Patents

Literature

46results about How to "High duty cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

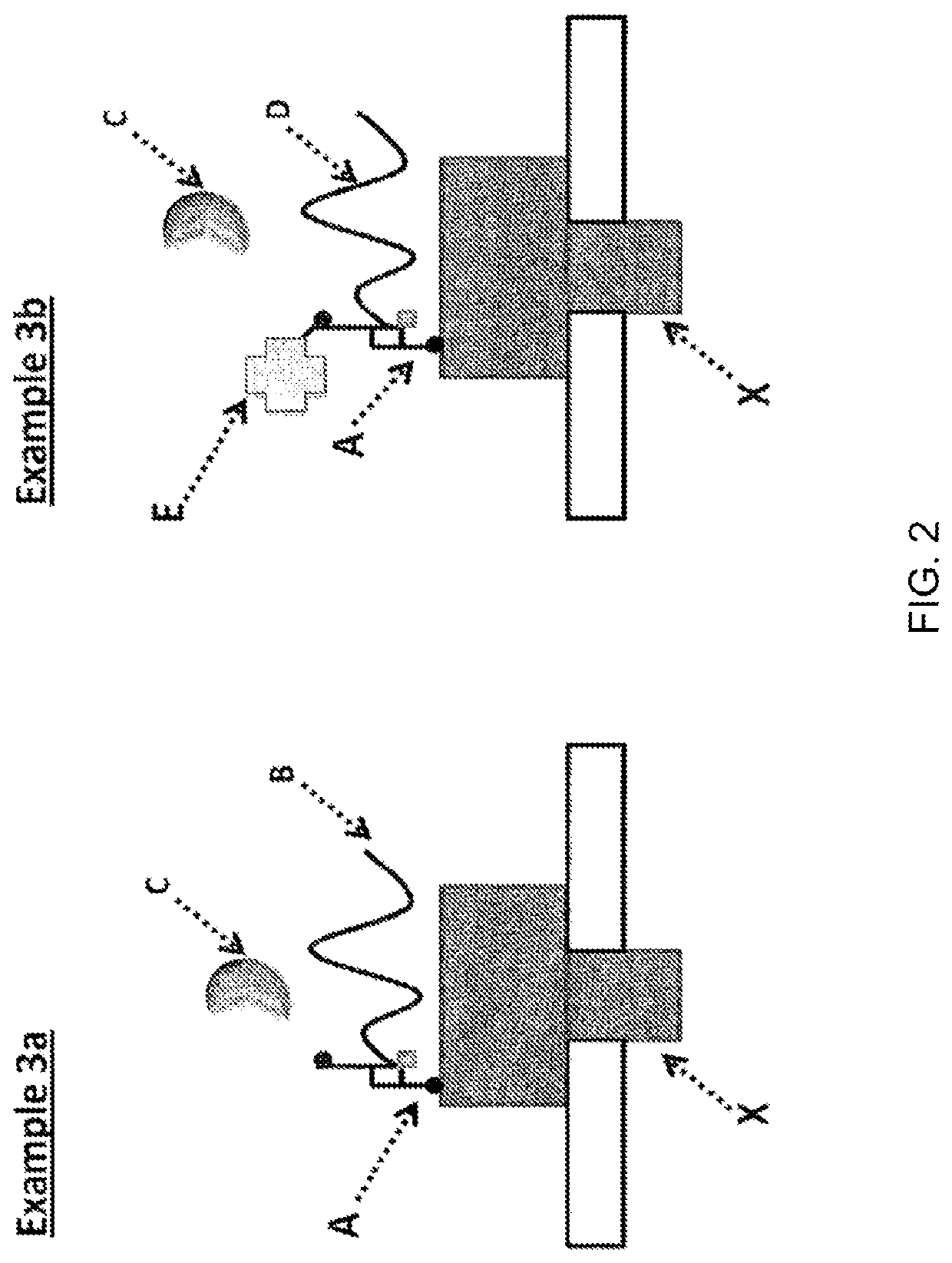

Mass spectrometer

InactiveUS6906319B2High sensitivityIncrease delay timeStability-of-path spectrometersTime-of-flight spectrometersIon trap mass spectrometryMass analyzer

