Patents

Literature

42results about How to "High oxygen content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low temperature process for polysilazane oxidation/densification

ActiveUS20060003596A1Easy to processHigh oxygen contentPretreated surfacesSemiconductor/solid-state device manufacturingPolysilazaneSilicon oxide

Semiconductor devices, structures and systems that utilize a polysilazane-based silicon oxide layer or fill, and methods of making the oxide layer are disclosed. In one embodiment, a polysilazane solution is deposited on a substrate and processed with ozone in a wet oxidation at low temperature to chemically modify the polysilazane material to a silicon oxide layer.

Owner:MICRON TECH INC

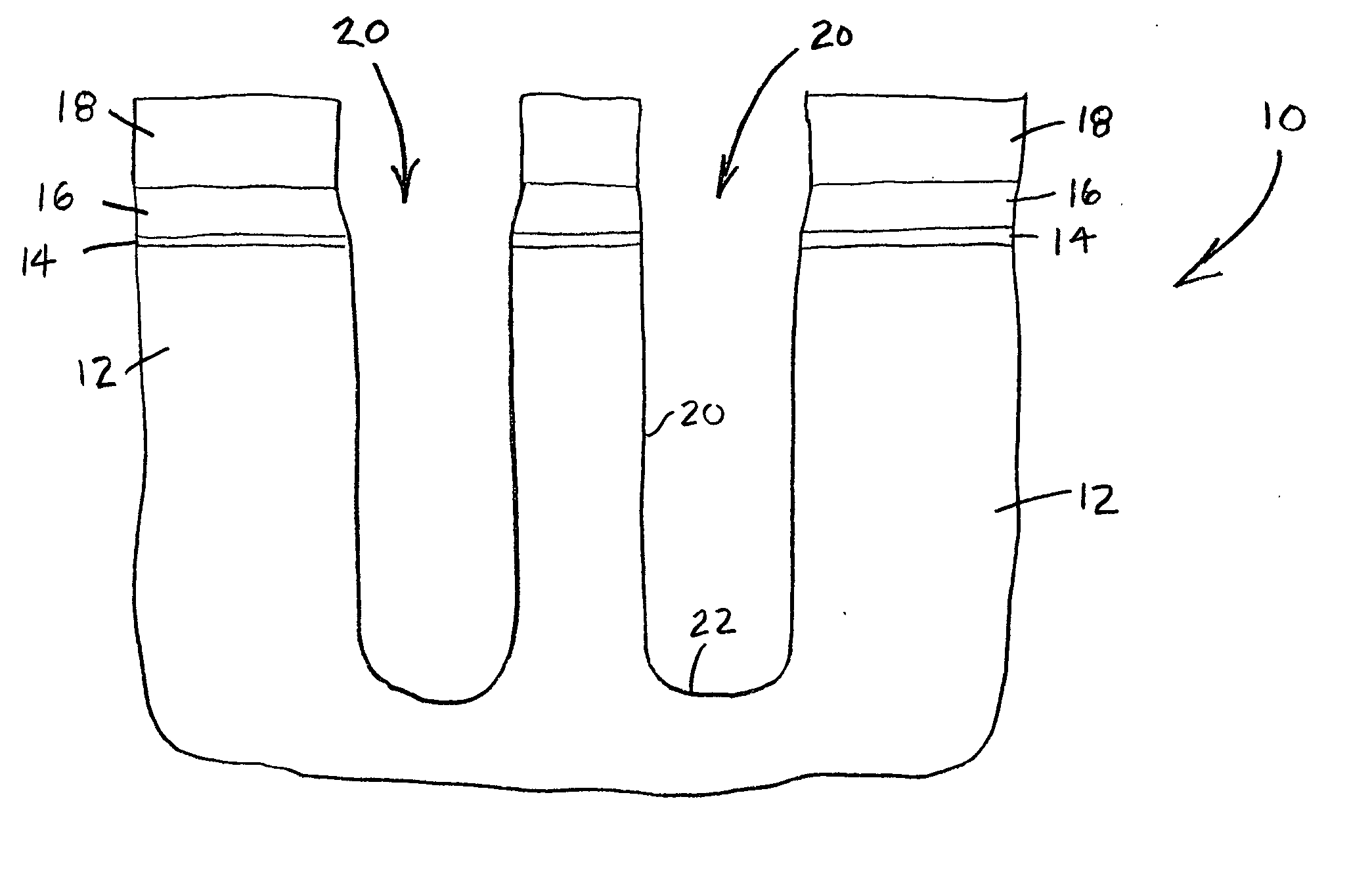

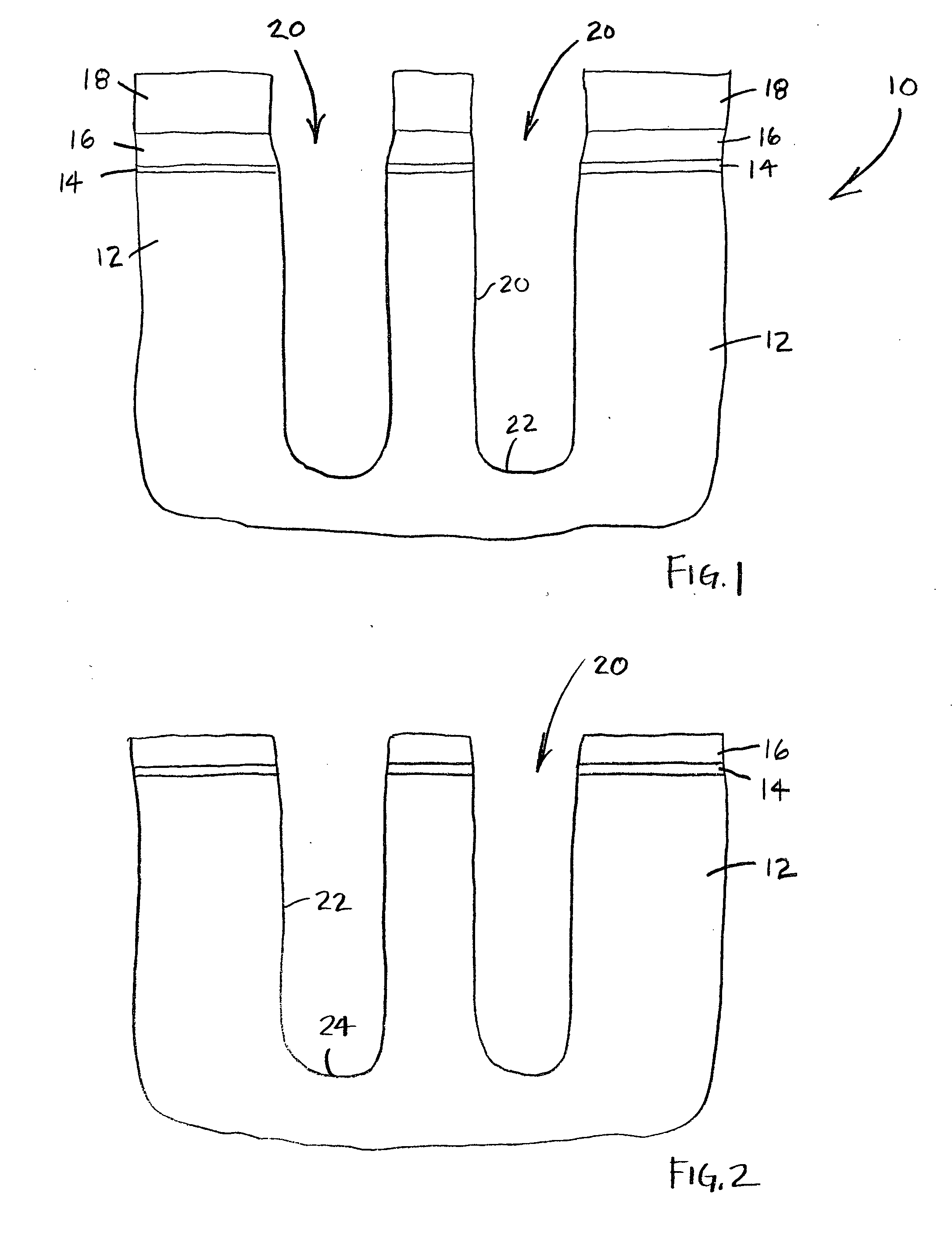

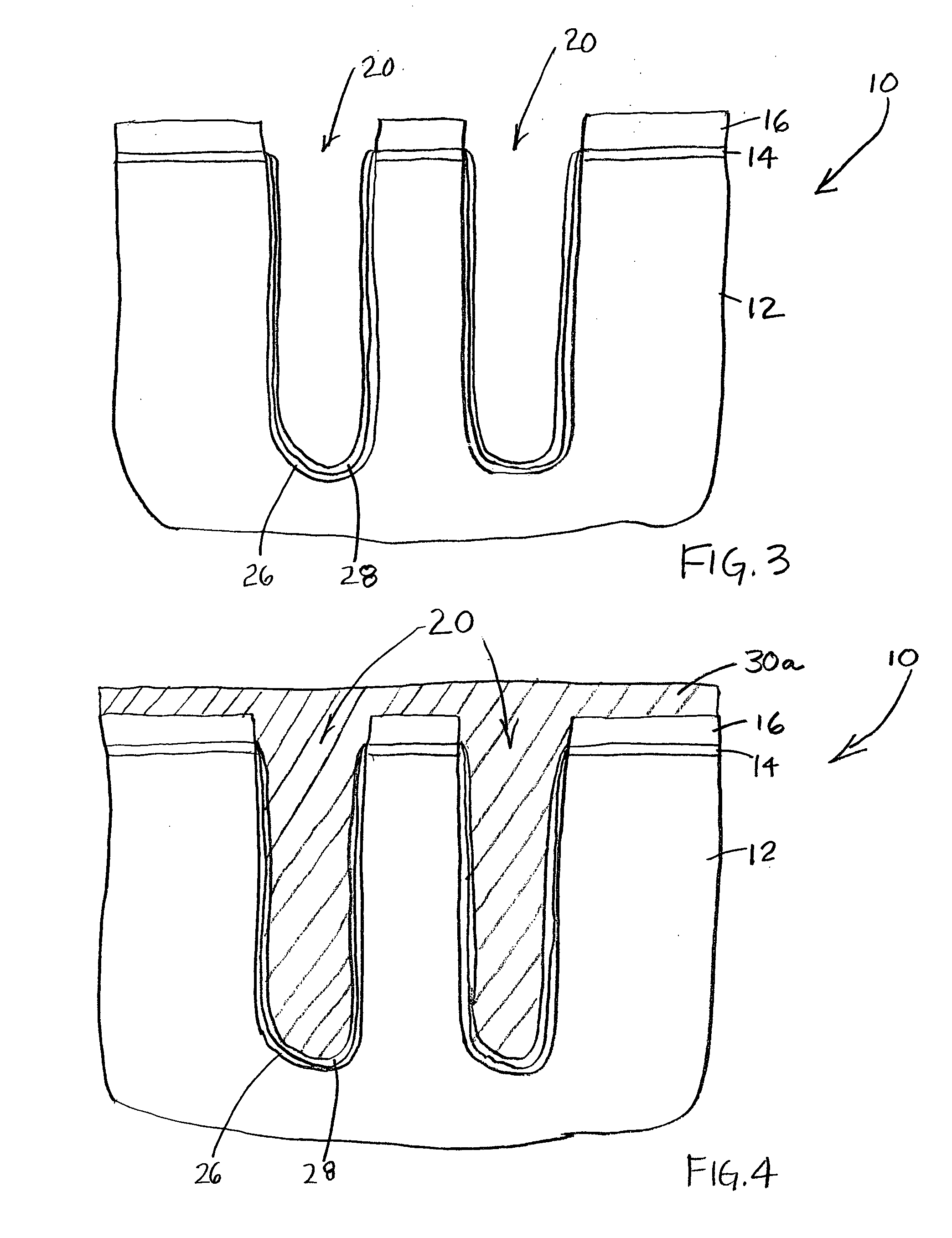

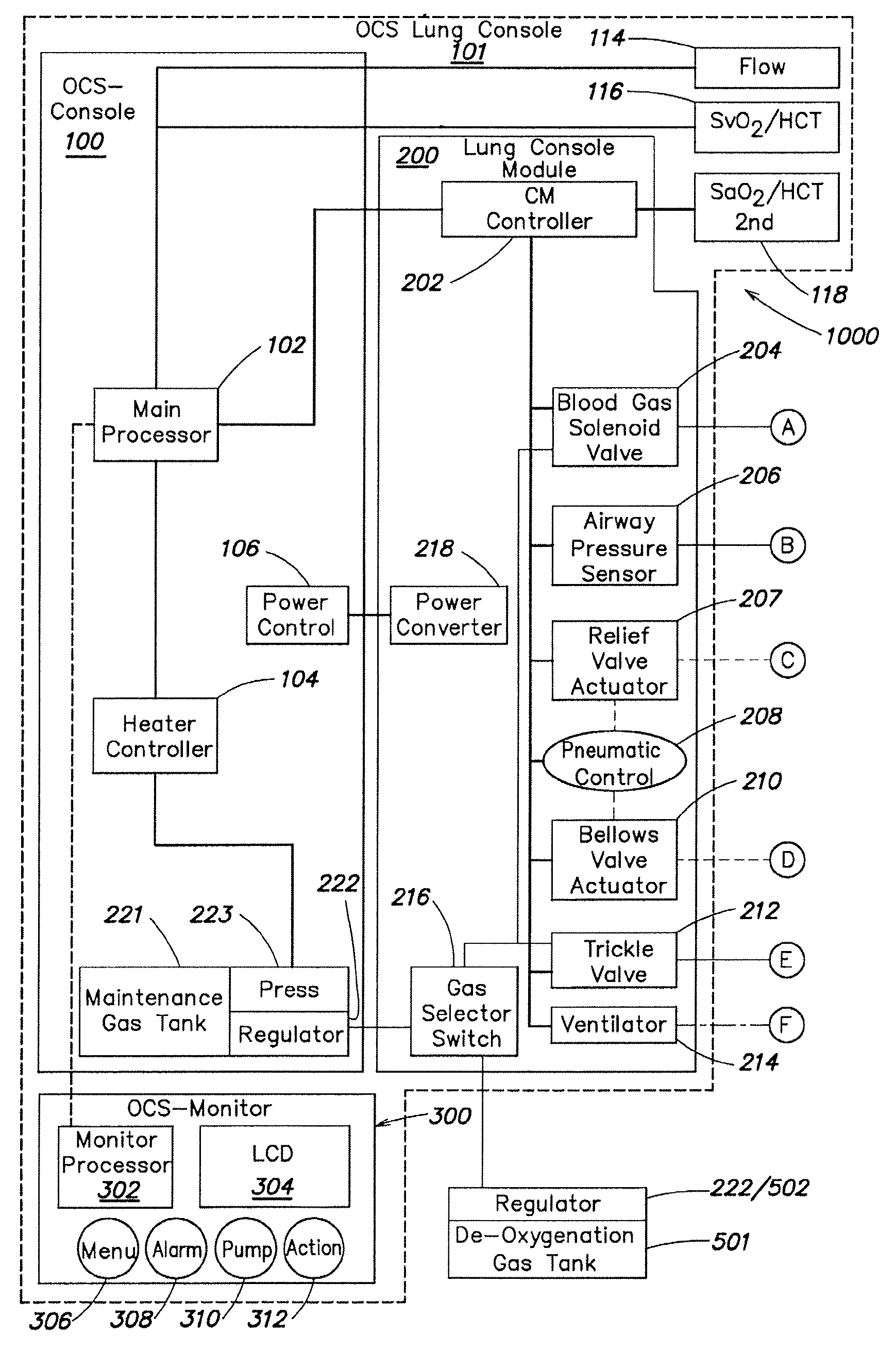

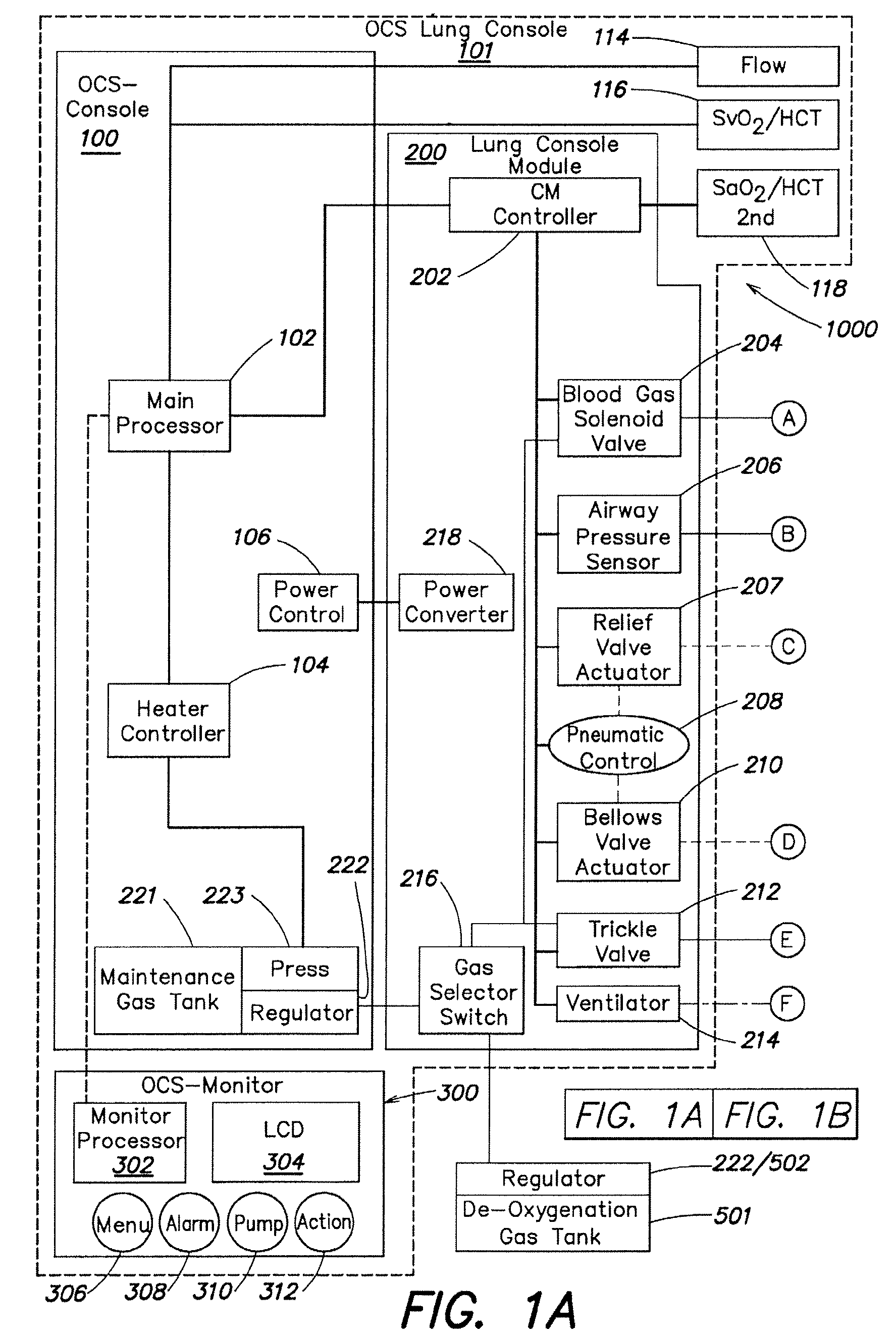

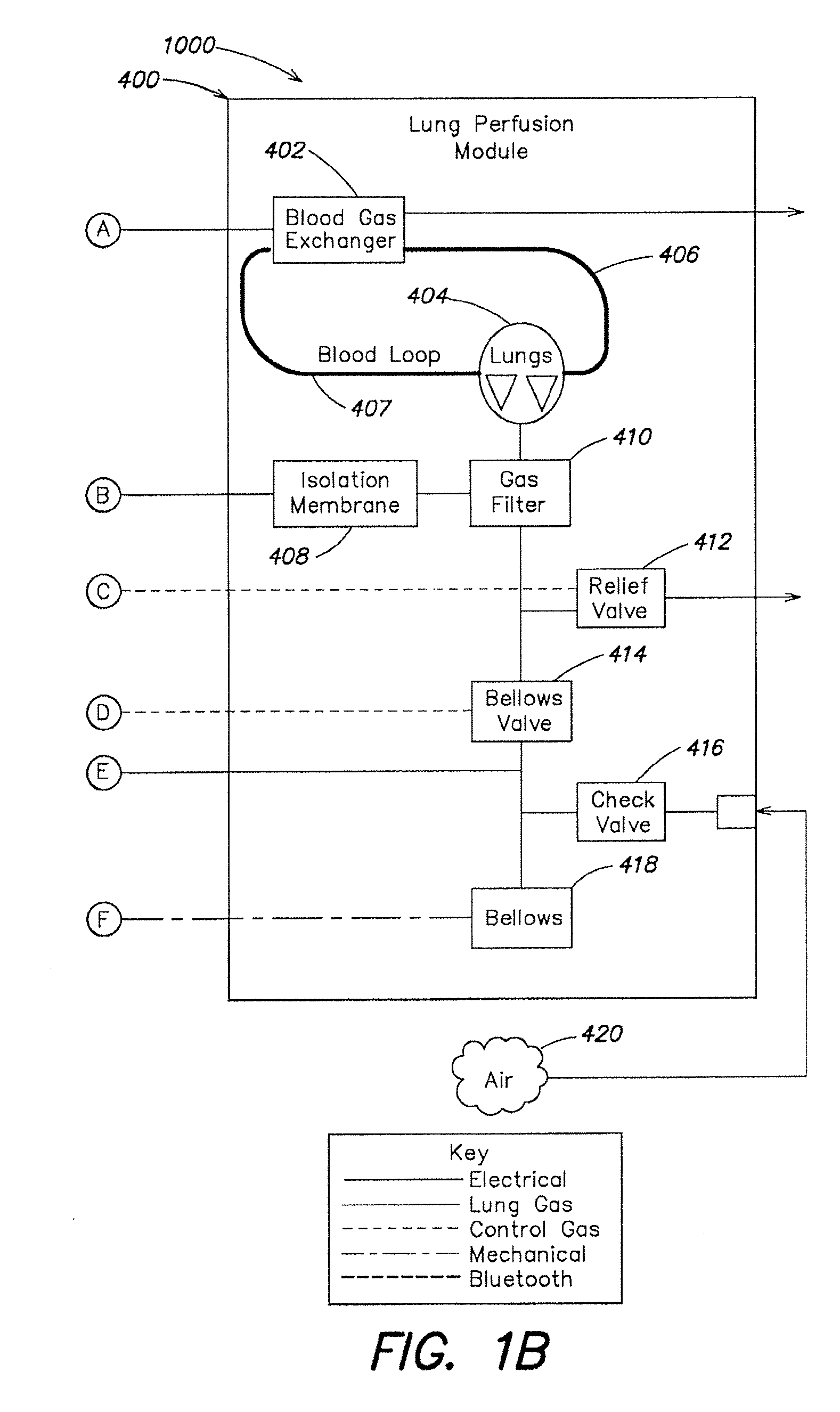

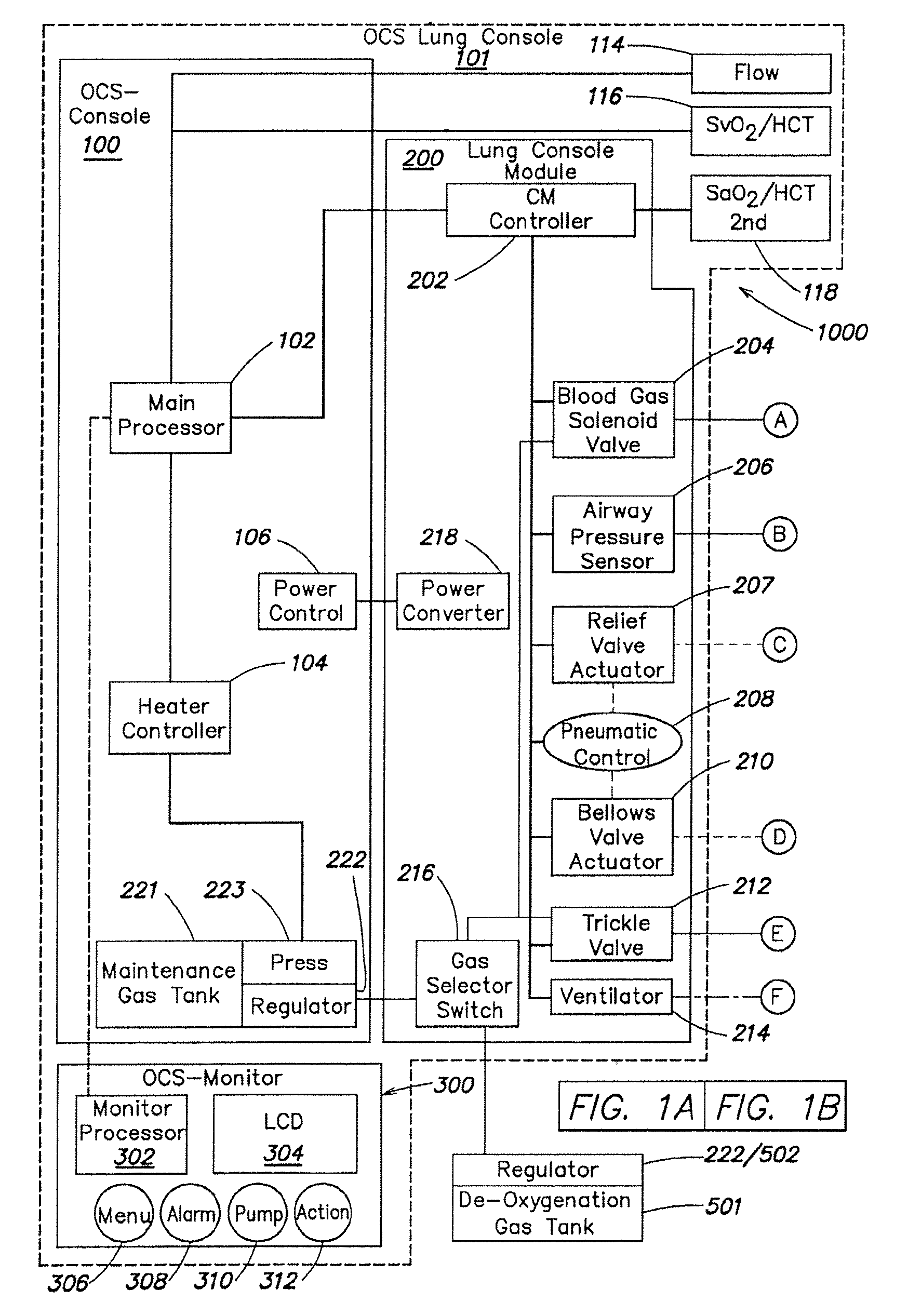

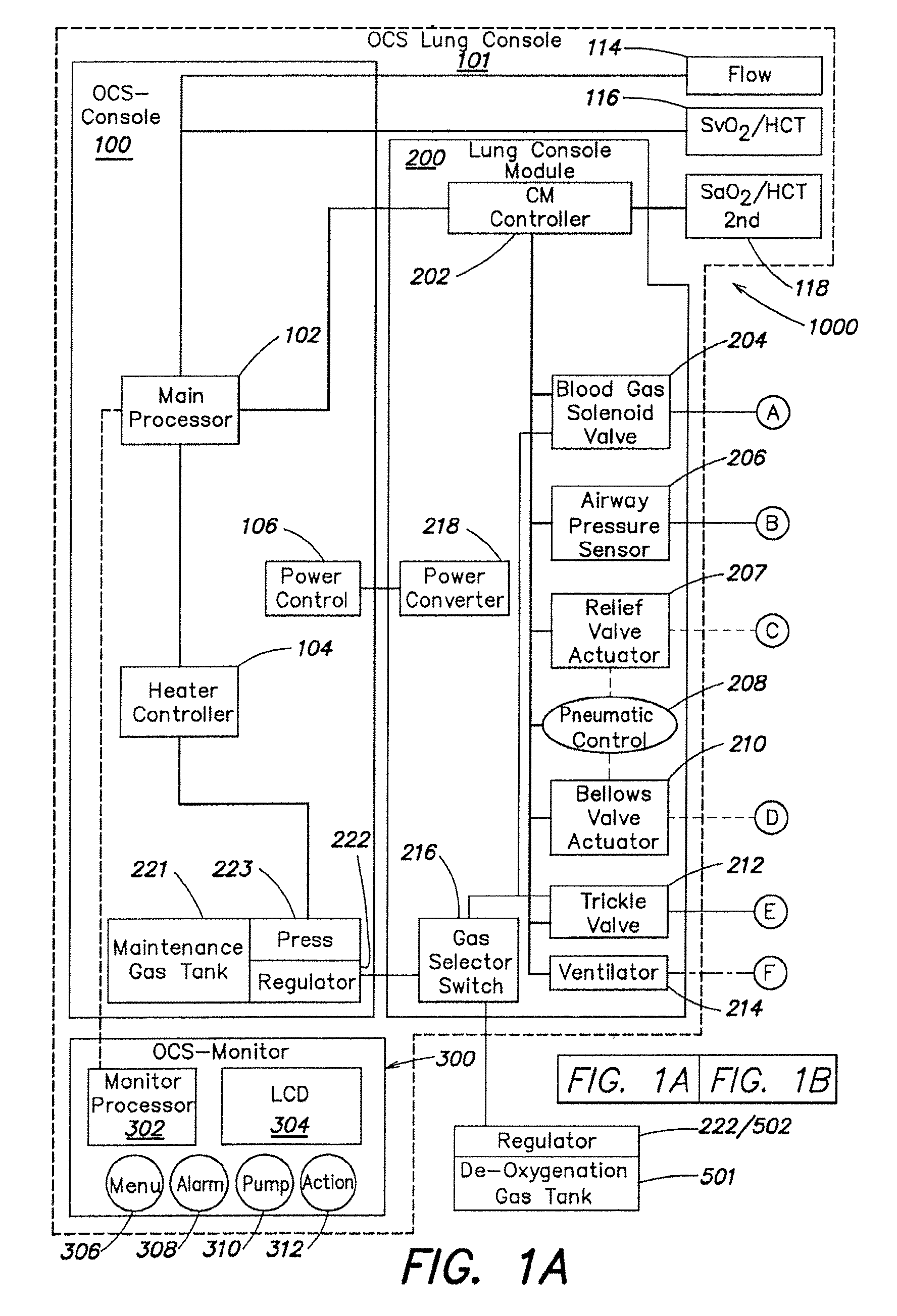

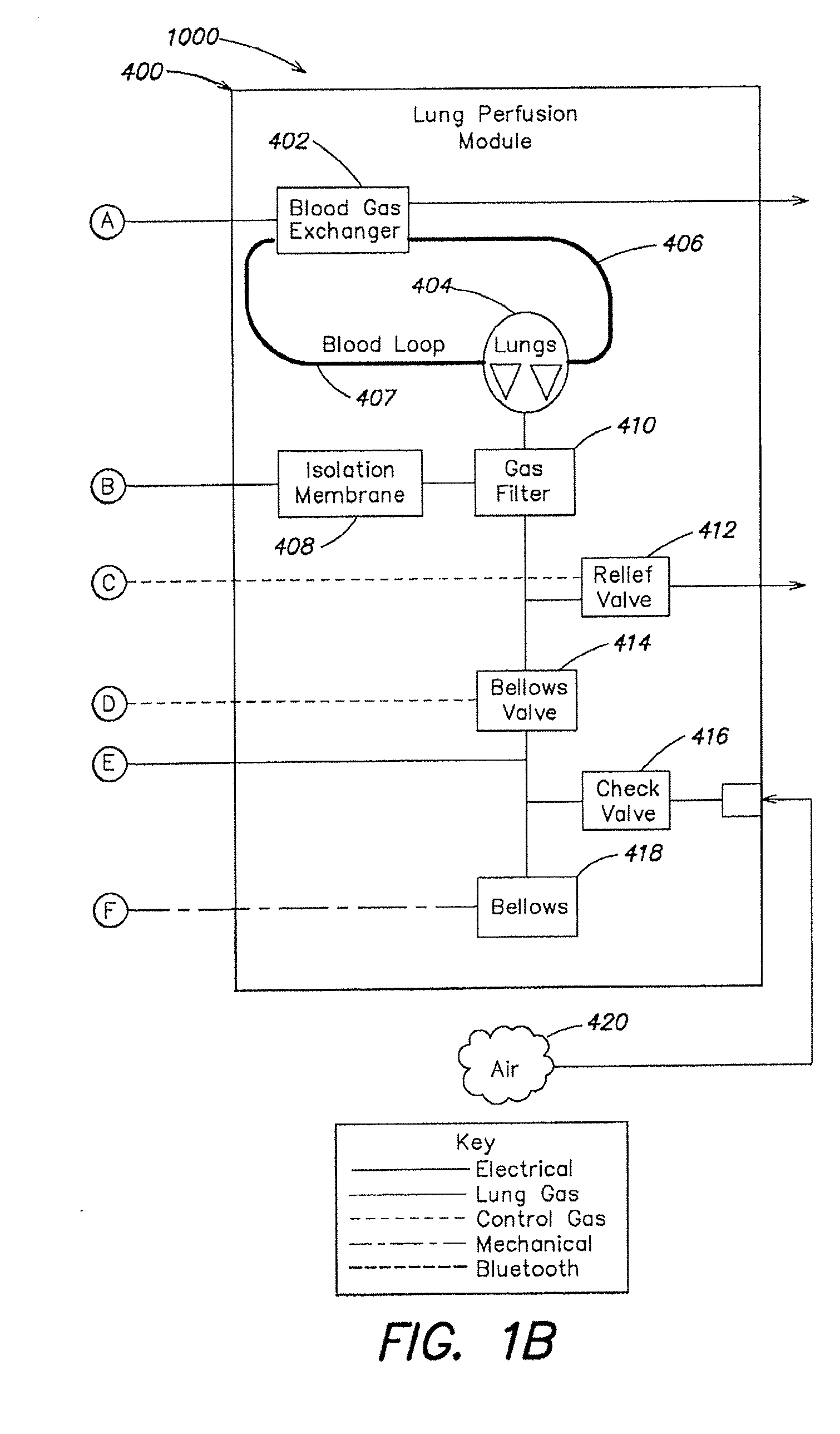

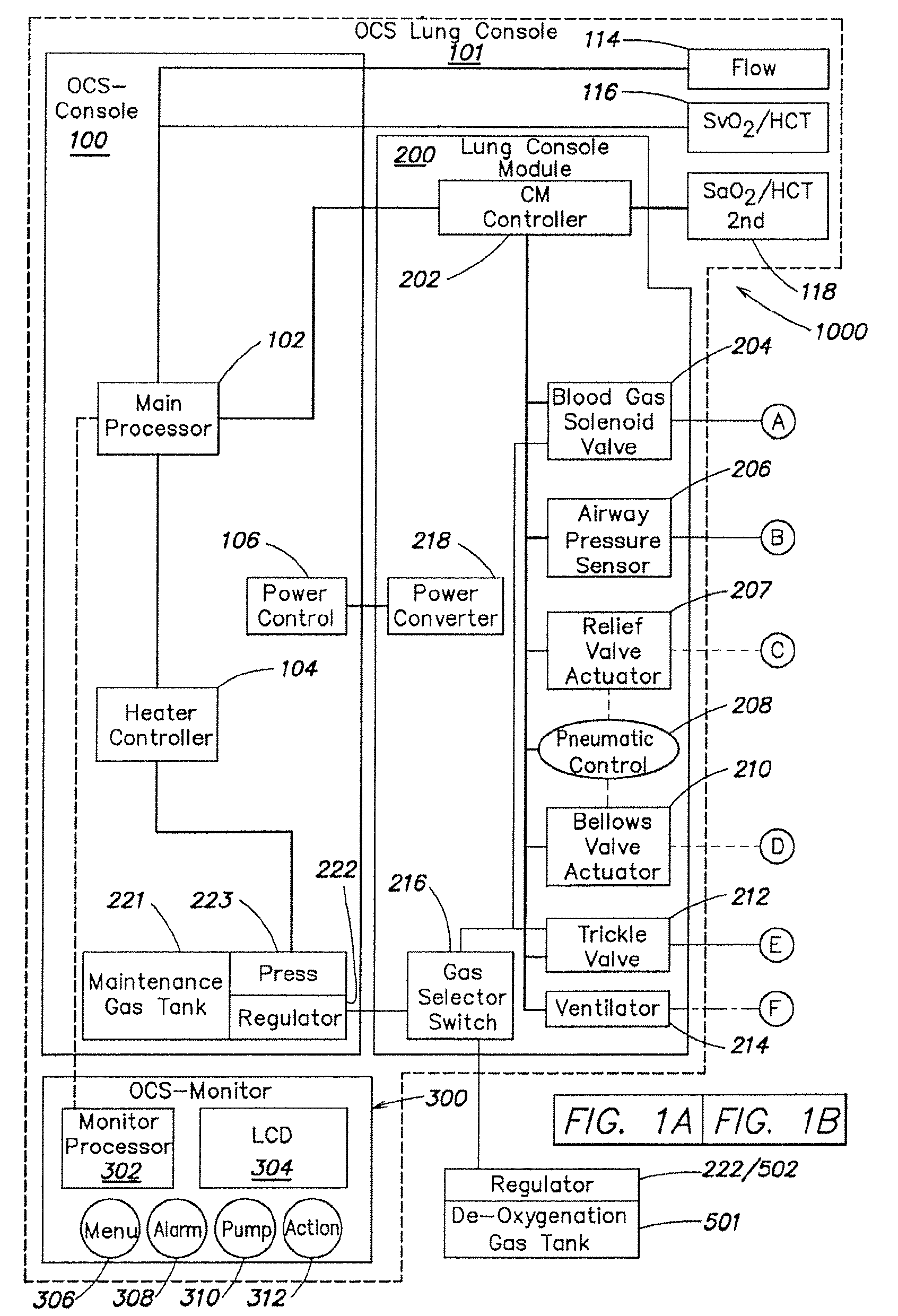

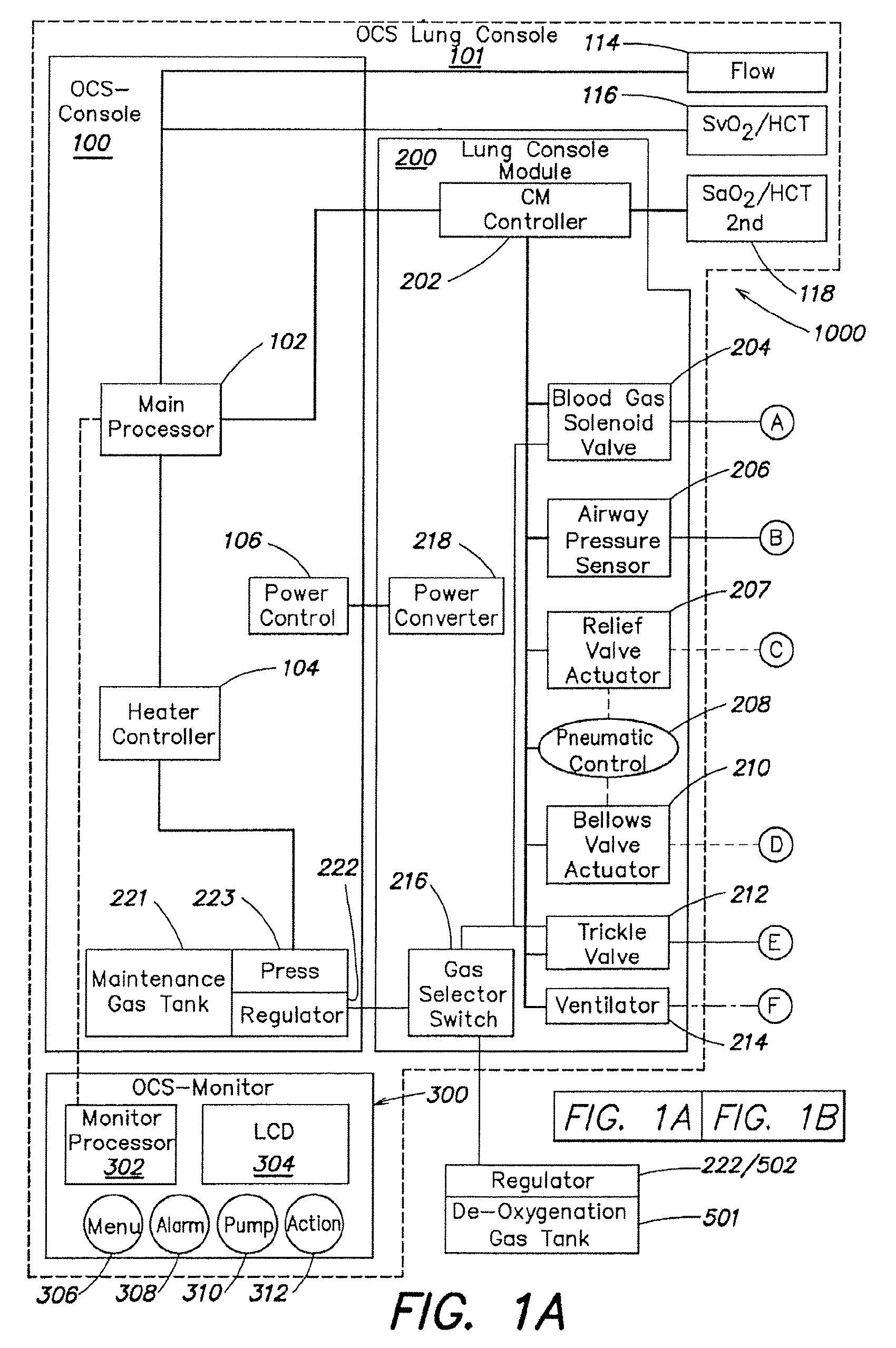

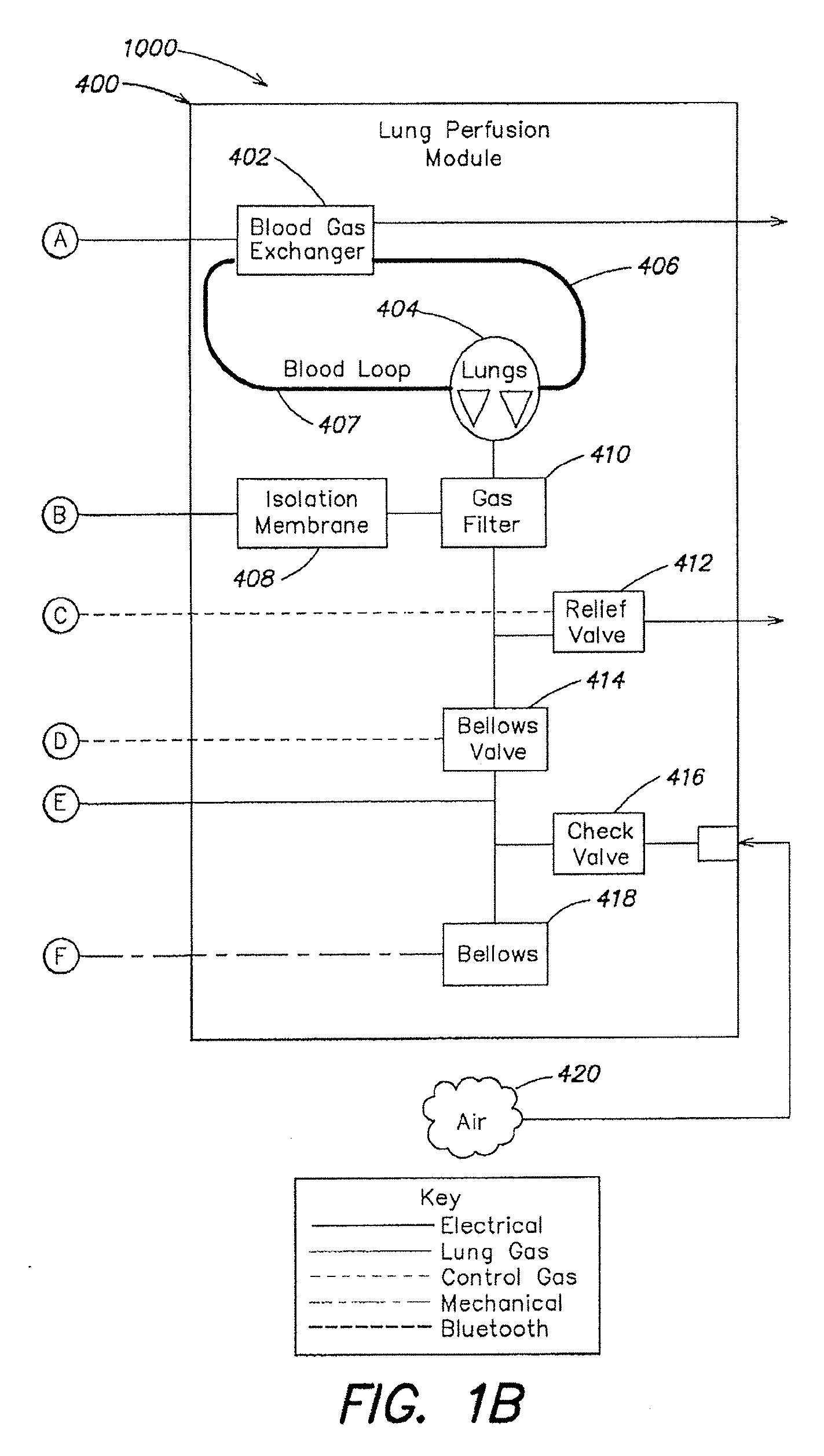

