Patents

Literature

573results about "Three-component magnetometers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

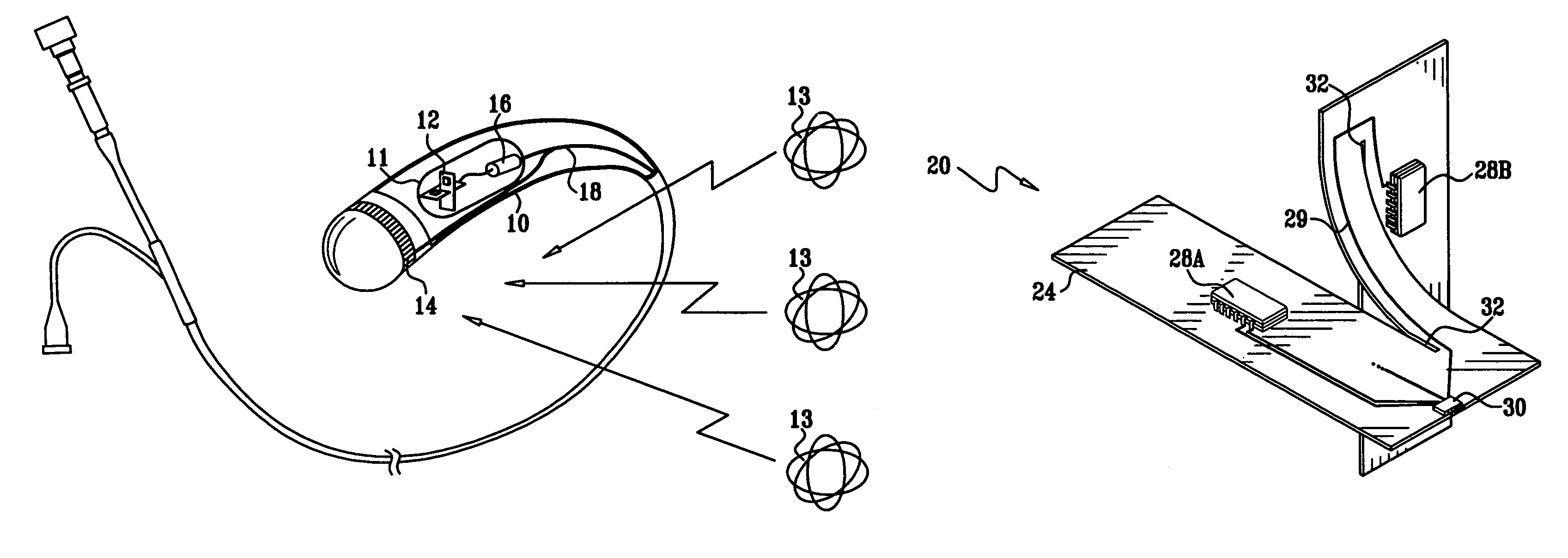

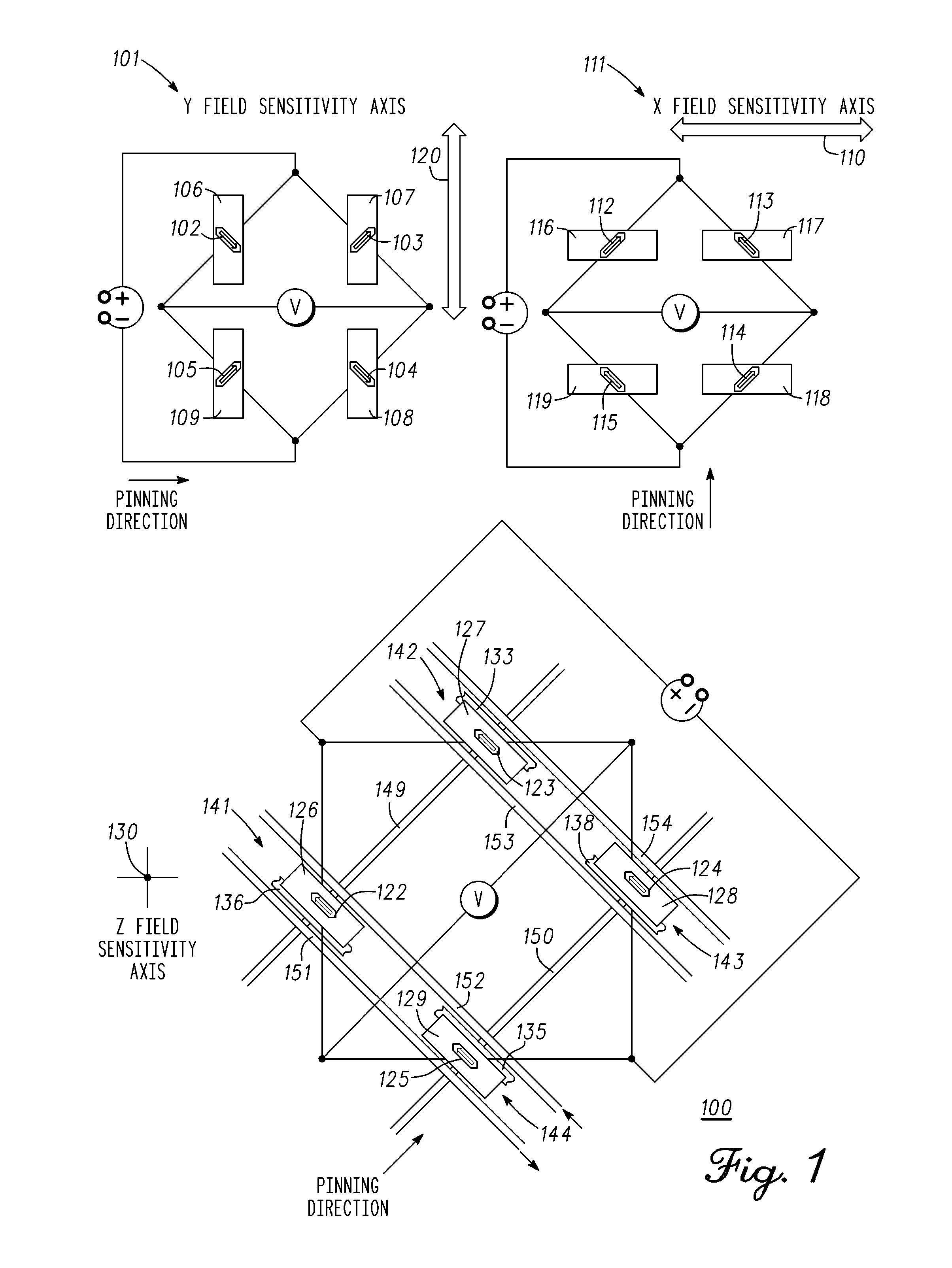

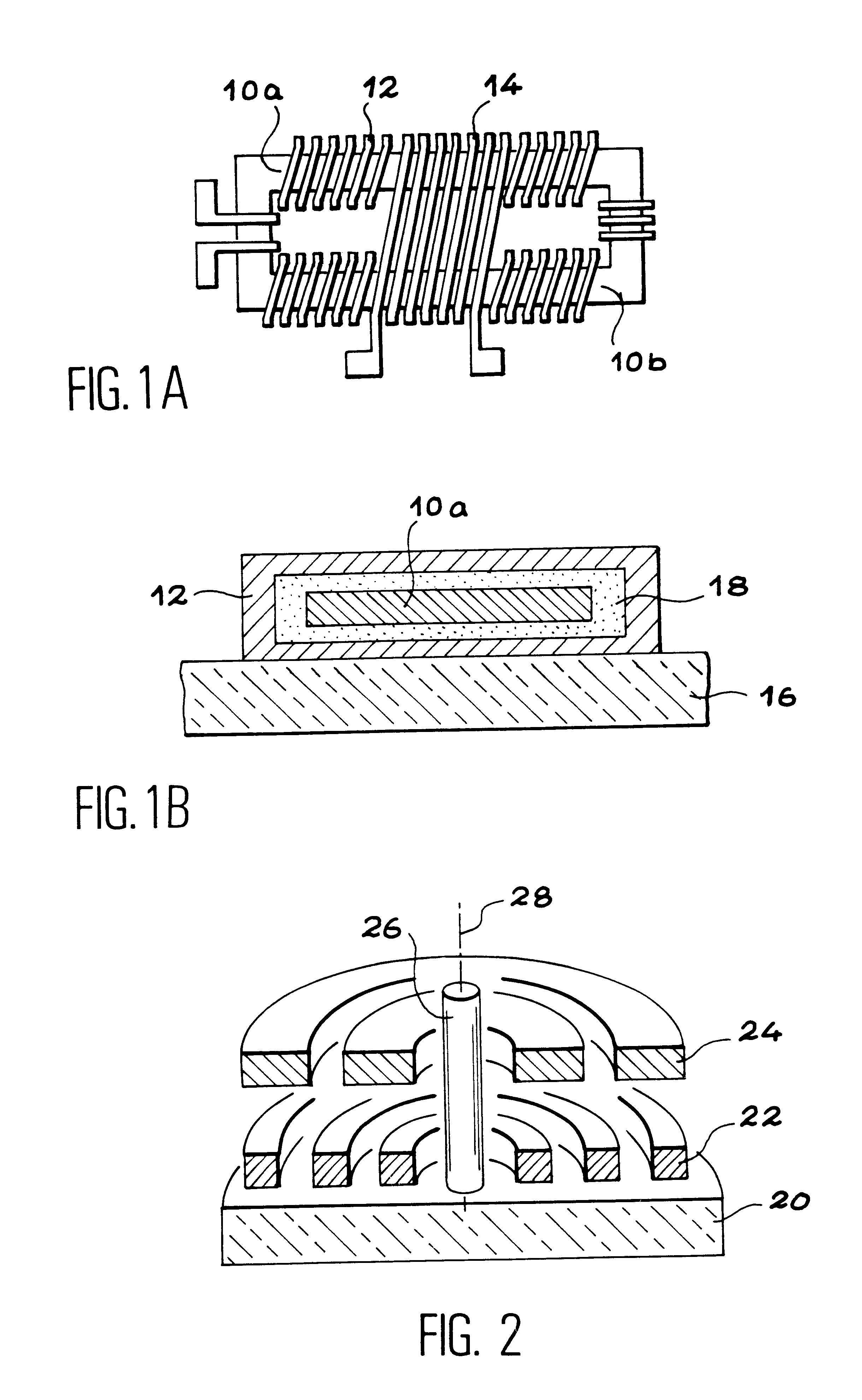

Magnetic sensor assembly

ActiveUS7301332B2Low costSmall profileSurgeryMagnetic-field-controlled resistorsSpatial OrientationsMagneto

Owner:BIOSENSE WEBSTER INC

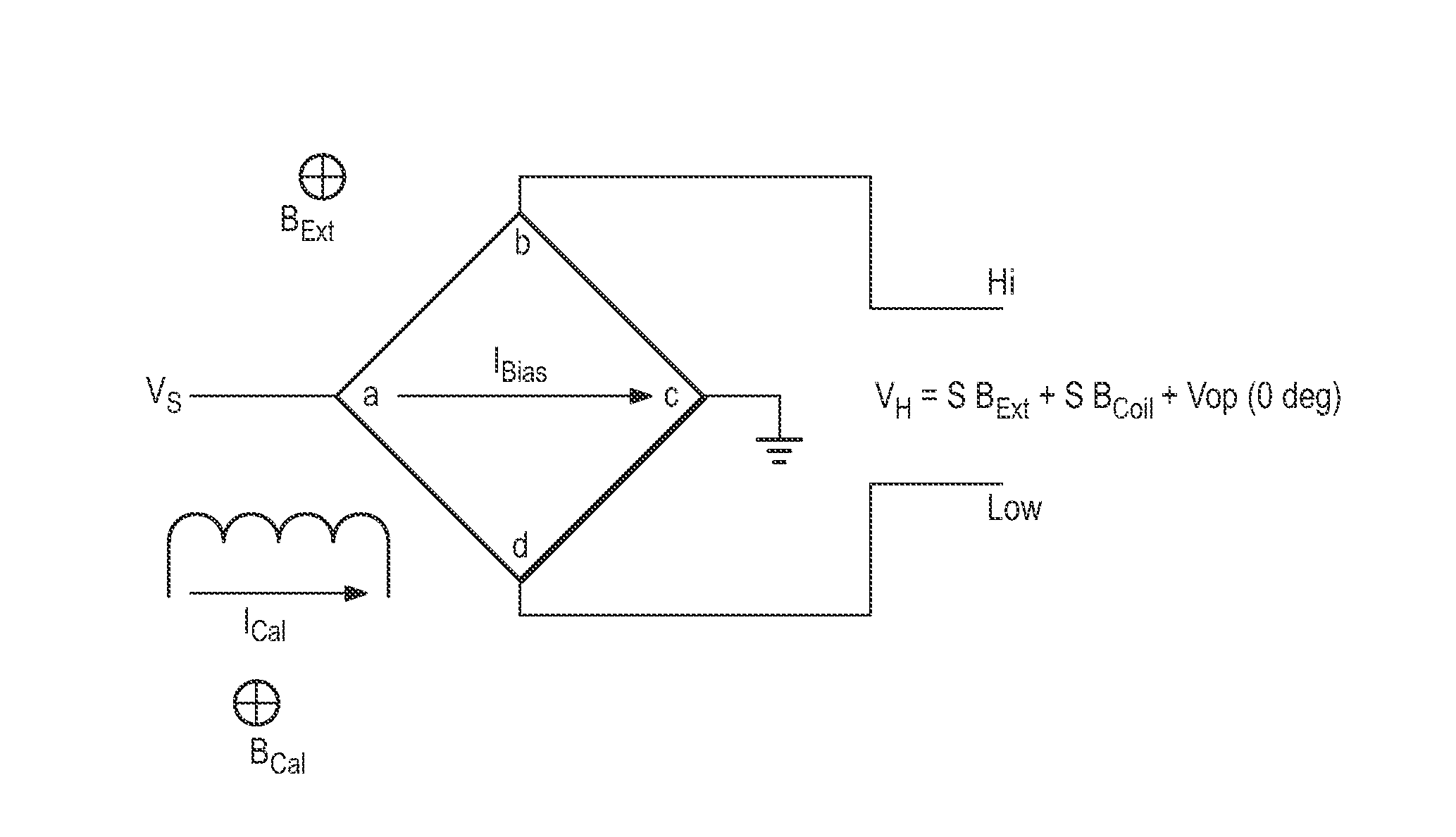

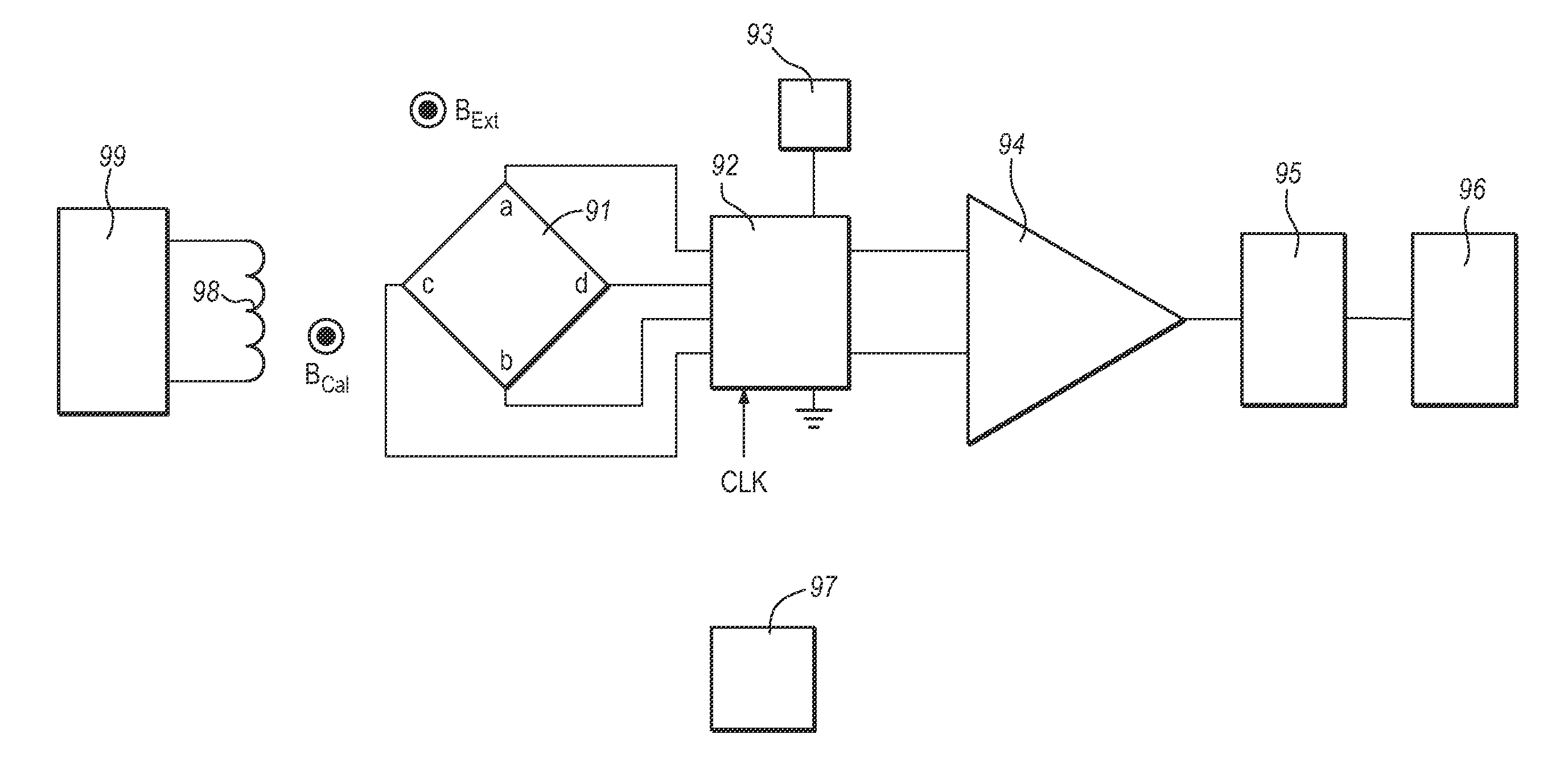

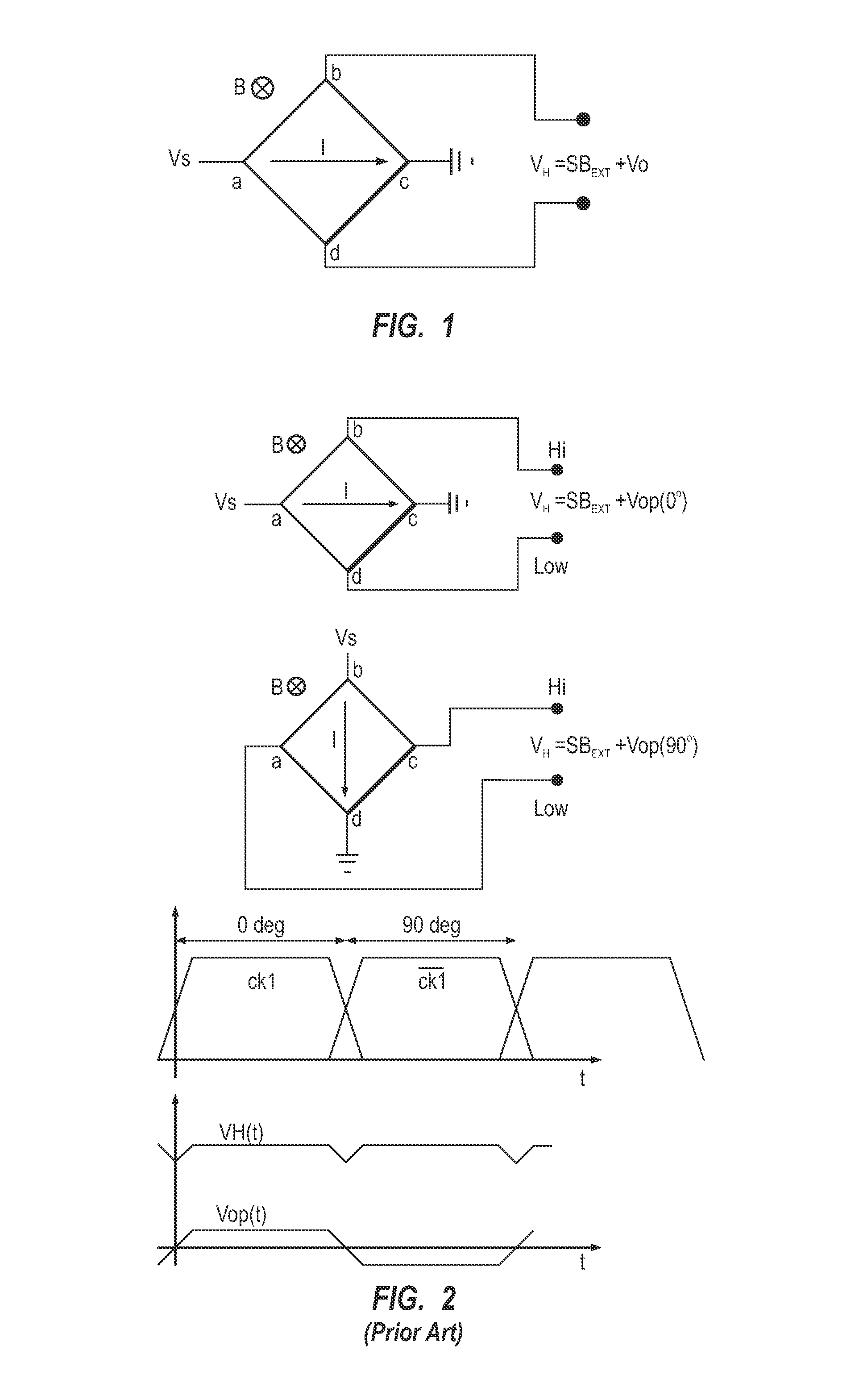

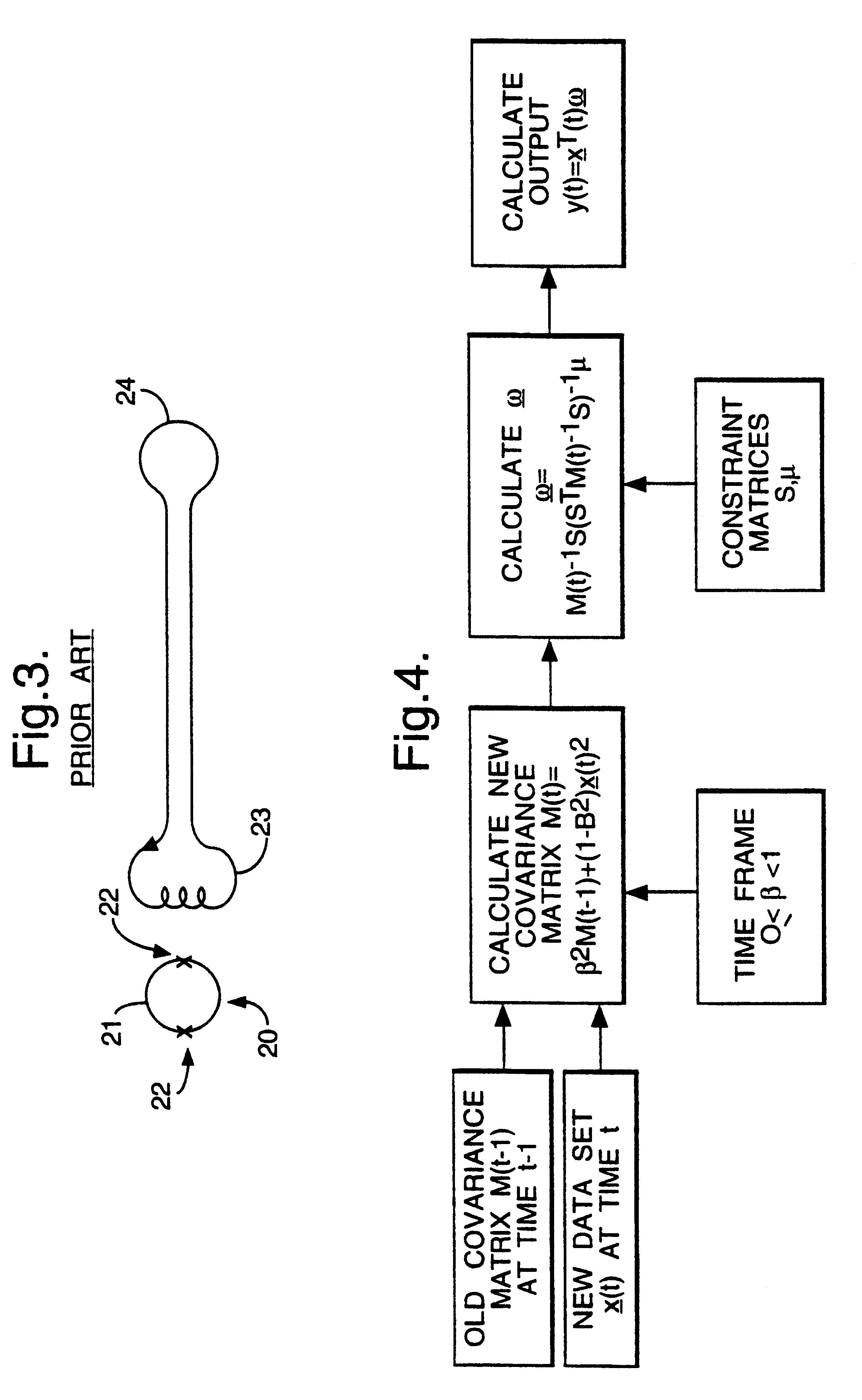

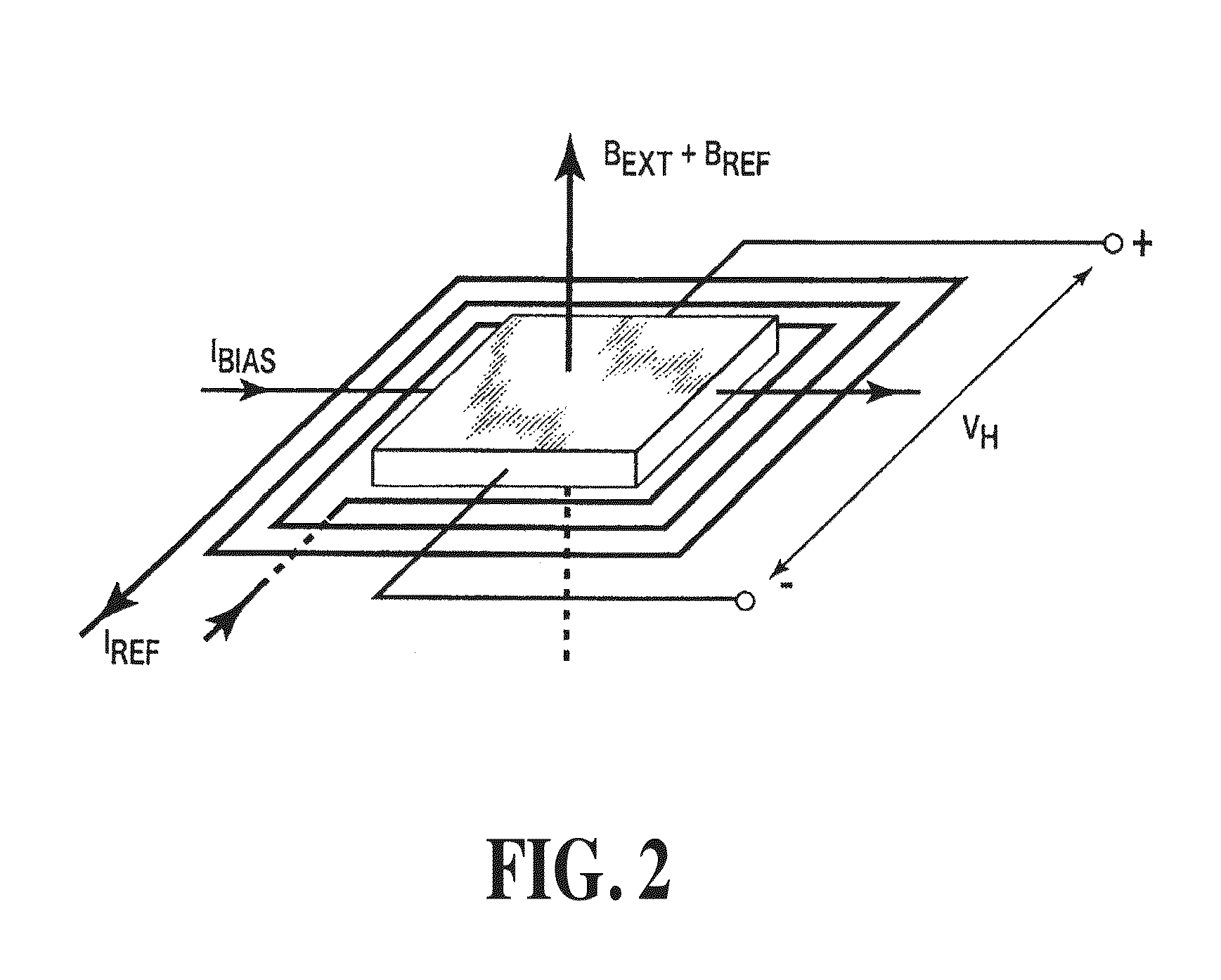

Auto-calibration of magnetic sensor

ActiveUS20080238410A1Magnetic field offset compensationMagnetic field measurement using galvano-magnetic devicesAtomic physicsAuto calibration

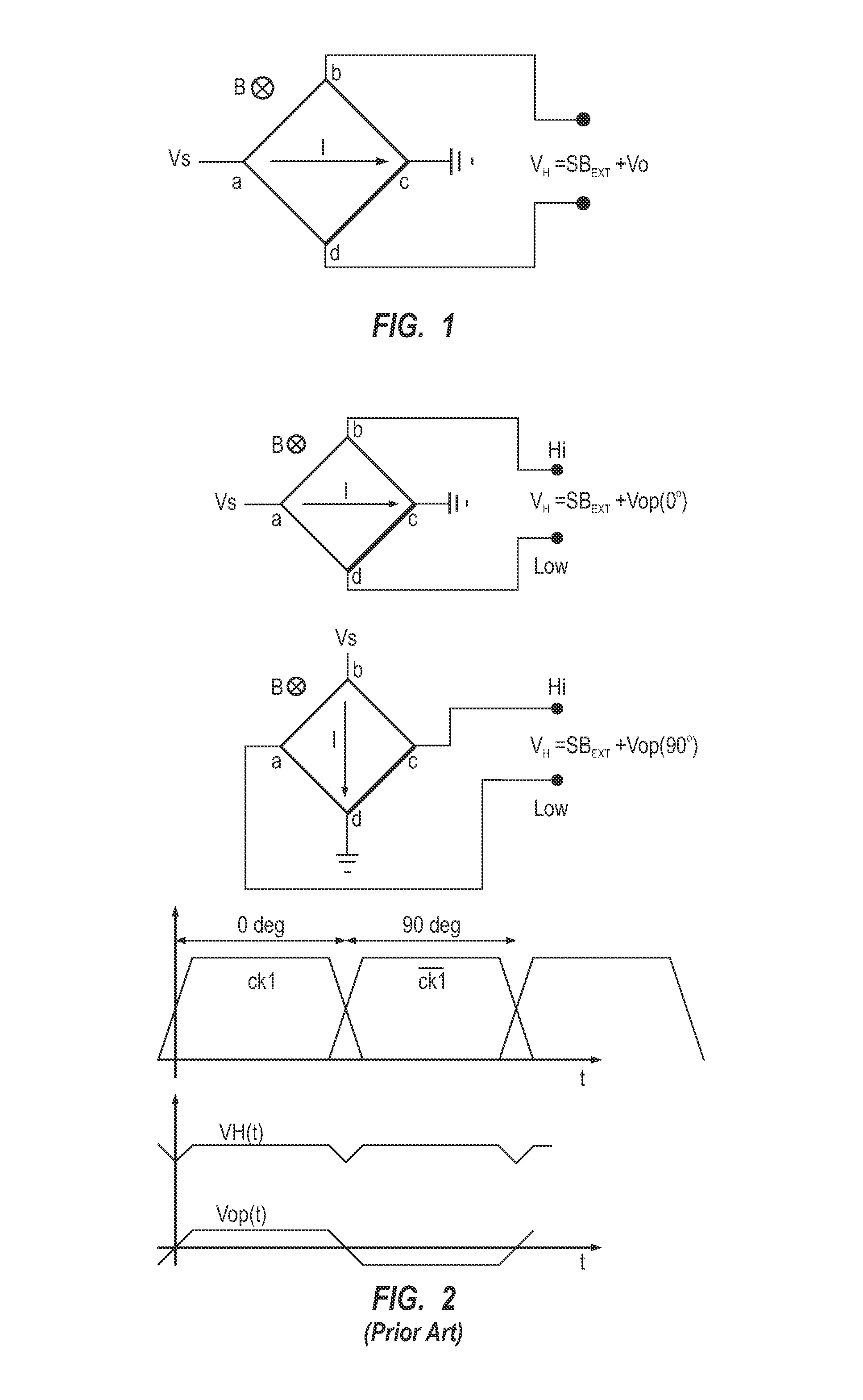

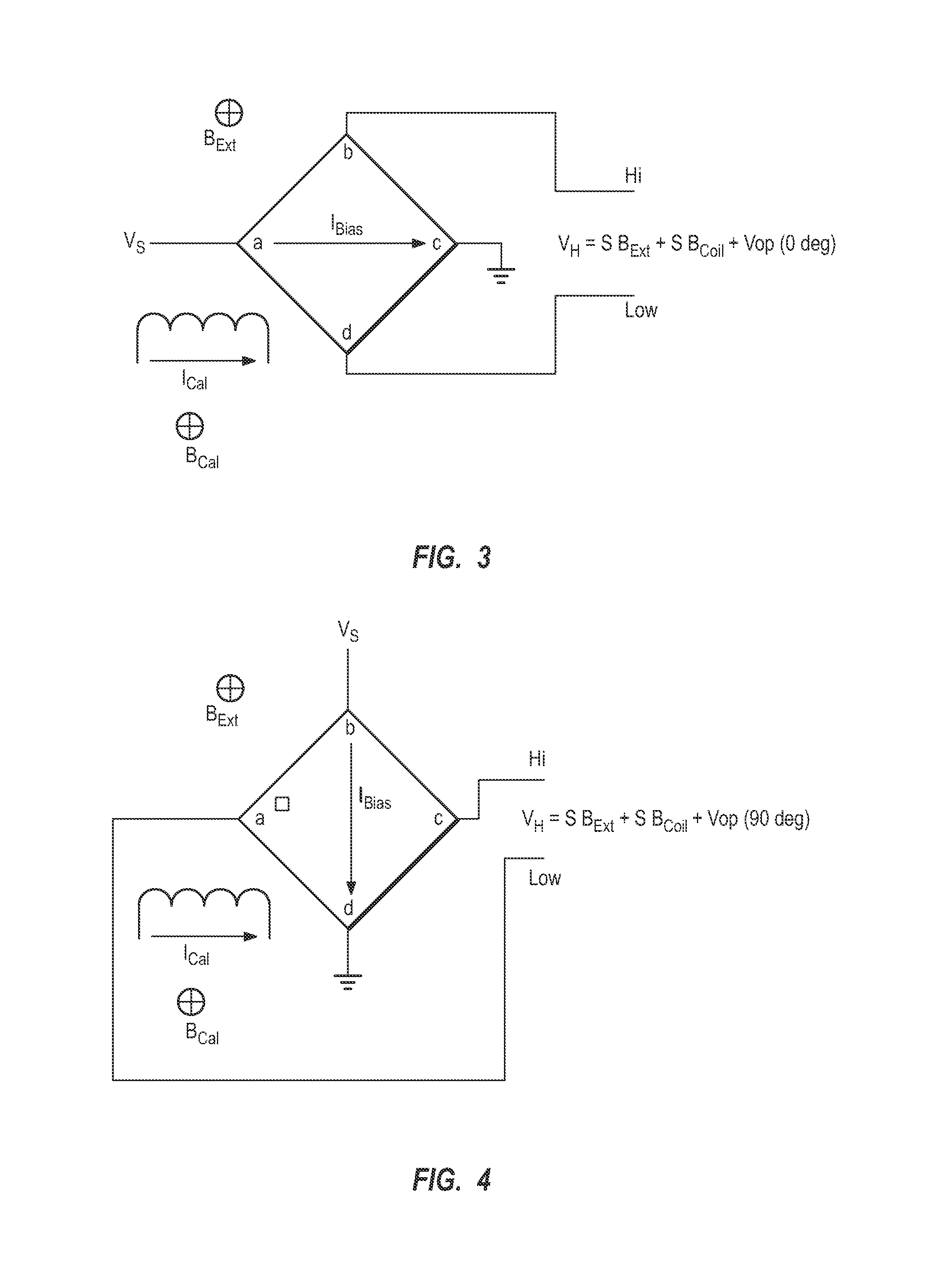

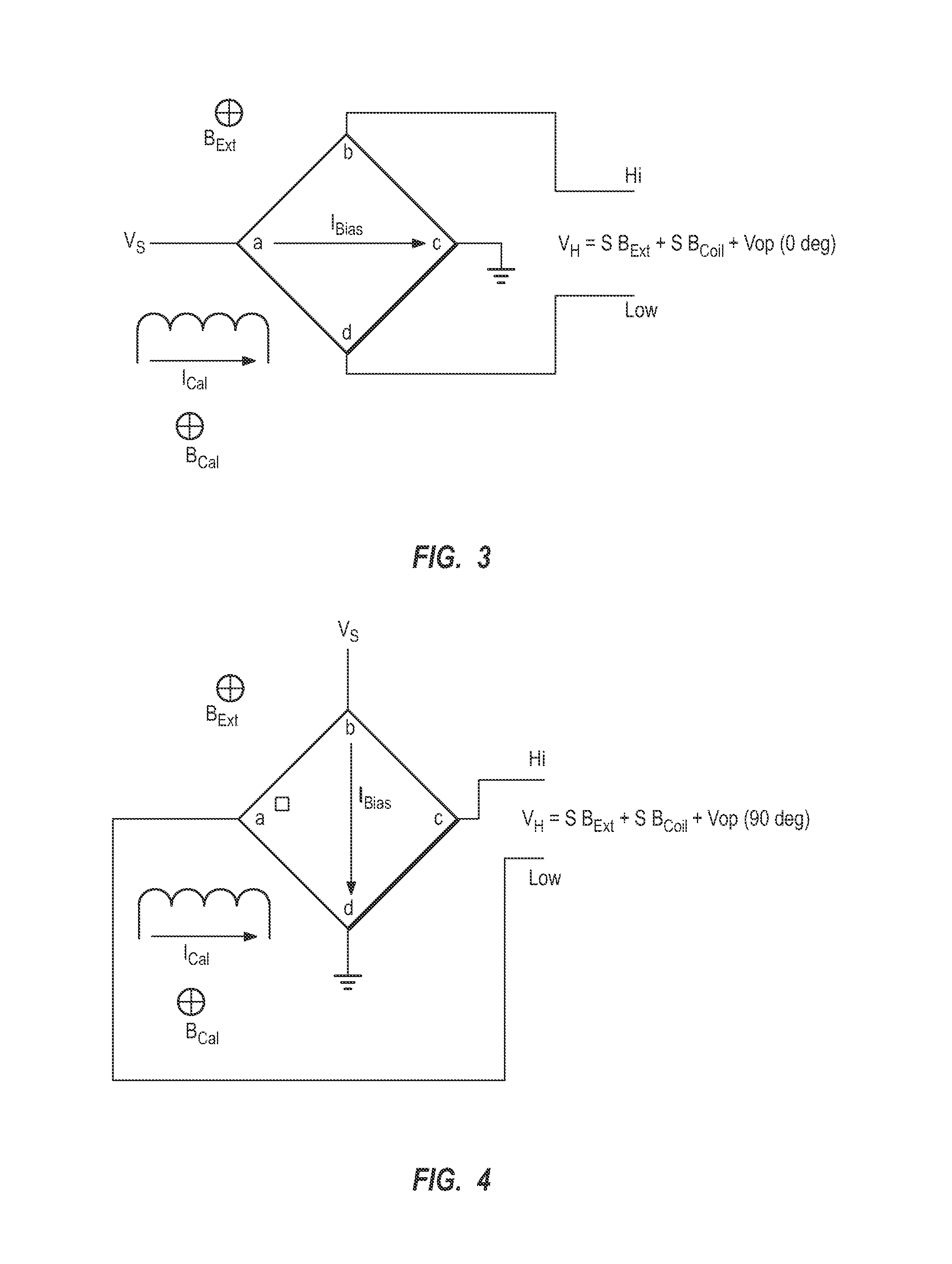

The present invention provides a method to compensate for the sensitivity drift of a magnetic field sensor for sensing a magnetic field. The magnetic field sensor comprises at least four electrodes. The method comprises a first step where a first set of two electrodes is used to bias the sensor and a second set of two electrodes is used to sense an output signal of the magnetic field sensor, and a second step where the second set of two electrodes is used to bias the sensor and the first set of two electrodes is used to sense an output signal of the magnetic field sensor. The method is characterized in that at least one of the first or the second step is subdivided in at least a first sub-step and a second sub-step. A reference magnetic field has first magnetic field parameters, e.g. a first amplitude and / or direction, in the first sub-step and second magnetic field parameters, a second amplitude and / or direction, in the second sub-step. An output signal is sensed in the first and in the second step, and within the first or the second step an output signal is sensed in the first and the second sub-step.

