Patents

Literature

61results about How to "Avoid carburization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stainless steel and stainless steel pipe having resistance to carburization and coking

ActiveUS20050045251A1Avoid carburizationRecord information storageMagnetic recordingSS - Stainless steelPetrochemical

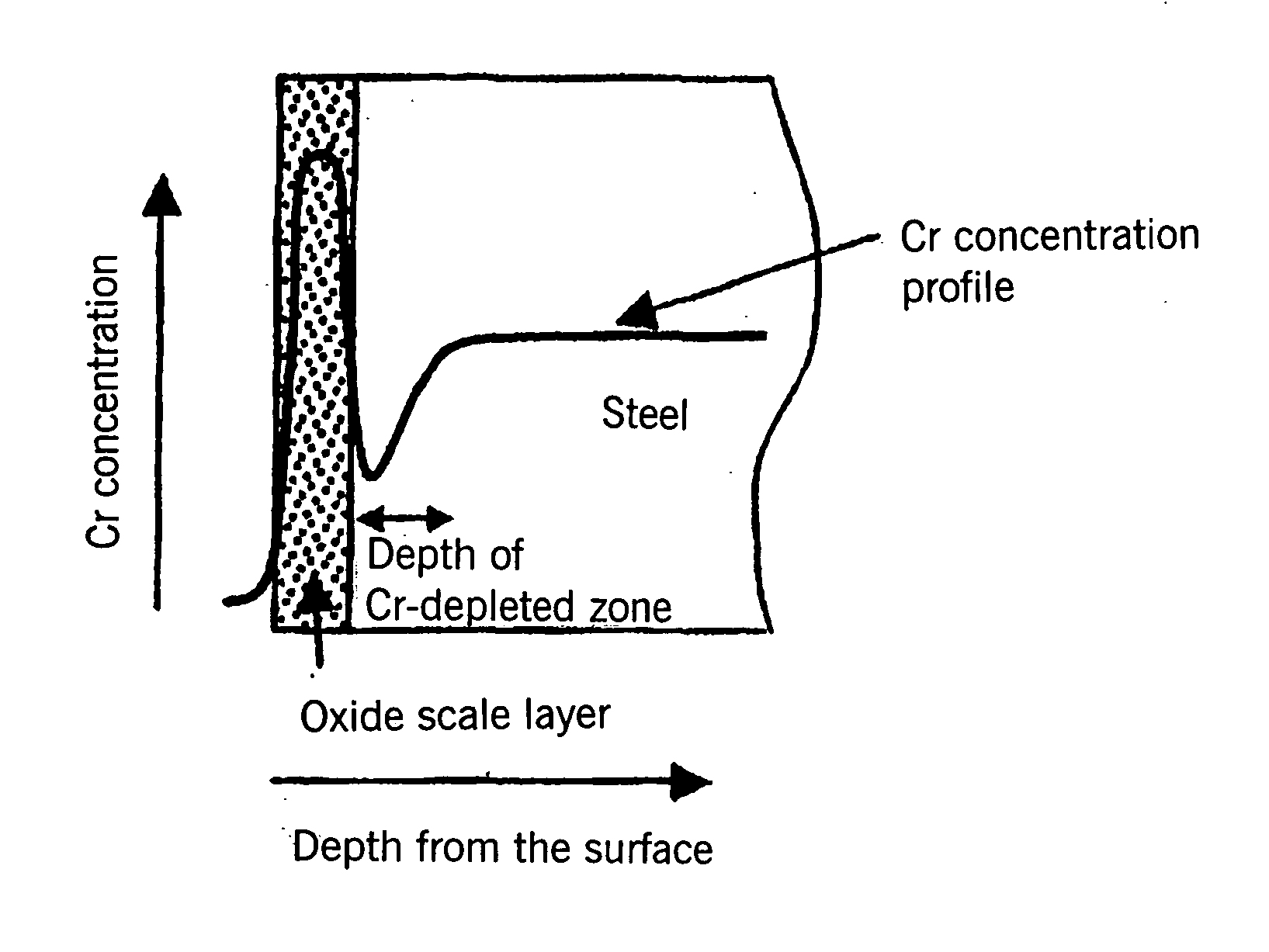

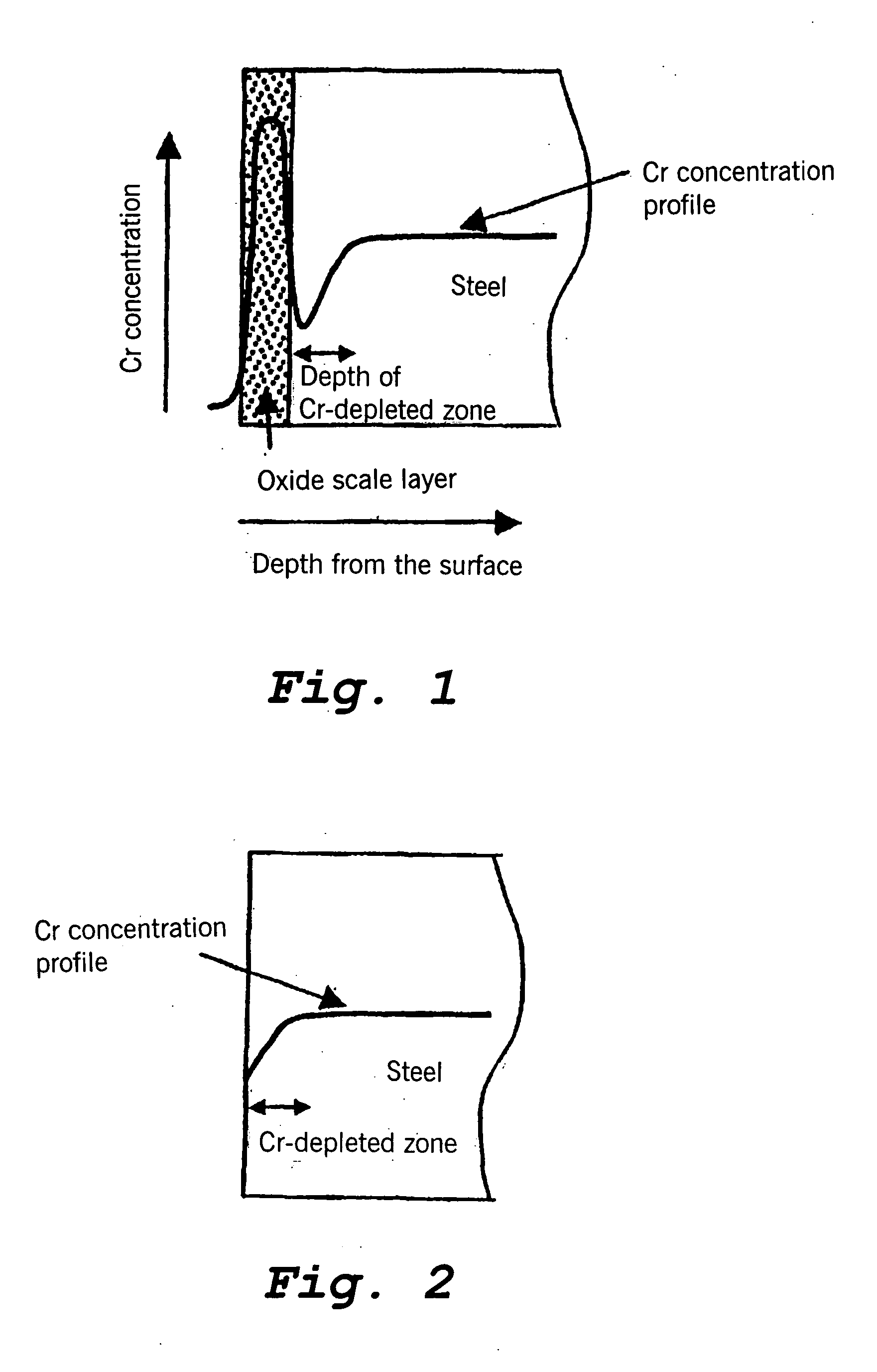

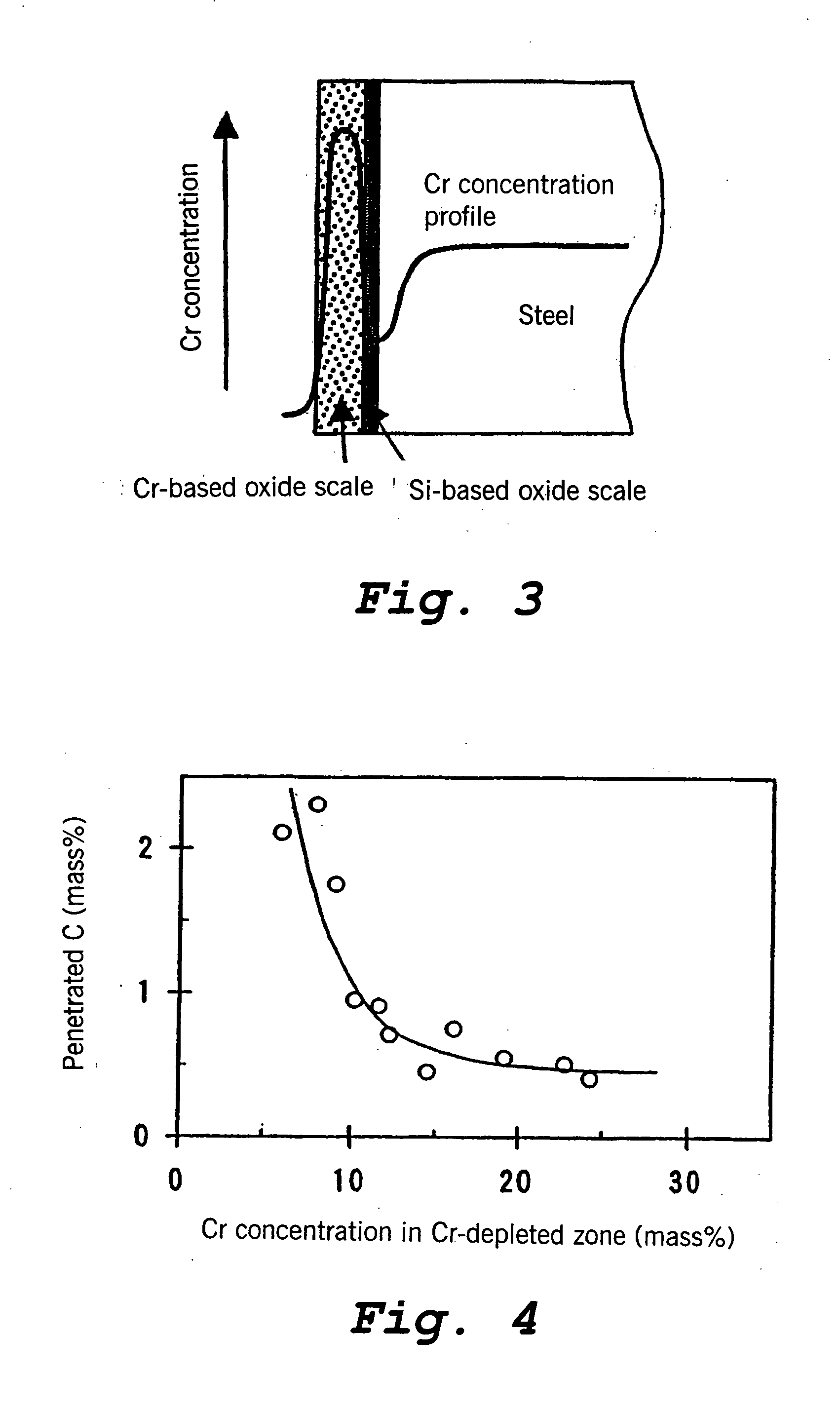

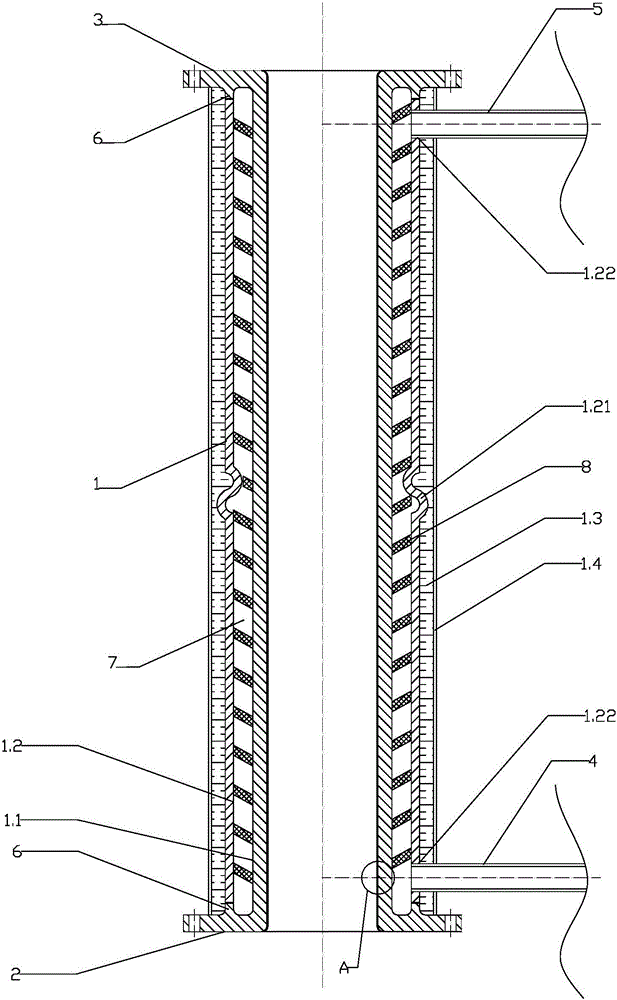

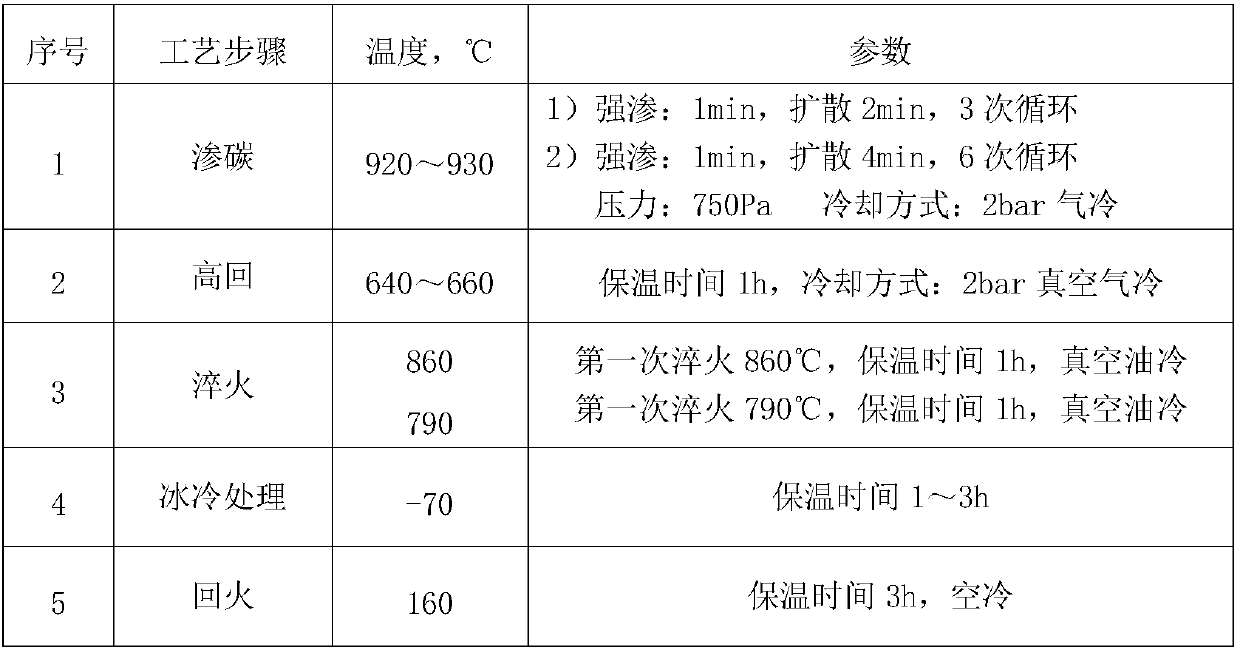

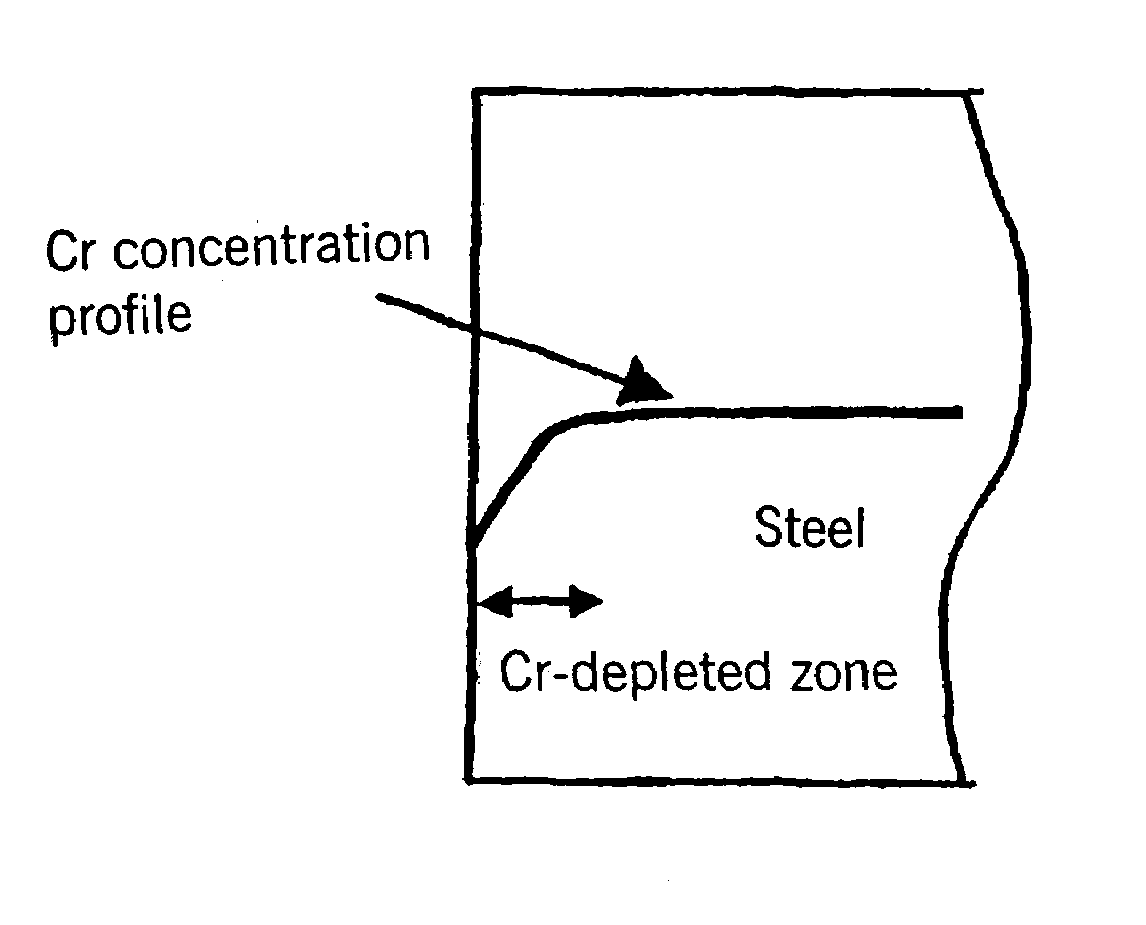

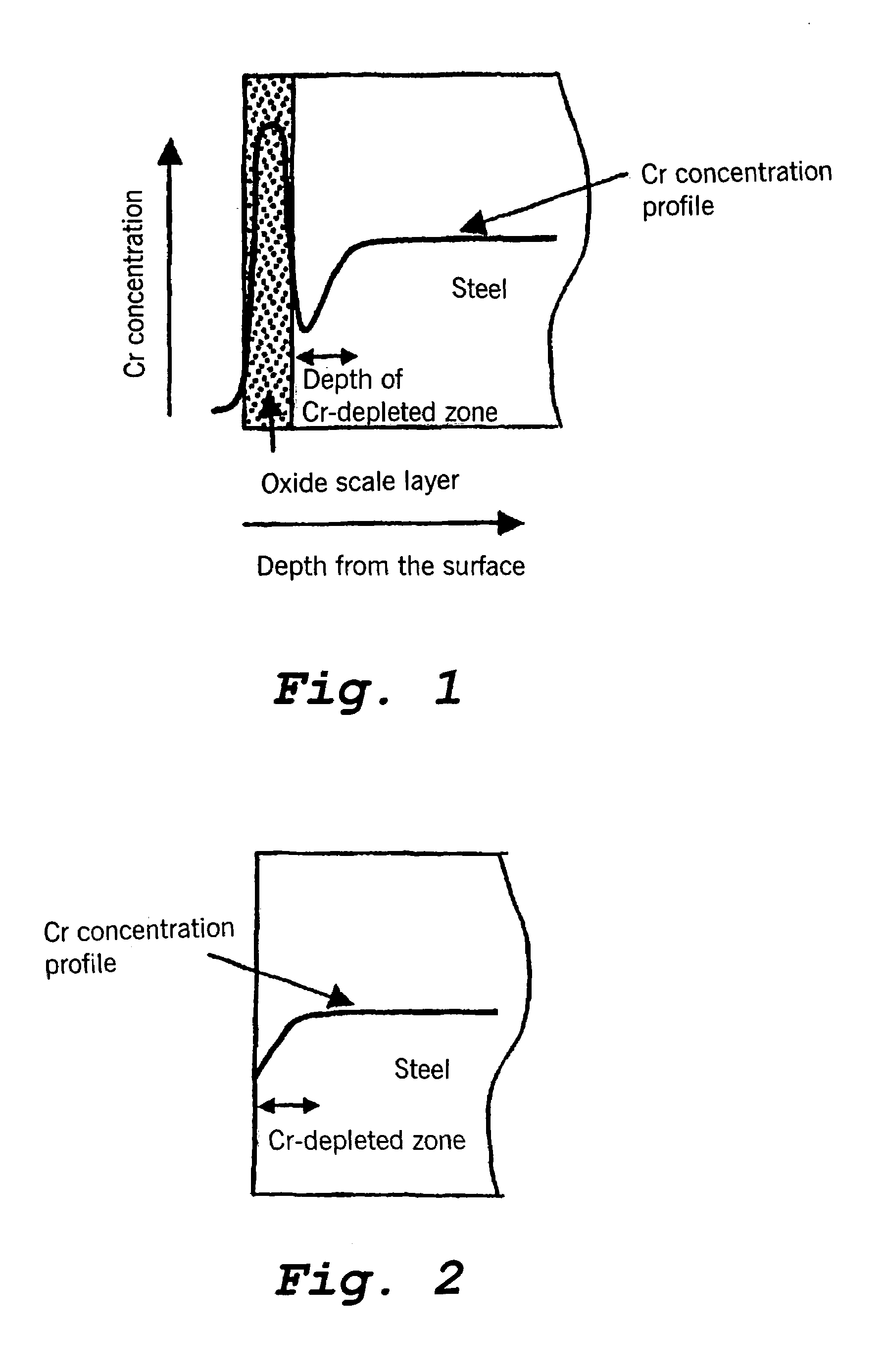

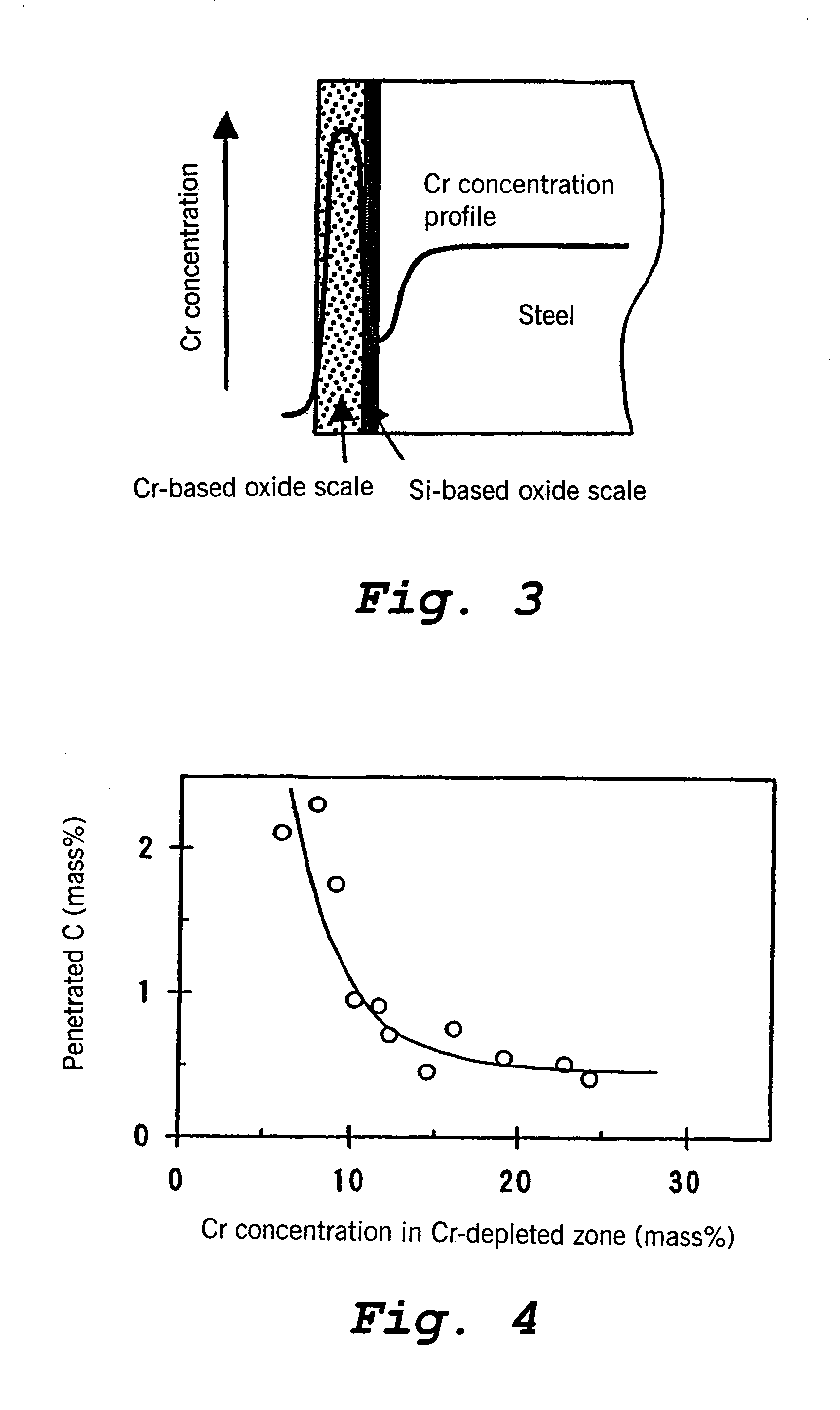

A stainless steel pipe includes a base metal containing 20-35 mass % of Cr, and a Cr-depleted zone is formed in the surface region of the pipe. The Cr concentration in the Cr-depleted zone is at least 10%, and the thickness of the Cr-depleted zone is at most 20 micrometers. A Cr-based oxide scale layer having a Cr content of at least 50% and a thickness of 0.1-15 micrometers may be provided on the outer side of the Cr-depleted zone. An Si-based oxide scale layer with an Si content of at least 50% may be provided between the Cr-based oxide scale layer and the Cr-depleted zone. The pipe is particularly suitable for use in petroleum refineries or petrochemical plants, such as for use as a pipe of a cracking furnace of an ethylene plant.

Owner:NIPPON STEEL CORP

Tundish magnesium dry-type stock adding aluminum hydroxide

The invention discloses a magnesia-based dry material for a tundish with aluminum hydroxide, which belongs to a refractory material. The magnesia-based dry material for the tundish with the aluminum hydroxide comprises the following compositions in percentage by weight: 1 to 15 percent of aluminum hydroxide fine powder, 82 to 89 percent of magnesia, and 1.5 to 6.5 percent of bonding agent. During the baking and use, the aluminum hydroxide fine powder is decomposed to produce activated alumina and vapor, the vapor moistens the surfaces of particles inside the dry material to ensure that the surfaces of the magnesia and silica fume in the dry material are hydrated, and the bonding agent is partially dissolved and diffused to bond with the surface of the magnesia. The generated activated alumina has a spinel reaction with magnesia fine powder at a temperature higher than 900 DEG C to form a large quantity of fine magnesium aluminate spinels, which remarkably improves the penetration-resistant action of the dry material on molten steel and steel slag and plays a role in ceramic bonding. The dry material does not depend on carbon-containing bonding agents such as phenolic resin, asphalt, which avoids the carburization to molten steel of low carbon steel and also reduces the poisonous fume emission. The construction of the magnesia-based dry material adopts a dry-press process, and then the dry material is subjected to heat conduction through the heating on a metal mold to make the bonding agent fused or solidified to form a fixed tundish working lining for receiving the molten steel.

