Patents

Literature

900 results about "Boiler feedwater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler feedwater is an essential part of boiler operations. The feed water is put into the steam drum from a feed pump. In the steam drum the feed water is then turned into steam from the heat. After the steam is used it is then dumped to the main condenser. From the condenser it is then pumped to the deaerated feed tank. From this tank it then goes back to the steam drum to complete its cycle. The feed water is never open to the atmosphere. This cycle is known as a closed system or Rankine cycle.

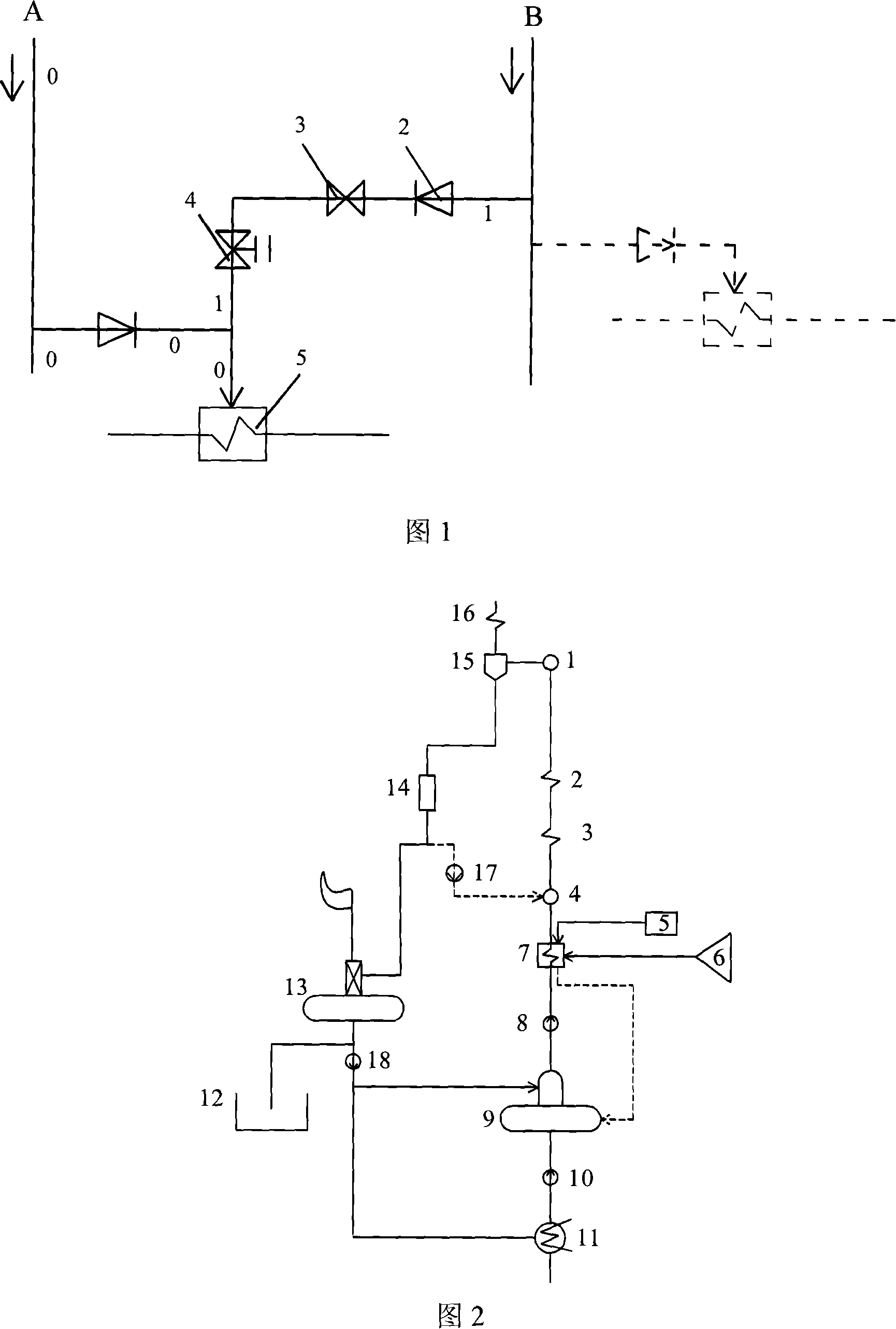

Solar energy desalination system

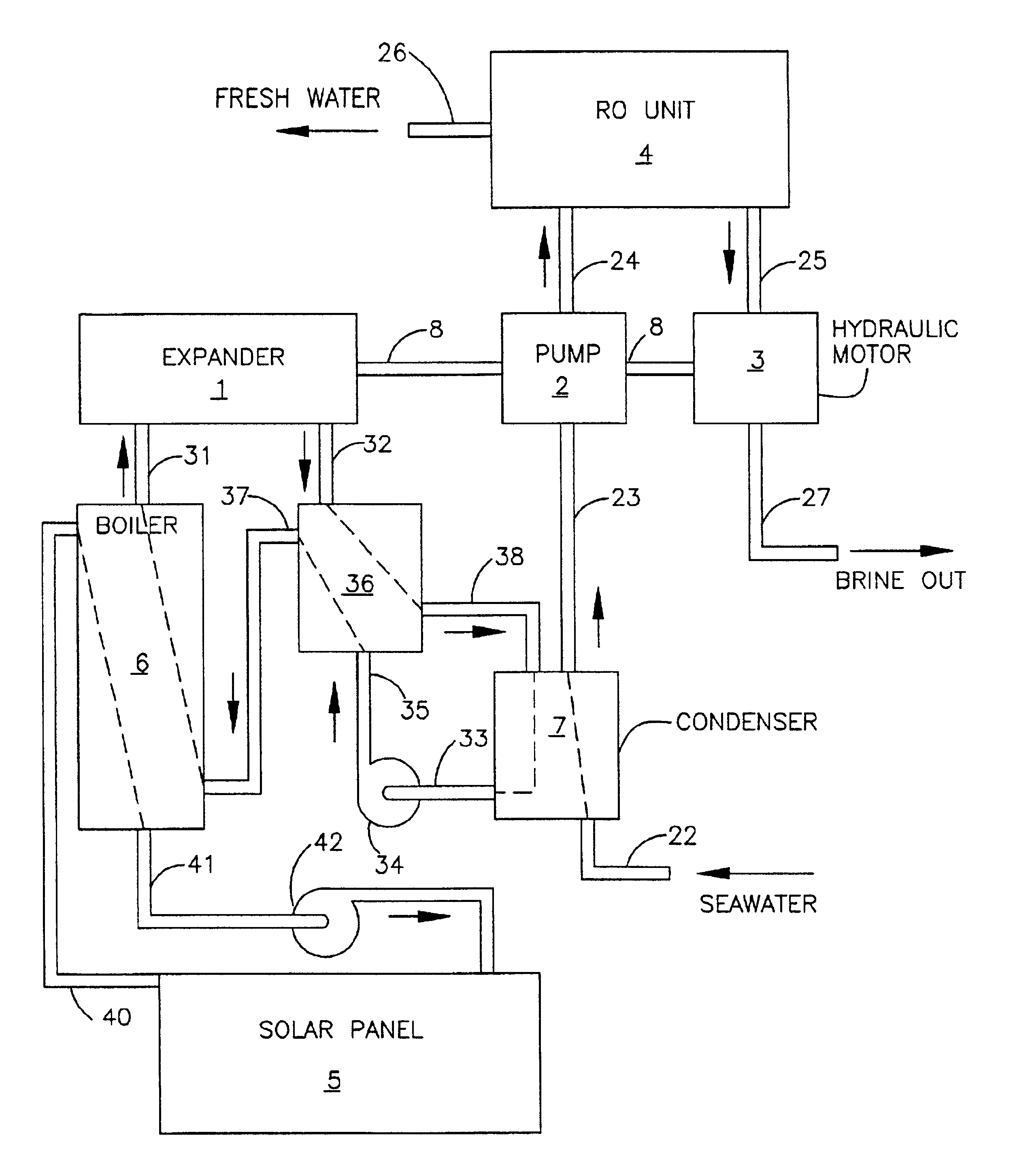

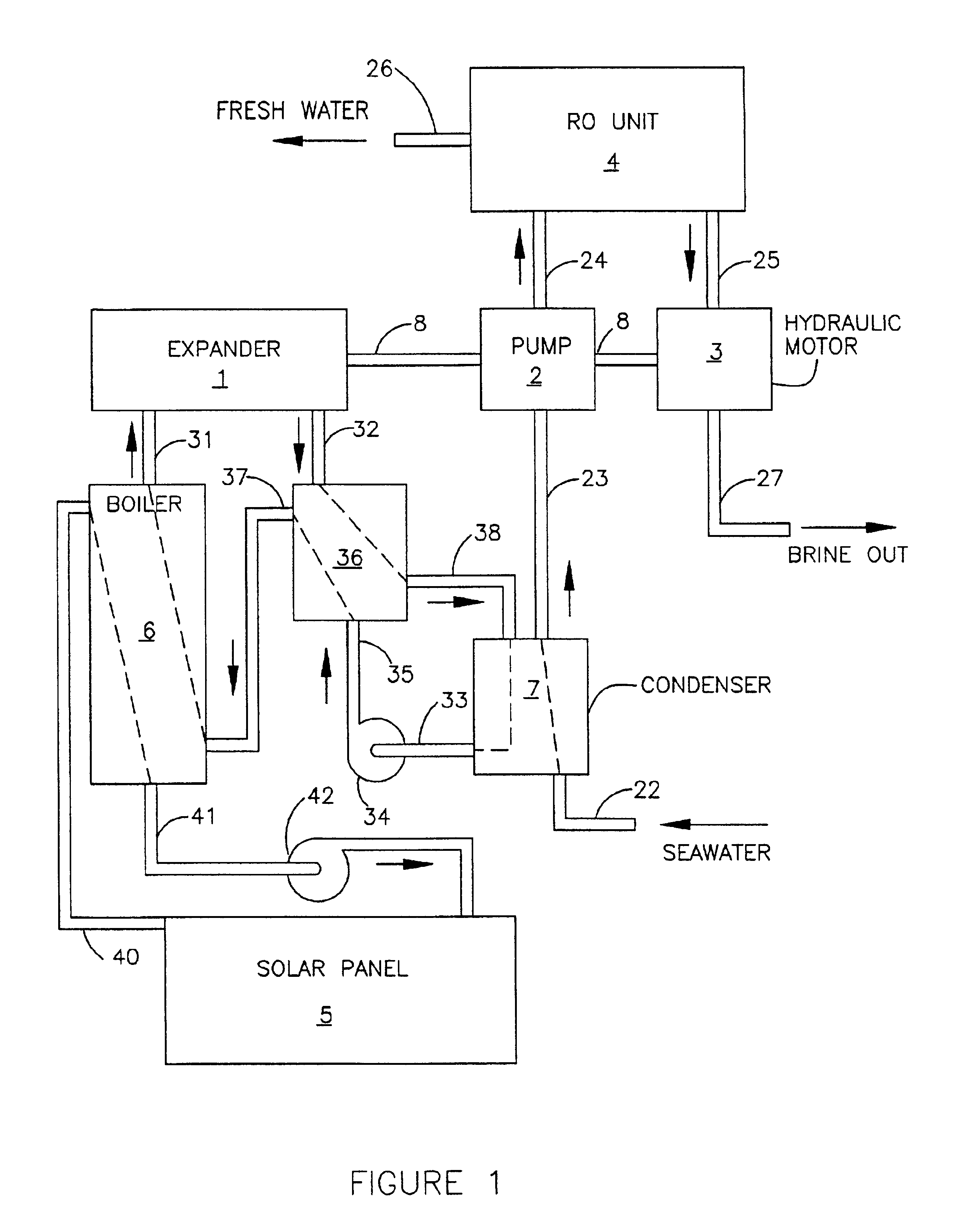

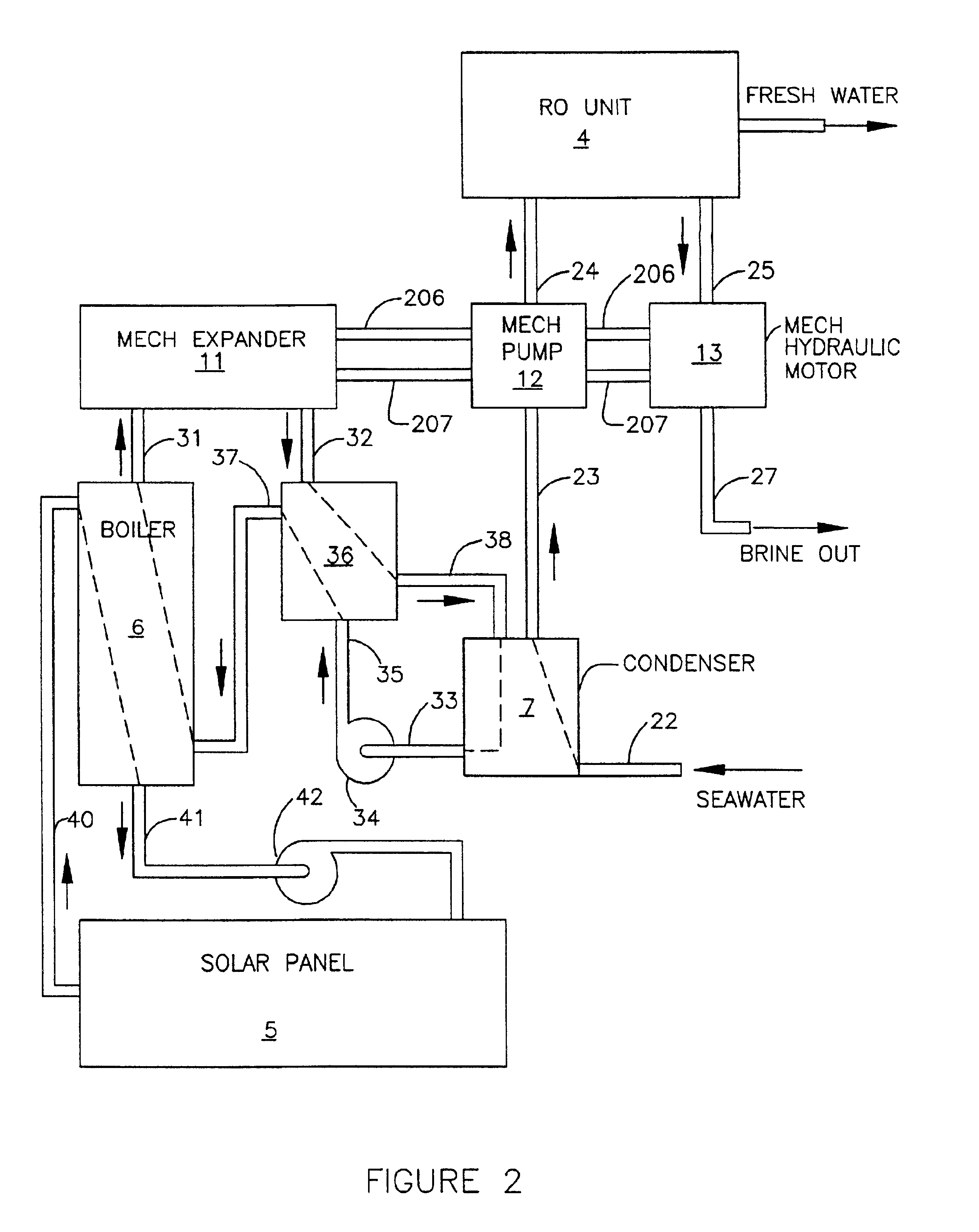

A desalination system is driven by a solar powered boiler that outputs a pressurized vapor to drive an expander that generates output motive force. A pump is responsive to the motive force to output pressurized saline water. A reverse osmosis unit receives the pressurized saline water to output fresh water and pressurized brine. A recuperator that transfers heat from the expander exhaust to the boiler feed liquid is incorporated to improve the efficiency of the system. In a particular embodiment, a hydraulic motor receives the pressurized brine and outputs an augmenting motive force to the pump. In another embodiment, a novel motorless boiler feed pump is defined.

Owner:PRUEITT MELVIN L

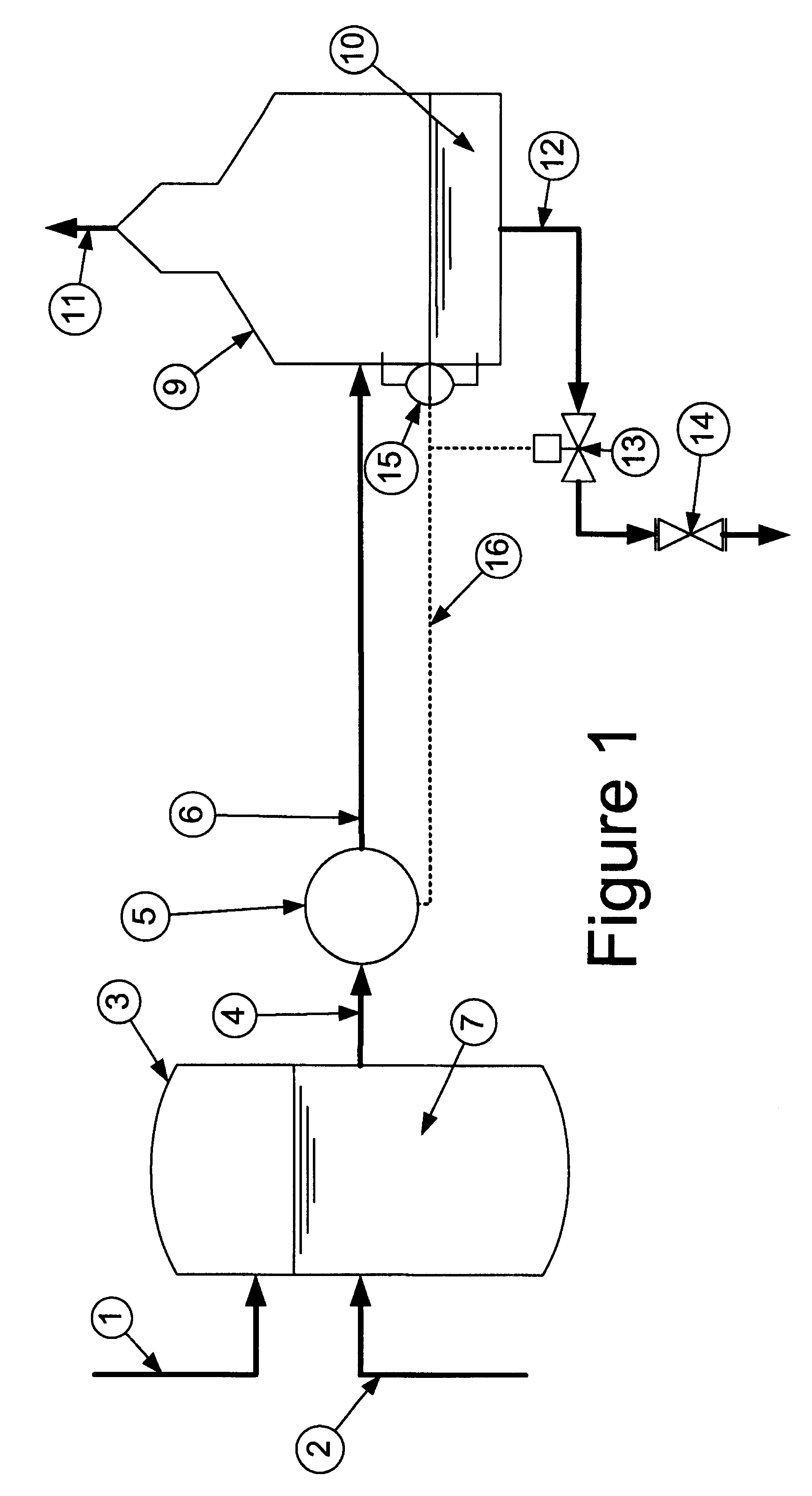

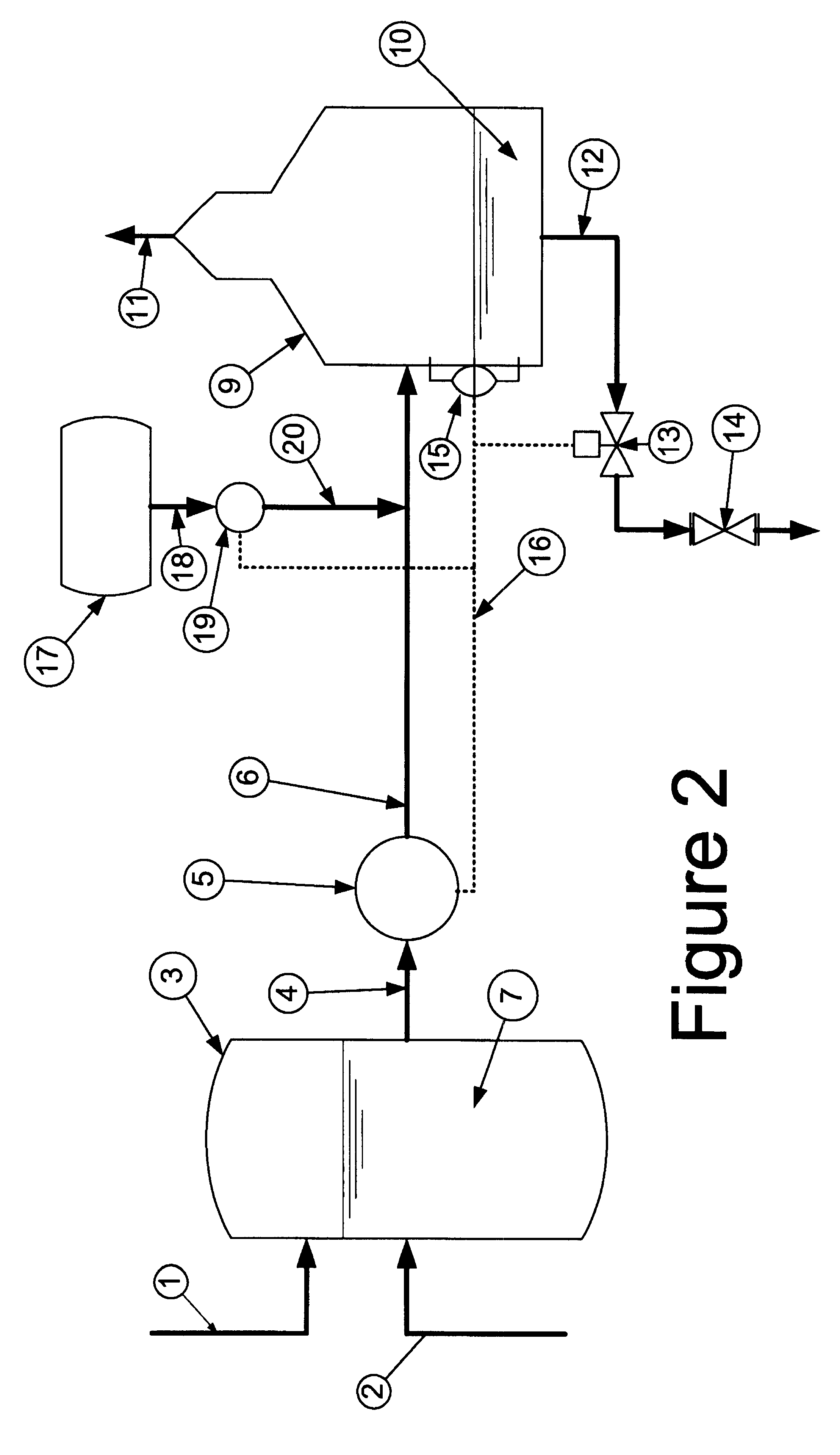

Boiler water blowdown control system

InactiveUS6655322B1Constant flowThe process is simple and accurateBoiler cleaning apparatusMachines/enginesControl systemEngineering

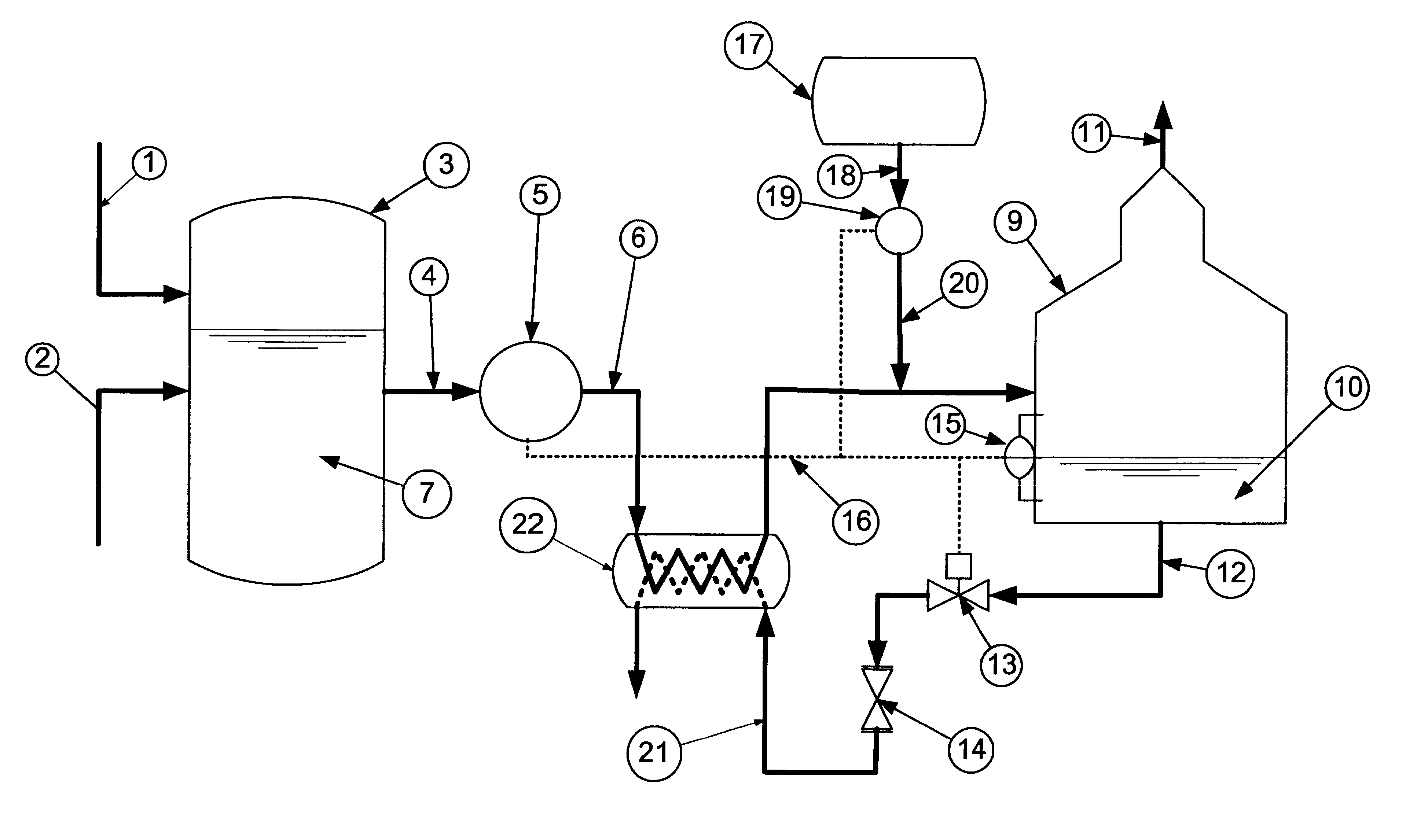

The present invention relates to a method for automatically maintaining the concentration of scale forming minerals in boiler water for boiler systems utilizing bimodal feedwater pumps that deliver a substantially constant feedwater flow to the boiler drum when activated. According to the present invention, the feedwater supply pump and blowdown rate control valve are synchronized to remove boiler water at a predetermined rate when the feedwater pump is activated. The present invention thereby provides a simplified and less expensive method for controlling the concentration of dissolved solids in boiler water despite variations in the steam loads and / or other boiler operation parameters.

