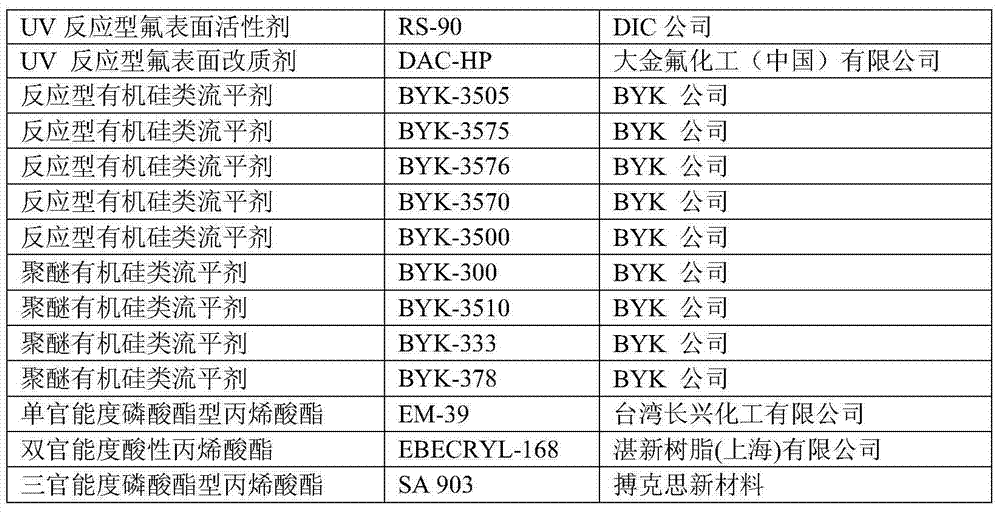

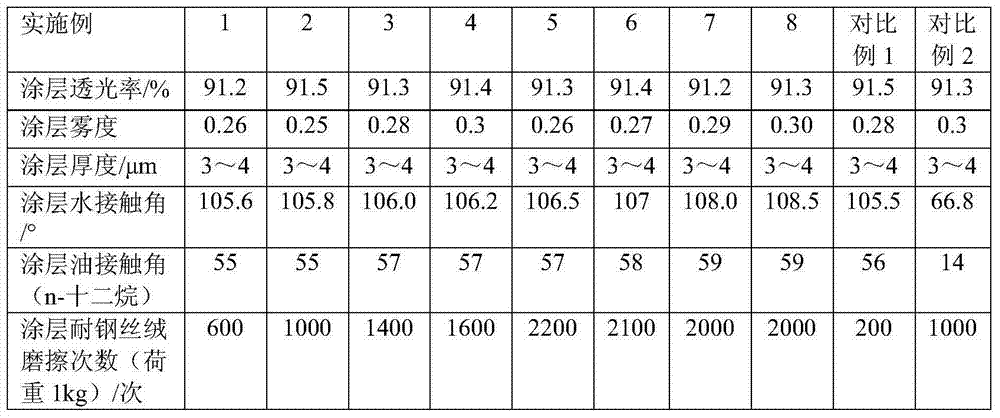

UV curing coating, wear-resistant and antifouling coating layer and mobile phone protection film containing wear-resistant and antifouling coating layer

ActiveCN104845521AHigh reactivityIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesWear resistantPolysilazane

The invention provides an UV curing coating, a wear-resistant and antifouling coating layer and a mobile phone protection film containing the wear-resistant and antifouling coating layer. The coating comprises, in parts by weight, 10-95 parts of a first prepolymer, 5-60 parts of a second prepolymer, 0.05-8 parts of a polysilazane-based polymer, 0.05-8 parts of a fluorine-containing aid, 1-15 parts of a photoinitiator and 100-300 parts of a solvent, wherein the first prepolymer is a urethane acrylate prepolymer with a functionality degree of 4-8; the second prepolymer is an acrylate prepolymer with a functionality degree of 9-18. The wear resistance of the coating layer formed after curing the UV curing coating can be improved by the first prepolymer and the second prepolymer with high functionality degrees, improvement for the wear resistance of the coating layer and prolonging for the service life of the coating layer are benefited due to the adding of the polysilazane-based polymer and a polar compound, and the good antifouling performance of the coating layer can be ensured, and the reduction of the antifouling performance of the coating layer can be suppressed due to the fluorine-containing aid. The coating layer has both good antifouling performance and wear resistance.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

