Patents

Literature

629results about "Steel manufacturing process aspects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

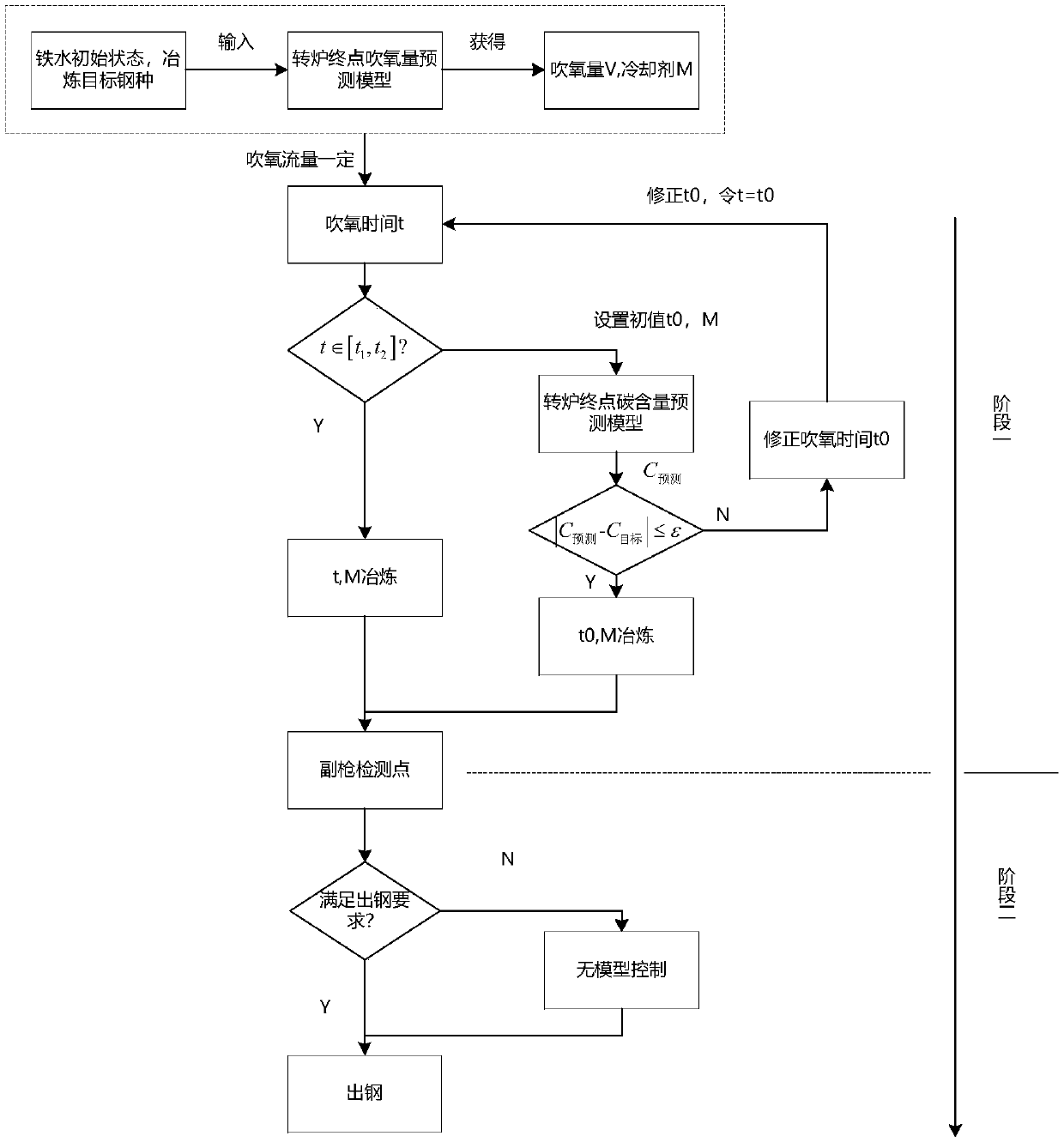

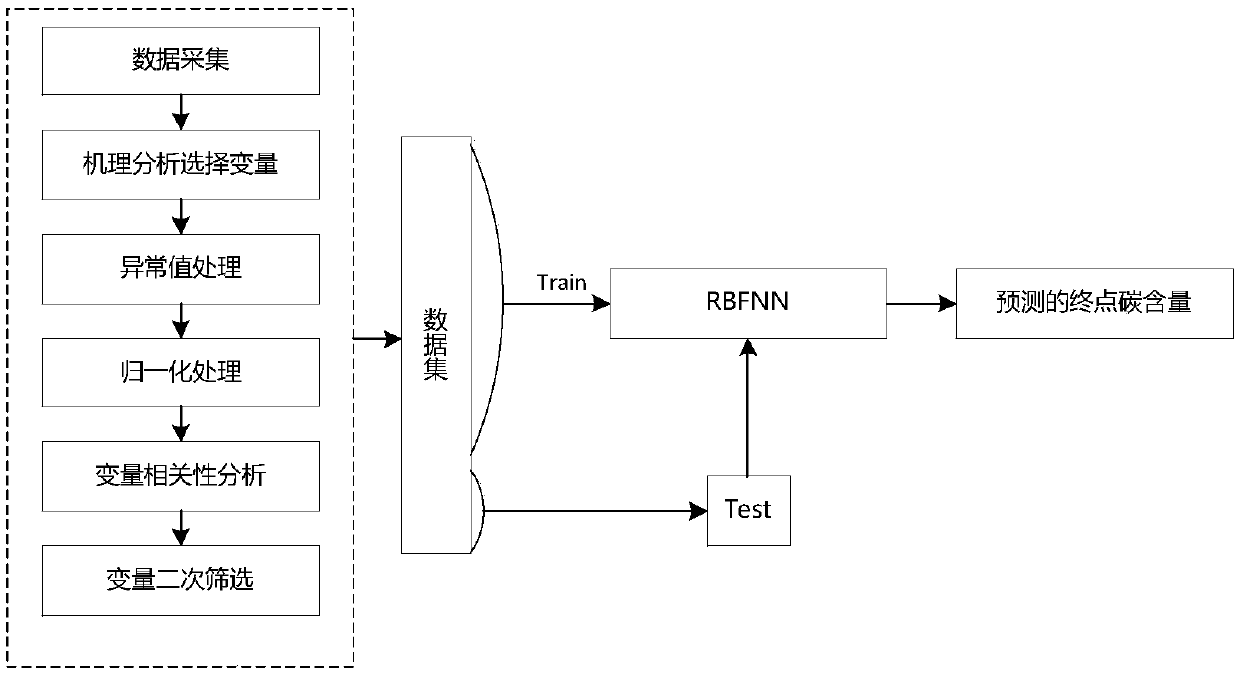

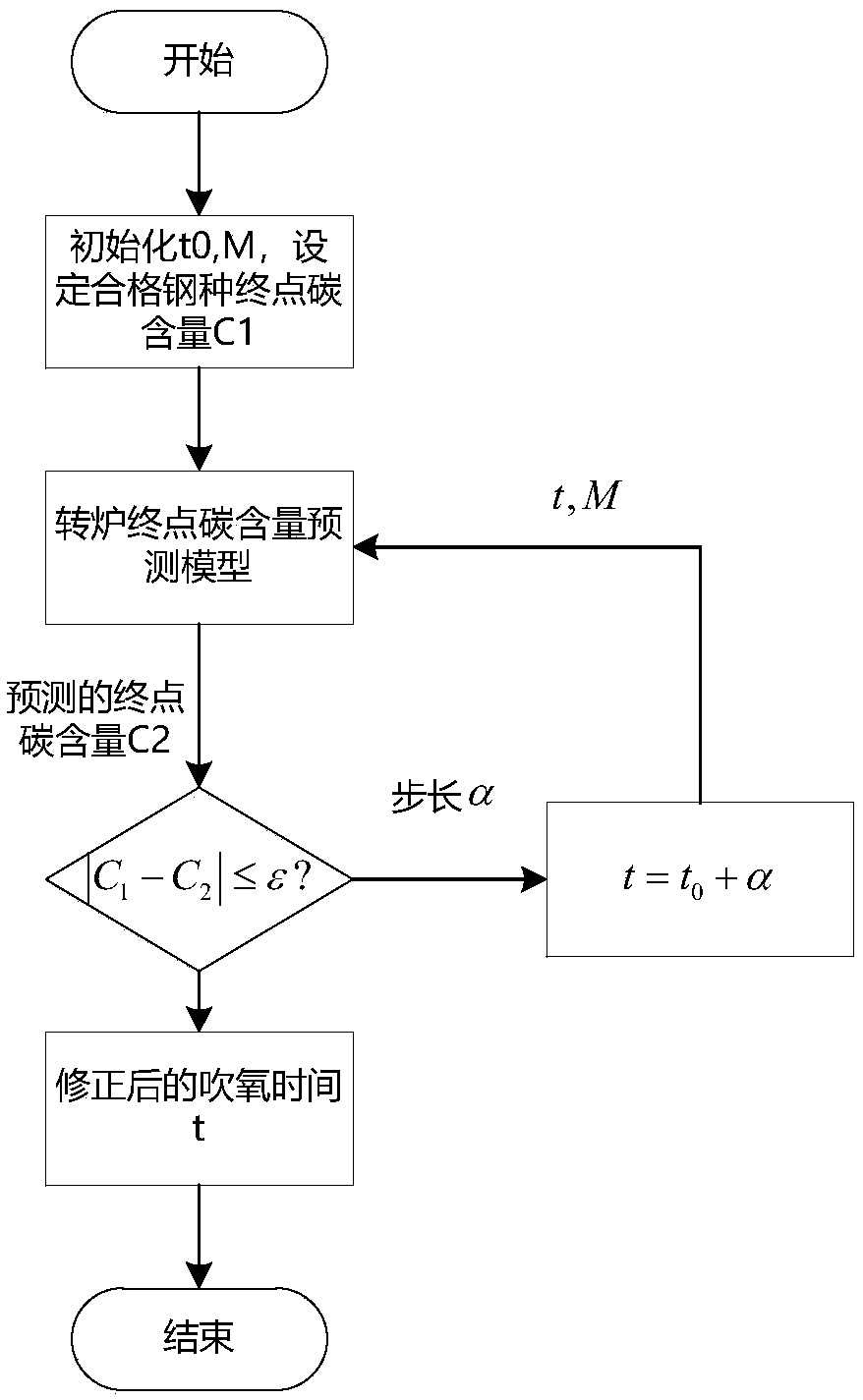

Converter steelmaking endpoint carbon content and temperature control method

ActiveCN108676955AReduce mistakesTo overcome the shortcomings of insufficient precisionSteel manufacturing process aspectsIncreasing energy efficiencyTemperature controlDemarcation point

The invention provides a converter steelmaking endpoint carbon content, a temperature control method and equipment. The method comprises the following steps that: a first detection point of a sublanceis taken as a demarcation point, and a converter steelmaking process is divided into a first stage and a second stage; in the first stage, according to characteristic parameters of an initial state of molten iron and smelting requirements of a target steel, an endpoint carbon content and a temperature are controlled based on an oxygen blowing prediction model and an endpoint carbon content prediction model; in this way, the shortcoming of insufficient precision due to artificial experience prediction is overcome, at the same time, influence of uncertain factors such as molten steel splash andlate decarburization reaction deviation is considered; if carbon content and the temperature of the first detection point of the sublance do not meet tapping requirements when the first stage is completed, the second stage is performed until the carbon content and the temperature meet the tapping requirements, and therefore precision of smelting control is improved; in addition, the endpoint carbon content prediction model has more tapping cycles for training samples, and parameters for training neural networks are complex, and obtained neural network error is small.

Owner:CENT SOUTH UNIV

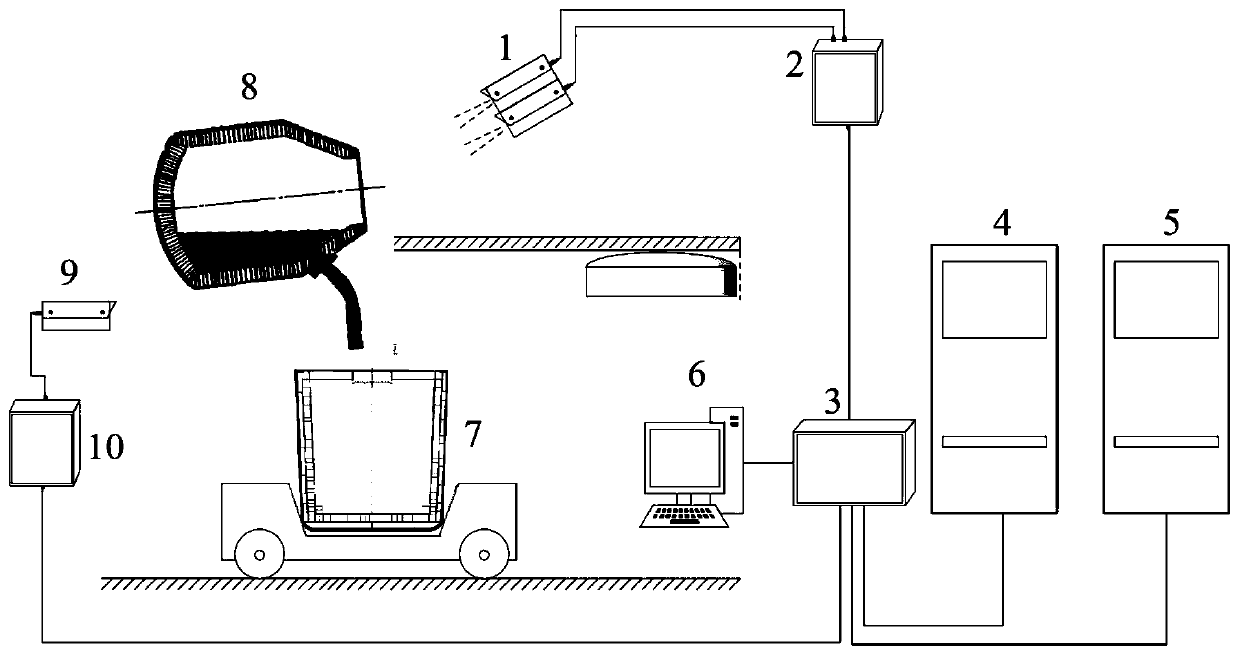

Converter intelligent tapping device and control method

PendingCN110438284AShorten tapping timeImprove tapping efficiencySteel manufacturing process aspectsIncreasing energy efficiencySteelmakingControl signal

The invention relates to metallurgical steelmaking technologies, and aims to provide a converter intelligent tapping device and a control method. The device comprises a converter steelmaking secondarycontrol system, a converter deslag detection system, a taphole slag blocking system, a converter opening monitoring module, a tapping monitoring module, a communication control module and a deep learning host, wherein the converter opening monitoring module is provided with a converter opening monitoring probe and a converter opening monitoring and processing unit; the tapping monitoring module is composed of a tapping monitoring probe and a tapping monitoring and processing unit; and the communication control module is connected with the deep learning host, the converter opening monitoring module, the tapping monitoring module, the converter steelmaking secondary control system, the converter deslag detection system and the taphole slag blocking system, so that two-way intercommunicationof data information and control signals is achieved. Intelligent prediction and control of converter tapping can be achieved, the tapping time is shortened, and the tapping efficiency is improved; the tapping process is reproducible, traceable and high in safety; and the molten steel quality is improved while the yield of molten steel is increased.

Owner:杭州谱诚泰迪实业有限公司

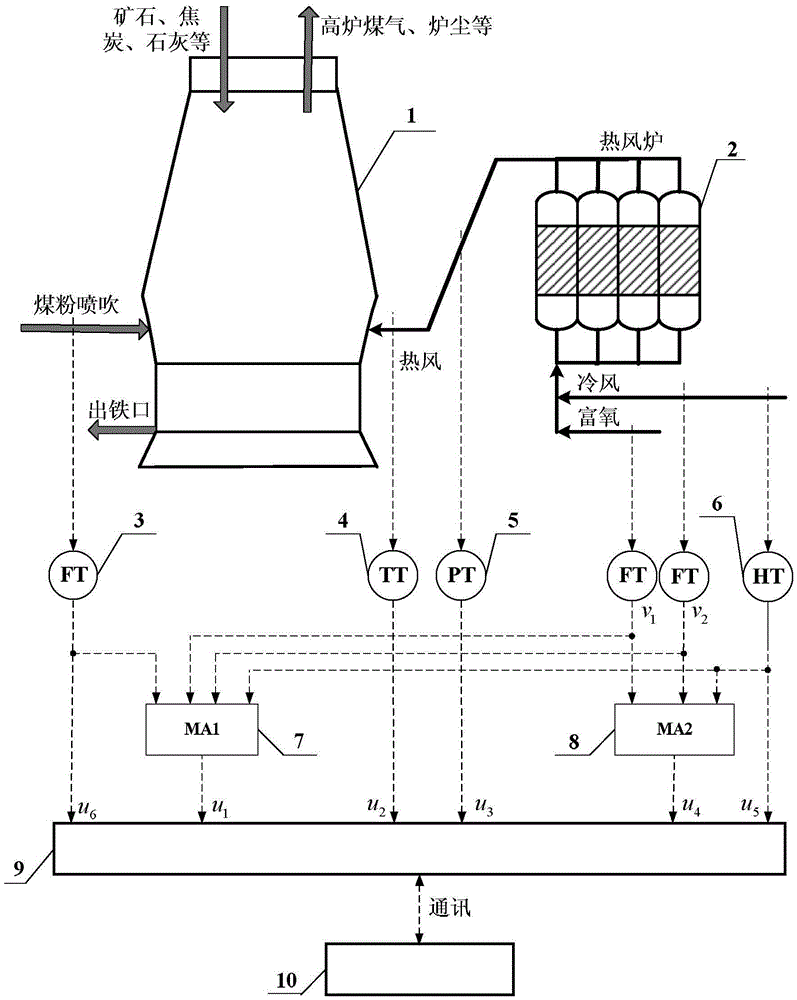

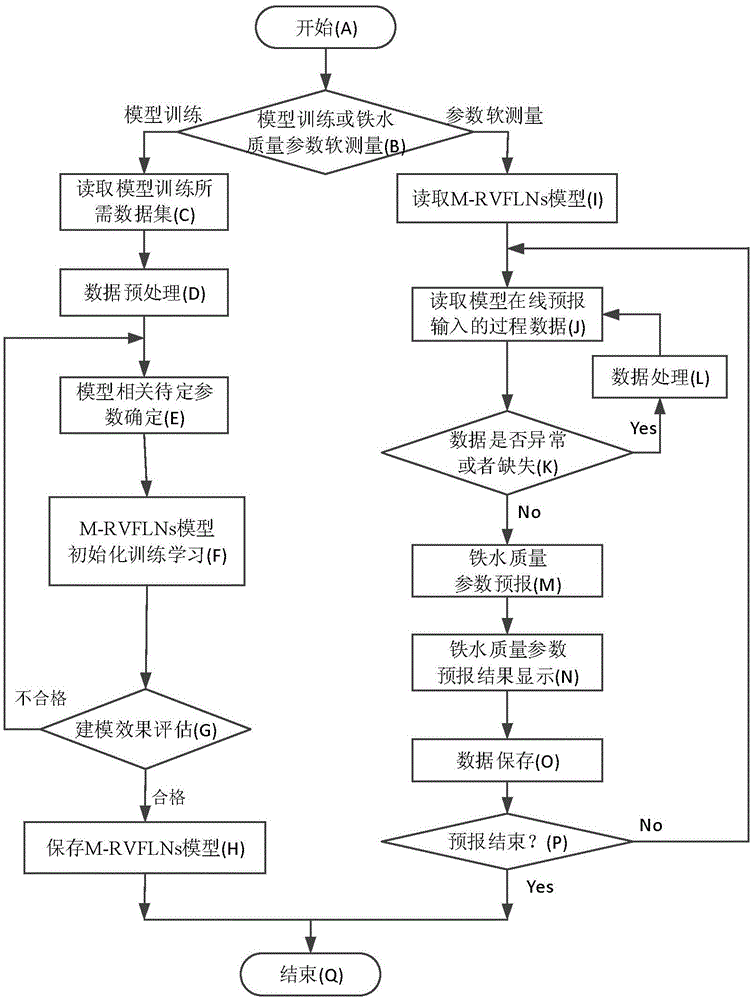

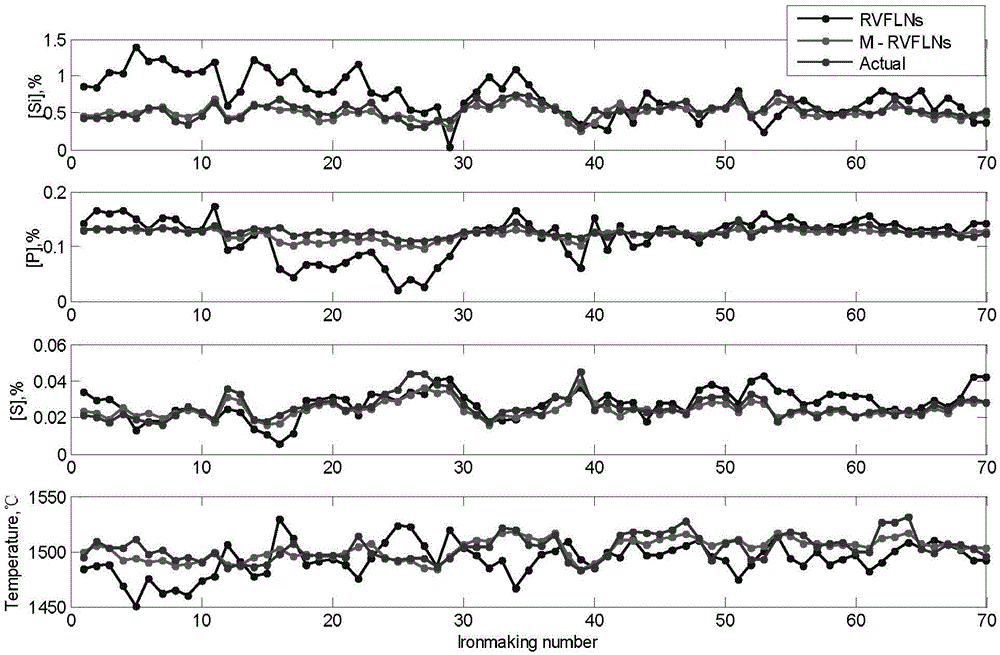

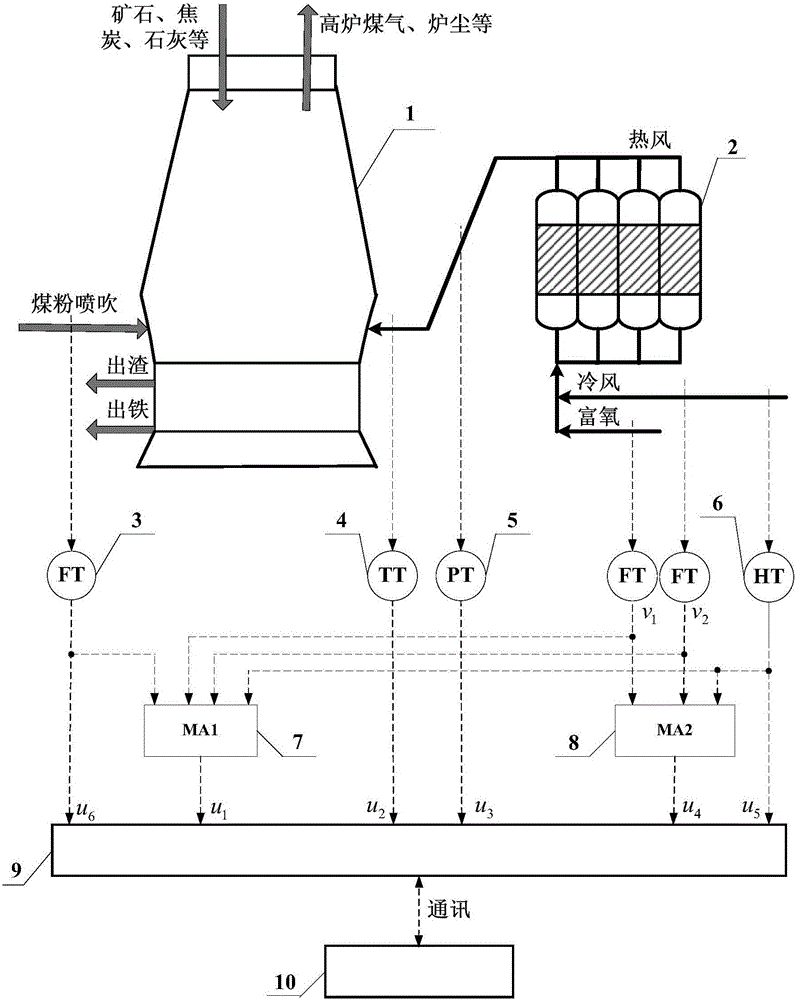

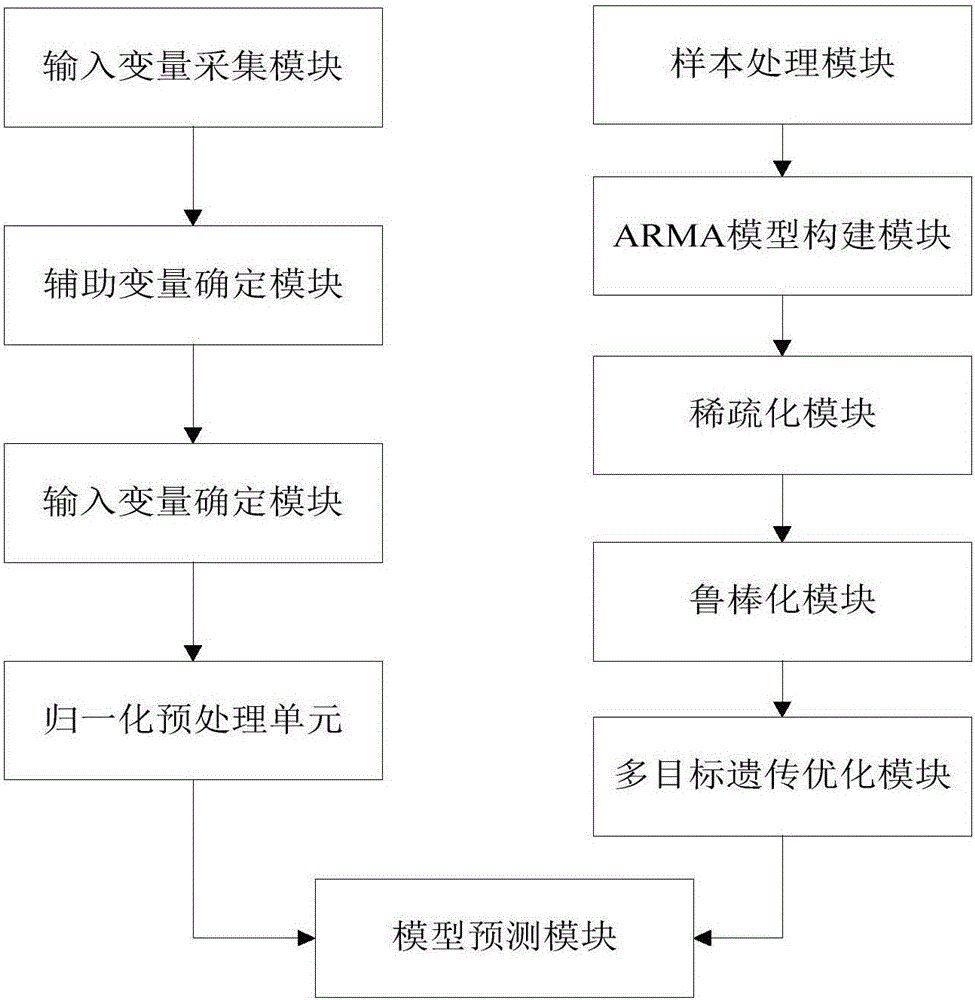

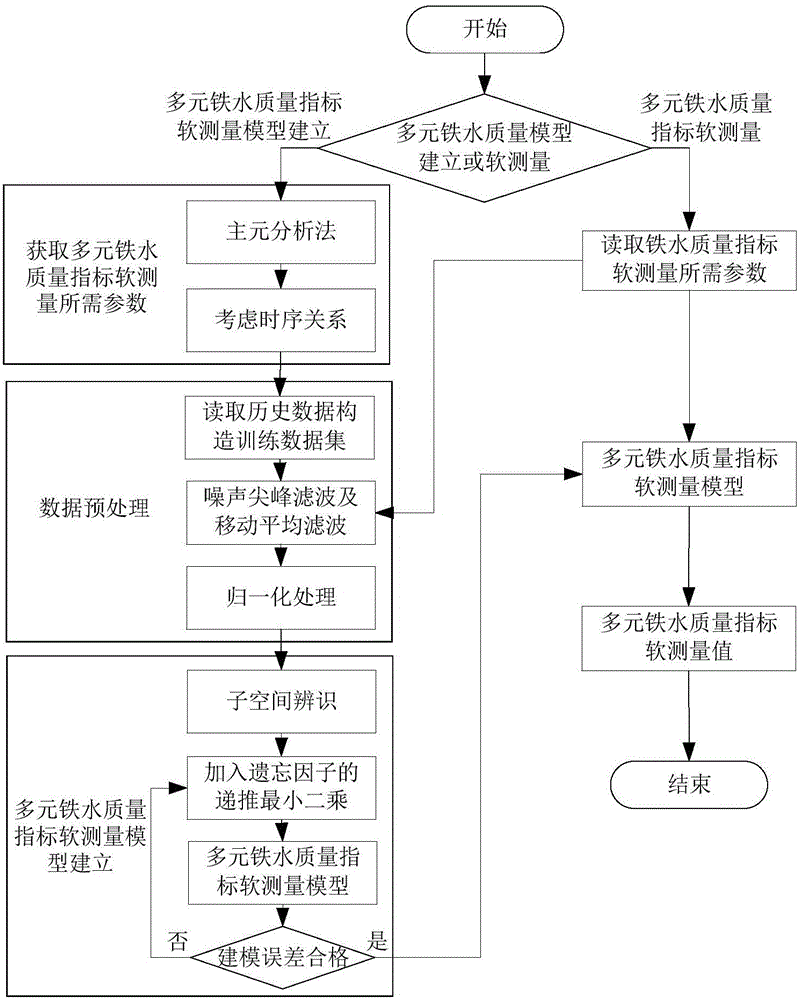

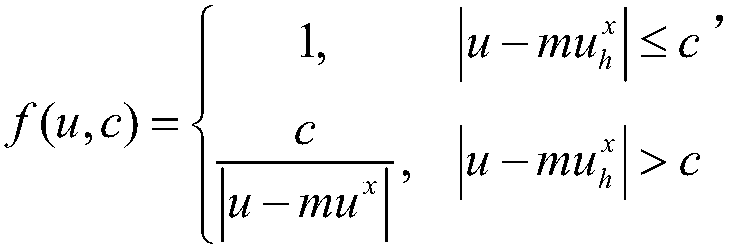

Robust random-weight neural network-based molten-iron quality multi-dimensional soft measurement method