Owner:CHEMTREAT

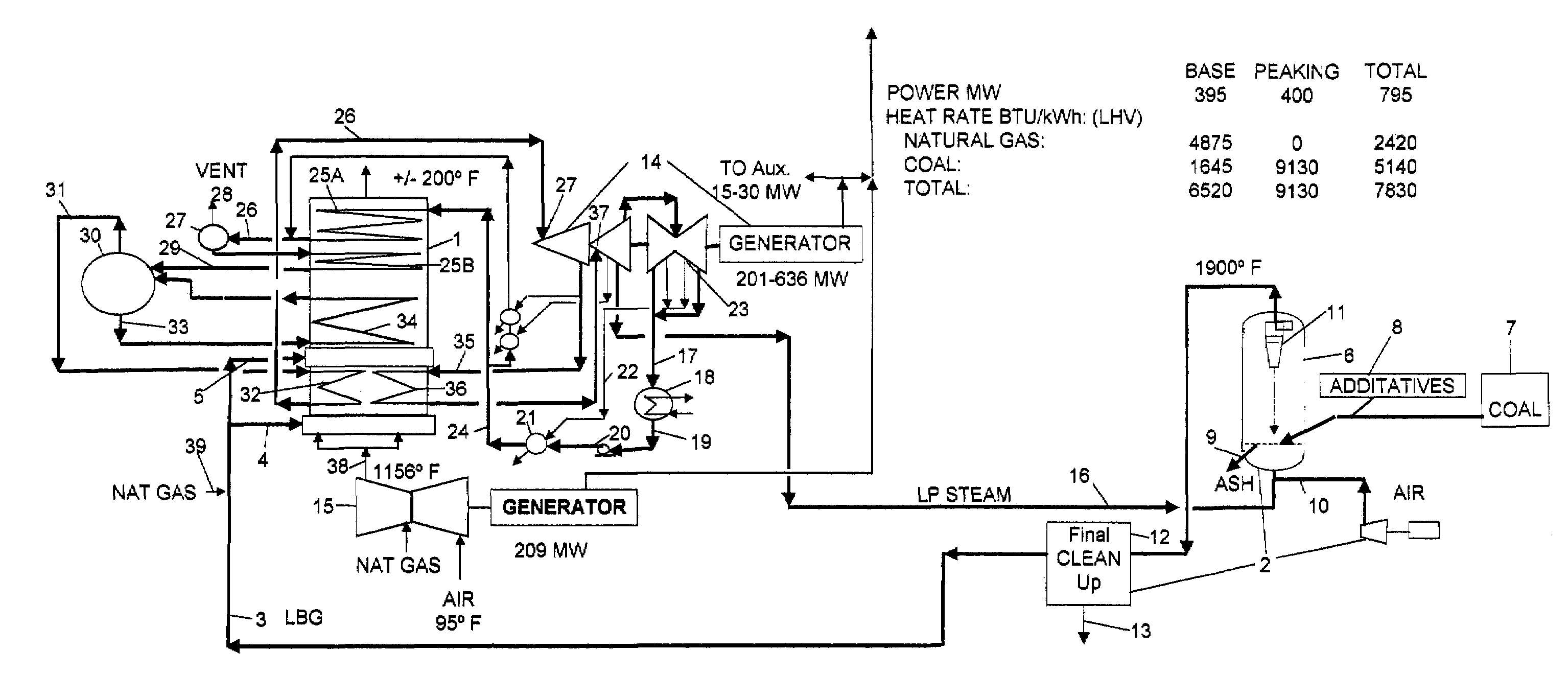

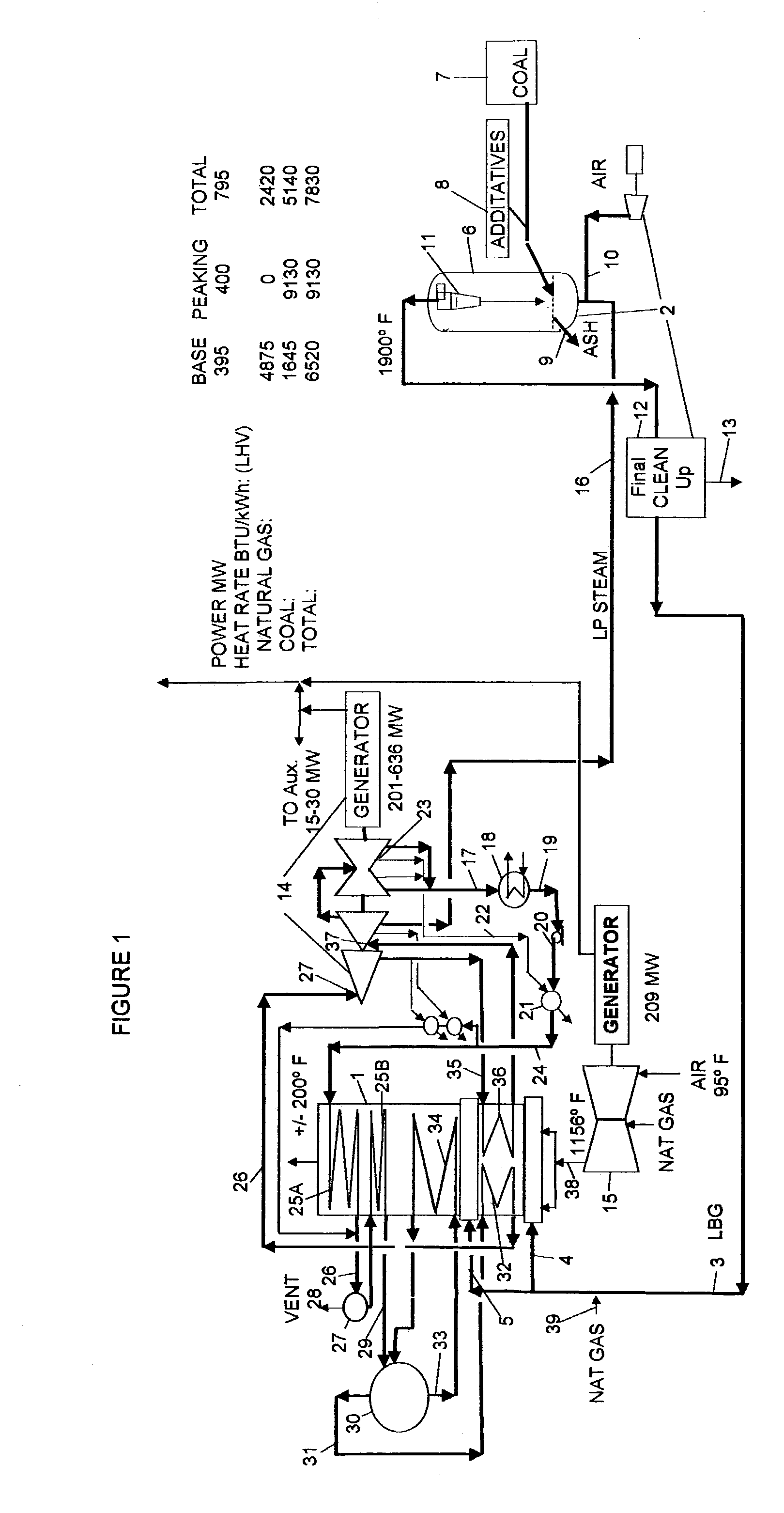

Combined cycle for generating electric power

InactiveUS6966190B2Low costImprove fuel efficiencyBiofuelsCombustion enginesBrown coalHydrocotyle bowlesioides

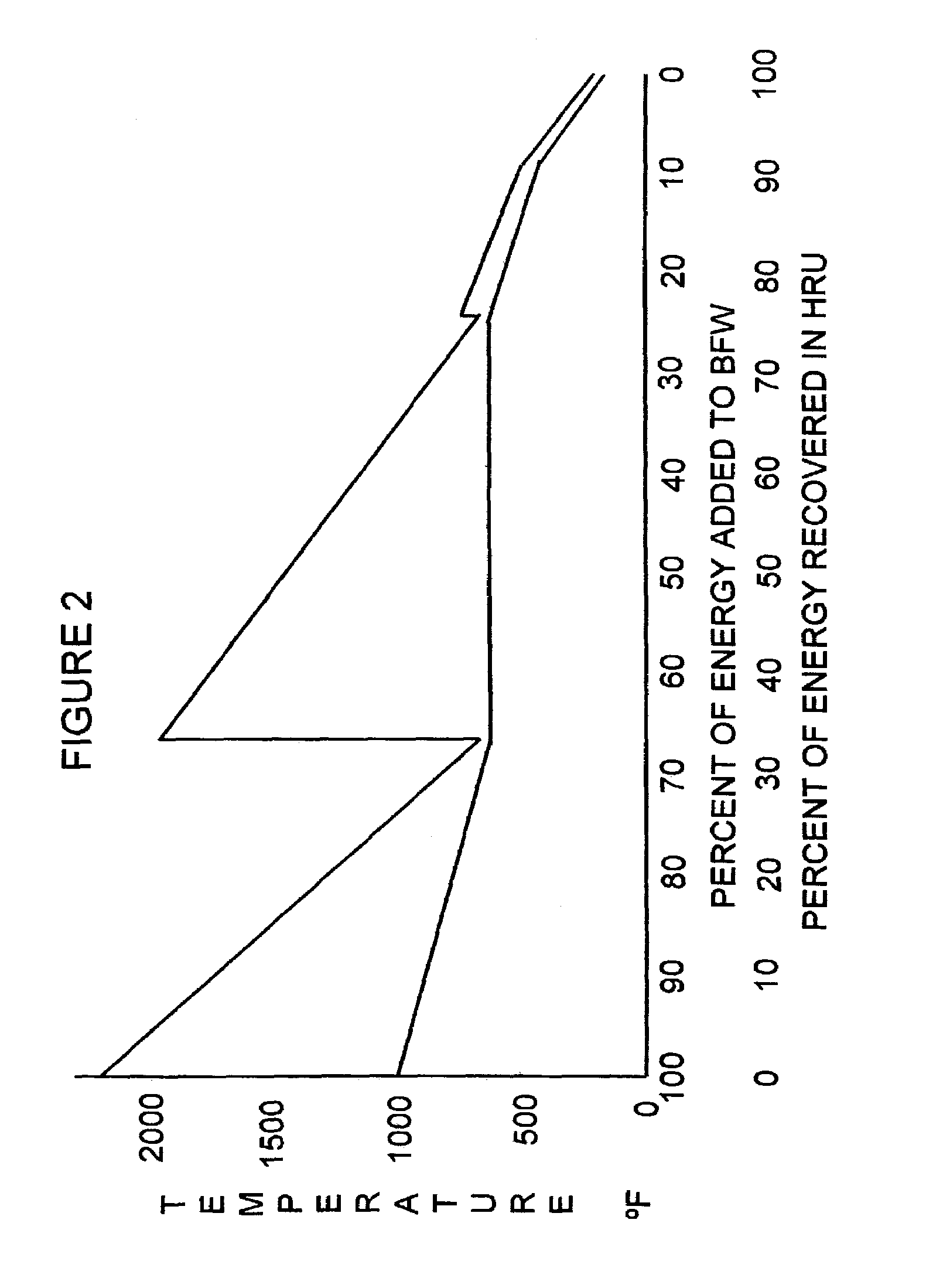

A combined cycle process that includes gas turbines, a steam turbine train, a heat recovery unit, and a gasification unit that produces low or mid BTU fuel gas from coal, lignite, coke, biomass, or other suitable hydrocarbon containing material wherein the fuel gas is burned in the heat recovery unit at one or more points to increase steam rate to the steam turbine train.The fuel gas injection flow rates into the heat recovery unit are controlled to avoid exceeding peak temperatures in the heat recovery unit of about 2500 F.Optionally, the fuel gas from the gasification unit is cooled by transferring sensible heat to condensate from the steam turbine train to convert the condensate to high pressure steam for driving the steam turbine train.Optionally, a steam boiler unit is integrated into the combined cycle process to raise additional high pressure steam for the steam turbine train. The steam boiler feed water is condensate from the steam turbine train. The steam boiler produces saturated high pressure steam that is superheated in the heat recovery unit.

Owner:WYLIE INVENTIONS

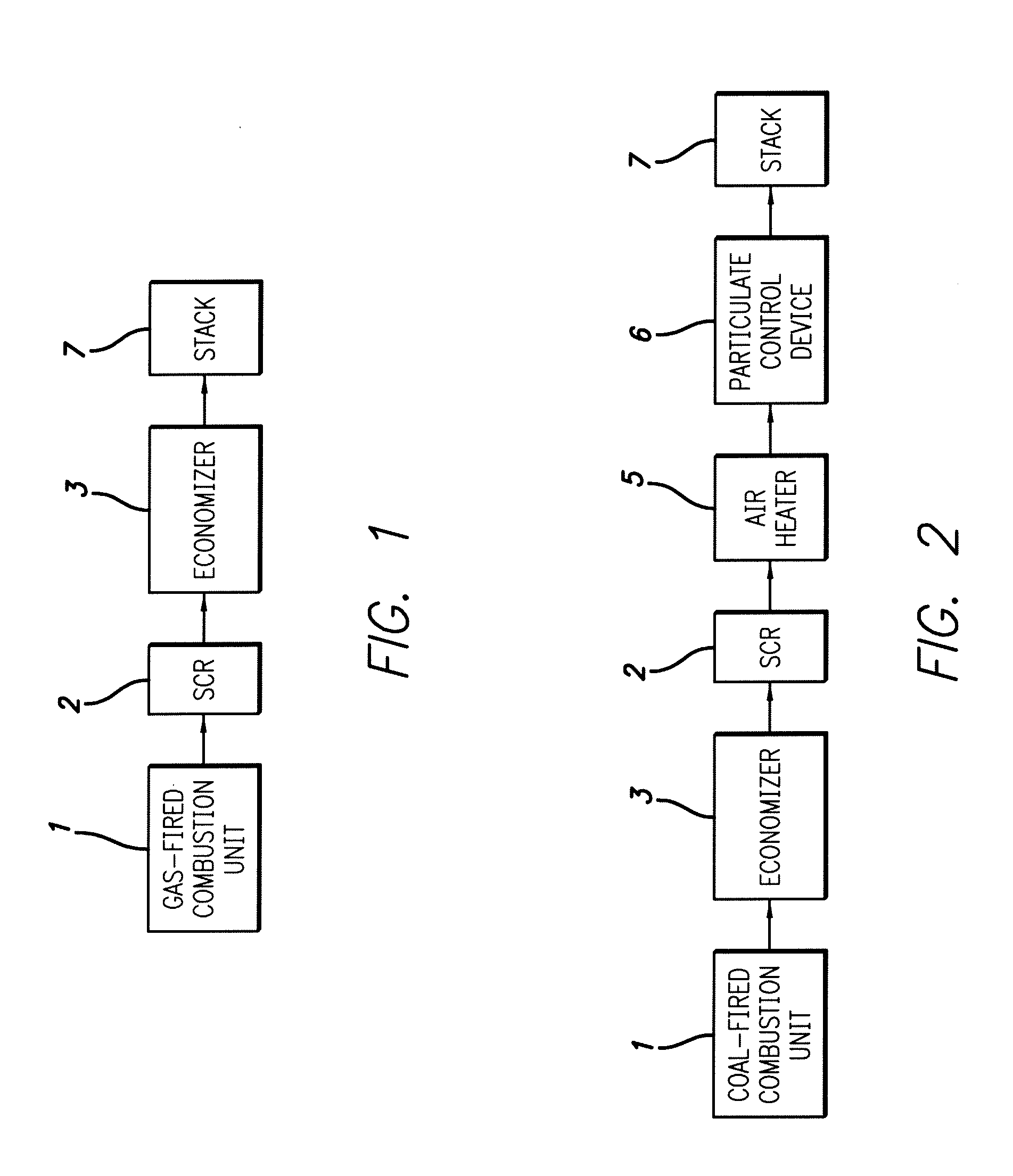

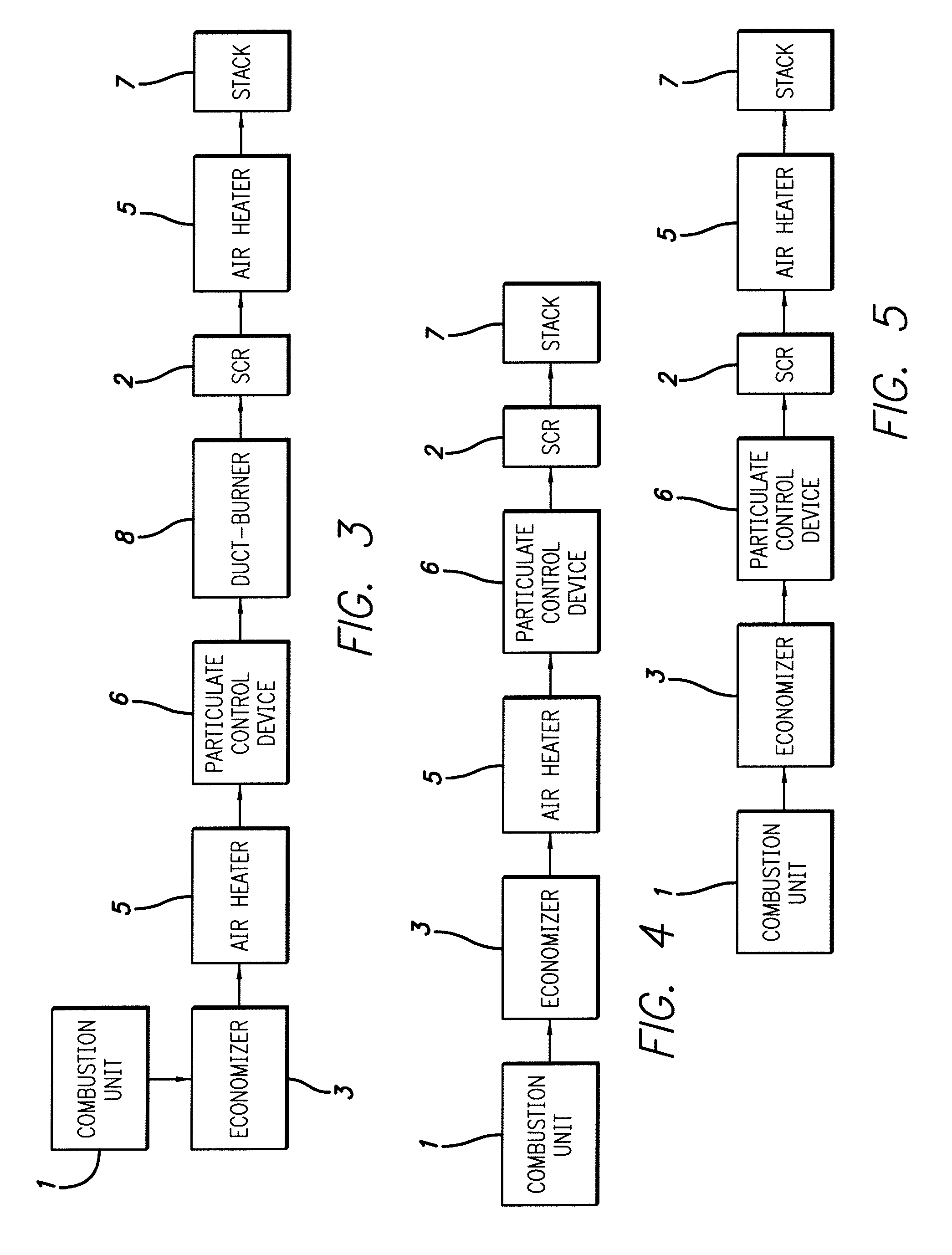

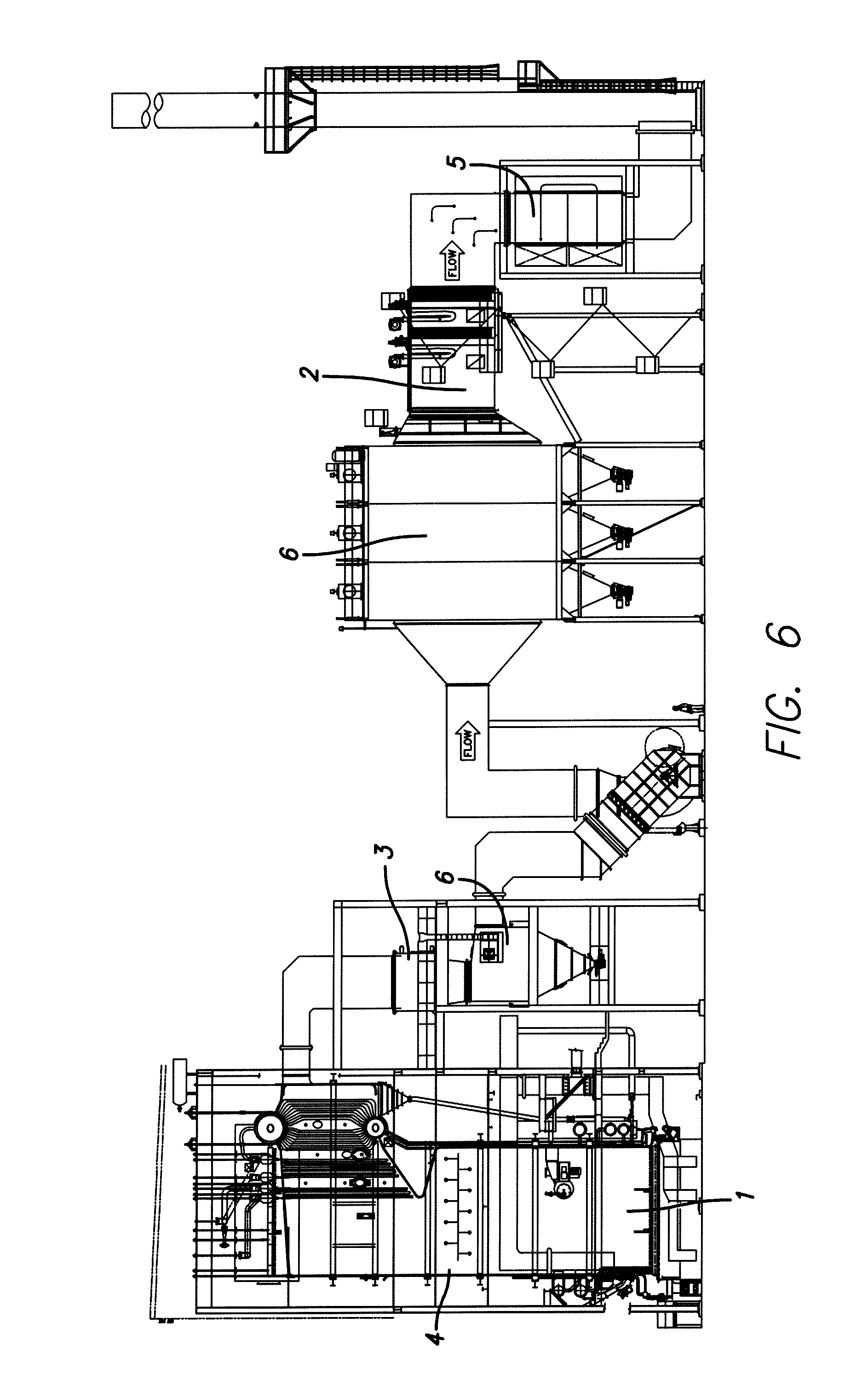

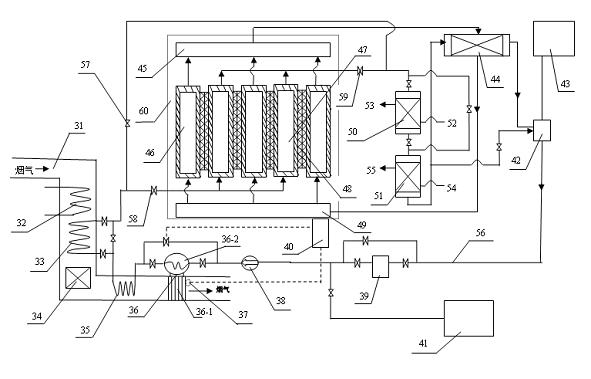

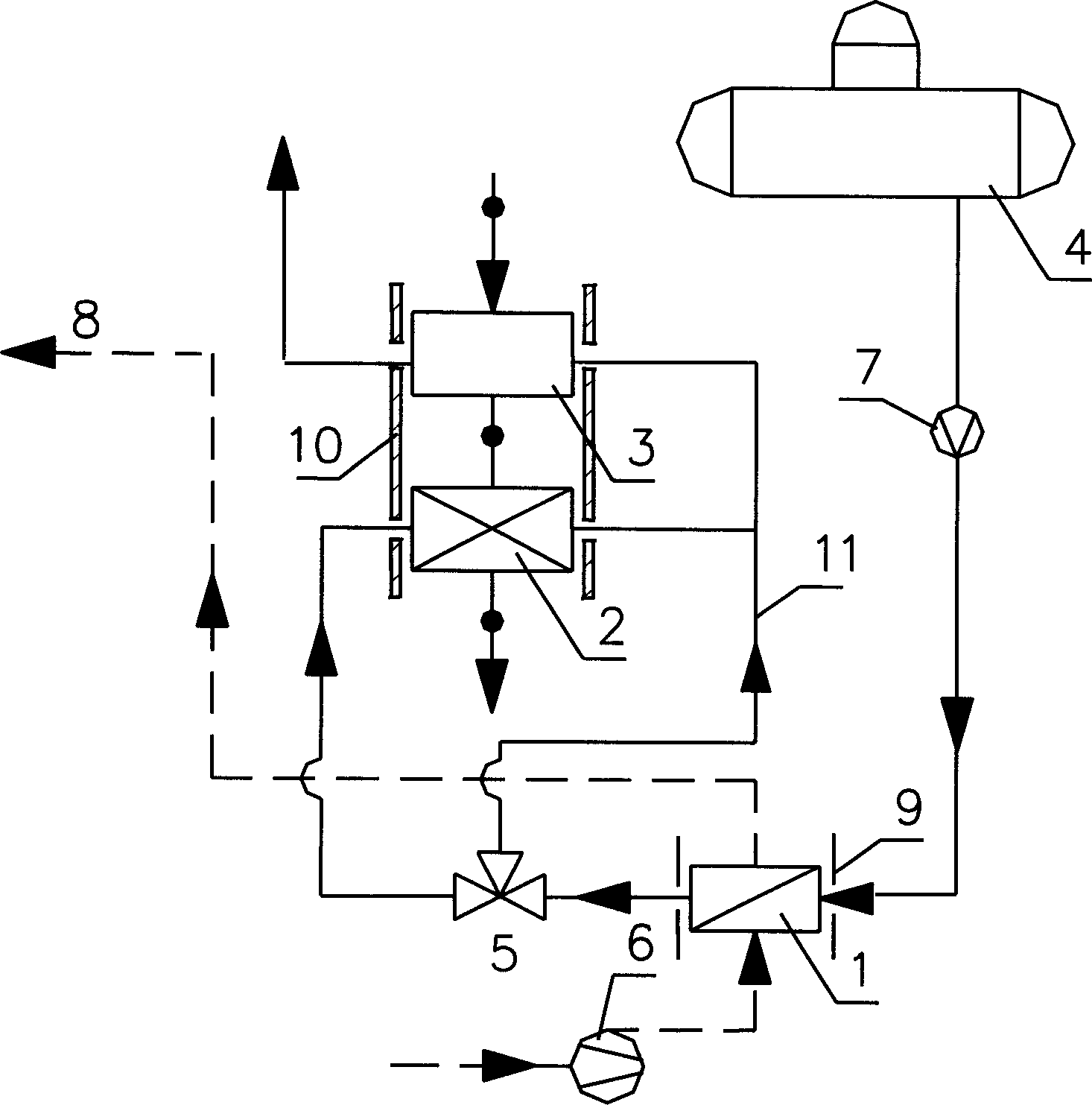

BIOMASS BOILER SCR NOx AND CO REDUCTION SYSTEM

InactiveUS20110311424A1High NOx control efficiencyWide temperature rangeCombination devicesNitrogen compoundsParticulatesFlue gas

A selective catalytic reduction system and method for reducing nitrogen oxide (NOx) emissions comprising a boiler producing flue gas emissions, a particulate control device receiving flue gas emissions from the boiler, a selective catalytic reduction unit (SCR) receiving flue gas emissions from the particulate control device and reducing nitrogen oxide (NOx) emissions, and a heat exchanger located downstream of the selective catalytic reduction unit (SCR) for removing heat from the flue gas for preheating at least one of boiler feed water and combustion air for the boiler.

Owner:2E ENVIRONMENTAL

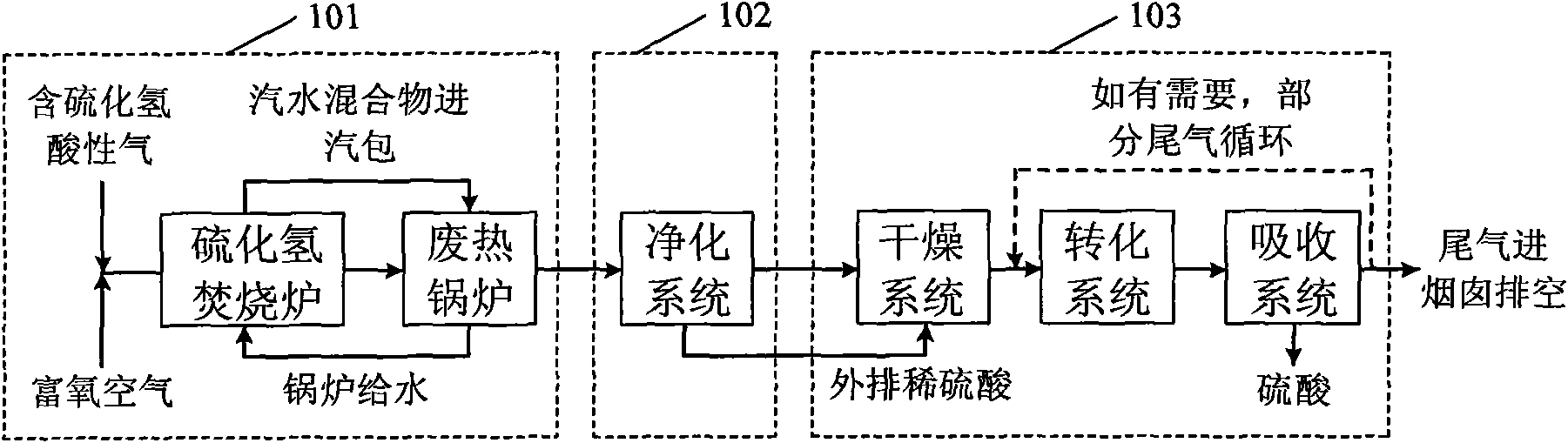

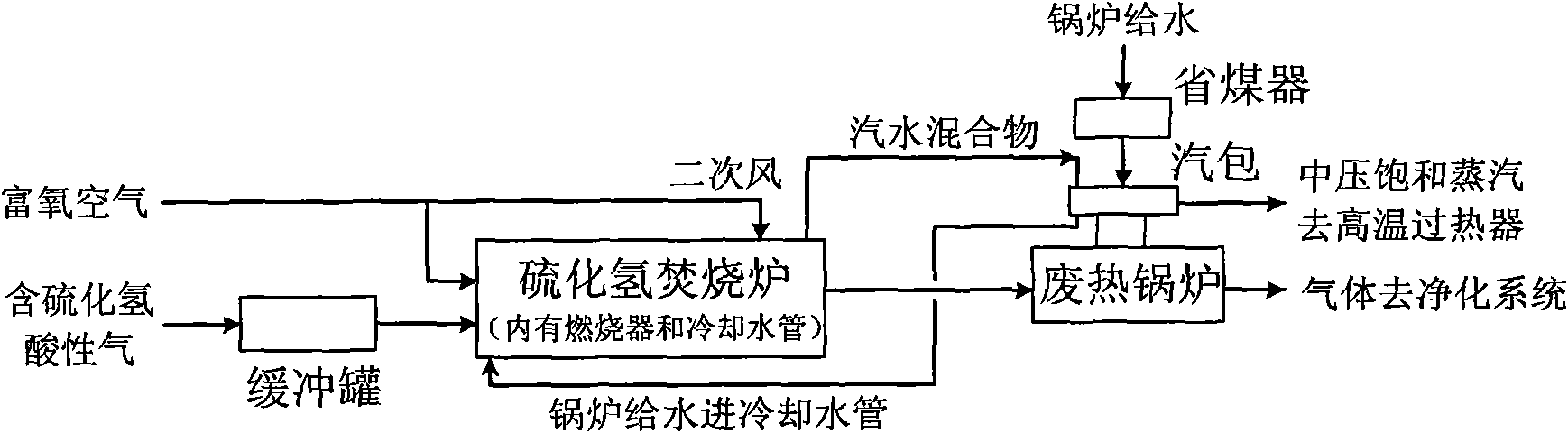

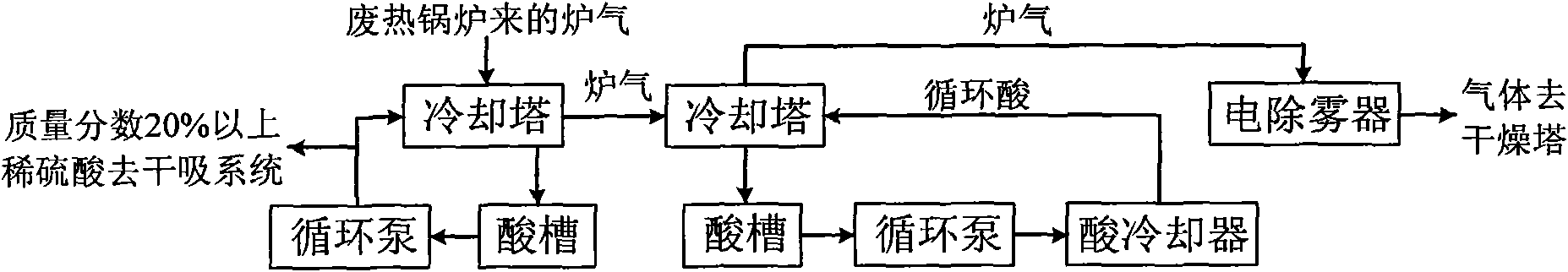

Method for producing sulfuric acid by oxygen-enriched air incineration of acid gas containing hydrogen sulfide

InactiveCN102371108AIncinerate completelyImprove waste heat recovery efficiencyDispersed particle separationSulfur compoundsThermal energyPollution

A method for producing sulfuric acid by oxygen-enriched air incineration of acid gas containing hydrogen sulfide belongs to the technical field of environment protection technology and comprises the following steps of: sending the acid gas containing hydrogen sulfide and oxygen-enriched air into a hydrogen sulfide incinerator for incineration, discharging the furnace gas after incineration, and recovering high-temperature furnace gas heat energy of an outlet; adding water into the furnace, and heating by the utilization of heat released from incineration; using dilute sulfuric acid discharged from a purification system as addendum water; demisting and drying the cooled furnace gas, entering into a conversion system for heat exchange preheating so as to generate sulfur trioxide, carrying out heat exchange on the discharged conversion gas, and entering into an absorbing tower for absorption. According to the invention, high and medium grade heat energy generated during the sulfuric acid production process is fully utilized, and dilute sulfuric acid is fully recovered and used, thus realizing less investment, low cost, high recovery rate of waste heat, clean production and no pollution in the production of sulfuric acid.

