Patents

Literature

139results about How to "Increase weld penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

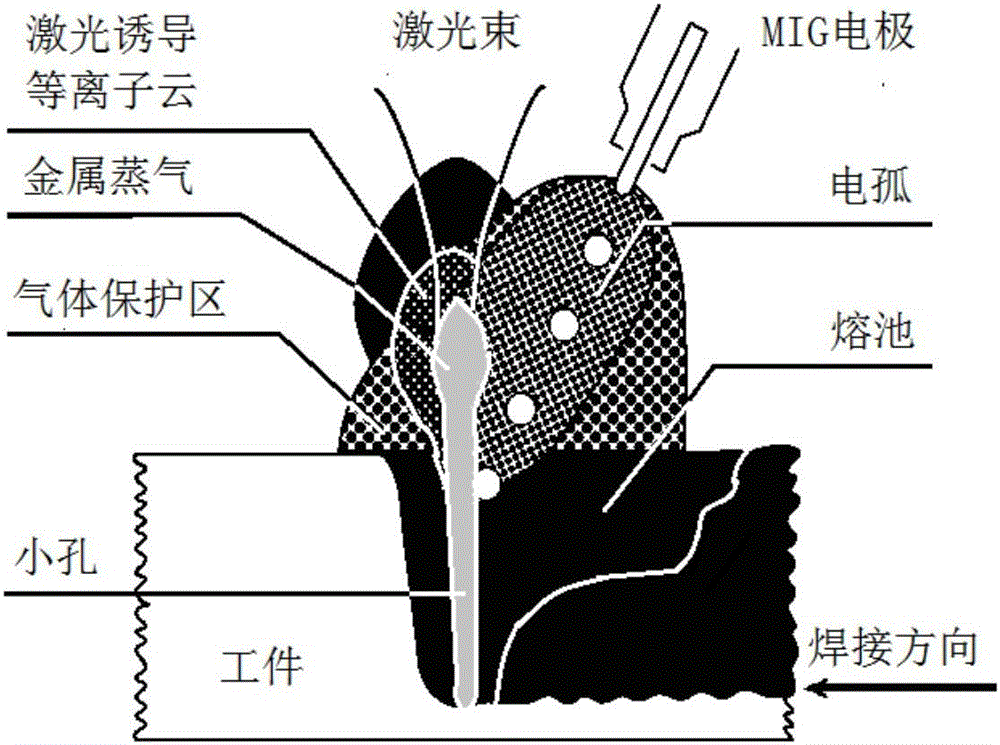

Laser and MIG (metal-inert gas) arc composited welding method for high-nitrogen steel

The invention discloses a laser and MIG (metal-inert gas) arc composited welding method for high-nitrogen steel. The laser and MIG arc composited welding method is characterized by comprising the following steps of: design of a welding joint; design of a welding mode; setting of a composite way and heat source spaces; selection of protective gas for the composite welding; setting of welding technology parameters according to the composite way; and synchronous implementation of the composite welding. Compared with the prior art, the laser and MIG arc composited welding method has the advantages of being capable of implementing the welding of the high-nitrogen steel with middle thickness and achieving weld joints which have clean and smooth surfaces and are good in forming and free from sunken parts; and meanwhile, the welding method has the characteristics of low loss and uniform distribution of nitrogen elements at connectors, high welding penetration, high welding speed, small deformation of workpieces, low assembly requirements and the like.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

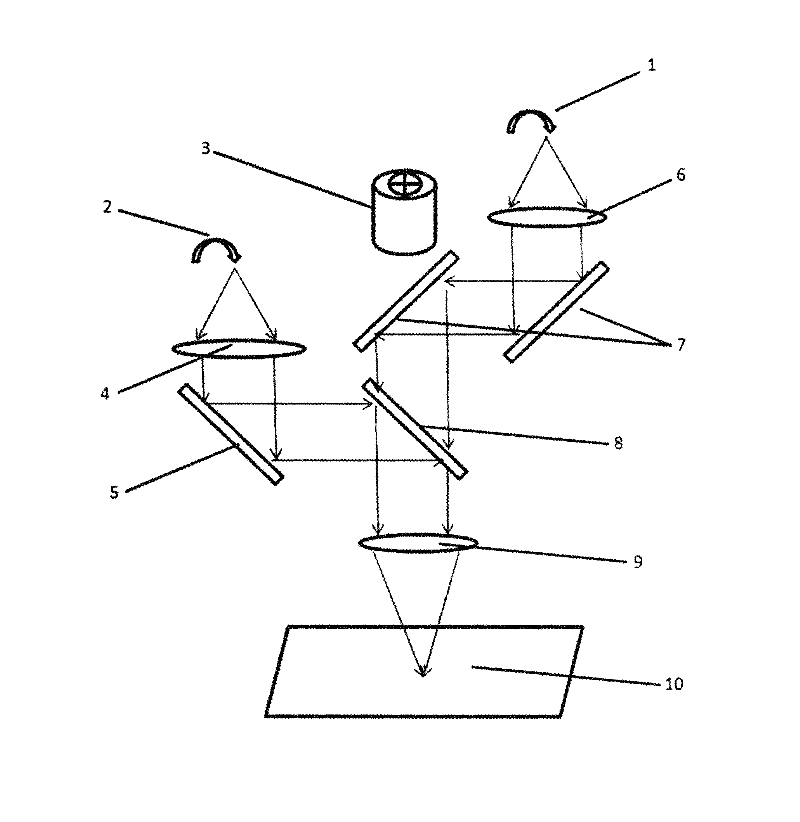

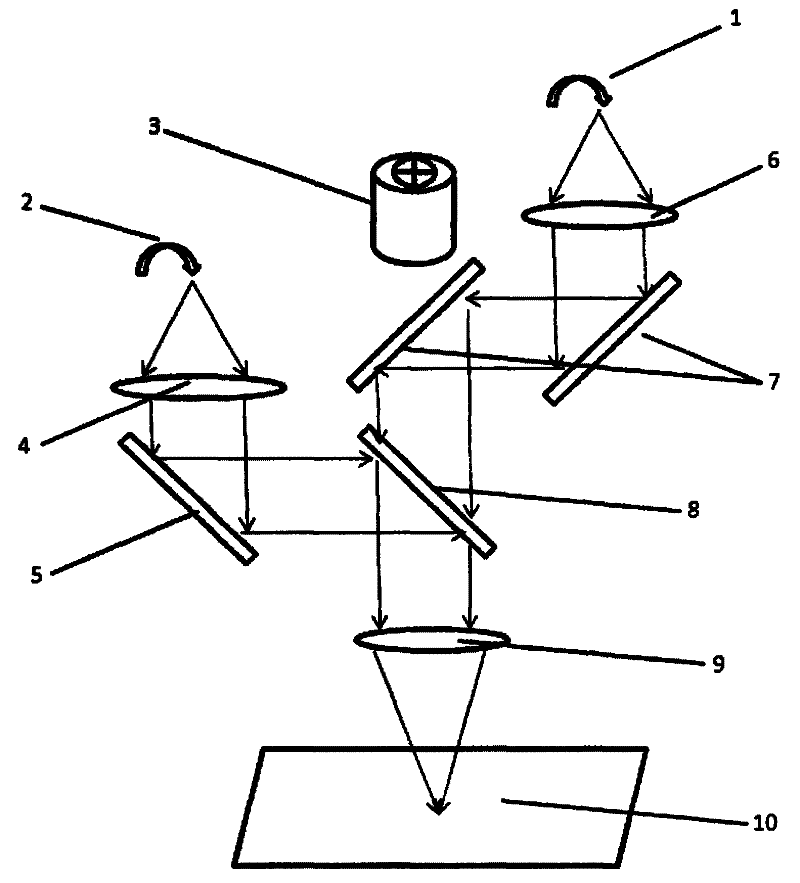

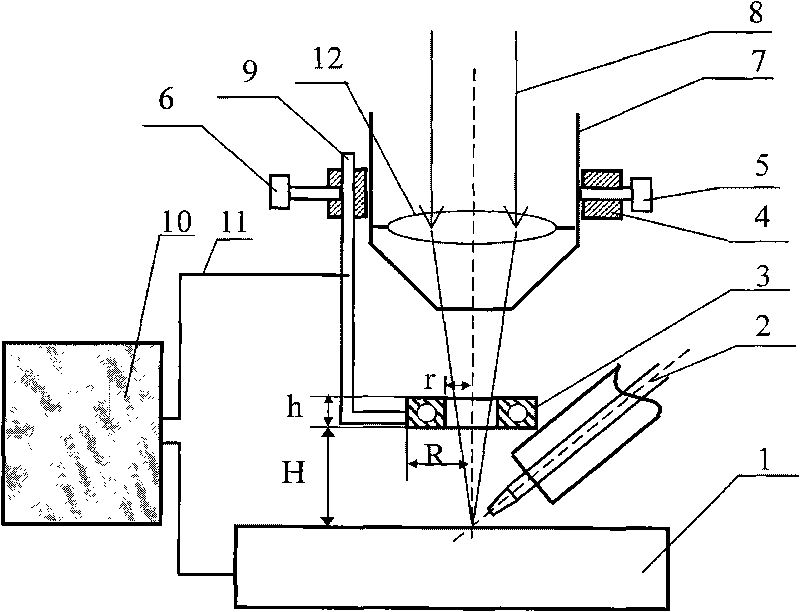

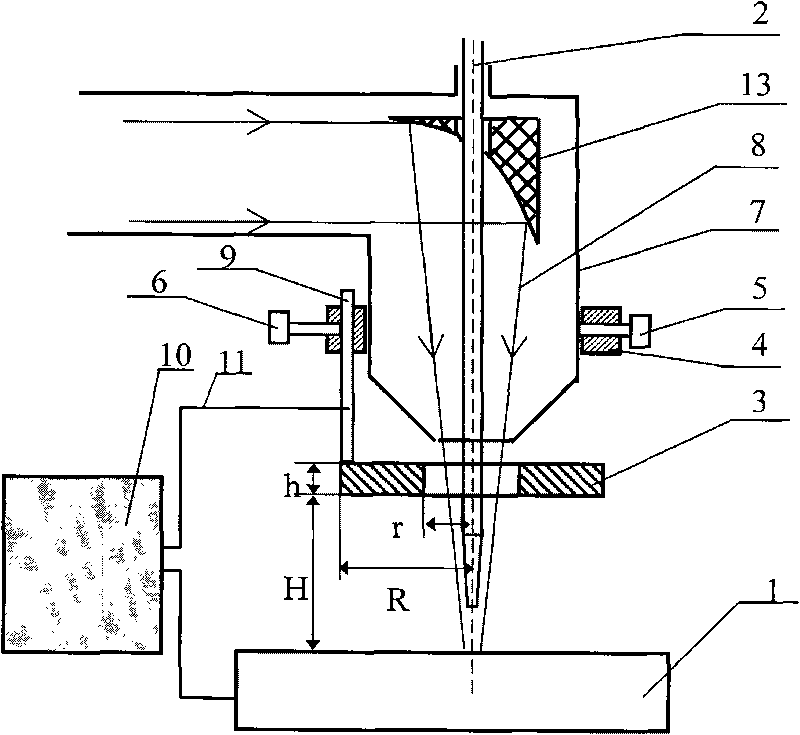

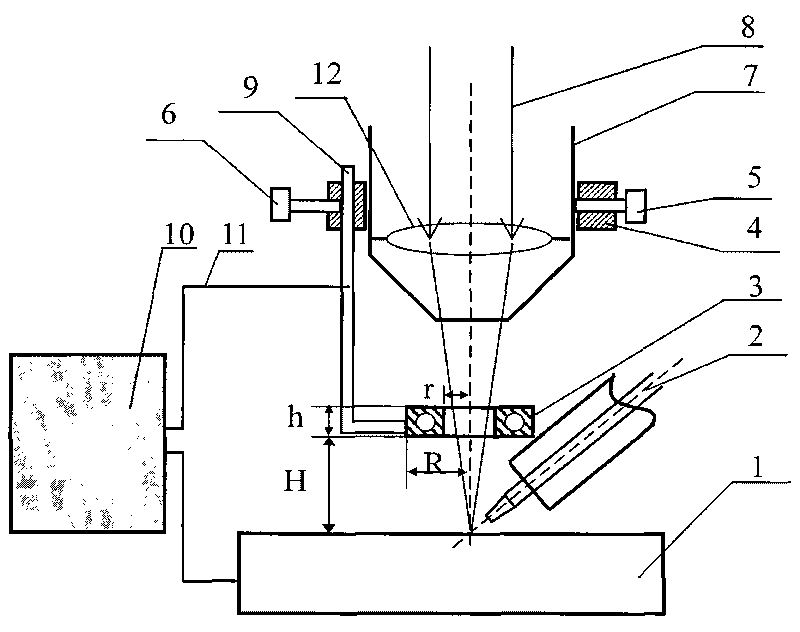

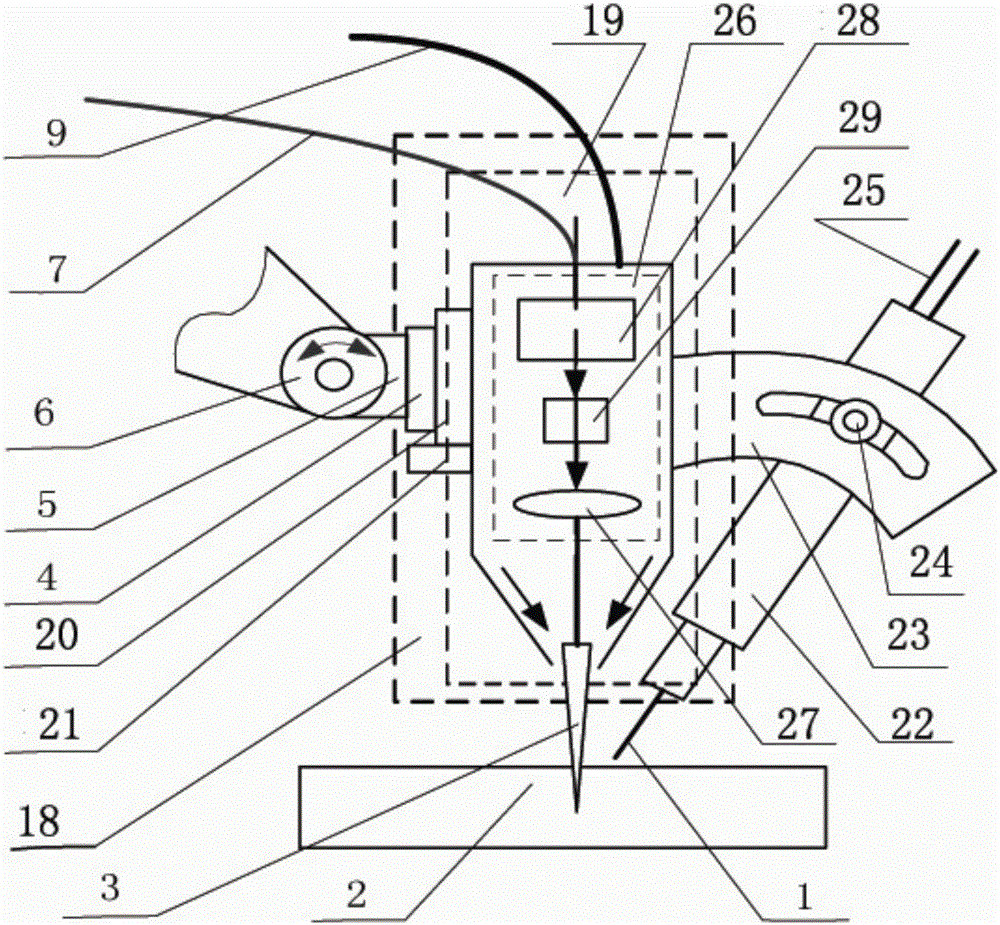

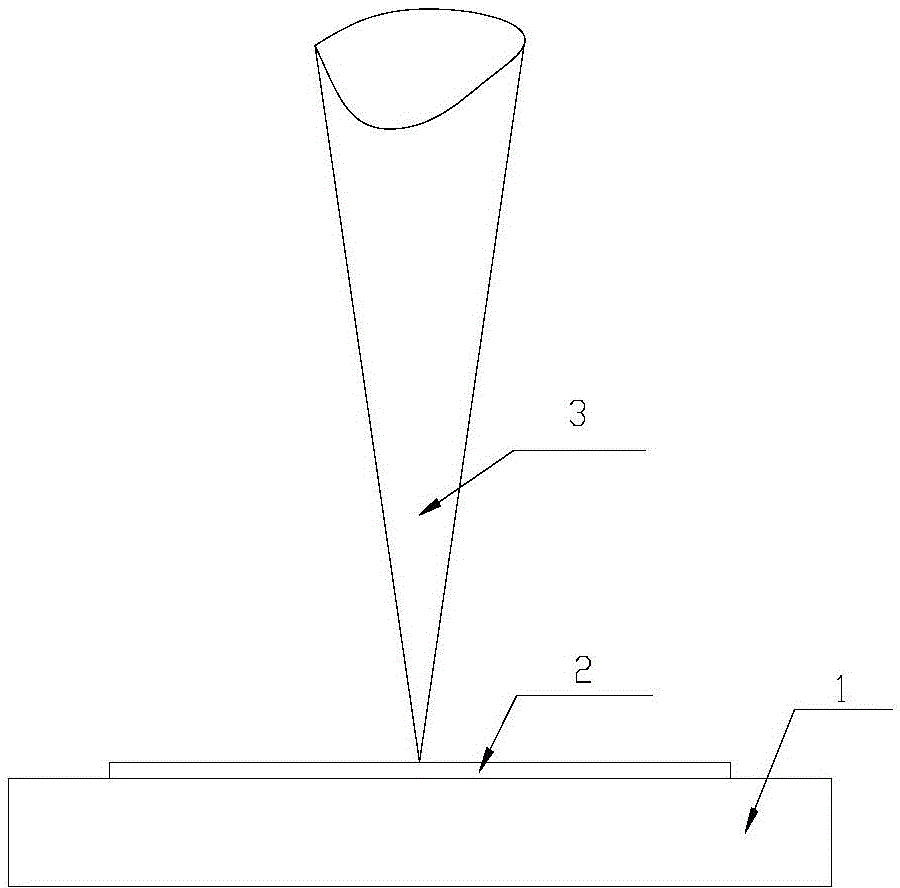

Dual-laser beam hybrid welding device and hybrid welding method

InactiveCN102500919AImprove absorption efficiencyCompact structureLaser beam welding apparatusNd:YAG laserErbium lasers

The invention provides a dual-laser beam hybrid welding device and a hybrid welding method. The dual-laser beam hybrid welding device comprises an ND: YAG (Neodymium-Doped Yttrium Aluminum Garnet) laser beam light path, and a dual-laser beam light path which is provided with a semiconductor laser beam light path and is arranged on a vertical dual-laser beam lens cone body. The dual-laser beam light path is provided with an ND: YAG total reflection lens, a semiconductor total reflection and ND: YAG total transmission combined lens, and a semiconductor and ND: YAG total transmission gathering lens in sequence from top to bottom. According to the invention, the high-freedom degree welding machining can be realized; the structure of the dual-laser beam hybrid welding device is simple and small; the alignment position is more accurate; and the automation is easy to realize. The dual-laser beam hybrid welding device can be used for welding positions which cannot be welded in a conventional manner, and a high-reflection and high-thermal conductivity material which cannot be welded by single laser, so that the application field of laser welding is enlarged, particularly a working piece is pre-heated by using a continuous semiconductor laser. The absorption efficiency of a material of the working piece to ND: YAG laser is improved, the welding fusion depth is increased, the welding speed and the welding efficiency are improved, and the occurrence of air vents and cracks in the welding process of working pieces is avoided.