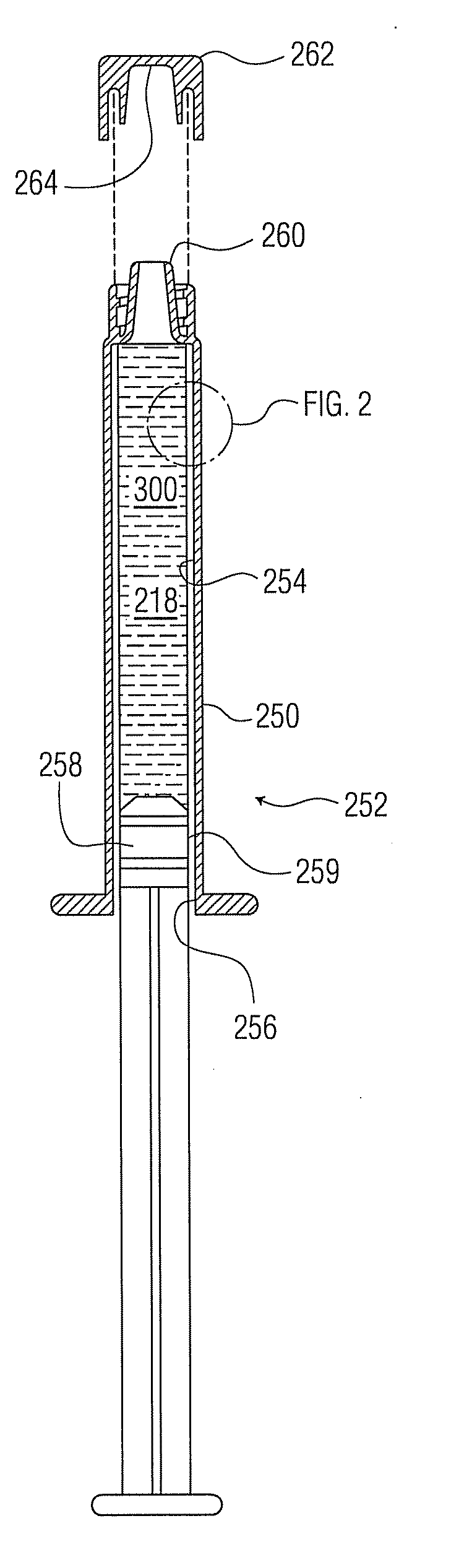

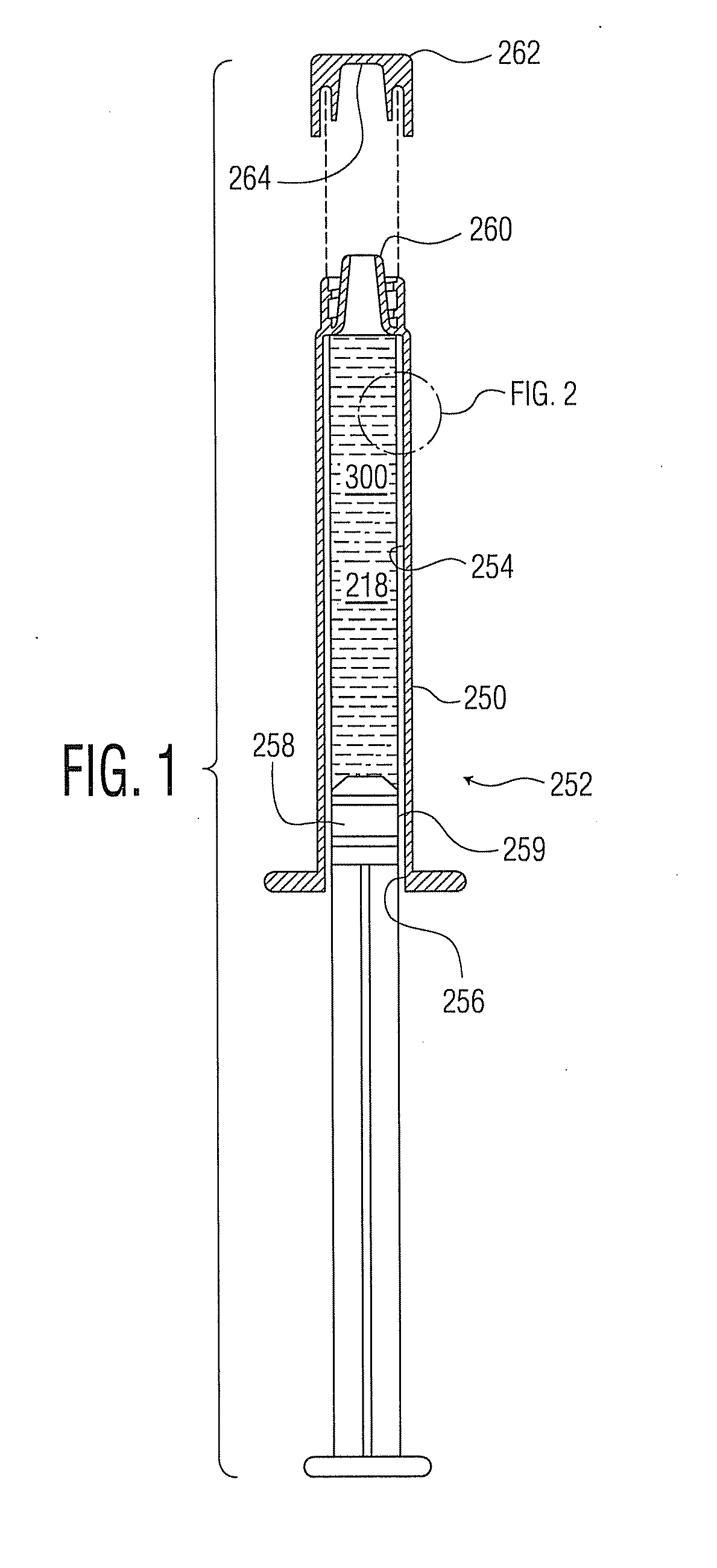

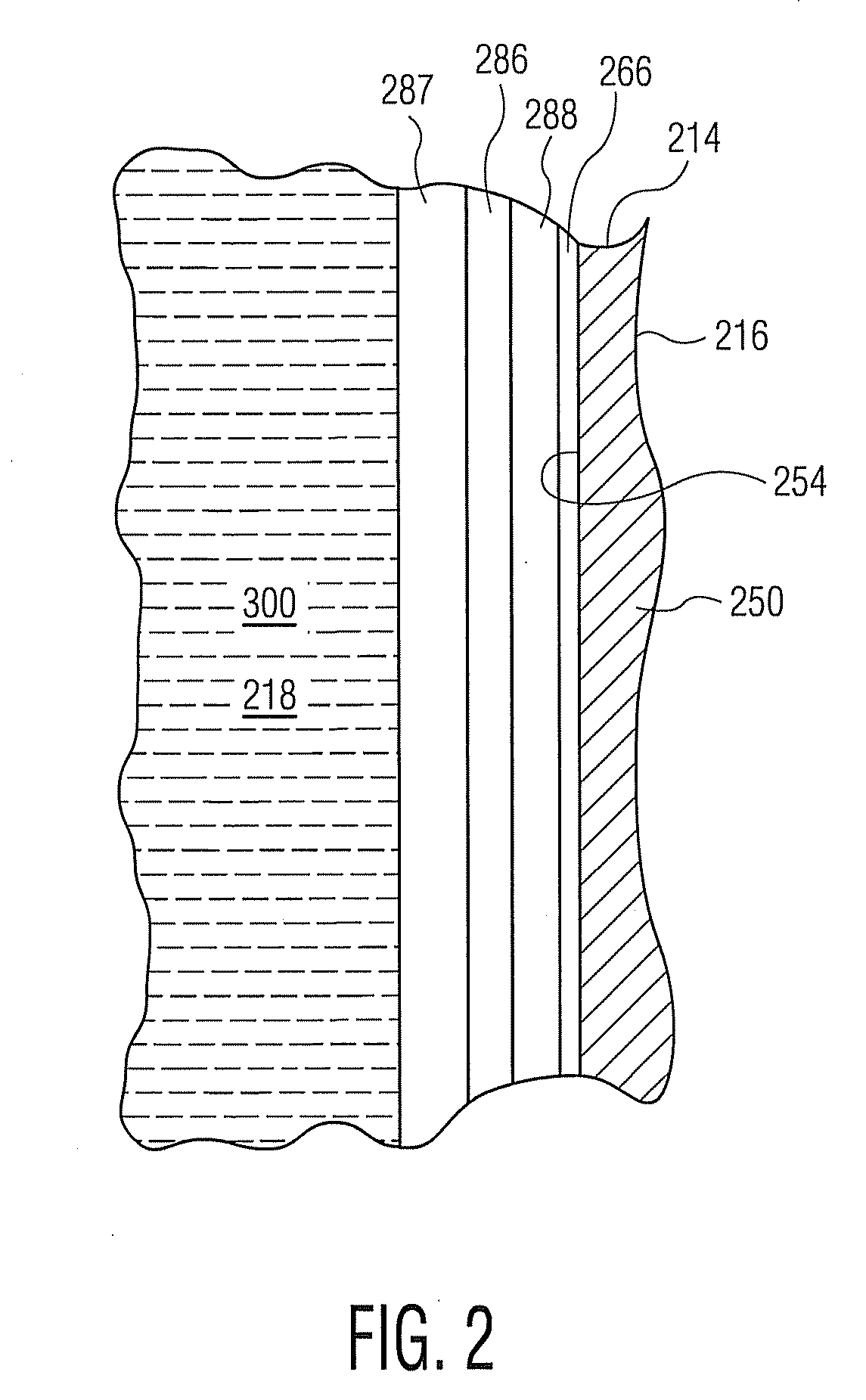

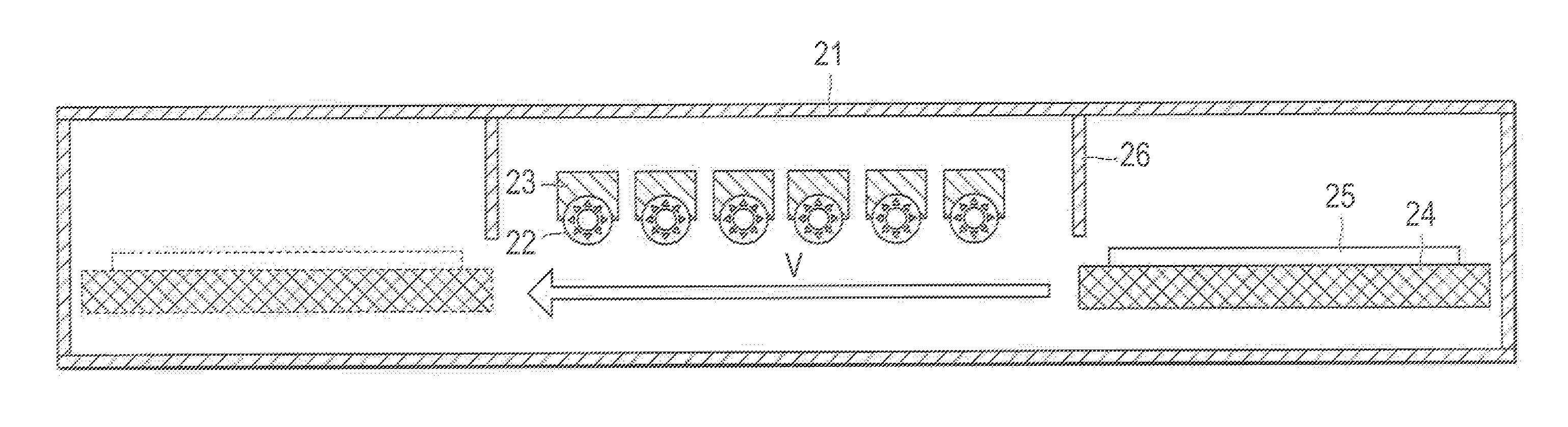

Plasma or CVD pre-treatment for lubricated pharmaceutical package, coating process and apparatus

ActiveUS20140249484A1Improve the lubrication effectReduce sliding frictionInfusion syringesSurgeryPolymer sciencePre treatment

An article is described including an article surface, a primer coating or layer of SiOx, SiOxCy or SiNxCy applied to the article surface, and a deposit of lubricant applied to the primer coating or layer. The primer coating or layer of SiOx, SiOxCy or SiNxCy is applied by chemical vapor deposition of a polysiloxane or polysilazane precursor in the presence of oxygen. A first deposit of lubricant is applied to the primer coating or layer. The primer coating or layer improves the adhesion or wetting of the lubricant on the surface to be lubricated. Examples of such an article are a prefilled syringe having a barrel with a lubricated interior portion and a plunger tip that slides along it. Another example of such an article is a vial having a lubricated opening to receive a septum. Another aspect of the invention is a method of making such an article.

Owner:SI02 MEDICAL PRODS

Method For Modifying Surface Of Substrate, Substrate Having Modified Surface, And Method For Producing Same

InactiveUS20080138611A1Excellent abrasion resistanceGood chemical resistanceSilicaSynthetic resin layered productsPolysilazaneOrganic group

A method for modifying the surface of a substrate includes the following steps: (1) a step for forming a polysilazane coating by applying a polysilazane onto the surface of a substrate; (2) a step for applying an organic compound of which main backbone comprises an organic group represented by the following formula [1]: —[(R)mO]n— (wherein R represents an alkylene group, and m and n respectively represent a positive number of not less than 1) onto the surface of the polysilazane coating; and (3) a step for heating the substrate having undergone the steps (1) and (2), thereby converting the polysilazane to silica and bonding the organic compound to the silica of the silica layer.

Owner:UNIVERSITY OF TOKUSHIMA

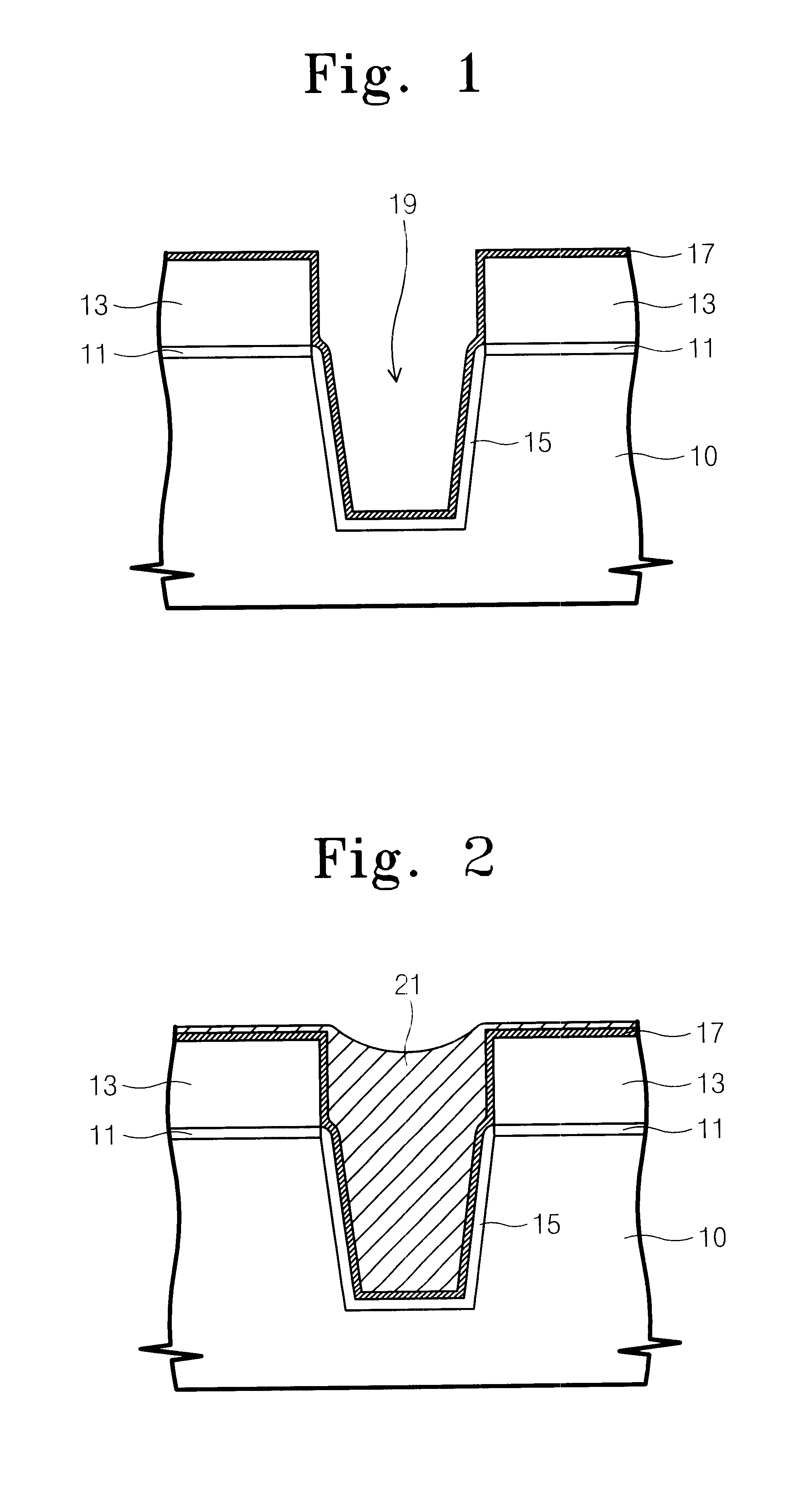

Coating composition for forming oxide film and method for producing semiconductor device using the same

InactiveUS20080305611A1Increase ratingsSuppress the volume expansion coefficientSemiconductor/solid-state device manufacturingCoatingsDielectricPolysilane

A coating composition for forming an oxide film, which can suppress the phenomenon of an increased wet etching rate caused by a part of the SOG film embedded inside a groove becoming low-density, and which can suppress the volume expansion coefficient to a low level, and a method for producing a semiconductor device using the same are provided. An oxide film is formed inside a groove by: coating a coating composition for forming an oxide film, which contains a polysilazane or a hydrogenated silsesquioxane, and a polysilane, on a substrate having a groove; and thereafter heat treatment in an oxidizing atmosphere. This method is suitable for forming a device isolation region and a wiring interlayer dielectric film.

