Patents

Literature

278results about How to "Improve scrubbing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

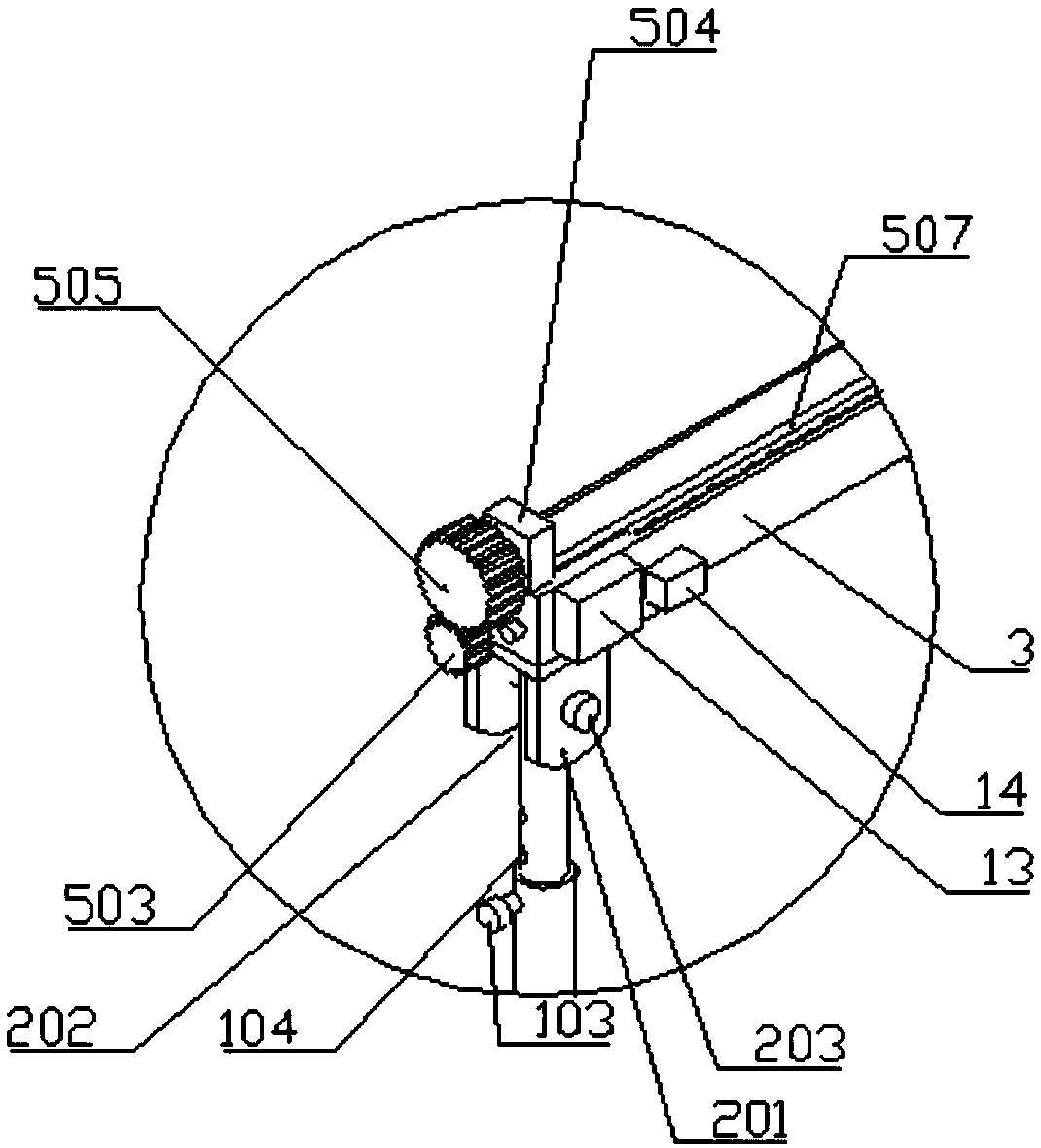

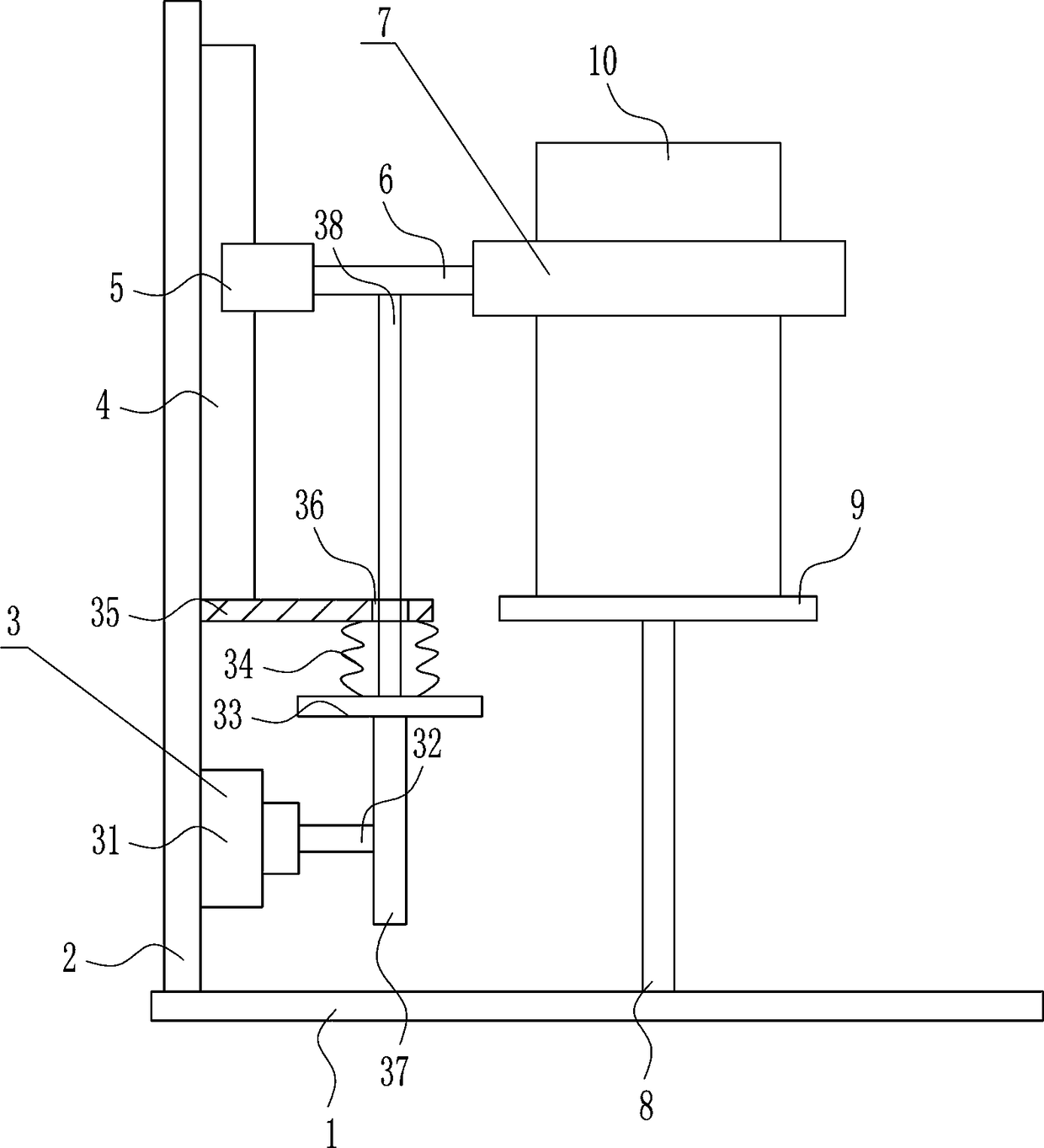

Automatic insulator scrubbing device

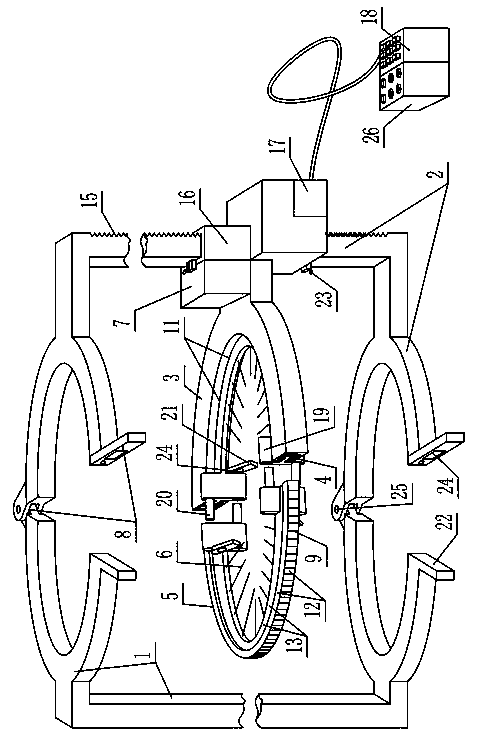

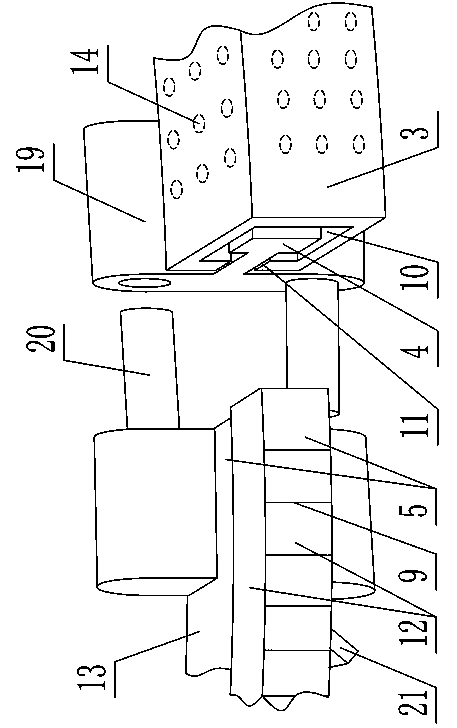

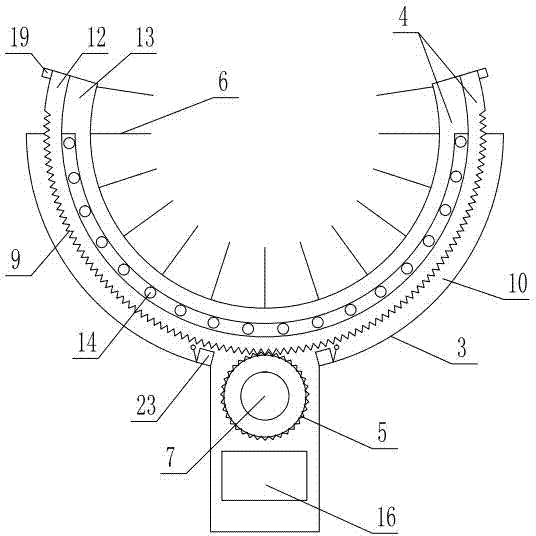

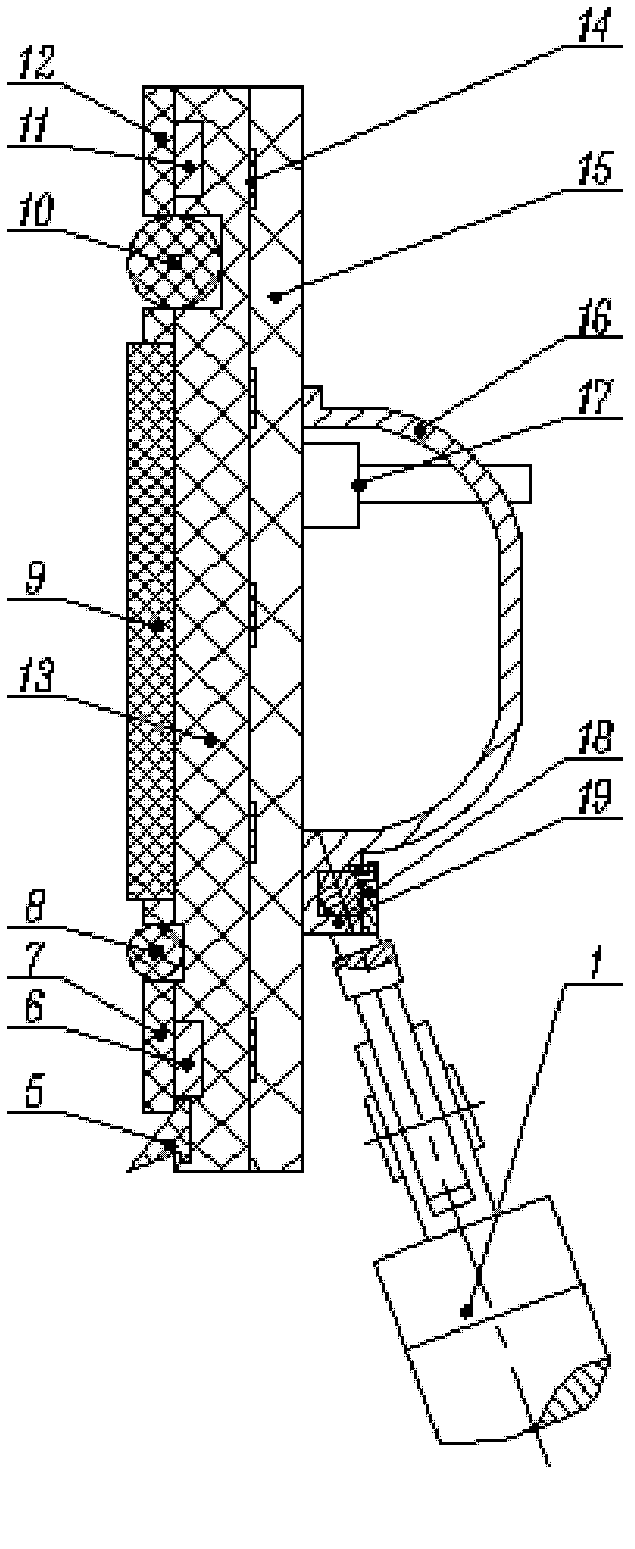

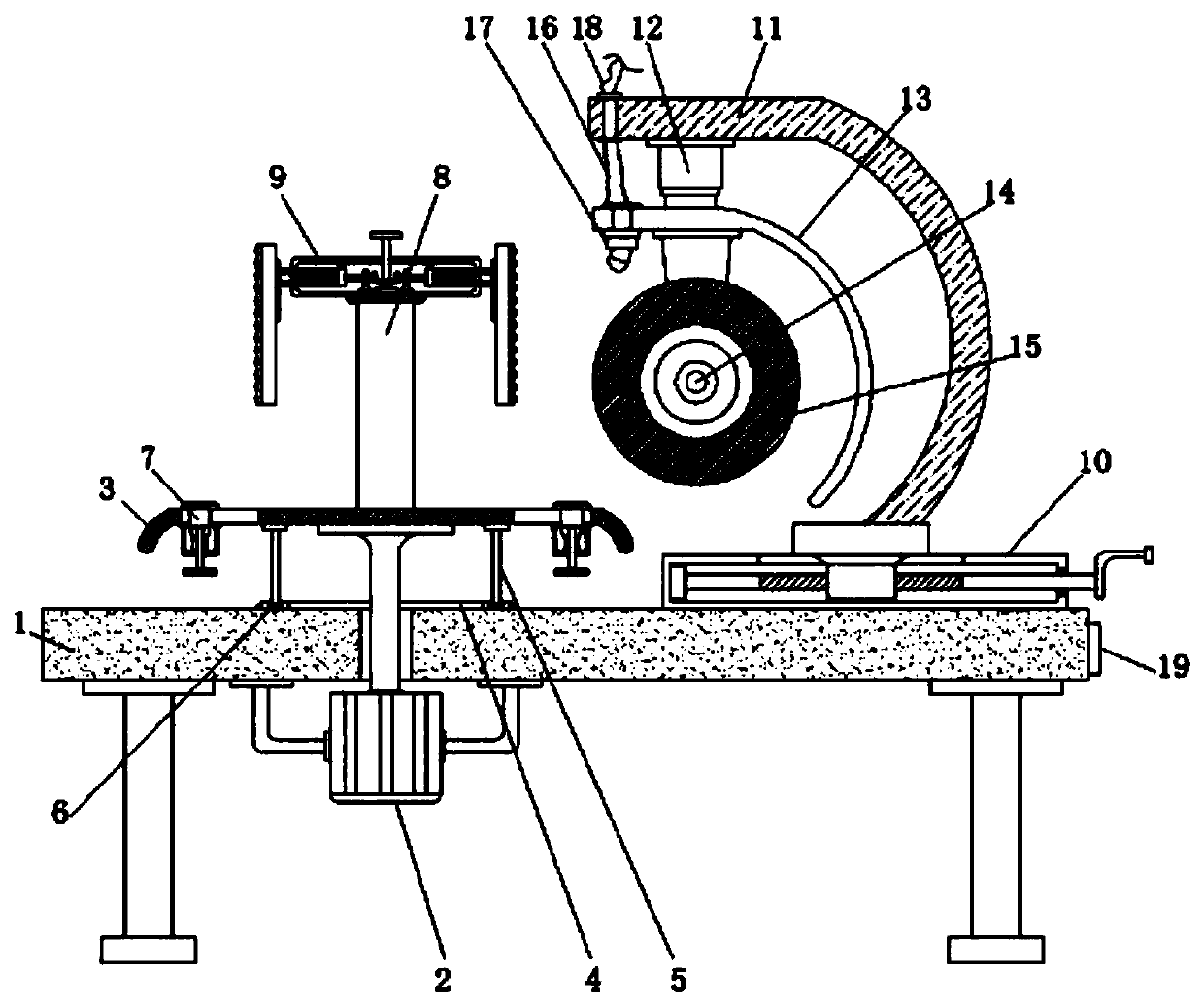

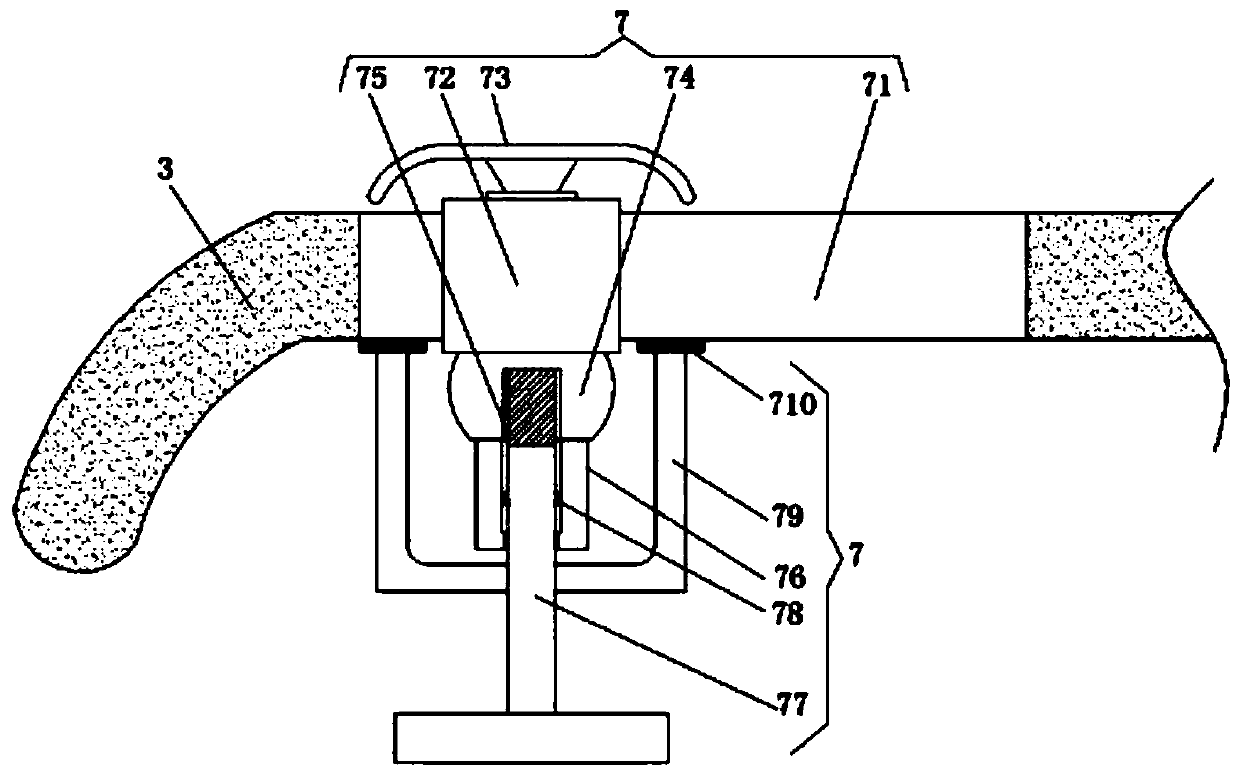

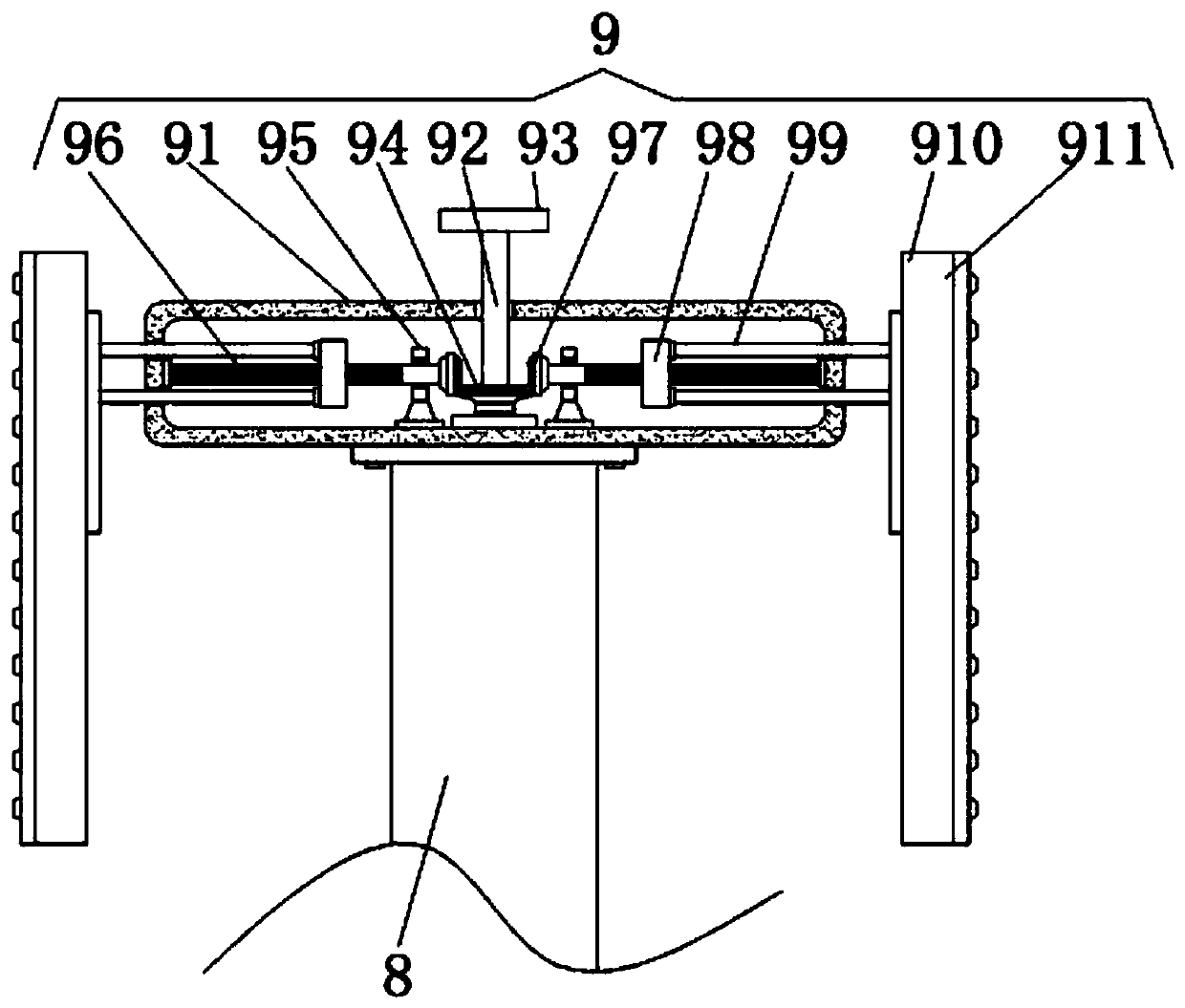

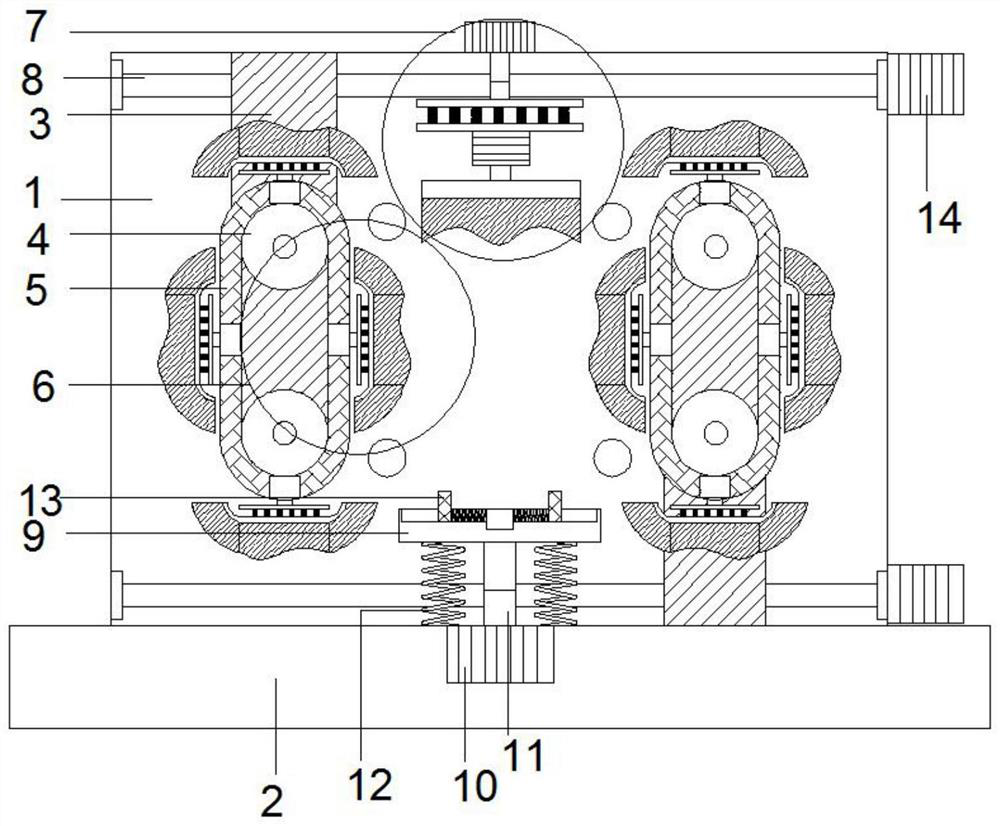

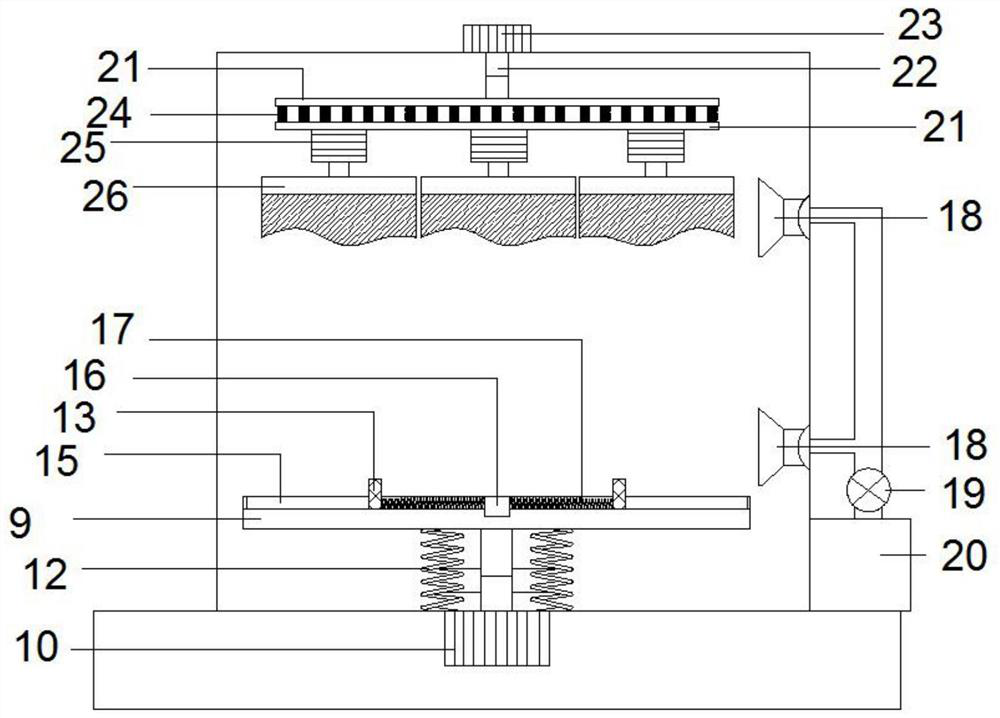

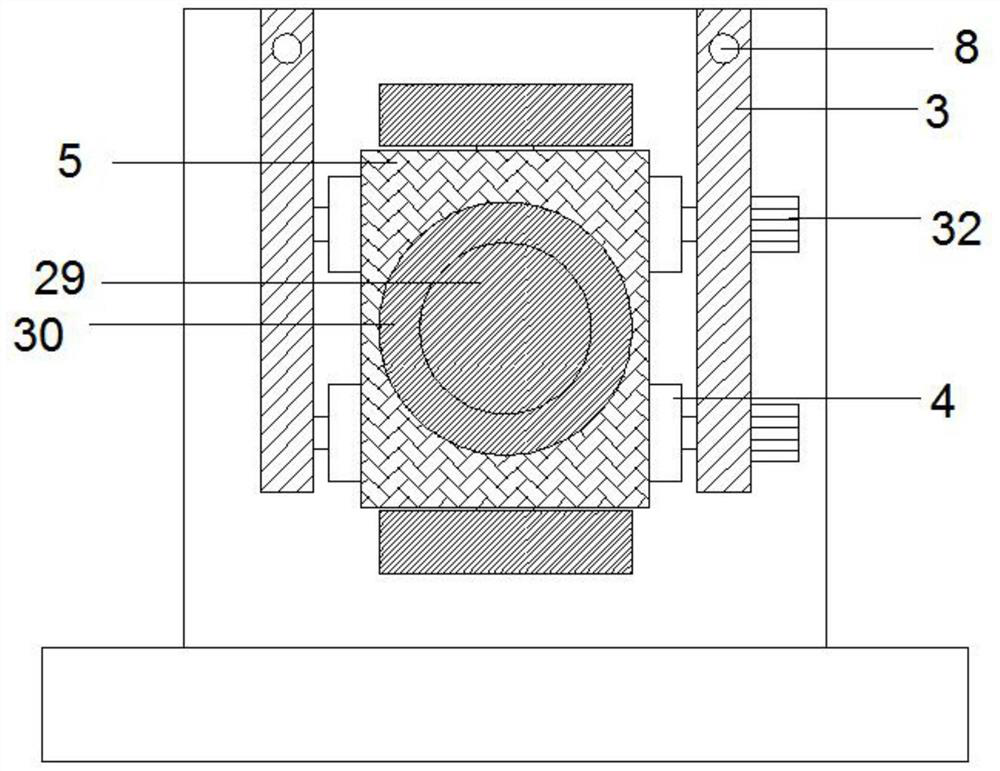

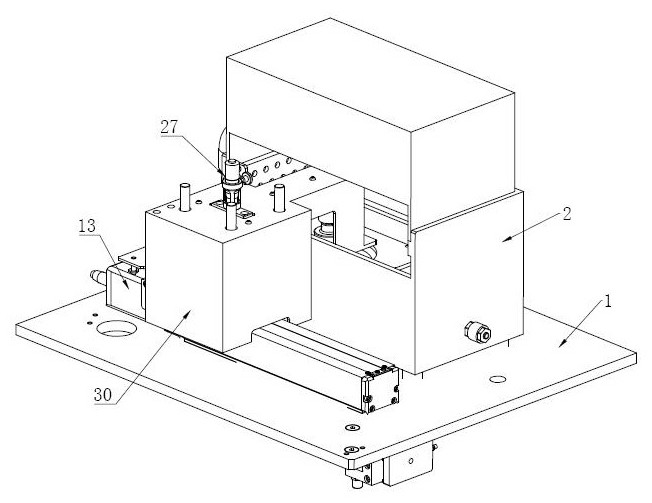

The invention discloses an automatic insulator scrubbing device. The automatic insulator scrubbing device comprises a left cover and a right cover, wherein the left cover and the right cover are in fixed butt joint on the periphery of an insulator through connecting mechanisms, clamping parts in clamping fit with the two end portions of the insulator are arranged at the two ends of the left cover and the two ends of the right cover, a semi-ring rail is arranged on the left cover or the right cover through a lifting mechanism, a main semi-ring and an auxiliary semi-ring are arranged on the semi-ring rail in a sliding mode and are capable of rotating around the axial line of the semi-ring rail, the main semi-ring and the auxiliary semi-ring are fixedly connected to form a circular ring through butt-joint mechanisms, hairbrushes corresponding to the outer wall of the insulator are arranged on the inner ring wall of the main semi-ring and the inner ring wall of the auxiliary semi-ring, a scrubbing motor is arranged on the lifting mechanism, a driving gear is arranged on an output shaft of the scrubbing motor, and gear teeth meshed with the gear are evenly distributed on the outer ring wall of the main semi-ring and the outer ring wall of the auxiliary semi-ring. Through the adoption of the structure, the automatic insulator scrubbing device is reasonable in structure, capable of assisting in cleaning the insulator, free of cleaning dead angles, good in cleaning effect, capable of saving time and labor in operation, low in cost and beneficial to improving scrubbing efficiency.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

