Patents

Literature

283 results about "Limescale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Limescale is a hard, off-white, chalky deposit often found in kettles and hot water boilers and on the inside of hot water pipework. It is also often found as a similar deposit on the inner surfaces of old pipes and other surfaces where "hard water" has evaporated.

Machine cleaner

InactiveUS20060172910A1Minimizing moisture pickMaximize the effectSoap detergents with inorganic compounding agentsDetergent materialsLimescaleWater soluble

Owner:THE PROCTER & GAMBLE COMPANY

Medicament for treating composite water in hot water boiler as well as preparation method and use method thereof

ActiveCN103183417ADoes not reduce corrosion inhibitionWill not reduce the effect of anti-scalingScale removal and water softeningInorganic phosphatePhosphoric acid

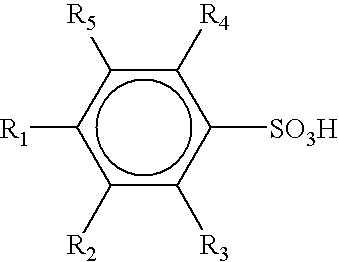

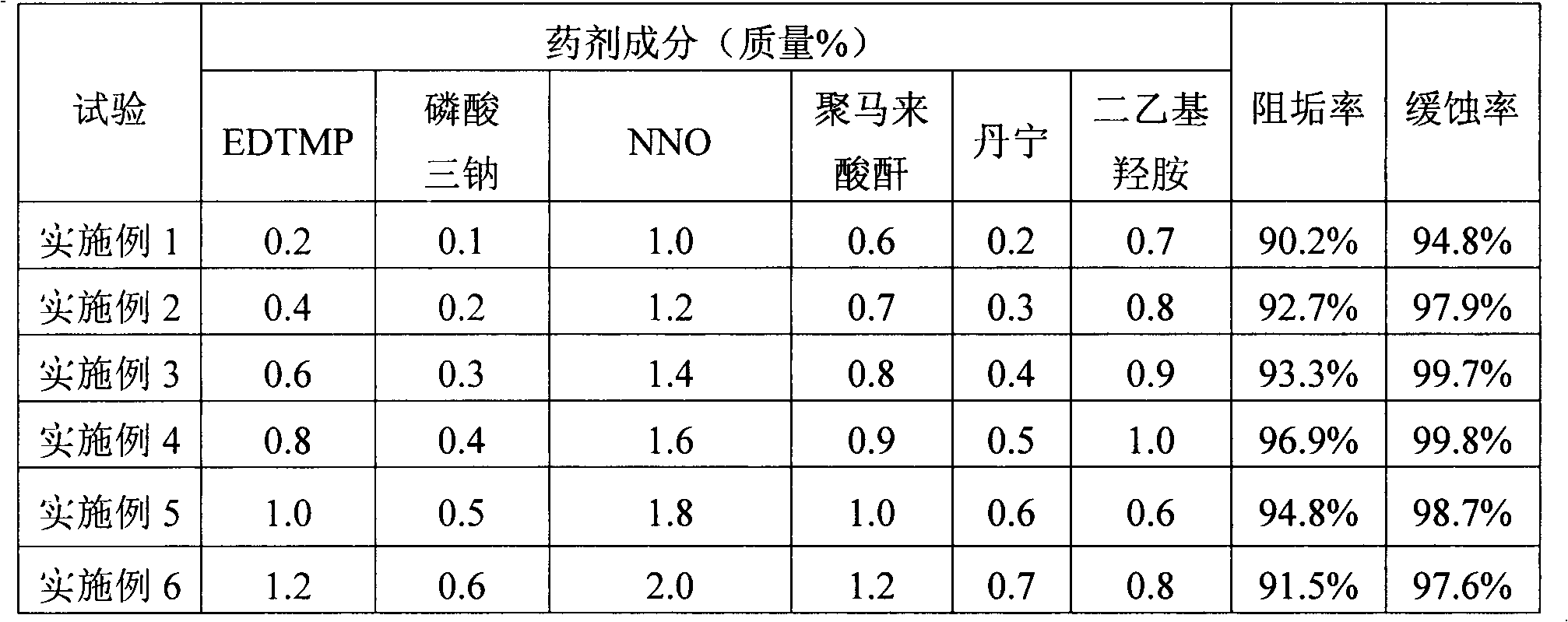

The invention discloses a medicament for treating composite water in a hot water boiler. The medicament comprises the following components by mass percent: 0.1-3% of inorganic phosphate, 0.1-2% of organic phosphoric acid and / or organic phosphate, 0.1-4% of component A, 0.1-3% of component B, 0.6-1.0% of organic amine deoxidizer, 0.1-2% of tannin and / or chitosan and the balance of water, wherein the mass percent of the components is 100%, the component A is one or more of an organic antisludging agent, an organic dispersant and an organic dispersible antisludging agent, and the component B is one or more of an organic carboxylic acid corrosion inhibitor, an organic carboxylate corrosion inhibitor and sodium methylene dinaphthalenesulfonate. The invention further discloses a preparation method and a use method of the medicament, the preparation process is clean, and the medicament is low in toxicity for body health and environment in the using process. The medicament is excellent in corrosion resistance and scale inhibition effects and simple and convenient to store and transport, and the corrosion and scale inhibition effects cannot be reduced after the medicament is stored and transported for a long term.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

Methods for prevention and reduction of scale formation

InactiveUS20110089115A1Preventing and reducing scale formationPreventing and reducing and corrosionIon-exchange process apparatusIon-exchanger regenerationProcess equipmentCorrosion

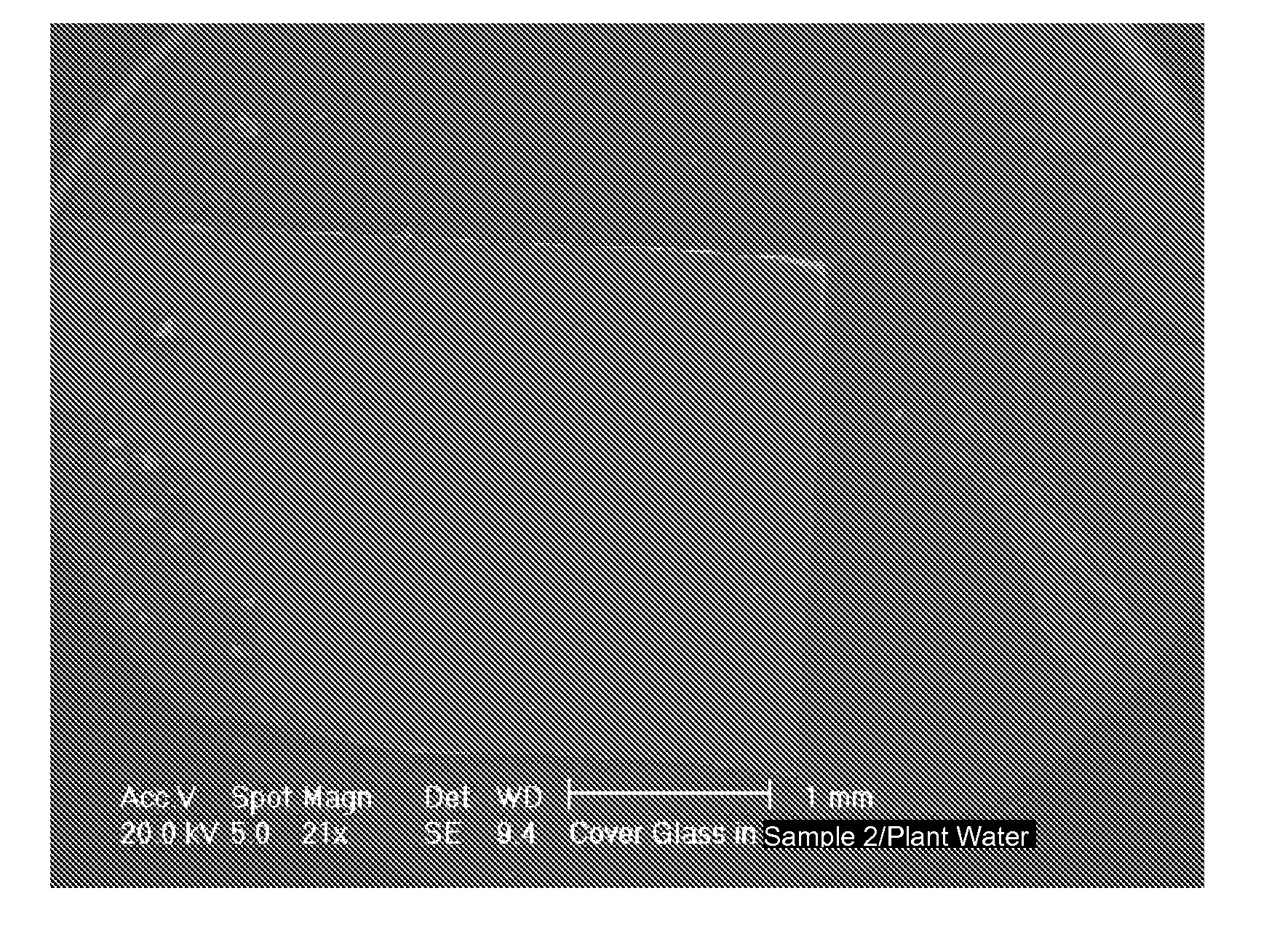

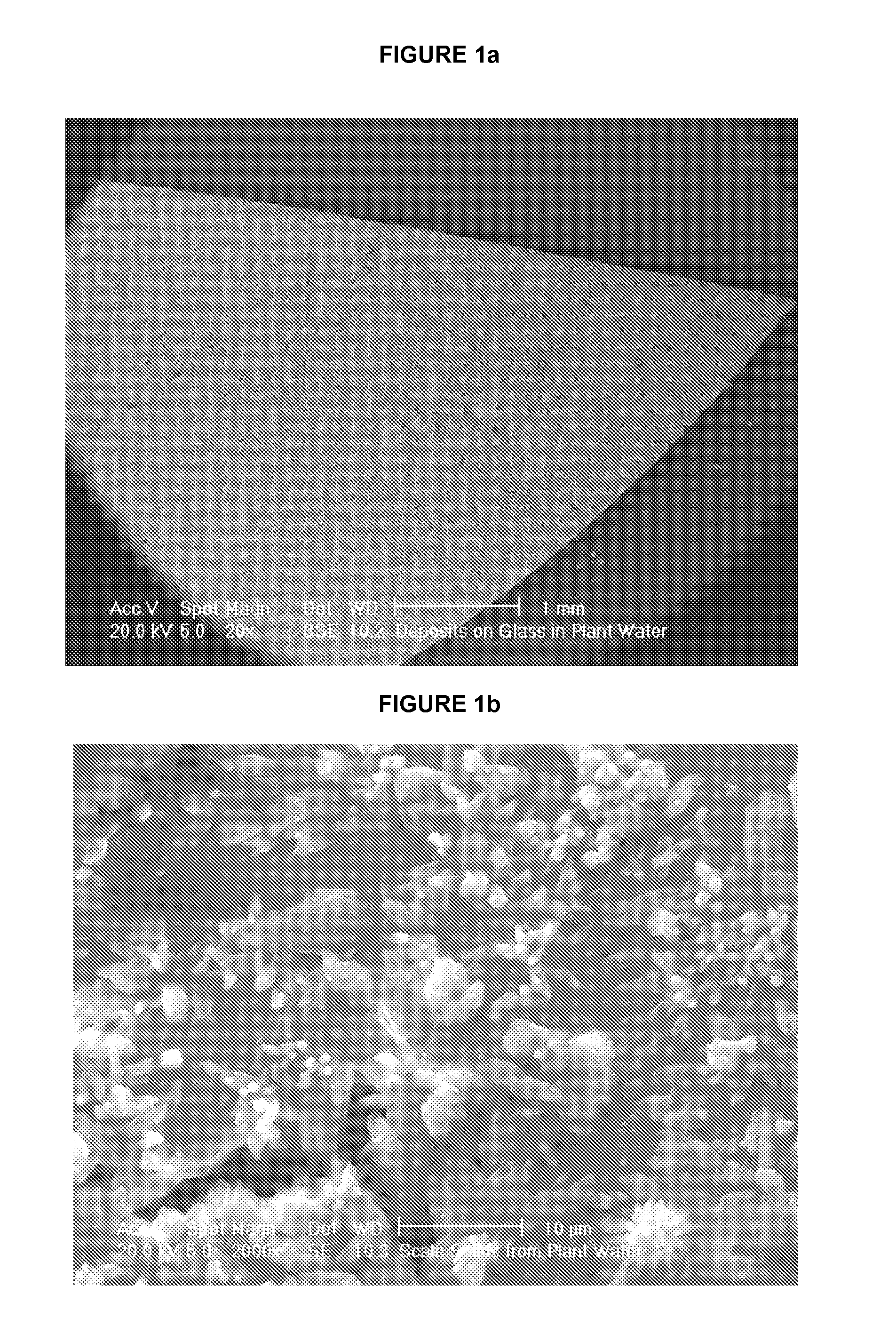

Disclosed herein are methods of preventing or reducing scale formation or corrosion by combining at least one scale-forming fluid comprising at least one scaling compound with at least one anti-scale material chosen from at least one scale-adsorbent agent. The methods may reduce or prevent the formation of scale on surfaces of liquid-related process equipment, such as boilers and heat exchangers.

Owner:IMERYS FILTRATION MINERALS

Cooling water scale and corrosion inhibition

A methods of the present invention for inhibiting silica scale formation and corrosion in aqueous systems where soluble silica residuals (SiO2) are maintained in excess of 200 mg / L, and source water silica deposition is inhibited with silica accumulations as high as 4000 mg / L (cycled accumulation) from evaporation and concentration of source water. The methods of the present invention also provides inhibition of corrosion for carbon steel at corrosion rates of less than 0.3 mpy (mils per year), and less than 0.1 mpy for copper, copper alloy, and stainless steel alloys in highly concentrated (high dissolved solids) waters. The methods of the present invention comprise pretreatment removal of hardness ions from the makeup source water, maintenance of electrical conductivity, and elevating the pH level of the aqueous environment. Thereafter, specified water chemistry residual ranges are maintained in the aqueous system to achieve inhibition of scale and corrosion.

Owner:WATER CONSERVATION TECH INT +1

Cleaning implement with erodible foam substrate and controlled release system of active agent

ActiveUS20070161533A1Easy to cleanExtended service lifeLayered productsOrganic/inorganic per-compounds compounding agentsParticulatesControlled release

A cleaning implement comprises an erodible foam substrate, such as a melamine foam substrate and a controlled release system comprising an active agent. The controlled release system comprises a component selected from the group consisting of a polymer matrix, a microcapsule, a particulate porous carrier, a complexing agent, a semi-permeable film and a combination thereof and the active agent is selected from the group consisting of a surfactant, a bleaching agent, a limescale reducing agent, a biocide, a solvent and a mixture thereof.

Owner:THE PROCTER & GAMBLE COMPANY

Cooling water scale and corrosion inhibition

ActiveUS20050150834A1Avoid corrosionIncrease ionic strengthDrying using combination processesAuxillariesLimescaleEvaporation

A methods of the present invention for inhibiting silica scale formation and corrosion in aqueous systems where soluble silica residuals (SiO2) are maintained in excess of 200 mg / L, and source water silica deposition is inhibited with silica accumulations as high as 4000 mg / L (cycled accumulation) from evaporation and concentration of source water. The methods of the present invention also provides inhibition of corrosion for carbon steel at corrosion rates of less than 0.3 mpy (mils per year), and less than 0.1 mpy for copper, copper alloy, and stainless steel alloys in highly concentrated (high dissolved solids) waters. The methods of the present invention comprise pretreatment removal of hardness ions from the makeup source water, maintenance of electrical conductivity, and elevating the pH level of the aqueous environment. Thereafter, specified water chemistry residual ranges are maintained in the aqueous system to achieve inhibition of scale and corrosion.

Owner:WATER CONSERVATION TECH INT +1

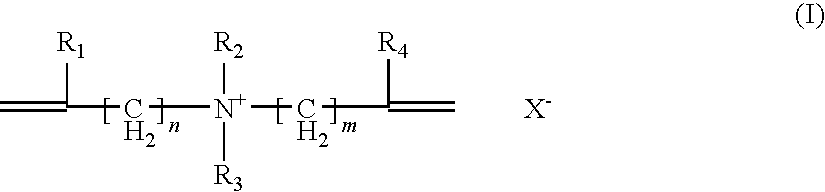

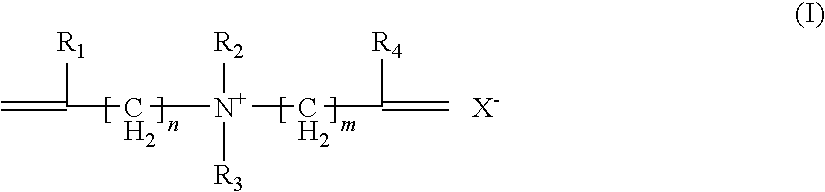

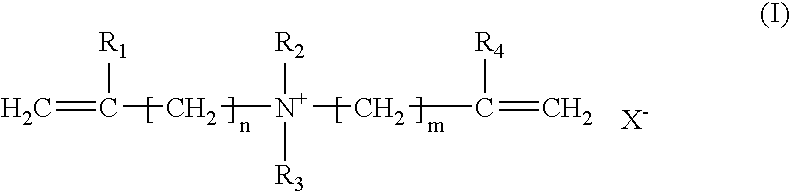

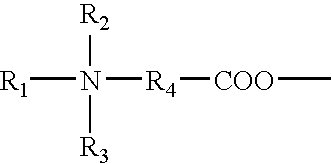

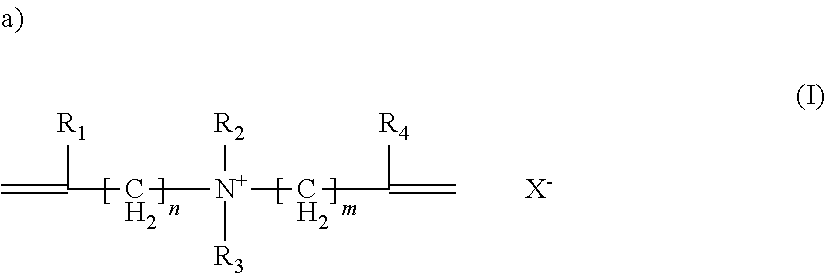

Amphoteric polymer for treating hard surfaces

InactiveUS20090324964A1Organic detergent compounding agentsOther chemical processesParticulatesMetallurgy

The present invention is directed to the use of hydrophilic terpolymers in hard surface cleaners which provide easier cleaning for surface soils such as hard water stains, soap scum, limescale, mud, food, toilet stains, oil, grease, particulates and the like as well as anti-fog effects on hard surfaces such as glass, mirrors, ceramic and plastic by causing water droplets to coalesce into a film.

Owner:BASF AG

Acidic Cleaning Composition Containing a Hydrophilizing Polymer

InactiveUS20070105737A1Organic detergent compounding agentsDetergent mixture composition preparationLimescaleHydrophilization

Owner:COLGATE PALMOLIVE CO

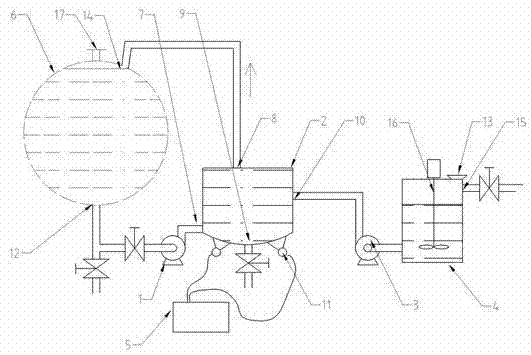

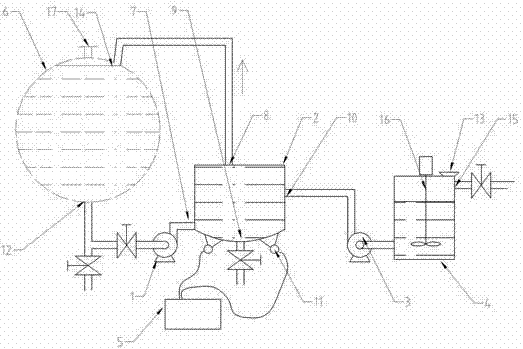

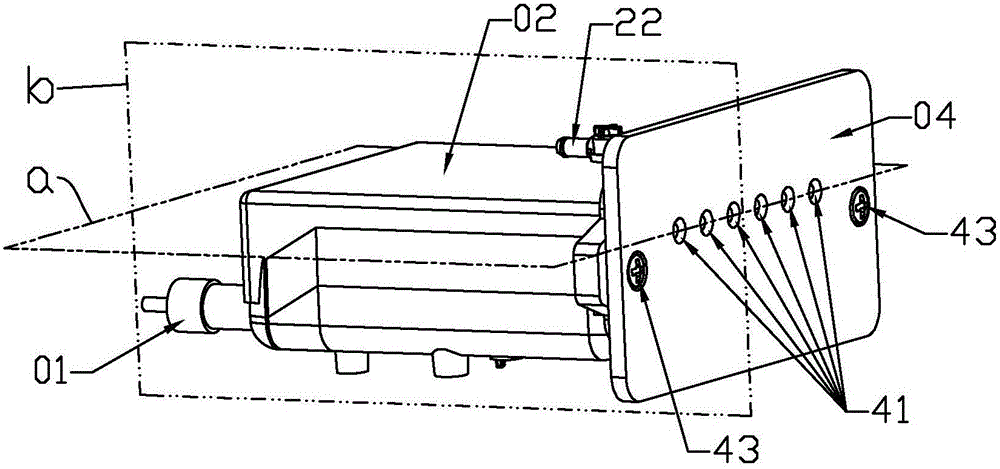

Chemical for cleaning boiler, using method and cleaning device thereof

InactiveCN102418104ALow cleaning temperatureShorten the timeMetallic material coating processesCetyldimethylbenzylammonium chlorideHydrazine compound

The invention relates to a chemical for cleaning a boiler, a using method and a cleaning device thereof, and belongs to the technical field of the chemical cleaning of equipment. A corrosion-inhibiting acid-washing agent comprises acid liquor, 1,3,5,7-tetraaza-adamantane, hydrazine hydrate, silicic acid, cetyl dimethyl benzyl ammonium chloride, ammonium thiocyanate and the like; a bleaching agent is citric acid solution; and a passivant consists of hydrogen peroxide and other additives. The cleaning device consists of a cleaning circulating pump, a cleaning fluid processing tank, a water injection pump and a water replenishing tank; and a plurality of ultrasonic energy converters are arranged on the outer surface of the cleaning fluid processing tank uniformly. The using method comprises the following steps of: establishing a cleaning pump station, testing under the pressure, cleaning scale deposits, bleaching the boiler and a system, passivating and performing water washing. The chemical has a simple process, is low in cost, energy-saving and environment-friendly, and avoids sour corrosion to the boiler.

