Patents

Literature

1820results about How to "Efficient crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

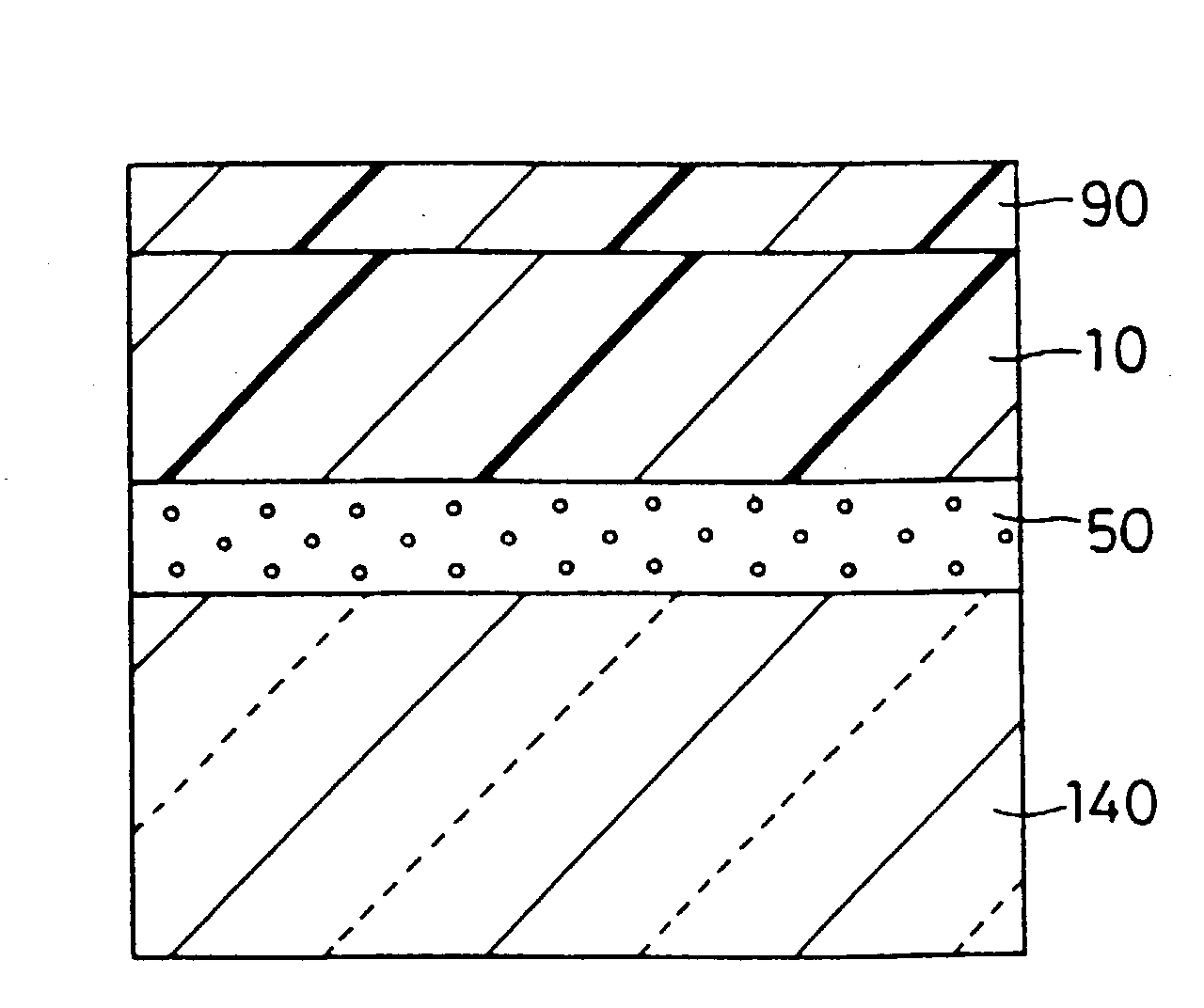

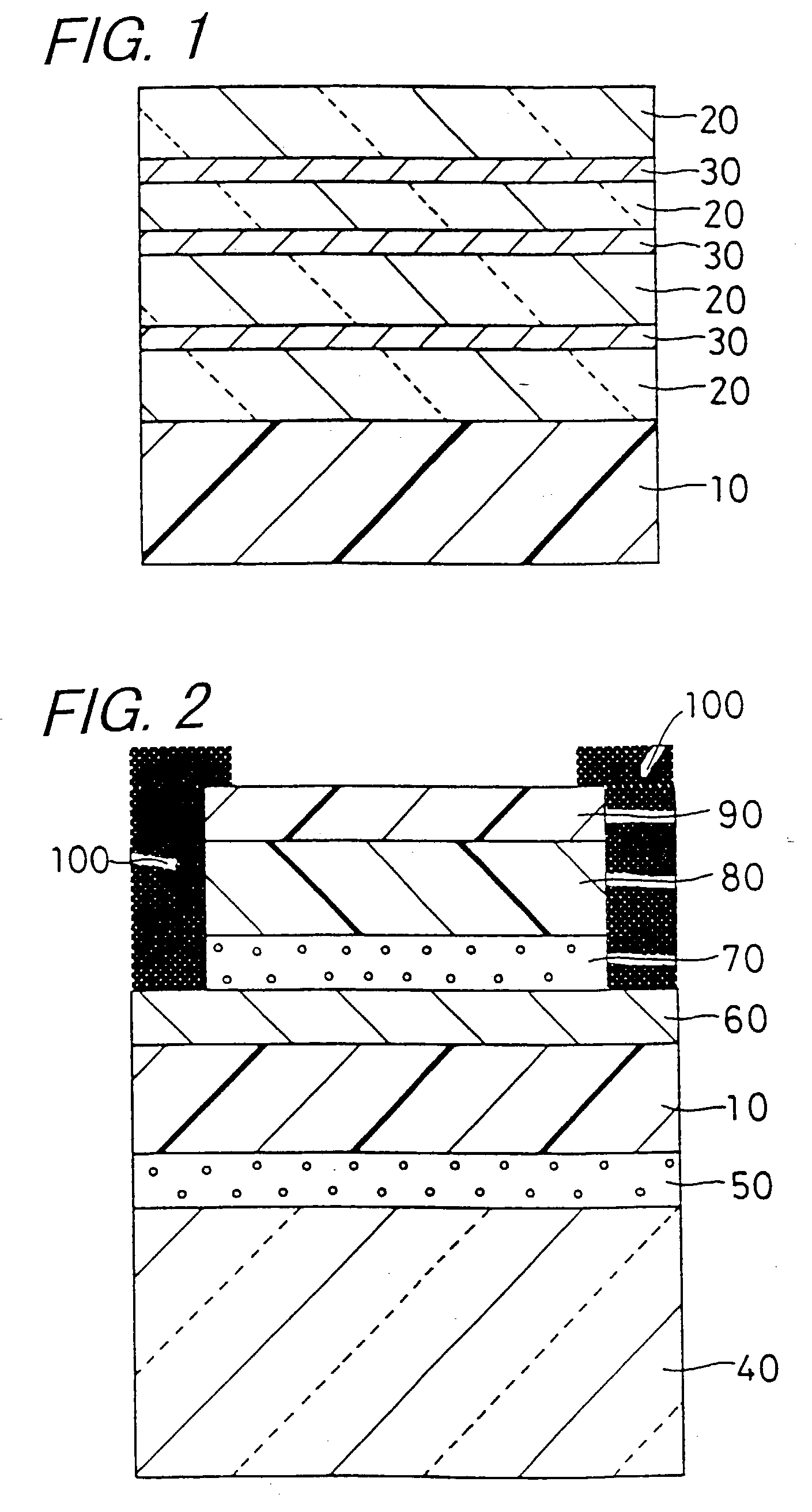

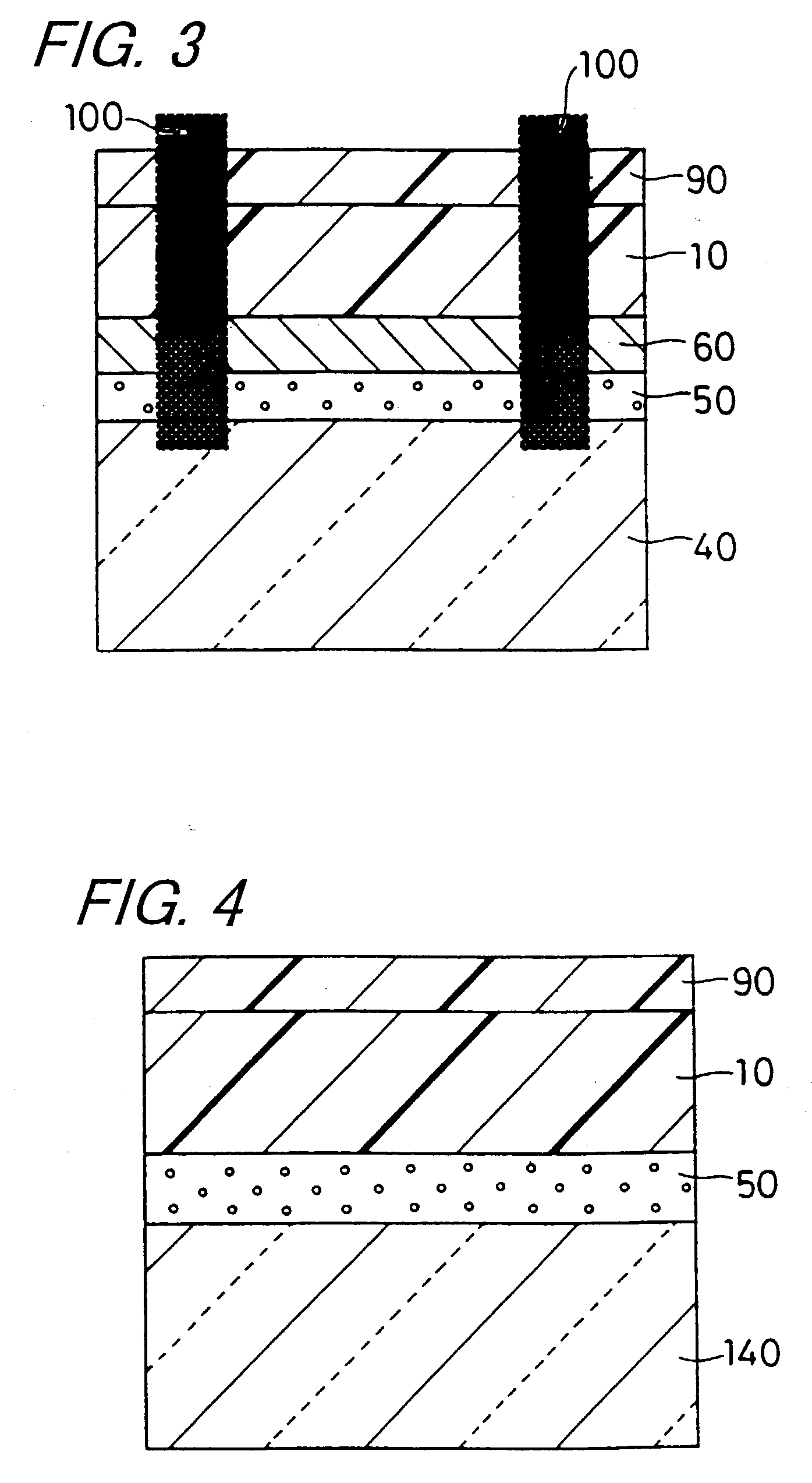

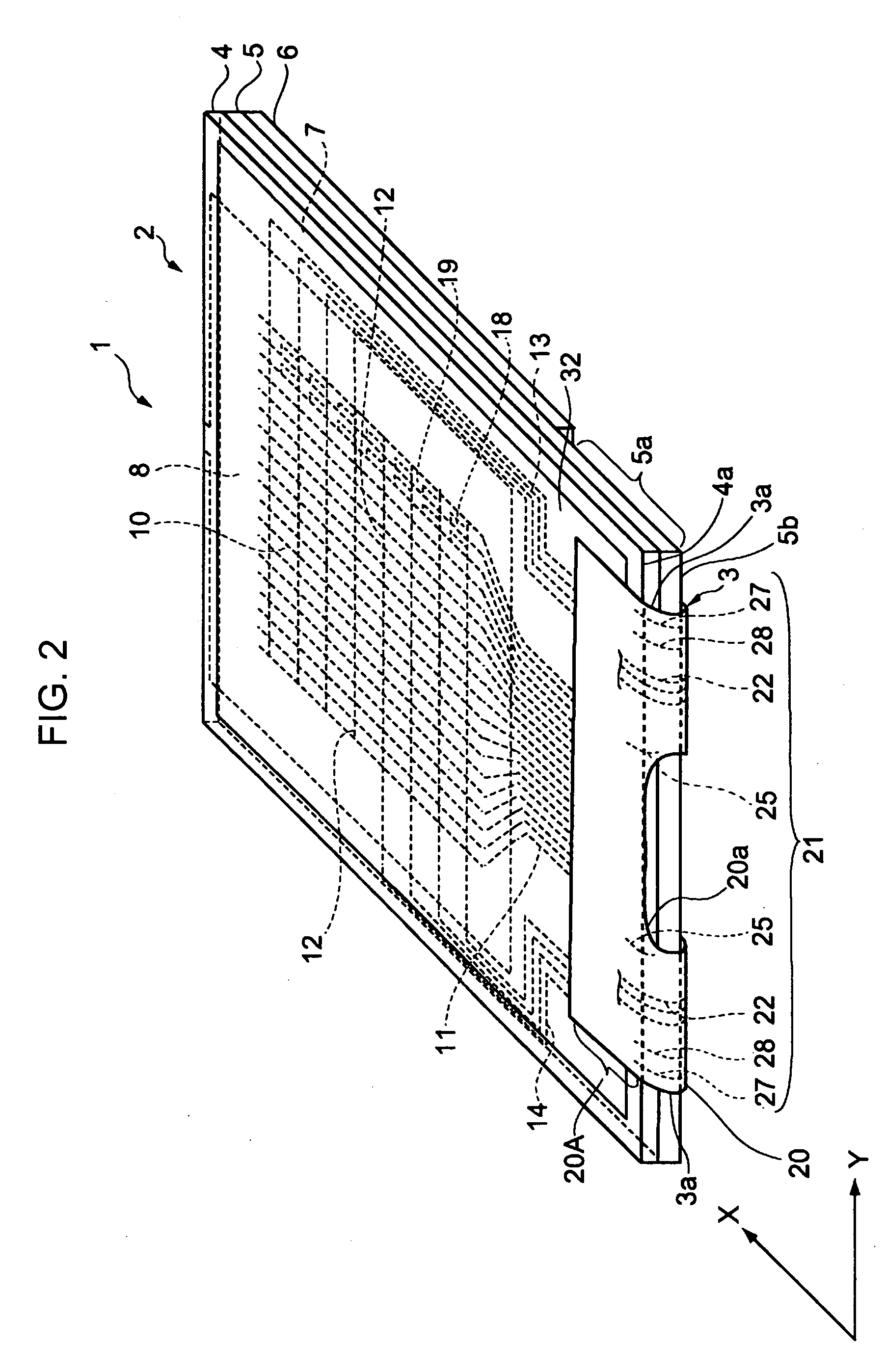

Laminate body and display device using the laminated body

InactiveUS20030176124A1Reduce deteriorationWeak elasticityCathode ray tubes/electron beam tubesMagnetic/electric field screeningDisplay deviceYoung's modulus

A laminate which can easily attain safety standards such as impact resistance, while cost reduction is aimed for, for example, when the laminate is provided on a display viewing surface, and a display apparatus using this laminate are provided. By using a filter for a display having a specified parameter and a specified thickness, the impact resistance is enhanced. By using the filter for the display containing a transparent adhesive layer having a specified Young's modulus and a specified thickness, the impact resistance is enhanced. By using the filter for the display containing a transparent resin layer having a specified Young's modulus and a specified thickness, the impact resistance is enhanced. By using the filter for the display containing an impact absorption layer having a specified penetration and a specified thickness, the impact resistance is enhanced.

Owner:MITSUI CHEM INC

Production method for non-oil instant edible fungus chips

The invention discloses a production method for non-oil instant edible fungus chips and belongs to the technical field of agricultural product deep processing. The production method for the edible fungus chips comprises the following steps: selecting, cleaning, precisely cutting, ironing, bleaching, deactivating enzyme and cooling the edible fungus raw materials, and then performing ultrasonic auxiliary dipping, leachating, quick-freezing, vacuum freeze drying, vacuum microwave puffing drying, seasoning and packaging on the pretreated edible fungus raw materials. In the production method, a new process of ultrasonic auxiliary dipping, vacuum freeze drying and follow-up vacuum microwave staged combination drying is adopted, thereby reserving the thermal sensitivity nutritive components andbiological activity functional components of the edible fungus to the largest extent, obviously shortening the drying time and saving the production cost. The product has the characteristics of non-frying property, high puffing rate, attractive color, crisp mouthfeel, and the like, and is natural and environmentally-friendly as well as healthy. Compared with the vacuum freeze drying, the process has the advantages that the production period of the finished product can be greatly shortened, the production cost is saved, the puffing effect of the product is good, the mouthfeel of the product iscrisp and the drying quality of the product is improved. A new practical and feasible way for deep processing of the edible fungus is provided.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