Owner:AMI SEMICON BELGIUM

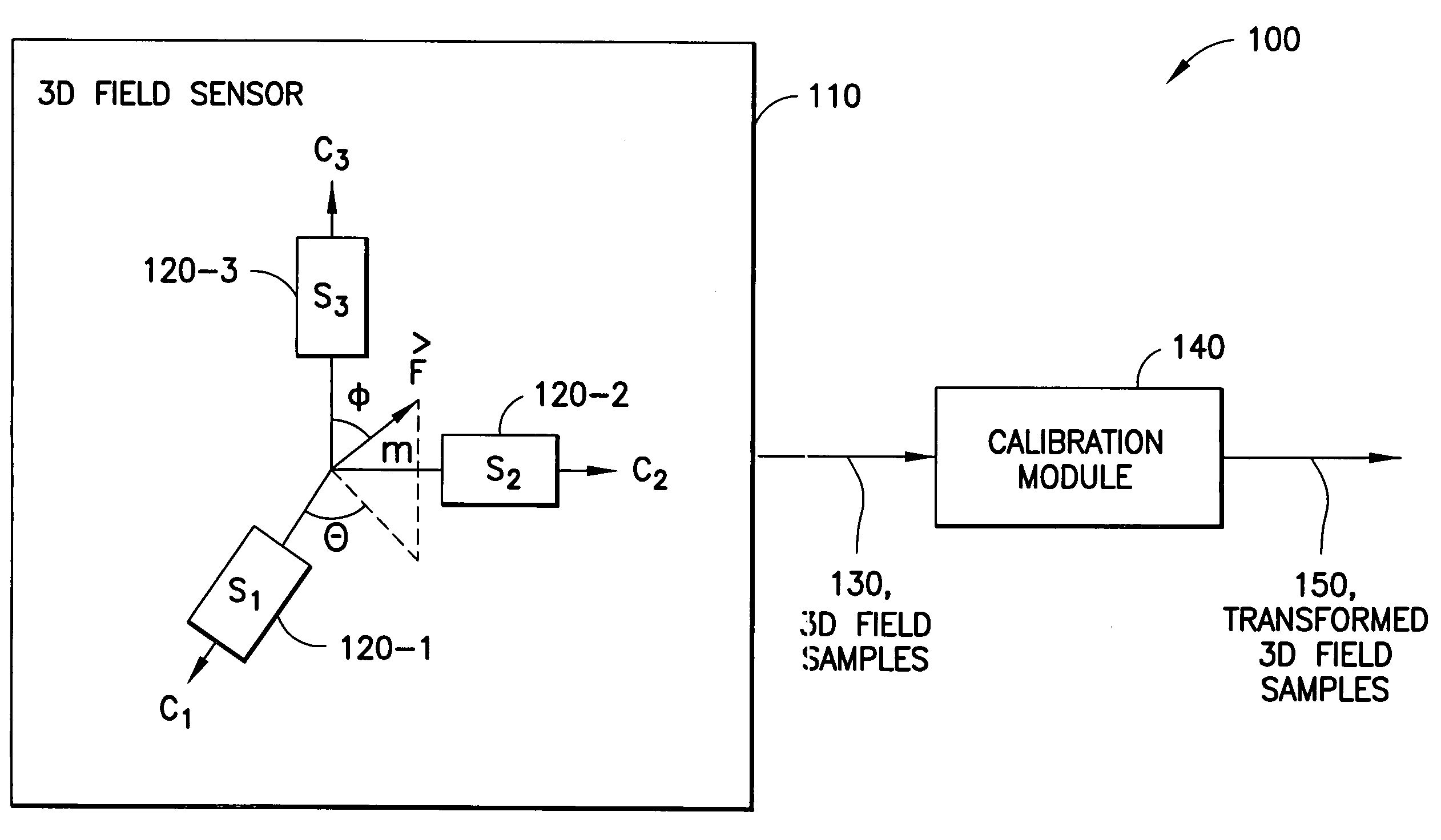

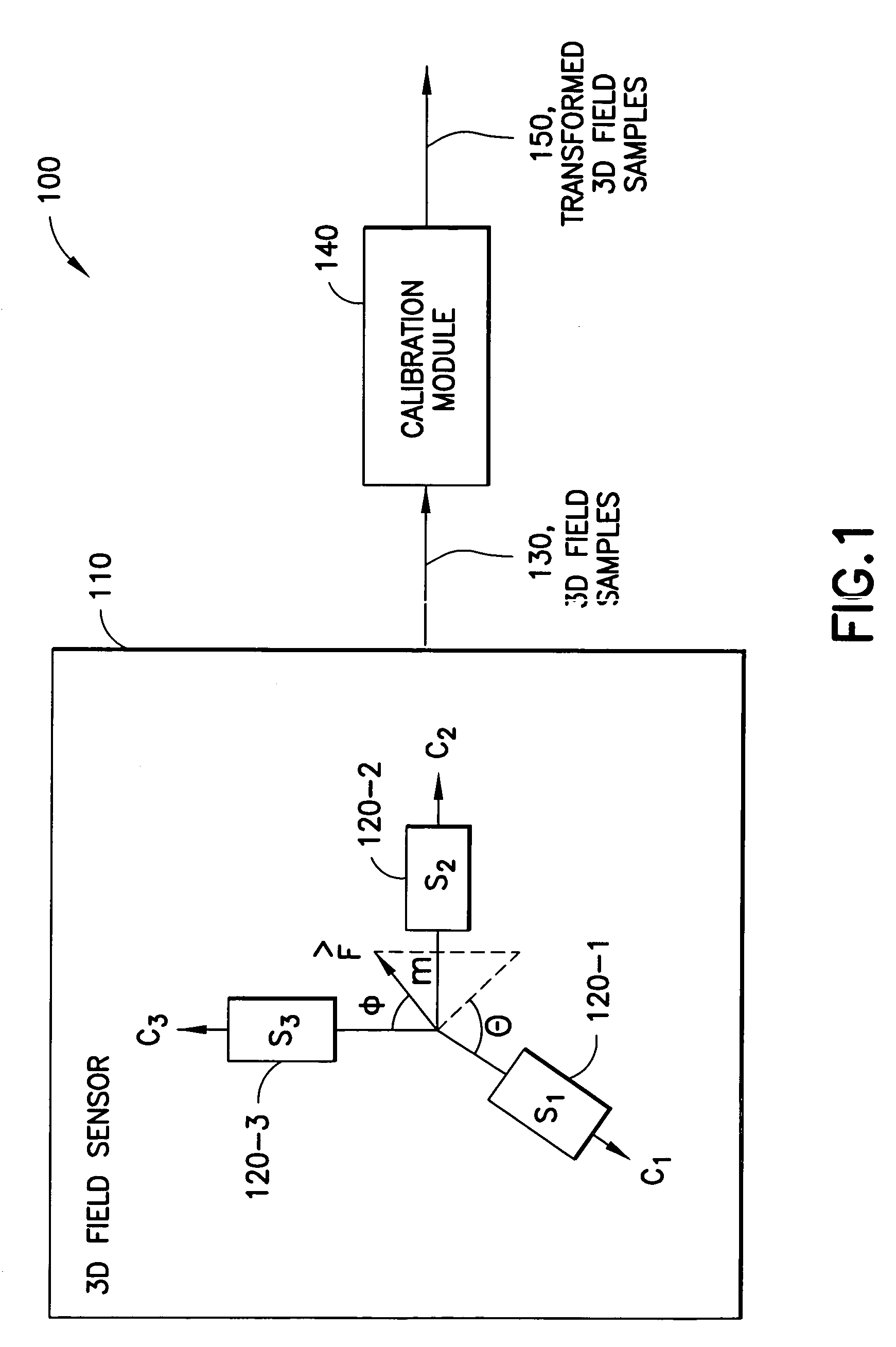

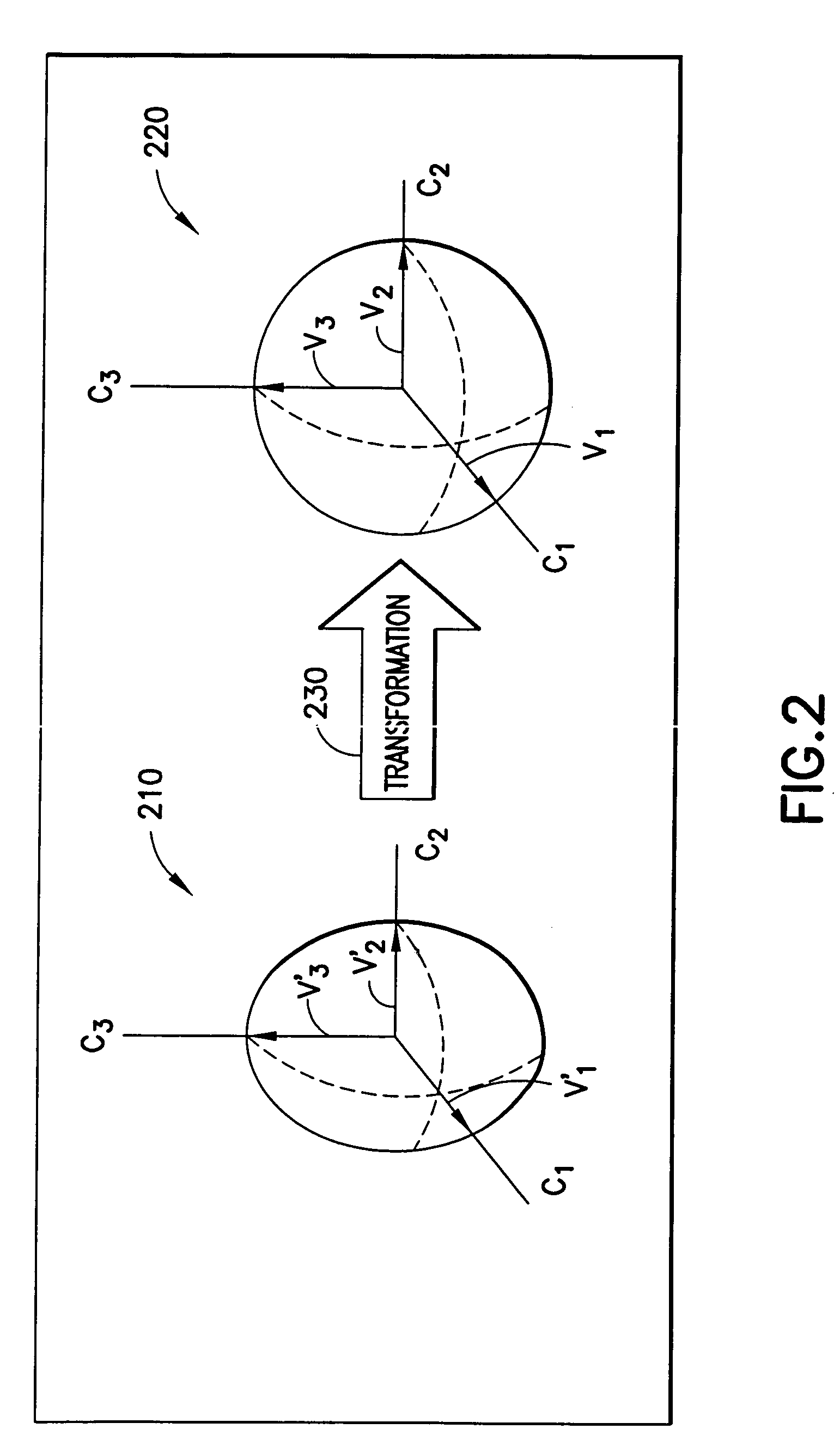

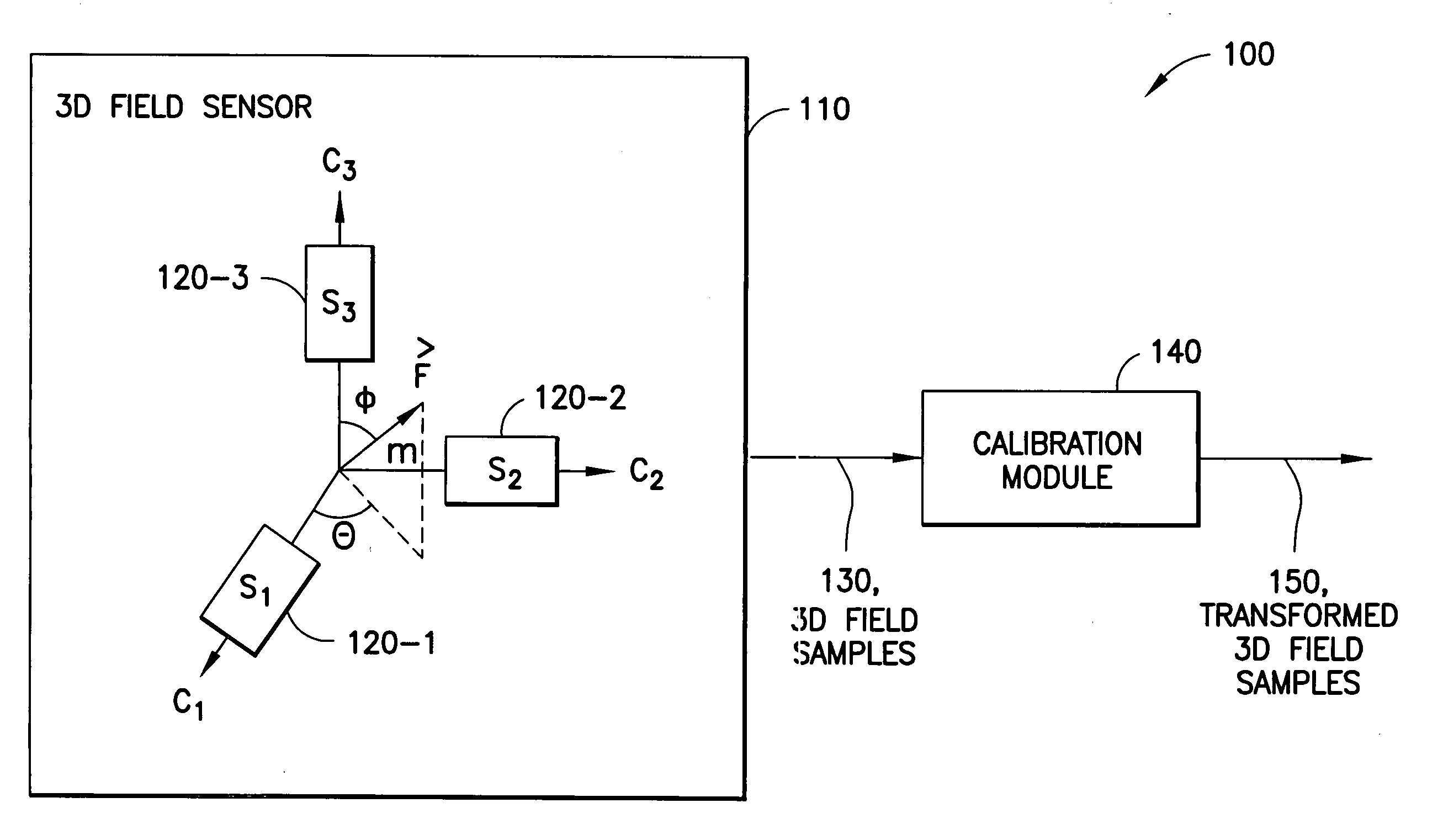

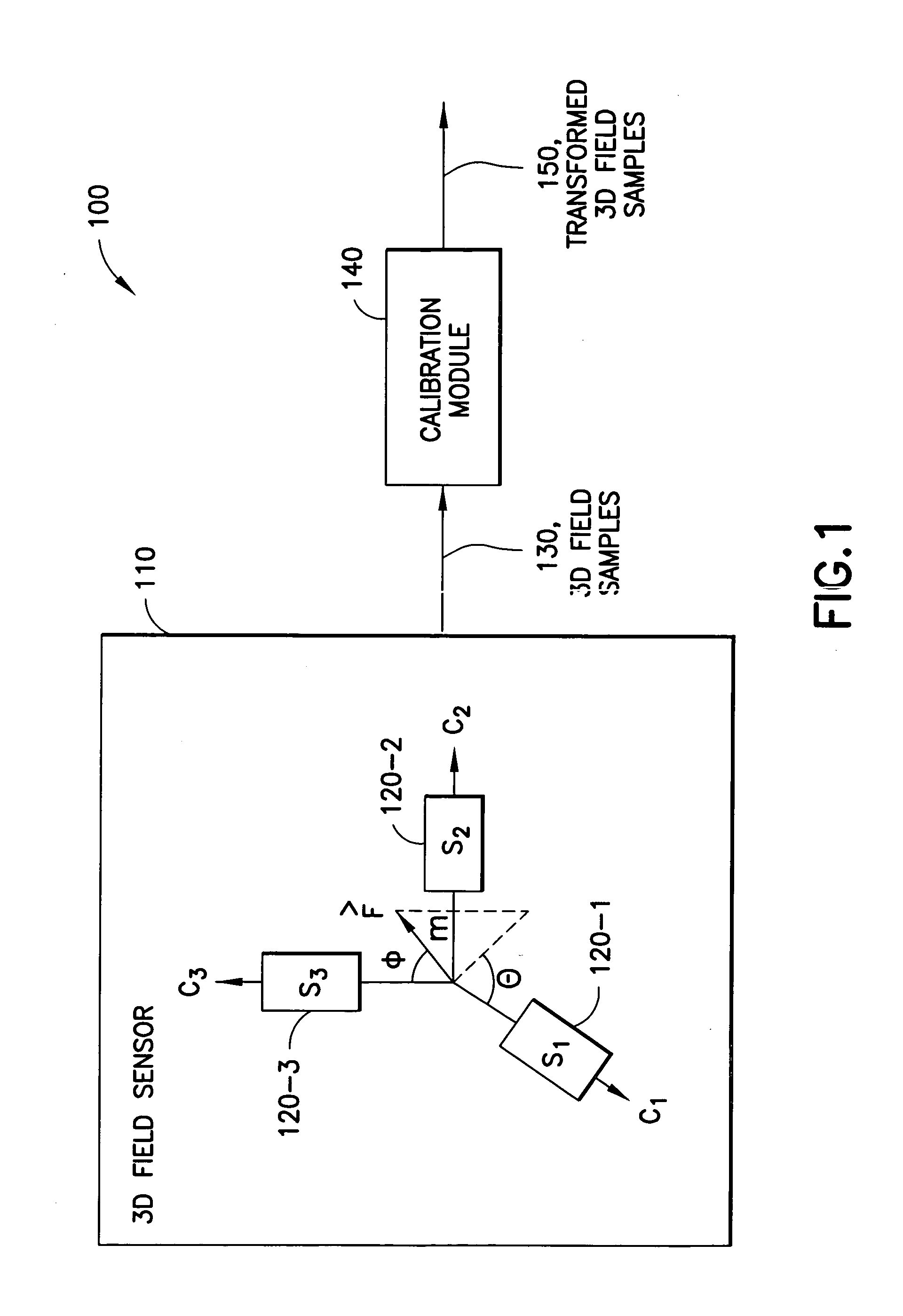

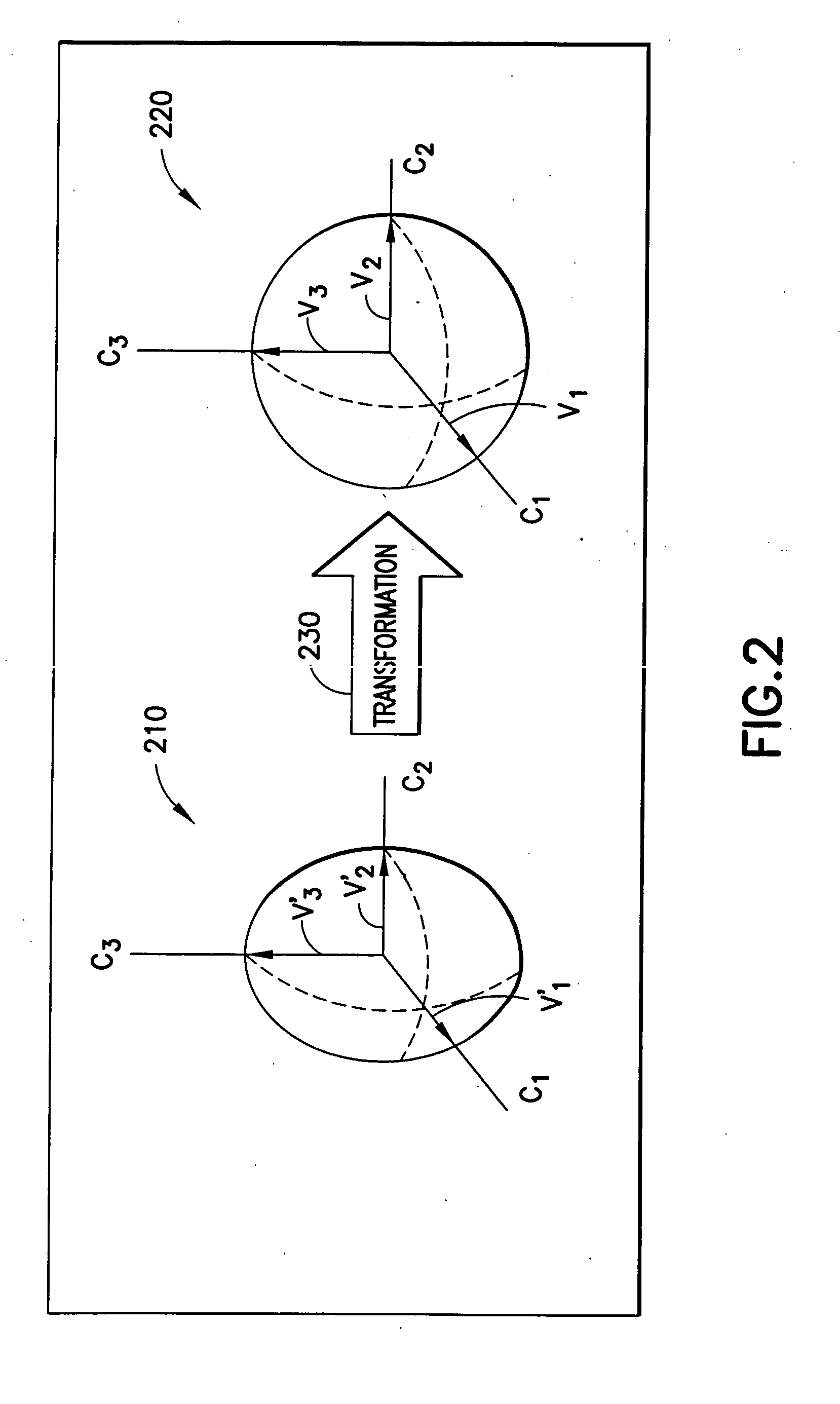

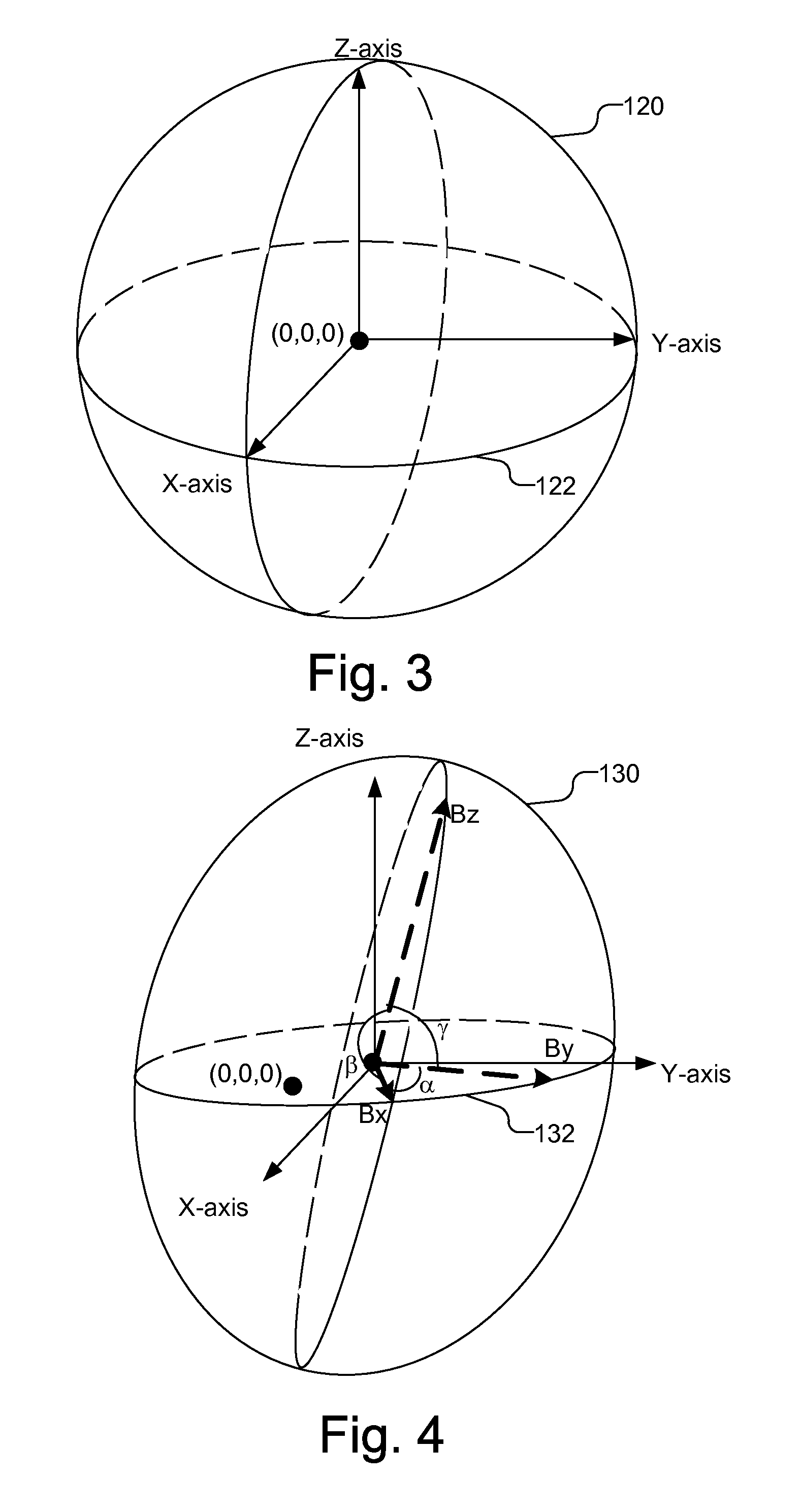

Calibration of 3D field sensors

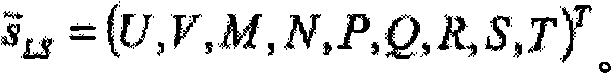

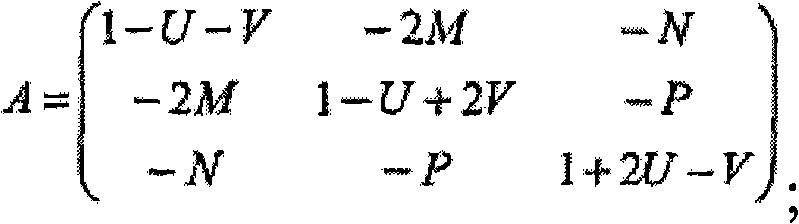

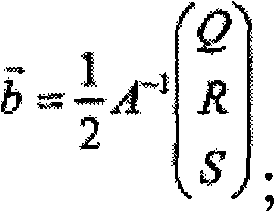

ActiveUS7275008B2Electrical measurementsTesting/calibration of speed/acceleration/shock measurement devicesCondensed matter physicsEllipsoid

An apparatus-based method is disclosed for calibration of a 3D field sensor. The method includes accessing a plurality of samples, where the samples are from the 3D field sensor. Each sample represents a magnitude and an orientation of a three-dimensional field sensed by the 3D field sensor. Using the plurality of samples, a plurality of parameters is determined of an ellipsoid. The determination of the plurality of parameters is performed so that the ellipsoid fits the plurality of samples. A transformation is determined that transforms the ellipsoid into a sphere. The transformation is applied to a sample to create a transformed sample. Apparatus and signal bearing media are also disclosed.

Owner:NOKIA TECHNOLOGLES OY

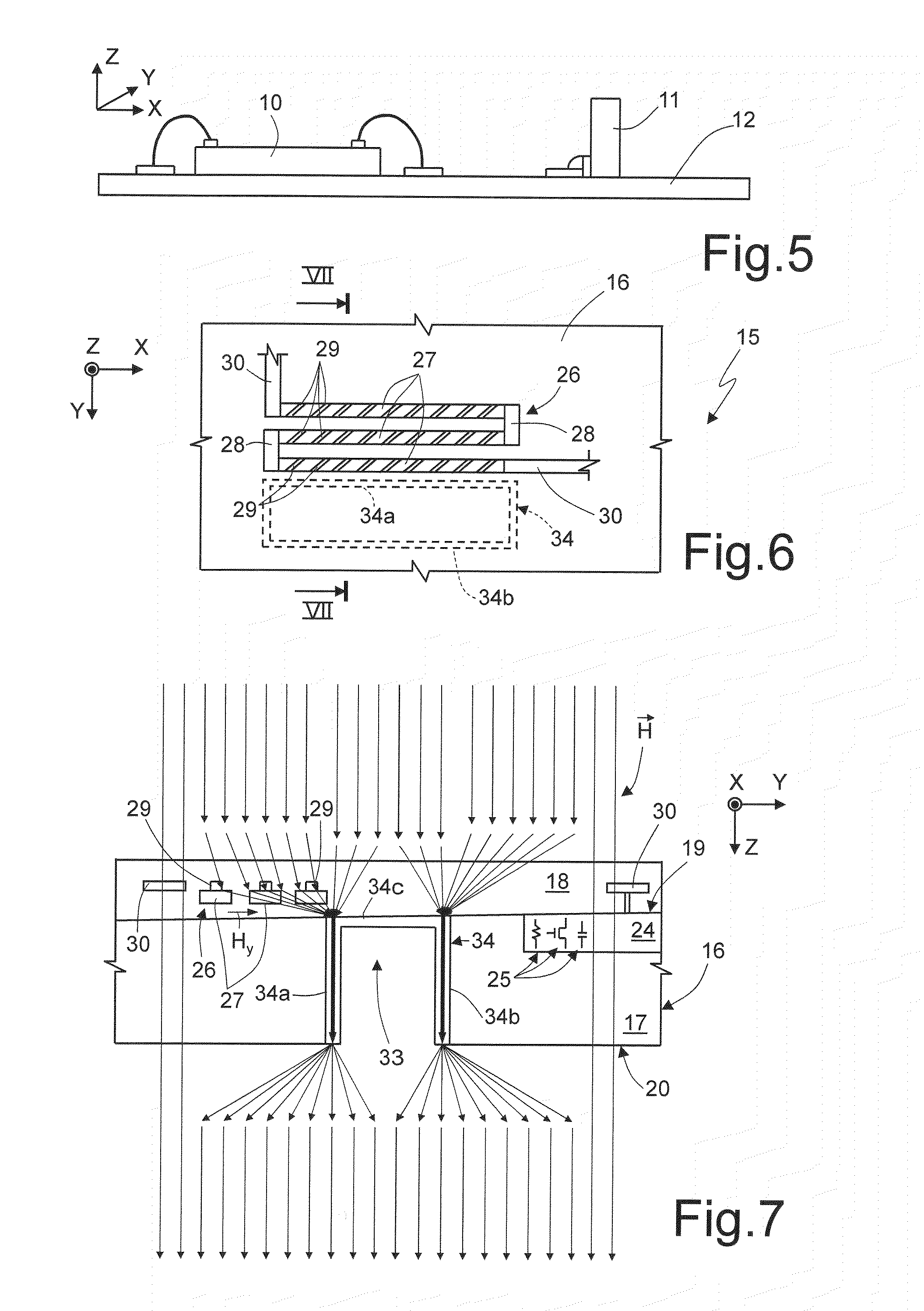

Magnetic sensor

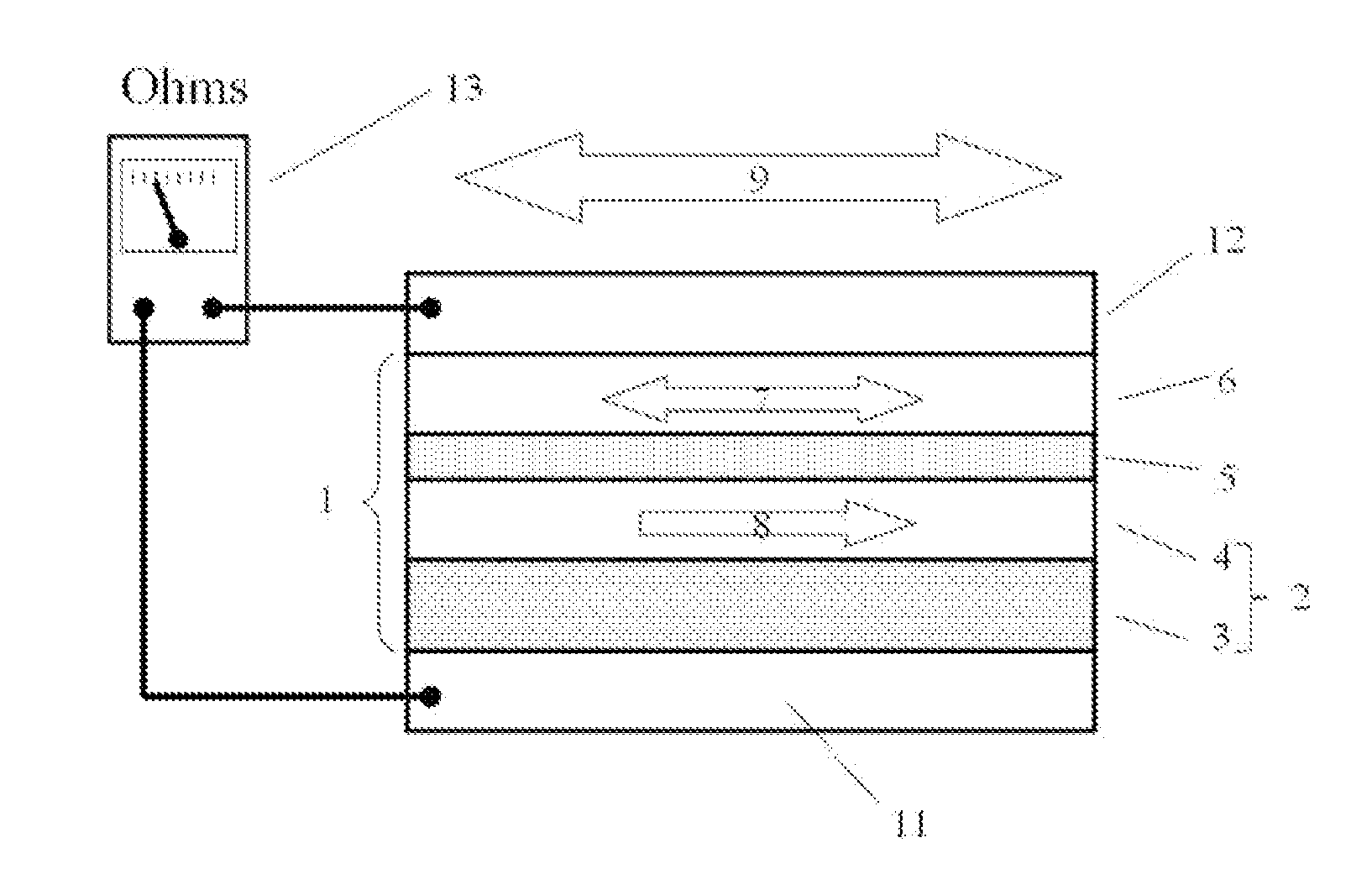

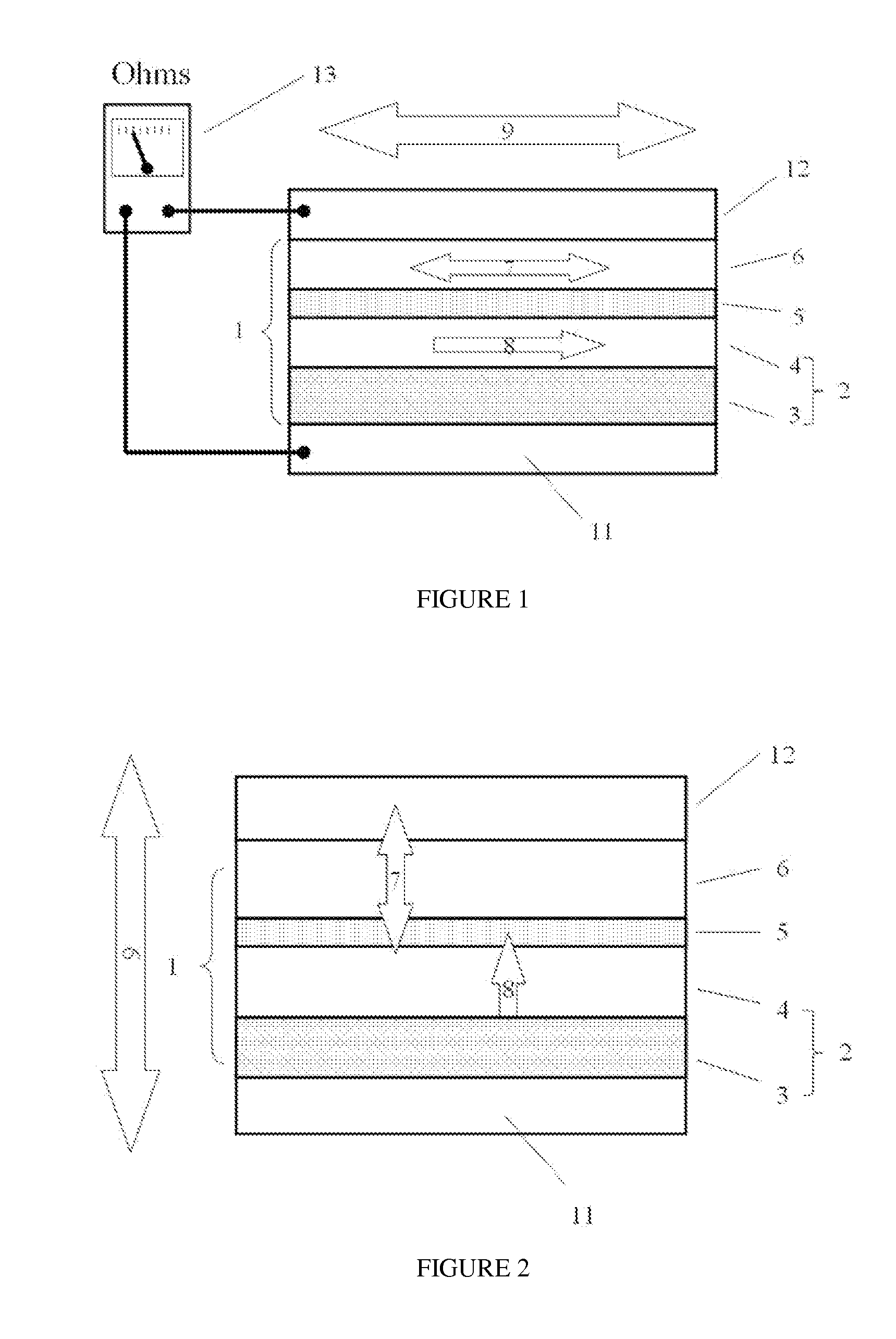

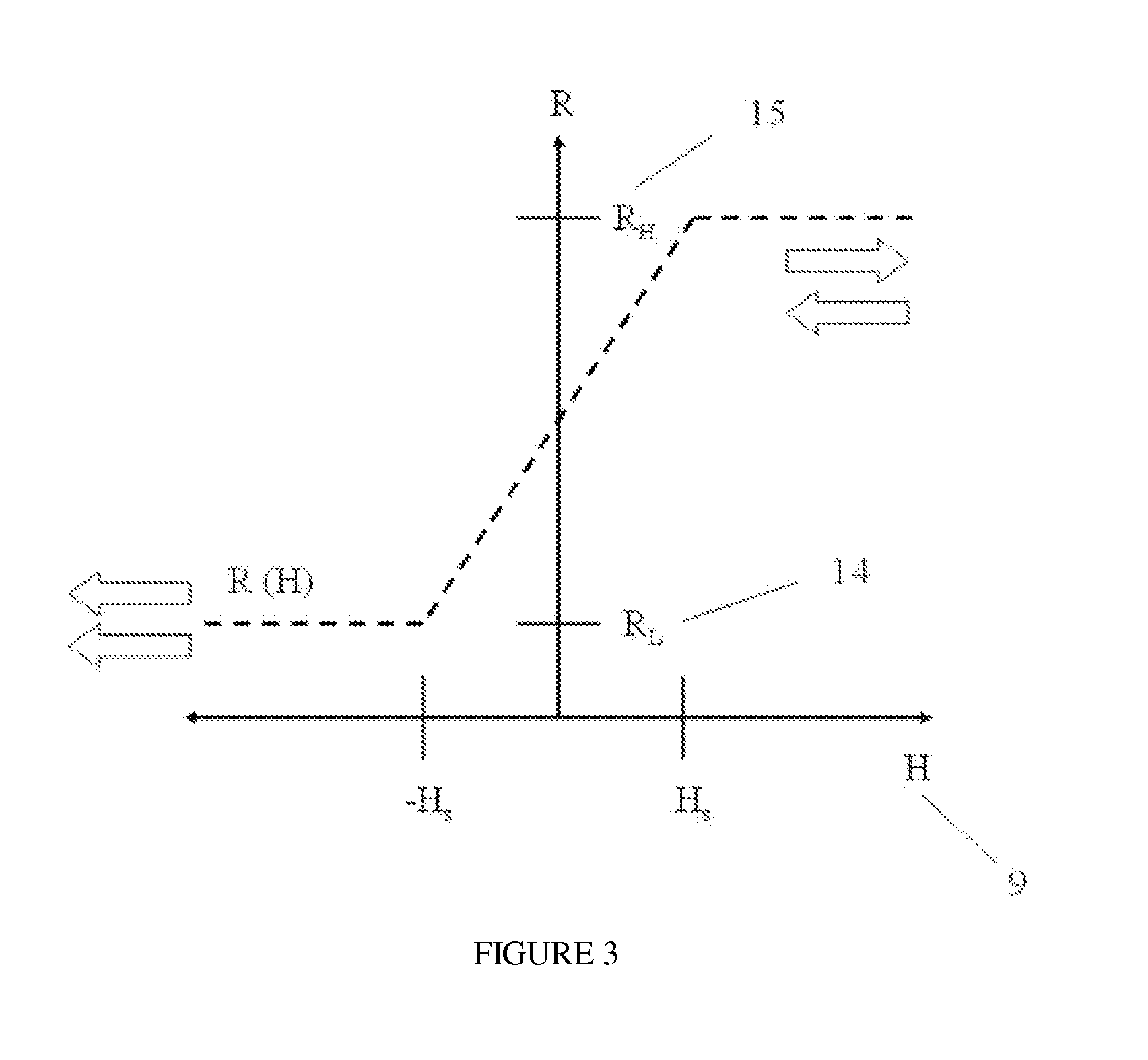

ActiveUS20120200292A1Simple configurationLow costNanomagnetismMagnetic-field-controlled resistorsMagnetizationPerpendicular magnetic field

A magnetic sensor includes magnetoresistive elements and a soft magnetic body. The magnetoresistive elements have multi layers including a magnetic layer and a nonmagnetic layer on a substrate, and exert a magnetoresistance effect. The soft magnetic body is electrically disconnected with the magnetoresistive elements, and converts a vertical magnetic field component from the outside into a magnetic field component in a horizontal direction so as to provide the magnetoresistive elements with the horizontally converted magnetic field component. The magnetoresistive elements have a pinned magnetic layer having a fixed magnetization direction and a free magnetic layer having a variable magnetization direction. The free magnetic layer is stacked on the pinned magnetic layer with a nonmagnetic layer interposed between the free magnetic layer and the pinned magnetic layer. The magnetization directions of the pinned magnetic layers of the magnetoresistive elements are the same direction. The magnetoresistive elements form a bridge circuit.

