MOSFET (metal-oxide-semiconductor field effect transistor)-based inverter type welding equipment by sdie inlet air

A welding equipment and inverter technology, which is applied in the field of inverter welding equipment, can solve problems such as poor heat dissipation of high-frequency transformer components, uneven heat dissipation of MOSFETs, and poor consistency of multi-tube correlations, etc., so as to improve load duration and improve Cooling conditions, various effects of functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

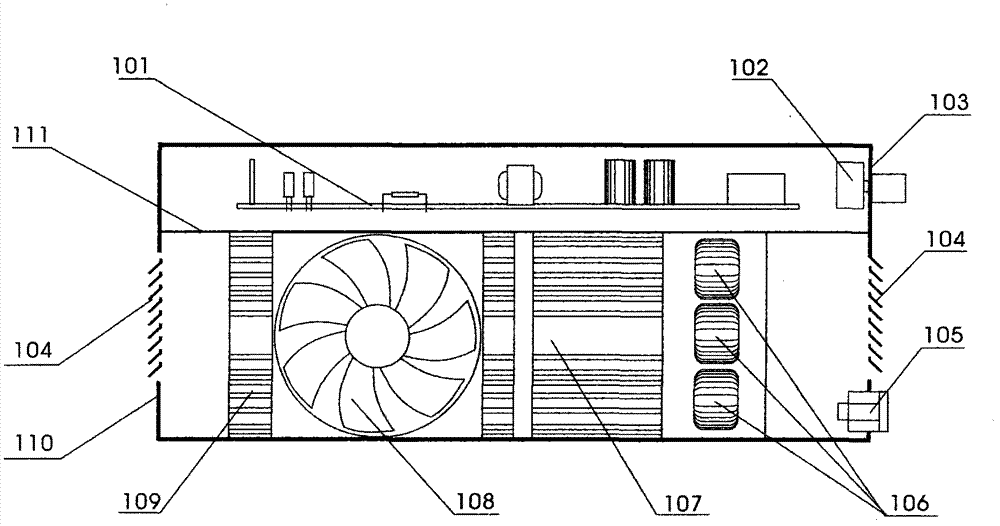

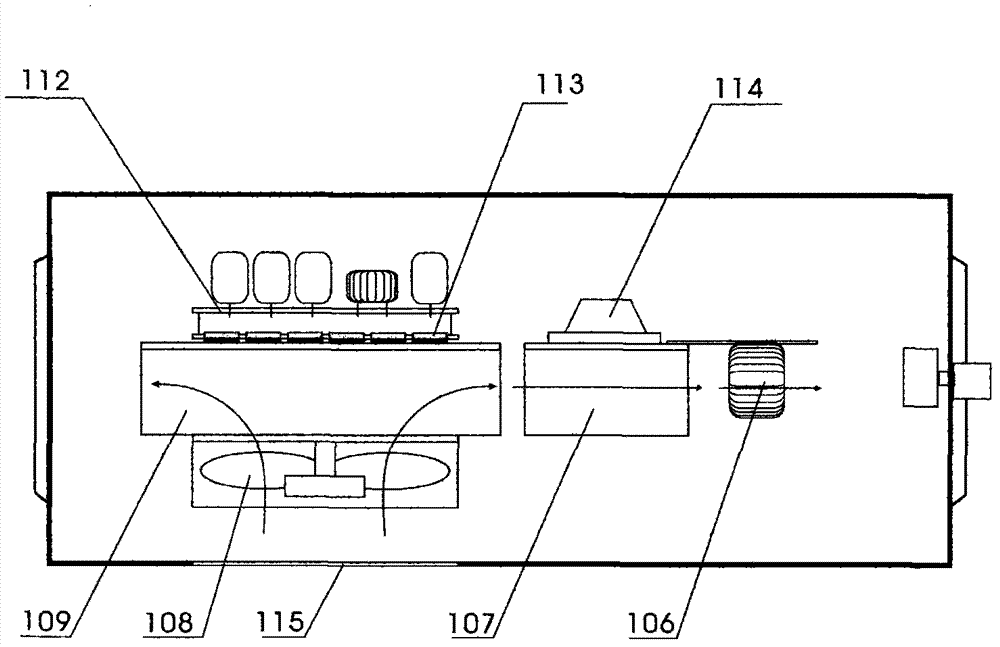

[0035] Picture 1-1 It is a side view of the basic structure diagram of the inverter welding equipment with side air intake, Figure 1-2 It is a top view of the distribution of cooling components in the space below the partition. Figure 1-2 The direction of the arrow in is the direction of cooling air flow.

[0036] In the figure, 101 is the control circuit board, 102 is the control knob, 103 is the front panel, 104 is the air outlet, 105 is the welding output terminal, 106 is the high-frequency transformer, 107 is the rectifier module radiator, 108 is the fan, 109 is the inverter Module radiator, 110 is the rear panel, 111 is the partition; 112 is the driver board, 113 is the MOSFET device, 114 is the rectifier module, 115 is the air inlet.

[0037]Wherein the MOSFET devices 113 are installed on the circuit board in groups, and then fixed on the plane side of the E-type radiator 109, the heat dissipation surface of the MOSFET device is located on the same plane, and its hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com