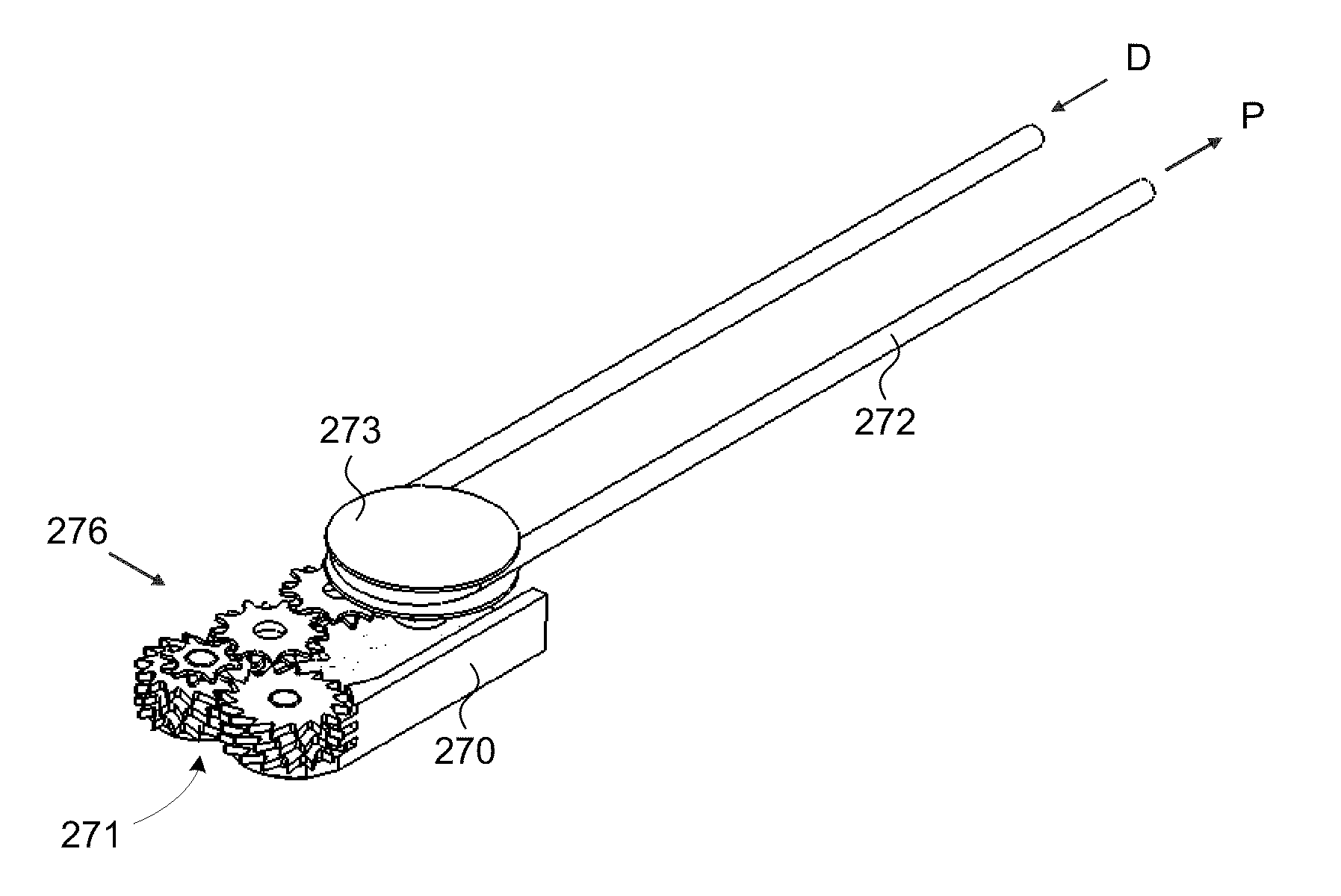

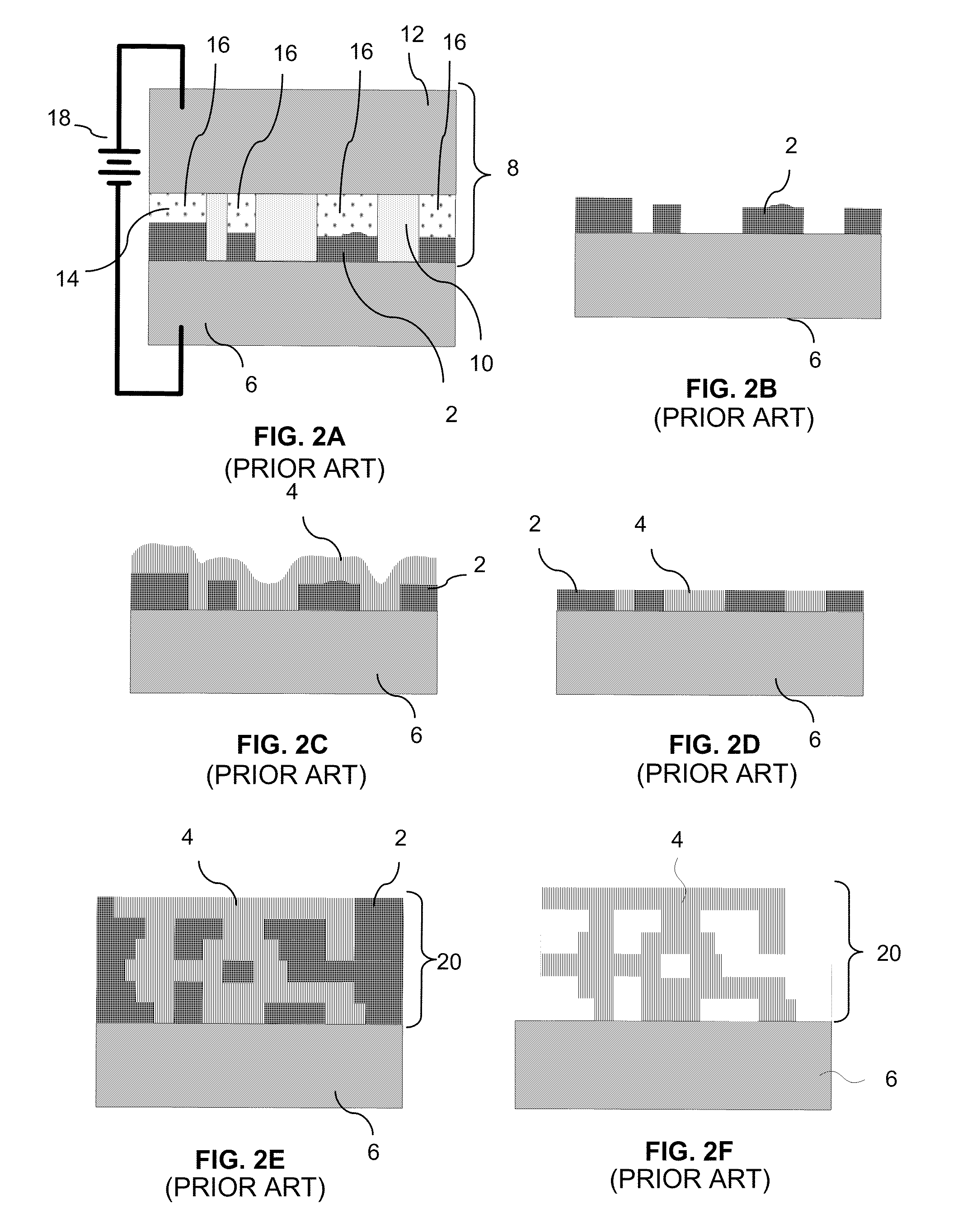

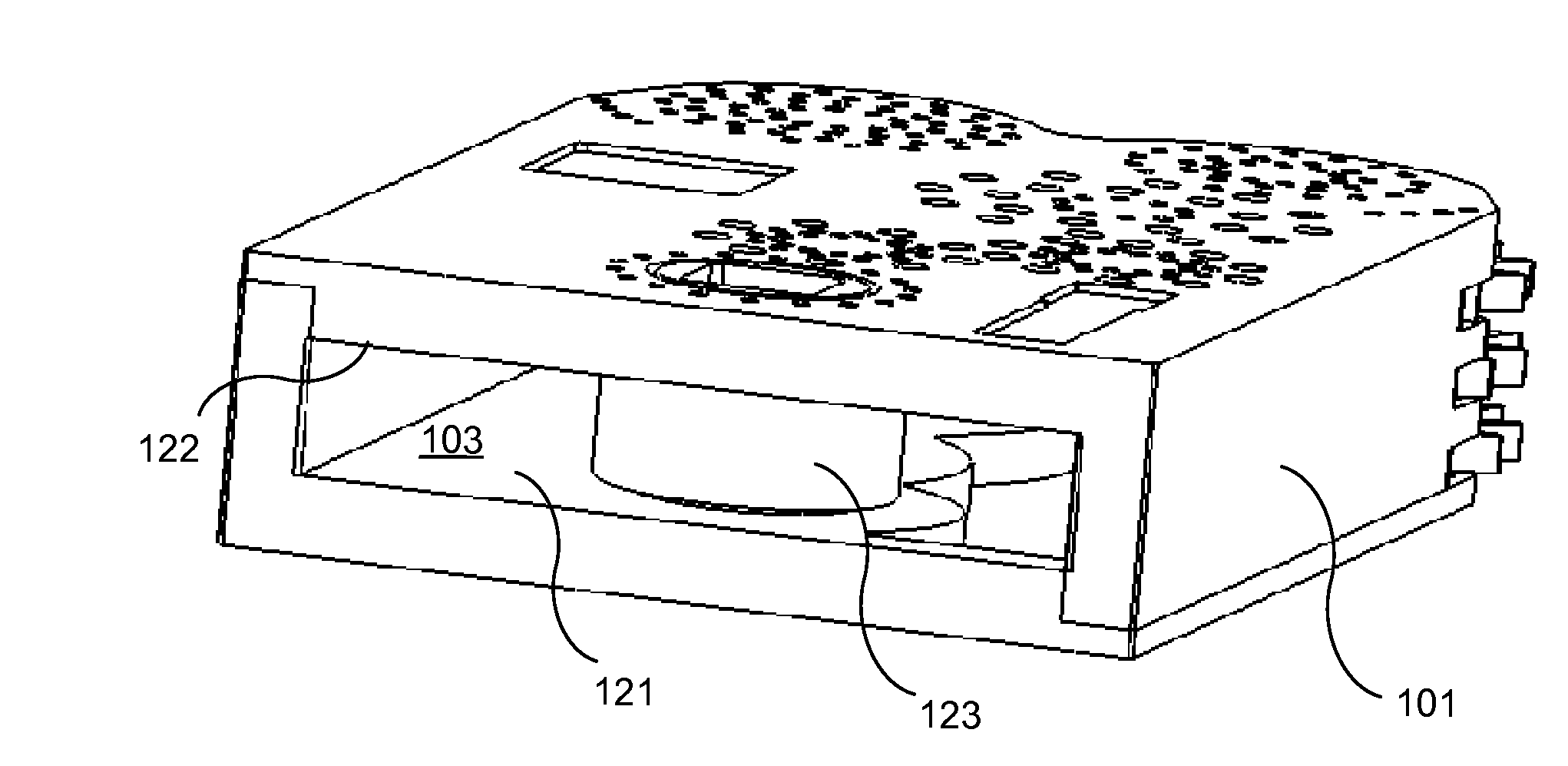

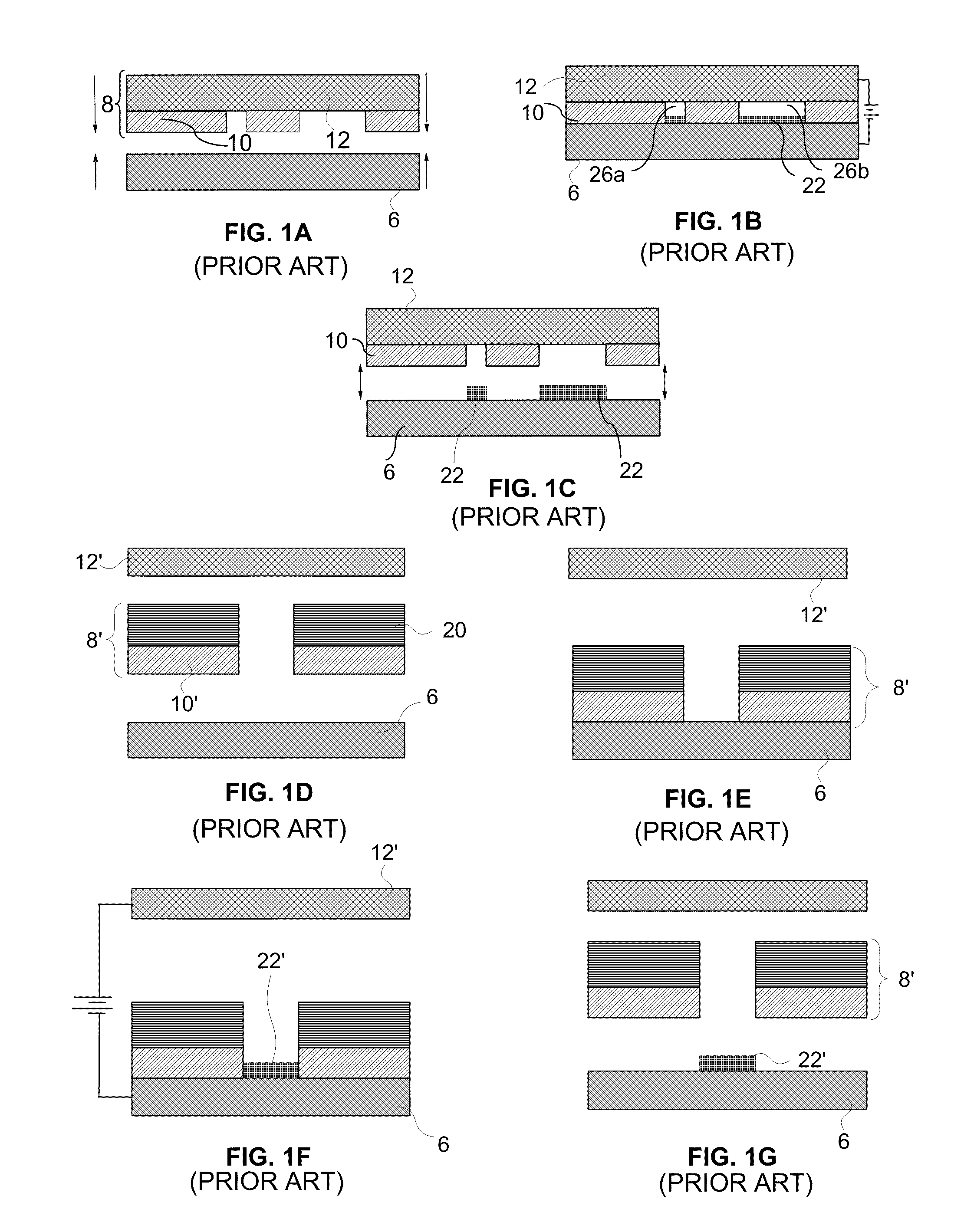

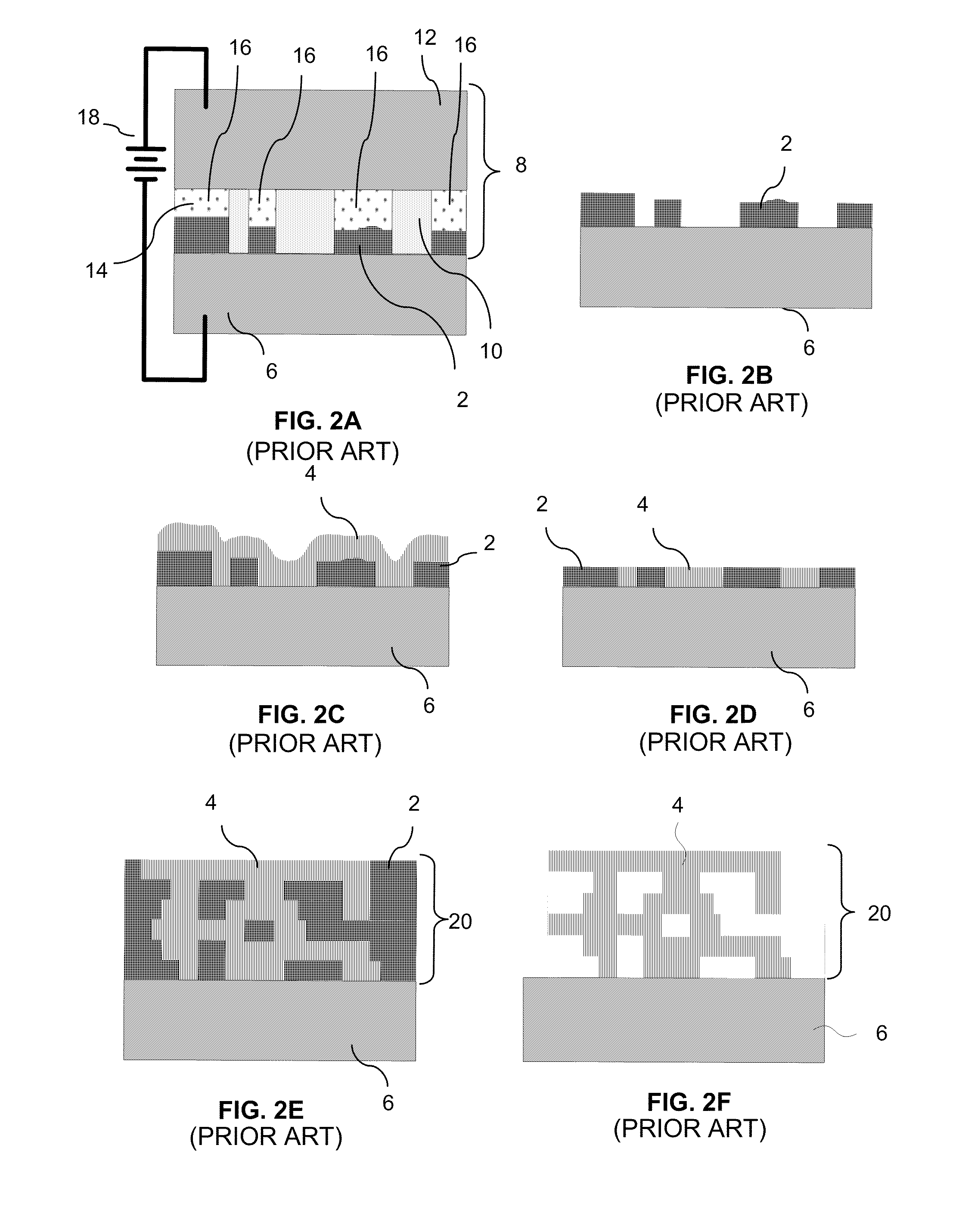

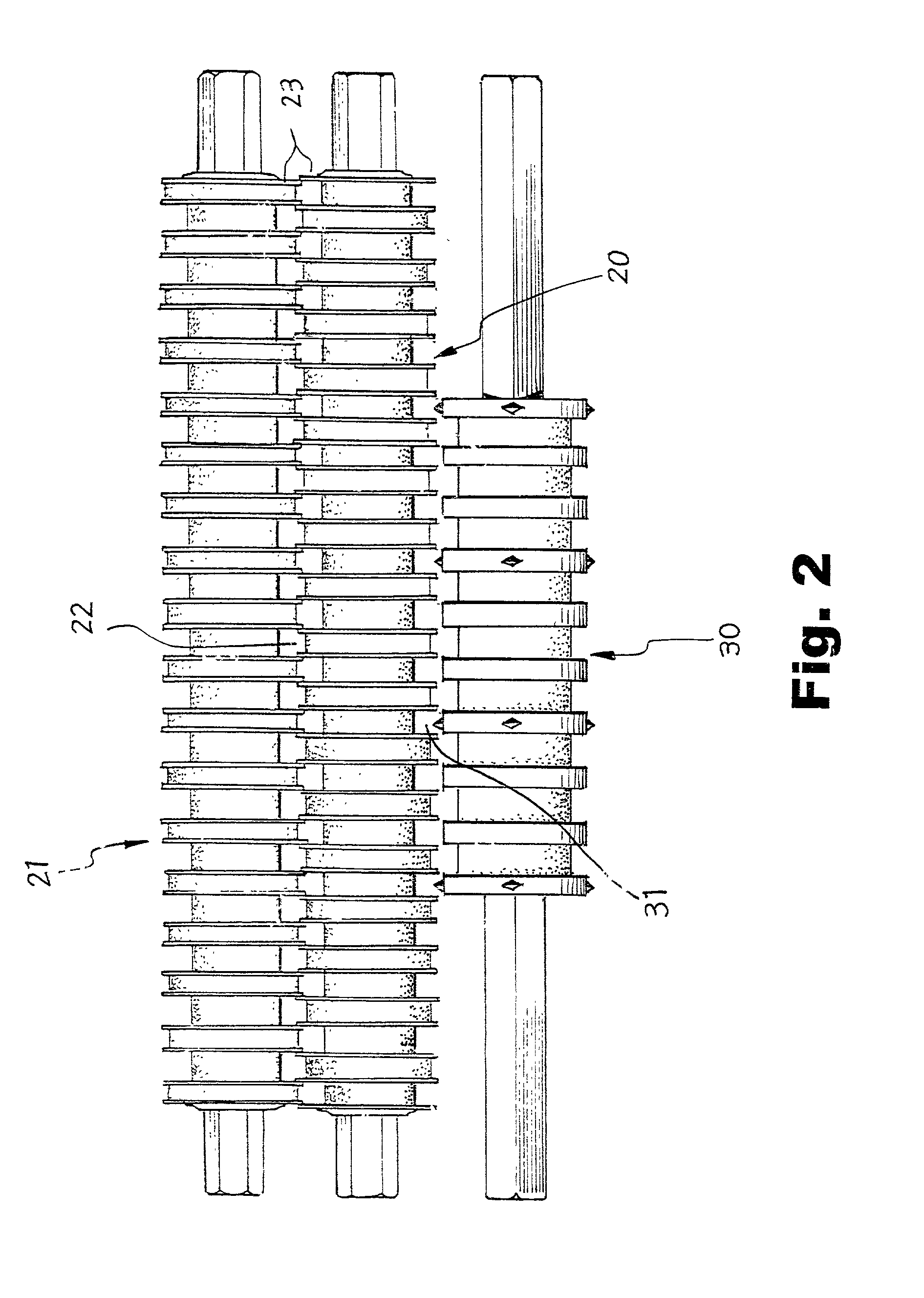

Miniature Shredding Tool for Use in Medical Applications and Methods for Making

ActiveUS20100010525A1Enhanced etchant accessEasy accessAdditive manufacturing apparatusDiagnosticsMulti materialThrombus

The present invention relates generally to the field of micro-scale or millimeter scale devices and to the use of multi-layer multi-material electrochemical fabrication methods for producing such devices with particular embodiments relate to shredding devices and more particularly to shredding devices for use in medical applications. In some embodiments, tissue removal devices are used in procedures to removal spinal tissue and in other embodiments, similar devices are used to remove thrombus from blood vessel.

Owner:MICROFAB

Method for producing instant pleurotus eryngii chips

The invention relates to a method for producing instant pleurotus eryngii chips, and belongs to the technical field of the deep processing of agricultural products. The main pleurotus eryngii chip production process comprises: performing pretreatment such as conventional selection, washing, precise segmenting, blanching, enzyme killing, cooling and the like on pleurotus eryngii, and performing ultrasonic auxiliary dipping, hot-air drying, vacuum frying and dewatering, centrifugal deoiling, seasoning and packaging. In the method, due to the adoption of a new process of combining the ultrasonic auxiliary dipping, the hot-air drying, the vacuum frying and dewatering, the dipping efficiency is improved, the moisture content of pleurotus eryngii pieces is reduced due to hot-air predrying, and the vacuum frying time is shortened greatly; and products of the pleurotus eryngii chips have the characteristics of high puffing rate, low oil content, excellent sensory quality and the like. In the method, the pleurotus eryngii is not processed by conventional freezing, so the production period of the finished products is shortened greatly, the production cost is saved, and a feasible new path is provided for the deep processing of the pleurotus eryngii.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Miniature Shredding Tool for Use in Medical Applications and Methods for Making

ActiveUS20100010492A1Enhanced etchant accessEasy accessAdditive manufacturing apparatusDiagnosticsMulti materialThrombus

The present invention relates generally to the field of micro-scale or millimeter scale devices and to the use of multi-layer multi-material electrochemical fabrication methods for producing such devices with particular embodiments relate to shredding devices and more particularly to shredding devices for use in medical applications. In some embodiments, tissue removal devices are used in procedures to removal spinal tissue and in other embodiments, similar devices are used to remove thrombus from blood vessel.