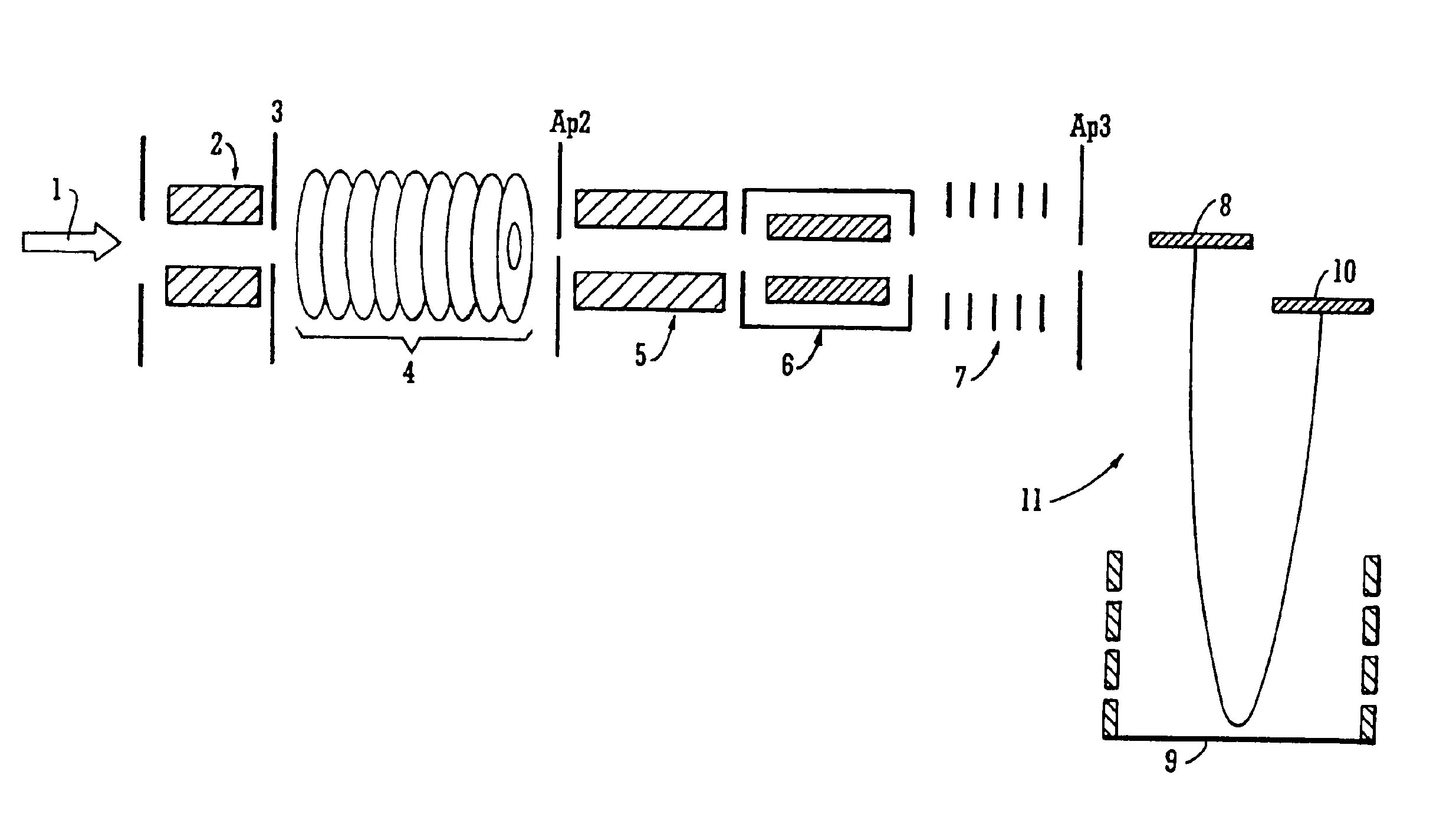

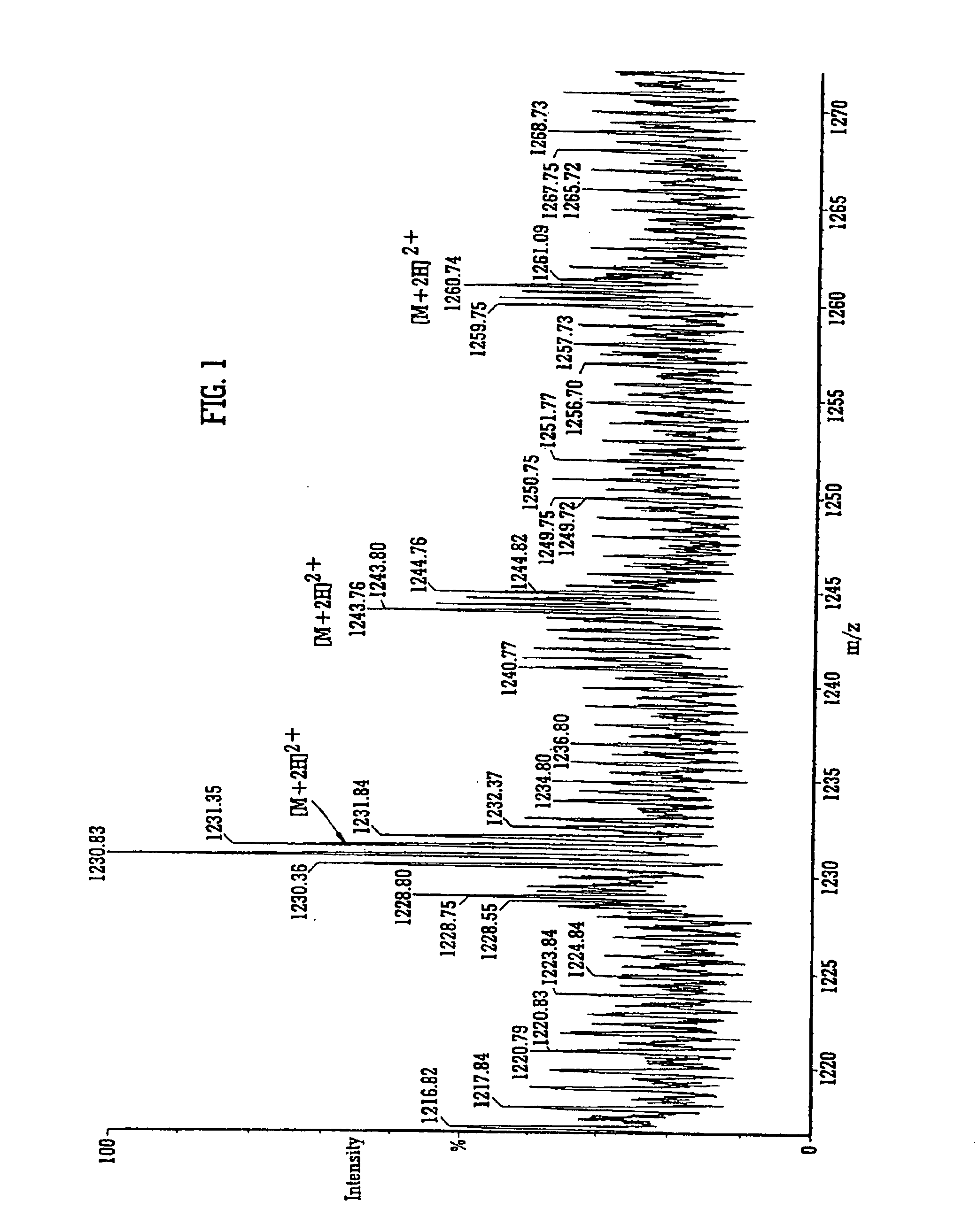

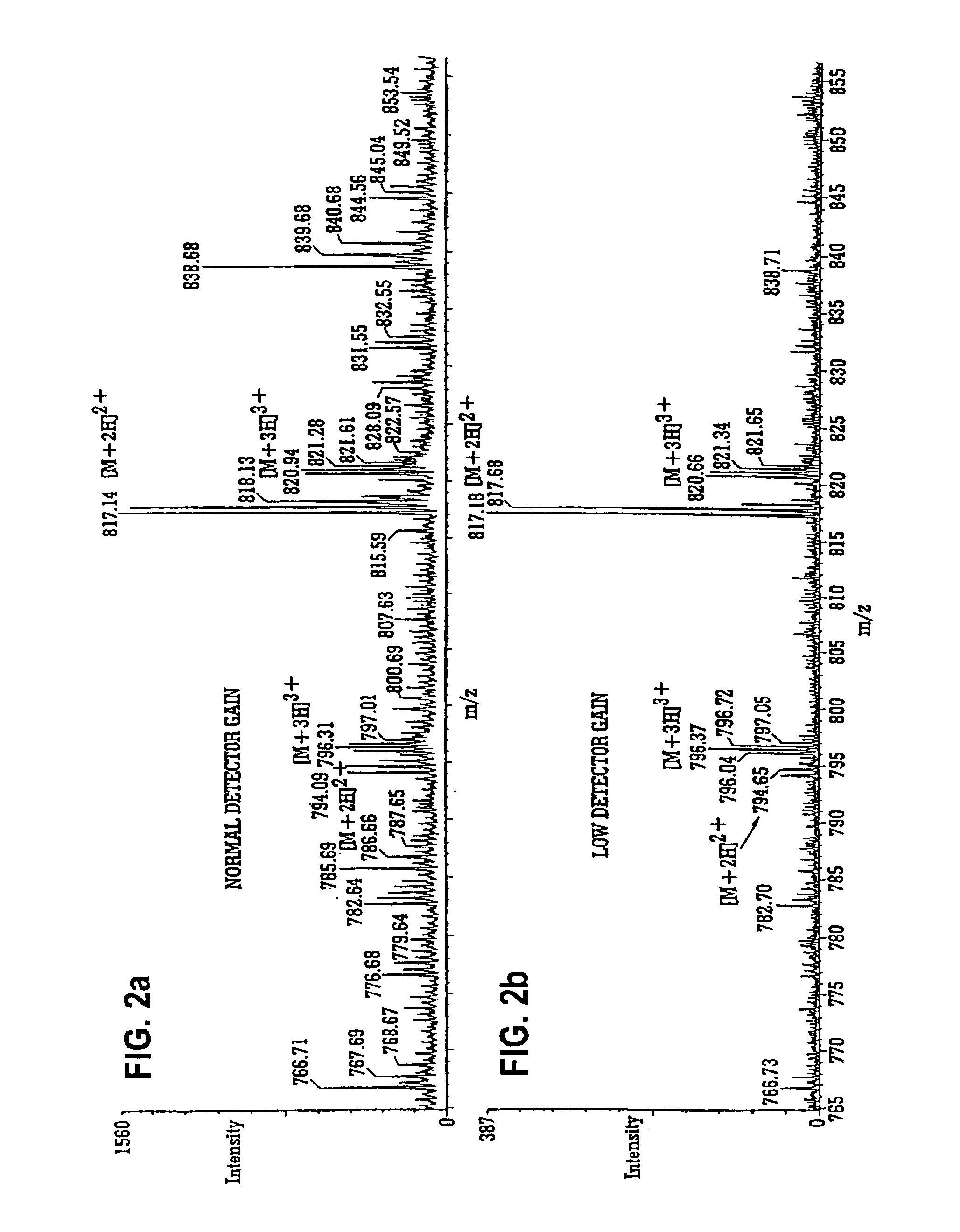

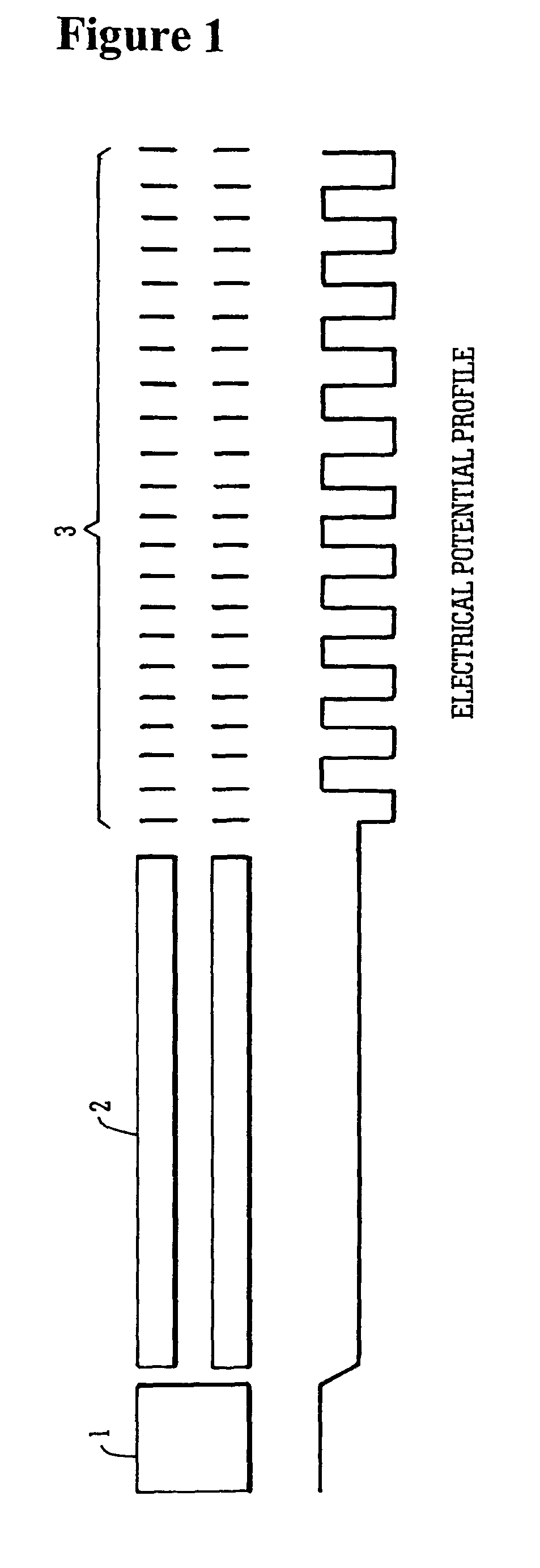

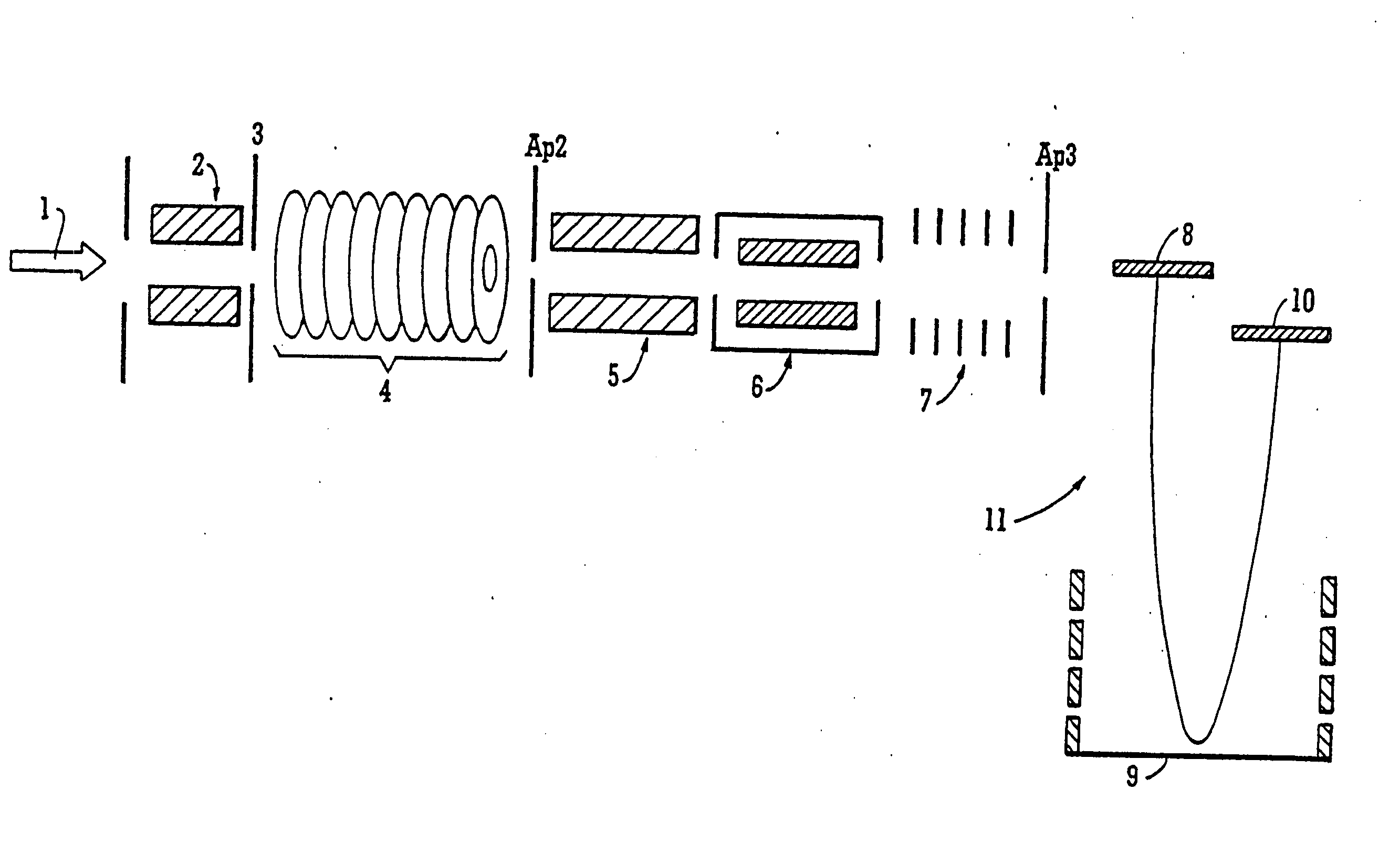

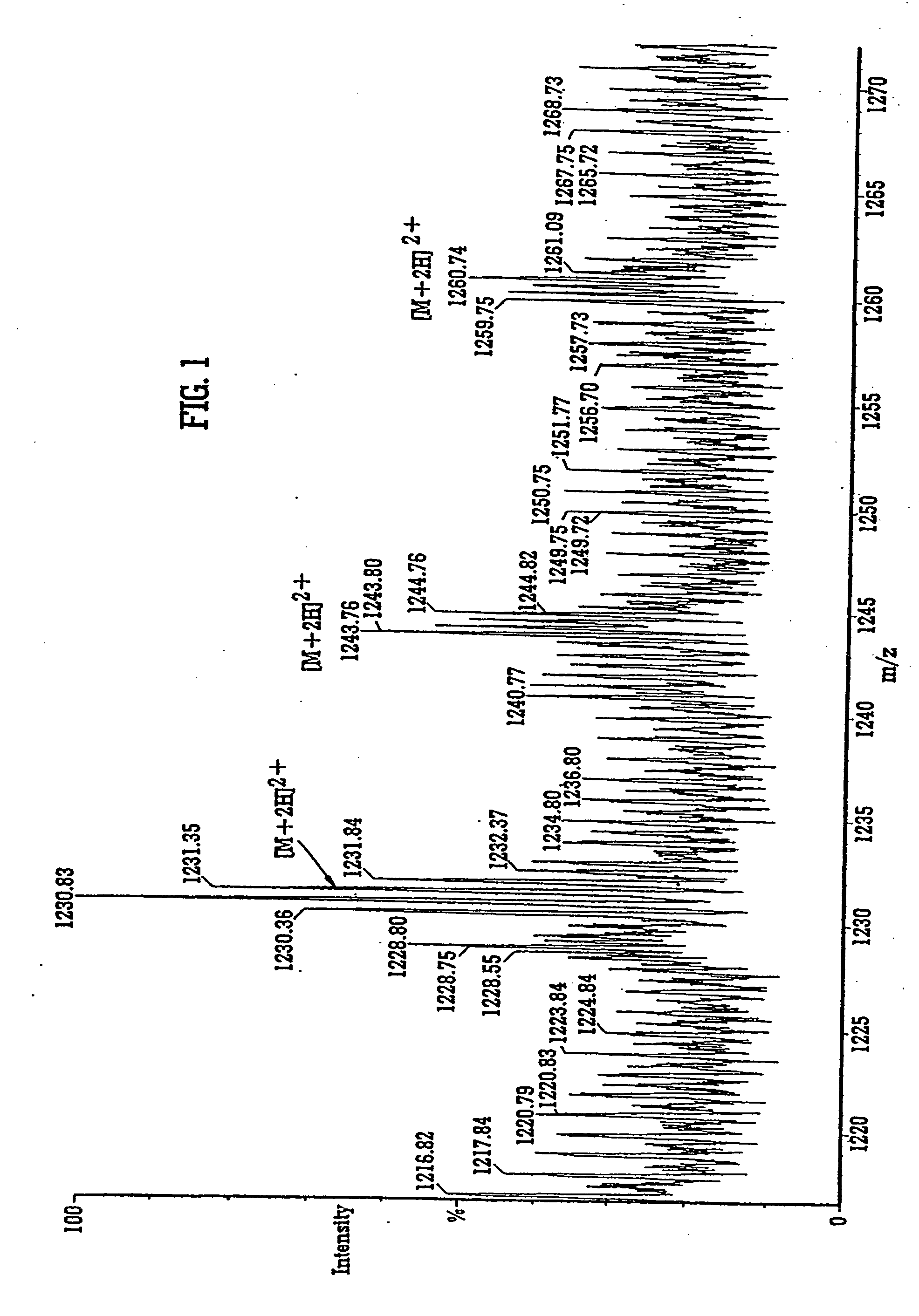

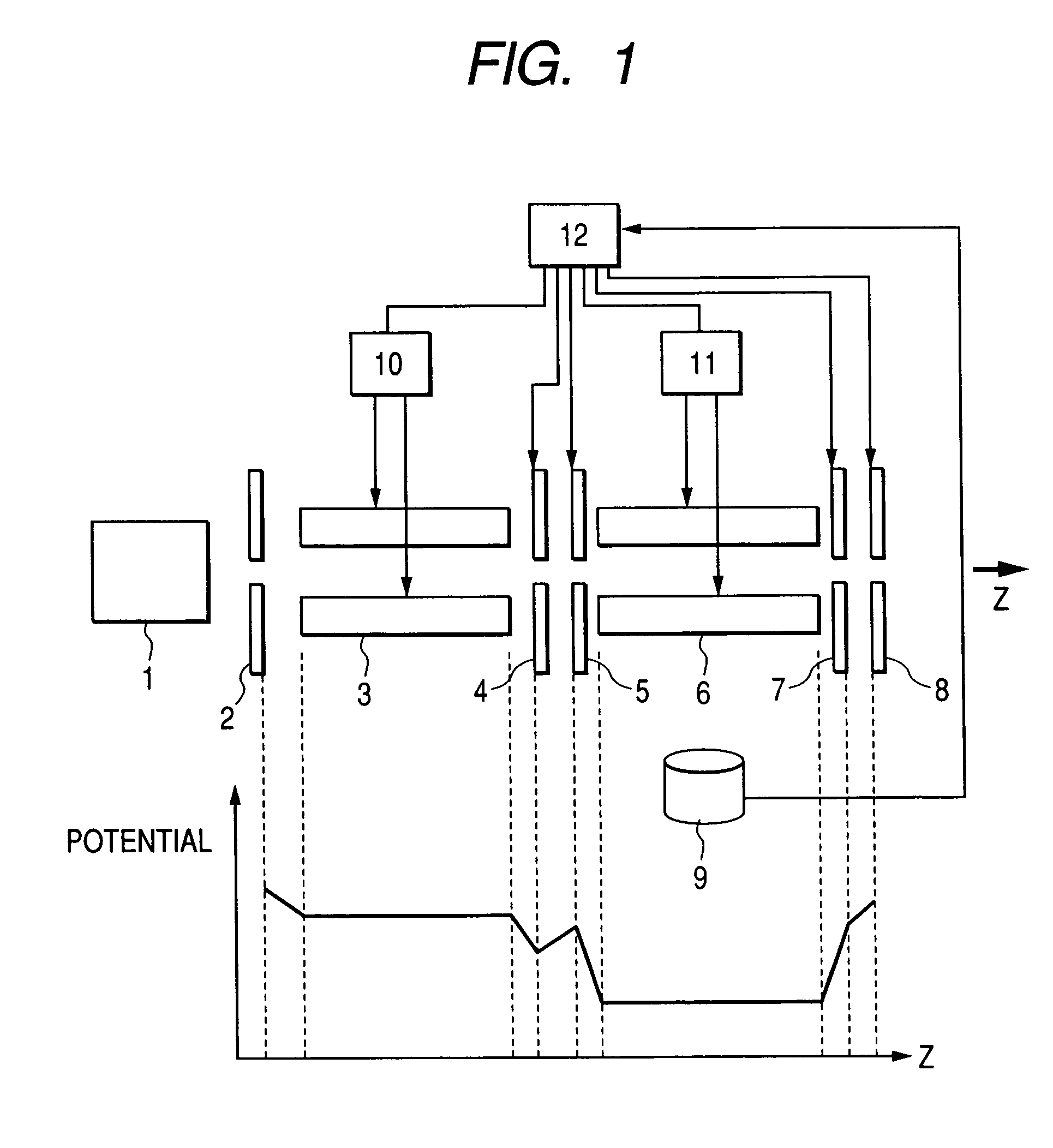

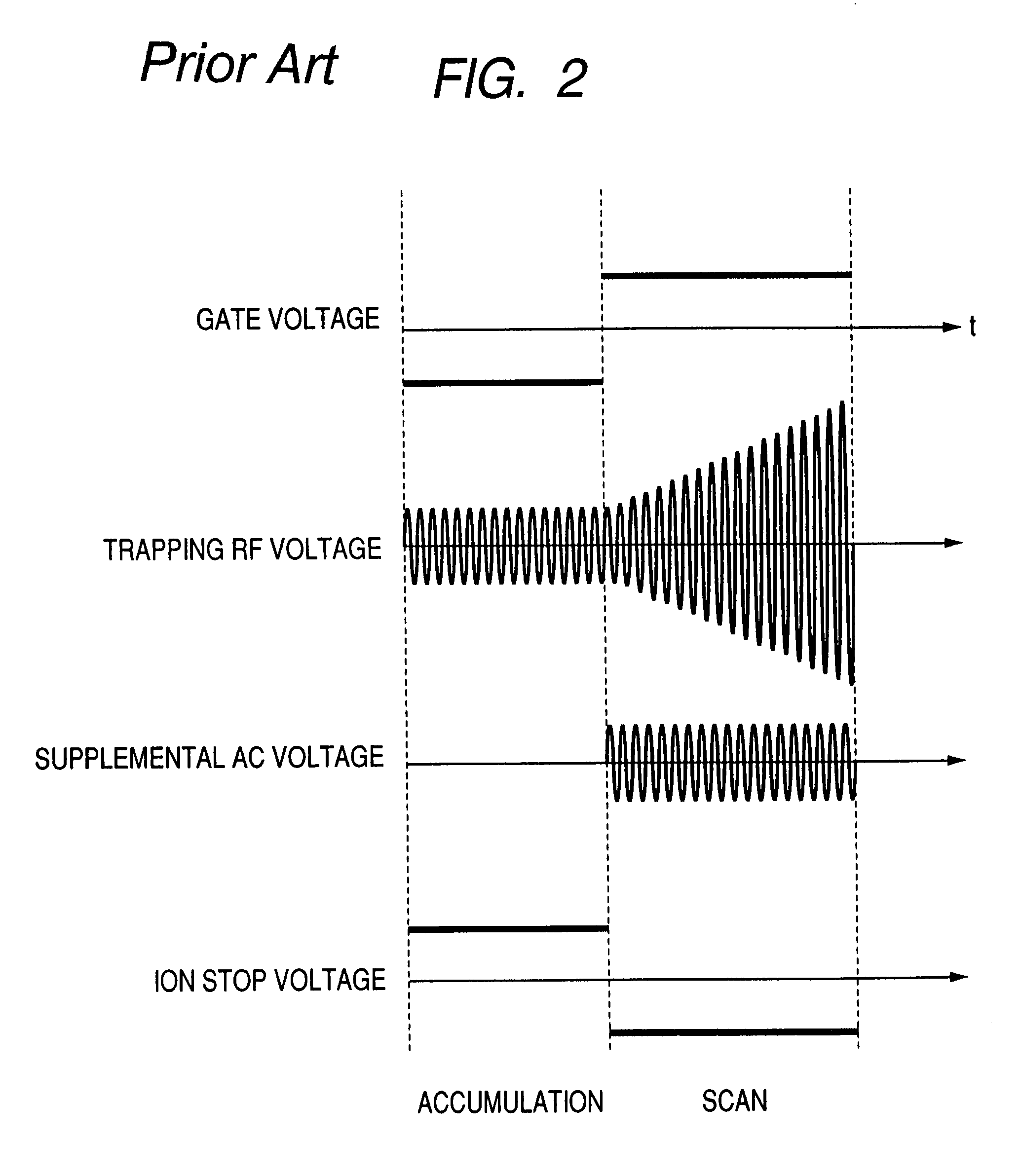

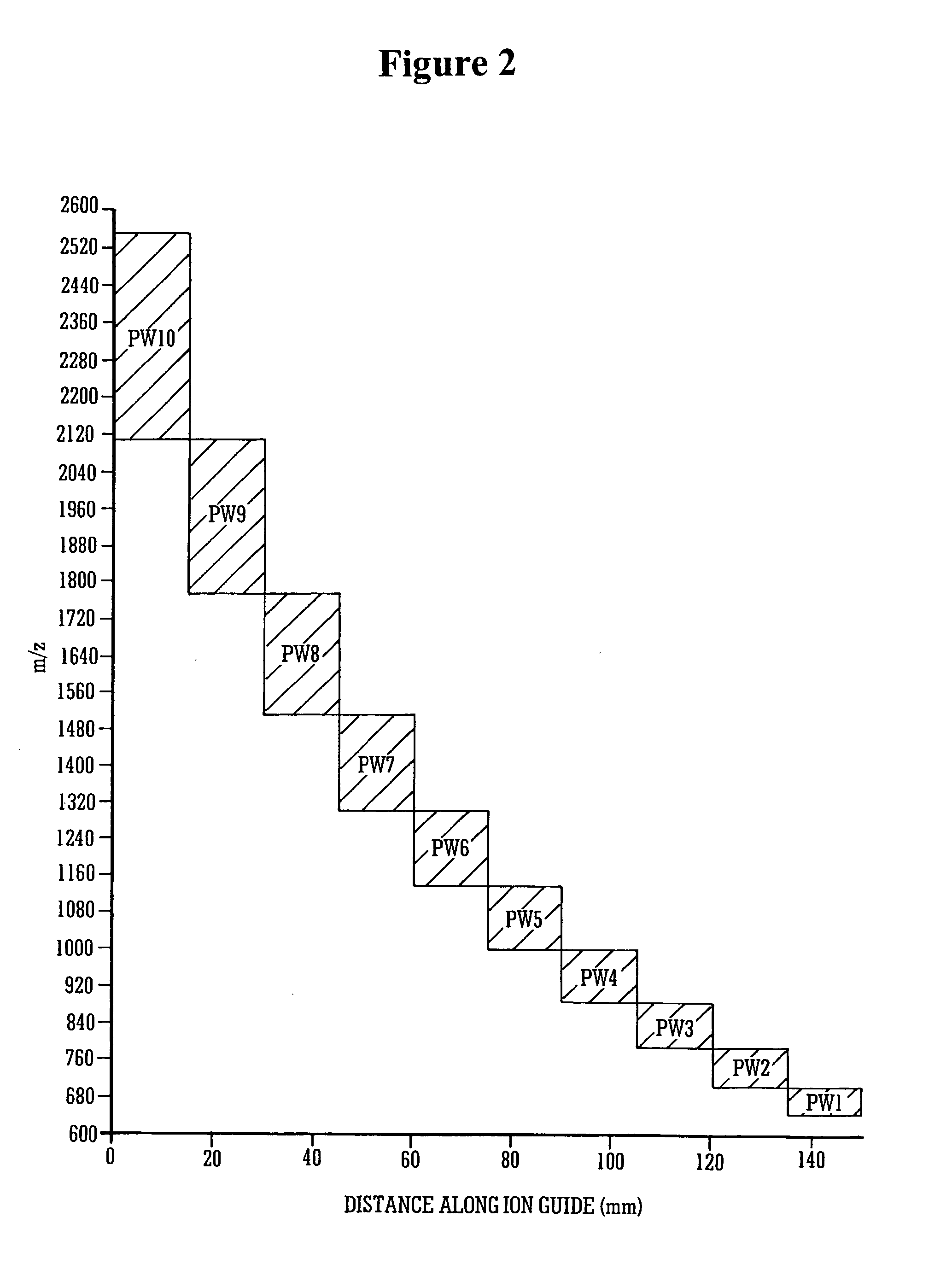

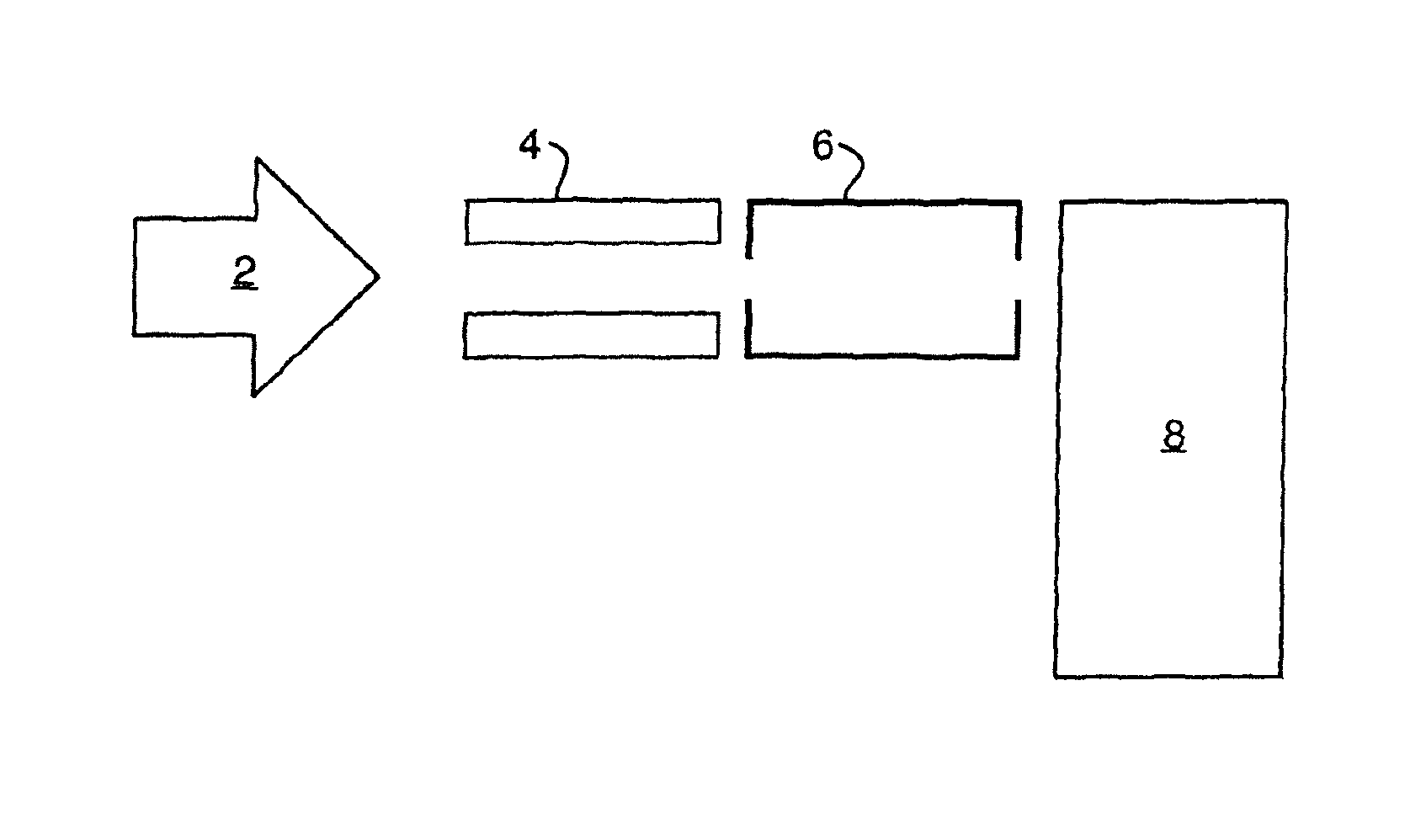

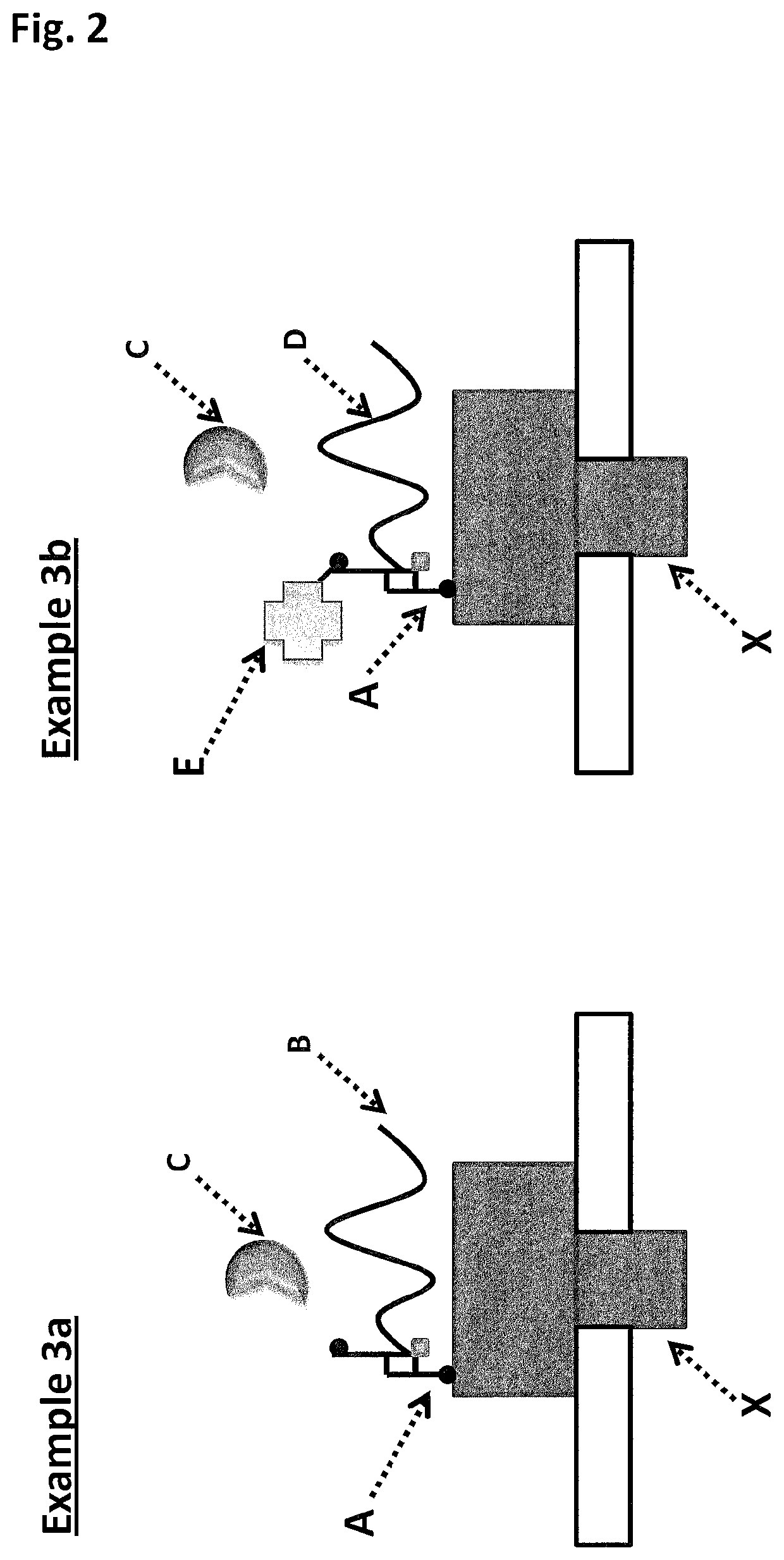

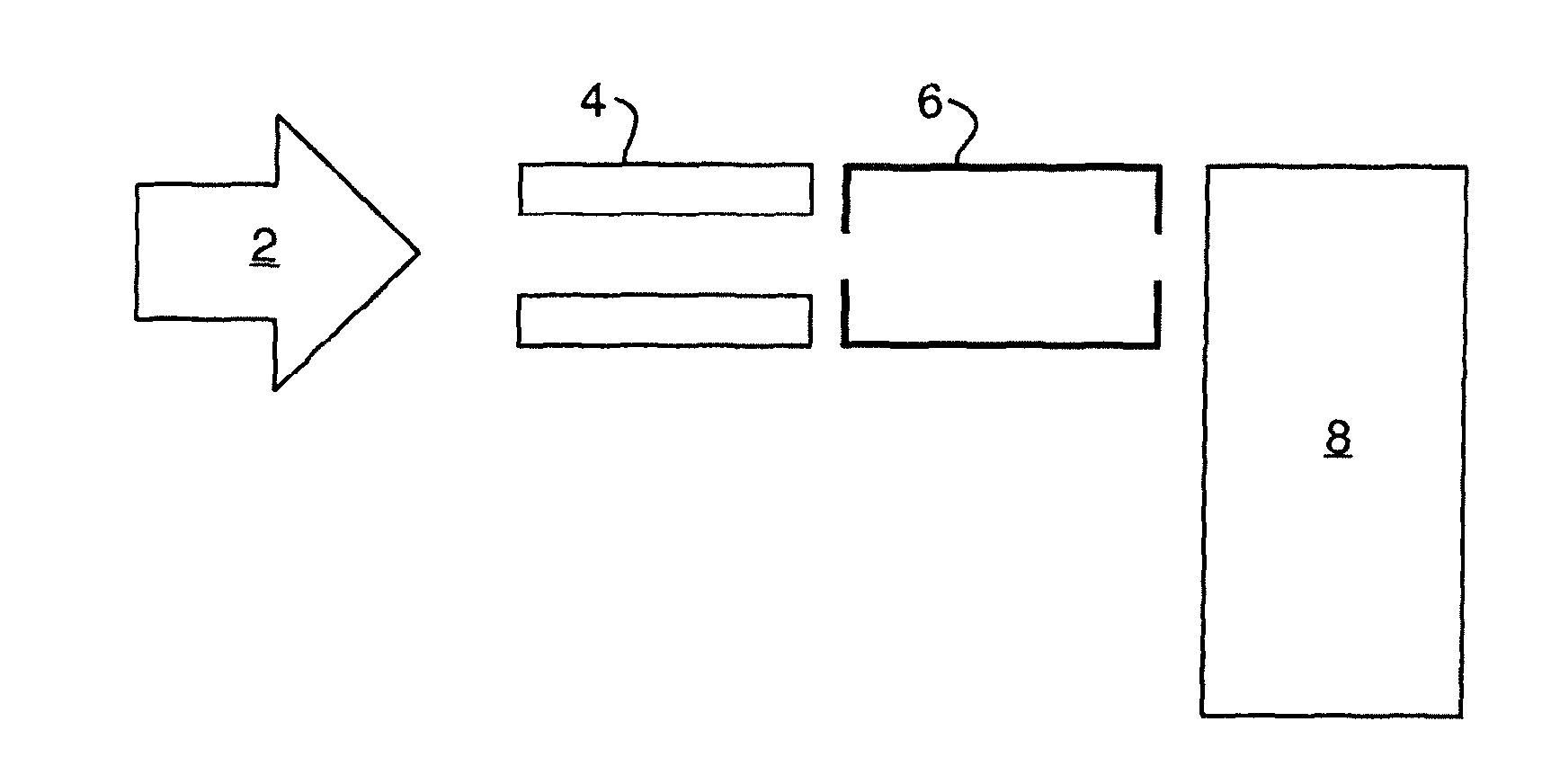

A mass spectrometer is disclosed wherein ions having a particular desired charge state are selected by operating an ion mobility spectrometer in combination with a quadrupole mass filter. Precursor ions are fragmented or reacted to form product ions in a collision cell ion trap and sent back upstream to an upstream ion trap. The fragment or product ions are then passed through the ion mobility spectrometer wherein they become temporally separated according to their ion mobility. Fragment or product ions are then re-trapped in the collision cell ion trap before being released therefrom in packets. A pusher electrode of a time of flight mass analyzer is energized a predetermined period of time after a packet of ions is released from the collision cell ion trap. Accordingly, it is possible to select multiply charged precursor ions from a background of singly charged ions, fragment them, and mass analyze the fragment ions with a near 100% duty cycle across the whole mass range.