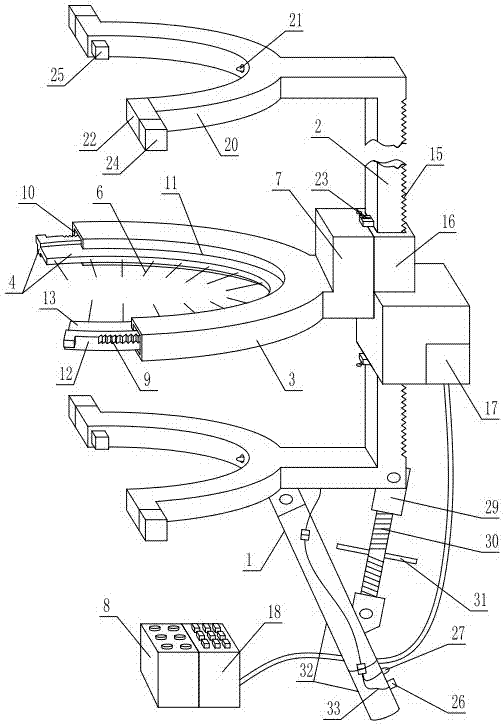

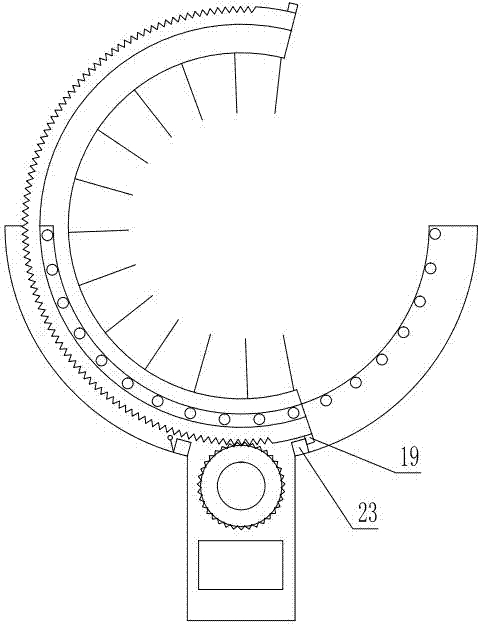

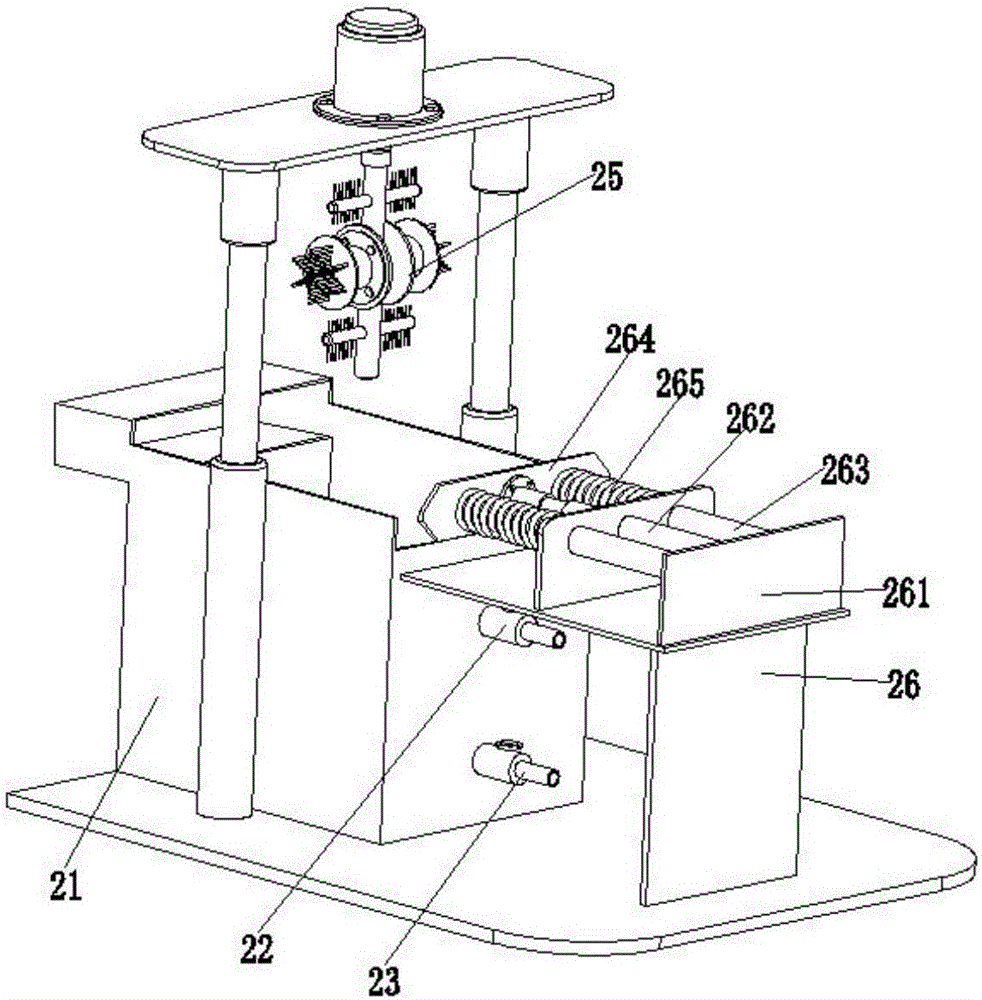

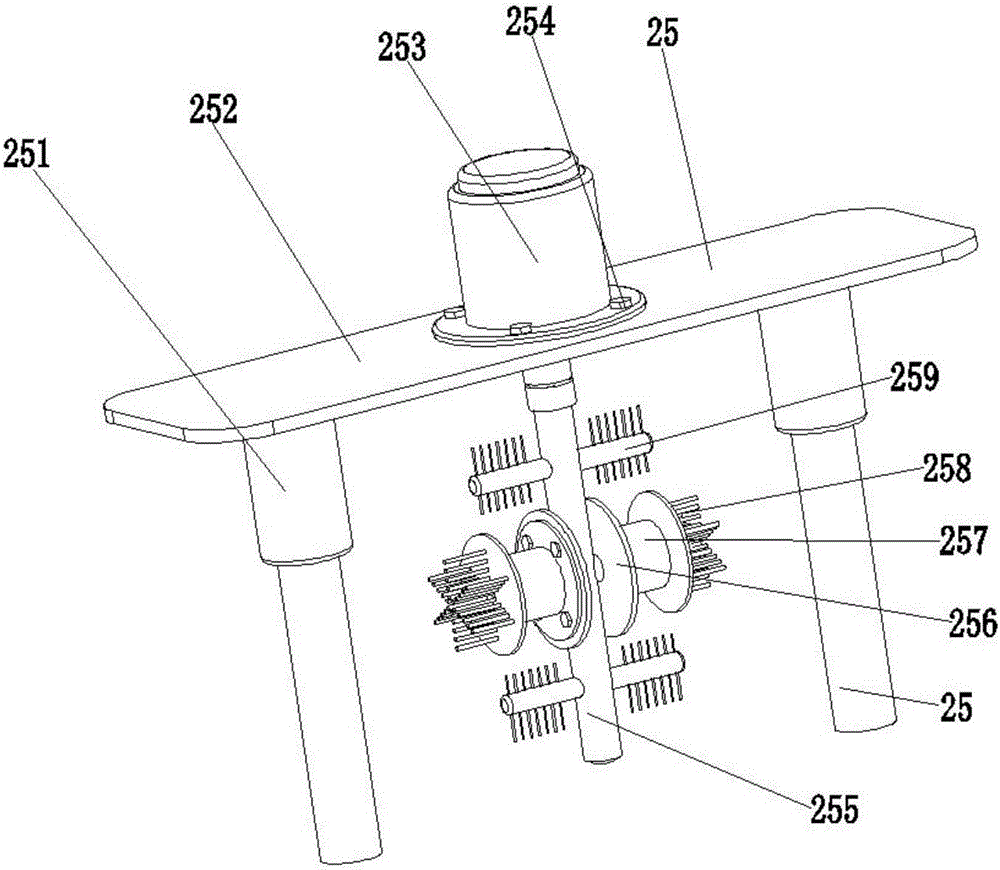

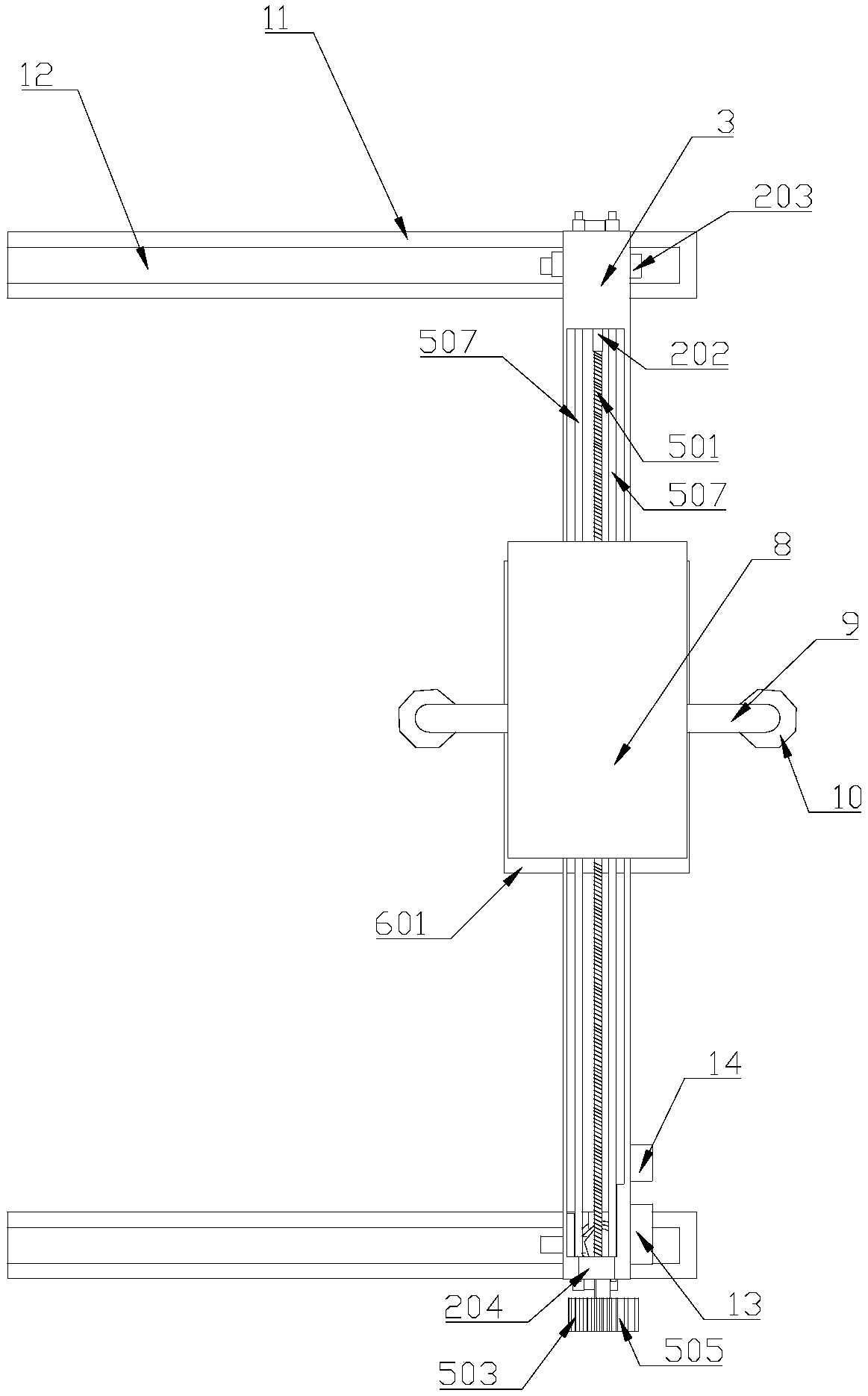

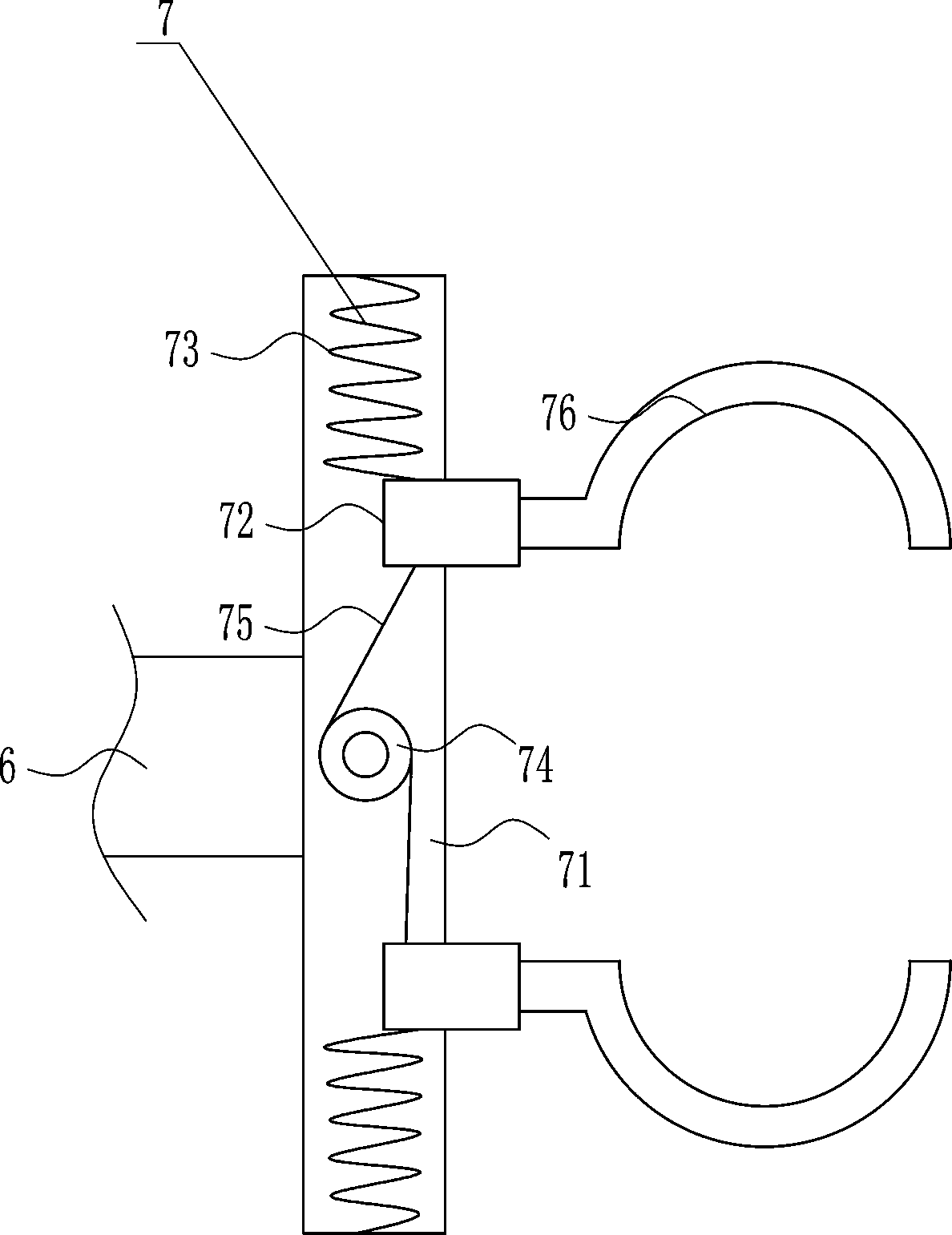

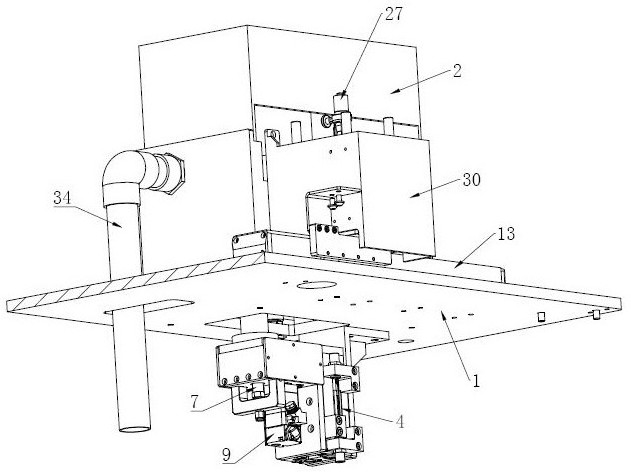

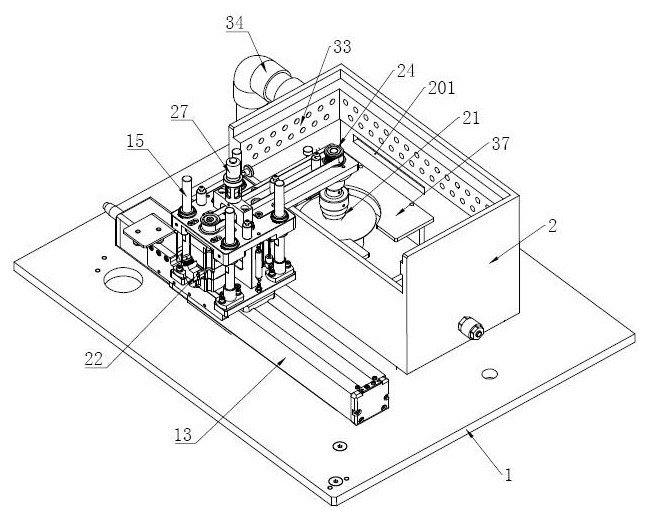

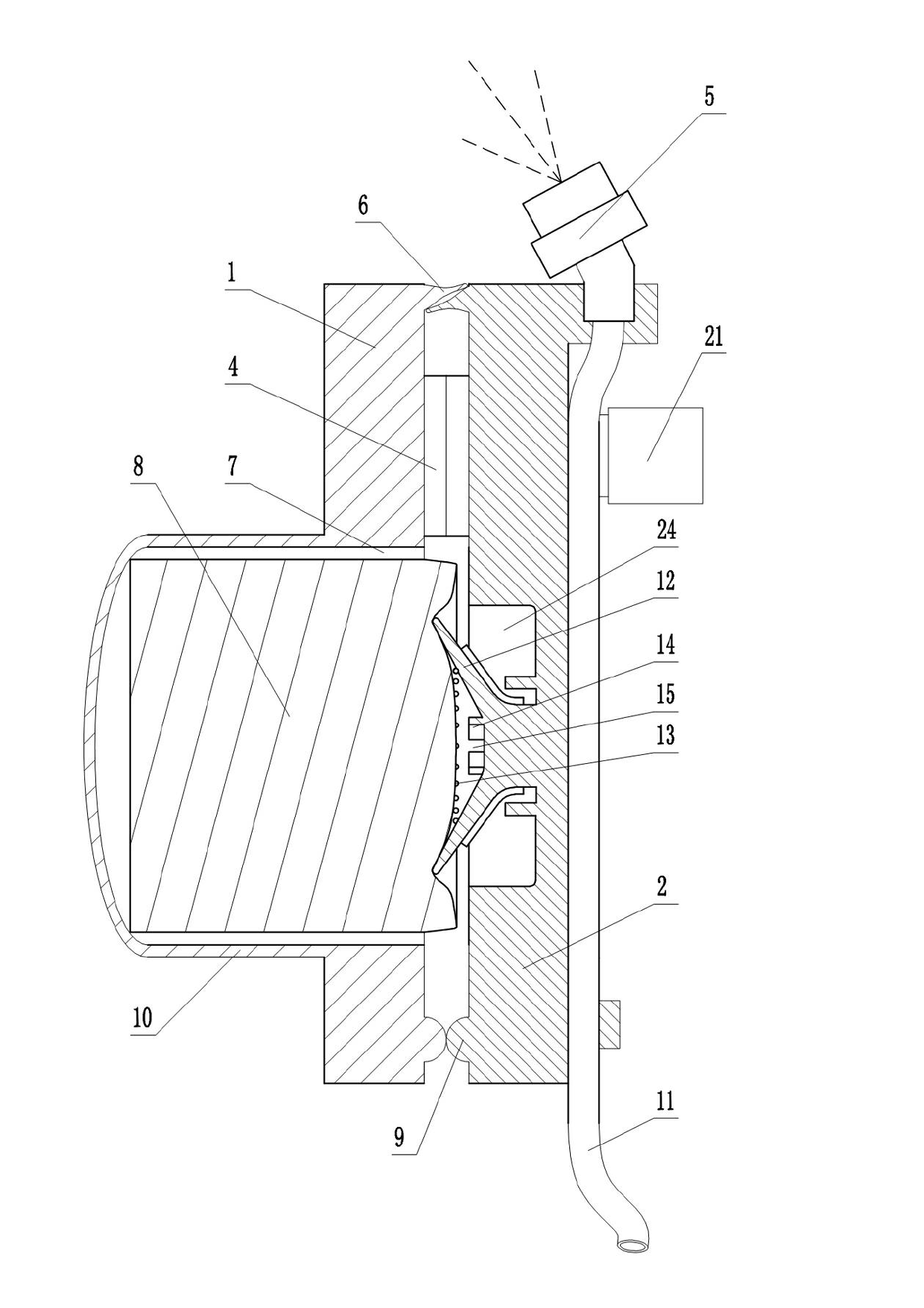

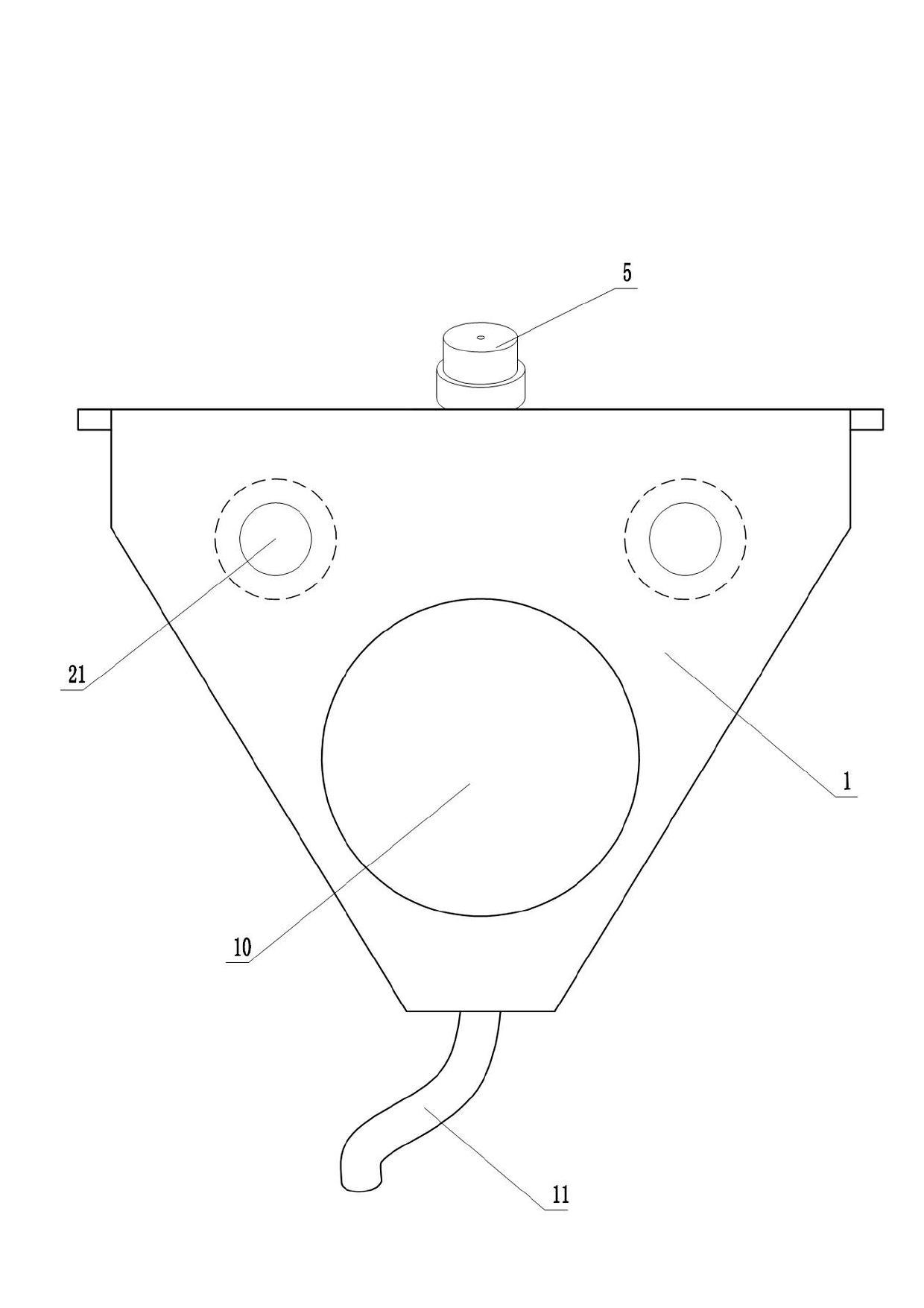

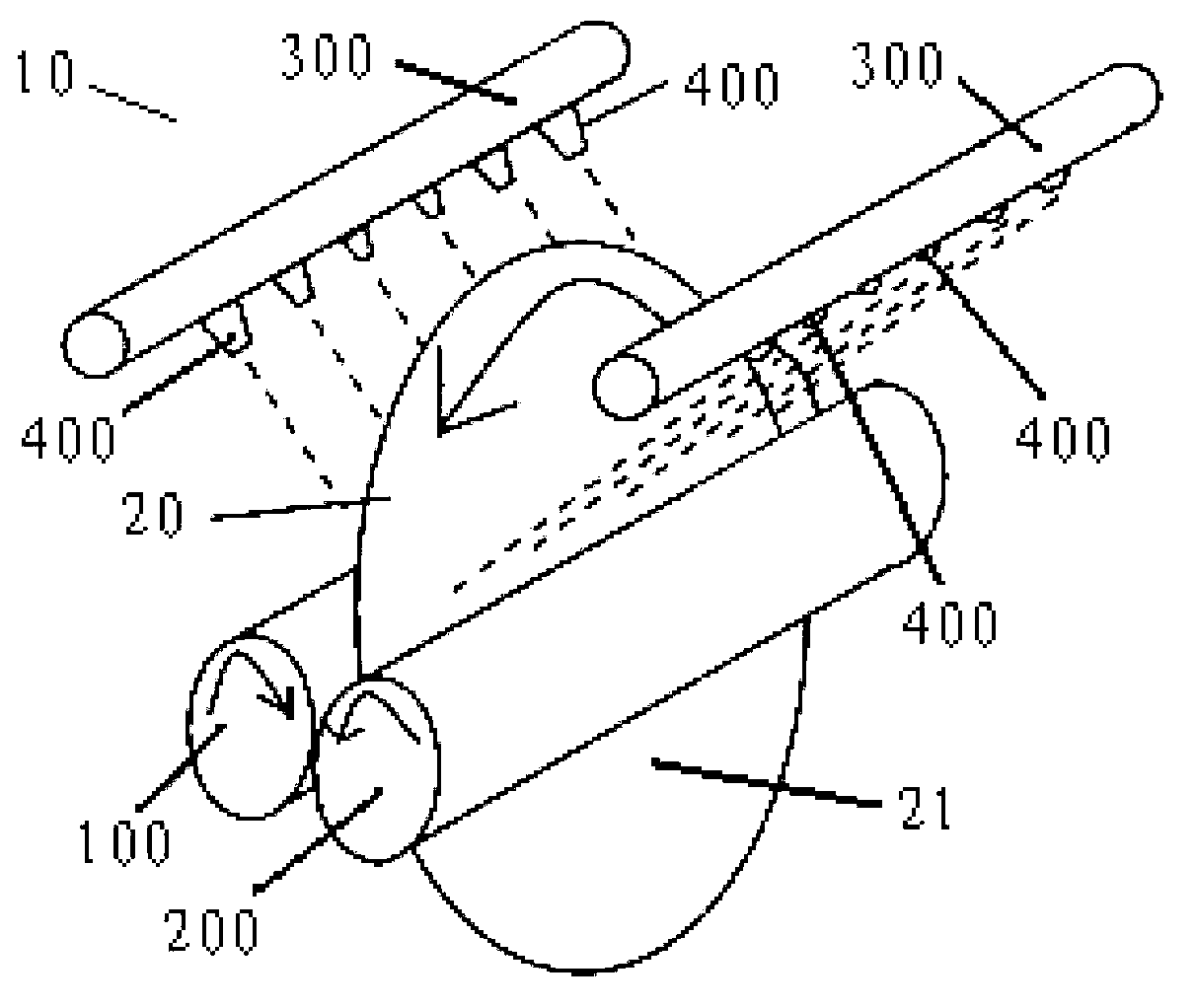

Ascent-free automatic scrubbing device for insulator

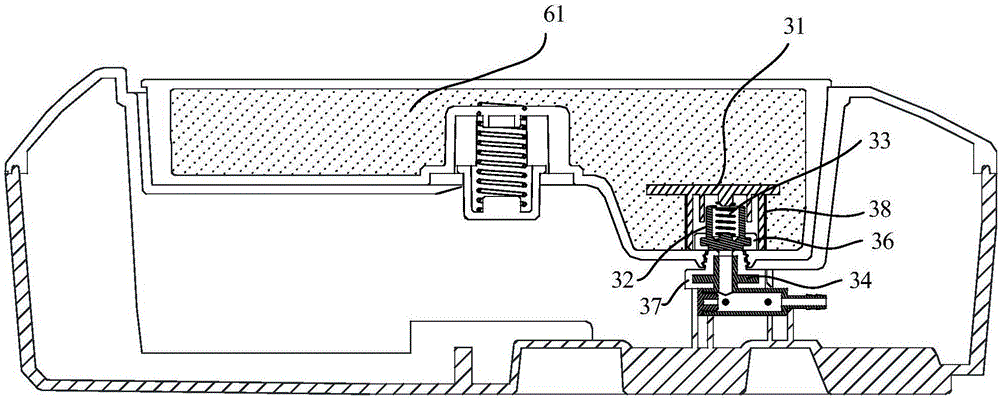

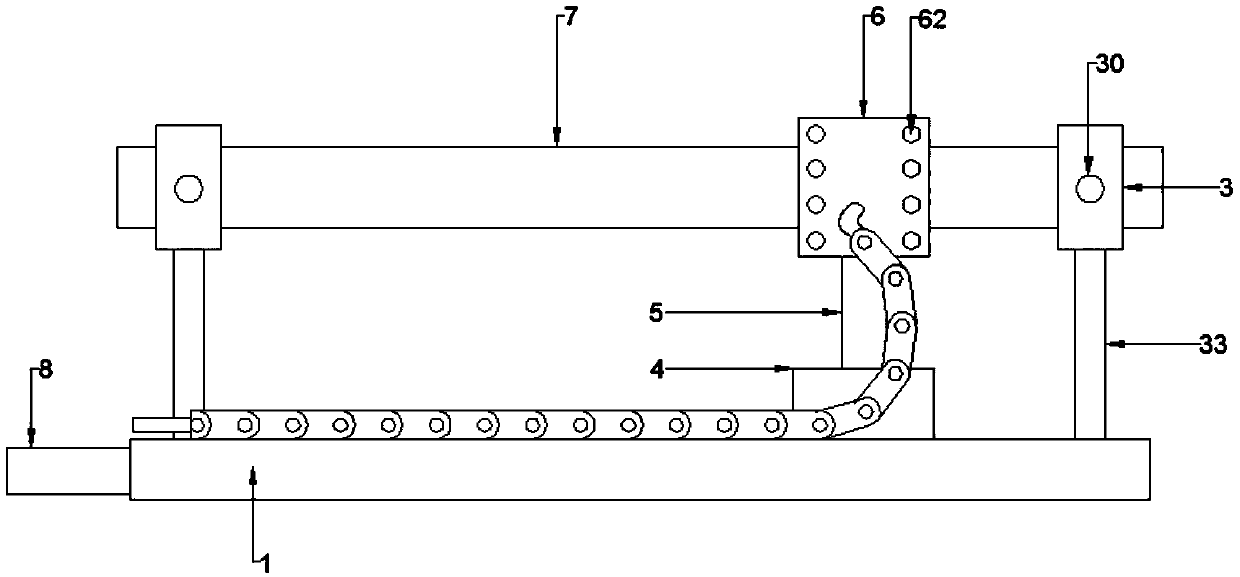

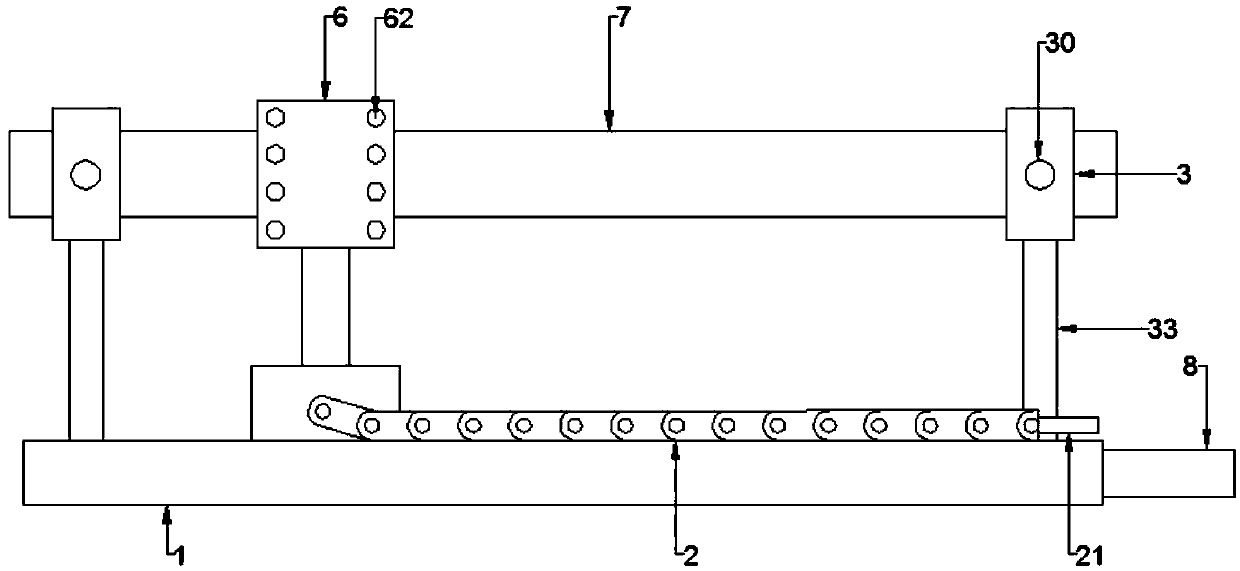

InactiveCN103567168AReasonable structureNo cleaning cornerCleaning using toolsLocking mechanismGear wheel

The invention discloses an ascent-free automatic scrubbing device for an insulator. The ascent-free automatic scrubbing device for the insulator comprises a support arranged at the upper end of a supporting rod, locking mechanisms capable of being in locking fit with the two end portions of the insulator are arranged at the two ends of the support, a semi-ring rail capable of going up and down is arranged on the support through a lifting mechanism, a semi-ring sliding block capable of rotating around the axial line of the semi-ring rail is arranged on the semi-ring rail in a sliding mode, brushes corresponding to the outer wall of the insulator are arranged on the inner ring wall of the semi-ring sliding block, a scrubbing motor is arranged on the lifting mechanism, a driving gear is arranged on the output shaft of the scrubbing motor, gear teeth meshed with the gear are evenly distributed on the outer ring wall of the semi-ring sliding block, lugs are fixedly arranged at the two ends of the semi-ring sliding block, a position sensor matched with the lugs is arranged in the middle of the semi-ring rail, and the ascent-free automatic scrubbing device further comprises a controller controlling the scrubbing motor to rotating forwards and backwards automatically according to the signals of the position sensor. The ascent-free