Patents

Literature

621 results about "Mill scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, consisting of the mixed iron oxides iron(II) oxide (FeO), iron(III) oxide (Fe₂O₃), and iron(II,III) oxide (Fe₃O₄, magnetite).

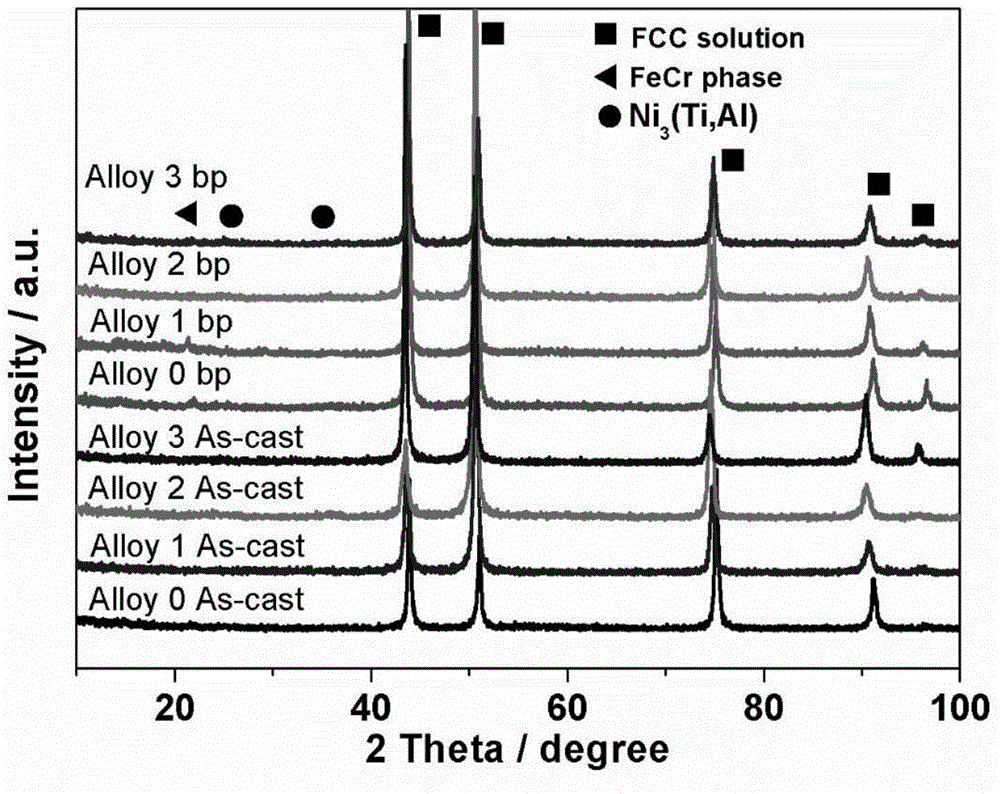

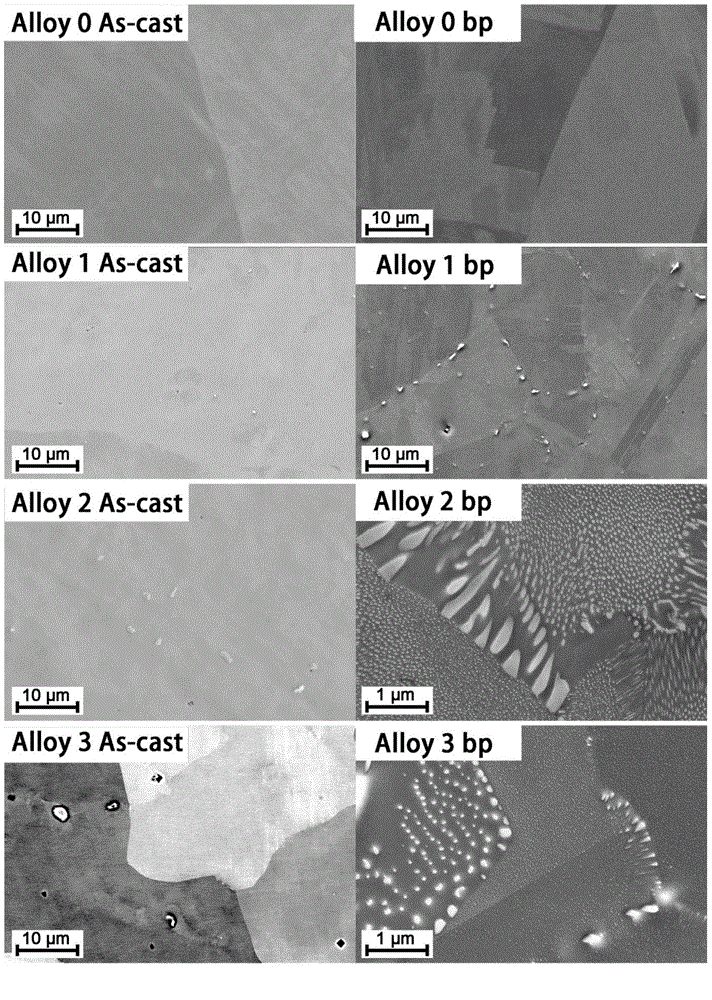

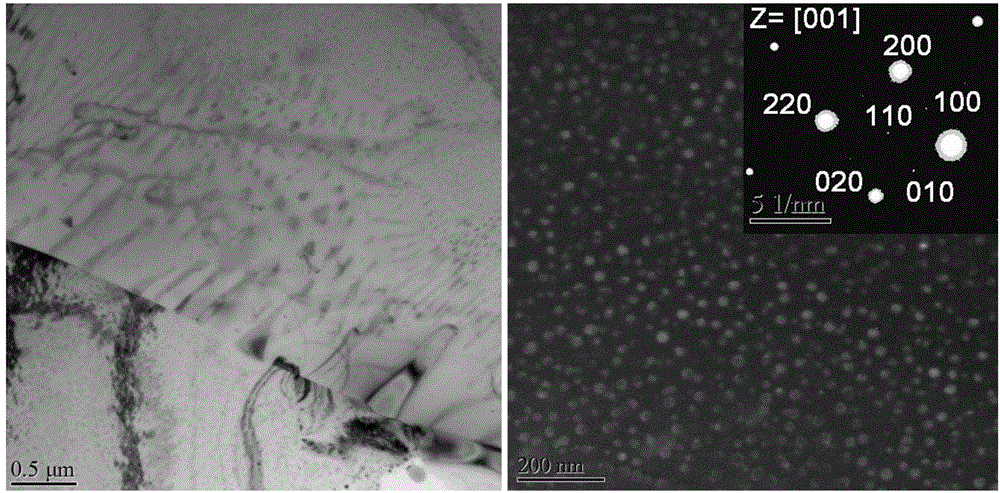

High-entropy alloy with dispersion nano-sized precipitate strengthening effect and preparing method thereof

ActiveCN104694808AWide range of ingredientsControl mechanical propertiesElectric arc furnaceHigh entropy alloys

The invention discloses high-entropy alloy with the dispersion nano-sized precipitate strengthening effect and a preparing method thereof. The method comprises the steps of removing oxidized skin of a metal material, and then conducting weighing and burdening accurately according to a ratio; conducing smelting in an electric-arc furnace in an argon shield atmosphere of titanium absorbed oxygen to obtain an initial high-entropy alloy ingot, and conducting cold rolling, wherein rolling reduction is 20-50%; placing the ingot in a heat treatment furnace with a temperature ranging from 900 DEG C to 1000 DEG C for heat preservation for 0.5-2 hours, and conducting quenching; placing the ingot in a heat treatment furnace with a temperature ranging from 700 DEG C to 800 DEG C for heat preservation for 2-18 hours, and conducting quenching. By means of precipitation strength, on the premise that high plasticity is kept, yield strength and tensile strength are improved greatly. The room-temperature tensile strength of (FeCoNiCr)94Ti2Al4 in the final state reaches 1094 MPa, plastic elongation is 35%, work hardening effect is remarkable, comprehensive room-temperature mechanical property is prominent, high-temperature tensile strength can reach 400 MPa at the temperature of 800 DEG C and strain rate of 10<-3>, steady creep rate is smaller than or equal to 10<-8> under the stress of 100 MPa and at the temperature of 750 DEG C, and high-temperature tensile strength and creep mechanical property are excellent.

Owner:UNIV OF SCI & TECH BEIJING

Coating material for protecting metals, especially steel, from corrosion and/or scaling, method for coating metals and metal element

InactiveCN101360796AVarious usabilityImprove conductivityPretreated surfacesAnti-corrosive paintsAfter treatmentSpot welding

The invention surprisingly finds that when a suitable binder including a suitable filler is used during the high temperature treatment of a curing process, the coating materials of the invention change in such a manner that electrically conducting reactive layers are formed that allow welding and especially spot welding together with the metal substrate even after treatment at temperatures of more than 800 DEG C.

Owner:NANOX

Nitrogen-strengthened TiZrHfNb-based high-entropy alloy and preparation method thereof

ActiveCN105671392AThe scope of application of large ingredientsBroad preparation conditionsCrucibleHigh entropy alloys

Owner:UNIV OF SCI & TECH BEIJING

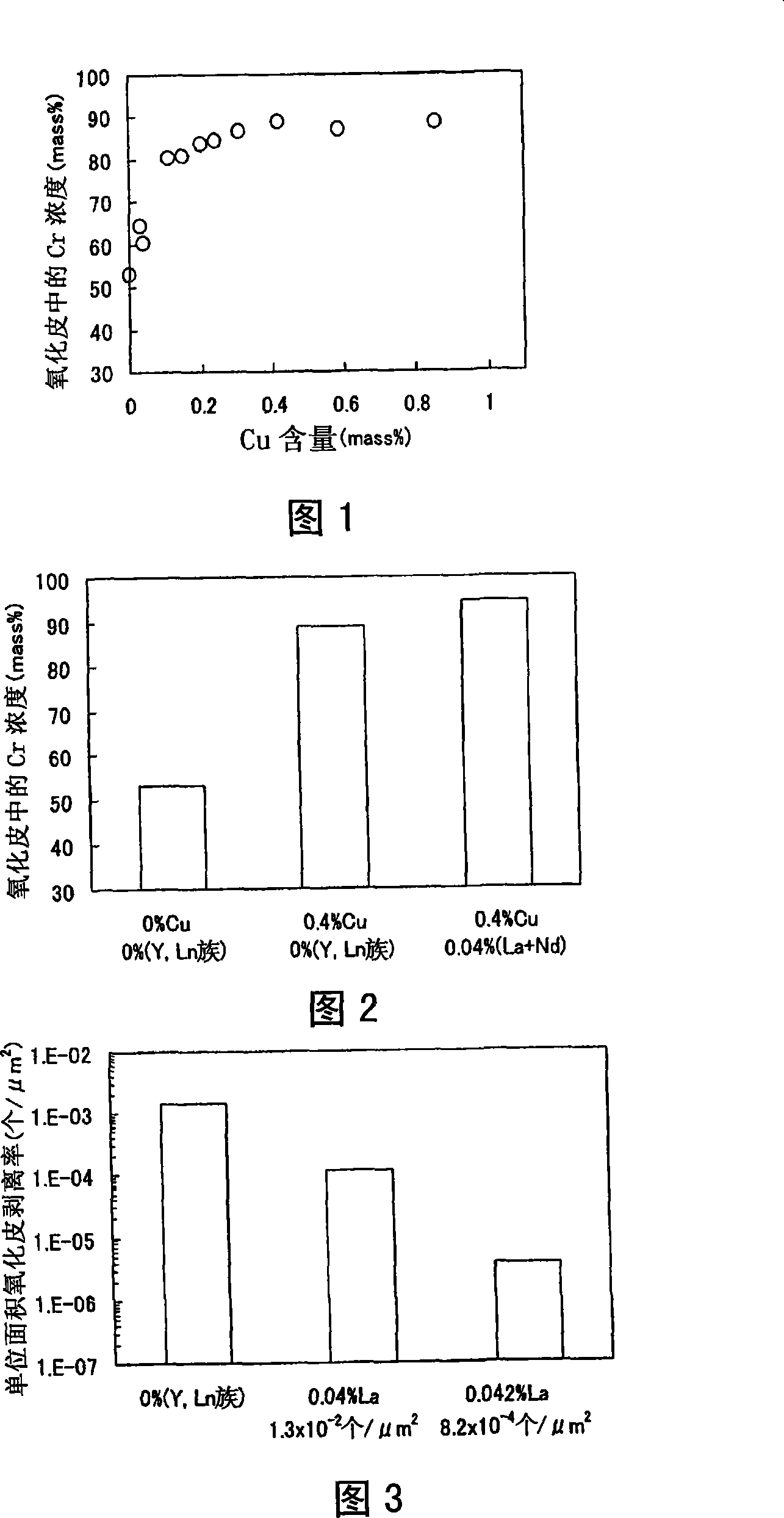

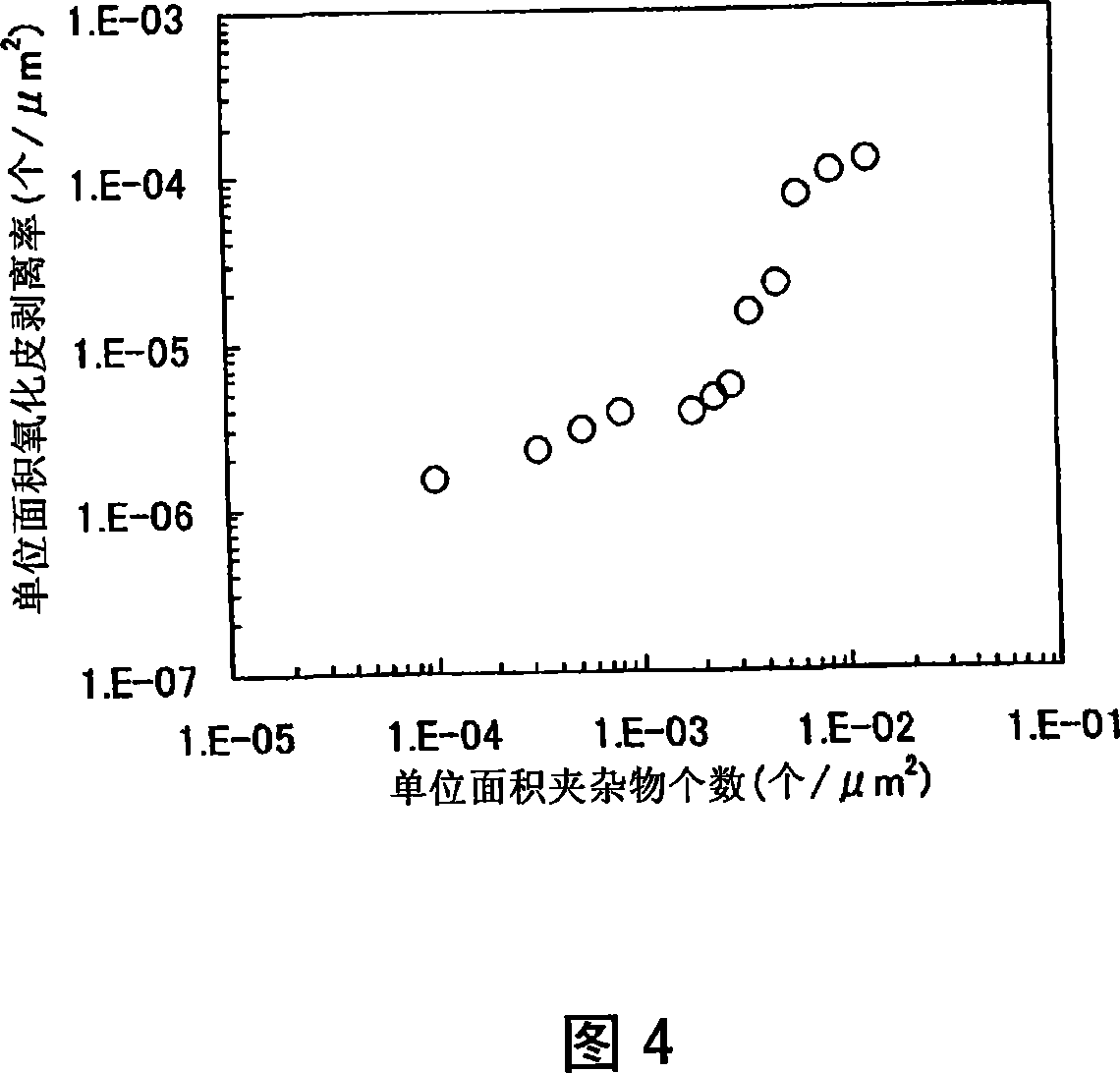

Austenitic stainless steel

ActiveCN101194037APrevent peelingIncreased durabilityHeat exchange apparatusRare-earth elementSS - Stainless steel

Even after repeated high-temperature heating-cooling cycles, it still has excellent scale peeling resistance that can inhibit the peeling of protective oxide scales formed on the steel surface, and can be used in high temperature, especially high temperature humidified gas environments above 1023K. System stainless steel with the following steel composition: C: 0.01-0.15%, Si: 0.01-3%, Mn: 0.01-2%, Cu: 0.1-2.5%, Cr: 23-30%, Ni: 16-25% , Al: 0.005 to 0.20%, N: 0.001 to 0.40%, P: 0.04% or less, S: 0.01% or less, and one or more rare earth elements selected from the Y and Ln groups: total 0.005 to 0.1%, the balance is substantially composed of Fe and unavoidable impurities, and the inclusions containing Y and Ln group elements on the steel surface are 5×10-3 / μm2 or less.

