Patents

Literature

57results about How to "Long time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

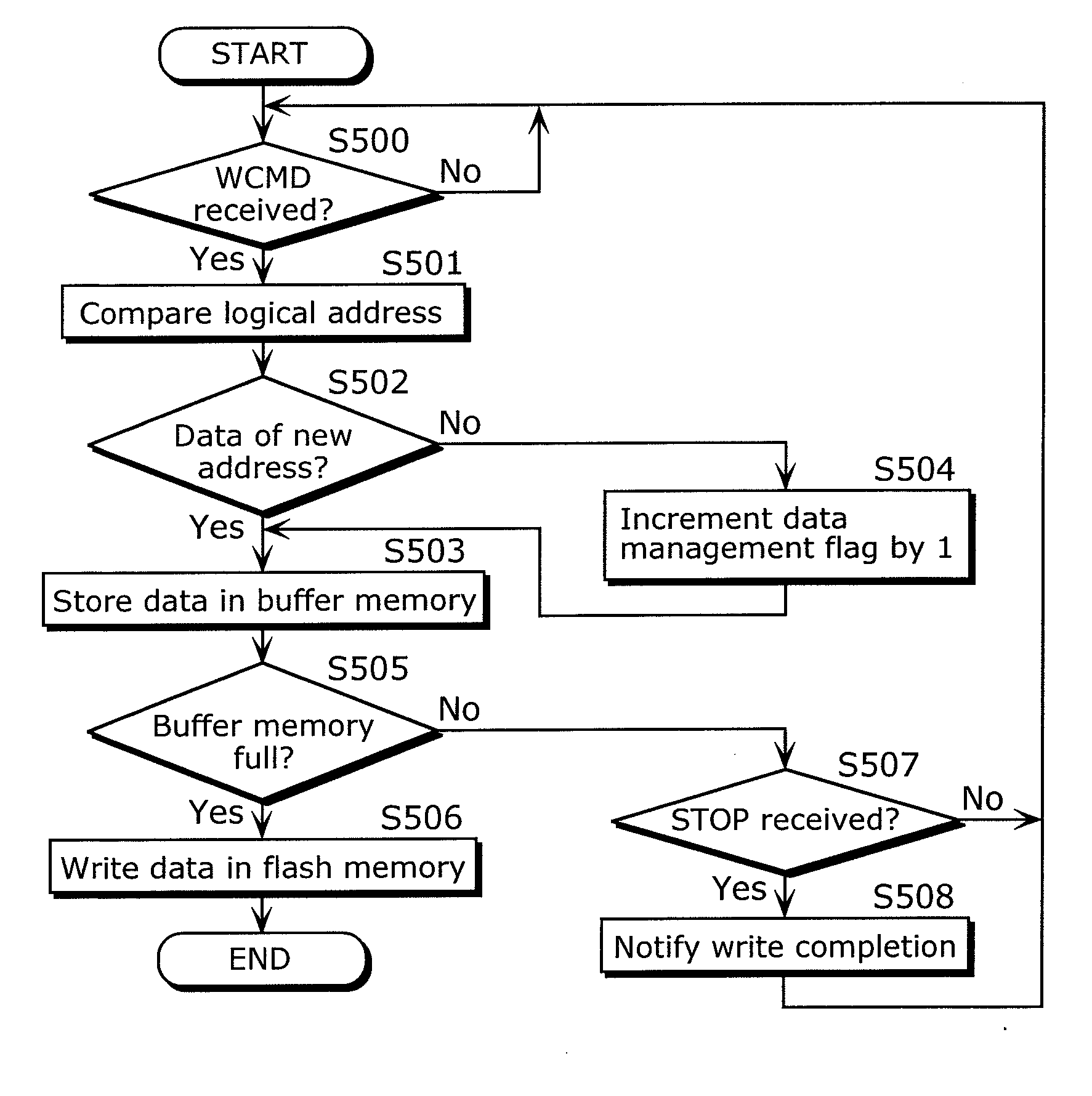

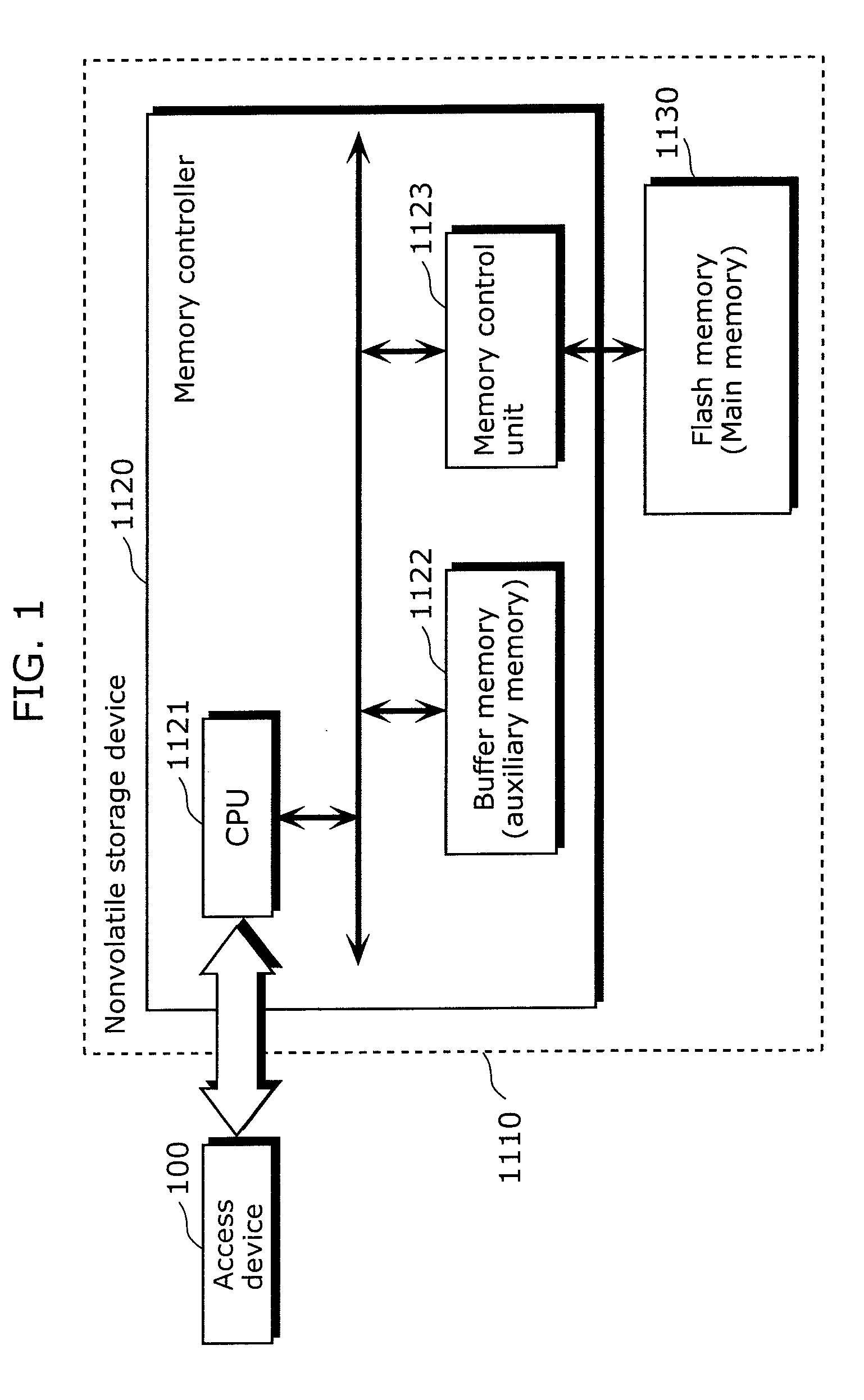

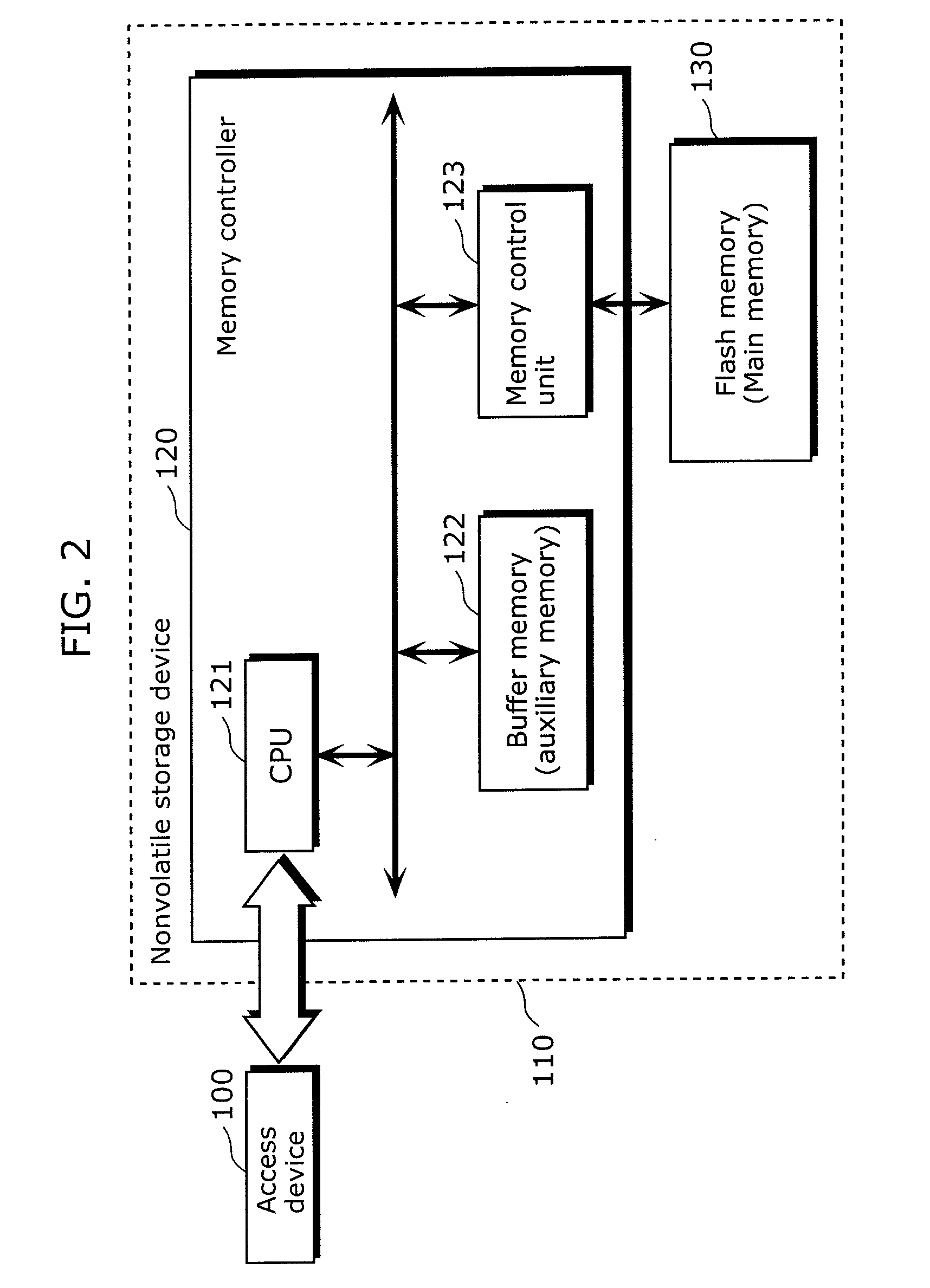

Nonvolatile storage device and data writing method thereof

InactiveUS20070214309A1Operation speed decreaseLong timeMemory architecture accessing/allocationMemory systemsData memoryAuxiliary memory

A nonvolatile storage device according to the invention is a nonvolatile storage device into which data is inputted from an external device on a sector unit, and includes: a main memory which is nonvolatile and in which data is written on a page unit, the page unit being larger than the sector unit; an auxiliary memory which holds at least a single page worth of the input data; a memory judging unit that judges whether or not data held in the auxiliary memory is equal to or larger than data of the page unit; and a memory control unit that writes, in a new page of the main memory on the page unit, the data held in the auxiliary memory when the memory judgment unit judges that the data held in the auxiliary memory is equal to or larger than data of the page unit.

Owner:PANASONIC CORP

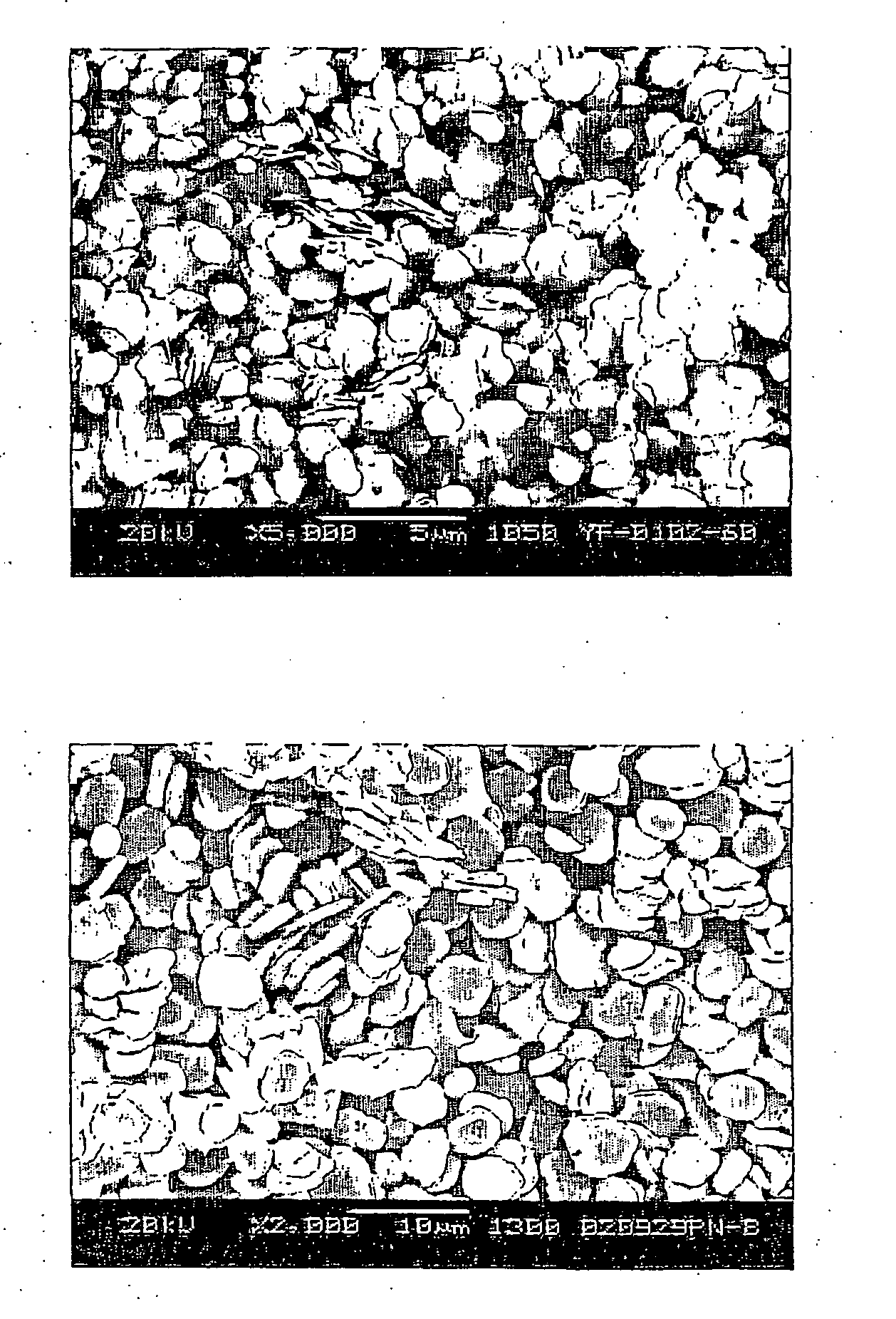

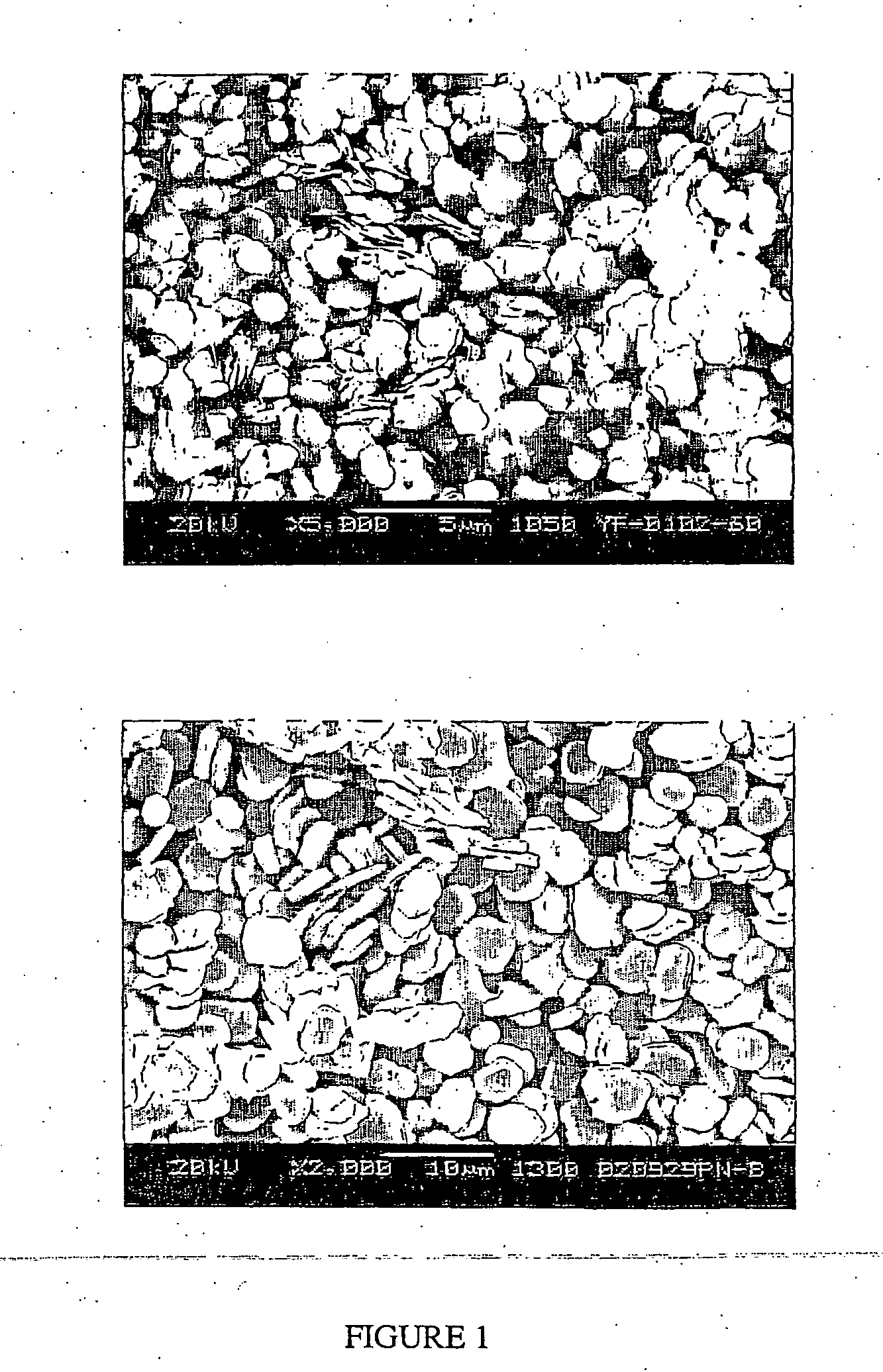

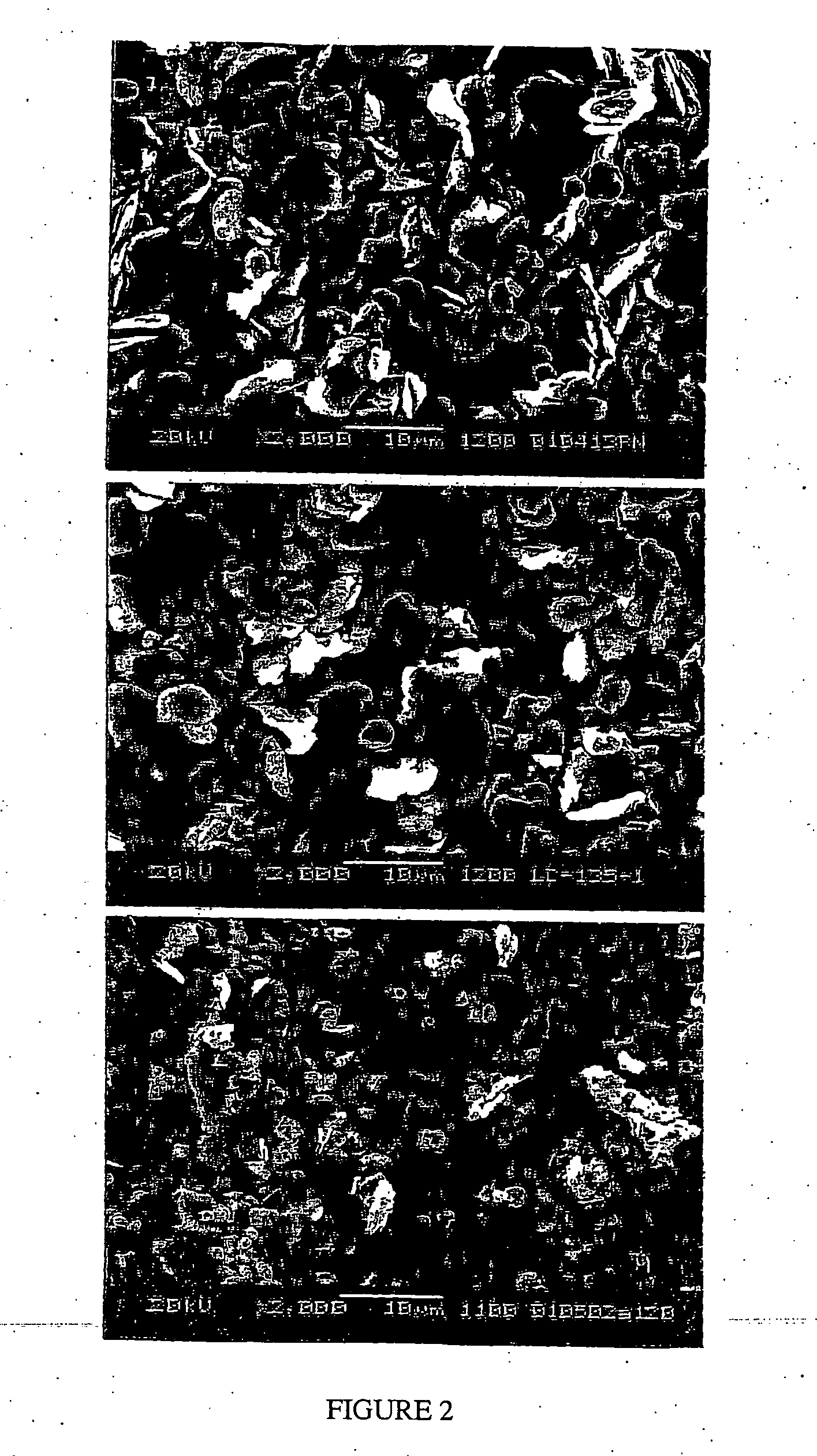

Copper flake powder, method for producing copper flake powder, and conductive paste using copper flake powder

InactiveUS20060137488A1Long timeExcellent performanceTransportation and packagingSemiconductor/solid-state device detailsHigh energyBall mill

The present invention is mainly for providing a flake copper powder for a conductive paste with particle properties which are defined by that the particle thickness is thinner being possible for use to form an electrode or a circuit, and a production process thereof. To achieve the object of producing the following particles, each powder particles shape is plastically processed into a flake-shape, wherein the flake copper powder has a cumulative particle diameter D50 of 10 μm or smaller measured with laser diffraction scattering particle size distribution method. The D10, D50 and D90 measured with the laser diffraction scattering particle size distribution method are illustrative and the SD / D50 value measured by the standard deviation of particle distribution with the laser diffraction scattering particle size distribution, is 0.55 or larger and / or a D90 / D10 of 4.5 or smaller. The flake copper powder is compressed with a high energy ball mill whose media beads having fine particle diameter which plastically deforms the copper particles into flake-shaped particles, so that stable flake copper powder is produced.

Owner:MITSUI MINING & SMELTING CO LTD

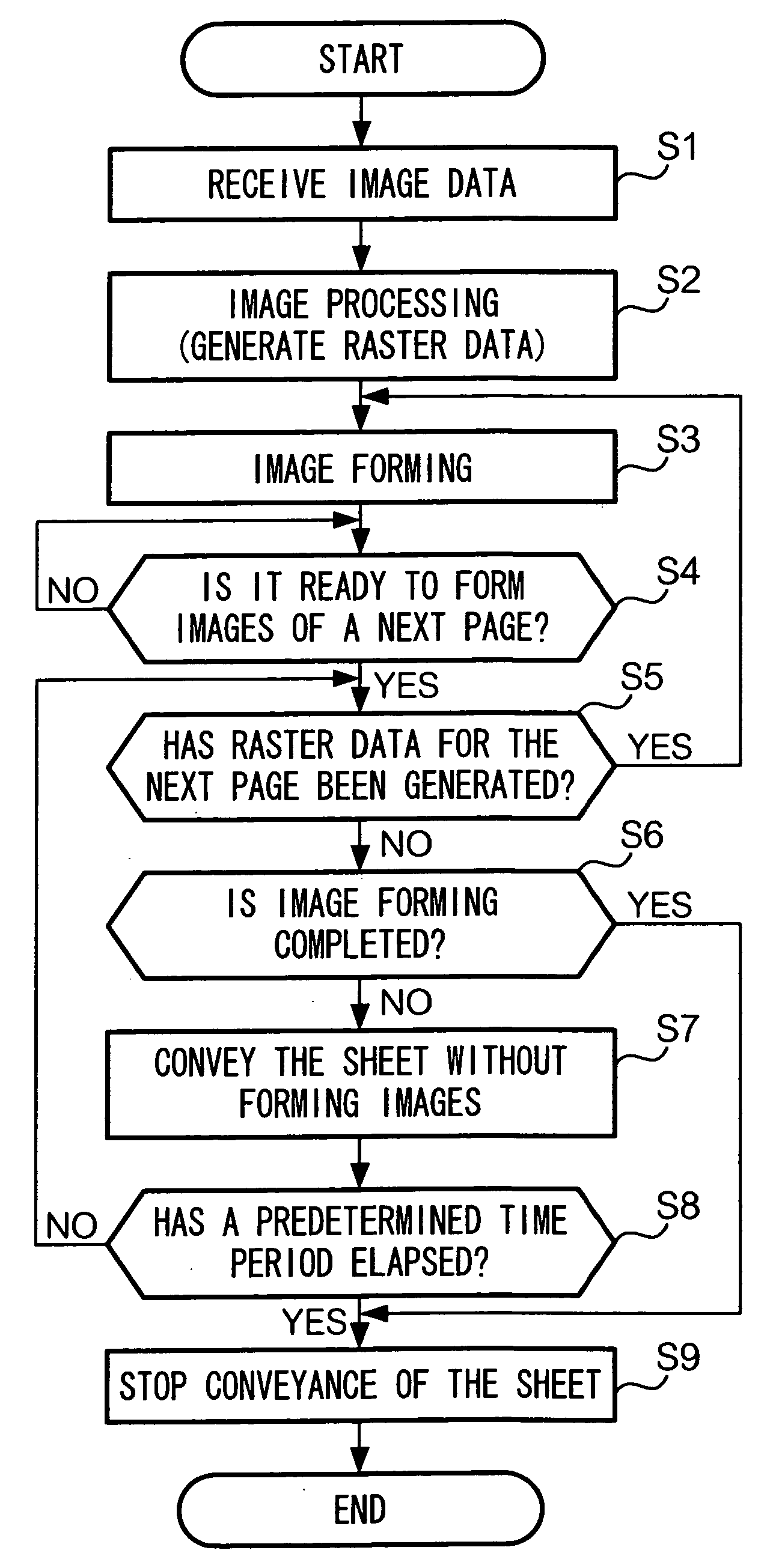

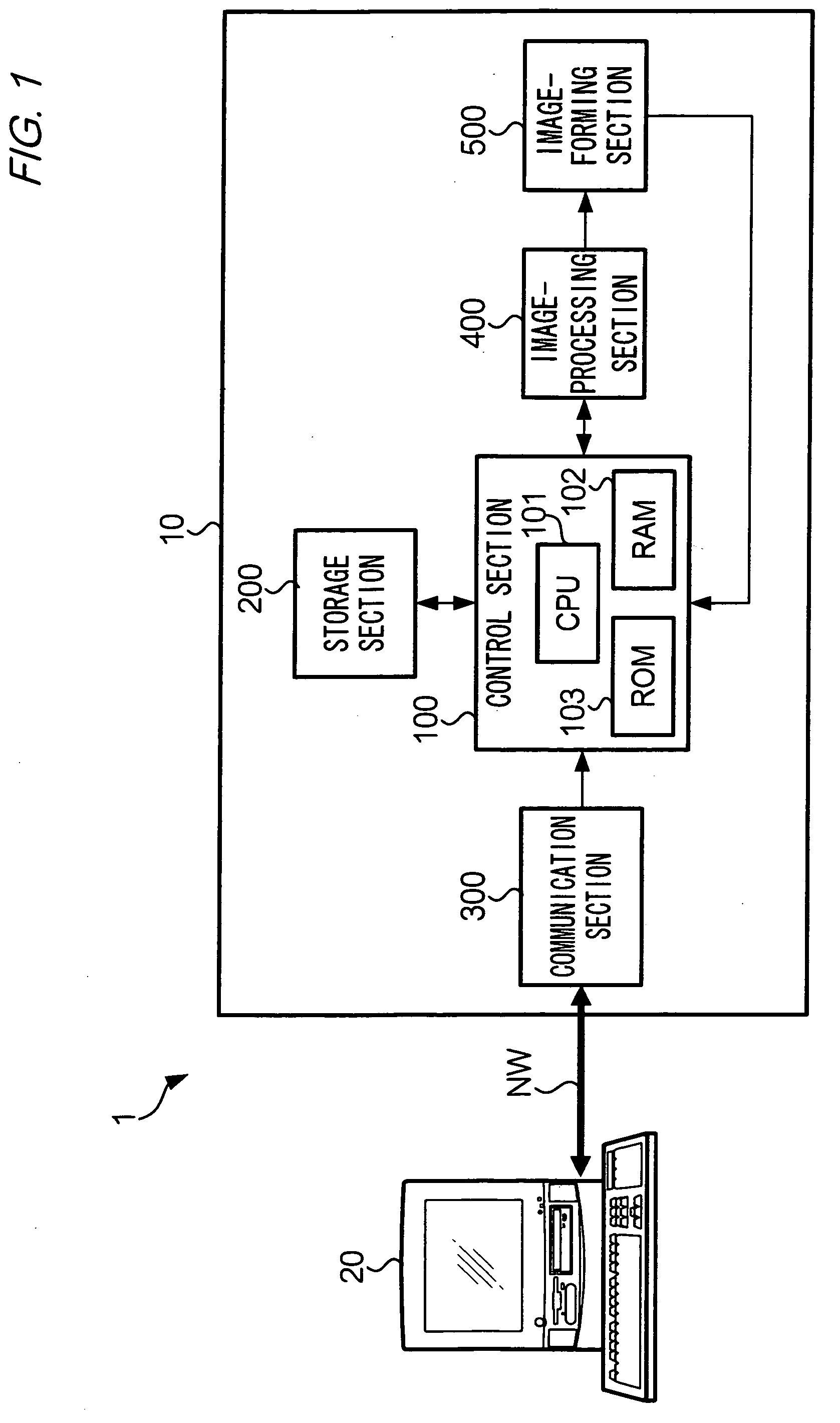

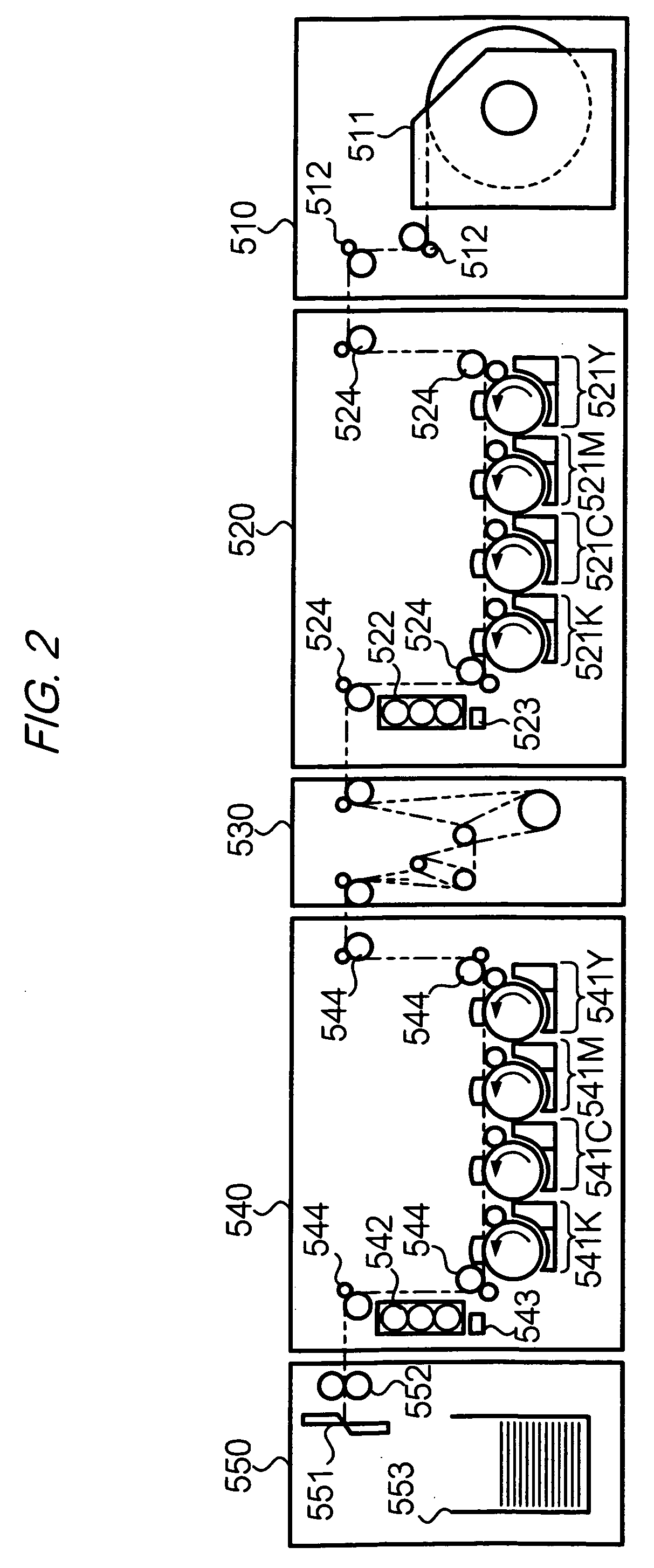

Image-forming apparatus, image-forming method, and recording medium

ActiveUS20080007800A1Lose amountLong timeRecording apparatusDigitally marking record carriersEngineeringElectrical and Electronics engineering

Owner:FUJIFILM BUSINESS INNOVATION CORP

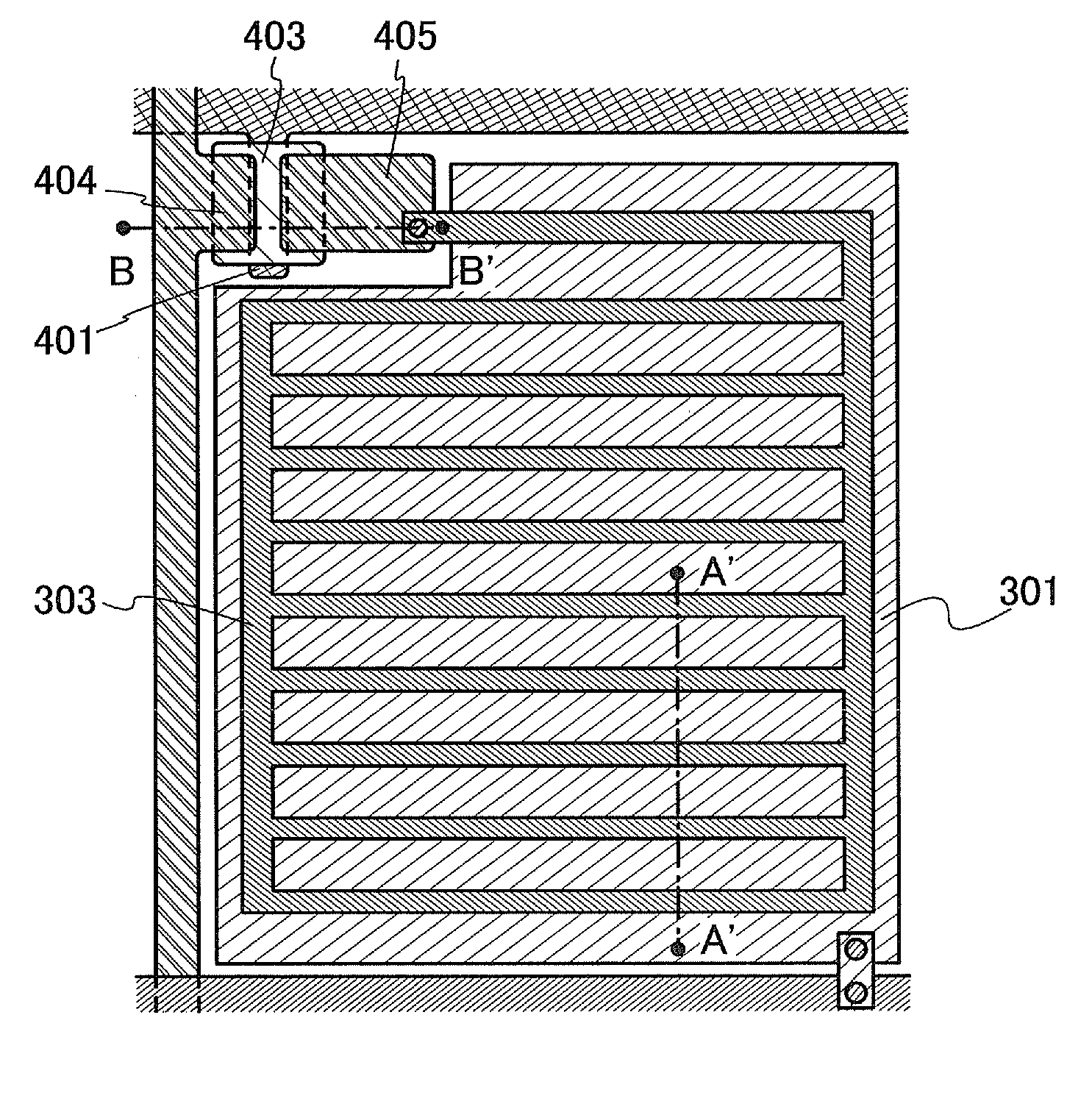

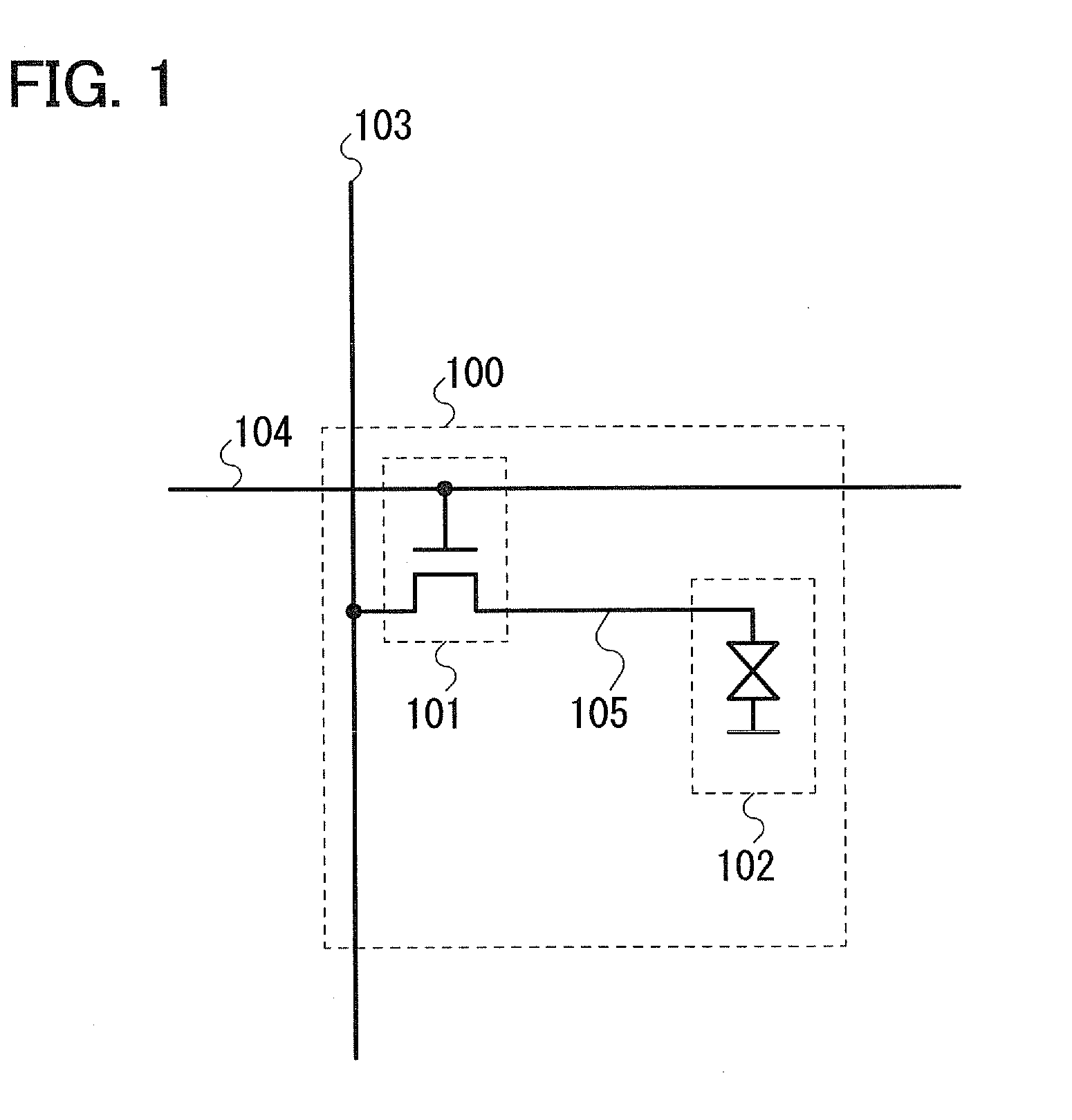

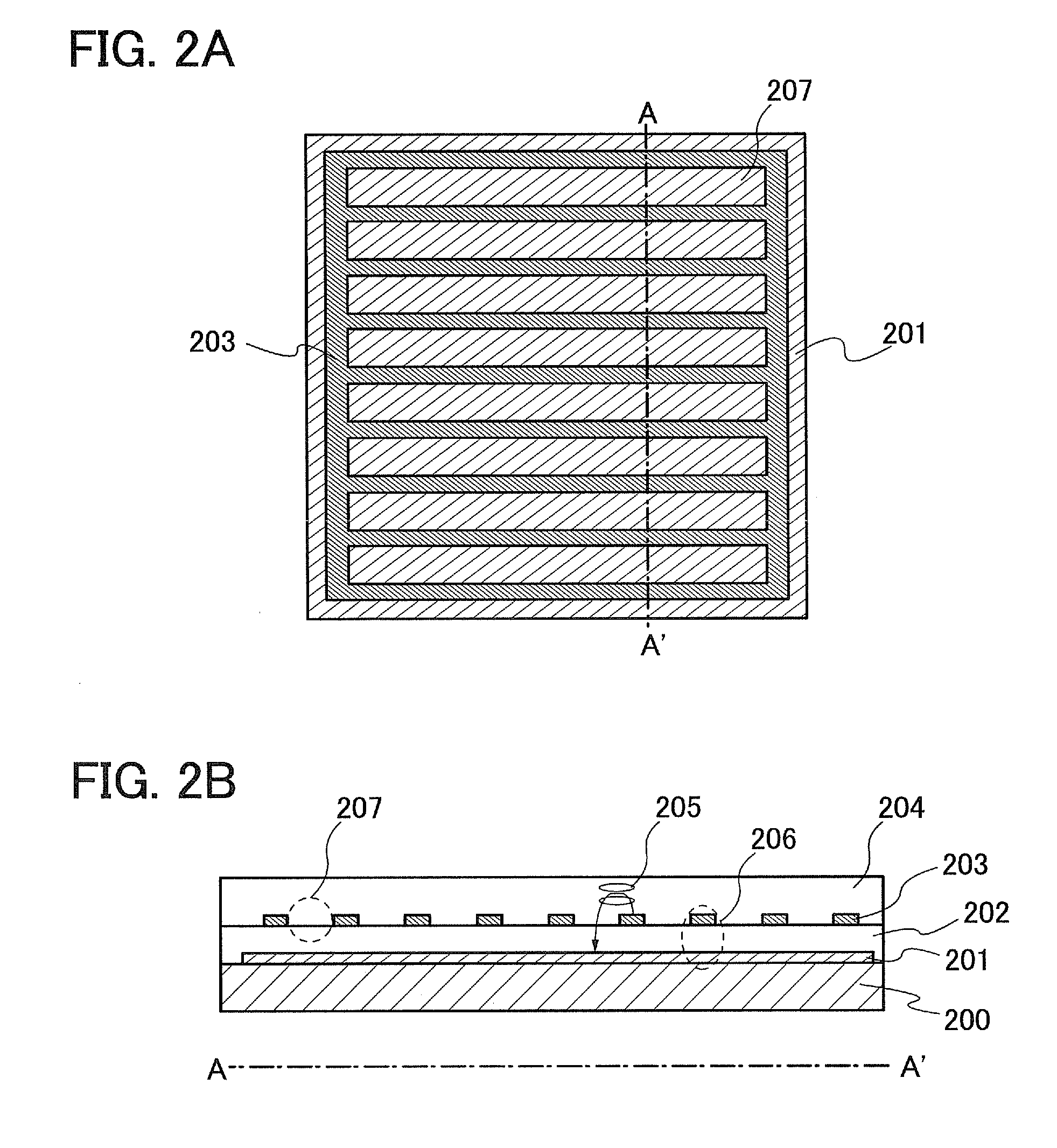

Display device

ActiveUS20110134345A1Long timeReduce carrier densityTelevision system scanning detailsStatic indicating devicesOxide semiconductorLiquid crystal

The time taken to write a signal to a pixel is shortened in a display device. Further, a signal is written at high speed even when high voltage is applied. The display device includes a pixel including a transistor and a liquid crystal element electrically connected to a source or a drain of the transistor. The transistor includes an intrinsic or substantially intrinsic oxide semiconductor as a semiconductor material and has an off-state current of 1×10−17 A / μm or less. The pixel does not include a capacitor. Since it is not necessary to provide a capacitor, the time taken to write a signal can be shortened.