Owner:CHANGSHA BLUECLEAN TECH

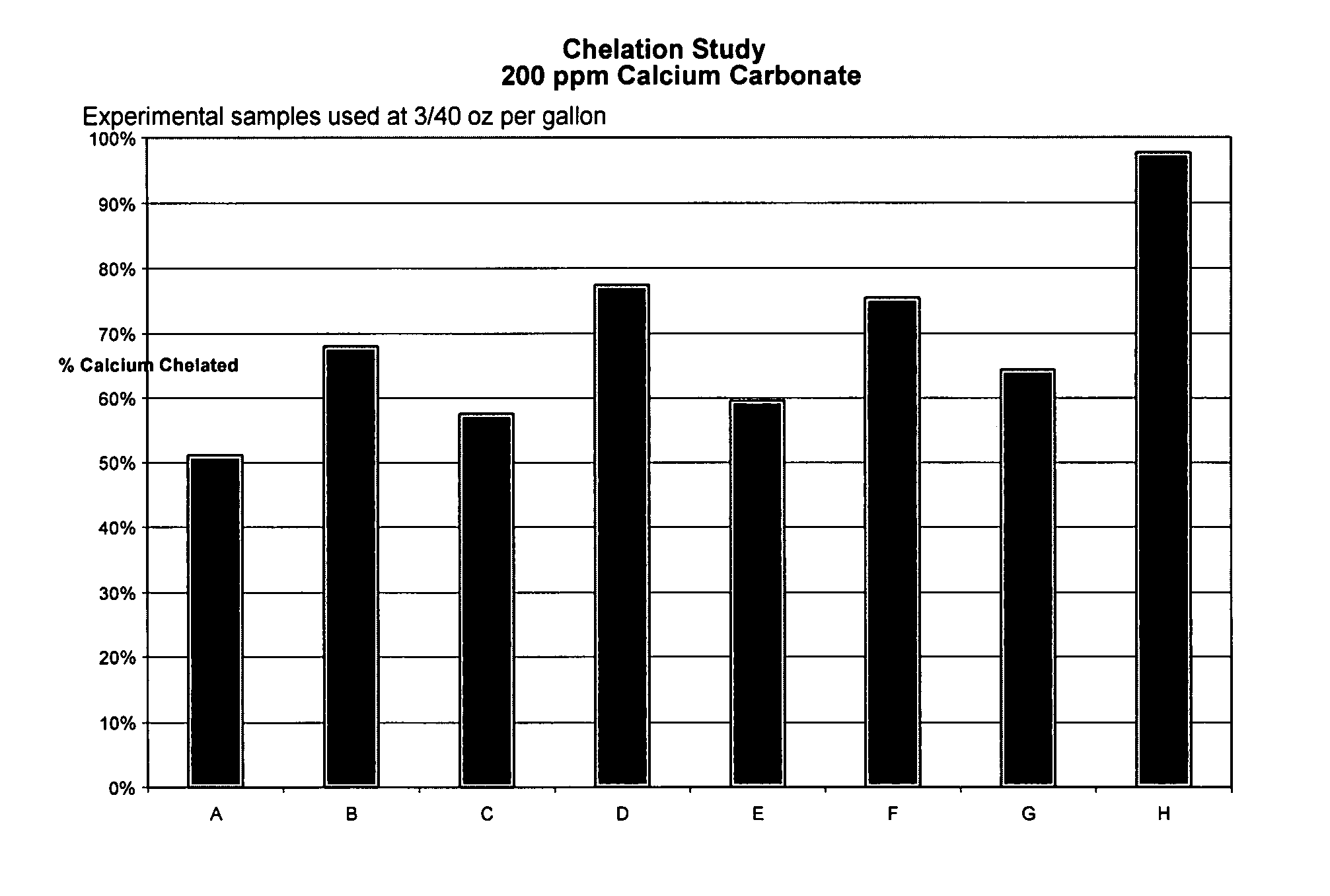

Biodegradable detergent concentrate for medical instruments and equipment

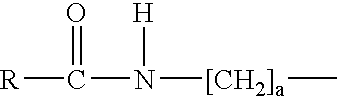

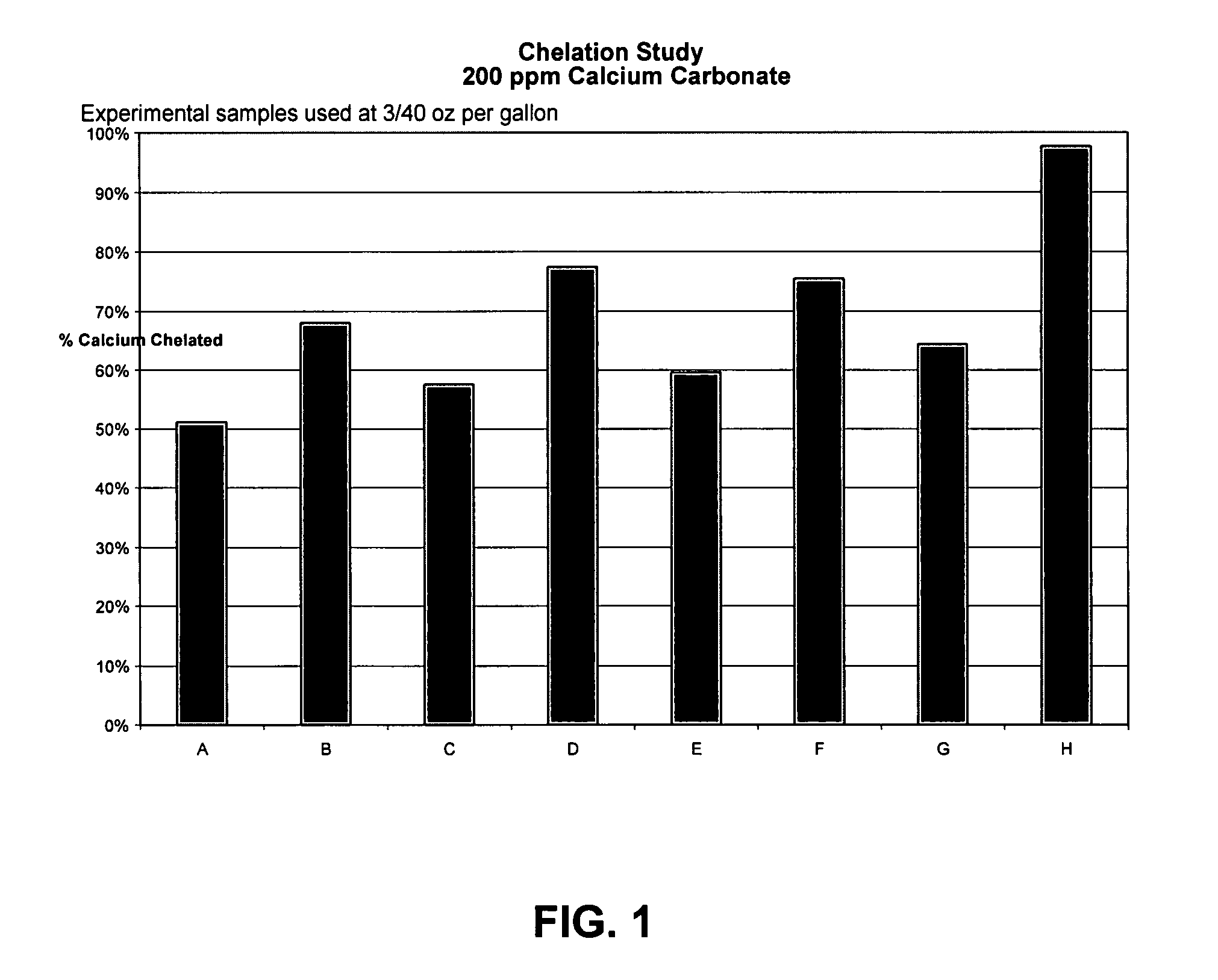

ActiveUS7597766B2Safe handlingCost effectiveInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsLimescalePotable water

An aqueous, concentrated neutral detergent composition for use in cleaning medical instruments and metal components (parts, tools, utensils, vessels, equipment, and surfaces) having scale control and corrosion inhibition properties when diluted to about 1 / 40 ounce per gallon to about 1 / 10 ounce per gallon in potable water. In addition, the concentrate may be applied directly to metal surfaces, such as stainless steel, to remove rust and other stains, without causing any additional corrosion or other damage to the metal surface.

Owner:AMERICAN STERILIZER CO

A method for inhibiting fouling of double-alkali flue gas desulfurization process

InactiveCN102284237ASolve the problem of easy fouling in the delivery pipelinePrevent scalingDispersed particle separationCarboxylic acidCalcium sulfite

The invention relates to a method for inhibiting scaling of a double-alkali flue gas desulfurization process, comprising adding a scale inhibitor to the desulfurization regeneration liquid to prevent calcium sulfite and calcium sulfate from scaling, wherein the scale inhibitor consists of at least one organic phosphine acid and at least one organic carboxylic acid polymer. After the scale inhibitor of the present invention is added to the desulfurization regeneration liquid, the Ca2+ deposition rate is greatly reduced, which can effectively inhibit the formation of calcium scale in the double-alkali flue gas desulfurization process. On the one hand, the present invention can solve the problem that the lye of saturated calcium sulfite and calcium sulfate after regeneration is easy to scale in the conveying pipeline; In addition, the pH value of the absorption liquid is neutral, so that calcium sulfite and calcium sulfate are supersaturated and precipitated, resulting in fouling of the absorption tower and affecting long-term operation.

Owner:CHINA PETROLEUM & CHEM CORP

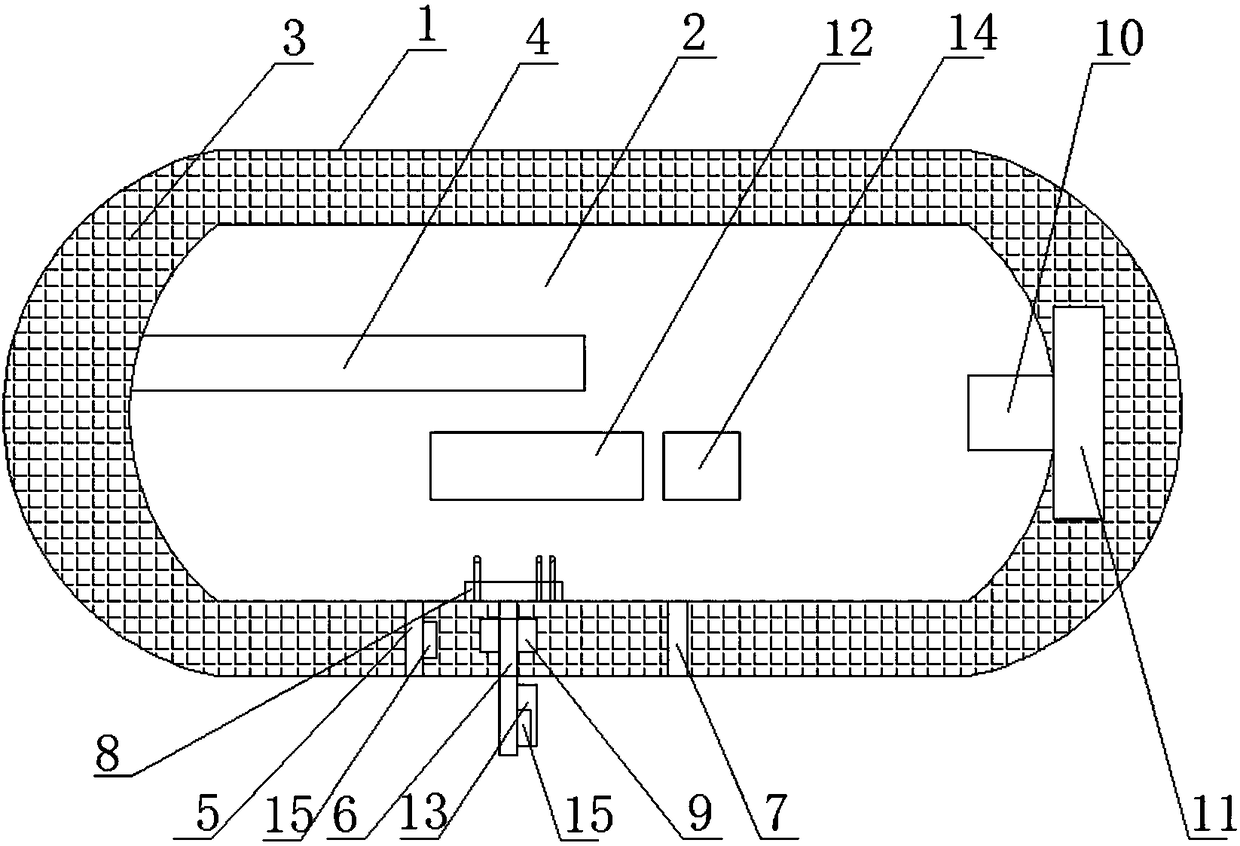

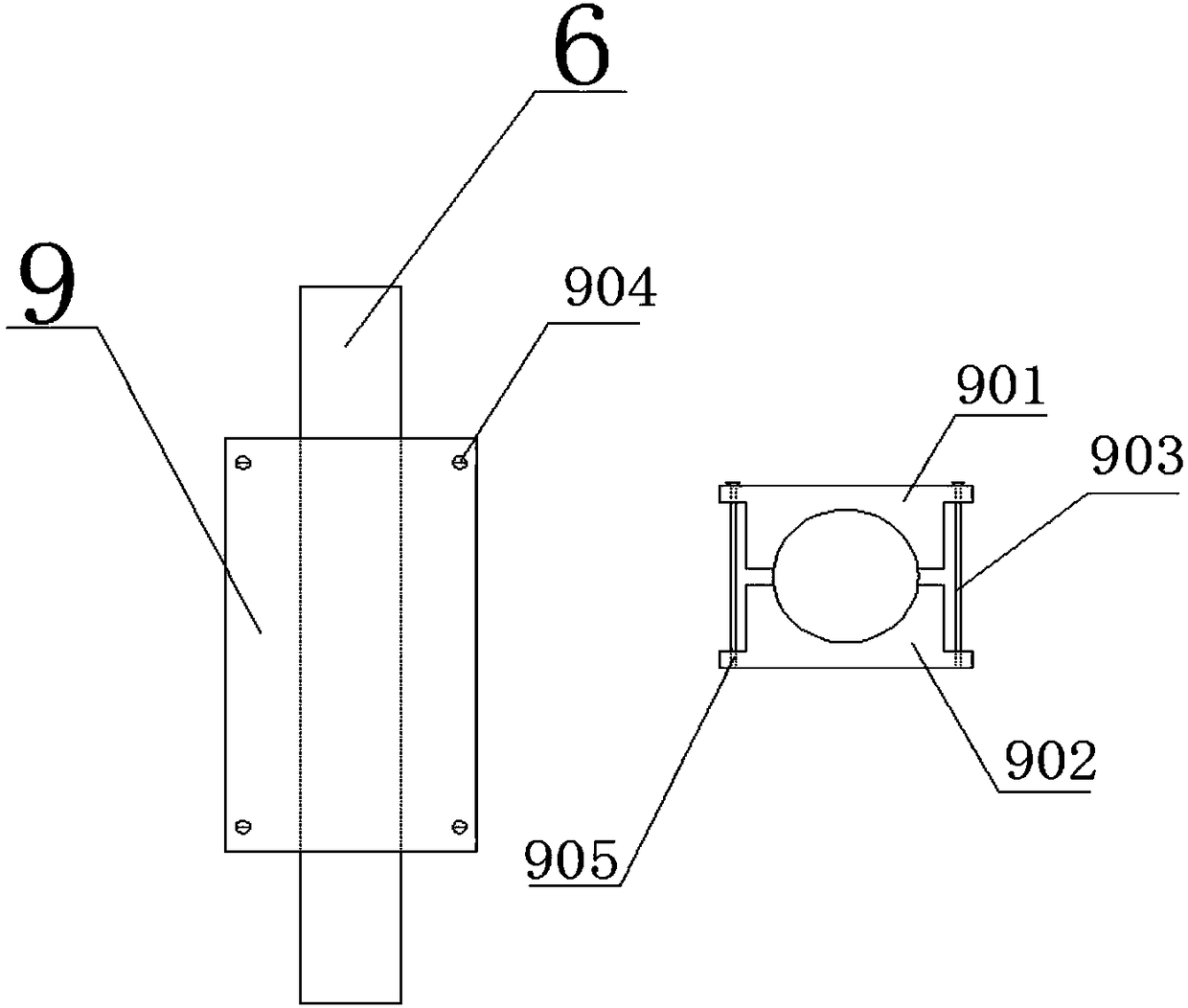

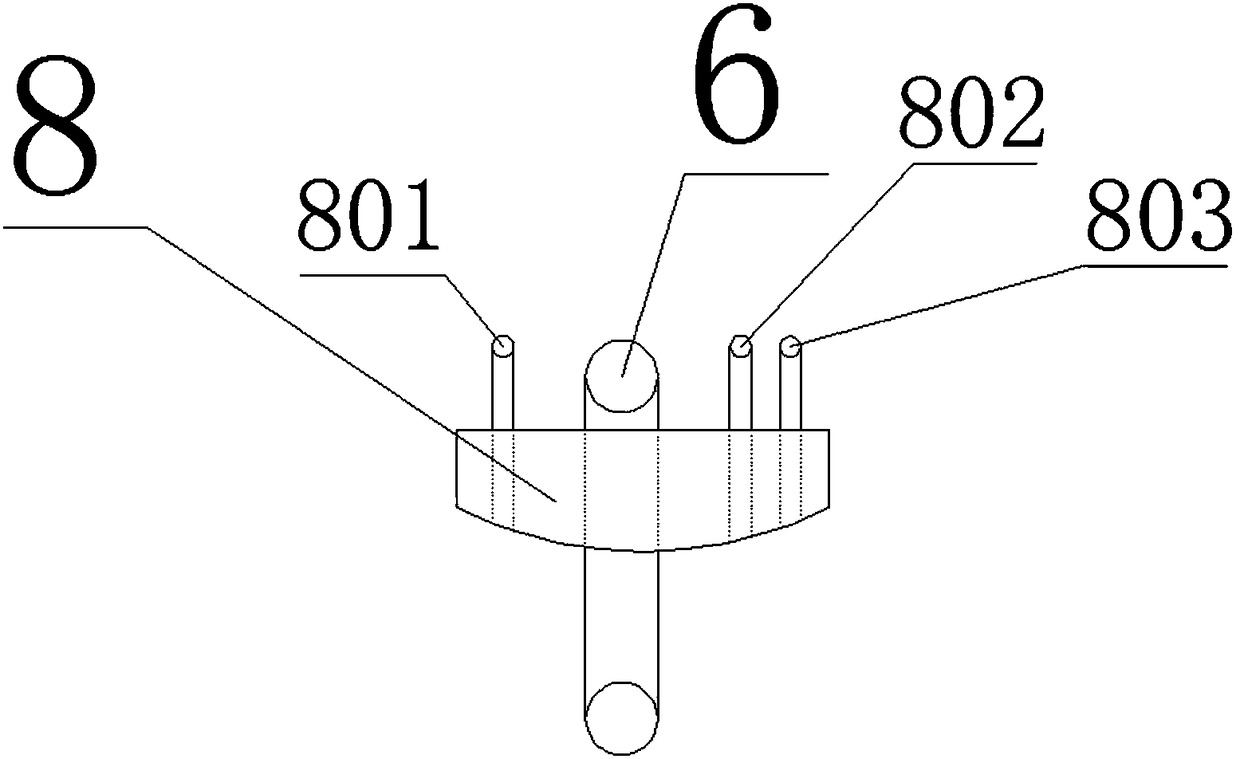

Electric water heating device with automatic limescale removal function

InactiveCN108253621AAvoid it happening againClean up thoroughlySpecific water treatment objectivesScale removal and water softeningLimescaleTap water

The invention provides an electric water heating device with an automatic limescale removal function. The electric water heating device comprises an electric water heating device shell, an electric water heating device liner, a filler, a heating device, a drain outlet, a water inlet, a water outlet, a TDS monitoring module, a magnetization module, an ultrasonic vibrator, an ultrasonic generator, adisplay module, a limescale removal adding device, a control module and an electromagnetic valve. By adopting an intelligent control mode, through the magnetization module, ordinary tap water is converted into magnetic water, limescale is prevented from being generated, the water quality in the electric water heating device liner is detected through the TDS monitoring module so as to judge whether limescale removal needs to be conducted on the electric water heating device liner or not, the ultrasonic vibrator and the ultrasonic generator generates ultrasonic waves to wash limescale, the limescale removal adding device delivers a liquid limescale removal agent into the electric water heating device liner through the water inlet, and through a preventing and removing combined method, the limescale is thoroughly removed.

Owner:HUZHOU GUOXIN MATERIALS

Cooling water scale and corrosion inhibition

ActiveUS20050150838A1Avoid corrosionIncrease ionic strengthDrying using combination processesAuxillariesLimescaleEvaporation

A methods for inhibiting silica scale formation and corrosion in aqueous systems where soluble silica (SiO2) can be maintained at residuals below 200 mg / L, but more preferably maintained at greater than 200 mg / L as SiO2, without silica scale and with control of deposition of source water silica accumulations as high as 4000 mg / L (cycled accumulation) from evaporation and concentration of source water. The methods of the present invention also provide highly effective inhibition of corrosion for carbon steel, copper, copper alloy, and stainless steel alloys. The methods of the present invention comprise pretreatment removal of hardness ions from the makeup source water, maintenance of electrical conductivity, and elevating the pH level of the aqueous environment. Thereafter, specified water chemistry residual ranges are maintained in the aqueous system to achieve inhibition of scale and corrosion.