Owner:MICROMASS UK LTD

Mass spectrometer

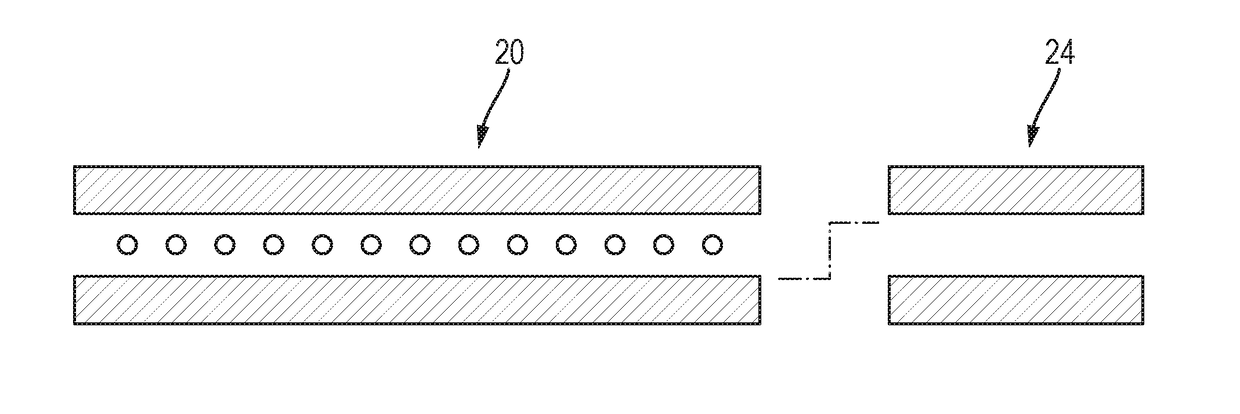

ActiveUS7071467B2Eliminate the effects ofHigh duty cycleStability-of-path spectrometersTime-of-flight spectrometersIon trap mass spectrometryTrapping region

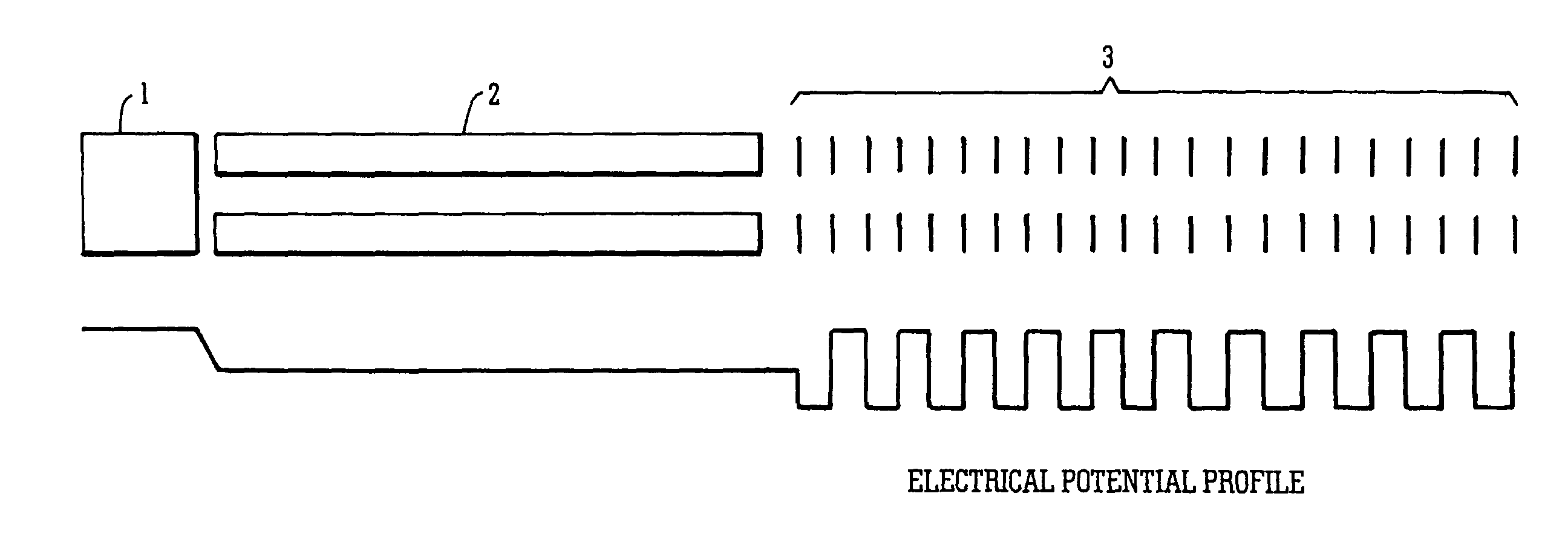

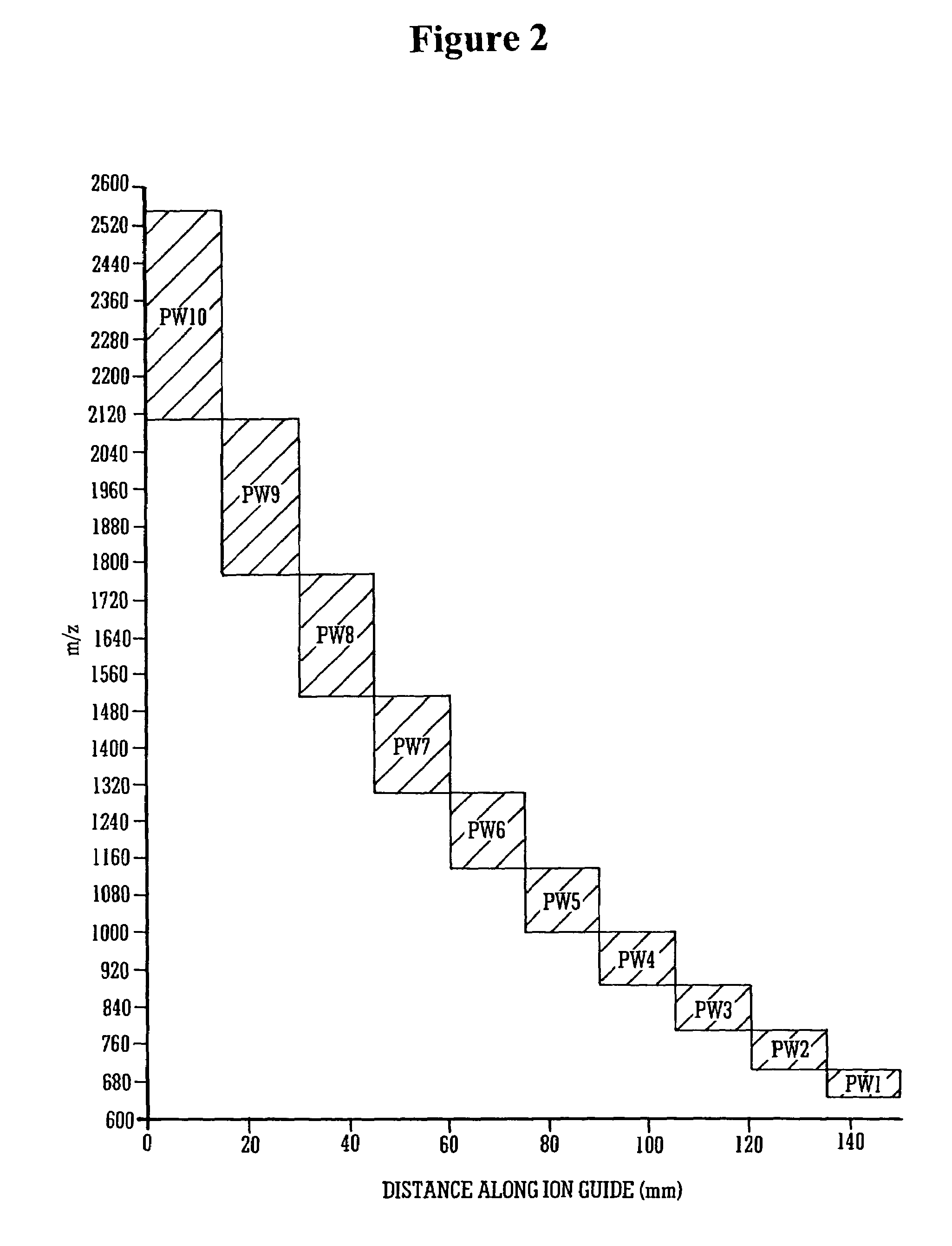

A mass spectrometer is disclosed comprising an ion trap wherein ions which have been temporally separated according to their mass to charge ratio or ion mobility enter the ion trap. Once at least some of the ions have entered the ion trap, a plurality of ion trapping regions are created along the length of the ion trap in order to fractionate the ions. Alternatively, the ions may be received within one or more axial trapping regions which are translated along the ion trap with a velocity which is progressively reduced to zero.

Owner:MICROMASS UK LTD

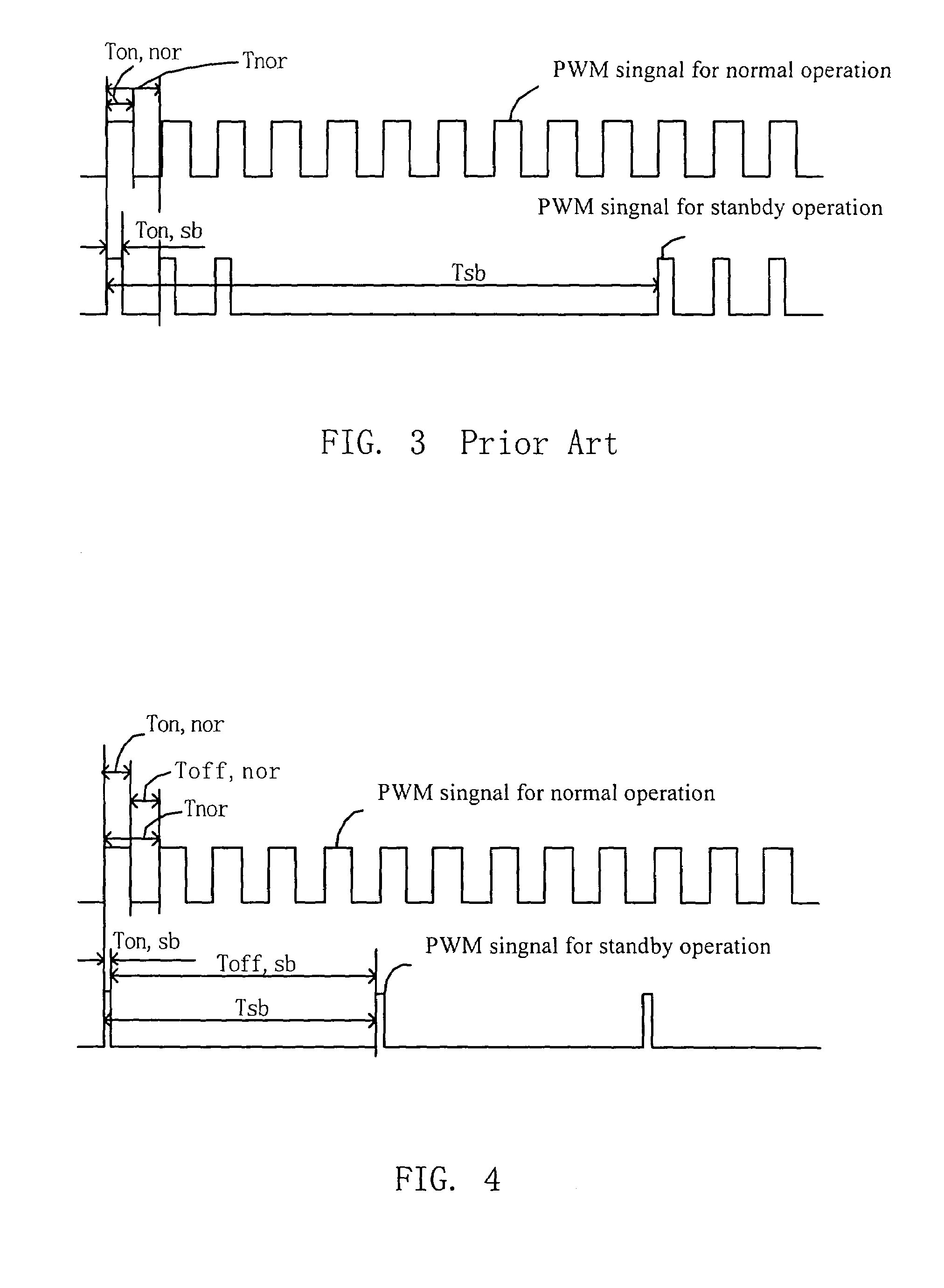

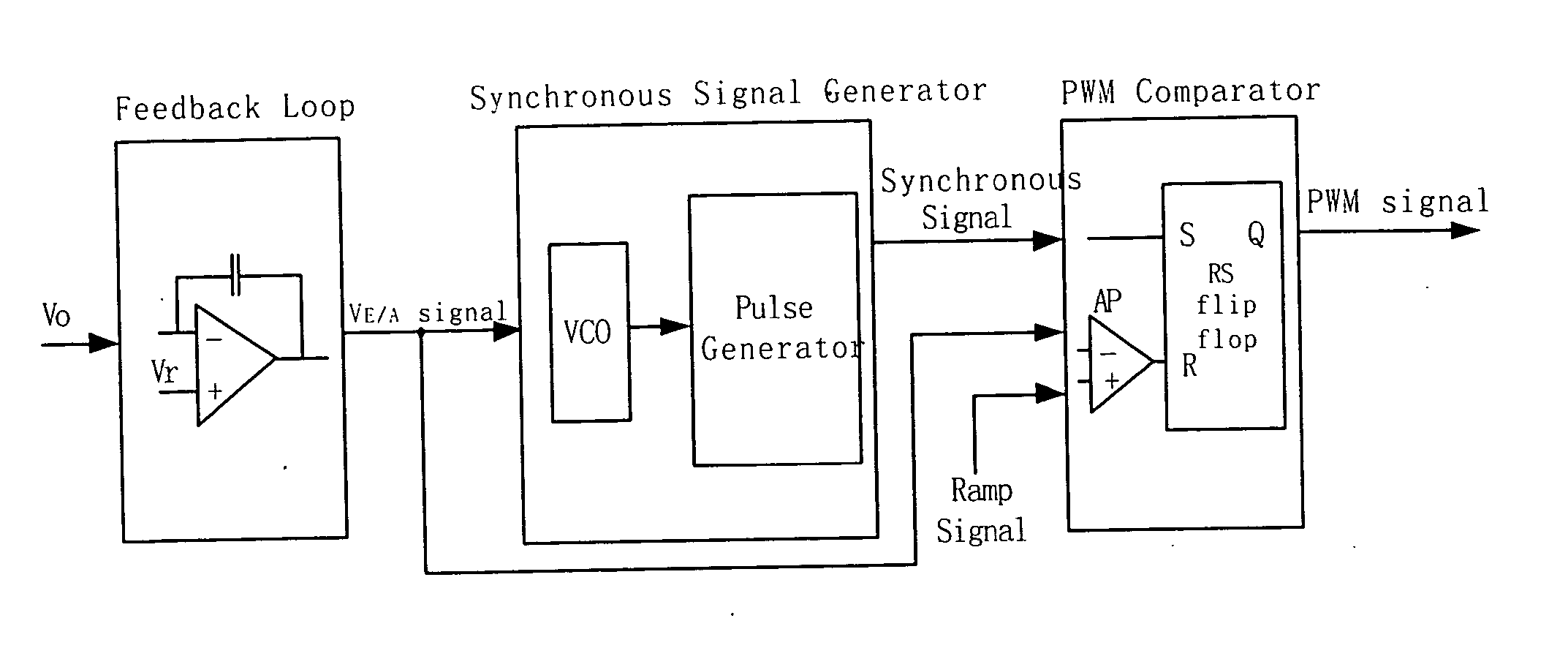

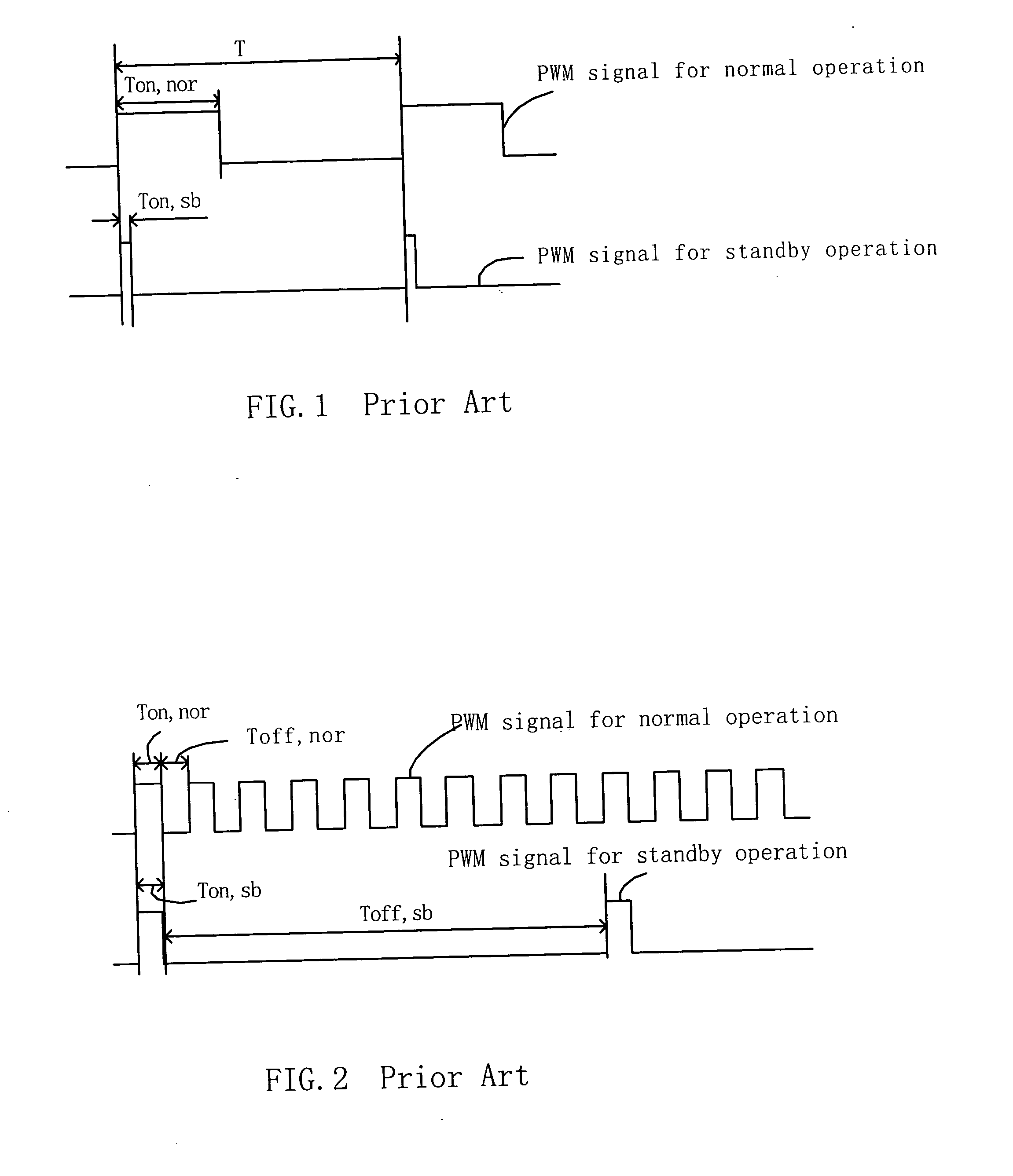

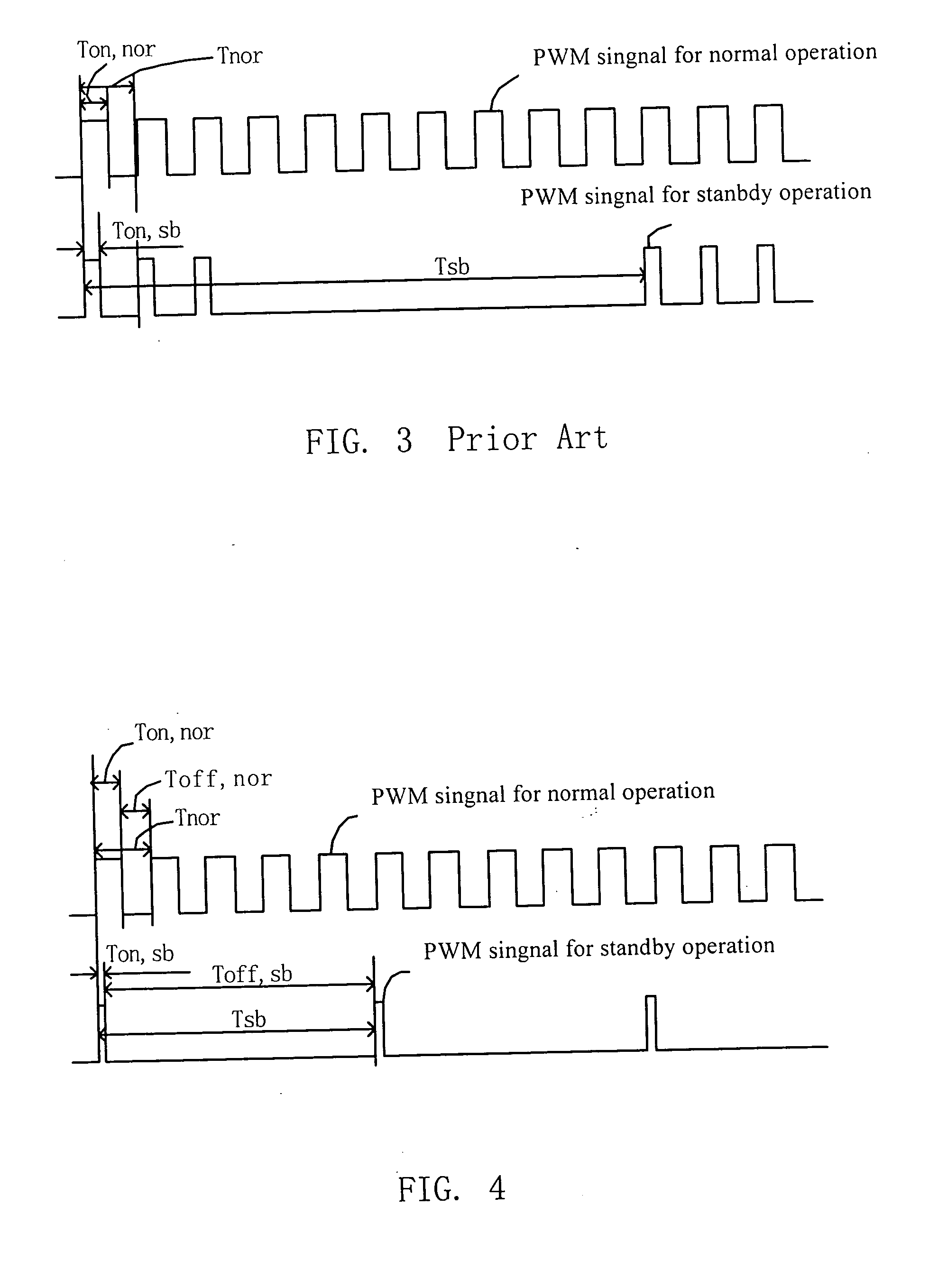

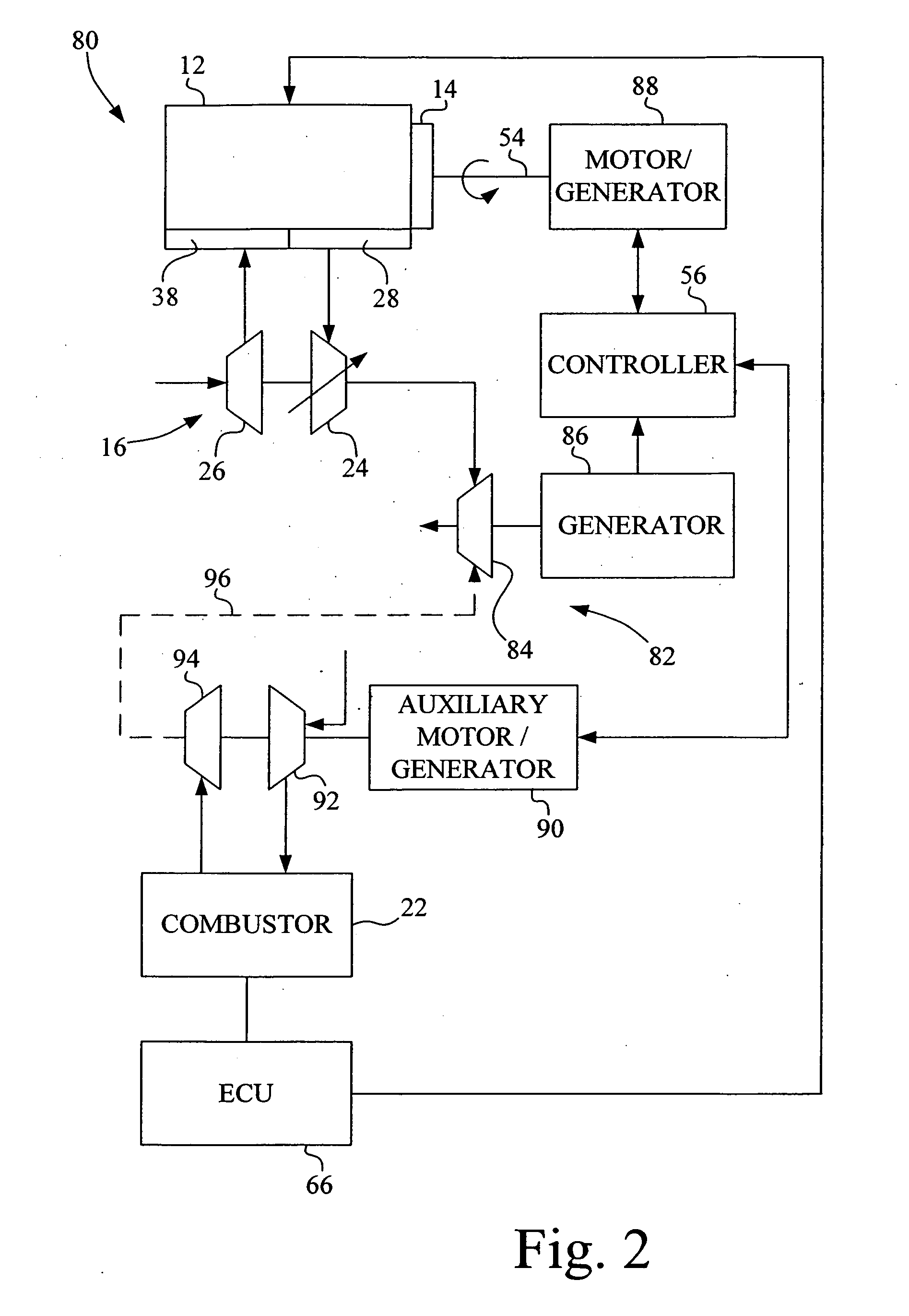

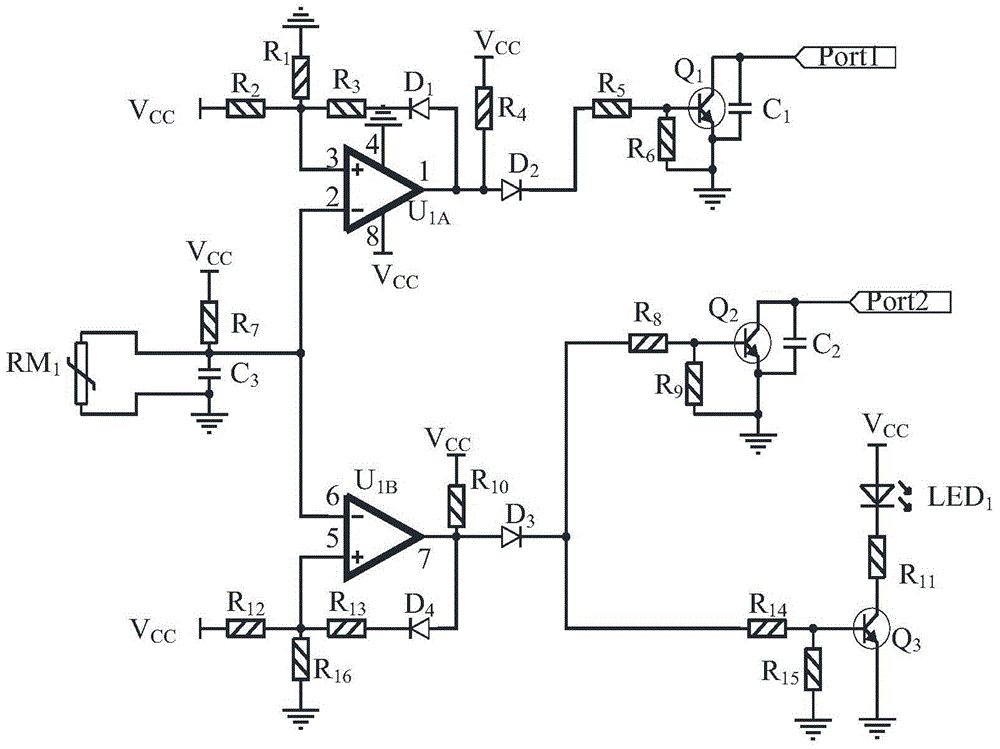

Variable frequency PWM controller circuit

ActiveUS7106130B2Short timeReduce frequencyAc-dc conversion without reversalEfficient power electronics conversionControl theoryPwm signals