Owner:江苏苏嘉集团新材料有限公司

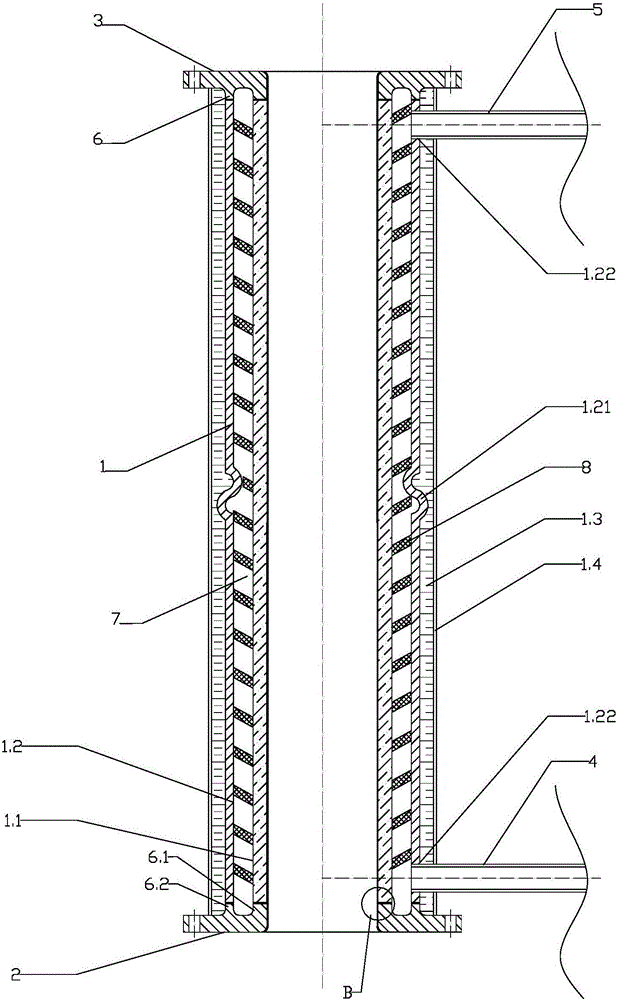

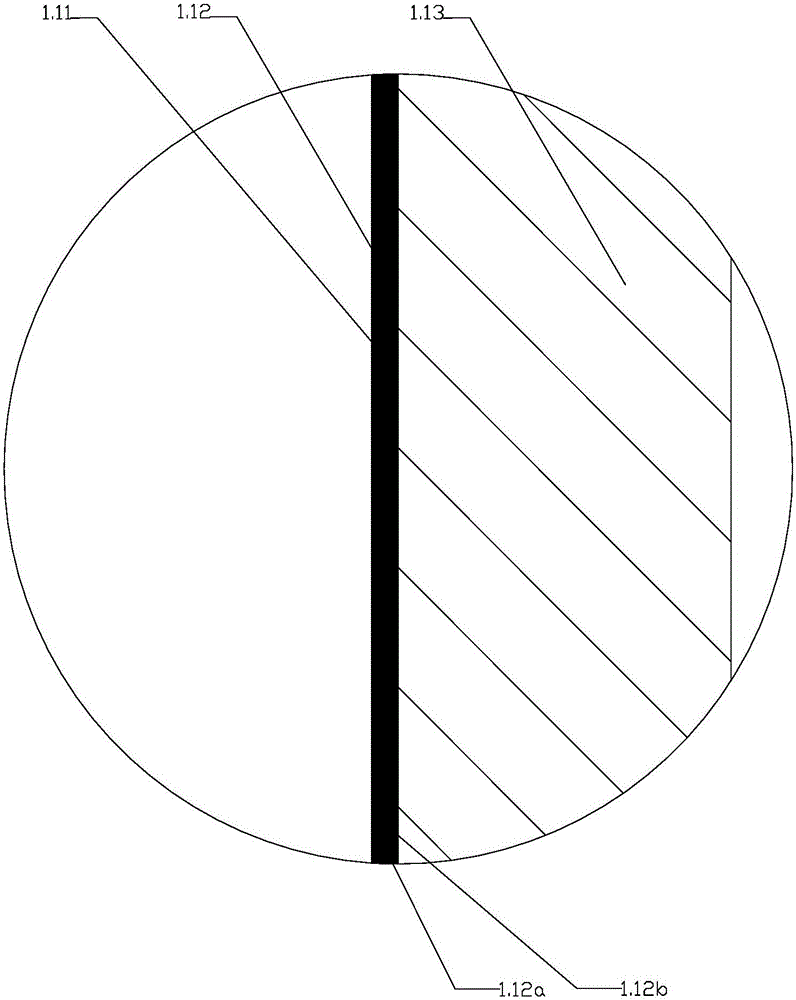

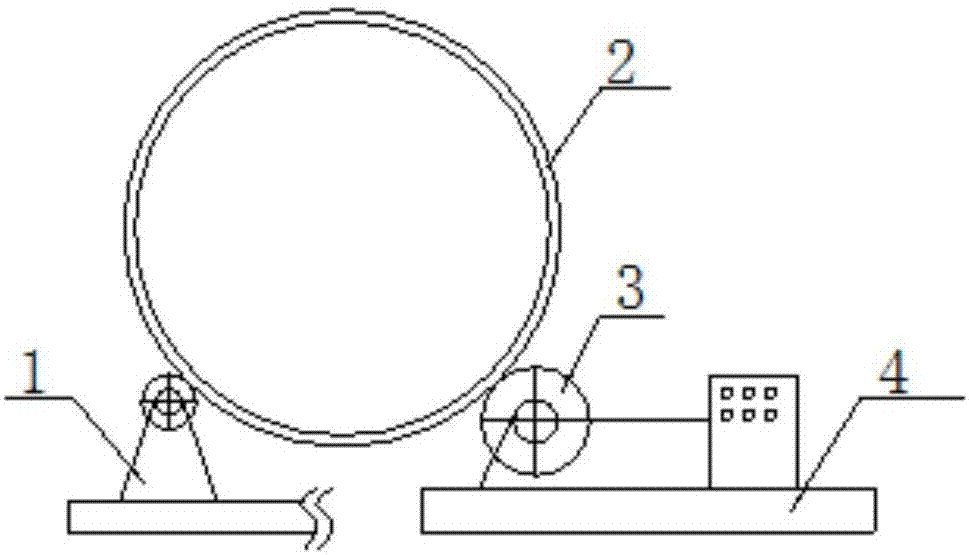

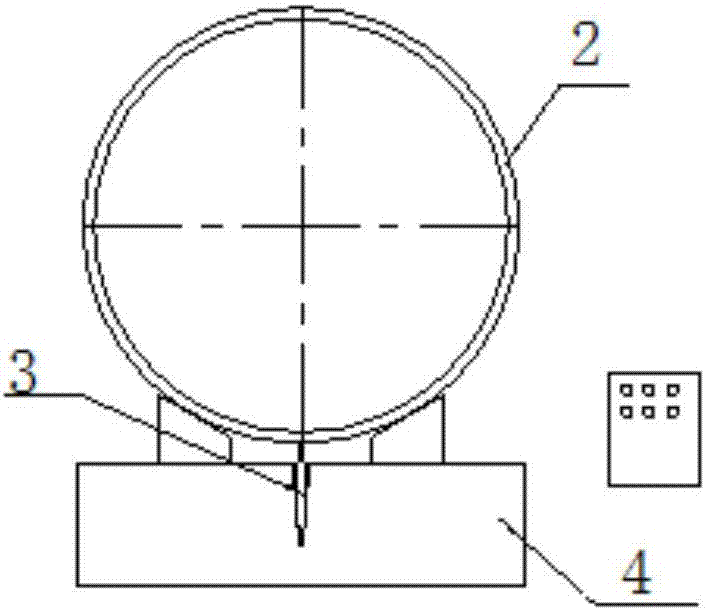

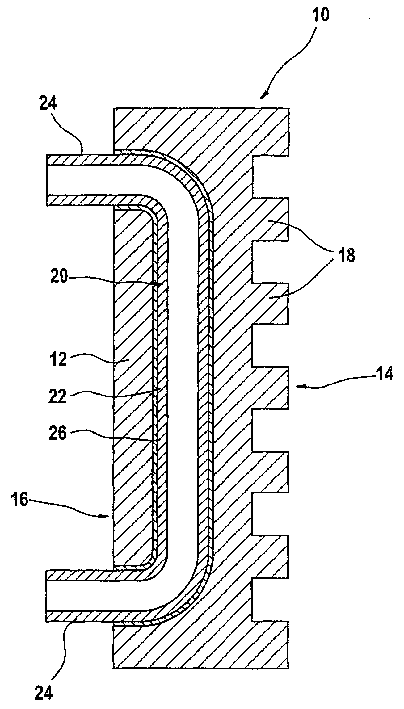

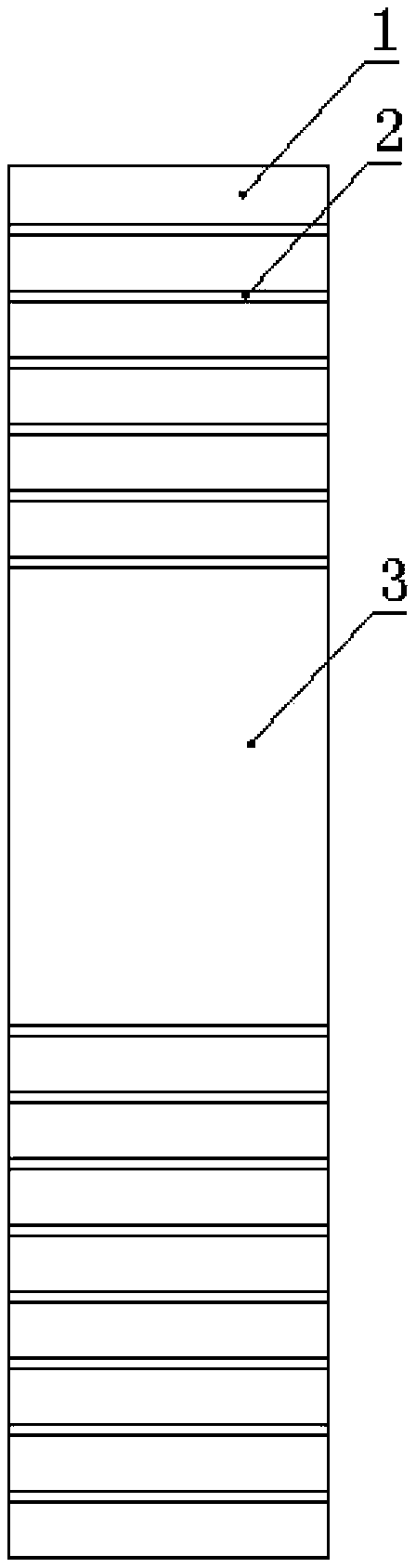

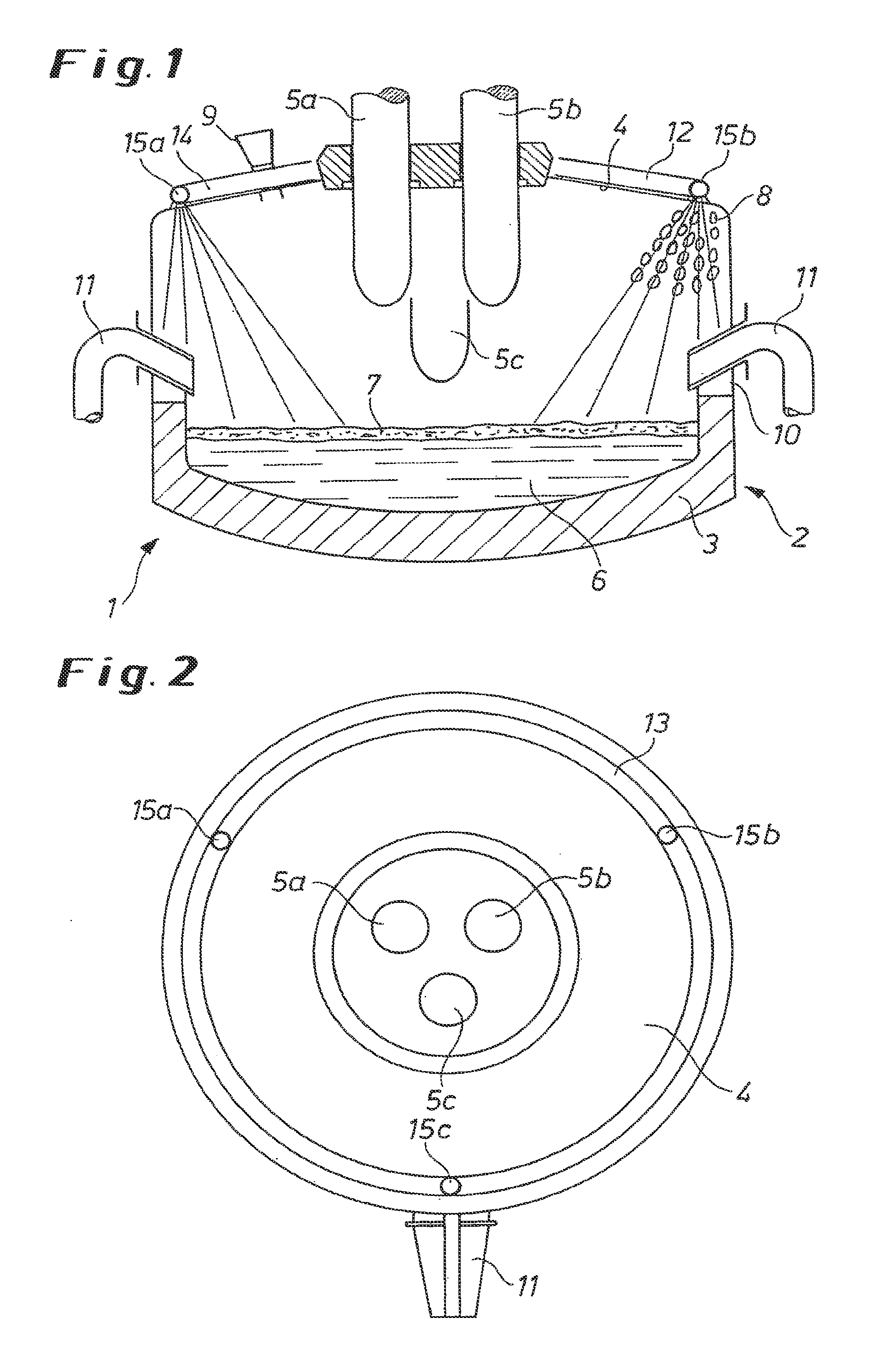

Coke oven ascension pipe raw gas evaporative cooling device and preparation method thereof

InactiveCN105043117APrevent oxidationAvoid carburizationIncreasing energy efficiencyWaste heat treatmentEngineeringCoke oven

The invention discloses a coke oven ascension pipe raw gas evaporative cooling device and a preparation method thereof. The device comprises a cooling pipe, a raw gas inlet flange and a raw gas outlet flange, wherein the raw gas inlet flange and the raw gas outlet flange are connected with the two ends of the cooling pipe respectively. The cooling pipe is sequentially composed of an inner sleeve, an outer sleeve, a heat preservation layer and a protection layer from inside to outside. Through holes are formed in the two ends of the side wall of the outer sleeve respectively. A water inlet steel pipe is installed on the through hole close to the raw gas inlet flange. A vapor outlet steel pipe is installed on the through hole close to the raw gas outlet flange. An annular expansion joint section is arranged at the portion, between the water inlet steel pipe and the vapor outlet steel pipe, of the outer sleeve. The high temperature structural strength and high temperature breakage resistant capacity of the cooling device are remarkably improved, the heat transfer behavior of the pipe wall of the inner sleeve of the cooling device is improved, the radial temperature distribution of the pipe wall is optimized, the efficient function coordination of multiple layers of materials is achieved, and the comprehensive use performance of the inner sleeve is improved; the aim of long-term efficient and stable running of the ascension pipe raw gas evaporative cooling device is finally achieved.

Owner:武汉钢铁有限公司

Welding joint and technique for longitudinal seam and circumferential seam of medium-thick plate

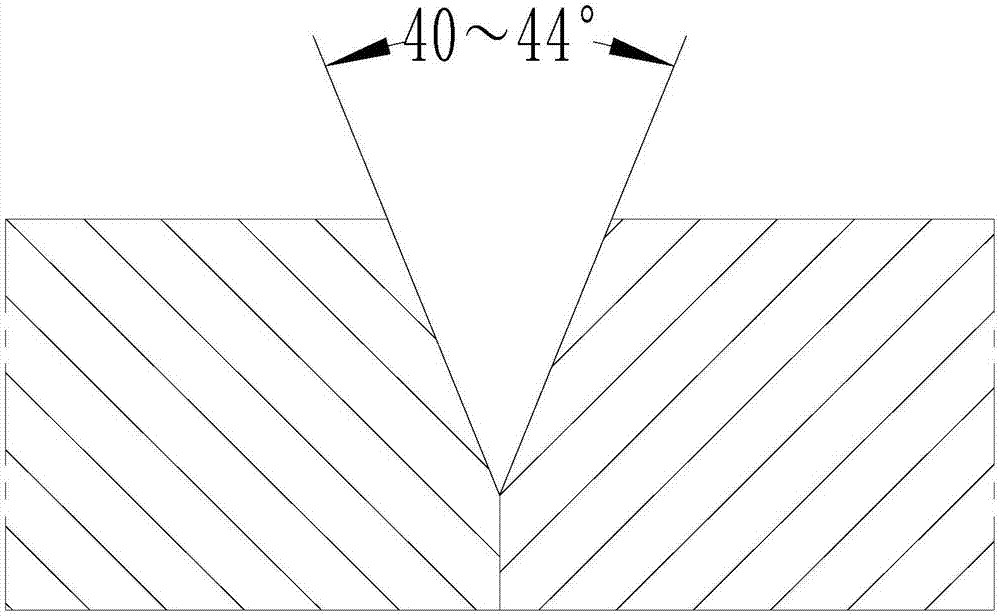

InactiveCN107442891AReduce fillingReduce the amount of weldingWorkpiece edge portionsWelding accessoriesThick plateEngineering

The invention discloses a welding joint and technique for a longitudinal seam and a circumferential seam of a medium-thick plate. The welding technique for the longitudinal seam and the circumferential seam of the medium-thick plate comprises the following steps that a groove inside the plate is machined; then, the surface and the two sides of the groove are cleaned; a priming layer, a filling layer and a surface covering layer of the internal groove are welded in a submerged-arc welding mode; then mechanical back chipping is conducted, and the back-chipped groove is detected nondestructively; and finally, a priming layer, a