ActiveCN105608492AImplementing Multivariate Robust Soft SensingImplement soft sensingSteel manufacturing process aspectsBlast furnace detailsAutomatic controlPrincipal component analysis

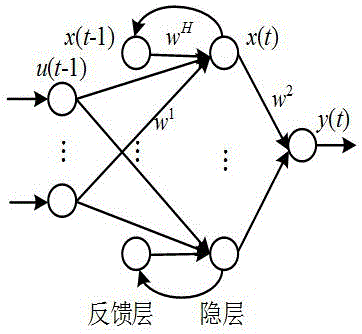

The invention relates to a robust random-weight neural network-based molten-iron quality multi-dimensional soft measurement method which belongs to the blast-furnace smelting automatic control field, in particular to a Cauchy distribution weighted M-estimation random-weight neural network (M-RVFLNs) based method for multi-dimensional parameter-dynamic soft measurement of the molten-iron quality in the blast-furnace smelting process. According to the method of the invention, the principal component analysis (PCA) method is adopted to chose main parameters which affect the blast-furnace molten iron quality as model input variables, a molten-iron quality multi-dimensional dynamic prediction model which has an output self-feedback structure and takes into account input-output data at different moments is constructed, and it is possible to carry out multi-dimensional dynamic soft measurement of the main parameters Si content, P content, S content and molten iron temperature which represent the blast-furnace molten iron quality. The method of the invention comprises the following steps of (1) choosing auxiliary variables and determining model input variables and (2) training and using the M-RVFLNs soft measurement model.

Owner:NORTHEASTERN UNIV

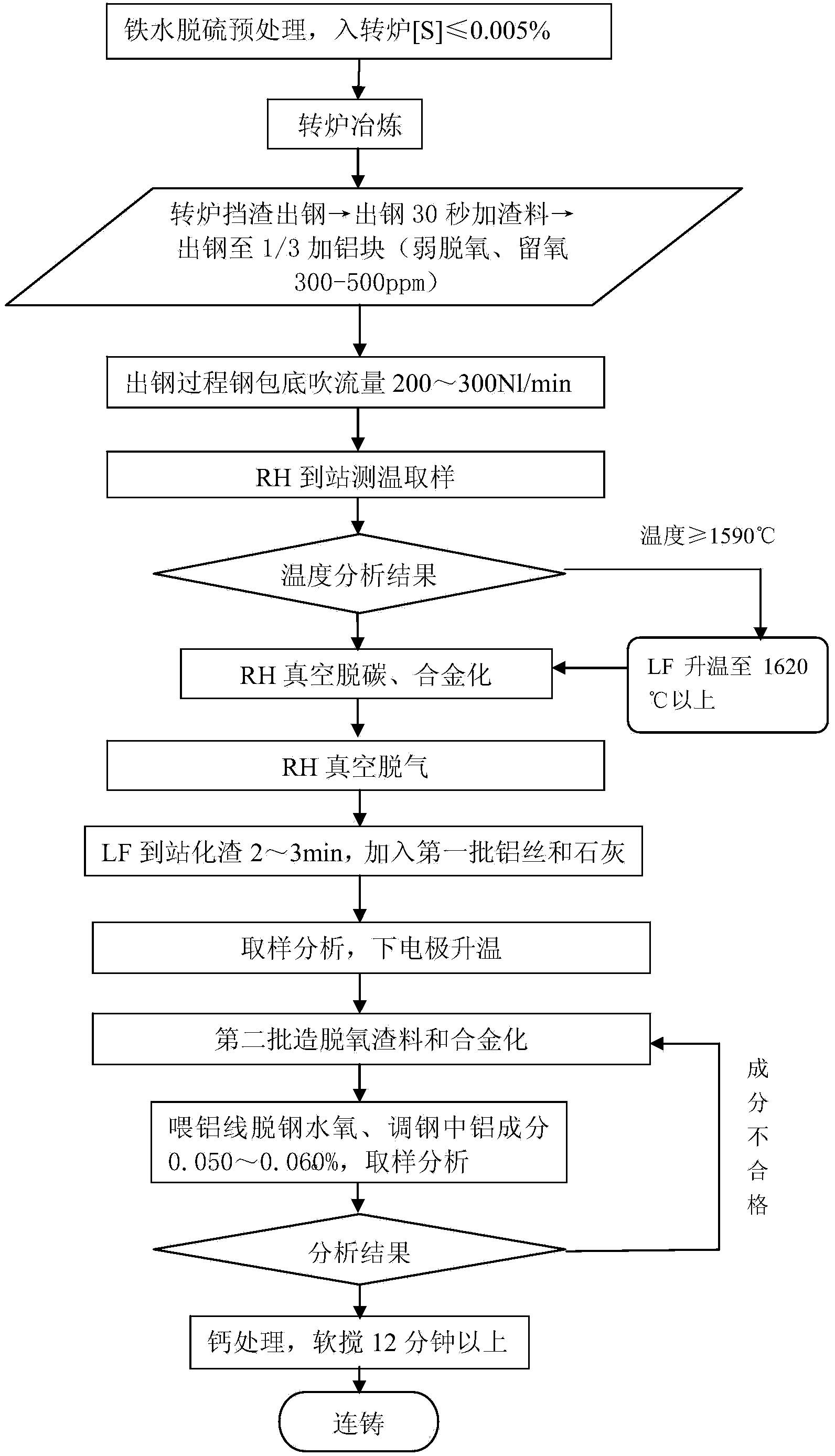

Low-carbon ultra-low sulfur steel smelting method

InactiveCN104232831AThe amount added is accurateStable flaw detection pass rateSteel manufacturing process aspectsManufacturing convertersSmelting processOxygen

The invention discloses a low-carbon ultra-low sulfur steel smelting method. The method comprises the following technological processes: pouring molten iron into a tank, pretreatment of molten iron, oxygen remaining operation of a converter, RH furnace vacuum decarburization, alloying and vacuum degassing in an RH furnace, deoxidization of aluminium yarn / aluminium wire in an LF refining furnace, slagging by using lime and CCM. Through combination of molten iron desulphurization and drossing, optimization of a converter steel tapping and oxygen remaining system and a slagging system, the vacuum decarburization, alloying and degassing control in the RH furnace, and the aluminium wire diffusing deoxidation slagging and aluminium wire sediment deoxidation in the LF furnace, deep decarburization and desulphurization are carried out. With an emphasis on combination of convertor steel tapping and oxygen remaining operations, RH deep decarburization and LF furnace deep desulphurization, technical optimization is carried out; due to reasonable ladle argon bottom blowing control in the smelting process, carbon content control and metallurgical thermodynamics and dynamics conditions of desulphurization are given a full play; the RH furnace decarburization is stable; LF furnace slagging and desulphurization and recarburization control effects are obvious; and low-carbon ultra-low sulfur steel smelting is achieved.

Owner:NANJING IRON & STEEL CO LTD

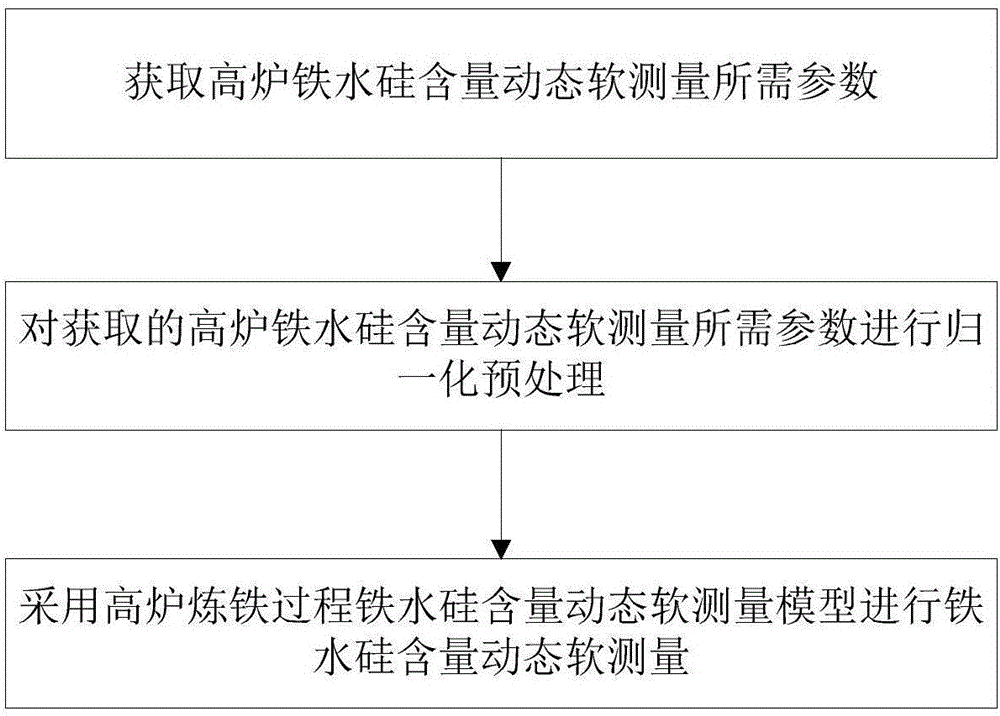

System and method for dynamical soft measurement of molten iron silicon content in blast furnace ironmaking process

ActiveCN105886680AAchieve sparsificationReduce workloadSteel manufacturing process aspectsBlast furnace detailsClosed loopSilicon

The invention provides a system and method for dynamic soft measurement of the molten iron silicon content in the blast furnace ironmaking process. The system comprises an actual data collection unit, a normalization pretreatment unit and a dynamic soft measurement unit. The method includes the steps that the parameters required by dynamic soft measurement of the blast furnace molten iron silicon content are obtained and comprise the operating parameters of the current furnace charge, the operating parameters of the previous furnace charge and the molten iron silicon content of the previous furnace charge; normalization pretreatment is conducted on the obtained parameters required by dynamic soft measurement of the blast furnace molten iron silicon content; and dynamic soft measurement of the molten iron silicon content is conducted through a model of dynamic soft measurement of the molten iron silicon content in the blast furnace ironmaking process. Compared with existing manual measurement or analysis of the molten iron silicon content, the workload of operators is reduced, measurement uncertainty introduced by manual operation is lowered, measurement timeliness and accuracy are improved, and the confidence level is high. The method has universality in prediction of the molten iron silicon content in the blast furnace ironmaking process, and closed-loop integrated control over the blast furnace molten iron quality and optimized operation can be achieved easily.

Owner:NORTHEASTERN UNIV

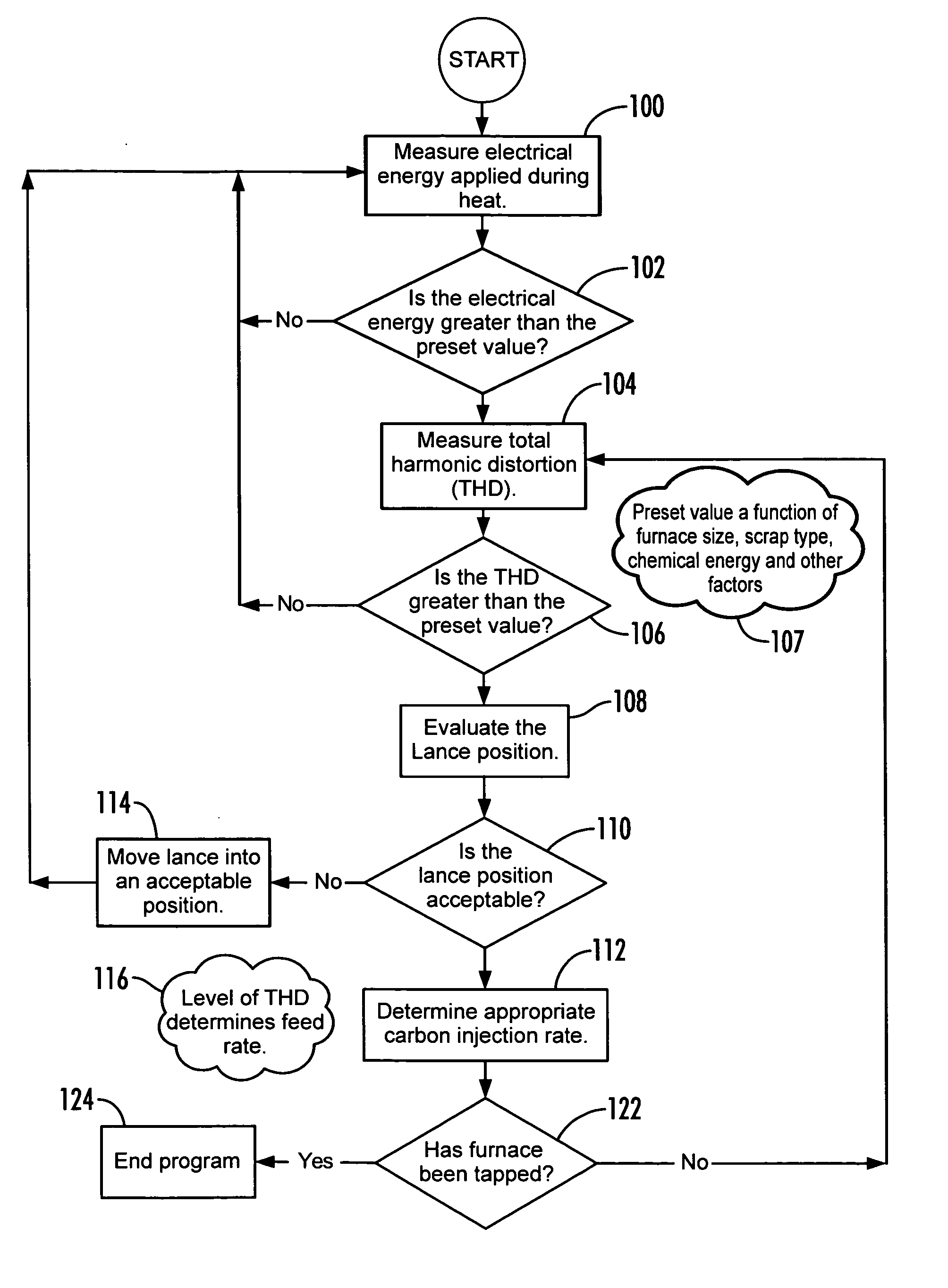

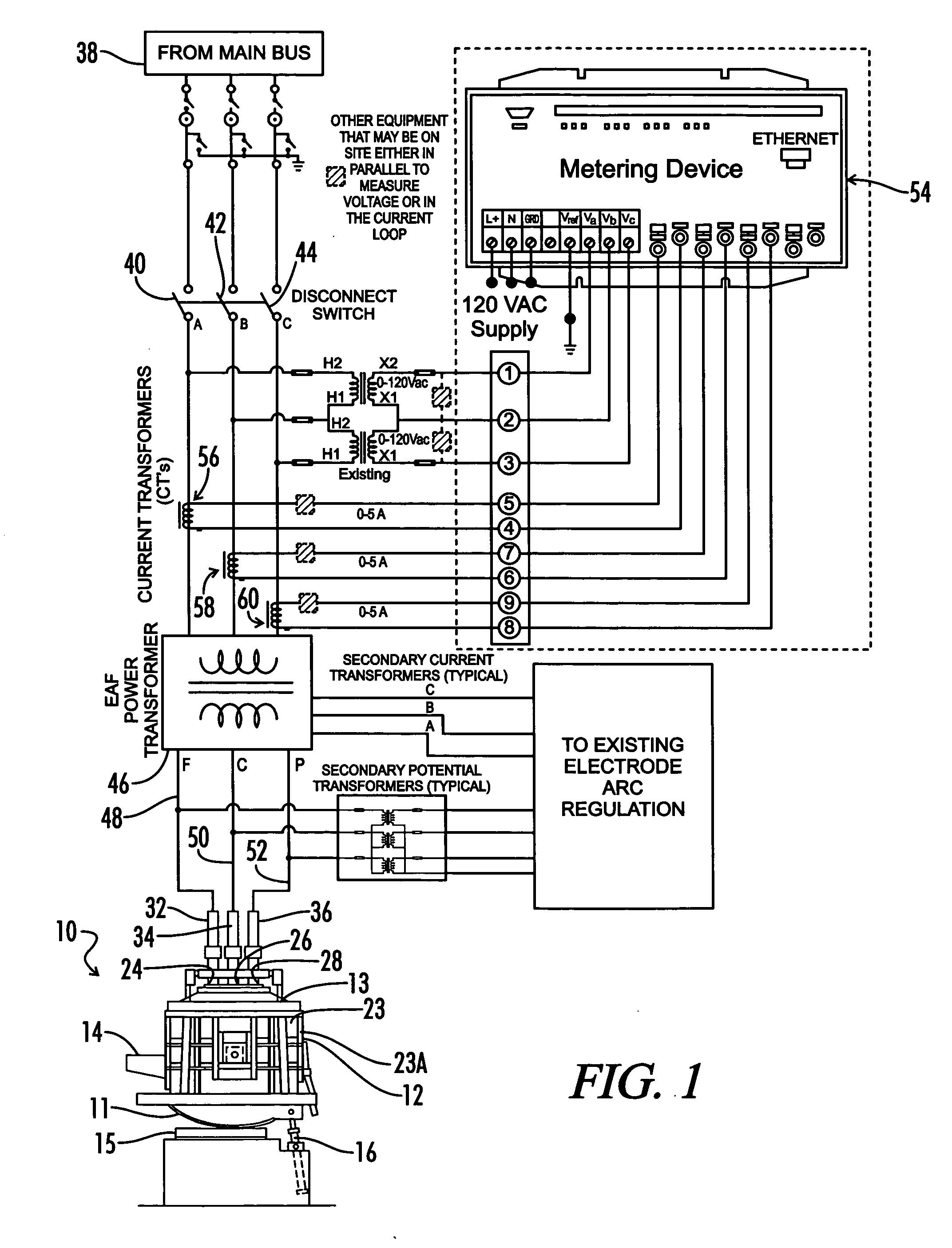

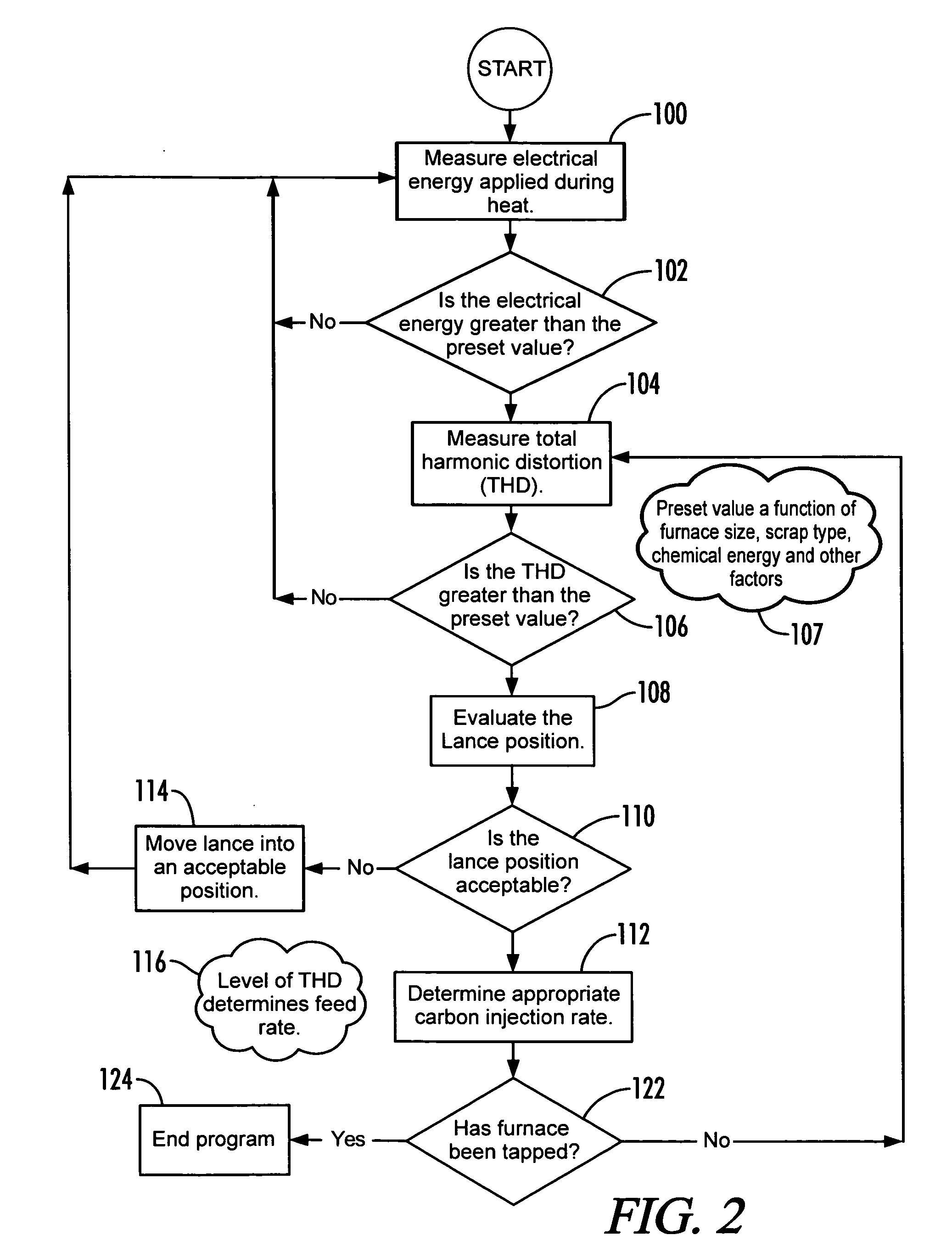

Method for controlling foaming of slag in an electric arc furnace

InactiveUS20070133651A1Arc stabilizationSimple methodSteel manufacturing process aspectsIncreasing energy efficiencyElectric arc furnaceFoaming agent

A method for controlling the foaming of slag in an electric arc furnace is disclosed. The furnace comprises at least one electrode column. Current is applied to the electrode column, causing an arc to form between the tip of the electrode column and the scrap, melting the scrap. Impurities in the molten scrap metal rise to the surface forming slag. A meter determines the total harmonic distortion associated with the system. If the total harmonic distortion is greater than a predetermined set point, and the scrap metal is sufficiently molten, then a foaming agent is added thereto.