Owner:NIPPON STEEL CORP

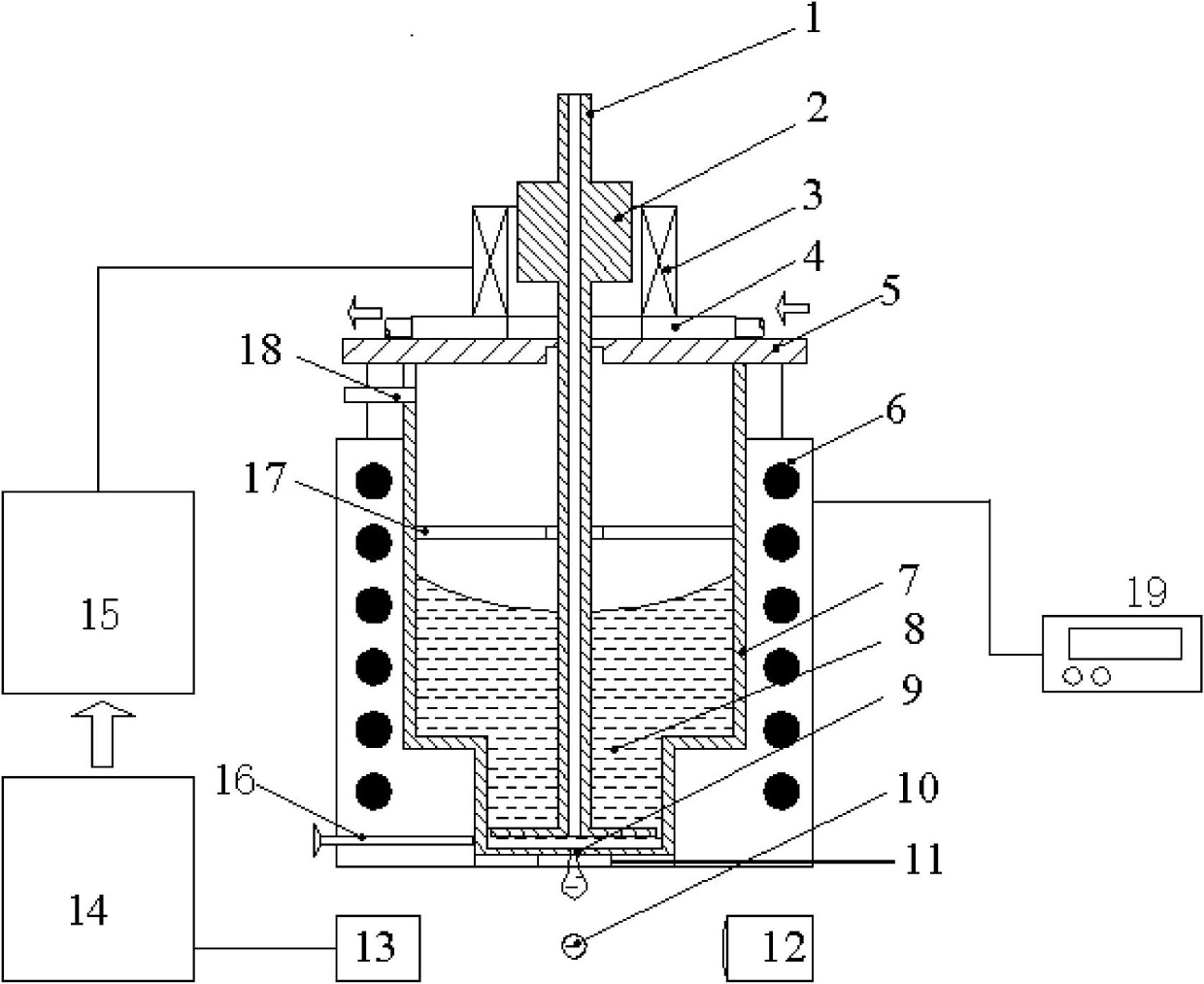

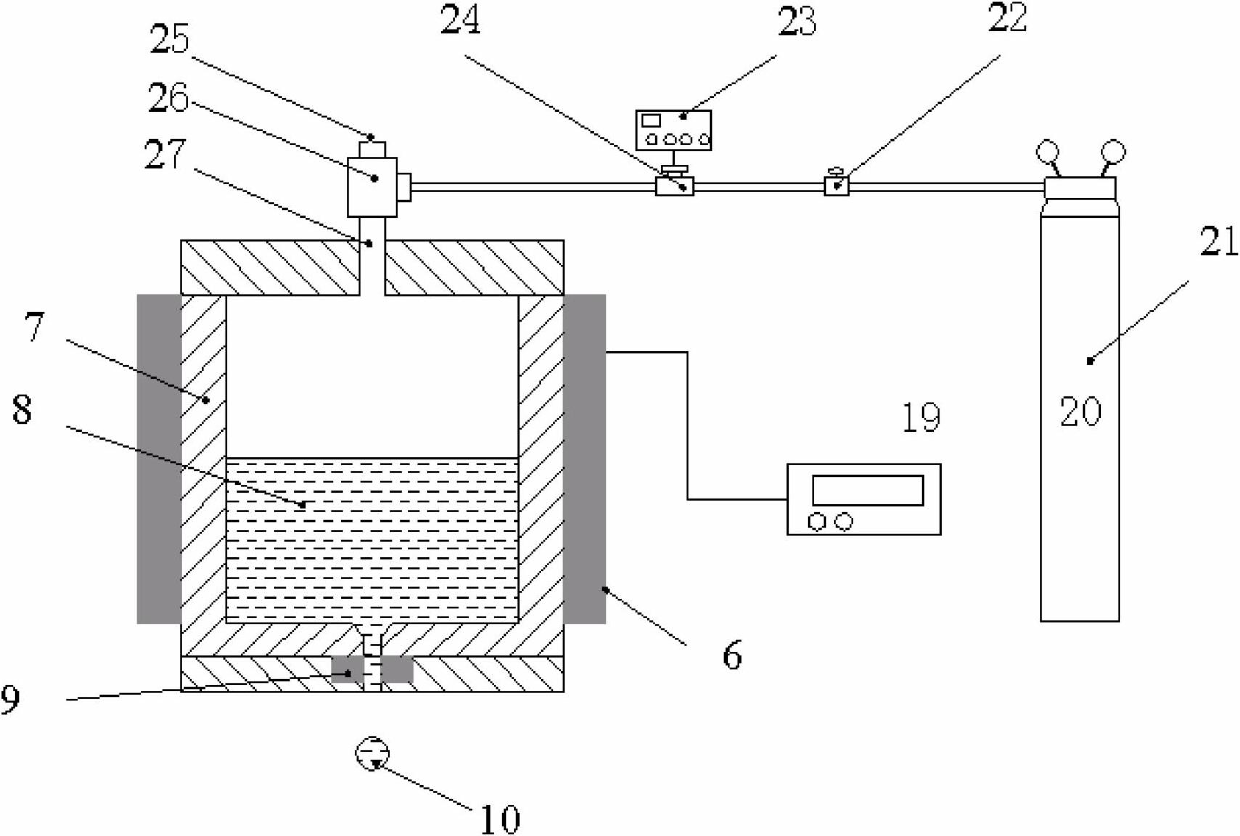

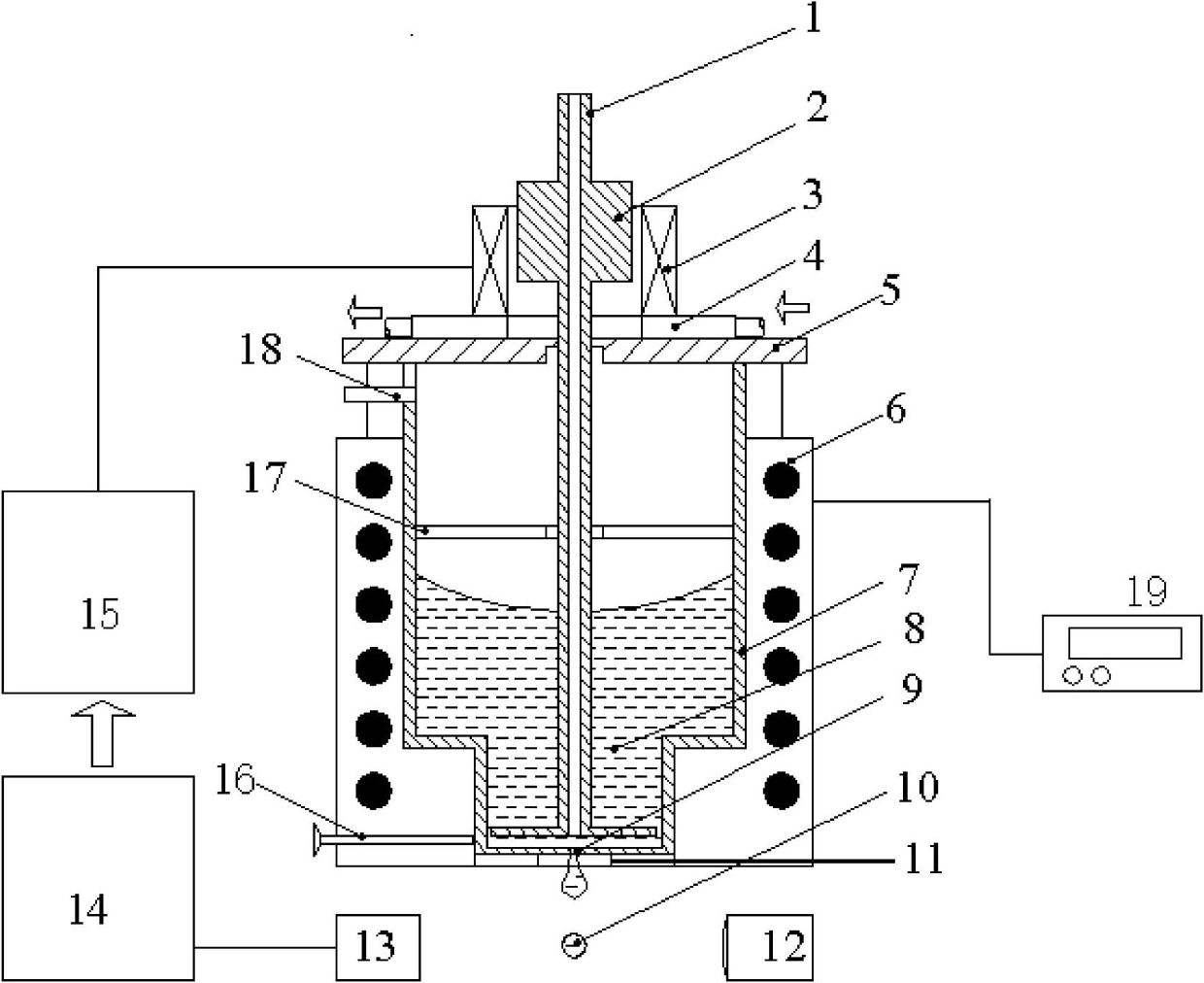

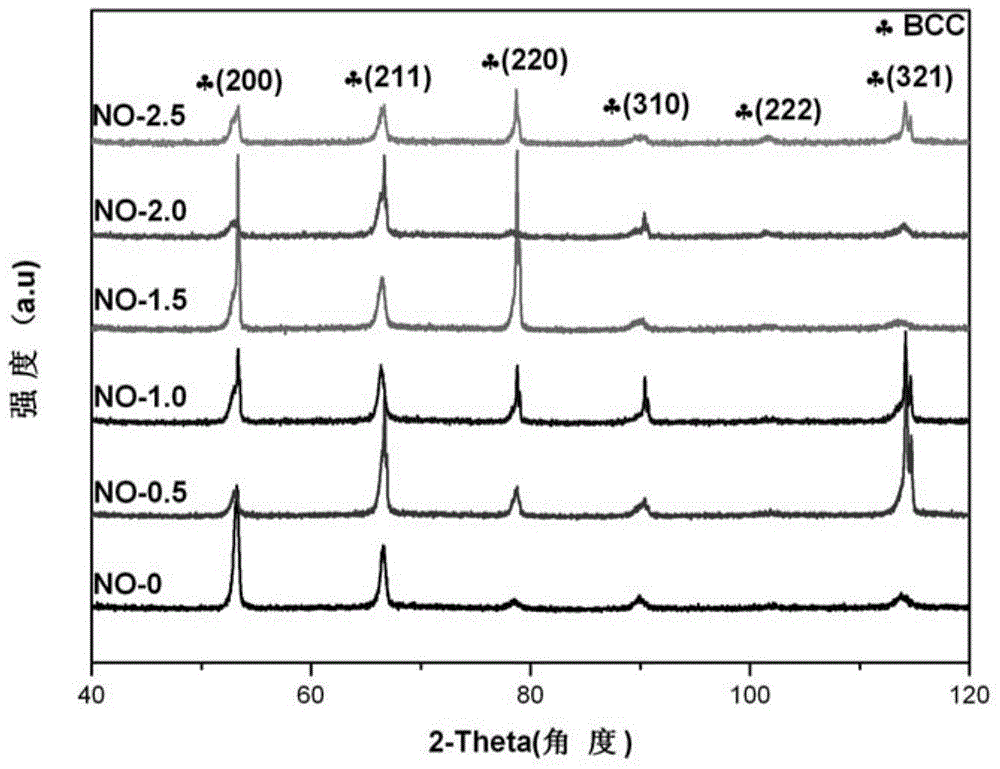

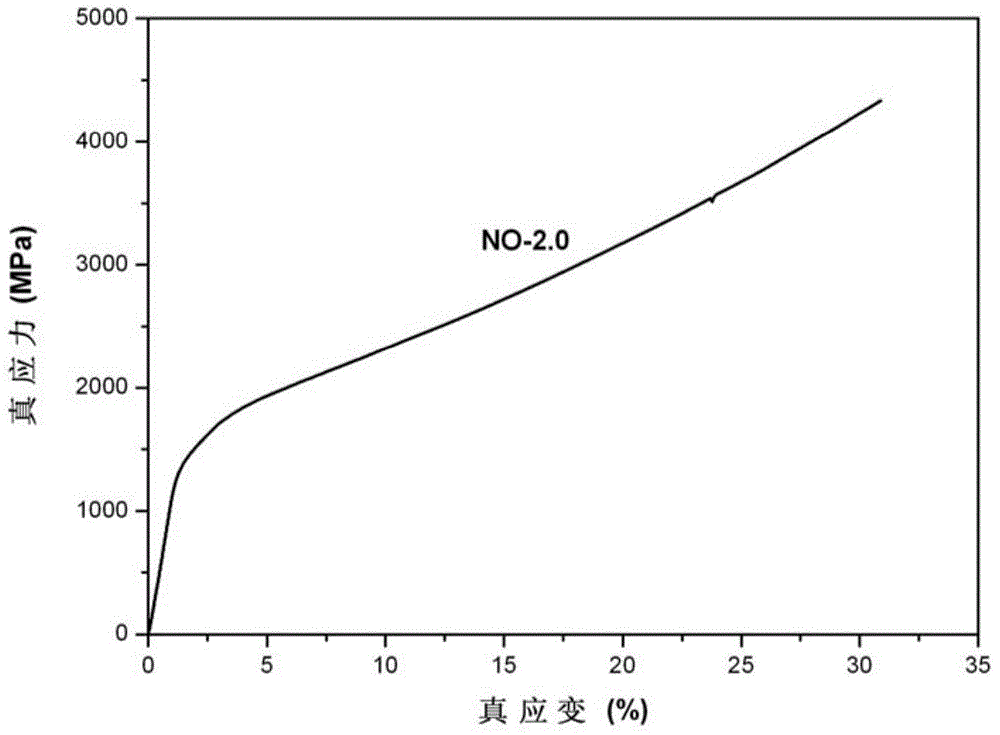

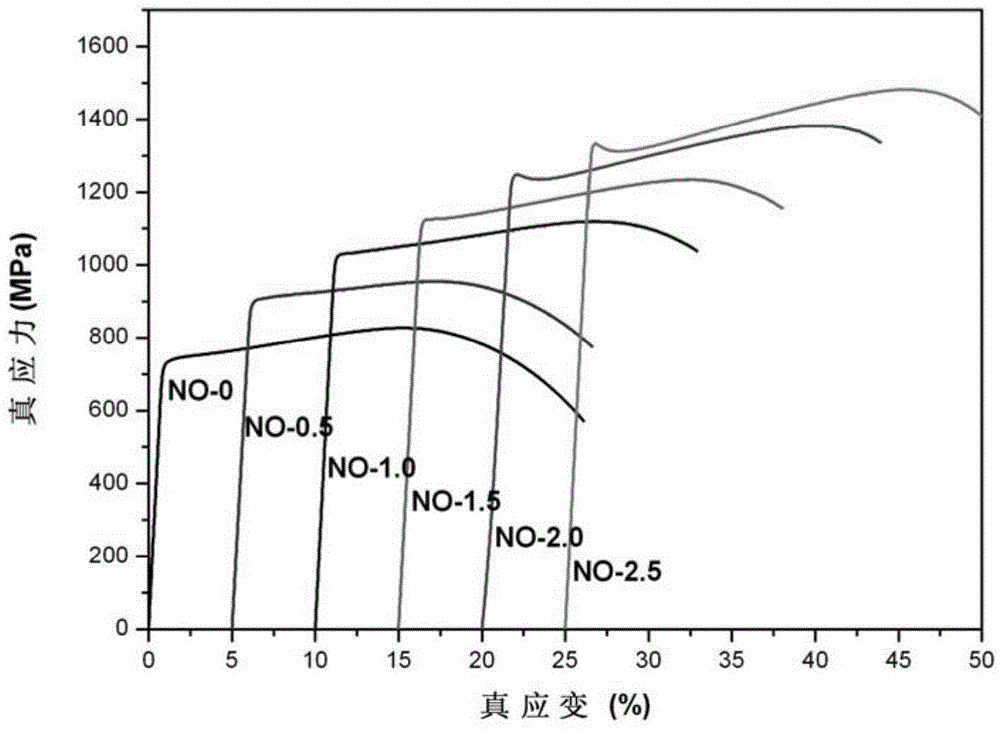

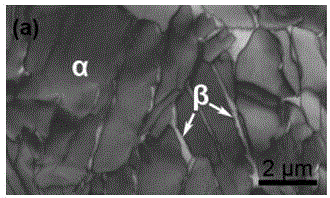

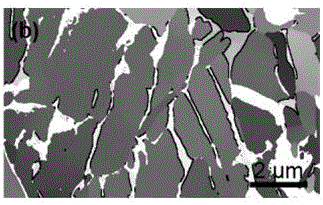

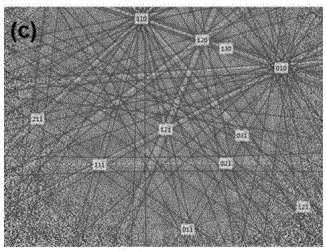

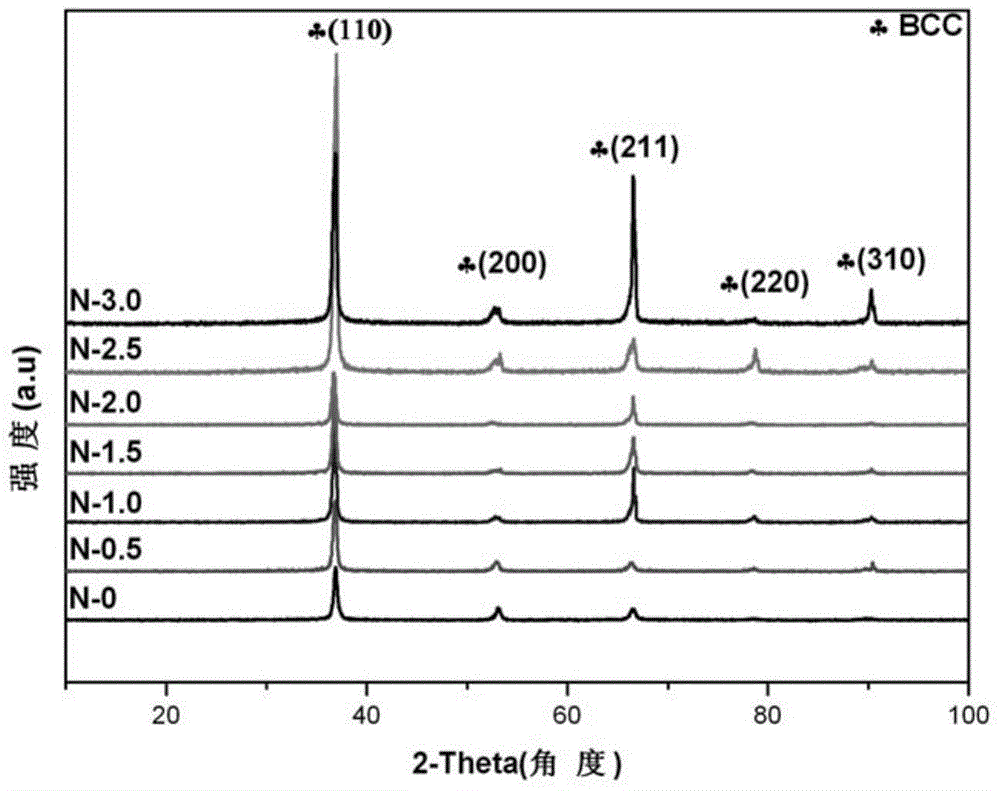

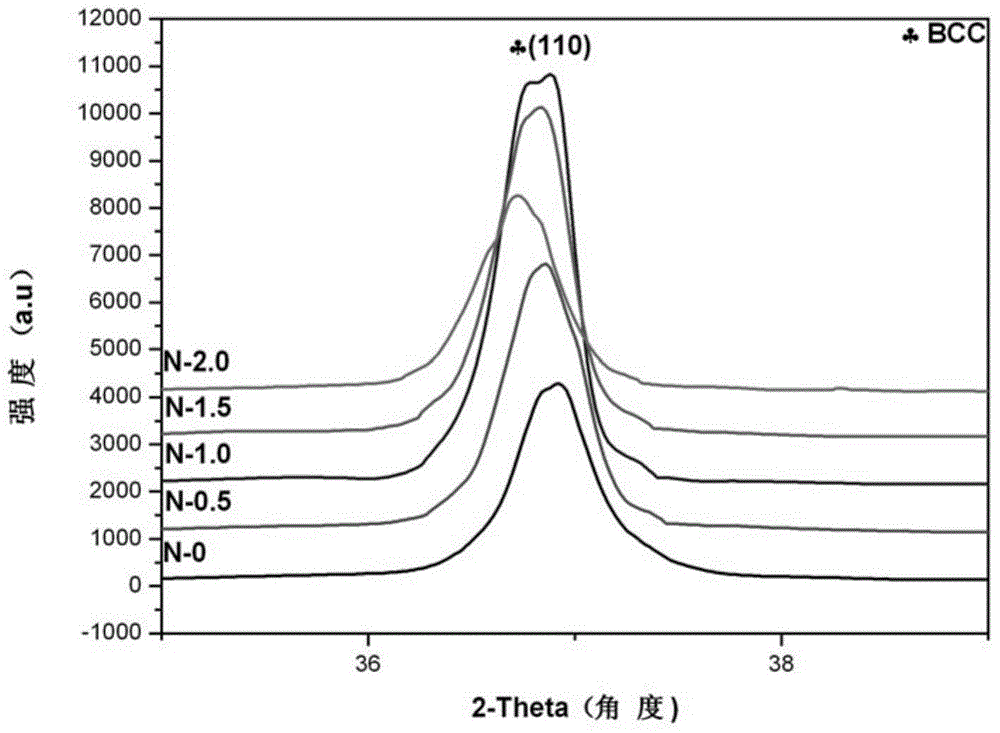

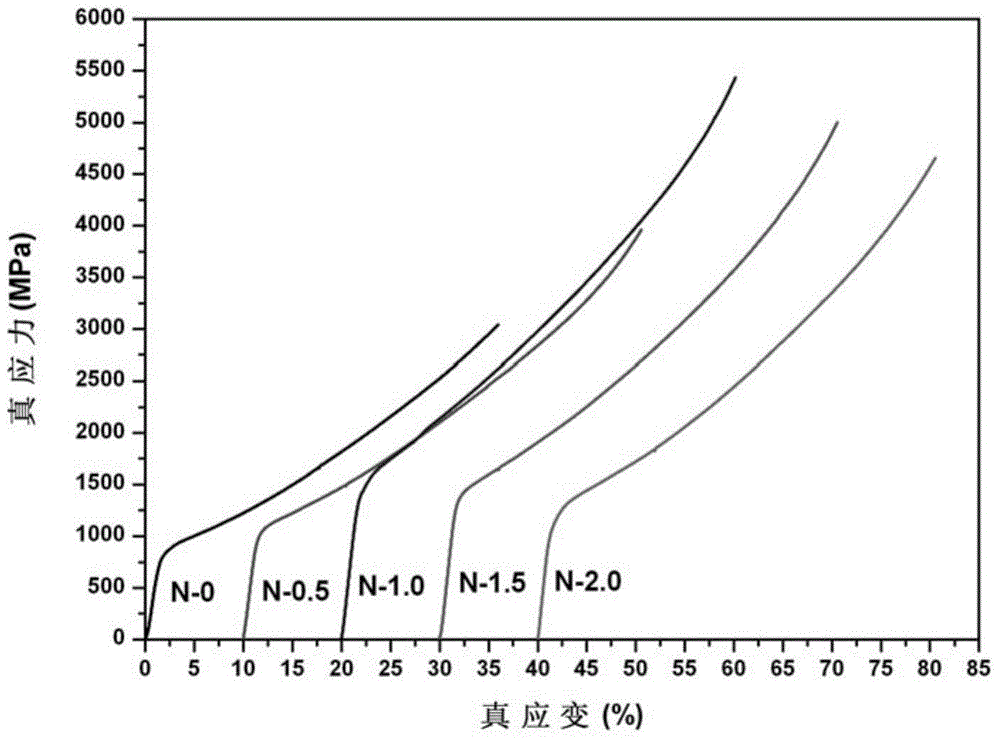

TiZrNbVMo[x] high entropy alloy and preparation method thereof

The invention relates to a high entropy alloy material and a preparation method thereof, the high entropy alloy composition is TiZrNbVMo[x], wherein x is the molar ratio with a value range of x = 0 ~ 1.0. The preparation method comprises the following steps: using a mechanical method to remove oxide skin of metallurgical raw materials of Ti, Zr, Nb, V and Mo elements, then accurately weighing according to the molar ratio; respectively melting intermediate alloys of MoTi and TiZrNbV in a non self-consumable vacuum electric-arc furnace or a cold crucible suspension furnace, finally putting the intermediate alloys together to melt into target alloys, melting each alloy for more than 3 times to ensure uniformity of the composition; taking a specific mass of a master alloy to preparing a rod or plate sample by use of vacuum suction casting or pouring equipment. Compared with traditional crystal materials, the high entropy alloy disclosed by the invention exhibits high hardness, yield strength and fracture strength, and compared with other high-strength body-core-structure high entropy alloys, the high entropy alloy disclosed by the invention has better plastic deformation ability.

Owner:UNIV OF SCI & TECH BEIJING

Metal molten drop ejecting device and method for ejecting high-melting-point metal molten drops using same

The invention discloses a metal molten drop ejecting device and a method for ejecting high-melting-point metal molten drops using the same. The metal molten drop ejecting device is used for solving the technical problem that the existing metal molten drop ejecting device is poor in stability in the ejecting forming process when ejecting high-melting-point light reactive metal molten drops. The metal molten drop ejecting device maintains stable ejecting of the high-melting-point metal molten drops by means of a nozzle automatic dredge device and an ejecting state detection system. The nozzle dredge device and a metal molten drop ejecting state monitoring and feedback system for high-melting-point metal ejecting are adopted; when the molten drop ejecting state monitoring and feedback systemdetects unstable ejecting state and transmits cleaning signals, an excitation rod is lowered, large positive or negative pressure is led into an inner channel of the excitation rod instantly, so thatmolten metal or gas at the position of a nozzle flows fast to bring out scale cinder or impurities adhered onto the inner wall of the spraying orifices, the aim of cleaning and dredging tiny nozzles can be achieved, and accordingly the ejecting forming process of high-melting-point metal molten drops is stable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

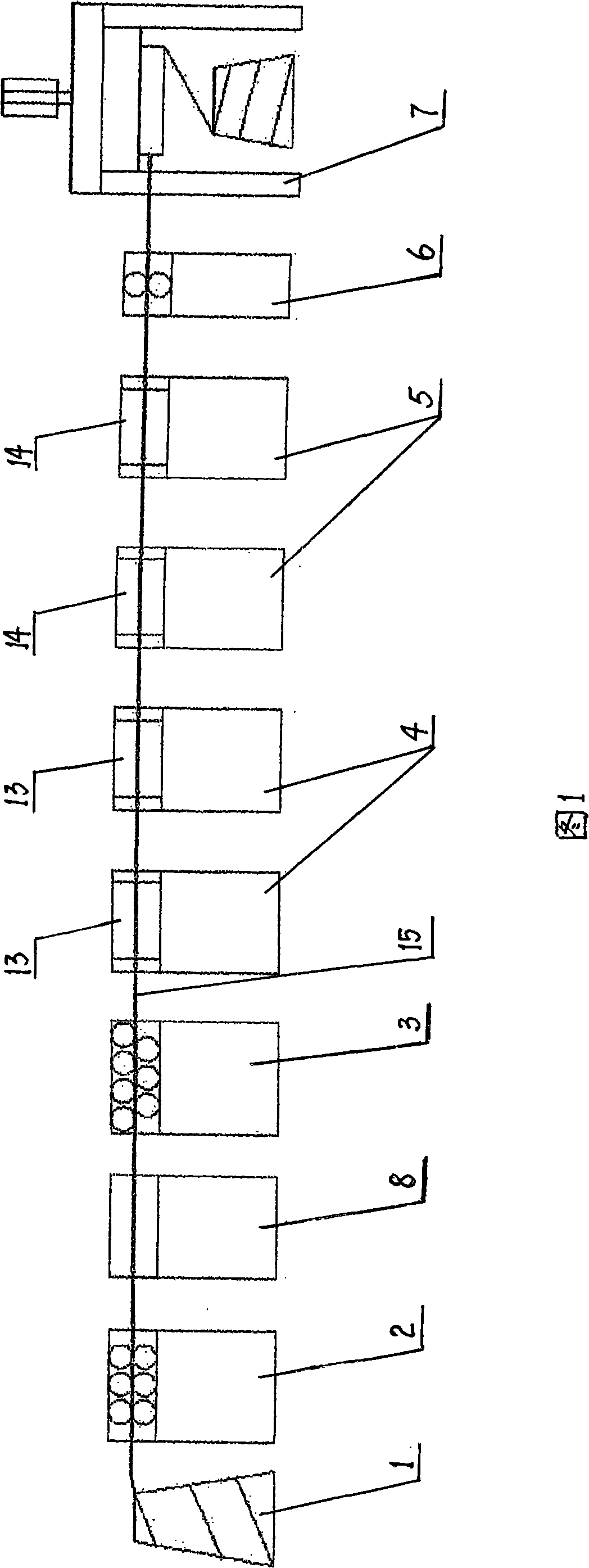

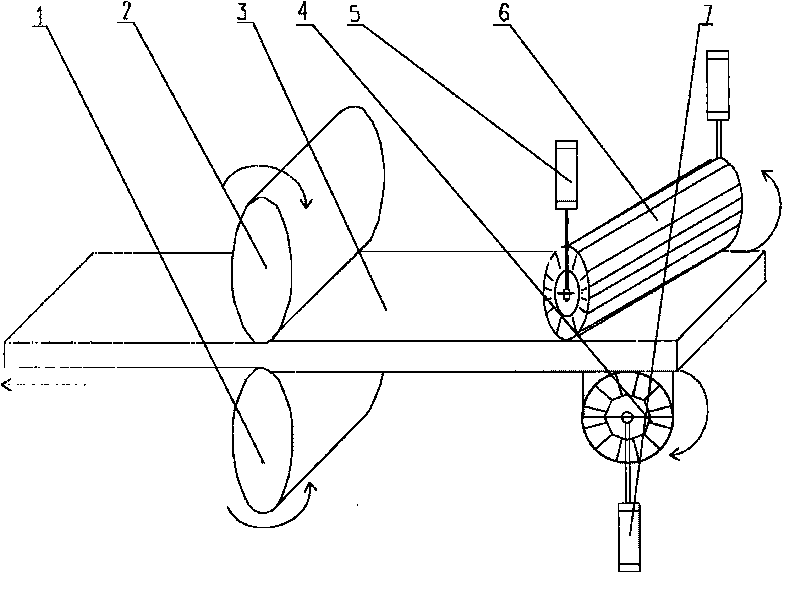

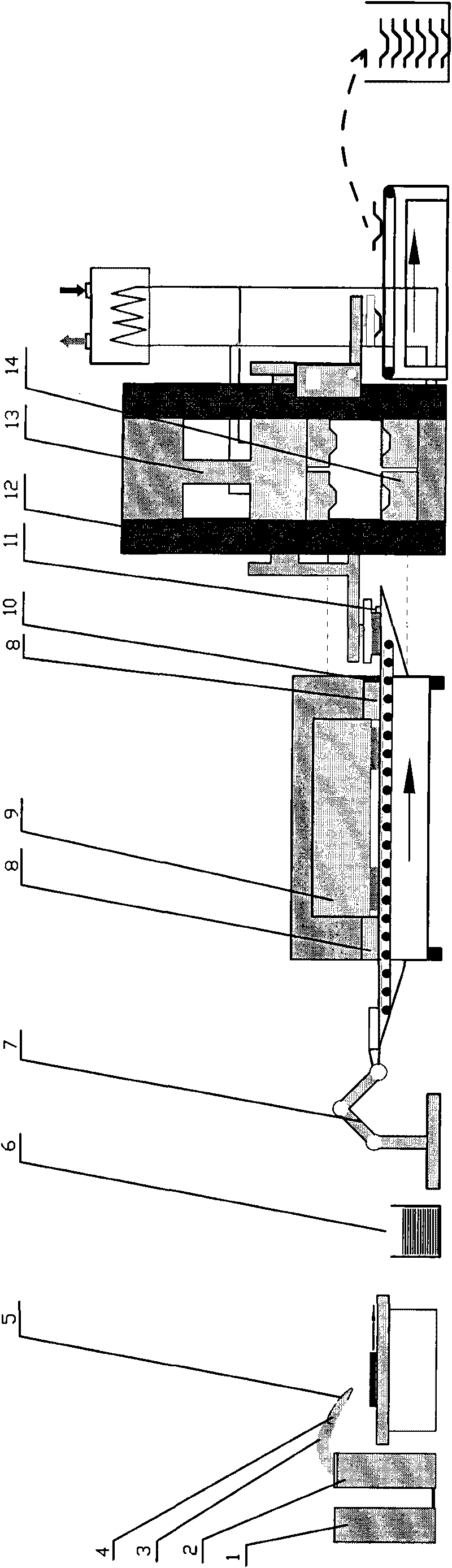

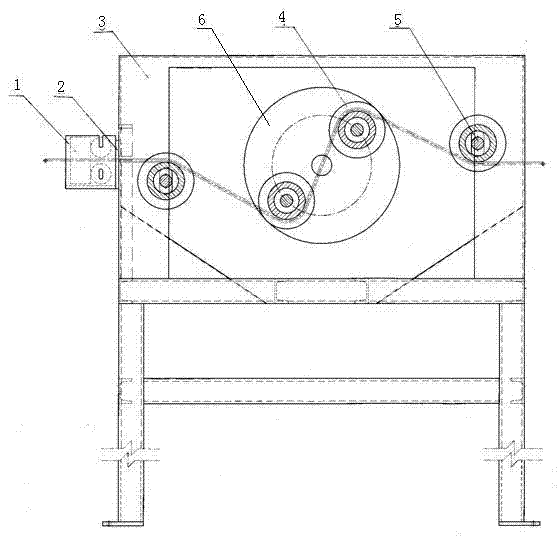

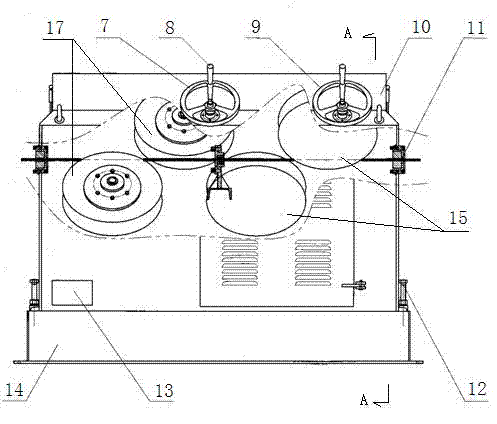

Method and equipment for removing oxidizing layer of titanium and titanium alloy wire material