filling layer and a surface covering layer of an external groove are welded in a submerged-arc welding mode. By optimizing the groove type, the welding material filling amount is decreased, and the welding efficiency is improved; groove machining and welded seam back chipping are conducted through mechanical back chipping, base material hardening caused by rapid heating and cooling through carbon arc air gouging back chipping is avoided, the carburization phenomenon on the two sides of the groove of a stainless steel material is avoided, secondary polishing caused by using of a polishing machine is avoided, the back chipping efficiency is improved by about 50%, the labor intensity of workers is greatly reduced, the air environment is improved, and the welding quality of a cylinder is improved.

Owner:LUXI IND EQUIP

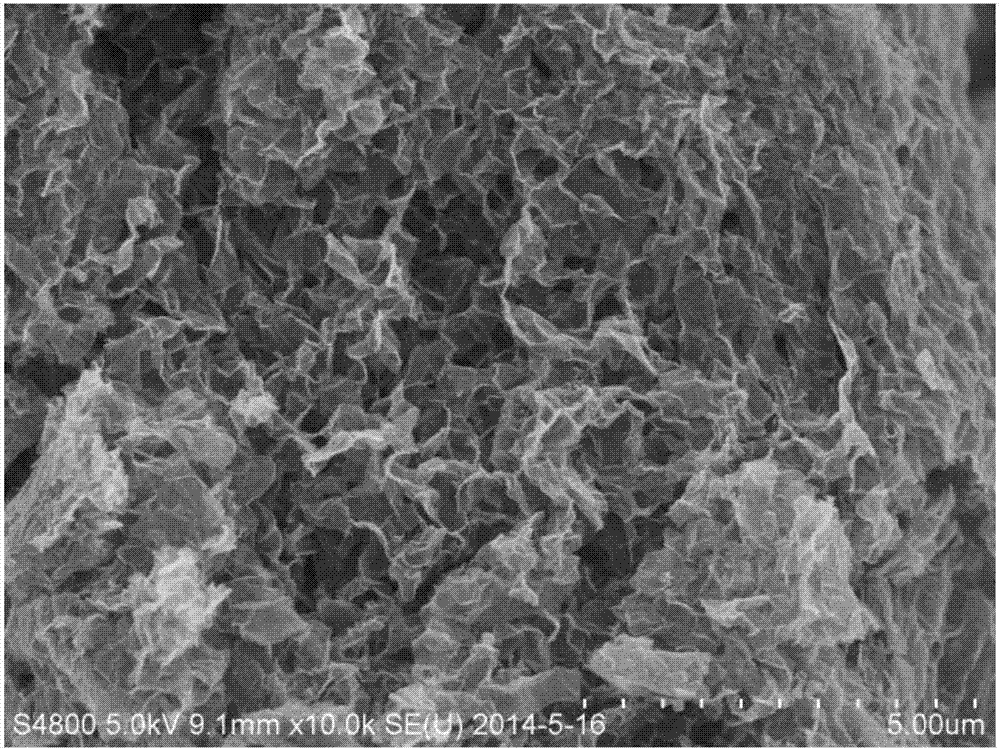

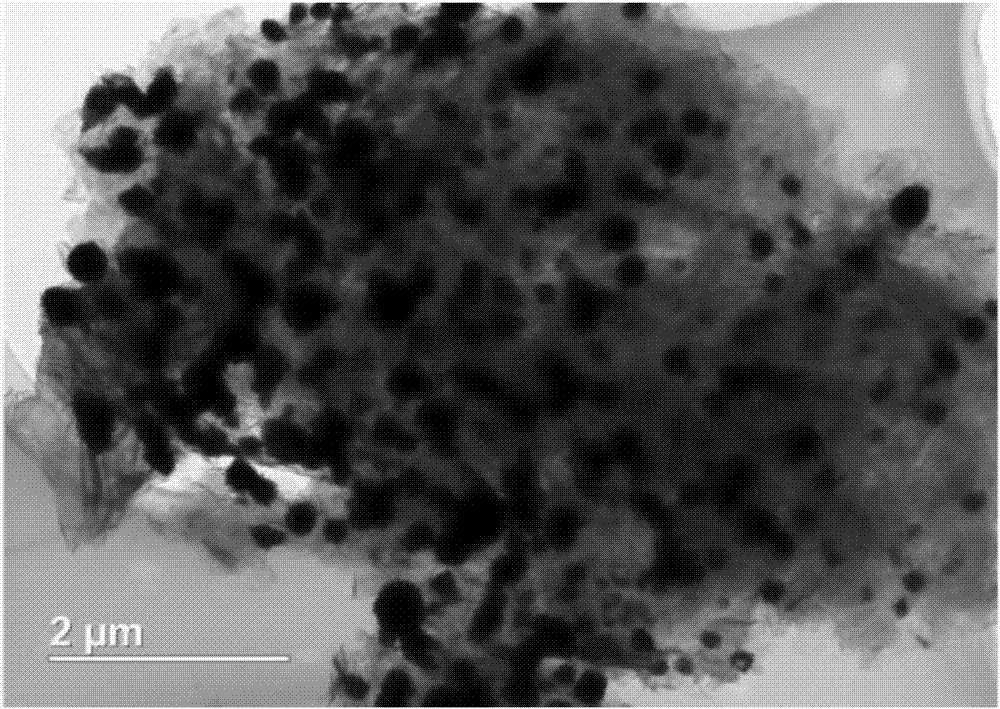

Lead-carbon super battery anode material and preparation method thereof

The invention provides a lead-carbon super battery anode material which is a graphene / Pb nano composite material. The lead-carbon super battery anode material is prepared by mixing a lead salt solution with a graphite oxide solution, carrying out hydrothermal reaction, and then carrying out macro body freeze drying and burning. The lead-carbon super battery anode material is prepared from 91 to 99.5 percent of lead and 0.5 to 9 percent of graphene. The lead salt solution is prepared by dissolving soluble lead salt into deionized water; the soluble lead salt is one or several of lead-containing nitrate, acetate, carbonate, hydrochloride, sulfate and complex salt. The invention further provides a preparation method of the lead-carbon super battery anode material. The preparation method provided by the invention has the advantages of high efficiency, environmental friendliness, high uniformity and the like; the prepared lead-carbon super battery anode material is high in uniformity, high in stability and wide in application prospect.

Owner:江苏强劲新能源科技有限公司

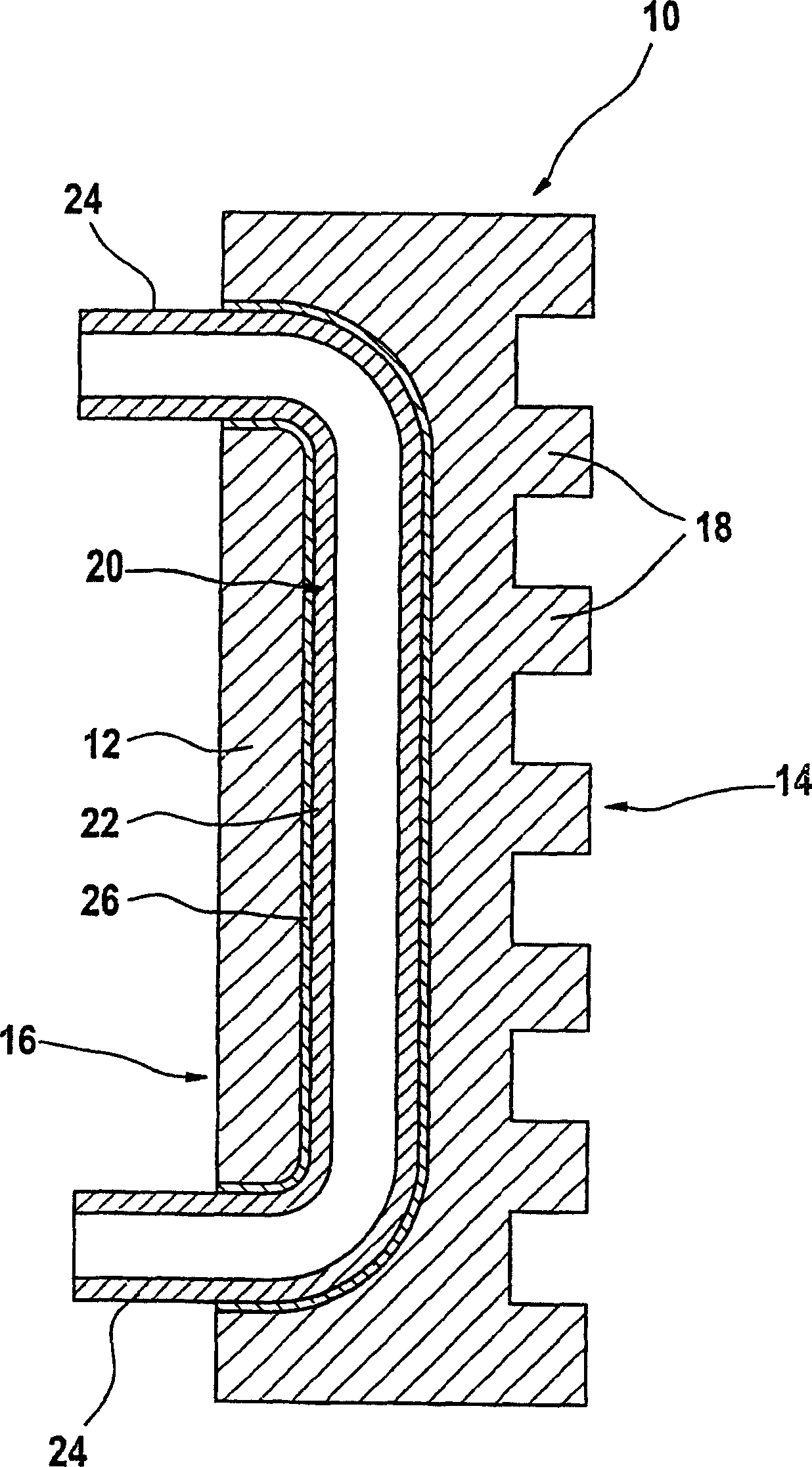

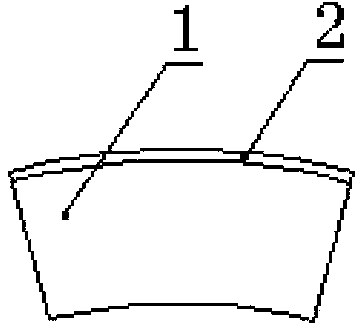

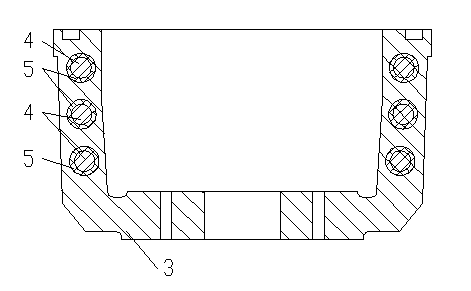

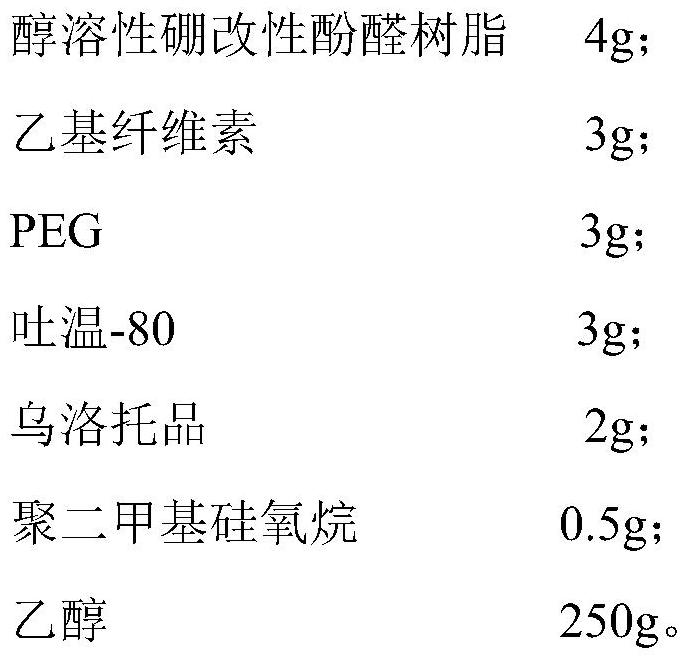

Cooling plate for a metallurgical furnace and method for manufacturing such a cooling plate

InactiveCN1615371AImprove thermal conductivityImprove wear resistanceCooling devicesFurnace cooling arrangementsNickel alloyMetallic Nickel

A cooling plate (10) for a metallurgical furnace comprises a cast cooling plate body (12) made of a ferrous metal and at least one steel cooling pipe (20) cast in the cooling plate body (12). A metallic jacket (26) having a thickness in the millimetre range is provided on the outer surface of the steel cooling pipe (20) in the cooling plate body (12), the metallic jacket (26) being made from a metal selected from the group consisting of copper, copper alloys, nickel and nickel alloys.

