Novel water turbine activity guide vane vertical surface gap optimizing method based on finite element analysis

A movable guide vane and finite element technology, applied in the field of vertical clearance optimization of hydraulic turbine movable guide vanes, can solve the problems of increased guide vane weight, blind and untargeted repair plan, etc., to save material costs and reduce water leakage , the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

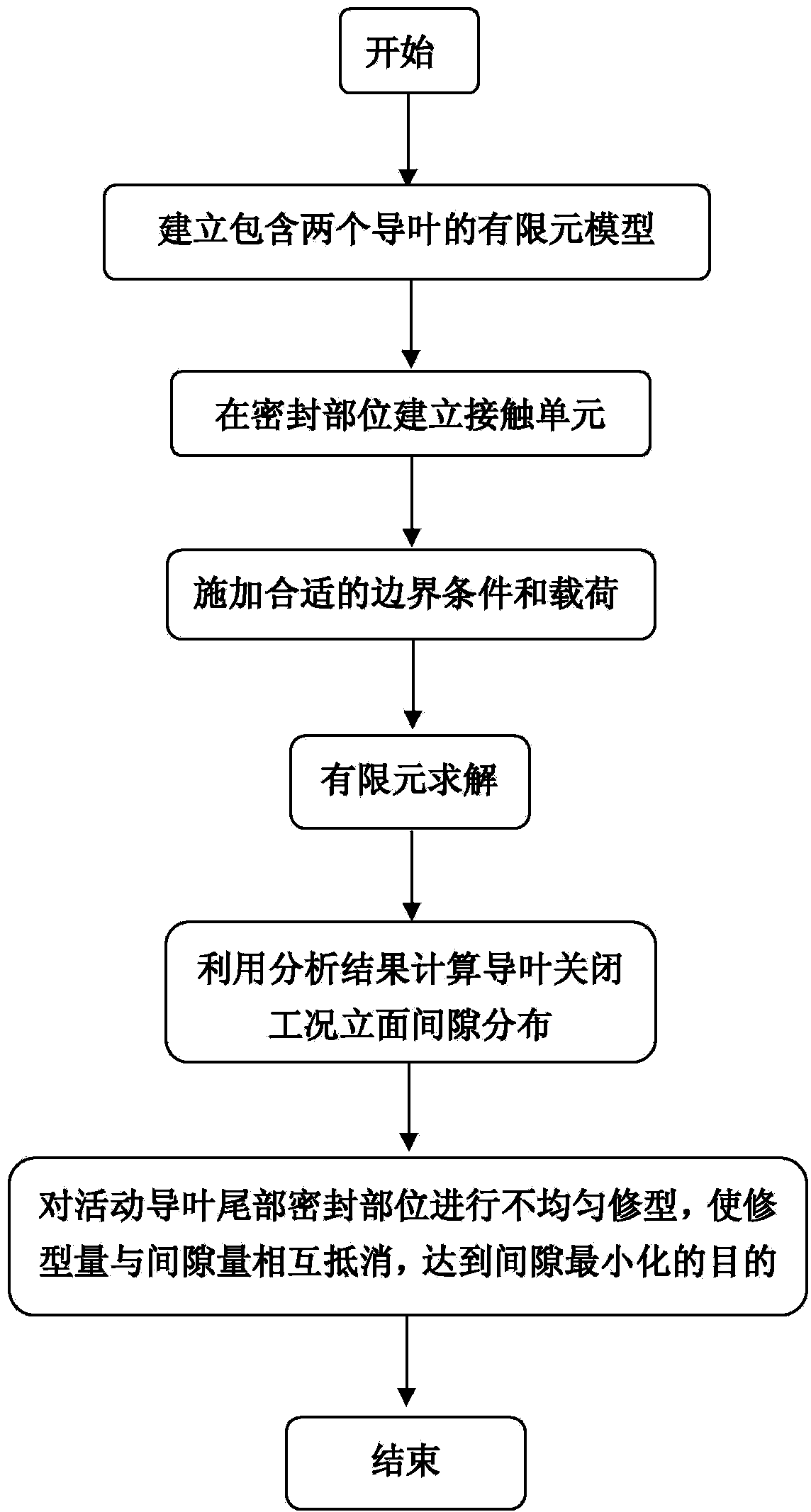

[0029] Such as figure 1 , figure 2 As shown, a new method based on finite element analysis for the optimization of the façade clearance of movable guide vanes of hydraulic turbines, the operation steps are as follows:

