Patents

Literature

67results about How to "Save water resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Volvaria volvacea cultivation method

InactiveCN101692771AMeet the nutritional requirements for growth and developmentFull of nutritionBio-organic fraction processingOrganic fertiliser preparationEcological environmentAdditive ingredient

The invention relates to a volvaria volvacea cultivation method and belongs to the edible mushroom cultivation technology. The ingredients of compost include 7-8 parts of fresh corn coating and 2-3 parts of fresh corn stigma. The method includes the steps of simultaneously processing the fresh corn coating and the fresh corn stigma with a grinding rubbing machine so that the corn coating is processed into soft threadiness and the corn stigma is cut short and snapped, meanwhile fully mixing the two processed raw materials and controlling the water content of the compost within 65-70 percent; and after processed, the compost can then be used for volvaria volvacea cultivation or filled in a container or a storage room to be compacted, sealed and stored. The method utilizes the waste materials after processing sweet corns to produce nuisanceless volvaria volvacea yearly, thus changing waste materials into things of value, recycling resources, saving water resource, reducing sewage discharge, protecting the ecological environment, reducing the production cost, improving the product quality and increasing economic benefit.

Owner:广州市白云区农业科学试验中心 +1

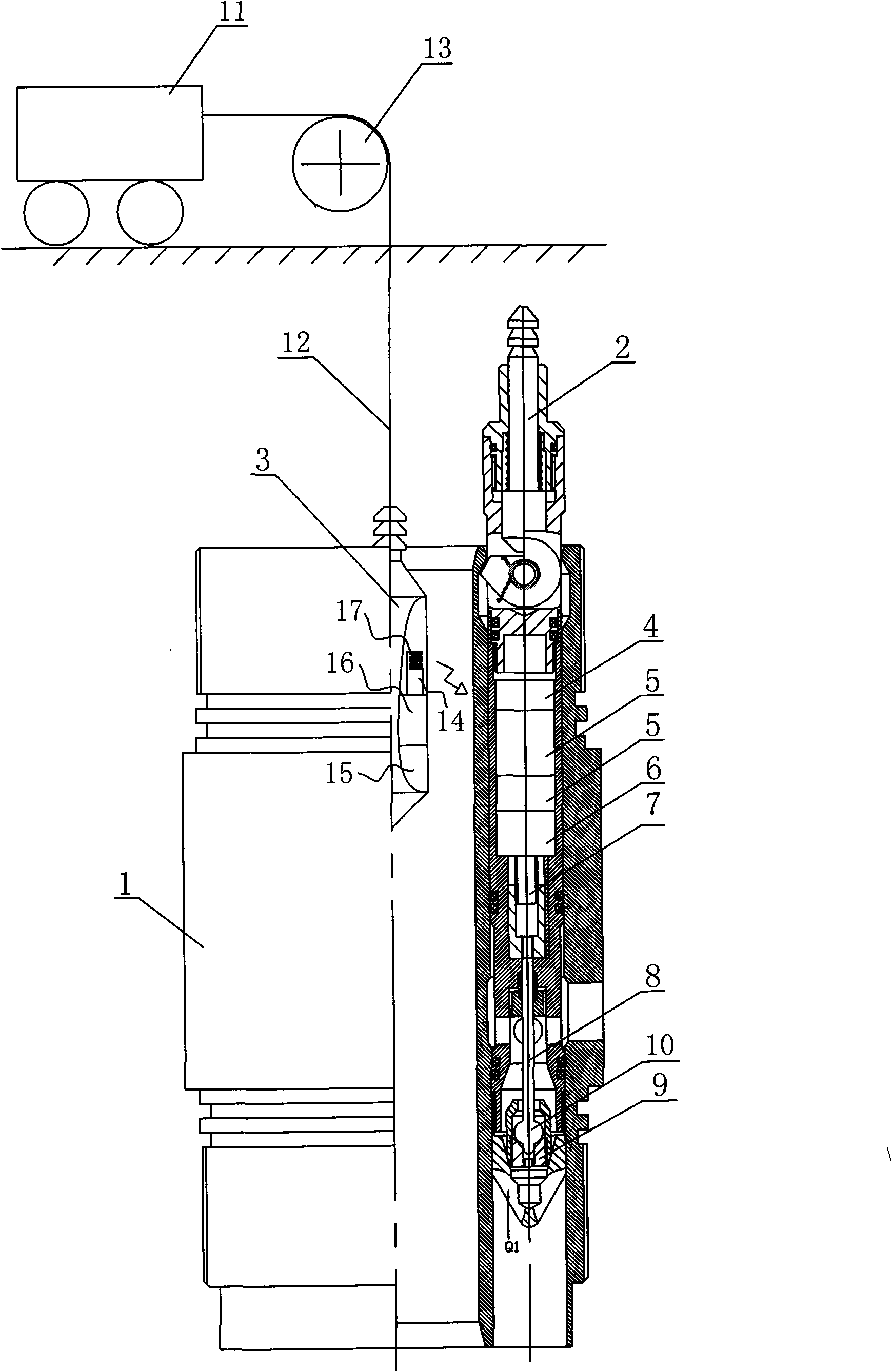

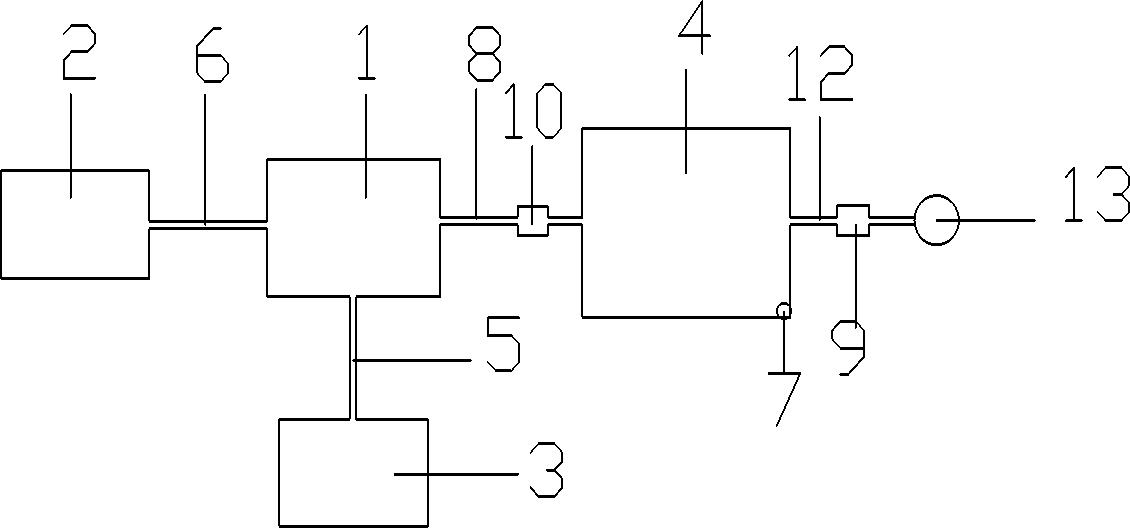

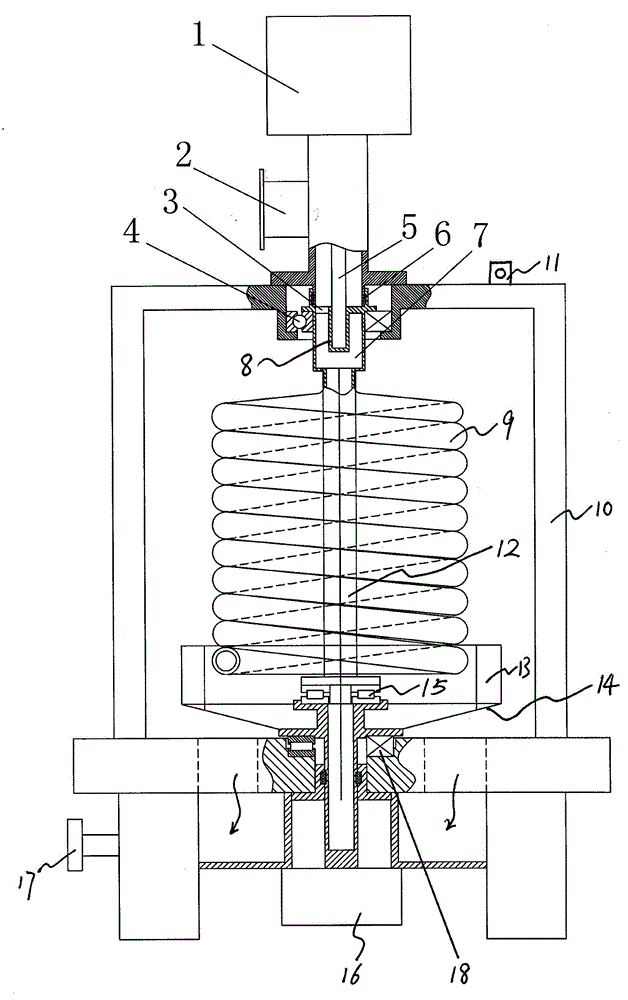

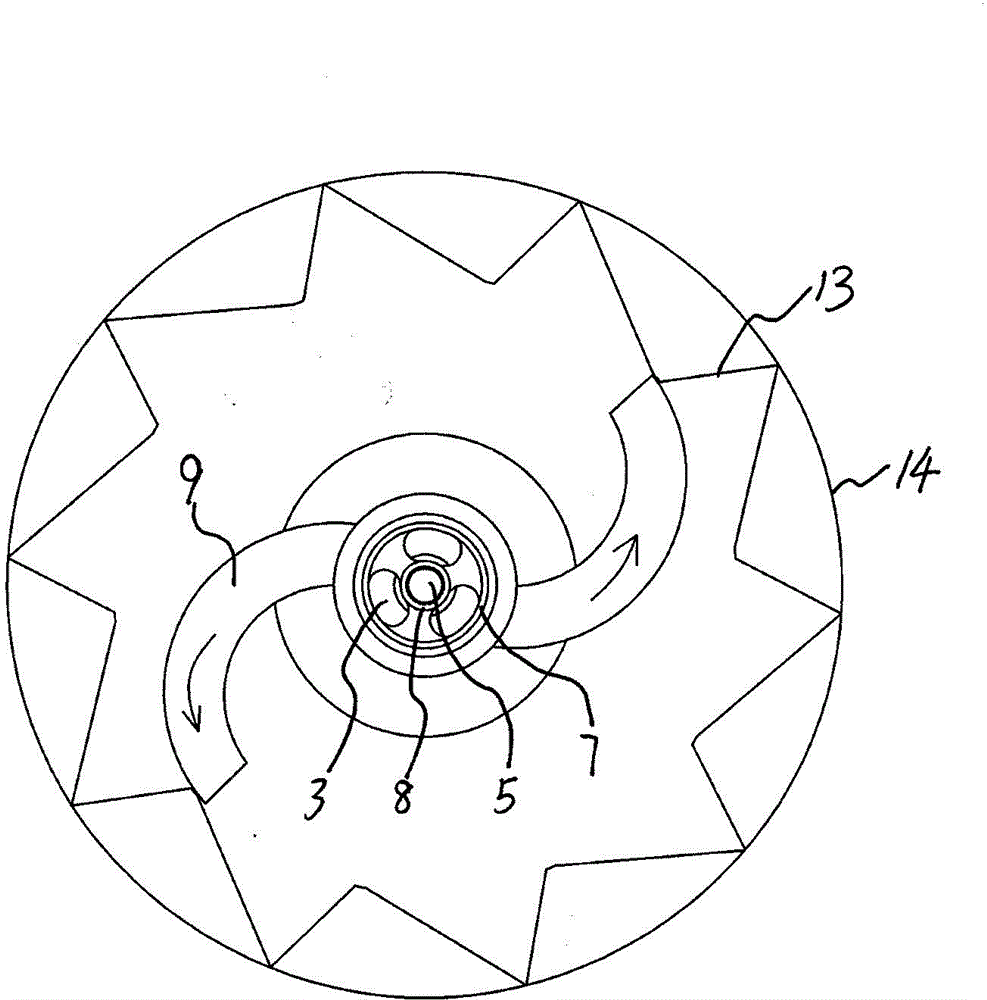

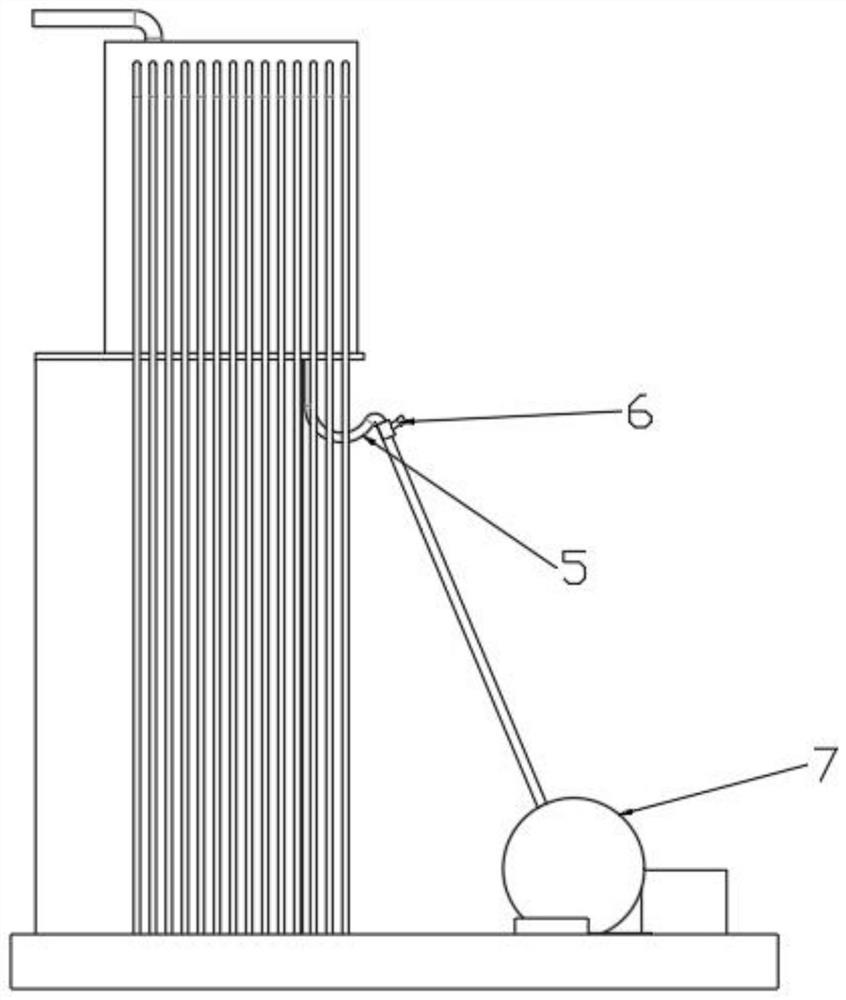

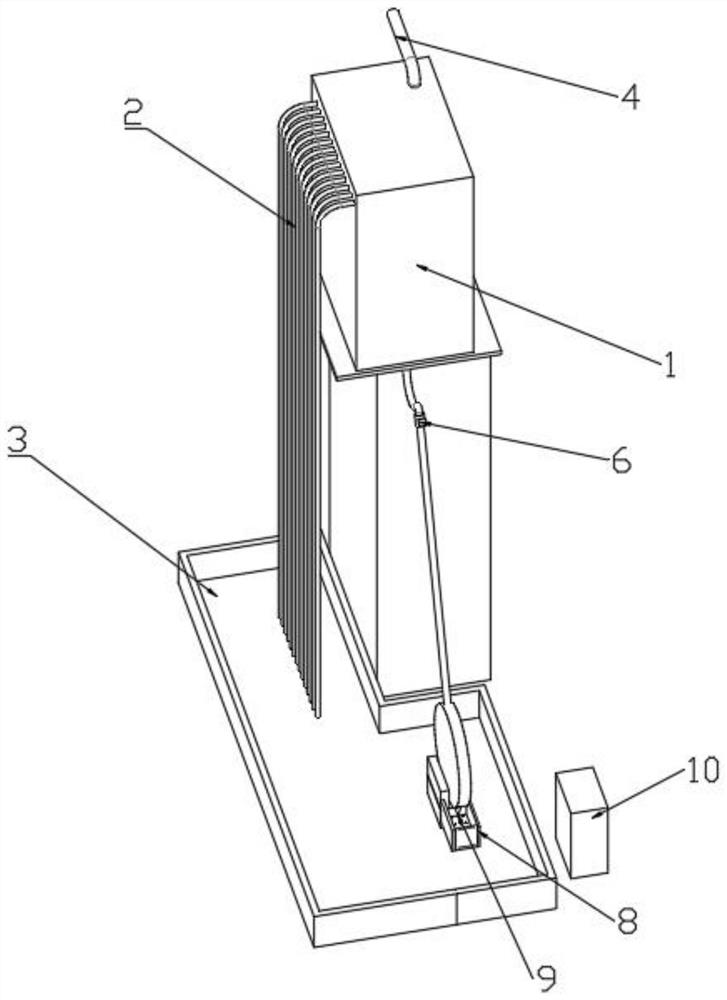

Electromagnetical linearly adjusted flux device for down-hole injection-production

InactiveCN101260800ASolving challenges in compounding productionSave water resourcesFluid removalEngineeringDrive motor

The invention relates to a device for electromagnetic linear adjustment of underground injection production flow rate, which consists of an adjustable electromagnetic signal emitter arranged in a position of an underground pipe column corresponding to an offset bottom-hole regulator; the pipe column of the bottom-hole regulator is provided with an electromagnetic signal receiver, a connecting electric drive controller and a connecting drive motor in turn; an output shaft of the drive motor is in spiral connection with a valve handle; and the lower end of the valve handle is connected with a valve ball on a valve seat. The electromagnetic signal emitter is overhung in the underground pipe column by steel wire pulled by a winch through a pulley; and an emitting window of the electromagnetic signal emitter corresponds to the electromagnetic signal receiver. An electronic testing and adjusting device is arranged on an eccentric hole of each layer of the bottom-hole regulator in the water injection well, automatically tracks according to measured results and carries out on-line measurement and adjustment to the water injection volume in each layer. The device for electromagnetic linear adjustment of underground injection production flow rate can set the water injection volume of each underground layer on the ground and automatically track steady-flow water injection according to the injection allocation volume, thereby radically solving the difficult problems in the injection allocation production of the oil field water injection well, reasonably utilizing the resource to exploit petroleum and saving water resource.