Owner:ELPIDA MEMORY INC

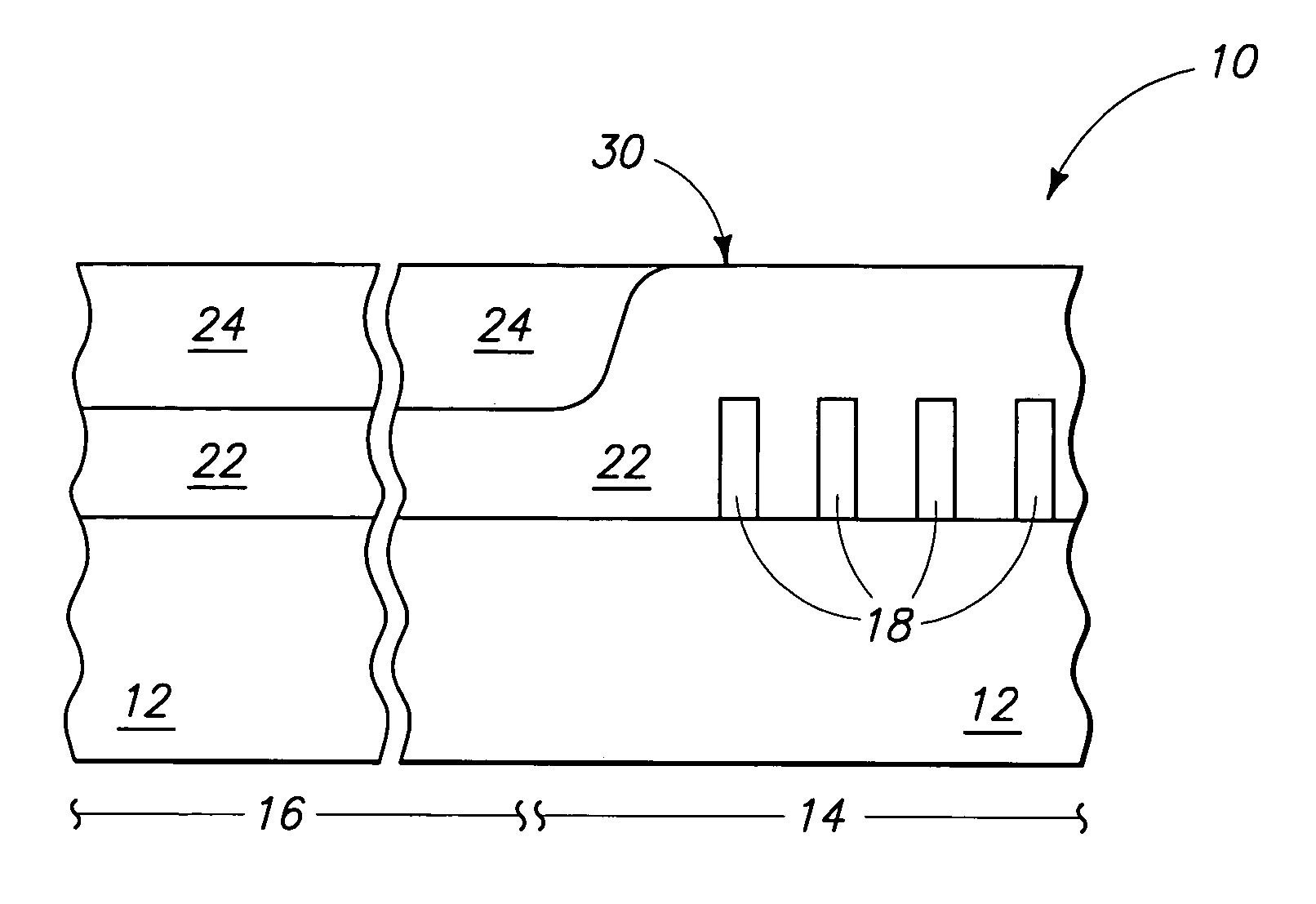

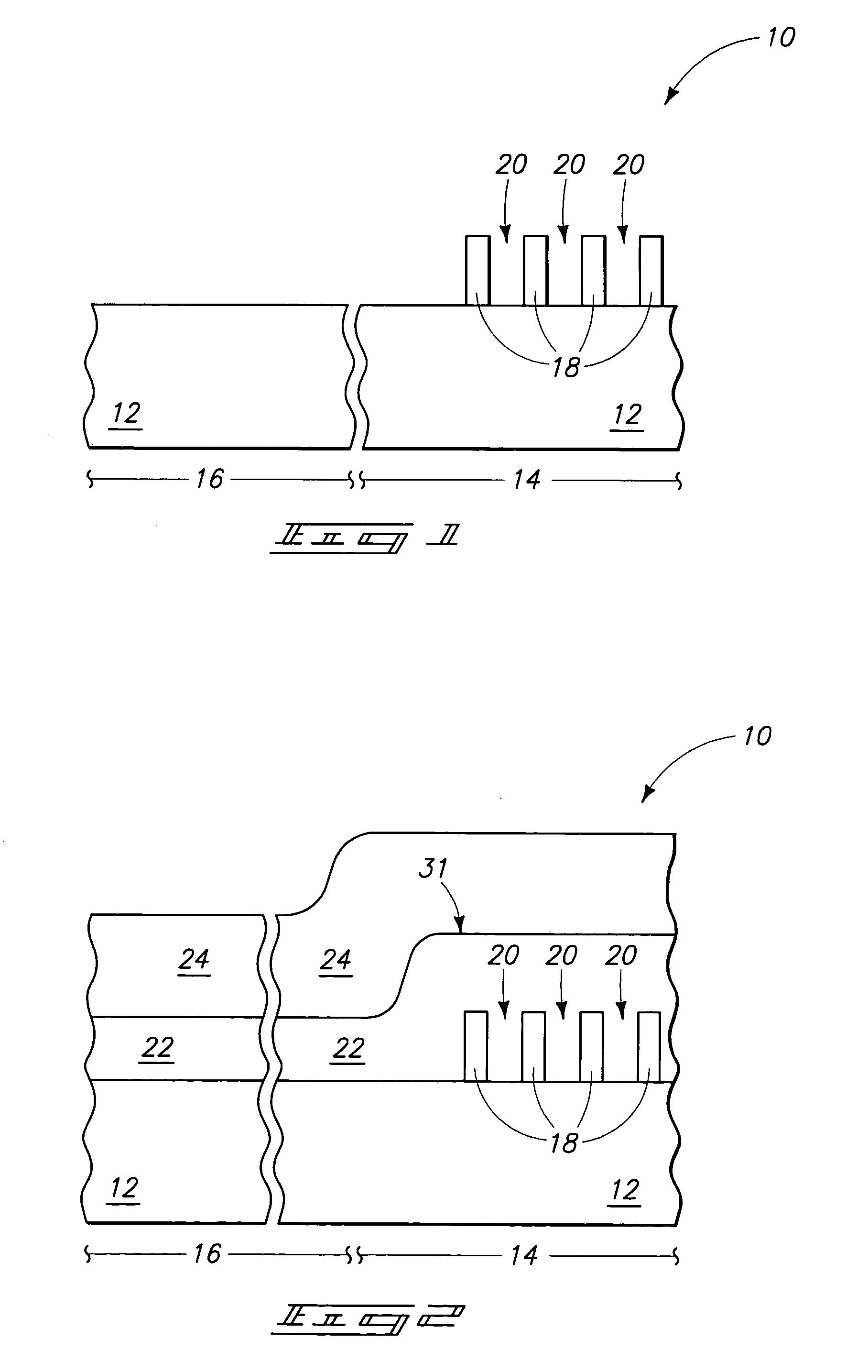

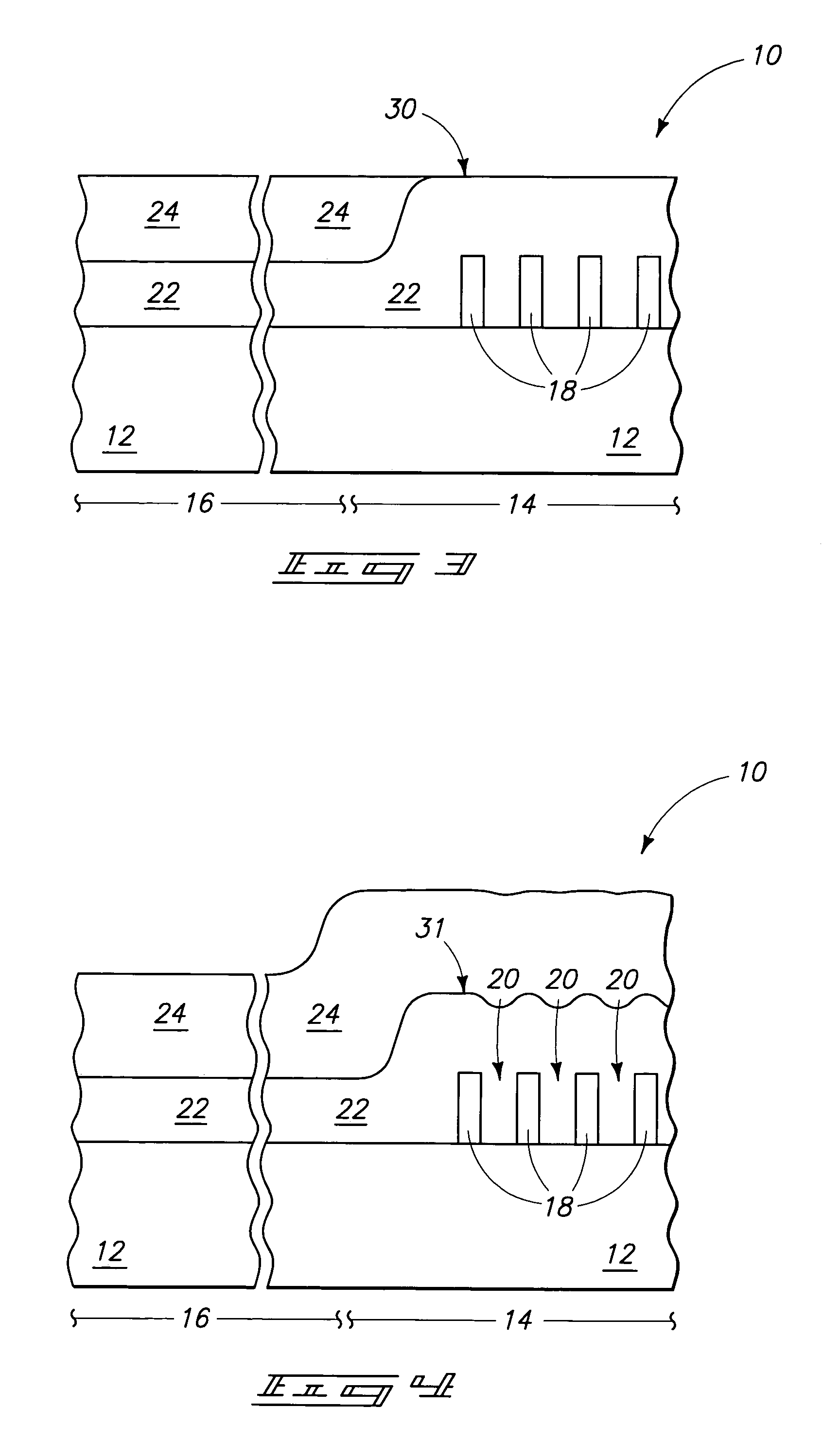

Methods of forming planarized surfaces over semiconductor substrates

The invention includes a method of forming a planarized surface over a semiconductor substrate. A substrate is provided which includes a memory array region and a peripheral region proximate the memory array region. The memory array region has a higher average elevational height than the peripheral region. Polysilazane is formed over the memory array region and over the peripheral region. The polysilazane is densified. A material is formed over the polysilazane. The material is planarized while using the densified polysilazane as a stop. The planarization forms a planarized surface which extends over the memory array and peripheral regions. The planarized surface comprises both the densified polysilazane and the material.