ActiveCN101269397AEnsure consistencyGuaranteed uniformityWire articlesBurnishing machinesProduction lineTitanium

The invention relates to a method for removing an oxidation layer on titanium and titanium alloy wires and a device thereof. The method includes the following steps: 1. straightening: a straightening machine is used for straightening the titanium and titanium alloy wires; 2. phosphorus removal: a steel wheel phosphorus removal machine is used for removing the oxidation layer on the surface of the titanium and titanium alloy wires; 3. polishing: a sand belt wheel polisher is used for polishing the surface of the titanium and titanium alloy wires. The device is sequentially provided from left to right with a pay-off stand (1), a clamping device (2), a heating device (8), a straightening device (3), two steel wheel phosphorus removal machines (13), sand belt wheel polishers (14), a guide and guard (6) and a vertical down drawing machine (7). On the basis of the present steel wheel phosphorus removal machine, the method is additionally provided with a heating device, a phosphorus removing and polishing machine, a cooling device, a dust removing device and a tension device, thereby forming a production line for removing the oxidation layer on a large and heavy titanium alloy wire, so as to reach the purpose of removing the oxidation layer and polishing.

Owner:BAOJI TITANIUM IND

Austenitic stainless steel with excellent polishing performance and manufacturing method thereof

InactiveCN102162075AImprove grinding effectImprove surface polishing performanceTemperature control deviceFurnace typesElectrolysisAcid washing

The invention discloses an austenitic stainless steel with excellent polishing performance. The austenitic stainless steel comprises the following chemical components in percentage by weight: 16 to 20 percent of Cr, 7 to 15 percent of Ni, less than or equal to 2 percent of Mn, 0.2 to 2 percent of Cu, less than or equal to 0.05 percent of Al, less than or equal to 0.5 percent of Si, 0.03 to 0.1 percent of C, less than or equal to 0.05 percent of N, 0.01 to 0.06 percent of P, 0.003 to 0.05 percent of S, 0.05 to 0.5 percent of V, and the balance of iron and inevitable impurities. A manufacturing method for an austenitic stainless steel cold-rolled plate comprises the following steps of: heating a continuous cast plate blank to the temperature of between 1,100 and 1,300 DEG C; performing rough rolling at the temperature of between 1,000 and 1,250 DEG C; performing final rolling at the temperature of between 950 and 1,100 DEG C; performing quick cooling; coiling at the temperature of less than 700 DEG C; performing hot rolling to form a hot-rolled plate of the required specification; annealing the hot-rolled plate at the temperature of between 950 and 1,200 DEG C; removing oxide skin by adopting a continuous acid washing process of phosphorus breakage, shot blasting, electrolysis and mixed acid washing; performing cold rolling, wherein the overall reduction rate is more than 50 percent; and performing continuous annealing at the temperature of between 950 and 1,200 DEG C, or performing full-hydrogen bright annealing at the temperature of between 950 and 1,200 DEG C. The austenitic stainless steel cold-rolled plate has completely improved grinding performance and surface polishing performance, and is particularly suitable for the industries of building decoration, plastic dies, food sanitation, electronics and the like with strict polishing performance requirements.