Owner:GRAFTECH INT HLDG INC

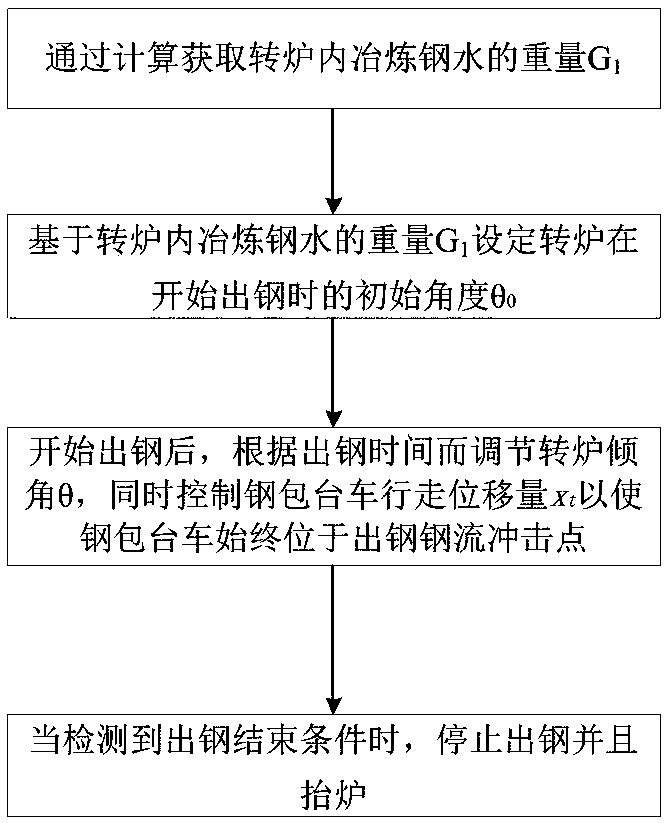

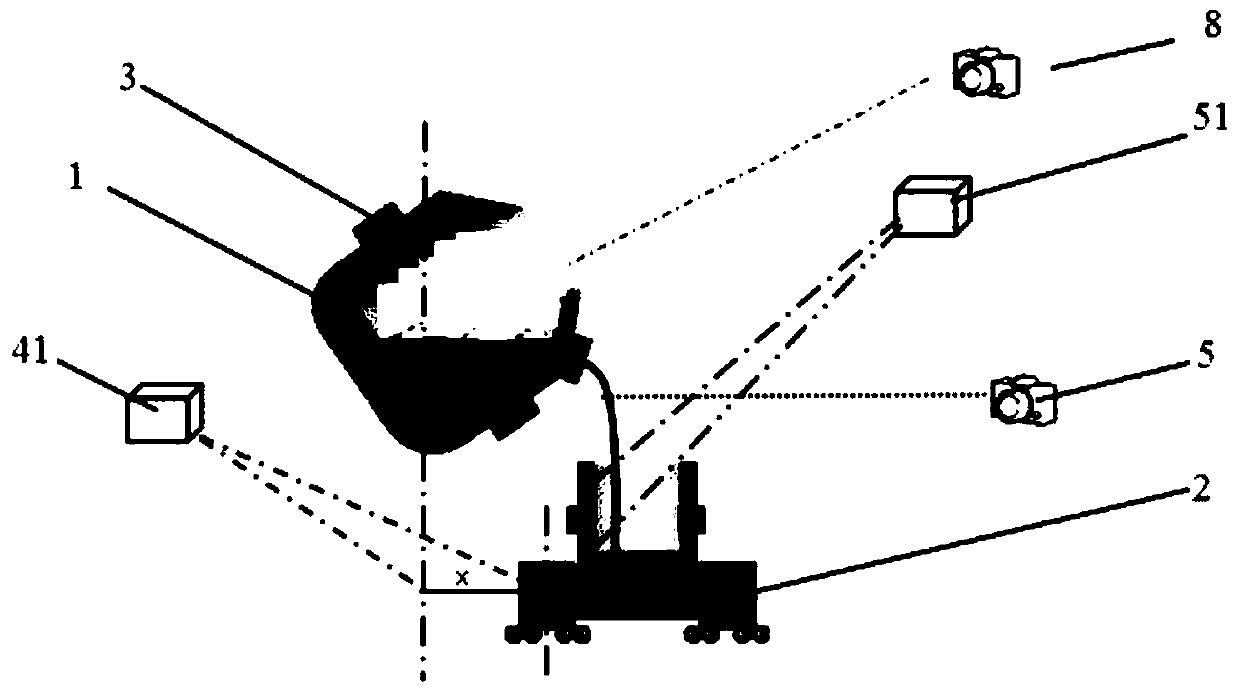

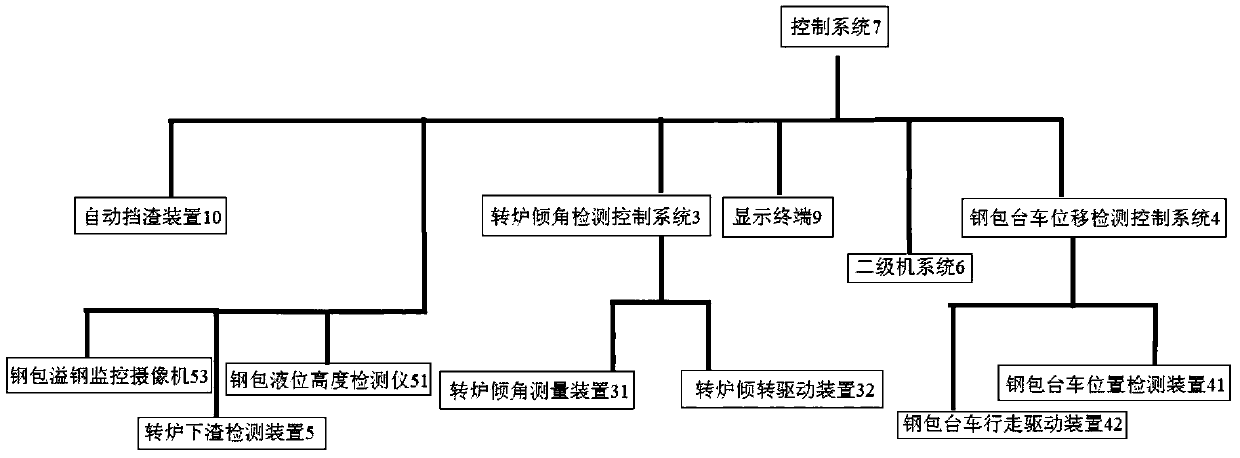

Full-automatic steel tapping method and system of converter

InactiveCN110616288AReduce incidenceLess investmentSteel manufacturing process aspectsManufacturing convertersMeasurement deviceMicrocomputer system

The invention discloses a full-automatic steel tapping method of a converter. The method comprises the steps of (1) obtaining the weight G1 of smelting molten steel in the converter through calculation; (2) based on the weight G1 of the smelting molten steel in the converter, setting the initial angle theta 0 when steel tapping of the converter begins; (3) after steel tapping begins, adjusting theinclination angle theta of the converter according to the steel tapping time, and meanwhile, controlling the walking displacement xt of a steel ladle trolley, so that the steel ladle trolley is located at a steel tapping steel flow impact point all the time; (4) when a steel tapping end condition is detected, stopping steel tapping and lifting up the converter. The invention further discloses a full-automatic steel tapping system of the converter. The system comprises the converter, the steel ladle trolley, a second-level microcomputer system storing steel grade smelting information, a converter inclination angle measurement device for measuring the inclination angle of the converter, a converter tilting driving device connected with the converter, a steel ladle trolley position detectiondevice for detecting the position of the steel ladle trolley in the walking direction, a steel ladle trolley walking driving device connected with the steel ladle trolley, a slag discharging device and a control system.

Owner:BAOSHAN IRON & STEEL CO LTD

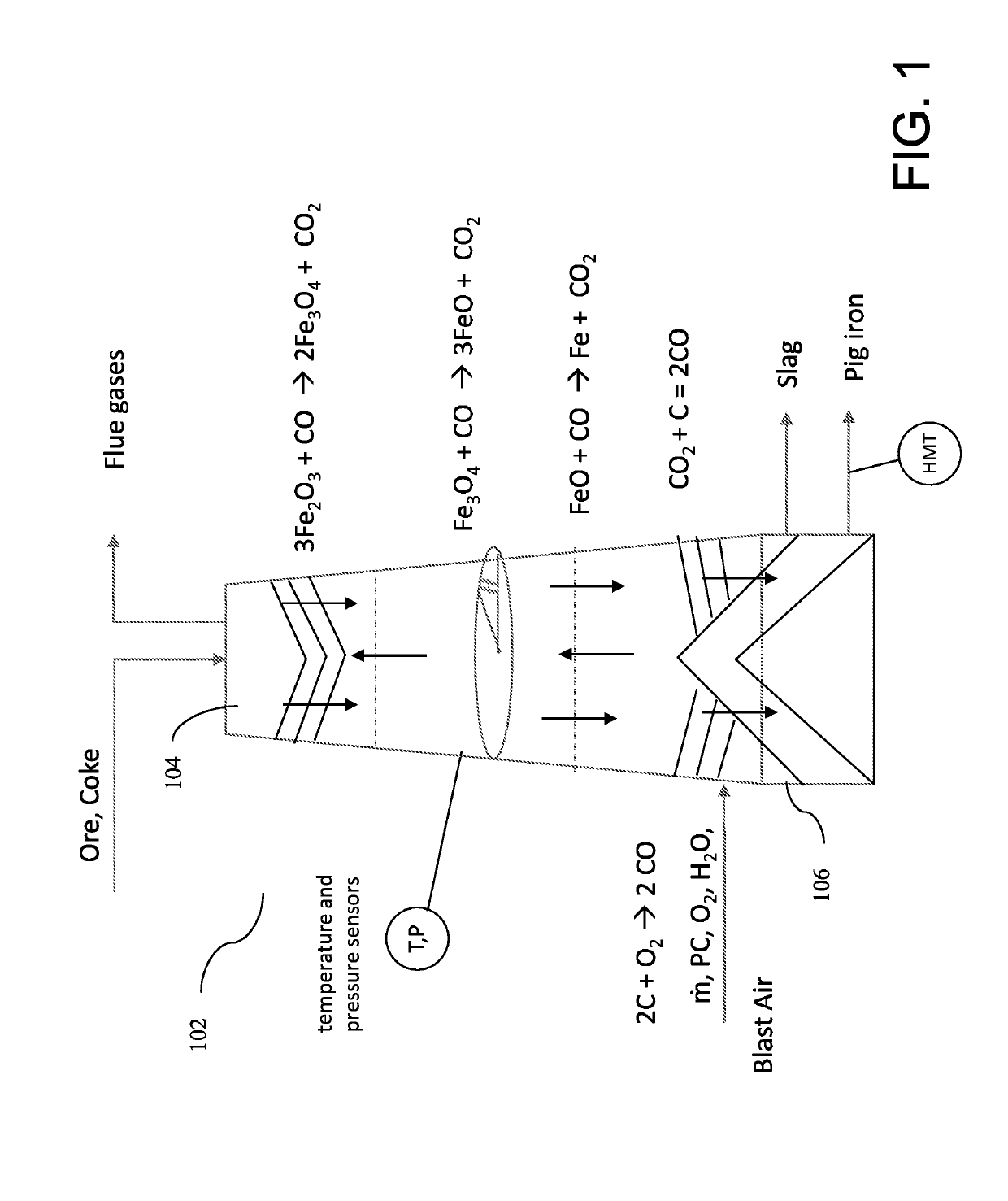

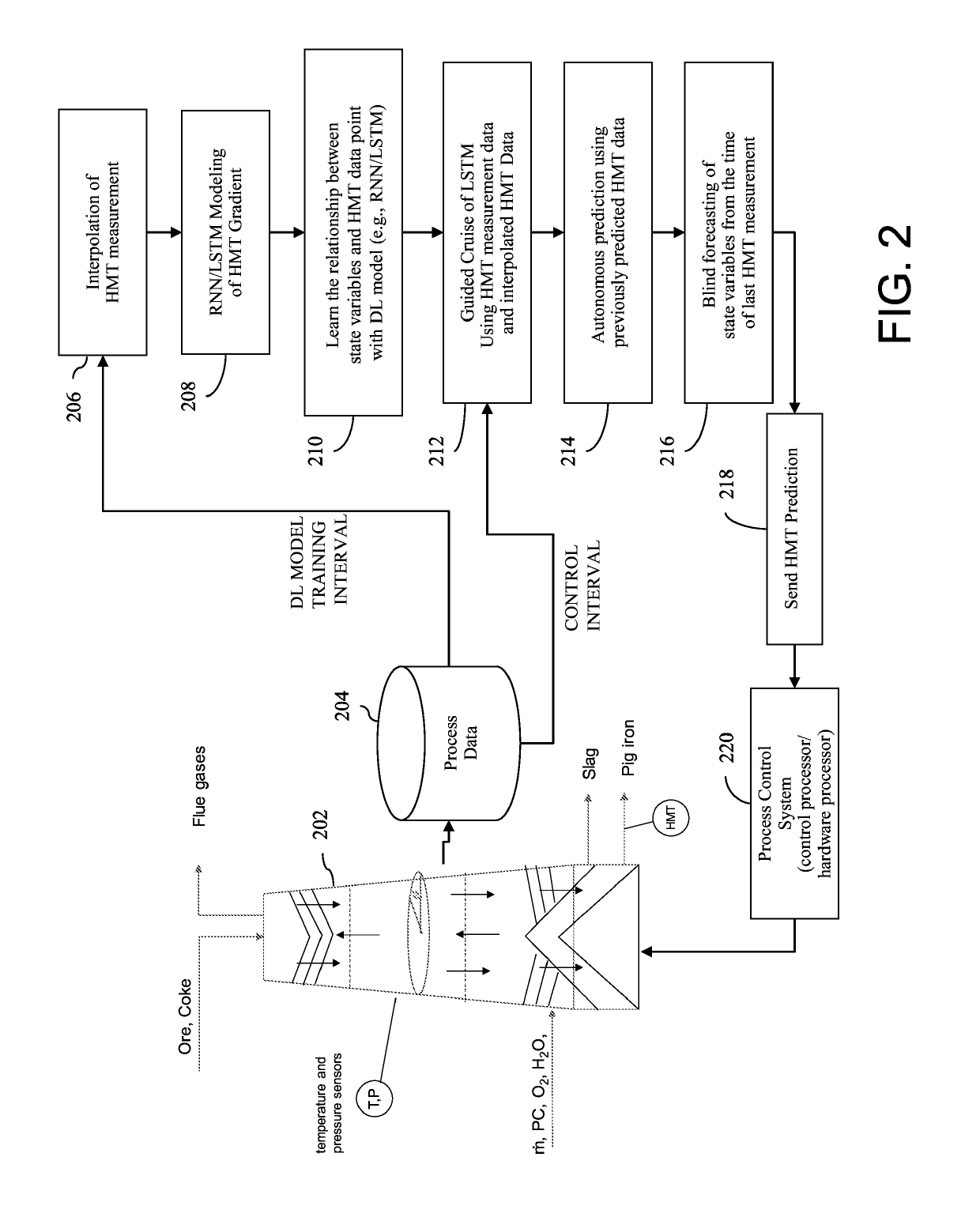

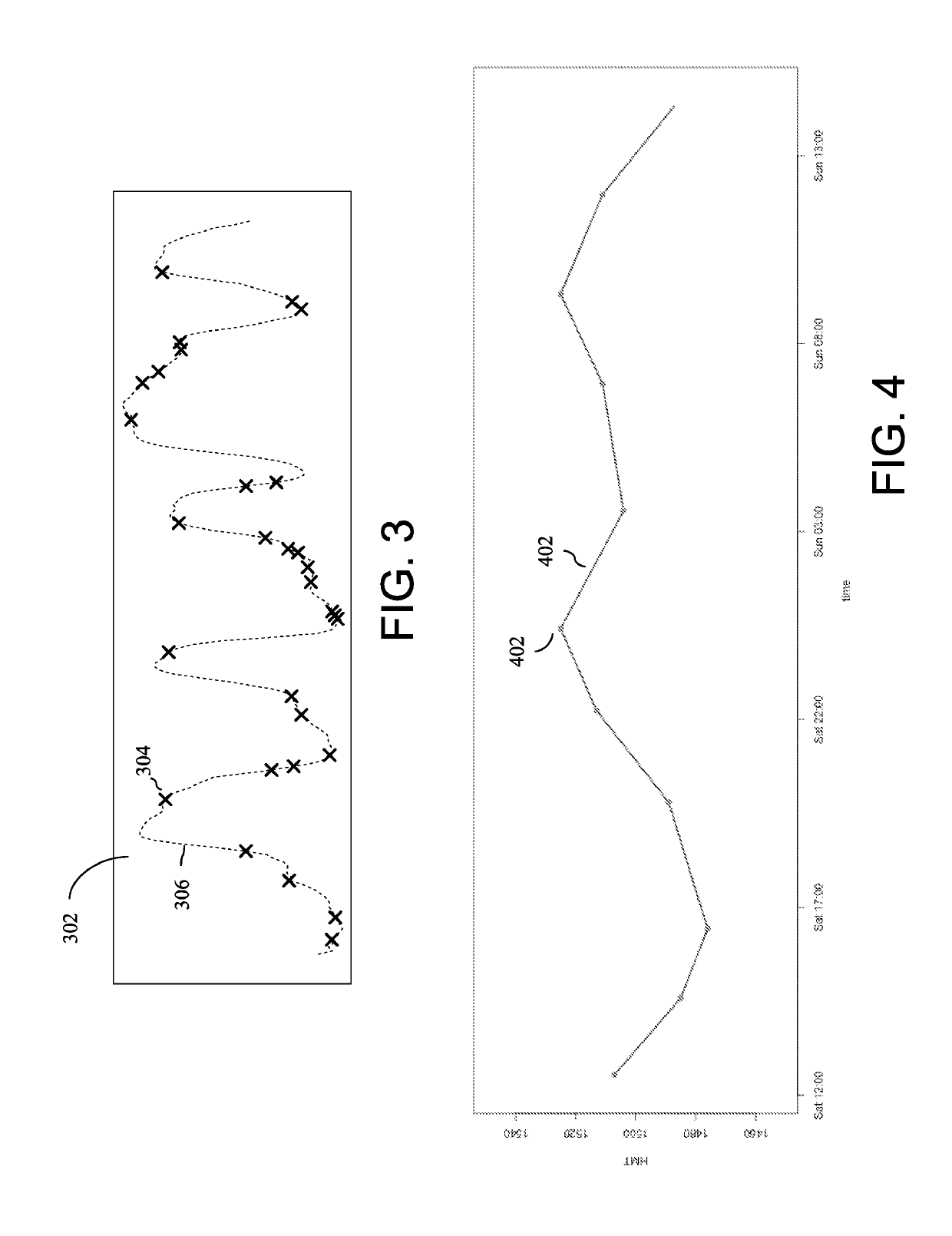

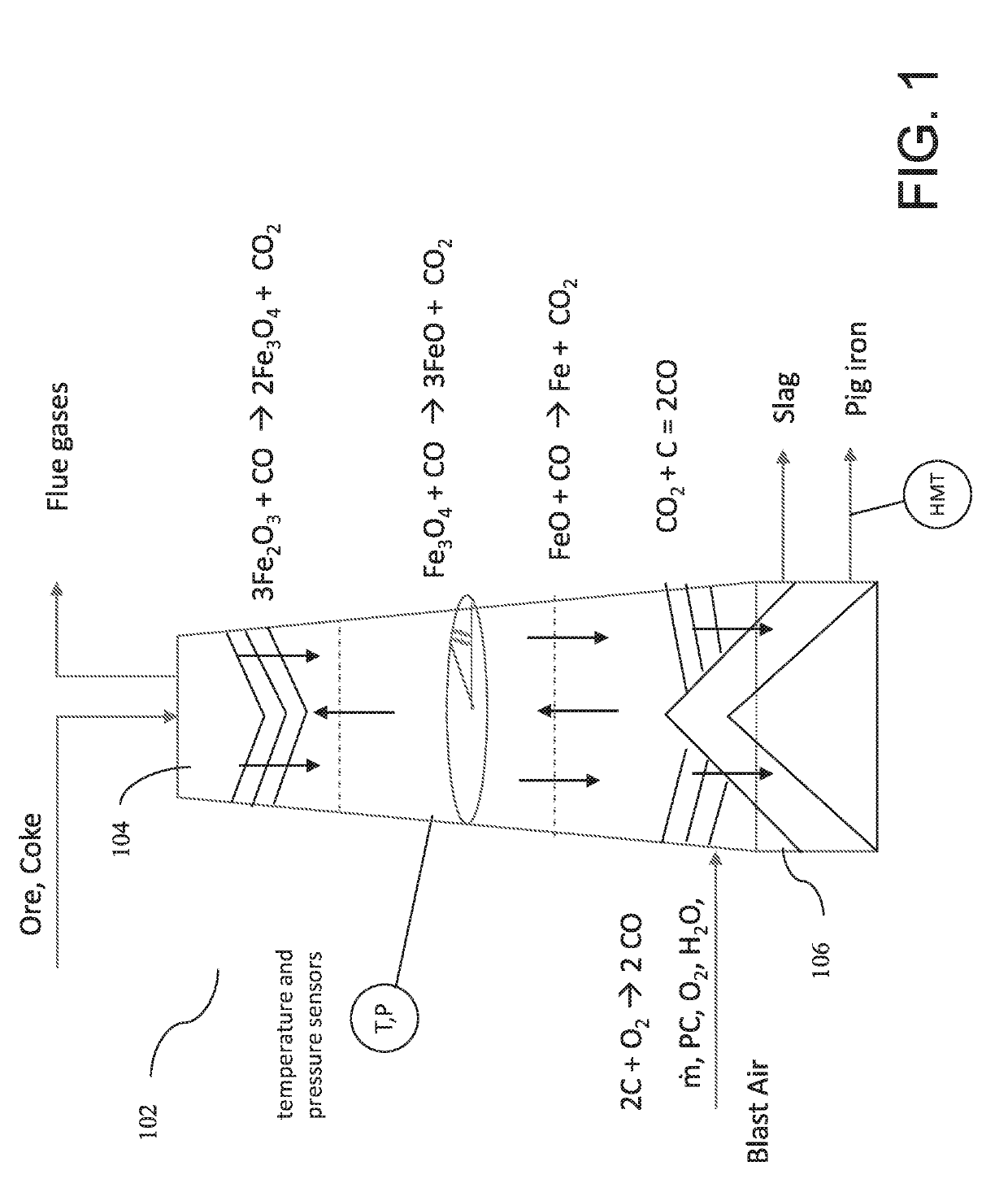

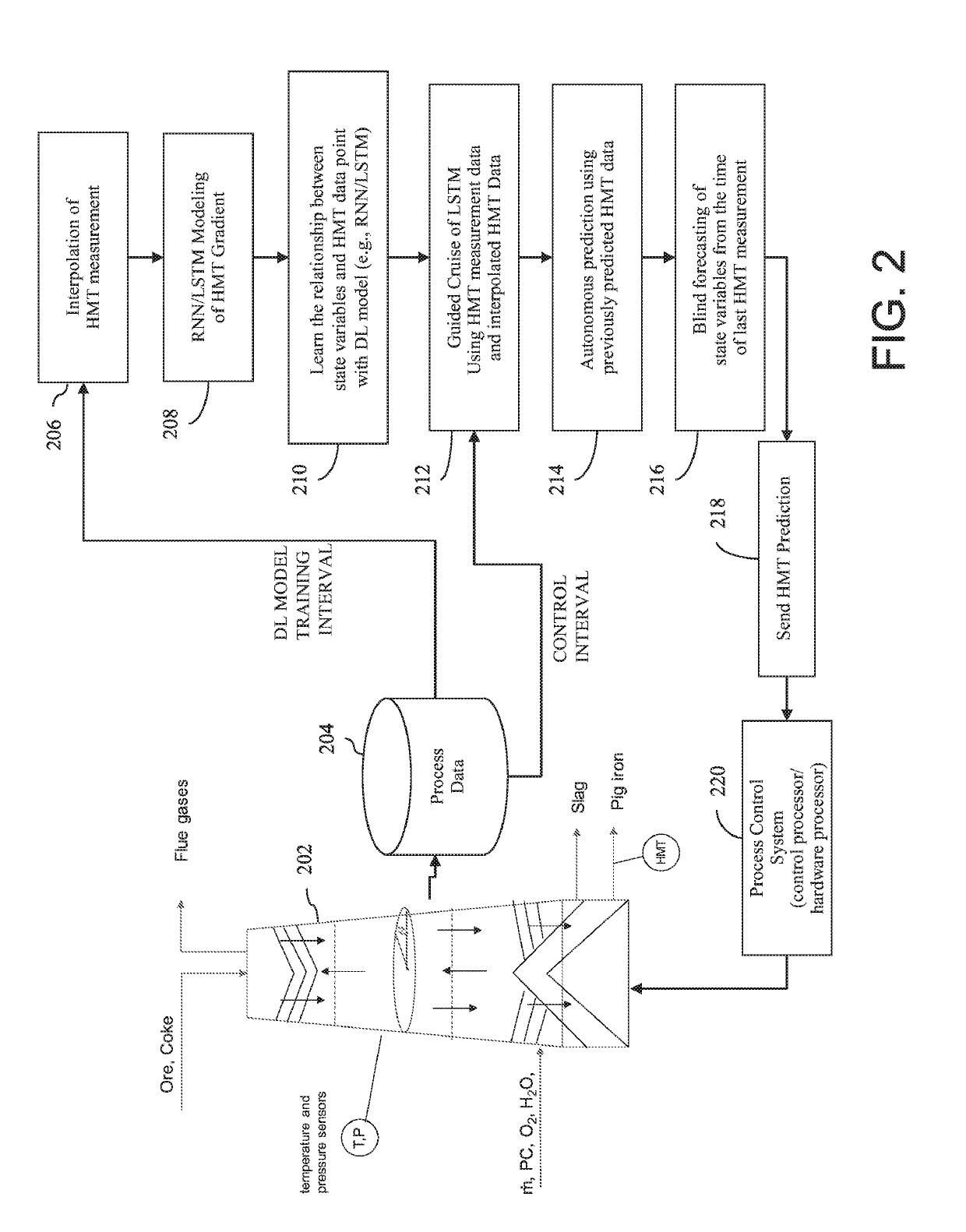

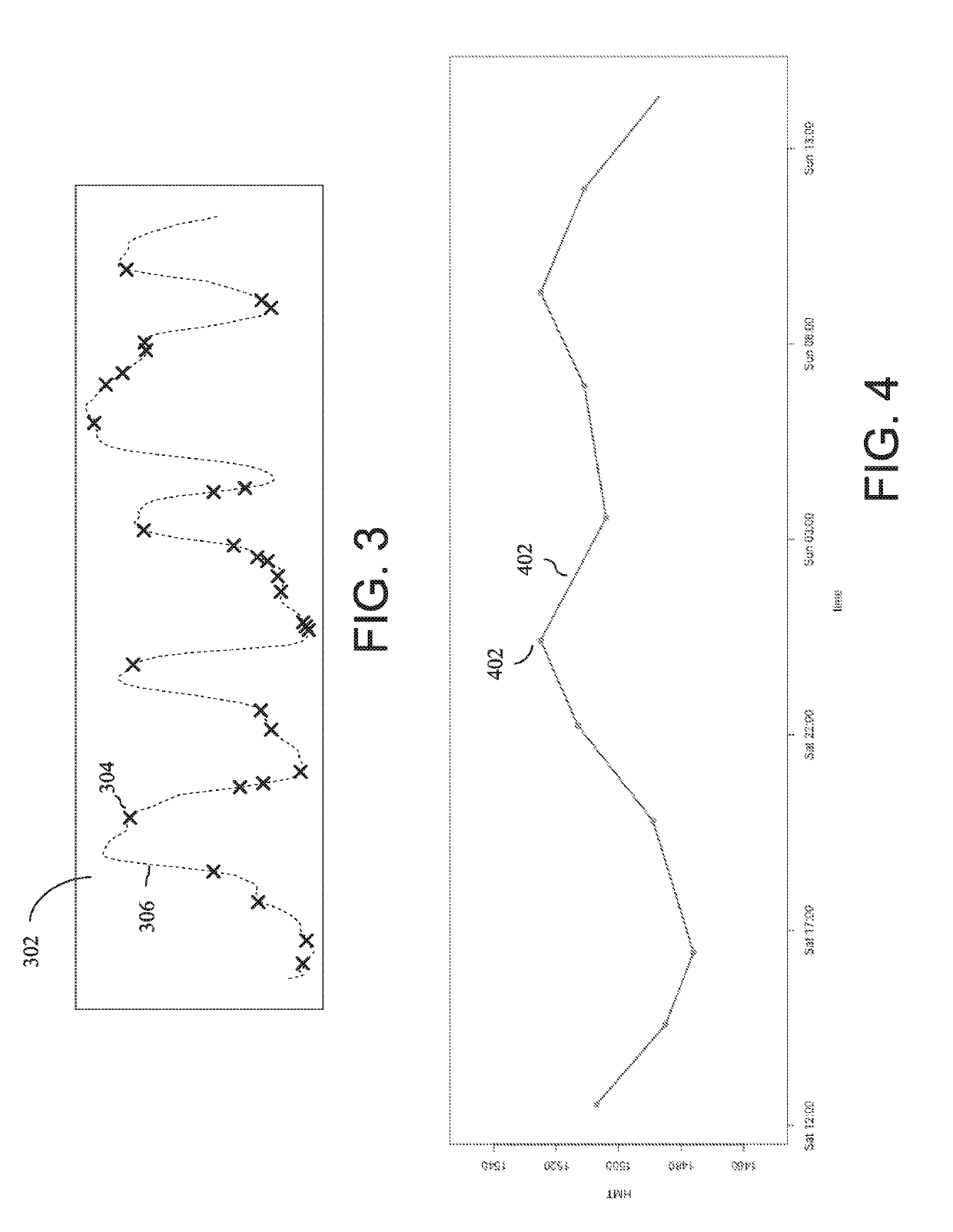

Manufacturing process control with deep learning-based predictive model for hot metal temperature of blast furnace

ActiveUS20190093186A1Thermometers using mean/integrated valuesMaterial thermal conductivityControl systemState variable

A blast furnace control system may include a hardware processor that generates a deep learning based predictive model for forecasting hot metal temperature, where the actual measured HMT data is only available sparsely, and for example, measured at irregular interval of time. HMT data points may be imputed by interpolating the HMT measurement data. HMT gradients are computed and a model is generated to learn a relationship between state variables and the HTM gradients. HMT may be forecasted for a time point, in which no measured HMT data is available. The forecasted HMT may be transmitted to a controller coupled to a blast furnace, to trigger a control action to control a manufacturing process occurring in the blast furnace.