Owner:张建

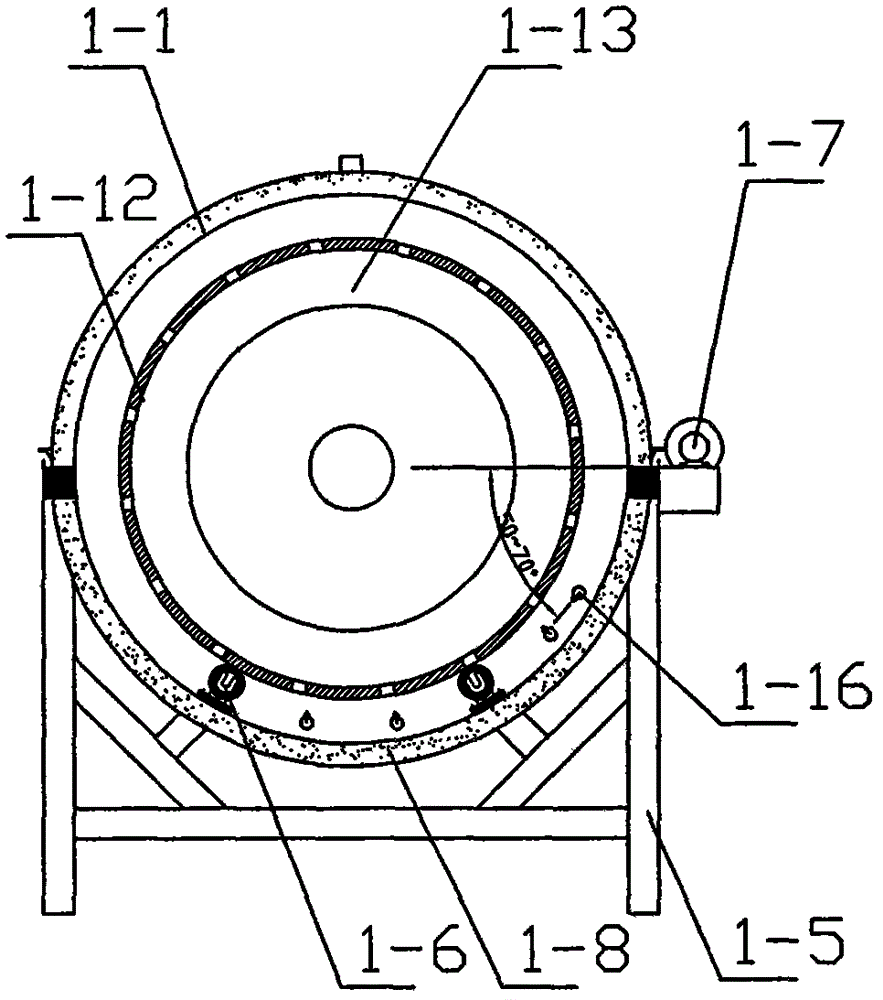

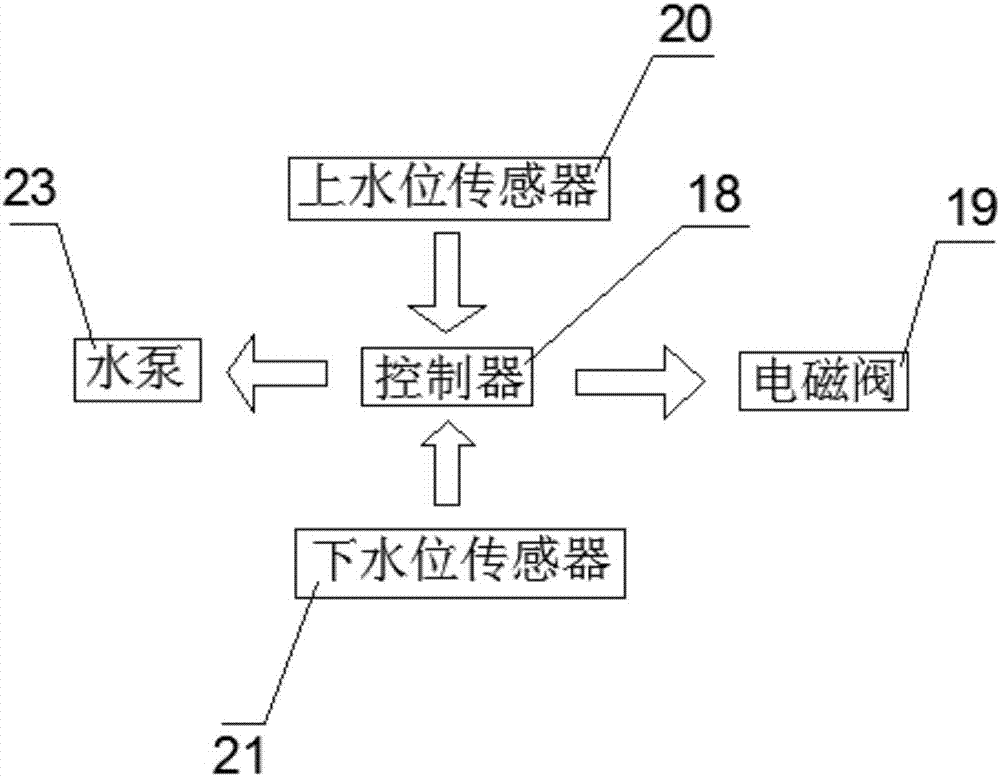

Water-saving washing machine and using method thereof

InactiveCN102041662ASave water resourcesOther washing machinesControl devices for washing apparatusWater savingTurbidity

The invention discloses a water-saving washing machine and a using method thereof. The washing machine comprises a water quality detector, a valve, a controller and a drainage switch, wherein the water quality detector is positioned at the bottom of a washing drum in a box body; the controller is positioned on the inner wall of the box body; the drainage switch is positioned at the bottom of the box body and connected with the water quality detector; the water quality detector is connected with the controller; the controller is connected with the valve; and the valve is connected with a water inlet pipe. After washing is finished, the drainage switch is turned on to drain water, and the water quality detector detects turbidity of the water drained by the washing drum; when the turbidity is more than or equal to 1ntu, the water inlet pipe continuously feeds water to clean clothes after the drainage is finished; and when the turbidity is less than 1ntu and after the washing drum drains water, the water quality detector transmits a closing signal to the controller, the controllers turns off the valve, and the water inlet pipe stops feeding water. Rinsing frequency is determined through the cleanness of the drained water, so the conservation of a water resource is facilitated.

Owner:余媛媛

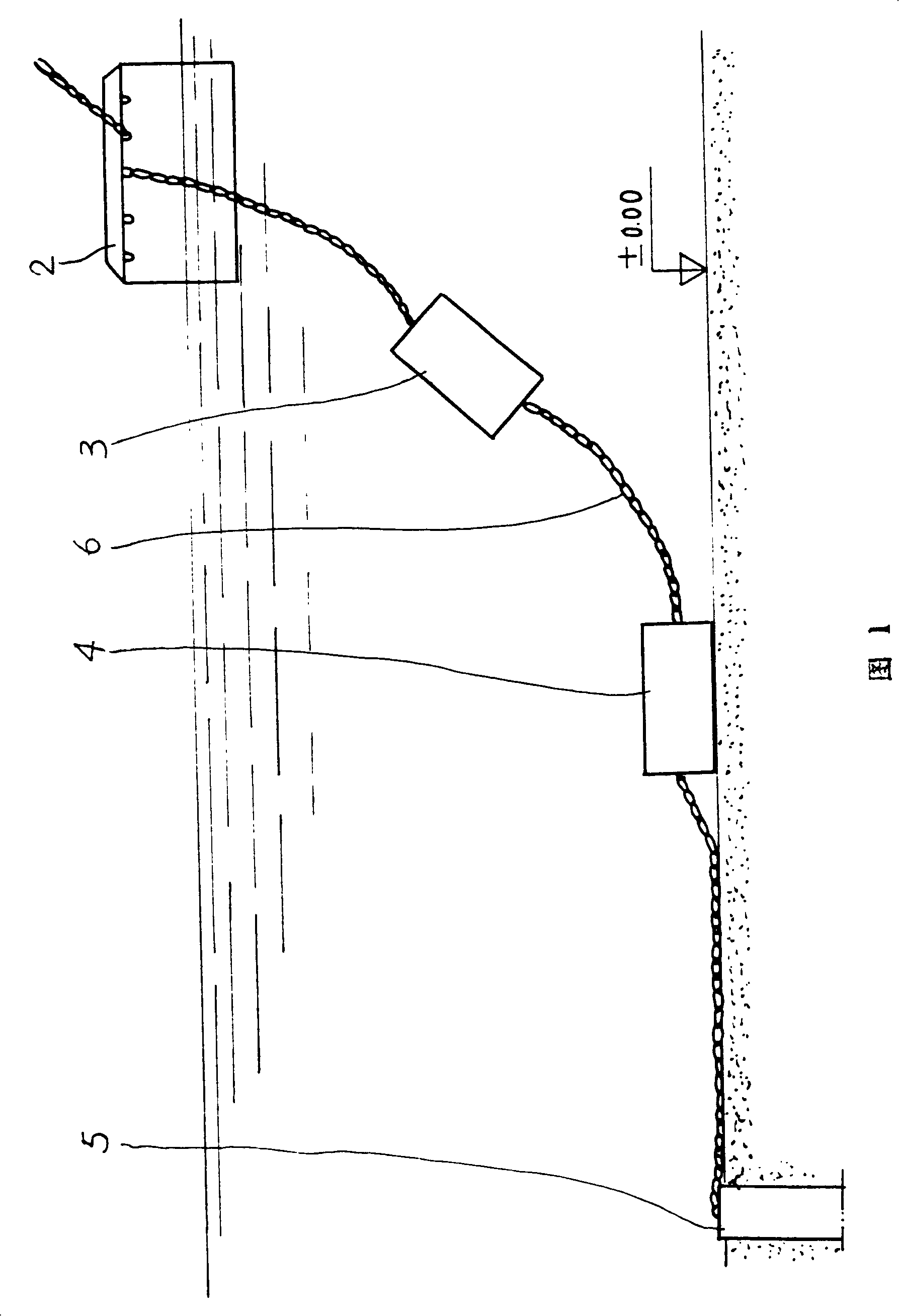

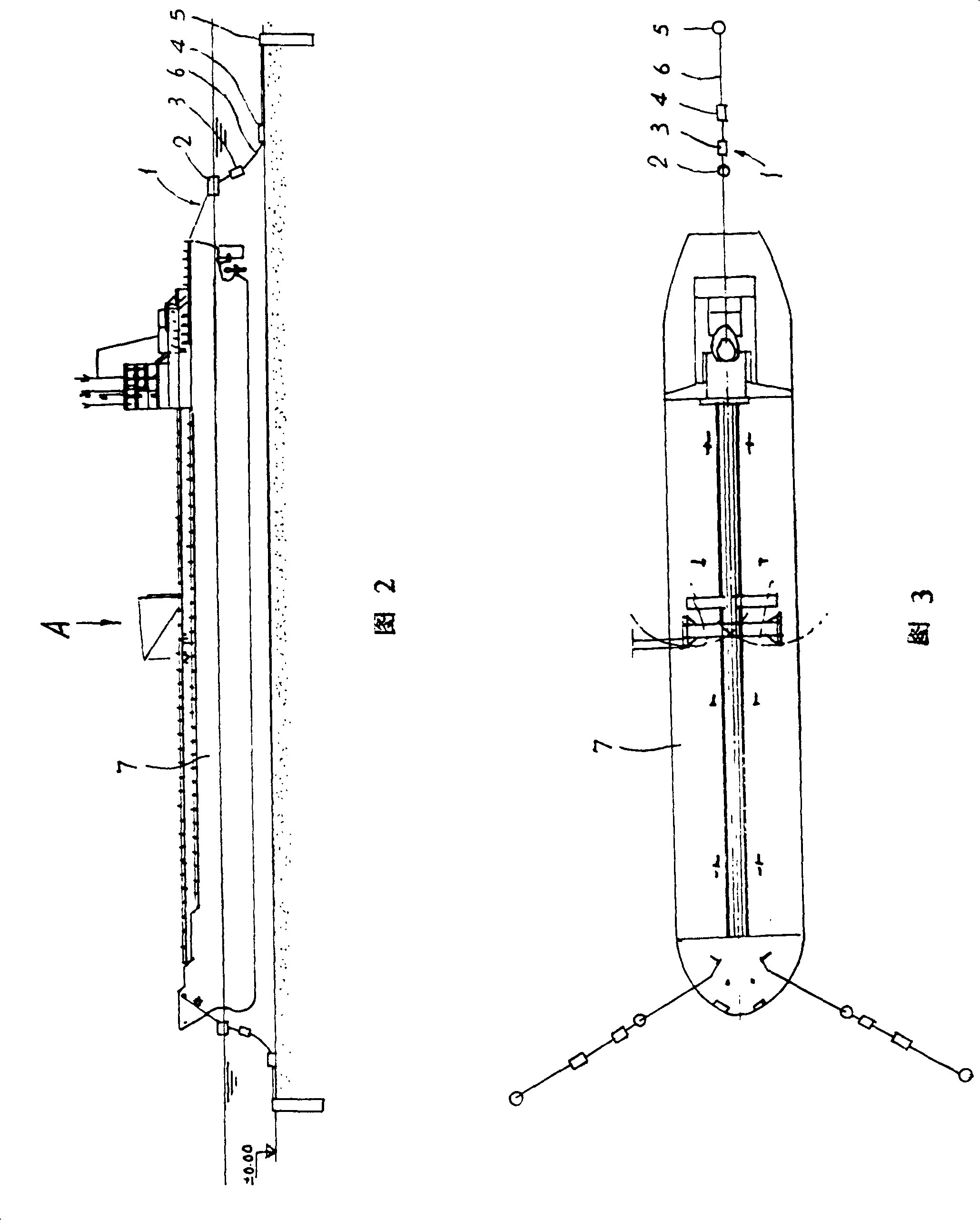

Off land loading and unloading anchoring system and anchoring method for liquid bulk cargo carrier

InactiveCN101157378AIncreased vertical downward forceImprove stabilityAnchorsBulk cargoMooring system

The invention relates to an offshore loading, unloading and mooring system for liquid bulk carriers as well as a mooring method, and the invention is characterized in that the mooring system consists of three sets of mooring device; the mooring device is formed by using connecting components to connect a buoy, a suspension bullback-weight, a chassis bullbacke weight and a anchoring base one by one; when in mooring, each set of mooring device connects the buoy and a carrier together by connecting components, wherein, two sets of mooring device are connected with the head of the liquid bulk carrier; another set of the mooring device is connected with the stern of the liquid bulk carrier; the three sets of mooring device are in Y-shaped arrangement; the mooring system can anchor the liquid bulk carrier in an off-shore sea area to load or unload materials; compared with the prior art, the invention has the advantages of small occupation sea area, low investment, short construction cycle, convenient operation, safety and reliability. Moreover, the invention does not take up shore-line resources, and is easy to be recovered and ruled, as well as especially suitable for the loading and unloading of the liquid bulk carriers.

Owner:陈杰诚

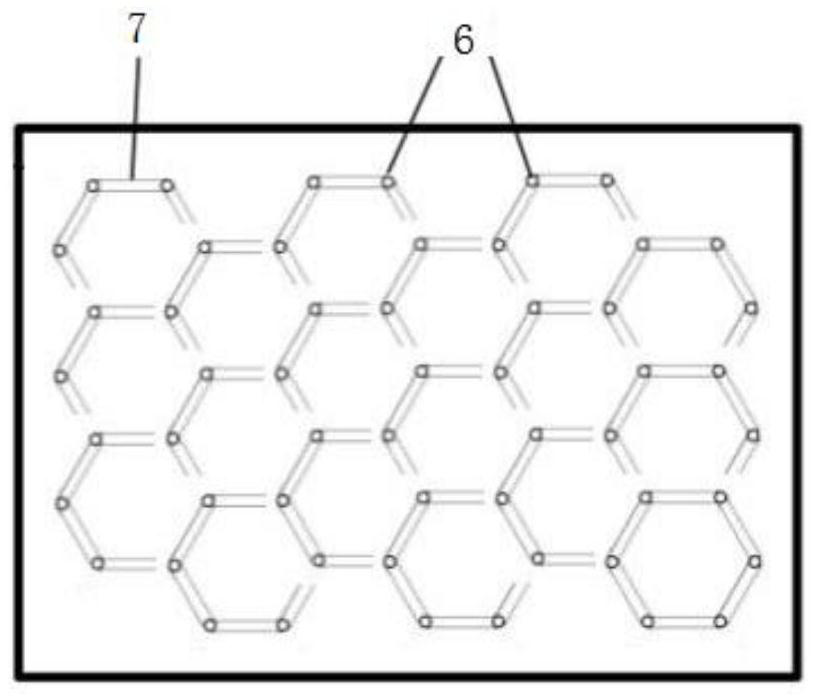

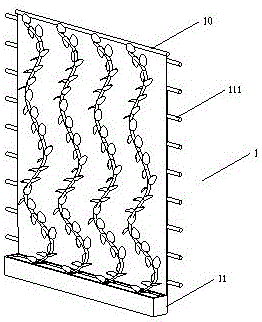

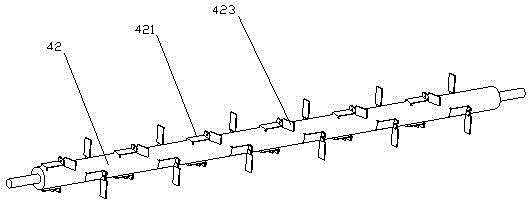

Automatic spraying plant outer wall for henhouse

ActiveCN106489780AAchieve appearance color imageAchieve flushingWatering devicesCultivating equipmentsEngineeringDrive motor

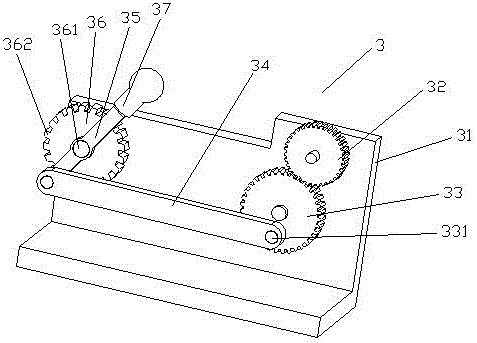

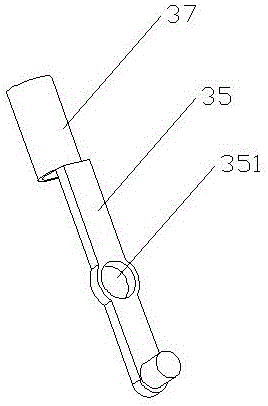

The invention discloses an automatic spraying plant outer wall for a henhouse and belongs to the technical field of livestock outer walls. According to the technical scheme, the automatic spraying plant outer wall for the henhouse comprises two isolating walls oppositely arranged on the side of a henhouse body, guiding mechanisms are arranged on the isolating walls, the isolating walls are net-shaped walls made of a flexible material, rosa multiflora green plant cultivation boxes are arranged on the outer sides of the bottoms of the isolating walls, spraying mechanisms are arranged between the cultivation boxes and the tops of the isolating walls, and the tops of the isolating walls are provided with draw-off mechanism. The automatic spraying plant outer wall has the advantages that by controlling a control valve of a water conveying pipe, a master controller controls a driving motor to drive a driving gear to rotate, the driving gear is meshed with an eccentric gear and drives the eccentric gear to rotate, a swing rod is driven by a connecting rod A to swing, a wedge-shaped limiting block is located in a notch formed by adjacent limiting check blocks, and by controlling the swing rod to swing in a left-right mode, plant blade surfaces on the isolating walls are sprayed and cleaned.