Owner:ALPS ALPINE CO LTD

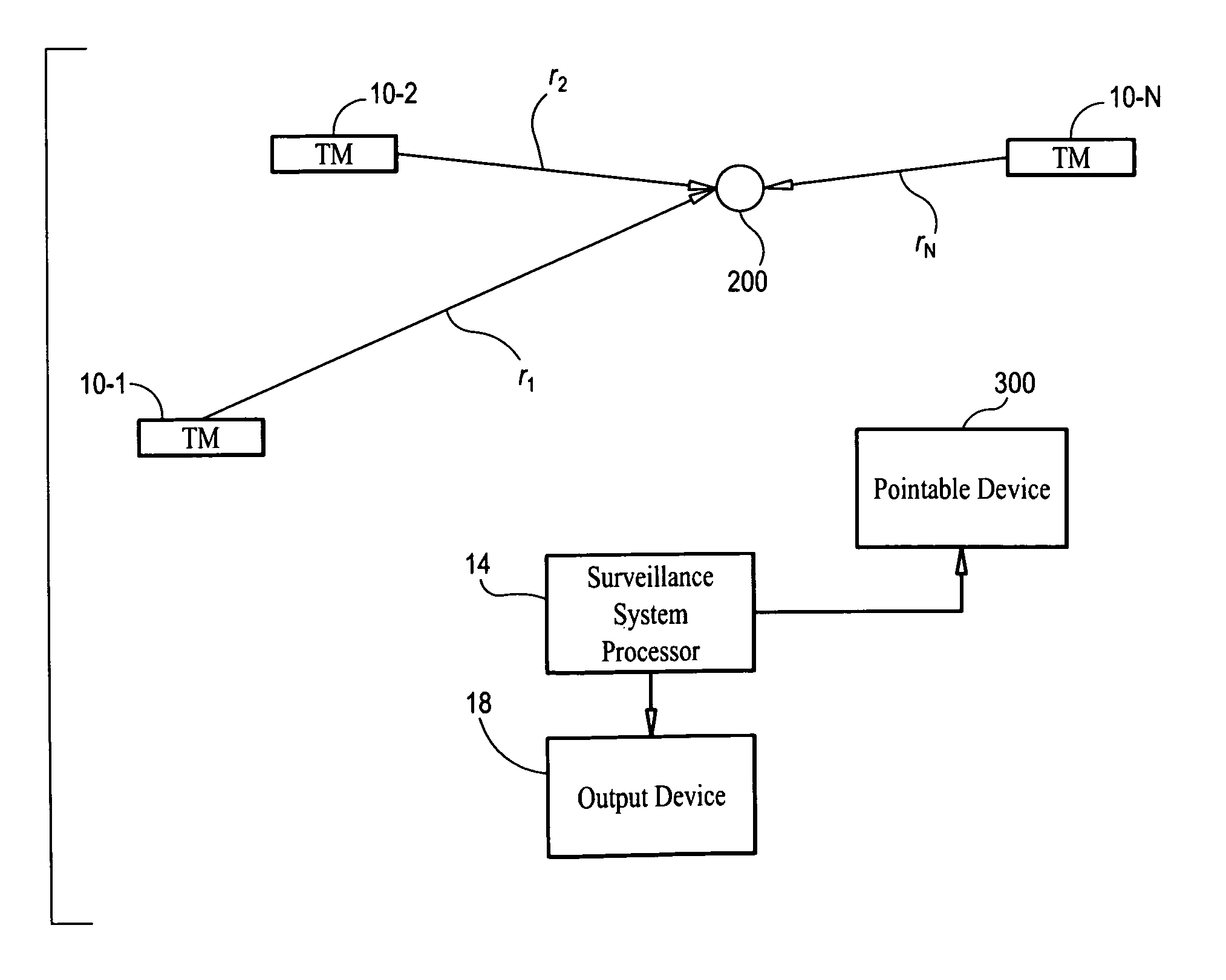

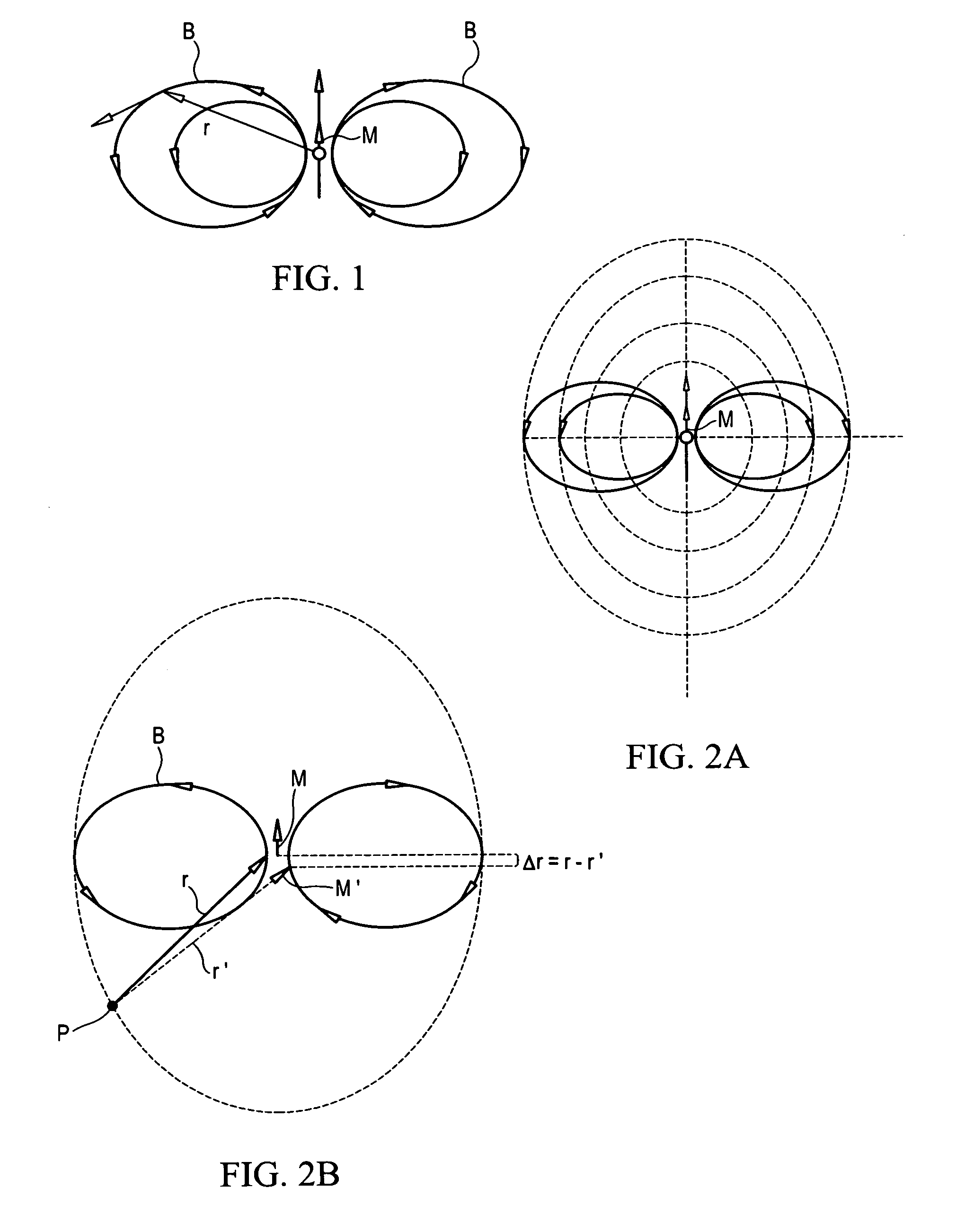

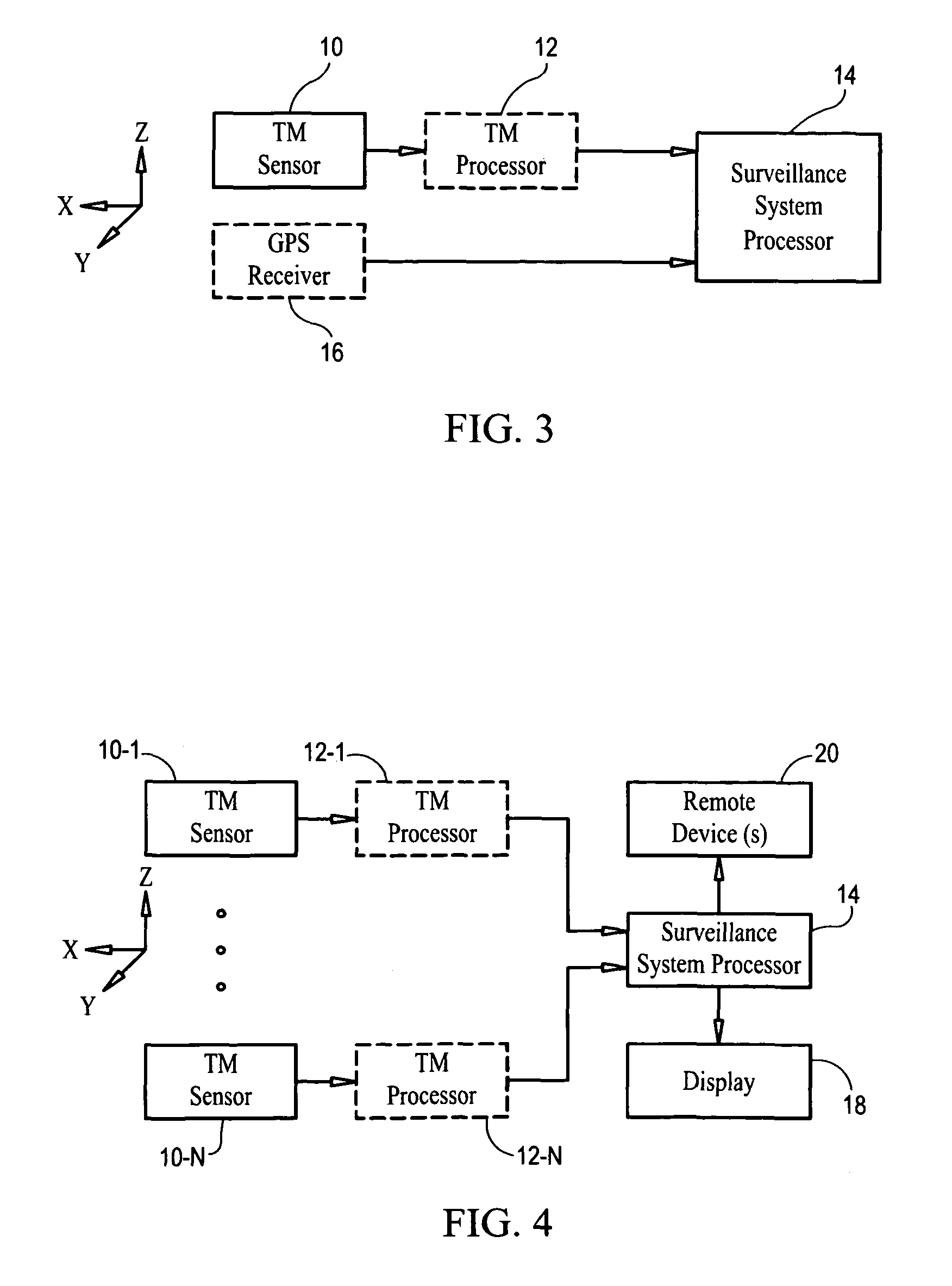

Magnetic anomaly surveillance system using spherical trilateration

InactiveUS8575929B1Digital computer detailsSpeed measurement using gyroscopic effectsOutput deviceMagnetic anomaly

A magnetic anomaly surveillance system includes triaxial magnetometer (TM) sensors arranged at known locations in an array. A processor coupled to the TM sensors generates a scalar magnitude of a magnetic anomaly field measured at each of the TM sensors. The scalar magnitude is indicative of a spherical radius centered at the known location associated with a corresponding one of the TM sensors. The processor also generates a comparison between each scalar magnitude and a threshold value. The processor then determines at least one magnetic anomaly location in the coordinate system via a spherical trilateration process that uses each spherical radius and each scalar magnitude associated with selected ones of the TM sensors for which the threshold value is exceeded. One or more output devices coupled to the processor output data indicative of the one or more magnetic anomaly locations.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

Calibration of 3D field sensors

ActiveUS20070055468A1Electrical measurementsTesting/calibration of speed/acceleration/shock measurement devicesCondensed matter physicsEllipsoid

An apparatus-based method is disclosed for calibration of a 3D field sensor. The method includes accessing a plurality of samples, where the samples are from the 3D field sensor. Each sample represents a magnitude and an orientation of a three-dimensional field sensed by the 3D field sensor. Using the plurality of samples, a plurality of parameters is determined of an ellipsoid. The determination of the plurality of parameters is performed so that the ellipsoid fits the plurality of samples. A transformation is determined that transforms the ellipsoid into a sphere. The transformation is applied to a sample to create a transformed sample. Apparatus and signal bearing media are also disclosed.

Owner:NOKIA TECHNOLOGLES OY

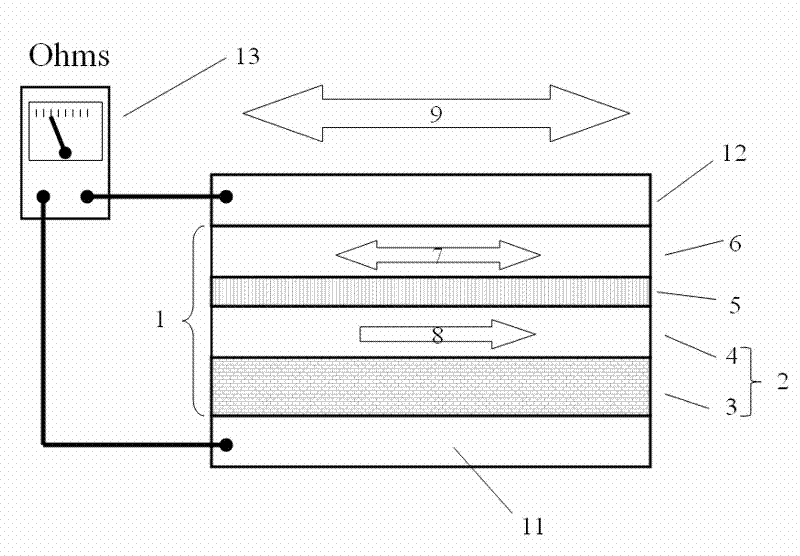

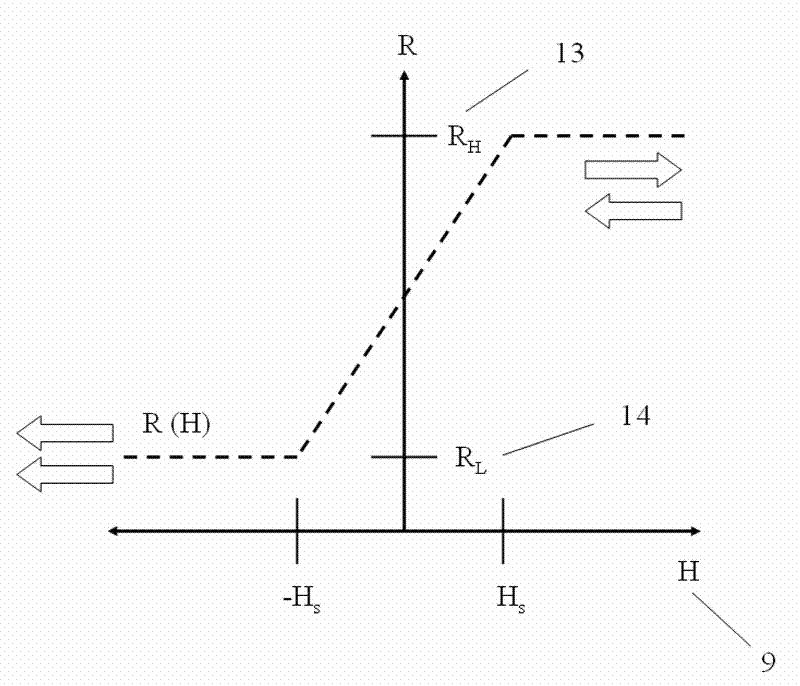

Method of auto calibrating a magnetic field sensor for drift and structure therefor

ActiveUS8134358B2Magnetic field offset compensationMagnetic field measurement using galvano-magnetic devicesAtomic physicsMagnetic field

The present invention provides a method to compensate for the sensitivity drift of a magnetic field sensor for sensing a magnetic field. The magnetic field sensor comprises at least four electrodes. The method comprises a first step where a first set of two electrodes is used to bias the sensor and a second set of two electrodes is used to sense an output signal of the magnetic field sensor, and a second step where the second set of two electrodes is used to bias the sensor and the first set of two electrodes is used to sense an output signal of the magnetic field sensor. The method is characterized in that at least one of the first or the second step is subdivided in at least a first sub-step and a second sub-step. A reference magnetic field has first magnetic field parameters, e.g. a first amplitude and / or direction, in the first sub-step and second magnetic field parameters, a second amplitude and / or direction, in the second sub-step. An output signal is sensed in the first and in the second step, and within the first or the second step an output signal is sensed in the first and the second sub-step.

Owner:AMI SEMICON BELGIUM

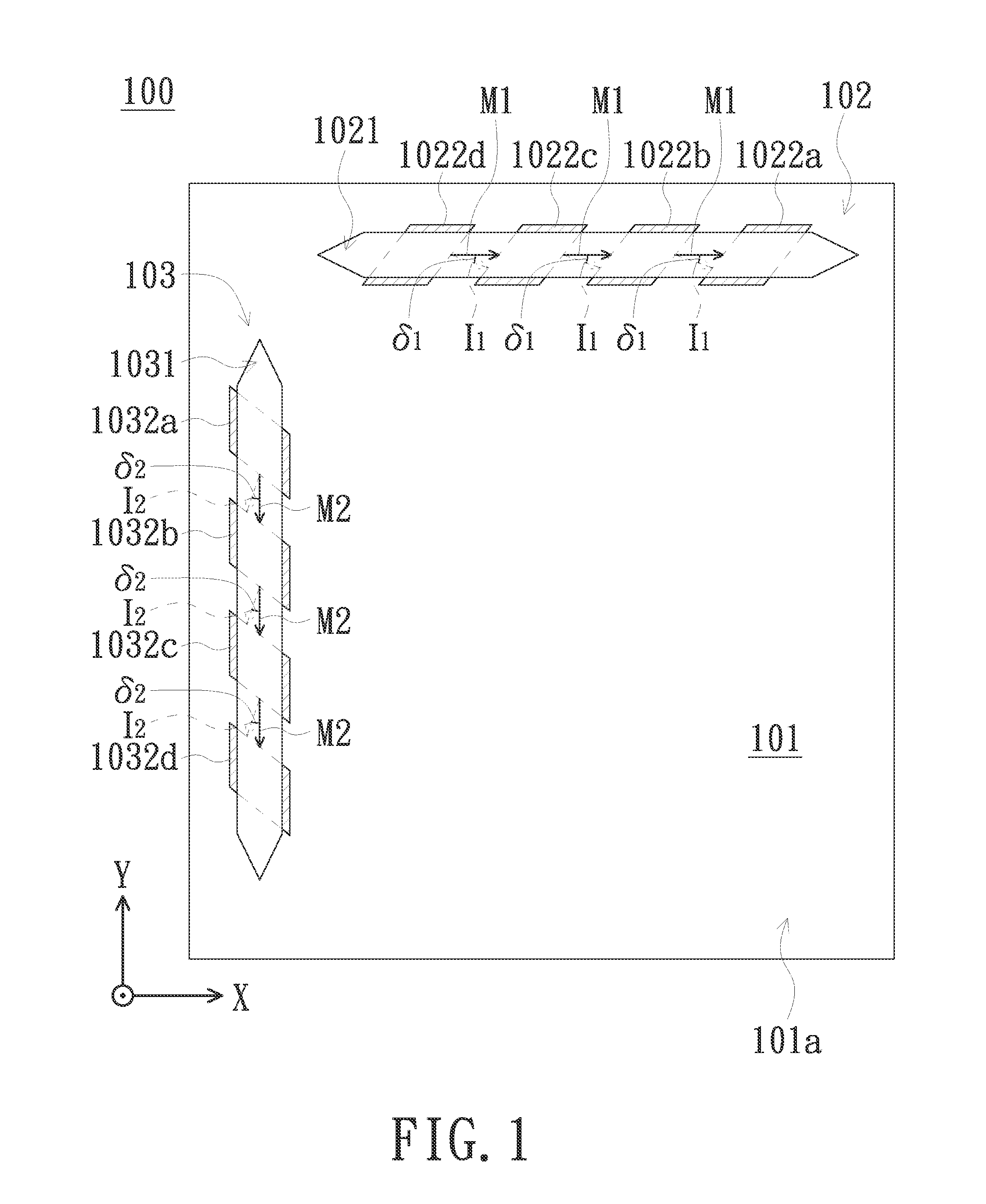

Magnetic 3D Sensor Calibratable During Measurement Operation

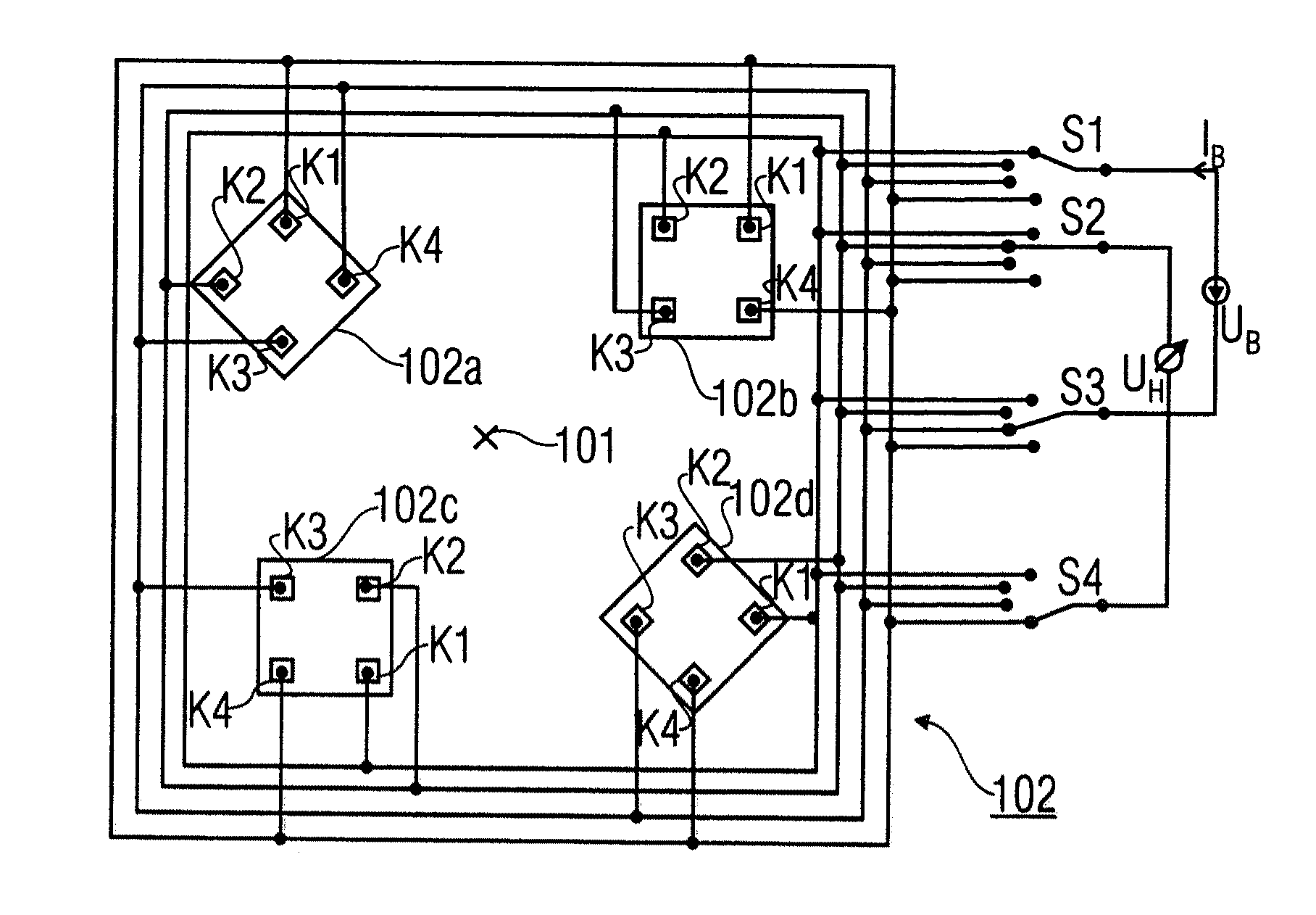

ActiveUS20120016614A1Component can be removedSimple and uncomplicated test optionMagnetic field offset compensationElectrical measurements3d sensorAcoustics

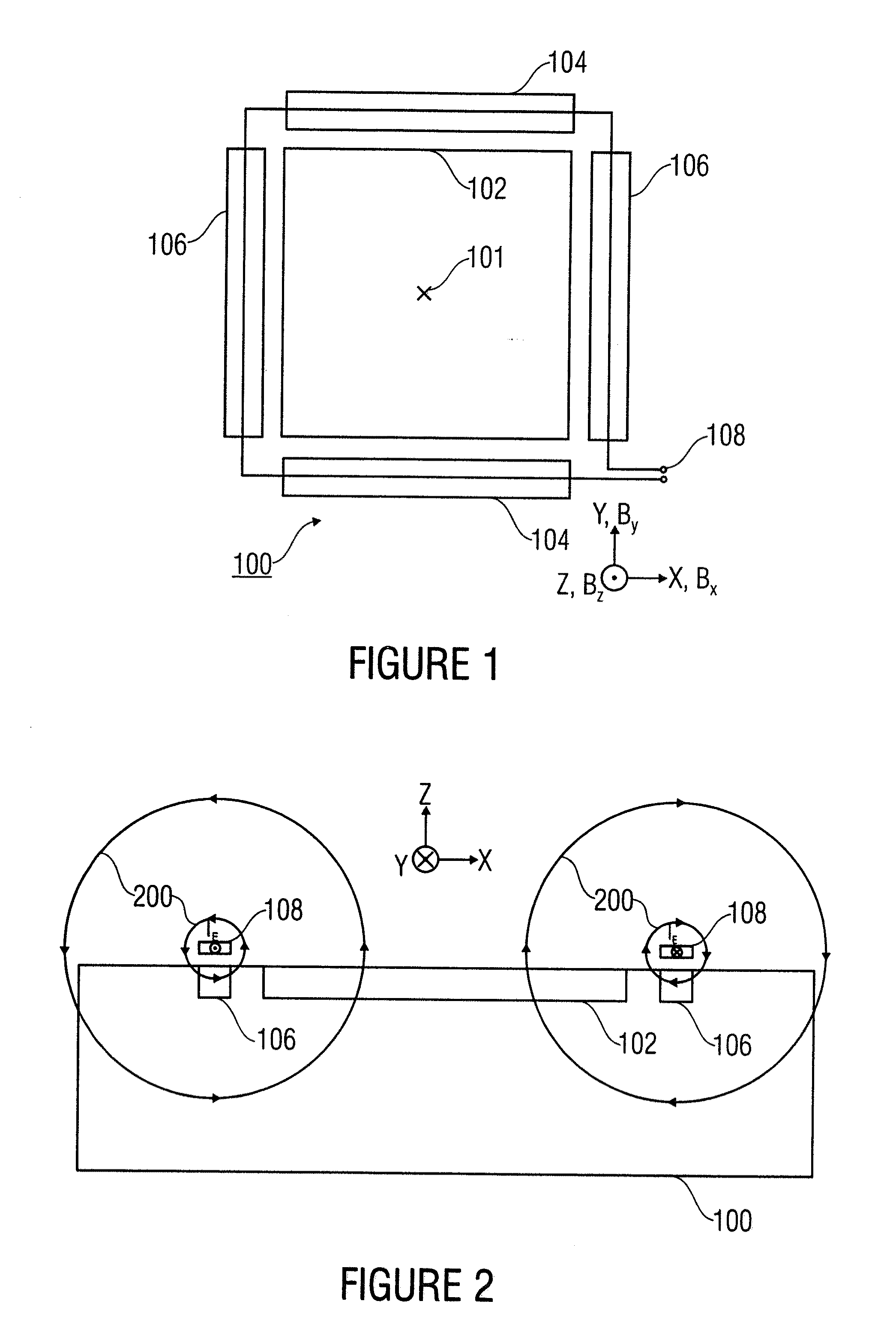

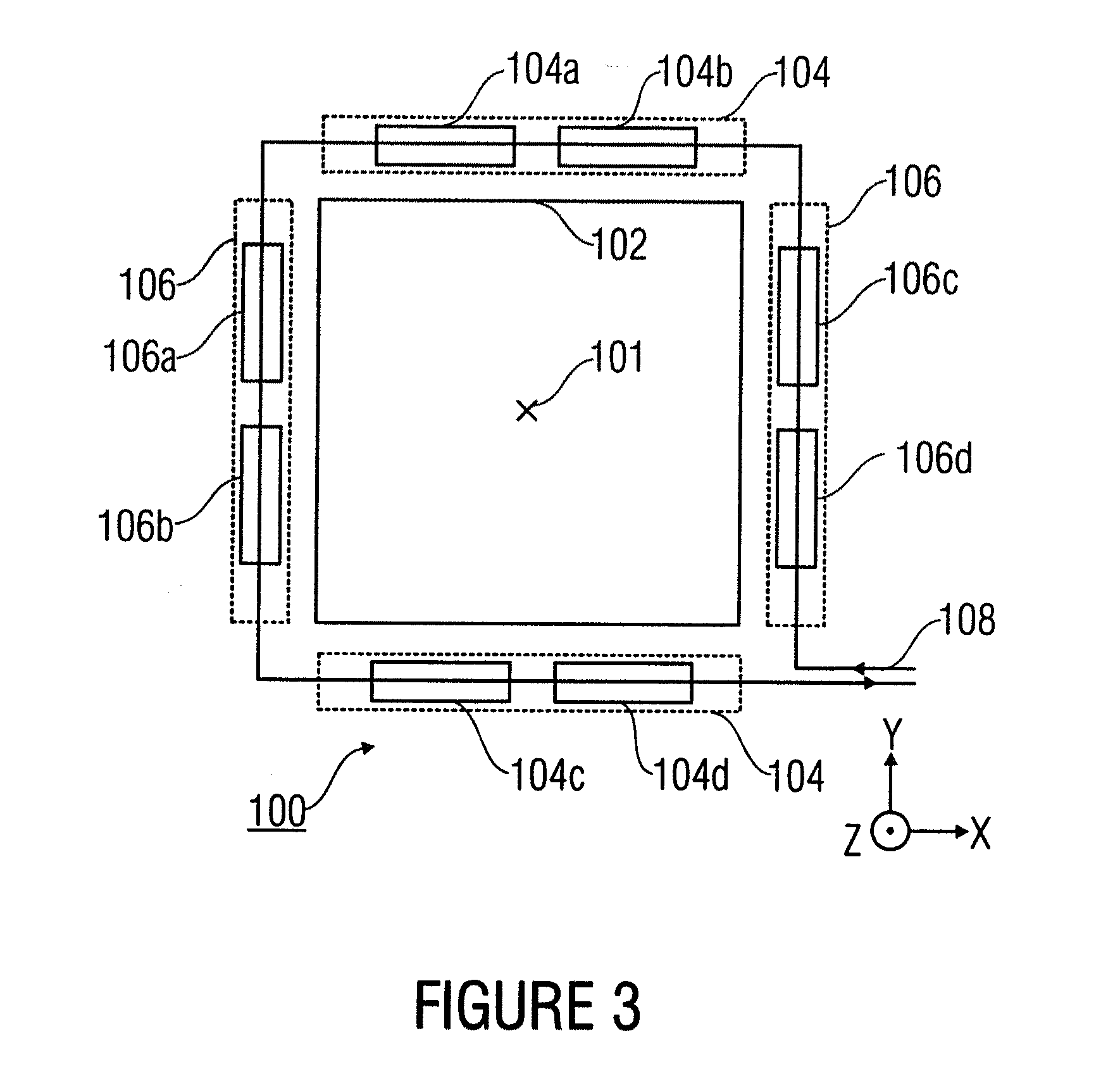

A magnetic field sensor for detecting first, second, and third spatial components of a magnetic field at a reference point includes a first sensor element arrangement for detecting the first magnetic field component having a first measurement field component and a first calibration field component with respect to a first spatial axis at a reference point, a second sensor element arrangement for detecting the second magnetic field component having a second measurement field component and a second calibration field component with respect to a second spatial axis y at the reference point and a third sensor element arrangement for detecting the third magnetic field component having a third measurement field component and a third calibration field component with respect to a third spatial axis x at the reference point. An excitation line is arranged such with respect to the three sensor element arrangements that when impressing a predetermined current into the excitation line respective predetermined calibration field components with respect to the spatial axes in the sensor element arrangements are generated.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