Owner:MICRON TECH INC

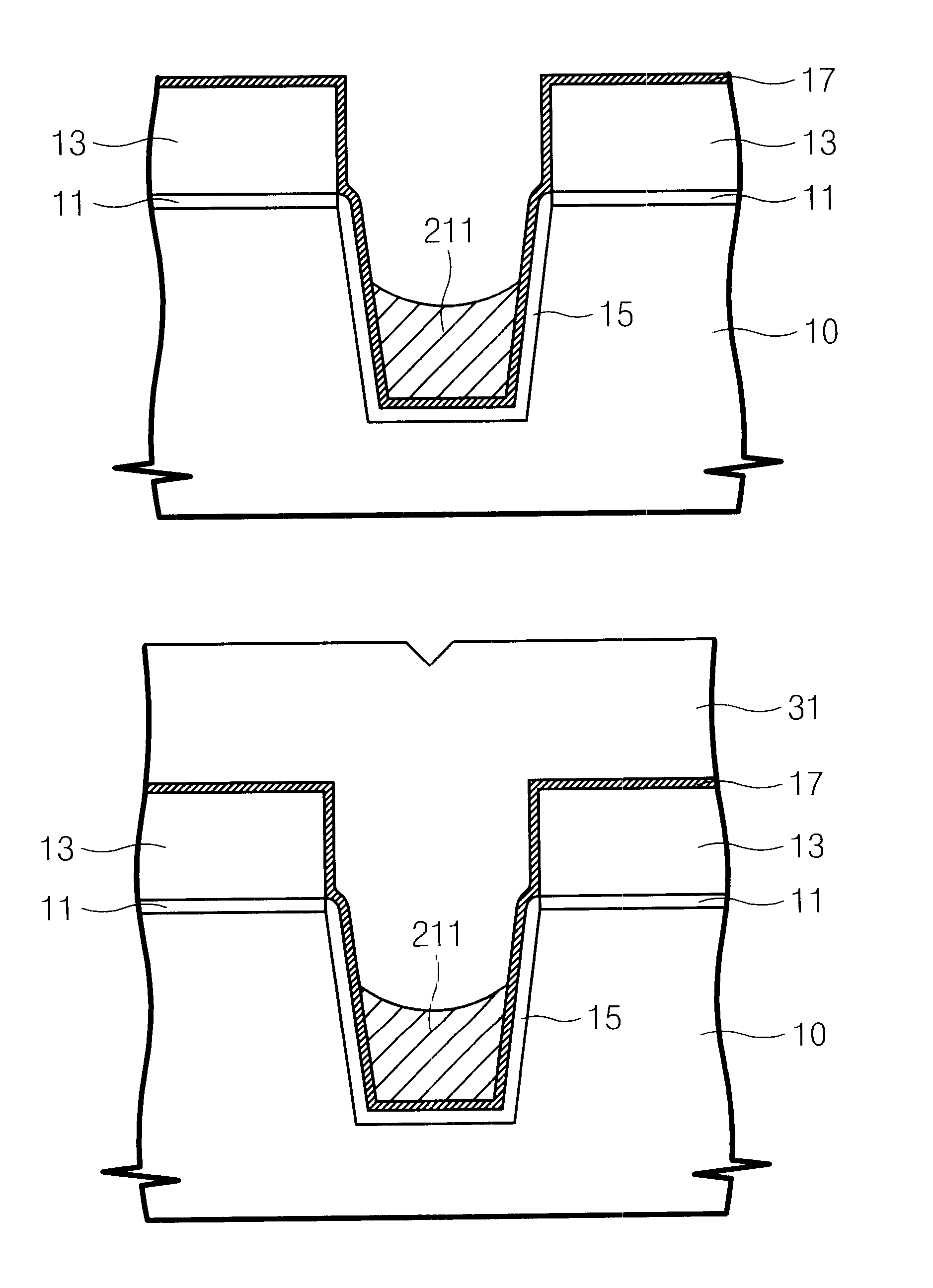

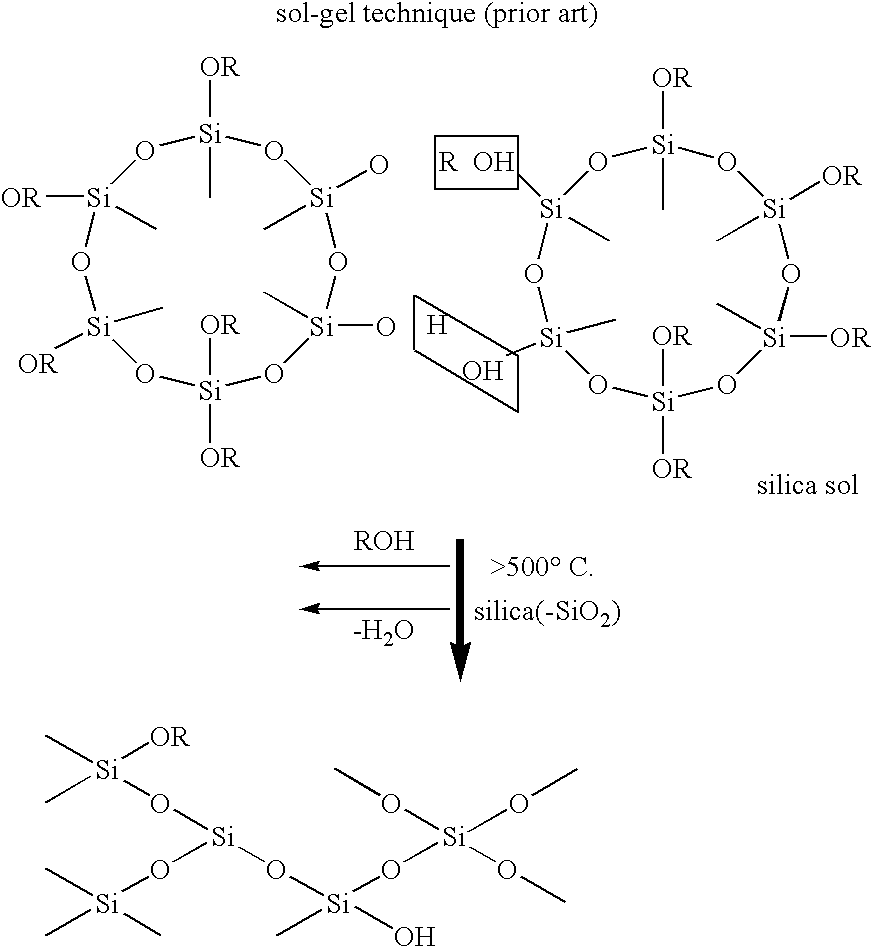

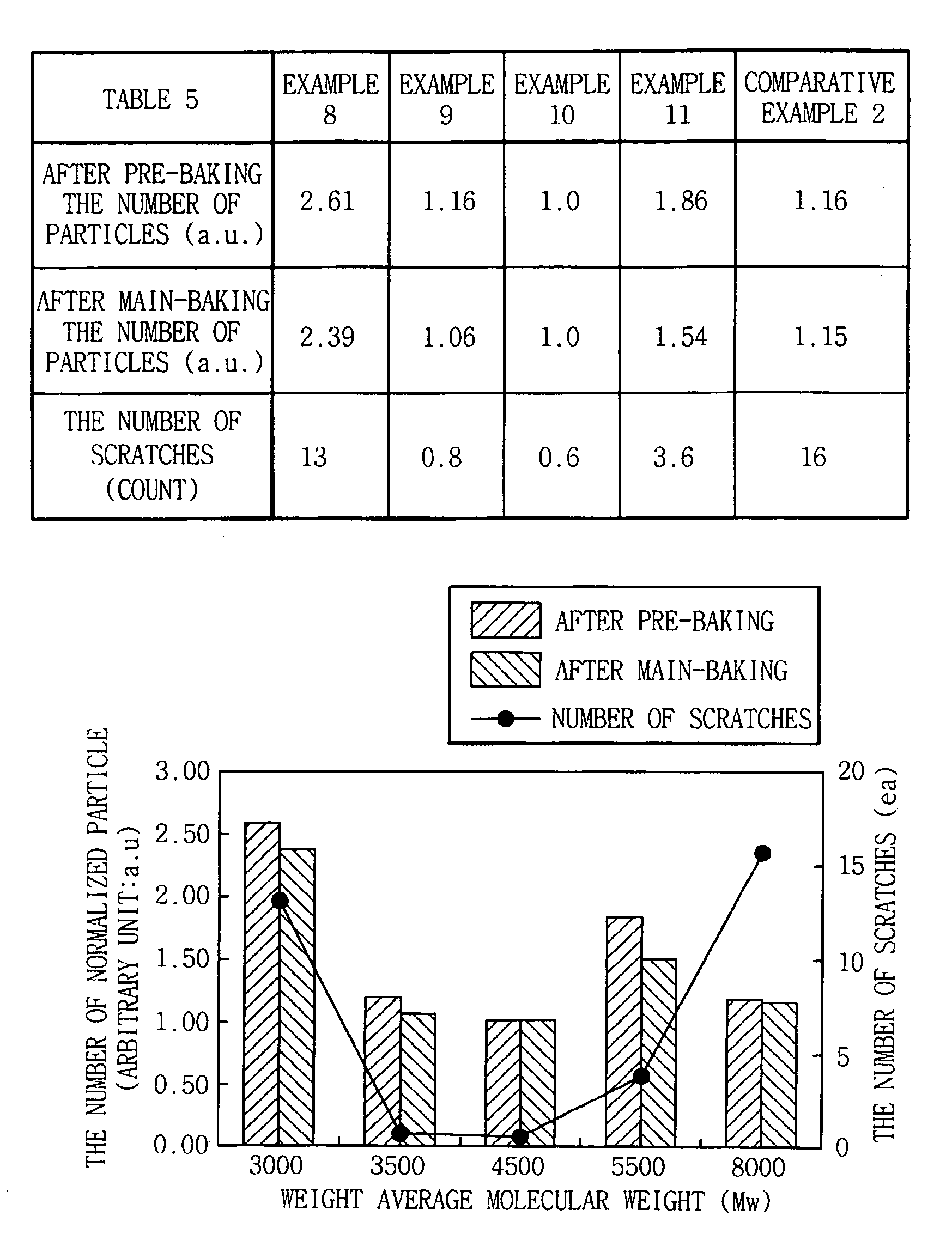

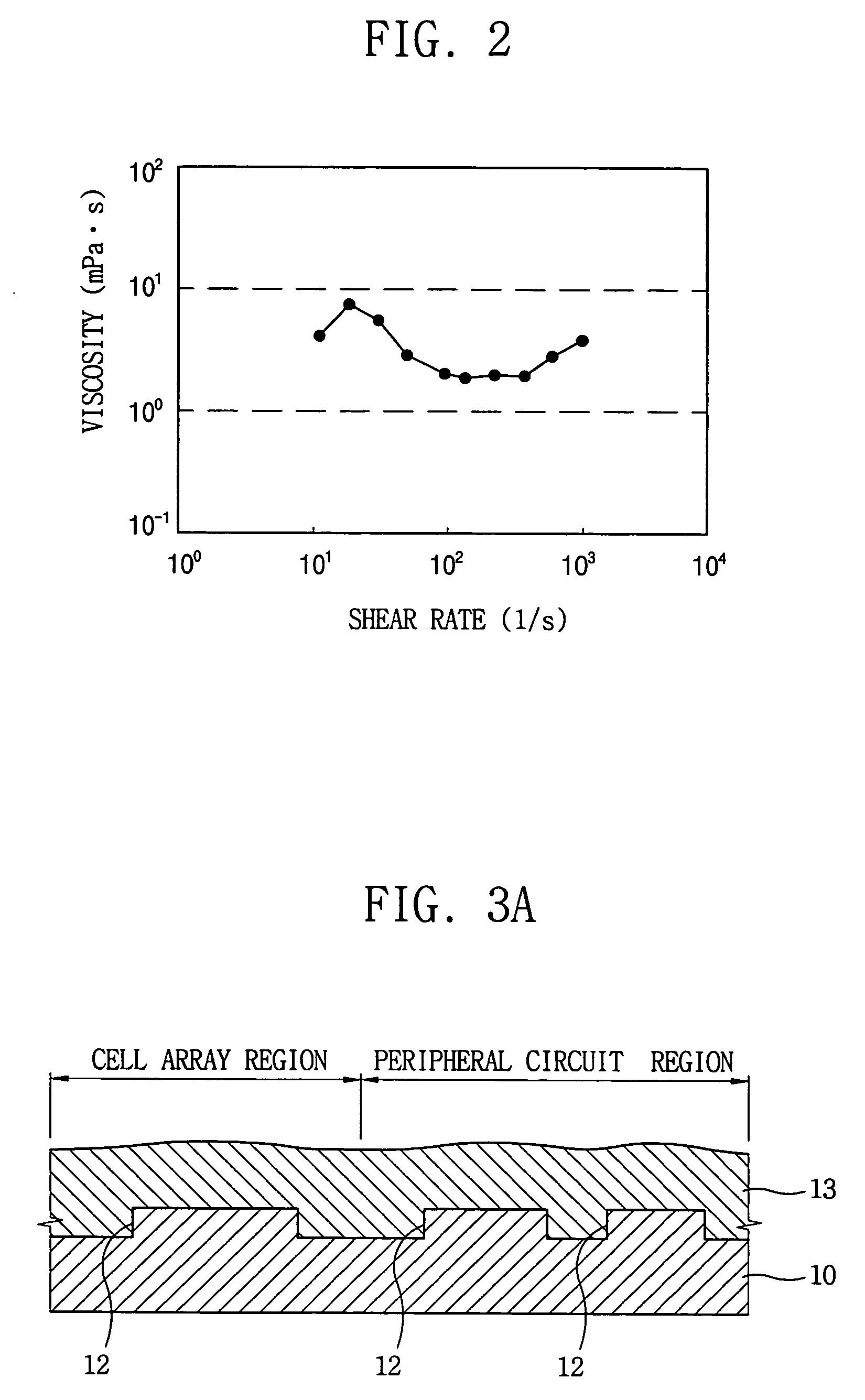

Spin-on glass composition and method of forming silicon oxide layer in semiconductor manufacturing process using the same

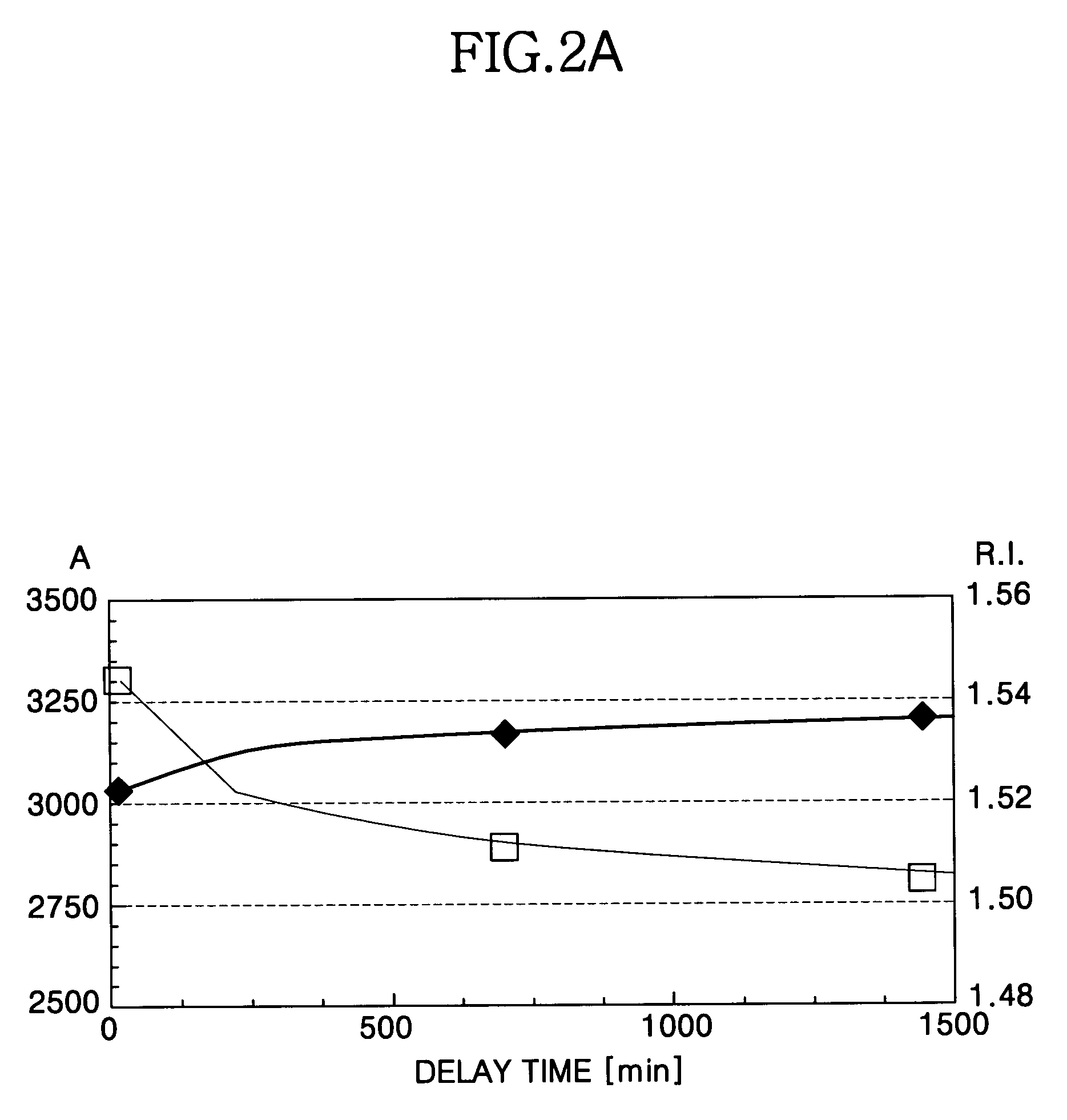

InactiveUS7270886B2High bulk densityLarge aspect ratioLayered productsSolid-state devicesPolysilazaneSilicon oxide

A spin-on glass (SOG) composition and a method of forming a silicon oxide layer utilizing the SOG composition are disclosed. The method includes coating on a semiconductor substrate having a surface discontinuity, an SOG composition containing polysilazane having a compound of the formula —(SiH2NH)n— wherein n represents a positive integer, a weight average molecular weight within the range of about 3,300 to 3,700 to form a planar SOG layer. The SOG layer is converted to a silicon oxide layer with a planar surface by curing the SOG layer. Also disclosed is a semiconductor device made by the method.

Owner:SAMSUNG ELECTRONICS CO LTD

Anti-staining coating solution comprising inorganic polysilazane

By applying the solution comprising 0.5 to 10 % by weight of an inorganic polysilazane having repeating units represented by the general formula below and soluble in a solvent and a catalyst such as 4,4'-trimethylenebis (1-methylpiperidine) etc. onto the surfaces of the bodies and wheels of automobiles, dentures, tombstones, the interior and exterior of a house, products used with water in toilets, kitchens, washrooms, bathtubs, etc., signboards, signs, plastic products, glass products, etc., a rigid and dense silica coating is formed to confer a long-durable hydrophilic effect and anti-fouling effect on the surfaces. The solvent is properly selected from mineral spirit, paraffin type solvents, aromatic solvents, alicyclic solvents and mixture thereof depending on the article being coated.

Owner:CLARIANT FIANCE (BVI) LTD

Optical information medium and evaluation method

InactiveUS6576320B2Less susceptible to marLess susceptible to flawRecord carriersLayered product treatmentPolysilazaneRecording layer

An optical information medium has a light-transparent substrate and an information recording layer, wherein optical recording and / or reading is performed with a laser beam that enters the information recording layer from the light-transparent substrate side. A cured polysilazane film is disposed on the laser beam incident side of the light-transparent substrate, and the light-transparent substrate or the light-transparent substrate having the cured polysilazane film integrated thereon has a tensile modulus of at least 200 MPa. The medium on its laser beam incident side surface is improved in mar resistance.

