Method for using biomass in blast furnace

A biomass and biomass coke technology, applied in blast furnaces, biofuels, blast furnace details, etc., can solve problems such as high moisture content and low calorific value, and achieve the effect of increasing calorific value and reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

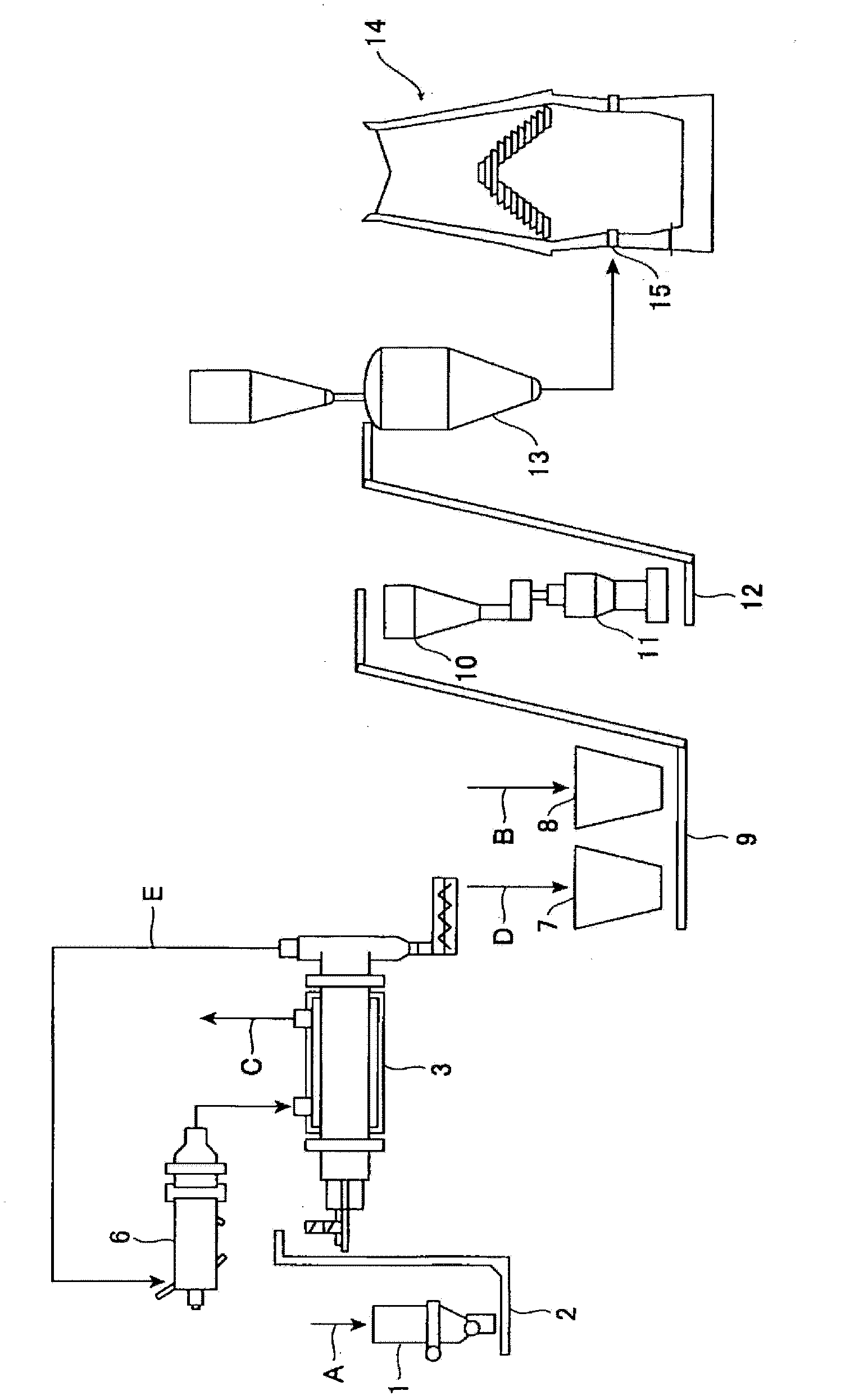

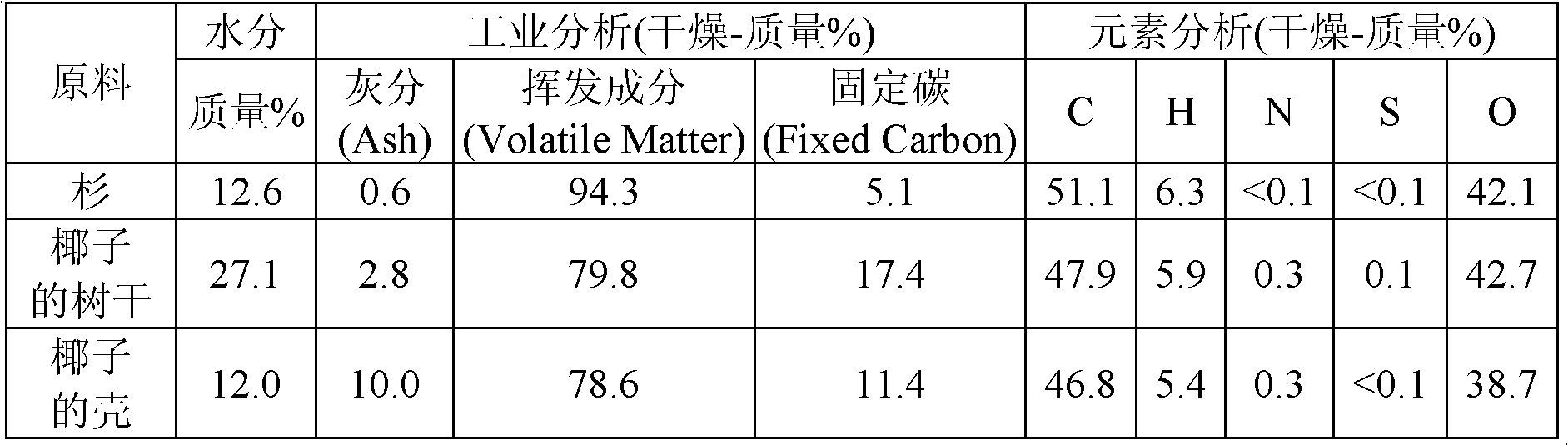

[0045] use figure 1 The shown equipment was used to carry out the dry distillation experiment of biomass. Among them, the heating method of the rotary kiln is a three-stage (3 division) electric heating. The inner diameter of the rotary furnace is 15 cm, the length is 1.0 m, and the inclination angle is 1 degree, and the carbonization time is adjusted by changing the rotational speed of the rotary furnace. As the biomass, cedar waste wood crushed and classified into 3 to 10 mm, coconut trunks, and coconut shells were used. The composition of the biomass used is listed in Table 1.

[0046] [Table 1]

[0047]