Owner:BAOSHAN IRON & STEEL CO LTD

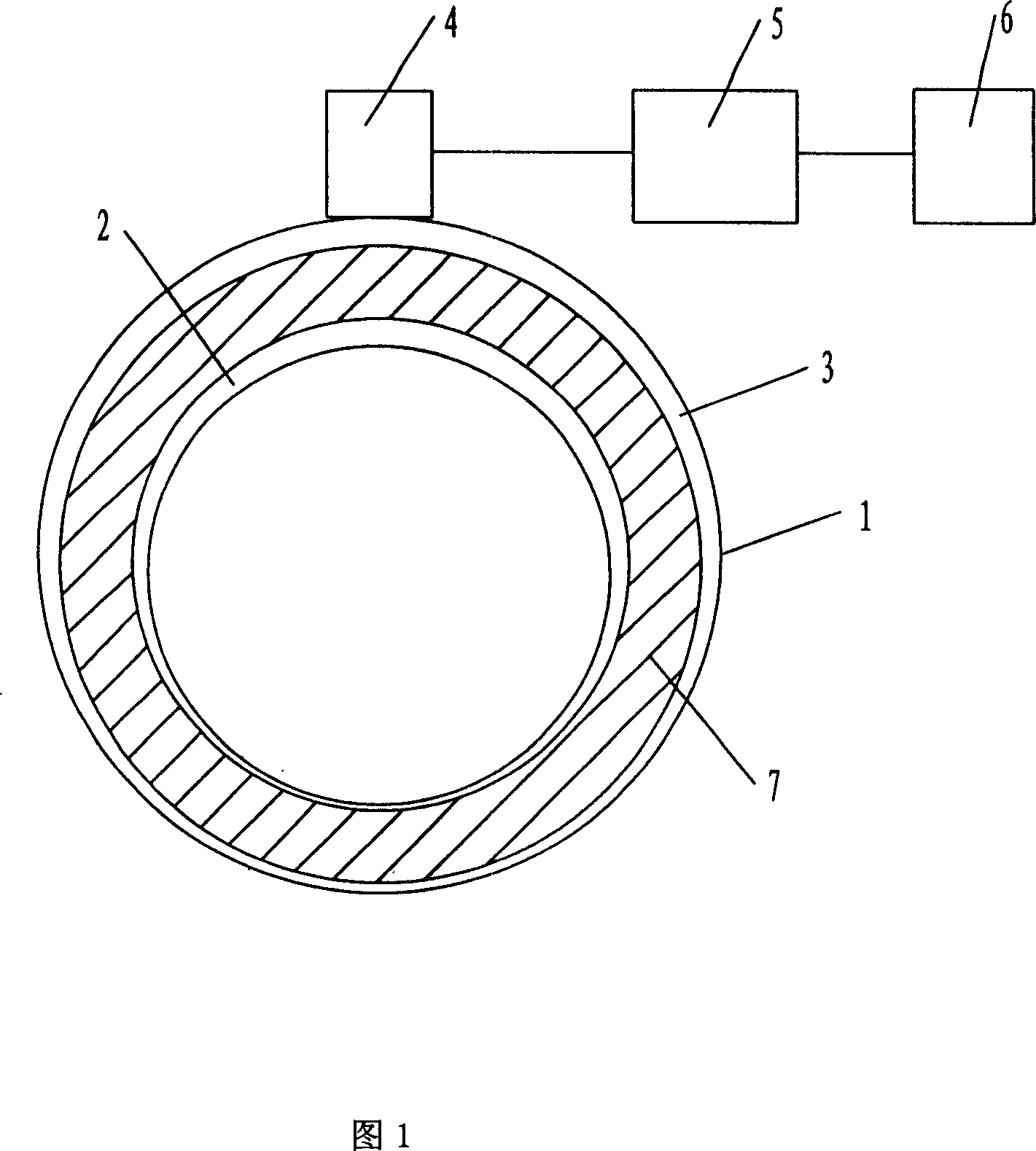

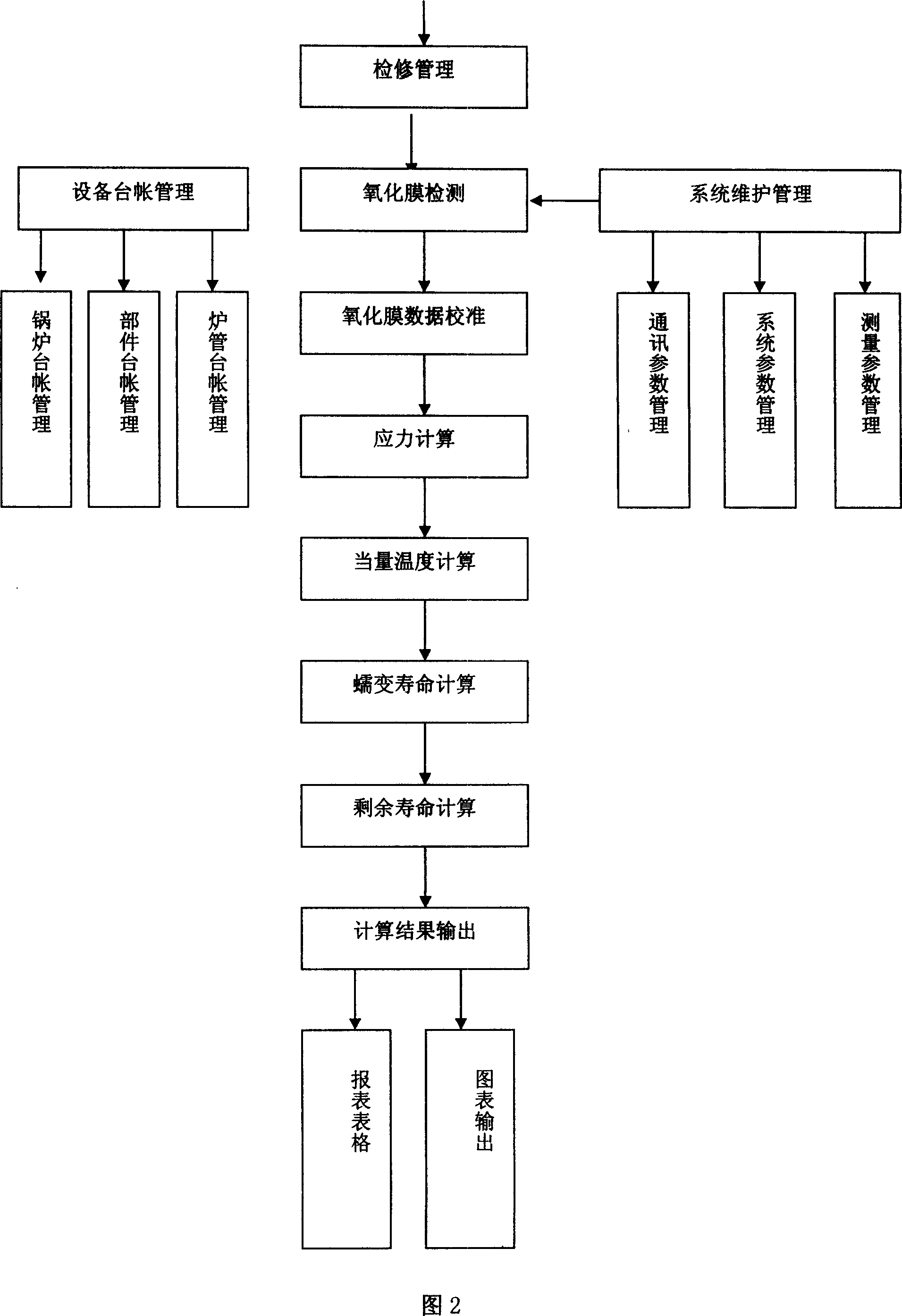

High temperature furnace pipe residue lifetime estimation method and device

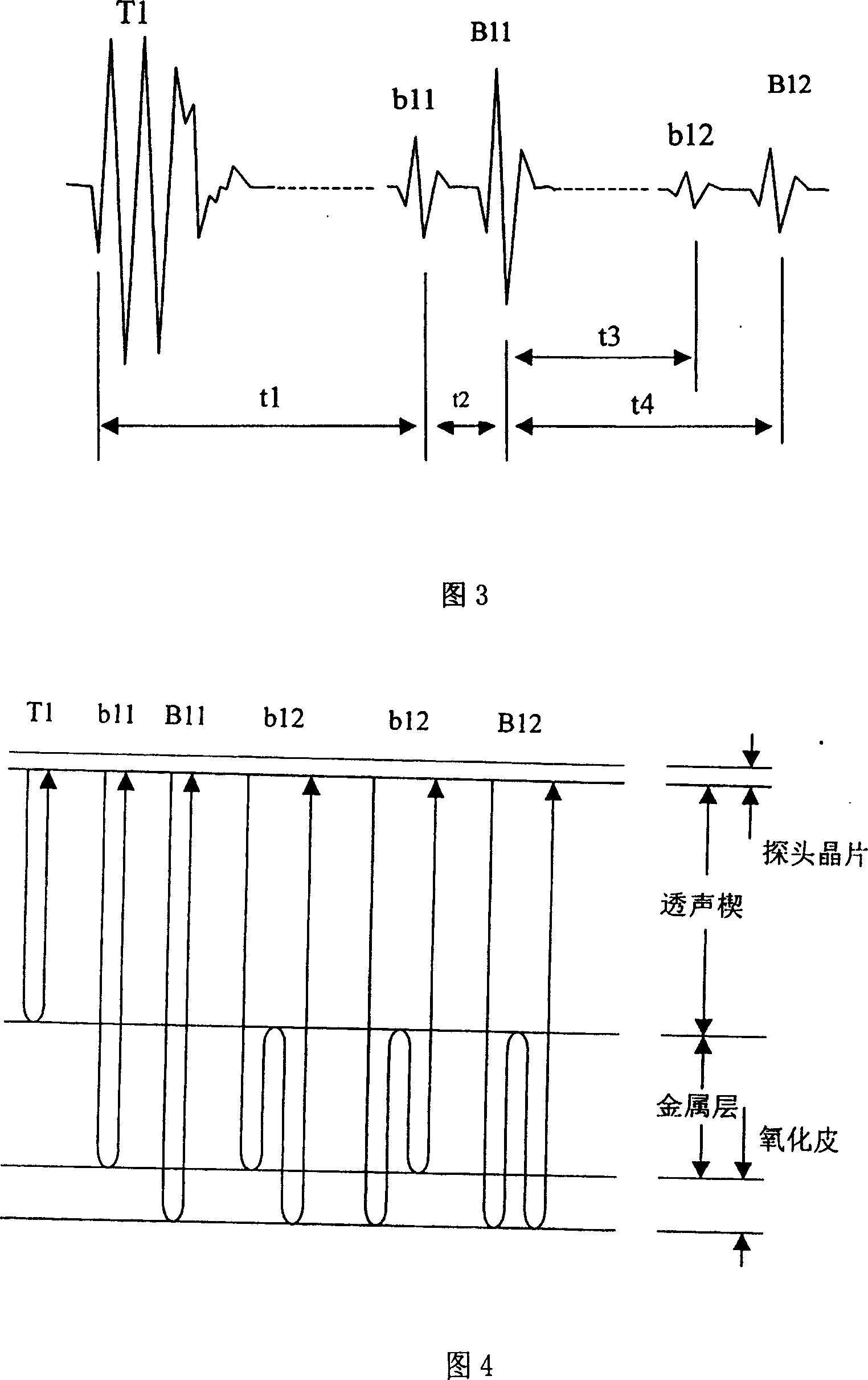

InactiveCN101013067AAvoid Boiler AccidentsAvoid accidentsUsing subsonic/sonic/ultrasonic vibration meansStructural/machines measurementOxygenData treatment

The invention provides a high-temperature furnace tube remaining life assessment method, including the following steps: (a) according to the propagation velocity of the ultrasound in the oxygen skin, to calculate thickness of the inner wall oxygen skin; (2) according to the propagation velocity of the ultrasonic in the high temperature furnace tube matrix, to calculate the metal layer thickness; (3) establish the relationship database of the high temperature metal inner wall oxygen skin thickness, the running time and the equivalent temperature, to calculate the equivalent temperature when high temperature furnace tube running; (4) calculate the high-temperature furnace tube operation stress, and establish the relationship database of the high temperature furnace tube equivalent temperature, remaining life, and operation stress, and forecast the high temperature furnace tube remaining life. At the same time, it provides a high-temperature furnace tube remaining life assessment device, and the device includes the waveform acquisition device, the waveform display and receiving device, and the data-processing system. The invention can calculate and predict the high temperature furnace tube remaining life, and according to the remaining life, it can replace in advance the high-temperature furnace tube during the life end state.

Owner:JINAN FENGCAI ELECTRONICS TECH

TiZrHfNb based high-entropy alloy with nitrogen and oxygen alloyed together and preparation method thereof

ActiveCN105671404AWide range of ingredientsWide range of preparation conditionsHigh entropy alloysOxygen

The invention relates to TiZrHfNb based high-entropy alloy with nitrogen and oxygen alloyed together and a preparation method thereof. Particularly, the tensile strength and tensile ductility of the alloy are remarkably improved by simultaneously microalloying N and O elements. The preparation method includes the following steps that metal raw materials of Ti, Zr, Hf and Nb are accurately weighed according to the molar ratios after oxide skin is removed; other added elements are accurately weighed according to the molar ratios after oxide skin is removed and the elements are washed with alcohol; the N element is added in the form of nitride, and the O element is added in the form of oxide; and target alloy is smelted in a nonconsumable vacuum arc furnace or cold crucible shower furnace, and the alloy is obtained through vacuum suction casting or casting equipment. The tensile property of the high-entropy alloy is improved remarkably by simultaneously adding the N and O elements, the tensile strength of (TiZrHfNb)97.5(NO)2.5 based high-entropy alloy reaches 1300 MPa, meanwhile, the tensile ductility exceeds 15%, the work-hardening rate is low, and the comprehensive tensile property is excellent.

