Rotating electrical machine

A technology of rotating electrical machines and rotors, which is applied in the field of rotating electrical machines to achieve the effect of high duty ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

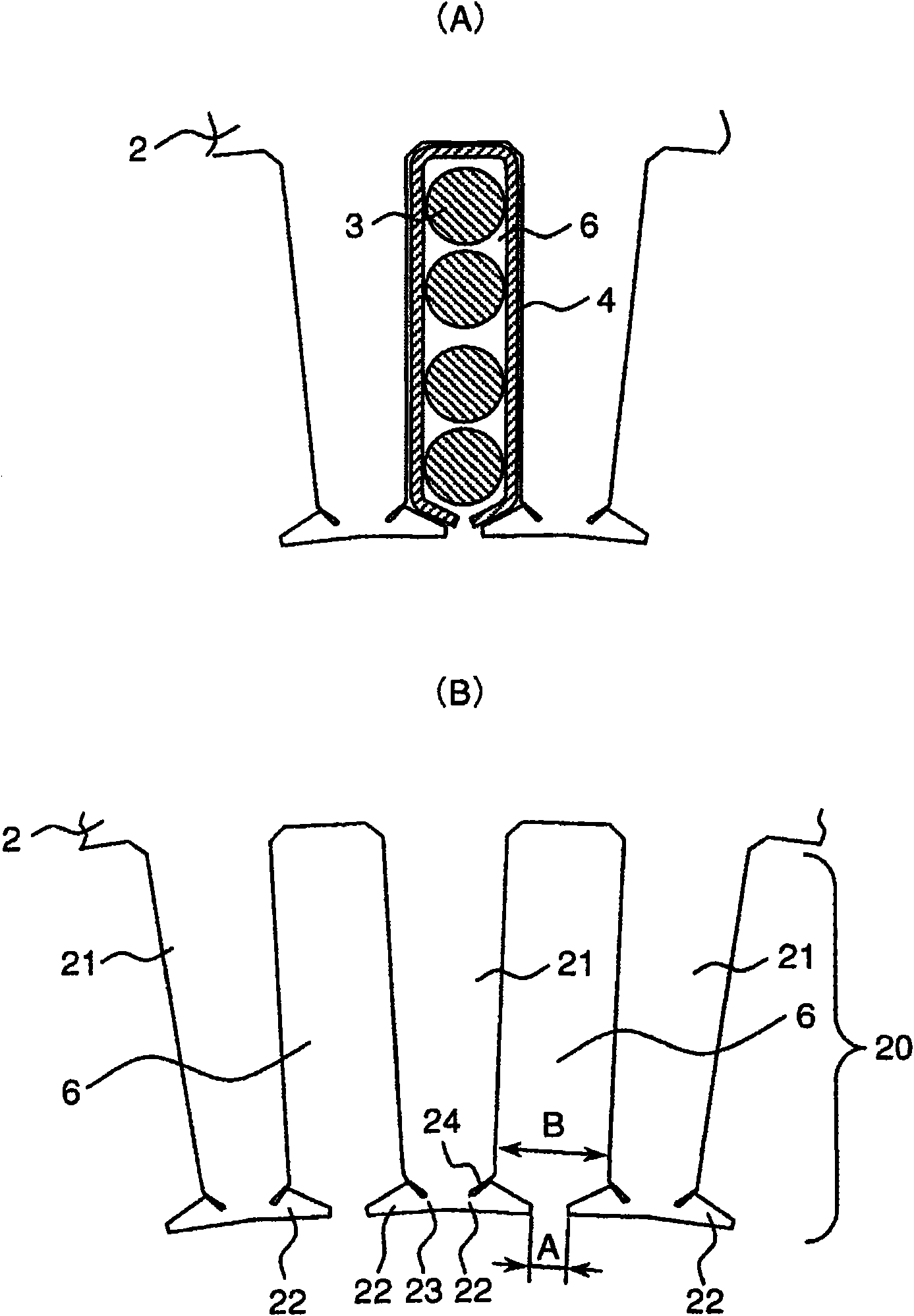

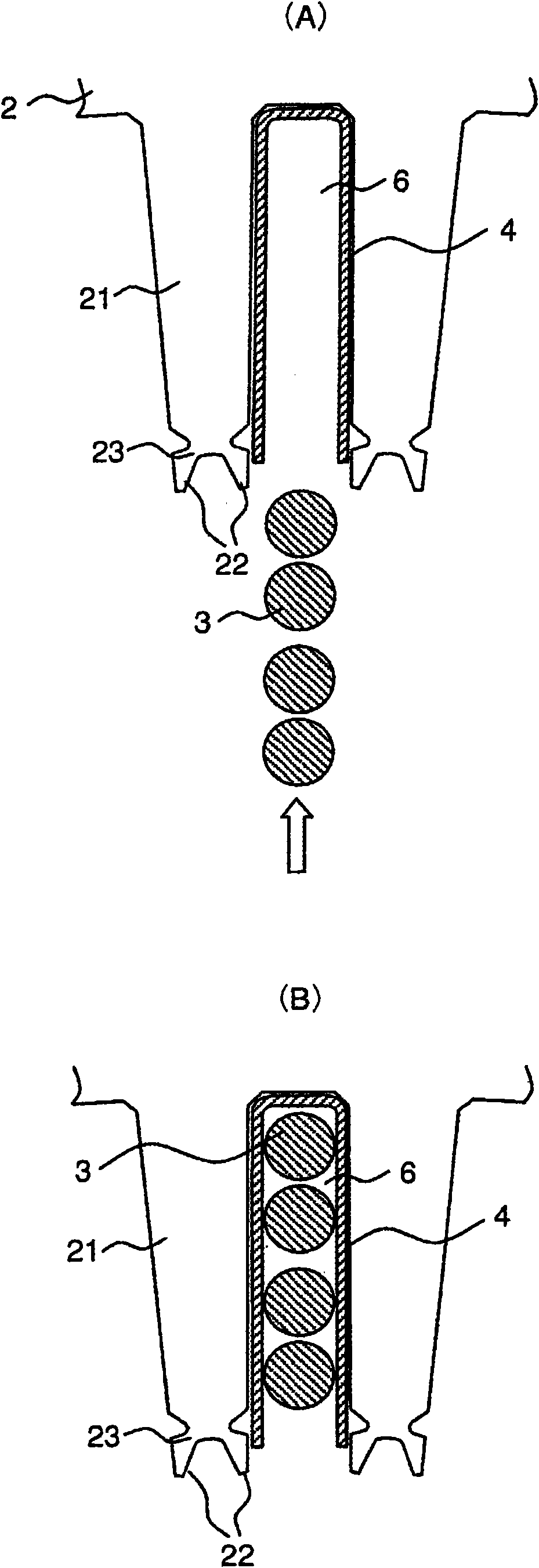

Embodiment Construction

[0024] The embodiments shown below are related to rotating electric machines such as electric motors and generators and their manufacturing methods, and relate to rotating electric machines equipped with a core stator (stator) with semi-closed slots formed by opening the teeth tip. .

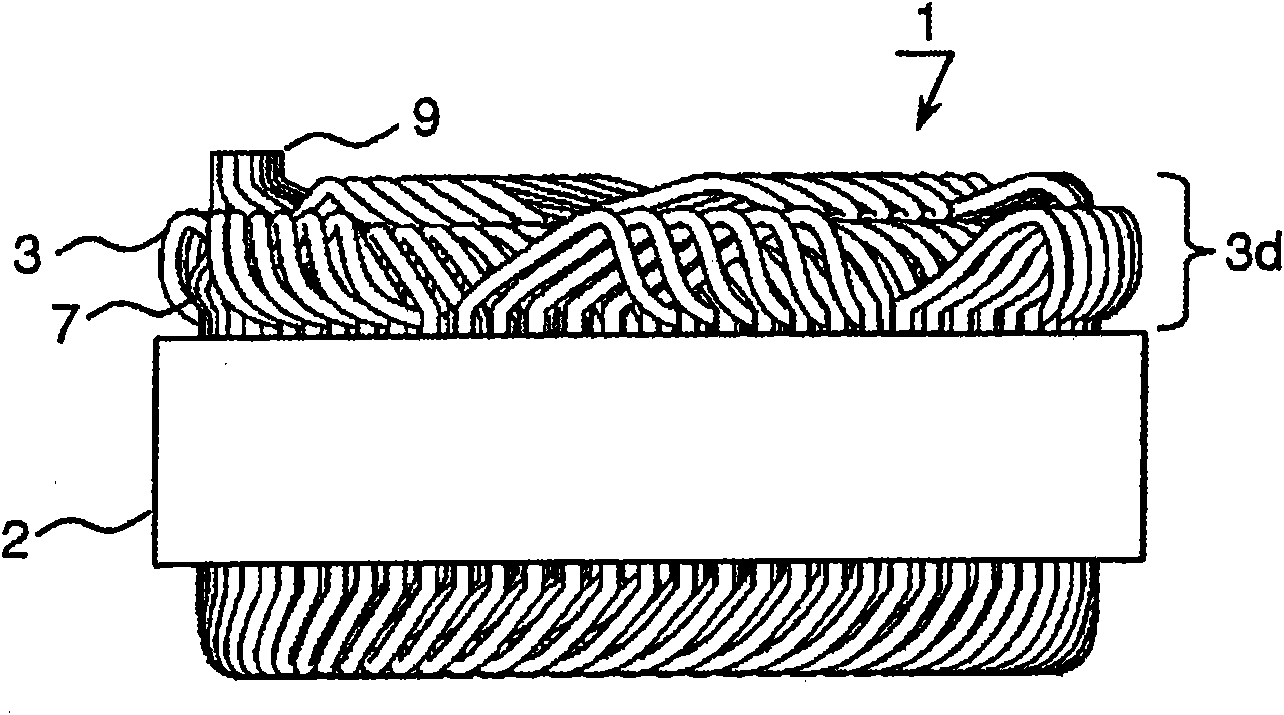

[0025] figure 1 This is a rotating electrical machine constituting one embodiment of the present invention. A stator 1 is shown in which coils are wound such that two stator poles formed by coil turns in the same phase are arranged within 360 degrees of the electrical angle formed by the magnetic poles of the rotor. Hereinafter, the coil formed by winding is referred to as a dispersed winding coil. Details of the dispersed winding coil will be described later.

[0026] figure 1 A front view of the stator 1 viewed from the side of the stator core 2 is shown, and the dispersed winding coil 7 is assembled to the stator core 2 and the end portion 9 of the wire 3 is connected. With this structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com