Owner:CHINA PETROCHEMICAL CORP +1

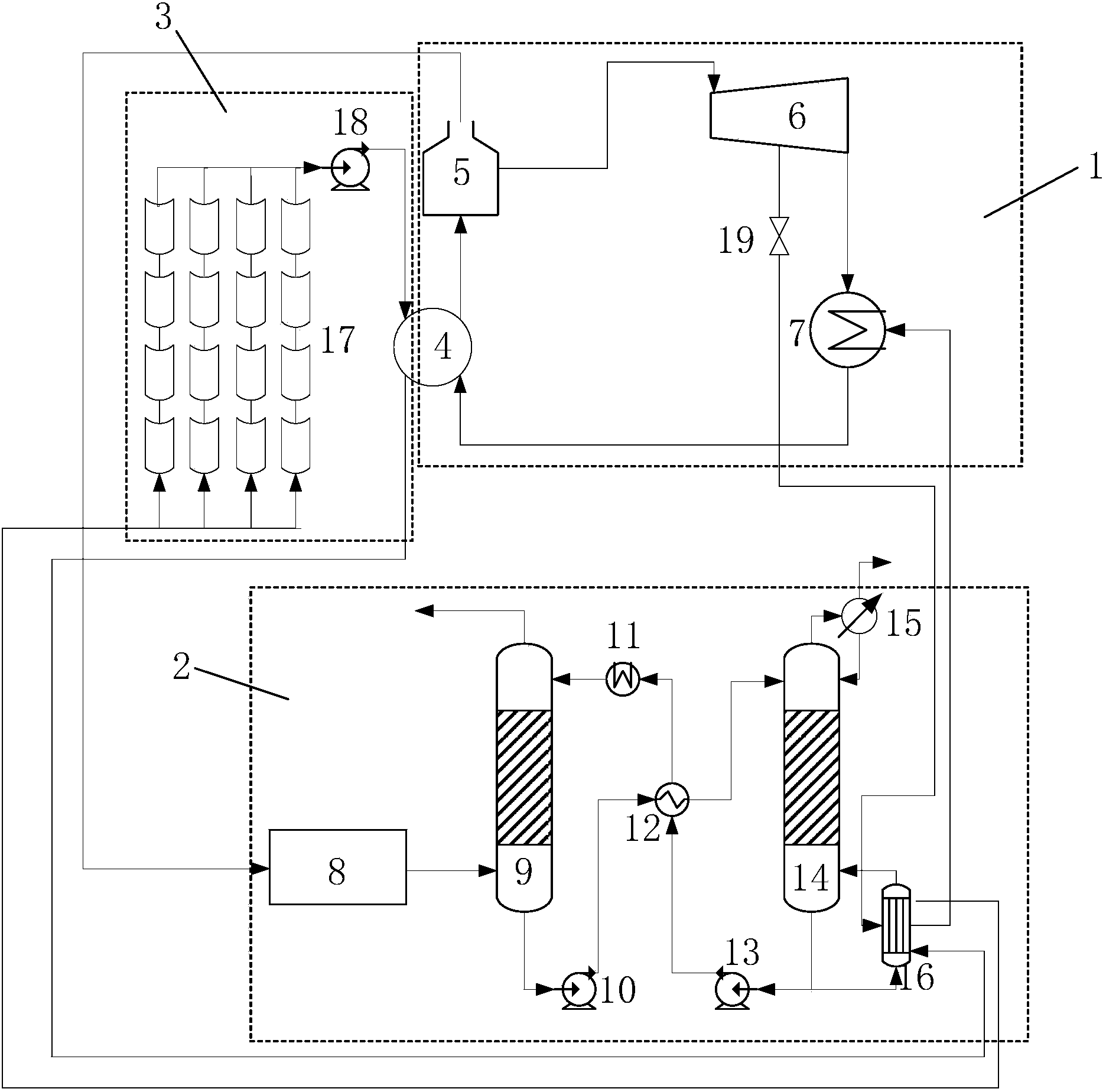

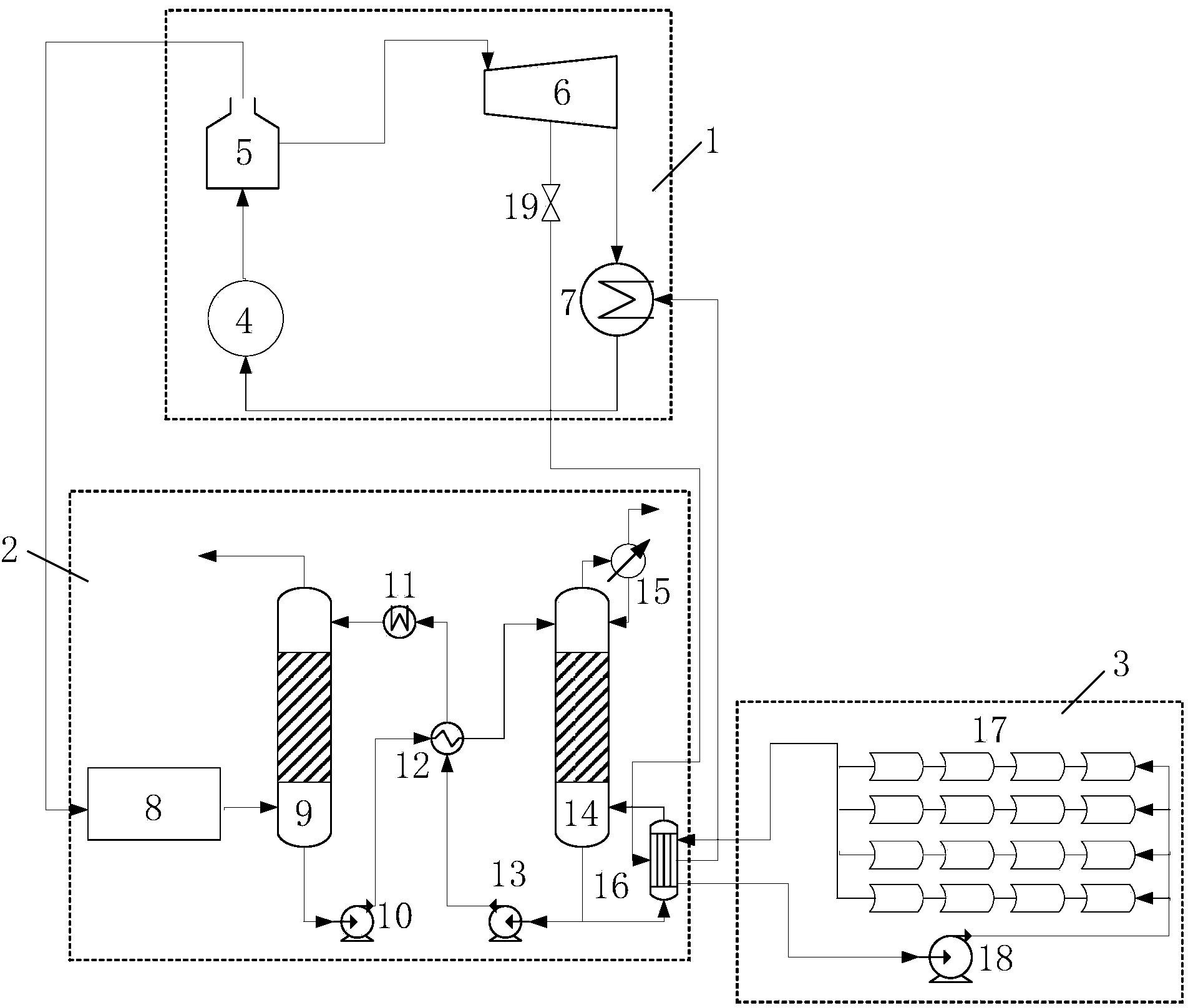

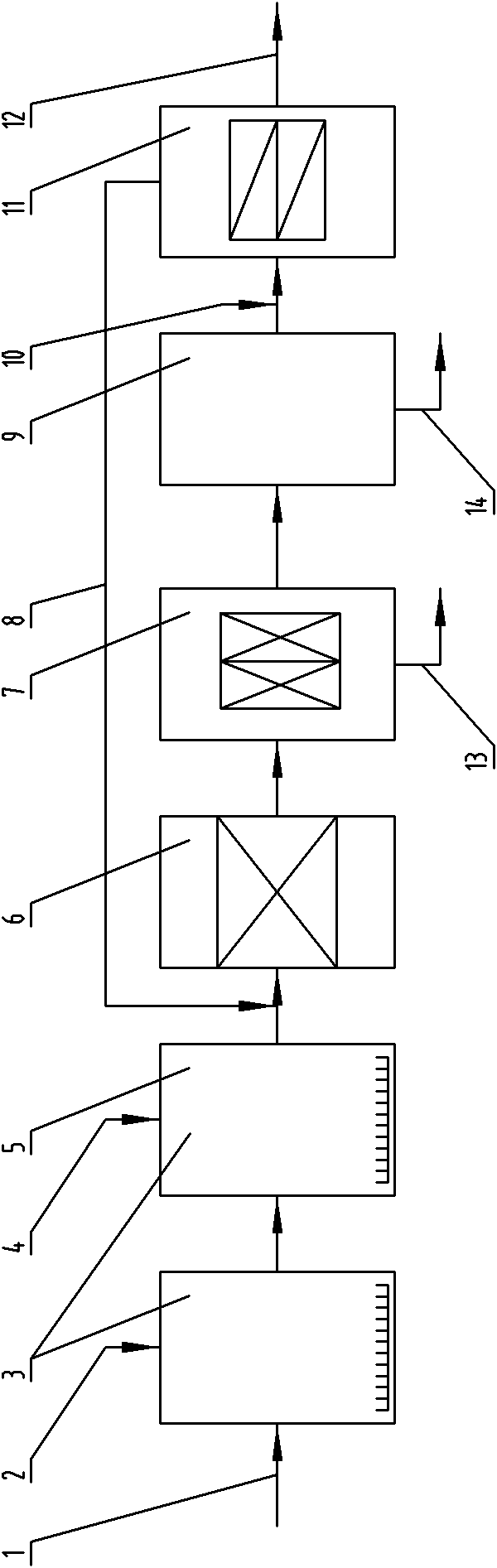

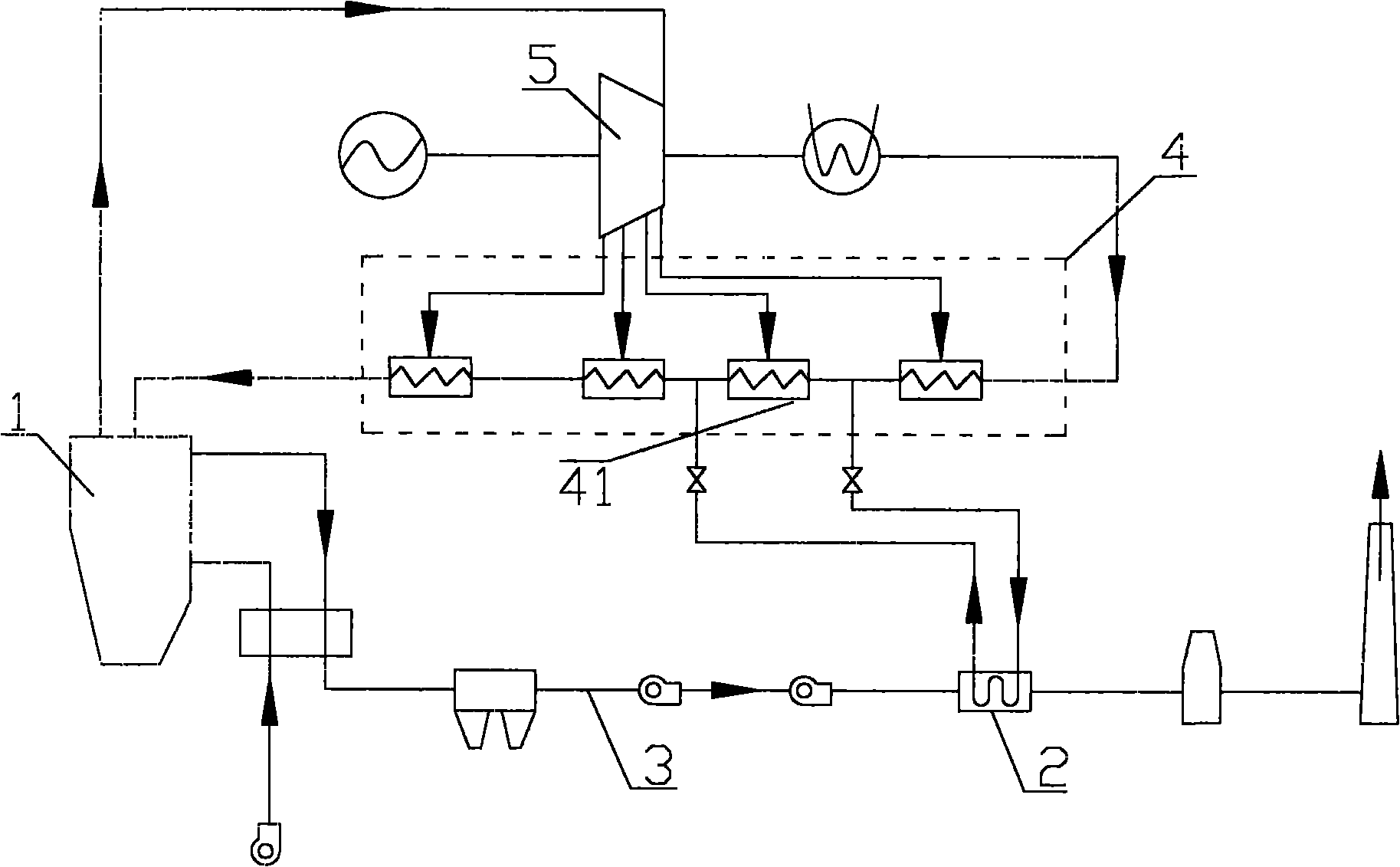

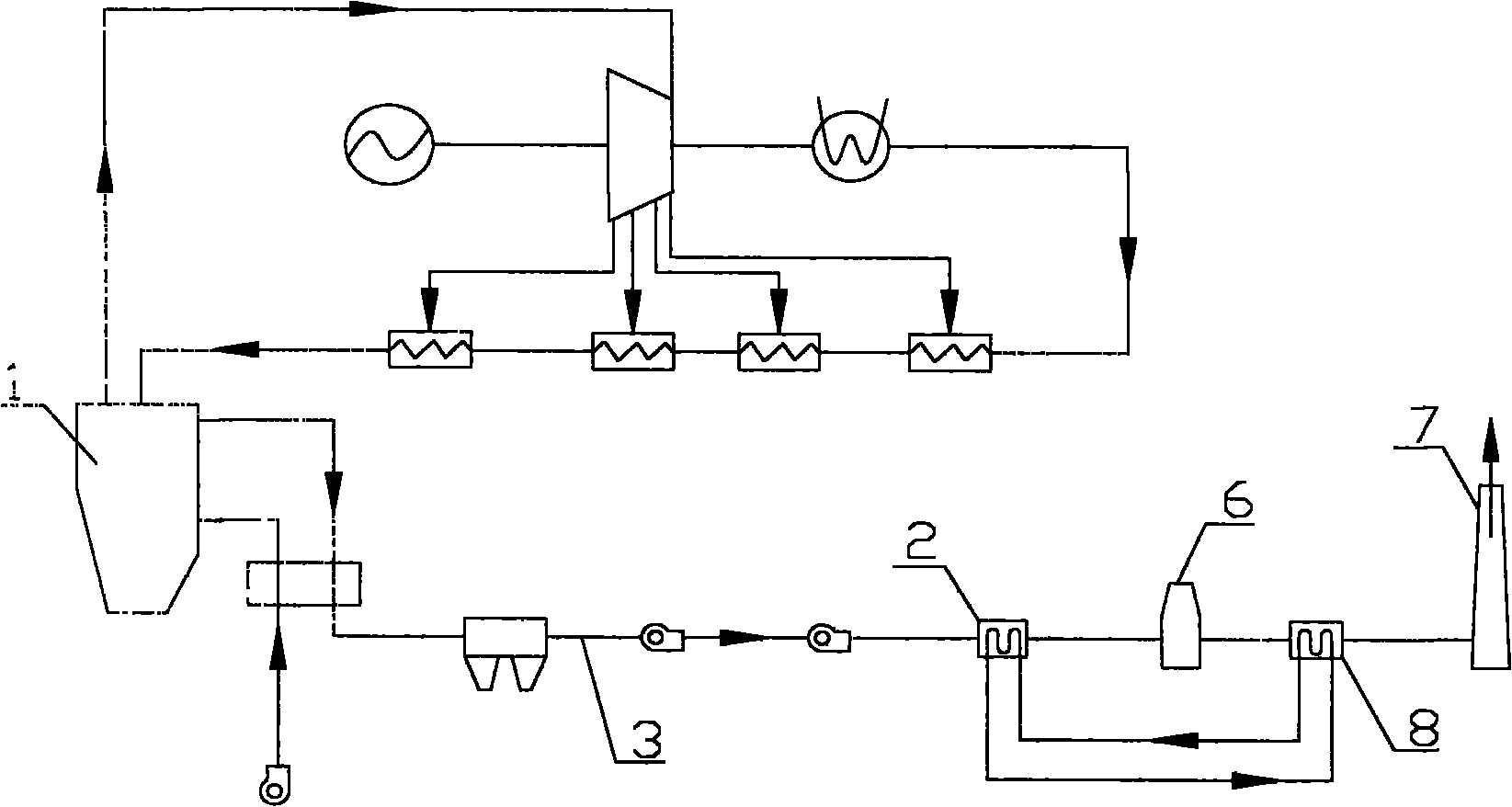

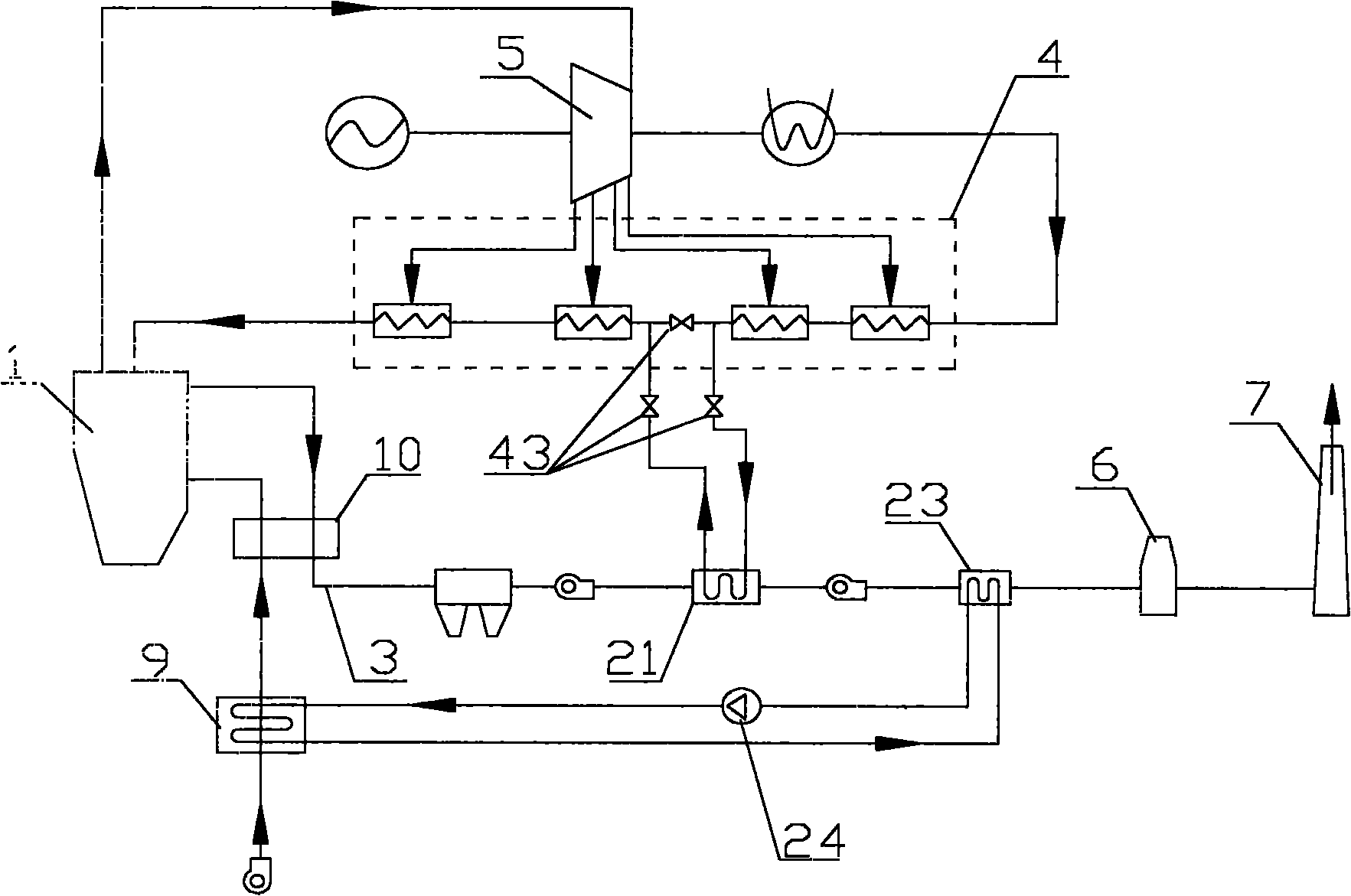

Solar aided carbon dioxide trapping integrated system

ActiveCN103752142ATake full advantage of high heat collection efficiencyReduced capture efficiencyCarbon compoundsSolar heat devicesReboilerTrapping

The invention discloses a solar aided carbon dioxide trapping integrated system, which mainly comprises three parts, i.e. a power generation subsystem, a carbon dioxide trapping subsystem and a solar heat collection subsystem, wherein the subsystems are connected mainly through a boiler feed water heater, a reboiler and a flue gas pretreatment device to form the whole integrated system. According to the system, the high and low energy requirements of related parts among the solar heat collection subsystem, the power generation subsystem and the carbon dioxide trapping subsystem are reasonably allocated and integrated in different connecting ways at the heat output end of the solar heat collection subsystem to realize the gradient utilization of energy, so that the energy consumption of extraction of vapor from a steam turbine of a power plant can be greatly reduced, the stability of the power plant can be maintained, the dual effects of utilizing renewable energy resources and reducing the carbon dioxide emission of the power plant are achieved, and the large-scale application of solar energy and an integrated flue gas trapping technology in China are forcefully promoted.