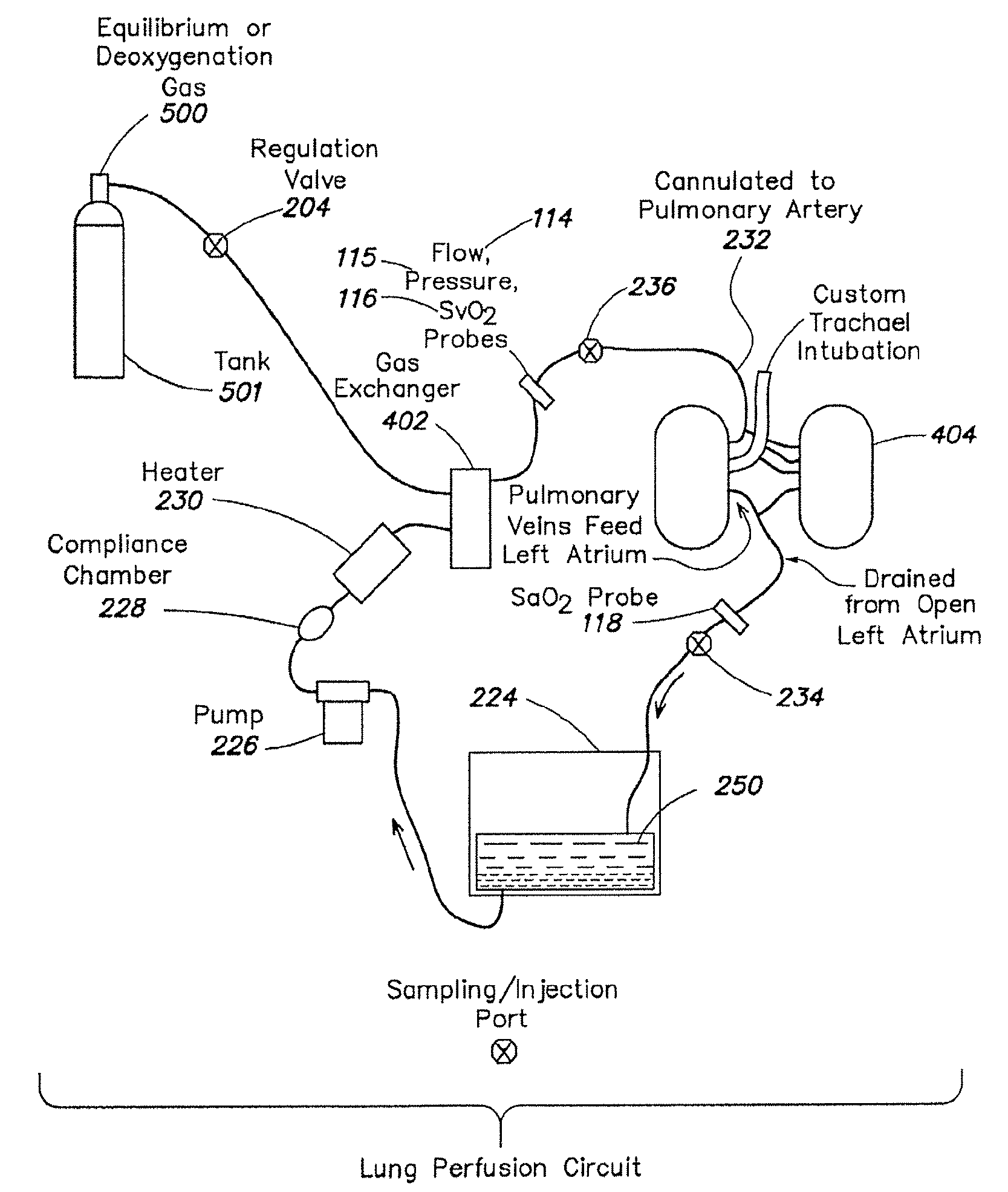

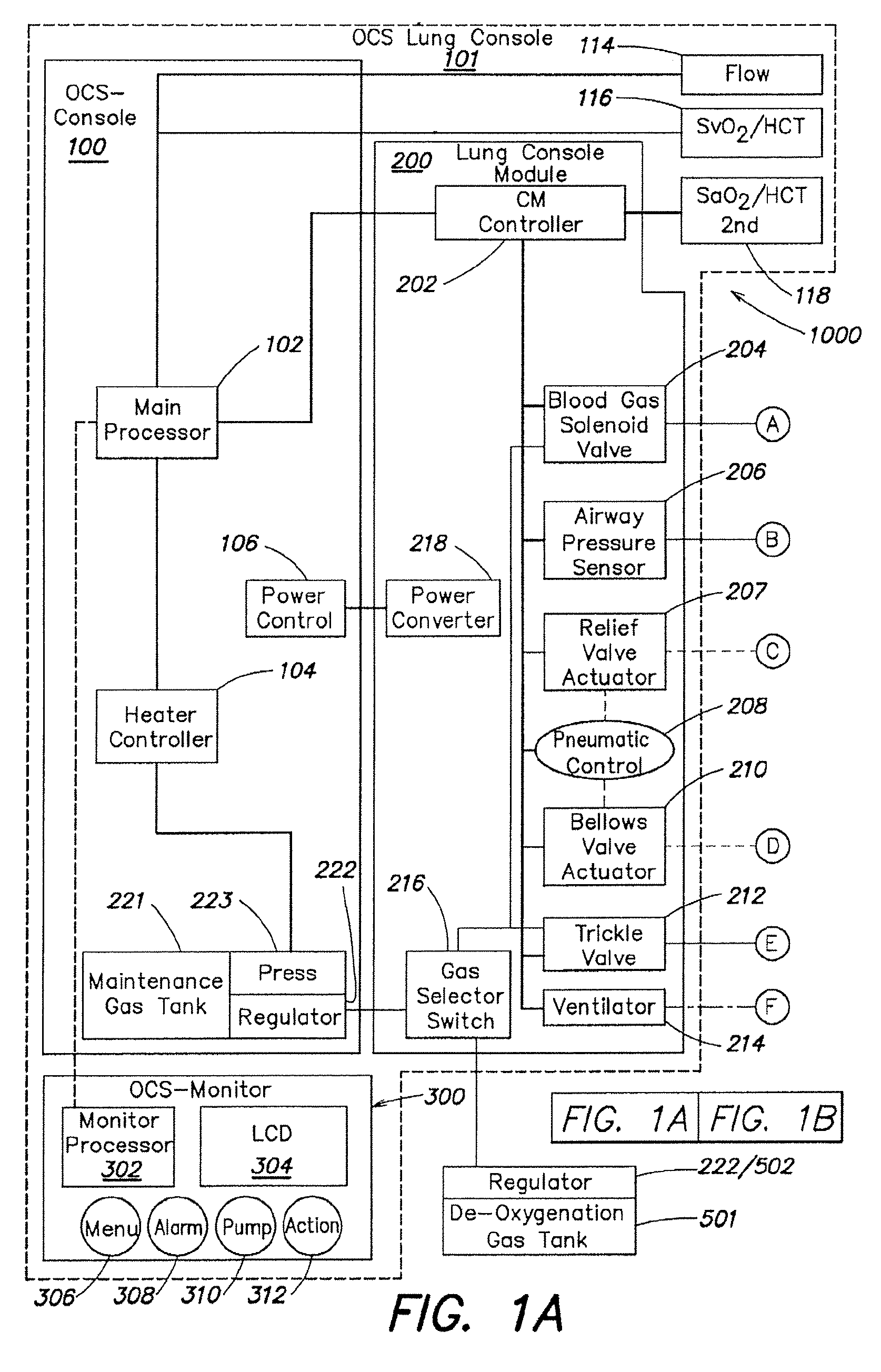

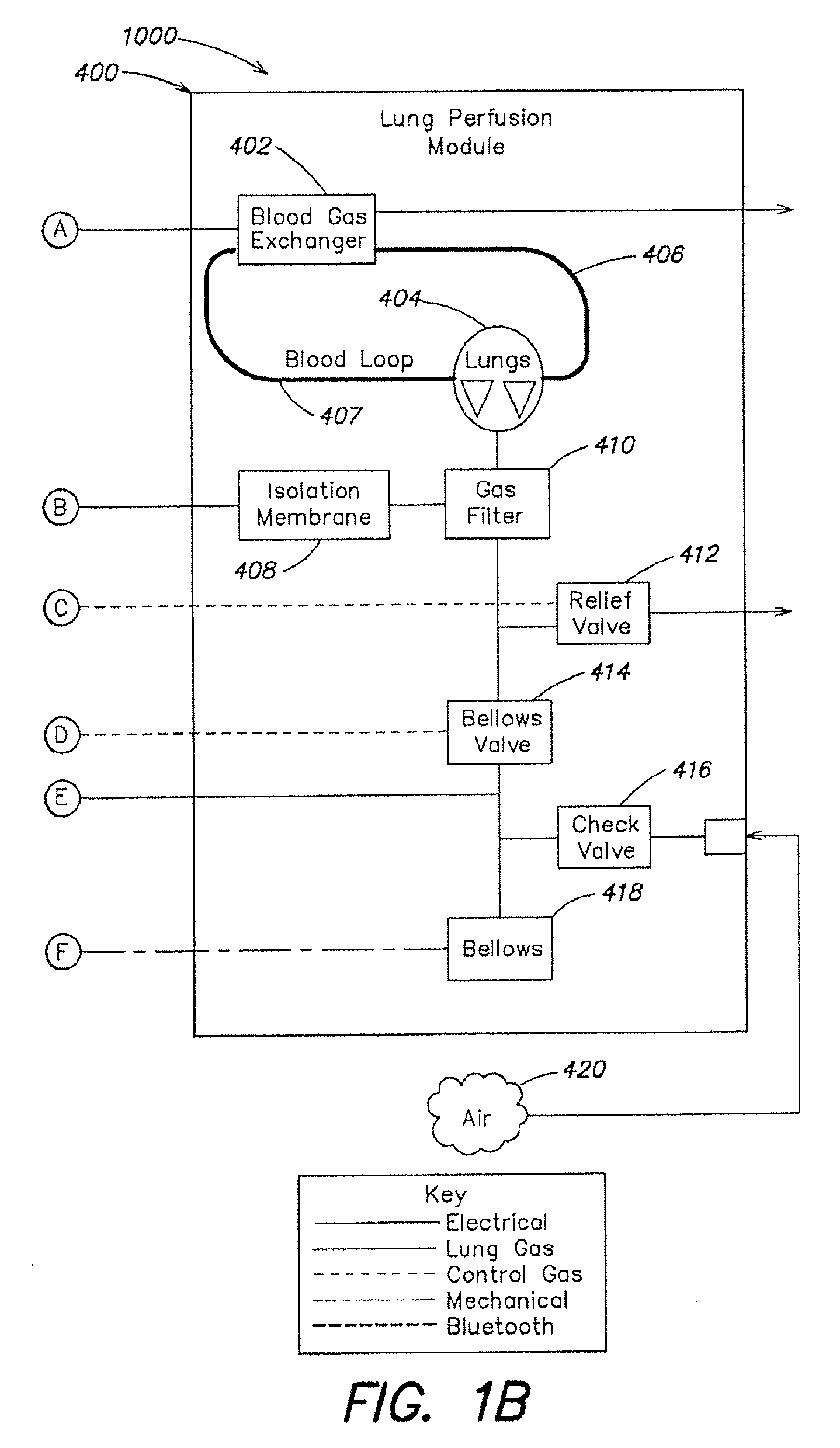

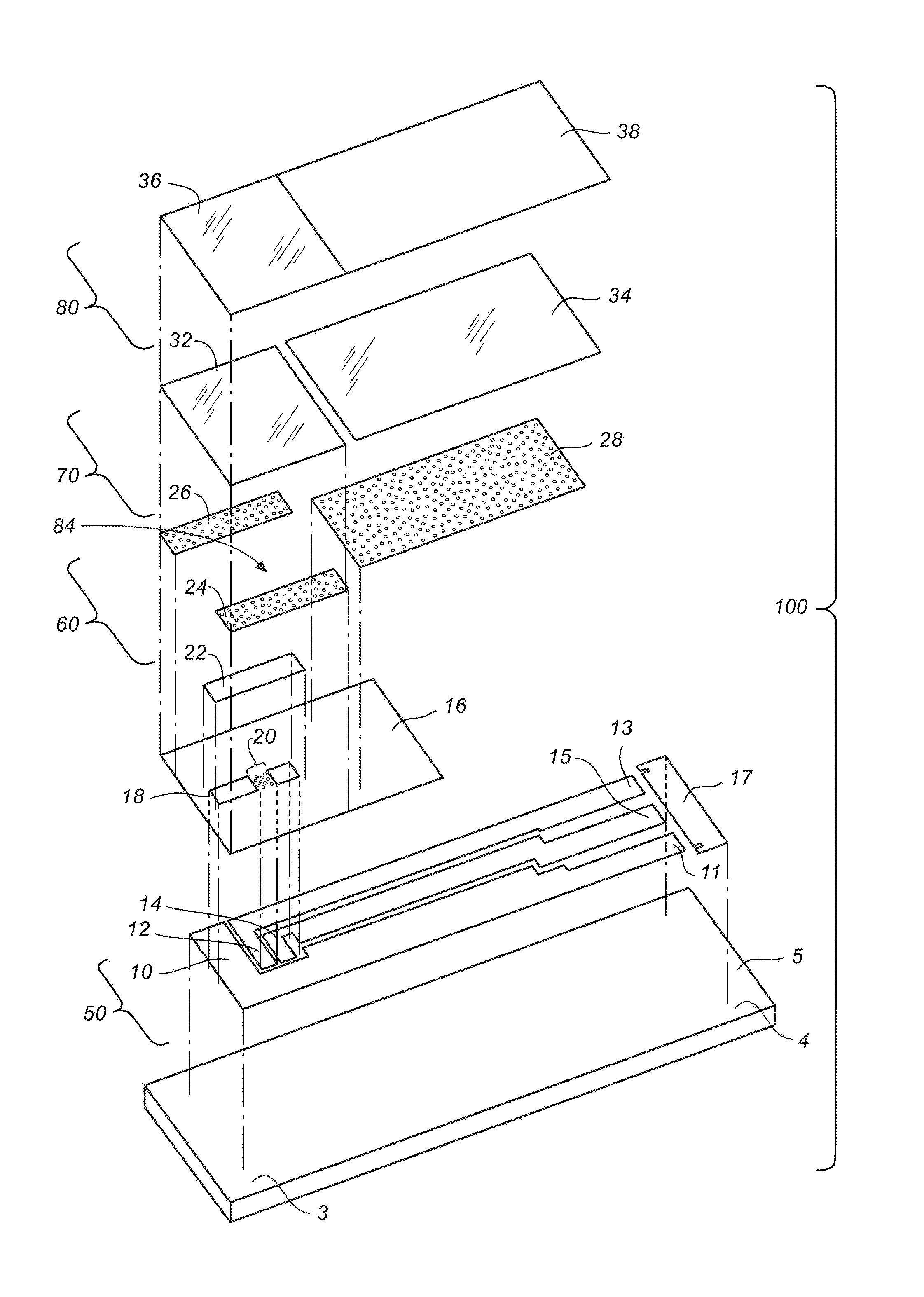

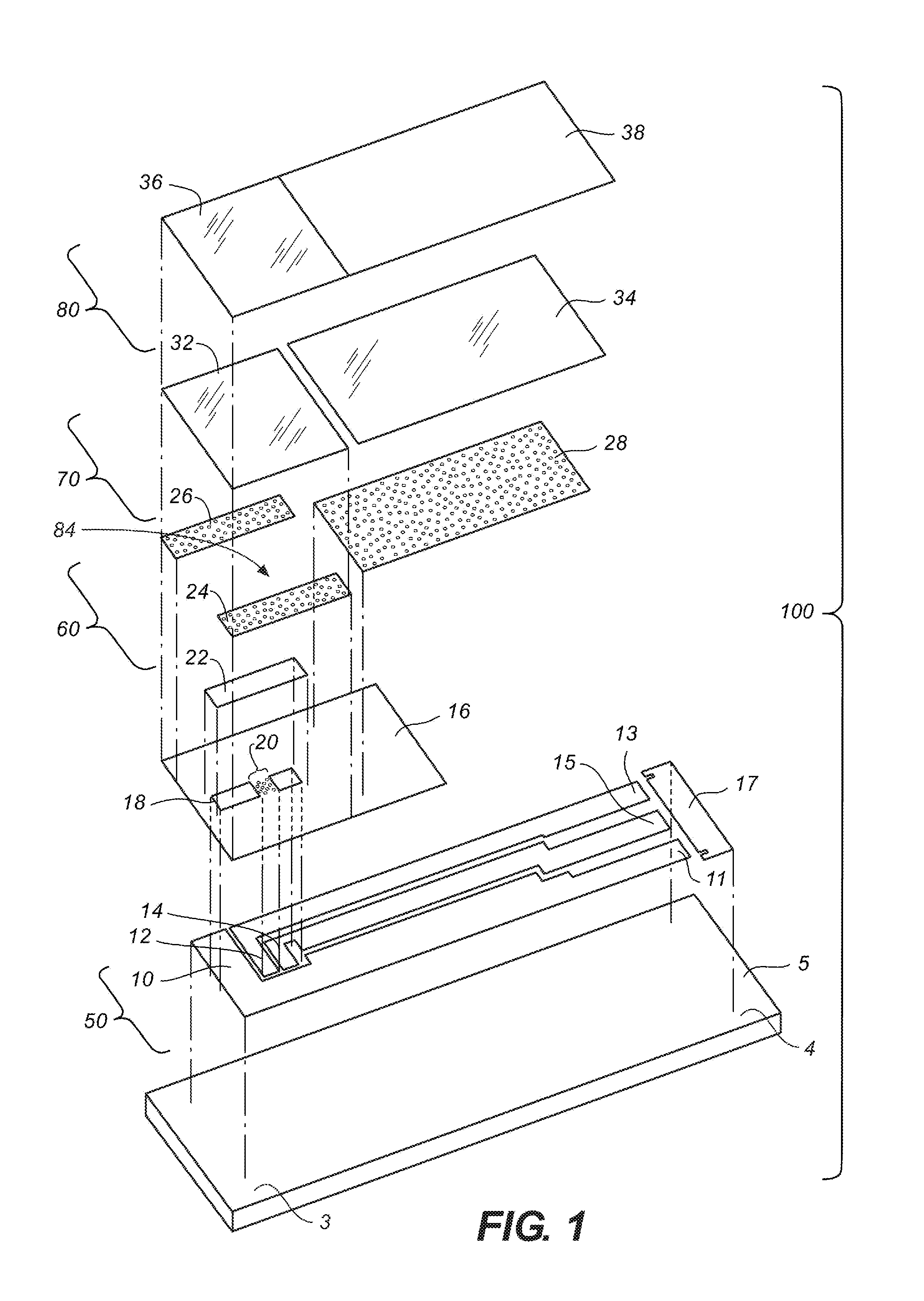

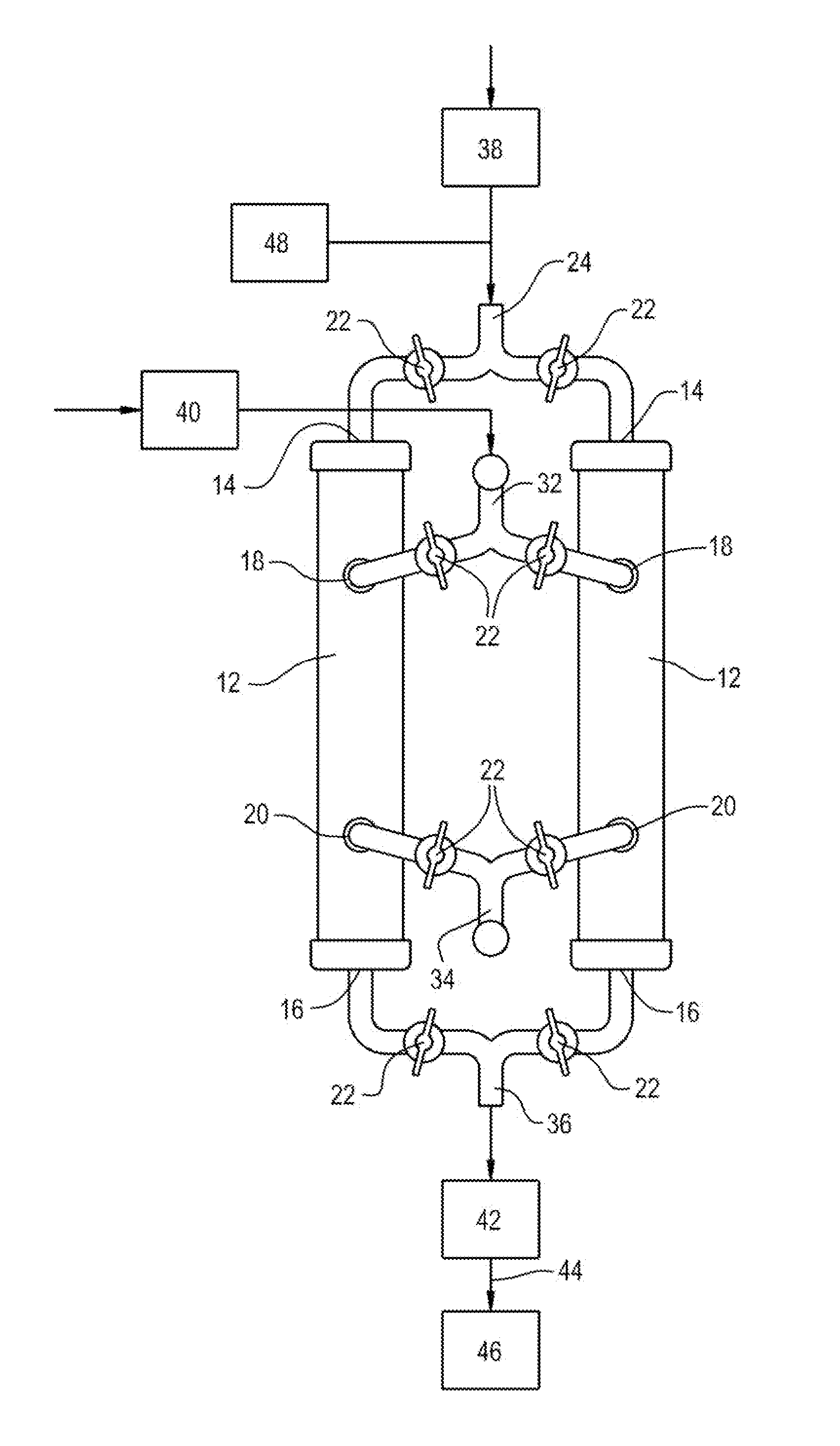

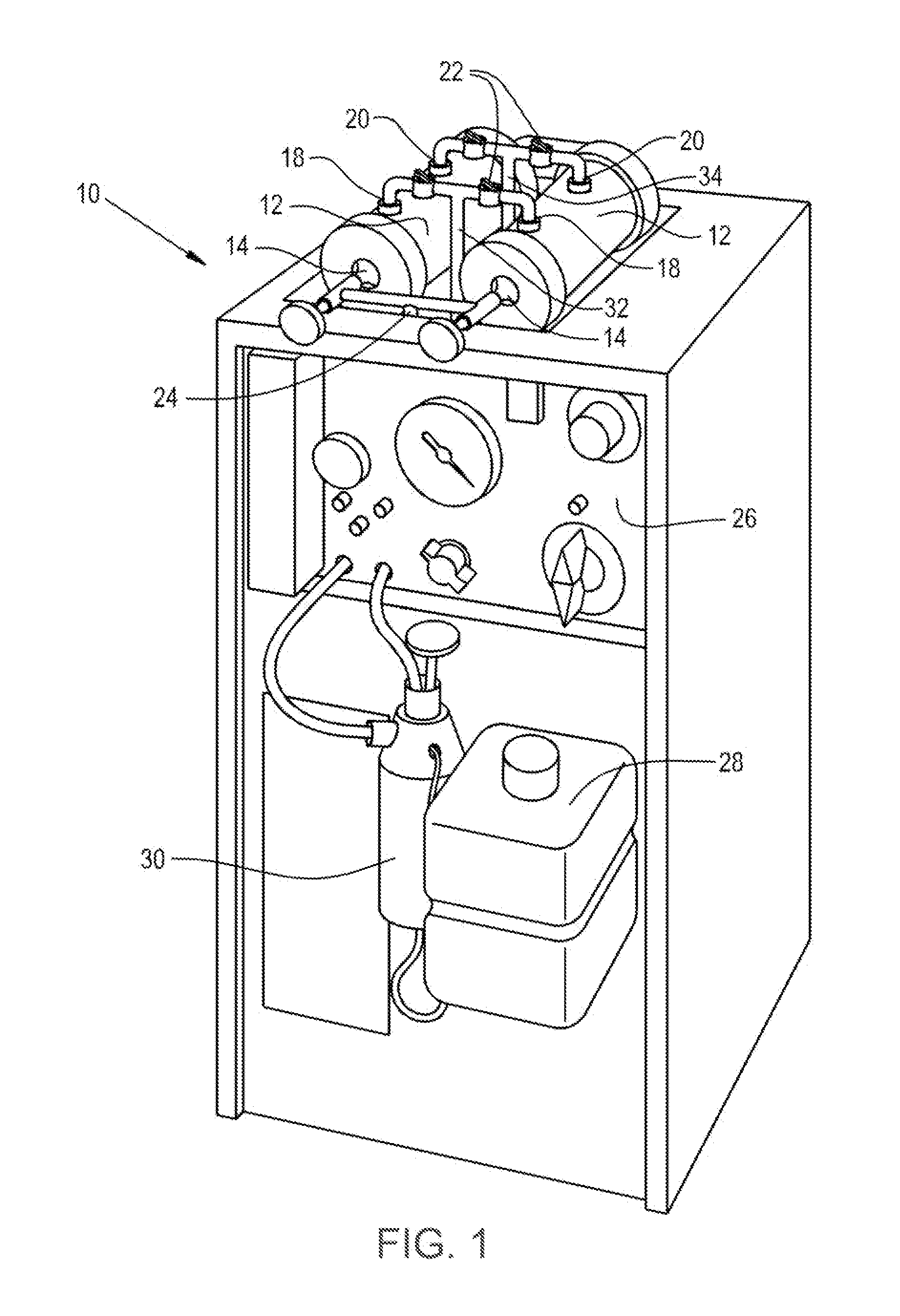

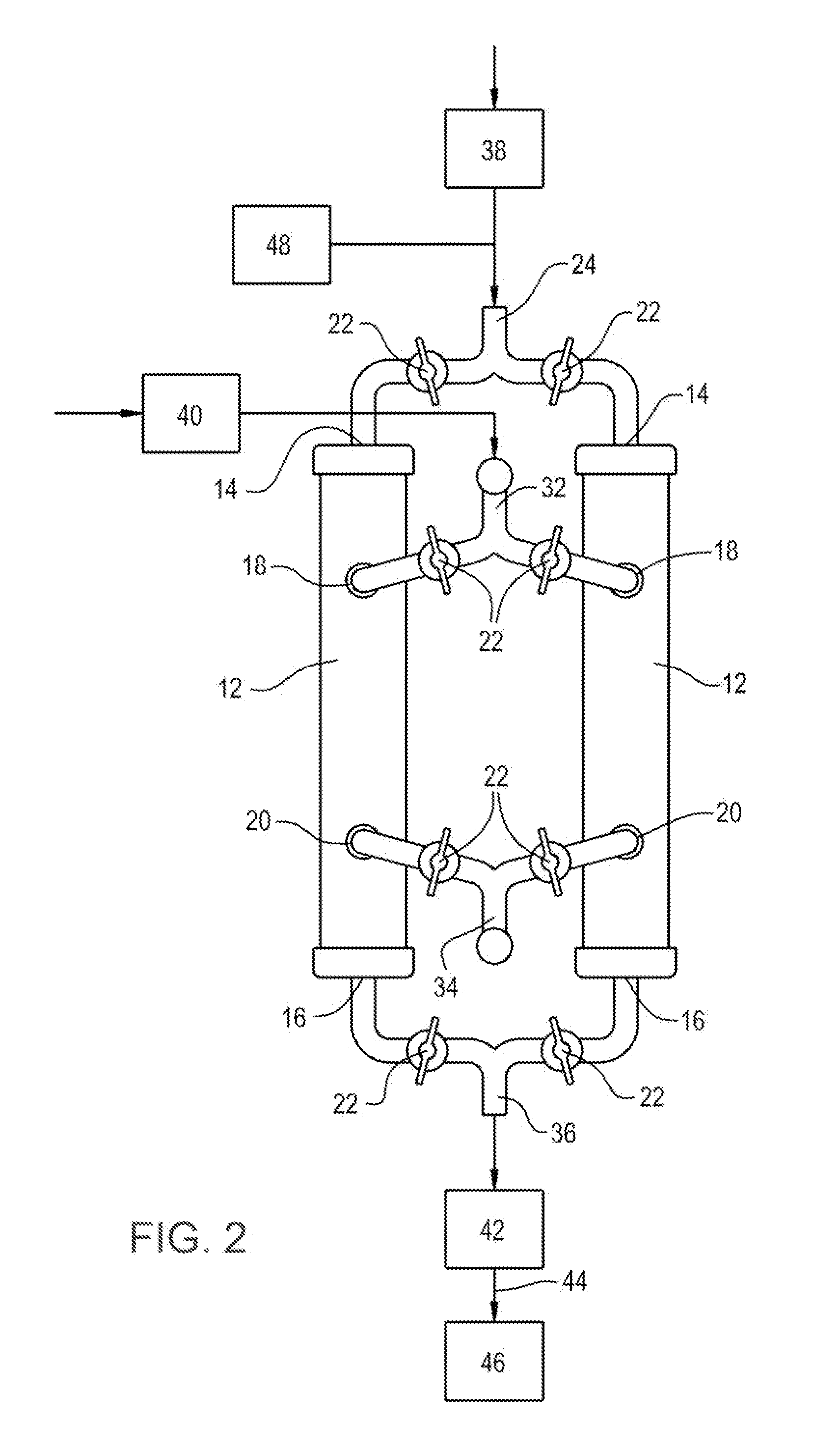

Systems and methods for ex vivo lung care

Methods and systems of maintaining, evaluating, and providing therapy to a lung ex vivo. The methods and systems involve positioning the lung in an ex vivo perfusion circuit; circulating a perfusion fluid through the lung, the fluid entering the lung through a pulmonary artery interface and leaving the lung through a left atrial interface; and ventilating the lung by flowing a ventilation gas through a tracheal interface. Maintaining the lung for extended periods involves causing the lung to rebreath a captive volume of air, and reaching an equilibrium state between the perfusion fluid and the ventilation gas. Evaluating the gas exchange capability of the lung involves deoxygenating the perfusion fluid and measuring a time taken to reoxygenate the perfusion fluid by ventilating the lung with an oxygenation gas.