Owner:JOHN L KUBIS +1

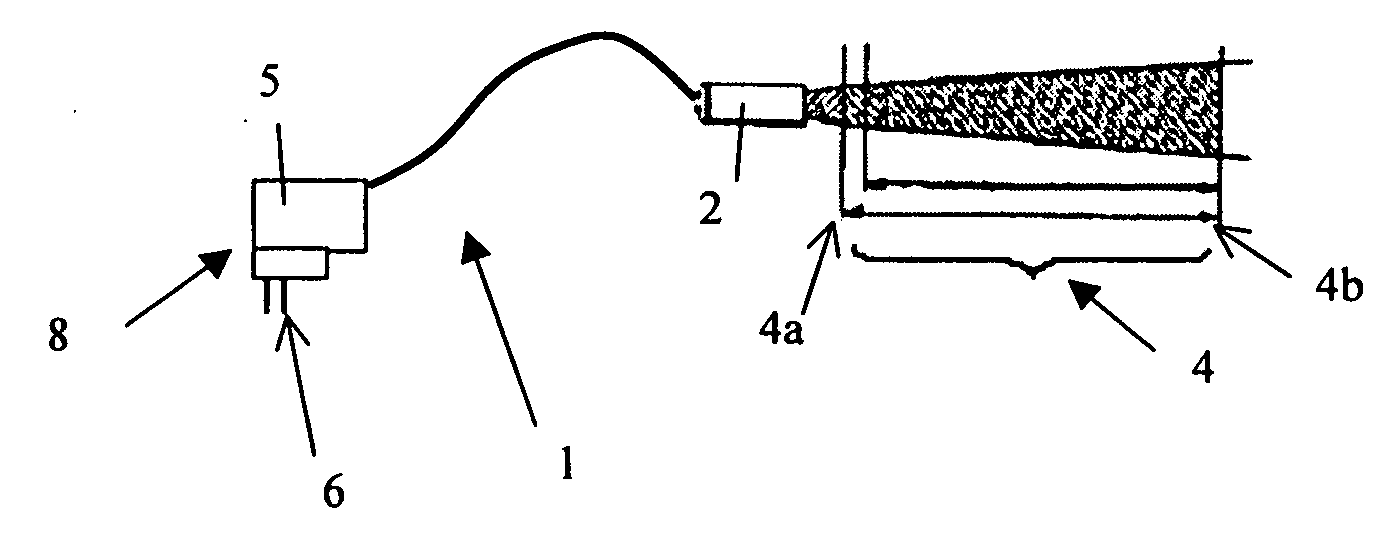

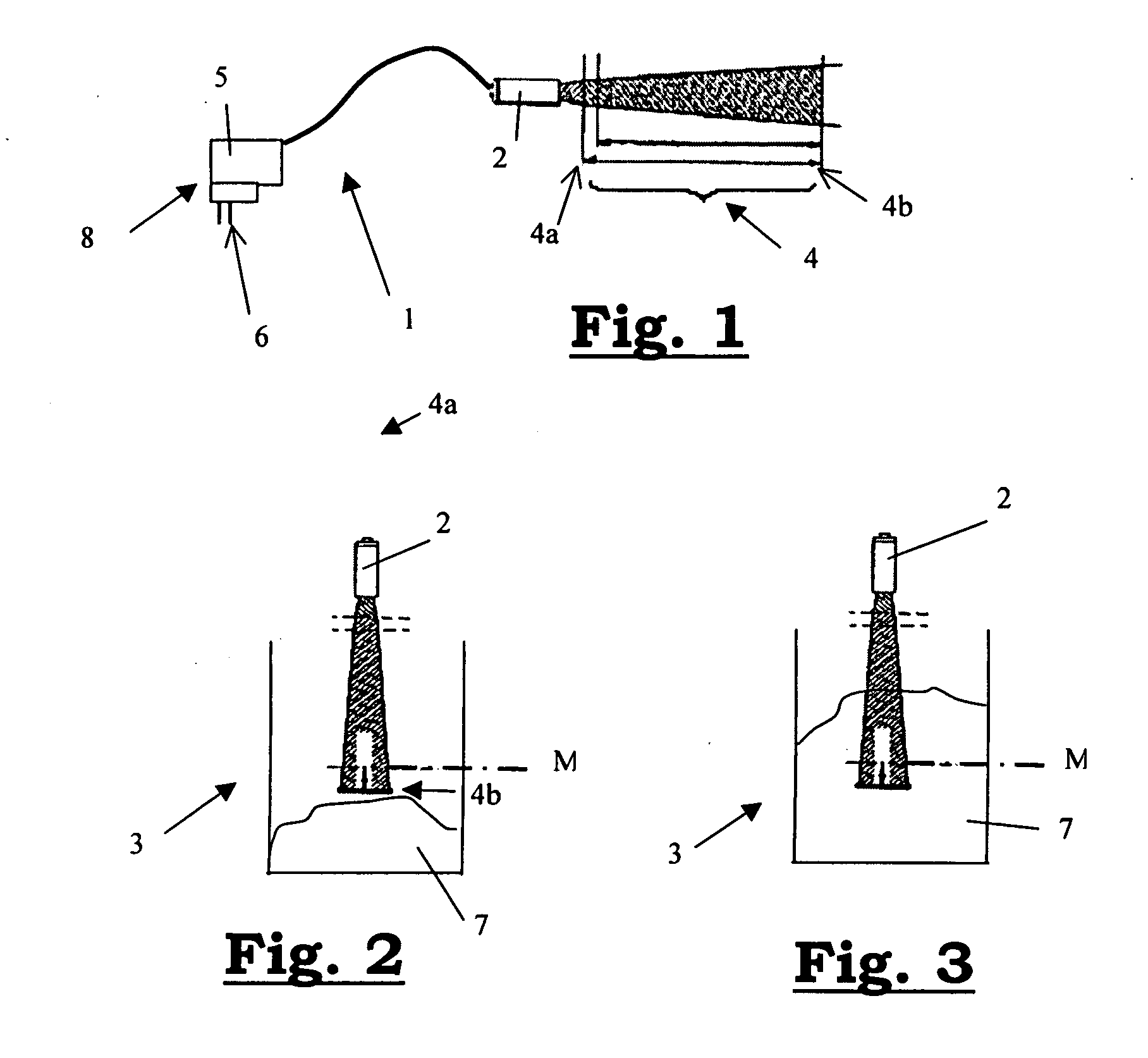

Level detector

InactiveUS20060114593A1Filamentary/web record carriersRecord information storageLimescaleUltrasonic sensor

The present invention concerns a level detector (1) for a domestic or industrial water softener in which the said detector (1) comprises a sensor (2) which is equipped to detect the salt level in the brine tank (3) of the water softener. As a result, the salt level is watched at all times so that it is impossible that the brine tank falls empty and that the appliances connected to the water supply system are damaged due to limescale deposits. The sensor used preferably is an ultrasonic sensor that is placed at the top of the water softener and that is equipped to detect within a detection area (4).

Owner:ABUHAGIAR HISHAM

Amphoteric polymer for treating hard surfaces

InactiveUS8741831B2Organic detergent compounding agentsGlass/slag layered productsOil and greaseHard-surface cleaner

The present invention is directed to the use of hydrophilic terpolymers in hard surface cleaners which provide easier cleaning for surface soils such as hard water stains, soap scum, limescale, mud, food, toilet stains, oil, grease, particulates and the like as well as anti-fog effects on hard surfaces such as glass, mirrors, ceramic and plastic by causing water droplets to coalesce into a film.

Owner:BASF AG

Scale dissolver fluid

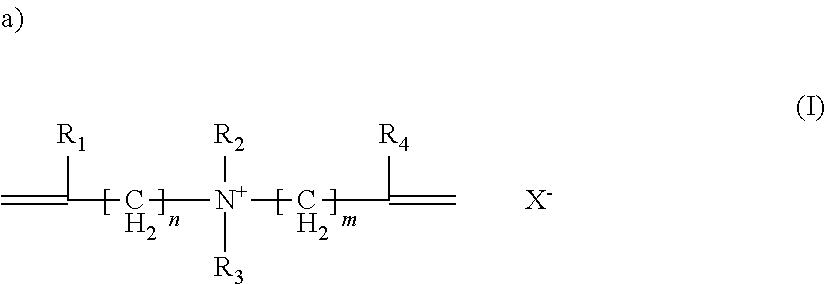

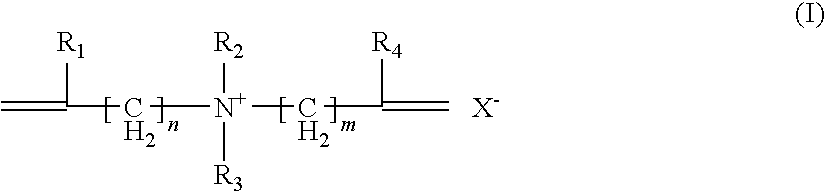

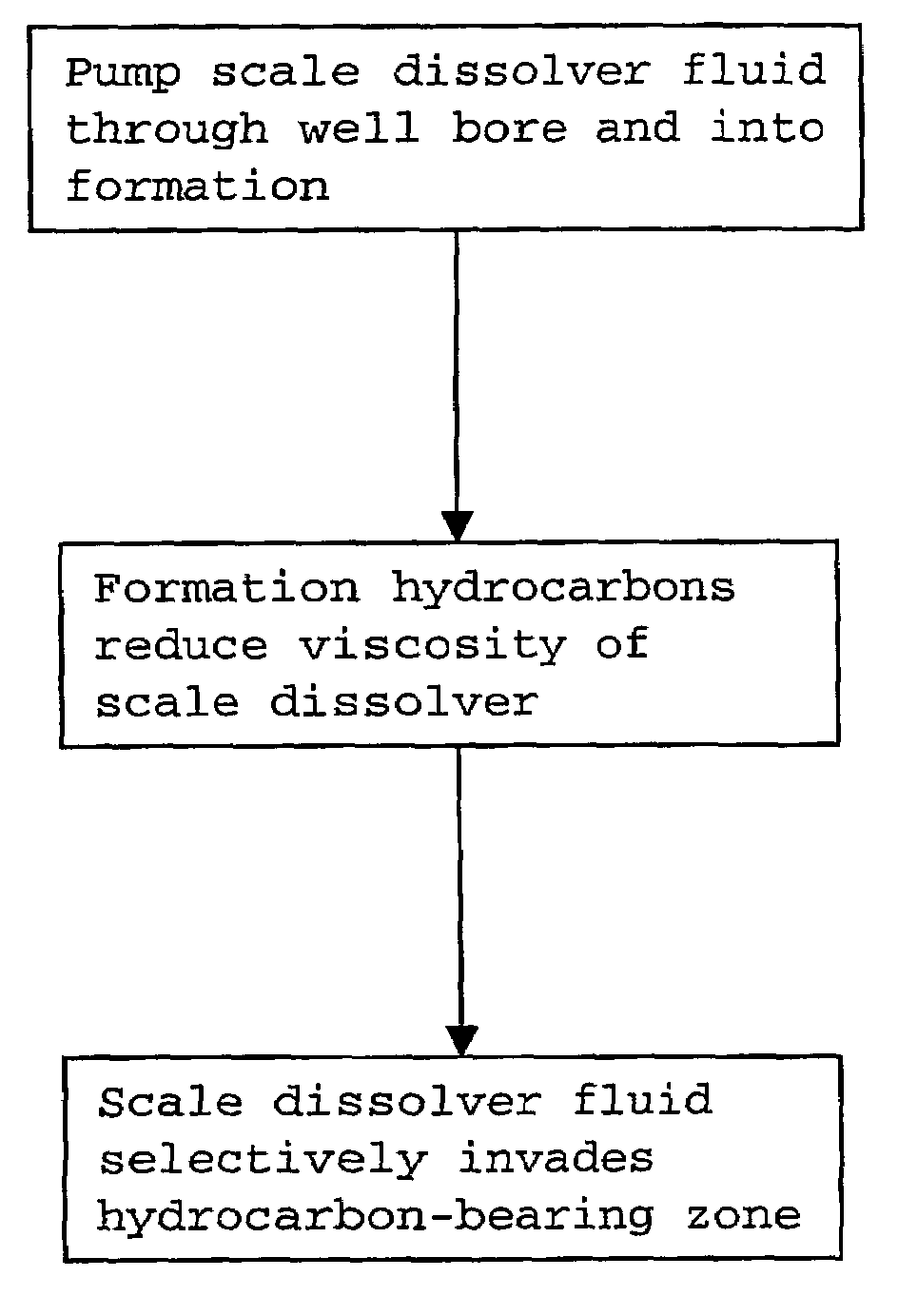

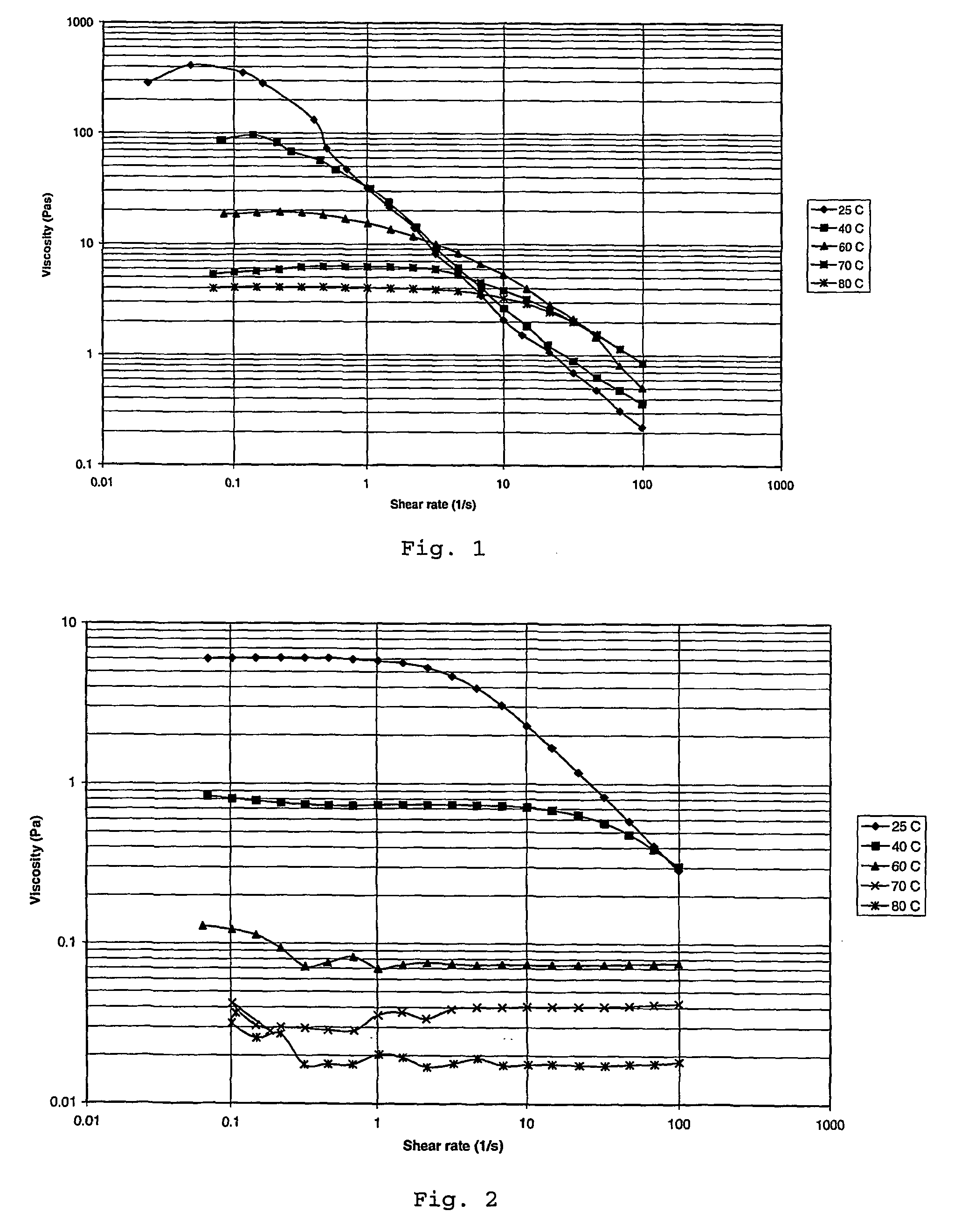

InactiveUS7156177B2Increase in water cutFacilitate production of hydrocarbonTransportation and packagingCleaning apparatusLimescaleFluid viscosity

A scale dissolver fluid for dissolving scale in a subterranean hydrocarbon-bearing formation comprises an effective amount of a scale dissolver formulation and an effective amount of a surfactant for controlling the viscosity of the fluid. In use, formation hydrocarbons act on the surfactant to reduce the viscosity of the fluid so that the fluid selectively invades a hydrocarbon-bearing zone of the formation.

Owner:SCHLUMBERGER TECH CORP

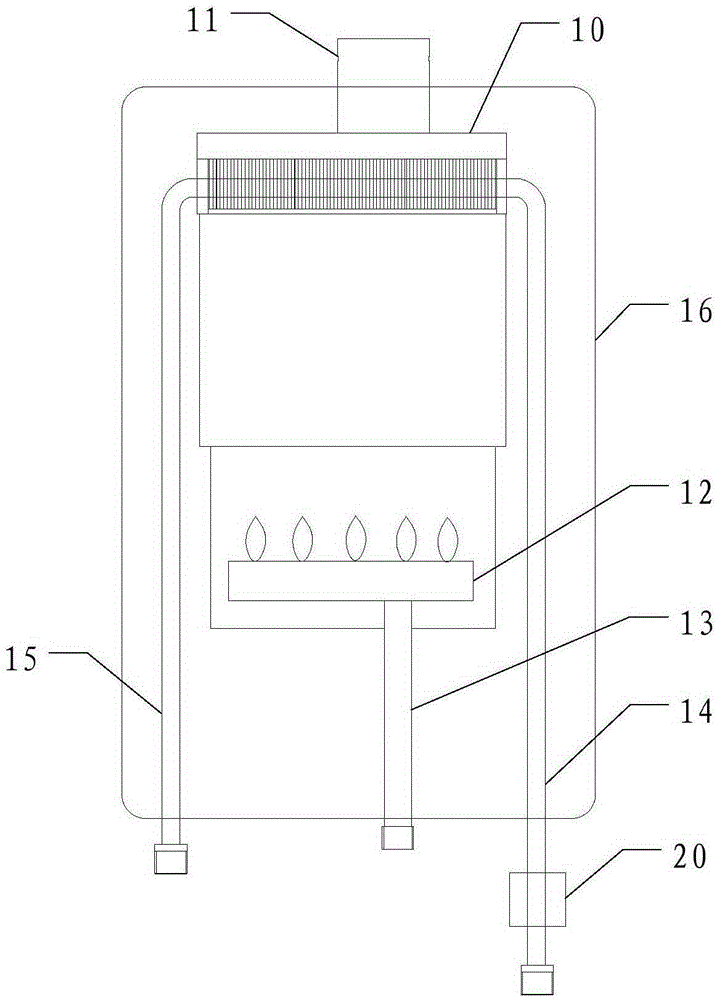

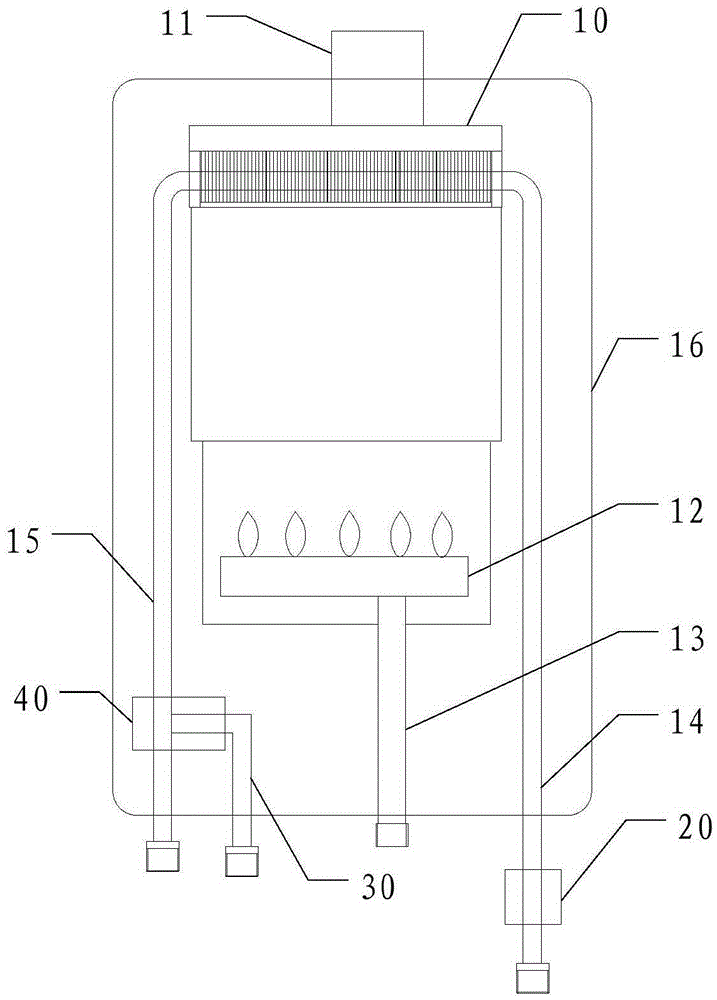

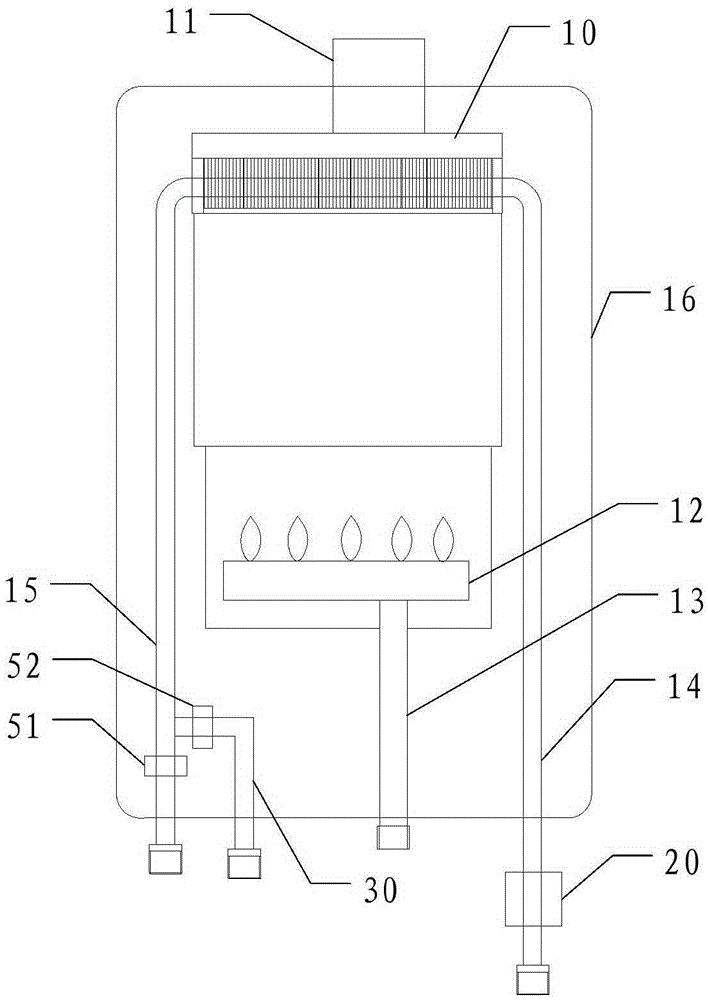

Gas water heater

ActiveCN105258338AImprove heat transfer efficiencyImprove water qualityFluid heatersLimescaleWater quality