Owner:TIANJIN UNIV

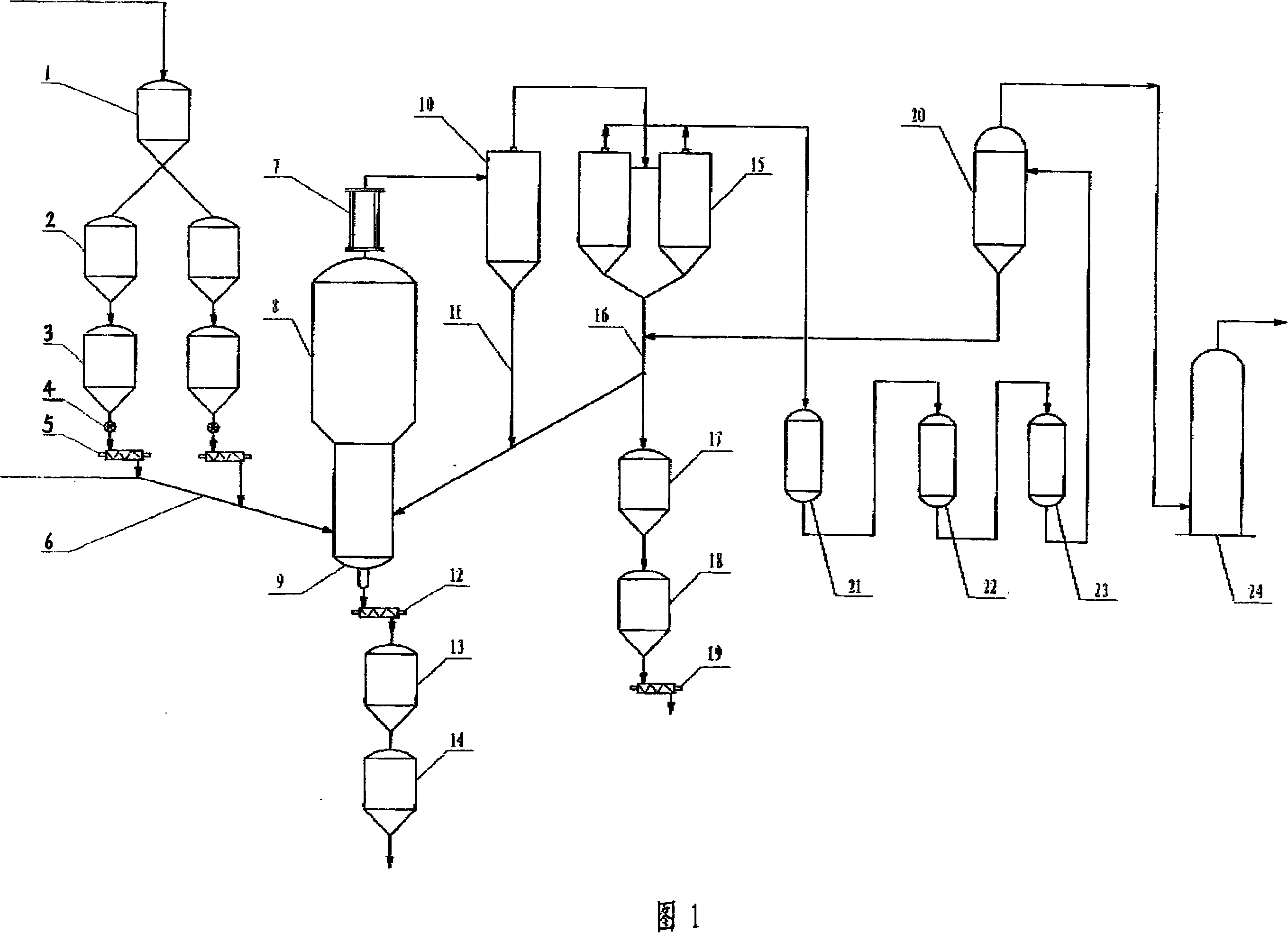

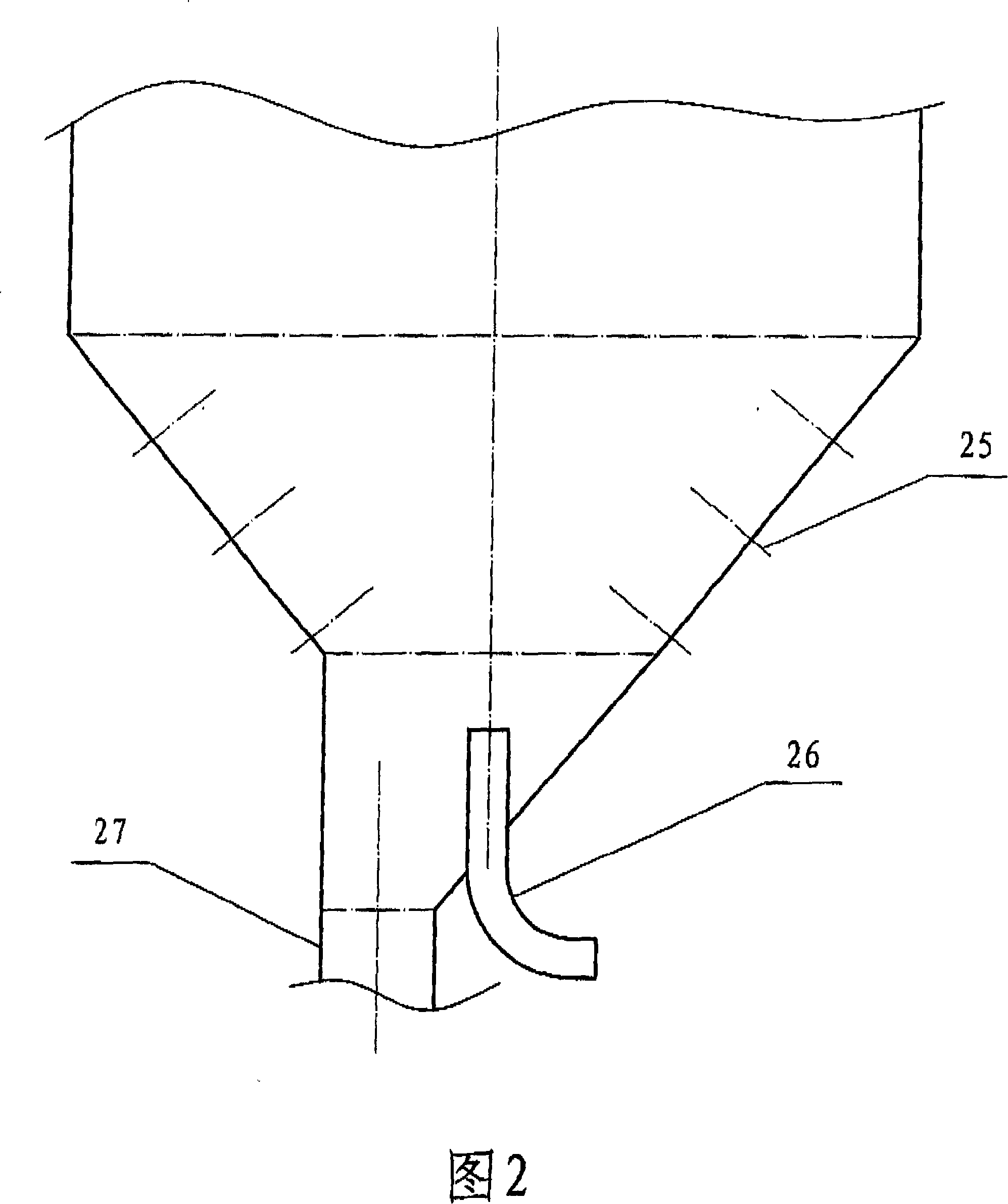

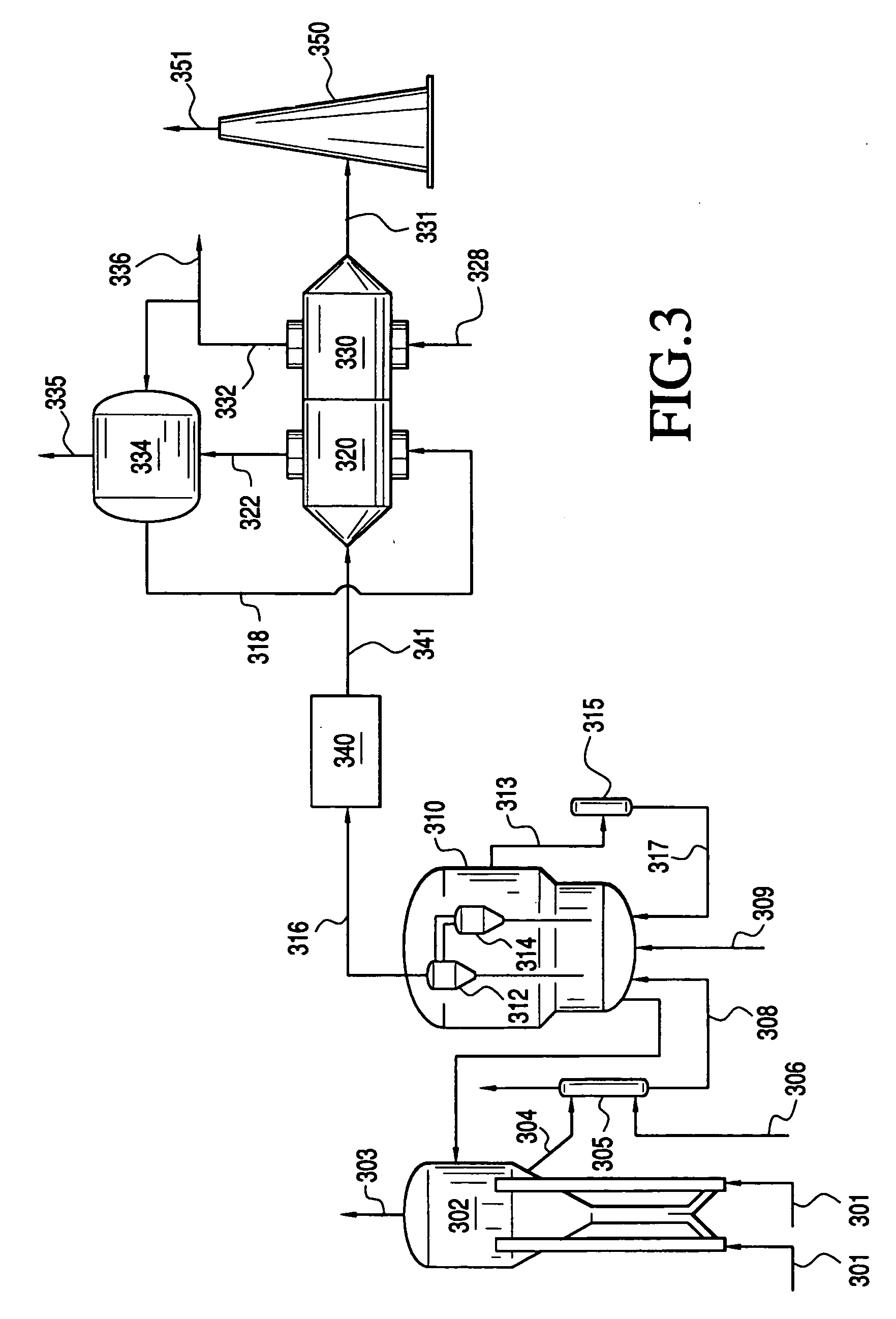

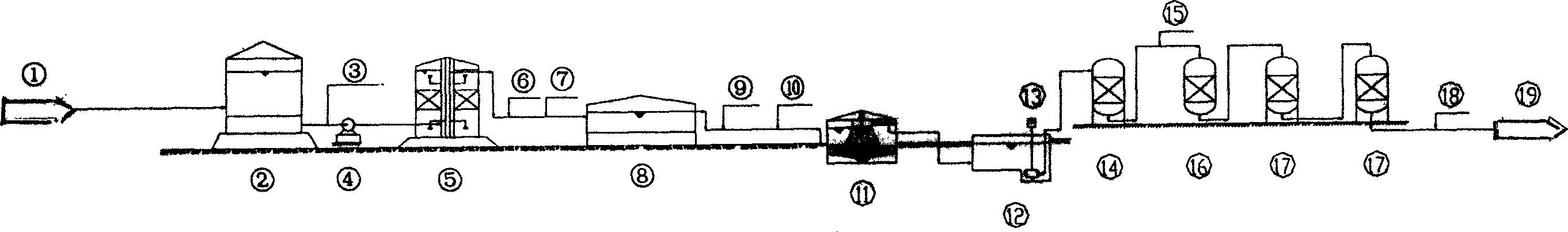

Gray melting poly-fluid bed powder coal gasification method

ActiveCN101108986AAdaptableEasy to operateCombined combustion mitigationGranular/pulverulent flues gasificationCycloneCooling tower

An ash agglomerating fluidized bed gasification method is provided. First, the coal powder is added in a gasification furnace; the gasification agent enters the bottom of the gasification furnace through a nozzle of a gas distributor, a central tube and a ring canal to make the coal powder gasified to produce gas under the fluidization state; the gas enters a first dust collector cyclone and a secondary dust collector cyclone after entering a first steam generator from the top of the gasification furnace, and enters a secondary steam generator to produce the saturated steam and enters a steam superheater and a boiler feed water preheater to continuously recycle the after heat of the gas, and then enters a final washing and cooling tower of the gas to further remove dust and reduce temperature and send to a follow-up system after dust removal via a deduster. The invention adopts the theory of fluidization to add the powder coal of the raw materials continuously in the dense phase of the gasification furnace. The gasification agent is blown in from the bottom of the gasification furnace to make the coal particle boiled and fluidized. The gas phase and solid phase are fully mixed and contact under the high temperature caused by combustion to carry out the thermolysis and the viscosity of the coal and the oxidation-reduction reaction of the carbon to realize the complete gasification of the coal finally.

Owner:陕西华祥能源科技集团有限公司

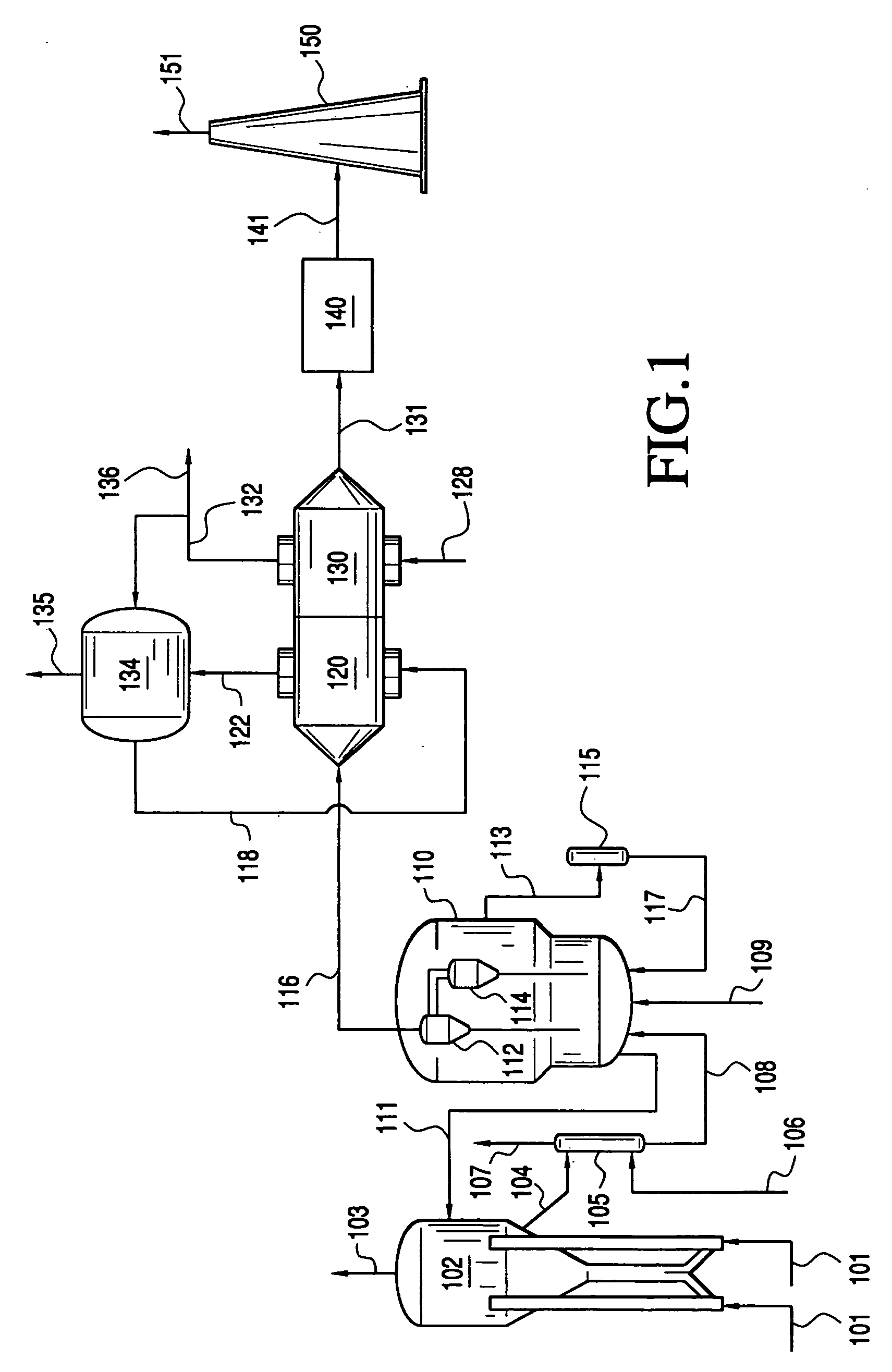

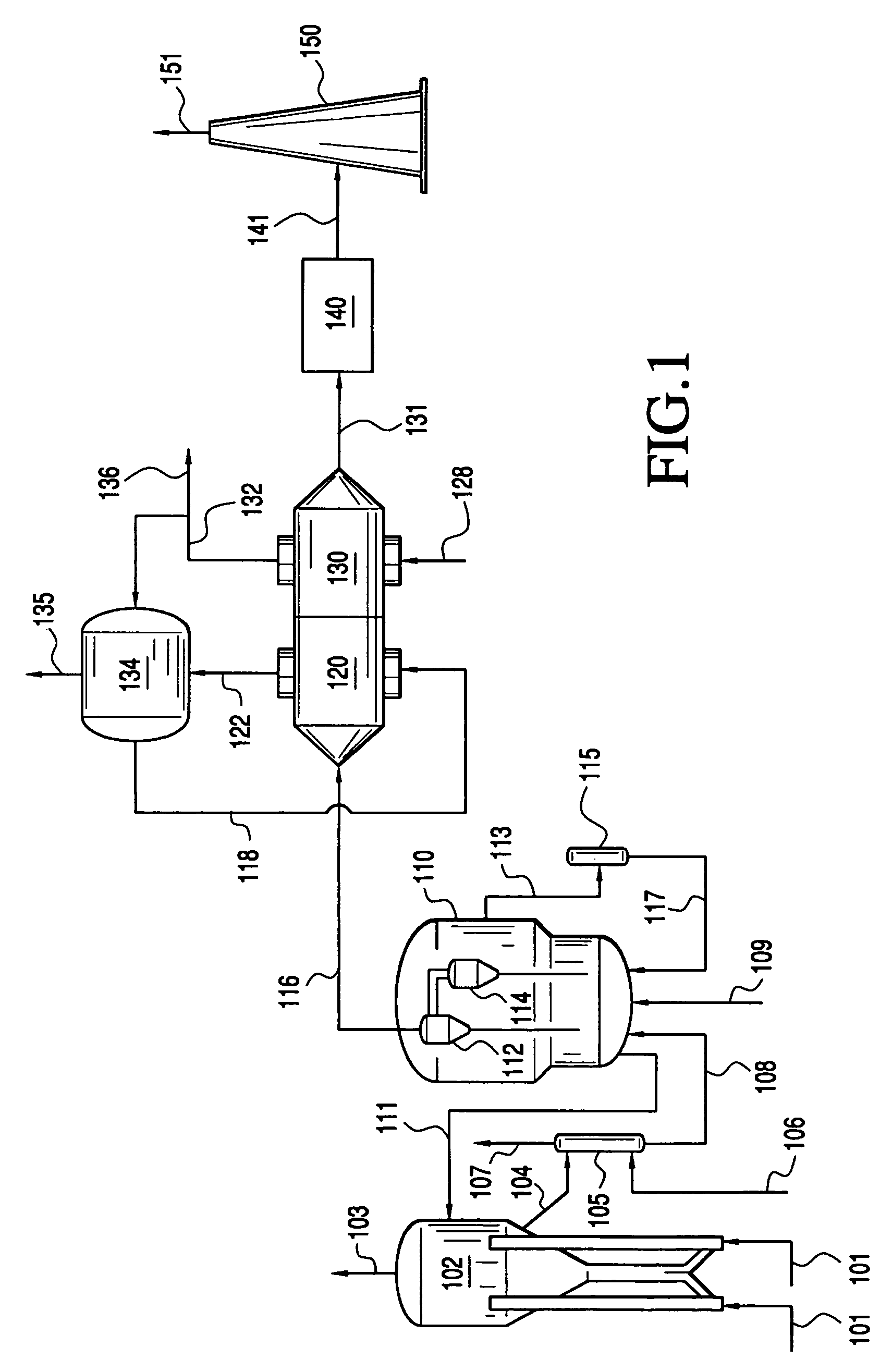

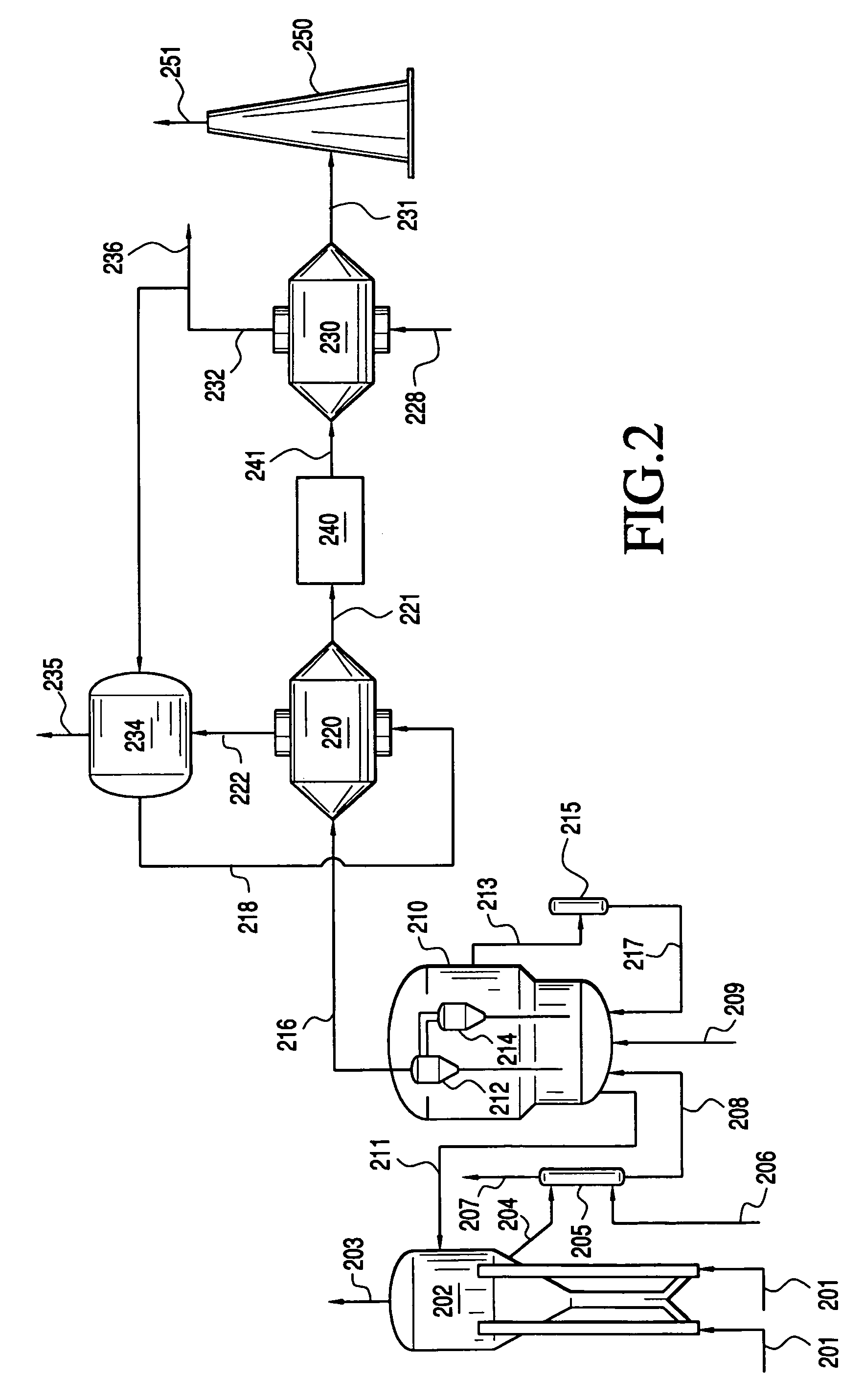

Heat recovery technique for catalyst regenerator flue gas

ActiveUS20050238548A1Effective recoveryIncrease steamThermal non-catalytic crackingCatalytic crackingFlue gasProcess engineering

A technique for recovering heat from a high temperature effluent stream from catalyst regeneration or the like, comprising processes and means for: (a) passing the effluent stream in heat exchange relationship in a steam generator with boiler feed water to produce high pressure steam and partially cool the effluent stream; (b) passing the partially cooled effluent stream from the steam regenerator in heat exchange relationship to preheat high pressure boiler feed water and further cool the effluent stream; and (c) passing the preheated boiler feed water to the steam generator. The apparatus and processes for thermal energy recovery may be used to treat hot regenerator effluent from FCC or OTO-type processes, thereby producing a cooled flue gas stream to discharge to ambient atmosphere.