Owner:UNIV OF SCI & TECH BEIJING

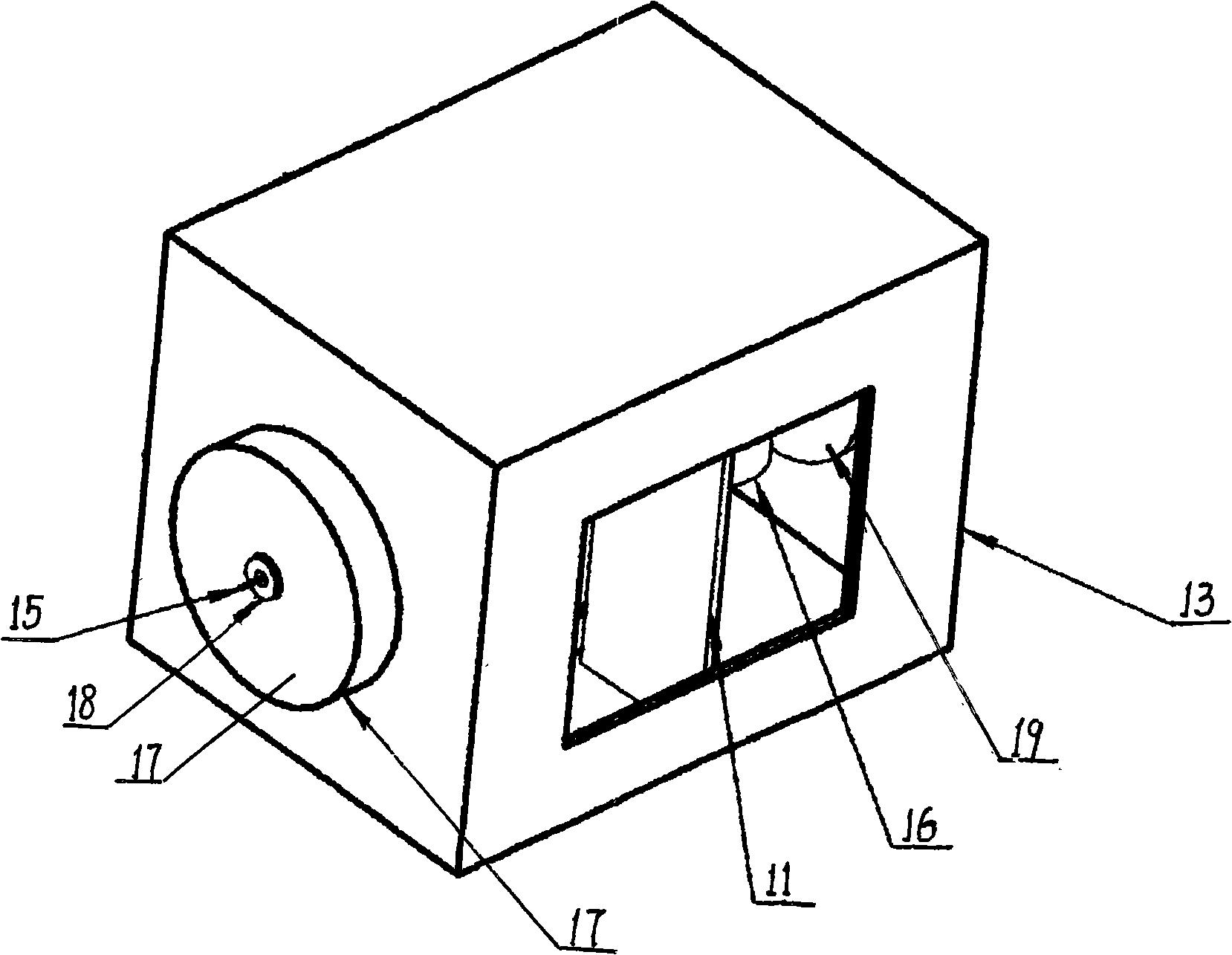

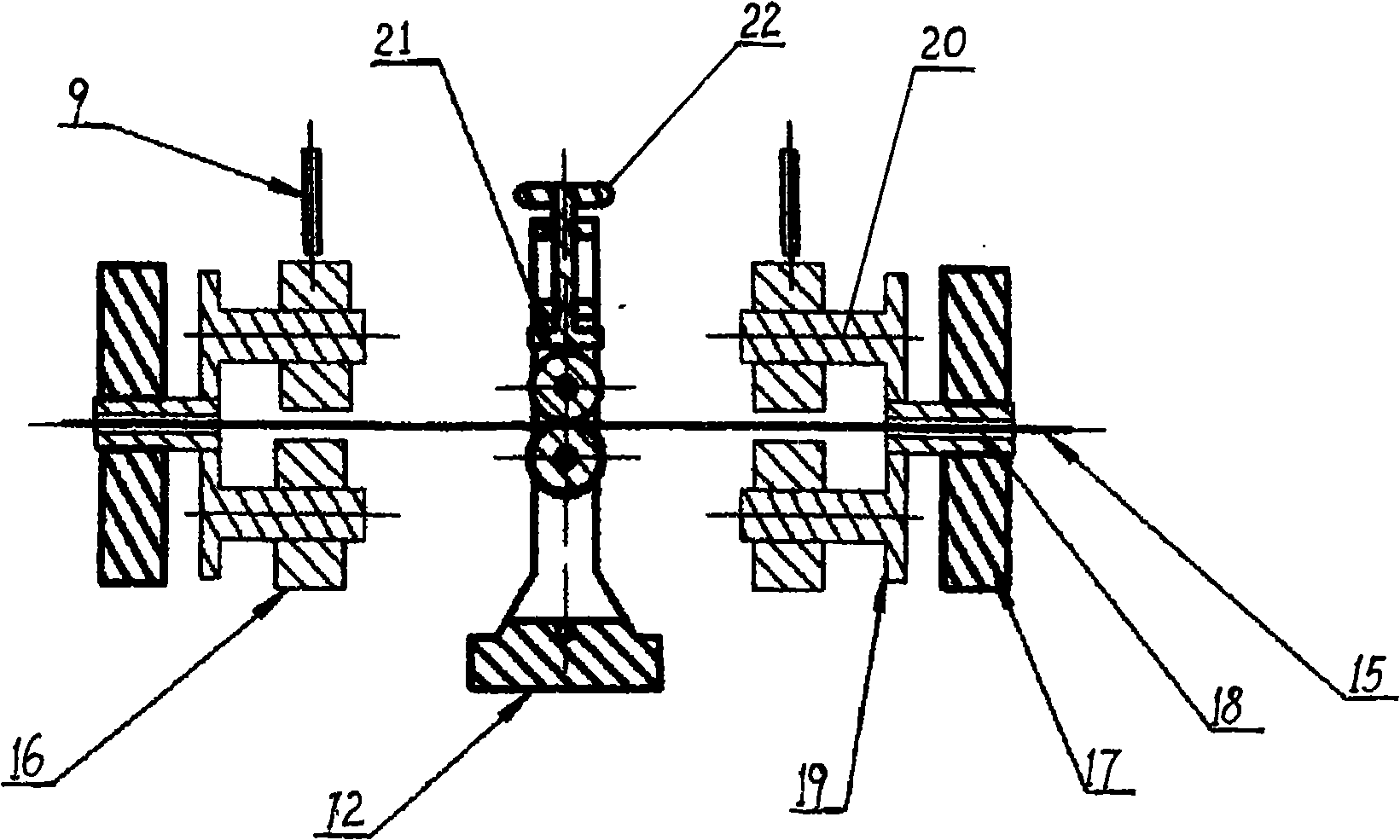

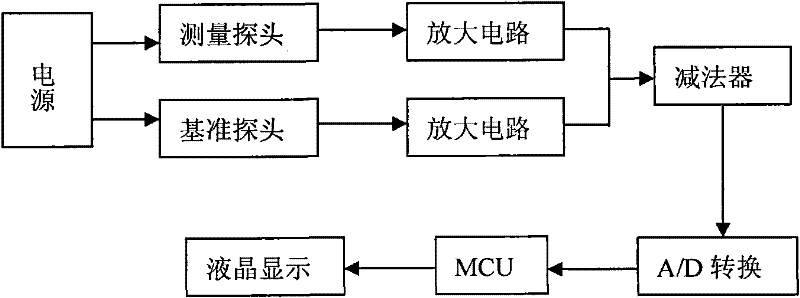

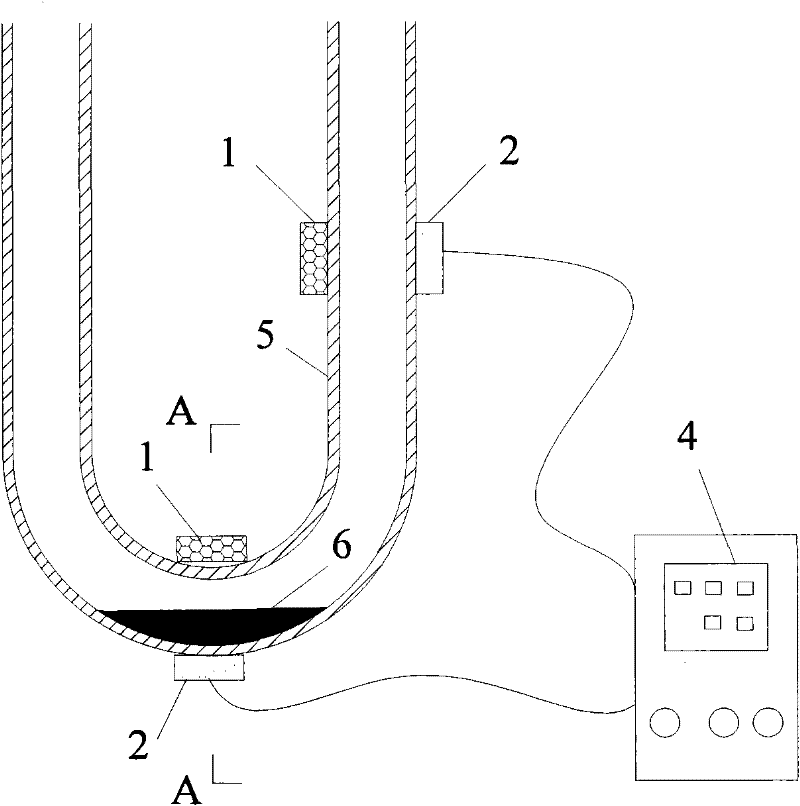

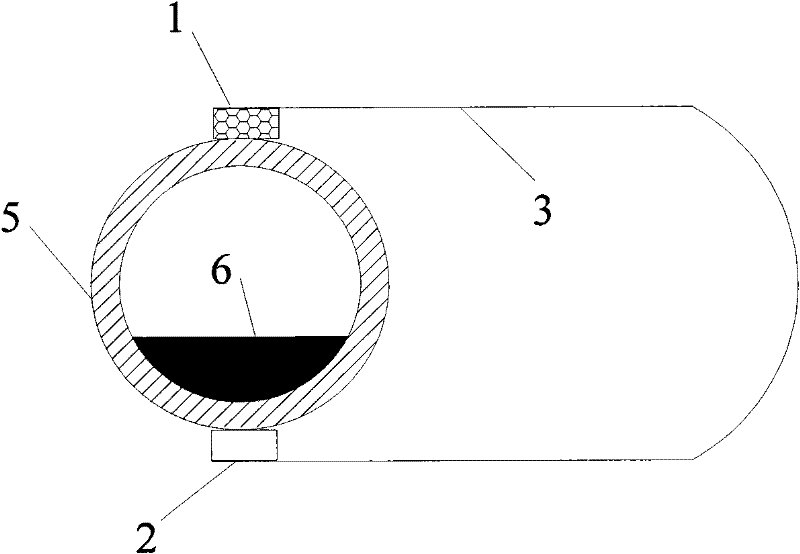

Scale detecting instrument in tube on high-temperature heating surface of supercritical boiler and detection method

InactiveCN101750011AWide detection rangeBaseline consistentElectrical/magnetic thickness measurementsSupercritical steam generatorMicrocontroller

The invention discloses a scale detecting instrument in a tube on a high-temperature heating surface of a supercritical boiler and a detection method. The detecting instrument comprises a measuring probe, a reference probe, an amplifying circuit, a subtracter, an A / D converter, a singlechip and a display. In the detection method, magnetic signals from a position to be detected and a scale-free position of the detected tube are respectively converted into voltage signals by the measuring probe and the reference probe; after the two voltage signals are amplified by the amplifying circuit, differential voltage signals are acquired through the subtracter and converted into digital signals by the A / D converter; and the digital signals are sent to the display for displaying after being processed by the singlechip. According to the difference value of magnetic flux density detected by the measuring probe and the reference probe, the scale detecting instrument can detect the thickness of scales in the tube on the heating surface quantitatively, and thus the scale detecting instrument can perform quantitative detection quickly and conveniently on the accumulation thickness of the scales in the tube on the high-temperature heating surface of the boiler.

Owner:GUANGDONG TOPKEY POWER TECHN DEV +1

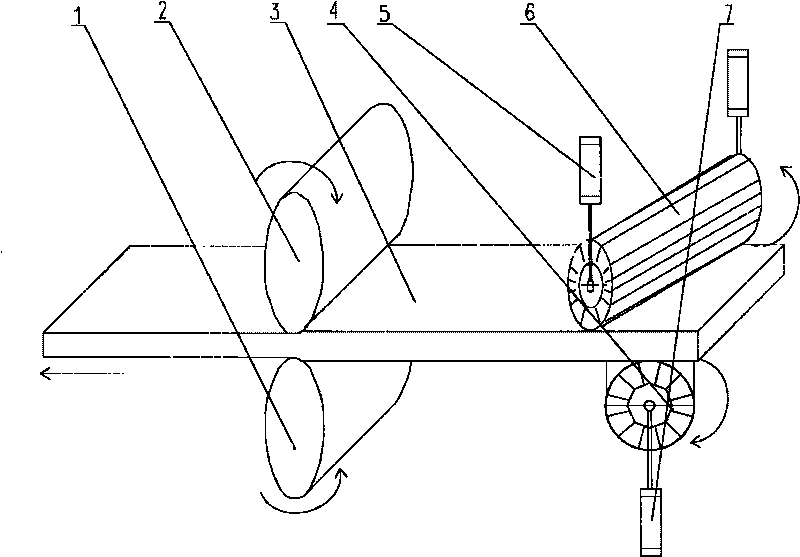

Novel process for on-line removing of scale at surface of hot-rolled copper plate belt

InactiveCN101698197ASuperiorRemove in timeWork treatment devicesCleaning using toolsSurface oxidationIngot

The invention discloses a novel process for the on-line removing of scale at the surface of a hot-rolled copper plate belt, which is a process for scraping, brushing and purging scale at the surface of a blank ingot during hot rolling. The process comprises the following steps: scraping and brushing the scale on the upper surface or the lower surface of a rolled piece (3) by a scraping and brushing roller at the inlet side and the outlet side of a working roller, scraping off the scale which already turns up because of hot rolling, and avoiding pressing into the inside of the rolled piece during rolling; the process can solve the long-term puzzling problem of the pressing-in of the scale in the hot-rolling process of a copper plate belt, can be used for common hot-rolling materials, also can be used for hot-rolling quenching materials, can lower the energy consumption and the cost, can improve the labour production conditions of workers and can better produce a blank used for a cold-rolling copper plate belt with no scale pressed into the surface.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

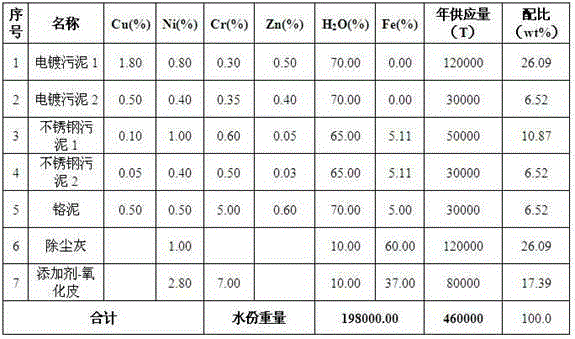

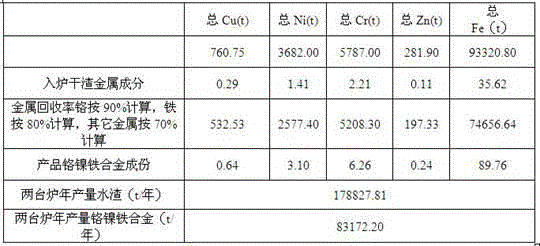

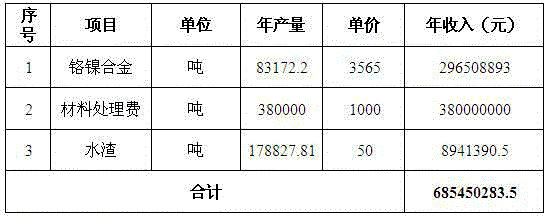

Heavy metal sludge recycling and comprehensive utilization method

InactiveCN104561525AAvoid secondary pollutionSave resourcesProcess efficiency improvementSludgeDust control

The invention belongs to the field of reutilization of heavy metal sludge, and particularly relates to a heavy metal sludge recycling and comprehensive utilization method. The method comprises the following steps: mixing stainless steel sludge, electroplating sludge, chromium sludge, dedusting ash generated in the chromium-nickel-iron alloy production process, and additive scales, predrying, carrying out reduction roasting, smelting to obtain a chromium-nickel-iron alloy, and using the byproduct smelting slag in preparing the cement additive. The dedusting ash and smelting slag generated in the whole technical process can be recycled, and thus, the method does not generate secondary pollution, maximally saves the resources and energy, lowers the production cost, and has obvious economic benefits.

Owner:FUJIAN NONNON RENEWABLE RESOURCES TECH

Stainless steel and stainless steel pipe having resistance to carburization and coking

ActiveUS20050045251A1Avoid carburizationRecord information storageMagnetic recordingSS - Stainless steelPetrochemical

