Technique for feeding water to boiler of reclaiming heat from treating sewage of thick oil

A technology for heavy oil sewage and boiler feed water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, ion-exchanged water/sewage treatment, etc. The effect of saving water resources, convenient operation and saving heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

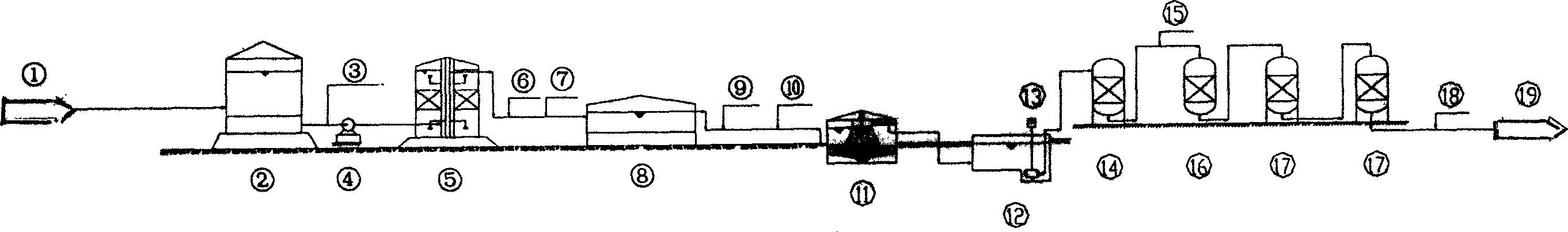

[0018] Embodiment 1: The main technological process of sewage treatment, using heavy oil sewage 1 to be transported to the regulating tank 2 through the PPR non-metallic pipeline, then adding chemical agents 3 into the pipeline, and lifting the sewage into the high-efficiency degreaser 5 with the lifting pump 4, Then add chemical coagulant 6 and coagulant 7 to the pipeline to send the dosing sewage into the flotation machine 8, add magnesium salt 9 and liquid sodium oxide 10 to the sewage with coagulant and coagulant , and then let the sewage enter the mechanical acceleration clarifier 11 from the pipeline to settle, then enter the filter suction tank 12 through the pipeline for buffering, send it to the filter pump 13, pressurize and lift the sewage, send it into the coarse filter 14, and then Add filter aid 15 to the sewage in the outlet pipeline, send it into the fine filter 16 and ion exchange softener 17 and add chemical agent 18 to remove dissolved oxygen in the water, an...

Embodiment 2

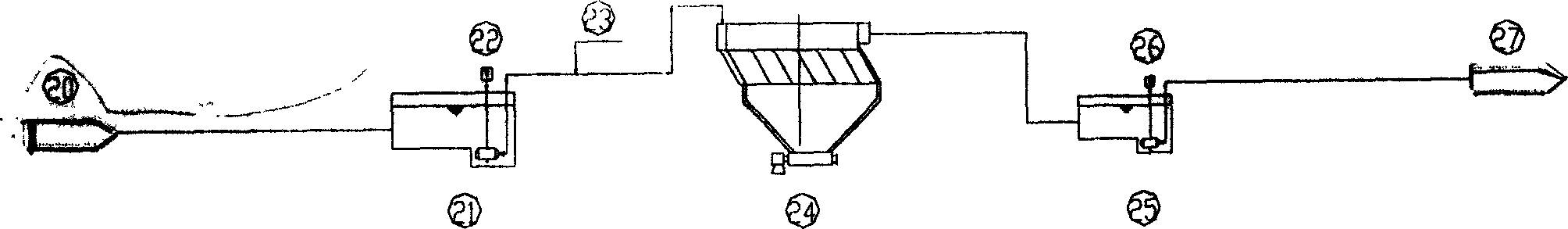

[0019] Embodiment 2: Sewage treatment sub-process (to the treatment of the relatively dirty sewage 20 from the coarse filter, fine filter and ion exchange softener), flow into the sewage pool A21 through the pipeline, and then pressurize and lift the sewage by the lift pump 22 , and add coagulant 23 into the pipeline and send it to the coagulation settler 24, so that the sewage enters the sewage pool B25 from the pipeline for buffering, and then pressurizes with the lifting pump 26B to lift the sewage, and the water is discharged at this time It is sent to the regulating water tank and the mechanical acceleration clarifier to continue the sewage recycling treatment.

Embodiment 3

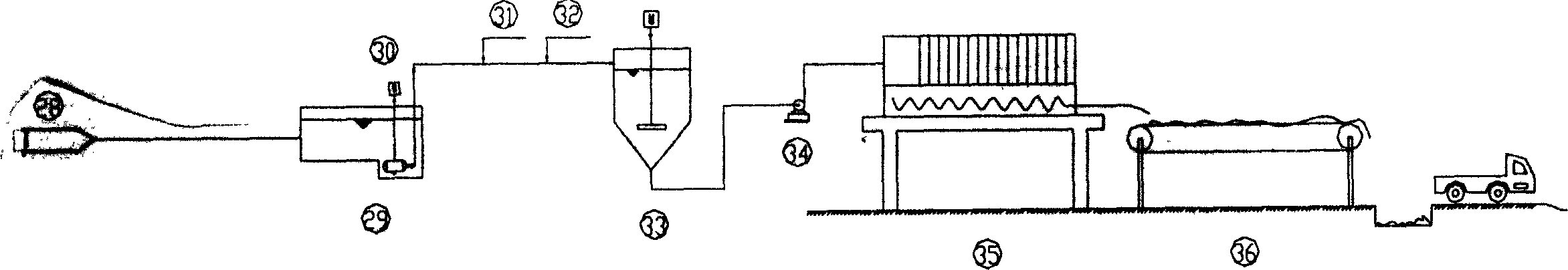

[0020] Embodiment 3: Sludge dehydration process: (by the sludge 28 that mechanically accelerates the clarifier filter pump and fine filter outlet blowdown place to produce)

[0021] Enter the sludge tank 29 from the pipeline, lift with the sludge lift pump A30, add the coagulation agent 31, and the coagulant aid 32 enters the van compressor 35 after passing through the sludge thickener 23 and the sludge lift pump 34 , and then the dehydrated sludge is transported out with belt conveyor 36.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com