Method for smelting hydrogen storage alloy containing titanium from BaZrO3 refractory material by vacuum induction

A vacuum induction smelting and hydrogen storage alloy technology, applied in the field of vacuum metallurgical smelting, can solve problems such as uneven structure of titanium-based hydrogen storage alloys, carbon increase in ingots, waste of energy, etc. Low, stable chemical composition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0019] Specific embodiments of the present invention are now described in the following:

Embodiment

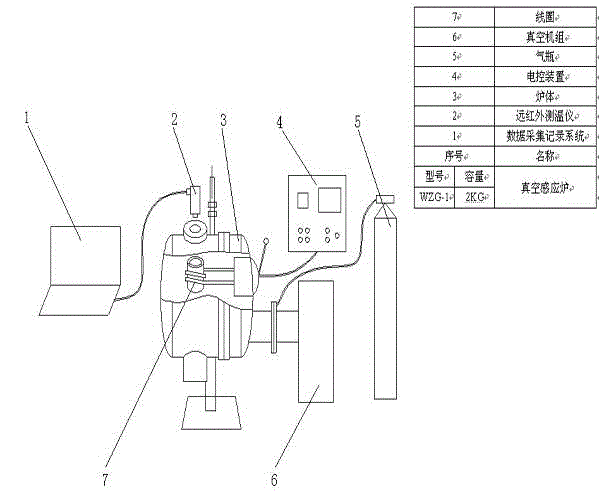

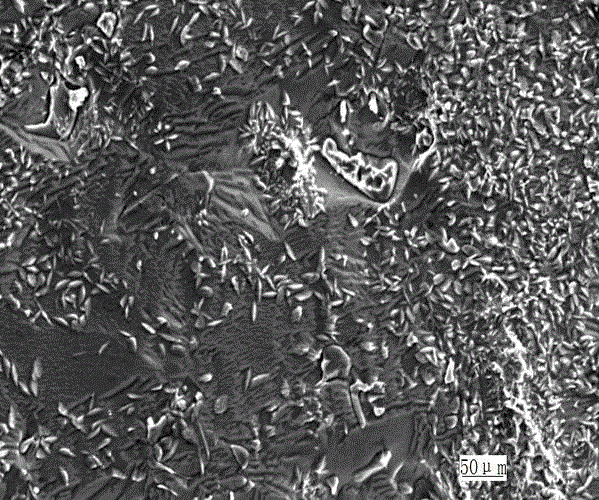

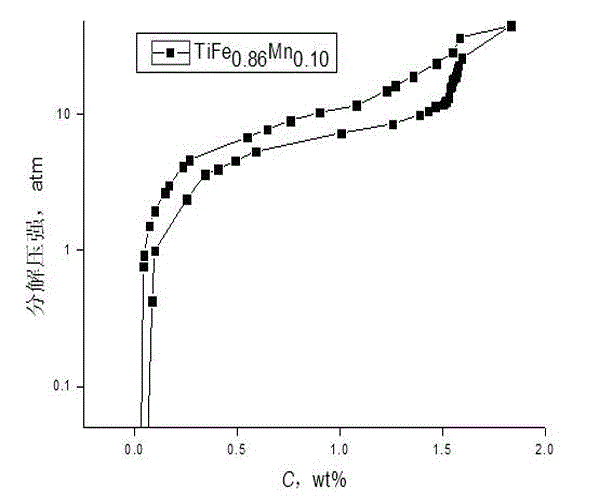

[0021] Using vacuum induction melting process and high stability BaZrO 3 Crucible melting TiFe 0.86 mn 0.10 hydrogen storage alloy

[0022] a) Ingredients and calculation: 99.9wt% pure iron, 99.9wt% sponge titanium, electrolytic manganese as TiFe 0.86 mn 0.10 The raw materials of the hydrogen storage alloy, according to the mass percentage: wt (Fe)% = 47.3736, wt (Ti) % = 47.2162, wt (Mn) % = 5.4102, while considering the burning loss rate of Mn is 1~8%, weigh the raw materials , the raw materials are pickled with dilute hydrochloric acid or dilute sulfuric acid in advance, then cleaned by ultrasonic waves for 5 minutes, and then dried in a muffle furnace at 150°C for 10 hours;

[0023] b) Charging: laying down the smelting TiFe 0.86 mn 0.10 Alloys of BaZrO as highly stable refractory materials 3 The crucible and its lining, the feeding order is Fe→Ti→Mn from bottom to top, take out the dried ingredients from the muffle furnace, and put BaZrO, a high-stable refractory m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com