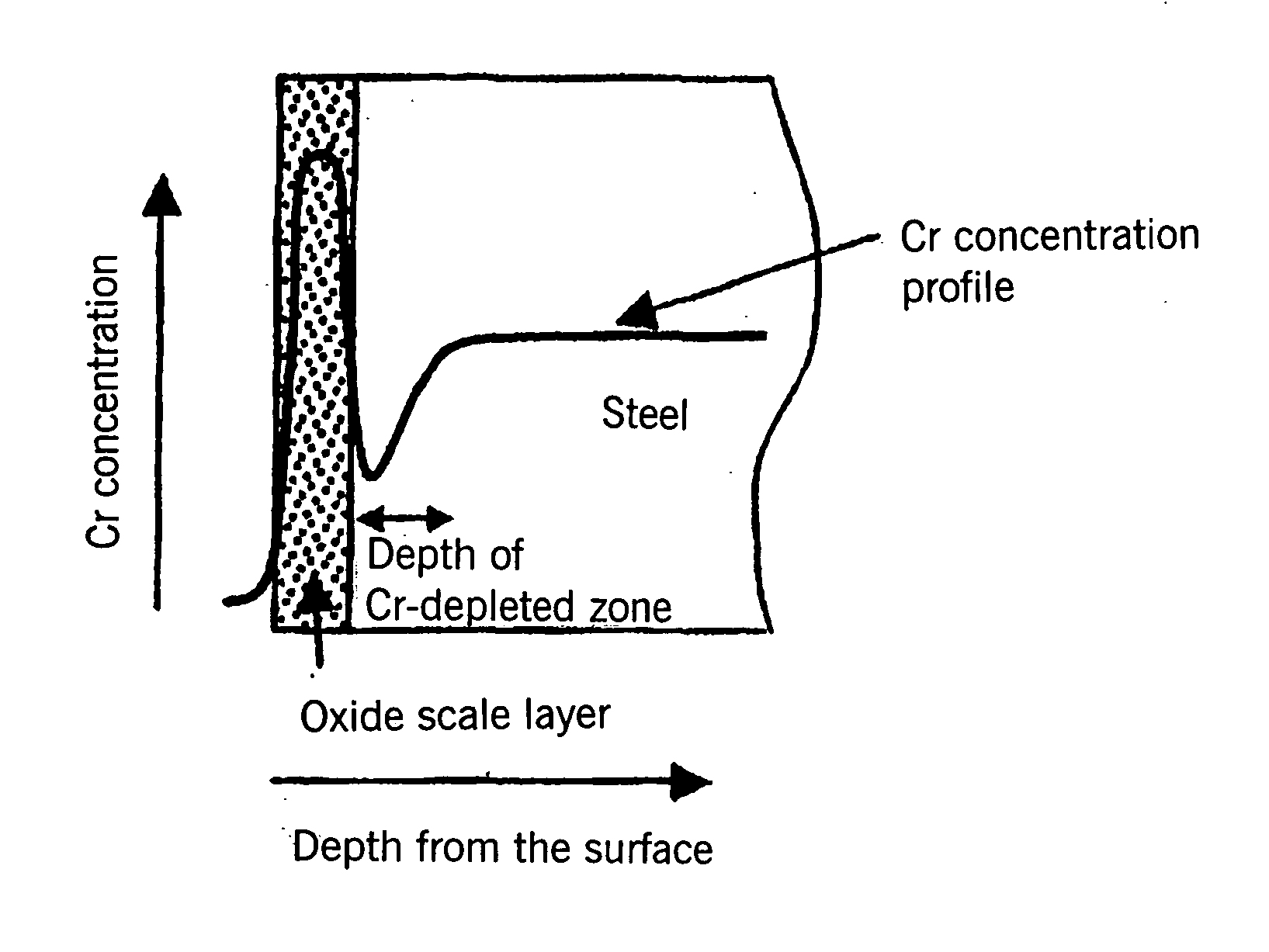

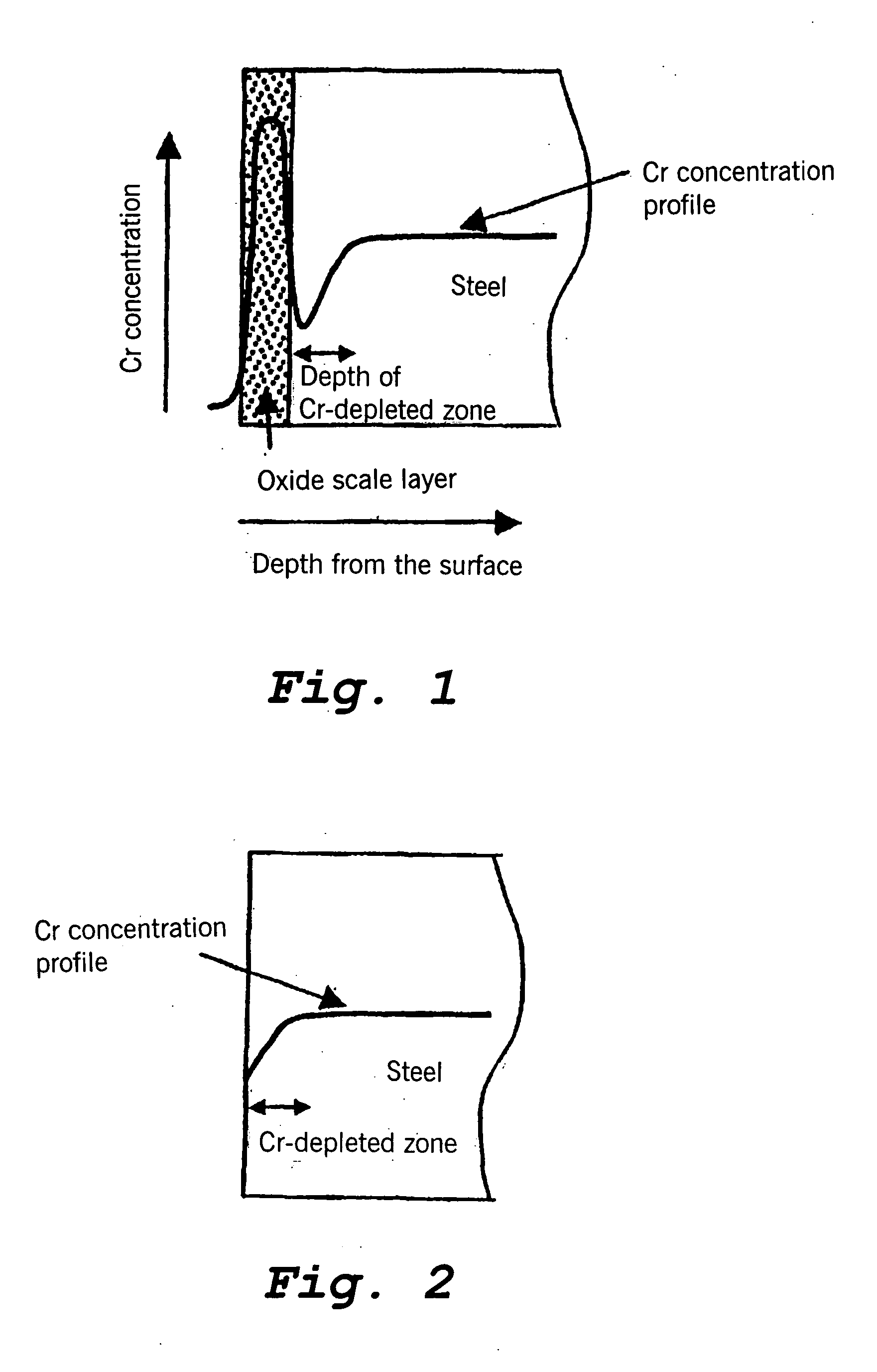

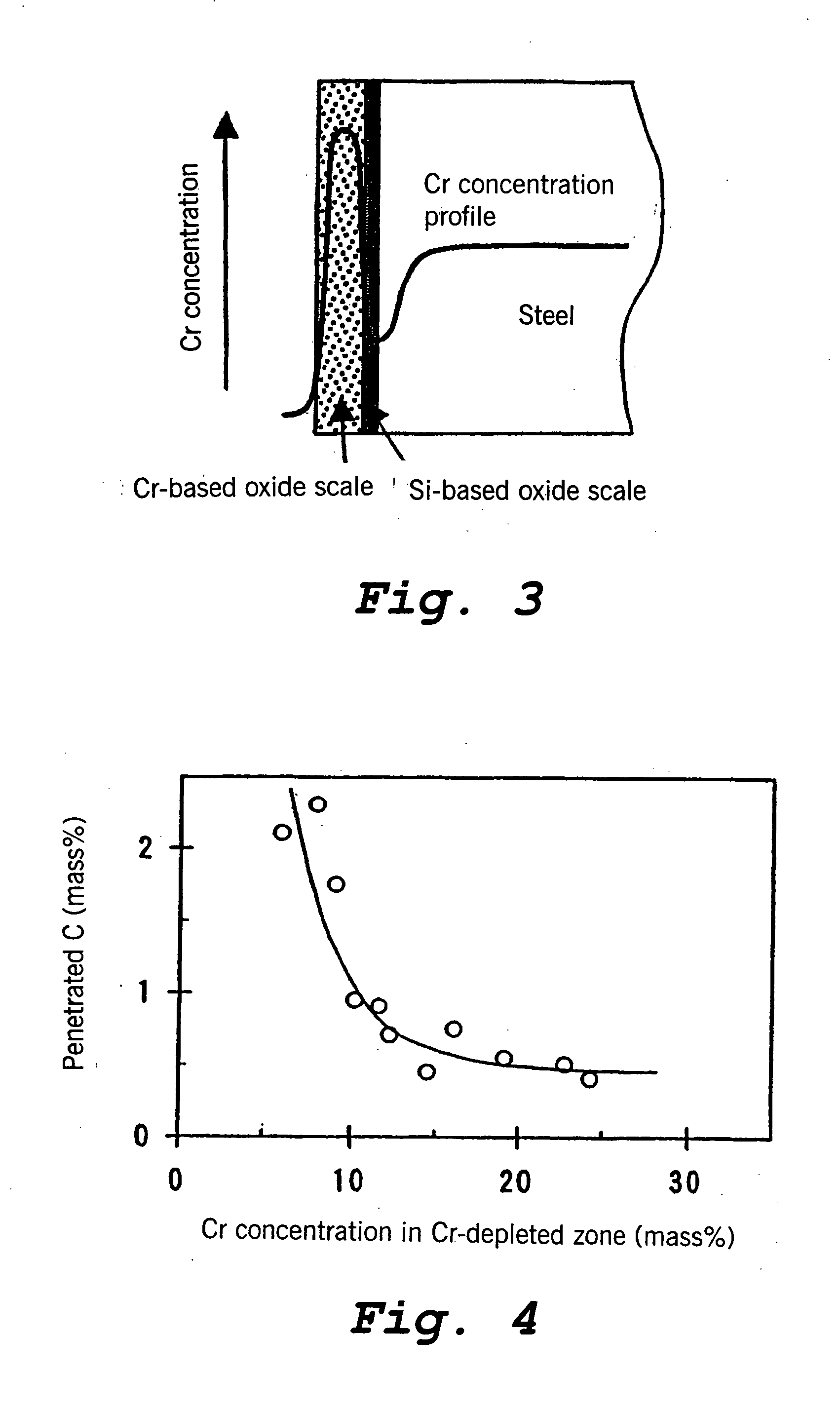

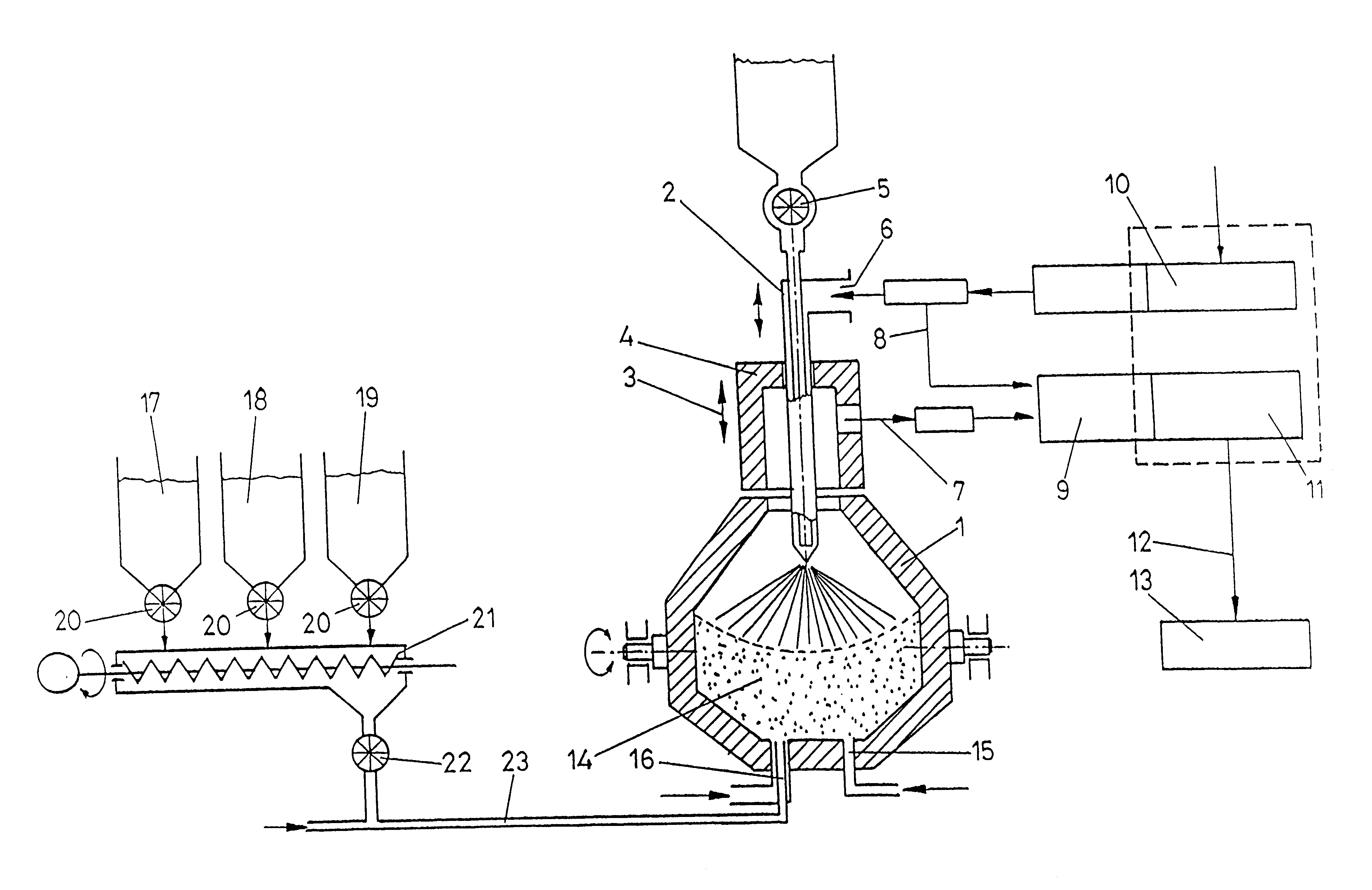

A stainless steel pipe includes a base metal containing 20-35 mass % of Cr, and a Cr-depleted zone is formed in the surface region of the pipe. The Cr concentration in the Cr-depleted zone is at least 10%, and the thickness of the Cr-depleted zone is at most 20 micrometers. A Cr-based oxide scale layer having a Cr content of at least 50% and a thickness of 0.1-15 micrometers may be provided on the outer side of the Cr-depleted zone. An Si-based oxide scale layer with an Si content of at least 50% may be provided between the Cr-based oxide scale layer and the Cr-depleted zone. The pipe is particularly suitable for use in petroleum refineries or petrochemical plants, such as for use as a pipe of a cracking furnace of an ethylene plant.

Owner:NIPPON STEEL CORP

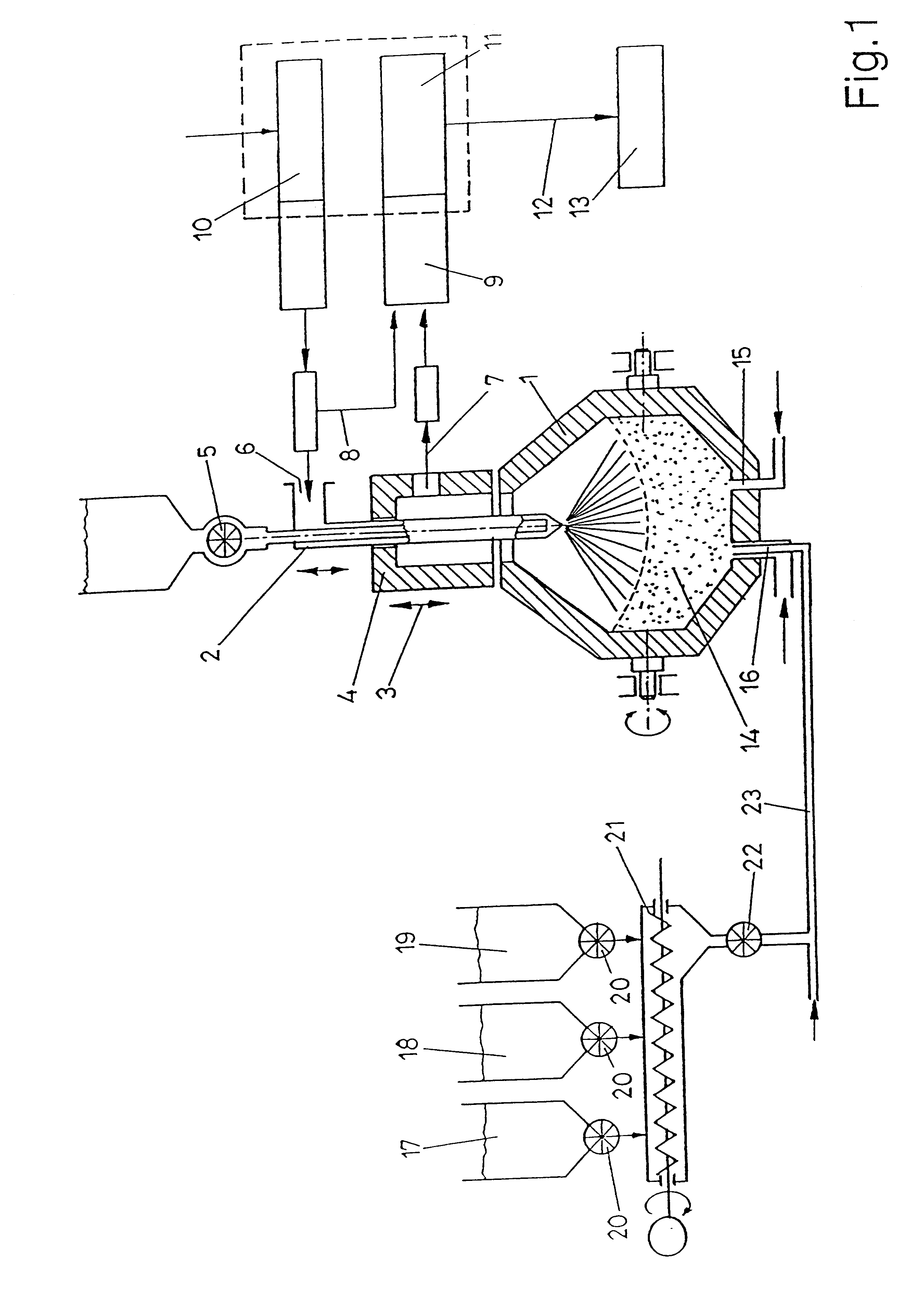

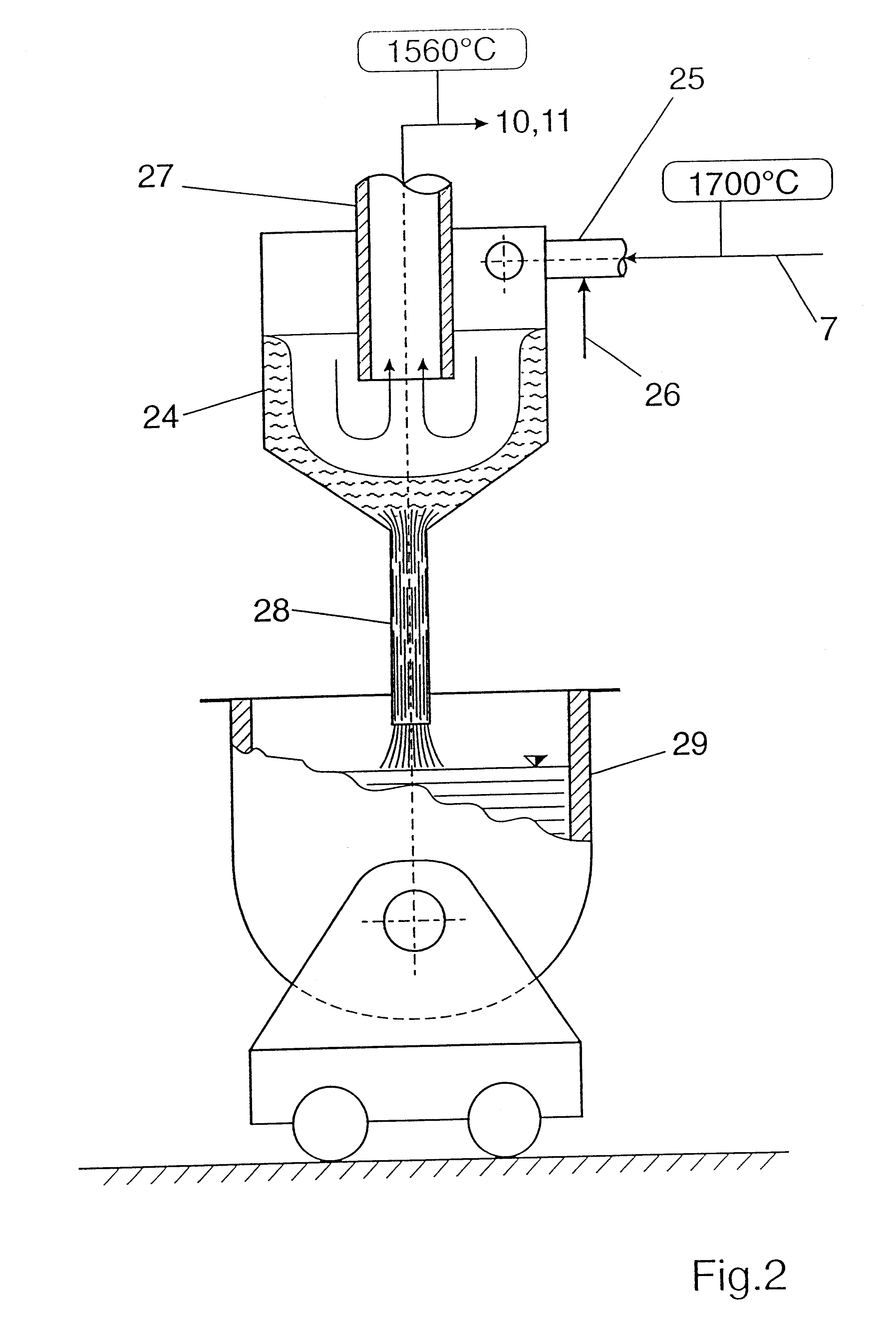

Process for working up steel slags and iron carriers for obtaining pig iron and environmentally safe slags

InactiveUS6332910B1Improve heat transfer performanceExtended service lifeManufacturing convertersProcess efficiency improvementAlkalinityNitrogen

In a process for working up steel slags and iron carriers such as, e.g., electric furnace slags, converter slags, fine ores, dusts from steel production, mill scales for obtaining pig iron and environmentally safe slags, the volume ratio of molten slag to iron bath is chosen to be larger than 0.5 to 1 and, preferably, 0.8:1 to 1.5:1 and the slags are supplemented with SiO2 carriers such as, e.g., foundry sands, metallurgical sands and / or fine ores so as to adjust a slag basicity (CaO / SiO2) of between 1.0 and 1.8 and, preferably, 1.2 and 1.8 at an Al2O3 content of between 10 and 25% by weight, based on the slag. In doing so, hot blast is top-blown and coal, optionally along with an inert gas and, in particular, nitrogen and, furthermore, optionally oxygen or hot air is blown through the iron bath.

Owner:HOLCIM

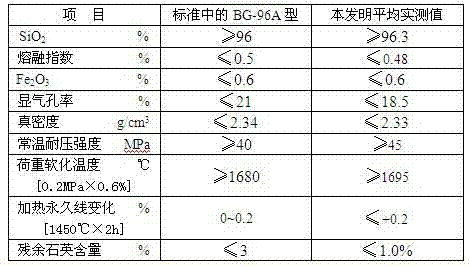

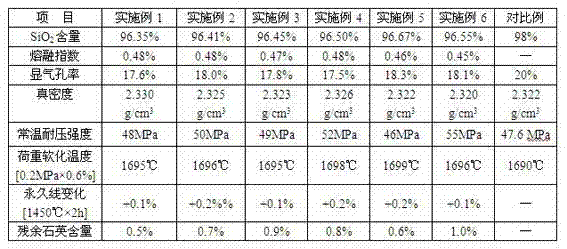

Silica brick for glass furnace

ActiveCN102515801ASmall volume expansionReduce crackingGlass furnace apparatusGlass productionPorosityBrick

The invention discloses a silica brick for a glass furnace, and belongs to the technical field of refractory materials. The silica brick for a glass furnace comprises: by weight, 30 to 45% of silica having particle sizes of 3 to 1.0mm, 5 to 25% of silica having particle sizes of 1.0 to 0.5mm, 30 to 50% of silica having particle sizes less than 0.5mm, an additive and a composite additive, wherein the weight of the additive is 5 to 15% of the total weight of the silica and the weight of the composite additive is 2 to 10% of the total weight of the silica. SiO2 content of the silica is great than or equal to 99%. Al2O3 content of the silica is less than or equal to 0.25%. Fe2O3 content of the silica is less than or equal to 0.45%. The additive is a waste silica material having SiO2 content great than or equal to 96%. The composite additive is a mixture of lime milk, mill scales and calcium lignosulphonate. The silica brick for a glass furnace has high SiO2 content, a high yield, low impurity content, low apparent porosity, good high-temperature performances and a long service life. A preparation technology of the silica brick for a glass furnace is simple and is suitable for large-scale production.