Owner:TRANSMEDICS

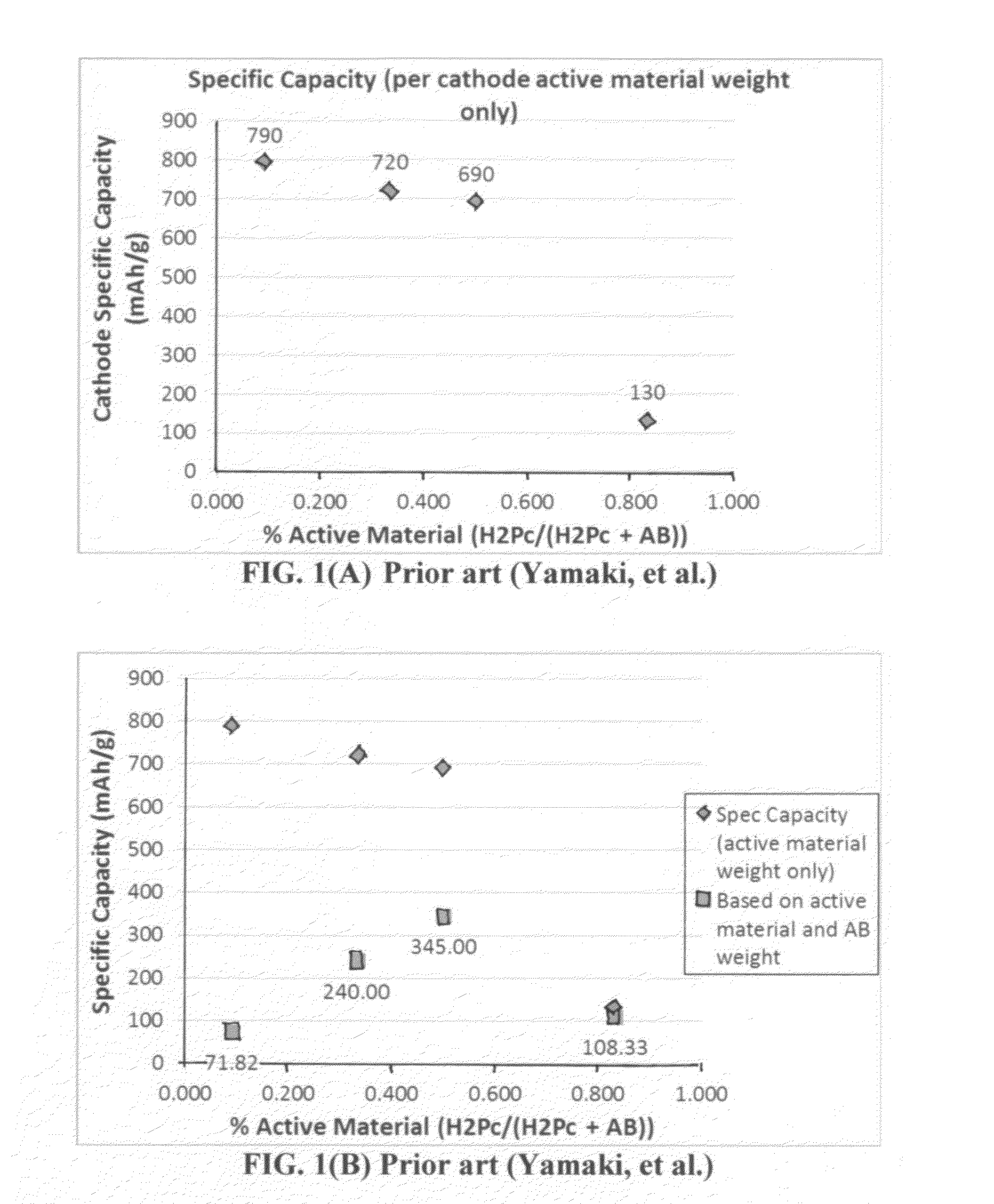

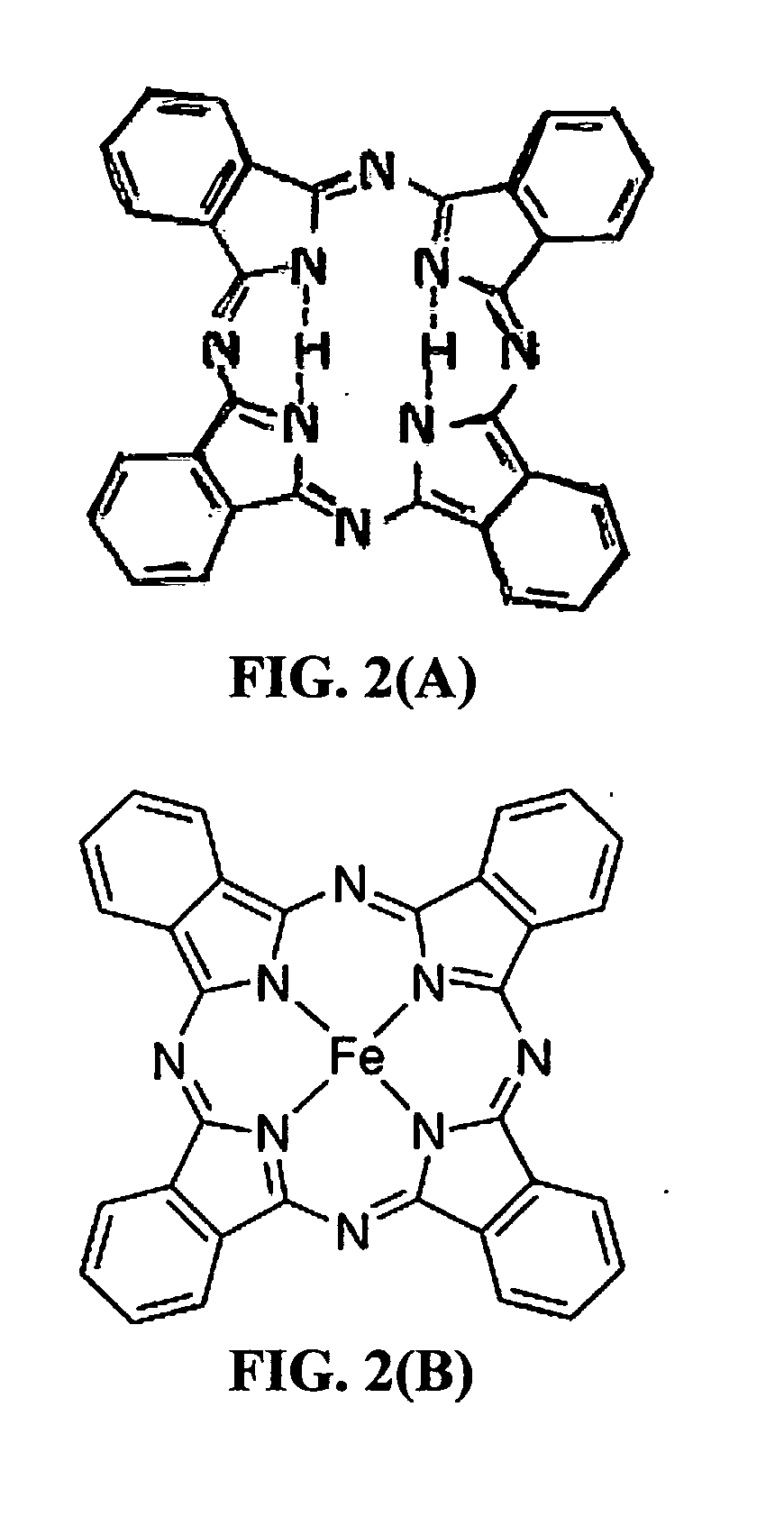

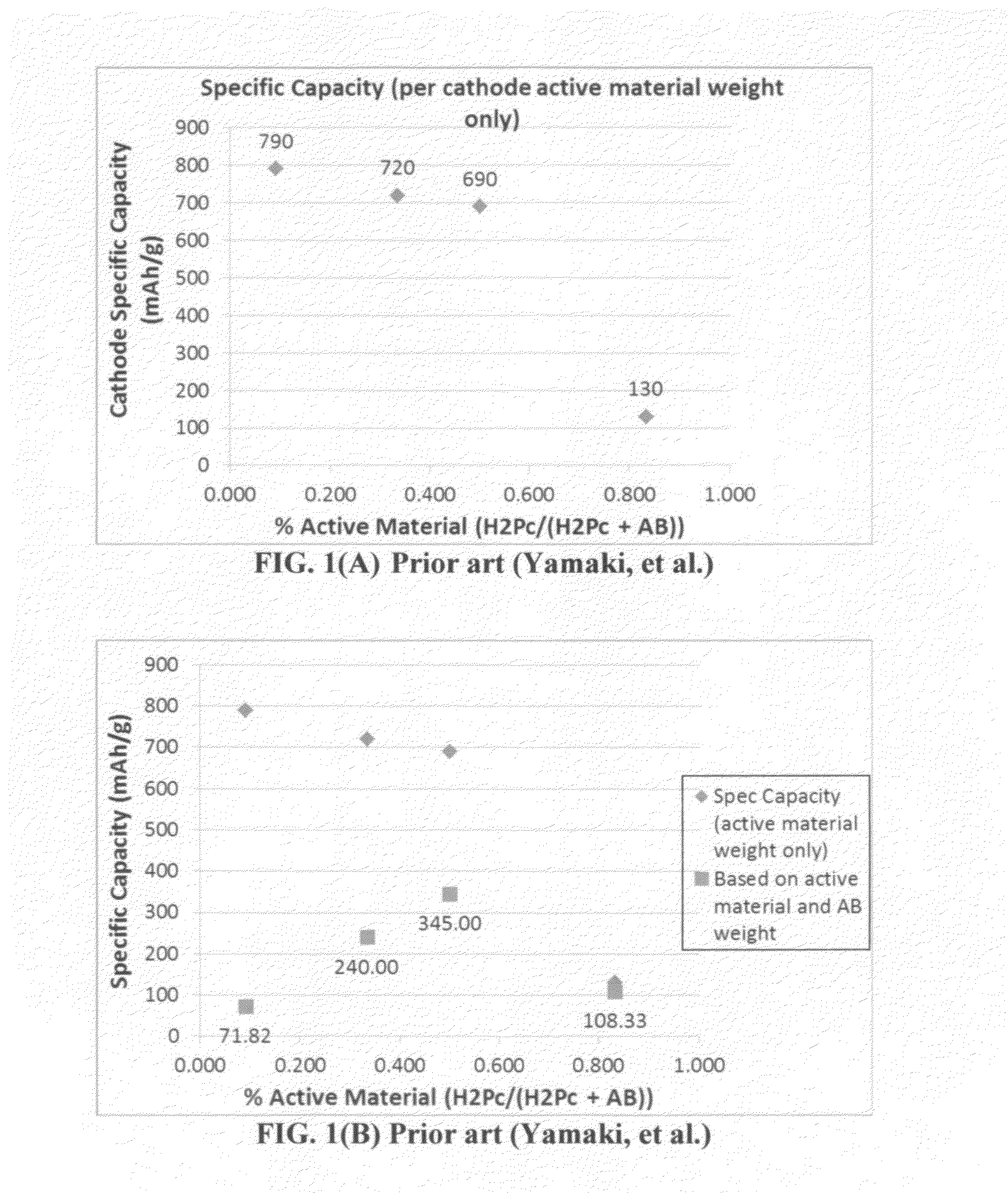

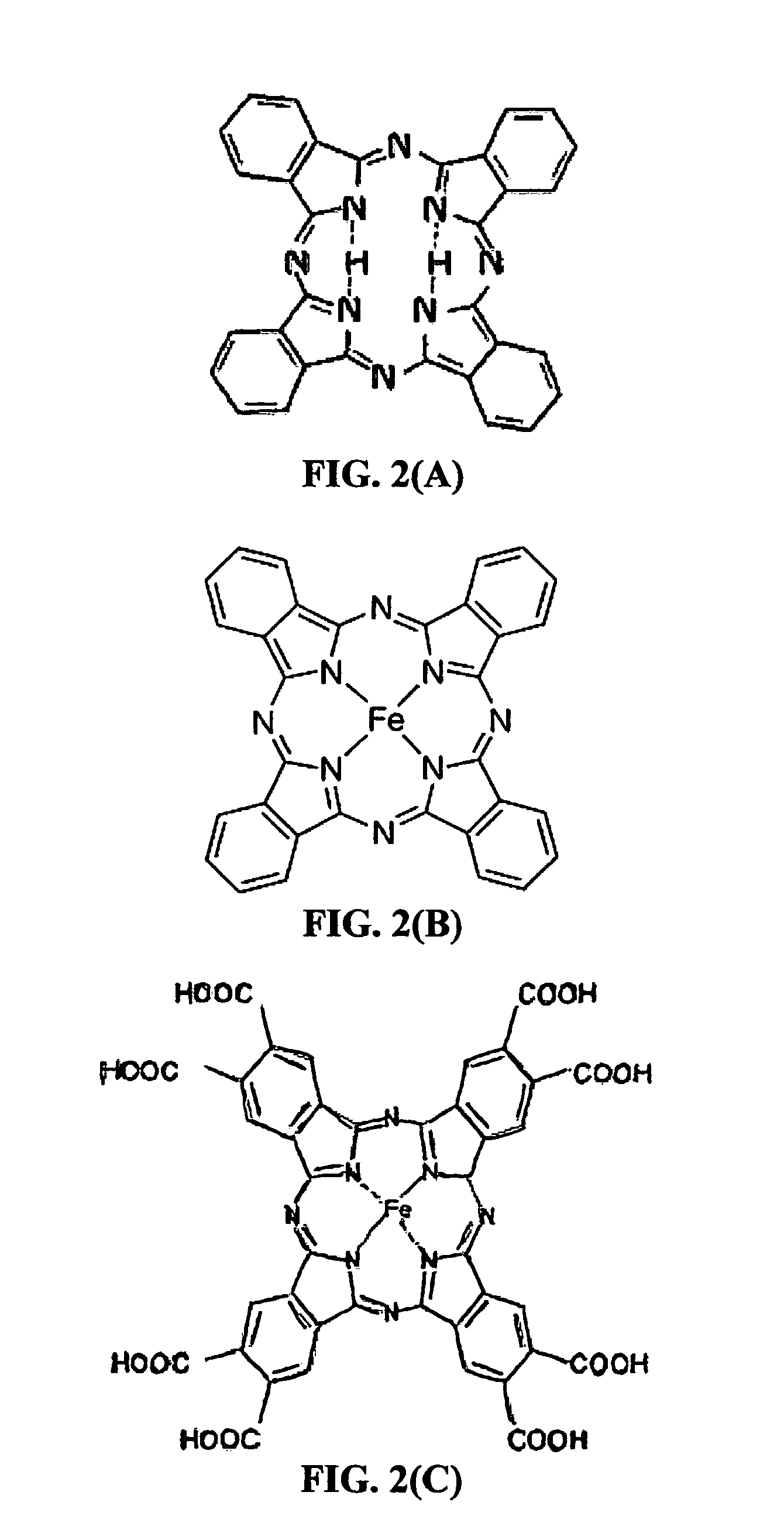

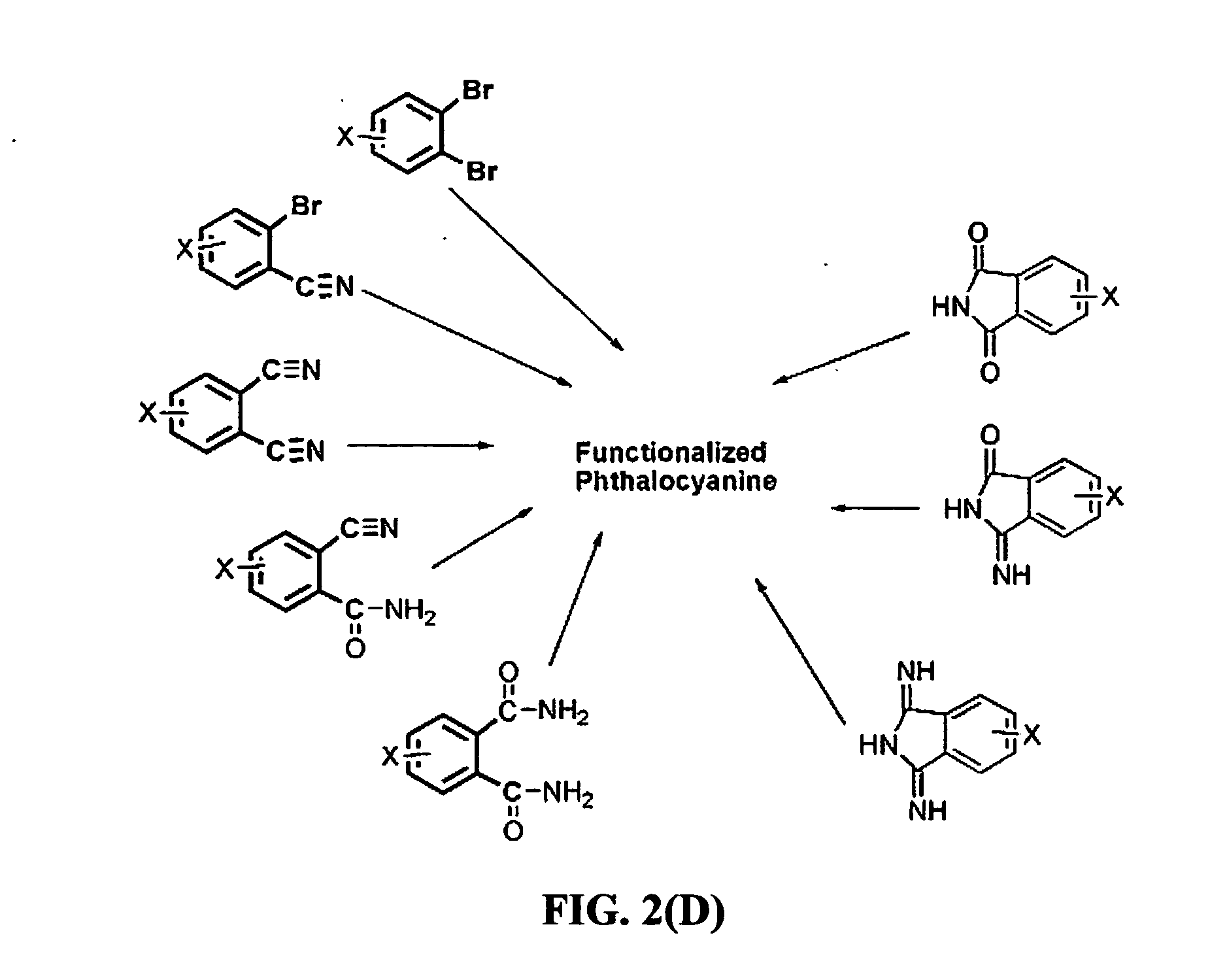

Rechargeable lithium cell having a meso-porous conductive material structure-supported phthalocyanine compound cathode

ActiveUS20130330611A1High oxygen contentIncreased riskMaterial nanotechnologyElectrode carriers/collectorsConductive polymerConductive materials

A rechargeable lithium cell comprising: (a) an anode comprising a prelithiated lithium storage material or a combination of a lithium storage material and a lithium ion source; (b) a hybrid cathode active material composed of a meso-porous structure of a carbon, graphite, metal, or conductive polymer and a phthalocyanine compound, wherein the meso-porous structure is in an amount of from 1% to 99% by weight based on the total weight of the meso-porous structure and the phthalocyanine combined, and wherein the meso-porous structure has a pore with a size from 2 nm to 50 nm to accommodate phthalocyanine compound therein; and (c) an electrolyte or electrolyte / separator assembly. This secondary cell exhibits a long cycle life and the best cathode specific capacity and best cell-level specific energy of all rechargeable lithium-ion cells ever reported.

Owner:GLOBAL GRAPHENE GRP INC

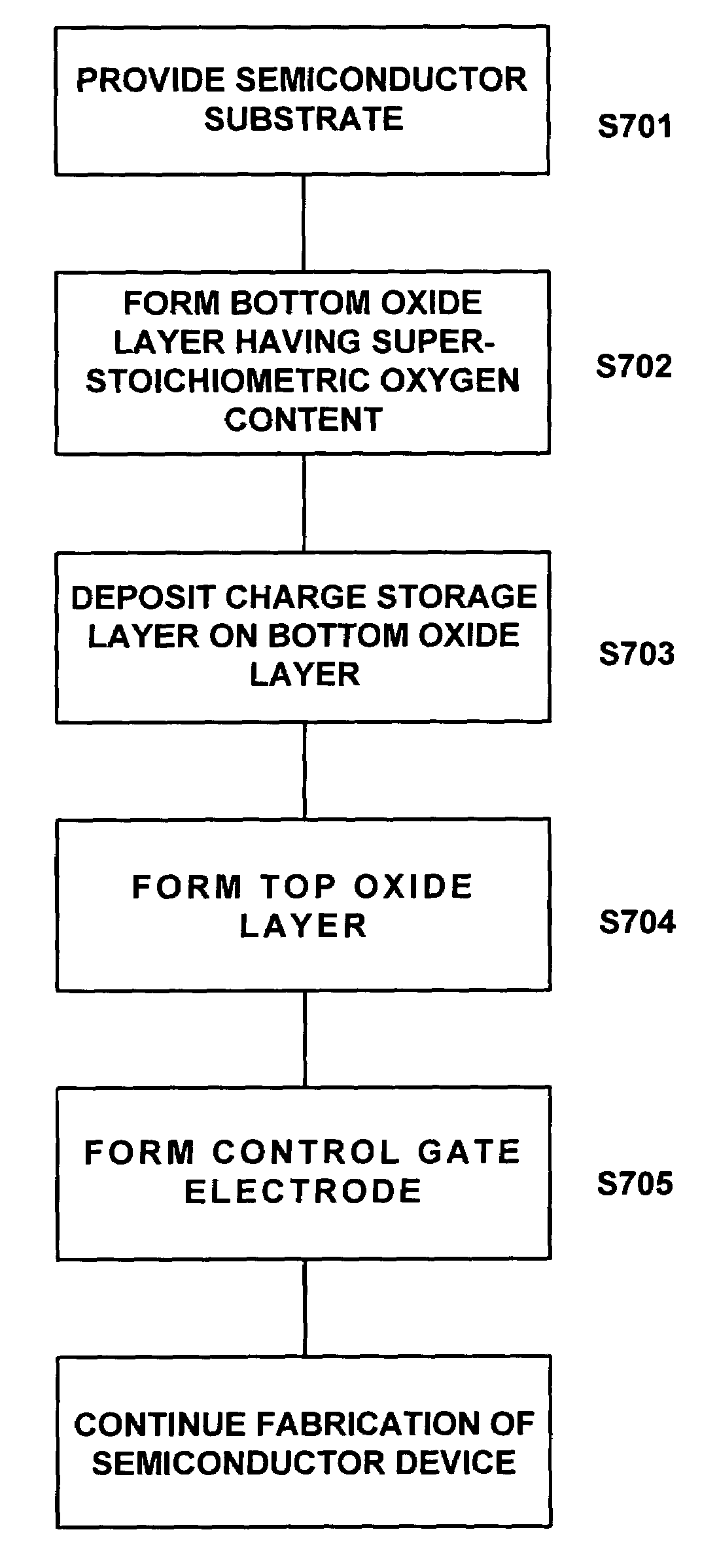

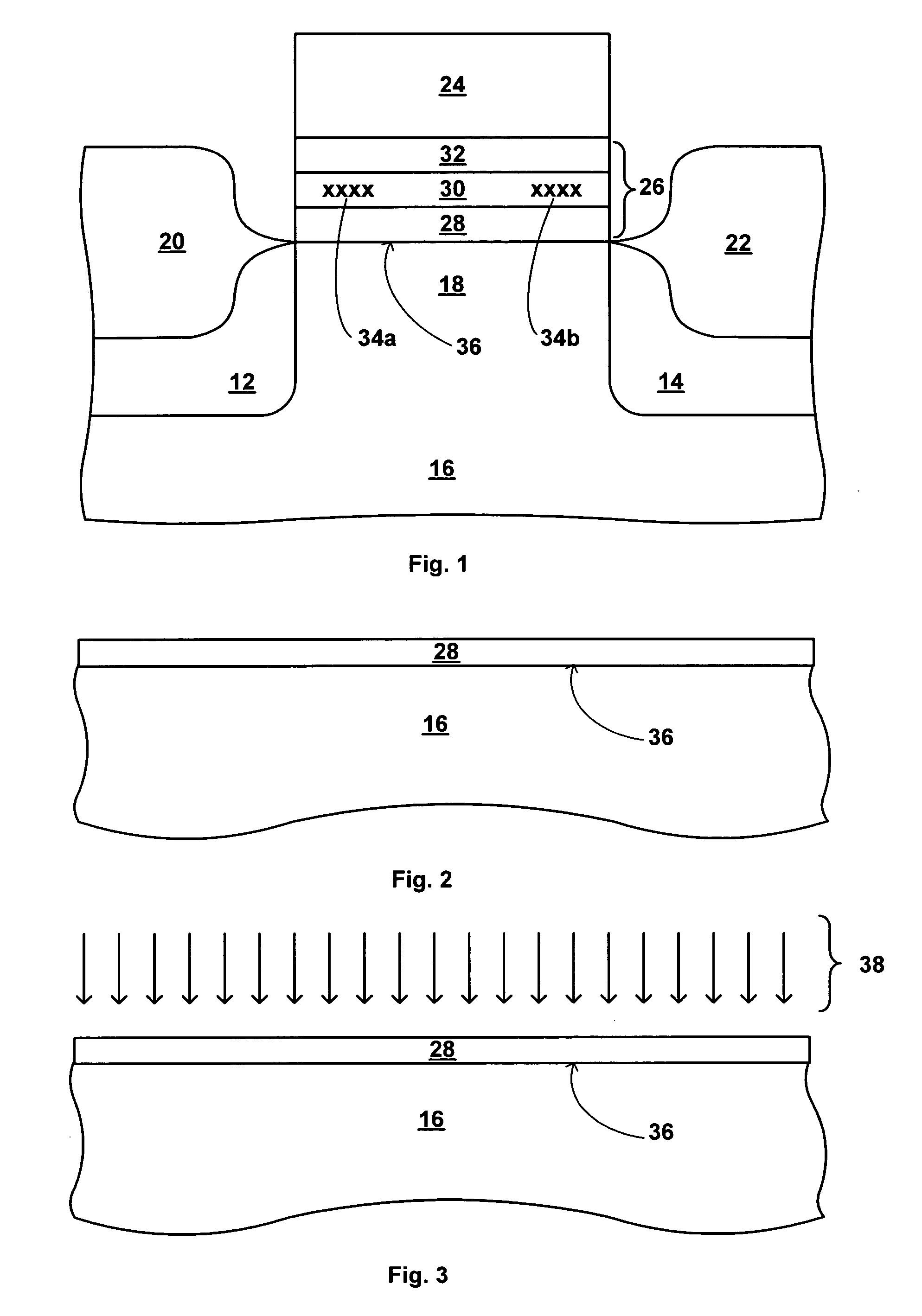

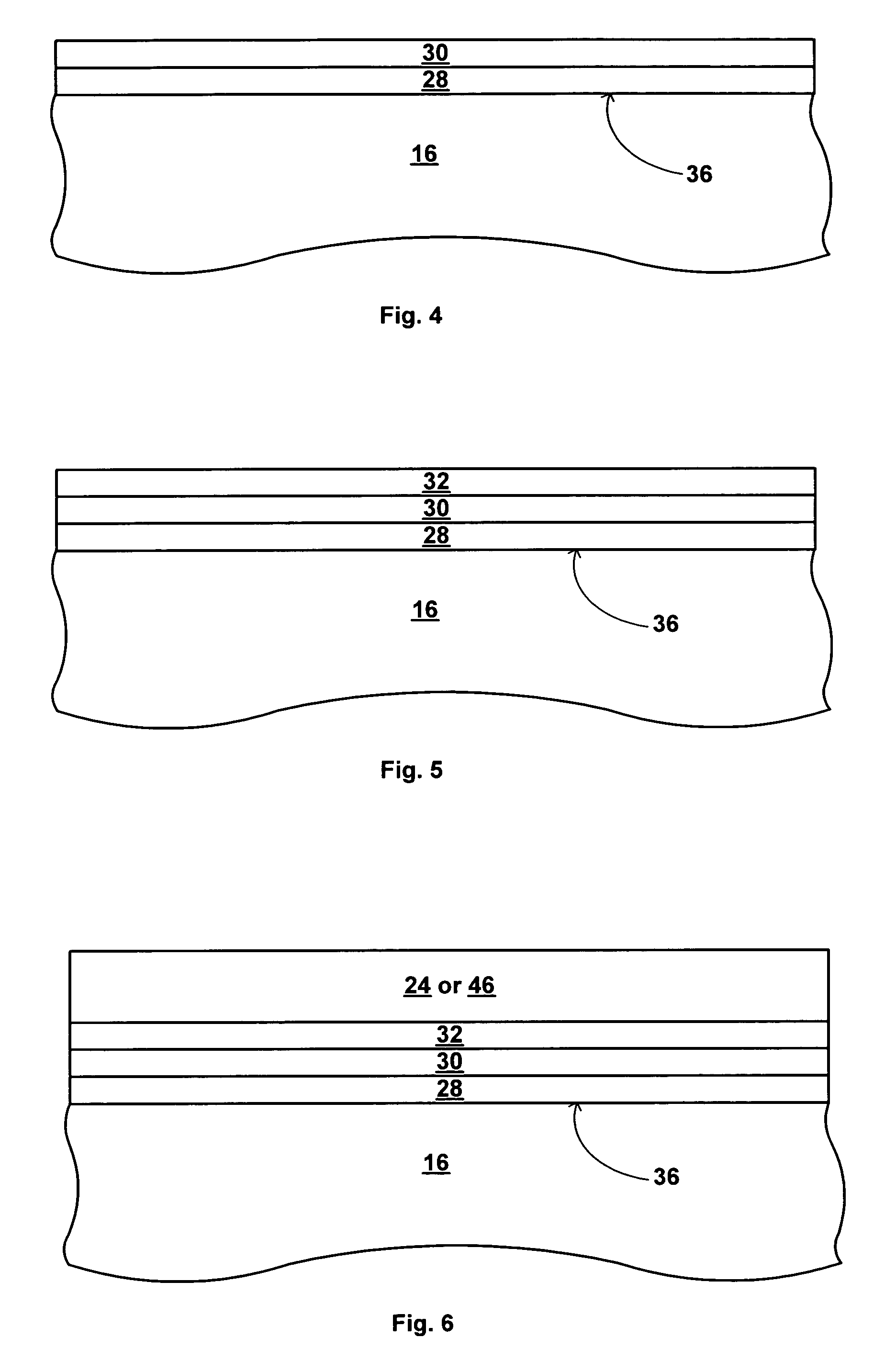

ONO fabrication process for increasing oxygen content at bottom oxide-substrate interface in flash memory devices

InactiveUS7033957B1Increase oxygen contentThermal budgetSemiconductor/solid-state device manufacturingSemiconductor devicesOxygen contentNitride

Process for reducing charge leakage in a SONOS flash memory device, including in one embodiment, forming a bottom oxide layer of an ONO structure on the semiconductor substrate to form an oxide / silicon interface having a first oxygen content adjacent the oxide / silicon interface; treating the bottom oxide layer to increase the first oxygen content to a second oxygen content adjacent the oxide / silicon interface; and depositing a nitride charge-storage layer on the bottom oxide layer. In another embodiment, process for reducing charge leakage in a SONOS flash memory device, including forming a bottom oxide layer of an ONO structure on a surface of the semiconductor substrate having an oxide / silicon interface with a super-stoichiometric oxygen content adjacent the oxide / silicon interface; and depositing a nitride charge-storage layer on the bottom oxide layer.

Owner:LONGITUDE FLASH MEMORY SOLUTIONS LTD

SYSTEMS AND METHODS FOR Ex vivo LUNG CARE

Methods and systems of maintaining, evaluating, and providing therapy to a lung ex vivo. The methods and systems involve positioning the lung in an ex vivo perfusion circuit; circulating a perfusion fluid through the lung, the fluid entering the lung through a pulmonary artery interface and leaving the lung through a left atrial interface; and ventilating the lung by flowing a ventilation gas through a tracheal interface. Maintaining the lung for extended periods involves causing the lung to rebreath a captive volume of air, and reaching an equilibrium state between the perfusion fluid and the ventilation gas. Evaluating the gas exchange capability of the lung involves deoxygenating the perfusion fluid and measuring a time taken to reoxygenate the perfusion fluid by ventilating the lung with an oxygenation gas.

Owner:TRANSMEDICS

Rechargeable lithium cell having a chemically bonded phthalocyanine compound cathode

ActiveUS20140072871A1High oxygen contentIncreased riskMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesPhthalocyanineLongest cycle