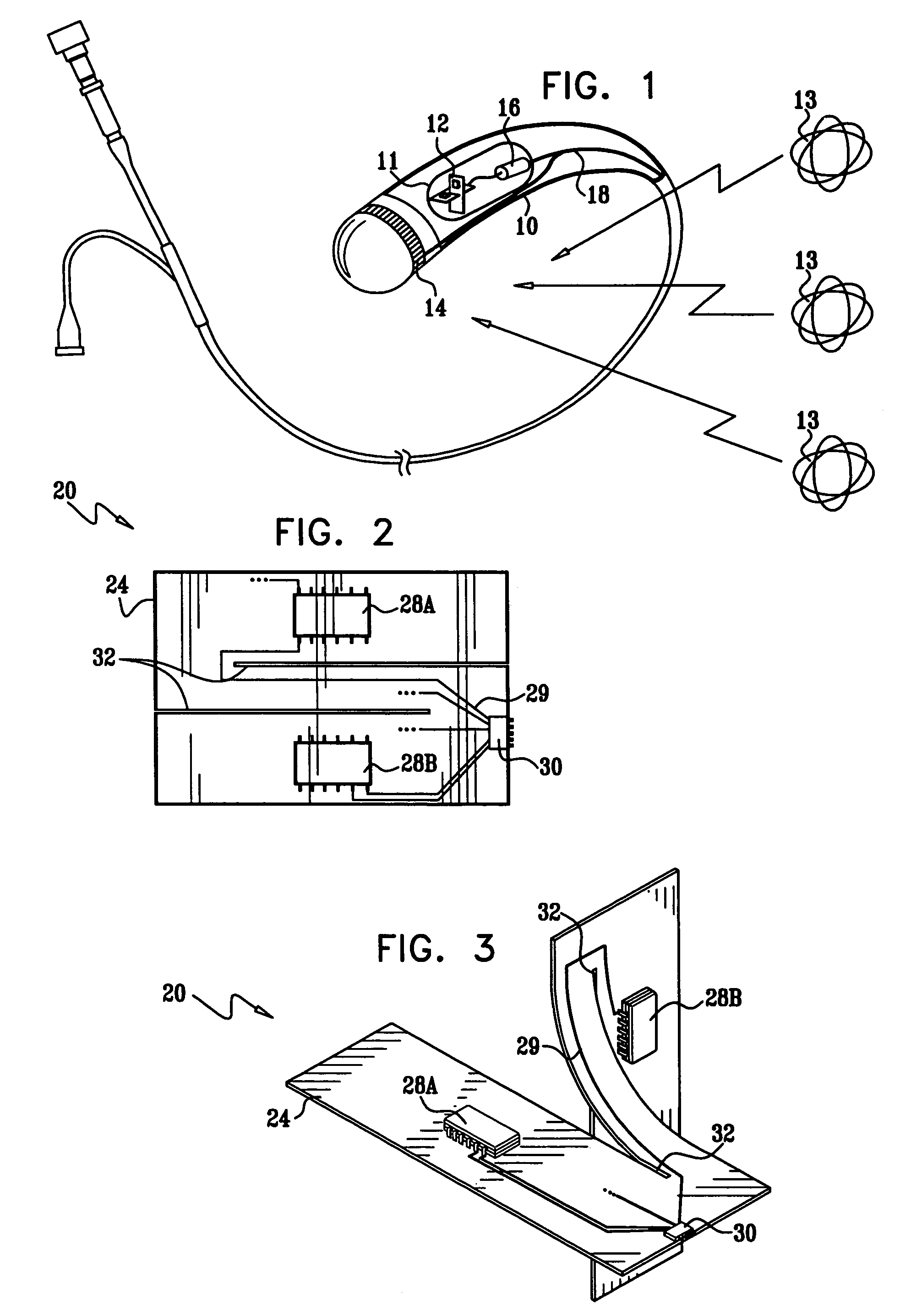

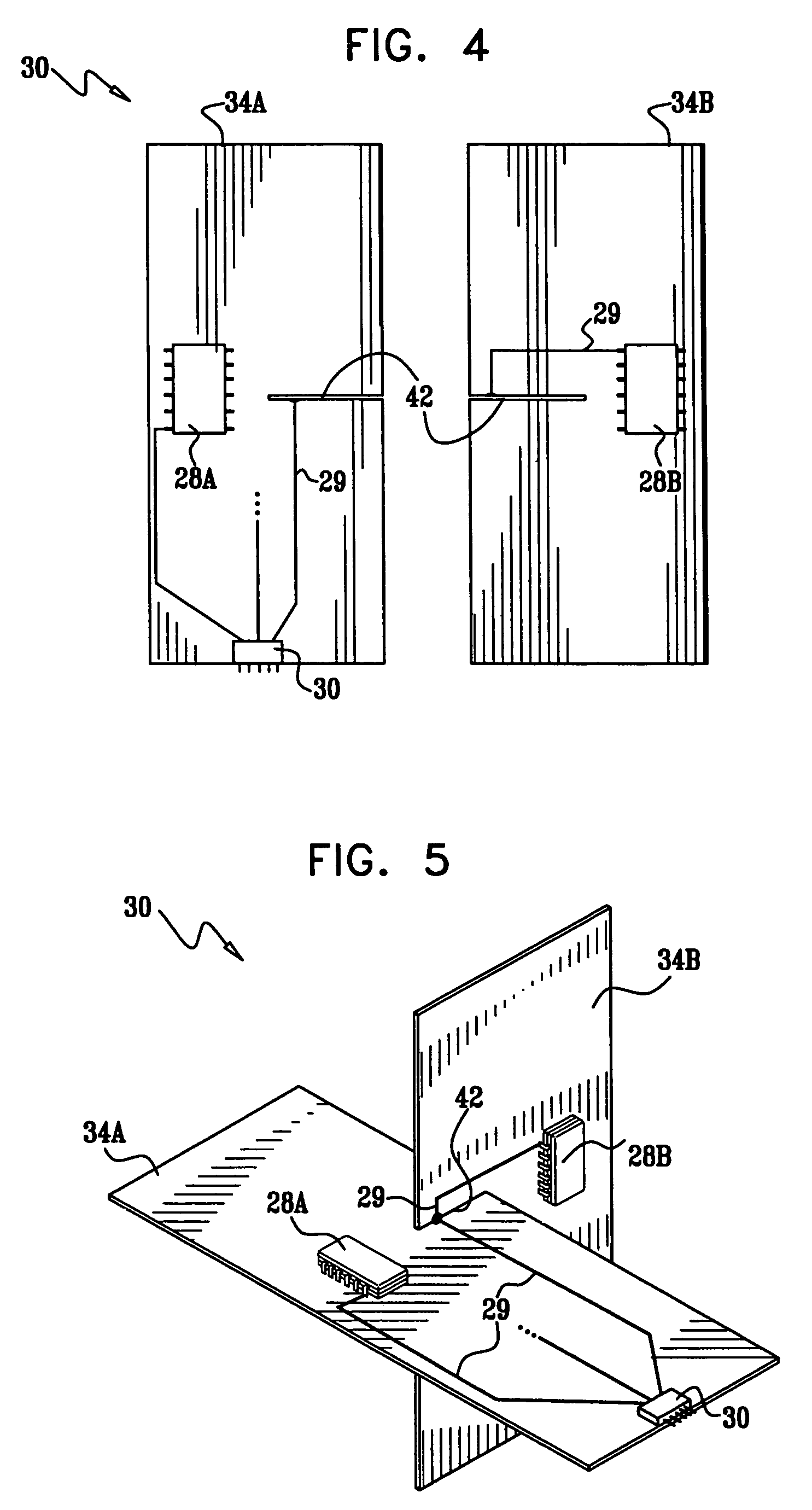

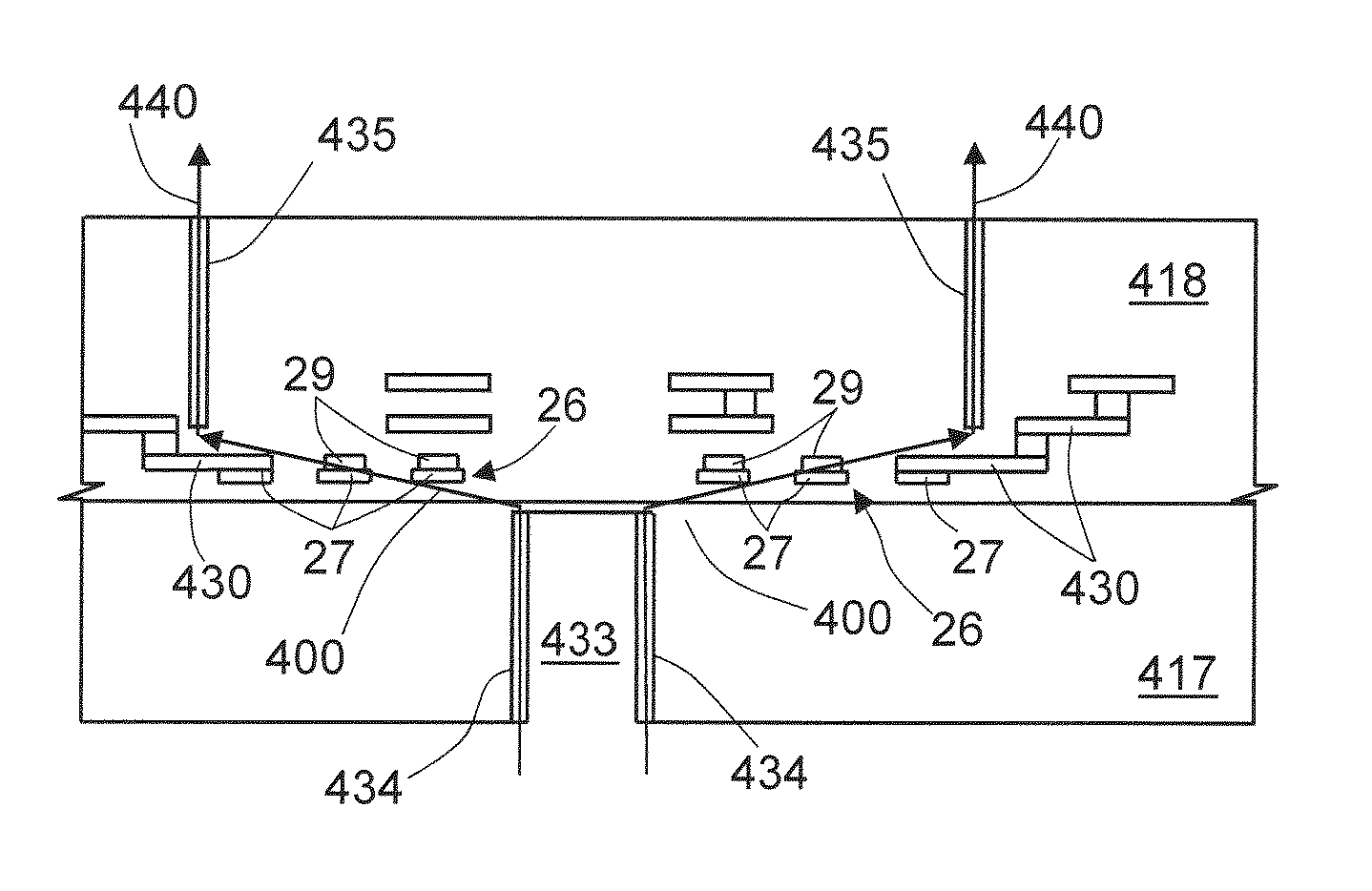

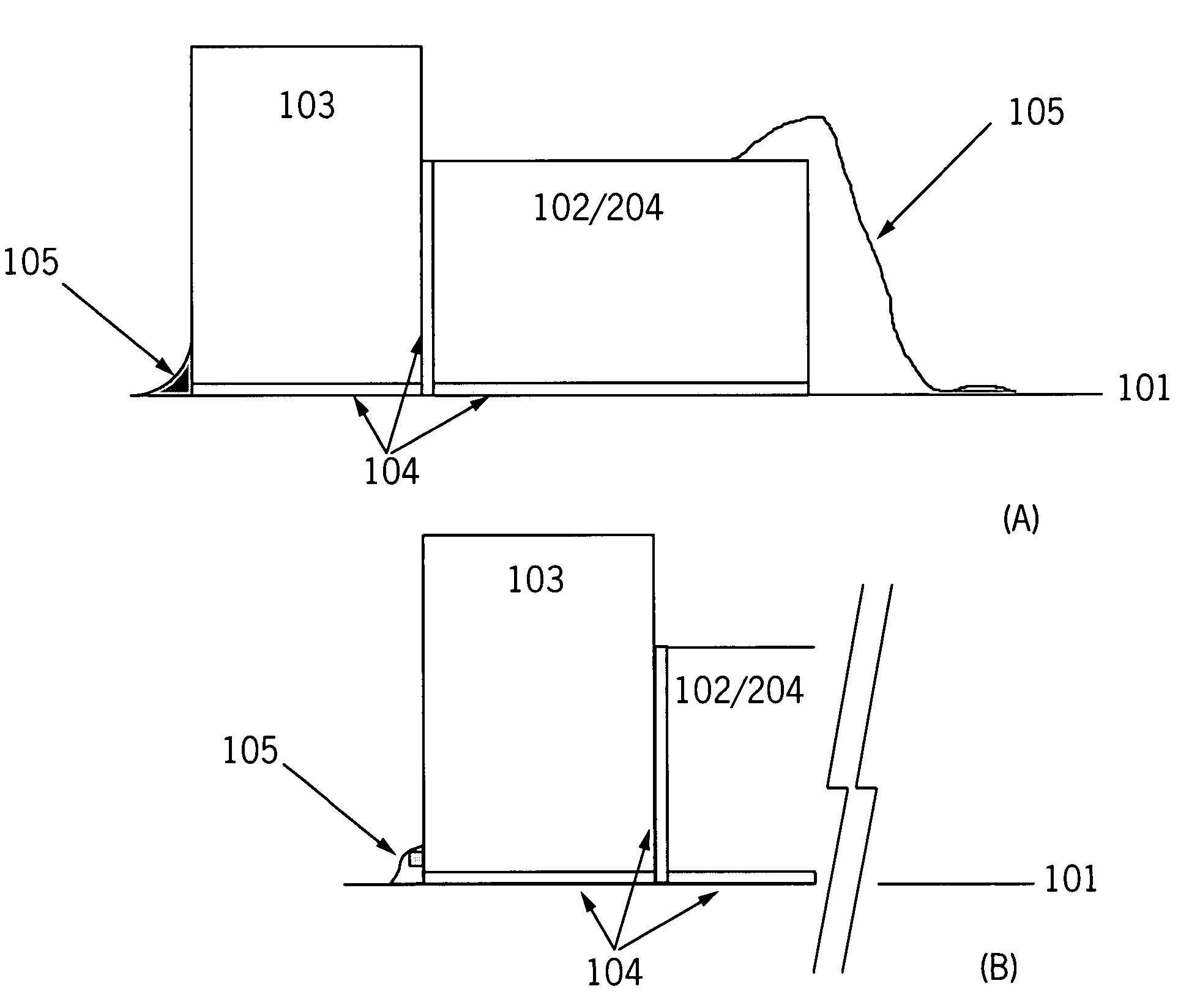

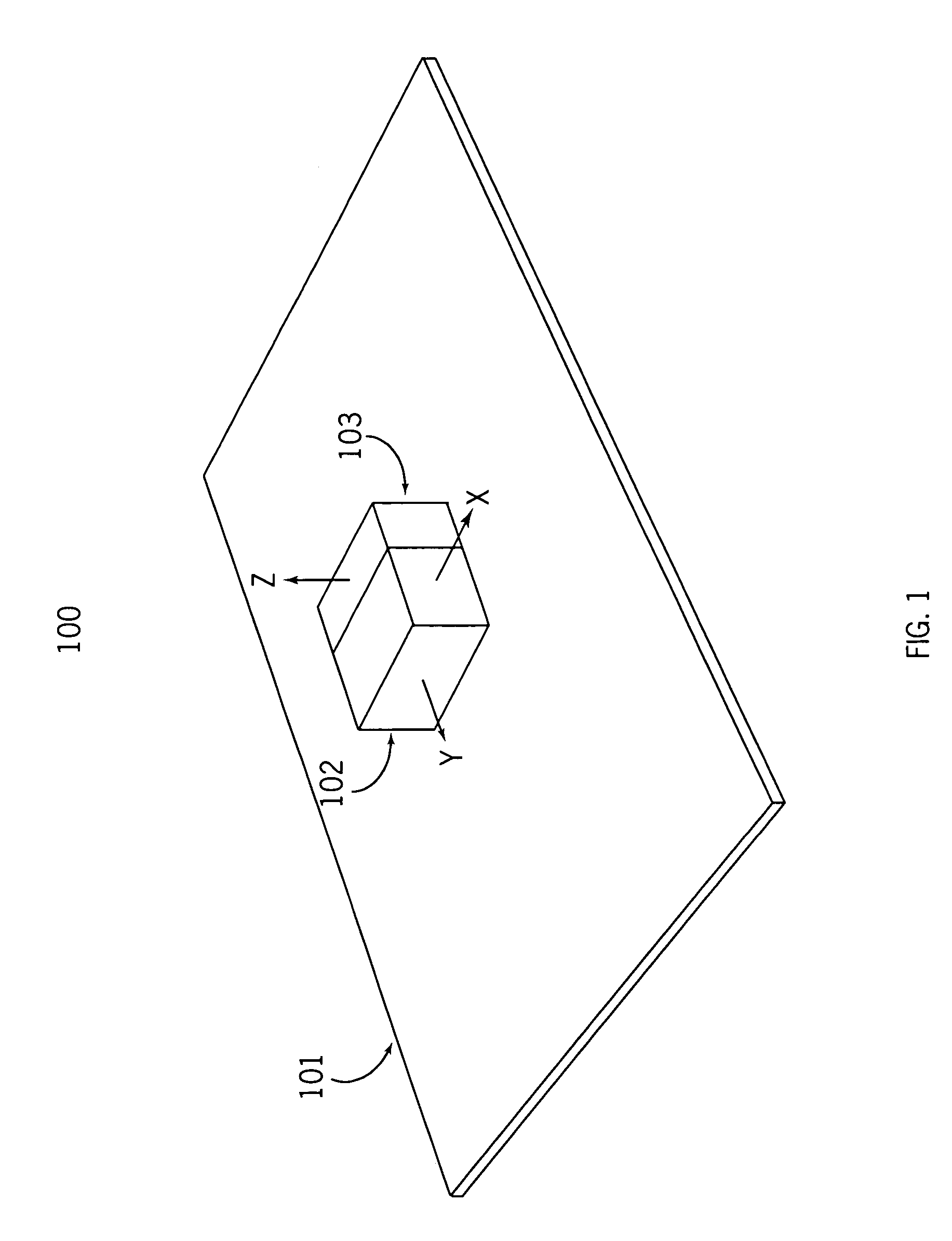

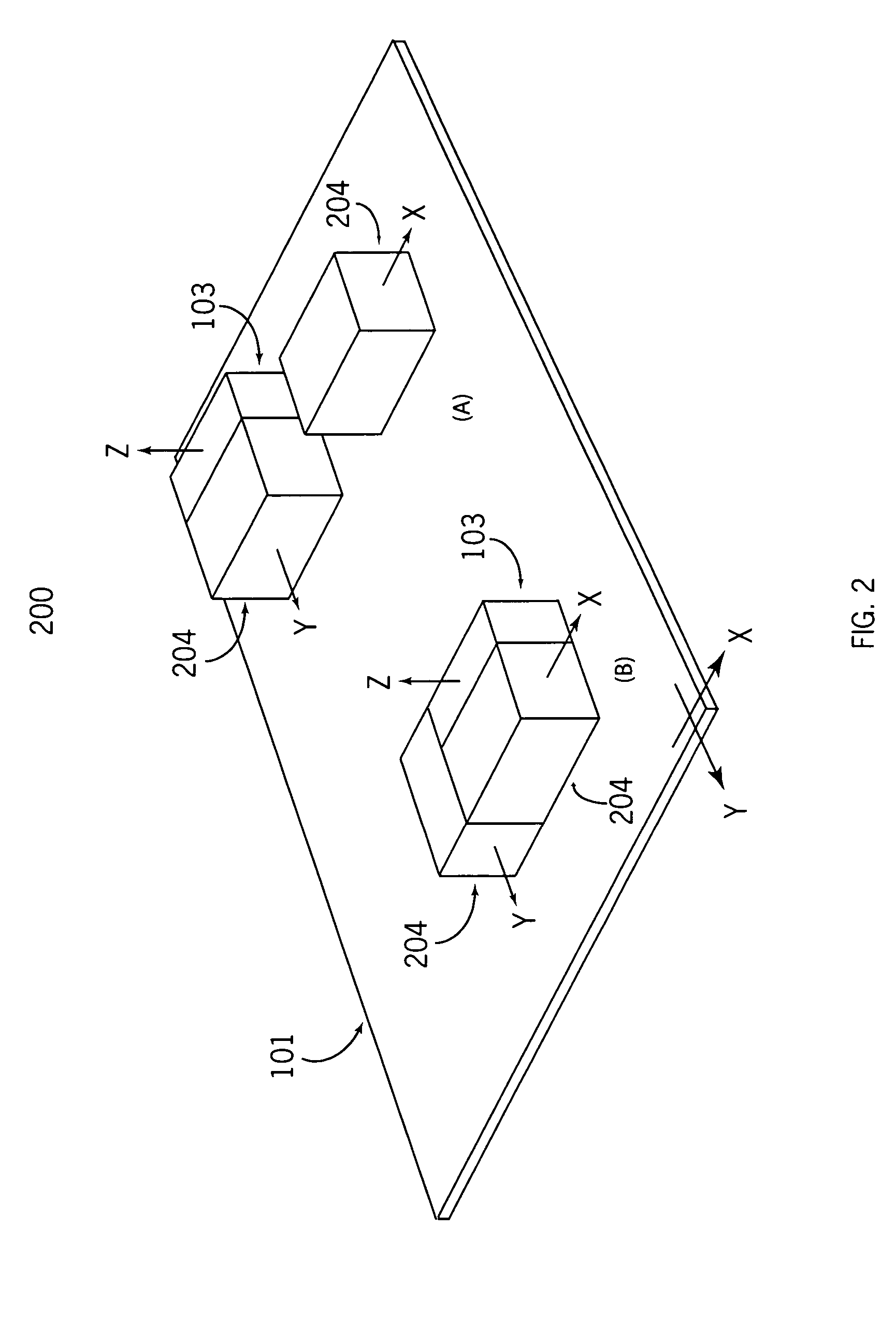

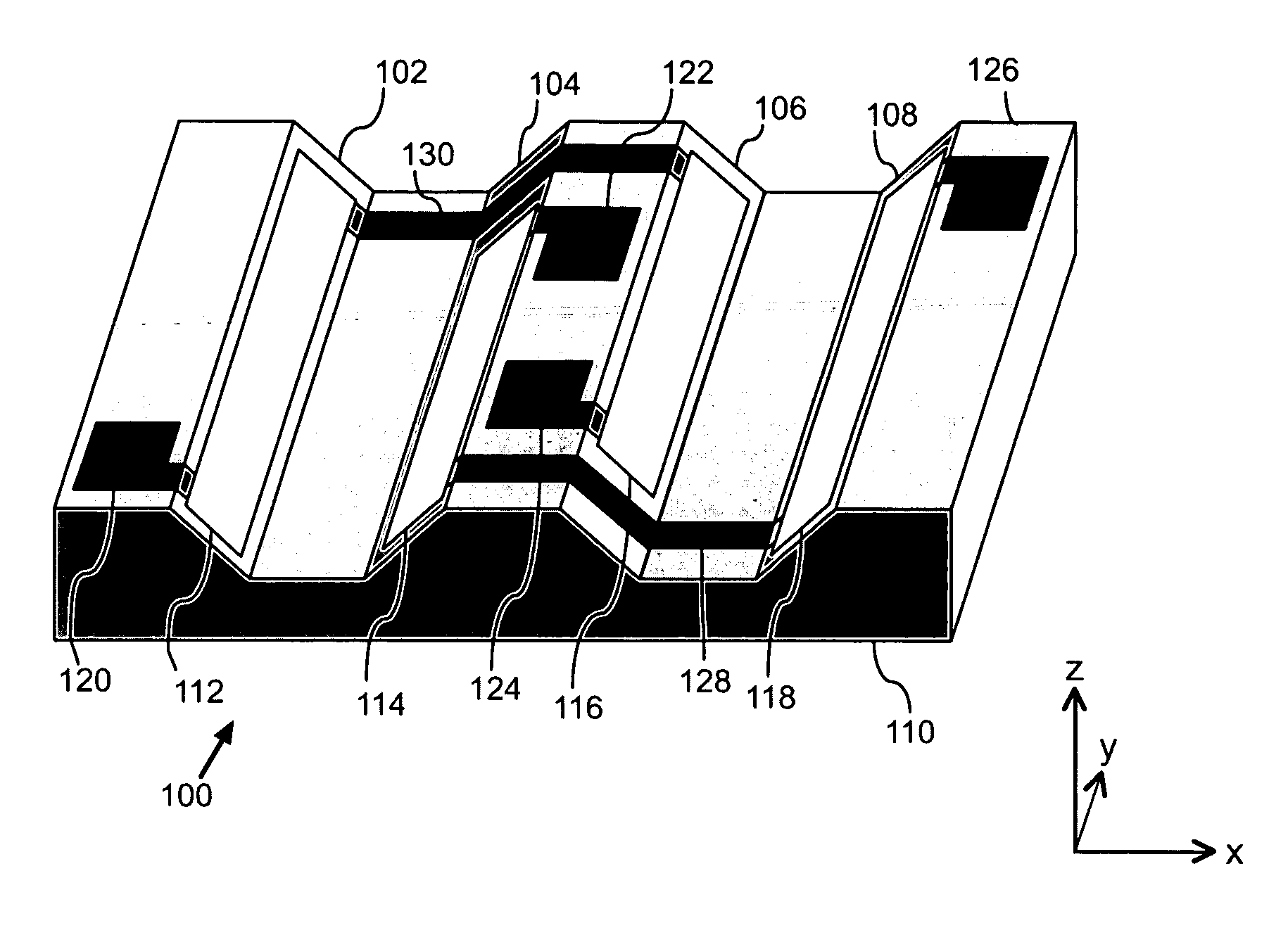

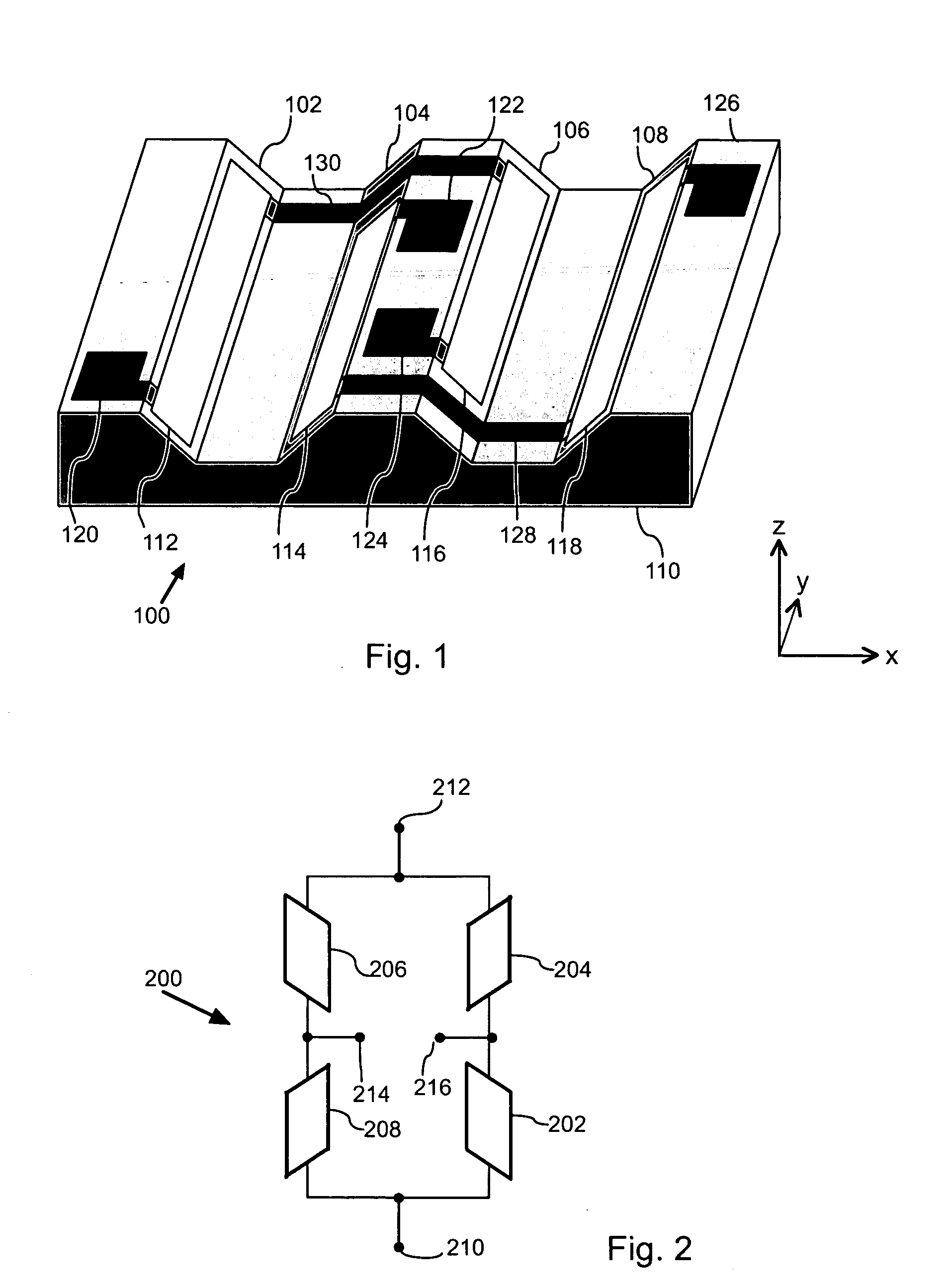

Vertical die chip-on-board

Methods and apparatus for vertical die chip-on-board sensor packages are provided. Such vertical die chip-on-board sensor packages can comprise a vertical sensor circuit component comprising a first face, a second face, a bottom edge, a top edge, two side edges, input / output (I / O) pads and at least one sensitive direction wherein the I / O pads are arranged near the bottom edge. Such vertical die chip-on-board sensor packages can also comprise one or more horizontal sensor circuit components comprising a top face, a printed circuit board (PCB) mounting face, a vertical sensor circuit component interface edge, two or more other edges, and one or more sensitive directions wherein the vertical sensor circuit component interface edge supports the vertical sensor circuit component along the Z axis and conductively or non-conductively connects to the vertical sensor circuit component. The methods and apparatus provided include a multi-axis magnetometer for measuring the magnetic field intensity along three orthogonal axes comprising one or more magnetic field sensing circuit components mounted by their PCB mounting face to a PCB and a vertical magnetic sensor circuit component mounted to the PCB such that the vertical magnetic sensor circuit component is attached to and supported by the magnetic field sensing circuit component.

