Patents

Literature

46results about How to "Low oxygen content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

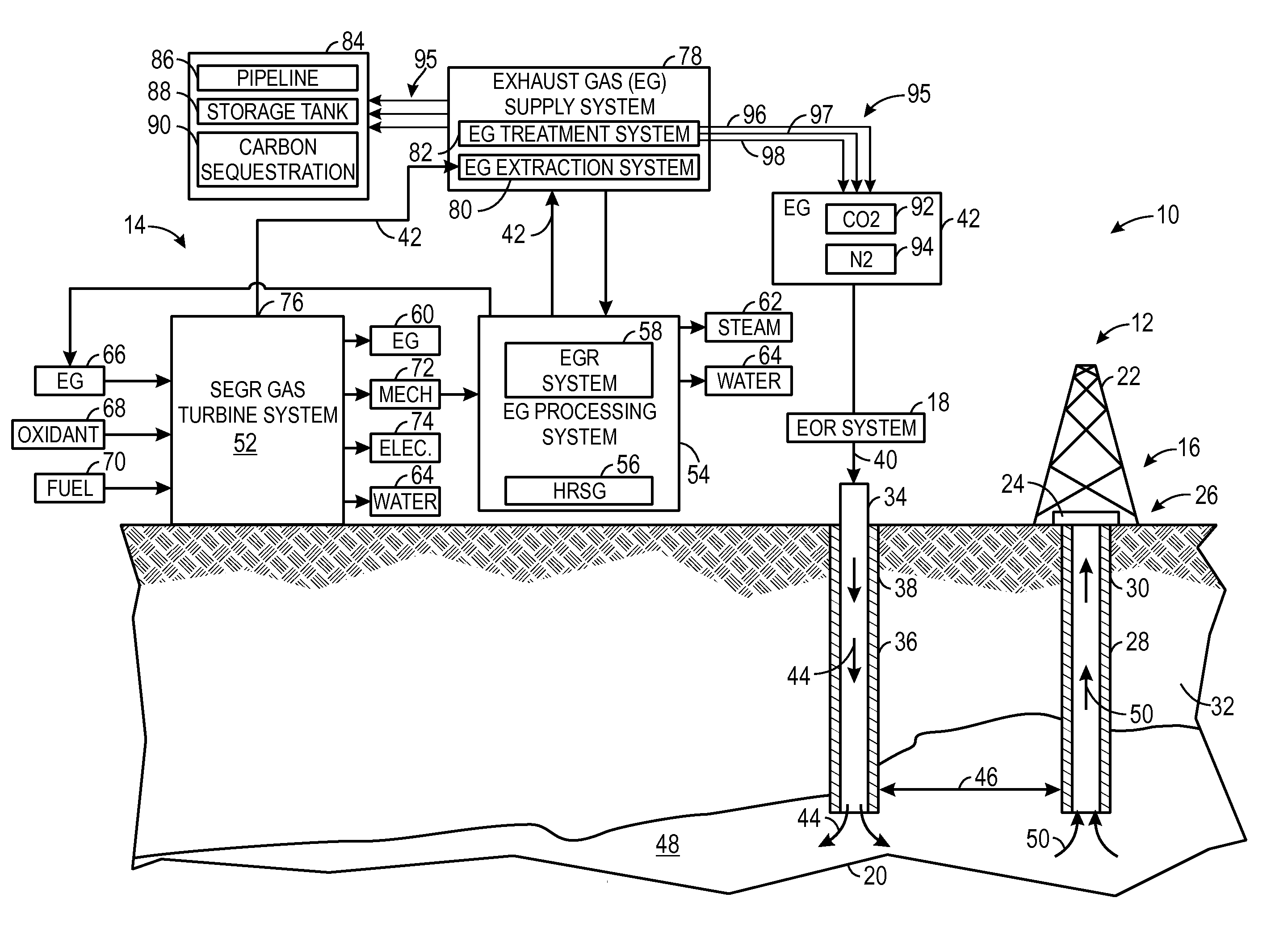

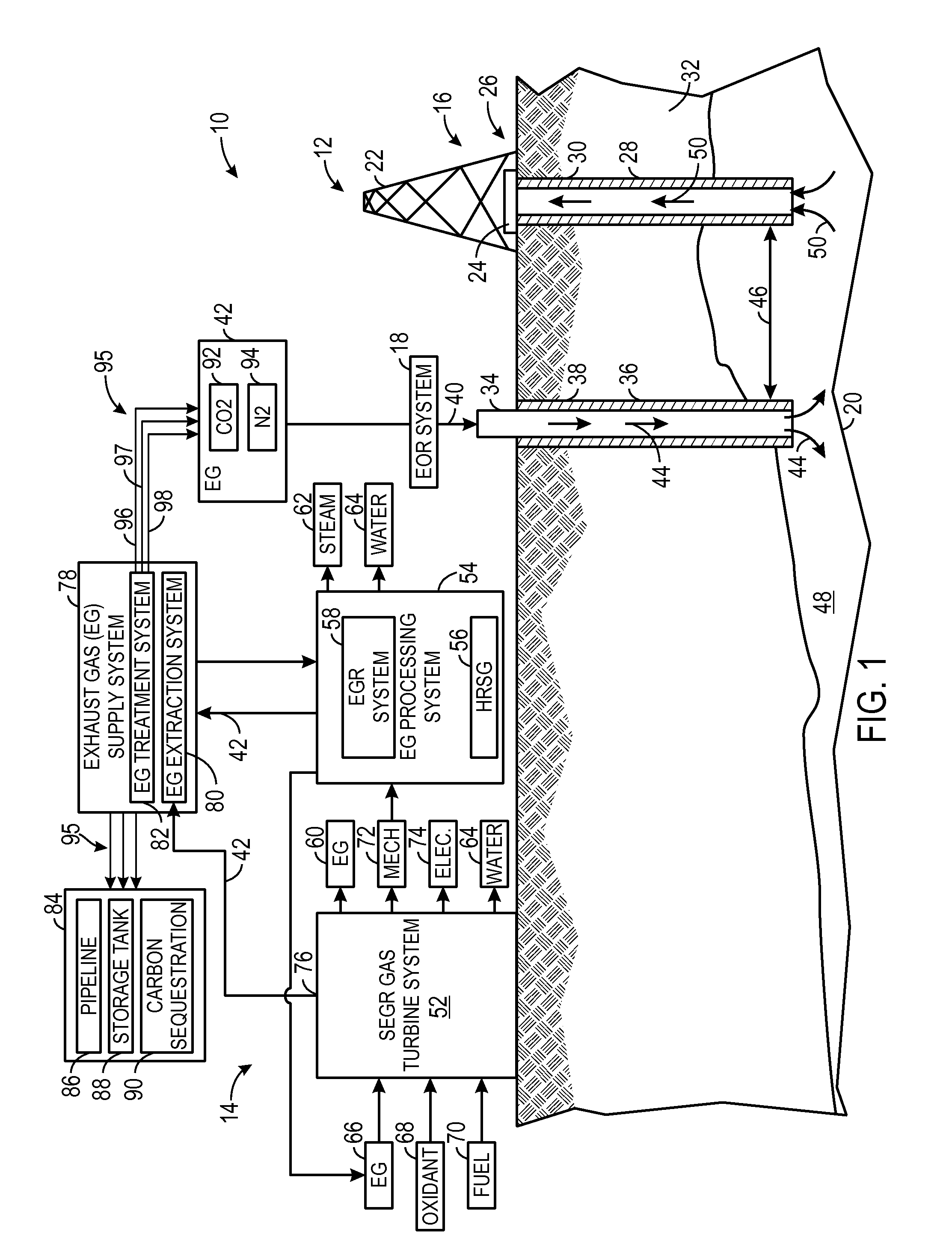

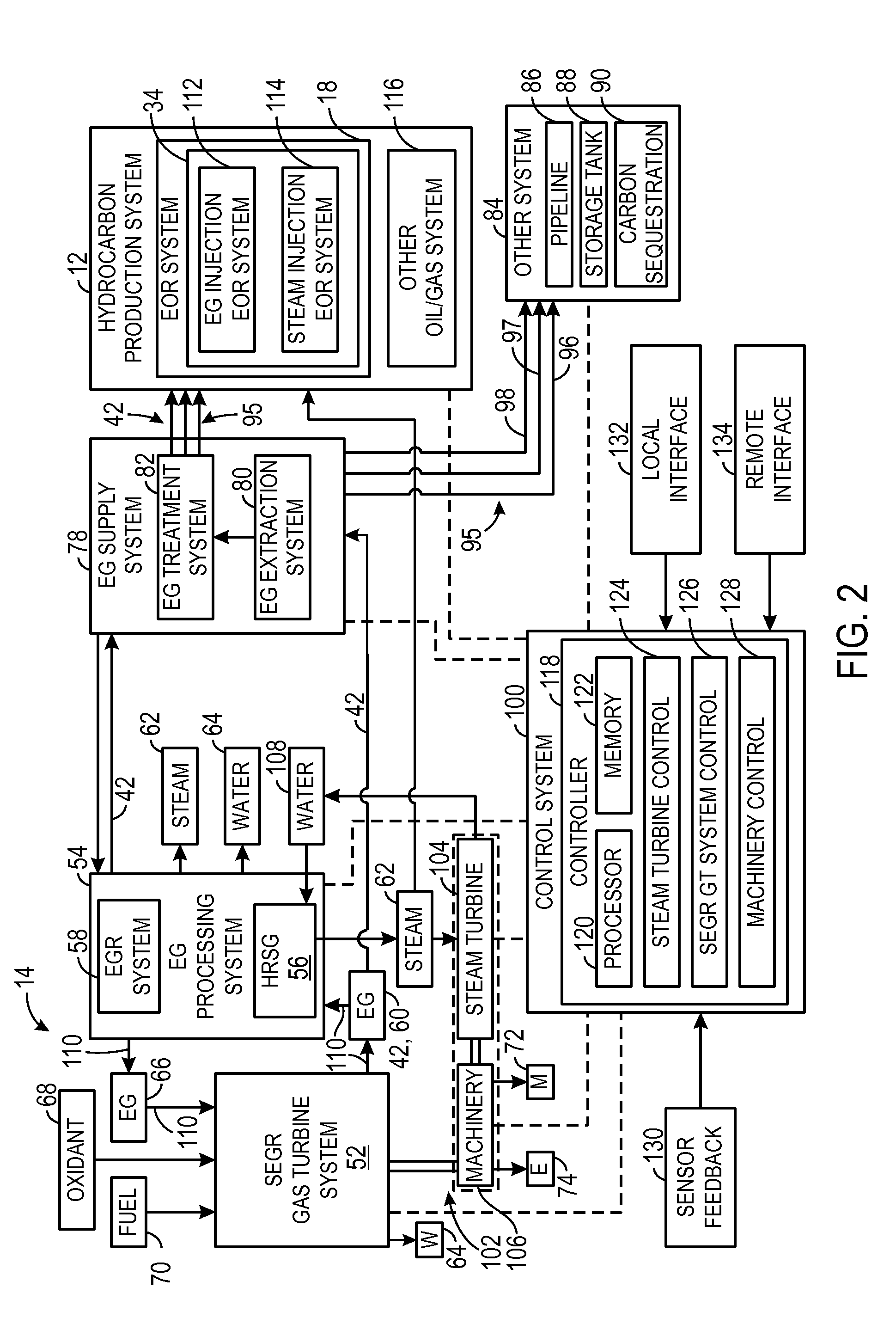

System and method for diffusion combustion with fuel-diluent mixing in a stoichiometric exhaust gas recirculation gas turbine system

ActiveUS20140123668A1High pressureLow oxygen contentTurbine/propulsion fuel supply systemsGaseous fuel feeder/distributionExhaust fumesGas turbines

A system is provided with a turbine combustor having a first diffusion fuel nozzle, wherein the first diffusion fuel nozzle has first and second passages that separately inject respective first and second flows into a chamber of the turbine combustor to produce a diffusion flame. The first flow includes a first fuel and a first diluent, and the second flow includes a first oxidant. The system includes a turbine driven by combustion products from the diffusion flame in the turbine combustor. The system also includes an exhaust gas compressor, wherein the exhaust gas compressor is configured to compress and route an exhaust gas from the turbine to the turbine combustor along an exhaust recirculation path.

Owner:GENERAL ELECTRIC CO +1

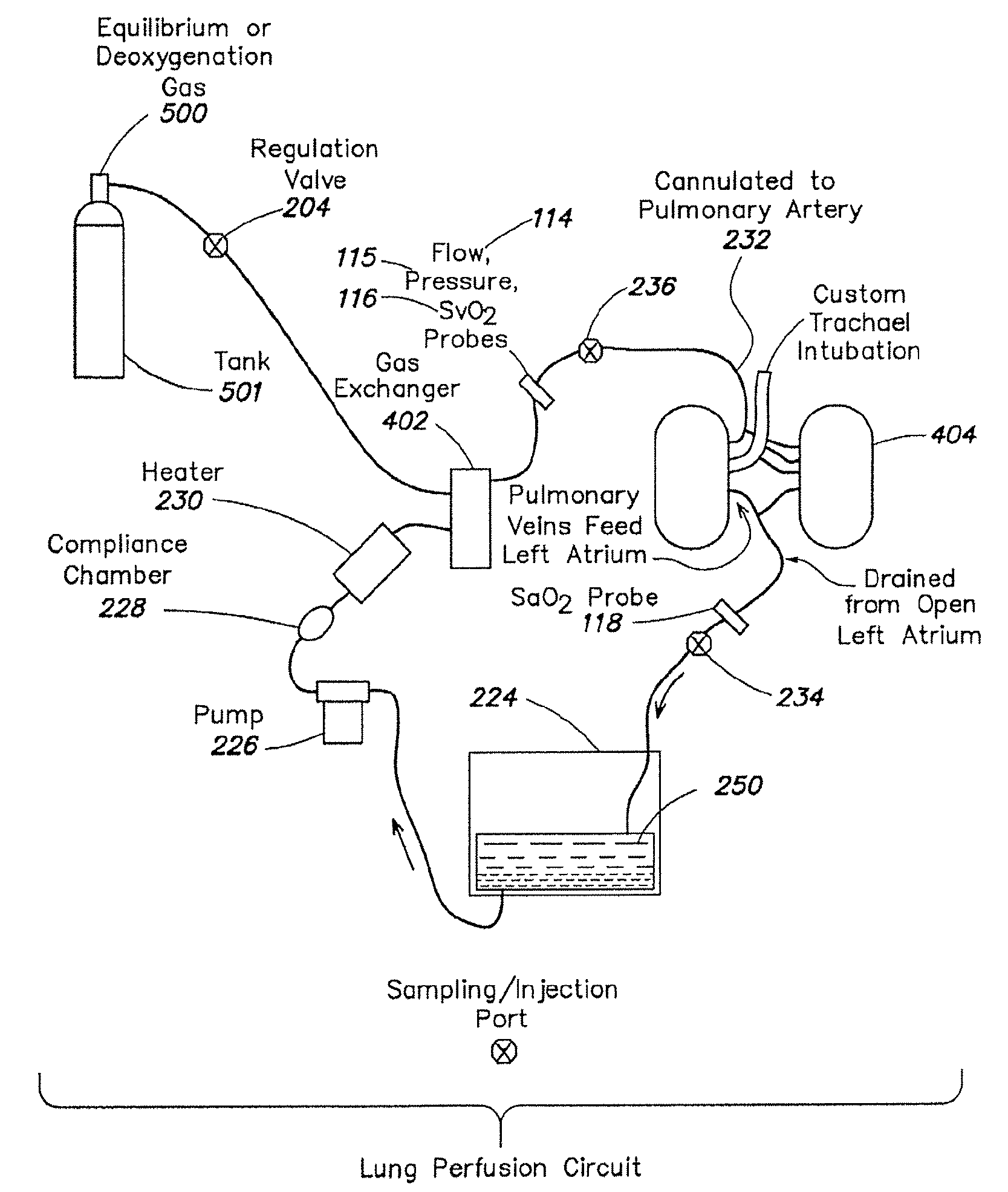

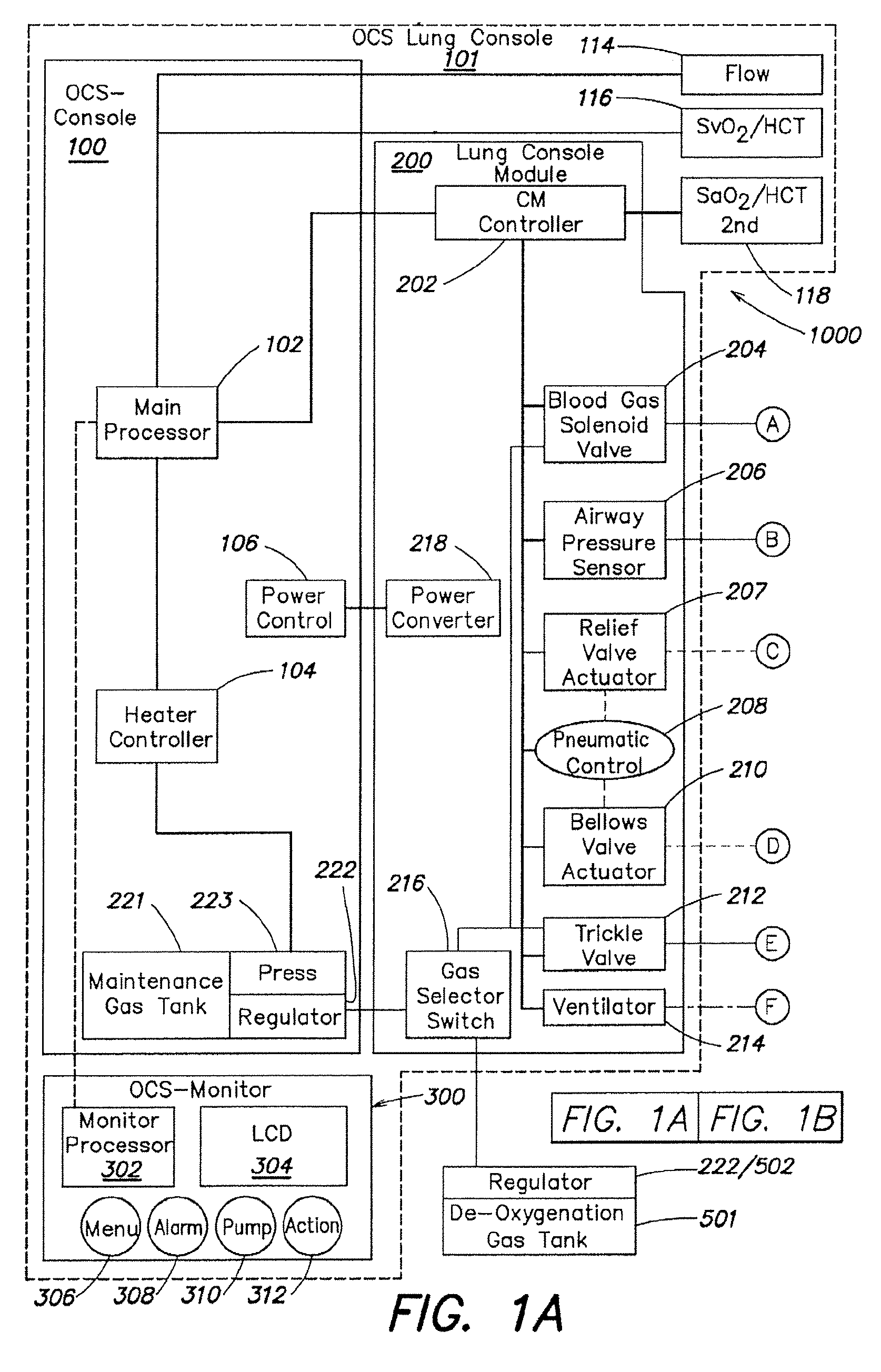

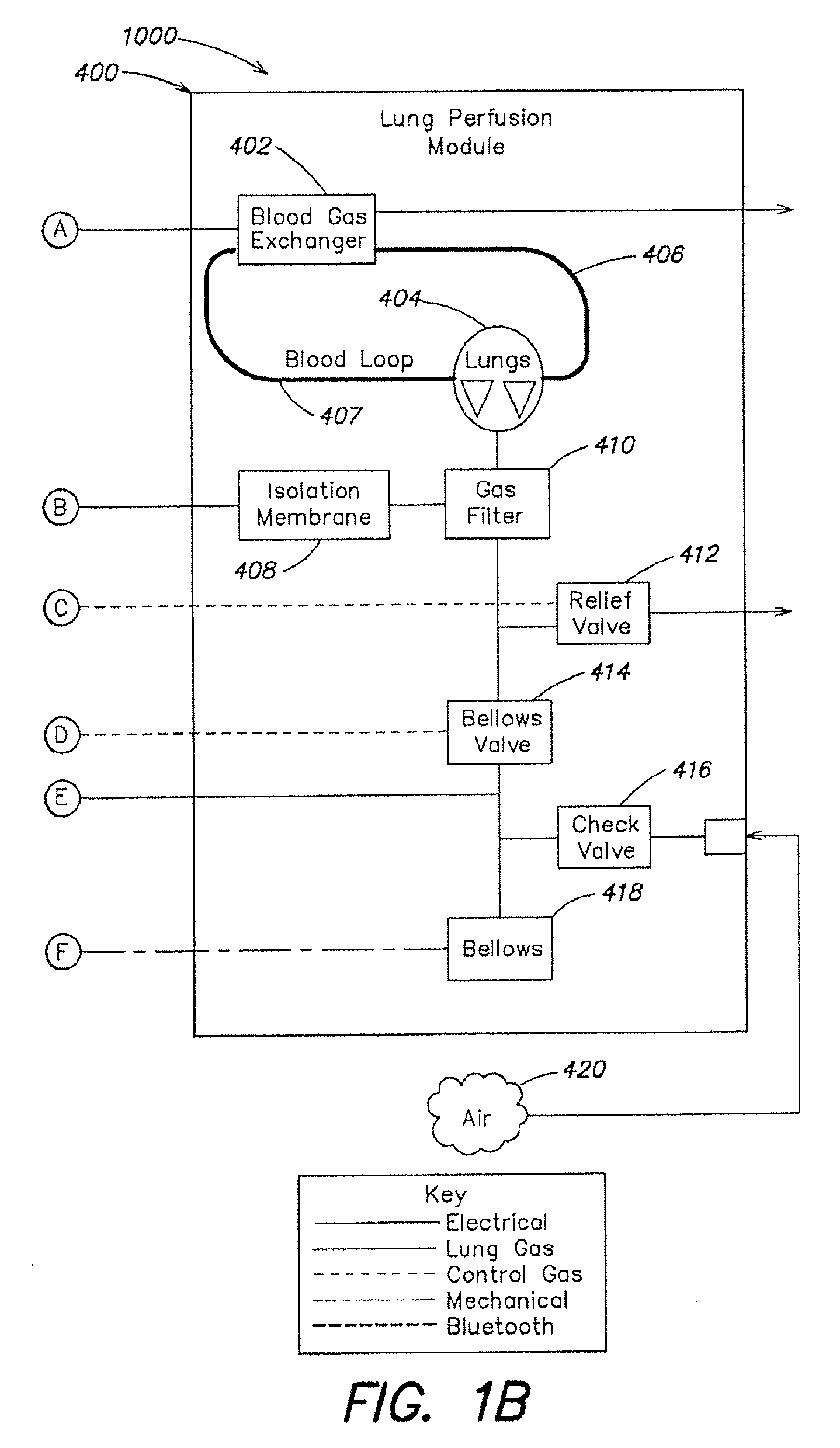

Systems and methods for ex vivo lung care

ActiveUS20090197292A1Low oxygen contentHigh oxygen contentBioreactor/fermenter combinationsBiological substance pretreatmentsPerfusion fluidPulmonary artery

Methods and systems of maintaining, evaluating, and providing therapy to a lung ex vivo. The methods and systems involve positioning the lung in an ex vivo perfusion circuit; circulating a perfusion fluid through the lung, the fluid entering the lung through a pulmonary artery interface and leaving the lung through a left atrial interface; and ventilating the lung by flowing a ventilation gas through a tracheal interface. Maintaining the lung for extended periods involves causing the lung to rebreath a captive volume of air, and reaching an equilibrium state between the perfusion fluid and the ventilation gas. Evaluating the gas exchange capability of the lung involves deoxygenating the perfusion fluid and measuring a time taken to reoxygenate the perfusion fluid by ventilating the lung with an oxygenation gas.