A rechargeable lithium cell comprising: (a) an anode comprising an anode active material; (b) a cathode comprising a hybrid cathode active material composed of an electrically conductive substrate and a phthalocyanine compound chemically bonded to or immobilized by the conductive substrate, wherein the phthalocyanine compound is in an amount of from 1% to 99% by weight based on the total weight of the conductive substrate and the phthalocyanine compound combined; and (c) electrolyte or a combination of electrolyte and a porous separator, wherein the separator is disposed between the anode and the cathode and the electrolyte is in ionic contact with the anode and the cathode. This secondary cell exhibits a long cycle life, the best cathode specific capacity, and best cell-level specific energy of all rechargeable lithium-ion cells ever reported.

Owner:GLOBAL GRAPHENE GRP INC

Systems and methods for ex vivo lung care

Methods and systems of maintaining, evaluating, and providing therapy to a lung ex vivo. The methods and systems involve positioning the lung in an ex vivo perfusion circuit; circulating a perfusion fluid through the lung, the fluid entering the lung through a pulmonary artery interface and leaving the lung through a left atrial interface; and ventilating the lung by flowing a ventilation gas through a tracheal interface. Maintaining the lung for extended periods involves causing the lung to rebreath a captive volume of air, and reaching an equilibrium state between the perfusion fluid and the ventilation gas. Evaluating the gas exchange capability of the lung involves deoxygenating the perfusion fluid and measuring a time taken to reoxygenate the perfusion fluid by ventilating the lung with an oxygenation gas.

Owner:TRANSMEDICS

Systems and methods for ex vivo lung care

ActiveUS20090197292A1Low oxygen contentHigh oxygen contentBioreactor/fermenter combinationsBiological substance pretreatmentsPerfusion fluidPulmonary artery

Methods and systems of maintaining, evaluating, and providing therapy to a lung ex vivo. The methods and systems involve positioning the lung in an ex vivo perfusion circuit; circulating a perfusion fluid through the lung, the fluid entering the lung through a pulmonary artery interface and leaving the lung through a left atrial interface; and ventilating the lung by flowing a ventilation gas through a tracheal interface. Maintaining the lung for extended periods involves causing the lung to rebreath a captive volume of air, and reaching an equilibrium state between the perfusion fluid and the ventilation gas. Evaluating the gas exchange capability of the lung involves deoxygenating the perfusion fluid and measuring a time taken to reoxygenate the perfusion fluid by ventilating the lung with an oxygenation gas.

Owner:TRANSMEDICS

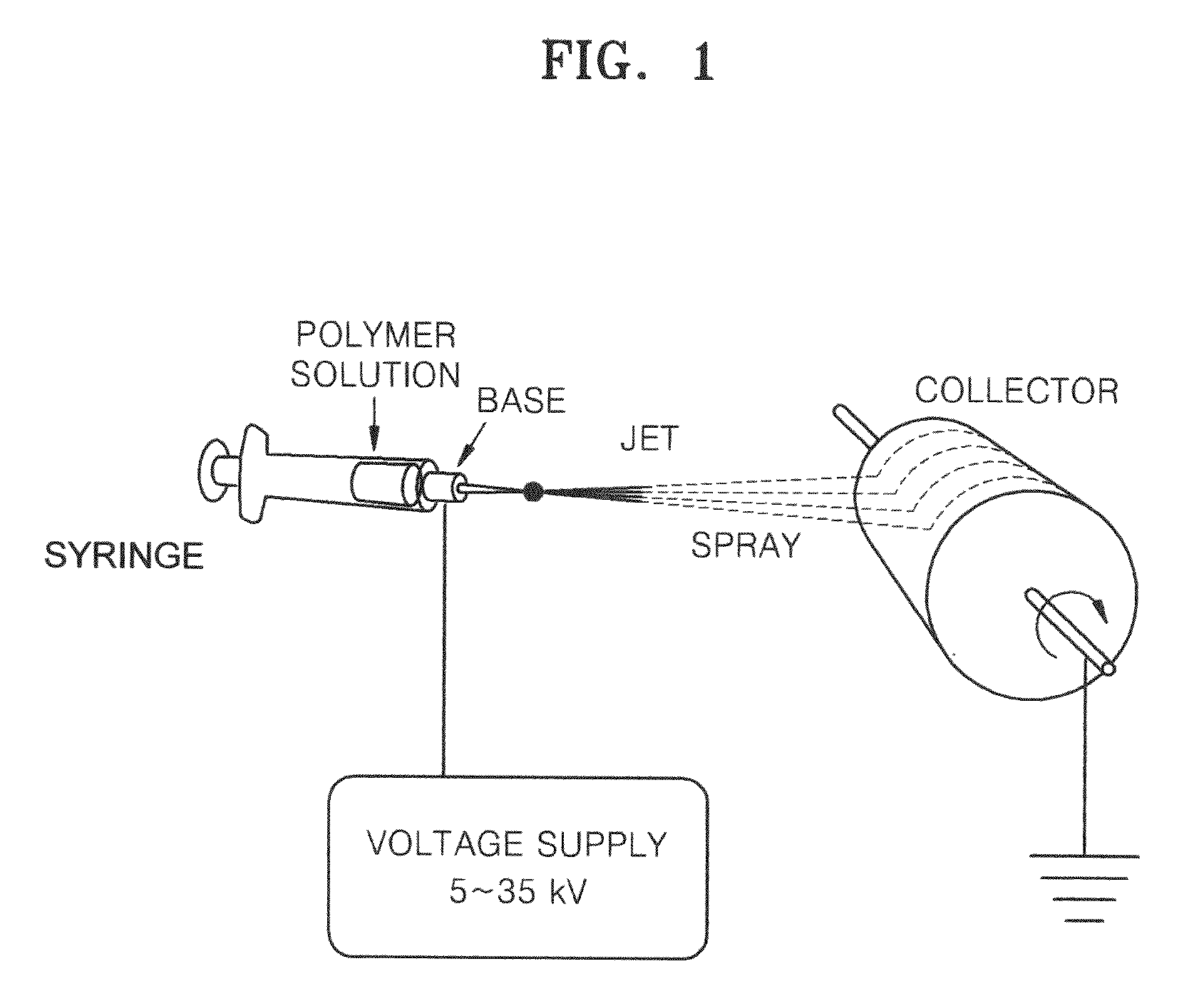

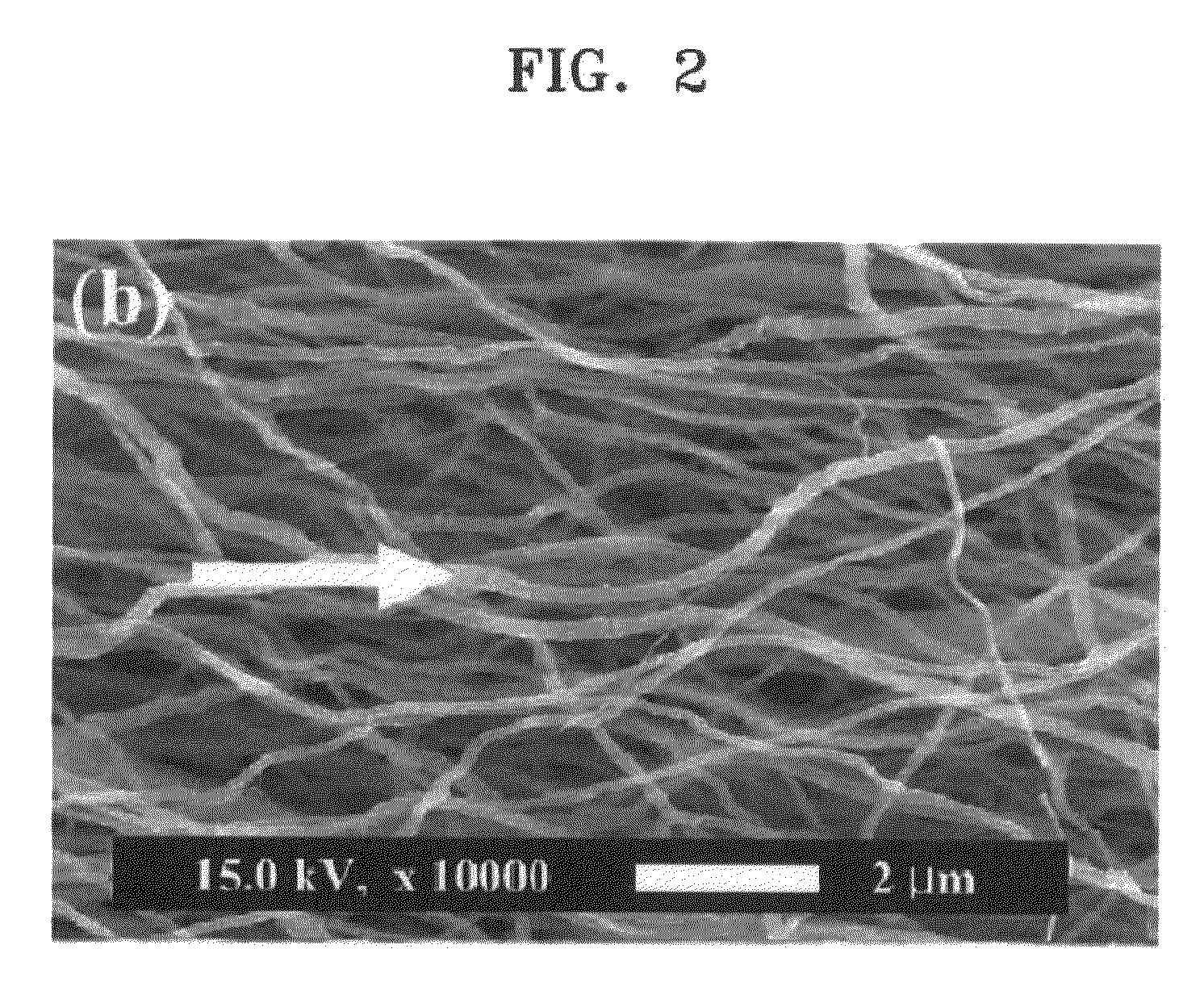

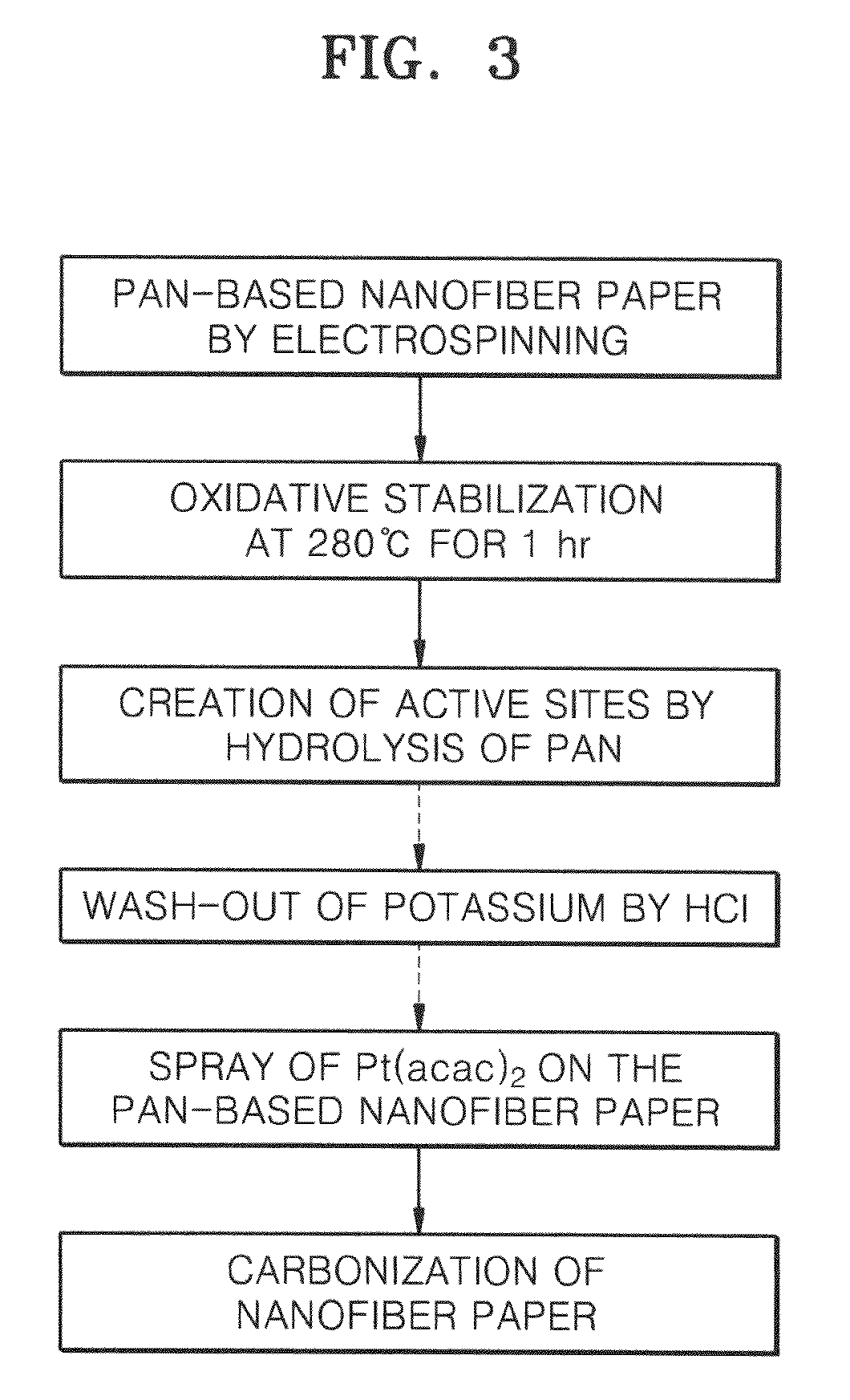

Nanocomposite for fuel cell, method of preparing the nanocomposite, and fuel cell including the nanocomposite

InactiveUS20080176129A1High oxygen contentHigh electrochemical efficiencyMaterial nanotechnologyElectric discharge heatingFiberCarbon fibers

Provided is a nanocomposite for the catalyst layer of a fuel cell electrode including: a carbon nanofiber; and metal catalyst particles uniformly applied to the surface of the carbon nanofiber, wherein the carbon nanofiber has a surface oxygen content of at least 0.03 calculated by the formula: Oxygen content=[atomic percentage of oxygen / atomic percentage of carbon] using atomic percentages of oxygen and carbon, respectively calculated from an area of an oxygen peak having a binding energy of 524 to 540 eV, an area of a nitrogen peak having a binding energy of 392 to 404 eV, and an area of a carbon peak having a binding energy of 282 to 290 eV in X-ray photoelectron spectroscopy. The nanocomposite according to the present invention has high surface oxygen content and has metal catalyst nano particles densely and uniformly distributed on the outer wall of the carbon fibers, thereby having high electrochemical efficiency. Thus, efficiency of fuel cells can be improved using the nanocomposite.