Owner:MICROFAB

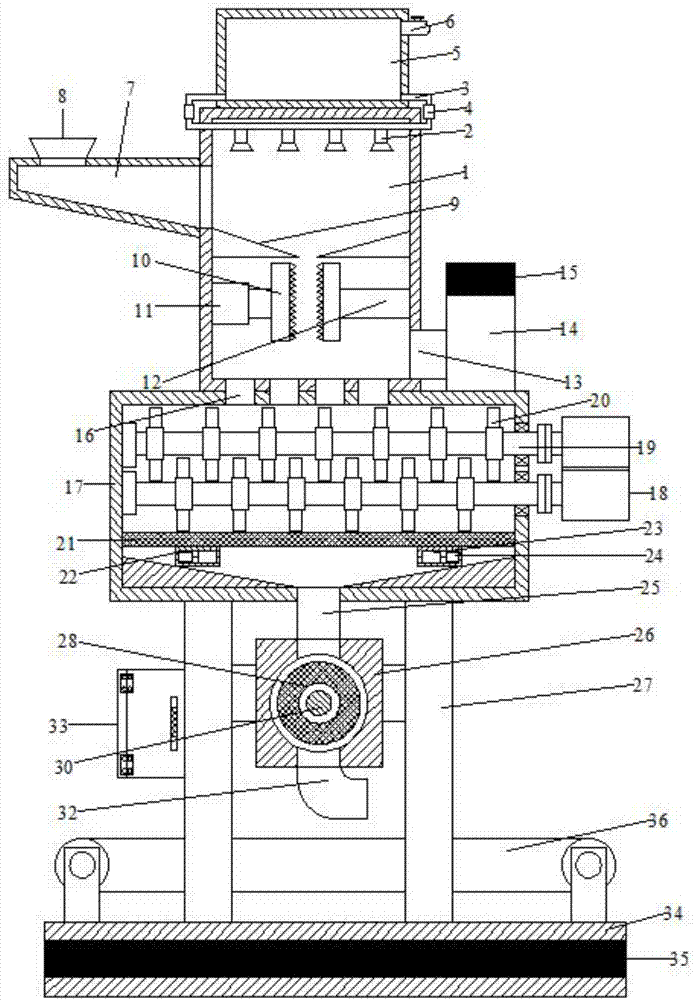

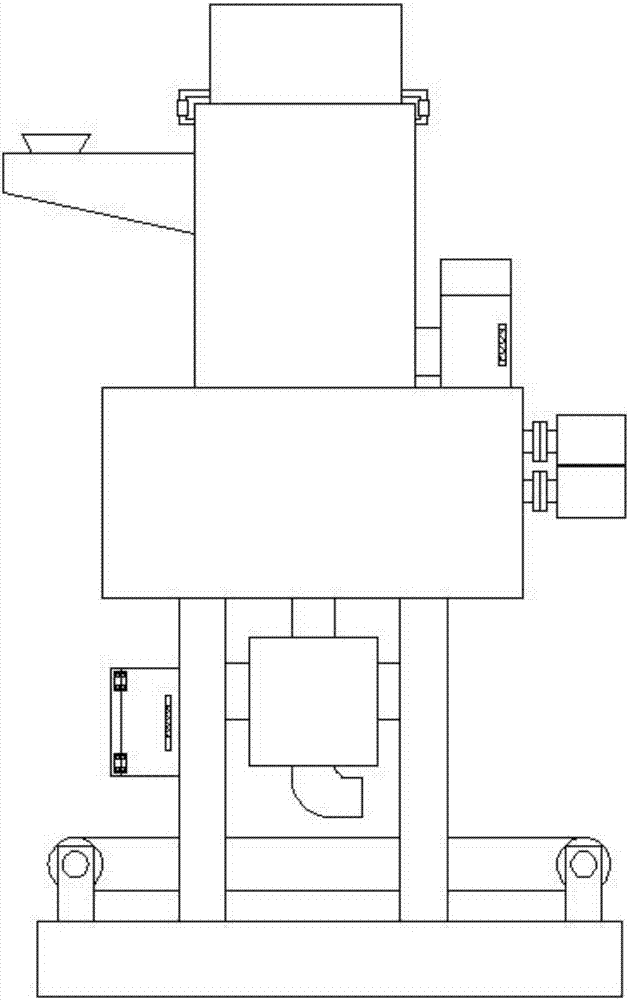

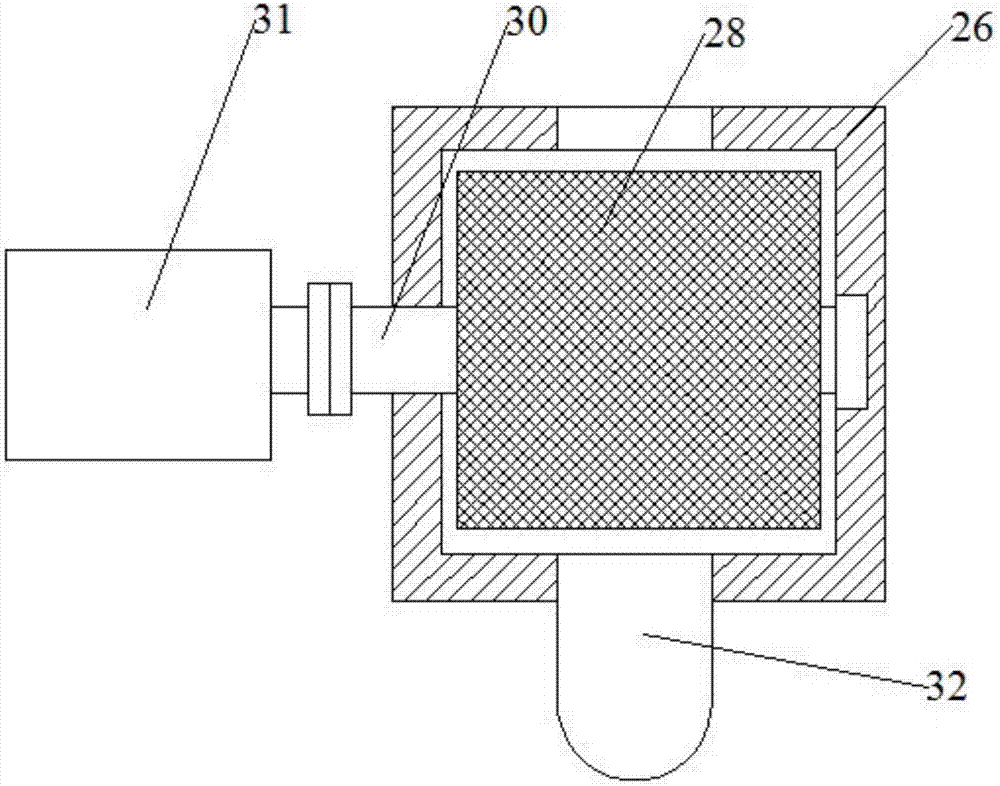

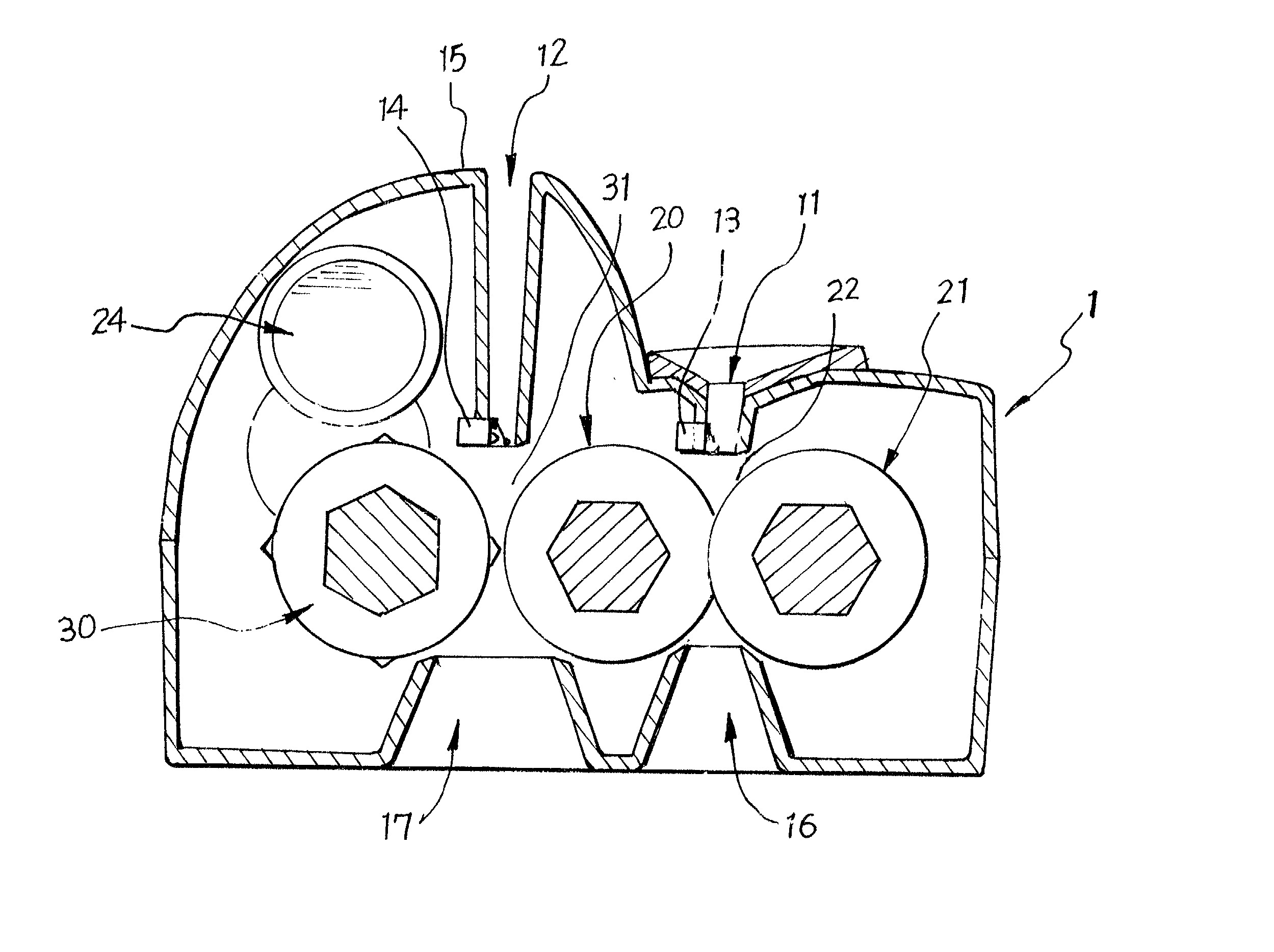

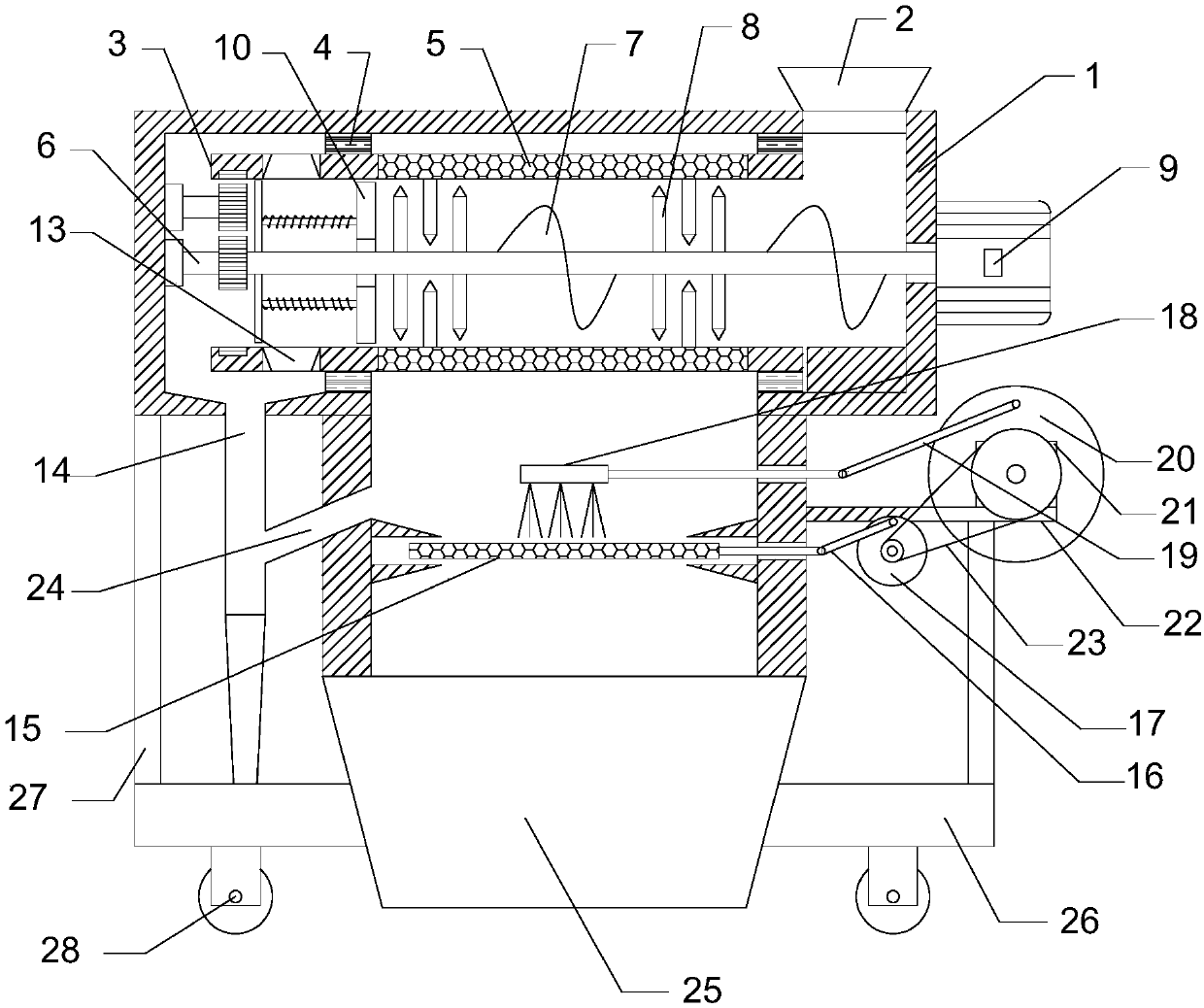

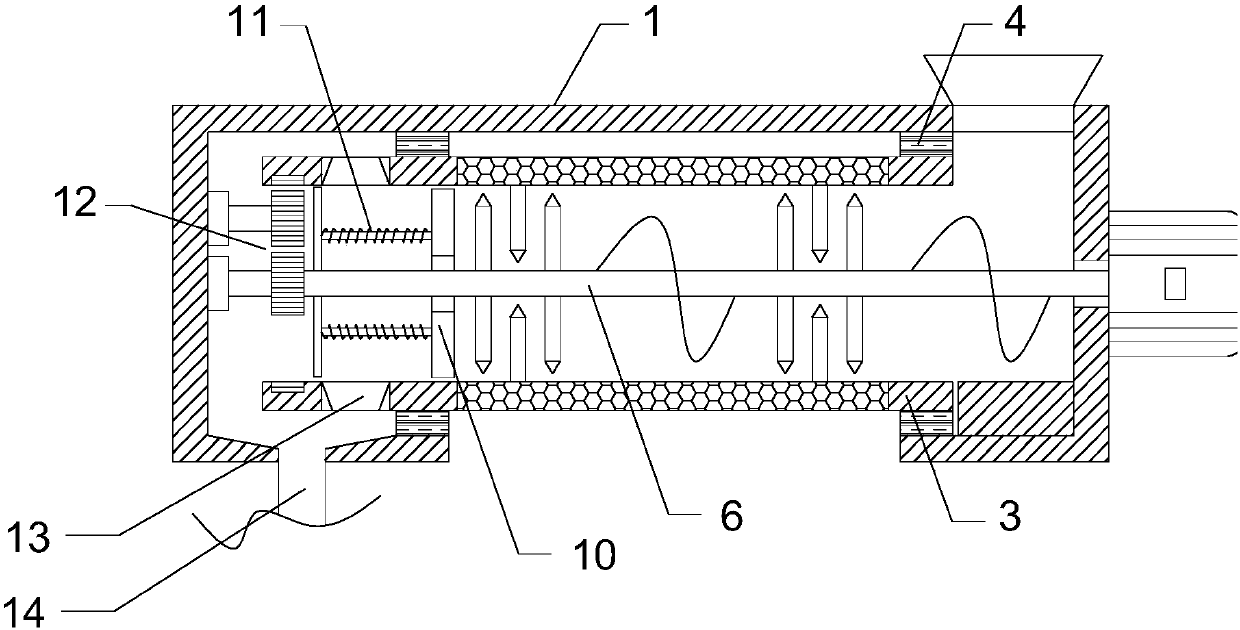

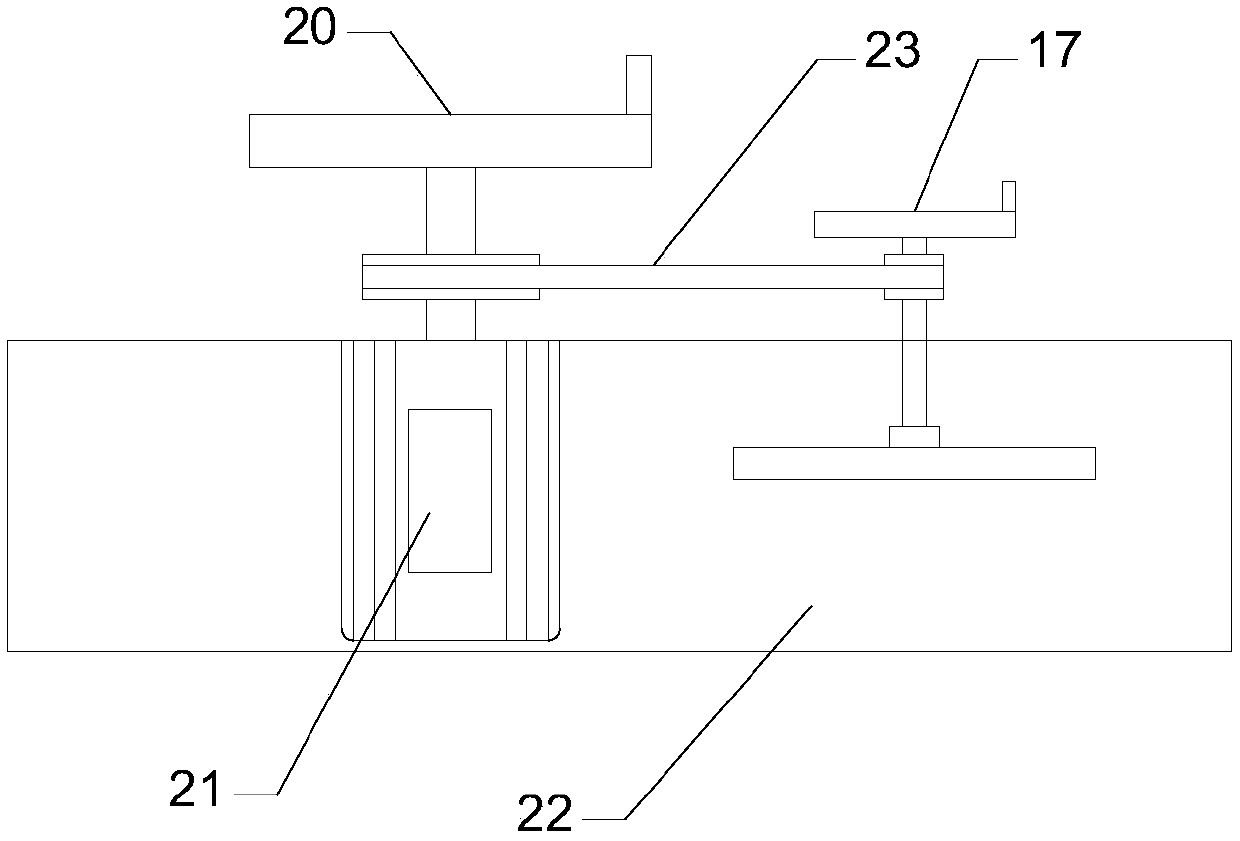

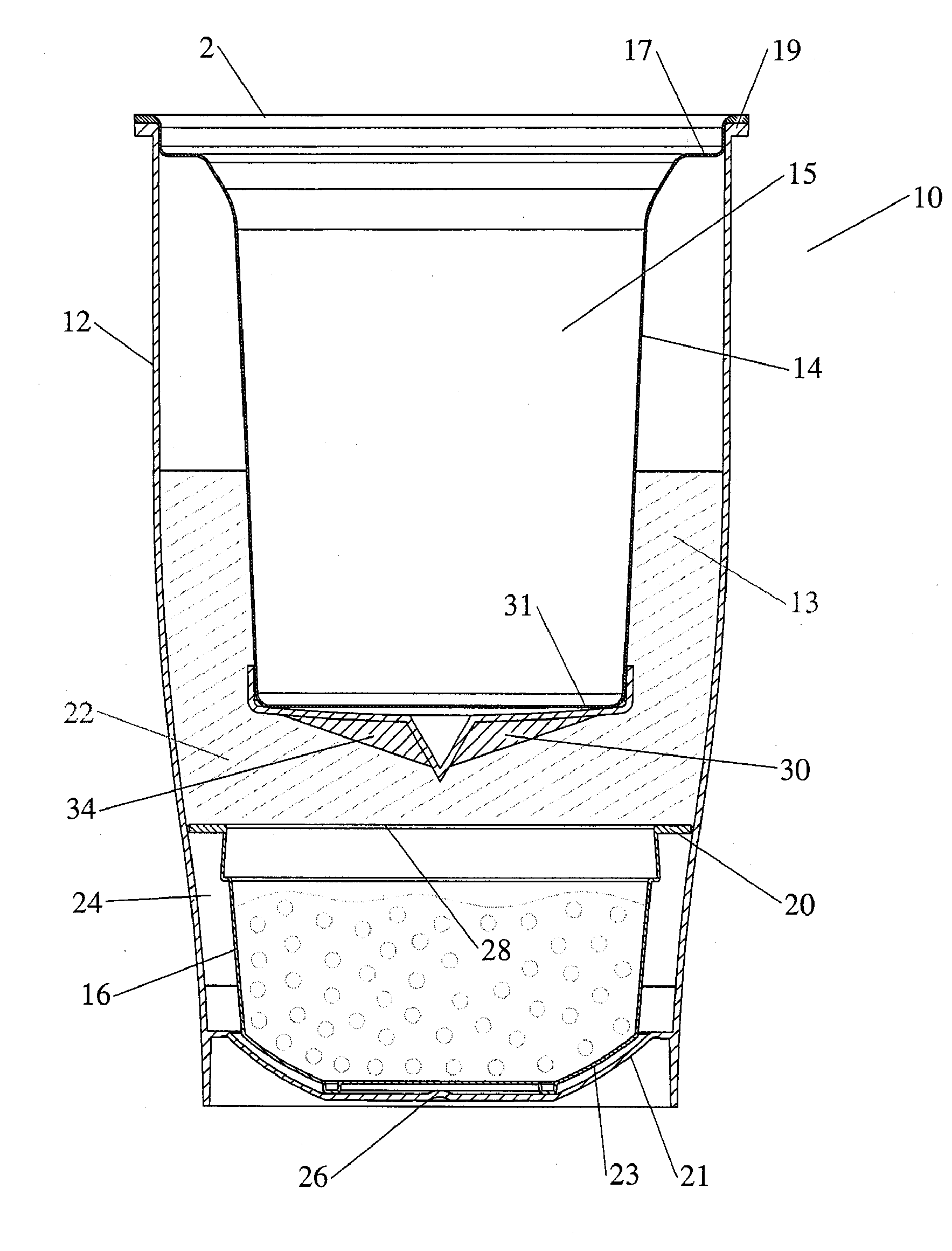

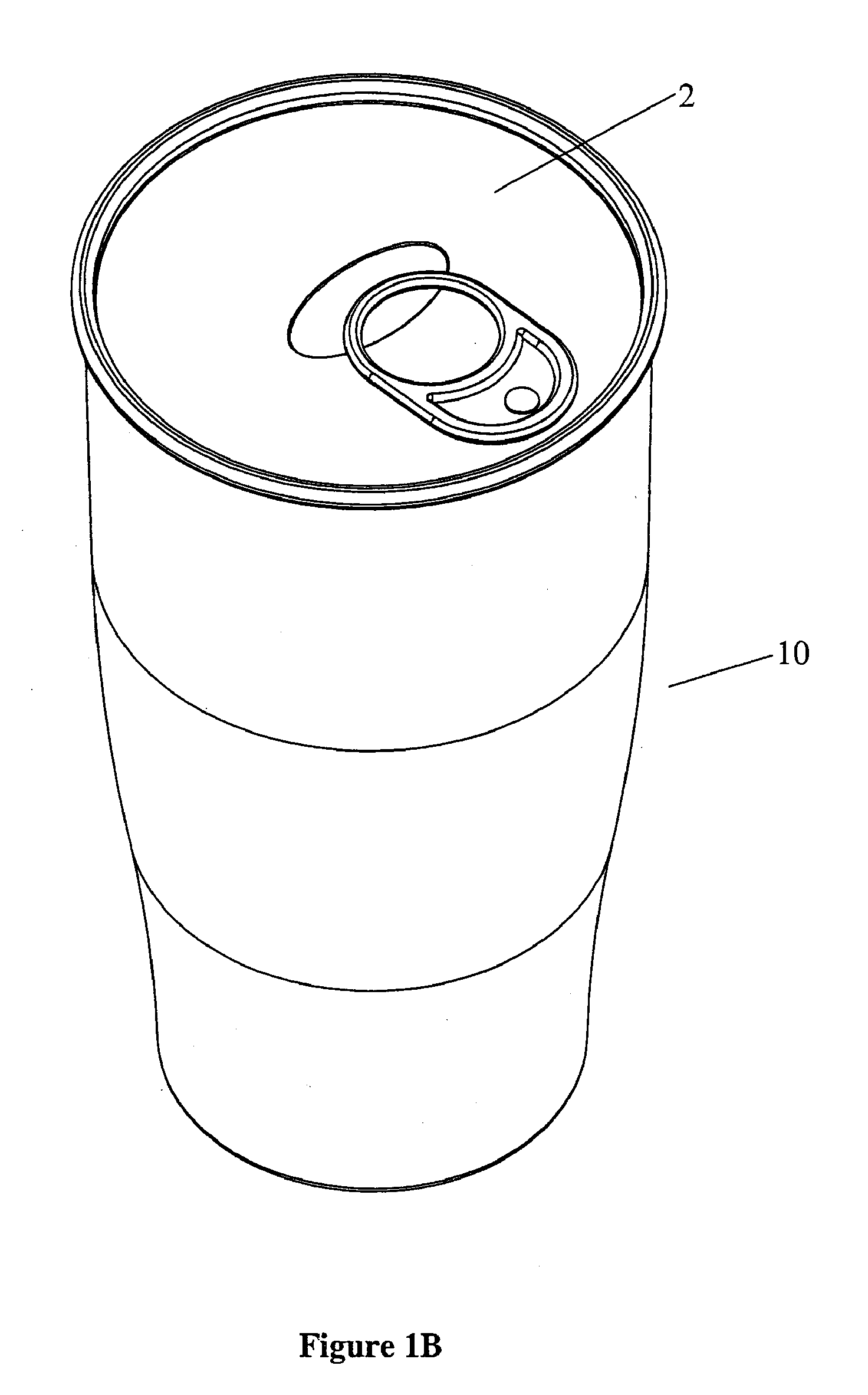

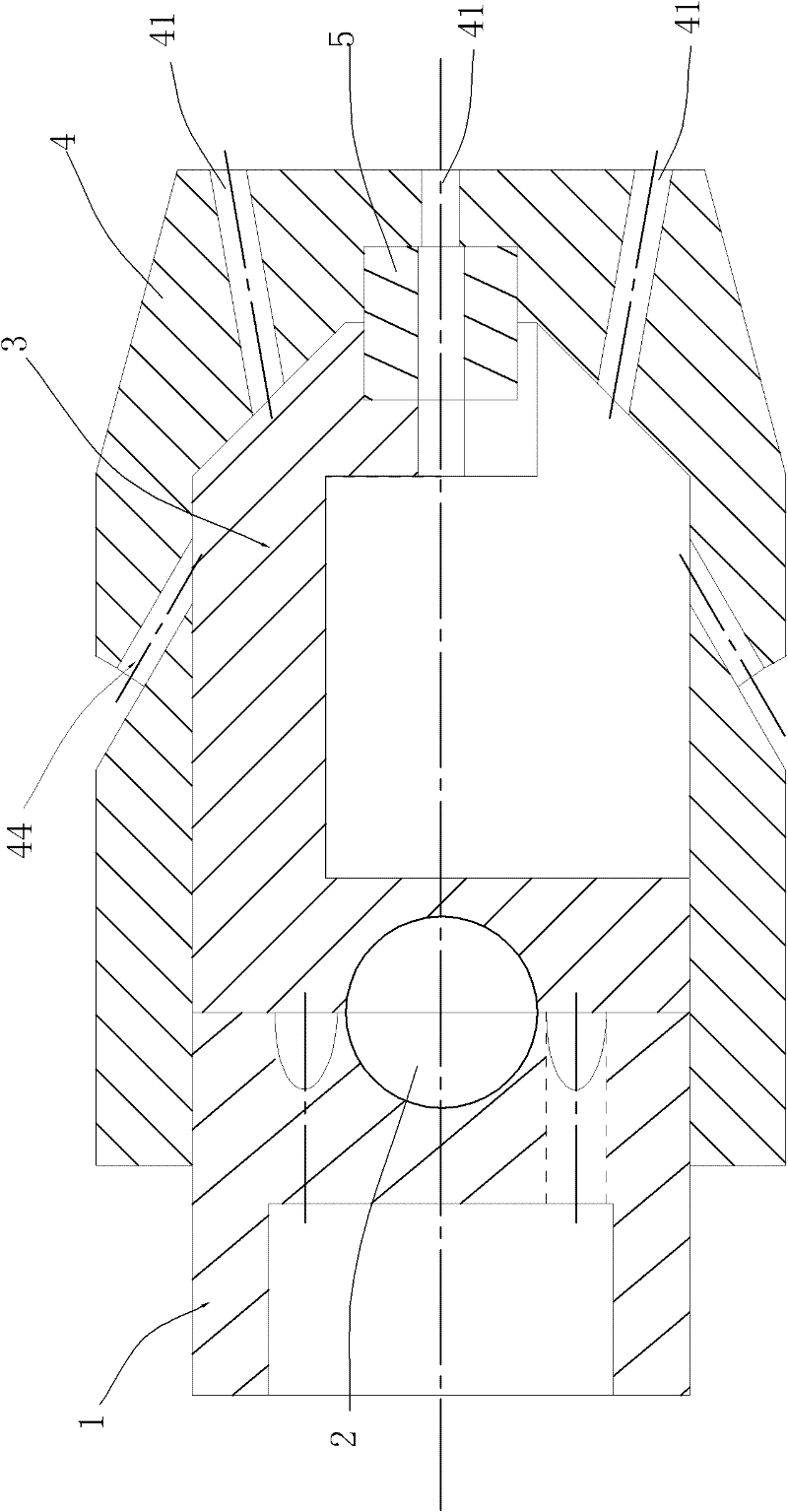

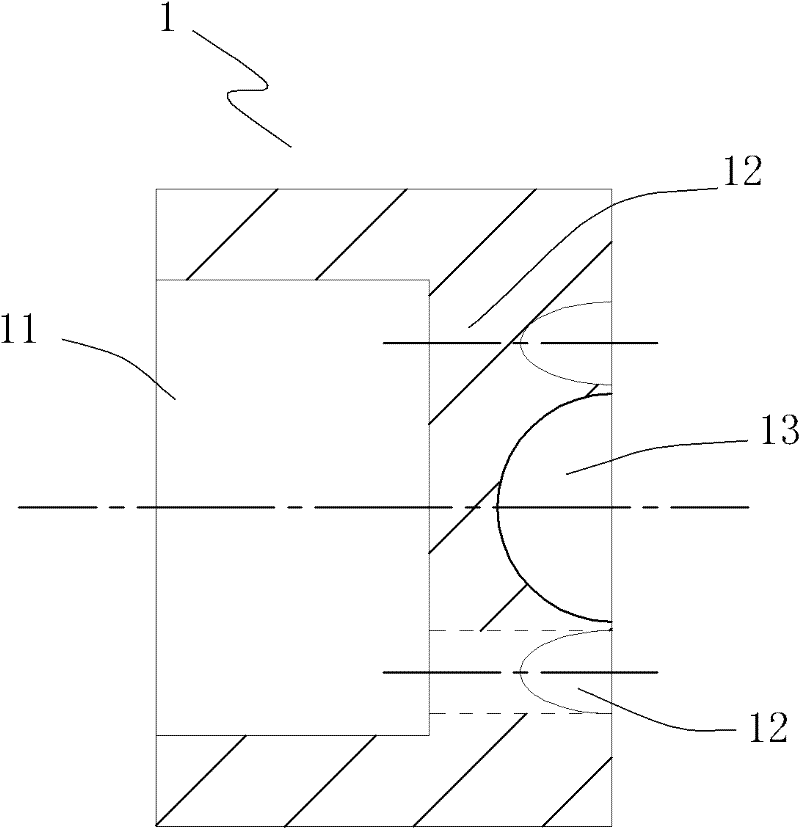

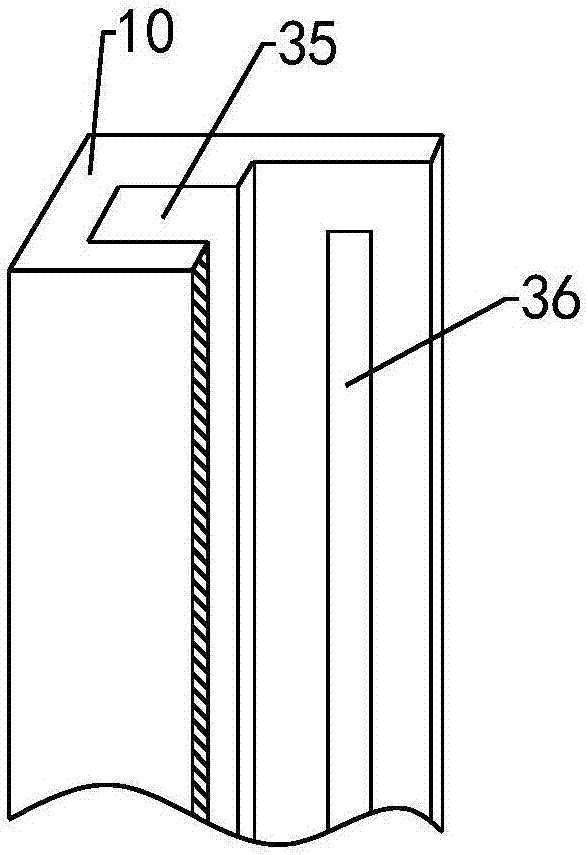

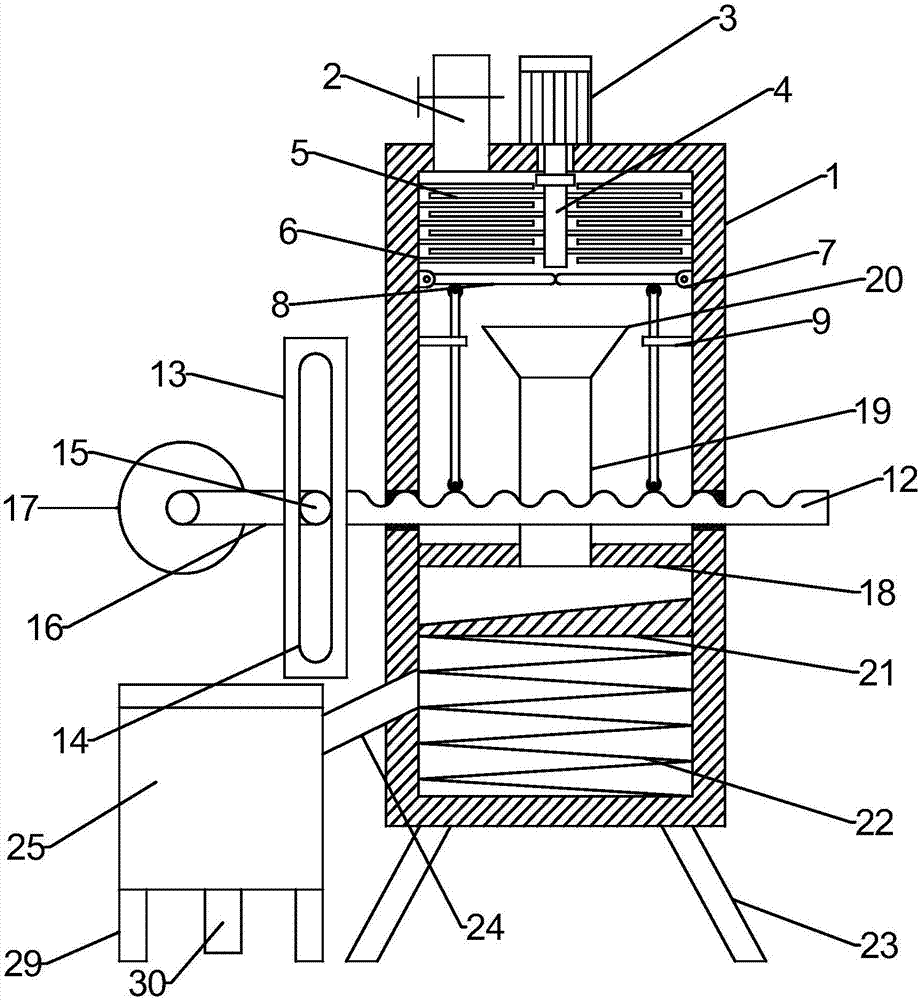

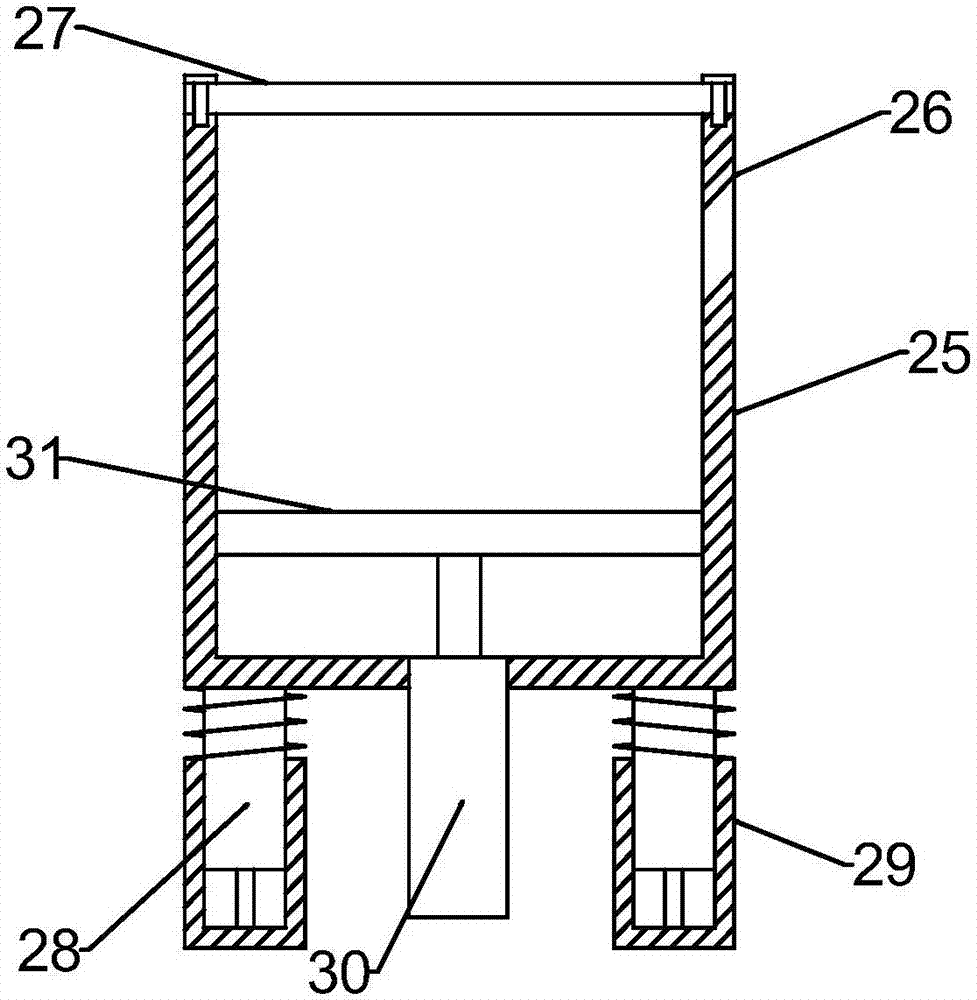

Construction waste treatment device

InactiveCN107214179AEfficient crushingPromote fragmentationConstruction waste recoverySolid waste disposalWater storageArchitectural engineering

The invention discloses a construction waste treatment device, which comprises a crushing chamber, an atomizing nozzle is arranged on the upper side of the crushing chamber, a water suction pipe is arranged on the upper side of the atomizing nozzle, a water storage chamber is arranged inside the upper end of the suction pipe, and a water storage chamber is arranged on the left upper side of the crushing chamber. There is a feeding pipe, the lower end of the right side of the feeding pipe is provided with a drainage plate, the lower side of the drainage plate is provided with a crushing plate, the lower left end of the crushing chamber is provided with a connecting pipe, the right side of the connecting pipe is provided with a rebar storage chamber, and the upper end of the rebar storage chamber is provided with a There is an electromagnet, there is a discharge port on the lower side of the crushing chamber, a crushing chamber is provided on the lower side of the discharge port, a screen is provided at the lower end of the crushing chamber, a discharge pipe is provided in the middle of the lower side of the crushing chamber, and a discharge pipe is provided on the lower side of the discharge pipe. There is a grinding chamber, the four corners of the lower side of the crushing chamber are provided with support columns, the lower side of the grinding chamber is provided with a discharge pipe, the lower side of the support column is provided with a base, the inside of the base is provided with a vibration-damping pad, and the upper middle of the base is provided with a pulley. The construction waste is crushed, separated, crushed, screened, ground and transported, which can effectively protect the environment and save resources.

Owner:彭利辉

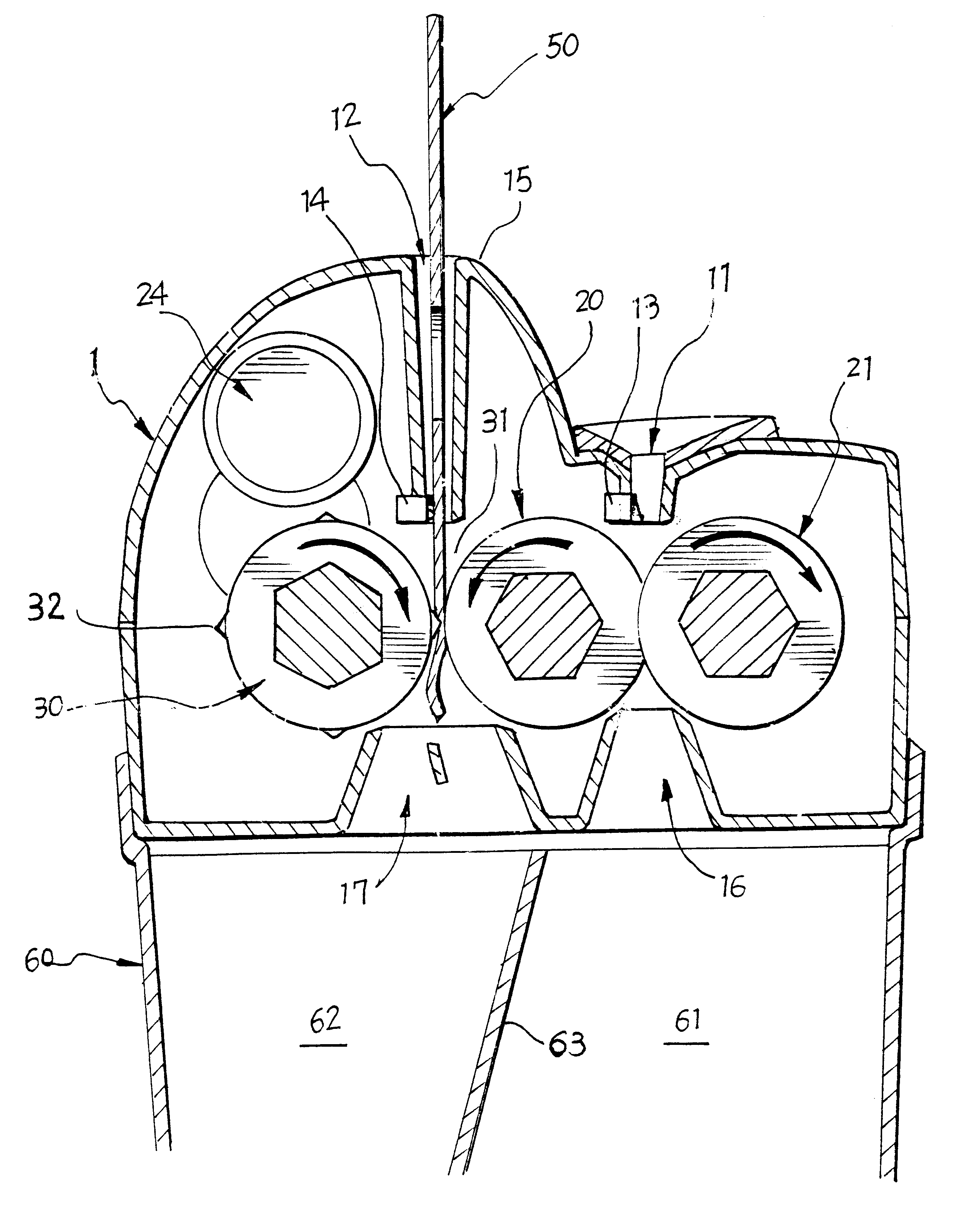

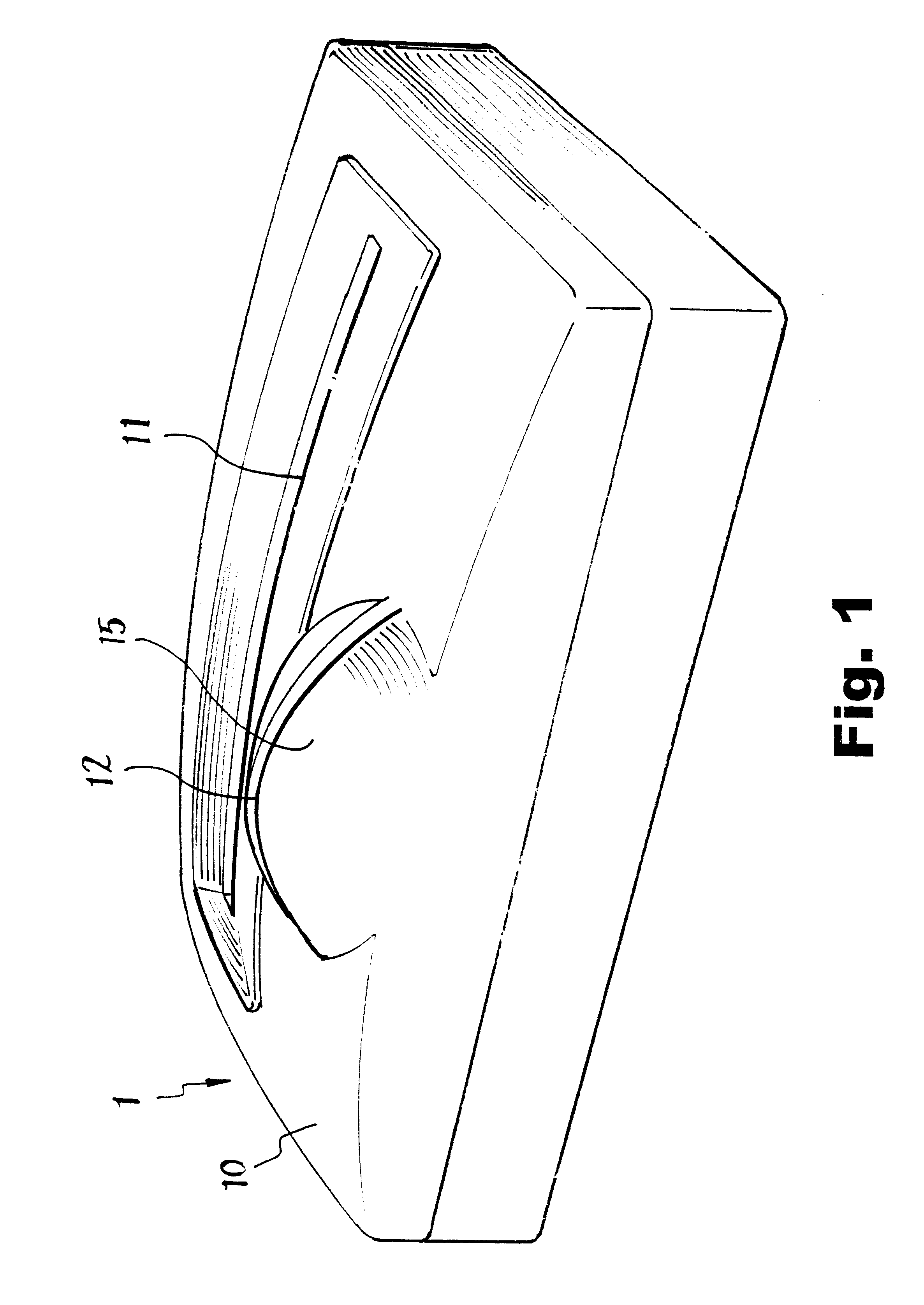

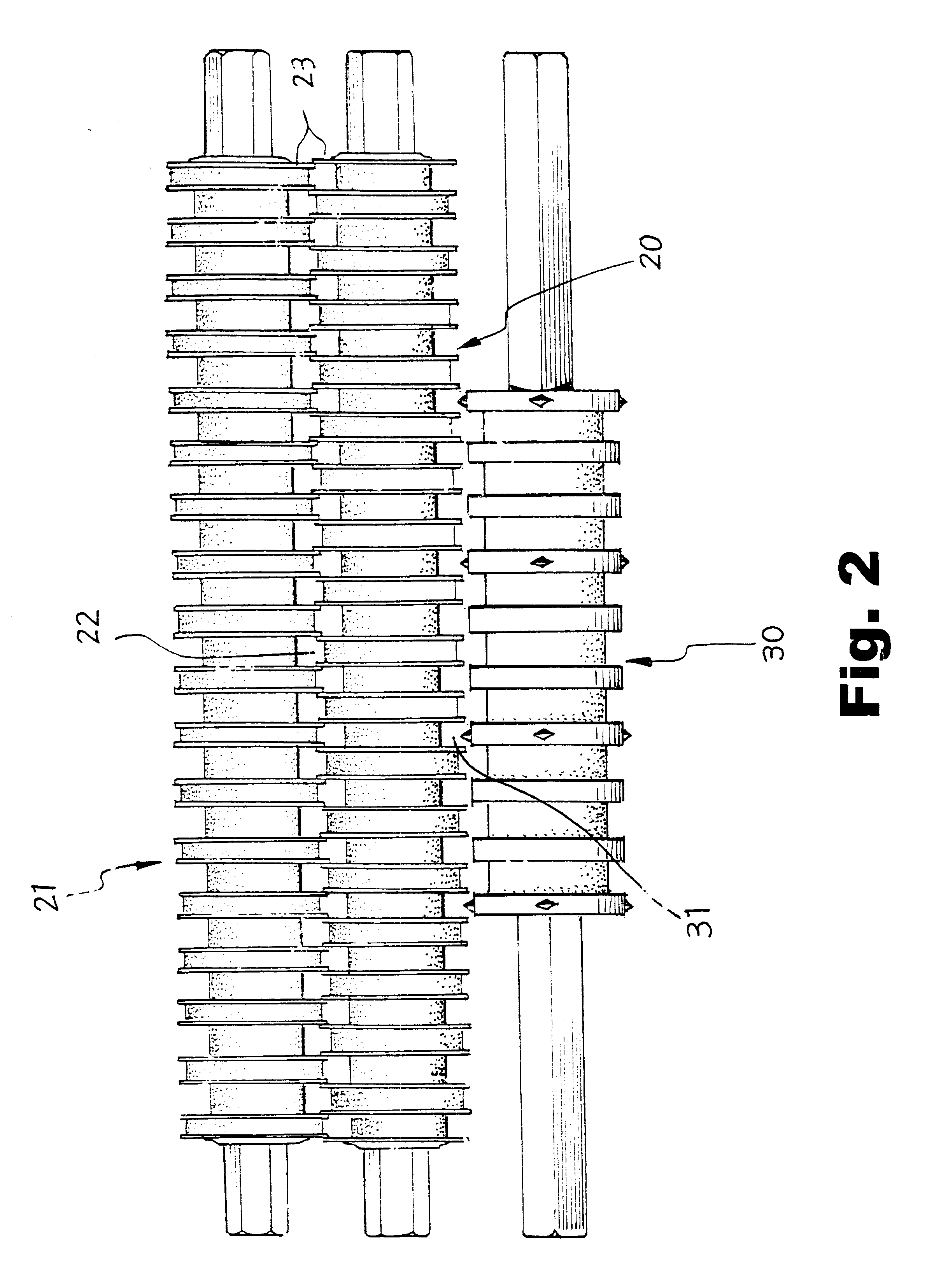

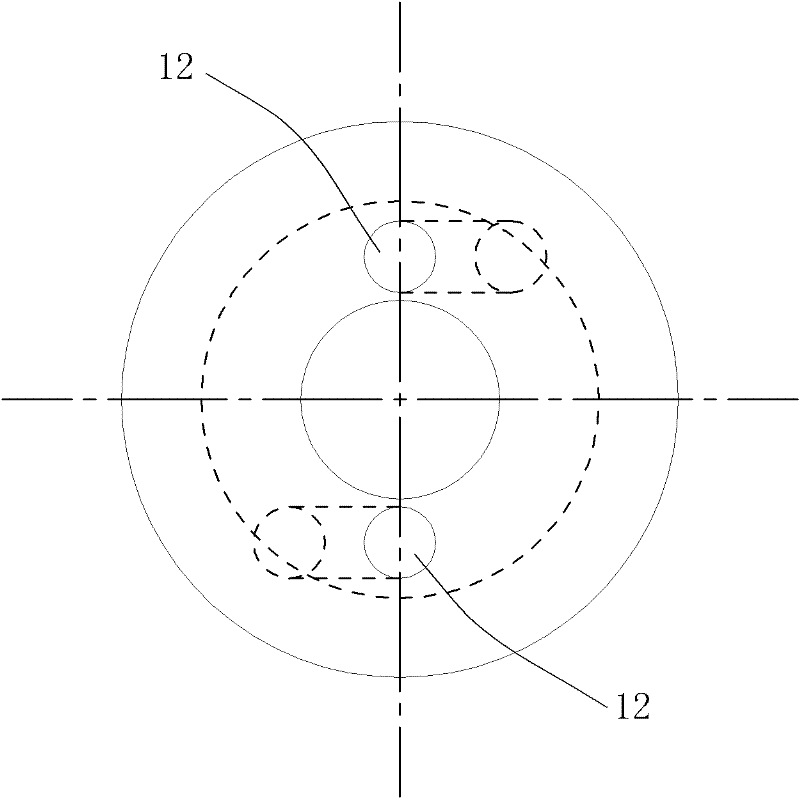

Paper shredder having the function of breaking a compact disc

InactiveUS20030006330A1Mitigate and obviate disadvantageEfficient crushingBalingThreshersCredit cardImpeller

A paper shredder having the function of breaking a compact disc includes juxtaposed first and second rolling blade wheels which are used for shredding paper, and rotated relative to each other. The paper shredder is additionally provided with a third rolling blade wheel that is especially used for breaking a compact disc or a credit card. The surface of the housing of the paper shredder is provided with a paper inlet and a compact disc inlet. The paper may be passed through and shredded by the first rolling blade wheel and the second rolling blade wheel. The compact disc or credit card may be passed through and broken by the second rolling blade wheel and the third rolling blade wheel.