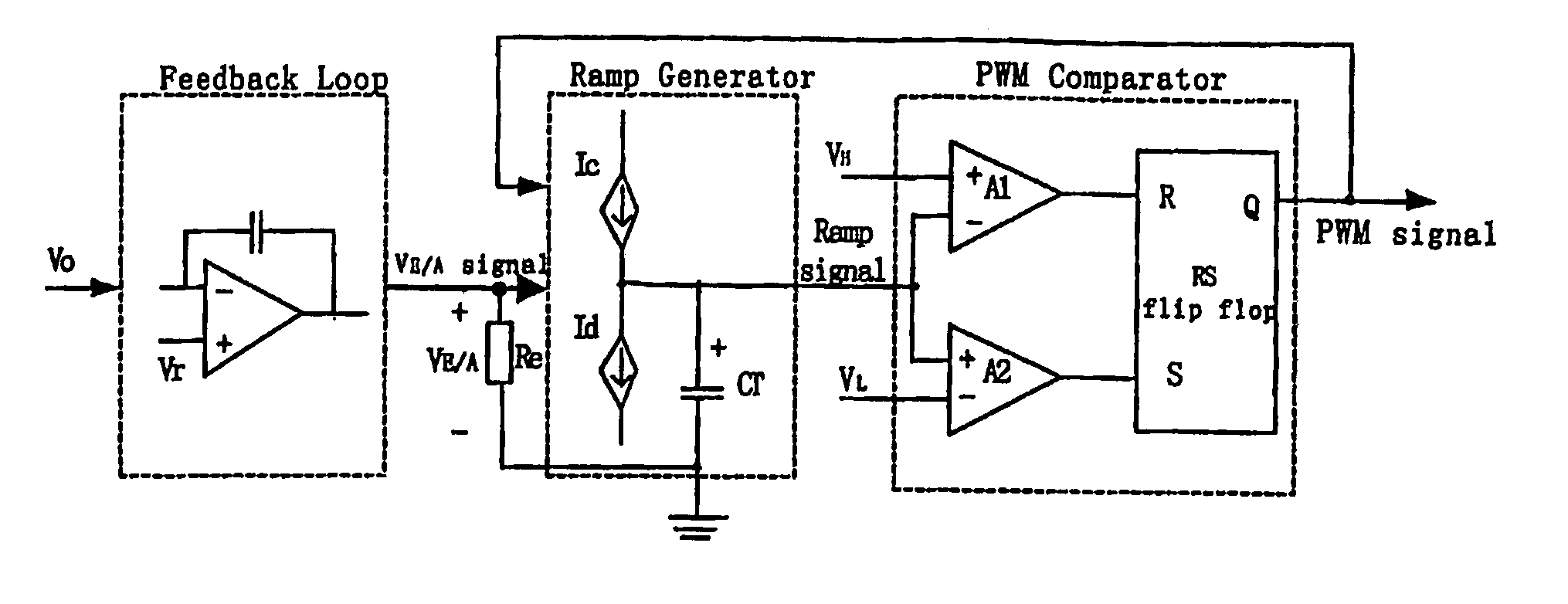

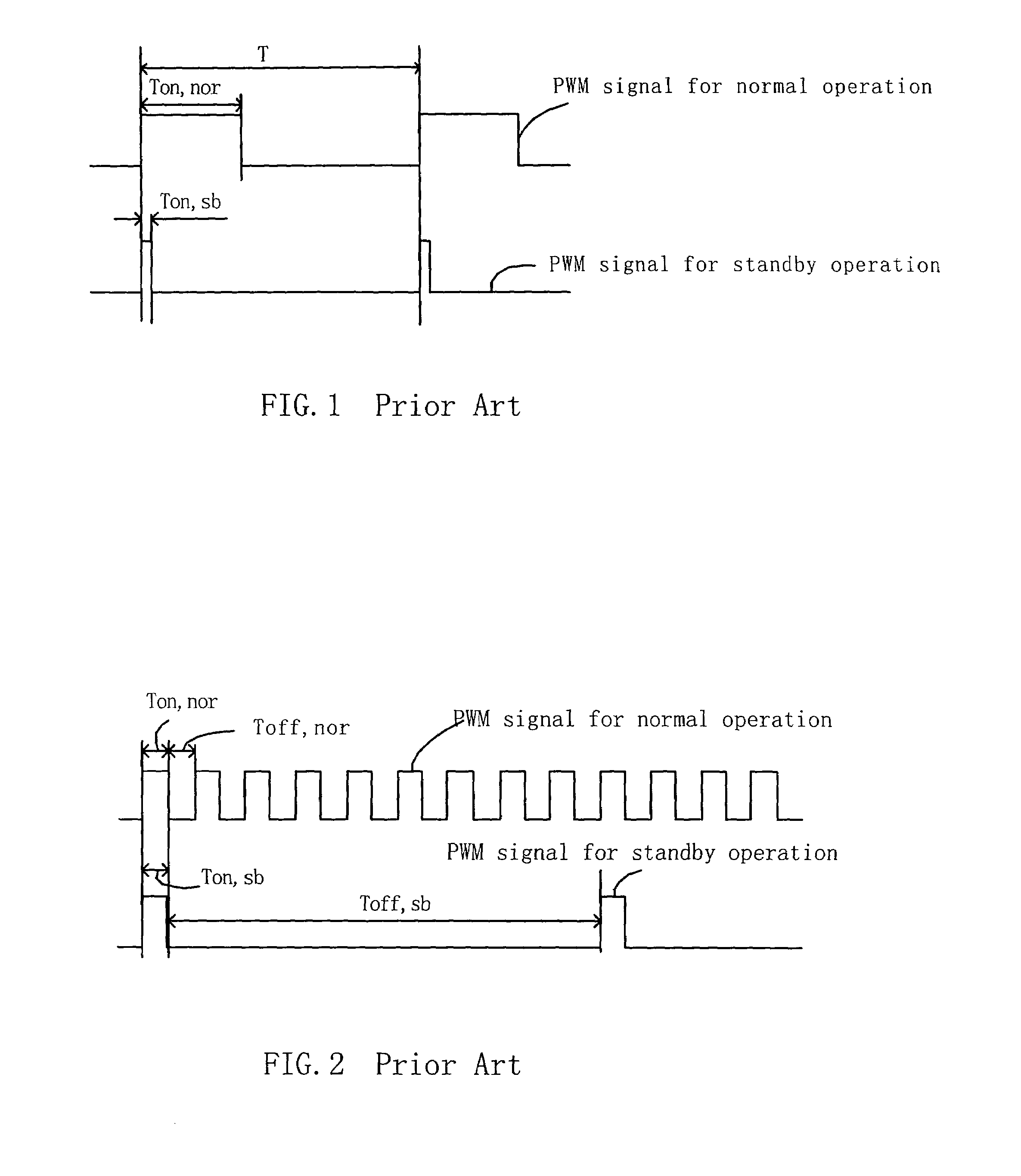

The present invention discloses a circuit that generates a variable frequency pulse width modulation (VF PWM) signal. Different from the conventional PWM controller, the frequency and duty cycle of the output PWM signal vary with the error-amplified voltage of the feedback loop simultaneously in this invention. The higher the error-amplified voltage of the feedback loop is, the lower the duty cycle with lower frequency will be. A very low duty cycle PWM signal can be generated stably while its frequency is very low.

Owner:DELTA ELECTRONICS INC

Variable frequency PWM controller circuit

ActiveUS20050052249A1Ripple and noise be eliminateShort timeAc-dc conversion without reversalEfficient power electronics conversionPwm controllerLow frequency

The present invention discloses a circuit that generates a variable frequency pulse width modulation (VF PWM) signal. Different from the conventional PWM controller, the frequency and duty cycle of the output PWM signal vary with the error-amplified voltage of the feedback loop simultaneously in this invention. The higher the error-amplified voltage of the feedback loop is, the lower the duty cycle with lower frequency will be. A very low duty cycle PWM signal can be generated stably while its frequency is very low.

Owner:DELTA ELECTRONICS INC

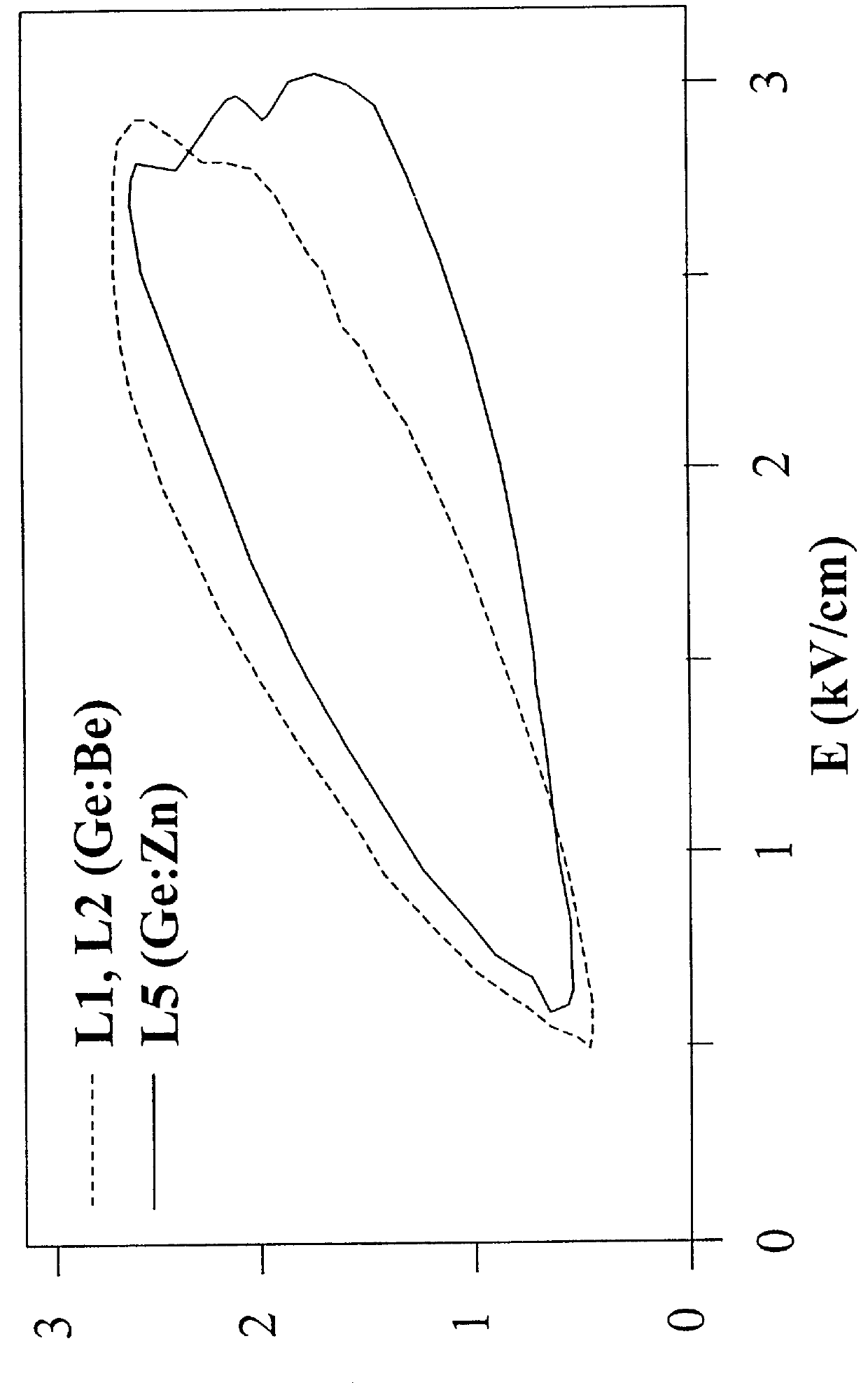

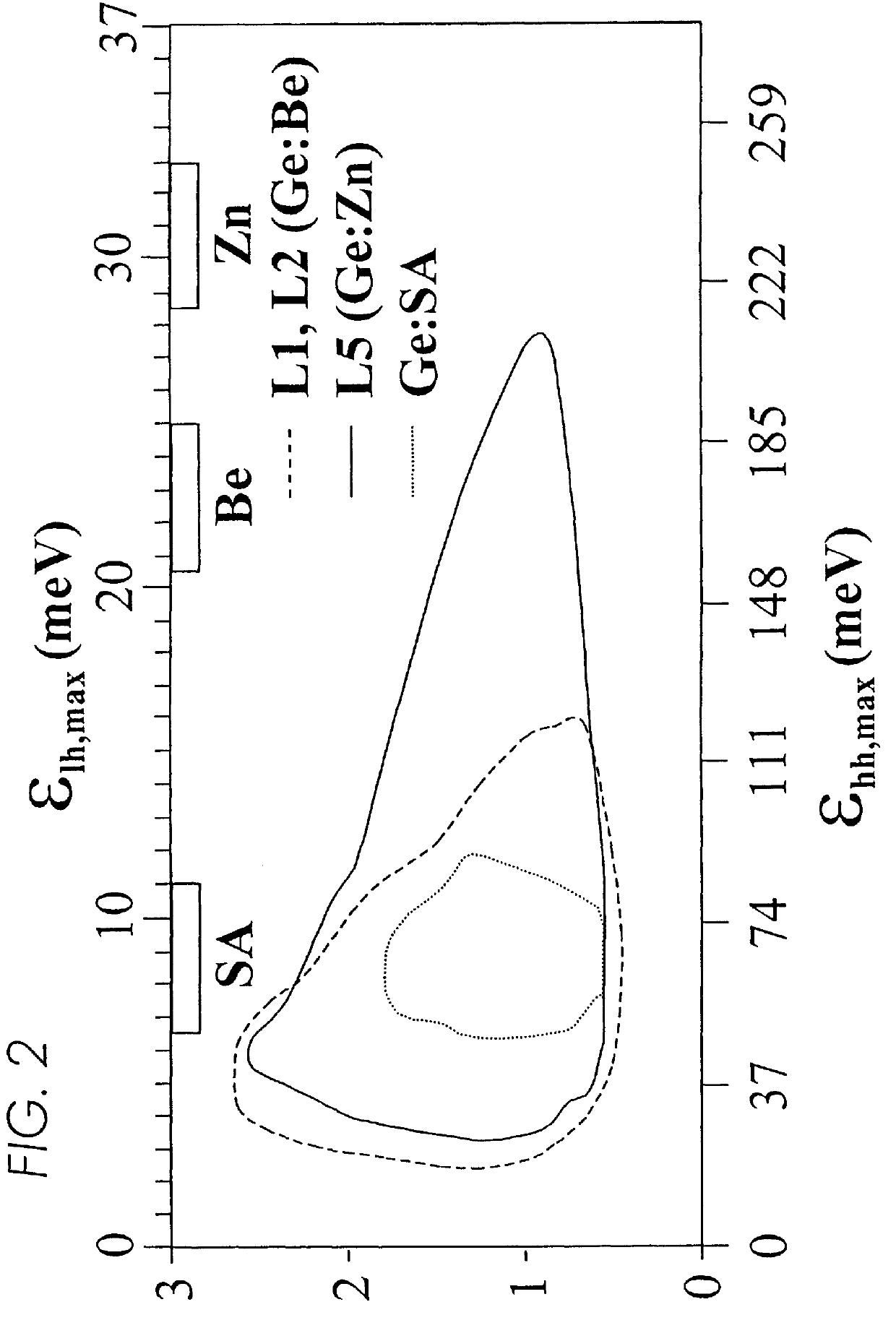

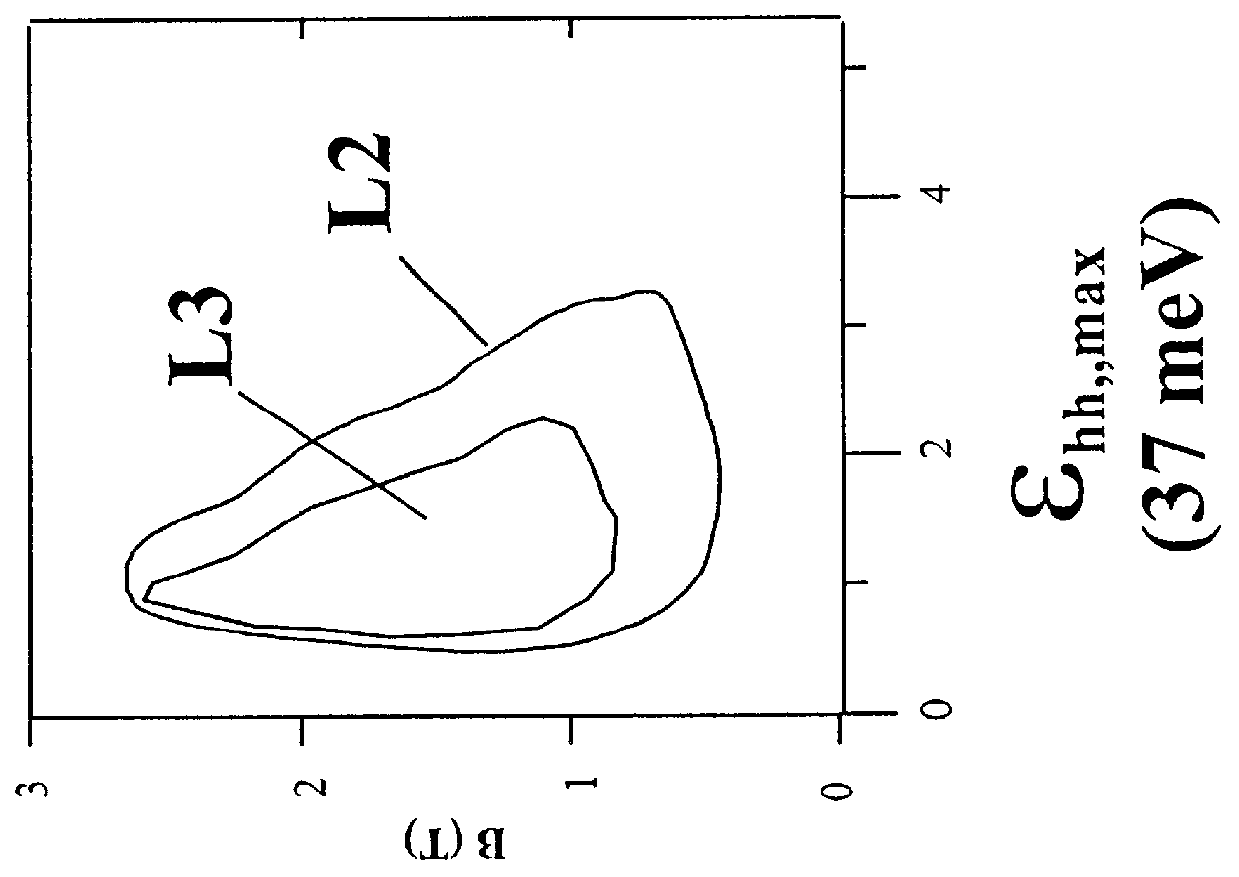

Doping of germanium and silicon crystals with non-hydrogenic acceptors for far infrared lasers

InactiveUS6011810AIncrease powerHigh duty cycleLaser detailsLaser active region structureAcceptor dopantFar infrared

A method for doping semiconductors used for far infrared lasers with non-hydrogenic acceptors having binding energies larger than the energy of the laser photons. Doping of germanium or silicon crystals with beryllium, zinc or copper. A far infrared laser comprising germanium crystals doped with double or triple acceptor dopants permitting the doped laser to be tuned continuously from 1 to 4 terahertz and to operate in continuous mode. A method for operating semiconductor hole population inversion lasers with a closed cycle refrigerator.

Owner:LAWRENCE BERKELEY NAT LAB

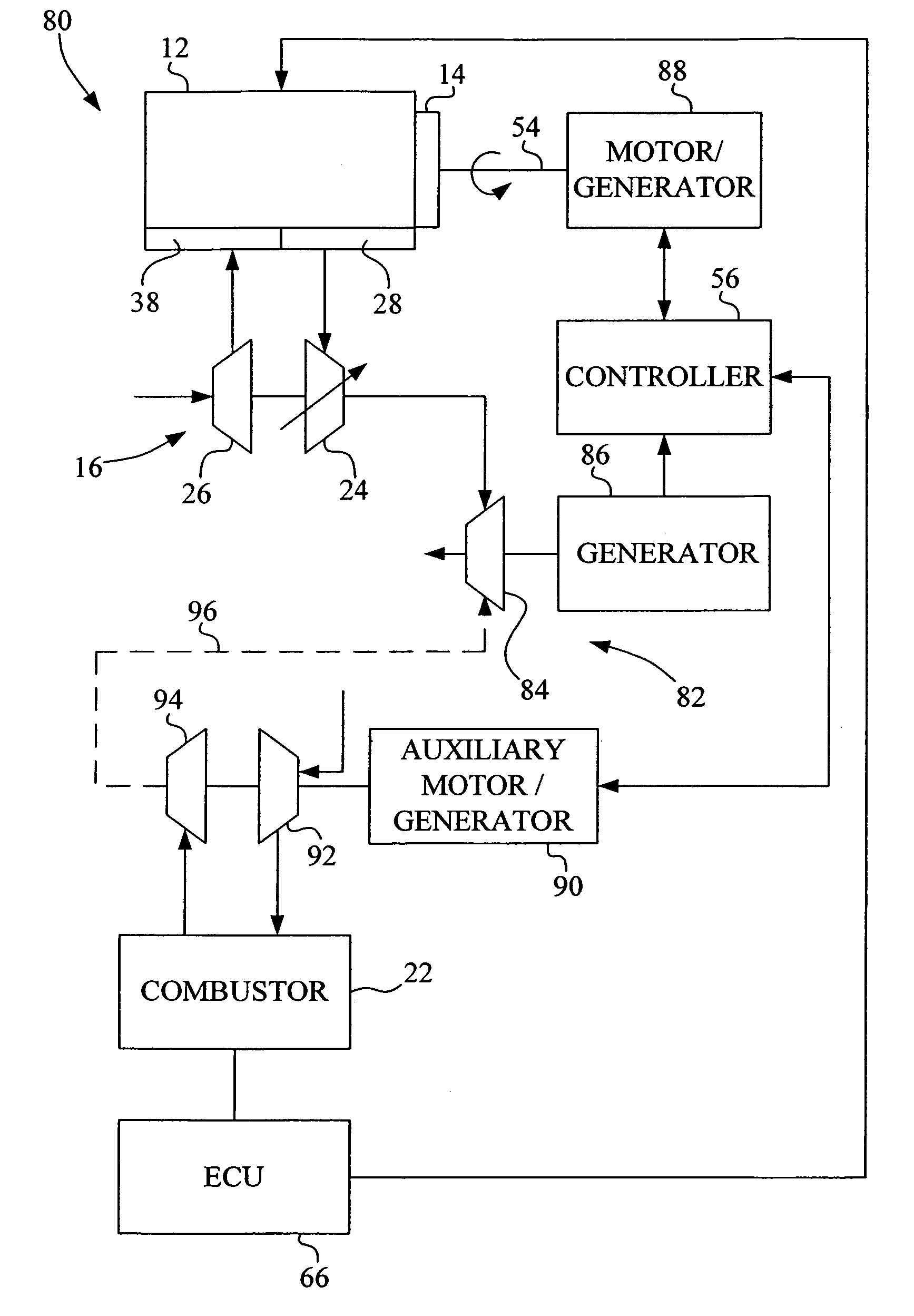

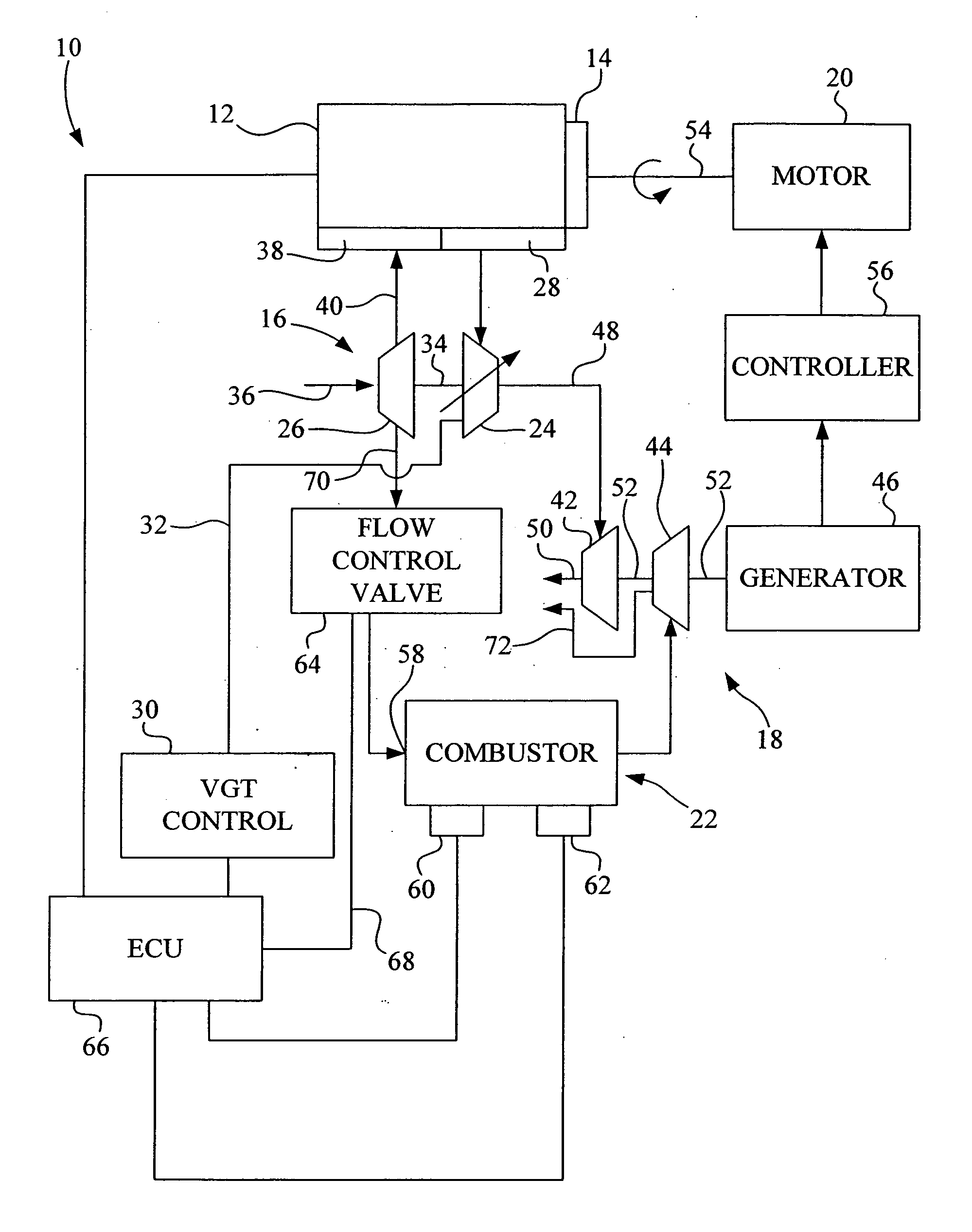

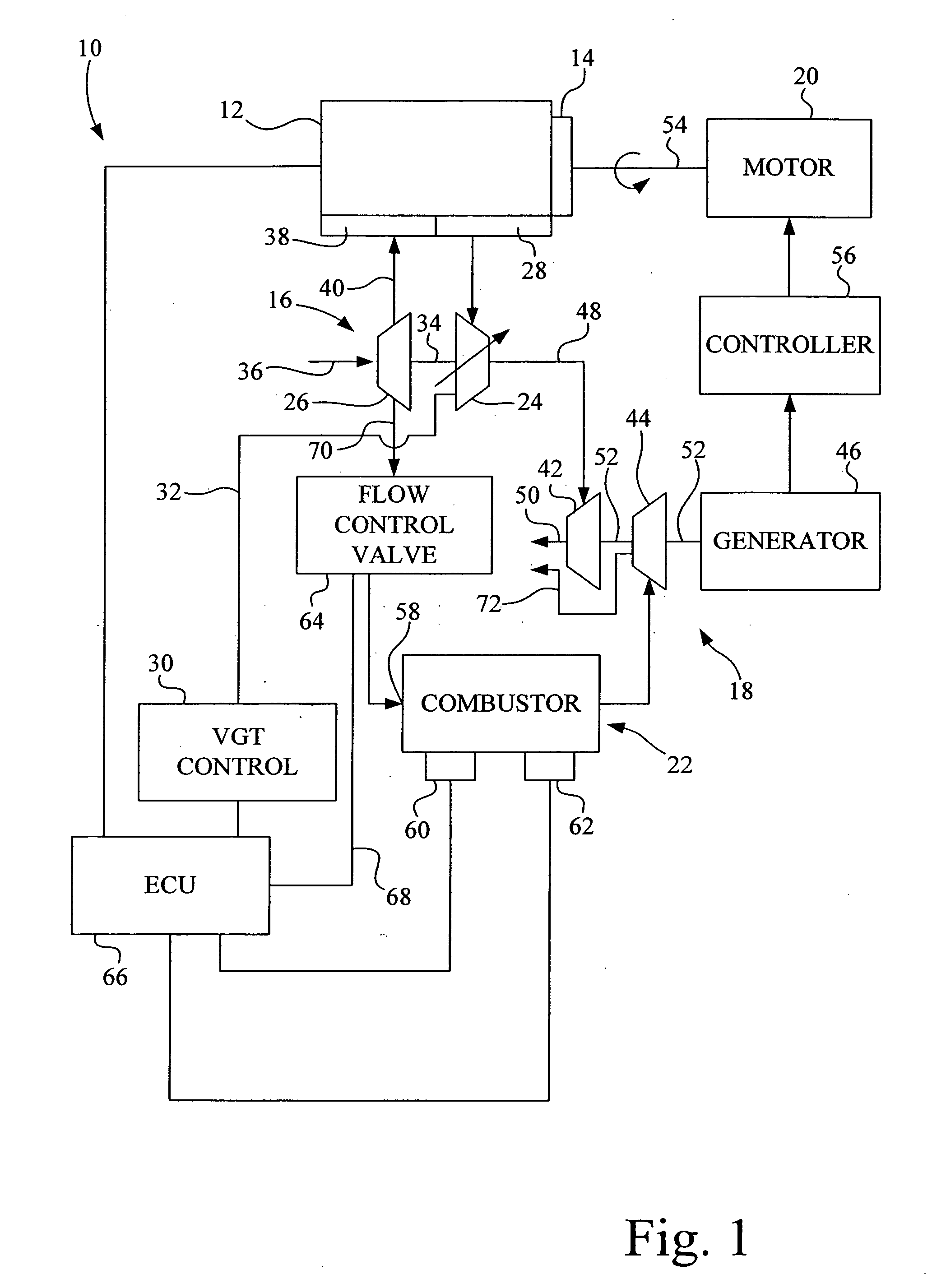

Hybrid engine

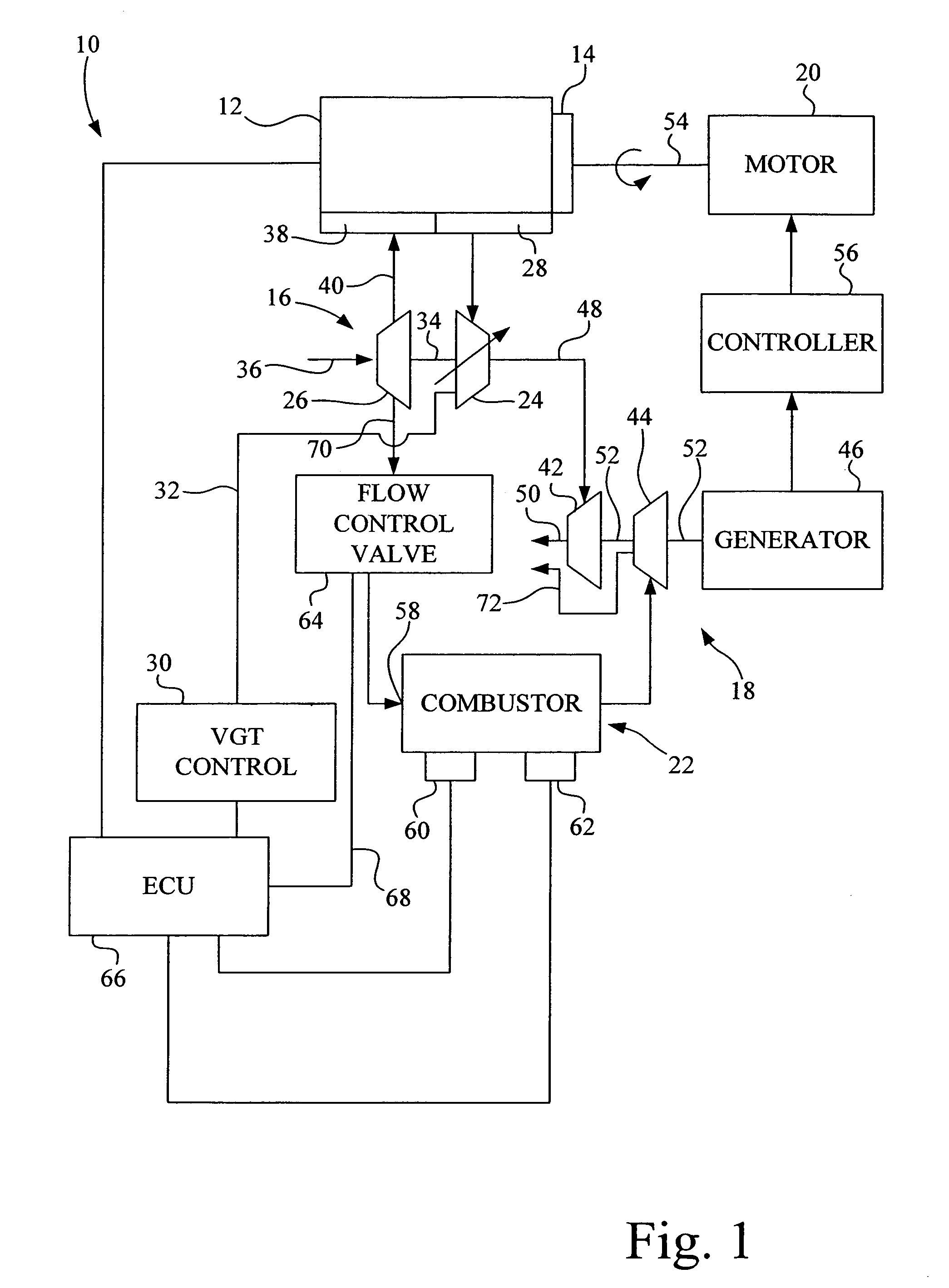

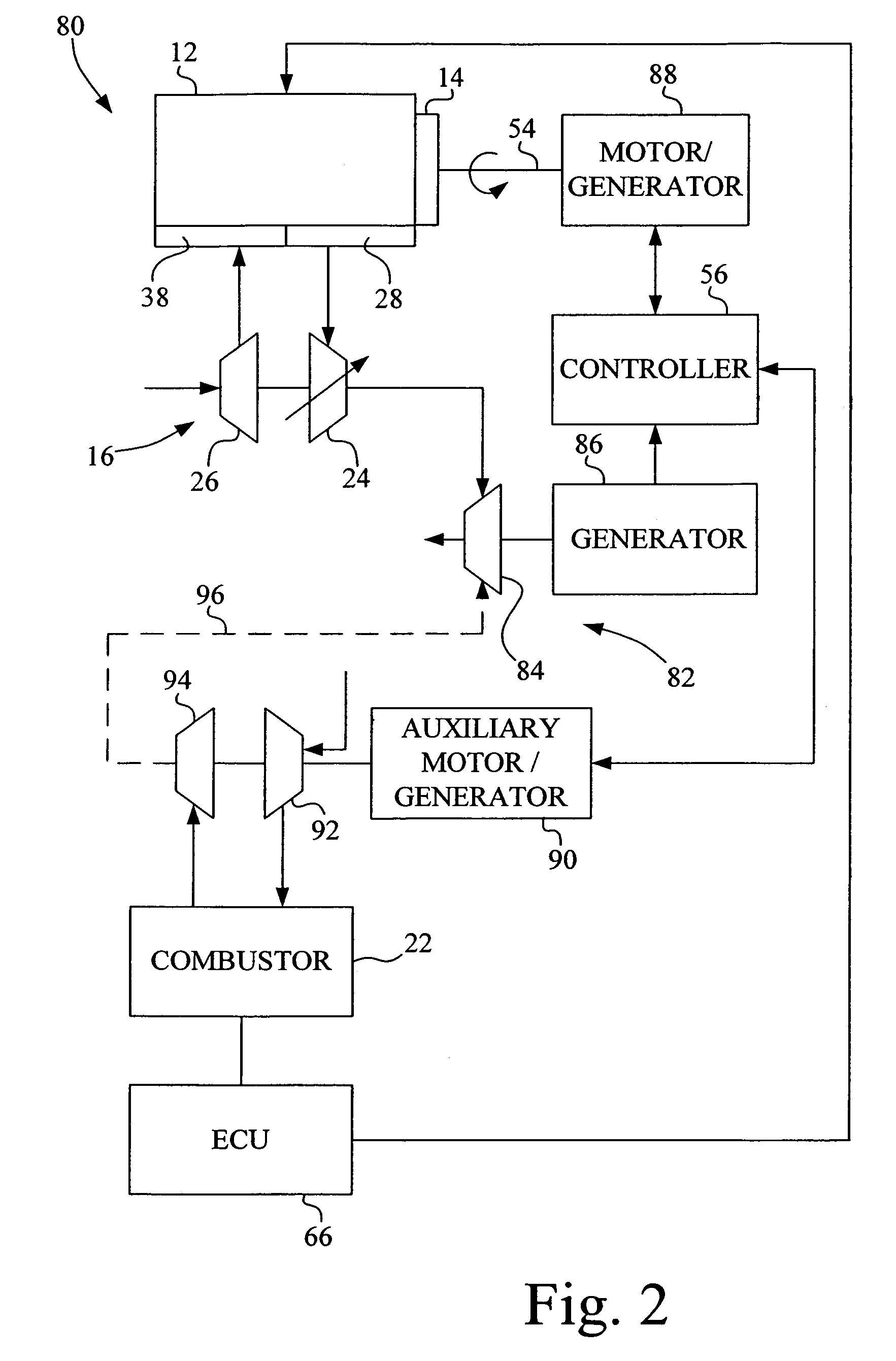

ActiveUS7383684B2Improve rendering capabilitiesImprove efficiencyInternal combustion piston enginesExhaust apparatusCombustorTurbocharger

An internal combustion engine includes an exhaust manifold; an intake manifold; and a turbocharger including a turbine in communication with the exhaust manifold, and a compressor in communication with the intake manifold. An electrical generator is coupled with the turbine. A motor receives electrical input power from the generator and provides mechanical output power. A combustor selectively provides additional input power to the motor.