Owner:UNITED WINNERS LASER CO LTD

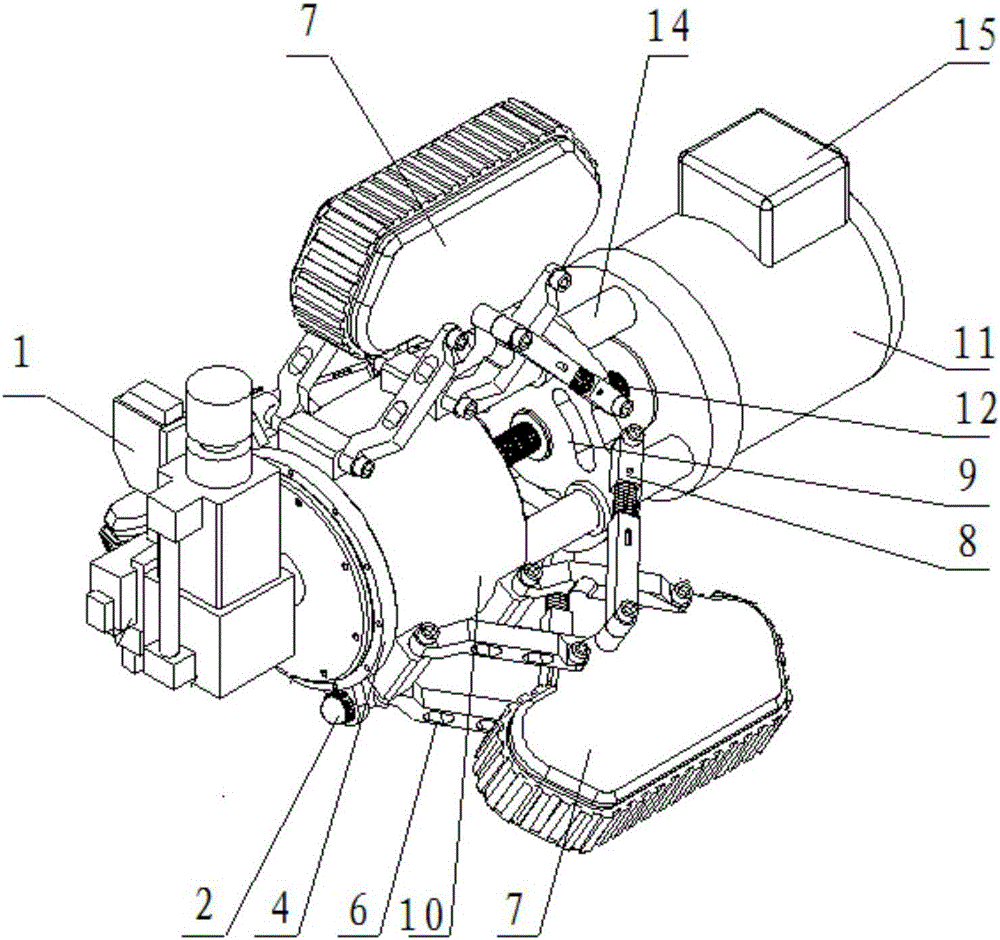

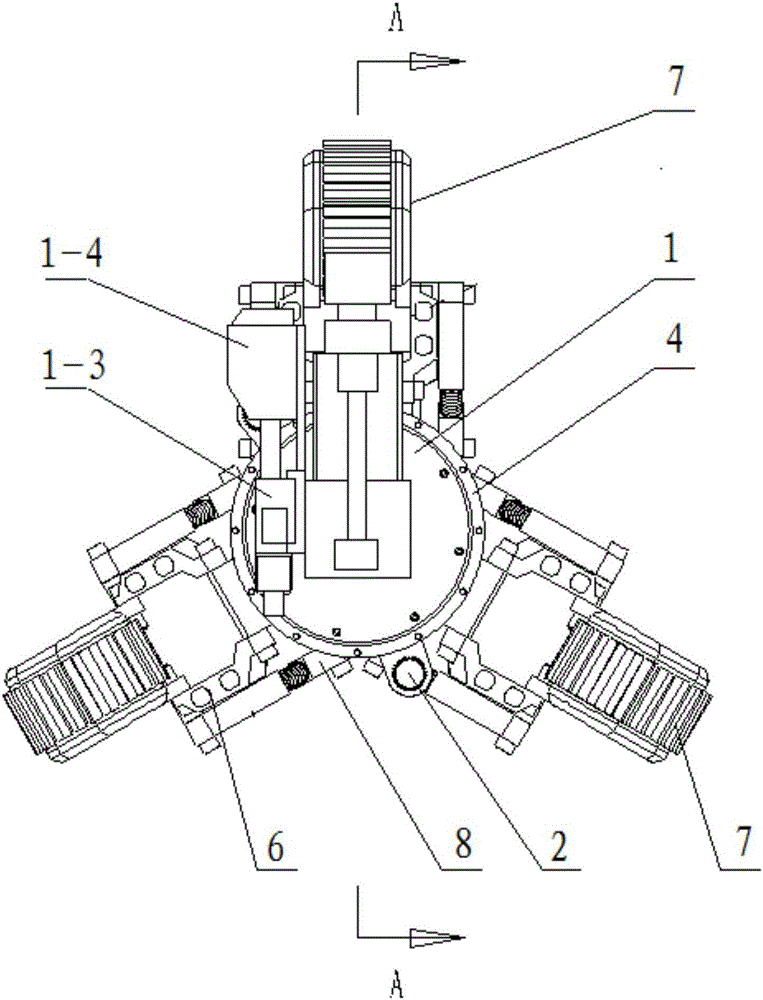

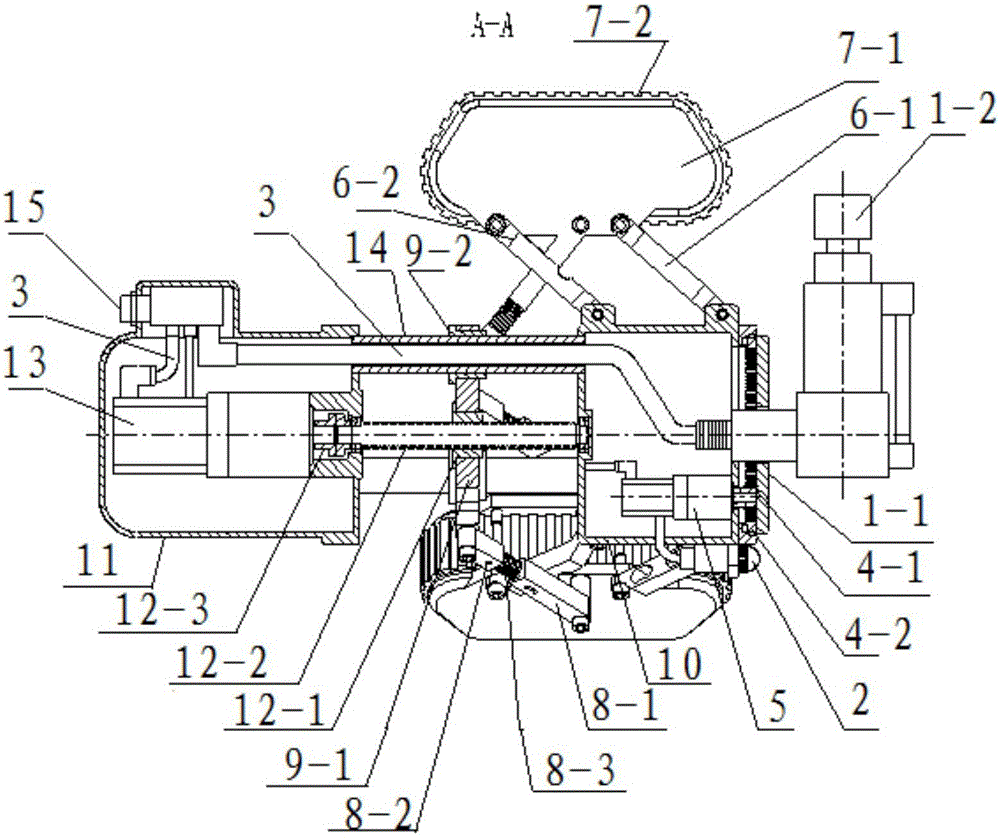

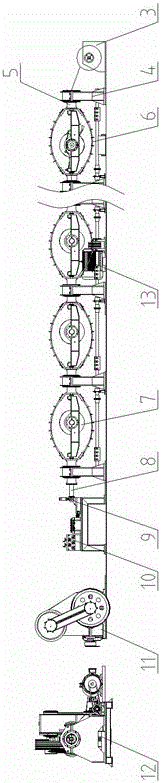

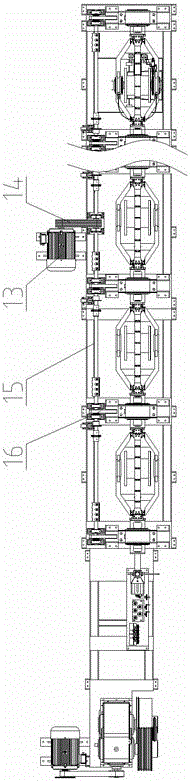

Laser root welding robot inside pipeline

ActiveCN105834586AAccurate guidanceQuality assurancePipeline systemsEndless track vehiclesEngineeringPipe welding

The invention discloses a laser root welding robot inside a pipeline and belongs to the technical field of pipeline welding. The laser root welding robot inside the pipeline comprises a weld joint welding device. A first transmission device is connected with the weld joint welding device. A front end machine base is connected with the first transmission device. A first gear motor is arranged in the front end machine base. One end of a connecting device is movably connected with the front end machine base. A crawler type traveling device is movably connected with the other end of the connecting device. One end of a pushing device is movably connected with the crawler type traveling device. A driving device is movably connected with the other end of the pushing device. A second transmission device is connected with the driving device. One end of the second transmission device is movably connected with the front end machine base. According to the laser root welding robot inside the pipeline, the welding fusion depth is large, the welding speed is high, accurate welding track guidance is provided for a laser welding head, and the quality of laser root welding is guaranteed.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

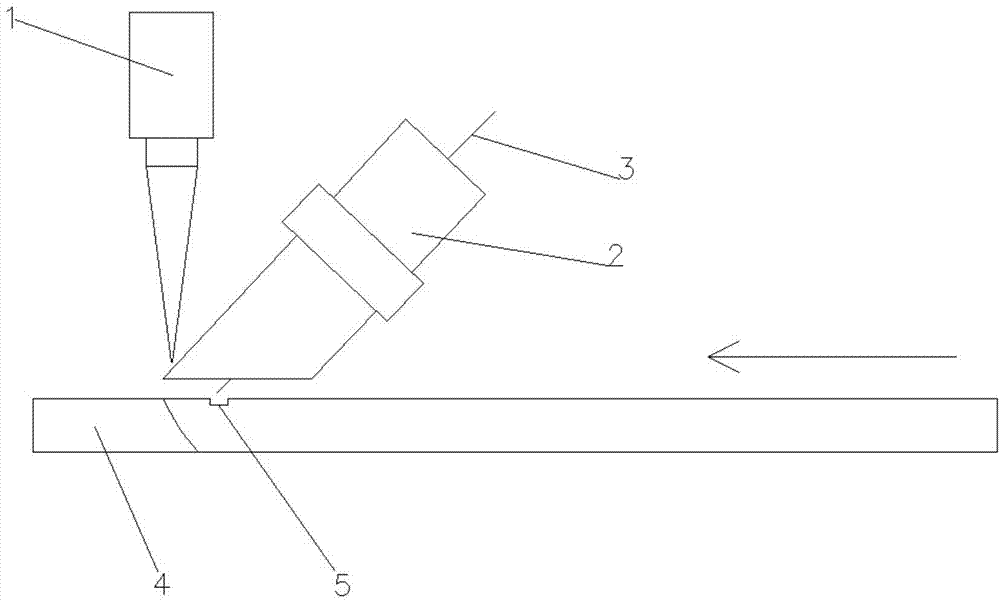

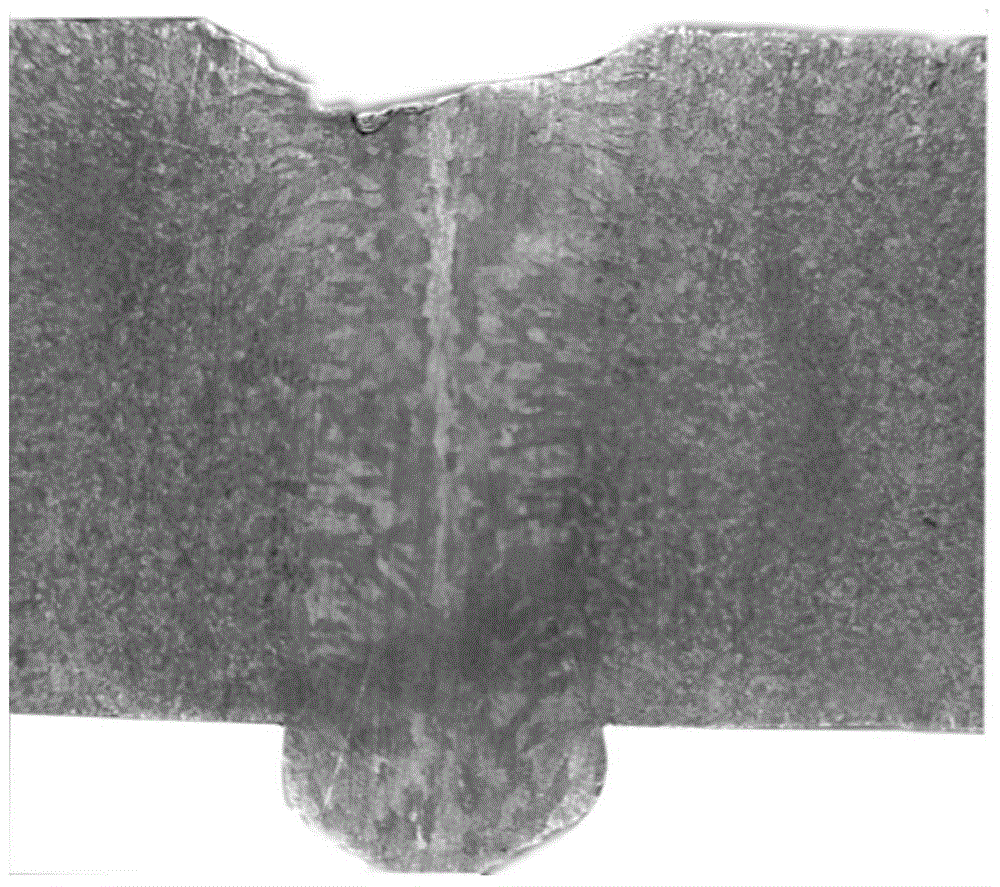

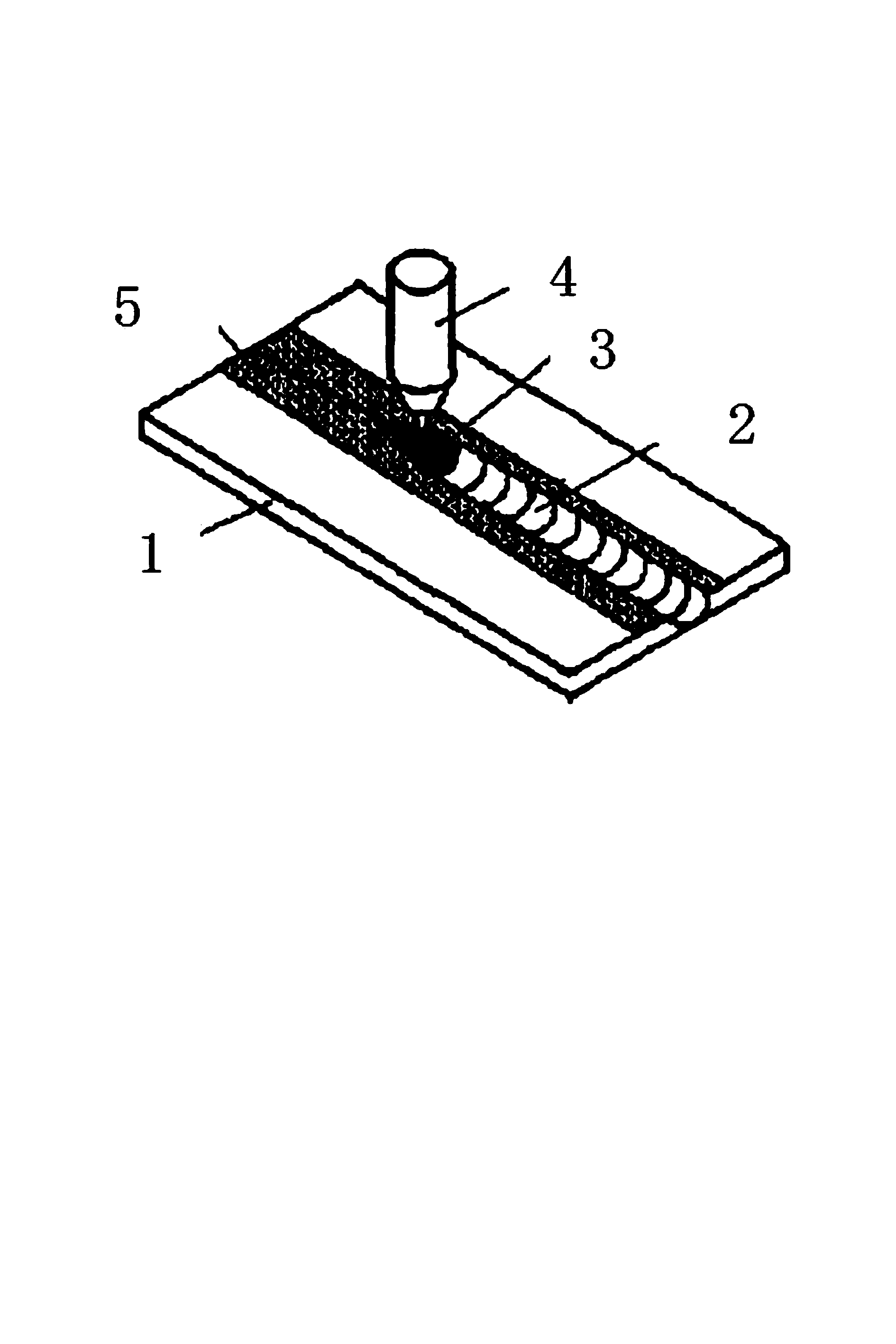

Active welding method and activating agent for aluminum and aluminum alloy

InactiveCN101347859AEasy to shapeIncrease weld penetrationArc welding apparatusWelding/cutting media/materialsBoiling pointHigh resistivity

The invention discloses an active welding method for aluminum and aluminum alloy and a surfactant. The main component of the surfactant is halide with low melting point, low boiling point and low electrical resistivity. Before the traditional TIG welding, the surfactant is coated evenly on the central area of on the surface of a welding bead to be welded. The width of the surfactant coating is not more than 10mm; a surfactant with high melting, high boiling point and high electrical resistivity is coated at both sides of the surfactant in the area respectively. The total width of the coating at both sides and in middle is more than 20mm, the surfactant of the coating at both sides is SiO2; the surfactant of the coating in middle consists of ZnF2, MnCl2, CdCl2 and Te, the weight percentage content is 5 percent to 15 percent of ZnF2, 40 percent to 55 percent of MnCl2, 20 percent to 35 percent of CdCl2 and 5 percent to 20 percent of Te.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