automatic scrubbing device for the insulator has the advantages of being capable of assisting the cleaning of the insulator without the needs for ascent, free of cleaning dead angles, good in cleaning effect, capable of saving time and labor in cleaning, low in cost and beneficial to improving scrubbing efficiency.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

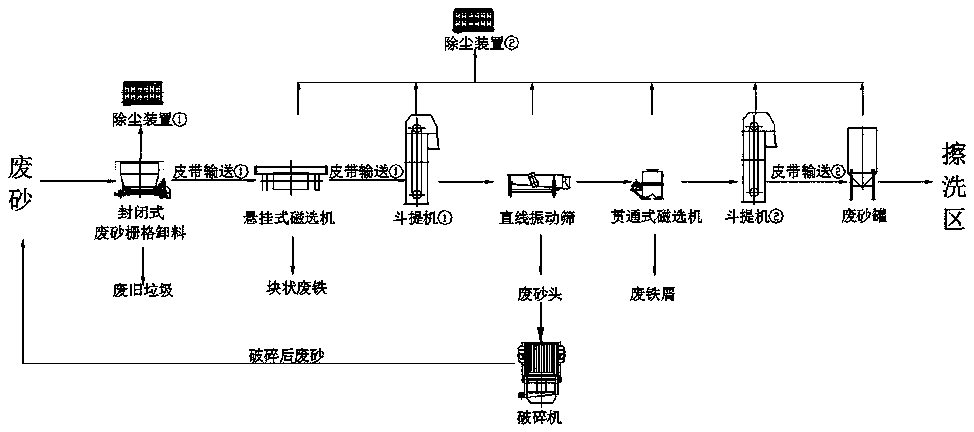

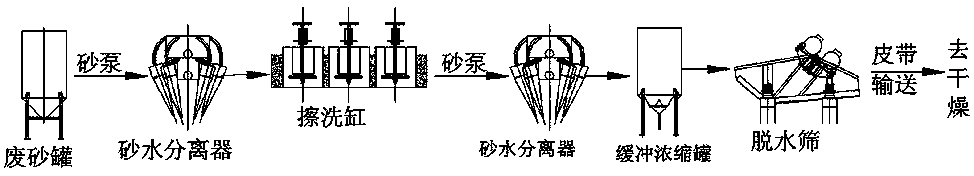

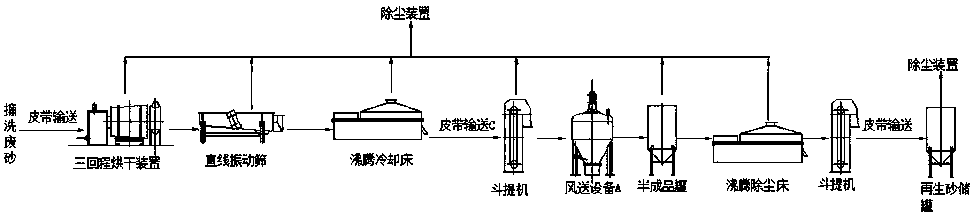

Foundry waste sand regeneration and reuse method and device

ActiveCN103406490ALow impurity contentReduce workloadMould handling/dressing devicesMagnetic separatorIon

A foundry waste sand regeneration and reuse method comprises the following steps: pretreatment of waste sand: the original waste sand is removed with waste garbage through a closed grid unloader, removed with waste iron through a suspension type magnetic separator, removed with large-particle waste sand through a linear vibrating screen, and removed with waste scrap ions through a cut-through magnetic separator, and then enters a waste sand storage tank for storage; cleaning of waste sand: the pretreated waste sand is conveyed to a cleaning area through a sand pump, is introduced to the sand-water separator to remove part of water, then enters a scrubbing-cleaning combined tank for scrubbing and cleaning, enters a buffering concentration tank for sedimentation and concentration, and finally enters a dewatering screen to get rid of part of the water; drying: after the above processing, the waste sand is subjected to low-temperature drying or high-temperature roasting to obtain reclaimed sand, then the reclaimed sand is put into a regeneration sand tank for storage; lamination of regenerated sand: the measured regenerated sand is heated to a certain temperature through a heater, and is put into a precoated sand blender together with adhesive to mix evenly, then the mixture is cooled to room temperature to obtain the precoated sand, and the precoated sand is put into a bucket for storing finished sand.