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

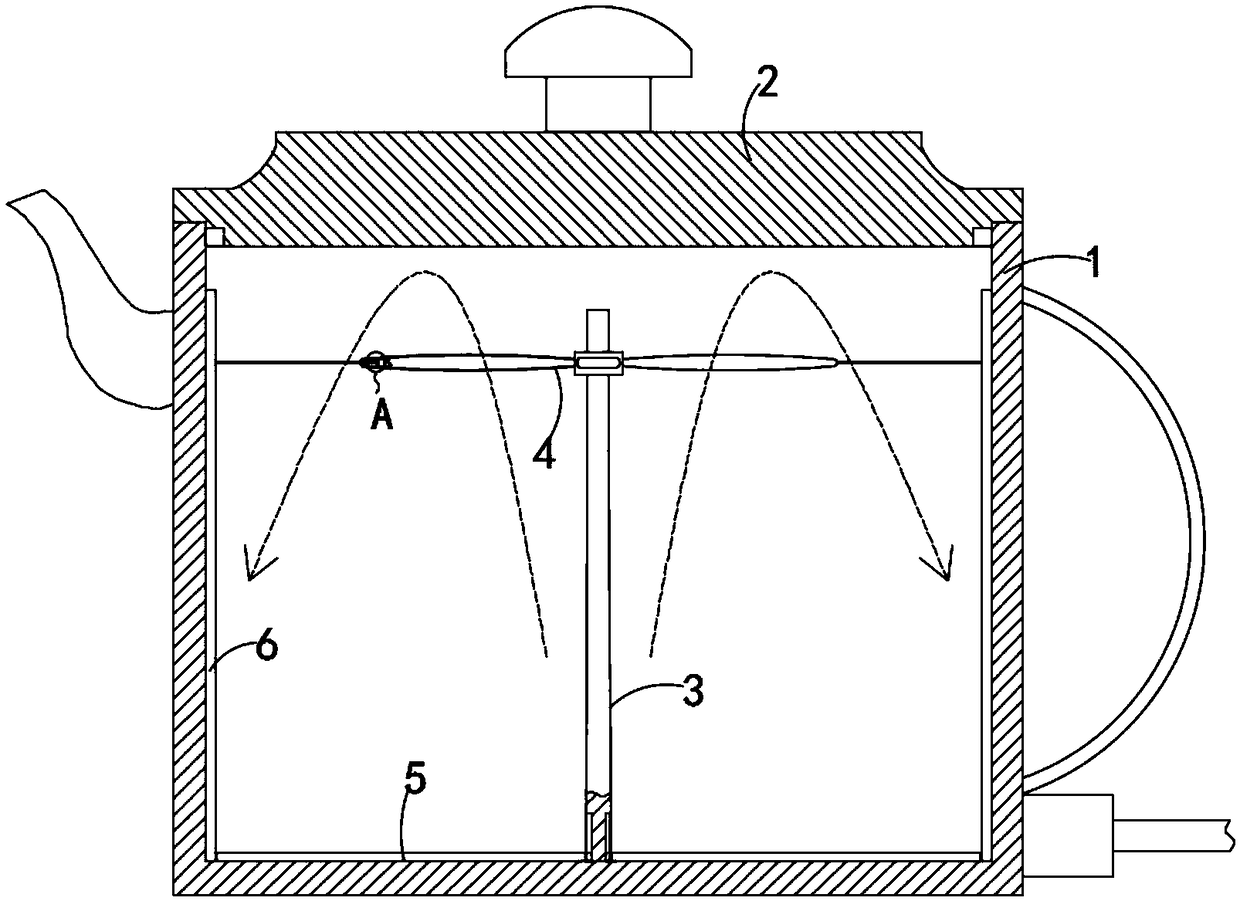

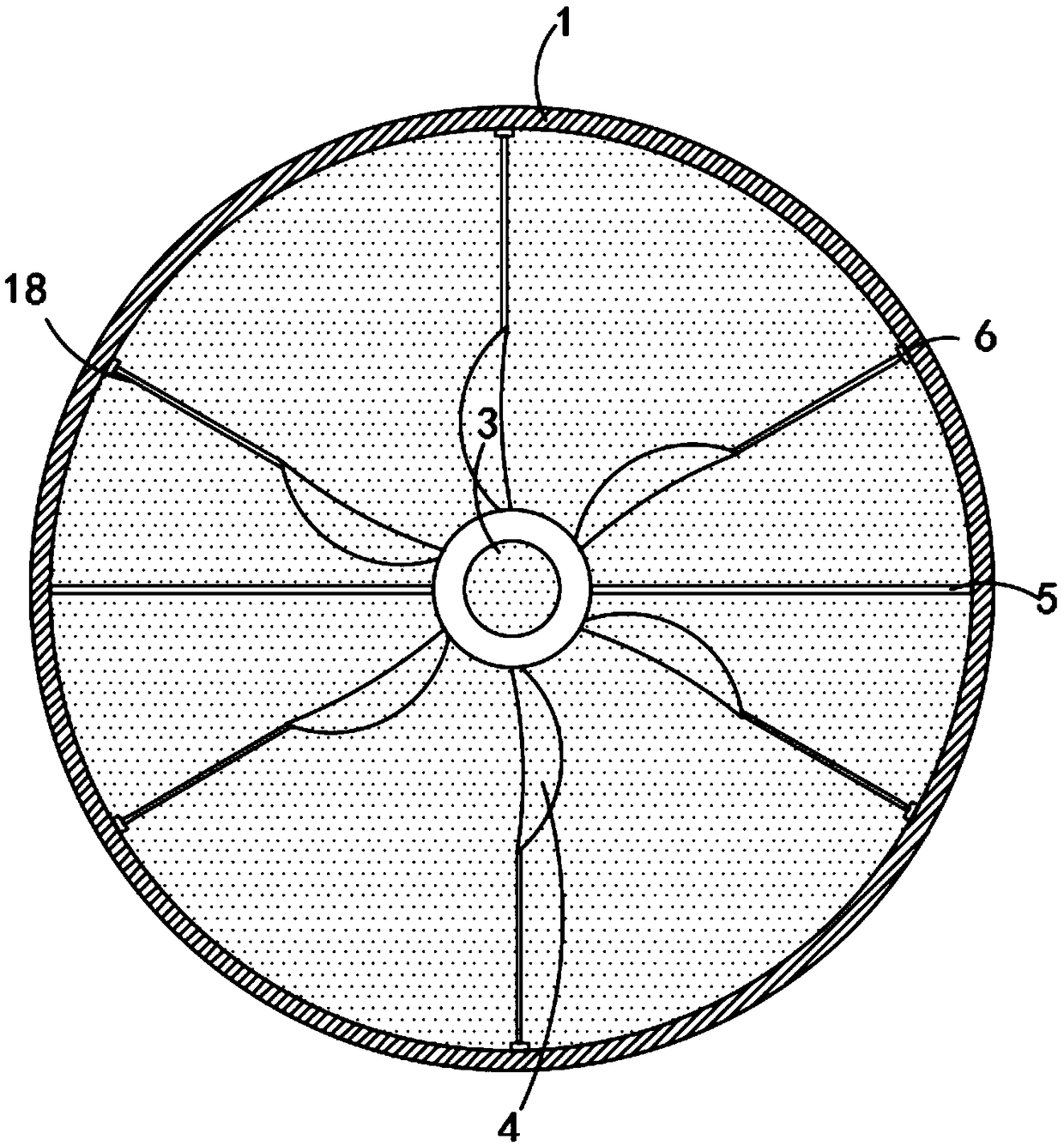

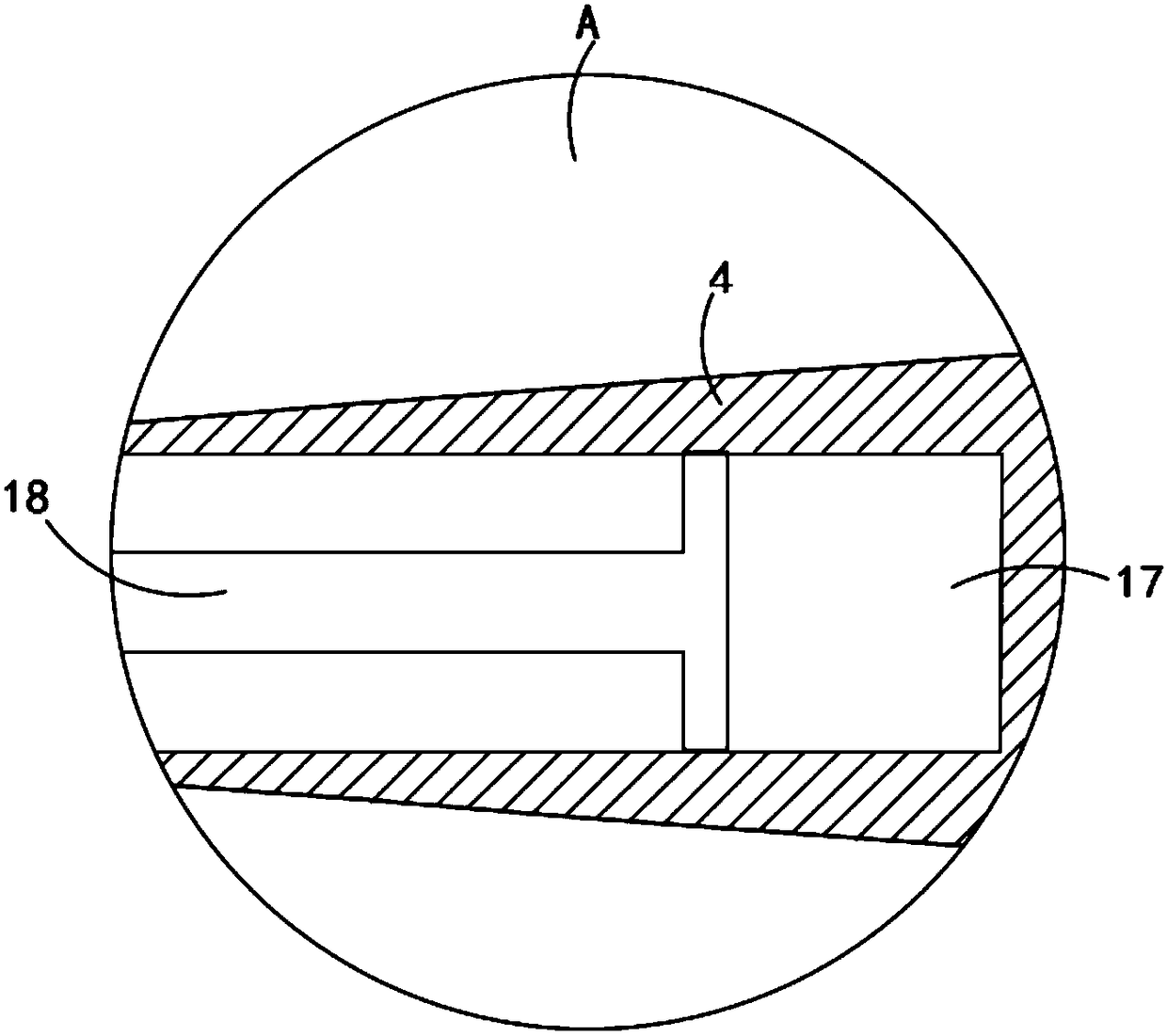

Hot water kettle with scale removing and heat preservation

ActiveCN109106209AWith descaling insulationGuaranteed heating efficiencyWater-boiling vesselsCooking utensils shields/jacketsLimescaleImpeller

The invention belongs to the technical field of hot water bottles, in particular to a hot water kettle with scale removing and heat preservation, including a pot body, a matching lid is arranged at the mouth of the kettle body, the bottom of the kettle body is rotatably connected with a rotating shaft, the rotating shaft is coaxially fixedly connected with an impeller driven by bubbles, sliding holes are arranged on the side walls of the free ends of a plurality of blades of the impeller, sliding rods matching with the sliding holes are arranged, and the sliding rods are freely and fixedly connected with a second scraper for cleaning the inner wall of the kettle body. The advantages are: the invention can drive the blade to rotate through bubbles in boiling water, so that the first scraperand the second scraper can synchronously rotate to remove the scale from the inner wall and the bottom of the hot water kettle, in addition, the steam generated when the water boils has a higher temperature, and the steam generated is collected into the heat preservation chamber to heat preservation the hot water kettle and recover and utilize the heat in the steam.

Owner:临沂鸿泰建材有限公司

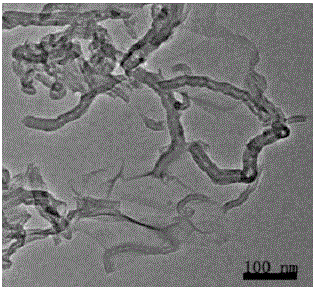

Method capable of removing limescale and heavy metal ions in water

ActiveCN106829933AImprove adsorption capacityLarge adsorption capacityWater contaminantsGrapheneFiltrationCarbon nanotube

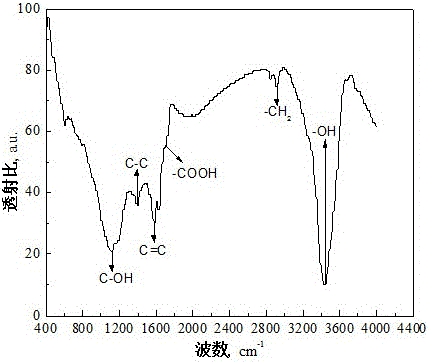

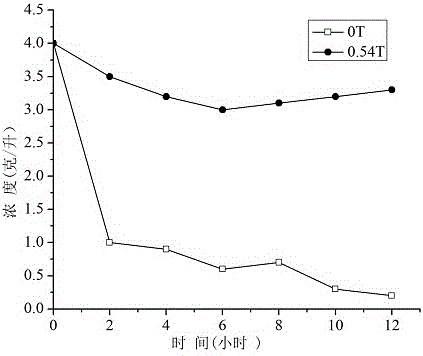

The invention discloses a method capable of removing limescale and heavy metal ions in water and relates to the water treatment technology. The method capable of removing the limescale and the heavy metal ions in the water includes the steps of ultrasonically dispersing purified carbon nanotubes in anhydrous ethanol, mixing the dispersion liquid with dispersion liquid of oxidized graphene in the anhydrous ethanol, and subjecting the mixed liquid to ultrasonic treatment prior to suction filtration and vacuum drying so as to obtain oxidized graphene / carbon nanotube composite materials. The composite materials belonging to nanomaterials have excellent properties and comprise multiple kinds of active groups such as hydroxyl and carboxyl on the surfaces. The method capable of removing the limescale and the heavy metal ions in the water has the advantages that the method can remove pollutants through adsorptive effect of the surface groups and the heavy metal ions in sewage and is synergistic with the composite materials under the action of an applied magnetic field to remove the limescale; the method with secondary-pollution-free and adsorptive functions is simple in technological process and reliable in property so as to be applicable to such fields as targeted drug preparation, environment protection and pollutant monitoring; the method is simple in material preparation and low in cost and can be produced massively.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Heat exchanger capable of effectively preventing incrustation scale hazard

InactiveCN102889805AHazards are predictable and controllableNo harmStationary tubular conduit assembliesTubular elementsLimescaleSlag

The invention discloses a heat exchanger capable of effectively preventing incrustation scale hazard. The heat exchanger comprises a heat exchanger shell and fire tubes arranged in the heat exchanger shell, wherein the sections of the fire tubes are square; the lower parts of the fire tubes are vertical fire inlets; the middle parts of the fire tubes are bent; and the upper parts of the fire tubes are vertical fire outlets. The incrustation scale layers at edges or corners easily cracke under stress effects due to square fire tubes; unbalanced temperature difference on the surfaces of the fire tubes and line expansion difference due to expansion and contraction between stainless steel and the incrustation scale can cause continuous cracking of the incrustation scale layers; the motive power produced by convection and evaporation when water is heated can flush the accumulated incrustation scale according to the design of water flow channels, so that the incrustation scale is difficult to accumulate and easy to fall off; and the regularly arrayed fire tubes make the falling off incrustation scale directionally move towards a incrustation scale storage groove and then stored. The motions are continuous and repeated, so that the incrustation scale does not seriously affect heat exchanging process after being produced. And the manual cleaning can be regularly performed through all slag holes.

