Patents

Literature

117 results about "Central pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

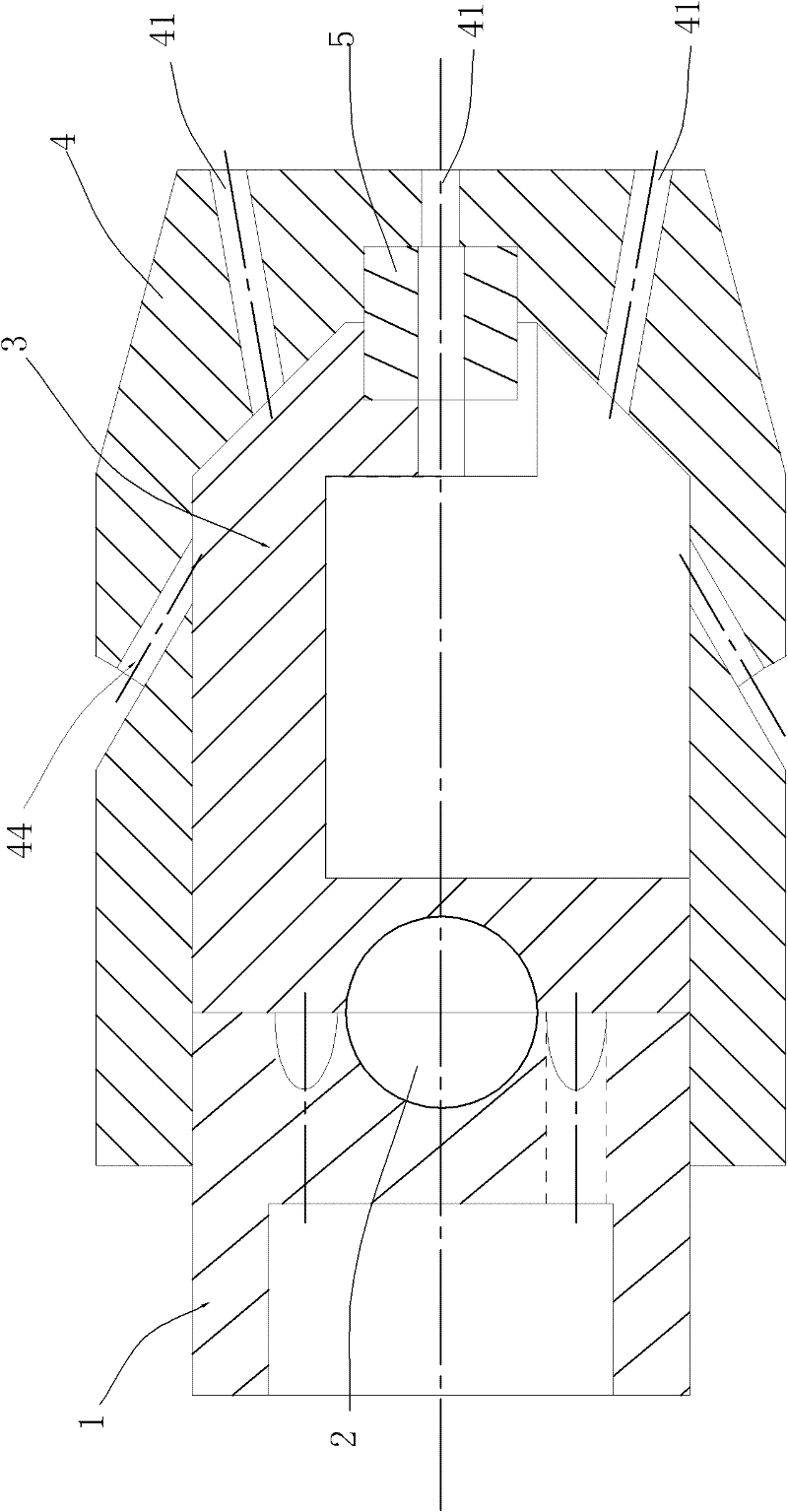

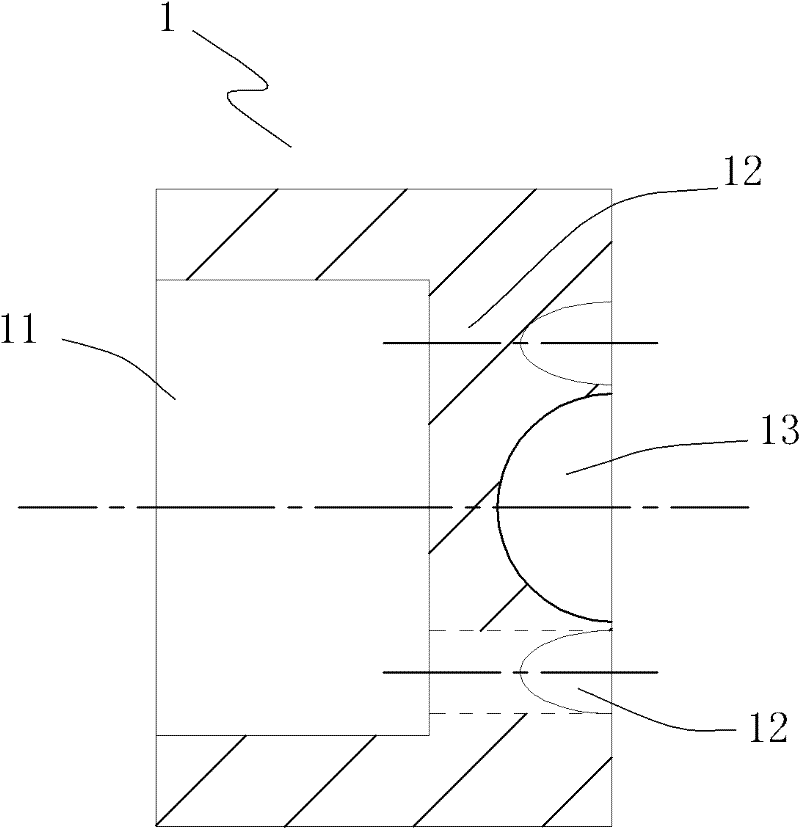

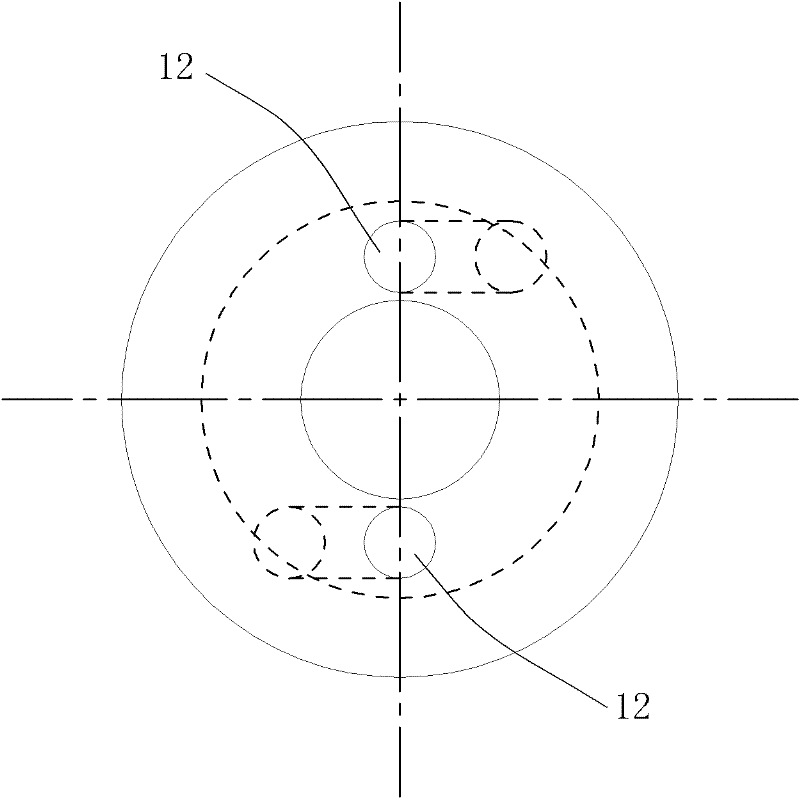

Self-propelled drilling method and pulsed cavitation swirling jet nozzle

The invention relates to a self-propelled drilling method and a nozzle. The self-propelled drilling method is formed by coupling a pulsed jet method, a cavitation jet method and a swirling jet method, wherein, an impeller body arranged in the nozzle can rotate under the impact action of a fluid, a part of forward jet orifices arranged at the head of the nozzle as well as a part of backward jet orifices which are arranged on the nozzle and are opposite to the forward jet orifices can be closed during the rotation process of the impeller body, the fluid is ejected from the other part of the forward jet orifices and the backward jet orifices so as to form jet flow, and the forward jet orifices are alternately closed so as to generate pulsed jet during the rotation process of the impeller body; the fluid entering the nozzle is driven to rotate by the rotating impeller body, and then the rotating fluid is ejected from the jet orifices so as to generate swirling jet; and the central pressure in the nozzle can be reduced by means of rotation of the impeller body so as to form cavitation jet. In the self-propelled drilling method, advantages of the three types of jet flow are integrated so as to greatly improve the drilling efficiency; and the self-propelled drilling method and the nozzle are applicable to drilling holes in a ground layer.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

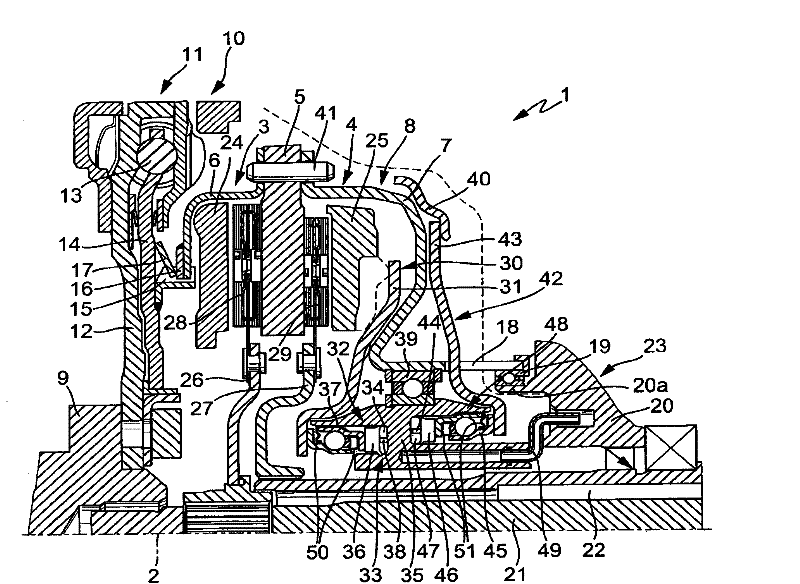

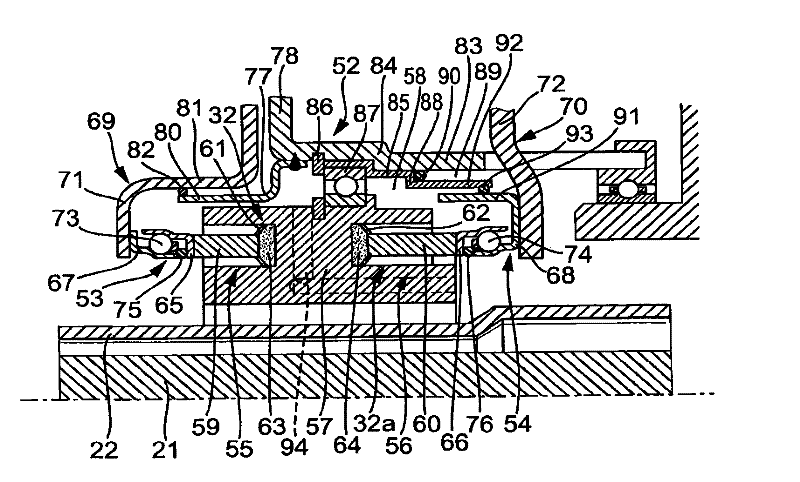

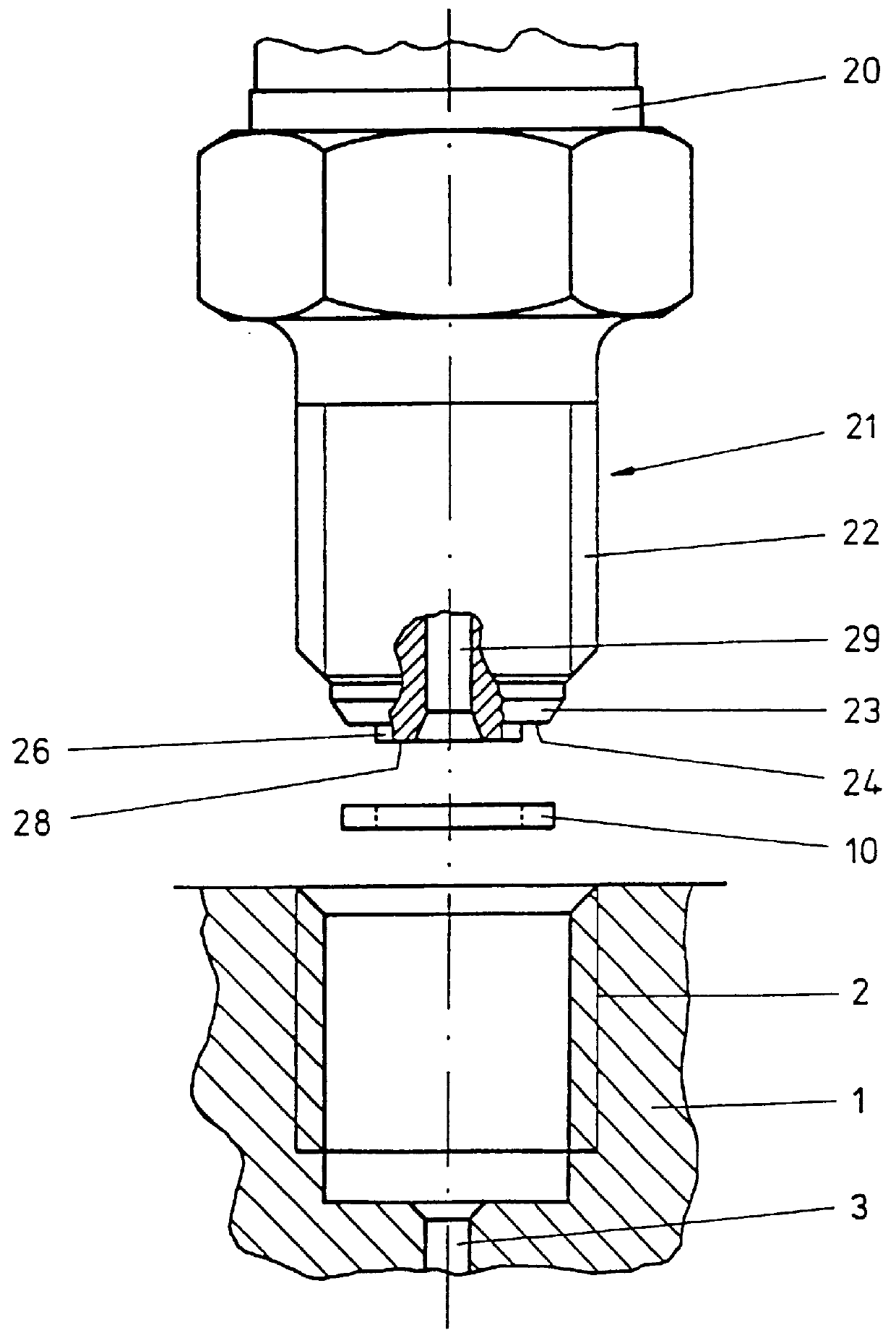

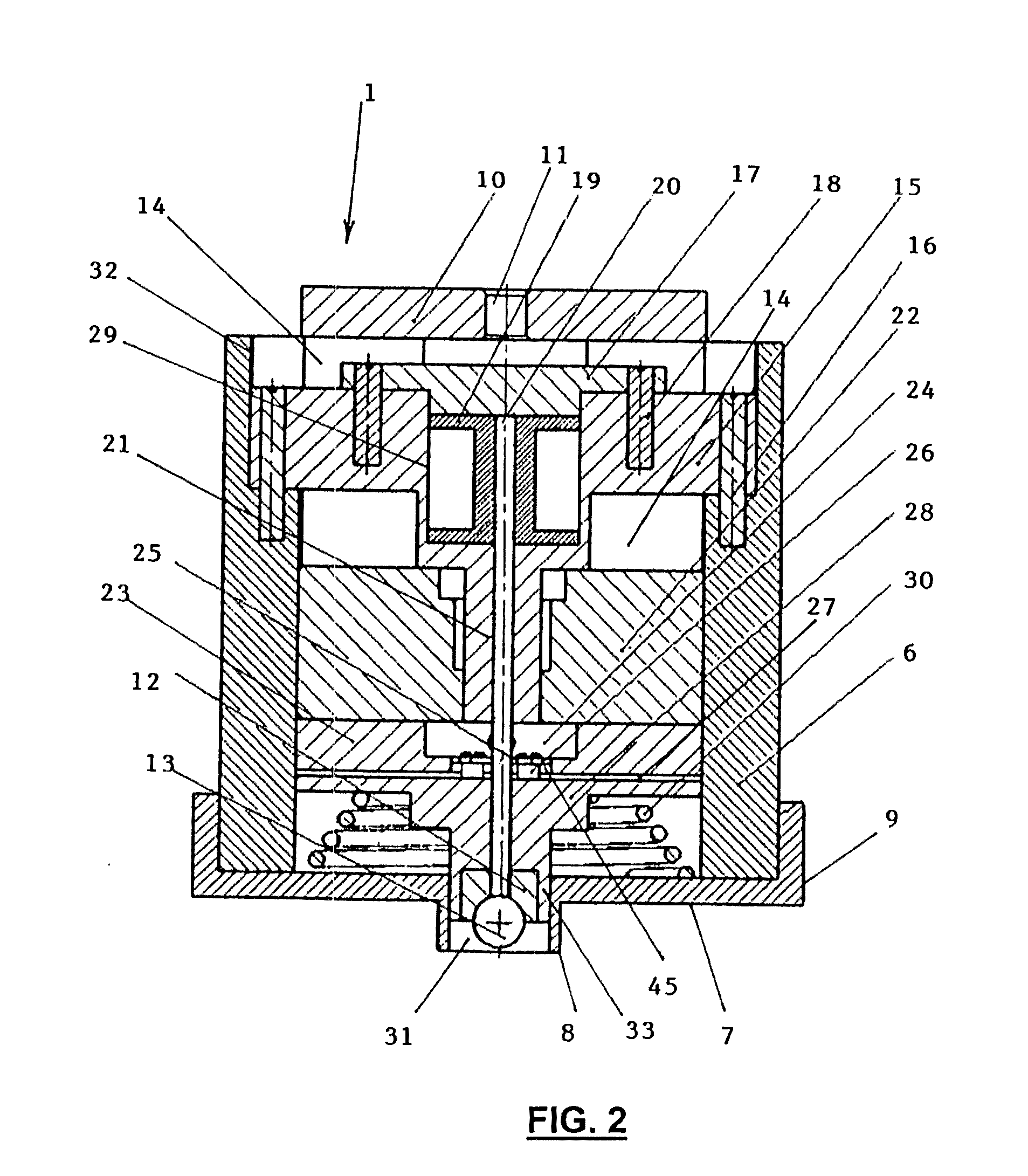

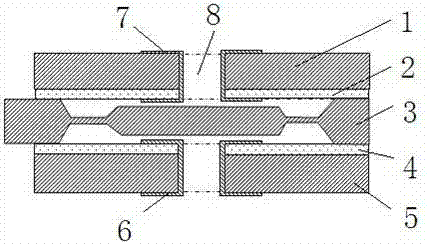

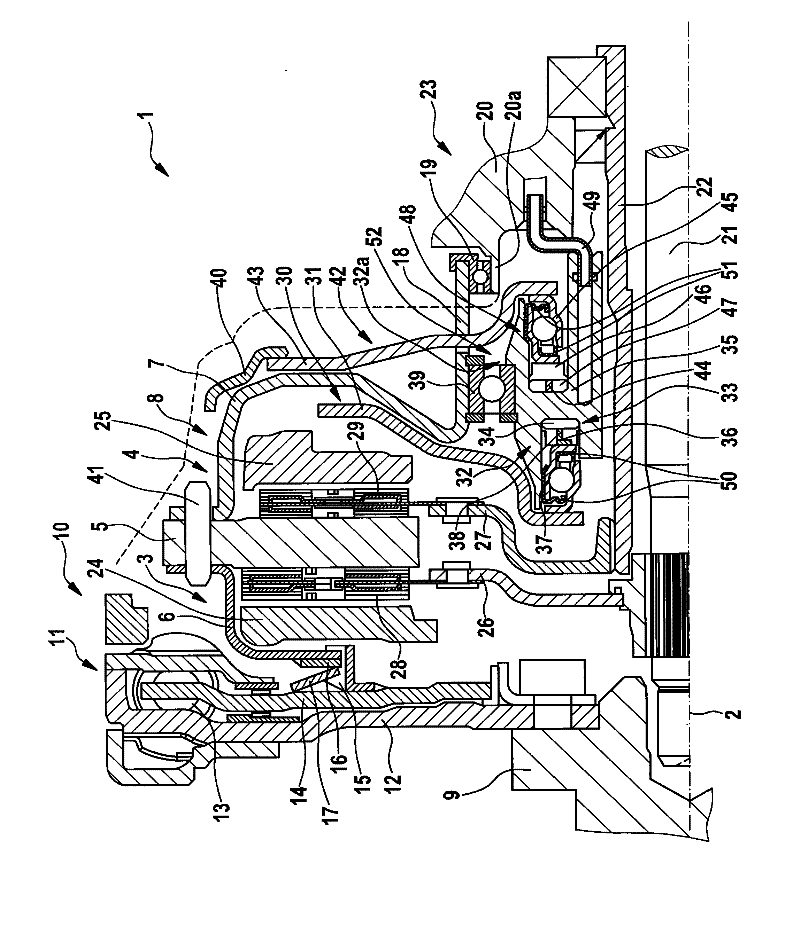

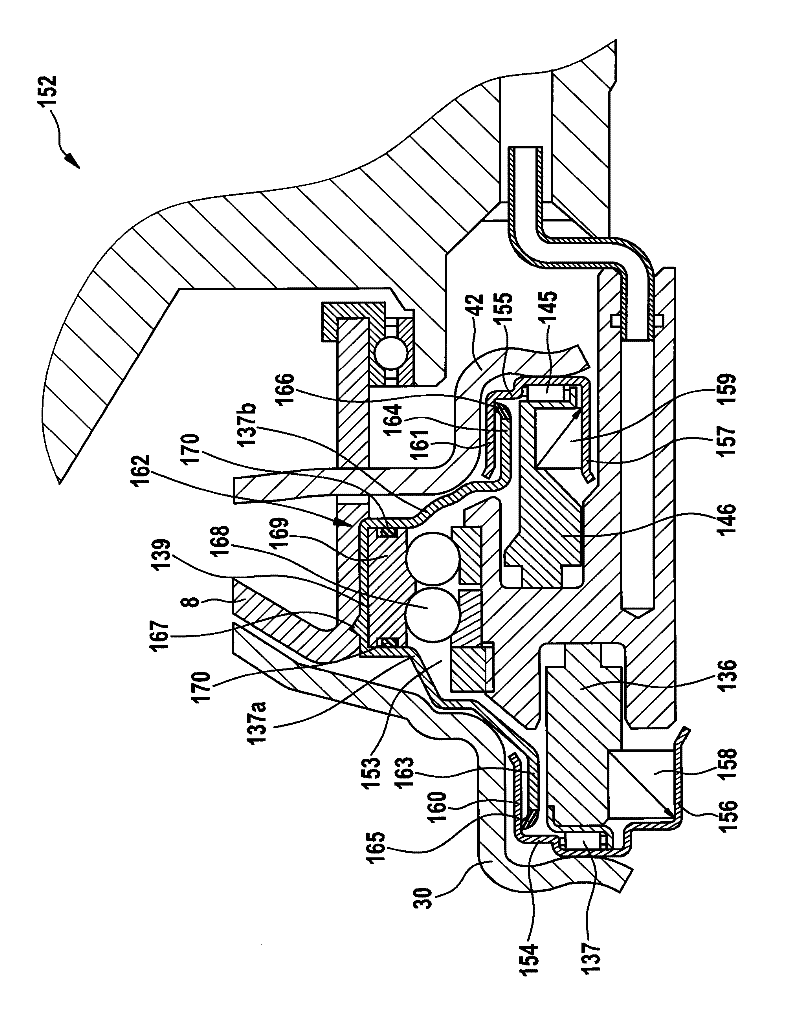

Dual clutch

InactiveCN102099595ACorrectly designedAvoid vibrationRolling contact bearingsMechanical actuated clutchesCentral pressureEngineering

The invention relates to a dual clutch (1) having two friction clutches (3,4), having a central pressure-exerting plate (5) and having two pressure plates (24,25) which are axially movable relative to said pressure-exerting plate (5) with the interposition of the friction linings (28,29) of two clutch disks (26,27), which mesh with in each case one gearbox input shaft (21,22), of actuating devices (32,32a). Here, the pressure plates (24,25) are advantageously acted on by transmission elements (30,42,69,70) by the actuating devices (32,32a) directly without a lever action. Furthermore, for the cooling and lubrication of the actuating devices (32,32a) and the transmission elements (30,42,69,70), an annular chamber (58) can be formed which has an increased fluid volume.