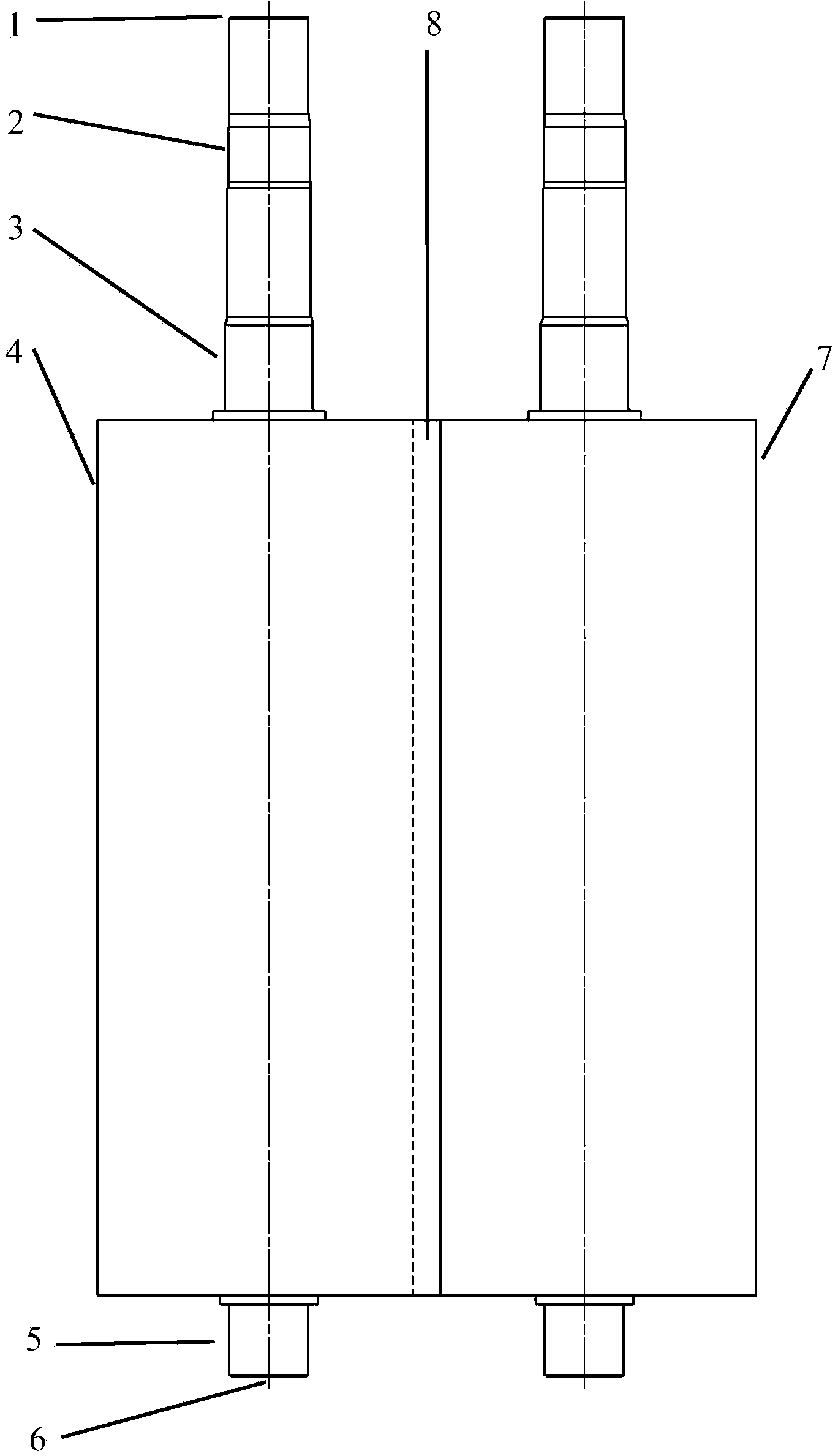

[0030] 1) Use commercial software to establish a three-dimensional model including two complete movable guide vanes of a water turbine, use the 20-node hexahedron element SOLID95 to divide the grid, and define the elastic modulus of the guide vane material as: 2.068e5MPa, Poisson's ratio 0.3;

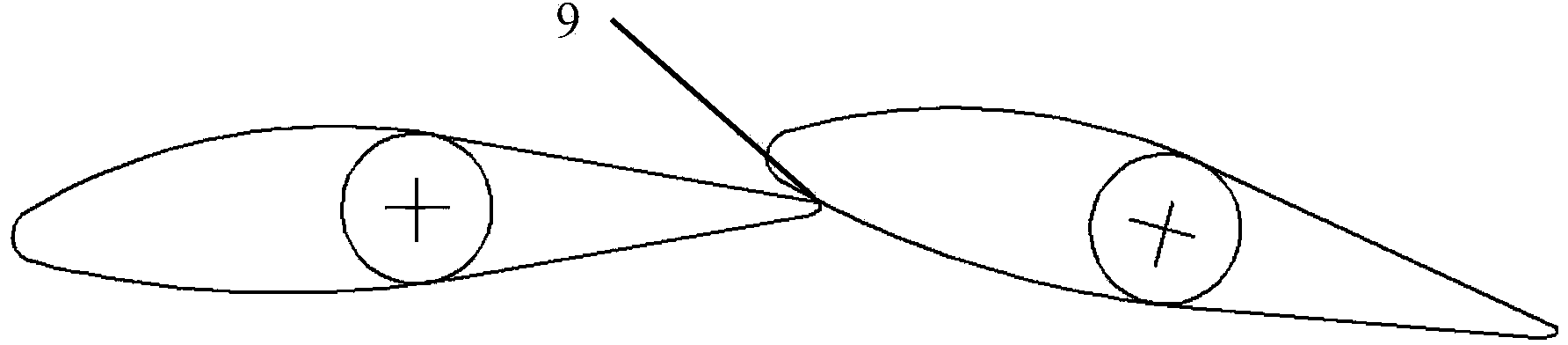

[0031] 2) Establish contact elements in the movable guide vane head 4 and guide vane tail 7 and guide vane seal contact area 8, the unit types are CONTA174 and TARGE170;

[0032] 3) apply the degree of freedom coupling constraints at the corresponding positions of the two movable guide vane heads 4, and apply the degree of freedom coupling constraints at the corresponding positions of the two guide vane tails 7;

[0033] 4) Calculate the torsional moment acting on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com