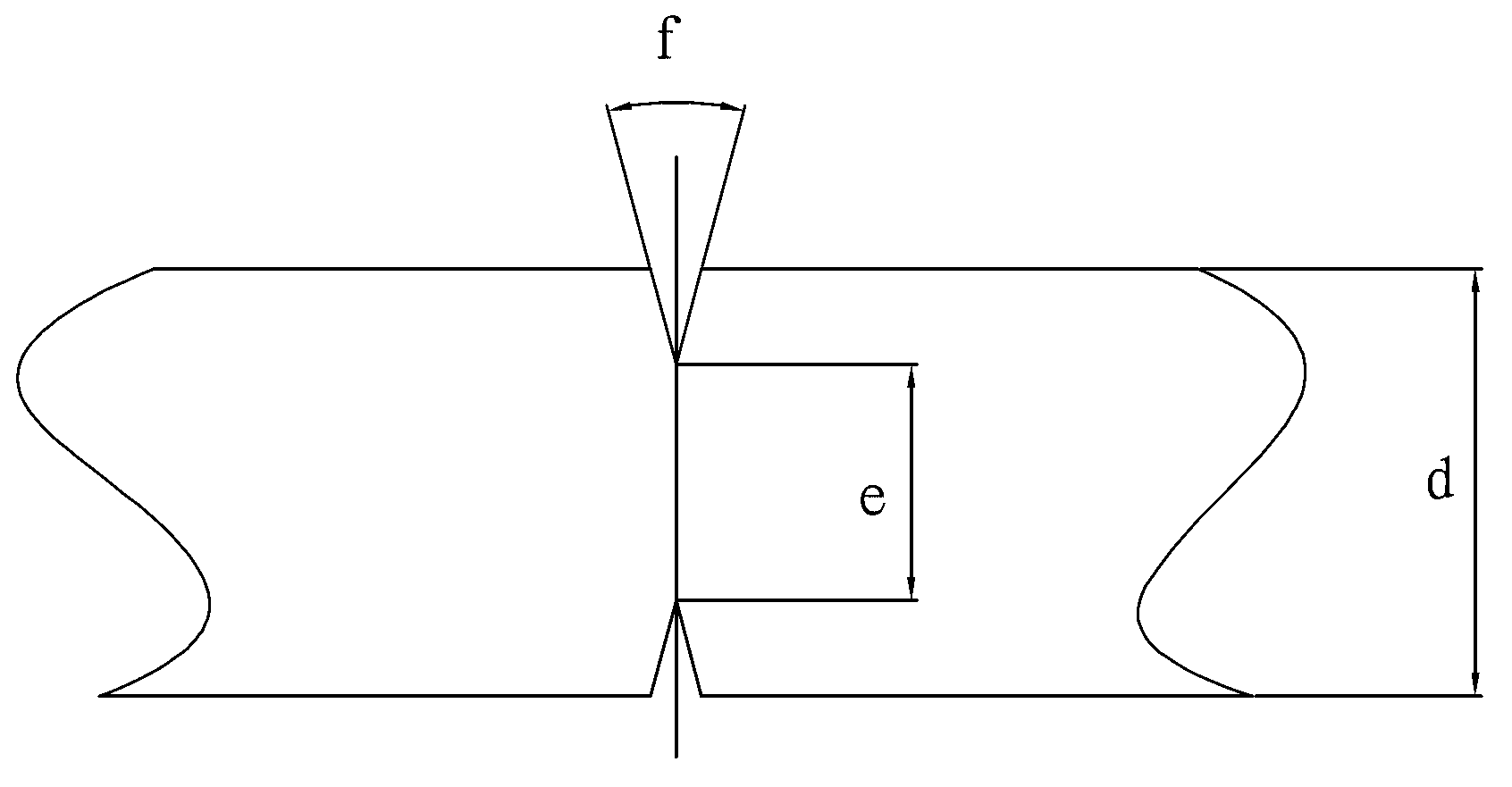

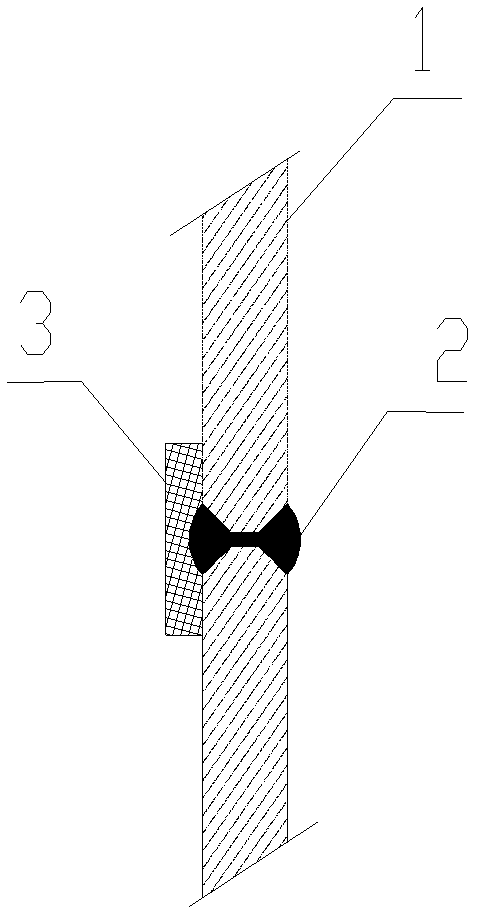

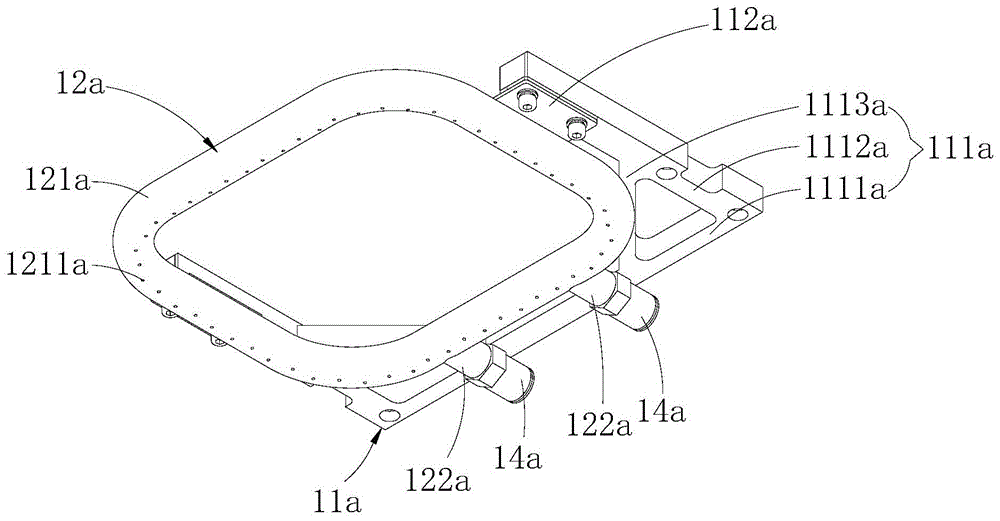

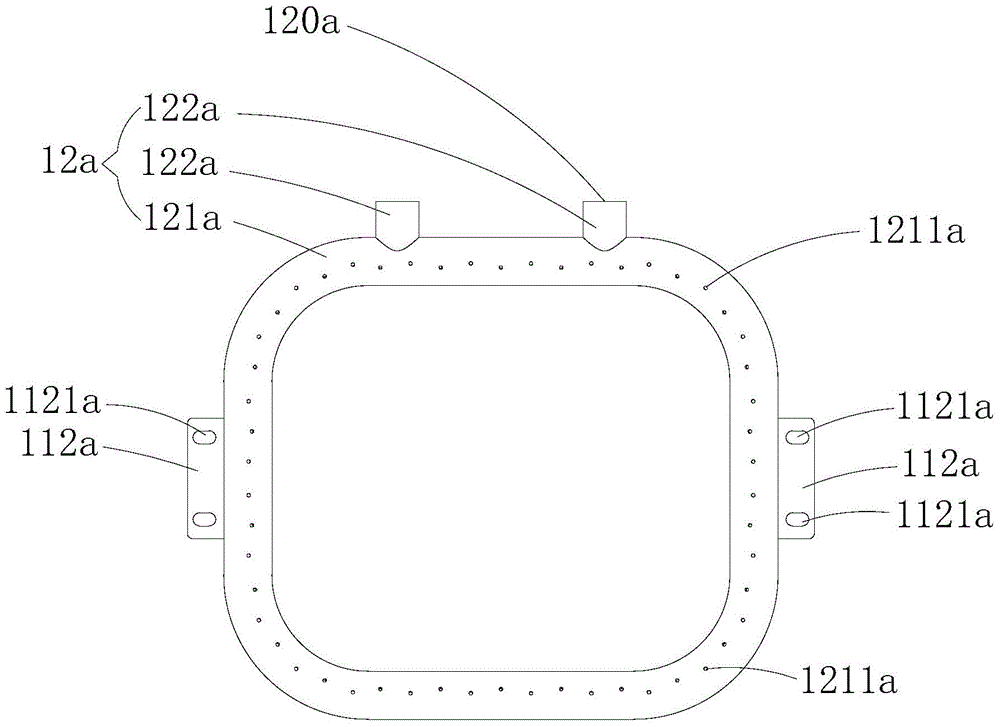

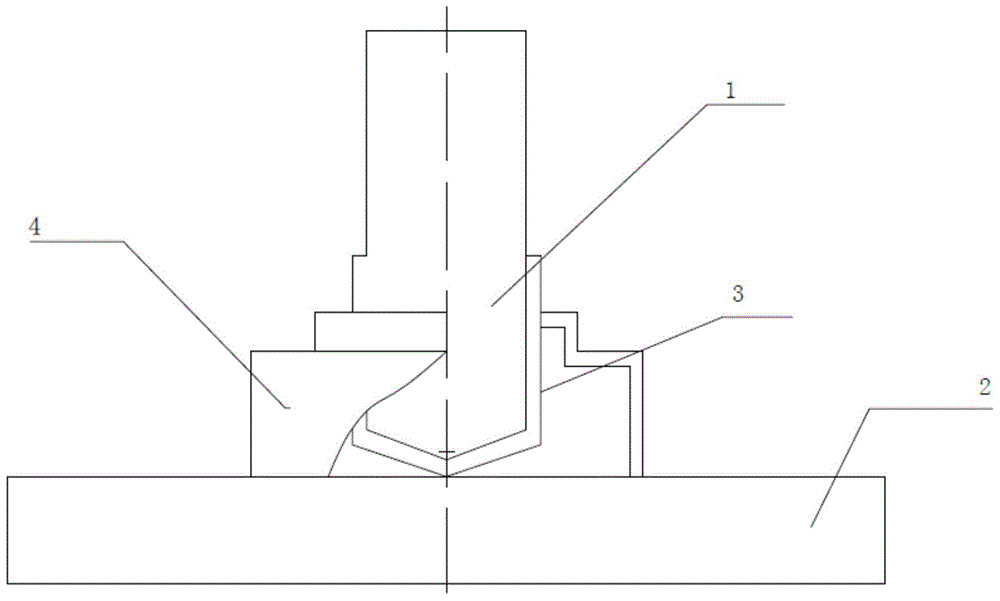

Large tank singe-face-weld double-face-forming method and weld joint forming pad

InactiveCN102489830AHigh technical levelReduce consumptionWelding accessoriesEngineeringWeld penetration

The invention provides a large tank singe-face-weld double-face-forming method, which comprises arranging a weld joint forming pad on the back face of a weld joint of a weld part, wherein the weld joint forming pad is provided with a weld joint forming groove with the shape matched with that of the weld joint; fixedly and tightly attaching the weld joint forming pad on the back face of the weld joint to enable the center of the weld joint to align at the center of the weld joint forming groove; welding the front face of the weld joint; using large weld current for weld penetration of a weld part at one step; and enabling a weld puddle to be cooled and solidified on the weld joint forming groove. Compared with a traditional double-face-weld method, the weld joint is formed by one step, weld quality is better, production efficiency is improved, and production cost is reduced.