Owner:SCHAEFFLER TECH AG & CO KG

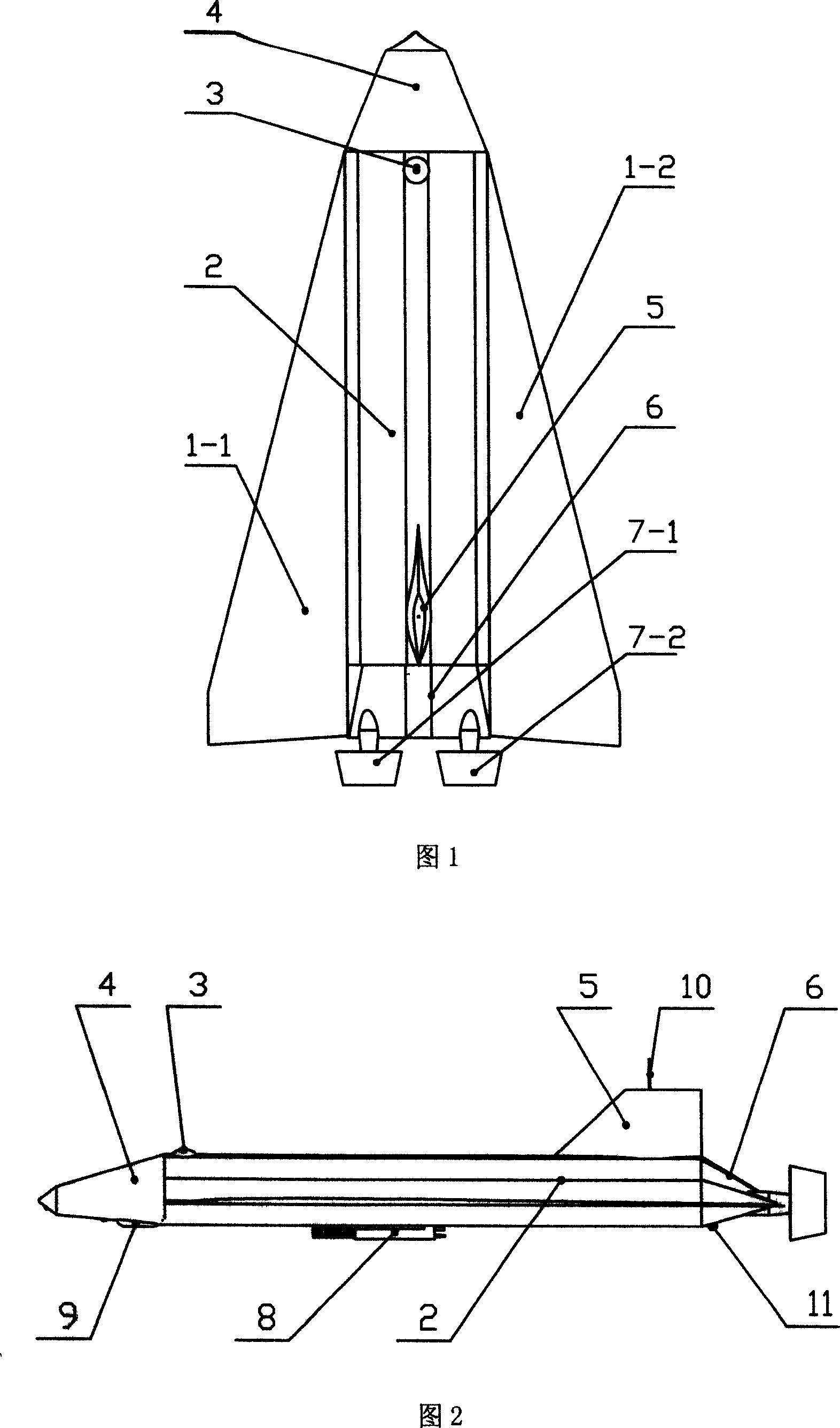

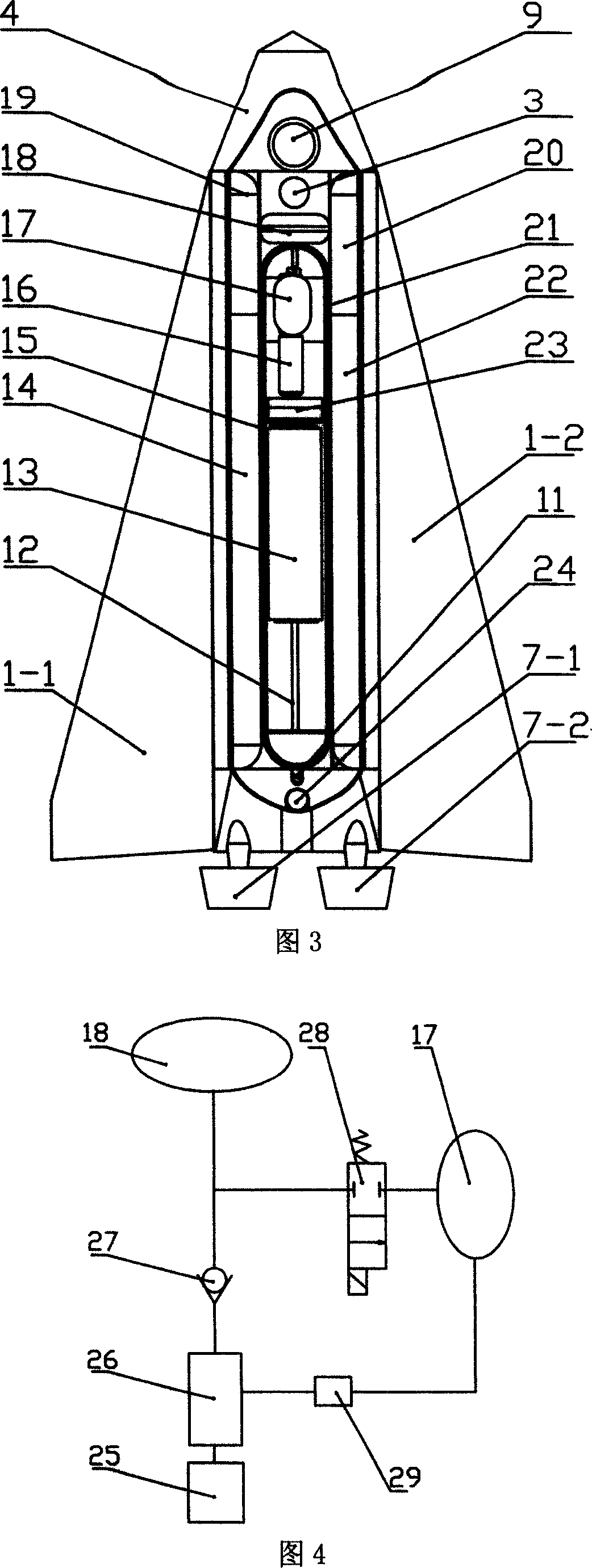

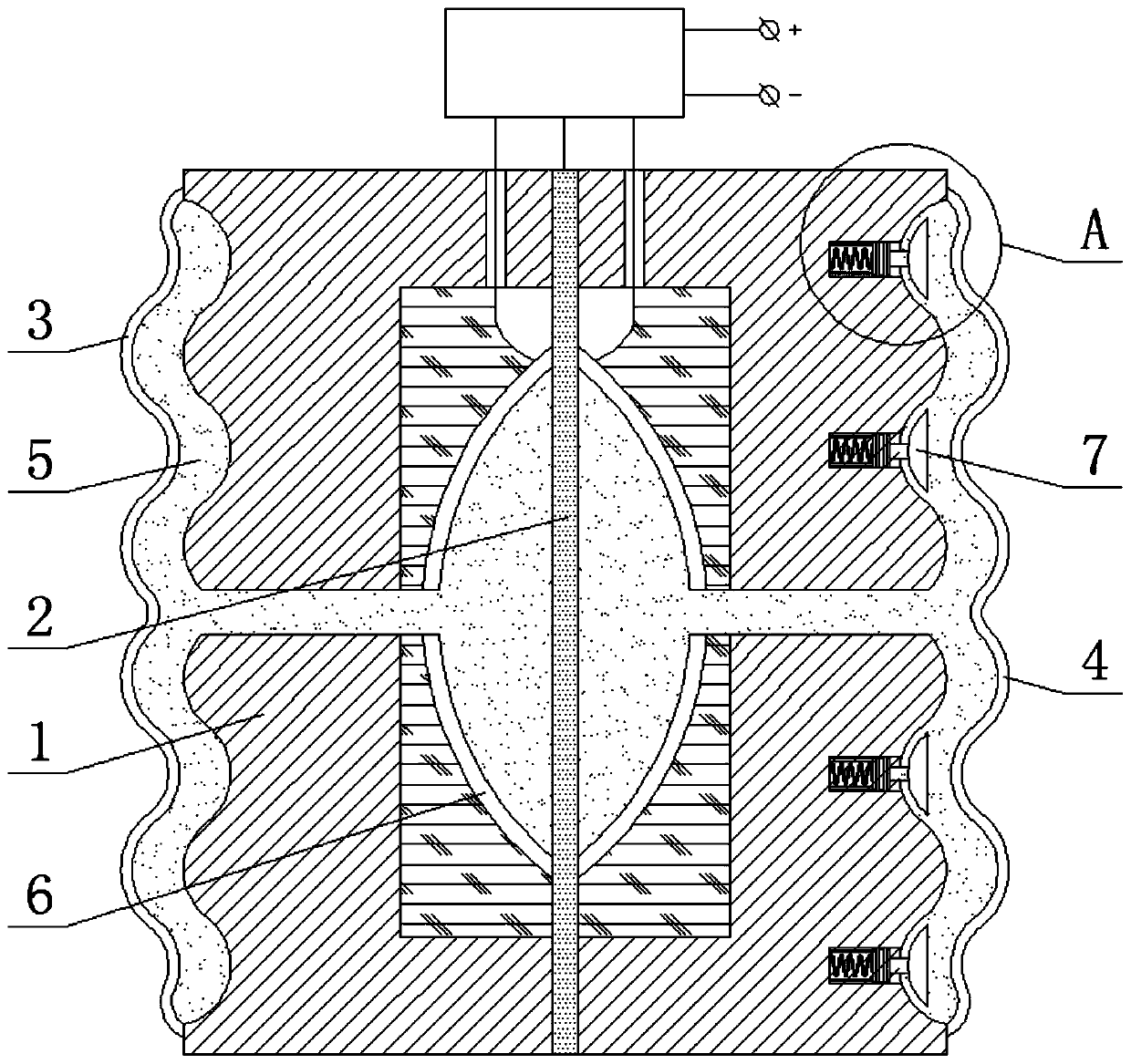

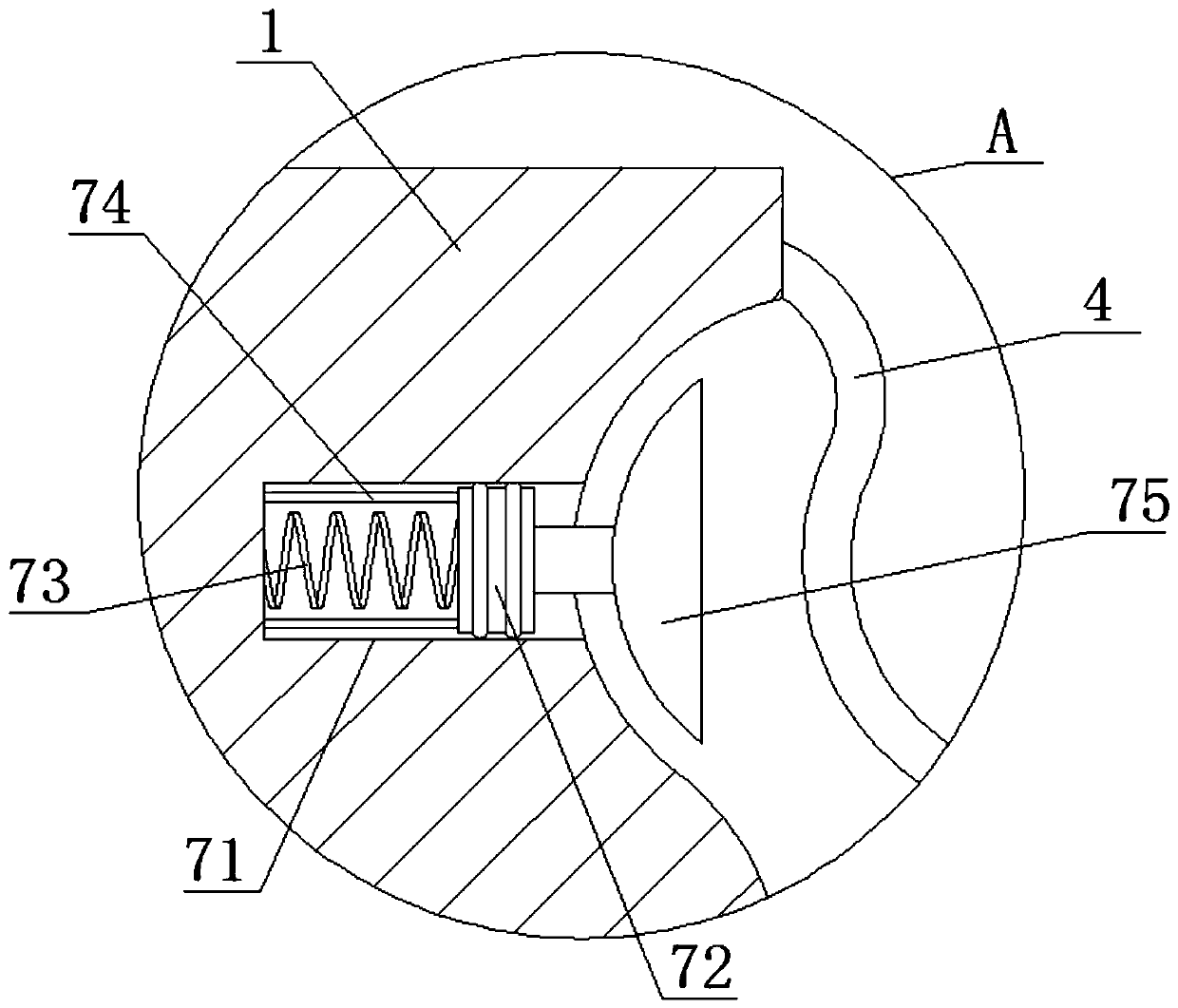

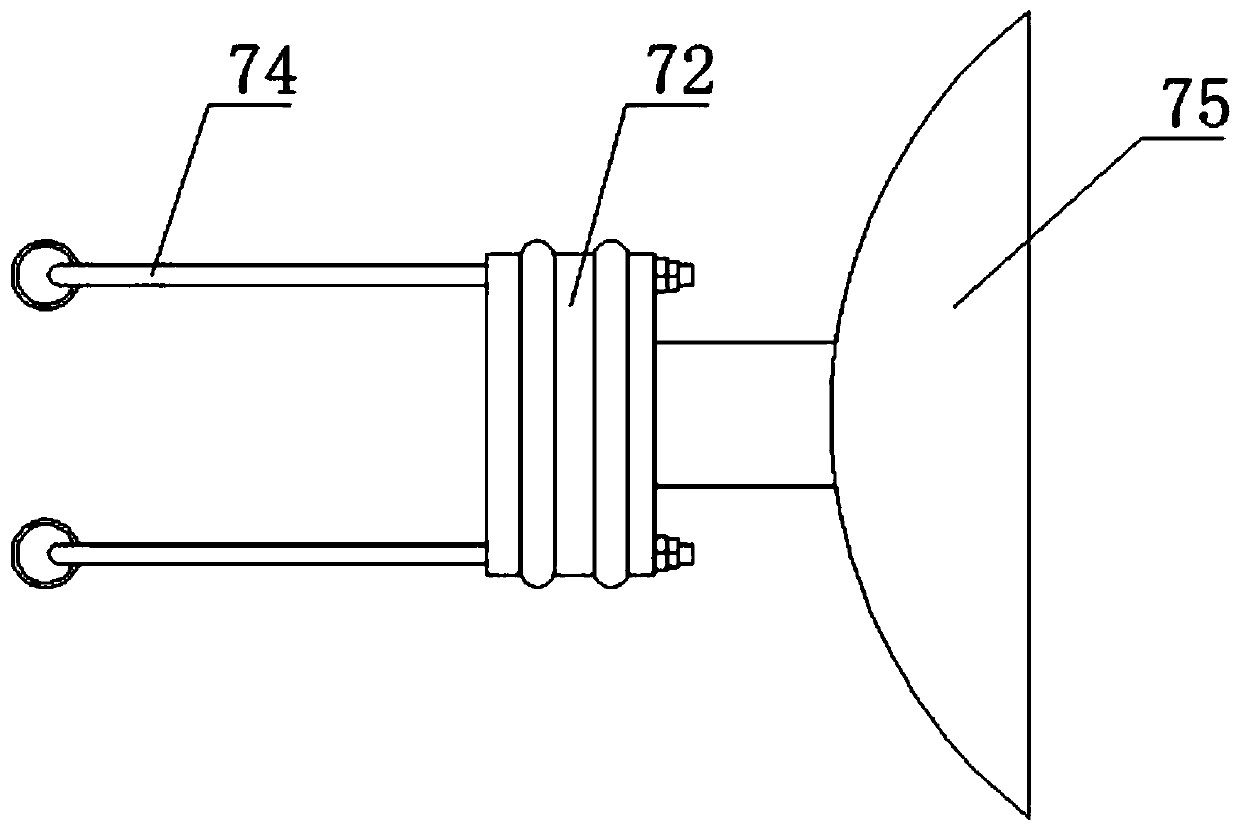

Hybrid type underwater sailing device

ActiveCN101007566ASimple structureEasy to manufactureNavigation by speed/acceleration measurementsUnderwater vesselsHybrid typeControl system

A hybrid underwater craft. It includes framework consisting of head shield, body shield and tail shield; triangular wings and vertical fixing tail rudder installed out the body shield; height gauge installed below the tail shield; navigational module installed in head shield; central pressure resistance cabin installed in the body shield; left and right pressure resistance cabins installed in the body shield; underwater sound communication module installed in the body shield; buoyant force drive system, control system, pitching adjusting module installed between the body shield and central pressure resistance cabin and pitching adjusting module supporting bar used for support pitching adjusting module; two conduit airscrew propeller connected on the rear-end of tail cup firmly and symmetrically. The invention uses the delta wing which both has gliding property and AUV operating performance as wings of craft, the loaded corresponding measuring sensor and the task module can realize monitoring and investigation of large area waters long term, and can monitor, expedite and trace the specific target precisely and rapidly.

Owner:TIANJIN UNIV

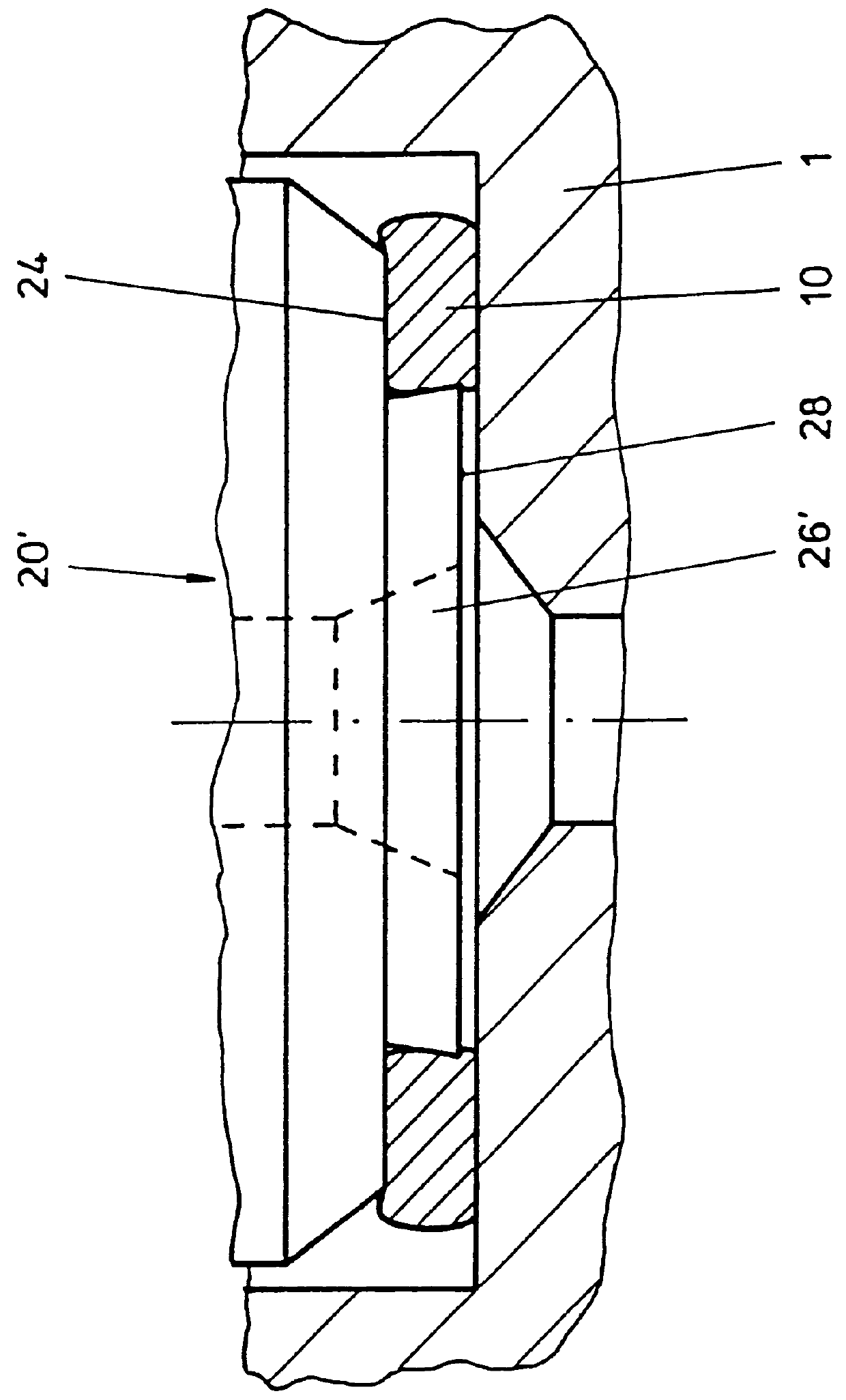

Sealing unit for a fuel pressure sensor

PCT No. PCT / DE96 / 01420 Sec. 371 Date Jun. 25, 1997 Sec. 102(e) Date Jun. 25, 1997 PCT Filed Jul. 31, 1996 PCT Pub. No. WO97 / 23771 PCT Pub. Date Jul. 3, 1997The invention relates to a sealing unit for a fuel pressure sensor for sealing an at least virtually flat sealing joint between the sensor and a component that carries it via a screw connection, wherein a round sealing washer with a central bore is disposed between the threaded bolt-shaped end of the sensor housing with its central sensor bore and the bottom of the threaded bore of the component with its central pressure fluid opening. A pin is formed onto the threaded bolt-shaped end of the sensor housing, which pin centers the sealing washer, fixing it in a positive and / or frictional, non-positive manner, and rises above an end face that serves as a bearing surface for the sealing washer. The pin ends in an end face and has a length that is shorter than the thickness of the sealing washer. A sealing unit is produced that assures a reliable sealing function and permits a simple installation and disassembly of the sealing washer while reclaiming the sealing washer in a sealing position.