Owner:TRANSMEDICS

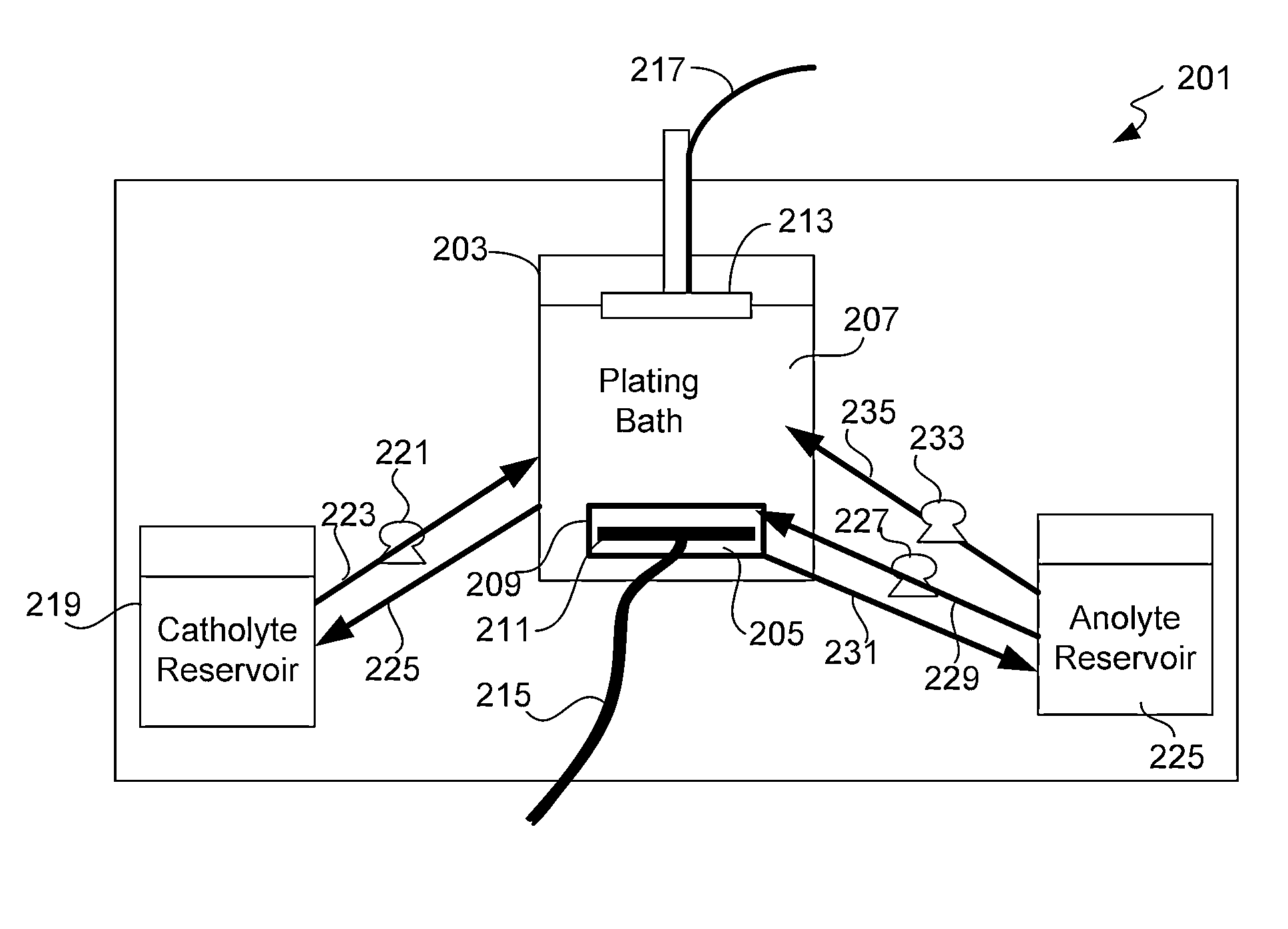

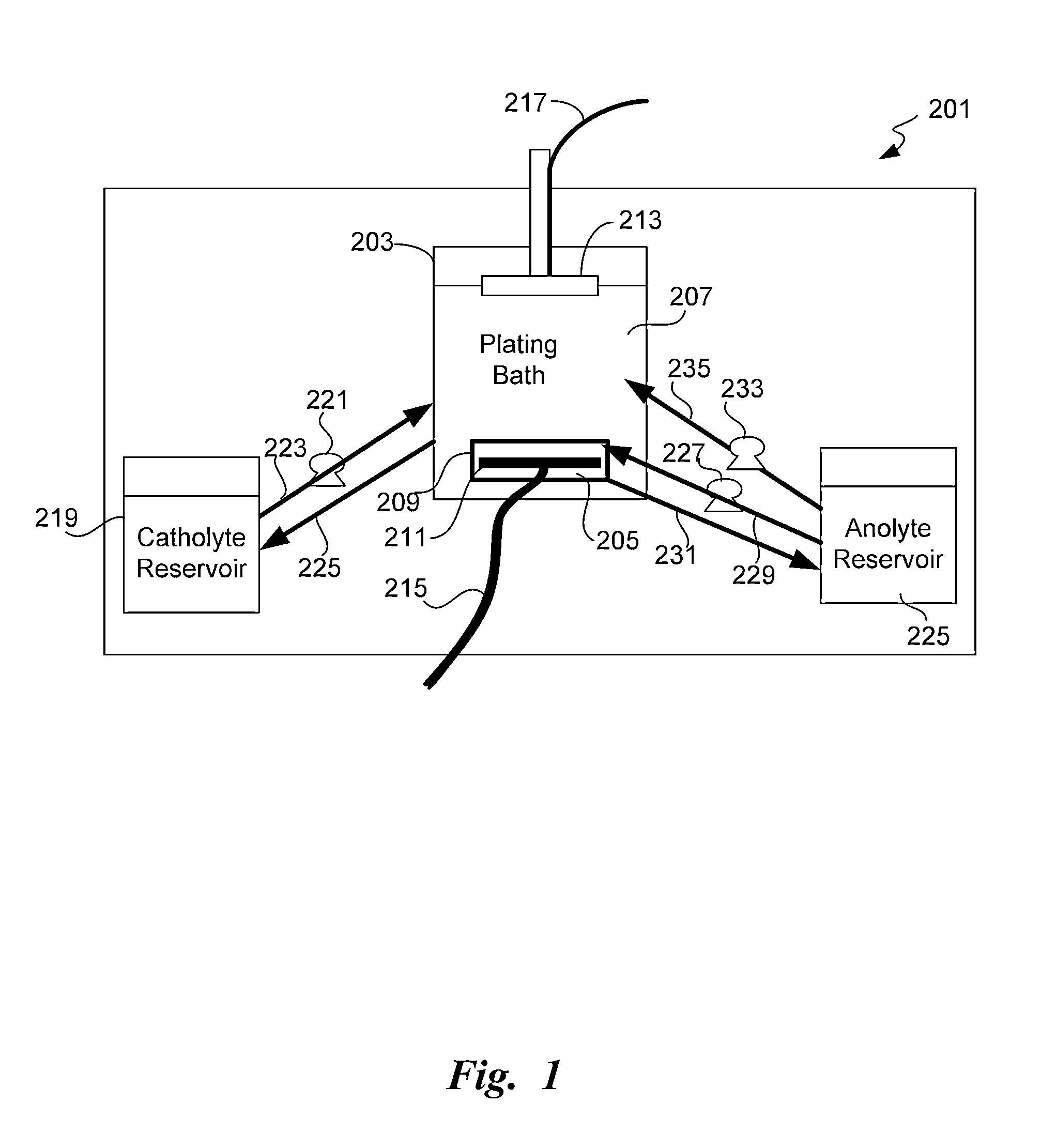

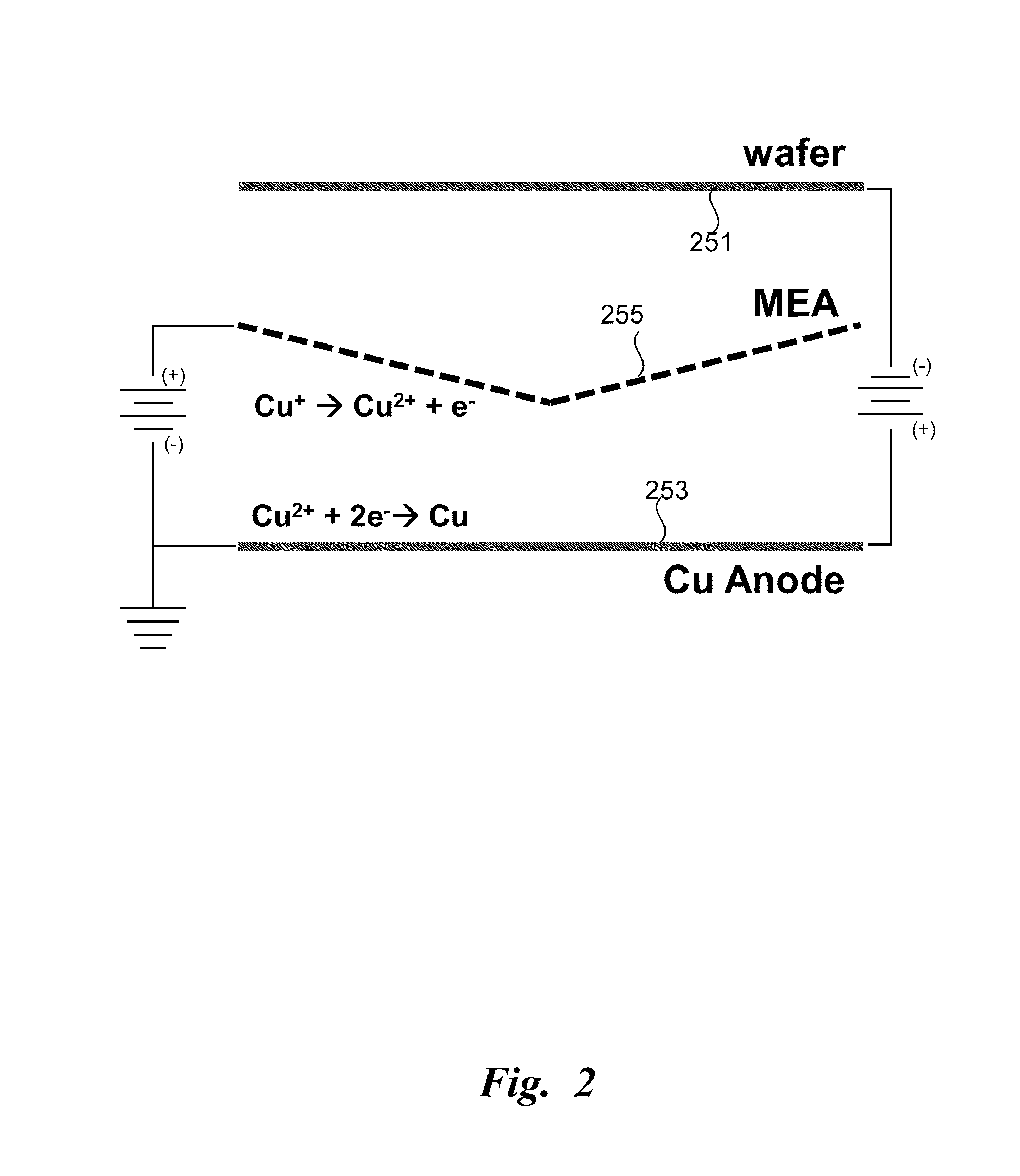

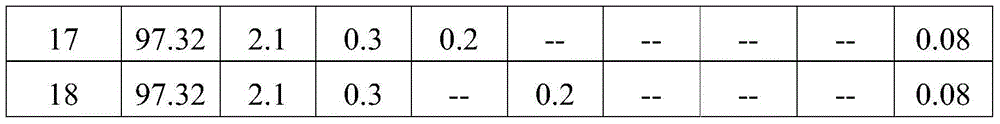

Method and apparatus for electroplating semiconductor wafer when controlling cations in electrolyte

ActiveUS20130284604A1Reduced organic additive degradationMinimized chemical waste generationAnodisationCellsElectrolytic agentPower flow

Apparatus and methods for electroplating metal onto substrates are disclosed. The electroplating apparatus comprise an electroplating cell and at least one oxidization device. The electroplating cell comprises a cathode chamber and an anode chamber separated by a porous barrier that allows metal cations to pass through but prevents organic particles from crossing. The oxidation device (ODD) is configured to oxidize cations of the metal to be electroplated onto the substrate, which cations are present in the anolyte during electroplating. In some embodiments, the ODD is implemented as a carbon anode that removes Cu(I) from the anolyte electrochemically. In other embodiments, the ODD is implemented as an oxygenation device (OGD) or an impressed current cathodic protection anode (ICCP anode), both of which increase oxygen concentration in anolyte solutions. Methods for efficient electroplating are also disclosed.

Owner:NOVELLUS SYSTEMS

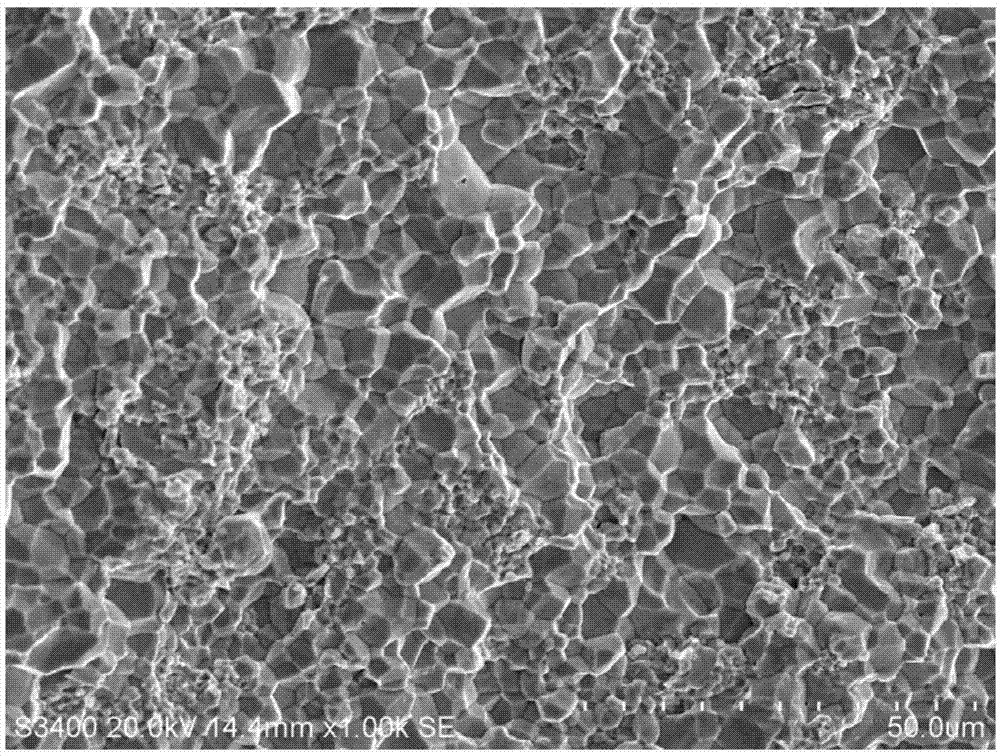

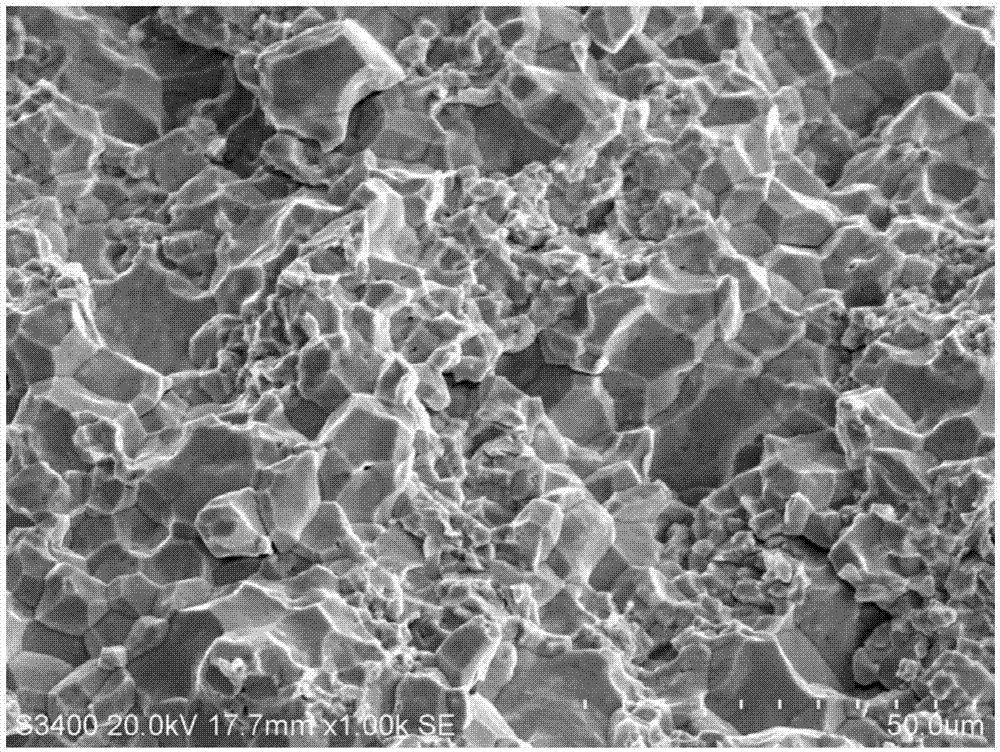

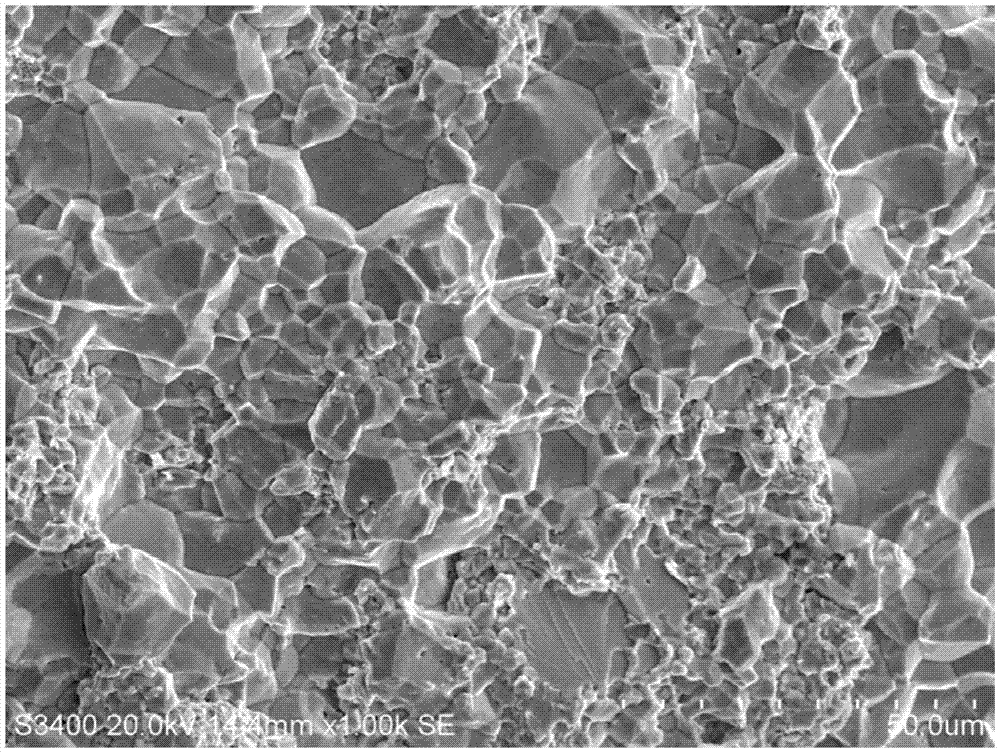

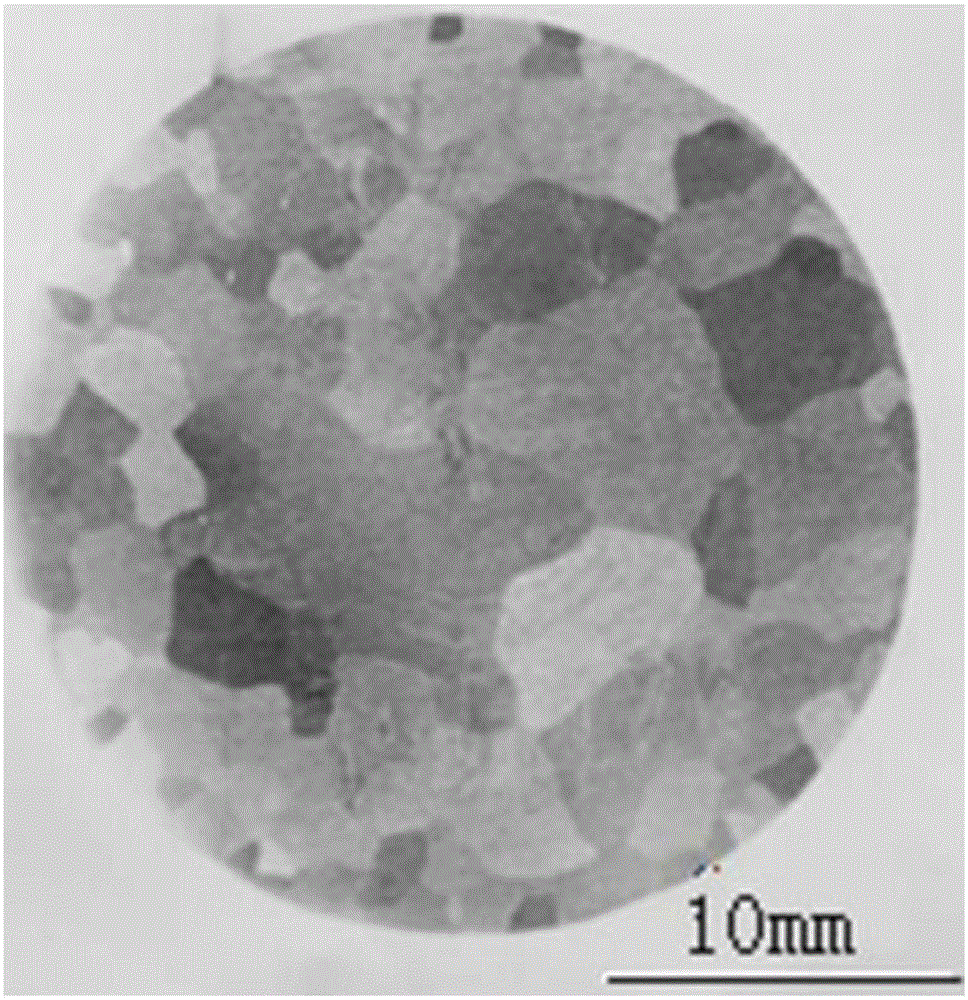

Preparation method of molybdenum-niobium alloy sputtering target

ActiveCN105441884AEasy to prepareSave raw materialsVacuum evaporation coatingSputtering coatingHot isostatic pressingSurface grinding

The invention discloses a preparation method of a molybdenum-niobium alloy sputtering target. The method comprises the following steps: (1) molybdenum powder and niobium powder are put in a mixing tank of a mixing machine for uniformly mixing to obtain mixed powder; (2) the cold isostatic pressing is performed for the mixed powder to obtain a slab; and the slab is pre-sintered under the vacuum or hydrogen atmosphere protection condition to obtain a molybdenum-niobium alloy prefabricated blank; (3) the surface of the molybdenum-niobium alloy prefabricated blank is turned and milled; and the hot isostatic pressing is performed to obtain a molybdenum-niobium alloy part; and (4) the mechanical processing and the surface grinding are performed for the molybdenum-niobium alloy part to obtain the molybdenum-niobium alloy sputtering target. The preparation method is simple in process, and saves raw materials; the introduction of impurity elements can be reduced in the preparation process; the prepared molybdenum-niobium alloy sputtering target is uniform in components, free of segregation and fine in grains; the theoretic density can reach above 99%; the oxygen mass content is lower than 500 ppm; and the requirements of the sputtering target can be preferably satisfied.