Owner:IBM CORP

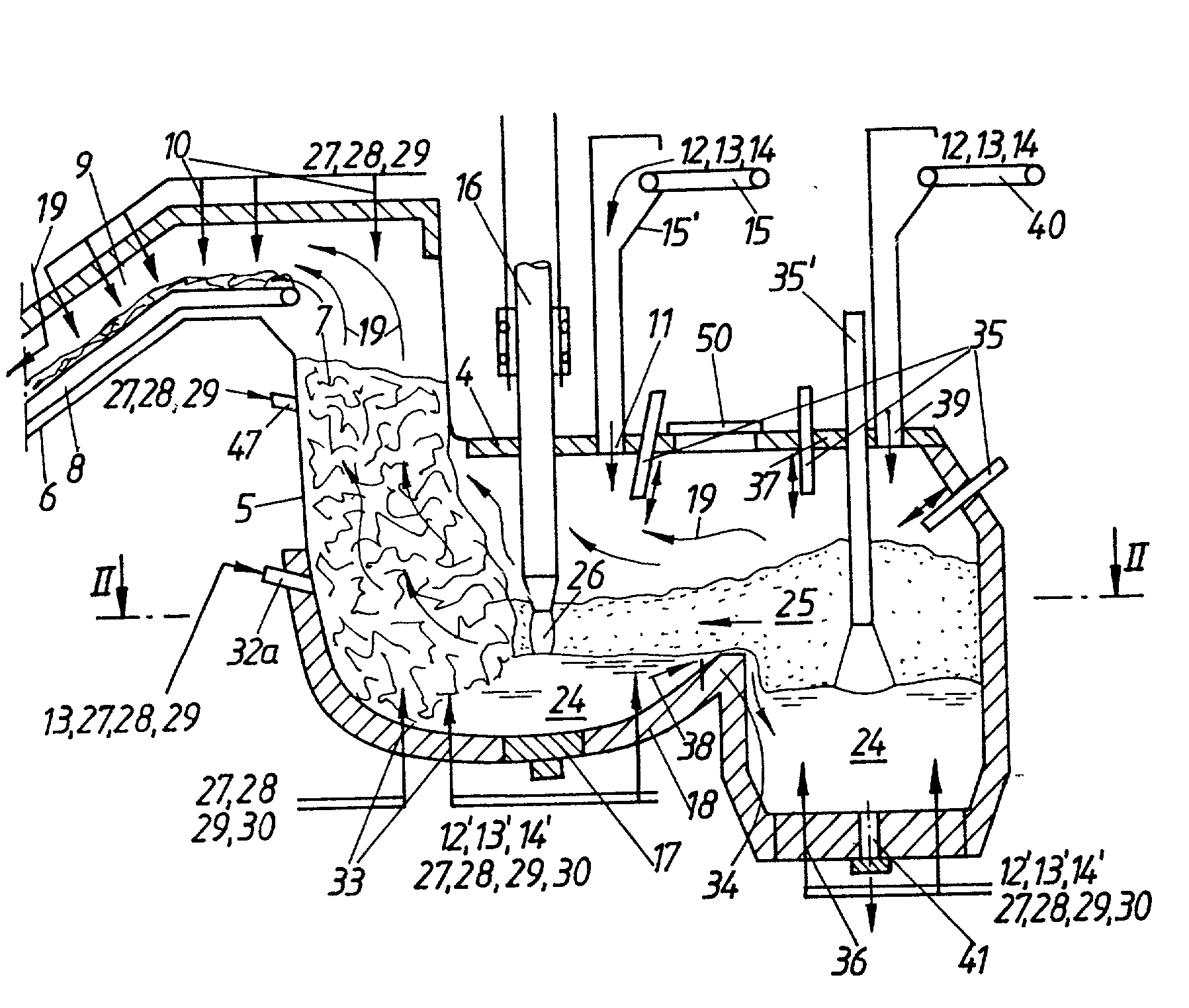

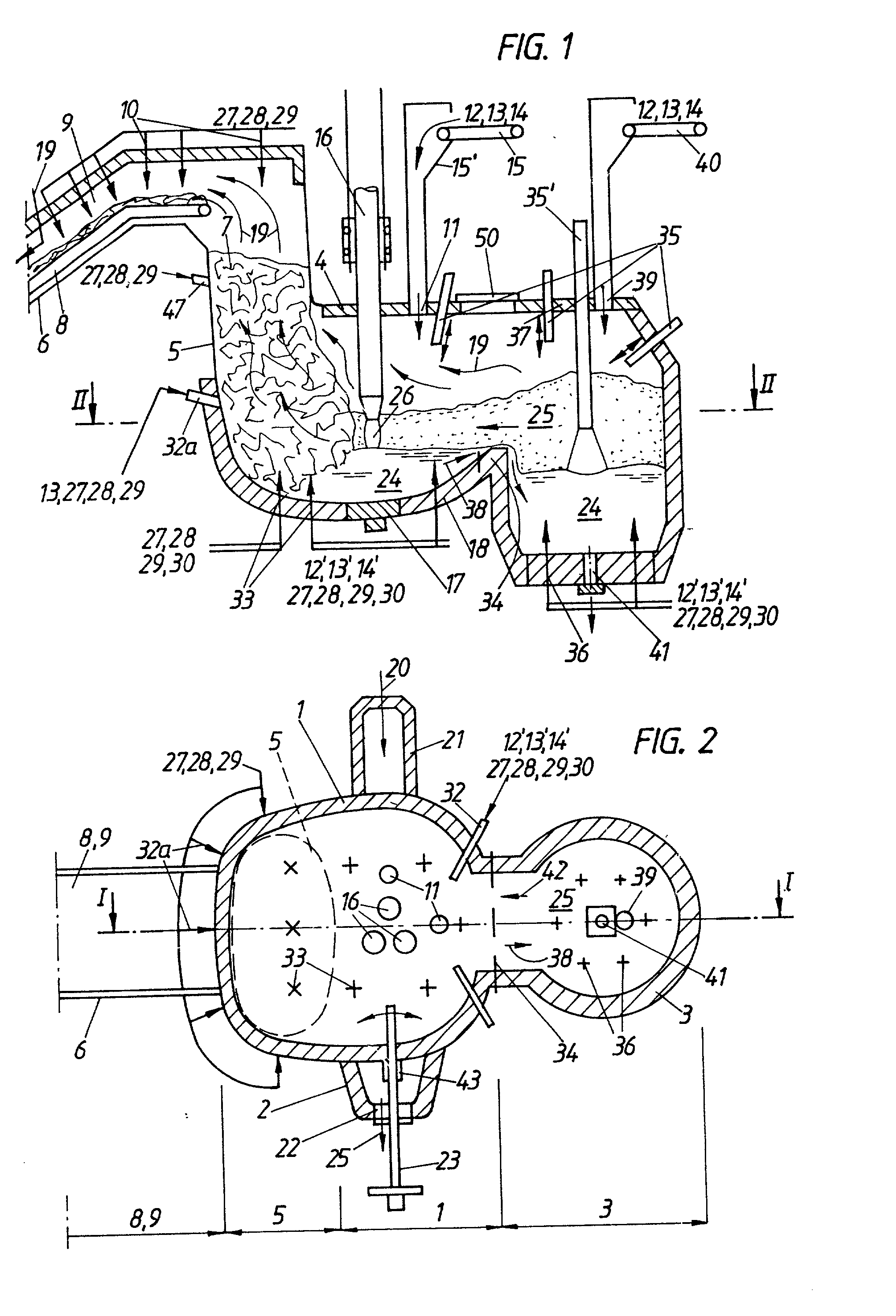

Process for the production of metal melts

InactiveUS20020005083A1Steel manufacturing process aspectsManufacturing convertersElectric arc furnaceSlag

To be able to produce metal melts using any metal carriers incurring in metallurgical practice as the charging materials, namely in the most diverse quantitative compositions, a plant for producing metal melts is provided with the following characteristic features: an electric arc furnace vessel (1) provided with one charging opening (11, 21) for a metal melt and / or scrap and / or direct educed metal, in particular direct reduced iron, and / or ore and at least one electrode (16) and one slag tapping means (22), an oxygen-blowing converter vessel (3) provided with one melt tapping means (41), wherein the oxygen-blowing converter vessel (3) and the electric arc furnace vessel (1) form a unit which is connected via an overflow weir (34) and which is rigidly mounted on the foundation and, wherein the bath surface related specifically to the bath volume is smaller in the oxygen-blowing converter vessel (3) than in the electric arc furnace vessel (1) and the oxygen-blowing converter vessel (3) shares a common reaction space with the electric arc furnace vessel (1), which space is arranged above the bath level of these vessels.

Owner:VOEST ALPINE AG

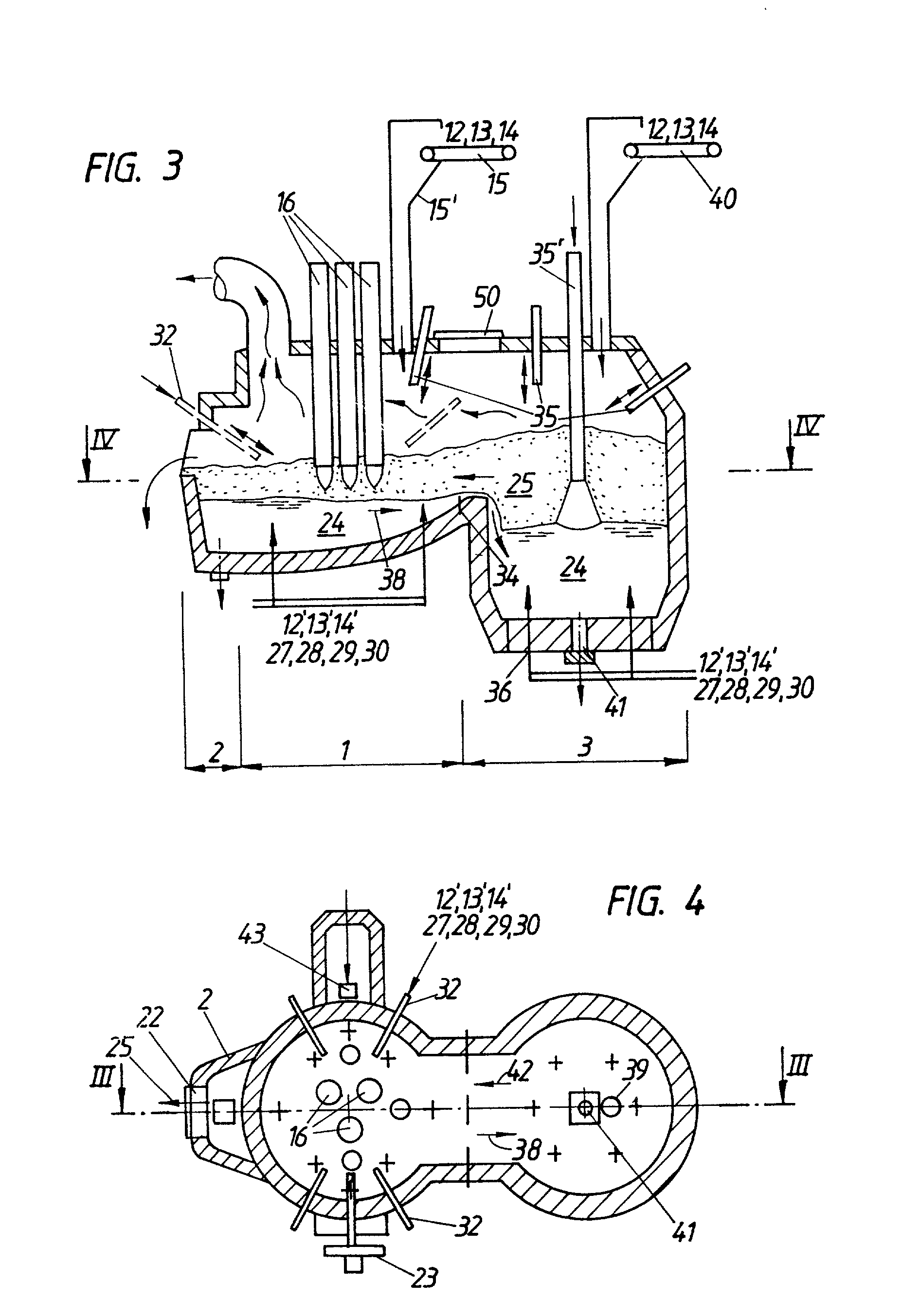

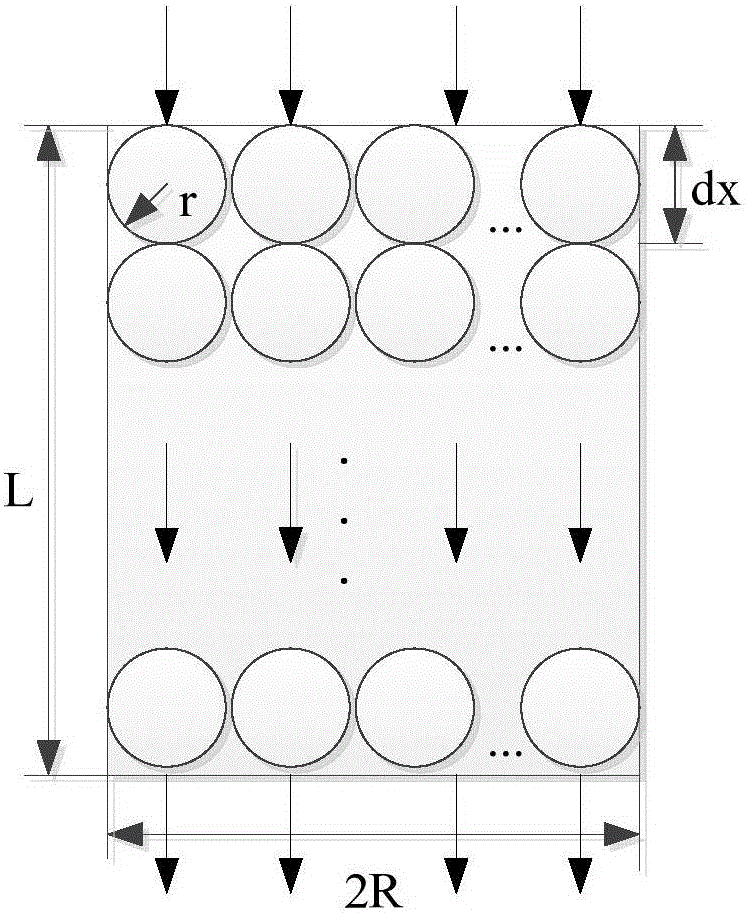

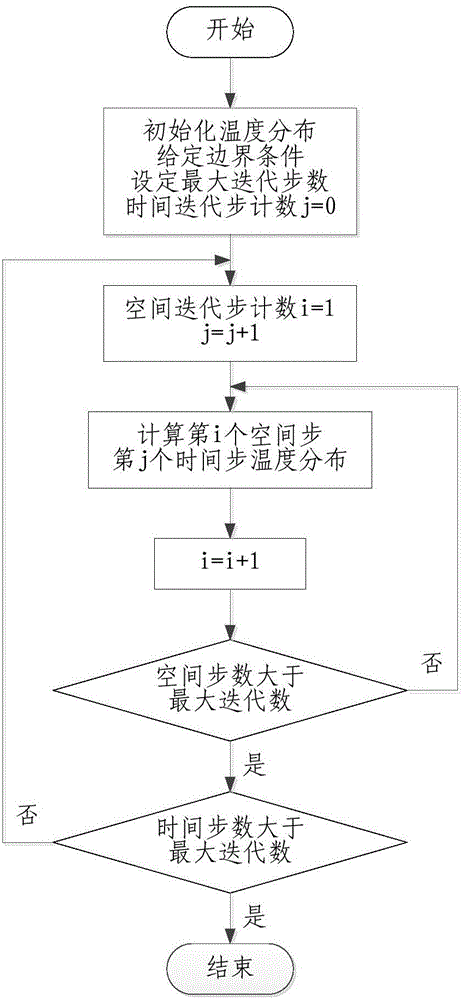

Method and system for ball type hot blast furnace sintering process modeling and energy consumption optimization

ActiveCN105907906ARealize automatic burning furnaceForecast temperatureSteel manufacturing process aspectsBlast furnace detailsTransient heat transferHot blast

The invention discloses a method and system for ball type hot blast furnace sintering process modeling and energy consumption optimization, and can realize purposes of energy saving and cost reduction. The method includes the steps: S1, according to heat transfer and fluid mechanics principles, establishing a regenerative chamber transient heat transfer model of a hot blast furnace in two stages of furnace sintering and air feeding, and providing boundary conditions and initial conditions for model calculation; S2, calculating the regenerative chamber transient heat transfer model, according to the calculated results of the regenerative chamber transient heat transfer model and with combination of a working system of the hot blast furnace, establishing an optimization model taking the coal gas volume as an optimized target and meeting the dome temperature, the exhaust gas temperature, the hot air flow quantity and temperature, the thermal efficiency and other constraint conditions by a method of time-dividing optimization of the coal gas flow quantity; S3, solving the optimization model, to obtain a change curve of the coal gas flow quantity having minimum energy consumption along with the time; and S4, controlling the coal gas flow quantity of the ball type hot blast furnace sintering process according to the change curve of the coal gas flow quantity along with the time.

Owner:CENT SOUTH UNIV

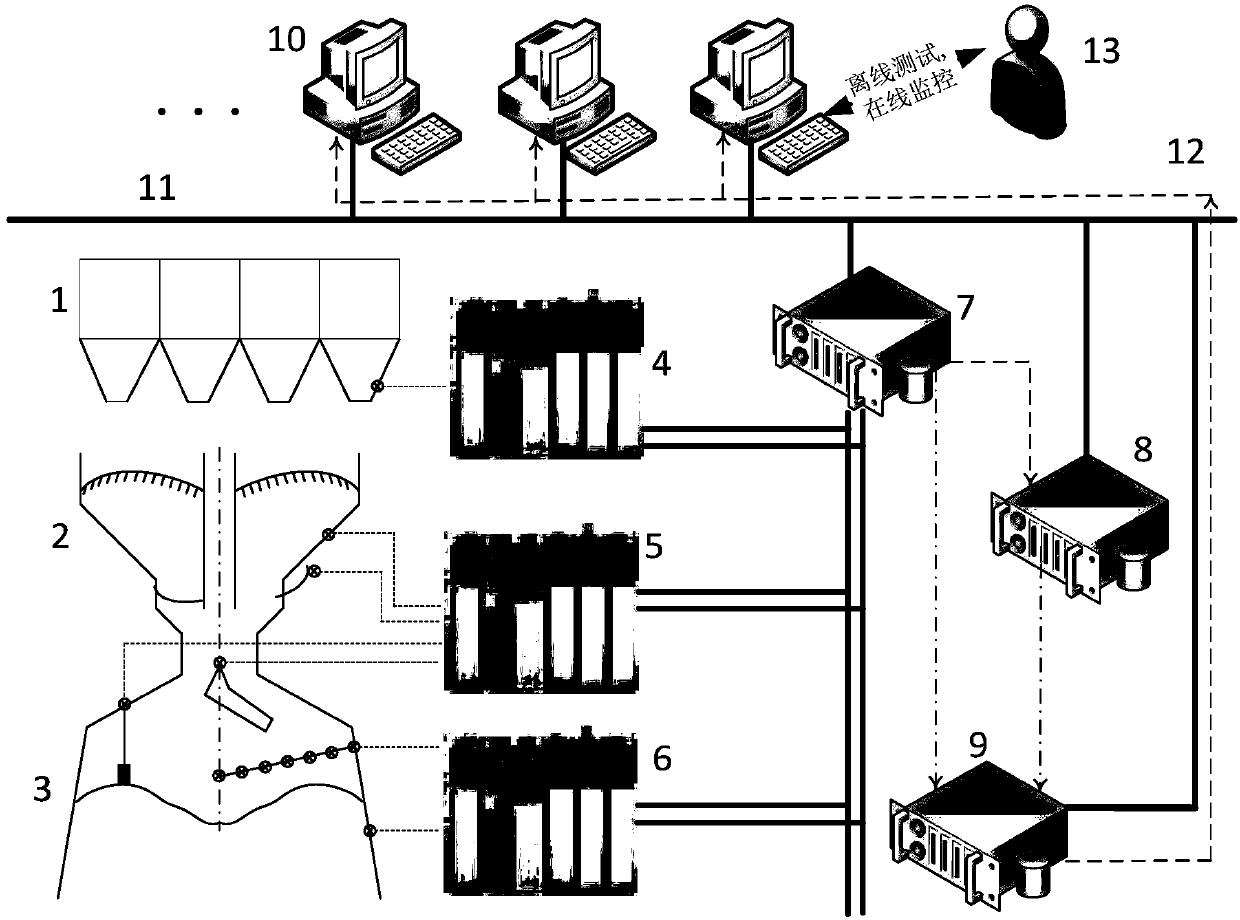

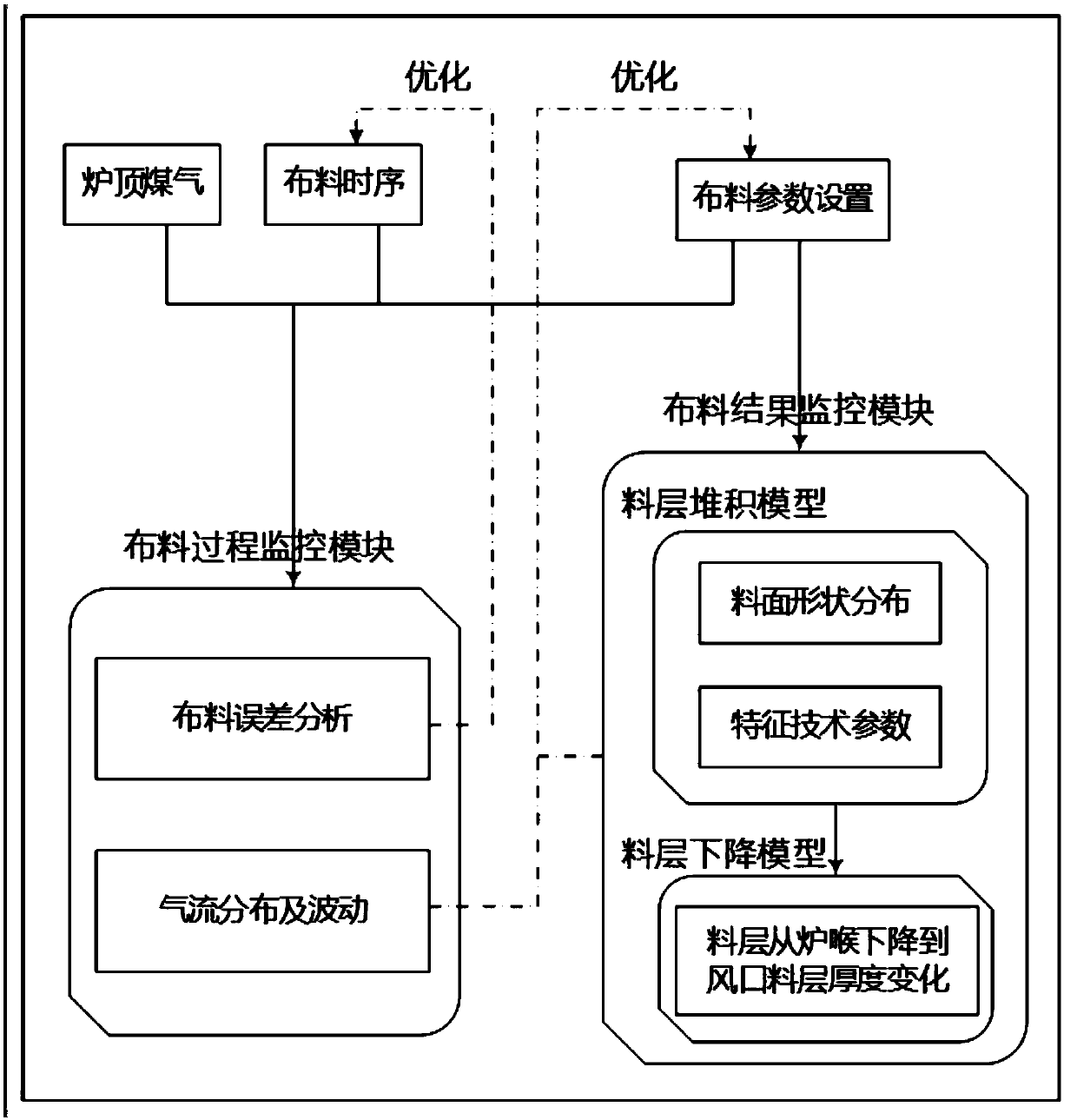

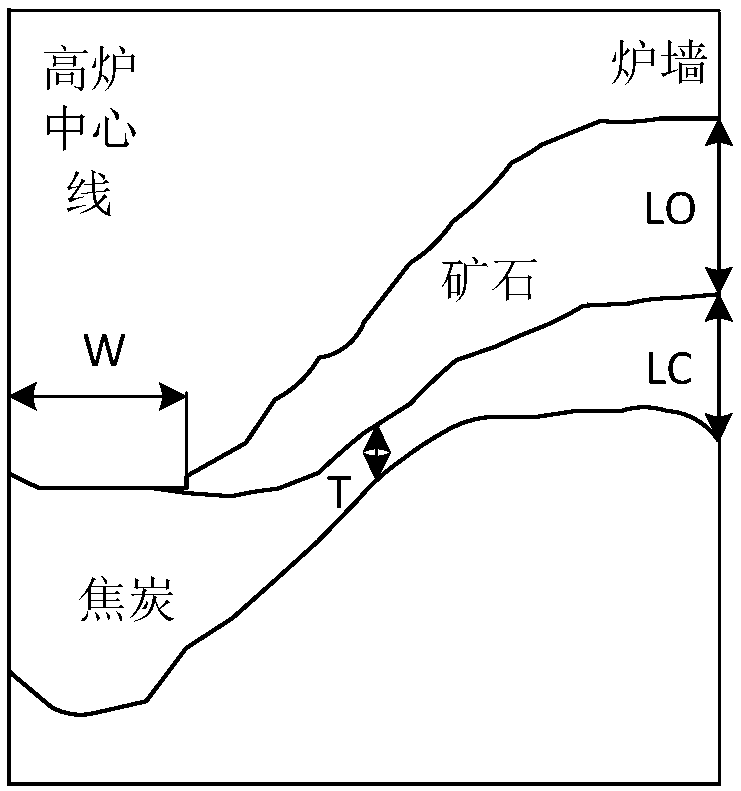

Blast furnace burden distribution intelligent monitoring system and adjusting method