Owner:广西兰科资源再生利用有限公司

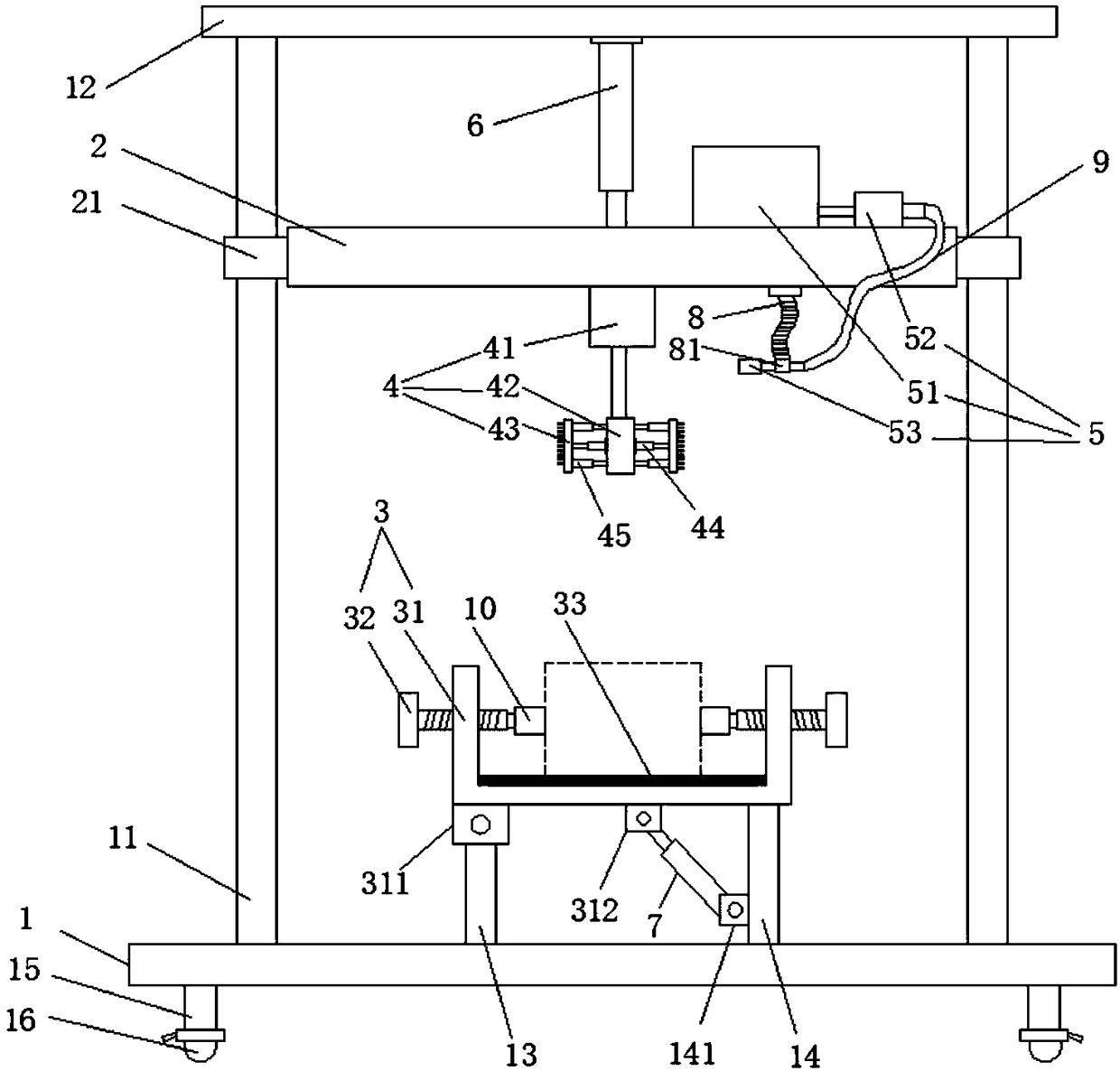

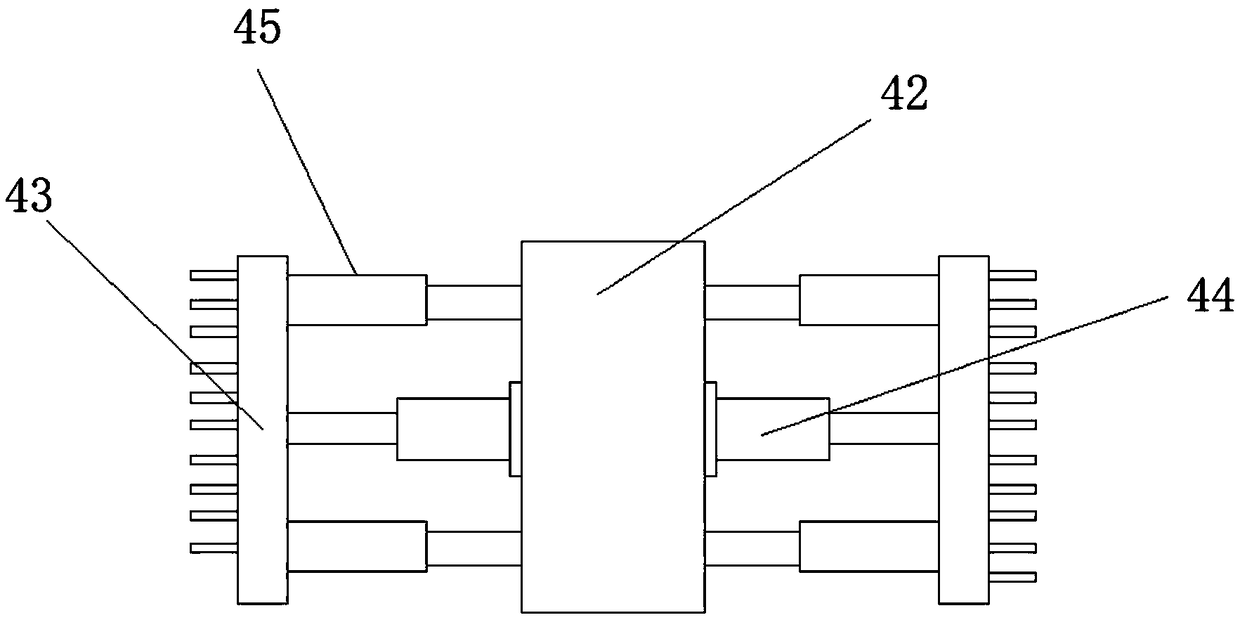

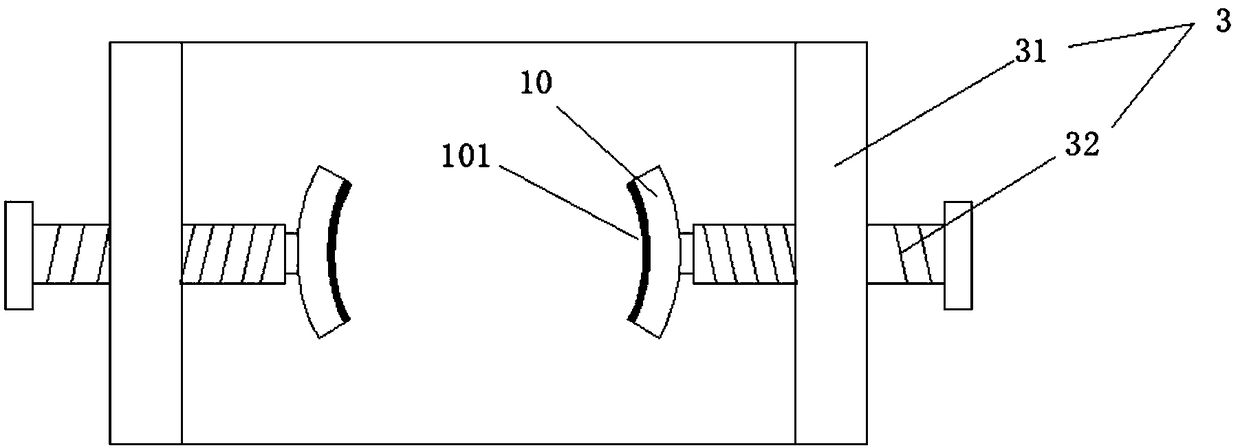

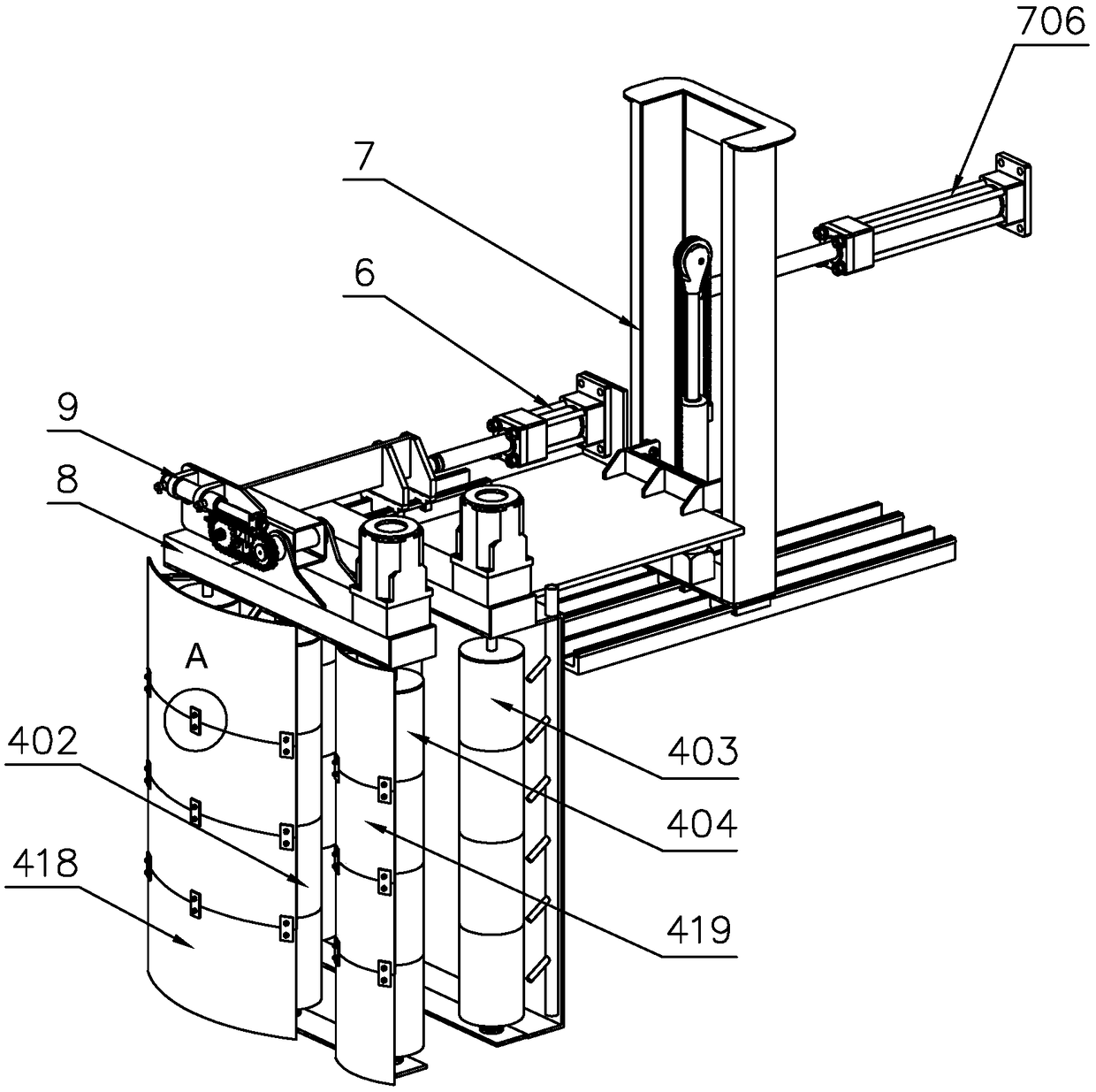

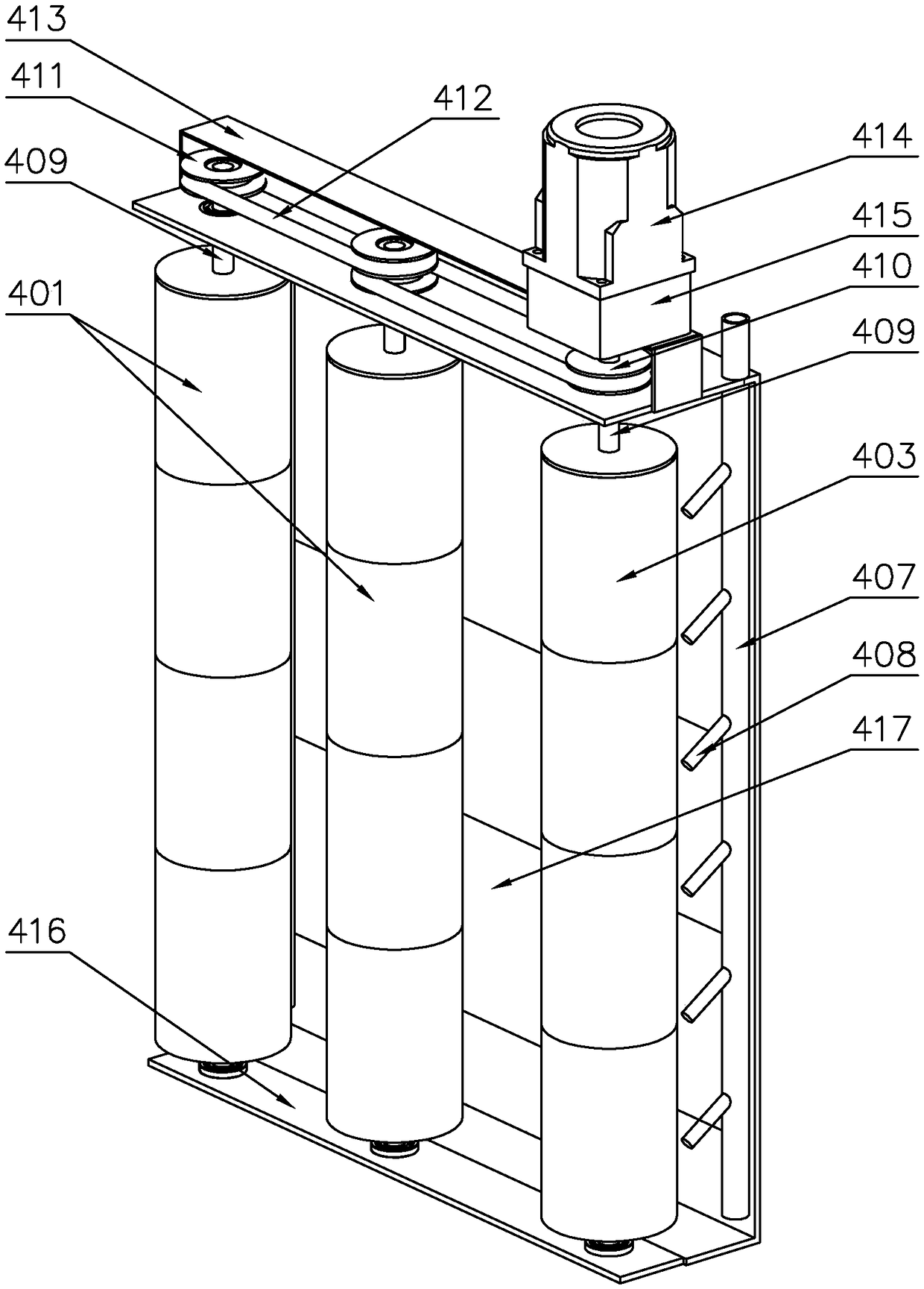

Scrubbing device for industrial barrel

The invention discloses a scrubbing device for an industrial barrel. The scrubbing device for the industrial barrel comprises a base body, a placement table, a clamping device, a scrubbing device bodyand a water flushing device, wherein two stand columns are arranged at the upper end of the base body, a cross plate is welded between the upper ends of the stand columns, the placement table is connected with the stand columns in a sliding mode, and a first hydraulic lifting rod is arranged between the placement table and the cross plate; the clamping device comprises a U-shaped placement plateand two locking bolts, the scrubbing device comprises a motor, a scrubbing sleeve part and two brush heads, wherein the motor is fixedly arranged on the lower end face of the placement table through amounting base, and third hydraulic telescopic rods are symmetrically arranged outwards on the two sides of the scrubbing sleeve part, the two brush heads are fixedly arranged at the end parts of thethird hydraulic telescopic rods; and the water flushing device comprises a water tank, a water pump and a spray head, wherein a water outlet of the water pump is connected with the spray head througha hose. According to the device, a barrel body is fixed conveniently and stably, manual cleaning is replaced by machinery, a cleaning device is adjustable and is suitable for barrels with a pluralityof diameters, the cleaning device is more rapid and efficient, and waste water can be conveniently poured after the barrel is cleared.

Owner:季晓鸣

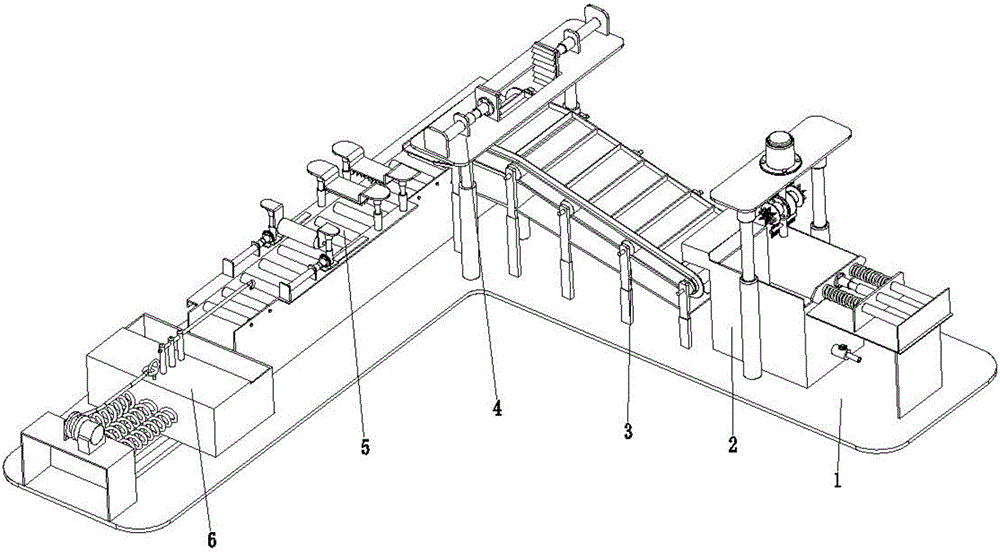

Environment-friendly recycling treatment system for waste plastic bottles

ActiveCN106608004AAvoid pollutionProtect the ecologyPlastic recyclingMechanical material recoveryPollutionMechanization

The invention relates to an environment-friendly recycling treatment system for waste plastic bottles. The environment-friendly recycling treatment system comprises a base plate, a cleaning and feeding device, a conveying device, a squeezing device, a crushing device and a storage device. The base plate is of an L-shaped structure. The cleaning and feeding device is located at the front side end of the base plate. The conveying device is located right on the rear portion of the cleaning and feeding device, and the conveying device and the cleaning and feeding device are located on the same straight line. The squeezing device is located at an outlet in the rear side of the conveying device. The crushing device and the conveying device are vertically arranged, and the crushing device is fixedly connected with the base plate. The storage device is installed at the left side of the crushing device. By means of the environment-friendly recycling treatment system, the waste plastic bottles can be cleaned, pushed, fed, conveyed, squeezed, crushed and stored, and the whole recycling treatment of the waste plastic bottles is realized; moreover, the treatment process is high in degree of mechanization, a large number of labor force is saved, and treatment efficiency is improved; and meanwhile, pollution to the environment by the waste plastic bottles is avoided, and the environment and ecology are protected.