Owner:PAUL WURTH SA

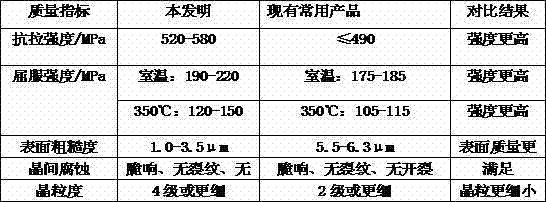

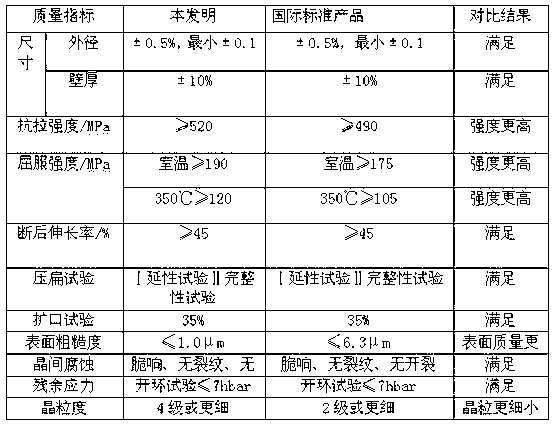

Stainless steel seamless steel tube for sulfuric acid waste heat recovery device

ActiveCN103710644AImprove hardenabilityImprove corrosion resistanceUltimate tensile strengthMaterials science

The invention relates to a stainless steel seamless steel tube for a sulfuric acid waste heat recovery device. The stainless steel seamless steel tube comprises the following components: 0.05-0.06 percent of C, 1.5-2.0 percent of Mn, 19.0-22.0 percent of Ni, 24.0-26.0 percent of Cr, 0.45-0.60 percent of Nb, 0.4-0.6 percent of Si, 0.1-0.15 percent of N, less than or equal to 0.2 percent of Cu, less than or equal to 0.015 percent of s, less than or equal to 0.025 percent of p, 0.3-0.5 percent of Mo, 2-4 percent of Al, 0.4-0.6 percent of Ti, 0.0018-00022 percent of v, 0.5-0.8 percent of composite rare earth and the balance of Fe. According to the operations of limiting the components and technological parameters, adding the composite rare earth and performing bright heat treatment on pure nitrogen protective gas, the stainless steel tube has excellent corrosion resistance, low roughness of inner and outer surfaces, high yield strength and high tensile strength.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

Flange for wind power drum and manufacturing technique thereof

ActiveCN103045960APrevent precipitationGuaranteed corrosion resistanceFlanged jointsTemperingChemical composition

The invention provides a flange for a wind power drum, and a manufacturing technique thereof. The flange comprises the chemical compositions in percentage by weight: 0.15-0.22 percent of C, 0.55-0.65 percent of Si, 0.65-0.75 percent of Mn, 5-8 percent of Ni, 4-6 percent of Cr, 0.65-0.85 percent of Nb, 0.25-0.45 percent of Cu, 0.05-0.07 percent of N, 0.05-0.07 percent of Mo, 0.7-0.9 percent of Al, 0.02-0.03 percent of S, 0.08-0.09 percent of Ti, 0.01-0.04 percent of V, 0.002-0.003 percent of B, 1-2 percent of rare earth lanthanide series and the balance of Fe. According to the invention, with the heating processing procedures of two-time normalization and two-time tempering, the excellent corrosion resistance of the flange is ensured, and meanwhile, high tensile strength and high yield strength are achieved; and the flange is ensured to have smaller surface roughness, more uniform and stable tissue, and less air holes and sand holes.

Owner:WUXI HUAERTAI MACHINERY MFG

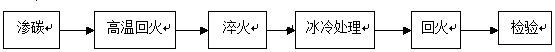

Vacuum carburizing heat treatment process of 12CrNi3A materials

InactiveCN107829064AImprove fatigue performanceFast penetrationSolid state diffusion coatingCarburizingMachine building

The invention relates to a vacuum carburizing heat treatment process of 12CrNi3A materials and belongs to the technical field of carburizing. The vacuum carburizing heat treatment process of 12CrNi3Amaterials is a chemical heat treatment method of the machine building industry. Through the process tests of vacuum carburizing and subsequent heat treatment, and through quality evaluation and performance analysis of a carburizing sample as well as the diffusion layer tissue and the core tissue of a part, technological parameters of vacuum carburizing of the 12CrNi3A materials and a post-carburizing heat treatment process are optimized. The vacuum carburizing technology is a more advanced technology at present. The vacuum carburizing technology mainly has specialities that high temperature short time carburizing can be conducted; grain boundary oxidation is not existed; surface incomplete quenching layer is not produced; carburizing layer controlling is simple; and complex shape carburizing such as slim hole and blind hole can be conducted.

Owner:JIANGXI HONGDU AVIATION IND GRP

Ni-Cr-Fe alloy and Ni-Cr-Fe alloy pipe having resistance to carburization and coking

A stainless steel pipe includes a base metal containing 20-35 mass % of Cr, and a Cr-depleted zone is formed in the surface region of the pipe. The Cr concentration in the Cr-depleted zone is at least 10%, and the thickness of the Cr-depleted zone is at most 20 micrometers. A Cr-based oxide scale layer having a Cr content of at least 50% and a thickness of 0.1-15 micrometers may be provided on the outer side of the Cr-depleted zone. An Si-based oxide scale layer with an Si content of at least 50% may be provided between the Cr-based oxide scale layer and the Cr-depleted zone. The pipe is particularly suitable for use in petroleum refineries or petrochemical plants, such as for use as a pipe of a cracking furnace of an ethylene plant.

Owner:NIPPON STEEL CORP

Heat treatment method for automobile SCM435 steel high-strength fastener

InactiveCN107502708AAvoid crackingReduce processing timeFurnace typesHeat treatment furnacesCarbon potentialQuenching

The invention discloses a heat treatment method for high-strength fasteners made of SCM435 steel for automobiles, comprising steps: (1) In the heating stage, the fasteners are sent into a heating furnace, the heating temperature is controlled at 870°C ± 5°C, and methanol is passed through , the feed rate is 20-40ml / min, feed propane, control the carbon potential to be 0.40%±0.04%, and the heating time is 50-80 minutes; (2) quenching stage, the heated fastener enters the oil tank for quenching, When quenching and cooling, the oil temperature is 60-70°C, and the quenching oil is stirred in circulation; (3) Tempering stage, after quenching, the fastener enters the tempering furnace, and the tempering time is 130-170min; when the hardness requirement is 33-38HRC, tempering The temperature is 500-530°C; when the hardness requirement is 38-42HRC, the tempering temperature is 430-460°C. Passing methanol and controlling the carbon potential at 0.40±0.04% can better balance the carbon concentration inside and on the surface of the workpiece to avoid carburization and ensure that no cracks appear on the surface of the workpiece.

Owner:厦门真冈热处理有限公司

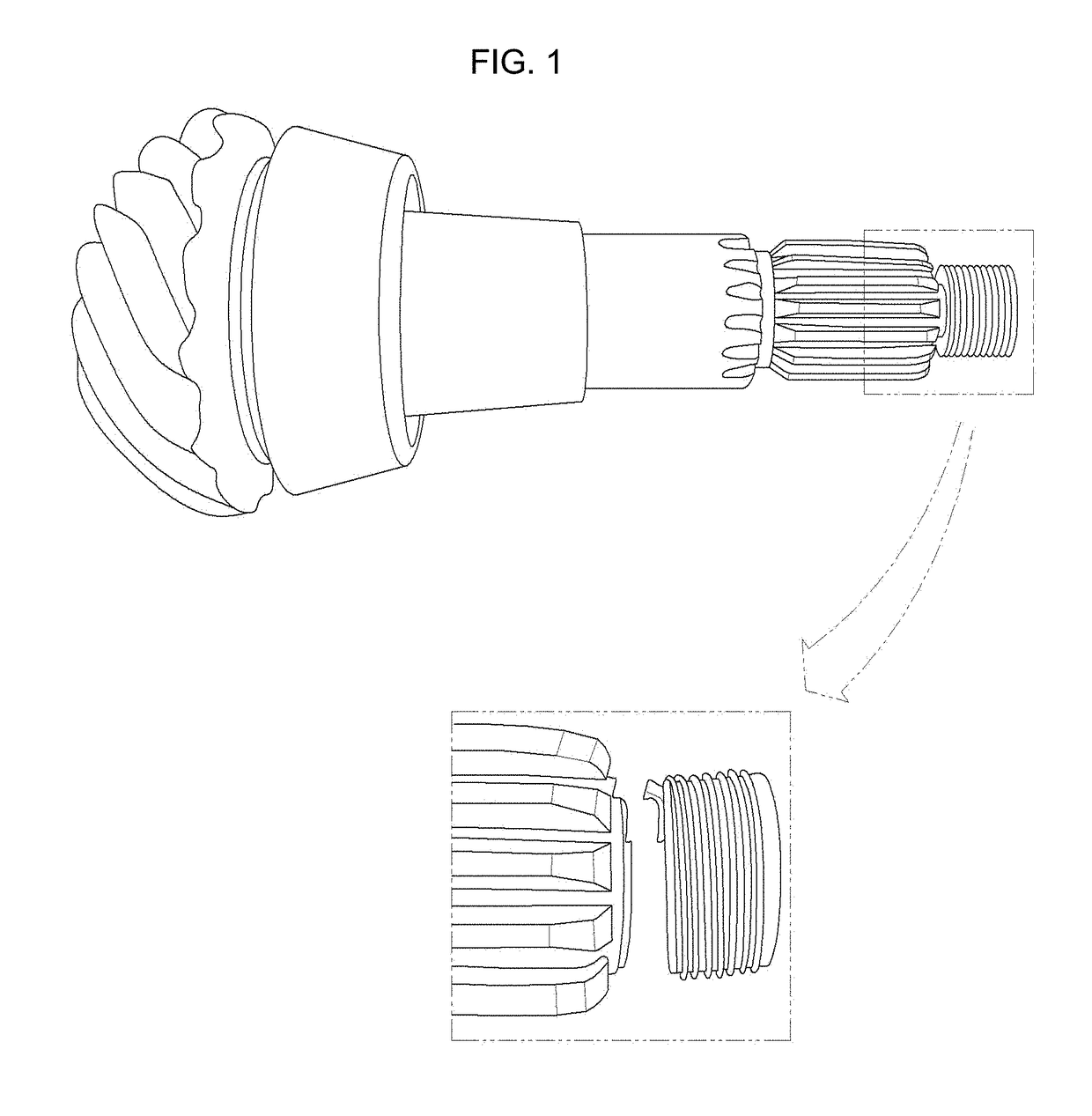

Driven gear heat treatment method

ActiveCN106555154ALow costControl carburizing qualitySolid state diffusion coatingFurnace typesCopper platingOil cooling

The invention relates to a driven gear heat treatment method. According to the scheme of the driven gear heat treatment method, a copper plating layer on the surface of the area where carburization is needed is removed through machining after copper plating treatment is carried out on the whole surface of a driven gear workpiece, then, carburization treatment is carried out, and the purpose that carburization is carried out only in the local area can be achieved; before quenching treatment is carried out, the cavity area, likely to be damaged, of the copper plating layer is coated with an anti-carburization coating, dual-layer protection is carried out on the cavity area, coal oil is added during quenching for atmosphere protection, decarburization on a carburization face can be effectively prevented, carburization can be effectively avoided due to the protection of the anti-carburization coating on the cavity area, and follow-up machining is convenient; and a pressure quenching machine tool is used for oil cooling after quenching, and shrinkage distortion is effectively reduced. By means of the method, the technical effects that carburization is carried out on the designated area of the driven gear, a carburization layer is free of decarburization after carburization is completed and carburization is avoided for the cavity area can be effectively achieved, volume production is easy, and the cost is low.

Owner:CHINA HANGFA CHANGZHOU LANXIANG MACHINERY CO LTD

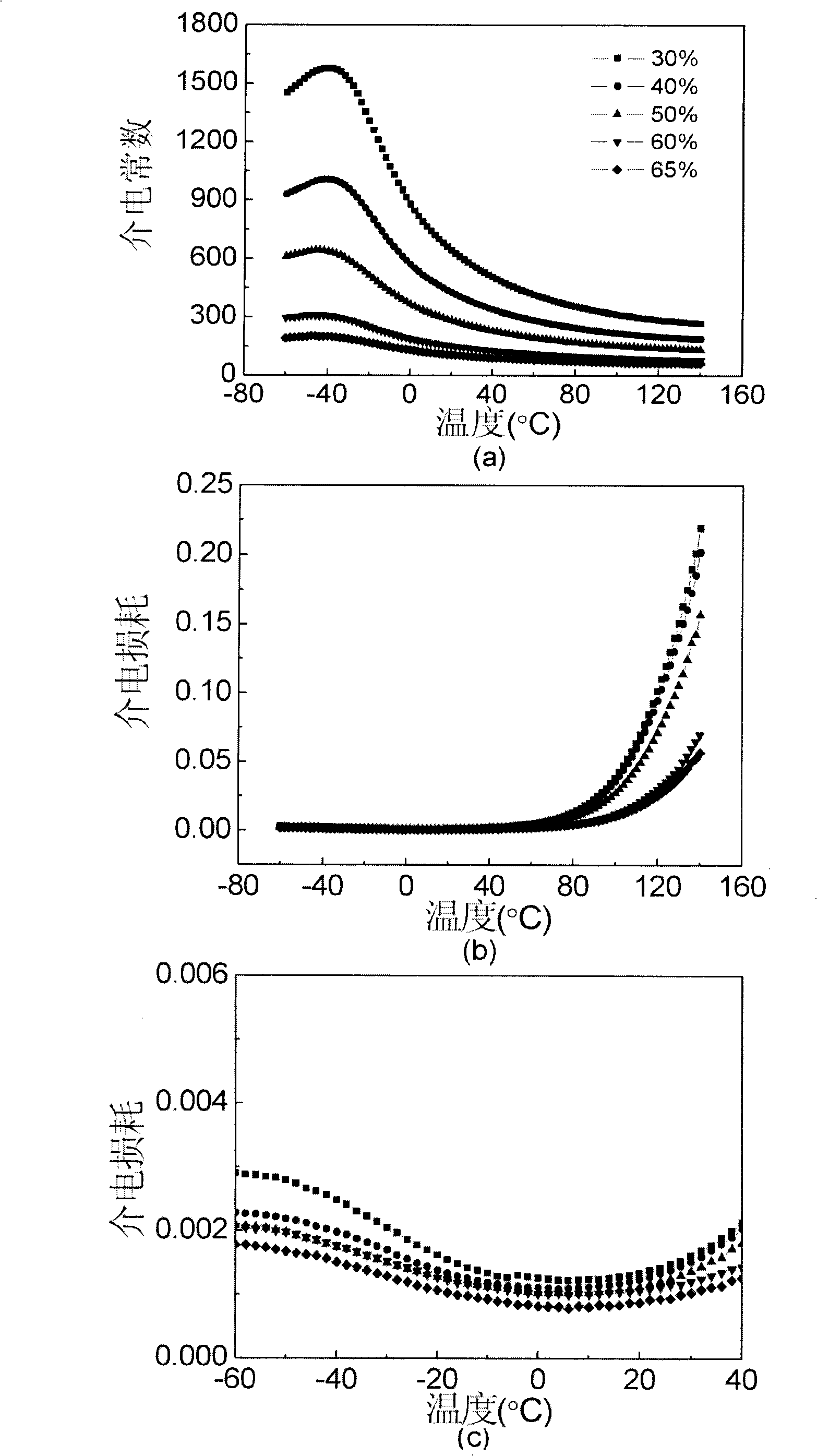

Pressure control adjustable strontium barium titanate-based composite ceramic materials and method for preparing same

ActiveCN101337812AImprove sintering performanceLow dielectric lossBarium strontium titanateComposite ceramic

The invention belongs to the technical field of preparation of microwave ceramics, in particular relates to a pressure control adjustable barium strontium titanate-base compound ceramic material and a preparation method thereof. The compound ceramic material is prepared as follows: Ba(1-x)SrxTiO3 is compounded with Mg(1-y)ZnyO with low dielectric constant and low dielectric loss; little Ta2O5 is added to modify the compound ceramics of (1-m)Ba(1-x)SrxTiO3-mMg(1-y)ZnyO so as to meet the performance requirements of pressure control adjustable microwave ceramics with proper dielectric constant, low microwave dielectric loss, high pressure control adjustability and so on. The barium strontium titanate-base compound ceramic material prepared by adopting the solid reaction process or the coprecipitation coating process is cold isostatic compacted without adding any forming agent and is sintered under atmospheric pressure, thus obtaining high density and high purity ceramic blocks. The pressure control adjustable barium strontium titanate-base compound ceramic material is applicable for such microwave devices as phased array phasers, adjustable filters, delay lines, oscillators, resonators and so on.