Owner:ROBERT BOSCH GMBH

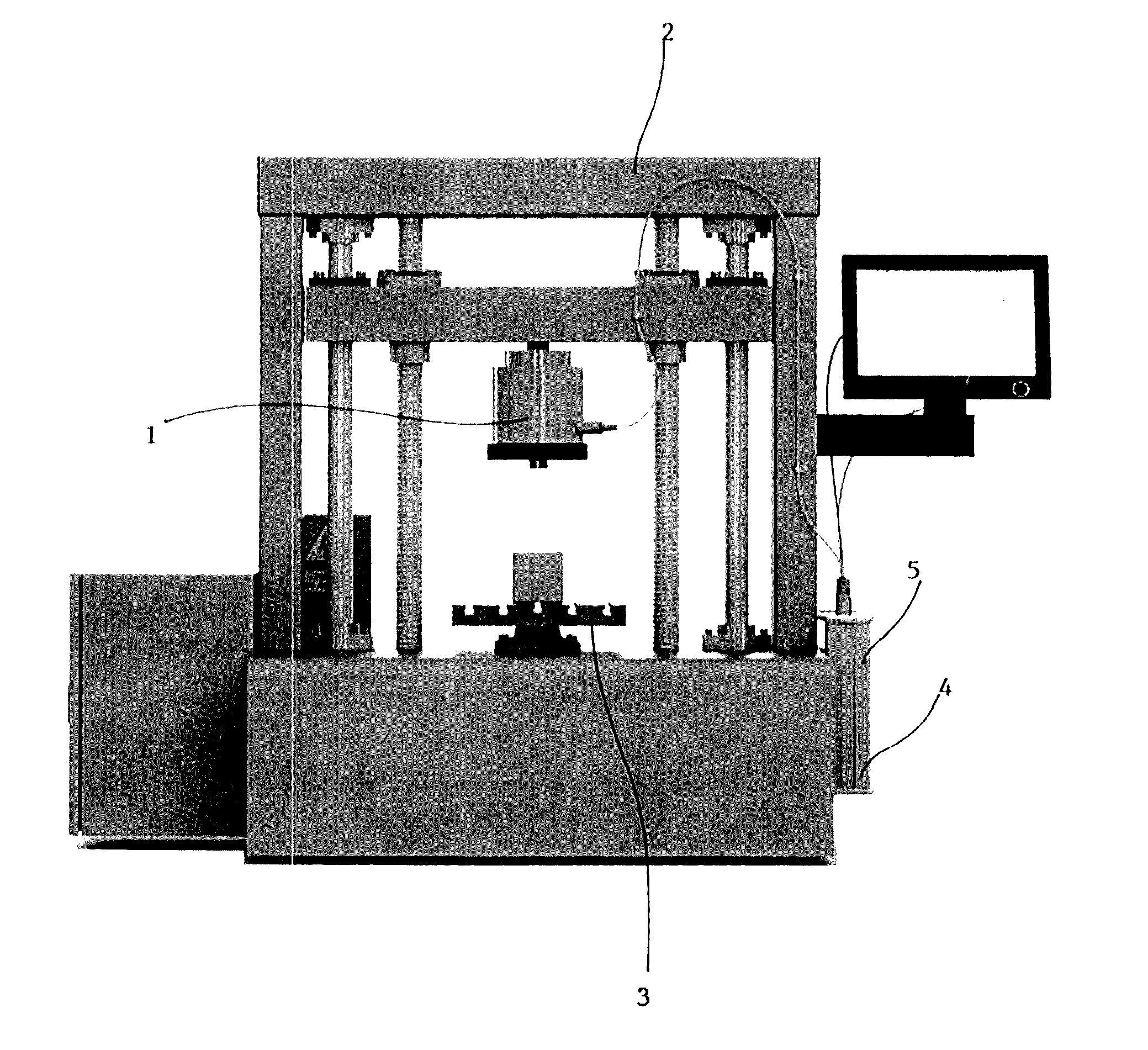

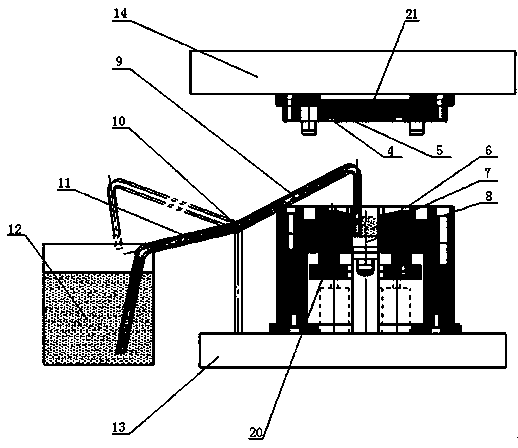

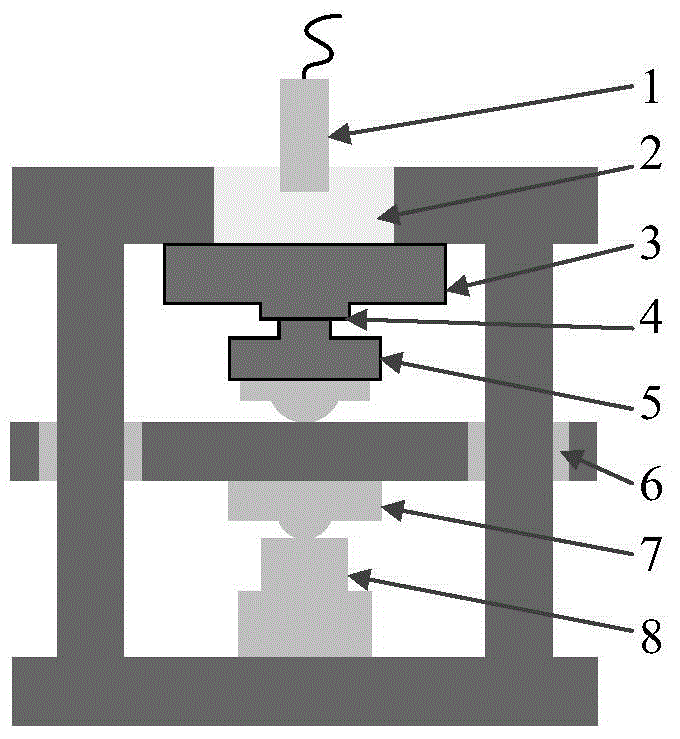

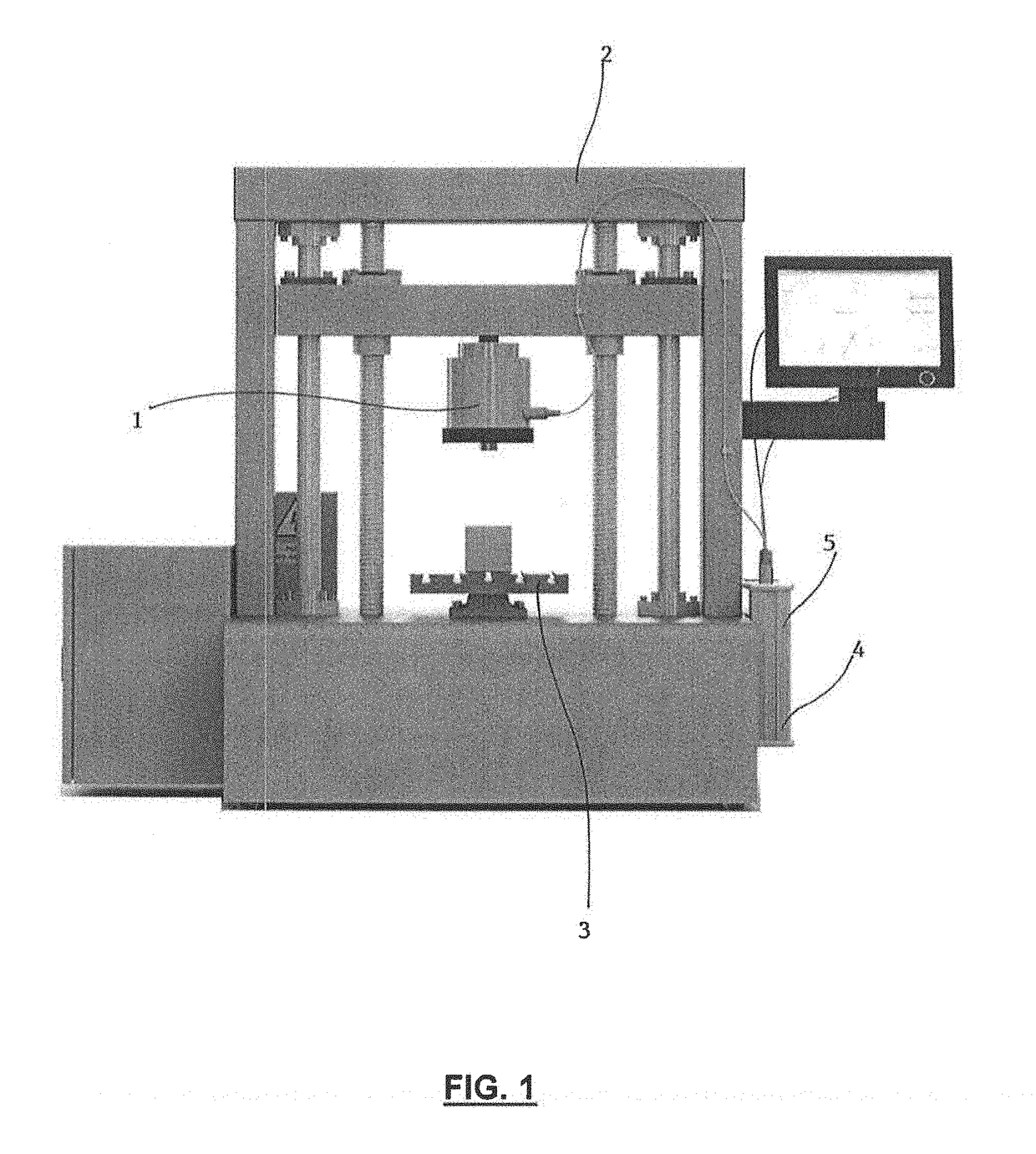

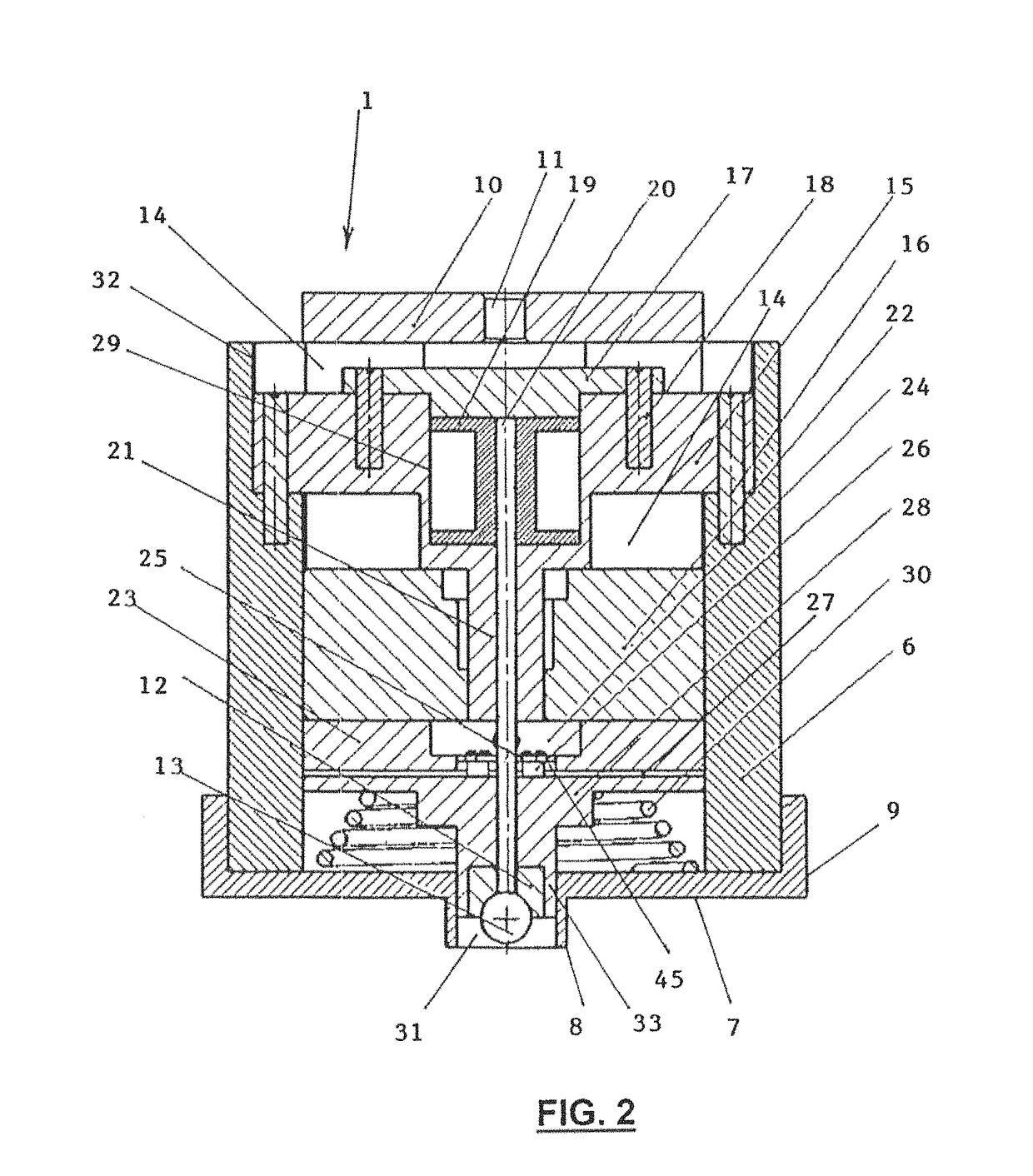

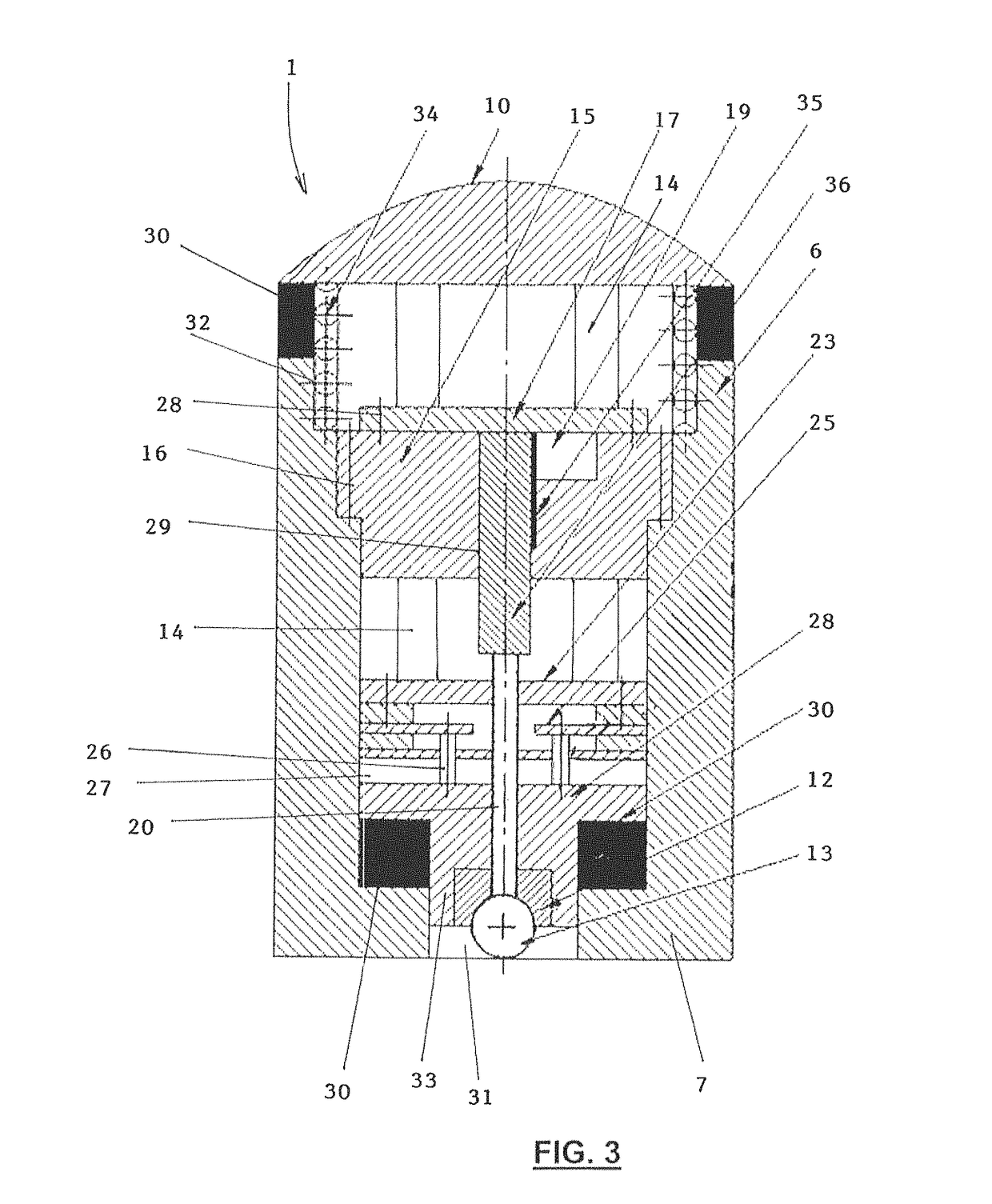

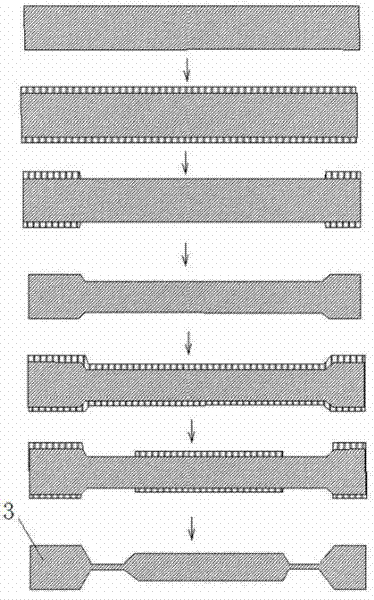

An indentation device, instrumented measurement system, and a method for determining the mechanical properties of materials by the indentation method

InactiveUS20160377518A1Excellent and adequate accuracyEliminate generationElectric/magnetic position measurementsAcceleration measurementCentral pressureStrength of materials

Owner:CZECH TECH UNIV IN PRAGUE

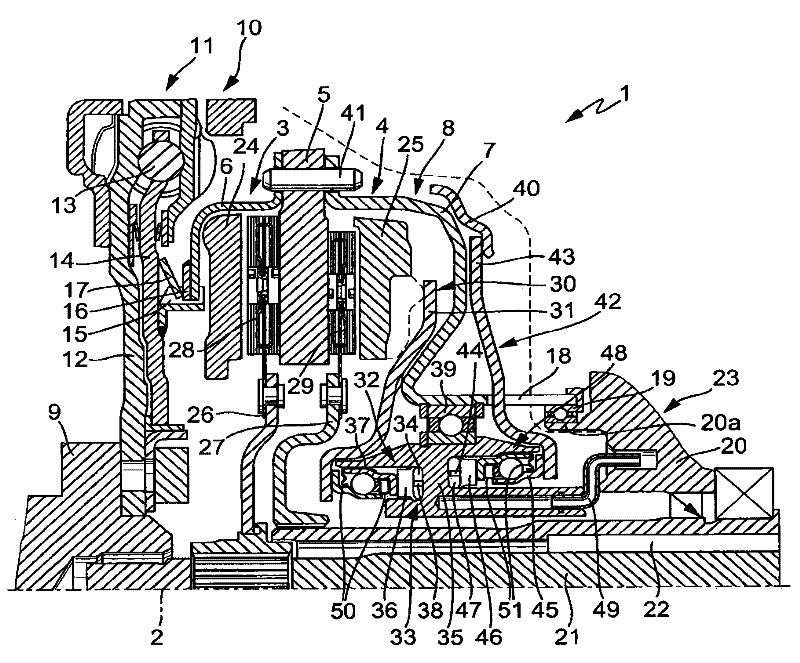

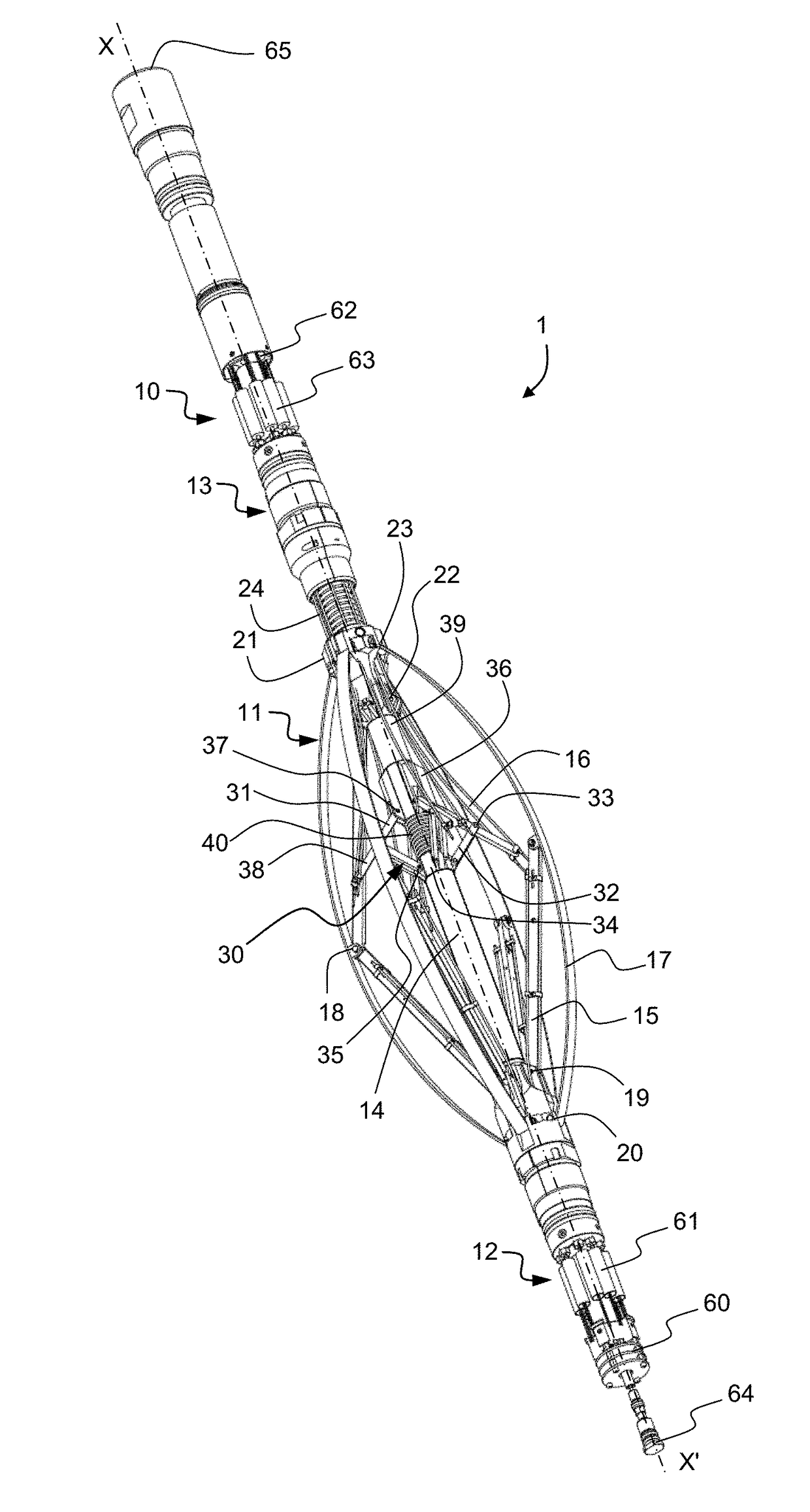

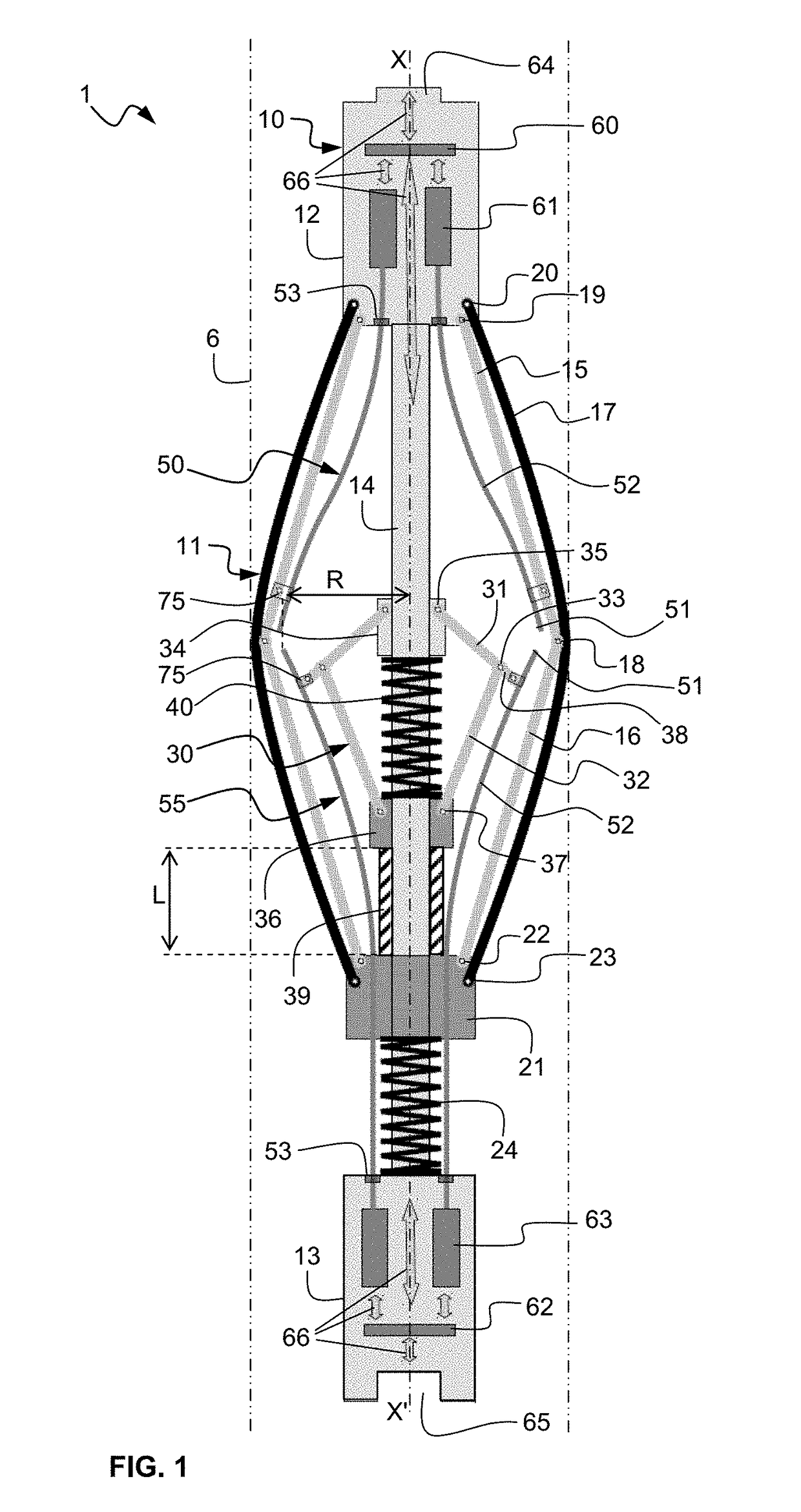

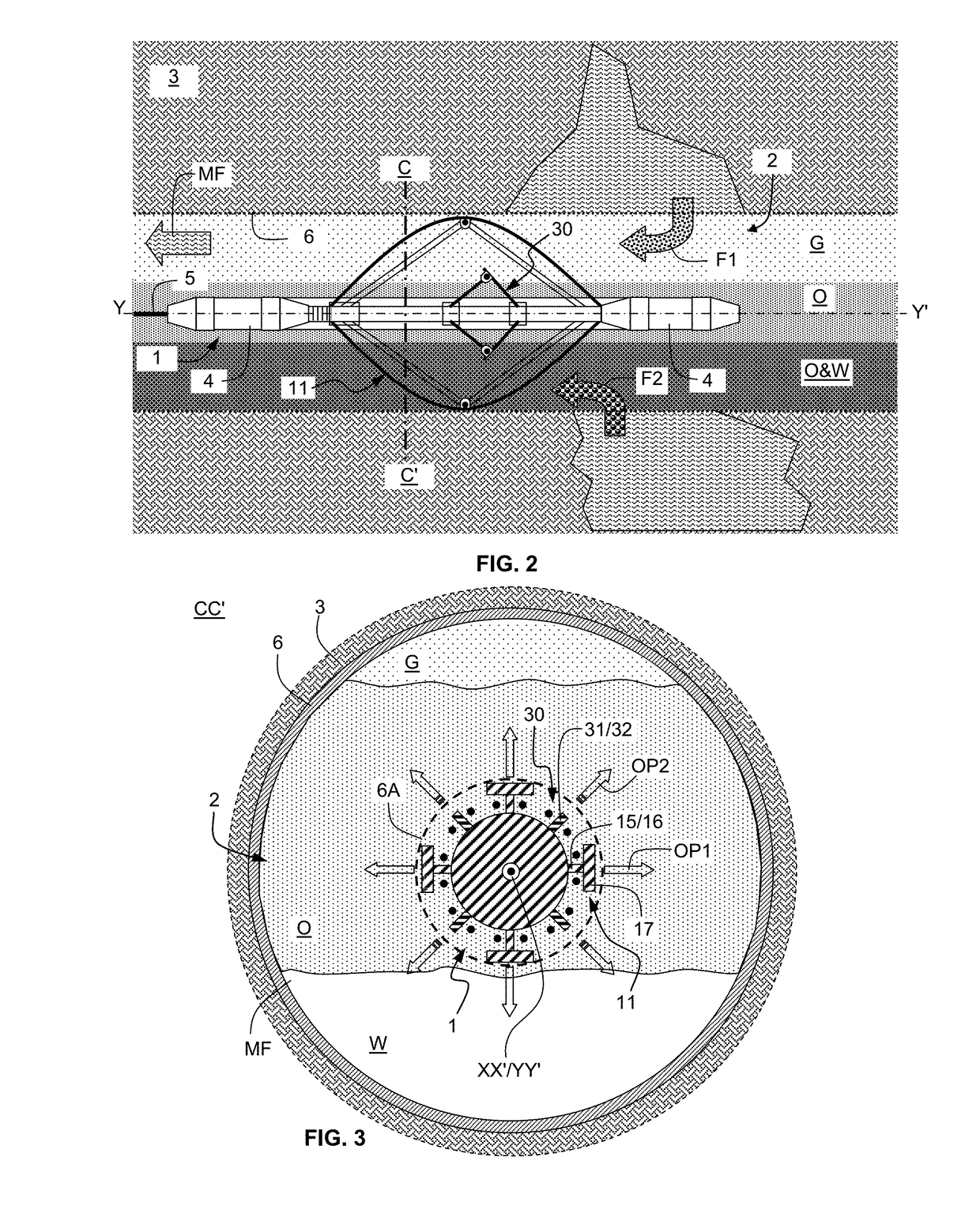

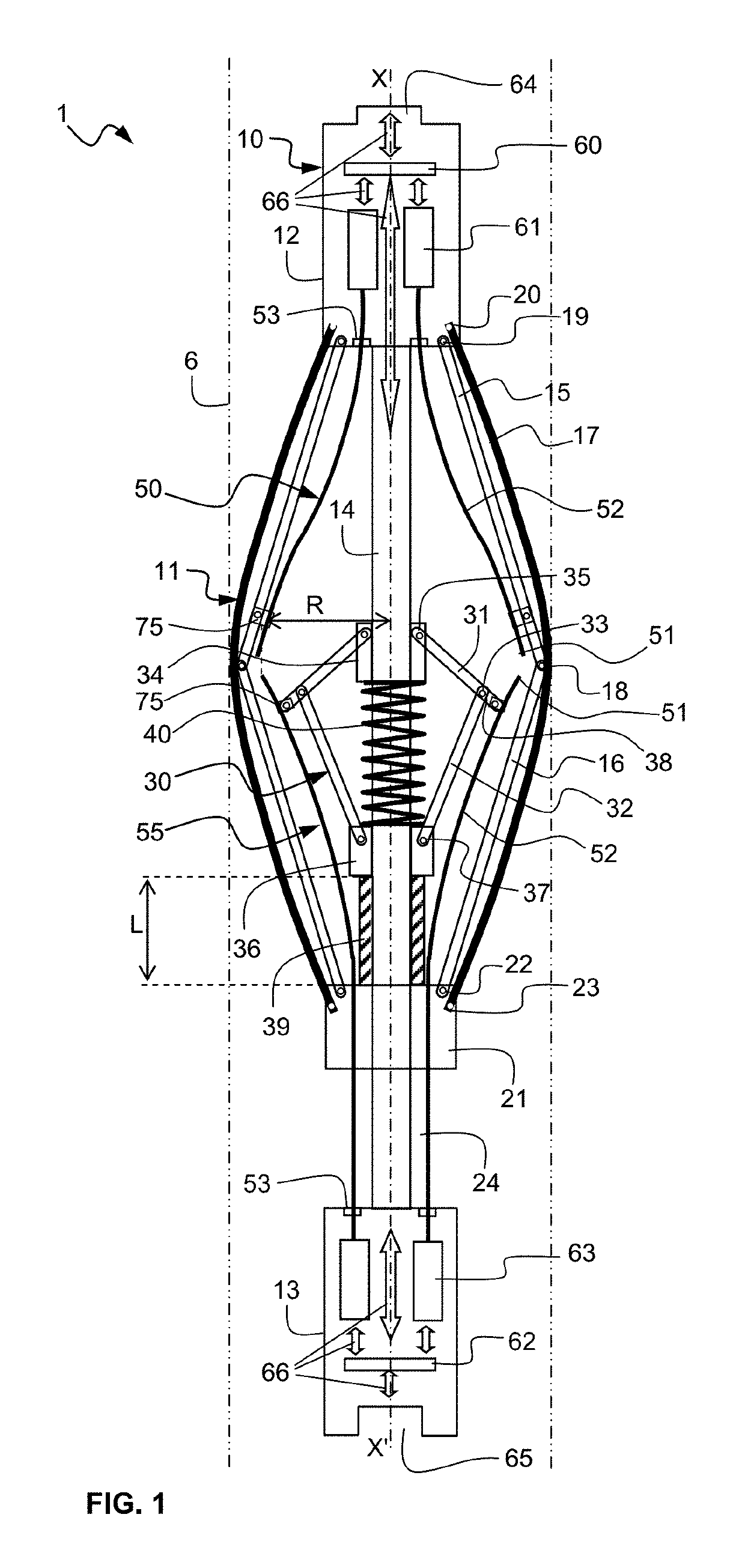

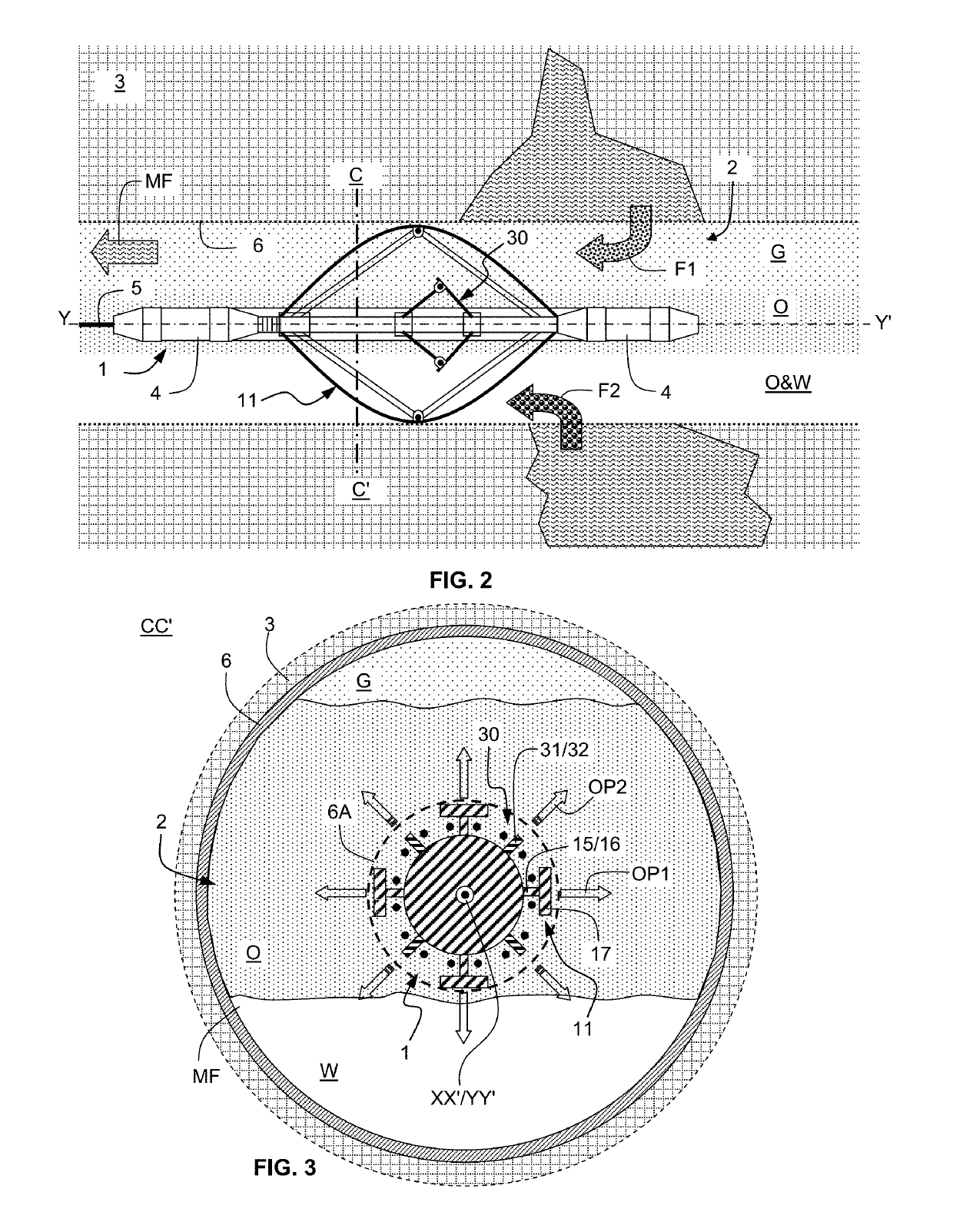

Production logging tool and downhole fluid analysis probes deploying method, in particular for deviated and horizontal hydrocarbon well

ActiveUS20180003027A1Overcome limitationsSimple and compact structureSurveyDrilling rodsCentral pressureEngineering

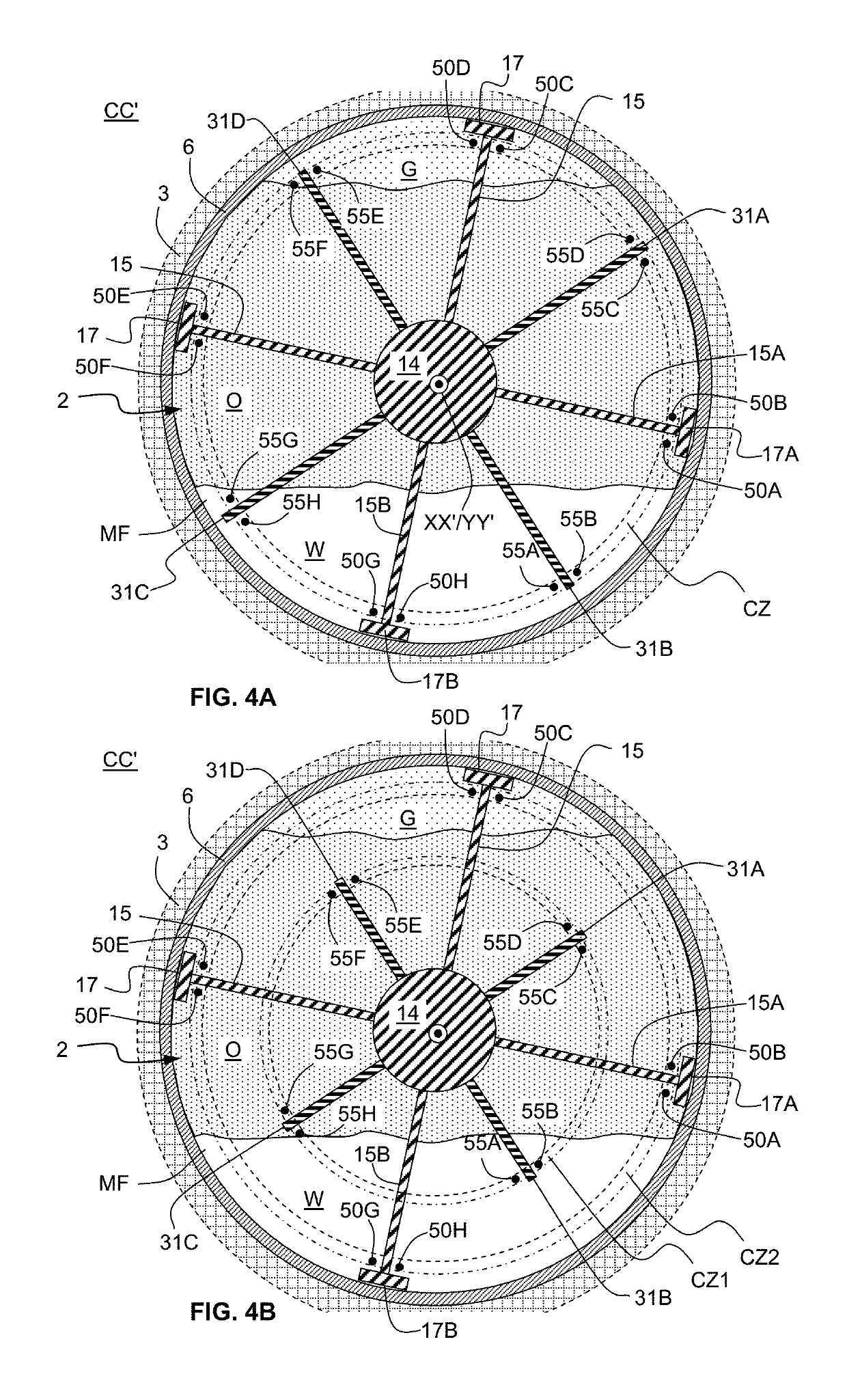

A production logging tool (1) to analyze at least one property of a multiphase fluid mixture (MF) flowing in a hydrocarbon well (2) has an elongated cylindrical housing (10, 12, 13, 14) shape and comprises a central pressure-resistant rigid housing (10, 12, 13, 14) carrying a centralizer arrangement (11) comprising multiple external centralizer arms (15, 16) circumferentially distributed about said housing (10, 12, 13, 14) and adapted for contact with a production pipe wall (6) of a hydrocarbon well (2) and operable from a retracted configuration into a radially extended configuration, the centralizer arms (15, 16) being coupled at a first side to the housing (10, 12, 13, 14) and at a second side to a first sliding sleeve (21) and a first spring (24). The production logging tool (1) further comprises a deploying arrangement (30) nested within the centralizer arrangement (11), the deploying arrangement (30) comprising:a plurality of deploying arms (31, 32) circumferentially distributed about said housing (10, 12, 13, 14) and being coupled at a first side to the housing (10, 12, 13, 14) and at a second side to the centralizer arrangement (11) by means of at least one second sliding sleeve (36) such that each deploying arm (31, 32) is circumferentially positioned between two centralizer arms (15, 16) whatever the retracted or radially extended configuration of the centralizer arrangement (11),at least one downhole fluid properties analysis probe (55, 55A-55H) being secured on each deploying arm (31, 32) such as to expose a tip (51) of said, at least one, probe to the multiphase fluid mixture (MF) flowing in the hydrocarbon well (2).The second sliding sleeve (36) comprises a mechanical coupler (39) coupled to the first sliding sleeve (21) such that the deploying arrangement (30) follows radial movements imposed by the centralizer arrangement (11) to radially and / or angularly position the tip (51) of said, at least one, probe (55, 55A-55H) associated with each deploying arm (31, 32) in a first circumferential zone (CZ1) of a hydrocarbon well section substantially perpendicular to a longitudinal axis (XX′) of said well (2).