Owner:同信生态环境科技有限公司

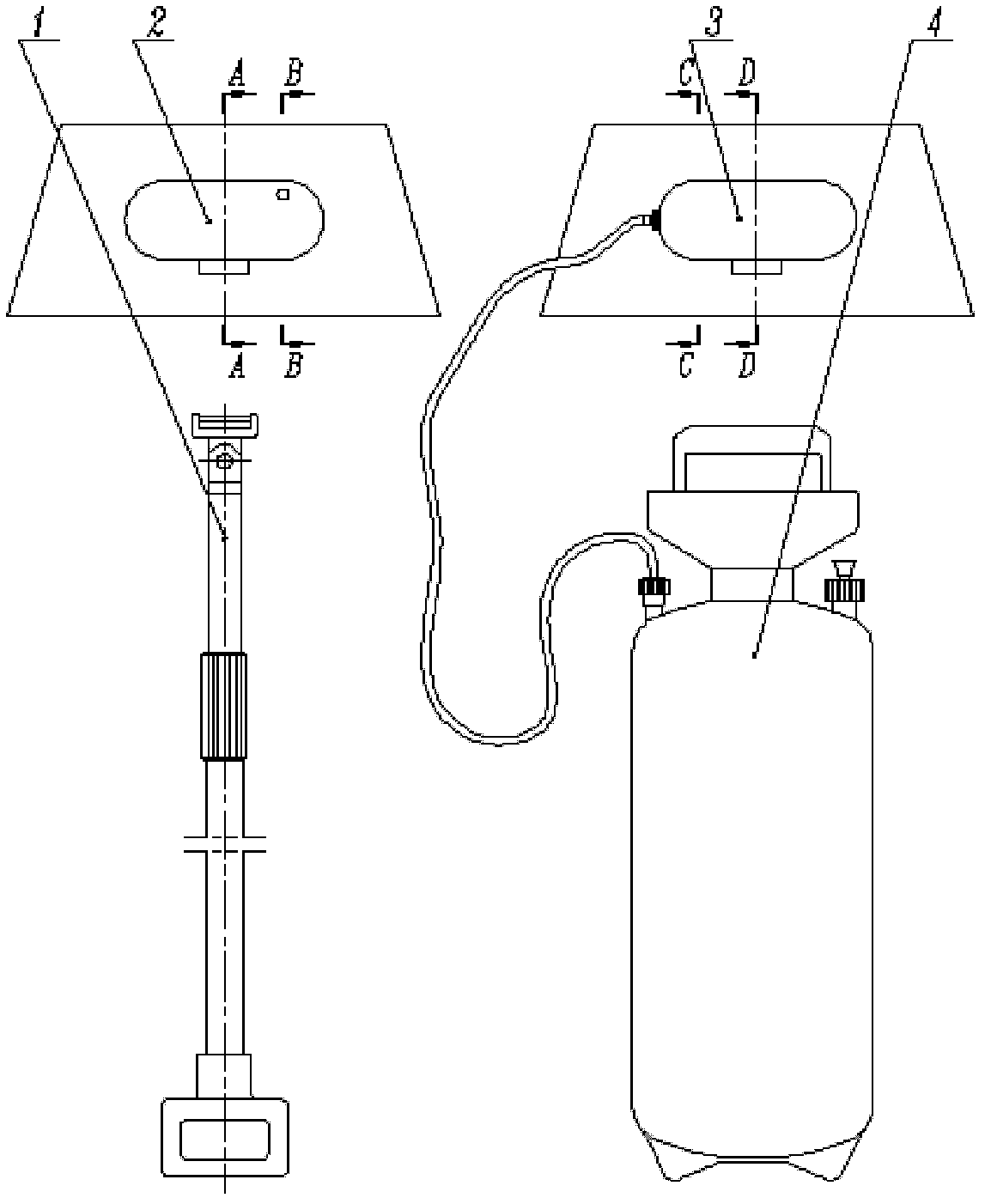

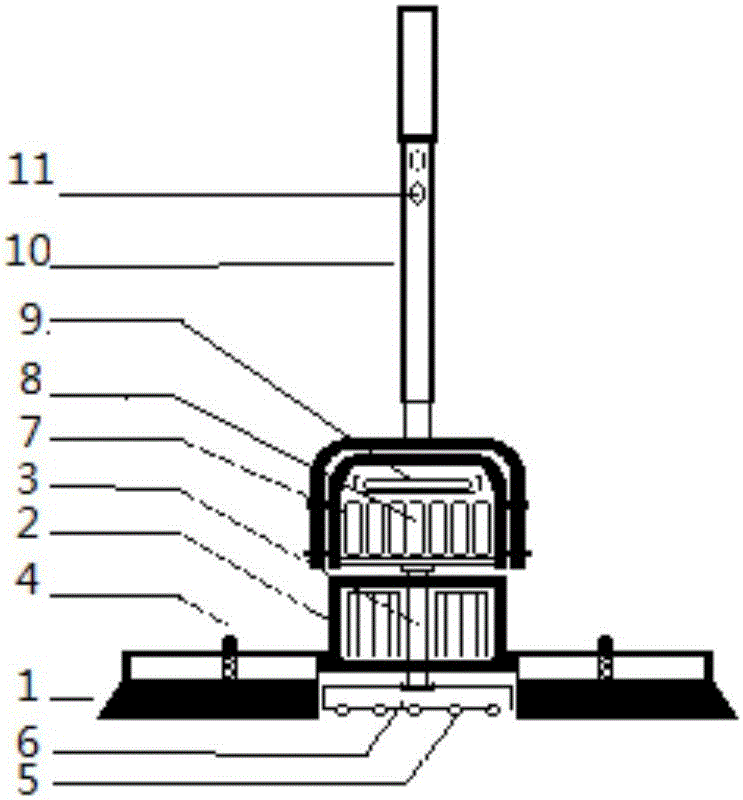

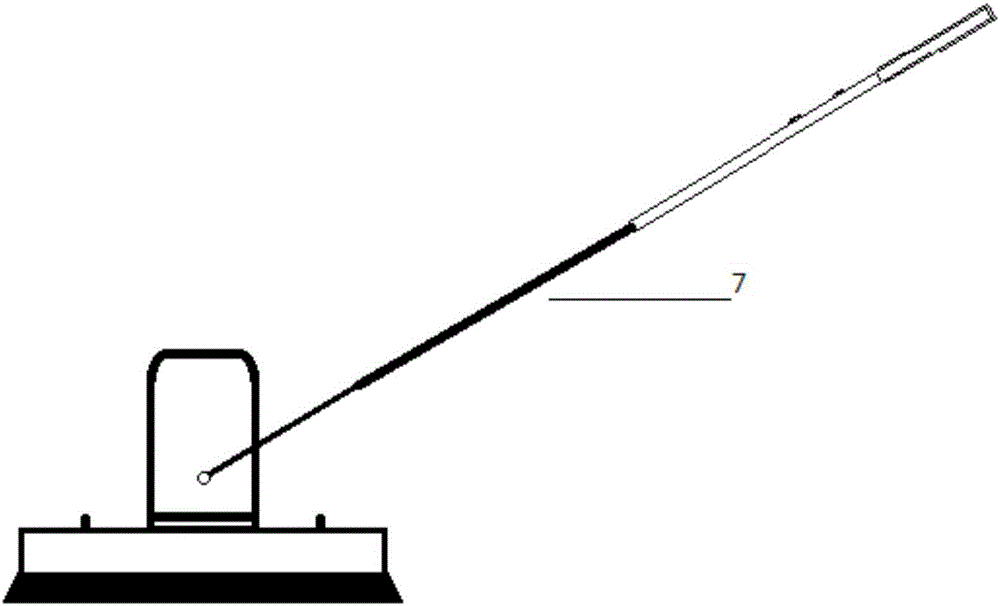

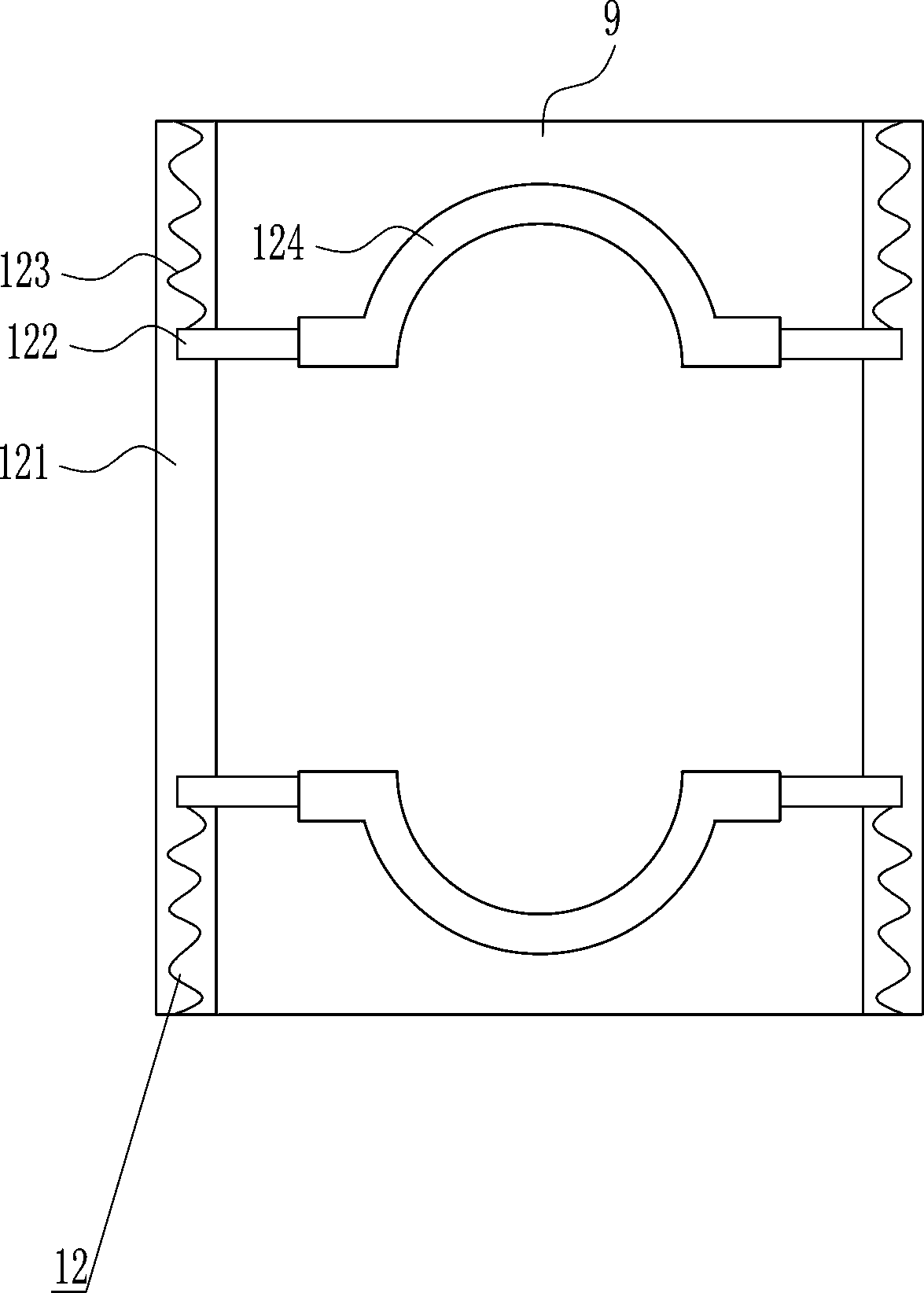

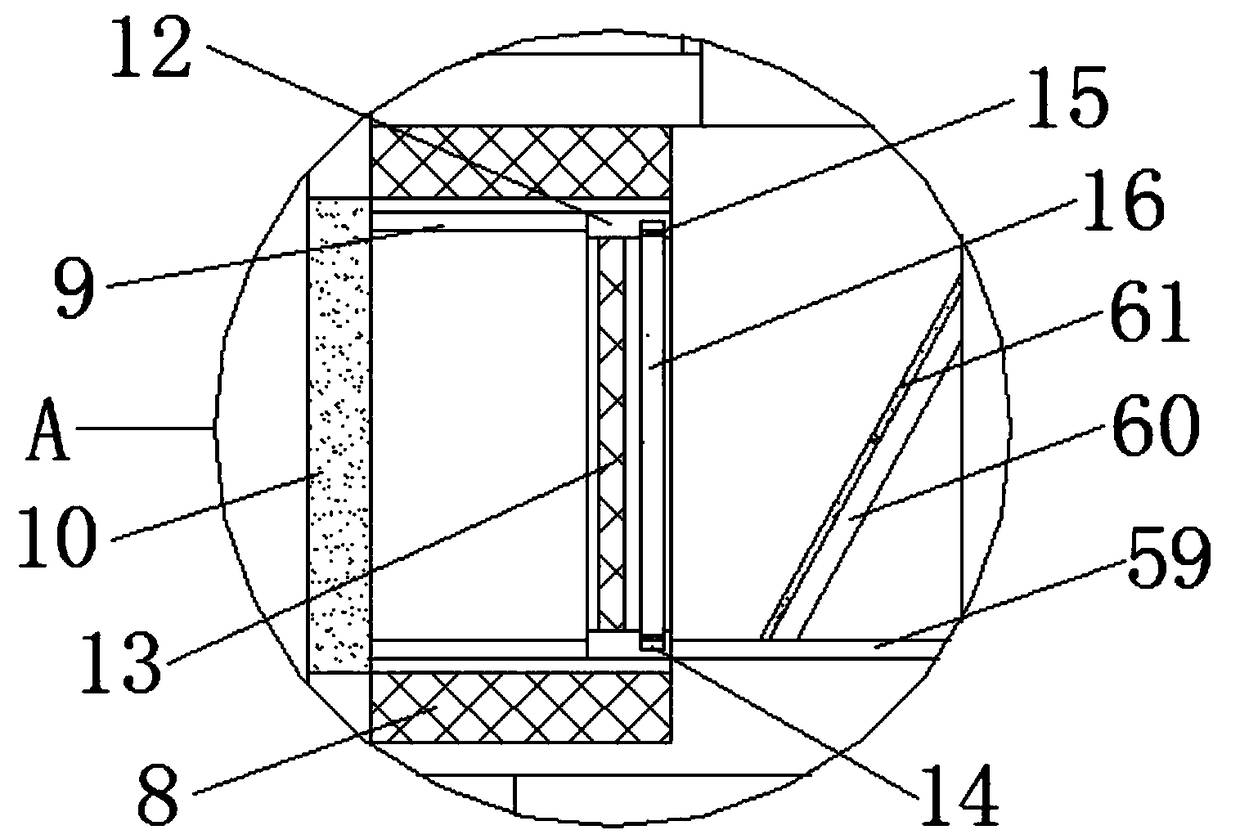

Magnetic attraction type glass cleaner

InactiveCN102319039AHas self-cleaning abilityAvoid the hassle of changing waterWindow cleanersInter layerElectrical and Electronics engineering

The invention relates to a magnetic attraction type glass cleaner. According to the technical scheme of the invention, a glass wiper comprises an lengthening rod (1), an internal wiper body (2), an external wiper body (3) and a manual spraying barrel (4), wherein an water outlet of the manual spraying barrel (4) is connected with the external wiper body (3) through a flexible pipe. An external side face of an internal wiper body interlayer (13) is provided with 3-10 first magnetic substances (6), 2-10 first rollers (10), internal wiper body wiping cloth (9), 2-10 second rollers (8), 3-10 second magnetic substances (6) and an internal wiper body scraping plate (5) in sequence from top to bottom; the external side face of an external wiper body interlayer (36) is provided with 3-10 third magnetic substances (34), 2-10 third rollers (33), a strip-shaped groove (30), external wiper body wiping cloth (29), a fourth roller (28), a fourth magnetic substance (26) and an external wiper body scraping plate (25) in sequence from top to bottom, wherein the trip-shaped groove (30) is provided with a spraying control device (32) and 1-7 atomizing nozzles (31). The magnetic attraction type glasscleaner is convenient to use, and the wiper bodies cannot drop easily; and the magnetic attraction type glass cleaner has excellent scrubbing effect, and is suitable for scrubbing glass with different cambered surfaces.

Owner:涂超群

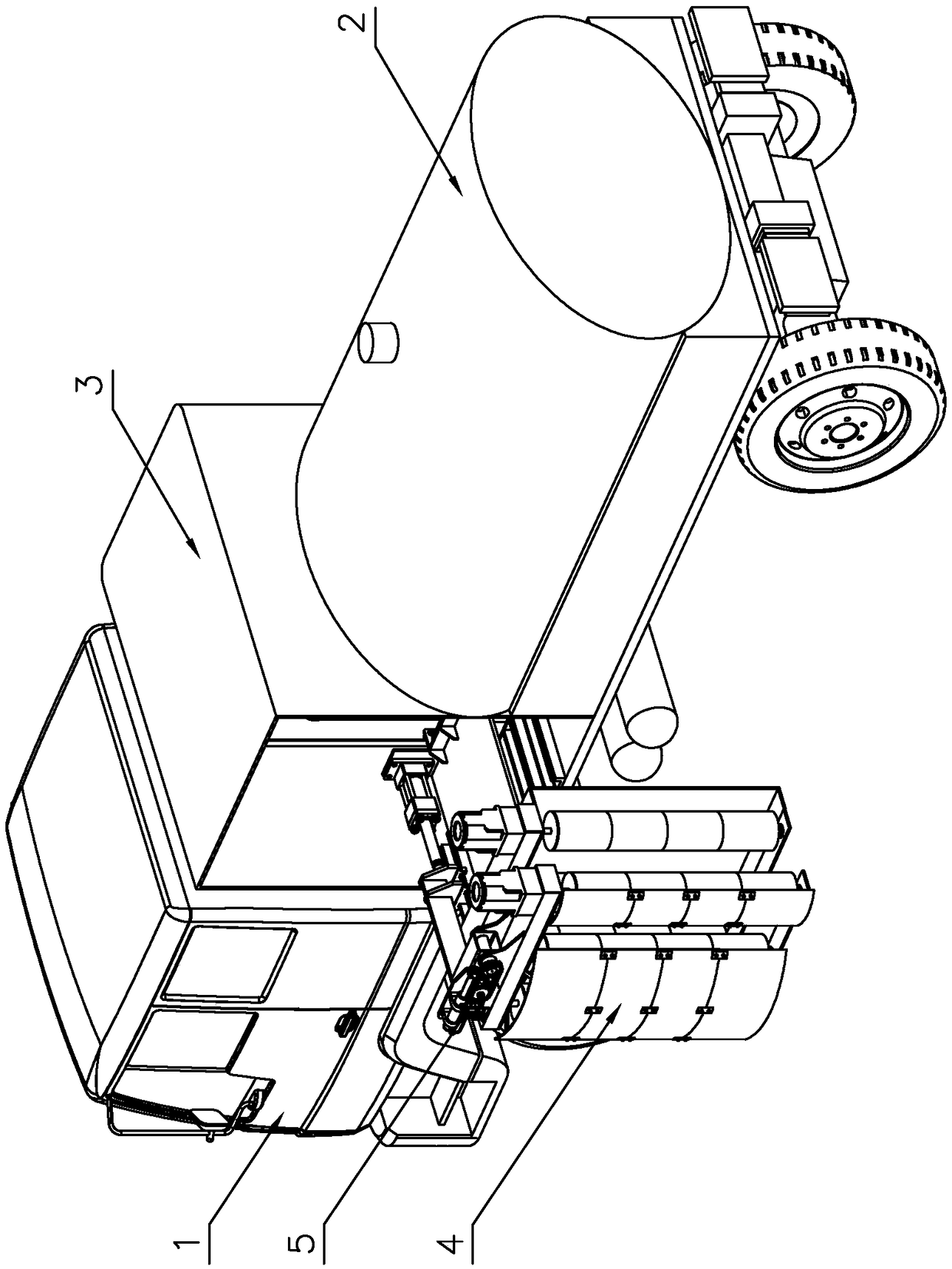

Vehicle-mounted road fence cleaning device for municipal use

InactiveCN109183689AAvoid repositioningImprove scrubbing efficiencyRoad cleaningWater storage tankSprocket

The invention discloses a vehicle-mounted road fence cleaning device for municipal use. A water storage tank is arranged on a sprinkler vehicle body and a storage tank is arranged on one side of the water storage tank. A lifting device is arranged in the contain box, and the lifting device comprises a lifting frame, a lifting cylinder, a sprocket wheel III, a chain and a sliding block; a cleaningdevice is arranged on one side of the lifting device, and the cleaning device comprises a fixed brush roller, an adjusting brush roller, a transmission box and a transmission device, wherein the transmission box is provided with a transmission device; a high-pressure water pipe is arranged on one side of the fixed brush roller; the other side of the guard rail is provided with an adjusting brush roller symmetrical to the fixed brush roller, and the structure and size of the adjusting brush roller are consistent with those of the fixed brush roller. The upper part of the transmission box of theadjusting brush roller is provided with an obstacle overtaking device. When the invention meets obstacles such as traffic indication signs, the adjusting brush roller is folded up by using a flippingdevice and a retracting device, and the adjusting brush roller is reset by using the flipping device and the retracting device after the flipping device and the retracting device pass over the obstacles, thereby avoiding the repositioning of the cleaning device and improving the scrubbing efficiency.

Owner:房思群

Brushing and screening equipment for potatoes

The invention discloses a potato scrubbing and screening device, which comprises a casing, a feeding port, a first motor, a conveyor belt, a water tank, a brush plate and a collecting box; a feeding port is installed on the upper surface of the casing, and a partition is arranged inside the feeding port , the left side wall of the casing is fixedly connected with a collection box, the bottom of the feed inlet is provided with a conveyor belt, the top of the casing is fixedly connected with a water spray pipe and a water tank, and a turntable is arranged on the right side of the water spray pipe, and the surface of the turntable is fixed near the edge. A fixed rod is connected, a rotating shaft is set under the turntable, a half gear is set on the rotating shaft, a brush plate is set under the half gear, a sewage tank is set under the conveyor belt, and a sieve plate is set under the right end of the conveyor belt, and the potatoes are put into the feeder. At the feeding port, use the active roller and the driven roller to brush away the soil and other sundries on the surface of the potatoes, and use the brush plate to move left and right to scrub the potatoes with high scrubbing efficiency. The potatoes are screened according to the volume of the potatoes, scrubbing, screening, and drying Simultaneously, greatly improving work efficiency.