Owner:JINDUICHENG MOLYBDENUM CO LTD

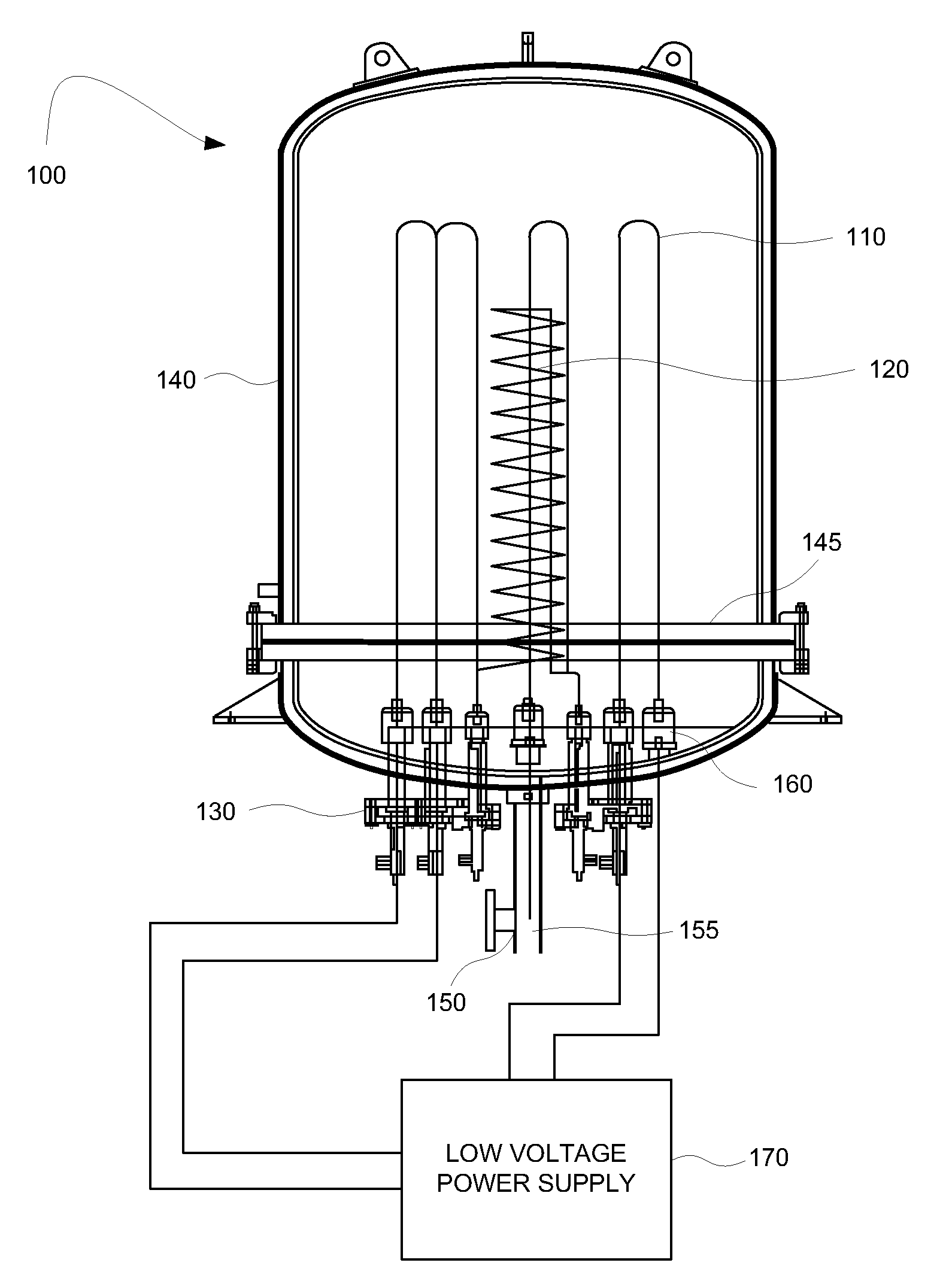

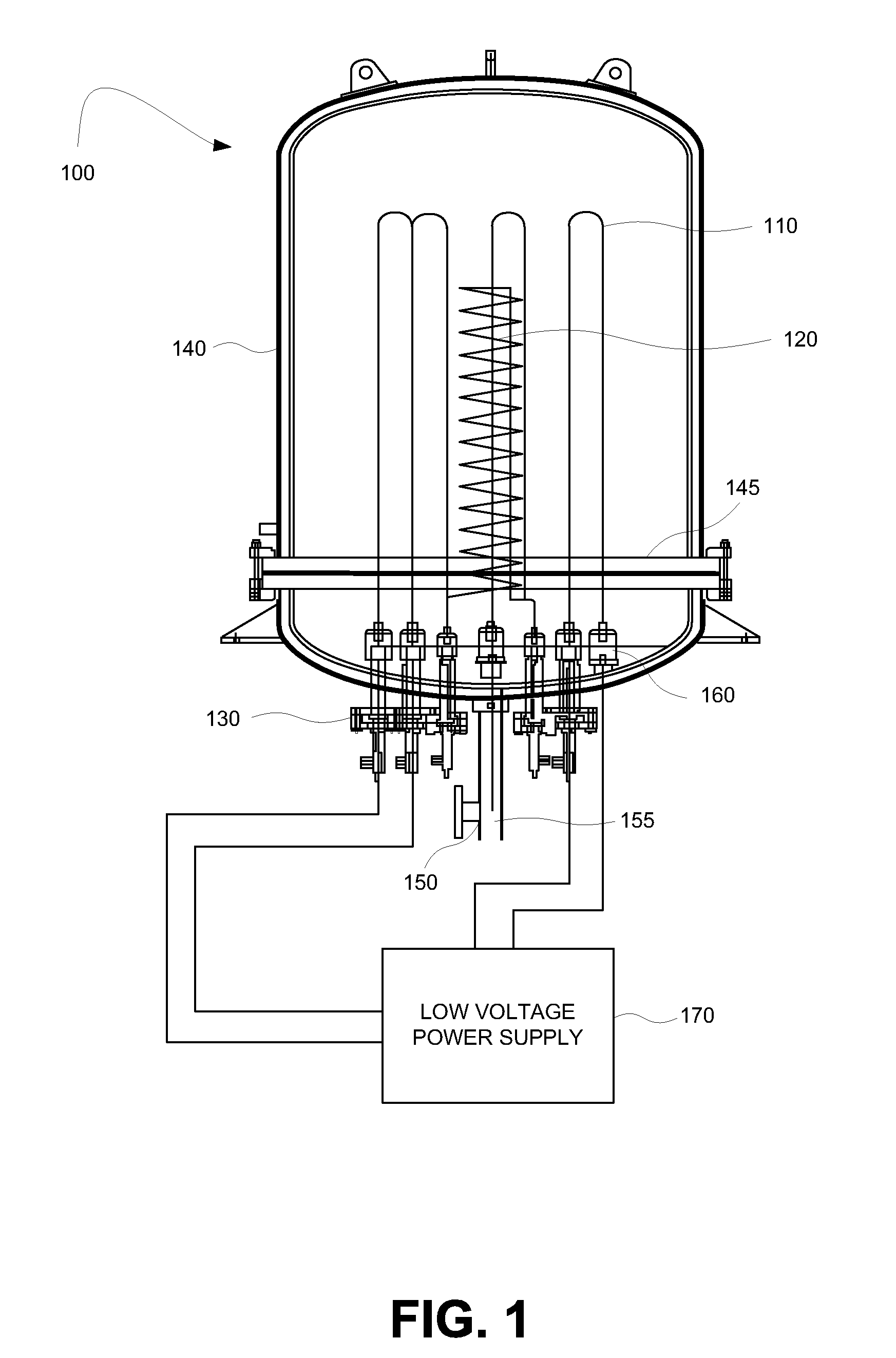

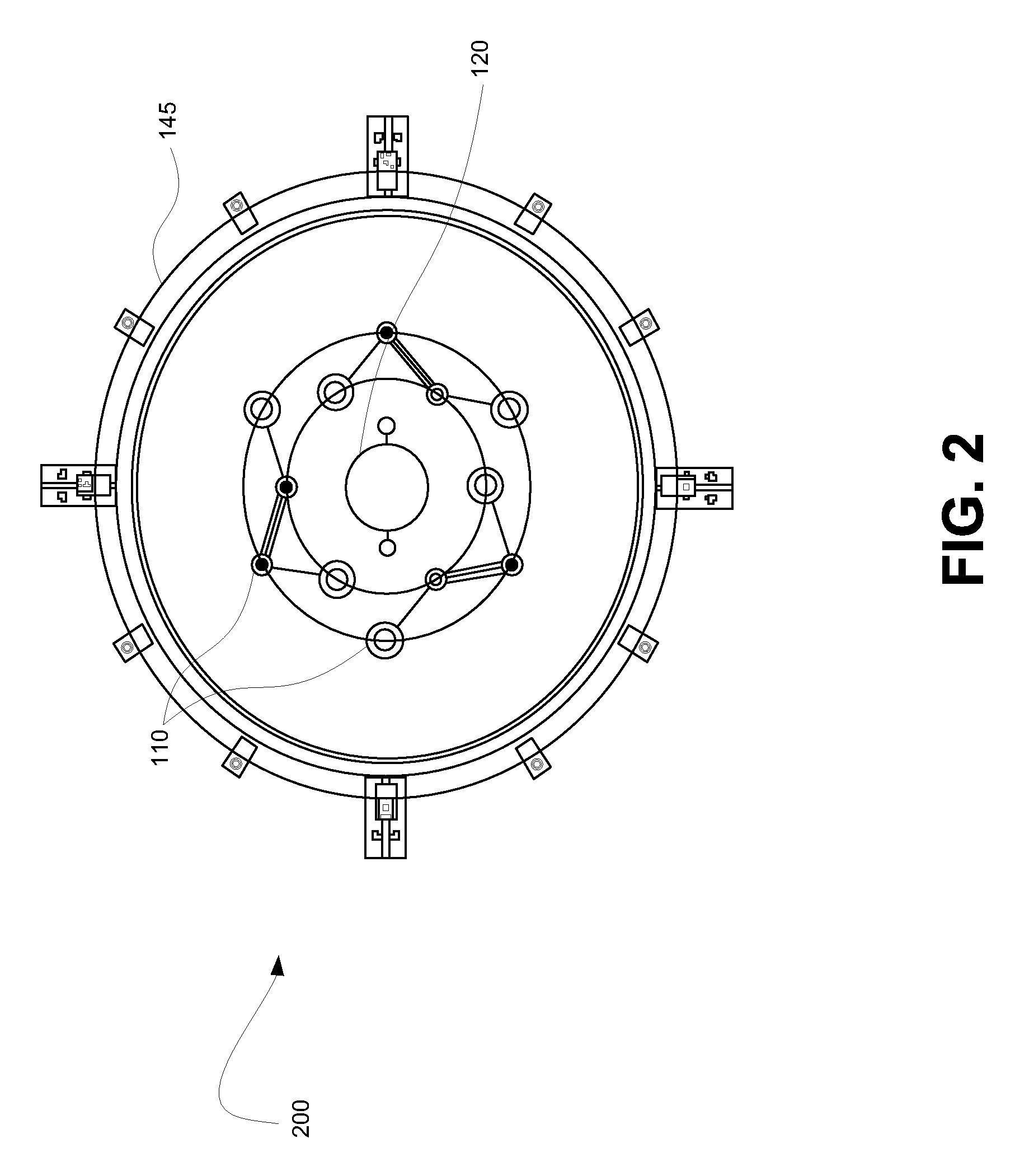

Method and apparatus for simpified startup of chemical vapor deposition of polysilicon

InactiveUS20090191336A1Simplify techniqueLow oxygen contentChemical vapor deposition coatingSilicon compoundsProduct gasPolycrystalline silicon

A simplified startup CVD technique for Siemens type of reactors is disclosed. In one embodiment, a method for production of bulk polysilicon in a CVD reactor assembly includes evacuating stainless steel envelope to have substantially low oxygen content, applying radiant heat (e.g., using a heating element coated with silicon) to the stainless steel enclosure sufficient for raising silicon rods to a firing temperature, flowing process gas (H2) ladened with a silicon reactant material via a process gas inlet and outlet port, applying sufficient current using low-voltage power supply until the silicon rods reach a deposition temperature of the process gas and upon the silicon reactant material reaching the firing temperature, turning off the radiant heat upon reaching the firing temperature, flowing gaseous byproducts of the CVD process out through the process gas outlet port, and removing as a bulk polysilicon product from the stainless steel enclosure.

Owner:SEMI SOLAR TECH

Method for recycling copper from acid waste etching solution

InactiveCN104962742AHigh purityLow oxygen contentPhotography auxillary processesProcess efficiency improvementEtchingCu2 ions

The invention discloses a method for recycling copper from an acid waste etching solution. The method is characterized by comprising the following steps that firstly, an organic phase and the acid waste etching solution are subjected to 1-5 levels of extraction according to the volume ratio of 1-30:1, and copper is extracted; secondly, the load organic phase obtained in the first step and purified water are subjected to 1-5 levels of washing according to the volume ratio of 0.1-10:1; thirdly, the load organic phase washed in the second step and a copper sulphate solution including sulfur acid of 130-250 g / L and copper ions of 1-50 g / L are subjected to 1-3 levels of back extraction according to the volume ratio of 1-10:1, the organic phase obtained through back extraction is returned to the first step to be repeatedly used, and a water phase is a copper sulphate solution; fourthly, metal stainless steel 304 or stainless steel 316 or metal titanium is used as a cathode, the copper sulphate solution obtained in the third step is electroplated under the current density of 50-400 A / m<2>, electroplated copper is obtained, and the copper sulphate solution obtained after the copper is electroplated is returned to the third step to be repeatedly used. According to the method for recycling copper from the acid waste etching solution, the copper can be separated selectively from the acid waste etching solution, the technology is simple, and the separation effect is good.

Owner:陈飙

Mo-Si-B intermetallic compound rod and preparation method thereof

The invention discloses a Mo-Si-B intermetallic compound rod. The Mo-Si-B intermetallic compound rod is prepared by the following raw materials in percentage by atom: 8-17% of silicon, 20-30% of boron, and the balance of molybdenum and inevitable impurities. In addition, the invention further discloses a method for preparing the Mo-Si-B intermetallic compound rod; and the method comprises the following steps: (1) raw materials are dried after ball milling to obtain mixed powder; (2) the mixed powder is pressed to form a blank, and is sintered to obtain a Mo-Si-B intermetallic compound sintered body; (3) the Mo-Si-B intermetallic compound sintered body is smelted by an electronic beam to obtain a Mo-Si-B intermetallic compound ingot, and is cut to form a semi-finished rod; and (4) the semi-finished rod is smelted in an electronic beam area to obtain the Mo-Si-B intermetallic compound rod. The Mo-Si-B intermetallic compound rod has the characteristics of high purity and low oxygen mass content, and is broad in application prospect under an ultrahigh-temperature bad extreme environment.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

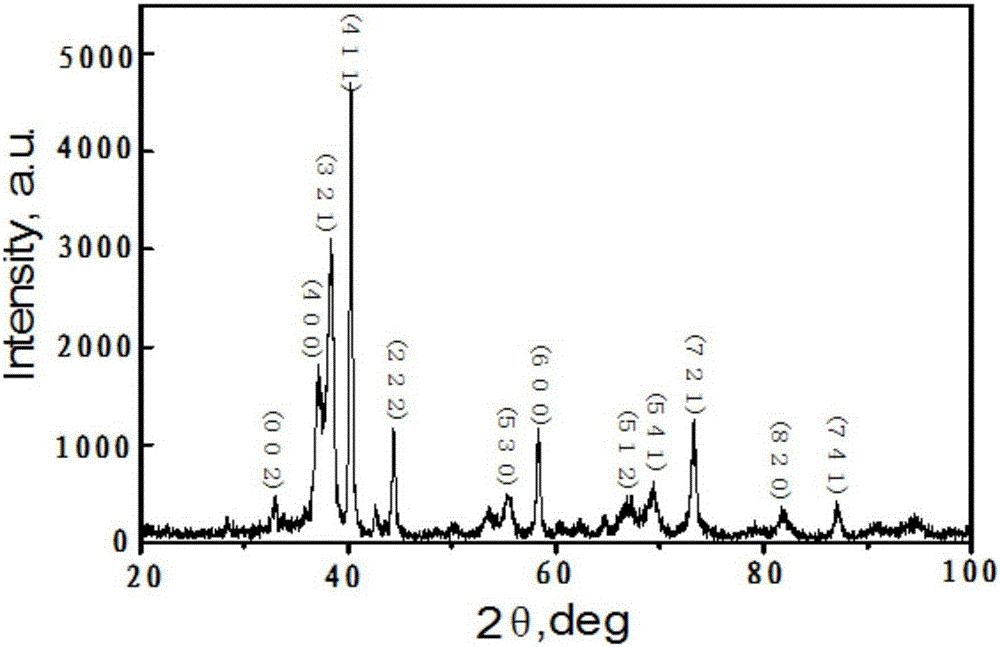

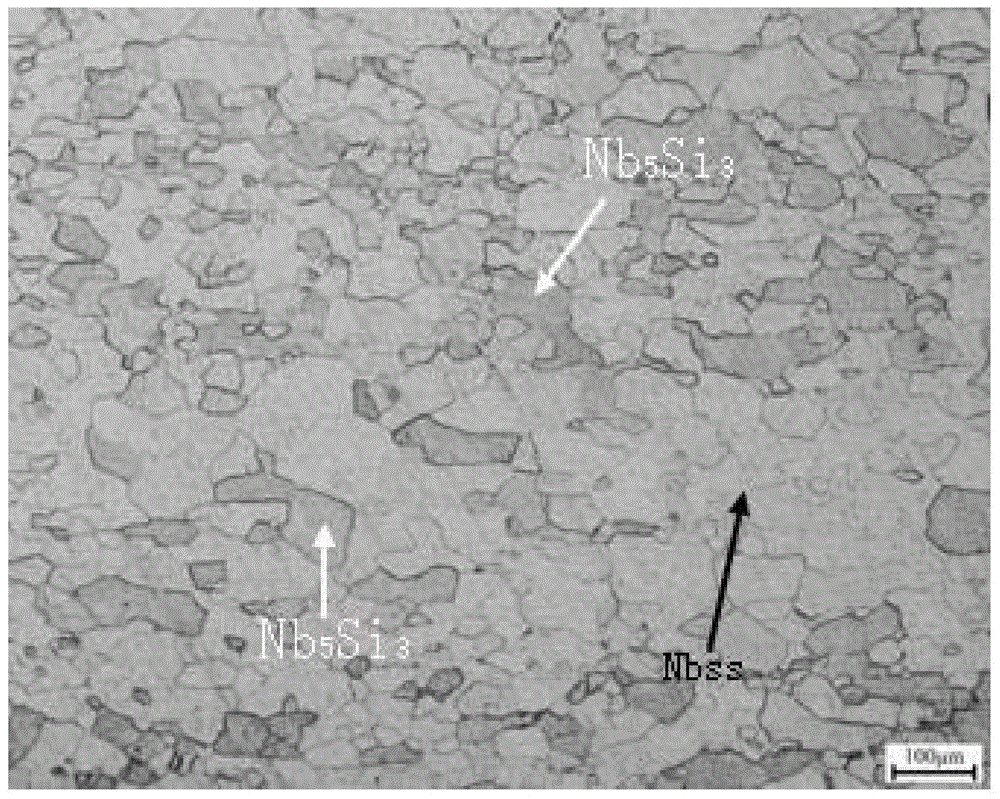

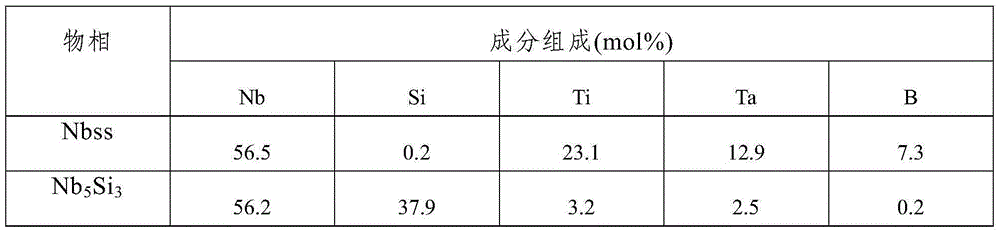

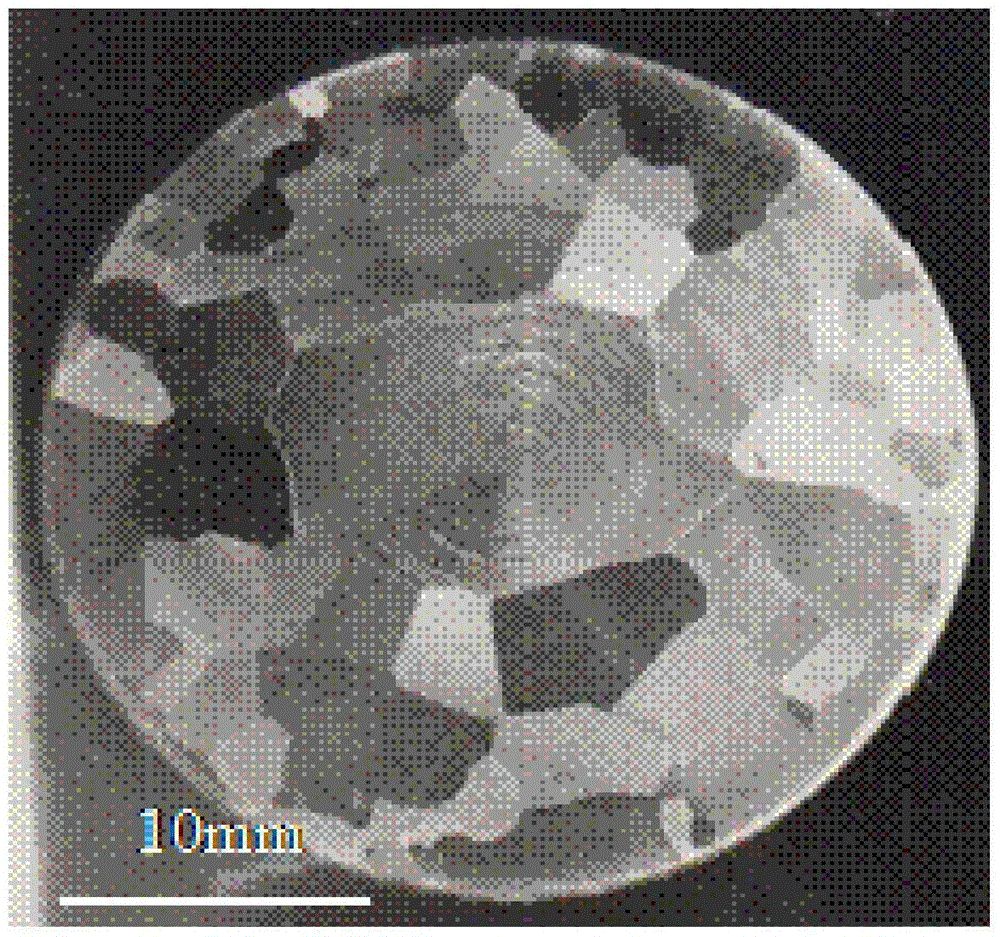

Nb-Si-Ti-Ta-B alloy material and preparation method thereof

ActiveCN105200295ARoom temperature ductility balanceBalance of Mechanical PropertiesNiobiumMechanical property

The invention discloses an Nb-Si-Ti-Ta-B alloy material which is prepared from the following raw materials according to the following atom percentage: 6-20% of Si, 16-30% of Ti, 5-15% of Ta, 2-8% of B and the rest of Nb and unavoidable impurities. In addition, the invention also discloses a method for preparing the Nb-Si-Ti-Ta-B alloy material. The method comprises the following steps: 1, silicon powder, titanium powder, tantalum powder, boron powder and niobium powder are uniformly mixed and the mixture is compacted to form an electrode, and electric arc melting is carried out to obtain an alloy ingot; and 2, the alloy ingot undergoes extrusion so as to obtain the Nb-Si-Ti-Ta-B alloy material. Tensile strength of the Nb-Si-Ti-Ta-B alloy material under the condition of 1300 DEG C is 267MPa-425MPa. Ductility and toughness at room temperature, room-temperature mechanical property and high temperature tensile strength of the Nb-Si-Ti-Ta-B alloy material are well balanced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Nb-Si intermetallic compound bar and preparation method thereof

The invention discloses an Nb-Si intermetallic compound bar. The Nb-Si intermetallic compound bar is prepared from, by atomic percentage, 35%-45% of silicon, and the balance niobium and inevitable impurities. The invention further discloses a preparation method of the Nb-Si intermetallic compound bar. The preparation method includes the steps that 1, silicon powder and niobium powder are ball-milled and dried to obtain mixed powder; 2, a blank is formed after compression molding, the blank is sintered, and then an Nb-Si intermetallic compound sintered body is obtained; 3, an Nb-Si intermetallic compound cast ingot is obtained after electric arc melting, and a semi-finished bar is obtained after cutting; and 4, the Nb-Si intermetallic compound bar is obtained after electron beam zone melting. The Nb-Si intermetallic compound bar has the beneficial effects of being high in quality and purity, low in oxygen mass content and uniform in component distribution, the bar is further crushed into powder to serve as a raw material for preparing a high-temperature oxidation-resistant coating and also serve as a strengthening phase of a super-high-temperature oxidation-resistant material, and broad application prospects are achieved in the aerospace field.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for recovering copper from acid waste etching solution

InactiveCN103233128AHigh purityLow oxygen contentPhotography auxillary processesProcess efficiency improvementElectricityEtching

The invention relates to a method for recovering copper from an acid waste etching solution. The method is characterized by comprising the following steps of: (1) preparing an organic phase by adopting an Lix series extraction agent with the volume ratio of 5-20% and 80-90% of kerosene or No. 200 solvent oil; (2) performing copper extraction by using the organic phase and the acid waste etching solution according to the volume ratio of (1-30): 1; (3) washing the loaded organic phase obtained in the step (2) and pure water according to the volume ratio of (0.1-10): 1; (4) performing back extraction by using the loaded organic phase after washing in the step (3) and a copper sulfate solution according to the volume ratio of (1-10): 1, and returning the organic phase after back extraction to the step (2) for reuse, wherein a water phase is the copper sulfate solution; and (5) performing copper electrodeposition on the copper sulfate solution obtained in the step (4), and returning the copper sulfate solution after copper electrodeposition to the step (4) for reuse. According to the method for recovering the copper from the acid waste etching solution, disclosed by the invention, the copper can be selectively separated from the acid waste etching solution, the process is simple and the separation effect is good.