Owner:吴鸣海

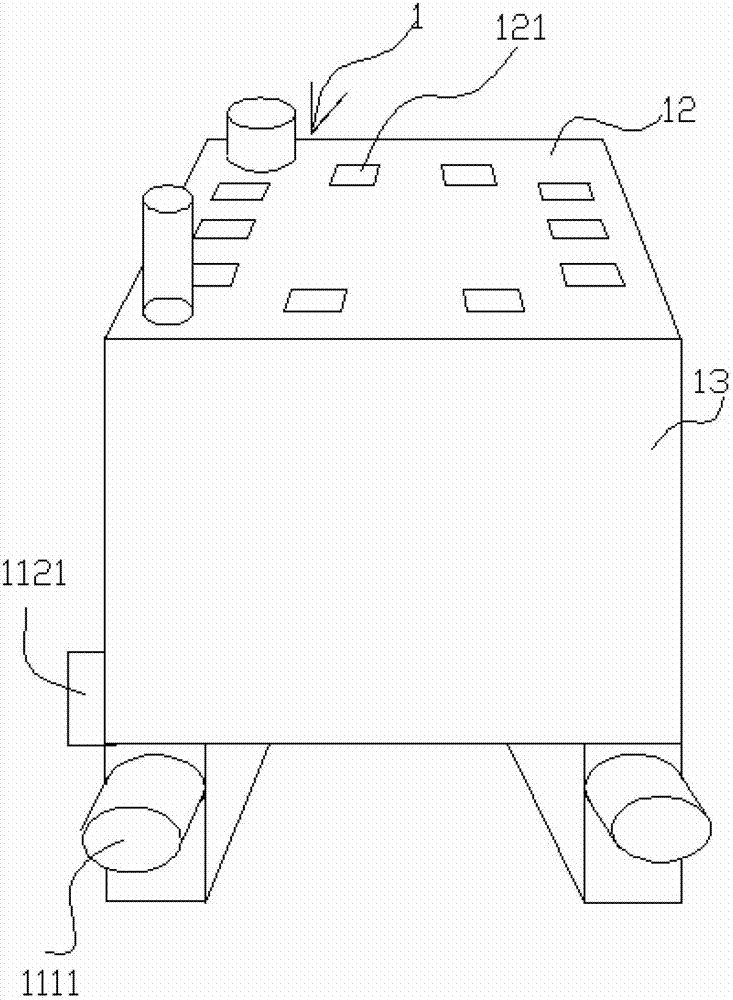

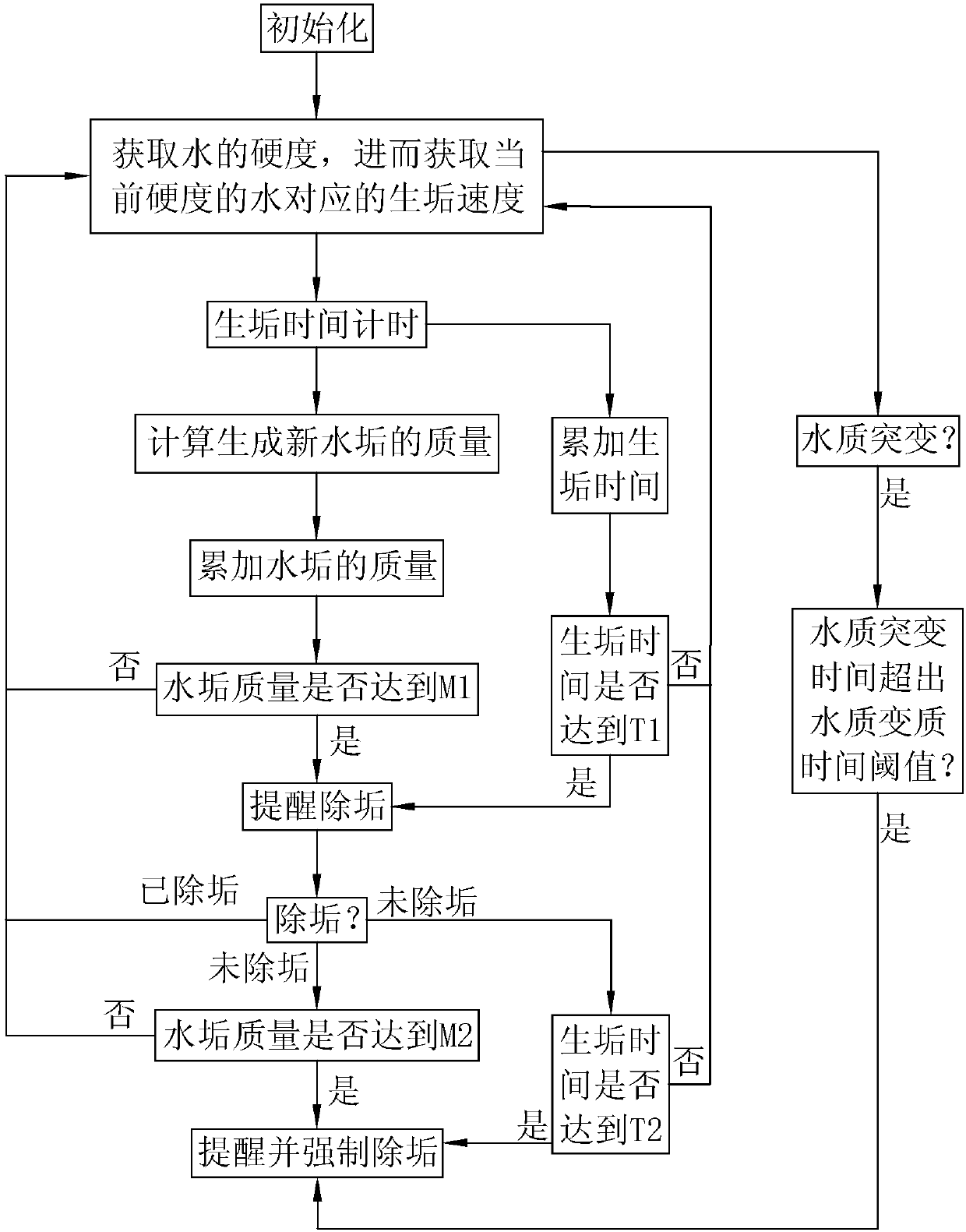

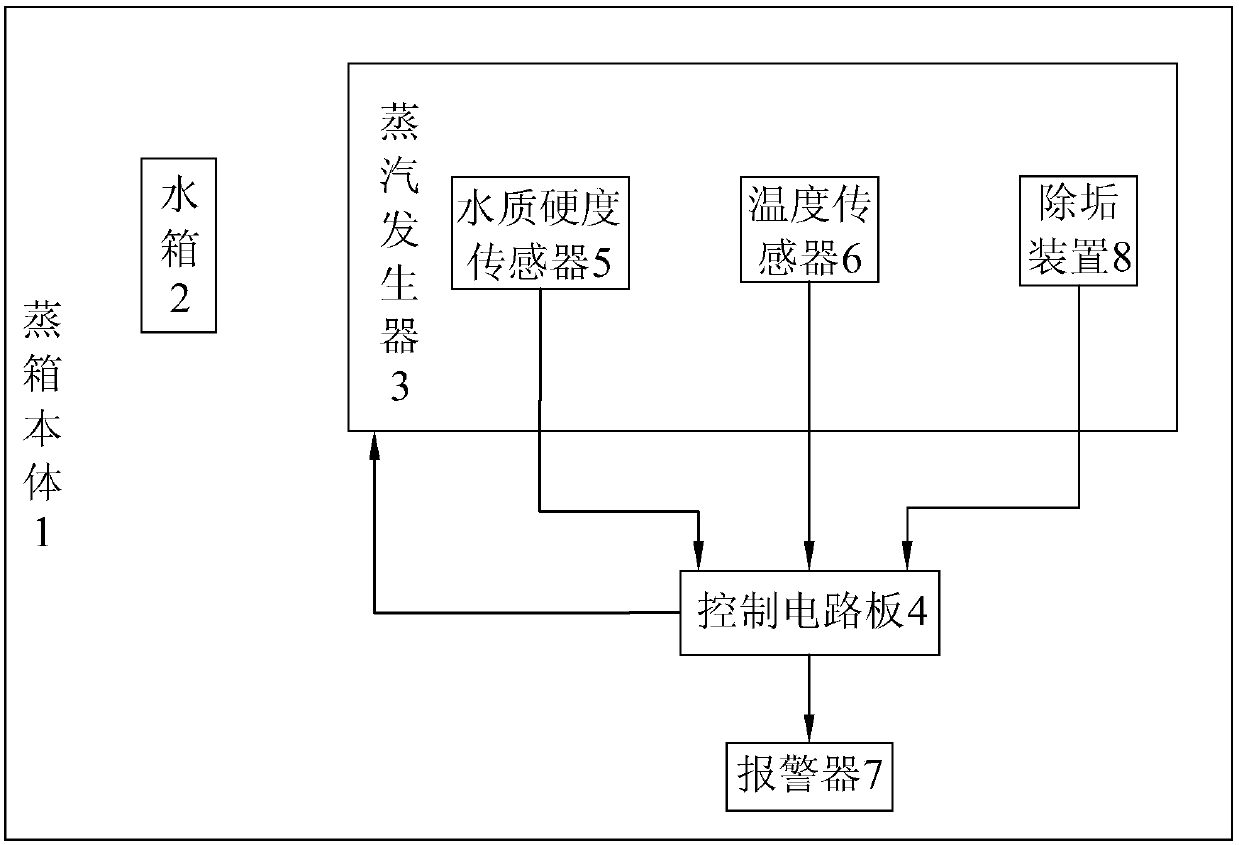

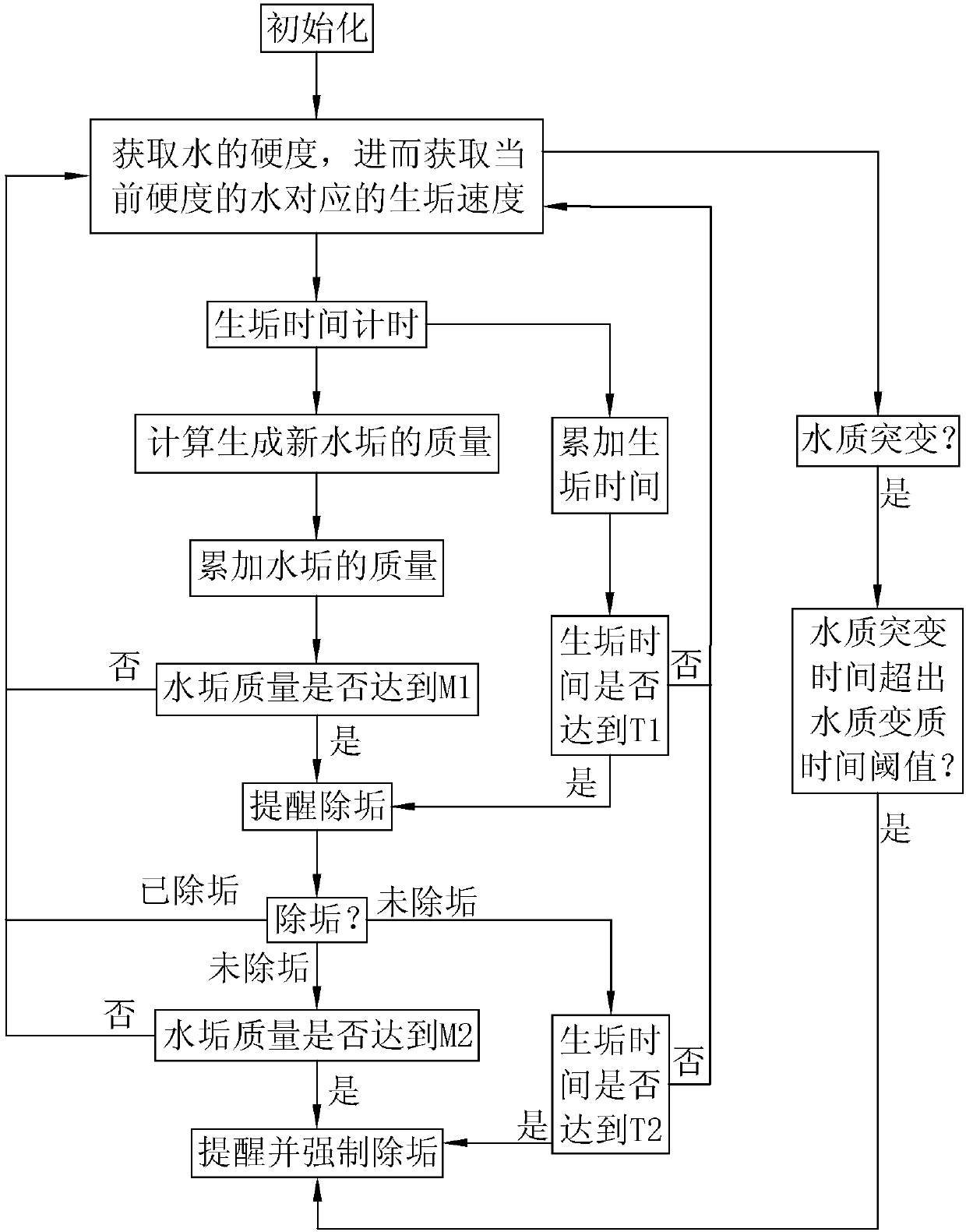

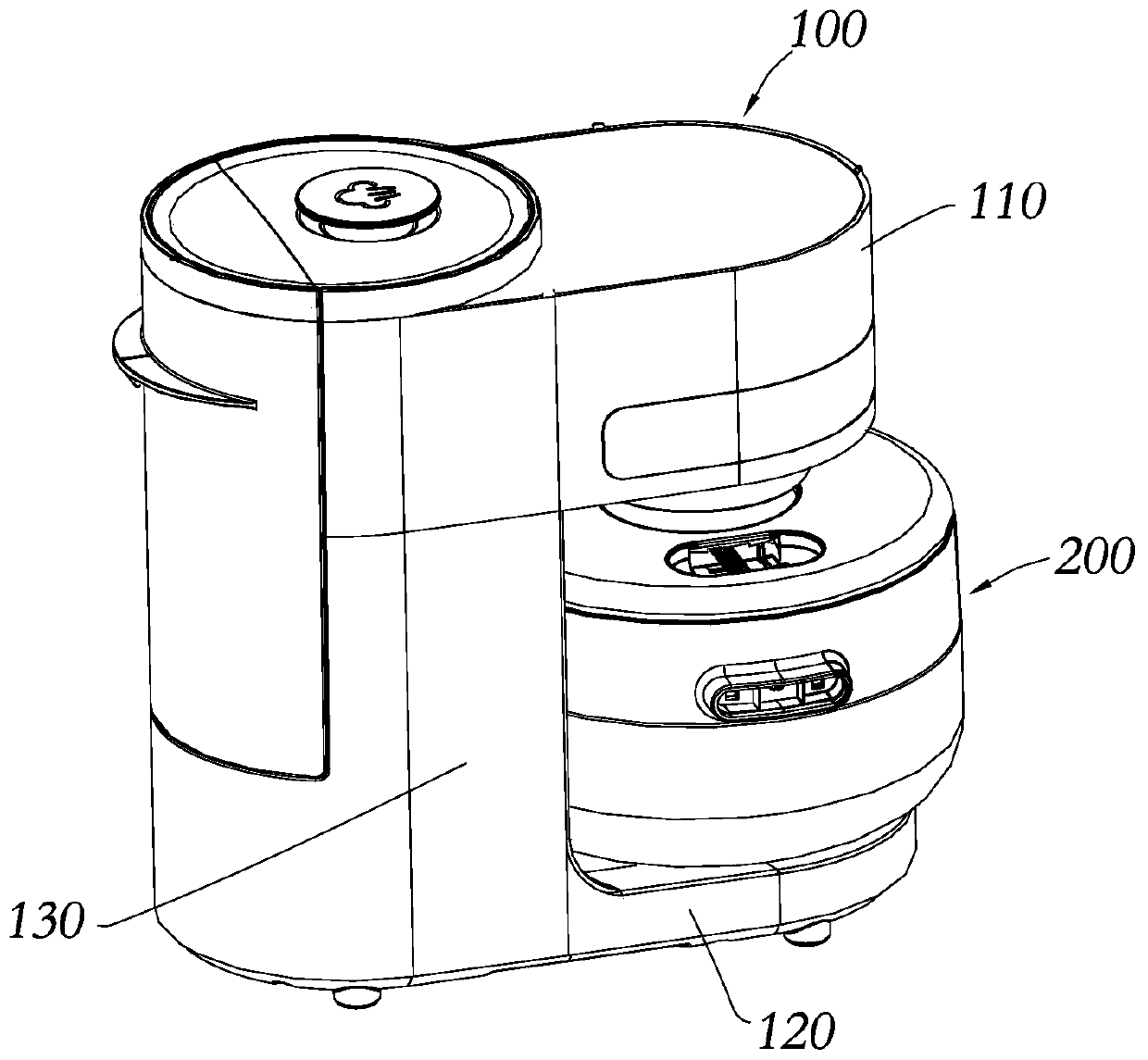

Limescale monitoring method and electric steam box applying limescale monitoring method

PendingCN109984572AReal-time hardness valueObtain hardness value in real timeBoiler cleaning apparatusSteam cooking vesselsLimescaleWater quality

The invention relates to a limescale monitoring method. The method comprises the following steps that the limescale generation speed of water different in hardness is initialized, and the alarm limescale mass corresponding to a descaling alarm is initialized; the current water hardness is detected and acquired, and the corresponding limescale generation speed is acquired; the limescale generationtime of the water with the current hardness is acquired; the mass of new limescale generated by the water with the current hardness is calculated; the calculated new limescale mass is accumulated to the history limescale mass to form the current limescale mass, and the current limescale mass is used as the new history limescale mass for storage; whether or not the current limescale mass reaches the alarm limescale mass is judged, and if yes, descaling reminding and a descaling response are conducted. According to the limescale monitoring method, even the situation occurs that when the water quality is replaced, the hardness of the water is changed, the real-time limescale generation amount can be accurately calculated, and an alarm is given in time. The invention further relates to an electric steam box applying the limescale monitoring method. The use convenience is improved, and the user experience is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

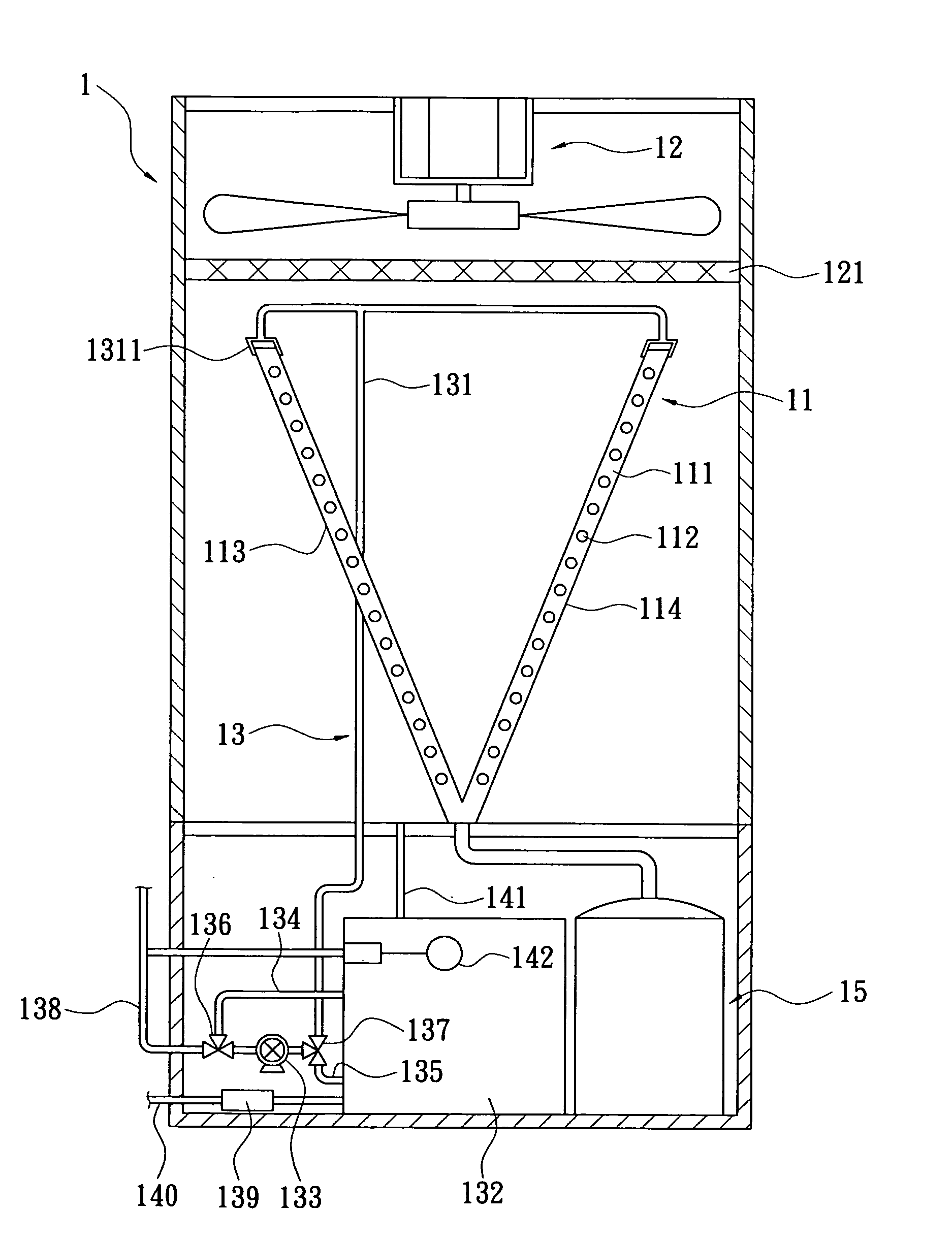

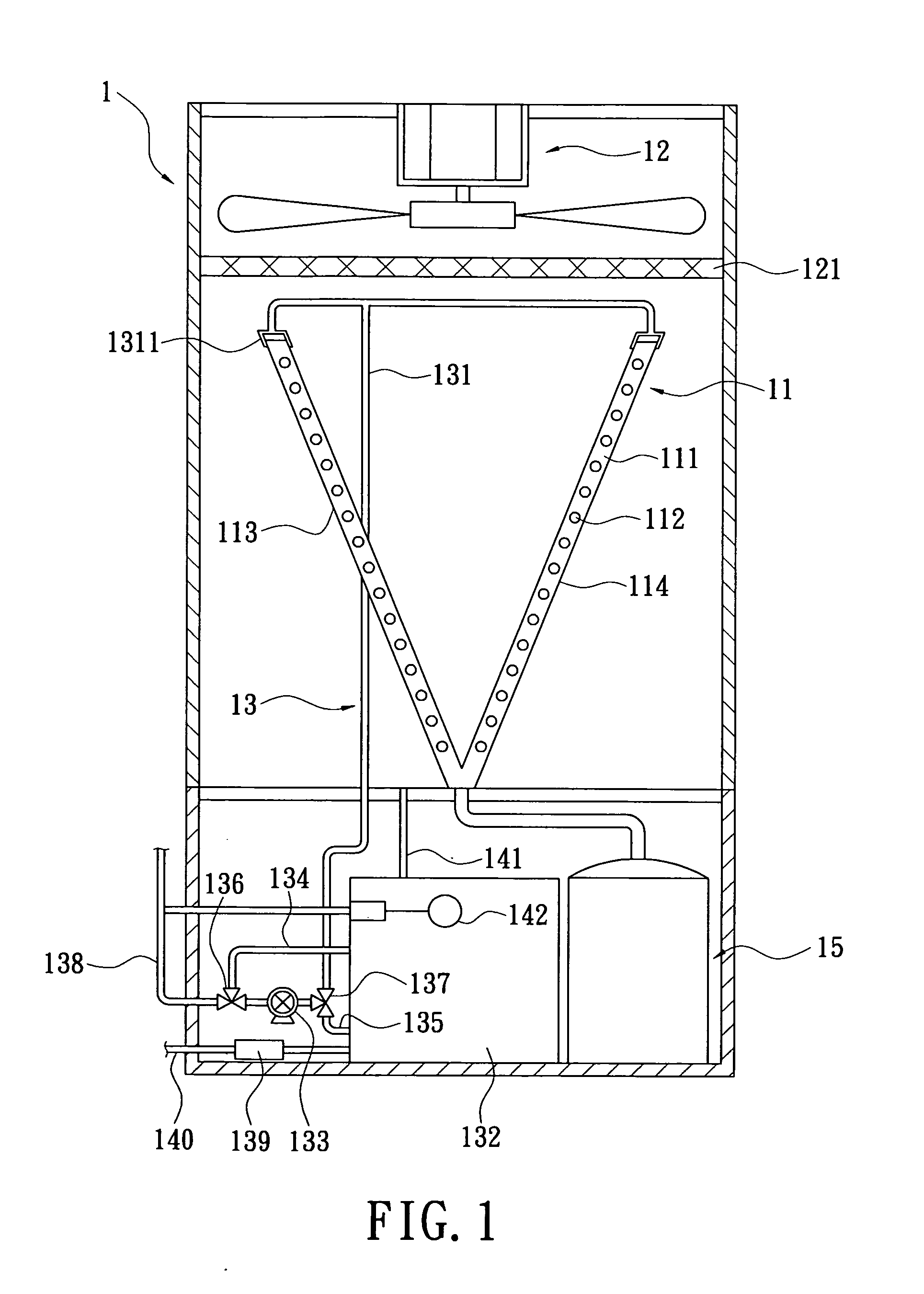

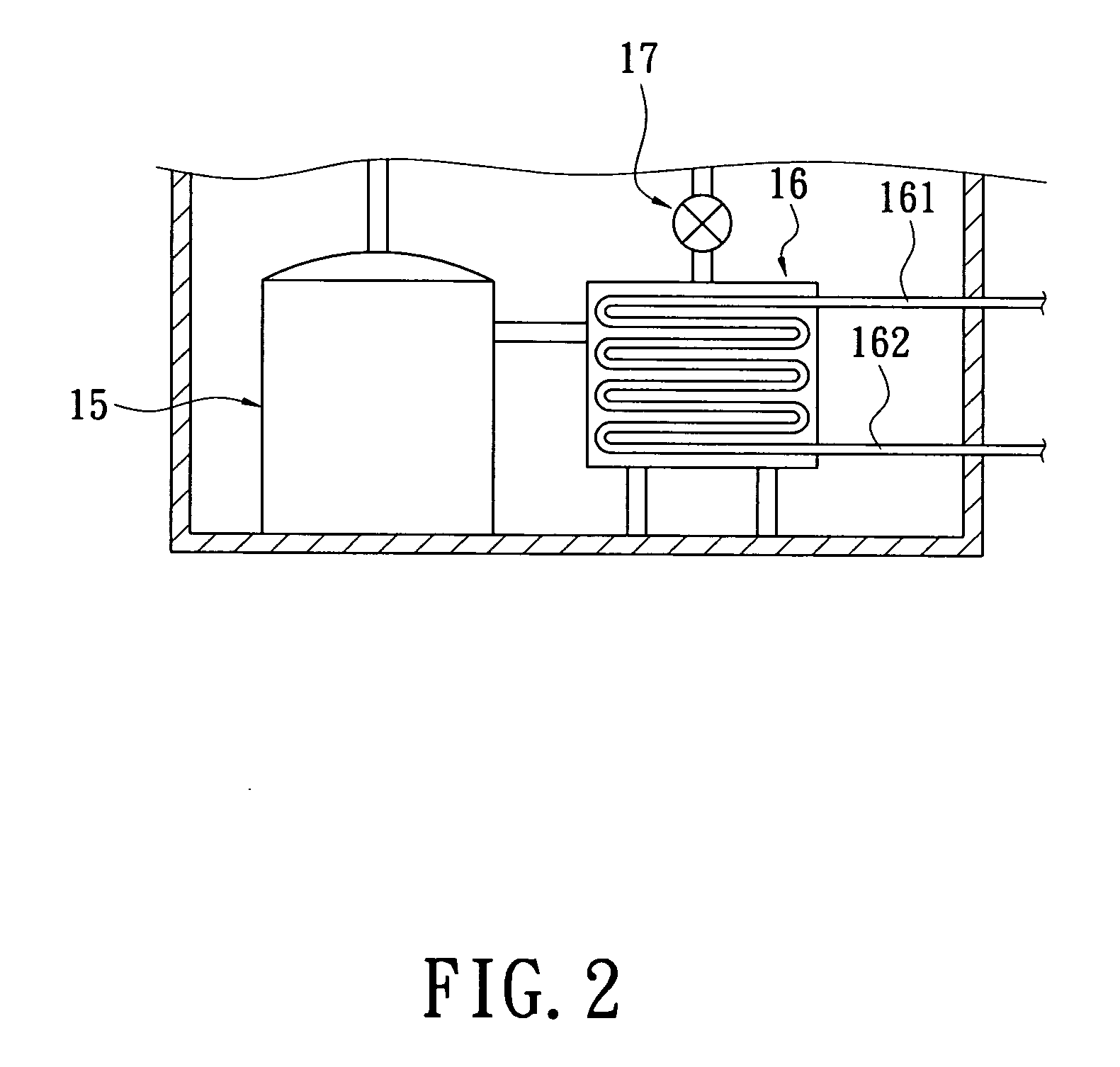

Water quality control method for an evaporative cooling water chiller and a system thereof

InactiveUS20090065188A1Benefiting environmentExtended service lifeDomestic stoves or rangesFree-cooling systemsLimescaleWater quality

A water quality control method for an evaporative cooling water chiller uses a water pump to transport cooling water from a water tank to a water-spraying element via a water pipe. The cooling water is sprayed onto fins and a refrigerant pipe of a first heat exchanger, flows along the fins and is collected in the water tank. Thereby, the cooling water reduces the temperature of the heat exchanger. The water pump is set to operate for a first period and to stop for a second period so that the temperature of the fins and the refrigerant pipe increases. Thereby, the limescales attached to the heat exchanger are detached and drop into the water tank. Subsequently the water pump is turned on again. The cooling water in the water tank flushes out the accumulated particles on the bottom of the water tank, and clean cooling water is added.