Owner:SEMICON ENERGY LAB CO LTD

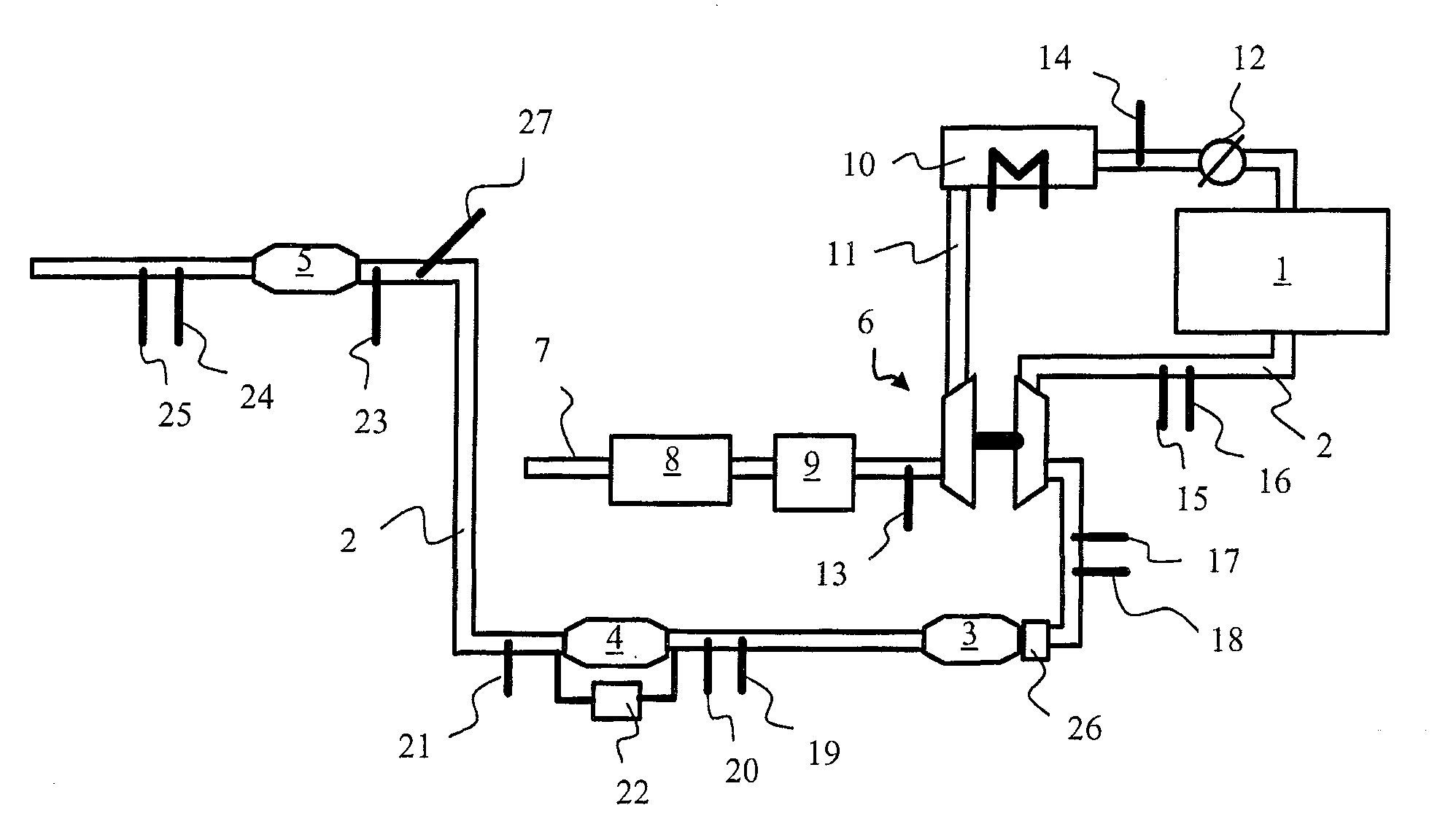

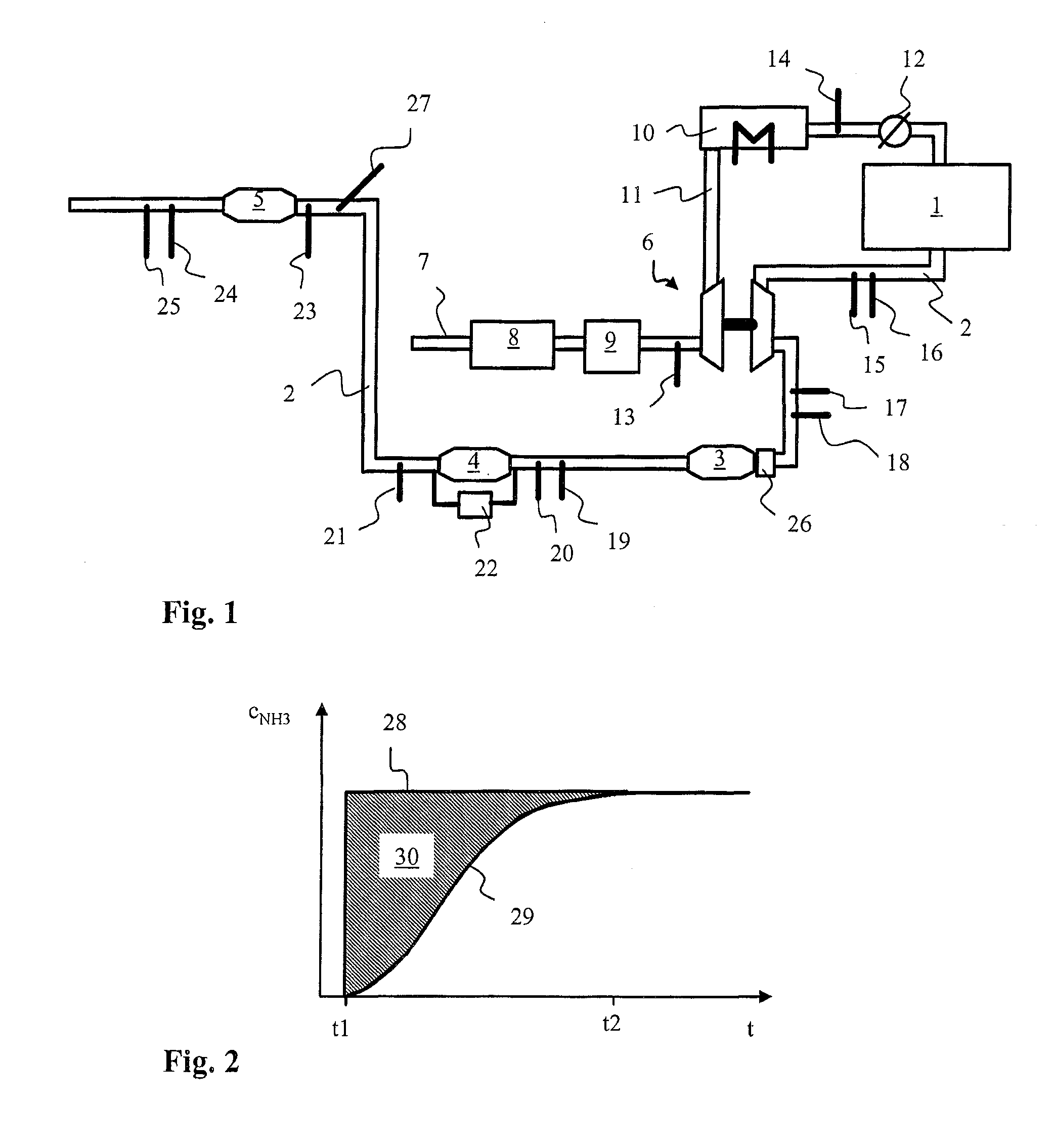

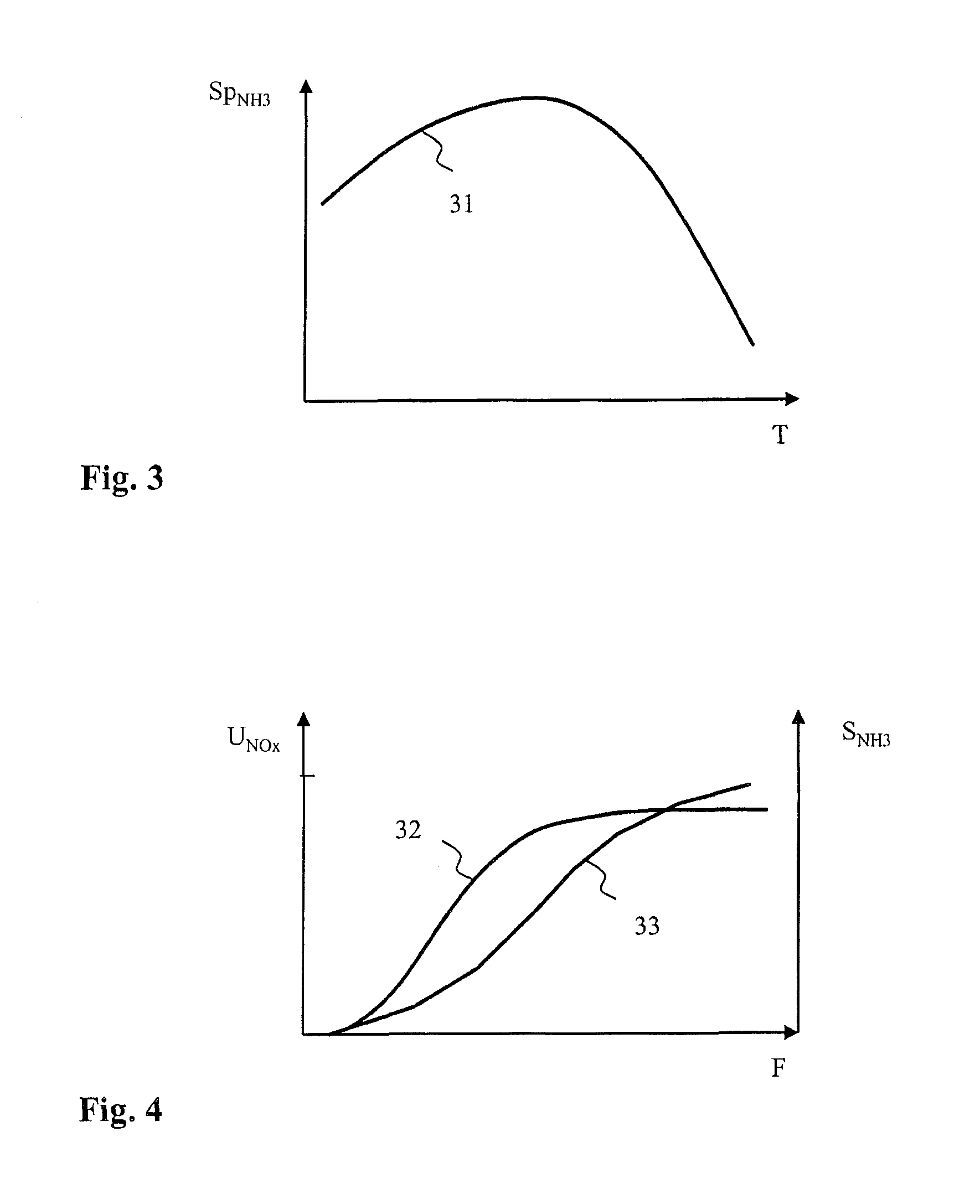

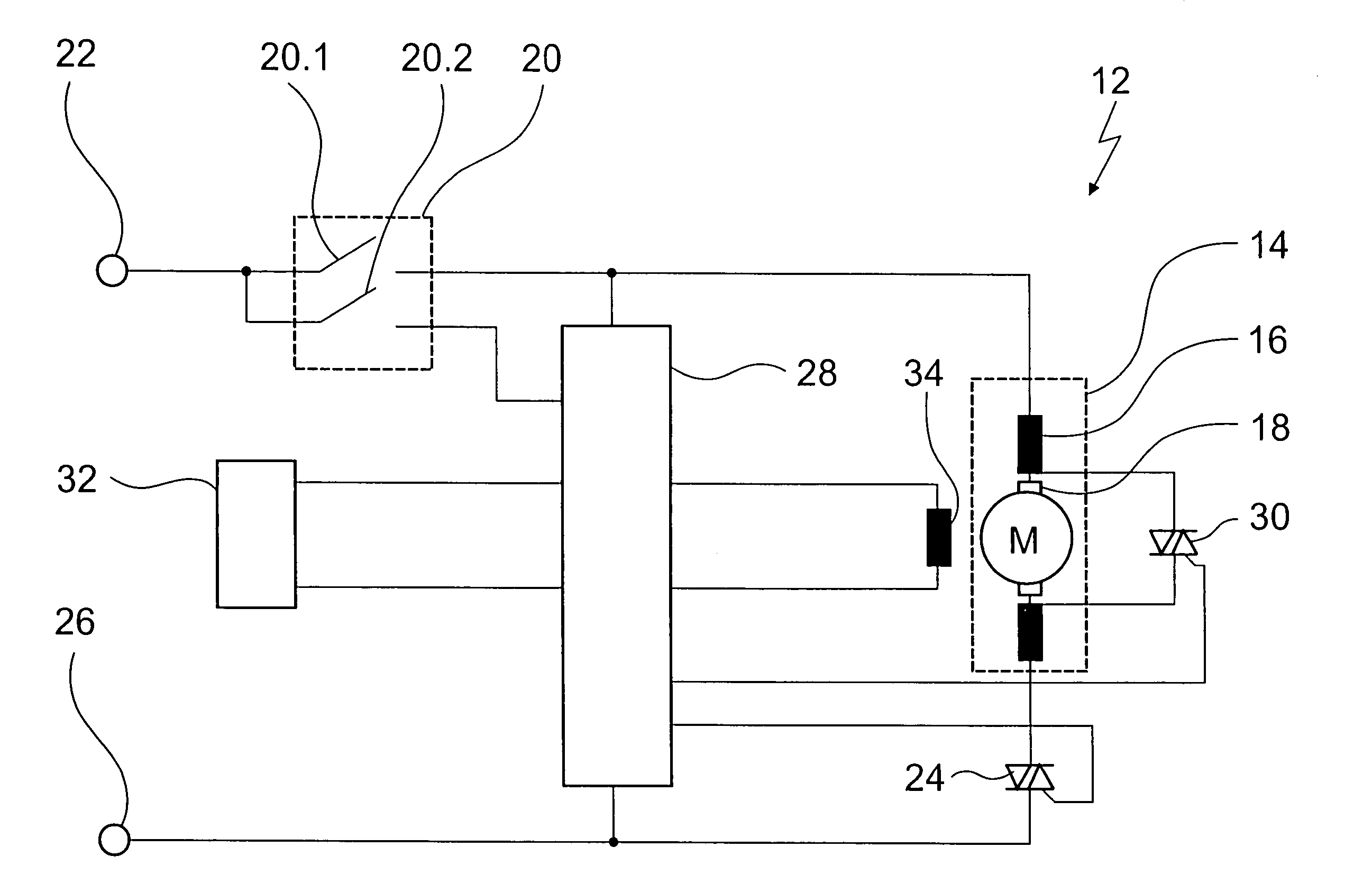

Method for Operating an Exhaust Gas Treatment System Having an SCR Catalytic Converter

ActiveUS20110113753A1Long timeReduce cleaningGas treatmentInternal combustion piston enginesOperating variablesProcess engineering

Owner:DAIMLER AG

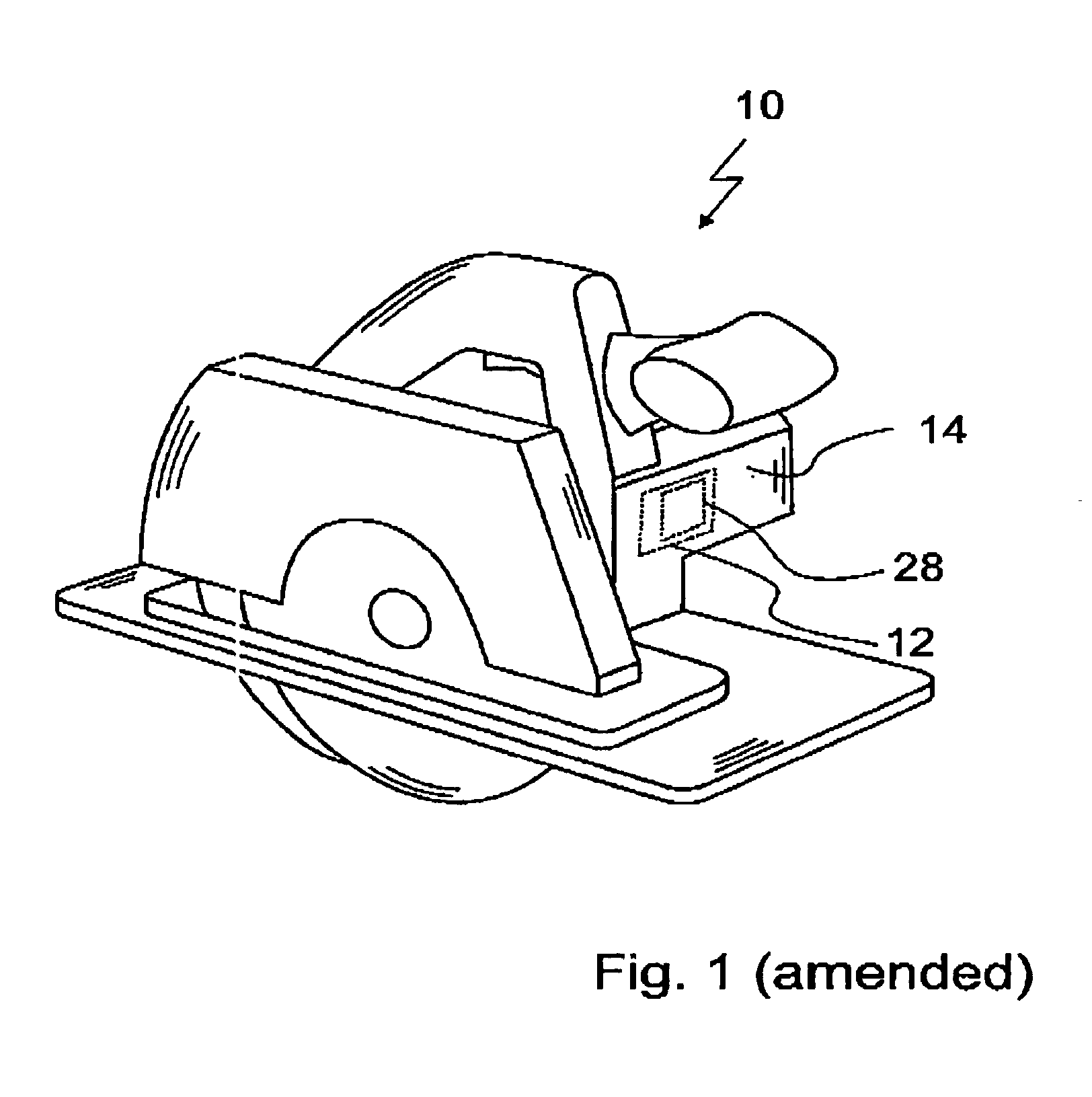

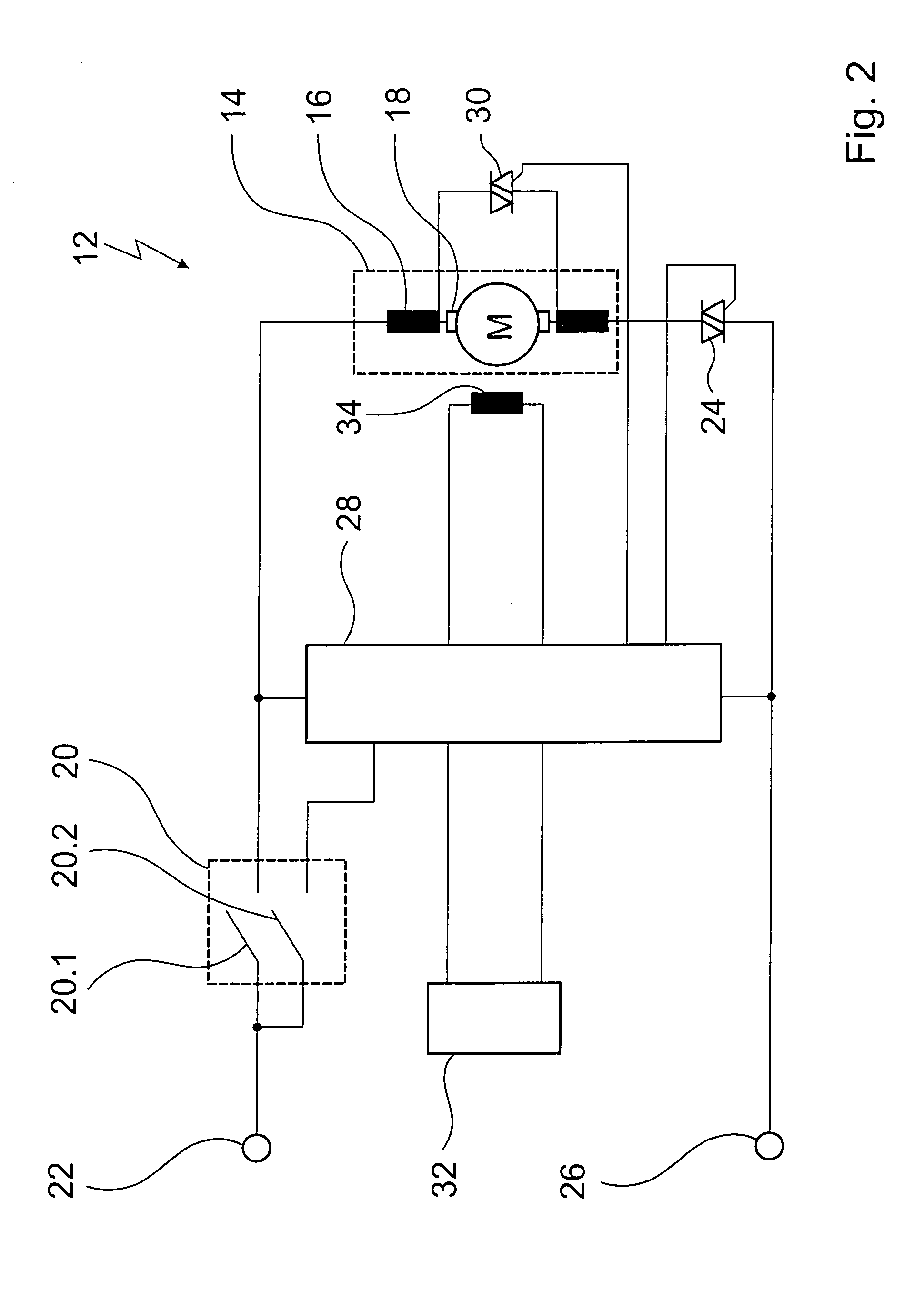

Braking device for an electric motor, electrical apparatus provided with the braking device, and a method of braking

ActiveUS7071645B2Danger be increaseLong timeElectric motor controlDc motor stoppersPower toolPhase control

A braking device for an electric motor of a power tool has a short circuit switch for short circuiting an armature winding of the electric motor during a braking process, the short circuit switch for controlling its switch condition having a control input, a control unit connected with the control input of the short circuit switch for performing a phase control of the short circuit switching during the braking process in order to avoid brush fire; also an electrical device with such a braking device and a braking method are proposed as well.