Owner:陈飙

Method for recycling copper from basic waste etching liquid

ActiveCN103397341AHigh extraction rateSimple processPhotography auxillary processesProcess efficiency improvementKeroseneSolvent

The invention provides a method for recycling copper from a basic waste etching liquid. The method is characterized by comprising the following steps of: (1) extracting copper by adopting an organic phase of Lix<R> series extractant:N235 extractant: kerosene or 200#solvent oil and a basic waste etching liquid; (2) washing the loaded organic phase obtained in the step (1) by using a diluted sulfuric acid solution; (3) performing back-extracting on the loaded organic phase washed in the step (2) and a copper sulfate solution, and returning the back-extracted organic phase to the step (1) for recycling, wherein the water phase is a copper sulfate solution; and (4) electrically depositing the copper sulfate solution in the step (3) by adopting a metal cathode to obtain acid copper, and returning the copper sulfate solution after the step of electrically deposited the copper to the step (3) for recycling. The method for recycling copper from an acid waste etching liquid can be used for selectively separating copper from a basic waste etching liquid, and is simple in process and good in separation effect.

Owner:广东柏宇新材料科技有限公司

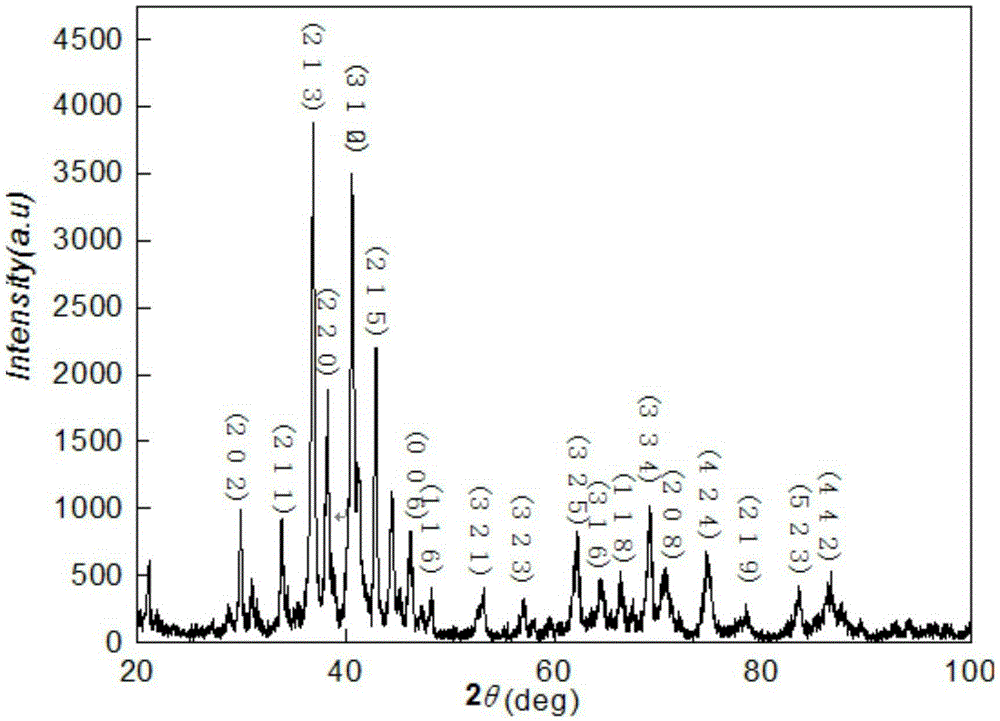

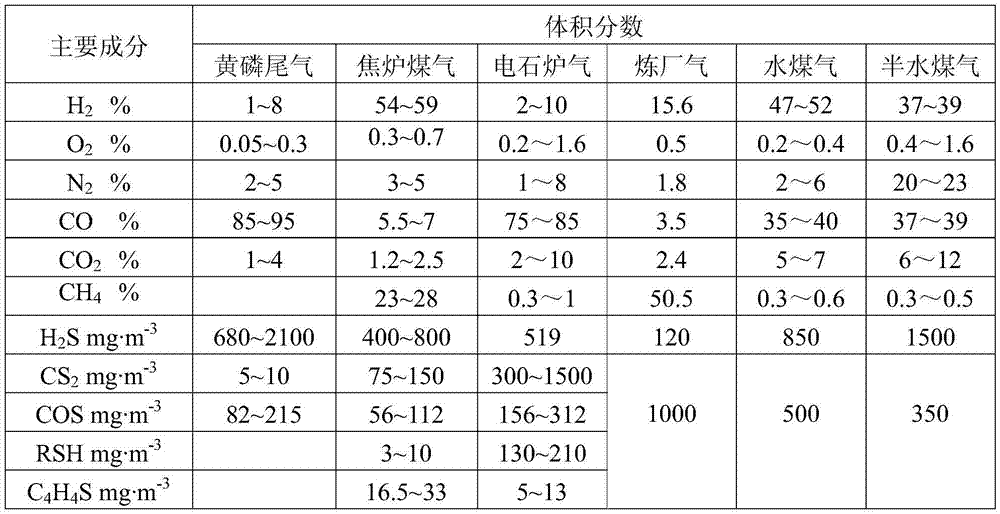

Deoxidation and organic sulfur hydro-conversion bifunctional catalyst, and preparation method and application thereof

ActiveCN105435806ALow oxygen contentEasy to prepareHeterogenous catalyst chemical elementsDispersed particle separationOperabilityOxygen

The invention relates to a deoxidation and organic sulfur hydro-conversion bifunctional catalyst, and a preparation methods and an application thereof, and belongs to the technical field of gas purification. The catalyst, by oxide, comprises, by mass, 1-50 parts of an active component, 0.1-20 parts of an active assistant and 30-89.1 parts of a carrier. The invention also relates to three preparation methods of the catalyst. The catalyst has deoxidation and organic sulfur hydro-conversion bifunctions, and can be used in the purification process of raw gases of sulfur-containing and CO-and-H2-containing industrial coal-to-water gas, semi-water gas, coke oven gas and carbide furnace gas. The catalyst can simultaneously realize deoxidation and organic sulfur hydro-conversion purposes, shortens the process flow, simplifies the flow, reduces the energy consumption and saves the cost. The preparation methods of the catalyst have the advantages of simplicity, strong operability and low preparation condition requirements. The catalyst has a high deoxidation rate and a high organic sulfur hydro-conversion rate, and allows the volume content of oxygen in an obtained product obtained after deoxidation to be lower than 100ppm and the organic sulfur conversion rate to be greater than 95%.

Owner:HAO HUA CHENGDU TECH

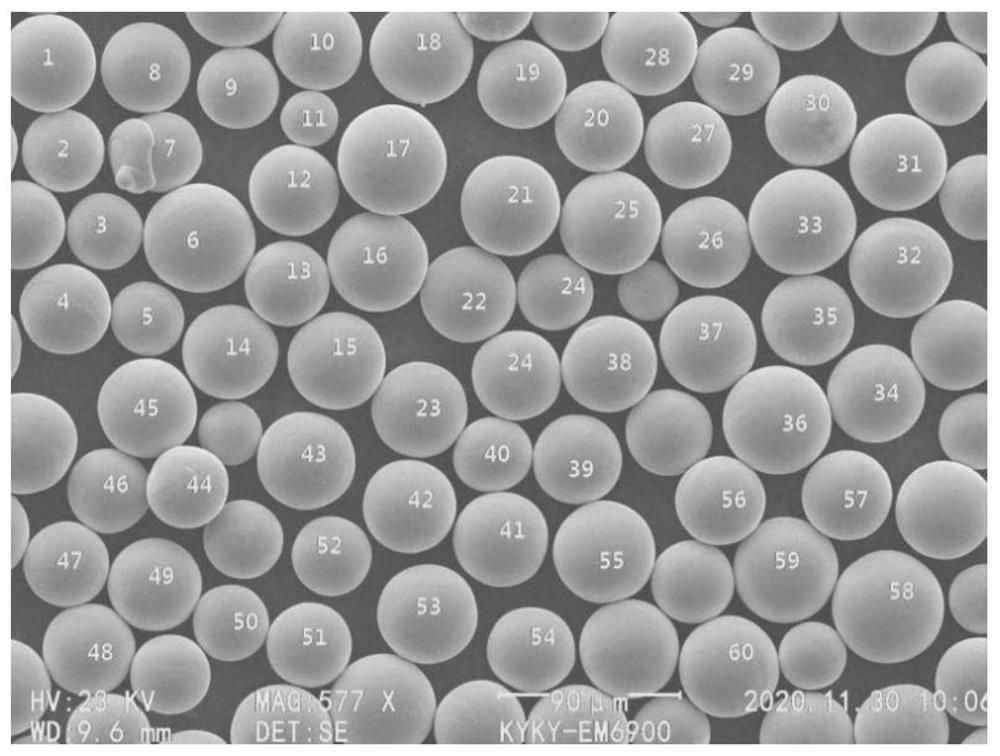

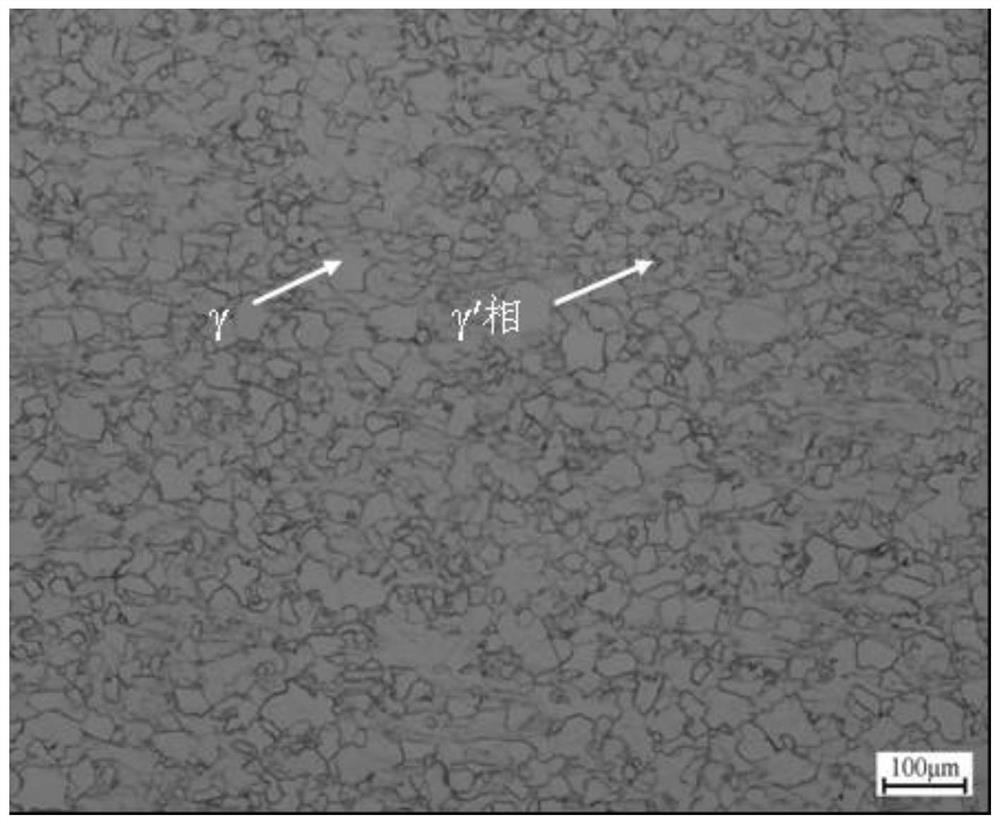

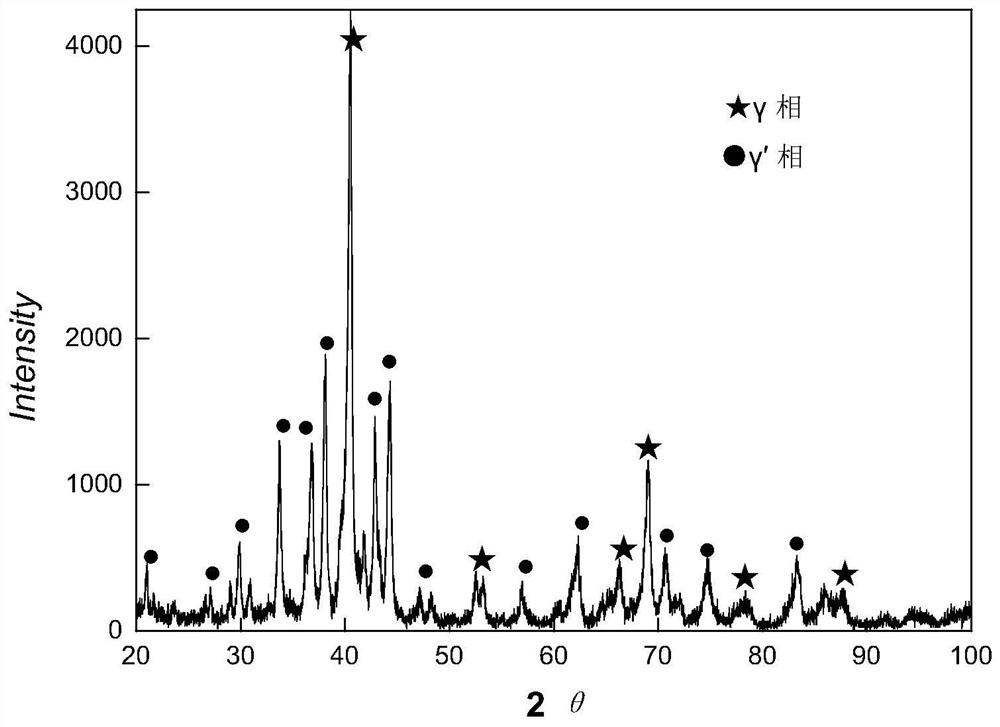

High-purity nickel-based high-temperature alloy and preparation method of spherical powder of high-purity nickel-based high-temperature alloy

PendingCN113817935AHigh purityHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyIngotSuperalloy

The invention discloses a high-purity nickel-based high-temperature alloy and a preparation method of spherical powder of the high-purity nickel-based high-temperature alloy. The alloy comprises the following steps of selecting high-purity metal ingredients, smelting in a vacuum induction suspension smelting furnace, realizing pure smelting by controlling parameters such as smelting vacuum degree, refining temperature, time and the like, then pouring to obtain a steel ingot, and preparing the steel ingot into a bar; carrying out smelting, atomizing and powdering on the bar through EIGA and PREP technologies to obtain spherical metal powder; adopting vibrating screening and airflow classification, and classifying spherical powder under the protection of inert gas. According to the method, the content of nonmetal impurities is effectively controlled through raw material smelting control, atomization process control and post-treatment control, so that chemical elements of the powder have extremely high purity, and the high-purity high-temperature alloy spherical powder is not prone to generating cracks and other defects in the subsequent laser additive printing and laser cladding process and is good in binding force, high in strength, good in toughness and good in mechanical property, and the powder can be used for repairing high-end parts.

Owner:盘星新型合金材料(常州)有限公司

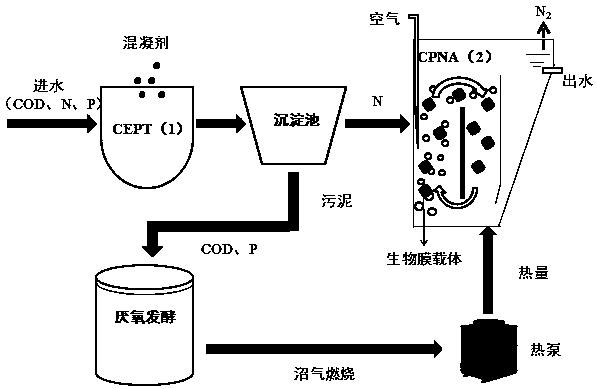

High-altitude municipal wastewater treatment method based on nitrogen and phosphorus capture and whole-course autotrophic nitrogen removal

ActiveCN110395851ARealize resource utilizationReduce processing energy consumptionWater contaminantsTreatment with anaerobic digestion processesEcological environmentHigh energy

The Tibet region in China has the characteristics of high altitude, low air oxygen content, large day and night temperature difference and low night temperature, so that a traditional activated sludgeprocess adopted for domestic sewage treatment at present confronts with the problems of low aeration efficiency, high energy consumption, weak functional microorganism activity and the like when being applied to the Tibet region; meanwhile, the treatment of a large amount of residual sludge threatens the ecological environment of the Tibet region. According to the method, a chemical enhanced primary treatment (CEPT) process and an integrated partial nitrosation-anaerobic ammonia oxidation (CPNA) process are combined, so that the capture of carbon and phosphorus in the inlet water and the whole-course autotrophic nitrogen removal under a low-oxygen condition are realized. The captured carbon source is used for producing biogas through anaerobic fermentation, and can supplement heat for a CPNA process under a low-temperature condition. The CEPT-CPNA process has the advantages of low energy consumption and less residual sludge generation, can solve many problems in the traditional method, and belongs to a sustainable sewage treatment process suitable for a high-altitude environment.