Owner:ZHEJIANG ZHAOSHAN SILICEOUS REFRACTORY MATERIAL

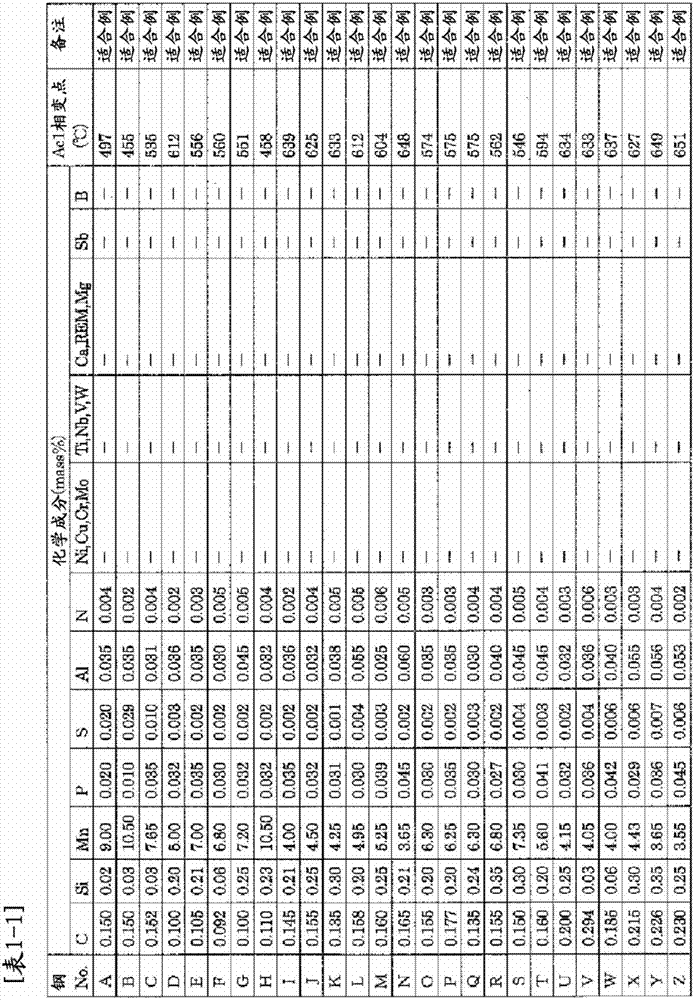

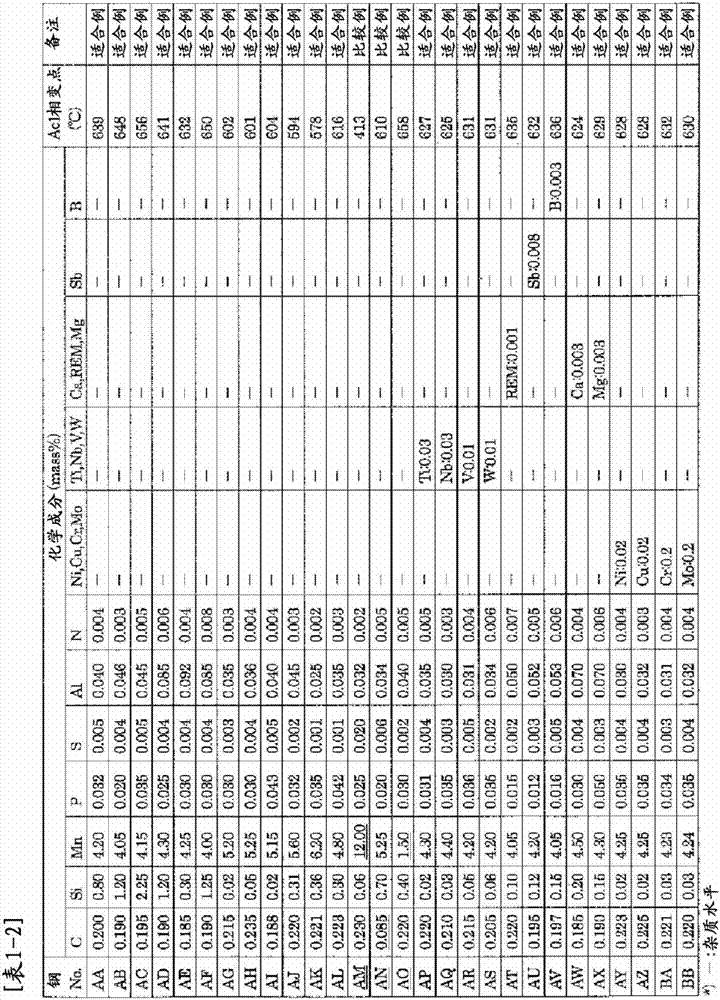

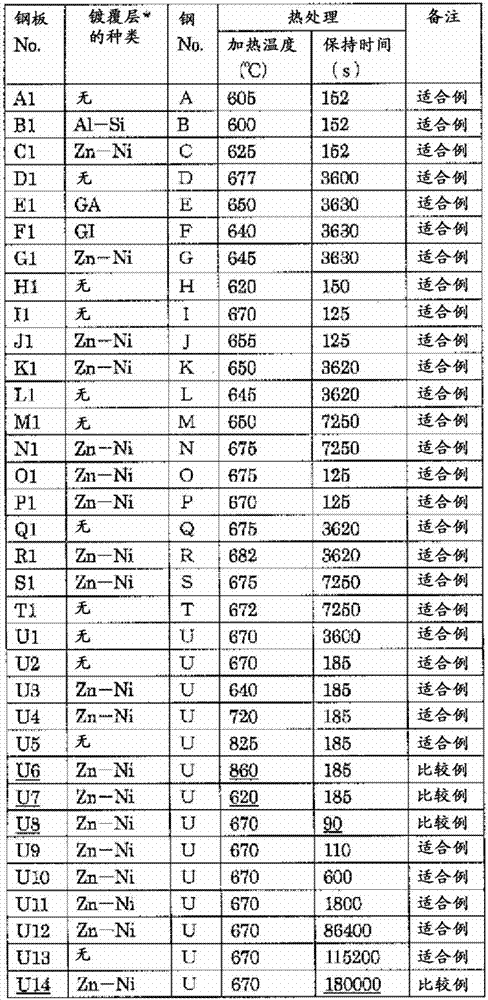

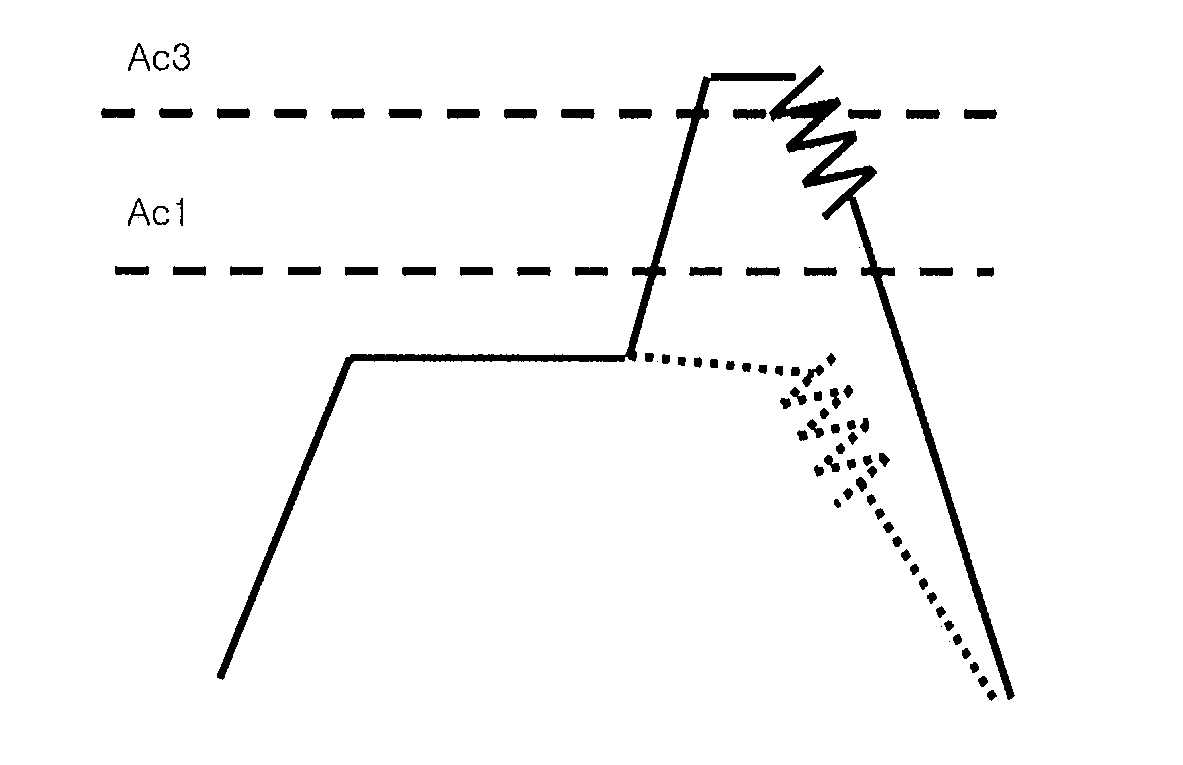

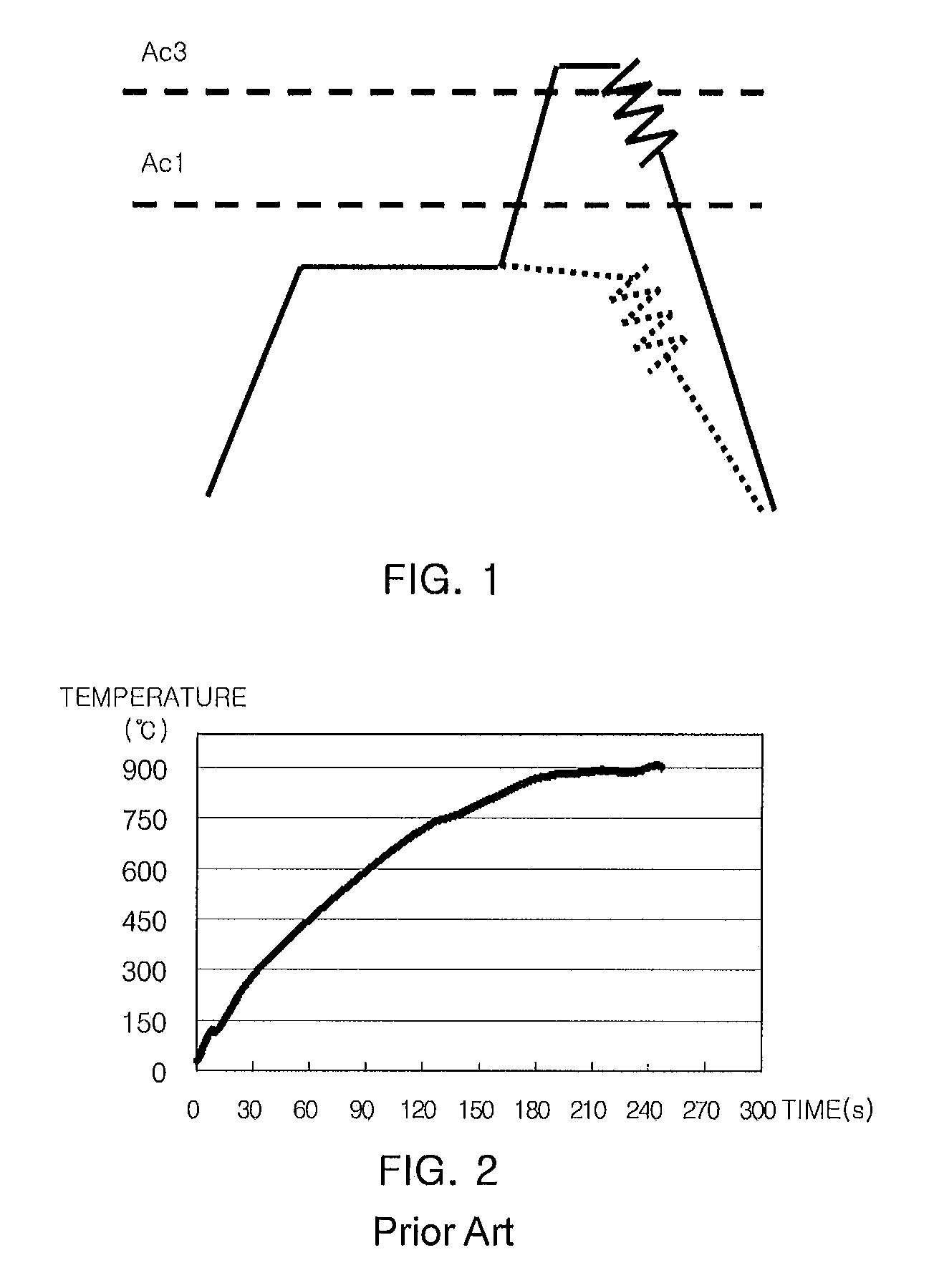

High-strength hot-pressing member and method for producing same

ActiveCN107109553ASimple and cheap to manufactureRealize thin wallHot-dipping/immersion processesFurnace typesUltimate tensile strengthMartensite

Owner:JFE STEEL CORP

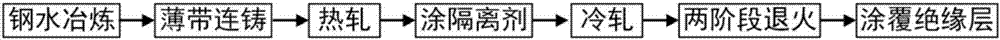

Method for preparing {100} surface developed-texture non-oriented silicon steel thin strip based on thin-strip continuous casting

The invention belongs to the technical field of metallurgy, in particular to a method for preparing a {100} surface developed-texture non-oriented silicon steel thin strip based on thin strip continuous casting. The method comprises the steps of smelting molten steel according to set components, wherein the set components comprise, by weight percentage, 0.002-0.005% of C, 2.2-3.5% of Si, 0.2-0.3% of Mn, less than or equal to 0.005% of Al, 0.08-0.20% of P, 0.002-0.005% of S and the balance Fe and inevitable impurities; (2) carrying out thin-strip continuous casting to form a cast strip with the thickness of 1.5-2.5mm; (3) carrying out one-pass hot rolling under an inert atmosphere condition; (4) carrying out single-stage multi-pass cold rolling on the hot rolled strip after clearing oxide skin of the hot rolled strip; (5) carrying out two-stage annealing on the cold rolled coil; and (6) applying an insulating layer to obtain a high-performance non-oriented silicon steel finished product. The method is based on the thin-strip continuous casting, the low-melting-point element P is added, the segregation characteristic of the P on the surface and the grain boundary is utilized, and therefore the intensity of {100} texture in the finished product plate can be enhanced. The method has the advantages that the technological process is short, the energy is saved, the consumption is reduced, and the anisotropy of the finished product plate can be obviously reduced.

