Integral construction method for air bag of tunnel sewer ditch

A technology of overall construction and sewage ditch, applied in drainage, earthwork drilling, mining equipment and other directions, can solve the problems of large consumption of formwork materials, slow construction progress, high cost, etc., to improve construction quality, reduce project cost, and ensure the quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] The overall construction method of the tunnel sewage ditch airbag includes:

[0042] (1) Cleaning the working surface: Before construction, the base of the sewage ditch should be cleaned, and the joint surface of the sewage ditch and the cable trough should be chiseled to ensure that the concrete of the sewage ditch constructed after the construction is firmly bonded to the base and the wall of the cable trough. , will not crack or fall off. After chiseling the joint surface of the cable trough, clean the loose ballast and debris on the base of the sewage ditch, and rinse the joint surface and the base after the chisel with high-pressure water.

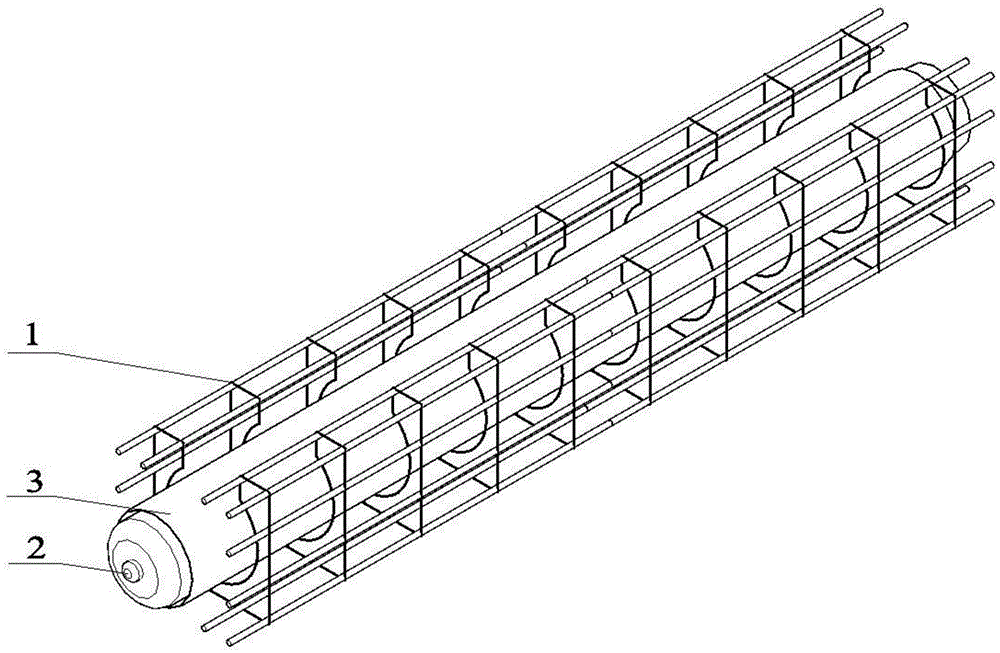

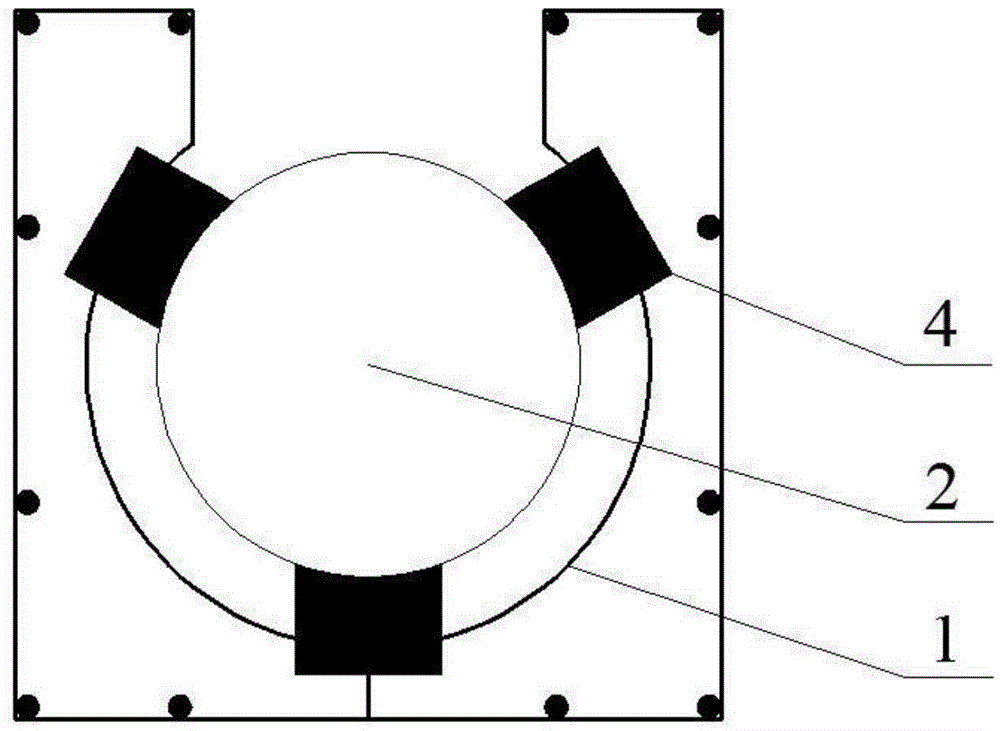

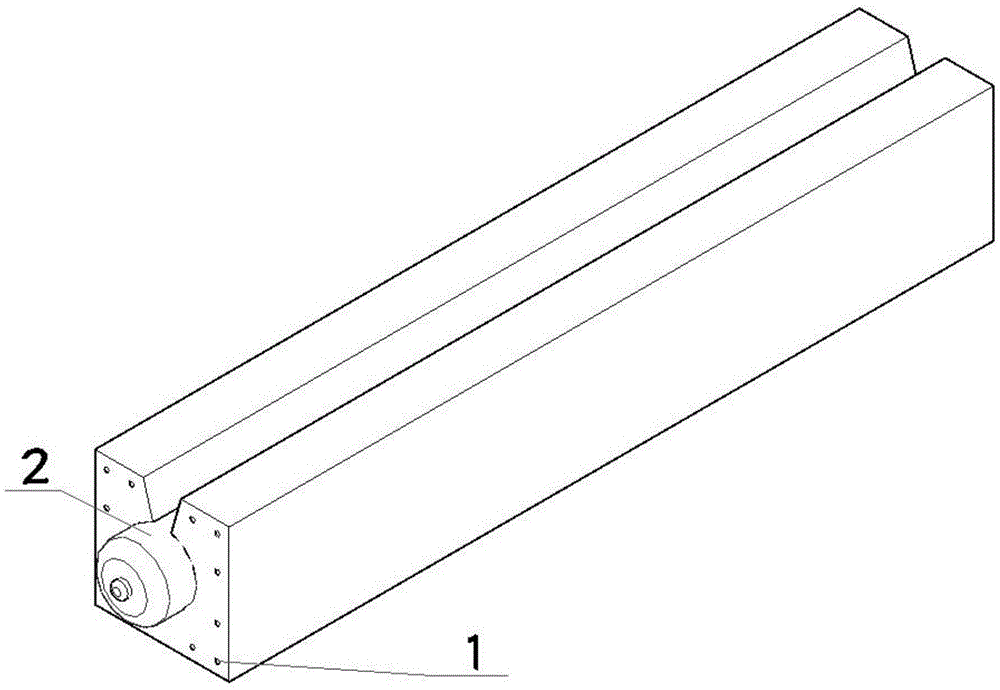

[0043] (2) Place the steel cage 1 and the air bag 2: After measuring and setting out, determine the location of the sewage ditch and the elevation control point. Position the pre-bundled steel cage 1 accurately, and check the steel wire joints and wire rolling head of the steel cage 1 (cut off the excessively long part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com