Owner:TDK CORPARATION

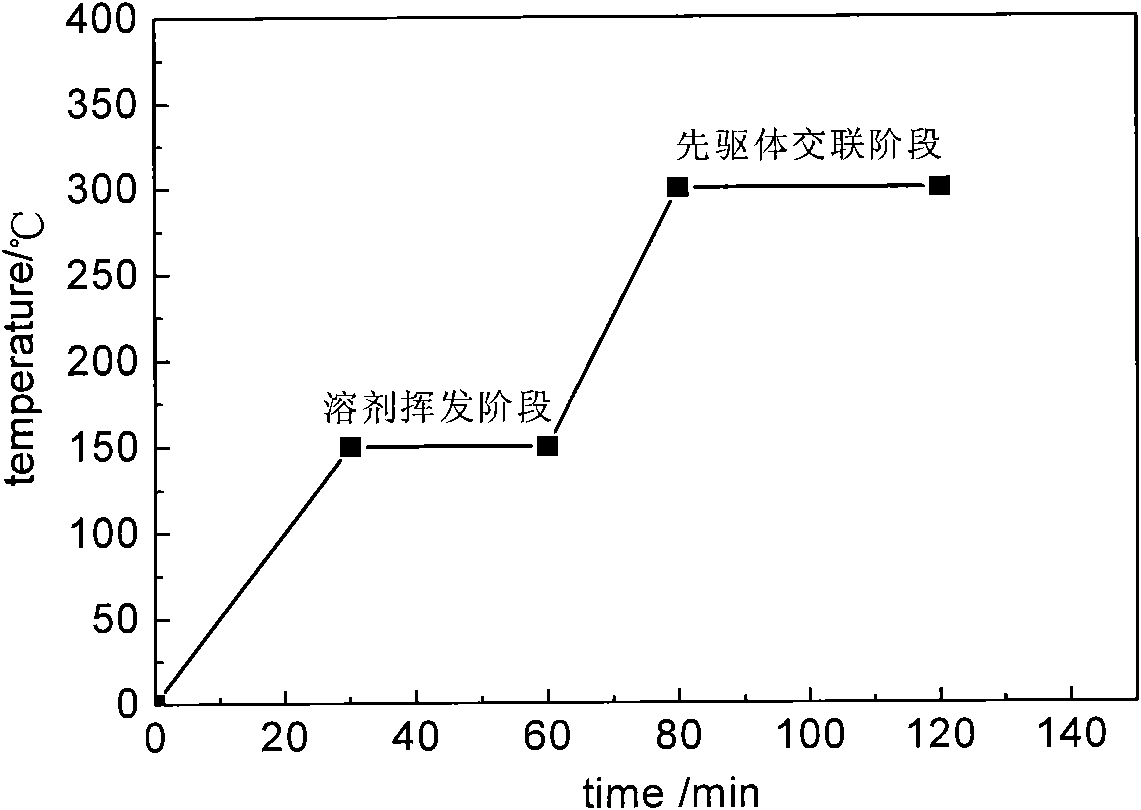

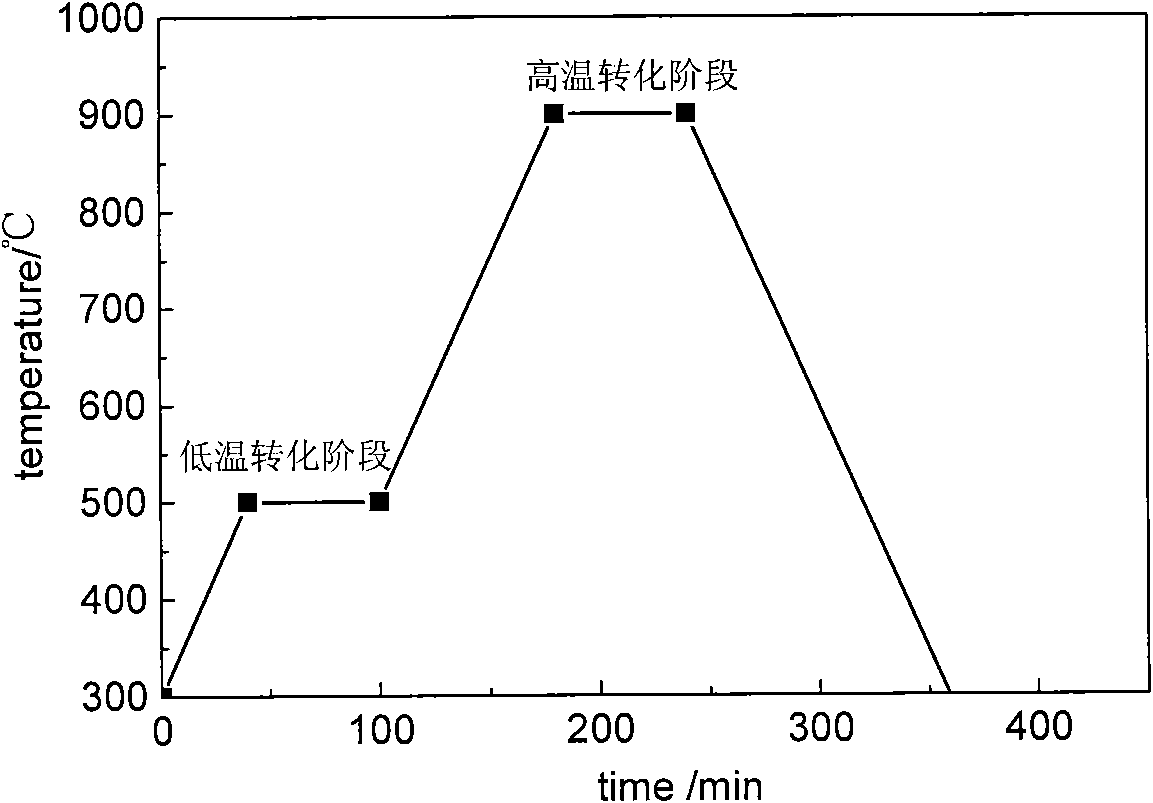

Method for preparing insulating heat conducting ceramic coating from polymer precursor

InactiveCN101654778ASimple preparation processEasy to operateSolid/suspension decomposition chemical coatingCross-linkHeat conducting

The invention relates to a method for preparing an insulating heat conducting ceramic coating, which is prepared from one or more of polymer precursors such as polysilazane, polysiloxane and polycarbosilane serving as a base material, and multiple kinds of ceramic packing and active fillers as well as solvent and various auxiliary agents, and is prepared by the following steps of: 1, adding a certain amount of fillers, solvent and auxiliary agents into a polymer precursor, stirring the mixture evenly, and preparing the mixture into slurry after high-speed grinding; 2, coating the slurry on thesurface of a treated substrate material (comprising metal, ceramic, graphite, a C / C composite material and the like) in a brush coating or spray coating mode; 3, performing vacuum heat treatment on the substrate material with a coating at a temperature of between 100 and 300 DEG C for 1 to 2 hours to ensure that the polymer precursor performs a cross-linking reaction; and 4, performing high-temperature treatment on the treated material under the protection of a gas, namely treating the material at a temperature of between 400 and 1,000 DEG C for 1 to 5 hours, and then naturally cooling to obtain a ceramic coating on the surface of the substrate material. The insulating heat conducting ceramic coating has the characteristics of simple coating and heat treatment technology, excellent insulating property and heat conductivity, good high temperature resistance, excellent high-temperature cracking resistance and the like. The method can be widely applied in electronic and electrical industry.

Owner:BEIJING PANTIAN NEW TECH

Surface treatment and deposition for reduced outgassing

InactiveUS20130149462A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaHydrogen

A method of forming a dielectric layer is described. The method first deposits a silicon-nitrogen-and-hydrogen-containing (polysilazane) layer by radical-component chemical vapor deposition (CVD). The silicon-nitrogen-and-hydrogen-containing layer is formed by combining a radical precursor (excited in a remote plasma) with an unexcited carbon-free silicon precursor. A silicon oxide capping layer may be formed from a portion of the carbon-free silicon-nitrogen-and-hydrogen-containing layer to avoid time-evolution of underlying layer properties prior to conversion into silicon oxide. Alternatively, the silicon oxide capping layer is formed over the silicon-nitrogen-and-hydrogen-containing layer. Either method of formation involves the formation of a local plasma within the substrate processing region.

Owner:APPLIED MATERIALS INC

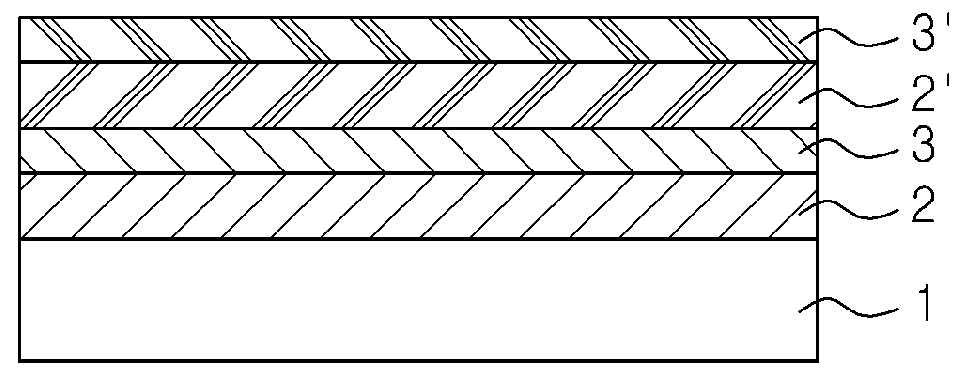

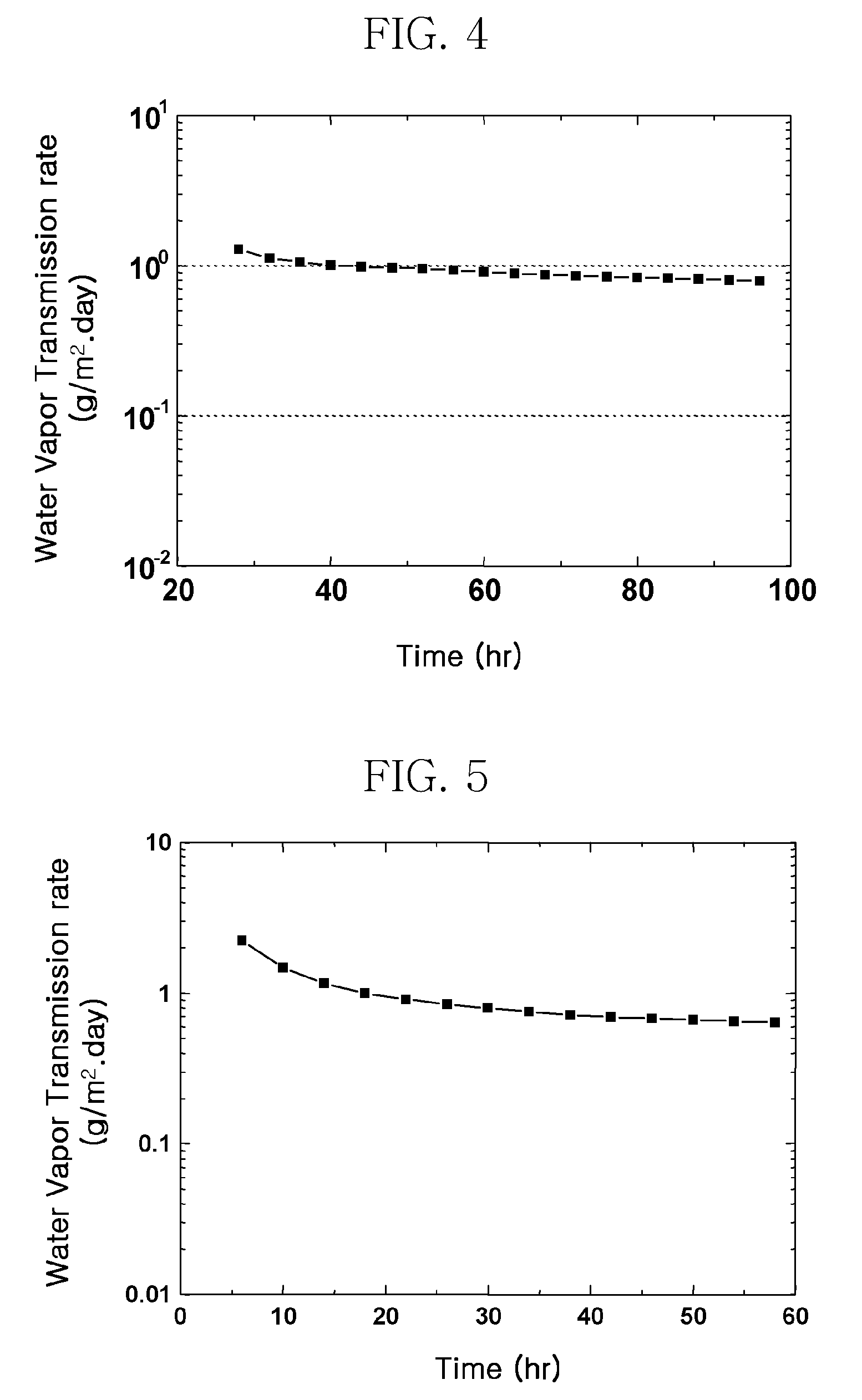

Protective film and encapsulation material comprising the same

ActiveUS20090252975A1Prevent moisture penetrationIncrease flexibilitySynthetic resin layered productsCoatingsOptical transmittancePolysilazane

Disclosed herein is a protective film. The protective film is produced by alternate coating of a polysilazane-based polymer and a flexible polysiloxane-based polymer. The polysilazane-based polymer is cured at low temperature to form silica, thereby achieving high hardness and high light transmittance. The protective film has improved interfacial adhesion between the respective coating films, which prevents permeation of moisture and oxygen. In addition, the protective film can be easily produced by low-temperature wet processes. Also disclosed herein is an encapsulation material comprising the protective film.