Owner:HONEYWELL INT INC

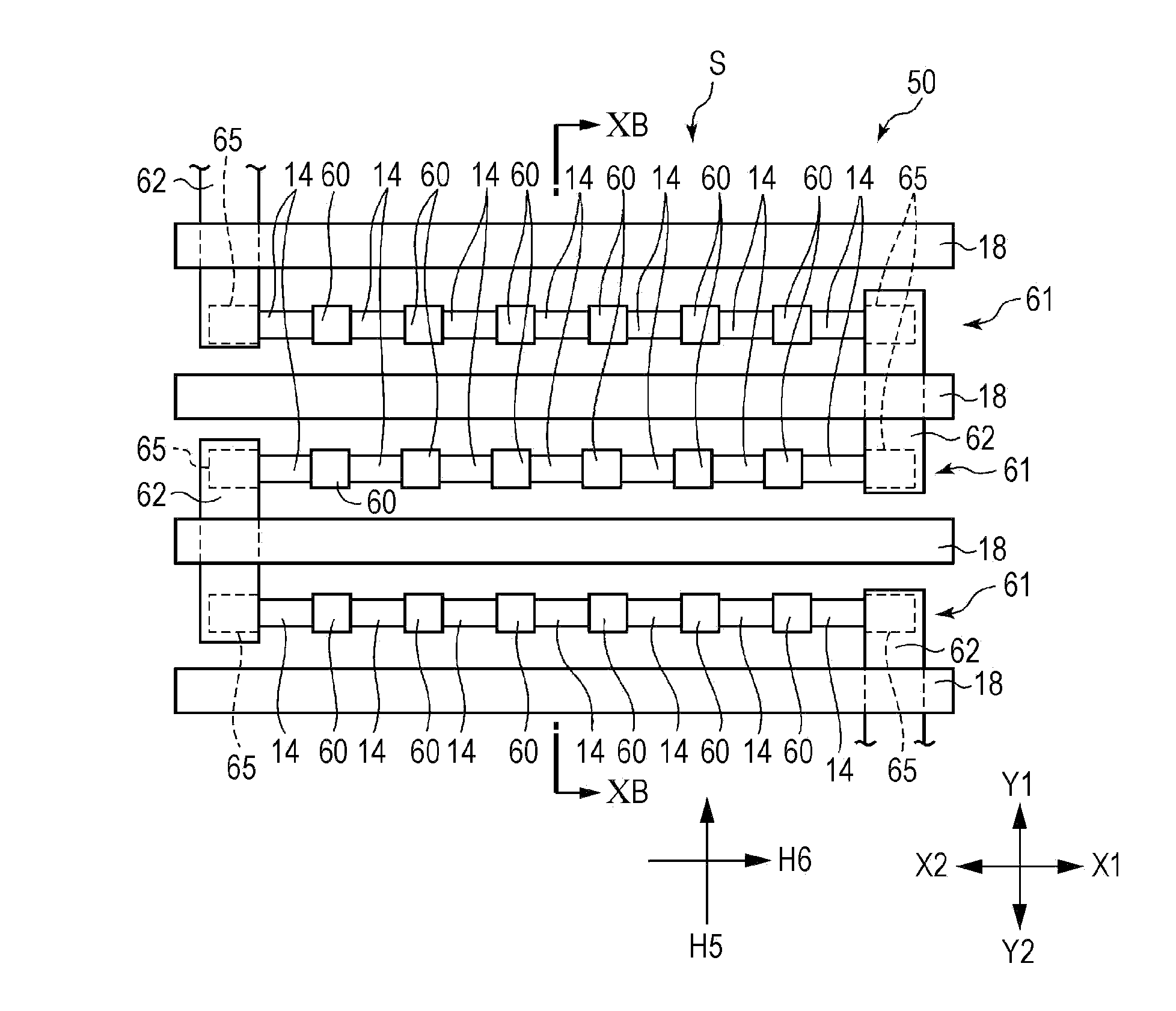

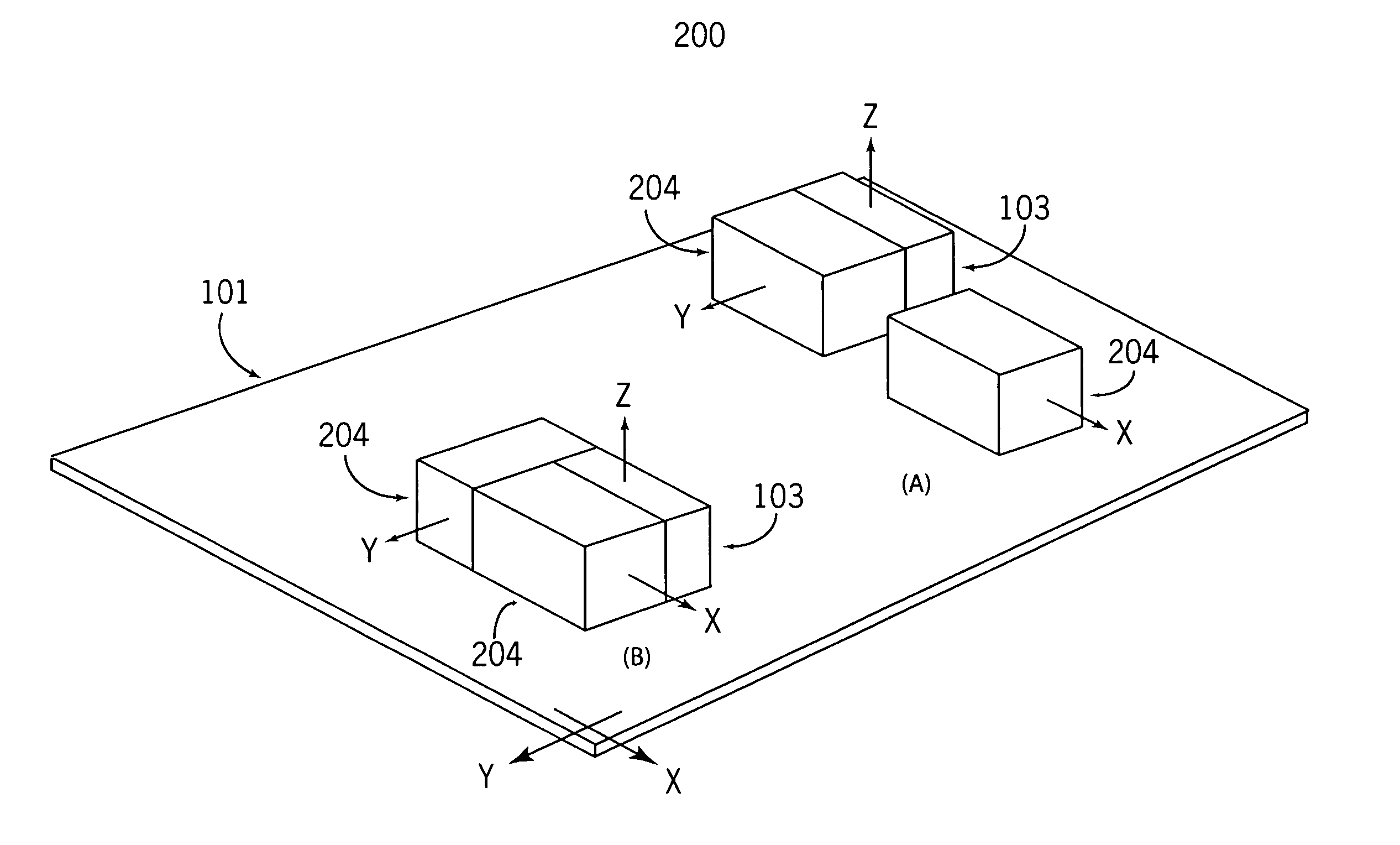

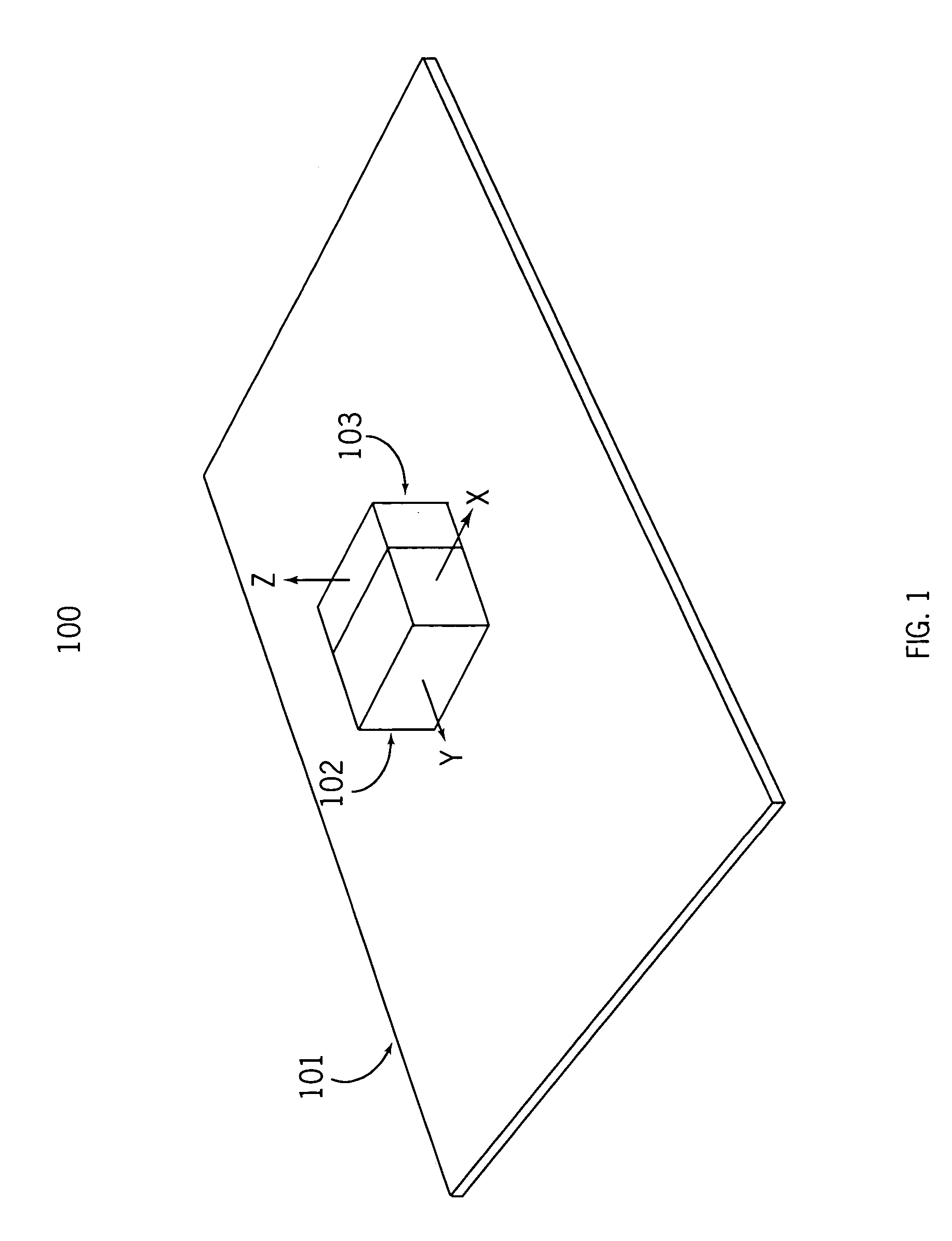

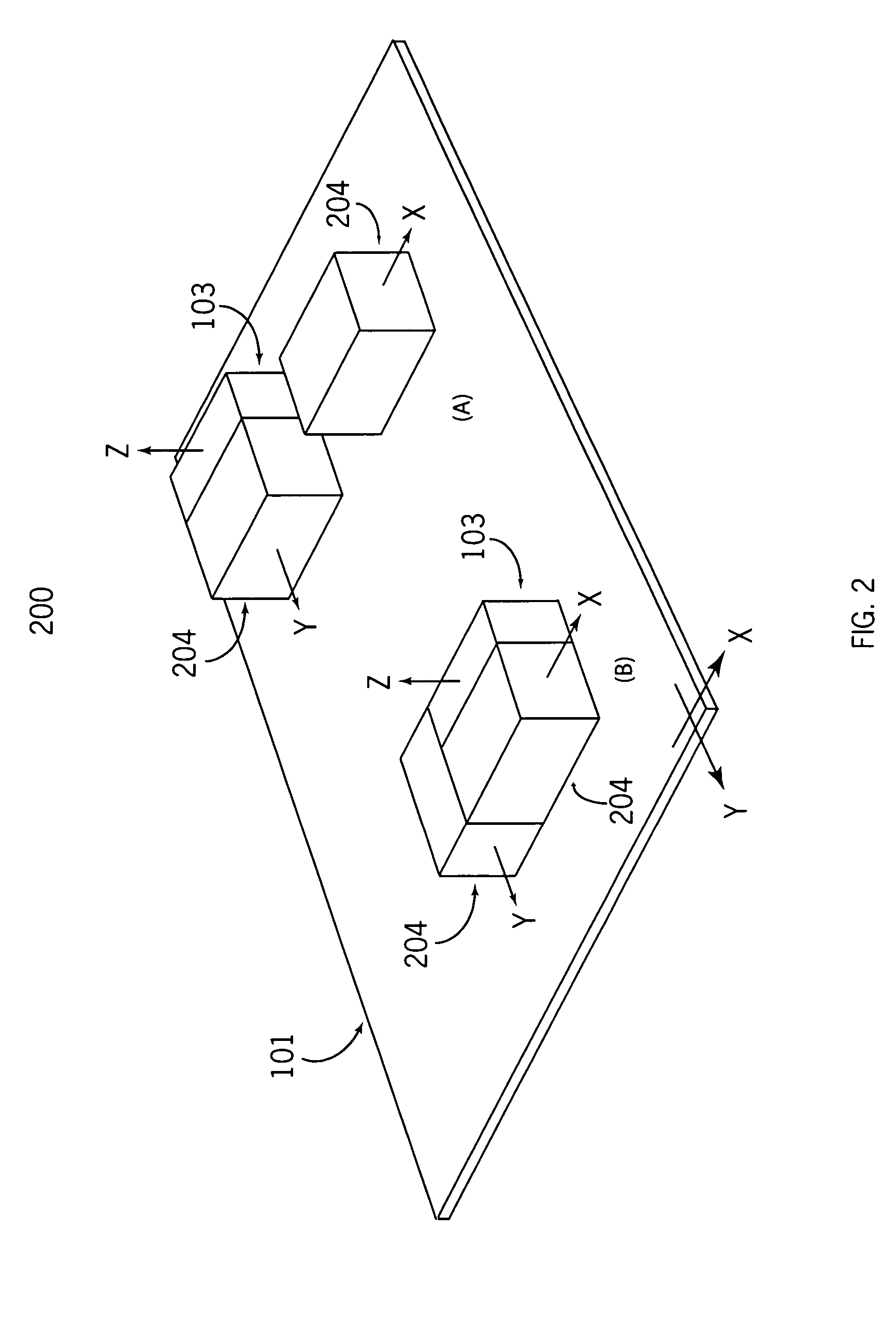

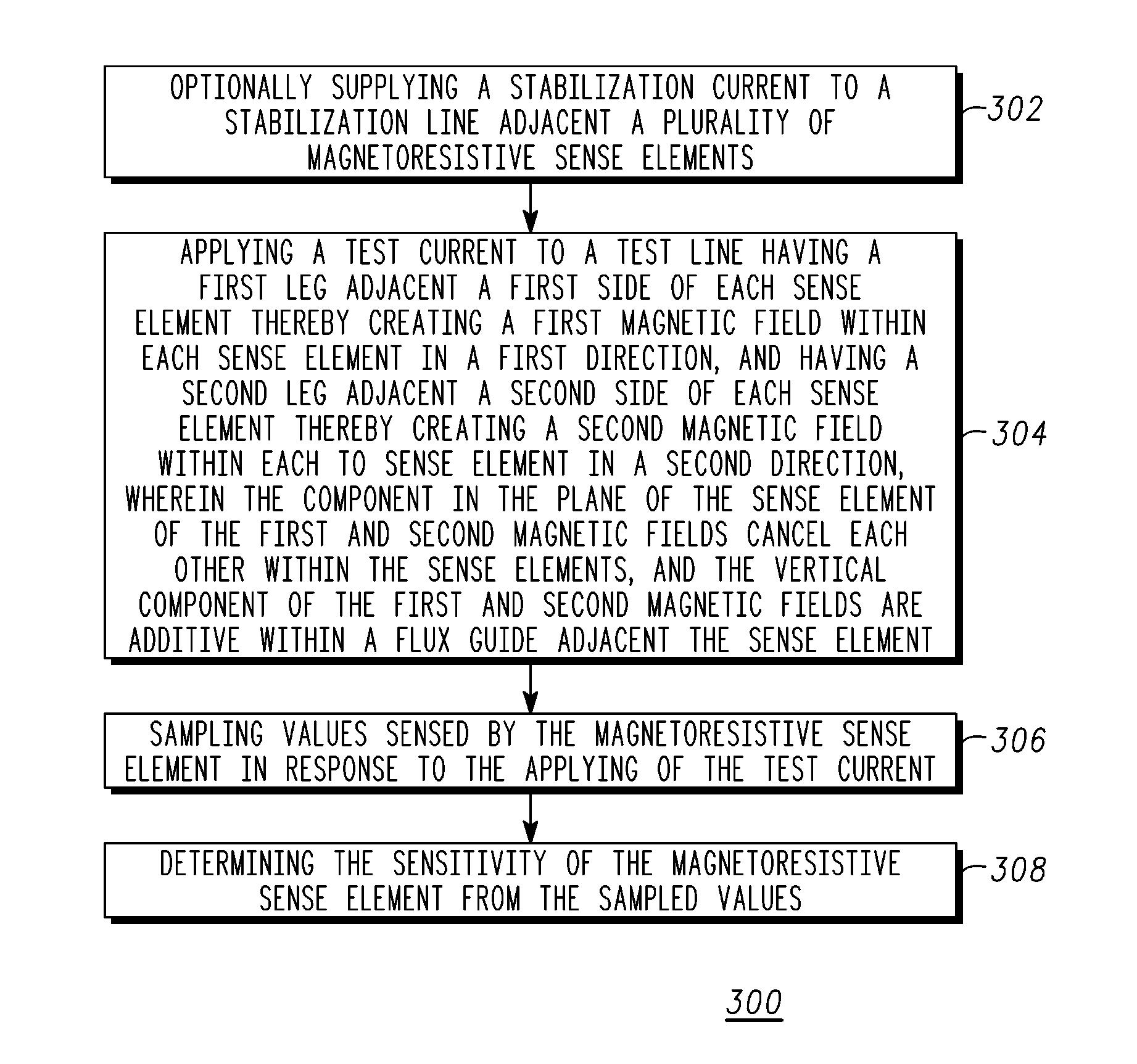

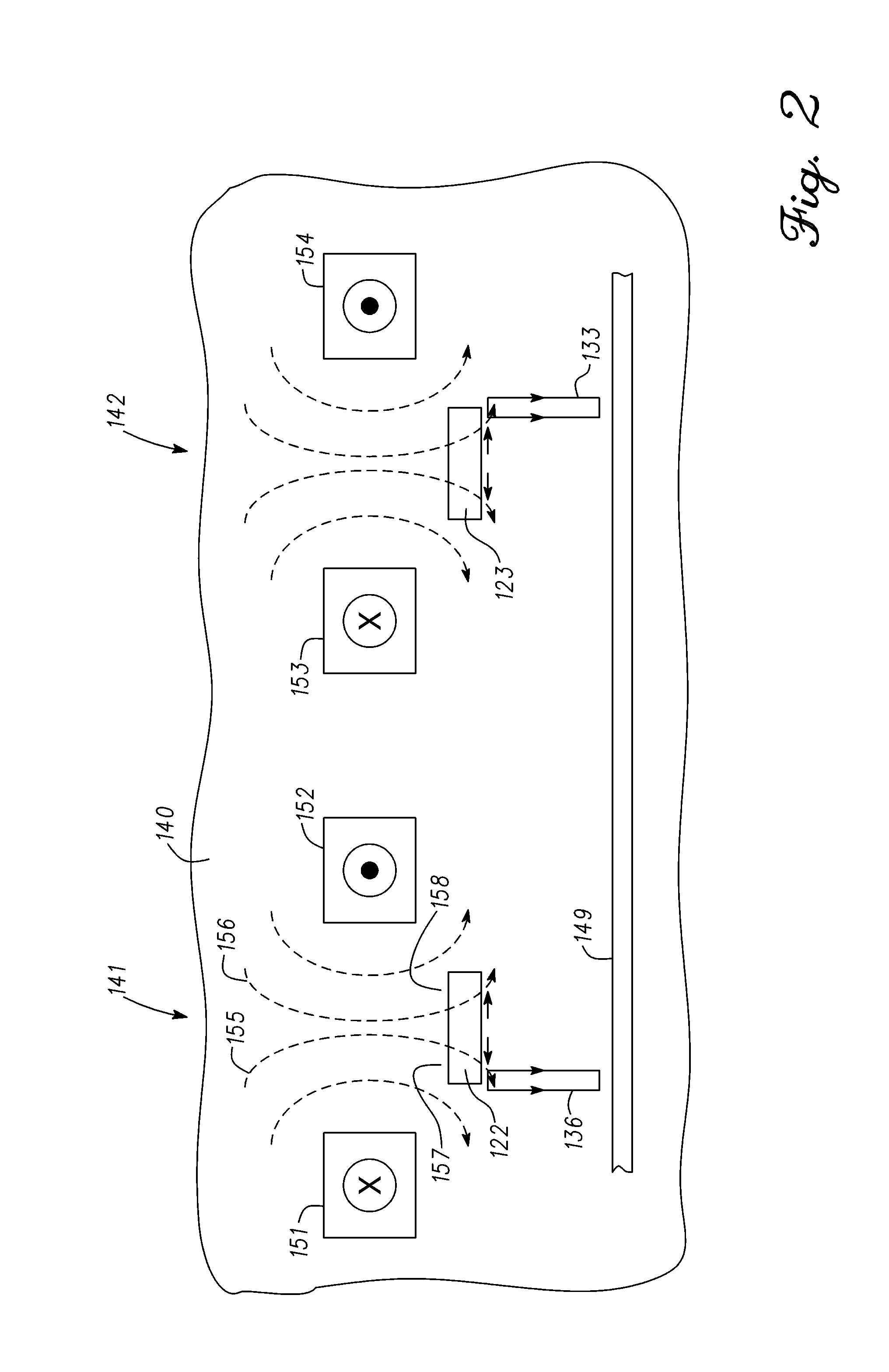

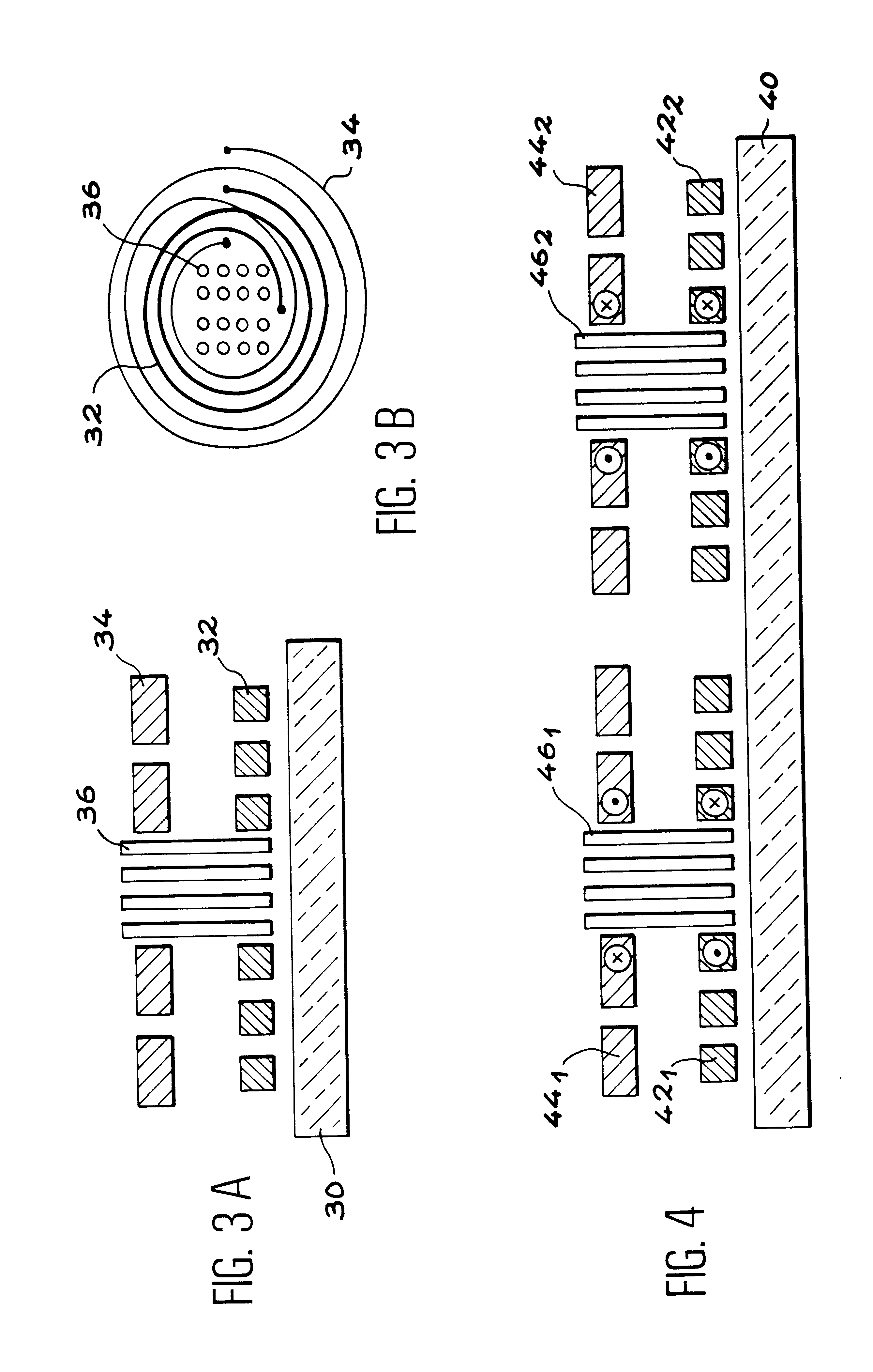

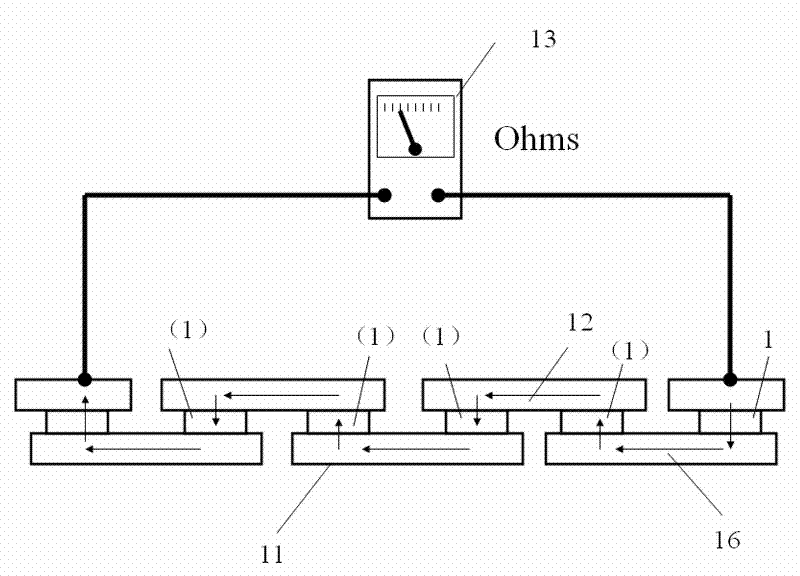

Method and structure for testing and calibrating three axis magnetic field sensing devices

ActiveUS20130300402A1Electrical measurementsThree-component magnetometersLine pairElectrical current

A structure and method are provided for self-test of a Z axis sensor. Two self-test current lines are symmetrically positioned adjacent, but equidistant from, each sense element. The vertical component of the magnetic field created from a current in the self-test lines is additive in a flux guide positioned adjacent, and orthogonal to, the sense element; however, the components of the magnetic fields in the plane of the sense element created by each of the two self-test current line pairs cancel one another at the sense element center, resulting in only the Z axis magnetic field being sensed during the self-test.

Owner:EVERSPIN TECHNOLOGIES

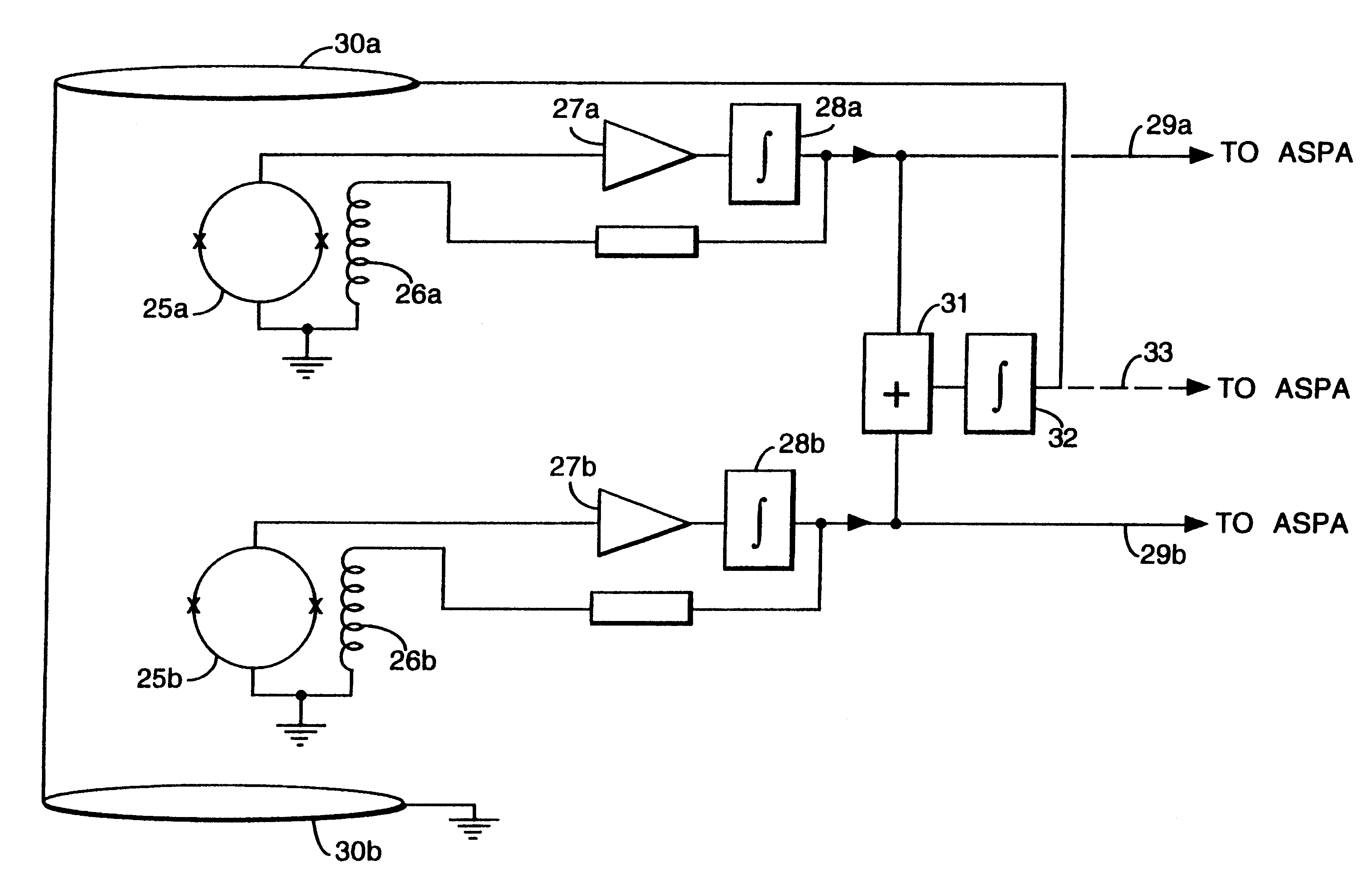

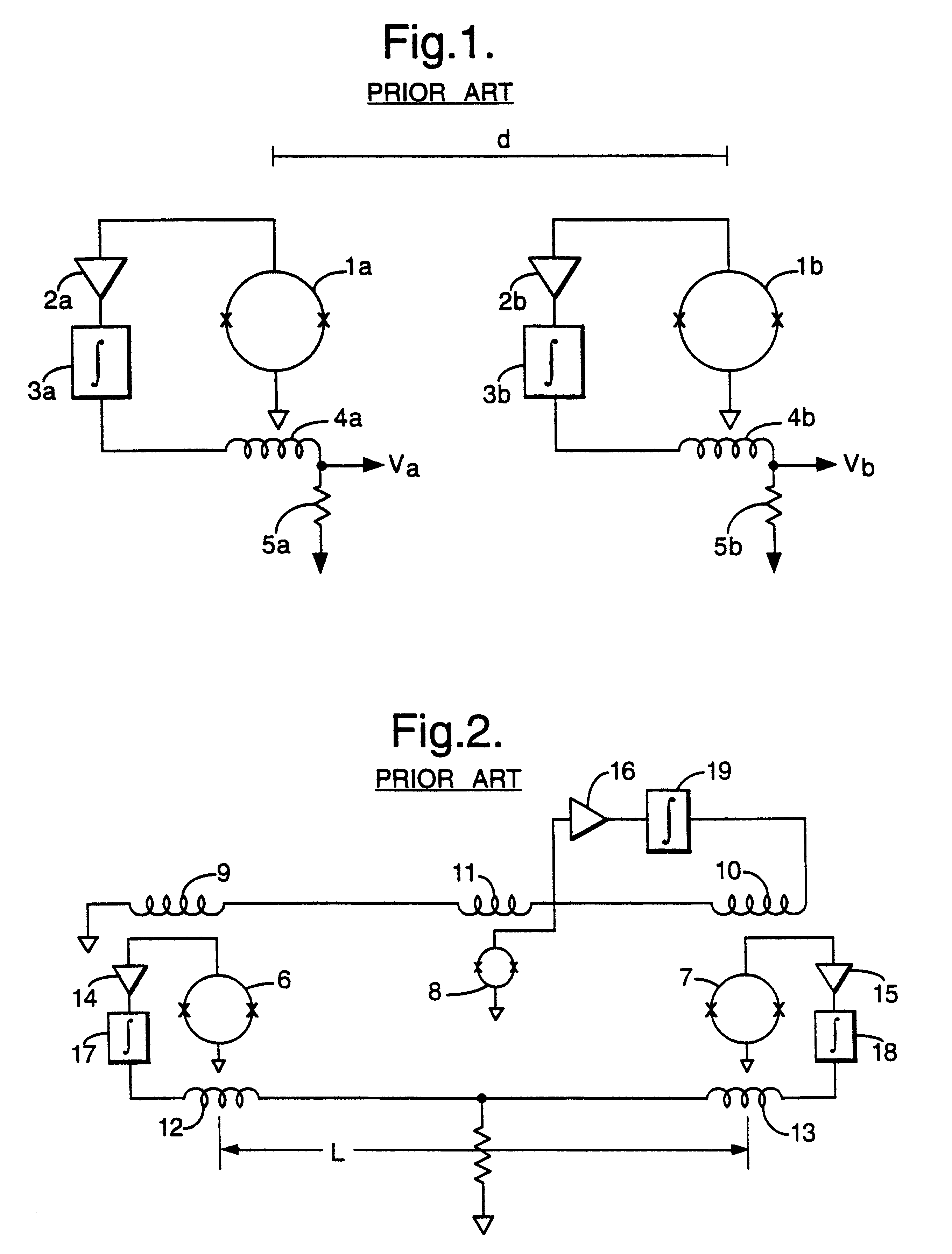

Magnetic gradiometer incorporating global feedback

InactiveUS6339328B1Minimizing energySufficient dynamic rangeMagnetic field measurement using flux-gate principleMagnetic field measurement using galvano-magnetic devicesMagnetic field gradientGradiometer

A gradiometer for measuring properties of a magnetic field and in particular, for measuring magnetic field gradient components, comprising at least two magnetic sensors wherein at least two of the magnetic sensors are arranged to sense the magnetic field component in substantially the same direction. The magnetic sensors may be super conducting quantum interference device (SQUID) magnetometers, Hall probes, flux gates or magneto-resistive magnetometers. The gradiometer also includes a computer processor loaded with an adaptive signal-processing algorithm, for performing adaptive signal balancing of the magnetometer outputs. In a preferred embodiment the gradiometer may comprise at least eight magnetometers in a three-dimensional arrangement, and a set of three orthogonal global feedback coils, one for each direction x, y, z, such that the five independent magnetic field gradient components may be measured. The gradiometer may also be used to measure second or higher order magnetic field gradient components.

Owner:QINETIQ LTD

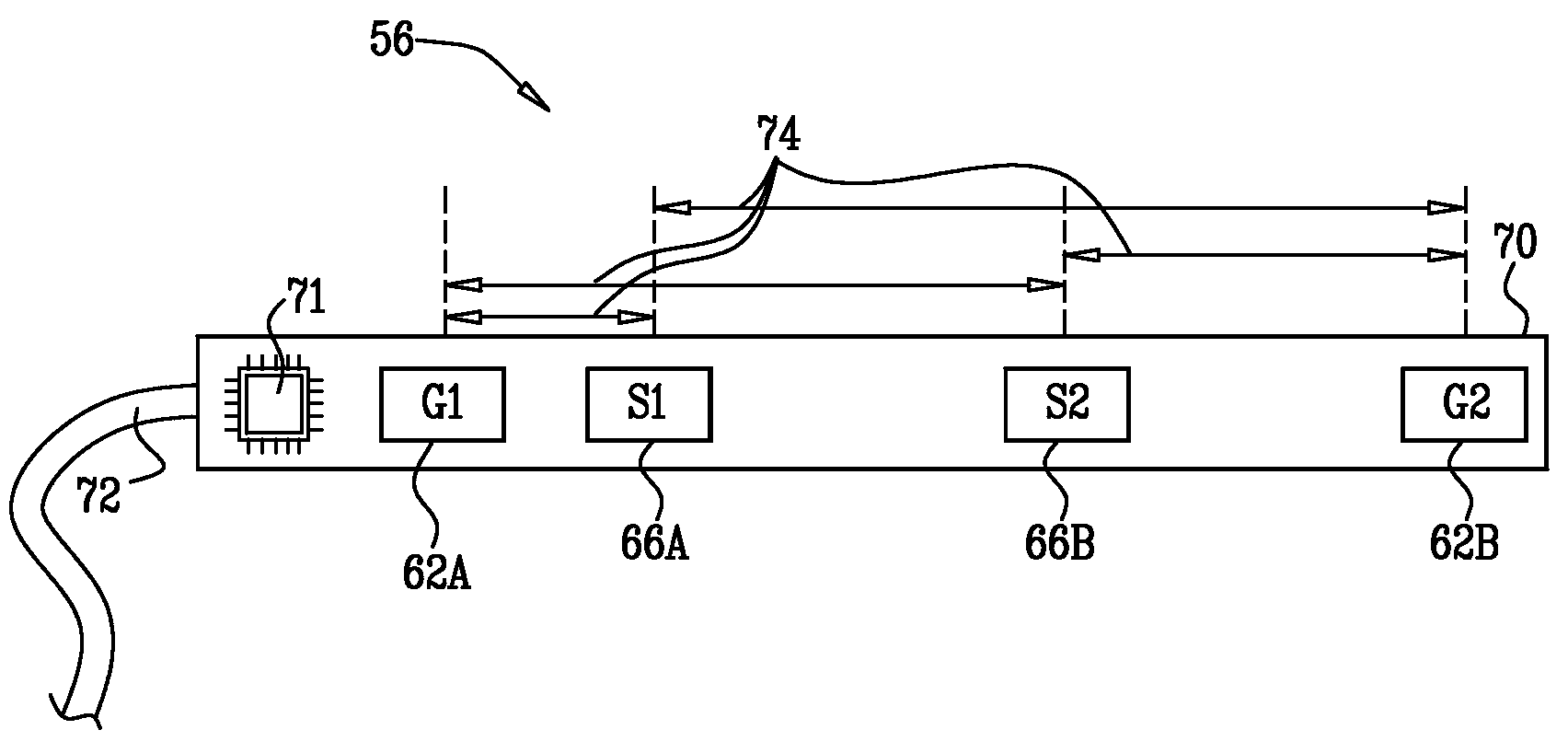

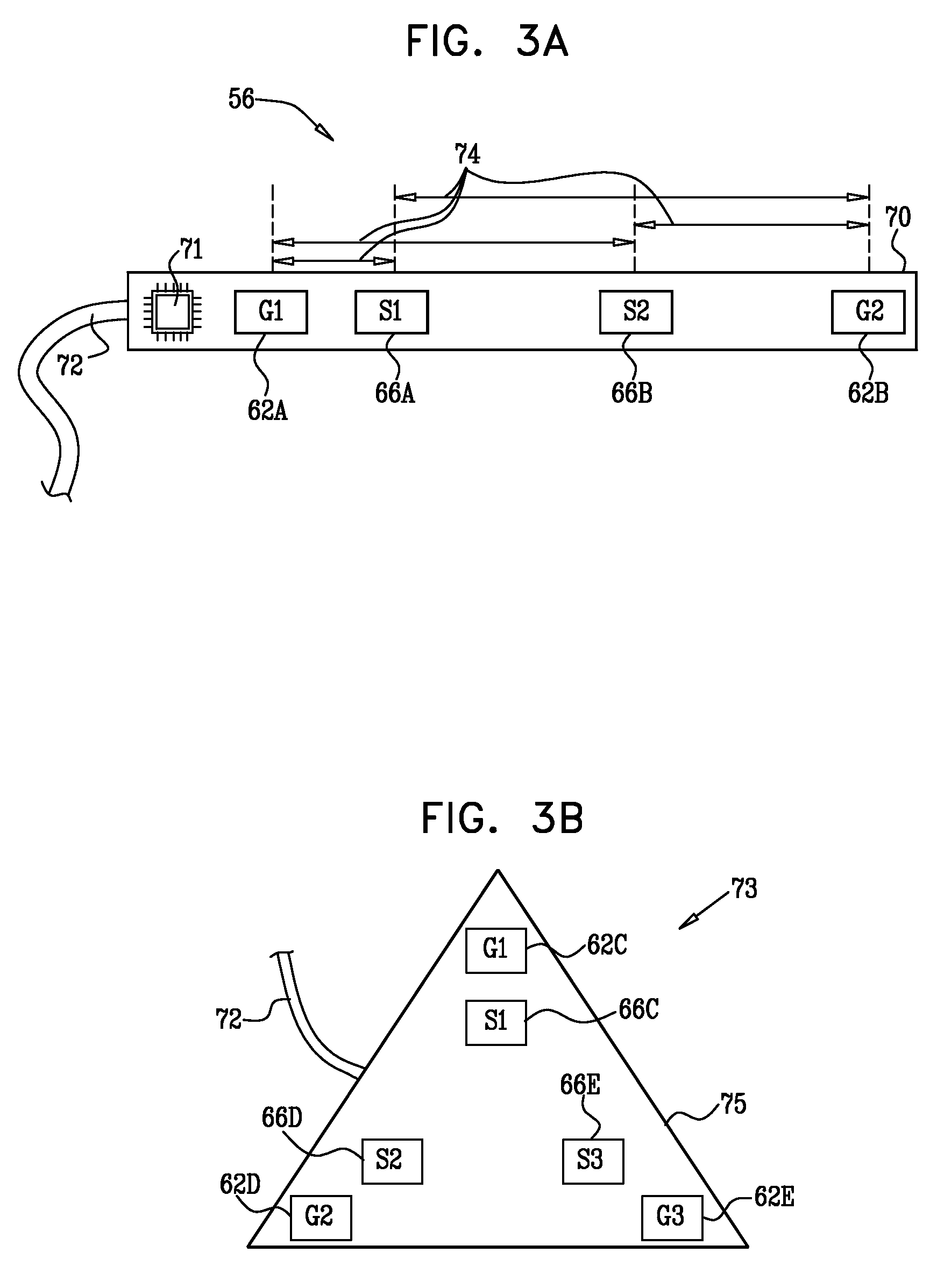

Probe for assessment of metal distortion

InactiveUS7688064B2Direction finders using radio wavesCurrent/voltage measurementAcousticsDistortion

Apparatus for assessing field distortion includes a probe and a processor. The probe includes a mechanical fixture for placement at a location to be tested, and one or more field generators, which are attached to the mechanical fixture and are arranged to generate respective magnetic fields. The probe further includes one or more field sensors, which are attached to the mechanical fixture at known positions with respect to the one or more field sensors and are arranged to sense the magnetic fields generated by the one or more field generators and to output signals responsively to the sensed magnetic fields. The processor is arranged to process the signals so as to assess a distortion of the magnetic fields sensed by the field sensors at the tested location.

Owner:BIOSENSE WEBSTER INC

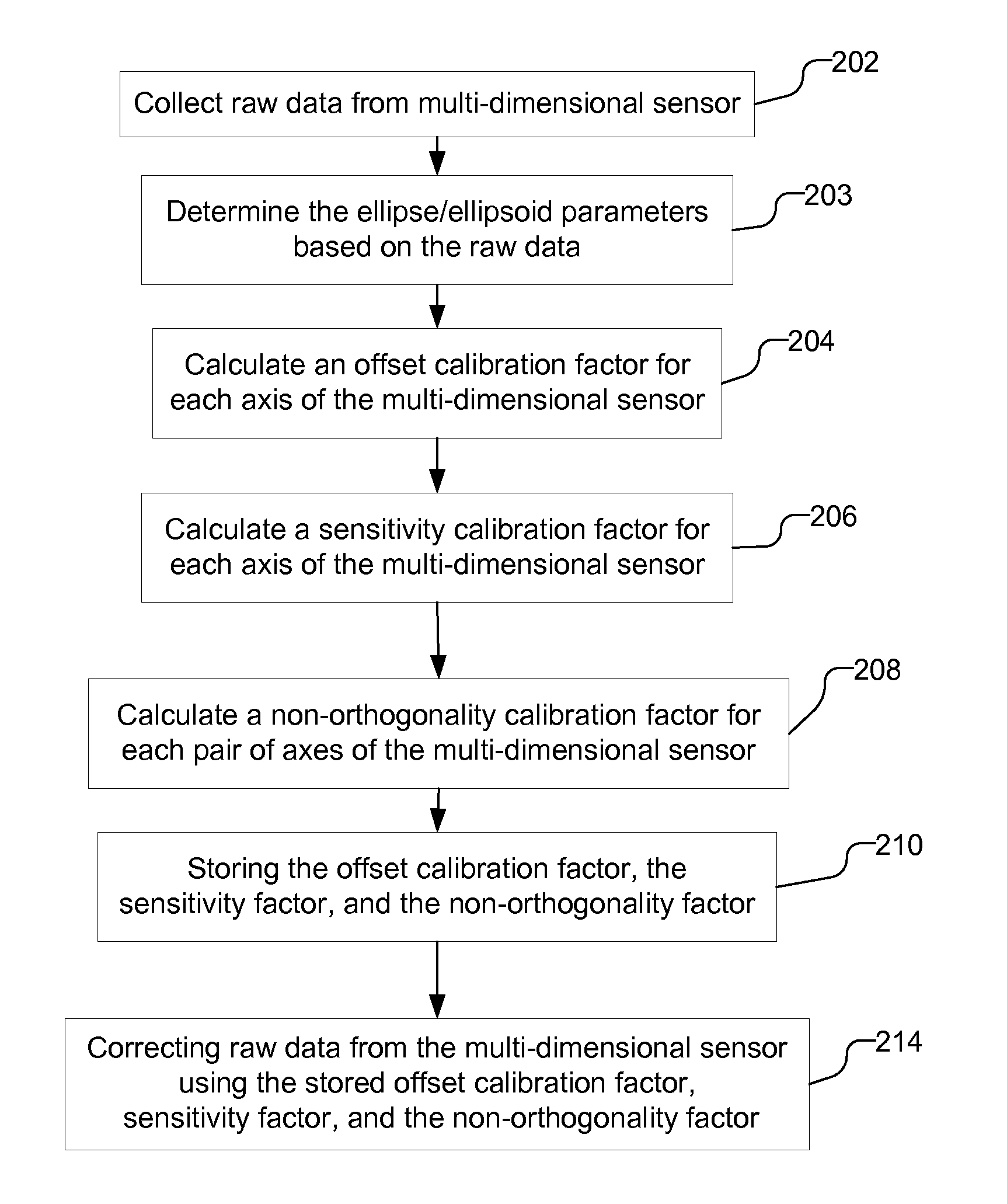

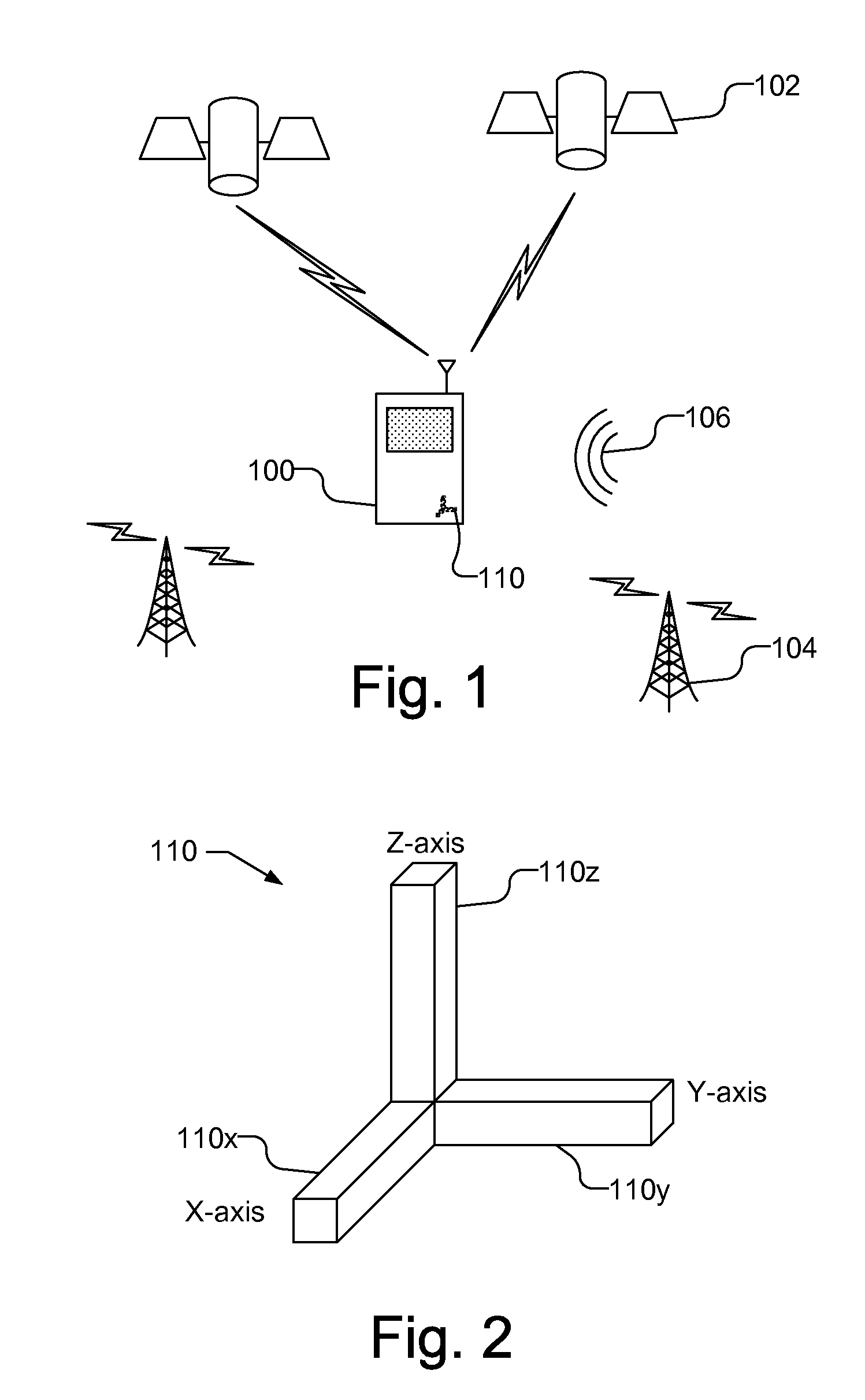

Calibrating multi-dimensional sensor for offset, sensitivity, and non-orthogonality

InactiveUS20110106477A1Testing/calibration apparatusSpeed measurement using gyroscopic effectsAccelerometerEllipse

A multi-dimensional sensor, a magnetometer or accelerometer, is calibrated based on the raw data provided by the sensor. Raw data is collected and may be used to generate ellipse or ellipsoid parameters, for a two-dimensional or three-dimensional sensor, respectively. An offset calibration factor is calculated based on the raw data, e.g., the determined ellipse or ellipsoid parameters. A sensitivity calibration factor is then calculated based on the offset calibration factor and the raw data. A non-orthogonality calibration factor can then be calculated based on the calculated offset and sensitivity calibration factors. Using the offset, sensitivity and non-orthogonality calibration factors, the raw data can be corrected to produce calibrated data.