Owner:SOUTHEAST UNIV +1

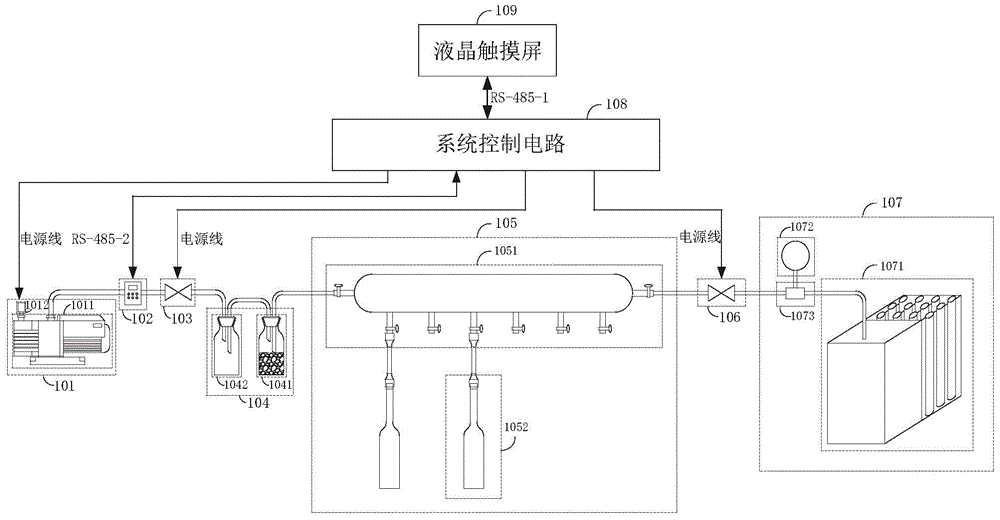

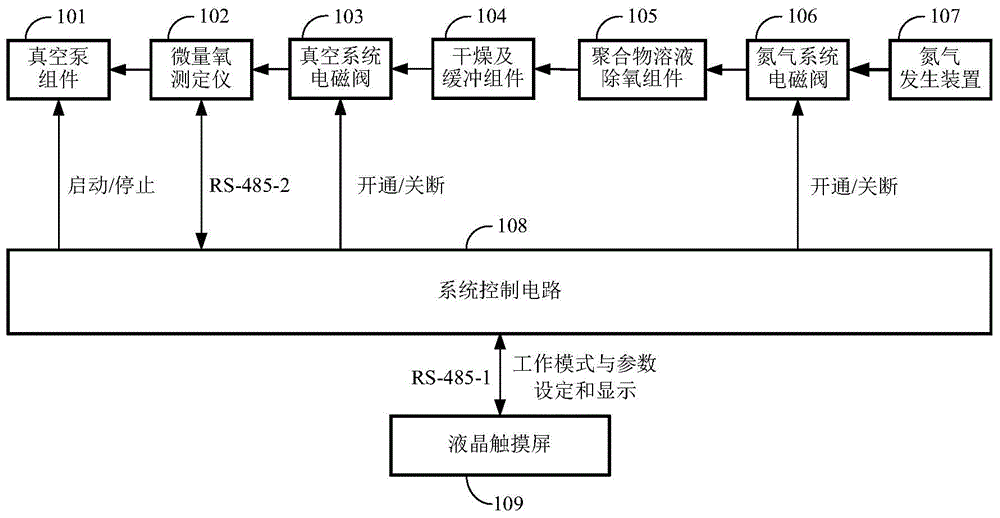

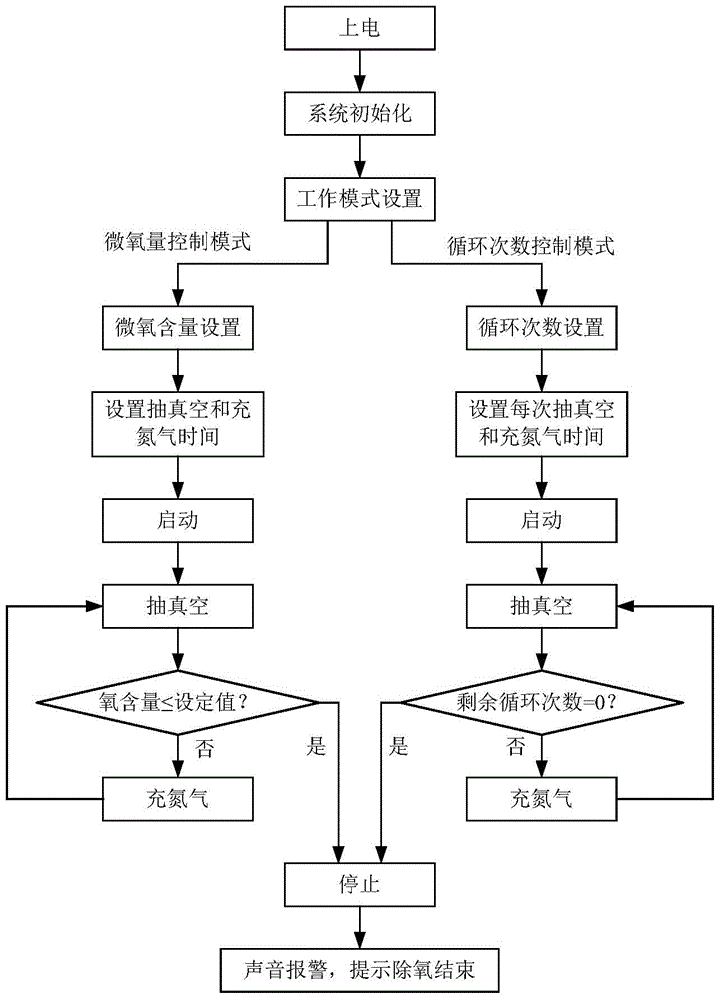

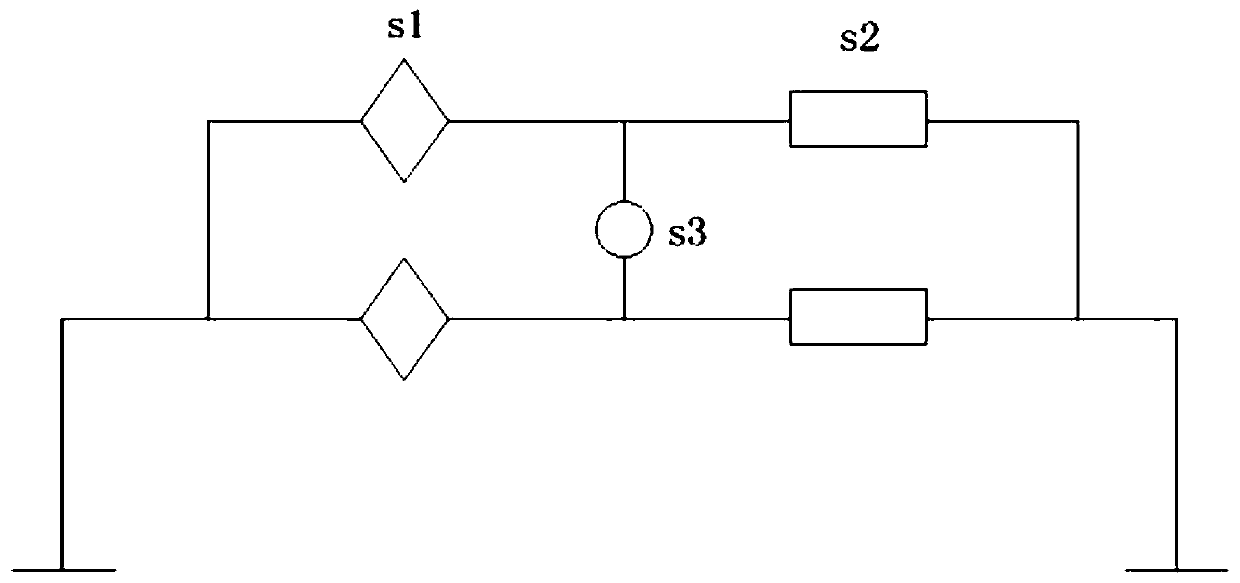

Novel intelligent efficient polymer solution deoxidizing system

InactiveCN104964867AGuaranteed accuracyImprove efficiencyPreparing sample for investigationNitrogen generatorOxygen meters

A novel intelligent efficient polymer solution deoxidizing system comprises a vacuum pump assembly, a trace oxygen meter, a vacuum system electromagnetic valve, a drying and buffering assembly, a polymer solution deoxidizing assembly, a nitrogen system electromagnetic valve, a nitrogen generator, a system control circuit and a liquid crystal touch screen. The intake end of the vacuum pump assembly is connected with the output end of the trace oxygen meter through a stainless steel pipe. The input end of the trace oxygen meter is connected with one end of the vacuum system electromagnetic valve through a stainless steel pipe, and the other end of the vacuum system electromagnetic valve is connected with the output end of the drying and buffering assembly through a silicone tube; the input end of the drying and buffering assembly is connected with the suction end of the polymer solution deoxidizing assembly; the charge end of the polymer solution deoxidizing assembly is connected with one end of the nitrogen system electromagnetic valve; the other end of the nitrogen system electromagnetic valve is connected with the output end of the nitrogen generator through a stainless steel pipe; a system control circuit is connected with the vacuum pump assembly, the vacuum system electromagnetic valve and the nitrogen system electromagnetic valve through power lines.

Owner:北京东航科仪仪器有限公司

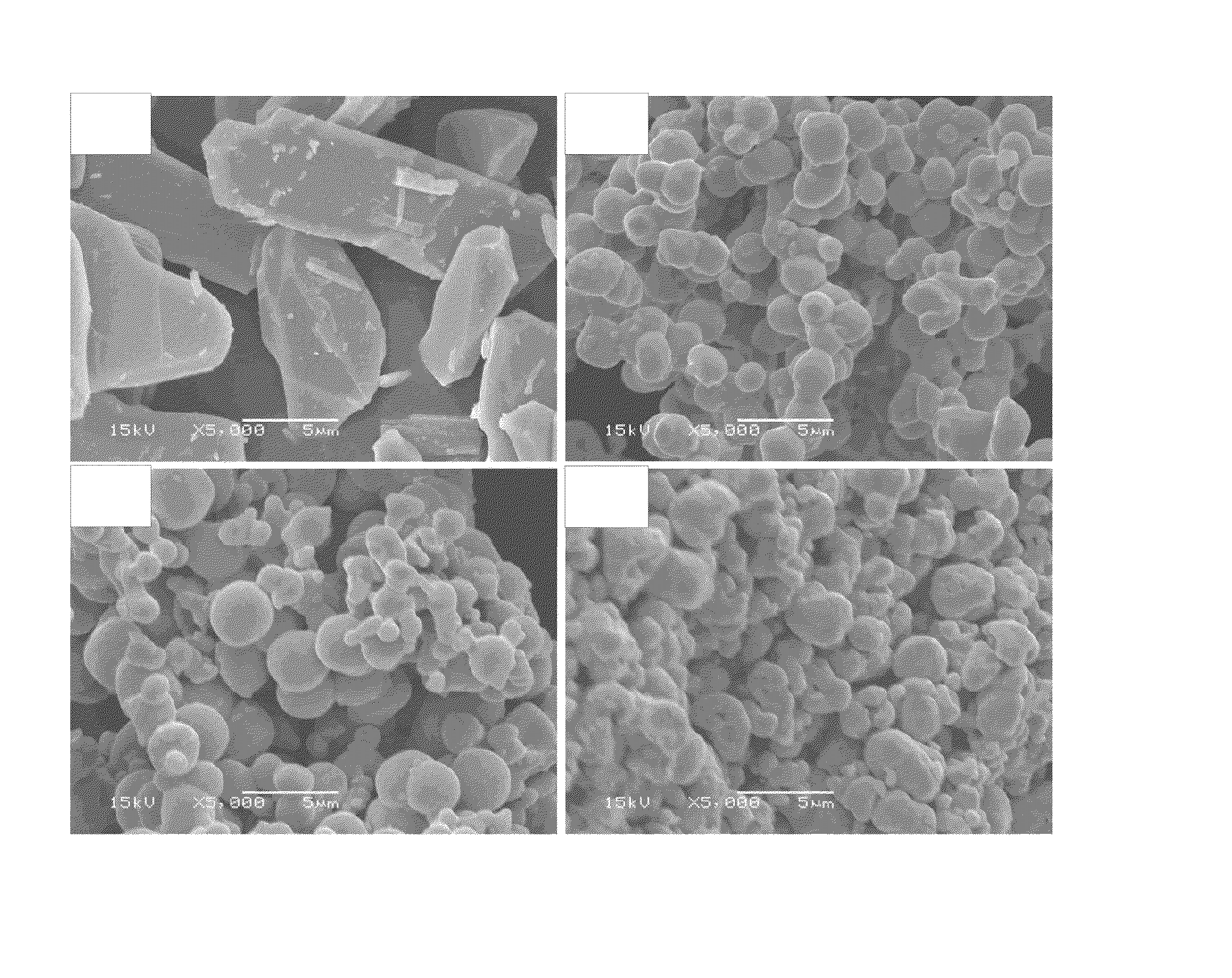

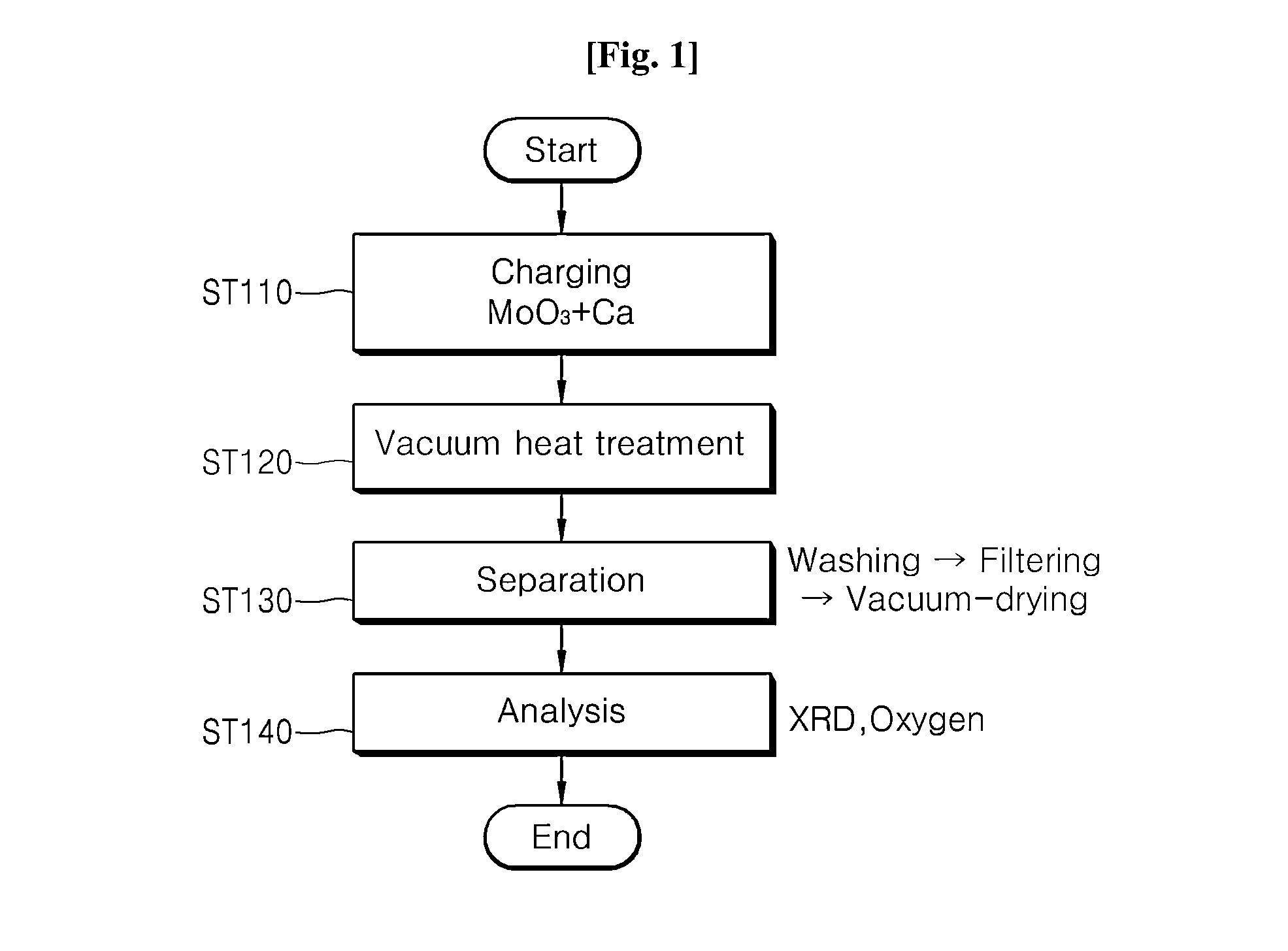

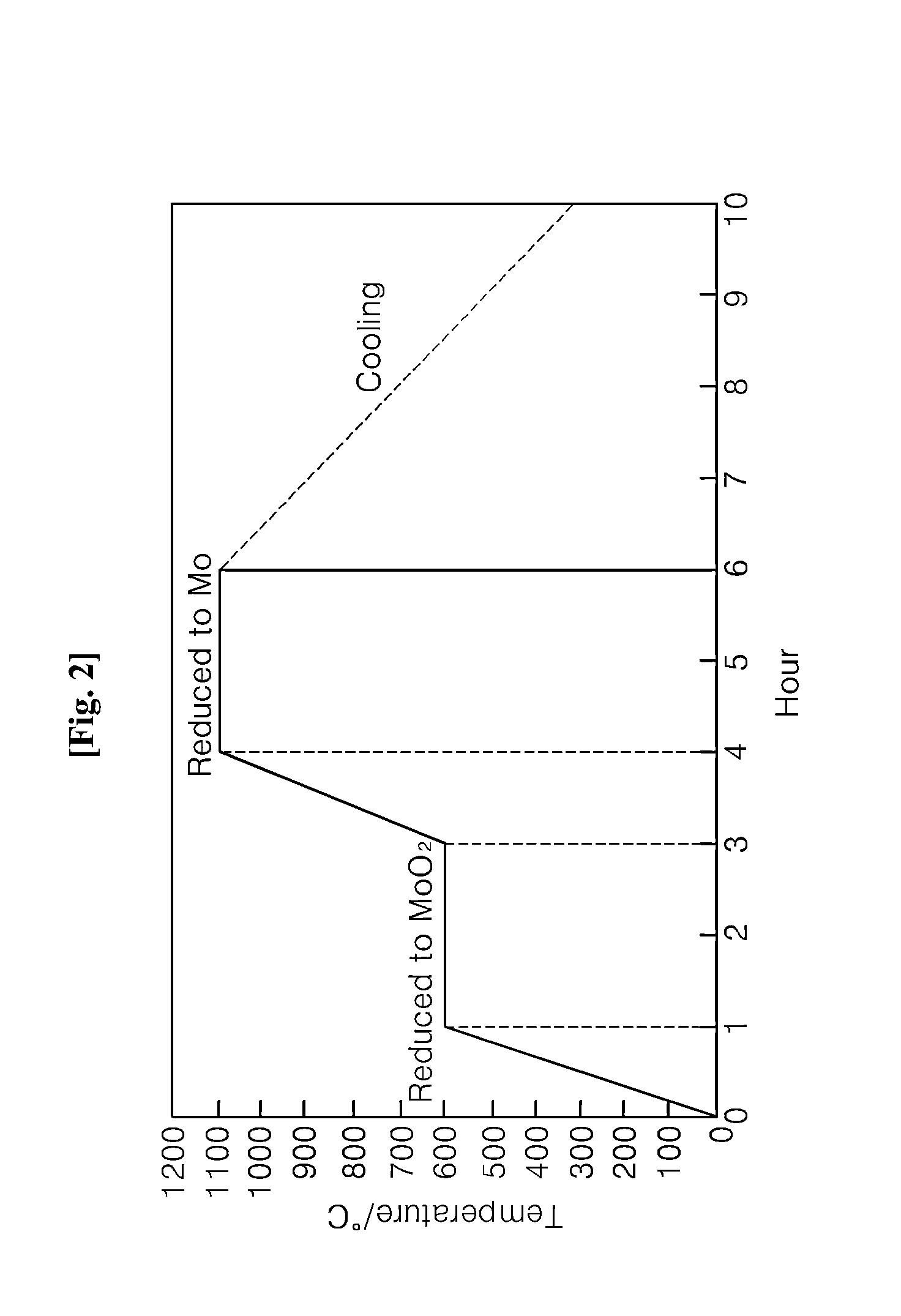

Method of producing low oxygen-content molybdenum powder by reducing molybdenum trioxide

Disclosed is a method of producing low oxygen-content molybdenum powders by reducing molybdenum trioxide, which includes charging a first reducing agent and the molybdenum trioxide, which are in the direct contact with each other on a micro-sieve on an upper portion of a bracket in a body, charging a second reducing agent in the bracket under the micro-sieve, coupling the body with a cover to close the body, and performing a reduction reaction by raising an internal temperature of the body by performing the first reduction reaction due to direct contact between the first reducing agent and the molybdenum trioxide, and performing the second reduction reaction due to evaporation of the second reducing agent. The first and second reduction reactions are performed at a temperature in a range of 550° C. to 650° C., and a temperature in a range of 1000° C. to 1200° C., respectively.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

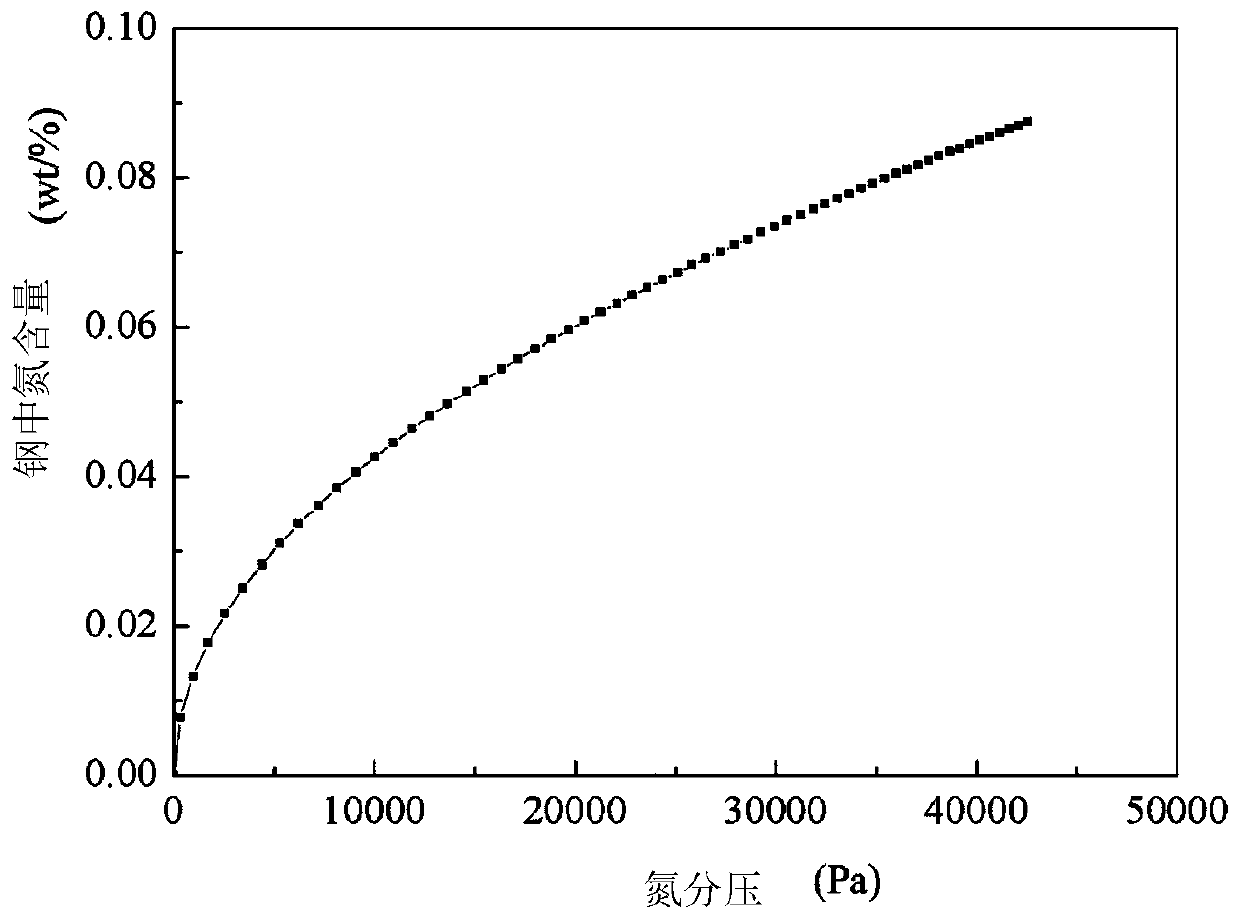

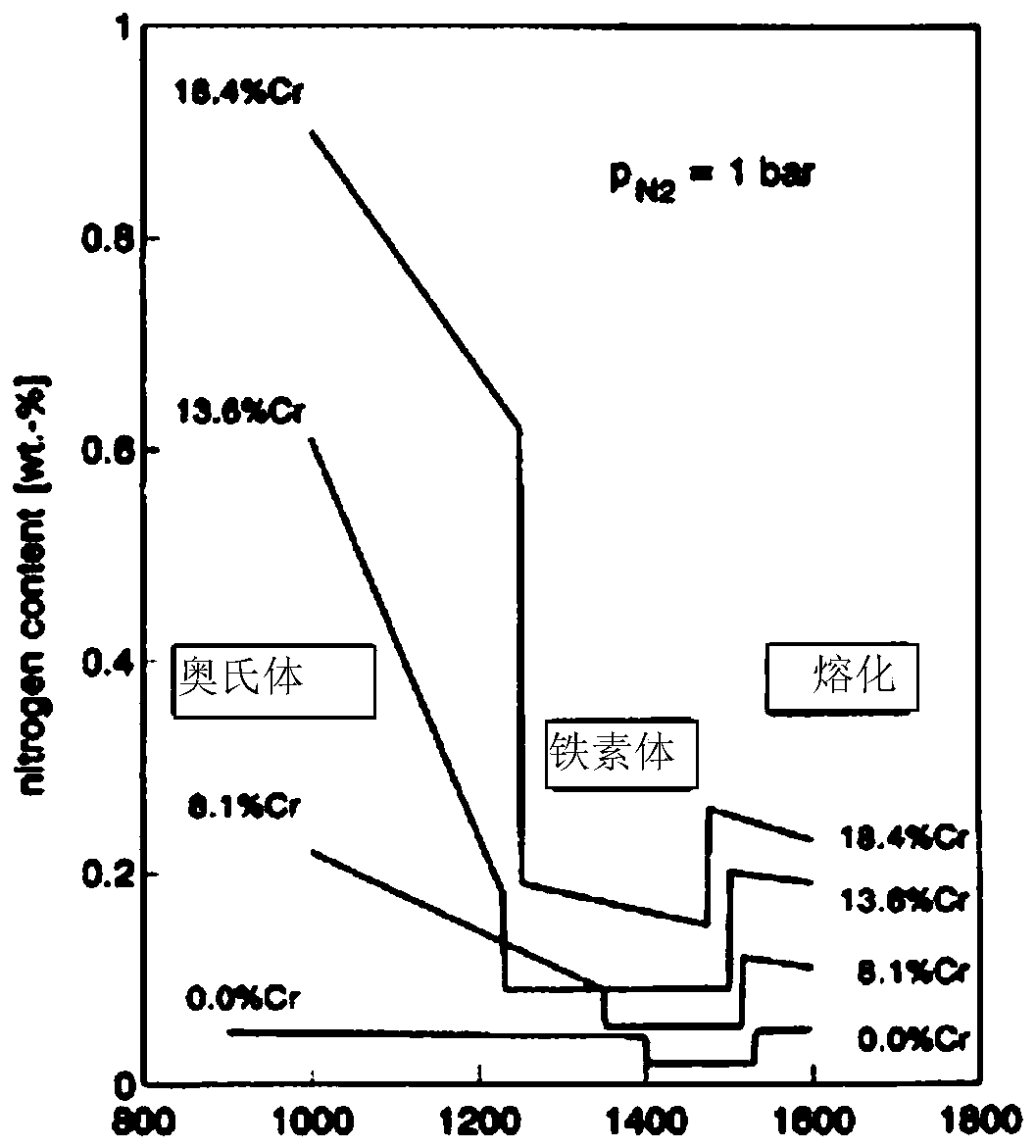

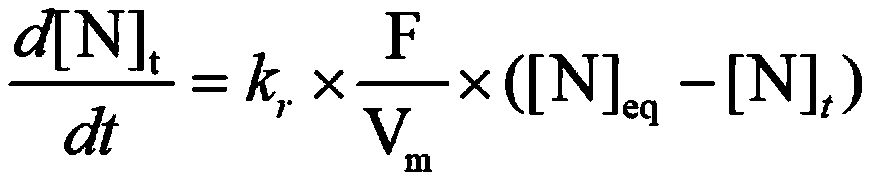

Method for smelting COST-FB2 steel through gas-phase nitriding under negative pressure condition