Owner:CHEIL IND INC +1

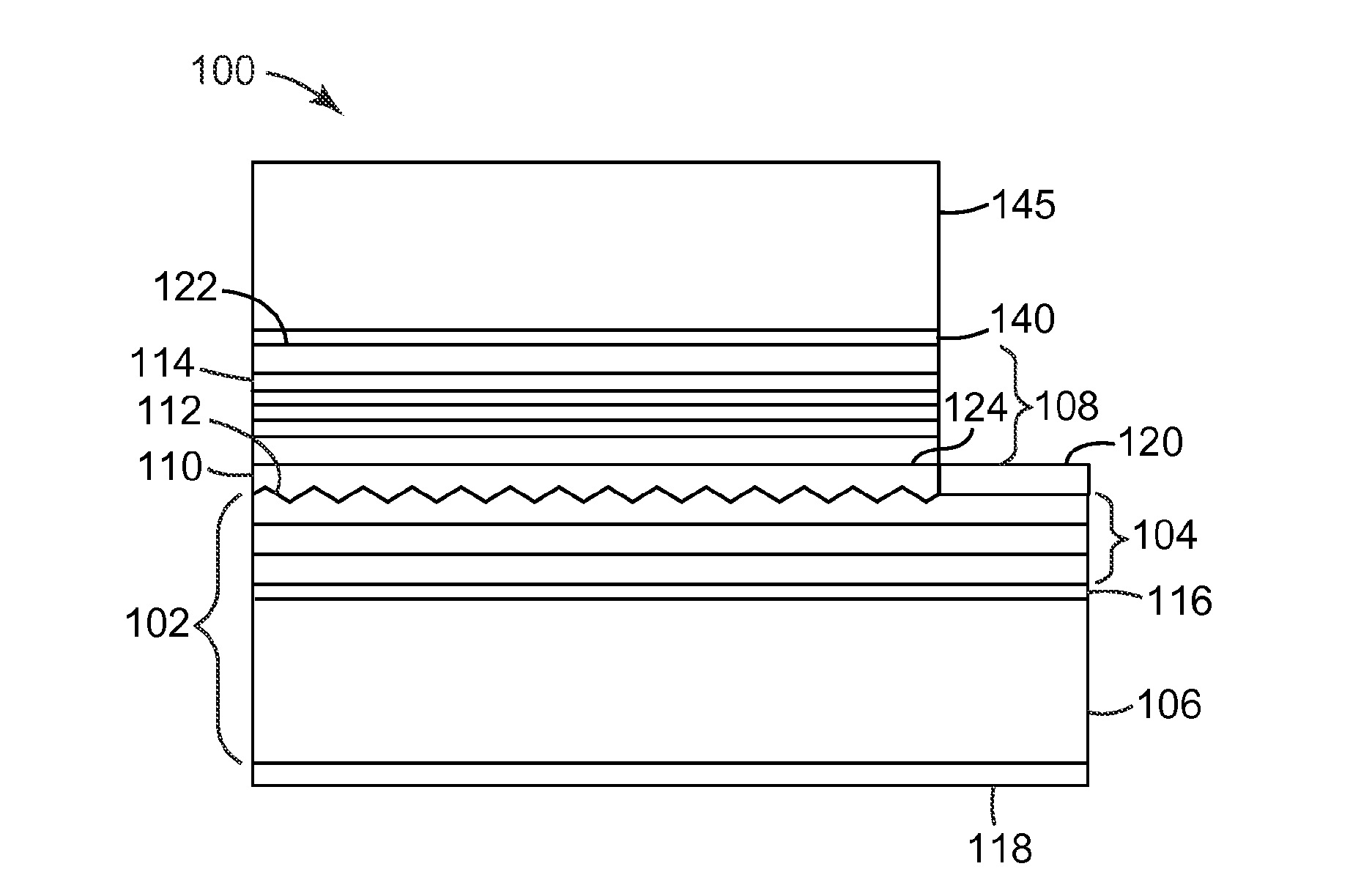

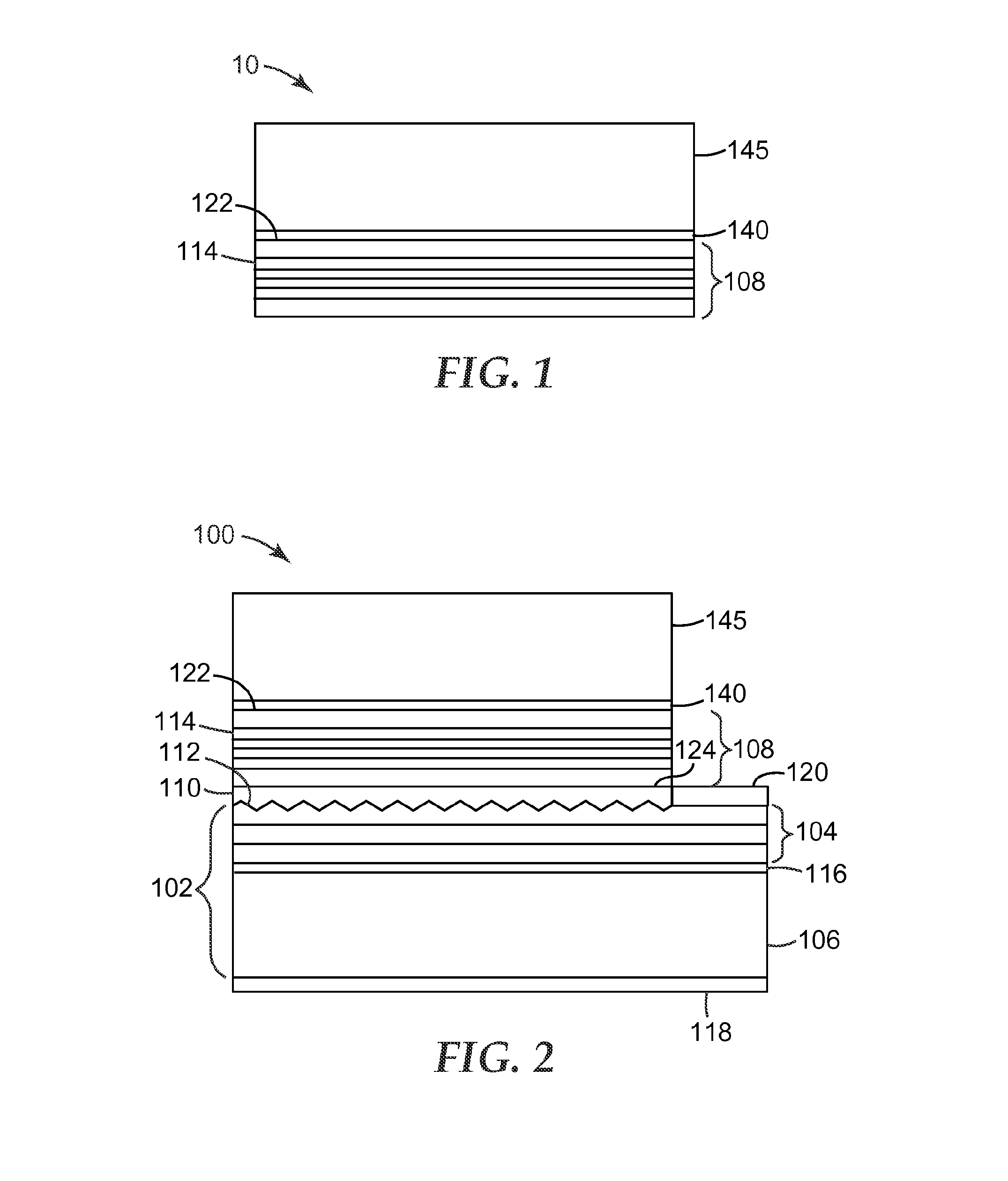

Light emitting diode component comprising polysilazane bonding layer

ActiveUS20130221393A1Good optical clarityImprove thermal stabilitySolid-state devicesSemiconductor devicesPhosphorPolysilazane

In one embodiment, a semiconductor component, such as a wavelength converter wafer, is described wherein the wavelength converter is bonded to an adjacent inorganic component with a cured bonding layer comprising polysilazane polymer. The wavelength converter may be a multilayer semiconductor wavelength converter or an inorganic matrix comprising embedded phosphor particles. In another embodiment, the semiconductor component is a pump LED component bonded to an adjacent component with a cured bonding layer comprising polysilazane polymer. The adjacent component may the described wavelength converter(s) or another component comprised of inorganic material(s) such as a lens or a prism. Also described are methods of making semiconductor components such as wavelength converters and LED's.

Owner:3M INNOVATIVE PROPERTIES CO

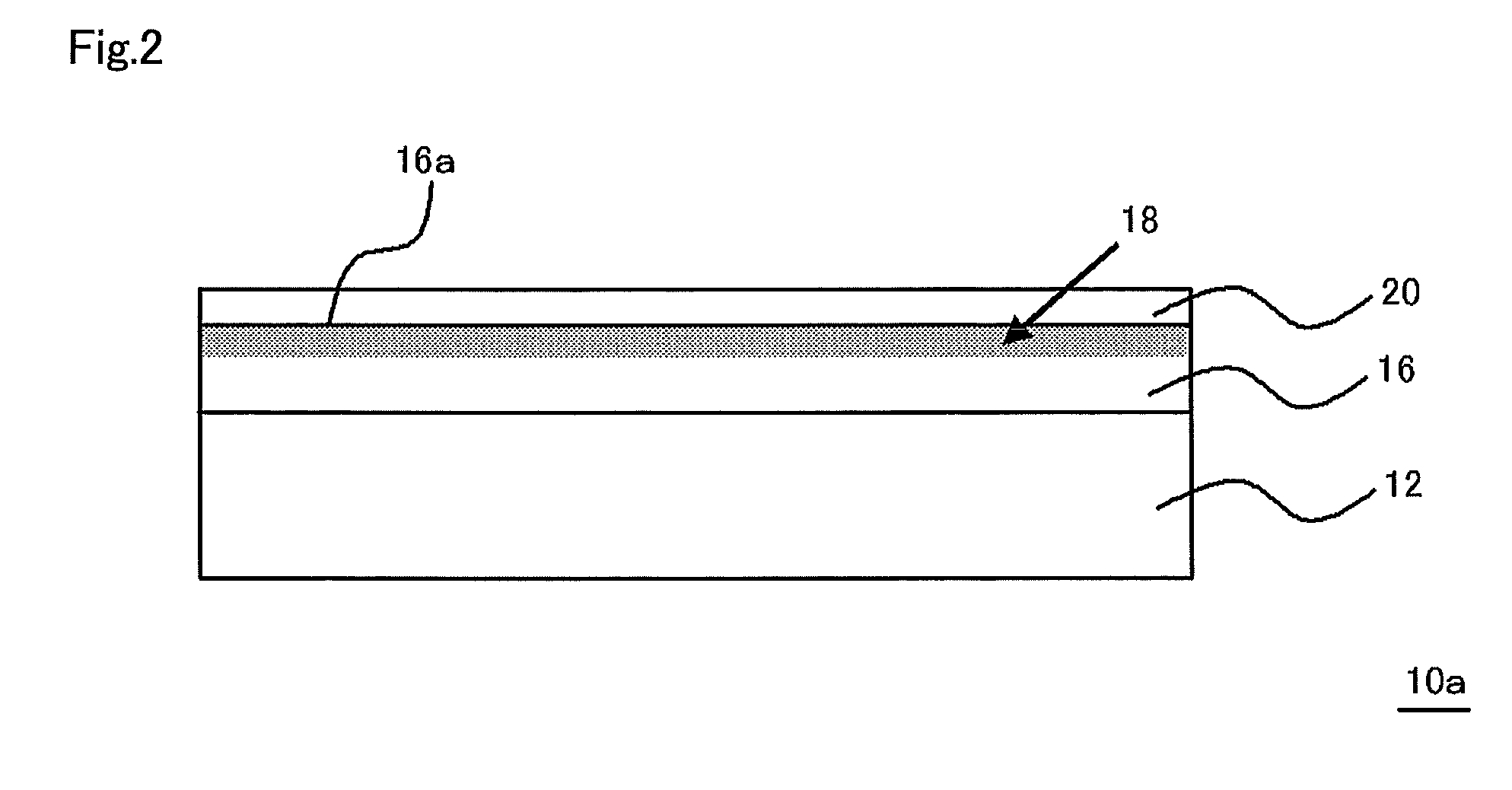

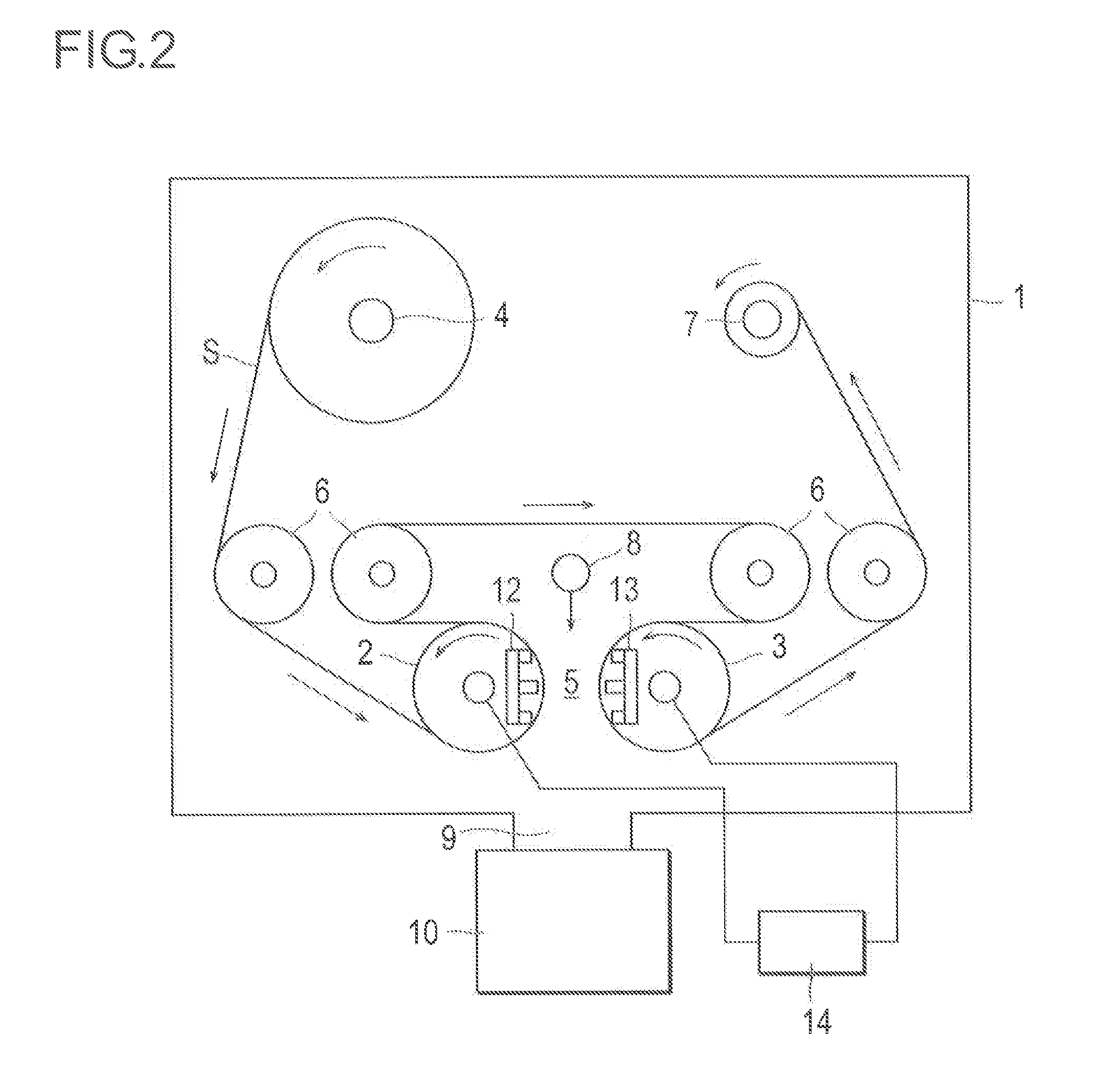

Gas barrier film and electronic device

ActiveUS20130280521A1Improve productivityImprove the heating effectLayered productsSemiconductor/solid-state device detailsHeat resistanceUltraviolet