Owner:浦江县宏创科技开发有限公司

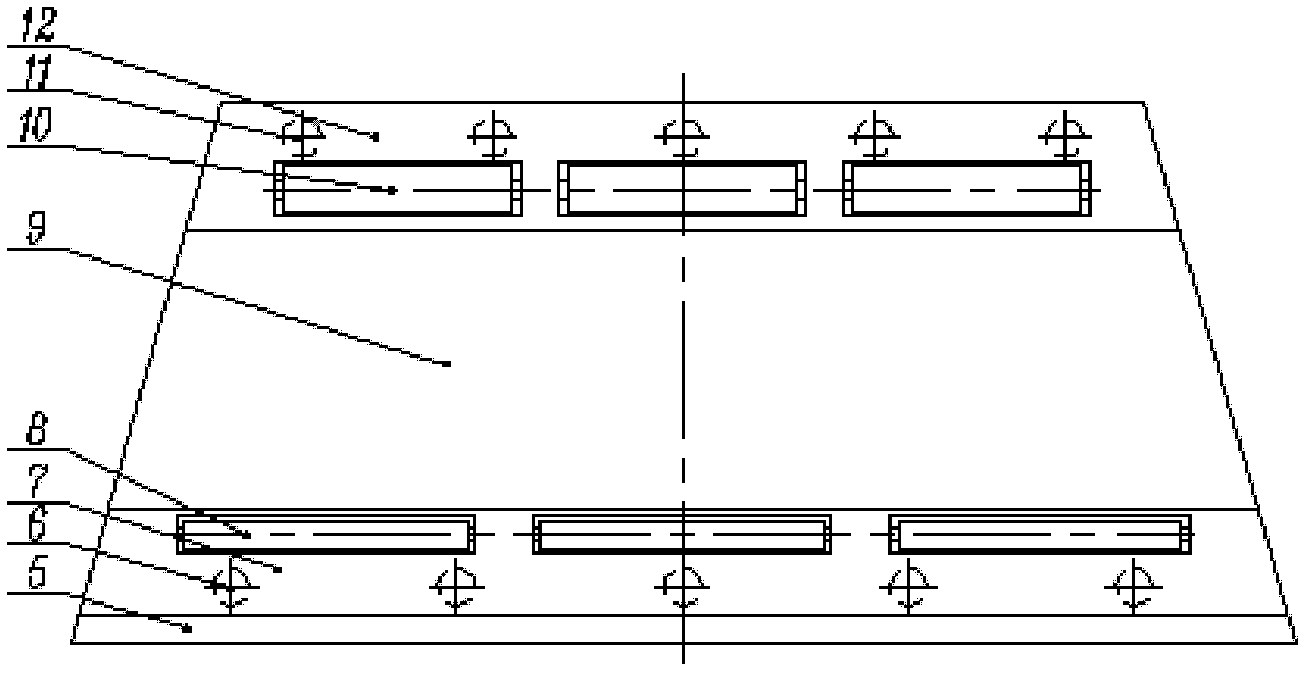

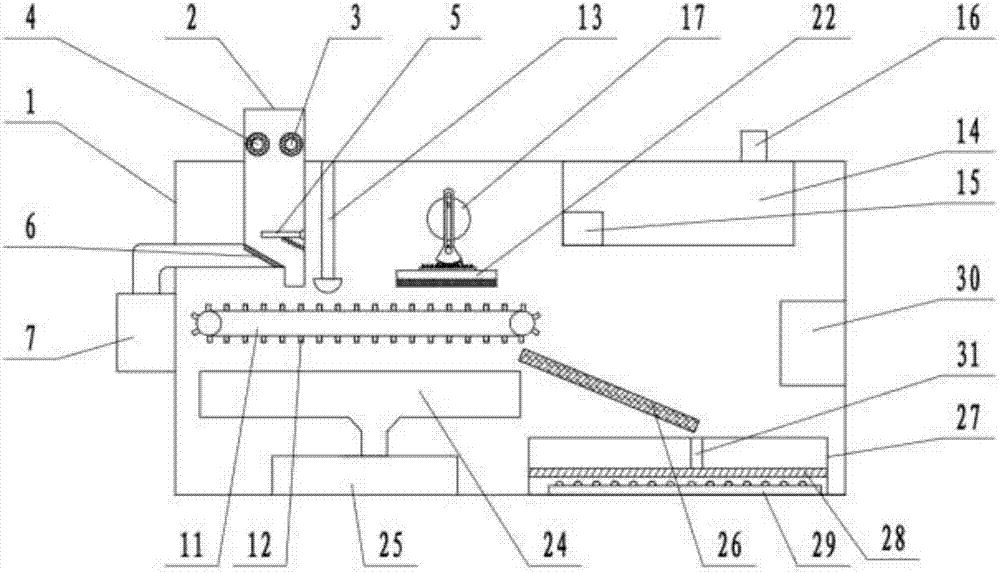

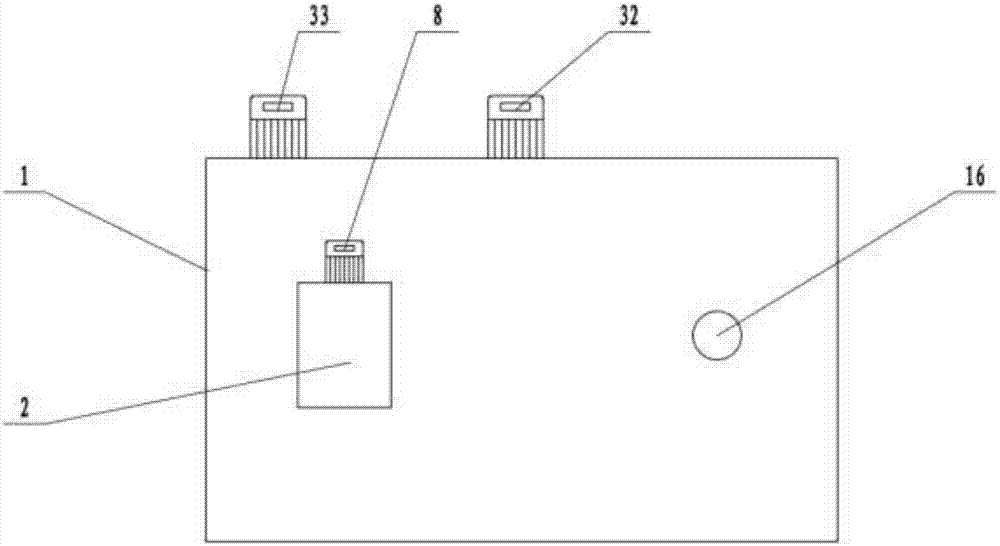

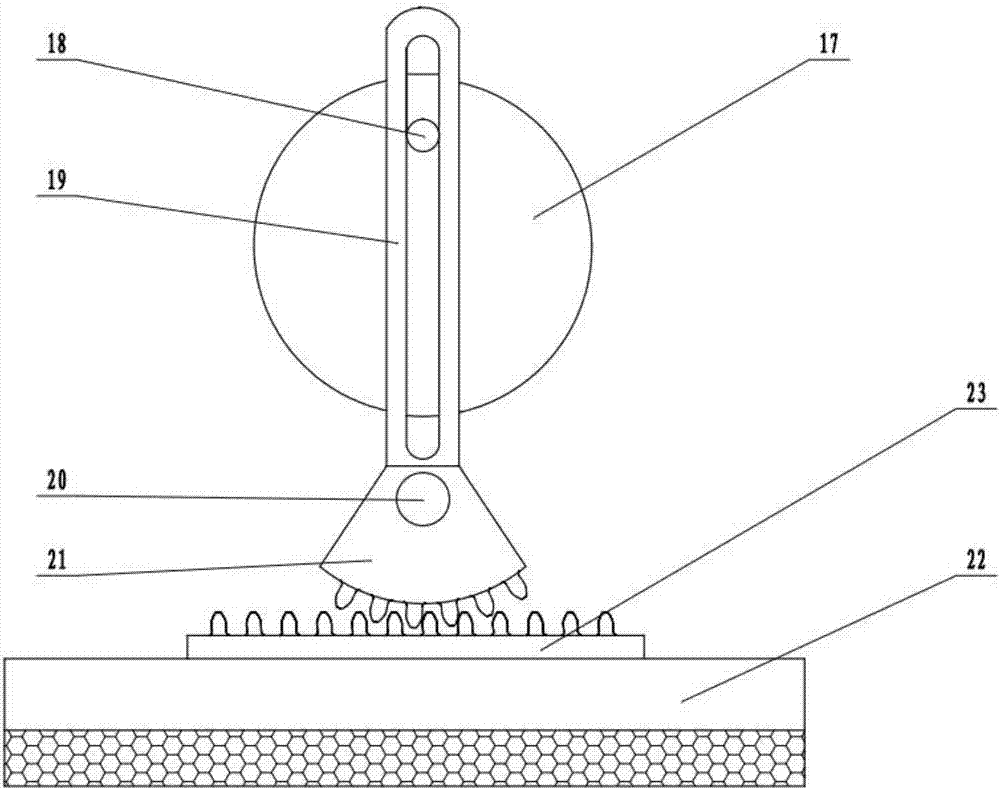

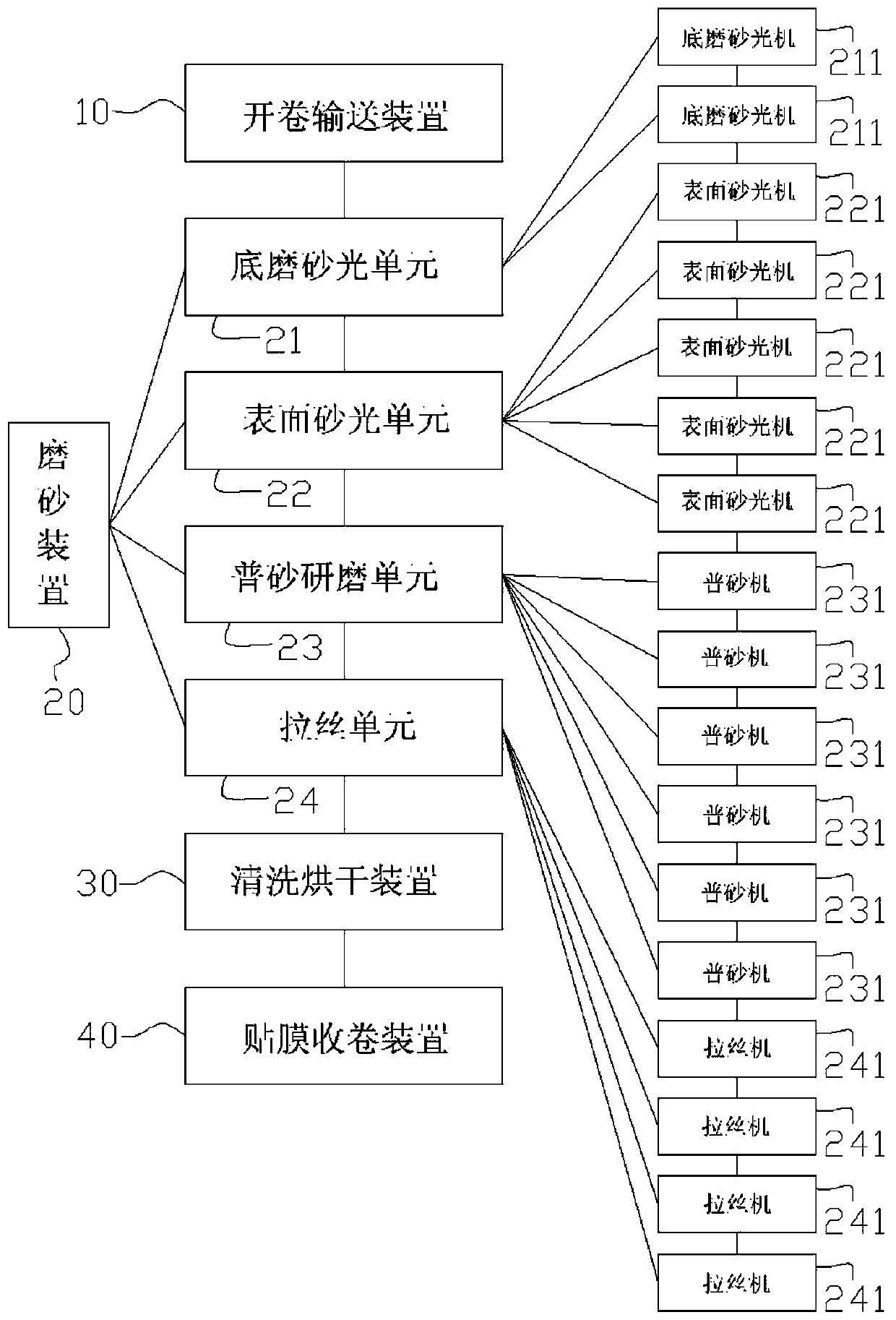

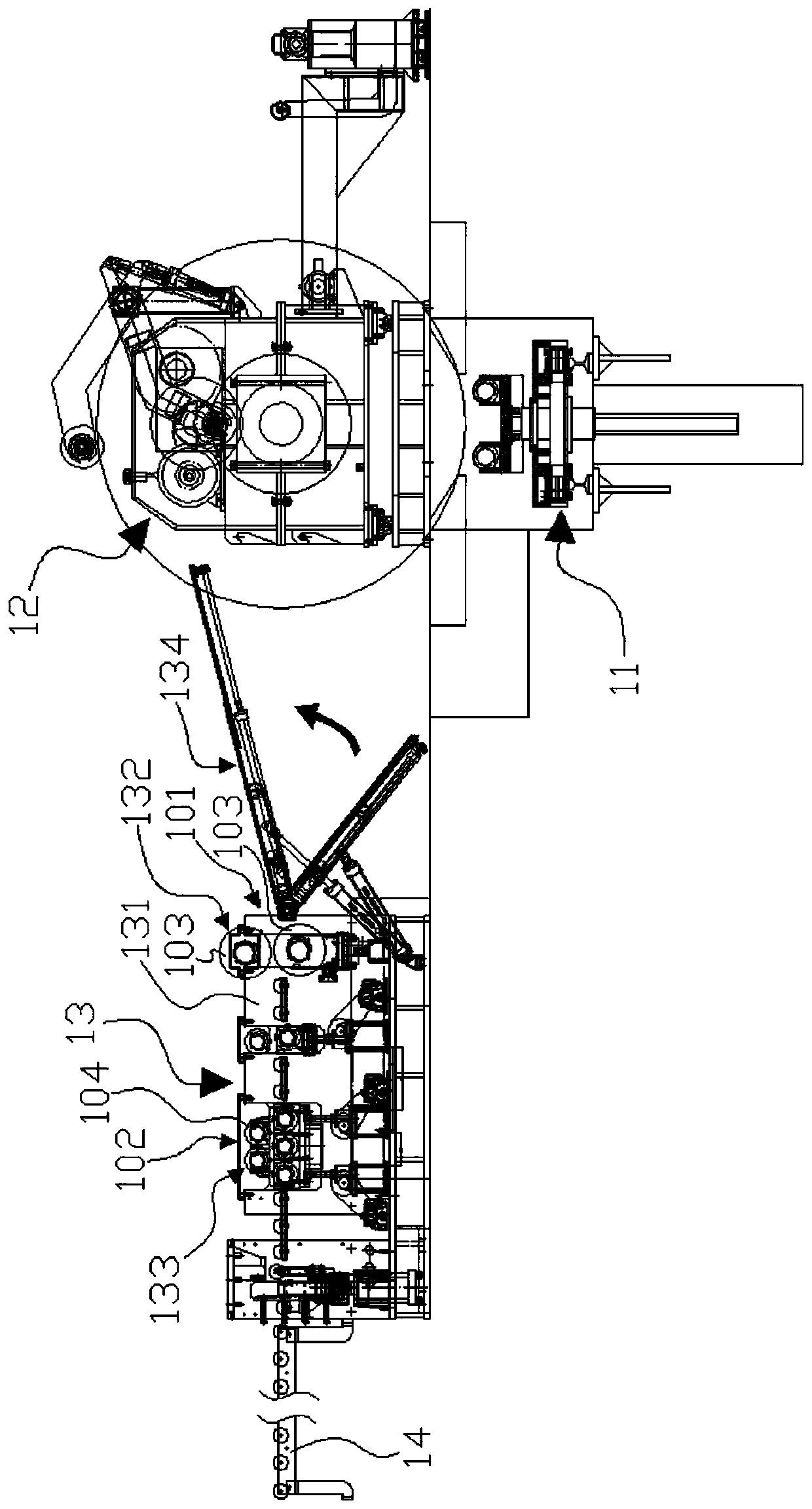

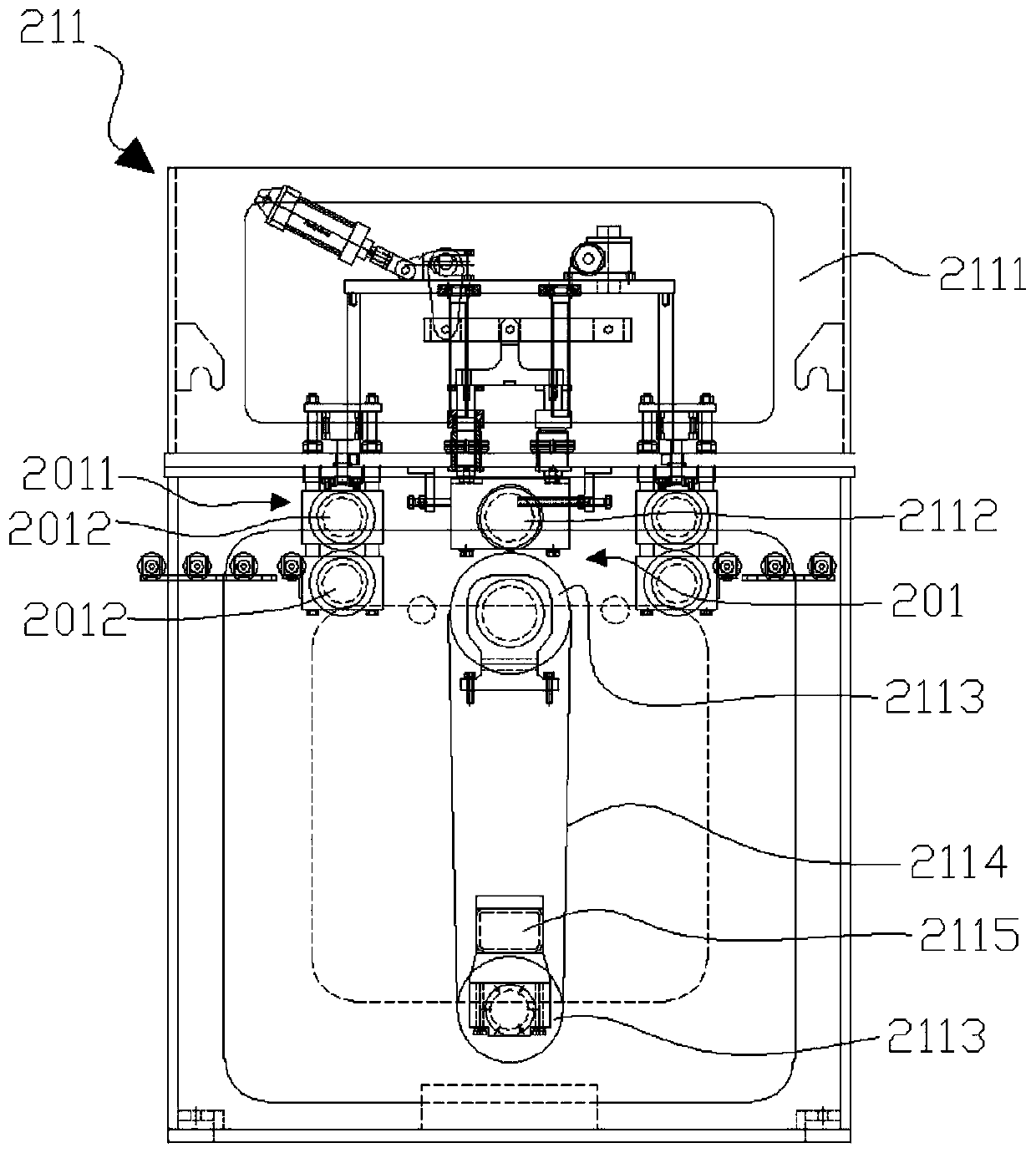

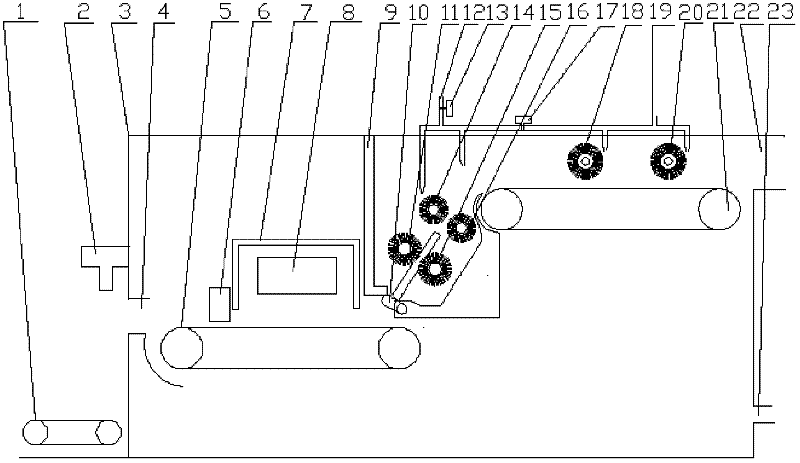

Stainless steel overall roll grinding automatic production line

PendingCN110539236AHigh degree of automationImprove scrubbing efficiencyFilament handlingBelt grinding machinesAutomationWire drawing

The invention discloses a stainless steel overall roll grinding automatic production line which comprises an unrolling and conveying device, a grinding device, a cleaning and drying device and a filmattaching and rolling device. The unrolling and conveying device is used for unrolling of overall stainless steel rolls, flattening the overall stainless steel rolls and then conveying the overall stainless steel rolls to the grinding device. The grinding device comprises a bottom grinding and sanding unit, a surface sanding unit, a common sand grinding unit and a wire drawing unit which are arranged side by side at intervals. The bottom grinding and sanding unit is used for grinding the bottom face of band steel. The surface sanding unit is used for conducting polishing and finish grinding onthe surface of the band steel. The common sand grinding unit is used for conducting further grinding treatment on the surface of the band steel. The wire drawing unit is used for conducting wire drawing grinding on the surface of the band steel. The cleaning and drying unit is used for cleaning the band steel output from the grinding device, removing dirt and impurities on the band steel and thenconveying the band steel to the film attaching and rolling device after the band steel is dried. The film attaching and rolling device is used for conducting film attaching treatment and rolling on the surface of the band steel. The stainless steel overall roll grinding automatic production line is high in automation degree.

Owner:ZHAOQING HONGWANG METAL IND

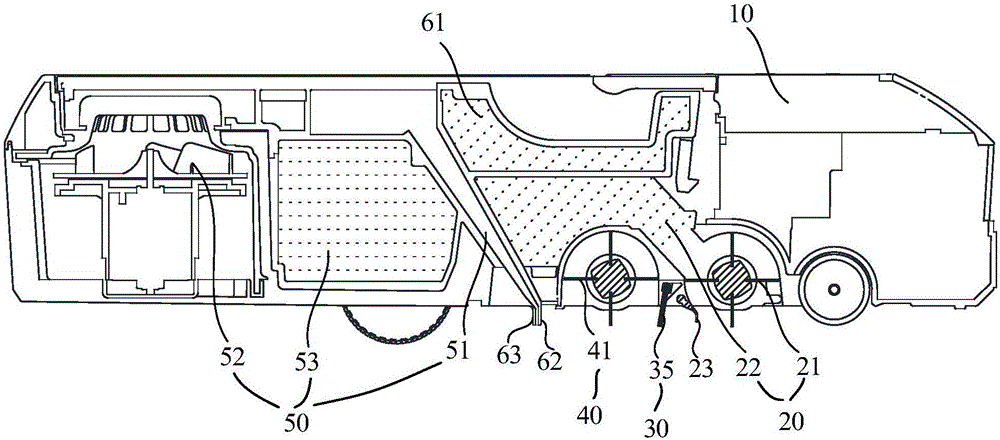

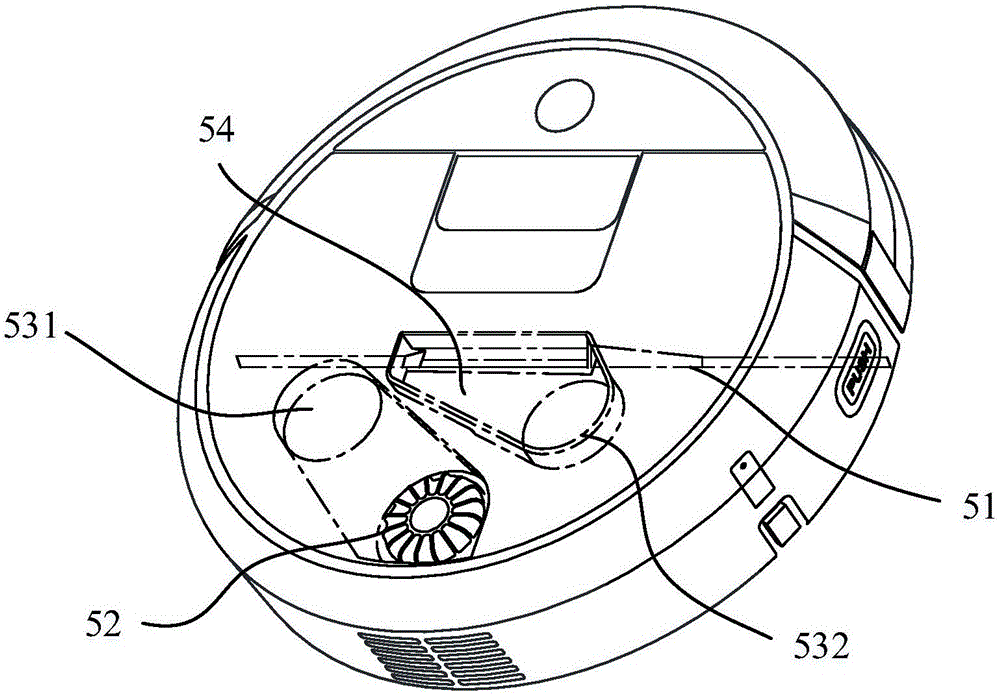

Household floor scrubber

InactiveCN106175613AEasy to cleanImprove scrubbing efficiencyCarpet cleanersFloor cleanersEngineeringWater diversion

The invention discloses a household floor washing machine, which includes a body, the body includes a cleaning mechanism for cleaning a target area in the ground, a water diversion mechanism for drawing washing water to the target area, and a cleaning mechanism for cleaning the target area where the washing water remains , and a water absorbing mechanism for sucking away the dirty water left after cleaning the target area; The middle position of the body, and the water diversion mechanism is set close to the cleaning mechanism, and the cleaning mechanism is located between the water diversion mechanism and the water absorption mechanism. The technical solution of the invention can improve the cleaning effect of the floor washing machine and improve the floor washing efficiency.

Owner:SHENZHEN REECOO ELECTRONICS CO LTD

Pipeline outer-wall reciprocating cleaning device

ActiveCN109092807AImprove scrubbing efficiencyEasy to cleanHollow article cleaningDrive motorHigh pressure water

The invention discloses a pipeline outer-wall reciprocating cleaning device. The pipeline outer-wall reciprocating cleaning device comprises a track bottom plate, two track boxes, supporting rings, adriving box, a supporting rod, a cleaning sleeve and a control box. The two track boxes are arranged on the front and rear sides of the top surface of the track bottom plate. A high-pressure water pipe and a power line are separately arranged in the track boxes in a penetrating mode. The supporting rings are fixed to the left and right sides of the top surface of the track bottom plate. A pipelineis arranged between the supporting rings in a penetrating mode. The pipeline is sleeved with the cleaning sleeve, and a cleaning structure is arranged in the cleaning sleeve. The high-pressure waterpipe is connected to the front side surface of the cleaning sleeve through the track boxes, the supporting rod is fixed to the bottom of the cleaning sleeve, the driving box is fixed to the bottom ofthe supporting rod, a driving motor in the driving box is connected with a power line through the track boxes, a driving structure is arranged at the bottom of the driving box, the control box is fixed to the left side wall of the track bottom plate, and a driving circuit for controlling the forward and reverse rotation of the driving motor in the driving box is arranged in the control box. The pipeline outer-wall reciprocating cleaning device can automatically perform left-right reciprocating cleaning action on the outer side wall of the pipe wall.

Owner:深圳市天德立科技有限公司

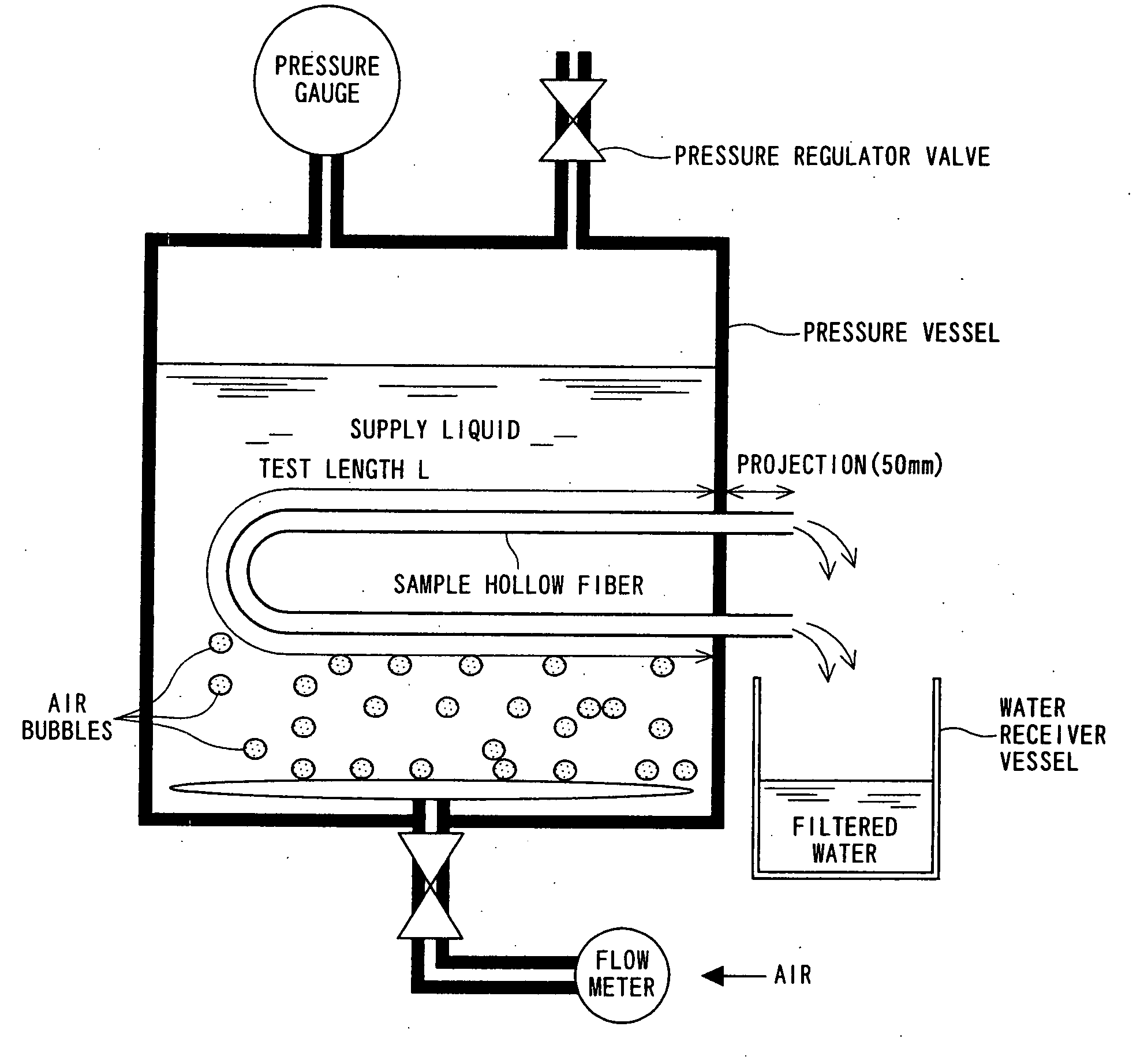

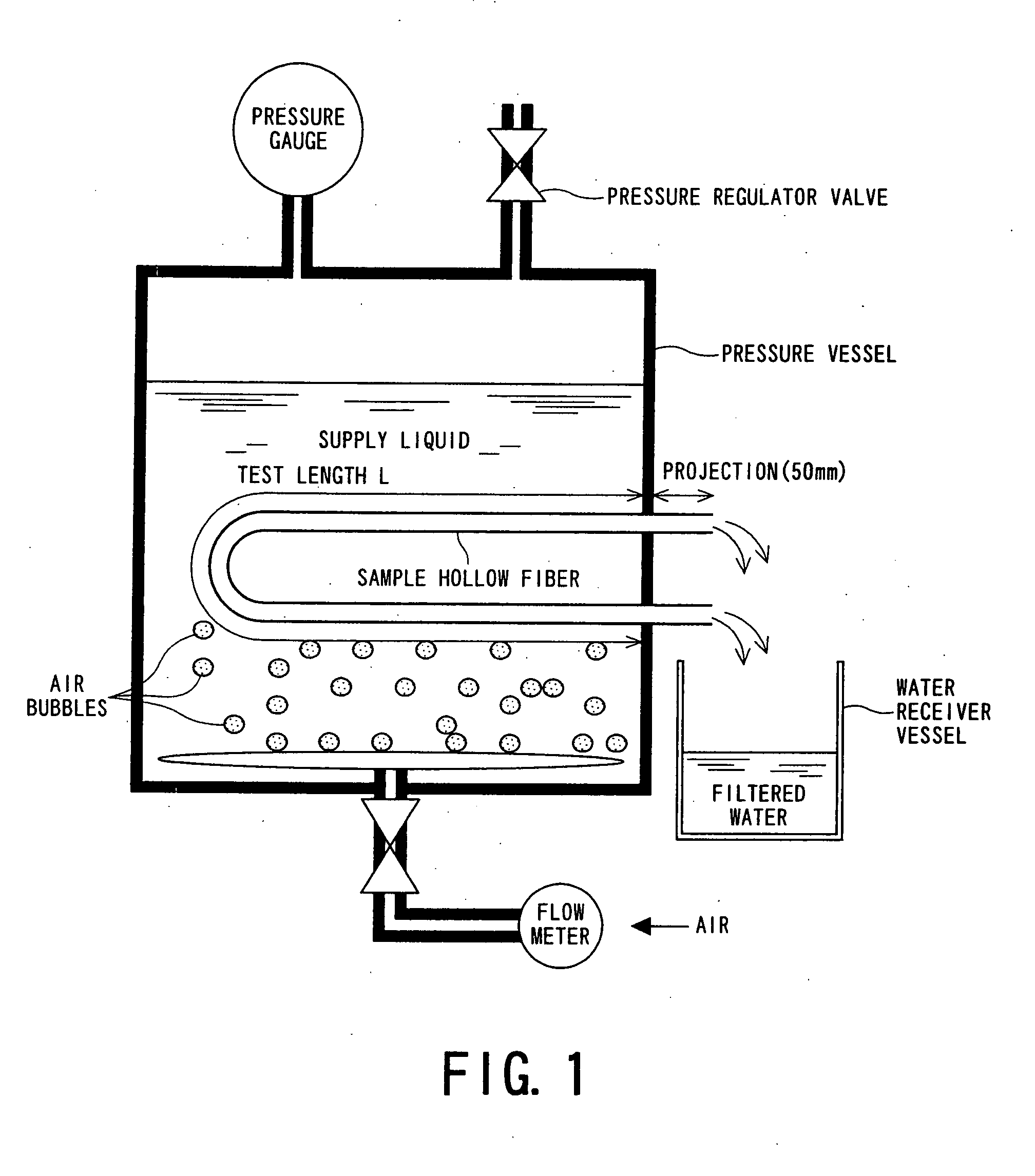

Vinylidene Fluoride Resin Hollow Filament Porous Membrane, Water Filtration Method Using the Same, and Process for Producing Said Vinylidene Fluoride Resin Hollow Filament Porous Membrane

InactiveUS20090206035A1Excellent in not mechanical strengthGood water permeabilitySemi-permeable membranesMembranesFiberPlasticizer

A hollow-fiber porous membrane, comprising a hollow fiber-form porous membrane in a network texture of vinylidene fluoride resin showing a pore size distribution in a direction of its membrane thickness including an outer surface-average pore size P1 as measured by a scanning electron microscope and a membrane layer-average pore size P2 as measured by half-dry method giving a ratio P1 / P2 of at least 2.5. The hollow-fiber porous membrane is excellent in long-term water filtration performance including efficiency of regeneration by air scrubbing. The hollow-fiber porous membrane is produced through a process, wherein a mixture of vinylidene fluoride resin, a plasticizer and a good solvent for vinylidene fluoride resin, is melt-extruded in a hollow-fiber film and cooled and formed into a solidified film within a cooling medium containing at least a certain proportion of a good solvent for vinylidene fluoride resin.