Owner:SU PIN TSAN

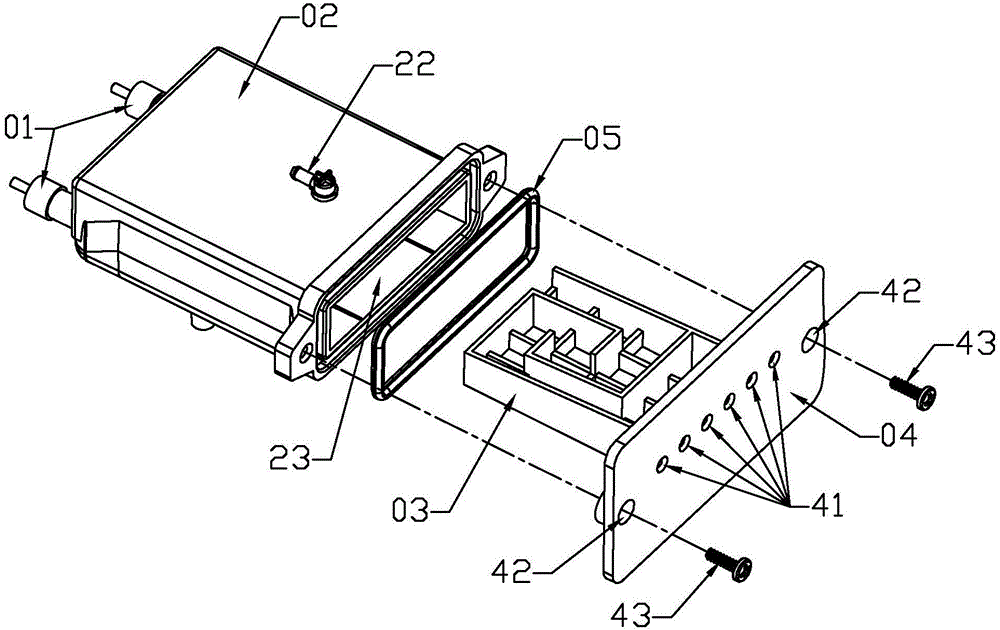

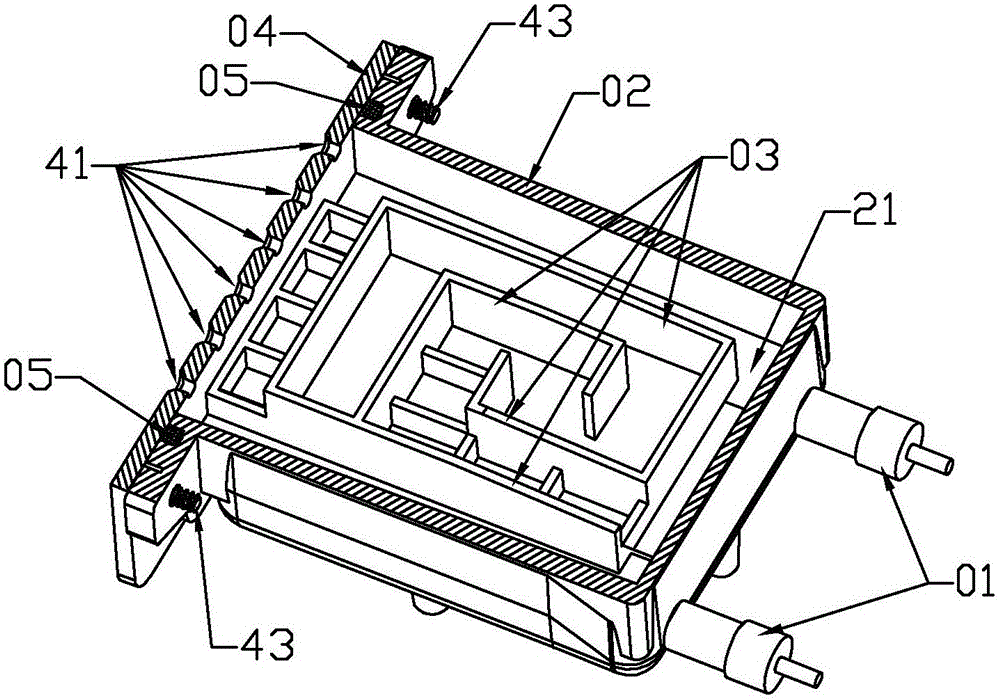

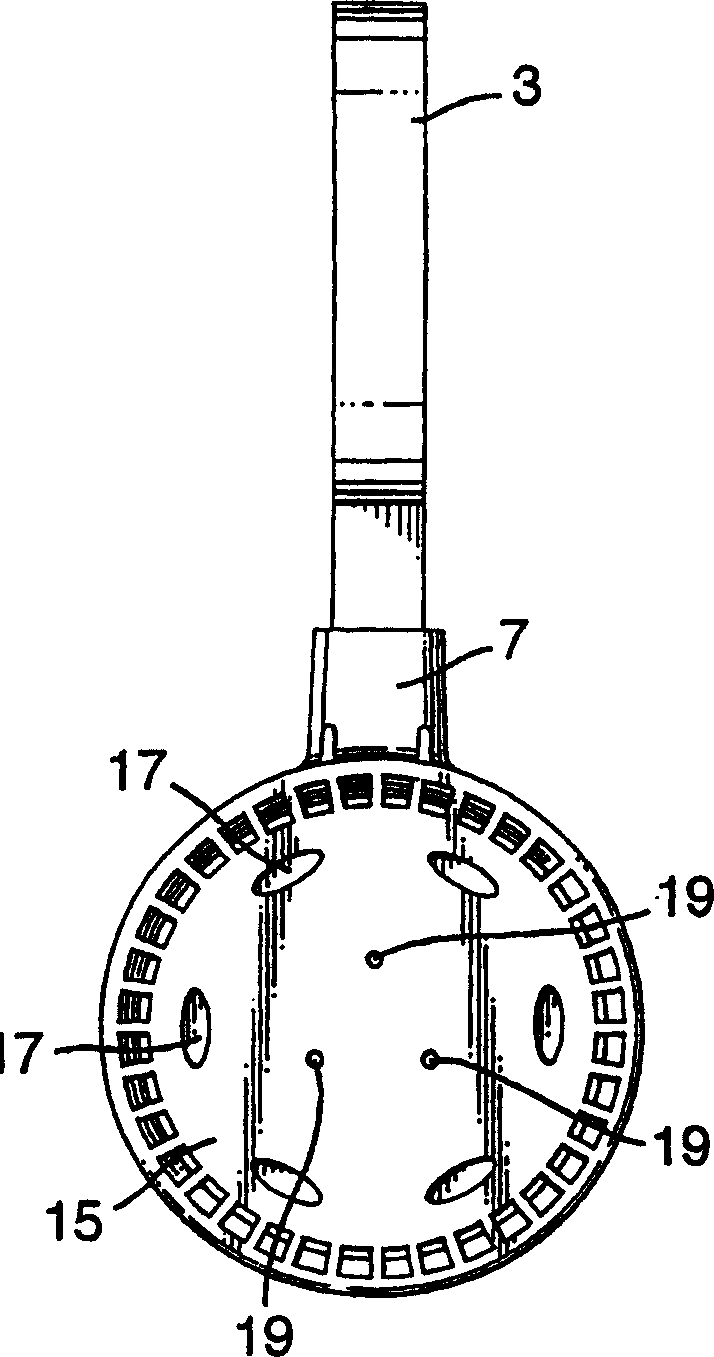

Vaporizing boiler capable of removing scale and steam brush

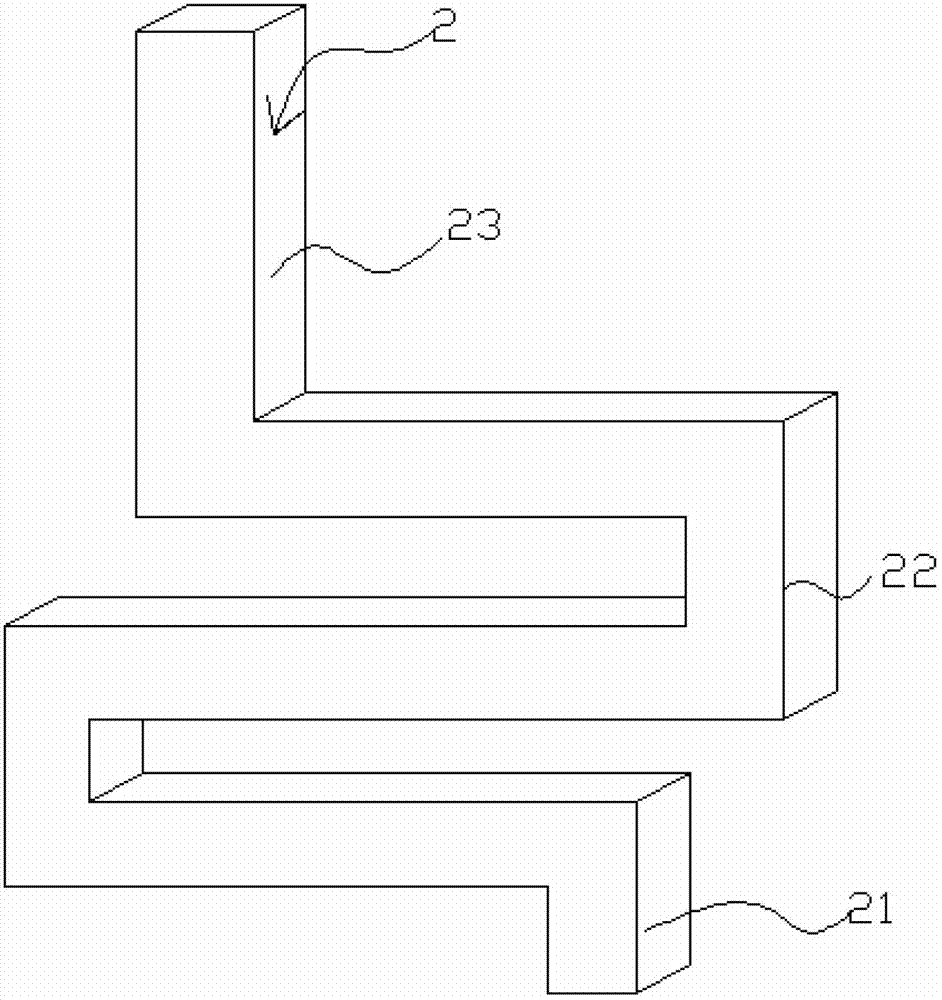

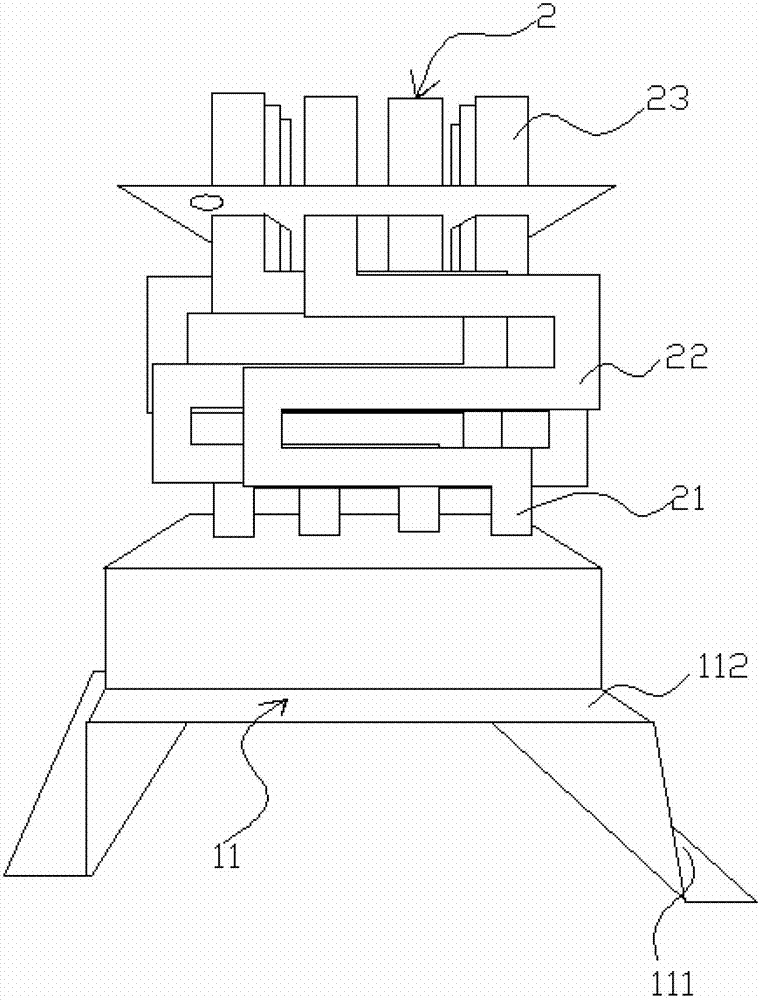

The invention discloses a vaporizing boiler capable of removing scale and a steam brush, and belongs to clothes ironing equipment. By the aid of the vaporizing boiler and the steam brush, the problem of incapability of clearing water scale of existing vaporizing boilers can be solved. The vaporizing boiler and the steam brush have the advantages that an opening is formed in an inner cavity of a boiler, a flow channel and the boiler are separately arranged, accordingly, the flow channel can be taken out from the inner cavity via the opening and can be cleaned, and the scale can be removed; particularly, a steam outlet panel and the flow channel are integrated or connected with each other, only the steam outlet panel needs to be detached when the scale is required to be cleaned, and accordingly the steam outlet panel and the flow channel can be conveniently taken out of the inner cavity of the boiler together; the steam outlet panel and the flow channel are separately arranged, and accordingly application modes of the vaporizing boiler can be increased.

Owner:NINGBO KAIBO GROUP

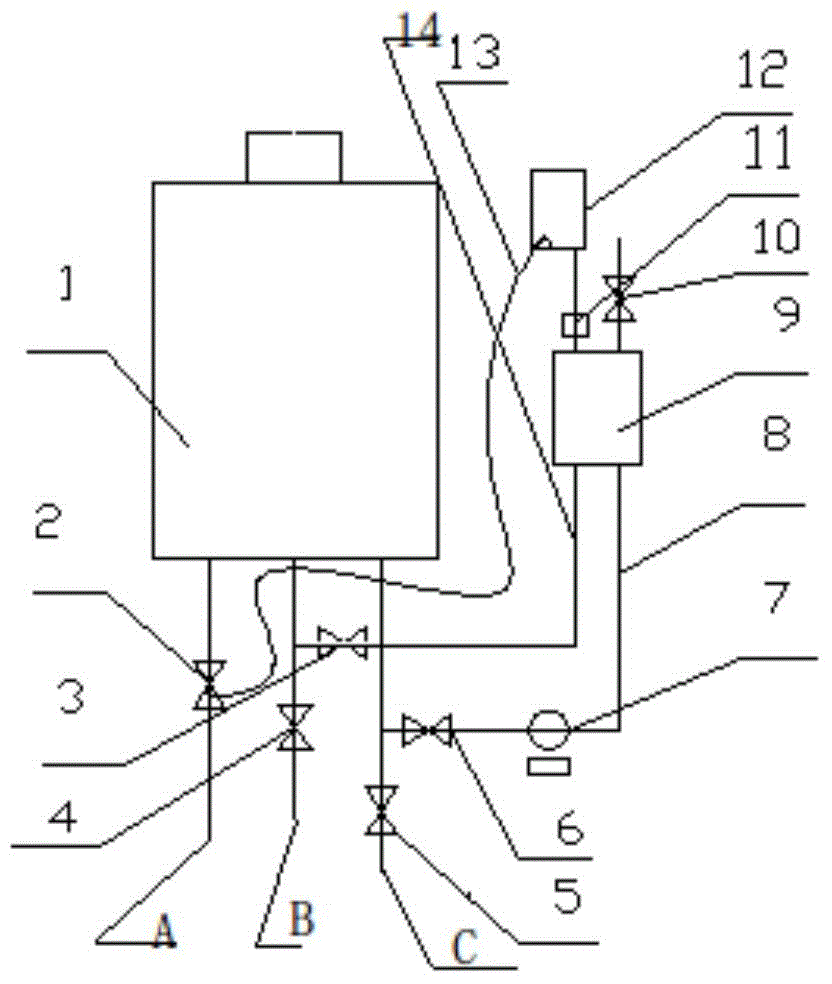

Gas water heater descaling device and descaling method thereof

InactiveCN104406303AImprove descaling efficiencyDescaling time can be controlled freelyFluid heatersTreatment using complexing/solubilising chemicalsLimescaleChemical reaction

The invention relates to a gas water heater descaling device and a descaling method thereof. The gas water heater descaling device is characterized in that the chemical reaction principle is utilized, a descaling agent is added into a water tank of the gas water heater, the water temperature is raised and maintained to certain temperature through heating, a water pump is started to enable the water in the water tank to circulate, the descaling agent and the main components of the accumulated scale generate chemical reaction, then the firm accumulated dirt is loosened or dissolved, and the accumulated scale is cleaned. The gas water heater descaling device has the advantages that the descaling agent can react with the water scale in the circulating flowing process, the descaling efficiency is higher, the descaling time can be freely controlled, and the accumulated scale is more thoroughly cleaned at higher temperature; after the descaling agent is added, the concentration is controlled to be stable, the descaling agent is freely added to guarantee the proper concentration, and the reaction of the accumulated scale is favorably realized; the bulky water scale is fully dissolved, the cleaning effect is good, the heating surface is clean, the good heat transfer effect is realized, and the gas consumption is saved; the structure is simple, the convenience in use is realized, the safety and reliability are realized, the descaling efficiency is high, and the usage amount of descaling amount is saved.