Owner:NEW HOPE LIUHE FEED

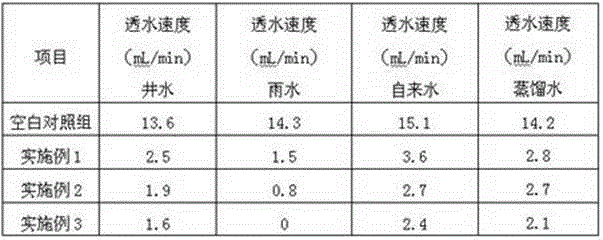

Water-preserving materials and process for preparing same

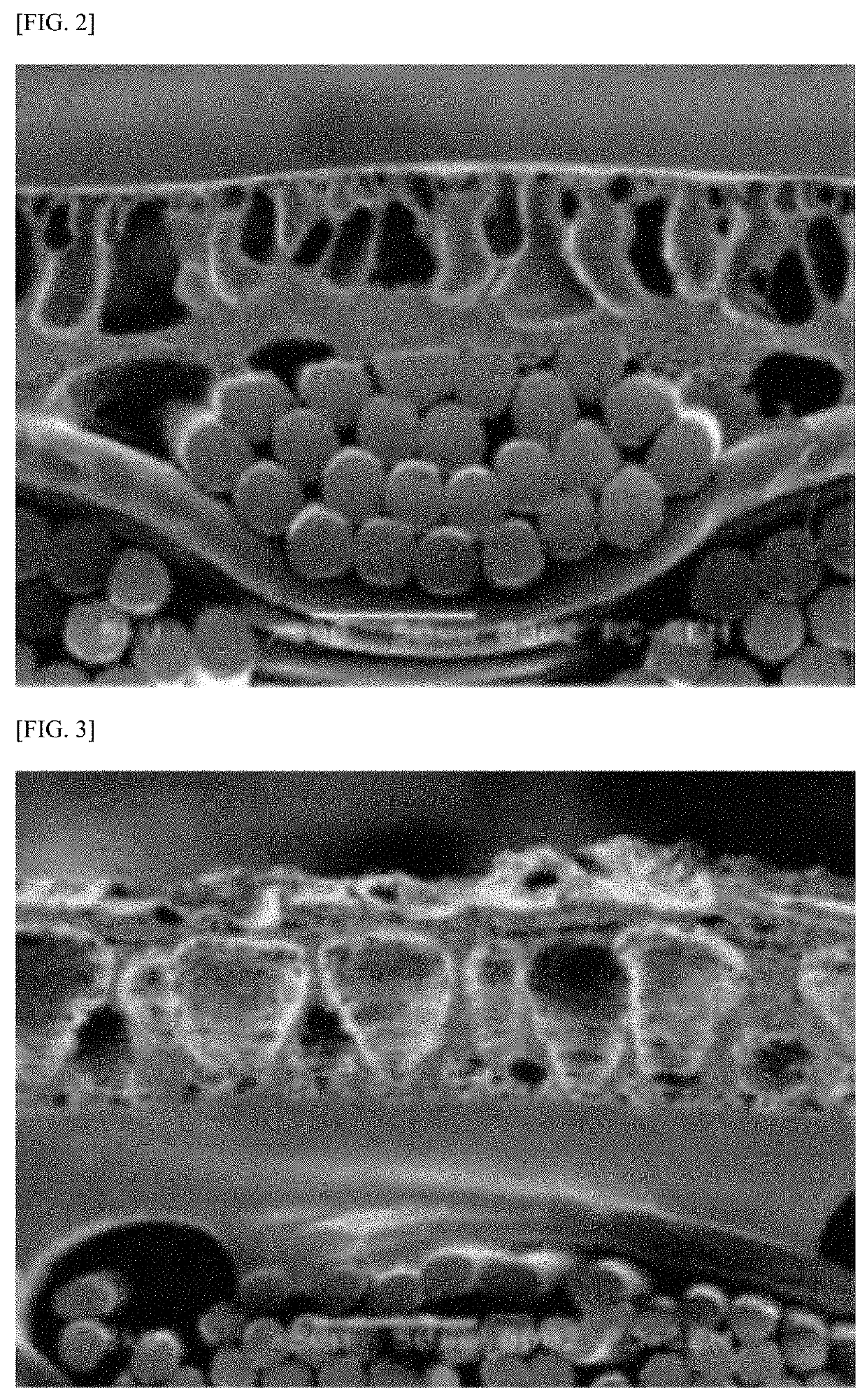

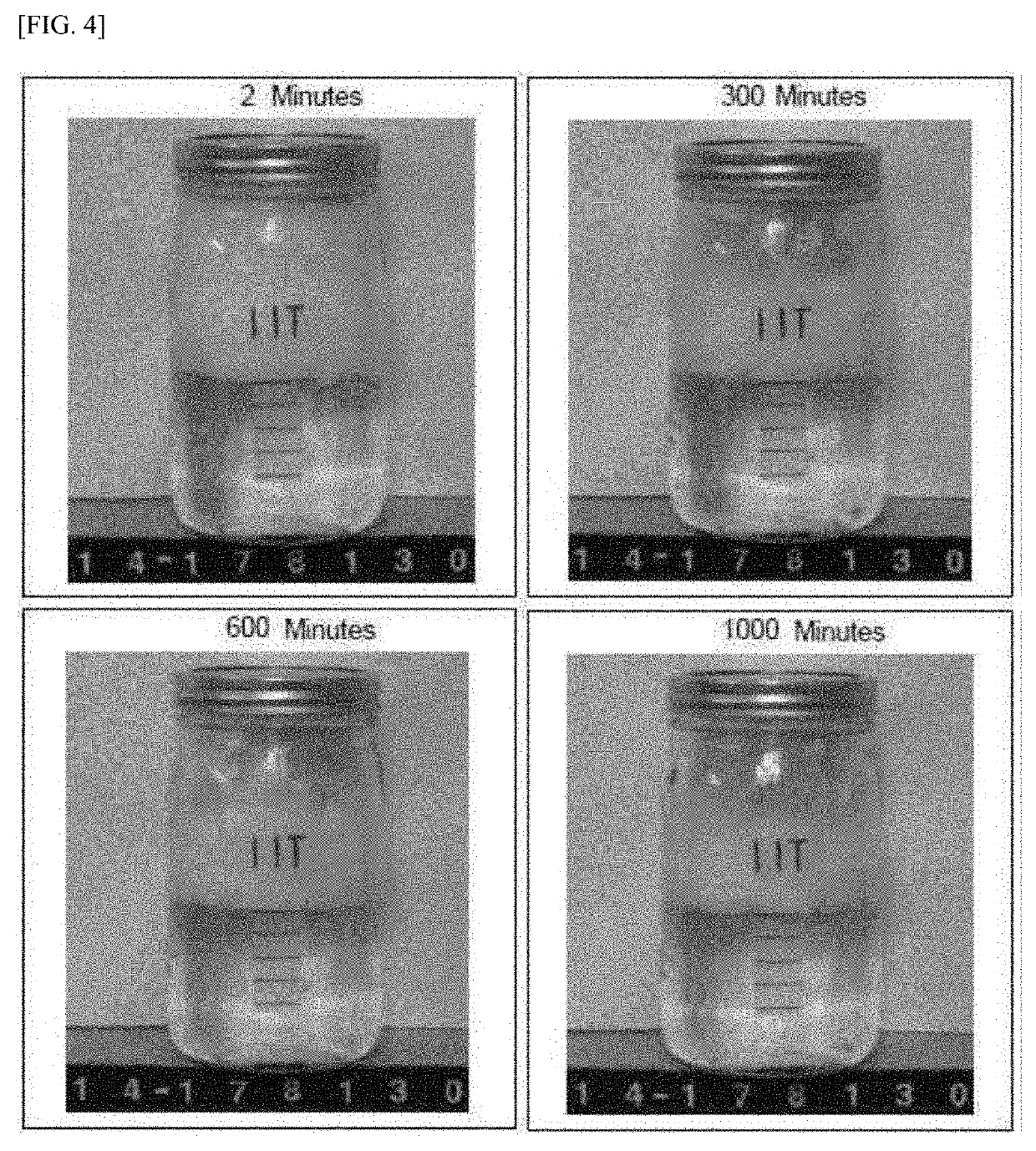

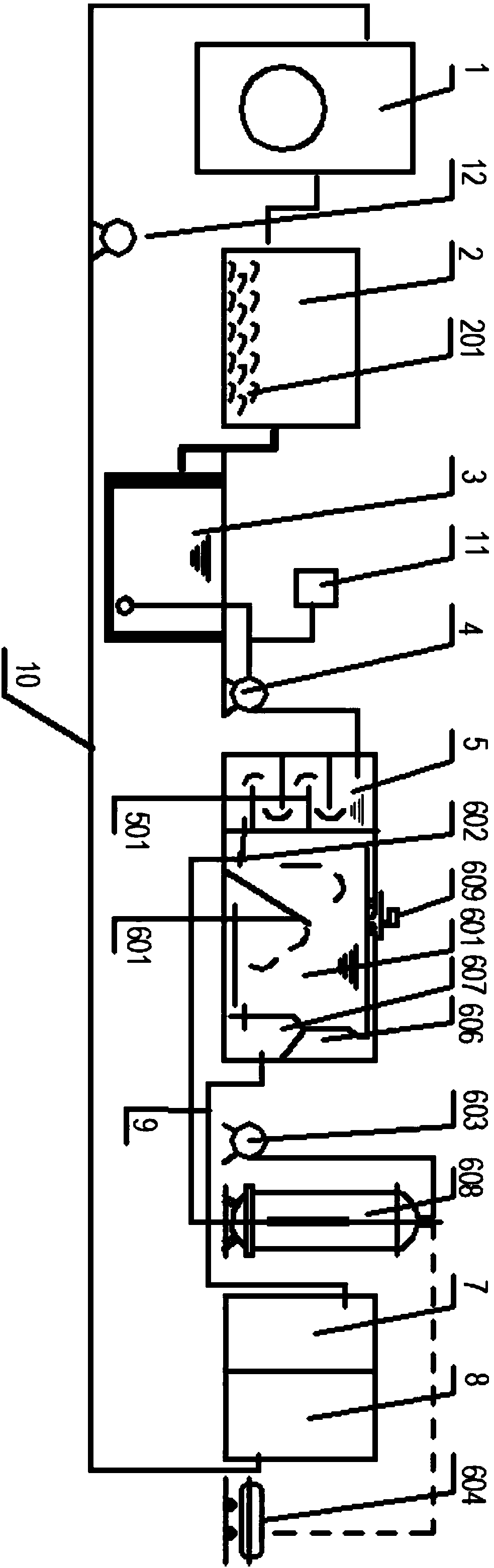

The invention discloses a repeatedly-usable water reserving material and its preparation. The water reserving material comprises alta-mud of size of 1-300nm, 0.1-1 wt% of polyacrylamide and water. The invention comprises the following steps: (1) emulsifying nanometer alta-mud in water for 5 minutes-2 hour under normal temperature; (2) adding polyacrylamide in mixing process; (3) agitating until polyacrylamide and alta-mud incompletely mix to produce said water reserving material. The invention is a high-consistency jelly.

Owner:太原市纳威科技贸易有限公司

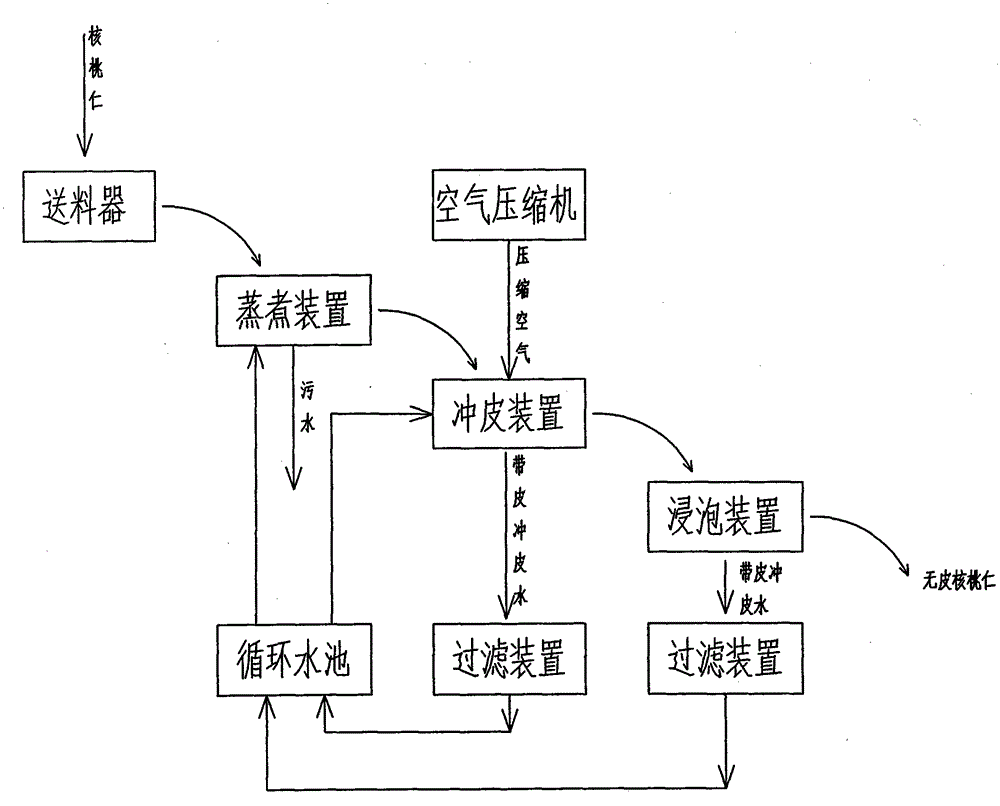

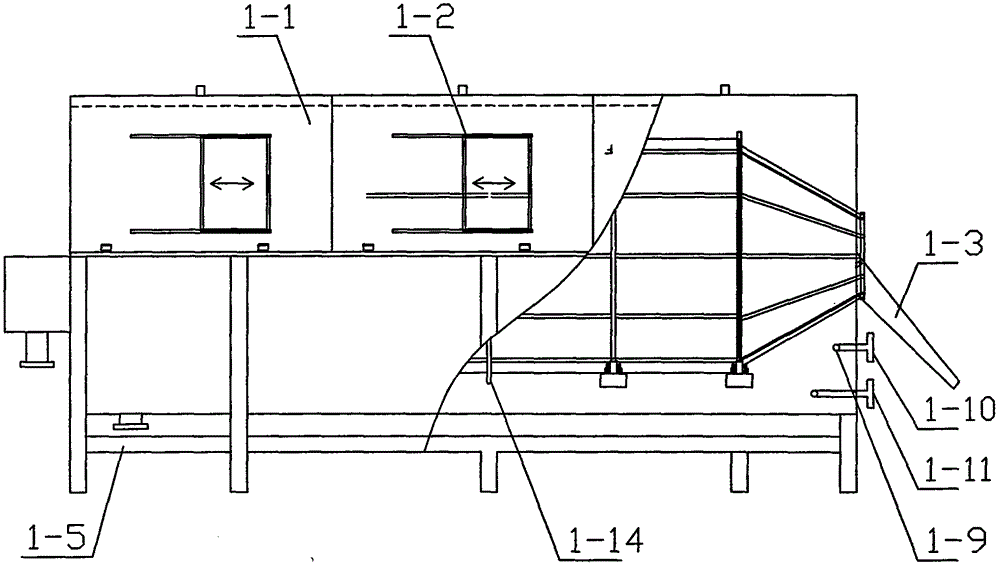

Walnut kernel peeling process

The invention discloses a walnut kernel peeling process. According to the walnut kernel peeling process, steaming and peeling are separated, and a soaking process is added and a rotary drum is used for realizing continuous production; the walnut kernel peeling process is suitable for a flow production line; a steaming rotary drum is used for realizing even steaming, steam is used for heating and the problems of walnut kernel floating and walnut kernel going out upwards due to the rotation of the rotary drum are solved by virtue of steam injection directions; a water-steam mixture is used for peeling; above 20-30% of water resources can be saved; the steam injection directions swing back and forth within a certain angle; peeling by use of a water gun is simulated, so that the walnut kernels can be turned over and peeled sufficiently, and the peeling effect is uniform and consistent and far better than that of artificial water gun peeling, and the peeling treatment rate is above 99.5%; meanwhile, the labor is greatly saved, and more than 95% of labor can be saved; soaking water is used for peeling or supplied to a steaming water tank by use of a water circulating system; the peeling water can be further applied peeling; only when the steaming water is high in color concentration, the water is discharged; the water consumption amount for treating 1 ton of walnut kernels is reduced to 0.6 ton now from 1.2 tons in the past, and the water is saved.