Owner:CHANG FR

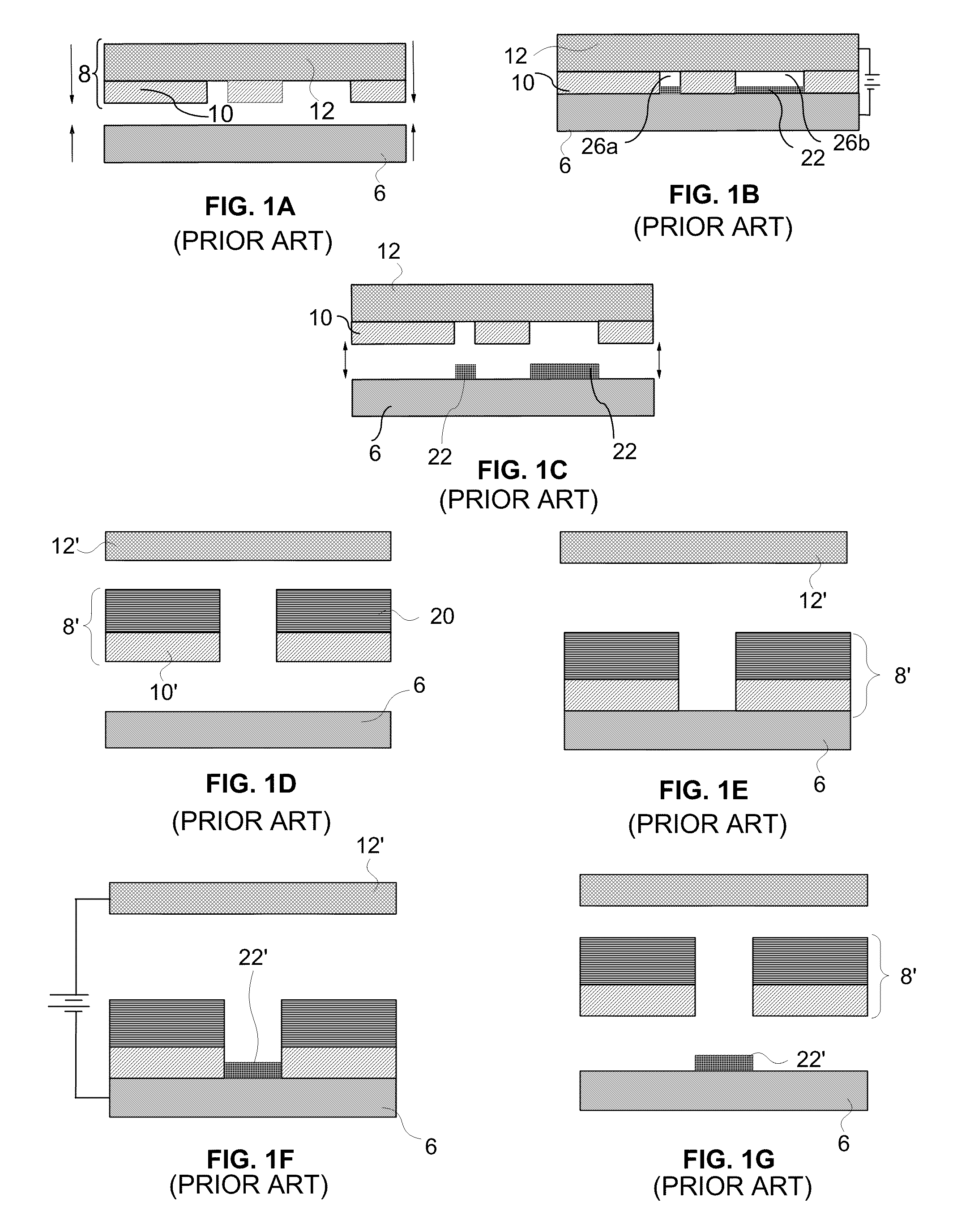

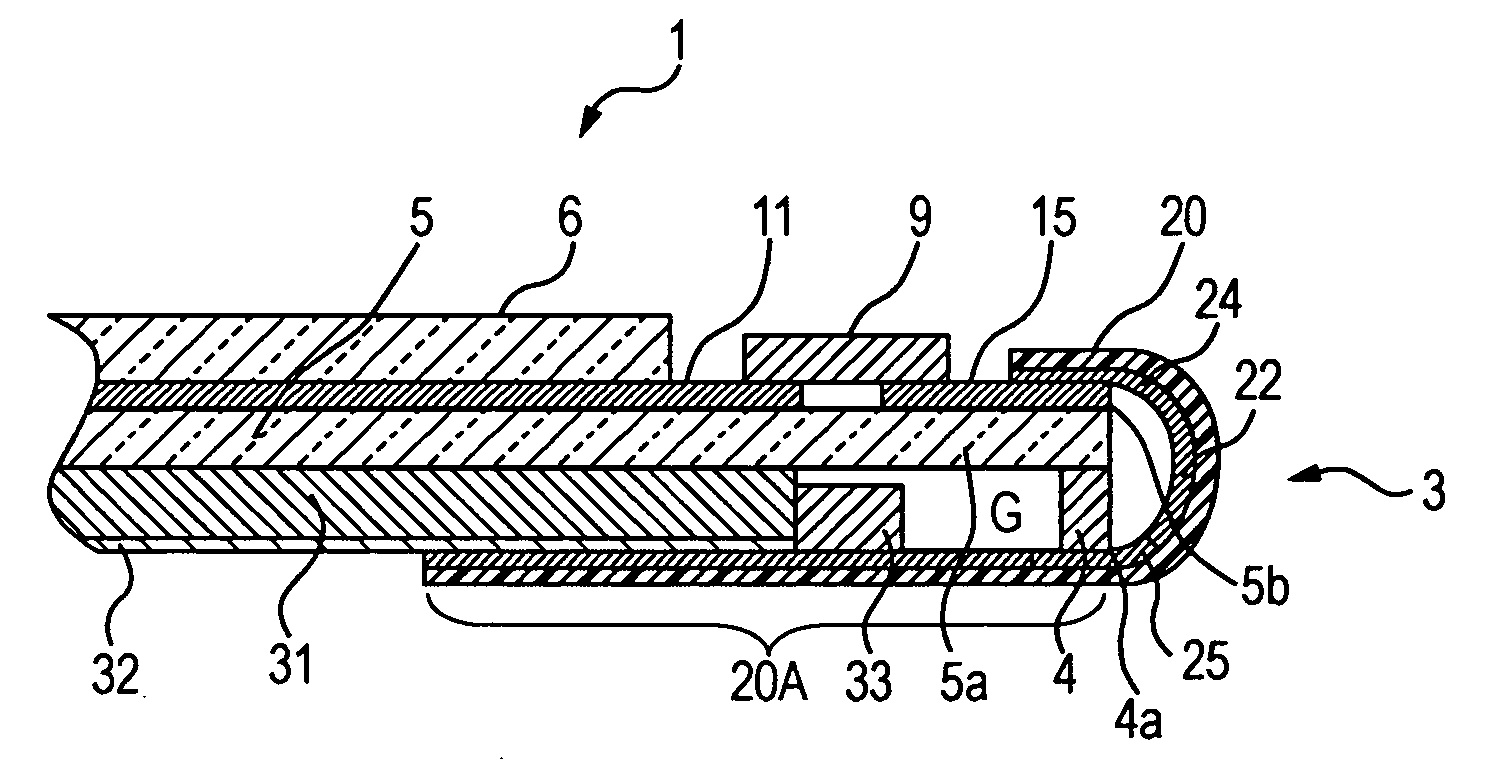

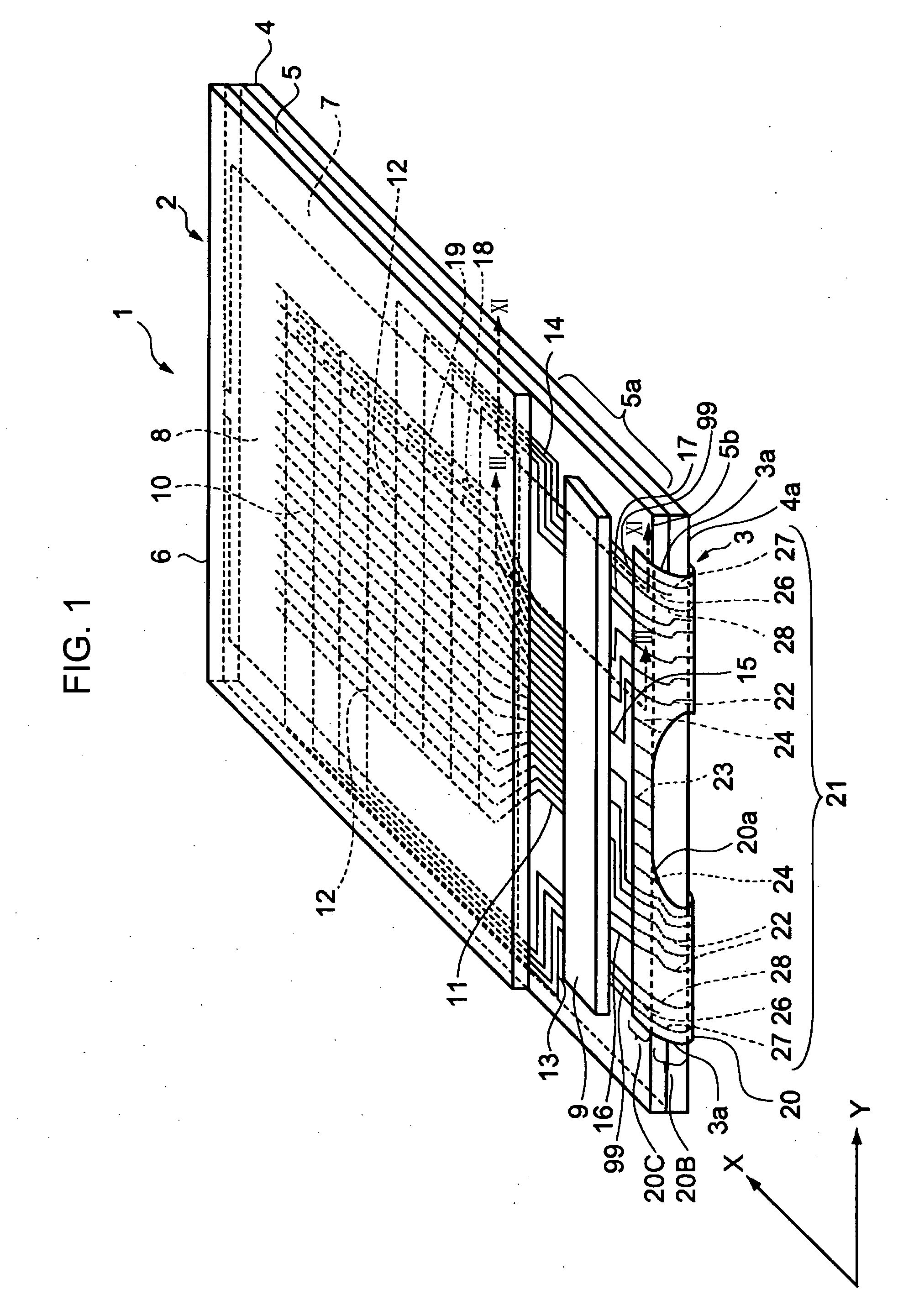

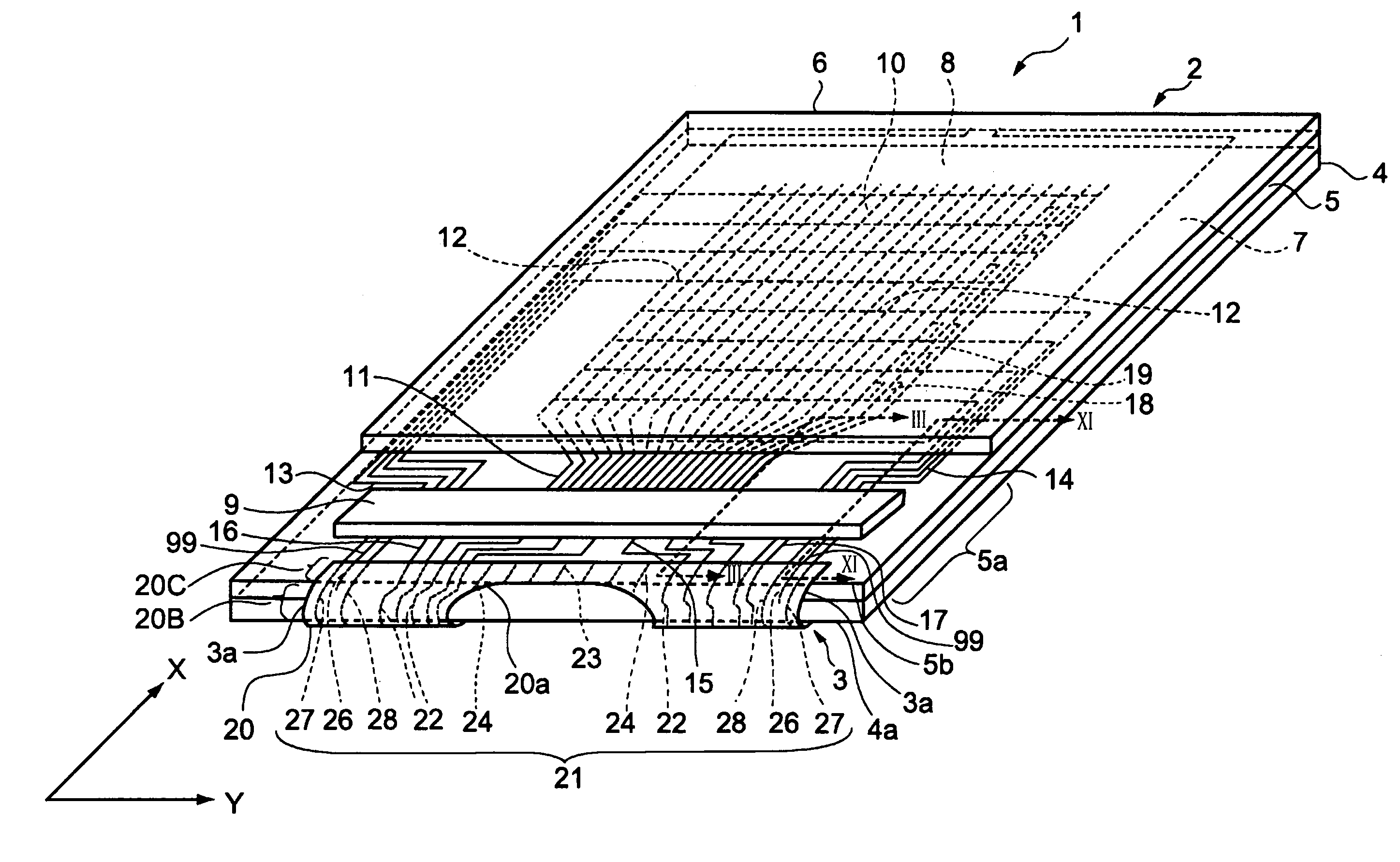

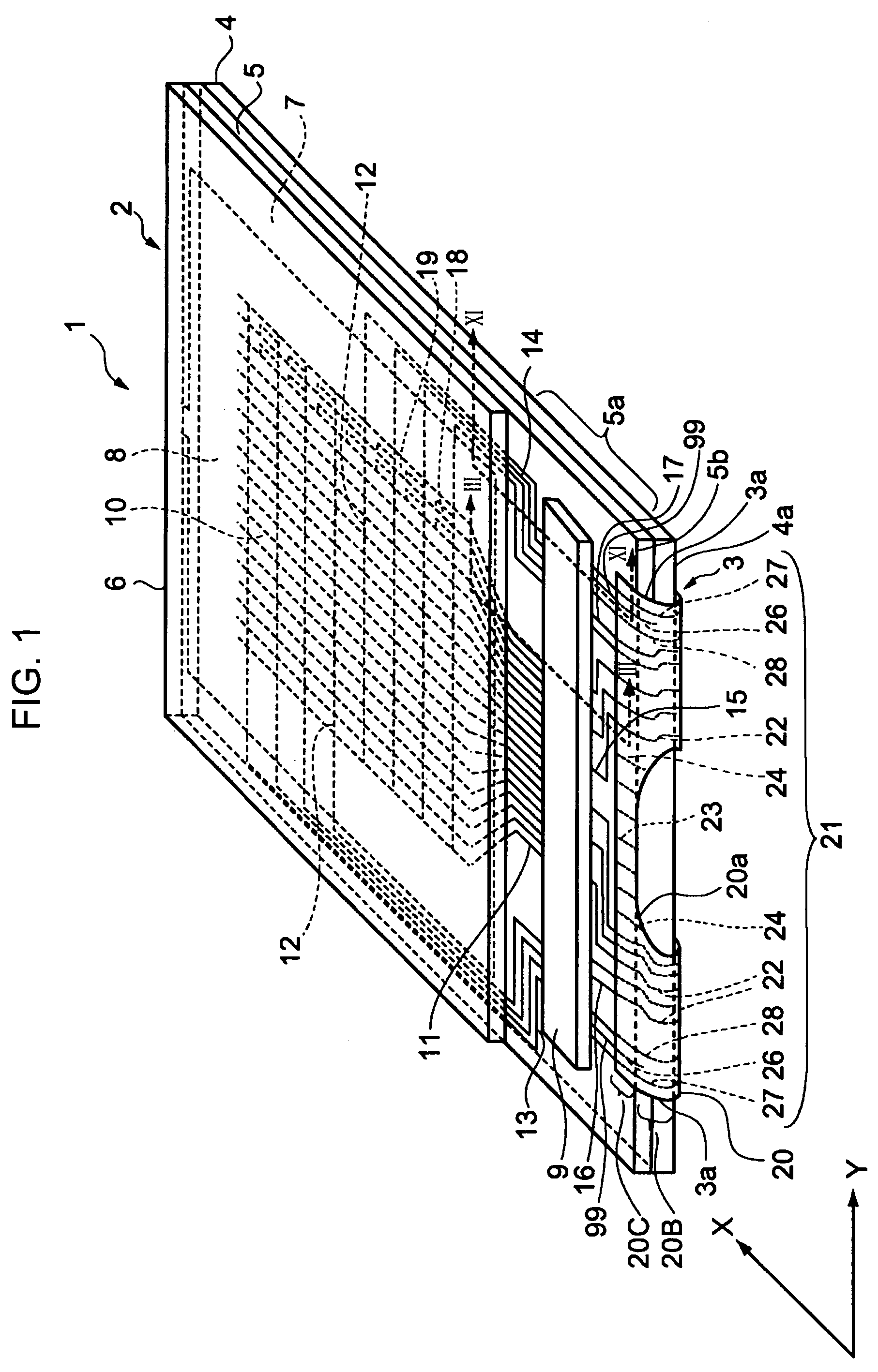

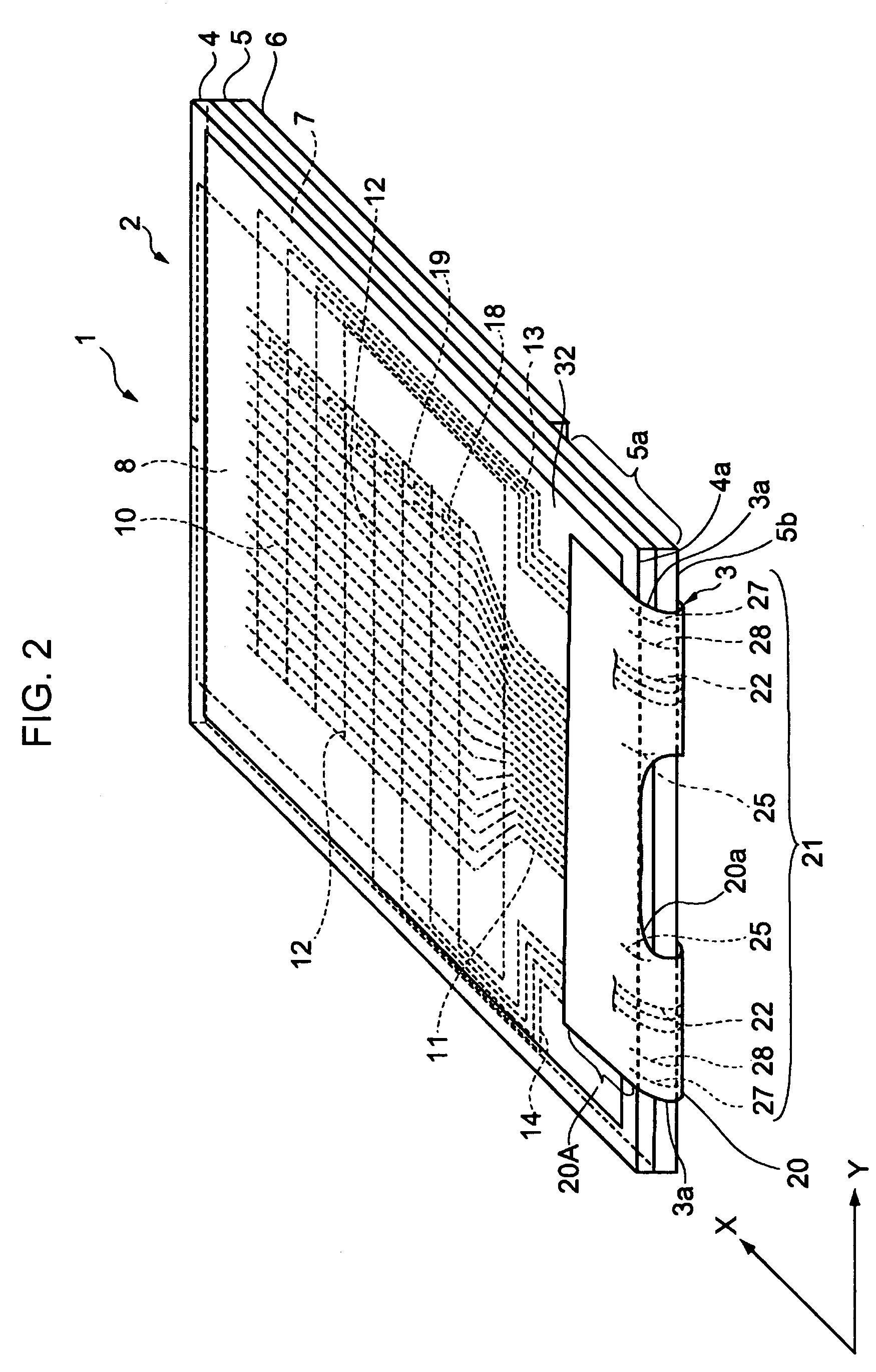

Mounting structure, electro-optical device, and electronic apparatus

ActiveUS20060109394A1Avoid breakingEasily brokenCircuit bendability/stretchabilitySemiconductor/solid-state device detailsEngineeringEdge crossing

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

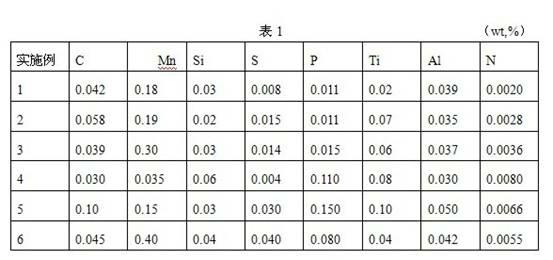

Steel plate and method thereof used for producing water heater linear enamel by flexible thin slab rolling line

ActiveCN102181805AStable recoveryExcellent anti-scale explosion performanceRoll mill control devicesMetal rolling arrangementsThin slabManganese

The invention relates to a steel plate and a process method thereof used for producing water heater linear enamel by a flexible thin slab rolling line (FTSR), belonging to the production field of enamel steel plates. The steel plate comprises the following chemical components in percentage by weight: 0.03-0.10wt% of carbon, 0.15-0.40wt% of manganese, less than or equal to 0.06wt% of silicon, 0.004-0.040wt% of sulphur, less than or equal to 0.15wt% of phosphorus, 0.03-0.05wt% of aluminum, 0.002-0.008wt% of nitrogen, 0.02-0.10wt% of titanium and the balance of ferrum and inevitable impurities. The tissue of the water heater linear enamel contains fine grain ferrite and a small quantity of pearlite tissues, and the granularity level of the water heater linear enamel is more than or equal to 10 levels. According to reasonable ingredient design and the FTSR process, steel for manufacturing water-storage water heater linear enamel for home appliances is produced; the steel plate has good enamel adhesion and scaling resistance, and also has the characteristics of few added alloy elements, few production working procedures, low production cost and the like; and a hot rolling scouring plate is used for replacing a cold rolling annealing plate.