Owner:ROBERT BOSCH GMBH

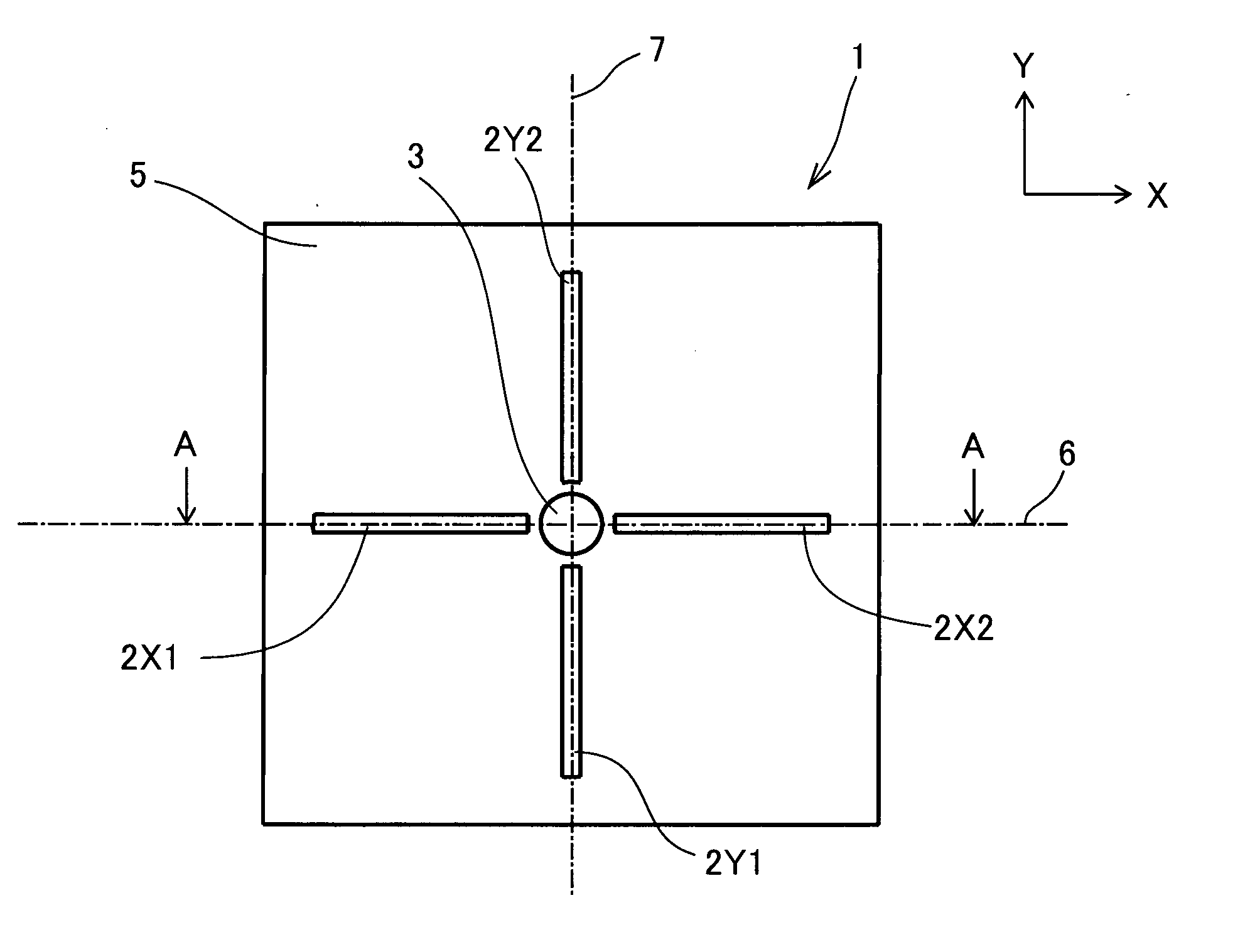

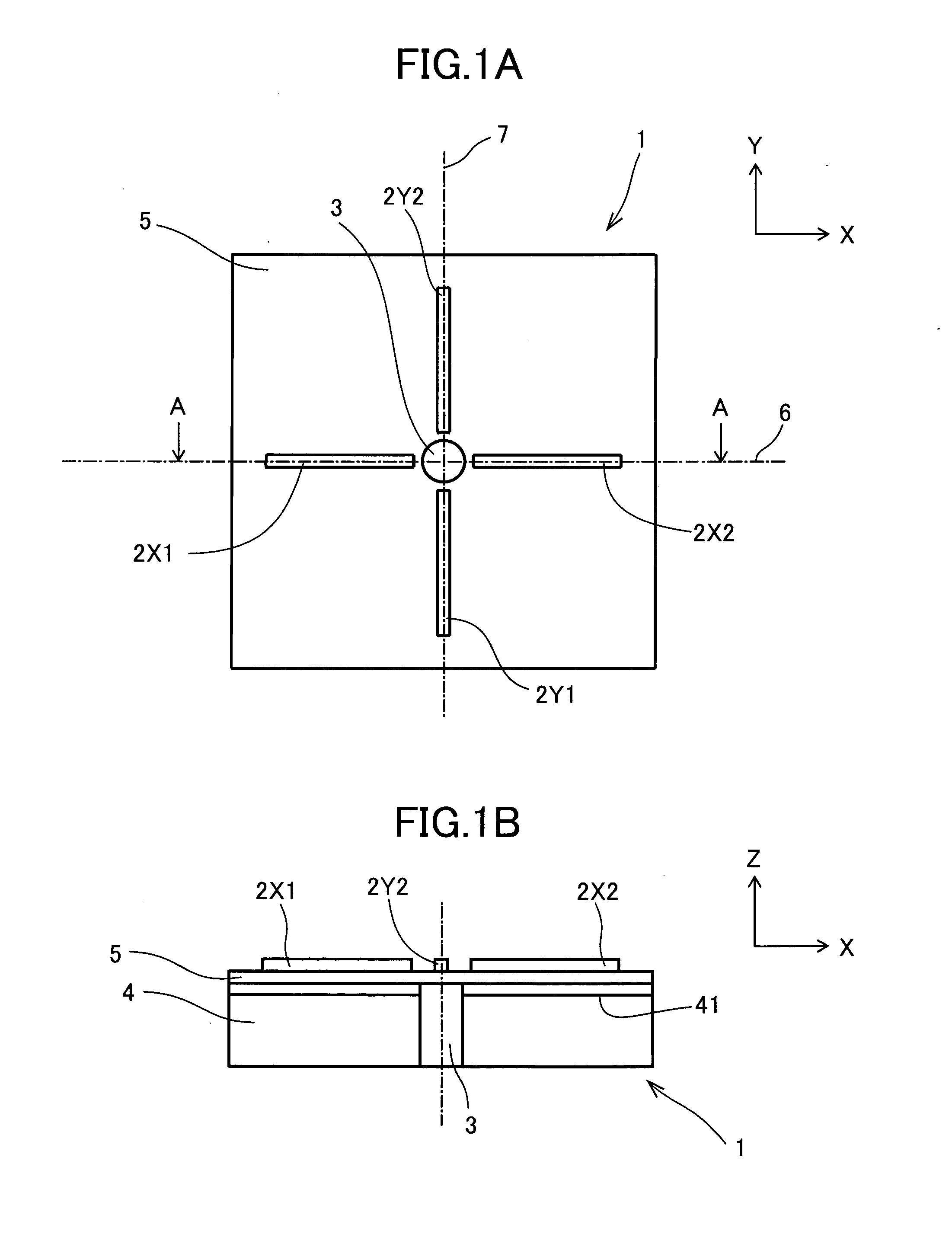

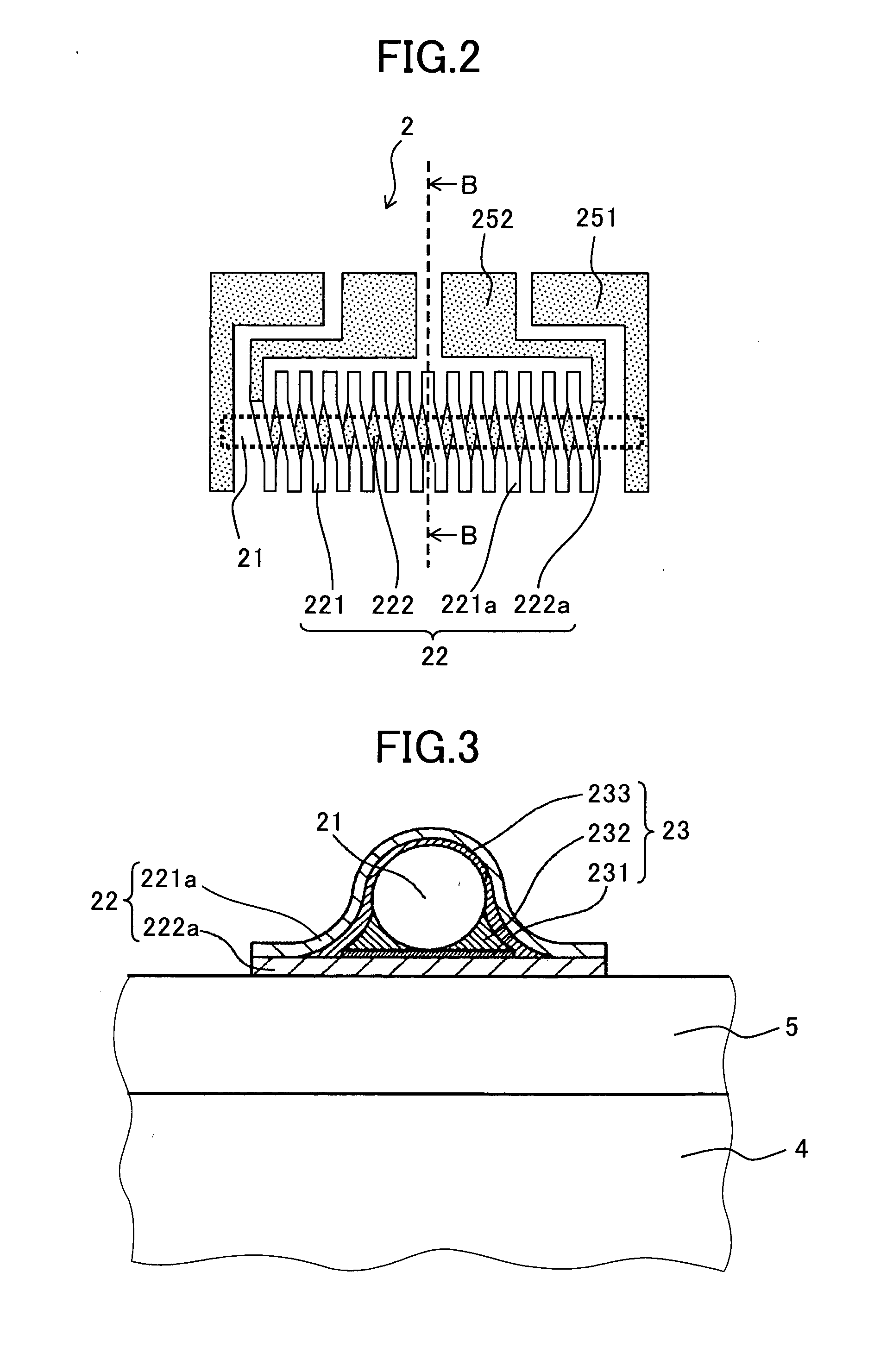

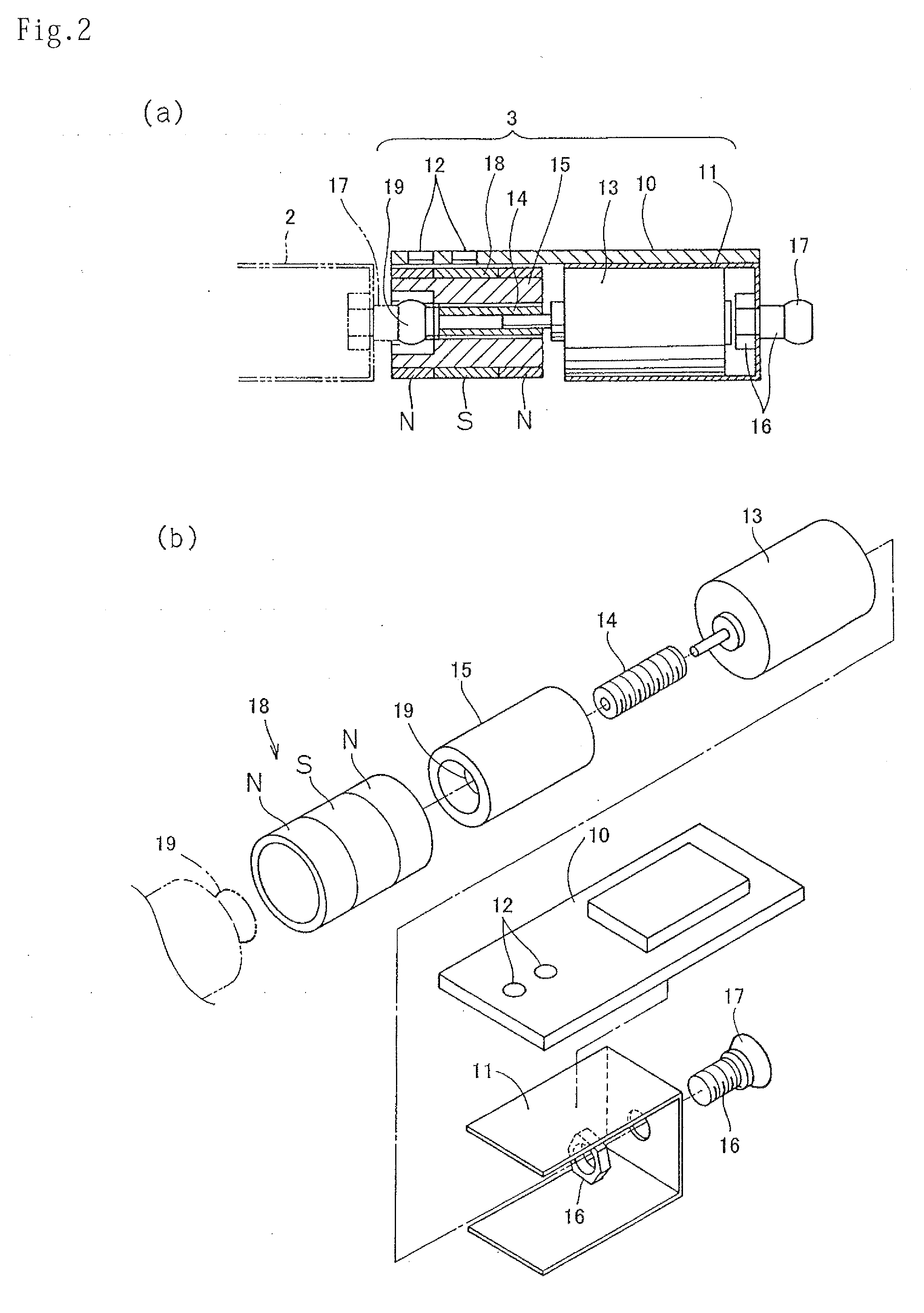

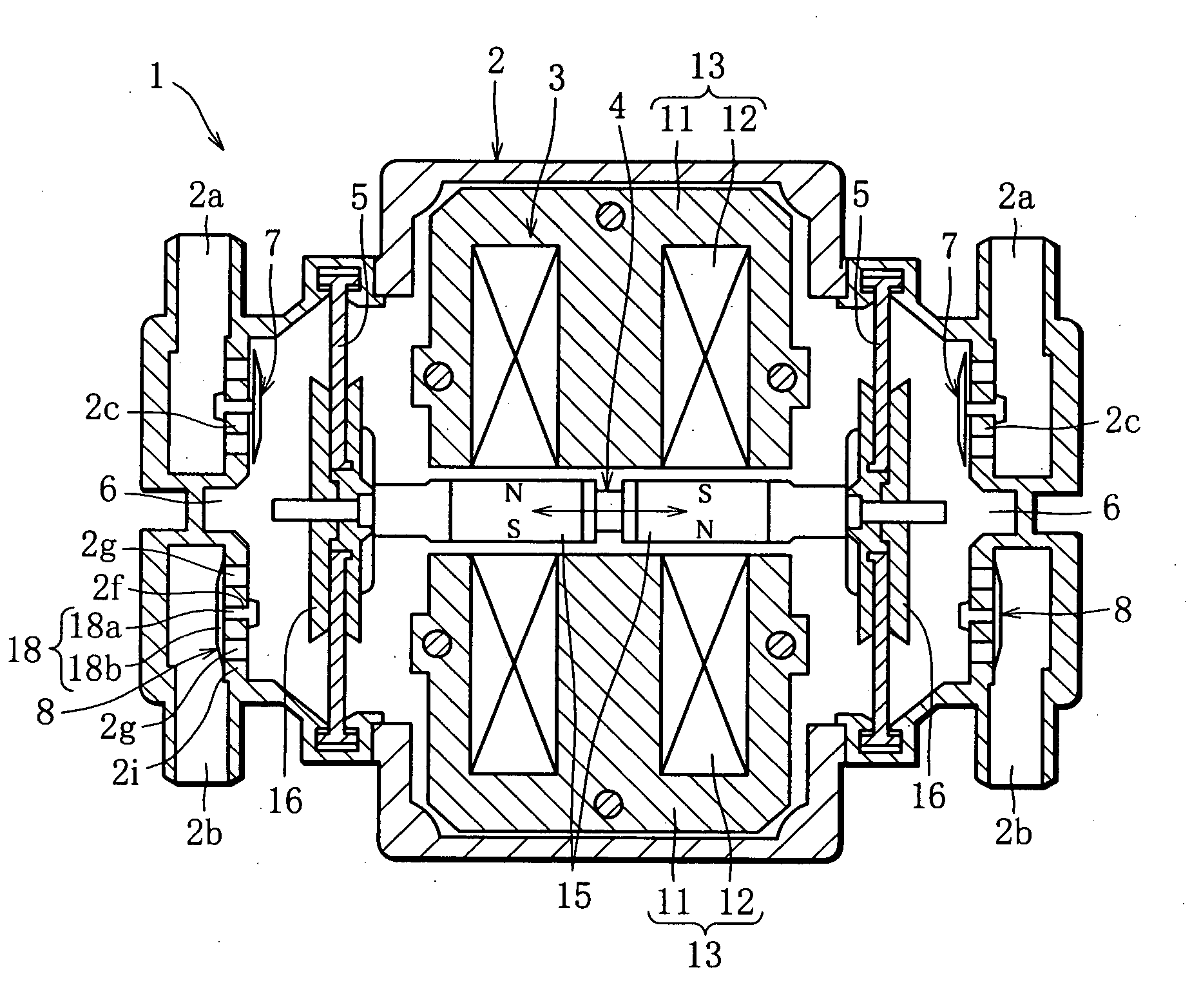

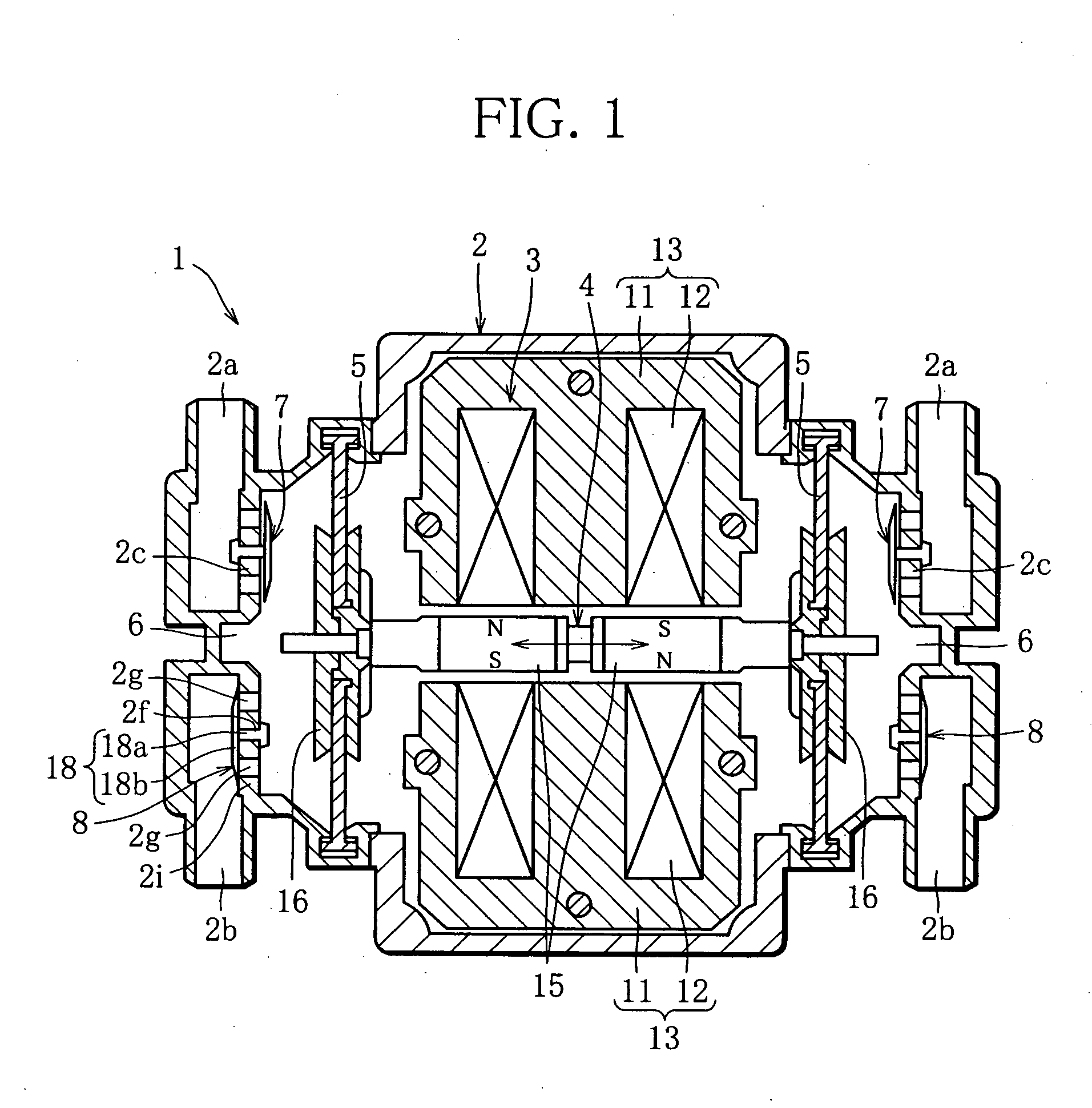

Magnetic detection device

ActiveUS20120013332A1Reduce in sizeLong timeElectric/magnetic detectionThree-component magnetometersNuclear magnetic resonanceMagnetic orientation

A magnetic detection device of the present invention includes at least one pair of first magnetosensitive bodies each comprising a soft magnetic material extending in a first axis direction and being sensitive to an external magnetic field oriented in the first axis direction; and a magnetic field direction changer comprising a soft magnetic material and changing an external magnetic field oriented in a different axis direction from the first axis direction into a measurement magnetic field having a component in the first axis direction which can be detected by the at least one pair of first magnetosensitive bodies. With this magnetic detection device, the external magnetic field oriented in the different axis direction can be detected by way of the first magnetosensitive bodies. As a result, while attaining magnetic detection with high accuracy, the magnetic detection device can be reduced in size or thickness by omitting a magnetosensitive body extending long in the different axis direction.

Owner:AICHI STEEL

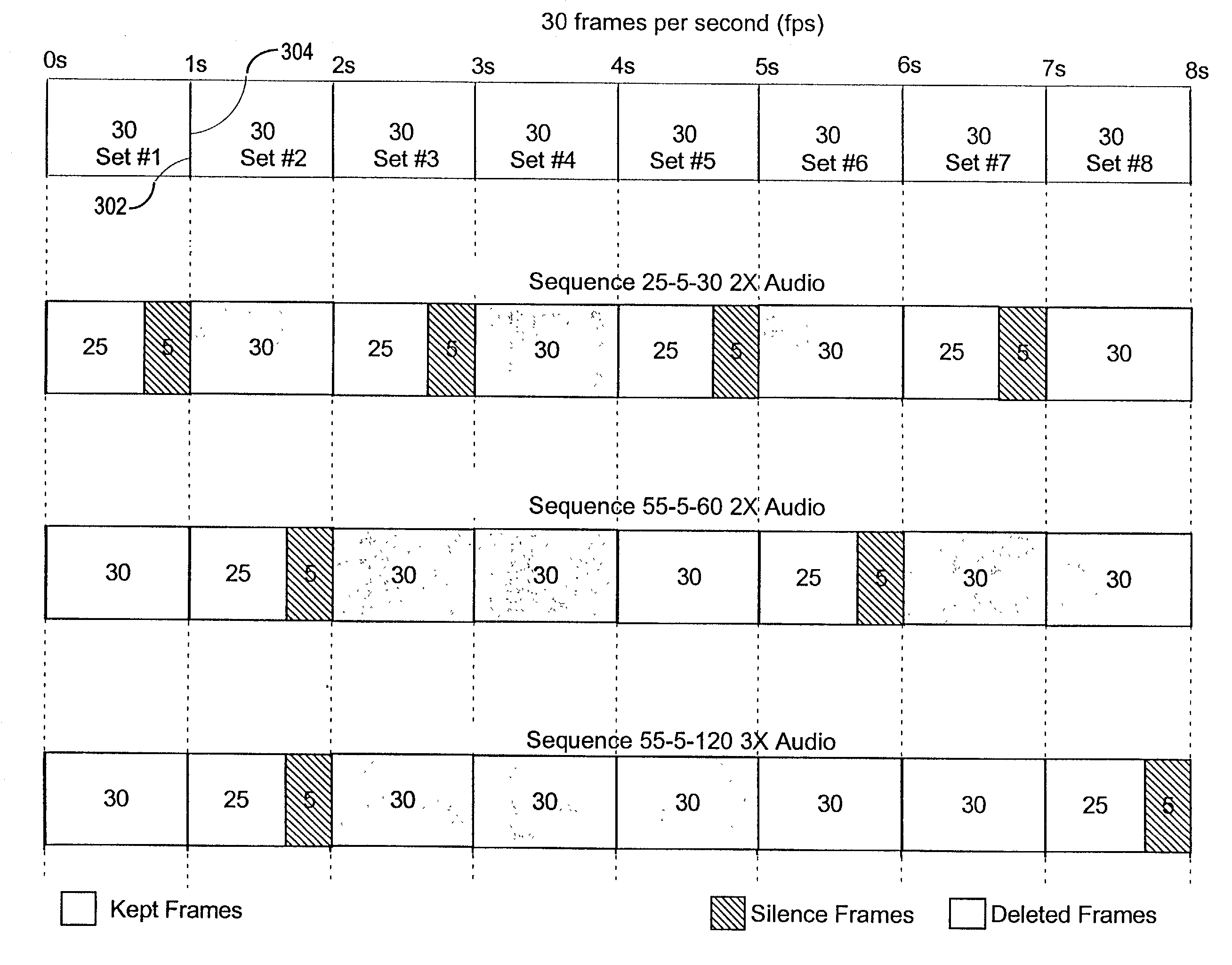

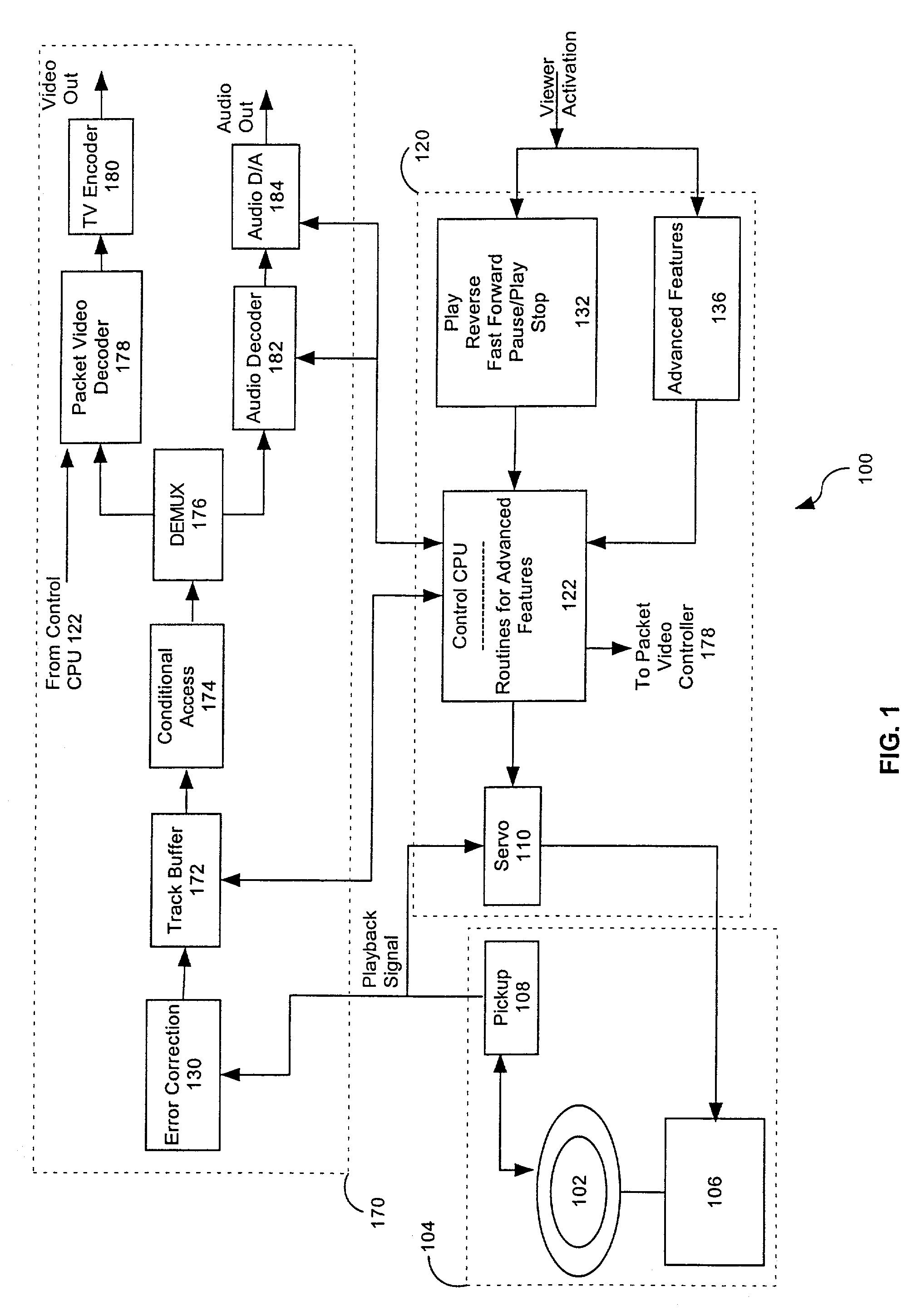

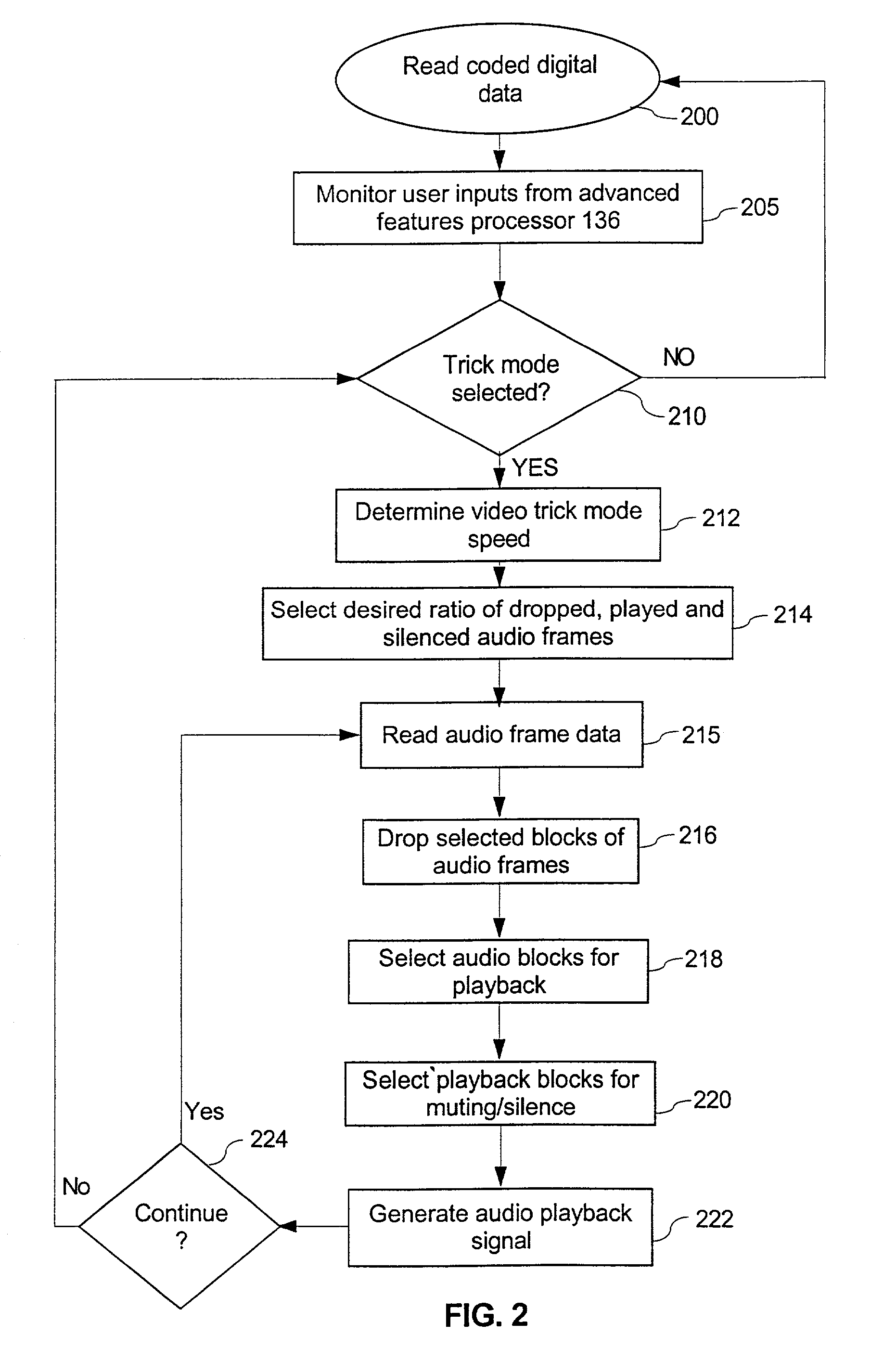

Audio data deletion and silencing during trick mode replay

ActiveUS7130528B2Enhance intelligibilityLong timeTelevision system detailsColor television detailsDigital dataAudio frequency

The invention concerns a method and apparatus for audio program playback during fast forward playback video trick modes. A storage medium reader can be configured to read coded digital data from a storage medium such as a DVD. The coded digital data can be a video presentation having correspondingly formatted video and audio frames. An audio processor can insert silence frames in a selected block of the audio frames and portions of the audio frames can be deleted to compensate for video trick mode playback. Resulting audio frames can be concatenated to create 1× audio for various video trick modes playback.

Owner:THOMSON LICENSING SA

Method and device for estimating remaining capacity of battery

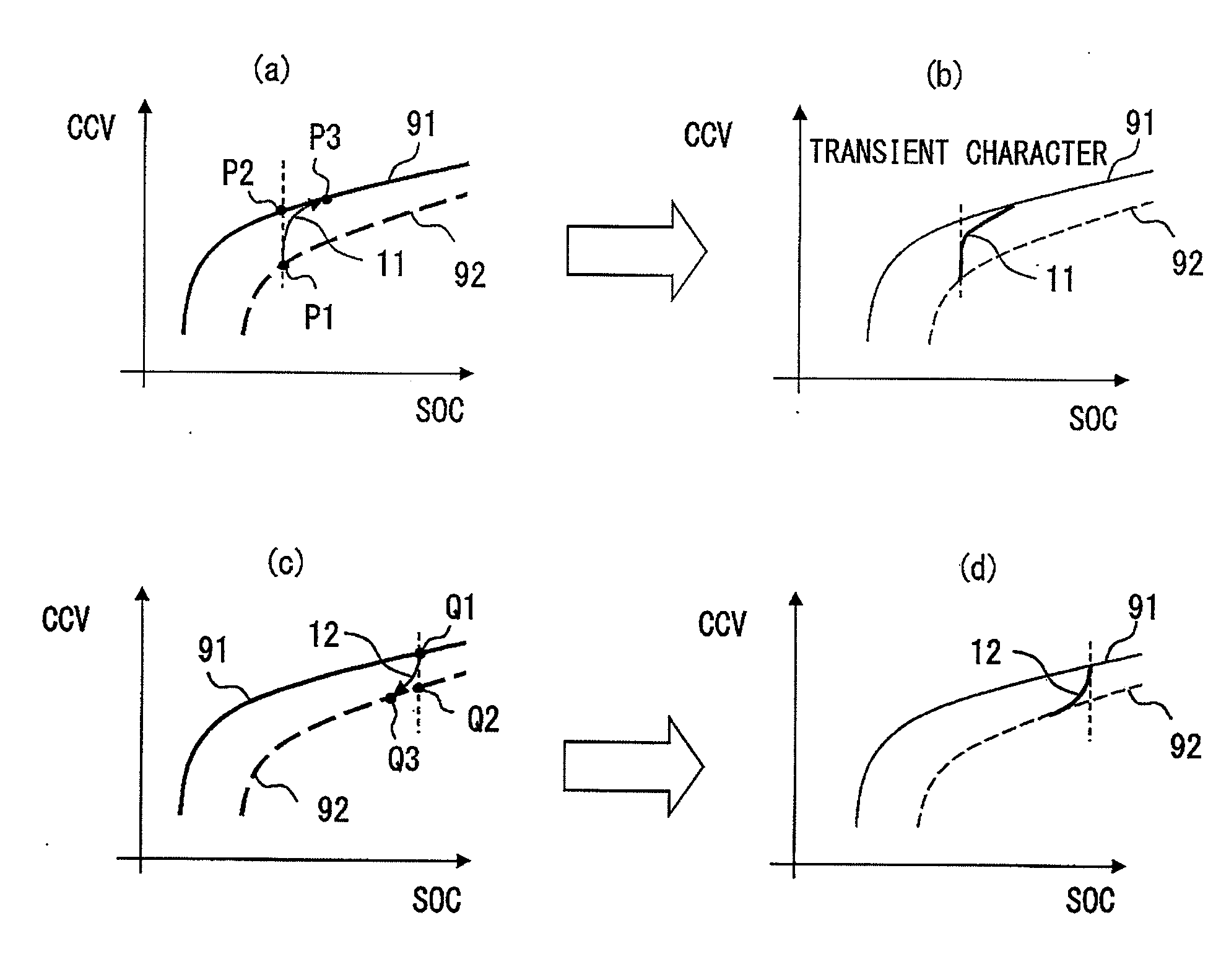

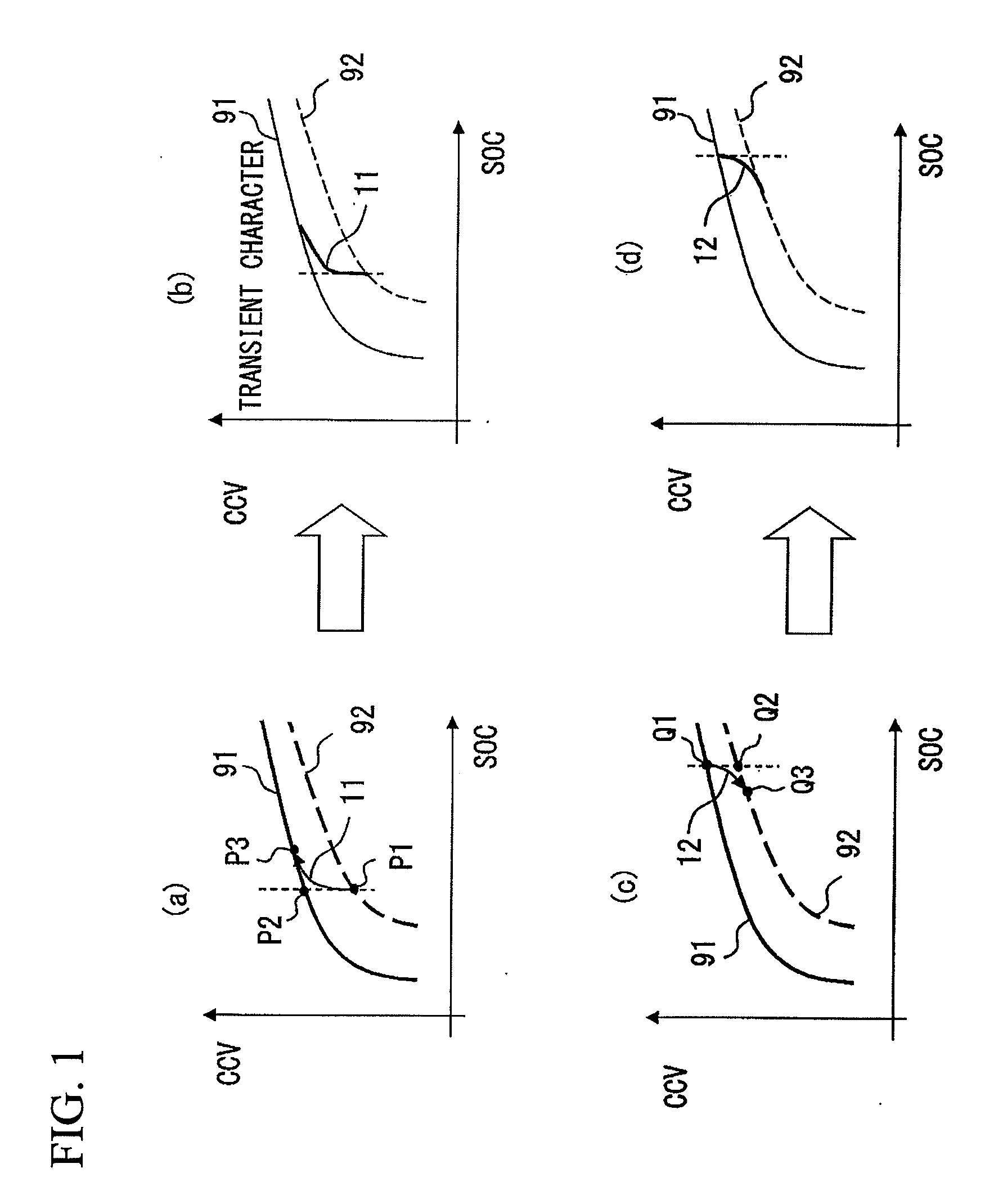

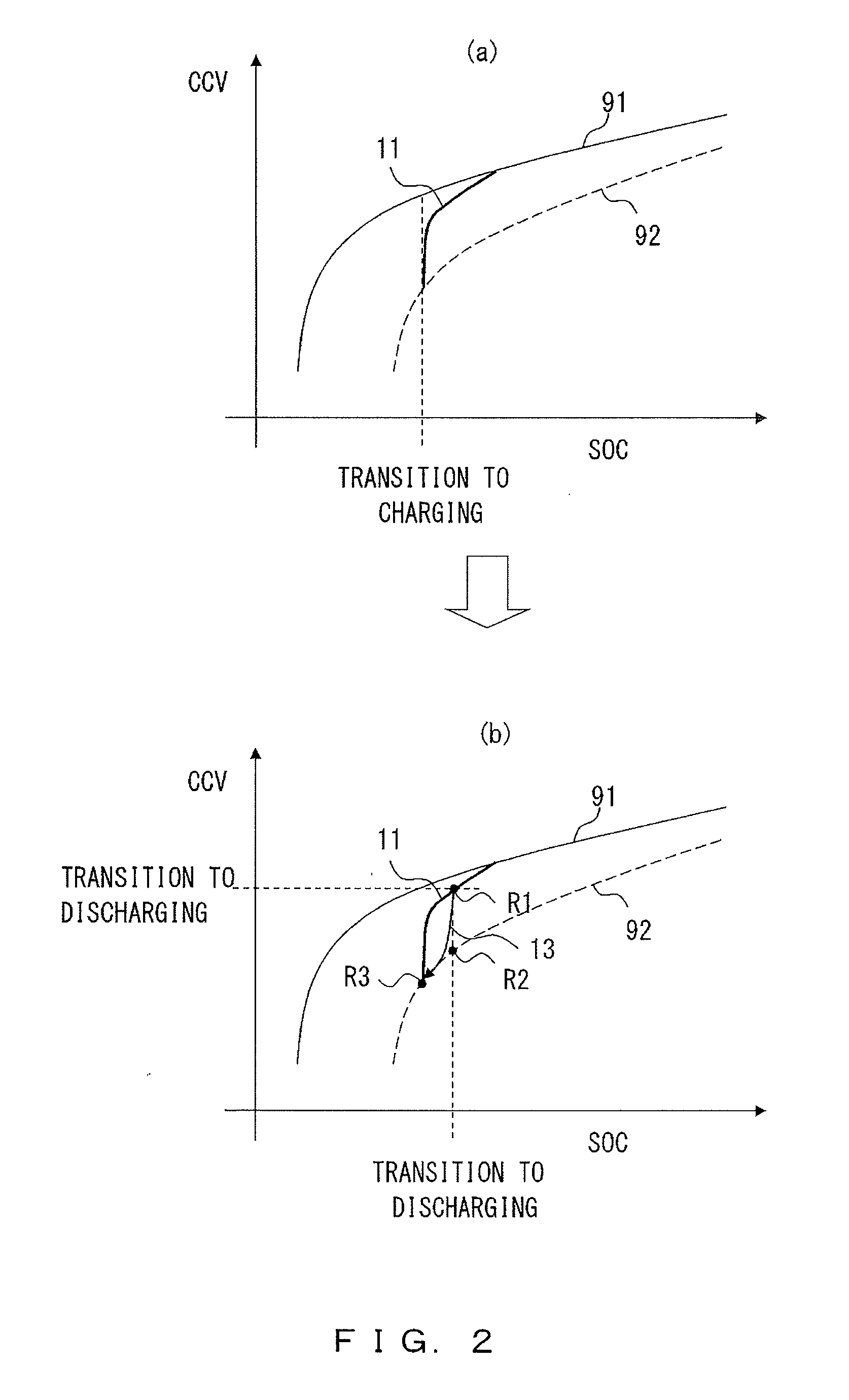

ActiveUS20150369869A1Long timeHighly accurately estimateCircuit monitoring/indicationMaterial analysis by electric/magnetic meansCharge and dischargeClosed circuit

A method and a device are provided for estimating a remaining capacity of a battery. Transient characteristics are generated that represent a correlation between the remaining capacity and a closed circuit voltage, the correlation transitioning from one of a charging-side and a discharging-side characteristic to the other when the charging / discharging of the battery has been switched, on the basis of map data of a charging-side characteristic that is only conducted from a fully-discharged to a fully-charged state and a discharging-side characteristic that is only conducted from the fully-charged to the fully-discharged state, the characteristics representing a correlation between the remaining capacity and the Closed Circuit Voltage of the battery. When charging and discharging of the battery have been switched, the remaining capacity of the battery is estimated from the Closed Circuit Voltage of the battery by using the transient characteristics until polarization of the battery enters a saturated state.

Owner:TOYOTA IND CORP

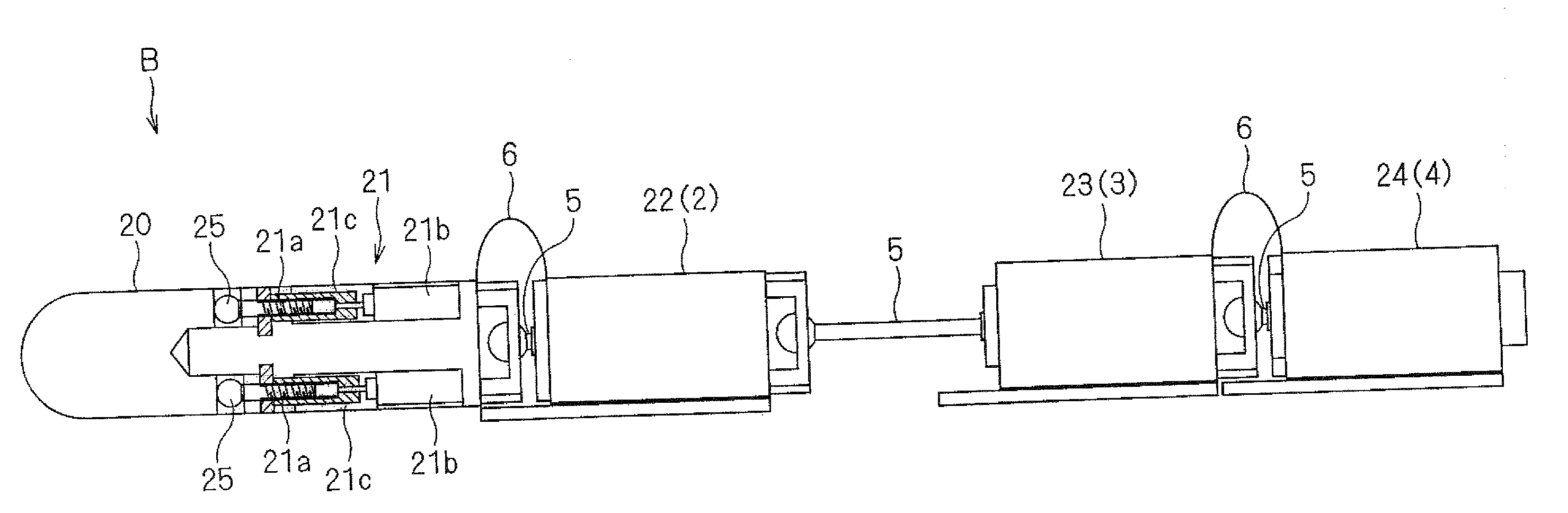

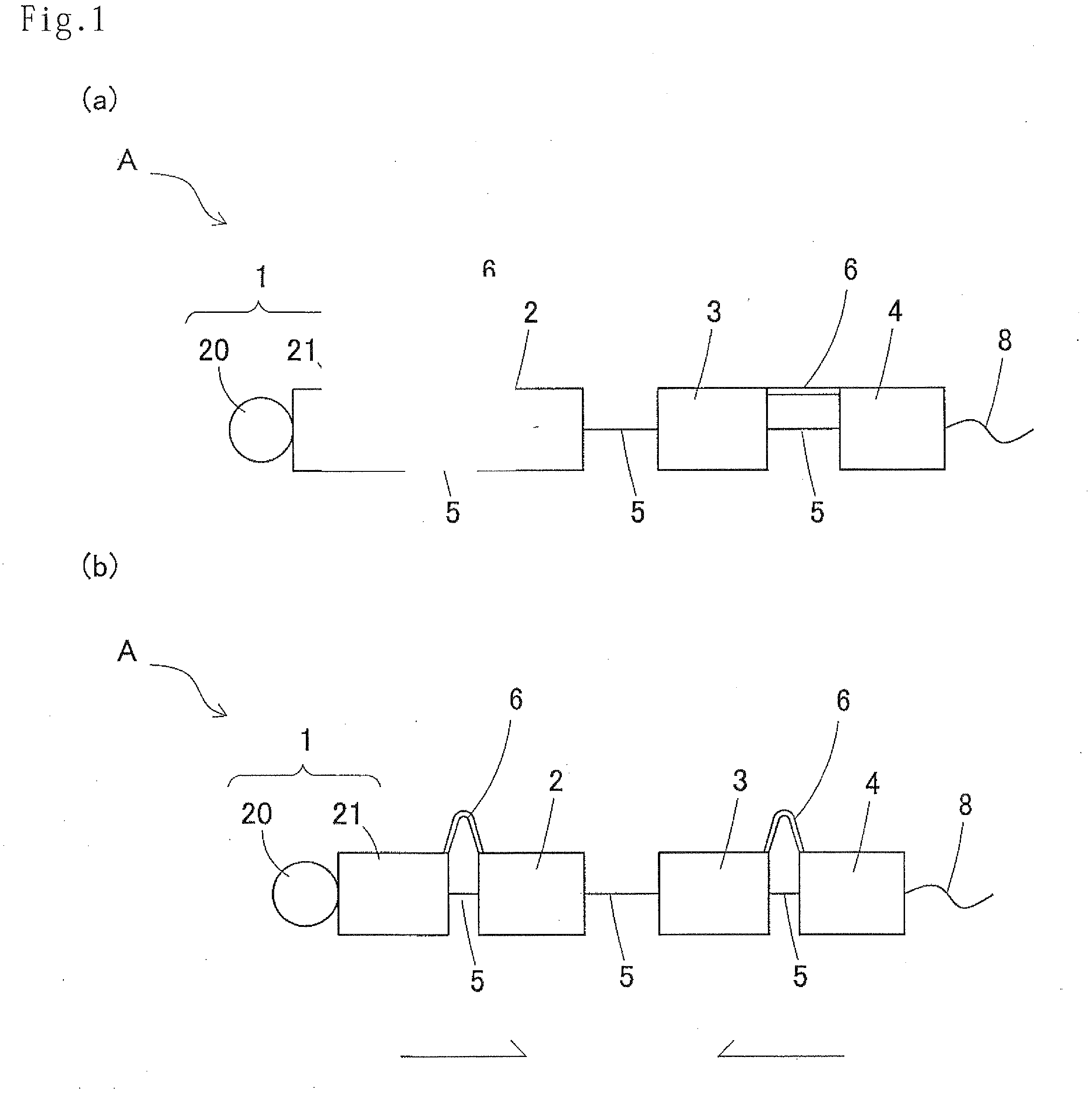

Moving device in a pipe line

A moving device in a pipeline, including: more than three segments, including a front segment, arranged in series; an extendable interconnecting element to connect adjacent segments; and an engaging force changing component to change engaging force of a segment that is to be moved with the inside of the pipeline to a smaller force, smaller than the engaging force of a remaining segment with the inside of the pipeline. The front segment has a head part, a body part, a joint part to turn the head part centering around the body part, and a drive unit to move the head part around the body part. The drive unit have a magnet provided in the head part and an electromagnet provided in the body part.