Owner:SAMSUNG SDI CO LTD

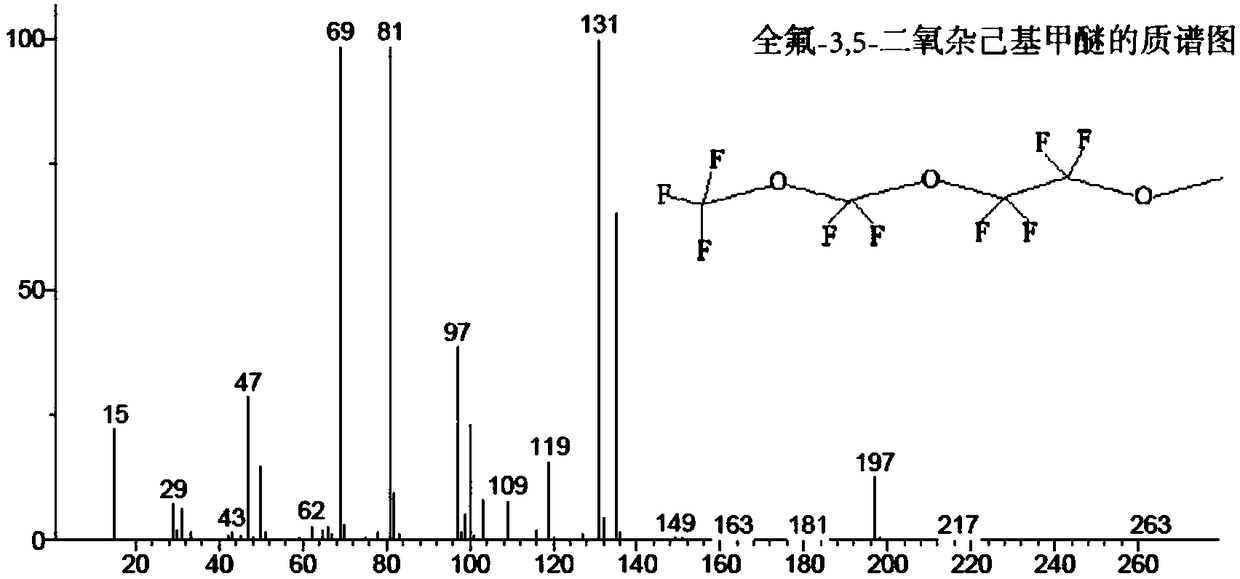

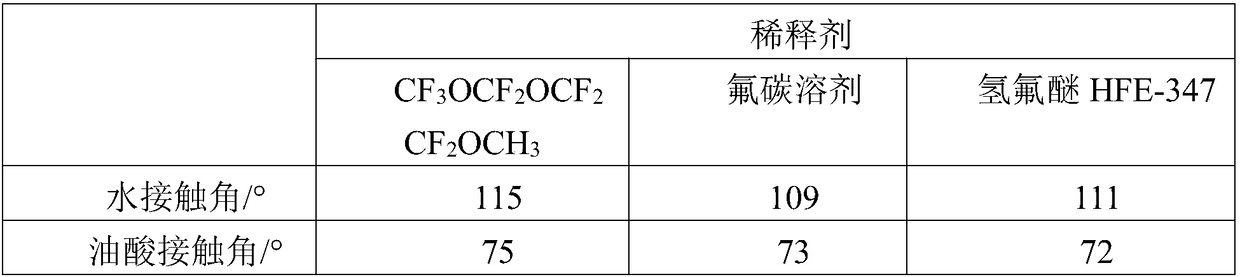

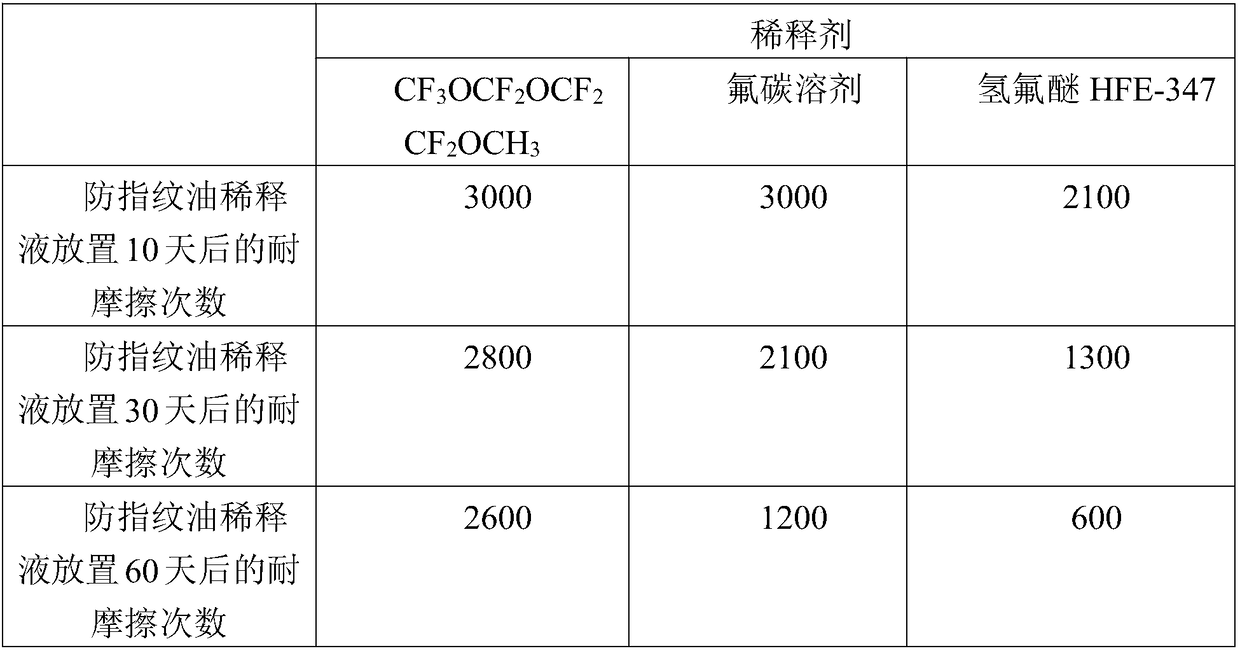

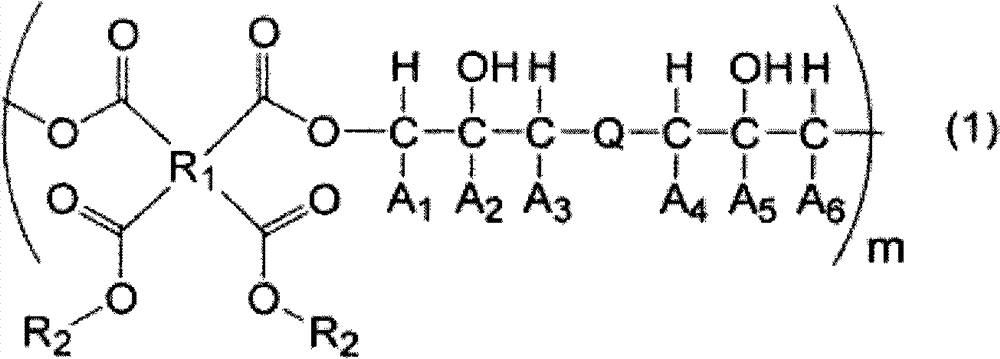

New oxahydrofluoroether compounds and preparation method and application of new oxahydrofluoroether compounds

ActiveCN108467339AHigh oxygen contentReduce surface tensionOrganic chemistryAntifouling/underwater paintsHydrofluoroetherOxygen

This invention relates to oxahydrofluoroether compounds and a preparation method and application of the new oxahydrofluoroether compounds. The oxahydrofluoroether compounds are compounds represented by a general formula of CF3O(CF2O)mCF2CF2R, wherein R is OR1 or (OCF(CF3)CF2)nOR2 or OCF2CF2OR3, and R1, R2 and R3 are linear-chain or branched-chain C1-C3 alkyl groups. The designed new oxahydrofluoroether compounds have a structure with high content of the oxygen element, extremely low surface tension and stronger permeability than those of other hydrofluoroether solvents, and can be applied to cleaning agents so as to ensure thorough cleaning; meanwhile, due to high content of oxygen and a short atmospheric lifetime, the hydrofluoroether compounds can be easily degraded to CO2 and fluoride salts, and have a low GWP value which is the greenhouse effect potential value; the oxahydrofluoroether compounds have good application in anti-fingerprint liquid diluents, dilution of a fluorine-containing treating agent, removal of contaminants in equipment components, preparation of foamed plastics, welding in a vapor phase, transfer of heat, deposition of coatings on substrates and cutting or grinding aspects.

Owner:SANMING HEXAFLUO CHEM CO LTD

Method for determining hematocrit corrected analyte concentrations

InactiveUS20130240375A1Reduce probabilityLess producedWeather/light/corrosion resistanceMicrobiological testing/measurementAnalyteLinear regression

The method includes: providing a test strip comprising a reference electrode and a working electrode coated with a reagent layer; applying a fluid sample to the test strip for a reaction period; applying a test voltage between the reference electrode and the working electrode; measuring a test current as a function of time; measuring a steady state current value when the test current has reached an equilibrium; calculating a ratio of the test current to the steady state current value; plotting the ratio of the test current to the steady state current value as a function of the inverse square root of time; calculating an effective diffusion coefficient from the slope of the linearly regressed plot of the ratio of the test current to the steady state current value as a function of the inverse square root of time; and calculating a hematocrit-corrected concentration of analyte.

Owner:LIFESCAN IP HLDG LLC

Inclusion control method for ultrapure austenitic stainless steel for cold-rolled sheets

InactiveCN108559818AStrong resistance to salt spray corrosionReduce in quantitySS - Stainless steelDeoxidization

The invention discloses an inclusion control method for ultrapure austenitic stainless steel for cold-rolled sheets. The preparation method comprises the following steps: I, performing decarburizationblowing, silicon iron reduction and preliminary dexidation on stainless steel mother liquid in an AOD furnace, and adjusting basicity of slag to 1.8 or higher; II, performing slagging-off treatment on ladle slag after tapping; III, performing refining treatment on an LF furnace; IV, performing continuous casting to obtain a continuous casting billet; V, performing hot rolling and cold rolling onthe continuous casting billet, thereby obtaining the stainless steel plate. According to the control method disclosed by the invention, deep deoxidization of aluminum is adopted, and the total oxygencontent is lower than 20 ppm; due to a small amount of inclusion, the prepared stainless steel is high in salt spray resistance and corrosion resistance; the inclusion type in the stainless steel prepared in the invention is mainly fine magnesium aluminate spinel, and the stainless steel does not extend in a rolling process and does not form defects on the cold drawing surface.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

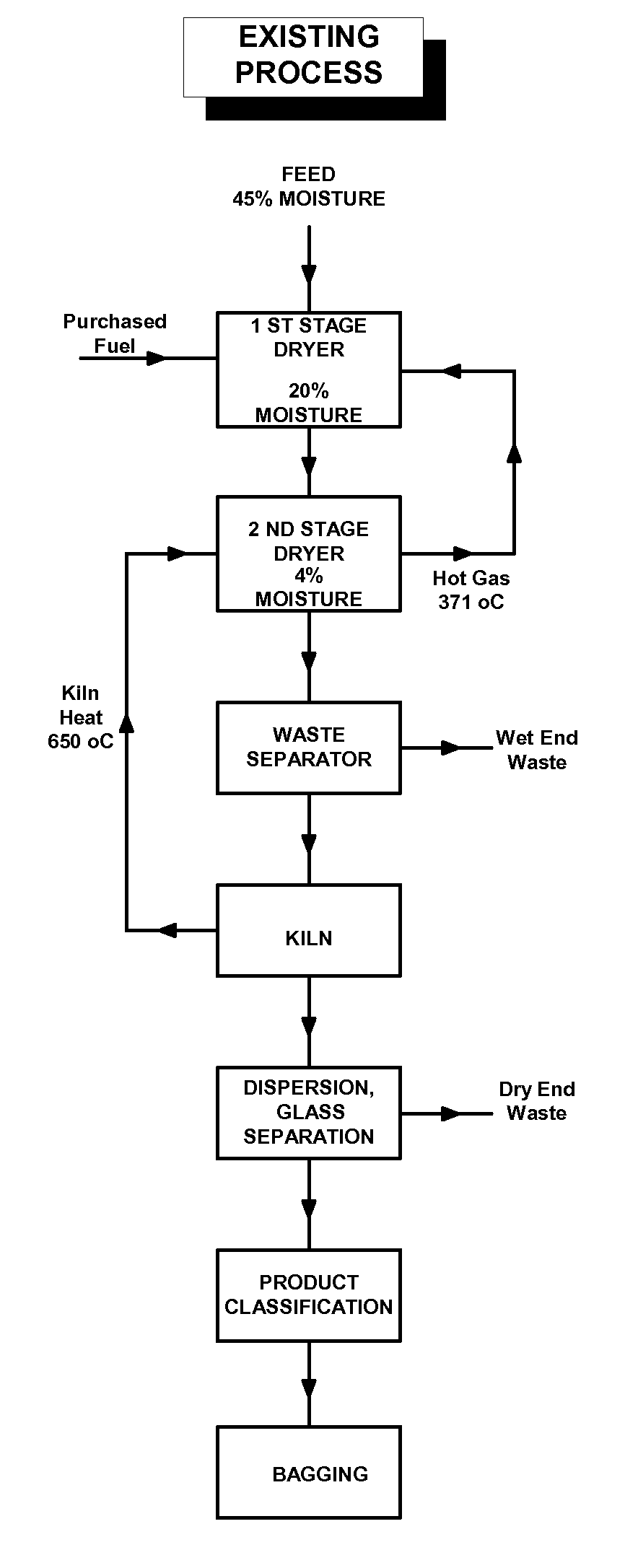

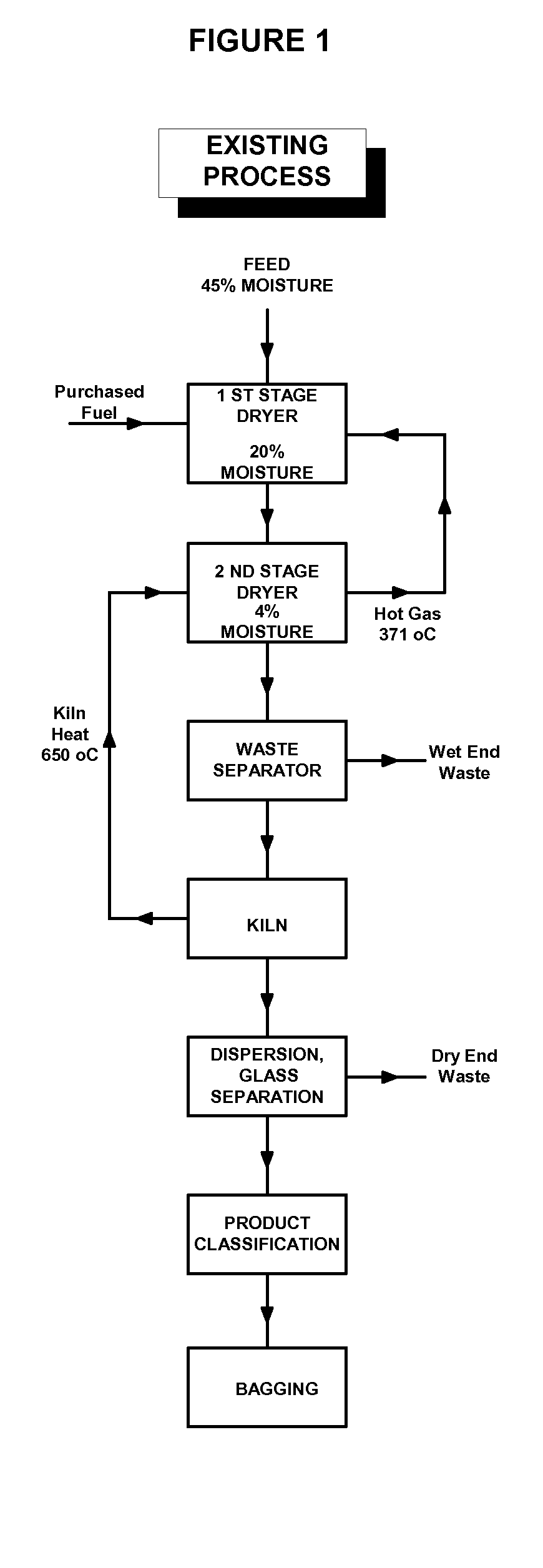

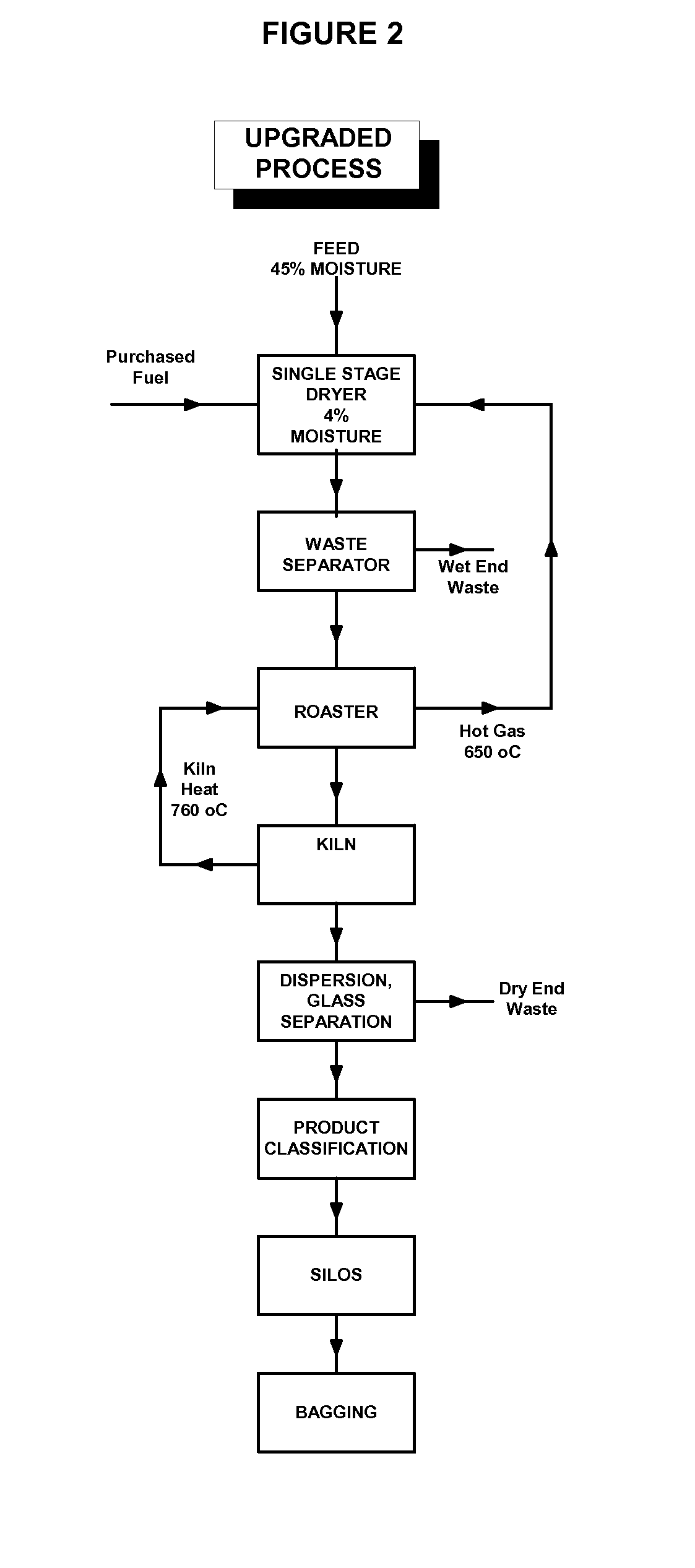

Process for Roasting Diatomaceous Earth Ore to Reduce Organic Content

InactiveUS20100167921A1High oxygen contentOther chemical processesInorganic pigment treatmentCounter currentLoss on ignition

Disclosed herein is a method for processing diatomaceous earth ore comprising roasting a diatomite feed at a temperature ranging from about 850 to about 1600° F. Also disclosed herein is a method for processing a diatomite feed comprising at least one impurity to produce a diatomite product having at least one of reduced loss-on-ignition, reduced impurity content, reduced beer soluble iron content, and improved brightness as compared to the feed composition. Further disclosed herein is a system for processing a diatomite feed comprising a first heating zone for roasting the diatomite at a temperature ranging from about 850 to about 1600° F., a second zone for calcining the diatomite at a temperature of at least about 1600° F., and a counter-current flow of gas from the second heating zone to the first heating zone.