Owner:GRIMAT ENG INST CO LTD

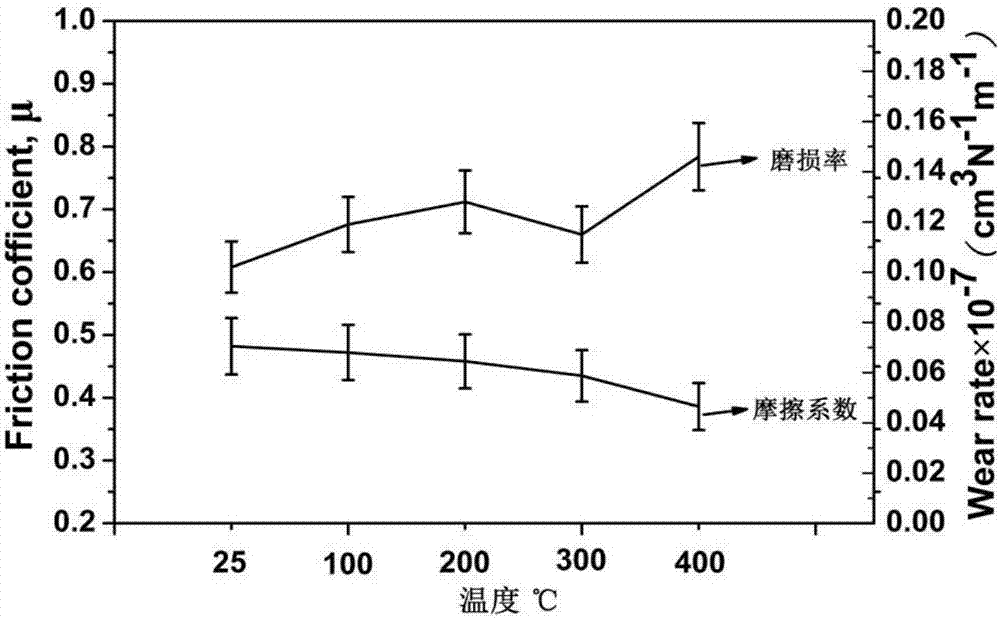

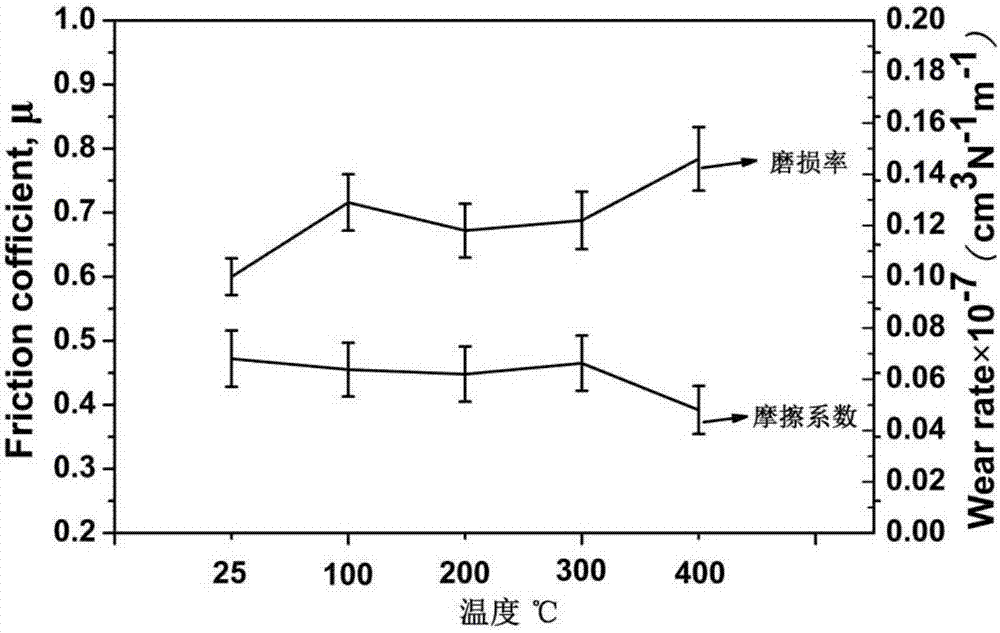

Laser melting deposition-based automobile clutch facing and preparation method thereof

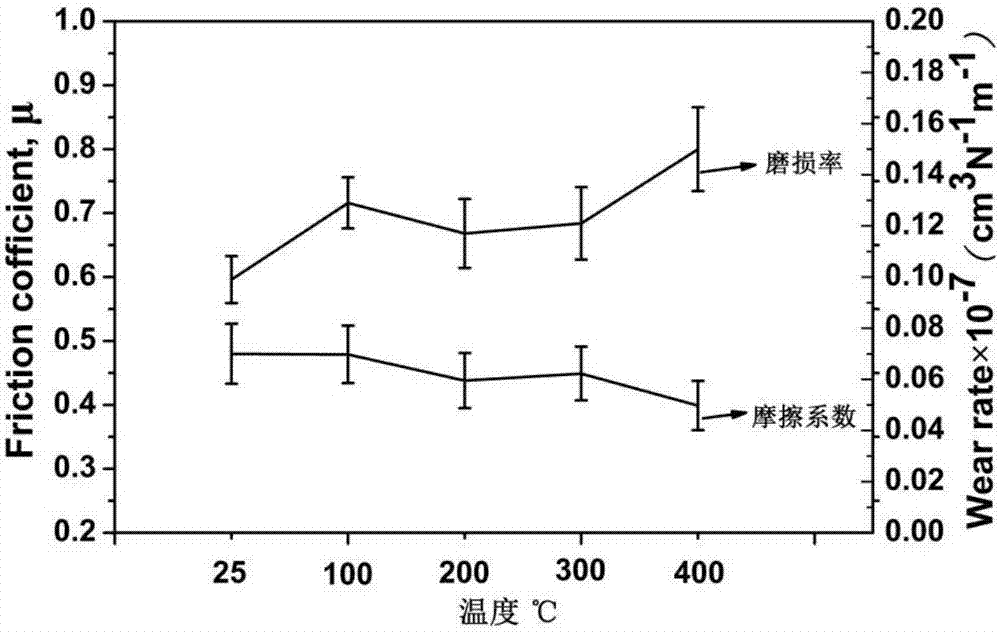

InactiveCN107400886AImprove wear resistanceStable tribological propertiesTransportation and packagingMetal-working apparatusAl powderHexagonal boron nitride

The invention discloses a preparation of a laser melting deposition-based automobile clutch facing. The laser melting deposition-based automobile clutch facing is prepared by sequentially carrying out melting, high-pressure water atomization and laser melting deposition on the TiC powder, hexagonal boron nitride (hBN) powder, B powder, Ni powder and Al powder which are taken as raw materials. The clutch facing has good physical and mechanical properties and better friction properties and thermal stability. Furthermore, the technological parameters are easy to control in a preparation process, so that the preparation method of the laser melting deposition-based automobile clutch facing is suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

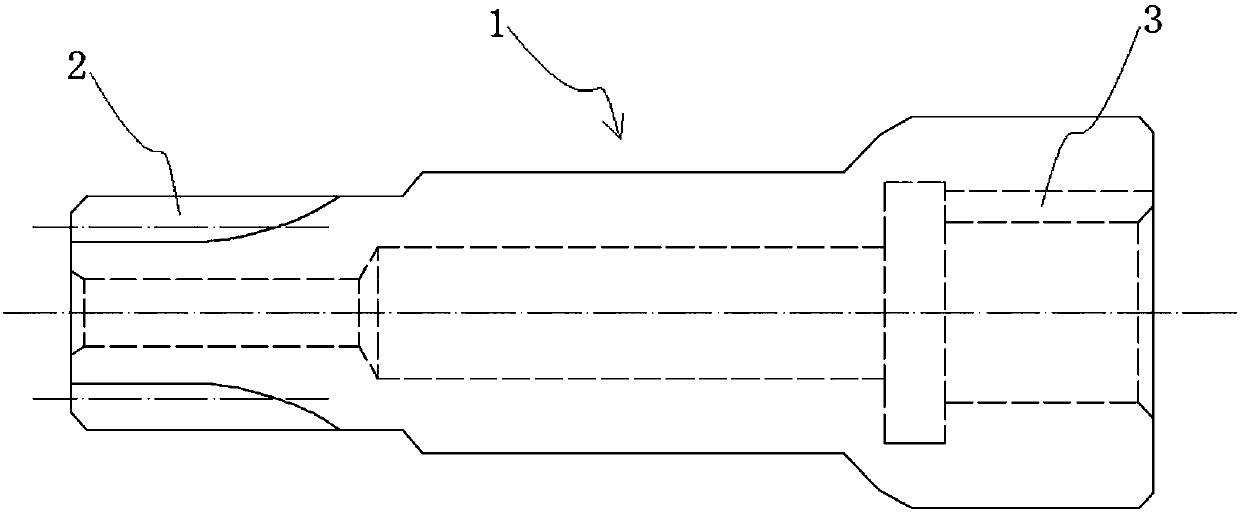

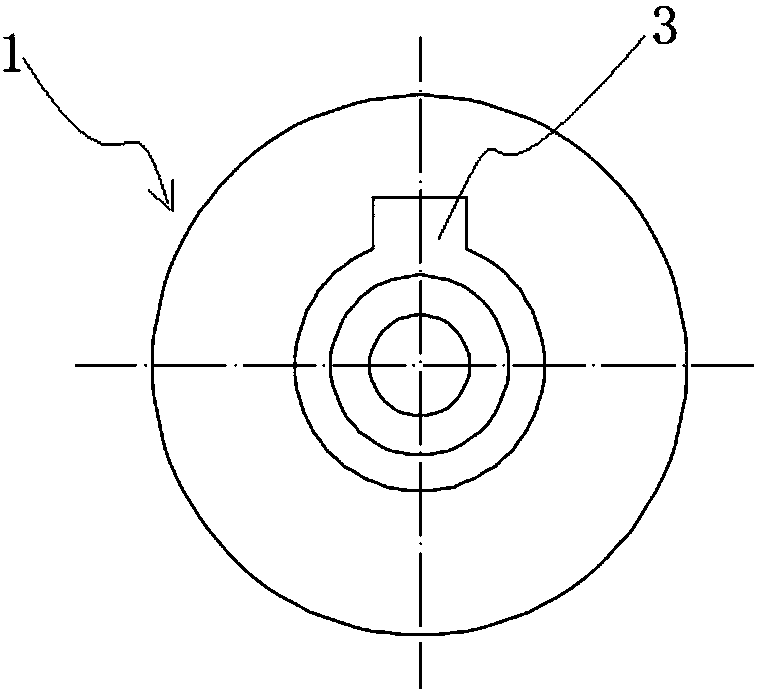

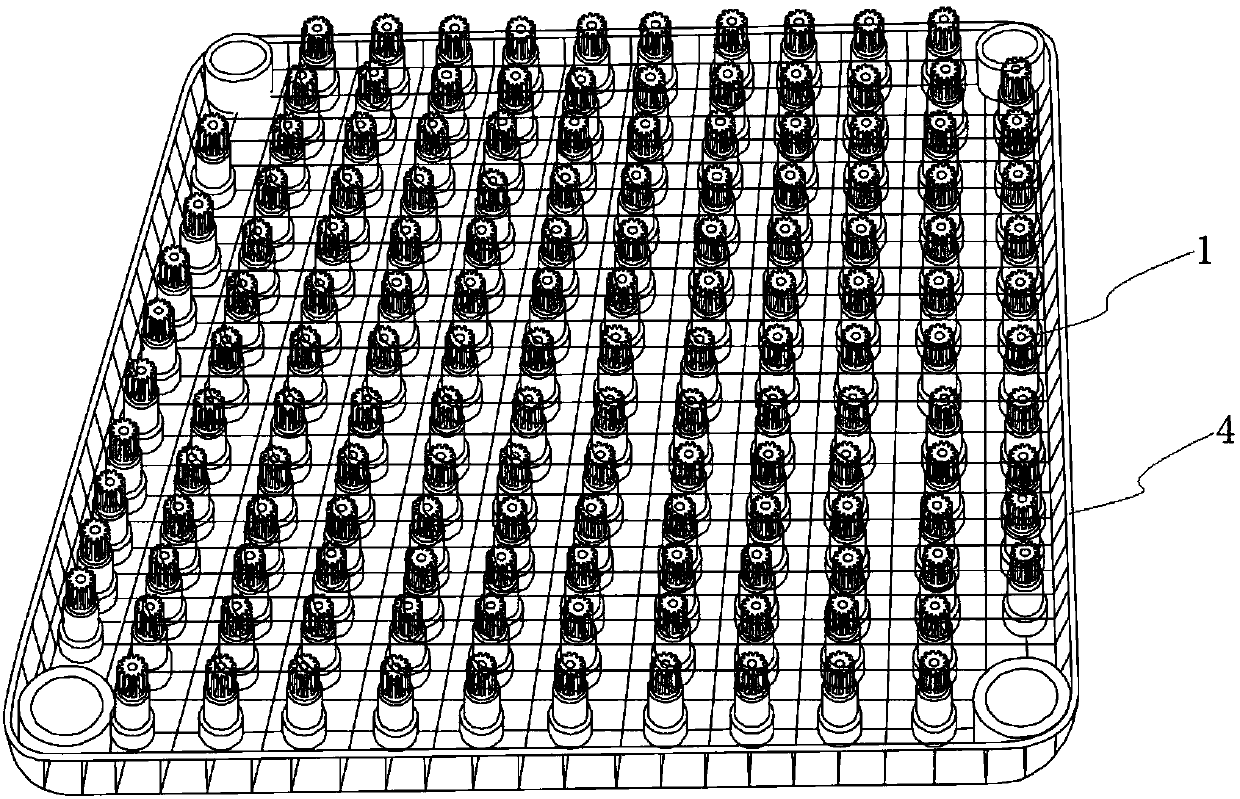

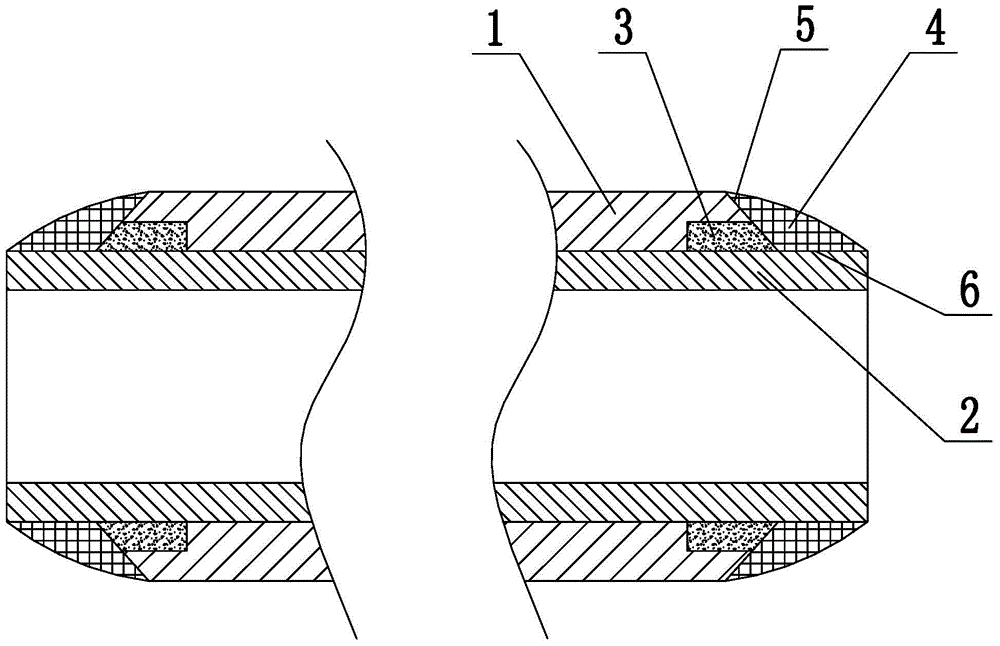

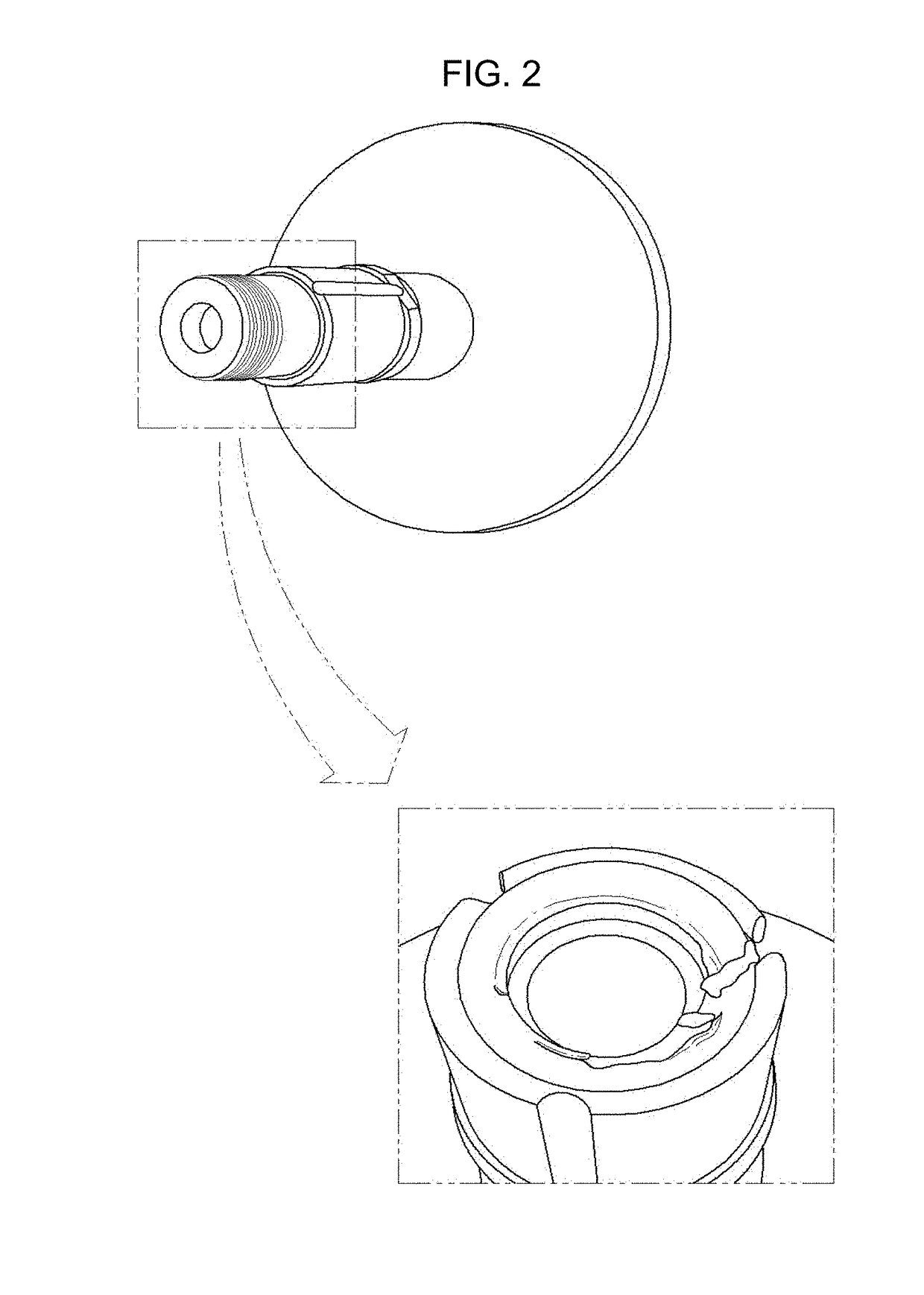

Method for quenching slip inserts

InactiveCN104232874AAvoid carburizationHigh strengthFurnace typesHeat treatment furnacesTransverse planeCarburizing

The invention relates to a method for quenching slip inserts, which comprises the following steps: 1)producing a steel ring through a forming machine or a die, and coaxially arranging several same annular slip inserts at interval along the radial direction of the outer rim of the steel ring; 2)coating a quenching medium to several annular slip inserts, respectively filling or smearing an antiseepage carbon material on upper transverse plane and lower transverse plane of the steel ring and the bore of the steel ring; 3)placing the steel ring in a quenching furnace and quenching the slip inserts; 4)removing the residual antiseepage carbon material, and respectively cutting the inner wall of the steel ring and the upper transverse plane and lower transverse plane of the steel ring; and 5)dividing the cut steel ring into equal arc blocks along the radial direction, wherein the arc block is the final slip inserts finished product. According to the invention, the thickness and height balance of the slip body can be made by prefabricating the steel ring, the anti-carburizing treatment is carried out on the balance, the balance is removed, real slip body is exposed, unnecessary carburizing of the slips body during the quenching process can be avoided, slips body intensity can be increased, and the influence for removal of an anti-carburizing layer to the acutance of the slip inserts can be reduced.

