Method of avoiding low temperature corrosion of boiler air preheater

An air preheater and low-temperature corrosion technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve problems such as low-temperature corrosion on the flue gas side, prevent low-temperature corrosion and ash plugging, reduce operating costs, avoid low-temperature corrosion and The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

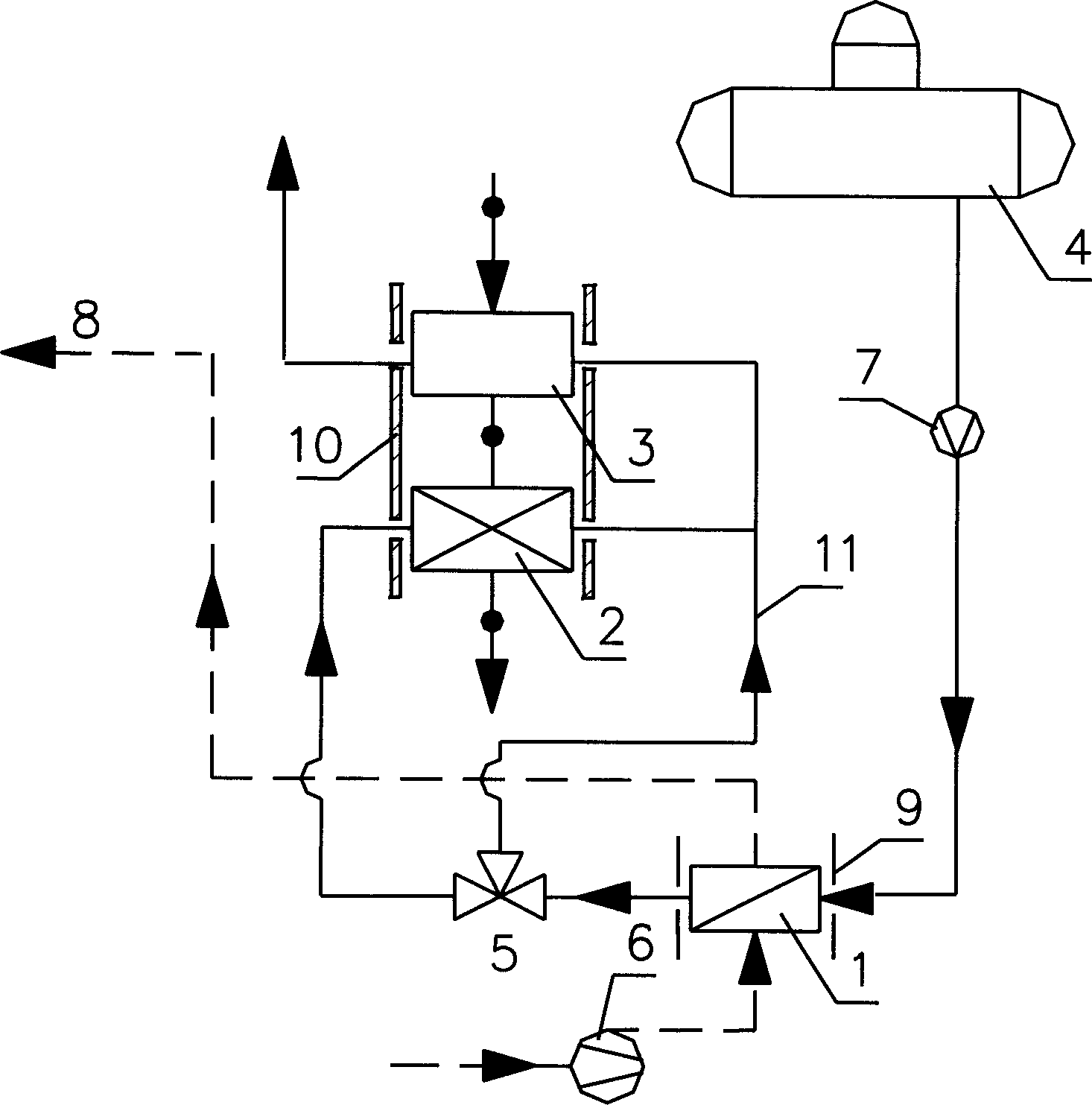

[0022] figure 1 Among them, a method to avoid low-temperature corrosion of the boiler air preheater, an air preheater 1 is arranged in the air duct 9 supplying air to the boiler burner, and the inside of the air preheater is composed of finned tubes and bare tubes The heating surface of the tube bundle or other structural forms, the heated working medium in the air preheater 1 is air; available hot water in other parts. After the air in the air duct 9 passes through the air preheater, it absorbs part of the heat in the hot water, and the heated hot air is directly used as boiler air distribution, and the water cooled by the air preheater 1 leaves the air preheater 1 Finally, it enters the water supply control valve 5, and is divided into two paths by the water supply control valve 5 outlet. All the way into the flue gas cooler 2, the flue gas cooler 2 is a tube bundle composed of finned tubes, light tubes or other structural forms of the heating surface, set in the boiler fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com