Owner:IMERYS FILTRATION MINERALS

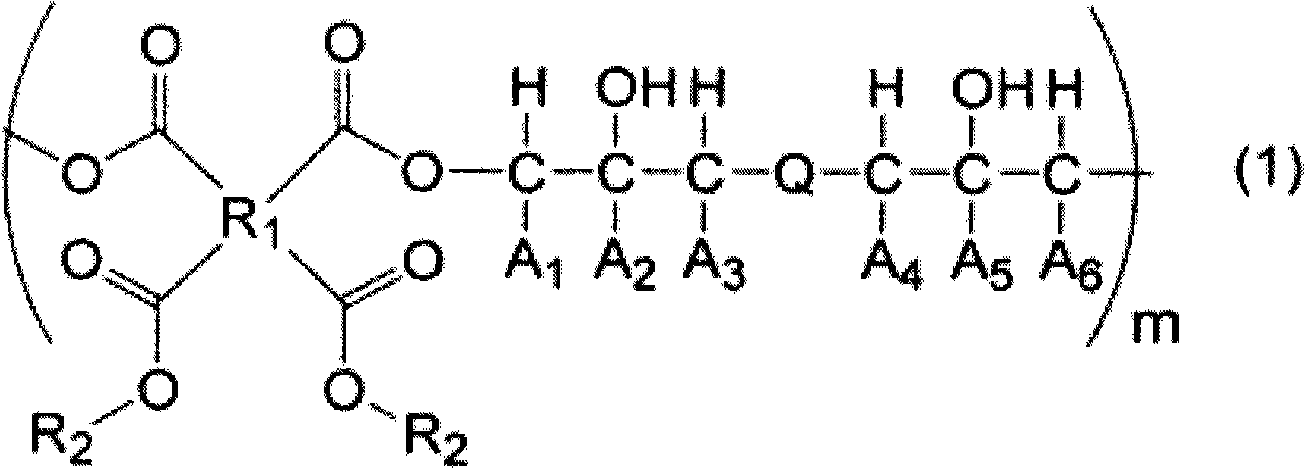

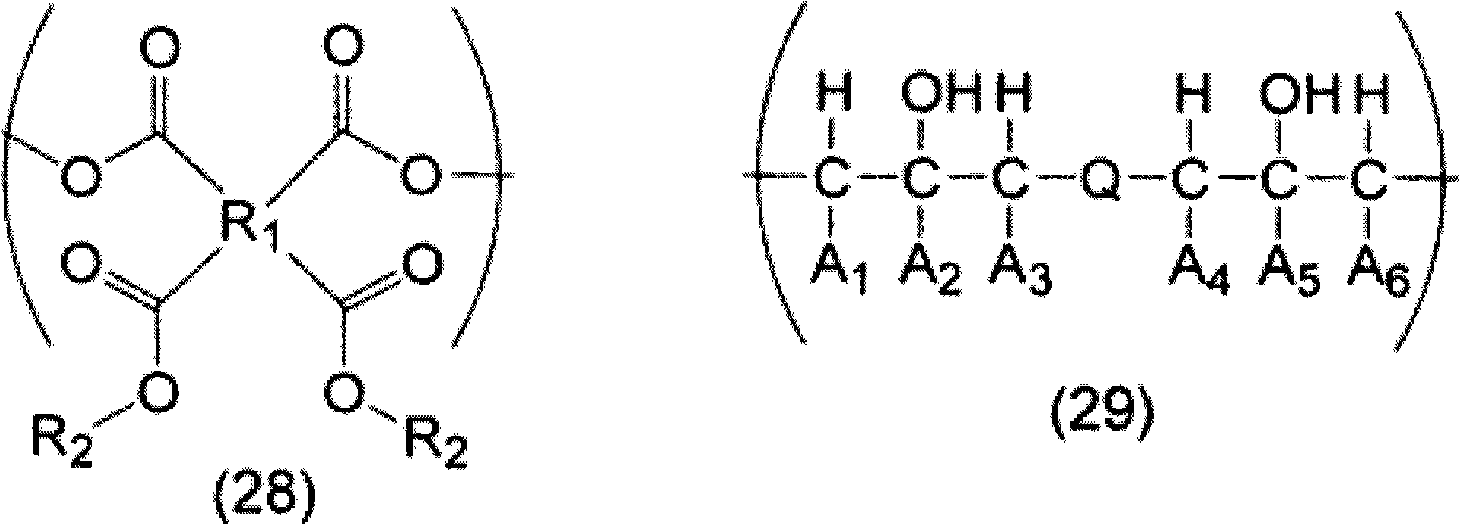

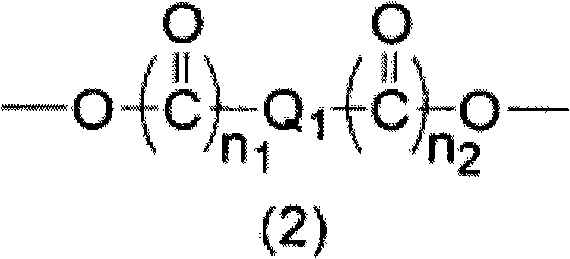

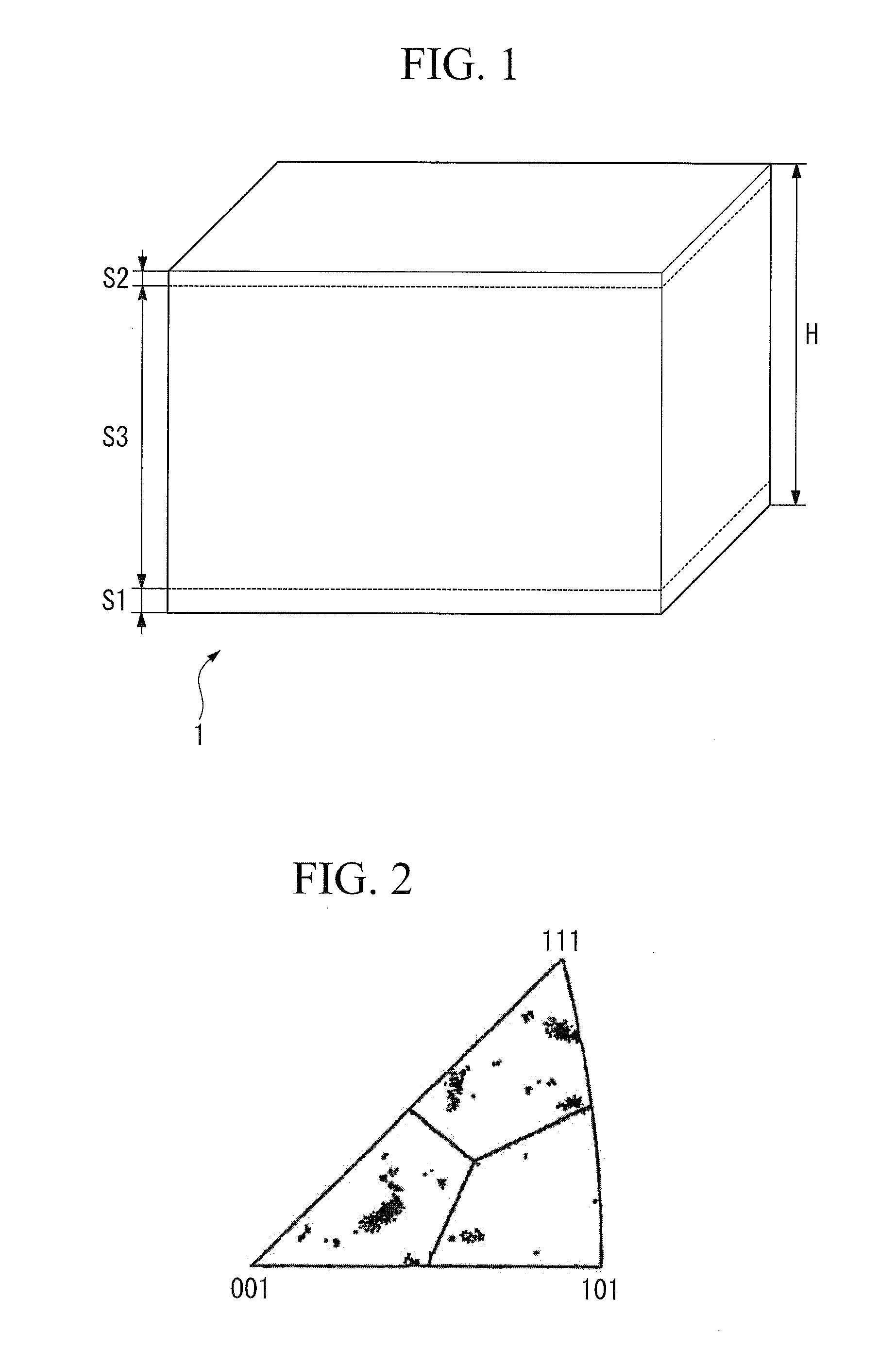

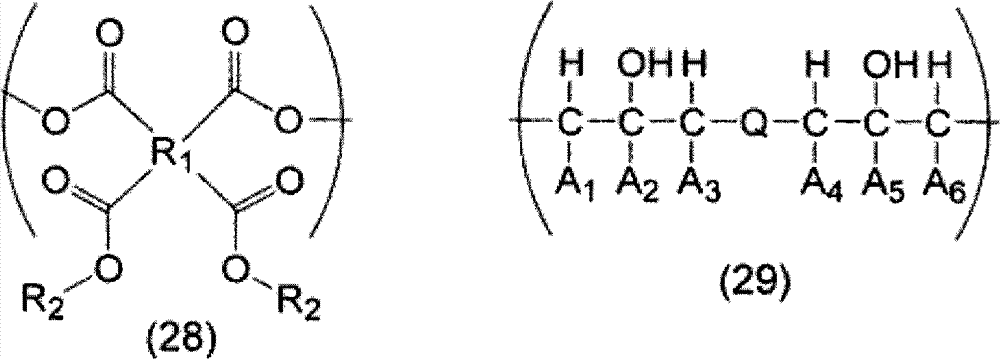

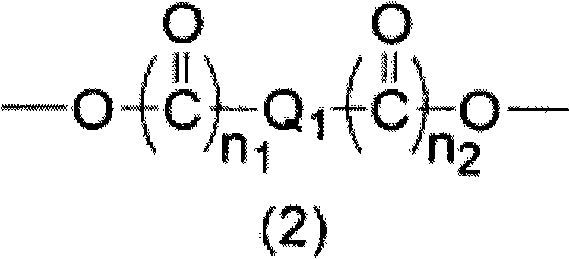

Composition for forming resist underlayer film and method for forming resist pattern using the same

ActiveCN101946210AHigh oxygen contentHigh transparencyPhotosensitive materials for photomechanical apparatusSemiconductor/solid-state device manufacturingResistOrganic solvent

Disclosed is a composition for forming a resist underlayer film having high selectivity ratio of etching rate, while having desired k value and n value for a short wavelength such as an ArF excimer laser. Specifically disclosed is a composition for forming a resist underlayer film, which contains a polymer and a solvent. The polymer is obtained from a reaction using at least a tetracarboxylic acid dianhydride having an alicyclic structure or an aliphatic structure and a diepoxy compound having two epoxy groups, which reaction is performed together with an organic solvent containing an alcoholcompound having an OH group.

Owner:NISSAN CHEM IND LTD

Personal airway humidification and oxygen-enrichment apparatus and method

A personal airway humidification and oxygen-enrichment apparatus includes at least two membranes adapted to produce a conditioned gas. At least a first of the membranes is adapted to produce a first gas and at least a second of the membranes is adapted to produce a second gas having an oxygen content higher than the first gas. The conditioned gas includes the first gas, the second gas, or a combination thereof from the membranes. The membranes are adapted to produce the first gas and the second gas so that the conditioned gas contains gaseous water to about 100 percent saturation. The apparatus includes means for delivering water to the membranes, means for delivering an initial gas to the membranes, and a delivery hose adapted to receive the conditioned gas from one or more of the membranes and deliver the conditioned gas to a delivery device.

Owner:JARECKI STEVEN RAY

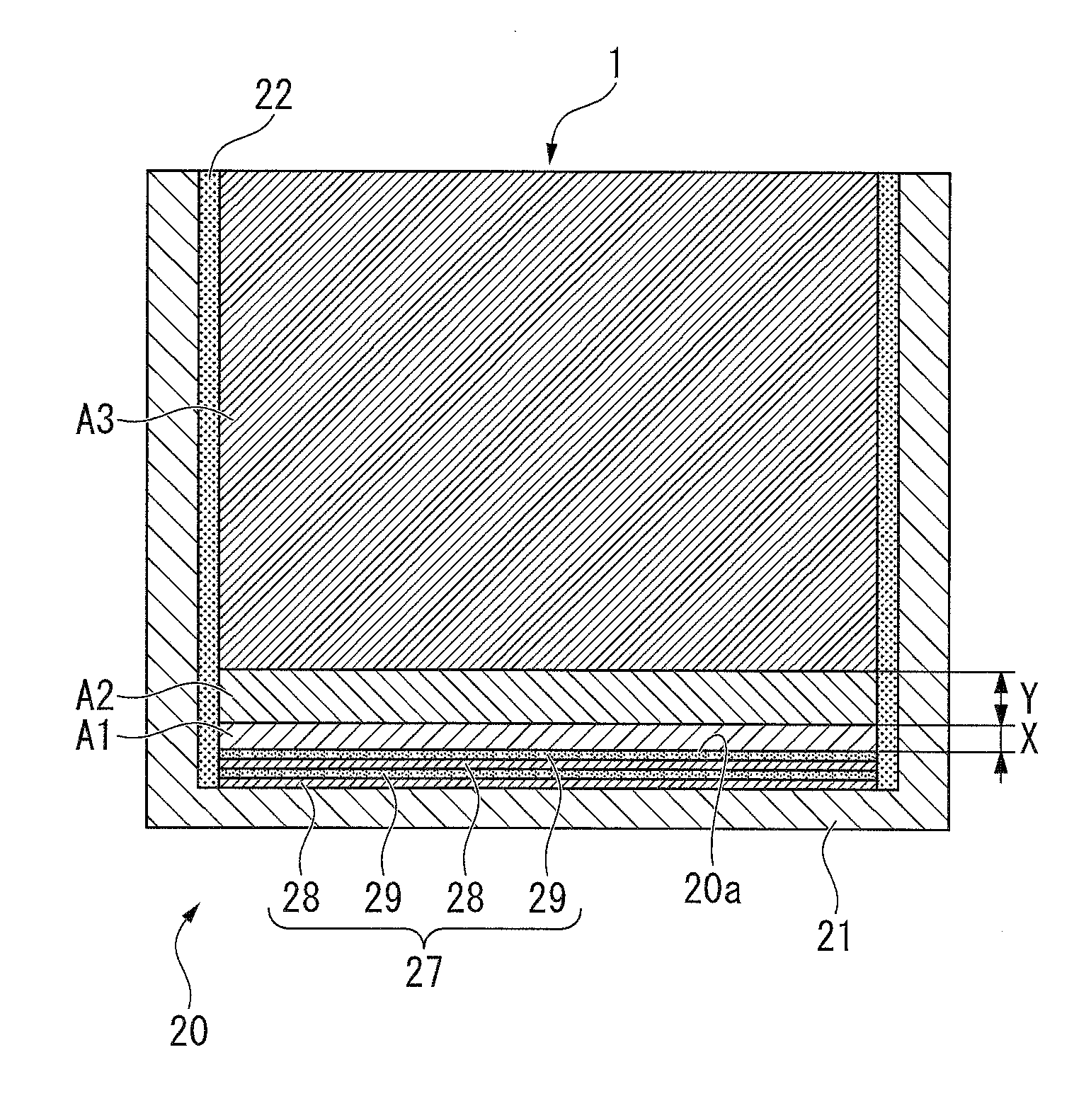

Method for manufacturing polycrystalline silicon ingot, and polycrystalline silicon ingot

ActiveUS20130008371A1Improve production yieldHigh oxygen contentPolycrystalline material growthSiliconMolten siliconPolycrystalline silicon

A method for manufacturing a polycrystalline silicon ingot includes unidirectionally solidifying a molten silicon upwardly from the bottom of a crucible, wherein the crucible is provided with silica deposited on the bottom of the crusible; and then dividing the degree of solidification in the crucible into a first zone from 0 mm to X in height (10 mm≦X<30 mm), a second zone from X to Y in height (30 min≦Y<100 mm) and a third zone of Y or more in height, based on the bottom of the crucible, wherein a solidification rate V1 in the first zone is set in the range of 10 mm / h≦V1≦20 mm / h and a solidification rate V2 in the second zone is set in the range of 1 mm / h≦V2≦5 mm / h.

Owner:MITSUBISHI MATERIALS ELECTRONICS CHEM CO LTD

Deoxygenating method for molten steel smelting

InactiveCN104962684AImprove purityHigh affinityProcess efficiency improvementElectric furnaceElectric arc furnaceMolten steel

The invention relates to a deoxygenating method during smelting, in particular to a deoxygenating method for molten steel smelting. The deoxygenating method for molten steel smelting comprises a deoxygenating method of molten steel in an arc furnace and a deoxygenating method of molten steel in a refining furnace. The deoxygenating method for molten steel smelting is unique, molten steel is deoxygenated by using composite deoxygenating agent, the mass fraction of the main residual elements in the deoxygenating agent is controlled, the purposes of reducing the size of inclusions in molten steel and improving the shape of the inclusions are realized, the number of the inclusions is reduced, the purity of molten steel is improved and the mechanical property of castings is improved at the same time.

Owner:KOCEL STEEL

Method for preparing titanium alloys based on aluminothermic self-propagating gradient reduction and slag-washing refining

ActiveUS20190241994A1High oxygen contentEasy to operateProcess efficiency improvementPre treatmentTitanium alloy

The invention relates to a method for preparing titanium alloys based on aluminothermic self-propagating gradient reduction and slag-washing refining, and belongs to the technical field of titanium-aluminum alloys. The method comprises the following steps of pre-treating raw materials, weighing the raw materials in the mass ratio of rutile or high-titanium slags or titanium dioxide to aluminum powder to V2O5 powder to CaO to KClO3 being 1.0:(0.60-0.24):(0.042-0.048):(0.12-0.26):(0.22-0.30), performing an aluminothermic self-propagating reaction in a gradient feeding manner to obtain high-temperature melt, performing a gradient reduction melting, performing heat insulation and separating the melt after the feeding is completed, then adding CaF2—CaO—TiO2—V2O5 based refining slags into the high-temperature melt, performing slag washing refining, and finally removing slags to obtain titanium alloys. This method has the advantages including short flow, low energy consumption, easy operation, easy control on Al and V contained in alloys, and so on.

Owner:NORTHEASTERN UNIV

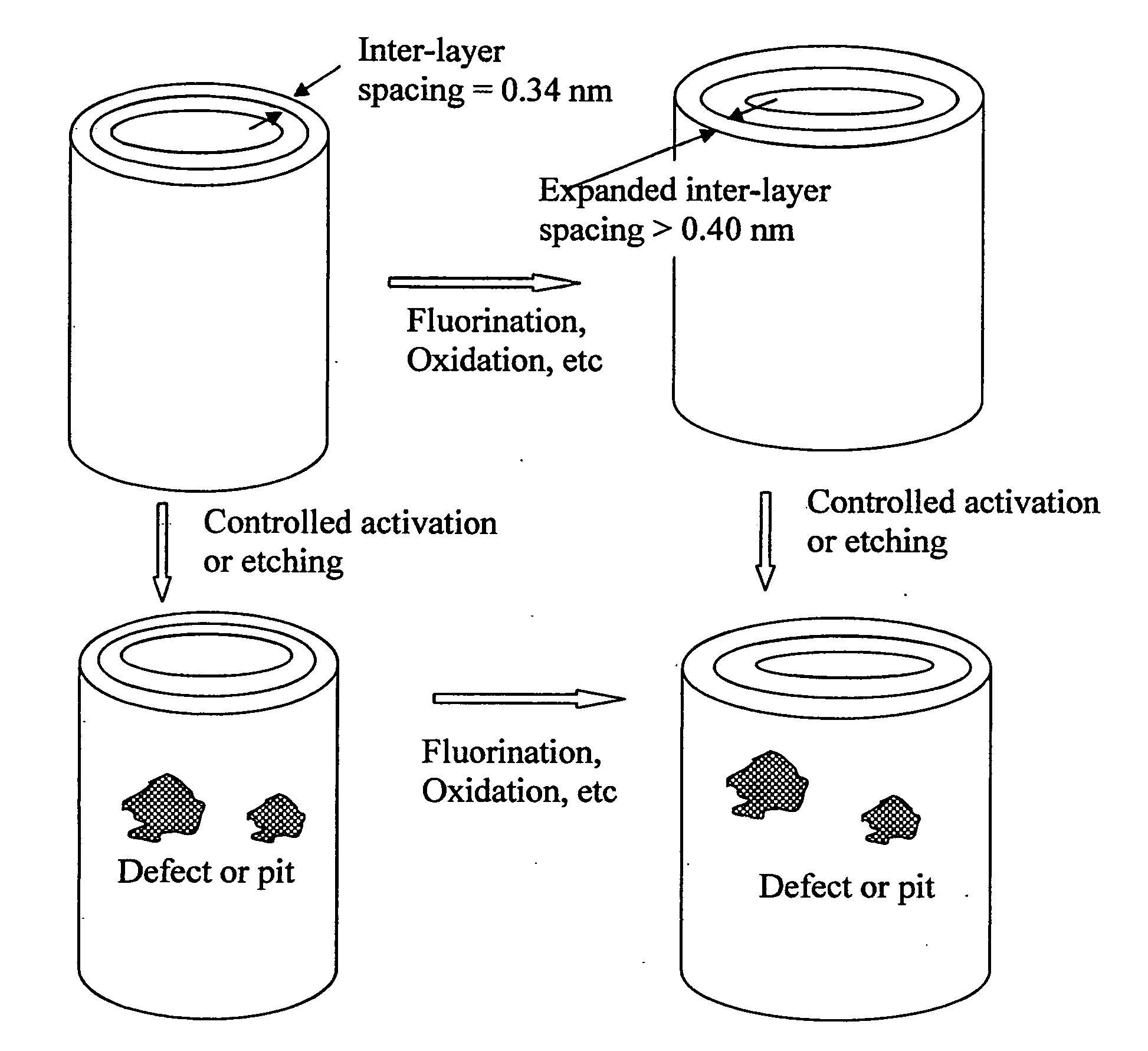

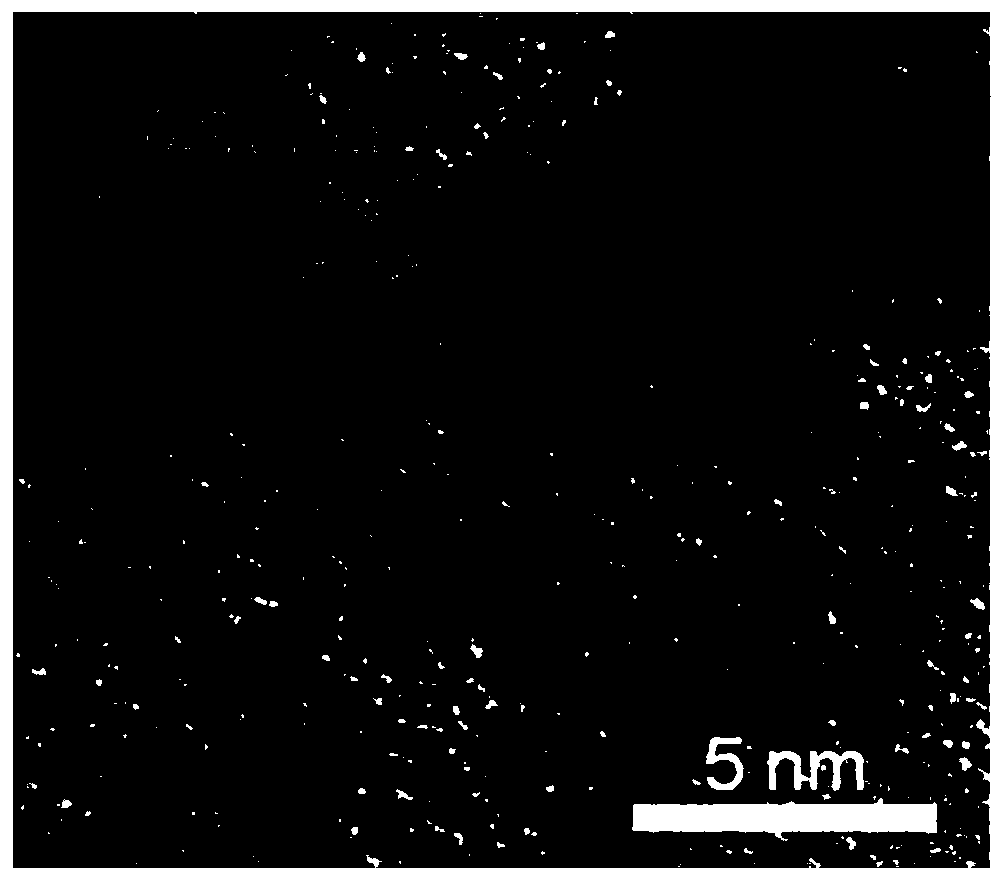

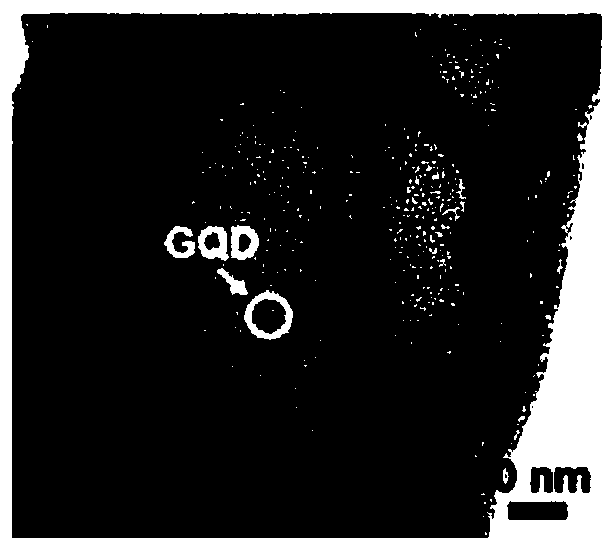

Method for dispersion of multi-walled carbon nanotubes

InactiveCN110629242AGood compatibilitySmall sizeMaterial nanotechnologyElectrolysis componentsElectrolysisOxygen

The invention discloses a method for dispersion of multi-walled carbon nanotubes. The method utilizes a large number of cheap graphene carbon dots to disperse multi-walled carbon nanotubes, the oxygencontent of the graphene carbon dots is adjustable, therefore when the graphene carbon dots are used for dispersing multi-walled carbon nanotubes, the dispersion concentration can be adjusted between0.4mg / mL and 0.8mg / mL. The method selects vitrifiable polyimide, polyacrylonitrile, asphalt and other carbon industrial waste as the anode raw materials, which are subjected to electrolysis by clean electrochemical method for efficient preparation of graphene carbon dots. Moreover, the aforementioned vitrifiable industrial waste is prepared in large scale along with the production of industrial products at present, the price is low, and the preparation cost of the graphene carbon dots is reduced. The graphene carbon dots and the multi-walled carbon nanotubes are carbon in nature, so that the problem of compatibility between a dispersing agent and a dispersed body can be solved by using the hydrophilic graphene carbon dots to disperse the hydrophobic multi-walled carbon nanotubes.

Owner:HANGZHOU GAOXI TECH CO LTD

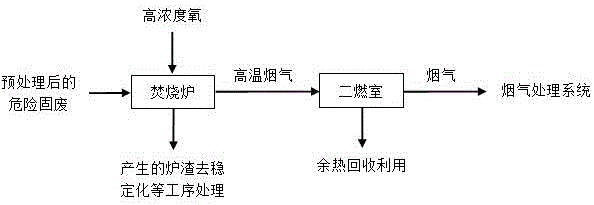

Method for incinerating dangerous solid wastes by utilizing high-concentration oxygen

InactiveCN106402902AHigh oxygen contentBurn fullyIndirect carbon-dioxide mitigationIncinerator apparatusHigh concentrationCombustion chamber

The invention discloses a method for incinerating dangerous solid wastes by utilizing high-concentration oxygen. According to the method, the dangerous solid wastes have full contact with high-concentration oxygen after being pretreated and are then incinerated; high-temperature flue gas generated by incineration is completely combusted in a secondary-combustion chamber; generated furnace slag is subjected to treatment procedures such as destabilization; afterheat generated by incineration is used for preheating the high-concentration oxygen for incineration. The method is an environment-friendly effective dangerous solid waste treatment method which is capable of effectively increasing the incineration temperature, restraining generation of secondary pollutants such as dioxin, greatly reducing emission load of flue gas and fully utilizing the heat generated in an incineration process.