There are provided a gas barrier film which is excellent in gas barrier performance and heat resistance; and an electronic device excellent in durability, in which the gas barrier film is used. The gas barrier film including, on a base, a first gas barrier layer which is formed by a physical vapor deposition method or a chemical vapor deposition method and contains Si and N; and a second gas barrier layer which is formed by coating a solution containing a polysilazane compound, wherein the second gas barrier layer is subjected to conversion treatment by being irradiated with a vacuum ultraviolet ray; and, when the composition of each layer is represented by SiOxNy, the distribution of the composition SiOxNy of the second gas barrier layer in a thickness direction satisfies a condition specified in the following (A): (A) the second gas barrier layer includes 50 nm or more of a region of 0.25≦x≦1.1 and 0.4≦y≦0.75 in the thickness direction.

Owner:KONICA MINOLTA INC

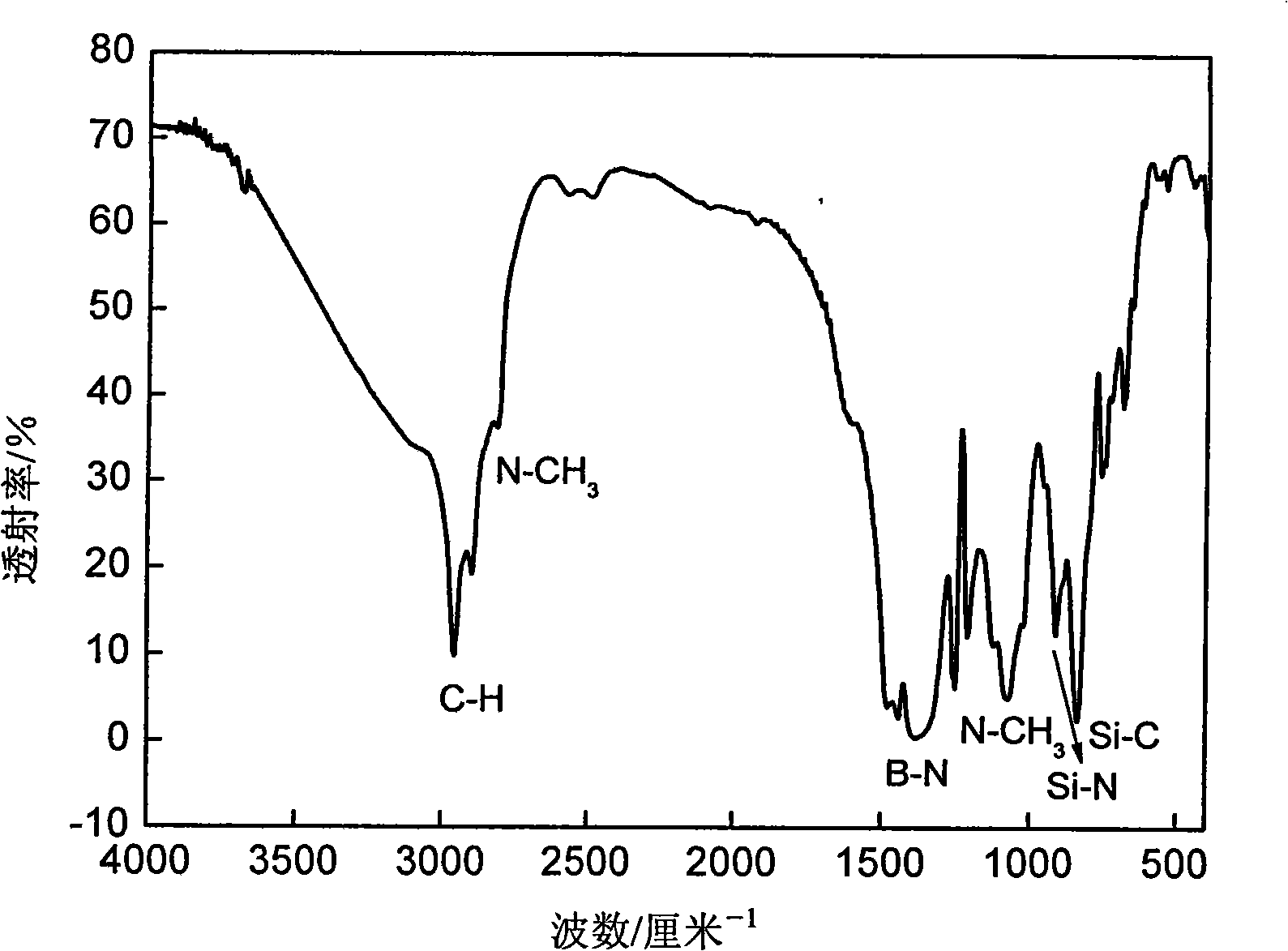

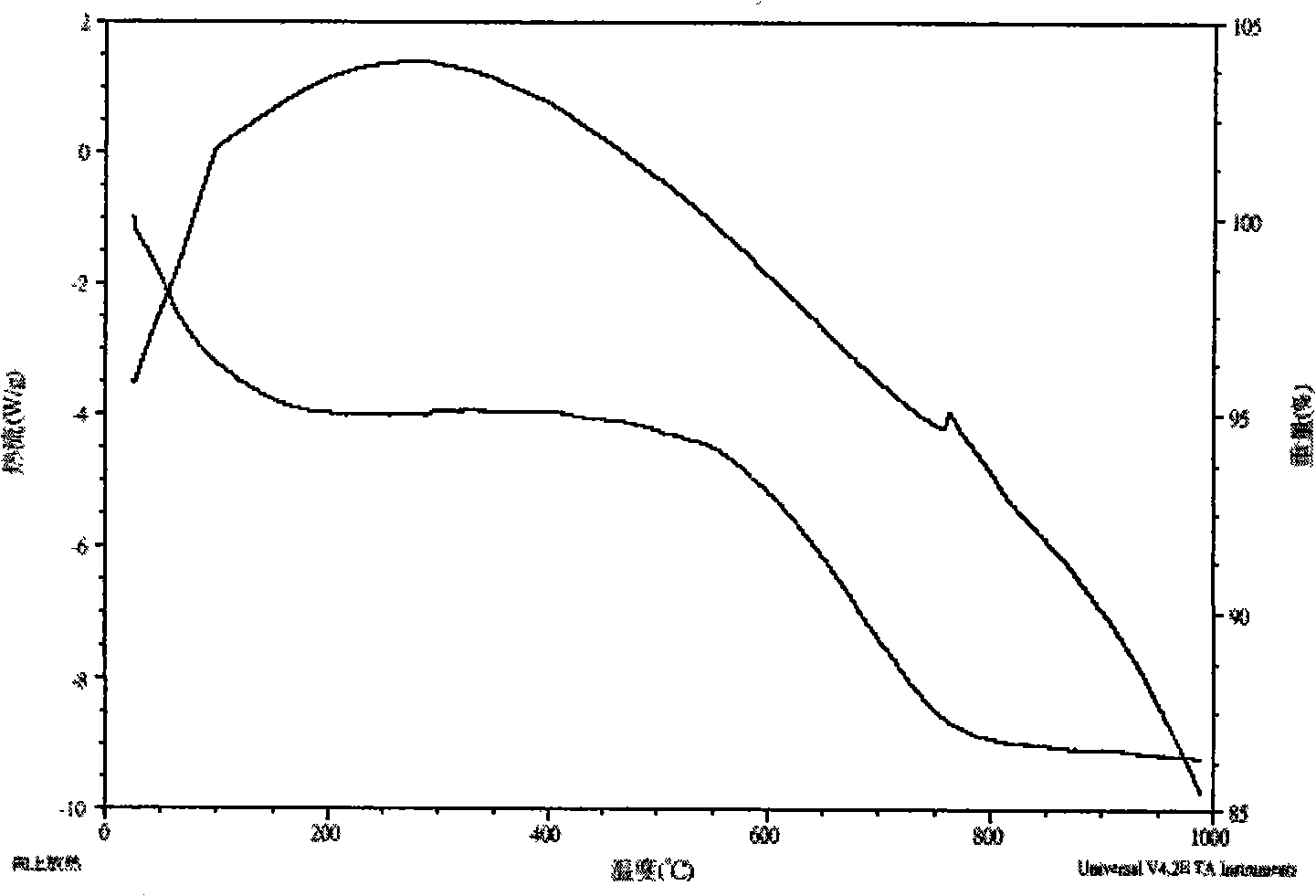

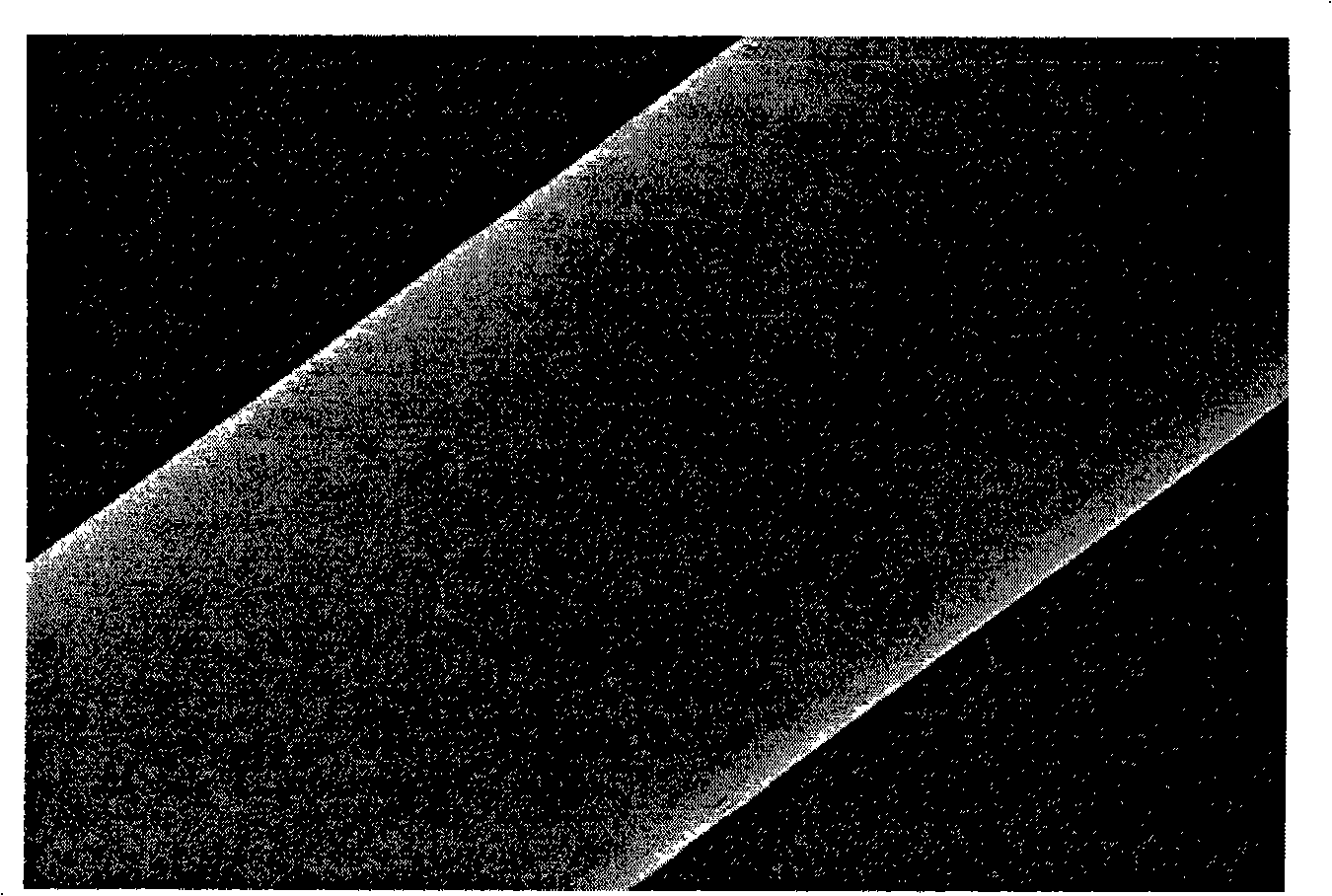

Method for preparing SiBN(C) ceramic fibre

The present invention provides a preparation method of SiBN(C) ceramic fiber. In the preparation method, silicon haloganide, boron halide and disilazane of small molecules are used as starting materials and are mixed according to a certain ratio; the temperature is raised to be between 150 and 500 DEG C and is maintained for a certain period; after the temperature is lowered, the mixture is processed through vacuum distillation and is cooled to be at the room temperature; thus the precursory of solid boron-containing polysilazane can be prepared and is then used for fusing filature to prepare precursor fiber of SiBN(C) ceramic fiber. Compared with the existing method, the preparation method has the advantages of low costs in raw materials, reliable source, higher synthetic yield, simple process and one-step preparation of the precursor; the fiber of the precursor is treated through chemical crosslinking that has high efficiency and is conducive to the integrative operation of spinning, non-melting treatment and sintering.