Owner:EXXONMOBIL CHEM PAT INC

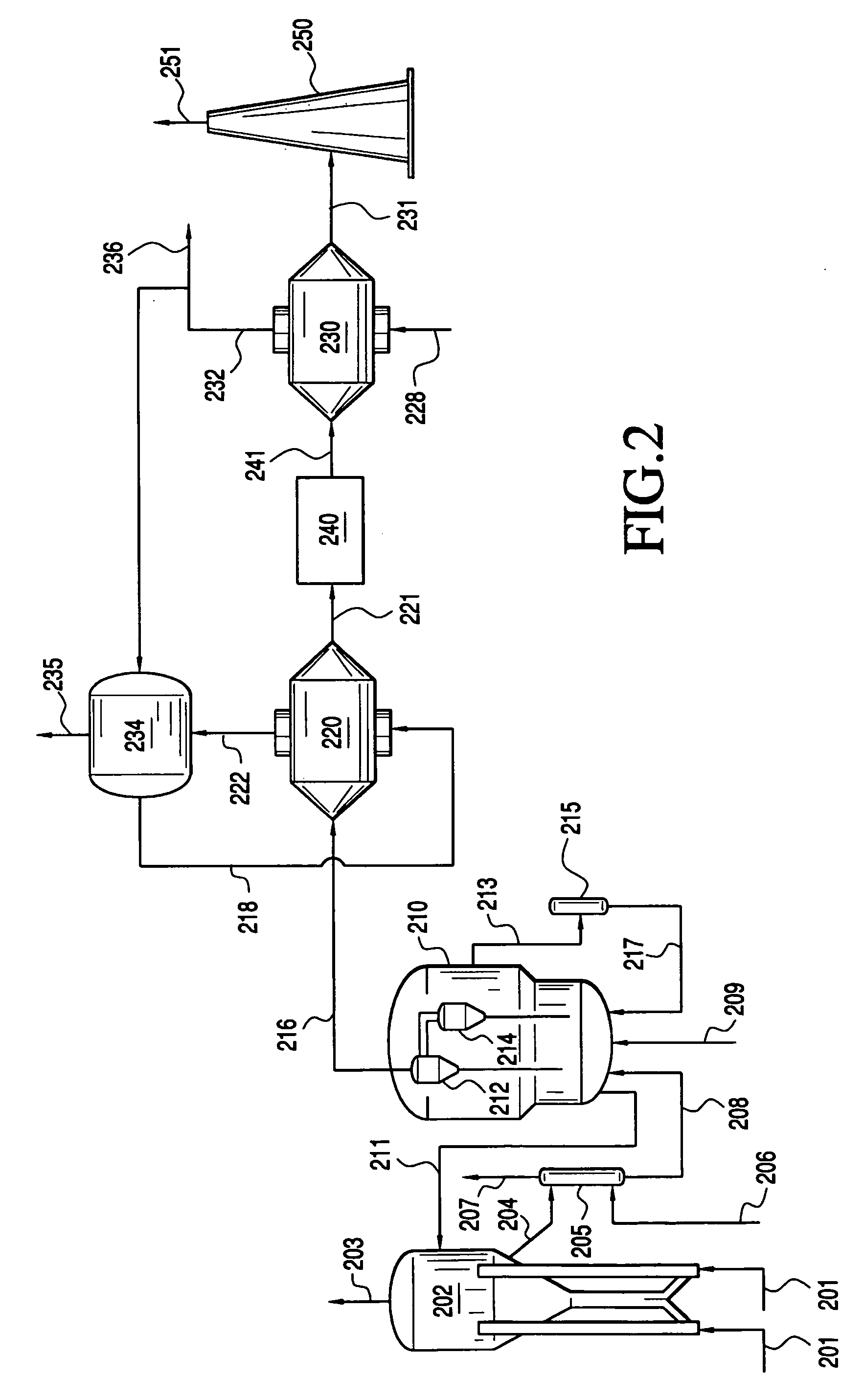

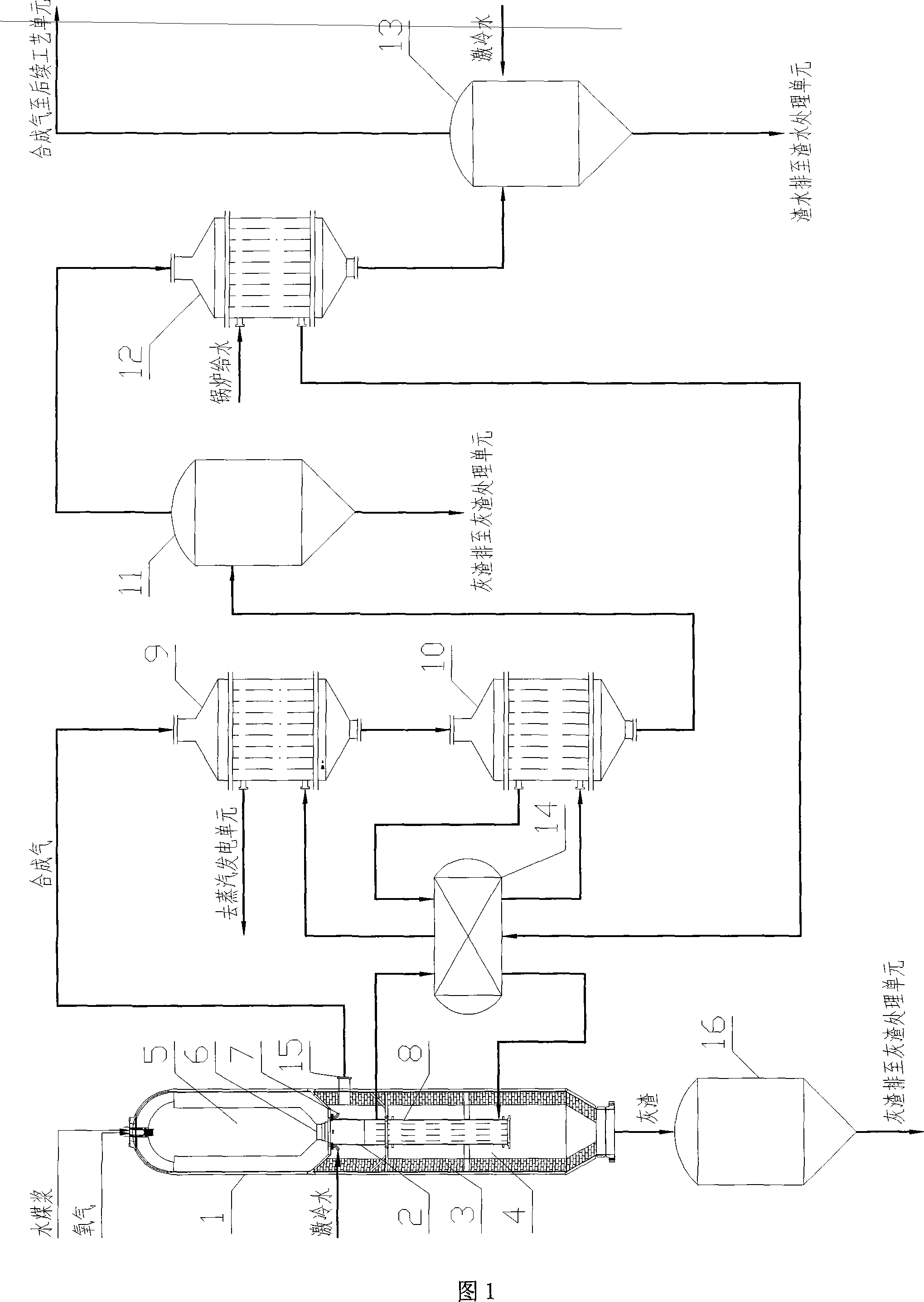

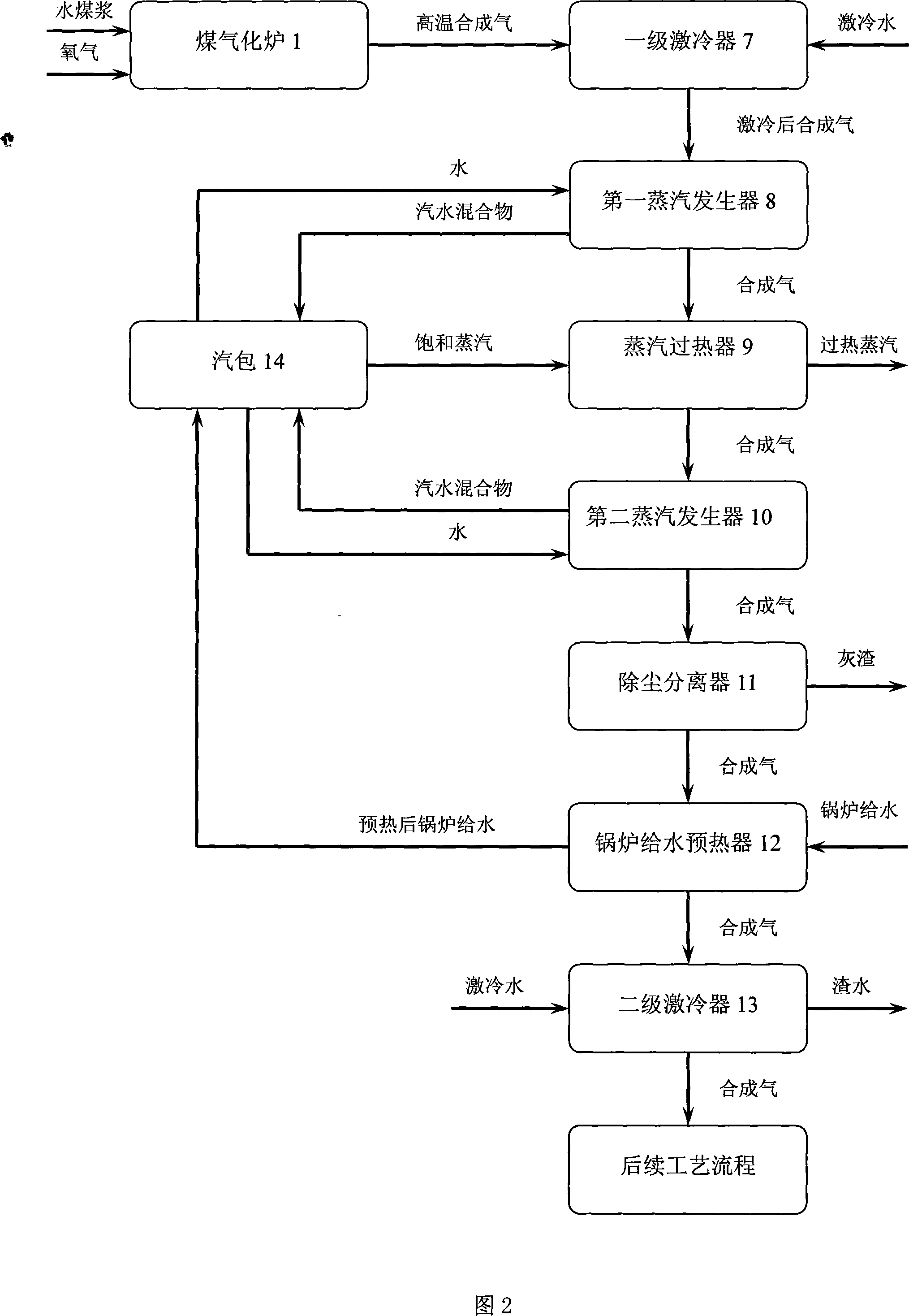

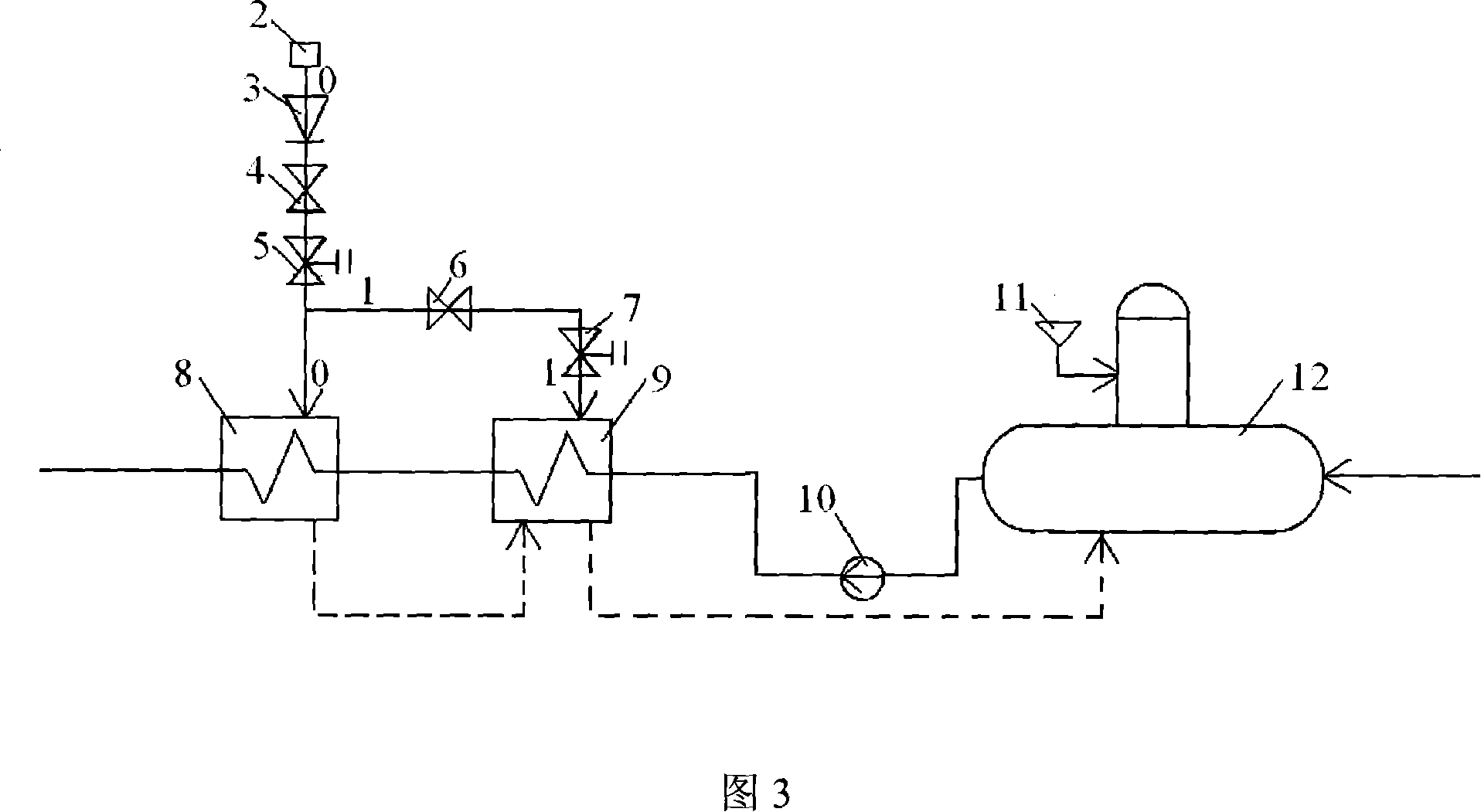

Heat recovering technique for synthetic gas production process by coal gasification

ActiveCN101161792AImprove use valueAvoid stickingChemical industryCombined combustion mitigationThermal energySyngas

The invention discloses a heat recovery technological method for making synthetic gas during coal gasification, including the following steps: the high-temperature synthetic gas and the scoria are generated inside the vaporizer of a coal gasification furnace; chill water is sprayed into the outlet of the furnace through a primary chiller to chill the synthetic gas and the scoria below ash fusion point T1; the chilled synthetic gas and scoria are fed into a first steam generator, a steam superheater and a second steam generator for reclaiming the afterheat of the synthetic gas; moreover, part fine clinker is removed through a dust separator and residual fine clinker is removed inside a secondary chiller after further heat recovery through a boiler feeding preheater; meanwhile, the synthetic gas is humidified and then is fed into a next process unit. The invention increases the unitization value of recycled heat energy and prevents scoria from solidifies on the tube wall of the first steam generator, thereby further reducing energy consumption of equipment.

Owner:WISON ENG

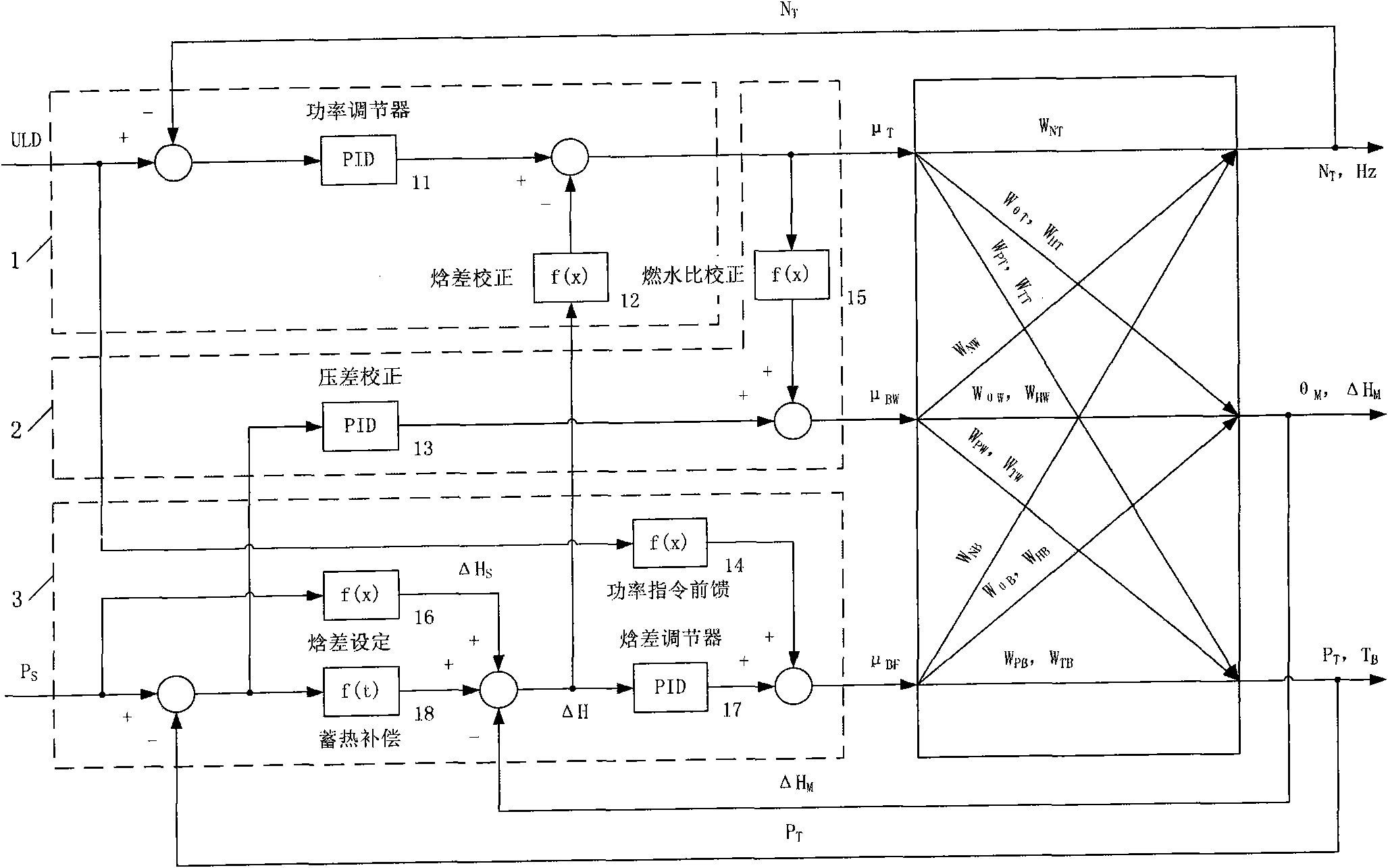

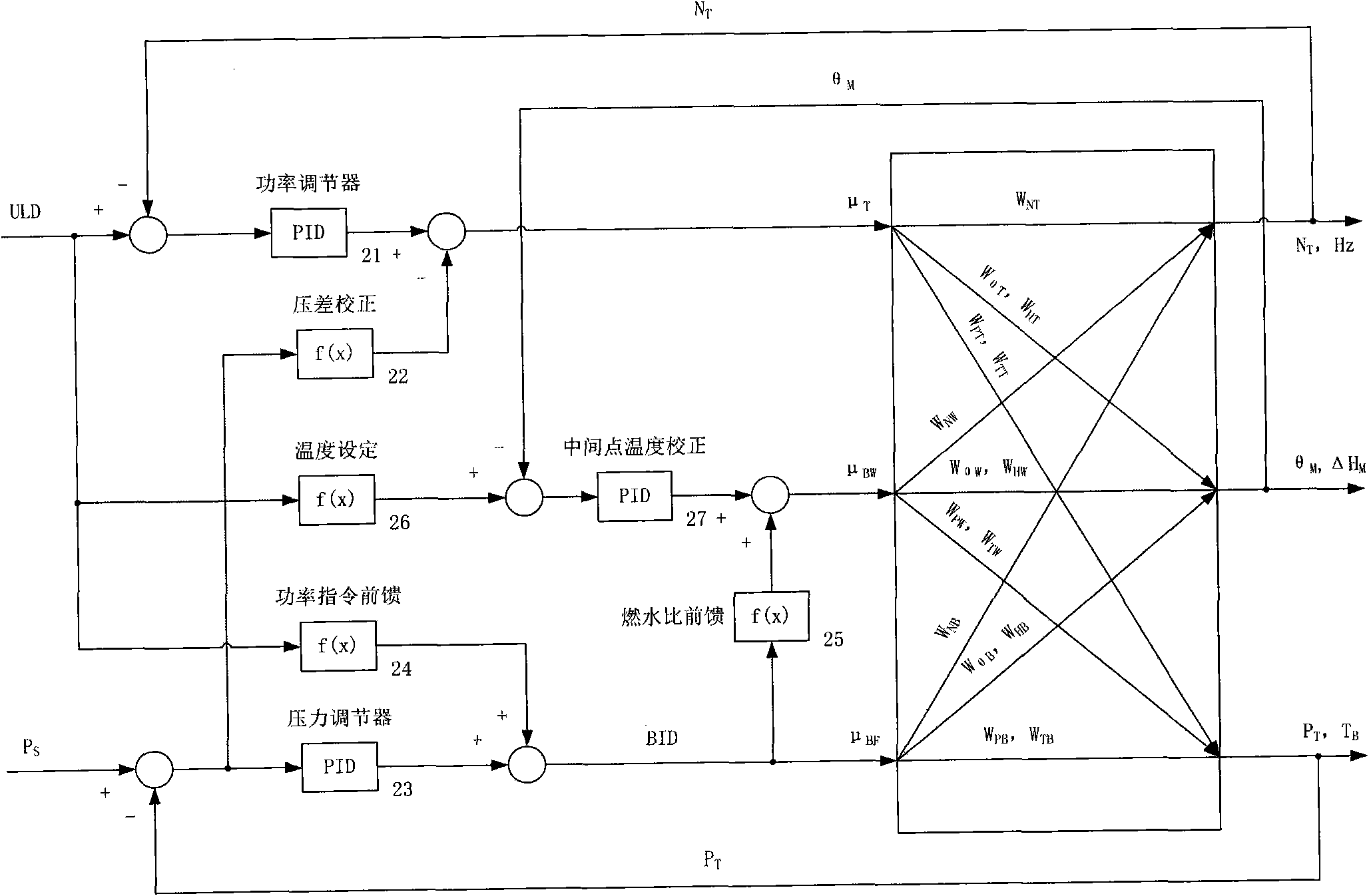

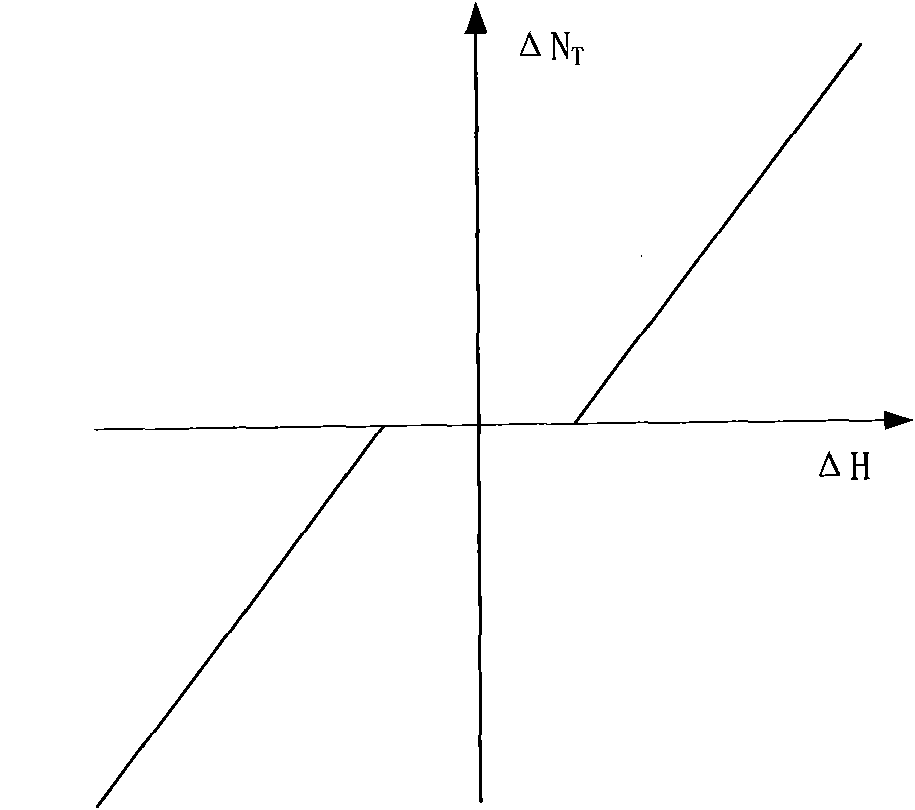

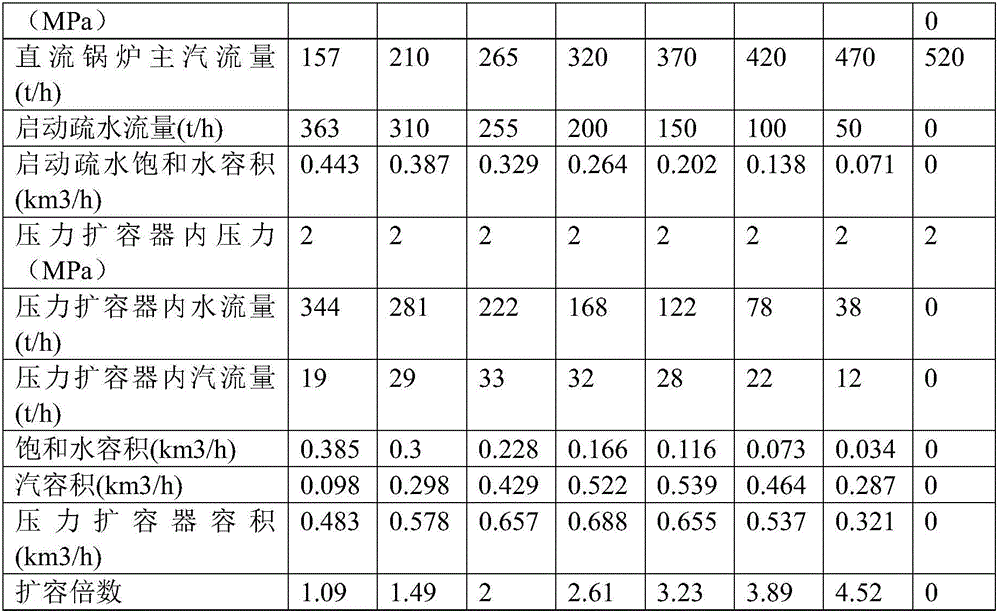

Direct mass balancing and coordinating control system of direct current boiler unit

ActiveCN102323748AImprove dynamic response characteristicsImprove stabilityEngine componentsSteam engine plantsEnergy balancingEvaporation

The invention respectively adopts a direct energy balancing mechanism to realize the dynamic decoupling between a steam turbine power regulating loop and a boiler burning regulating loop and a direct mass (flow) balancing mechanism to realize the dynamic decoupling between a steam turbine power regulating loop and a boiler water supply regulating loop, and decouples a usual direct current boiler unit 3*n multi-variable parallel control system onto a decoupling control loop in a hierarchical control structure. The boiler burning regulating loop cancels an usual front side pressure series regulator, and takes the enthalpy increased deviation of an evaporation heated surface of a boiler as the control input; and the boiler water supply regulating loop is designed into fuel-water ratio regulation with a steam turbine power instruction as the input; and the dynamic compensation between boiler burning and water supply is designed. The method best eliminates the coupling impact among all the regulating loops, so that the adjustment is convenient, and the control quality of the direct current furnace unit coordinating control system under the working conditions of variable pressure and variable load is improved.

Owner:BEIJING GUODIAN ZHISHEN CONTROL TONGDY

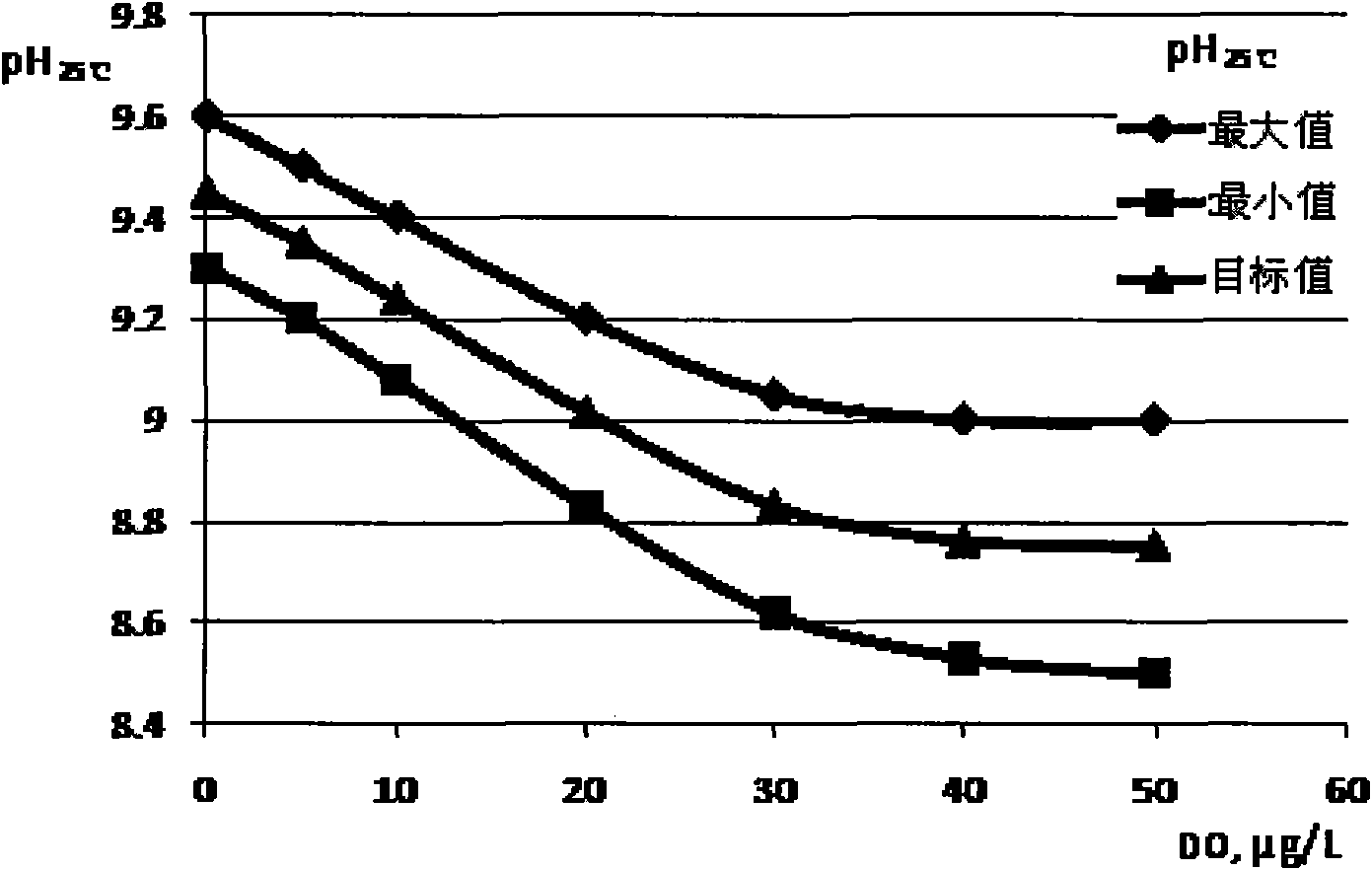

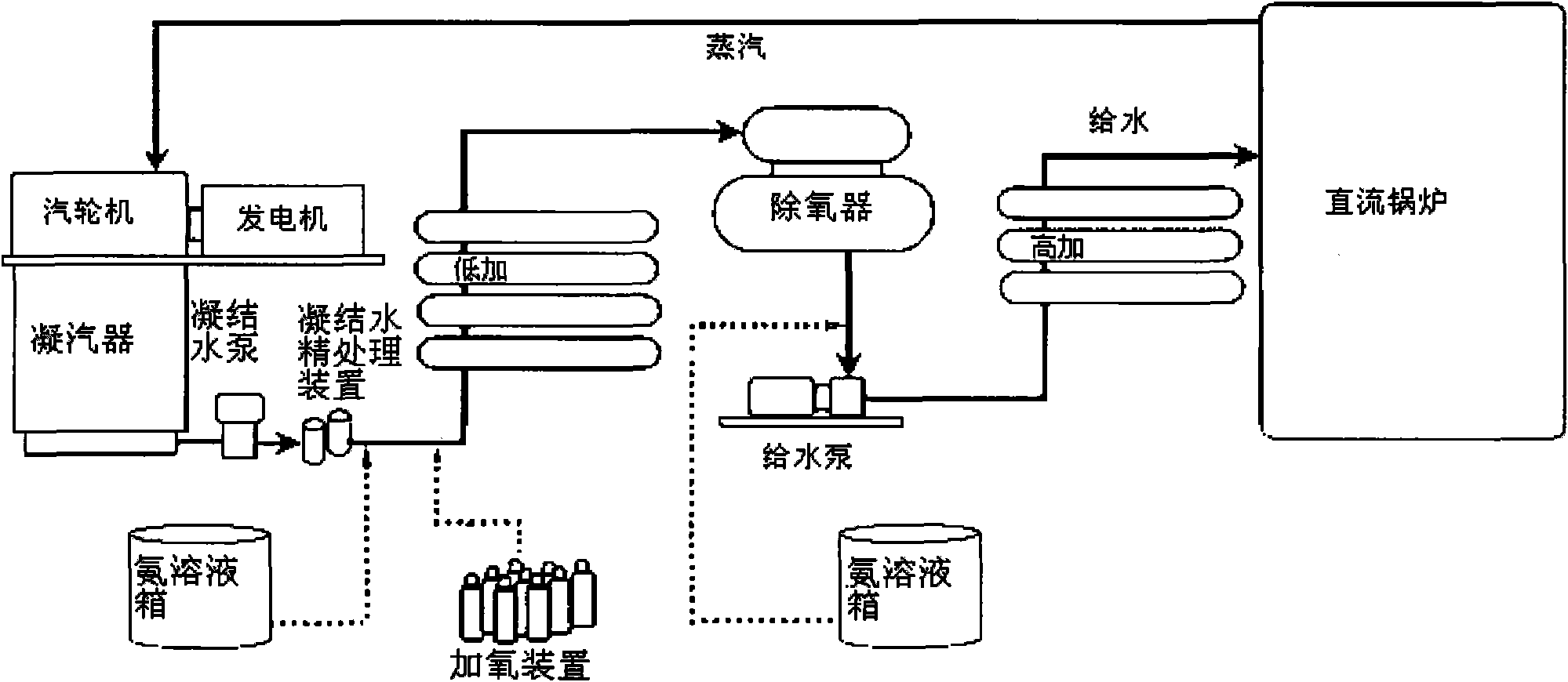

Intrinsically-safe water-feeding and oxygen-adding treatment method of once-through boiler

ActiveCN101880092AAvoid fatigueInhibit sheddingScale removal and water softeningExhaust valveDeaerator

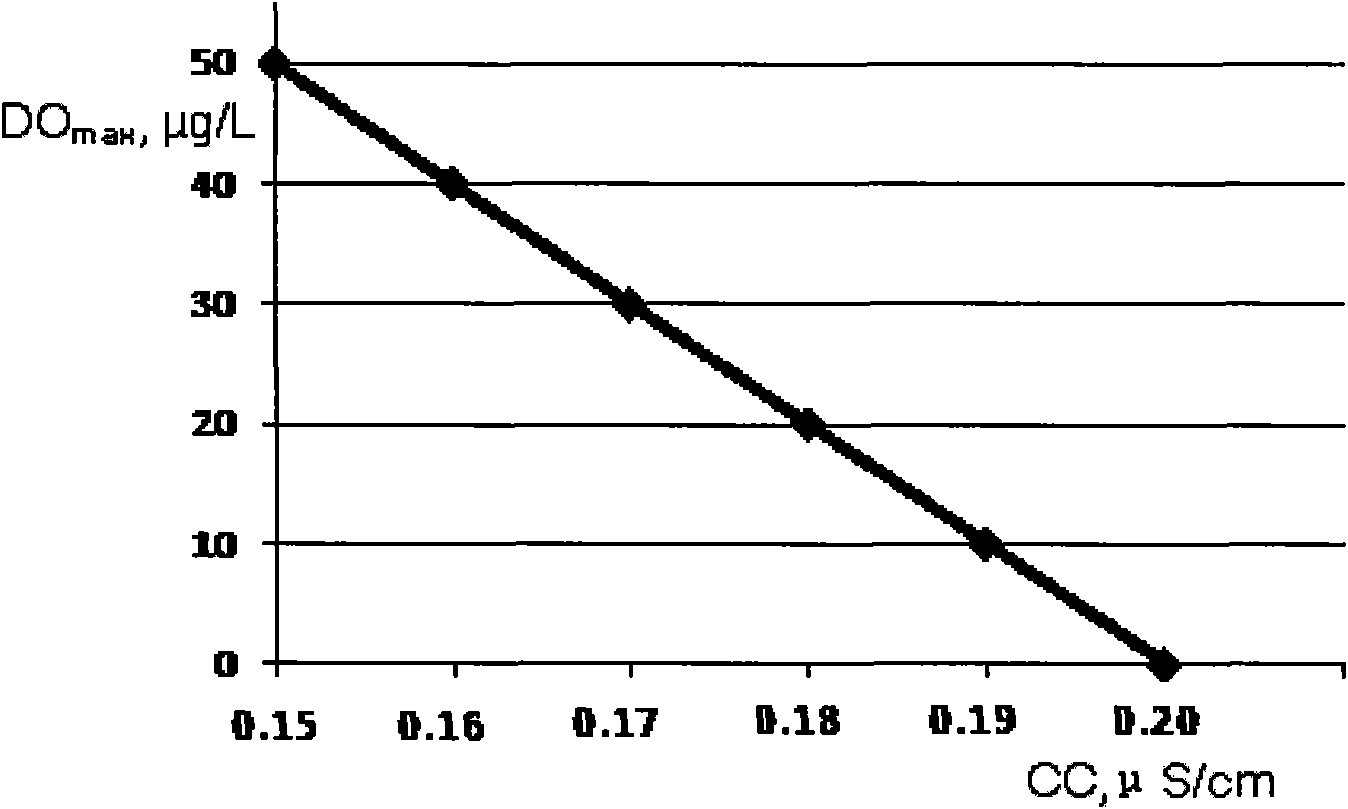

The invention discloses an intrinsically-safe water-feeding and oxygen-adding treatment method of a once-through boiler, comprising the following steps of: (1) adopting independent ammonia-adding treatment as a water-feeding treatment mode before adding oxygen of a copper-free system of a thermal power unit and adjusting the pH value at 25DEG C of water fed before the boiler to be 9.3-9.6 by adding ammonia; (2) closing an exhaust valve of a deaerator after meeting certain conditions; (3) adding oxygen at an oxygen adding point of a condensed water precision treatment outlet of the unit; (4) controlling that the content of dissolved oxygen at an inlet of a coal economizer is in the range of 5-50mu g / L and the oxygen content of main steam is not remarkably increased compared with the before adding oxygen; (5) reducing the control range of the pH value at 25DEG C of water fed before the boiler to be 8.8-9.3 after the electrical conductivity (CC) of anions of water fed before the boiler is reduced to be less than 0.15mu S / cm; (6) improving the pH value at 25DEG C of water fed before the boiler before the unit stops to be 9.3-9.6 until the unit halts; and (7) stopping the operation of the boiler and maintaining. The treatment method can be used for enhancing the buffer capacity of the water-feeding and oxygen-adding treatment and reducing the fluctuation of the dissolved oxygen content of the fed water and other parameters.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +1