Owner:DEERE & CO

Mass spectrometer

InactiveUS20050092911A1High sensitivityIncrease delay timeStability-of-path spectrometersTime-of-flight spectrometersIon trap mass spectrometryMass spectrometric

A mass spectrometer is disclosed wherein ions having a particular desired charge state are selected by operating an ion mobility spectrometer in combination with a quadrupole mass filter. Precursor ions are fragmented or reacted to form product ions in a collision cell ion trap and sent back upstream to an upstream ion trap. The fragment or product ions are then passed through the ion mobility spectrometer wherein they become temporally separated according to their ion mobility. Fragment or product ions are then re-trapped in the collision cell ion trap before being released therefrom in packets. A pusher electrode of a time of flight mass analyser is energised a predetermined period of time after a packet of ions is released from the collision cell ion trap. Accordingly, it is possible to select multiply charged precursor ions from a background of singly charged ions, fragment them, and mass analyse the fragment ions with a near 100% duty cycle across the whole mass range.

Owner:MICROMASS UK LTD

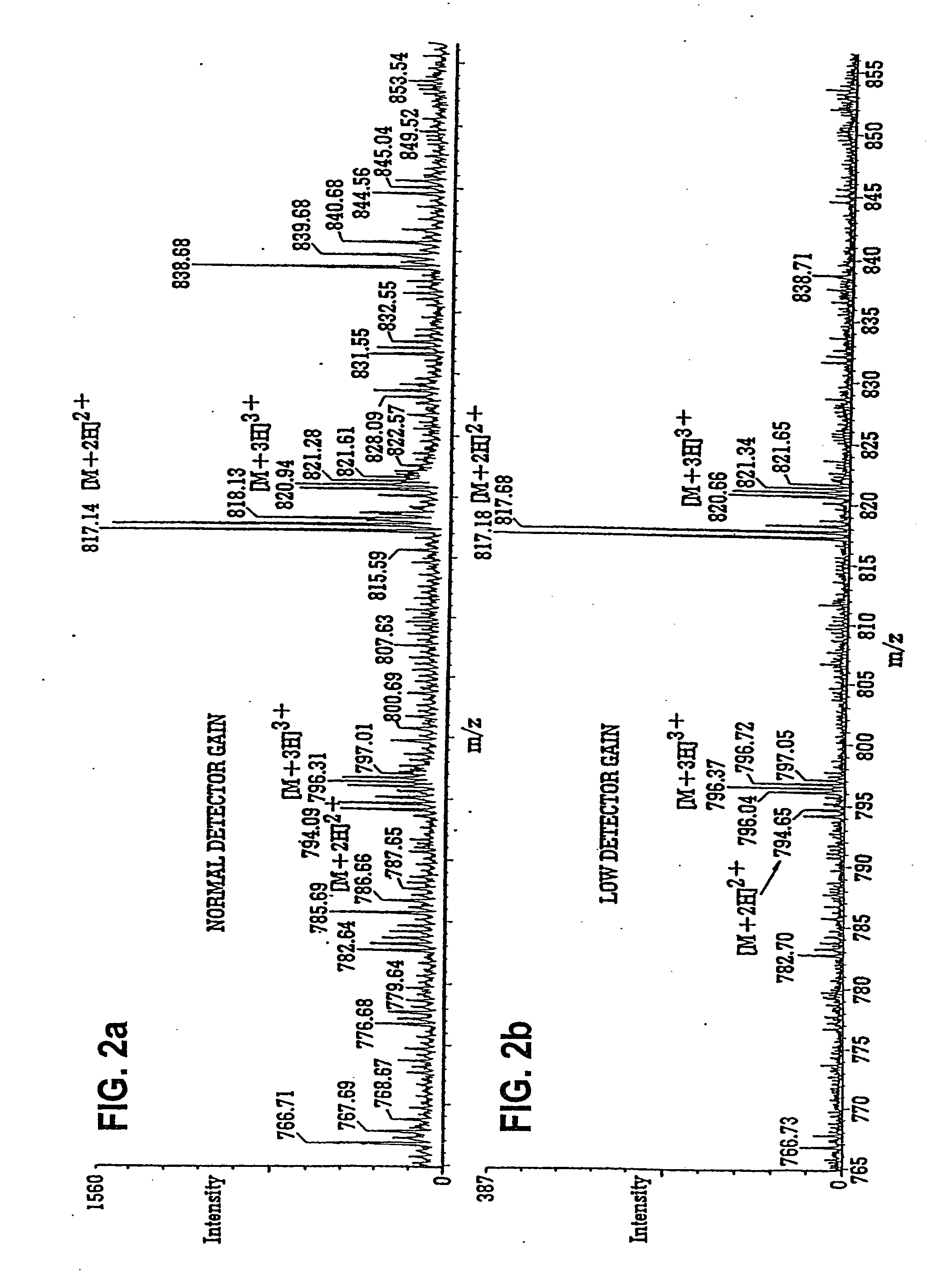

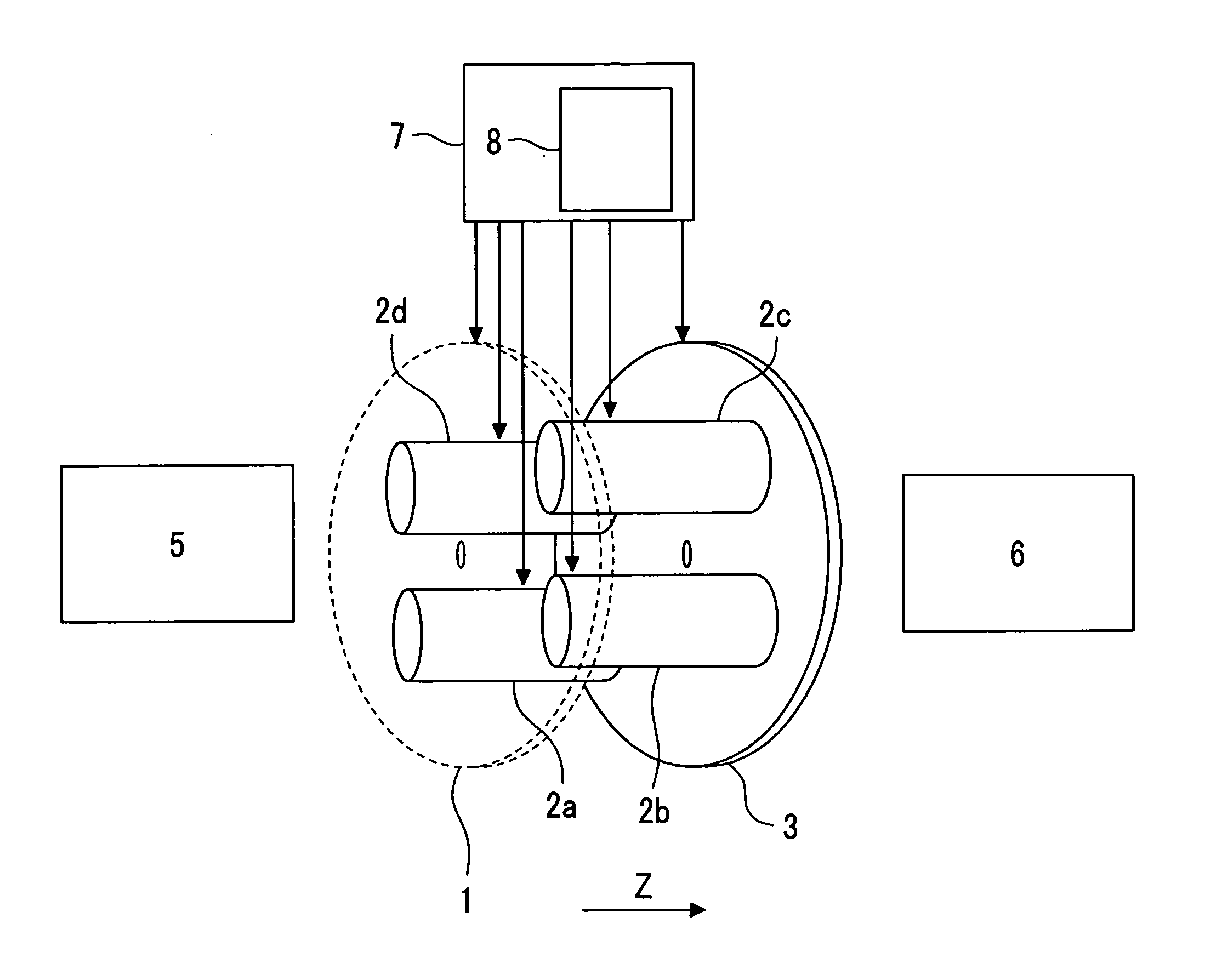

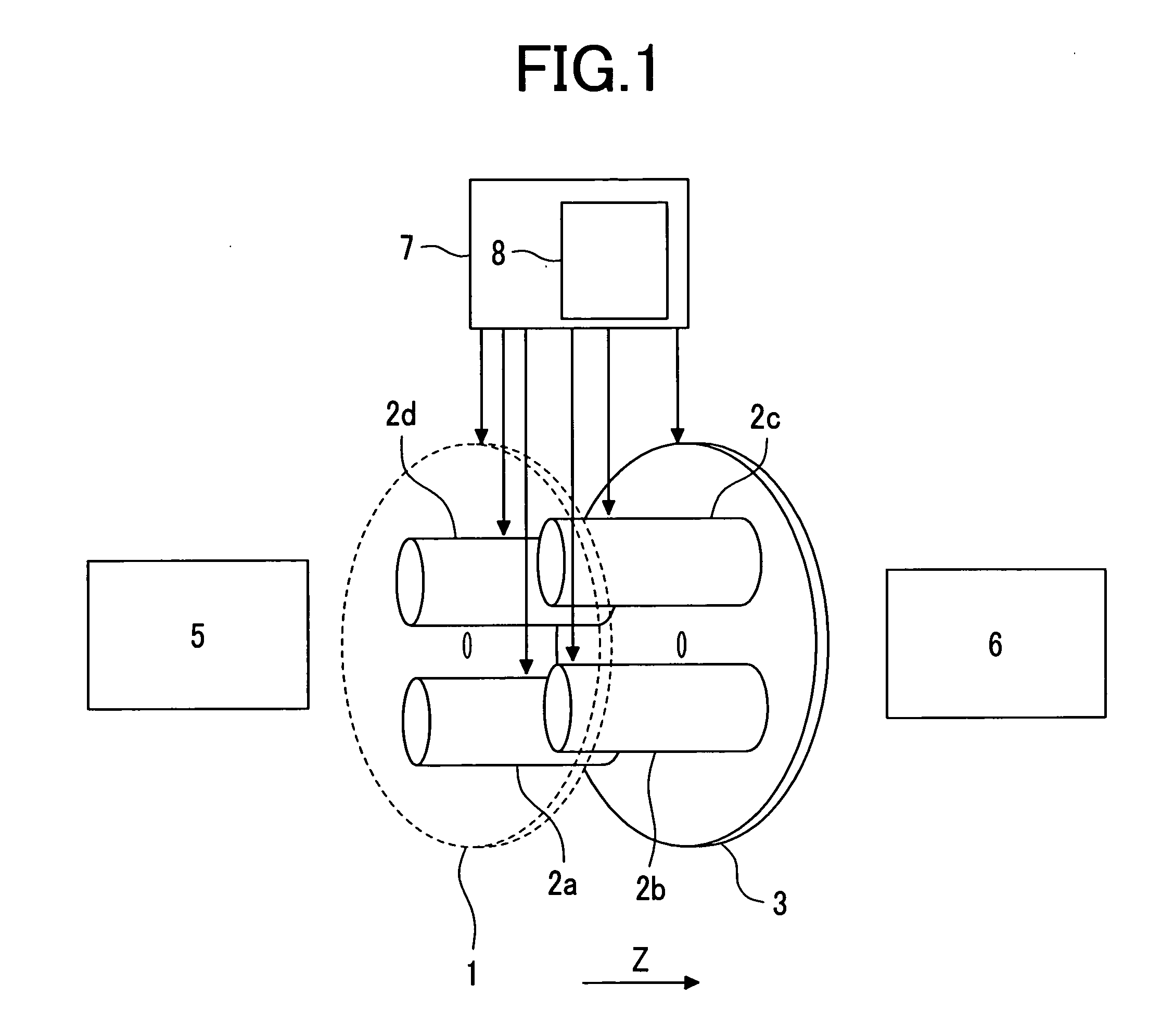

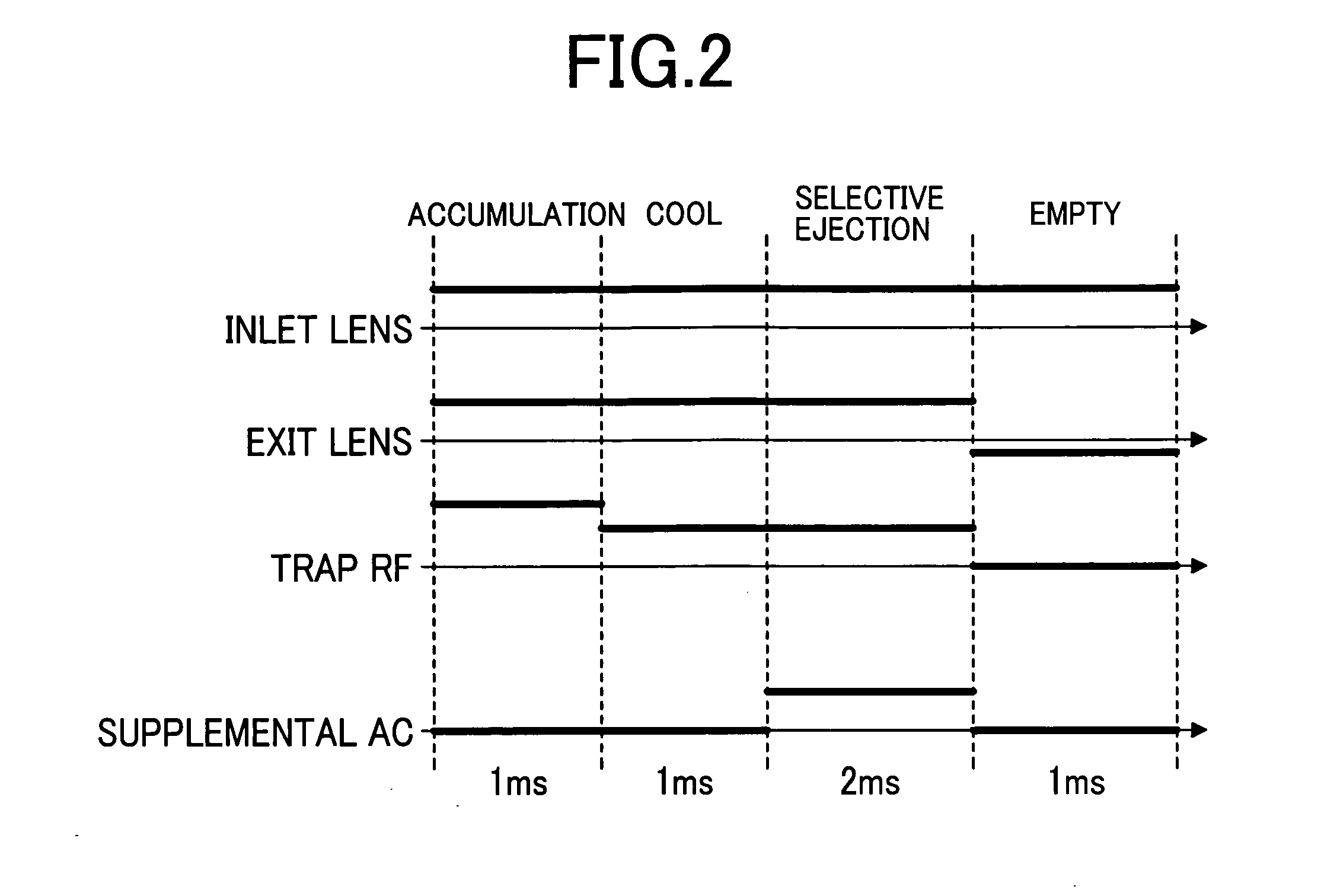

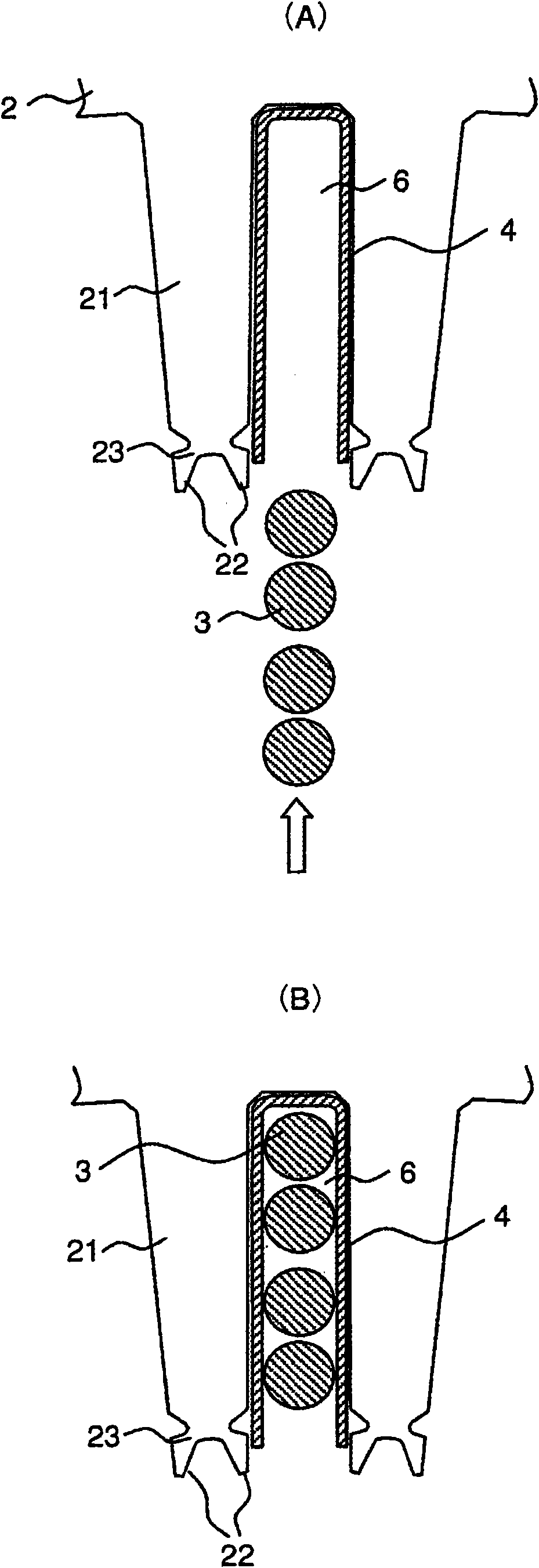

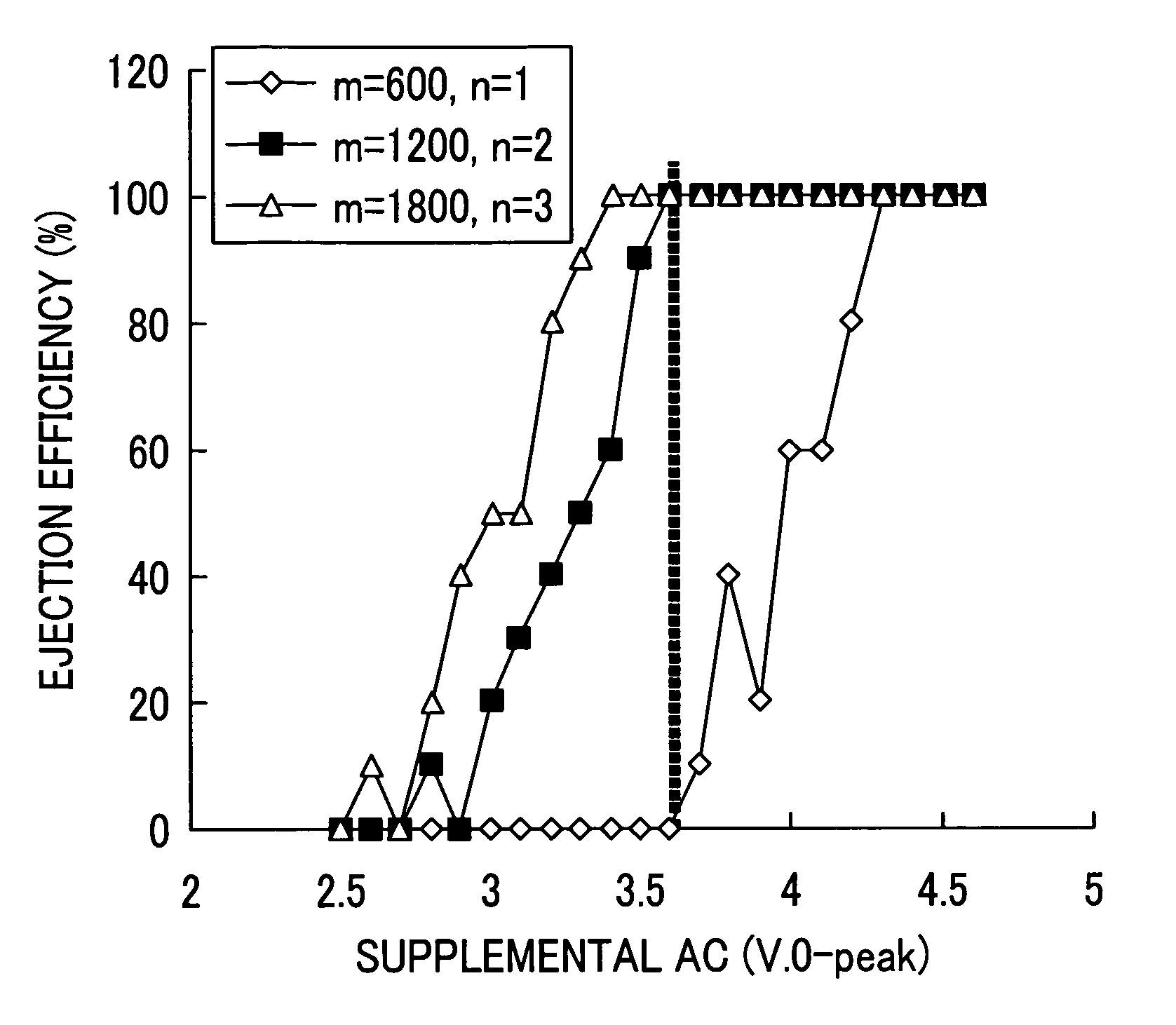

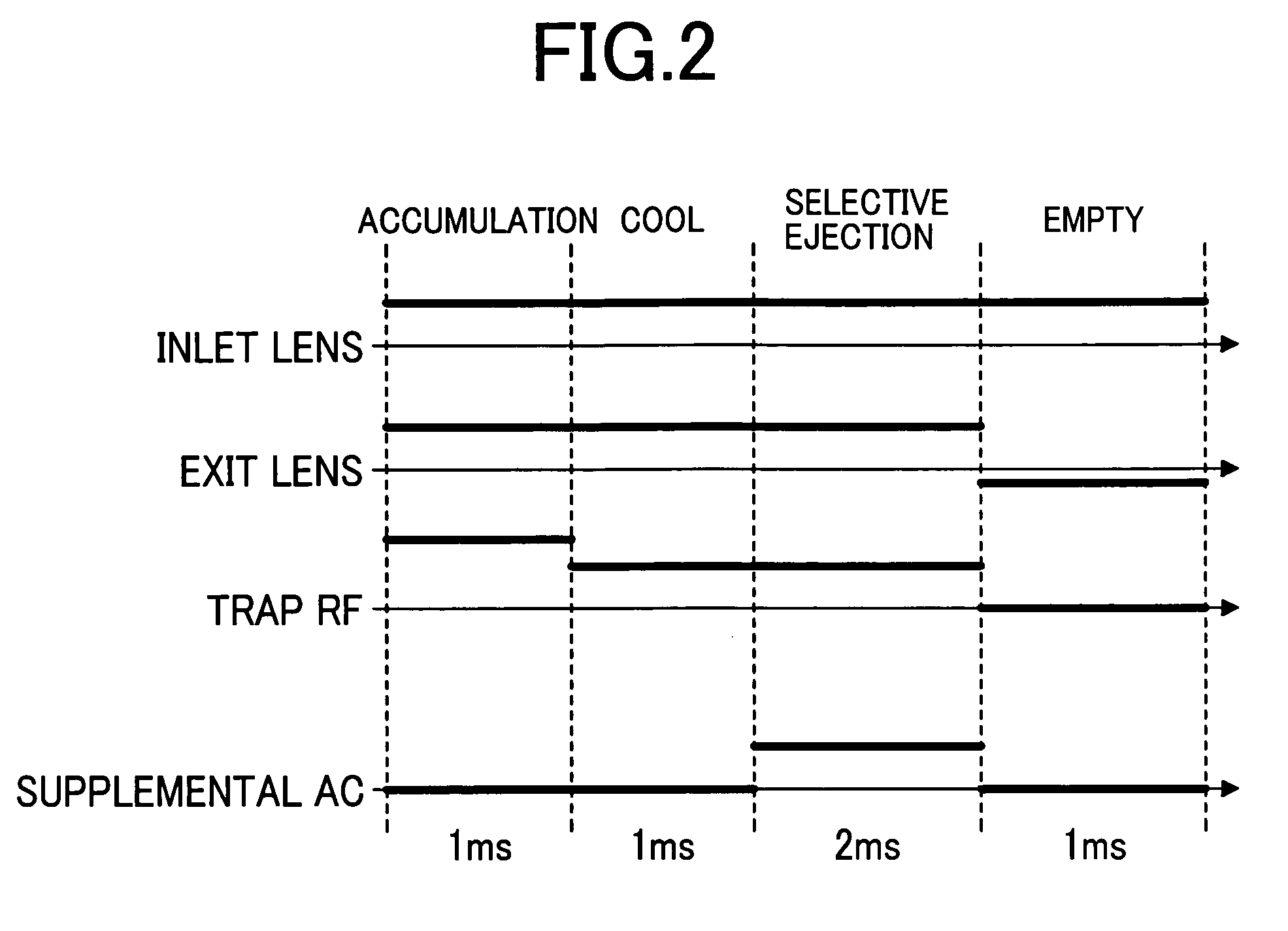

Mass spectrometer and mass analysis method

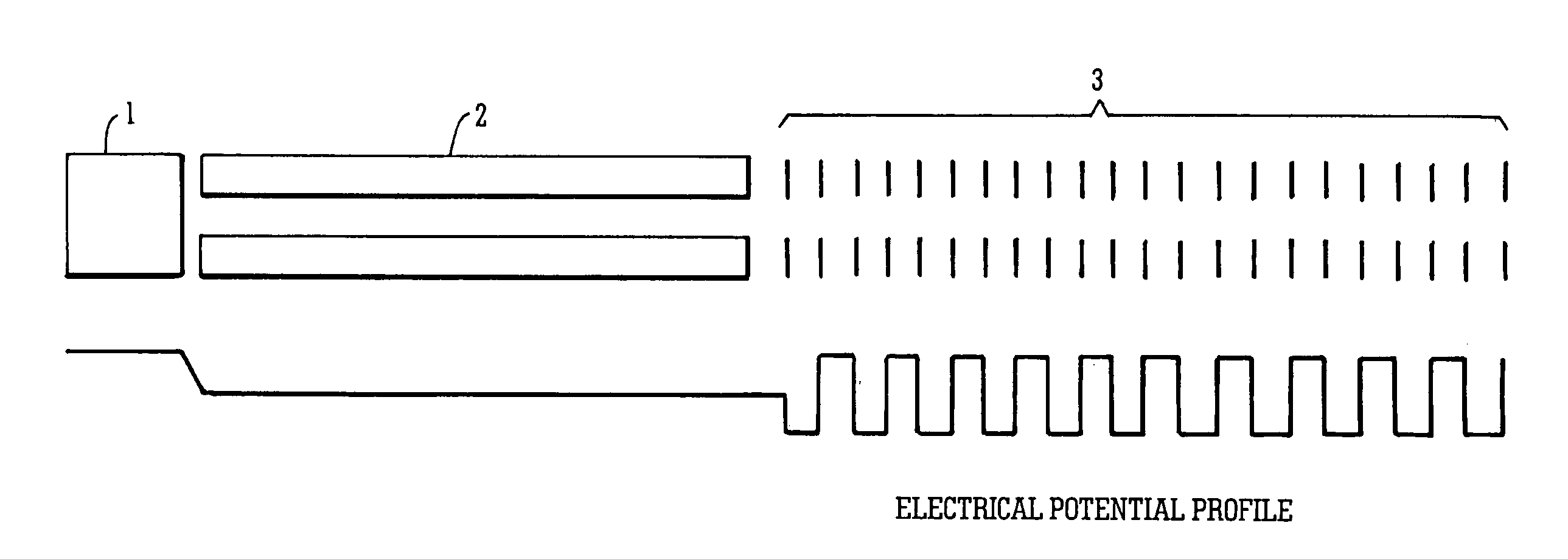

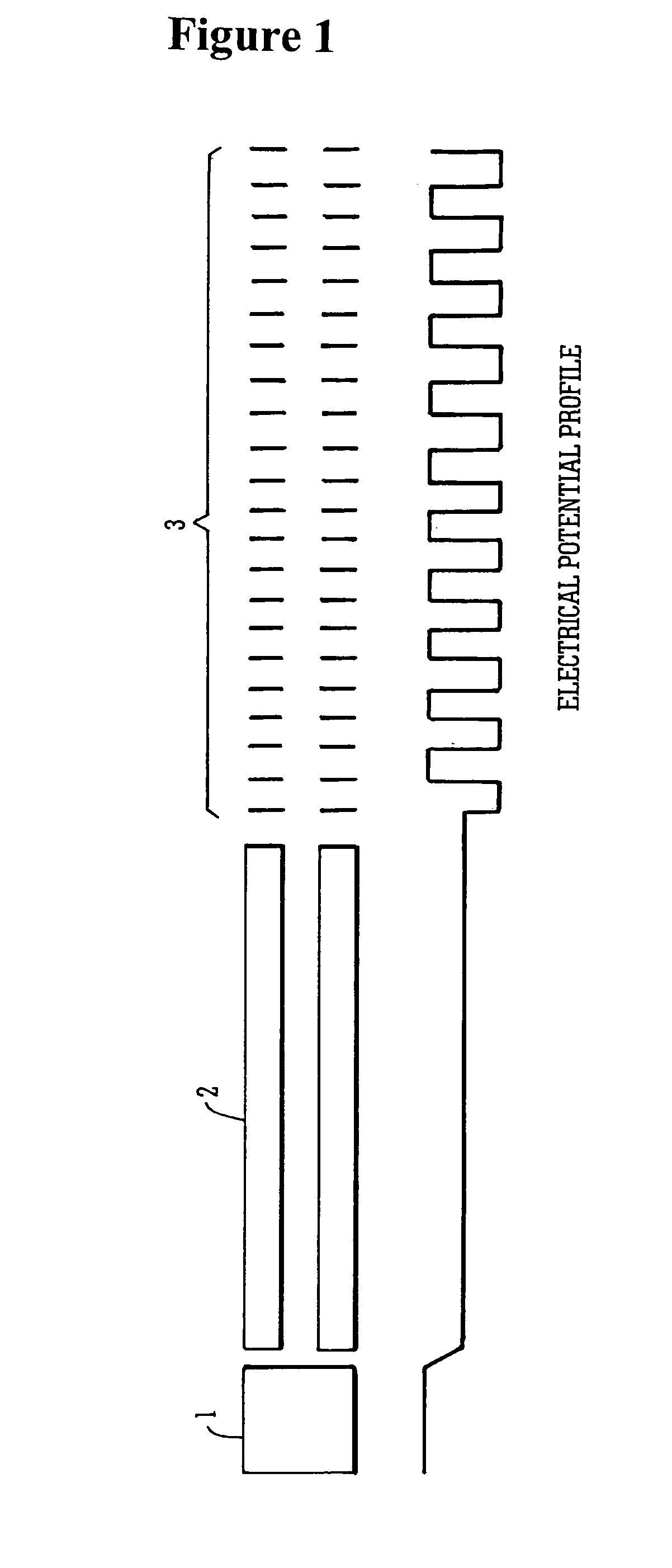

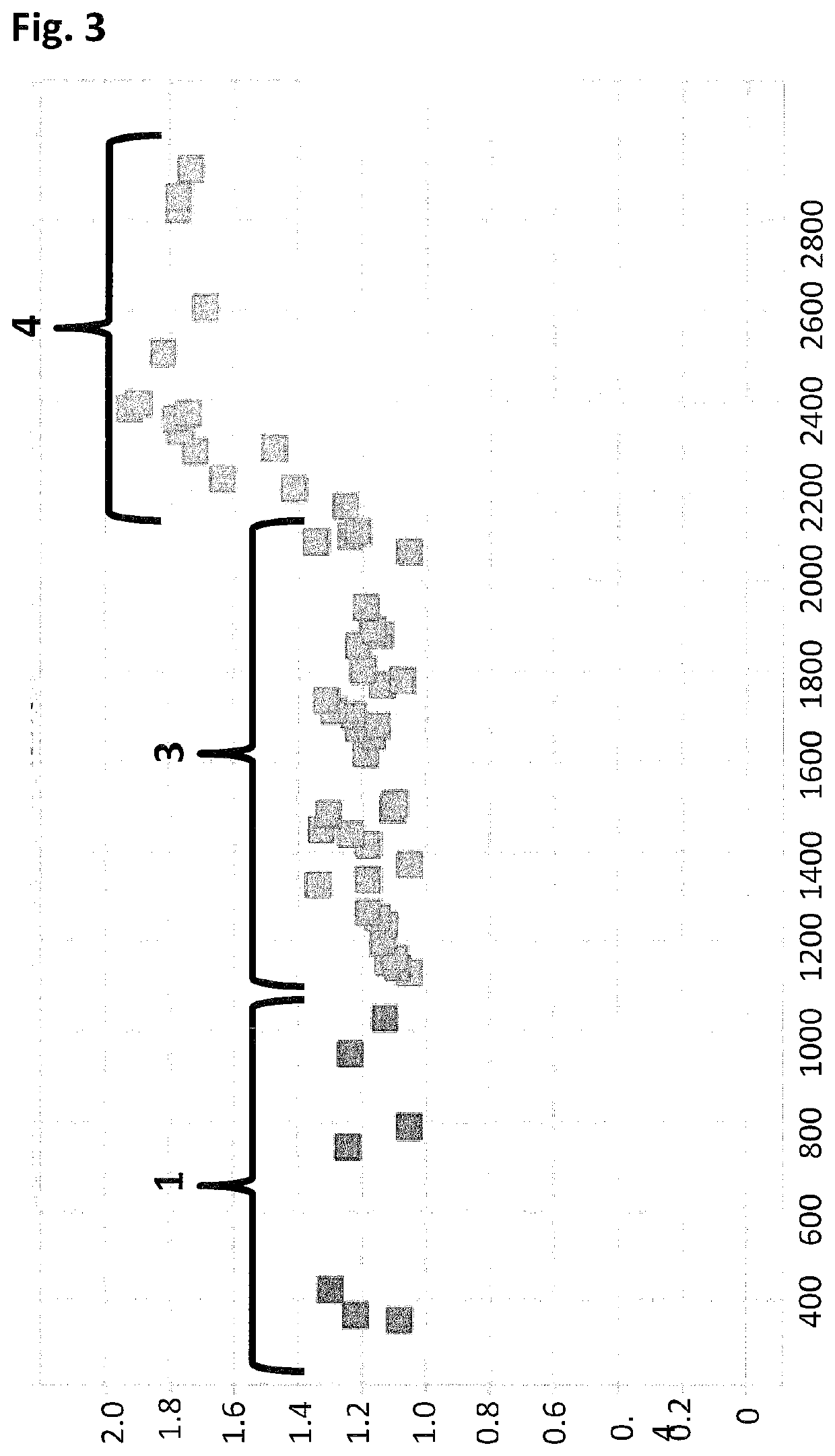

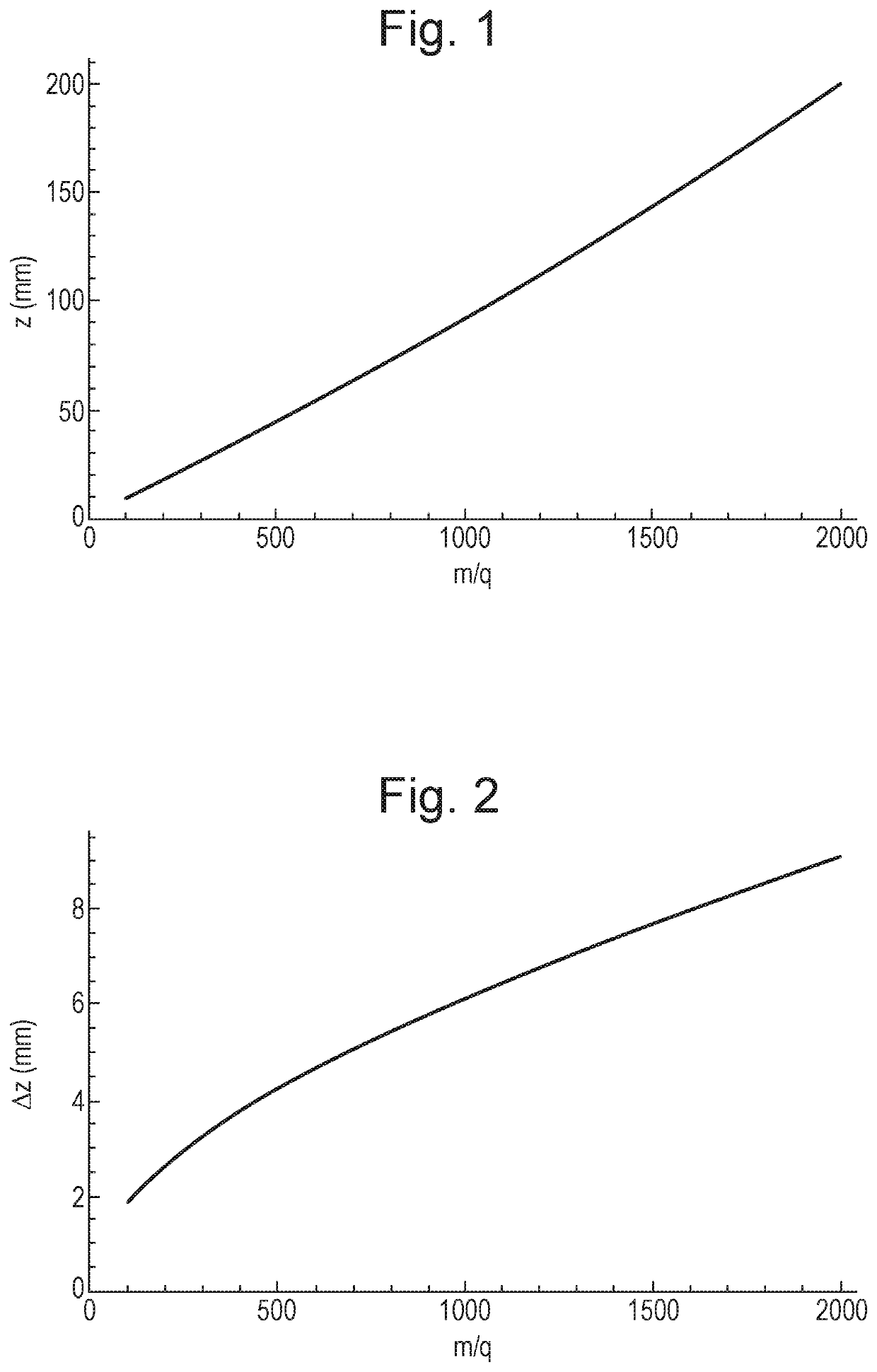

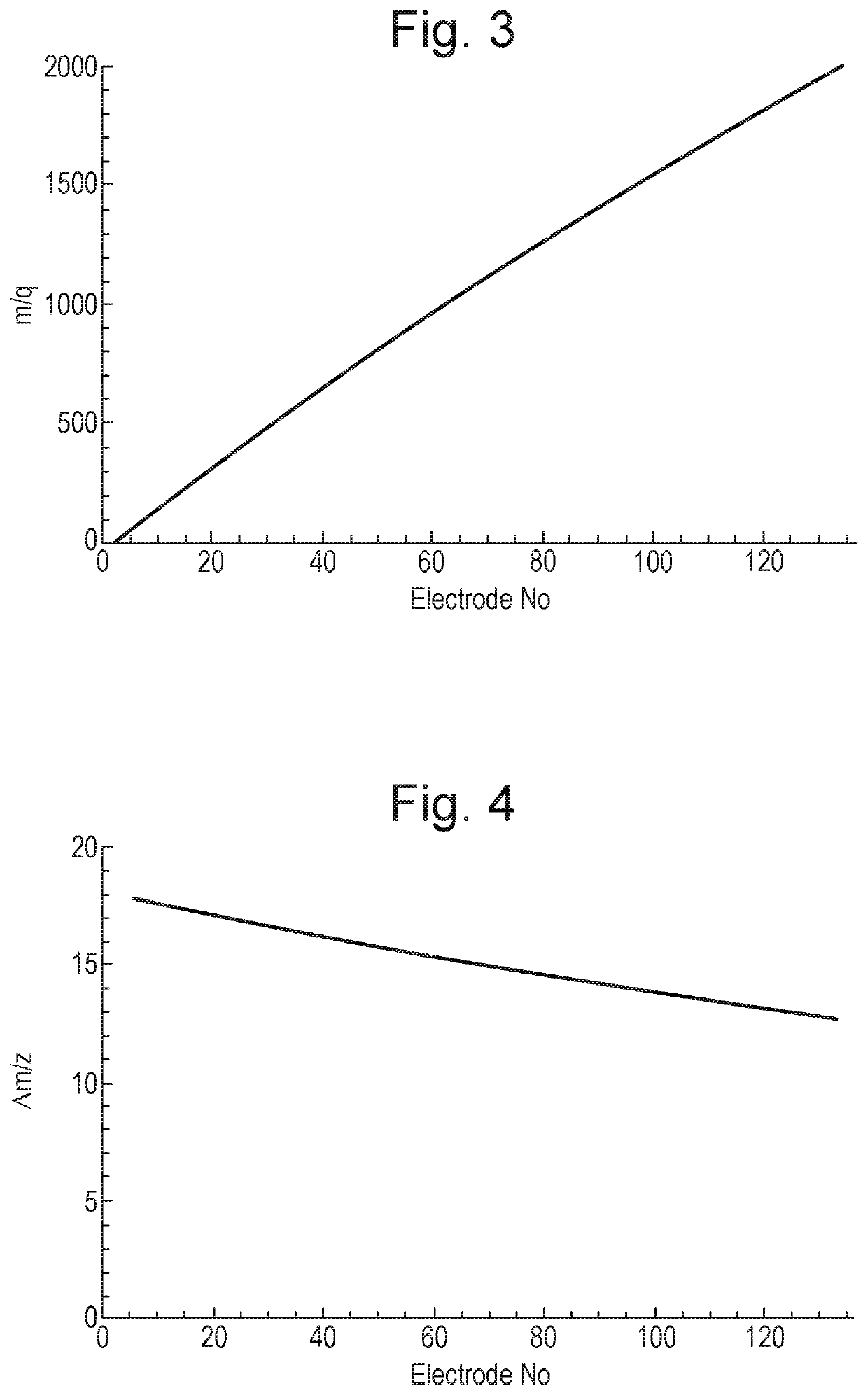

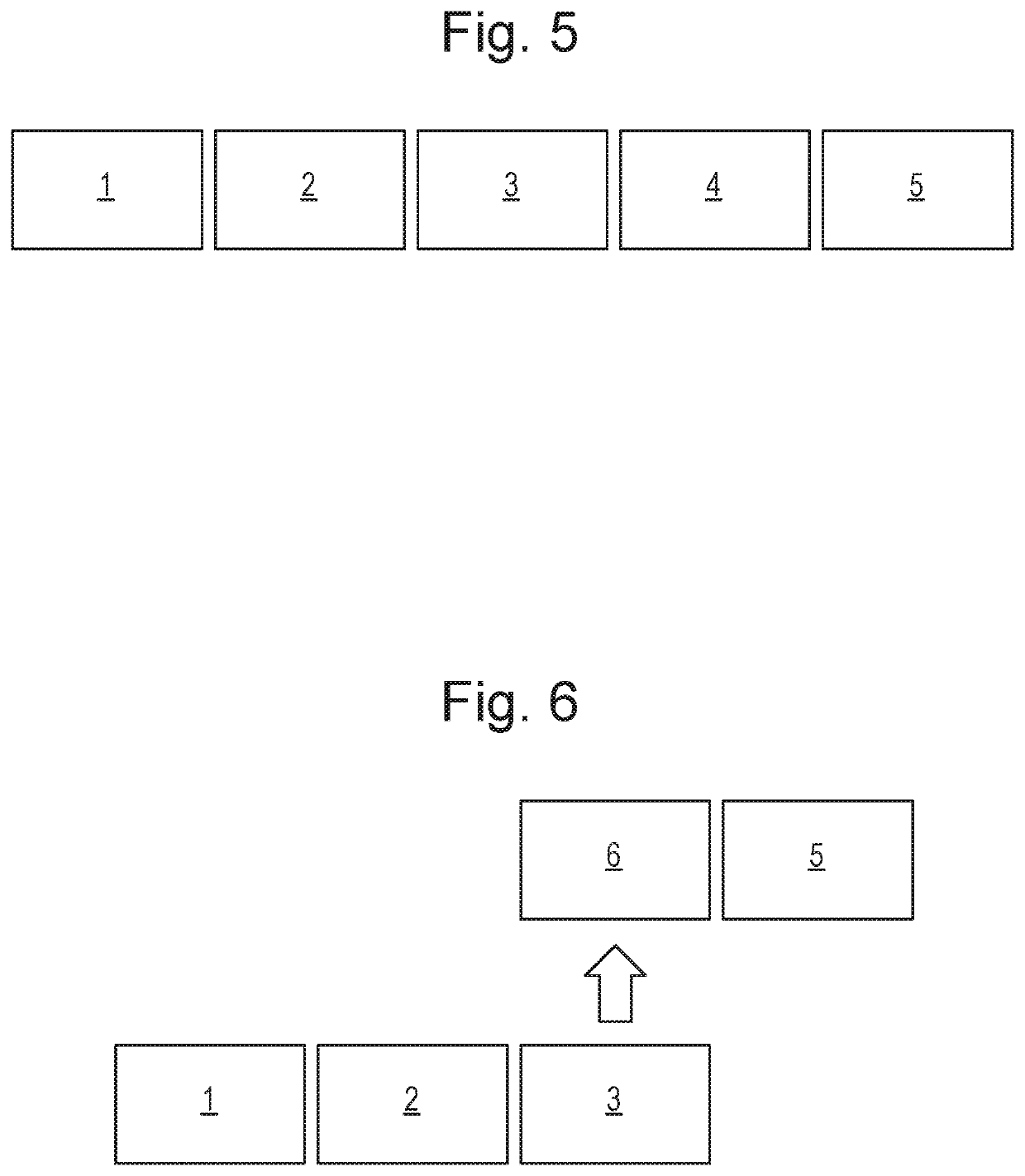

ActiveUS20060219896A1High sensitivityEffective separation of ion mobilityDispersed particle filtrationParticle spectrometer methodsIon trap mass spectrometryCharge separation

A linear trap which allows for charge separation and ion mobility separation in a speedy manner, and enables measurement with high duty cycle. A mass spectrometer comprises an ion source, an ion trap for trapping ions ionized by the ion source, an ion trap controller for controlling a voltage on an electrode included in the ion trap, and a detector for detecting the ions ejected from the ion trap. The ion trap controller includes a table for each mass-to-charge ratio, the table containing a frequency of the voltage used for charge separation, and a gain of the voltage for ejecting a first ion with a first charge outside the ion trap, and retaining in the ion trap a second group of ions with a second charge that is lower than that of the first charge. The ion trap controller controls the voltage based on the mass-to-charge ratio set. The mass spectrometer has significantly improved sensitivity, as compared to the prior art.

Owner:HITACHI HIGH-TECH CORP

Hybird engine

ActiveUS20070234721A1Added system outputImprove efficiencyInternal combustion piston enginesExhaust apparatusCombustorTurbocharger

An internal combustion engine includes an exhaust manifold; an intake manifold; and a turbocharger including a turbine in communication with the exhaust manifold, and a compressor in communication with the intake manifold. An electrical generator is coupled with the turbine. A motor receives electrical input power from the generator and provides mechanical output power. A combustor selectively provides additional input power to the motor.

Owner:DEERE & CO

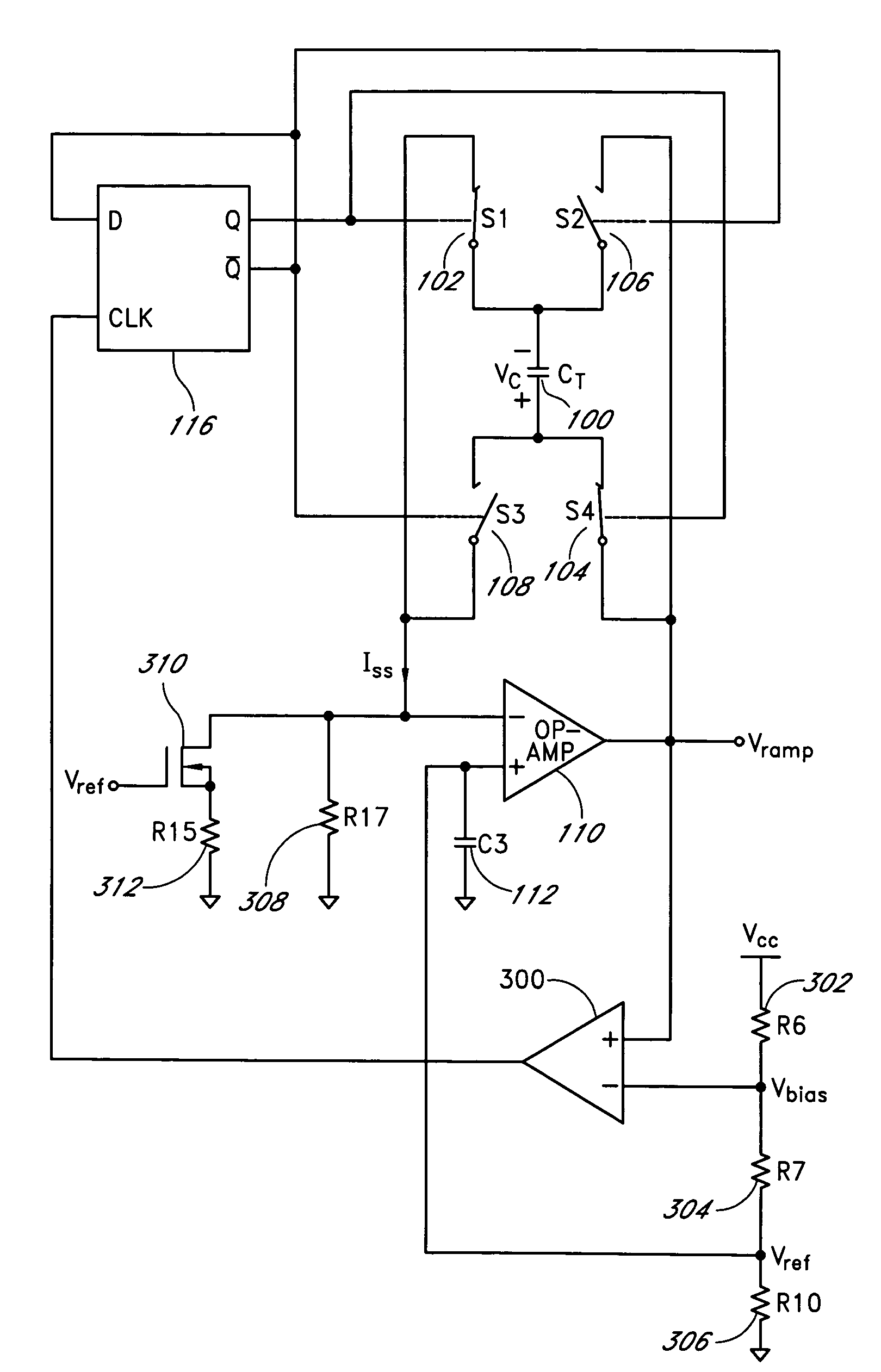

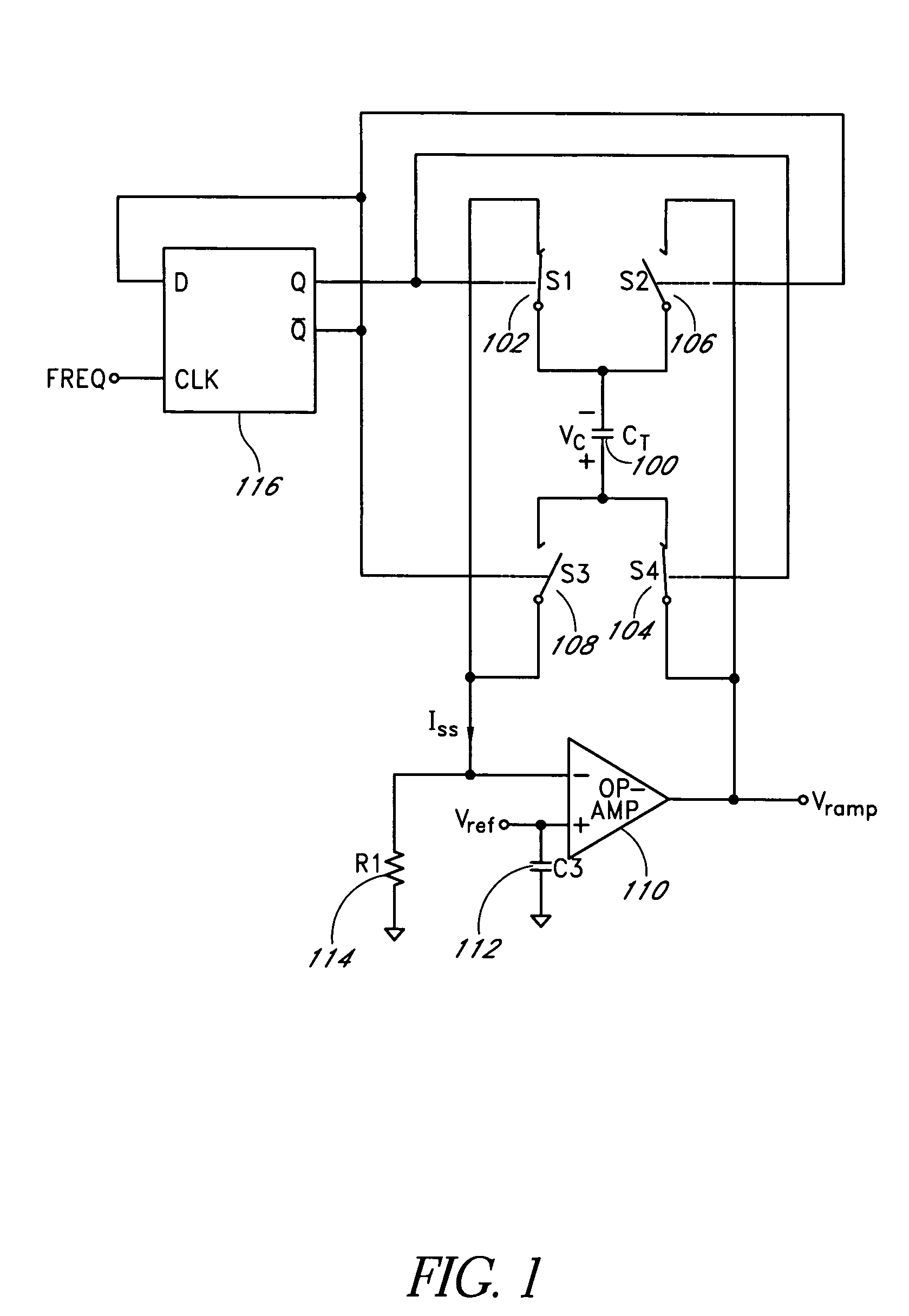

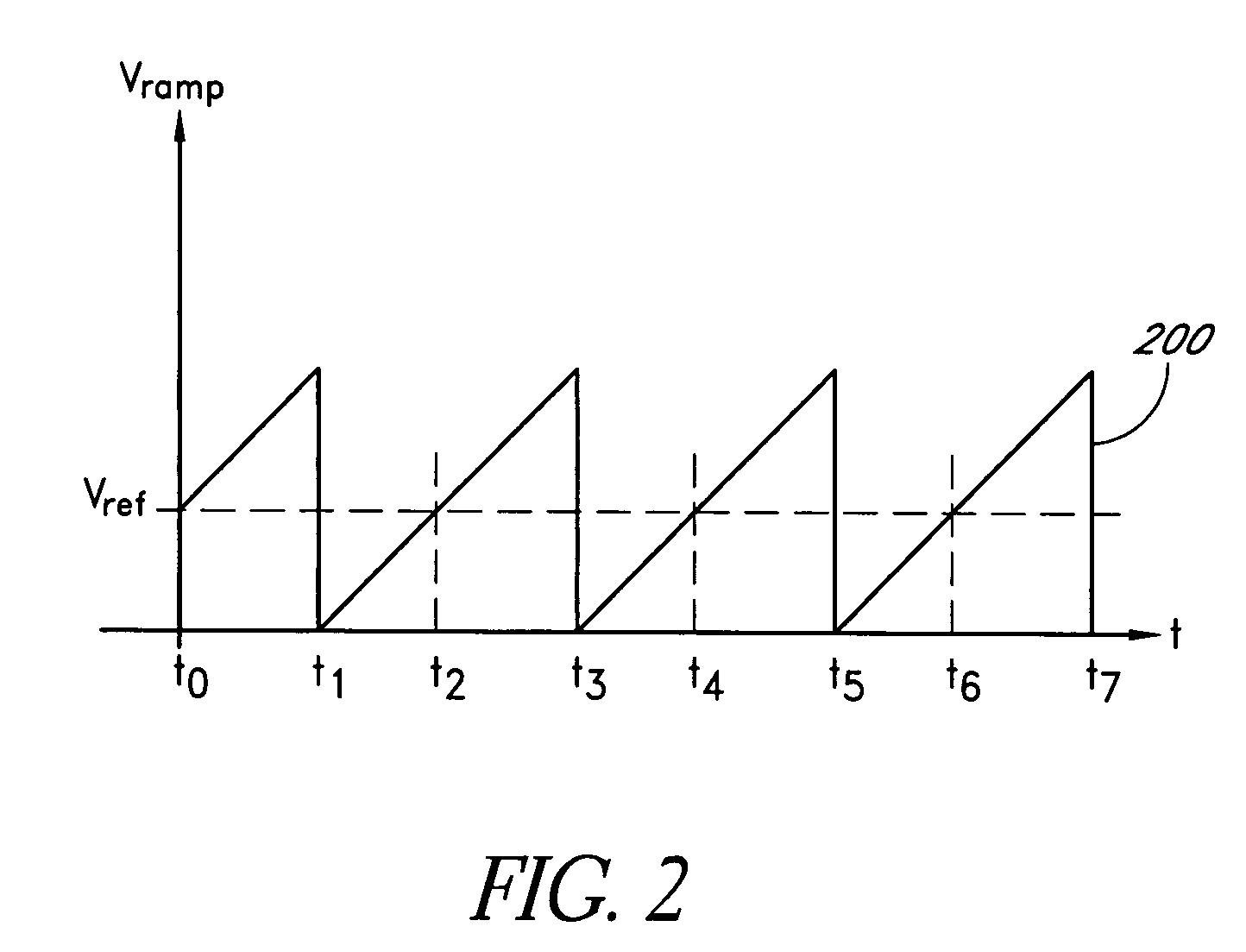

Ramp generator with fast reset

InactiveUS7388413B1Eliminate the problemHigh duty cyclePulse generatorAnalogue/digital conversion calibration/testingAudio power amplifierEngineering

An efficient ramp generator uses a reversing switch array to couple a timing capacitor in alternating polarities between an input terminal and an output terminal of an operational amplifier to generate a periodic ramp signal without discharging the timing capacitor between voltage ramps. The reversing switch array includes at least four semiconductor switches controlled by a flip-flop circuit or a latch circuit. The flip-flop circuit or the latch circuit can be driven by an external clock signal or an internal clock signal with a variable frequency.

Owner:MICROSEMI

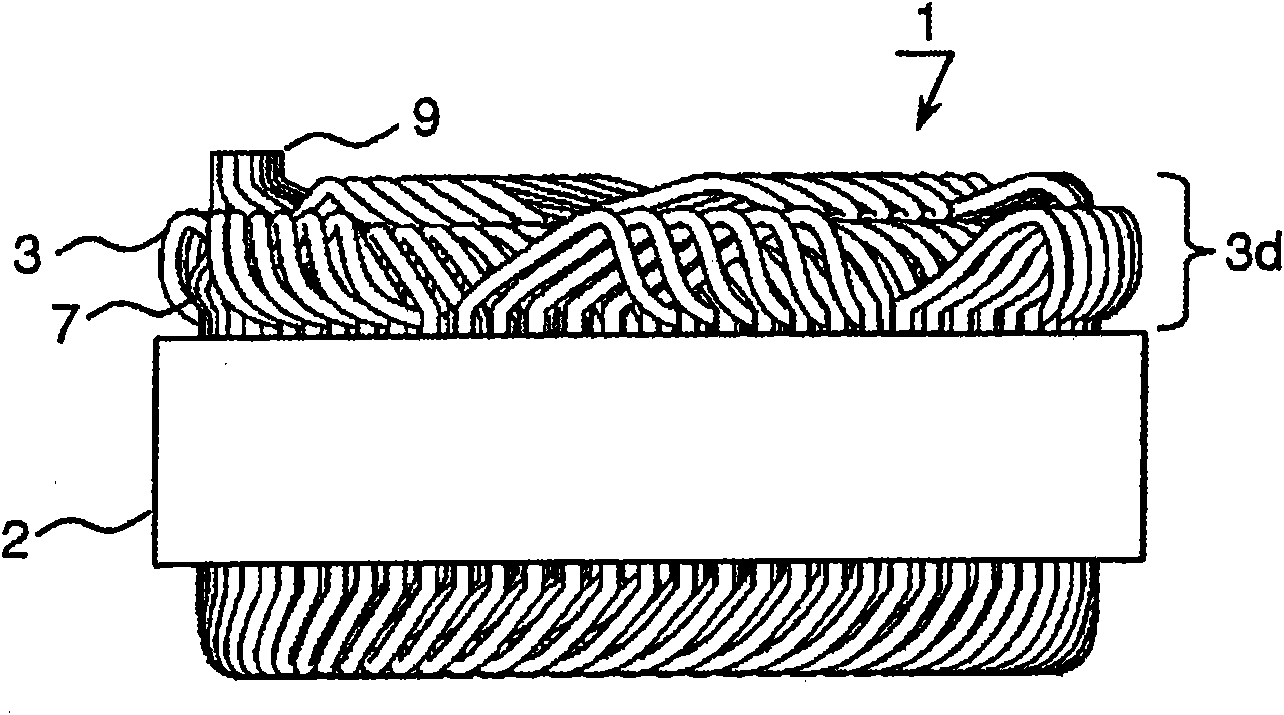

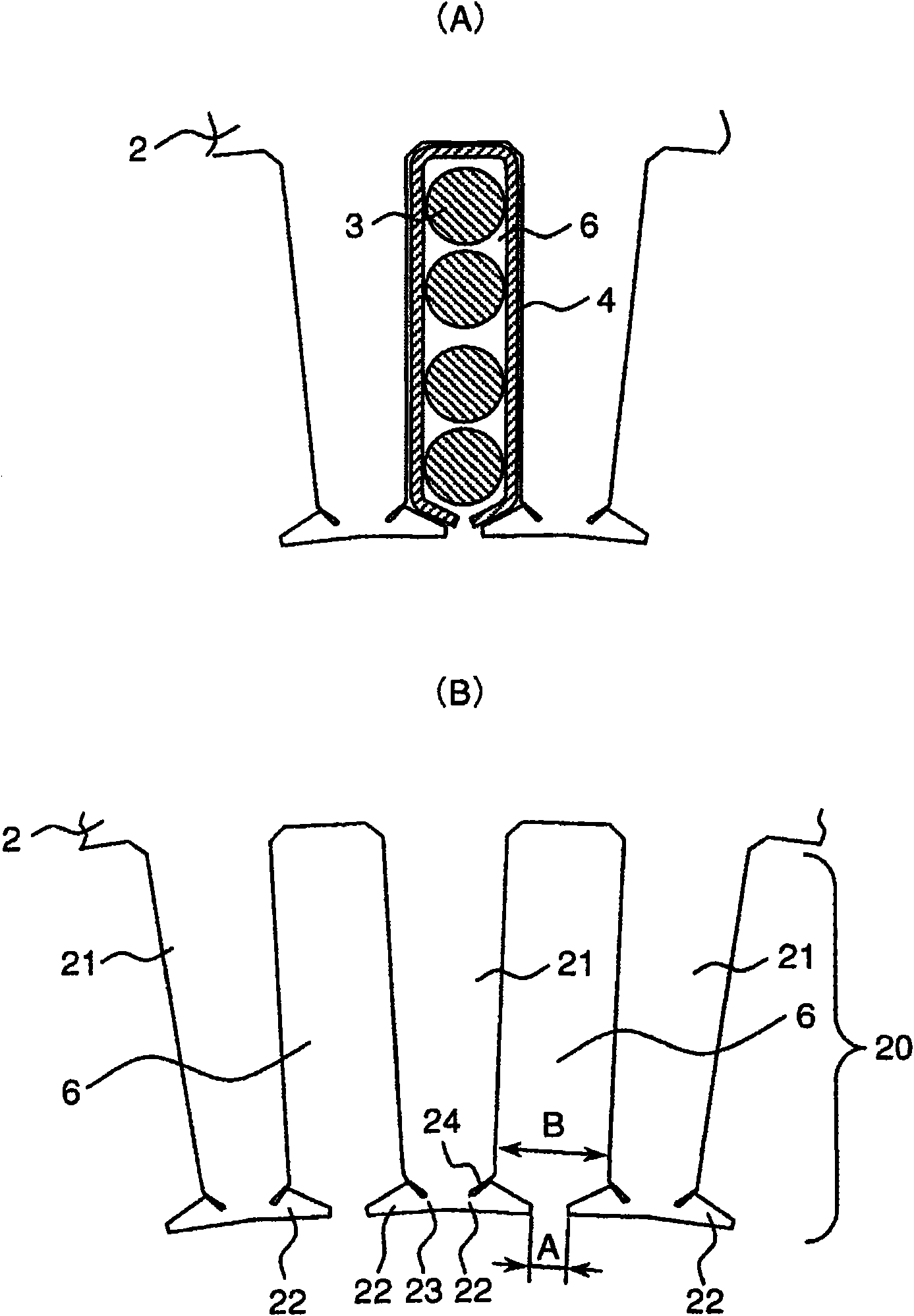

Rotating electrical machine

InactiveCN101989772AHigh duty cycleWindingsMagnetic circuit rotating partsElectric machineEngineering

The invention provides a rotating electrical machine. A tooth main body is connected with tooth tip edge portions by connecting portions with slits being formed in the coil sides of the connecting portions; and the slits extend from opening portions towards the centers of the tooth tip edge portions in circumferential direction, and are formed so that their tooth main body sides and their tip edge portion sides, that together define the opening portions of the slits, contact one another; with the gaps between adjacent ones of the tooth tip edge portions in circumferential direction being smaller than a width of the slot. The high duty ratio of the iron core in the iron core groove is high, the coil winding is simplified and the electronic characteristic is excellent.