Owner:天津市正瀚石油设备制造有限公司

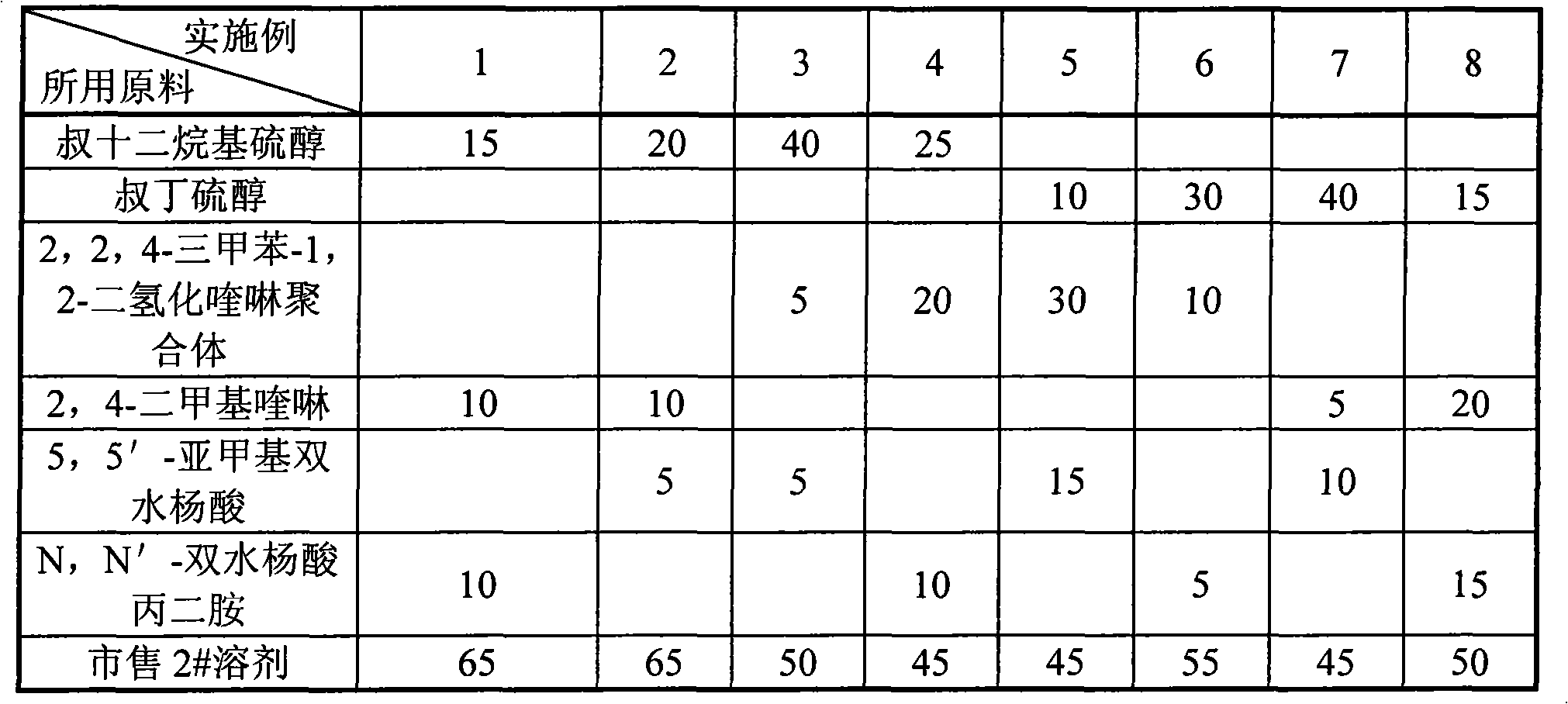

Ethylene cracking furnace coking restrainer and its use method

InactiveCN101318872APassivation of metal surfacesExtended service lifeThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingThiolOrganic solvent

The present invention relates to a coking depressor for an ethylene cracking furnace, and a method for using the same. The depressor consists of a thiol compound, a quinoline compound, a disalicylic acid compound and an organic solvent. The coking depressor not only overcomes the shortcomings in the prior depressor that the manufacturing cost is high, the injection operation is difficult, the distribution in the cracking furnace tube is uneven, and the depressor erodes the inner wall of the furnace tube, etc., but also effectively prolongs the service life of the cracking furnace and improves the yield of ethylene, the usage of the material and the load of an ethylene device. The producing amount of CO and CO2 is largely reduced, and thus the depressor is safe and environment-friendly.

Owner:北京斯伯乐科学技术研究院

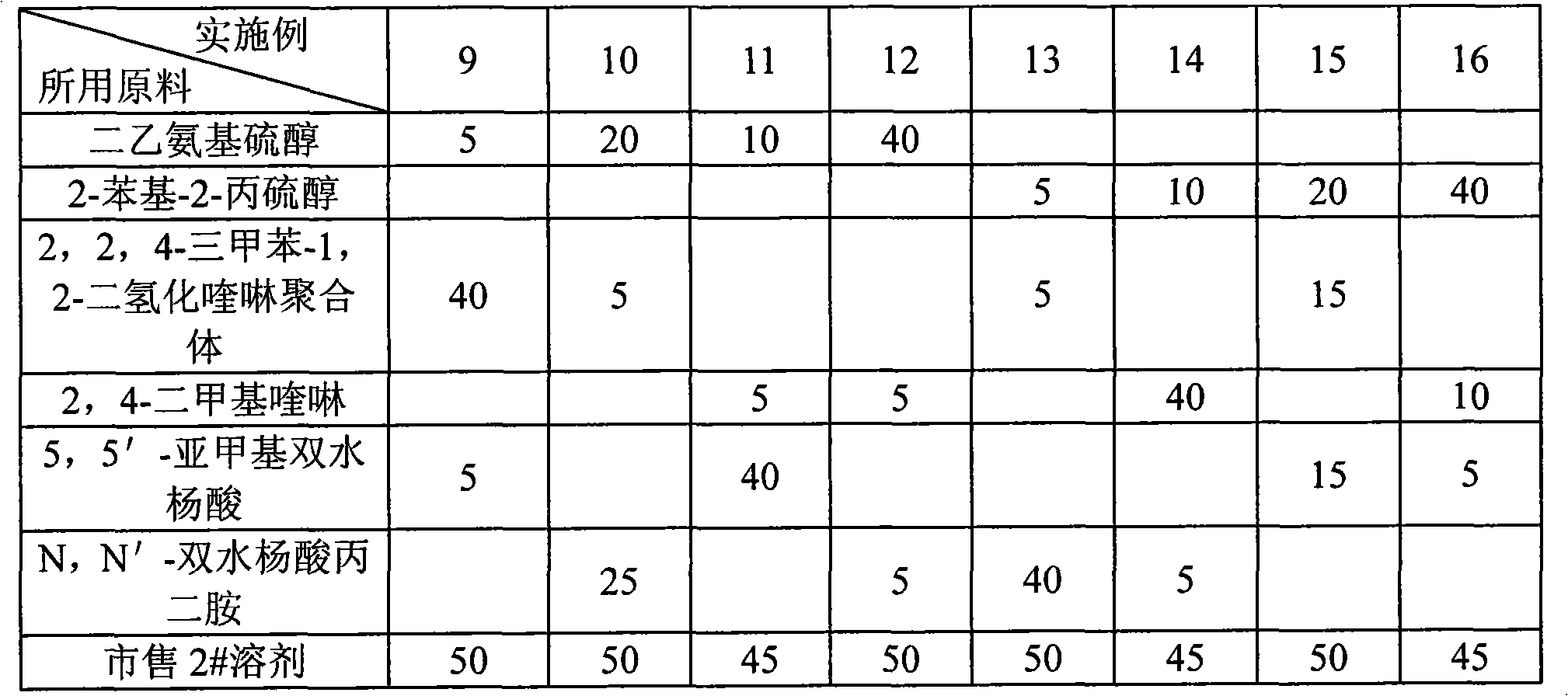

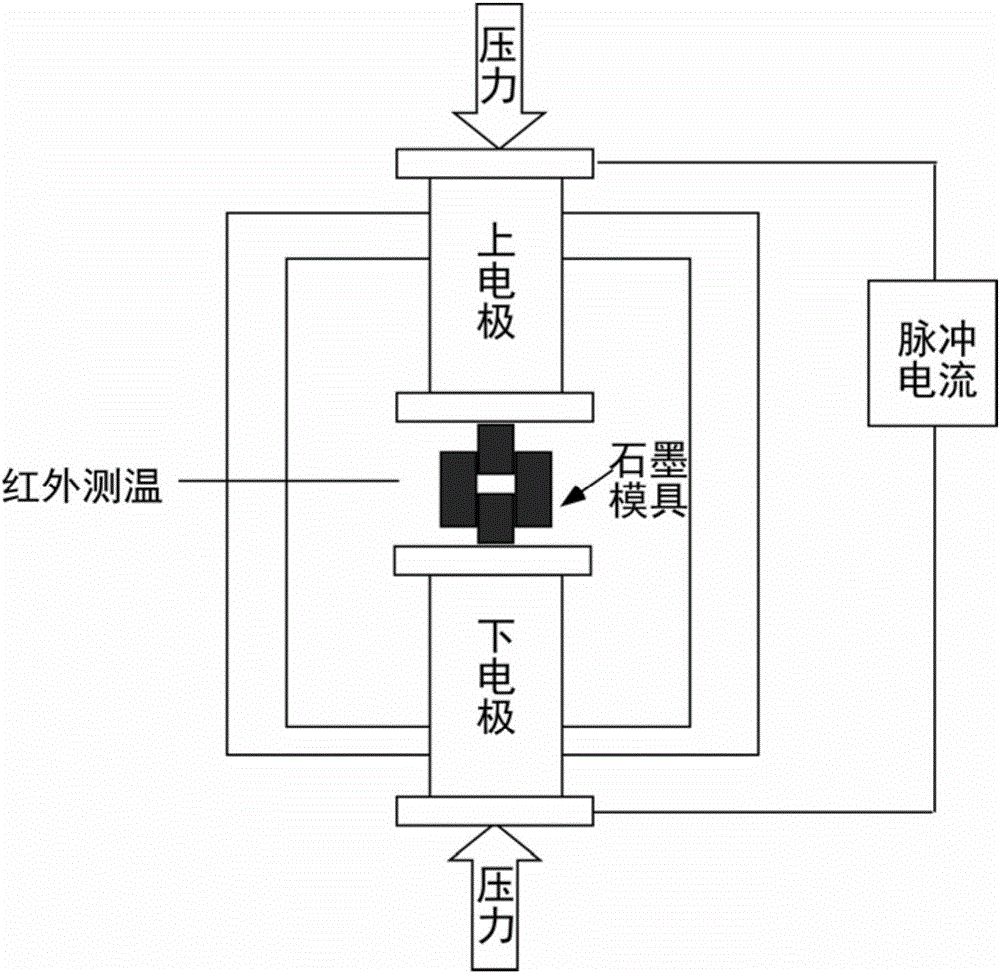

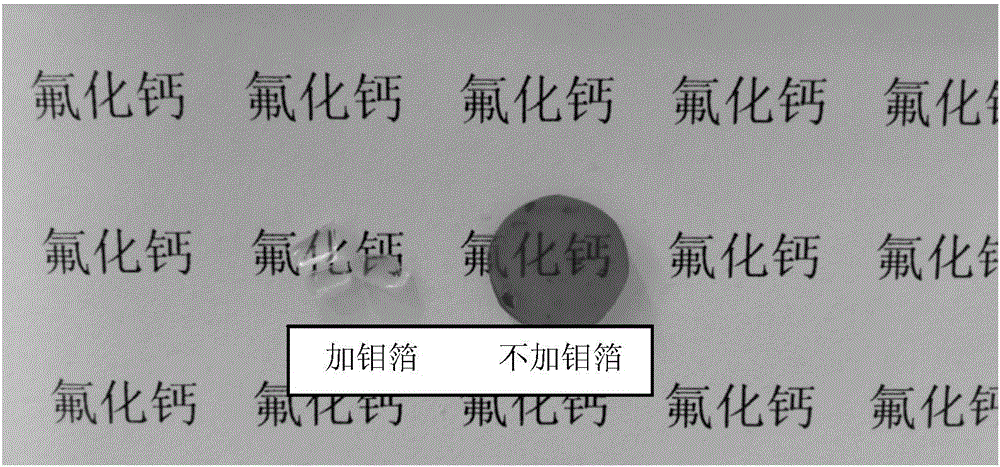

Method for preparing transparent calcium fluoride ceramics

The invention relates to a method for preparing transparent calcium fluoride ceramics. The method comprises the following steps: 1) loading powder materials, namely coating the inner wall of a graphite jig by using a metal foil, filling calcium fluoride powder into the graphite jig, and coating the outer wall of the jig by using a carbon felt so as to insulate heat; 2) sintering transparent ceramics, namely putting the graphite jig into a discharge plasma sintering furnace for sintering; and 3) performing sample treatment, namely taking out the sintered sample, coarsely grinding and polishing, thereby obtaining the transparent calcium fluoride ceramics. Compared with the prior art, the method disclosed by the invention has the advantages that with the adoption of the method disclosed by the invention, carbon pollution can be eliminated, light transmittance of the transparent calcium fluoride ceramics is improved, the maximum transmittance in an ultraviolet-visible band can be greater than 87%, and the problem in the traditional discharge plasma sintering technology that a carbon pollution sample is caused by carburization of the graphite jig at a high temperature is solved.

Owner:WUHAN UNIV OF TECH

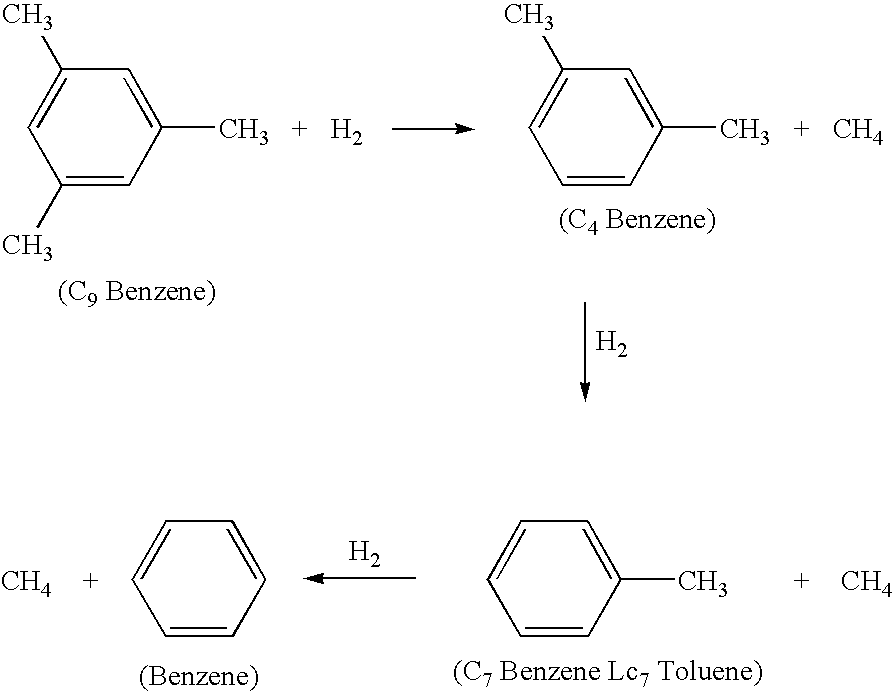

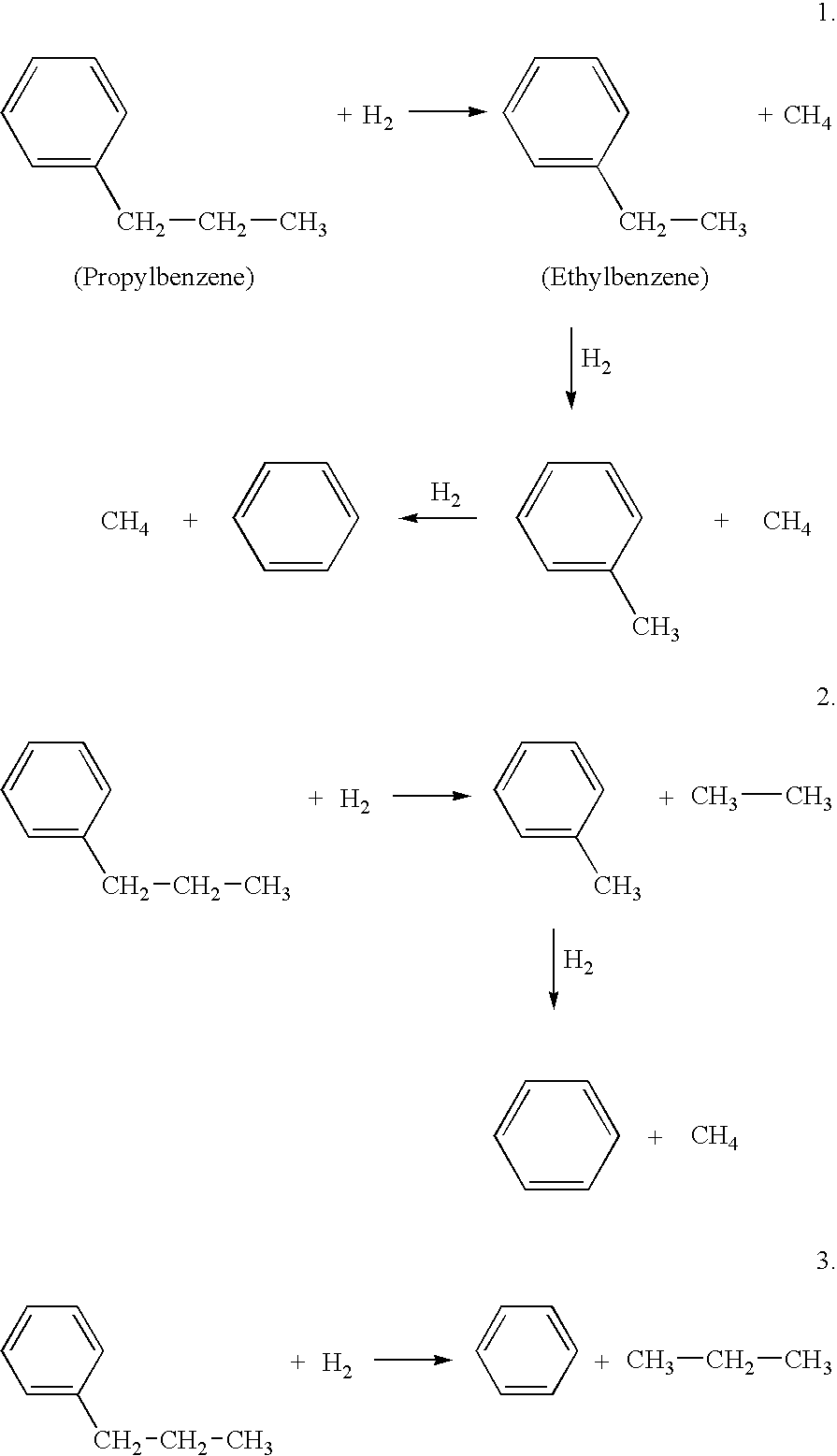

Hydrodealkylation processes

InactiveUSRE38532E1Reduce sulfide corrosionImprove product valueHydrogenOrganic compound preparationMetal dustingEngineering