Owner:欧承晏

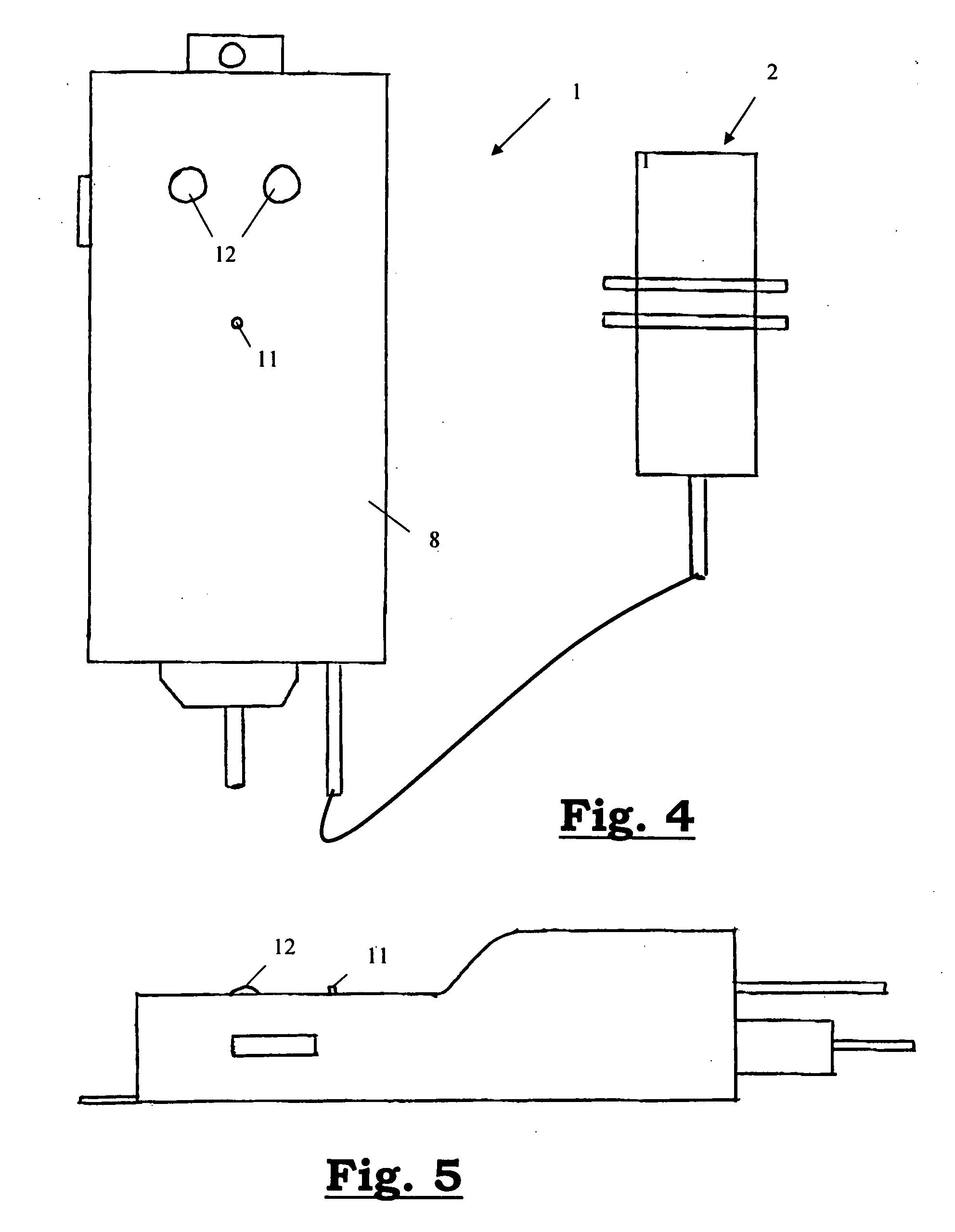

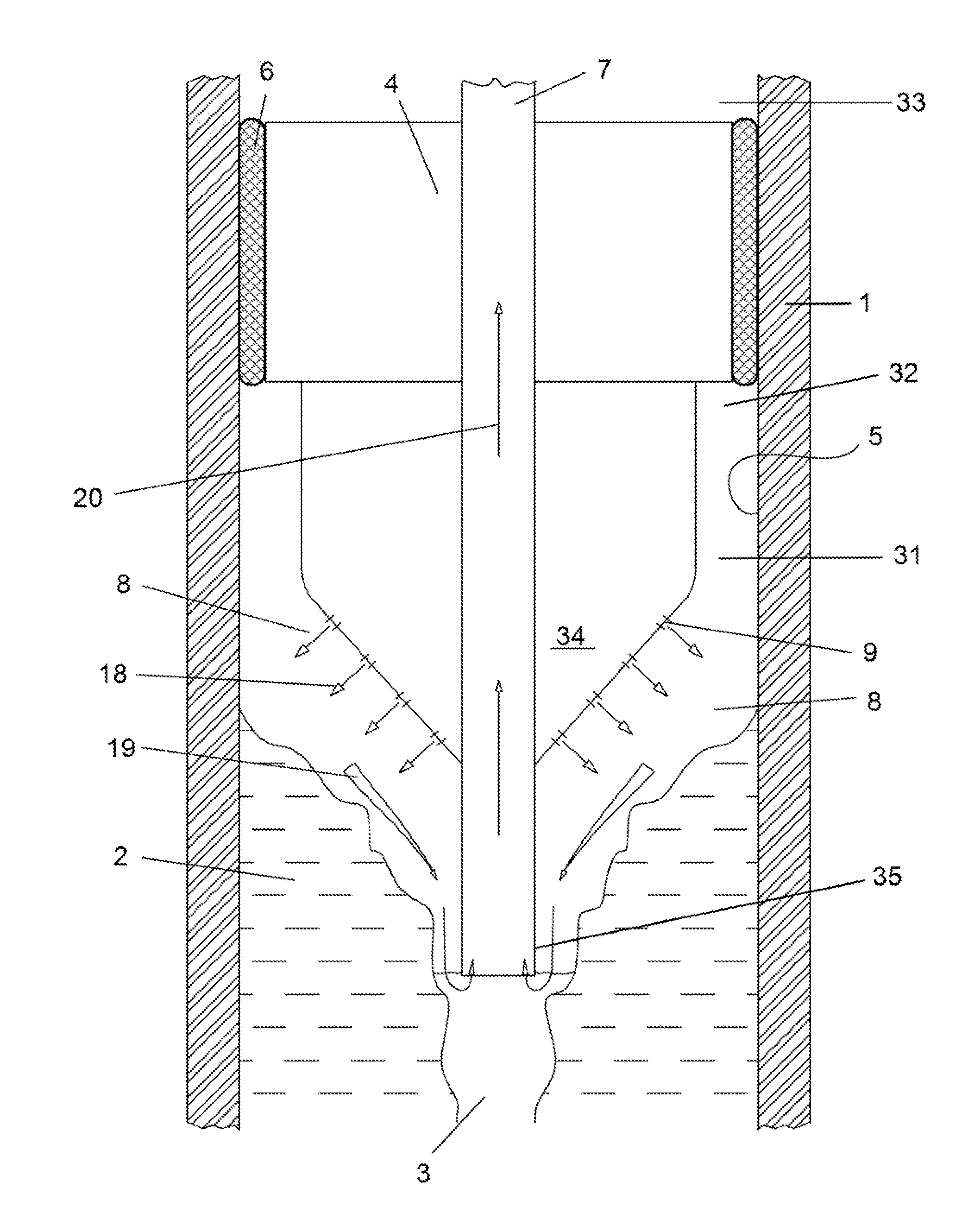

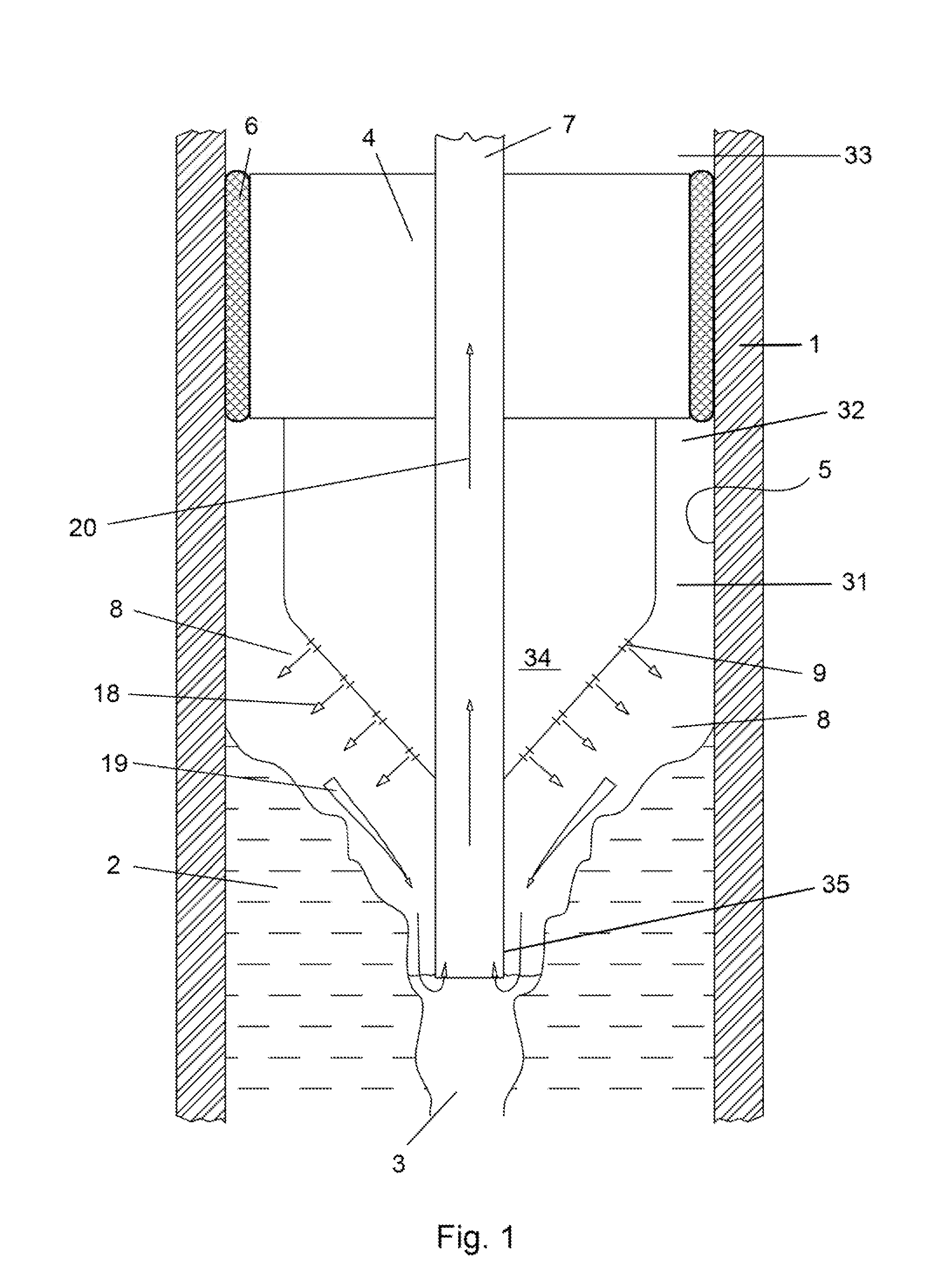

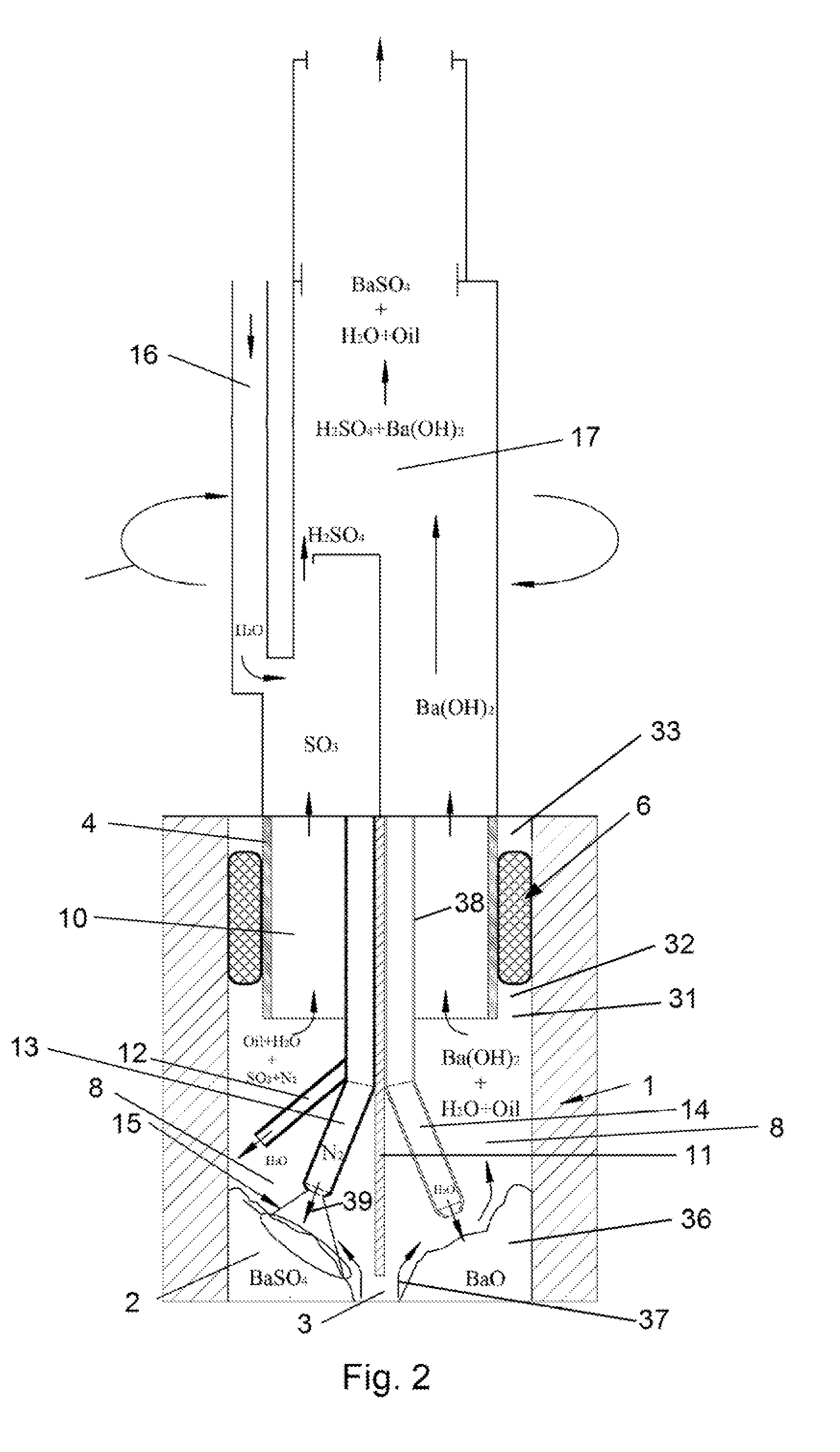

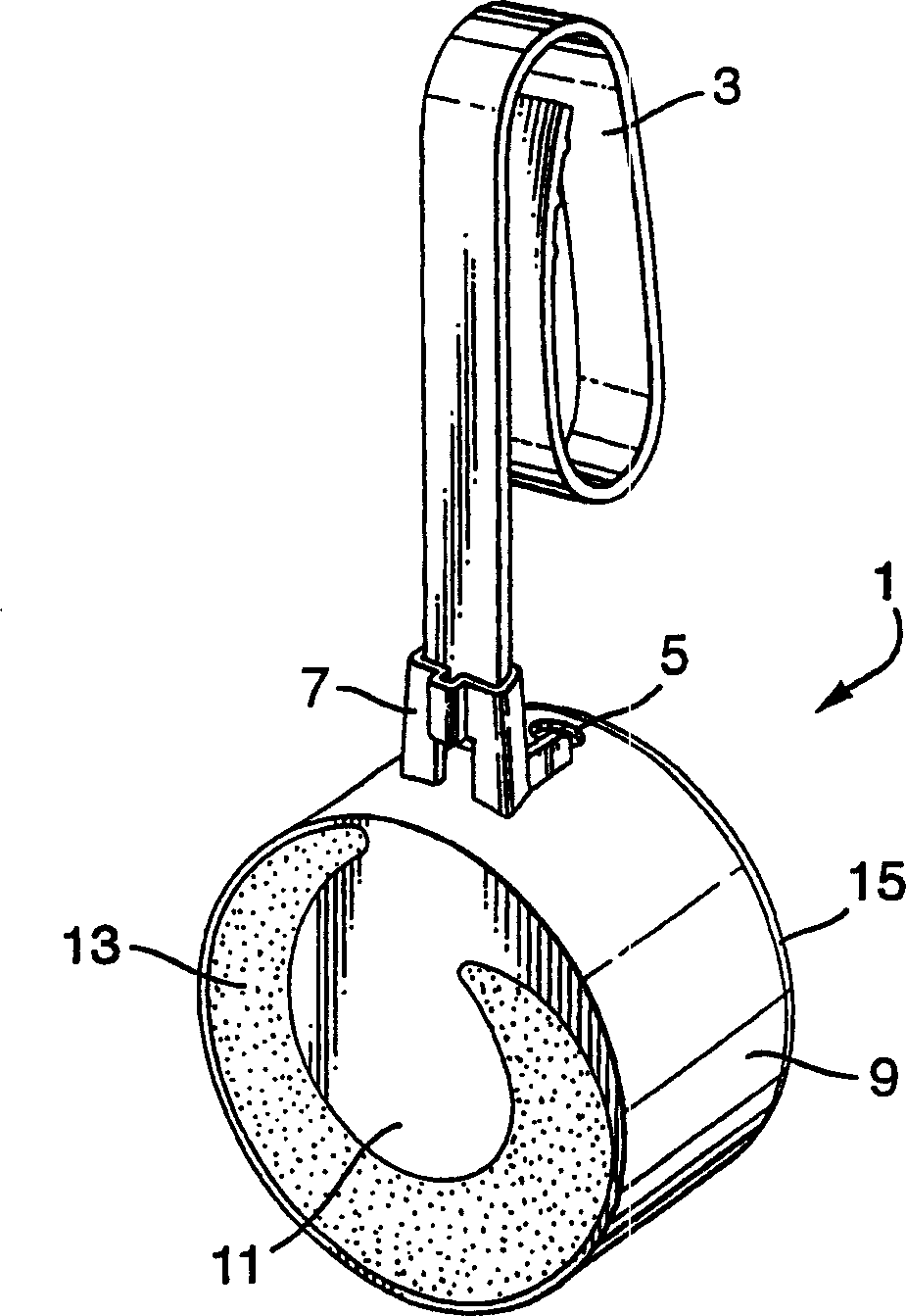

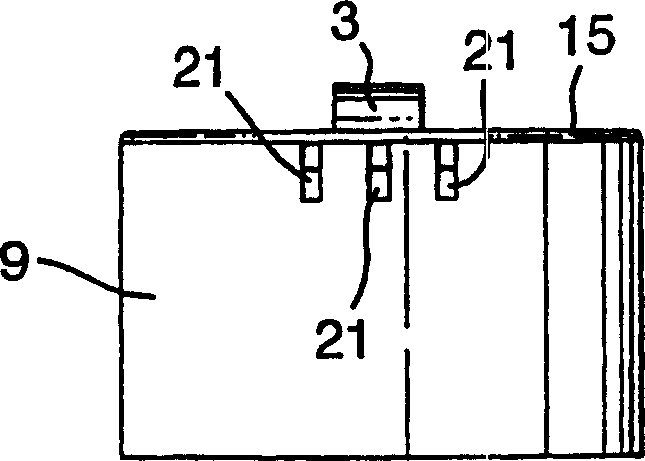

Apparatus for removal of alkaline earth metal salt scale and method

InactiveUS20150165497A1Improve solubilityEasy to removeLighting and heating apparatusCleaning apparatusMill scaleEngineering

A method to remove an alkaline earth metal salt scale deposits from a pipe comprises introducing a laser head (4) into a pipe (1), isolating a pipe section to be cleaned (8) adjacent to a scale deposit (2) on an interior wall of a pipe using a packer (6), filling the section of the pipe to be cleaned (8) with gas to displace laser-obstructing materials, activating a laser element in the laser head (4) to heat a surface layer of the scale deposit (2) above a thermal decomposition temperature, and washing the thermally decomposed scale deposit (2) with water. The thermally decomposed scale deposit (2) becomes at least partially soluble and removable as a result of being heated.

Owner:SLD ENHANCED RECOVERY

Improvements for water closet cleaning wares

InactiveCN1585819ANon-ionic surface-active compoundsAnionic-cationic-non-ionic surface-active compoundsLimescaleFlush toilet

The present invention provides an in the toilet bowl article where the active compositions, for example, a cleaning, disinfecting, and / or lime scale removing composition is separate from a perfume. The composition and perfume are placed in a housing such that the composition is in the path of the flushing toilet water and the perfume is not in the path of the flushing toilet water.

Owner:RECKITT BENCKISER (UK) LTD

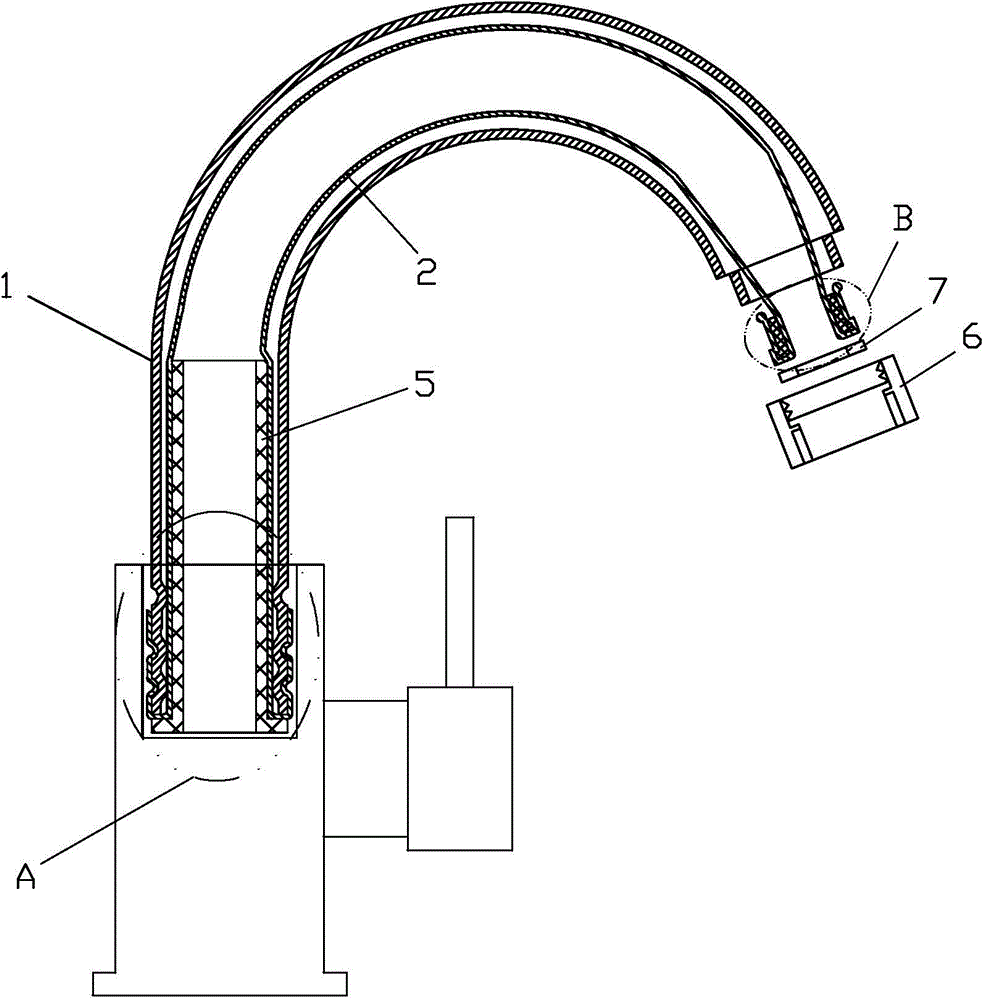

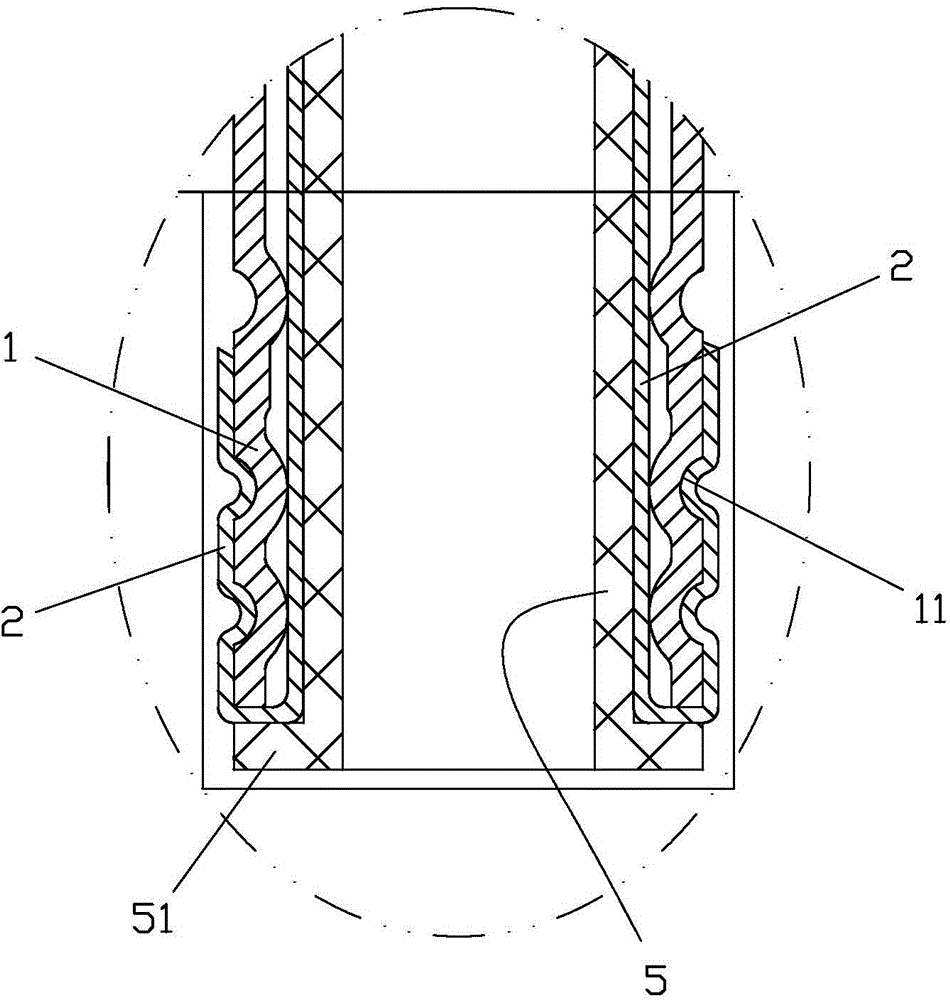

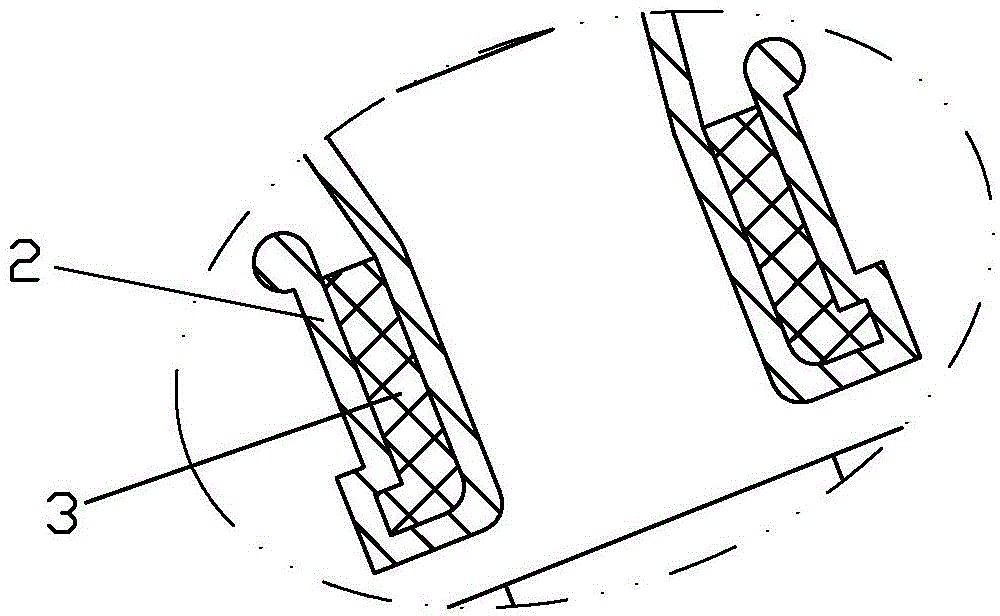

Safe, non-toxic, water-tight and non-scale water outlet pipe structure of faucet

ActiveCN104154291AAvoid health effectsNot easy to cause water leakageValve housingsLimescaleWater flow

The invention discloses a safe, non-toxic, water-tight and non-scale water outlet pipe structure of a faucet. The safe, non-toxic, water-tight and non-scale water outlet pipe structure comprises a water outlet pipe of the faucet and a rubber film pipe. The rubber film pipe is inserted in the water outlet pipe of the faucet, one end of the rubber film pipe extends out of a water inlet of the water outlet pipe of the faucet and then sleeves the water outlet pipe of the faucet in an outwardly turned manner, the other end of the rubber film pipe extends out of a water outlet of the water outlet pipe of the faucet and then is connected with a T-shaped sleeve, and one end of the T-shaped sleeve is clamped at the water outlet of the water outlet pipe of the faucet after the other end of the T-shaped sleeve is arranged in the water outlet pipe of the faucet; sealing grooves are formed in the outer wall of the water outlet pipe of the faucet, and the rubber film pipe extends out of the water inlet of the water outlet pipe of the faucet and then sleeves the sealing grooves in an outwardly turned manner. The safe, non-toxic, water-tight and non-scale water outlet pipe structure has the advantages that when water flows into the safe, non-toxic, water-tight and non-scale water outlet pipe structure, the water outlet pipe, which is of a metal structure, of the faucet is not in contact with the water, accordingly, safe, non-toxic, water-tight and non-scale effects can be realized, and the like.