Owner:HI-LEX CORPORATION

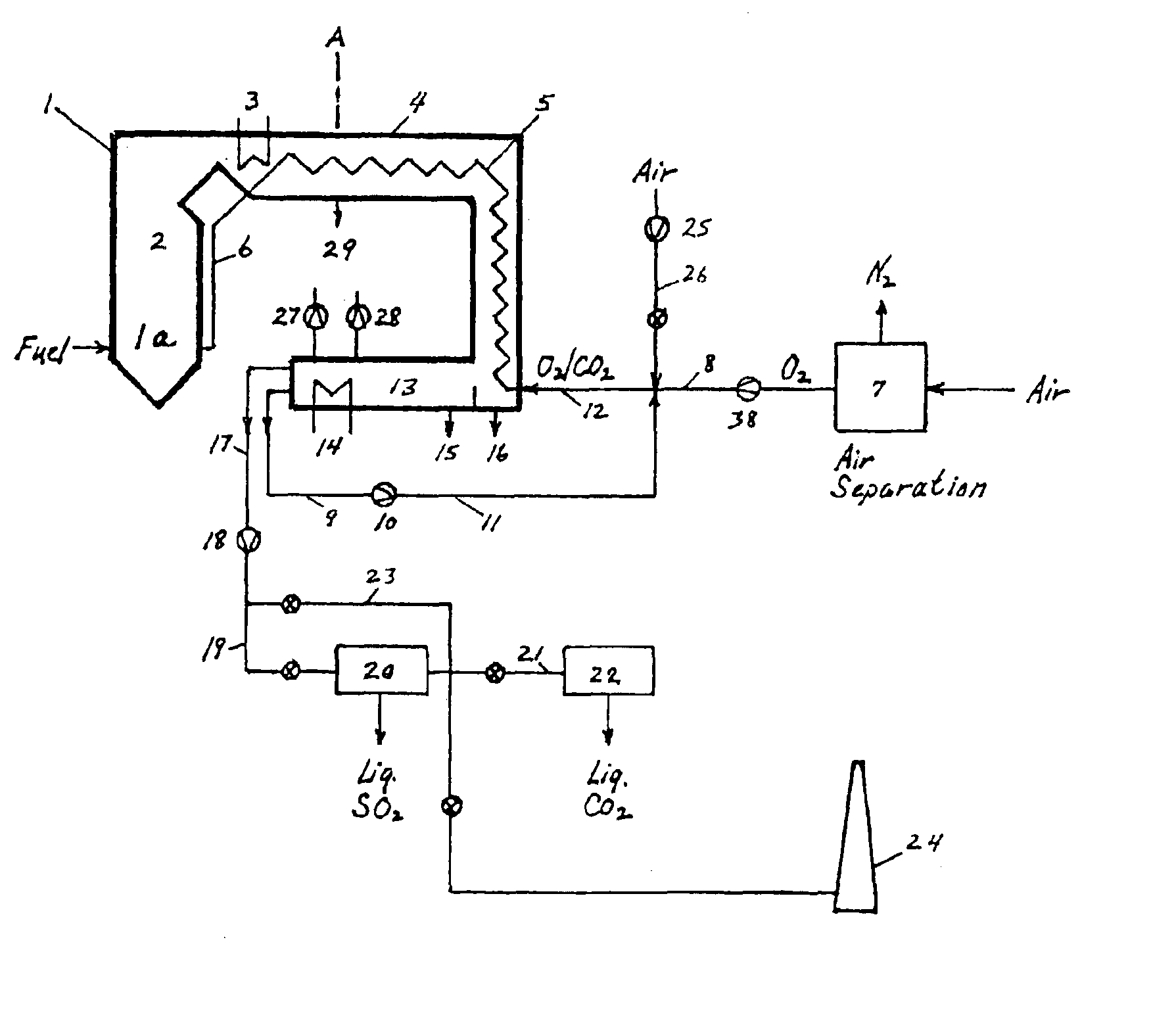

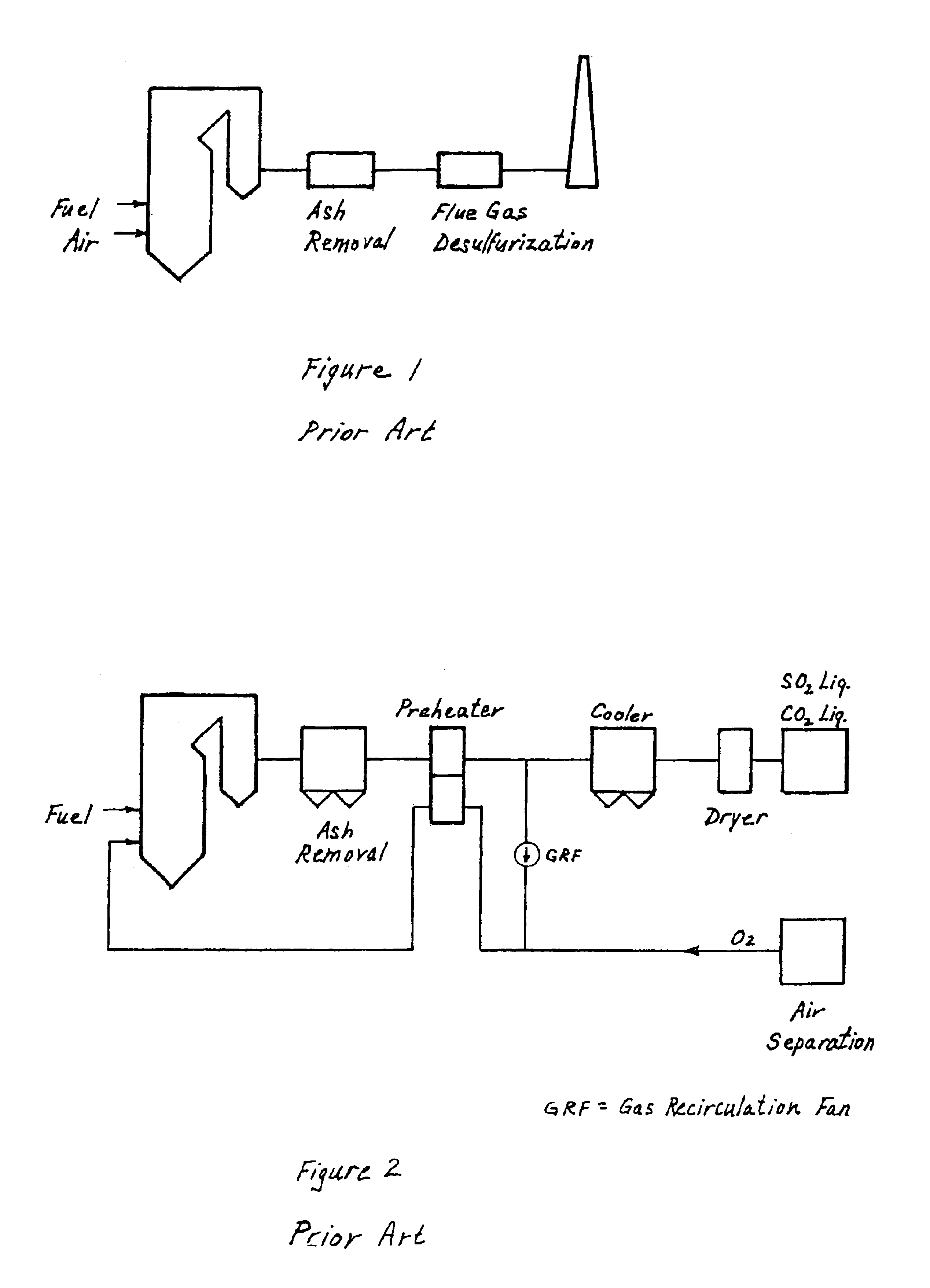

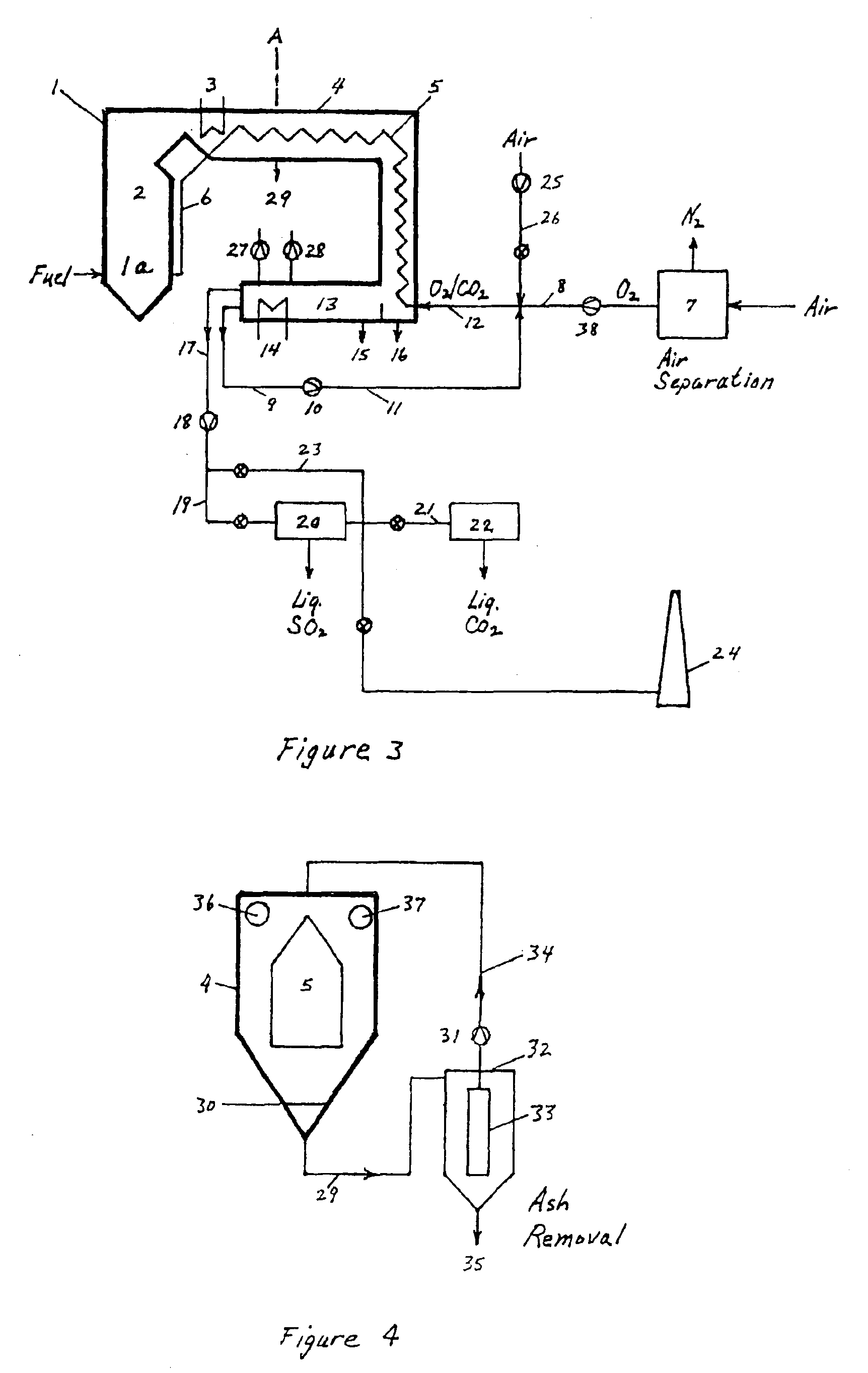

Boiler improvements with oxygen-enriched combustion for increased efficiency and reduced emissions

InactiveUS6907845B2Reduce fuel and oxygen consumptionLong timeFluidized bed combustionSolid waste disposalHigh oxygenCarbon dioxide

A method and apparatus to conduct 02 / CO2 combustion or oxygen-enriched combustion. The boiler exhaust gas passes through a Gas Primer Sector (GPS) combined with the boiler to effect heat transfer to the combustion gas in indirect counter-flow heat exchange. Sharply reduced gas flows result from using largely moisture-free CO2 as diluent for O2 in the combustion gas which allows long residence time at low velocity for maximum heat transfer from the exhaust gas to the combustion gas. Most particulate drops out and most moisture is condensed from the cooled mostly CO2 exhaust gas. The larger portion is blended with oxygen for the combustion gas and reheated and returned to the boiler through the integrated GPS; the smaller portion is cleaned and separated, the CO2 released or recovered. The complete exhaust gas-combustion gas cycle may be 30 to 90 seconds and preferably about 60 seconds. The high heat capacity of CO2 allows a much higher oxygen content in the combustion gas compared to open-cycle air combustion with a large nitrogen content of lower heat capacity. Efficiency is increased. Final exhaust gas separation and recovery is simplified. Condensate is processed to boiler feedwater or potable water quality. NOx, is eliminated, mercury fume captured and CO2 output reduced.

Owner:KREBS & SISLER LP

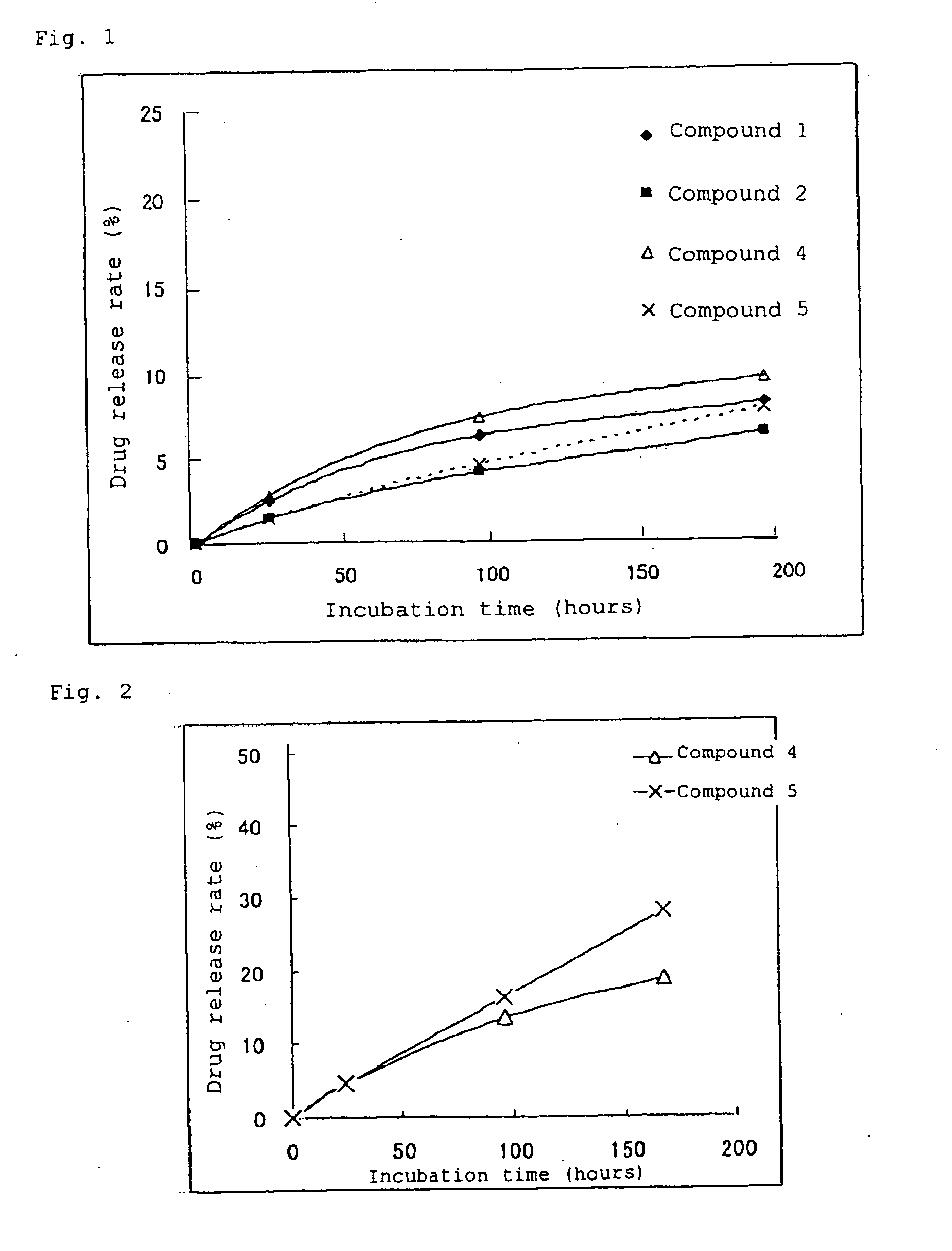

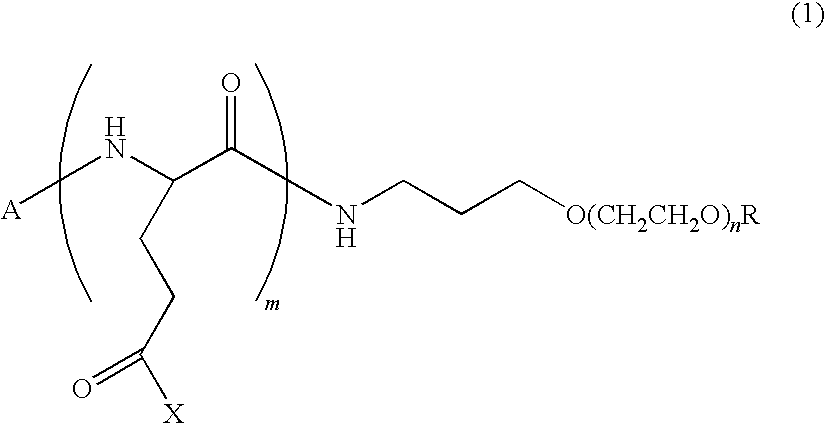

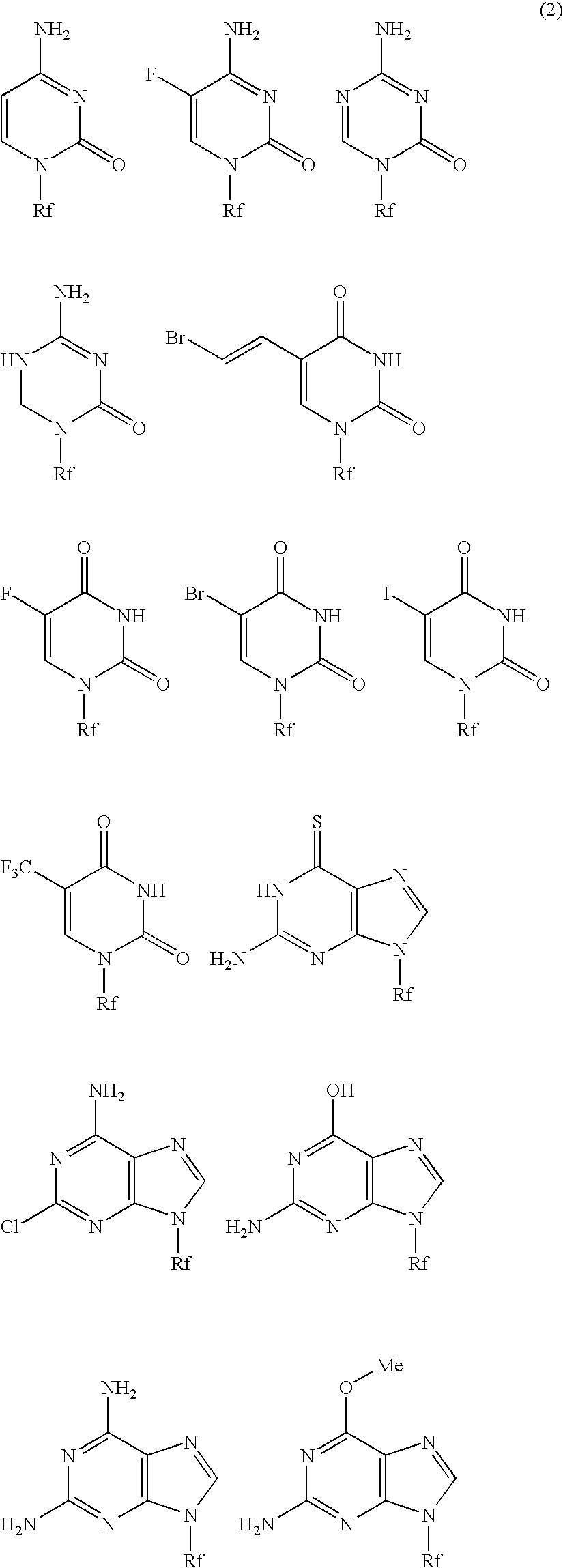

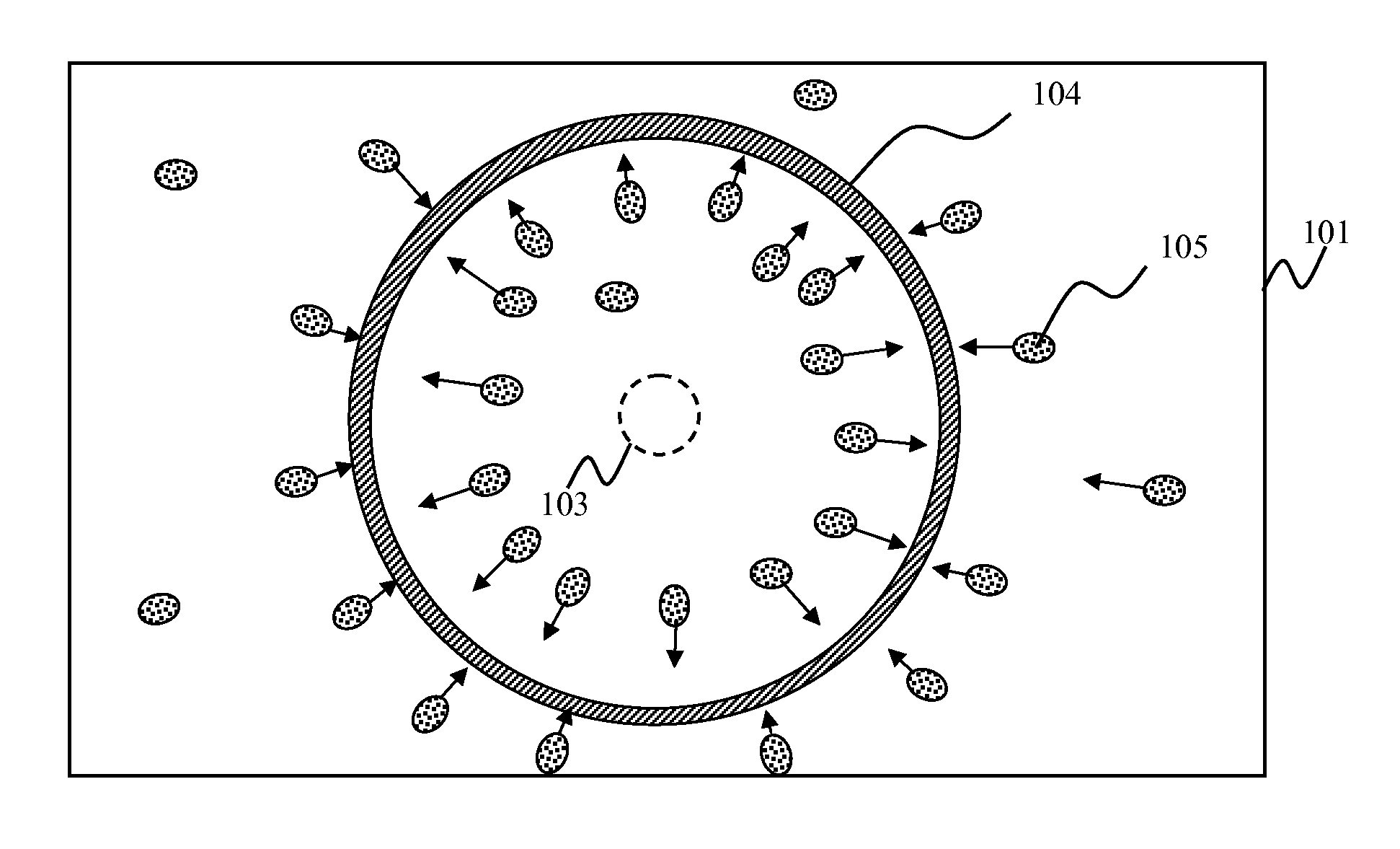

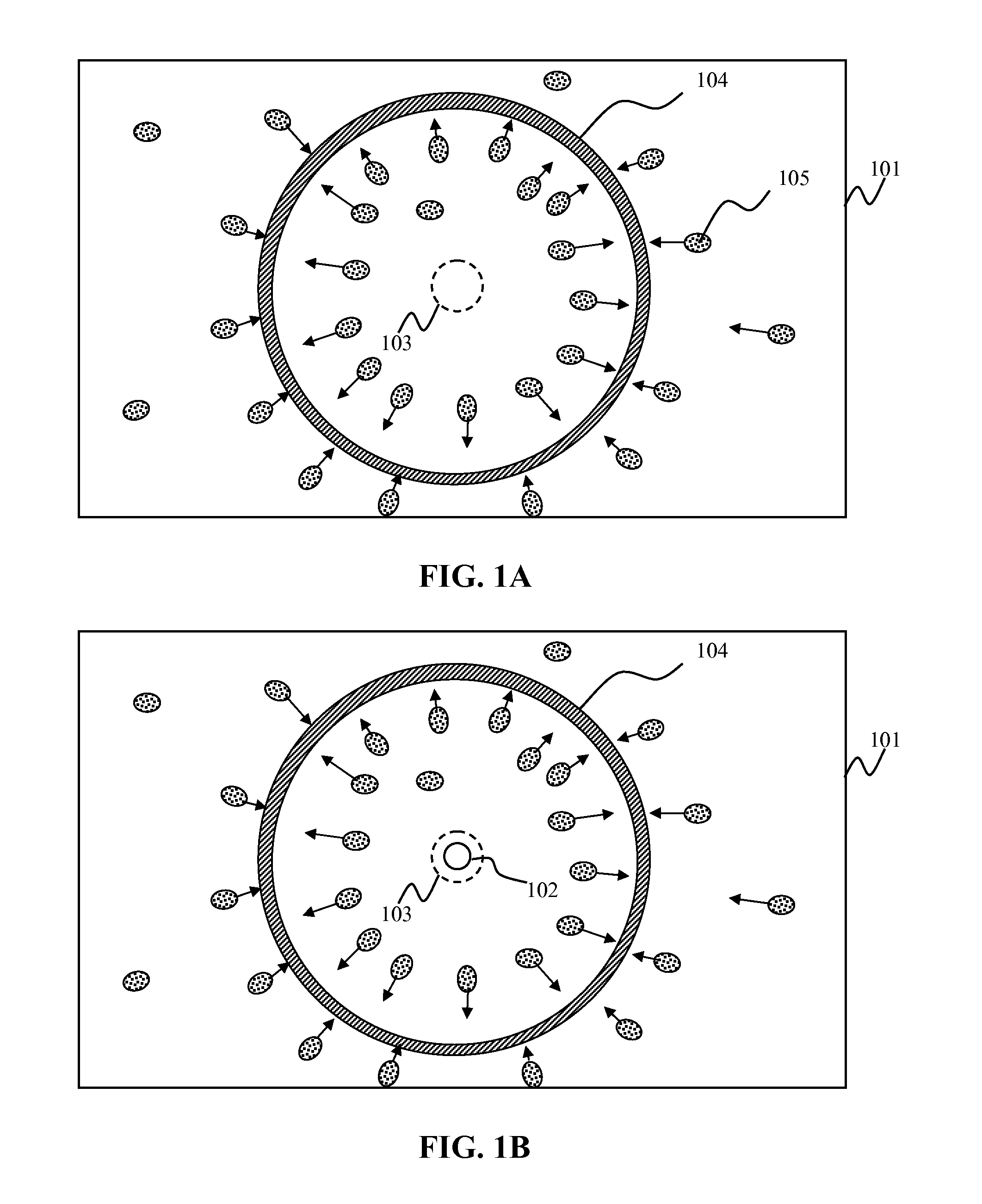

High-molecular weight derivative of nucleic acid antimetabolite

ActiveUS20090281300A1Excellent therapeutic effectLong timeOrganic active ingredientsSugar derivativesAntimetaboliteChemistry

[Problems] A derivative of a nucleic acid antimetabolite is demanded which can show a high therapeutic effect at a low dose.[Means For Solving Problems] Disclosed is a high molecular weight derivative of a nucleic acid antimetabolite, which is characterized by comprising a high molecular weight compound comprising a polyethylene glycol moiety and a polymer moiety having a carboxyl group in a side chain and a nucleoside derivative which can act as a nucleic acid antimetabolite, wherein the carboxyl group in the side chain is bound to a hydroxyl group in the nucleoside derivative via an ester bond. Also disclosed is a method for producing the high molecular weight derivative.

Owner:NIPPON KAYAKU CO LTD

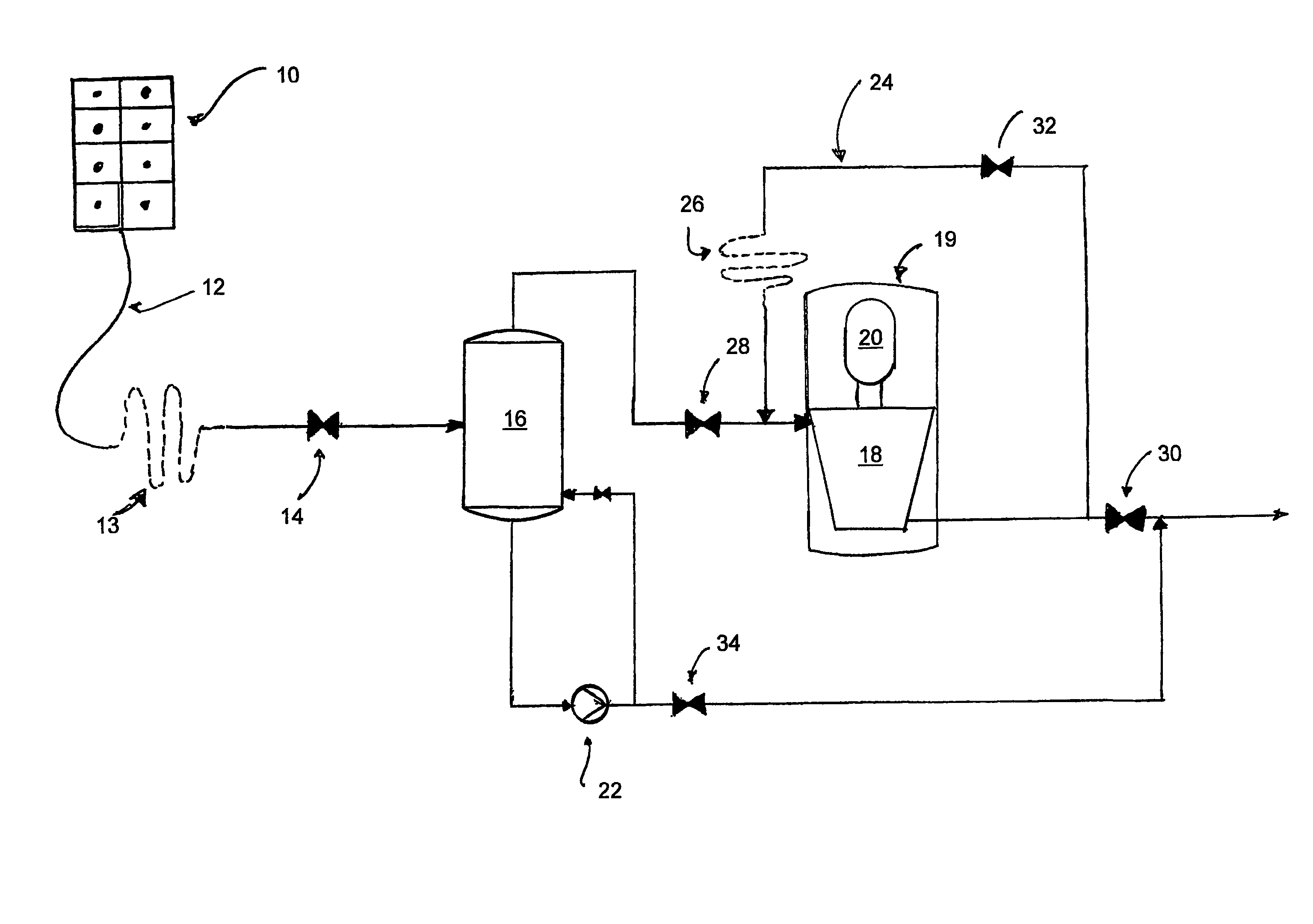

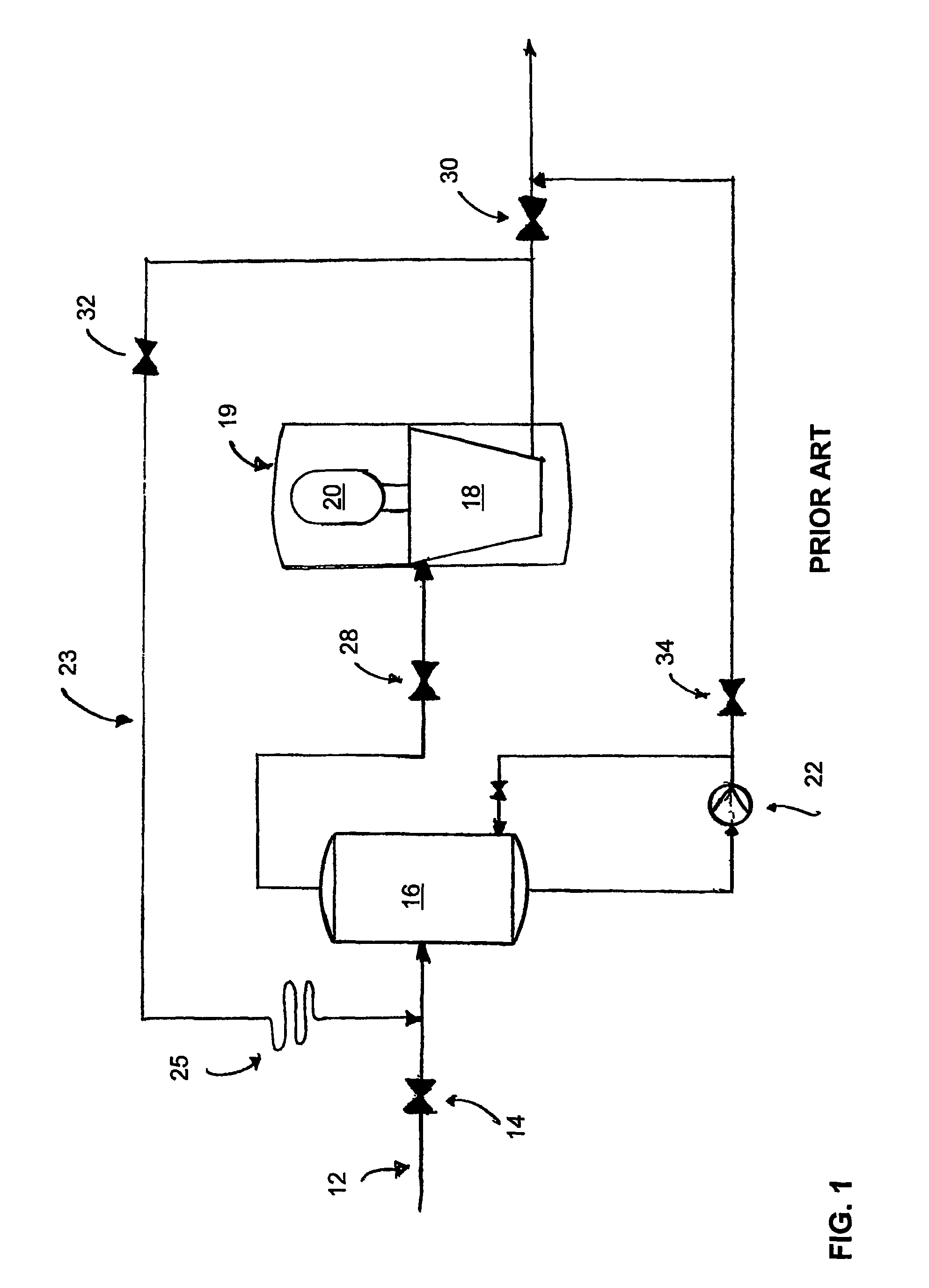

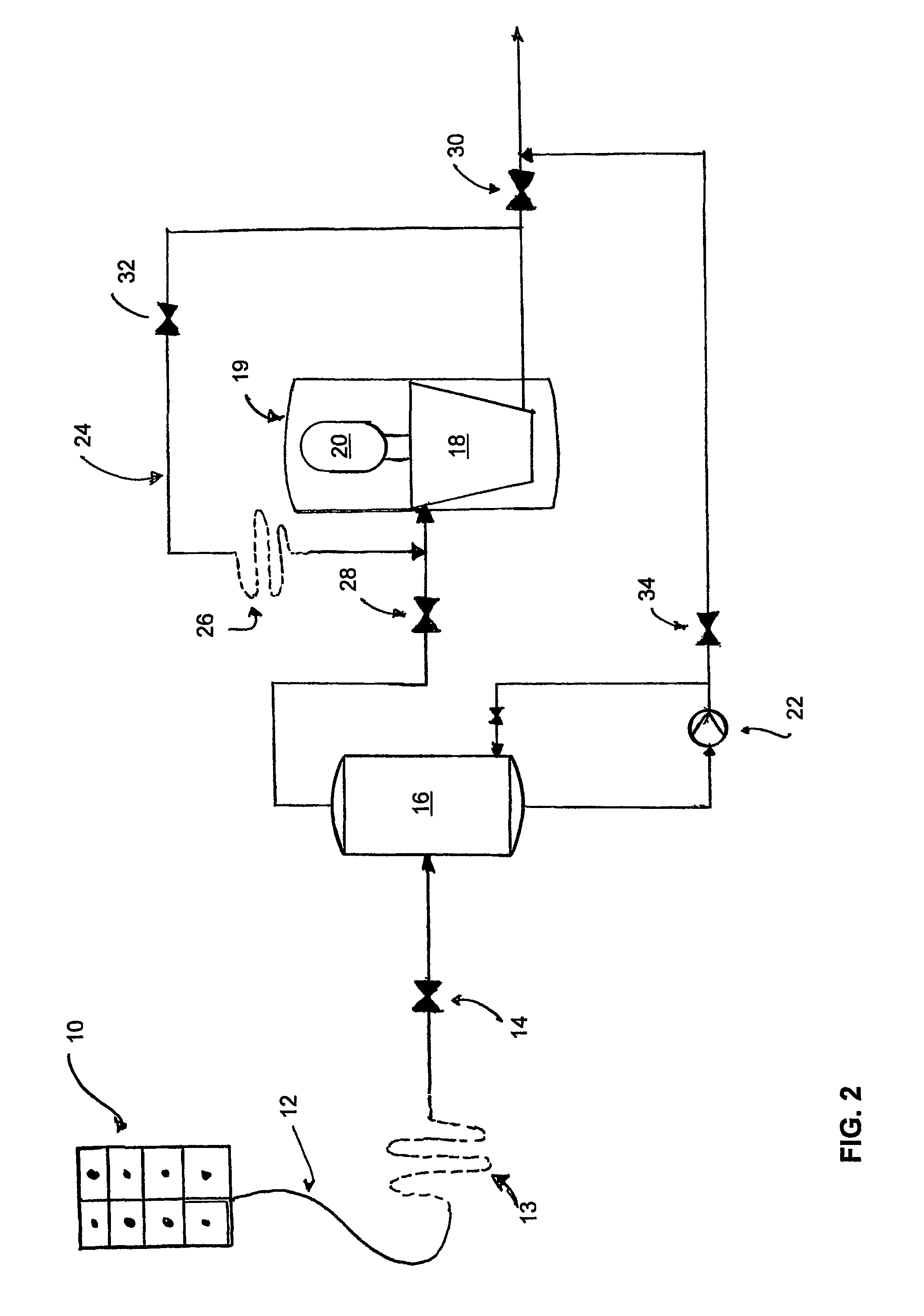

Subsea compression system and method

InactiveUS7819950B2Short start-up timeLong timeOrganic chemistryUsing liquid separation agentSeawaterEngineering

A subsea compression system and method wherein a wellstream fluid is flowed through a flow line (12) from a reservoir (10) and into a separation vessel (16) for subsequent compression in a compressor (18; 18′, 18″) prior to export of gas. A recycle line (24; 24′, 24″) is fluidly connected at a first end to the compressed wellstream at the outlet side of the compressor (18; 18′, 18″) and at a second end to the wellstream at a location between the separation vessel (16) and the inlet side of the compressor (18; 18′, 18″), the recycle line being capable of controllably (32) feeding fluid due to surge back to the compressor inlet side and avoiding the need to feed the fluid into the separation vessel, because the re-circulated gas is dry both due to having been separated at seawater temperature, and then being heated during recirculation.