Owner:OPENFIELD

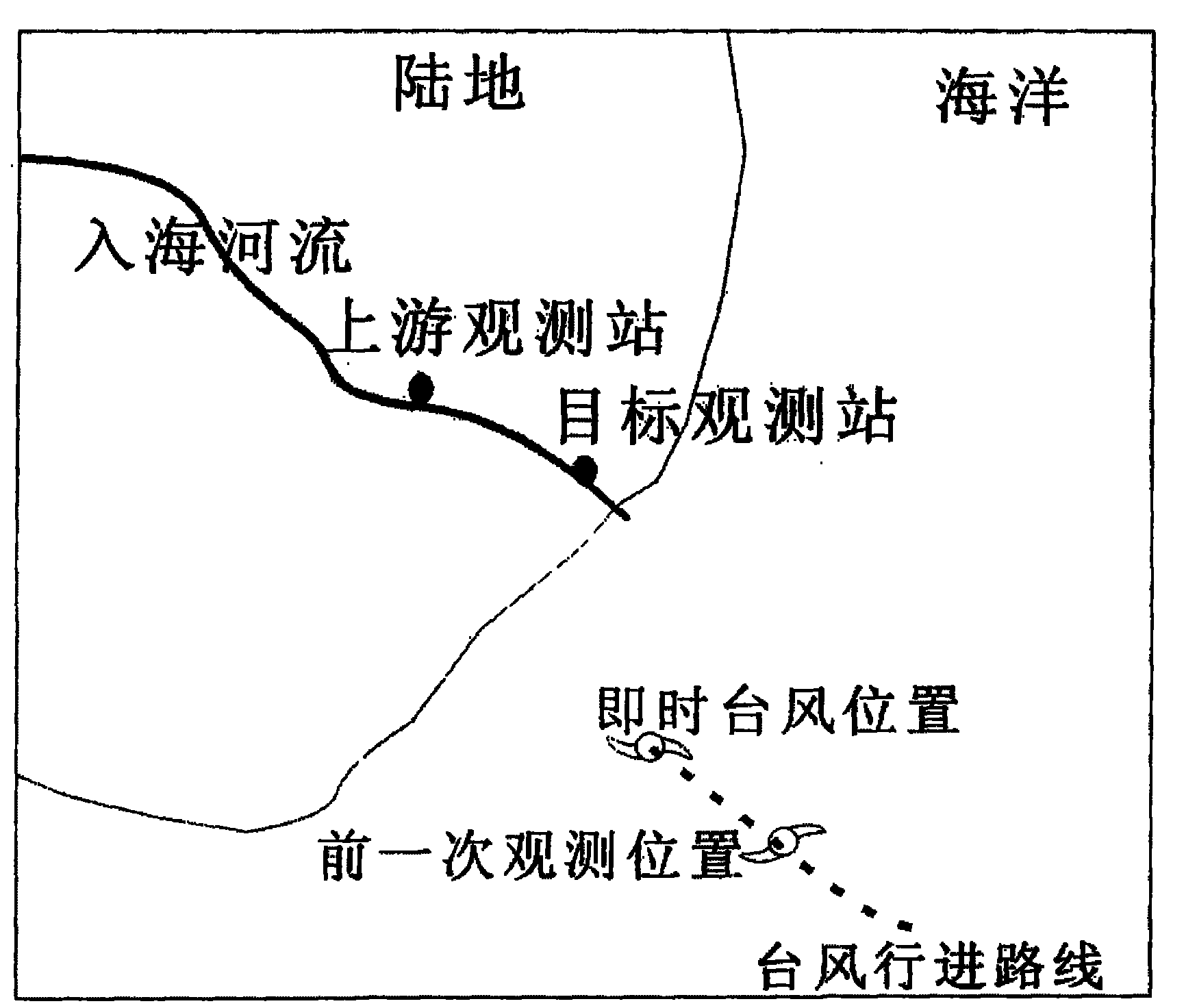

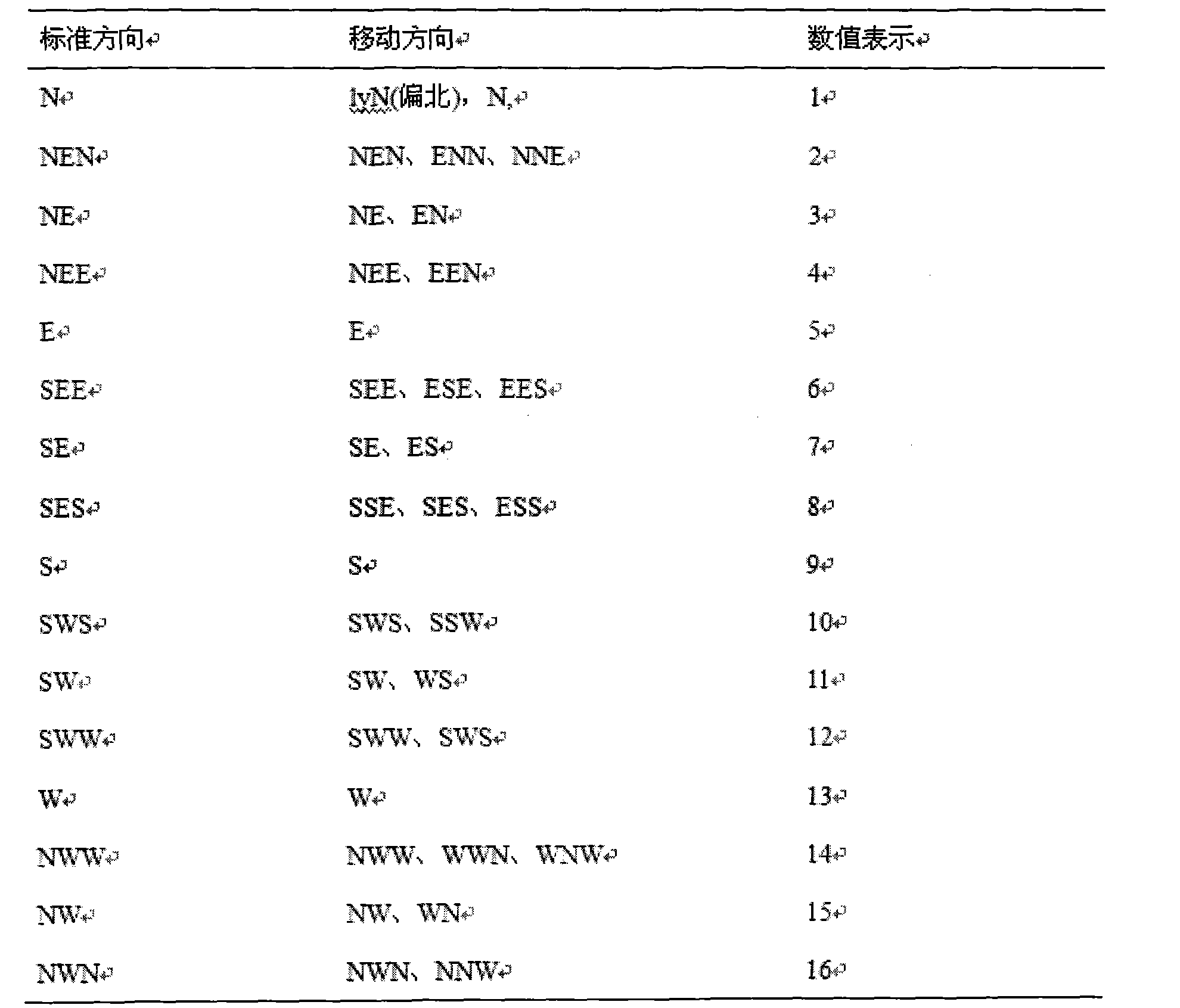

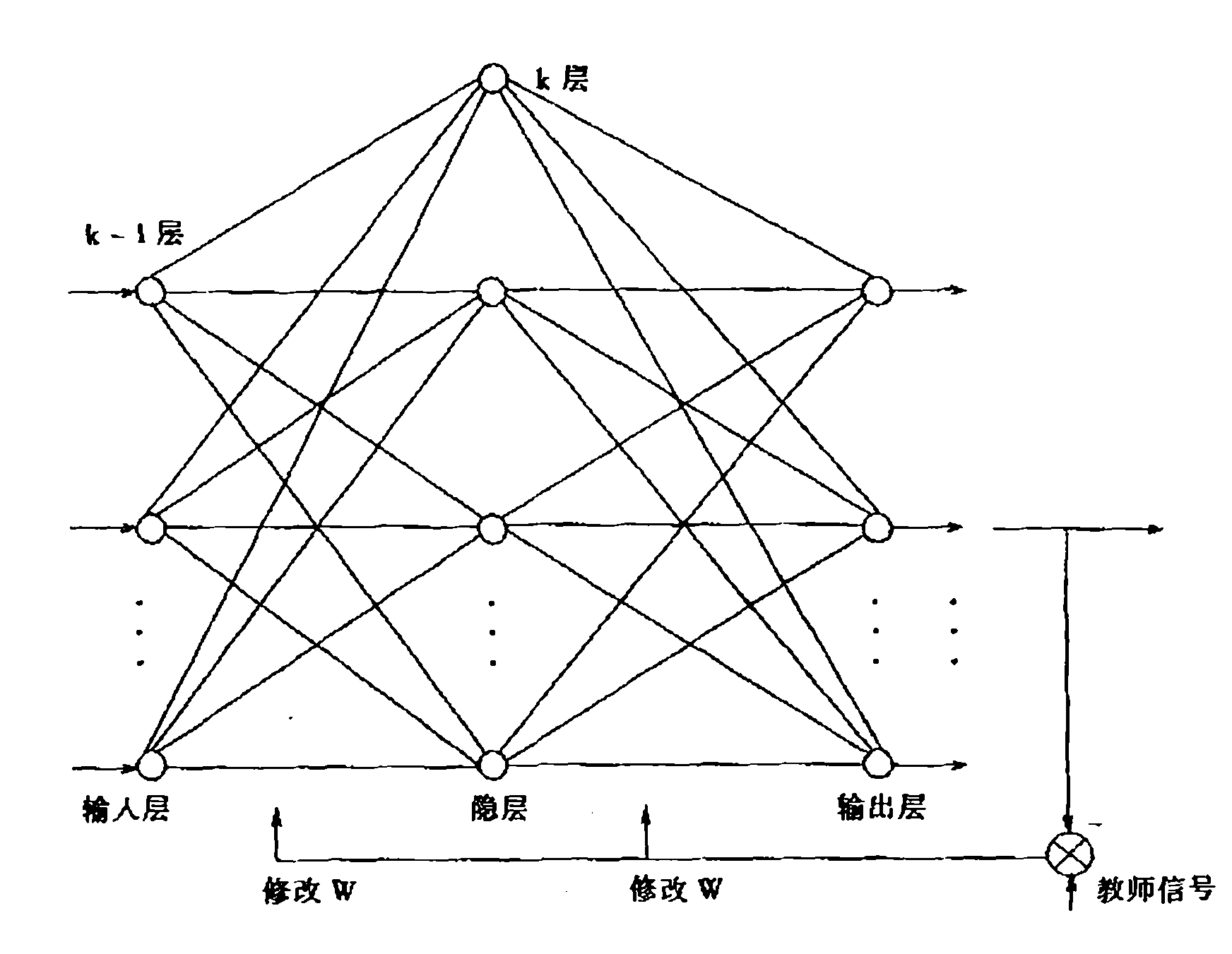

System and method for predicting typhoon surge based on artificial intelligence

InactiveCN102109619AAdd water intelligenceWater-increasing predictive intelligenceWeather condition predictionBiological neural network modelsMathematical modelCentral pressure

The application discloses an intelligent method for predicating surge when a typhoon occurs at a land stream hydrometric station (target reading station), and information of typhoon high tide surge and high tide level when the typhoon occurs at the target reading station after 12 hours can be intelligently predicted. The method includes prediction parameters selected for predicting the typhoon surge and comprehensively influencing the march route and intensity of the typhoon, and parameters influencing height of storm tide of the typhoon, wherein the prediction parameters consist of real-time typhoon observation data, longitude, latitude, central pressure of the typhoon, the maximum wind speed, move speed, move direction of the last typhoon observation data (before 6 hours) before the real-time observation time, information of upstream inflow of a river (observation surge information 12 hours before the target prediction time of an upstream reading station located in an upstream area of the river target reading station), and historic surge information of the target reading station (including surge information of two high tides in 24 hours before the target prediction time). The historic typhoon surge information of the target reading station is simulated through a mathematical model used for predicting typhoon surge and established through an artificial neural network, then the real-time typhoon surge information as well as the historic typhoon surge information of the upstream reading station and the target reading station are input, so that the typhoon surge information of the target reading station at the target observation time can be predicted.