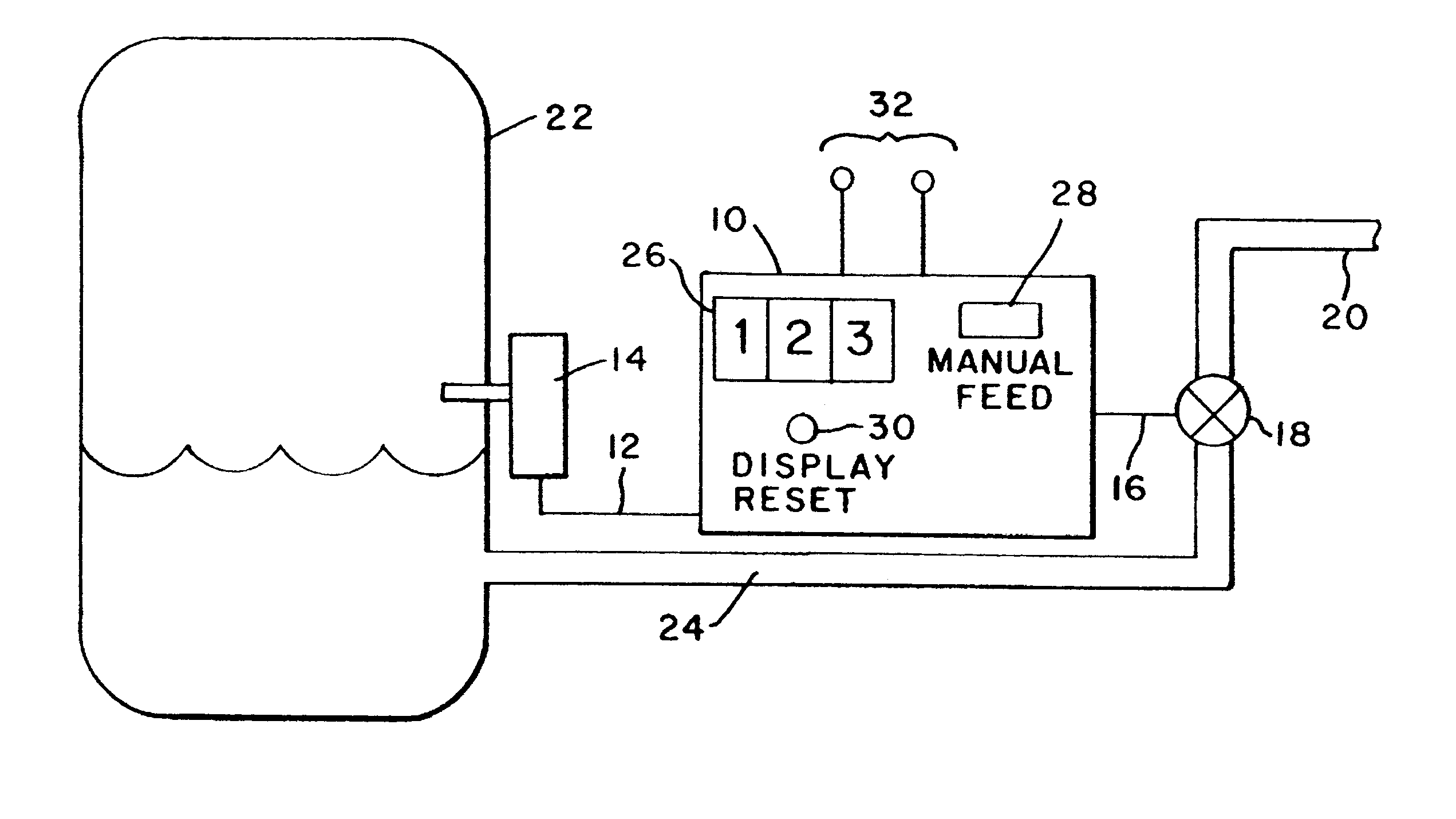

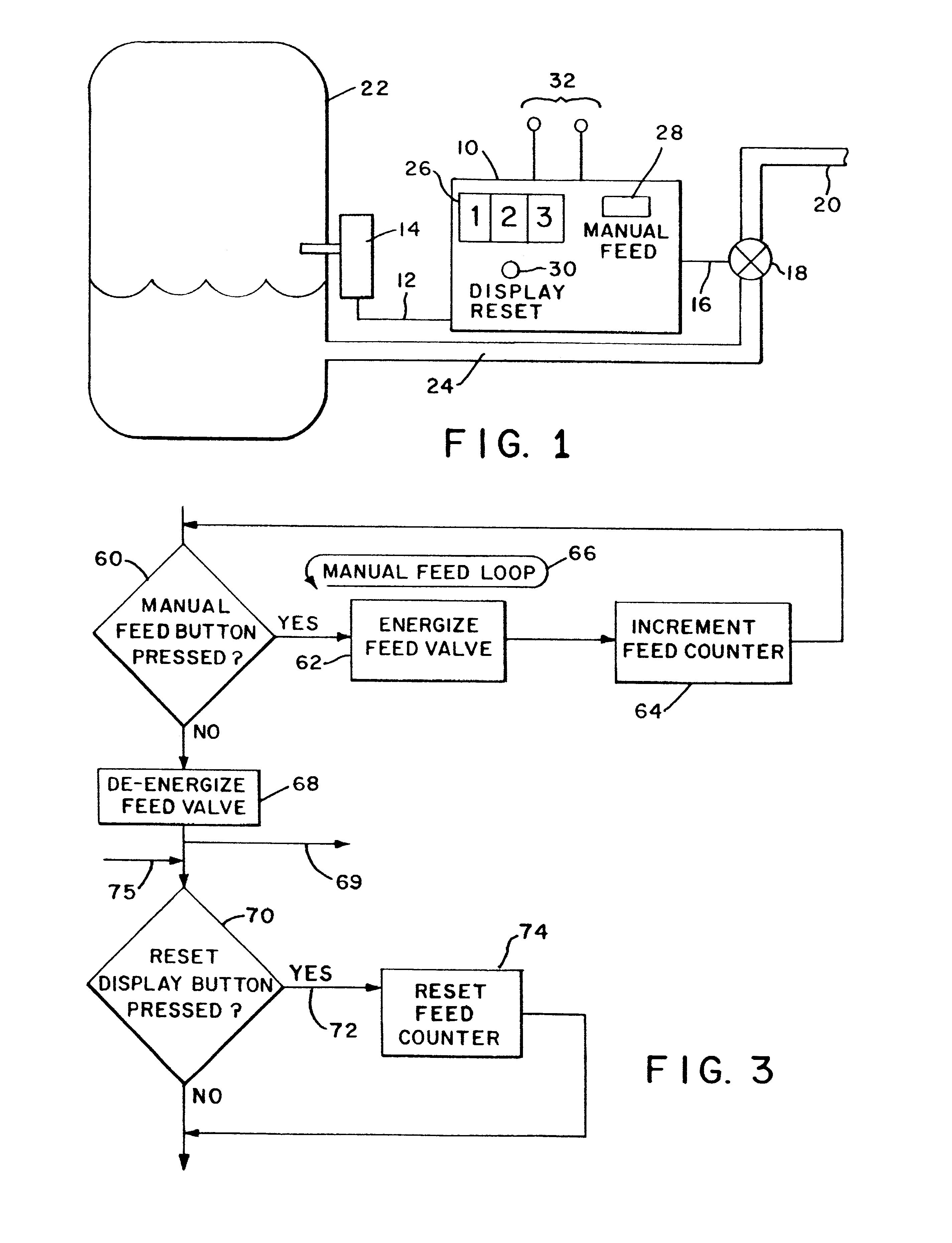

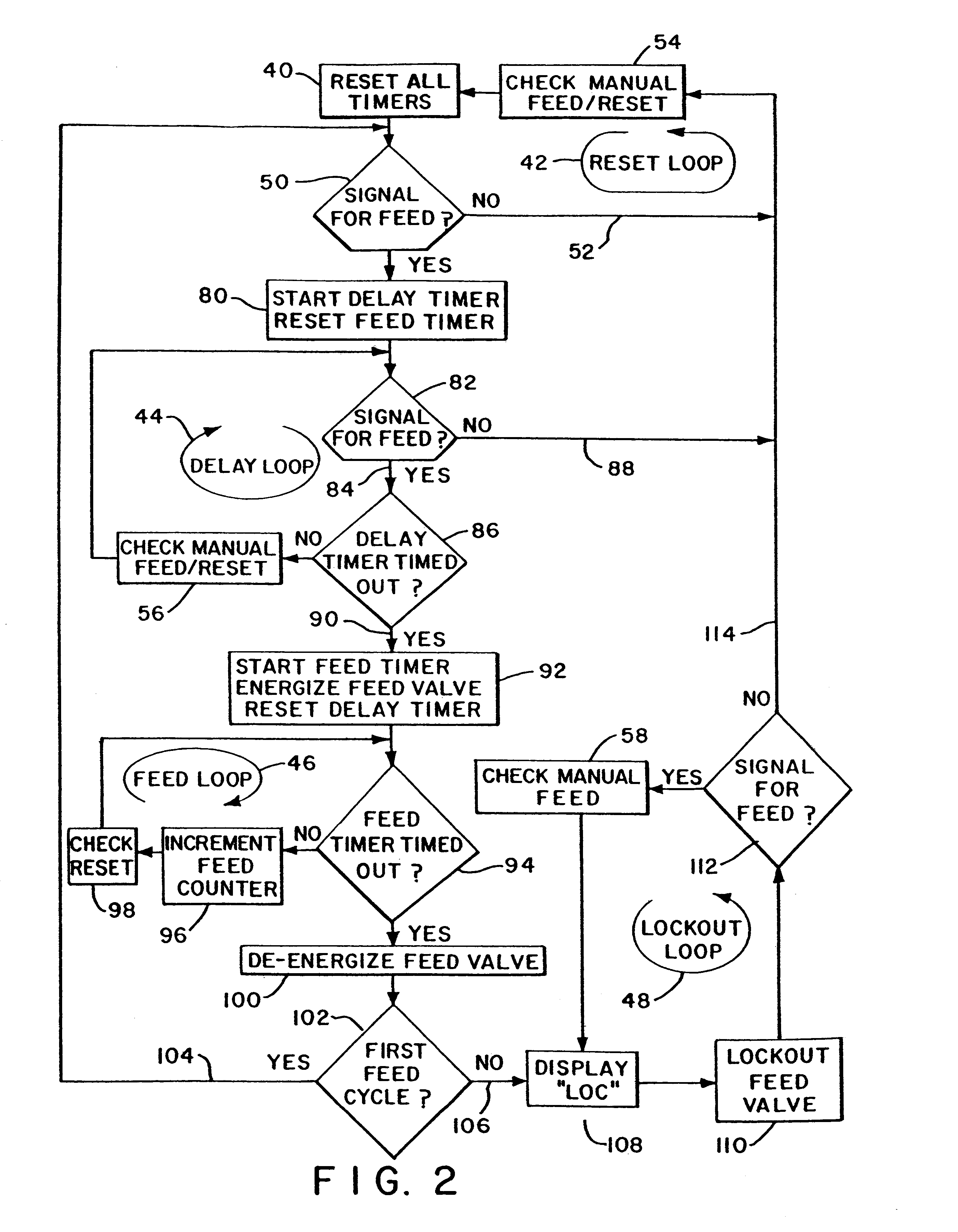

Water feeder controller for boiler

A water feeder controller for a boiler monitors a low water cutoff sensor in a boiler and uses a feed timer to feed water to the boiler for a predetermined feed period of time. The feed timer brings the water level in the boiler well above the low water cutoff sensor. The feed timer supplies water to the boiler only if the low water cutoff sensor continues to indicate a low water level for a delay period of time measured by a delay timer. A resettable display indicates the quantity of water supplied by the water feeder to the boiler based on a feed counter incremented during water feeding. A manual feed button allows water to be manually fed to the boiler. The quantity of water manually supplied to the boiler is also shown on the display. The feed timer and delay timer are preferably implemented in software in a microcontroller in the water feeder controller. A lockout loop in the software prevents overfeeding of water to the boiler in the event of a failure of the low water cutoff sensor.

Owner:COWLES OPERATING CO

Start-up method with circulating-stove-water pump monotube boiler near steam heating boilers

ActiveCN101135433AShorten oiling timeReduce fuel consumptionSteam generationEngineeringHigh pressure

This invention declares a starting process of once-through boiler with by neighboring steam heating in which the high pressure heater is connected by the pipeline receiving exogenous heating steam. The mentioned process includes: heating the water in the unit boiler with the exogenous steam through the high pressure heater, heating the heat delivery surface of the boiler indirectly when starting up at cold, warm or hot status, starting the boiler water circulating pump and air-gas system when the temperature is close to the saturation temperature of the exogenous steam, ignition of the boiler, increasing the thermal load with bypass system after the is started, switching off the fuel when the thermal load of the coal exceeds the minimum oil-break thermal load and switching to the general starting process; when starting at the extreme hot status, ignition of the boiler after purging, after the coal pulverizing system is started, switching off the fuel when the thermal load of the coal exceeds the minimum oil-break thermal load and switching to the general starting process. The starting process will shorten the starting duration, and save fuel, coal and water.

Owner:冯伟忠

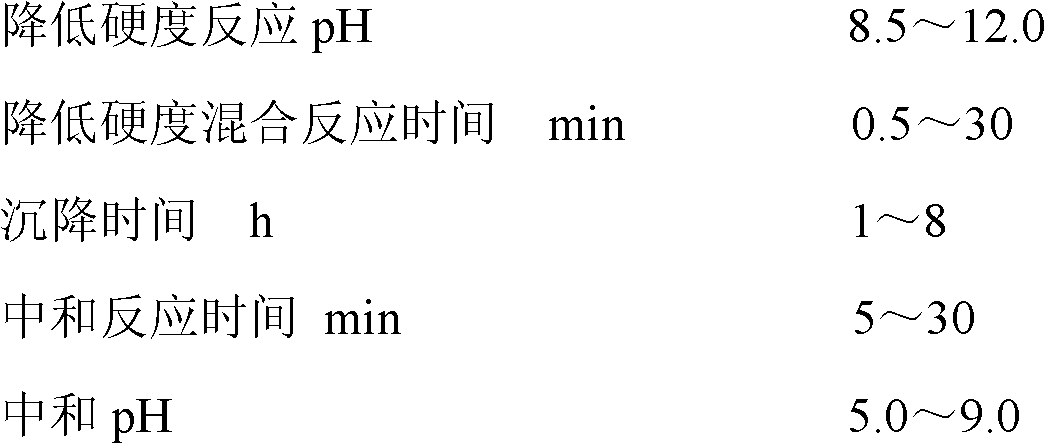

Deep stage treatment method for industrial wastewater

ActiveCN102616962AInfluent water quality requirements are lowReduce energy consumptionDispersed particle separationWater softeningWater qualityReverse osmosis

The invention discloses a deep stage treatment method for industrial wastewater. The method comprises the following steps of: 1, primarily reducing hardness, settling, and neutralizing; 2, filtering; 3, performing electro-adsorption to appropriately remove salt; and 4, performing reverse osmosis to deeply remove salt. According to deep stage treatment method for the industrial wastewater, the water quality application range is wide, a process can run stably, salt can be deeply removed by the method, and a small amount of sewage which is produced by a treatment system and meets the standard is discharged, and secondary pollution is avoided; and the treated industrial wastewater can be used as industrial circulating water, industrial circulating cooling water, and boiler water. The problems that a reverse osmosis membrane is easy to pollute, and reverse osmosis concentrated water which does not meet standard is discharged, and the problem of low running stability are solved; all the discharged sewage which is discharged meets the standard; and the produced water has various water qualities, and the recycling range is widened.

Owner:CHINA PETROLEUM & CHEM CORP

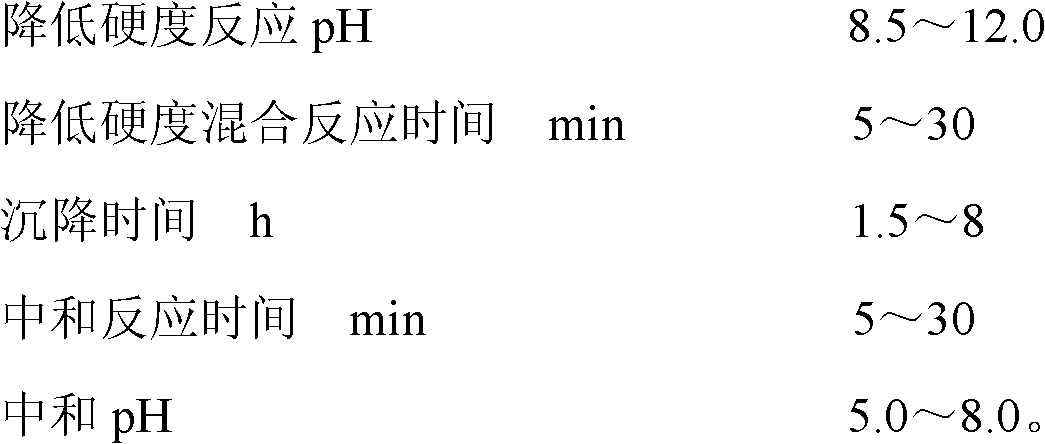

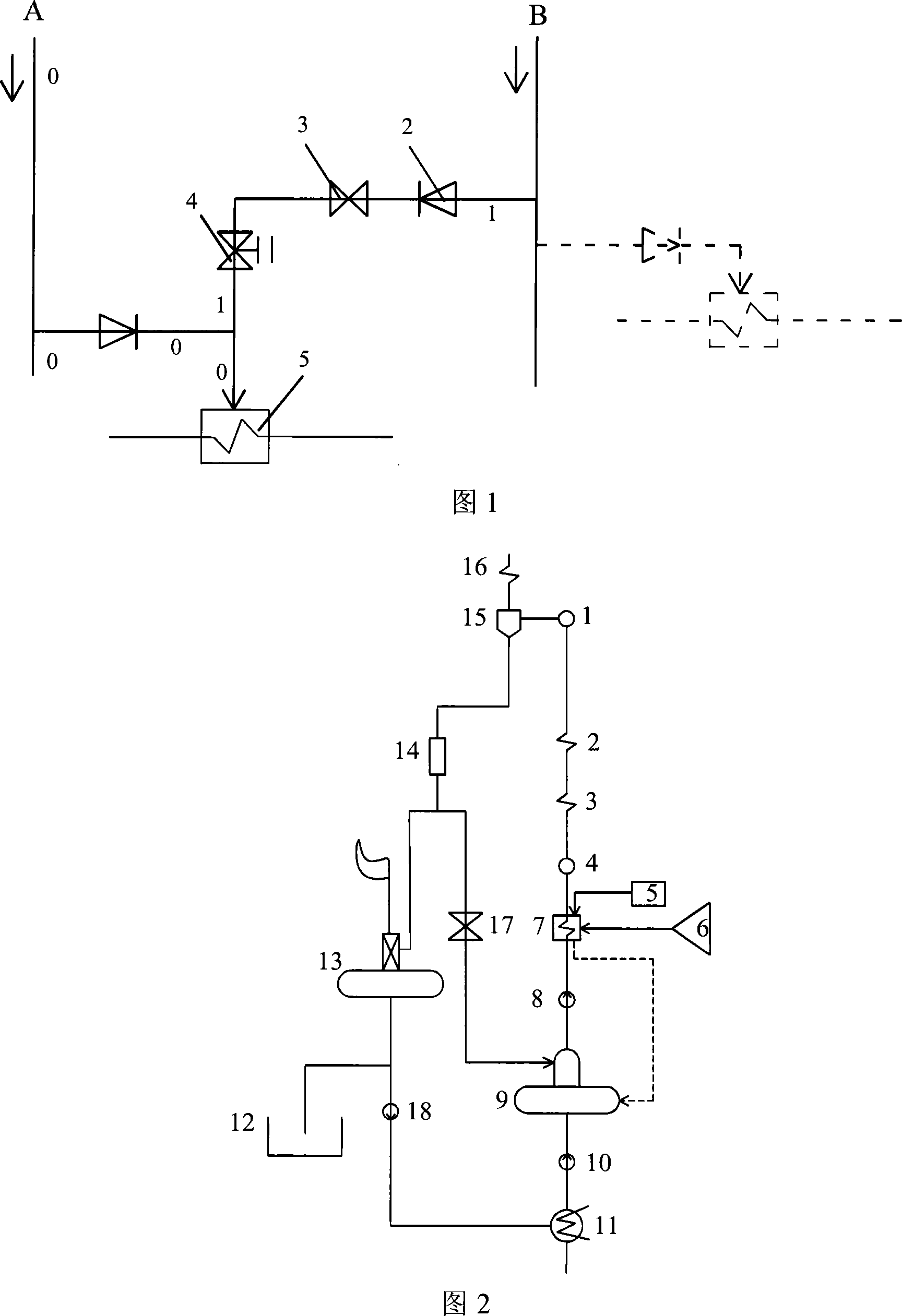

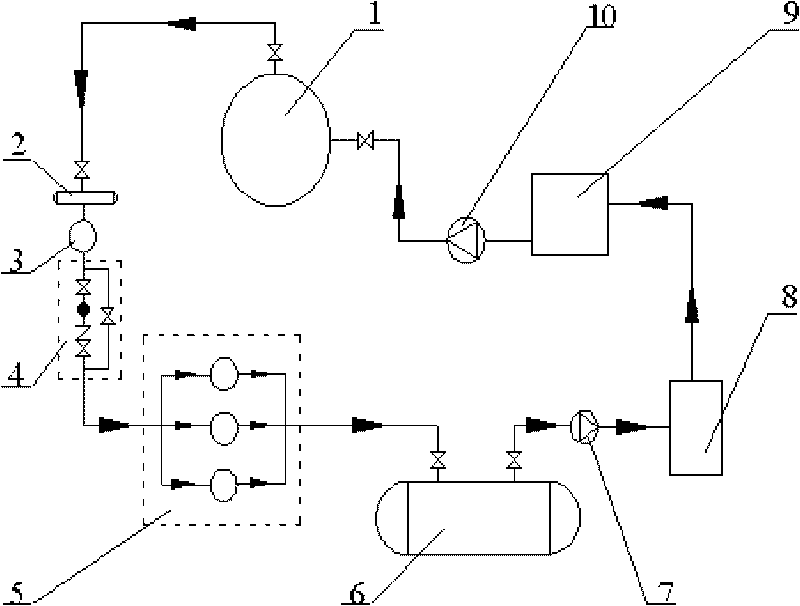

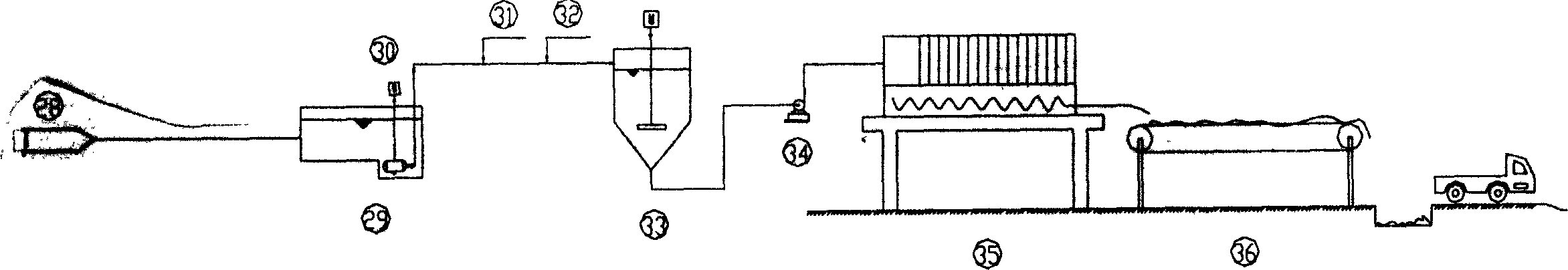

Boiler water replenishing system capable of collecting waste heat and condensed water

ActiveCN102607014AHydration does not affectReduce consumptionFeed water supplyExpansion tankBoiler blowdown

The invention discloses a boiler water replenishing system capable of collecting waste heat and condensed water. A boiler blowdown pipe of a boiler is connected with a blowdown expansion tank, a steam outlet of the blowdown expansion tank is connected into a hot water tank through a blowdown flash steam pipe, a blowdown water pipe of the blowdown expansion tank is connected into a continuous-discharge heat exchanger which is further connected with a softened water feeding pipe, the softened water feeding pipe is connected with a water softening station through a water supply pump, the softened water feeding pipe for the continuous-discharge heat exchanger is connected with a boiler secondary energy saver prior to being connected into the hot water tank, and the hot water tank is connected with a hot water outlet pipe which is sequentially connected with a circulating pump, a heat deaerator and a boiler water feeding pump prior to being connected into a boiler water inlet. The boiler water replenishing system has the advantages that centralized use of the waste heat and the condensed water is achieved, steam consumption of the deaerator is reduced, waste heat absorption effect is enhanced, connection of the deaerator is simplified, pollution of the heat and the condensed water to the environment is reduced, and water replenishing for the boiler is unaffected when heat exchange equipment fails.