Owner:KVAERNER OILFIELD PROD AS

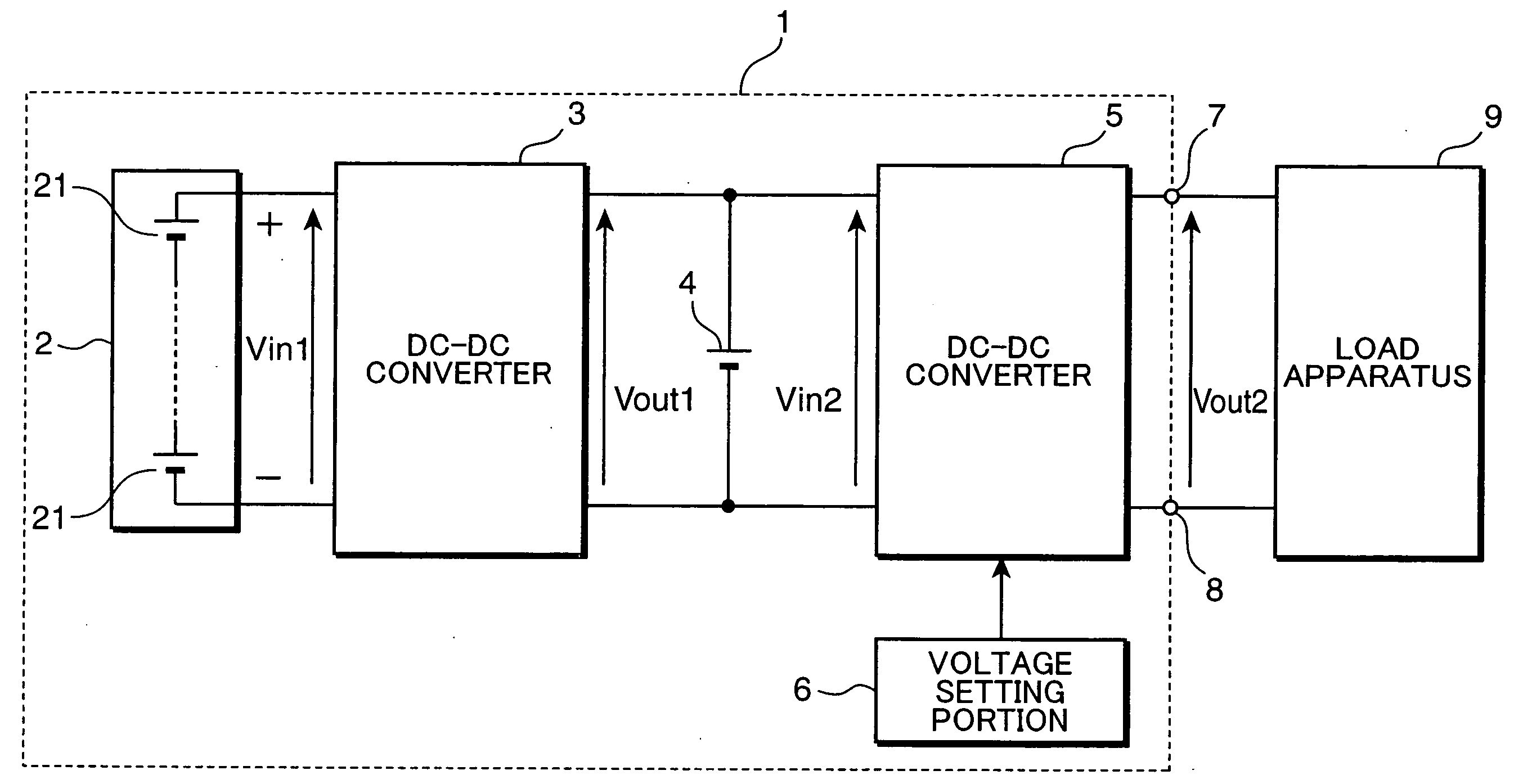

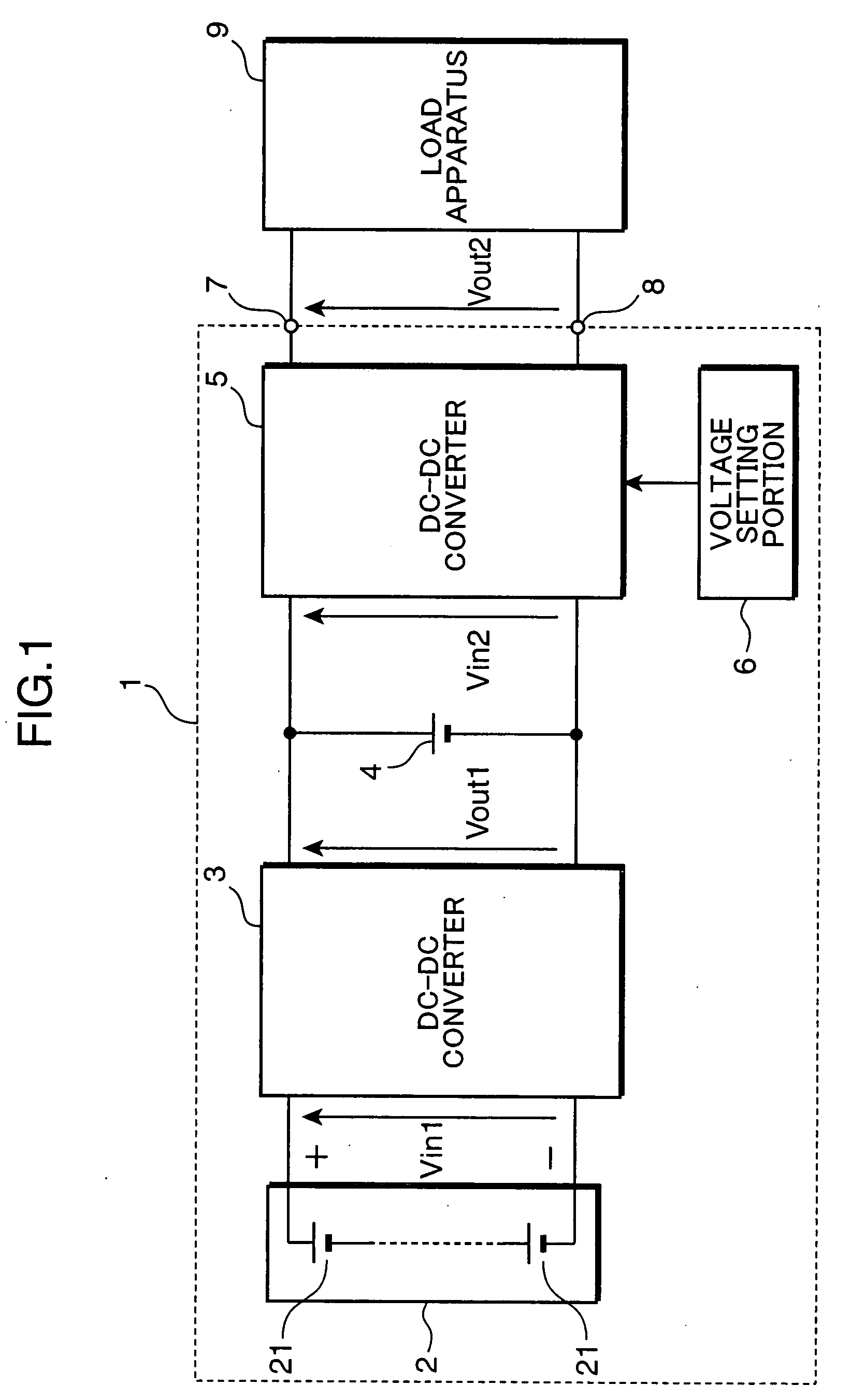

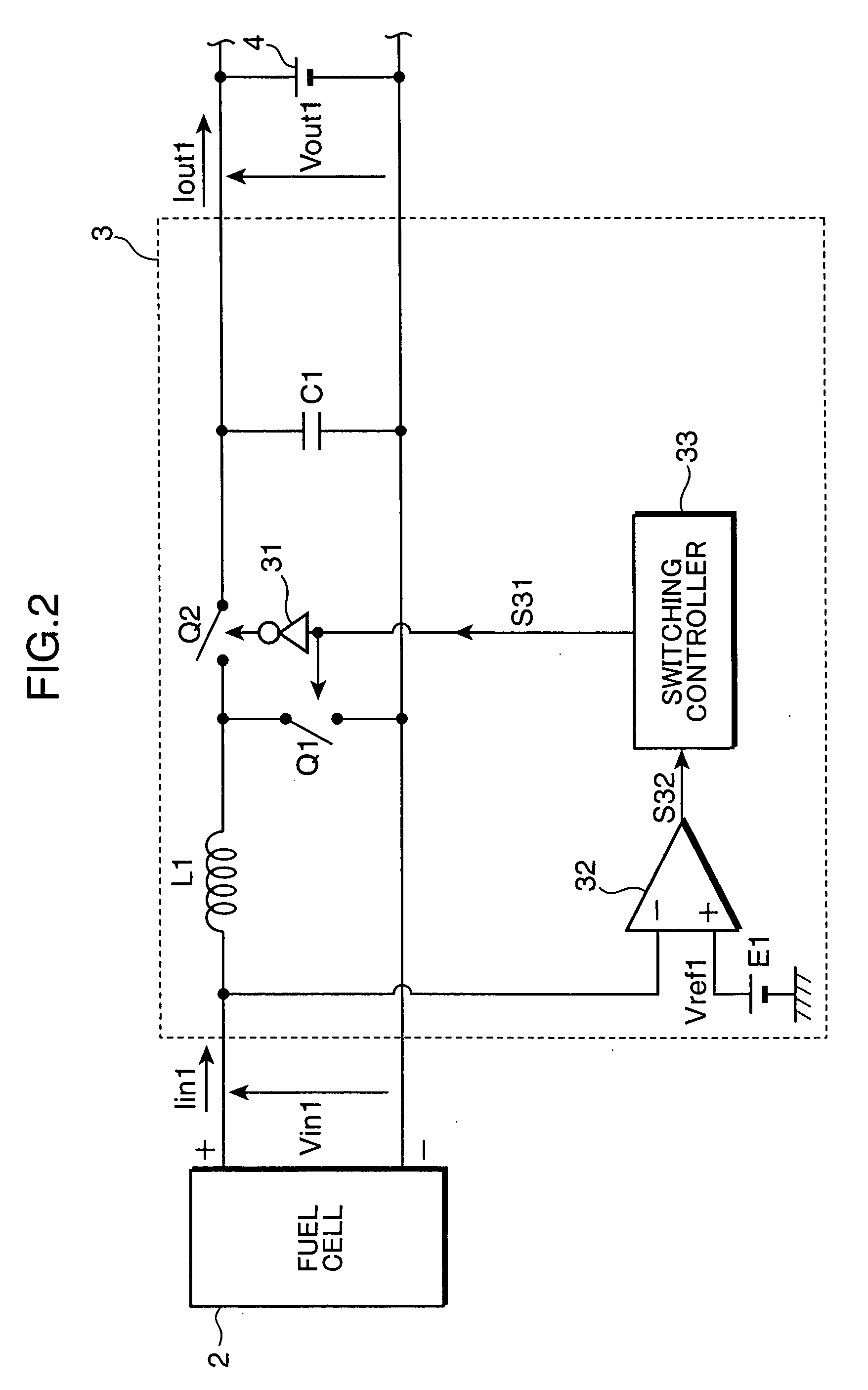

Power supply apparatus

InactiveUS20070278968A1Stable output voltageLong timeBatteries circuit arrangementsElectric lighting sourcesVoltage converterCharge voltage

A power supply apparatus is provided which includes: a fuel cell; a power storage device which stores electric power; a connection terminal for connecting a load; a charge-used voltage converter which converts the output voltage of the fuel cell into a charging voltage for charging the power storage device and charges the power storage device; and an output-used voltage converter which converts the output voltage of the power storage device into a predetermined set output voltage and outputs it to the connection terminal.

Owner:PANASONIC CORP

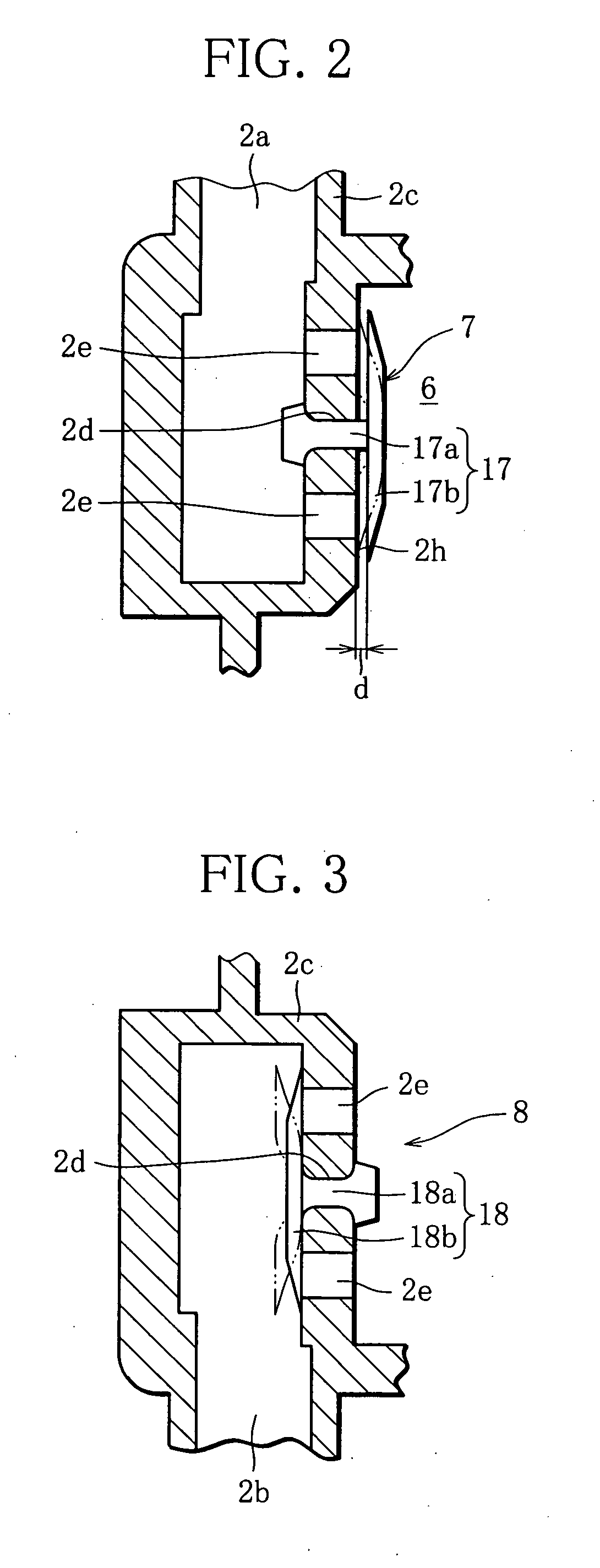

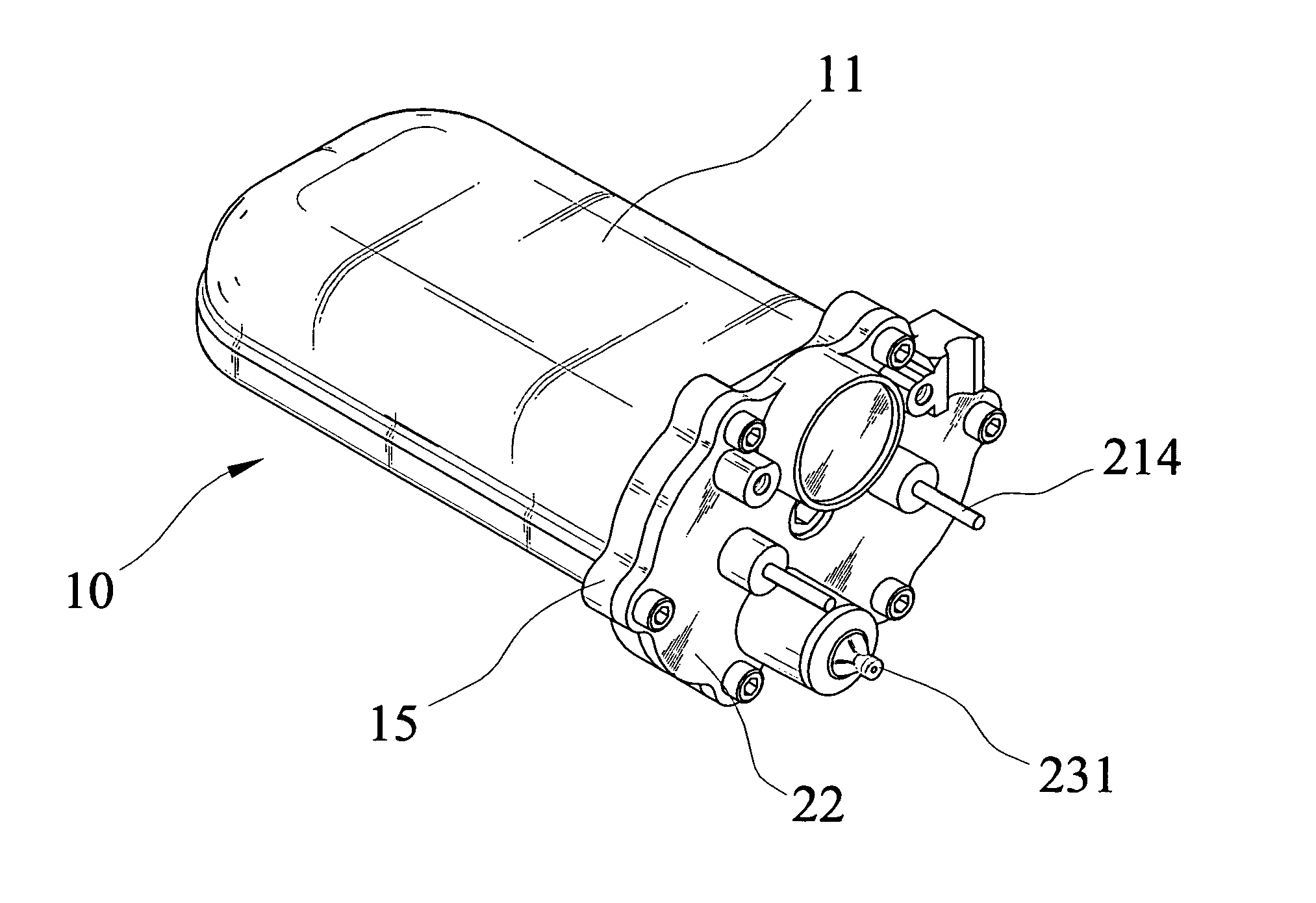

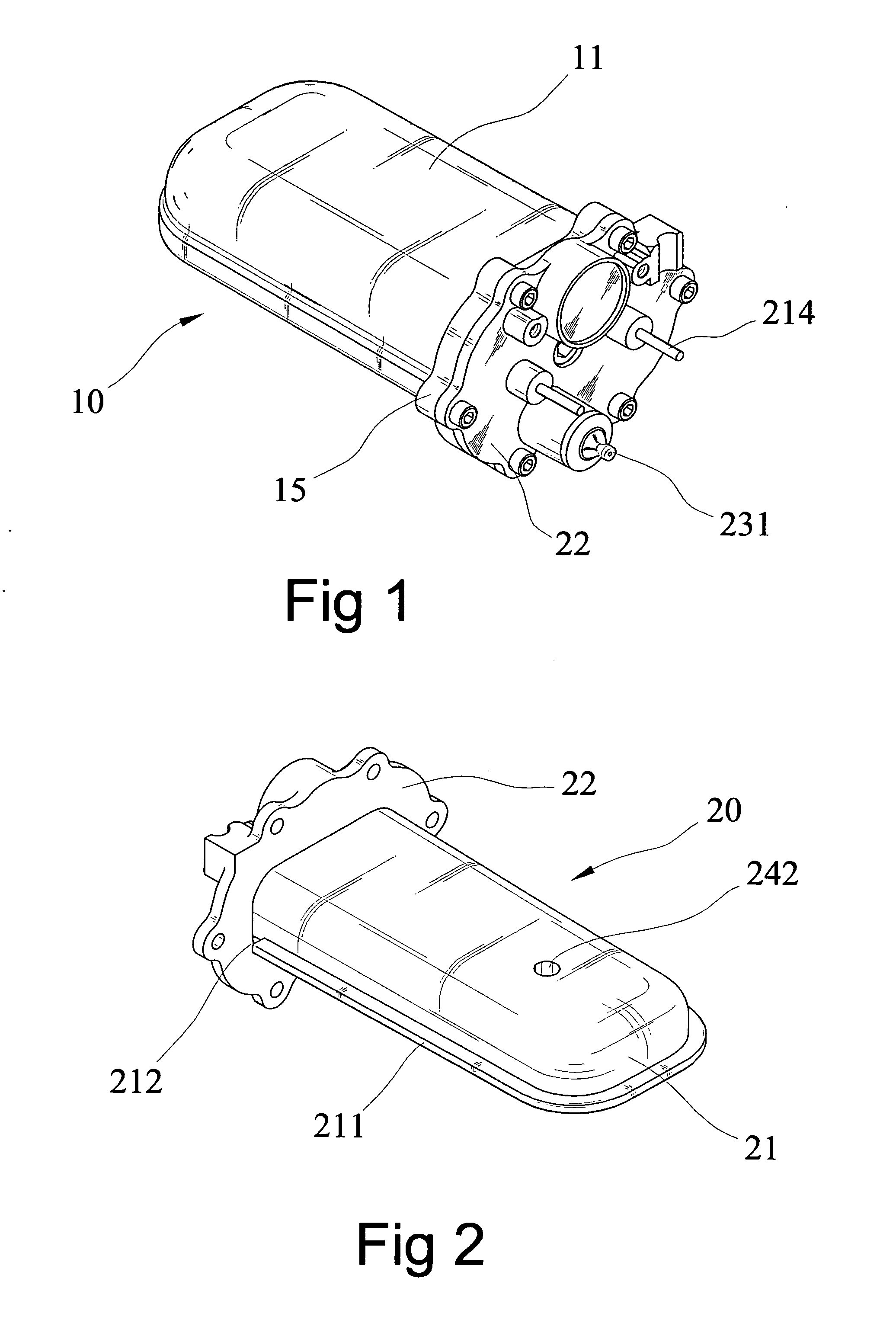

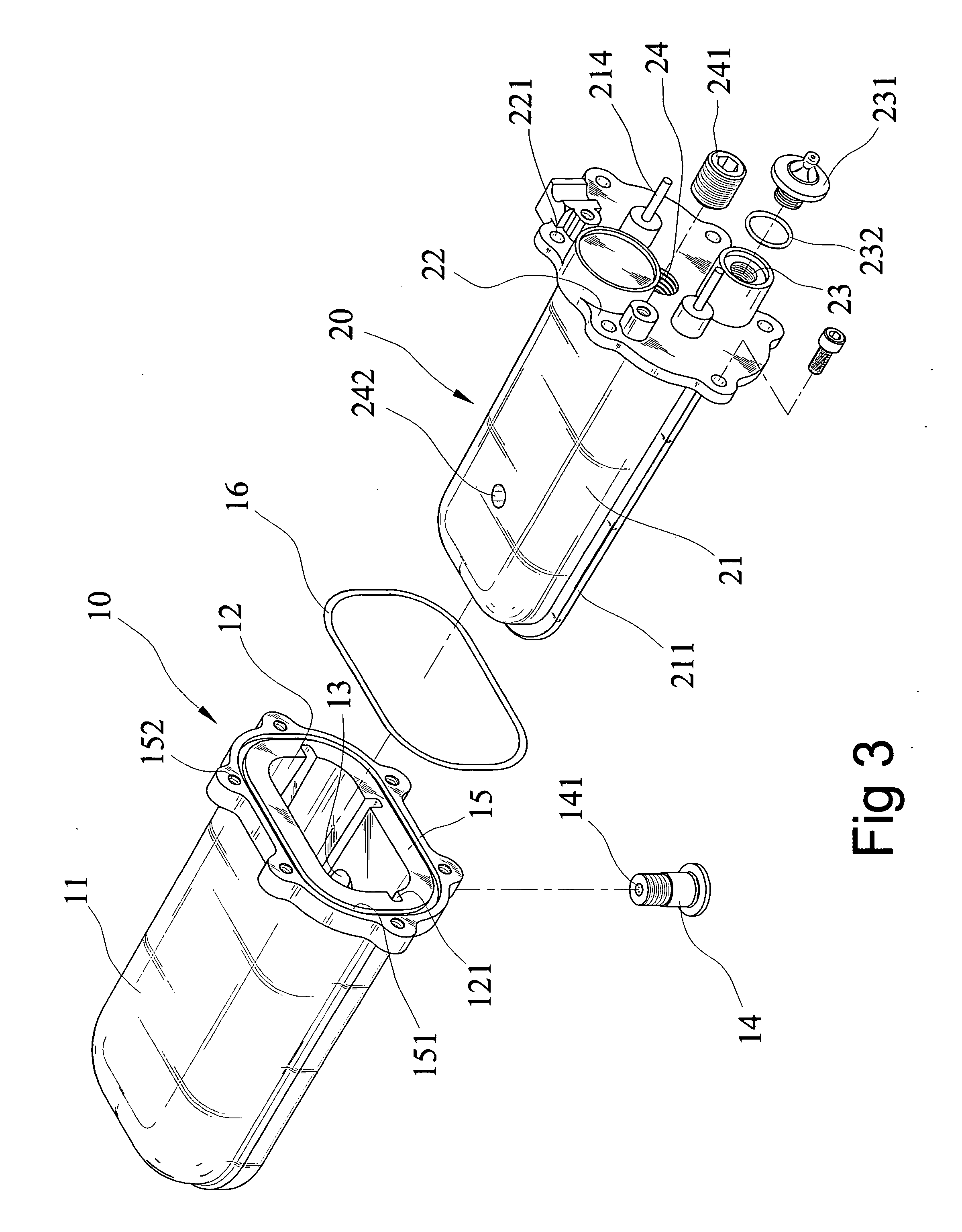

Diaphragm pump

InactiveUS20070258835A1Reduce loadLong timePositive displacement pump componentsFlexible member pumpsEngineeringCheck valve

A diaphragm pump comprising a pressure chamber arranged such that the volume of the pressure chamber is expanded and contracted by oscillation of a diaphragm (5), a suction-side check valve (7) for sucking air into the pressure chamber and a discharge-side check valve (8) for discharging air from the pressure chamber. The suction-side check valve is arranged to close by a valve body (17) being elastically deformed and brought into close contact with a valve seat, and open by the valve body elastically returning to the normal shape and coming out of contact with the valve seat. The discharge-side check valve is arranged to open by a valve body (18) being elastically deformed and producing a space relative to a valve seat, and close by the valve body elastically returning to the normal shape and coming into close contact with the valve seat.

Owner:YASUNAGA AIR PUMP

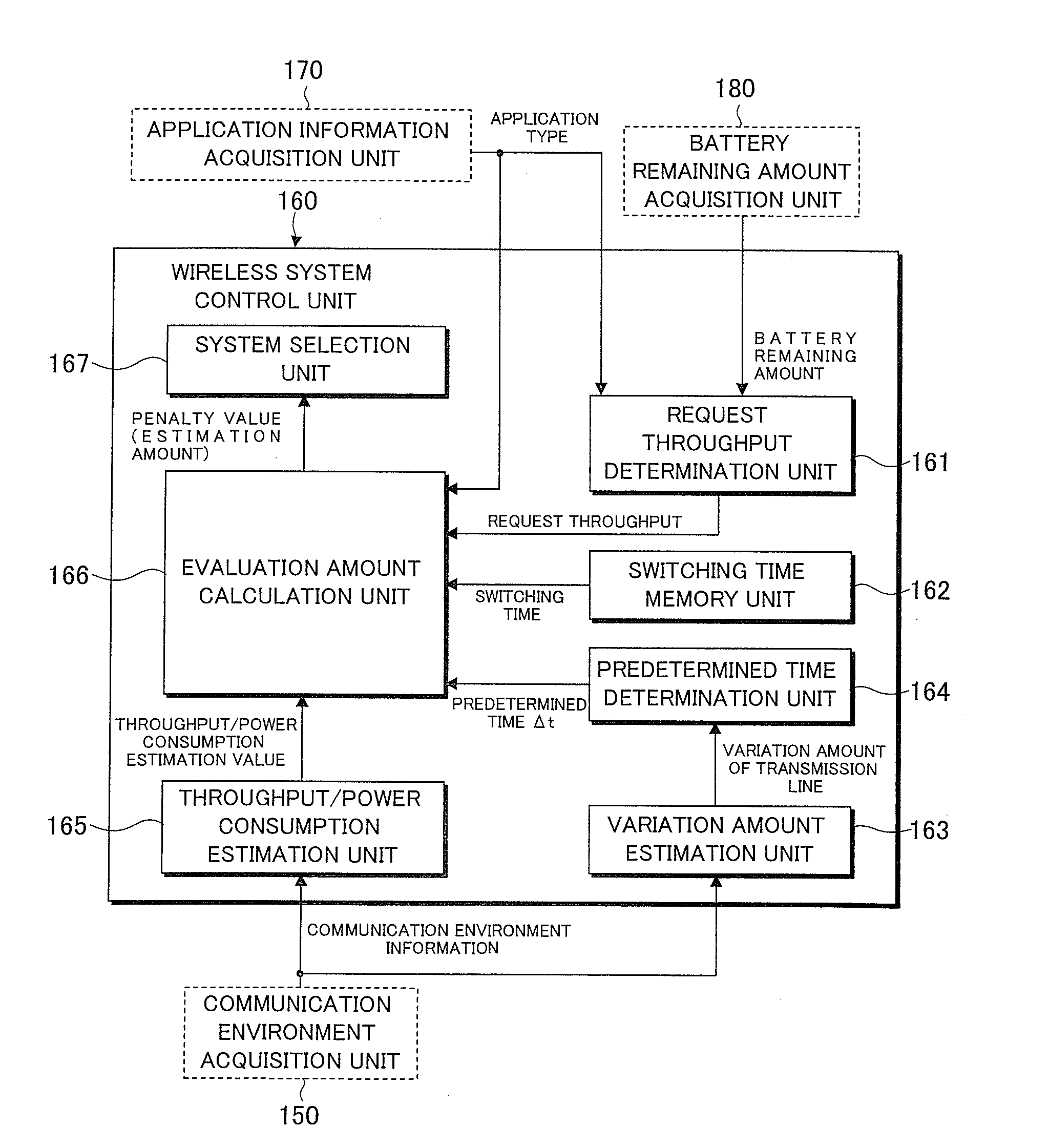

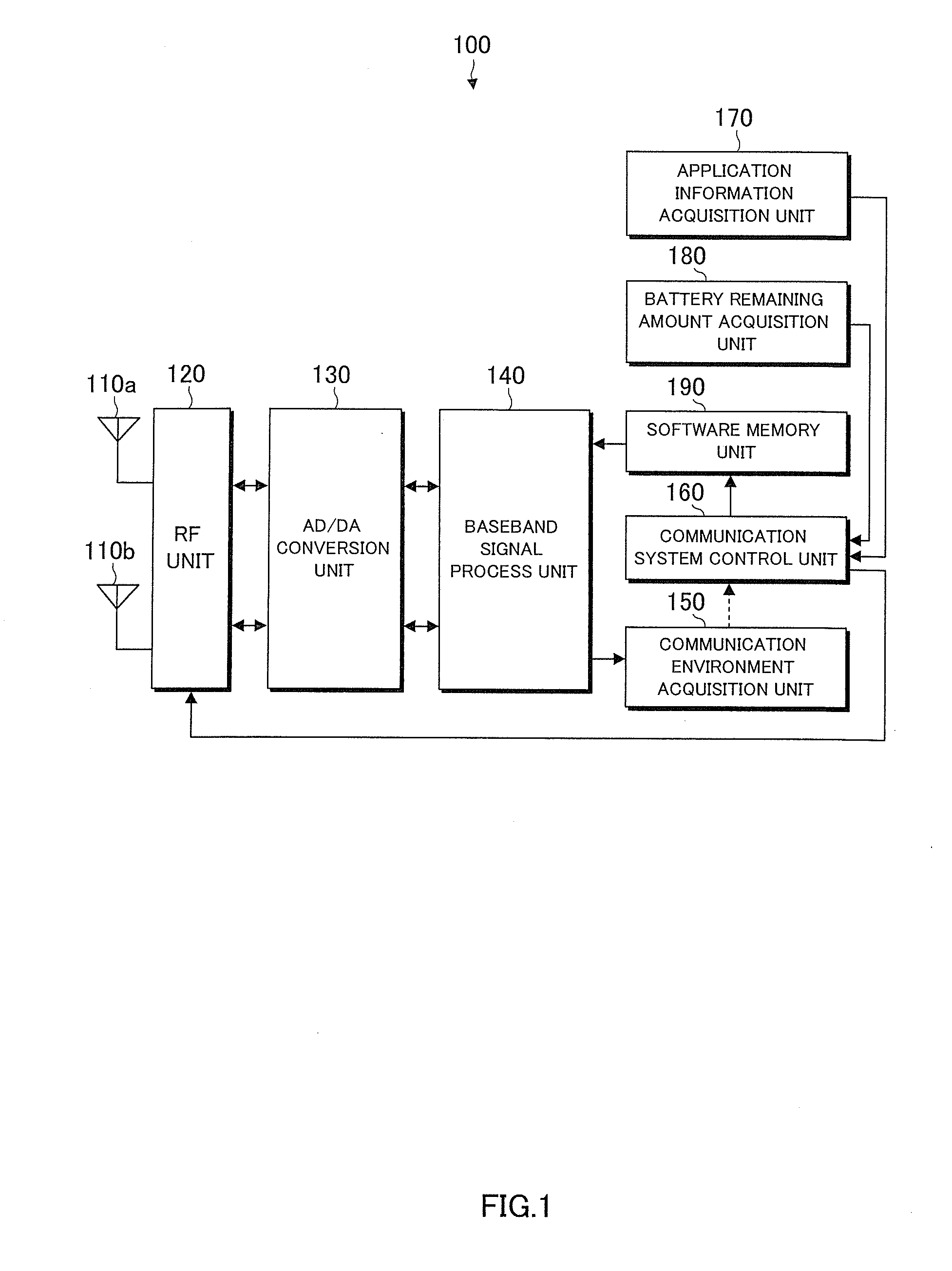

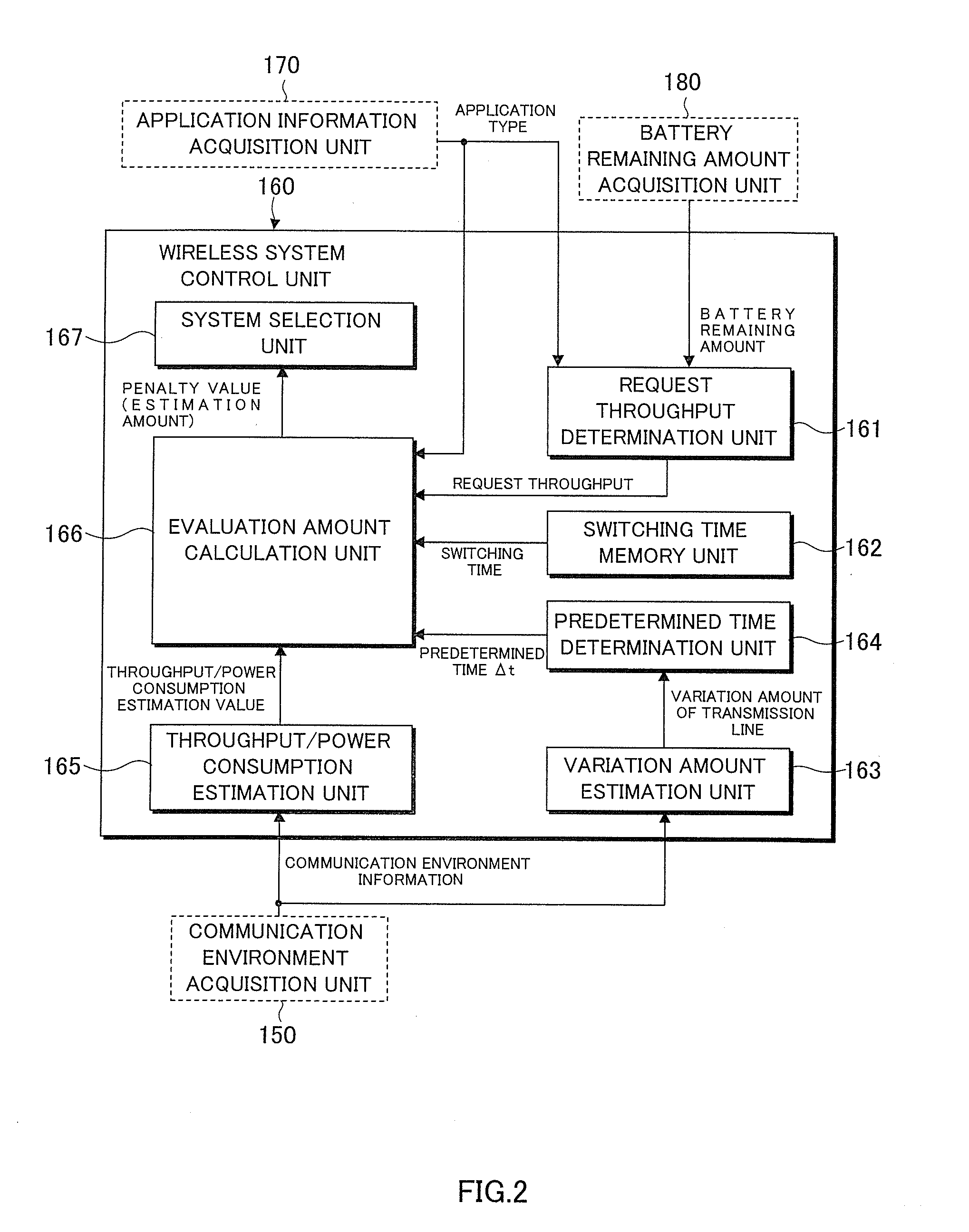

Wireless communication terminal and communication system selection method

InactiveUS20110055363A1High battery usage efficiencyLong timeAssess restrictionDigital computer detailsReal-time computingSelection method

A wireless communication terminal and a communication system selection method are capable of selecting a communication system having high battery usage efficiency by keeping battery remaining time long and satisfying throughput required by the application depending on scenes. The wireless communication terminal 100 capable of selecting plural communication systems comprises an application information acquisition unit 170 for acquiring a type of used application;an evaluation amount calculation unit 166 for changing a communication system selection criterion in response to the type of application thus acquired and calculating an evaluation amount with respect to time adding predetermined time to communication system switching time; and a system selection unit 167 for comparing the evaluation amounts thus calculated and selecting any one of communication systems. Therefore, it is possible to select / switch to the communication system having high battery usage efficiency among plural systems in response to a real-time requirement of the application.

Owner:KDDI CORP

Method of replenishing lithium for the negative plate of a li-ion battery

InactiveUS20140079961A1Long timeEfficient productionPrimary cell maintainance/servicingCell electrodesChemistryLithium metal

The invention pertains to the technical field of a Li-ion battery, in particular to a method of replenishing lithium for the negative plate of a Li-ion battery. Under inert atmosphere, organic lithium solution is sprayed or dripped on the negative plate surface so that lithium-ion in the organic lithium solution is reduced to lithium metal which is embedded in the negative plate, and then the negative plate is dried. Compared with the prior art, in the invention, the organic lithium solution is uniformly sprayed or dripped on the negative plate surface for realization of lithium replenishment by way of a wet process, thus effectively avoiding floating of lithium metal powder in the air during lithium replenishment by way of a dry process, which not only guarantees production safety, but also is characterized by simple process and lower cost.