Owner:HEBEI YANGYUAN ZHIHUI BEVERAGE

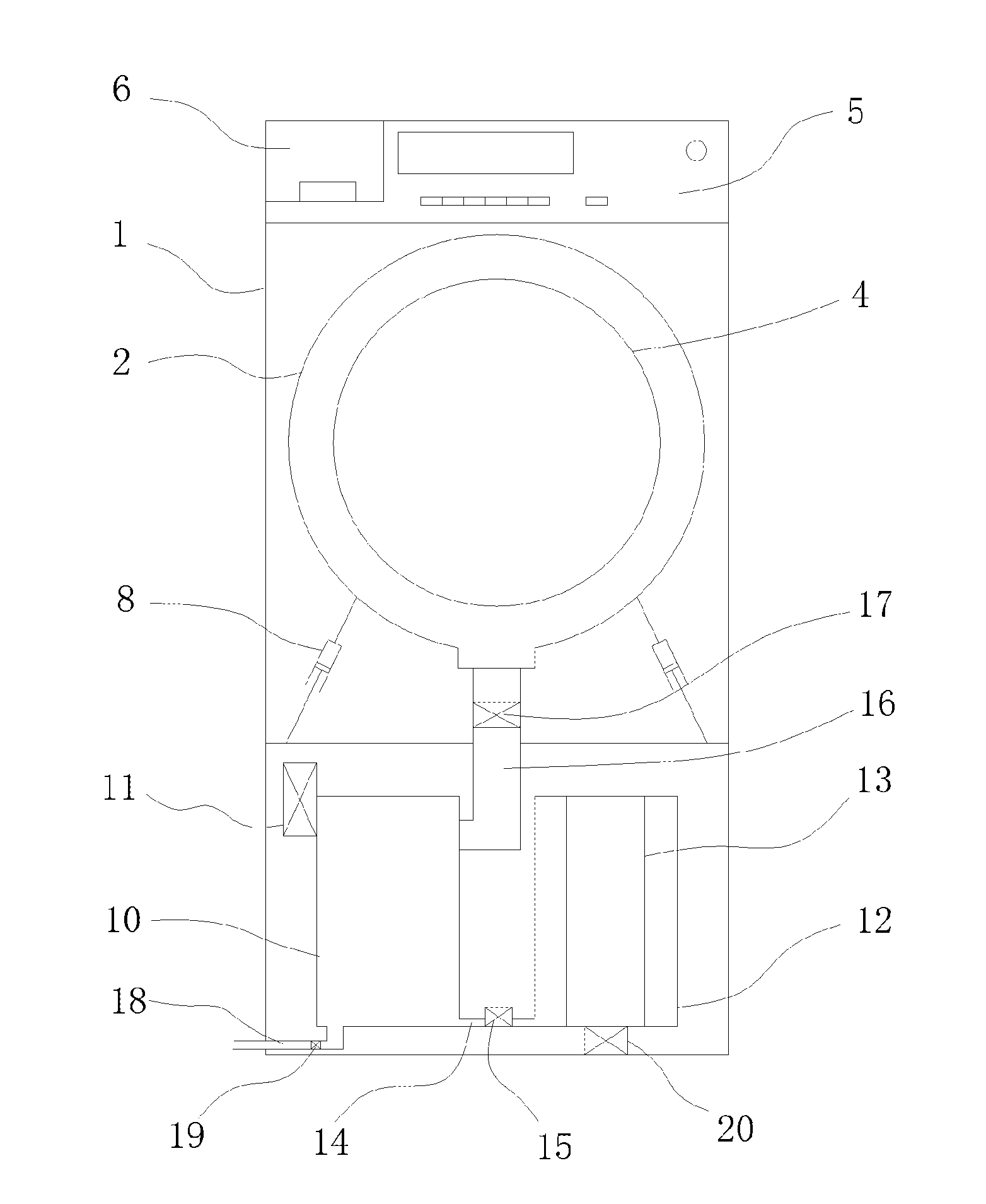

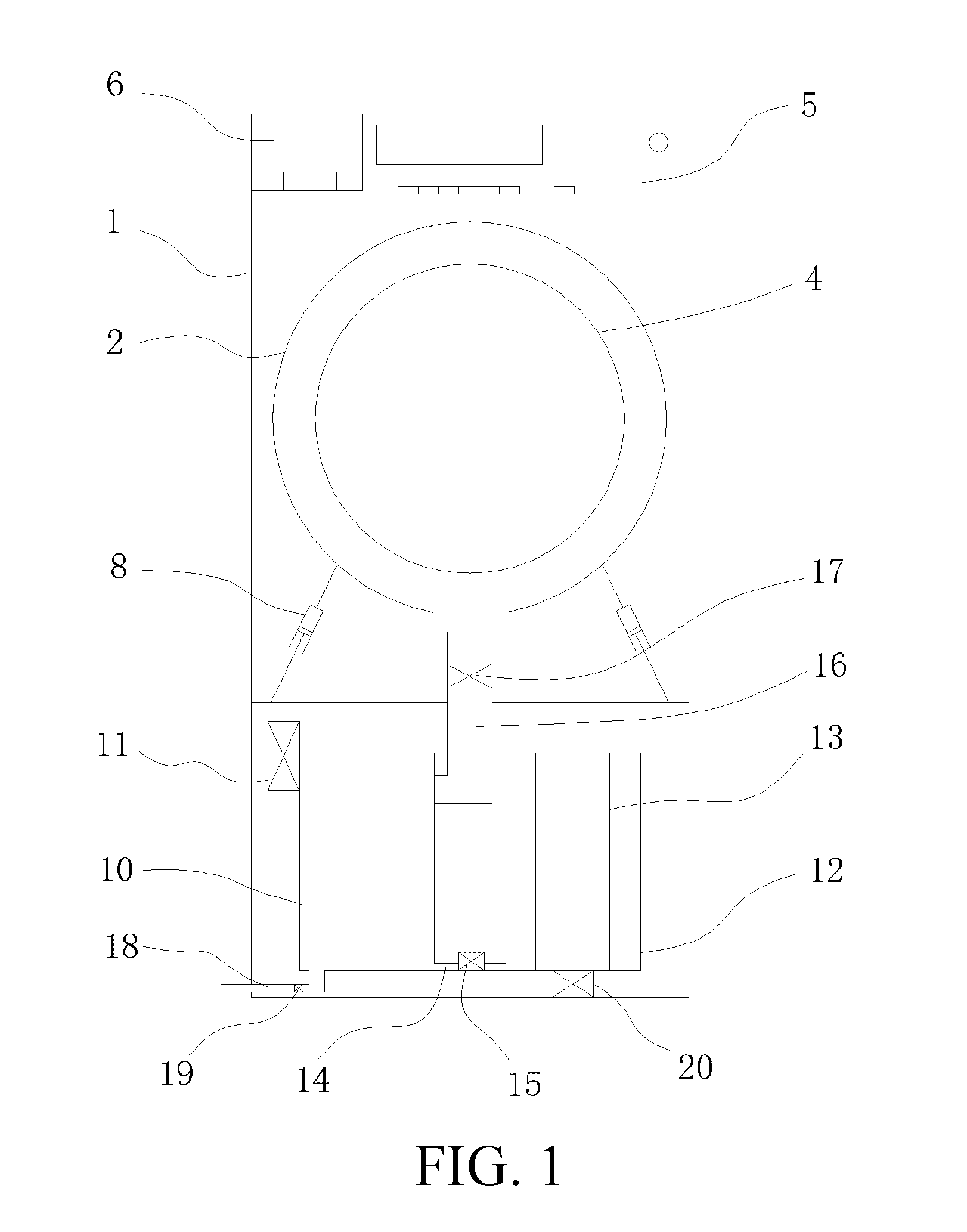

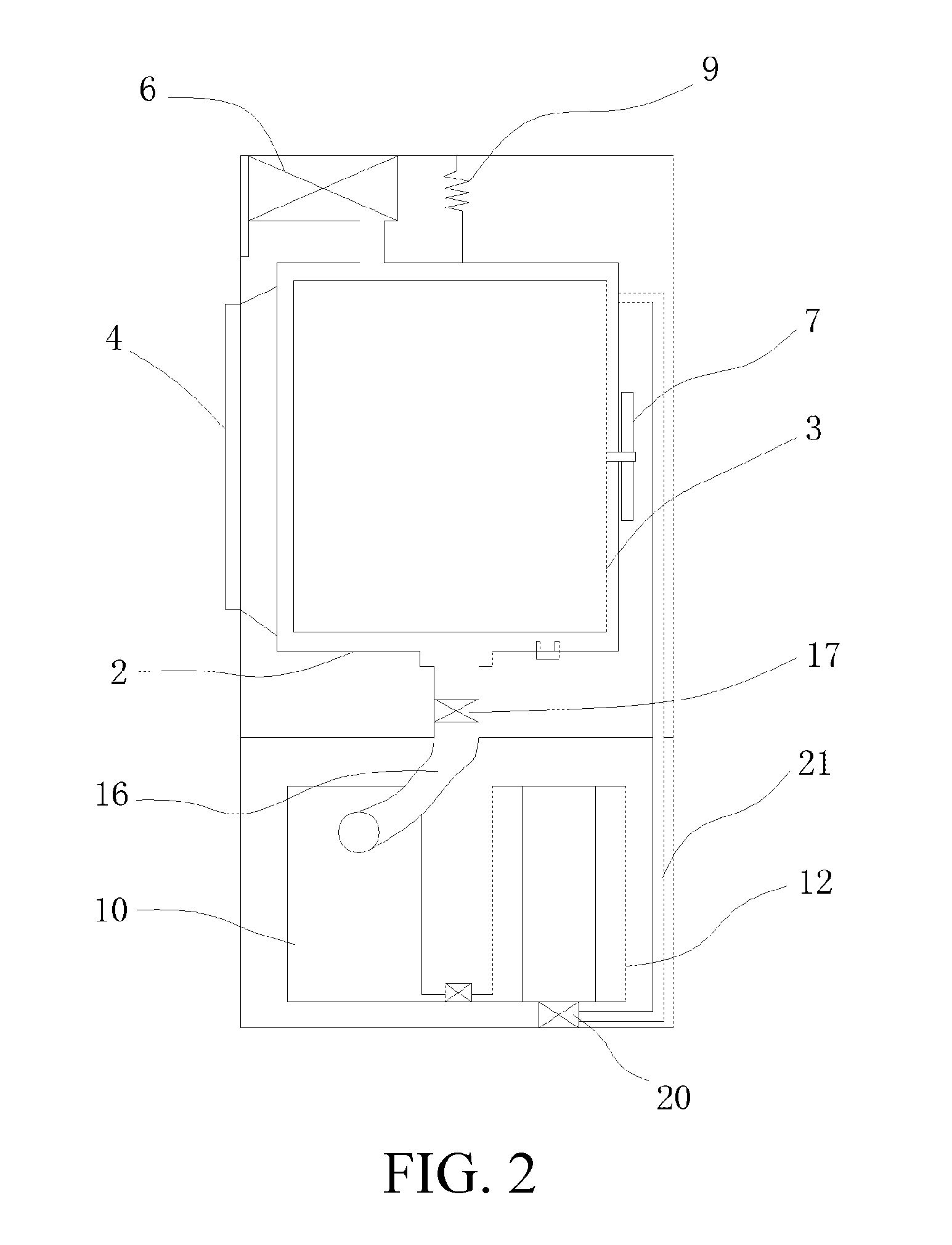

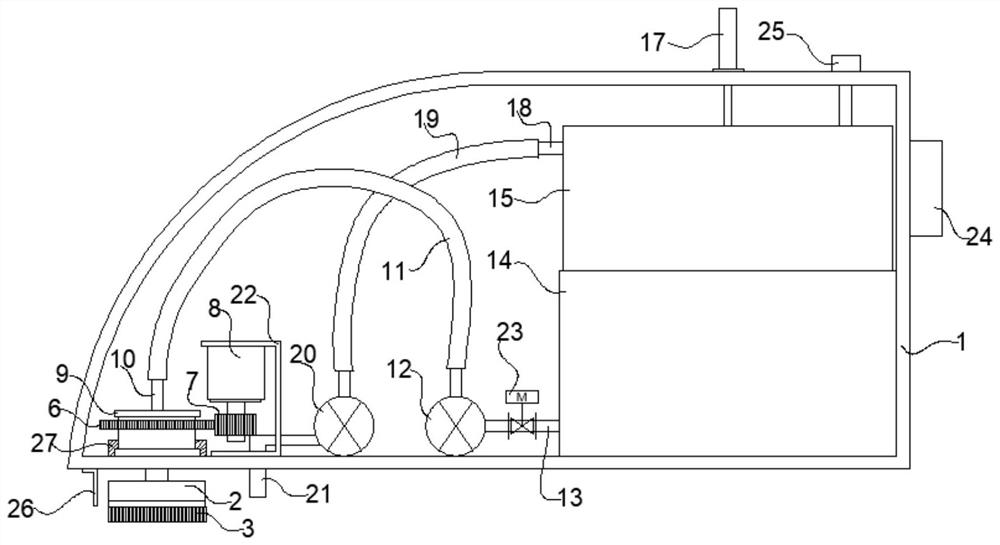

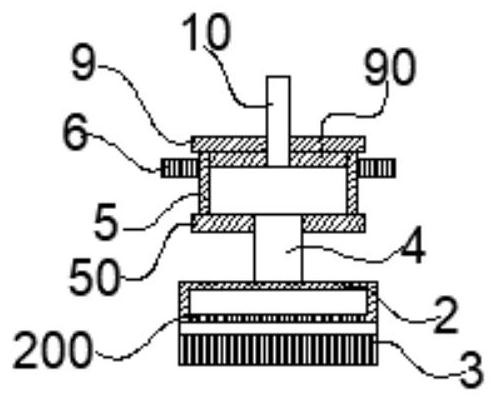

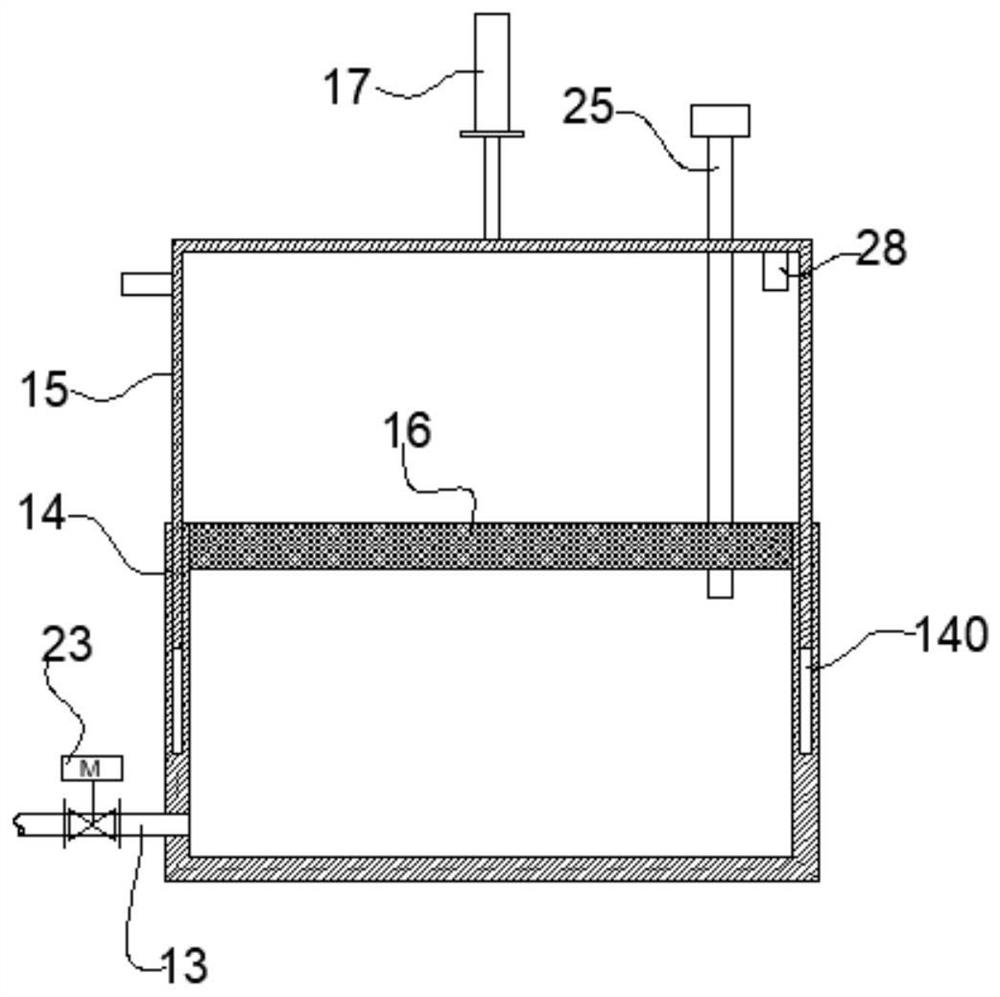

Washing machine with circulated water treatment function and control method therefor

InactiveUS20160201249A1Save water resourcesEnvironmental degradationOther washing machinesDetergent compounding agentsWater treatmentTreatment unit

A washing machine includes a water containing drum, a washing structure arranged inside the water containing drum and a circulated water treatment device arranged under the water containing drum. The circulated water treatment device includes a flocculation treatment unit and a filtering unit. The flocculation treatment unit includes a flocculation container connected to the water containing drum and a flocculation agent dosing device for dosing a flocculation agent into the flocculation container, where water is discharged from the water containing drum to the flocculation container for flocculation treatment. The filtering unit includes a filtering container and a filter net arranged inside the filtering container, the filtering container is in communication with the flocculation container and the water containing drum, respectively, for filtering the water having been flocculation-treated in the flocculation container and discharging same again into the water containing drum for reuse.

Owner:HAIER GRP CORP +1

Water curtain paint spraying chamber and paint spraying method thereof

InactiveCN107225064AIncrease the areaOptimizing the Filtration ProcessLiquid surface applicatorsSpraying apparatusLacquerAgricultural engineering

The invention discloses a water curtain paint spraying chamber. The water curtain paint spraying chamber comprises an overflow tank, a box-shaped frame, a water tank, a water replenishing tank, a high-pressure spraying plate, a spraying water tank, a circulating pump, a circulating loop, a gas-liquid separation bin, a draught fan and a water curtain device. The water curtain paint spraying chamber is characterized in that the overflow tank is fixedly installed on the top of the water curtain paint spraying chamber, the spraying water tank is installed under the overflow tank, and the water curtain device is located on the right side of the spraying water tank; a sliding block is slidably installed on a sliding rail, a hoisting device is fixedly installed under the sliding block, the spraying water tank is installed on the left side of the water curtain device, and the upper end of the spraying water tank is connected with the bottom of the overflow tank. According to the water curtain paint spraying chamber, the water curtain area is increased, the paint mist filtering procedure is optimized, and therefore air is filtered more thoroughly; meanwhile, water in the water tank is reutilized after being filtered, therefore, the processing cost is reduced, and water supply sources are reduced.

