Central negative-pressure arc welding device and method

An arc welding and negative pressure technology, applied in arc welding equipment, welding equipment, electrode accessories, etc., can solve the problems of high welding environment requirements, high technical requirements for workers, narrow welding process window, etc., and achieve simple and convenient adjustment, broaden the Process window, effect of increasing penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

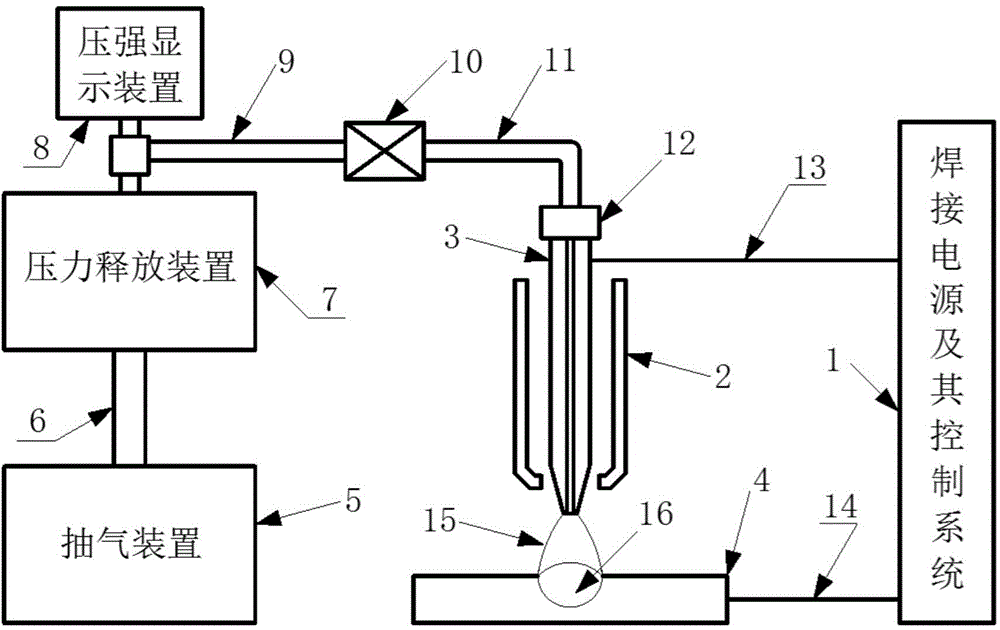

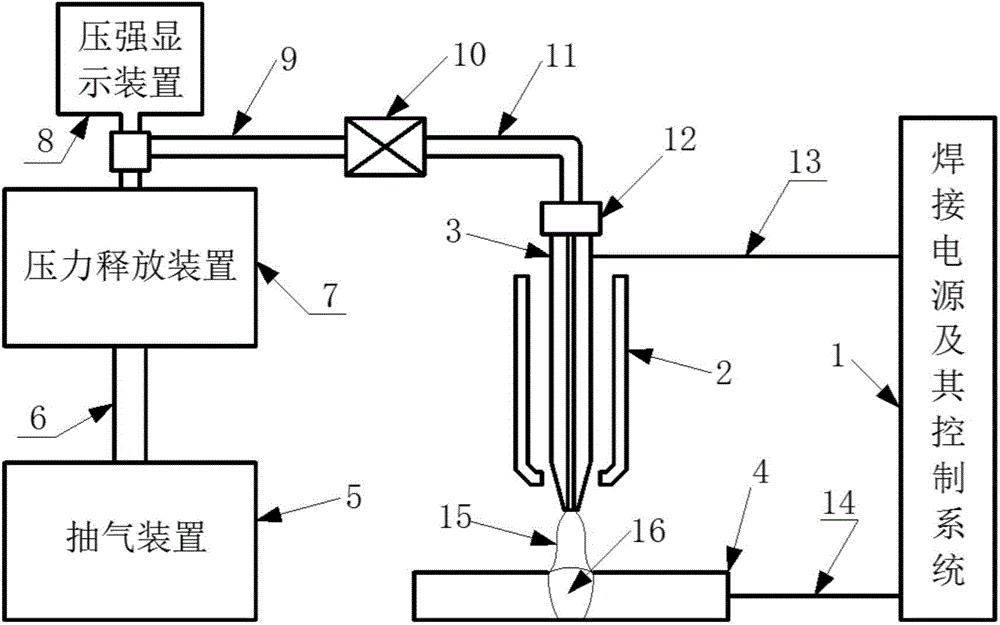

[0026] Embodiments of the present invention will be specifically described below with reference to the drawings. As shown in the figure, the central negative pressure arc welding device mainly includes a welding power supply and its control system 1, a non-melting electrode welding torch 2, a hollow tubular electrode 3, a welding workpiece 4, an air extraction device 5, a pressure release device 7, and a pressure display device 8. Valve 10, in which air extraction device 5——air guiding line A 6——pressure release device 7——air guiding line B 9——valve 10——air guiding line C 11——connecting joint 12——hollow tubular The electrode 3 forms a gas pipeline, and the pressure display device 8 is connected with the pressure release device 7; welding power source and its control system 1——welding cable B 14——welding workpiece 4——non-melting electrode welding torch 2——welding cable A 13——Welding power supply and its control system 1, which constitutes an electrical circuit. The gas and wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com