Owner:DONGGUAN AMPEREX TECH +1

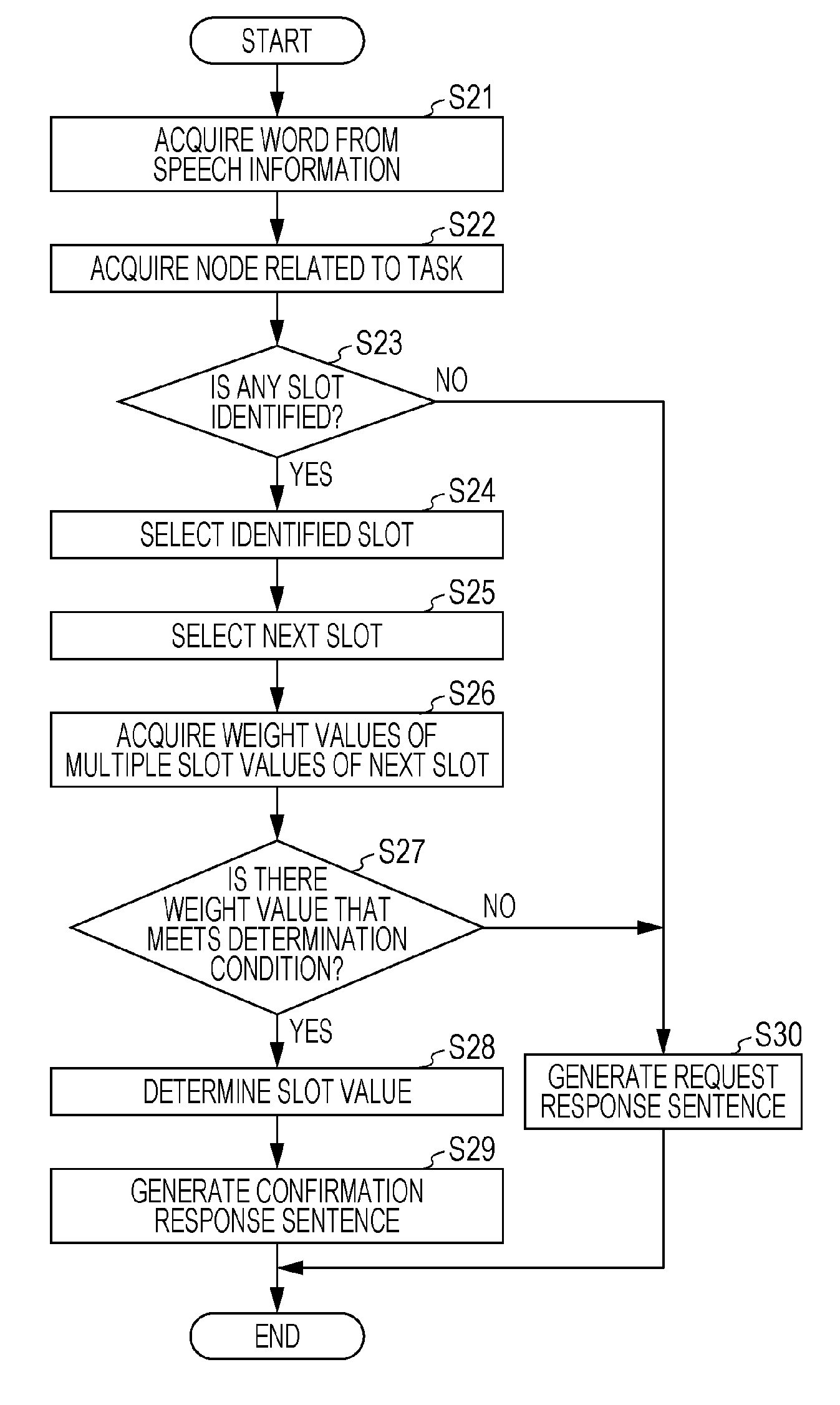

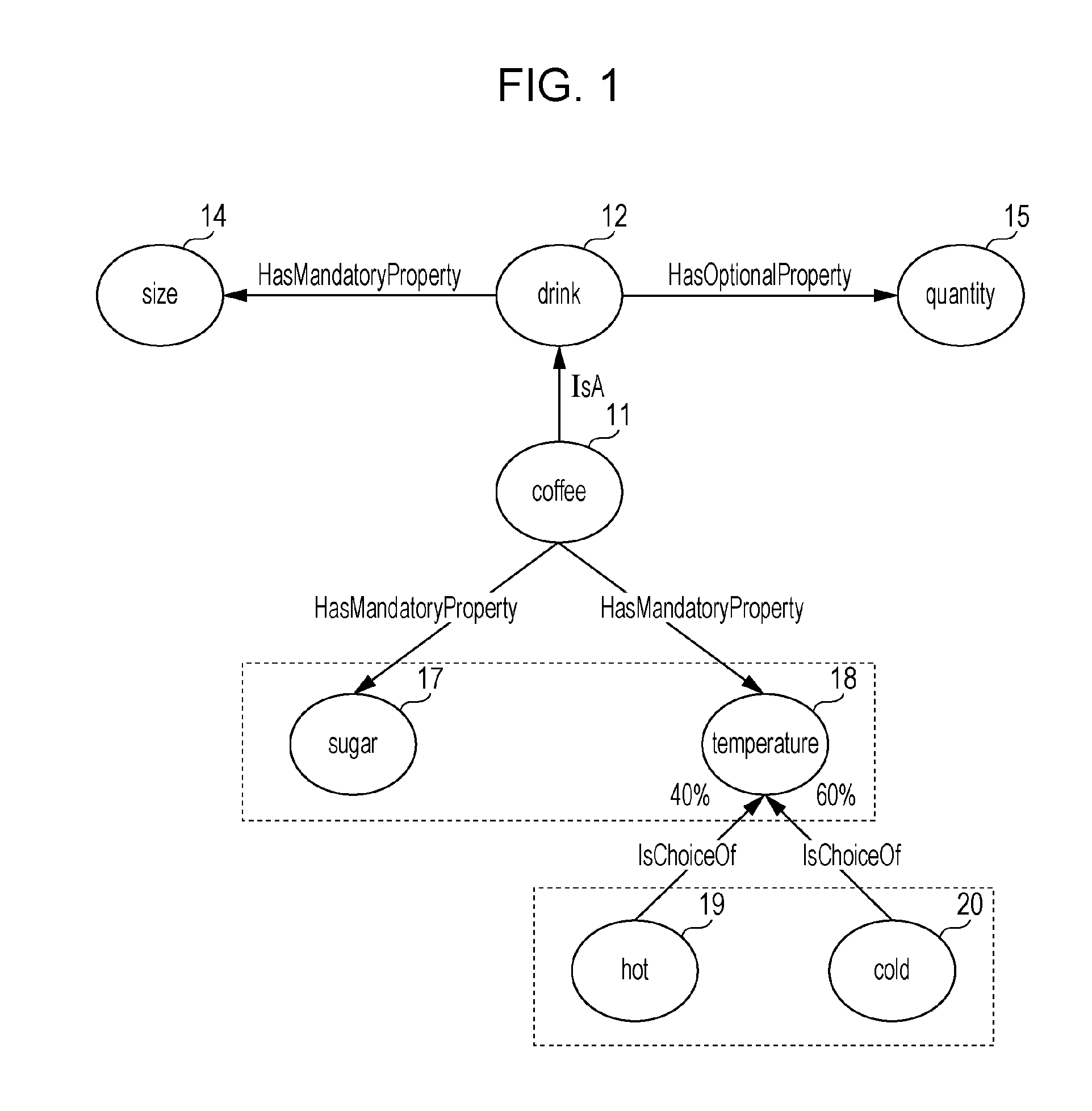

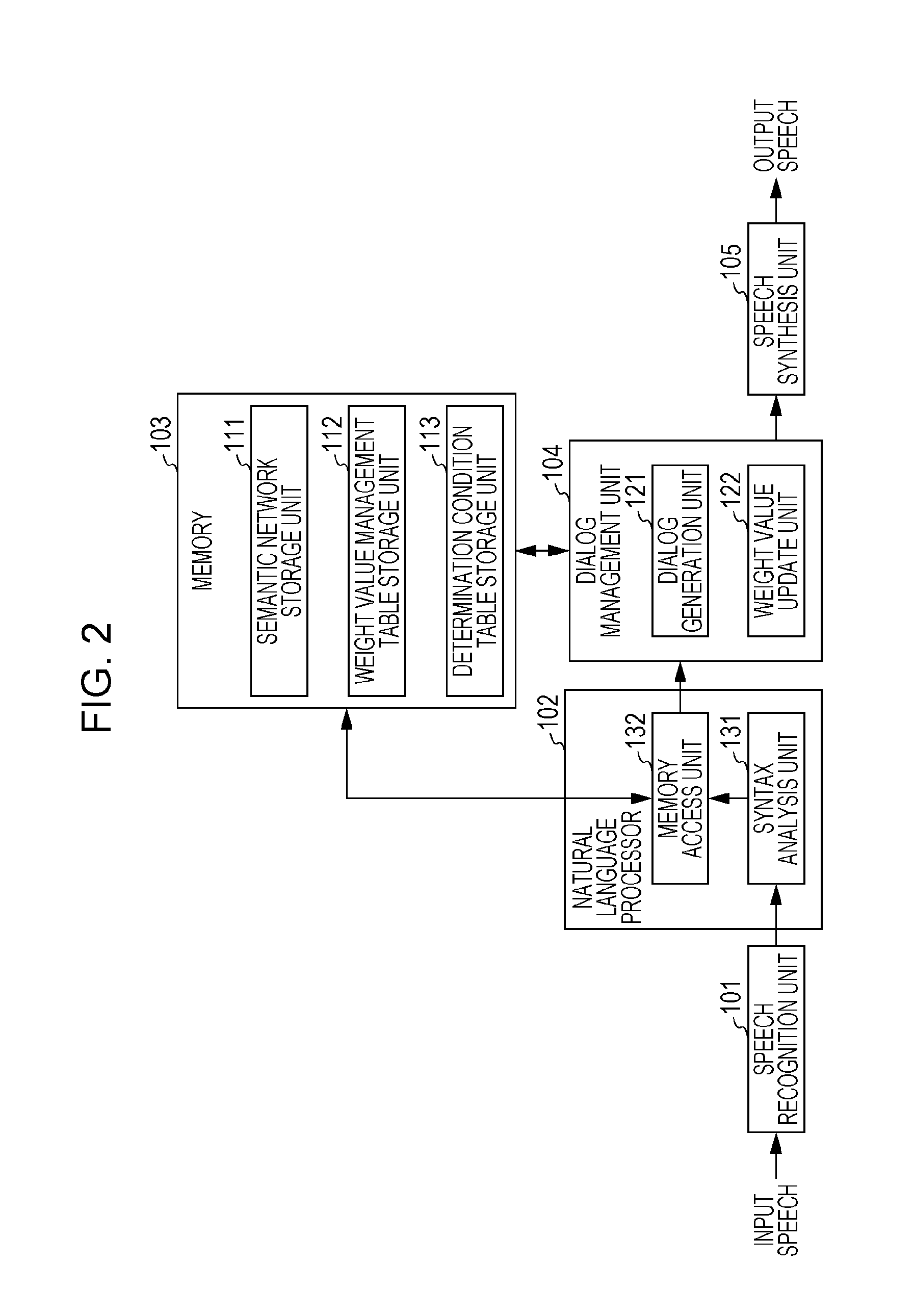

Computer-implemented method for generating a response sentence by using a weight value of node

ActiveUS20160293162A1Long timeLong processing timeSemantic analysisSpeech recognitionWeight valueNatural language

A semantic network storage unit stores multiple nodes necessary for performing a task of generating a response sentence to user's speech while associating the nodes with each other. A natural language processor acquires speech information indicating content of the user's speech and identifies a primary node corresponding to the speech information from multiple nodes. A conversation generation unit selects one secondary node from multiple secondary nodes associated with the identified primary node, based on weight values each related to one of the multiple secondary nodes and generates a response sentence corresponding to the selected one secondary node.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

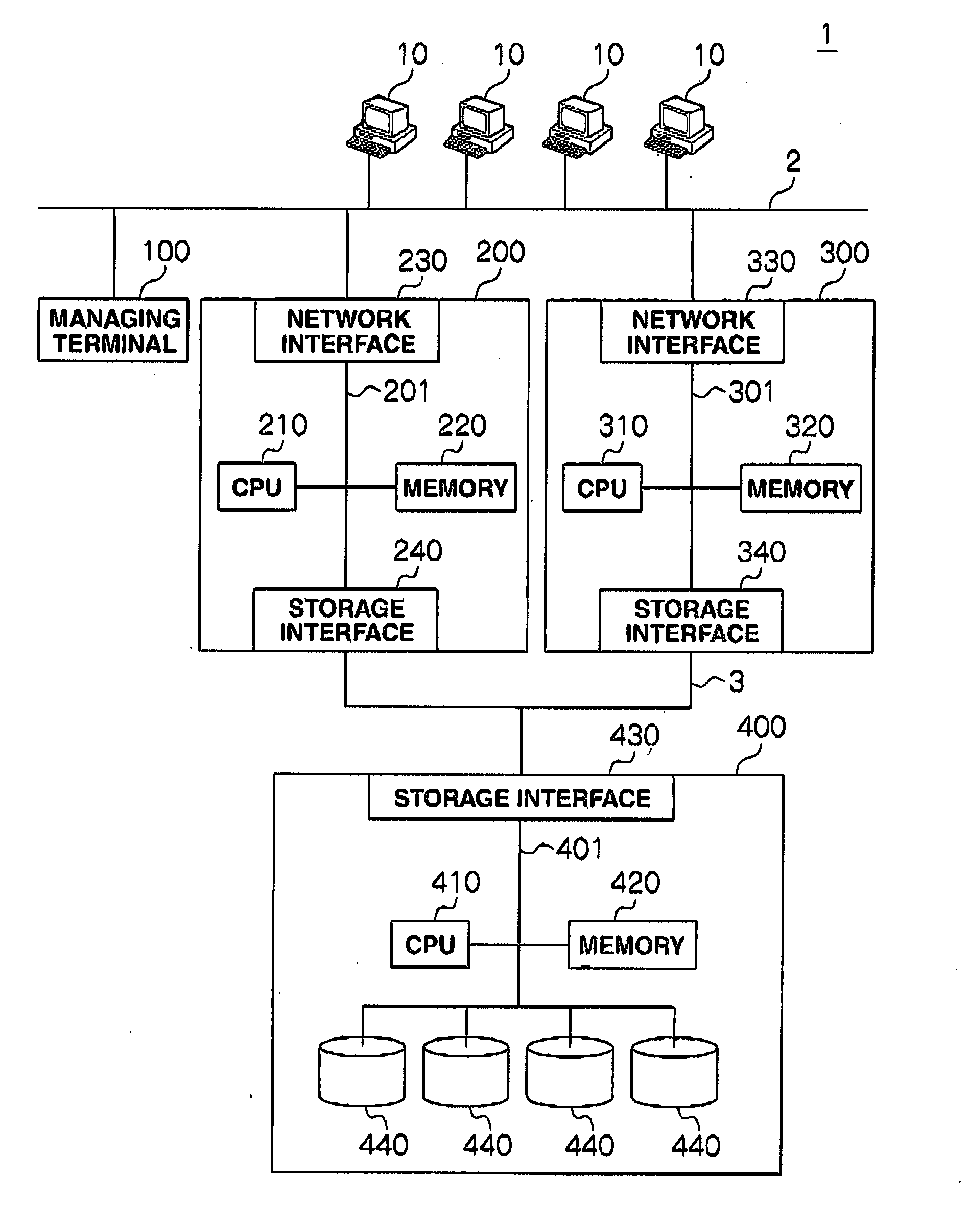

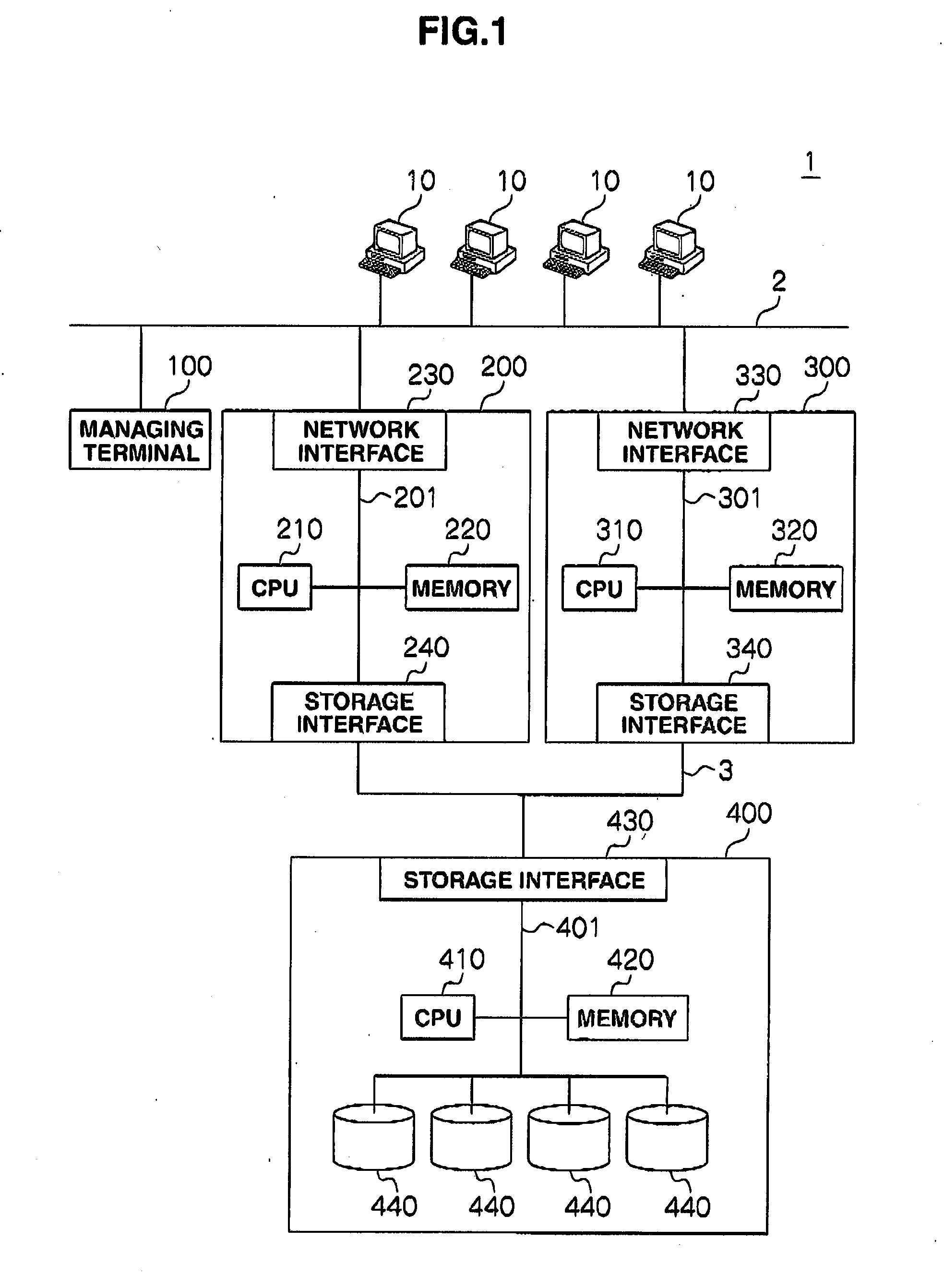

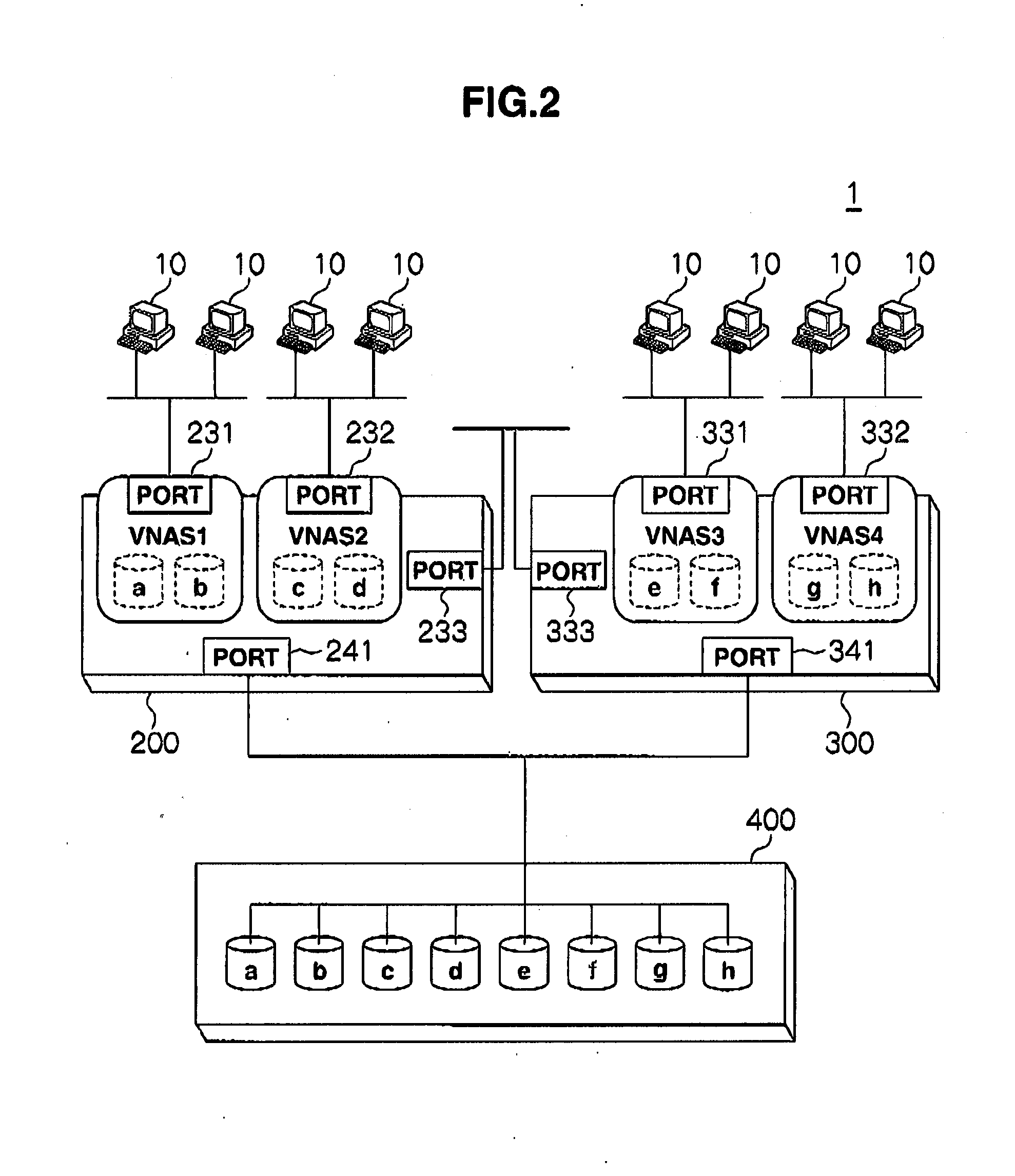

Storage system and volume managing method for storage system

InactiveUS20090248847A1Long time synchronizationLong timeDigital computer detailsSpecial data processing applicationsCluster systemsData processing

A time and an amount of data for setting information which is necessary to execute an exclusion process which is necessary when data is stored in a cluster system are reduced. A storage system included in the cluster system includes a plurality of volumes, and a plurality of virtual servers utilizing at least one or more volumes of the plurality of volumes for a data processing, each of the plurality of virtual servers can access all the plurality of volumes, and the volume utilized by the plurality of virtual servers to process data corresponds to the virtual servers.

Owner:HITACHI LTD

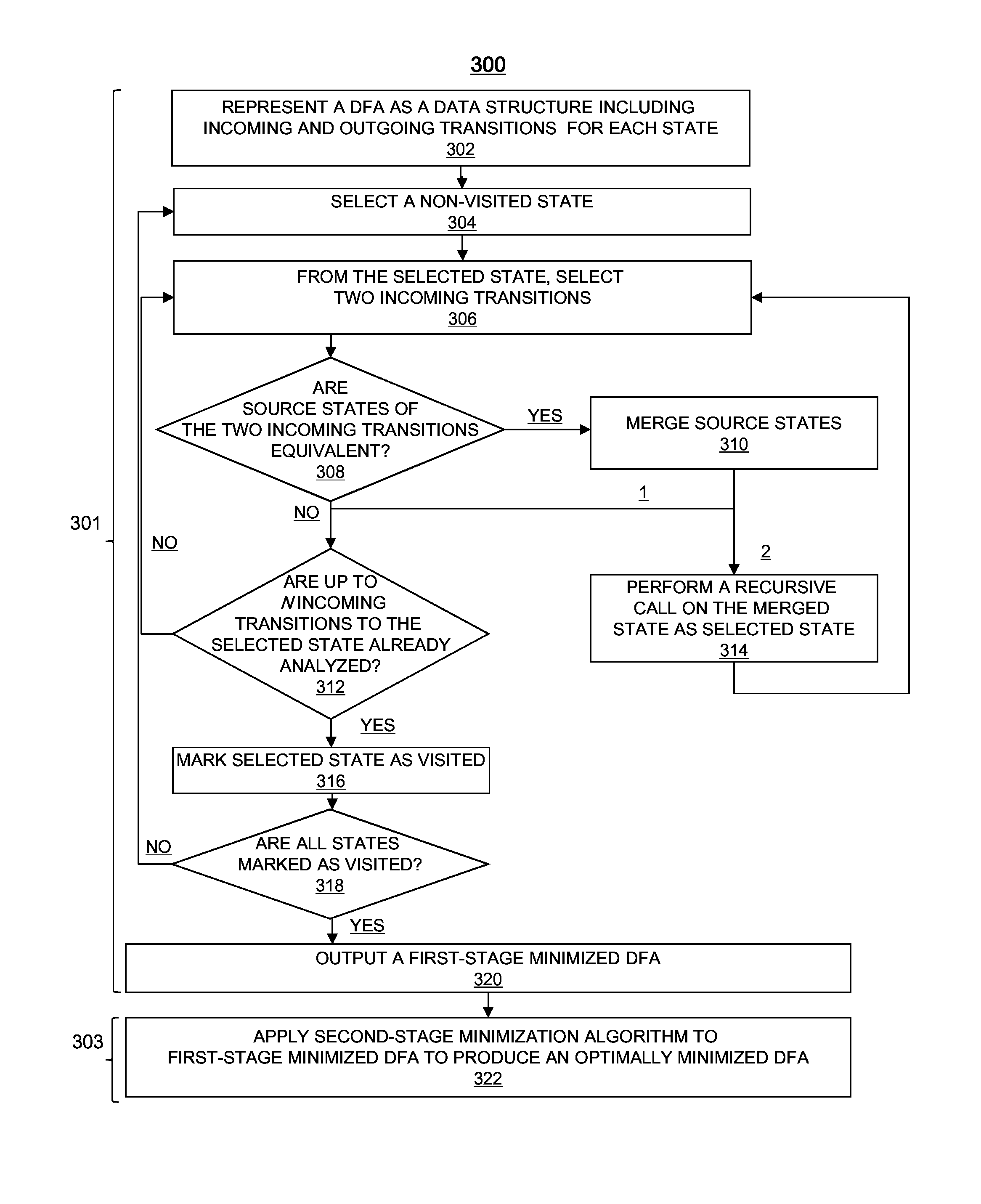

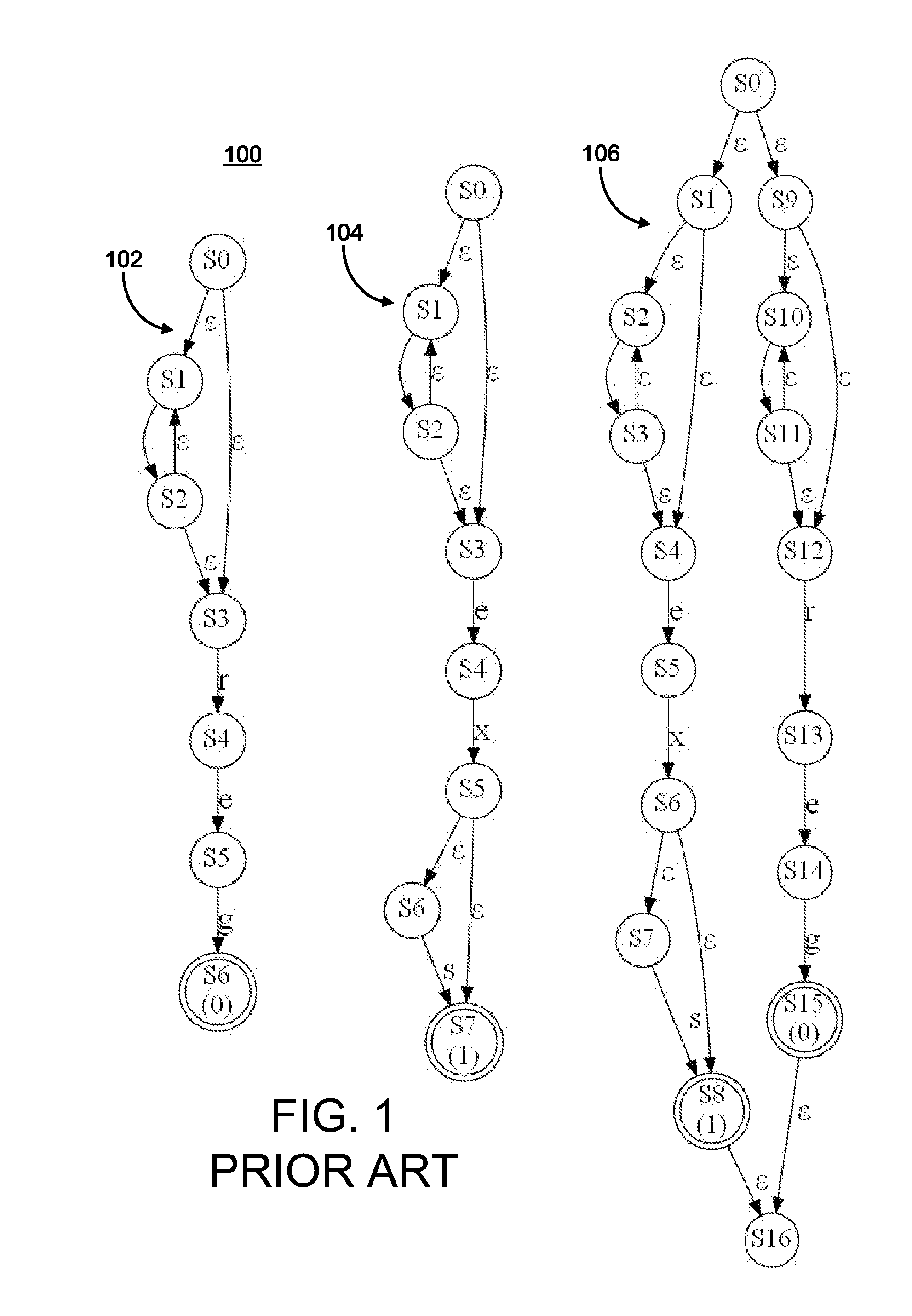

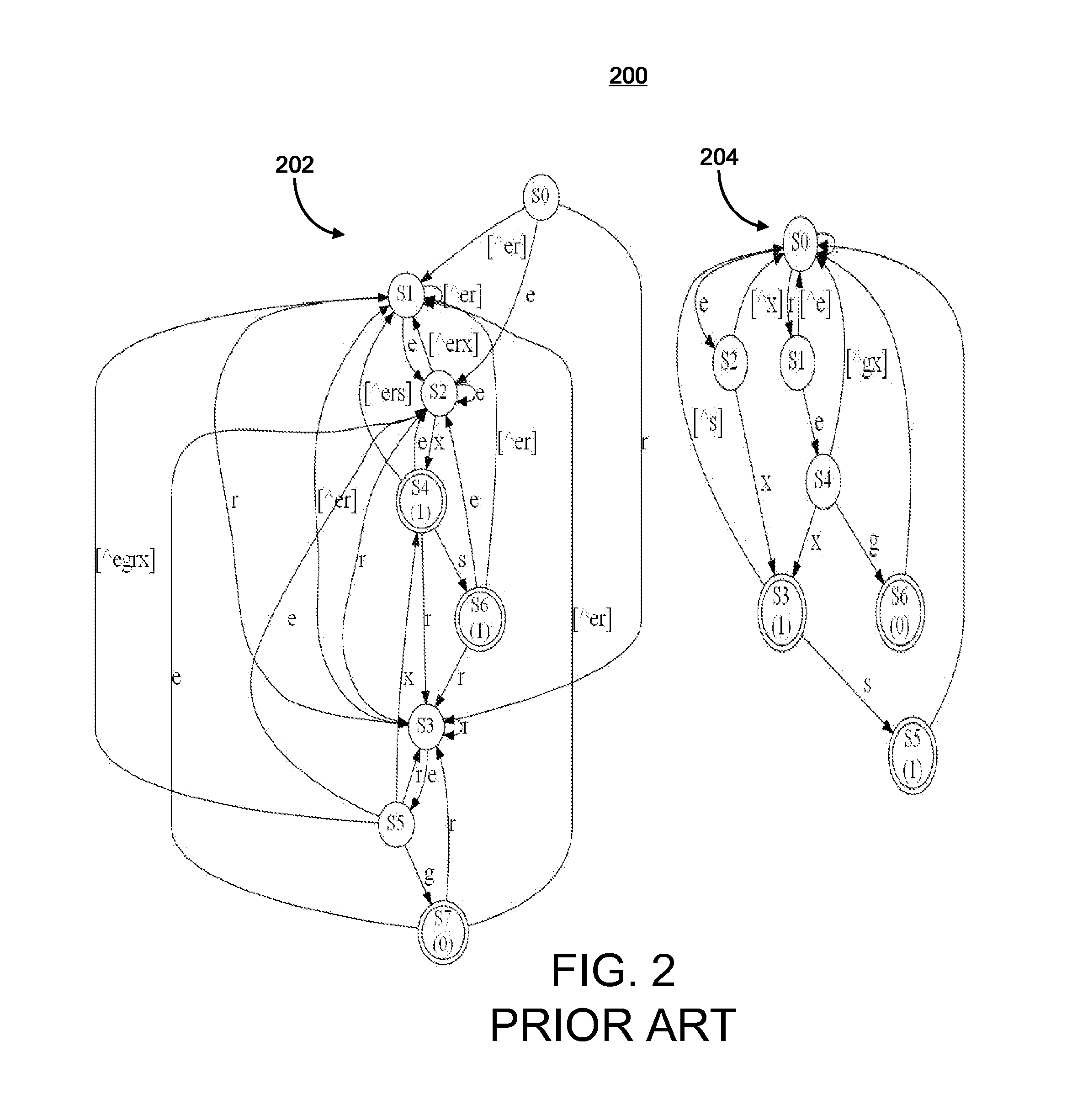

Deterministic finite automation minimization

InactiveUS20130282649A1Large DFAsLong timeSoftware engineeringChaos modelsDeterministic finite automatonState form

Deterministic finite automaton (DFA) minimization includes representing a DFA as a data structure including a plurality of states, incoming transitions for each state, and outgoing transitions for each state. A state of the plurality of states is selected as a selected state. The incoming transitions are analyzed for the selected state. A computer determines whether source states of the incoming transitions for the selected state include a pair of equivalent states. The pair of equivalent states is merged based on determining that two of the source states of the incoming transitions for the selected state form the pair of equivalent states.

Owner:IBM CORP

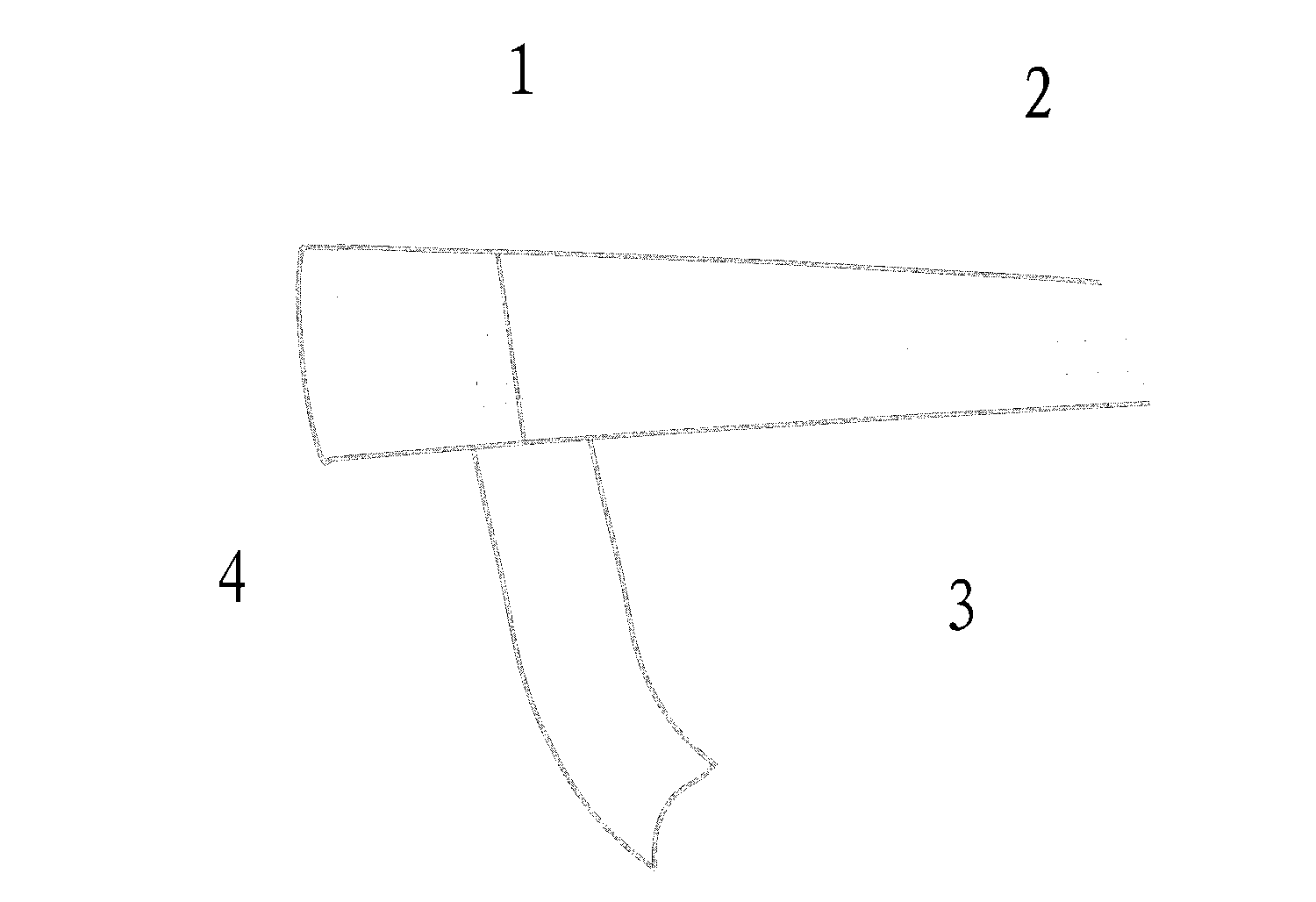

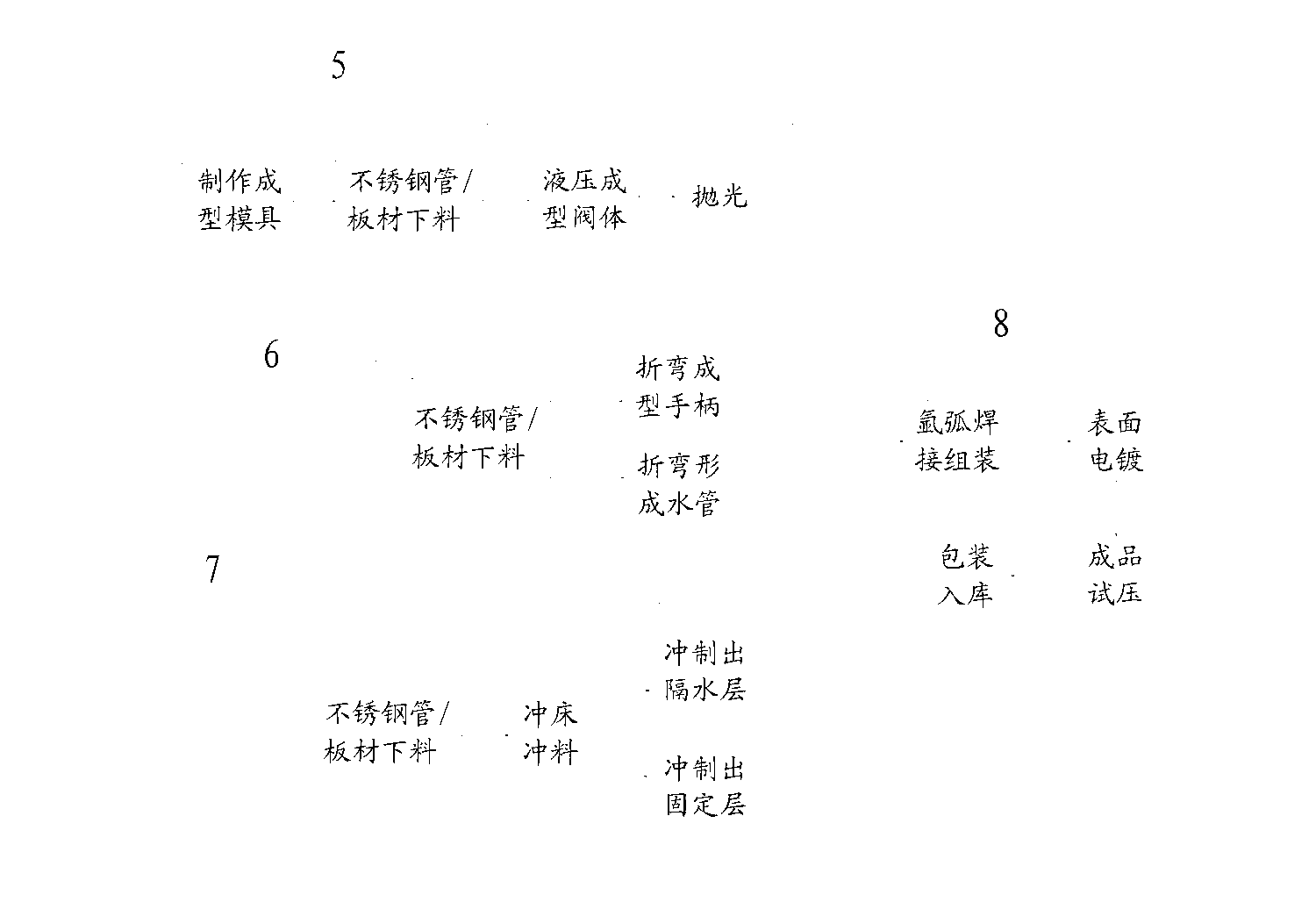

Manufacturing method of stainless steel faucet

A manufacturing method of a stainless steel faucet includes the following steps of manufacturing outer contours of a valve body of the stainless steel faucet, manufacturing a stainless steel handle, manufacturing a hot-water inlet pipe, a cool-water inlet pipe and a mixed water pipe, manufacturing a water-resisting layer, manufacturing a water inflow fixed layer, conducting argon arc welding assembly and integration of the valve body, and conducting polishing treatment. Compared with the prior art, the manufacturing method of the stainless steel faucet effectively avoids phenomena such as sand holes, bubbles and the like caused by pouring of a traditional method due to the fact that ready-made stainless steel pipes and stainless steel panels are used for manufacturing the stainless steel faucet through hydraulic forming, punching of a punch and argon arc welding connection. In addition, the surface of the ready-made stainless steel pipes and stainless steel panels is easy to process, not prone to being oxidized and free from leading to secondary pollution to drinking water and a phenomenon of excessive heavy metal. In addition, the duration time of the brightness of the stainless steel pipes is longer than that of other materials and the service life of the stainless steel pipes is longer than that of other materials.