Owner:YANCHENG CITY LONGQIANG MACHINERY MFG

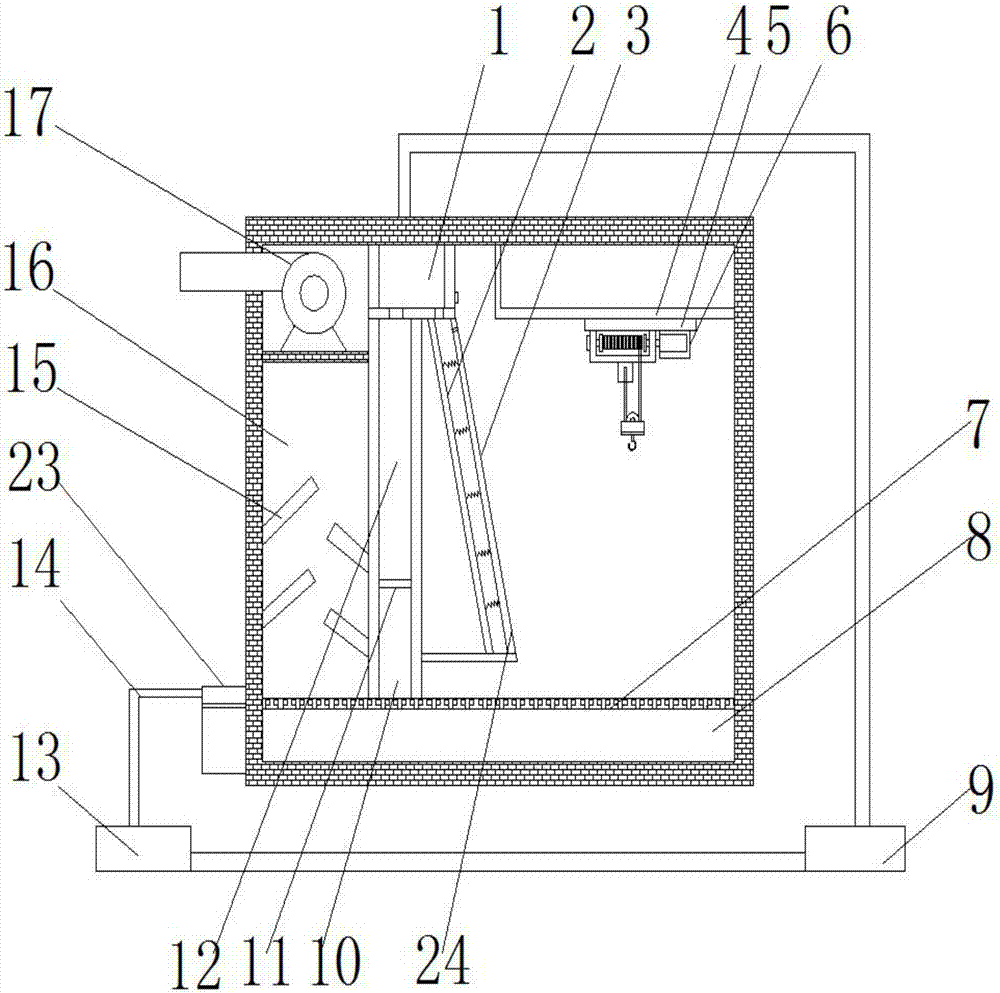

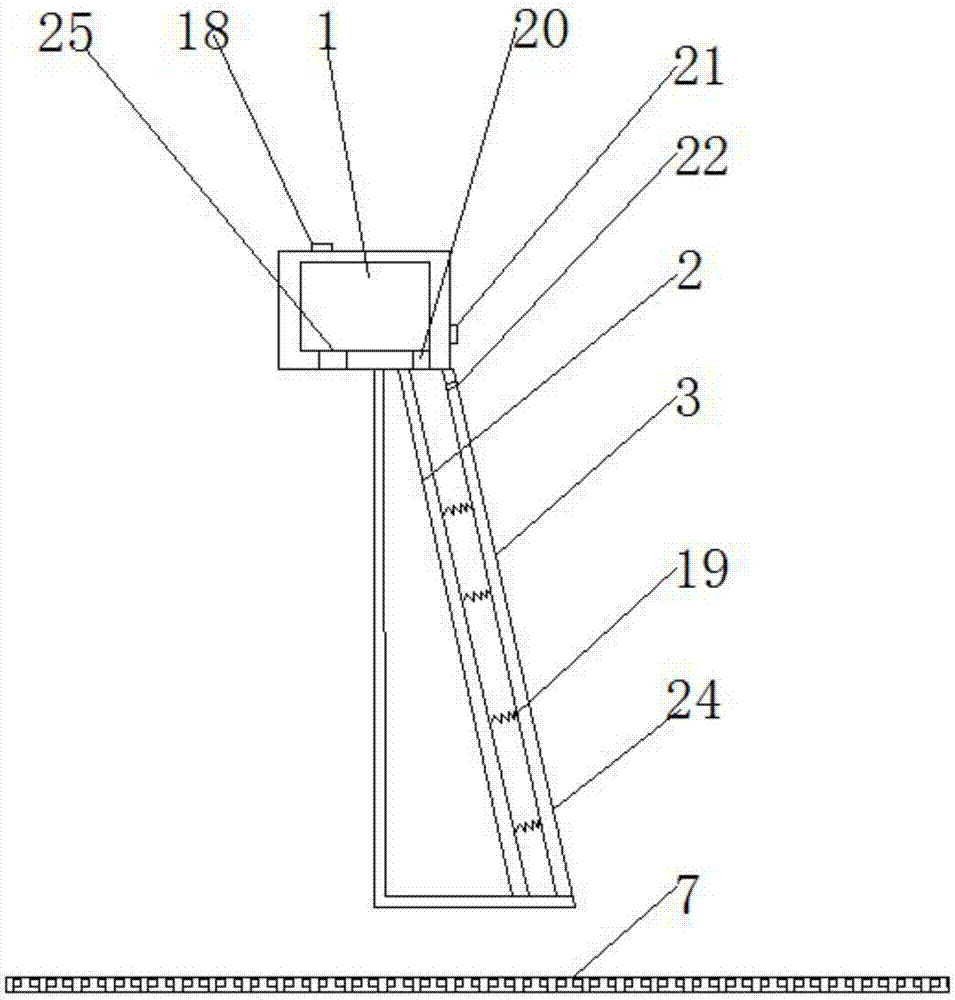

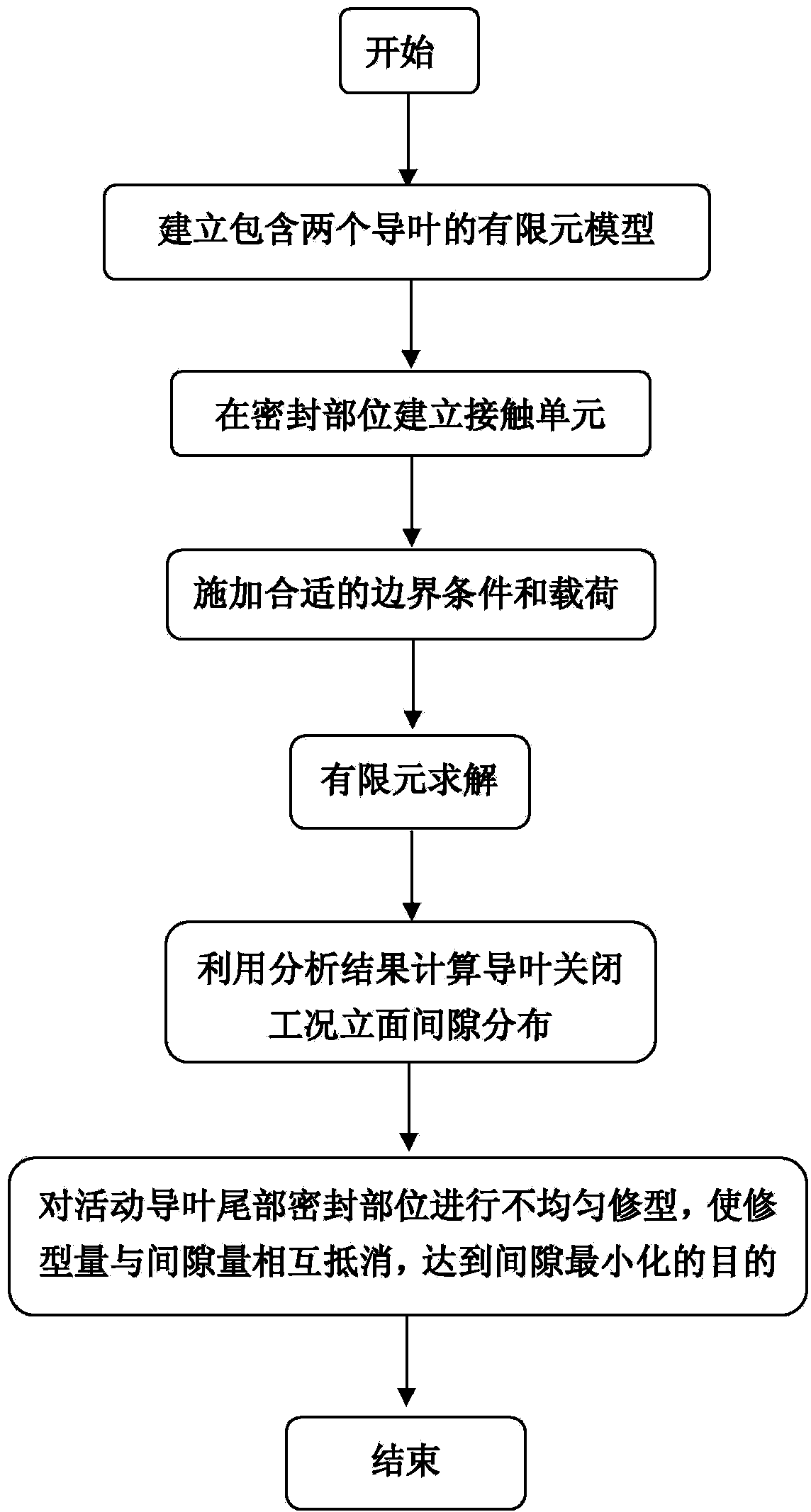

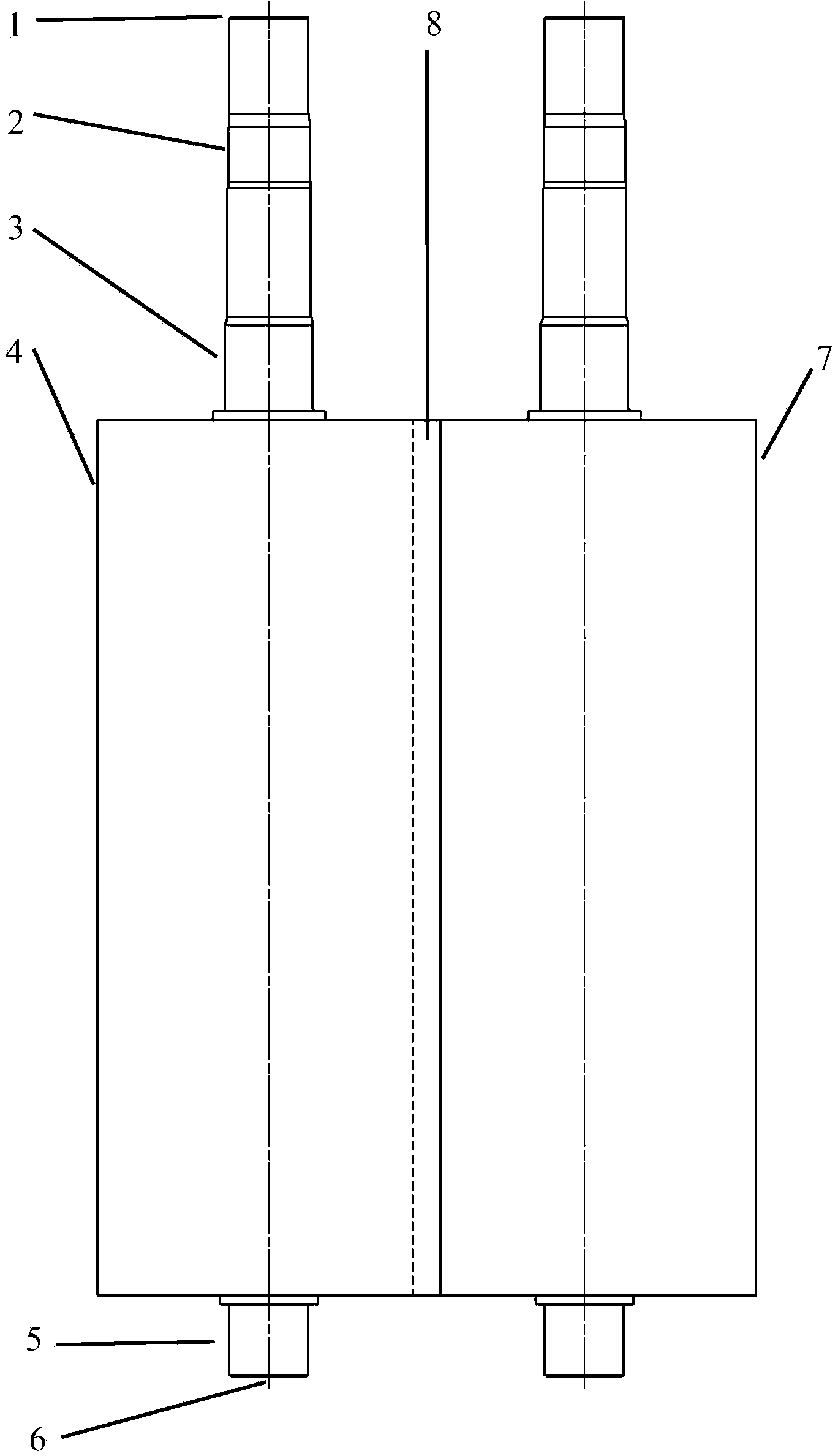

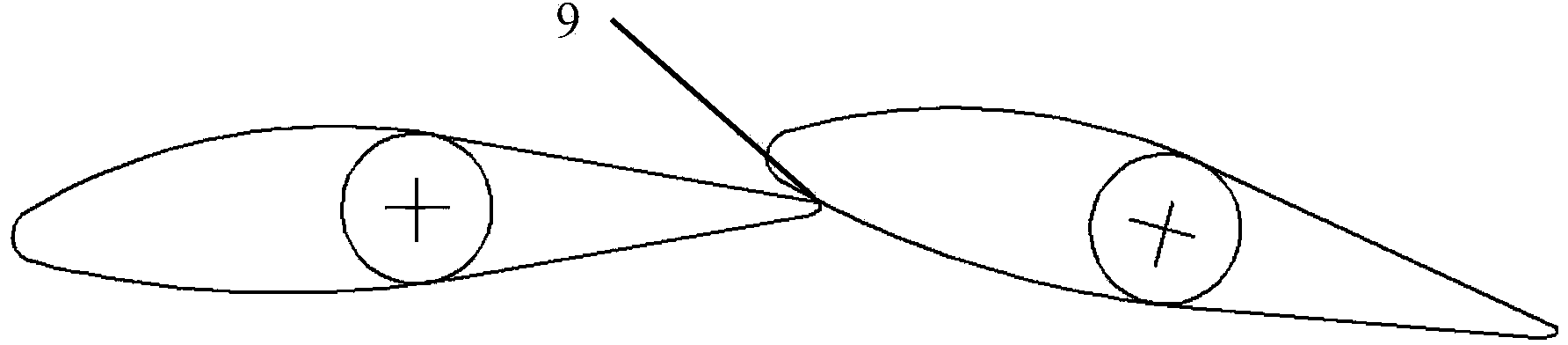

Novel water turbine activity guide vane vertical surface gap optimizing method based on finite element analysis

ActiveCN103530475AReduce water leakageImprove performanceSpecial data processing applicationsWater turbineElement analysis

The invention discloses a novel water turbine activity guide vane vertical surface gap optimizing method based on finite element analysis. The tail shape of a water turbine activity guide vane is modified, the activity guide vane vertical surface gap can be reduced effectively, and the problem that large amount of water leaks when a unit is shut down is solved. According to the method, a contacting unit is utilized to simulate deformation conditions of water turbine activity guide vane hydrostatic shut-down conditions, and a gap, between the head and tail seal lines of a guide vane, calculating method can be derived according to geometry structure and arrangement position of the activity guide vane. Uneven shape modifying is performed on the tail sealed position of the activity guide vane according to acquired a vertical surface gap distributing curve so as to guarantee that the amount of shape modifying and that of the gap are canceled and allow the shape-modified guide vane vertical surface gap to be minimum. By the aid of the method, water leakage amount can be reduced effectively when the guide vane is closed, a large amount of water can be saved, and huge economical benefits are provided to a plant; and meanwhile, material cost increase since a manufacturer blindly pursuits guide vane deformation amount reduction is avoided.

Owner:HARBIN ELECTRIC MASCH CO LTD

Wastewater recycling device and use method

InactiveCN107879554AHigh precisionHigh reuse rateMultistage water/sewage treatmentActivated carbonUltrafiltration

The invention discloses a wastewater recycling device and relates to the technical field of wastewater treatment. The wastewater recycling device comprises a water inlet pipe, a filter tank is arranged on the right side of the water inlet pipe, an acid-alkali neutralizing box is connected to the bottom of the right side of the filter tank by a connecting water pipe, an ultrasonic cleaner is connected to the bottom of the right side of the acid-alkali neutralizing box through a connecting water pipe, an ozone oxidizer is connected to the bottom of the ultrasonic cleaner, an HBR composite biochemical reactor is connected to the bottom of the right side of the ozone oxidizer through a controllable water pipe, a solenoid valve is disposed on the controllable water pipe, an ultrafiltration tankis connected to the bottom of the right side of the HBR composite biochemical reactor through a connecting water pipe, a plasma-purification activated carbon adsorption net is disposed in the inner cavity of the ultrafiltration tank, and a disinfection device is connected with the bottom of the ultrafiltration tank. The wastewater recycling device can ensure full degradation of organic matter andremove nitrogen and phosphorus, so that the water quality reaches the purification standard, chemical production wastewater is purified efficiently, the water recycling rate is improved, and economicbenefits are good.

Owner:叶子毓

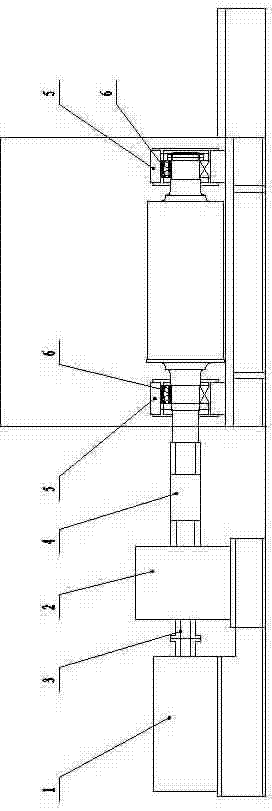

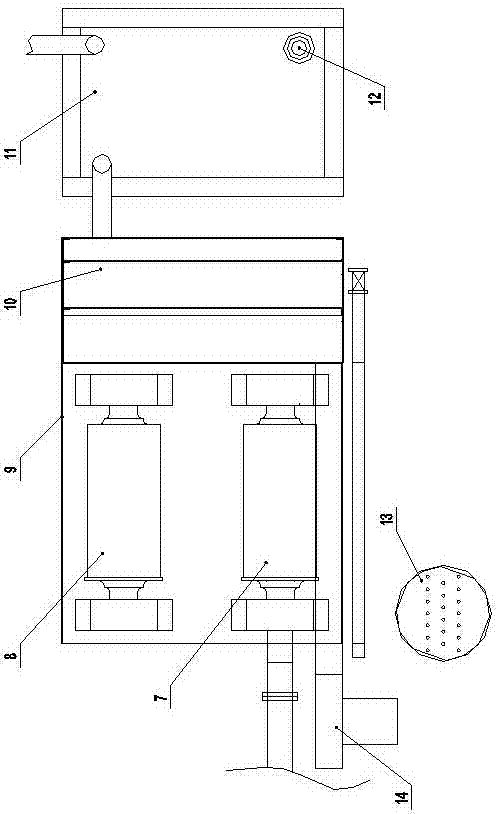

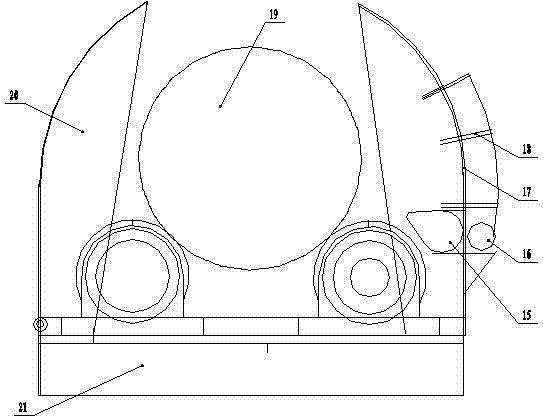

Roller spray quenching equipment

InactiveCN104846169AUniform hardnessComply with different hardness requirementsFurnace typesHeat treatment furnacesPressure stabilizationPore water pressure

The invention relates to roller spray quenching equipment. A motor in the transmission system refers to a frequency-conversion adjustable-speed motor; the motor is connected with a driving tug by virtue of a reducer with a certain speed ratio so as to provide corresponding linear velocity for the roller; a water supply system comprises a water collection tank for collecting wastewater; the water collection tank is connected with a filtering water tank; the filtering water tank is connected with a circulating water pool; the circulating water pool provides cooling water for a pressure stabilization tank by virtue of a water pump; the pressure stabilization tank provides injection water for a water nozzle by virtue of a water distributor; a safety shield is arranged on the upper part of the rack in a supporting system; and a high-temperature roller positioned in a rotating state is enclosed in the safety shield. The linear velocity of the roller body is changed by virtue of the frequency-conversion adjustable-speed motor, so that a good spray quenching effect is achieved; all the pipelines of the water supply system pass through the same pressure stabilization tank, the water pressure of each water nozzle is constant, the water nozzles are basically positioned in the same water pressure state, the uniformity of axial hardness of the roller body is guaranteed, and the water resources can be well saved by virtue of the water circulation system; and moreover, the equipment safety can be improved by virtue of the safety shield.