Owner:QUALCOMM INC

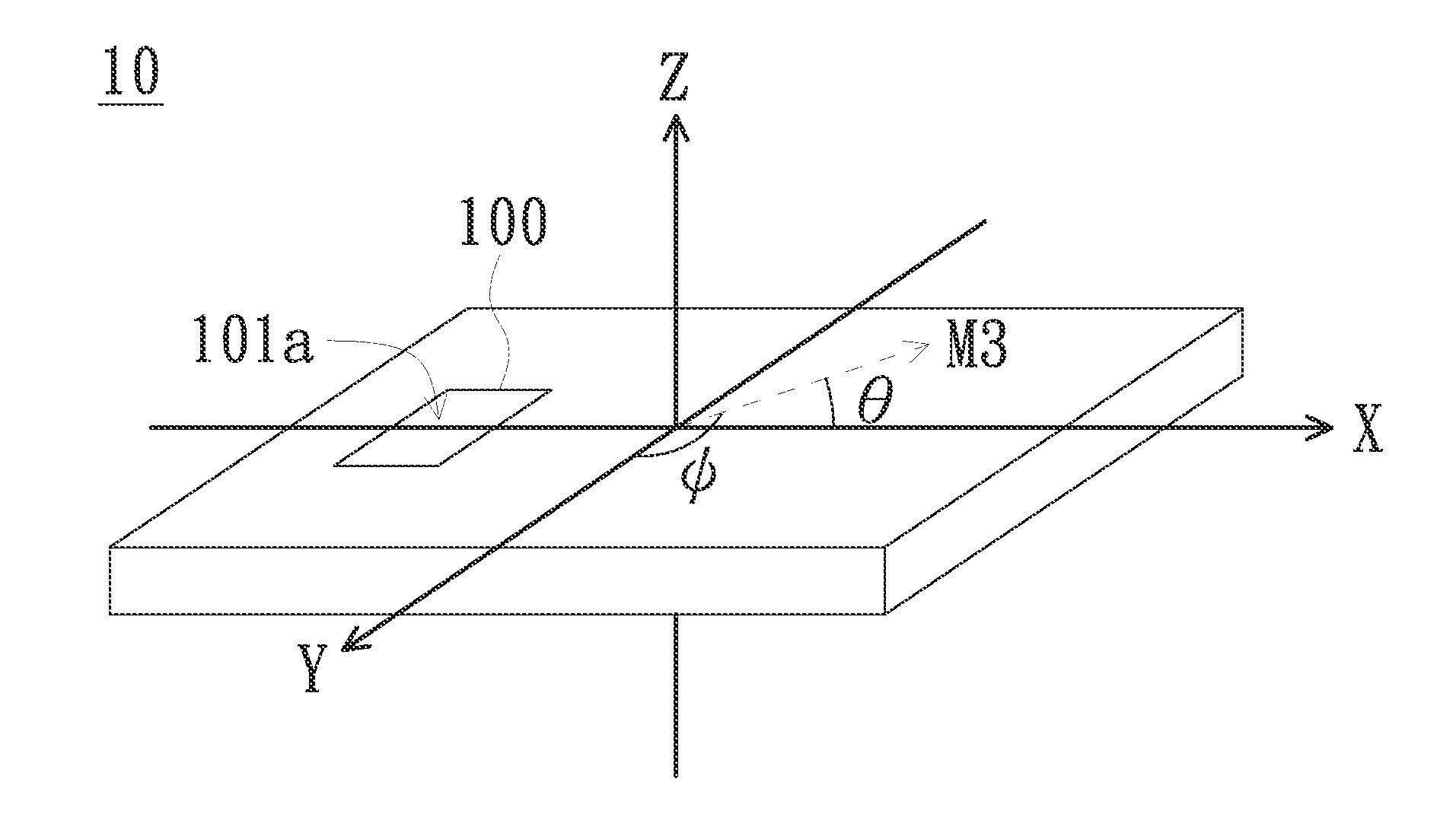

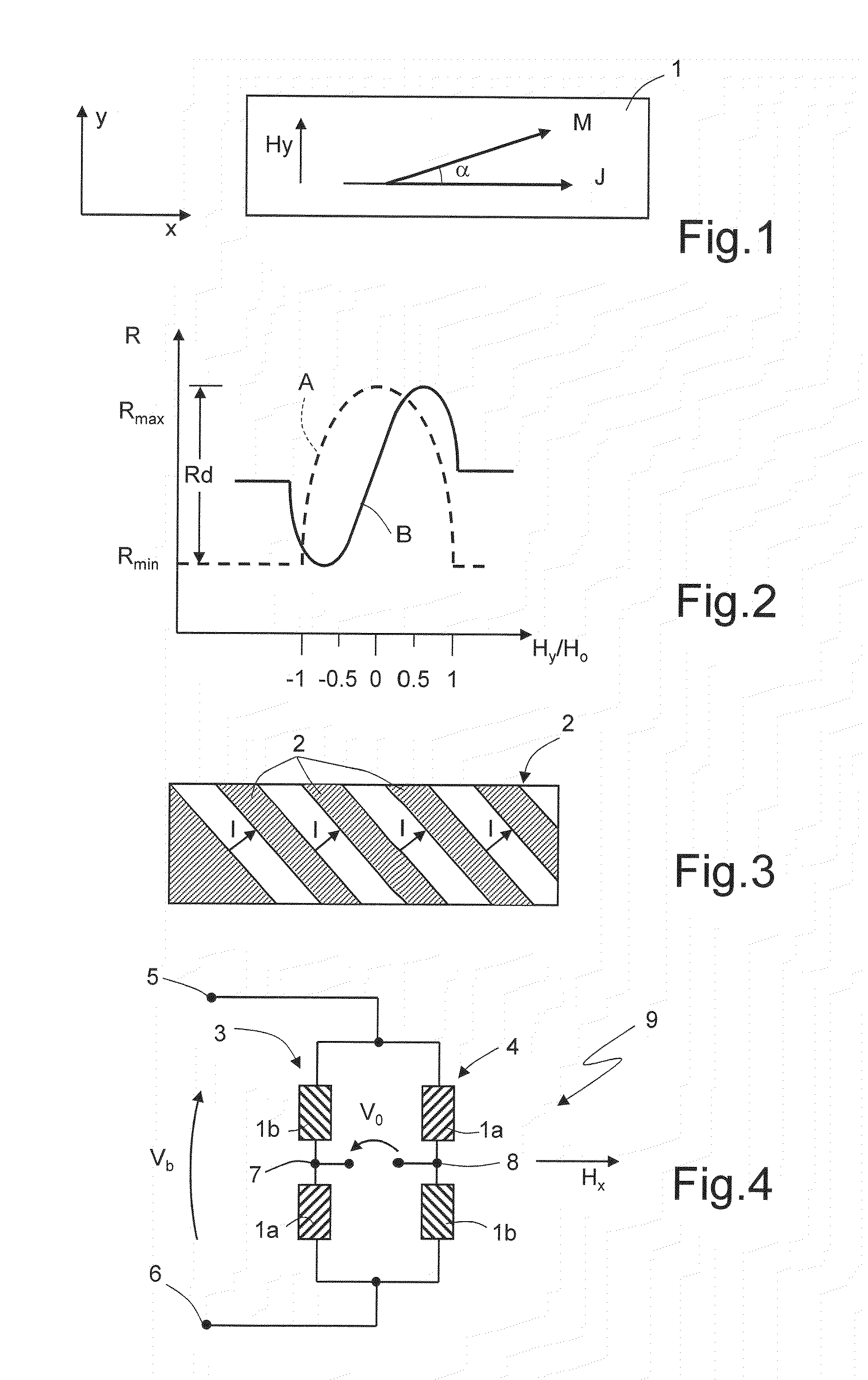

Magnetic-Field Sensing Method

InactiveUS20150128431A1Reduce manufacturing costReduce yieldThree-component magnetometersCompassesClassical mechanicsMagnetic field

A magnetoresistive sensing device is provided. A first sensed magnetic-field component in parallel with the x-axis and a second sensed magnetic-field component in parallel with the y-axis of an external magnetic field forming a first inclination angle with the x-axis and a second inclination angle with the y-axis are determined. A virtual plane is defined so as to render a magnetic-field component perpendicular to the virtual plane of the external magnetic field is essentially zero. The first inclination angle and the second inclination angle are adjusted with reference to the virtual plane. An x-axis magnetic-field component in parallel with the x-axis, a y-axis magnetic-field component in parallel with the y-axis and a z-axis magnetic-field component in parallel with the z-axis of the external magnetic field are estimated according to the adjusted first inclination angle, the adjusted second inclination angle, the first sensed magnetic-field component and the second sensed magnetic-field component.

Owner:VOLTAFIELD TECH

Magnetic sensor and sensitivity measuring method thereof

ActiveUS20100117638A1Magnetic property measurementsElectrical measurementsUltimate tensile strengthDecision unit

The present invention relates to a magnetic sensor with a sensitivity measuring function and a method thereof. Magnetic sensitivity surfaces detect flux density, and a switching unit extracts magnetic field intensity information of each axis, and inputs it to a sensitivity calculating unit. The sensitivity calculating unit calculates the sensitivity from the magnetic field intensity information about the individual axes from the magnetic sensitivity surfaces. The sensitivity calculating unit includes an axial component analyzing unit for analyzing the flux density from the magnetic sensitivity surfaces into magnetic components of the individual axes; a sensitivity decision unit for deciding the sensitivity by comparing the individual axial components of the magnetic field intensity from the axial component analyzing unit with a reference value; and a sensitivity correction unit for carrying out sensitivity correction in accordance with the sensitivity information from the sensitivity decision unit.

Owner:ASAHI KASEI ELECTRONICS CO LTD

Integrated magnetoresistive sensor, in particular three-axis magnetoresistive sensor and manufacturing method thereof

ActiveUS20130299930A1NanomagnetismSemiconductor/solid-state device manufacturingSemiconductor materialsMagnetic flux

An integrated magnetoresistive device, where a substrate of semiconductor material is covered, on a first surface, by an insulating layer. A magnetoresistor of ferromagnetic material extends in the insulating layer and defines a sensitivity plane of the sensor. A concentrator of ferromagnetic material including at least one arm, extending in a transversal direction to the sensitivity plane and vertically offset to the magnetoresistor. In this way, magnetic flux lines directed perpendicularly to the sensitivity plane are concentrated and deflected so as to generate magnetic-field components directed in a parallel direction to the sensitivity plane.

Owner:STMICROELECTRONICS SRL

Vertical die chip-on-board

Methods and apparatus for vertical chip-on-board sensor packages can comprise a vertical sensor circuit component comprising a first face, a second face, a bottom edge, a top edge, two side edges, input / output (I / O) pads and at least one sensitive direction wherein the I / O pads are arranged near the bottom edge. Such vertical die chip-on-board sensor packages can also comprise one or more horizontal sensor circuit components comprising a top face, a printed circuit board (PCB) mounting face, a vertical sensor circuit component interface edge, two or more other edges, and one or more sensitive directions wherein the vertical sensor circuit component interface edge supports the vertical sensor circuit component along the Z axis and conductively or non-conductively connects to the vertical sensor circuit component. The methods and apparatus provided include a multi-axis magnetometer for measuring the magnetic field intensity along three orthogonal axes comprising one or more magnetic field sensing circuit components mounted by their PCB mounting face to a PCB and a vertical magnetic sensor circuit component mounted to the PCB such that the vertical magnetic sensor circuit component is attached to and supported by the magnetic field sensing circuit component.

Owner:HONEYWELL INT INC

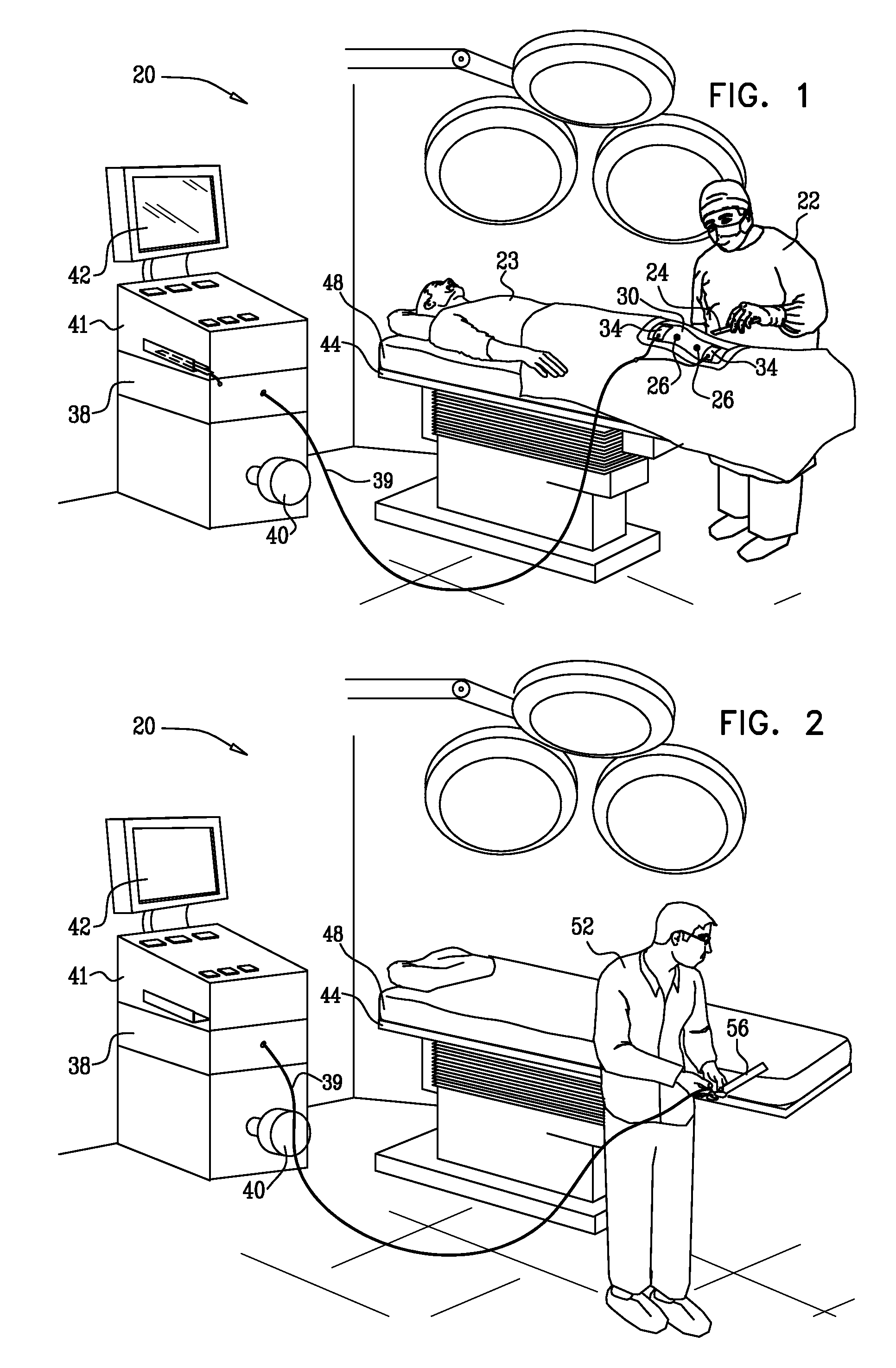

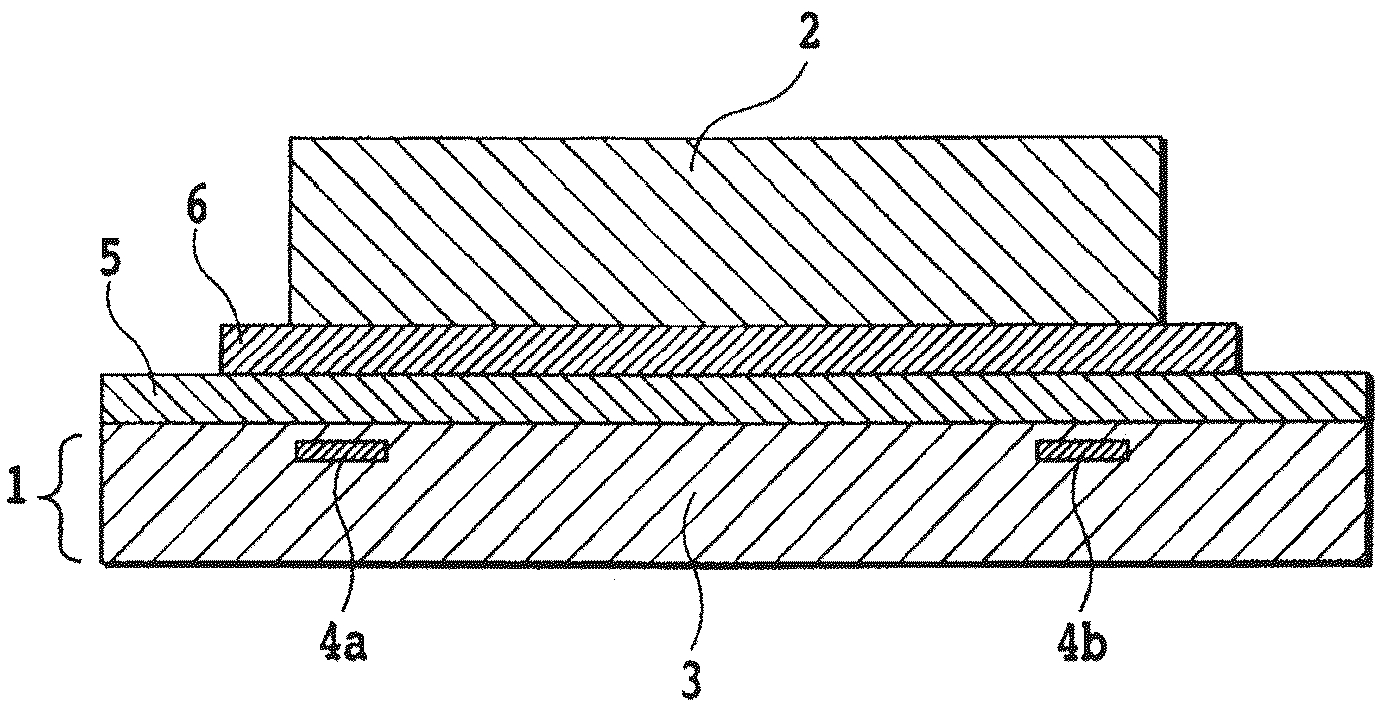

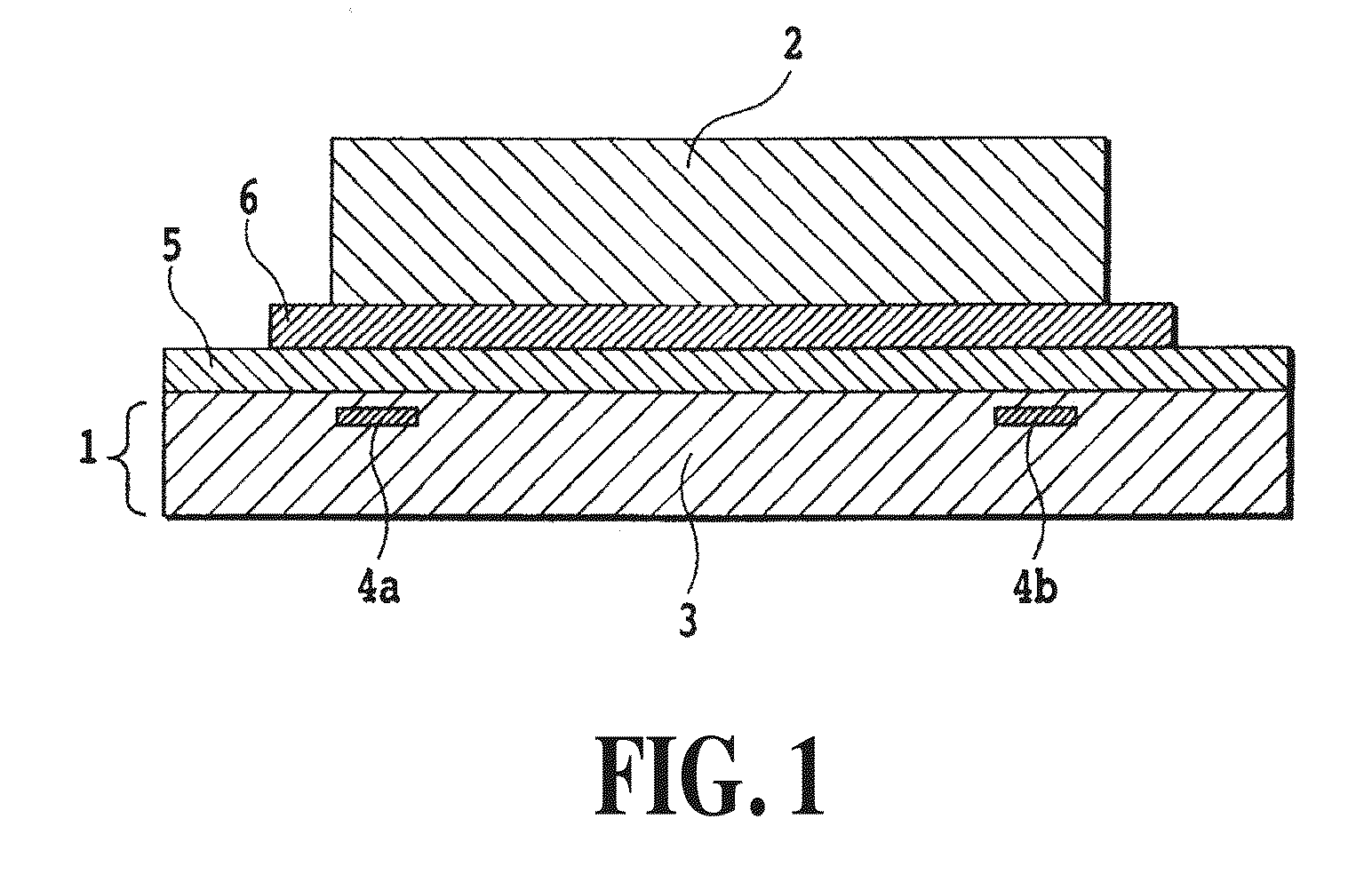

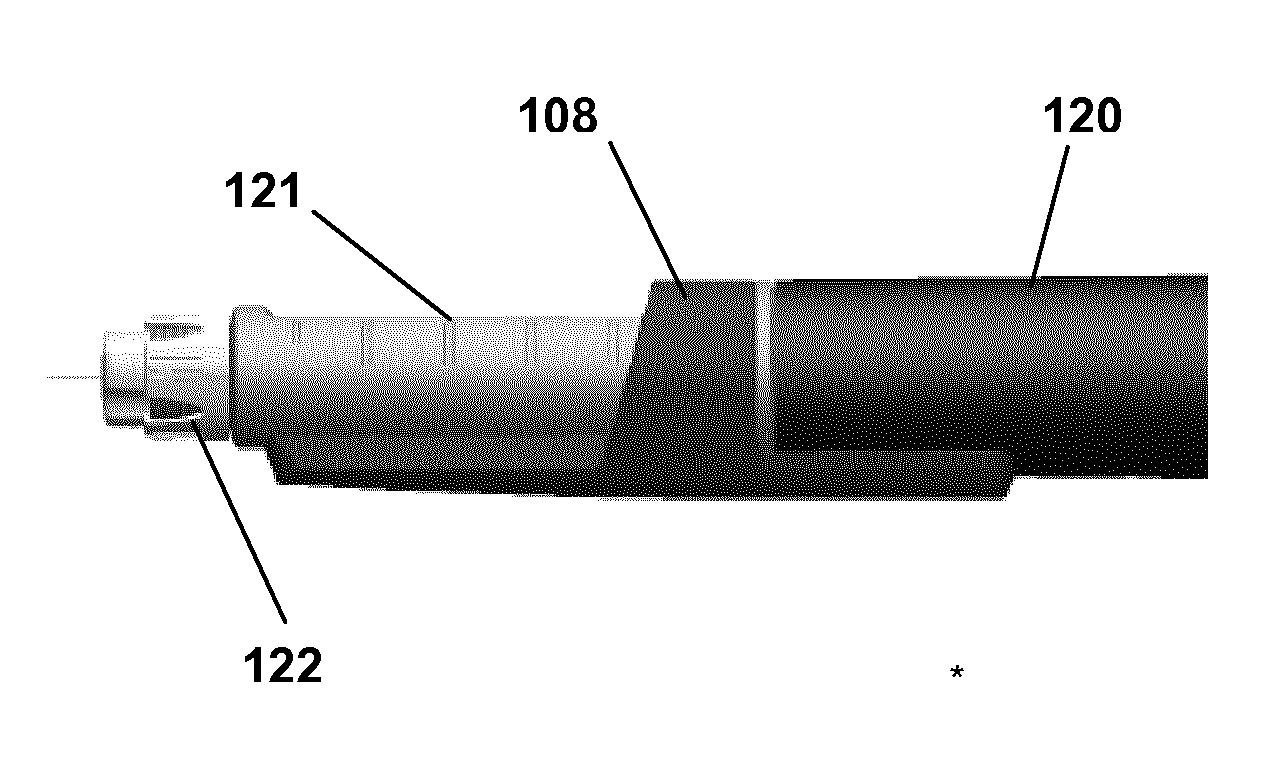

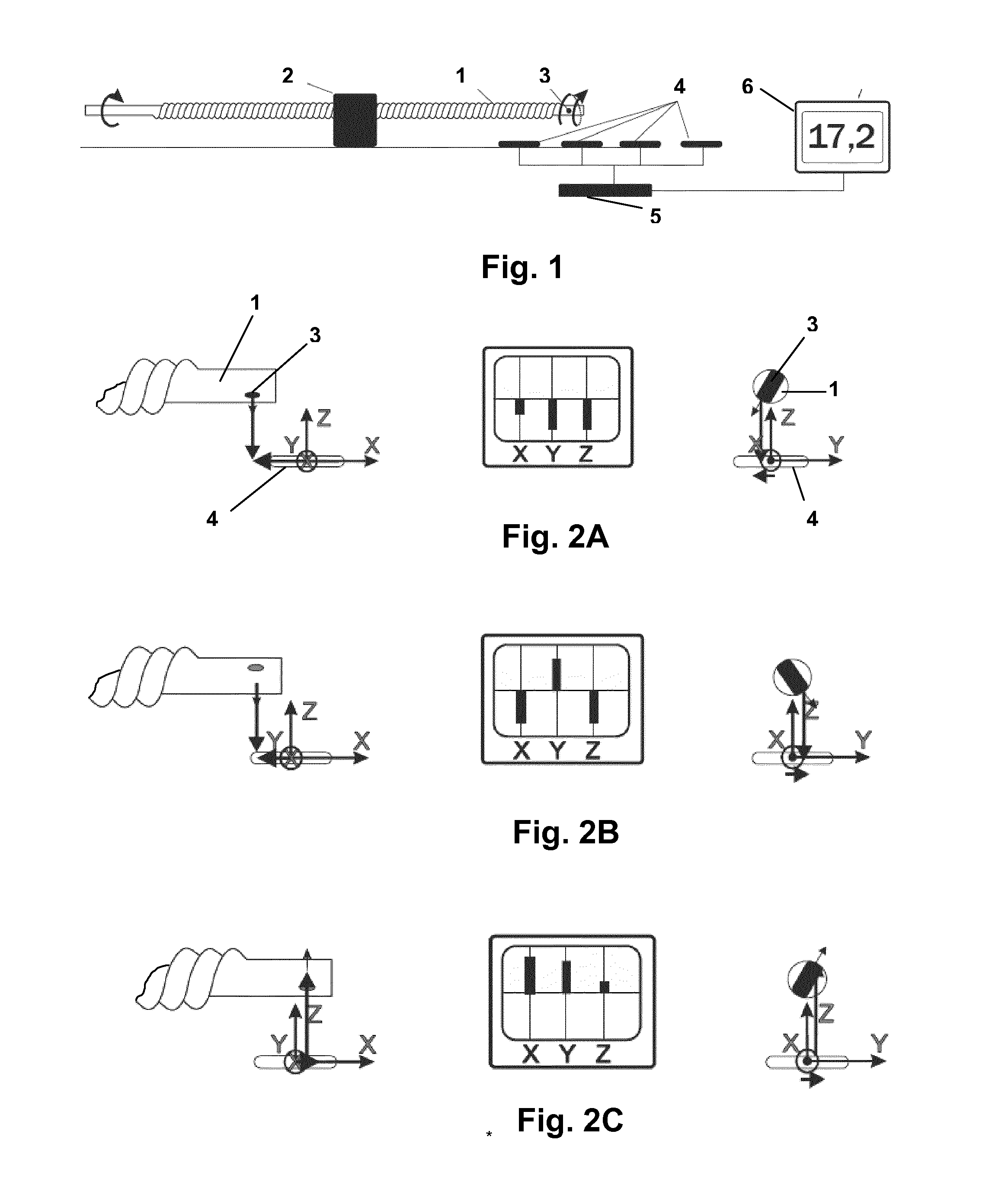

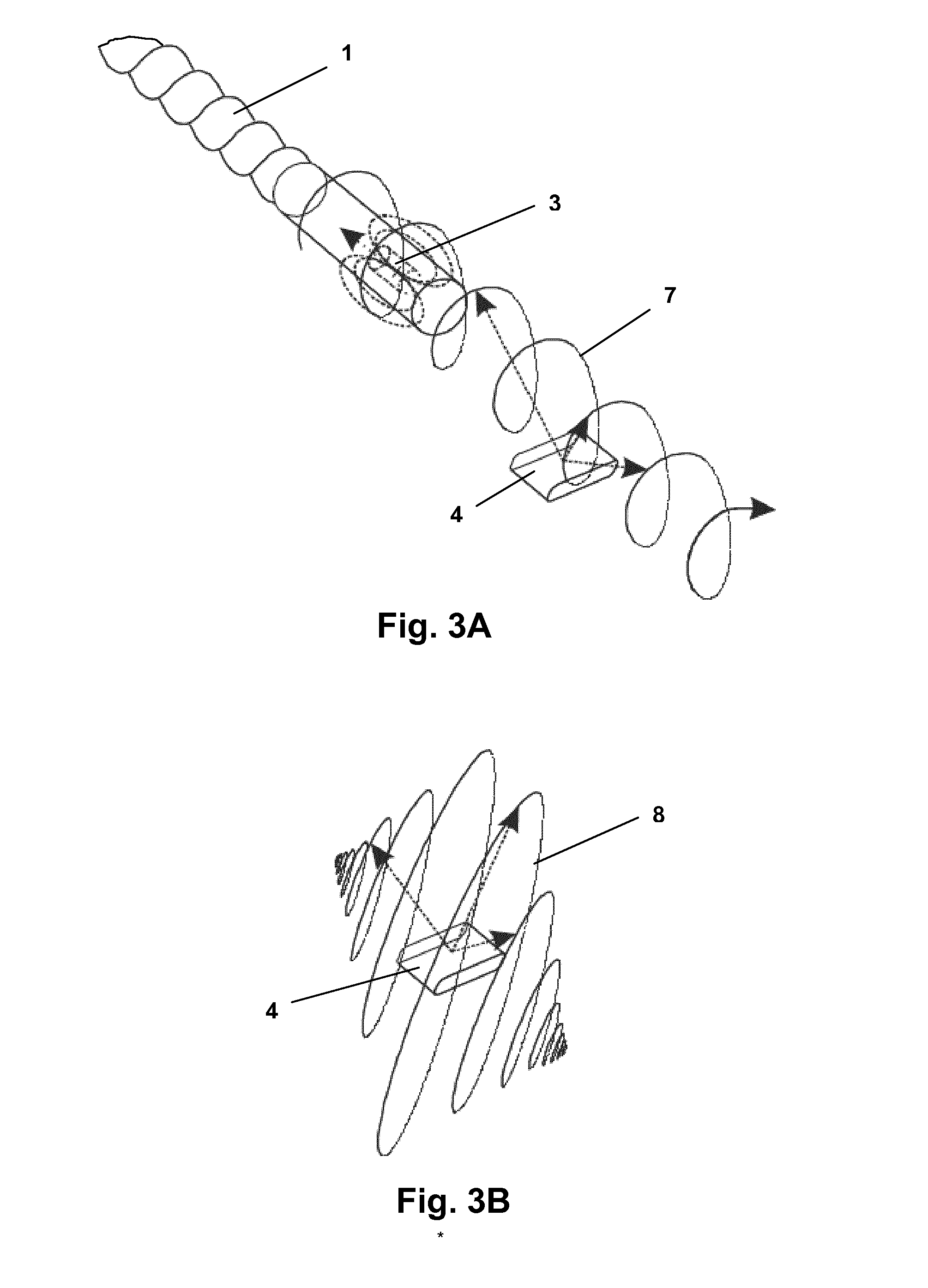

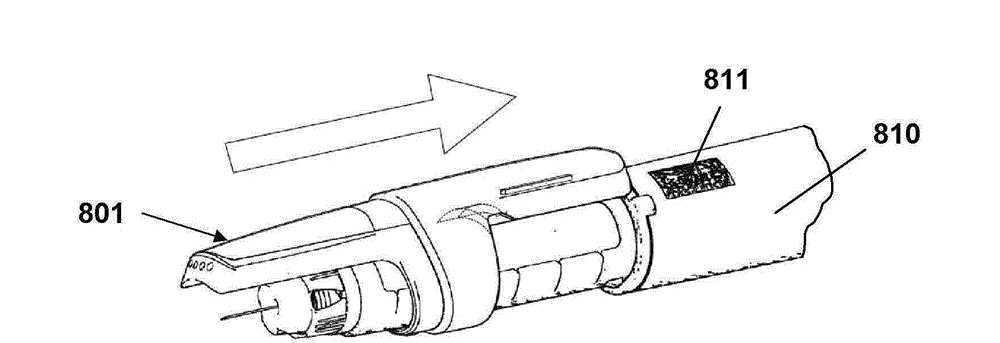

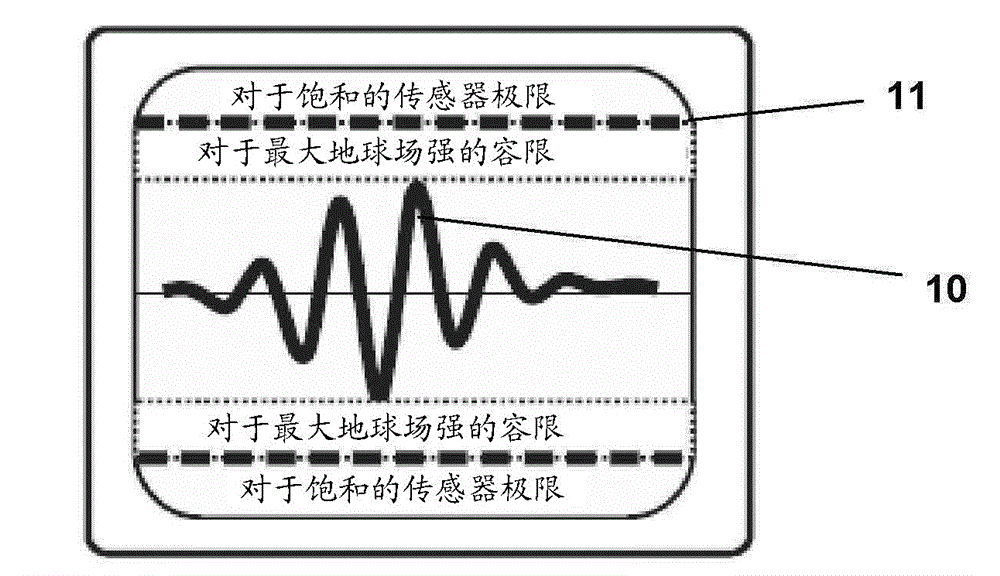

System for Determining Position of Element

ActiveUS20140243750A1Simpler and more cost efficient productionImprove securityAmpoule syringesMedical devicesEngineeringMagnet

System comprising a sensor assembly (3, 4, 5, 6) adapted to measure a magnetic field, and a moveable element (1) adapted to be moved relative to the sensor assembly between two positions by a combined axial and rotational movement, the rotational movement having a pre-determined relationship to the axial movement. A magnet (3) is mounted to the moveable element and configured to generate a spatial magnetic field which relative to the sensor assembly varies corresponding to both the axial and rotational movement of the magnet and thus the moveable element. A processor is configured to determine on the basis of measured values for the magnetic field an axial position of the moveable element.

Owner:NOVO NORDISK AS

System for determining position of element

ActiveCN103957961AImprove securityLow costAmpoule syringesDiagnosticsMoving between two positionsMagnet

System comprising a sensor assembly adapted to measure a magnetic field, and a moveable element adapted to be moved relative to the sensor assembly between two positions by a combined axial and rotational movement, the rotational movement having a pre-determined relationship to the axial movement. A magnet is mounted to the moveable element and configured to generate a spatial magnetic field which relative to the sensor assembly varies corresponding to both the axial and rotational movement of the magnet and thus the moveable element. A processor is configured to determine on the basis of measured values for the magnetic field an axial position of the moveable element.

Owner:NOVO NORDISK AS

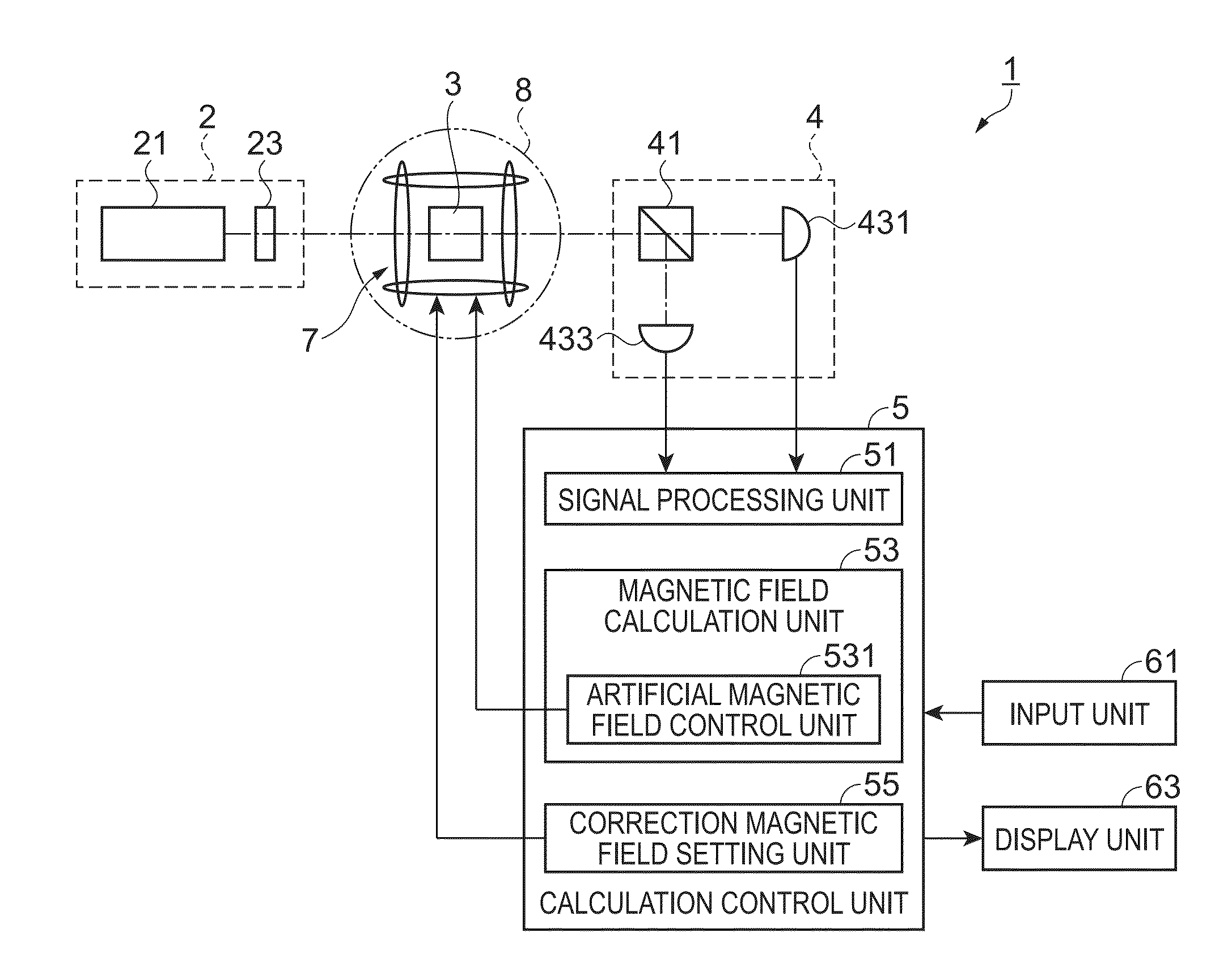

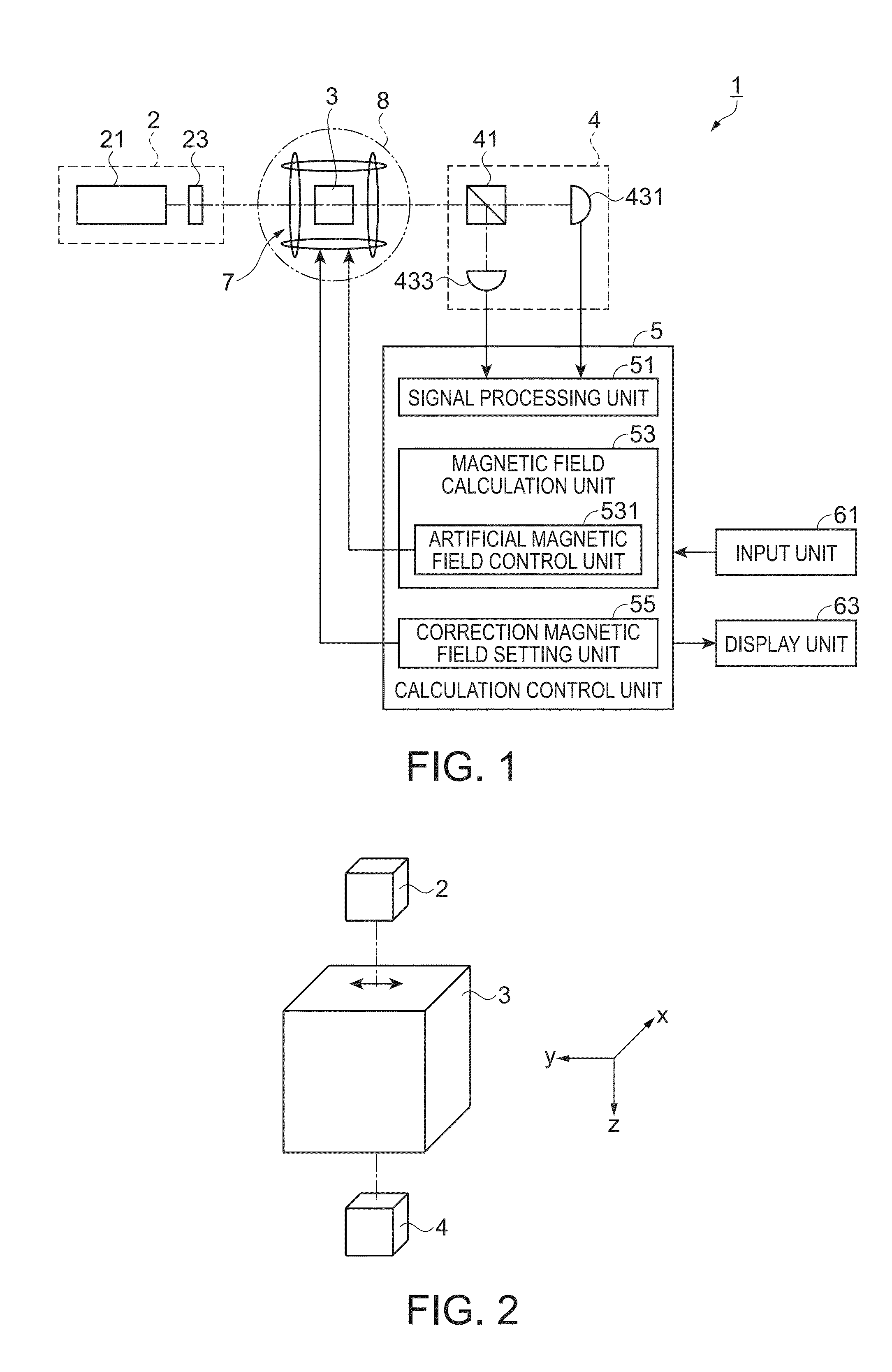

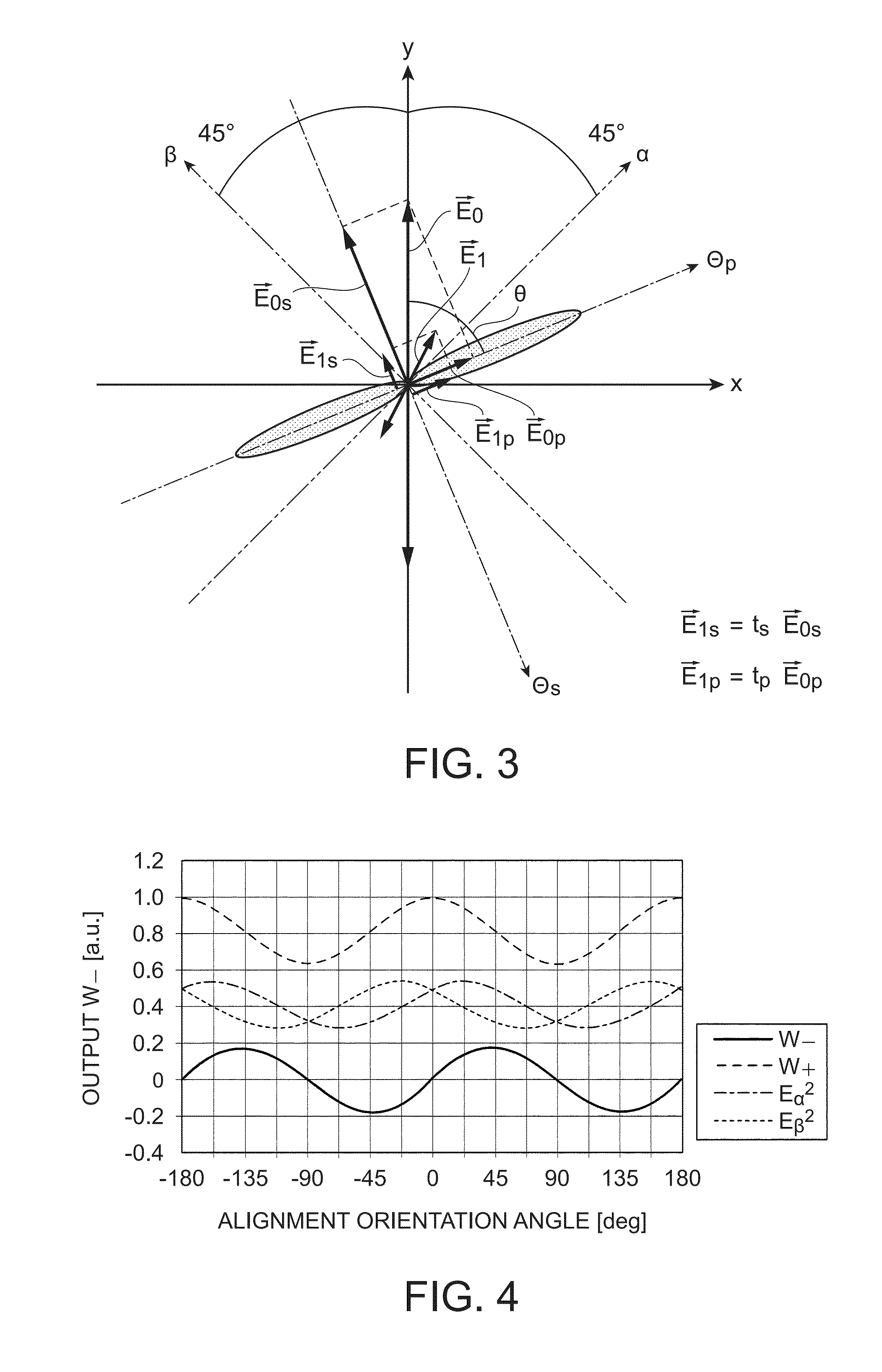

Magnetic field measurement method and magnetic field measurement device

A light source unit irradiates a gas cell disposed in a measurement region with linearly polarized light in which the direction of travel is a z-axis direction and the vibration direction of an electric field is a y-axis direction. A polarimeter detects optical characteristics of light passing through the gas cell. A magnetic field generator applies an artificial magnetic field, capable of varying an x-axis component, a y-axis component, and a z-axis component, to the measurement region. A calculation control unit generates a plurality of artificial magnetic fields, calculates a magnetization value or a value corresponding to the magnetization value on the basis of the detection results of the polarimeter, and calculates an original magnetic field present in the measurement region, using an artificial magnetic field when the magnetization value or the value corresponding to the magnetization value satisfies a condition for external value.