ActiveCN107723399APrevent steepReduce airflow fluctuationsSteel manufacturing process aspectsBlast furnace detailsReal-time dataProgrammable logic controller

The invention discloses a blast furnace burden distribution intelligent monitoring system and an adjusting method. The blast furnace burden distribution intelligent monitoring system is characterizedin that a communication server is used for transmitting setting parameters and real time data of a Programmable Logic Controller (PLC) of a system under a trough of a blast furnace, a PLC of a furnacetop burden distribution system and a PLC of a blast furnace body to a data acquisition server; and a function server is used for processing and modeling the data of the data acquisition server, establishing a burden distribution process monitoring module and a burden distribution result monitoring module and passing back results to each client through a browser / server framework. An operator optimizes the time sequence of burden distribution and adjusts the parameters of burden distribution through the burden distribution process monitoring module and the burden distribution result monitoringmodule on each client, so that the accurate control over the burden distribution is realized; and the design and optimization of burden distribution parameters are carried out by using the off-line function of the burden distribution result monitoring module, so that the airflow stability of the burden distribution process is ensured, the reasonable distribution of airflow is realized, and the optimized parameters are used for the operation control of the practical blast furnace. The system realizes the whole internet availability after being installed at one place, and is convenient to use and simple to maintain.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

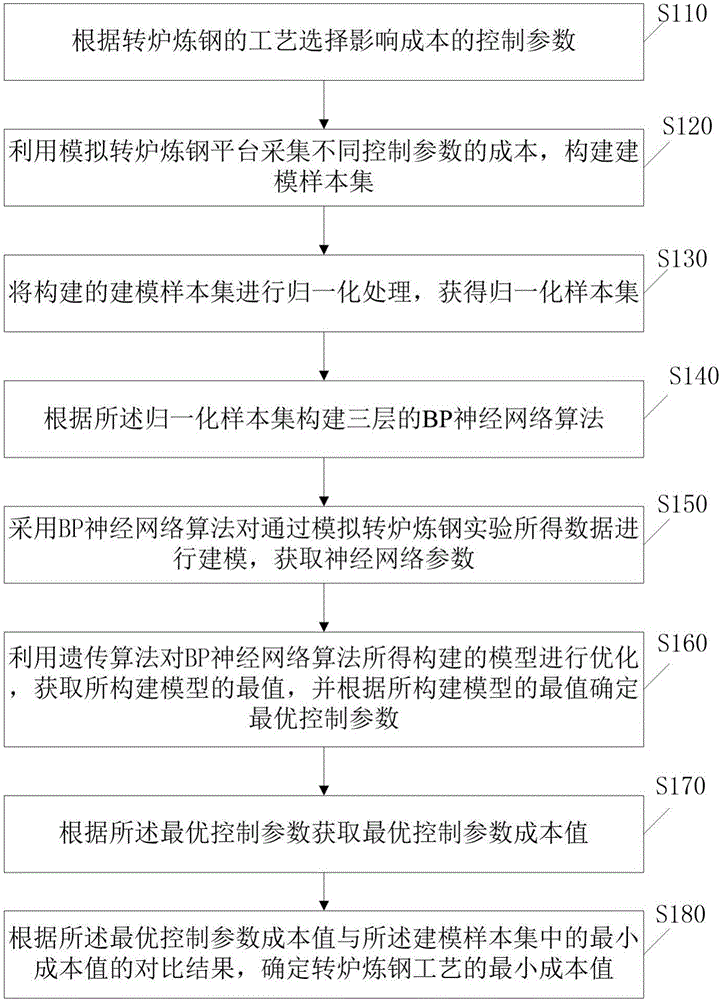

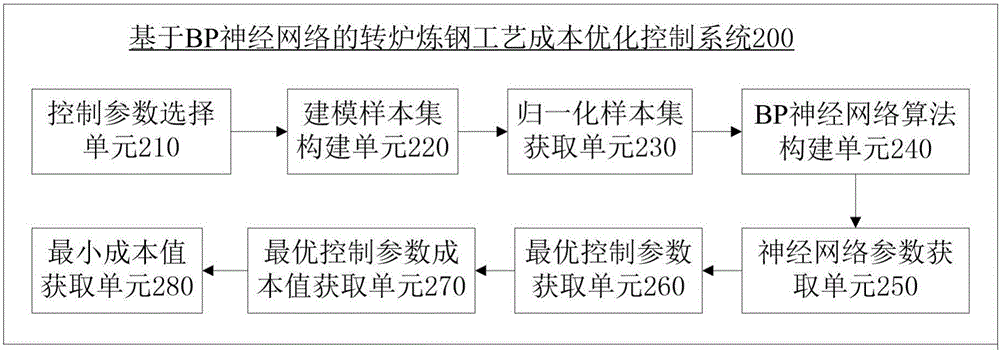

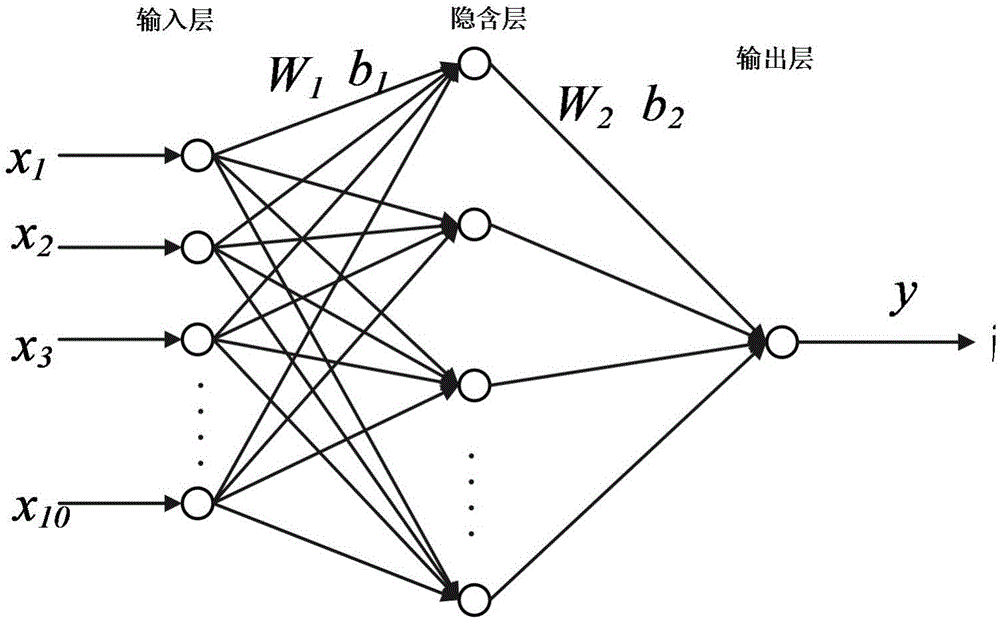

Converter steelmaking process cost control method and system based on BP neural network

ActiveCN106119458ASolve the problem of high cost of converter steelmakingHigh cost of solutionSteel manufacturing process aspectsIncreasing energy efficiencyModel sampleSteelmaking

The invention provides a converter steelmaking process cost optimal control method and system based on the BP neural network. The method comprises the steps that control parameters affecting the cost are selected according to a converter steelmaking process; a modeling sample set is established; a uniformization sample set is obtained; three layers of BP neural network algorithms are established; modeling is conducted on data obtained through converter steelmaking simulation experiments by adoption of the BP neural network algorithms, and neural network parameters are obtained; by use of a genetic algorithm, models established through the BP neural network algorithms are optimized, extremums of the established models are obtained, and optimal control parameters are determined according to the extremums of the established models; and the minimum cost value of the converter steelmaking process is determined according to the comparison results of obtained optimal control parameter cost values and the minimum cost values in the modeling sample set. The problem of the high cost of the converter steelmaking can be solved by use of the converter steelmaking process cost control method and system based on the BP neural network.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Manufacturing process control with deep learning-based predictive model for hot metal temperature of blast furnace

ActiveUS20190093187A1Thermometers using mean/integrated valuesMaterial thermal conductivityControl systemState variable

A blast furnace control system may include a hardware processor that generates a deep learning based predictive model for forecasting hot metal temperature, where the actual measured HMT data is only available sparsely, and for example, measured at irregular interval of time. HMT data points may be imputed by interpolating the HMT measurement data. HMT gradients are computed and a model is generated to learn a relationship between state variables and the HTM gradients. HMT may be forecasted for a time point, in which no measured HMT data is available. The forecasted HMT may be transmitted to a controller coupled to a blast furnace, to trigger a control action to control a manufacturing process occurring in the blast furnace.

Owner:IBM CORP

Method for treating converter mouth slag through oxygen blowing by oxygen lance

InactiveCN106367557AImprove converter operating rateWill not harmSteel manufacturing process aspectsIncreasing energy efficiencyWorking pressureSlag

The invention discloses a method for treating converter mouth slag through oxygen blowing by an oxygen lance. The method includes the steps of arranging the position of the oxygen lance and setting the oxygen pressure. Specifically, the method includes the steps of building a mathematic model between the position h of the oxygen lance and an impact converter mouth diameter Dimpact, the number M of spraying holes of the oxygen lance, the included angle alpha between the spraying holes and the center of the oxygen lance as well as the expansion angle beta of spraying holes of a Laval nozzle and determining the position h of the oxygen lance through the mathematic model, wherein h is equal to Dimpact / [(M+1)*tan(alpha+beta)] according to the mathematic model; and setting the oxygen pressure of the oxygen lance to be 60-65% of the normal work pressure of the oxygen lance, and carrying out slag removal operation in the sample waiting process after converting, lance lifting, temperature measuring and sampling. According to the method, by reasonably arranging the position of the oxygen lance and setting the work pressure and the oxygen blowing time, the converter mouth slag is treated through oxygen blowing by the oxygen lance, and damage to converter equipment and converter linings is avoided. Compared with methods of treating the slag through a converter disassembly machine, the method has the advantages that 25 minutes is saved each time, the production and operation efficiency is greatly improved, the operation is safe and fast, and the slag clearing effect is good.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

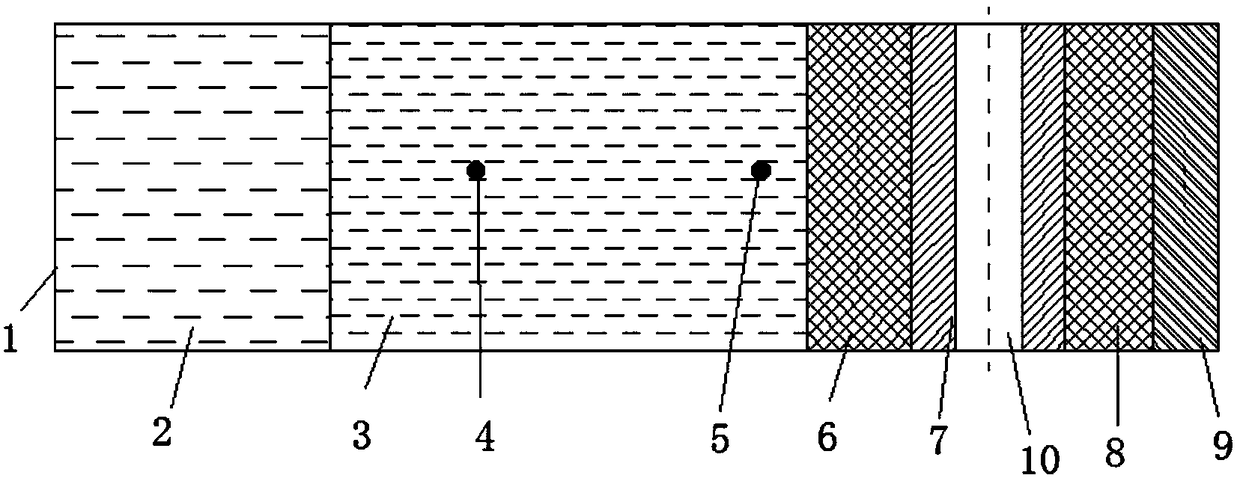

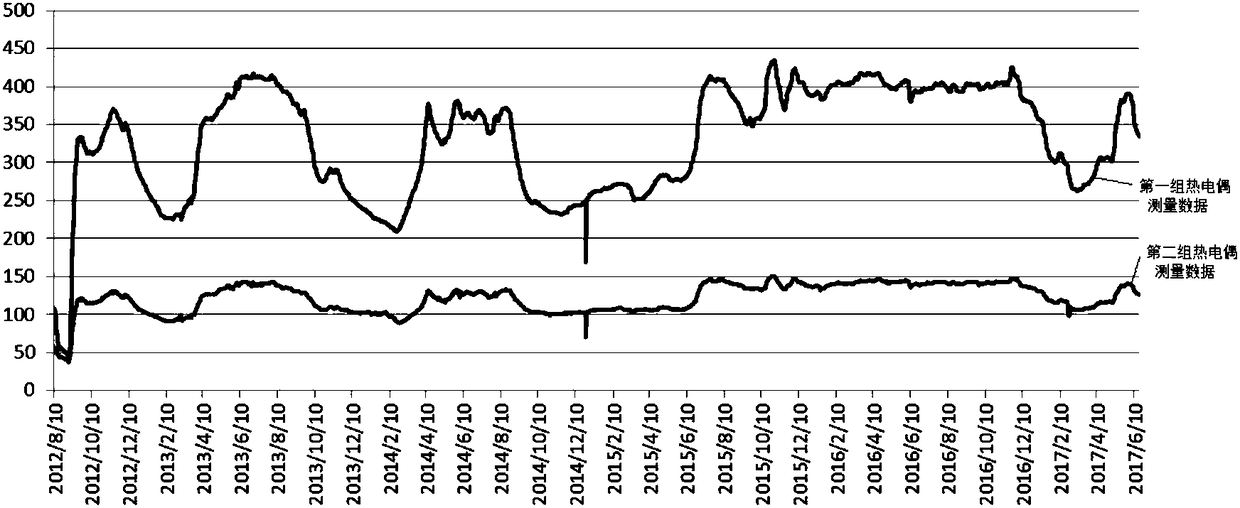

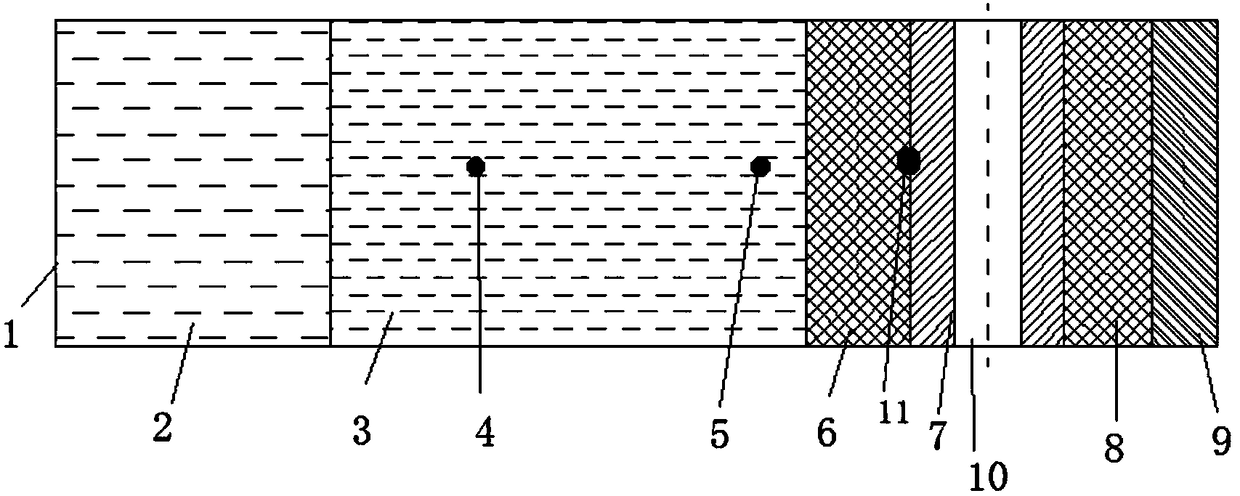

Blast furnace hearth sidewall monitoring method

InactiveCN108517384AEliminate false positivesPracticalSteel manufacturing process aspectsBlast furnace detailsBrickHeat flow

The invention provides a blast furnace hearth sidewall monitoring method. According to the monitoring method, the angular heat flow densities of hearth sidewall monitoring positions are obtained, thetemperature is detected by a thermocouple arranged in carbon bricks of the hearth, based on the angular heat flow densities, the temperature, and the angular heat flow density of the hearth lining, the heat resistant values of different positions can be calculated, and the damages of the hearth sidewall can be diagnosed. According to the method, the change rules of onsite detected variables such as temperature are used to judge the situation of a blast furnace hearth; through the thermal resistant values of different positions and change rates in a certain period, the hearth can be diagnosed,the wrong judgment caused by onsite interference, fluctuation of the furnace situations, and change of cooling conditions can be eliminated, and multiple types of damages can be effectively diagnosedat the same time.

Owner:CENT SOUTH UNIV

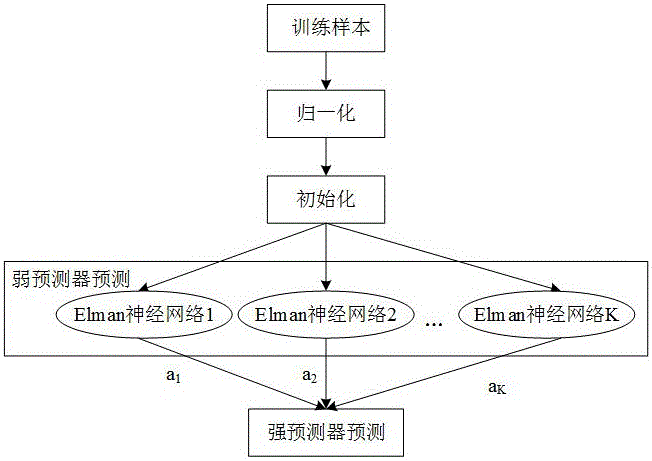

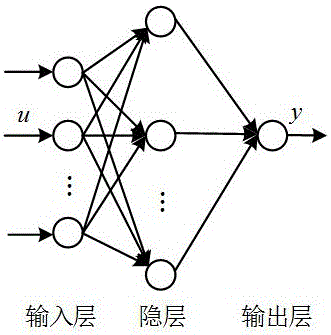

Method for predicting content of silicon in molten iron on basis of Elman-Adaboost strong predictor

InactiveCN106096637AEasy to think ofEasy to implementSteel manufacturing process aspectsBlast furnace detailsAdaboost algorithmModeling and simulation

The invention discloses a method for predicting content of silicon in molten iron on the basis of an Elman-Adaboost strong predictor, and belongs to the fields of monitoring, modeling and simulation of industrial process. The method comprises the following steps of: firstly selecting proper input variables, normalizing the input variables to serve as inputs of K weak predictors; secondly, determining an initial weight value of a training sample; thirdly, respectively training the K weak predictors, updating the weight value of the sample according to the training results, and carrying out repeated training; and finally, calculating the weights of the weak predictors, and fusing the plurality of weak predictors to obtain a prediction result of the strong predictor. Through the dynamics of a blast furnace ironmaking process, the precision of predicting the content of the silicon in the molten iron is not high; aiming at the problem, the method selects Elman neural networks with relatively good dynamics as weak predictors, and fuses the plurality of weak predictors according to an Adaboost algorithm to obtain the Elman-Adaboost strong predictor; and the researches of the method applied to predicting the content of the silicon still belong to a blank space. Compared with the conventional methods, the method disclosed by the invention has higher precision of predicting the content of the silicon in the molten iron.