Owner:栗小东 +2

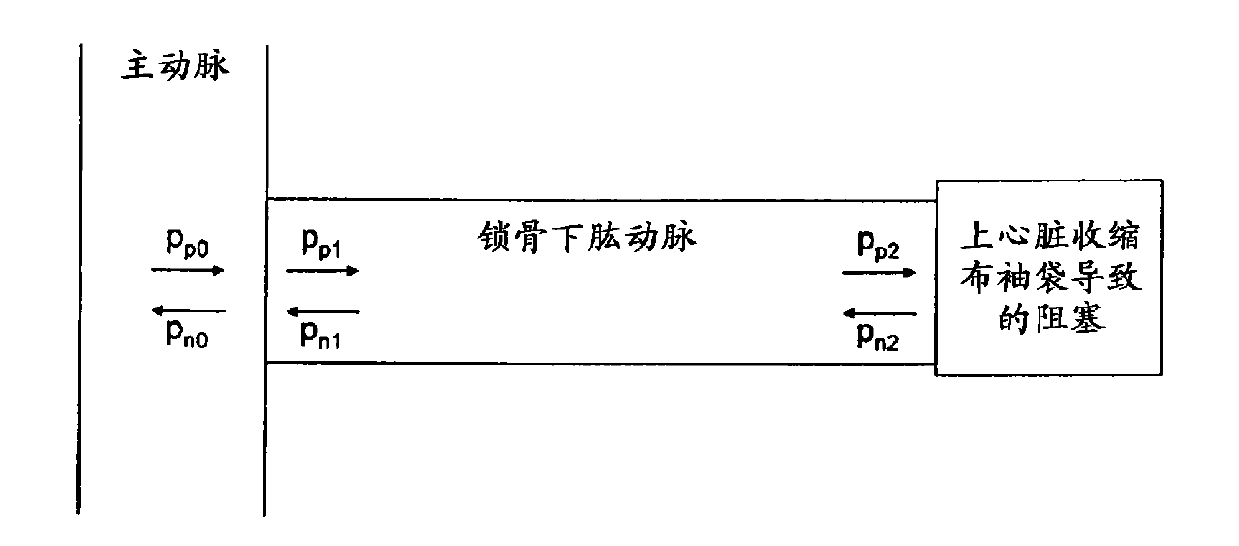

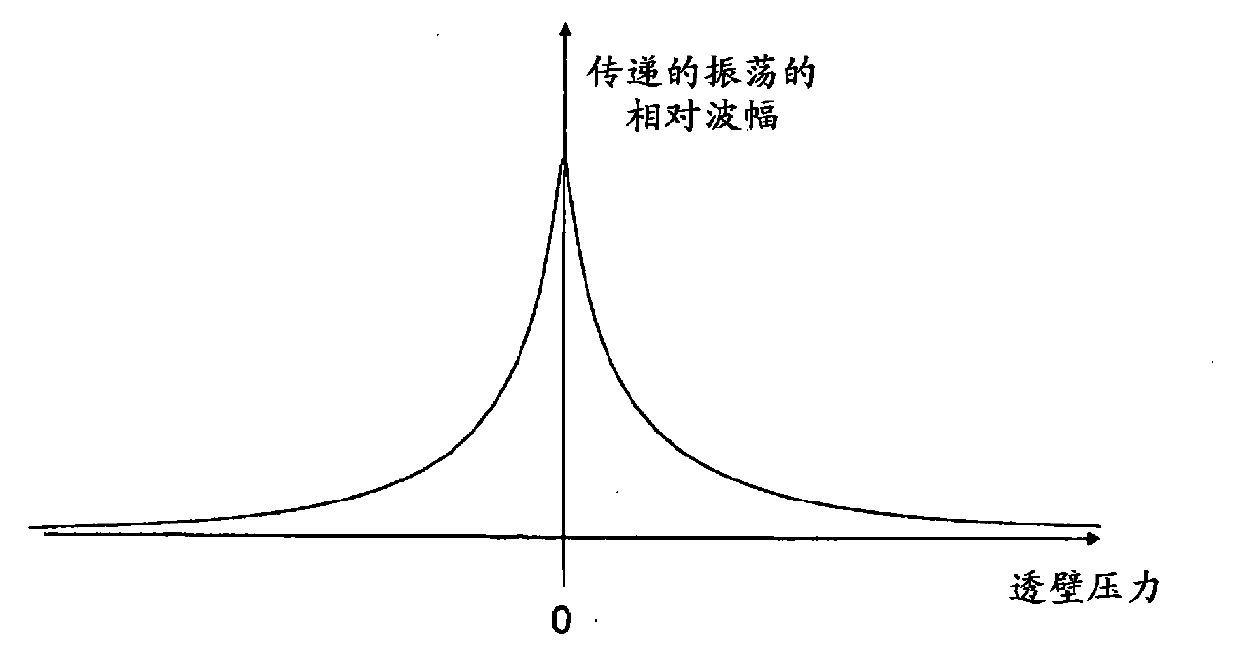

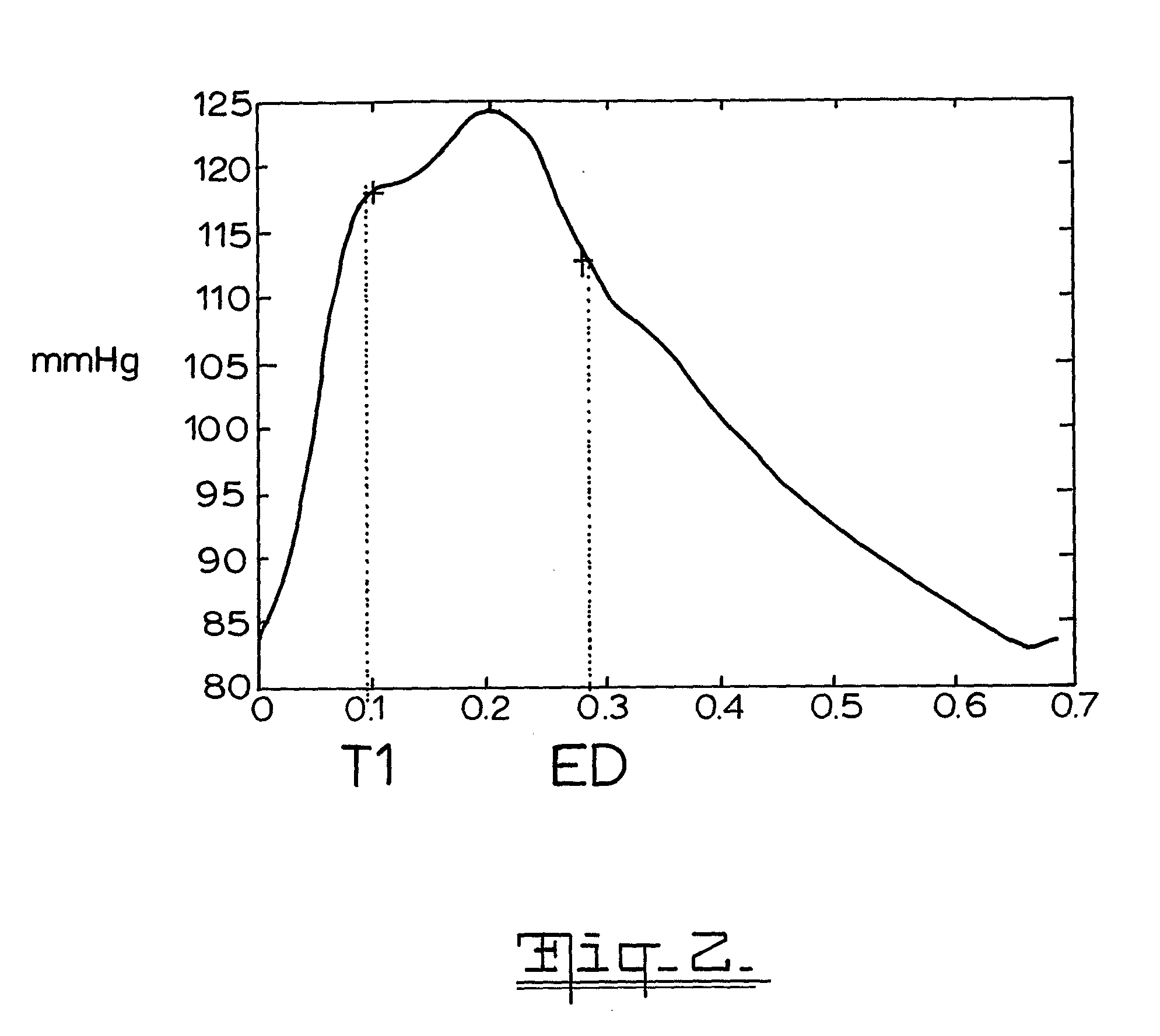

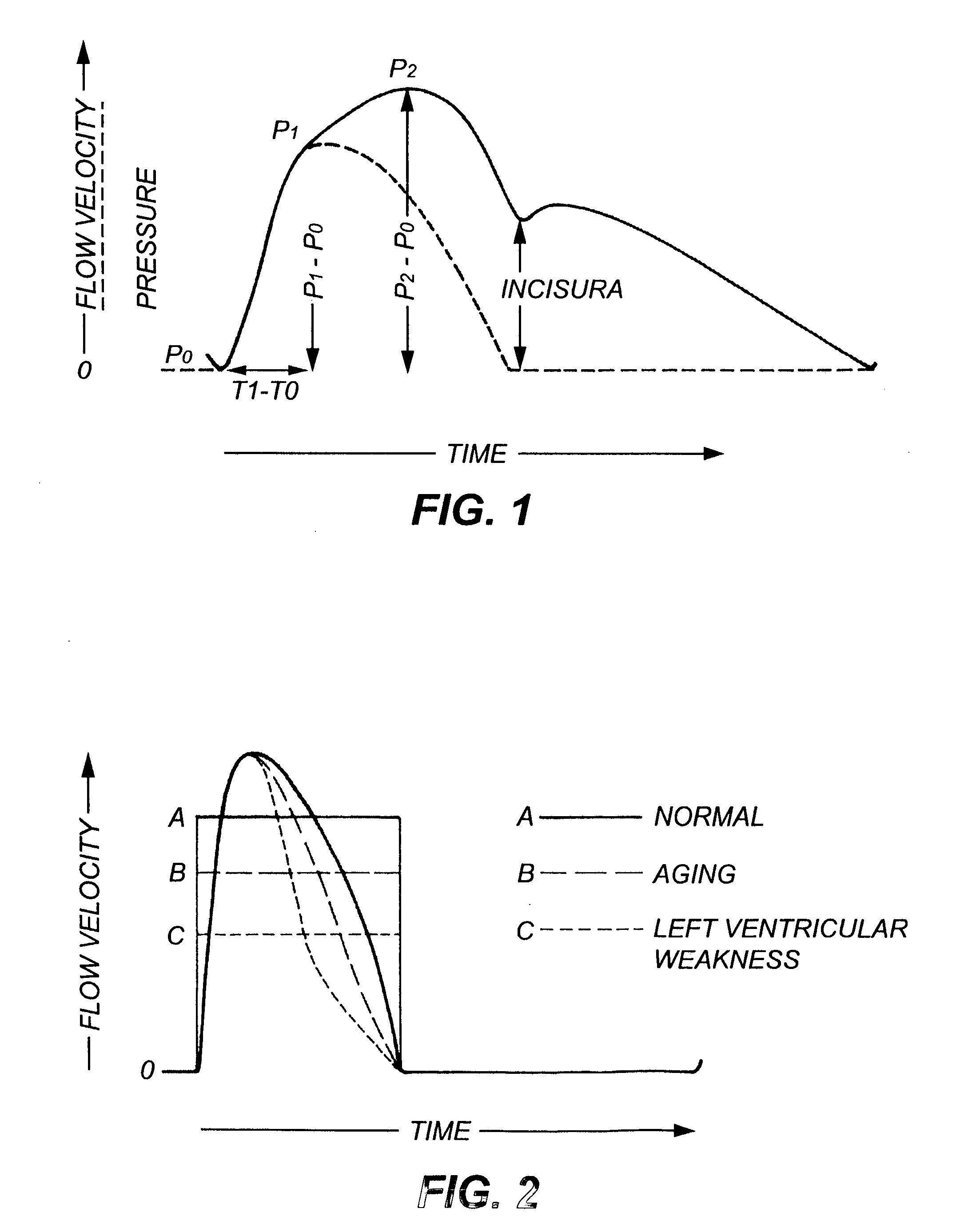

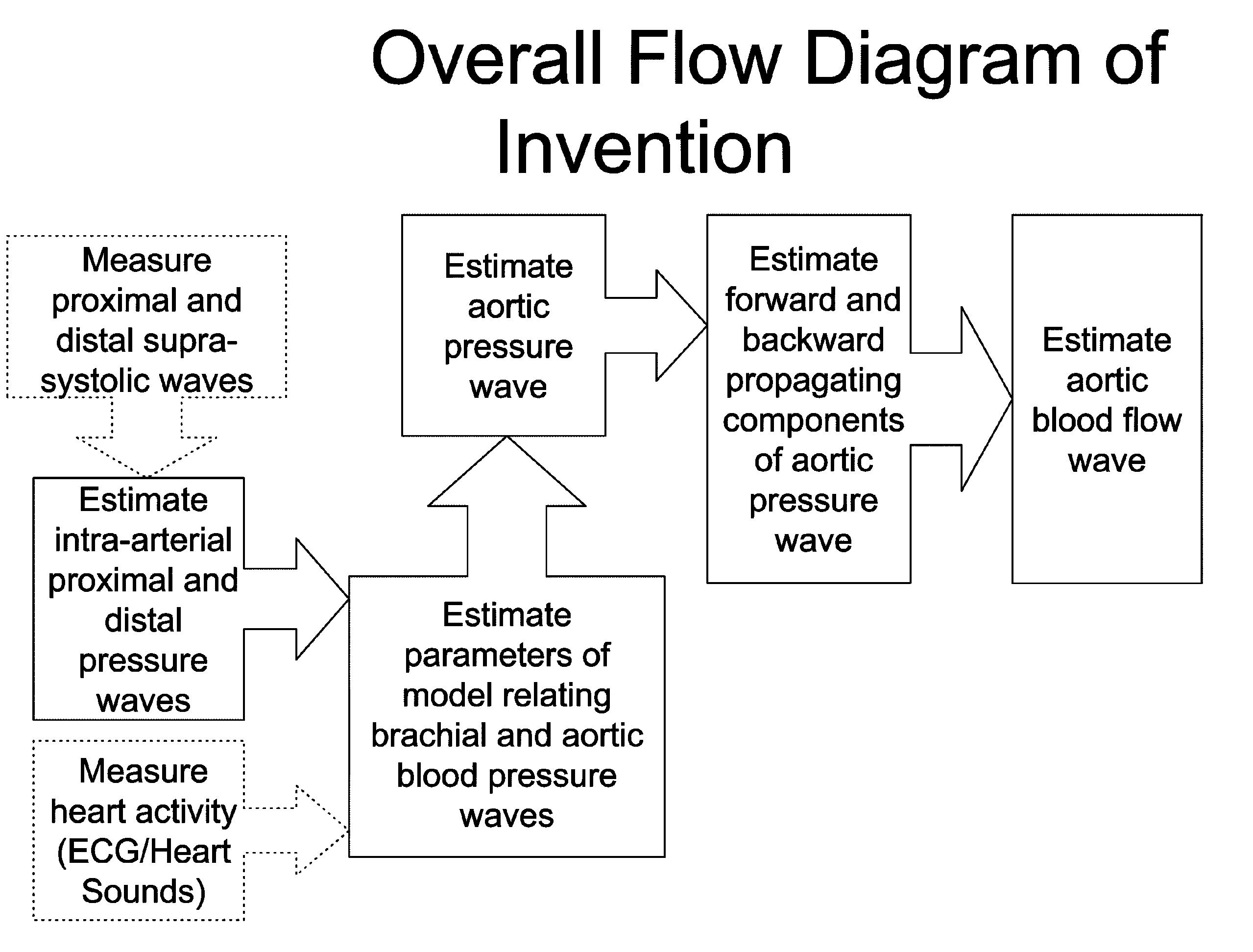

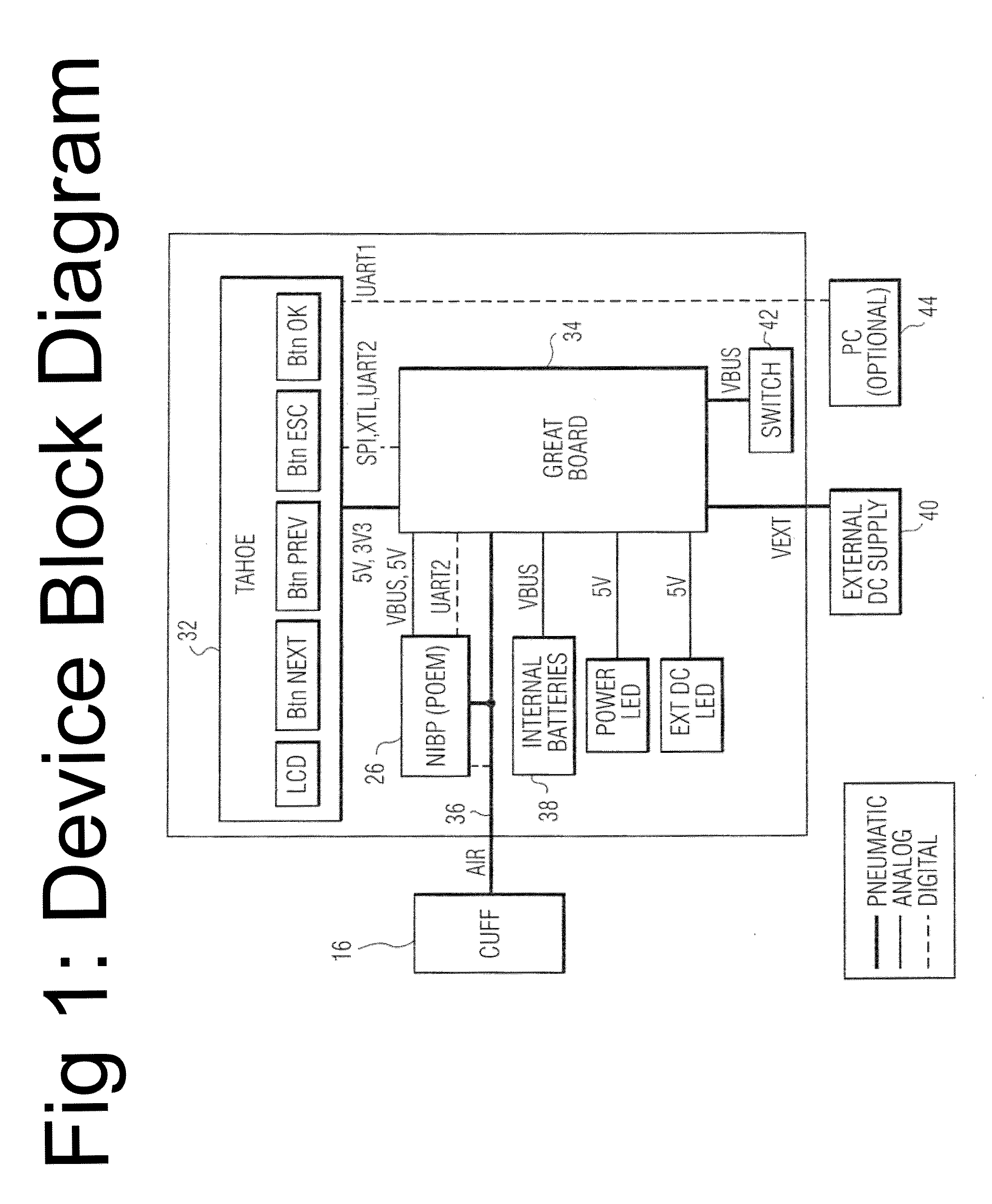

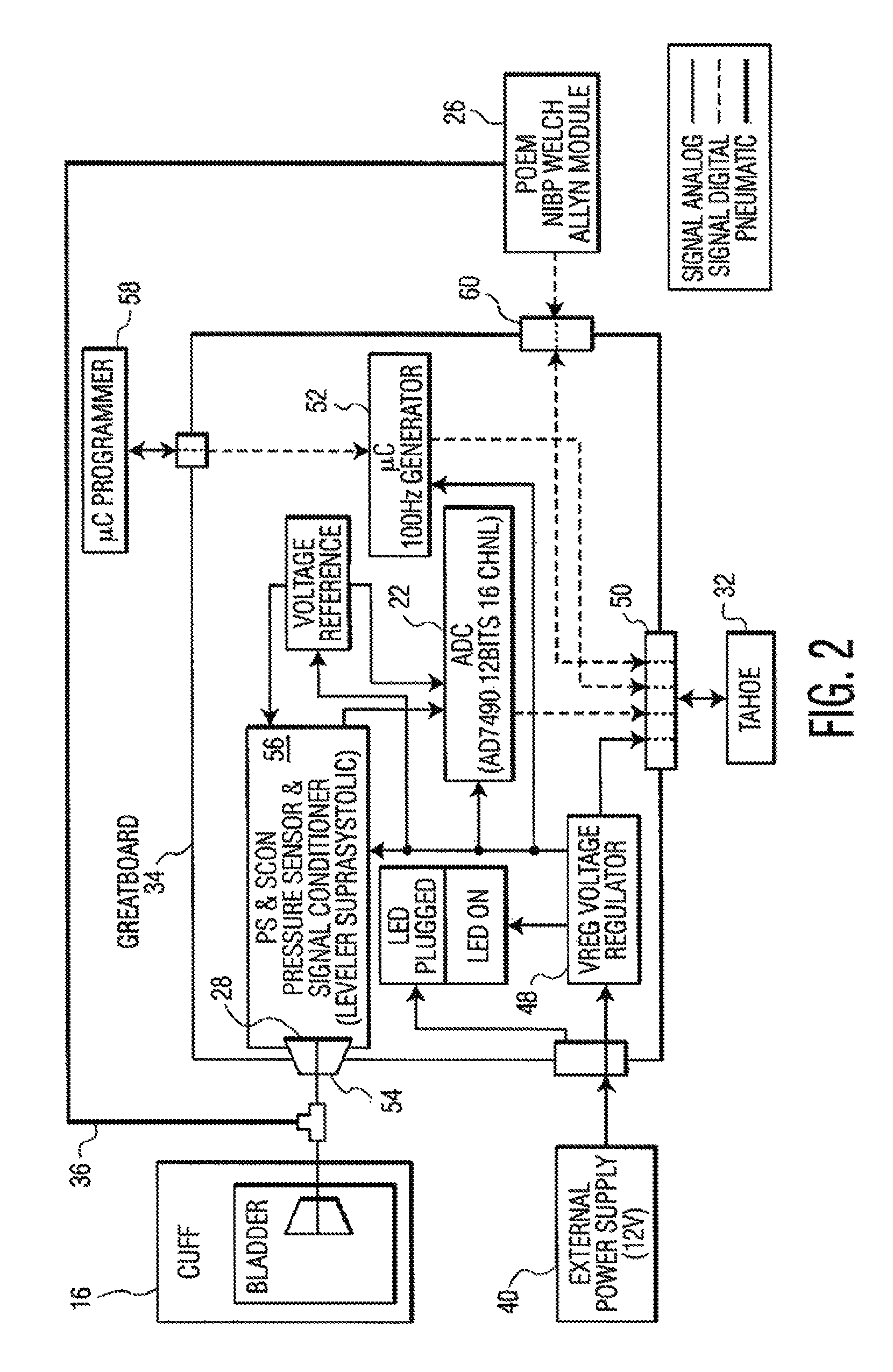

Method for estimating a central pressure waveform obtained with a blood pressure cuff

A physics-based mathematical model is used to estimate central pressure waveforms from measurements of a brachial pressure waveform measured using a supra-systolic cuff. The method has been tested in numerous subjects undergoing cardiac catheterisation. Central pressure agreement was within 11 mm Hg and as good as the published non-invasive blood pressure agreement between the oscillometric device in use and the so-called ''gold standard.'' It also exceeds international standards for the performance of non-invasive blood pressure measurement devices. The method has a number of advantages including simplicity of application, fast calculation and accuracy of prediction. Additionally, model parameters have physical meaning and can therefore be tuned to individual subjects. Accurate estimation of central waveforms also allow continuous measurement (with intermittent calibration) using other non-invasive sensing systems including photoplethysmography.

Owner:PULSECOR LTD

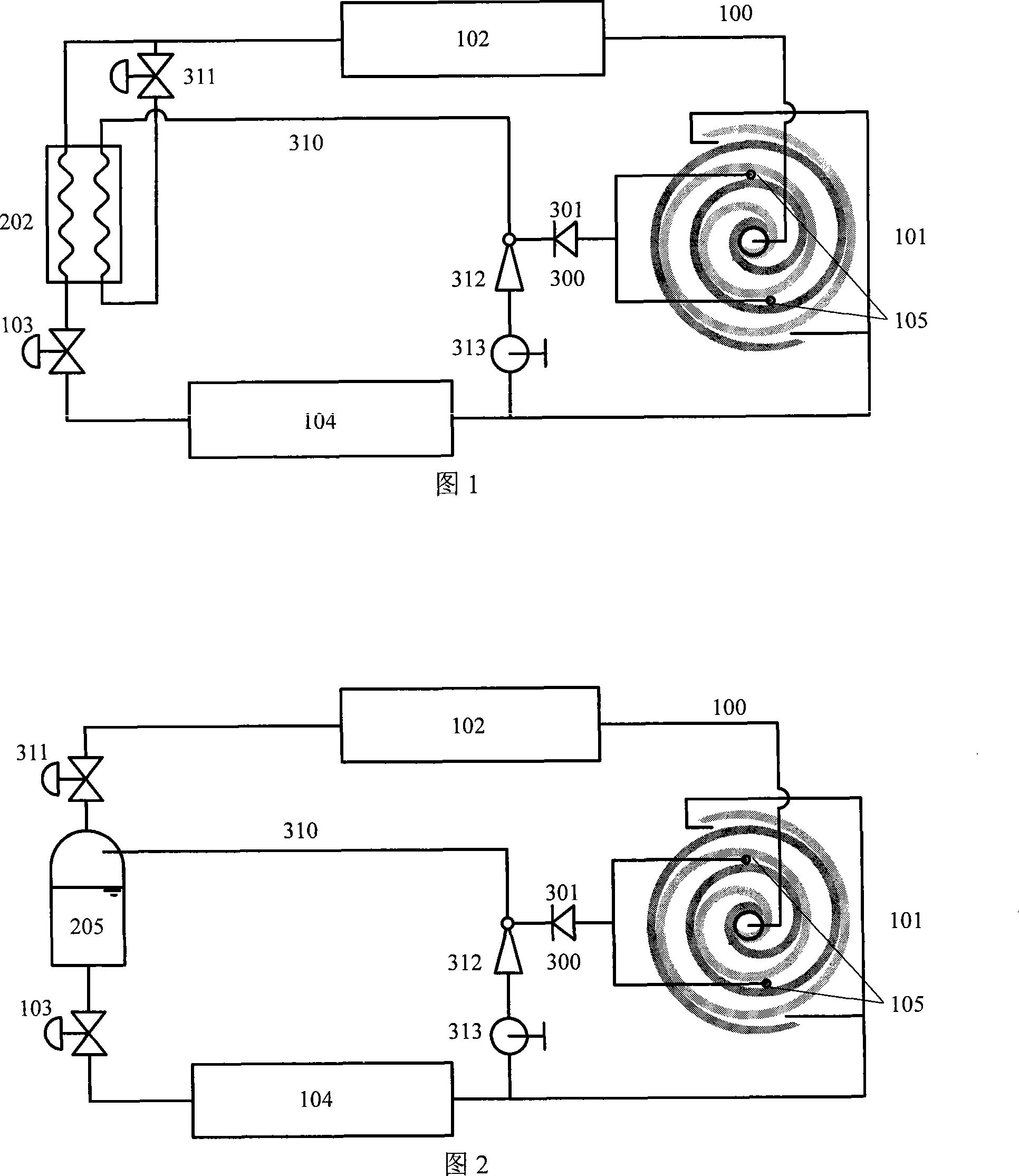

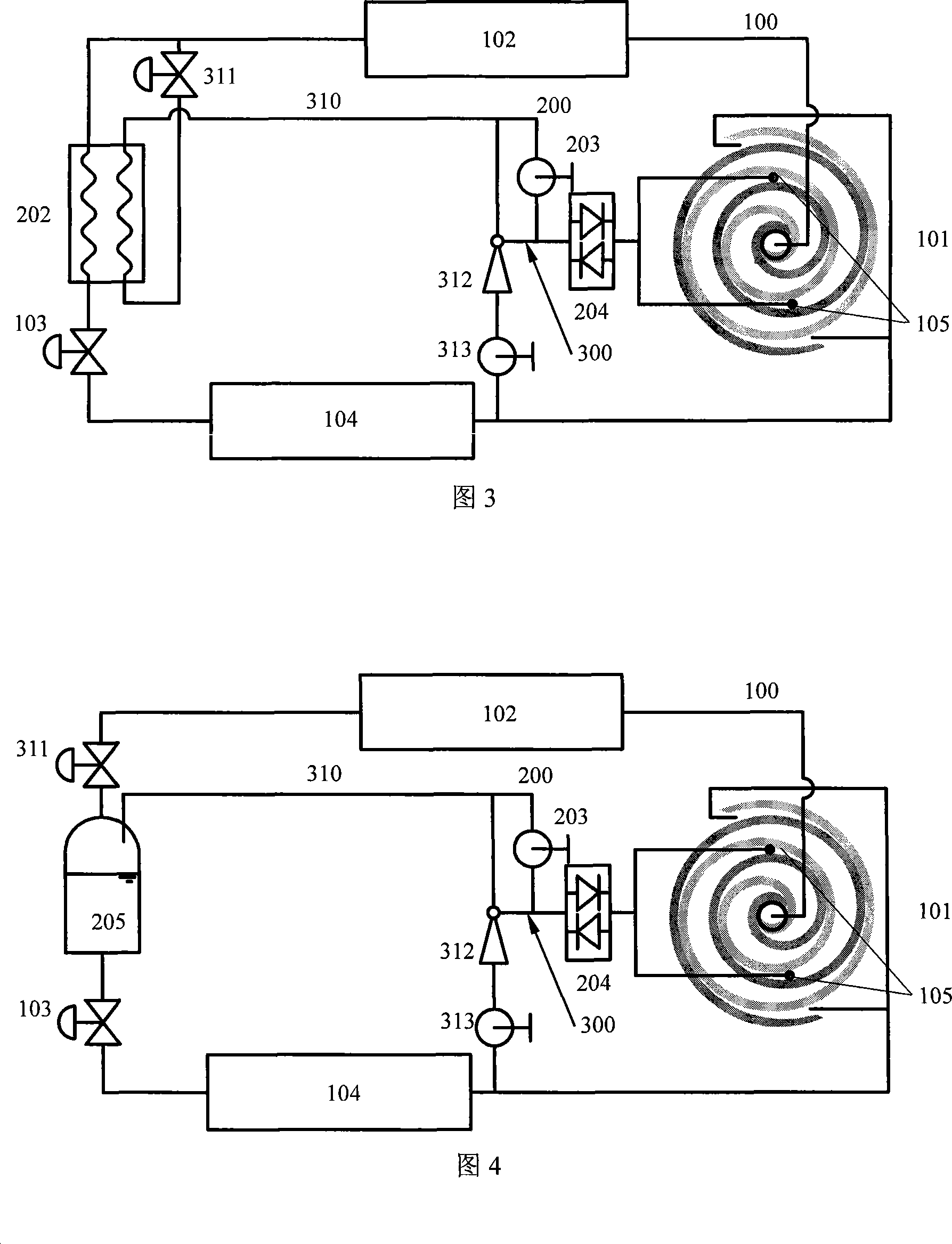

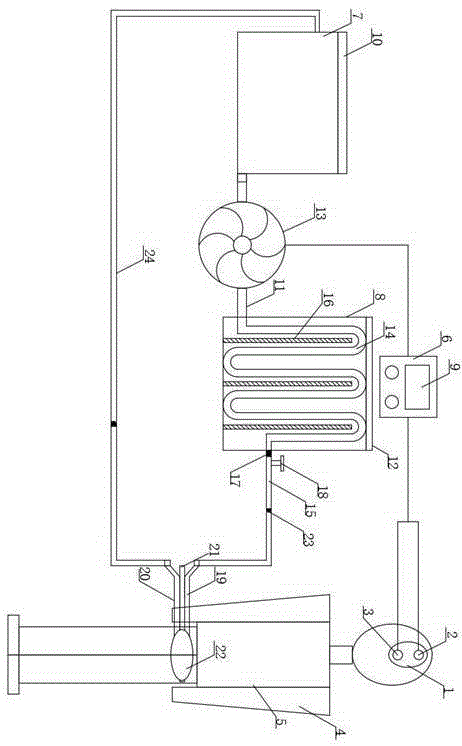

Capacity adjustable vortex compressor refrigeration system with mediate loop installed with ejector

InactiveCN101169292AAchieve leakageAchieve couplingCompression machines with non-reversible cycleFluid circulation arrangementCentral pressureEngineering

The invention relates to a capability adjustable volution compressor refrigerating system with a jet apparatus arranged on a central loop, and belongs to the refrigerating and air-condition field. A central pressure loop is arranged between an exit of a condenser and an entrance of a compressor, the top of the loop is provided with a jet apparatus, the invention uses the jet apparatus to lead and shoot the refrigerating fluid discharged from the compressed central section toward the low pressure side by utilizing the pressure difference between the central pressure loop and the inhaling mouth of the compressor, thereby strengthening the discharging function of the system refrigeration fluid and elevating the unloading ability of the volution compressor. Simultaneously, the combination of the strengthened refrigerating fluid discharging technique and the refrigerating fluid ejecting technique greatly elevates the capability changing ability toward the two directions of big and small of the volution compressor refrigerating system. The technique can be used for the refrigeration / heating pump system in the air-condition refrigeration field containing the volution compressor, can effectively change the efficiency, system capability and capacity of the compressor, and make the system work with high efficiency in a much bigger working condition range, thereby elevate the applicability under the condition of the working condition changing in a bigger range of the system.

Owner:TSINGHUA UNIV

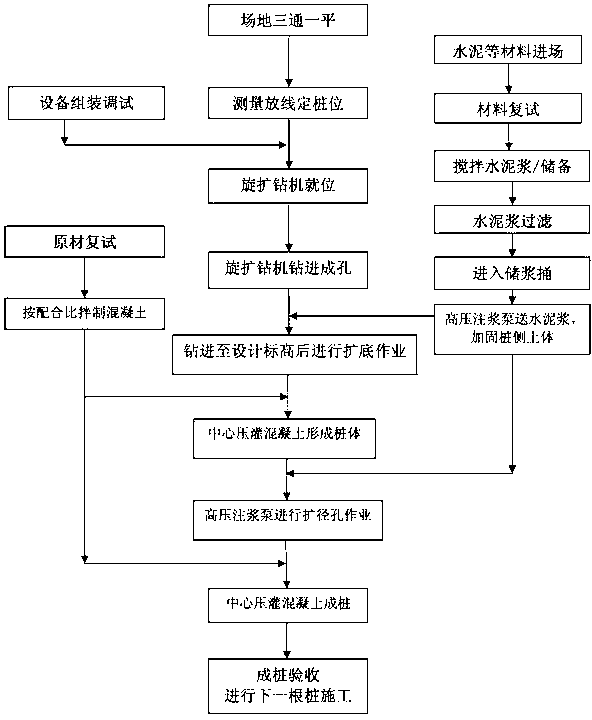

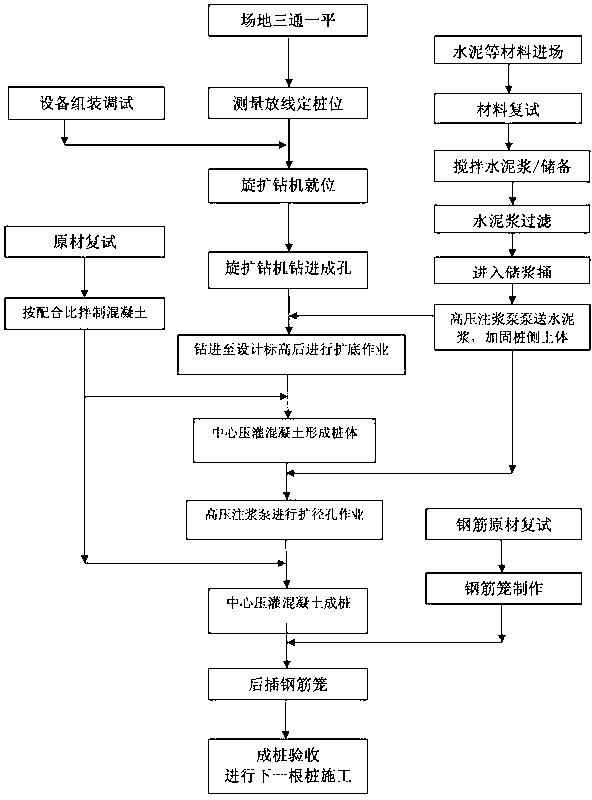

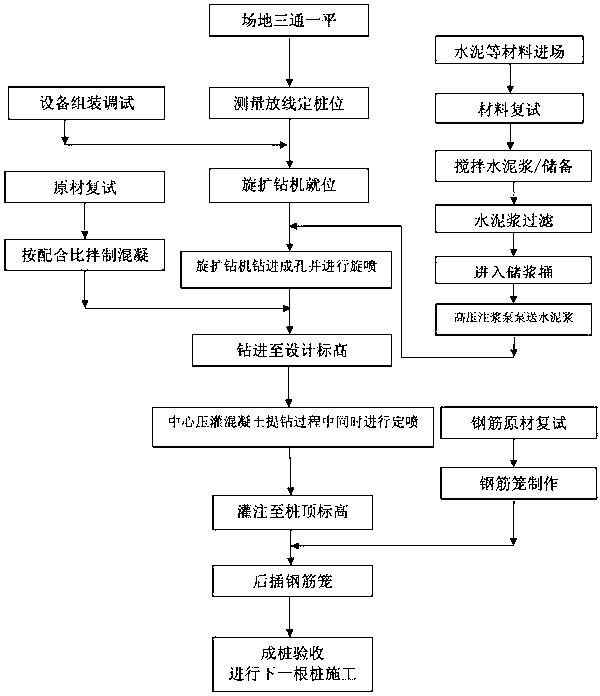

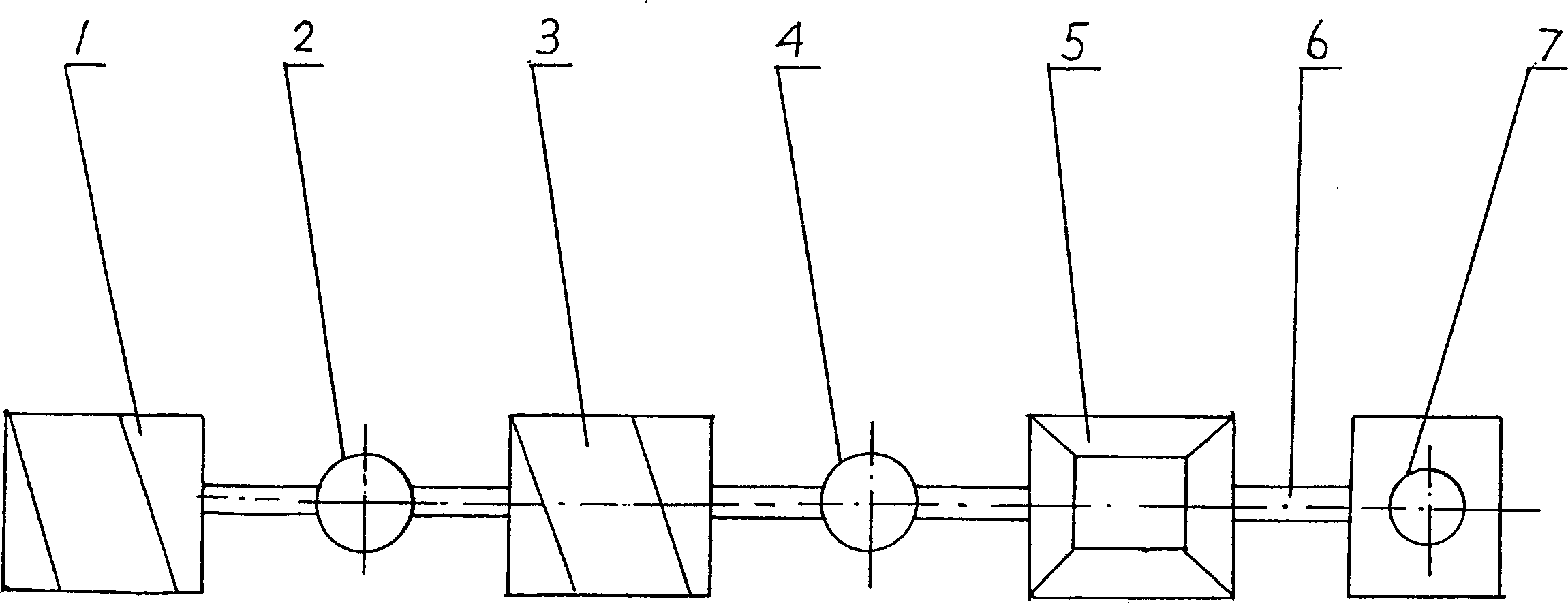

Process and device for rotating and extending pile and slurry feed device

ActiveCN103233469AStrong stratum adaptabilityThe process is clearBulkheads/pilesCentral pressureEngineering

The invention provides a process and device for a rotating and extending pile and a slurry feed device. The process includes that a brand new mechanism for reinforcing the side and the bottom of a pile is provided on the basis of mature processes of spiral drill hole-forming and pile-forming through central pressure filling of pumping concrete; when a pile rotating and extending drill is used for hole forming, a high pressure grouting pump is started to form cement slurry high pressure spray through a slurry spraying device, the cement slurry high pressure spray is used for generating destroying and cutting effects on soil mass structures on the side and at the bottom of the pile, soil mass in a certain range of the side or the bottom of the pile and cement slurry are mixed fully, physical and mechanical properties of the soil mass on the side or at the bottom of the pile are changed effectively, resistance of the pile is improved substantially, and pile diameter of a pile body needs to be expanded at the design position according to engineering design; after bottom expanding or diameter expanding is finished, concrete is pressed and filled through a center of a concrete pump, slurry mixtures during the bottom expanding and the diameter expanding are replaced, a pile bottom expanding head and a pile side diameter expanding are formed, and end resistance and side resistance of the pile are improved effectively; and then a pile body portion is formed through the central pressure filling of the pumping concrete. The process and device for the rotating and extending pile and the slurry feed device are simple in mechanical structure, do not need to dissemble a drilling rod repeatedly, do not need to lead holes, and do not need to be provided with a post pressure grouting device.