Carburization and metal-dusting while hydrodealkylating a hydrodealkylatable hydrocarbon are reduced even in the substantial absence of added sulfur.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

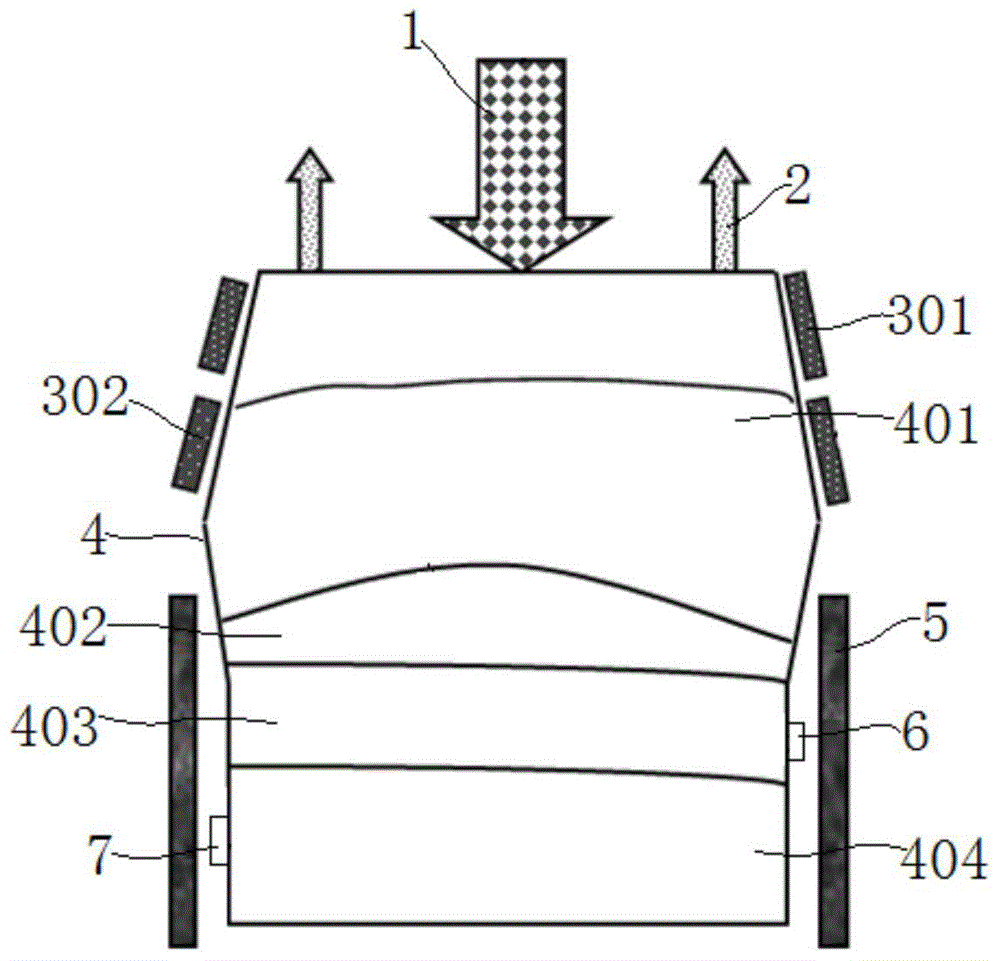

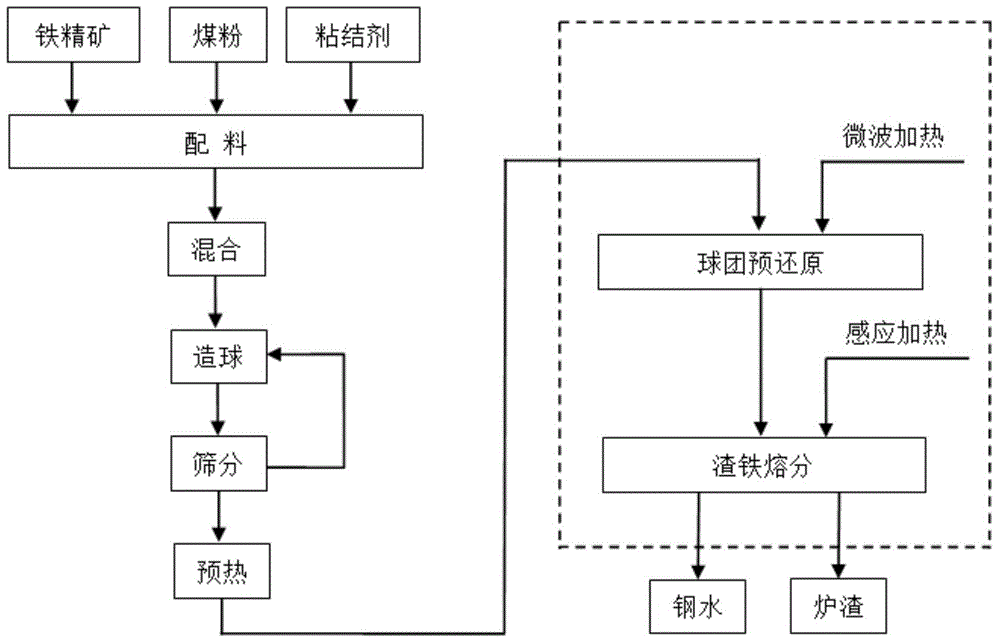

Electromagnetic heating carbon-bearing pellet continuous direct steelmaking device

ActiveCN104988268AStrong electromagnetic stirringImprove liquidityElectric furnaceSteelmakingMicrowave

The invention discloses an electromagnetic heating carbon-bearing pellet continuous direct steelmaking device and belongs to the technical field of ferrous metallurgy. The electromagnetic heating carbon-bearing pellet continuous direct steelmaking device comprises a steelmaking furnace body, a material distributing port and a coal gas outlet are formed in the top of the steelmaking furnace body, a double-circular-truncated-cone structure is composed of a material distributing area, a reduction area and a soft melting area of the steelmaking furnace body, and an iron slag melting separation area is of a cylindrical structure. At least two rows of microwave heating devices are arranged on the parts, in the material distributing area and the reduction area, of the periphery of the furnace body, and electromagnetic induction heating devices are arranged on the parts, in the soft melting area and the iron slag smelting separation area, of the periphery of the furnace body. By means of the electromagnetic heating carbon-bearing pellet continuous direct steelmaking device, an iron smelting and manufacturing device and a steelmaking device can be integrated, qualified high-quality molten steel can be produced directly through carbon-bearing pellets without blowing, the problem that secondary decarburization is needed in traditional furnace slag foaming and molten iron carburization is solved, the production efficiency is high, continuous steelmaking is achieved, and the capital construction cost and equipment investment are greatly saved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

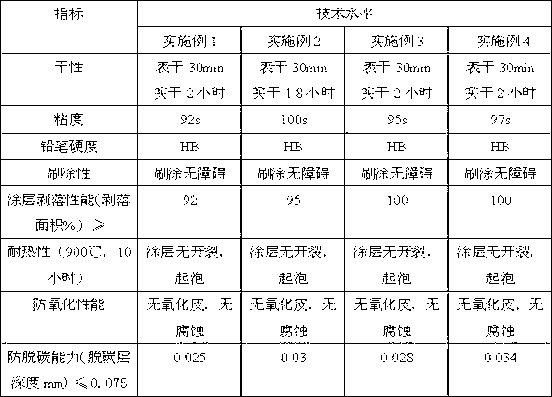

Protective paint for heat treatment of metal

The invention provides protective paint for heat treatment of metal, which is characterized by being prepared from the following raw materials in parts by weight: 2-5 parts of W type ethyl cellulose resin, 5-10 parts of organobentonite paste having an organobentonite content of 20%, 10-15 parts of 11# frit, 10-12 parts of 04# frit, 5-13 parts of M-1 frit, 5-8 parts of industrial grade barium metaborate, 1-6 parts of 400-mesh mica powder, 5-8 parts of industrial grade rubellan iron oxide, 3-11 parts of industrial grade pigment and 20-50 parts of ethanol. In an environment of 900 DEG C, the paint can achieve favorable drying property and excellent physical and chemical properties through secondary film forming of the combined frit; and meanwhile, a coating formed by the paint also has favorable self-releasing property.

Owner:西安经建油漆有限责任公司

Processing method for high-tenacity metal embedded part in iron casting, embedded part and brake drum

InactiveCN103302273AImprove toughnessReduce carbon contentLiquid surface applicatorsBraking drumsBrakeNonferrous metal

The invention discloses a processing method for a high-tenacity metal embedded part in an iron casting, the embedded part and a brake drum. The processing method comprises the steps of: carrying out an anti-carburization treatment on the peripheral surface of the high-tenacity metal embedded part before casting the iron casting, wherein the anti-carburization treatment is to electrically plate nonferrous metals or coat an anti-carburization coating; an anti-carburization protective layer is formed on the peripheral surface of the high-tenacity metal embedded part main body; the anti-carburization protective layer is a plating layer made of the nonferrous metals, such as copper or nickel or a coating layer made of the anti-carburization coating; the brake drum comprises a brake drum main body and the annular high-tenacity metal embedded part combined with the brake drum main body through a casting way. The processing method for the high-tenacity metal embedded part in the iron casting, the embedded part and the brake drum have the beneficial effects of avoiding the casting being carburized in the casting process to keep the tenacity efficiently, improving tensile strength and fatigue strength of the iron casting, improving comprehensive mechanical performances and service life of the casting, and achieving long service life and high safety of the brake drum.

Owner:CHONGQING DIYANG MACHINERY MFG

Method for removing oil of inner surface of small-caliber cold-rolling pipe

ActiveCN102962269AAvoid carburizationGood degreasing effectWork treatment devicesMetal rolling arrangementsEngineeringCleansing Agents

The invention belongs to the field of steel pipe processing and manufacturing and particularly relates to a method for removing oil of an inner surface of a small-caliber cold-rolling pipe. A water-soluble cleaning agent and ultrasonic vibration are adopted, an inner wall is subjected to sand blasting washing, and oil stains of the inner surface of the small-caliber cold-rolling pipe are removed. The method comprises the steps of filling a material and immersing the pipe, conducting ultrasonic vibration, washing the inner wall by using a solution, washing the pipe by using hot water for the first time, subjecting the inner wall to sand blasting washing, cleaning the inner wall by using clean water, washing by using hot water for the second time, and checking. According to the method, the oil stains of the inner wall of the small-caliber cold-rolling pipe which is immersed in the water-soluble cleaning agent are subjected to vibration stripping through ultrasonic waves, the inner wall is washed by the solution which flows circularly, the oil stains of the inner wall are removed, the hot water and clean water are used for washing the inner wall respectively, and finally the inner wall is subjected to ceramic sand blasting, cleared completely and cleaned by using hot water. According to the method, the oil stains which are attached to the inner surface of the small-caliber cold-rolling pipe can be cleared completely, the problem that carburization of the inner wall of the steel pipe is caused during subsequent heat treatment due to the fact that the oil stains are carbonized is solved, and the method is pollution-free for the environment and causes no damage to a processed material.

Owner:JIANGSU TOLAND ALLOY

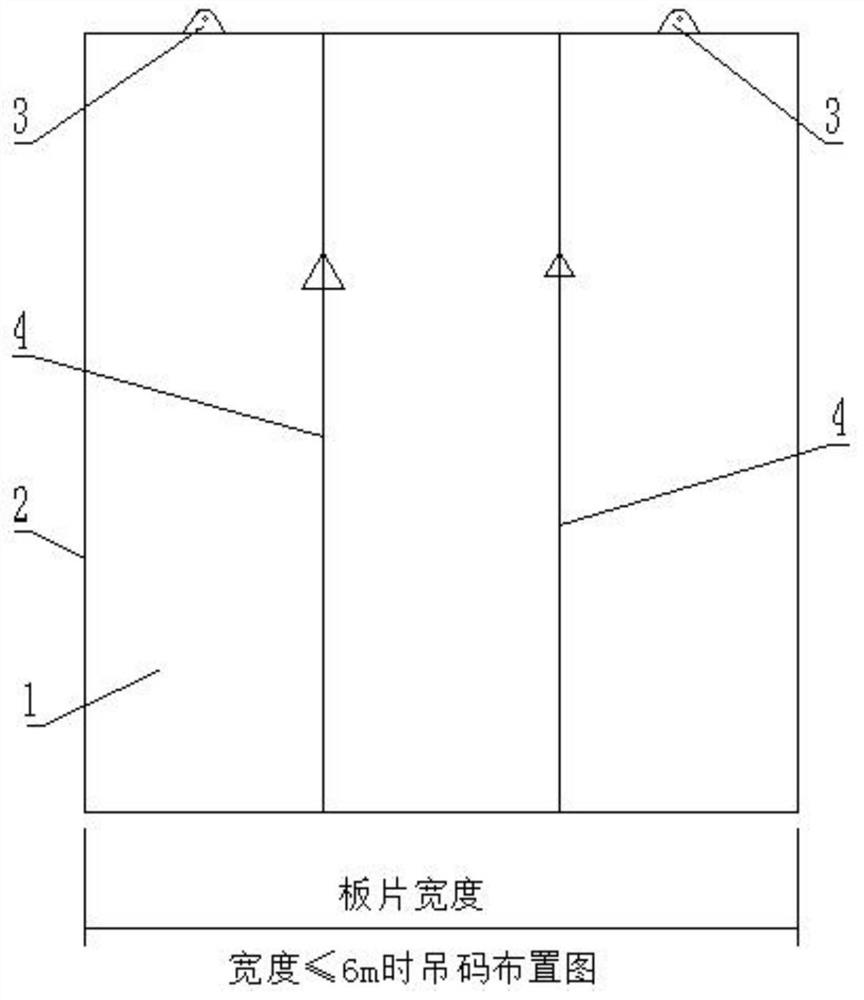

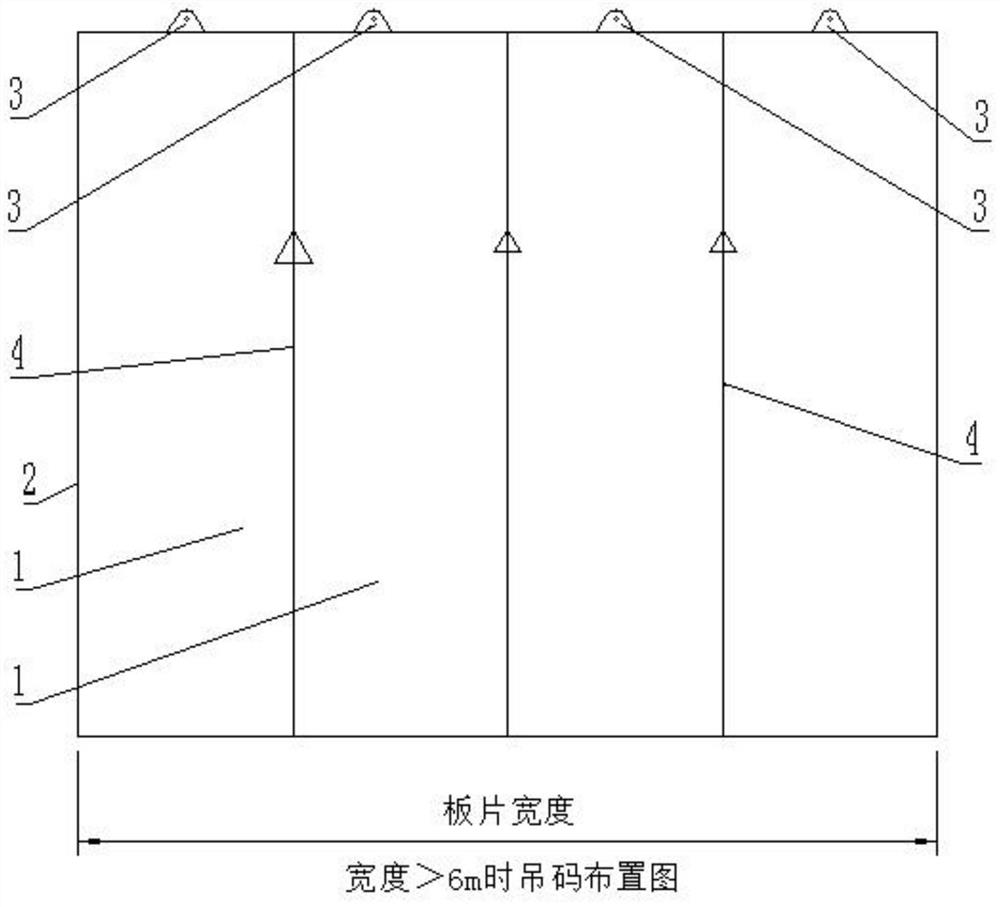

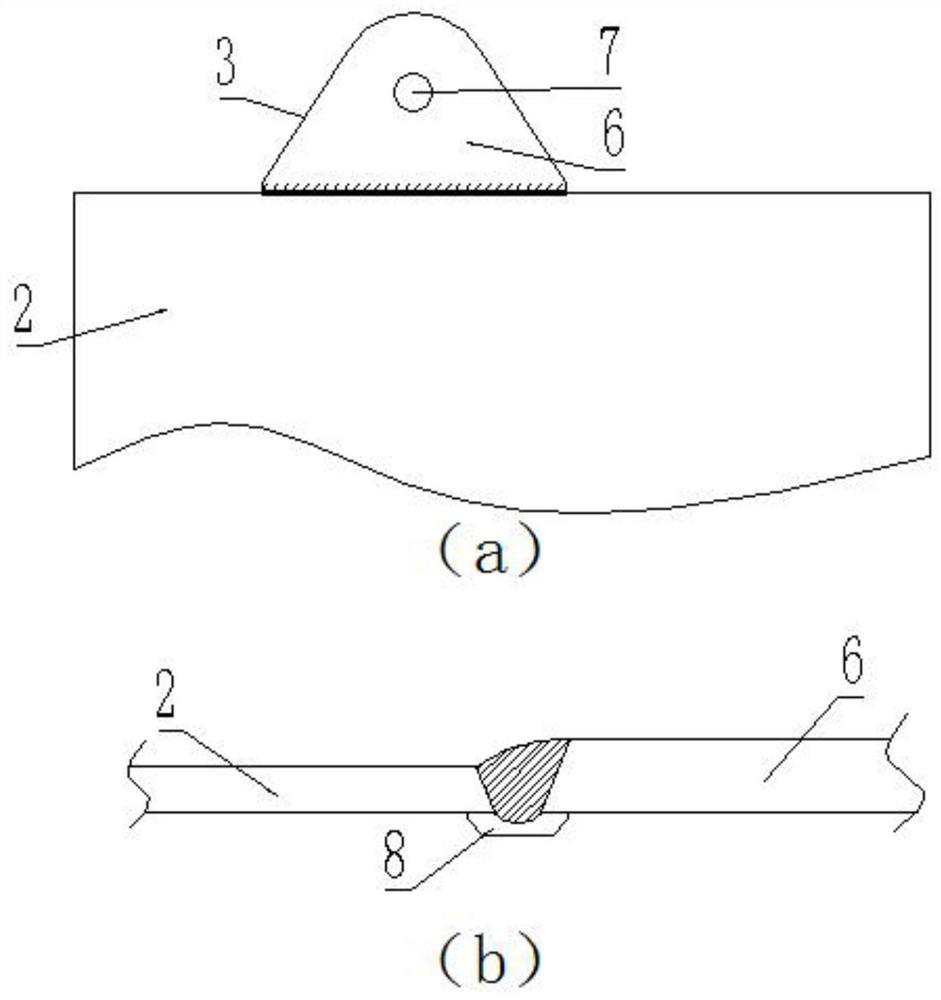

Hoisting method for 2205 duplex stainless steel chemical tanker manufacturing process

ActiveCN112009641AAvoid damageGuaranteed smoothWaterborne vesselsLoad-engaging elementsStructural engineeringSS - Stainless steel

The invention discloses a hoisting method for a 2205 duplex stainless steel chemical tanker manufacturing process. The hoisting method comprises the following steps: hoisting a stainless steel plate by adopting a vacuum chuck or a stainless steel plate clamp after the stainless steel plate arrives; hoisting spliced plates obtained after stainless steel plates are welded, hoisting flat plate pressing rib plane sheet bodies, hoisting subsections, including hoisting of double-layer bottom subsections, hoisting of bilge subsections, hoisting of broadside subsections and hoisting of deck subsections, and reasonably arranging the positions and materials of hangers to prevent the carbon steel hangers from making direct damage contact with the stainless steel plates. According to the hoisting method for the 2205 duplex stainless steel chemical tanker manufacturing process, the corrosion resistance of 2205 duplex stainless steel is effectively protected against damage.