ActiveCN110093582APrecise temperature controlUniform compositionSolid state diffusion coatingGas phaseManganese

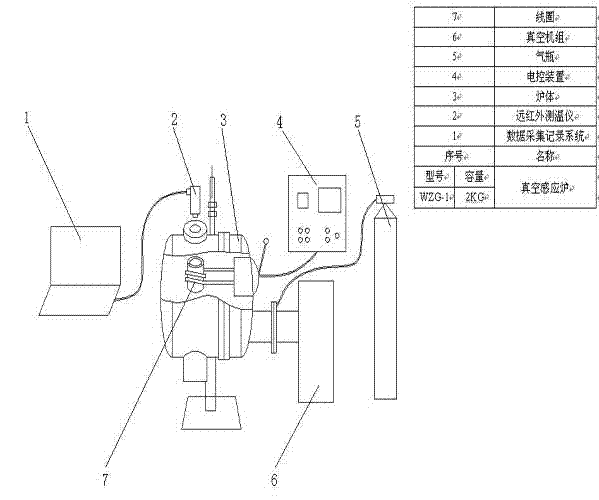

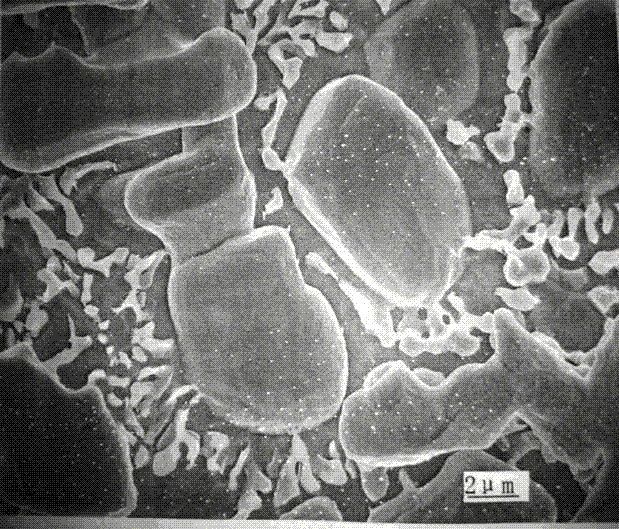

The invention relates to a method for smelting COST-FB2 steel through gas-phase nitriding under a negative pressure condition. The method comprises the following steps that firstly carbon deep deoxidation is performed under the condition of high vacuum degree, deoxidation is completed after the surface of molten steel is stable and bubbles do not rush out any longer; then an alloy element for promoting nitrogen dissolution is added and completely molten, and then gas-phase nitriding is started; during gas-phase nitriding, nitriding pressure during gas-phase nitriding is calculated by using thermodynamic calculation software Factsage, the molten steel temperature is accurately controlled, and the nitriding time is calculated and determined through the surface area of the molten steel, the volume of the molten steel and the nitrogen balance content; when gas-phase nitriding is about to be completed, the alloy element boron and the volatile manganese are added, then through argon filling,pressurization is performed until the high pressure is reached, pressurization casting is performed under the condition that the nitrogen partial pressure is kept unchanged, the under-pressure stateis kept in the solidification process, vacuum breaking is performed after complete solidification, and a COST-FB2 steel cast ingot which has the content of N being 0.015%-0.03% and the content of O being less than or equal to 0.0035%, is uniform in component and compact in structure is prepared.

Owner:NORTHEASTERN UNIV

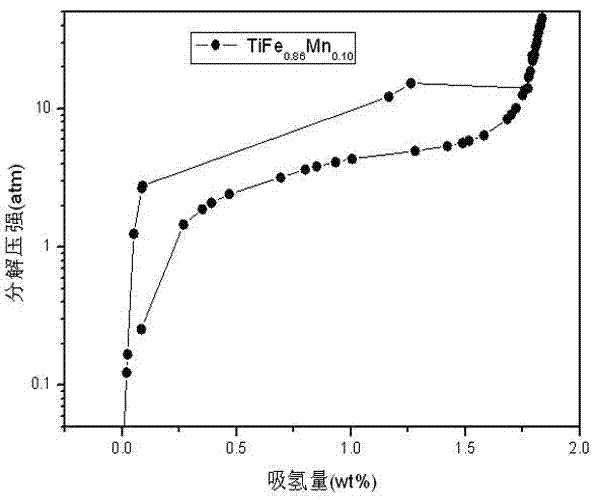

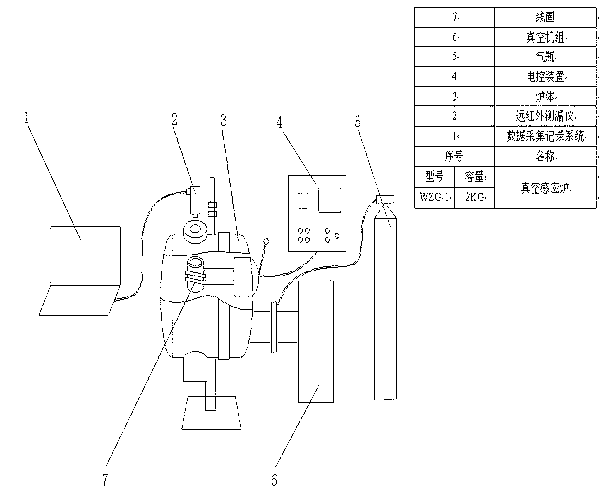

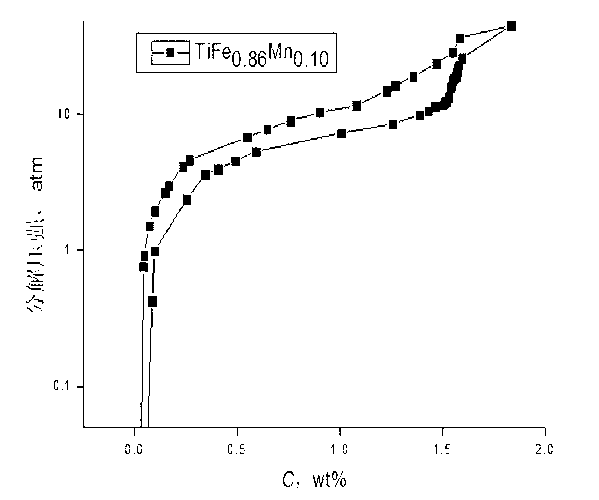

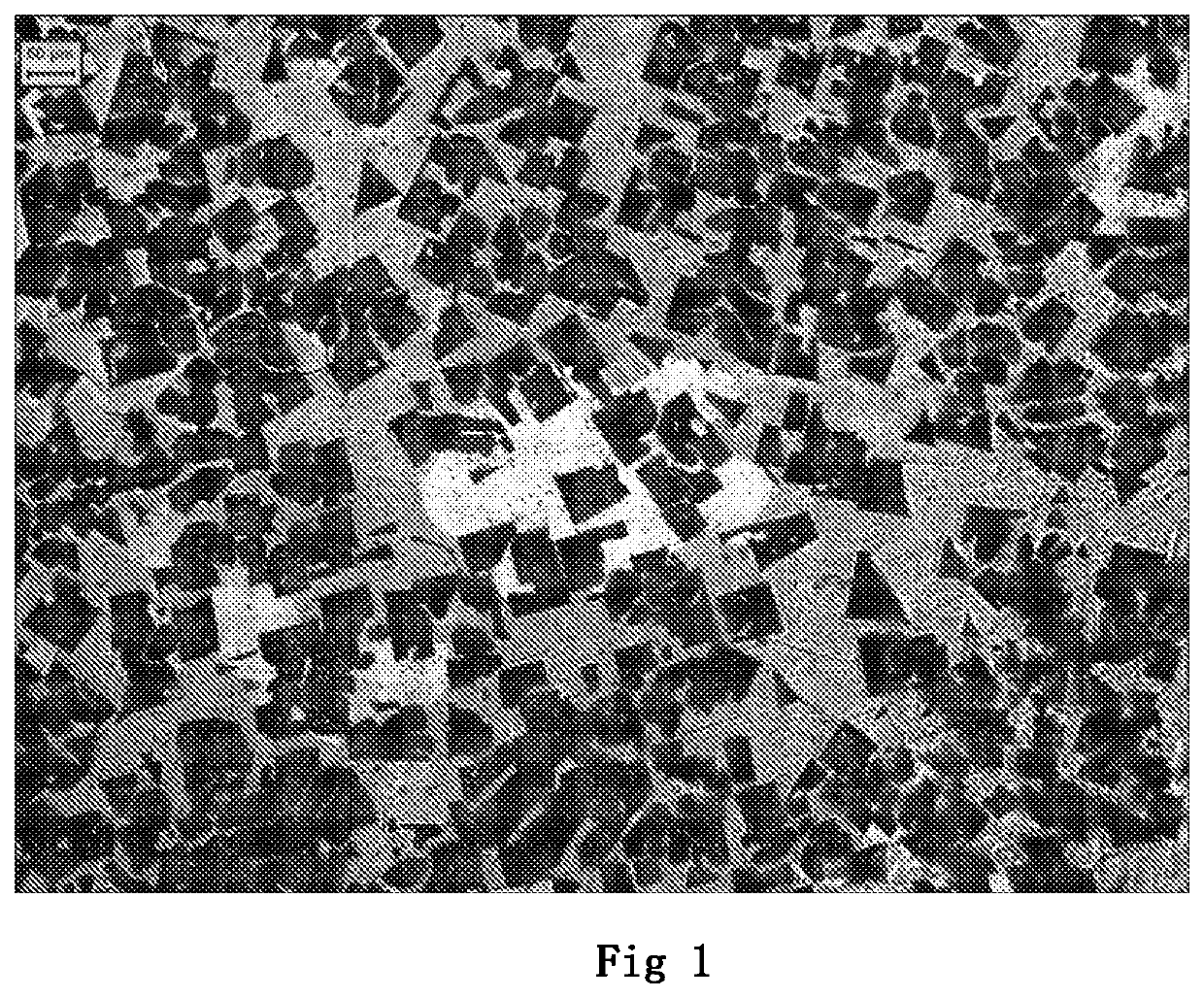

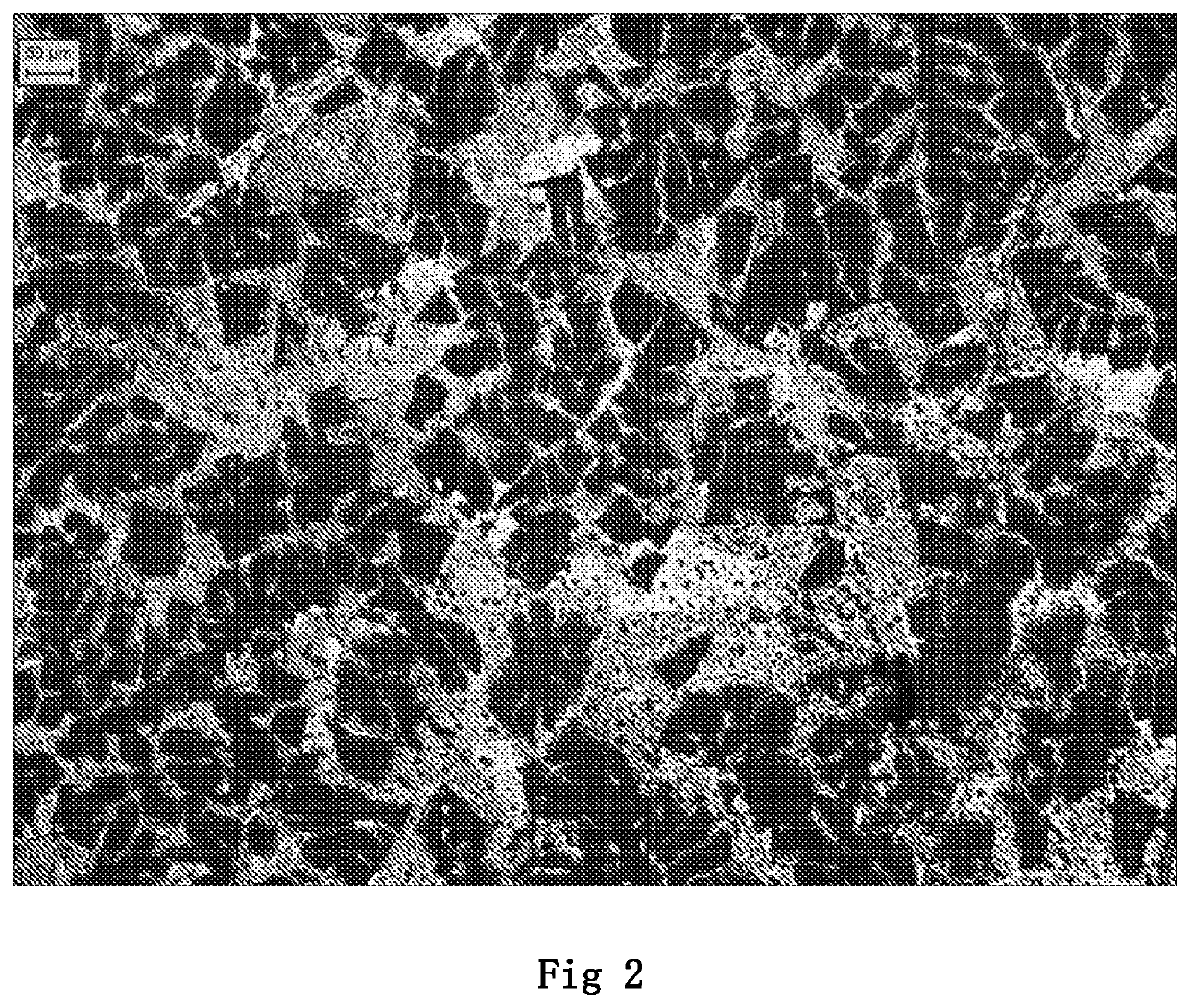

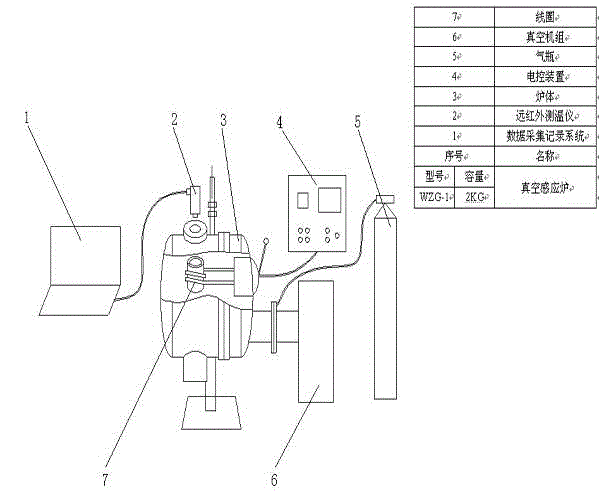

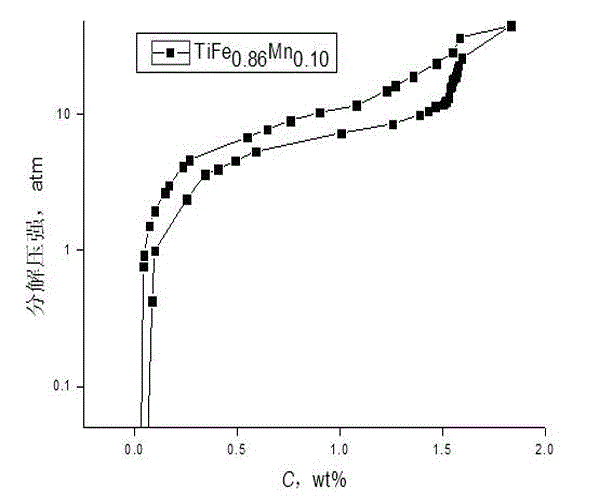

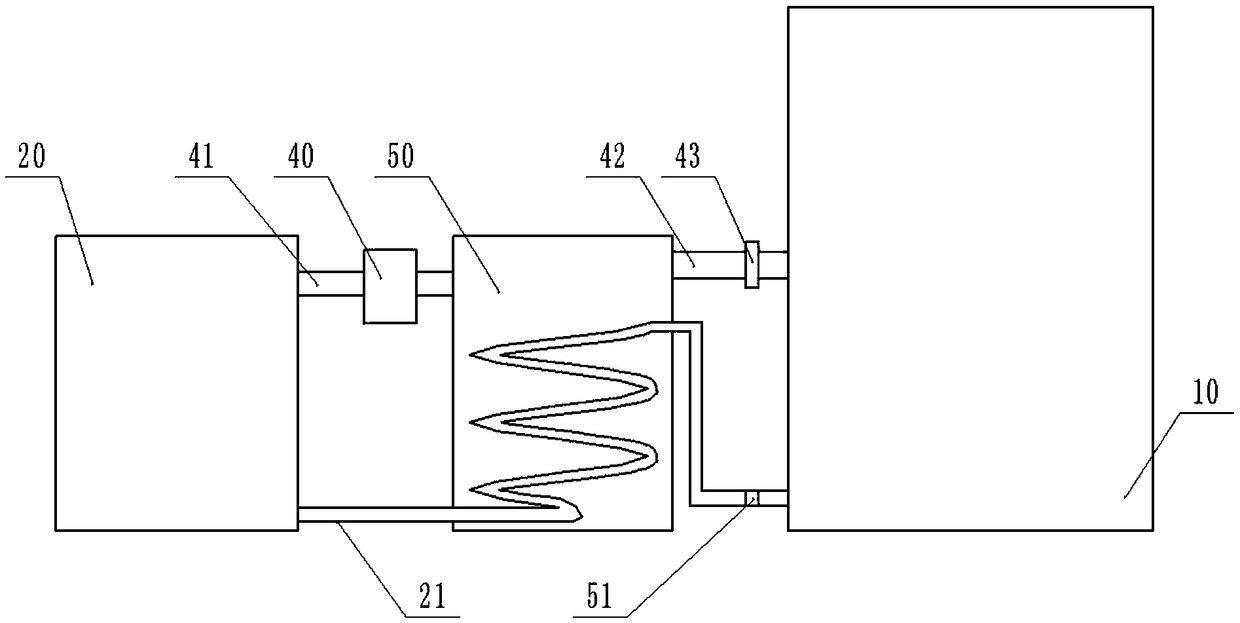

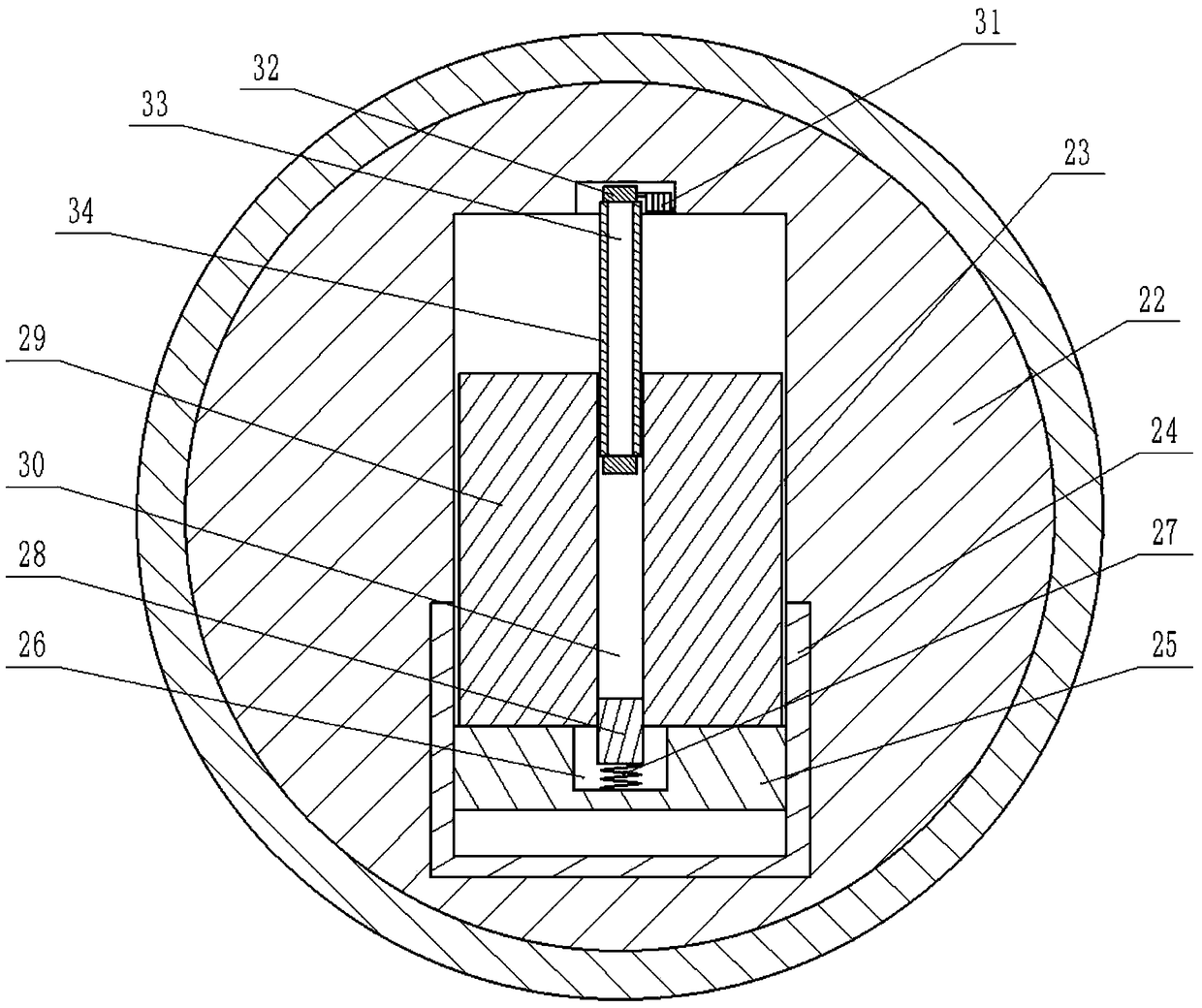

Process for vacuum induction melting of titaniferous hydrogen storage alloy by using CaZrO3 refractory material

The invention discloses a process for vacuum induction melting of titaniferous hydrogen storage alloy by using a CaZrO3 refractory material. According to the process, a crucible made of CaZrO3 refractory materials is used to prepare titaniferous hydrogen storage alloy by using the vacuum induction melting technology, using the component titaniferous hydrogen storage alloy as a raw material and an inert gas as a protective gas or under the vacuum condition; an infrared temperature measurement instrument is used to measure the melting temperature; the temperature rising speed of melting is controlled to be 1-50 DEG C / min by adjusting the power of a vacuum induction furnace, and the melting temperature is controlled to be 10-50 DEG C higher than the melting point of the titaniferous hydrogen storage alloy, and the melting time is 10-120 minutes. Based on relevant detection, the oxygen content of the titaniferous hydrogen storage alloy melted by the process is low, the alloy components are effectively controlled, the alloy is easily activated and easily absorbs and desorbs hydrogen at room temperature, and the hydrogen absorption amount is large.