Owner:BEIJING RONGCHUANG GEOTECHNICAL ENG CO LTD

Method of estimating pulse wave velocity

A method of estimating blood pressure Pulse Wave Velocity (PWV) in the aorta from a recording of a pressure waveform at a single site. The method comprises the following steps: 1. measuring the patient's arterial pressure relative to time in order to estimate a central pressure waveform (CPW); 2. estimating the patient's aortic pressure pulse transit time (PPTT) from the CPW; 3. estimating the patient's carotid to femoral arterial distance from the patient's physical characteristics; and 4. dividing the patient's estimated carotid to femoral arterial distance by the patient's estimated PPTT to estimate the patient's PWV.

Owner:ATCOR MEDICAL

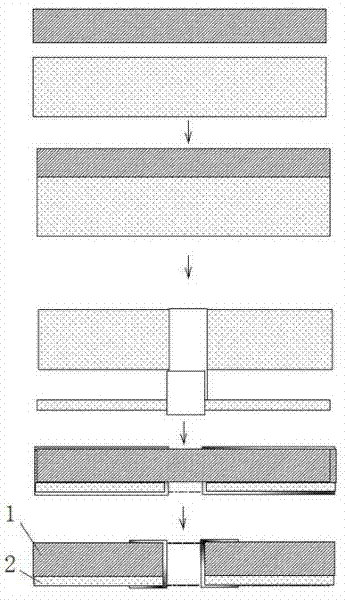

Contact planarization apparatus

InactiveUS20080153405A1Effective contactLower Level RequirementsGrinding drivesPhotomechanical apparatusCentral pressureBottom pressure

A contact planarization apparatus includes a lower membrane assembly, an upper membrane assembly, a differential pressure assembly, and a curing or reflowing assembly. The lower membrane assembly supports a substrate to be planarized and biases it toward the upper membrane assembly under the influence of the pressure differential assembly. The upper membrane assembly planarizes the coating on the substrate under the influence of the differential pressure assembly and includes a flexible sheet which is supported above the substrate stage and below the curing or reflowing assembly via a vacuum force applied by the differential pressure assembly. The differential pressure assembly moves the lower and upper membrane assemblies relative to one another to planarize the coating on the substrate entirely through the application of vacuum and pressure forces. The differential pressure assembly includes atop pressure chamber positioned above the upper face of the upper sheet, a bottom pressure chamber positioned below the lower face of the lower sheet, and a central pressure chamber positioned generally between the lower face of the upper sheet and the upper face of the lower sheet.

Owner:BREWER SCI

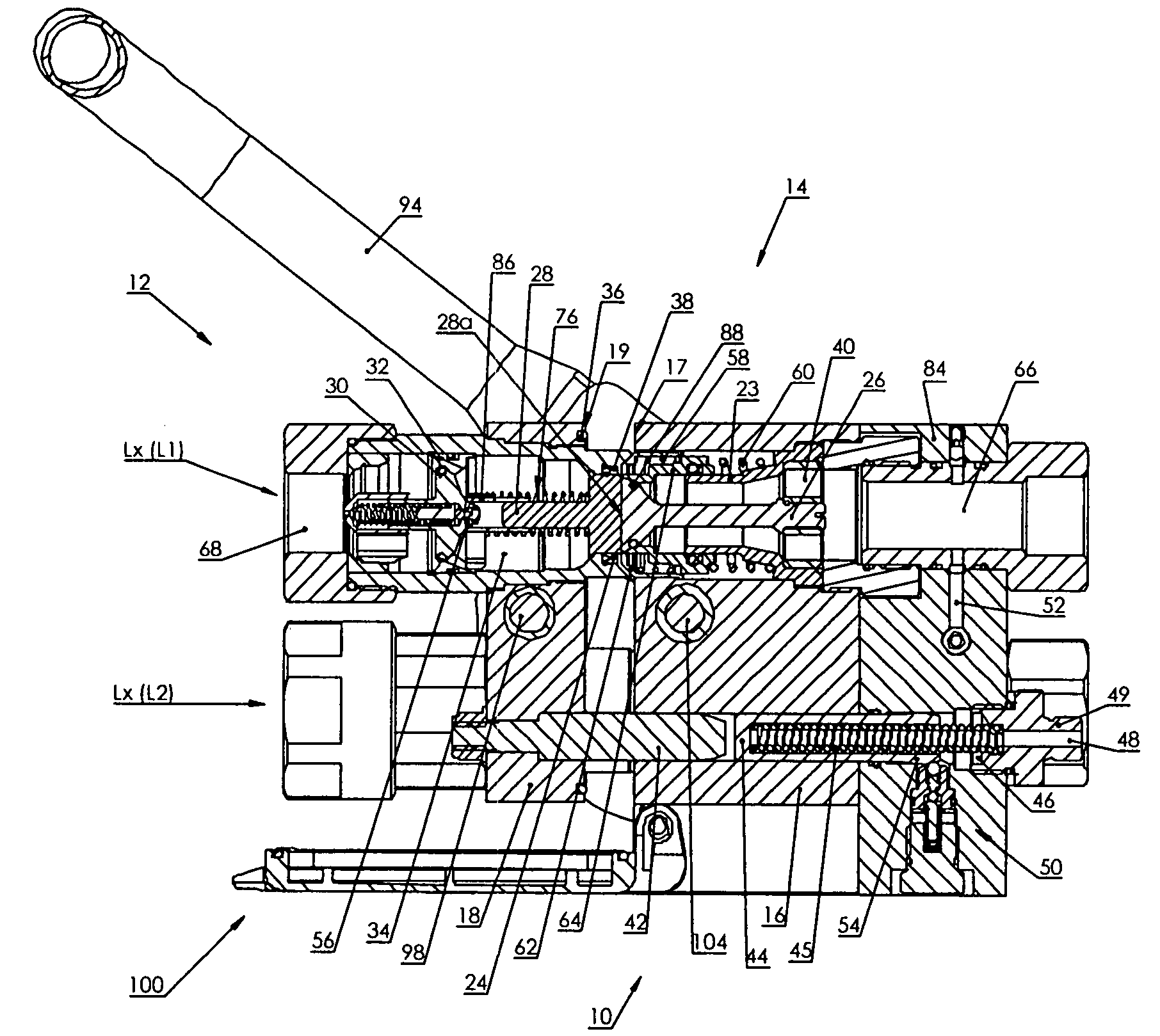

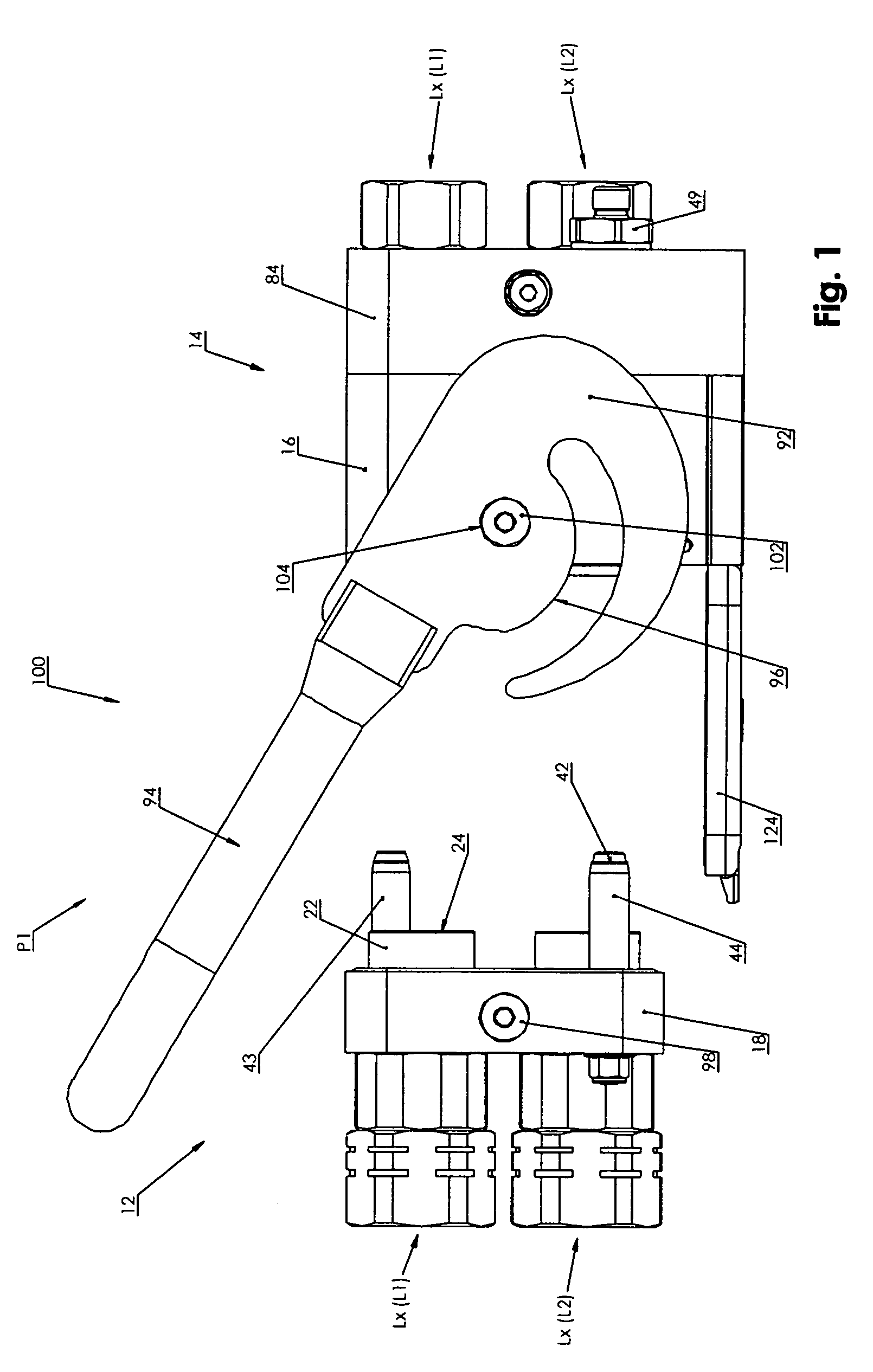

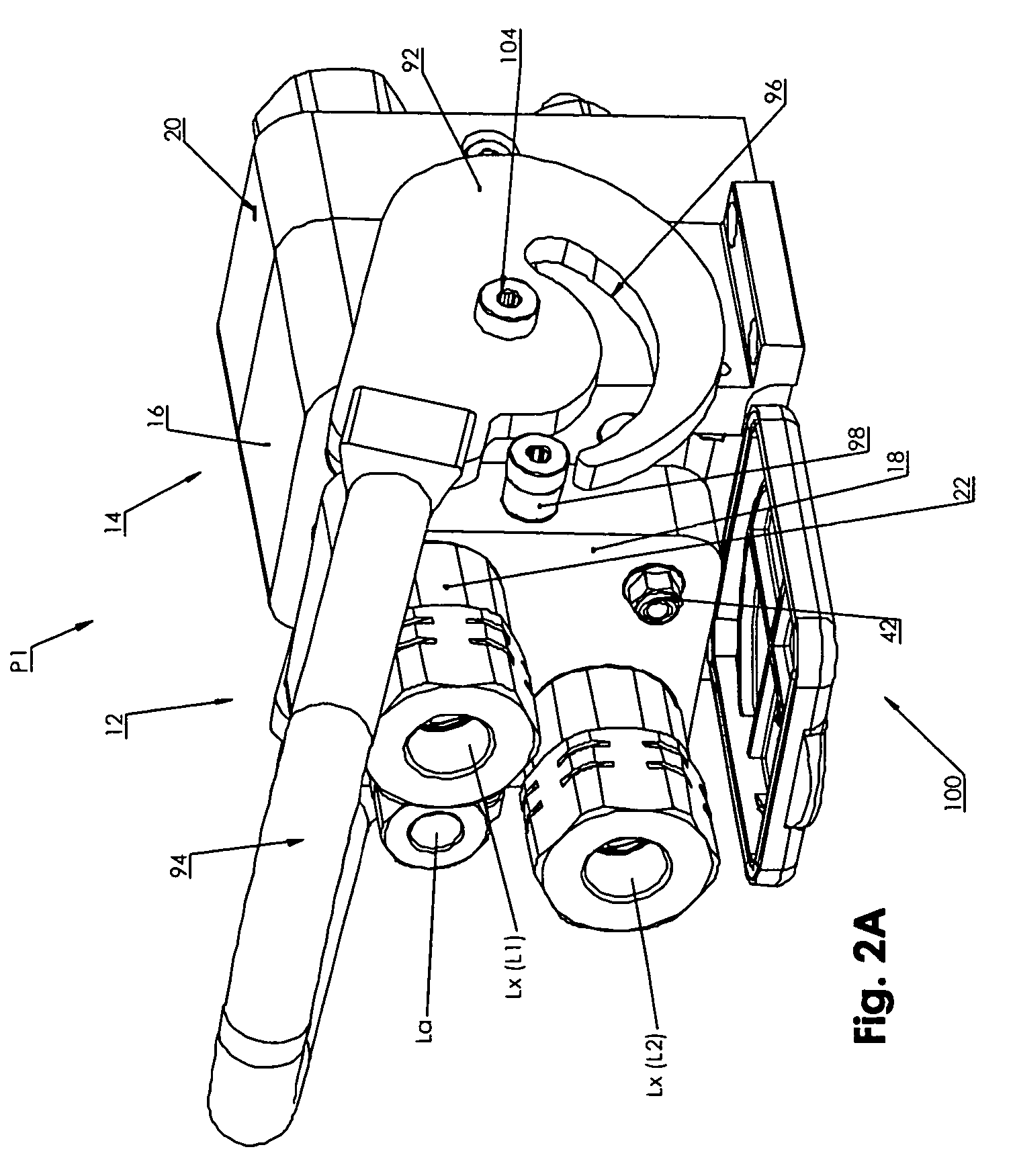

Quick coupling having pressure relief device for multiple pressurized lines

InactiveUS7389794B2Simple designSimple guideOperating means/releasing devices for valvesAdjustable jointsCouplingCentral pressure

In order to create a quick coupling for connecting at least two pressurised lines to a first coupling part that is connectable to a second coupling part so as to be pressure-proof, which quick coupling in a simple manner makes possible easy coupling while avoiding the mentioned disadvantages in all pressure ranges, it is provided for an externally arranged central pressure relief device (70) which is integrated in a second coupling part, or arranged on the second coupling part in an additional block (84), to be connectable to the pressurised lines (Lx) by way of pressure-relief connection lines (52A to 52D), and for the coupling parts to be able to be reversibly brought by a lever element (92) from a non-coupled position (P1) to a coupled position (P2), and to be lockable in place.

Owner:TEMA MARKETING

Processing technique of hemerocallis miner-polygala tenuifolia tea

The invention relates to the processing field of tea, and in particular to a processing technique of hemerocallis miner-polygala tenuifolia tea. The processing technique comprises the following steps of: 1, picking up leaves; 2, withering; 3, kneading; 4, fermenting; and 5, drying. The tea prepared by the process has strong tea aroma and compact and black branches, and the process is simple and convenient to operate. After being taken for a long time, the tea can inhibit absorption of alcohol by a human body to protect liver activity, has the functions of soothing the nerves, nourishing mind, inducing diuresis for treating strangurtia, and resisting mutant and cancers, also has a transitory central pressure reducing effect.

Owner:叶永开

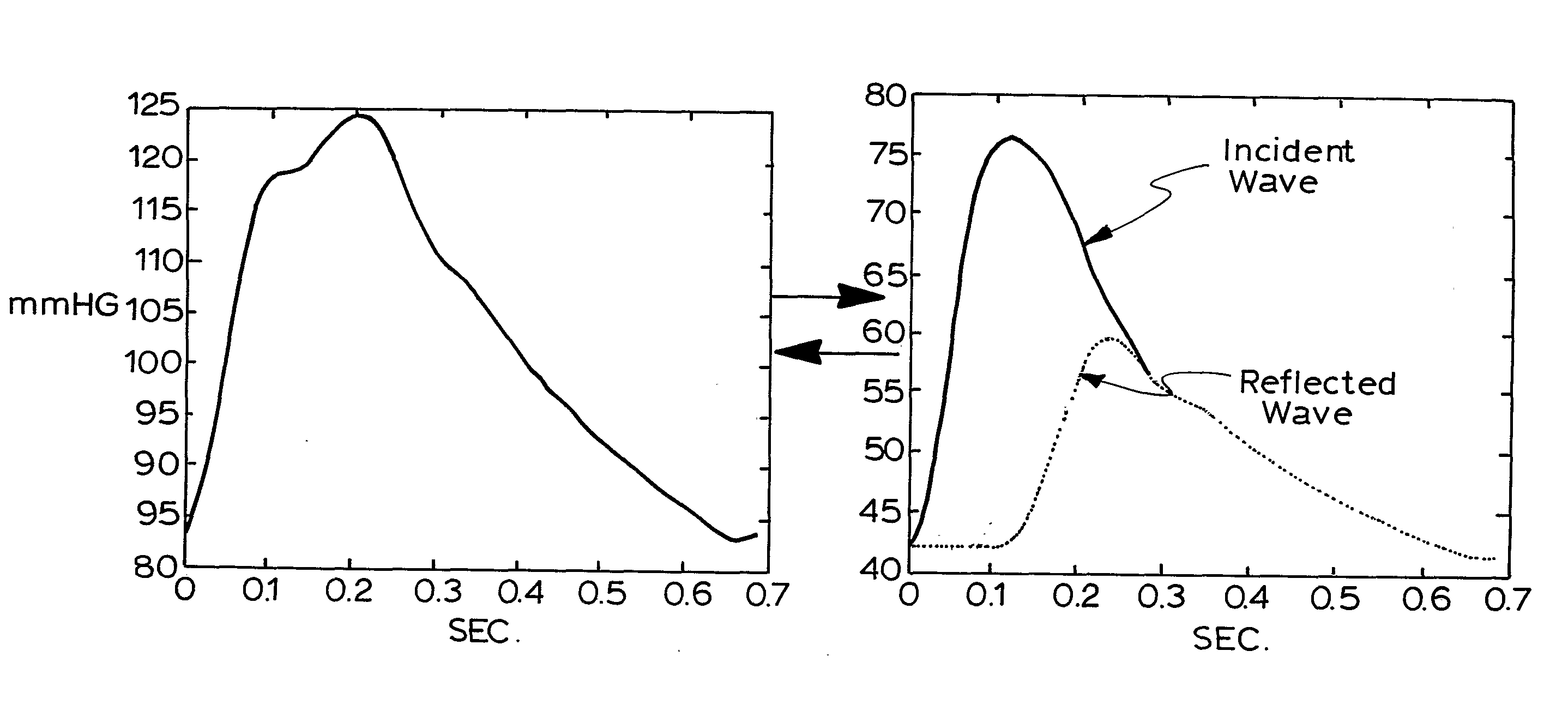

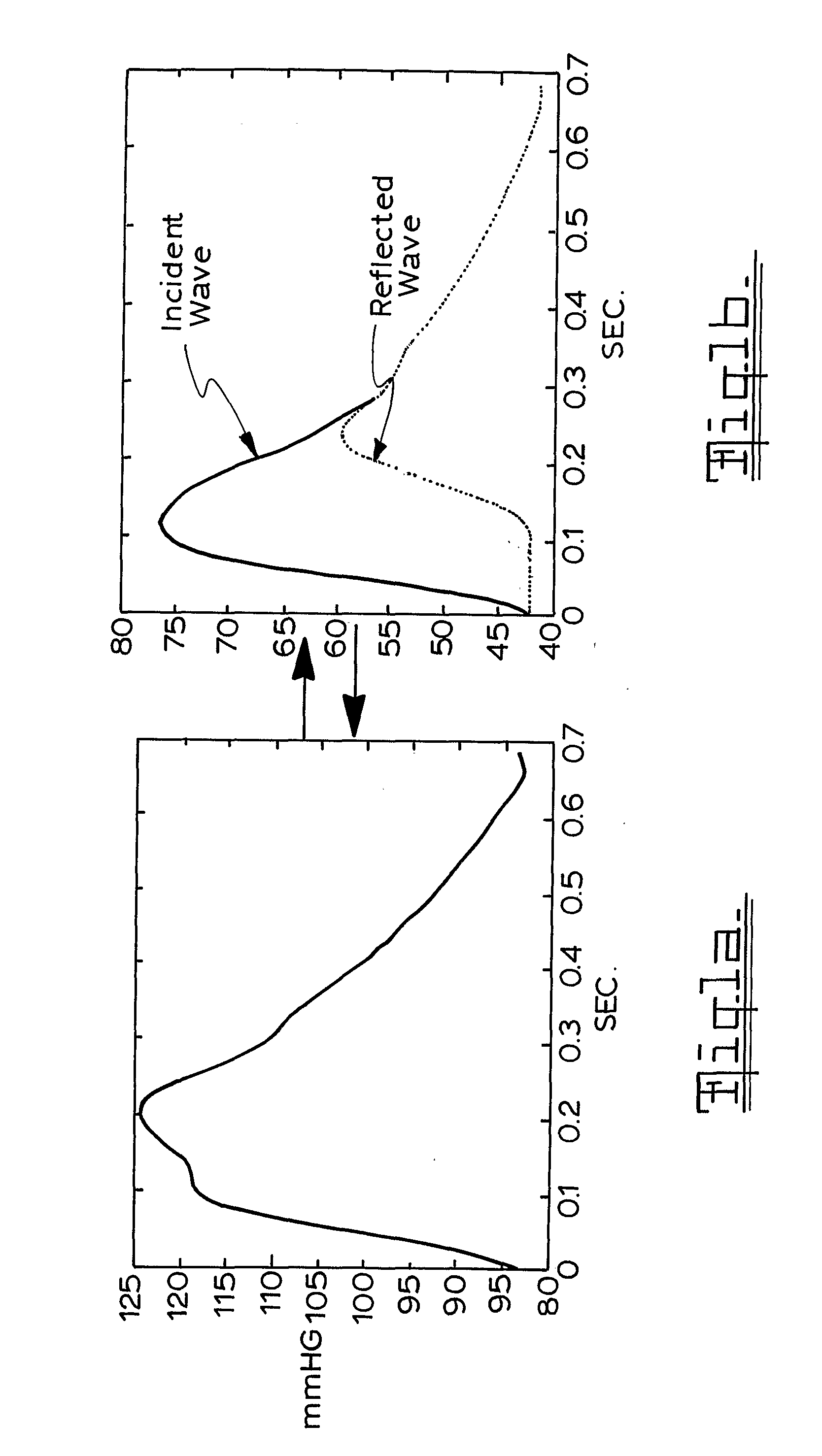

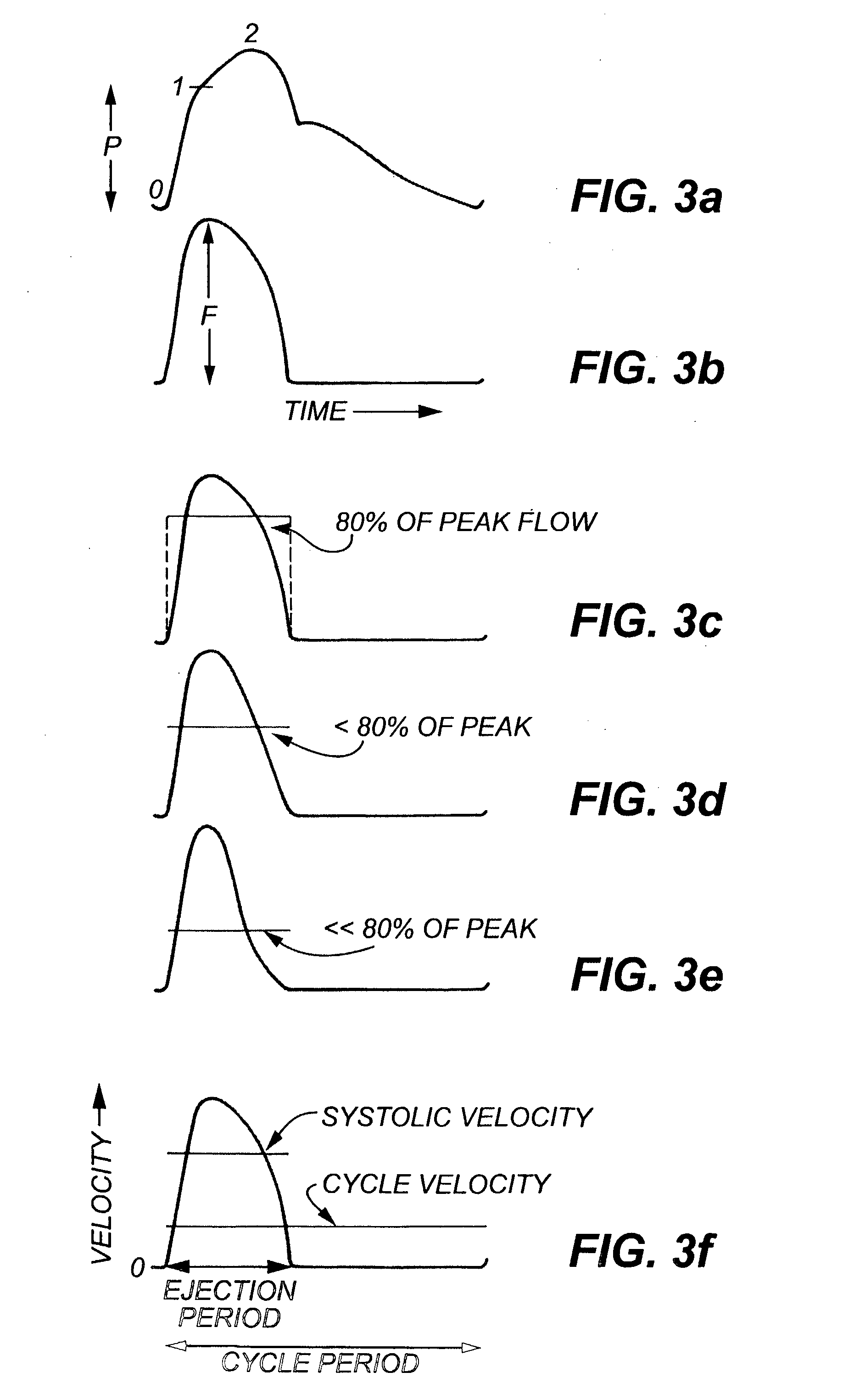

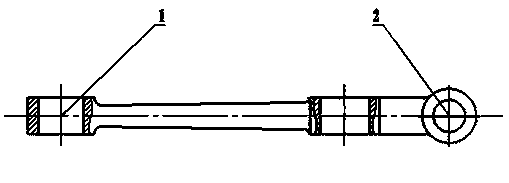

Method and apparatus for determination of cardiac output from the arterial pressure pulse waveform

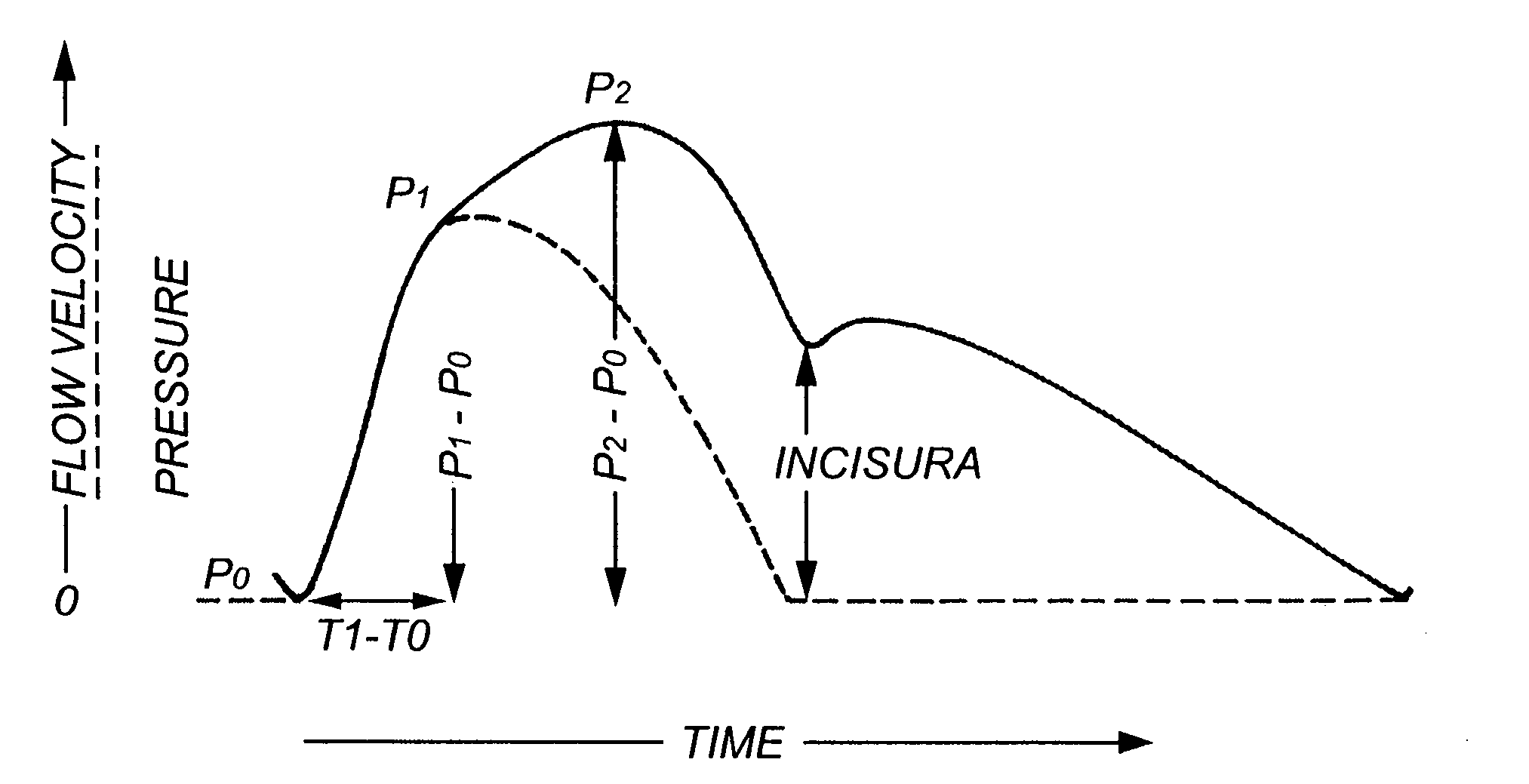

InactiveUS20070197924A1Reduce flow rateEvaluation of blood vesselsCatheterArterial velocityCentral pressure

A method for calculating aortic flow velocity from the directly or indirectly measured arterial, aortic, or carotid pressure and / or diameter waveform in which the reflected component of the pressure wave is excluded and the peak systolic flow velocity V is calculated from the amplitude P1 of the central pressure waveform using the formula (I) where C is the aortic pulse wave velocity.