Owner:KUNMING UNIV OF SCI & TECH

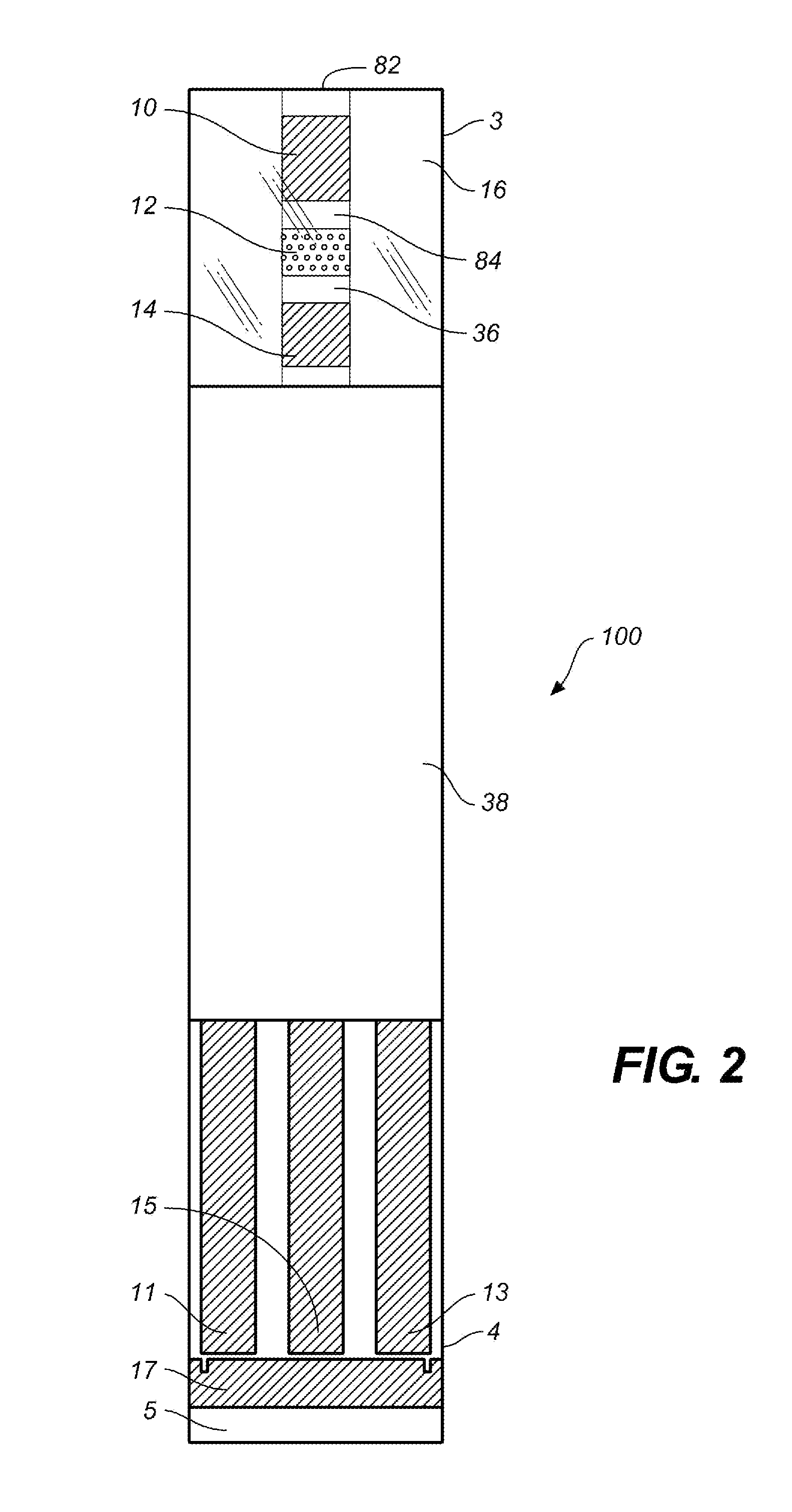

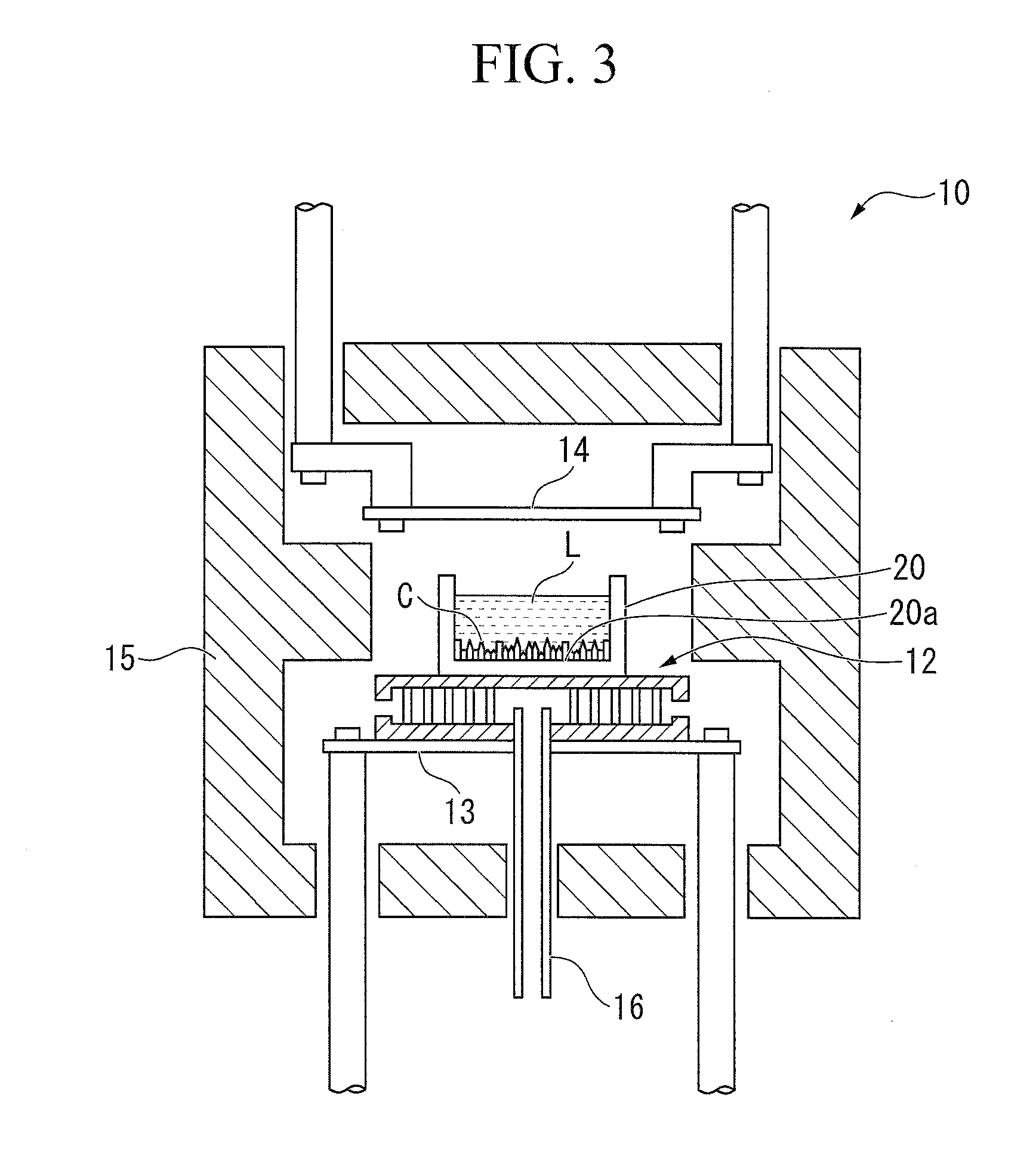

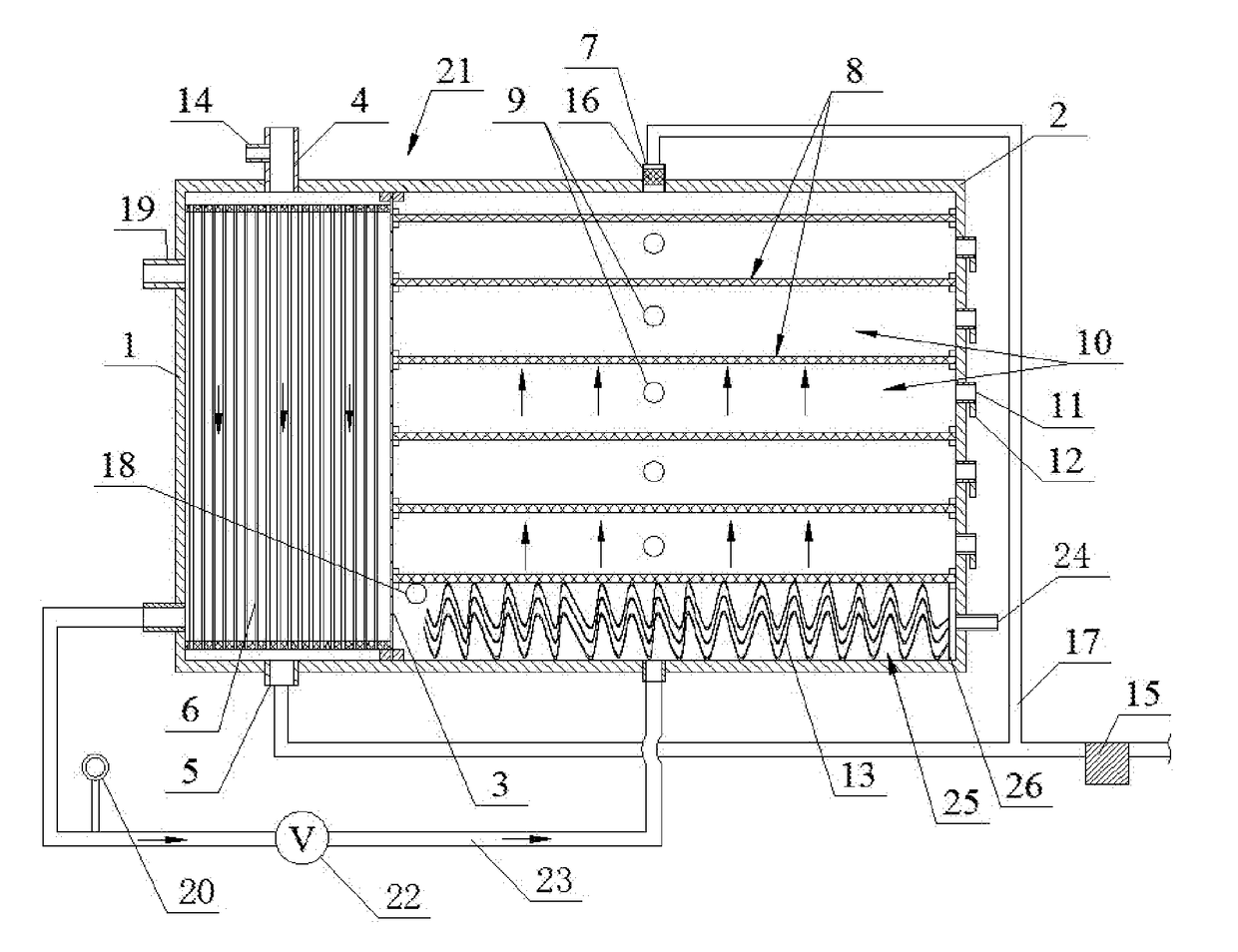

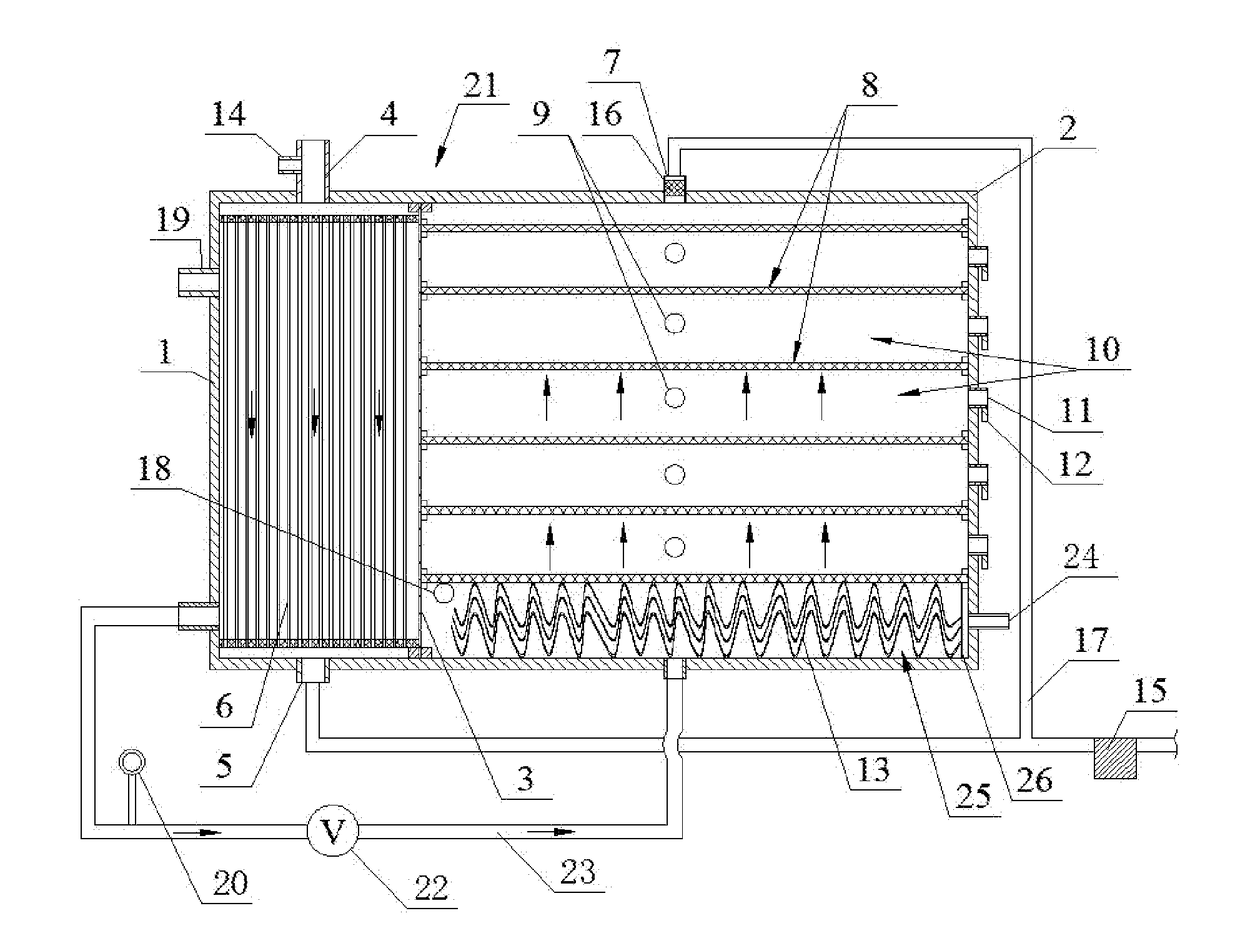

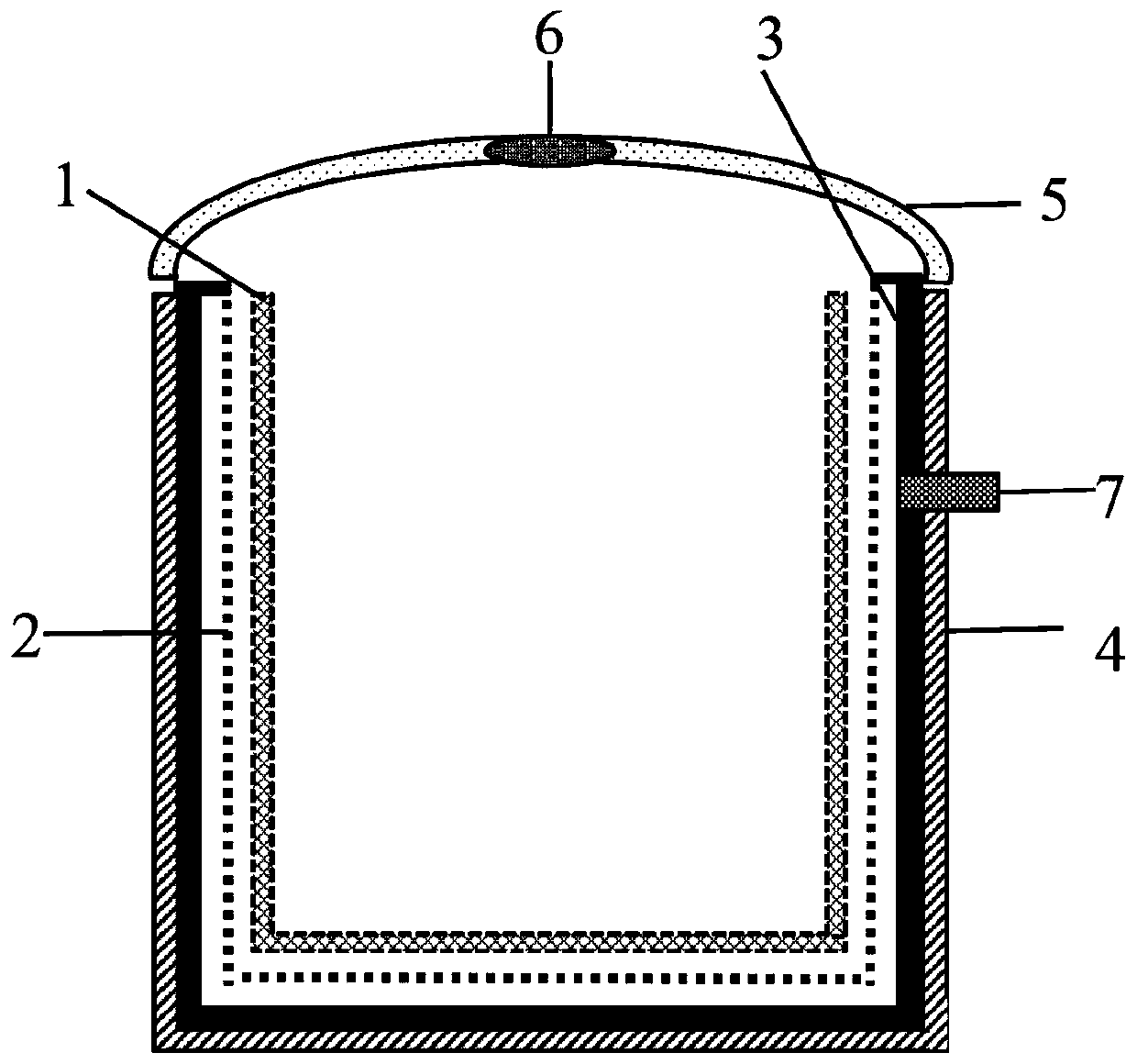

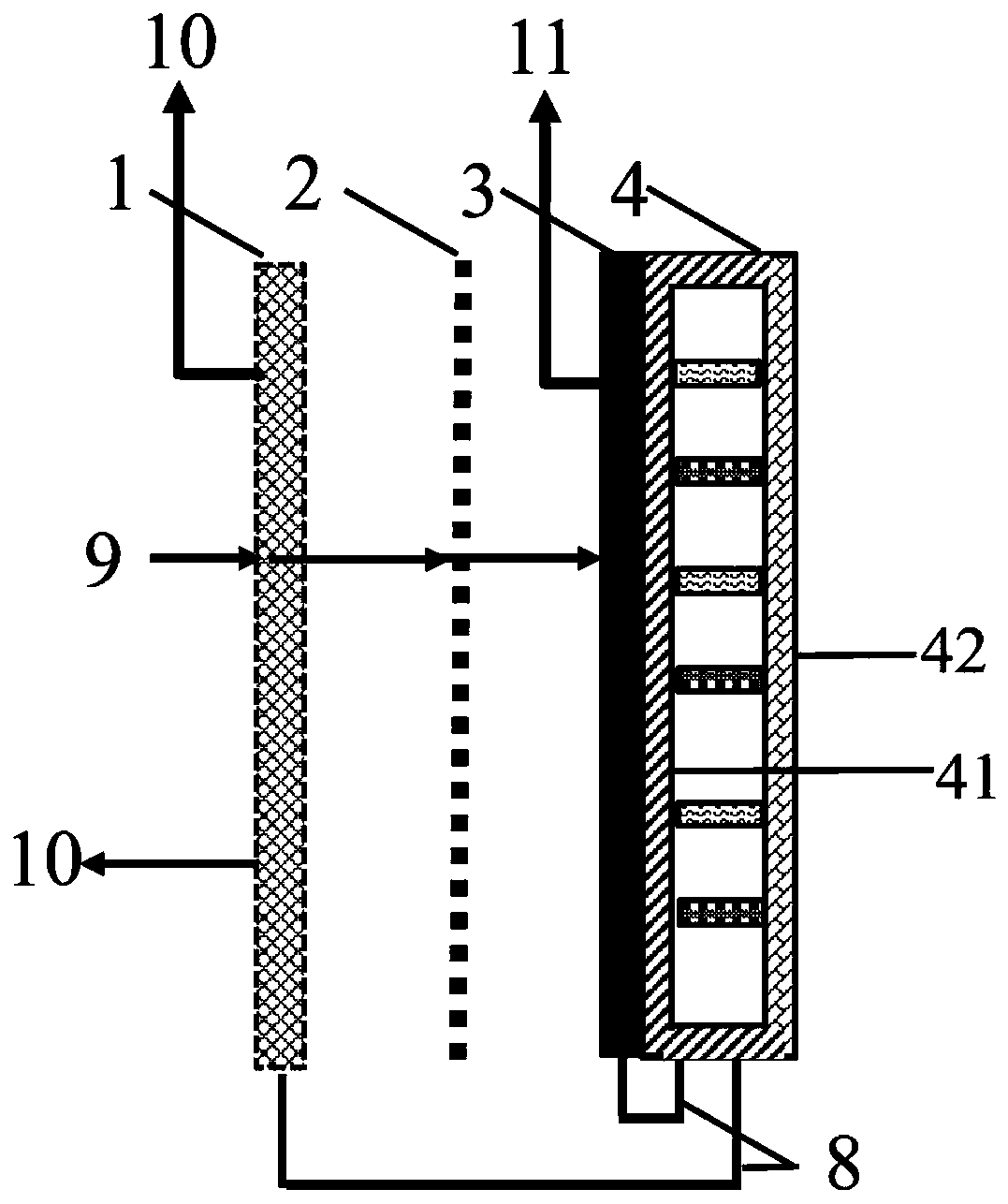

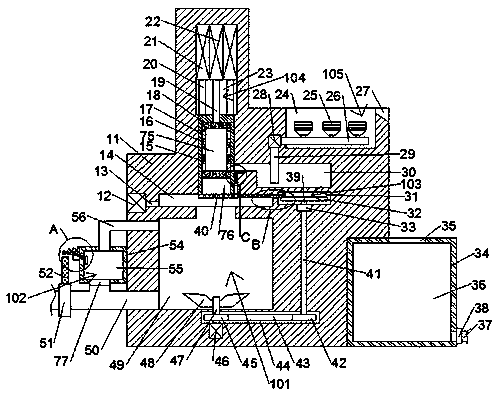

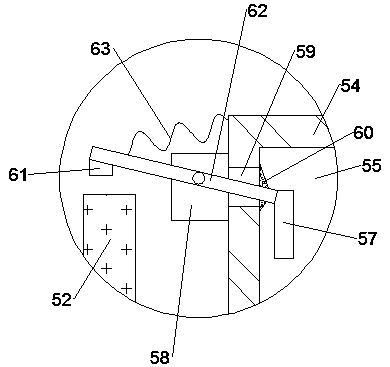

Bioartificial liver device

ActiveUS20180117236A1Good effectUniform and stable flowBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpBioartificial liver device

A bioartificial liver device including a bioreaction chamber having a plurality of semi-permeable membranes and a plurality of filter spaces each confined by two adjacent semi-permeable membranes; a plurality of liver cell perfusion ports each communicating with one of the filter spaces for introducing the liver cells into the filter spaces, and a positive peristaltic pump. In the device, the semi-permeable membranes are disposed substantially horizontal with respect to the ground, and the positive peristaltic pump is adapted to drive the plasma flow from the bottom wall of the device to the top wall. The device of the invention improves the cell loading and the area for substance exchange between the blood and the liver cells.

Owner:WUHAN TOGO MEDITECH CO LTD

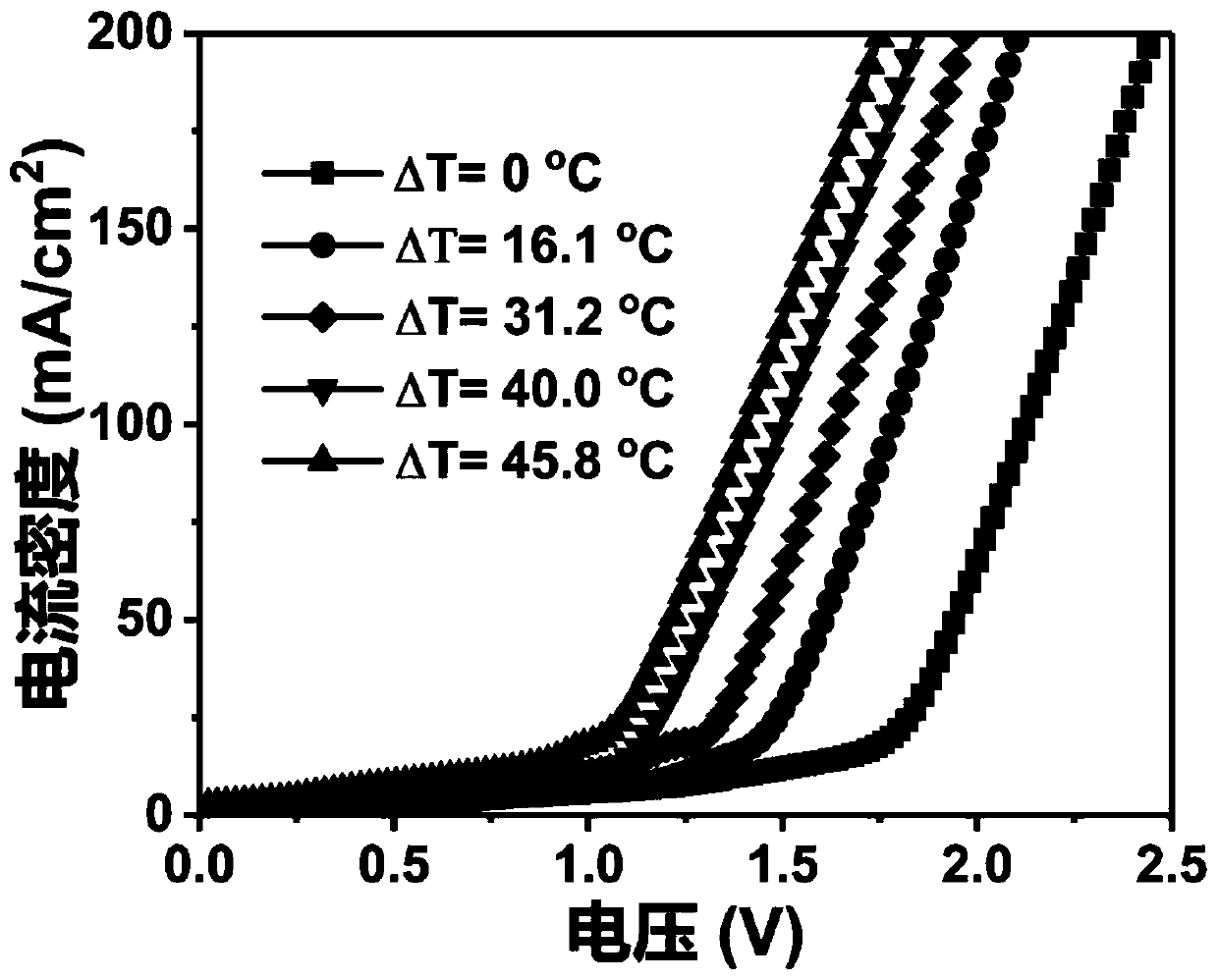

Temperature difference oxygen production cup and application thereof

The invention relates to a temperature difference oxygen production cup and application thereof. The temperature difference oxygen production cup comprises a cup body and a cup cover, and the cup bodyis provided with a temperature difference power generation piece, an anode oxygen evolution electrode and a cathode hydrogen evolution electrode which are connected with the temperature difference power generation piece and a porous diaphragm located between the two electrodes. Temperature difference power generation is achieved through the temperature difference between the interior of the cup and the environment in the hot water cooling process, water in the cup is decomposed into oxygen and hydrogen through electric energy, the oxygen is gathered into the cup and supplied back to the humanbody in a pure oxygen or oxygen-enriched water mode, fatigue is eliminated, oxygen deficit is improved, and the oxygen is used for household oxygen production, oxygen-enriched cups, first aid or outdoor oxygen. Hydrogen is released or collected through the gas outlet for hydrogen treatment. The temperature difference oxygen production cup has the characteristics of energy conservation, simplicity, safety, effectiveness, portability, timely oxygen supply and the like.

Owner:UNIV OF JINAN

Method for culturing whitefish through running water

InactiveCN106172102AGood current conditionsHigh oxygen contentClimate change adaptationPisciculture and aquariaFisherySilt

A method for breeding white fish in running water, which relates to the technical field of fish farming, comprising the following steps: constructing fish ponds, constructing fish ponds in rows and in steps, and building them with cement, and the water surface area of a single fish pond is 10 to 200 square meters The depth of the water is between 1.5 and 2 meters. There are water hole grooves between the adjacent single fish ponds for continuous disinfection. The disinfection kits are wrapped with gauze and bound to the edge of the most upstream single fish pond; white fish Stocking, raising 8 to 12 seedlings per unit square; daily management: replenish water to the most upstream fish ponds every day, and the water in the upstream fish ponds flows downstream continuously to ensure the water flow rate of each fish pond , every 15 to 20 days to clean up the silt at the bottom of the pond to ensure that the thickness of the bottom silt is less than 10cm. The invention has good water flow conditions and high oxygen-enriched content, is convenient for rapid growth of white fish, and has high quality of white fish.

Owner:全椒县管坝民族村综合养殖专业合作社

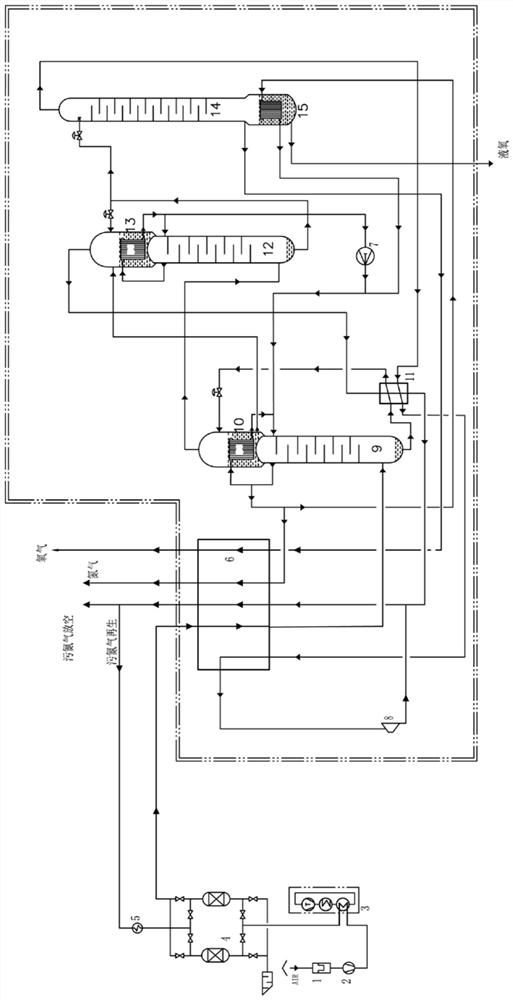

Low-energy-consumption three-tower nitrogen and oxygen preparation process for flue gas circulation of cement kiln

ActiveCN113566494AHigh extraction rateReduce separation workSolidificationLiquefactionPhysicsMolecular sieve

The invention provides a low-energy-consumption three-tower nitrogen and oxygen preparation process for flue gas circulation of a cement kiln. A device required during preparation comprises a filter, a turbine air compressor, an air pre-cooling unit, a molecular sieve adsorber for alternate use, an electric heater, a main heat exchanger, a rectifying tower I, a main condensation evaporator I, a rectifying tower II, a main condensation evaporator II, a rectifying tower III, a main condensation evaporator III, a subcooler, an expansion machine and a liquid nitrogen pump, According to the low-energy-consumption three-tower nitrogen and oxygen preparation process for flue gas circulation of the cement kiln provided by the invention, an air compressor system matched with an original cement kiln is used for providing raw material compressed air, three-tower rectification is adopted, a nitrogen product with pressure and an oxygen product with certain pressure are prepared at the same time, and an oxygen product with certain pressure is used for being mixed with circulating flue gas of the cement kiln rich in carbon dioxide so as to be used as coal feeding air, axial flow air, rotational flow air and the like of the cement kiln, and the nitrogen product with pressure is returned to a user for dust removal of a dust collector.