Owner:HITACHI LTD

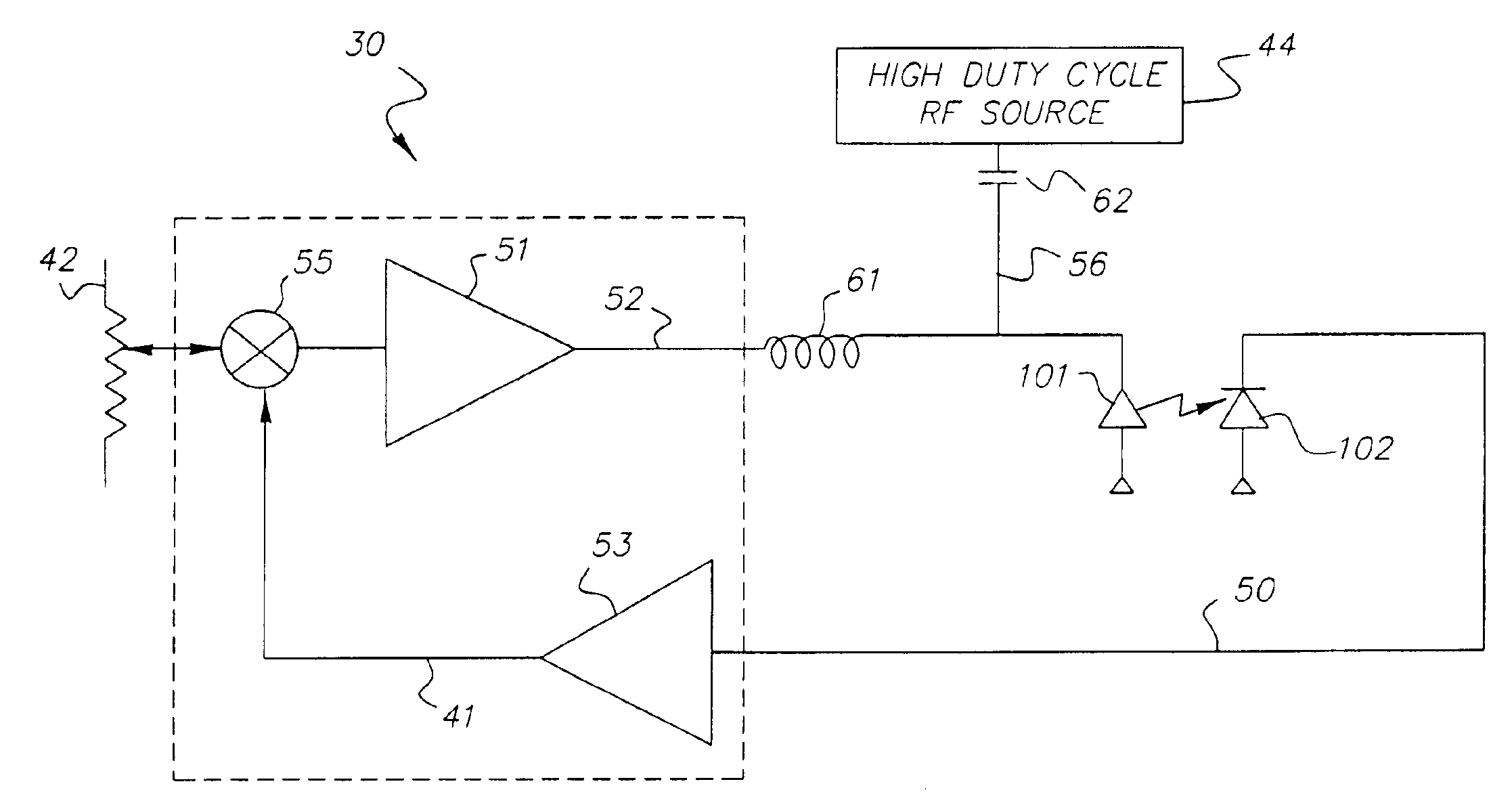

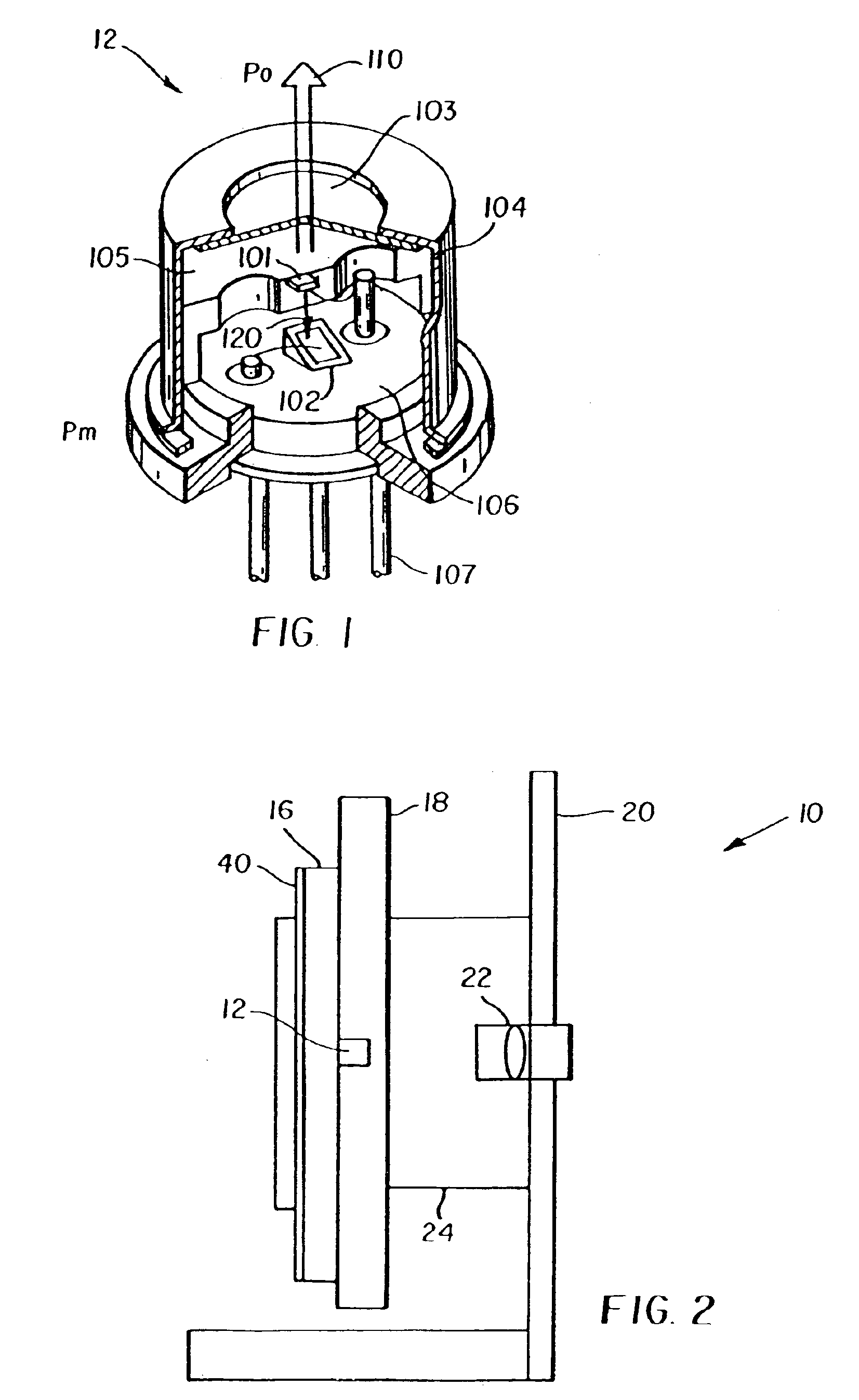

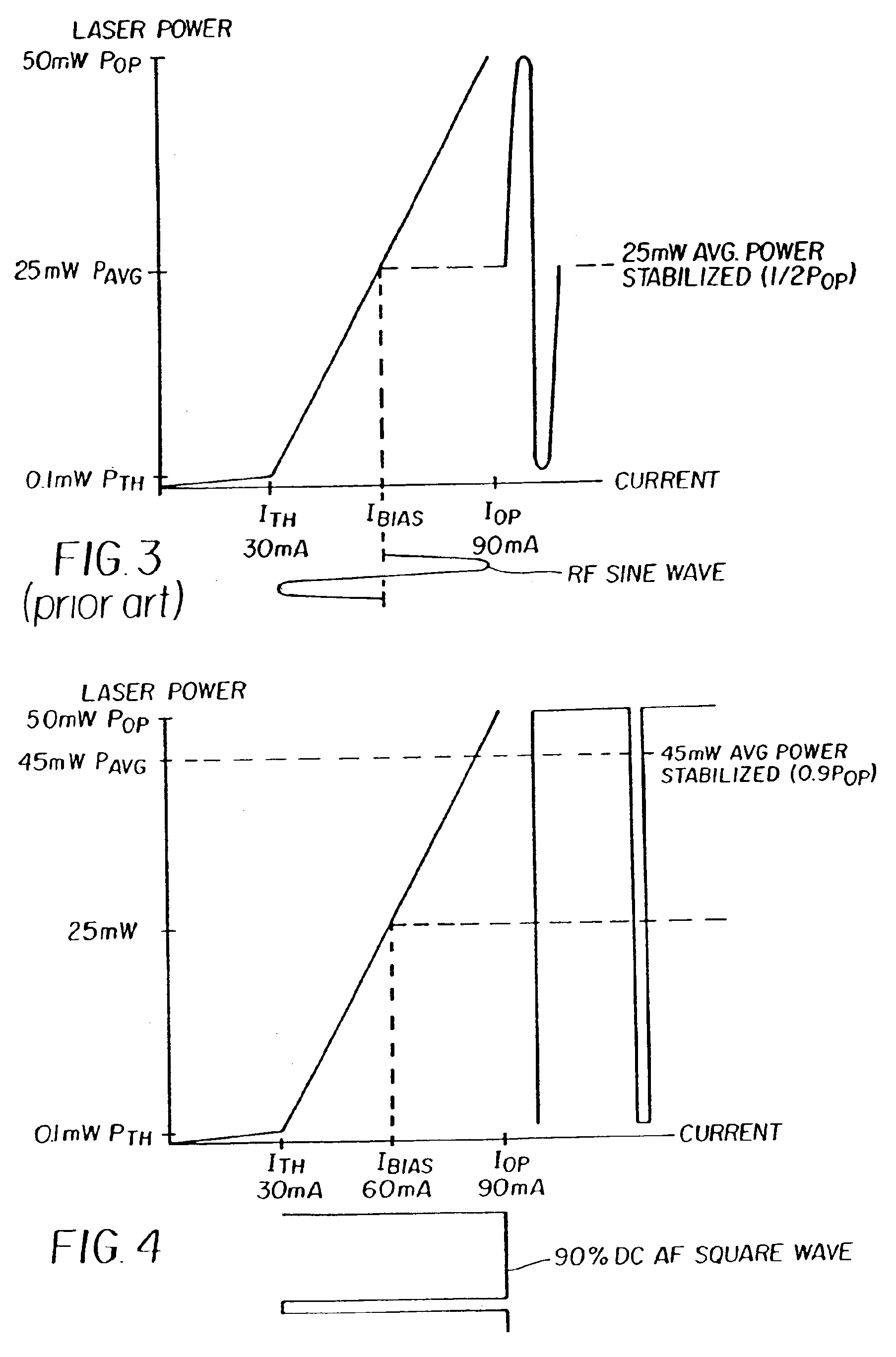

System and method for improving laser power and stabilization using high duty cycle radio frequency injection

InactiveUS6999838B2High output powerImprove stabilityPhotometry using reference valueMaterial analysis by optical meansEngineeringPhotodiode

A system and method of stabilizing laser output levels includes a laser (10), an injection circuit for injecting a radio frequency waveform, and a control circuit for energizing and stabilizing the laser. The radio frequency waveform injected by the injection circuit has a high duty cycle to maintain high output power while providing a stable multimode spectrum. A back facet photodiode sensor (102) detects radiation emitted from a back facet semiconductor laser (101) and provides a feedback signal to the control circuit (41) for maintaining the laser output power. The response of the photodiode is not fast enough to track intensity variations due to the RF waveform, and thus provides feedback to the control circuit (41) only when there is a substantial need to adjust laser power.

Owner:IMAX THEATERS INT

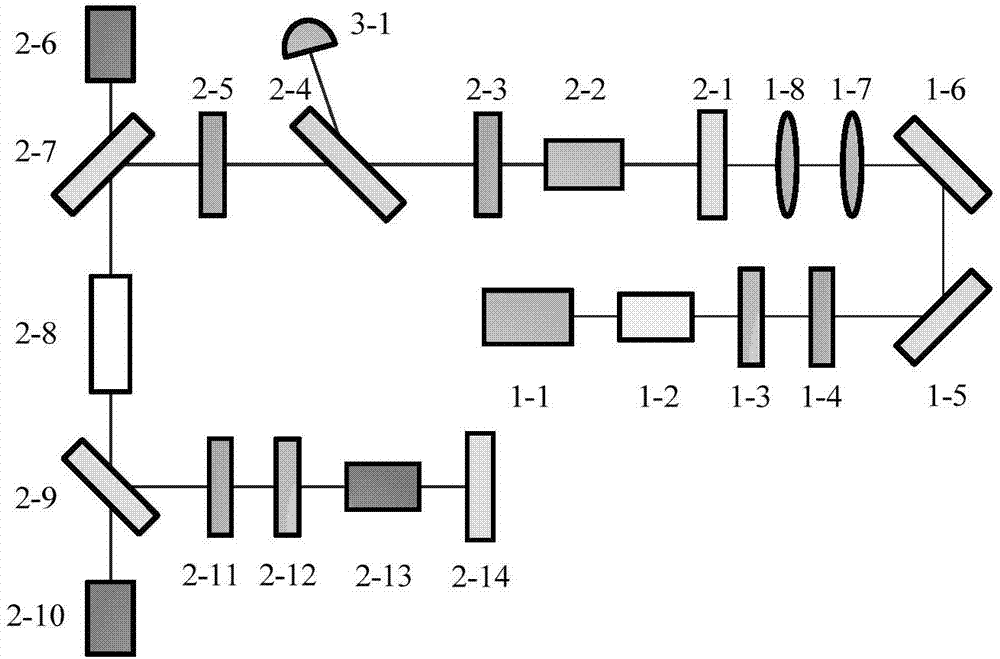

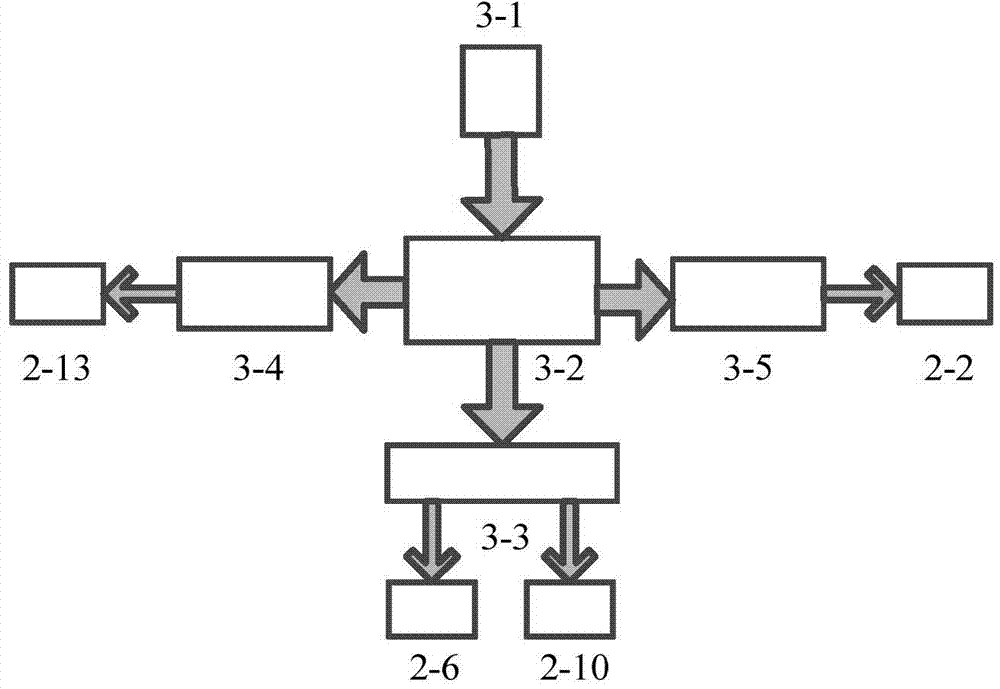

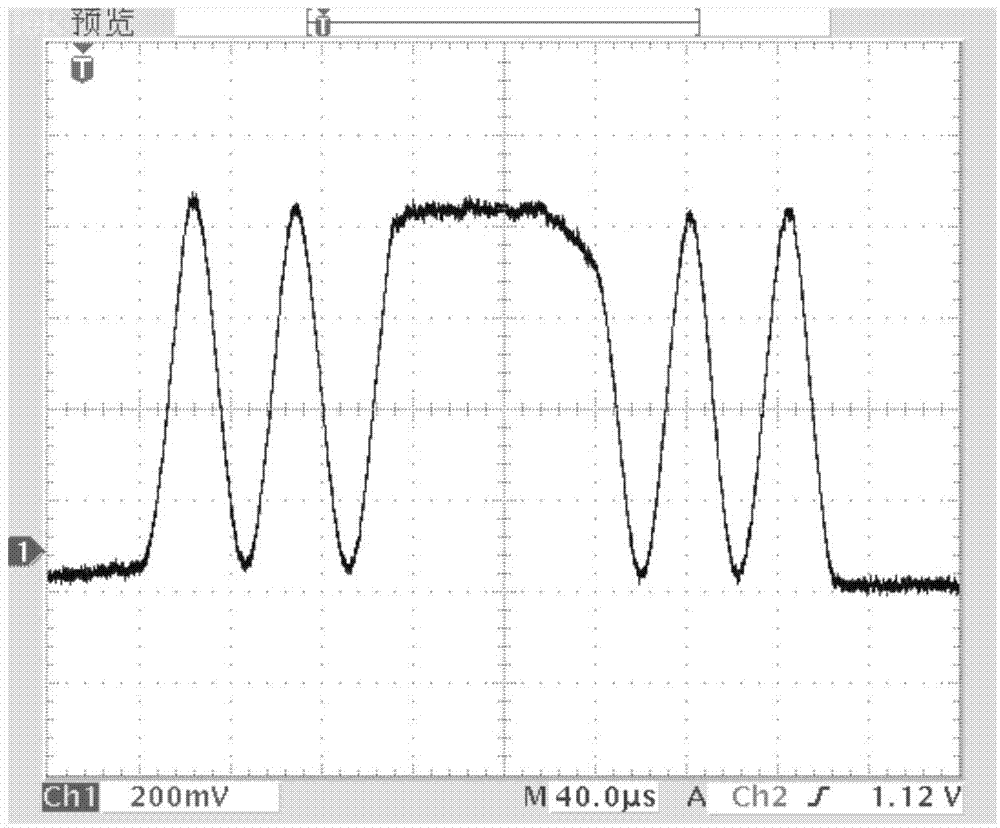

Seed injection single-frequency pulse laser based on tunable cavity length of electro-optical crystal

ActiveCN103779776AExtended service lifeHigh duty cycleLaser detailsFrequency stabilizationRefractive index

The invention relates to a seed injection single-frequency pulse laser based on the tunable cavity length of an electro-optical crystal. By using an electro-optical effect of the electro-optical crystal, an external electric field is enabled to not change the polarization state of seed light but only change the phase thereof through adjusting the direction of the electro-optical crystal in a driven cavity. In each pump cycle, the electro-optical crystal driving power supply apples linear ramp voltage to the electro-optical crystal, the refractive index of the electro-optical crystal is changed, thereby changing the length of an optical cavity. A Q-adjusting switch is turned on after a photodiode detects a peak value of interference signals formed by the seed light passing through the driven cavity, thereby outputting single-frequency pulse laser. The laser has the characteristics of high working repetition frequency, high frequency stability, high interference resisting capacity, long service life and compact structure, not only can adapt to general requirements for a working environment, but also can adapt to airborne and satellite-borne requirements.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

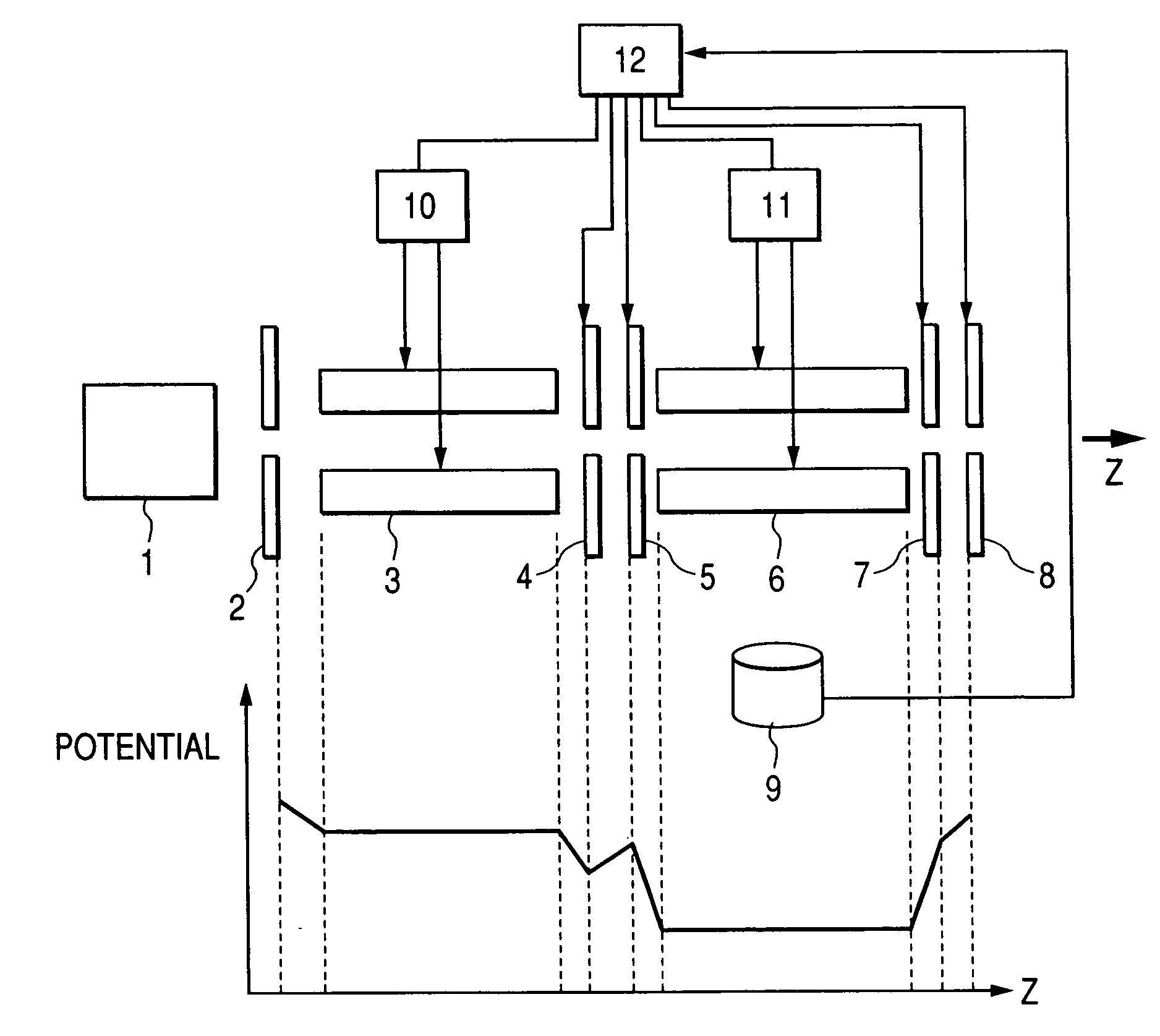

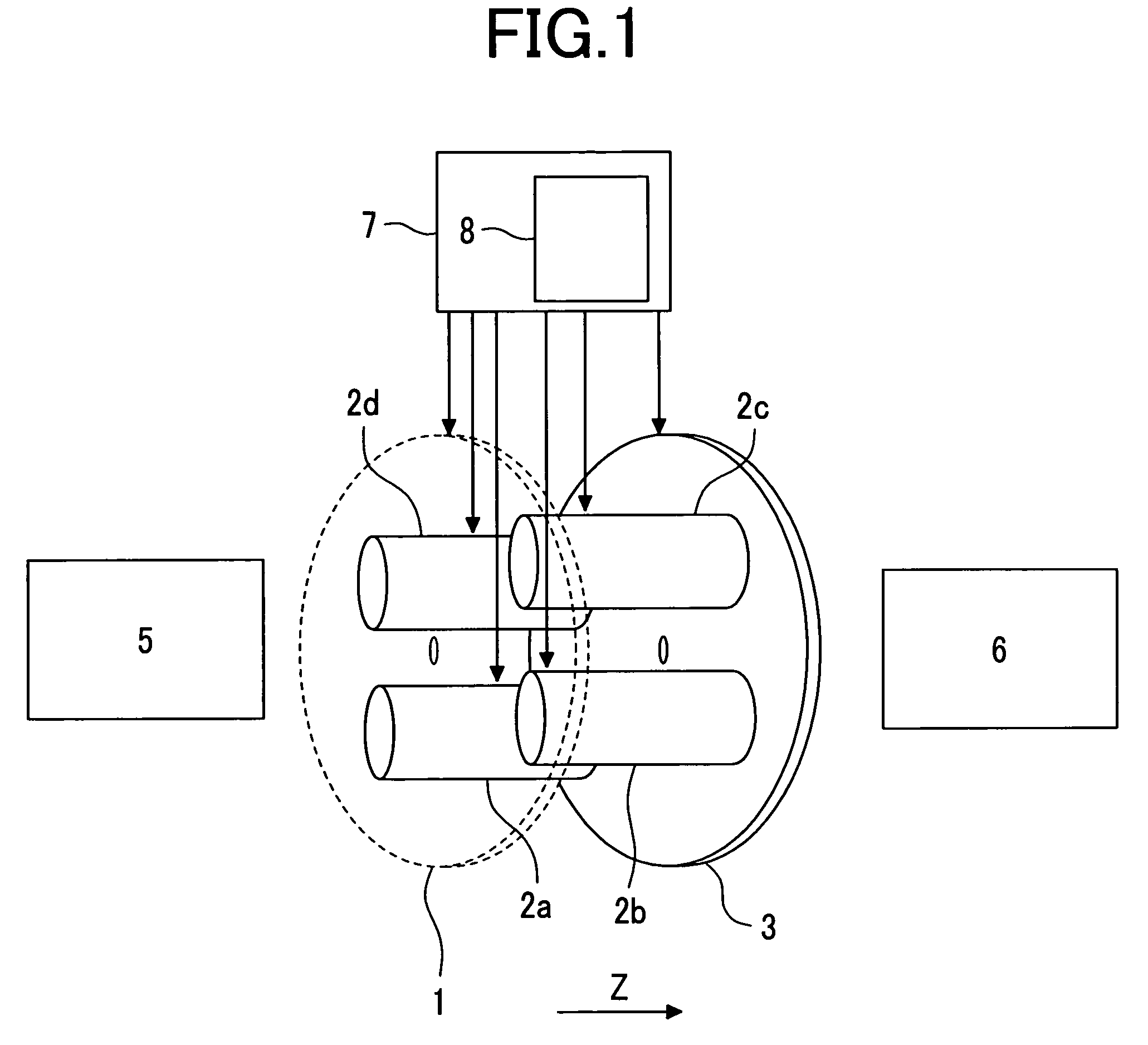

Mass spectrometer

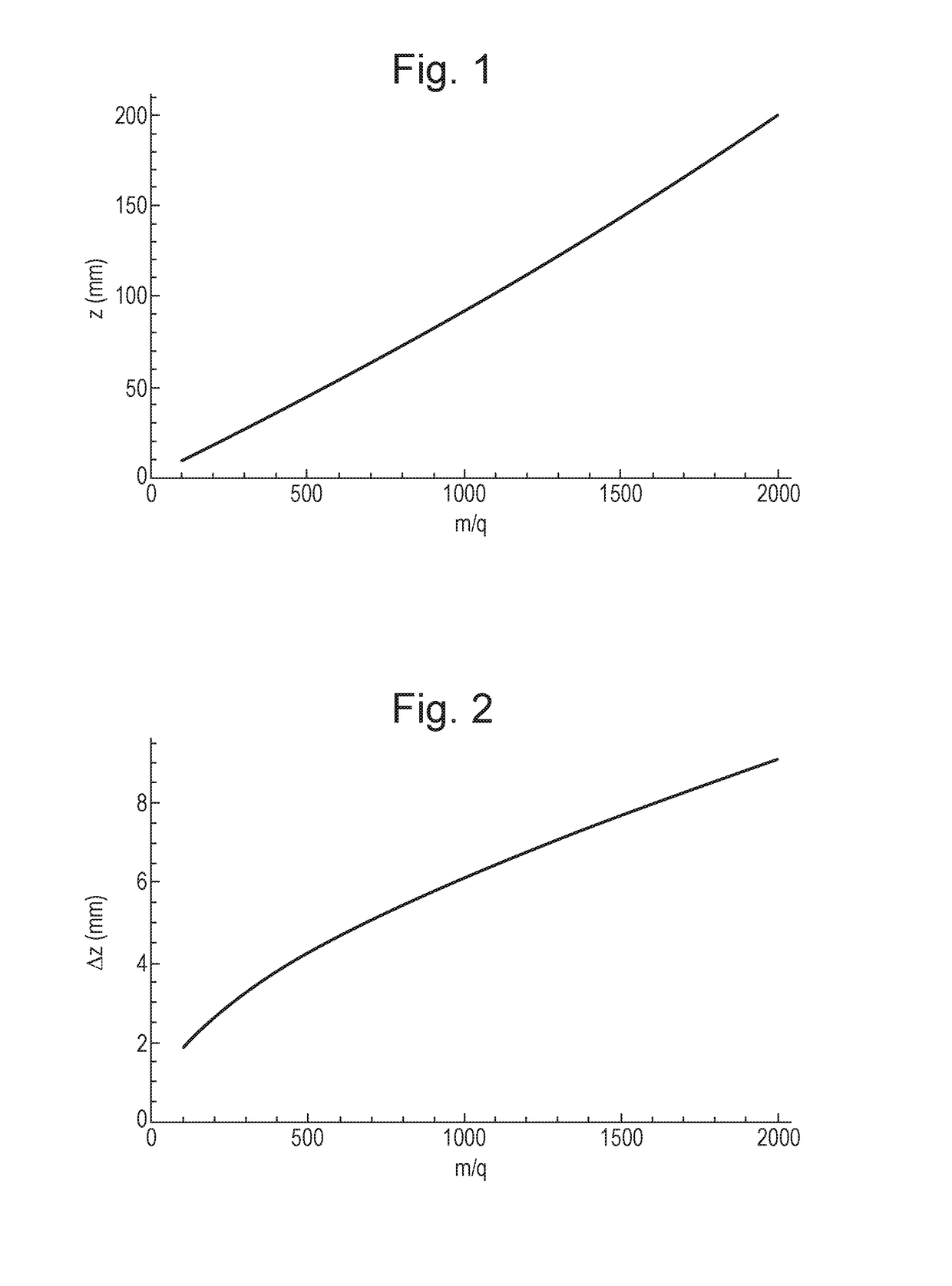

ActiveUS7348554B2Space charge suppressionHigh Duty CycleStability-of-path spectrometersTime-of-flight spectrometersIon trap mass spectrometryMass analyzer

A mass spectrometer includes: an ion source for ionizing a specimen to generate ions, an ion transport portion for transporting the ions, a linear ion trap portion for accumulating the transported ions by a potential formed axially, and a control portion of ejecting the ions within a second m / z range different from a first m / z range, from the linear ion trap portion, and substantially at the same timing as the timing of accumulating the ions within the first m / z range from the transport portion into the linear ion trap portion. The ion transportation portion having a mass selection means for selecting the ions in the first m / z range.

Owner:HITACHI HIGH-TECH CORP

Mass spectrometer

InactiveUS20070023638A1High duty cycleStability-of-path spectrometersIsotope separationIon trap mass spectrometryTrapping region

A mass spectrometer is disclosed comprising an ion trap wherein ions which have been temporally separated according to their mass to charge ratio or ion mobility enter the ion trap. Once at least some of the ions have entered the ion trap, a plurality of ion trapping regions are created along the length of the ion trap in order to fractionate the ions. Alternatively, the ions may be received within one or more axial trapping regions which are translated along the ion trap with a velocity which is progressively reduced to zero.

Owner:MICROMASS UK LTD

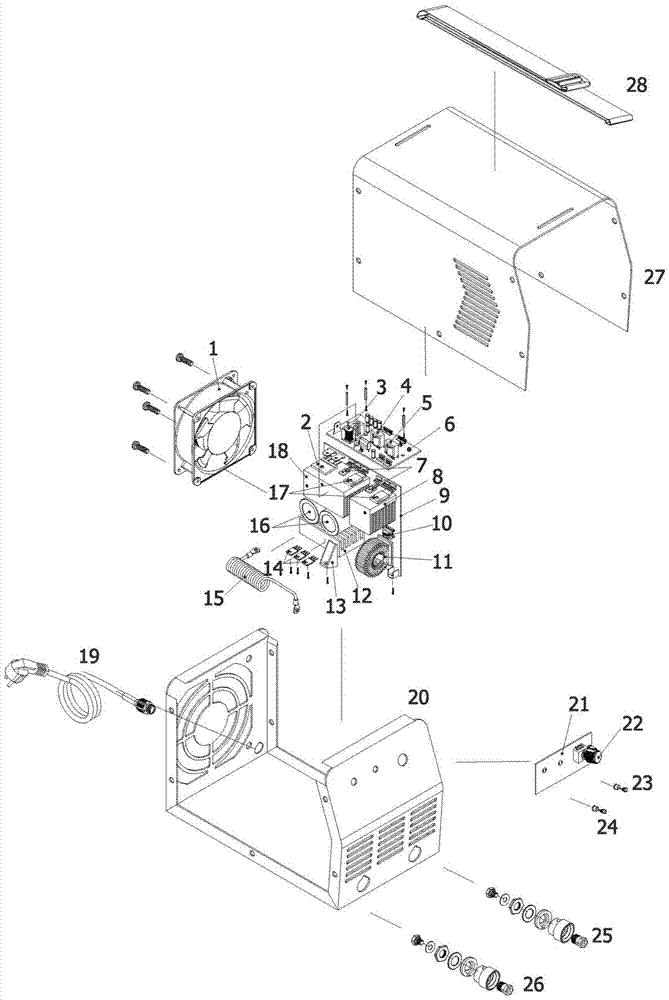

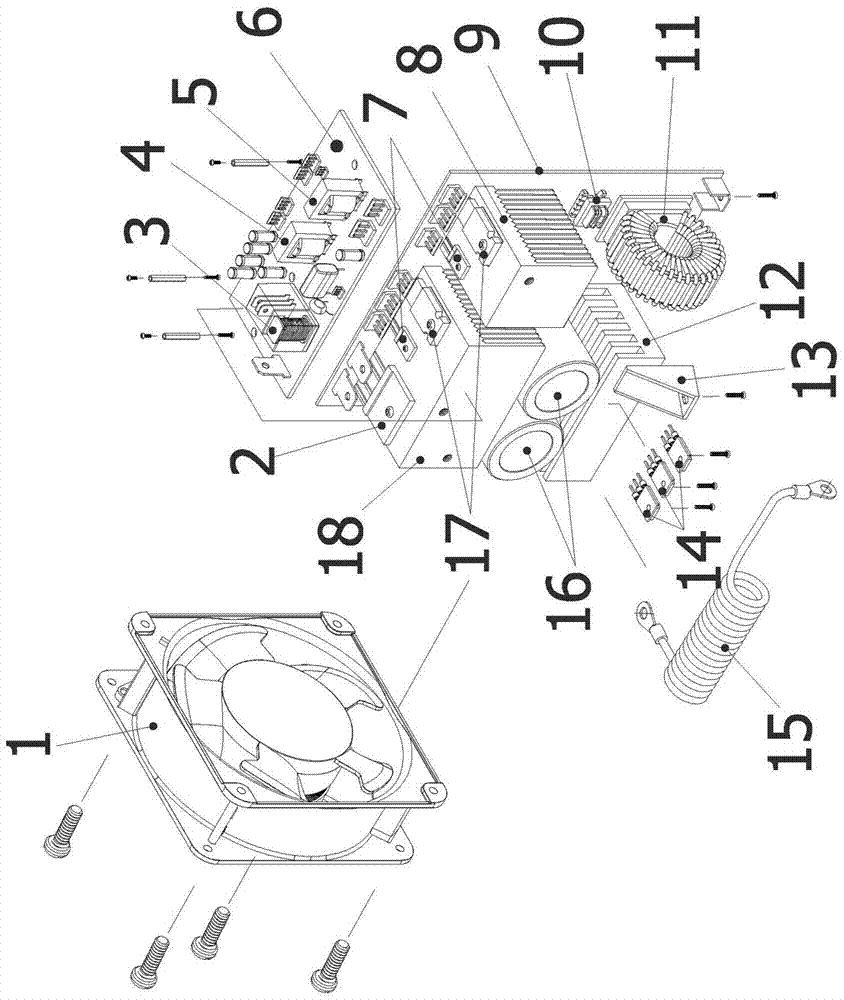

MOSFET (metal-oxide-semiconductor field effect transistor)-based inverter type welding equipment by sdie inlet air

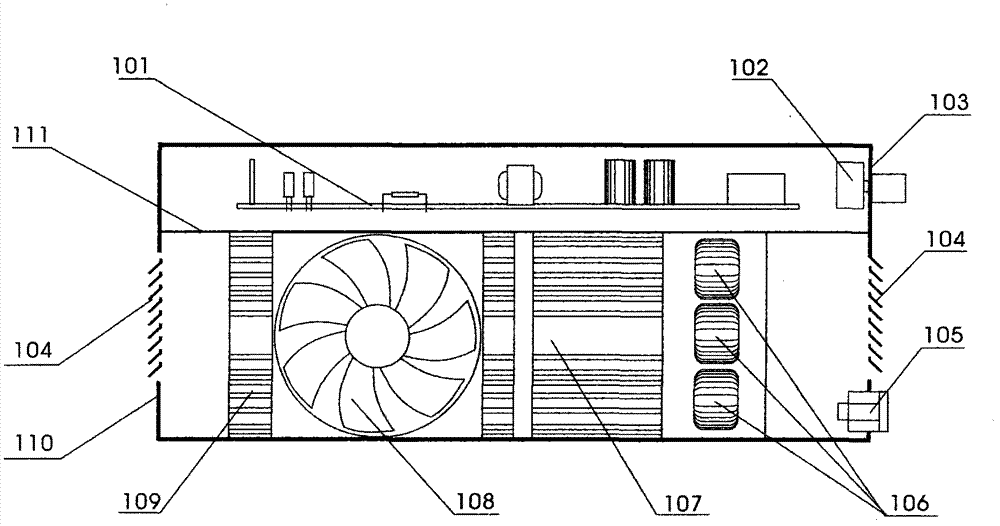

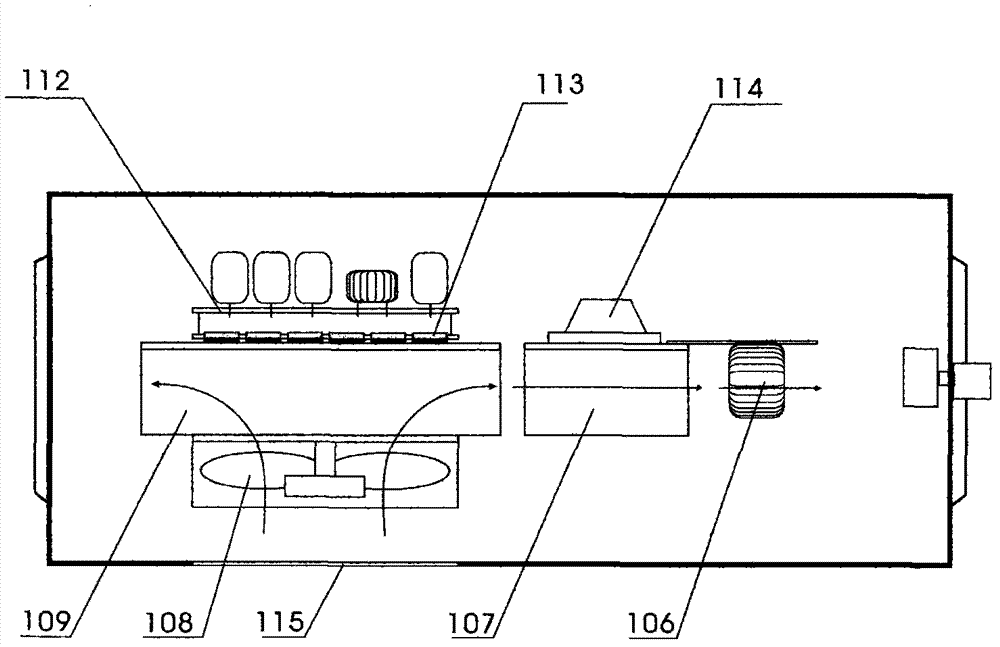

InactiveCN102785005ALow costFunction increaseWelding/cutting auxillary devicesAuxillary welding devicesMOSFETTransformer

The invention discloses inverter type welding equipment by using side inlet air. The inverter type welding equipment comprises a front panel, a rear panel, a rectifier and filter circuit, a control module, a driver module, MOSFET (metal-oxide-semiconductor field effect transistor) devices, an inverter module, a rectifier module, a high-frequency transformer, a current regulating device, an input power line, an output port, a fan, a rack and the like. The inverter type welding equipment is chracterized in that the fan is installed at the side of the rack, air outlets are arranged on the front panel and the rear panel, heat-transfer surfaces of the MOSFET devices are arranged on an identical plane which keeps close thermal contact with one same plane of E-shaped heat sinks and forms the inverter module by being installed together with a driver plate, a rectification module and the heat sinks are installed together to form the rectifier module, the fan is arranged above fins of the E-shaped heat sinks of the inverter module, airstream flows vertically to the fins of the heat sinks and flows along a flow channel formed by the fins of the heat sinks so as to continue to cool the rectification module and a main transformer; the airstream is discharged out of the rack from the air outlets on the front panel and the rear panel, so as to form the inverter type welding equipment which has high heat dissipation efficiency, high load rate and simple structure, and is stable and reliable.