Owner:CHINA TOBACCO HENAN IND

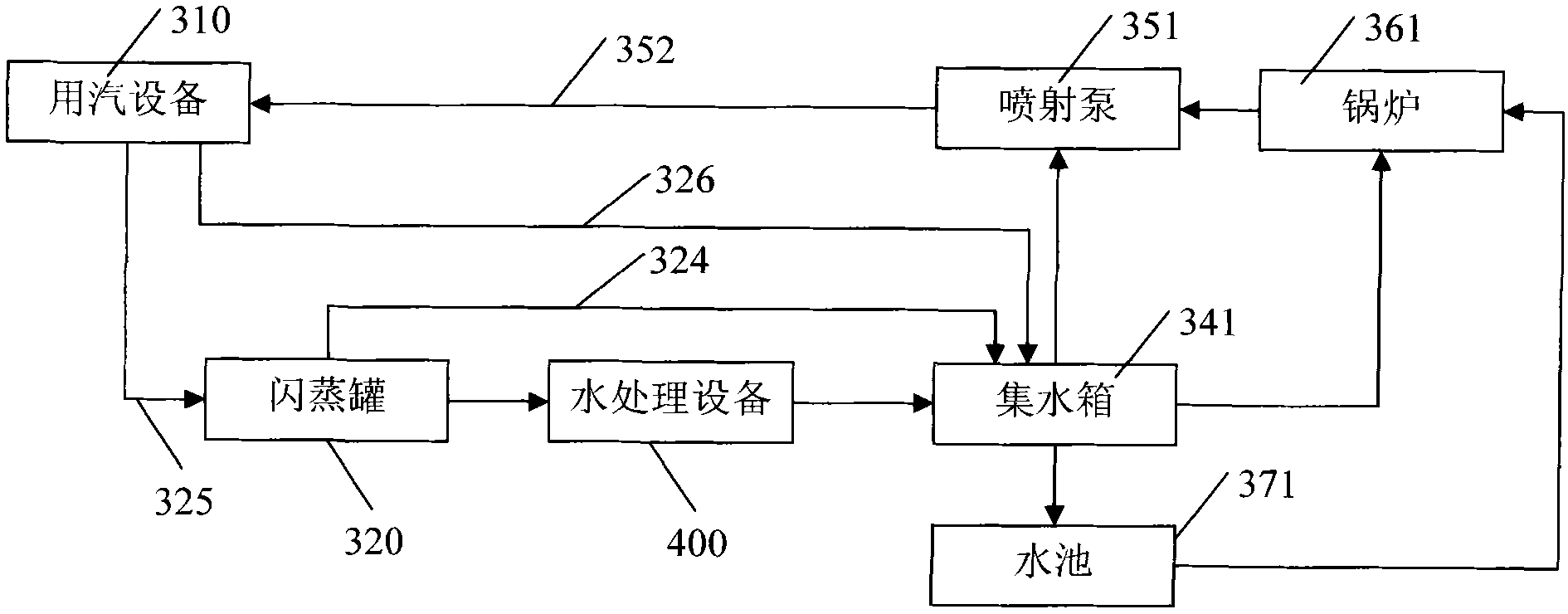

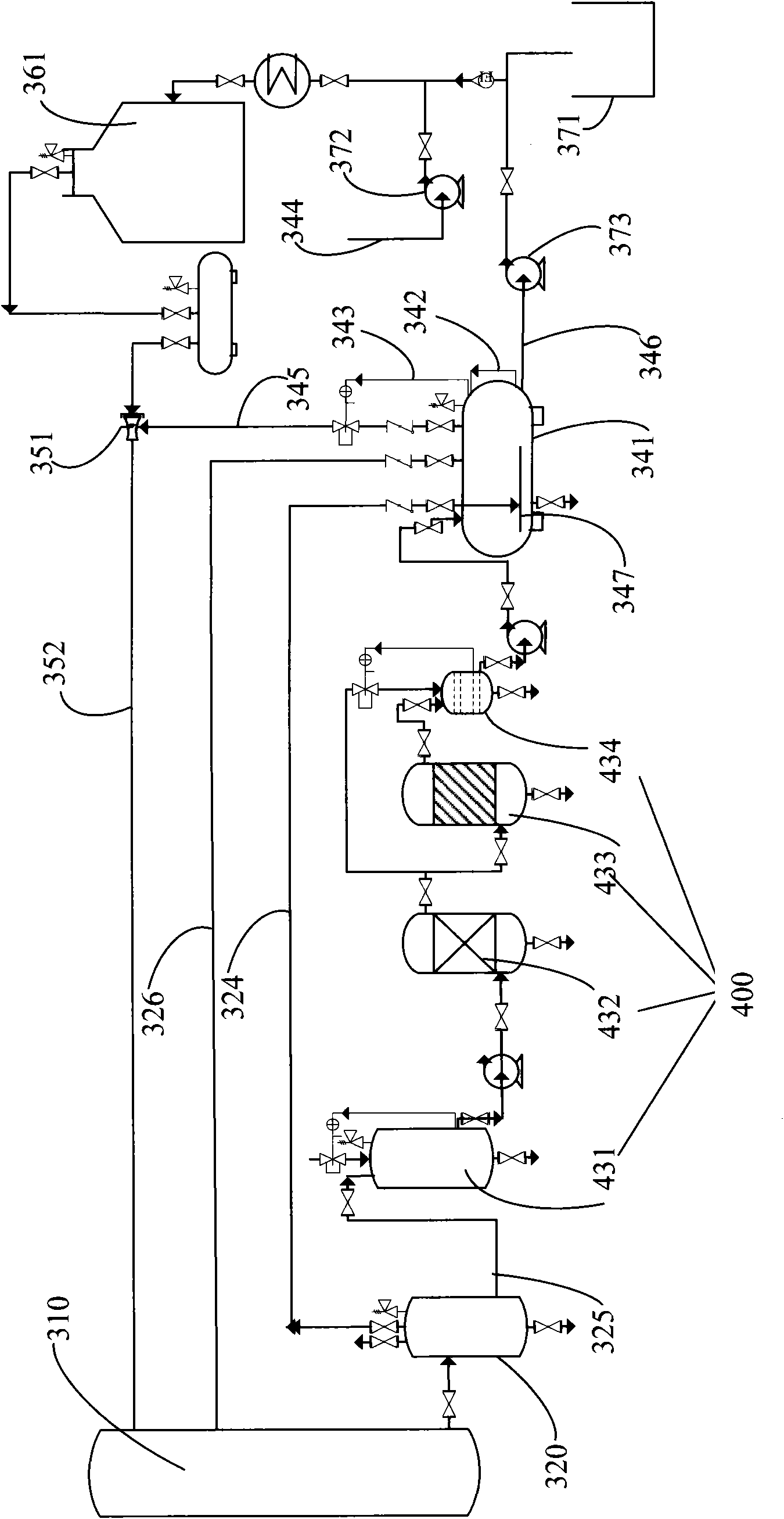

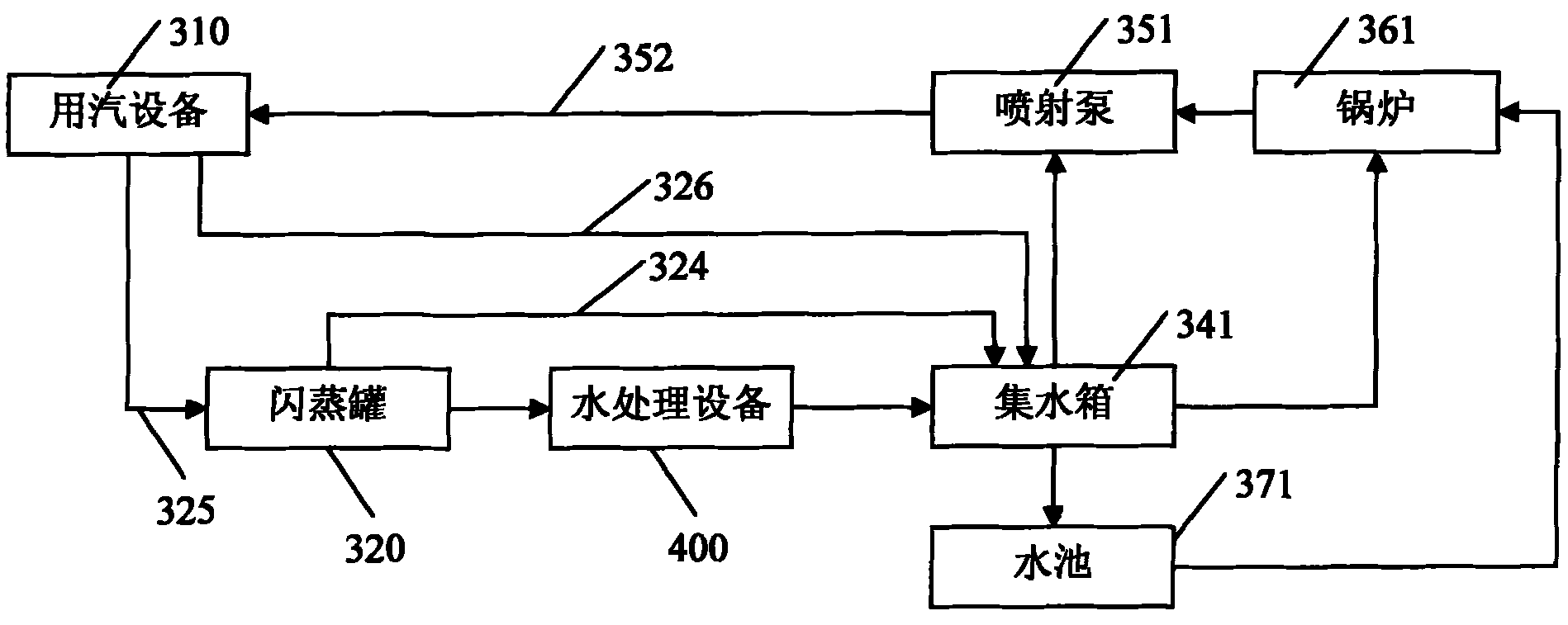

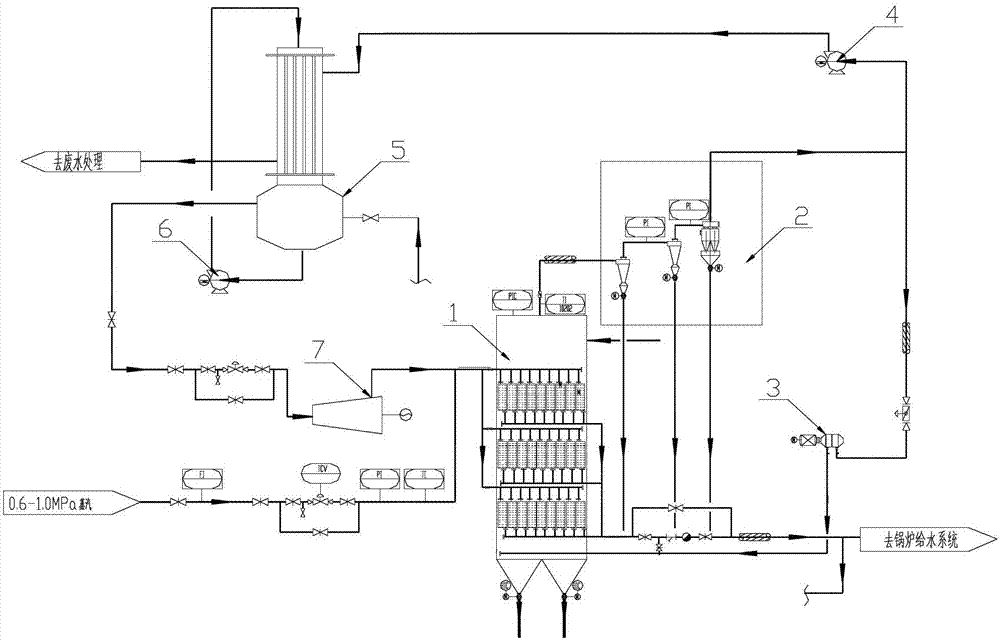

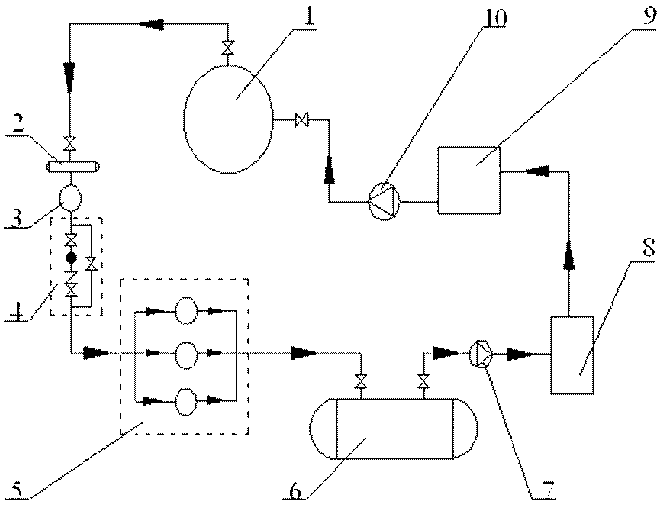

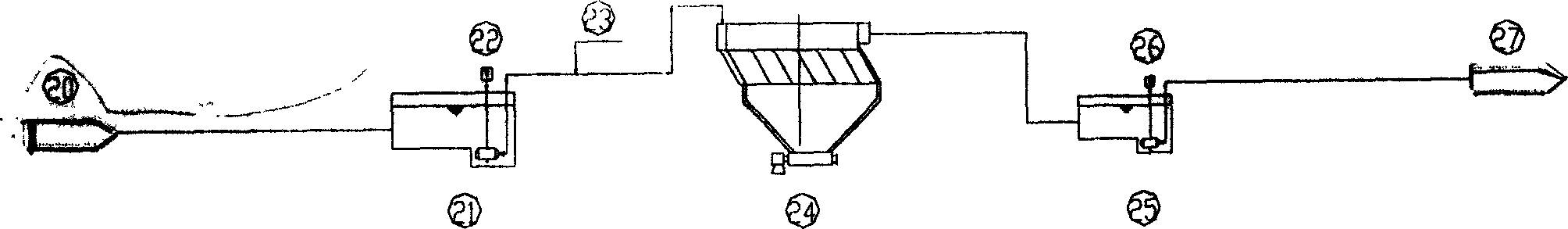

Comprehensive recovery method and system of condensation water and dead steam

InactiveCN101793390AAvoid damageAvoid heat lossFeed water supplyMultistage water/sewage treatmentRecovery methodWater saving

The invention discloses a comprehensive recovery method and a system of condensation water and dead steam. The method comprises the following steps: (1) transmitting the condensation water discharged by steam-consuming equipment to a flash drum to be performed with flash evaporation to obtain flash steam, and transmitting the flash steam and the dead steam discharged by the steam-consuming equipment to be below the liquid level of the condensation water in a water collecting tank; (2) transmitting the residual condensation water after flash evaporation to water processing equipment to be treated, and discharging to the water collecting tank to feed water for a boiler; (3) transmitting the condensation water in the water collecting tank to the boiler; and (4) when steam pressure in the water collecting tank exceeds the warning value, transmitting the steam in the water collecting tank to the steam-consuming equipment through a main boiler steam pipe by an injection pump. The temperature of the condensation water is lowered after flash evaporation, and then the condensation water is processed by the water processing equipment to prevent high temperature from damaging the water processing equipment; and meanwhile, the flash steam is directly recovered to the water collecting tank so as to take away most parts of heat of the condensation water, thus avoiding heat loss to the utmost degree, and realizing energy and water saving.

Owner:广东省特种设备检测院顺德分院

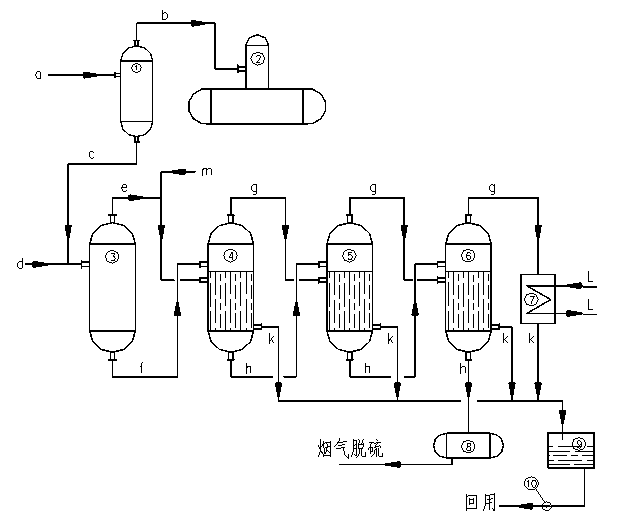

Comprehensive utilization method of thermal power plant boiler wastewater

The invention provides a comprehensive utilization method of thermal power plant boiler wastewater. The comprehensive utilization method comprises the following process steps: (1) continuous boiler wastewater goes into a continuous blowdown flash tank for reduced-pressure flashing; secondary steam generated after flashing is guided out of the upper part of the continuous blowdown flash tank and into a deaerator; (2) the hot wastewater at the bottom of the continuous blowdown flash tank is guided into a boiler periodic blowdown flash tank for further reduced-pressure flashing together with regular boiler wastewater; (3) the secondary steam generated by flashing from the periodic blowdown flash tank serves as a heat source and is guided into a low-temperature multiple-effect evaporator group, and bottom salt-containing wastewater also goes into the low-temperature multiple-effect evaporator group as the evaporated liquid; (4) the condensed water generated by the low-temperature multiple-effect evaporator group and the steam condensed water out of a cooler are collected to a condensed water tank by use of a condensation header and then fed into a boiler water supply system by use of a condensed water pump to be recycled; a thickened liquid generated by performing multiple-effect evaporation on the salt-containing wastewater is recycled into a thickened liquid recovery tank and then fed into a wet boiler flue gas desulphurization system used as a desulfurizing agent for desulphurization.

Owner:CHINA CEC ENG

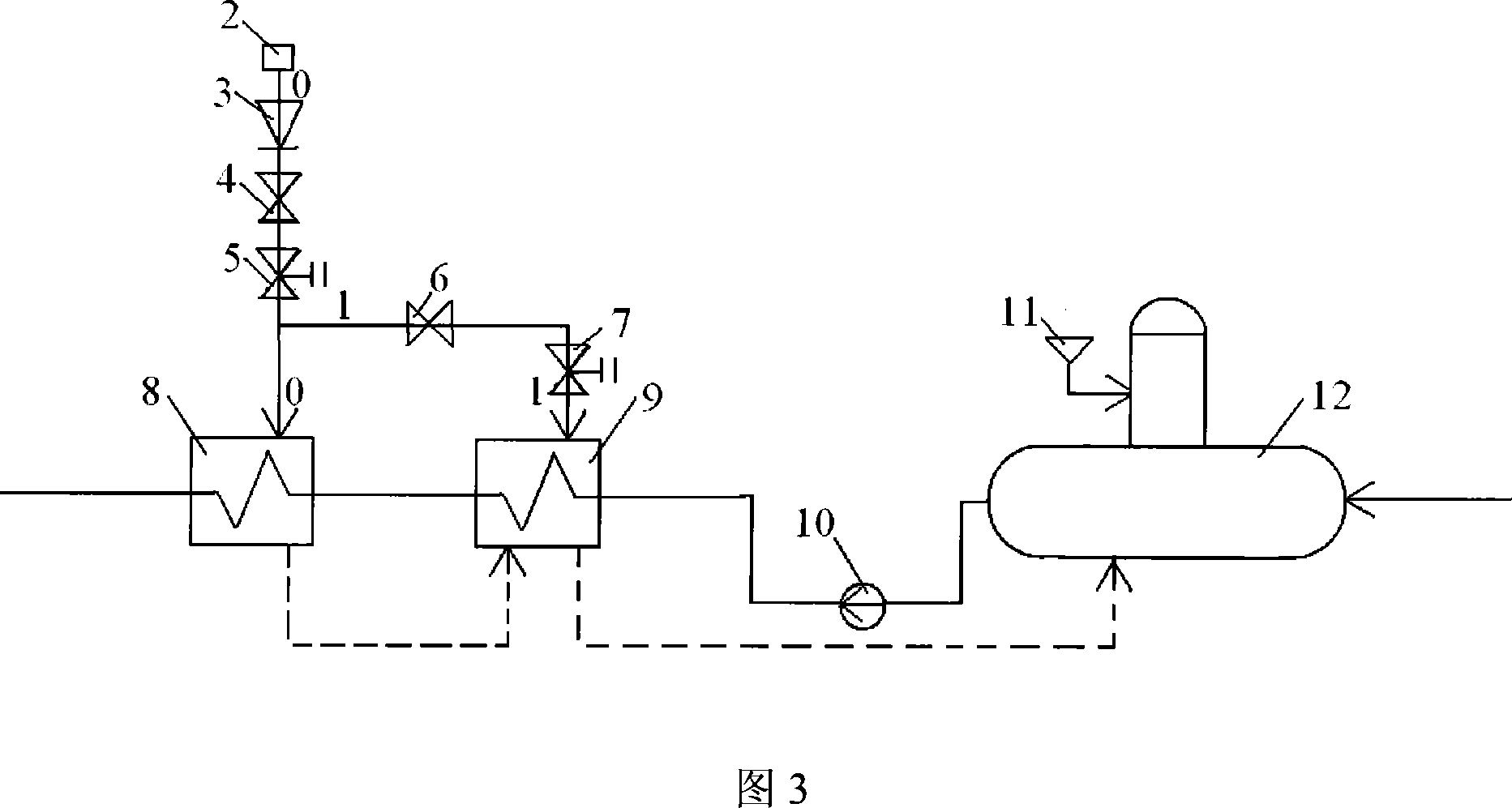

Lignite drying system and technology with superheated steam capable of recycling waste steam heat

ActiveCN102967121AImprove energy saving and reduce consumptionImprove energy savingDrying solid materials with heatDrying gas arrangementsFluidized bed dryingWater vapor

The invention discloses a lignite drying technology with superheated steam capable of recycling waste steam heat. The lignite drying technology comprises the steps that (1) after raw lignite is fed to an internal-heating fluid bed dryer after being crushed and sieved; (2) saturated steam from a backpressure unit of a factory enters a built-in heat exchanger in the internal-heating fluid bed dryer; the moisture the pulverized lignite is removed through indirect heat exchange; the pulverized lignite that is dried till the moisture content is qualified is discharged from the bottom end of the internal-heating fluid bed dryer; and (3) the saturated steam generates condensate water through the indirect heat exchange; a part of the condensate water is sent to a boiler feed water system; the rest of the condensate water is sent to an evaporator; the steam generated by removing the moisture from the pulverized lignite and fluidized carrier gas are in superheated steam states and are discharged from the top of the internal-heating fluid bed dryer; after the steam and the fluidized carrier gas are dedusted by multiple stages, the steam and the fluidized carrier gas partially return to the internal-heating fluid bed dryer again; and the rest is recycled. Meanwhile, the invention further discloses a system implementing the technology.

Owner:SHANDONG KEYUAN TIANLI ENERGY CONSERVATION ENG

Start-up method of dewatering capacity-enlarging start-up monotube boiler near steam heating boilers

ActiveCN101140059AShorten oiling timeReduce fuel consumptionSteam generation using hot heat carriersFeed-water heatersValue setTemperature difference

The invention discloses a starting method for an adjacent steam heating boiler of a drainage expansion starting once-through boiler; wherein a high-pressure heater of a starting unit is communicated with a pipeline for receiving the heating steam; the steam makes a unit boiler increase the temperature for water through the high-pressure heater; when starting in the cold, warm or hot state, the boiler heating surface is indirectly heated; when the temperature of the boiler heating surface is close to the saturation temperature of the steam, the feedwater flow is added up to the lowest ignition flow or above; a wind and smoke system is started, and the boiler is ignited; after starting a powder making system, the heat load is increased as soon as possible through a bypass system; the oil burning is cut off after the coal burning heat load is higher the lowest oil cut-off heat load in order to enter the conventional starting mode; when starting in the hot state and after finishing blowing, the feedwater flow is added up to the lowest ignition flow or above when the temperature difference of the cold wall of the feedwater and the boiler water is smaller than the value set by regulations, and the boiler is ignited; the oil burning is cut off after the coal burning heat load is higher the lowest oil cut-off heat load in order to enter the conventional starting mode. The method provided in the invention has the energy saving effects.

Owner:冯伟忠

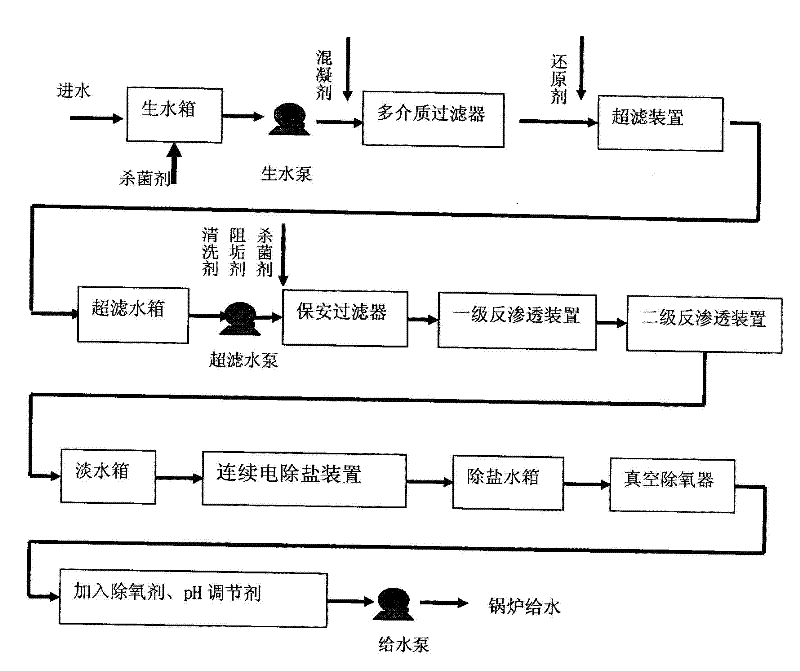

Novel water treatment method for boiler feedwater

ActiveCN102344215AAvoid breedingDecreased water conductivityGeneral water supply conservationMultistage water/sewage treatmentChlorine dioxideUltrafiltration

A novel water treatment method for boiler feedwater of the invention comprises the following steps: sterilization, that is adding liquid chlorine, sodium hypochlorite or stabilized chlorine dioxide into a raw water tank, controlling the residual chlorine amount in water to be 0.2-0.5 mg / L; filtration, that is adding a polyaluminium chloride coagulant before a multimedium filter with an amount of 10-20 mg / L, controlling the water turbidity of the ultrafiltration feedwater to be not more than 0.1 NTU and the SDI to be not more than 3; adding a reducing agent of sodium bisulfite before ultrafiltration with an adding amount of 3-5 mg / L; reverse osmosis, that is performing desalination treatment by a reverse osmosis membrane device, continuously adding a PTP-0100 scale inhibitor before a security filter with an adding amount of 3-5 mg / L; continuously adding a Micro Treat BIO bactericide with an adding amount of 3-5 mg / L; additionally adding cleaning agents of Dimamite and High Flux once a month with an amount of 3-5% of the water amount to be produced; desalination, that is performing desalination by an electrical desalination system (EDI); deoxygenation, that is performing deoxygenation by a vacuum deoxygenator, adding 10-20 microgram / L of deoxidants, controlling the agent residual amount to be 5-20 microgram / L, adding a corrosion-inhibiting pH regulator to control the pH value to be 8.8-9.3.