Owner:HANGZHOU TURNING ENERGY TECH DEV CO LTD

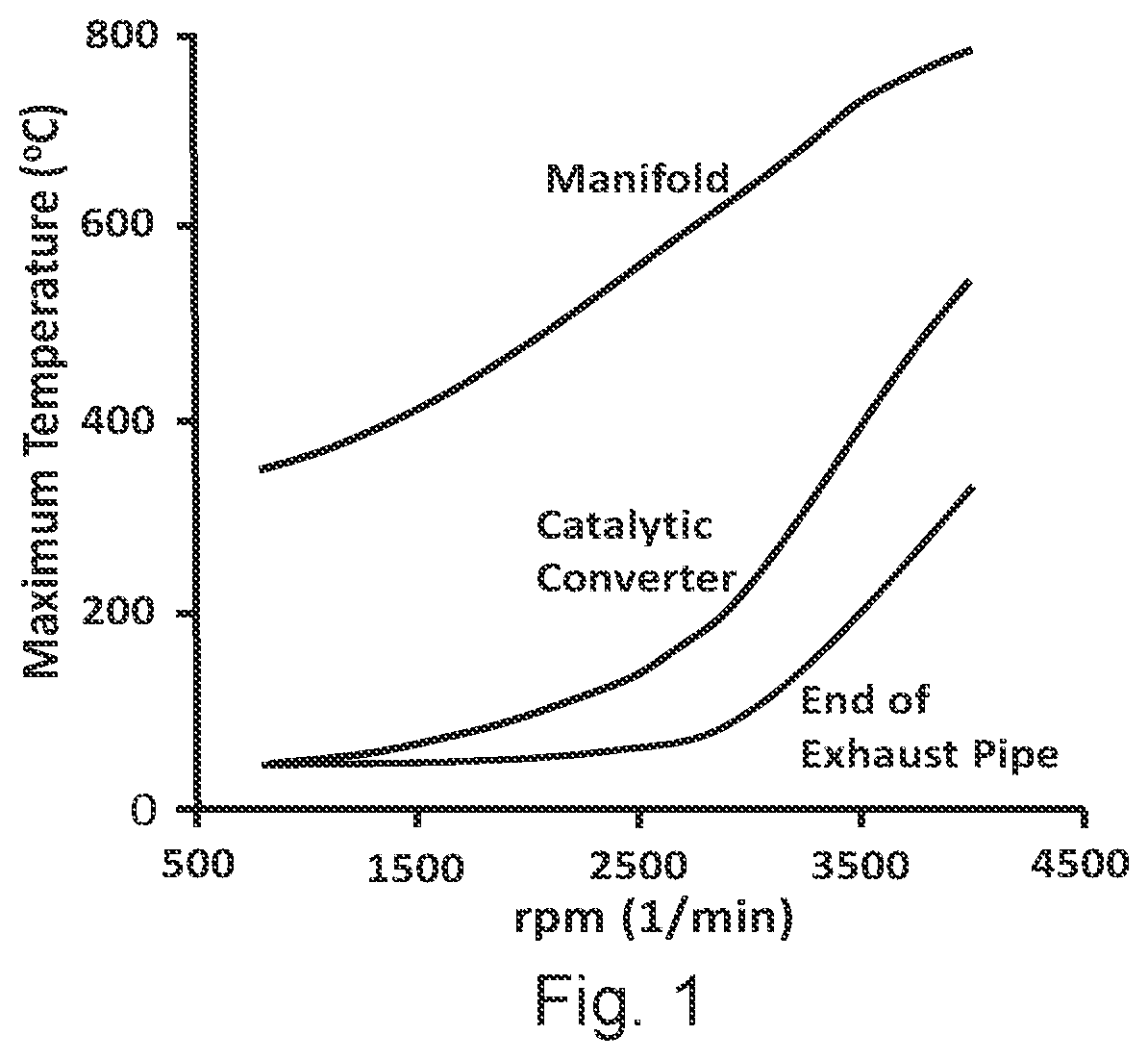

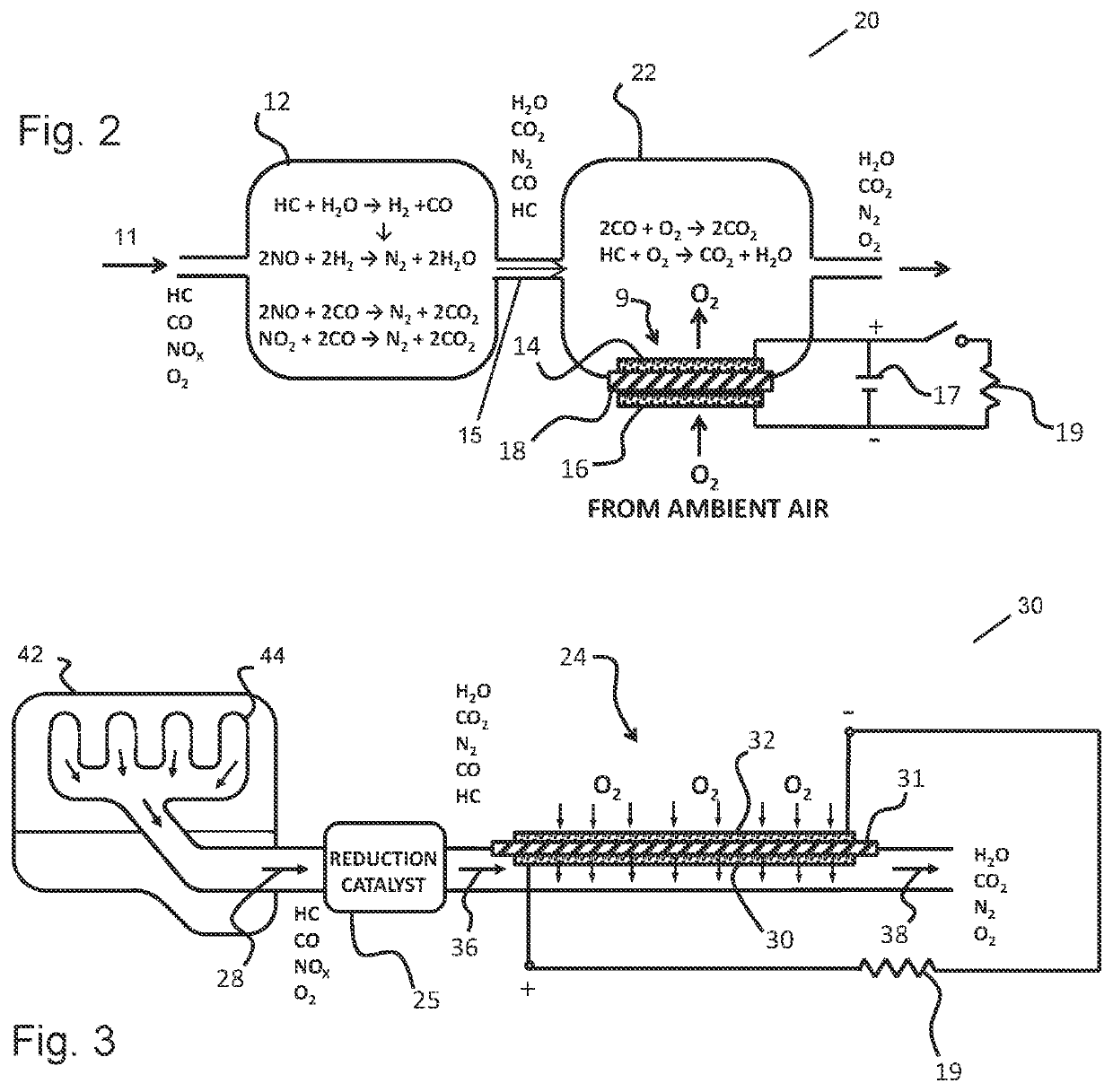

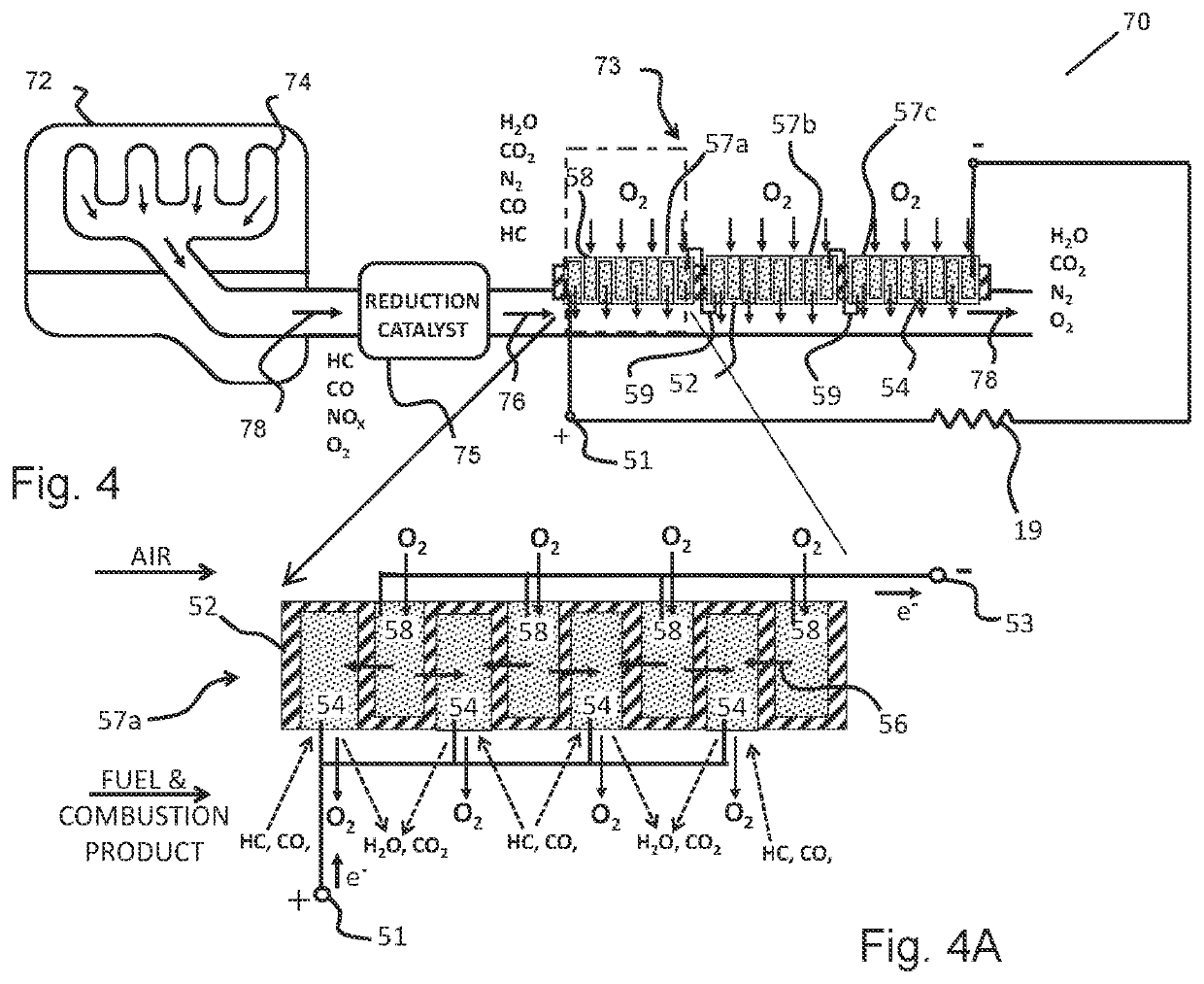

Exhaust gas energy recovery converter

ActiveUS20210310392A1High oxygen contentInternal combustion piston enginesExhaust apparatusPhysicsChemistry

An energy recovery converter for exhaust gases or waste heat is provided. The converter includes a membrane electrode assembly (MEA), an exhaust gas having a first molecular oxygen content, and an external electrical load. The MEA includes a first electrode, a second electrode and an oxygen ion conductive membrane sandwiched between the first and second electrodes. Each of the first and second electrodes includes at least one oxidation catalyst configured to promote an electrochemical reaction. The second electrode of the MEA is exposed to the exhaust gas and the first electrode of the MEA is exposed to a gas having a second molecular oxygen content. The second molecular oxygen content is higher than the first molecular oxygen content. The external electrical load is connected between the first and second electrodes of the MEA.

Owner:JTEC ENERGY INC

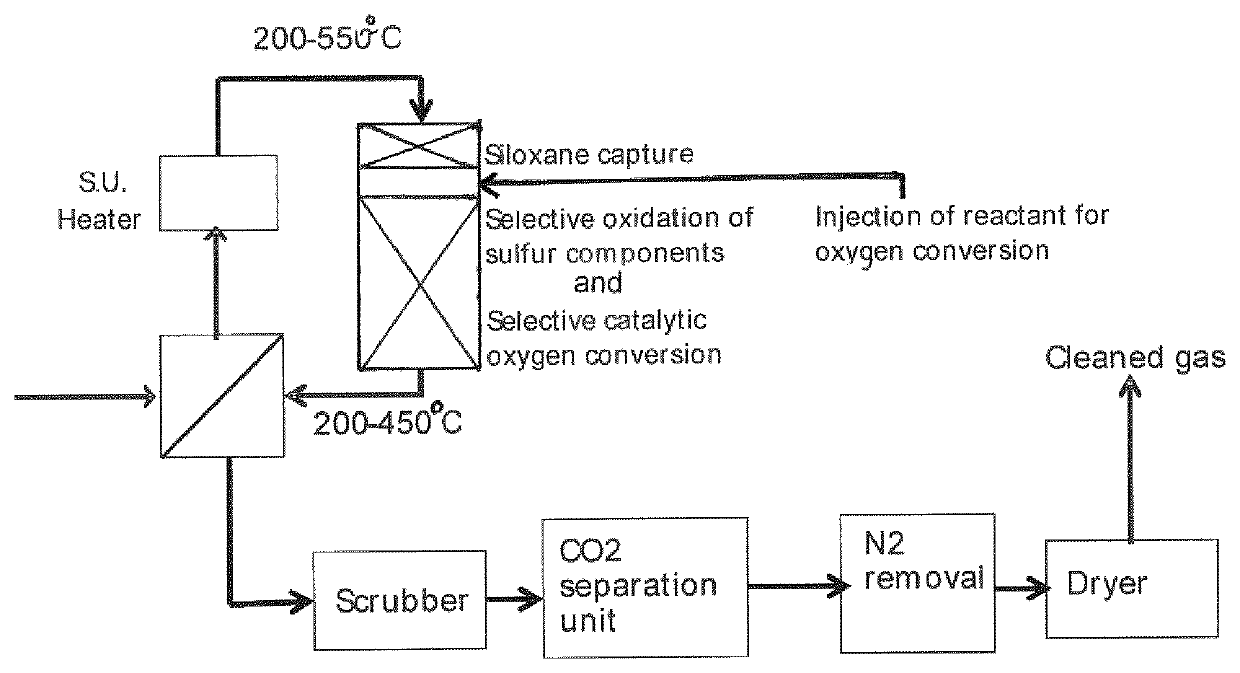

Method for the removal of oxygen from an industrial gas feed

ActiveUS10933372B2High oxygen contentPromote catalysisGas treatmentDispersed particle separationSilanolEnvironmental chemistry

Oxygen is removed from a gas feed such as a landfill gas, a digester gas or an industrial CO2 off-gas by heating the feed gas, optionally removing siloxanes and silanols from the heated feed gas, optionally removing part of the sulfur-containing compounds in the heated feed gas, injecting one or more reactants for oxygen conversion into the heated feed gas, carrying out a selective catalytic conversion of any or all of the volatile organic compounds (VOCs) present in the gas, including sulfur-containing compounds, chlorine-containing compounds and any of the reactants injected, in at least one suitable reactor, and cleaning the resulting oxygen-depleted gas. The reactants to be injected comprise one or more of H2, CO, ammonia, urea, methanol, ethanol and dimethyl ether (DME).

Owner:HALDOR TOPSOE AS

A multi-stage aeration device for sewage treatment

ActiveCN110330097BHigh oxygen contentQuick purificationTreatment using aerobic processesSustainable biological treatmentSewageSewage treatment

Owner:长沙经济技术开发区水质净化工程有限公司

Method for retarding emission of greenhouse gas by combusting fuel oil

InactiveCN102278752BReduce the total massOxygen and nitrogen increaseDomestic stoves or rangesLiquid heating fuelCombustion chamberFuel oil

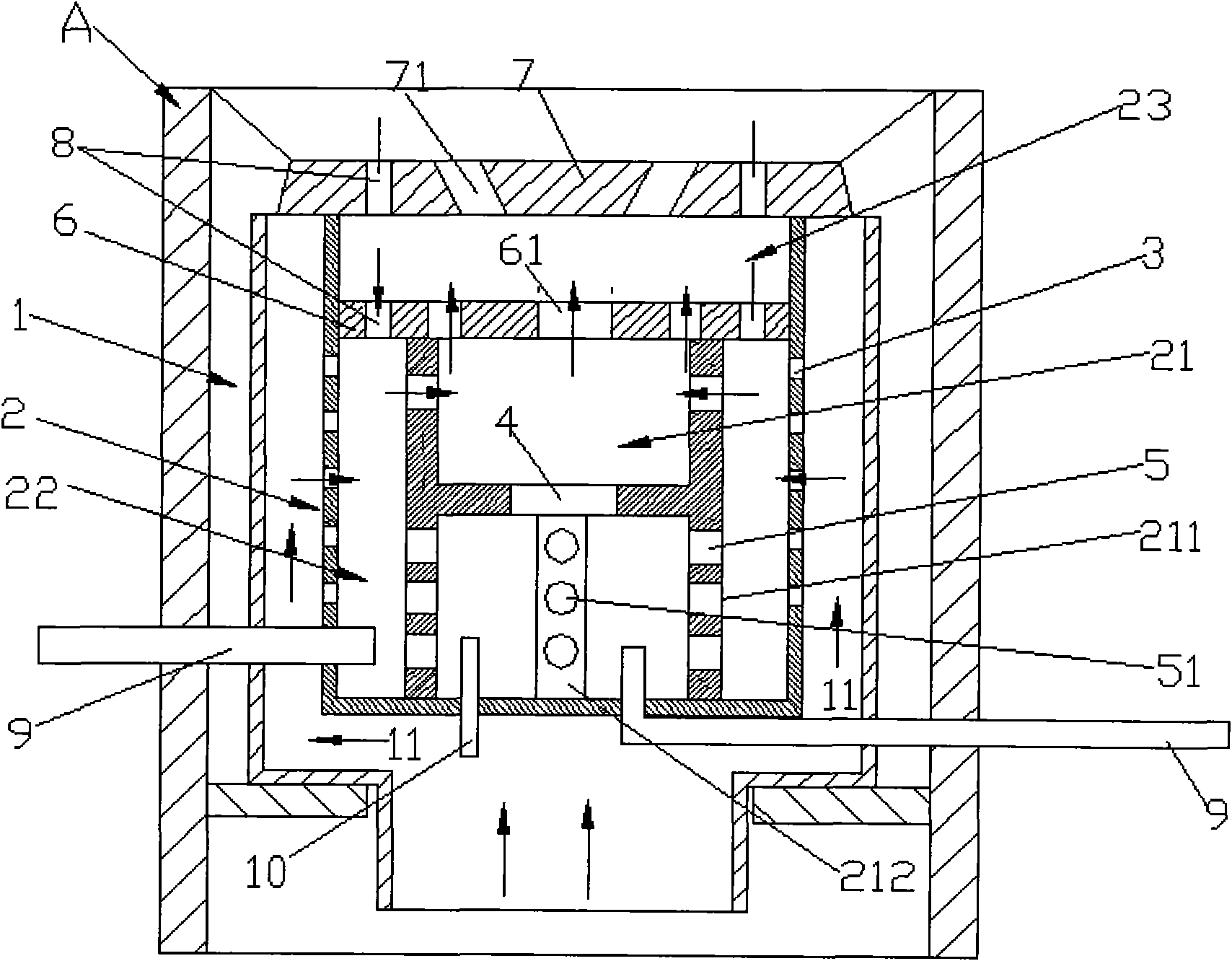

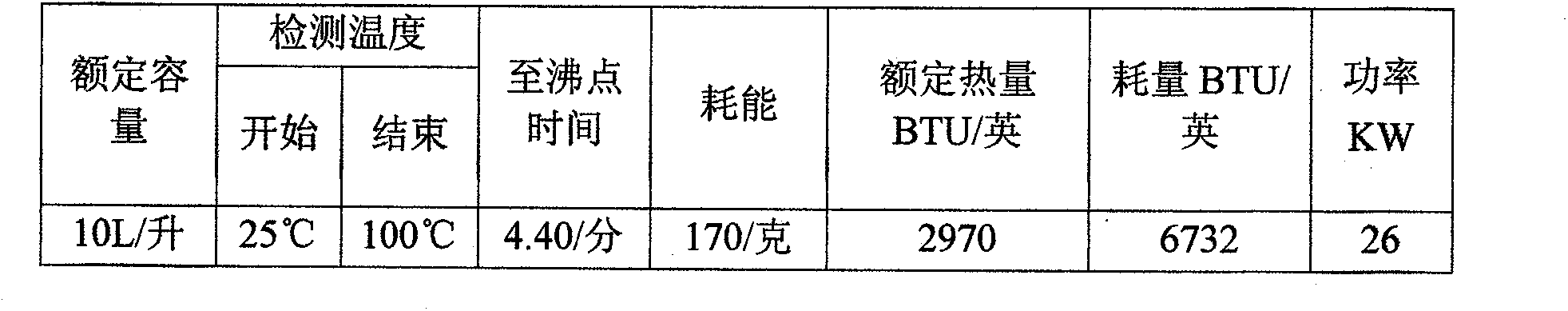

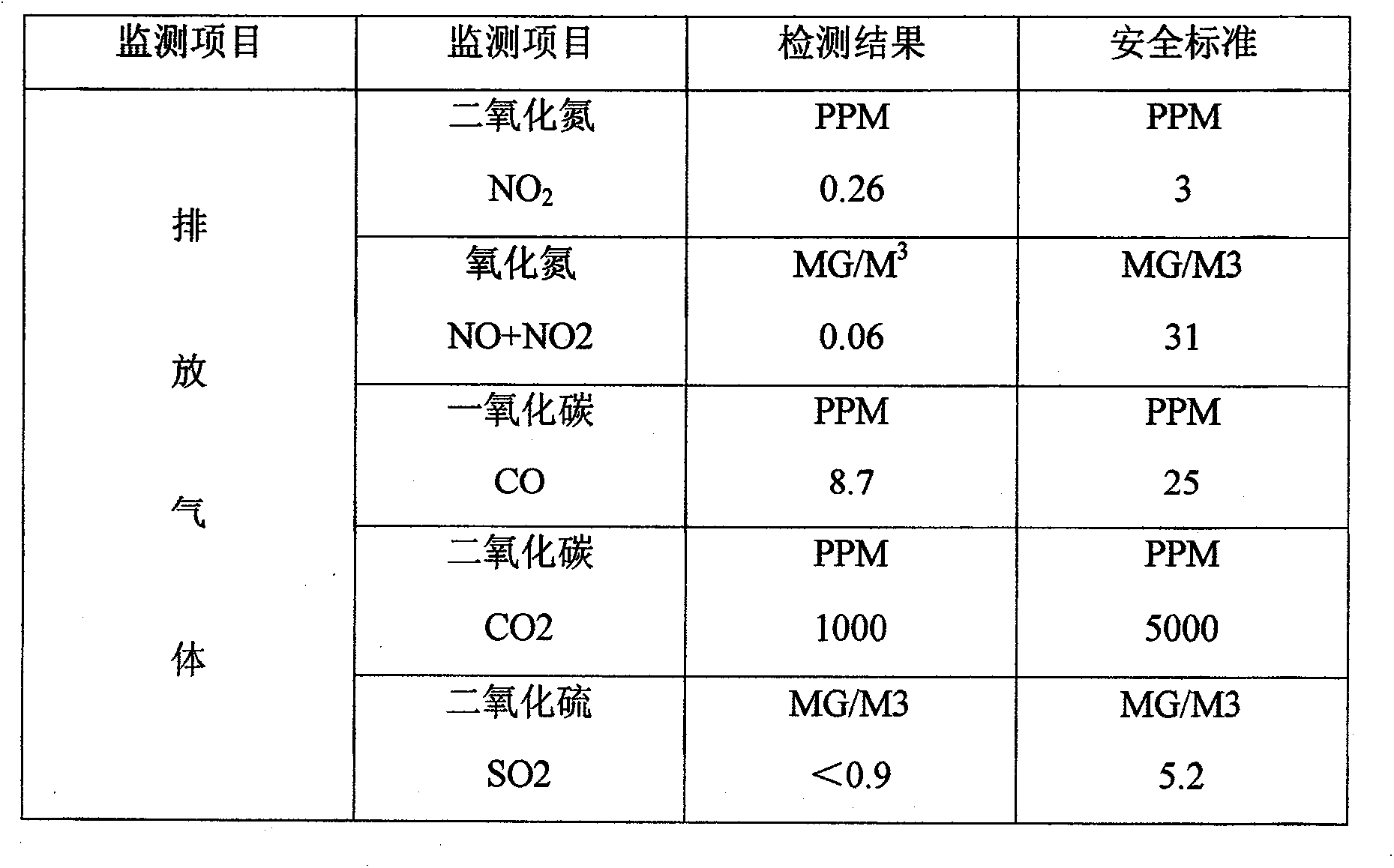

Disclosed is an oil combustion method for reducing greenhouse gas emissions in which an athermal radiation type oil burner is arranged on a stove. The athermal radiation type oil burner includes a furnace body (1) in which a hearth (2) is placed. The hearth (2) composed of a casing with multiple through holes (3) includes a primary oil supply combustion chamber (21), a secondary oil supply combustion chamber (22) and an obstruction chamber (23). The primary oil supply combustion chamber (21) is a casing (211) divided into an upper layer and a lower layer. An interconnected hole (4) is arranged between the two layers. Multiple through holes (5) are distributed on the casing (211) and communicated with the secondary oil supply combustion chamber (22), which is formed by the interval among the casing (211) of the primary oil supply combustion chamber (21), an isolation plats (6) with multiple through holes (61) arranged on the casing (211) and the hearth (2). The obstruction chamber (23) is composed of a sealing plate (7) on the furnace body (1) and the isolation plate (6). Flame holes (71) are arranged on the sealing plate (7). Air flow holes (8) are formed on the corresponding positions of the isolation plate (6) and sealing plate (7), respectively. The secondary oil supply combustion chamber (22) and the obstruction chamber (23) are interconnected with the air flow holes (8). Oil in the burner is continuously spilt, gasified, expanded and compressed for multiple times in the furnace body (1), and oil molecules completely release heat energy and do not release heat radiation again. The burner ensures that generated harmful gas is reduced.

Owner:伍镜清

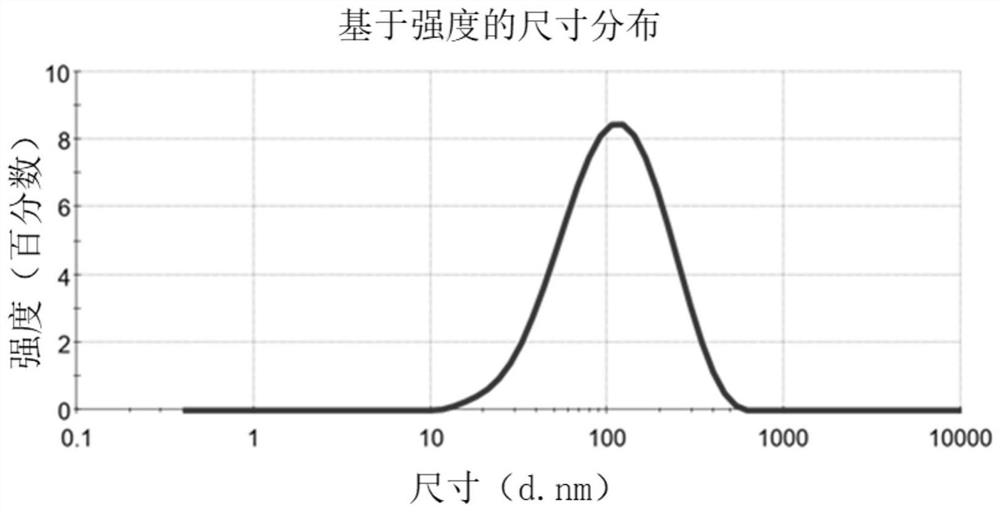

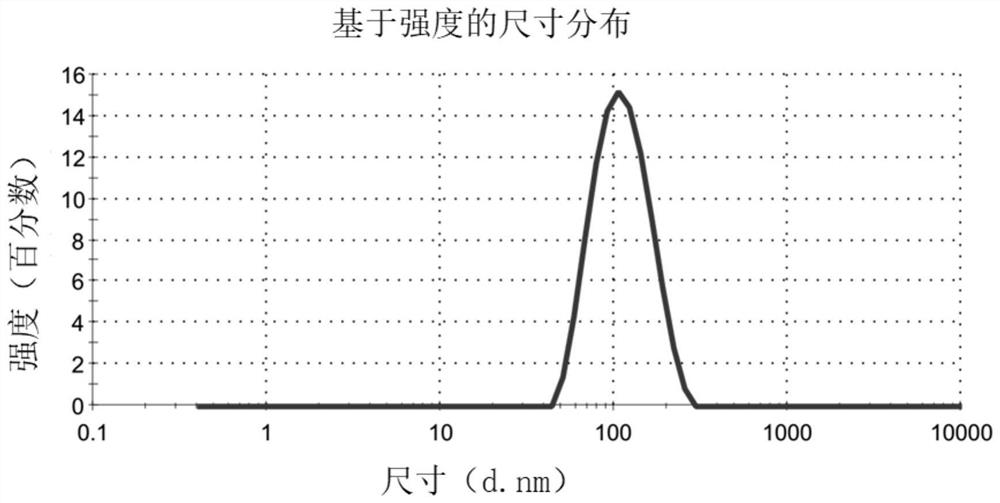

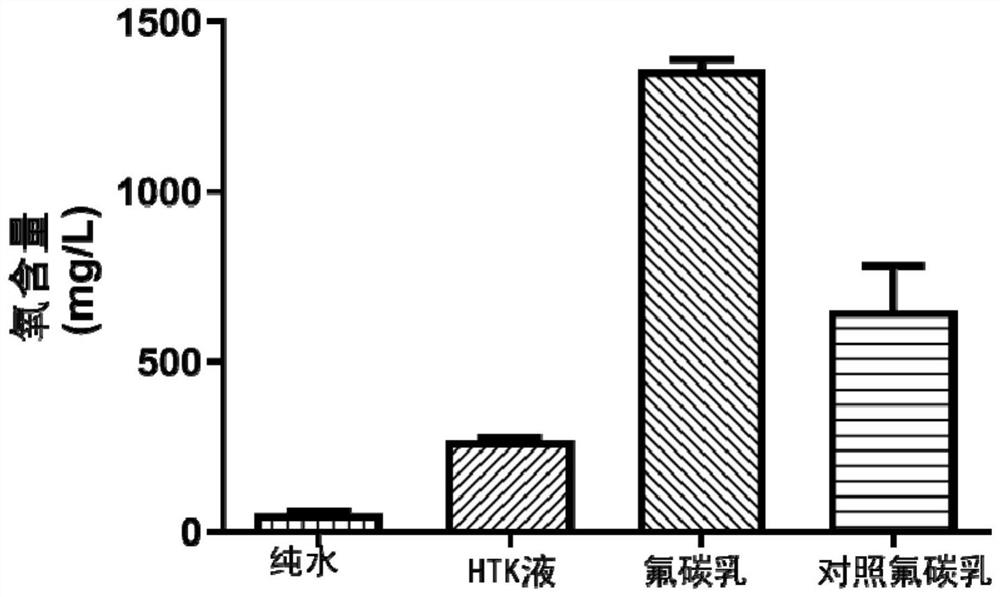

Emulsion type organ preserving fluid and preparation method thereof

The invention discloses an emulsion type organ preserving fluid and a preparation method thereof. The emulsion type organ preserving fluid comprises an oil phase component and a water phase component; the oil phase component comprises a fluorocarbon alkane oxygen carrying agent, an emulsifier and lactic acid; the water phase component comprises an osmotic pressure regulator, a buffer salt, an electrolyte and carbonate; and the volume ratio of the oil phase component to the water phase component is 1: (3-20). The oil phase and the water phase are mixed through a micro-fluidic method or a micro-jet high-pressure homogenization method, and the emulsion type organ preserving fluid which is appropriate in particle size, high in stability and high in oxygen carrying capacity is prepared. The emulsion type organ preserving liquid can prolong the organ preservation time and improve the organ preservation quality.

Owner:公卫复医(上海)生物科技有限公司

Composition for forming resist underlayer film and method for forming resist pattern using the same

ActiveCN101946210BHigh oxygen contentHigh transparencySemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusResistOrganic solvent

It is an object to provide a resist underlayer film forming composition having a large selection ratio of a dry etching rate, and having a k value and an n value at a short wavelength such as an ArF excimer laser, both of which exhibit desired values. There is provided a resist underlayer film forming composition containing a polymer obtained by reacting at least a tetracarboxylic dianhydride having an alicyclic structure or an aliphatic structure and a diepoxy compound having two epoxy groups with an organic solvent containing an alcohol-based compound having an OH group, and a solvent.

Owner:NISSAN CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com