Owner:唐山市国宗元裕龙重工有限公司

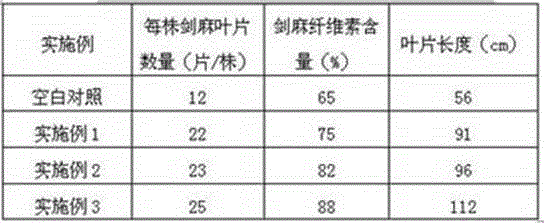

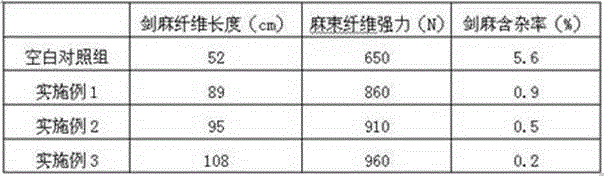

Seepage-proof material containing locust bean gum and method for planting agave sisalana in saline-alkali soil by using same

InactiveCN106047354AIncrease productionHigh in celluloseCultivating equipmentsPlant cultivationFiberSodium Bentonite

The invention provides a seepage-proof material containing locust bean gum. The seepage-proof material is characterized by further comprising gypsum powder, tea polyphenols, chelated iron fertilizer, bentonite, bio-fertilizer, pig bone collagen, taosha powder, hydroxy propyl starch and neem extract. The invention further provides a method for planting agave sisalana in saline-alkali soil by using the seepage-proof material containing locust bean gum. The seepage-proof material containing locust bean gum is characterized by comprising a flattening ditching step. When the seepage-proof material containing locust bean gum is adopted to plant agave sisalana in the saline-alkali soil, the seepage-proof material has effects of improving agave sisalana yield, increasing agave sisalana cellulose content and increasing length of agave sisalana. When the seepage-proof material containing locust bean gum is adopted to plant agave sisalana in the saline-alkali soil, the effects of increasing the length of agave sisalana, improving strong force of agave sisalana bundle fibers and reducing impurity rate of agave sisalana can be improved.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

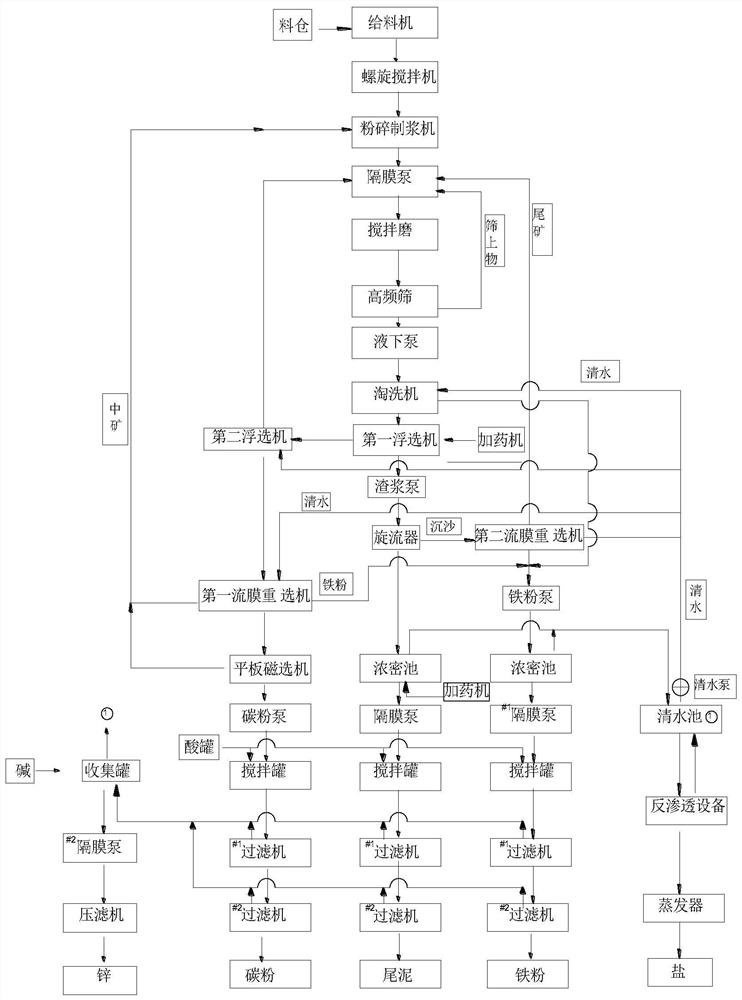

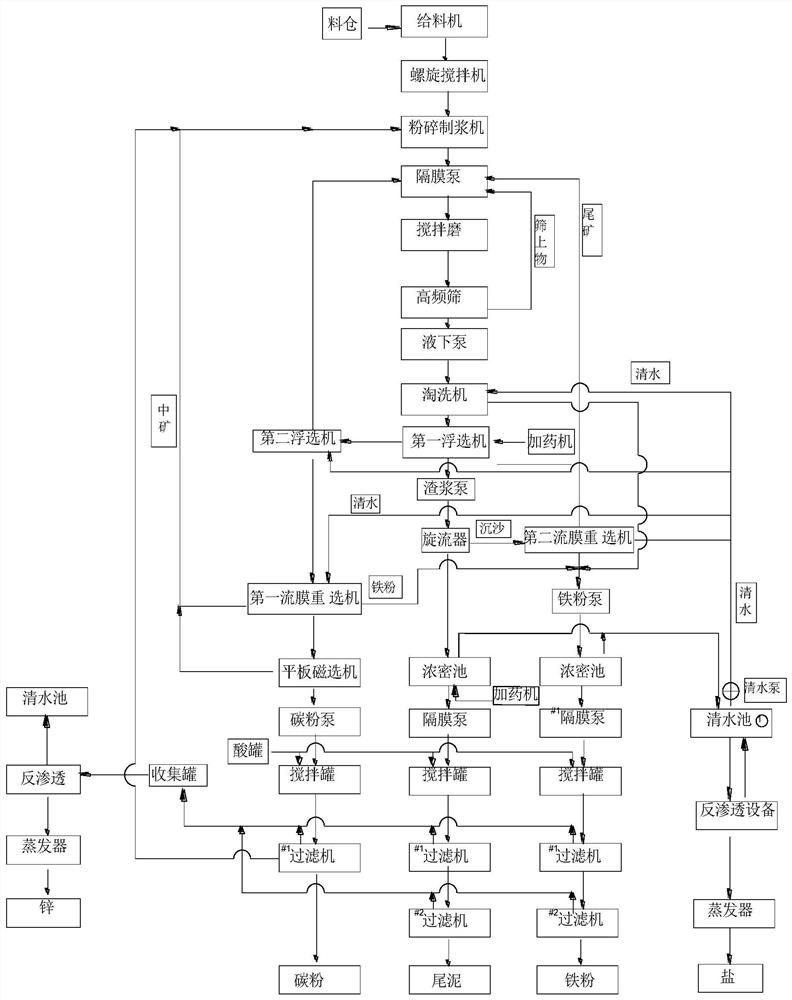

Cloth bag dedusting ash sorting process

The invention relates to the technical field of mineral machining, and provides a steel mill cloth bag dedusting ash sorting process which comprises the following steps that fluid materials enter a diaphragm pump to be ground, ground mortar is lifted to a high-frequency screen by a crushing pulping machine, undersize materials of the high-frequency screen automatically flow to an elutriator for sorting, a foaming agent and a collecting agent are added into tailing slurry discharged from the elutriator, the tailing slurry enters a mineralization tank, after mineralization, the tailing slurry enters a first flotation machine and a second flotation machine, then the tailing slurry enters a first flow film gravity separator, the first flow film gravity separator generates three products, namely iron powder, middlings and tailings, and carbon powder, iron powder, tailing mud cakes and salt are further separated. By means of the above technical scheme, the problem that blast furnace cloth bag dedusting ash is not fully recycled in the related technology is solved.

Owner:SHANXI TONGCAI IND & TRADE

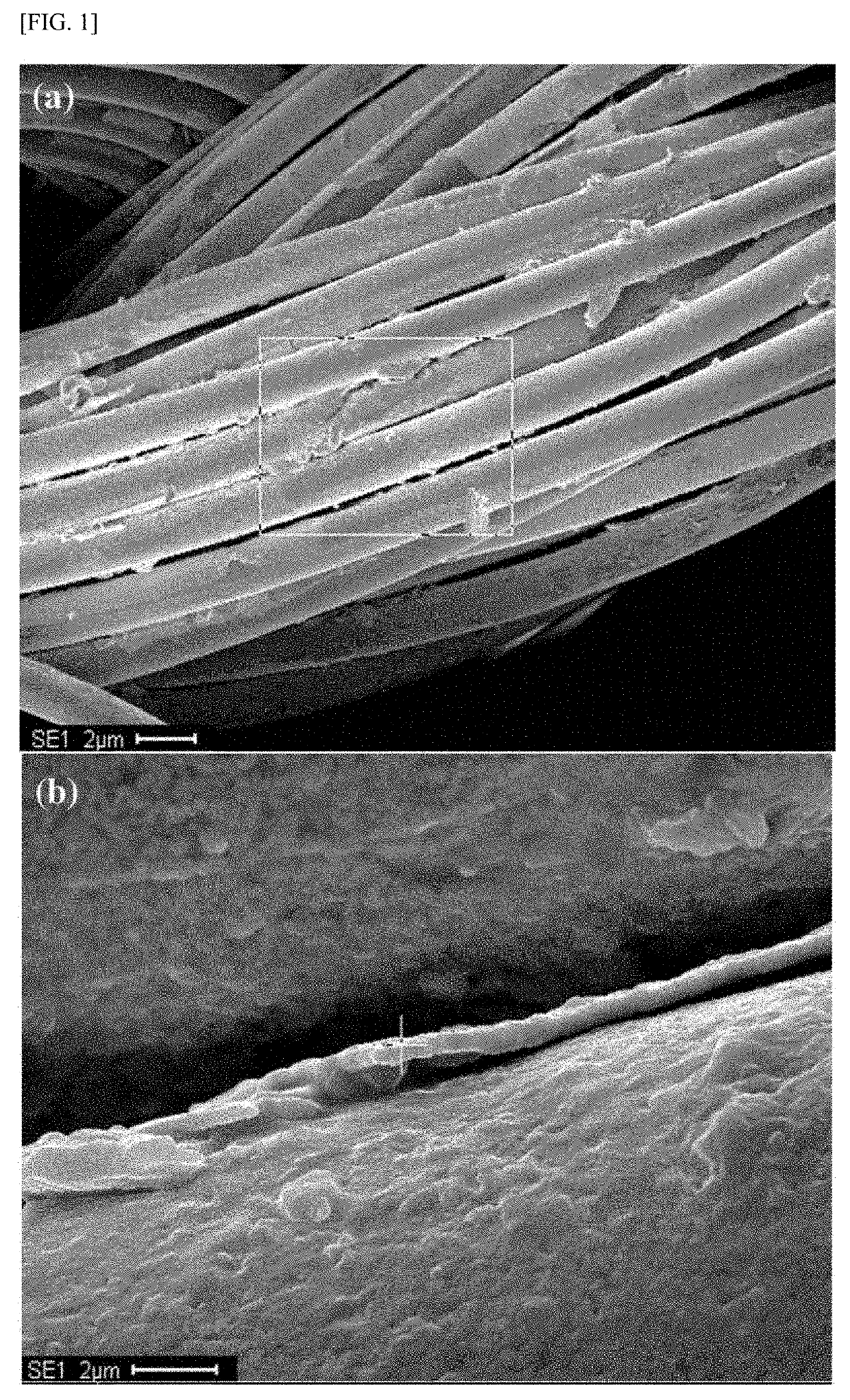

Water-repellent fabric and water-repellent down product comprising the same

ActiveUS20190352842A1Improve insulation effectReduce the number of washesSynthetic fibresLiquid repellent fibresEmulsionMoisture

A method of preparing a water-repellent and moisture-permeable fabric, includes: preparing a water-repellent fabric by: immersing a raw fabric in a non-fluorinated water-repellent emulsion containing a non-fluorinated water repellent and an aqueous blocked polyisocyanate crosslinking agent; and drying and curing the raw fabric, which has been immersed, at a temperature of 150° C. to 200° C.; applying a polyurethane-based moisture-permeable coating liquid to the water-repellent fabric; and drying the water-repellent fabric while increasing a temperature from 100° C. to 150° C.

Owner:DELIGHTS& GLOBAL CO LTD

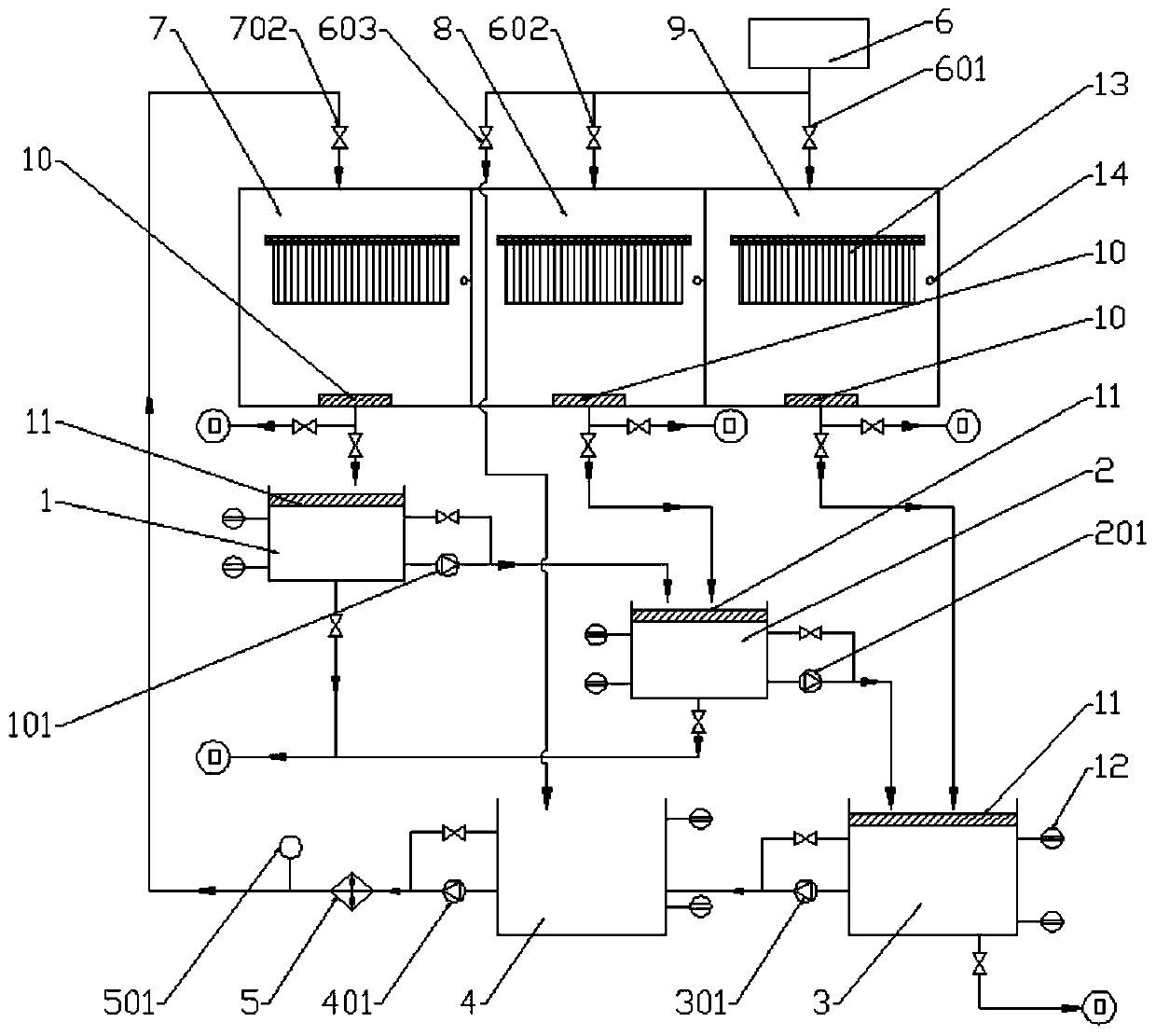

Washing wastewater recycling system

InactiveCN111099761AHigh cleaning time efficiencySmall footprintSpecific water treatment objectivesMultistage water/sewage treatmentChlorine dioxideActivated carbon filtration

The invention discloses a washing wastewater recycling system which comprises a water delivery pipeline, and a washing machine, a sedimentation tank, an air floatation treatment chamber, a sewage pump, a folded plate reaction chamber, an air floatation reaction chamber, an activated carbon filtering chamber and a chlorine dioxide disinfection chamber which are sequentially arranged on the water delivery pipeline, and a water return pipeline connected with the washing machine is further arranged on the chlorine dioxide disinfection chamber; an air floatation reaction unit comprises the air floatation reaction chamber, a releaser, an air dissolving pump, an air compressor and an air dissolving water pump; the bottom of the air floatation reaction chamber is connected with the bottom of a dissolved air tank through the releaser, one side of the upper end of the dissolved air tank is connected with the air dissolving pump, and the other side is connected with an air machine; a sludge tankis arranged at the upper part of the right end in the air flotation reaction chamber, and a dissolved air water storage tank is arranged at the lower part of the right end in the air flotation reaction chamber and is connected with the activated carbon filtering chamber through a water conveying pipeline. The washing wastewater recycling system can be independently suitable for each washing workshop, and is short in purification time, small in occupied area, high in sewage treatment efficiency and high in water resource utilization rate.