Owner:ZHEJIANG UNIV

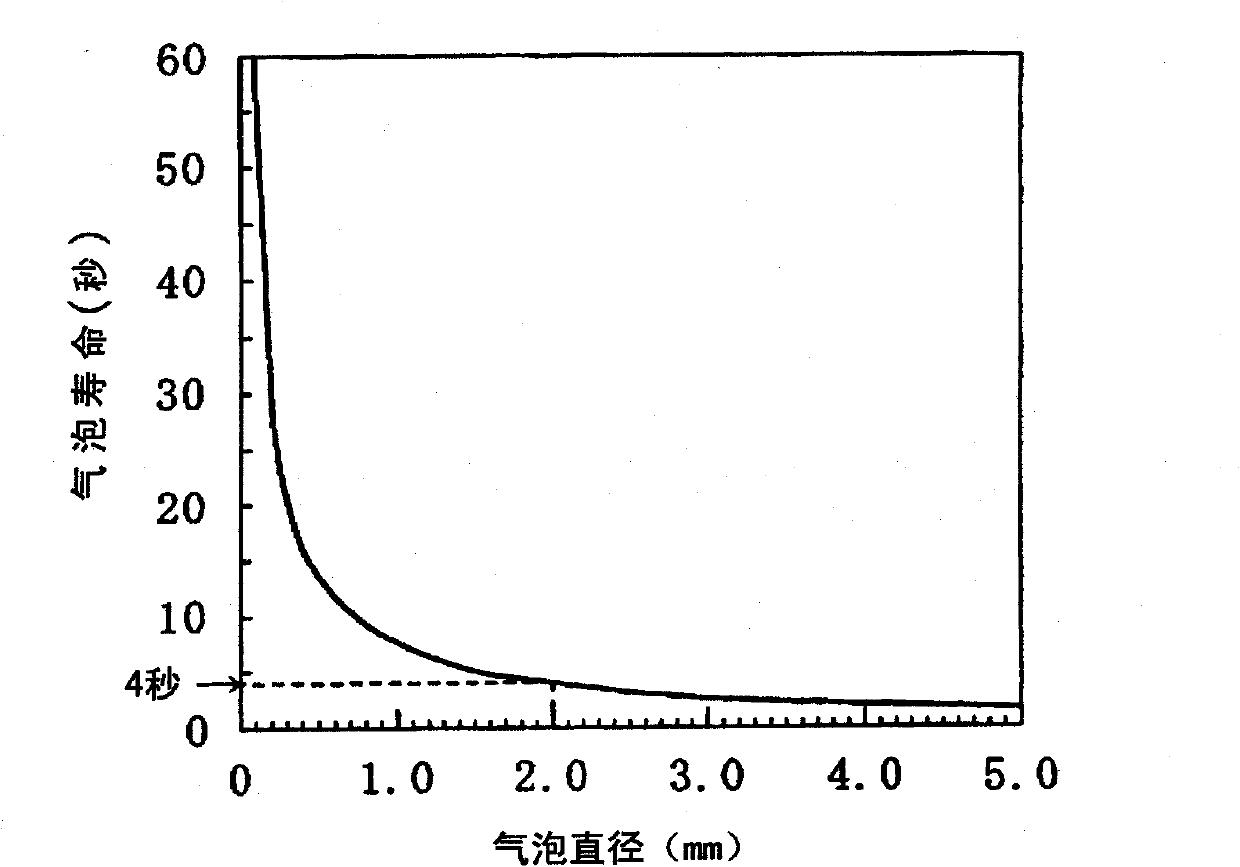

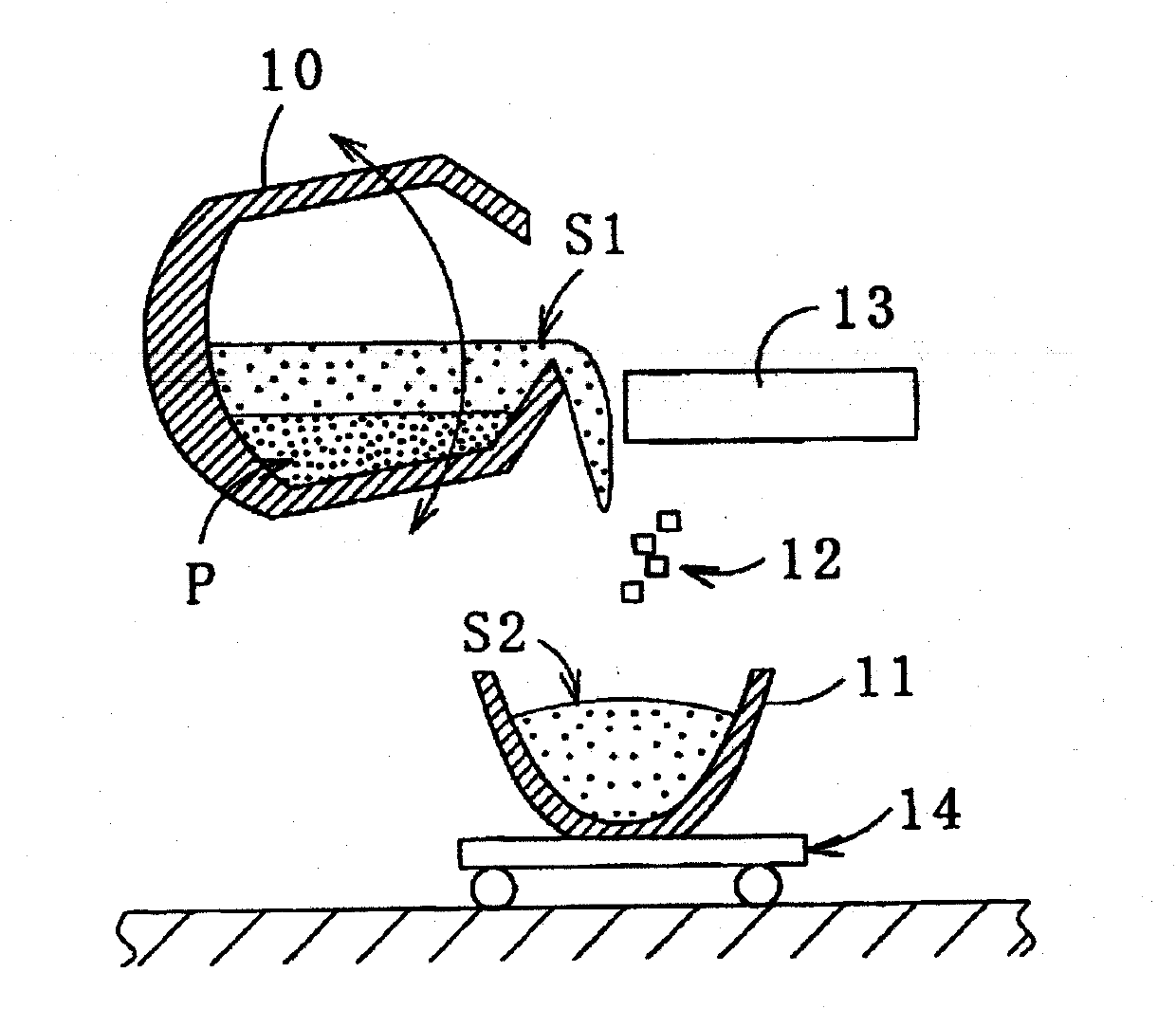

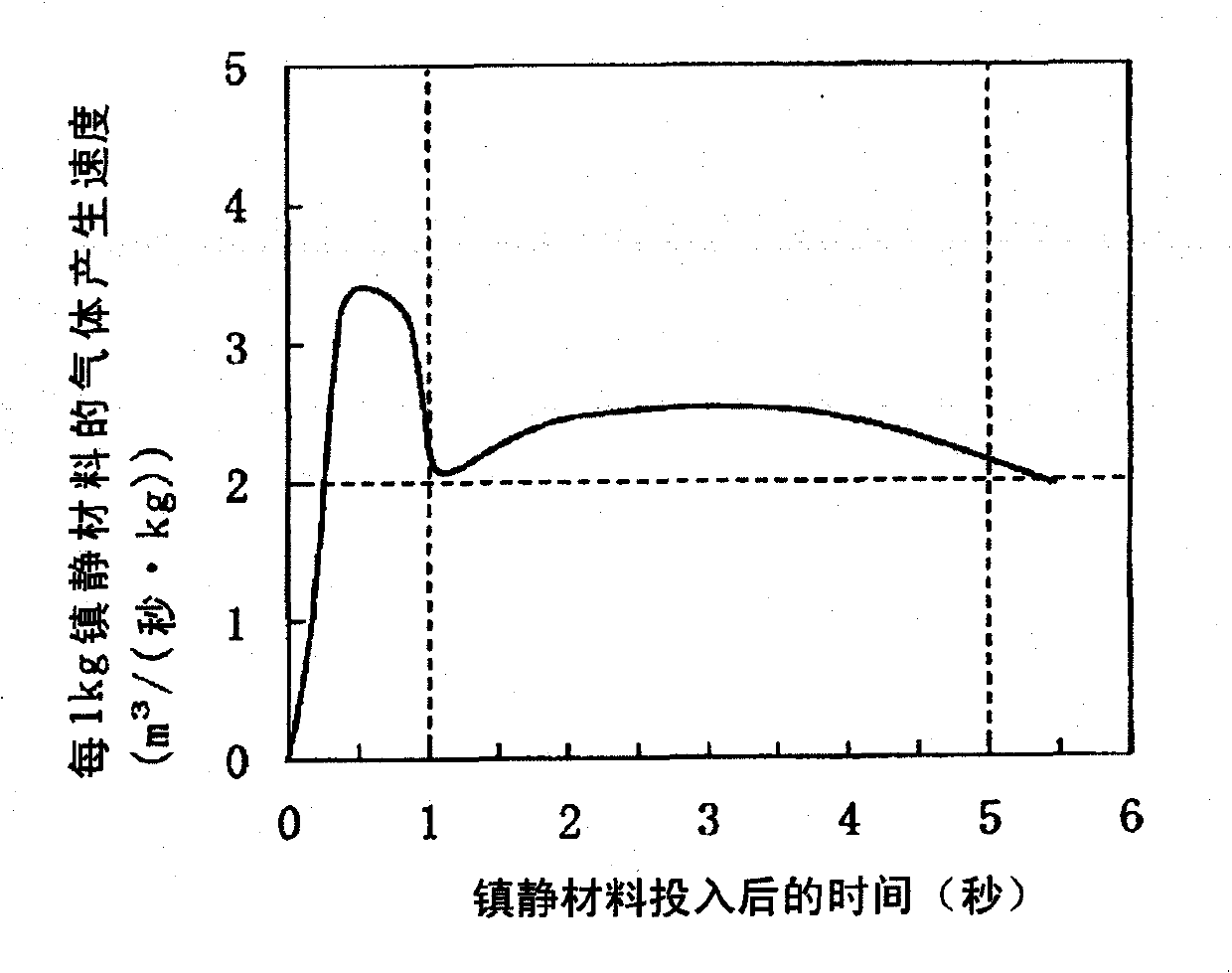

Slag foaming killing material, and slag foaming killing method

ActiveCN102016081ALow costAvoid foamingSteel manufacturing process aspectsManufacturing convertersSlagMoisture

Disclosed is a slag foaming killing material which comprises: a mixture comprising 20 to 40 mass% (inclusive) of a carbon powder having a grain size of 0.2 to 2 mm (inclusive) and 30 to 60 mass% (inclusive) of water; and a container comprising a moisture-impermeable combustible substance and having the mixture contained therein.

Owner:NIPPON STEEL CORP

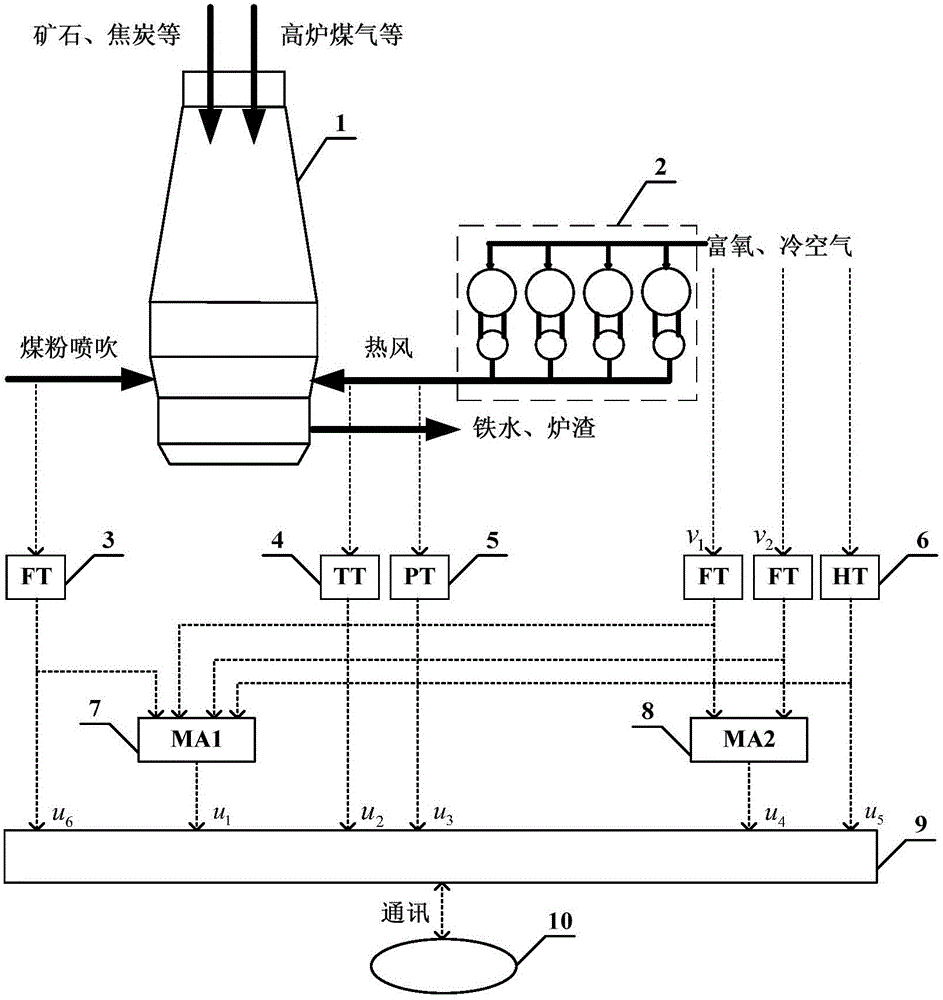

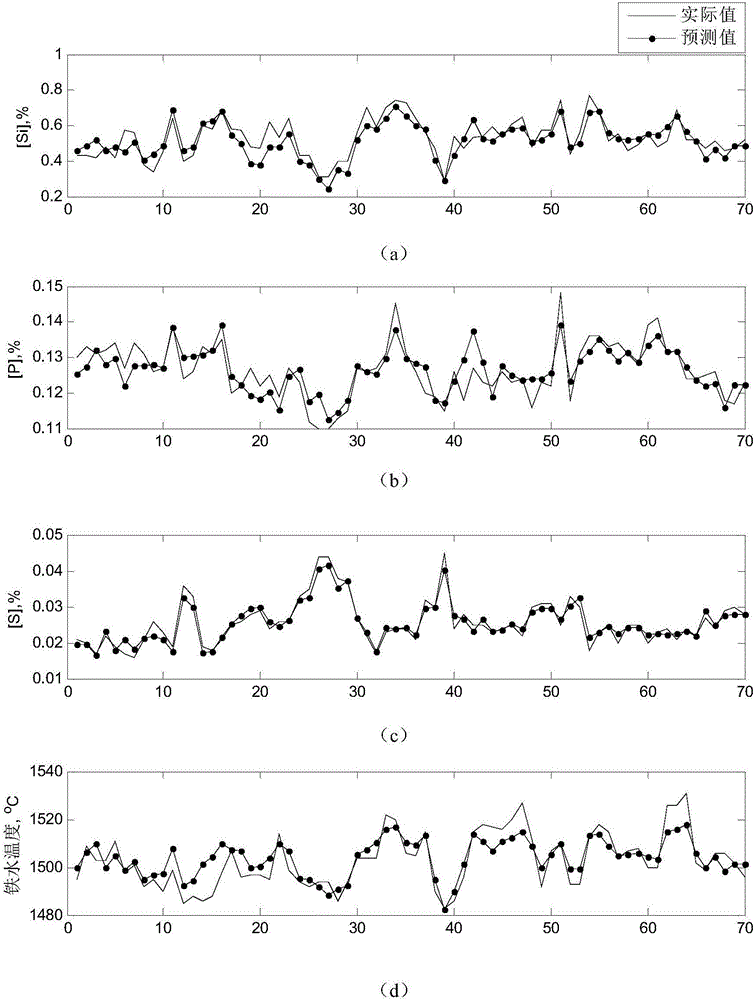

Soft measuring system and method for quality indexes of multielement molten iron of blast furnace

InactiveCN105821170ARealization of dynamic soft sensorSimple structureSteel manufacturing process aspectsForecastingHysteresisNoise removal

Provided are a soft measuring system and method for the quality indexes of multielement molten iron of a blast furnace. The system comprises a data collecting unit, a data preprocessing unit and a soft measuring unit. The method comprises the steps that parameters needed for soft measurement of the quality indexes of multielement molten iron of the blast furnace are acquired; the parameters needed for dynamic soft measurement of the quality indexes of multielement molten iron of the blast furnace are subjected to filtering, noise removal and normalization processing; dynamic soft measurement of multielement molten iron of the blast furnace is carried out through a blast furnace multielement molten iron quality index dynamic soft measurement model; and the parameters needed for soft measurement of the quality indexes of multielement molten iron of the blast furnace obtained after filtering and normalization processing are adopted as input, the current quality indexes of multielement molten iron of the blast furnace are adopted as output, output self-feedback is adopted, and the quality indexes of multielement molten iron of the blast furnace are dynamically predicted through online recurrence. The sequential relationship between the hysteresis characteristic of the blast furnace melting process and input and output variables is considered, the recurrence subspace intelligent modeling technology is adopted, and dynamic online soft measurement of the quality indexes of multielement molten iron of the blast furnace in the smelting process is achieved.

Owner:NORTHEASTERN UNIV

Automatic steelmaking method suitable for low-slag smelting

InactiveCN107502698ARealize "one-key" steelmakingImprove hit rateSteel manufacturing process aspectsIncreasing energy efficiencySteelmakingSmelting process

The invention relates to an automatic steelmaking method suitable for low-slag smelting, and belongs to the technical field of metallurgy steelmaking. The technical scheme is as follow: slag remaining amount and furnace slag information of a converter are collected, and an early-stage deslagging target of converting heat is determined; a heat converting control mode is determined according to feeding raw material information, the slag remaining amount and the tapping target requirements of the converter; a first-stage system of the converter is controlled to carry out automatic converting, and a one-key type steelmaking of the low-slag smelting process is realized; and online adjustment is carried out on the model calculation module by utilizing a self-learning function of a model, so that the hit rate of a converting endpoint is improved, production cost is reduced, and labor productivity is improved. According to the automatic steelmaking method, the online application can be realized only by relying on an existing sublance system and a computer system, cost is low, maintenance is convenient, and the stability is good; and when the blowing end point C error is within the range of + / - 0.02% and the temperature error is within the range of + / -10 DEG C, the hit rate can reach more than 92%.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

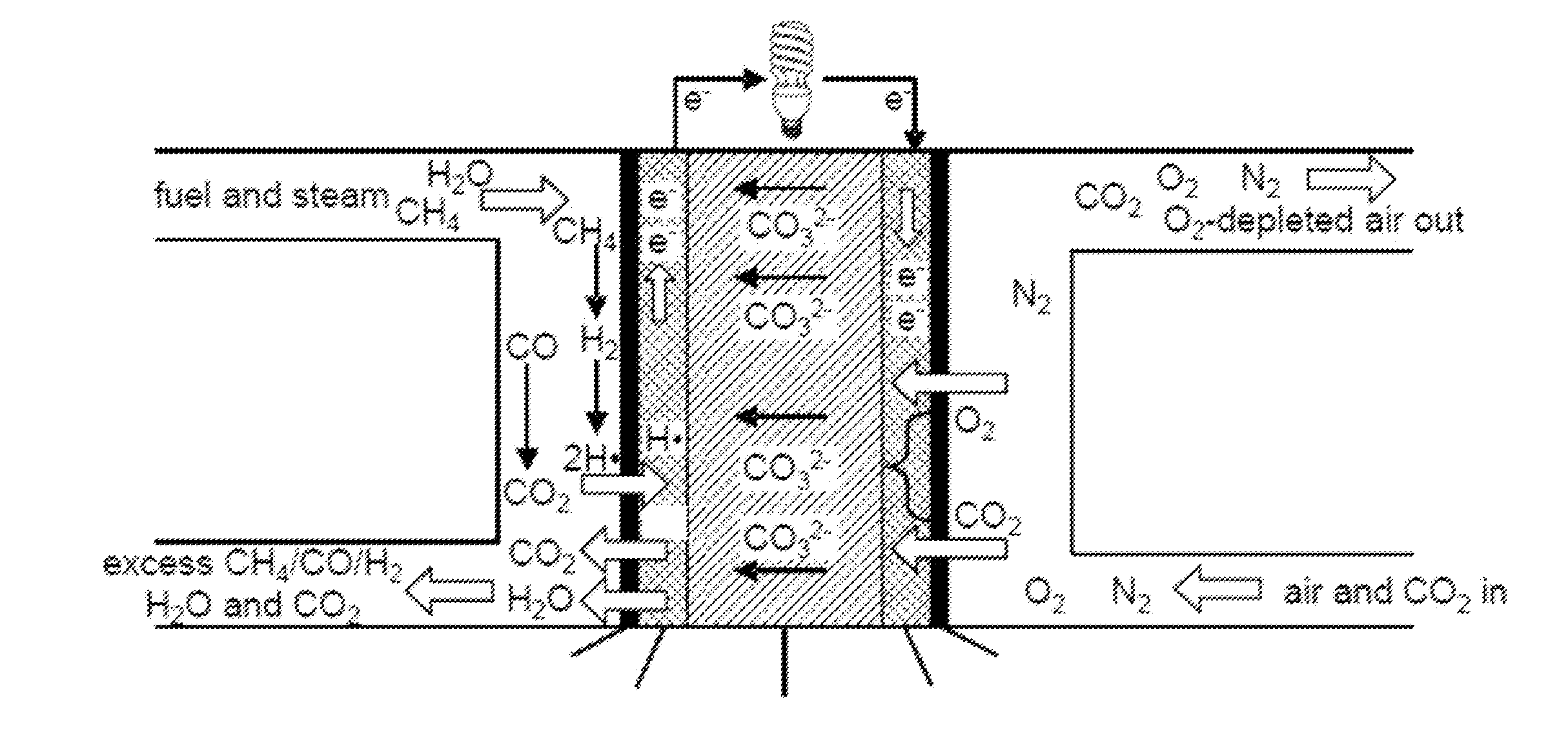

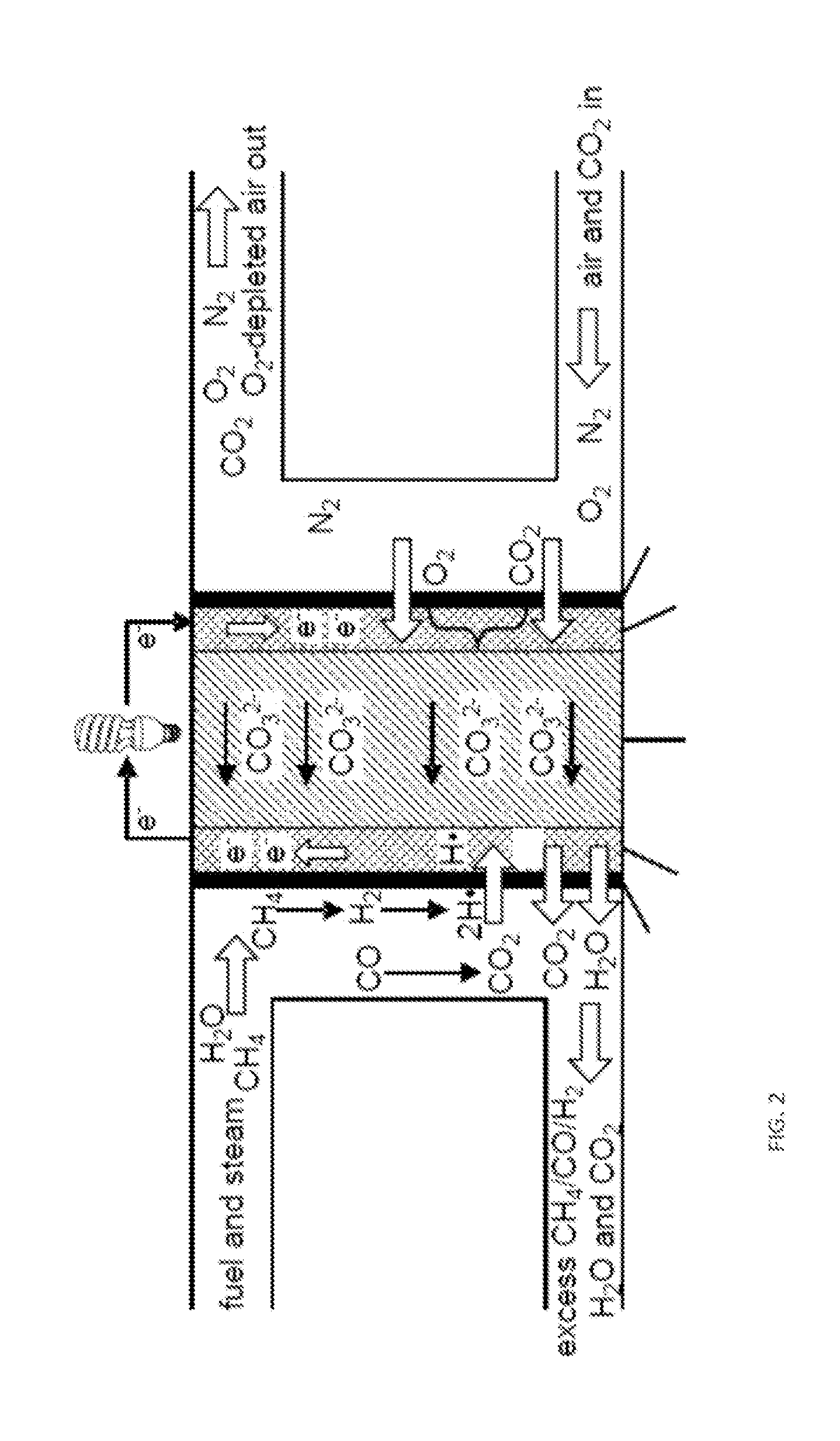

Integrated power generation and carbon capture using fuel cells

InactiveUS20140272618A1Internal combustion piston enginesFinal product manufactureFuel cellsCombustion

Systems and methods are provided for capturing CO2 from a combustion source using molten carbonate fuel cells (MCFCs). The fuel cells are operated to have a reduced anode fuel utilization. Optionally, at least a portion of the anode exhaust is recycled for use as a fuel for the combustion source. Optionally, a second portion of the anode exhaust is recycled for use as part of an anode input stream. This can allow for a reduction in the amount of fuel cell area required for separating CO2 from the combustion source exhaust and / or modifications in how the fuel cells are operated.