Owner:AVIC DINGHENG SHIPBUILDING

A heat treatment process for reducing the deformation of the gear shaft keyway

ActiveCN106119507BReduce distortionSmall amount of deformationSolid state diffusion coatingFurnace typesCarbon potentialEngineering

The invention discloses a heat treatment process of reducing key slot deformation of a small gear shaft, and belongs to the technical field of heat treatment. The heat treatment process comprises the steps of: 1) machining of a gear shaft part; 2) framing; 3) precleaning; 4) coating of carburization preventing paint at a key slot part of the gear shaft part; 5) carburizing and quenching: temperature homogenization of 830+-5 DEG C by 20+-1 min, and carbon potential of 0.60+-0.025%; strong seepage of 900+-5 DEG C by 60+-1 min, and carbon potential of 0.95+-0.025%; dispersion of 880+-5 DEG C by 40+-1 min, and carbon potential of 0.80+-0.025%; quenching temperature homogenization of 830+-5 DEG C by 35+-1 min, and carbon potential of 0.65+-0.025%; and cooling in quenching oil of 140+-5 DEG C; 6) after cleaning; 7) tempering; and 8) recleaning. The heat treatment method effectively reduces deformation of the key slot of the gear shaft after heat treatment, and can reach 100% of once pass percent of heat treatment.

Owner:常州新区河海热处理工程有限公司

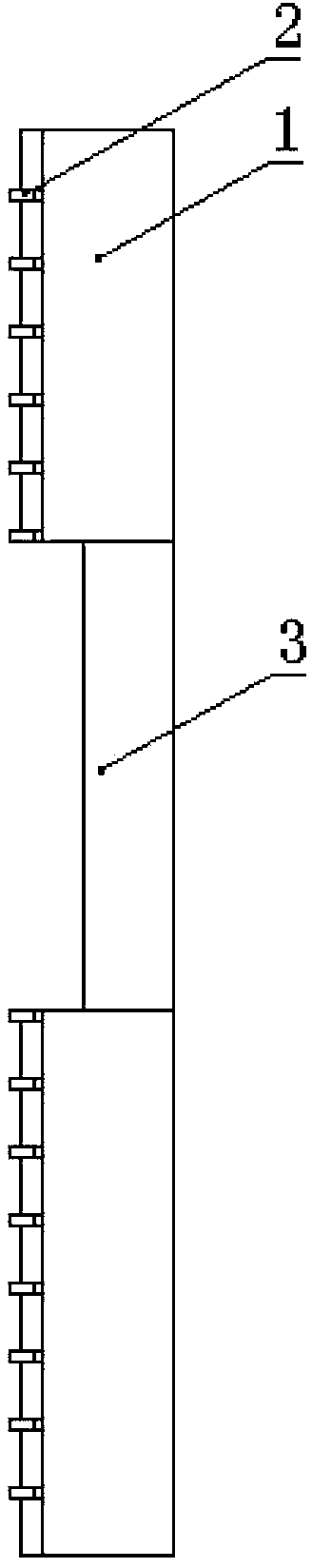

A kind of bimetal composite pipe and its manufacturing process

The invention discloses a double-metal composite tube which comprises a base tube and a lining tube arranged on the inner side of the base tube in a sleeved mode. The two ends of the base tube are provided with 20-degree to 50-degree beveled edges respectively. The inner walls at the two ends of the base tube are provided with annular grooves respectively in the peripheral direction of the base tube. Surfacing layers are arranged in the annular grooves. The lining tube exceeds the surfacing layers to form a truncated edge. The truncated edge is provided with a sealing and welding layer for welding the base tube, the surfacing layers and the lining tube together in the peripheral direction of the lining tube. Furthermore, the invention further discloses a manufacturing process of the double-metal composite tube. According to the double-metal composite tube and the manufacturing process of the double-metal composite tube, the inner walls at the positions of the beveled edges of the base tube are provided with the annular grooves, and the surfacing layers are arranged in the annular grooves, so that effective recombination of the base tube and the lining tube can be guaranteed, carburization at the beveled edge top ends when sealing and welding are conducted after recombination is conducted can be effectively avoided, the thickness of the lining wall of the composite tube can be reduced to 0.5 mm, and thus manufacturing cost of the composite tube can be effectively reduced.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

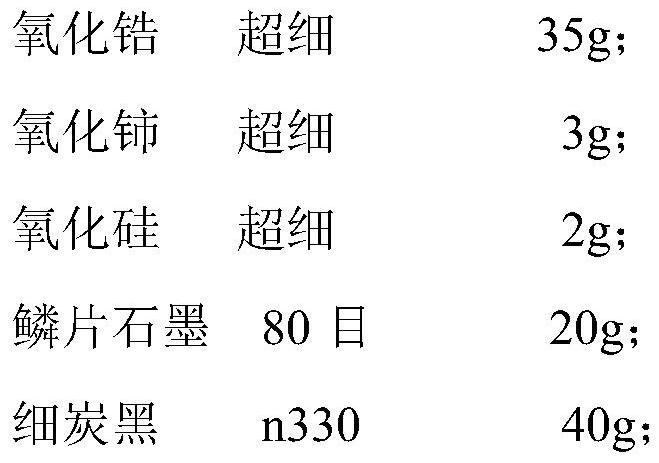

Hard alloy sintered anti-sticking coating adopting alcohol-soluble boron modified phenolic resin as well as preparation method and application of hard alloy sintered anti-sticking coating

InactiveCN112457738AImprove heat resistanceHigh bonding strengthCharge supportsCoatingsAdhesiveActive agent

The invention discloses a hard alloy sintered anti-sticking coating adopting alcohol-soluble boron modified phenolic resin as well as a preparation method and application of the hard alloy sintered anti-sticking coating; the anti-sticking coating is formed by mixing solid isolation powder and a liquid adhesive; the solid isolation powder comprises the components in parts by weight: 18-53 parts ofzirconium oxide, 1-6 parts of cerium oxide, 1-5 parts of silicon oxide, 10-30 parts of crystalline flake graphite and 5-45 parts of fine carbon black; and the liquid adhesive comprises the componentsin parts by weight: 3-10 parts of alcohol-soluble boron modified phenolic resin, 1-5 parts of a thickening agent, 2-5 parts of a dispersing agent, 3-5 parts of an active agent, 2-5 parts of a curing agent, 0.1-1.5 parts of a defoaming agent and 250-300 parts of a diluent. The anti-sticking coating has enough bonding strength and hardness after being brushed, and a coating layer is not prone to falling off and chipping in the hard alloy product placing, transporting and charging processes; after sintering, the coating layer can still keep high hardness and bonding strength, and the influence ofwater on the stability of an alloy product during sintering is avoided.

Owner:株洲润昌新材料股份有限公司

Method for producing foamed slag on high-chromium melts in an electric furnace

InactiveUS20130000446A1Increasing oxide contentReduced chromium contentSteel manufacturing process aspectsProcess efficiency improvementElectric arc furnaceSlag

The invention relates to a method for producing foamed slag on high-chromium steel melts in an electric furnace, whereby a mixture consisting of a metal oxide and carbon is introduced into the furnace, the metal oxide in the slag is reduced by the carbon, and the gases created in the slag form bubbles which thus foam up the slag. In order to be able to control the gas formation and thus the foaming process, the mixture consisting of a metal oxide and carbon and optionally an iron carrier is introduced as preforms, such as pellets, which are compressed and / or provided with a binding agent. The gas formation can be controlled in terms of location, type and time, by adjusting the characteristics of the pellets, especially the density and / or compression characteristics thereof.

Owner:SMS DEMAG AG

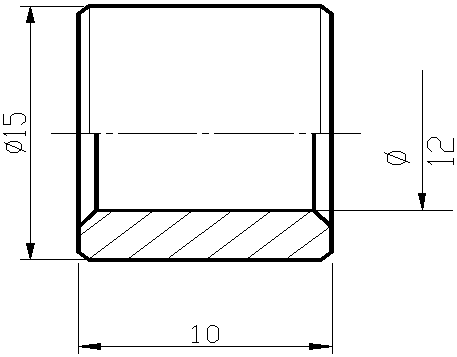

Precise stainless steel tube for nuclear power unit, and its making technology

ActiveCN103060709APrevent precipitationGuaranteed corrosion resistanceNuclear powerSS - Stainless steel

The invention relates to a stainless steel tube and its making technology, and concretely relates to a precise stainless steel tube for a nuclear power unit, and its making technology. The precise stainless steel tube comprises the following components, by mass, 0.04-0.05% of C, 0.15-0.3% of Si, 0.8-1% of Mn, 13-15% of Ni, 15-17% of Cr, 0.2-0.4% of Nb, 2.5-3.5% of Cu, 0.15-0.2% of N, 0.15-0.25% of Mo, 0.2-0.3% of Al, 6-8% of lanthanide rare earth, and the balance Fe. The limitation of the components and technological parameters, the addition of proper amounts of lanthanide rare earth elements, and the pure hydrogen protection gas bright-heat treatment operation make the stainless steel tube have a good corrosion resistance, and simultaneously the internal surface roughness, the external surface roughness, the yield strength, the tensile strength and the like of the precise stainless steel tube for a nuclear power unit are high.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

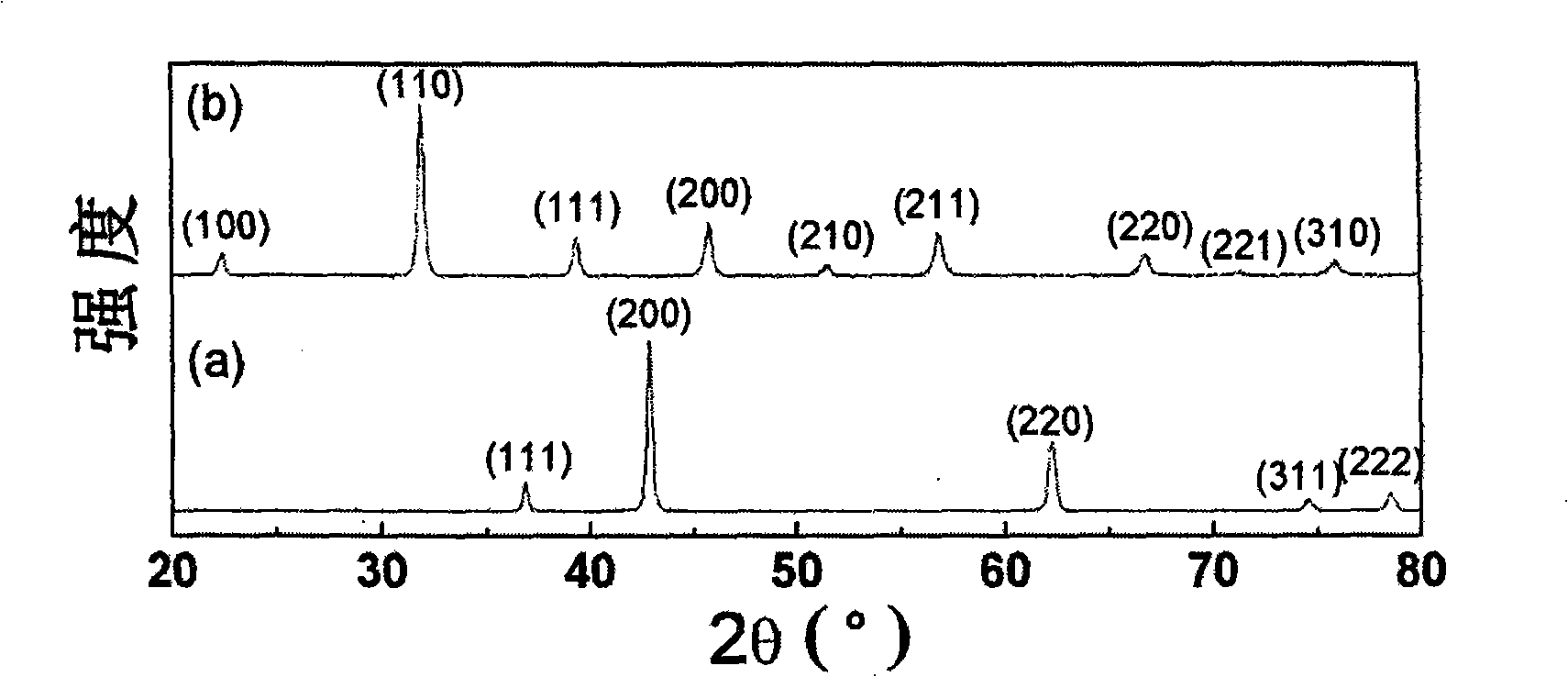

Alloy steel in which carburization is prevented by processing load and method of manufacturing the same

ActiveUS20180187295A1High processing loadAvoid carburizationSolid state diffusion coatingNiobiumManganese

Provided herein is an alloy steel in which carburization is prevented by a processing load, the alloy steel including: about 0.13 to 0.25 wt % of carbon (C), about 0.6 to 1.5 wt % of silicon (Si), about 0.6 to 1.5 wt % of manganese (Mn), about 1.5 to 3.0 wt % of chromium (Cr), about 0.01 to 0.1 wt % of niobium (Nb), about 0.01 to 0.1 wt % of aluminum (Al), about 0.05 to 0.5 wt % of vanadium (V), the balance iron (F), and impurities, based on the total weight of the alloy steel.

Owner:HYUNDAI MOTOR CO LTD +1

Casting powder for continuous casting crystallizer and preparation method of casting powder

ActiveCN113953473AReduce heat transfer efficiencyAvoid carburizationProcess efficiency improvementSlagSteel casting

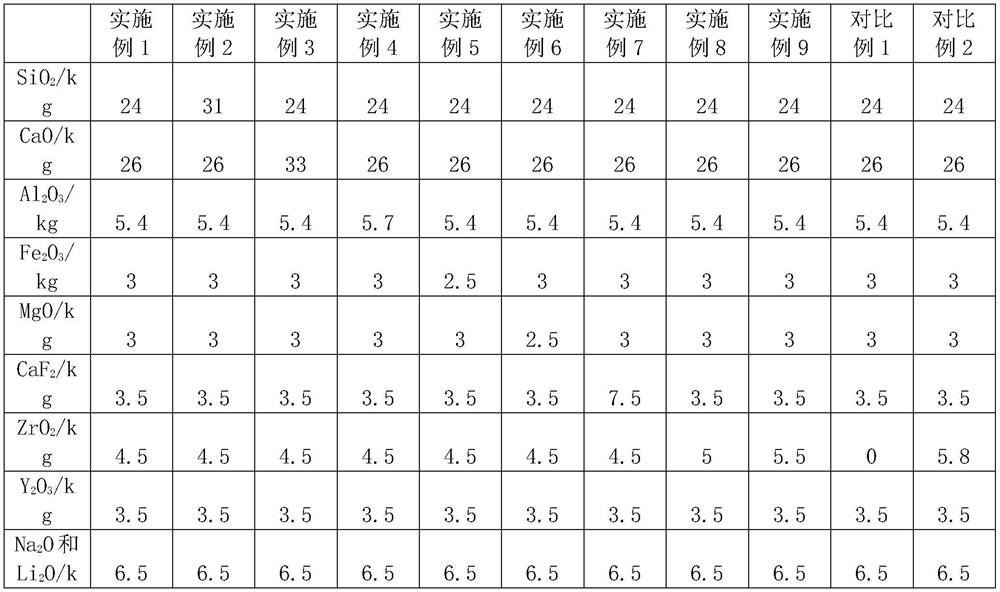

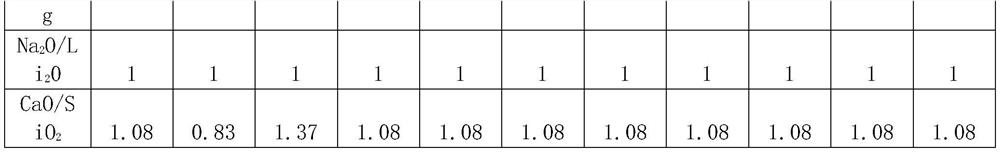

The invention relates to the field of cast steel, and particularly discloses casting powder for a continuous casting crystallizer and a preparation method of the casting powder. The casting powder of the continuous casting crystallizer comprises the following components of, in parts by weight, 24.00-31.00 parts of SiO2, 26.00-33.00 parts of CaO, 5.40-5.70 parts of Al2O3, less than or equal to 3.00 parts of Fe2O3, less than or equal to 3.00 parts of MgO, 6.50-10.50 parts of Na2O and Li2O, 3.50-7.50 parts of CaF2, 4.5-5.5 parts of ZrO2 and 3.5-4.5 parts of Y2O3. The preparation method comprises the following steps of uniformly mixing the components, and grinding to obtain the finished product casting powder slag which has the advantage of good heat insulation effect.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com