Composition for cleanser, cleanser and application thereof

A cleaning agent and composition technology, which is applied in the field of cleaning agent compositions, can solve the problems of clogging the system, high cost of pickling, and high system pressure, and achieves the effects of stable chemical properties, easy popularization and application, and simple treatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

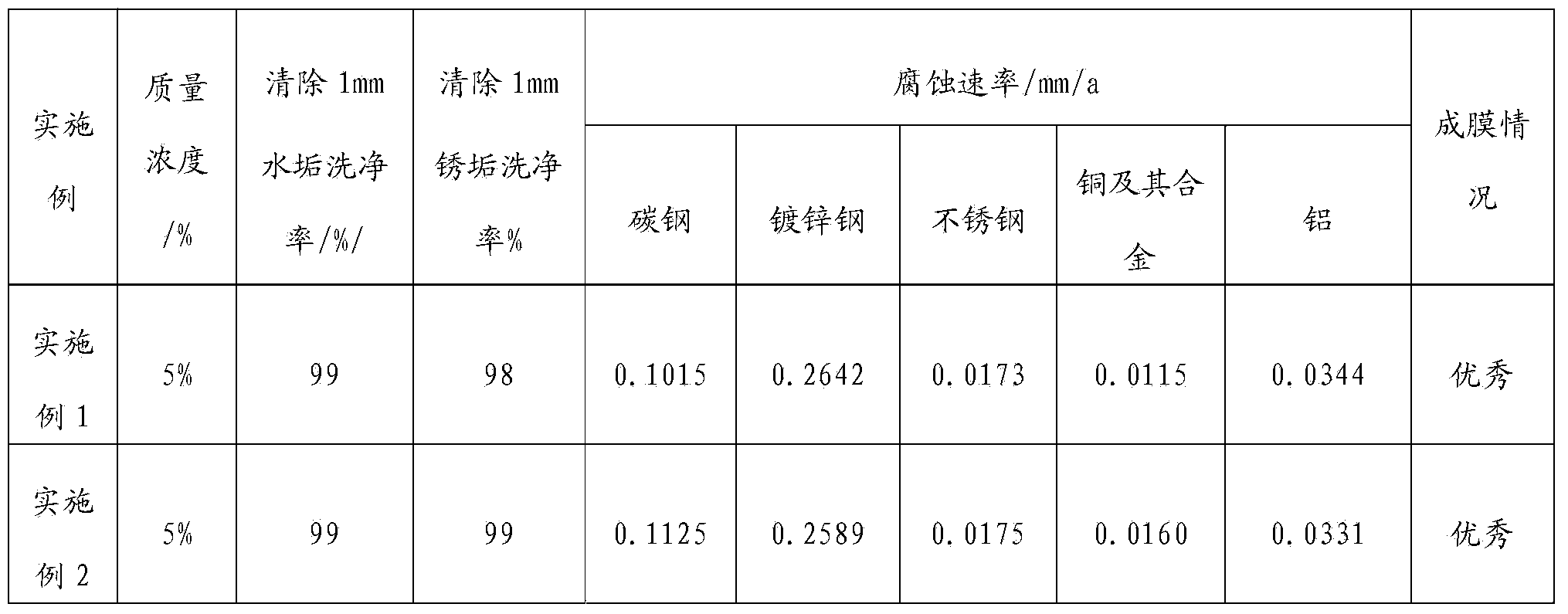

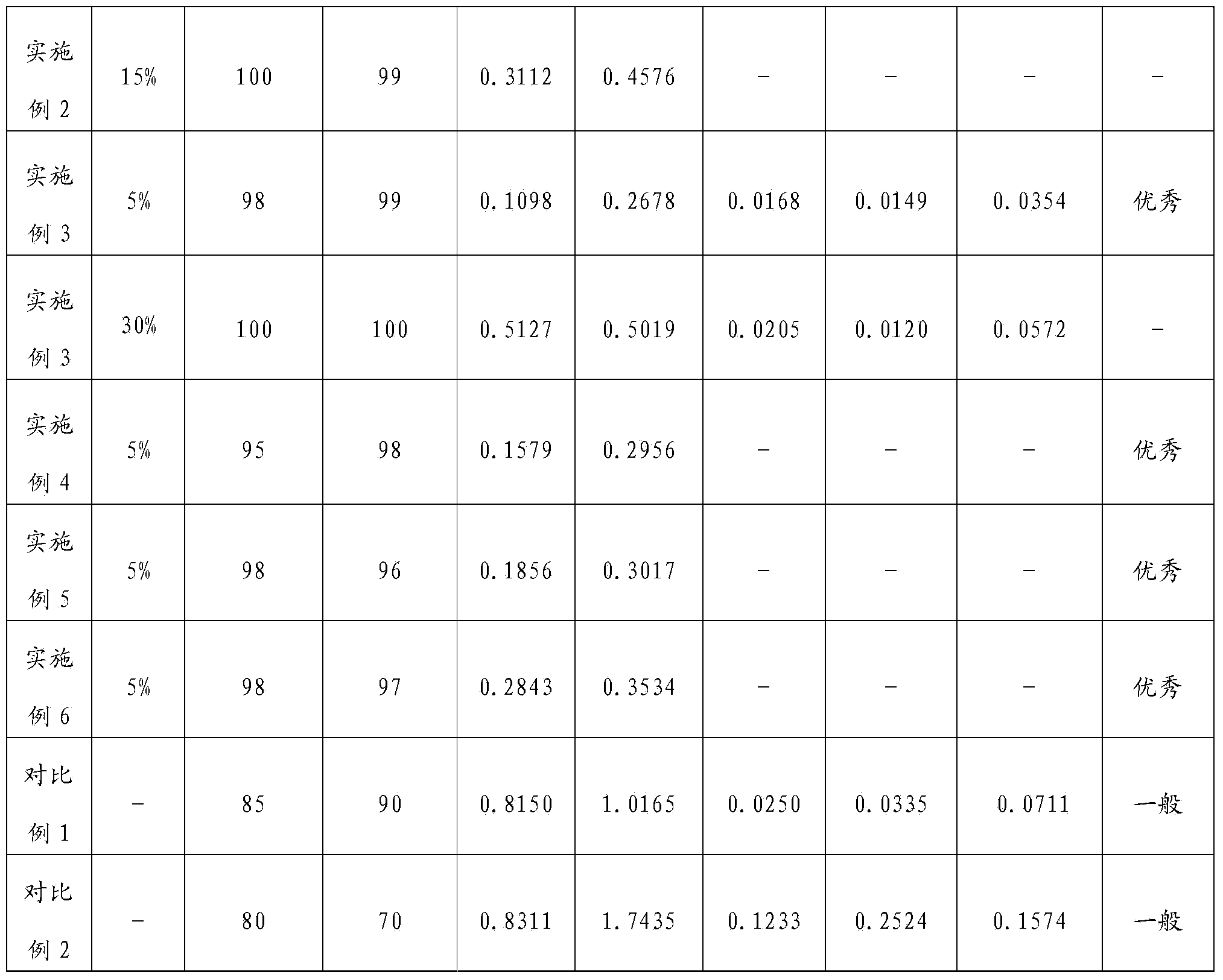

Examples

Embodiment 1

[0032] Weigh 10.0 grams of sodium hydroxyethylidene phosphonate, 5.0 grams of AA / AHPSE, 2.5 grams of sodium sulfite, 1.5 grams of dioctyl sodium succinate, 1.0 grams of TX-7, 0.25 grams of corrosion inhibitor (thiocyanate Sodium, mercaptobenzothiazole and hydrazine, the weight ratio of the three is 1:3.75:2), and stir evenly.

Embodiment 2

[0034] Weigh 10.0 g of sodium aminotrimethylene phosphonate, 3.0 g of AA / AMPS, 1.0 g of sodium erythorbate, 1.0 g of MOA-7, and 0.10 g of corrosion inhibitor (the same ingredients as in Example 1) and stir evenly.

Embodiment 3

[0036] Weigh 10.0 grams of sodium ethylenediamine tetramethylene phosphonate, 8.0 grams of AA / AHPSE / APES, 3.5 grams of sodium sulfite, 3.5 grams of dodecyl alcohol amide, and 0.35 grams of corrosion inhibitor (the same composition as in Example 1), and stir evenly .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com