Owner:HEBEI IRON AND STEEL

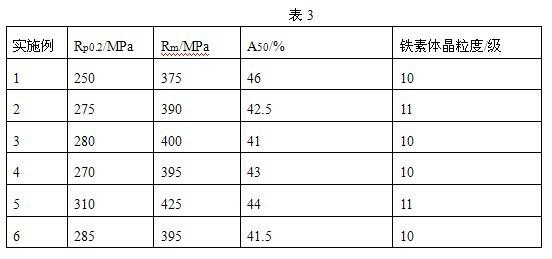

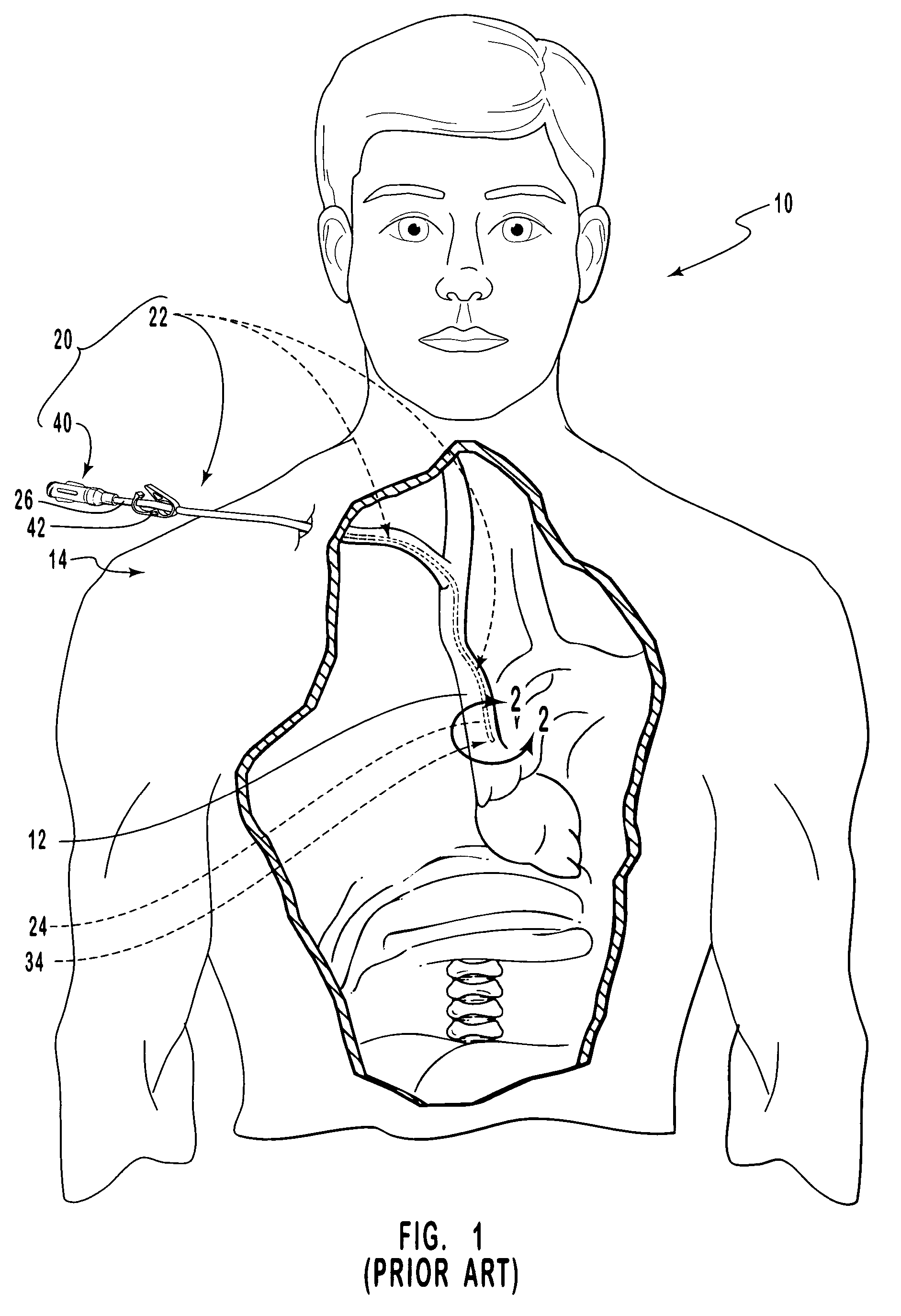

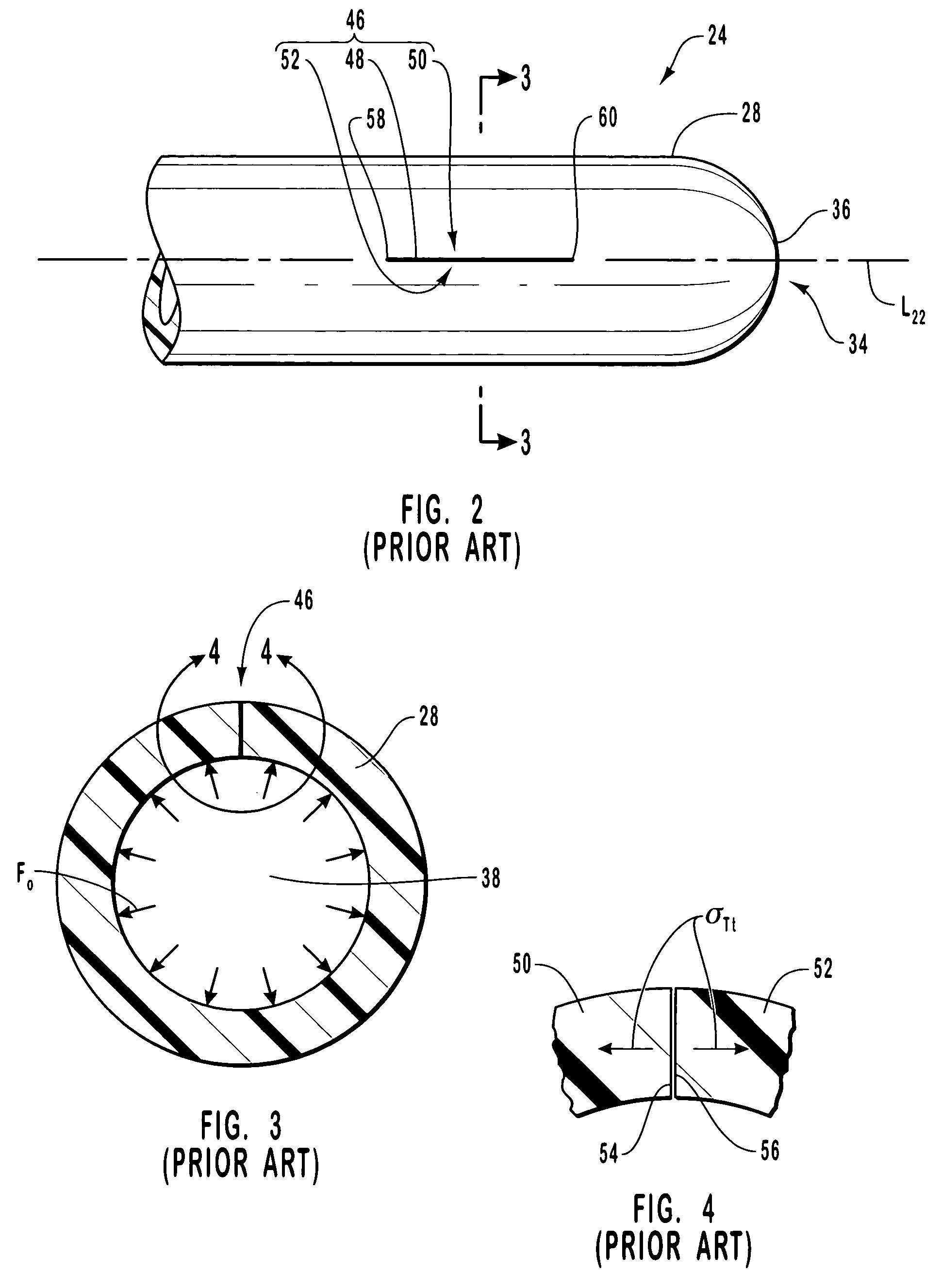

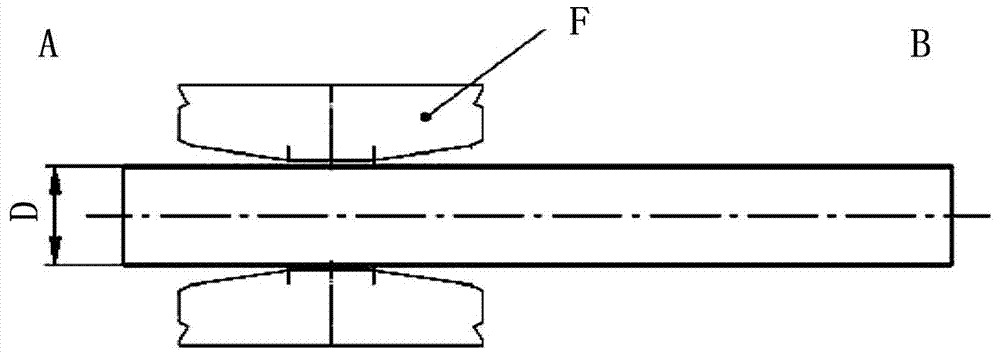

Cardiovascular access catheter with slit valve

ActiveUS7491192B2Minimize injuryIncreased durabilityCatheterIntravenous devicesPressure differenceBiomedical engineering

Two-way, three-position and one-way, two-position slit valves in cardiovascular access catheters with closed distal ends have slit geometries configured to overcome adhesion between opposed abutting slit faces, when pressure differentials are applied between the interior and the exterior of the catheter. Portions of the slit are oriented at a non-zero angle relative to the longitudinal axis of the catheter causing shear forces to be generated in abutting slit faces. Shear forces arise from tangential, radial, or longitudinal stresses generated in the catheter body. Slit geometries are planar or curved or include multiple end-to-end connected slit subsections. If a slit partially circumscribes a portion of the adjacent outer wall of the catheter body, restraint to outward and inward movement on that portion is reduced. Slit valves are configured to open inwardly to aspirate fluids, to open outwardly to infuse fluids, or both.

Owner:CR BARD INC

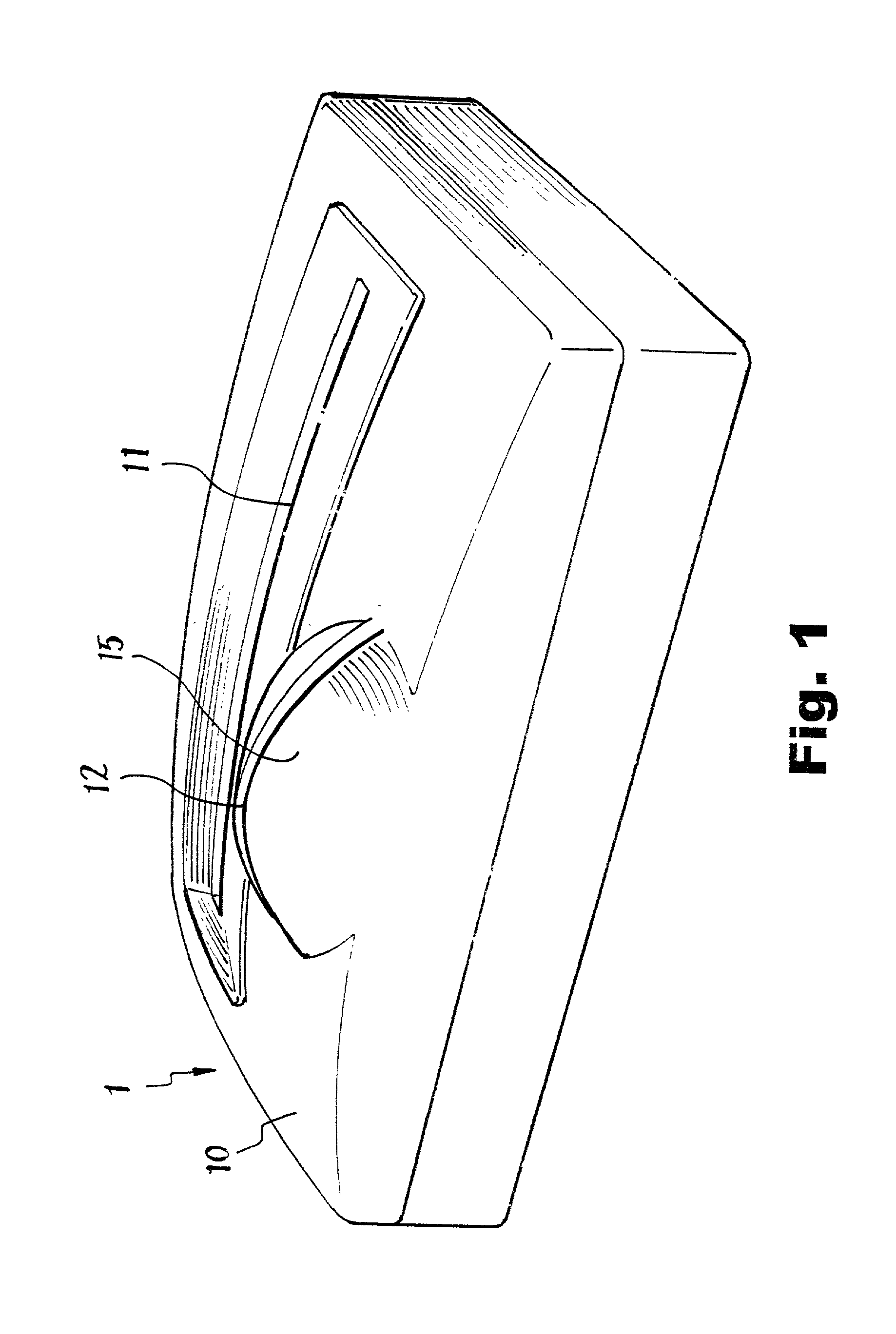

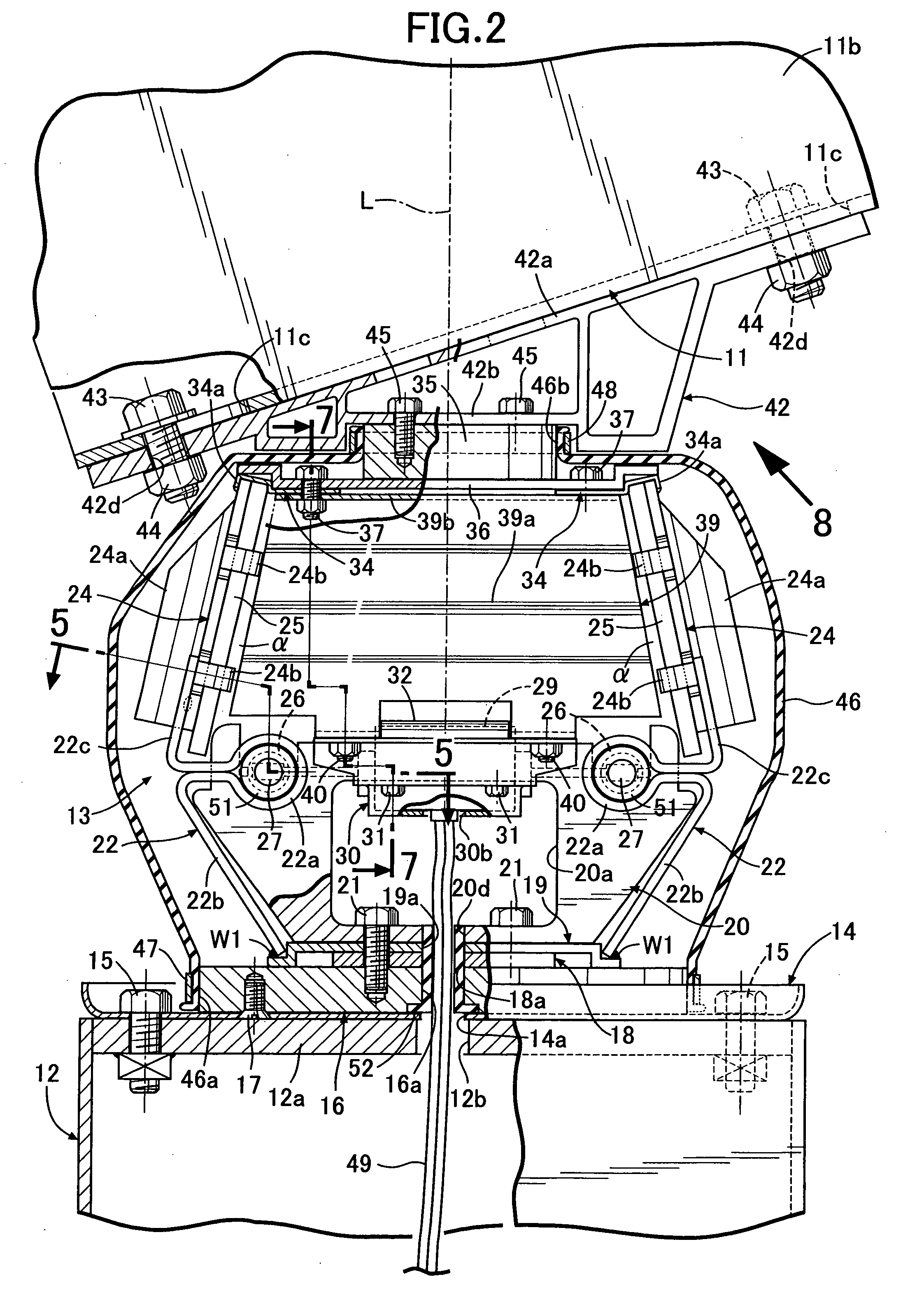

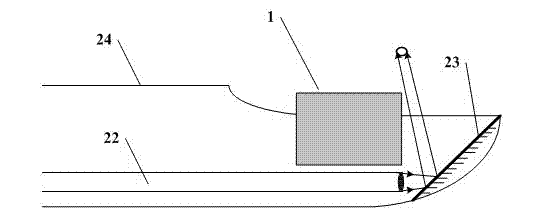

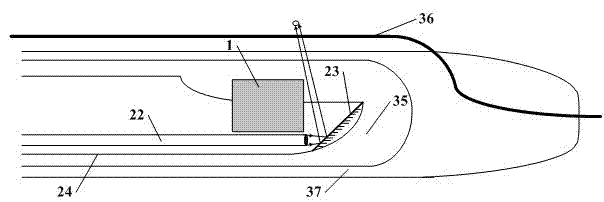

Crushable body strength adjusting device for a vehicle

A vehicle body strength adjusting system is provided in which a bumper beam includes a body portion which extends in a widthwise direction of a vehicle and inclined portions which extend from left and right opposite ends of the body portion and which are inclined in a longitudinal direction of the vehicle body. Further, the vehicle body strength adjusting system includes a variable crush-strength device which is disposed between the inclined portions of the vehicle body frames, which can be crushed when a collision with the vehicle occurs, and which has a variable crush-strength. A first bolt hole is formed in each of the inclined portions of the bumper beam and a second bolt hole is formed in the mounting bracket of the variable crush-strength device. At least one of the first bolt hole and the second bolt hole is an elongate hole. The first bolt hole and the second bolt hole are fastened to each other by a bolt.

Owner:HONDA MOTOR CO LTD

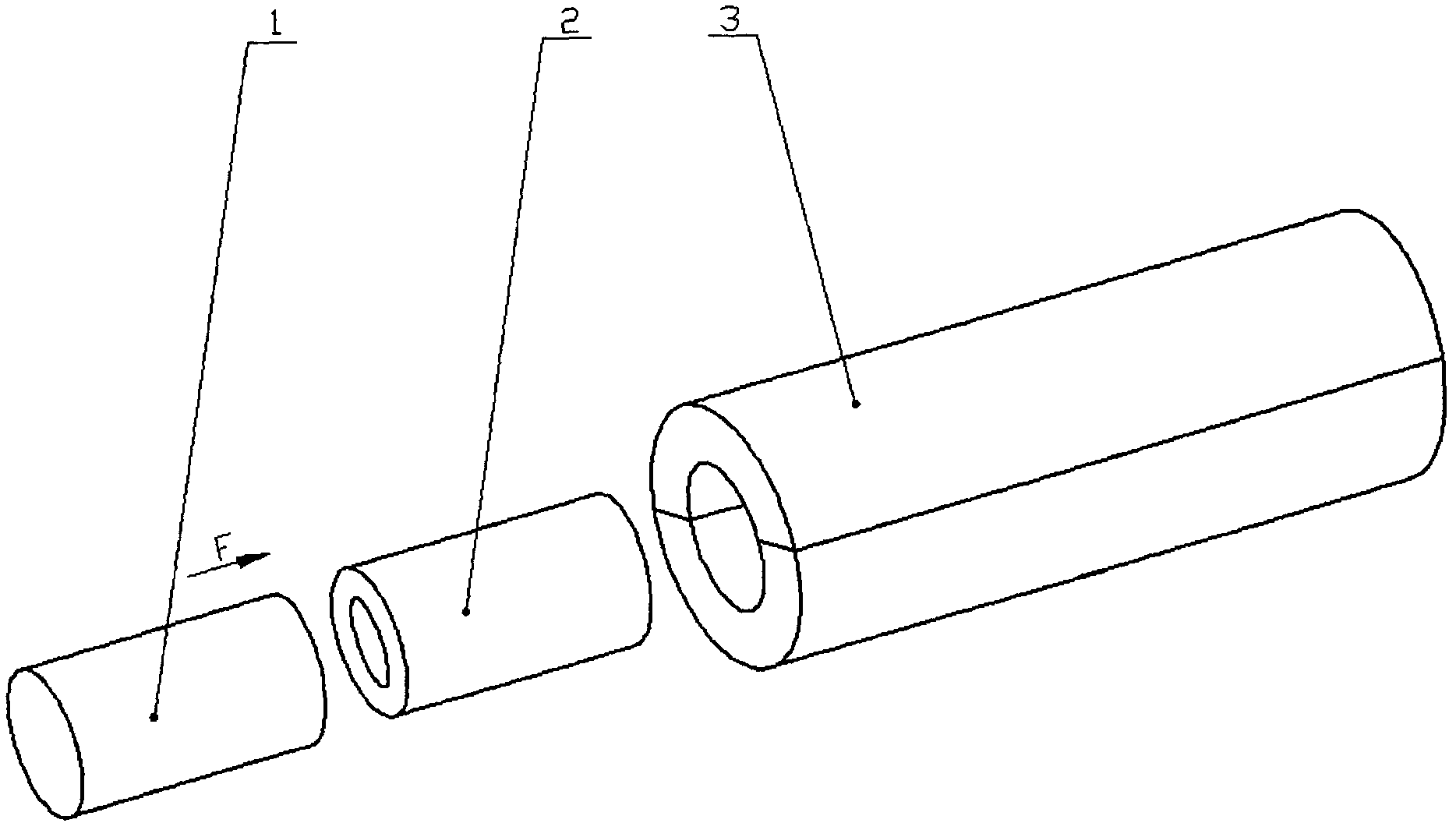

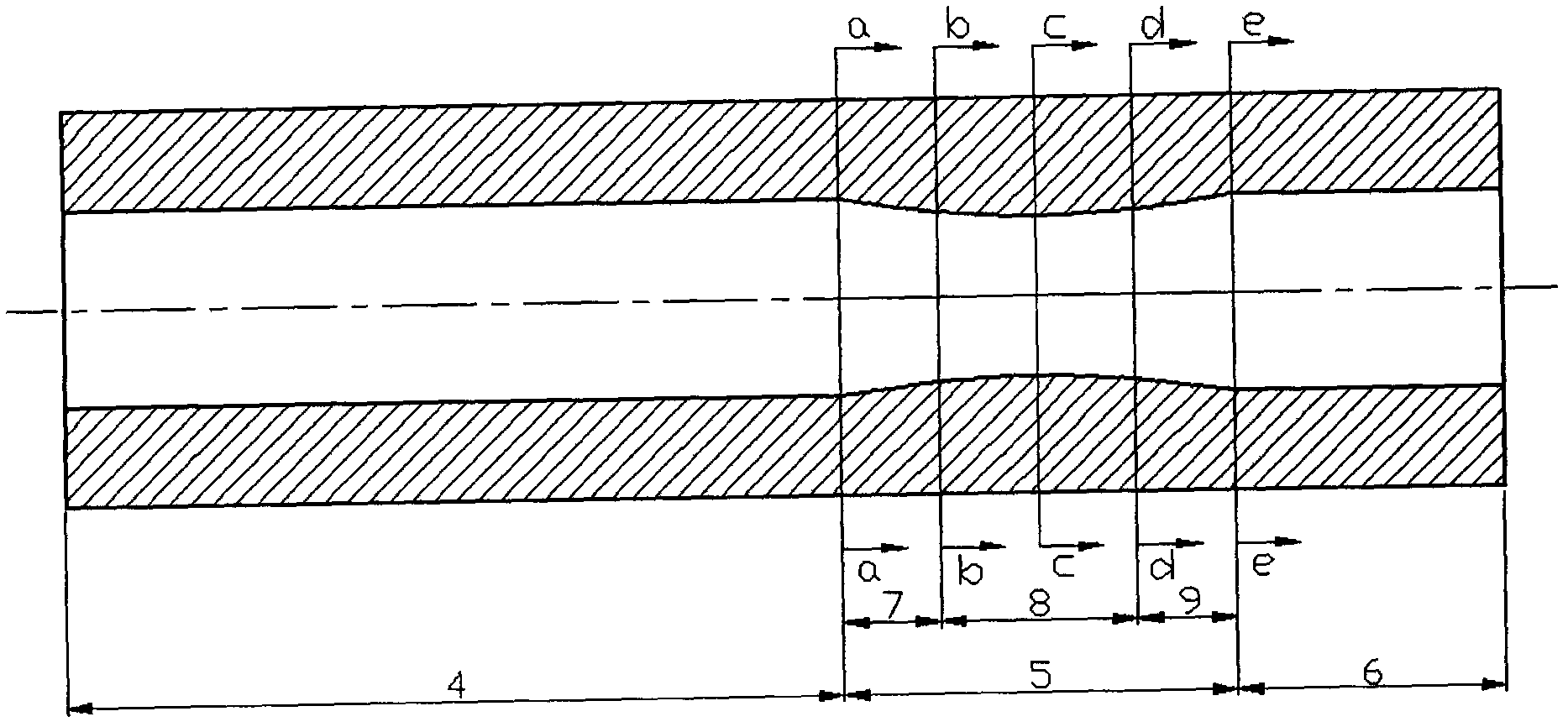

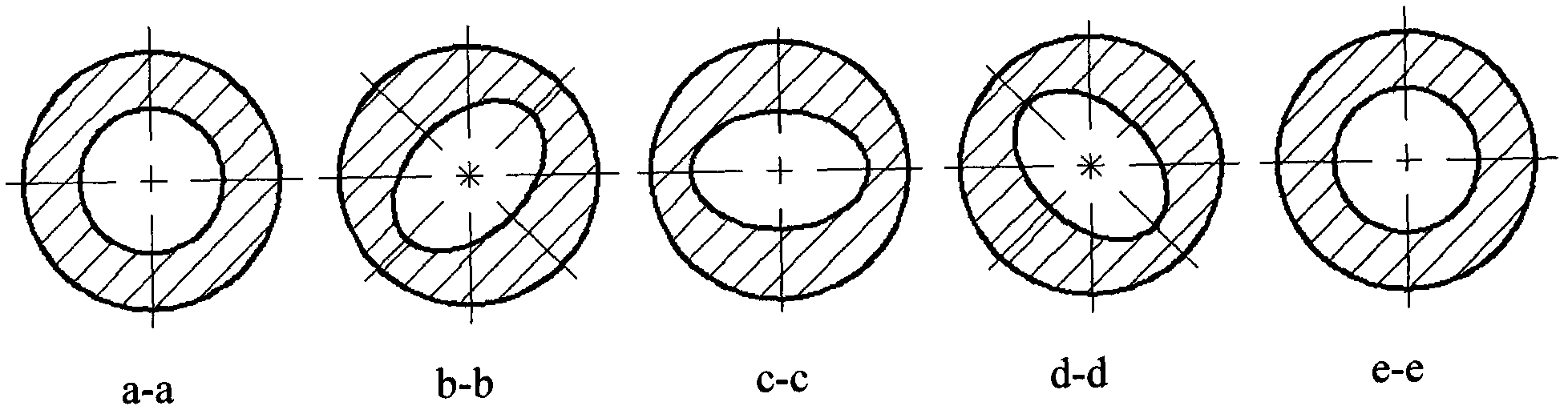

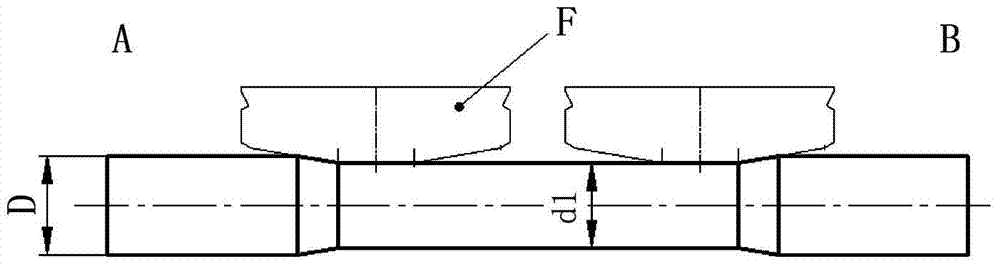

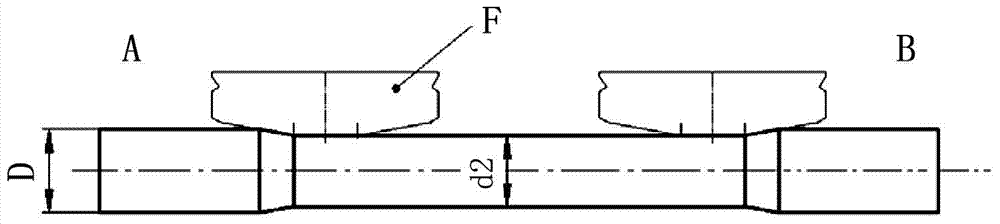

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Multistage high-efficiency anti-blocking sand screening device

InactiveCN107552397AImprove sand screening efficiencySave raw materialsSievingGas current separationSlagEngineering

The invention discloses a multistage high-efficiency anti-blocking sand screening device. The multistage high-efficiency anti-blocking sand screening device comprises a shell and a screen plate, wherein the upper part of the right side of the shell is connected to a feed hopper; a rotating drum is arranged in the shell; a screen mesh is arranged at the right side of the rotating drum; the screen plate is arranged below the screen mesh; and the upper part of the screen plate is leaned against a hair brush. The multistage high-efficiency anti-blocking sand screening device has the beneficial effects that hardened blocks in coarse sand are efficiently smashed by arranging the rotating screen drum and smashing cutter blades distributed in a staggering manner, thereby improving the sand screening efficiency of the screen drum and saving coarse sand raw materials; the multistage high-efficiency anti-blocking sand screening device is provided with a squeezing plate and a slag discharging opening which are used for collecting large-grained garbage screened out by the screen drum, thereby facilitating the continuous operation and improving the screening efficiency; the multistage high-efficiency anti-blocking sand screening device is provided with the reciprocating screen plate and the hair brush, and the hair brush is used for cleaning the screen plate in real time, thereby avoiding the blockage of the screen plate and improving the screening efficiency; the screening quality is improved through two-stage screening; and the multistage high-efficiency anti-blocking sand screening device is compact in structure and is suitable for screening small batches of coarse sand; and as the multistage high-efficiency anti-blocking sand screening device is provided with idler wheels, the multistage high-efficiency anti-blocking sand screening device is convenient to move and transport.

Owner:李云

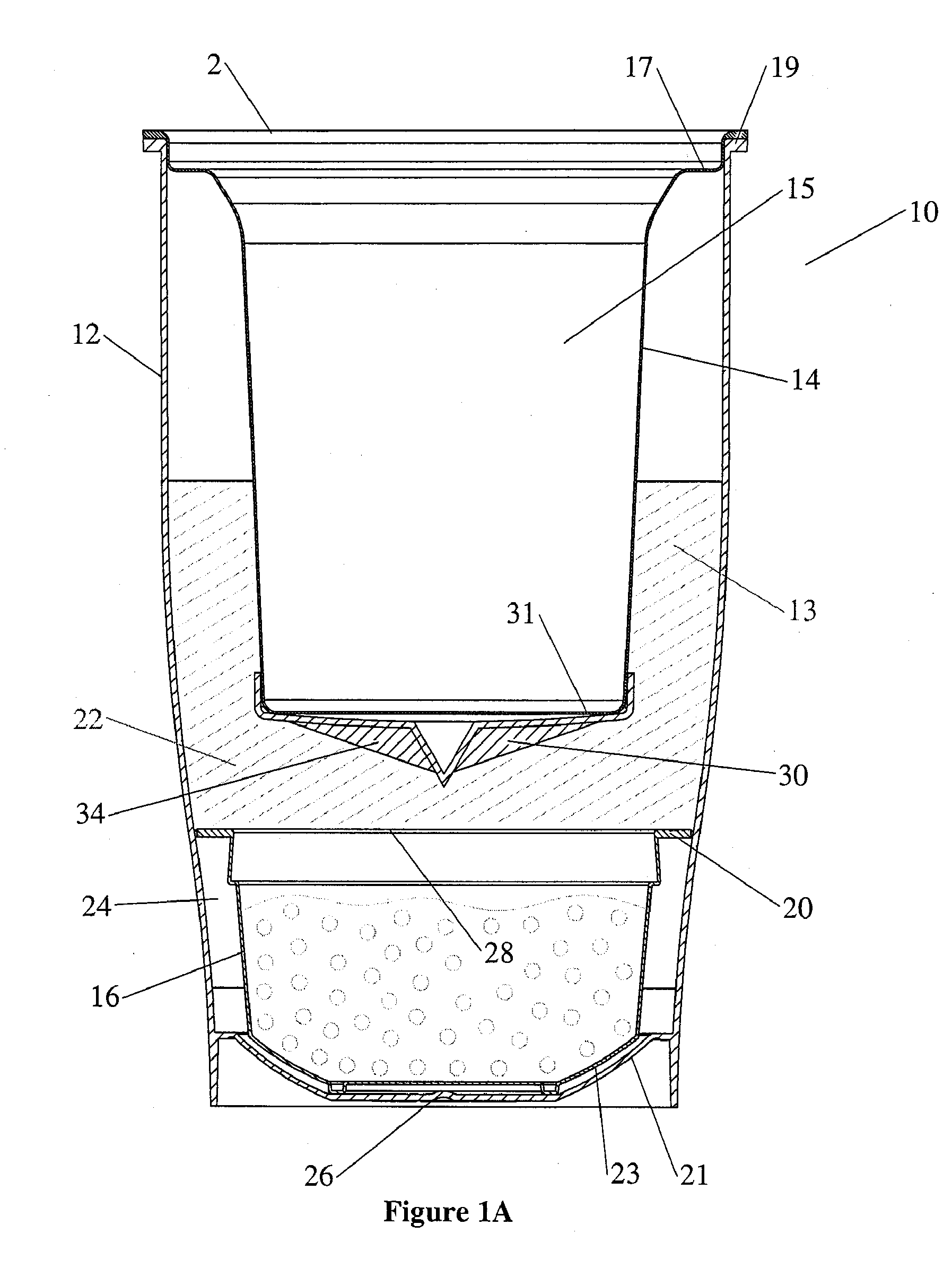

Self-heating container

InactiveUS20070131219A1Efficient crushingQuick releaseExothermal chemical reaction heat productionOther heat production devicesEngineeringHeat losses

Owner:HEAT WAVE TECH

Speed-adjustable dust collecting and crushing device used for crushing coal mines

InactiveCN104923340ASimple structureEasy to useDispersed particle filtrationDirt cleaningCoalExhaust pipe

A speed-adjustable dust collecting and crushing device used for crushing coal mines comprises a base unit, a frame, a collecting unit, two pushing units, dust collecting units, purifying units and crushing units. The base unit comprises a base, a rollers and a support plate, a first support, rectangular blocks and dust collecting buckets are arranged on the frame, each pushing unit comprises a first horizontal plate, a pushing plate, a pushing rod, a material pushing plate and a spring, each dust collecting unit comprises a dust collecting pipe and a fan, each crushing unit comprises a crushing plate, first crushing teeth, a crushing wheel and second crushing teeth, the collecting unit comprises a collecting box and a first filtering screen, each purifying unit comprises a purifying box, a second filtering screen, a second horizontal plate, a second support, an exhaust pipe and a sponge block, and a first through hole is arranged in the right surface of the purifying box. By the arrangement, dust generated from crushing can be recycled, fitness of workers is protected, and the device is small in size, low in cost and suitable for small enterprises and large-scale promotion and use.