Owner:CHONGQING POLYCOMP INT

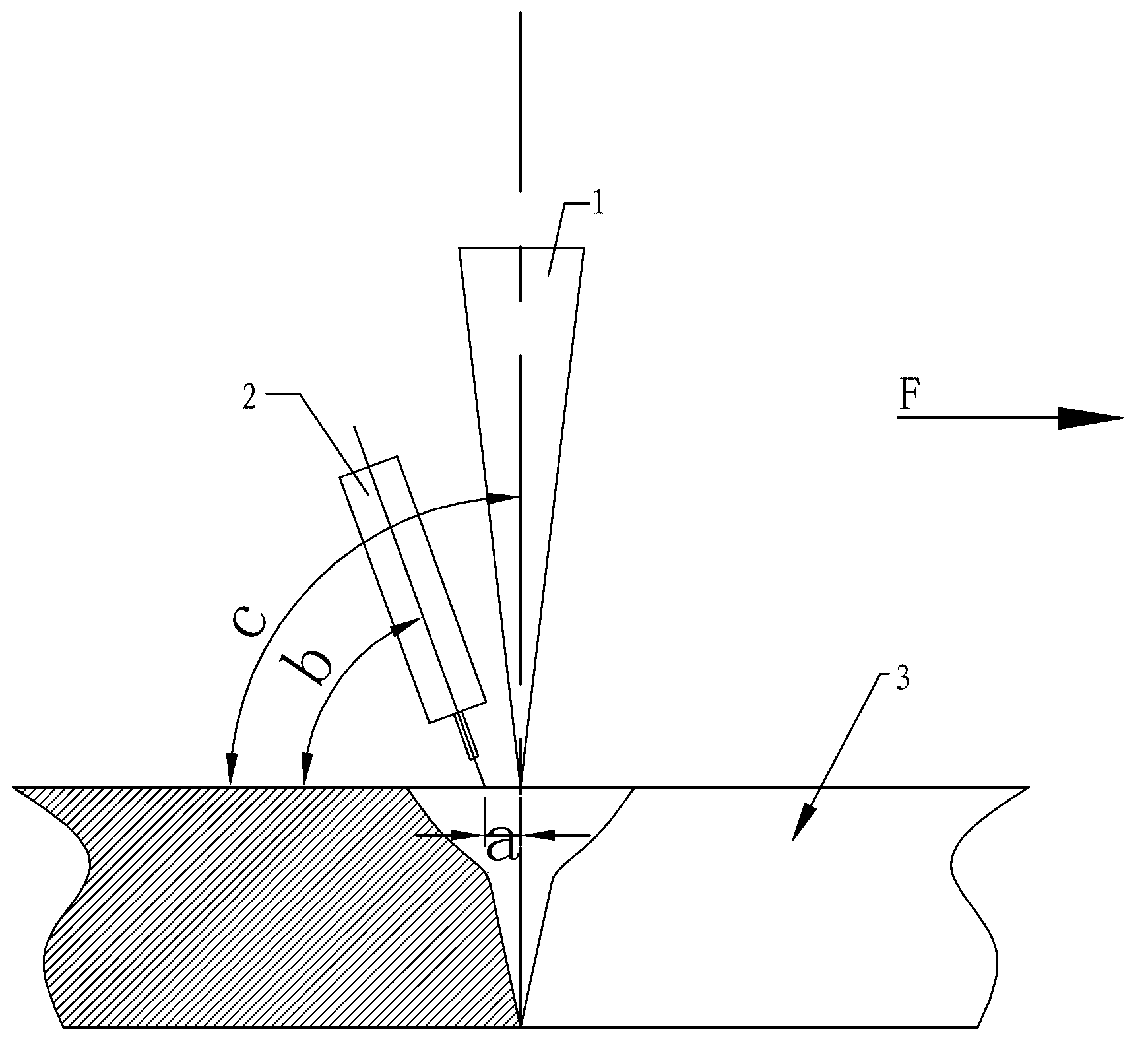

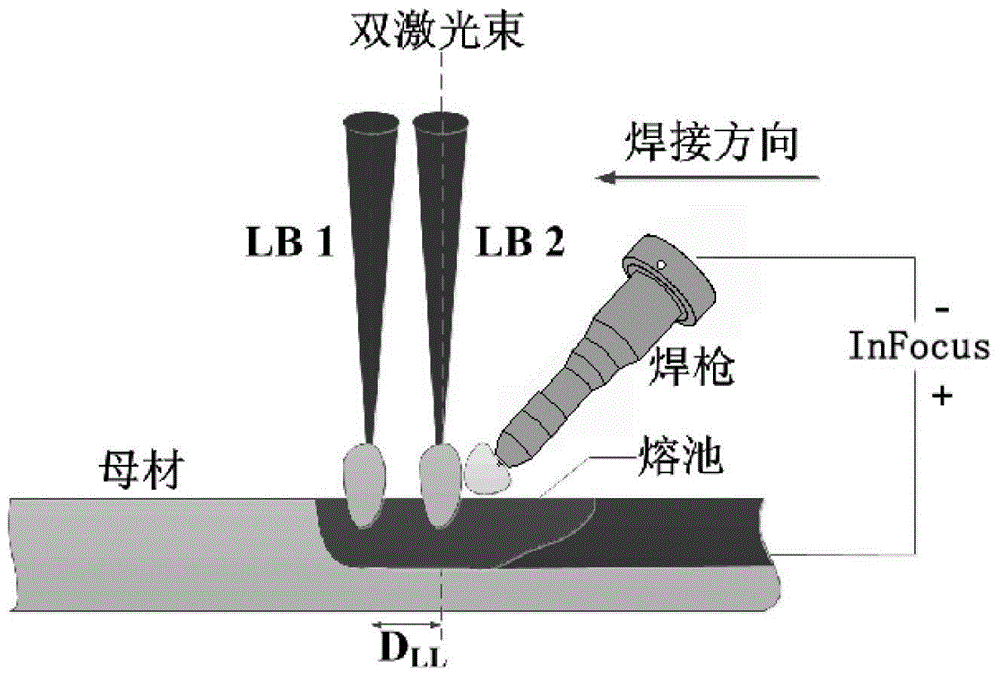

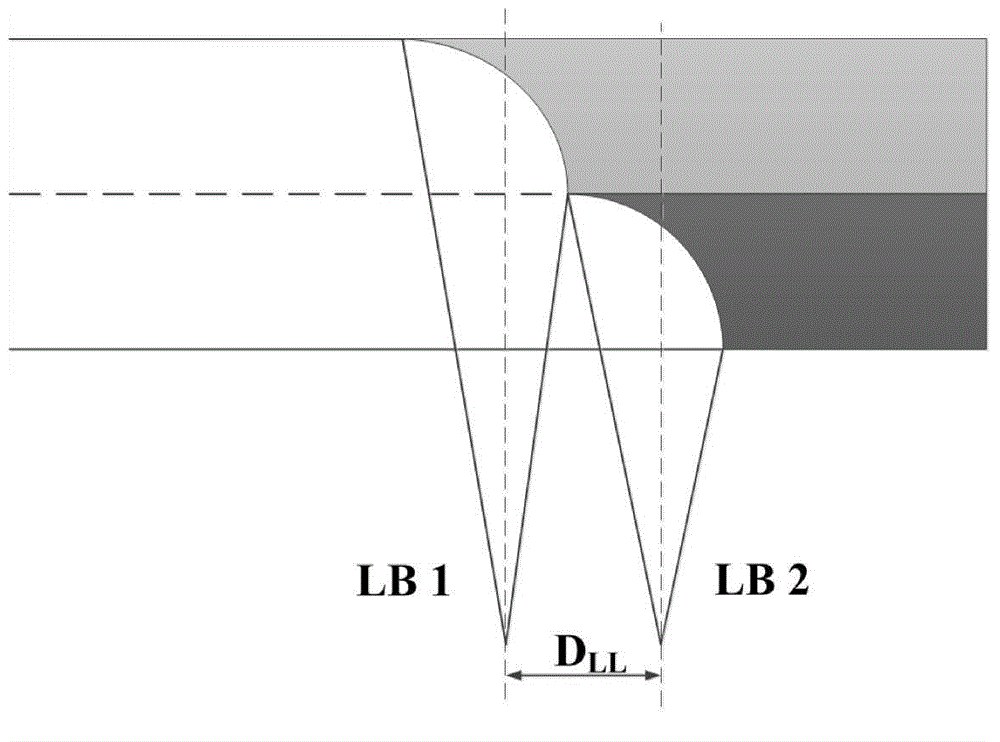

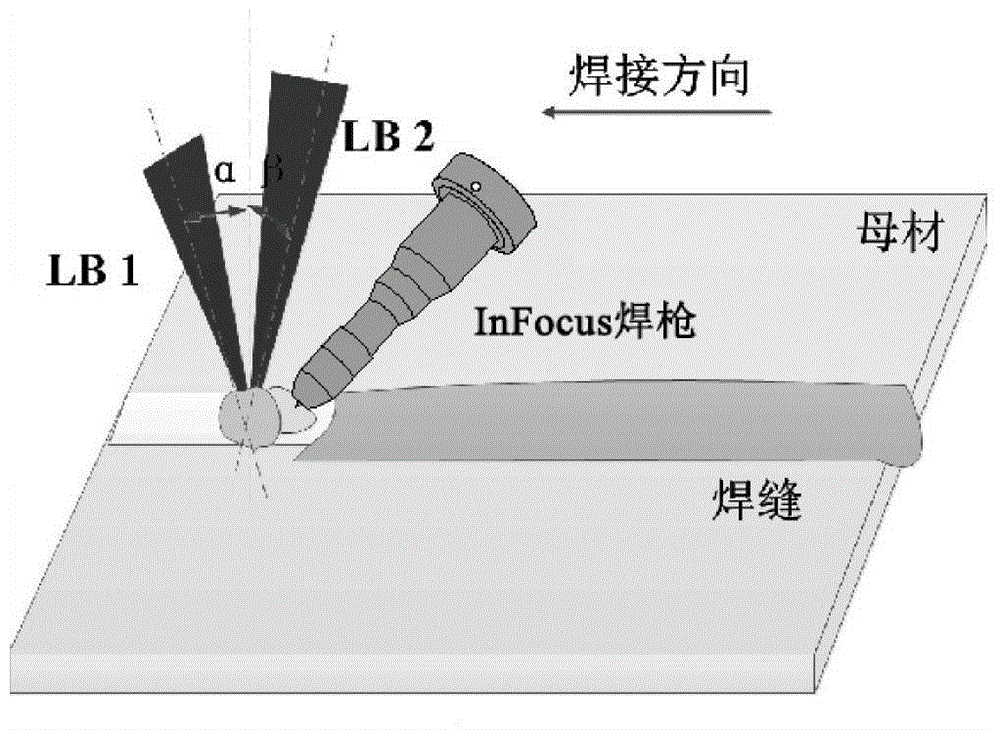

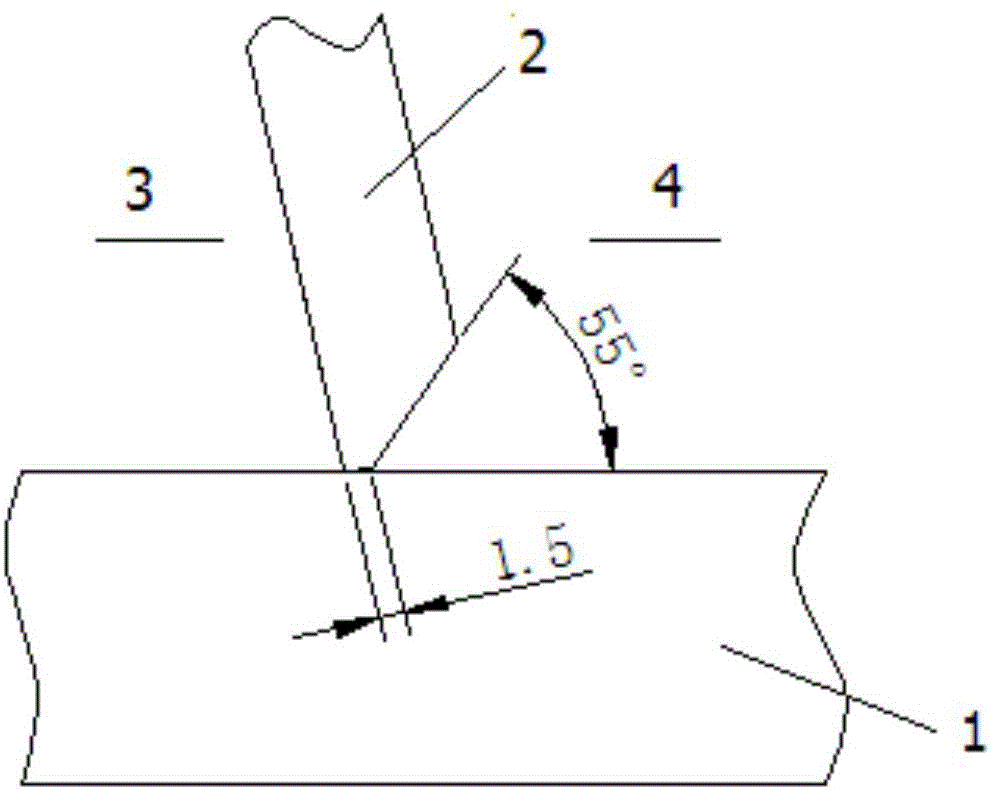

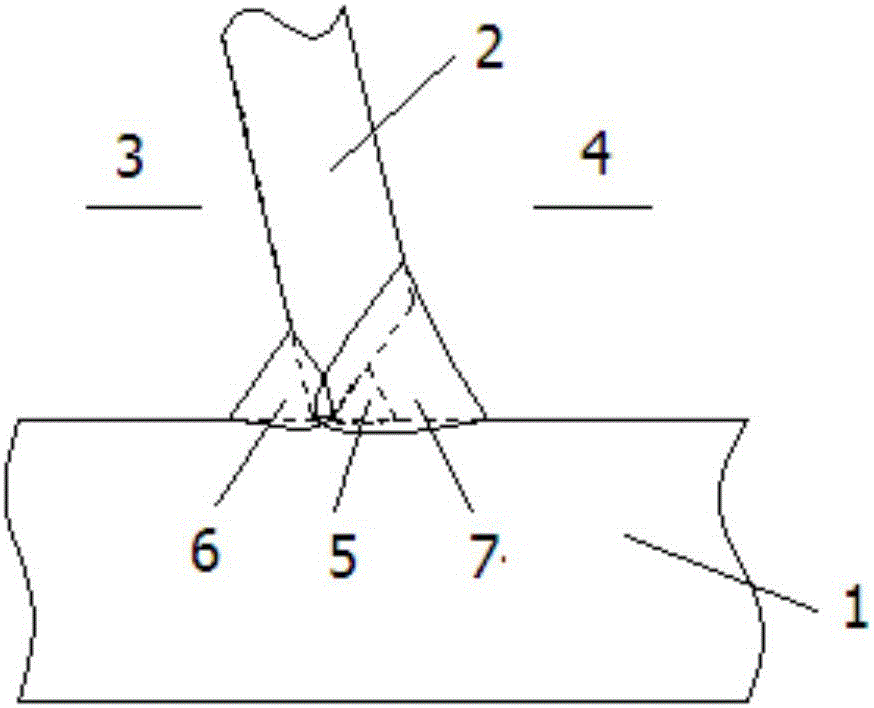

Bifocus laser and InFocus arc hybrid welding method

InactiveCN104985327AImprove energy utilizationIncrease weld penetrationLaser beam welding apparatusElectric arcEngineering

The invention discloses a bifocus laser and InFocus arc hybrid welding method, and relates to a welding method. The method includes the steps that (1) a to-be-welded workpiece is polished or washed; (2) the spot diameter is set to range from 0.1 mm to 0.5 mm, and the defocusing amount ranges from -3 mm to +3 mm; (3) welding parameters are set, wherein the arc current ranges from 50 A to 900 A, an included angle formed between a welding gun and the vertical direction ranges from 25 degrees to 55 degrees, the welding speed ranges from 100 mm / min to 1000 mm / min, the wire feeding speed ranges from 100 mm / min to 600 mm / min, the protection gas is inert gas, and the flow of the protection gas ranges from 15 L / min to 30 L / min; and (4) a switch is started, and laser-InFocus arc welding is carried out. According to bifocus lasers and InFocus, as the InFocus arc fusion depth is larger, and a key hole can be formed through welding, when a medium-thickness plate is welded, the lasers can directly act on the bottom of the key hole generated by the InFocus arc, and the fusion depth is continuously increased.

Owner:HARBIN INST OF TECH

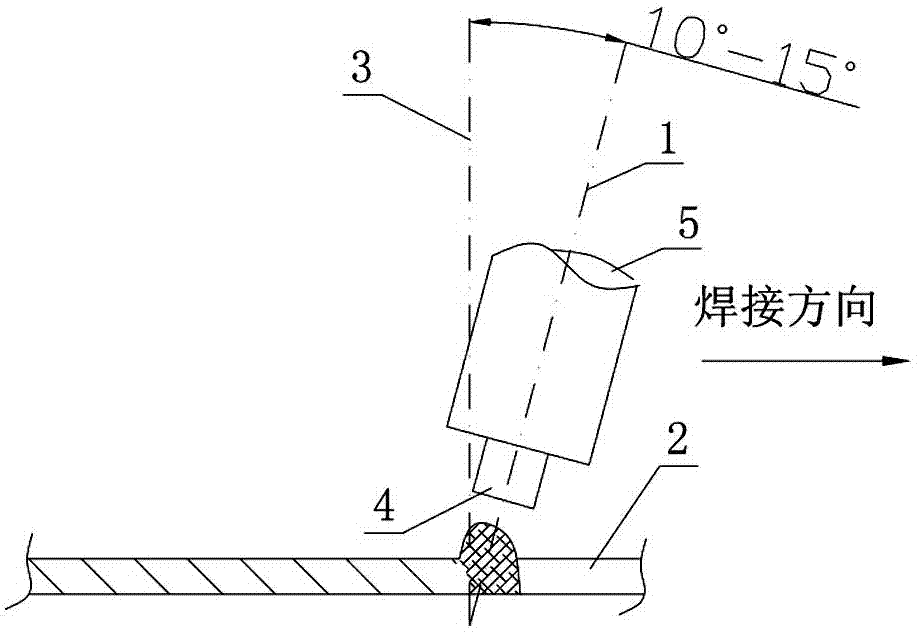

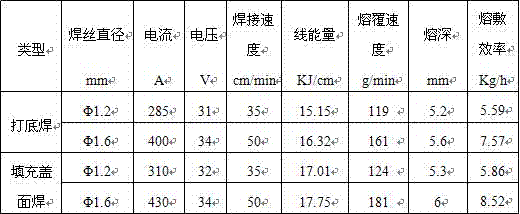

Method for automatically welding hydraulic support structural component through welding wires with diameter being 1.6 mm

ActiveCN106914686AMeet the requirements of the weldSolve serious burn damageArc welding apparatusFillet weldButt welding

The invention discloses a method for automatically welding a hydraulic support structural component through welding wires with the diameter being 1.6 mm. The method includes the steps that firstly, the part tolerance and the splicing precision of the hydraulic support structural component are checked before welding, and the depth tolerance of a welding groove and the angle tolerance of the welding groove are controlled; secondly, the two sides of a weld bead are ground before welding till metallic luster appears; thirdly, all to-be-welded weld joints of the hydraulic support structural component are located at flat welding or flat fillet welding positions; fourthly, off-line programming or on-site programming teaching is conducted on a welding robot; and fifthly, multi-layer and multi-channel welding is conducted on the to-be-welded weld joints through the welding robot by means of the welding wires with the diameter being 1.6 mm in a gas shielded welding manner. According to the method, robot welding is conducted through the welding wires with the diameter being 1.6 mm, and compared with traditional welding conducted through welding wires with the diameter being 1.2 mm, under the condition that the ton cost of the welding wires is not changed and all mechanical properties of the weld joints can meet requirements, the weld penetration of the weld joints is increased, efficiency is improved by 40% or above, and the comprehensive cost of welding conducted through each ton of welding wires is saved by RMB 1500 yuan or above.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

Laser-electric arc composite welding method through extra electric field

InactiveCN101745747AHigh strengthFacilitated ionizationLaser beam welding apparatusElectrical field strengthMaterials processing

The invention belongs to the technical field of material processing, which relates to a laser-electric arc composite welding method. The method comprises the following steps: installing an extra electrode in the position with the distance of 4 to 100 mm higher from the surface of a work piece to be welded in the direction vertical to the laser beam; forming a hole in the center of the extra electrode for passing the laser beam; and respectively connecting the extra electrode and the work piece to be welded to both ends of a DC stabilized voltage supply with the output voltage between 1 and 220 V at the electric field intensity between 1 and 220 V / cm. When the laser power is between 300 W and 500 W, the electric arc current is between 100 A and 300 A, and the electric arc current is between 20 V and 35 V, the optimum range of the extra electric field intensity is between 30 V / cm and 60 V / cm. The invention can fully utilize the energy of the laser and the electric arc, and can realize the effect of obtaining large composite hot source welding fusion depth under the condition of lower laser output power. Compared with the existing laser-electric arc composite welding method under the same process condition, the invention has the advantage that the fusion depth is increased by 15 percent to 40 percent.