Owner:XINJIANG DELAND

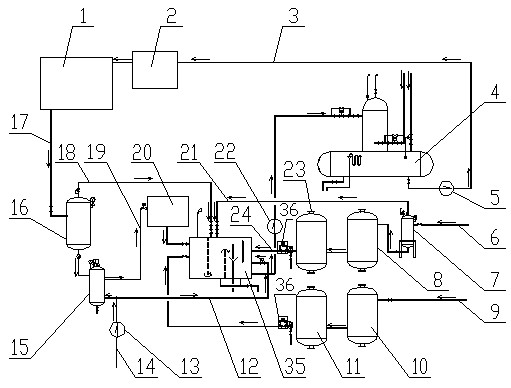

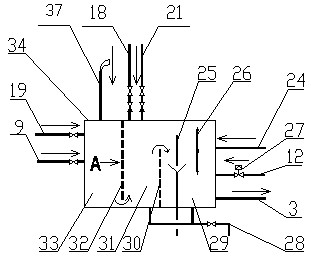

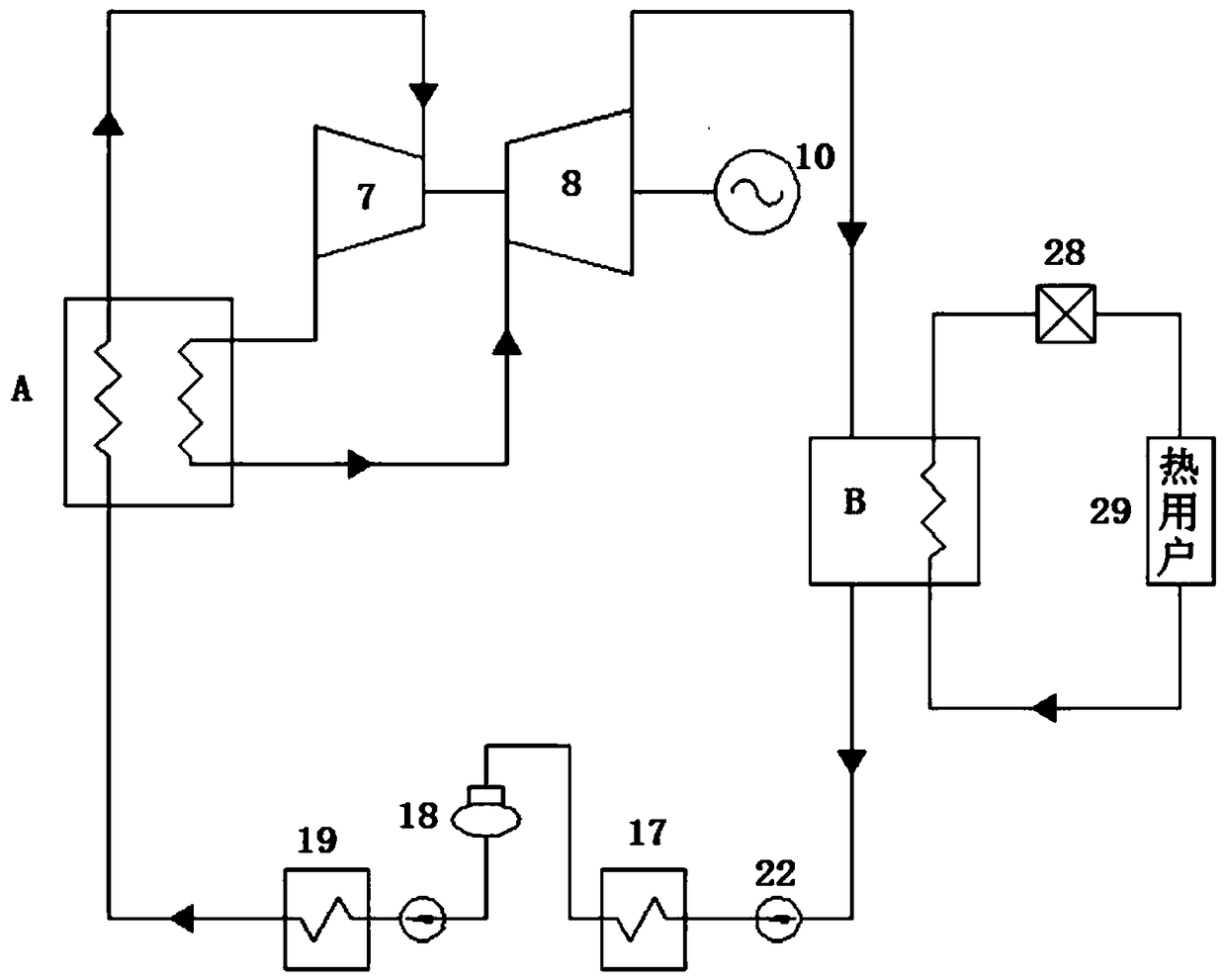

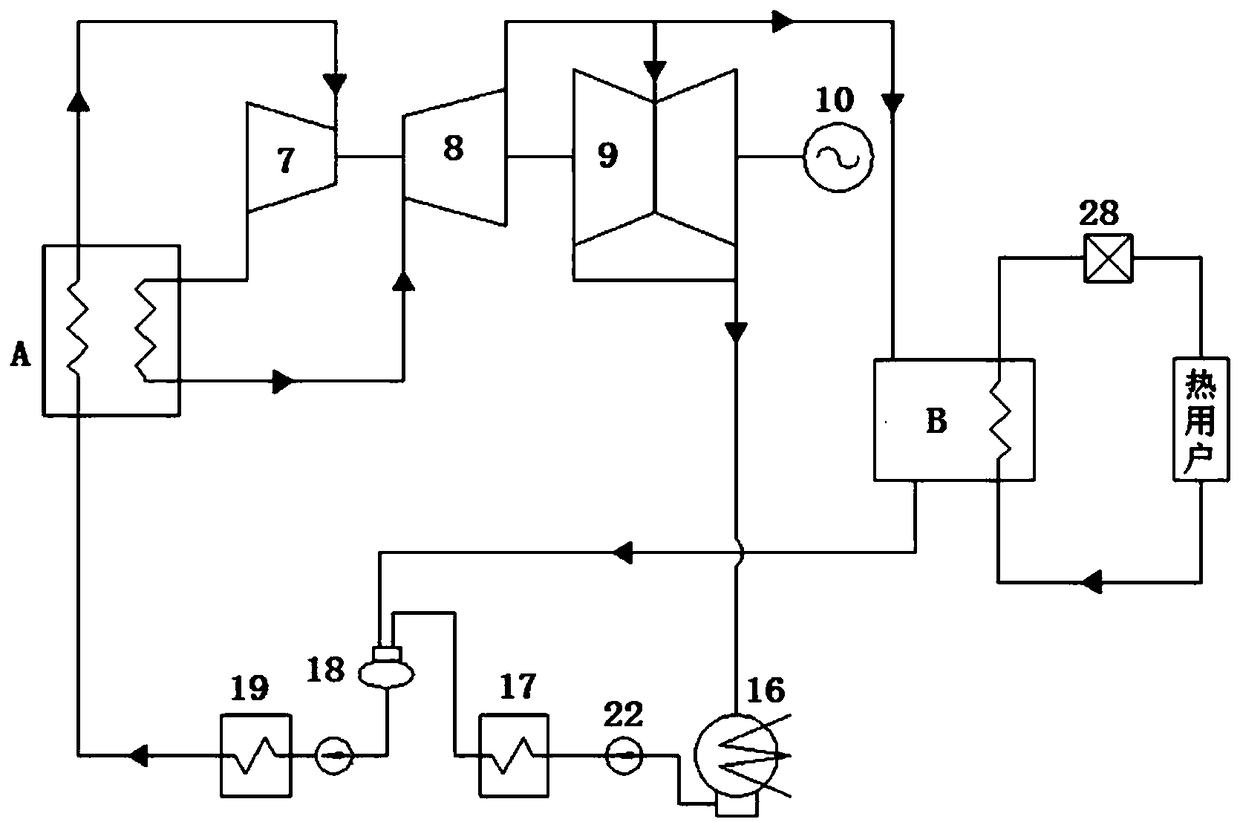

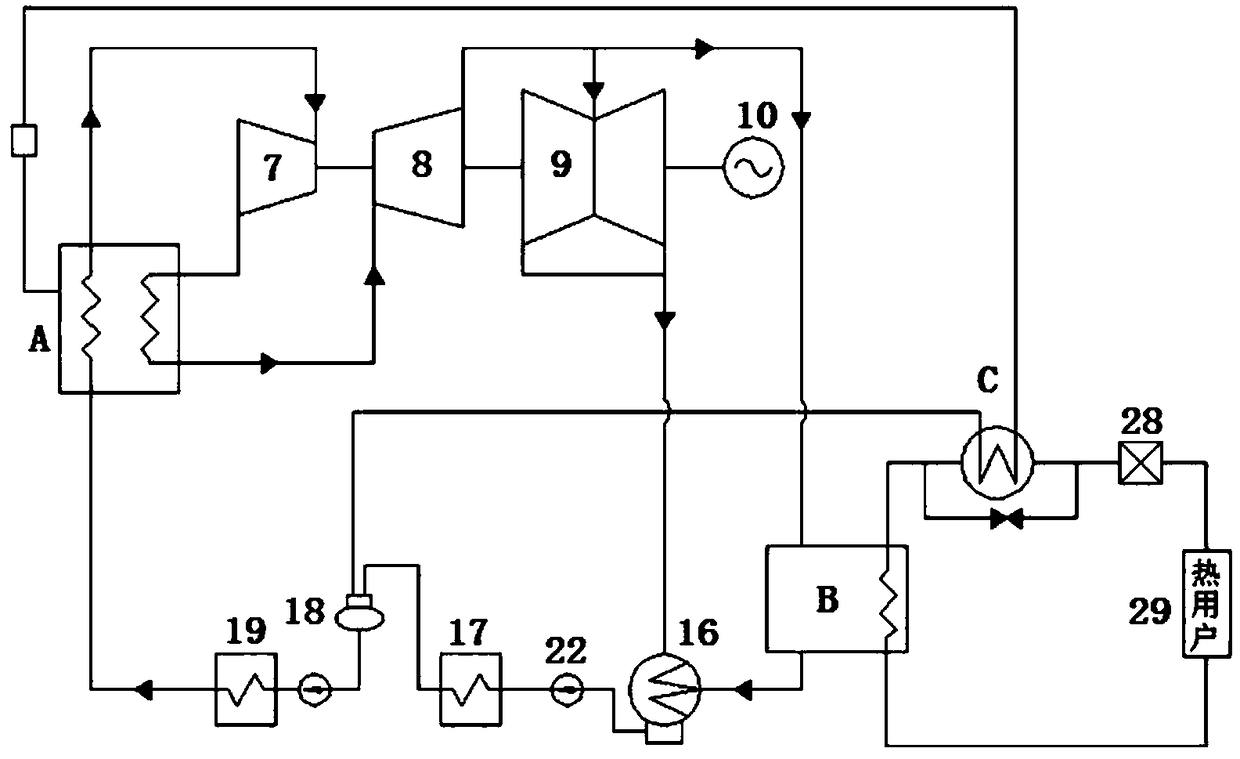

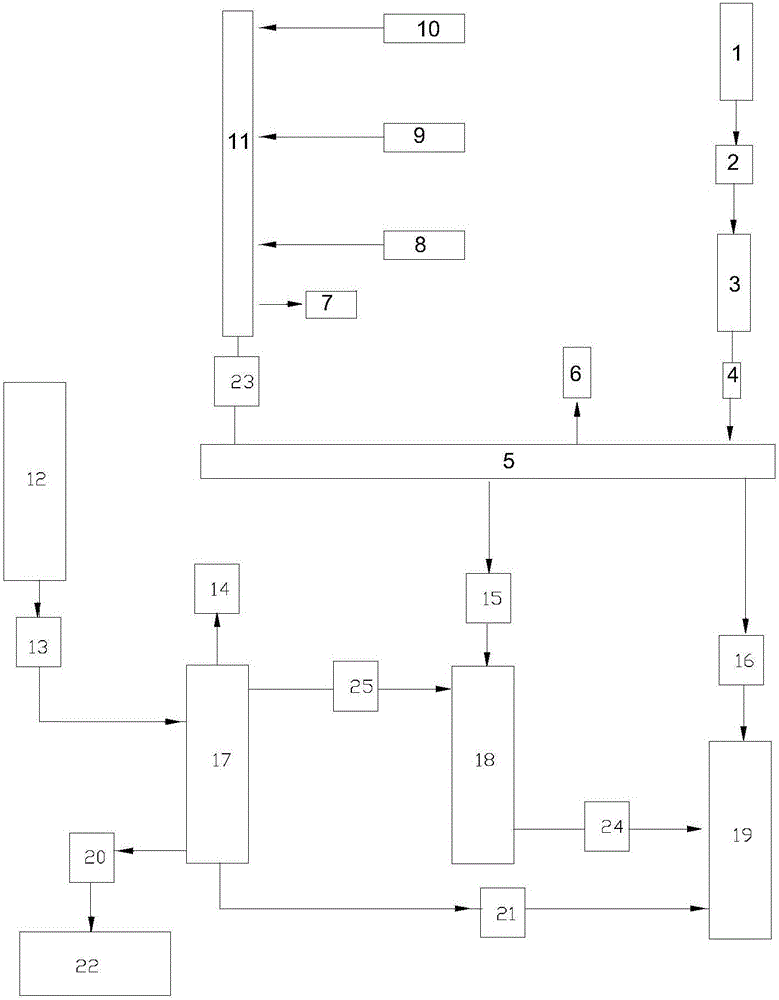

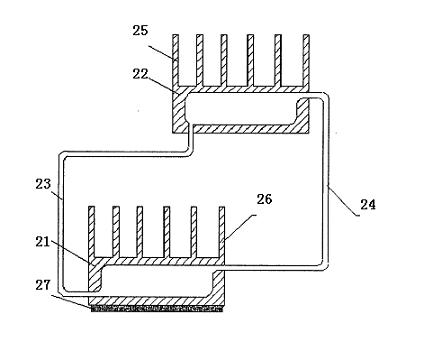

Thermodynamic system for improving heat supply unit electric output adjusting capacity

The invention relates to a thermodynamic system for improving heat supply unit electric output adjusting capacity. The thermodynamic system is characterized in that main steam or reheating section steam is subject to temperature and pressure reduction to directly serve as heat source steam for industrial heat users; an absorption heat pump 23 of a first-stage heat exchange device serves as a heatsource of a first-stage heat exchange station 25 in the heating period to supply heat to heat users 29 and supplies cold to the users in the non-heat supply period; a high-pressure electric boiler 24of a second-stage heat exchange device improves the boiler water feeding temperature, reduces heat absorbed by boiler fed water in an economizer 4, accordingly improves the boiler tail smoke discharging temperature, and guarantees normal running of an SCR denitration device 5; and according to a three-stage heat exchange device, exhaust steam of a turbine intermediate pressure cylinder 8 serves asheat source steam of a third-stage heat exchange station 27, the unit heat load is guaranteed, and the heat using requirement of the heat users 29 is met. The electric output adjusting capacity of the heat supply unit can be improved, it is guaranteed that the unit heat supply capacity is not decreased under the low load running working conditions, pyroelectric decoupling is achieved, and the electric output adjusting capacity of the heat supply unit is improved.

Owner:NORTHEAST DIANLI UNIVERSITY +2

Air preheating system and method performing steam extraction by utilizing steam turbine

InactiveCN103244944AReduce running power consumptionReduce power consumptionFeed-water heatersEngineeringAir temperature

The invention relates to an air preheating system of a thermal power generator set, in particular to an air pre-heating system and method performing steam extraction by utilizing a steam turbine. In the system, a primary air preheating subsystem and a secondary air preheating subsystem are coupled with a boiler system and a steam turbine system of the thermal power generator set to form a novel boil feed water preheating system. Primary air is heated by a four-stage air heater and a first-stage drain water cooler to reach primary air rated temperature. Secondary air is heated by a five-stage air heater to reach a secondary air rated temperature. The air preheating system effectively solves the air leakage problem, reduces operation power consumption of a primary fan, a forced draught blower and an induced draft fan and improves the generating efficiency of a coal-fired power plant. In addition, the primary air temperature and the secondary air temperature can be flexibly adjusted by adjusting steam extraction volume of the air heaters and opening degree of a drain water by-pass valve.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

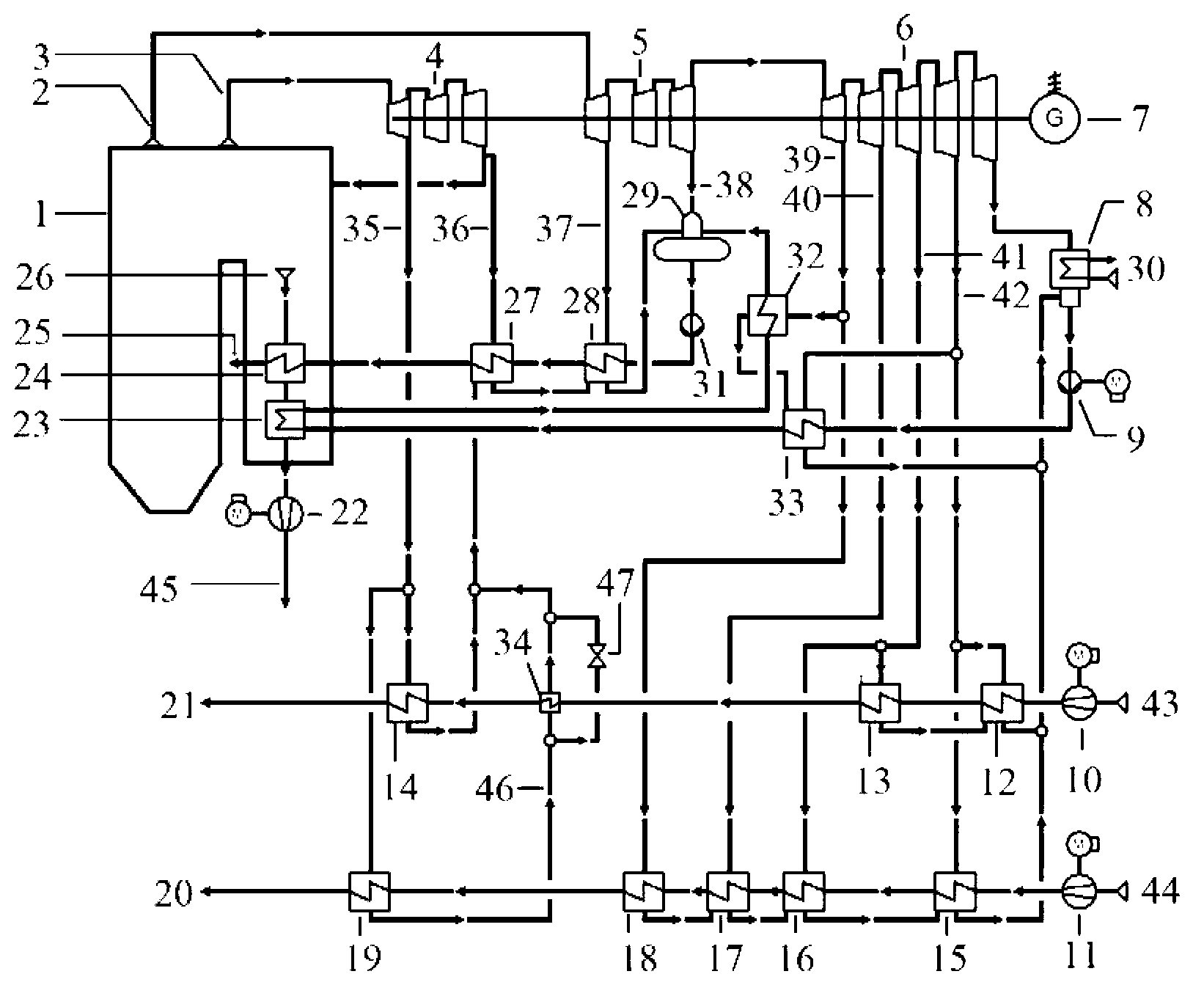

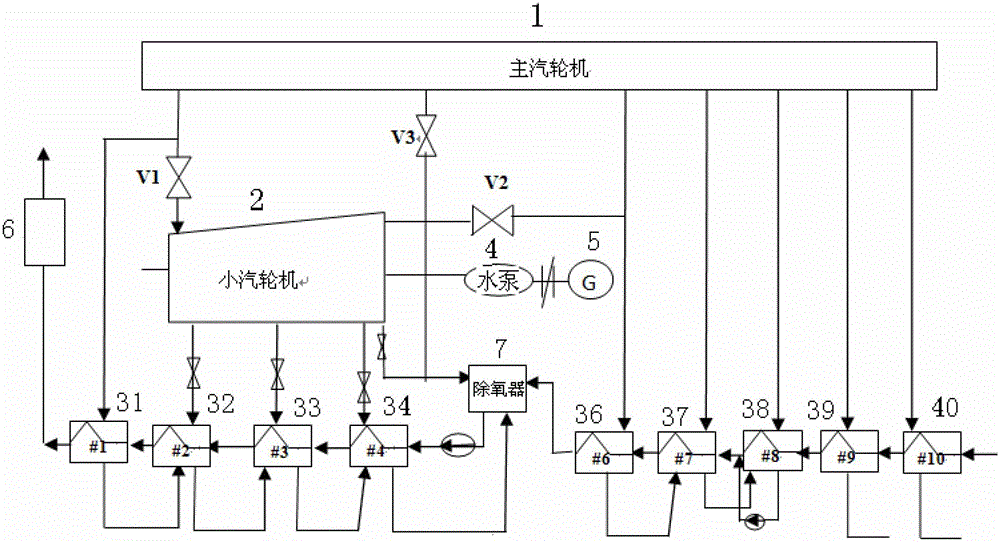

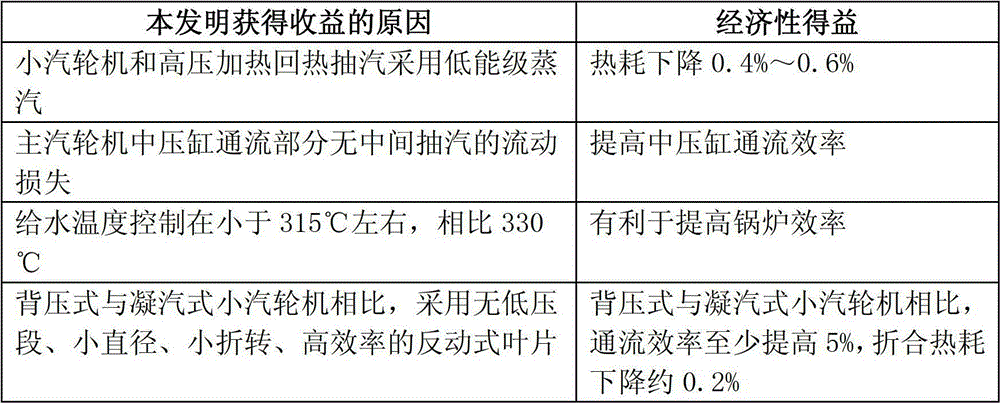

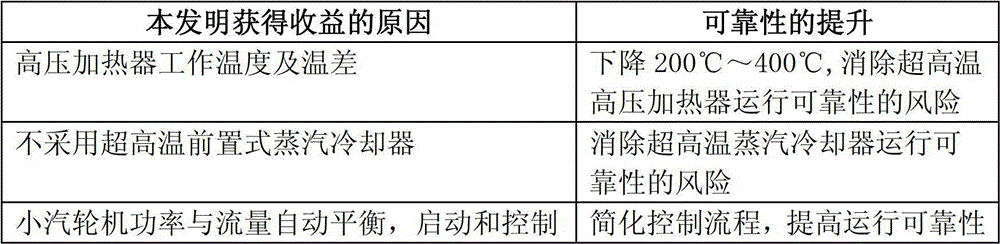

Dual-machine regenerative steam extraction steam thermodynamic system

ActiveCN102720550AReduce the temperatureImprove efficiencySteam useEnergy industryEngineeringIntermediate stage

The invention provides a dual-machine regenerative steam extraction steam thermodynamic system. In the system, the intermediate stage of a high pressure cylinder of a main steam turbine is provided with a high pressure steam extraction opening, the high pressure steam extraction opening is respectively connected with a steam inlet of a small steam turbine and one high pressure heater with the highest steam inlet parameter in a plurality of high pressure heaters through high pressure steam extraction pipelines, the intermediate stage of the small steam turbine is provided with a plurality of regenerative steam extraction openings which are connected with the rest high pressure heaters except the high pressure heater with the highest steam inlet parameter through regenerative steam extraction pipelines, and a steam exhaust port of the small steam turbine is connected with a deaerator through a steam exhaust pipeline of the small steam turbine. According to the system disclosed by the invention, a high-temperature preposed steam cooler can be omitted, and the feed-water temperature of a boiler is reduced, which helps to improve the efficiency of the boiler and reduce the heat consumption of a machine set; and flow loss can be effectively reduced, the circulation efficiency is improved, and the cost of equipment is reduced.

Owner:SHANGHAI TURBINE

Method for improving quality of recyclable exhaust waste heat in power plant boiler and progressively utilizing exhaust waste heat

ActiveCN102401369AImproving the quality of recyclable exhaust heatImprove efficiencyCombustion processIndirect carbon-dioxide mitigationCold airAir preheater

The invention discloses a method for improving the quality of recyclable exhaust waste heat in a power plant boiler and progressively utilizing the exhaust waste heat. A heat source for heating air entering an air pre-heater is connected in series to the front end of the air pre-heater of a boiler air input cold air duct, a first heat exchanger is connected in series to a boiler exhaust flue, andthe first heat exchanger is arranged in back of the air pre-heater of the boiler exhaust flue and in front of a desulfurizing tower and used for heating boiler water of a boiler heat recovery system.By using the method, the quality of the recyclable exhaust waste heat can be effectively improved, so that the recycling efficiency of the boiler exhaust waste heat is higher, the efficiency of the boiler and a steam turbine is improved, and the energy consumption for power generation is reduced.

Owner:CHENGXIN GREEN INTEGRATION

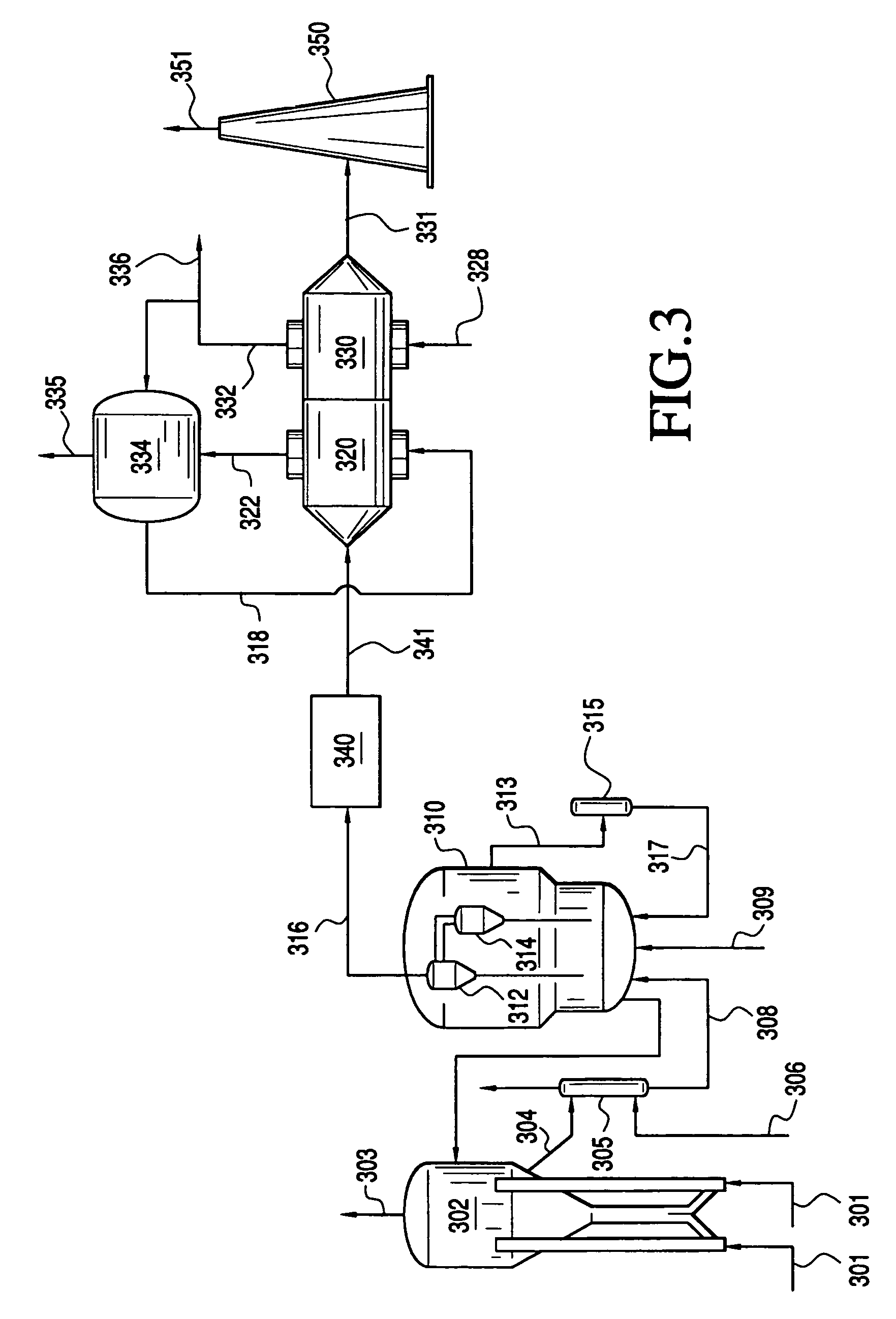

Heat recovery technique for catalyst regenerator flue gas

ActiveUS7404891B2Effective recoveryIncrease heightThermal non-catalytic crackingCatalytic crackingFlue gasProcess engineering

A technique for recovering heat from a high temperature effluent stream from catalyst regeneration or the like, comprising processes and means for: (a) passing the effluent stream in heat exchange relationship in a steam generator with boiler feed water to produce high pressure steam and partially cool the effluent stream; (b) passing the partially cooled effluent stream from the steam regenerator in heat exchange relationship to preheat high pressure boiler feed water and further cool the effluent stream; and (c) passing the preheated boiler feed water to the steam generator. The apparatus and processes for thermal energy recovery may be used to treat hot regenerator effluent from FCC or OTO-type processes, thereby producing a cooled flue gas stream to discharge to ambient atmosphere.

Owner:EXXONMOBIL CHEM PAT INC

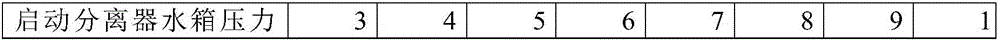

Once-through boiler starting system and method

ActiveCN106016230AReduce capacityLow reliabilityBoiler drums/headersLiquid degasificationWater storage tankAtmospheric air

The invention discloses a once-through boiler starting system and method. The system comprises a separator water storage tank, a pressure flash vessel, a high-pressure heater, a deaerator, a boiler side auxiliary steam header, a turbine side auxiliary steam header, a boiler reheater and a unit drainage groove. An outlet of the separator water storage tank is connected with an inlet of the pressure flash vessel. The pressure flash vessel is provided with two steam outlets, one steam outlet exhausts steam into atmosphere, and the other steam outlet exhausts steam to the high-pressure heater steam side. The pressure flash vessel is provided with two water outlets, one water outlet drains water to the deaerator, and the other water outlet drains water to the unit drainage groove. The boiler reheater supplies the steam to the boiler side auxiliary steam header, and the boiler side auxiliary steam header communicates with the turbine side auxiliary steam header. According to the method, by means of the pressure flash vessel, the water amount and the heat amount of once-through boiler starting drainage are recycled, and the temperature of boiler water supply is raised. The boiler reheater is used for supplying the steam to the boiler auxiliary steam header, dependency of unit starting on external steam is reduced, the steam exhausted to a condenser by means of a bypass is reduced, and the effects of saving energy and cost are achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

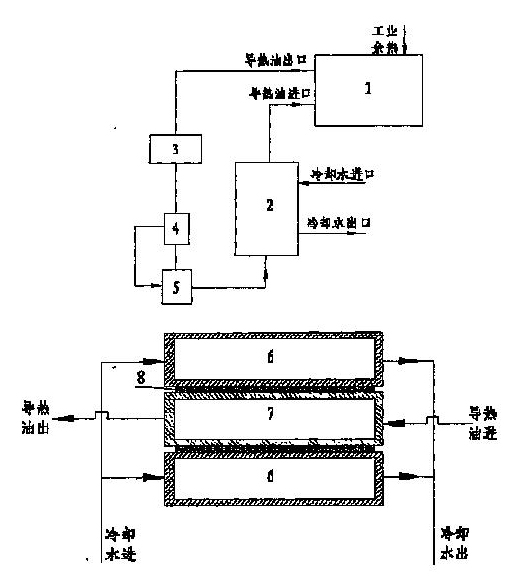

Industrial afterheat semiconductor power generation method and device using heat carrier as heating medium

InactiveCN101976987APrevent oxidative deteriorationExtended service lifeGenerators/motorsHeat carrierHeat conducting

The invention discloses an industrial afterheat semiconductor power generation method and an industrial afterheat semiconductor power generation device using heat carrier as heating medium, which use heat-conducting oil as a working medium for recovering and using afterheat. The device comprises a boiler flue, in-flue equipment, out-flue equipment and connecting pipes for connecting the boiler flue and the in-flue equipment and out-flue equipment, wherein at least one heat-conducting oil heater and at least one phase change heat exchange are arranged in the flue in turn; the phase change heat exchange comprises an evaporator and a condenser; the condenser cools steam by using an indirect heat exchange mode and by using heat-conducting oil as a cooling medium; the heat-conducing oil is heated and delivered to the heat-conducting oil heater for recovering the afterheat of flue gases continuously, the heat-conducting oil heated by the heat-conducting oil heater enters a semiconductor temperature-difference power generation device for generating power, the heat-conducting oil flowing out is used for heating feedwater and air, the feedwater and hot air are supplied to a system to be used after heat recovery and enters the condenser of the phase change heat exchanger in a power generation module, the heat at the cold end face of the semiconductor power generation module is recovered, gas is separated out through oil-gas separation and is exhausted from a high expansion groove, and the liquid heat-conducting oil can be recycled.

Owner:王海波

Method for recovering condensation water in production process of gas concrete and recovery system thereof

InactiveCN101700675AScientific and reasonable way of using energyMake full use of waste heatCeramic shaping apparatusRecovery methodUser device

The invention discloses a method for recovering condensation water in the production process of gas concrete. The method comprises the following steps of: firstly, sending the saturated steam produced by a boiler to a still kettle in which gas concrete slabs or blocks are placed, and heating the gas concrete product, wherein the saturated steam is cooled to form the condensation water through the heat exchange; secondly, sending the condensation water drained from the still kettle to a plurality of secondary heating user devices filled with materials, and pre-heating the materials by using the afterheat of the condensation water, wherein the saturated steam is cooled to form the secondary condensation water through the heat exchange; and thirdly, after the secondary condensation water drained from the secondary heating user device satisfies the requirement of boiler water feeding through the purification treatment, sending the secondary condensation water to the boiler of the first step for recycle. By adopting the method, the afterheat resources and water resources discharged from the production process are sufficiently, reasonably and gradually utilized, and the energy and resource consumptions and the production cost of product per unit are reduced.

Owner:TIANJIN UNIV

Method of avoiding low temperature corrosion of boiler air preheater

ActiveCN1619246AAvoid corrosionAvoid cloggingIncreasing energy efficiencyIndirect carbon-dioxide mitigationAir preheaterWorking fluid

The present invention relates to a method for preventing air preheater from producing low-temperature corrosion. Said method includes the following measures: placing the air preheater into an air duct for providing distributed air for boiler, making the interior heating working fluid boiler feedwater of the air preheater be flowed out from the air preheater and divided into two portions, making one portion be fed into the flue gas cooler set in the flue to cool hot flue gas in flue, and another portion can be directly fed into the coal-saving device placed in the fuel, so that it can prevent the heated surface of air preheater from producing low-temperature corrosion and ash plug.

Owner:DP CLEANTECH HONG KONG LTD

Technique for feeding water to boiler of reclaiming heat from treating sewage of thick oil

InactiveCN1562814APracticalImprove economyFatty/oily/floating substances removal devicesWater/sewage treatment by ion-exchangeChemical treatmentEngineering

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com