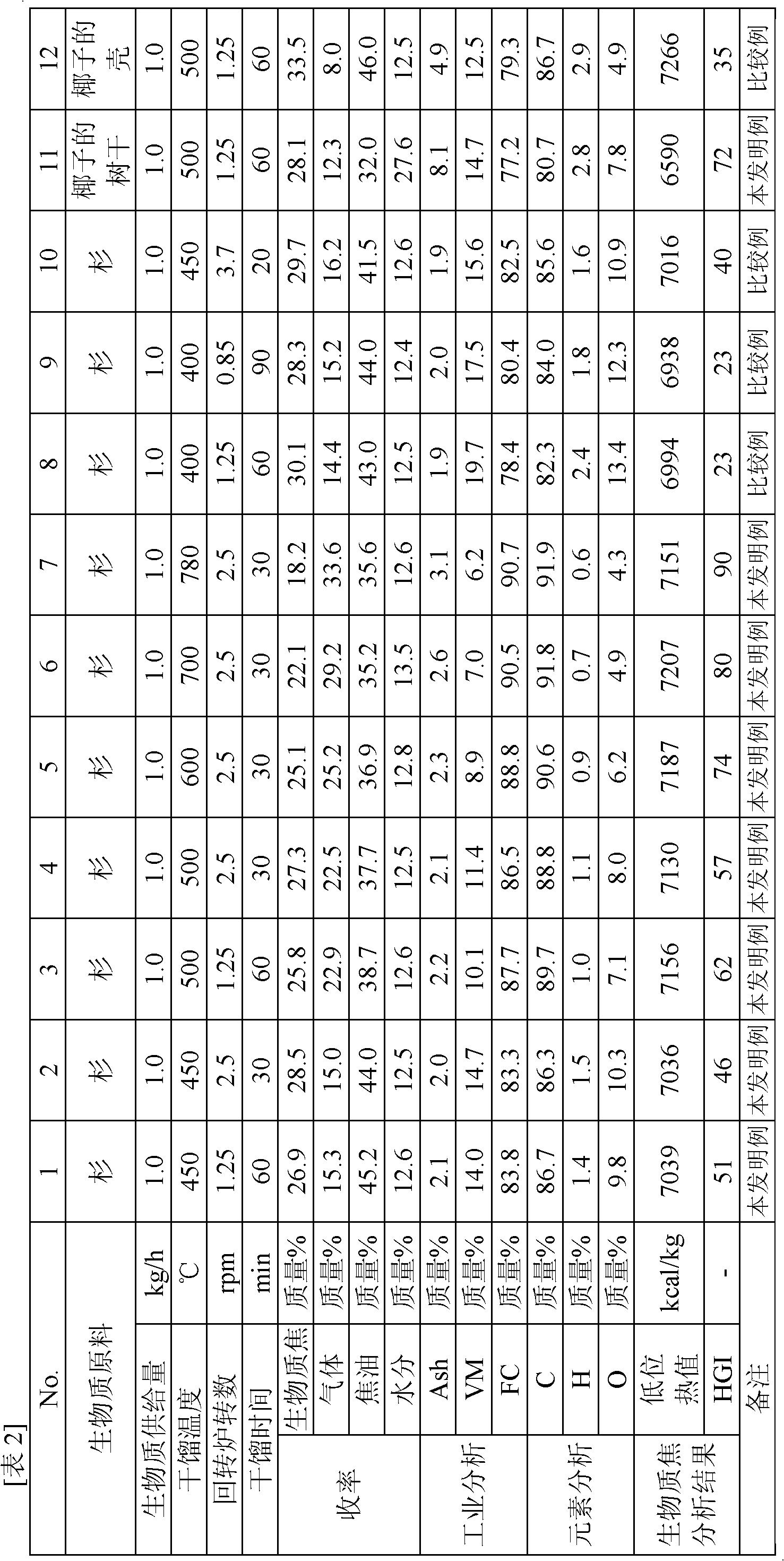

[0048] The feed rate of the biomass to the rotary kiln was 1.0 kg / h, and the carbonization temperature and carbonization time were changed to produce No. 1 to No. 12 biomass cokes. The HGI and calorific value of the obtained biomass char were measured. The test conditions and results are listed in Table 2.

[0049]

[0050] According to Table 2, by performing ...

Embodiment 2

[0052] Coal with an HGI of 86 was mixed with the biomass cokes Nos. 1 to 7 and 11 obtained in Example 1 at a mass ratio of biomass coke:coal=10:90, and the HGI was measured. The HGI of the mixture is in the range of 78 to 83, and it can be seen that there is no problem in pulverizing with a coal mill in a mixed state.

[0053] This mixture was pulverized by a roller mill until the particle size distribution was 74 μm or less and 80% by mass or more, and a pulverized coal injection device was used to perform a test of blowing it in from a blast furnace tuyere. There is no clogging in the blowing piping, and the same operation as normal pulverized coal blowing can be performed.

[0054] Symbol Description

[0055] 1 biomass feed hopper

[0056] 2 Conveyor (biomass conveying means)

[0057] 3 rotary kilns

[0058] 4 Biomass coke transportation means

[0059] 5 Dry distillation gas, tar delivery means

[0060] 6Heating gas generator

[0061] 7 Biomass char feeding hopper

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com