Owner:上海播利信息科技有限公司

Silicon wafer de-gluing machine and control method thereof

PendingCN110137113AReduce usageMeet the requirements of sprayingTreatment involving filtrationSemiconductor/solid-state device manufacturingWater dischargeWater source

The invention provides a silicon wafer de-gluing machine which comprises a primary filter box which is communicated with a first tank and used for recovering waste water discharged from the tank; a secondary filter box which is communicated with the primary filter box and used for filtering the water discharged from the primary filter box; a tertiary filter box which is communicated with the secondary filter tank and a third tank and used for filtering the water discharged from the secondary filter box and recovering the waste water discharged from the third tank; a water storage tank which iscommunicated with the tertiary filter box and the first tank and used for storing water discharged from the tertiary filter tertiary and supplying spray water to the first tank; a heater which is isarranged between the water storage tank and the first tank and used for heating water discharged from the water storage tank; a pure water source which replenishes the water storage tank with the spray water; and a controller which detects existence of silicon wafers sprayed in the spray tank by position sensors arranged in the first tank, the second tank and the third tank and discharges the spray water from the water storage tank and / or the pure water source. The invention also provides a control method of the silicon wafer de-gluing machine. The surface quality of the silicon wafer can be improved, the spray water can be recycled, the production cost can be reduced and the product quality can be improved.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

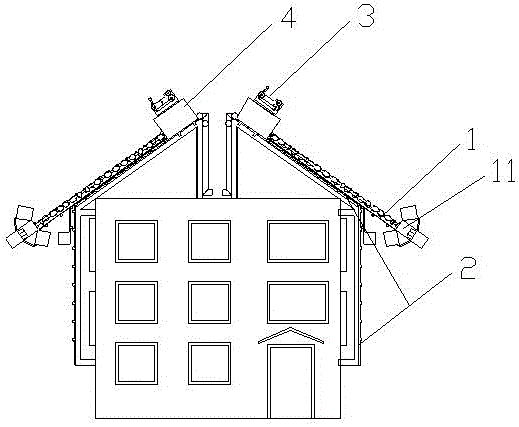

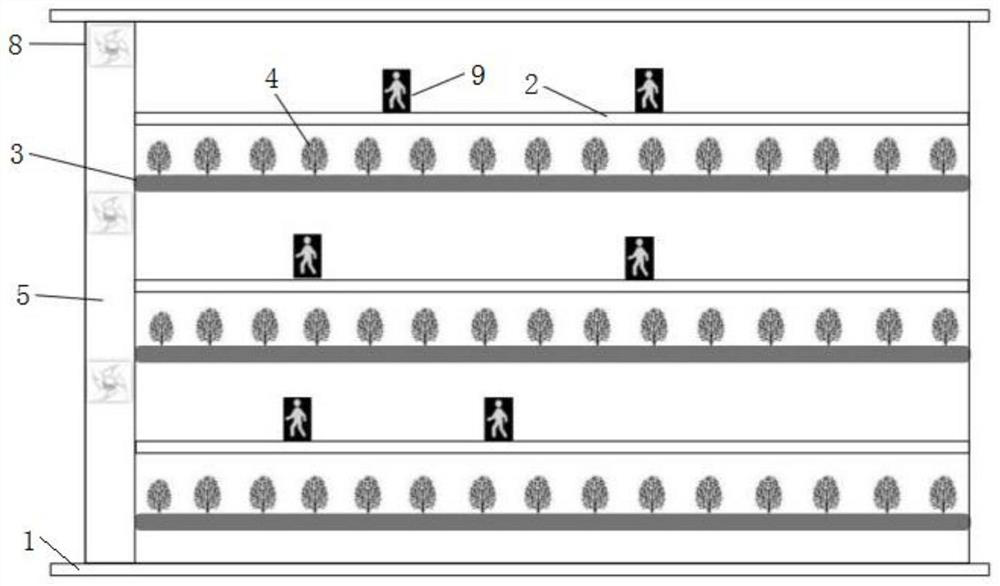

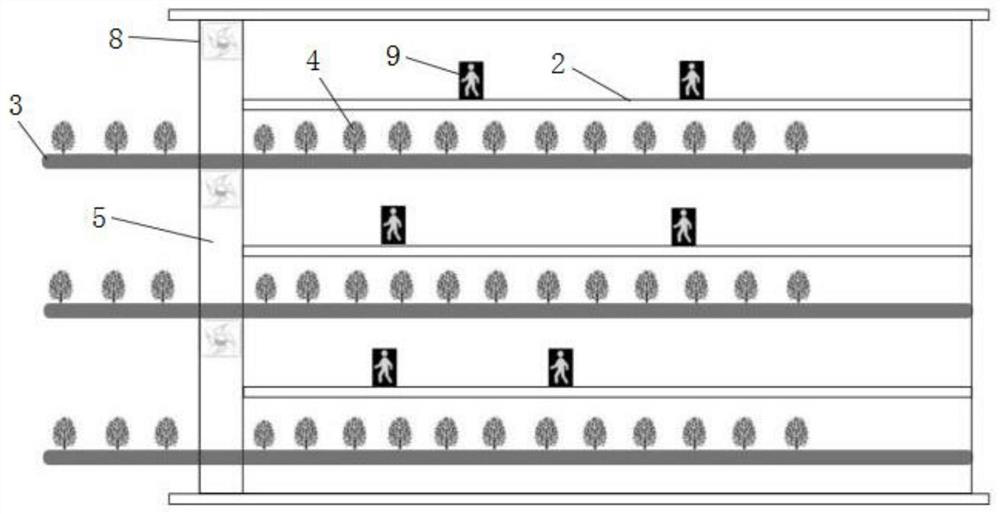

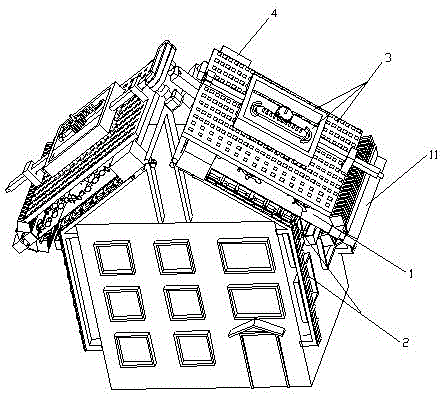

Ecological building system

InactiveCN113585816ARelieve stressSave water resourcesPlant cultivationCultivating equipmentsEnvironmental resource managementFresh air

The invention belongs to the technical field of ecological buildings, and particularly relates to an ecological building system. A telescopic plant planting layer is additionally arranged on the basis of an existing building, and the telescopic mode comprises but is not limited to a track and a caterpillar band. According to the actual requirements of plants planted on the plant planting layer, the plants are in a sunlight irradiation or rainwater irrigation state, the plant planting layer and a ventilation system of the building are connected with each other, ventilation is carried out in the building, and the nourishing of the plants and the building are effectively combined together, so that fresh air discharged by the plants forms an internal circulation in the building, residents can breathe fresh air at any time, enjoy beautiful scenery under feet, relax mood and relieve pressure to a certain extent, redundant waste water for irrigating the plants can also form an internal circulation in the building, and water resources are effectively saved; and the ecological building system is simple in structure, practical, effective and beneficial to urban development.

Owner:QINGDAO ZHIHUICHENGSHI IND DEV

Novel boiler

The invention discloses a novel boiler. The novel boiler comprises a boiler body. The novel boiler is characterized in that a water tank is arranged at the upper portion of the interior of the boilerbody; and a fuel filling opening is formed in the lower portion of the boiler body; a grate is arranged at the position, corresponding to the fuel filling opening, of the interior of the boiler body;a water inlet pipe is arranged on one side of the water tank, a water outlet pipe is arranged on the other side of the water tank, and an ash flushing backflow pipe is arranged at the position, corresponding to the grate, of the water outlet pipe; and a control valve is arranged at the connecting position of the water outlet pipe and the ash flushing backflow pipe, and the control valve can control water flow to flow into the dust flushing backflow pipe or flow into the water outlet pipe. The novel boiler has the advantages that coal ash is conveniently collected, water resources are saved, energy conservation and emission reduction are achieved, and incrustation in the water tank can be removed conveniently.

Owner:HEZE BOILER FACTORY

Shiitake mushroom culture method

InactiveCN105474984AEmission reductionReduce manufacturing costHorticultureEcological environmentWater resources

The invention relates to a shiitake mushroom culture method and belongs to the cultivation techniques of edible mushrooms. Compost in the shiitake mushroom culture method provided by the invention comprises the components in parts by weight: 8-9 parts of fresh corn coatings and 3-4 parts of fresh corn stigma. The method comprises the steps of: simultaneously processing the fresh corn coatings and the fresh corn stigma by using smashing and kneading machine to respectively process the corn coatings into flexible filaments, cutting the corn stigma short and snapping the corn stigma, and fully mixing the two processed raw materials at the same time, wherein the water content of the compost is controlled at 66-71%; and after the compost is processed, using the compost for shiitake mushroom culture or filling the compost in a storer and compacting the compost in a storage room and hermetically storing the compost. By virtue of annual production of harmless shiitake mushrooms by using waste materials after processing of sweet corn, wastes are turned to wealth, resources are recycled, water resources can be saved, sewage discharge is reduced, the ecological environment is protected, the production cost is lowered, the product quality is enhanced, and the economical benefit is increased.

Owner:QINGDAO SEIICHI INTPROP SERVICE CO LTD

Volvaria volvacea cultivation method

InactiveCN101692771BMeet the nutritional requirements for growth and developmentFull of nutritionBio-organic fraction processingOrganic fertiliser preparationEcological environmentAdditive ingredient

The invention relates to a volvaria volvacea cultivation method and belongs to the edible mushroom cultivation technology. The ingredients of compost include 7-8 parts of fresh corn coating and 2-3 parts of fresh corn stigma. The method includes the steps of simultaneously processing the fresh corn coating and the fresh corn stigma with a grinding rubbing machine so that the corn coating is processed into soft threadiness and the corn stigma is cut short and snapped, meanwhile fully mixing the two processed raw materials and controlling the water content of the compost within 65-70 percent; and after processed, the compost can then be used for volvaria volvacea cultivation or filled in a container or a storage room to be compacted, sealed and stored. The method utilizes the waste materials after processing sweet corns to produce nuisanceless volvaria volvacea yearly, thus changing waste materials into things of value, recycling resources, saving water resource, reducing sewage discharge, protecting the ecological environment, reducing the production cost, improving the product quality and increasing economic benefit.

Owner:广州市白云区农业科学试验中心 +1

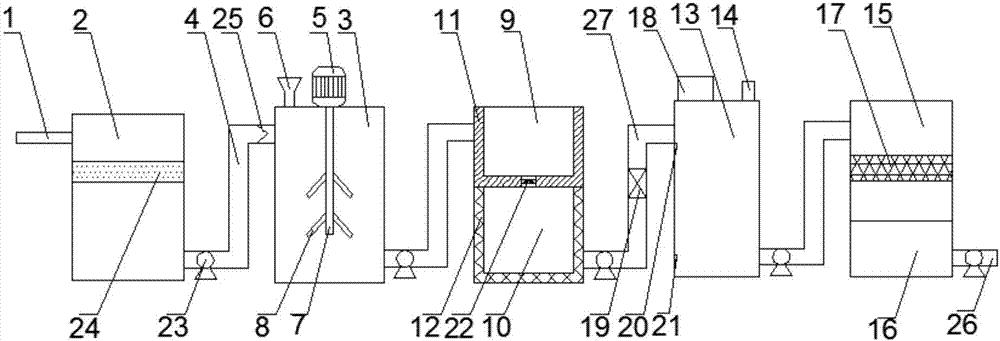

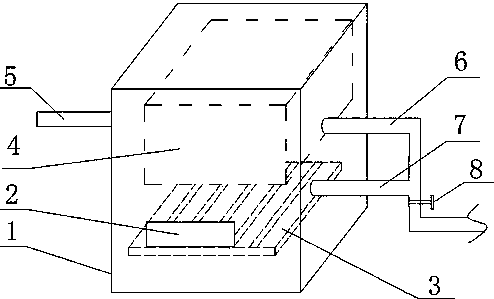

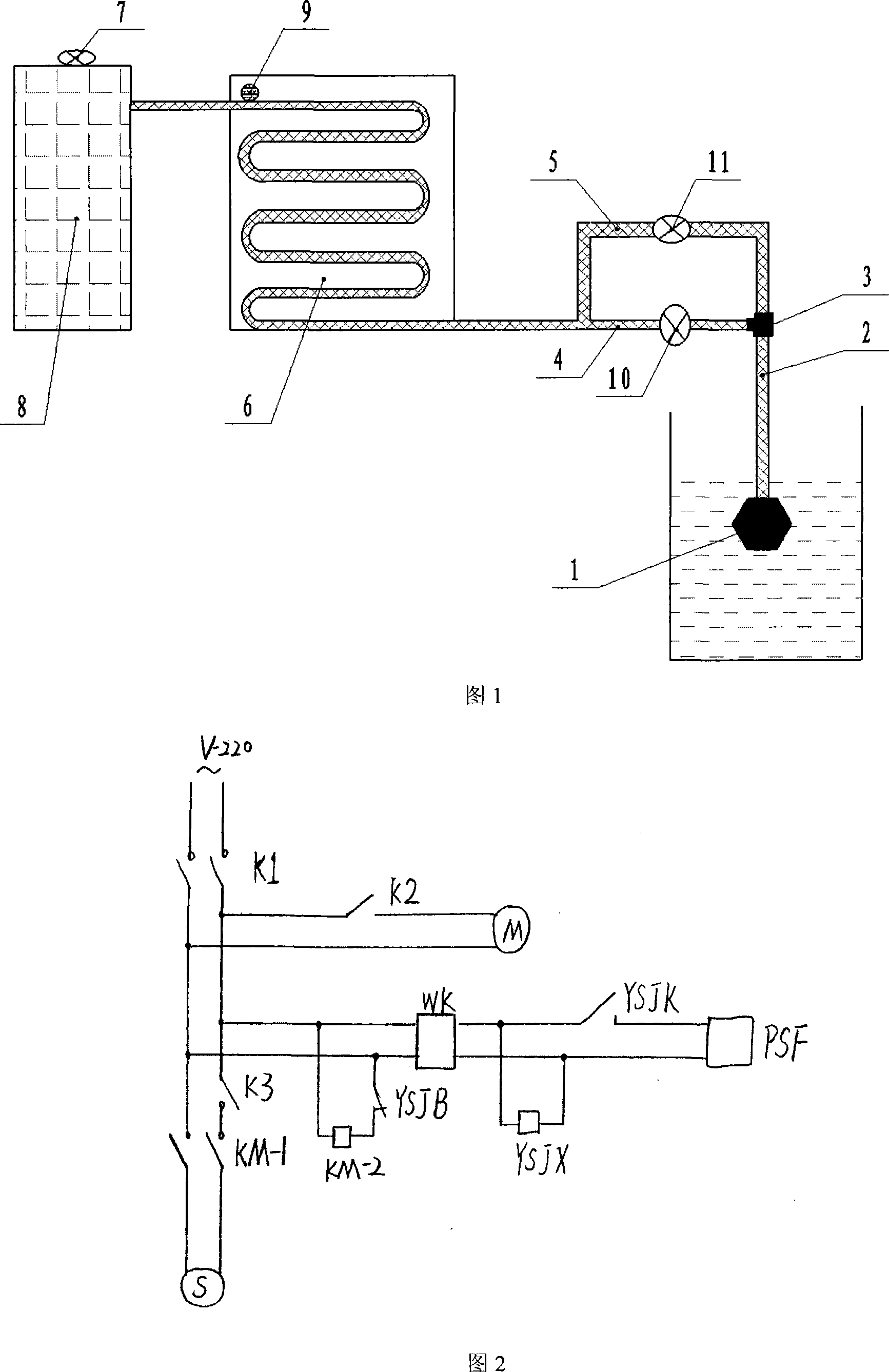

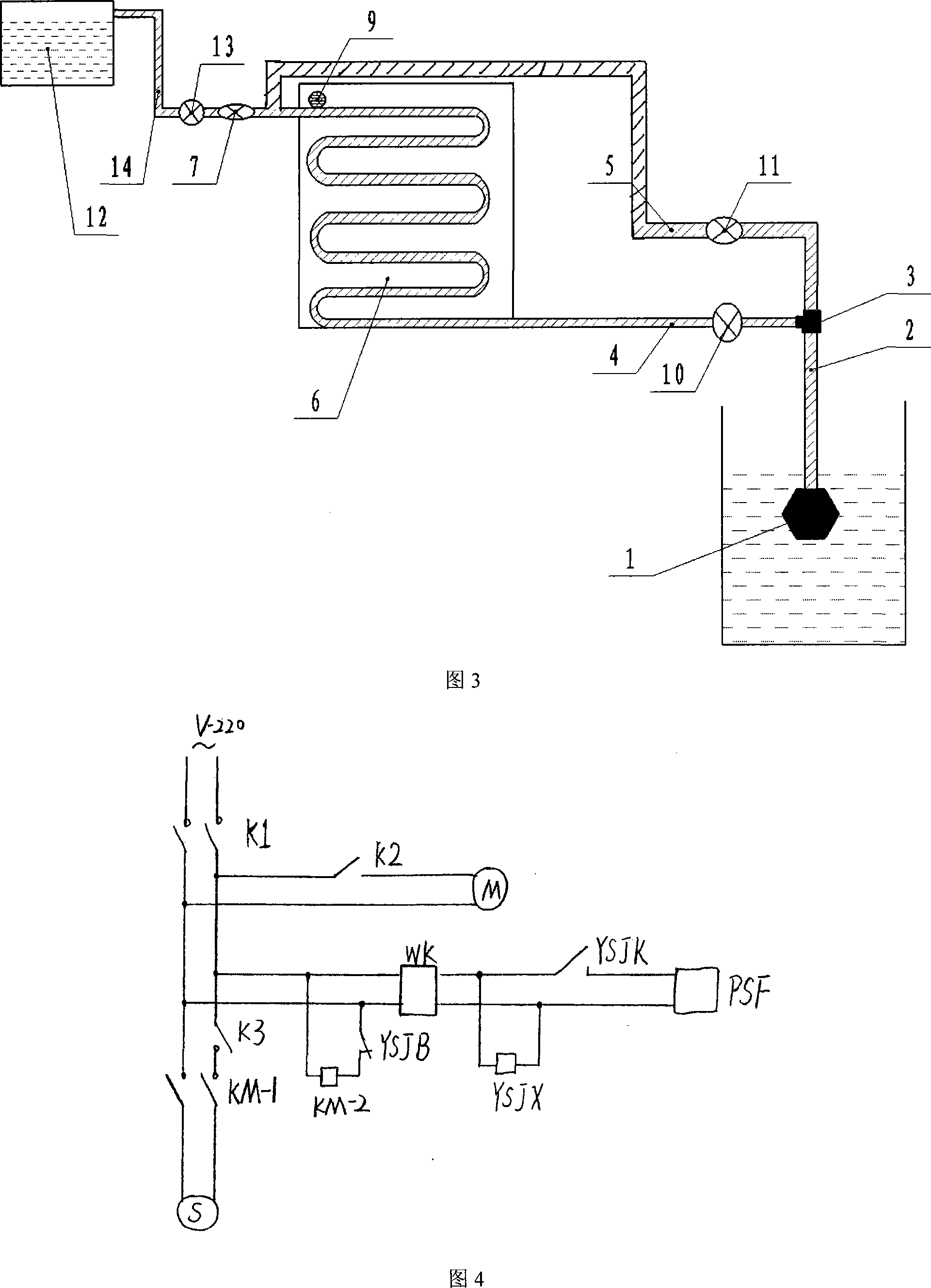

Full-automatic well water energy-saving air-conditioning system

InactiveCN101225985ASave on delivery linesSave electricityLighting and heating apparatusAir conditioning systemsElectricityRural area

The invention relates to a device adopting well water to regulate air temperature, in particular to a full automatic well water energy-saving air-conditioning system, which is characterized in that the full automatic well water energy-saving air-conditioning system can be divided into two parts, comprising a pipeline equipment part and a control circuit part; a shared pipe is adopted as water supply pipe as well as return pipe, saving the delivery pipe; the control circuit is adopted to control the operation of a water pump, water supply and water return, saving electricity; the control circuit can regulate each valve switch and the operation of the water pump, saving manual labor and realizing automatic control; the device can use the well water circularly, saving water conservancy resources. The device adopting well water to regulate air temperature has the advantages of simple structure, convenient use, and suitability for the popularized use in urban and rural areas.