Owner:王燕冰

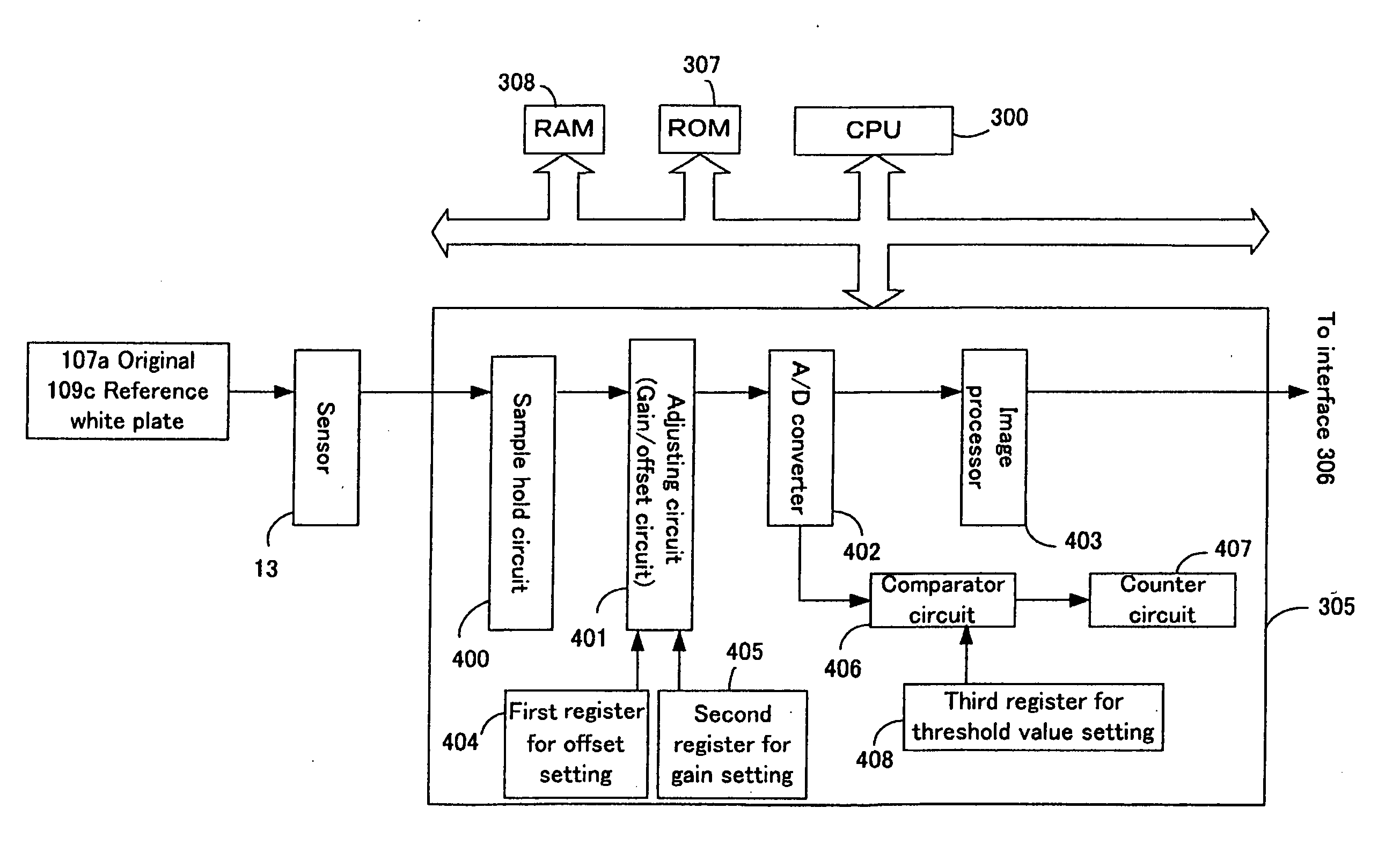

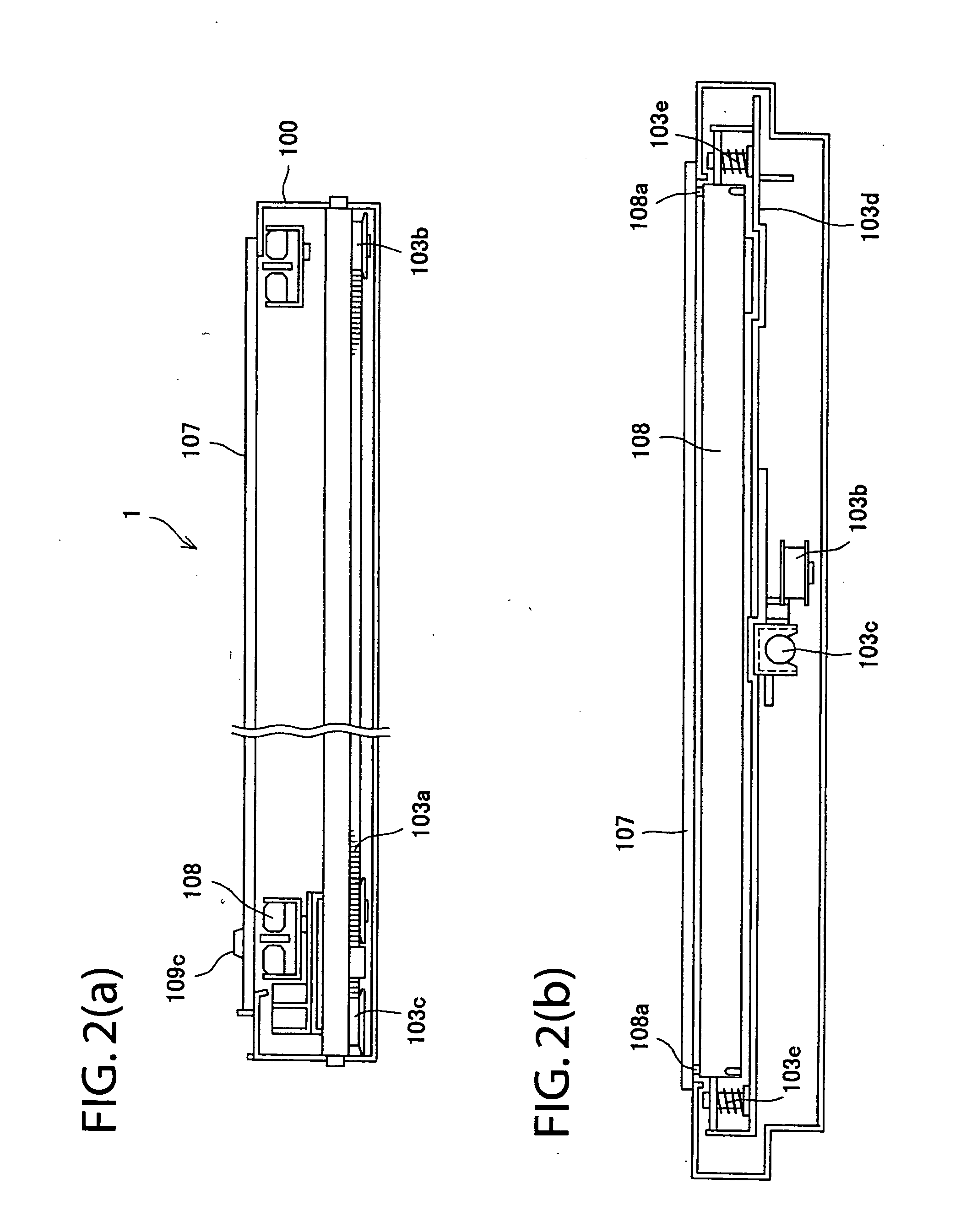

Image reading apparatus and method of determining gain value and offset value for image reading apparatus

ActiveUS20050024246A1Reducing time for adjustmentLong timeElectric signal transmission systemsAnalogue-digital convertersLight sourcePhotoelectric conversion

An image reading apparatus includes a light source for irradiating an original; a photoelectric converter for converting light reflected from the original to an analog signal; an A / D converter for converting the analog signal corresponding to each pixel from the photoelectric converter to the digital signal; and an adjusting device connected between the photoelectric converter and the A / D converter for performing an offset processing and a gain processing of the analog signal from the photoelectric converter. A memory stores a relational formula representing a correlation between an offset value for the offset processing and a gain value for the gain processing. An offset value calculating device obtains an offset value corresponding to a gain value used in the gain processing of the analog signal by using the gain value and the relational formula stored in the memory.

Owner:NISCA KK

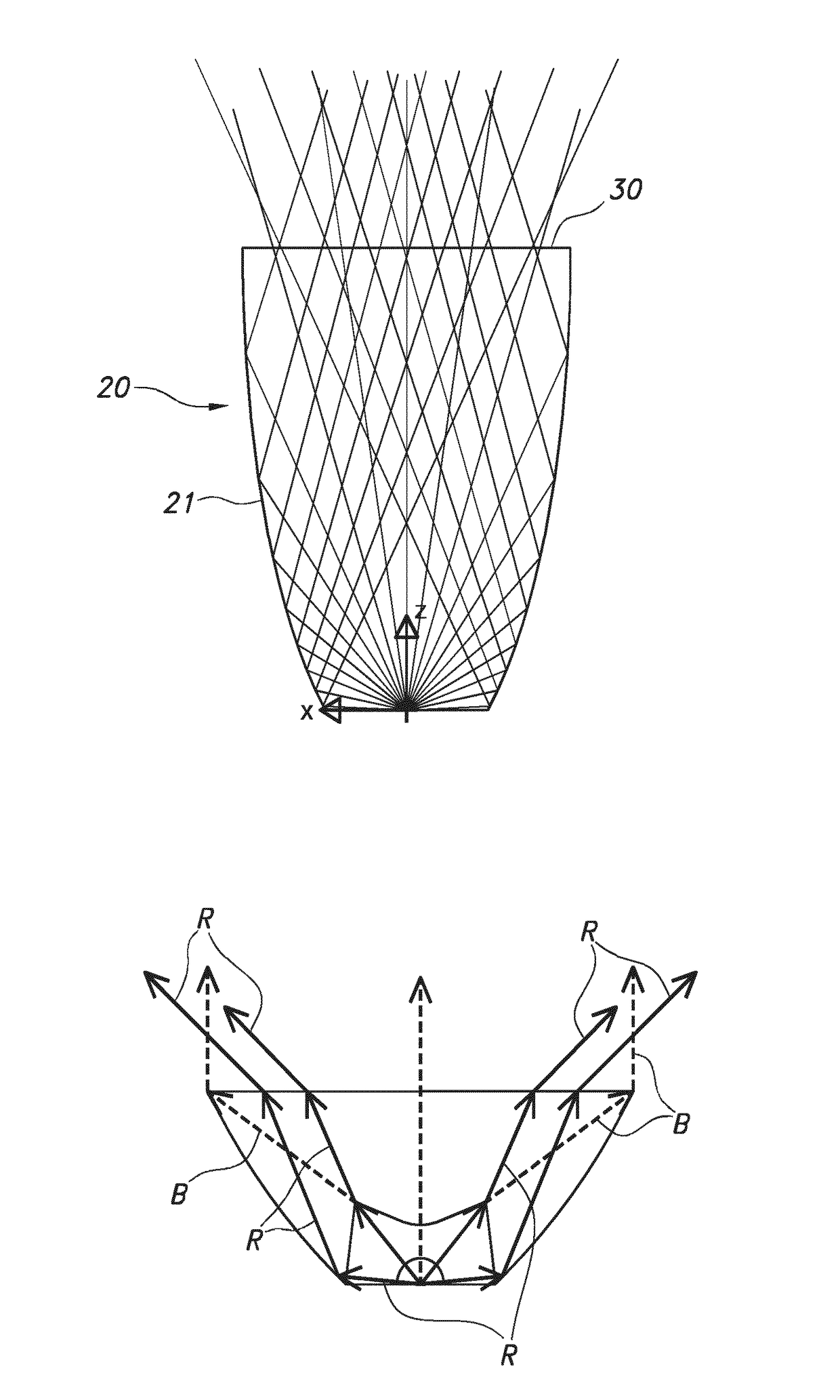

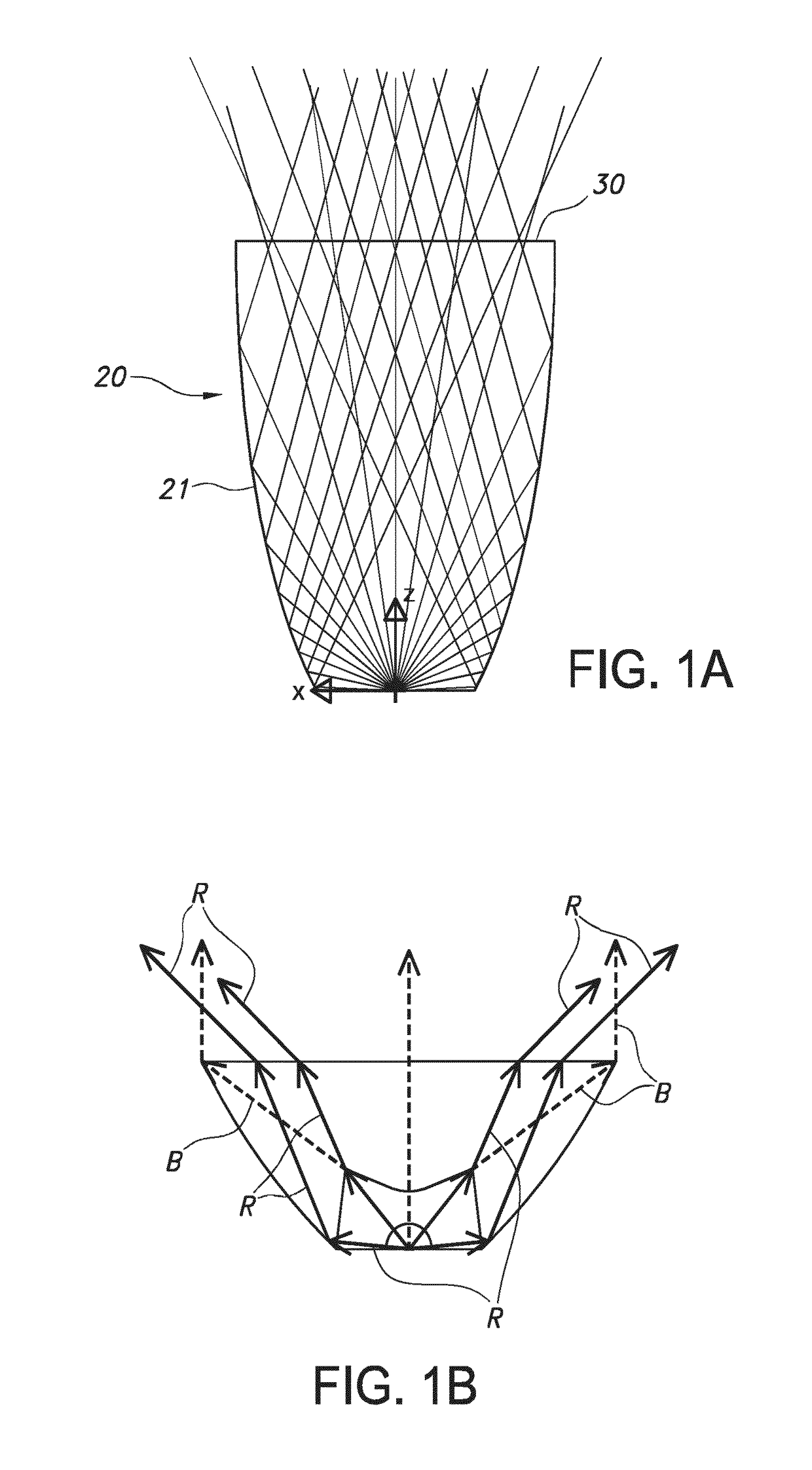

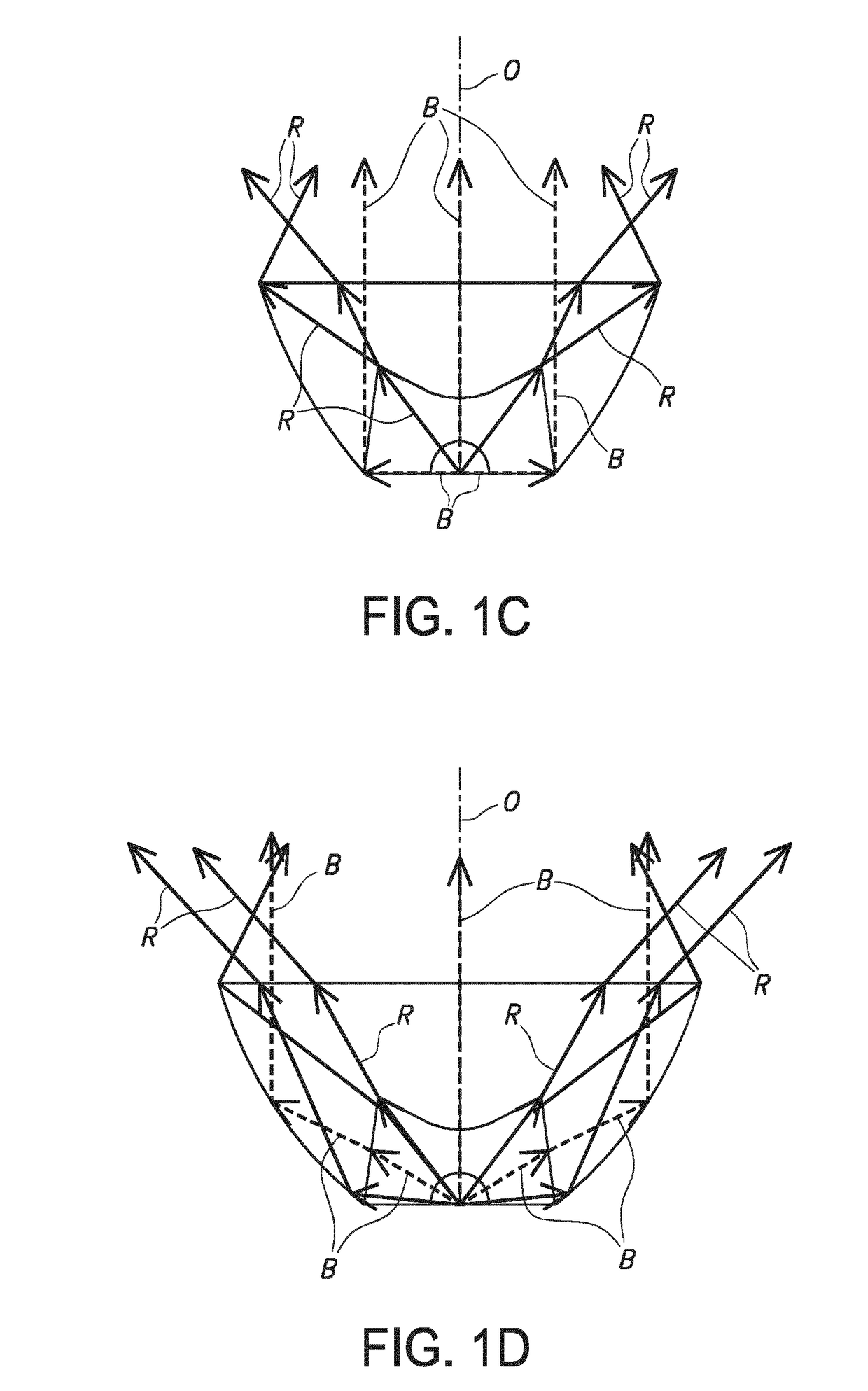

LED spot with customizable beam shape, beam color and color uniformity

ActiveUS20180195684A1Long timeAdd to overall heightAdditive manufacturing apparatusPoint-like light sourceBeam modifierLight source

The invention provides a lighting unit (1000) comprising a lighting device (100), wherein the lighting device (100) comprises a light source (10) configured to provide light source light (11) and beam shaping optics (20) configured to shape the light source light into a lighting device beam (101), wherein the lighting device (100) comprises a window (30) comprising an upstream face (31) directed to the light source (10) and a downstream face (32), wherein the lighting unit (1000) further comprises a beam modifier (200) configured adjacent to the window (30) and configured to intercept at least part of said lighting device beam (101), wherein the lighting device (100) and the beam modifier (200) are configured to modify said lighting device beam (101) to provide a lighting unit beam (1001) downstream from said beam modifier (200), wherein the beam modifier (200) comprises a printed beam modifying element (210).

Owner:SIGNIFY HLDG BV

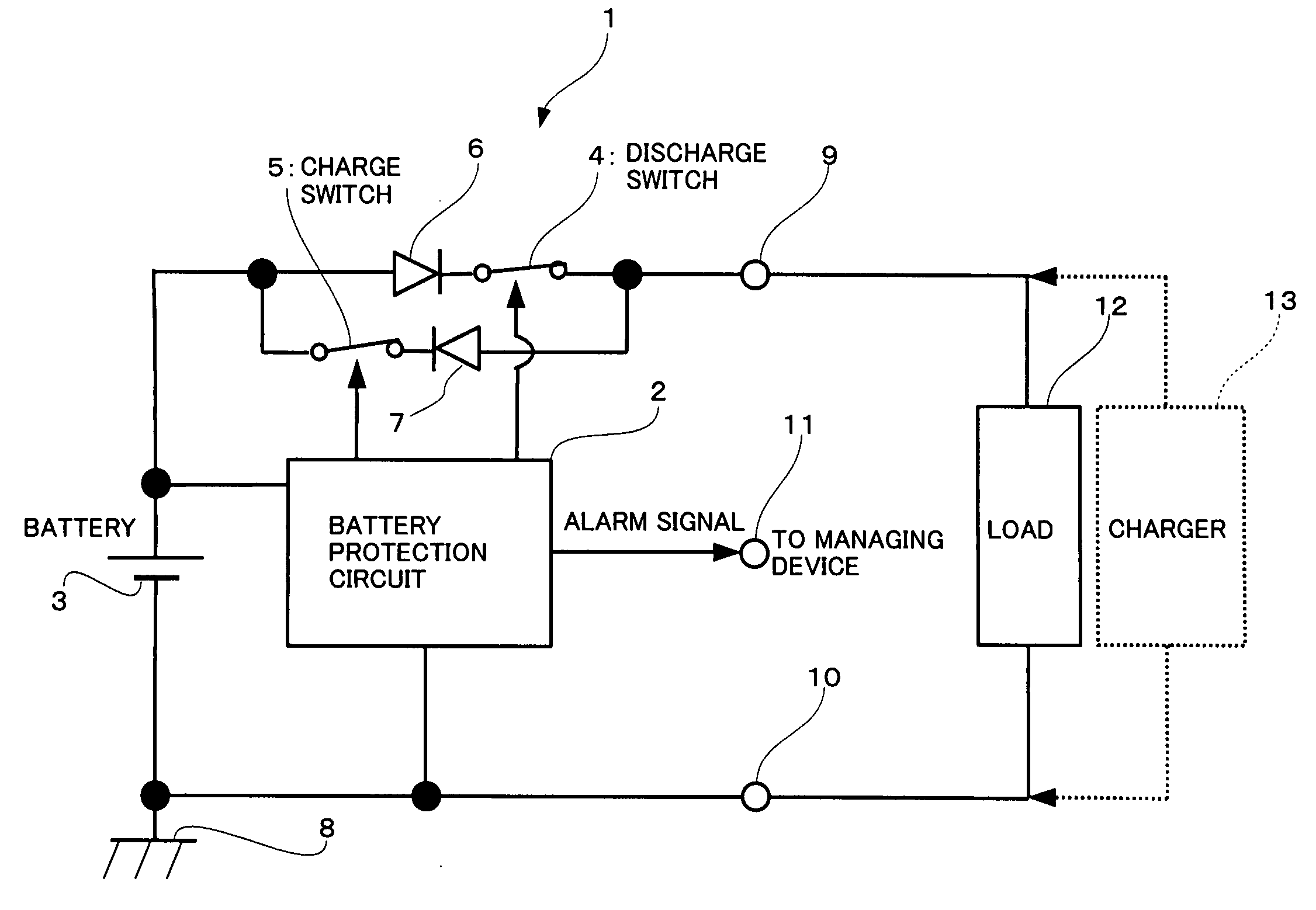

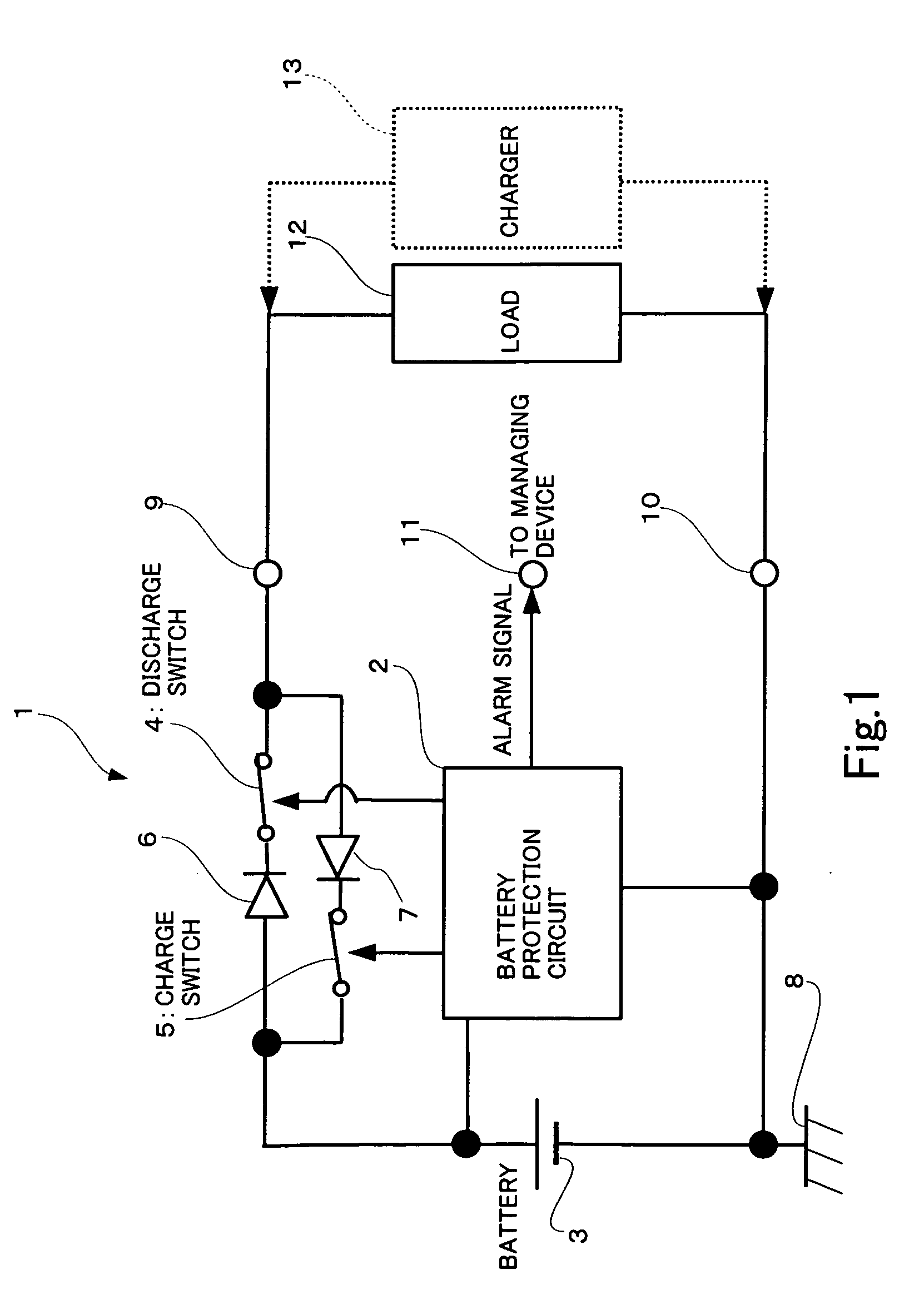

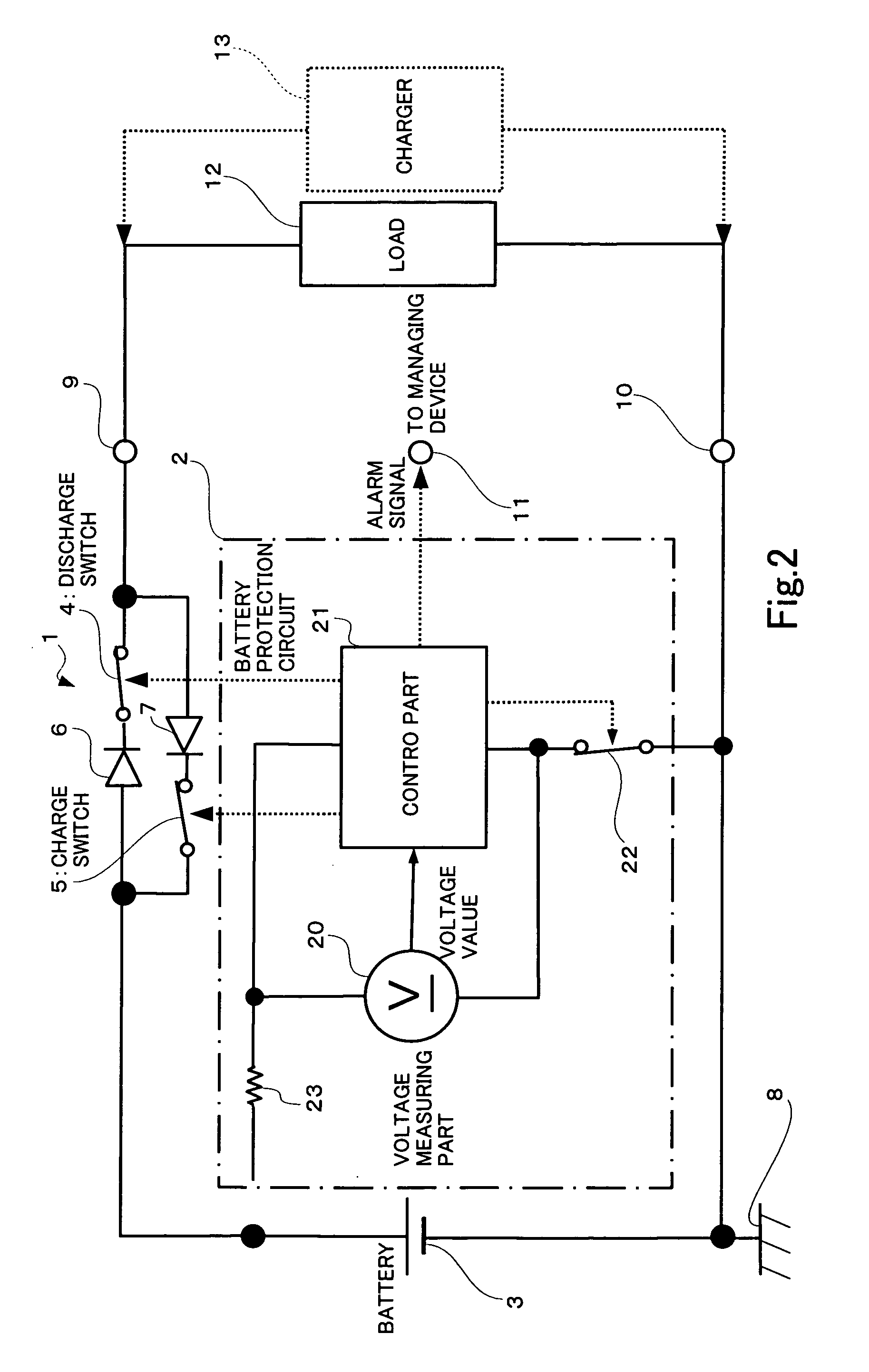

Battery protection circuit, method for protecting battery, power supply device and program

InactiveUS20100259222A1Long timeAvoid heatingCells structural combinationSecondary cells charging/dischargingPower switchingEngineering

A reusable period of a battery can be maintained for a long time by recharging while avoiding abnormal heating of the battery due to over discharge. A battery protection circuit comprises a control part that cuts off a discharge switch which is a discharge path to a load for a battery when a voltage value of the battery is equal to or less than a first threshold value, or when the voltage value of the battery is less than the first threshold value, wherein the control part cuts off a power switch as a power supply path to the control part itself when the voltage value of the battery is equal to or less than a second threshold value, or when the voltage value of the battery is less than the second threshold value which is lower than the first threshold value.

Owner:TDK LAMBDA CORP +1

Steam generating device

InactiveUS20070187389A1Long timeHigh temperatureSteam generation heating methodsMilk treatmentEngineeringForeign matter

Owner:CHIANG LI YUAN

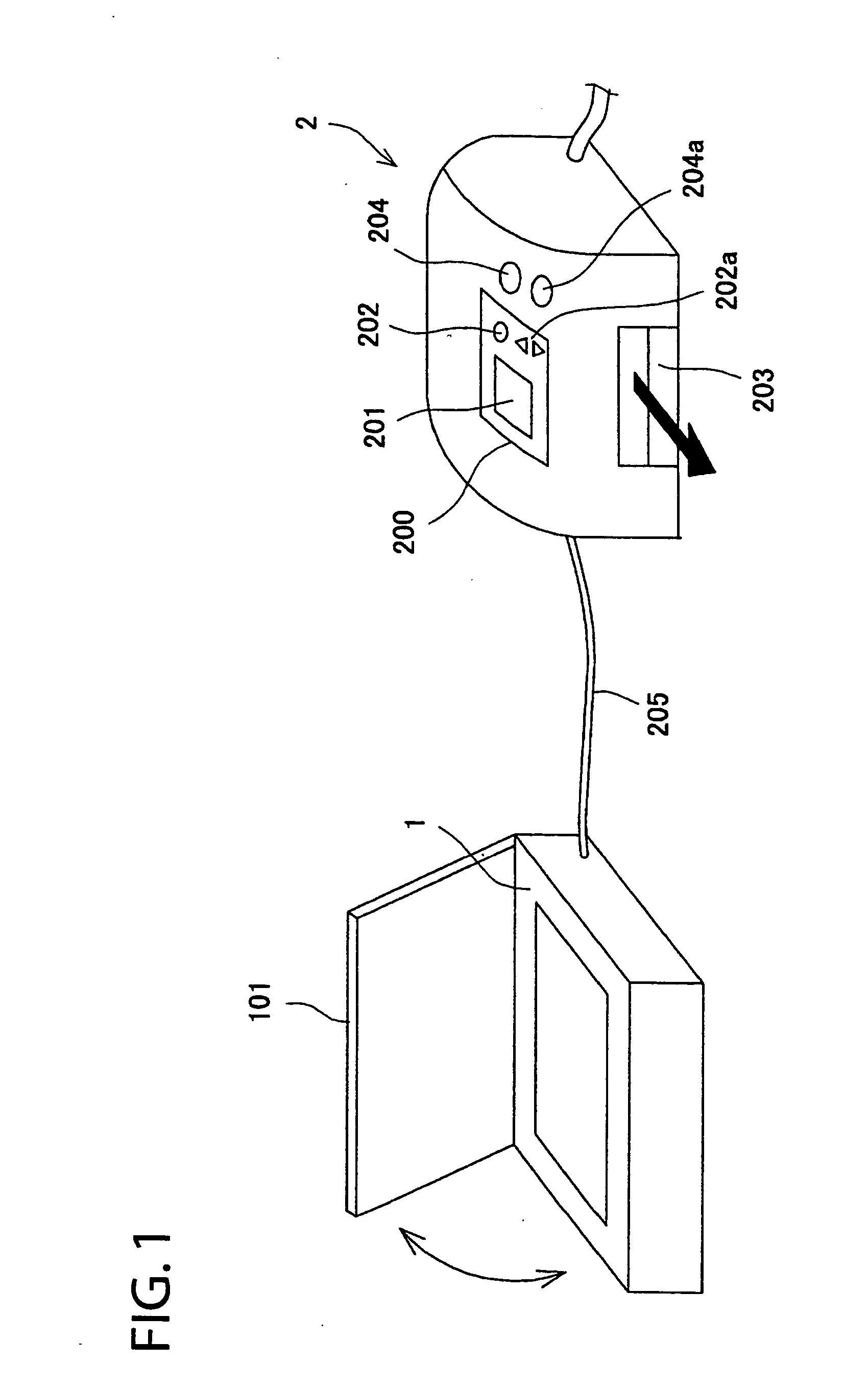

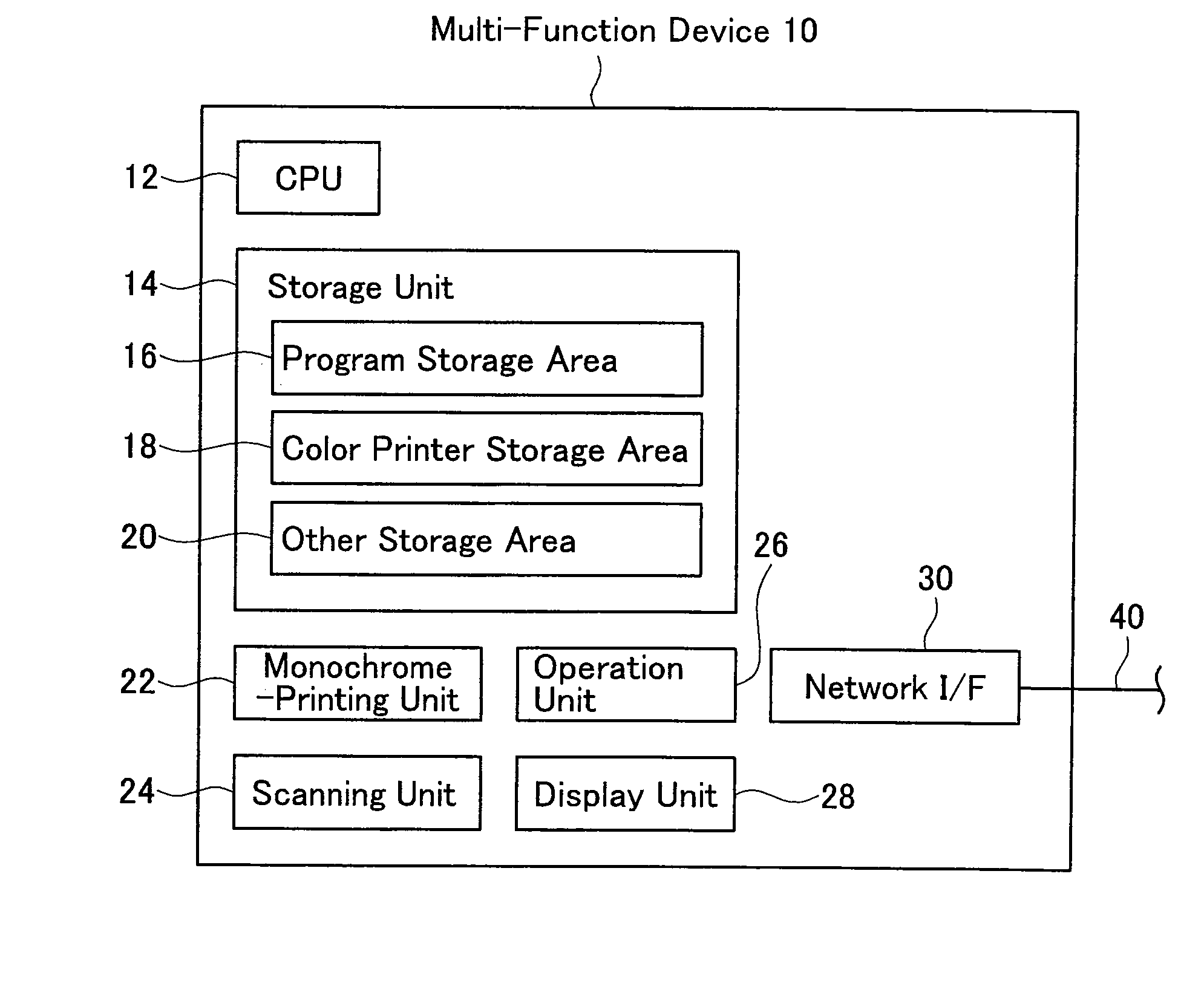

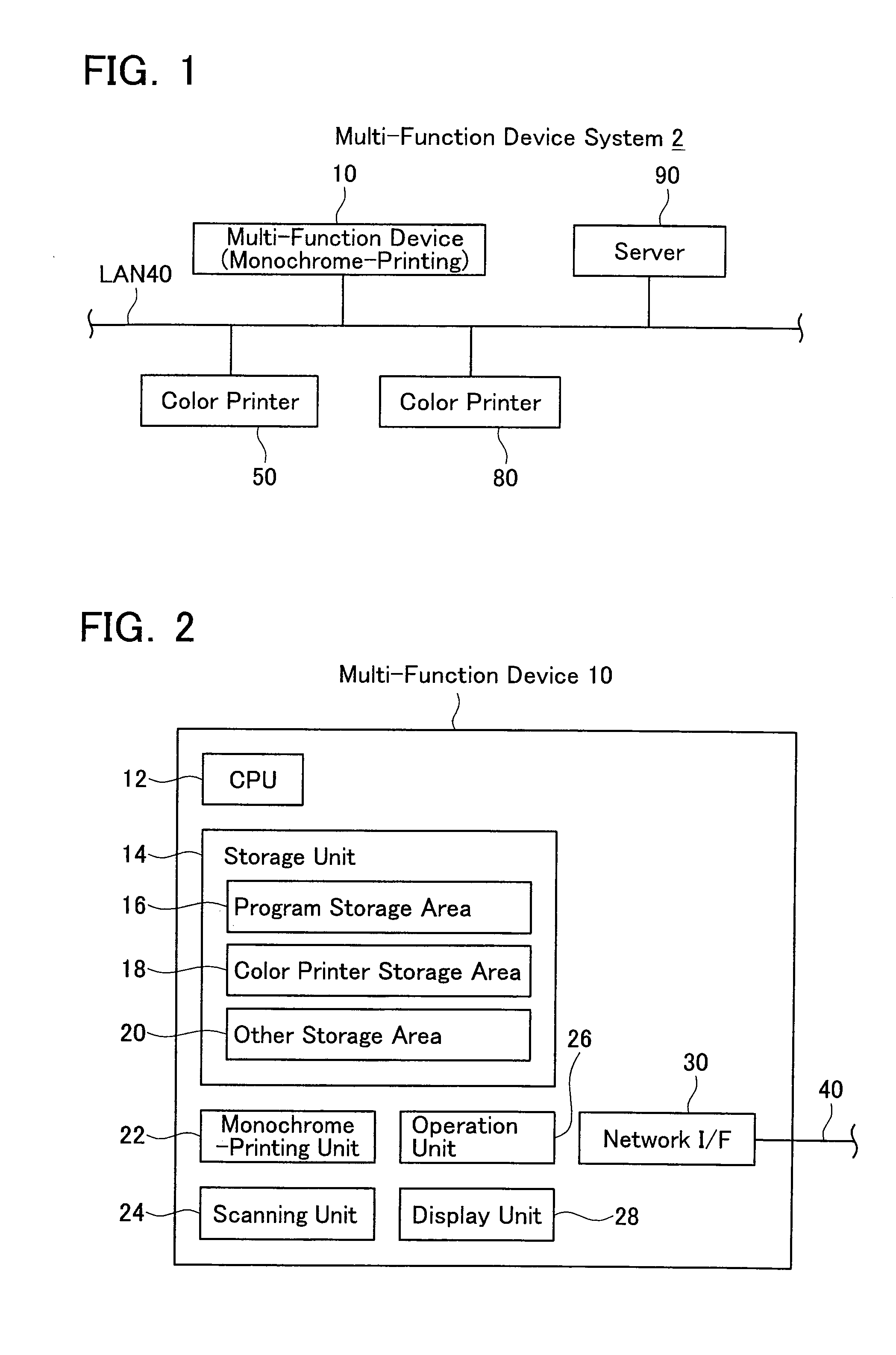

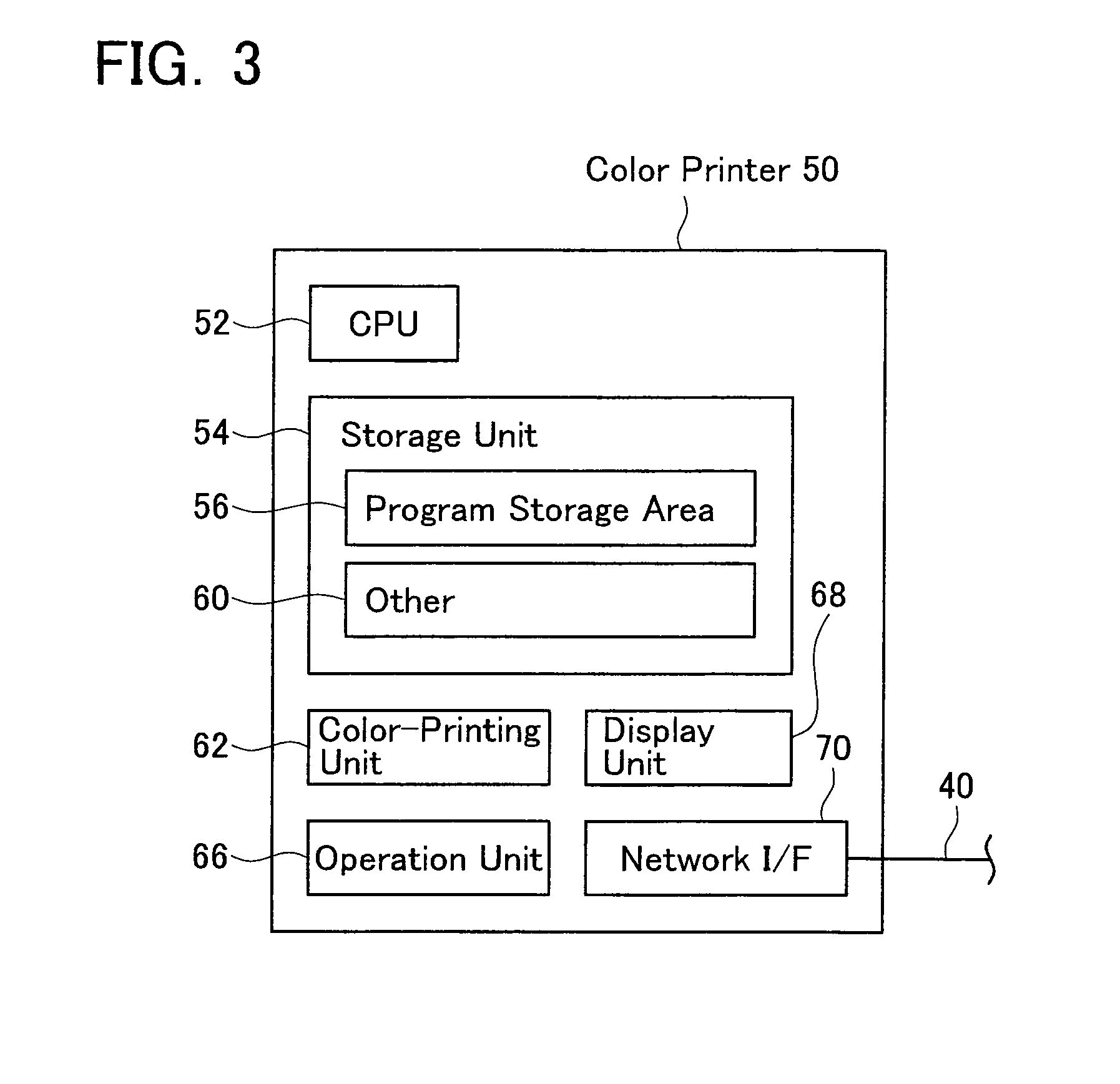

Multi-Function Device

ActiveUS20100053659A1Long timeShorten the timePictoral communicationDigital output to print unitsMultiple functionImaging data

A multi-function device may be connected with a color printer capable of printing in a communicable manner. The multi-function device may be configured to store identification information of the color printer, to color-scan an object to be scanned, to monochrome-print based on first image data representing an scanned object, to allow a user to input an instruction, and to send second image data representing a color-scanned object with the identification information of the color printer as a destination if a predetermined instruction is input.