Owner:SEIKO EPSON CORP

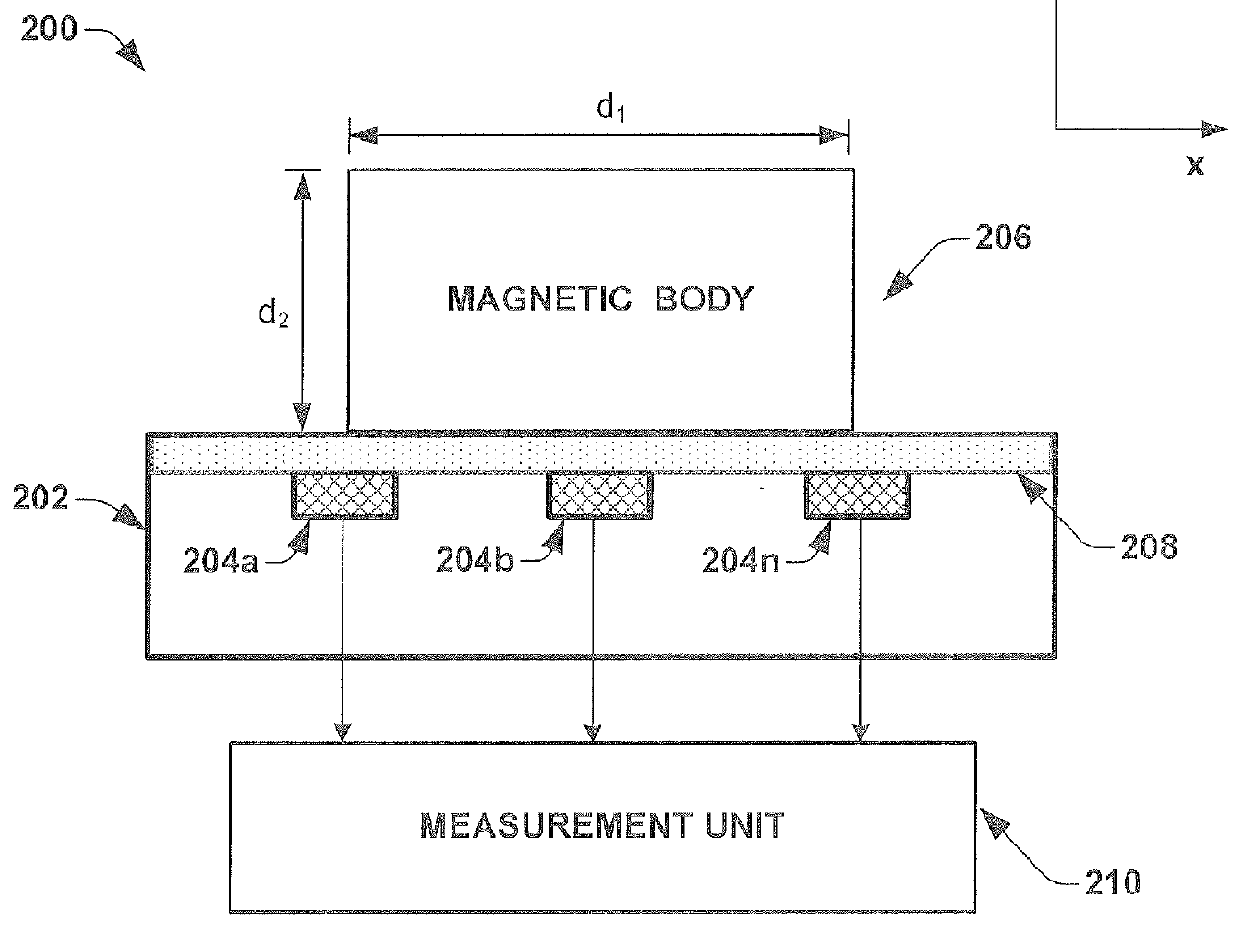

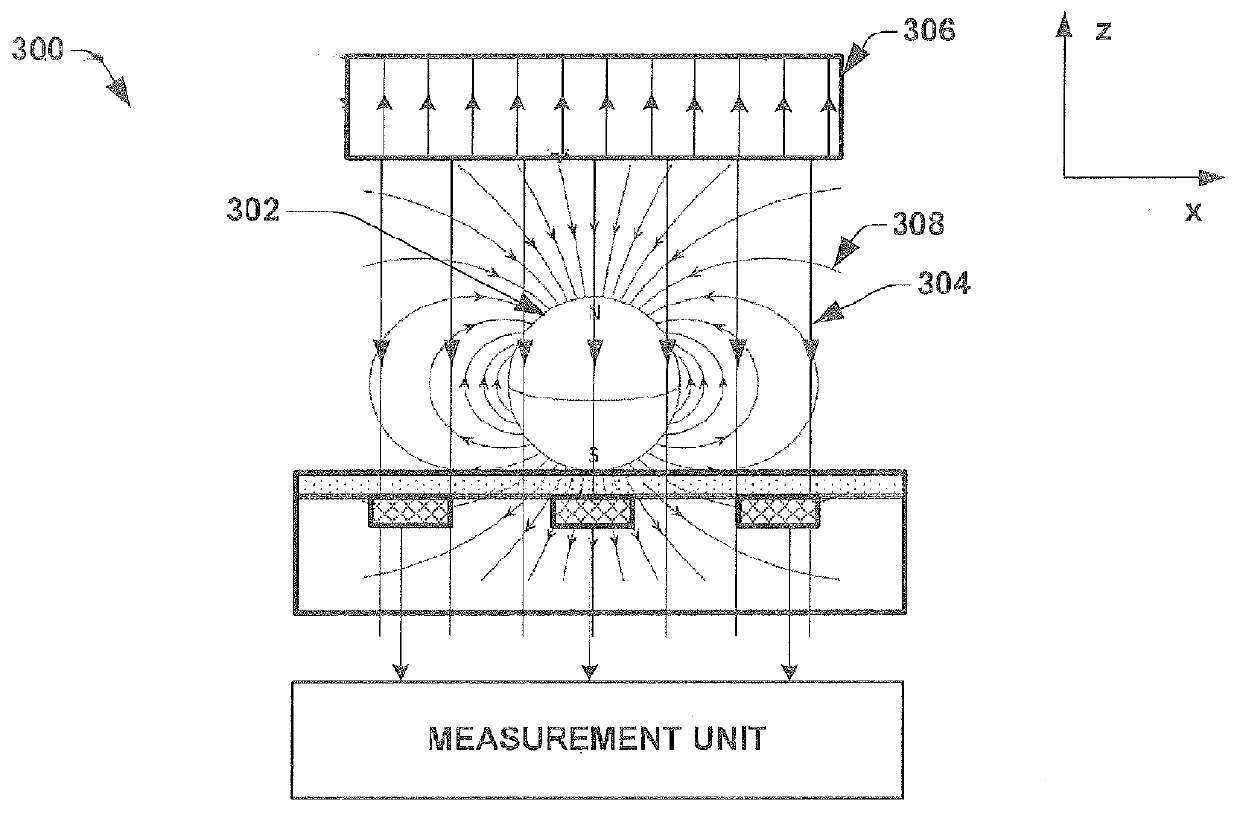

3-d magnetic sensor

InactiveUS20120217960A1Magnetic-field-controlled resistorsGalvano-magnetic hall-effect devicesSensor arrayCondensed matter physics

One embodiment of the present invention relates to a magnetic field sensor comprising a squat soft-magnetic body disposed on a surface of a substrate comprising a magnetic sensor array having a plurality of spatially diverse magnetic sensor elements disposed in a predetermined configuration. In the presence of an external magnetic field the squat soft-magnetic body becomes magnetized to generate a reactionary magnetic field. The plurality of magnetic sensor elements are respectively configured to measure a magnetic field value of a superposition of the external magnetic field and the reactionary magnetic field along a first axis (e.g., a z-axis), resulting in a plurality of spatially diverse measurements of the magnetic field component along the first axis. The plurality of spatially diverse measurements may be used to compute magnetic field components of the external magnetic field along a plurality of axes (e.g., x-axis, y-axis, and z-axis).

Owner:INFINEON TECH AG

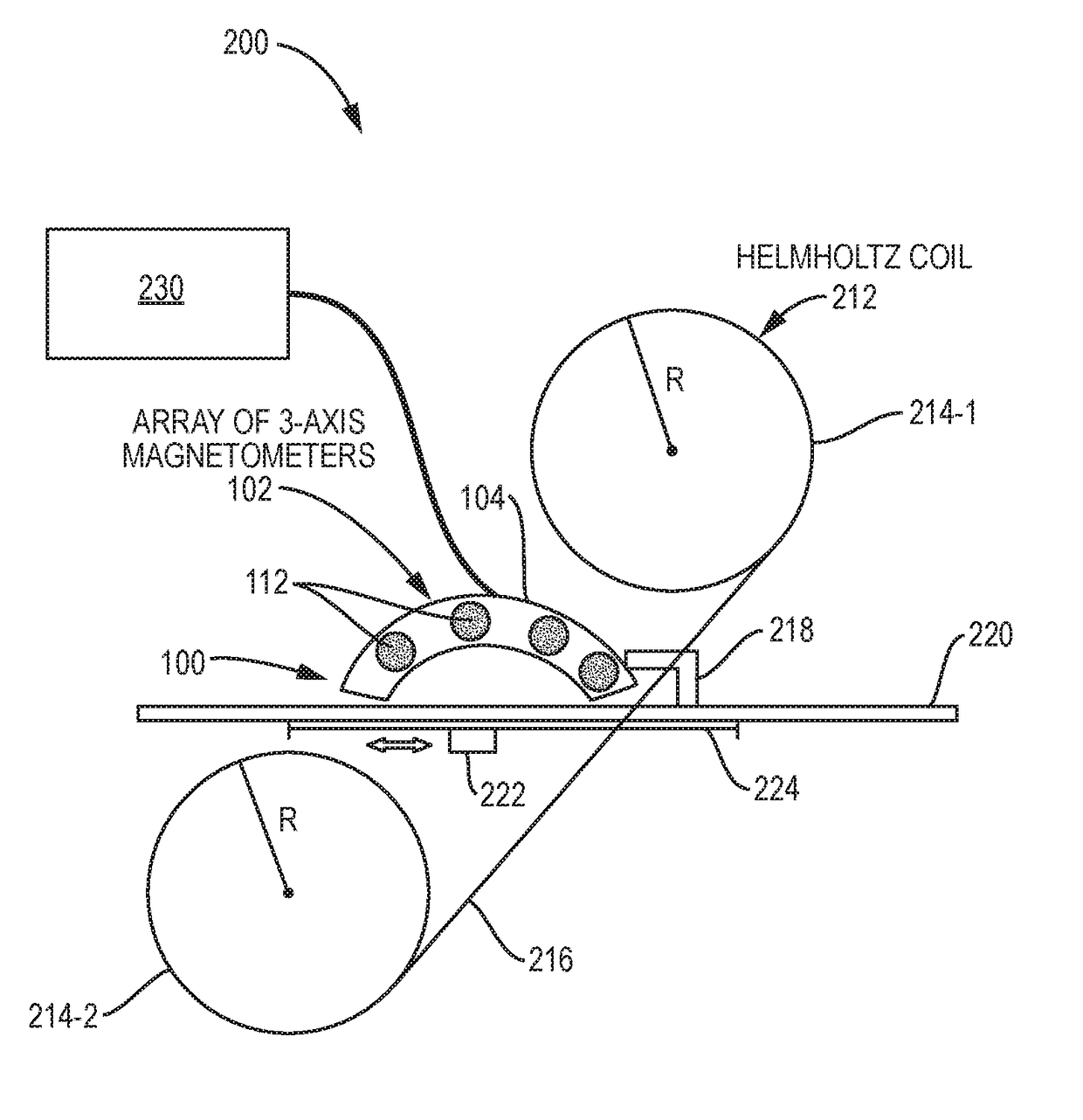

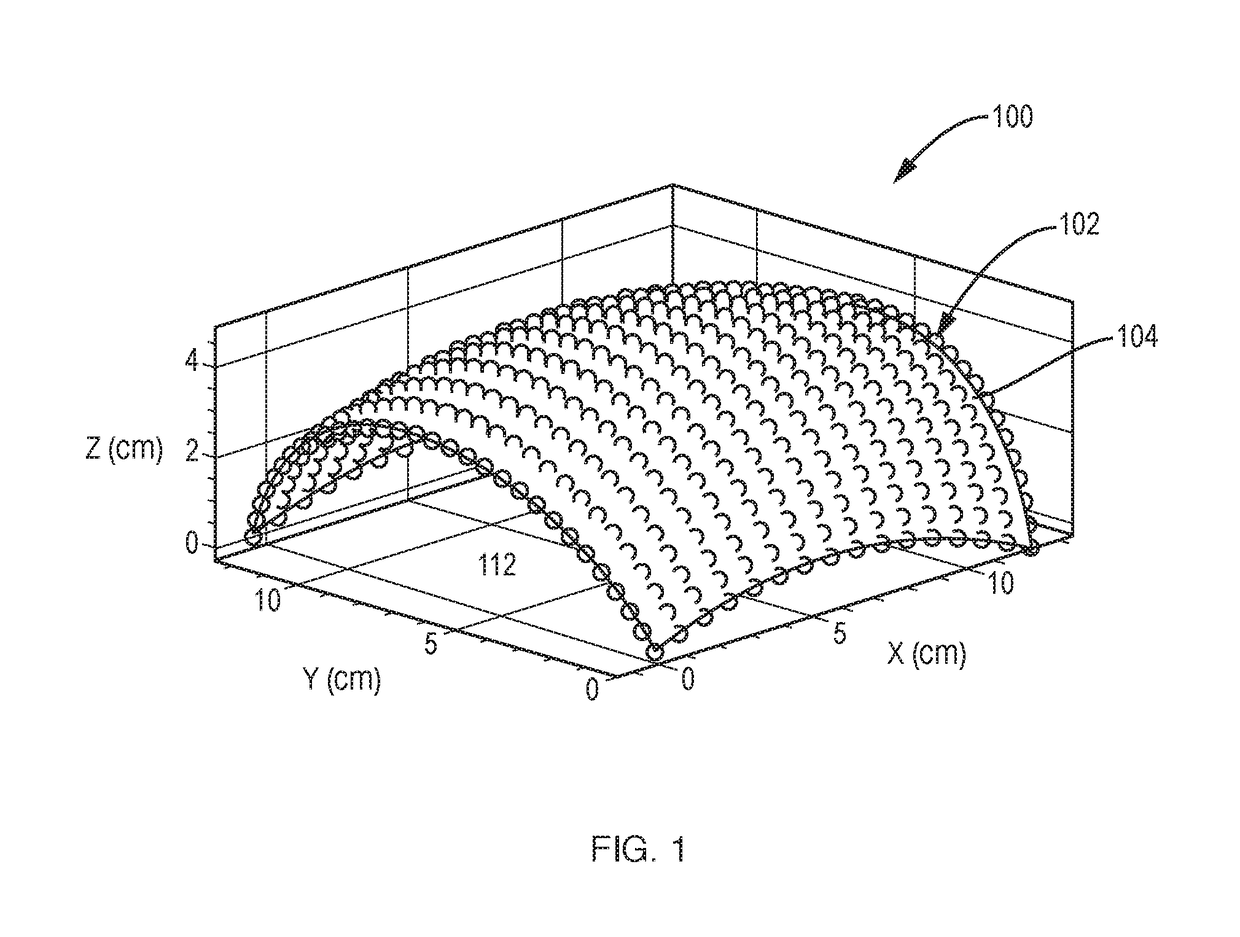

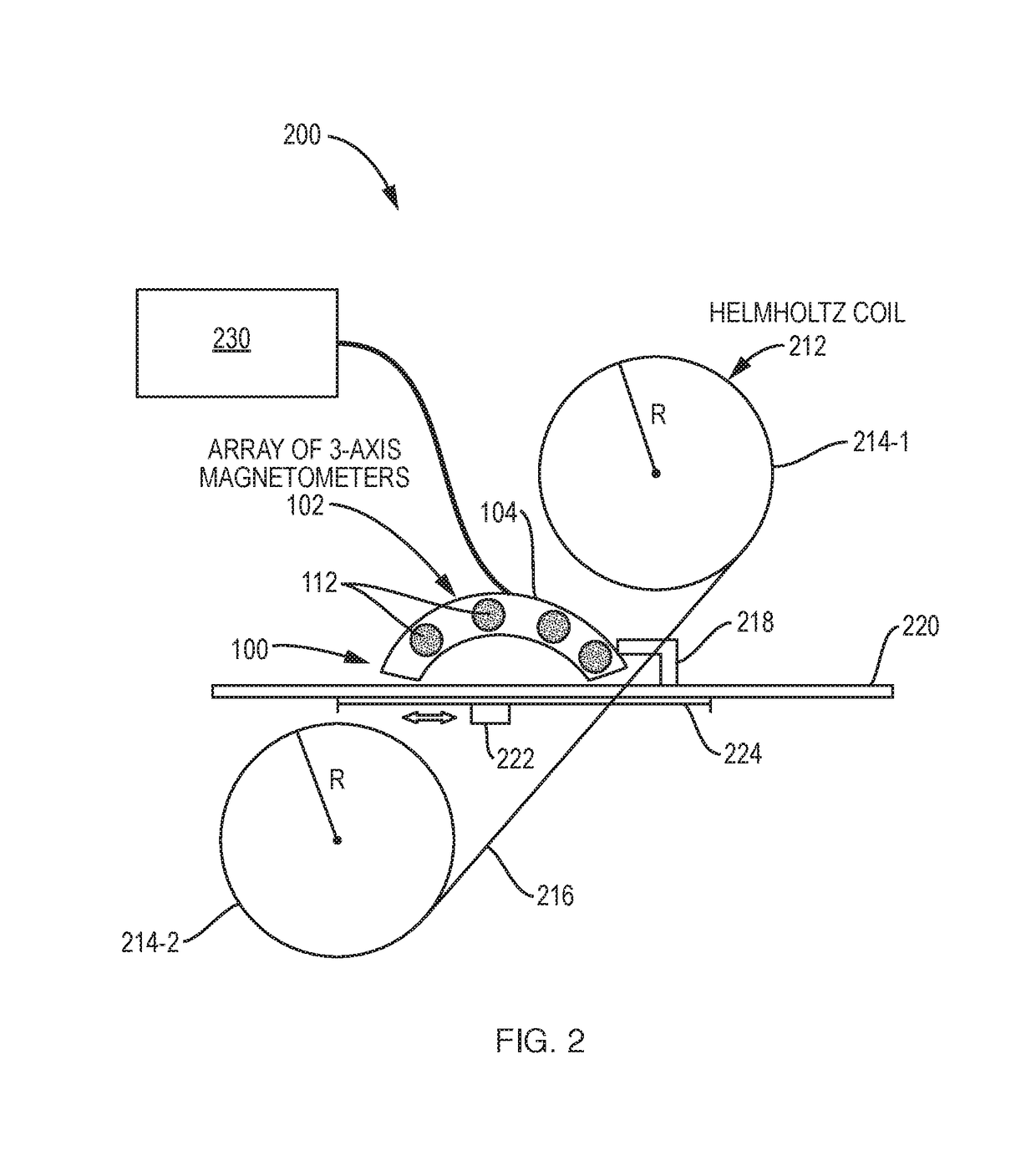

Calibration and Monitoring for 3-Axis Magnetometer Arrays of Arbitrary Geometry

ActiveUS20180003777A1Good reproducibilityShorten the timeElectrical measurementsThree-component magnetometersMagnetic tension forceMagnetometer

A system and method for calibrating rigid and non-rigid arrays of 3-axis magnetometers as disclosed. Such arrays might be used to analyze structures containing ferromagnetic material. The calibration determines scale factor and bias parameters of each magnetometer in the array, and the relative orientation and position of each magnetometer in the array. Once the parameters are determined, the actual magnetic field value at the magnetometer location can be simply related to magnetometer measurements. The method and system can be used to calibrate an array of 3-axis magnetometers in aggregate as opposed to individual magnetometers. This is critical in large arrays to increasing reproducibility of the calibration procedure and decreasing time required to complete calibration procedure.

Owner:CHARLES STARK DRAPER LABORATORY

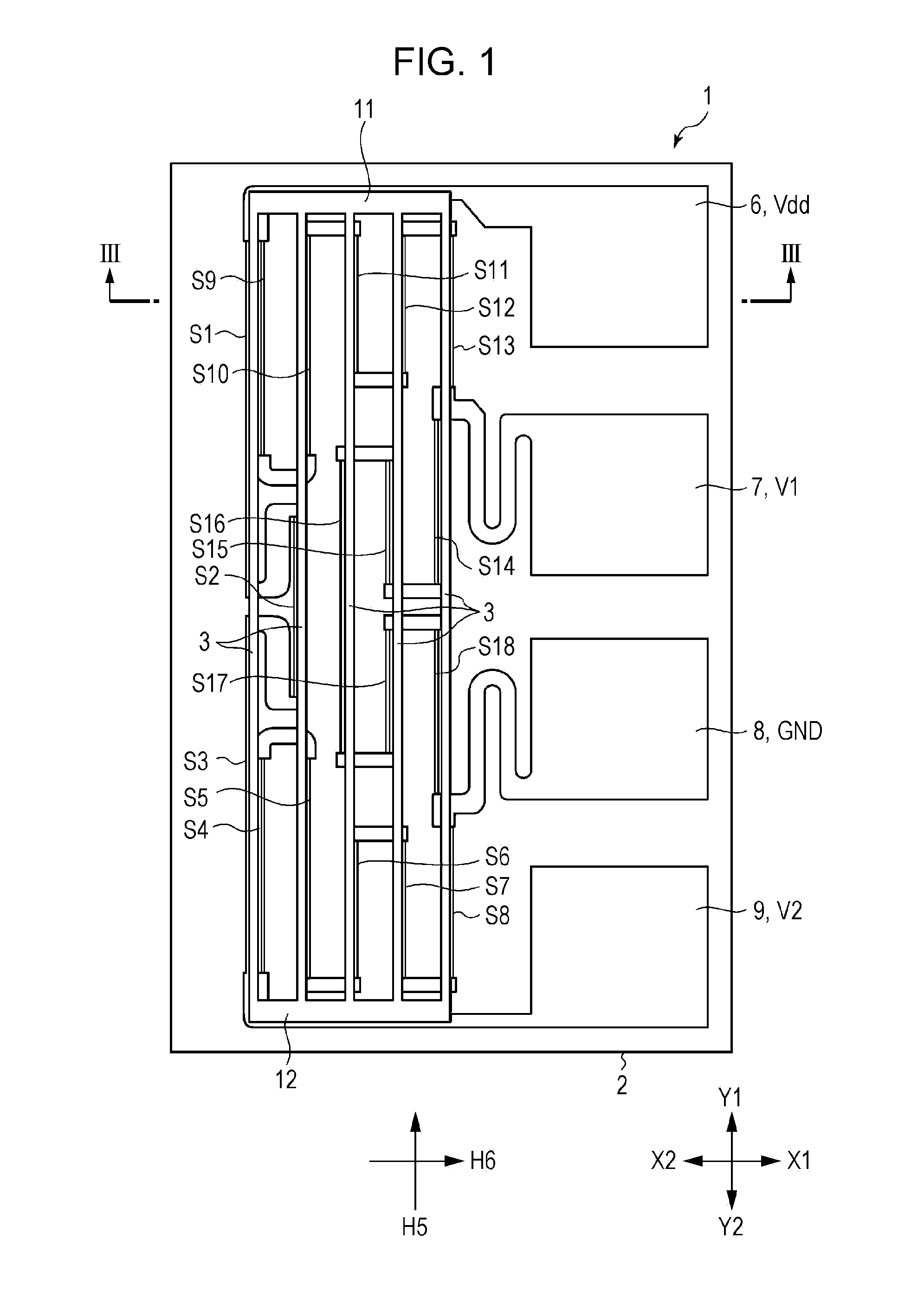

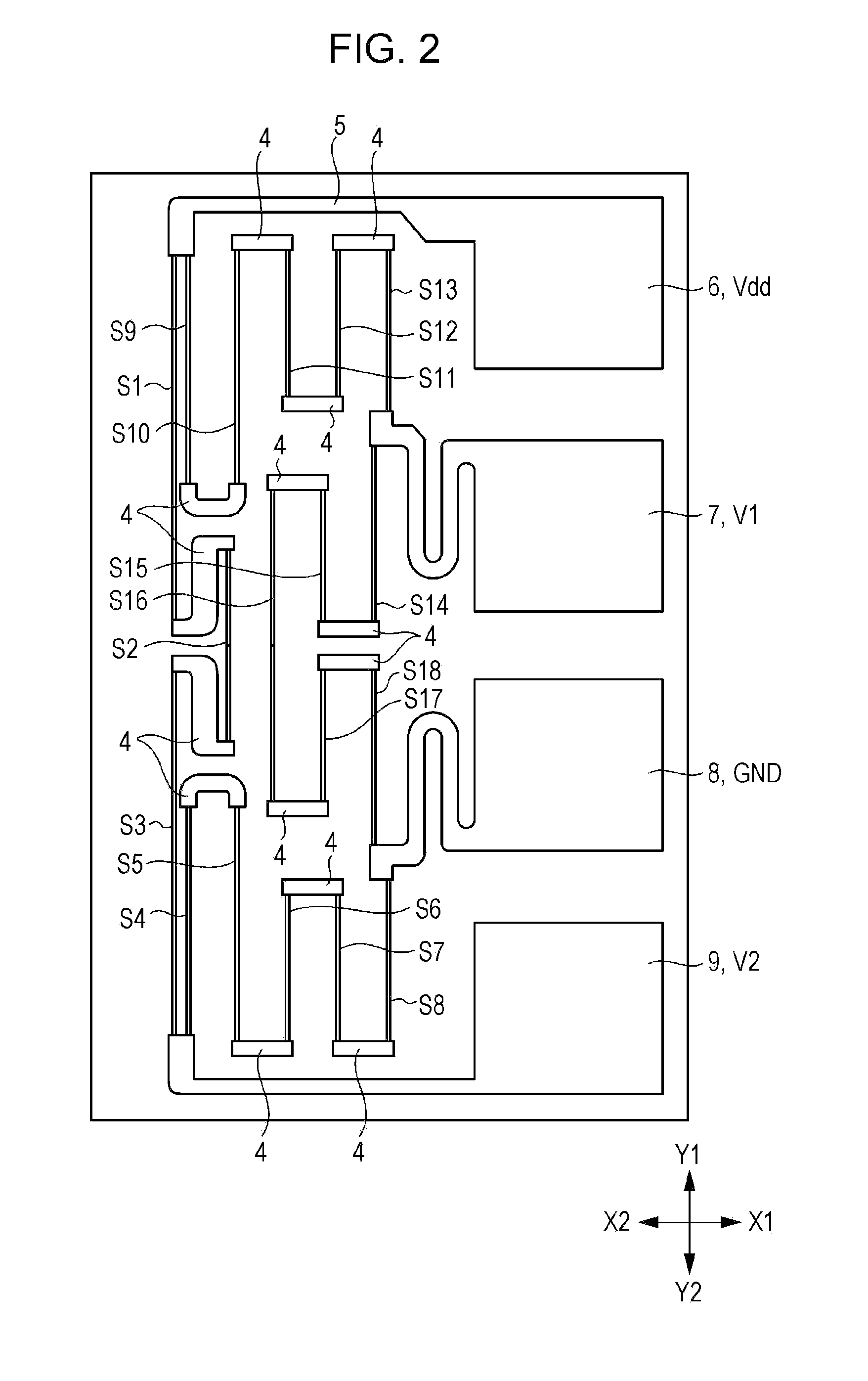

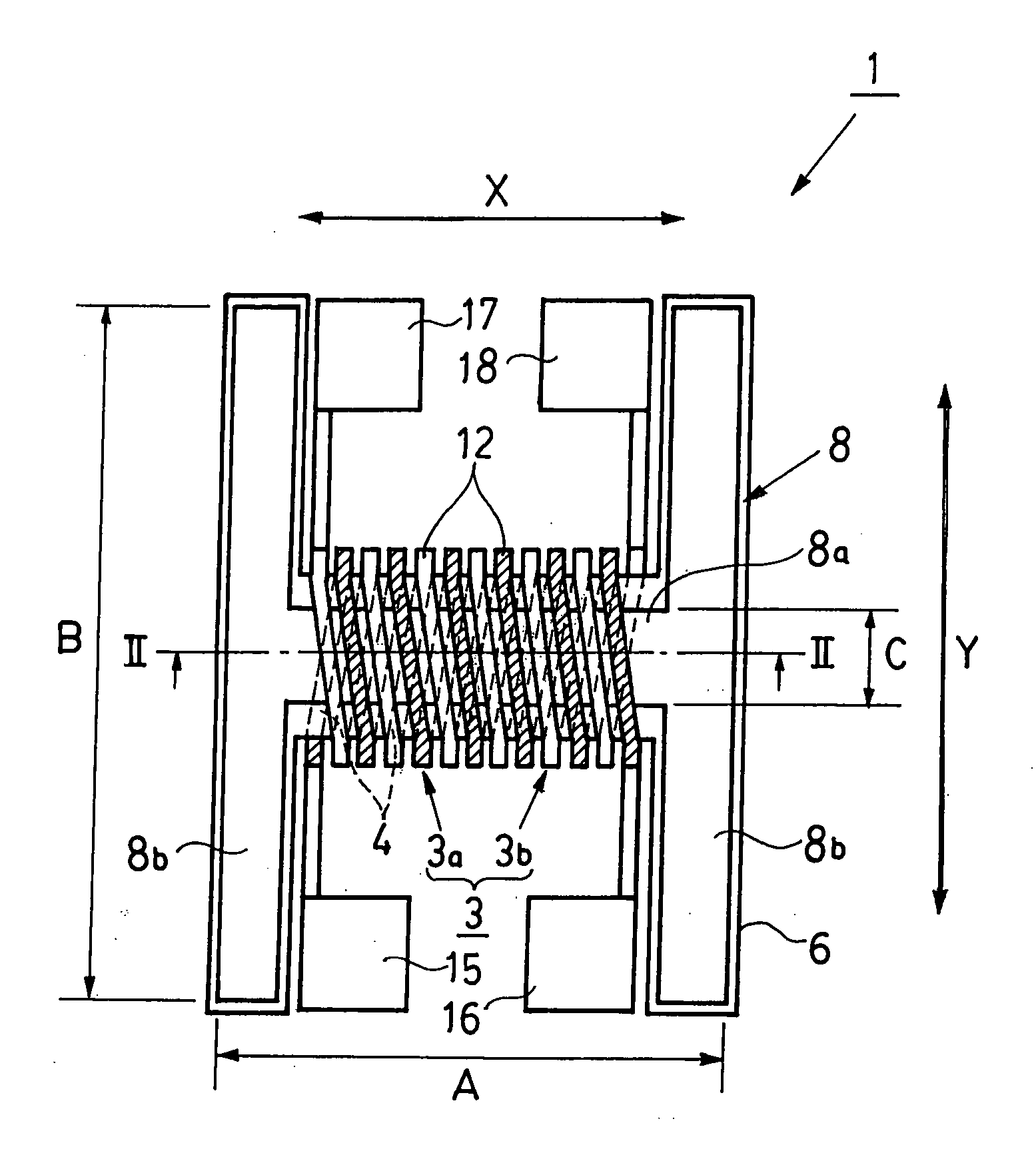

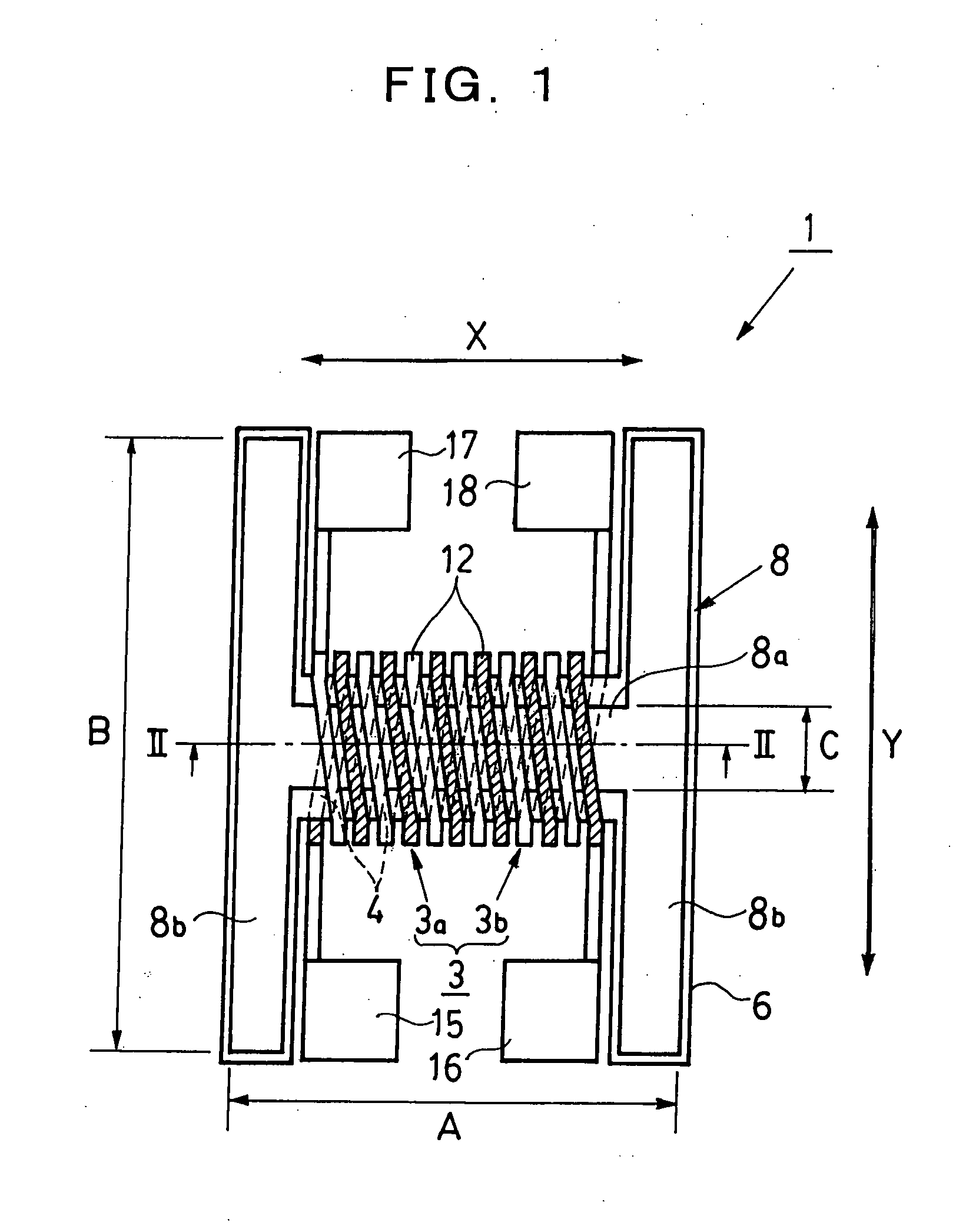

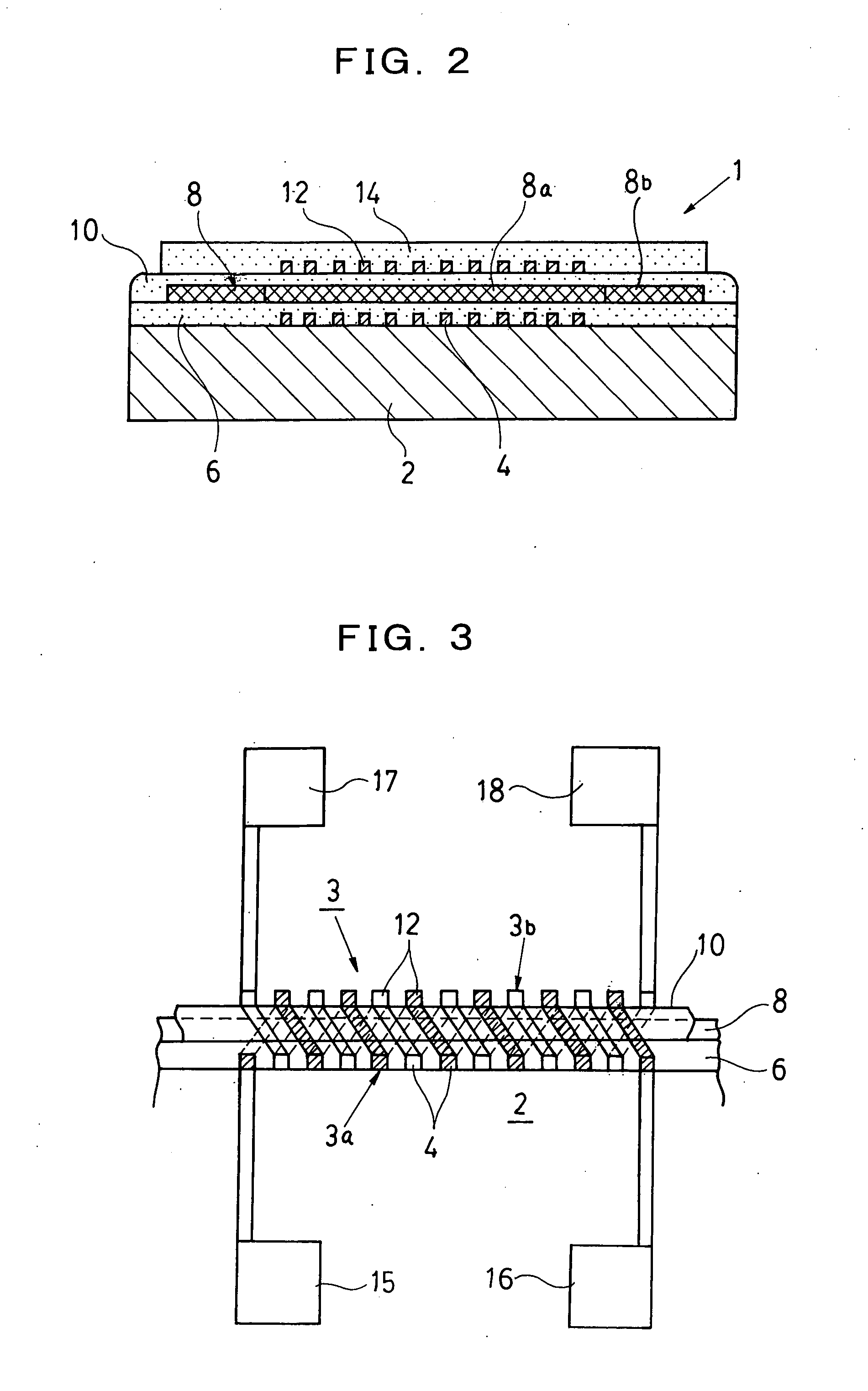

Magnetic sensor element and electronic directional measureing device

InactiveUS20070222441A1Reduce the overall heightSmall sizeMagnetic field measurement using flux-gate principleThree-component magnetometersMeasurement deviceMagnetic flux

A magnetic sensor element of a flux gate type comprising a magnetism sensitive part (8a) formed by winding a coil (3) around a magnetic core layer (8), and magnetism collective part (8b) for guiding magnetic fluxes to the magnetism sensitive part (8a). Respective central parts of the magnetism collective part (8b) are connected with the respective ends of the magnetism sensitive part (8a). Therefor the magnetic core layer (8) is formed so as to resemble a letter H in planar shape. And the coil (3) of the magnetism collective part (8b) is a thin-film coil comprising a plurality of upper coil thin-films (12) and a plurality of lower coil thin-films (4) formed on an upper surface and a lower surface of the magnetic core layer (8) via insulation layers by connecting together the respective lower coil thin-films (4) and the upper coil thin-films (12), at respective adjacent ends thereof, so as to be sequentially continuous with each other.

