Solar aided carbon dioxide trapping integrated system

A carbon dioxide, integrated system technology, applied in solar thermal power generation, solar thermal devices, inorganic chemistry, etc., can solve the problems of high energy consumption, reduce the efficiency of power plants, etc., to maintain stable operation, reduce adverse effects, and improve the overall efficiency of the system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

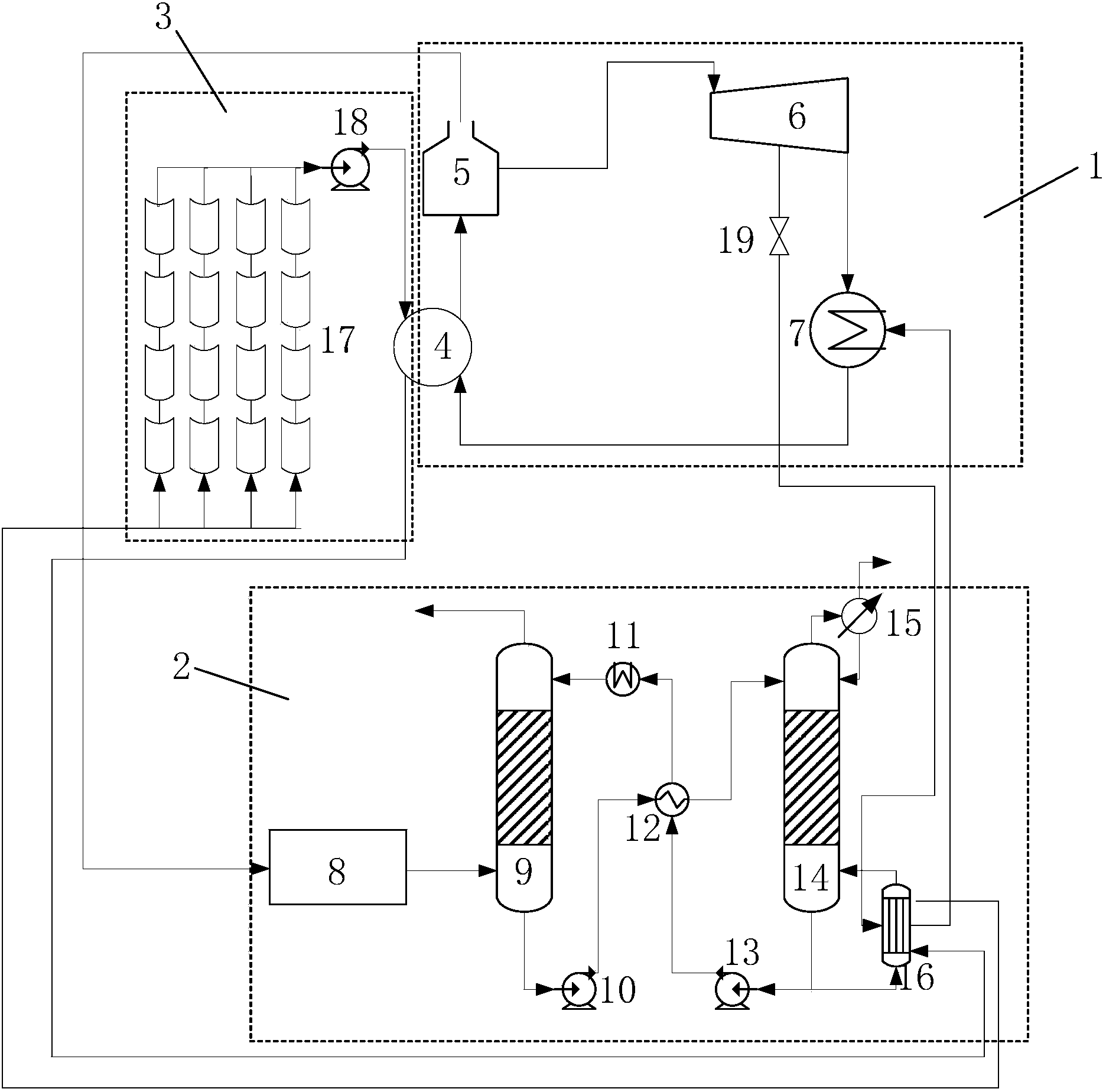

[0024] When the heat collection temperature of the solar heat collection subsystem 3 is medium temperature, the connection relationship is: figure 1 As shown, the outlet end of the working fluid in the solar heat collection subsystem 3 is connected to the high temperature side inlet of the water supply heat exchanger 4 in the power generation subsystem 1, and medium and high temperature solar heat collection heating is used to replace the extraction water heating, The high-temperature side outlet of the feedwater heat exchanger 4 is then connected to the high-temperature side inlet of the reboiler 16 in the carbon dioxide capture system 2, and the high-temperature side outlet of the reboiler 16 is connected to the solar heat collection subsystem The inlet ends of the working fluid of 3 are connected to form a solar heat collection cycle. The connection mode of embodiment 1 can collect the heat of the solar heat collection subsystem to a medium-high temperature of about 200-350℃,...

