Method for quenching slip inserts

A technology for tile teeth and quenching furnaces, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as undiscovered patent documents, and achieve the effect of ensuring strength, improving production efficiency and marking degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

[0023] A method for quenching slips, the steps of which are:

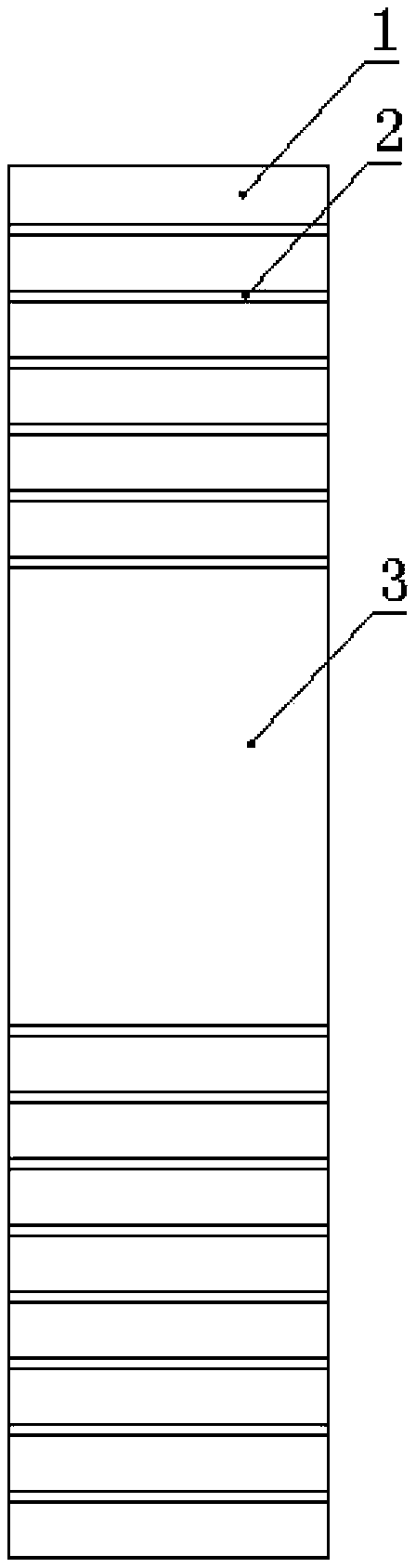

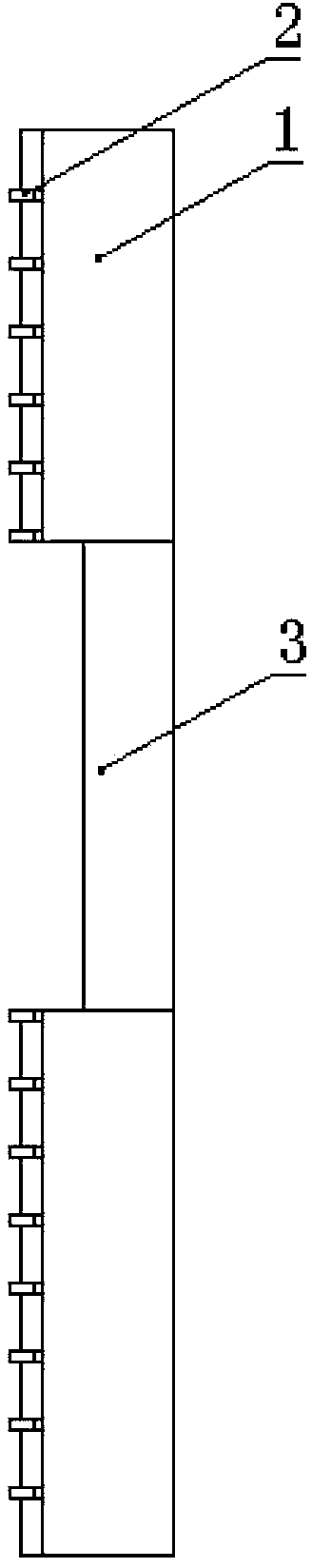

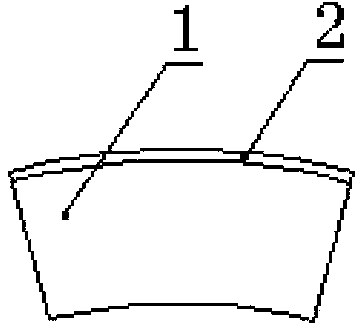

[0024] ⑴ see Figure 1~4 , a steel ring 5 is produced by a molding machine or a mold. The wall thickness of the steel ring is greater than the wall thickness of the slip body 1 to be made, and the height is higher than the height of the slip body to be made. The outer edge of the steel ring is spaced radially and coaxially Made with multiple identical annular slips 2;

[0025] (2) Apply quenching medium to multiple annular slips, fill or smear anti-carburizing materials into the inner hole of the steel ring and the upper and lower ends of the steel ring;

[0026] (3) Put the steel ring into the quenching furnace to quench the slips. Since the specific parameters such as equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com