Owner:BROTHER KOGYO KK

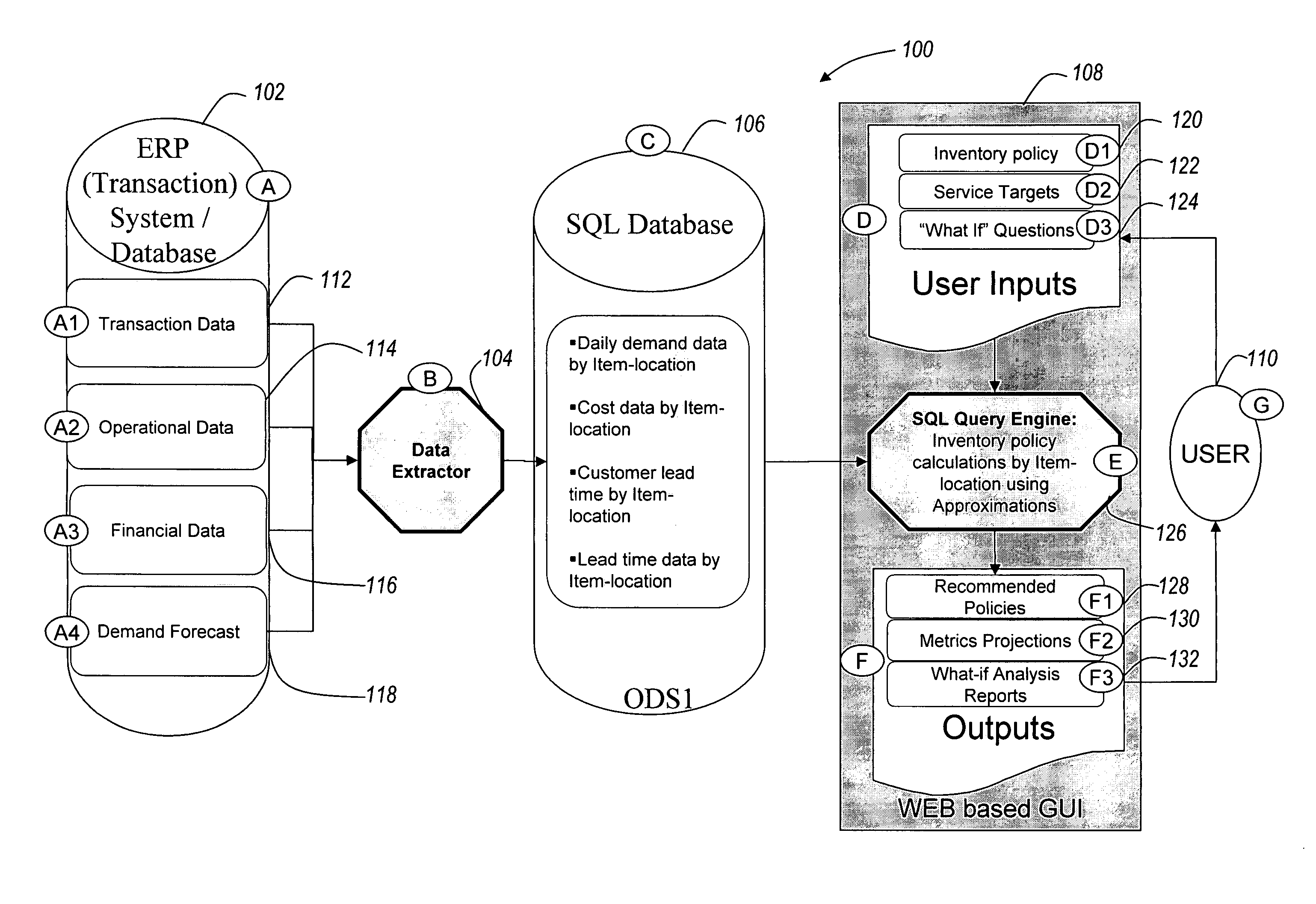

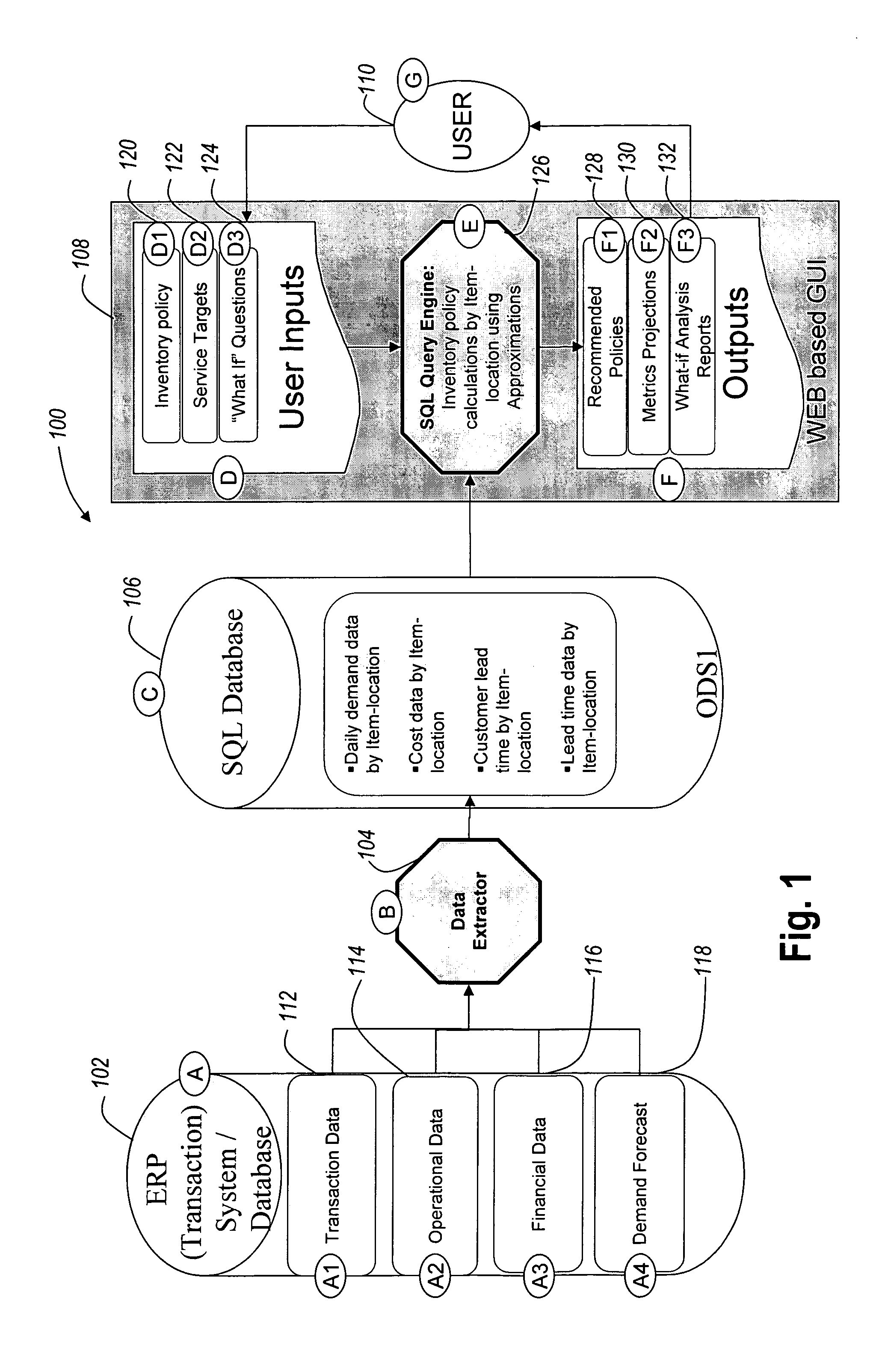

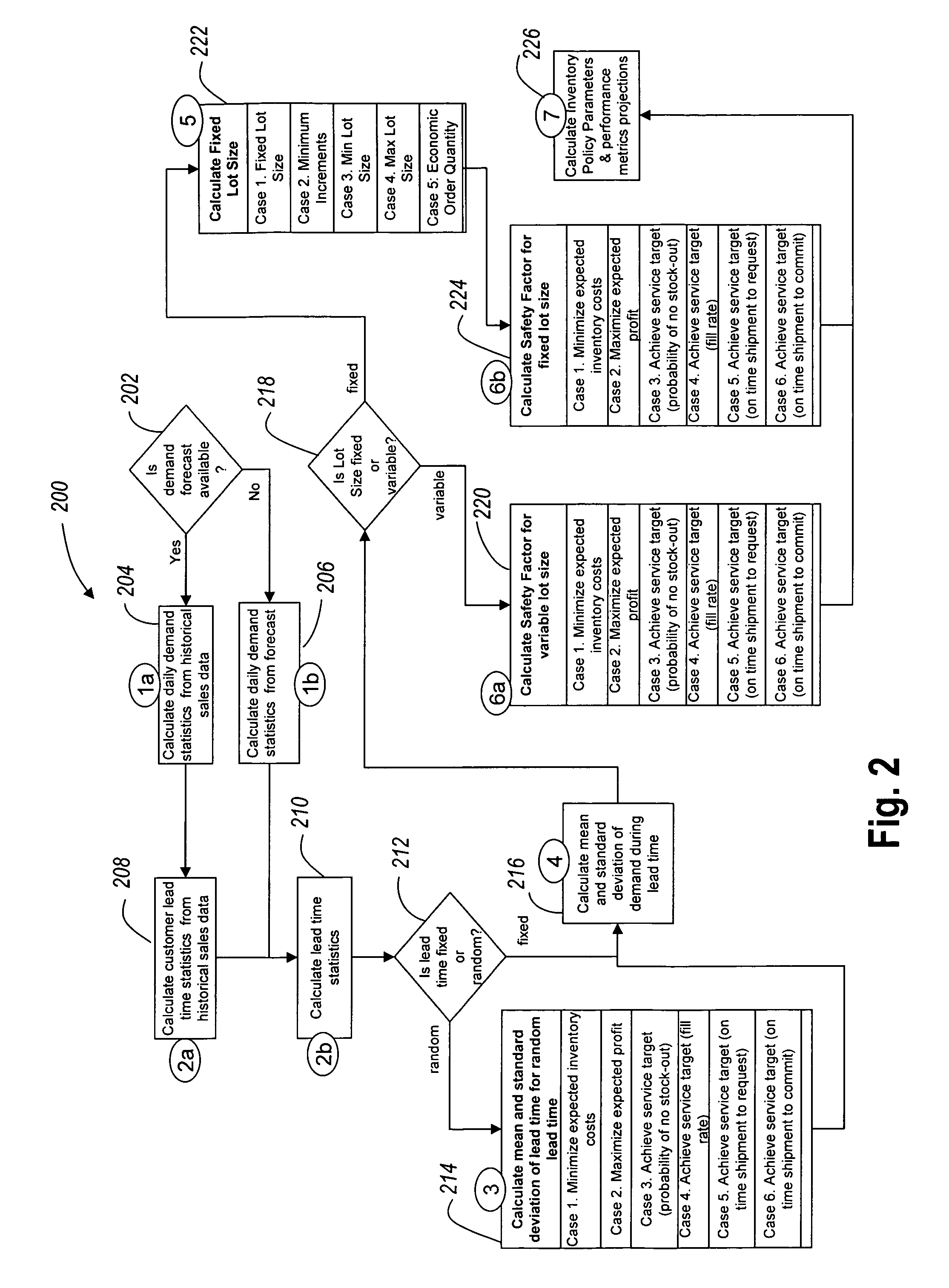

Methods and systems for inventory policy generation using structured query language

InactiveUS20070282803A1Save timeLong timeResourcesSpecial data processing applicationsRDF query languageQuery language

Methods and systems for generating a business policy, include receiving a query in a structured query language to generate a business policy, and optimizing the business policy using a structured query language program.

Owner:IBM CORP

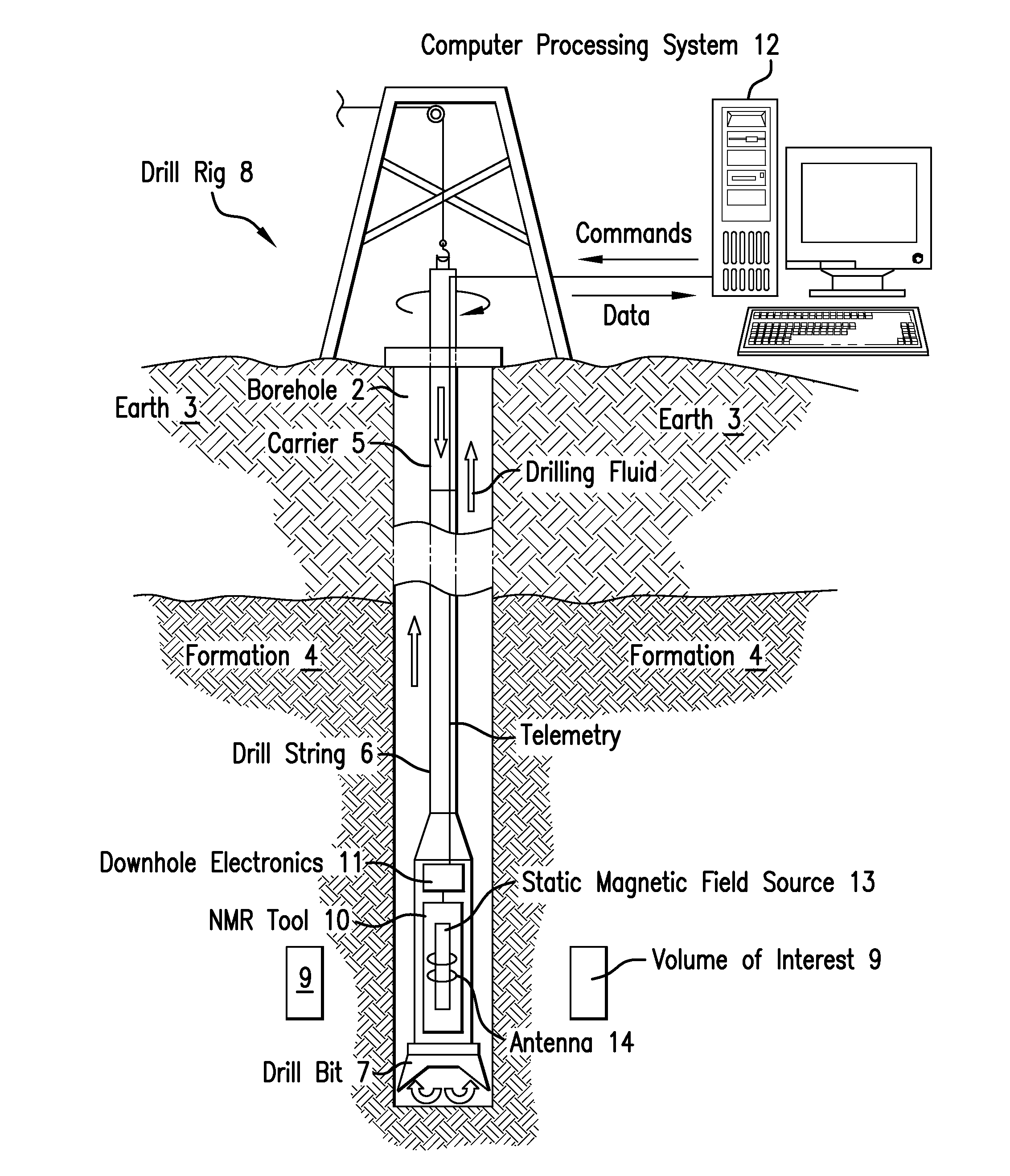

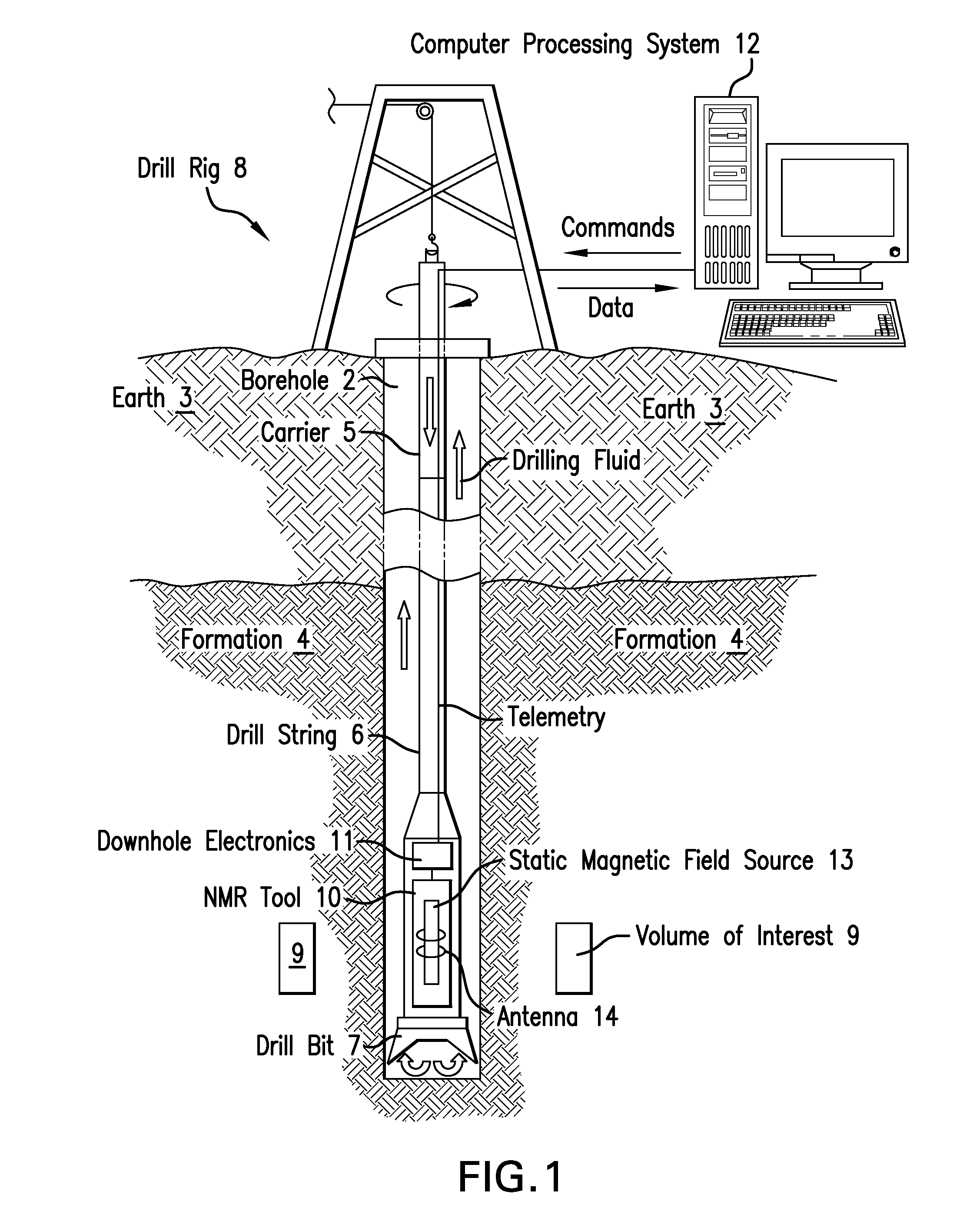

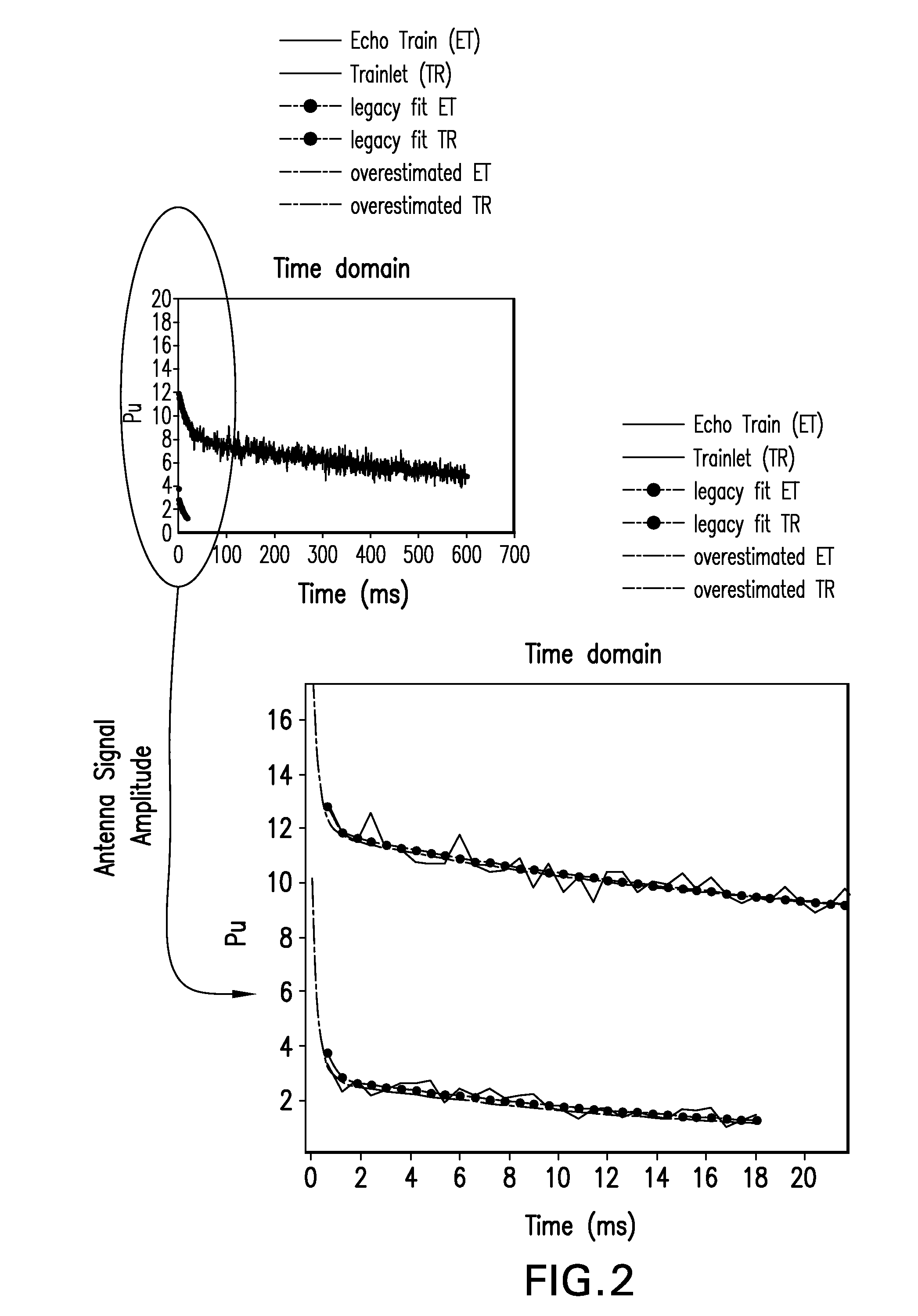

Nmr t2 distribution from simultaneous t1 and t2 inversions for geologic applications

ActiveUS20160320519A1Short timeLong timeElectric/magnetic detection for well-loggingSurveyNuclear magnetic resonanceVolume of interest

A method for estimating a property of a subsurface material includes conveying a carrier through a borehole penetrating the subsurface material and performing an NMR measurement in a volume of interest in the subsurface material using an NMR tool having an antenna disposed at the carrier. The method further includes receiving with the antenna a short build-up signal due to a short magnetization build-up time of the NMR measurement, an echo-train signal with short polarization time due to the NMR measurement, and an echo-train signal with long polarization time due to the NMR measurement. The method further includes inverting, simultaneously, the short build-up signal, the short-polarization-time echo-train signal, and the long-polarization-time echo-train signal using a processor to estimate the property; and transmitting a signal comprising the property to a signal receiving device.

Owner:BAKER HUGHES INC

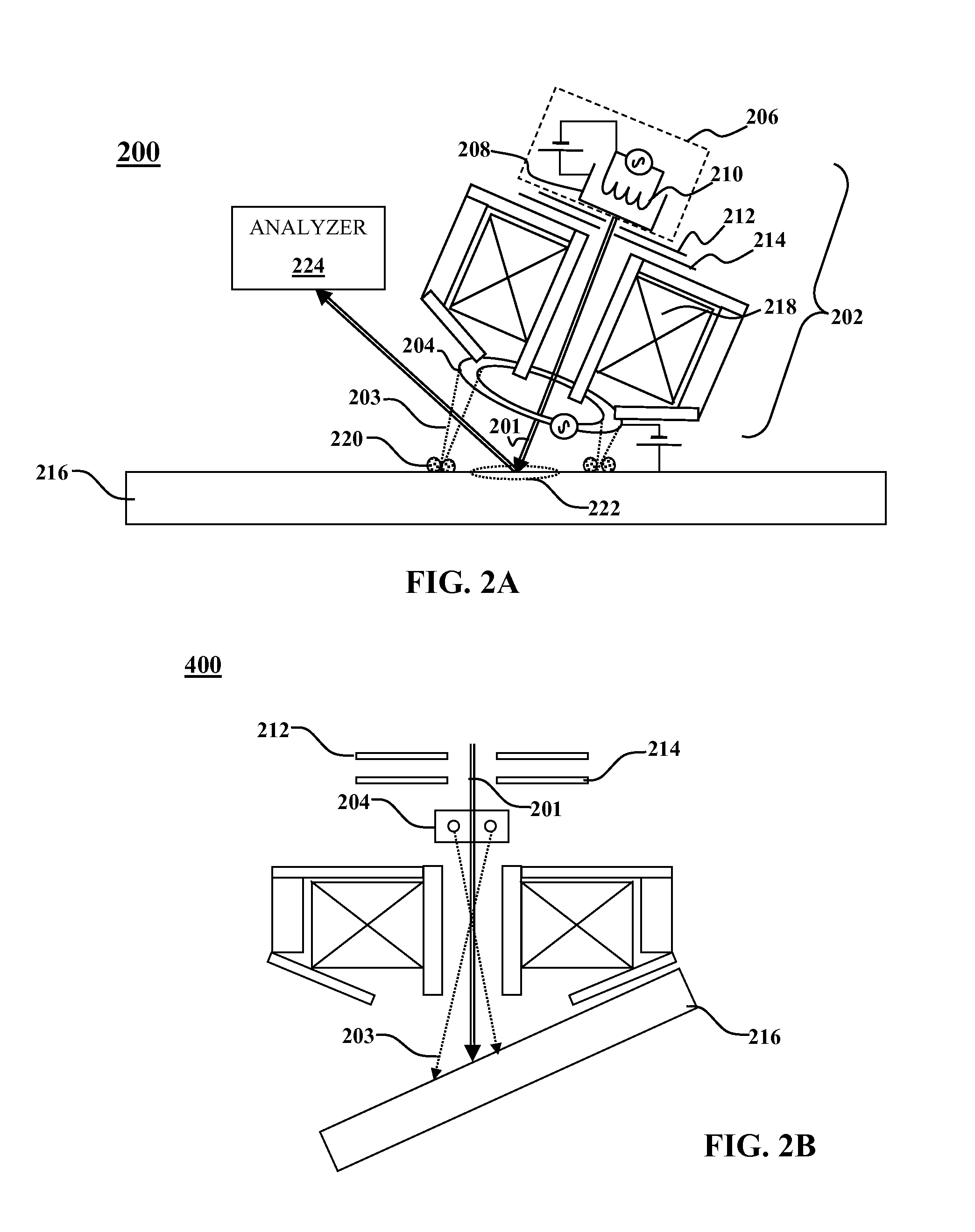

Contamination pinning for auger analysis

InactiveUS7855362B1Short period of timeLong timeMaterial analysis using wave/particle radiationPhotoelectric discharge tubesAuger analysisPollutant

Electron spectroscopy methods and apparatus are disclosed. A beam of primary electrons is applied to a measurement location on a surface of a sample. A pinning flux of electrons is applied to one or more pinning regions proximate the measurement location. The pinning flux is characterized by a location, size, shape, and electron flux configured such that contaminants preferentially migrate to the pinning region rather than the measurement location. Emissions from the surface resulting from interaction with the primary electrons and the surface of the sample at the measurement location are analyzed.

Owner:KLA TENCOR CORP

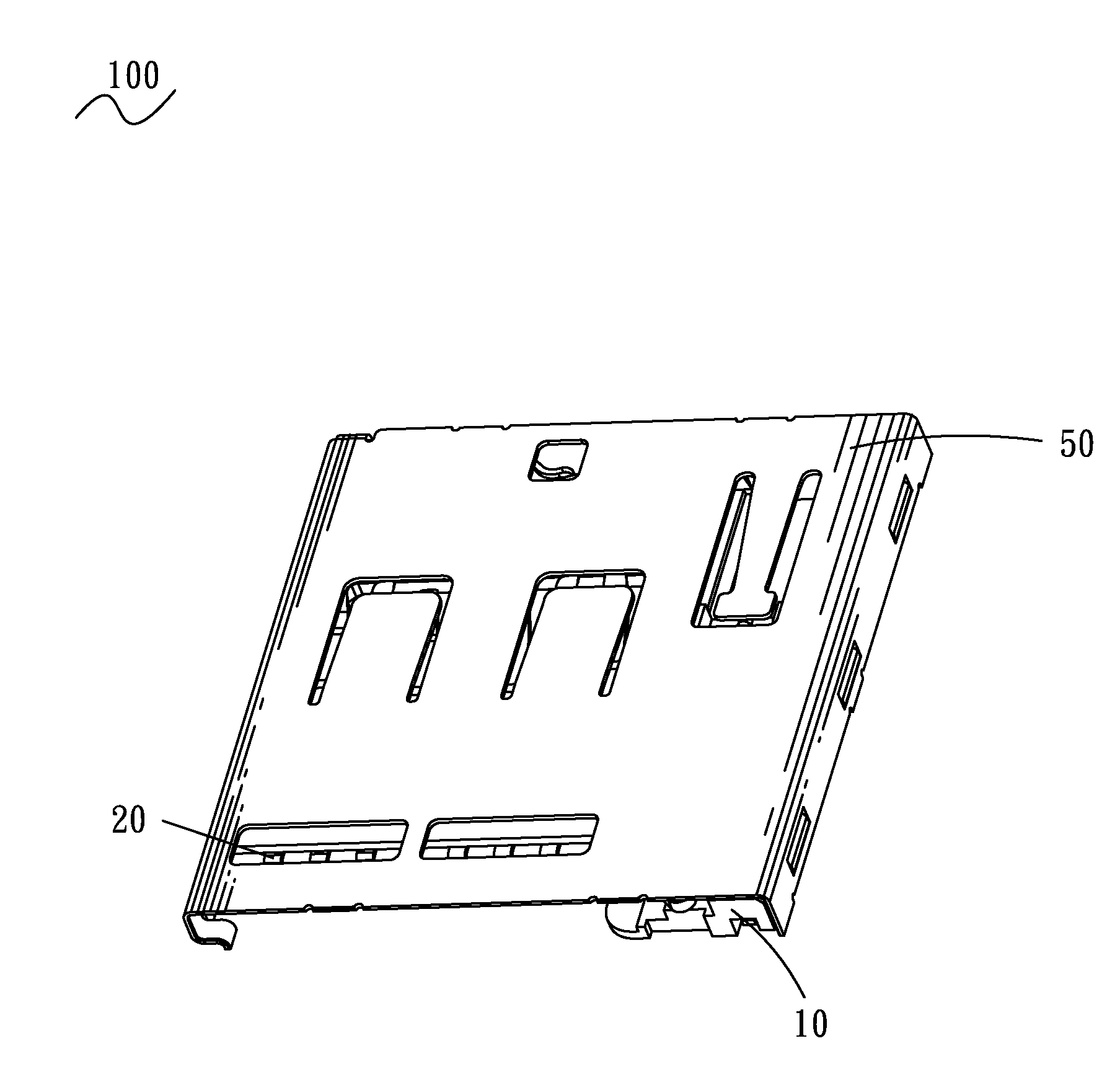

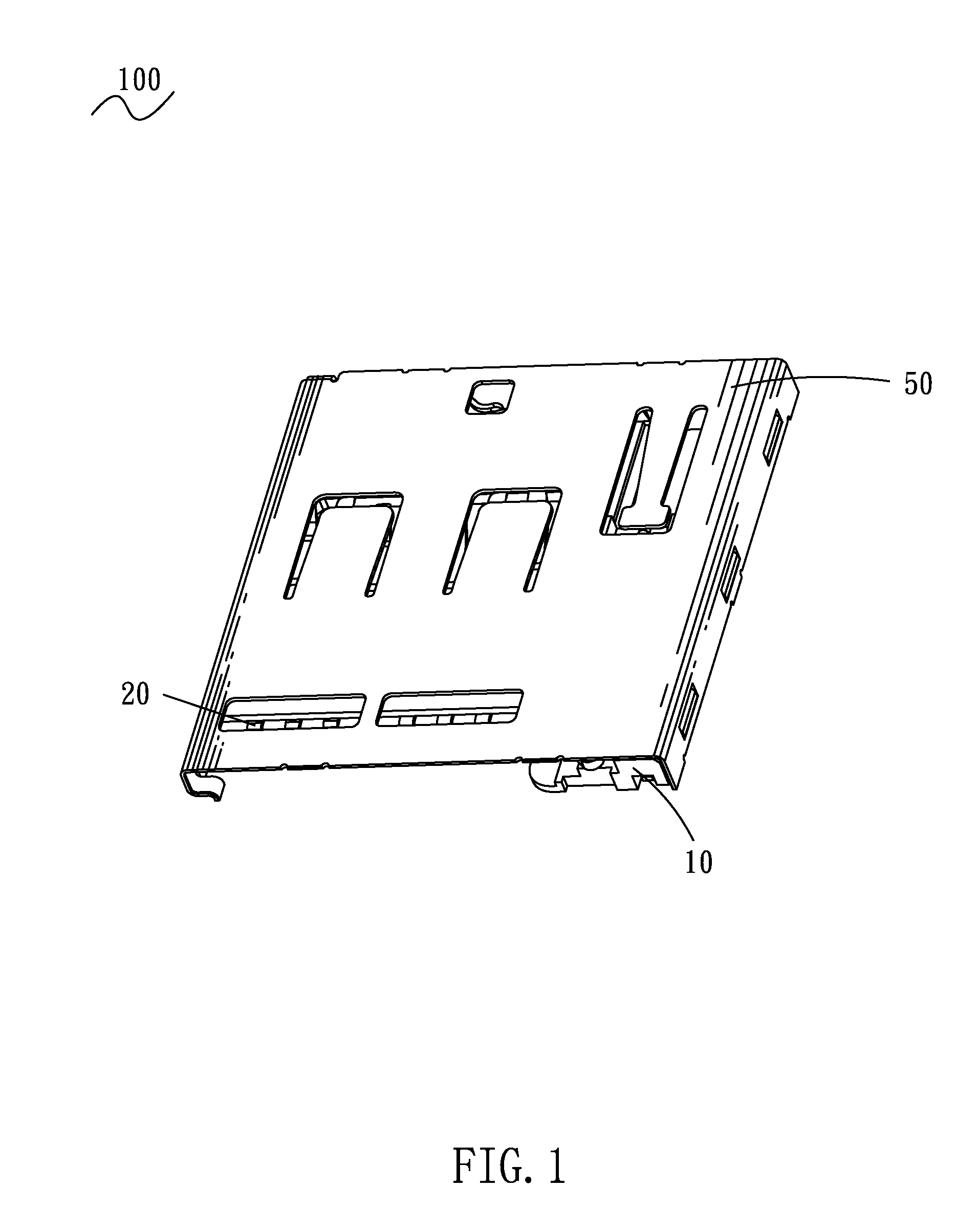

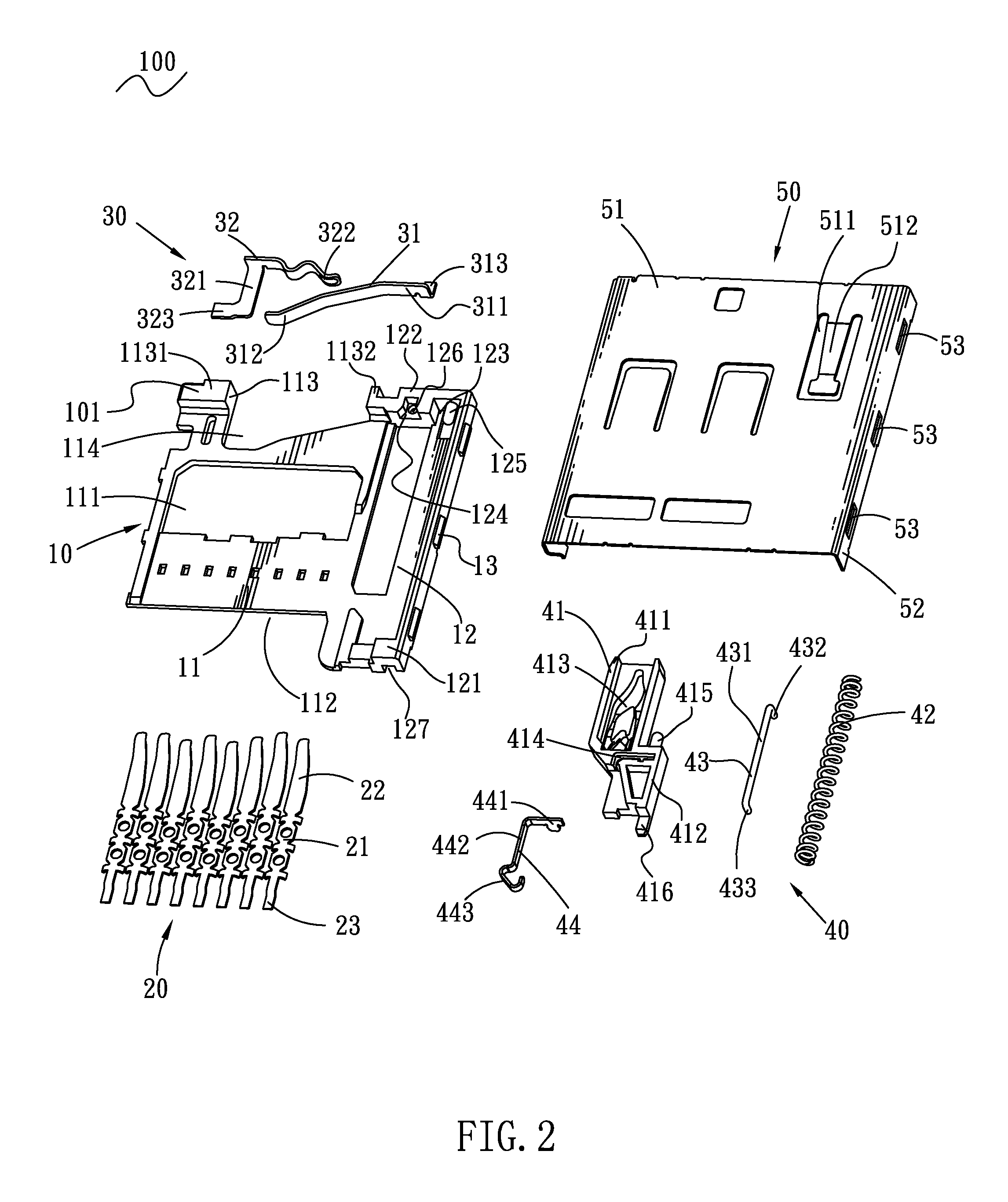

Card Connector

InactiveUS20110151695A1Save assembly timeLong timeEngagement/disengagement of coupling partsCamElectrical and Electronics engineering

A card connector has an insulating housing defining a top, a bottom opposite to the top. An ejection mechanism is disposed at one side of the insulating housing. The ejection mechanism includes a slider, an elastic element and a cam lever. Two opposite ends of the cam lever respectively have a first hook portion for being fixed in a receiving hole defined at the top of the insulating housing and a second hook portion for being movably arranged in the slider and different in length with the first hook portion. The bottom of the insulating housing defines an observation slot communicating with the receiving hole at a portion corresponding to the receiving hole. The height of the receiving hole is shorter than the length of one of the first and second hook portions and not shorter than the other of the first and second hook portions.

Owner:CHENG UEI PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com