Owner:DALIAN UNIV OF TECH

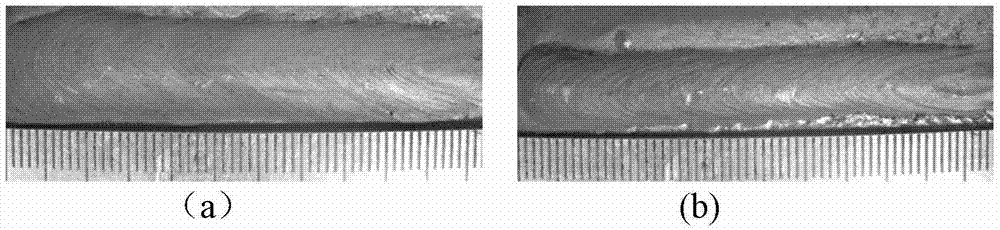

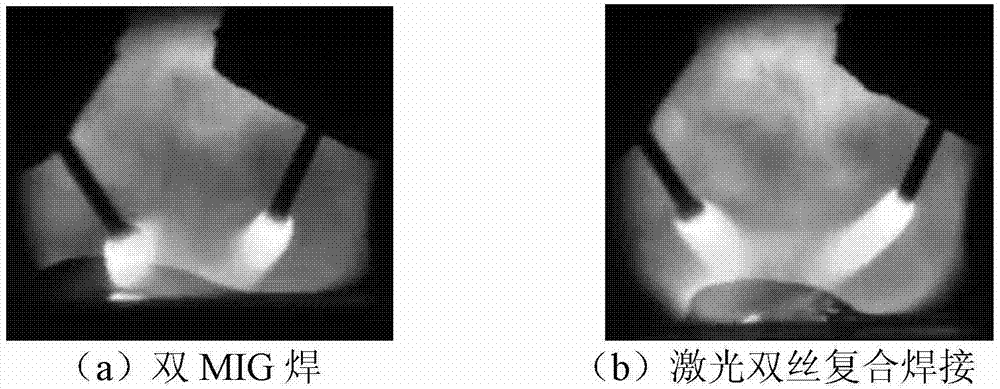

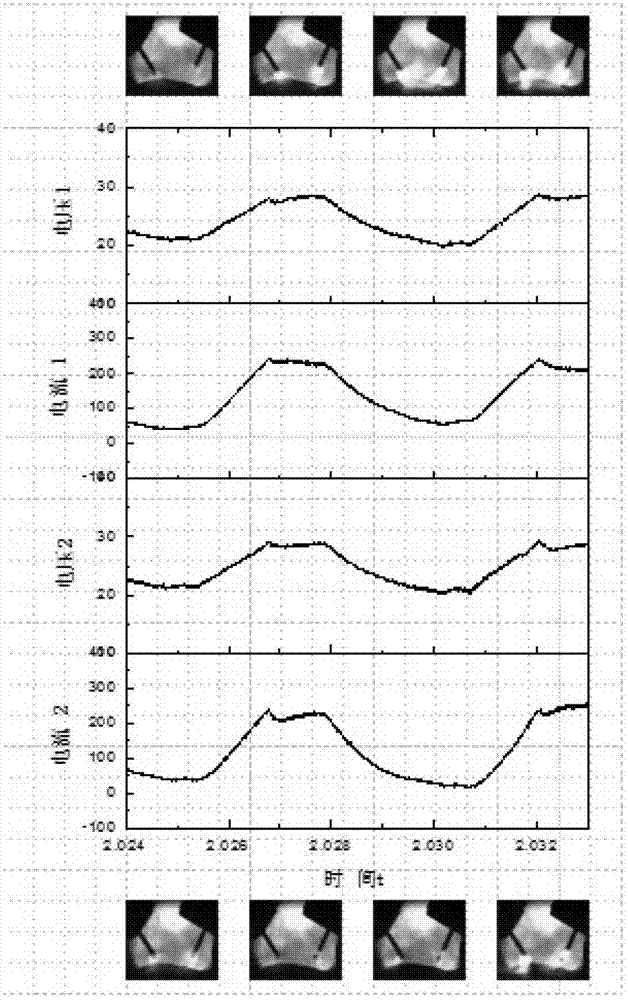

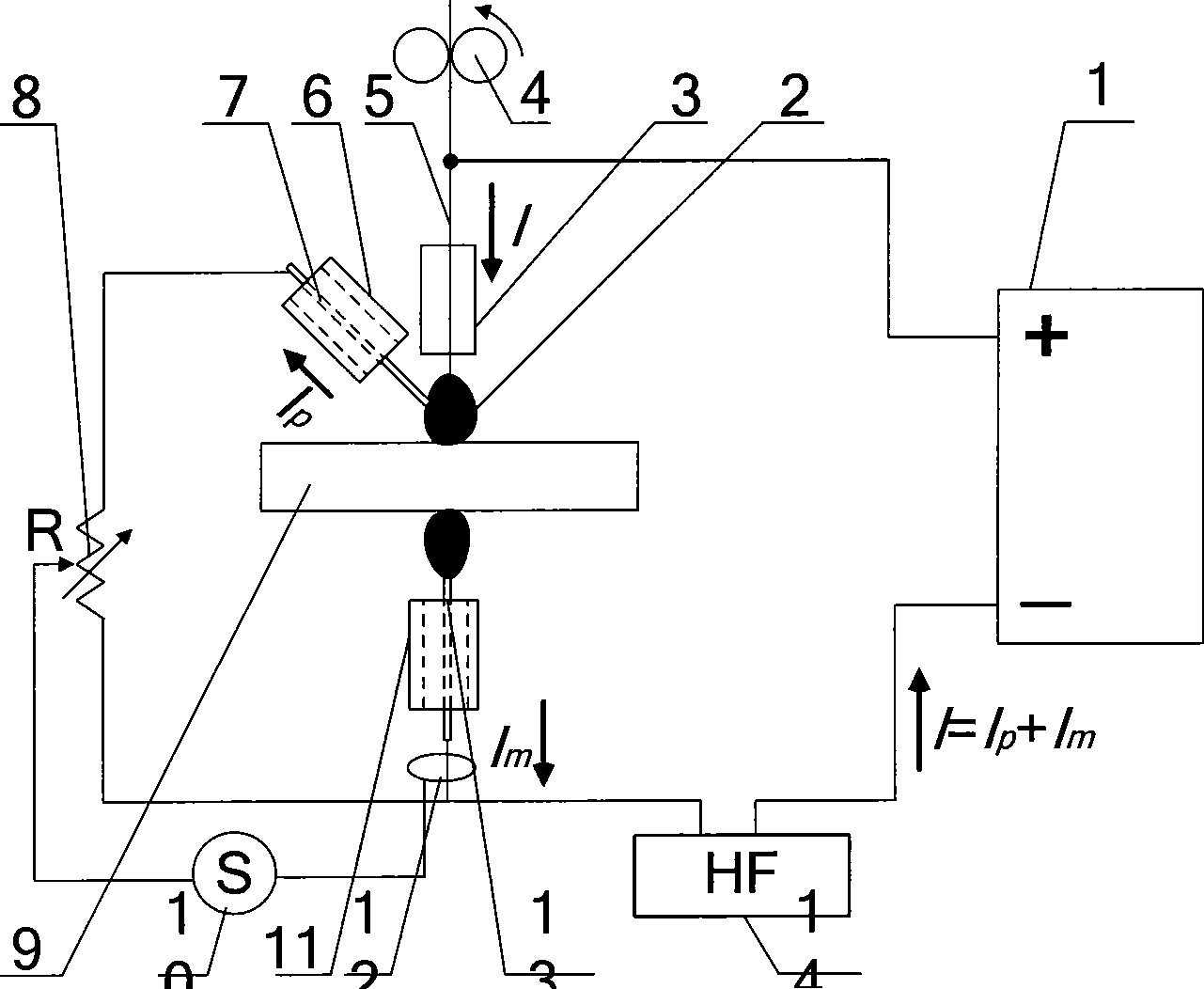

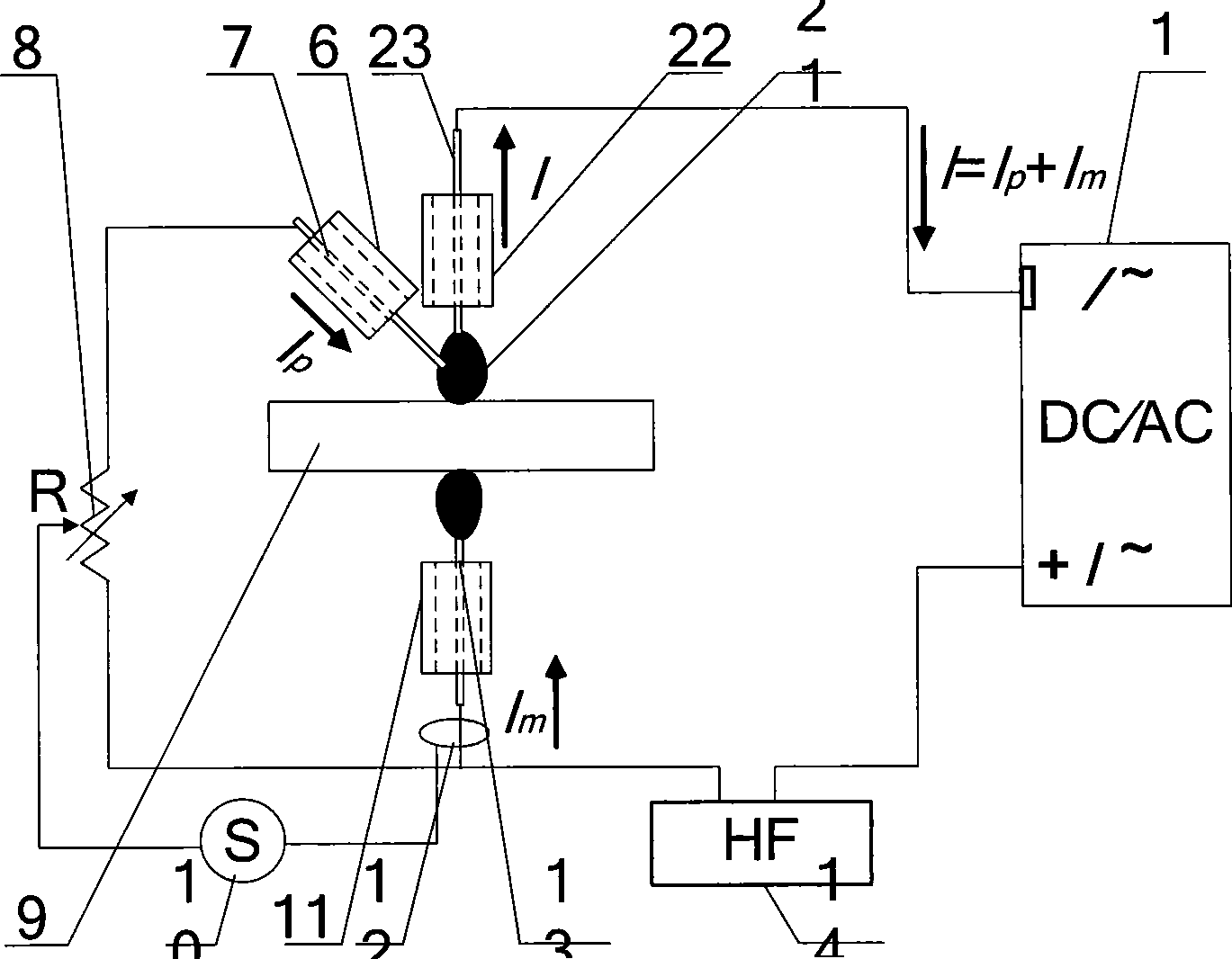

Laser-single power double-wire pulse arc hybrid welding system and use method for same

InactiveCN102848085AEasy to shapeRealize alternate arcingLaser beam welding apparatusElectricityElectric arc

The invention discloses a laser-single power double-wire pulse arc hybrid welding system and a use method for the laser-single power double-wire pulse arc hybrid welding system. The laser-single power double-wire pulse arc hybrid welding system comprises a first welding gun, a second welding gun, an electric welding machine and a laser device, wherein the laser device is used for generating laser beams, the electric welding machine is used for outputting signals to the first welding gun and the second welding gun, the first welding gun and the second welding gun are connected with the anode of the electric welding machine, and the cathode of the electric welding machine is connected with a work piece. According to the hybrid welding system provided by the invention, the laser is combined with the double-wire MIG (Metal-Inert Gas) welding, and the advantages of the laser and the double-wire MIG welding are integrated and the disadvantages thereof are overcome, so that the welding melting efficiency is improved, the depth of fusion is increased, the welding speed is improved, and steady welding is obtain excellent welding quality.

Owner:TIANJIN UNIV

Laser and MIG electric arc compound welding method for high-strength steel butt joints

InactiveCN103831541AReduced assembly requirementsReduce distortionWelding/soldering/cutting articlesLaser beam welding apparatusSand blastingButt joint

The invention discloses a laser and MIG electric arc compound welding method for high-strength steel butt joints. The laser and MIG electric arc compound welding method comprises the specific steps that (1) high-strength steel butt joints to be welded are machined to be provided with I-shaped grooves, wherein the high-strength steel butt joints are of a butt joint form; (2) the high-strength steel butt joints to be welded are assembled, and the size of an assembly gap between the high-strength steel butt joints is controlled to be smaller than or equal to 0.1delta; (3) welding wires are selected according to the materials of the high-strength steel butt joints to be welded, and pre-welding treatment such as oil removal, acid pickling, drying and sand blasting is carried out on the high-strength steel butt joints to be welded and the welding wires; (4) a laser source and an MIG thermal source are arranged, wherein a laser beam is perpendicularly incident from the position which is one to three millimeters away from the front portion of the MIG thermal source, the welding wires are fed into the upper surface of the high-strength steel butt joints to be welded through an MIG muzzle, and the angle between each welding wire and the horizontal plane ranges from 30 degrees to 60 degrees; (5) laser beam and MIG compound welding is carried out, and in an initial period, the maintenance time of lasers and the maintenance time of an electric arc range from 0 s to 0.5 s. The laser and MIG electric arc compound welding method for the high-strength steel butt joints, welding penetration is improved, the requirement for assembly conditions is reduced, welding quality is improved, and high welding performance is achieved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

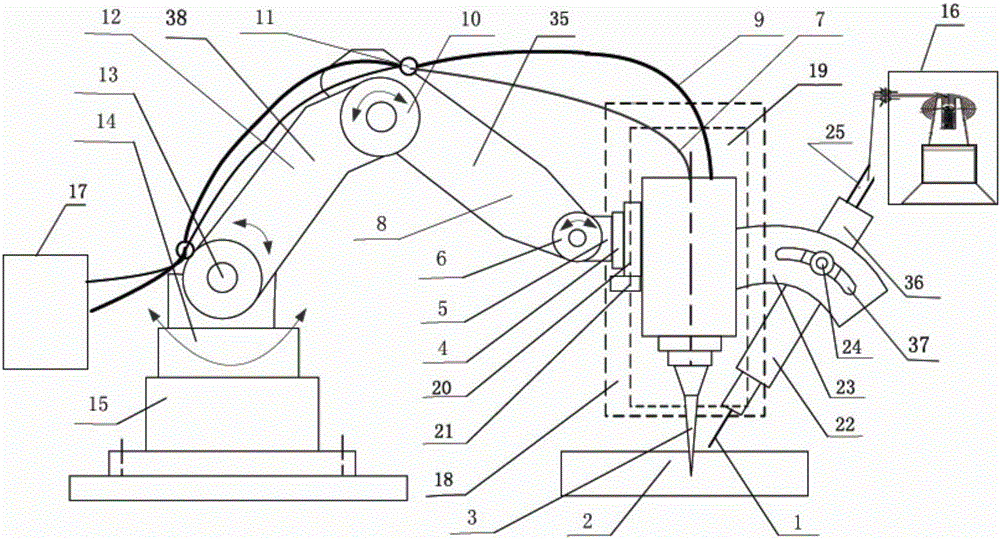

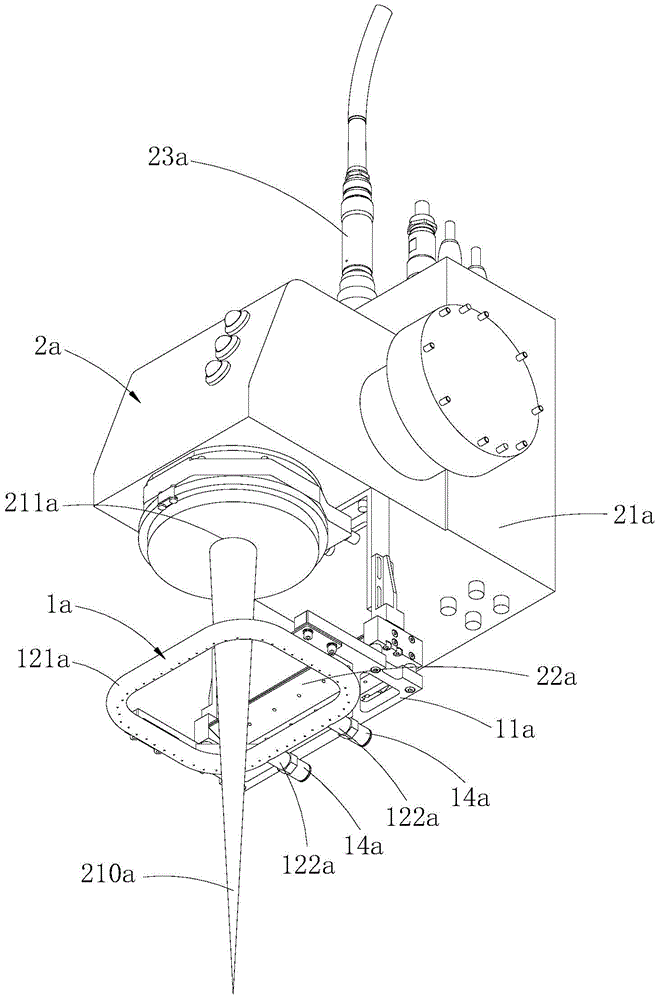

Robot laser-electric arc hybrid welding device and method

InactiveCN106166645ARealize 3D operationFully automatedLaser beam welding apparatusPetroleumElectric arc

The invention relates to the technical field of welding, in particular to a robot laser-electric arc hybrid welding device and method. The robot laser-electric arc hybrid welding device and method is composed of a robot laser welding device, an MIG welding device and a control unit. The robot laser welding device comprises an optical fiber laser, a control unit, a welding robot and a laser head unit. The MIG welding device comprises an electric arc welding gun, a welding gun adjusting fixing frame and an intelligent wire supplying device. The intelligent wire supplying device is connected with the tail portion of the electric arc welding gun and supplies welding wires to the electric arc welding gun. The electric arc welding gun is installed on the welding gun adjusting fixing frame. The welding gun adjusting fixing frame is installed on a laser head of the robot laser welding device. The control unit is connected with the robot laser welding device and the MIG welding device through a circuit and controls the robot laser welding device and the MIG welding device. The robot laser-electric arc hybrid welding device and method have the advantages that melting seams are deep, the speed, the efficiency, the stability and the welding line adaptability are high, and the cost is low, and can be widely applied to fields of large LNG storage tanks, automobiles, aerospace, the shipbuilding industry and petroleum pipelines.

Owner:CANGZHOU DWAYA LASER TECH CO LTD +1

Bypass shunt double-sided arc welding device and welding method

InactiveCN101530943AImprove carrying capacityAchieve high deposition rateArc welding apparatusElectrode erosionWelding power supply

The invention relates to a bypass shunt double-sided arc welding device and a welding method, which is characterized in that the device comprises a welding source, a main welding gun, an auxiliary welding gun, a bypass welding gun, an arc striker, a current sensor, a bypass resistor and a control system, etc. the main welding gun and the auxiliary welding gun are symmetrically arranged at both sides of a workpiece and are connected with two poles of the welding source; the bypass welding gun is argon tungsten-arc welding gun and is applied to one side of the main welding gun as a bypass to shunt partial welding current flowing through mother plates; therefore, the main welding gun can be connected with big current, reduce heat input acting on the mother plates while realizing high deposition efficiency and improve welding quality, while the auxiliary welding gun on the back of a molten pool is only connected with partial current, which is conductive to reducing electrode erosion and improving bearing capacity of the molten pool. As tungsten electrode electronic work function of the bypass welding gun is far lower than that of a metal workpiece, by the method, limit of welding wire shunt can be overcome and bypass current can be conveniently adjusted so as to ensure heat and force acting on the arc and molten pool are at ideal levels, therefore, the welding method is efficient and controllable.

Owner:HARBIN ENG UNIV

Variable-focus laser welding equipment, blowing protecting device thereof and blowing protecting method

ActiveCN104942436AQuality improvementImprove efficiencyLaser beam welding apparatusOptoelectronicsExhaust pipe

The invention is applicable to the technical field of laser welding, and discloses a variable-focus laser welding blowing protecting method, a variable-focus laser welding blowing protecting device and variable-focus laser welding equipment with the blowing protecting device. The variable-focus laser welding blowing protecting device is arranged on a side with a focusing lens of a variable-focus laser welding head, is used for restraining smoke and plasmas from flying towards the side with the focusing lens in a variable-focus laser welding process and comprises a connecting support, an exhaust pipe and a gas supplying component for delivering gas to the inside of the exhaust pipe; the exhaust pipe is provided with a hollow inner cavity, a gas inlet and a plurality of exhaust holes; and the exhaust holes are formed in a wall surface, which backs on to the variable-focus laser welding head, of the exhaust pipe. The technical problem that smoke and plasmas which are generated when a variable-focus laser welding technology is applied to work pieces with complex surface structures such as sheet metal parts of a body in white of an automobile affect laser welding quality and welding efficiency greatly is solved.

Owner:HANS LASER TECH IND GRP CO LTD

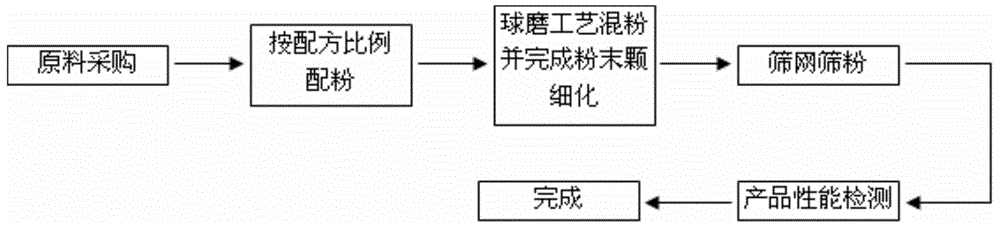

Stainless steel active rosin flux and preparation method thereof

InactiveCN102451962AIncrease weld penetrationArc welding apparatusWelding/cutting media/materialsWeld penetrationArc welding

The invention provides a stainless steel active rosin flux for arc welding and a preparation method thereof. A formula of the stainless steel active rosin flux for arc welding comprises the following components in percentage by weight: 25-35 percent of SiO2, 0.7-1.5 percent of B2O3, 7-10 percent of TiO2, 16-26 percent of Cr2O3 and 38-42 percent of CaF2. The stainless steel active rosin flux for arc welding is used in the arc welding process of a stainless steel material, so that the weld penetration depth is increased, and the problem that the one-time welding depth of the stainless steel material does not surpass 3 millimeter when the conventional arc welding is adopted is solved.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

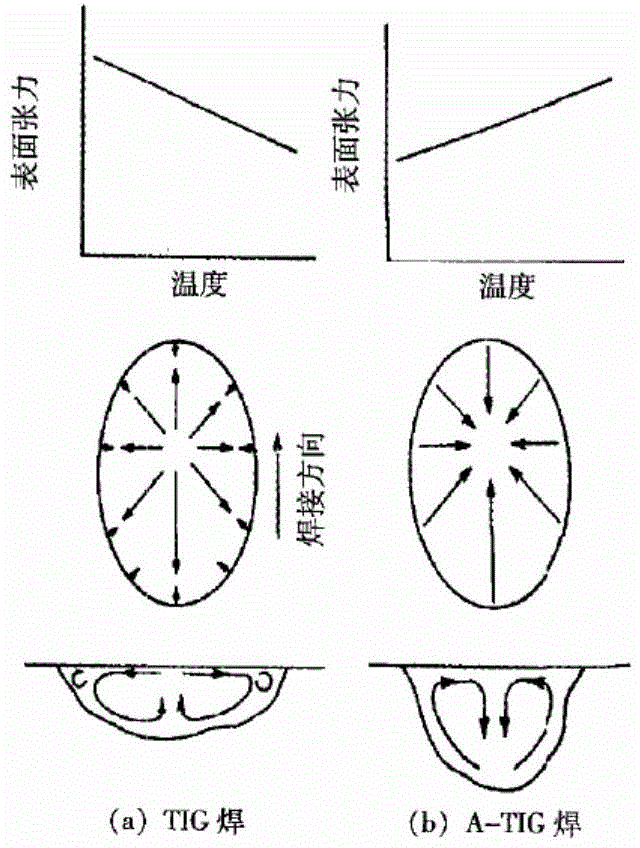

Fusing agent used for stainless A-TIG welding and using method thereof

InactiveCN101554690AReduce sensitivityLow heat inputArc welding apparatusWelding/cutting media/materialsTrace elementWeld seam

The invention relates to a fusing agent used for stainless A-TIG welding and a using method thereof. The fusing agent comprises a powder part and a liquid carrier; the powder part comprises the following components by weight percent (wt%): 5 to 8 of Al2O3, 5 to 8 of FeO, 30 to 43 of Si, 12 to 20 of Cr2O3, 7 to 8 of NaF, 8 to 11 of MnO2 and 20 to 30 of V2O5. When in use, the powder part is added into the liquid carrier so as to become pasty; the pasty fusing agent is coated on the surface of the workpiece to be welded; the width of the coating is 15 to 30mm; and welding is conducted after the liquid carrier is volatilized. Under the condition of same welding specification, the fusing agent can leads the weld penetration to be increased by three times; the fusing agent has simple use, can effectively reduce welding deformation, reduce the sensitivity of weld penetration to the fluctuation of trace elements of parent materials and has no influence to welding seam structures and mechanical performance of welding seams.