Owner:OROURKE MICHAEL FRANCIS

Central aortic blood pressure and waveform calibration method

ActiveUS20180263513A1Accurate measurementAccurate pressureHealth-index calculationEvaluation of blood vesselsValue setPeripheral pulses

Central systolic and diastolic pressures are measured non-invasively using a peripheral sensor to capture a patient's peripheral pulse waveform. Either the peripheral pulse waveform or a central pressure waveform generated, e.g., using a transfer method is recalibrated to account for differences between non-invasively measured systolic and diastolic pressure and invasively measured systolic and diastolic pressure. The recalibration is based, at least in part, on cardiovascular features of the patient's waveform. The determined central systolic and diastolic pressure values can be used to generate a corrected central pressure waveform having cardiovascular features preserved and maximum and minimum values set to the determined values.

Owner:ATCOR MEDICAL

Method for manufacturing automobile control arm body blank

The invention discloses a method for manufacturing an automobile control arm body blank. The method comprises the steps of 1) melting an alloy melt, namely taking waste mixed aluminum alloy as a raw material, preparing an Al-Si-Mg cast aluminum alloy, and after the chemical components, the temperature and the purity are satisfied, transferring into a heat preserving furnace for preserving heat for later use, 2) pouring the aluminum alloy liquid under a low pressure, namely exerting pressure to the cast aluminum alloy liquid in the heat-preserving furnace and pouring the aluminum alloy liquid into the central pressure chamber of a metal die by a set height by use of a delivery pipe, 3) performing pressured filling on the die cavity, namely fully charging the aluminum alloy liquid in the pressure chamber into the die cavity by pressurizing, 4) pressurizing for feeding and solidifying for molding under constant pressure, namely increasing the pressure for feeding and solidifying for molding, and 5) opening the die to take out the blank and performing heat treatment, namely opening the die to take out the blank and performing T6 heat treatment. The method for manufacturing the automobile control arm body blank has the advantages that the material utilization rate reaches up to 80%, the obtained blank is fine in internal structure without shrinkage cavity and shrinkage porosity defects, and excellent in mechanical properties, and can be applied to take the place of a forged aluminum alloy control arm and a steel control arm to realize light weight of the automobile.

Owner:吉林金城铸锻有限责任公司 +1

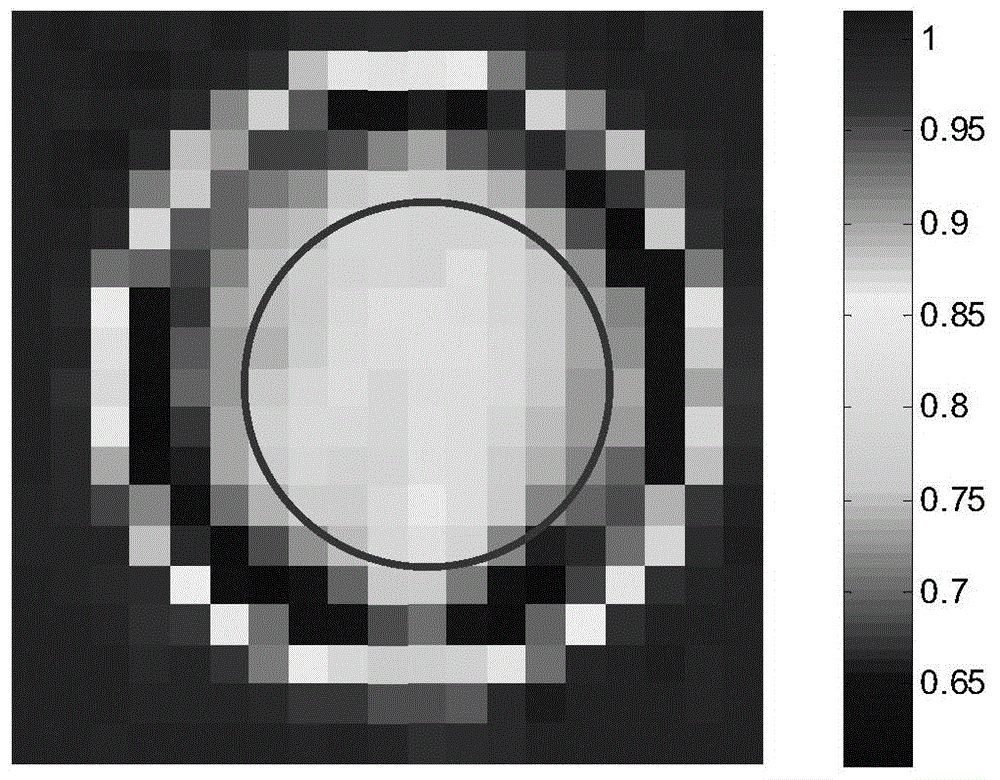

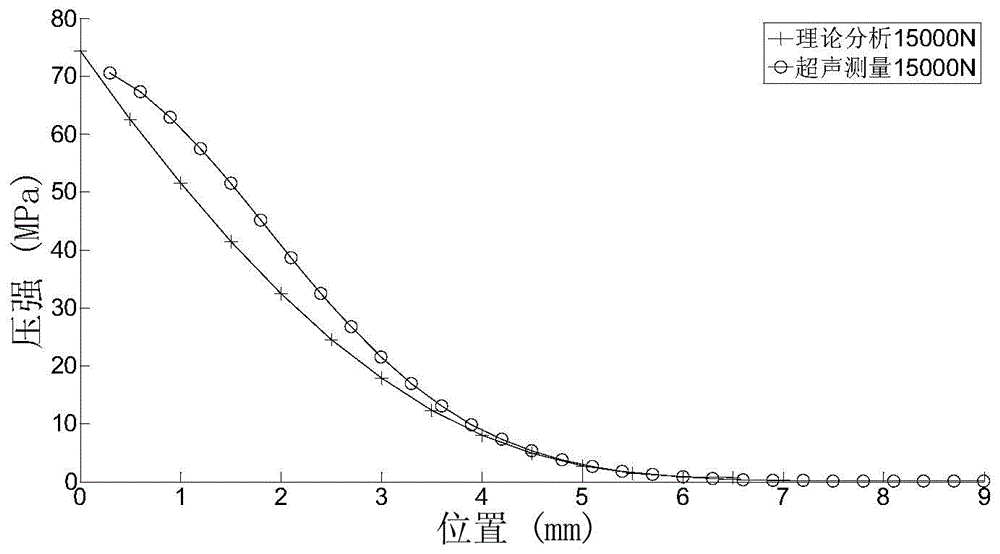

Method for establishing pressure intensity-ultrasonic reflectivity curve for pressure intensity detection on joint surface

ActiveCN103822968AThe difference between the calculation results is smallAccurate detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalContact pressureSonification

The invention discloses a method for establishing a pressure intensity-ultrasonic reflectivity curve for pressure intensity detection on a joint surface. The method comprises the following steps: firstly, calculating the ultrasonic reflectivity of each scanning point under different pressure intensities, subsequently fitting to calculate the initial pressure intensity-reflectivity relationship, calculating the pressure intensities of all scanning points under different pressures according to the initial pressure intensity-reflectivity relationship, so as to obtain the pressure F of the whole joint surface; calculating a calibration coefficient according to F and the actual pressure F0 measured through a pressure sensor, subsequently recalculating a pressure intensity value Pi of each scanning point to obtain a modified pressure intensity value Pi', calculating an average value P<alpha> of the pressure intensity value Pi' of the scanning points in a central pressure intensity distribution flat area of the joint surface under different pressures, refitting according to the obtained P<alpha> and an average reflectivity value R0 corresponding to the area so as to obtain a novel pressure intensity-reflectivity curve. According to the method, the pressure intensity-reflectivity curve is established in an iteration mode, the accurate pressure intensity-reflectivity is established, and accurate detection on the contact pressure intensity of the joint surface is achieved.

Owner:XI AN JIAOTONG UNIV

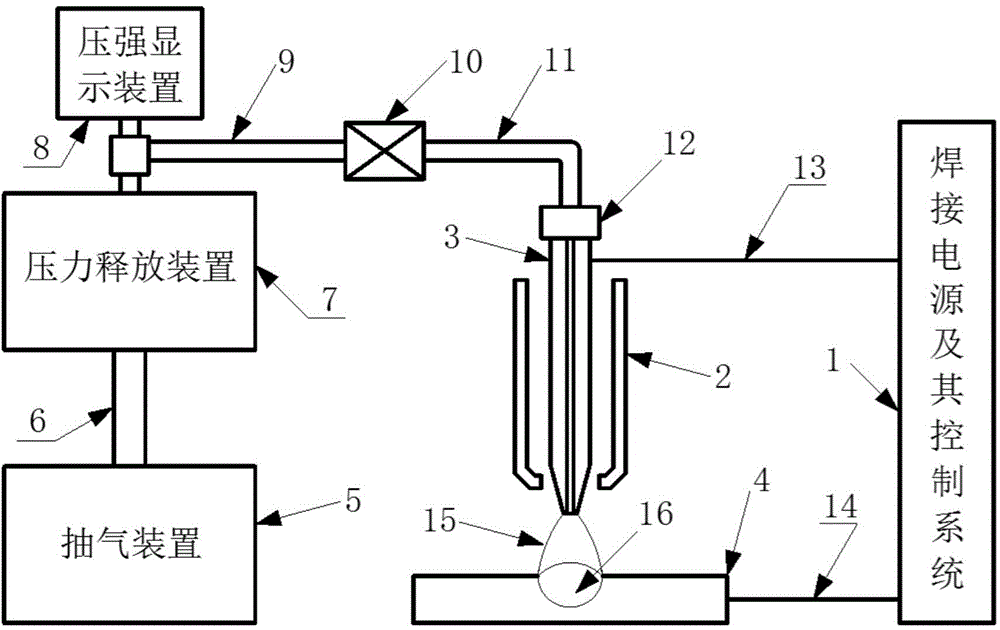

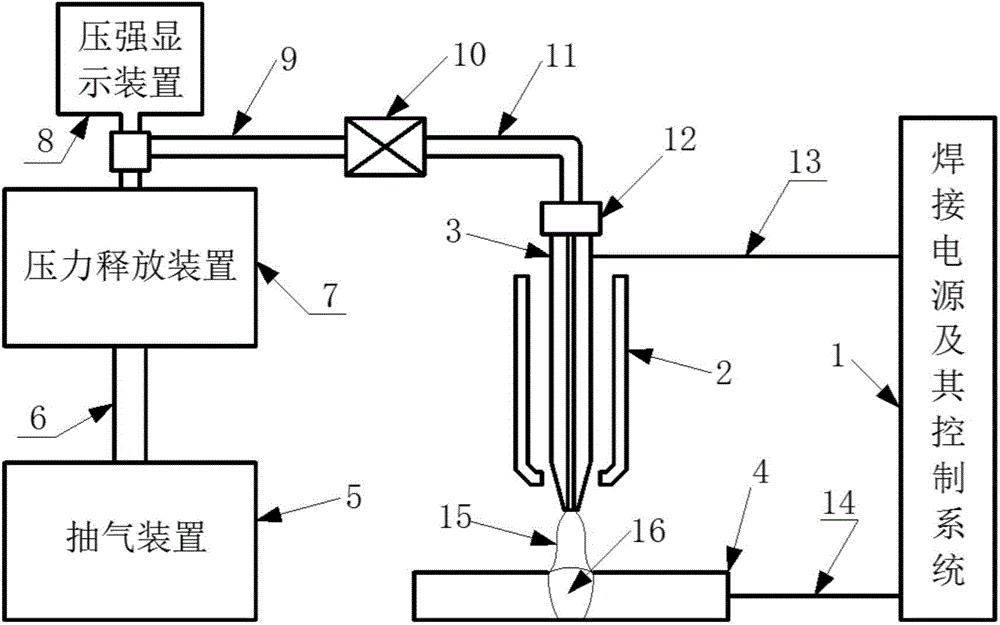

Central negative-pressure arc welding device and method

ActiveCN104308343AImproved arc stabilityStrong penetrating powerElectrode accessoriesHigh energyCentral pressure

The invention relates to a central negative-pressure arc welding device and method, and belongs to the technical field of welding equipment and methods. An inner cavity of a hollow tubular electrode and the center of an arc below the hollow tubular electrode enter a negative-pressure state by virtue of an air extraction device, the radial pressure gradient of the arc from the outside to the center of the arc is increased, and under the action of external atmospheric pressure, the arc is constricted into a high-energy density restrained arc. The magnitude of central pressure of the arc is regulated to regulate the magnitude of restraint intensity, energy density and voltage of the arc, thereby well controlling the welding heat input and the forming of a welding seam. According to the welding device and the welding method, high stability of a TIG (tungsten inert gas) welding arc and high energy density of a plasma arc are integrated, so that the defects of complexity in parameter regulation, narrow process window and the like of a plasma arc welding process are overcome, the detects of small welding penetration and low welding efficiency of the conventional TIG arc are overcome, the welding speed is greatly accelerated, the welding efficiency is greatly improved, and high-quality and efficient welding is unified.

Owner:BEIJING UNIV OF TECH

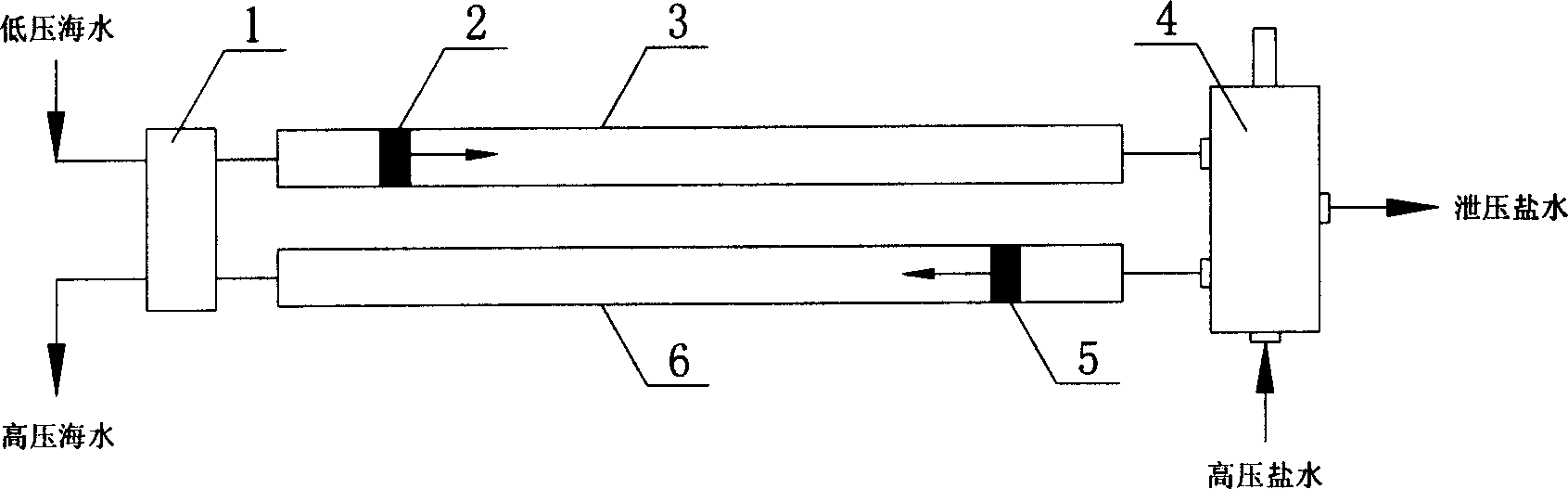

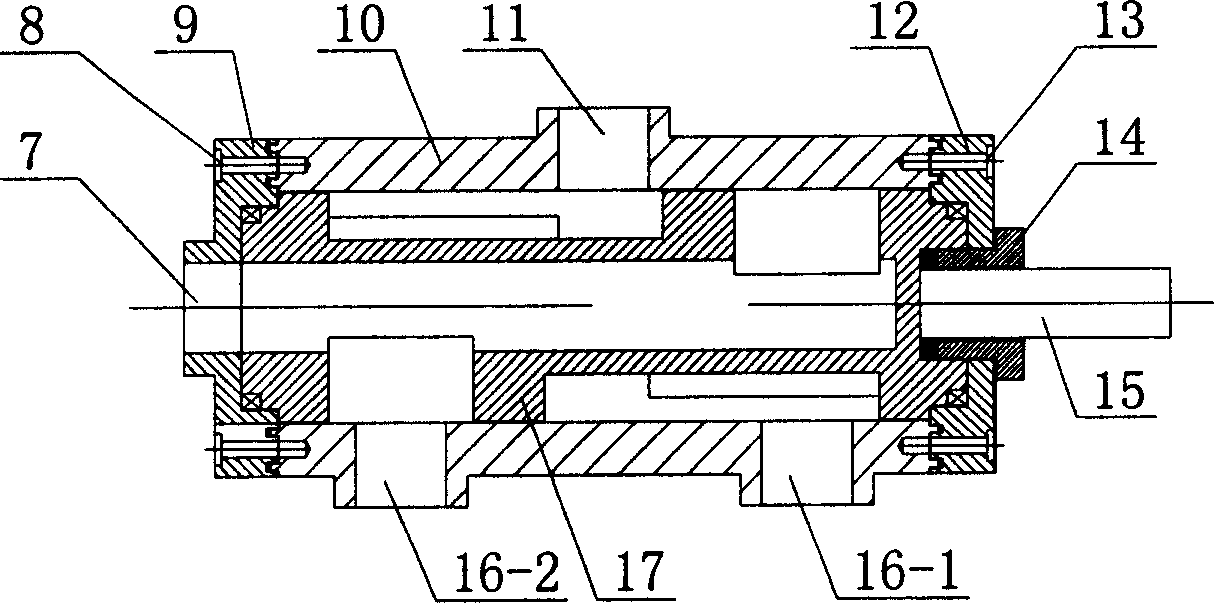

Multi-path pressure switcher for reverse osmosis sea water desalting energy recovery device

InactiveCN1821107ANon-fluctuating flowNo fluctuating pressureGeneral water supply conservationSeawater treatmentSaline waterCentral pressure

The present invention discloses one multipath pressure switcher for reverse osmosis sea water desalting energy recovering apparatus, and belongs to the field of liquid after-pressure recovering technology. The switcher is a casing, a rotating core and end caps assembled to ends. The casing is provided one axial joint and two other joints distributed symmetrically about the axial joint. The rotating core is one hollow cylinder and has sealed joints on two ends, and each of the joints has two radial fan-shaped slots, two fan-shaped holes communicated to the central hole of the rotating core and one central pressure releasing slot communicated to the two fan-shaped slots. The present invention has the advantages of no fluctuation in flow rate and pressure of inflow and outflow salty water and sea water, low rotation speed of the rotating core without noise, good sealing performance, and less leakage and back mixing of salty water and sea water.

Owner:TIANJIN UNIV

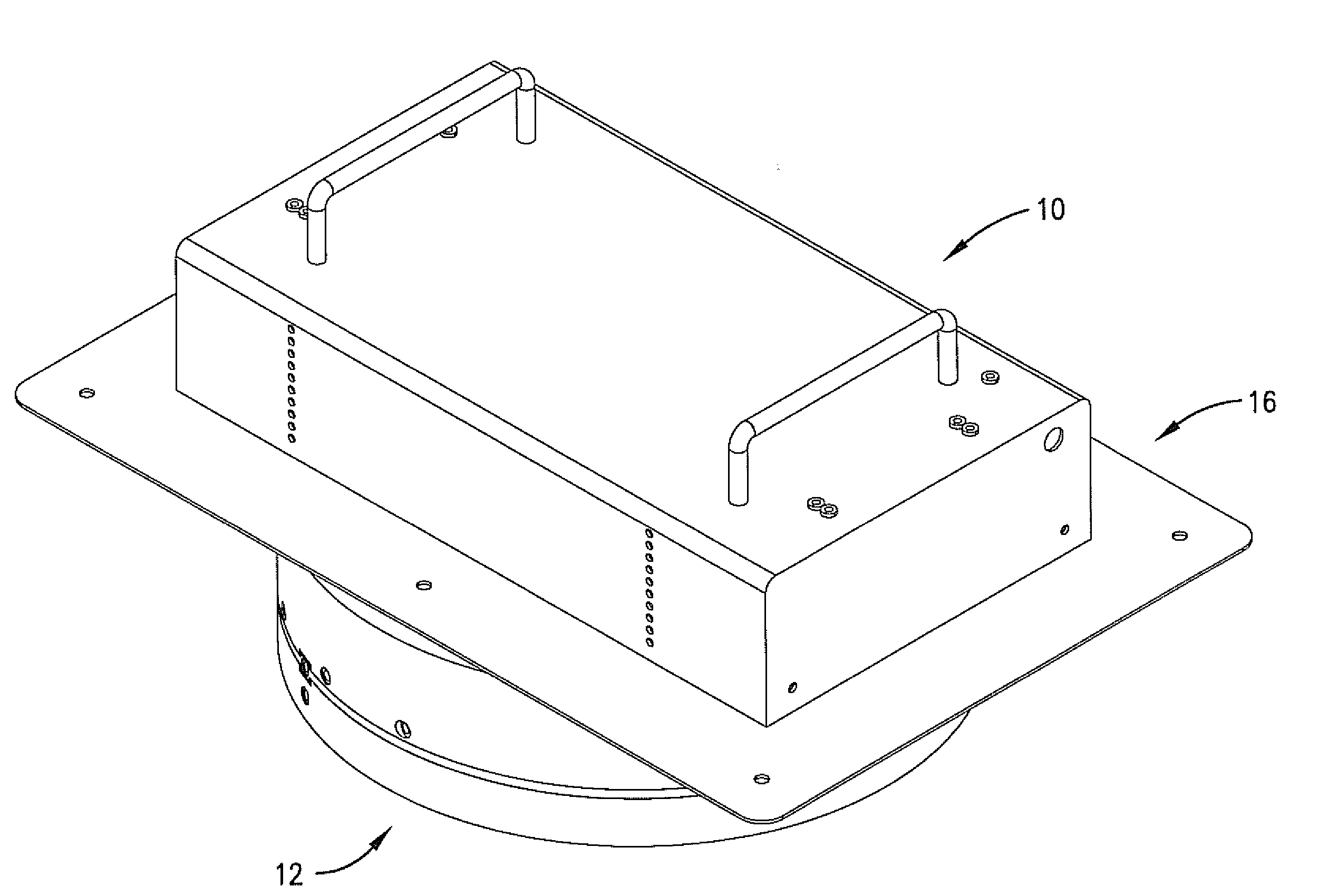

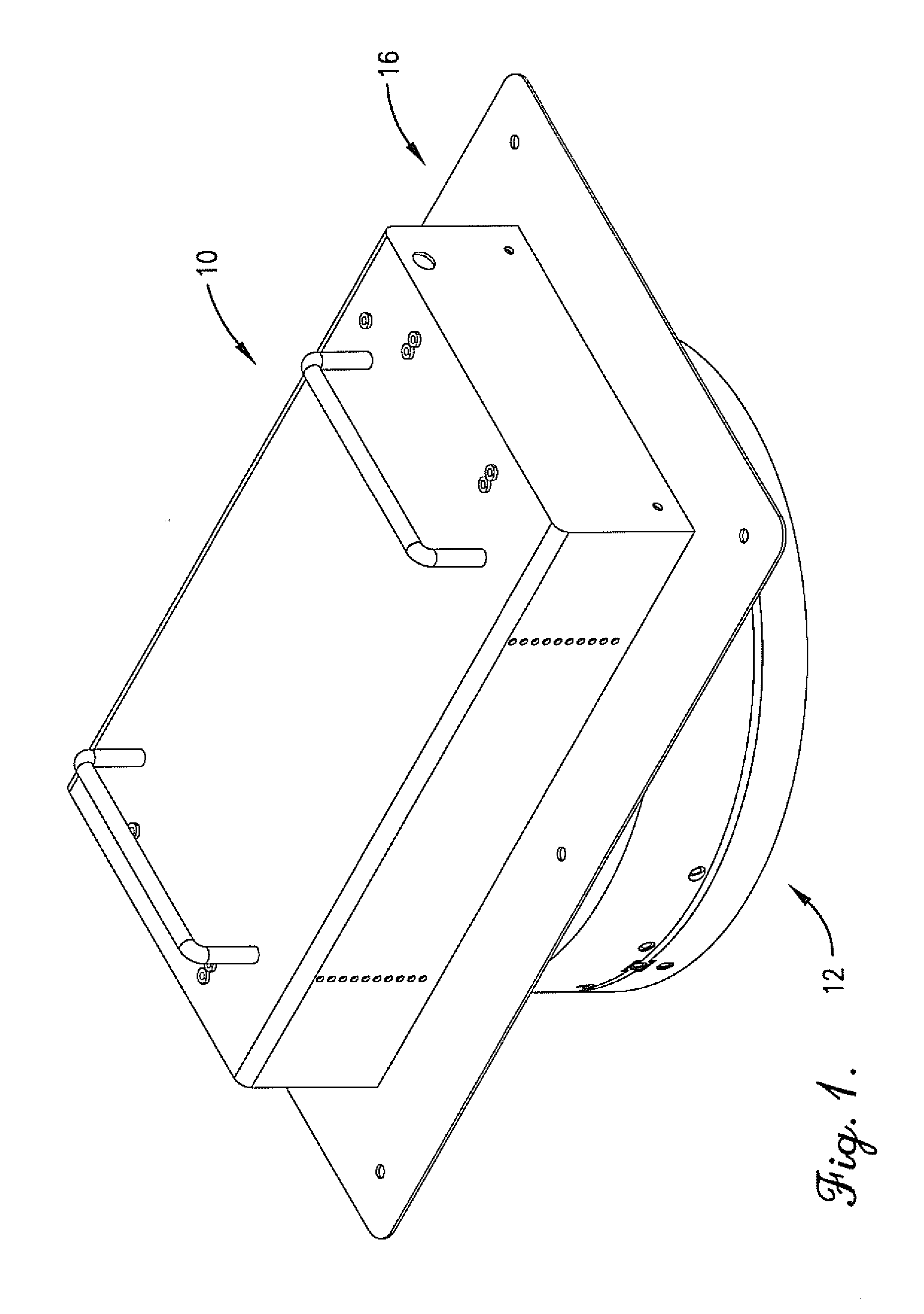

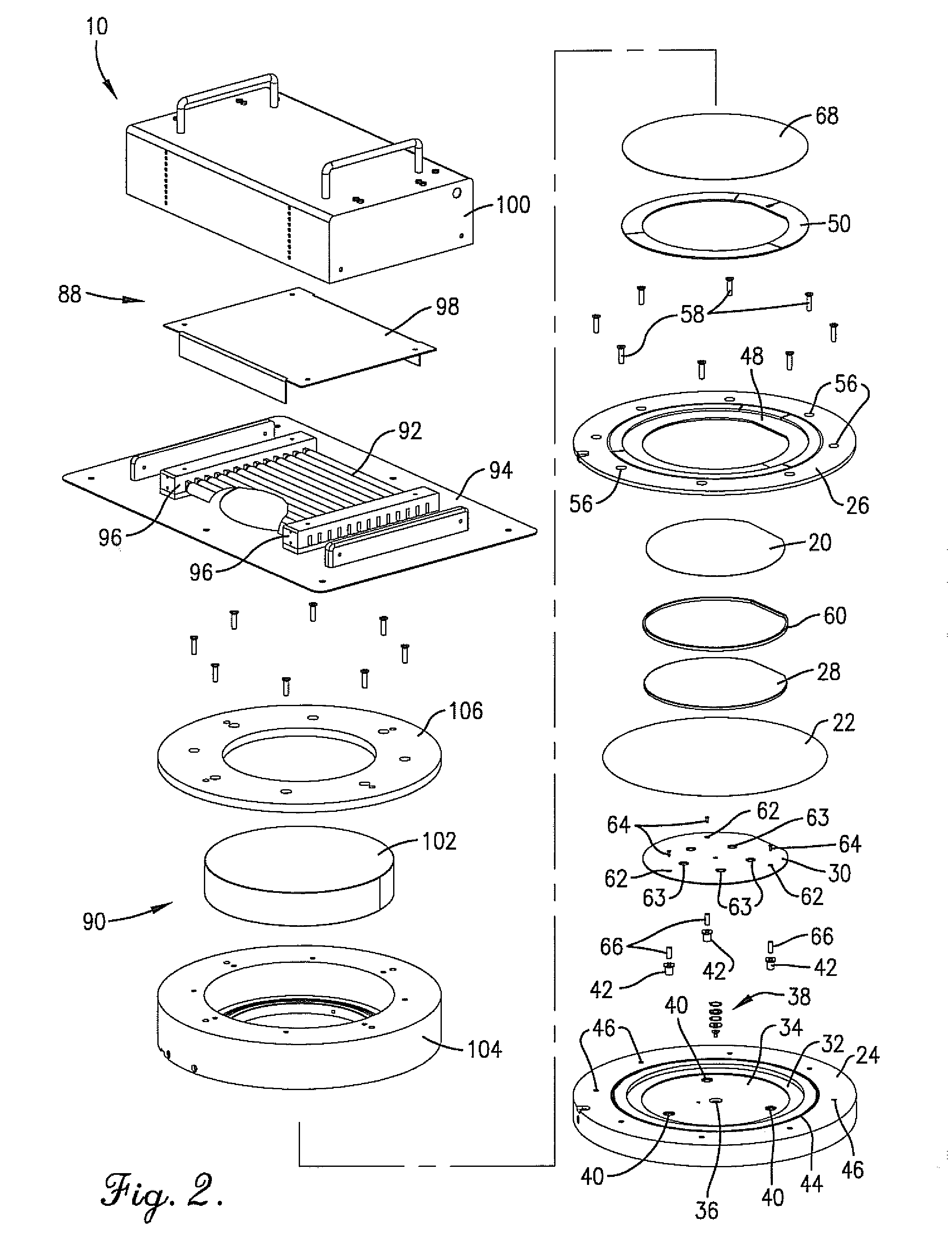

Indentation device, instrumented measurement system, and a method for determining the mechanical properties of materials by the indentation method

InactiveUS10139327B2Eliminate disadvantagesAccurate measurementElectric/magnetic position measurementsUsing electrical meansCentral pressureAnalog-to-digital converter

The instrumented indentation measurement system includes an indentation device, a loading mechanism, a table for the sample, an analog-digital converter and a computer. Inside a housing of the device there is arranged a holder for a displacement sensor, rigidly connected to the housing. Slidably positioned rod passing to the displacement sensor is arranged in the holder in the axis of the indenter. A pushing segment is equipped with supports engaging with a central pressure plate arranged slidably in the housing a lower pressure plate is arranged slidably in the housing and connected with the holder of the indenter. A first resilient member, a central pressure plate and the lower pressure plate are provided with holes for passage of the rod to the holder.