Owner:KAIPING QILONG SANITARY WARE TECH CO LTD

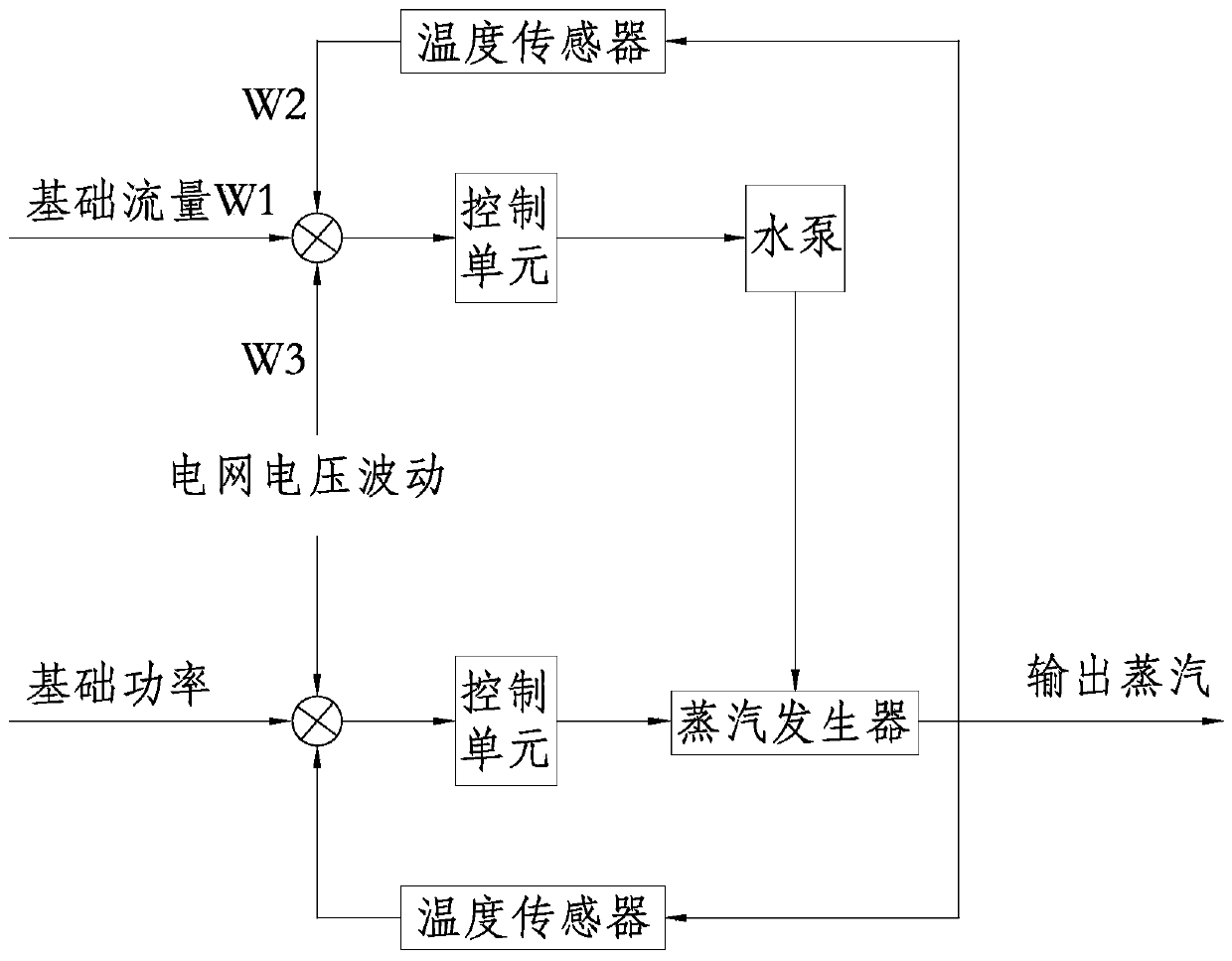

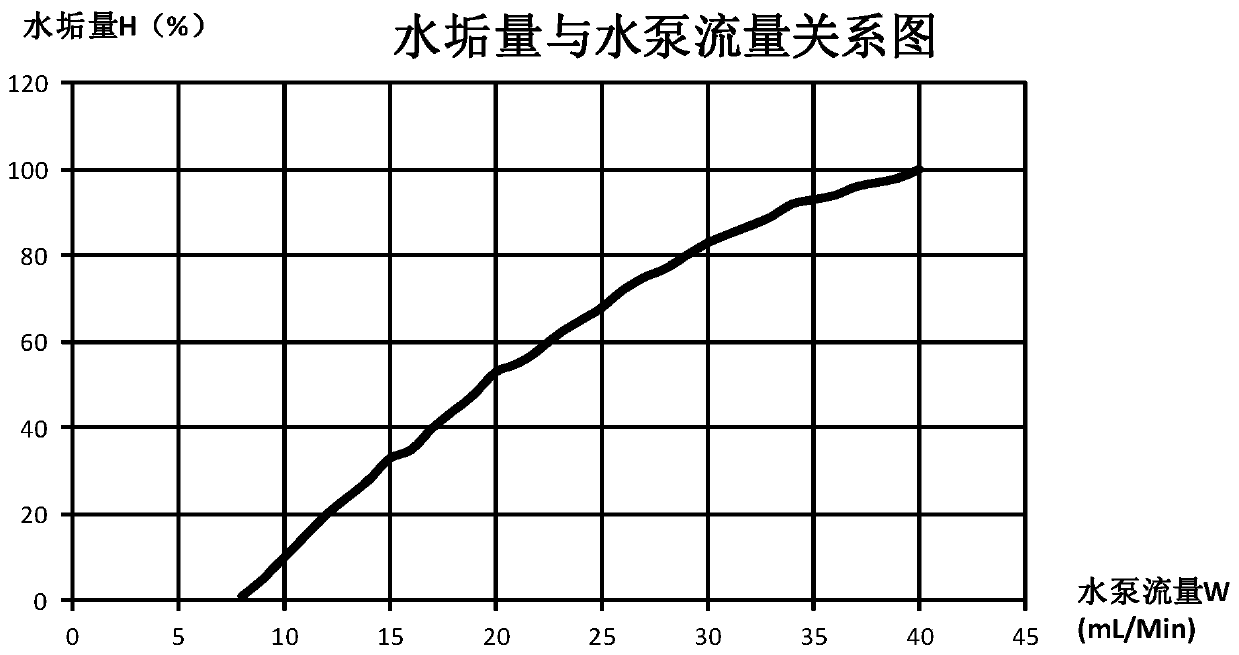

Limescale treatment method for steam heating type cooking appliance

ActiveCN111256103ATemperature controlThe test result is accurateBoiler cleaning apparatusBoiler controlLimescaleProcess engineering

The invention discloses a limescale treatment method for a steam heating type cooking appliance, belonging to the technical field of kitchen cooking appliance control. The limescale treatment method is used for solving the limescale detection problem of the existing steam heating type cooking appliance. The limescale treatment method for the steam heating type cooking appliance comprises the following steps of: obtaining the current temperature of a steam generator; adjusting the flow rate of a water pump according to the current temperature of the steam generator; and determining the amount of limescale in the corresponding steam generator according to the adjusted flow rate of the water pump. Compared with a method of judging the amount of limescale according to the service time in the prior art, the limescale treatment method has the advantages that the limescale detection in the limescale treatment method is not affected by factors such as water quality in different regions, the frequency of use of cooking appliances and the like, and the limescale detection result is more accurate. Compared with a method of detecting the amount of limescale by weighing and adding sensors, thelimescale treatment method has the advantages that the limescale detection in the limescale treatment method is realized by depending on the logic operation of a steam generation system per se, the addition of additional detection devices is not needed, the detection cost is low, and the limescale treatment method is easy to implement.

Owner:JOYOUNG CO LTD

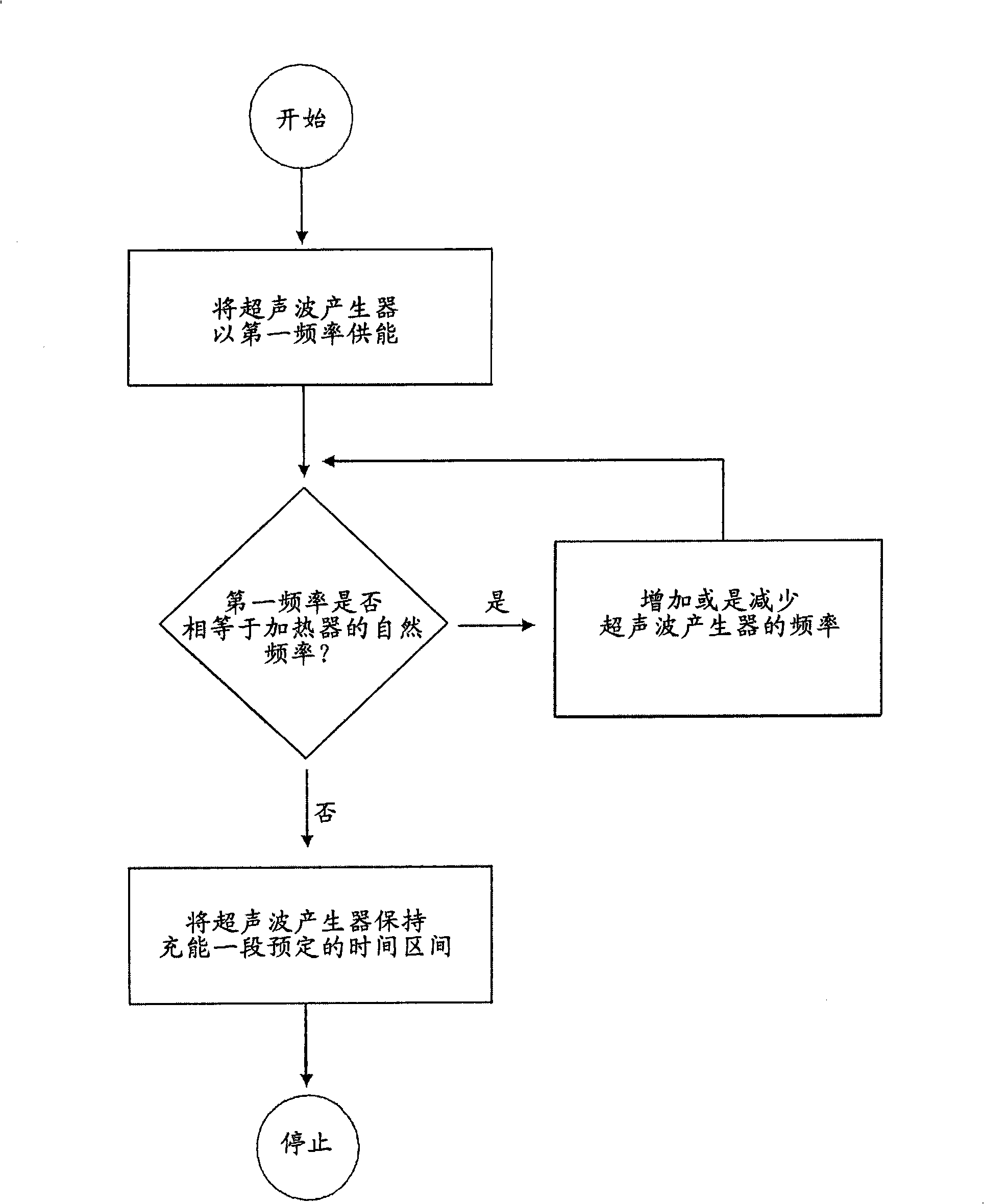

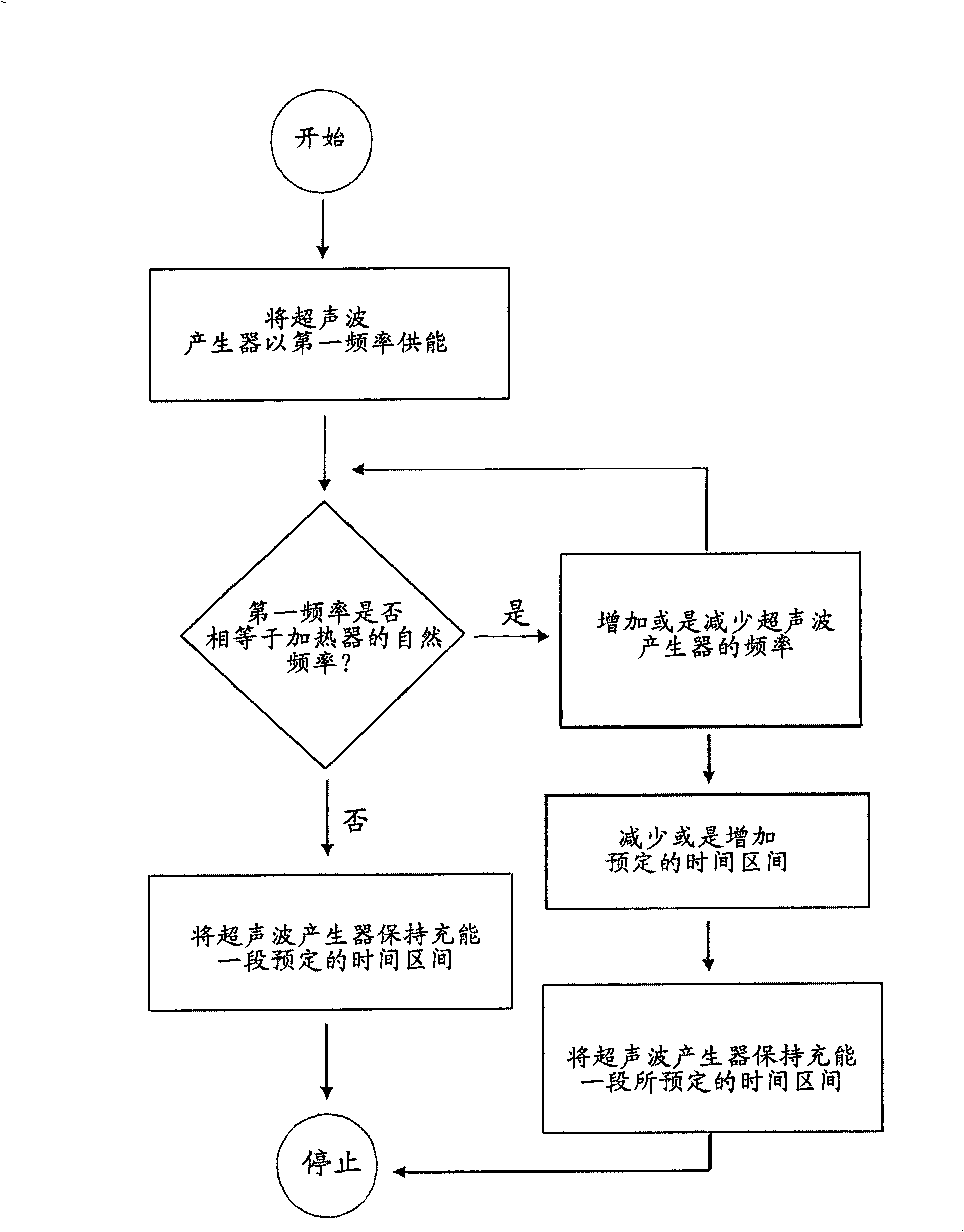

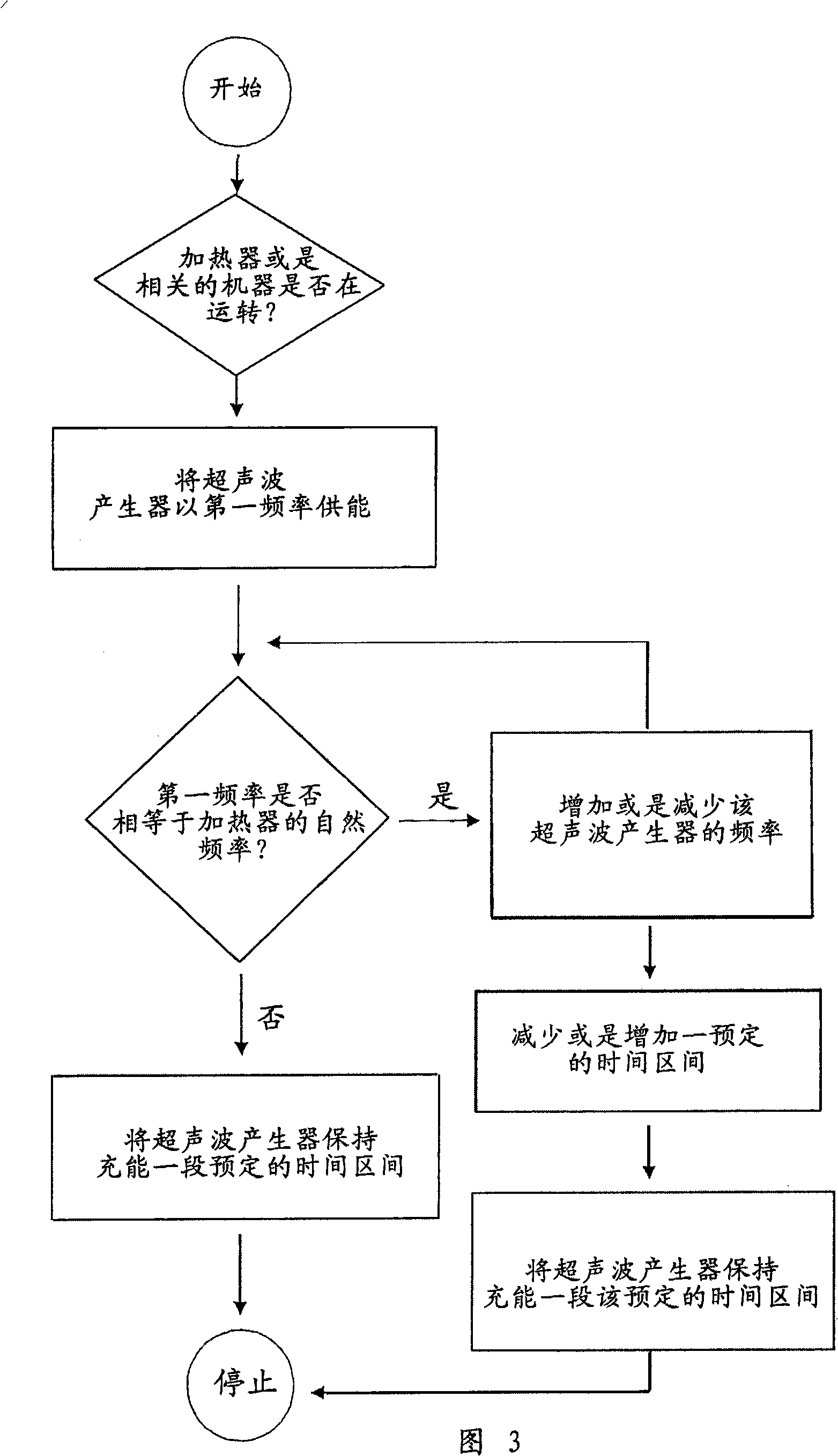

Method and apparatus for treating limescale deposits within water heaters in beverage dispensing machines

The present invention relates to a method and an apparatus (1) for removing, or substantially reducing, the limescale deposits within a water heater (5) of a beverage dispensing machine, by inducing ultrasonic vibrations through an ultrasonic generator (2). Advantageously the step of inducing ultrasonic vibrations is implemented discontinuously at high energy levels.

Owner:RHEA VENDORS SPA

Guanidyl disinfecting anti-scaling inhibitor for oilfield water reinjection

InactiveCN108402070AImprove securityHigh antibacterial activityWaste water treatment from quariesBiocideLimescaleSulfate-reducing bacteria

The invention provides a guanidyl disinfecting anti-scaling inhibitor for oilfield water reinjection. A production method includes: 1) mixing 100 parts by weight of guanidine hydrochloride and 120-180parts of amine to allow reacting at 80 DEG C, stirring while heating, holding the temperature of 80 DEG C, continuing to stir to allow reacting for 2 hours so as to synthesize aminoguanidine hydrochloride; 2) cooling the aminoguanidine hydrochloride to normal temperature, adding 200-300 parts by weight of water, adding 1-5 parts by weight of a surfactant, and stirring and dissolving to generate aminoguanidine hydrochloride solution; 3) allowing the aminoguanidine hydrochloride solution to react with 1-20 parts by weight of an acid to generate a finished functional guanidine hydrochloride solution, namely the guanidyl disinfecting anti-scaling inhibitor for oilfield water reinjection. The guanidyl disinfecting anti-scaling inhibitor for oilfield water reinjection has the advantages that the inhibitor has high antibacterial activity, broad-spectrum disinfecting performance, is especially efficient to kill sulfate-reducing bacteria, saprophytic bacteria, iron bacteria and the like in oilfield water, and can also remove scaling matters in the oilfield water and water scale generated on the inner wall of a duct.

Owner:东营利丰化工新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com