Pipe flow and jet grouting compound energy generator

A generator and pipe flow technology, which is applied in the field of pipe flow rotary jet regenerating generators, can solve the problems that restrict the popularization and application of hydropower technology among the people, the application range is not wide enough, and hydropower cannot be used in water-deficient areas, etc., and it is easy to promote , low cost, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

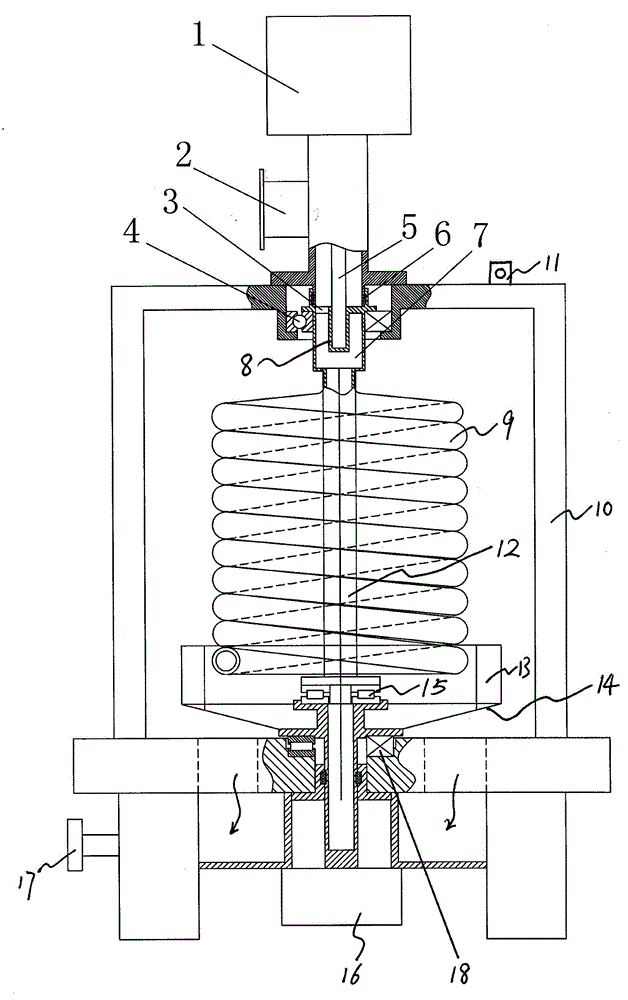

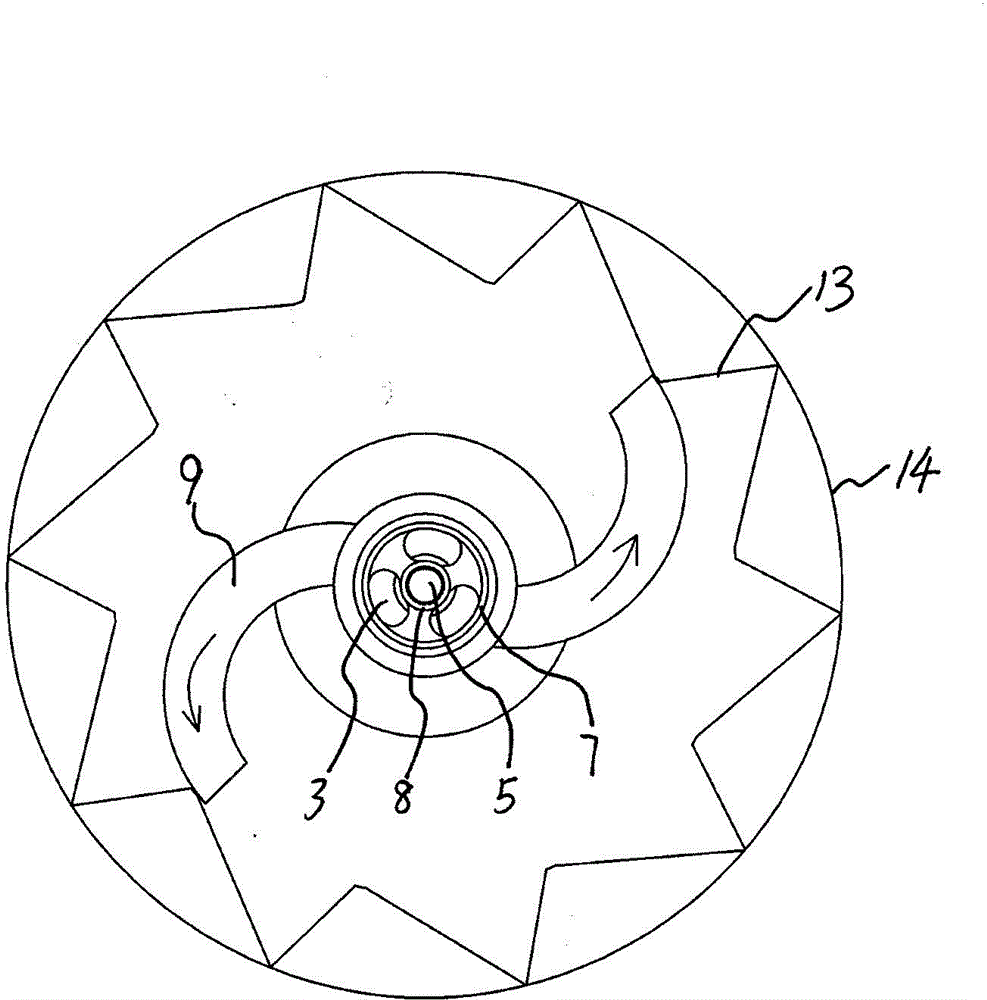

[0010] A kind of tube-flow swirl-jet compound energy generator, such as figure 1 , figure 2 As shown, it includes a closed casing 10 and a generator, the generators are two sets of upper and lower generators, and the upper generator 1 is vertically installed on the top of the water inlet pipe 2 in the center of the top surface of the closed casing, and the water inlet pipe 2 is connected with the water source or the high-pressure water pump. Connected, the lower part of the water inlet pipe 2 is connected to the center of the top surface of the housing 10 by a flange, and the lower generator 16 is vertically installed at the center of the bottom surface of the housing 10 .

[0011] Such as figure 1 , figure 2 as shown, A rotating water pipe assembly 9 with an S-shaped cross section is arranged in the upper part of the housing 10 , that is, the top view projection of the rotating water pipe assembly 9 in the horizontal plane is S-shaped. The rotating water pipe assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com