Owner:孙亚光

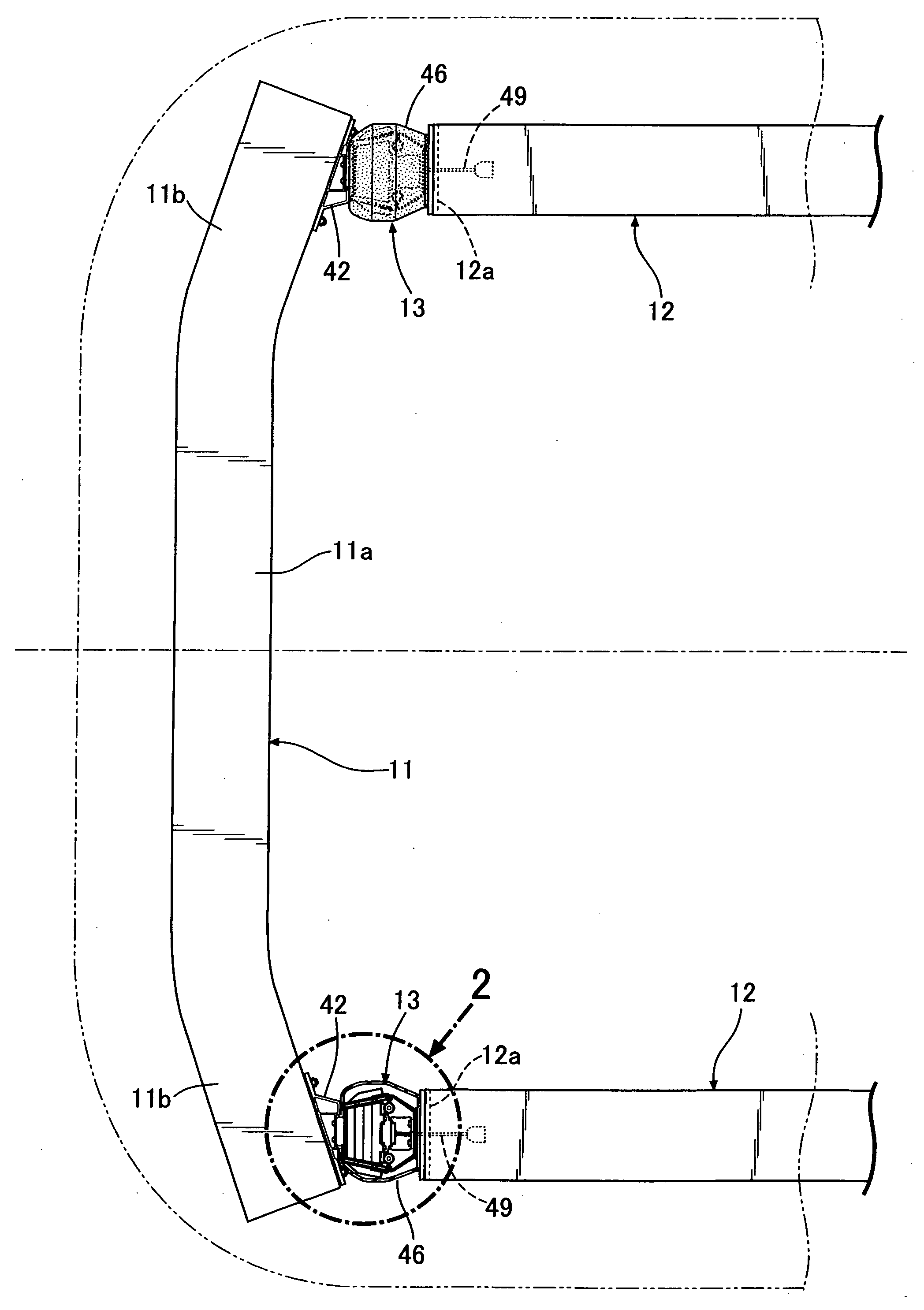

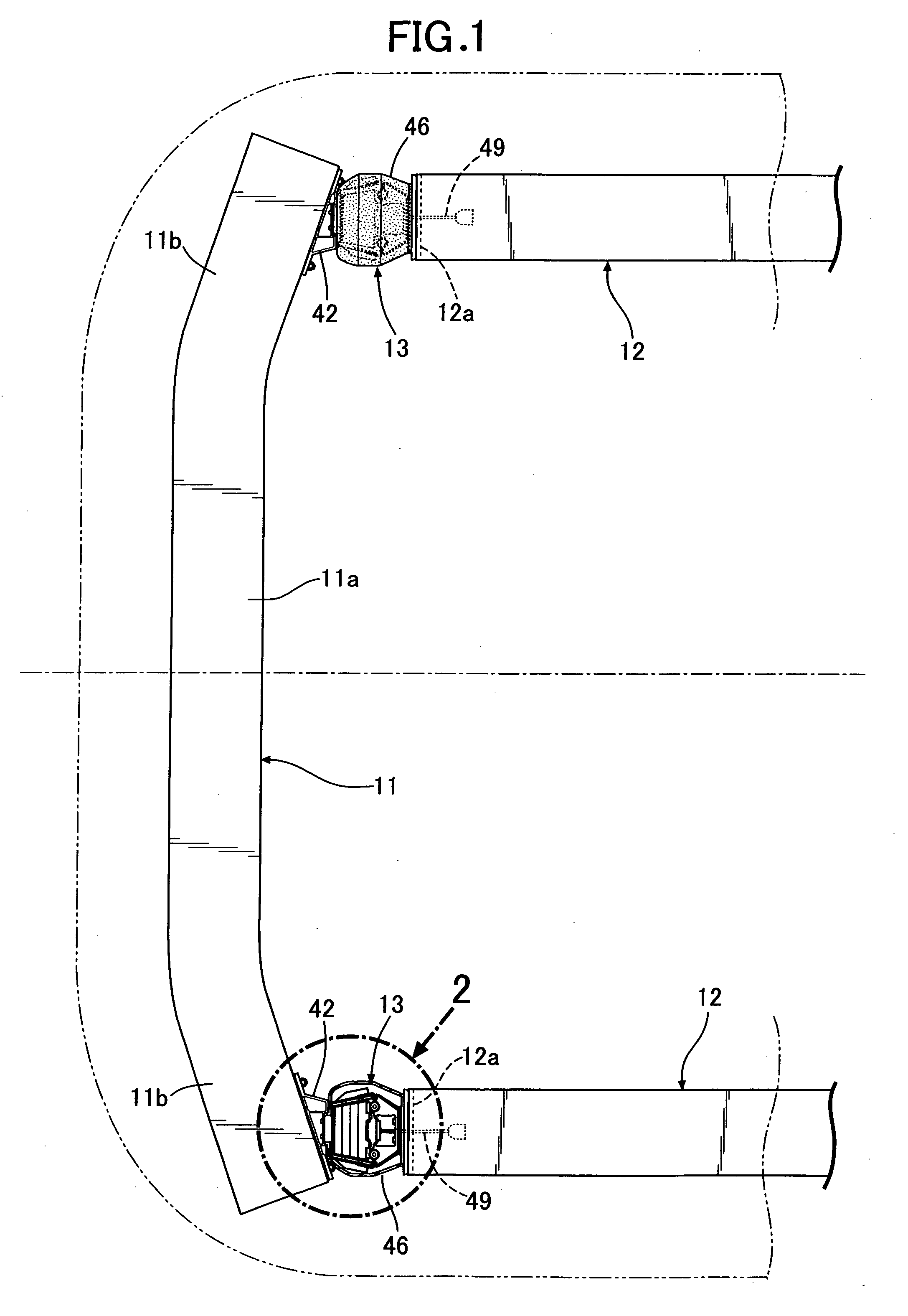

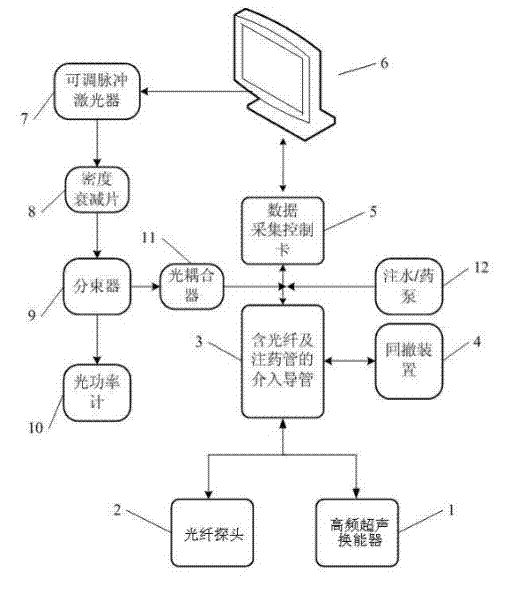

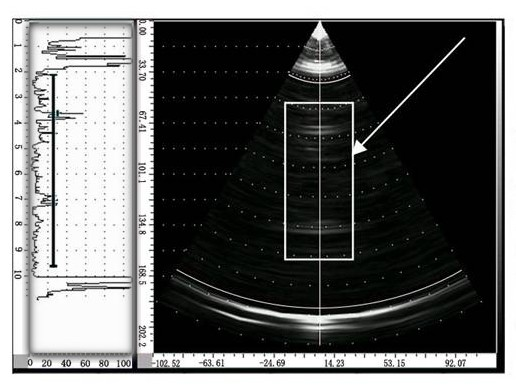

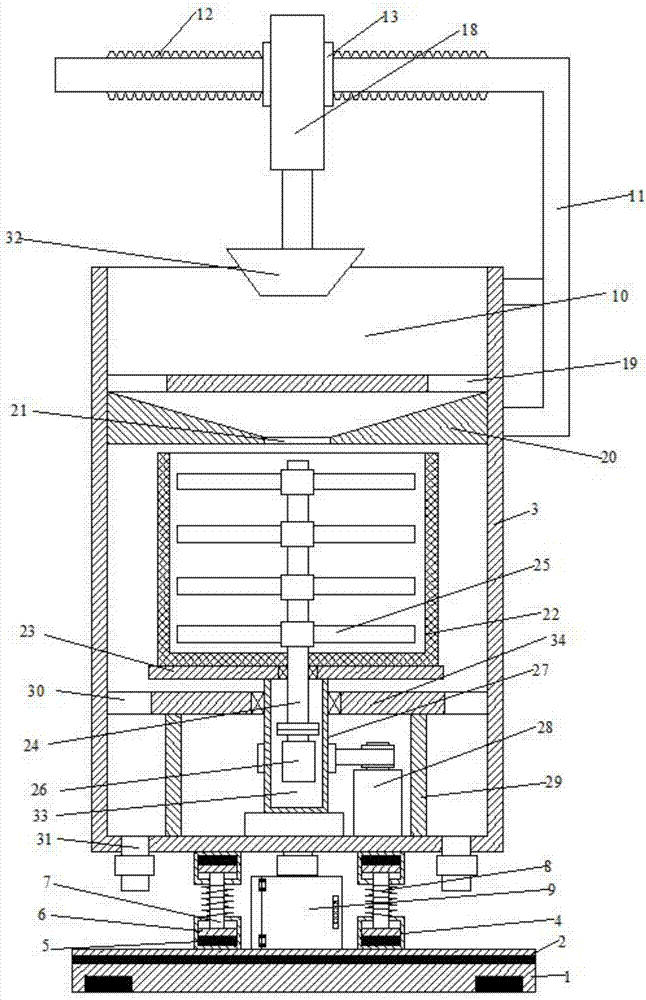

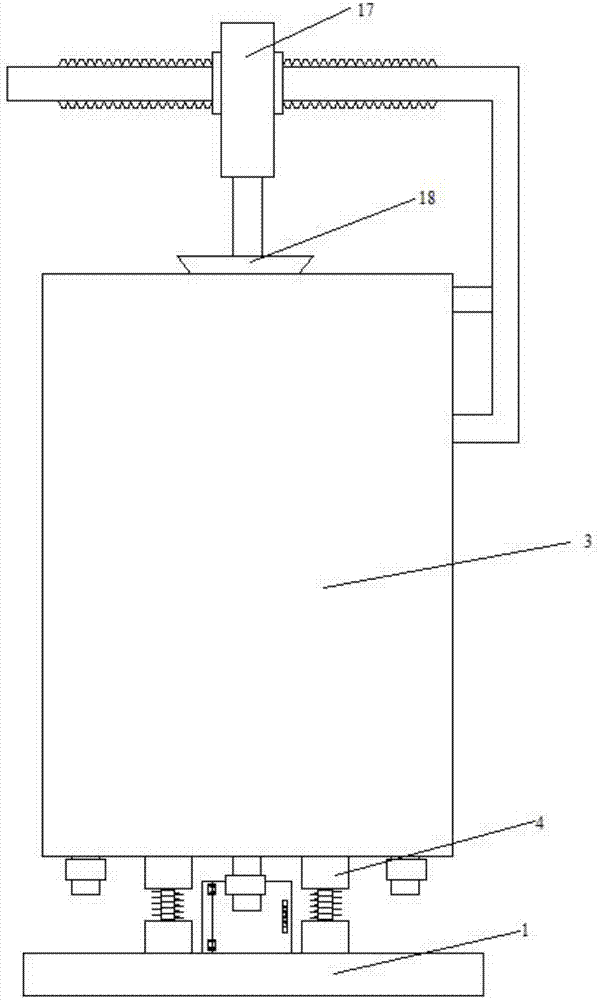

Intravenous ultrasound-based ultrasonic diagnosis and photoacoustic therapy device and therapeutic method thereof

ActiveCN102512206AUnobstructed blood vesselsLower surgery costsOrgan movement/changes detectionSurgeryThrombusIntravascular ultrasound

The invention provides an intravenous ultrasound-based ultrasonic diagnosis and photoacoustic therapy device and a therapeutic method thereof. The device comprises an interventional catheter, wherein a high-frequency ultrasonic transducer, a built-in optical fiber bundle and an automatic retraction device are arranged inside the interventional catheter; the automatic retraction device drives the transducer to rotate and move forward and backward through a guide wire which is arranged inside the interventional catheter; and a tunable pulsed laser for providing a laser source for photoacoustic therapy, a collection control card for detected data of the transducer and a computer with digital signal / image processing functions are arranged outside the interventional catheter. Based on the combination of intravenous ultrasound imaging and photoacoustic therapy technique, the device achieves synchronization of vascular ultrasound imaging and timely treatment of cardiovascular diseases and can ablate thrombi and break down plaques, so as to dredge blood vessels. With the device, doctors can grasp patient's conditions and carry out the treatment during interventional operations, the operation cost and treatment risk are reduced, and people are benefited.

Owner:苏州国科昂卓医疗科技有限公司

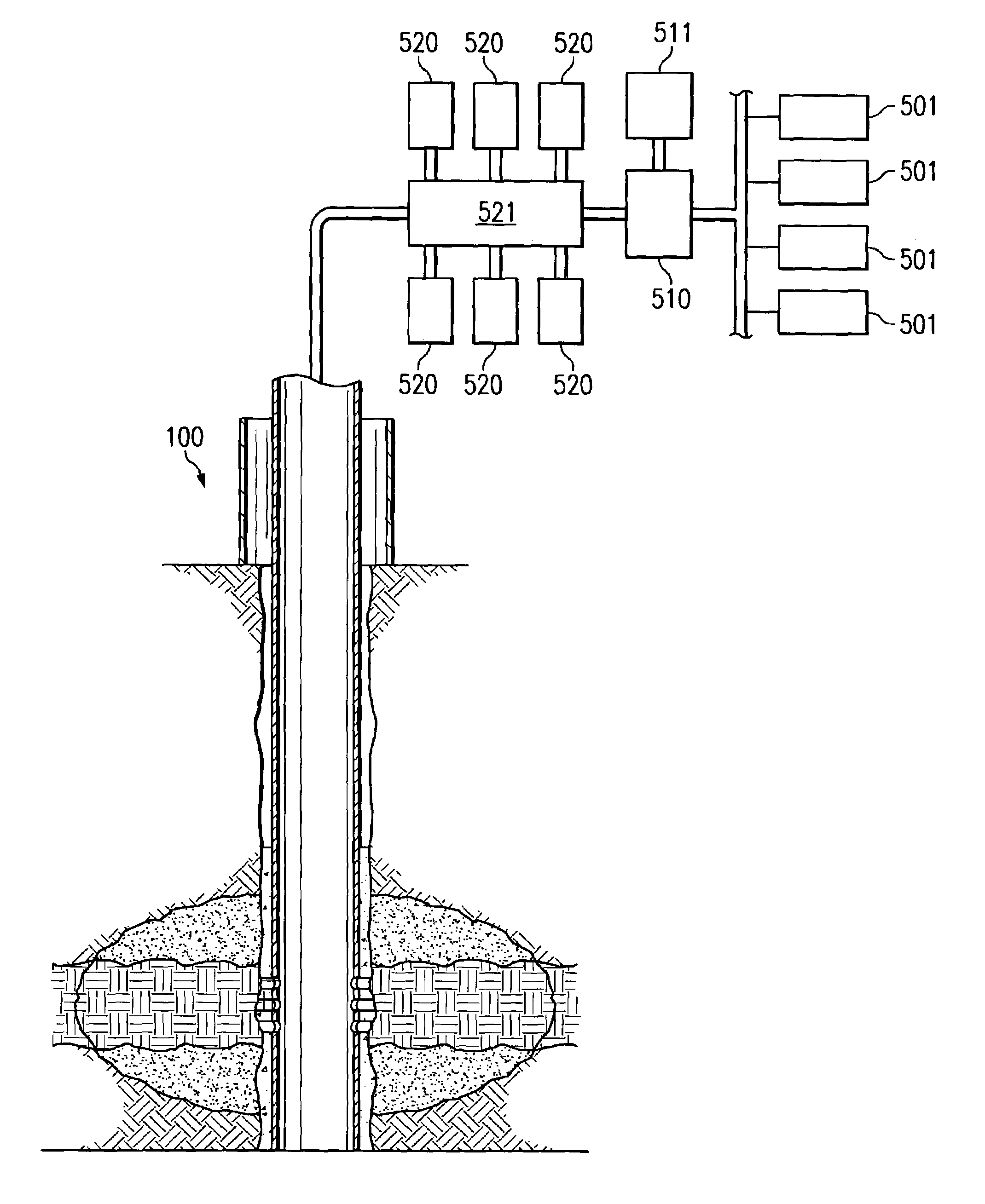

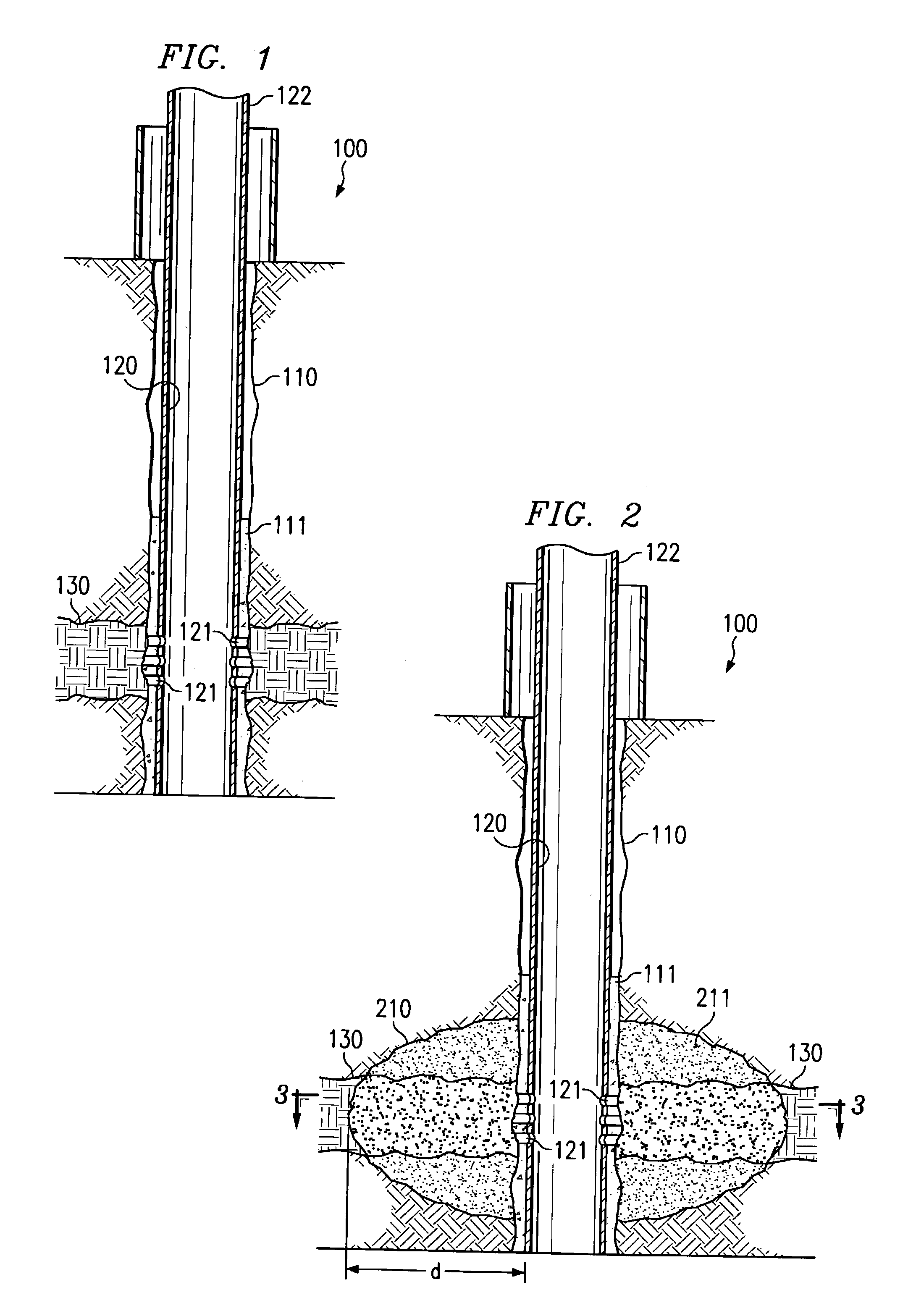

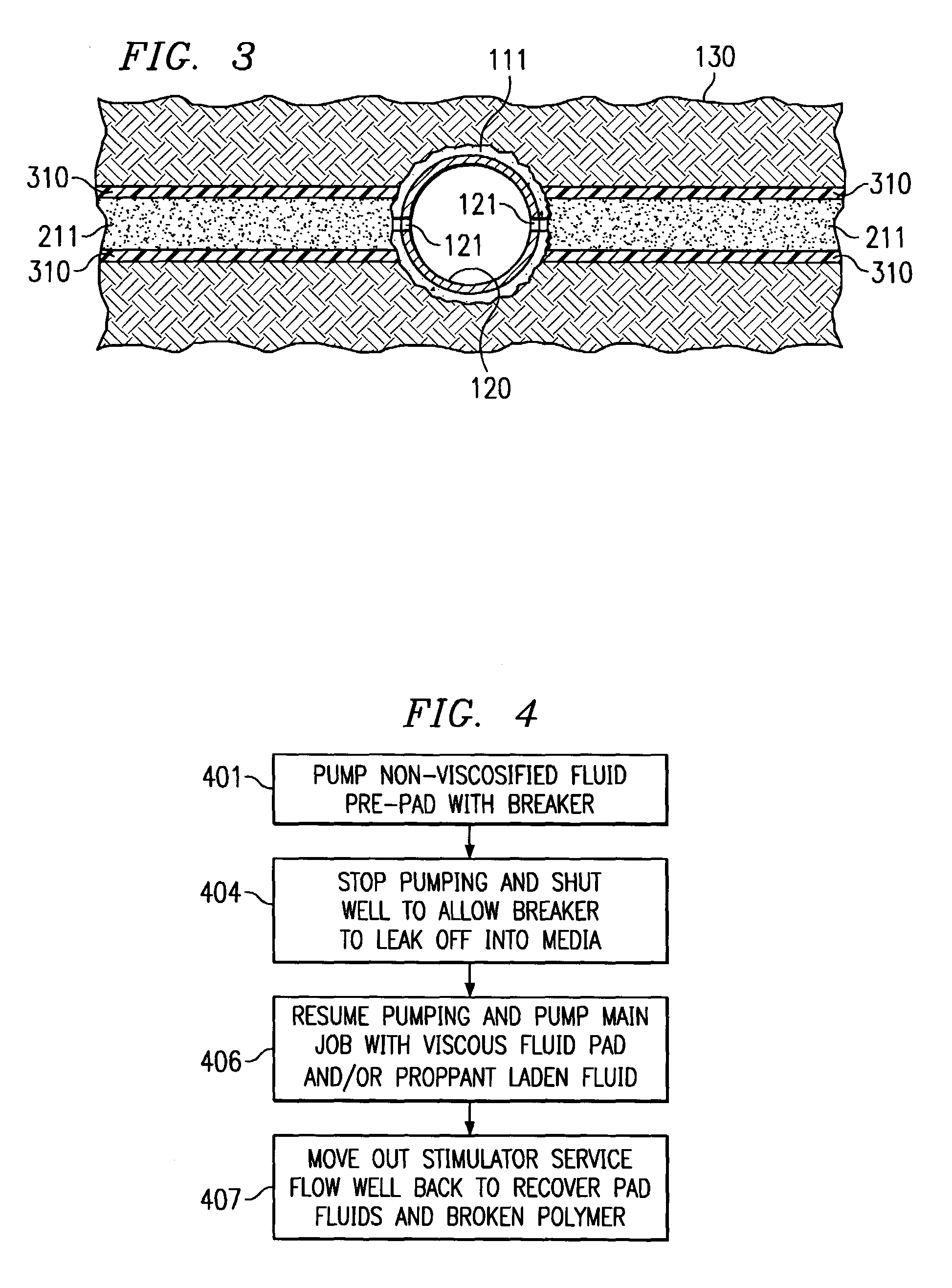

System and method for polymer filter cake removal

InactiveUS6935426B1Reduce formation damageReduce damageCleaning apparatusFluid removalEngineeringFilter cake

Embodiments provide systems and methods in which a non-viscous fluid, having a heavy concentration of an appropriate breaker, is pumped into a well in front of viscosified fluid, such as a cross-linked polymeric fracturing fluid, to saturate permeable media with a breaker agent. When a polymer filter cake is subsequently formed on the surfaces of the media the breaker is provided good communication with the polymer filter cake for its breakdown and removal. Communication between the breaker and the polymer filter cake is substantially controlled by an operator in that the breaker remains saturated in the permeable media until such time as the operator decreases hydraulic pressure within the well to a point at which the hydraulic pressure of the media forces the breaker back into the well.