Owner:KUREHA KAGAKU KOGYO KK

Dinner plate cleaning machine

InactiveCN102334967AQuick washReduce labor intensityTableware washing/rinsing machinesAgricultural engineeringUltimate tensile strength

The invention discloses a dinner plate cleaning machine, which comprises a belt pulley I, a shell, a plate outlet, a chain wheel, a disinfection cover, a high temperature heater, a partition plate, a stop block II and a belt pulley II, wherein the shell is provided with a cylindrical brush wheel I, a cylindrical brush wheel II, a cylindrical brush wheel III and a cylindrical brush wheel IV; the cylindrical brush wheel I, the cylindrical brush wheel II, the cylindrical brush wheel III and the cylindrical brush wheel IV are respectively arranged on the shell and horizontally form certain angles; the shell is also provided with a cylindrical brush wheel V and a cylindrical brush wheel VI which are respectively arranged on the shell and are horizontal; a water inlet and a cleaning solution inlet duct are arranged above the shell; the belt pulley II is arranged on the shell and right below the cylindrical brush wheel V and the cylindrical brush wheel VI; and the stop block II is connected to the shell through a shaft and sealed together with the partition plate, the partition plate is vertically connected to the shell, the disinfection cover is connected to the interior of the shell, and the high temperature heater is arranged in the disinfection cover. The dinner plate cleaning machine lightens the labor intensity of workers, and has high cleaning efficiency.

Owner:刘兵

Cleaning equipment and method for vertical motor shell outer side wall machining

ActiveCN111545498AAvoid stickingEfficient scrubbingManufacturing dynamo-electric machinesCleaning using toolsElectric machineMachine

The invention relates to the technical field of vertical motor shell outer side wall machining, and discloses cleaning equipment and method for vertical motor shell outer side wall machining. The cleaning equipment comprises a machine body, the left side of the bottom of the machine body is fixedly connected with a low-speed motor through a fixing frame, and an output shaft of the low-speed motorpenetrates through a bottom through hole of the machine body and is fixedly connected with a rotating platform; and an annular sliding groove is fixedly connected to the top surface of the machine body, an auxiliary supporting rod is fixedly connected to the lower surface of the rotating platform, and a sliding groove roller is movably connected to the tail end of the auxiliary supporting rod through a pin shaft and located on the inner side of the annular sliding groove. The cleaning equipment is provided with the machine body, the low-speed motor, the rotating platform, a radial supporting and adjusting mechanism, a fixed stand column, an inward extrusion mechanism, a transverse position adjusting mechanism, an arc-shaped supporting frame, an electric lifting rod, a rotating motor, a disc type brush and a control panel which are matched with one another, so that the problem that machining chippings on the outer side wall of an existing vertical motor shell are not thoroughly cleanedis effectively solved.

Owner:南京鸿达机电有限公司

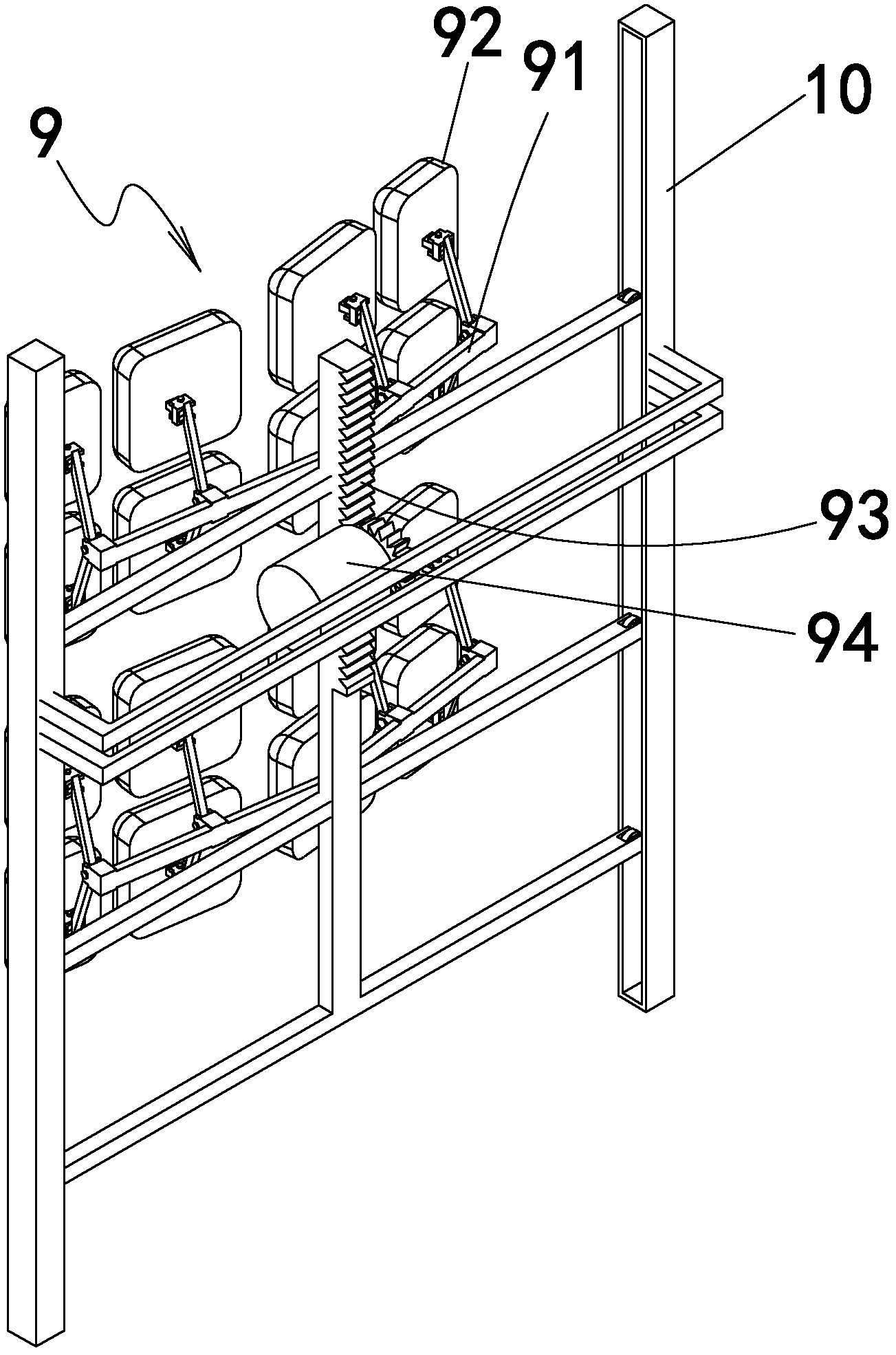

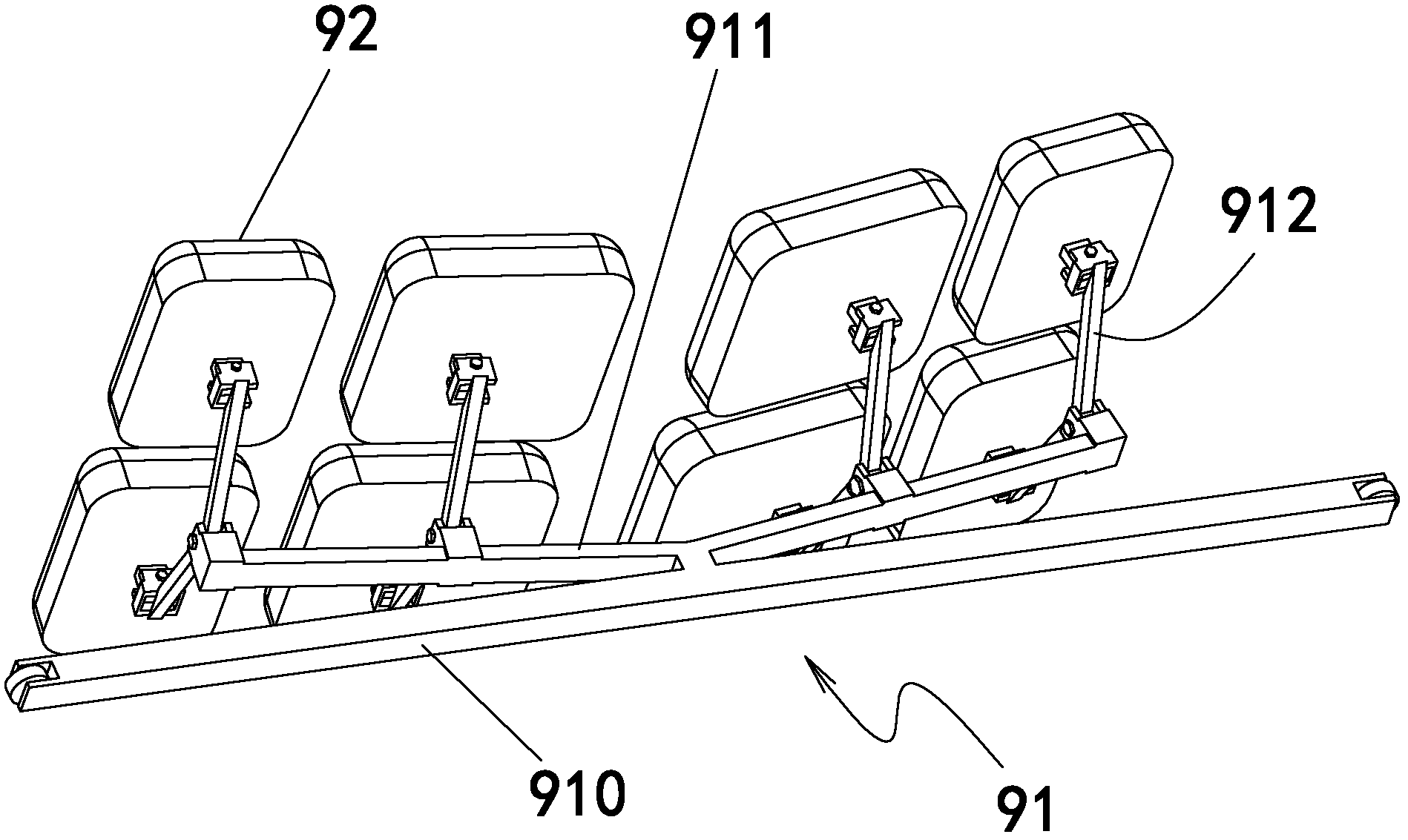

Cleaning apparatus for solar photovoltaic panels and photovoltaic panel cleaning method based thereon

PendingCN108906831AImprove cleaning efficiencyAdjust the fitPhotovoltaicsFlexible article cleaningReciprocating motionCleaning methods

Owner:BEIJING JIAYU DOOR WINDOW & CURTAIN WALL JOINT STOCK

Household electric floor mopping device

InactiveCN106491056AReasonable structureElegant appearanceCarpet cleanersFloor cleanersElectric machineryFuselage

Owner:王高圣

Novel ammonia gas leakage decontamination simulation experiment platform

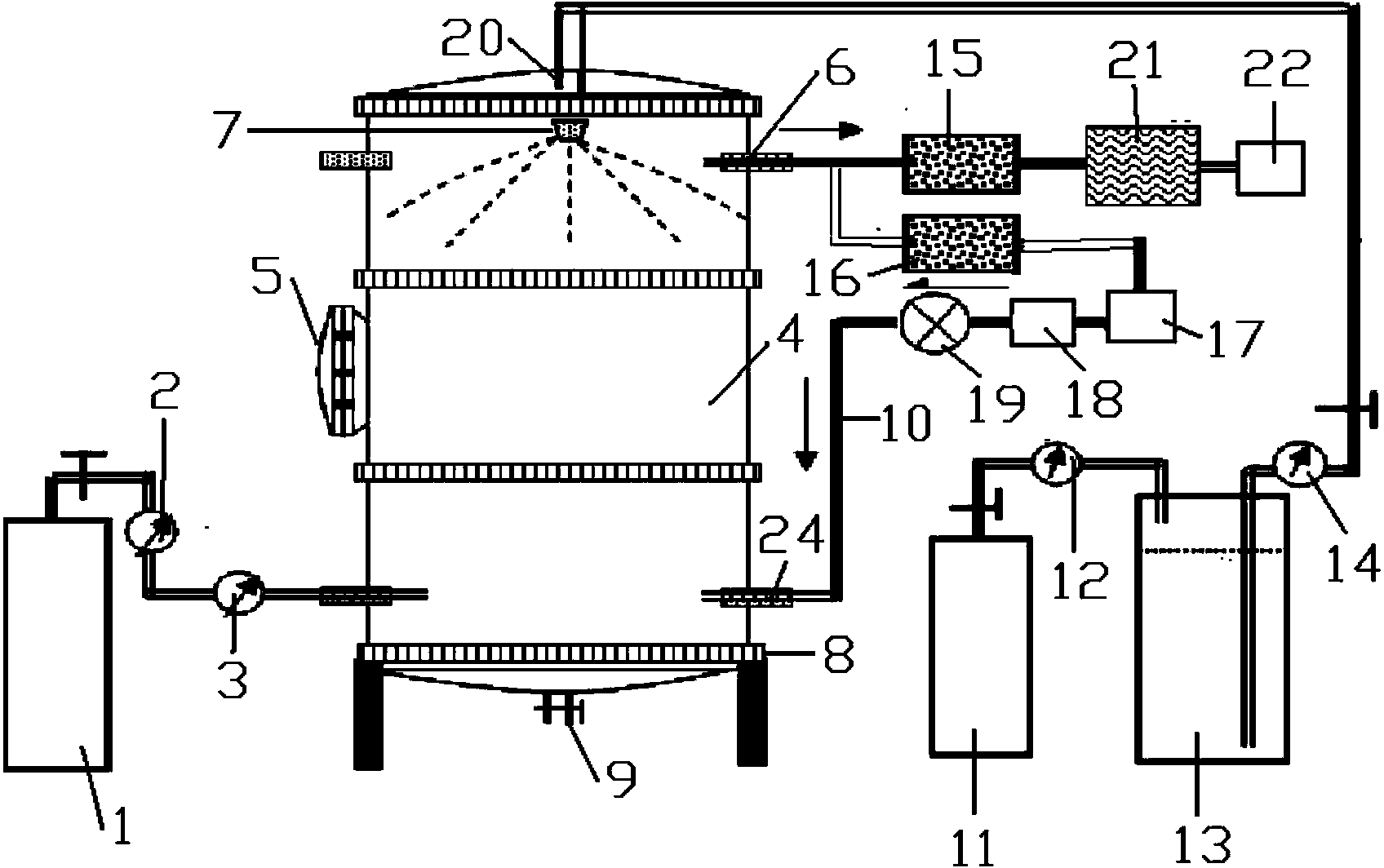

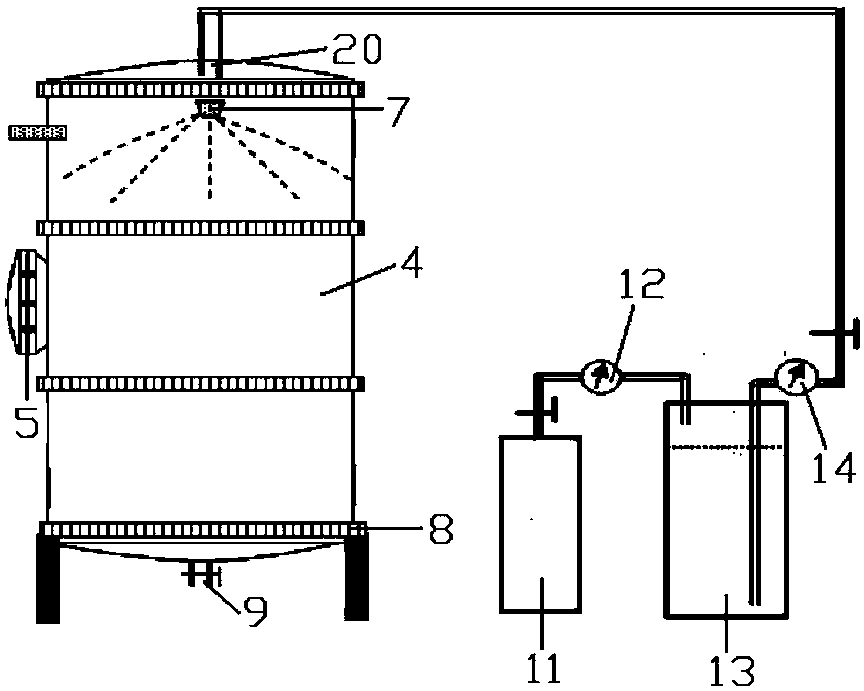

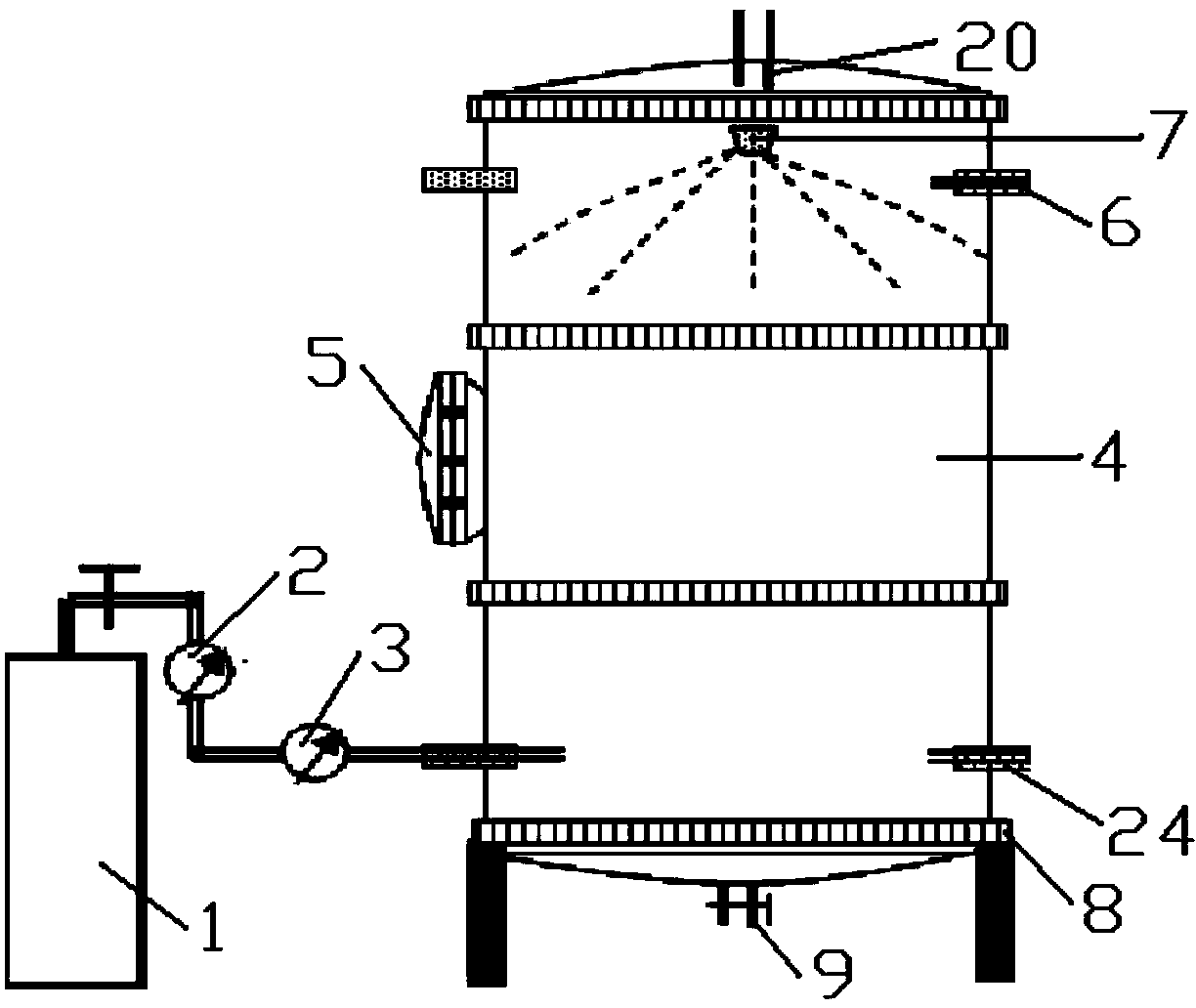

The invention relates to a novel ammonia gas leakage decontamination simulation experiment platform, which comprises an ammonia gas metering and feeding system, a gas circulating system, a data acquisition and analysis system, a water mist system and a decontamination chamber. The novel ammonia gas leakage decontamination simulation experiment platform device disclosed by the invention has good leak tightness and good test data repeatability, and each component is stable in work and operation, so that a quite good platform can be provided for researching decontamination of dangerous poison gases, and the novel ammonia gas leakage decontamination simulation experiment platform has an important significance for a fire brigade to improve the poison gas decontamination efficiency.