Owner:北京钢研新冶工程技术中心有限公司

Novel active agent used for TIG (Tungsten Inert Gas) welding of magnesium alloy

InactiveCN102343489AImprove ultimate tensile strengthChanging the temperature coefficient of surface tensionArc welding apparatusWelding/cutting media/materialsPorosityHydrogen

The invention discloses a novel active agent used for TIG (Tungsten Inert Gas) welding of magnesium alloy, belonging to the active agent welding technology. The active agent is characterized in that the active agent consists of, by weight percent, 60-65 TiO2 and 35-40 CaF2, and is prepared through the following steps: first, grinding and then mixing TiO2 and CaF2 active agent powder by proportion; second, adding acetone to the mixture to enable the mixture to turn to paste; and then evenly coating the pasty active agent on the upper surface of a test sample through a flat brush, wherein the coating width is about 40mm and the coating thickness is about 0.3mm. The active agent can be used for TIG welding after the acetone volatilizes. Compared with the welding joints without being coated with the active agent in the welding process, the welding joint obtained through the welding technique disclosed by the invention has the advantages that the weld penetration is improved by 43% and the tensile property is improved by 58%. In addition, porosity in the welding line is remarkably reduced after the active agent is coated, thus solving the difficulties of the existence of hydrogen pores and shallow weld penetration.

Owner:CHONGQING UNIV

Method for welding thick copper plate by fiber laser

ActiveCN104646825AImprove energy utilizationIncrease weld penetrationRadiation-absorbing paintsWelding/soldering/cutting articlesSpecific gravityLaser fiber

The invention is suitable for the field of a laser welding process, and provides a method for welding a thick copper plate by a fiber laser. The method comprises the following steps of spraying a welding line of the thick copper plate with a light absorbing coating layer, and welding the welding line, which is sprayed with the light absorbing coating layer, of the thick copper plate by focused laser emitted from the fiber laser, wherein the coating of the light absorbing coating layer comprises light absorbing coating and water-based resin; the light absorbing coating consists of the following components in mass percent: 50-60 percent of ZnO submicron particulates, 20-25 percent of Al2O3 submicron particulates, 20-25 percent of TiO2 submicron particulates; the mass percent sum of all the components is 100 percent. By preinstalling a layer of self-developed light absorbing coating on the surface of the thick copper plate, the energy utilization rate when the thick copper plate is welded by the fiber laser is greatly increased, the welding penetration is increased, and the welding efficiency is increased; ceramic clinker of which the proportion is less than that of copper alloy covers the surface of a weld pool, and therefore the weld pool can be effectively prevented from being oxidized; without welding shield gas, the higher welding line quality can also be obtained.

Owner:WUHAN HGLASER ENG CO LTD

Titanium alloy welding active agent and welding method

ActiveCN104646866AIncrease weld penetrationAspect ratio heightArc welding apparatusWelding/cutting media/materialsActive agentTitanium alloy

The invention provides a titanium alloy welding active agent and a welding method, which is suitable for welding titanium alloy such as TC4. The trademark of the titanium alloy welding active agent is A-TIG-Ti-01, and the titanium alloy welding active agent consists of CaF2, MgF2 and SrF2; the mass content of the CaF2 is 15 to 25 percent; the mass content of the MgF2 is 5 to 15 percent; the mass content of the SrF2 is the residual amount. By adopting the titanium alloy welding active agent, the welding melting depth of the titanium alloy can be increased, the connector performance is excellent, and the titanium alloy welding active agent is suitable for welding a titanium alloy plane structure and a titanium alloy curved structure.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

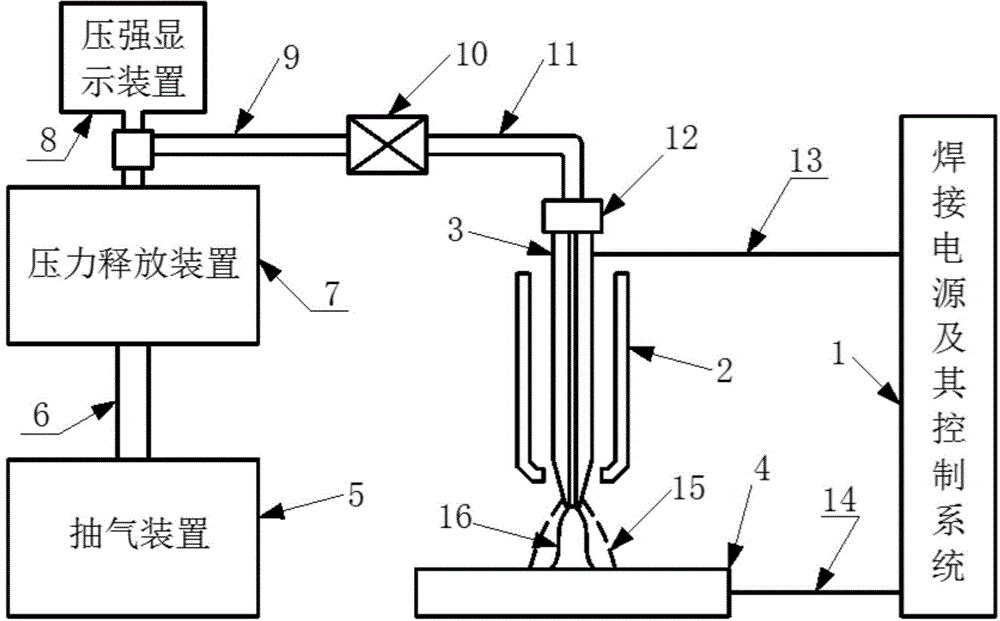

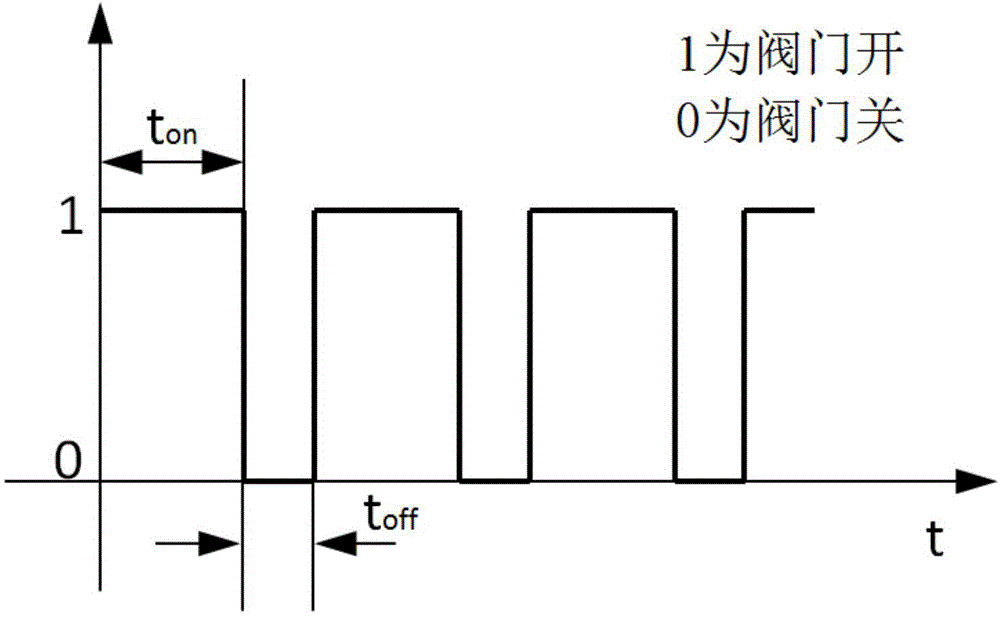

Central pulsation negative-pressure arc welding device and method

ActiveCN104308342AAchieve agitationAchieve oscillationElectrode accessoriesCompression actionEngineering

The invention relates to a central pulsation negative-pressure arc welding device and method, and belongs to the technical field of welding equipment and methods. An inner cavity of a hollow tubular electrode and the center of an arc below the hollow tubular electrode enter a periodic negative-pressure state by virtue of an air extraction device, and when the center of the arc is in a normal-pressure state, the arc is in a free arc form; when the center of the arc is in a negative-pressure state, the arc is in a restrained state under the compression action of external atmospheric pressure; therefore, the arc is switched between a free arc and a restrained arc to implement the central pulsation negative-pressure arc welding method. The pulsation arc produced by the welding device and method has oscillation and stirring functions for a welding pool, so that liquid metal forms tiny isometric crystals, the formation of air holes is suppressed, and the mechanical performance of a welding joint is improved; the pulsation frequency and duty ratio of the arc are regulated to accurately control the oscillation and stirring of the welding pool, the welding penetration and heat input.

Owner:BEIJING UNIV OF TECH

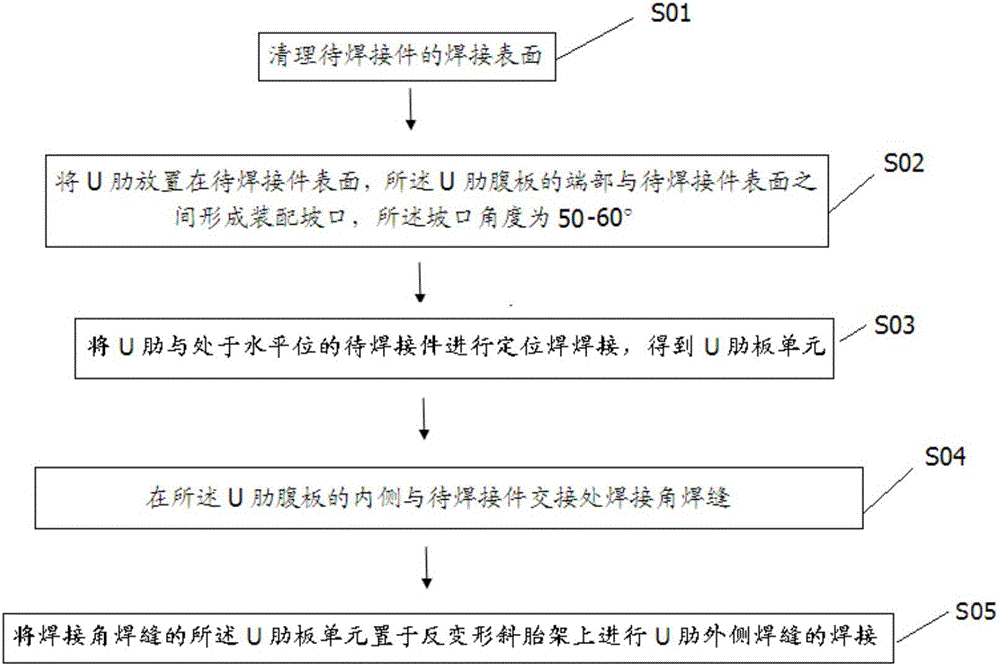

Two-sided welding method for U-shaped ribbed slab unit welding seam

InactiveCN106563868AReduced stress amplitudeAvoid Fatigue Cracking ProblemsArc welding apparatusSubmerged arc weldingEngineering

The invention provides a two-sided welding method for a U-shaped ribbed slab unit welding seam. The two-sided welding method comprises the following steps: cleaning the welding surface of a piece to be welded; placing a U-shaped rib on the surface of the piece to be welded, wherein an assembly groove is formed between the end part of a U-shaped ribbed web plate and the surface of the piece to be welded, and the groove angle is 50-60 degrees; carrying out positioning welding on the U-shaped rib and the piece to be welded in the horizontal position to obtain a U-shaped ribbed slab unit; welding a fillet welding seam at the jointing position of the inner side of the U-shaped ribbed web plate and the piece to be welded; and placing the U-shaped ribbed slab unit welded with the fillet welding seam on an anti-deformation slanting tension bed to carry out welding of an outer side welding seam, wherein a process of twin-wire submerged arc welding with single power supply is adopted. According to the two-sided welding method, a jointing welding seam between the U-shaped rib and the piece to be welded is changed into a two-sided fillet welding seam form from a single-sided fillet welding seam form in the prior art, so that stress amplitudes at a weld root and a weld toe are greatly lowered, the problem of initiation of fatigue cracks of the welding seam at the weld root is solved, and the fatigue performance at the weld toe is also improved.

Owner:WUCHUAN HEAVY ENG

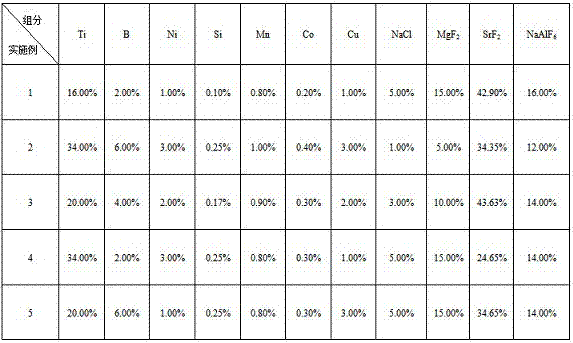

Welding agent-core welding wire for titanium and titanium alloy

ActiveCN107363433AAspect ratio heightEasy to cleanWelding/cutting media/materialsSoldering mediaHydrogenActive agent

The invention provides a welding agent-core welding wire for titanium and titanium alloy. The welding wire is composed of an outer skin and an internal active welding agent core. The outer skin is composed of a titanium belt in which the mass percent of titanium is not less than 98% and the mass percent of hydrogen is not more than 0.015%, and the internal active welding agent core consisting of metal power, Si powder, B powder and an active agent, and comprising the following components in percentage by weight: 16%-34% of Ti, 2%-6% of B, 0.2-0.4% of Co, 0.8-1% of Mn, 0.10%-0.25% of Si, 1%-3% of Ni, 1%-3% of Ni, 1%-3% of Cu, 1%-5% of chloride, 12%-16% of fluoroaluminate, 5%-15% of MgF2, and 20%-60% of SrF2, wherein the chloride, the fluoroaluminate, MgF2 and SrF2 are active agent components in the welding agent core. The welding wire is large in welding depth-to-width ratio and high in melting efficiency, so that the welding technology is simplified in process, and applicable to welding the titanium and titanium alloy.

Owner:HARBIN INST OF TECH AT WEIHAI

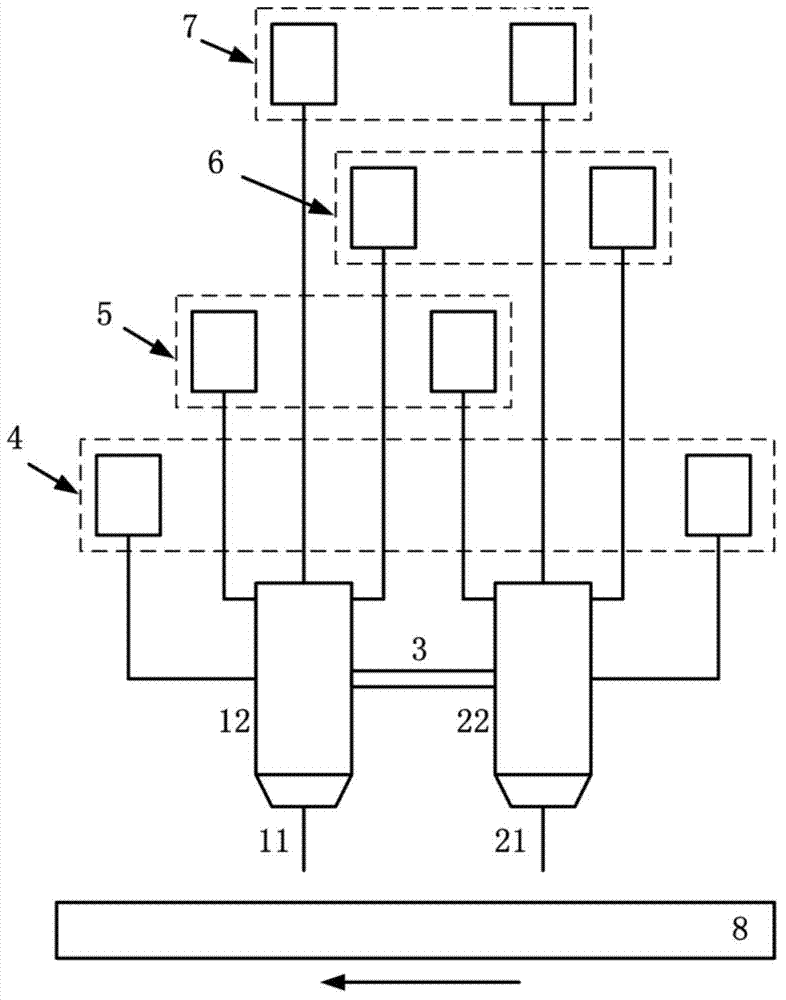

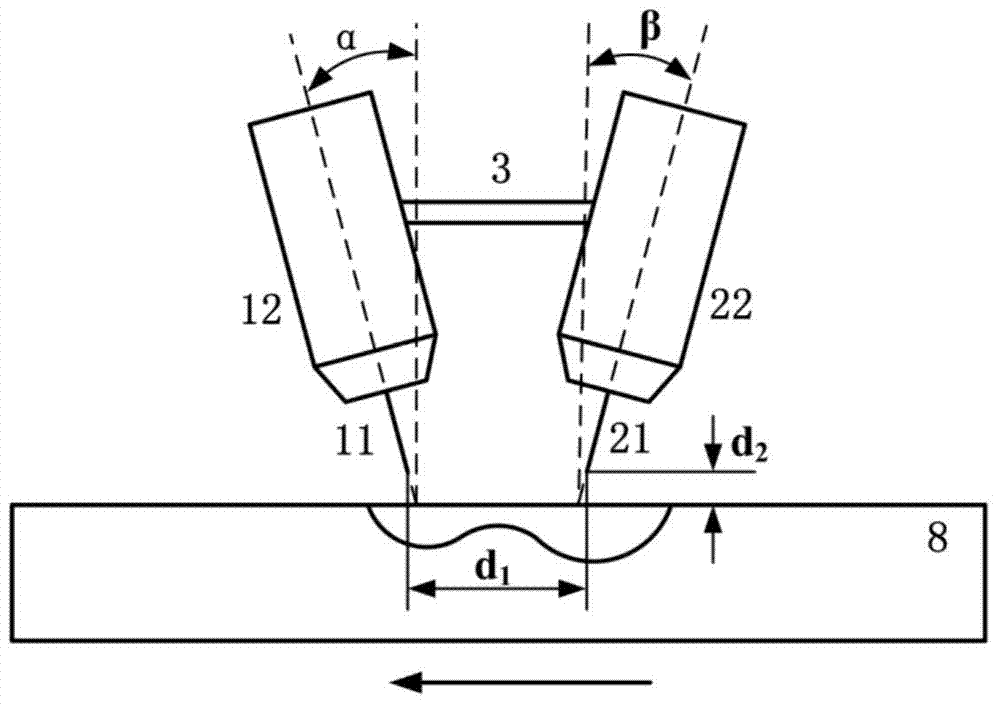

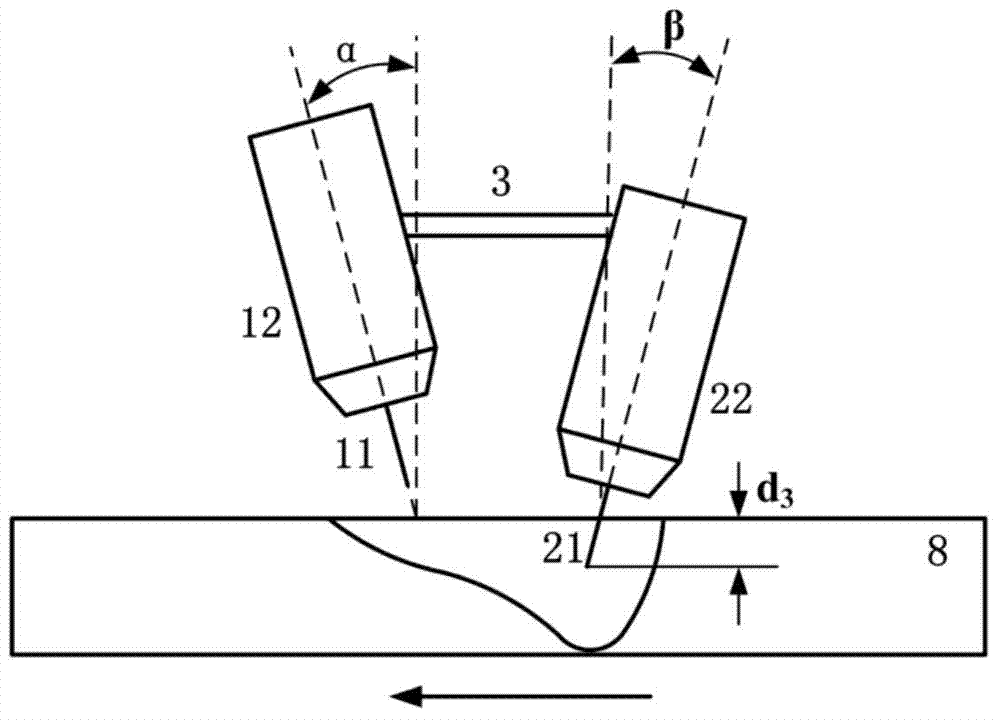

Application of double-TIG welding method to implementation of thick plate welding

InactiveCN104708179AIncrease weld penetrationAchieving one penetrationArc welding apparatusThick plateWelding power supply

The invention discloses an application of a double-TIG welding method to implementation of thick plate welding. A first welding gun provided with a first tungsten electrode and a second welding gun provided with a second tungsten electrode are installed on a welding machine, the first welding gun and the second welding gun are arranged in the welding direction in a front-back mode and are connected through a guide rail, and each welding gun is provided with a welding gun posture adjustment device, a protective gas system, a water cooling system and a welding power source. Through space arrangement of two welding guns and welding parameter matching of the two tungsten electrodes, the first tungsten electrode plays a part in primarily forming a welding pool, the second tungsten electrode plays a part in increasing the depth of fusion, and therefore a thick plate workpiece can be thoroughly welded at a time.