Owner:NAT UNIV OF DEFENSE TECH

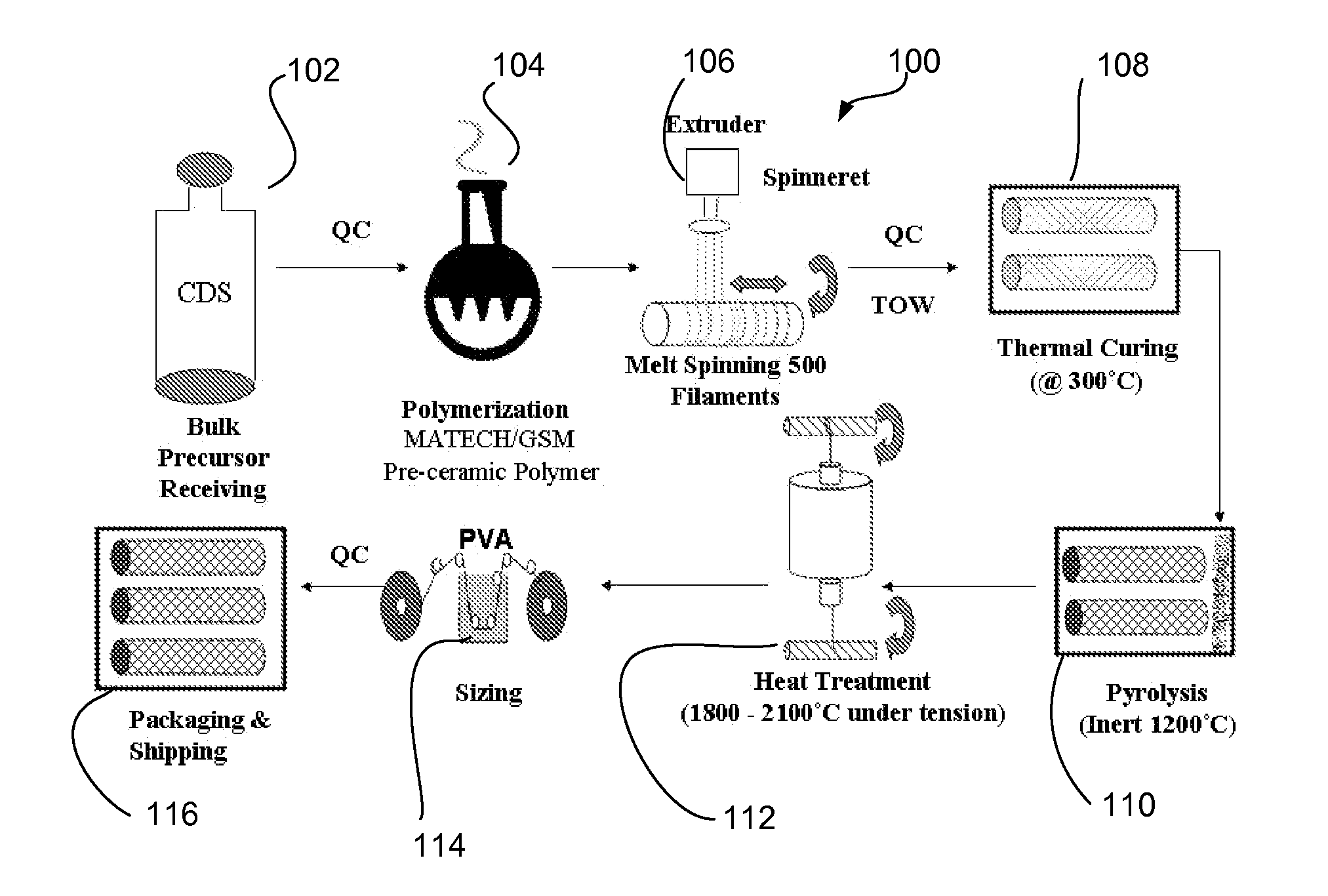

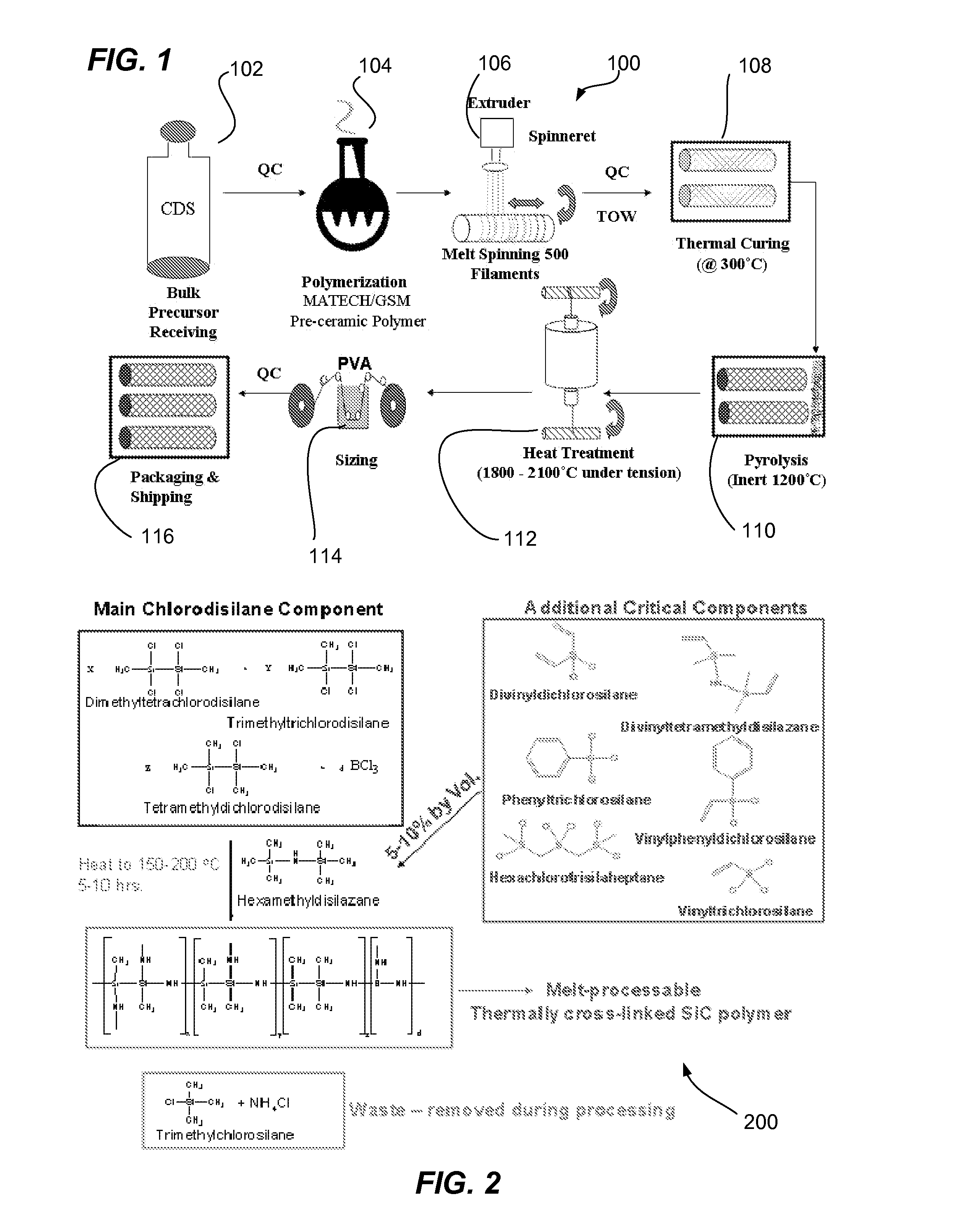

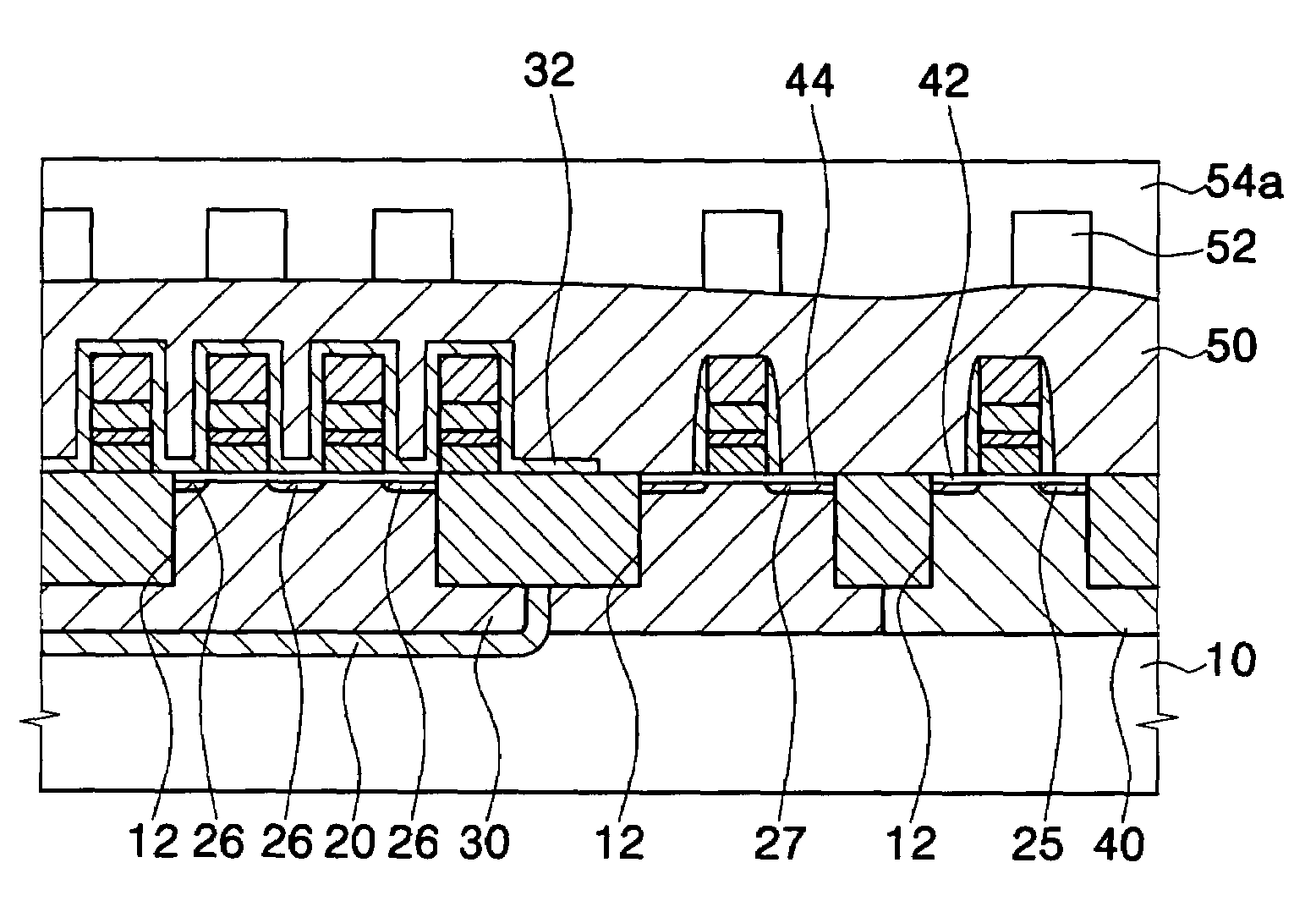

Stiochiometric silicon carbide fibers from thermo-chemically cured polysilazanes

ActiveUS20110212329A1Reduce manufacturing complexityReduce property variabilityNitrogen compoundsLayered productsPolymer sciencePolymer resin

A novel polycrystalline stoichiometric fine SiC fiber substantially free of impurities is produced using a novel pre-ceramic polymer. The pre-ceramic polymer is prepared by reacting a mixture of chlorodisilane, boron trichloride, and a vinyl chlorodisilane with an excess of hexamethyldisilazane to form the pre-ceramic polymer resin, which may then be melt-spun, cured, pyrolyzed and heat-treated to obtain the finished SiC fiber. The manufacturing process for the production of the fine SiC ceramic fiber allows for flexibility with respect to cross-linking, in that low-cost thermal treatments may replace more complex methods, while obtaining fibers with improved materials properties as compared to currently available SiC fibers.

Owner:GENERAL ELECTRIC CO

Method for forming a silicon oxide layer using spin-on glass

A method is provided for forming silicon oxide layers during the processing of semiconductor devices by applying a SOG layer including polysilazane to a substrate and then substantially converting the SOG layer to a silicon oxide layer using an oxidant solution. The oxidant solution may include one or more oxidants including, for example, ozone, peroxides, permanganates, hypochlorites, chlorites, chlorates, perchlorates, hypobromites, bromites, bromates, hypoiodites, iodites, iodates and strong acids.

Owner:SAMSUNG ELECTRONICS CO LTD

Laminate and process for production thereof

InactiveCN102470637ALess impact on precisionImprove productivitySynthetic resin layered productsCoatingsWater vaporSilicon membrane

A laminate comprising a base material and a silicon-containing film formed on the base material, wherein the silicon-containing film has a nitrogen-rich region composed of a silicon atom and a nitrogen atom or a silicon atom, a nitrogen atom and an oxygen atom, and wherein the nitrogen-rich region is formed by irradiating a polysilazane film that has been formed on the base material with an energy ray in an atmosphere where oxygen or water vapor is not contained substantially to thereby modify at least a part of the film; and a process for producing the laminate.

Owner:MITSUI CHEM INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com