Method and apparatus for treating limescale deposits within water heaters in beverage dispensing machines

A beverage dispenser and water heater technology, applied in the field of methods and devices, capable of solving problems such as mechanical failures, increased production costs, and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

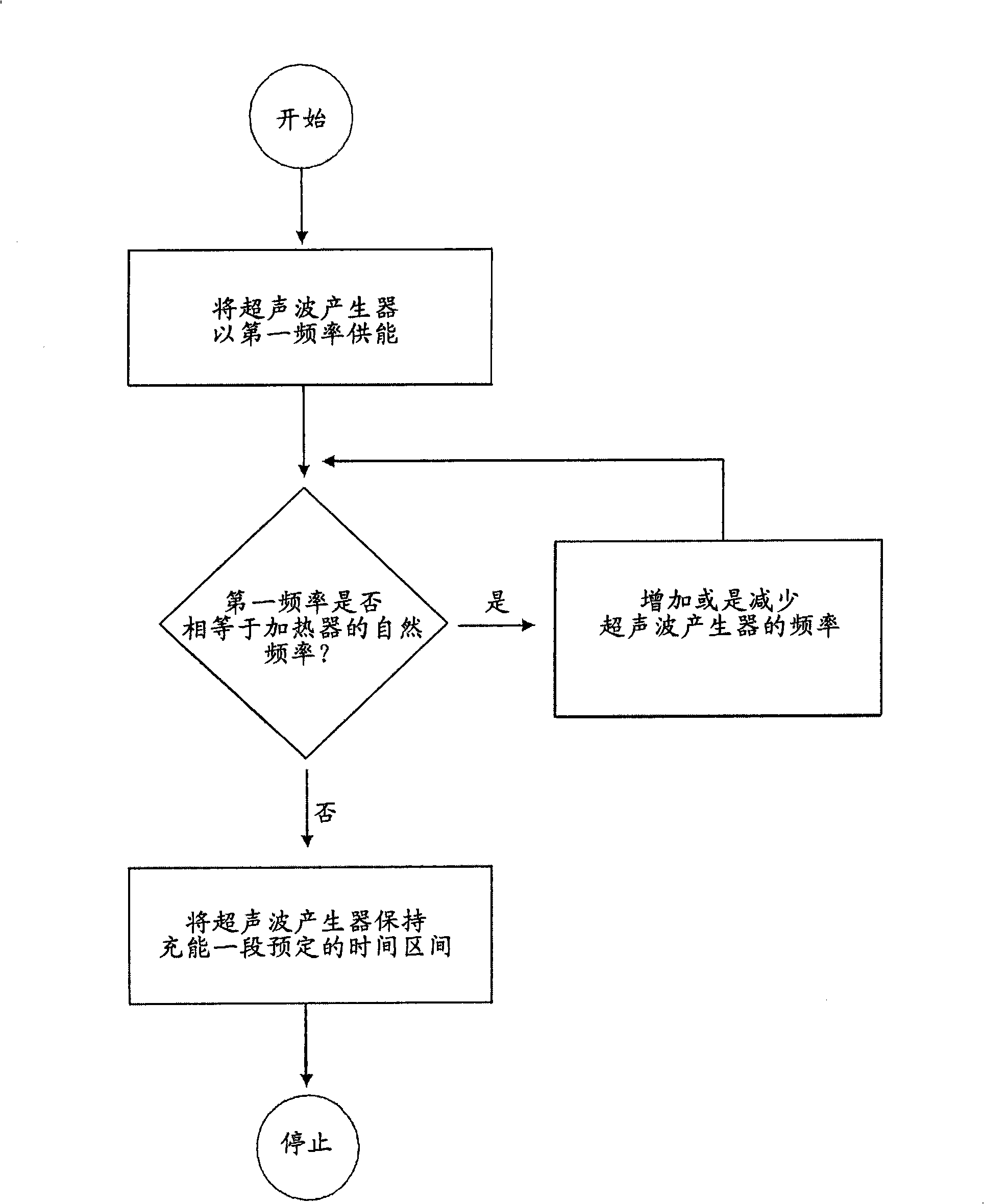

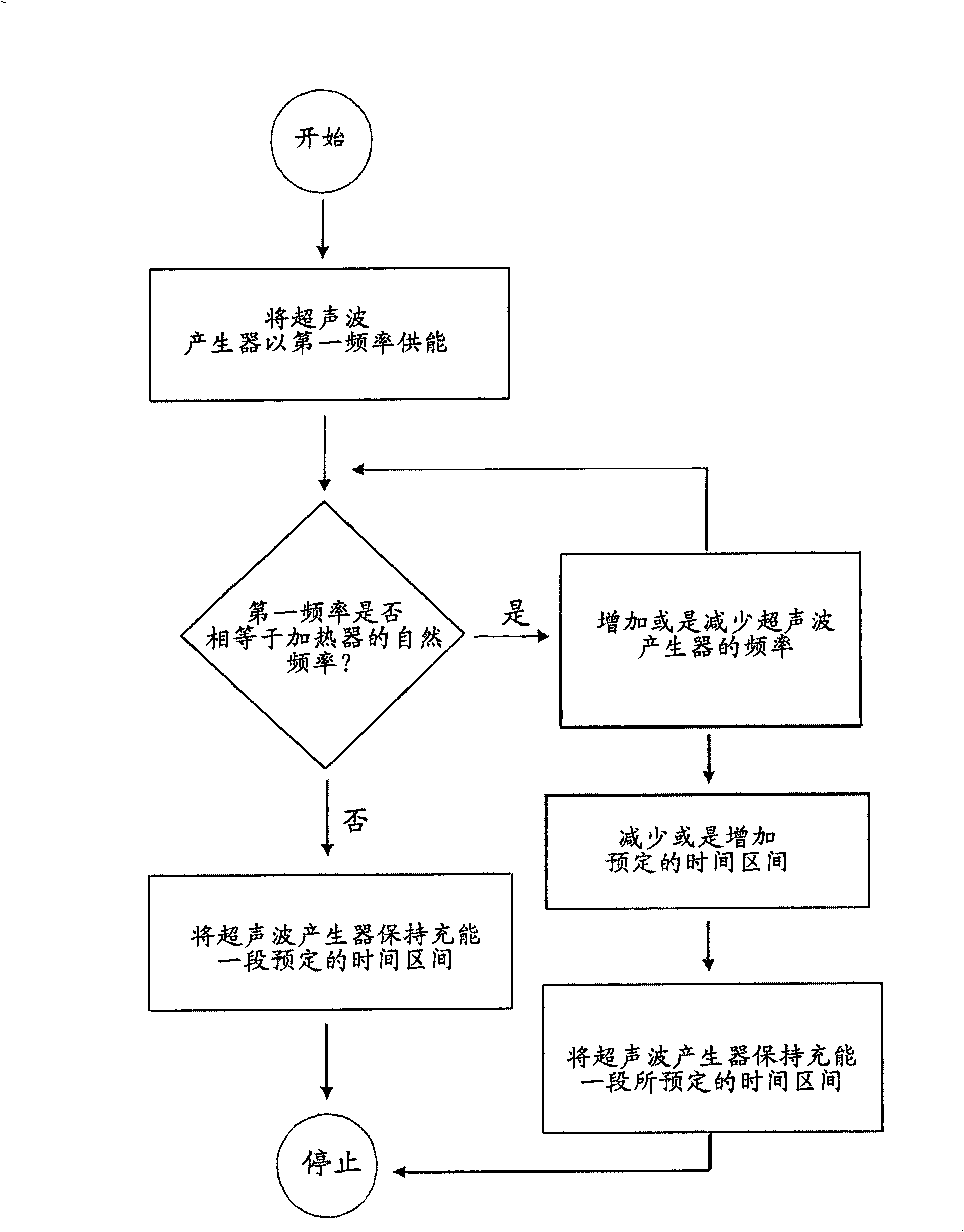

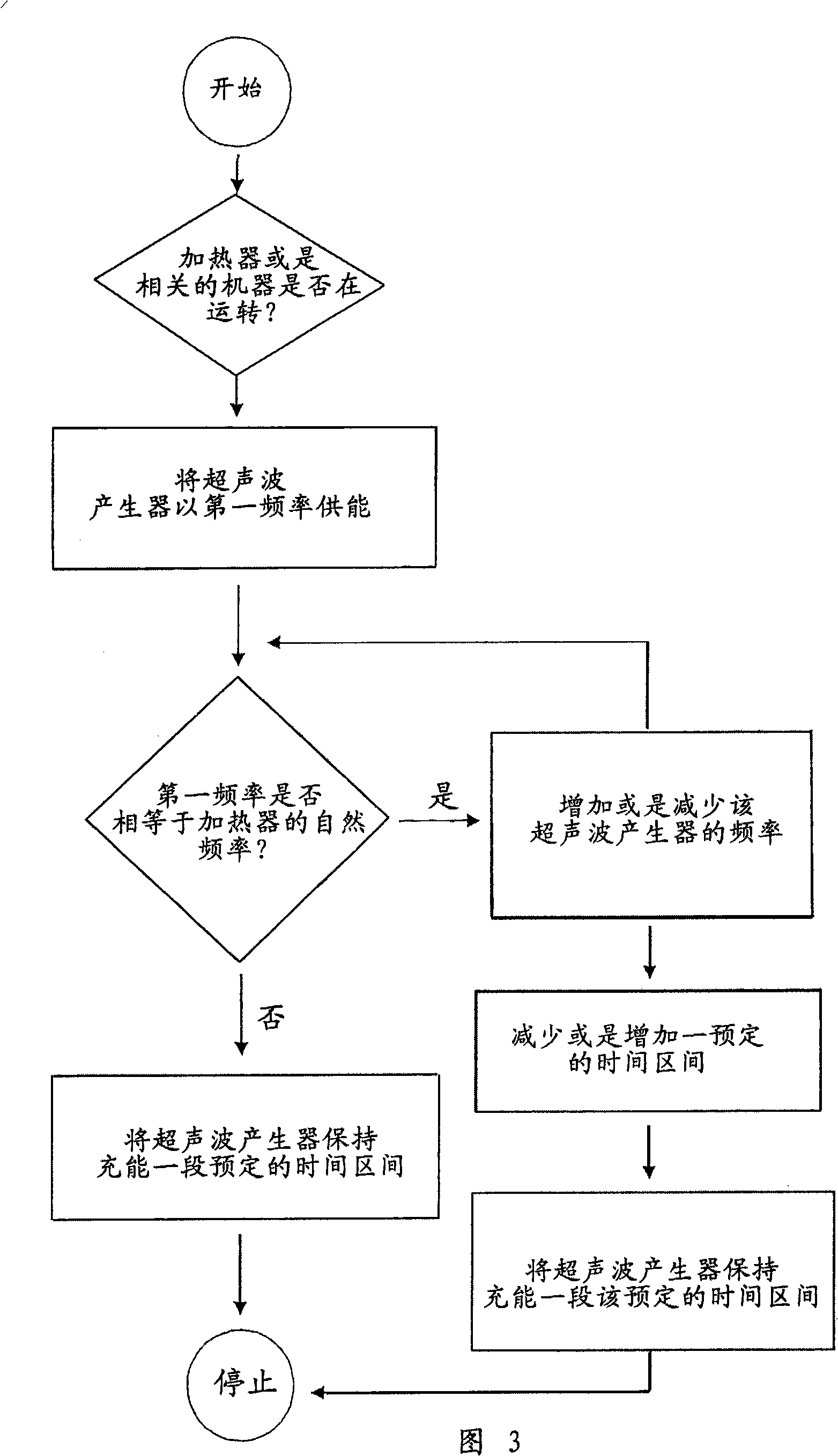

[0046] figure 1 A flowchart of the method according to the present invention is shown to remove or reduce scale deposits inside the beverage dispenser of the water heater. The method includes the step of inducing high-energy ultrasonic vibration of the water heater, by charging the ultrasonic generator, the ultrasonic generator is directly or indirectly connected to the same heater. For example, the water heater supplies hot water to the beverage dispenser to prepare coffee, chocolate, cappuccino, tea... etc.

[0047] Different from the method disclosed in the prior art, in the present invention, the ultrasonic vibration is caused discontinuously in a short discrete time interval, and it is preferable to vibrate at a frequency different from the natural frequency of the water heater. The resonance of the heater can be avoided to prevent excess mechanical pressure. in figure 1 In the evaluation of the natural frequency of the heater can be optionally added.

[0048] Vibration is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com