Owner:EXXON RES & ENG CO

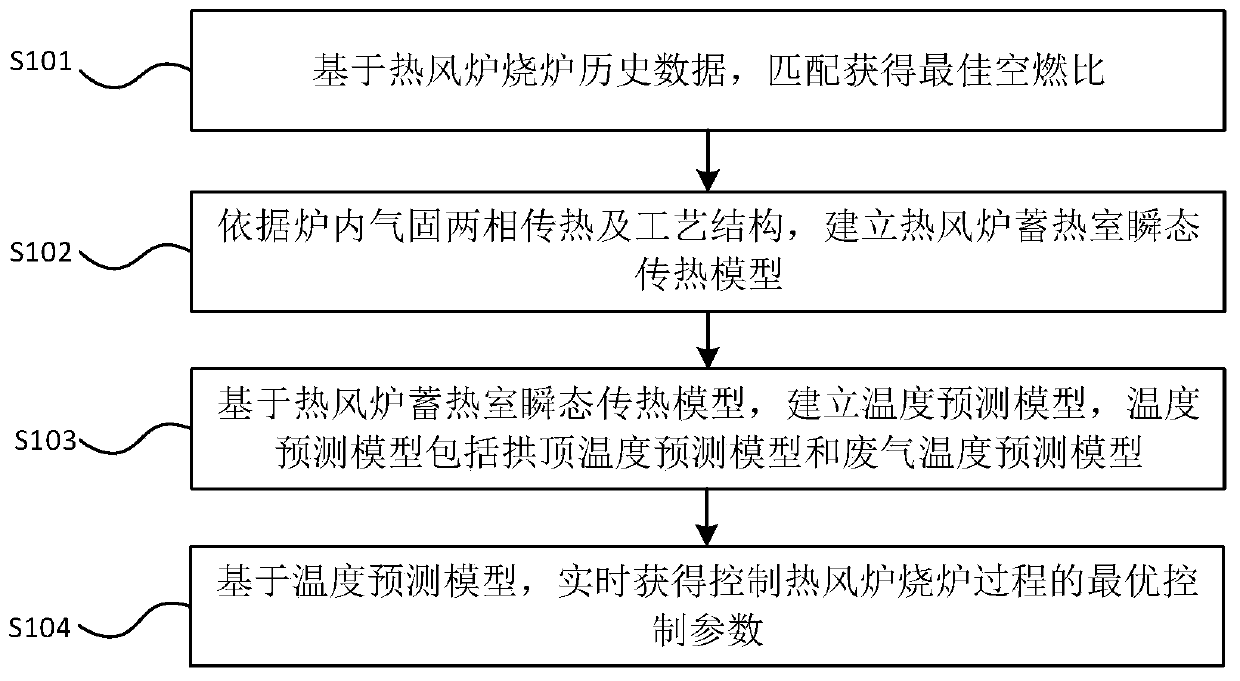

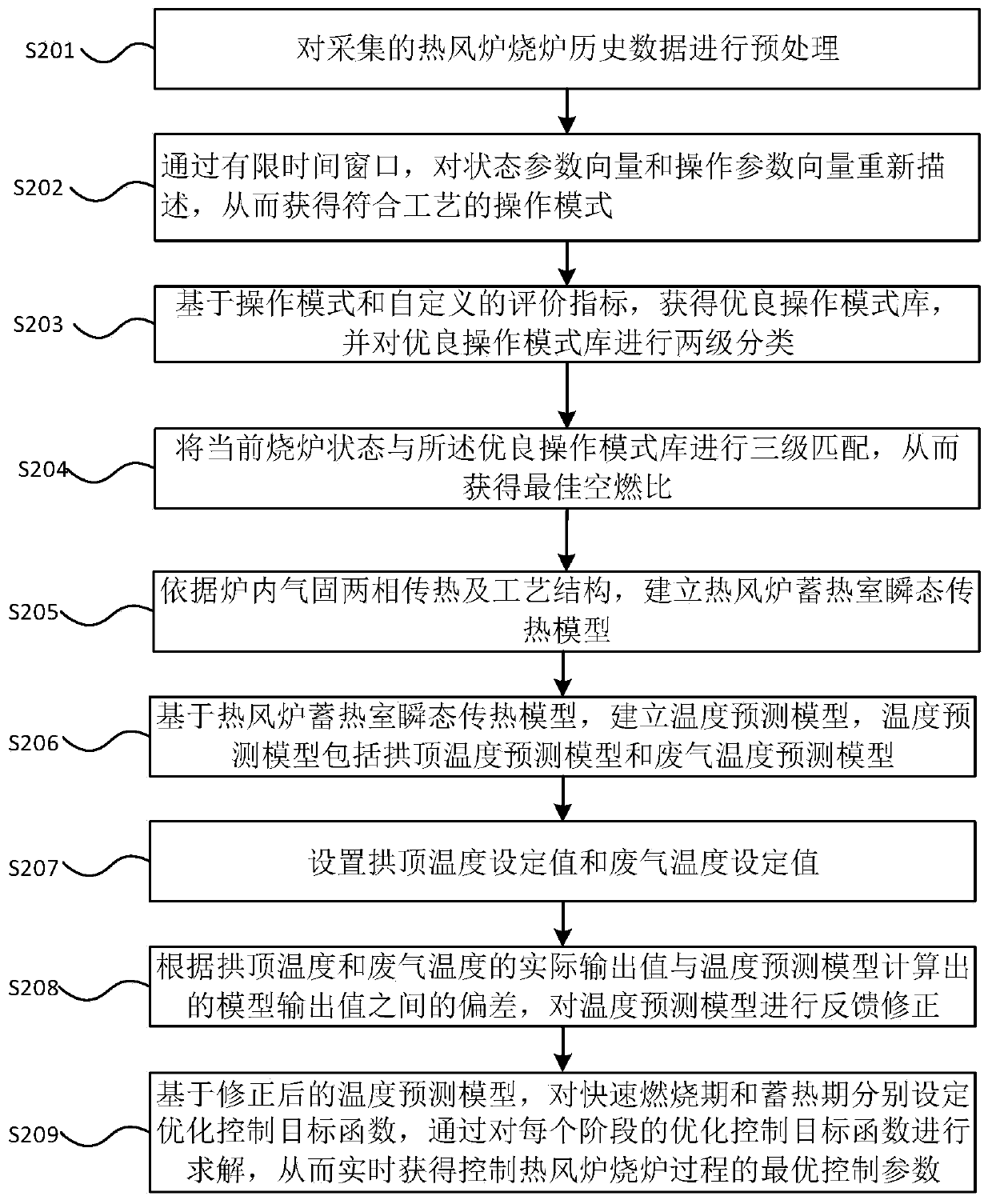

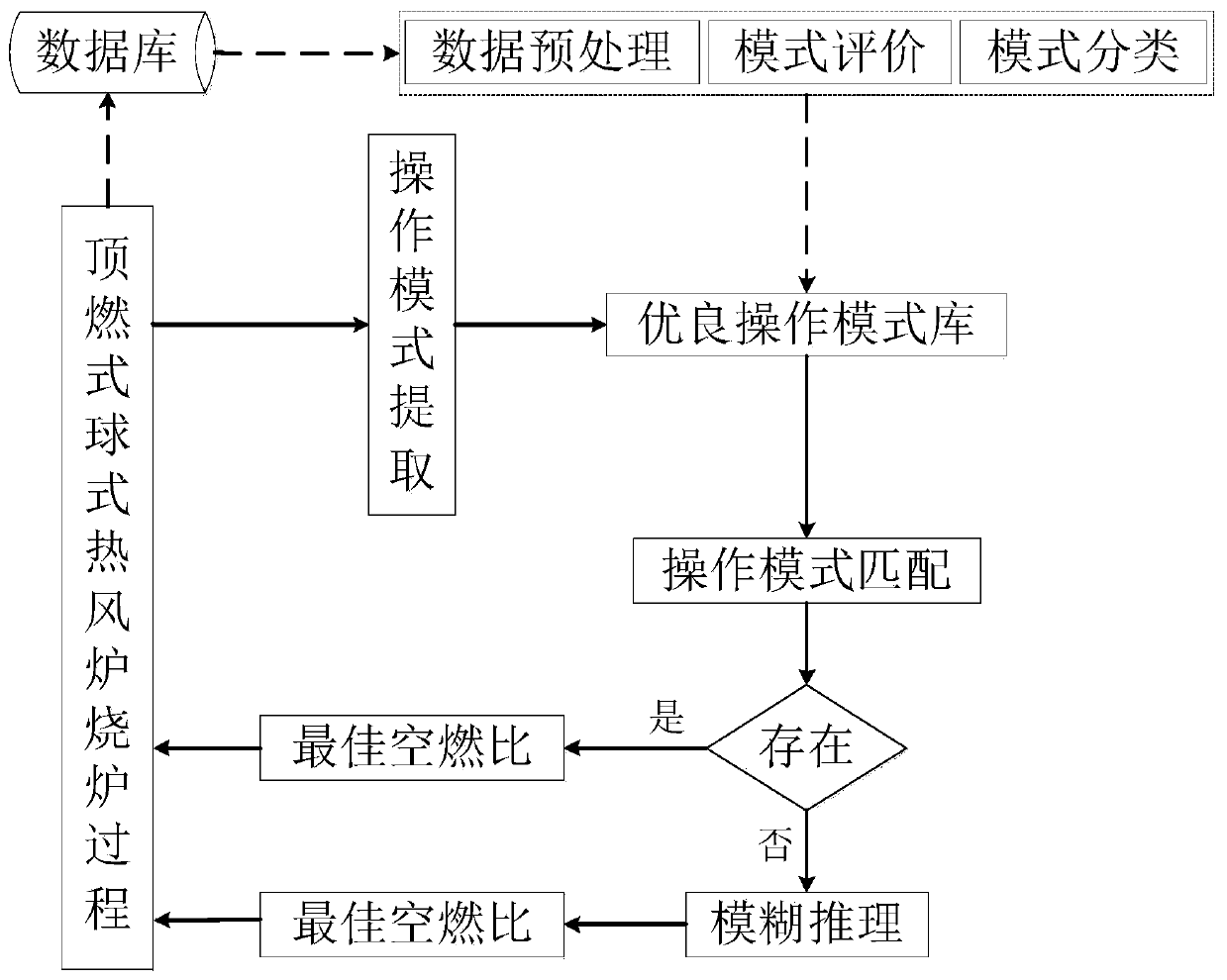

Ball type hot blast stove burning process control method and system

ActiveCN110257577AGood air-fuel ratioOptimal Control ParametersSteel manufacturing process aspectsBlast furnace detailsOptimal controlProcess engineering

The invention discloses a ball type hot blast stove burning process control method and system. The method comprises the steps that the optimal air-fuel ratio is obtained through matching based on hot blast stove burning historical data; a hot blast stove regenerative chamber transient heat transfer model is established according to stove inner gas-solid two-phase heat transfer and a process structure; temperature predicting models are established based on the hot blast stove regenerative chamber transient heat transfer model and include the vault temperature predicting model and the waste gas temperature predicting model; and the optimal control parameters for controlling the hot blast stove burning process are obtained in real time based on the temperature predicting models. The technical problem that the hot blast stove burning process is hard to control precisely in real time in the prior art is solved. By analyzing the ball type hot blast stove burning process, the air-fuel ratio is controlled from the data perspective according to a field process, the coal gas flow rate is controlled form the mechanical perspective, the air-fuel ratio and the coal gas flow rate are caused to reach the optimal values at the same time, in addition, the optimal coal gas flow rate is optimized in real time based on the matched optimal air-fuel ratio, and the hot blast stove burning process can be precisely controlled in real time.

Owner:CENT SOUTH UNIV

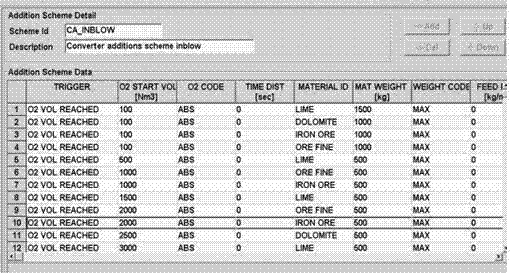

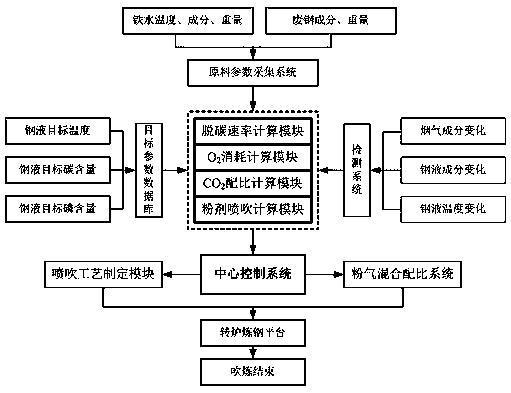

Method for dynamically controlling steelmaking process of bottom blowing O2-CO2-CaO converter

ActiveCN111500815AExtend your lifePromote reaction balanceSteel manufacturing process aspectsIncreasing energy efficiencySteelmakingProcess engineering

The invention discloses a method for dynamically controlling the steelmaking process of a bottom blowing O2-CO2-CaO converter, and belongs to the technical field of steelmaking. The method is suitablefor the steelmaking process of the 30-300t bottom blowing O2-CO2-CaO converter. According to a steelmaking process of the bottom blowing O2-CO2-CaO converter, O2 is adopted as top blowing gas, O2+CO2mixed gas is adopted as bottom blowing gas, lime powder is sprayed into the converter from a bottom blowing spray gun, and molten steel ingredients of the converter steelmaking process are predictedbased on material conservation in combination with the ingredient data of molten iron in the converter and waste steel, converter blowing process converter gas ingredient data and bottom blowing equipment work conditions; the top blowing oxygen amount, the bottom blowing gas ratio and the lime powder flow are dynamically adjusted by stages according to the blowing end point target ingredient requirements; while the fire blowing point area temperature is reduced, the converter molten pool stirring effect is enhanced, conduction of slag metal reaction balance is promoted, and the carbon contentand phosphorus content of molten steel are reduced; meanwhile, peroxidation of a converter blowing end point is avoided, deoxidizing alloy consumption is reduced, the number of occluded foreign substances in steel is reduced, and the quality of the molten steel is improved; and on the basis of an efficient metallurgy reaction, the metal yield is increased again, the production cost is reduced, andthe smelting period is shortened.

Owner:UNIV OF SCI & TECH BEIJING

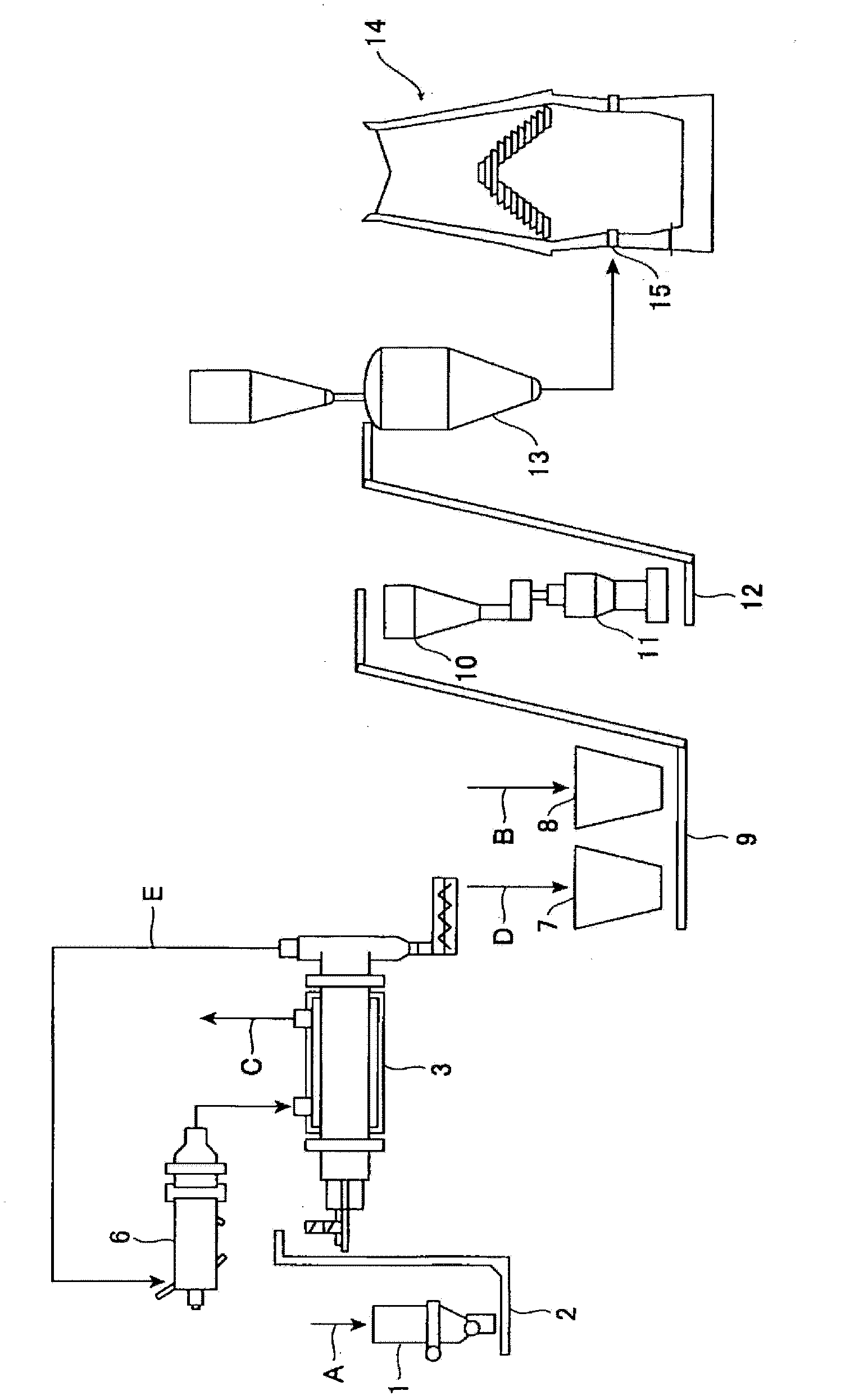

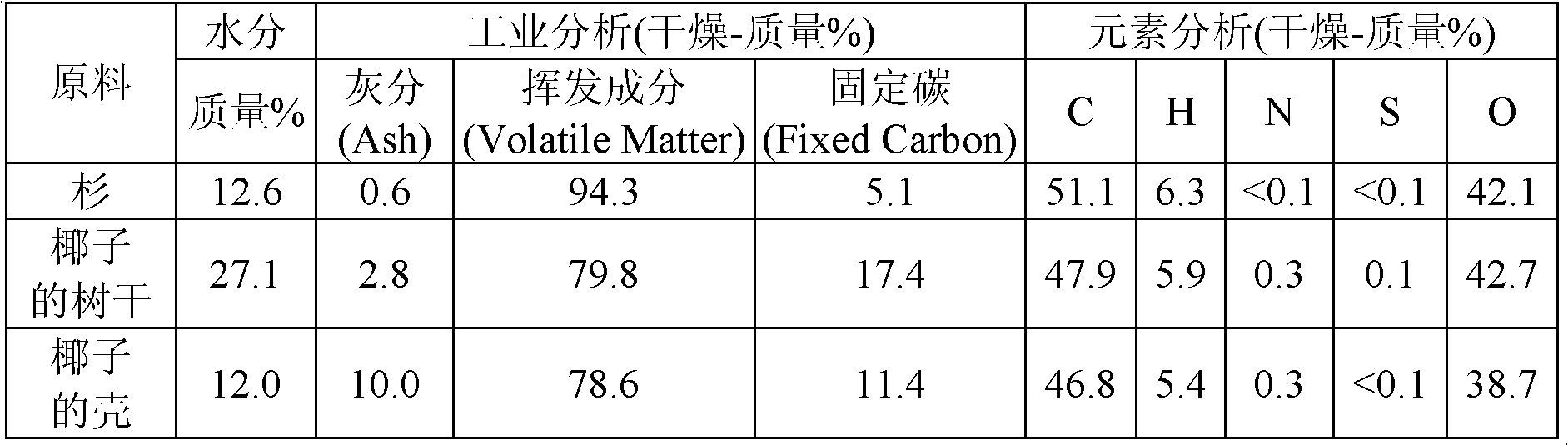

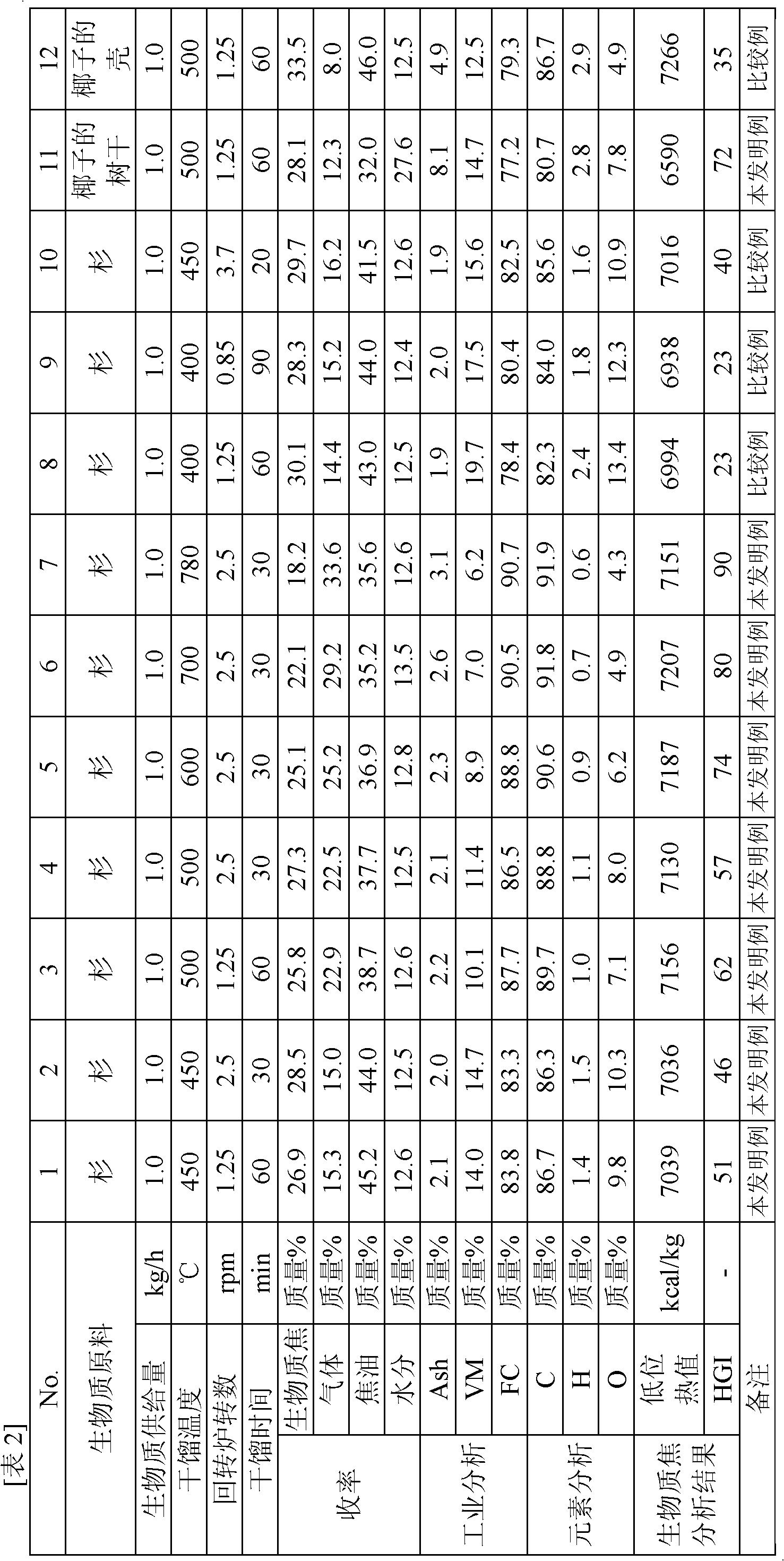

Method for using biomass in blast furnace

InactiveCN102666880AHigh calorific valueEasy dischargeSolid waste disposalSteel manufacturing process aspectsDistillationHot blast

Provided is a biomass using method capable of, when biomass is used as a blast furnace blowing material as a substitute for pulverized coal, increasing the flammability and heating value of the biomass to about the same level as those of the pulverized coal and capable of using conventional pulverized coal blowing equipment by enhancing the air transportability. A method for using biomass in a blast furnace is used, the method being characterized in that: biomass (A) is dried by distillation to manufacture biomass coal (D) showing a Hardgrove grindability index (HGI) of 45 or more; the biomass coal (D) is pulverized together with coal (B); and the pulverized powder is blown from a tuyere (15) as an auxiliary reducing material in a blast furnace (14). It is preferable that the biomass (A) is dried by distillation at 450 DEG C or higher for 30 minutes or longer to manufacture the biomass coal.

Owner:JFE STEEL CORP

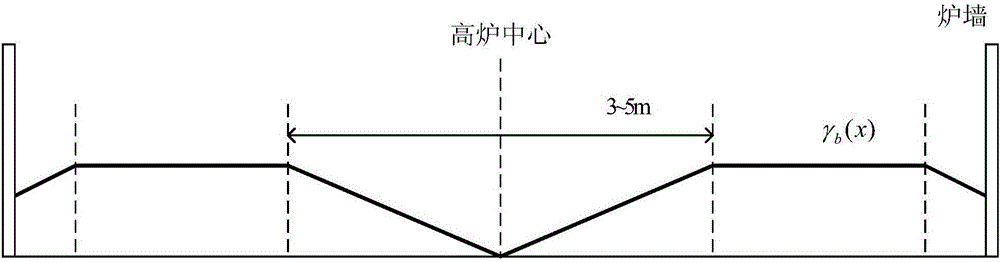

Blast furnace distribution process distribution matrix optimization method and system

ActiveCN106801114AAchieve regulationReasonable distributionSteel manufacturing process aspectsBell-and-hopper arrangementDistribution matrixOptimization system

The invention provides a blast furnace distribution process distribution matrix optimization method and a blast furnace distribution process distribution matrix optimization system. The method comprises the following steps: an ideal burden surface profile is set; by taking minimizing the deviation between a burden surface profile of a furnace burden in the next batch and the ideal burden surface profile as an objective, a distribution matrix is optimized; and the optimal distribution matrix obtained through optimization acts as the distribution matrix of the furnace burden in the next batch. The system comprises a setting unit, an optimization unit and an output unit. A basis is provided for the adjustment of the distribution matrix of a blast furnace, and operating personnel can adjust the distribution matrix in distribution operation of the blast furnace according to the distribution matrix obtained through the optimization by the method and the system. The burden surface profile under the distribution matrix optimized by the method and the system is close to the ideal burden surface profile. A blast furnace gas flow is distributed reasonably, a utilization ratio of a raw material is raised, and the effects of high yield and high efficiency of the blast furnace are achieved.

Owner:NORTHEASTERN UNIV

Robust soft measurement method for quality of blast-furnace hot metal

ActiveCN107299170AImprove robustnessPrevent overfittingSteel manufacturing process aspectsBlast furnace detailsHysteresisBlast furnace smelting

The invention provides a robust soft measurement method for the quality of blast-furnace hot metal. The robust soft measurement method comprises the following steps: acquiring blast furnace bosh gas volume, cold-blast air flow, oxygen enrichment flow, breathability, oxygen enrichment rate and theoretical combustion temperature at the current moment; carrying out normalization processing on acquired data; and carrying out robust soft measurement of the blast-furnace hot metal by using a blast-furnace hot metal quality robust soft measurement model constructed by a multiplex random weight neutral network to obtain a Si content estimation value, a P content estimation value, an S content estimation value and a hot metal temperature estimation value. According to the robust soft measurement method provided by the invention, blast-furnace body parameters obtained by real-time measurement are used as input data of the model, the sequential relationship between the hysteresis characteristic of the blast-furnace smelting process and input and output variables is sufficiently considered, and the blast-furnace hot metal quality robust soft measurement model with a nonlinear autoregression structure is constructed; and moreover, robust soft measurement of hot metal quality parameters such as Si content, P content, S content and hot metal temperature is realized, and hysteresis caused by offline testing and uncertainty caused by manual operation are avoided.

Owner:NORTHEASTERN UNIV LIAONING

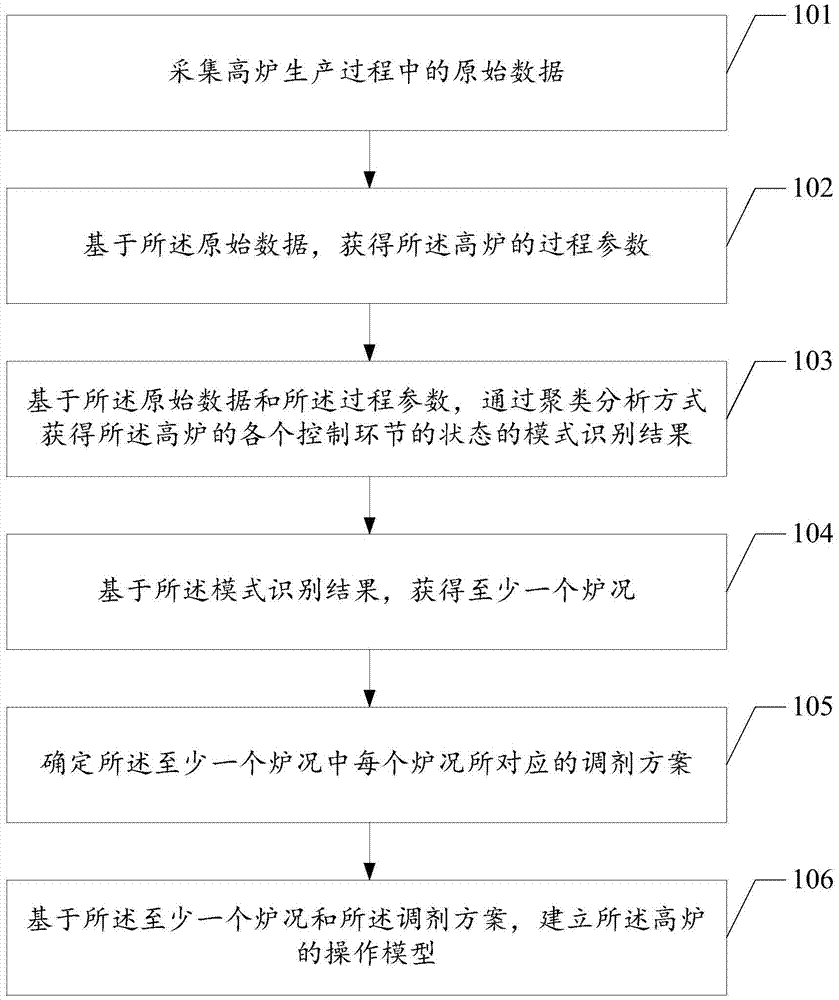

Method for establishing operating model of blast furnace

InactiveCN105441610AAvoid damageAccurate processingSteel manufacturing process aspectsBlast furnace detailsOriginal dataBlast furnace smelting

The invention relates to the technical field of blast furnace smelting and particularly relates to a method for establishing an operating model of a blast furnace. The method comprises the steps of acquiring original data in the production process of the blast furnace; acquiring a process parameter of the blast furnace on the basis of the original data; acquiring state mode recognition results of the blast furnace in various control links in a cluster analysis way on the basis of the original data and the process parameter; acquiring at least one furnace condition on the basis of the mode recognition results; determining a regulating scheme corresponding to each of the furnace conditions; and establishing the operating model of the blast furnace on the basis of the furnace conditions and the regulating schemes. Due to the establishment of the operating model of the blast furnace, different furnace conditions can be accurately and rapidly handled according to the operating model, it is not needed to judge the furnace conditions by experienced operating personnel on site, and furnace condition abnormality caused by temporal judgment faults of the operating personnel and blast furnace damage caused when effective handling measures are not taken in time are also avoided.

