Robust random-weight neural network-based molten-iron quality multi-dimensional soft measurement method

A neural network and soft sensor technology, applied in biological neural network models, iron and steel manufacturing processes, computer simulation, etc., can solve the problem of excessive consumables, outliers in measurement data, and inability to reflect the inherent dynamic characteristics of the blast furnace smelting process And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

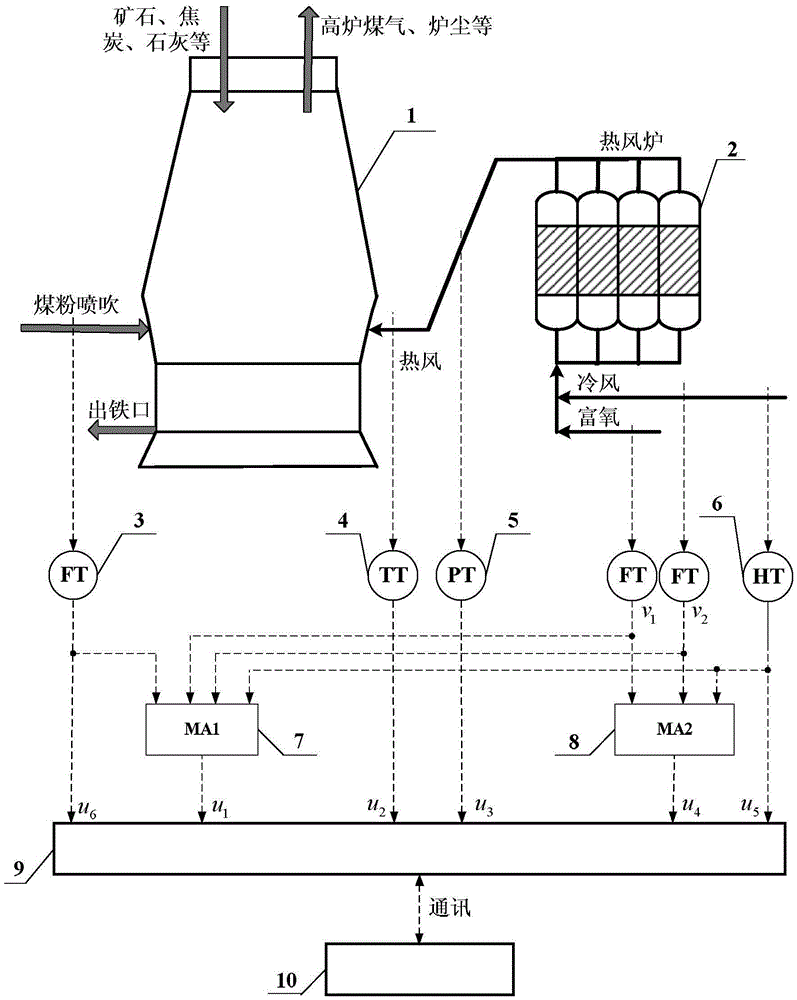

[0087] As shown in the figure, the present invention is based on the computer system composition of conventional measurement system, data collector, M-RVFLNs soft sensor software and operating software, and the detailed structure is as follows figure 1 shown. Conventional measuring instruments such as flowmeters, pressure gauges and thermometers are installed in various corresponding positions of the blast furnace smelting system. The data collector is connected to the conventional measurement system, and connected to the computer system running the online forecast software through the communication bus. The conventional measuring system mainly includes the following conventional measuring instruments including:

[0088] Three flowmeters are used to measure the pulverized coal injection volume, oxygen-enriched flow, and cold air flow of the blast furnace pulverized coal injection system on-line;

[0089] A thermometer for online measurement of the hot blast temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com