Owner:王明伟

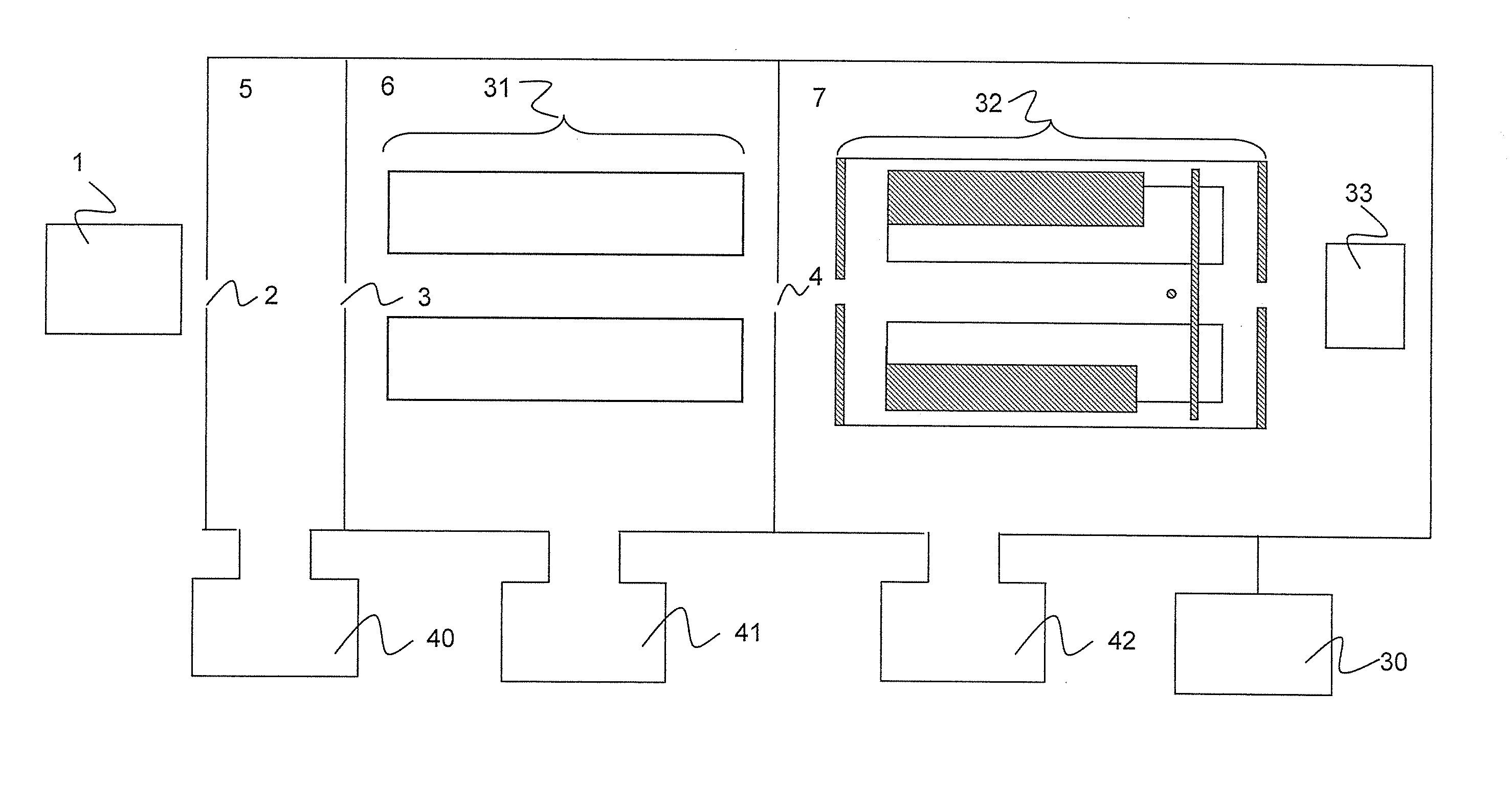

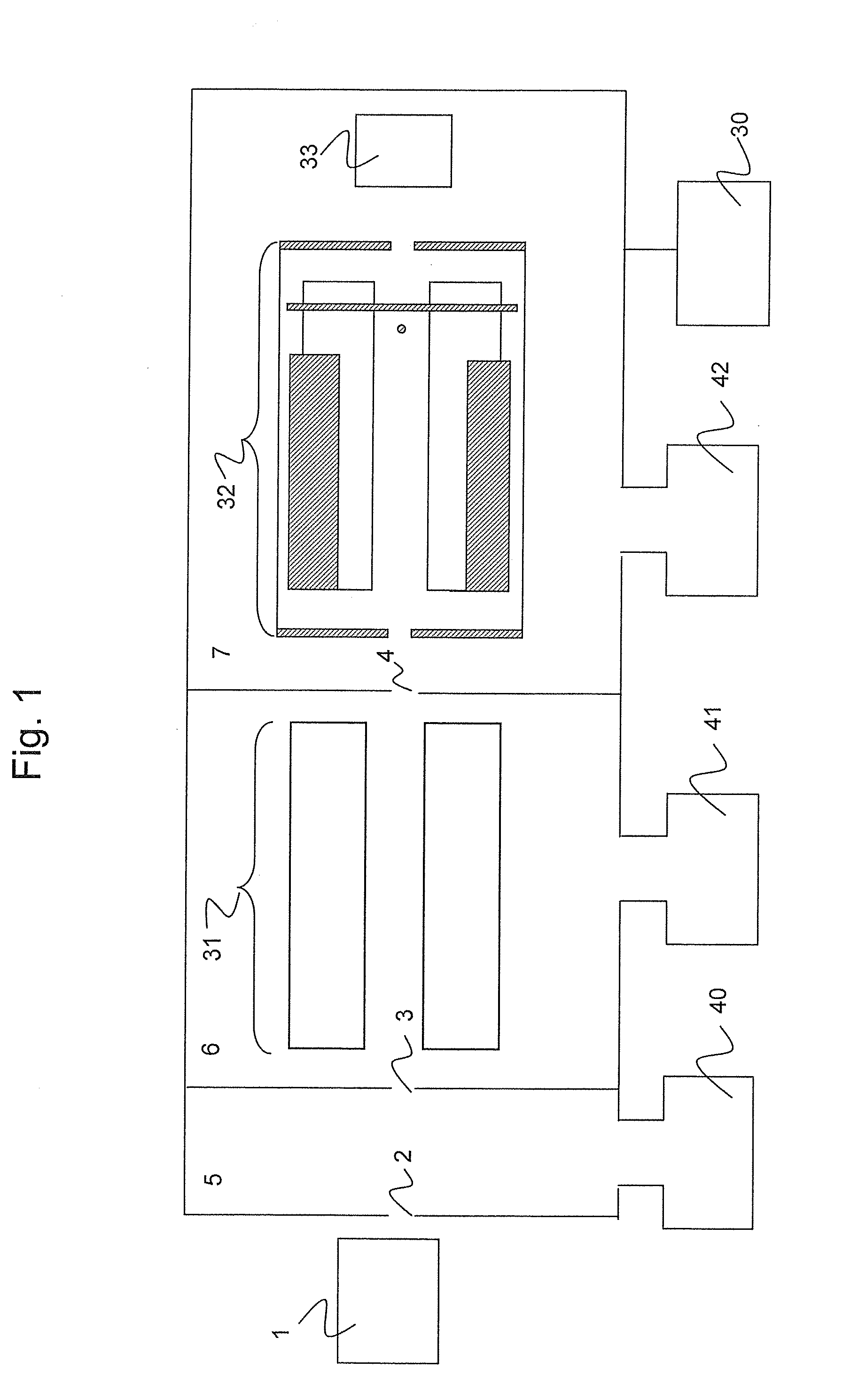

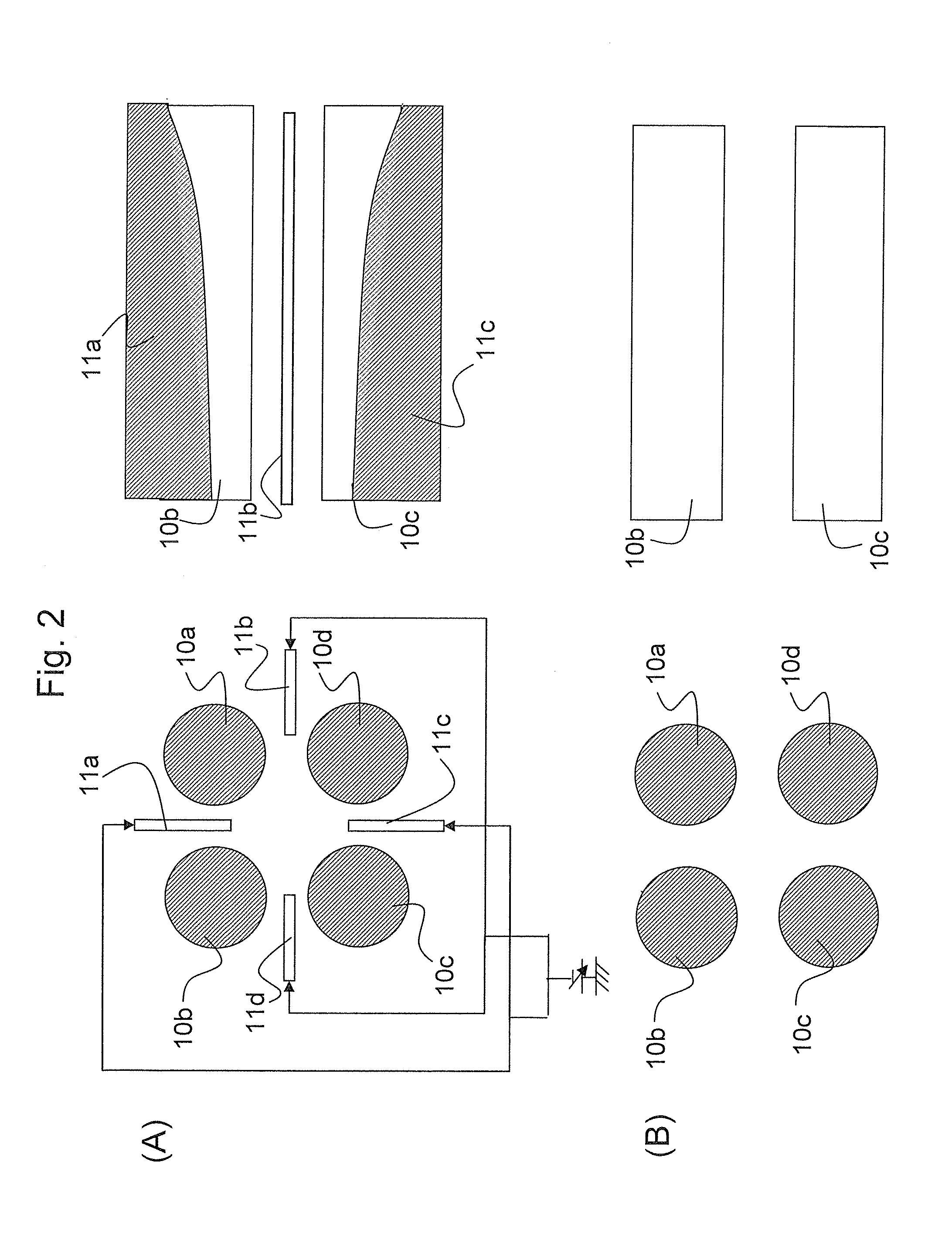

Mass spectrometer and mass spectrometry method

InactiveUS20120112059A1High duty cyclePositive/negative analyte ion analysis/introduction/generationIsotope separationIon trap mass spectrometryMass Spectrometry-Mass Spectrometry

An object is to measure both cations and anions with high duty cycle. In a mass spectrometer comprising an ion source (1), an ion guide part (31), and an ion trap (32), while ions are being mass-selectively ejected from the ion trap, ions having a polarity reverse to that of the ions trapped in the ion trap are introduced into the ion guide part.

Owner:HITACHI HIGH-TECH CORP

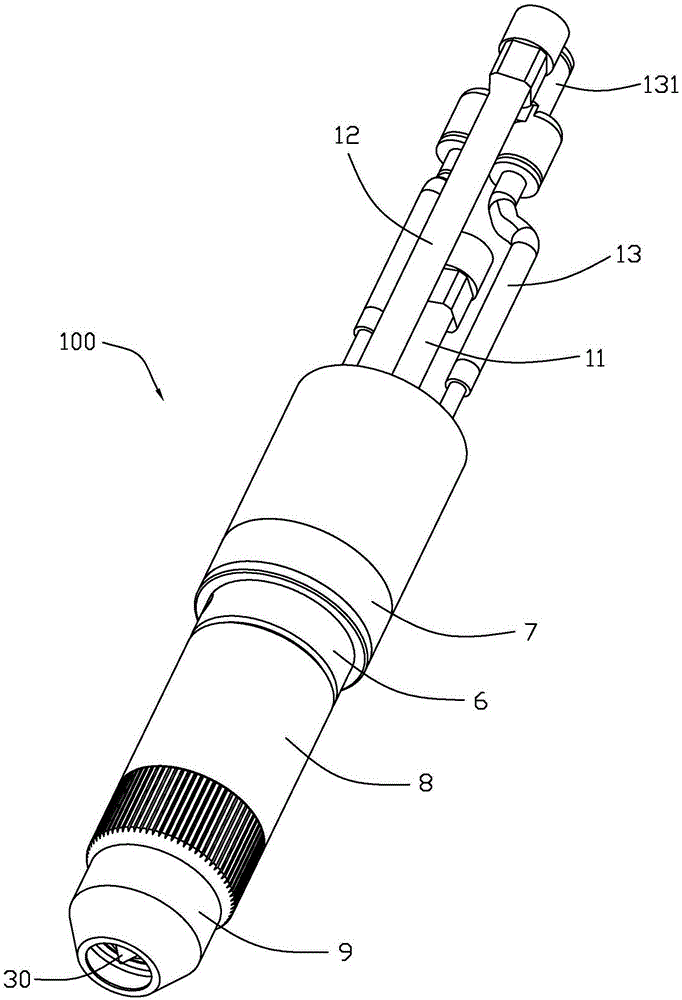

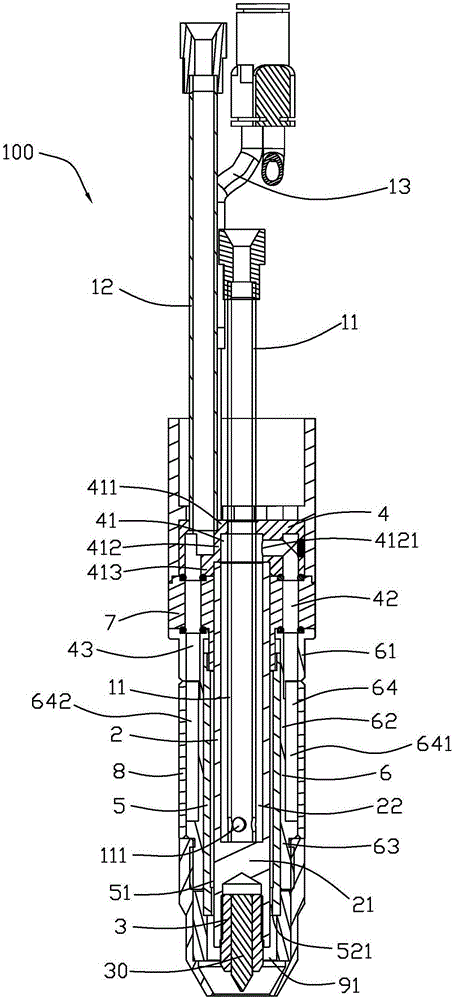

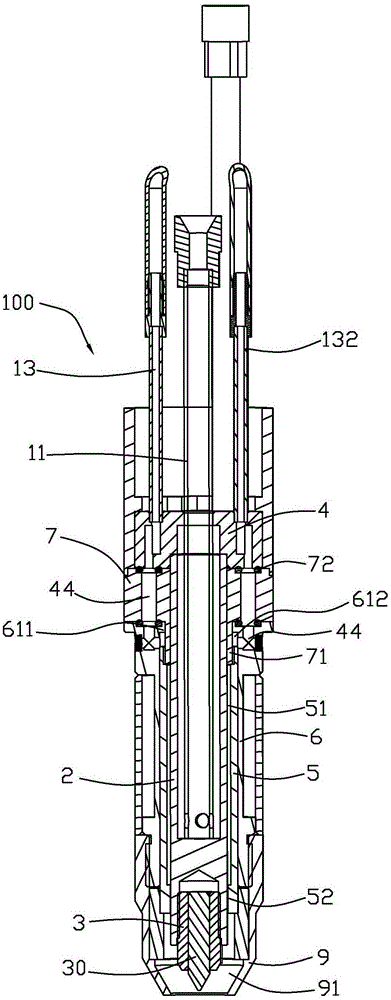

TIG welding gun

ActiveCN105171209AHigh duty cycleImprove welding qualityCooled electrode holdersElectrode accessoriesEngineeringWater cooling

The invention provides a TIG welding gun. The TIG welding gun comprises a water electric pipe positioned in the axis position, a core rod arranged at the outer periphery of the water electric pipe, a tungsten electrode clamp fixed at one end of the core rod, an electric conducting connection base fixed at the other end of the core rod and connected with the water electric pipe, a water cooling jacket arranged at the outer side of the core rod, an insulation block fixedly connected between the water cooling jacket and the electric conducting connection base in the axial direction, a shell fixed at the outer periphery of the water cooling jacket, and a water outlet pipe fixed on the electric conducting connection base. An isolation part is arranged in the core rod near the tungsten electrode clamp. The water electric pipe extends to the position of the isolation part, and is provided with a first water outlet hole penetrating through in the radial direction. A first water cavity communicated with the first water outlet hole is formed between the core rod and the water electric pipe. The electric conducting connection base is provided with a first water inlet communicated with the first water cavity. A second water cavity is formed between the water cooling jacket and the shell. The electric conducting connection base and the insulation block are formed with a first communication hole for communicating the first water inlet with the second water cavity and a second communication hole for communicating the second water cavity with the water outlet pipe.

Owner:HUAHENG WELDING

Laminate of magnetic base material and method for production thereof

InactiveCN1856847AHigh duty cycleFast heat conductionNanomagnetismRecord information storageThin metalMetal sheet

With respect to a laminate of a magnetic base material composed of a magnetic thin metal sheet and a polymer, to provide a laminate of a magnetic base material having an enhanced coefficient of thermal conductivity, since a conventional such laminate has a low coefficient of thermal conductivity and thus exhibits poor heat releasing property when the dissipation of the heat due to iron loss is intended. [MEANS FOR SOLVING PROBLEMS] Use is made of a laminate of a magnetic base material composed of a polymer layer and a magnetic thin metal sheet, characterized in that it has a coefficient of the volume resistance defined in JIS H 0505 in the direction perpendicular to the surface of the polymer layer of the laminate of less than 10<8> ohmcm. Said laminate can provide, when it is pressed, electroconductive points between the magnetic thin metal sheets, through the ejection of the polymer in the laminate to the outside thereof.

Owner:NAKAGAWA SPECIAL STEEL CO

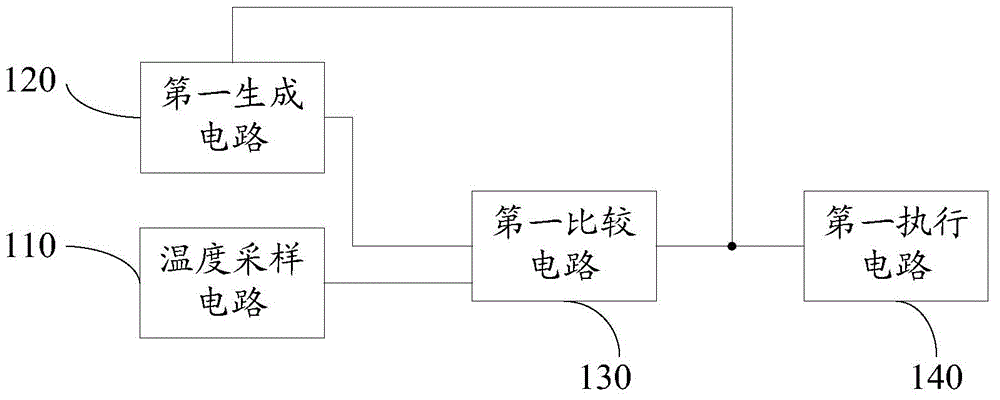

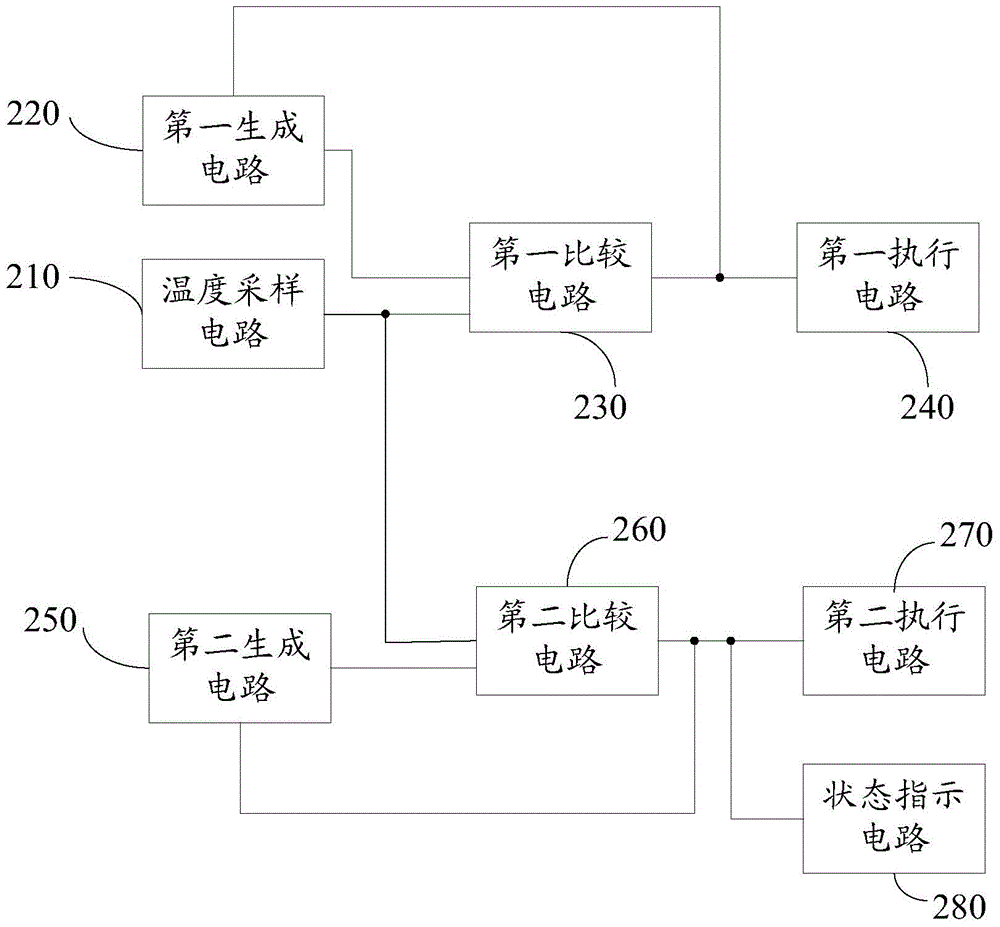

Temperature control circuit and temperature control method

InactiveCN104965536AAchieve temperature controlUniform internal temperatureTemperature control using electric meansTemperature controlEngineering

The invention relates to a temperature control circuit. The temperature control circuit is used for control of a temperature of a power device. The temperature control circuit comprises a temperature sampling circuit used for real-time sampling of an internal temperature of a power device and output of the sampled value, a first generation circuit used for generating a first protection parameter, a first comparison circuit used for generating a corresponding adjusting signal according to a magnitude relationship of a sampling value and the value of the first protection parameter, a first generation circuit used for changing and outputting the value of the first protection parameter when the adjusting signal changes, and a first execution circuit used for adjusting the work current of the power device according to the adjusting signal to achieve temperature control of the power device. The value of the first protection parameter is a first protection threshold or a second protection threshold. The temperature control circuit can ensure that the power device has a high load succession rate and meets usage requirements of users. The invention also relates to a temperature control method.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

Mass spectrometer and mass analysis method

ActiveUS7319222B2High duty cycleShort separation timeDispersed particle filtrationParticle spectrometer methodsIon trap mass spectrometryMass analyzer

Owner:HITACHI HIGH-TECH CORP

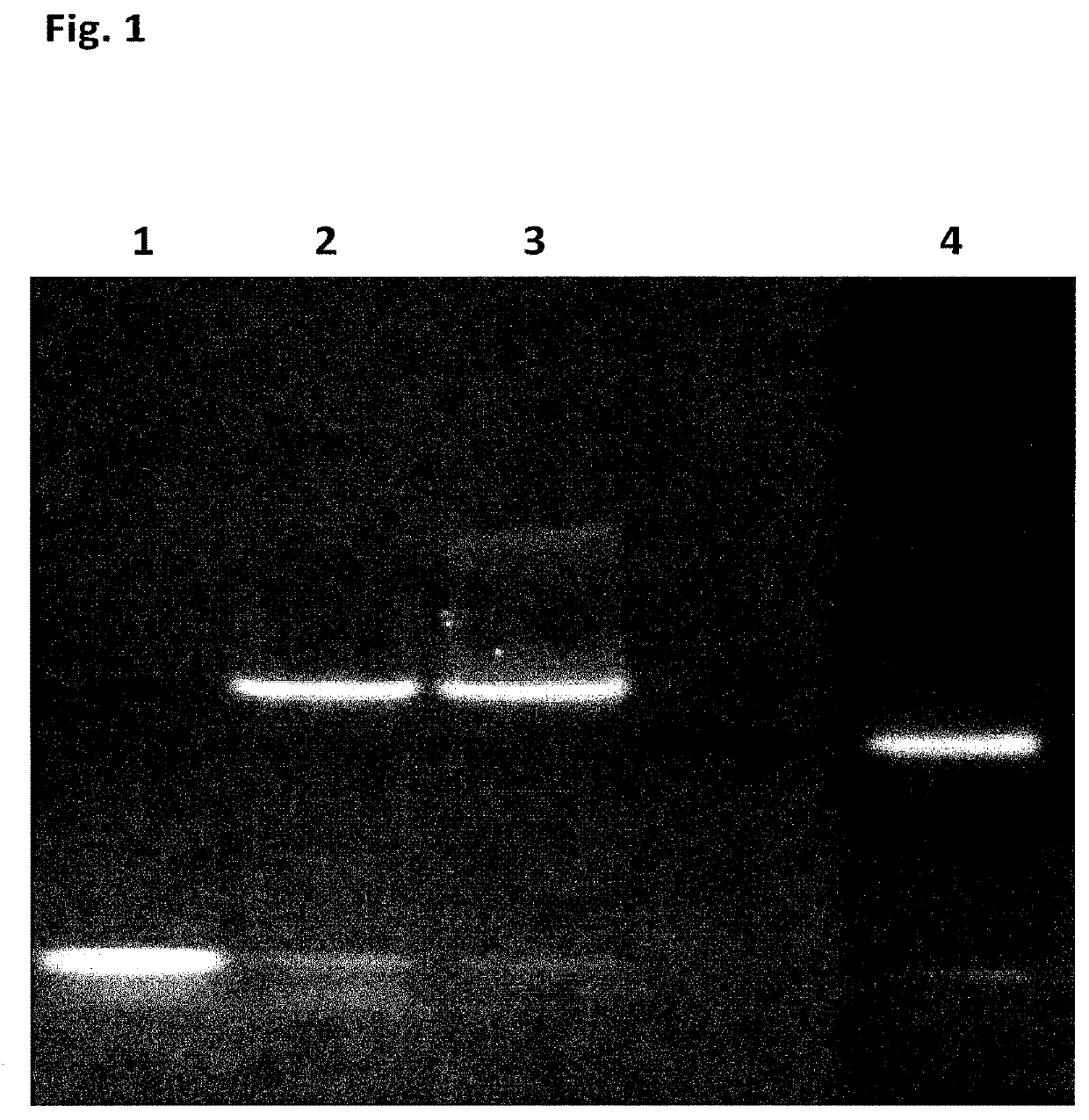

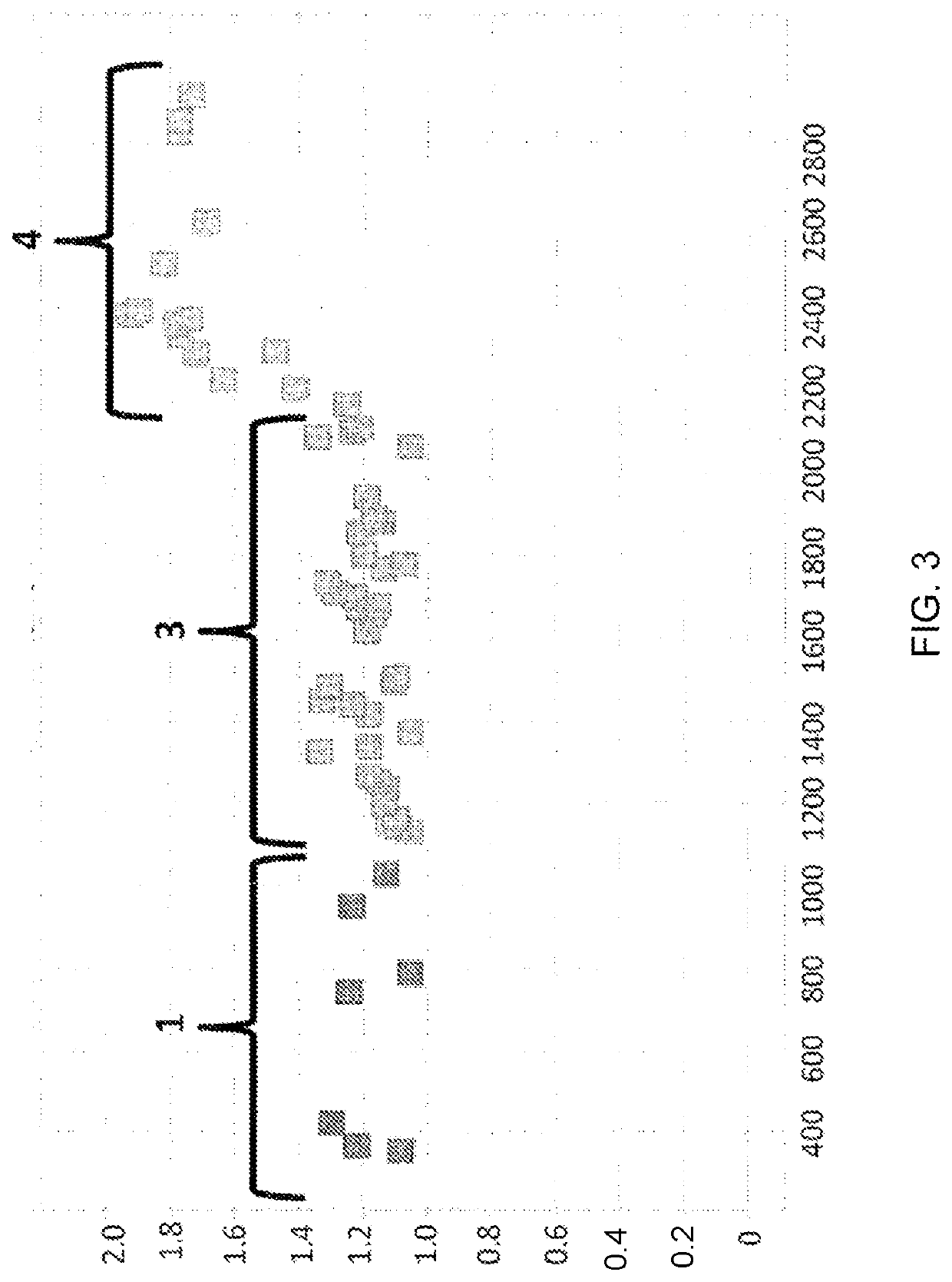

Method of identifying precursor ions

ActiveUS9460902B2Strong specificityReduce resolutionTime-of-flight spectrometersSpecific reaction combinationsImage resolutionMass Spectrometry-Mass Spectrometry

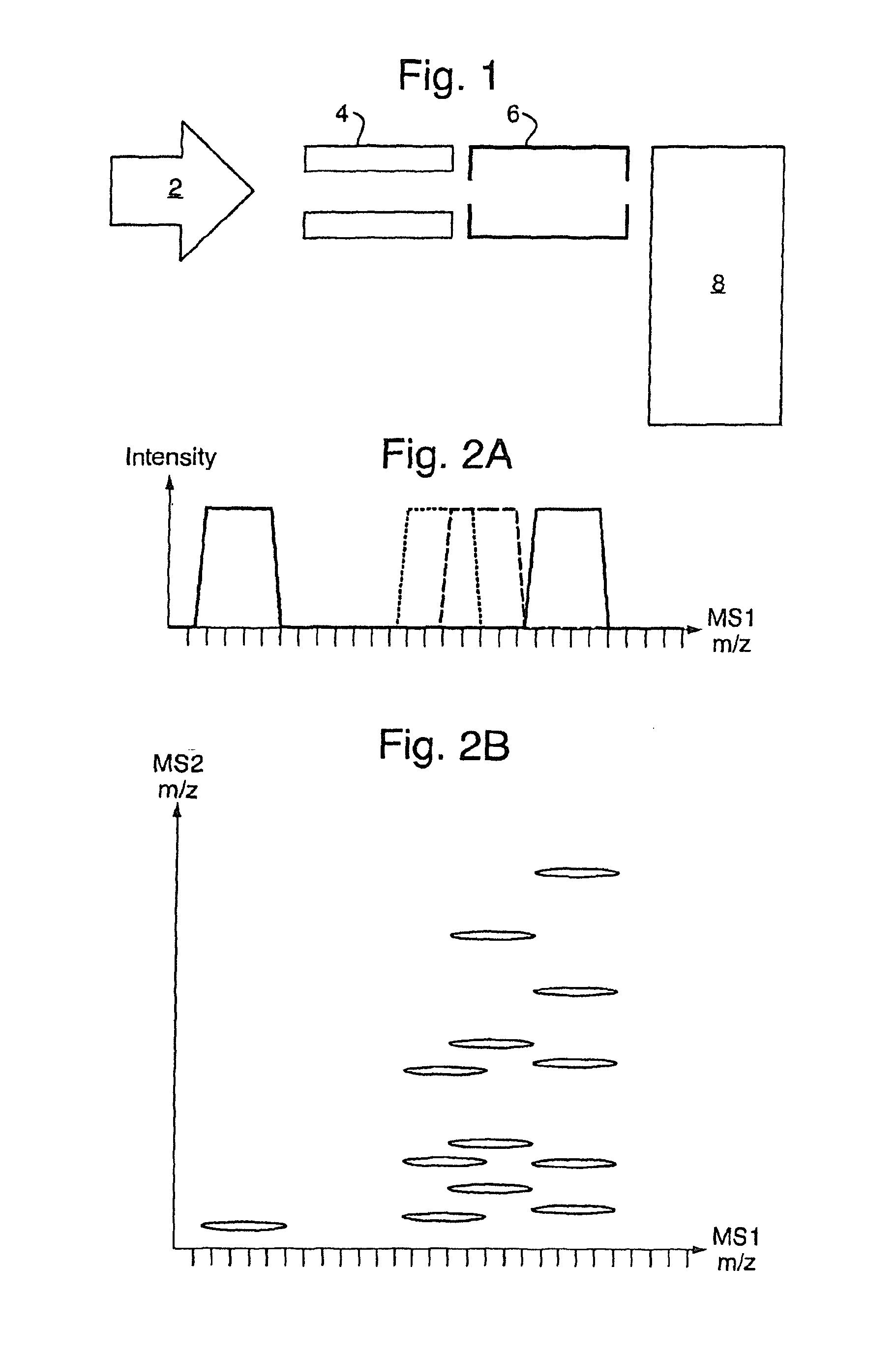

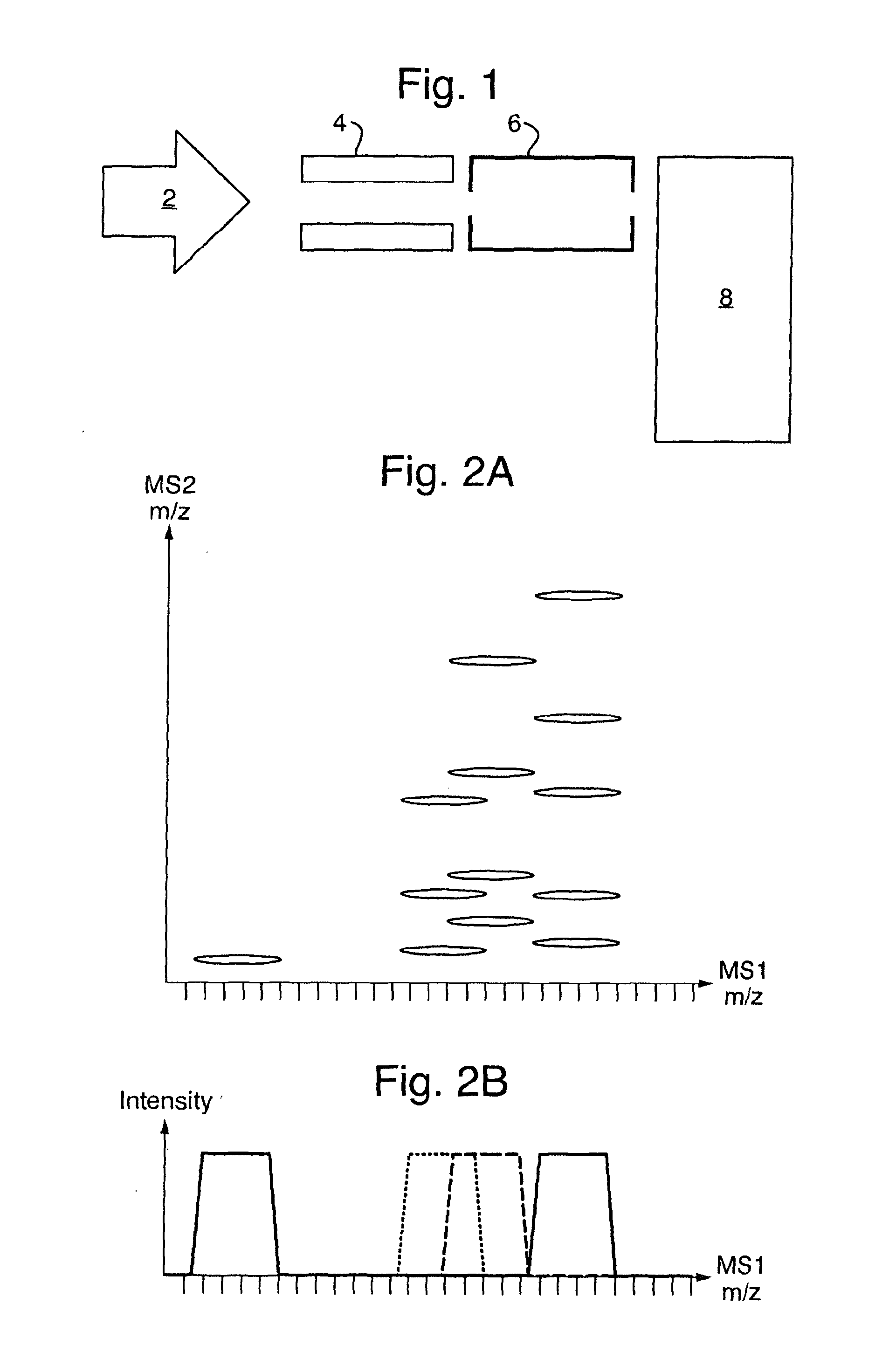

A method of mass spectrometry is disclosed comprising mass selectively transmitting precursor ions from a mass analyzer into a fragmentation or reaction device, wherein the mass to charge ratios of the ions transmitted varies with time; fragmenting the precursor ions in the fragmentation or reaction device so as to produce fragment or product ions; mass analyzing the fragment or product ions; determining the start and end times at which a first fragment or product ion is detected; using said start and end times to determine the start and end times at which a precursor ion of said first fragment or product ion is transmitted by said mass analyzer; and using the start and end times at which the precursor ion is transmitted by said mass analyzer to determine a mass to charge ratio of said precursor ion. The present invention enables precursor ion peaks to be resolved from the fragment data even when a low resolution mass analyzer is used to analyze the precursor ions.