Owner:TIANJIN UNIV

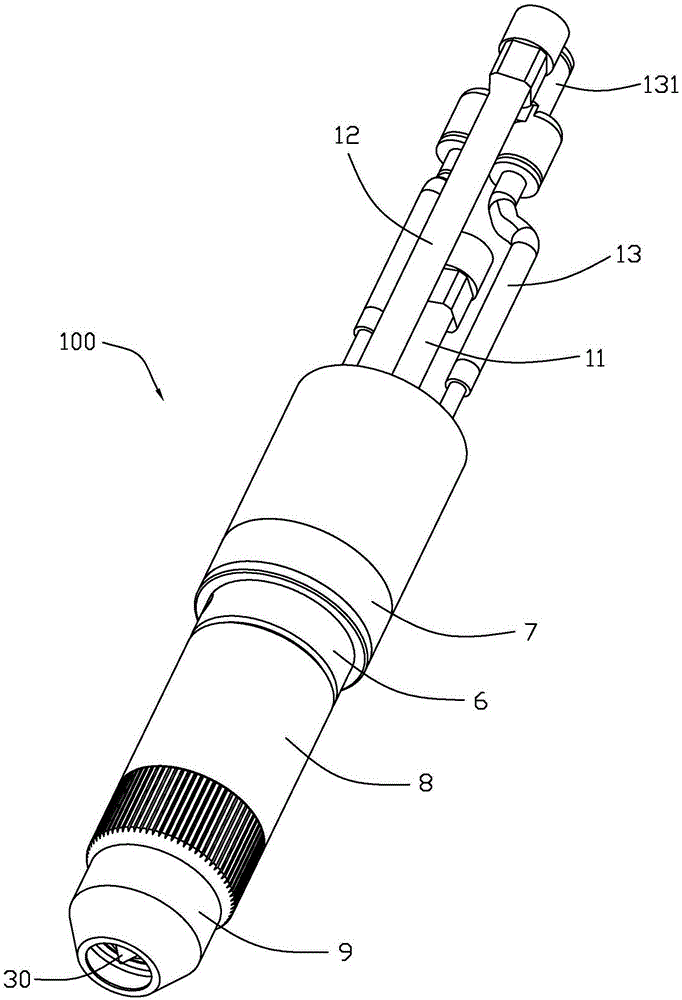

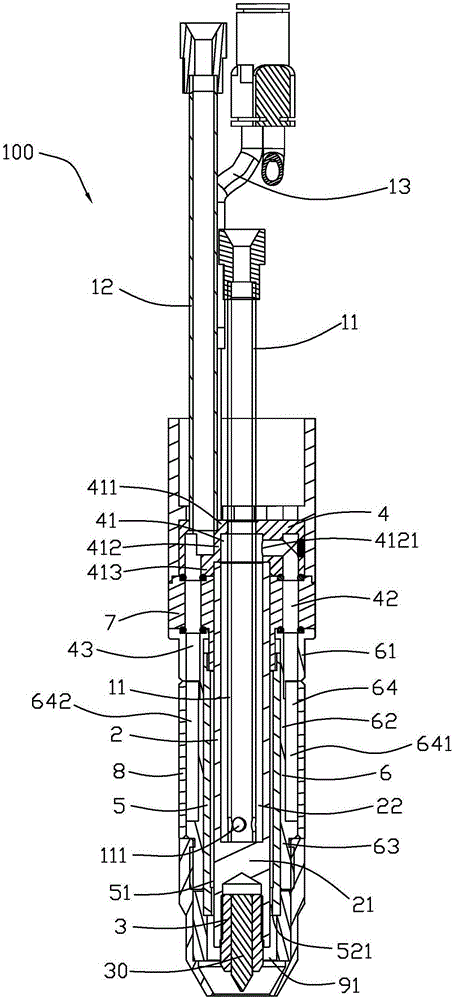

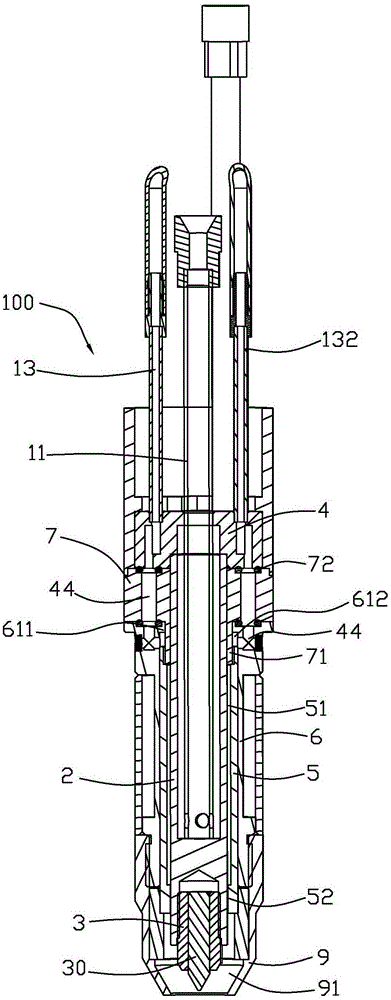

TIG welding gun

ActiveCN105171209AHigh duty cycleImprove welding qualityCooled electrode holdersElectrode accessoriesEngineeringWater cooling

The invention provides a TIG welding gun. The TIG welding gun comprises a water electric pipe positioned in the axis position, a core rod arranged at the outer periphery of the water electric pipe, a tungsten electrode clamp fixed at one end of the core rod, an electric conducting connection base fixed at the other end of the core rod and connected with the water electric pipe, a water cooling jacket arranged at the outer side of the core rod, an insulation block fixedly connected between the water cooling jacket and the electric conducting connection base in the axial direction, a shell fixed at the outer periphery of the water cooling jacket, and a water outlet pipe fixed on the electric conducting connection base. An isolation part is arranged in the core rod near the tungsten electrode clamp. The water electric pipe extends to the position of the isolation part, and is provided with a first water outlet hole penetrating through in the radial direction. A first water cavity communicated with the first water outlet hole is formed between the core rod and the water electric pipe. The electric conducting connection base is provided with a first water inlet communicated with the first water cavity. A second water cavity is formed between the water cooling jacket and the shell. The electric conducting connection base and the insulation block are formed with a first communication hole for communicating the first water inlet with the second water cavity and a second communication hole for communicating the second water cavity with the water outlet pipe.

Owner:HUAHENG WELDING

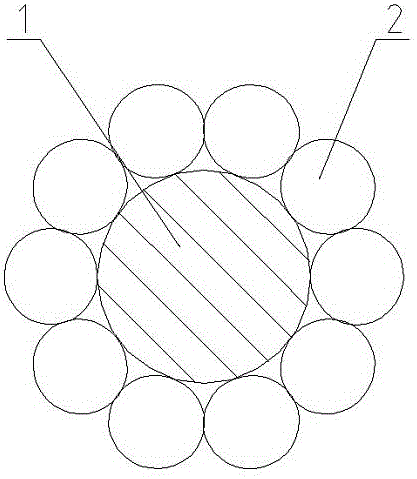

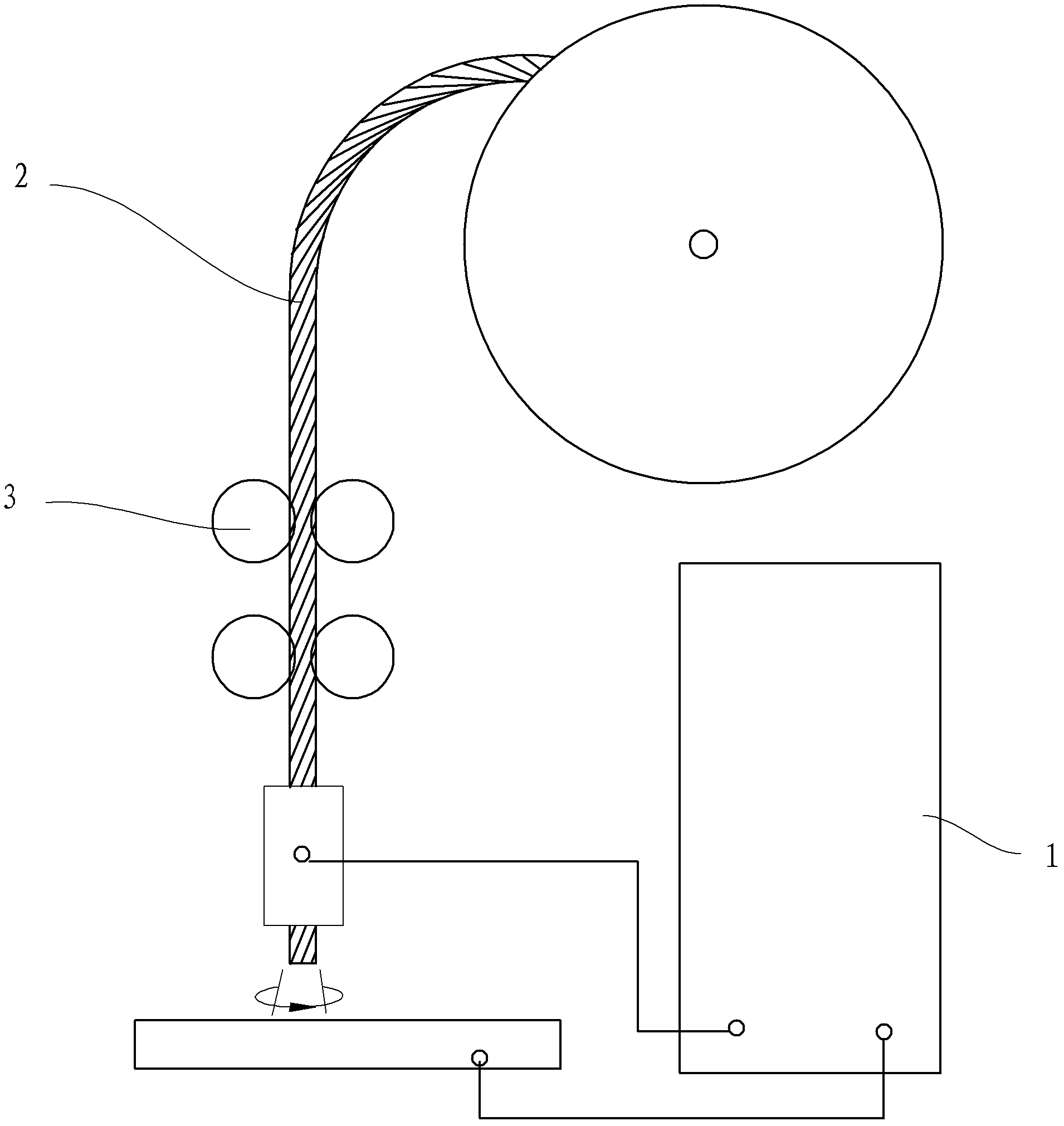

Twisted welding wire structure and manufacturing method thereof

InactiveCN106041351AThe solution is not easy to coilSolve rigid problemsWelding/cutting media/materialsSoldering mediaDiameter ratioEngineering

The invention relates to a twisted welding wire structure and a manufacturing method thereof, which belong to the technical field of metal welding. The twisted welding wire structure comprises a center wire (1), wherein multiple strands of peripheral wires (2) are spirally twisted on the periphery of the center wire (1), the diameter of the center wire (1) is not equal to that of each peripheral wire (2), and the diameter ratio of the peripheral wires (2) to the center wire (1) is 0.40 to 0.77. According to the twisted welding wire structure and the manufacturing method thereof, the problems that the diameter of a traditional welding wire is not big enough, the traditional welding wire is not likely to be wound when the diameter is increased, the rigidity is poor, energy consumption is high, deposition rate is high, welding quality is uneven and the like can be solved.

Owner:梁裕

Active agent for tungsten electrode argon arc welding and using method thereof

ActiveCN103769773AIncrease weld penetrationReduce weld widthArc welding apparatusWelding/cutting media/materialsActive agentArc welding

The invention relates to an active agent for tungsten electrode argon arc welding. The active agent is characterized by comprising, by weight, 18 to 22% of silicon dioxide, 9 to 16% of potassium dioxide and 62 to 73% of water and the active agent is placed in shade to be sealed and stored at room temperature. According to the active agent which is non-toxic and free of halide and fluoride, the composition is simple and the using method is simple; welding arcs can contract, the welding penetration can be increased, the welding efficiency can be improved, the welding cost can be reduced, the welding deformation can be reduced, satisfactory welding seams can be obtained, and residues are less; the active agent is suitable for welding of various stainless steel and carbon steel materials and a groove can be omitted, one-step welding penetration can be achieved, and one-side welding with two-sided forming can be achieved for abutting welding seams of the stainless steel and the carbon steel if the thickness of the stainless steel and the carbon steel is below 8.5 mm.

Owner:SHANGHAI SHIPBUILDING TECH RES INST +1

Novel nano-particle reinforced active tungsten argon arc welding method

InactiveCN103008845AImprove ultimate tensile strengthPromote nucleation and crystallizationArc welding apparatusWelding/cutting media/materialsAcetoneCrystallite

The invention discloses a novel nano-particle reinforced active tungsten argon arc welding method, and belongs to the active welding technology. The method is characterized by comprising the following steps of: before welding, mixing oxide activator powder and nano ceramic particles in proportion, and then adding acetone into the mixture so that the mixture is in pasty; then uniformly coating the pasty activator on the surface of samples by a flat brush, wherein the coating width is about 40mm, and the average coating amount is 5.mg.cm<-2>; and carrying out tungsten argon arc welding after the acetone is volatilized. The external waviness of the welding joints obtained by adopting the nano-particle reinforced active tungsten argon arc welding is smooth; compared with the welding joints obtained by the traditional tungsten argon arc welding, the fusion depth is increased by 110%; the crystal particles of the welding joint fusion region are obviously reduced compared with the active tungsten argon arc welding; and the tensile property of the welding joint is improved by 64.6% compared with the active tungsten argon arc welding. The problems that the tungsten argon arc welding fusion depth of magnesium alloy is shallow and the crystal particles of the active tungsten argon arc welding are thick are solved.

Owner:CHONGQING UNIV

Multi-wire rotating arc welding

InactiveCN102615391AWidely used valueImprove deposition efficiencyArc welding apparatusWelding/cutting media/materialsMetal alloyMolten bath

The invention relates to an arc welding, in particular to a multi-wire rotating arc welding, which is a rotating arc welding utilizing welding wires wound in a certain helical angle, automatically formed in the welding process and having stirring effects on a molten bath. The multi-wire rotating arc welding not only improves welding melting efficiency but also enables welding line metal alloy to be even in component, and grain refinement is achieved.

Owner:时振

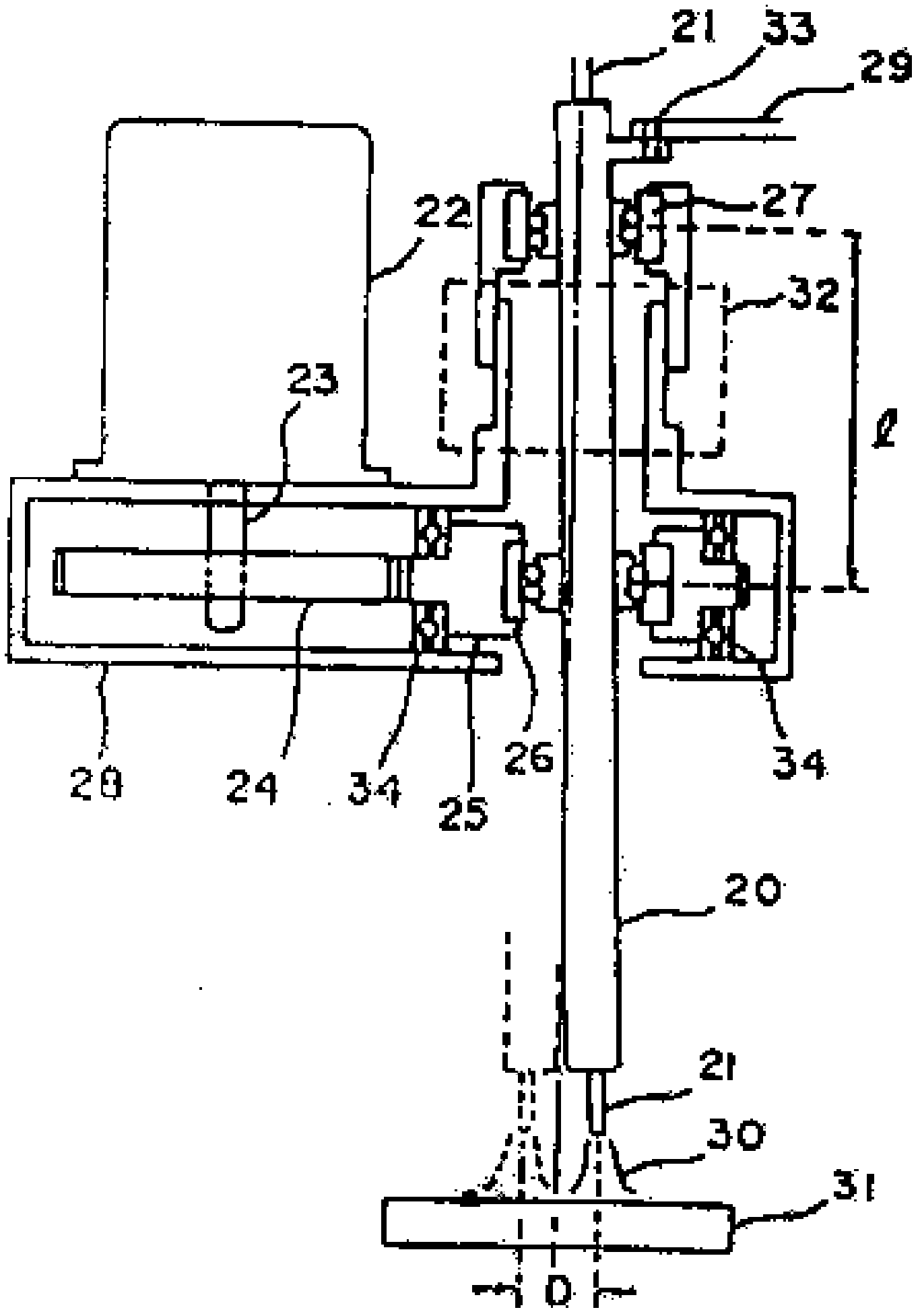

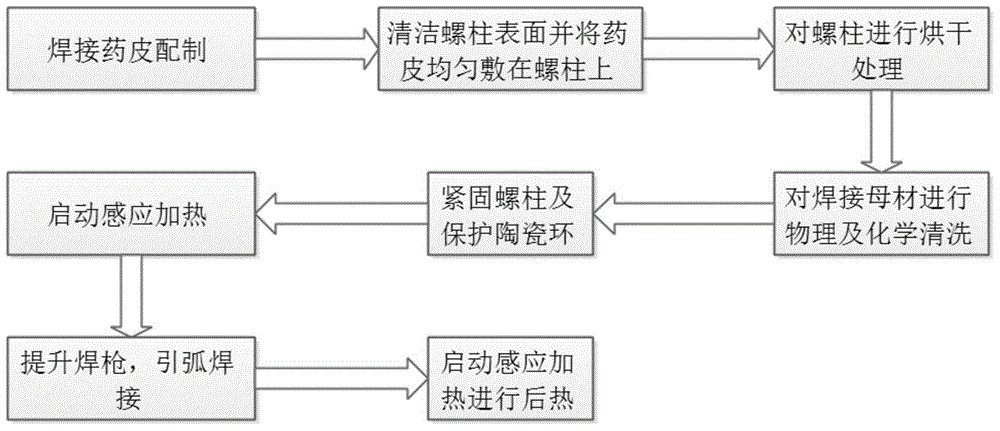

Stud welding method based on coating self-protection

InactiveCN105478972AAchieve no oxidation inclusionsReduce deflectionArc welding apparatusStud weldingWeld penetration