Owner:ENCANA OIL & GAS USA +1

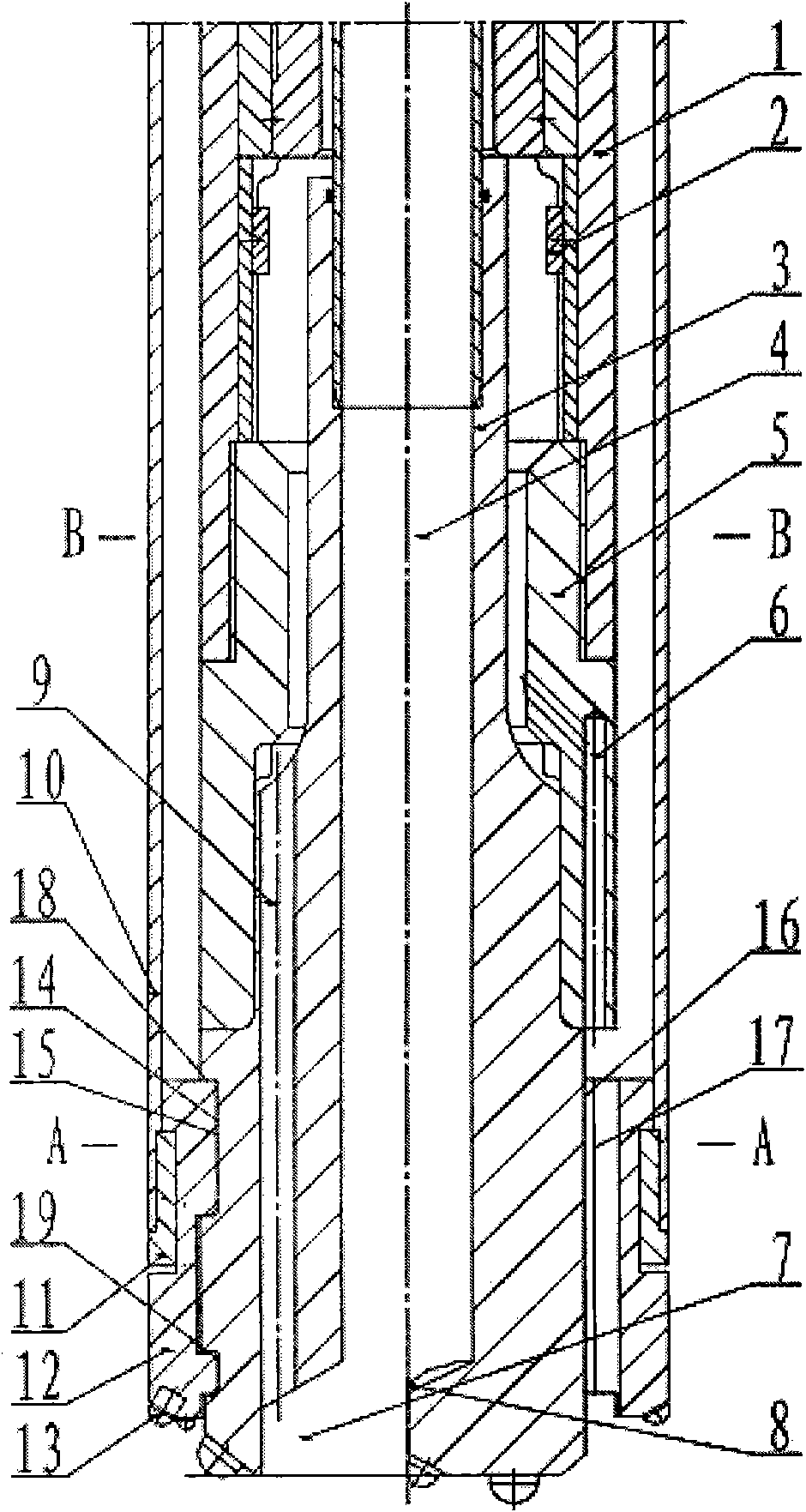

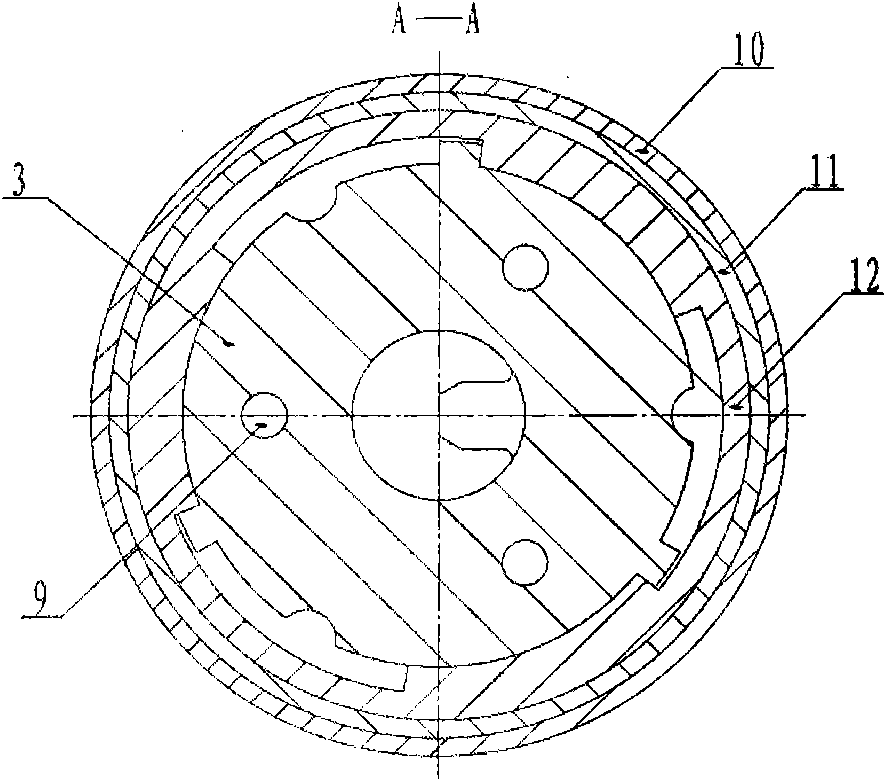

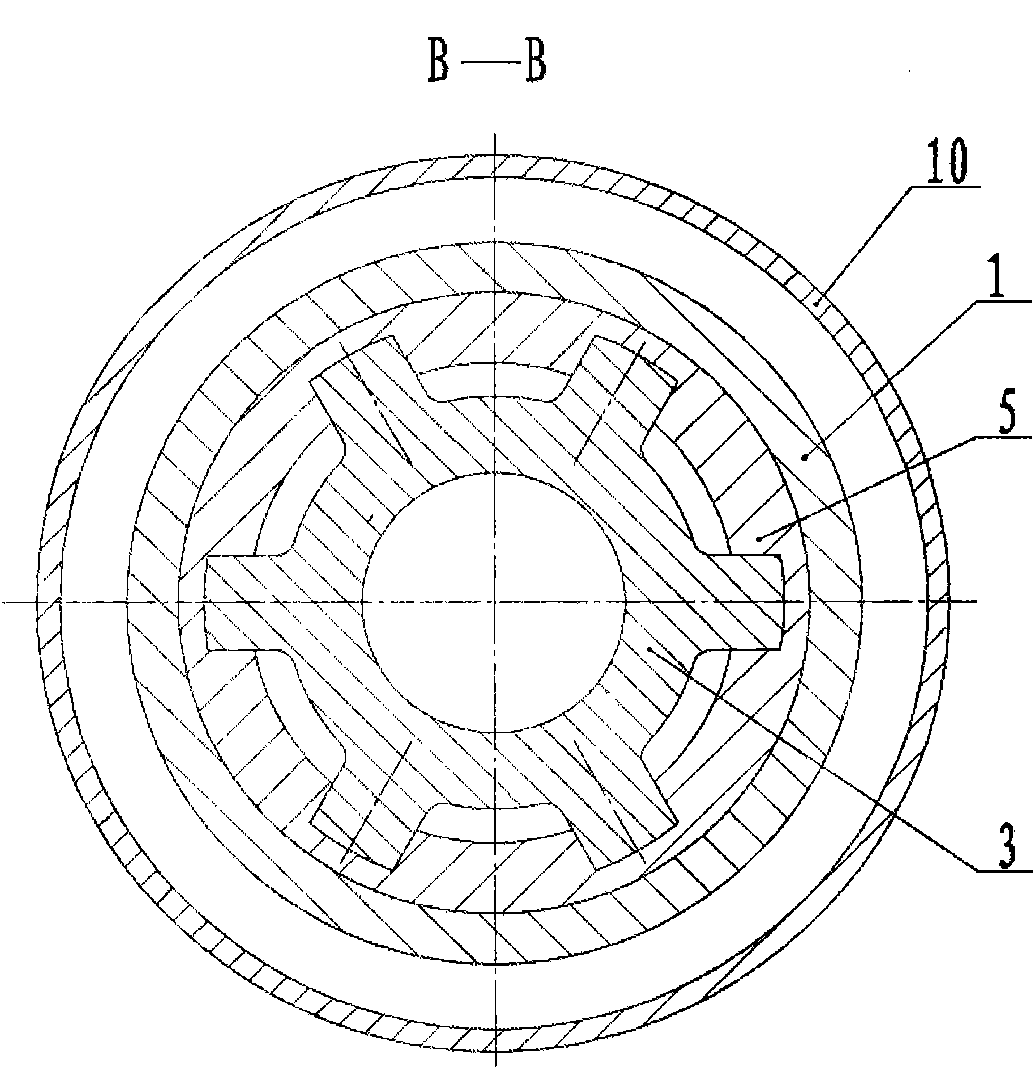

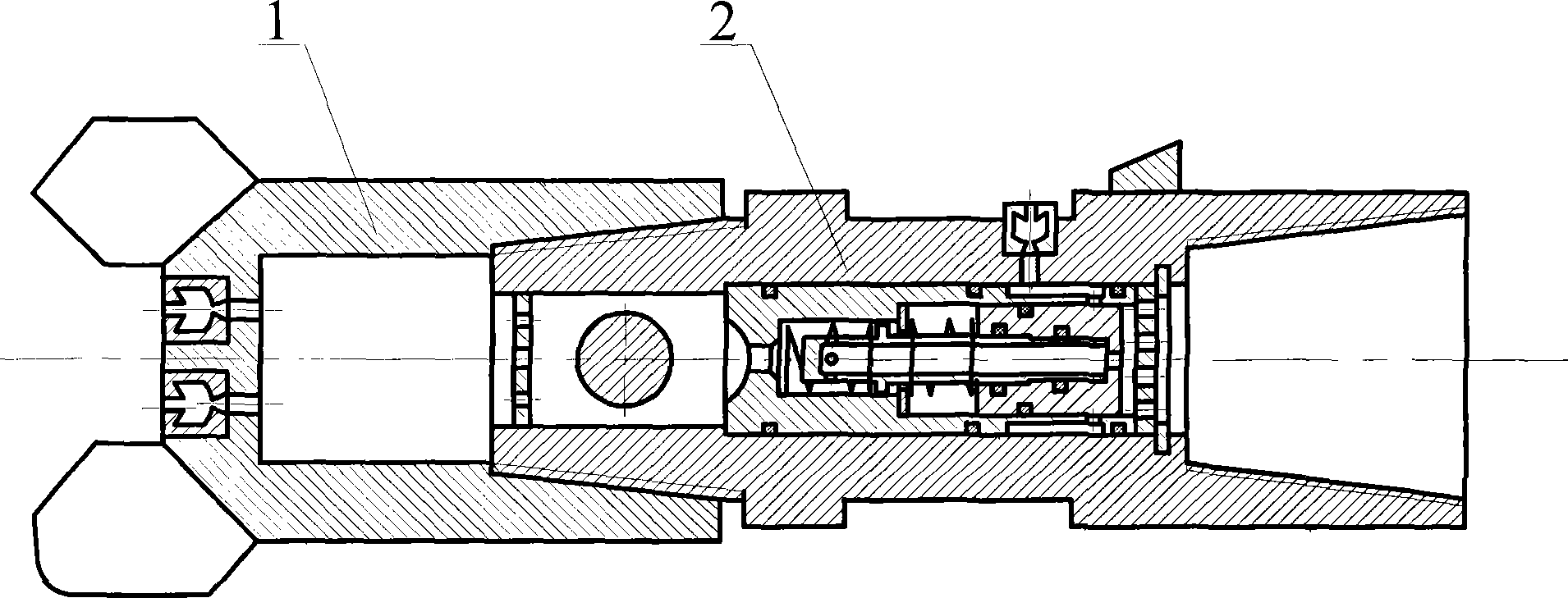

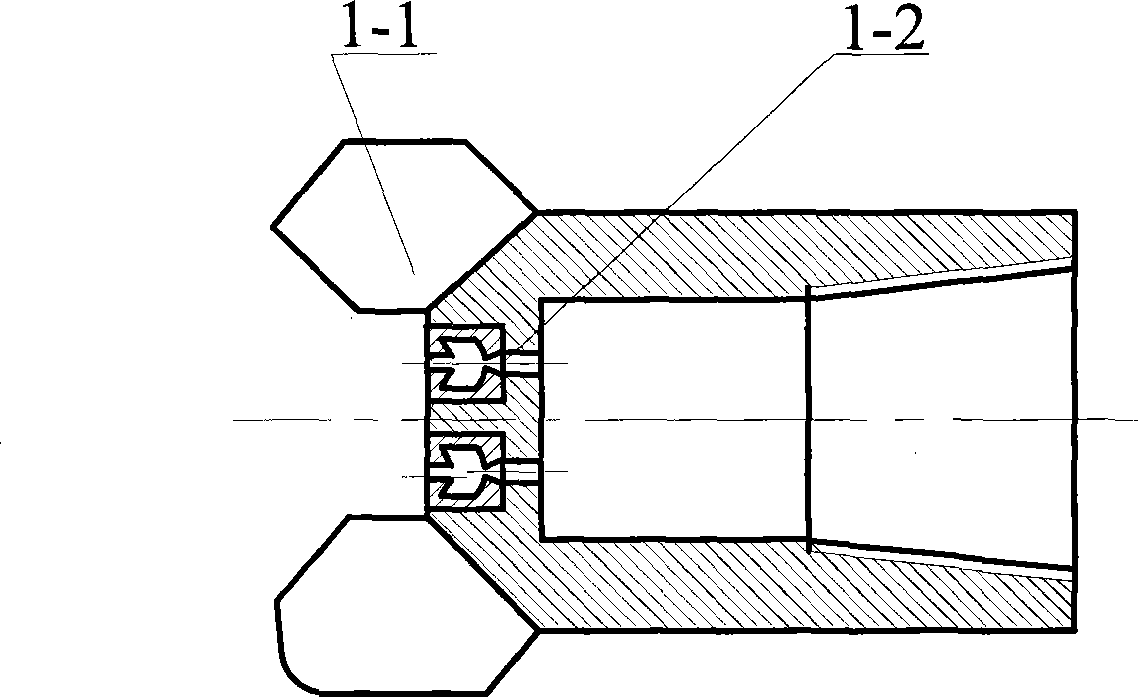

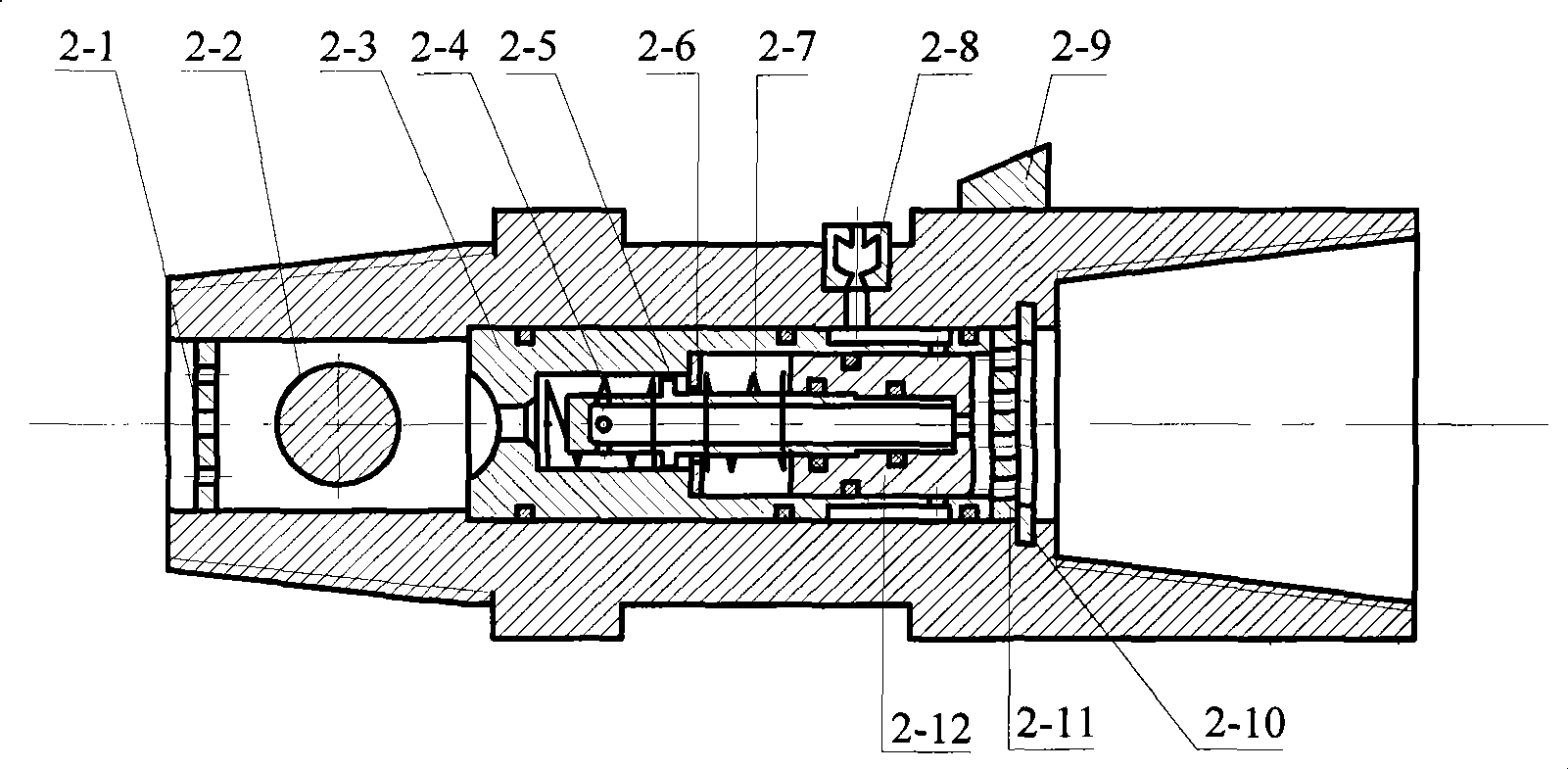

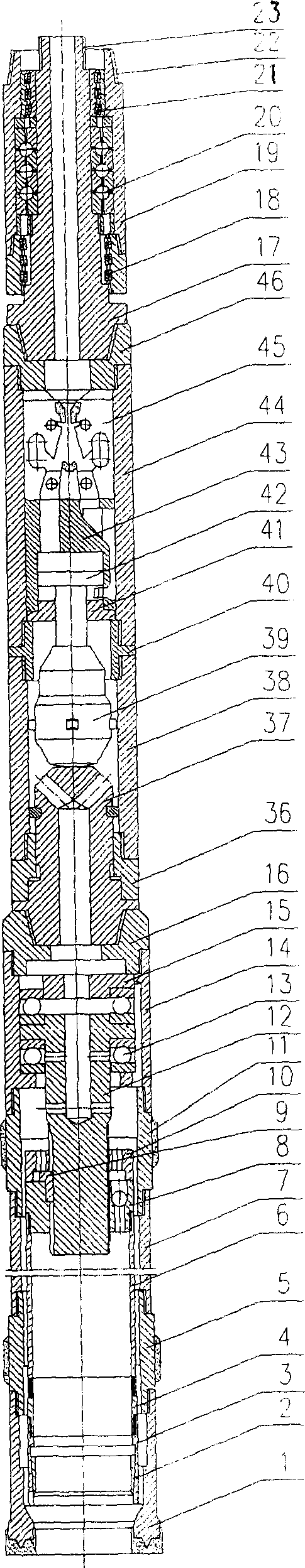

Down-the-hole hammer reverse concentric casing drilling tool

InactiveCN101956525AAvoid hole wall washout and flushing fluid lossExtended service lifeBorehole drivesPipingDrill bit

The invention relates to a down-the-hole (DTH) hammer reverse concentric casing drilling tool. A hollow DTH hammer is connected to a guiding drill through a semicircular block and a spline housing, wherein an outer spline which is arranged on the axial direction of the guiding drill is matched with an inner spline of an annular sleeve drill; the guiding drill 3 is designed as a reverse structure;and an annular casing drill is hung on the lower end of the sleeve through a pipe boot. Compared with the prior art, the guiding drill crashes rock in advance and transmits an impact load to the annular casing drill and drives the drill to rotate, in order to realize simultaneously performing three processes of concentrically crashing, wall protection through the casing and reverse slagging. The double air piping can simultaneously cool the spherical gear alloy of the inner and outer drills and prolong the service life of the drill. Reverse slagging can efficiently clean the hole bottom rock debris, avoid repeated crashing and prevent the drill from being blocked by the rock debris. After ending the casing drilling, the reverse drilling can be performed without exchanging the drill. The casing drill tool has simple structure, low processing cost, long service life and high drilling efficiency.

Owner:JILIN UNIV +1

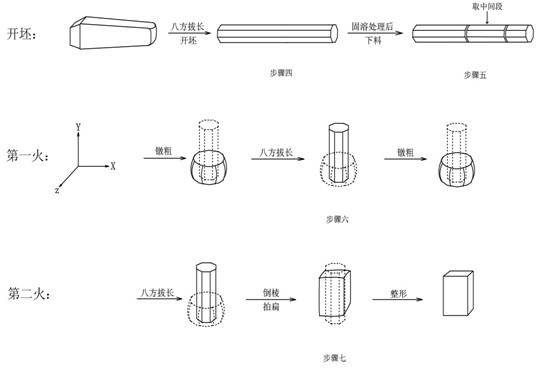

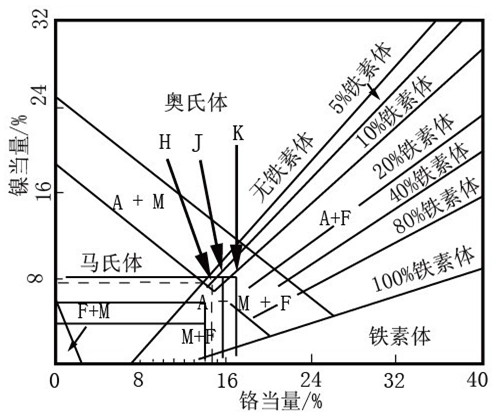

Manufacturing process of forging stock of steel forging piece for oil extraction equipment in deep sea

The invention discloses a manufacturing process of a forging stock of a steel forging piece for oil extracting equipment in a deep sea, which comprises the following steps of: with martensite precipitation hardening type stainless steel as a steel forging piece material, selecting a square ingot, heating to 1180DEG C, cogging along the length direction of the steel ingot to obtain an octagonal section steel billet, wherein the forging ratio is 2.0-2.2; heating the octagonal section steel billet to 1040DEG C and preserving heat for 360 minutes; carrying out oil cooling below 32DEG C; taking an intermediate section as a billet; axially upsetting the billet from the initial forging temperature of 1150DEG C to the final forging temperature of 990DEG C; when the billet is upset to half of the height of the original billet, drawing out the octagonal section of the upset billet according to the original axial direction; axially upsetting when the billet is drawn to the length of the original billet; when the billet is upset to half of the height of the original billet, drawing out the octagonal section of the upset billet according to the original axial direction; when axially forging and shaping the billet when the billet is upset to half of the height of the original billet, enabling the total forging ratio to be 5.5 and obtaining a rectangular forging piece; and air cooling to be 340-360DEG C, carrying out furnace insulating for 120 minutes and then carrying out furnace cooling to the room temperature.

Owner:NANJING DEV ADVANCED MFG

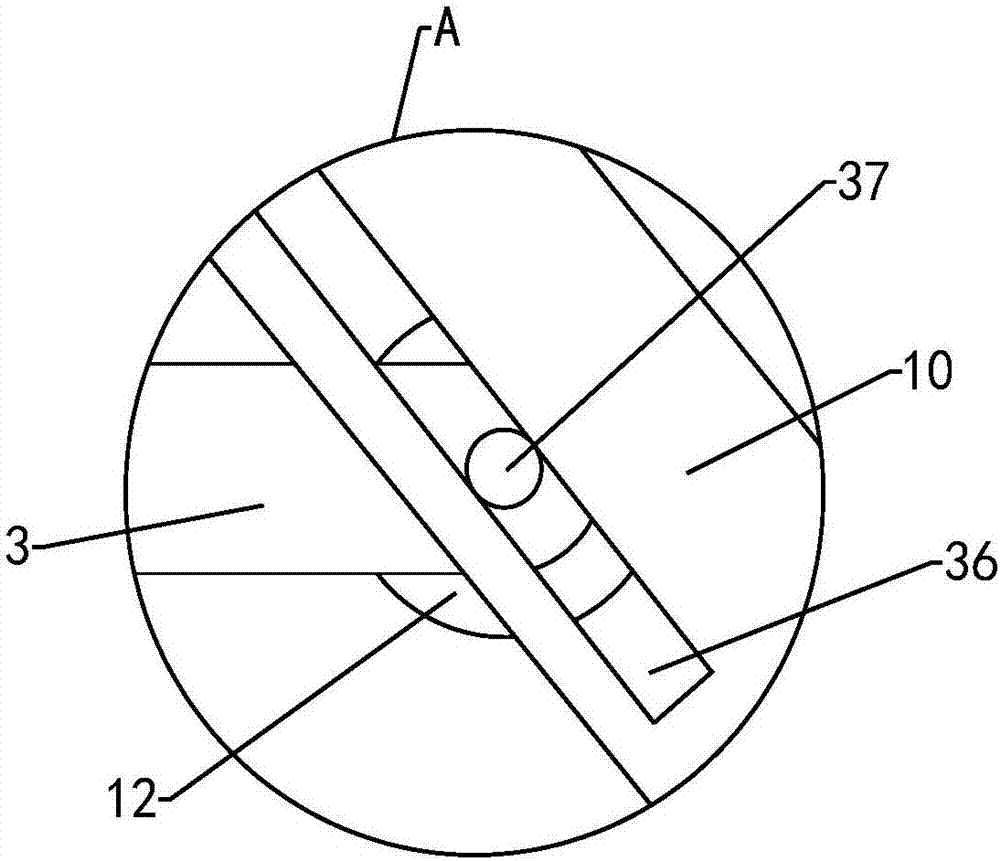

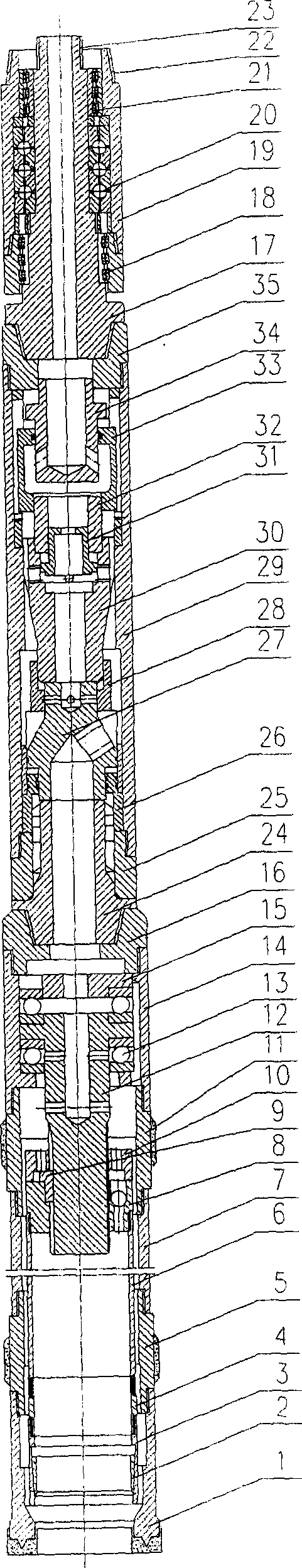

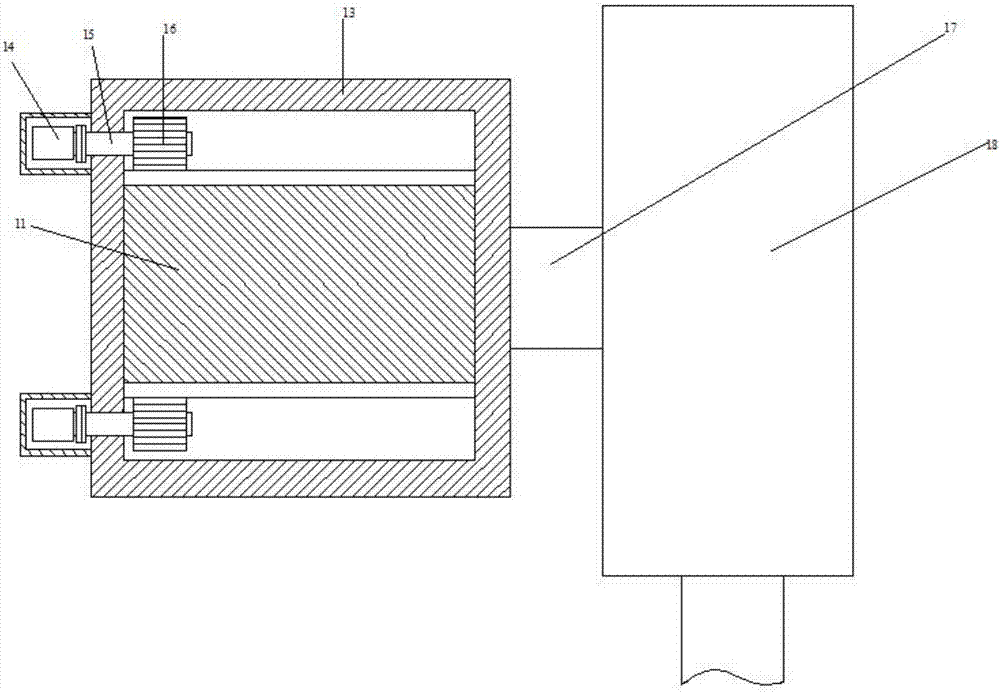

Self-propelled drilling method and pulsed cavitation swirling jet nozzle

The invention relates to a self-propelled drilling method and a nozzle. The self-propelled drilling method is formed by coupling a pulsed jet method, a cavitation jet method and a swirling jet method, wherein, an impeller body arranged in the nozzle can rotate under the impact action of a fluid, a part of forward jet orifices arranged at the head of the nozzle as well as a part of backward jet orifices which are arranged on the nozzle and are opposite to the forward jet orifices can be closed during the rotation process of the impeller body, the fluid is ejected from the other part of the forward jet orifices and the backward jet orifices so as to form jet flow, and the forward jet orifices are alternately closed so as to generate pulsed jet during the rotation process of the impeller body; the fluid entering the nozzle is driven to rotate by the rotating impeller body, and then the rotating fluid is ejected from the jet orifices so as to generate swirling jet; and the central pressure in the nozzle can be reduced by means of rotation of the impeller body so as to form cavitation jet. In the self-propelled drilling method, advantages of the three types of jet flow are integrated so as to greatly improve the drilling efficiency; and the self-propelled drilling method and the nozzle are applicable to drilling holes in a ground layer.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

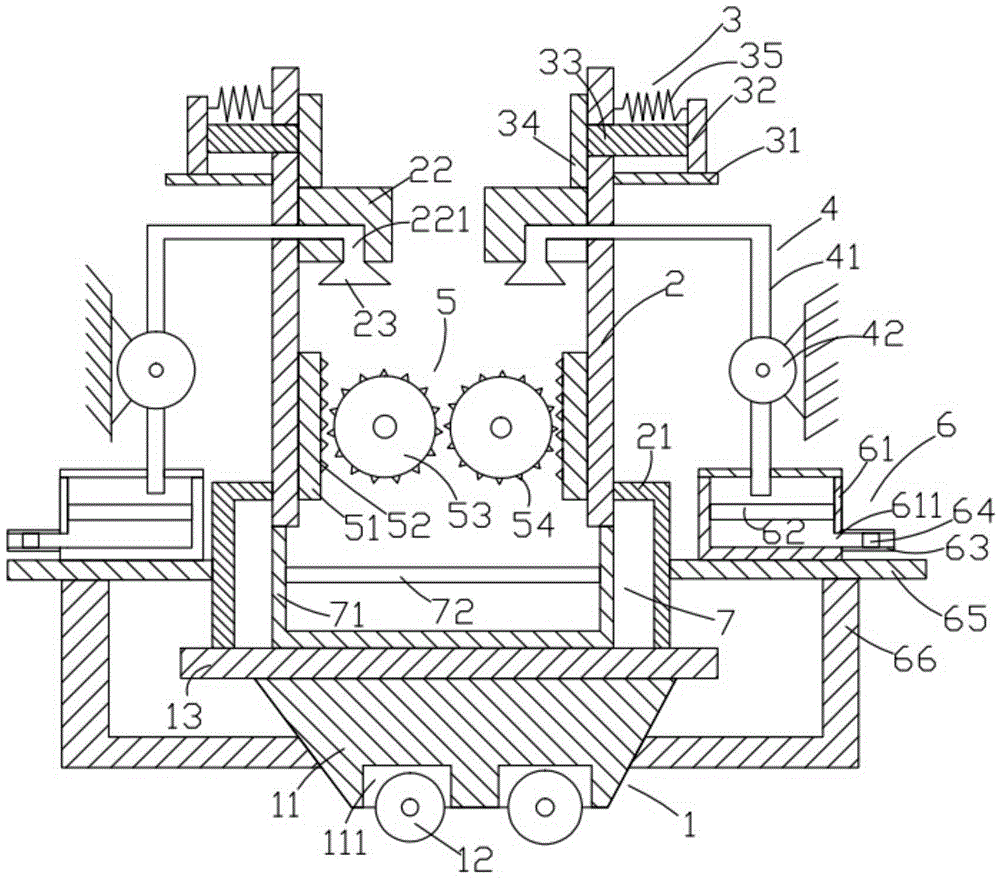

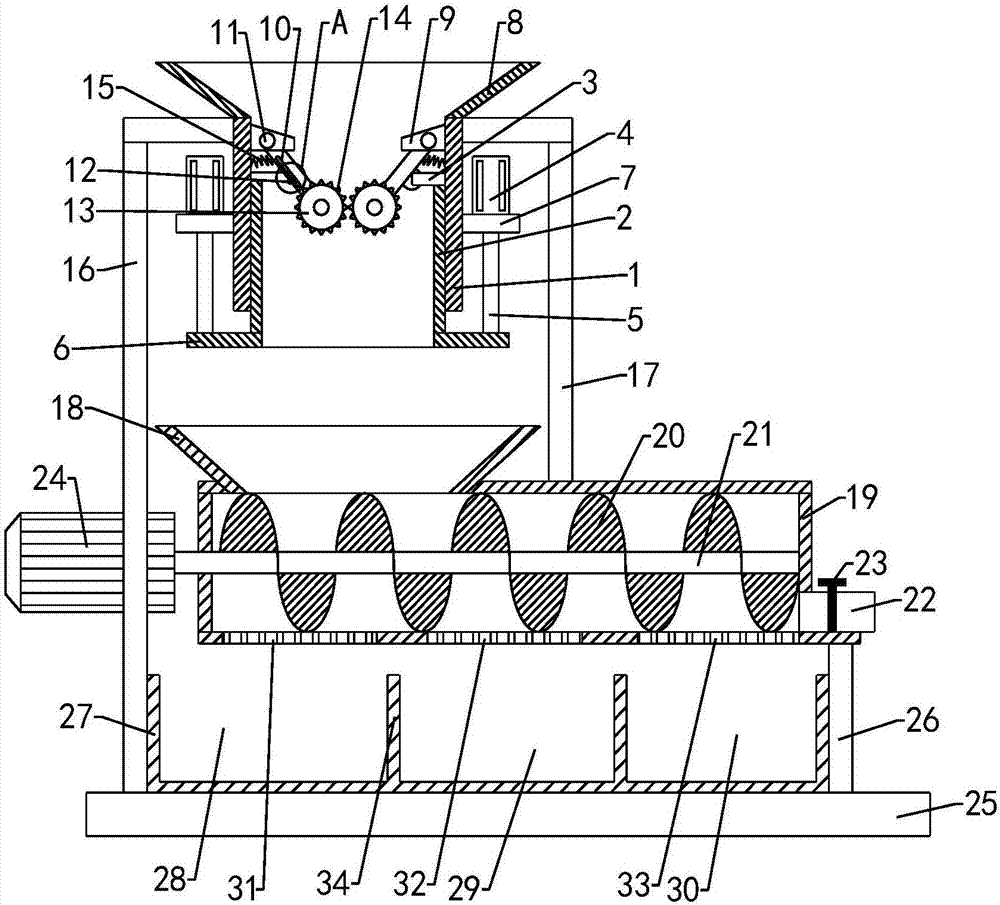

Ore crushing and screening integrated equipment for mineral exploration

InactiveCN107335503AEfficient crushingReduce labor intensitySievingScreeningHelical bladeEngineering

The invention discloses an ore crushing and screening integrated equipment for mining exploitation, which includes a crushing box, a lifting sleeve, a connecting rod, a crushing wheel, a screening box, a base and a collection box, and a material guide is fixedly arranged on the inner wall of the upper inner cavity of the crushing box The lower part of the crushing box is sleeved on the upper outer ring of the lifting sleeve. The lower surfaces of both ends of the material guide seat are connected to the connecting rod through the hinge shaft. The bottom end of the connecting rod is provided with a crushing device. The inner cavity of the screening box A rotating rod is installed in the middle through the bearing connection mode, and the outer ring of the rotating rod is equipped with a spiral blade. The first screen, the second screen and the third screen are arranged on the inner cavity plate of the screening box from left to right. The invention is simple in structure and reasonable in design, can effectively crush ore materials, and is suitable for different ore materials, and can screen the crushed ore materials at the same time, greatly reducing the labor intensity of workers and improving the efficiency of ore processing , suitable for promotional use.