Owner:叶旭润

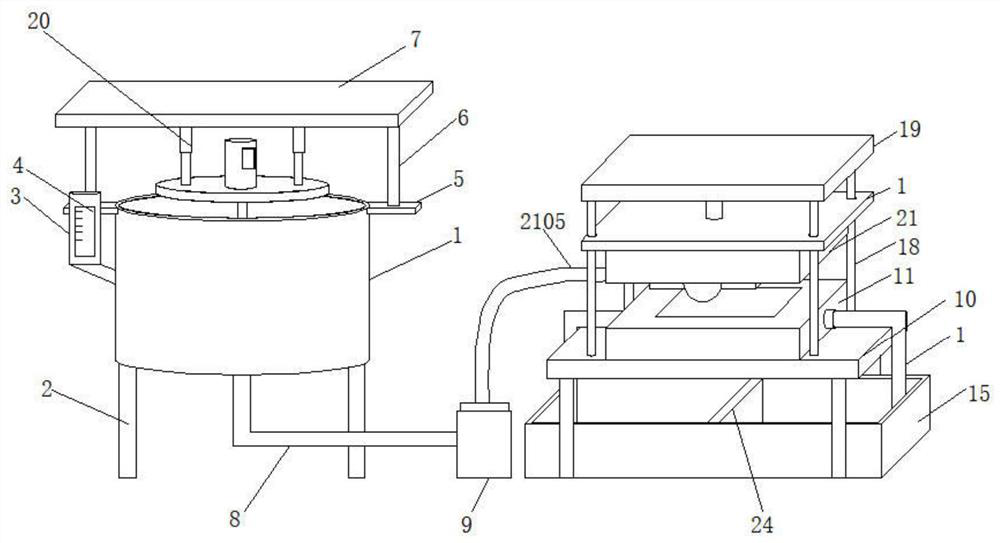

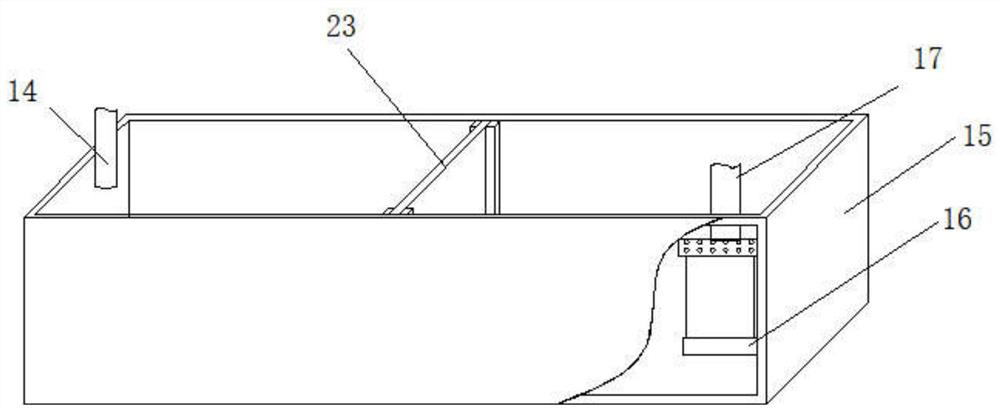

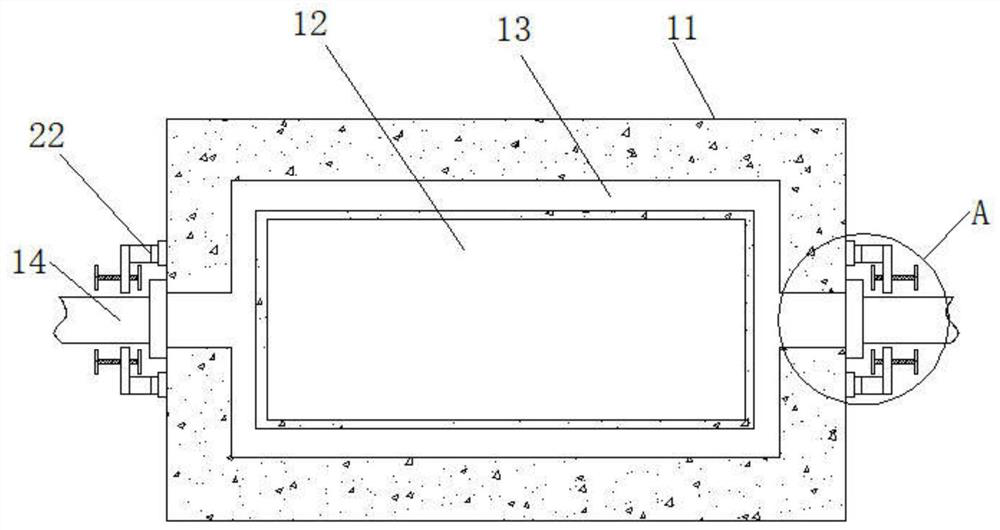

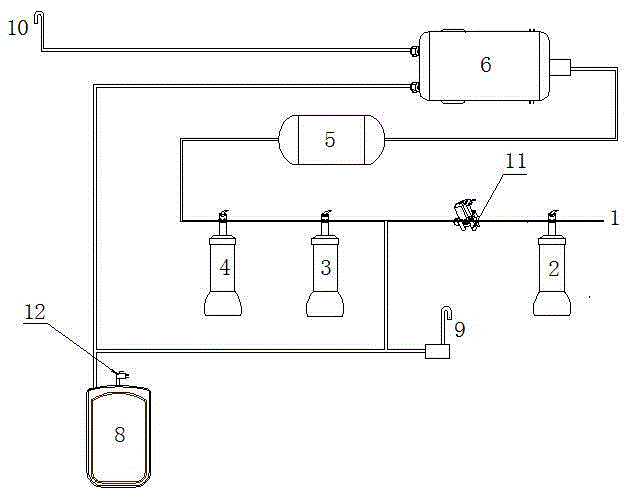

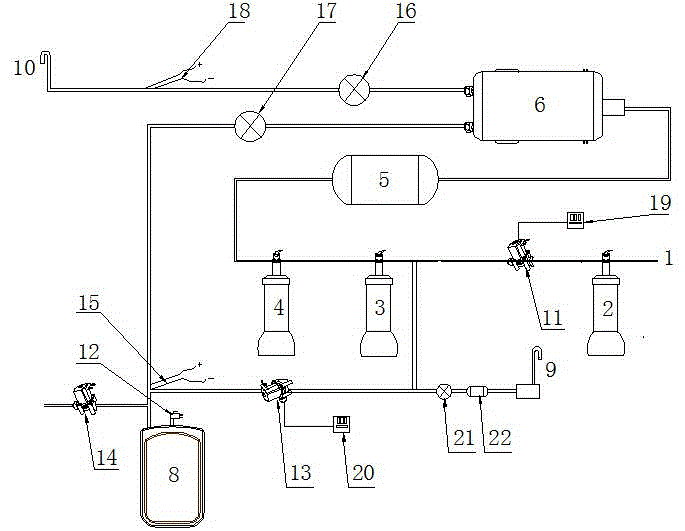

Engineering rainfall or rainwater recycling system

InactiveCN102155036AReduce engineering costsSave water resourcesGeneral water supply conservationDrinking water installationWater sourceEngineering

The invention discloses an engineering rainfall or rainwater recycling system. The system comprises an engineering rainfall tank, the water outlet of the engineering rainfall tank is connected with the first water inlet of a collecting sedimentation tank through a first water outlet pipe, the second water inlet of the collecting sedimentation tank is connected with the water outlet of a rainwater recycling tank through a second water outlet pipe, the water outlet of the collecting sedimentation tank is connected with the water inlet of an impounding reservoir through a water inlet pipe on which a lift pump is arranged, the water outlet of the impounding reservoir is connected with a field water facility through a drainage pipe on which a booster pump is arranged, and a floating ball valve control device of the lift pump is arranged in the impounding reservoir. By adopting the system, the supply of building engineering construction and production water basically depends on the recycle of engineering rainfall or rainwater, novel green energy-saving construction is realized, the engineering cost is reduced, and the system is favorable for saving water sources.

Owner:CHINA CONSTR SIXTH ENG DIV CORP +1

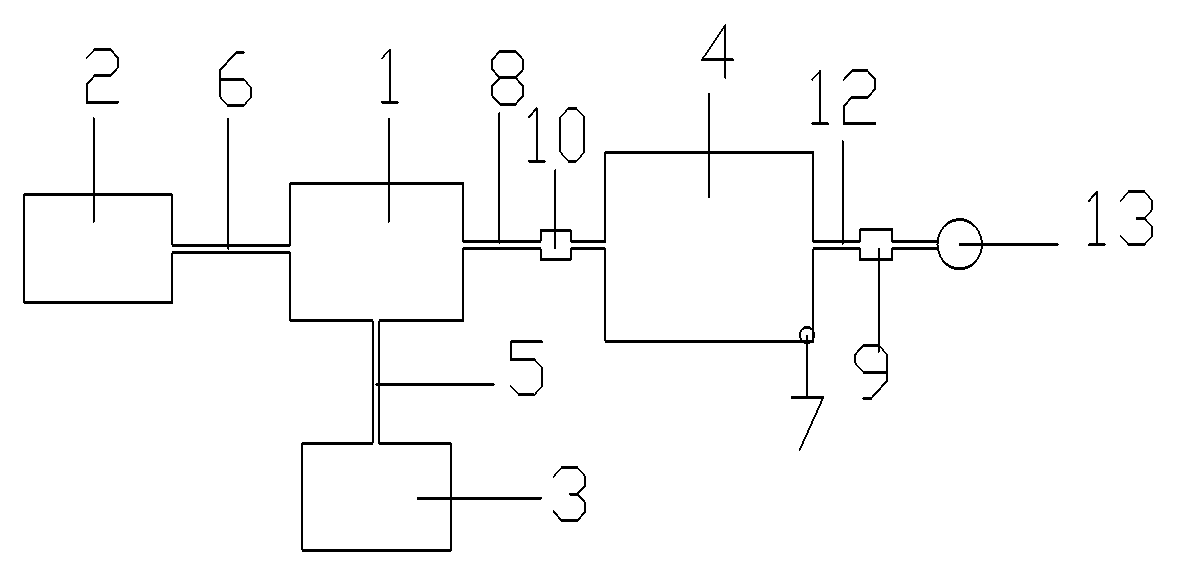

Low-concentration gas and ventilation air methane thermal oxidation generating system and method of coal mine

InactiveCN102011605BEnthalpy OxidationExtended Concentration LimitsMachines/enginesGas removalThermal energyMechanical energy

The invention relates to low-concentration gas and ventilation air methane thermal oxidation generating system and method of a coal mine. The system mainly comprises a multi-gas oxidation device, a water treatment device, a screw rod type expander, a generator, a condenser and the like. In the method, low-concentration gas and ventilation air methane of the coal mine are adopted to carry out periodic reciprocating flowing type superheated oxidation reaction in a porous ceramic oxidation bed, the reaction heat is extracted with work medium water through an internal heat exchanger, generated superheated vapor enters the screw rod type expander to do work, and the heat energy is converted to the mechanical energy to drive the generator to generate the power. The system and the method have the advantages of simpleness, reasonable single machine capacity matching, convenience in operation and good use effect.

Owner:CHINA UNIV OF MINING & TECH

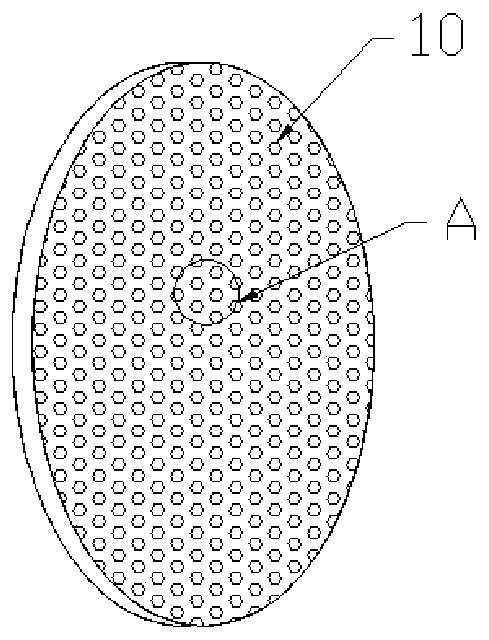

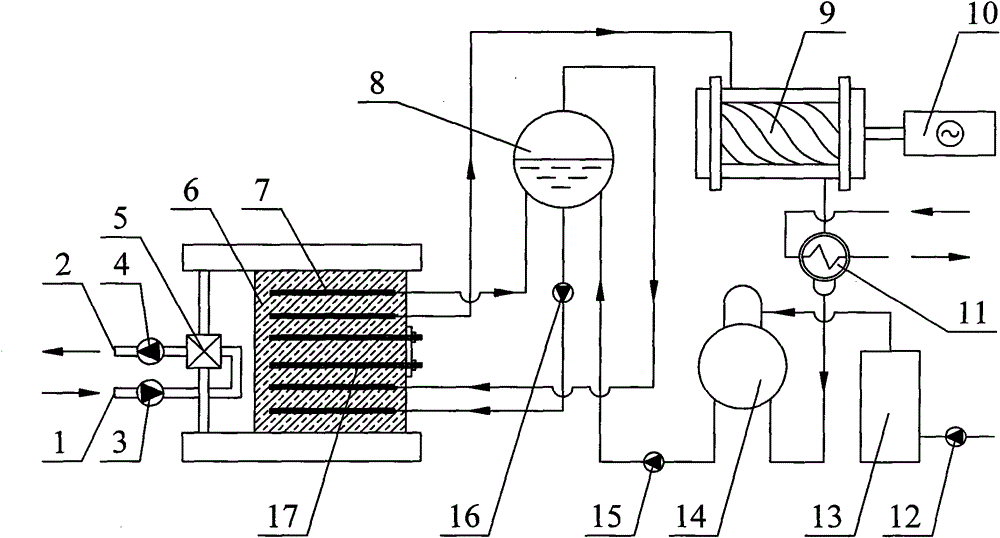

Preparation device and preparation method of porous light photocatalytic material

InactiveCN111890620AFast molding speedChanging the Free Cooling SituationWater useWater storage tank

The invention relates to a preparation device and a preparation method of a porous light photocatalytic material. The device comprises a stirring tank, the bottom end of the stirring tank is fixedly connected with support columns, one side of the stirring tank is connected with a feed pipe in an embedded mode, the surface of the feed pipe is connected with a measuring scale in an embedded mode, the two sides of the top end of the feed pipe are connected with bearing plates in a welded mode, a supporting rod is welded to the top end of each bearing plate, a first top plate is fixedly connectedwith the top ends of the supporting rods, a mixing mechanism is installed at the bottom end of the first top plate, and a discharging pipe is embedded into the bottom end of the stirring tank. According to the preparation device and the preparation method of the porous light photocatalytic material, cooling water can be pumped into a water through groove through a submersible pump, a forming moldin a forming cavity is rapidly cooled through the water through groove, the cooling effect is improved, the forming speed of the porous light photocatalytic material is increased, and then the production efficiency is improved; and besides, the cooling water can be guided back to a water storage tank through a first guide pipe, so that the cooling water is recycled, the water cost is reduced, andthe water resource is saved.

Owner:JIANGXI UNIV OF TECH

Water-saving emission-reducing water purifier

InactiveCN104150625AEnsure the safety of drinking waterSave water resourcesMultistage water/sewage treatmentWater savingWater storage

The invention discloses a water-saving emission-reducing water purifier which comprises a primary filtration device, a pressurizing device, a reverse osmosis treatment device, a tail water storage device and a connecting pipeline, wherein the primary filtration device at least comprises a primary filtration barrel; the water inlet of the primary filtration barrel is connected with a tap water inlet pipe; a water inlet solenoid valve is mounted at the water outlet of the primary filtration barrel; a domestic water faucet is mounted on a pipeline for connecting the water feeding and discharging hole of the tail water storage device with the water inlet solenoid valve; a water shortage command conversion switch is mounted on the tail water storage device or a pipeline of the water feeding and discharging hole of the tail water storage device and is used for controlling the water inlet solenoid valve to be opened and closed. According to the water purifier, tail water is recovered by virtue of the tail water storage device, the water inlet solenoid valve is controlled through the water shortage command conversion switch, and the tail water in the tail water storage device is preferentially used for domestic water with high consumption.

Owner:田宝科

Efficient water-saving scrubber

PendingCN112674659AEasy to pump clean water intoImprove scrubbing efficiencyCarpet cleanersFloor cleanersWater savingWater storage tank

The invention discloses an efficient water-saving scrubber which comprises a shell, the left side of the shell extends outwards to be provided with a water sprinkling disc, a brush disc is fixedly installed on the bottom end face of the water sprinkling disc, the top end face of the water sprinkling disc is connected to a water storage tank through a branch pipe, and a cover plate is arranged at the top opening end of the water storage tank in a running fit mode; the cover plate is connected to a lower clear water tank through a first drainage pipe, a clear water hose, a clear water pump and a second drainage pipe, an upper sewage tank is slidably assembled and connected to the lower clear water tank, a filter is installed at the top opening end of the lower clear water tank and the middle position of the top wall of the upper sewage tank is fixedly connected with the tail end of an electric push rod. The side wall of the top of the upper sewage tank is connected with the pipe opening end of one side of a second water inlet pipe through a first water inlet pipe, a sewage hose and a sewage pump, and the pipe opening end of the other side of the second water inlet pipe extends out of the shell. By the adoption of the technical scheme, the water storage tank and the water sprinkling disc play a water-saving role in buffering sucked water; and the sewage treatment liquid is convenient to recycle, the operation and the application are convenient, and the effect of saving clean water resources is achieved.

Owner:安徽丹泰仕机电设备有限公司

Cleaning device for leaves of rose green plants on outer wall of house

ActiveCN106499205ARealize appearance color imageAvoid damageSelf-acting watering devicesBuilding repairsEngineeringMaster controller

The invention discloses a cleaning device for leaves of rose green plants on an outer wall of a house and belongs to the technical field of architectural appearance equipment. According to the technical scheme, the cleaning device for the leaves of the rose green plants on the outer wall of the house comprises two isolated walls oppositely arranged on two sides of a building body, wherein guiding mechanisms are arranged on the isolated walls; the isolated walls are netted walls made of flexible materials; cultivation boxes for the rose green plants are arranged on the outer side at the bottom of the isolated walls; cleaning mechanisms are arranged between the cultivation boxes and the tops of the isolated walls; and drawing mechanisms are arranged at the tops of the isolated walls. The cleaning device has the beneficial effects that the design is reasonable; the drawing mechanisms are used for pulling the isolated walls to move up and down on vertical guide rails and inclined guide rails of the guiding mechanisms, so that the indoor light is more reasonable; driven gears in the cleaning mechanisms are meshed with limit rods on guiding bosses; the whole cleaning mechanisms are fixed in motion amplitude and high in stability; the driven gears are matched with the limit rods; the precision is high; and central control of a master controller is convenient.

Owner:谭家湾遗址公园运营管理(桐乡乌镇)有限公司

Pipe flow and jet grouting compound energy generator

InactiveCN101968024BIncrease rotation speedIncrease water pressureHydro energy generationEngine componentsWater flowEngineering

Owner:王治岳

Air pressure circulating water power generation device

PendingCN112855415ASimple structureSave water resourcesHydro energy generationMachines/enginesWater tanksWater pool

The invention discloses an air pressure circulating water power generation device. The air pressure circulating water power generation device comprises a water tank, a water pool and a water turbine, the water tank is located above the water pool, a water suction pipe is arranged on the side, close to the water pool, of the water tank, a water tank water supplementing pipe is arranged at the top of the water tank, a water tank water outlet pipe is arranged at the bottom of the water tank, and the position, close to the water tank, of the water tank water outlet pipe is of a U-shaped structure. A valve is arranged on a pipe body of the water tank water outlet pipe, the water tank water outlet pipe is fixedly connected with the water turbine, and the water turbine is provided with a water turbine water outlet pipe.

Owner:张宏库

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com