The invention discloses a stud welding method based on coating self-protection.The stud welding method based on coating self-protection comprises following steps: preparing and welding self-protective coating composition; machining steel studs to be of 150 degrees; grinding, cleaning and removing surface stains of the steel studs and a welding region of base material; applying prepared self-protective coating material to the welding positions of the surface of the steel studs and drying self-protective coating material; horizontally placing base material, downwardly placing the tapered end of the steel studs sleeved with matching ceramic rings to be vertical to base material and applying certain pressure; and lifting the steel studs, arching and finishing welding. The stud welding method based on coating self-protection has following beneficial effects: fine welding metallographic structure is obtained and welding quality is effectively improved; operation is performed easily and efficiency is significantly increased; arc deflection is prevented and splattering during a welding process is also prevented; high-quality welding joints without defects such as oxide inclusion, lack of penetration and incomplete fusion are achieved between the steel studs and base material; welding penetration of the steel studs is improved; and the stud welding method is suitable for the steel studs of more than 8 mm in different diameters and base material of different thicknesses.

Owner:NANJING UNIV OF SCI & TECH

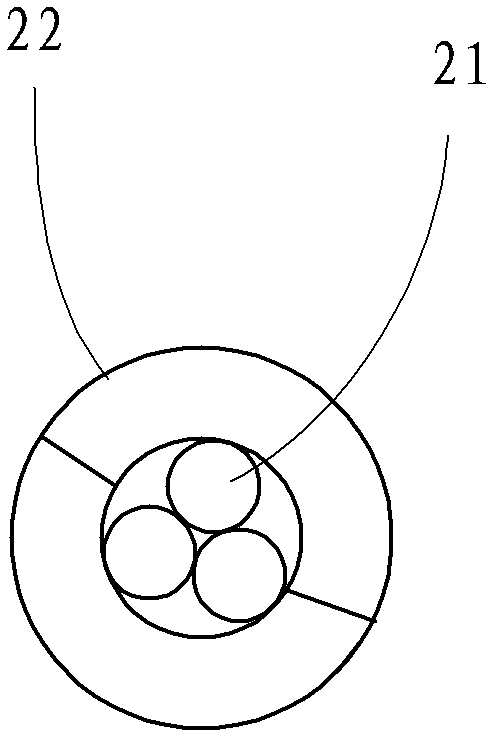

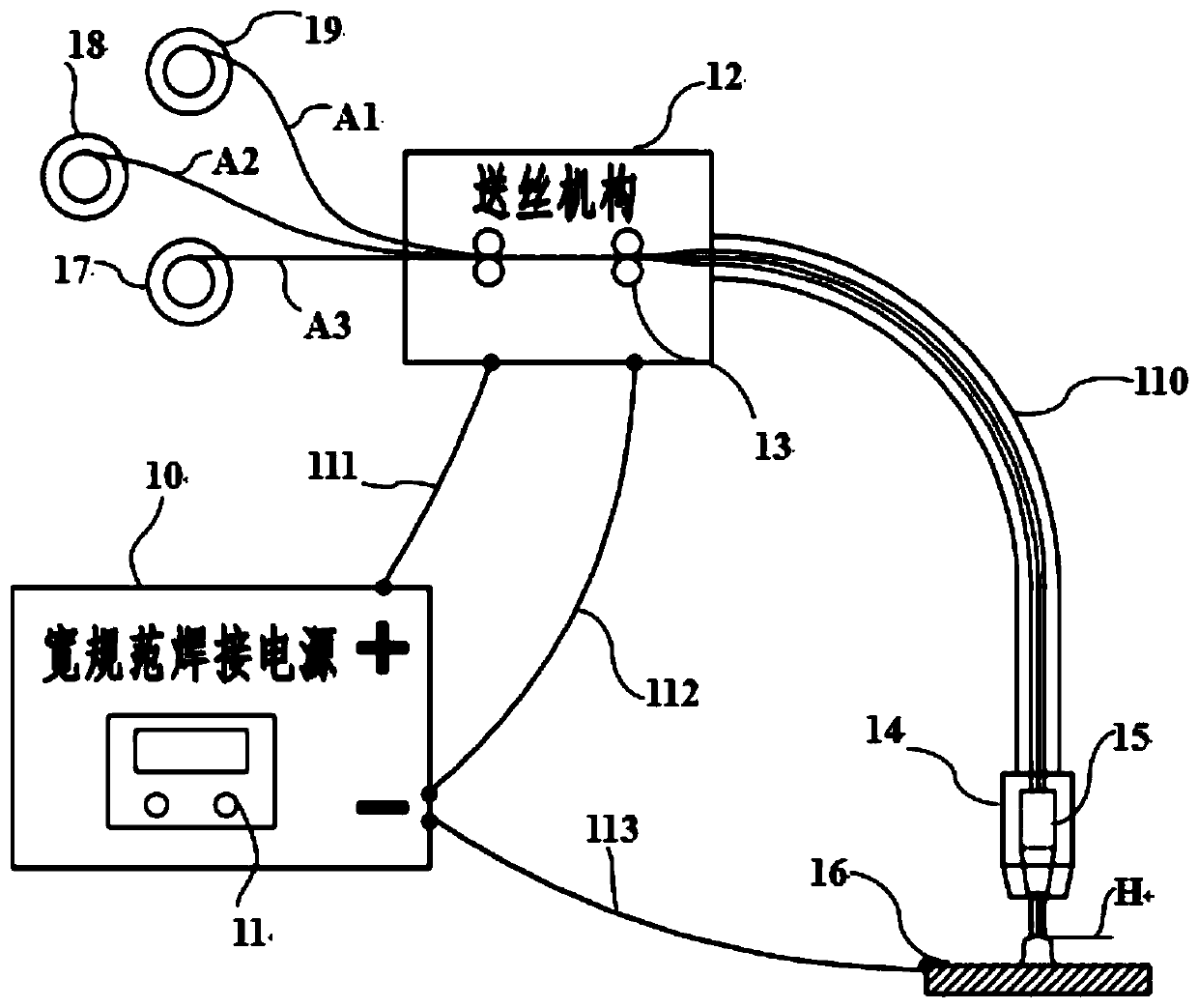

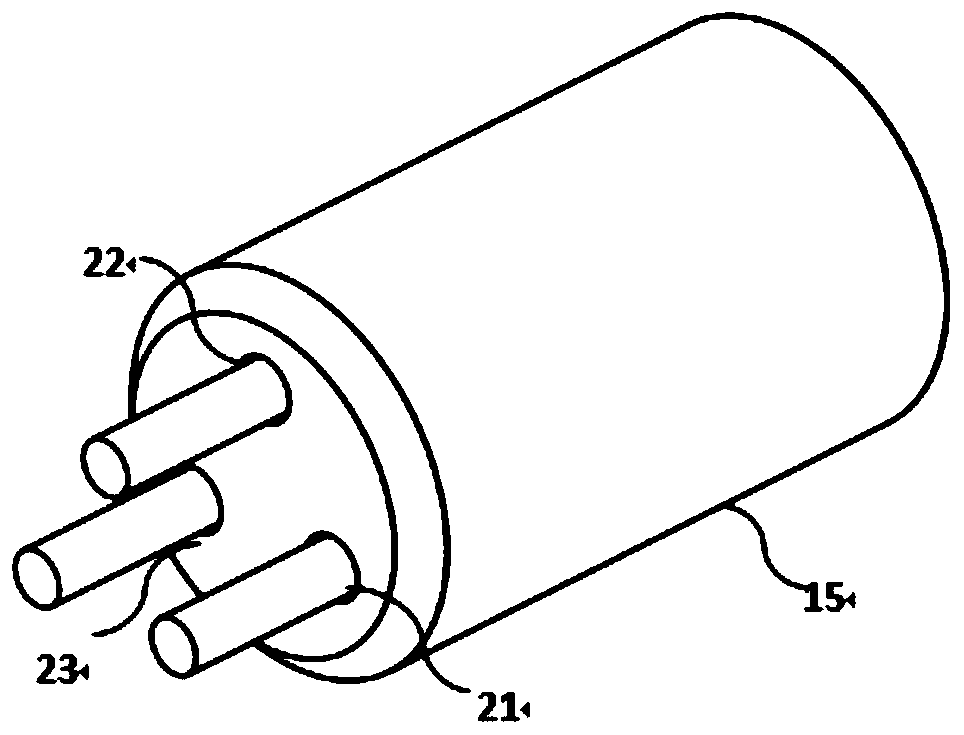

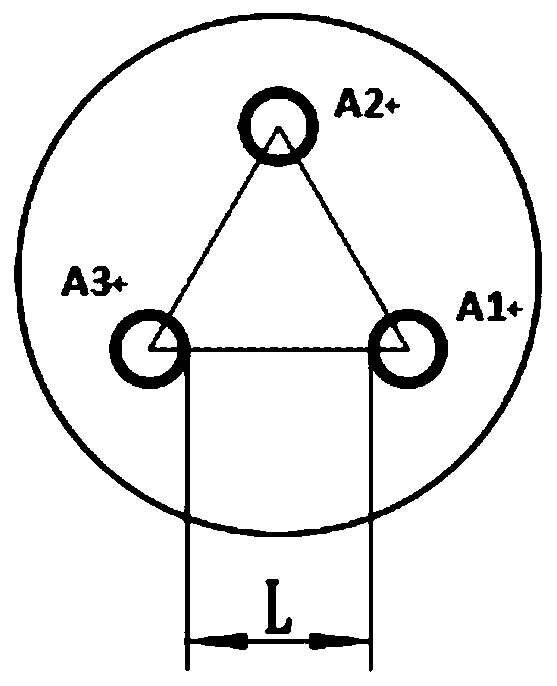

Parallel tri-wire welding system and method

PendingCN110125518ASame sizeNo arcing problemsArc welding apparatusWelding power supplySemi automatic

The invention discloses a parallel tri-wire welding system and method. The welding system comprises a wide-range welding power supply, a wire conveying mechanism with a tri-slot wire conveying wheel and a welding gun with a tri-hole conductive nozzle, wherein three welding wires are simultaneously conveyed to the welding gun through the wire conveying mechanism and separately penetrate through three independent holes which are distributed in the conductive nozzle at certain intervals; and welding waveforms output by the welding power supply are supplied to the welding wires through the conductive nozzle, and welding is carried out by simultaneously using the three wires. After the bottom ends of the three wires are molten, molten drops attract each other under electromagnetic action, and the molten drops stably and smoothly flow into a molten bath. The single-power-supply and parallel-tri-wire system has the advantages that the welding efficieny is increased, electric arc shapes and weld penetration size and contours are improved, welding flaws are reduced, and mechanical strength is improved; and at the same time, the three welding wires are stably conveyed by one wire conveying mechanism and go through one conventional welding gun, the operation is convenient, the reaching range of the welding gun is great, and manual, semi-automatic and robot welding demands can be simultaneously met.

Owner:AOTAI ELECTRIC

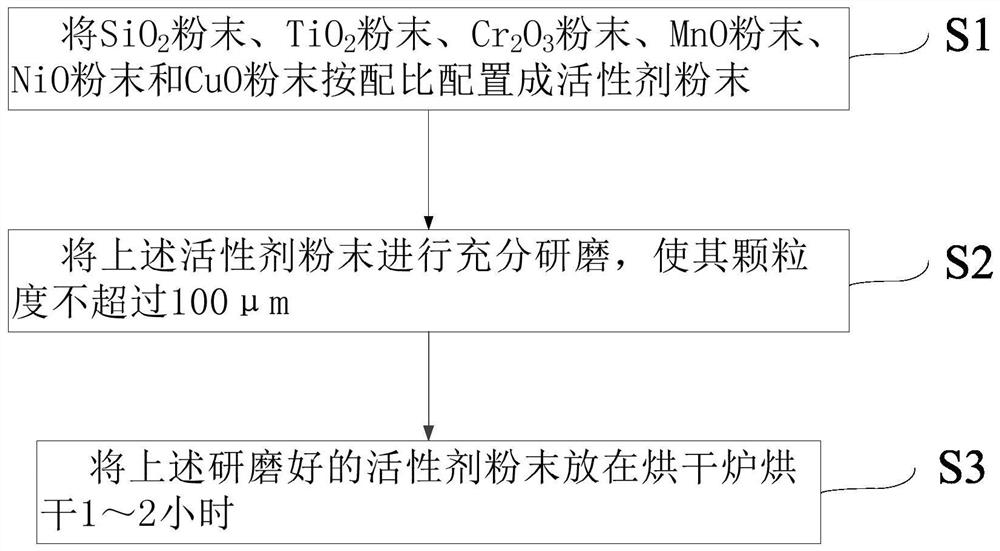

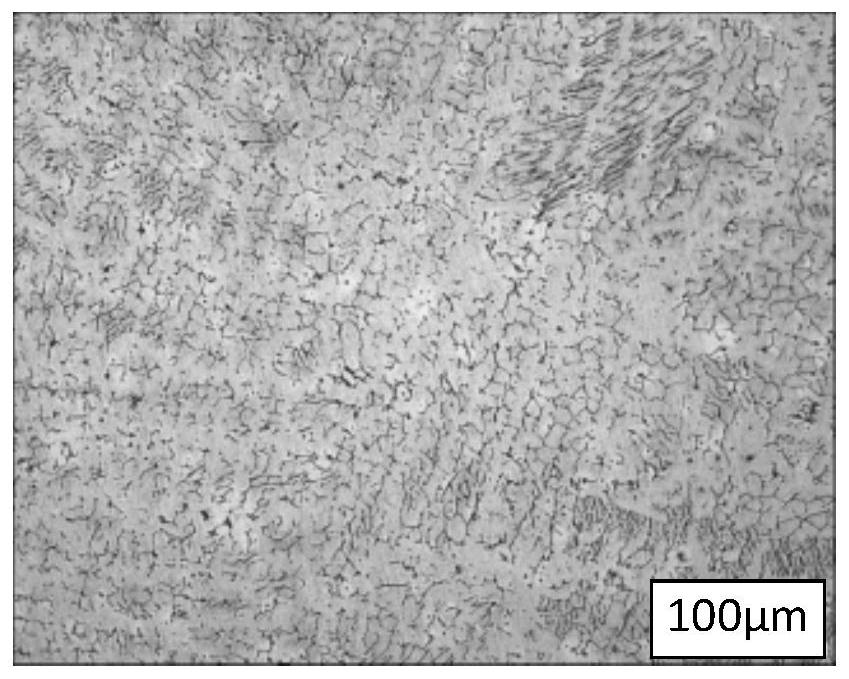

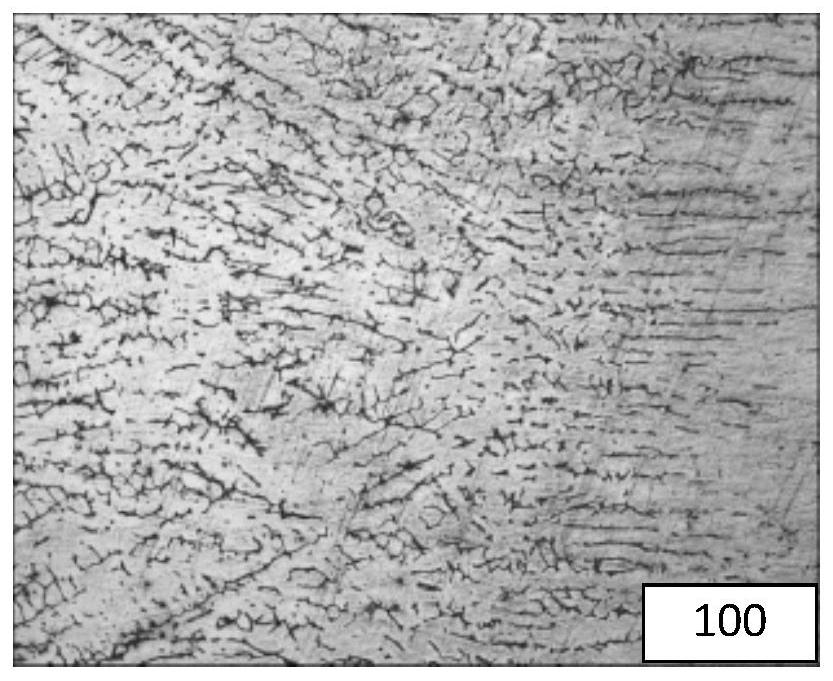

Stainless steel argon tungsten-arc welding active agent and preparation method and application thereof

InactiveCN111604618AQuality improvementLow costArc welding apparatusWelding/cutting media/materialsActive agentSS - Stainless steel

The invention belongs to the field of active agents for welding, and particularly relates to a stainless steel argon tungsten-arc welding active agent and a preparation method and application thereof.The stainless steel argon tungsten-arc welding active agent is prepared from the following components in percentage by weight: 35-45% of SiO2 powder, 20-25% TiO2 powder, 8-12% of Cr2O3 powder, 5-10%of MnO powder, 5-10% of NiO powder and 10-15% of CuO powder. The stainless steel argon tungsten-arc welding active agent does not contain precious metal, is low in cost, is non-poisonous and environmentally friendly, compared with methods such as general argon tungsten-arc welding, and the efficient active agent performs A-TIG welding on stainless steel and has the advantages of deep weld penetration, high production efficiency and reliable quality. The active agent is coated on the surface to be welded, the weld penetration is increased, the welding joint mechanical performance is obviously improved at the same parameter, 13mm welding by one side and molding by two sides can be realized, expensive welding equipment is not required, and good economic benefits and wide application prospectsare achieved.

Owner:JIUJIANG HAITIAN EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com