Embodiment 2

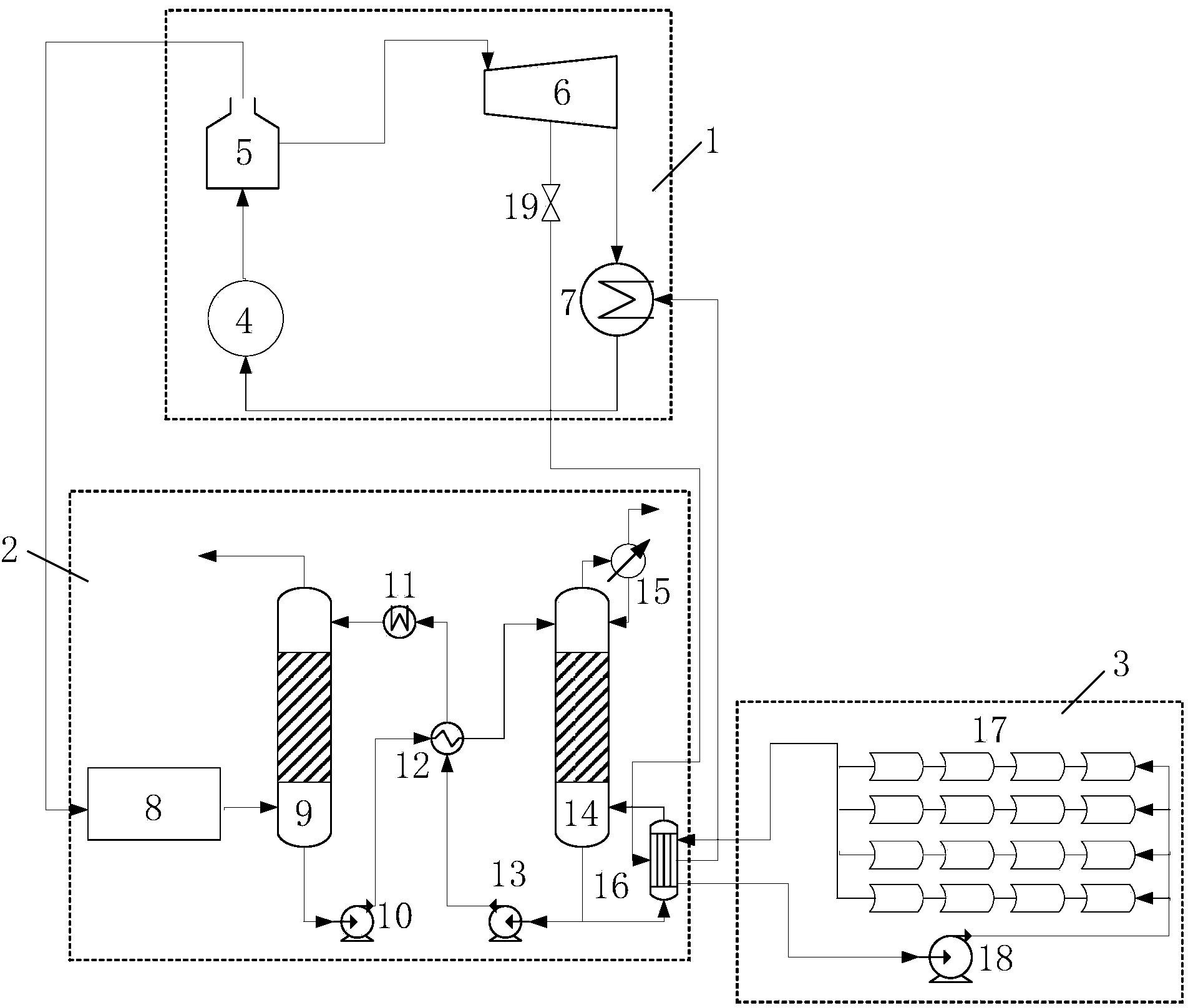

[0026] The working fluid outlet end of the solar heat collection subsystem 3 is connected to the high temperature side inlet end of the reboiler 16 in the carbon dioxide capture subsystem 2, and the high temperature side outlet of the reboiler 16 is connected to the solar collector The inlet ends of the working fluid of the thermal subsystem 3 are connected to form a solar heat collection cycle. The connection method of embodiment 2 can directly use the solar collector subsystem to collect the working fluid in the solar collector series to the temperature range required by the reboiler and supply it to the reboiler, which simplifies the system and makes full use of it. The solar heat collection system has higher heat collection efficiency at low temperature, and reduces the heat dissipation loss of the working fluid at high temperature.

[0027] In summary, the heat output end of the solar heat collection subsystem adopts different connection methods to reasonably allocate the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com