Owner:CZECH TECH UNIV IN PRAGUE

Intravascular sub-hypothermia therapeutic instrument for intensive care unit

InactiveCN105287095AImprove securityEase of workTherapeutic coolingTherapeutic heatingHuman bodyTriple lumen catheter

The invention provides an intravascular sub-hypothermia therapeutic instrument for an intensive care unit. The intravascular sub-hypothermia therapeutic instrument for the intensive care unit comprises a device in a human body and a device outside the human body, the device in the human body comprises a central temperature sensor probe and a central pressure sensor probe which are located on the forefoot position of the paracele of the human body and a three-cavity catheter located in a blood vessel of the human body, the device outside the human body comprises a control panel which conducts coordination treatment on the whole therapeutic instrument, a normal saline tank containing normal saline and a temperature regulating tank which contains cooling liquid and conducts regulation control on the temperature of the cooling liquid, and a complete circulation system is formed among the normal saline tank, the temperature regulating tank and the three-cavity catheter. The intravascular sub-hypothermia therapeutic instrument for the intensive care unit is simple in structure and convenient to use, the defects of an existing traditional cooling method are overcome, and the safety of a patient is improved by conducting heat exchange in the blood vessel; the temperature of a brain ventricle is measured, the temperature accuracy is guaranteed, and the safety is further improved; the temperature regulating chamber is arranged, rapid cooling and slow rewarming can be achieved, and the working difficulty of medical staff is reduced.

Owner:邹秀丽

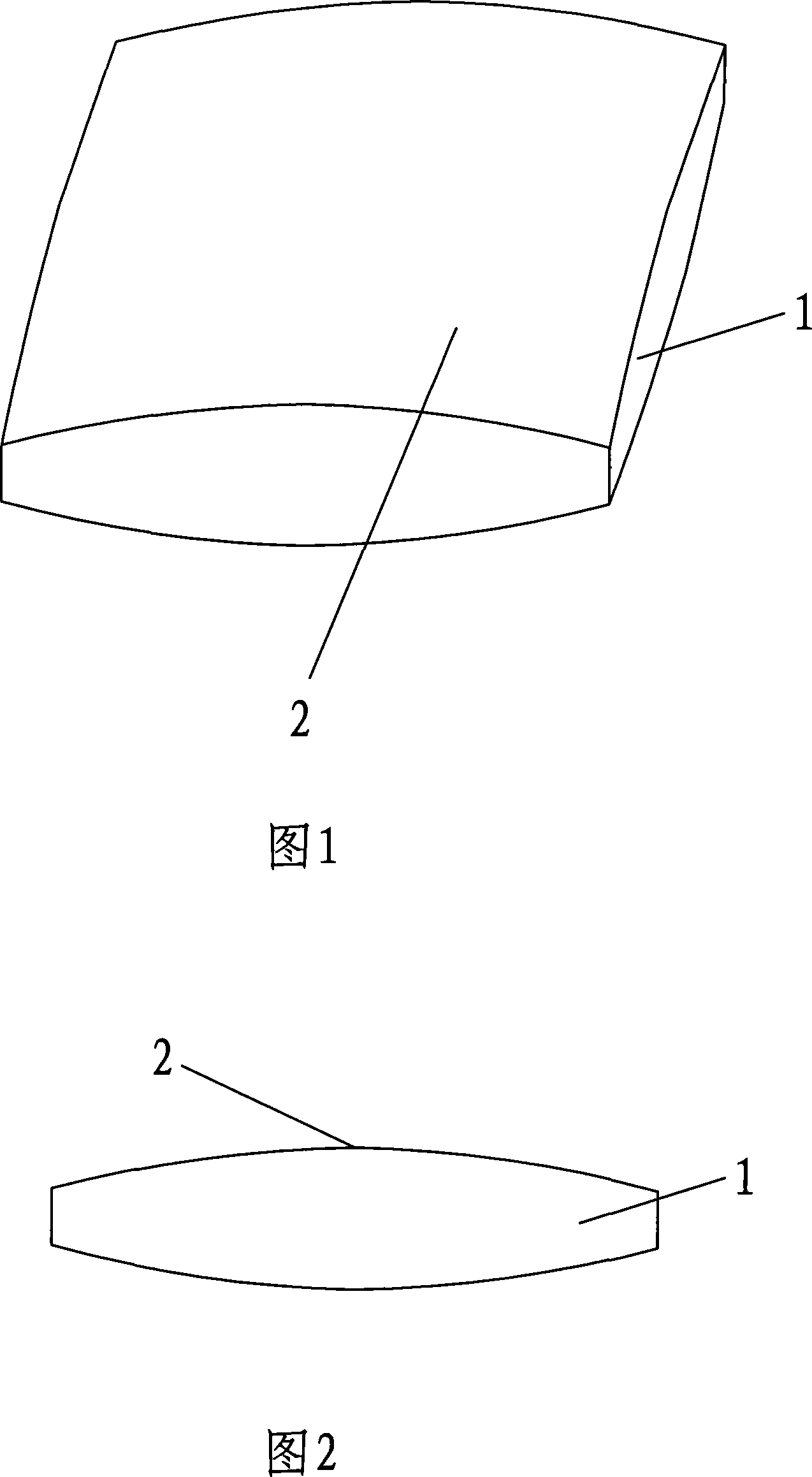

Backing board for laminating covered copper plate

InactiveCN101239508AImprove buffering effectImprove heat resistanceLaminationLamination apparatusFiberHeat resistance

The invention belongs to electronic material technology, and specially relates to a base plate used for copper clad laminating. The thickness of a basic body decreases gradually from the middle to the periphery, and the declining rate is from 5% to 50%, linear, stepped or not stepped. The basic body is cube, rectangular or cylindrical, and felt fabric pressed by heat-resistant fiber fabric and heat-resistant material. The plate can change the pressure field structure when laminating the copper clad, thereby forming a great central pressure and a smaller pressure on the edges, then changing the gummy property when laminating the copper clad, reducing the gum with a low pressure on the edges, and enhancing the percent of thickness pass of the product.

Owner:GUANGDONG SHENGYI SCI TECH

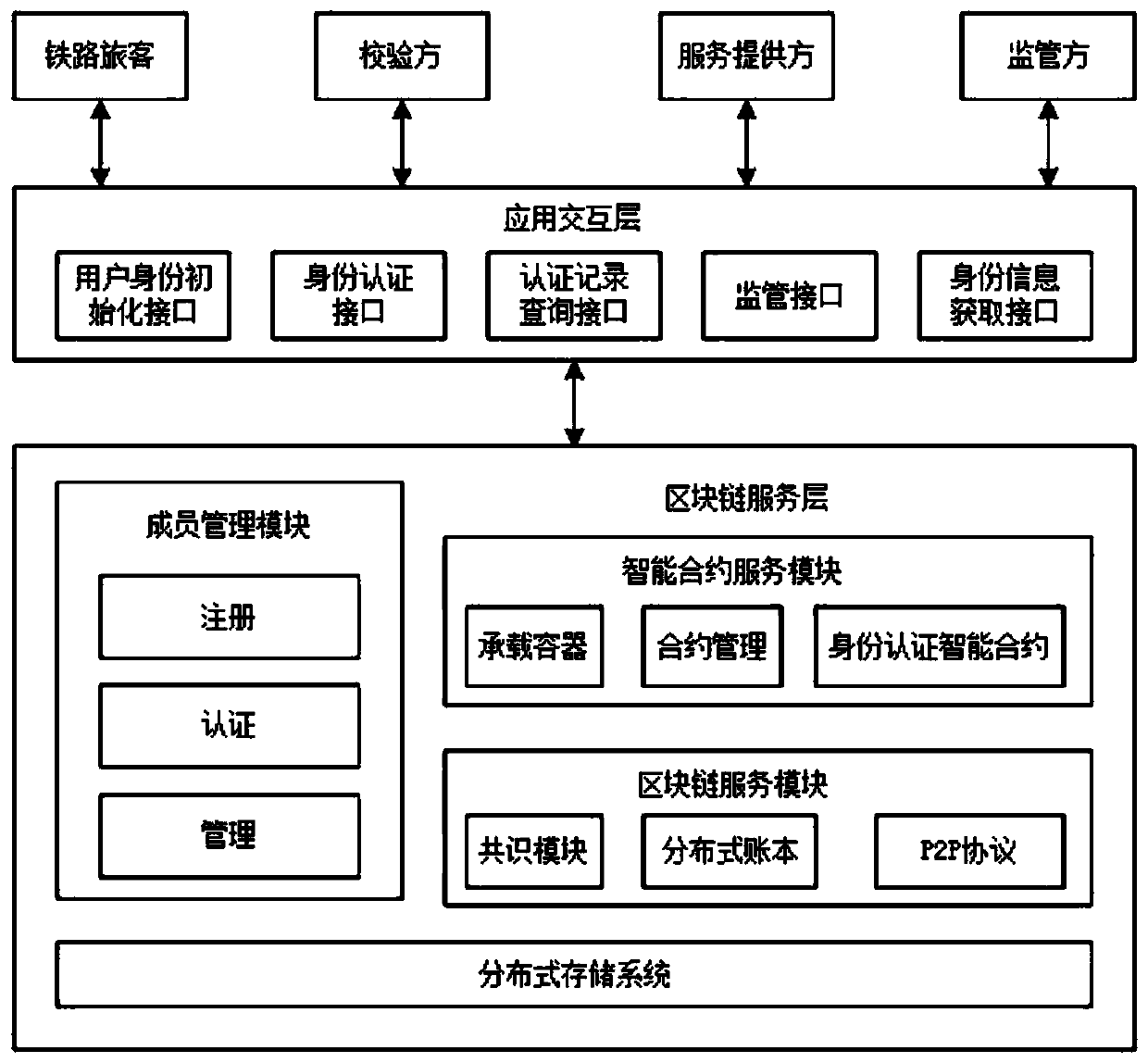

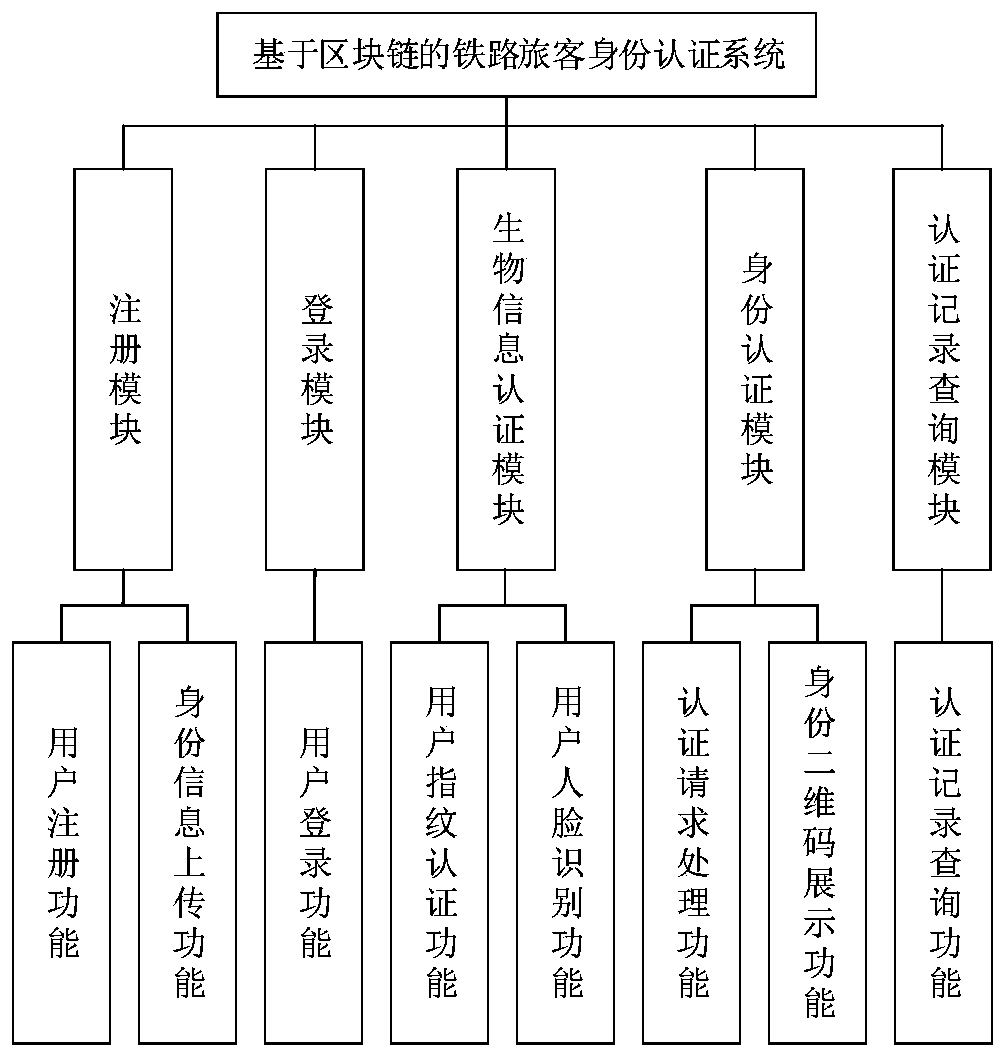

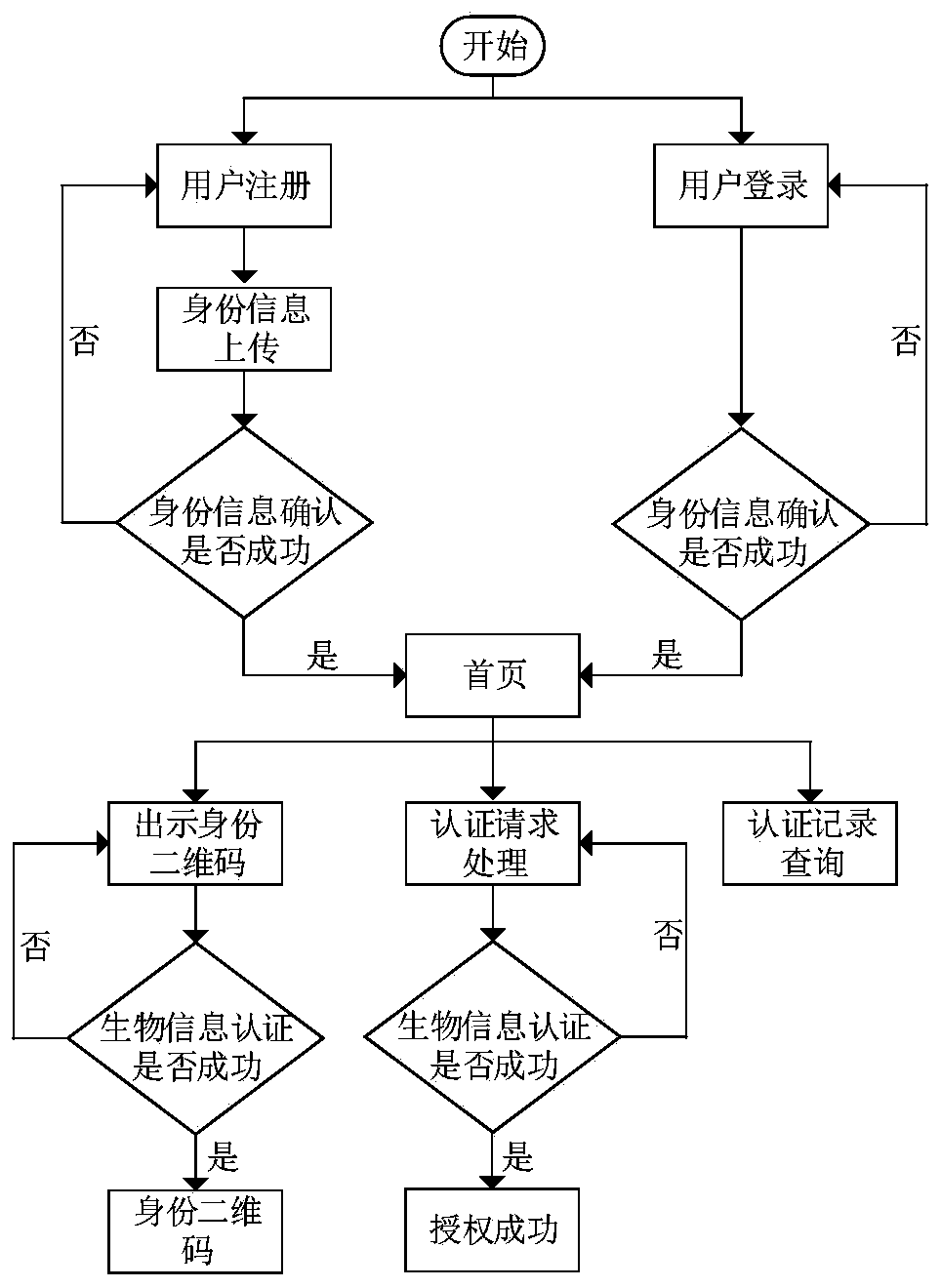

Railway passenger identity authentication system oriented to smartphone client

ActiveCN110120953AImprove the ride experienceHigh transparencyDigital data protectionTransmissionCentral pressureData access

The invention discloses a railway passenger identity authentication system oriented to a smartphone client. The system comprises a registration module, a login module, a biological information authentication module and an identity authentication module, the invention achieves a railway passenger identity authentication system oriented to a smart phone client based on a block chain. According to the railway passenger identity authentication system based on the block chain, local storage of user identities and verification on an information abstract chain can be realized; the central pressure ofa traditional identity authentication system under a central system architecture is weakened, the transparency and audibility of passenger identity information management are improved, fine-grained control over railway passenger identity information data access is achieved, safety of railway passenger identity information is guaranteed, and the riding experience of railway passengers is improved.

Owner:DALIAN JIAOTONG UNIVERSITY

Production logging tool and downhole fluid analysis probes deploying method, in particular for deviated and horizontal hydrocarbon well

ActiveUS10294771B2Overcome limitationsSimple and compact structureSurveyDrilling rodsRadial motionCentral pressure

A production logging tool to analyze at least one property of a multiphase fluid mixture flowing in a hydrocarbon well has an elongated cylindrical housing shape and comprises a central pressure-resistant rigid housing carrying a centralizer arrangement. The production logging tool further comprises a deploying arrangement nested within the centralizer arrangement comprising deploying arms circumferentially positioned between two centralizer arms, and downhole fluid properties analysis probes secured on each deploying arm such as to expose a tip of said, at least one, probe to the multiphase fluid mixture flowing in the hydrocarbon well. The deploying arrangement follows radial movements imposed by the centralizer arrangement to radially and / or angularly position the tip of the probes in a first circumferential zone of a hydrocarbon well section substantially perpendicular to a longitudinal axis of the well.

Owner:OPENFIELD

Pressure and differential pressure transmitter

ActiveCN109900415AImmune to spikesExtended service lifeFluid pressure measurement using capacitance variationCapacitancePositive pressure

The invention relates to the technical field of a sensor and discloses a pressure and differential pressure transmitter, which comprises a base and a positive pressure isolation diaphragm. A spike pulse filter device is arranged on the end surface of the base and located at the inner side of the positive pressure isolation diaphragm. The spike pulse filter device comprises a buffer slot, a seal piston, a buffer spring, a positioning pull rod and a pressure bearing member. Under the action of the compressed elastic force of the buffer spring, the positioning pull rod pulls and locates the sealpiston in the buffer slot. By arranging the spike pulse filter device in a high-pressure chamber of the base, and setting the compressed initial state of the buffer spring to a displacement limit obtained when the positive pressure isolation diaphragm reaches a nominal pressure value, when the system is under the action of the fluid spike or pulse, the pressure exceeding the threshold value preferentially acts on the pressure bearing member through the positive pressure isolation diaphragm to drive the seal piston to compress the buffer spring, and then, the pressure displacement exceeding thethreshold can be buffered by the silicon oil entering the buffer slot, thereby effectively protecting a central pressure sensing diaphragm and related capacitors from the spike pulse.

Owner:MAGNESIUM DAQING HUA INSTR WEIGHING

Silicon capacitance pressure sensor

InactiveCN102654426AAchieve performanceThickness can be adjustedFluid pressure measurement using capacitance variationCentral pressureParasitic capacitance

The invention relates to a silicon capacitance pressure sensor, comprising a silicon wafer layer and a glass layer. The silicon capacitance pressure sensor is characterized in that: a silicon fixed polar plate is respectively connected with the upper side and the lower side of a movable polar plate at the silicon center of an island film structure, and the silicon fixed polar plate comprises the silicon wafer layer and the glass layer, both of which are statically sealed in vacuum, and the thickness of the glass layer is 50-200 microns; a central pressure leading hole is formed at the middle part of the silicon fixed polar plate, and an aluminum film layer is arranged on the outer surface of the silicon fixed polar plate in the central pressure leading plate and close to the central pressure leading hole. The invention provides a new design realization scheme aiming at a core component of a present silicon capacitance pressure sensor. Even through silicon polar plates are connected through thin-layer glass through a static seal process without a high-temperature bonding furnace and an ultraclean environment, the process condition is simple and is directly compatible with the present processes, especially the thickness of the glass thin layer can be regulated, and interlayer parasitic capacitors are controlled in a certain range. Through the performance of the silicon capacitance pressure sensor disclosed by the invention, an effect approximating a silicon-silicon-silicon scheme is realized.

Owner:SHENYANG ACAD OF INSTR SCI

Method and apparatus for producing a central pressure waveform in an oscillometric blood pressure system

ActiveUS9433358B2High trafficEasy to understandLocal control/monitoringStethoscopeBrachial arteryBlood pressure cuffs

A central arterial blood pressure waveform is developed from pressure waveforms obtained from proximal and distal blood pressure cuffs on the brachial artery of an arm that are inflated to a supra-systolic pressure, The proximal and distal cuff pressure waveforms associated with at least one cardiac ejection cycle are sensed, The propagation times of a blood pressure pulse from the entry of the artery to the proximal cuff and from the proximal cuff to the distal cuff are calculated, permitting calculation of a reflection coefficient of the pressure pulse at one of the proximal and distal cuffs. Assuming a physical model of wave propagation along the artery between the aorta and the proximal and distal cuffs, an estimated pressure waveform at the opening of the artery can be determined.

Owner:USCOM

Sectional dynamic machine-oil pressure fault inspecting system of engine

ActiveCN1854473AAccurate detectionEasy to operateEngine testingSilencing apparatusCentral pressureOil cooling

The invention relates to a section dynamic testing system for the engine oil pressure fault, in which in the engine lubricating system consisting of an engine oil pump, an engine oil cooling filter, a main oil channel, an engine oil pipeline and an end pressure monitoring meter a first central pressure gage is mounted in series between the outlet of the engine pump and the inlet of the engine oil cooling filter and between the outlet of the engine oil cooling filter and the inlet of the main oil channel is mounted in series a second central pressure gage. In a running state of the engine, the changes of the three node pressure values are measured sectionally by the central pressure gages.

Owner:上海新动力汽车科技股份有限公司

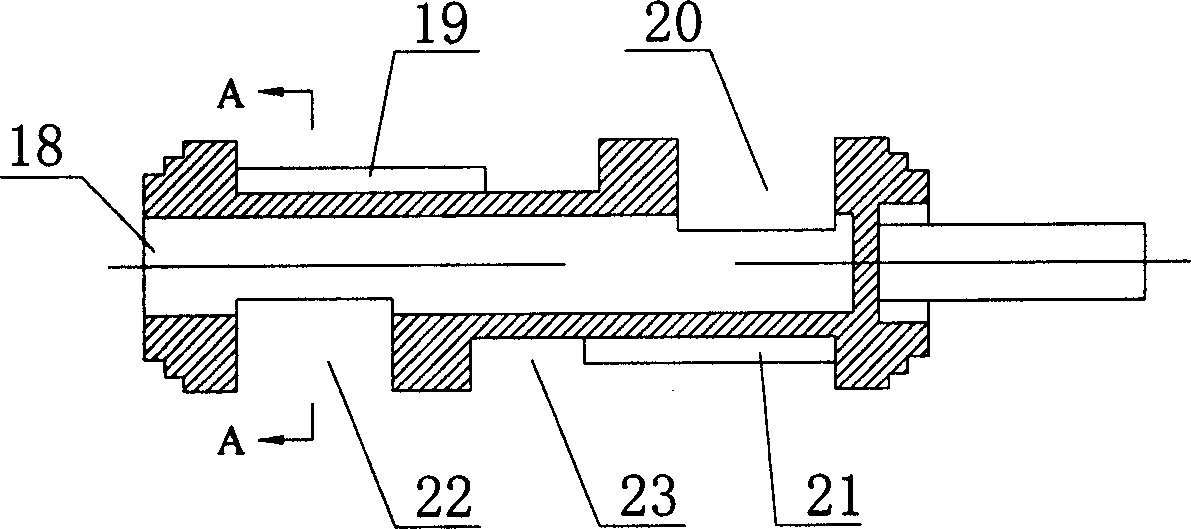

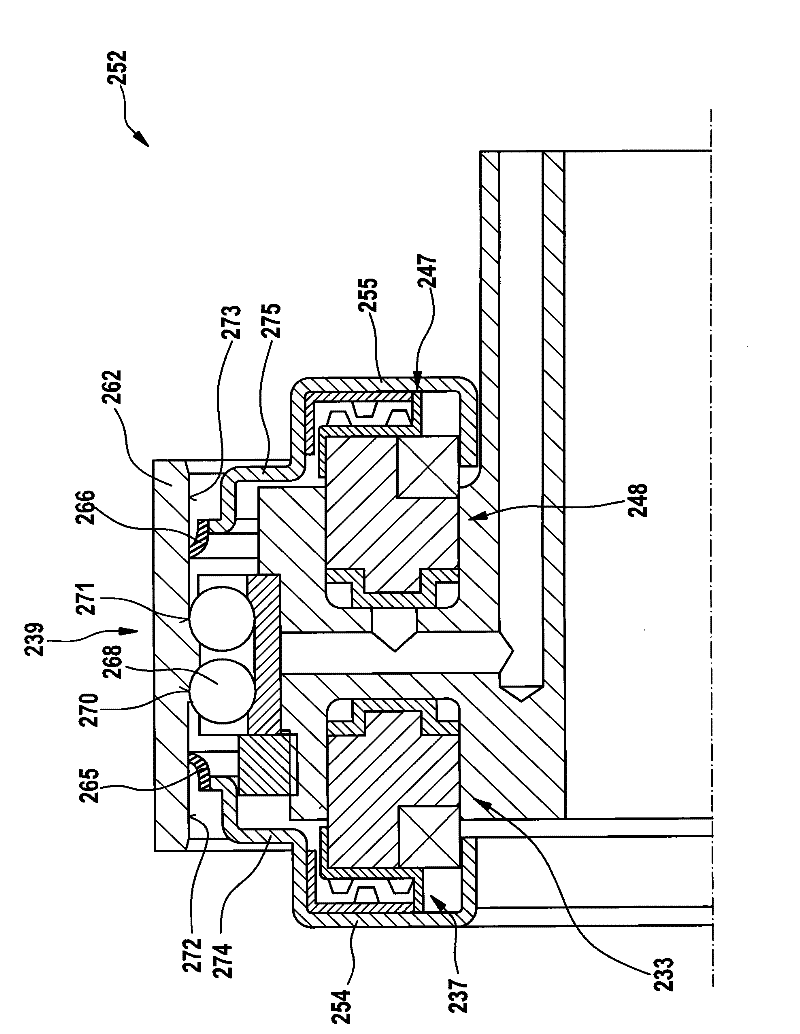

Dual clutch

InactiveCN102099592ACorrectly designedAvoid deadlockRolling contact bearingsMechanical actuated clutchesCentral pressureLubrication

The invention relates to a dual clutch (1) having two friction clutches (3,4), having a central pressure-exerting plate (5) and having two pressure plates (24,25) which are axially movable relative to said pressure-exerting plate (5) with the interposition of the friction linings (28,29) of two clutch disks (26,27), which mesh with in each case one gearbox input shaft, of actuating devices. Here, the pressure plates (24,25) are advantageously acted on by transmission elements (30,42) by the actuating devices (32,32a) directly without a lever action. Furthermore, for the cooling and lubrication of the actuating bearings (37,45) between the actuating devices (32,32a) and the transmission elements (30,42), an annular chamber (153) can be formed which has an increased fluid volume.

Owner:SCHAEFFLER TECH AG & CO KG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com