Owner:SHANGHAI UNIV

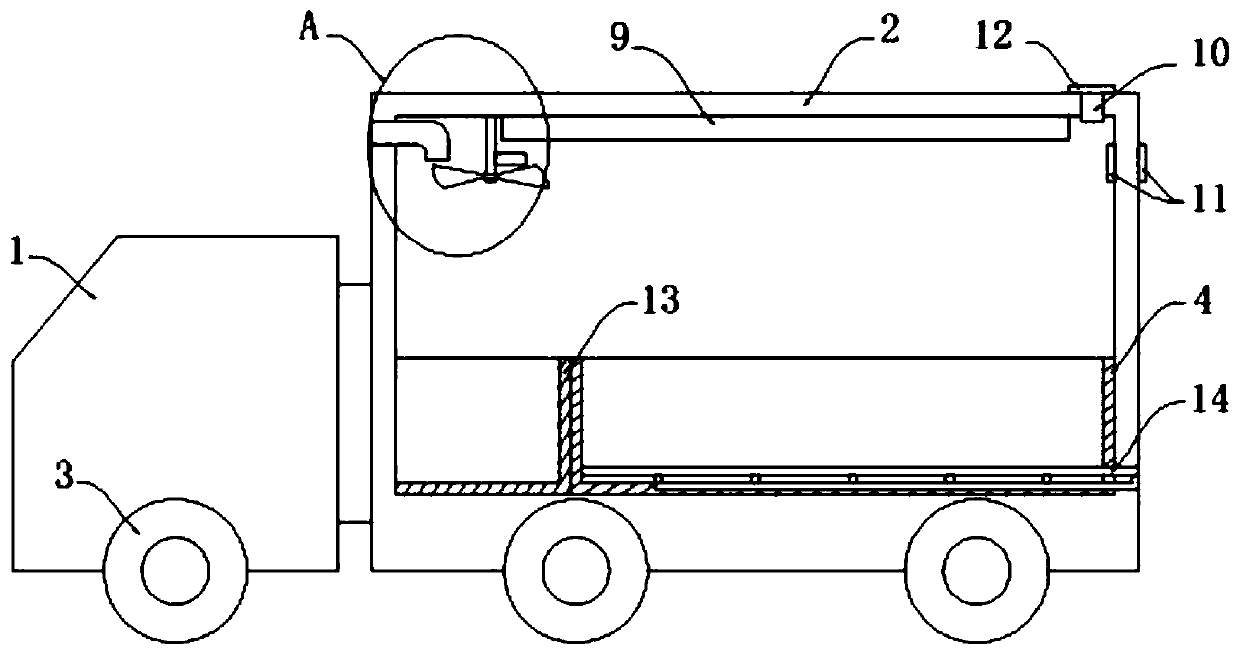

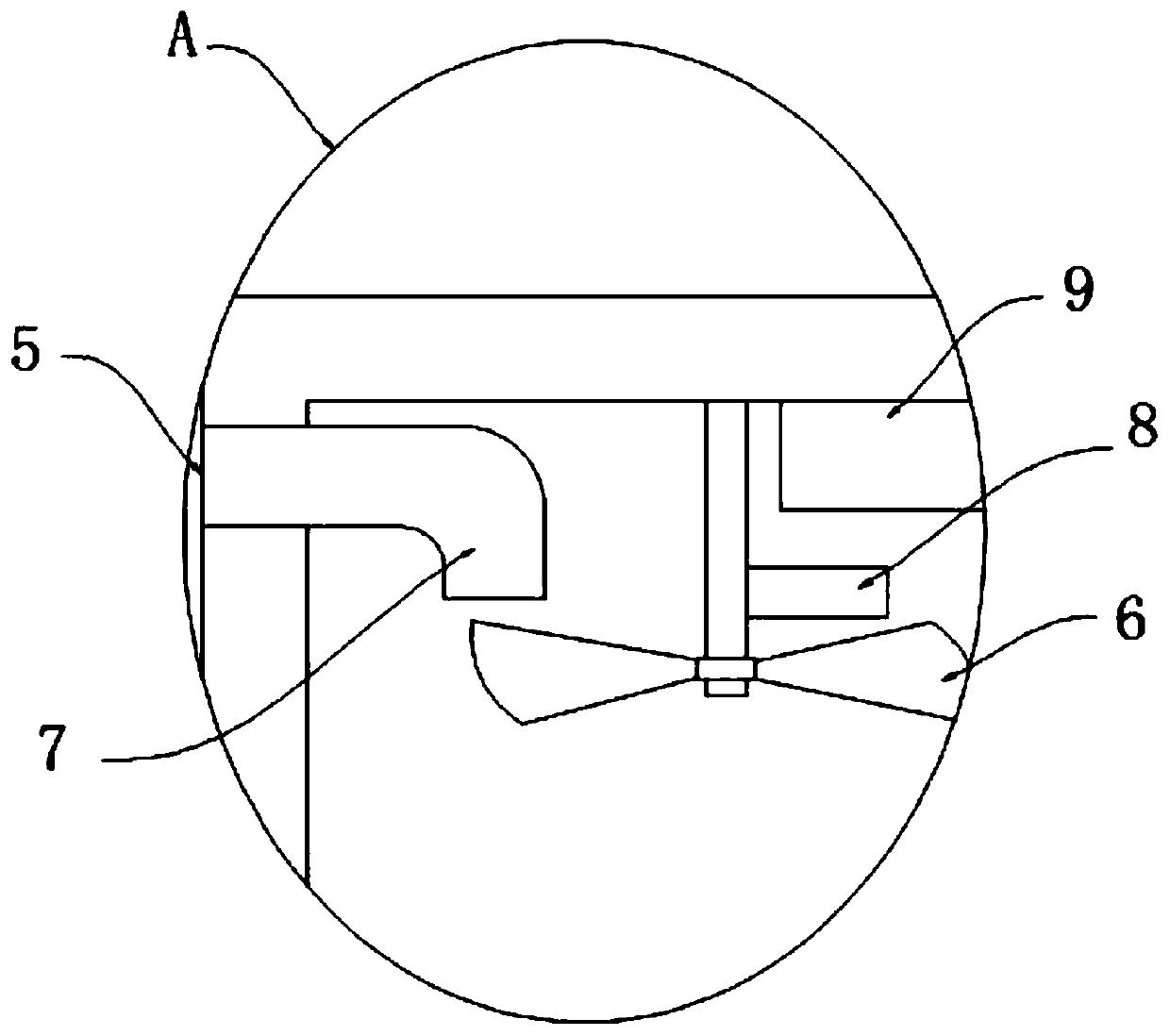

Transport vehicle for storing fresh fruits

InactiveCN111231804AReduce respirationInhibition of decay processAir-treating devicesSmall article transportationCartAutomotive engineering

The invention discloses a transport vehicle for storing fresh fruits. The transport vehicle comprises a head, a body and wheels, a storage box is fixedly connected into the vehicle body; a ventilationopening is formed in the side wall, close to the vehicle head, of the vehicle body. An impeller is rotationally connected to the part, close to the ventilation opening, in the vehicle body; the ventilation opening is in sealed connection with an air inlet pipe of a right-angle structure. The end, away from the ventilation opening, of the air inlet pipe directly faces blades of the impeller, a permanent magnet is fixedly connected to a rotating shaft of the impeller, an electromagnet is electrically connected to the magnetic plate, an air exchange opening is formed in the top of the side, awayfrom the ventilation opening, of the vehicle body, and an oxygen concentration meter is arranged in the air exchange opening in a communicating mode. The transport cart has the advantages that the impellers are driven to rotate through wind pressure generated when the transport cart runs, so that under the action of electromagnetic induction and thermoelectric power, on one hand, gas components are transferred through a magnetic field generated by the electromagnet, and on the other hand, the storage box absorbs heat to keep fruits in a low-oxygen and low-temperature environment, and the respiratory action is reduced.

Owner:刘红亮

Method for smelting hydrogen storage alloy containing titanium from BaZrO3 refractory material by vacuum induction

The invention discloses a method for smelting hydrogen storage alloy containing titanium from a BaZrO3 refractory material by vacuum induction. The method comprises the steps of using a crucible of the high-stability BaZrO3 refractory material, taking pure metal forming the hydrogen storage alloy containing titanium as the material, preparing the hydrogen storage alloy containing titanium by adopting a vacuum induction smelting process and by taking inert gases as protective gases or under a vacuum condition; measuring the smelting temperature with an infrared thermometer; controlling the temperature increase rate of smelting and keeping at 1-50 DEG C per minute by adjusting the power of a vacuum induction furnace, and controlling the smelting temperature, and keeping the smelting temperature 1-150 DEG C higher than the melting point of the hydrogen storage alloy containing titanium and the smelting time at 5-120min. The hydrogen storage alloy containing titanium smelted by the method is low in oxygen content in the alloy, easy to activate and strong in hydrogen absorption capacity by related detection; the alloying component is effectively controlled, and the hydrogen is absorbed and released at room temperature.

Owner:SHANGHAI UNIV

Preparation method of Y2O3 crucible and application in high-activity metal smelting

The invention discloses a preparation method of Y2O3 crucible and application in high-activity metal smelting. The Y2O3 crucible is prepared by pressing dried Y2O3 powder under 100-140 Mpa to be a crucible biscuit; and applying a solid phase sintering method. The high-activity alloy is smelted by a vacuum sensing furnace and the Y2O3 crucible prepared by the method; power is slowly increased during the smelting process, and Ar gas is back flushed in the smelting process; power is slowly reduced during the cooling process after smelting; thus shortcoming of hole formation caused by quick cooling of the high-activity alloy is avoided, and the crack of the Y2O3 crucible is avoided. After smelting, the alloy component is uniform, the crucible is complete; there is no obvious interface layer between the high-activity alloy and the crucible, and oxygen content in the high-activity alloy is low, and the high-activity alloy performance after being smelted is guaranteed; the technique can adjust corresponding technical parameter according to different alloy characteristics, and has excellent industrial application prospect.

Owner:SHANGHAI UNIV

Aluminum scandium alloy target and method of manufacturing the same

PendingUS20220290279A1Uniform internal structureHigh purityVacuum evaporation coatingSputtering coatingMetallic aluminumAlloy

Provided are an aluminum scandium alloy target and a method of manufacturing the same. The method comprises: preparing metal aluminum and metal scandium with purities of 99.99% or more respectively; mixing the metal aluminum into the metal scandium and smelting through a plurality of cycles to obtain a desired aluminum scandium alloy, in which the metal scandium account for 5-40 wt % and the metal aluminum account for 60-95 wt %; injecting the aluminum scandium alloy into a mold to obtain an aluminum scandium alloy target billet; and mechanically processing the billet to obtain the aluminum scandium alloy target. The method addresses the problems of the prior art in which uniform distributions of ingredients in the target are difficult to achieve, scandium is not uniformly distributed, and the target has a high oxide content, a low compactness, a low alloy purity and are unsuitable for manufacturing a sputter coating.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

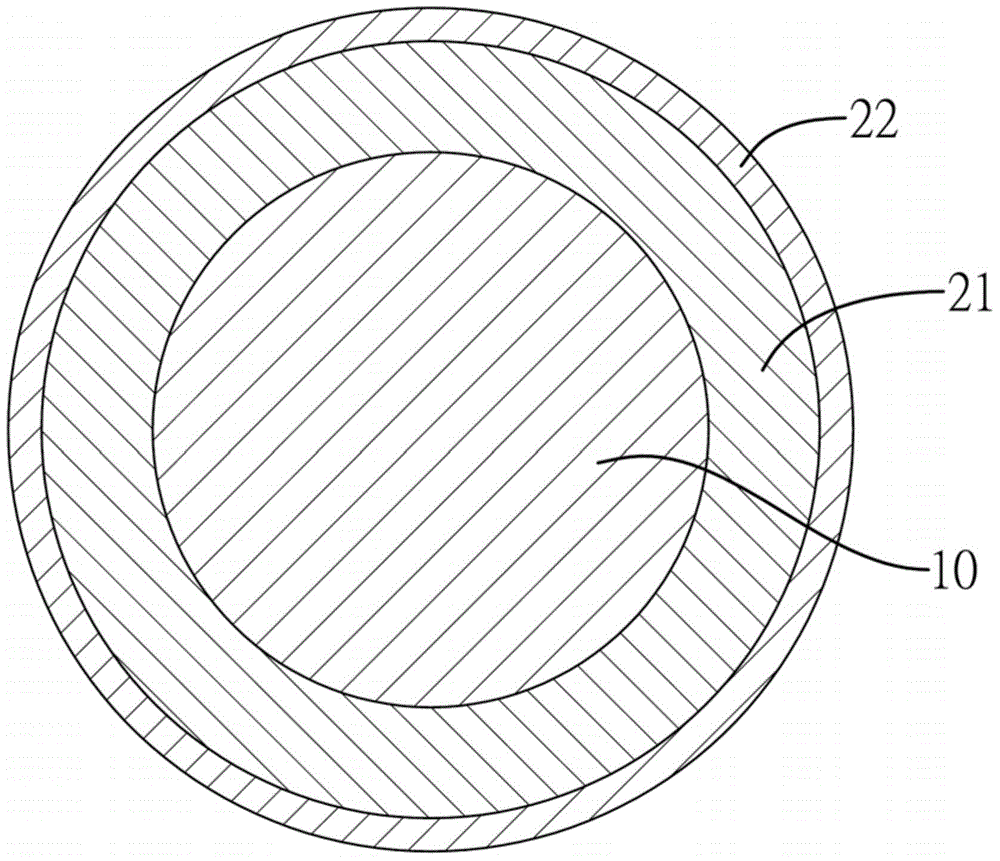

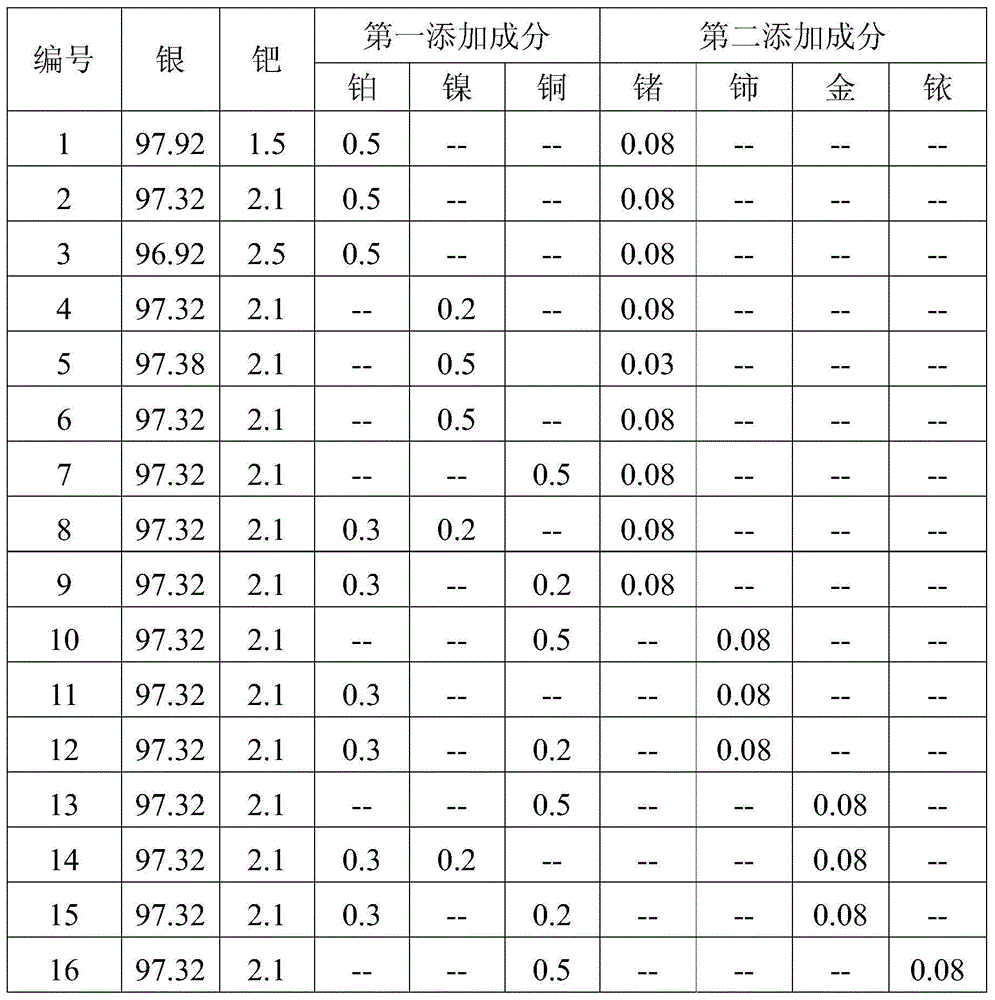

Silver alloy wire rod

ActiveCN105006513AImprove the bonding strength of the interfaceReduce oxygen contentSolid-state devicesMetal layered productsInterfacial bondingIridium

The invention provides a silver alloy wire rod, which includes a core wire, a gold plated layer, and a palladium plated layer formed between the gold plated layer and the core wire. The core wire includes silver, palladium, a first additive component, and a second additive component, wherein the first additive component may be platinum, nickel, or copper, and the second additive component may be germanium, cerium, gold, or iridium. The core wire comprises, based on the total weight, palladium with the content being more than or equal to 1.1 wt% and less than or equal to 2.8 wt%, the first additive component with the content being more than 0.1 wt% and less than 1 wt%, and the second additive component with the content being more than 0.02 wt% and less than 0.2 wt%. Therefore, the silver alloy wire rod has excellent conductivity, antioxidant ability, wire drawing operation performance, heading stability, PCT reliability, and u-HAST reliability, and the interfacial bonding strength between the silver alloy wire rod and a packaging material can be particularly improved.

Owner:SOLAR APPLIED MATERIALS TECHNOLOGY CORPORATION

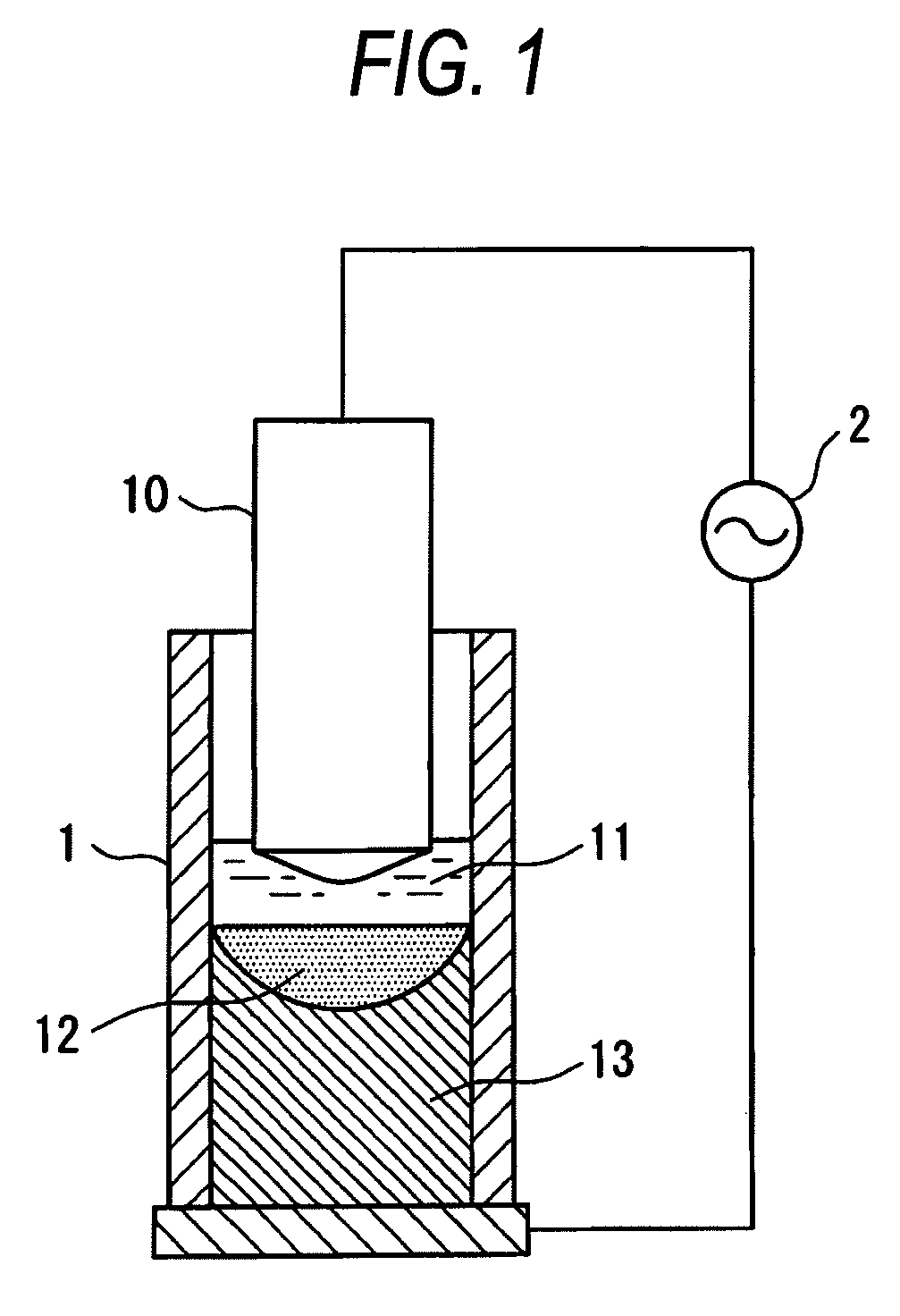

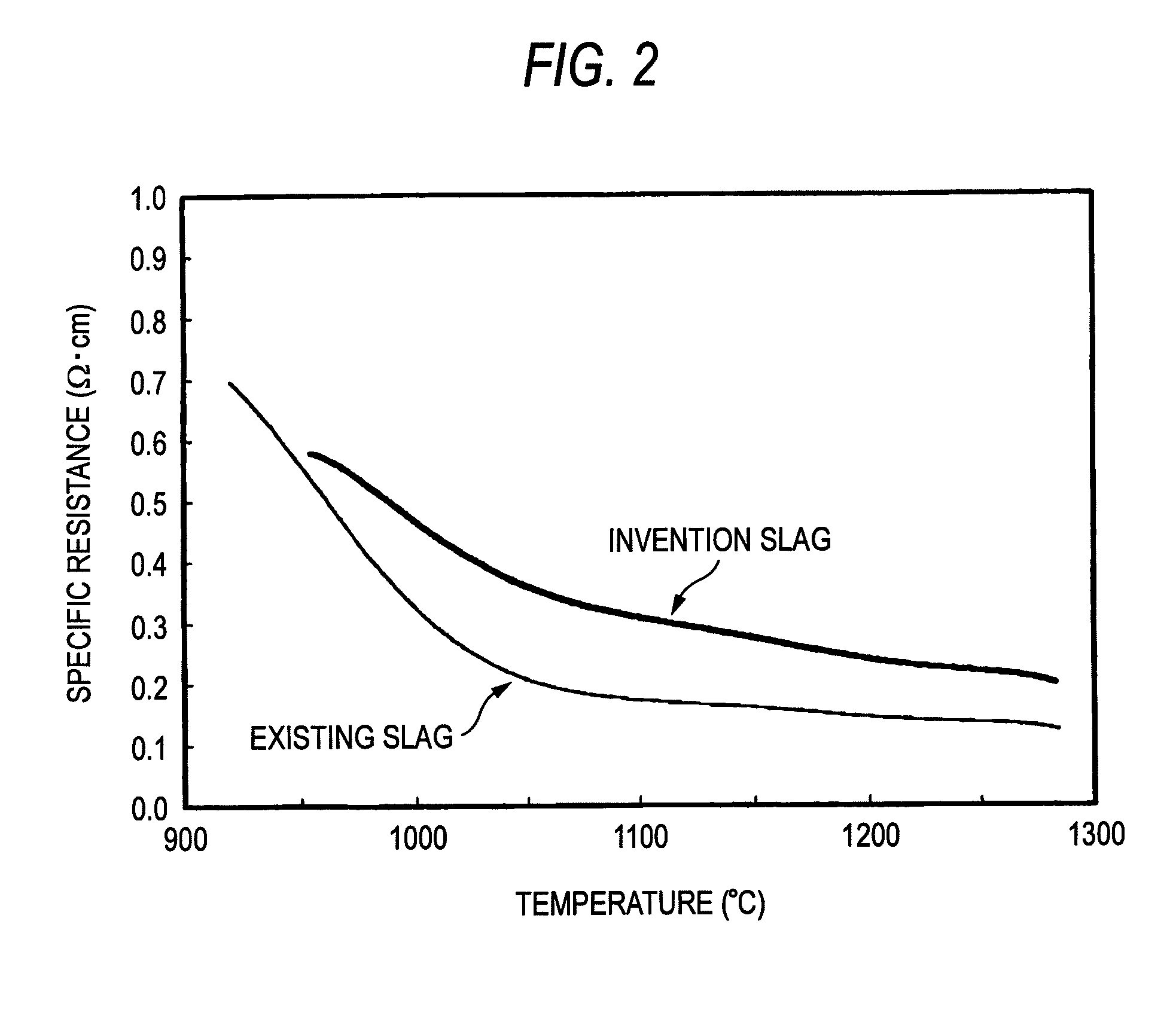

Slag for electroslag remelting for copper alloy and method for producing copper alloy material

InactiveUS8083830B2Fine surfaceMaintain good propertiesBlast furnace componentsBlast furnace detailsSlagImpurity

An object of the invention is to make it possible to produce a copper alloy in which the S content is reduced with no contamination with Al, which has a good casting surface and good internal properties and in which eutectic compounds are refined. The invention relates to a slag for electroslag remelting for copper alloy, including CaF2: 20 to 45% by mass, CaO: 10 to 30% by mass, SiO2: 10 to 30% by mass, LiF: 10 to 20% by mass, and ZrO2: 5 to 15% by mass with other impurities: at most 1% by mass, and satisfying a formula:17.0(LiF content+ZrO2 content)−556≦CaF2 content≦4.1(LiF content+ZrO2 content)−80.9,and the invention relates to a method for producing a copper alloy with the slag.