Owner:CITIZEN WATCH CO LTD

Calibration of 3d field sensors

ActiveCN101292131ATesting/calibration of speed/acceleration/shock measurement devicesThree-component magnetometersPhysicsEllipsoid

An apparatus-based method is disclosed for calibration of a 3D field sensor. The method comprises accessing a plurality of samples, where the samples are from the 3D field sensor. Each sample represents a magnitude and an orientation of a three-dimensional field sensed by the 3D field sensor. Using the plurality of samples, a plurality of parameters is determined of an ellipsoid. The determination of the plurality of parameters is performed so that the ellipsoid fits the plurality of samples. A transformation is determined that transforms the ellipsoid into a sphere. The transformation is applied to a sample to create a transformed sample. Apparatus and signal bearing media are also disclosed.

Owner:NOKIA TECH OY

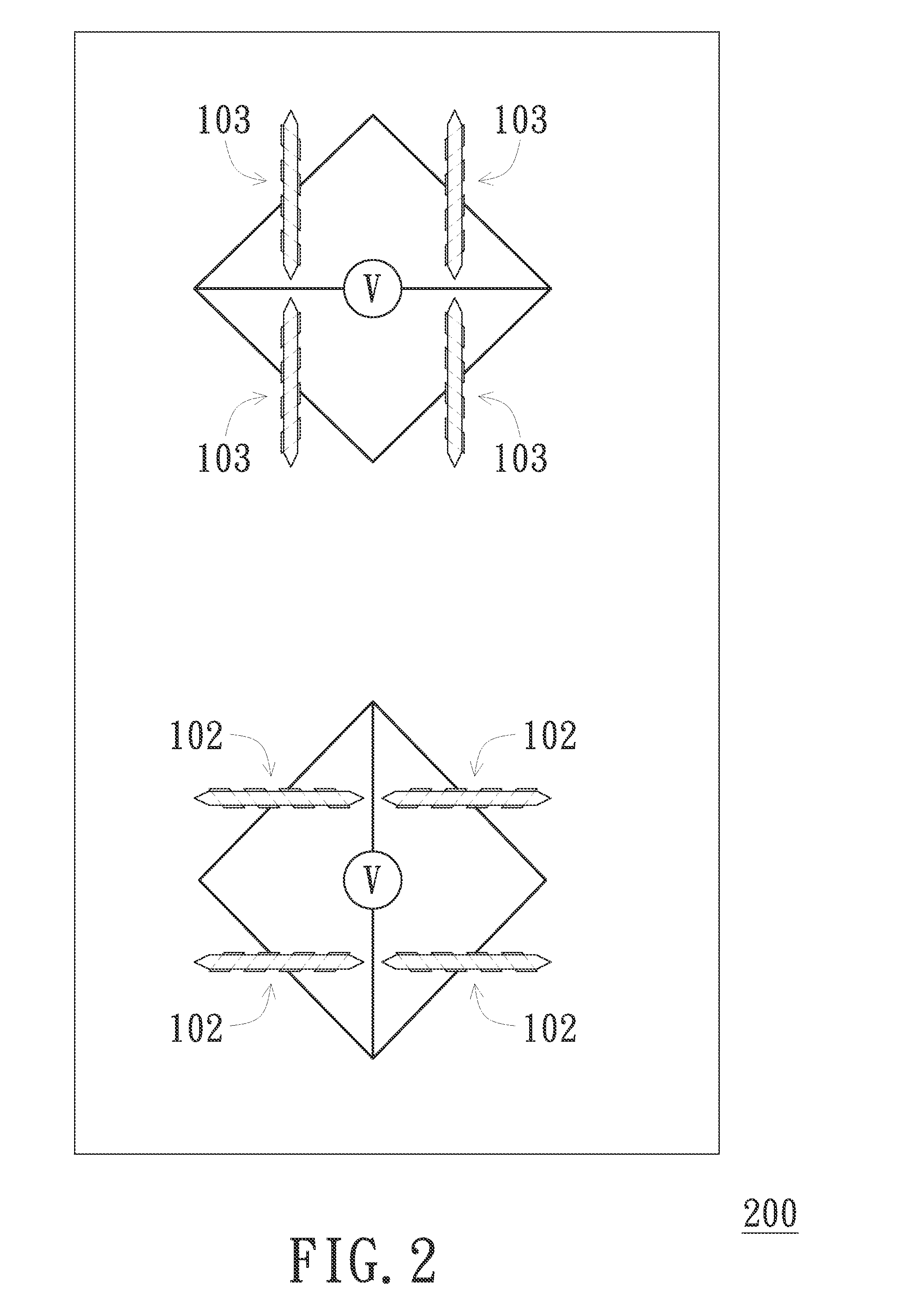

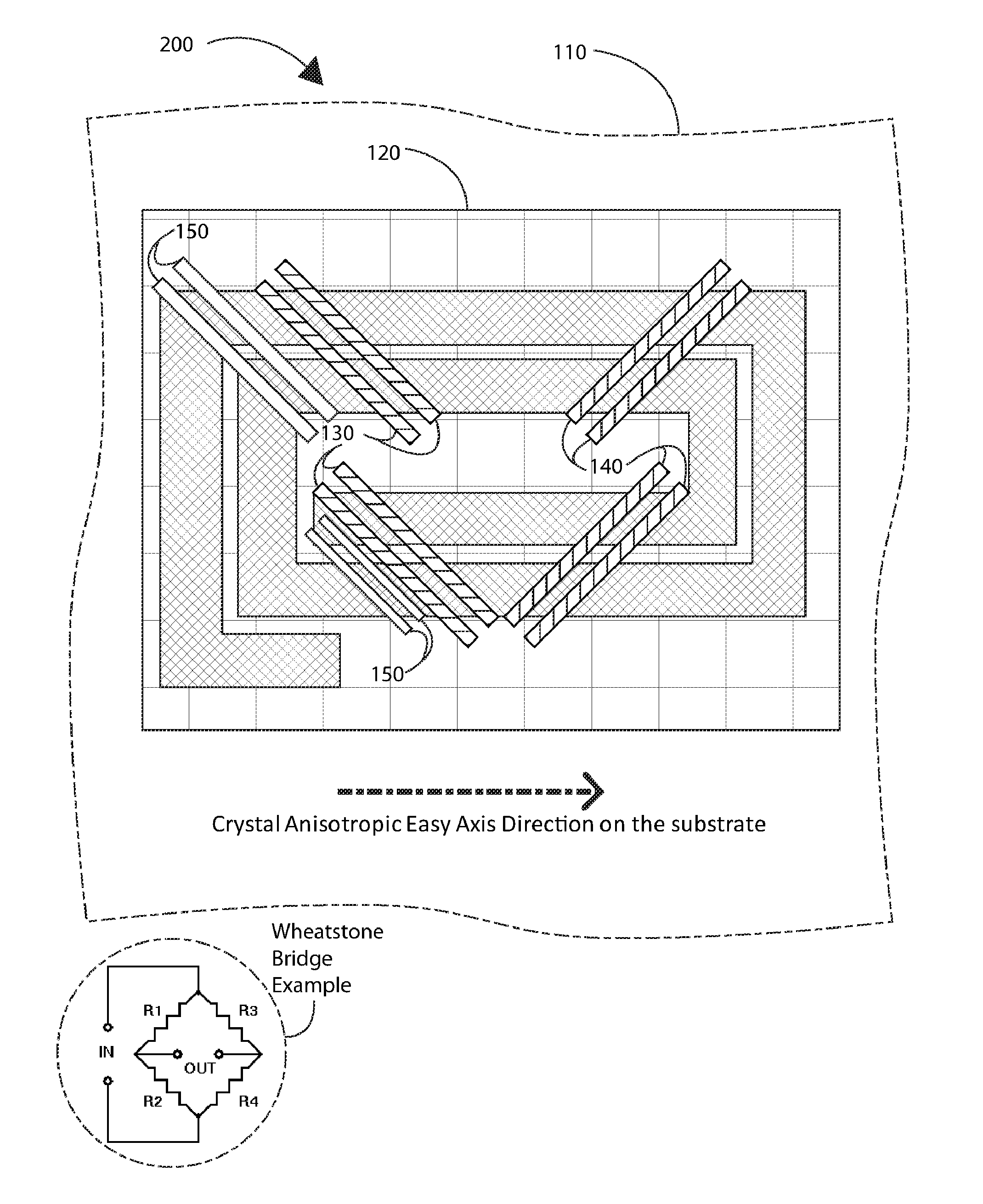

Three axis magnetic sensor device and method

ActiveUS8486723B1Easy to useHigh device yieldMagnetic-field-controlled resistorsSolid-state devicesCondensed matter physicsNickel

A method and structure for a three-axis magnetic field sensing device is provided. The device includes a substrate, an IC layer, and preferably three magnetic field sensors coupled to the IC layer. A nickel-iron magnetic field concentrator is also provided.

Owner:MOVELLA INC

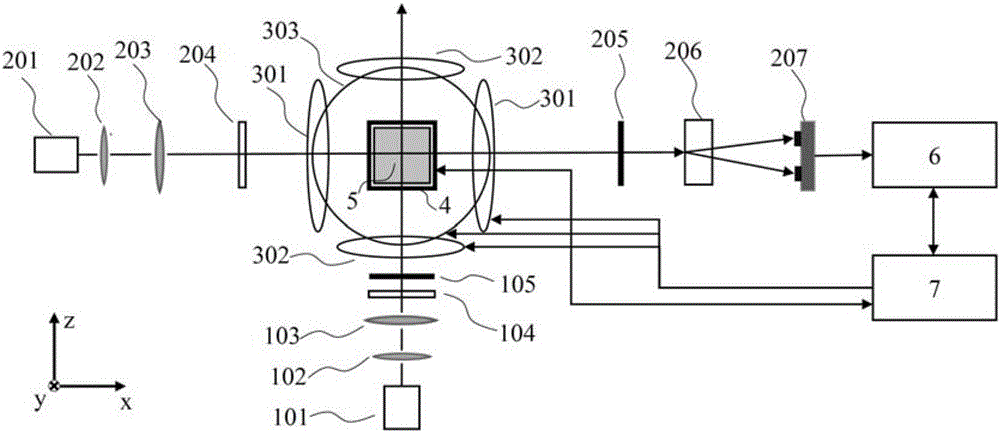

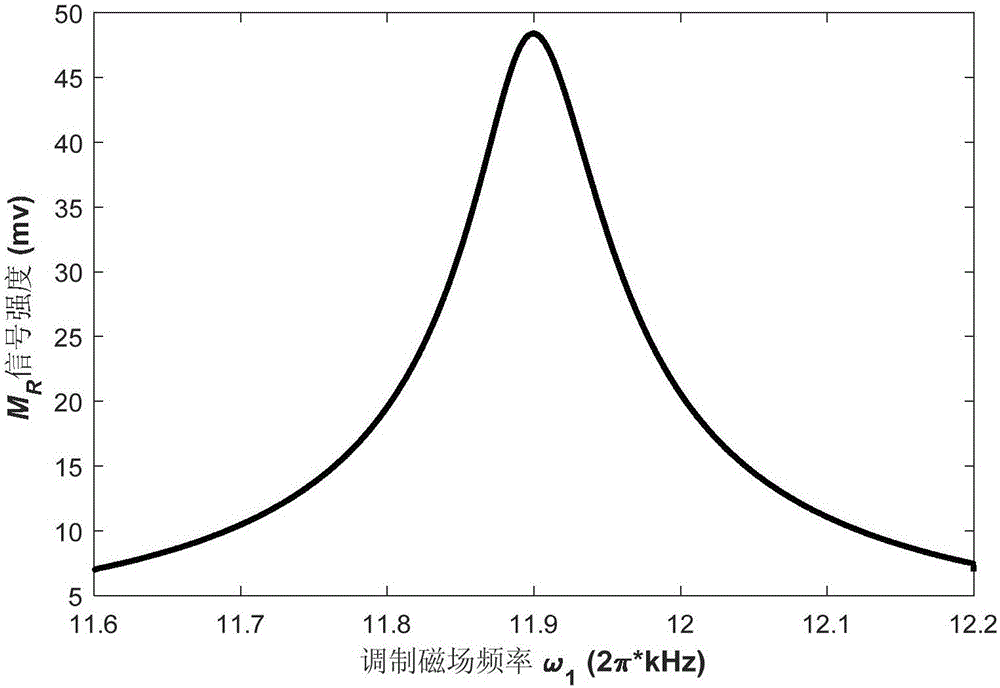

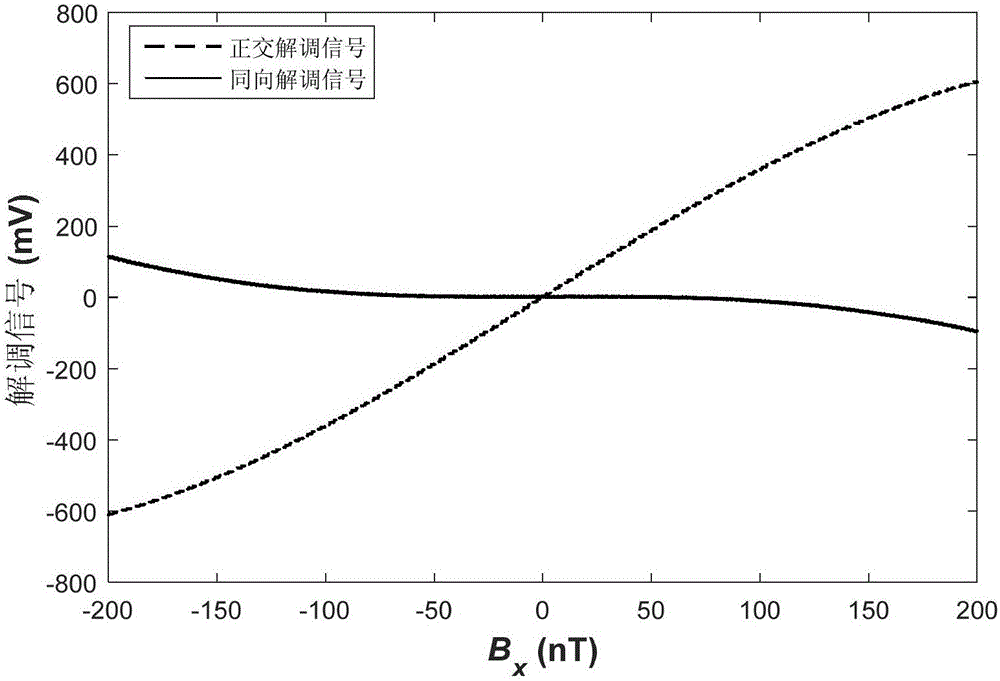

Longitudinal magnetic field modulation based three-axis vector atom magnetometer and use method thereof

ActiveCN106842074AImprove stabilityHigh sensitivityThree-component magnetometersHelmholtz coilWollaston prism

The invention relates to a longitudinal magnetic field modulation based three-axis vector atom magnetometer and use method thereof and belongs to the technical field of low-intensity magnetic field detection. The longitudinal magnetic field modulation based three-axis vector atom magnetometer comprises a pumping optical path composed of a No.1 895nm DFB semiconductor laser, a No.1 convex lens, a No.2 convex lens, a No. 1 linear polarizing film and a Gamma / 4 slide; a detection optical path composed of a No.2 895nm DFB semiconductor laser, a No.3 convex lens, a No.4 convex lens, a No. 2 linear polarizing film, a Wollaston prism and a balance detector; a three-dimensional magnetic field generating device composed of a No.1 Helmholtz coils, a No.2 Helmholtz coils and a No.3 Helmholtz coils in mutual orthogonality; a heating device; an atomic gas cell; a locking amplifier; and a signal processing system. According to the invention, since longitudinal magnetic field modulation is adopted, technical noise can be reduced in a comparatively large degree. Therefore, extremely high flexibility is achieved. Besides, by utilizing longitudinal magnetic field modulation, inter-axis crosstalk can be reduced, so that magnetic field direction detection becomes more accurate.

Owner:NAT UNIV OF DEFENSE TECH

Triaxial magnetic field sensor

ActiveUS20140247042A1Easy to integrateReduce magnetic noiseMagnetic sensor geometrical arrangementsElectrodynamic magnetometersThermal stabilitySingle chip

The present invention discloses a triaxial magnetoresistive sensor. It comprises a substrate integrated with a biaxial magnetic field sensor, a Z-axis sensor that has a sensing direction along Z-axis perpendicular to the two axes of the biaxial magnetic field sensor, and an ASIC. The biaxial magnetic field sensor comprises an X-axis bridge sensor and a Y-axis bridge sensor. The Z-axis sensor and the two-axis sensor are electrically interconnected with the ASIC. A single-chip implementation of the triaxial magnetic field sensor comprises a substrate, onto which a triaxial magnetic field sensor and an ASIC are stacked. The triaxial magnetic field sensor comprises an X-axis bridge sensor, a Y-axis bridge sensor, and a Z-axis bridge sensor. The above design provides a highly integrated sensor with high sensitivity, low power consumption, good linearity, wide dynamic range, excellent thermal stability, and low magnetic noise.

Owner:MULTIDIMENSION TECH CO LTD

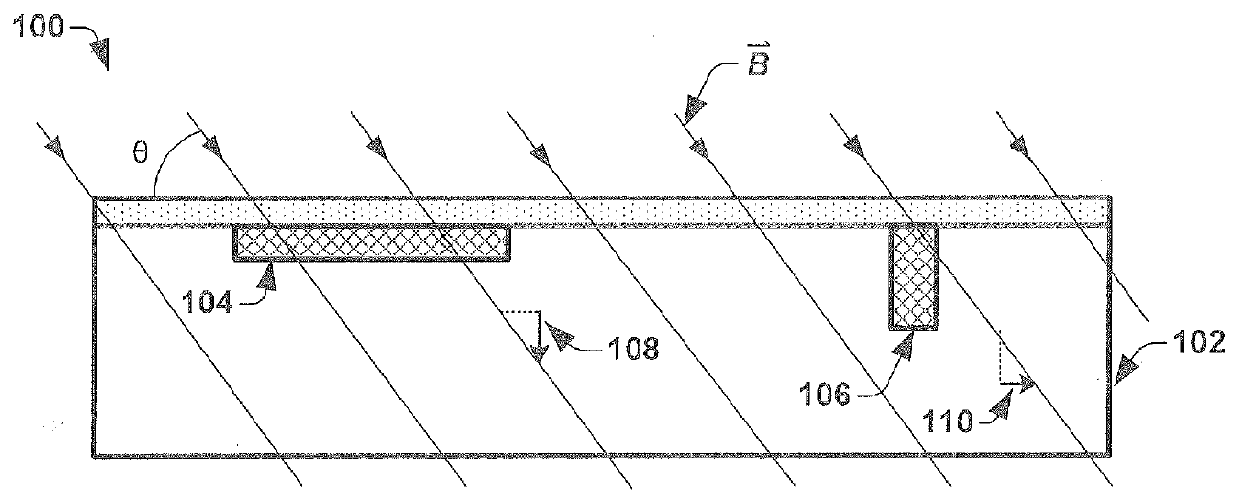

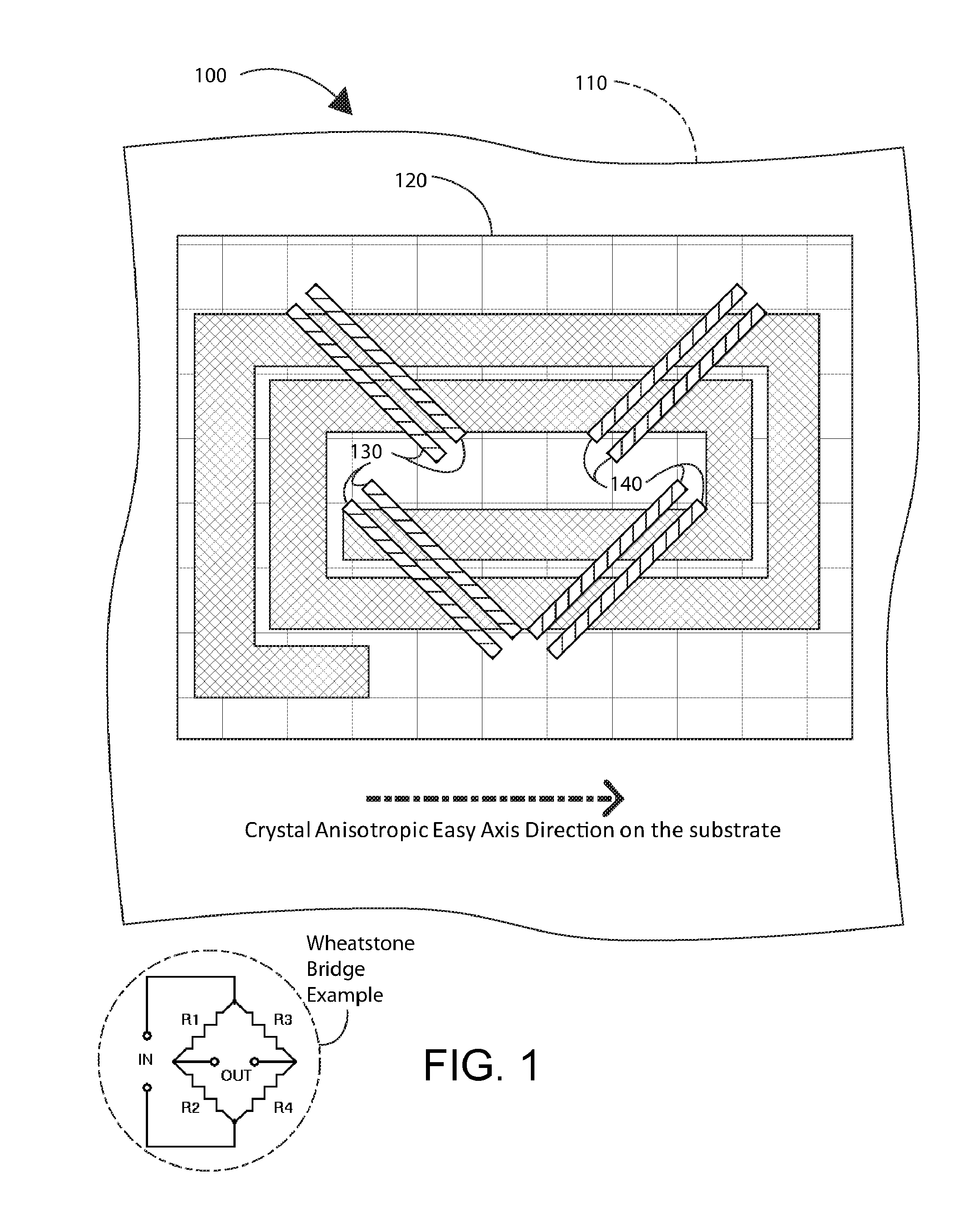

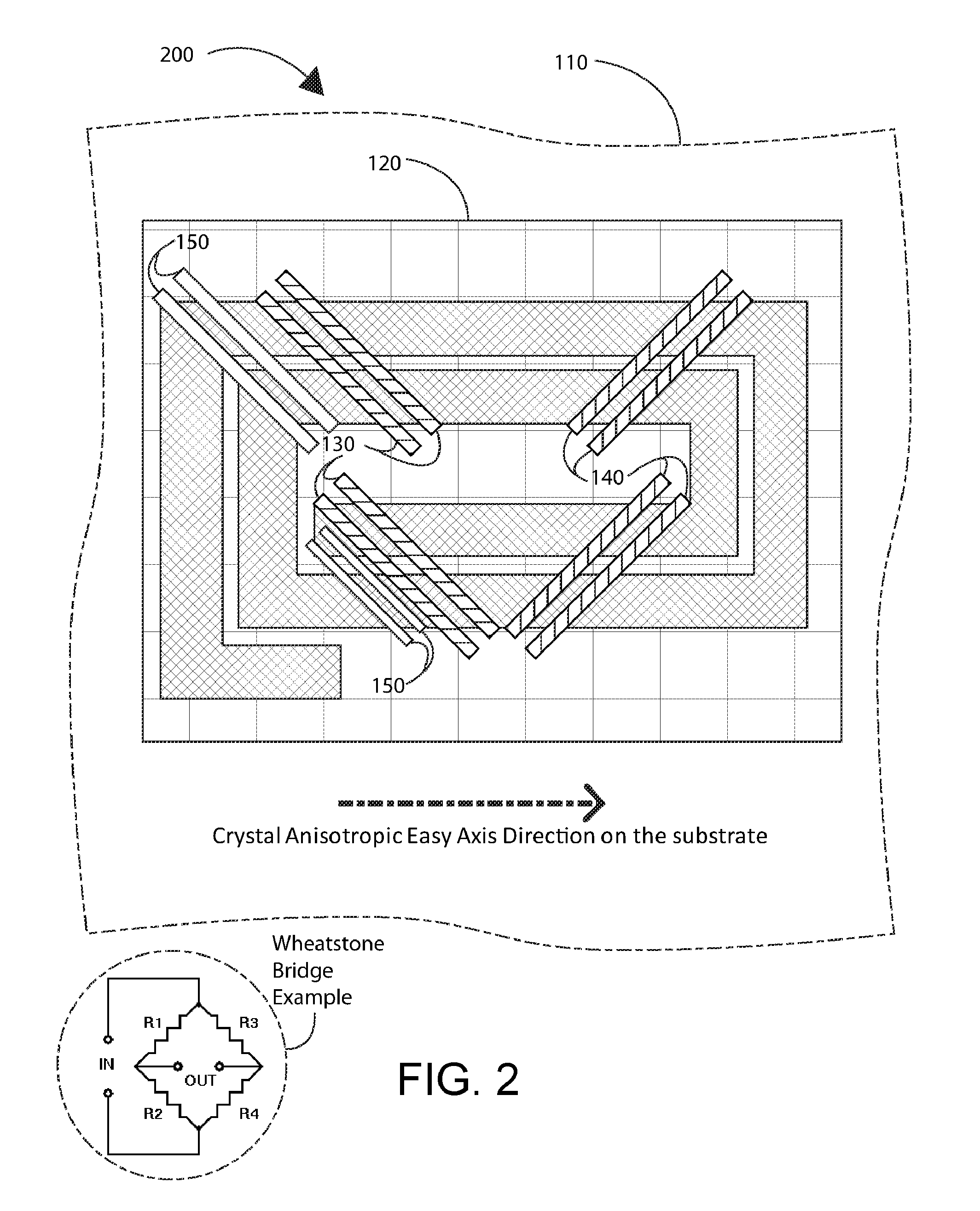

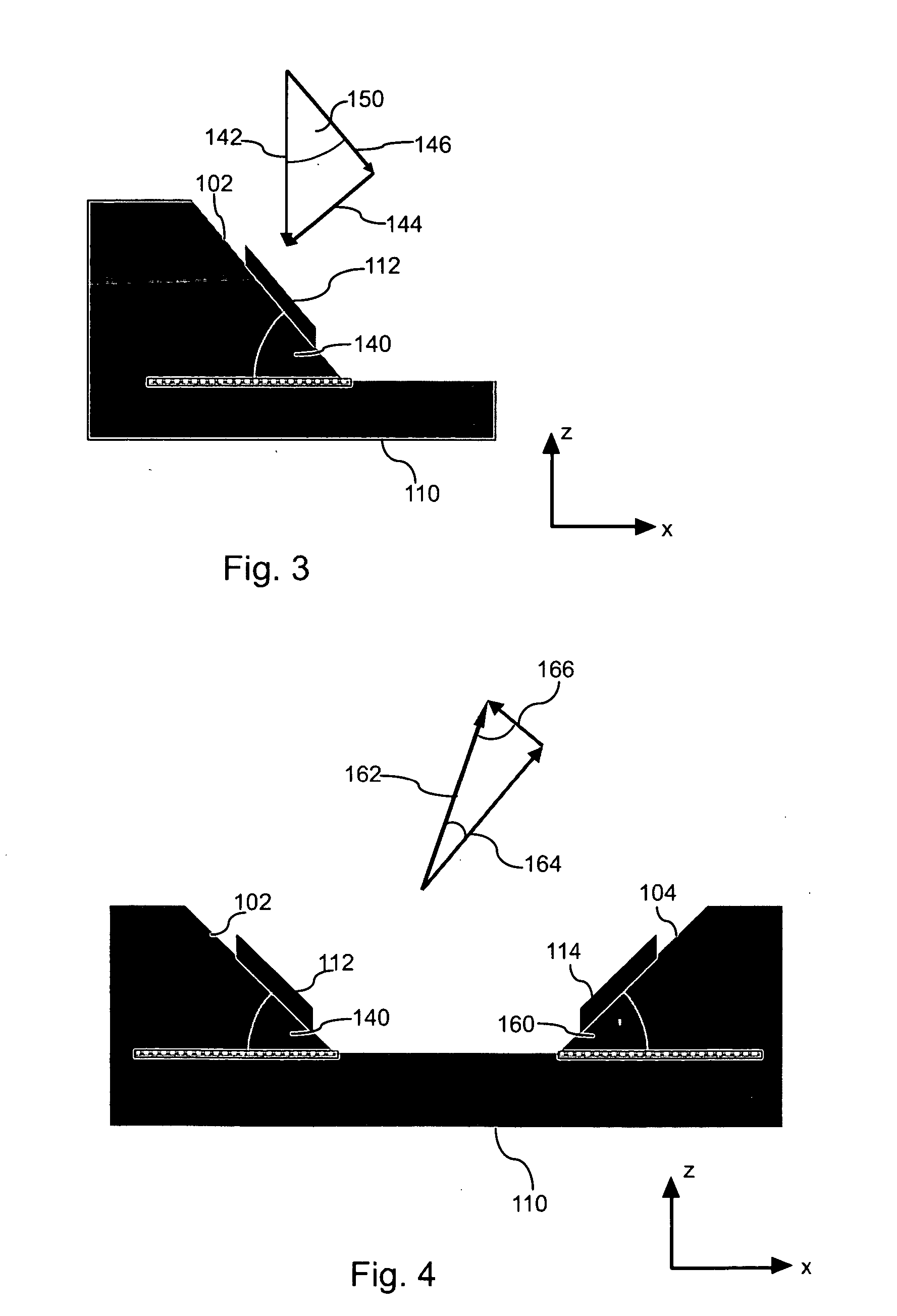

Magnetic sensor with tilted magnetoresistive structures

InactiveUS20060171081A1Record information storageManufacture of flux-sensitive headsEngineeringMechanical engineering

A magnetic field sensor device comprising a substrate having at least a first tilted planar section having a surface normal at a first angle with respect to a surface normal of the substrate, and at least a first magnetoresistive layered structure positioned at the at least first tilted section. Methods for manufacturing magnetic field sensor devices are also presented.

Owner:IBM CORP

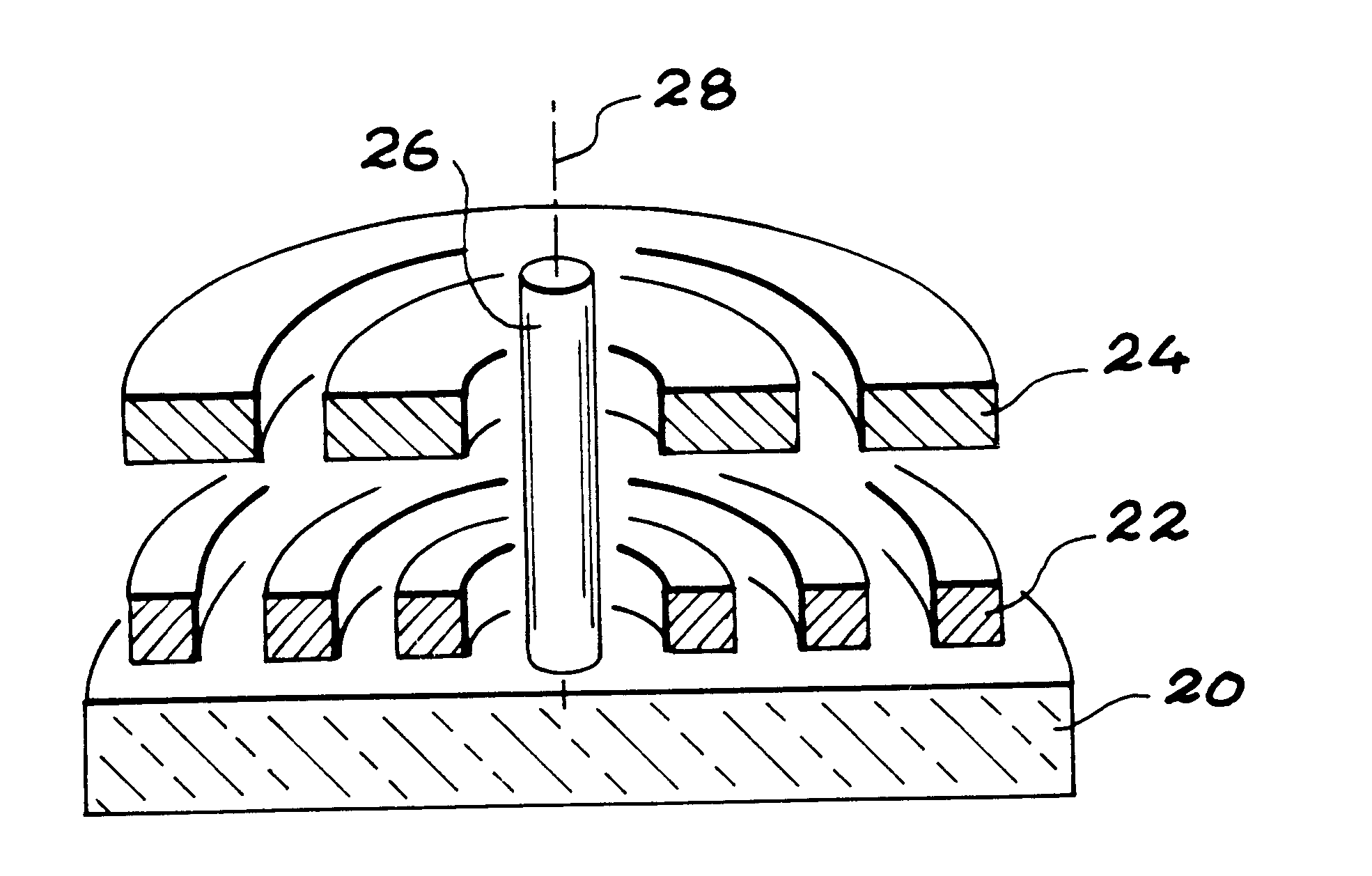

Perpendicular detection fluxgate micromagnetometer and method for the production thereof

InactiveUS6690164B1Magnetic field measurement using flux-gate principleThree-component magnetometersMagnetic measurementsMagnetometer

A fluxgate micro-magnetometer with perpendicular detection and a process of realization thereof. A ferromagnetic core is perpendicular to a substrate. The axes of excitation coils and pick-up coils are also perpendicular to the substrate. A magnetic field component which is perpendicular to the substrate is thus measured. The two other components can be measured by magnetometers of classical type whose core is parallel to the substrate. Such a device may find application in the domain of magnetic measurement, as an example.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Magnetic tunnel junction (MTJ) triaxial magnetic field sensor and packaging method thereof

ActiveCN102385043AMagnetic-field-controlled resistorsManufacture of electrical instrumentsEngineeringApplication-specific integrated circuit

The invention discloses a magnetic tunnel junction (MTJ) triaxial magnetic field sensor, which comprises an X-axis bridge magnetic field sensor with the X axis as the sensitive direction, a Y-axis bridge magnetic field sensor with the Y axis as the sensitive direction, a Z-axis bridge magnetic field sensor with the Z axis as the sensitive direction and an application specific integrated circuit (ASIC) chip connected and matched with the X-axis bridge magnetic field sensor, the Y-axis bridge magnetic field sensor and the Z-axis bridge magnetic field sensor. The Z-axis magnetic field sensor comprises a substrate and an MTJ element prepared on the substrate, the Z-axis magnetic field sensor clings to and covers the ASIC chip to form a clinging side, an included angle is formed between the clinging side and the lateral side adjacent to the clinging side on the Z-axis magnetic field sensor, the included angle is an acute angle or an obtuse angle, and the X axis, the Y axis and the Z axis are intersected with each other in orthogonality mode. By means of the structure, the MTJ triaxial magnetic field sensor is high in integrated degree, higher in sensitivity, low in power consumption, better in linearity, wide in dynamic range, better in temperature characteristics and strong in anti-jamming capability.

Owner:MULTIDIMENSION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com