Water-saving emission-reducing water purifier

A water purifier and tail water technology, applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of abandoning tail water recycling, waste of fresh water resources and waste of water resources and other issues to achieve the effect of saving water resources and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

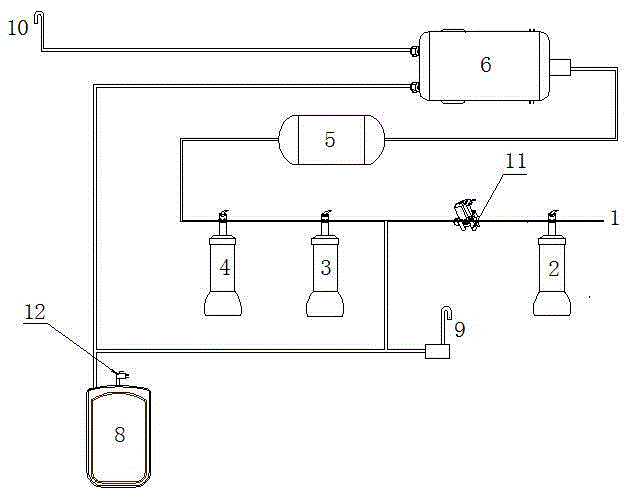

[0018] Embodiment 1: as figure 1 As shown, the water-saving and emission-reducing water purifier includes primary, secondary, and tertiary filter cartridges 2, 3, and 4, booster pump 5, RO membrane filter 6, tail water recovery pressure storage tank 8 and connecting pipes. The water inlet of the first-stage filter cartridge 2 is connected to the tap water inlet pipe 1, and the third-stage filter cartridge 4 is connected to the water inlet pipe of the RO membrane filter 6 through the booster pump 5, and the RO membrane filter 6 ends The water outlet is connected to the inlet and outlet pipes of the tail water recovery pressure water storage tank 8, and the water inlet solenoid valve 11 is installed at the water outlet of the first-stage filter cartridge 2, and the water inlet and outlet of the tail water recovery pressure water storage tank 8 are connected to the water outlet of the first stage filter cartridge 2. The pipeline connected to the water inlet solenoid valve 11 is ...

Embodiment 2

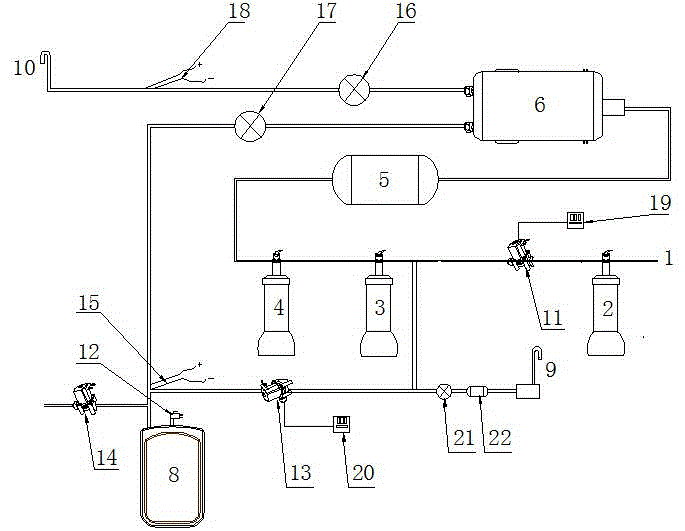

[0022] Embodiment 2: as figure 2 As shown, in order to avoid too low domestic water pressure, the improvement on the basis of embodiment 1 is as follows: the domestic water faucet 9 pipeline is equipped with a pressure control switch 21 and an increasing pump 22 to prevent the domestic water pressure from being too low.

Embodiment 3

[0023] Embodiment 3: as figure 2 As shown, the improvement on the basis of Embodiment 1 is as follows: a tail water solenoid valve 13 is also installed on the pipeline between the inlet and outlet of the tail water recovery pressure water storage tank 8 and the domestic water faucet 9, and the water shortage The command switch 12 is used to control the opening and closing states of the water inlet solenoid valve 11 and the tail water solenoid valve 13; the water inlet solenoid valve 11 and the tail water solenoid valve 13 are respectively connected with time relays 19 and 20 .

[0024] When in use, the time of the time relays 19 and 20 is set in advance according to the water production rate of the RO membrane filter 6 and the capacity of the tail water recovery pressure water storage tank 8. In order to better understand the technical solution, this embodiment assumes that the time is set Set at 30 minutes. After the tap water source of the water purifier is connected, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com