Owner:汪培杰

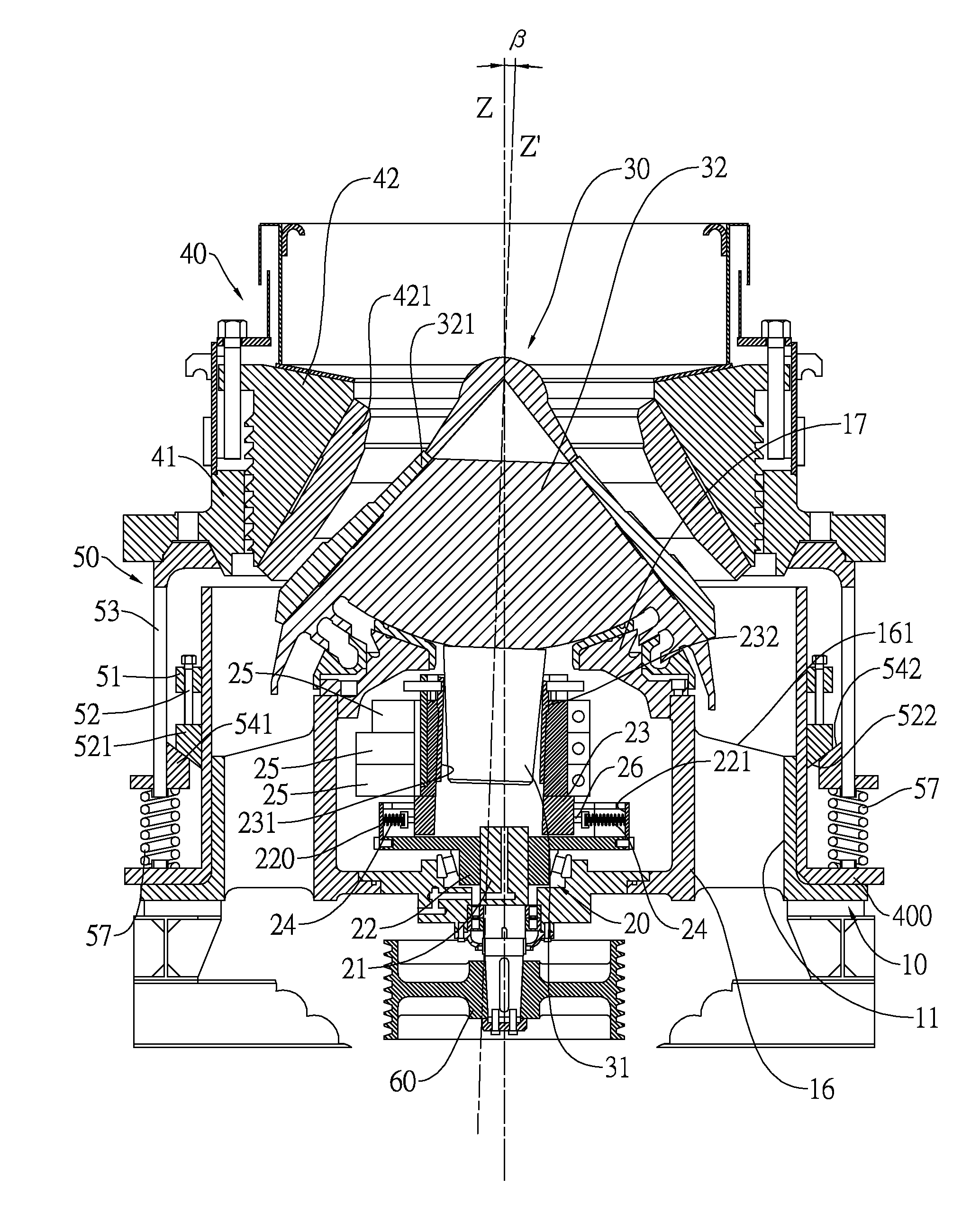

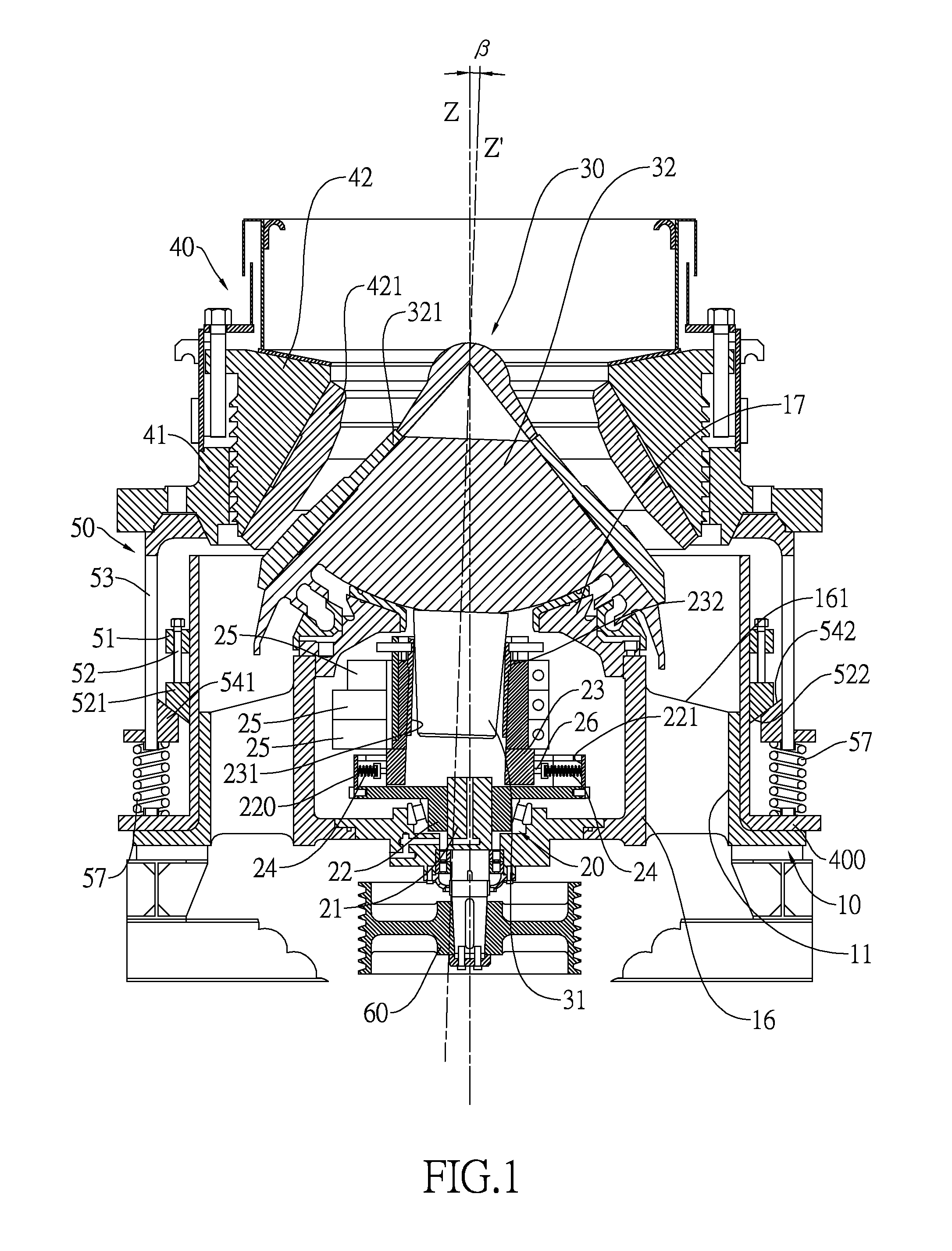

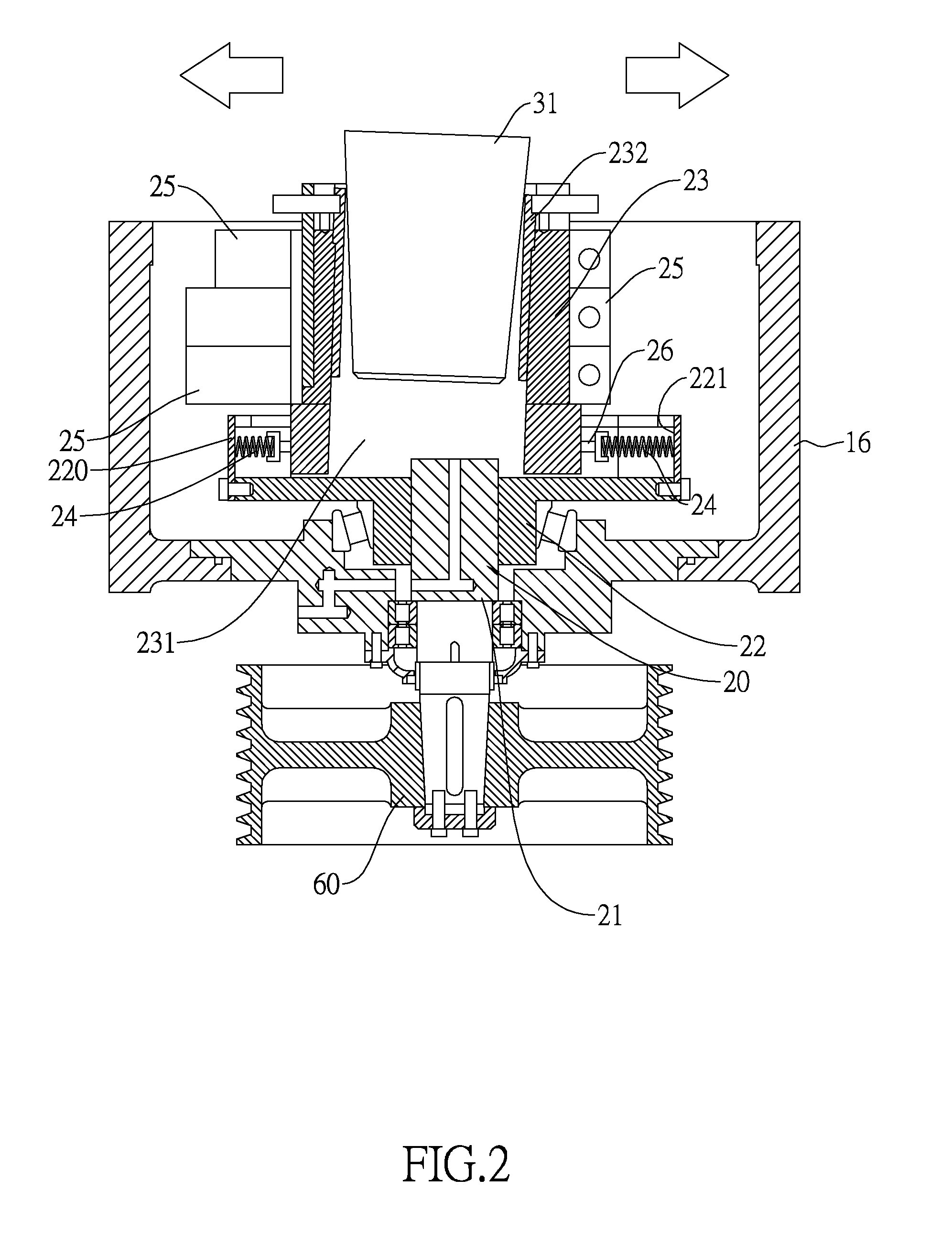

Vibrating cone crusher

A vibrating cone crusher is capable of crushing rigid raw materials such as rocks and has a base, a bowl assembly, a transmission assembly, an inertial transmission mechanism and a head assembly. The bowl assembly is capable of vibrating and swaying. The head assembly is capable of rotating eccentrically. When operating, the vibrating or swaying bowl assembly cooperates with the eccentrically rotating head assembly to effectively crush raw materials that are installed in the vibrating cone crusher.

Owner:FAN KUNG CHI

Mounting structure, electro-optical device, and electronic apparatus

ActiveUS7115980B2Avoid breakingEasily brokenCircuit bendability/stretchabilitySemiconductor/solid-state device detailsEngineeringEdge crossing

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Radial forging method for high temperature alloy step shaft

The invention provides a radial forging method for a high temperature alloy step shaft. The method includes: upsetting and drawing out a steel ingot, and providing a blank to a forging machine; forging the blank in multiple passes, and pre-forging to form a first step shaft; forging the middle of the first step shaft in multiple passages so as to form a middle step shaft, and forming a transition section between the first step shaft and the middle step shaft, wherein pulling speed for forming the first step shaft is controlled to be 3-5.5m / min, deformation of each pass for forming the middle step shaft is controlled to be 10-25%, and pulling speed for forming the middle step shaft is controlled to be 3-5.5m / min. By control on forging frequency, reduction in pass and pull speed of the radial forging method and by control on final forging temperature, the property structure of a step shaft product is controlled, quality stability and structure property uniformity of the product are improved greatly while comprehensive yield and qualified rate of the product are increased greatly.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

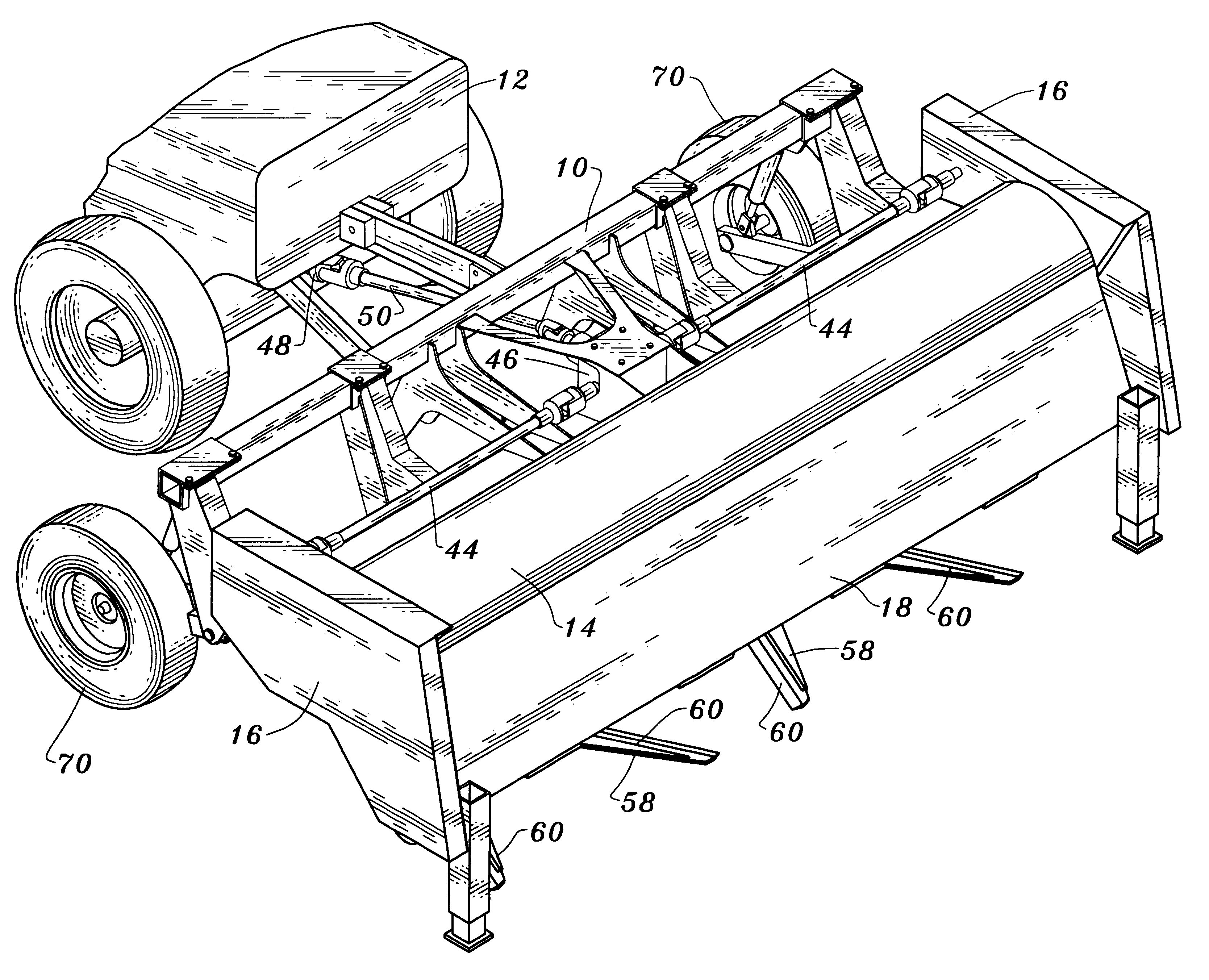

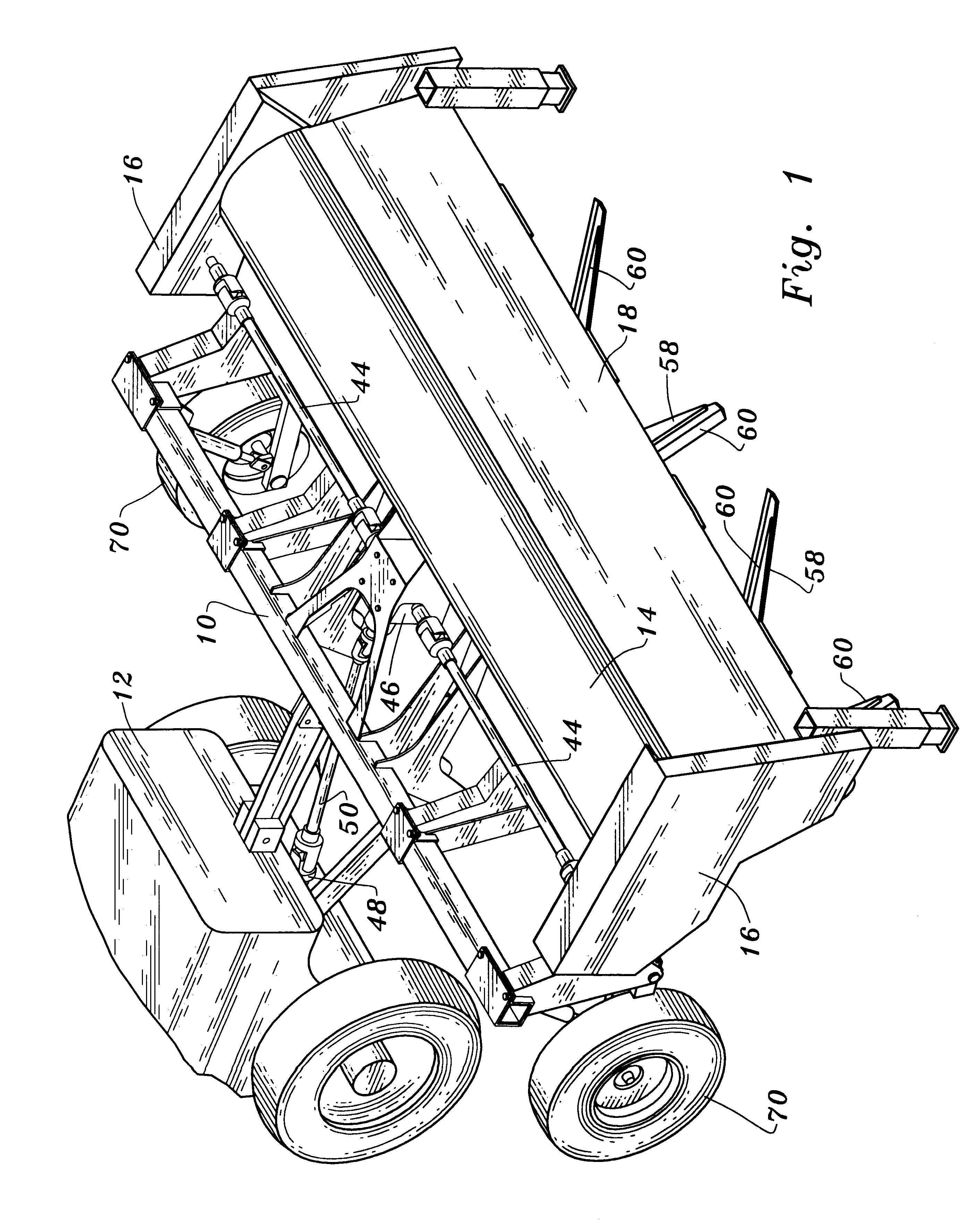

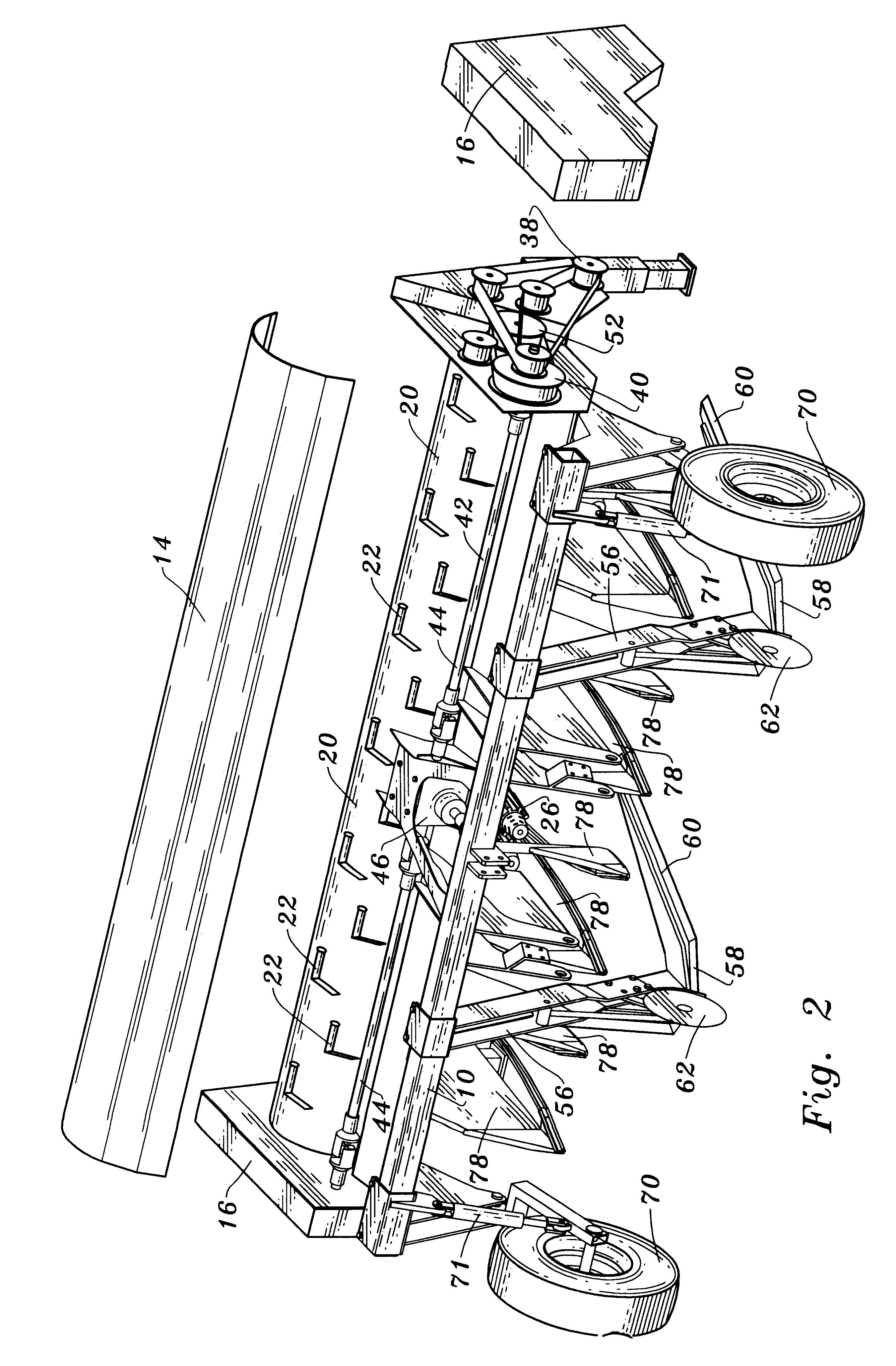

Apparatus and method for removing plant stalks from a field and shredding the plant stalks

A system for removing plant stalks from a field and shredding the plant stalks. The plant stalks are cut and passed through feed rollers which directly feed the plant stalk to a shredder. Compression of the plant stalks by the feed rollers increases as the plant stalks slide between the feed rollers in a variable nip formed by the feed rollers.

Owner:JOHNSON FARM MACHINERY

Pulverizing and recycling device for solid garbage

InactiveCN107052030AQuick smashEfficient crushingTransportation and packagingSolid waste disposalEngineeringKnife blades

The invention discloses a pulverizing and recycling device for solid garbage. The pulverizing and recycling device comprises a shell and a compression box. A feeding pipe, a first motor, a stirring shaft and a rotation pulverizing blade are arranged at the upper end of the shell. A fixed pulverizing blade, a rotation supporting plate, a material baffle, a sliding supporting plate, a sliding rod, supporting wheels and a guide rod are arranged on the side wall of the shell. A connecting plate, a sliding frame groove, a strip-shaped penetrating groove, a rotation sliding rod, a connecting swinging rod and a second motor are sequentially arranged at the left end of the guide rod. A partition plate, a material guiding pipeline, a material guiding hopper, a material guiding plate and a supporting spring are arranged in the shell. A support is arranged at the lower end of the shell. A discharging pipe and the compression box are arranged on the left wall of the shell. The compression box is provided with a feeding port, a cover plate, a supporting bottom rod, a supporting sleeve, an electric telescopic rod and a compression plate. According to the pulverizing and recycling device, materials are pulverized through cooperation of the rotation pulverizing blade and the fixed pulverizing blade; the guide rod is used for driving the sliding rod and the supporting wheels to support the rotary material baffle to conduct intermittent discharging, and the materials are guided into the compression box through the material guiding plate to be compressed and collected.

Owner:苏天平

Multifunctional self-oscillation flow jet flow drill

InactiveCN101413380AImprove permeabilitySimple structureLiquid/gas jet drillingVibration drillingJet flowSelf-oscillation

The invention relates to a multifunctional self-oscillation jet drill bit. The prior similar product not only has shallow drilling depth and complex structure but also has large resistance loss and short service life of a drill bit, can not repeatedly switch drilling and groove cutting during the drilling process, and limits the application scope. A crushing blade and a valve body are arranged inside a cutting head body of the drill bit; a first offsetting spring in the valve body is matched with a valve core A in the form of sliding; a valve core B is matched with a second offsetting spring for operation under the action of a lined ring, a washer and the valve body together; and the valve core and a limber hole of the valve body are matched for use with a self-oscillation nozzle. The multifunctional self-oscillation jet drill bit adopts high-pressure water as power to realize repeated switching between drilling and groove cutting of coal seam and terrane, not only has a simple structure and is flexible to switch but also can promote development of coal seam fissure through oscillation jet generated by the nozzle, strengthens the permeability of the coal seam, improves the gas extraction rate, particularly has obvious effect on low-permeability coal seam, and widely promotes and applies the fluid technology of the high-pressure water in the fields of drilling and gas extraction of the low-permeability coal seam.

Owner:CHONGQING UNIV

Combined core drilling system driven by downhole motor and impactor

InactiveCN1730898AEfficient crushingReduce wearConstructionsReciprocating drilling machinesGeological explorationCoring

The present invention relates to core drilling system in geological exploration, petroleum drilling, scientific drilling and other industry, and is especially one combined core drilling system driven with well motor and impactor for core drilling in hard rock and deep hole. The combined core drilling system includes coring tool and coring bit connected to the lower end of the coring tool as well as well motor and impactor with upper end connected to the lower end of the motor driving shaft and lower end connected to the upper end of the coring tool. The well motor provides the coring tool and the coring bit with rock crushing torque, and the impactor provides the coring tool and the coring bit with rock crushing impact force. The core drilling system can lower power consumption, reduce wear of drilling rod, raise drilling length each coring and prevent drilling hole from becoming inclined.

Owner:中国大陆科学钻探工程中心

Environment-friendly plastic recovery processing device

The invention discloses an environment-friendly plastic recovery processing device comprising a bottom plate. A processing box is arranged on the upper side of the bottom plate. A crushing cavity is formed in the upper end in the processing box. A support rod is arranged at the upper end of the right side of the processing box. Racks are arranged on the upper side and the lower side of the supportrod at the upper end and are provided with connecting seats. Telescopic rods are arranged on the front sides of the connecting seats. Crushing blocks are arranged on the lower sides of the telescopicrods. The lower side of the crushing cavity is provided with a flow guide groove. A screening barrel is arranged on the lower side of the flow guide groove. A rotary disc is arranged on the lower side of the screening barrel. A separation plate is arranged on the lower side of the rotary disc. A second rotary shaft is arranged on the lower side of the rotary disc. A second motor is arranged on the right side of the lower end of the second rotary shaft. A cavity is formed in the second rotary shaft. A third motor is arranged at the lower end in the cavity. A crushing shaft is arranged on the upper side of the third motor. Crushing blades are arranged on the left side and the right side of the upper end of the crushing shaft. Discharge pipes are arranged around the lower side of the processing box. Through the environment-friendly plastic recovery processing device, the crushing, smashing and screening process of plastic waste is facilitated effectively, in this way, plastic recovery isconvenient, the environment is protected, and resources are saved.

Owner:上海申第实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com