Owner:NORTHEASTERN UNIV

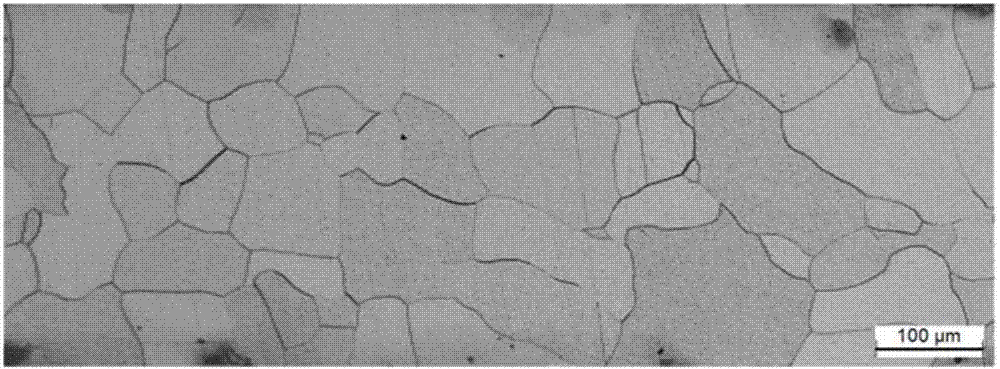

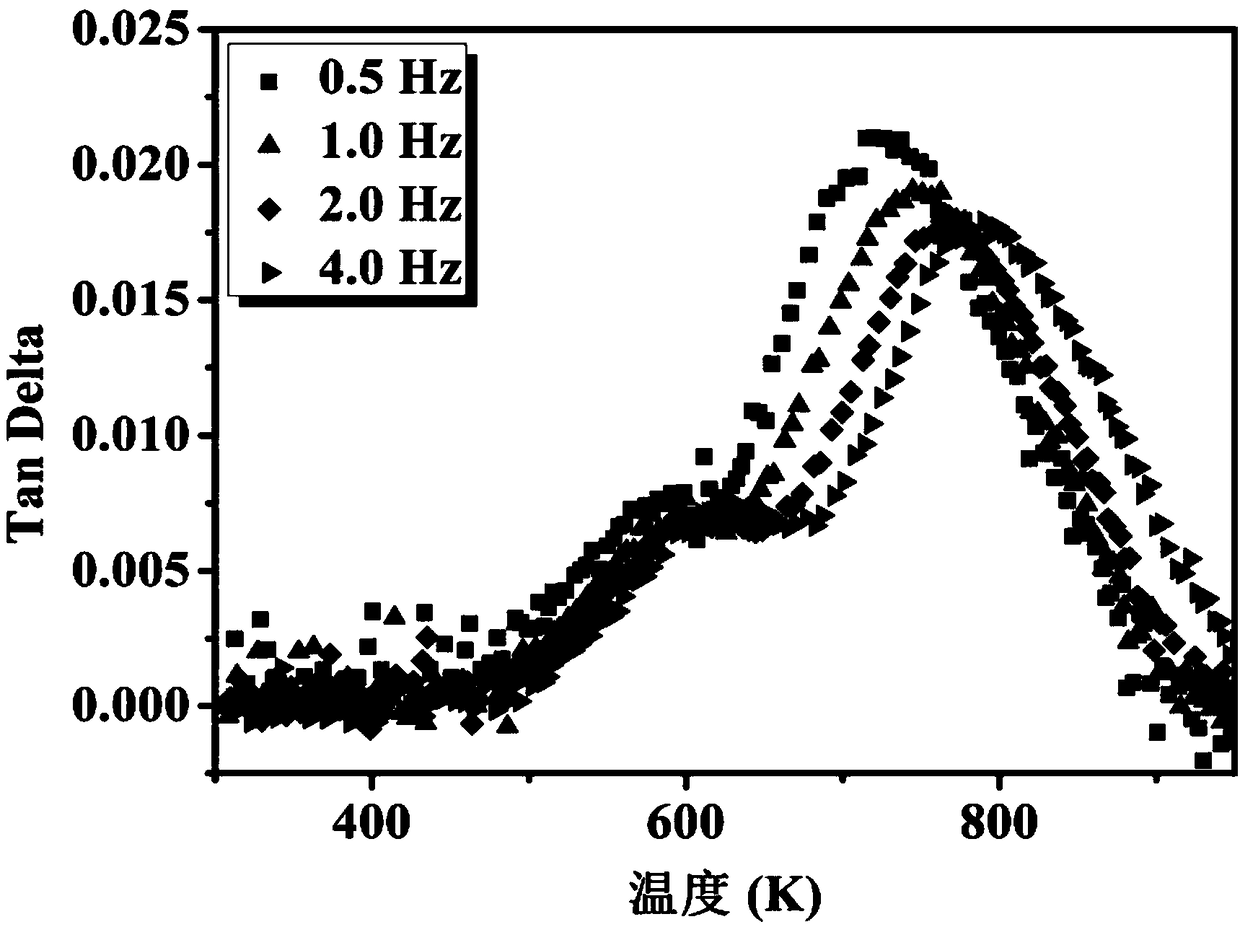

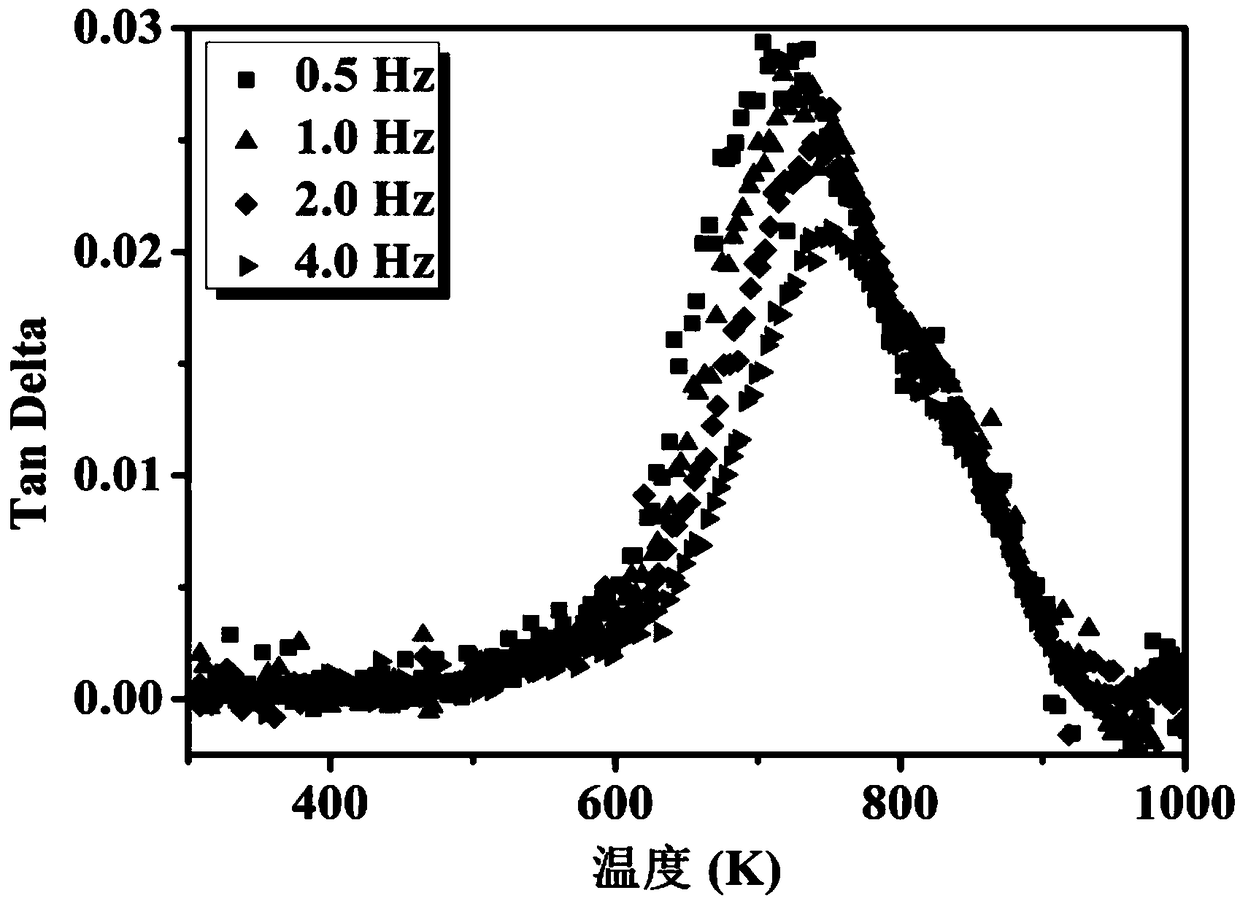

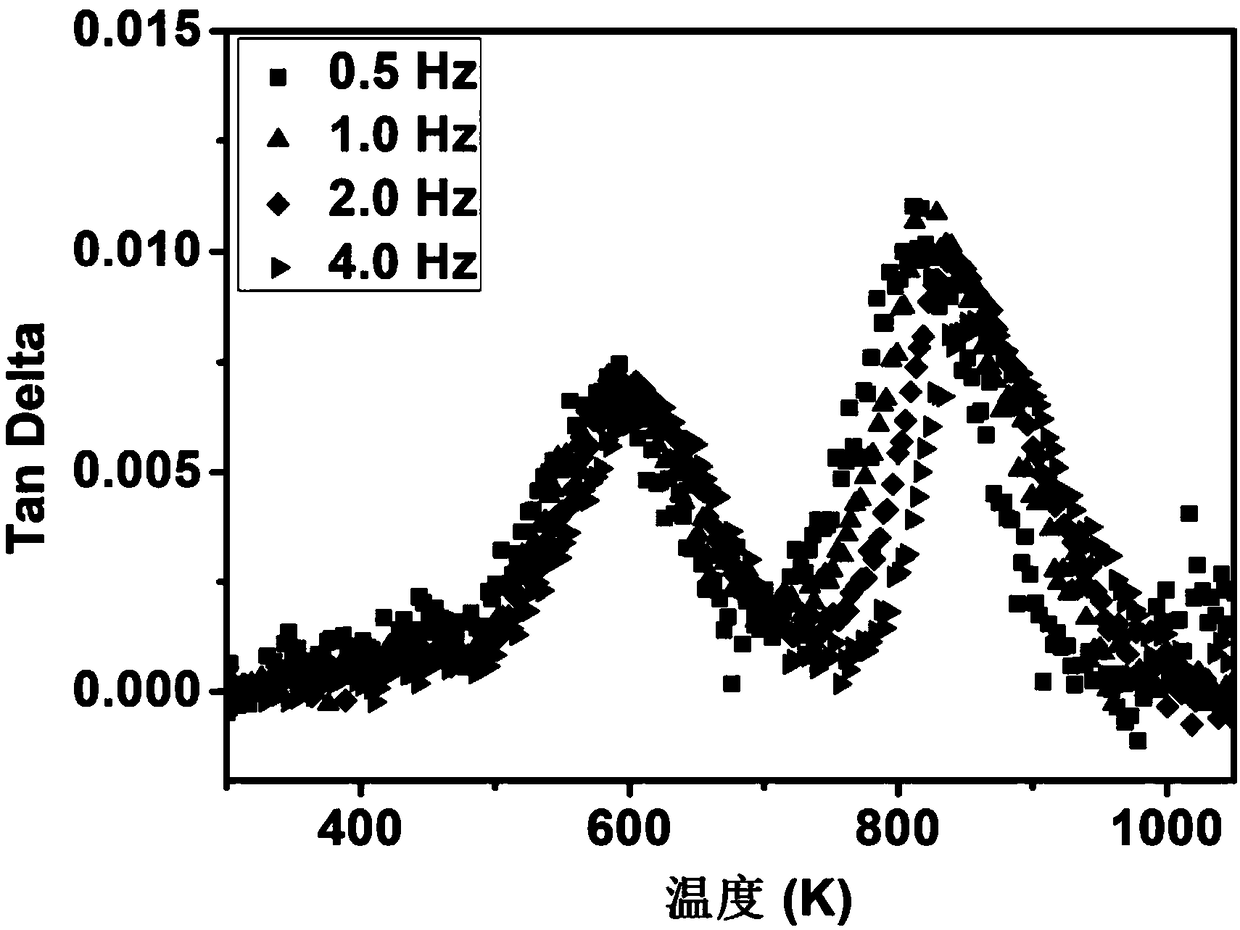

High temperature and high damping high entropy alloy and preparation method thereof

ActiveCN109338200AThe scope of application of large ingredientsBroad preparation conditionsElectric arc furnaceHigh entropy alloys

The invention relates to a high temperature and high damping high entropy alloy and a preparation method thereof. Due to the microalloying oxygen or nitrogen elements of a refractory high-entropy alloy matrix and utilizing high thermal stability of a high-entropy alloy matrix, the high temperature and damping capacity of the high entropy alloy is achieved. The process is as follows: the metal materials Ta, Nb, Hf, Zr, Ti, Mo, V, W, Al, etc. are subjected to mechanical removal of oxidized scale, and are weighted by the molar ratio; other added elements are mechanically scaled, ultrasonically cleaned or pickled, and weighted by the molar ratio; the oxygen element is added in the form of an oxide, and the nitrogen element is added in the form of a nitride; and the alloy is obtained by vacuumcasting or casting equipment through smelting in a non-consumable vacuum electric arc furnace or a cold crucible suspension furnace. The high temperature and high damping high entropy alloy and the preparation method thereof utilize the high structural stability of the high-entropy alloy, and significantly improves the high temperature damping performance and mechanical property of the alloy by small atom microalloying.

Owner:UNIV OF SCI & TECH BEIJING

Composite reinforced high strength and high elastic modulus titanium alloy and preparation method thereof

The invention discloses a compositely reinforced titanium alloy of high strength and high modulus of elasticity in the material preparation technical field and a preparation method thereof, which contains the following components by mass percent content: 5.1 percent to 6.5 percent of Al, 3.3 percent to 4.3 percent of V, 0.06 percent to 0.91 percent of B, 0.17 percent to 1.27 percent of C, and titanium as the rest. Titanium sponge, boron carbide, graphite, aluminum vanadium hardener and pure aluminum raw material are weighed and mixed evenly to be suppressed into an electrode which is installed in an arc furnace; titanium alloy cast ingot containing TiB and TiC of wild phase is obtained through smelting; billet forging is carried out to the titanium alloy cast ingot in beta phase area, then regular forging is carried out in alpha phase and beta phase, and after the completion of forging, the oxide skin on the surface of the titanium alloy, shrinkage holes, segregation and occluded defects are removed so that the titanium alloy is gotten. The invention is simple and rapid, and has low cost, more even distribution of wild phases, better combination of interfaces, high coefficient of thermal conductivity, low coefficient of linear expansion and outstanding comprehensive mechanical property.

Owner:SHANGHAI JIAO TONG UNIV

Anti-rust primer for elementary surface treatment of steel material, and manufacturing method thereof

InactiveCN101298536AImprove adhesionImprove rust resistanceLiquid surface applicatorsAnti-corrosive paintsPolyesterLacquer

The invention relates to an antirust primer with rust and with elementary surface treatment used for steel materials and a manufacturing method, wherein, fluid A is made by mixing, agitating and grinding bisphenol-A epoxy resin, dimethylbenzene, n-butyl alcohol, tannin, precipitated barium sulfate, zinc phosphate, saponite, iron oxide red, simethicone, polyester modified polyphosphonate compound and polyamide wax micropowder, while fluid B is made from polyamide resin, the dimethylbenzene and the n-butyl alcohol; when in use, mix and cure the fluid A and the fluid B to form the coating film. The antirust primer with rust and with elementary surface treatment has excellent adhesion and corrosion resistance, which can be coated on steel surfaces with uneven rust, solid oxide scale residuals or old paint, and can be directly used and matched as a primer with other finish paints without using any other primers.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Environment-friendly technology for copper and copper alloy surface treatment

The invention discloses an environment-friendly technology for copper and copper alloy surface treatment. The environment-friendly technology includes the following steps of (1) ultrasonic degreasing, (2) rinsing with clear water, (3) magnetic force polishing, (4) rinsing with clear water, (5) surface sealing, (6) centrifugal drying and (7) inspecting and packaging. A magnetic force polishing method is adopted to replace traditional three-acid pickling so as to conduct surface oxide skin removing operation on a copper alloy workpiece, and steel needles continuously collide and rub copper and the copper alloy workpiece so that surface oxide layers and tiny burrs can be removed and the purpose of surface smoothness can be achieved. The size of the copper alloy workpiece is not changed at all before and after treatment, and the poor size problem of the workpiece due to overpickling in the acid pickling process does not exist. A water-soluble environment-friendly sealing agent is adopted, the copper and the copper alloy workpiece with the smoothness surfaces after magnetic force polishing are subjected to sealing treatment, an organic closing membrane is used for replacing a chromic acid passivation membrane so that surface protection can be performed on the copper alloy workpiece, the adopted sealing agent is up to the ROSH standard and does not contain toxic and harmful substances, and the thickness of the surface closing membrane is controllable in the process; and moreover, the product has high fingerprint resistance, high salt spray resistance and high anti-tarnish performance.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Process for preparing high niobium Ti Al alloy large size cake material

The preparation of large high-Nb TiAl alloy cake includes the technological process of smelting, soakage treatment, turning, canning, forging and slow cooling. The preparation process features the smelitng including the first self-consuming, the self-consuming kish and the second self0consuming steps; the soakage treatment at 1100-1300 deg.c for 24-48 hr; turning to eliminate surface scale; canning with stainless steel pipe, titanium pipe and stainless steel plate; forging in a 3000-5000 oil press at deformation temperature of 1200-1350 deg.c after heating at 1250-1300 deg.c for 40-60 min in the furnace and preheating for 6-10 hr to produce deformatino amount of 60-80 % at the rate of 0.001-0.1 / s; and tempering at low temperature. The present ivnention has the advantages of fine crystal grains and excellent comprehensive mechanical performance.

Owner:UNIV OF SCI & TECH BEIJING

Hot press forming process of plated steel and hot press formed articles using the same

InactiveUS20120291510A1Prevent volatilizationShaping toolsHot-dipping/immersion processesUltimate tensile strengthElectroplating

Disclosed are a hot press forming method and a product formed using the hot press forming method, able to process a plated steel blank under appropriate heat treatment conditions to prevent the volatilization of a plated layer and the formation of oxidized scale, and which divisionally heats the plated steel blank in a secondary heating process to provide different strengths and physical properties to the product. The hot press forming method includes primarily and entirely heating the plated steel material to a predetermined temperature and maintaining the plated steel material at the predetermined temperature, secondarily and rapidly heating at least one portion of the plated steel material after the high temperature maintenance of the plated steel material, and performing a hot press forming and cooling process on the secondarily heated plated steel material.

Owner:POHANG IRON & STEEL CO LTD

Method for processing steel slags containing chromium

A method for processing steel slags and optionally iron carriers such as, e.g., electric furnace slags, converter slags, dusts derived from steel production, mill scale or secondary metallurgical residues, in which the molten steel slags or iron carriers are supplemented with chromium ores or chromium-containing and / or nickel-containing dusts in order to adjust a slag basicity of 1.2 to 1.6, whereby the bath temperature is maintained at above 1600° C., in particular between 1650° C. and 1800° C., and a carbon-containing iron bath is provided or formed. In addition to environmentally safe slags, a high-grade ferrochromium alloy may be recovered, thus enhancing the economy of the method.

Owner:HOLCIM

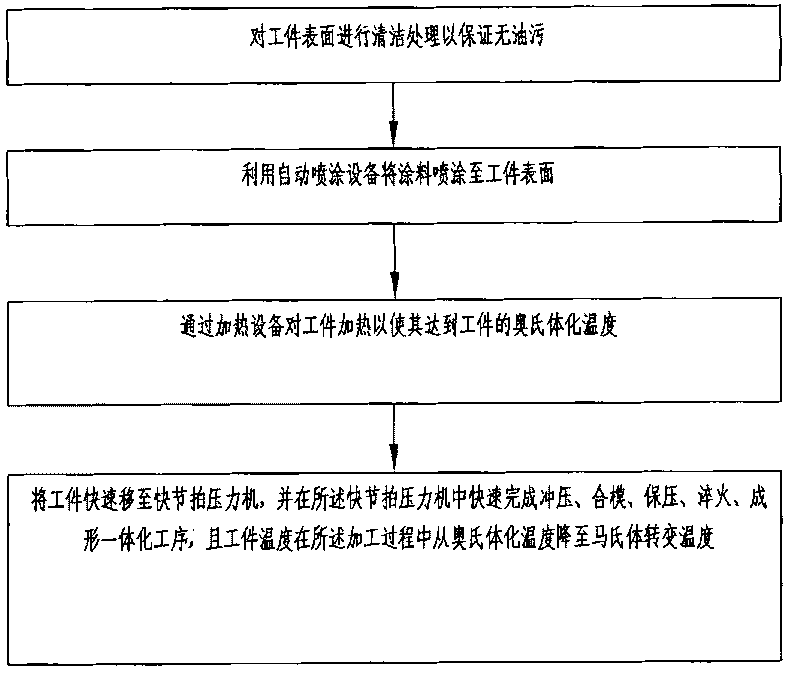

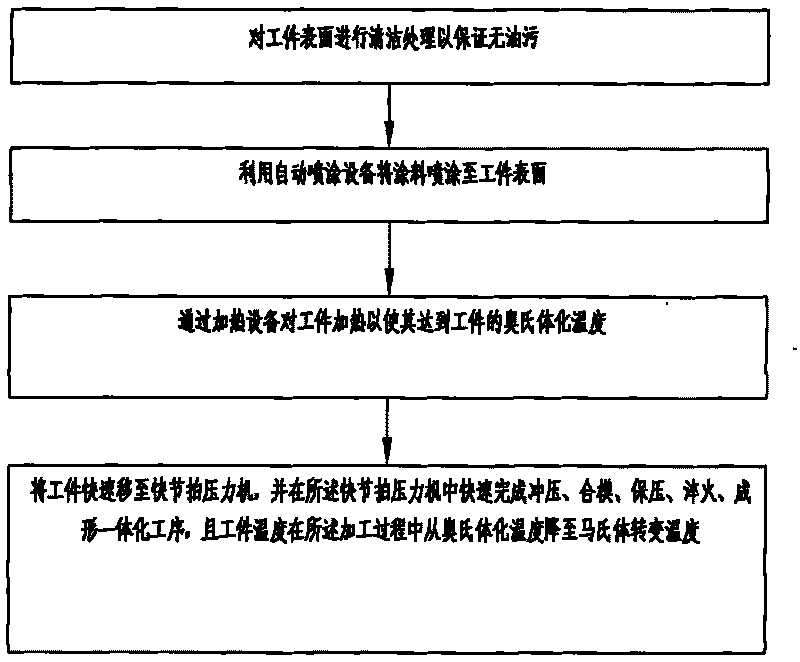

Steel plate hot forming method based on anti-oxidation coating and production line for implementing same

The invention discloses a steel plate hot forming method based on an anti-oxidation coating and a specifically designed hot forming production line for implementing the method. The method comprises the following steps: cleaning the surface of a workpiece to ensure that no oil contamination exists; utilizing automatic spraying equipment to spray coating on the surface of the workpiece; heating the workpiece by heating equipment to ensure the workpiece to reach austenitizing temperature thereof; transferring the workpiece to a rapid press machine, and rapidly finishing integration working procedures of pressing, compound die, pressure maintaining, quenching and forming in the rapid press machine; and lowering the temperature of the workpiece from austenitizing temperature to martensitic transformation temperature in the processing procedure. The hot forming production line comprises automatic spraying equipment, heating equipment, the rapid press machine and a transmission mechanism. The invention has the following beneficial effects of solving the problems of oxide skin generation in hot forming and causing the hot forming method to have lower cost, higher accuracy and simpler operation.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Hydrogen permeating superplasticity processing method for in-situ synthesized titanium-based composite material

InactiveCN101130840ALow costReduce superplastic processing temperatureMetal-working apparatusSolid state diffusion coatingTitanium matrix compositesBeta phase

The present invention relates to a hydrogen-permeating superplasticity processing method of in-situ autogenous titanium base composite material in the field of composite material technology. Said method includes the following steps: (1), utilizing vacuum consumable electroarc furnace to smelt and prepare titanium base composite material ingot containing TiB and TiC hybrid reinforcement; (2), in beta-phase zone breakdown forging the composite material ingot, then in alpha + beta two-phase zone making conventional forging operation, after the forging operation is completed, removing oxide skin and defects of piping, segregation and dirts, etc from material surface; (3), placing the composite material into a vacuum furnace and making hydrogen-permeating treatment; (4), contour forging or free forging the hydrogen-containing composite material, and making it into a component; and (5), placing said component into a vacuum annealing furnace and making vacuum hydrogen-removing treatment.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparation of double-phase zirconium alloy EBSD sample by electrolytic polishing

InactiveCN106556532AHigh surface finishExtensive sources of raw materialsPreparing sample for investigationMaterial analysis using radiation diffractionElectrolysisDouble phase

Owner:CHONGQING UNIV OF TECH

Dust-free corrosion-resistant coating process for steel materials

InactiveCN102489434AImprove cleanlinessProcessing speedPretreated surfacesCoatingsUltra high pressureSand blasting

The invention provides dust-free corrosion-resistant coating process for steel materials, which is characterized in that steps include 1, cleaning surfaces of a base material to be coated by the aid of high pressure water generated via ultra-high-pressure water jetting equipment so as to remove rust, scale cinder or old paint on the surface of the base material, and generating floating rust on the cleaned surface of the base material after the cleaned surface of the base material is dried; 2, coating water-based rust transform primer on the surface of the base material, and forming a transform membrane after the water-based rust transform primer is dried; and 3, spraying finish paint on the base material after the base material is painted or directly spraying finish paint on the base material. In the dust-free corrosion-resistant coating process, dust cannot be generated in construction, and cleanness of treated surfaces is far higher as compared with traditional sand blasting and shot blasting. Simultaneously, treatment speed is fast, and the speed of single gun treatment is higher than that of single gun sand blasting by three to four times.

Owner:SHANGHAI LUFENGDA SURFACE MATERIAL TECH

Acid Washing-free and drawing-free apparatus for steel strand

InactiveCN102357543AReduce consumptionReduce configurationExtrusion cleaning devicesAcid washingHardness

Owner:威海银兴预应力线材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![TiZrNbVMo[x] high entropy alloy and preparation method thereof TiZrNbVMo[x] high entropy alloy and preparation method thereof](https://images-eureka.patsnap.com/patent_img/2902361d-51ee-4238-b4c1-5d60d73103a3/HDA0000405578970000011.PNG)

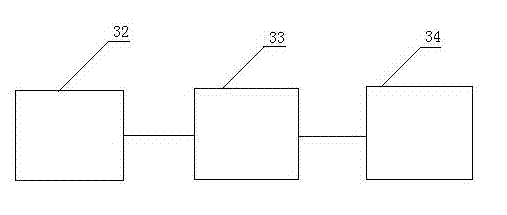

![TiZrNbVMo[x] high entropy alloy and preparation method thereof TiZrNbVMo[x] high entropy alloy and preparation method thereof](https://images-eureka.patsnap.com/patent_img/2902361d-51ee-4238-b4c1-5d60d73103a3/HDA0000405578970000021.PNG)

![TiZrNbVMo[x] high entropy alloy and preparation method thereof TiZrNbVMo[x] high entropy alloy and preparation method thereof](https://images-eureka.patsnap.com/patent_img/2902361d-51ee-4238-b4c1-5d60d73103a3/HDA0000405578970000031.PNG)