Owner:武汉钢铁有限公司

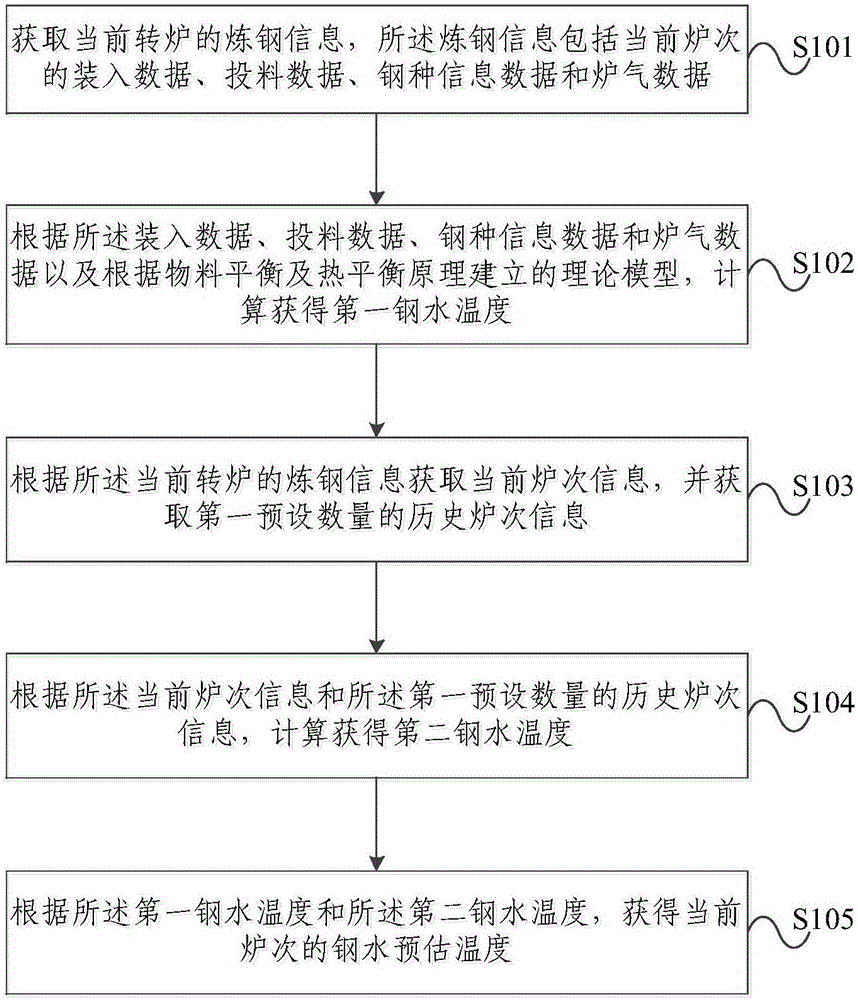

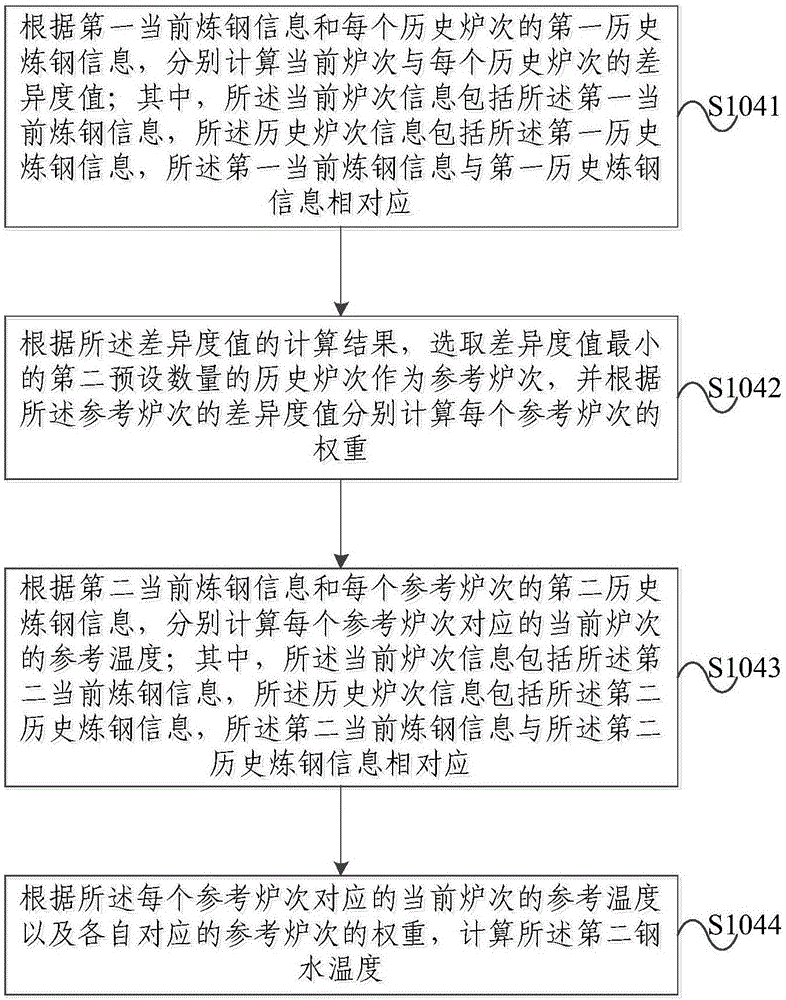

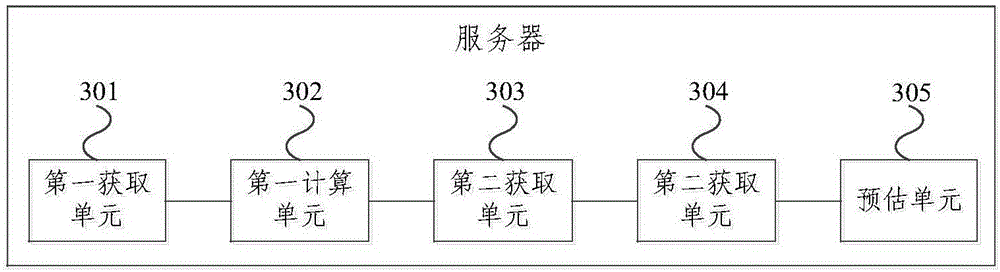

Method for predicting steel-making temperature of converter and server

ActiveCN106636530ALower control costsSteel manufacturing process aspectsManufacturing convertersTemperature controlMaterial balance

The invention discloses a method for predicting the steel-making temperature of a converter and a server. The method comprises the following steps: acquiring steel-making information of a current converter, wherein the steel-making information includes filling data, batch charging data, steel grade information data and furnace gas data of the current heat; calculating to obtain a first molten steel temperature according to a theoretical model which is established according to the filling data, batch charging data, steel grade information data and furnace gas data, as well as the material balance and thermal balance principle; acquiring information of current heat according to the steel-making information of the current converter, and acquiring first preset number of historical heat information; calculating a second molten steel temperature according to the current heat information and the first preset number of historical heat information; and acquiring a molten steel predicted temperature of the current heat according to the first molten steel temperature and the second molten steel temperature. The server is used for executing the method. According to the method for predicting the steel-making temperature of a converter and the server, the cost for controlling the final temperature of steel-making of a converter can be reduced.

Owner:BEIJING GUANGKEBOYE SCI & TECH

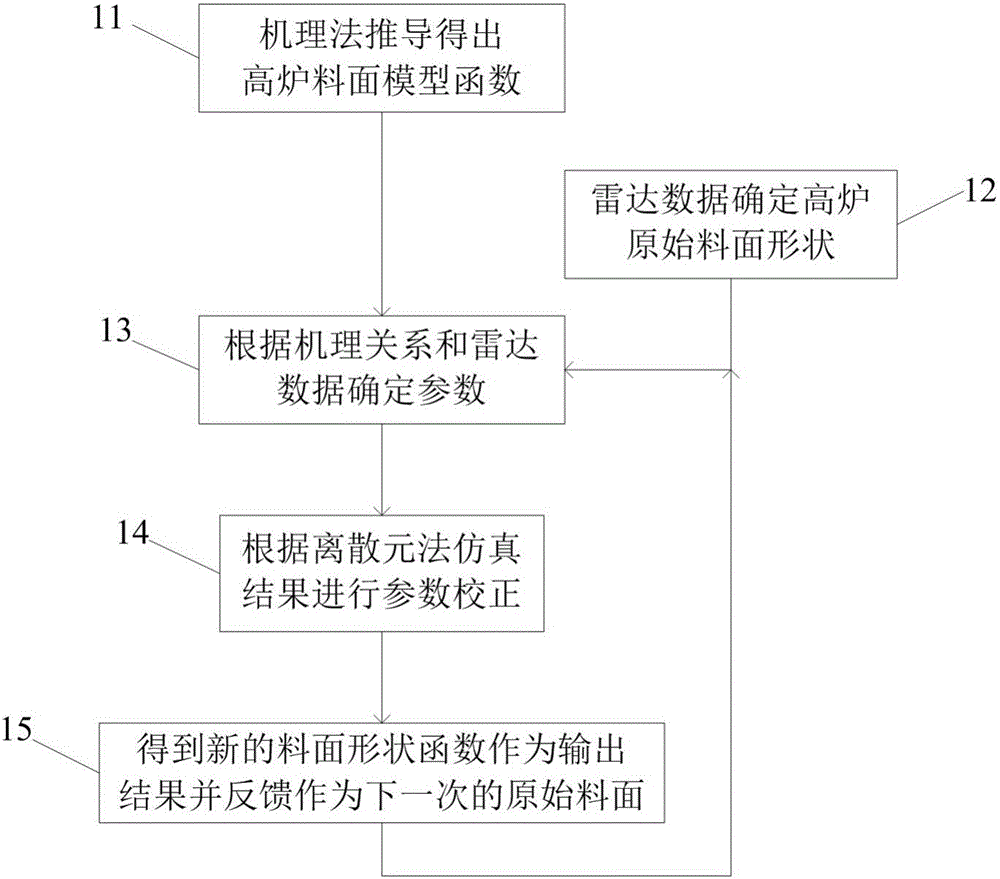

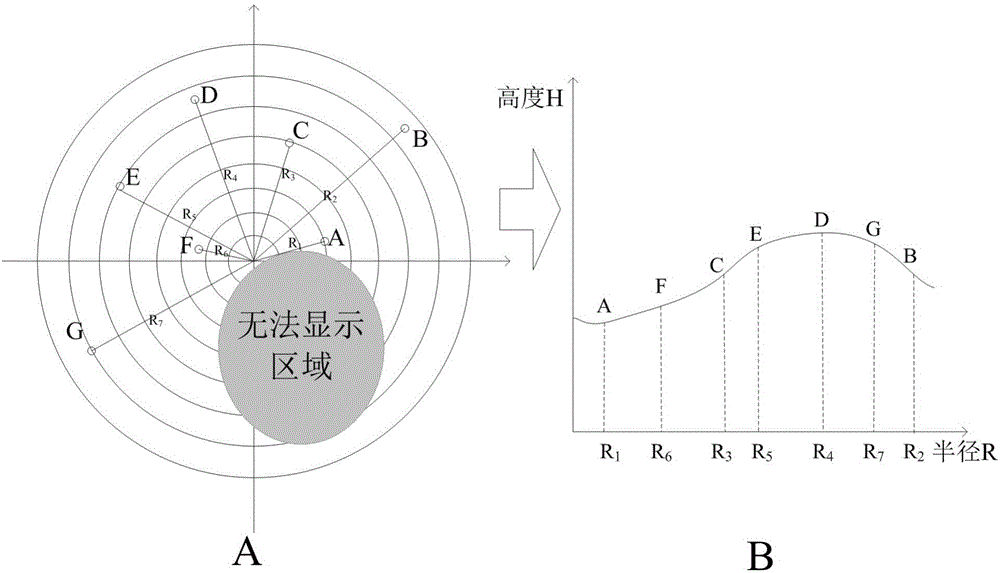

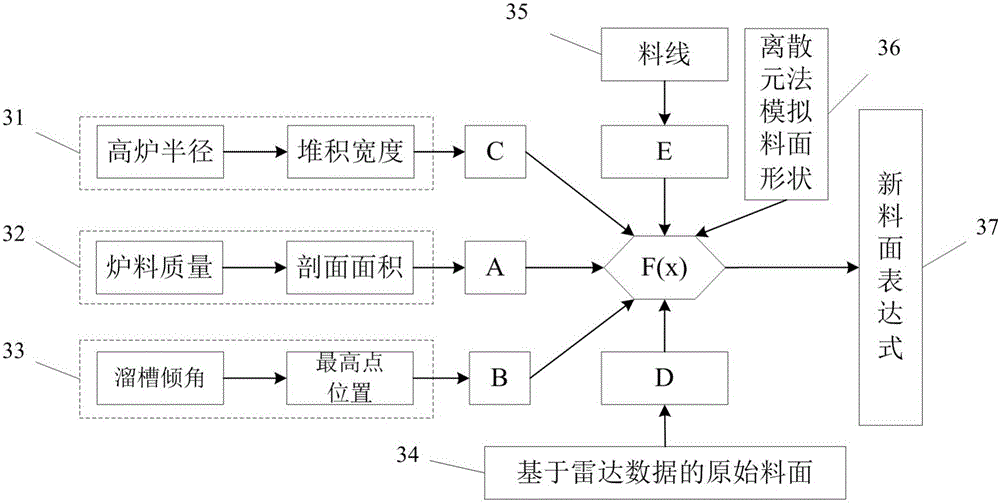

Multi-information fusion modeling method for shapes of burden surfaces in burden distribution process of blast furnace

ActiveCN105950807AImprove accuracyIncrease speedSteel manufacturing process aspectsBlast furnace detailsSupport vector machineRadar

The invention discloses a multi-information fusion modeling method for the shapes of burden surfaces in the burden distribution process of a blast furnace. The content of the multi-information fusion modeling method comprises: establishing a furnace burden stacking model according to hydromechanics and statistics rules, adopting a mechanism method to deduce a model function for burden surfaces in the burden distribution process of the blast furnace, establishing a parameterized prediction model, solving original burden surface shape parameters, and determining a furnace burden stacking equation; based on the fitting of radar scattered data regressed by a support vector machine, obtaining an original burden surface shape; according to data measured by a radar, solving the original burden surface shape parameters of the prediction model; using the radar to measure the height information of different radii of burden surfaces in multiple point positions of the blast furnace, and adopting the support vector machine which is applied to a regression problem to fit the height scattered points of the burden surfaces so as to obtain a burden surface function curve; determining related parameters according to a burden distribution mechanism relationship and the radar data, and correcting the prediction model according to the parameters; based on simulation results of a discrete element process, correcting the burden surface shape parameters; and obtaining a new burden surface shape function, using the burden surface shape function as an output result, and feeding the output result back as the next original burden surface.

Owner:YANSHAN UNIV

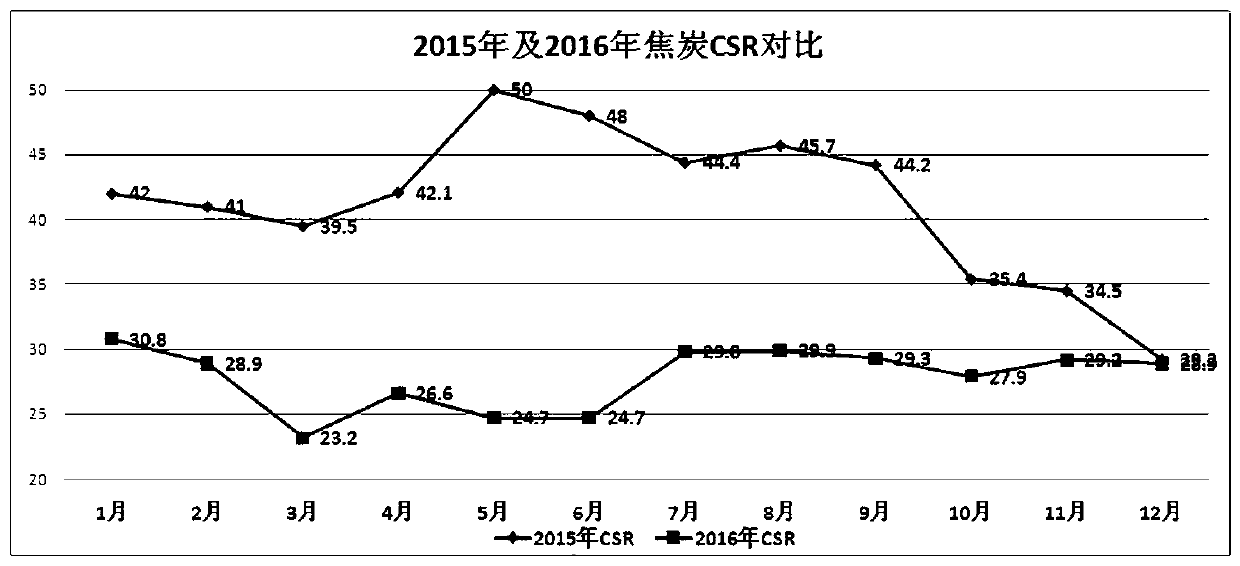

Production process for refining large blast furnace cokes by using high-ratio low-heat-state coals

InactiveCN106987665AReduce coal blending costsHigh priceSteel manufacturing process aspectsBlast furnace detailsDistribution systemMoisture

The invention discloses a production process for refining large blast furnace cokes by using high-ratio low-heat-state coals. The production process comprises the following operation steps: (a) the oxygen enrichment rate of a blast furnace is 5%; and the gas quantity of a bosh is adjusted; (b) the area of a wind port is reduced; the wind speed is guaranteed about 265 m / s; and the air blowing kinetic energy is about 11000 kg.m / s; (c) the proper theoretic combustion temperature of the wind port is 2180-2230 DEG C; the wind temperature is kept in 1130-1170 DEG C; and the moisture is increased to 20-30 g / t; (d) the coal ratio is increased to 150 kg / t; the coke ratio is kept invariable; the fuel ratio is increased to 565 kg / t; the proper gas quantity is kept; and the furnace top temperature is not lower than 120 DEG C; and (e) the distribution system and the ore batch weight are adjusted; the distribution mode is PWC12345 43321 PWO12345 33321; the ore batch is 62 t-64 t; and according to the top temperature, the ore coke batch weight is adjusted according to the same ratio to guarantee two coal gas flows of the center and the edge of the blast furnace. Meanwhile, a corresponding smelting operation system is formulated according to the method.

Owner:XINJIANG BAYI IRON & STEEL

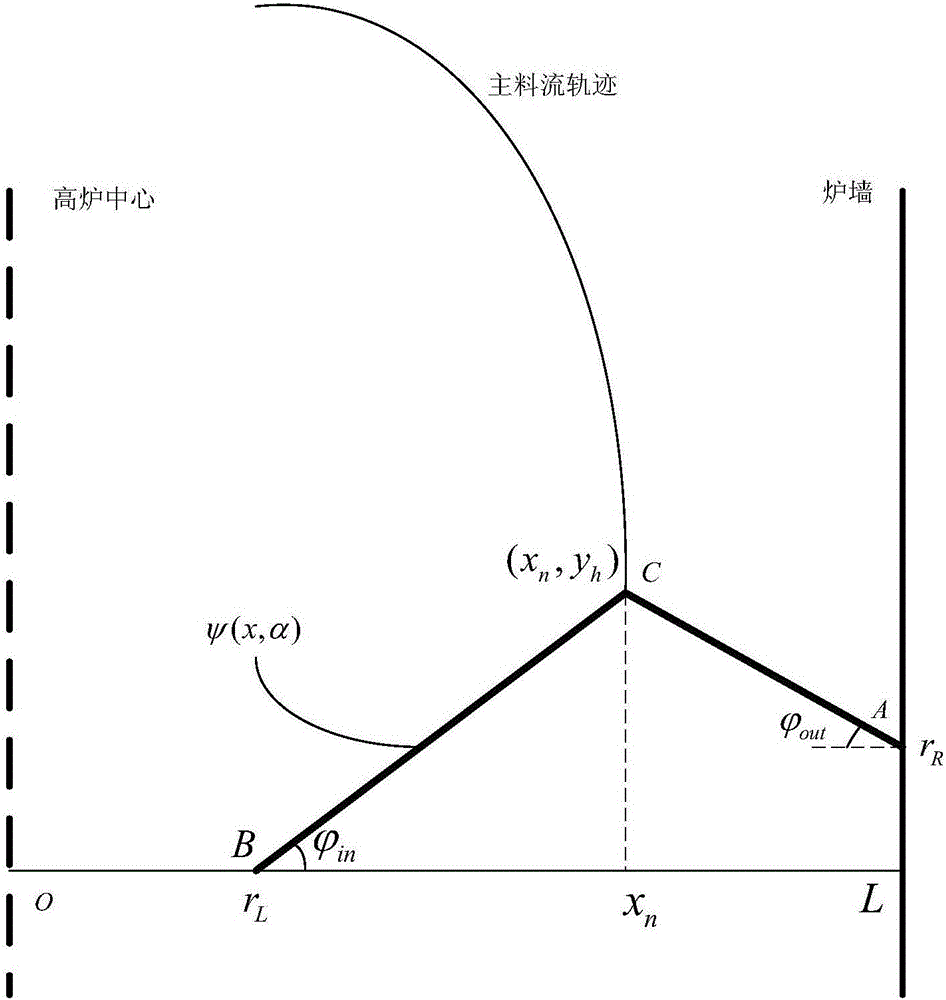

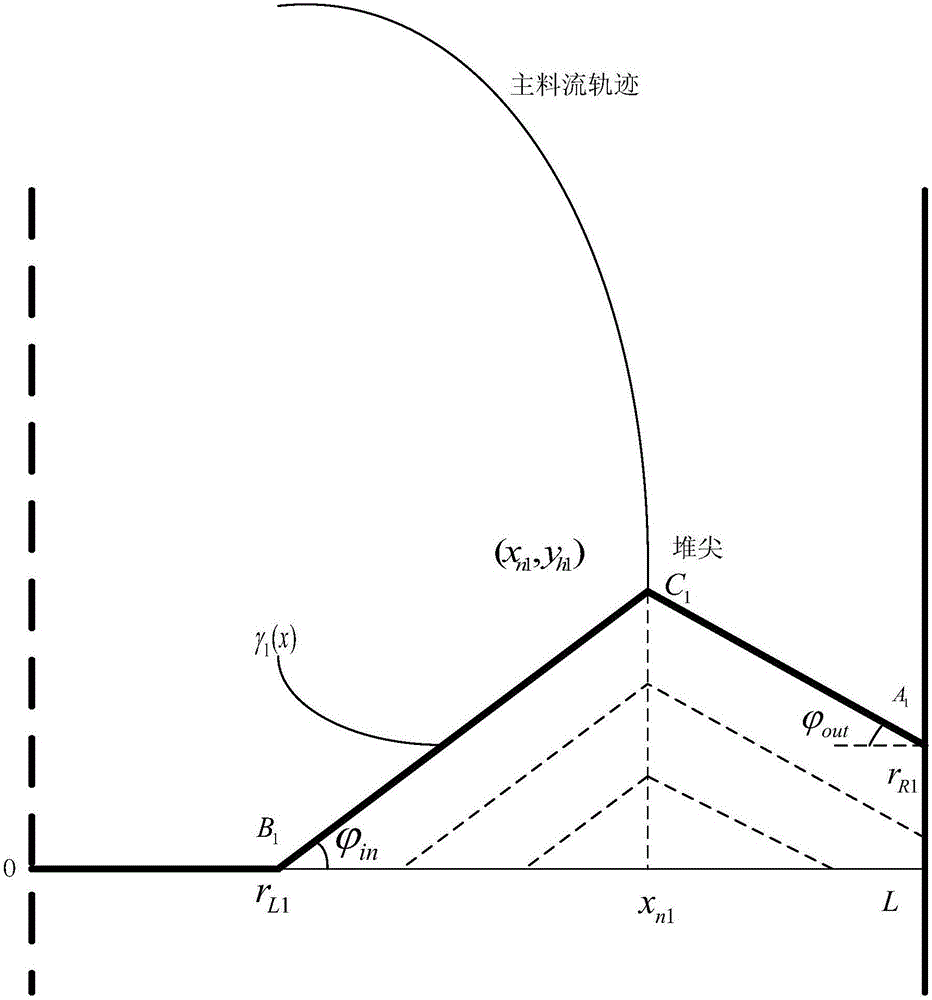

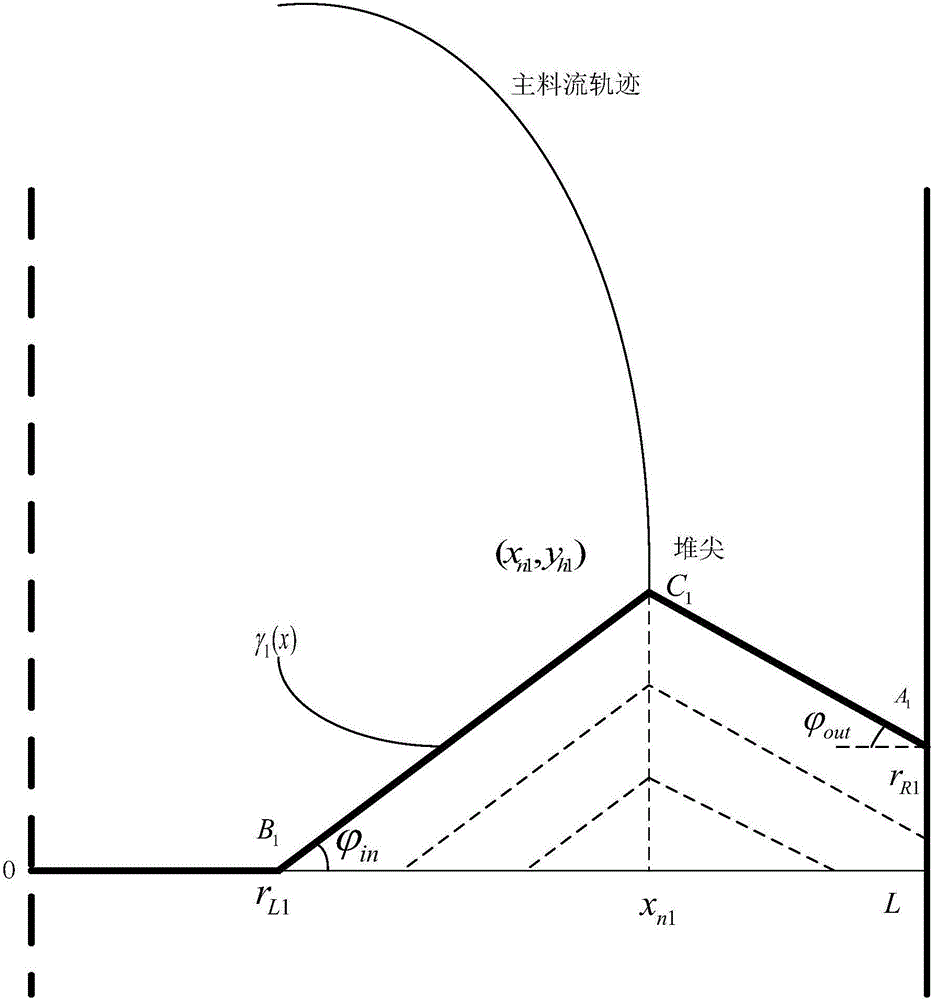

Method and system for estimating charge surface shapes in blast furnace charge distribution process

ActiveCN106011350AAccurate estimateChange distributionSteel manufacturing process aspectsBlast furnace detailsDistribution matrixDistribution system

The invention provides a method and system for estimating charge surface shapes in the blast furnace charge distribution process. The method includes the steps that the blast furnace charge distribution process parameters, the furnace charge parameters and the charge distribution matrix are obtained; the abscissa of the pile cuspidal point of a charge pile formed by the furnace charge at each chute dip angle is computed; the charge surface shape of the furnace charge at the first-chute dip angle is computed; and according to the volume constraint that the furnace charge at each chute dip angle meets, the charge surface shapes of the furnace charge at the previous chute dip angles and the charge surface shape of the basic charge surface, the charge surface shape at the second-chute dip angle is obtained, charge surface shape computing is conducted in a successive iteration manner till the nth charge surface shape of all the charge surface shapes at the chute dip angles is distributed and obtained, and the estimation result of the charge surface shapes in the blast furnace charge distribution process is obtained. The system comprises a collection module, an abscissas computing module, a first charge surface shape computing module and a charge surface estimation module. According to the method and system for estimating the charge surface shapes in the blast furnace charge distribution process, a computing basis is provided for the charge surface shapes under different charge distribution systems, precise estimation of the charge surface shapes in a blast furnace is achieved, the charge distribution system is adjusted in real time according to the furnace conditions, furnace charge distribution is changed, the gas utilization rate is increased, and therefore the blast furnace can operate stably and smoothly.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com