Owner:MICROMASS UK LTD

SSB method

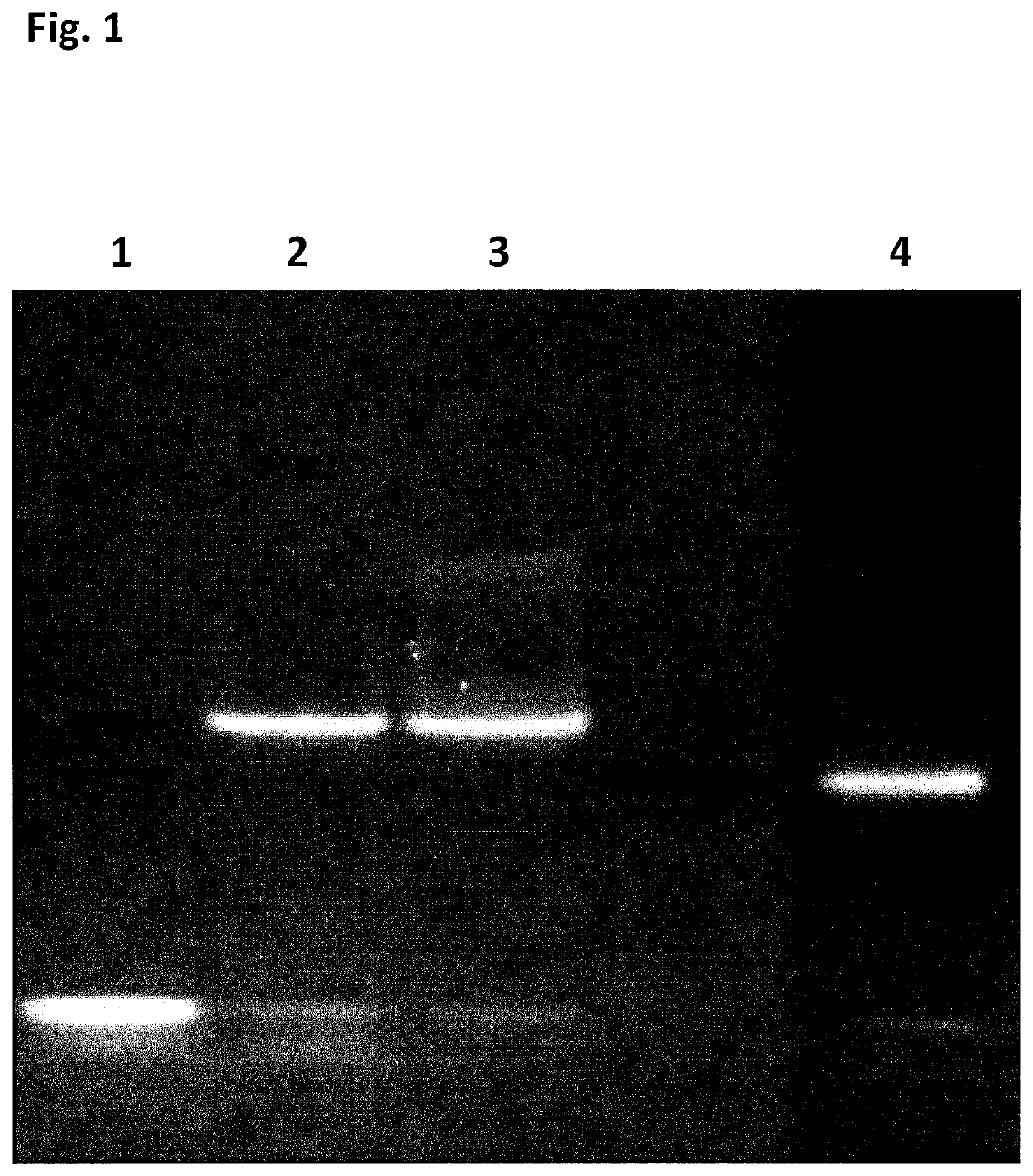

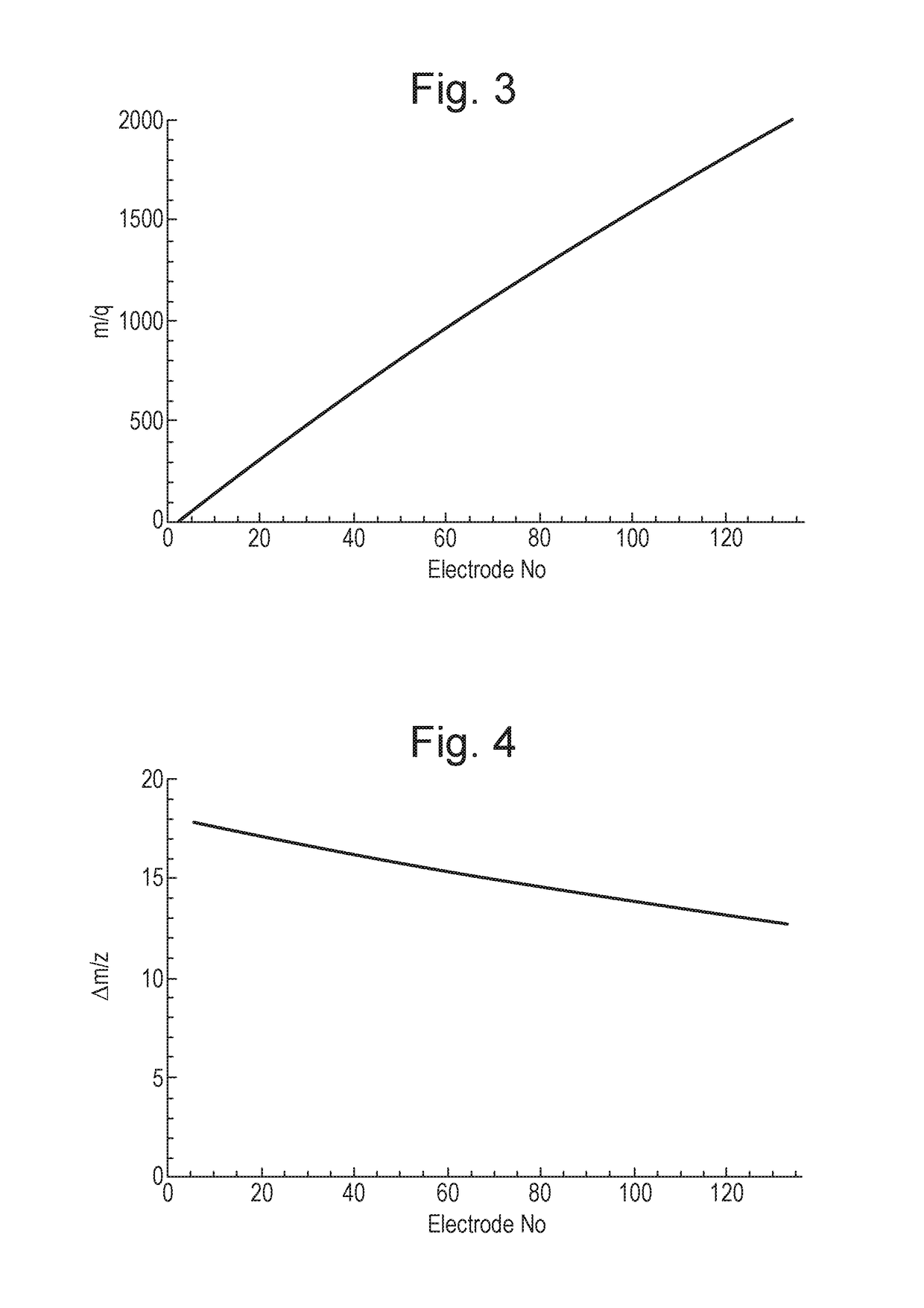

ActiveUS11155860B2High duty cycleAvoid structureMicrobiological testing/measurementSingle strandPolynucleotide

The invention relates to a method of characterising a target polynucleotide using a single-stranded binding protein (SSB). The SSB is either an SSB comprising a carboxy-terminal (C-terminal) region which does not have a net negative charge or a modified SSB comprising one or more modifications in its C-terminal region which decreases the net negative charge of the C-terminal region.

Owner:OXFORD NANOPORE TECH LTD

Separating ions in an ion trap

ActiveUS20180151339A1High duty cycleReduce space charge effectsStability-of-path spectrometersMaterial analysis by electric/magnetic meansIon trap mass spectrometryParticle physics

A method is disclosed comprising: trapping ions in an ion trap (40); applying a first force on the ions within the ion trap in a first direction, said force having a magnitude that is dependent upon the value of a physicochemical property of the ions; applying a second force on these ions in the opposite direction so that the ions separate according to the physicochemical property value as a result of the first and second forces; and then pulsing or driving ions out of one or more regions of the ion trap.

Owner:MICROMASS UK LTD

Ssb method

PendingUS20220145383A1High duty cycleAvoid structureMicrobiological testing/measurementSingle strandPolynucleotide

The invention relates to a method of characterising a target polynucleotide using a single-stranded binding protein (SSB). The SSB is either an SSB comprising a carboxy-terminal (C-terminal) region which does not have a net negative charge or a modified SSB comprising one or more modifications in its C-terminal region which decreases the net negative charge of the C-terminal region.

Owner:OXFORD NANOPORE TECH LTD

Method of Identifying Precursor Ions

ActiveUS20150136969A1Strong specificityReduce resolutionTime-of-flight spectrometersIsotope separationImage resolutionMass Spectrometry-Mass Spectrometry

A method of mass spectrometry is disclosed comprising mass selectively transmitting precursor ions from a mass analyser into a fragmentation or reaction device, wherein the mass to charge ratios of the ions transmitted varies with time; fragmenting the precursor ions in the fragmentation or reaction device so as to produce fragment or product ions; mass analysing the fragment or product ions; determining the start and end times at which a first fragment or product ion is detected; using said start and end times to determine the start and end times at which a precursor ion of said first fragment or product ion is transmitted by said mass analyser; and using the start and end times at which the precursor ion is transmitted by said mass analyser to determine a mass to charge ratio of said precursor ion. The present invention enables precursor ion peaks to be resolved from the fragment data even when a low resolution mass analyser is used to analyse the precursor ions.

Owner:MICROMASS UK LTD

Separating ions in an ion trap

ActiveUS10861687B2Reduce impactReduce space charge effectsStability-of-path spectrometersMaterial analysis by electric/magnetic meansIon trap mass spectrometryParticle physics

A method is disclosed comprising: trapping ions in an ion trap (40); applying a first force on the ions within the ion trap in a first direction, said force having a magnitude that is dependent upon the value of a physicochemical property of the ions; applying a second force on these ions in the opposite direction so that the ions separate according to the physicochemical property value as a result of the first and second forces; and then pulsing or driving ions out of one or more regions of the ion trap.

Owner:MICROMASS UK LTD

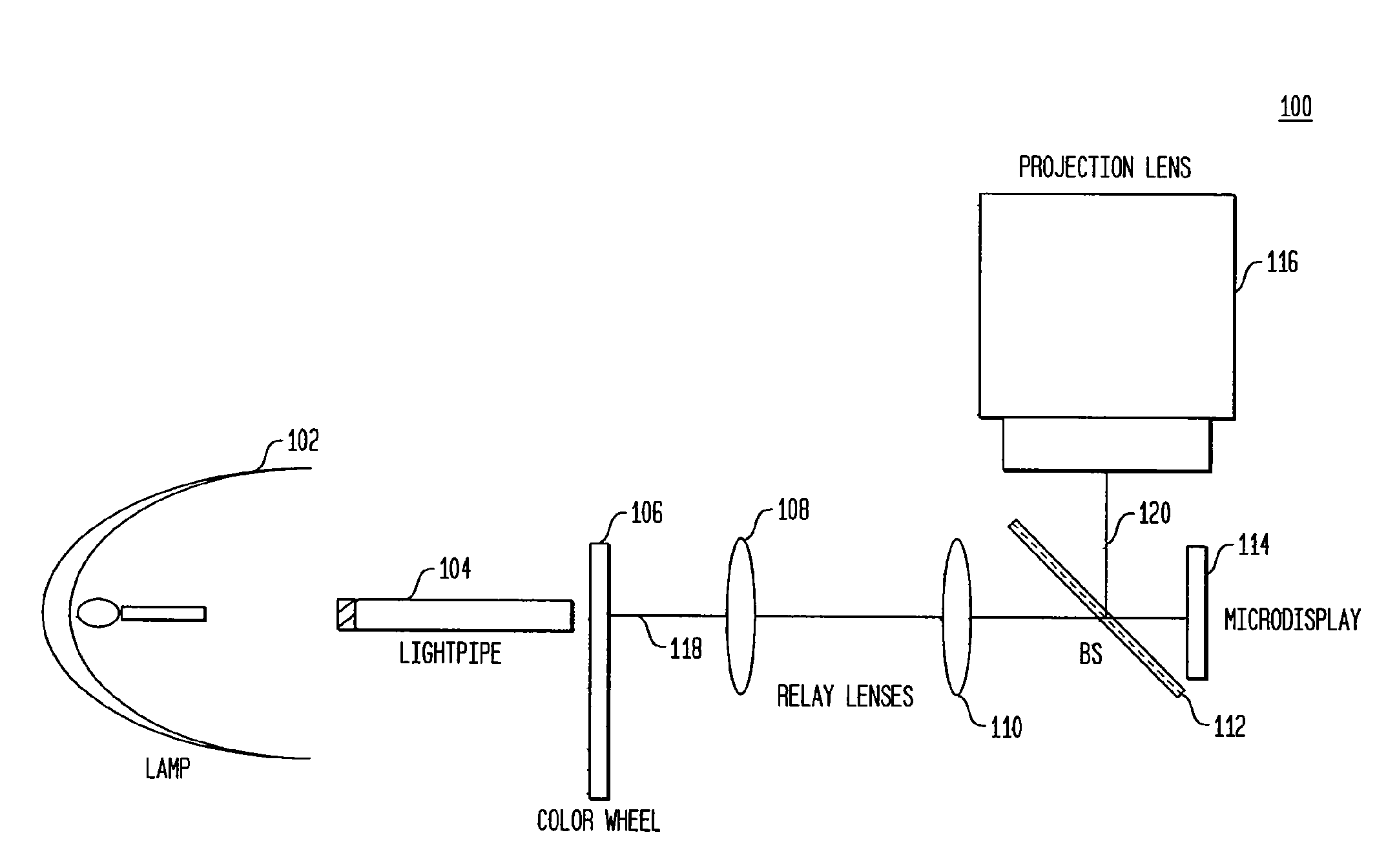

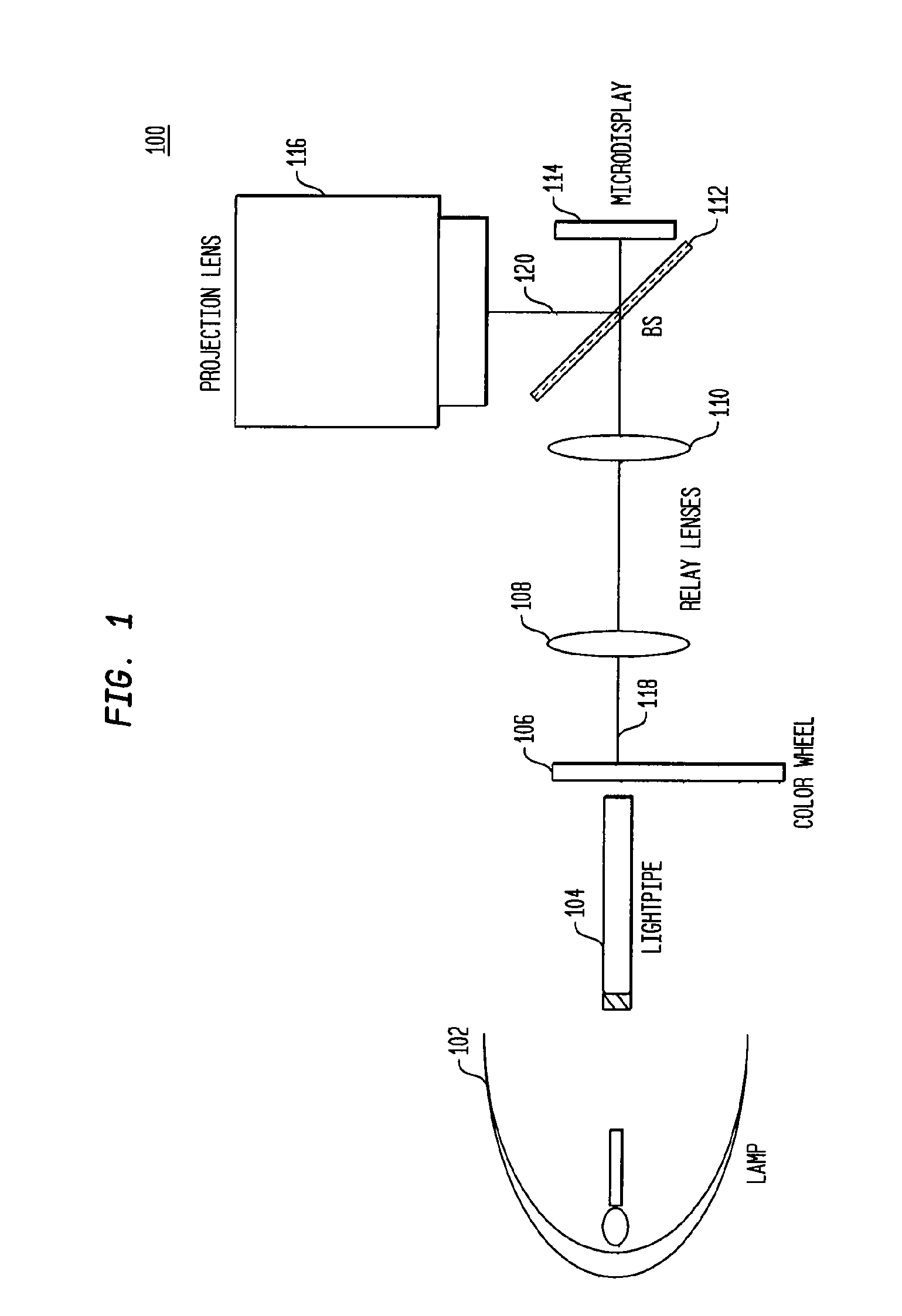

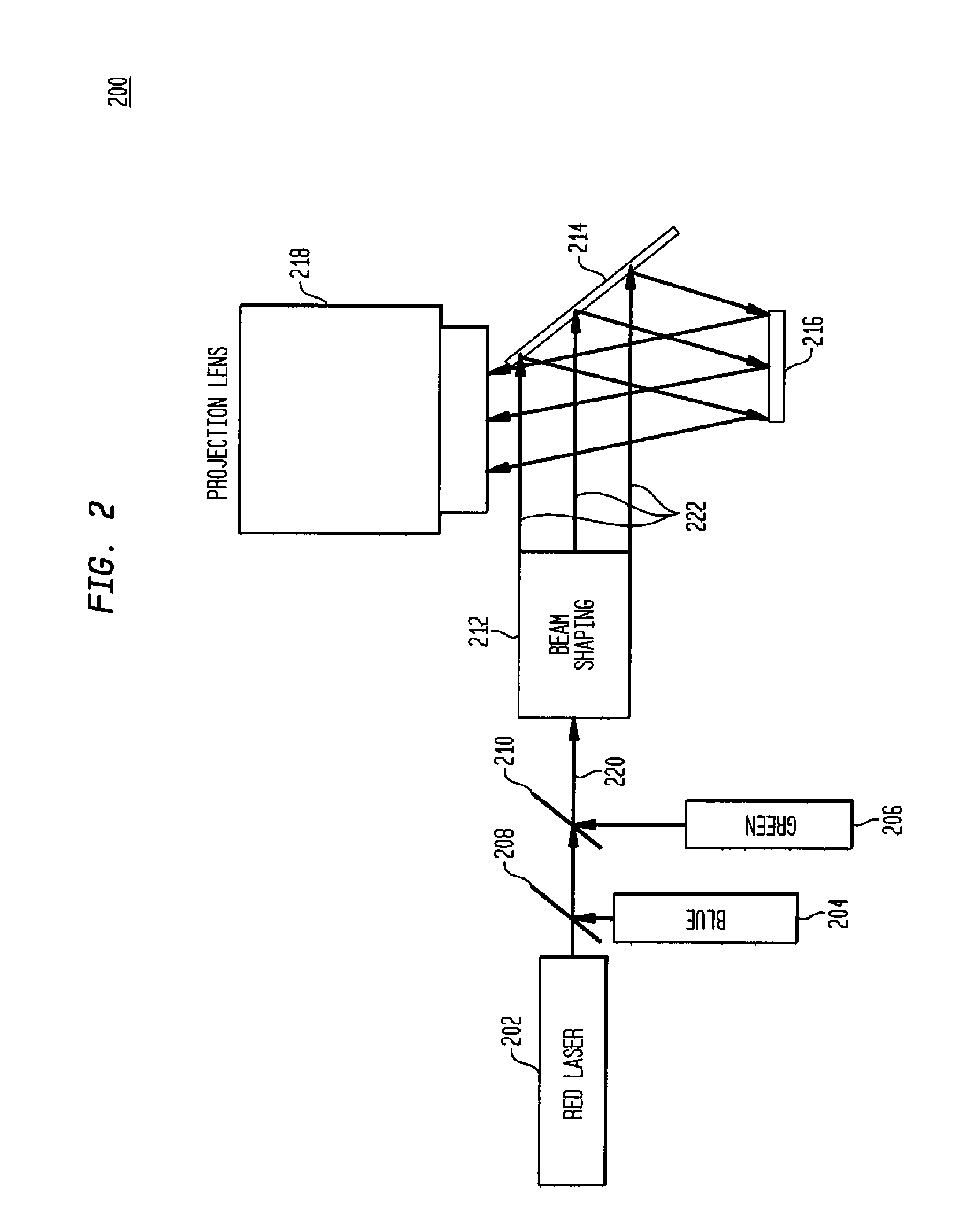

Laser scrolling color scheme for projection display

InactiveUS20130027436A1Increase brightnessImprove efficiencyCathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displayLaser light

Methods and systems for improved optical efficiency and brightness of display systems are provided herein. Embodiments use laser light sources in substantially continuous mode, thereby increasing the maximum overall output of an optical system. Embodiments exploit the small étendue of laser sources to lower the loss of throughput of an optical system. Embodiments enable a scrolling color scheme that allows a display system to be illuminated with two or more colors at any given time, thereby increasing the brightness of the display system. Embodiments can be used with liquid crystal displays and / or digital mirror displays. Embodiments can be used in single-panel and / or two-panel display systems.

Owner:ROSSELLA

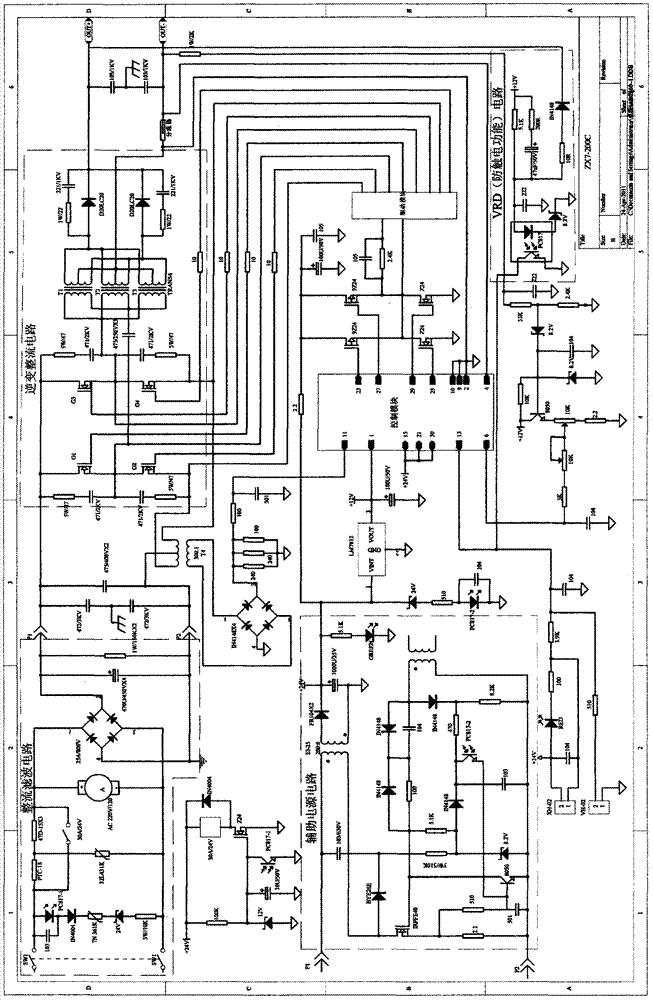

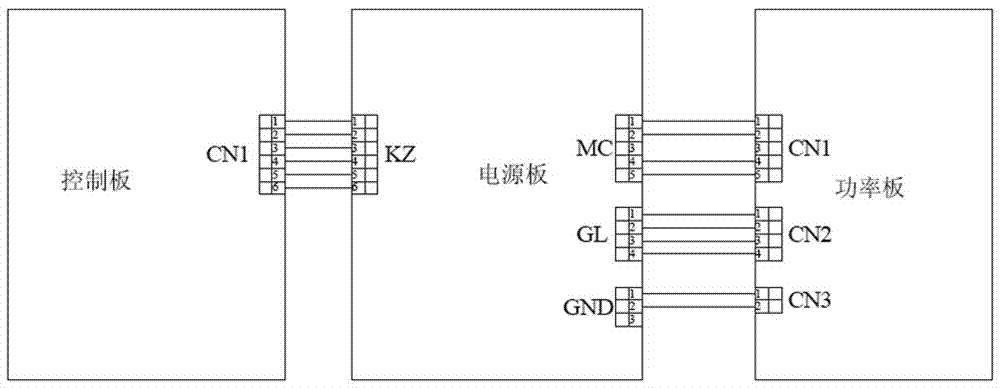

Mini-type inversing manual arc welding machine

InactiveCN107052514AImprove cooling efficiencyImprove reliabilityWelding accessoriesCapacitanceEngineering

The invention relates to a mini-type inversing manual arc welding machine. A control circuit board in the mini-type inversing manual arc welding machine is designed to comprise three parts including a power board, a power supply board and a control board; an arranged circuit of the power board mainly comprises a single-end normal-shock inversing circuit composed of a rectifier bridge, electrolytic capacitors, IGBTs, diodes, a main transformer, a current detection mutual inductor, output rectifier diodes and the like, radiators and part of components; the power supply board mainly comprises an electrifying buffer, a switch power supply and an IGBT driving circuit; the control board mainly comprises a PWM output characteristic control circuit, a non-load voltage limiting circuit, an overcurrent and overheat protection circuit and a long-time output short-circuit protection circuit. The three circuit boards are designed in order to not only take the size and the weight of the welding machine into account, but also take cost factors of transportation and after-sales maintenance into account, and advantages of being reasonable in design, convenient to maintain, stable and reliable are achieved.

Owner:朱宣东

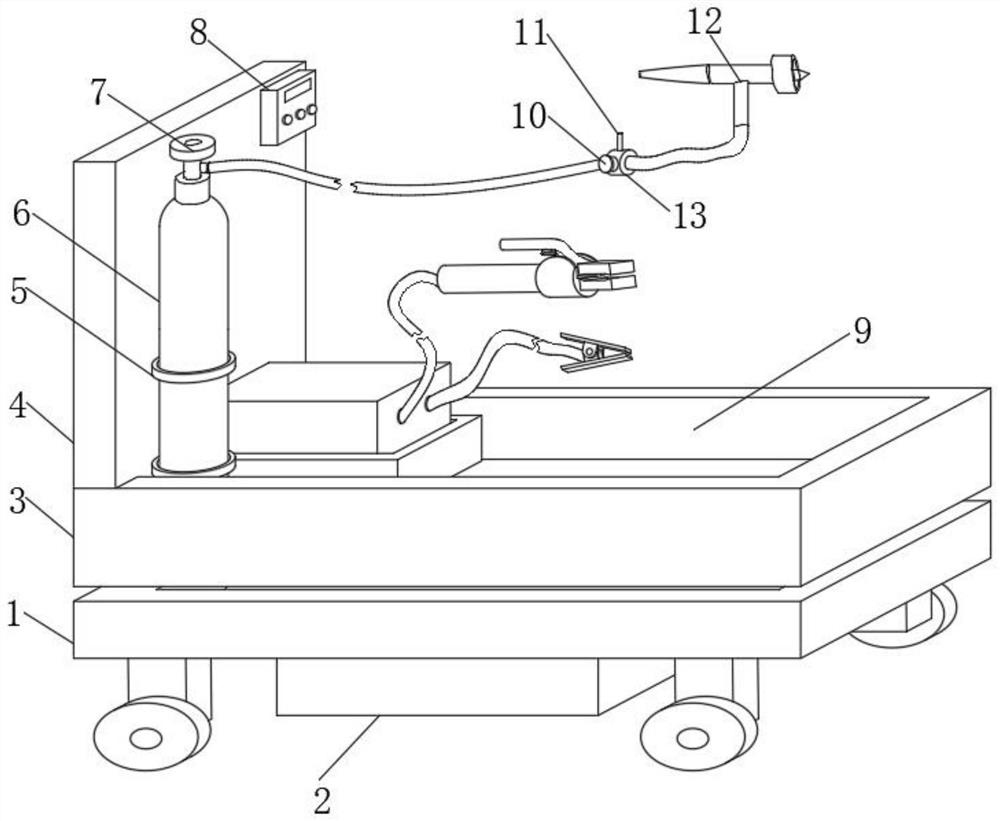

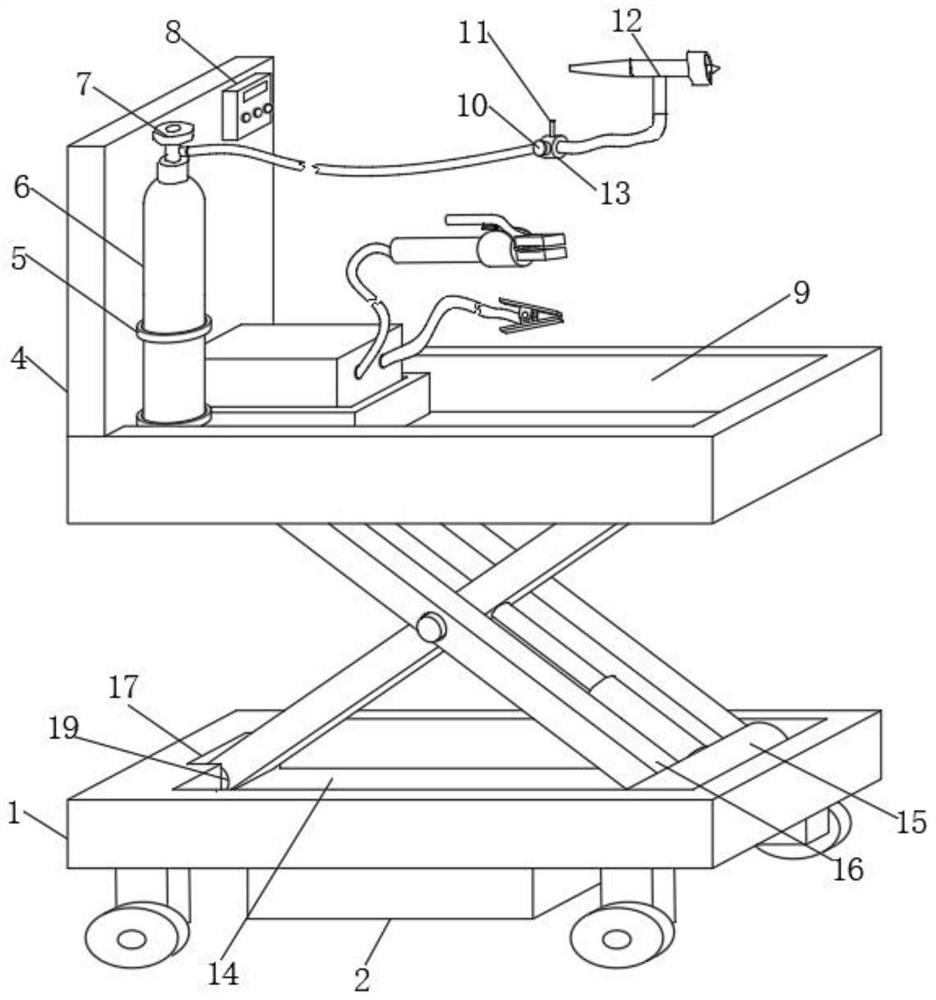

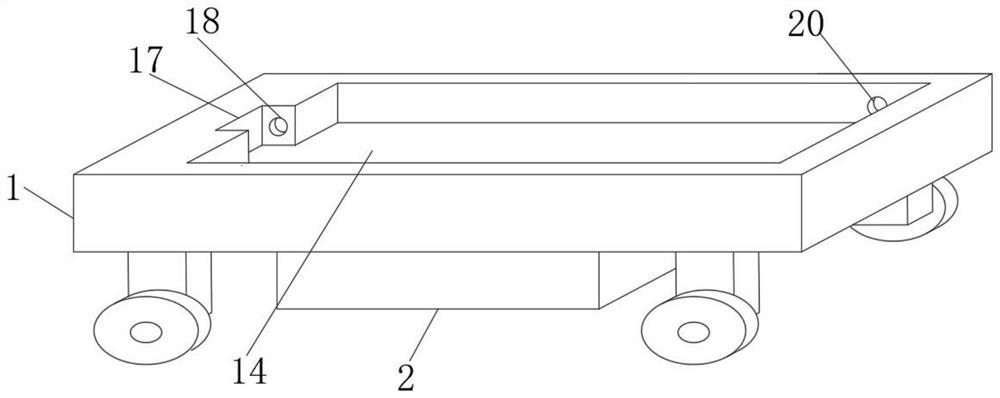

Convenient-adjusted welding device for forklift portal frame

InactiveCN112171153AInconvenient to operateEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesSlag (welding)Portal frame

The invention discloses a convenient-adjusted welding device for a forklift portal frame, comprising a base and rollers. A power box is arranged at the middle of the bottom end of the base; a bearingplate is movably installed above the base; a first groove is formed in the upper end of the bearing plate; a support plate is fixedly connected to the left end of the bearing plate; and a control panel is installed on the right side of the support plate and close to the top end. The convenient-adjusted welding device for the forklift portal frame can support the bearing plate, so that a user can perform high-distance operation, inconvenience in operation and easiness in falling damage when a ladder is used for welding are avoided; the control panel is arranged on the support plate, so that theoperation can be completed by a single person, the labor force is reduced, the operation of the user is facilitated, and welding is facilitated; by means of a limiting sleeve, an argon bottle can beprevented from falling down, so that the safety of users is guaranteed; the welding effect can be improved by using an argon arc welding gun; welding slag can be prevented from appearing in the welding process; and the convenient-adjusted welding device for the forklift portal frame is simple in structure, high in load duration and convenient to use.

Owner:HEFEI DONGLU MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com