Owner:JAPAN STEEL WORKS LTD

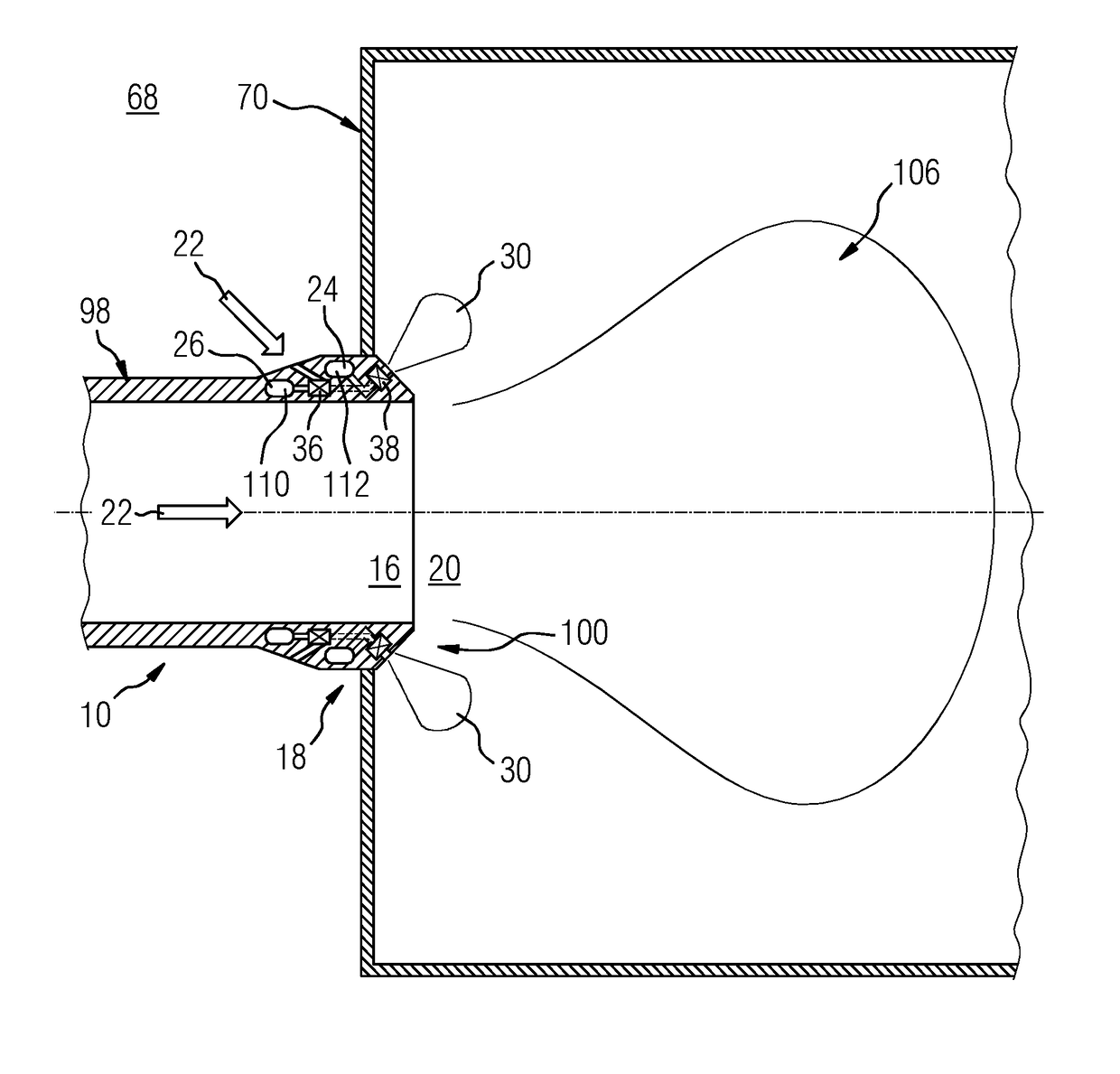

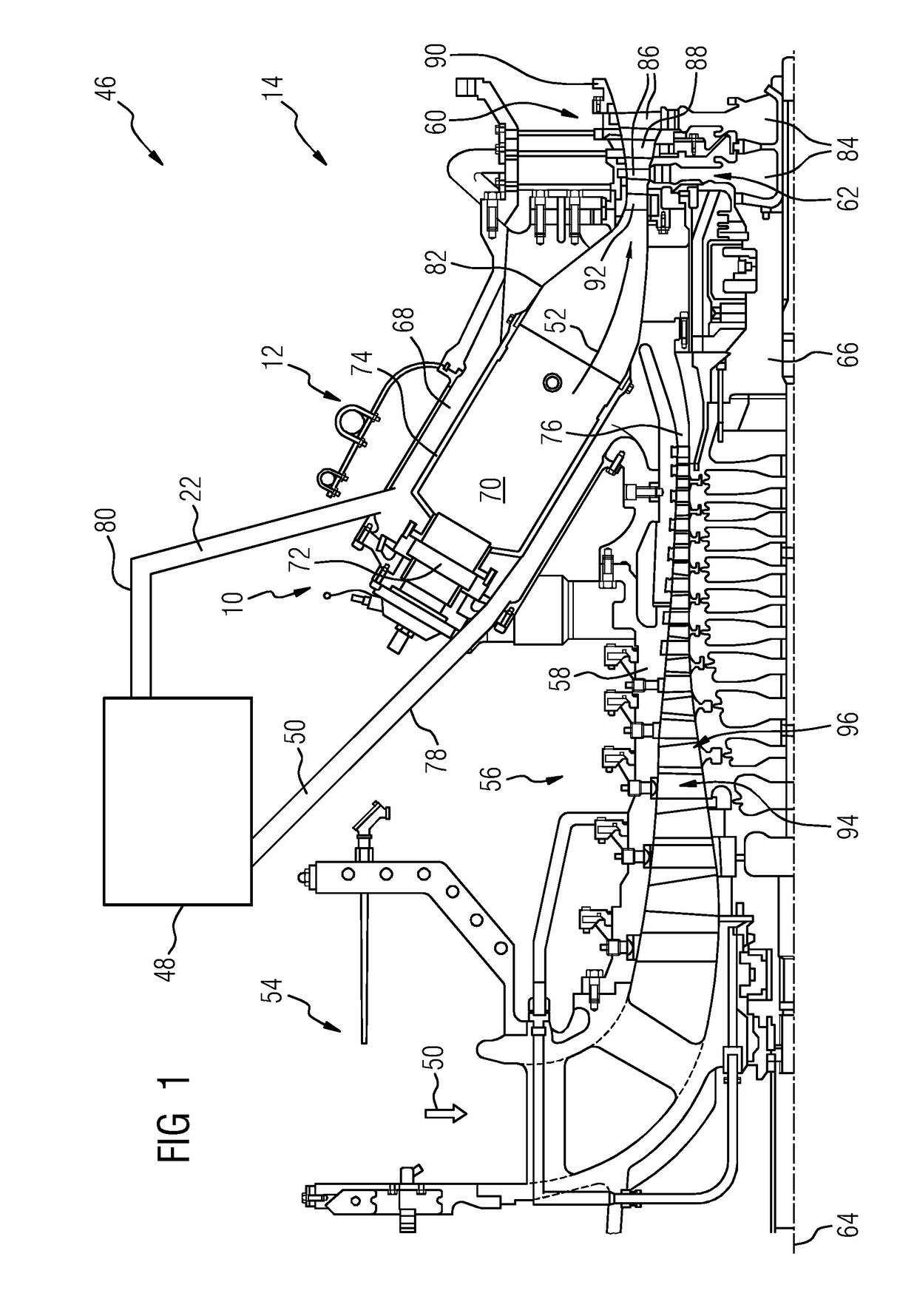

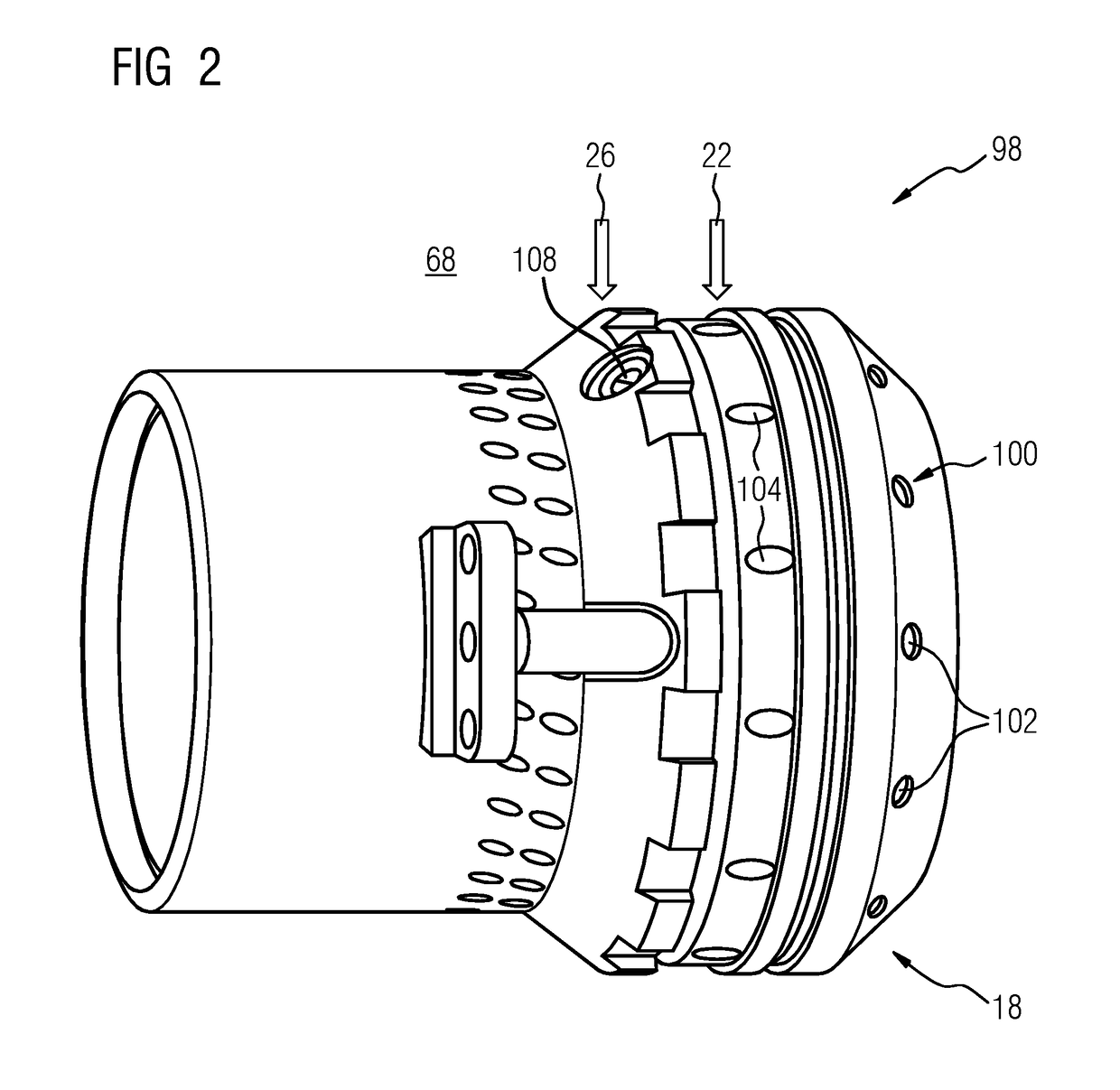

Method for operating a combustion system

InactiveUS20180058697A1Low oxygen contentCost reductionContinuous combustion chamberIndirect carbon-dioxide mitigationAutomotive engineeringGas turbines

A method for operating a combustion system of a combustion section of a gas turbine engine having at least one main burner arrangement and at least one pilot burner arrangement, wherein the at least one main burner arrangement and the at least one pilot burner arrangement are operated with an air-fuel mixture. The method includes: operating the at least one main burner arrangement with O2-lean air, enriching an air of the air-fuel mixture of the at least one pilot burner arrangement and / or a fuel of the air-fuel mixture of the at least one pilot burner arrangement and / or the air-fuel mixture of the at least one pilot burner arrangement with oxygen and preferably with pure oxygen.

Owner:SIEMENS AG

A kind of preparation method of sulfur dioxide gas in sugar industry

ActiveCN103569972BAdjustable production volumeLess sublimated sulfurSulfur compoundsCombustionSulfur

The invention relates to a preparation method of a sulfur dioxide gas in a sugar industry. The preparation method concretely comprises the following steps: adding concentrated sulfuric acid and sulphur to a reaction vessel; after material addition is finished, and heating till the reaction is started to generate the sulfur dioxide gas; cooling the generated sulfur dioxide gas to 60-70 DEG C, wherein the mass ratio of the concentrated sulfuric acid to the sulphur is (5-7):1, and the mass concentration of the concentrated sulfuric acid is 93%-98.3%. The method disclosed by the invention can be used for producing the sulfur dioxide gas by oxidizing elemental sulfur by utilizing the concentrated sulfuric acid, can well solve multiple problems of the sulfur dioxide gas used for preparing sugar through the traditional sulphur combustion, and has the advantages that quantity control of the sulfur dioxide gas is easy to control, and sublimed sulfur of the sulfur dioxide gas is little; the generated sulfur dioxide gas is high in purity, low in oxygen content, low in temperature and easy to cool; raw materials are easily obtained and low in cost and the quantity of the used sulphur is remarkably reduced; a device for preparing the sulfur dioxide gas is simple and small in occupied area.

Owner:中粮糖业辽宁有限公司

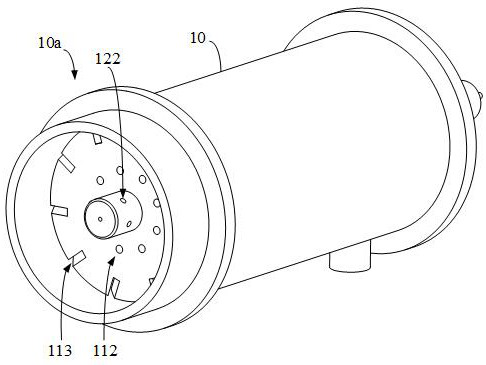

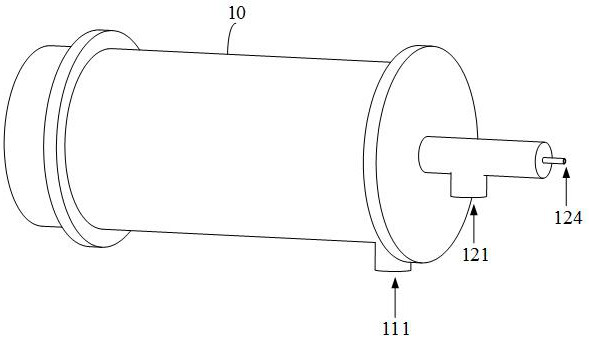

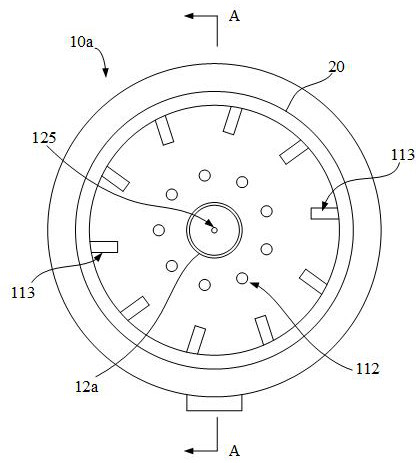

Burner

ActiveCN113883500ALow oxygen contentInhibition formationSolid fuel combustionNon-combustible gases/liquids supplyThermodynamicsCombustor

The invention discloses a burner. The burner comprises a main body; the main body is provided with a gas inlet, a first gas outlet, a second gas outlet, a fuel inlet and a fuel outlet; the gas inlet simultaneously communicates with the first gas outlet and the second gas outlet, the gas inlet is used for allowing a combustion-supporting medium to flow in, and the first gas outlet and the second gas outlet are used for allowing the combustion-supporting medium to flow out; a fuel channel is formed between the fuel inlet and the fuel outlet, is used for fuel circulation, and separates the combustion-supporting medium in the main body from the fuel; when the burner works, the fuel flowing out of the fuel outlet firstly makes contact with the combustion-supporting medium flowing out of the first gas outlet and then makes contact with the combustion-supporting medium flowing out of the second gas outlet. According to the technical scheme, the burner can reduce environmental pollution caused by combustion of the coal-based fuel.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

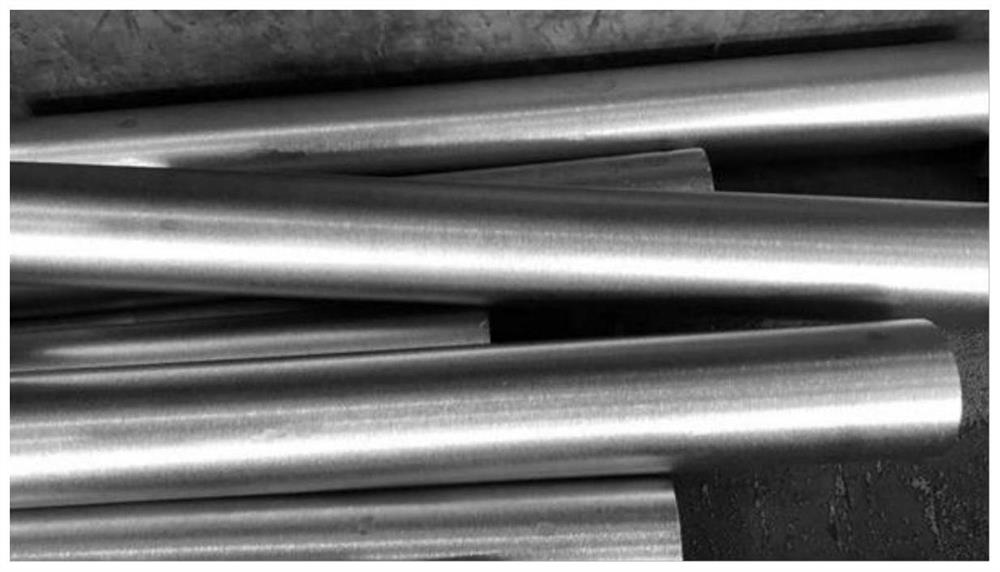

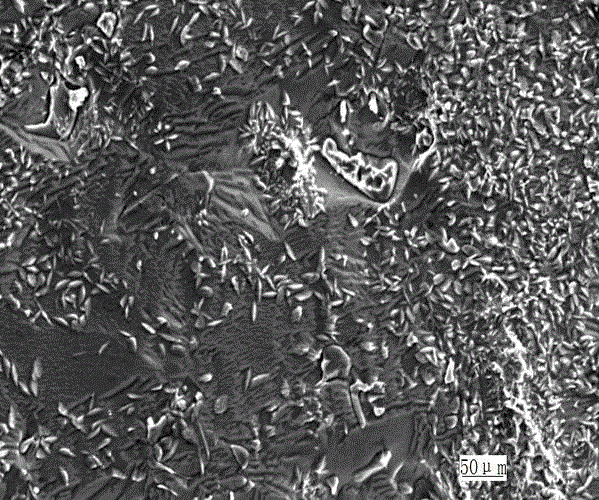

A kind of co-al-w alloy bar and preparation method thereof

The invention discloses a Co-Al-W alloy bar and a preparation method thereof. The Co-Al-W alloy bar is composed of the following mass percentages: aluminum 7%-11%, tungsten 8%-12% , and the balance is cobalt. The method of the present invention is specifically (1) drying the raw material powder after ball milling to obtain a mixed powder; (2) pressing and molding to obtain a blank, and sintering to obtain a Co-Al-W alloy sintered body; (3) electron beam smelting to obtain Co ‑Al‑W alloy ingots, cut into semi-finished rods; (4) Co‑Al‑W alloy rods obtained by electron beam regional melting. The Co-Al-W alloy bar of the present invention has the characteristics of high strength at room temperature and high temperature, high purity and low oxygen content, and is a key material for manufacturing advanced aero-engines and industrial gas turbine blades, which can increase the working temperature of aero-engine turbines and increase the thrust weight ratio, increasing engine thrust.

Owner:XIAN AEROSPACE XINYU ELECTRICAL & MECHANICAL EQUIP FACTORY

Method for smelting hydrogen storage alloy containing titanium from BaZrO3 refractory material by vacuum induction

The invention discloses a method for smelting hydrogen storage alloy containing titanium from a BaZrO3 refractory material by vacuum induction. The method comprises the steps of using a crucible of the high-stability BaZrO3 refractory material, taking pure metal forming the hydrogen storage alloy containing titanium as the material, preparing the hydrogen storage alloy containing titanium by adopting a vacuum induction smelting process and by taking inert gases as protective gases or under a vacuum condition; measuring the smelting temperature with an infrared thermometer; controlling the temperature increase rate of smelting and keeping at 1-50 DEG C per minute by adjusting the power of a vacuum induction furnace, and controlling the smelting temperature, and keeping the smelting temperature 1-150 DEG C higher than the melting point of the hydrogen storage alloy containing titanium and the smelting time at 5-120min. The hydrogen storage alloy containing titanium smelted by the method is low in oxygen content in the alloy, easy to activate and strong in hydrogen absorption capacity by related detection; the alloying component is effectively controlled, and the hydrogen is absorbed and released at room temperature.

Owner:SHANGHAI UNIV

Hard alloy coating furnace

ActiveCN108662911AGuarantee product qualityWill not deformStationary tubular conduit assembliesWaste heat treatmentSmokeCarbide coating

The invention belongs to the technical field of metallurgic assisting equipment, and specifically discloses a hard alloy coating furnace. The hard alloy coating furnace comprises a furnace body, a first cooling box and a second cooling box, wherein smoke under the temperature of 25-200 DEG C are stored in the first cooling box and the second cooling box; an air suction pipe communicates with the first cooling box; one end, far away from the first cooling box, of the air suction pipe penetrates the second cooling box and communicates with the inner part of the furnace body; a first air outlet pipe communicates with the first cooling box; one end, far away from the first cooling box, of the first air outlet pipe communicates with the second cooling box; an air pump is arranged on the first air outlet pipe; a second air outlet pipe is arranged on the second cooling box; and one end, far away from the second cooing box, of the second air outlet pipe communicates with the furnace body. Thehard alloy coating furnace aims at solving the problem of product deformation caused by fast cooling of a coating furnace in the prior art.

Owner:ZUNYI ZHONGBO CEMENTED CARBIDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com