Owner:CHINESE PEOPLES ARMED POLICE FORCE ACAD

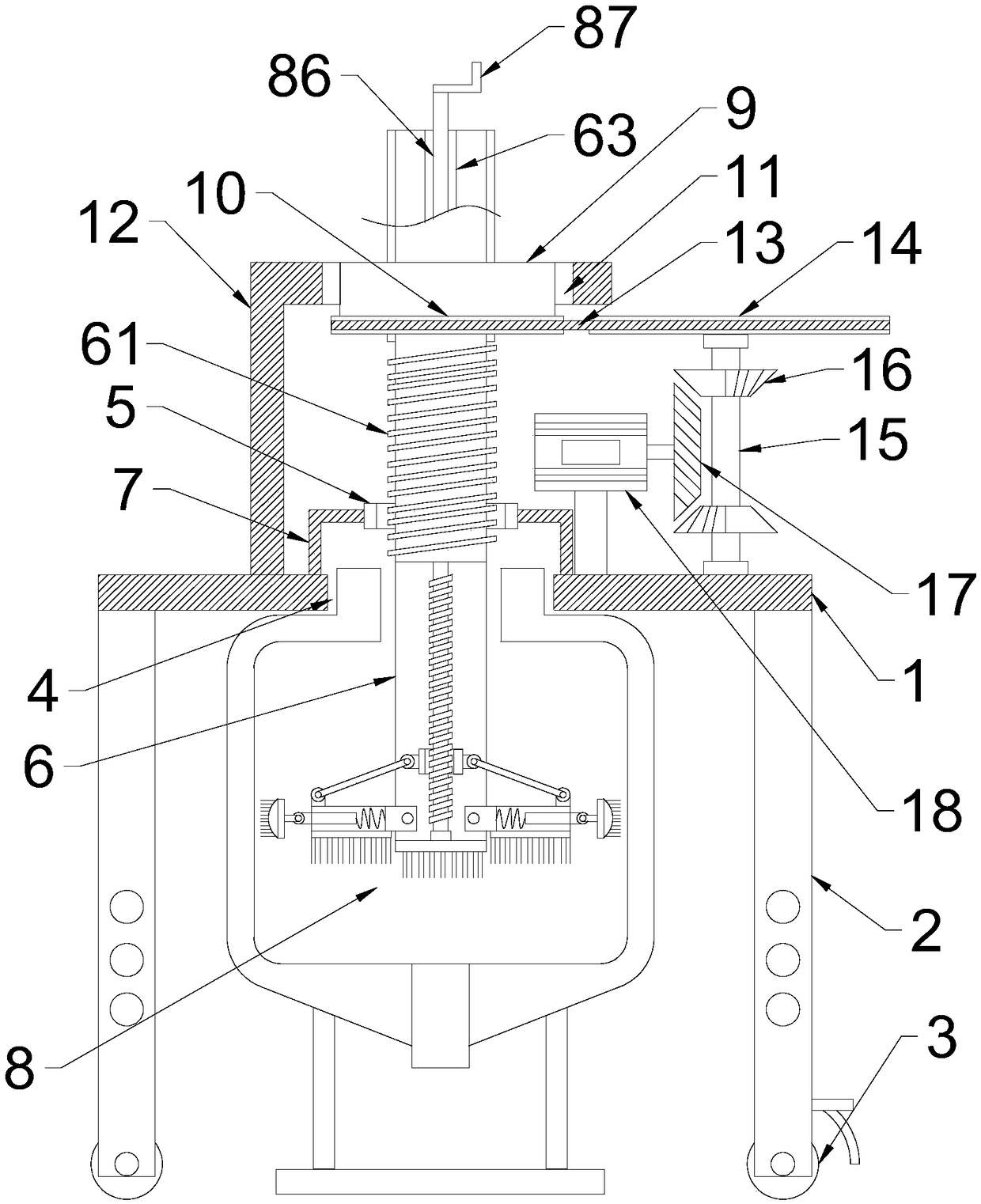

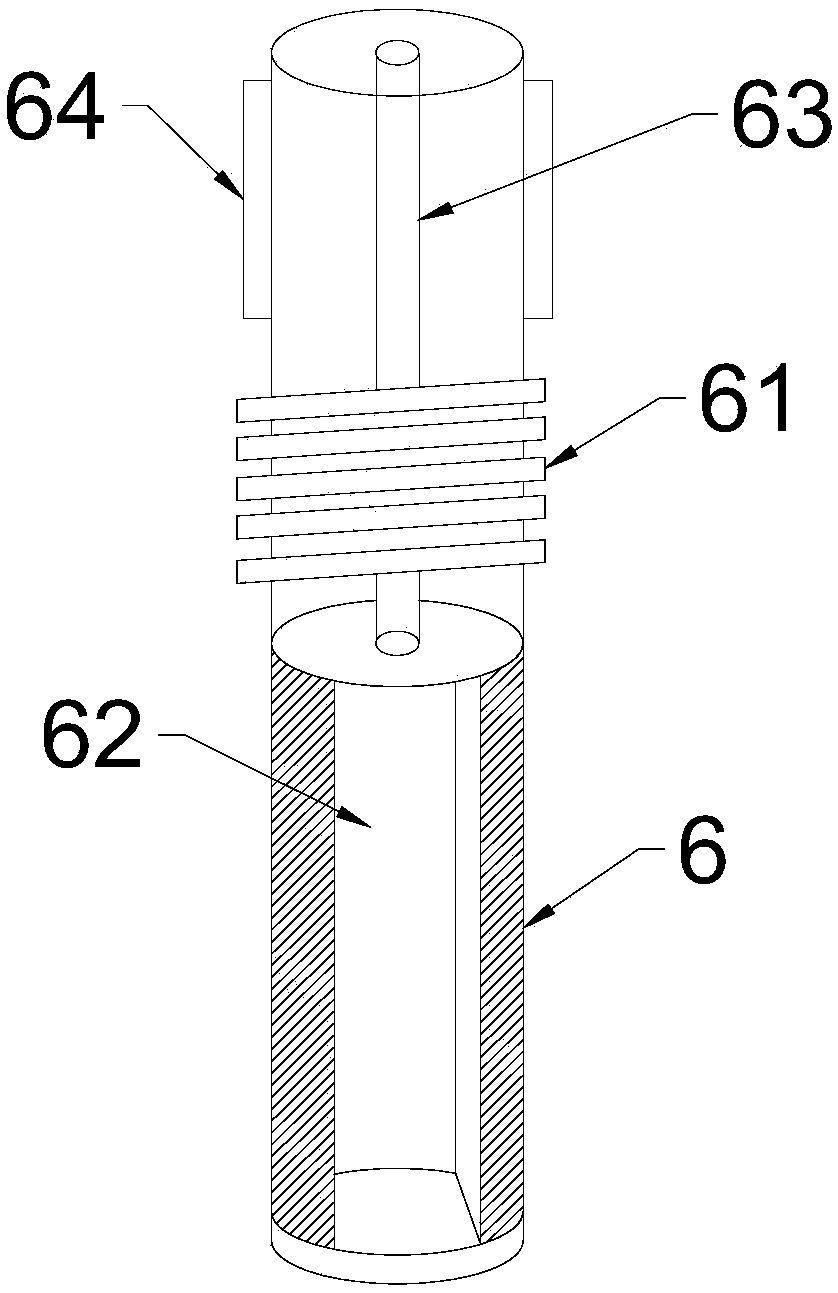

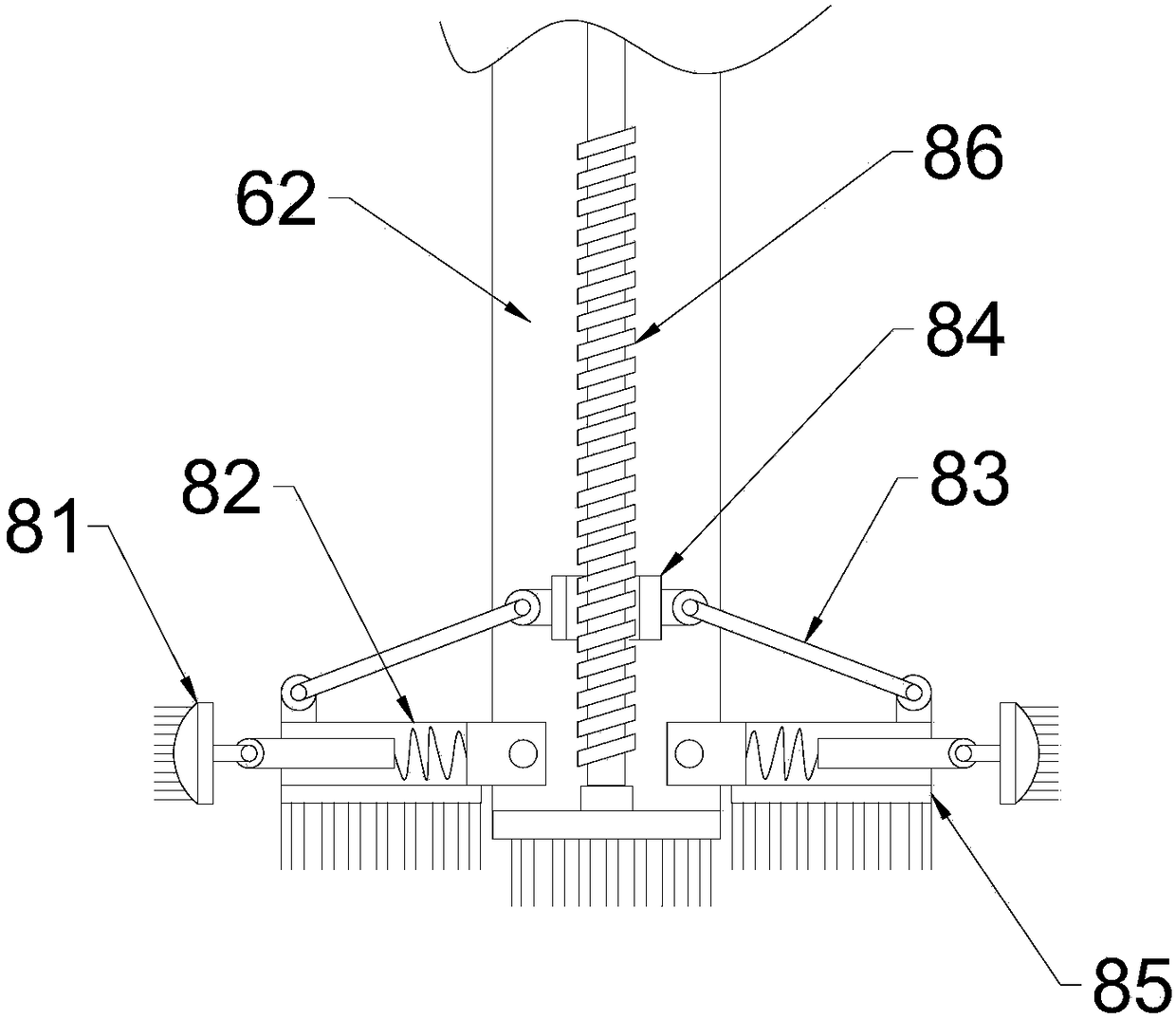

Mechanical cleaning device for glass reaction kettle

InactiveCN108246744AImprove scrubbing efficiencyImprove scrubbing effectHollow article cleaningElectric machineryDrive motor

The invention discloses a mechanical cleaning device for a glass reaction kettle. The mechanical cleaning device comprises a transverse plate, supporting legs, rollers and a driving motor, wherein central through holes are formed in the center of the transverse plate, threaded sleeves are arranged above the central through holes, and the threaded sleeves are in threaded connection with sleeve columns; and the sleeve columns are provided with external threads matched with the threaded sleeves, and the cleaning device is arranged below the sleeve columns. According to the cleaning device, the sleeve columns containing scrubbing heads and scrubbing plates are arranged, the cleaning device is conveyed into a kettle body from kettle openings, and the cleaning device is unfolded through the rotating handle; the cleaning device can be adapted to scrubbing operation of glass reaction kettles of different specifications; and the device is provided with the driving motor and a forward and reverse rotation transmission mechanism, the cleaning device is driven to move up and down, and compared with the manual work, the scrubbing efficiency and the scrubbing effect are greatly improved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

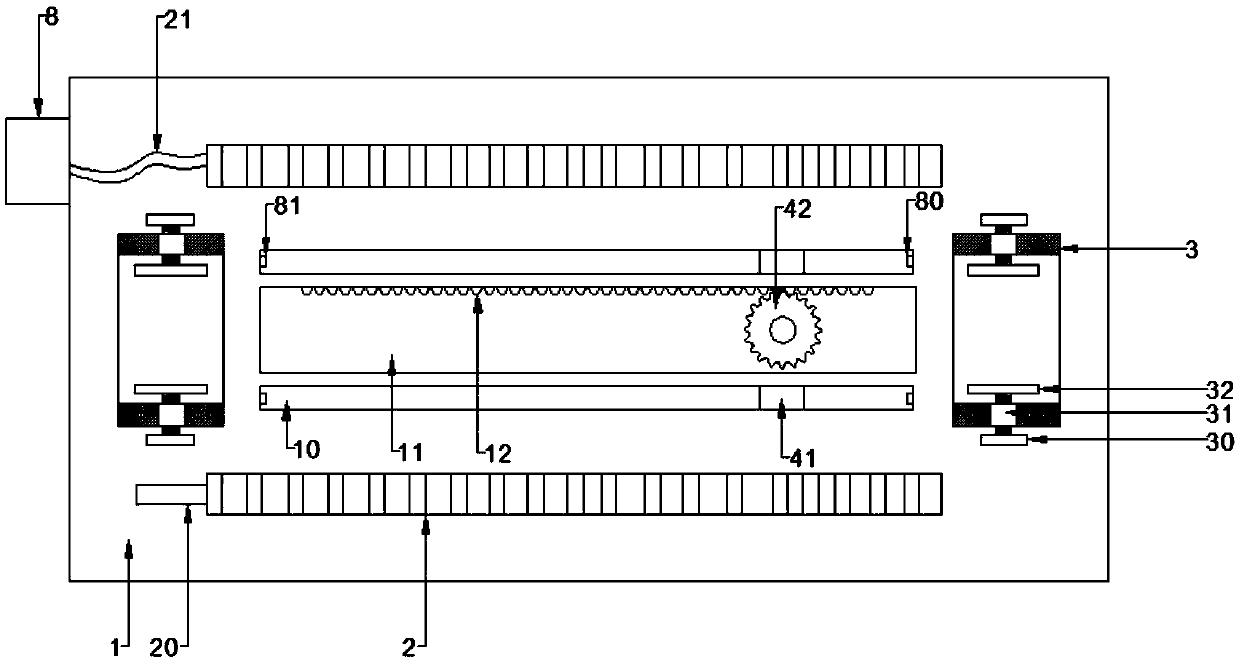

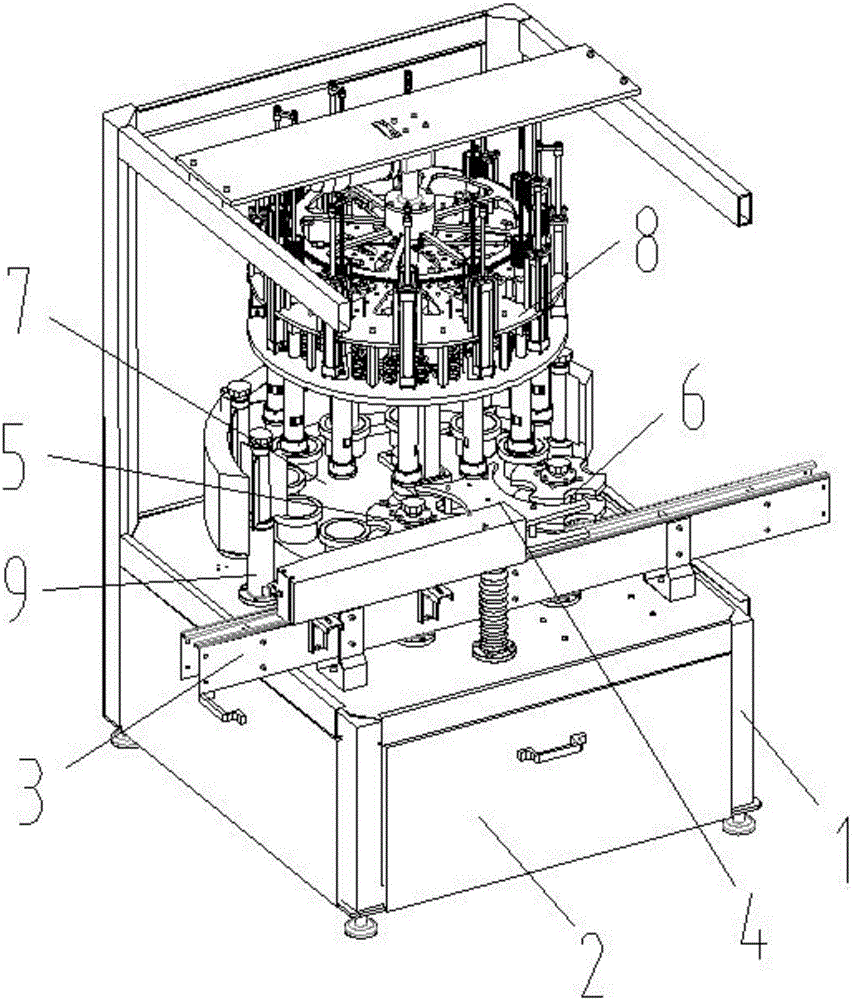

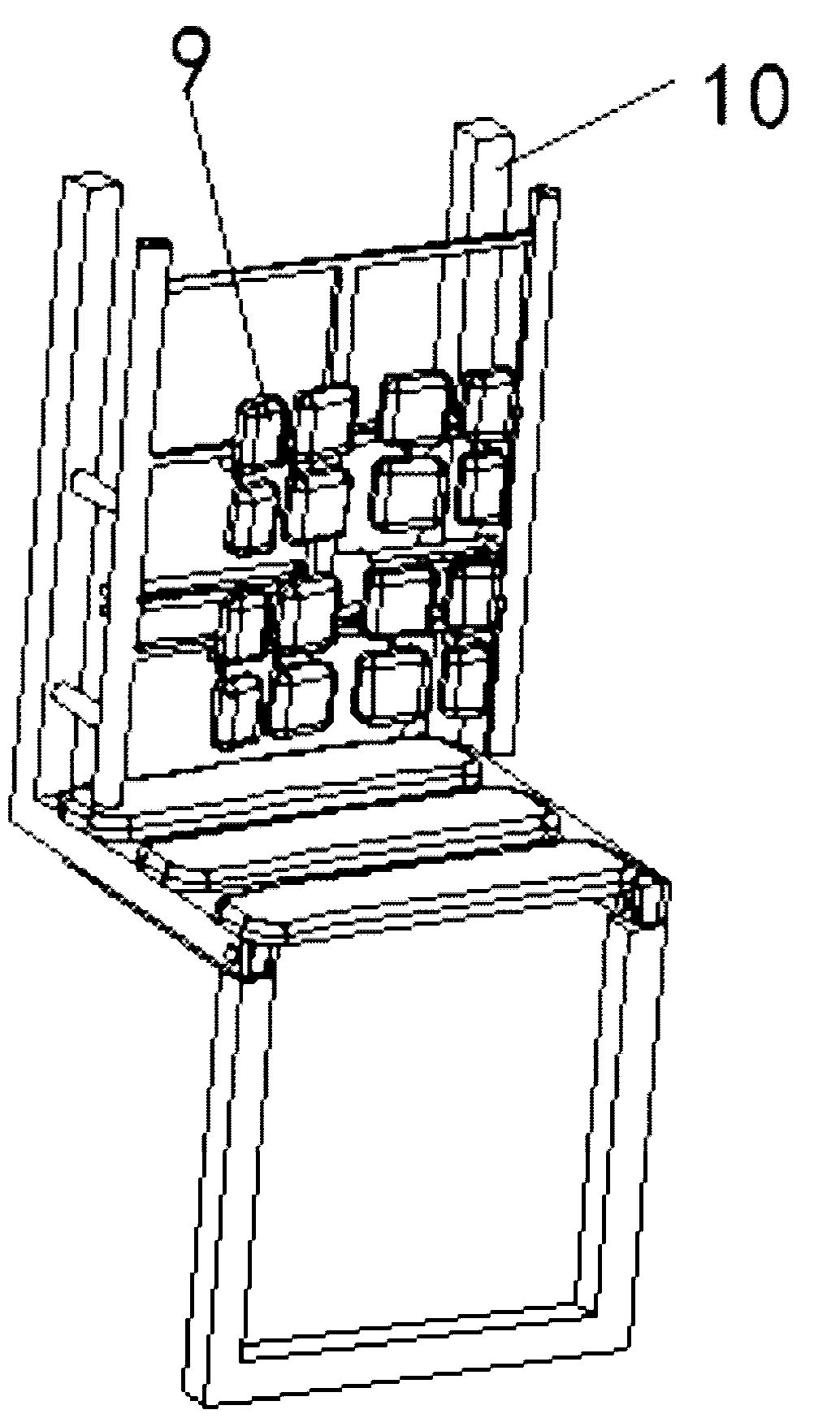

Automatic cleaning machine for bottles

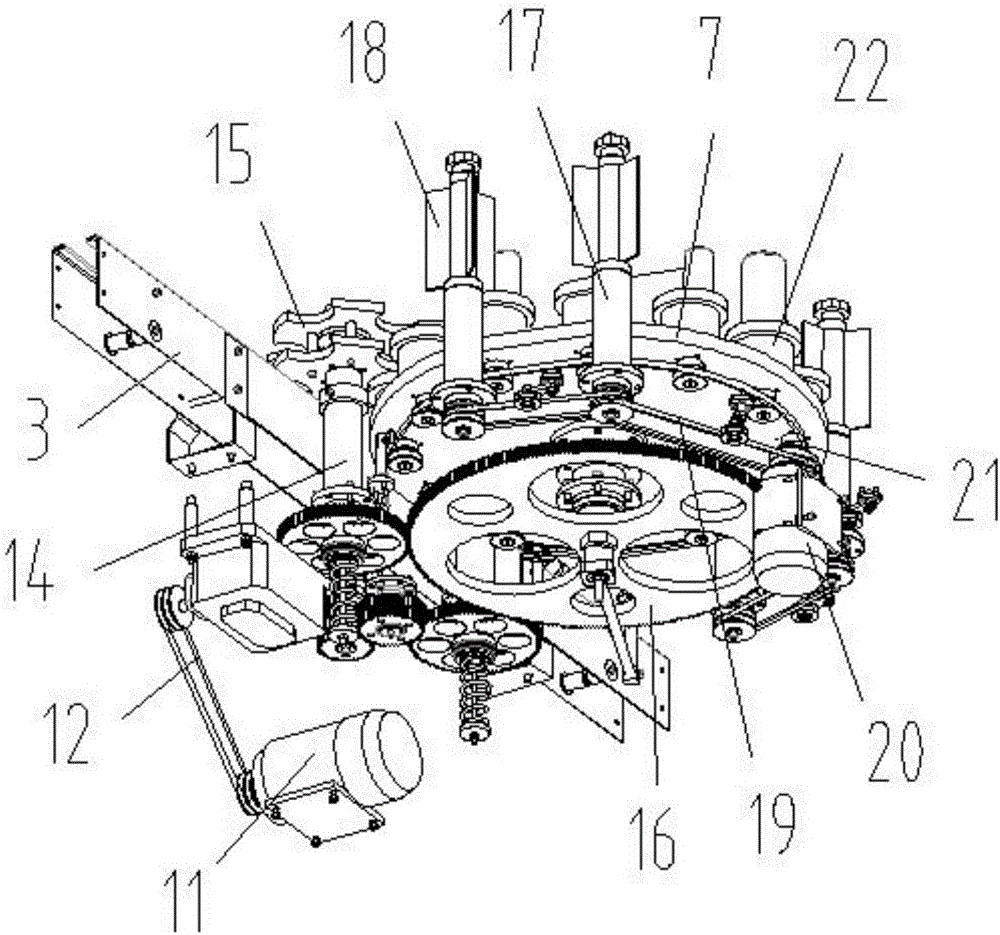

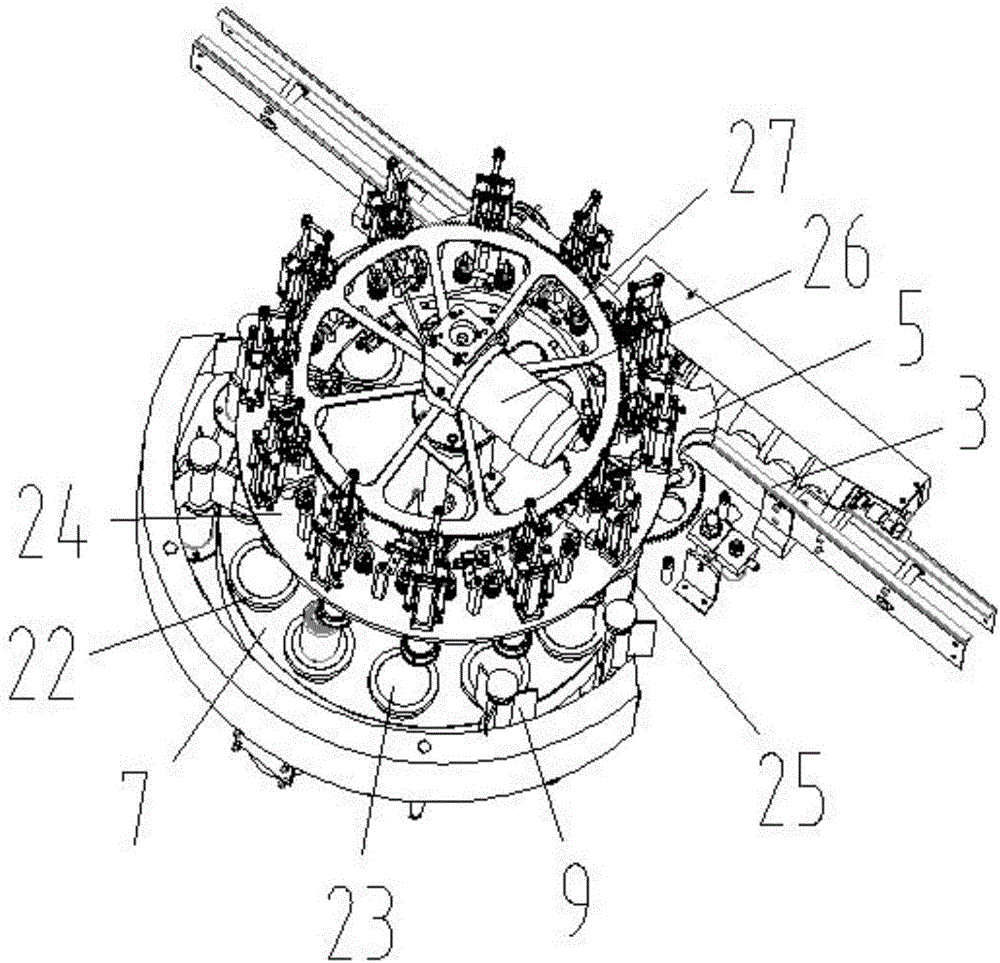

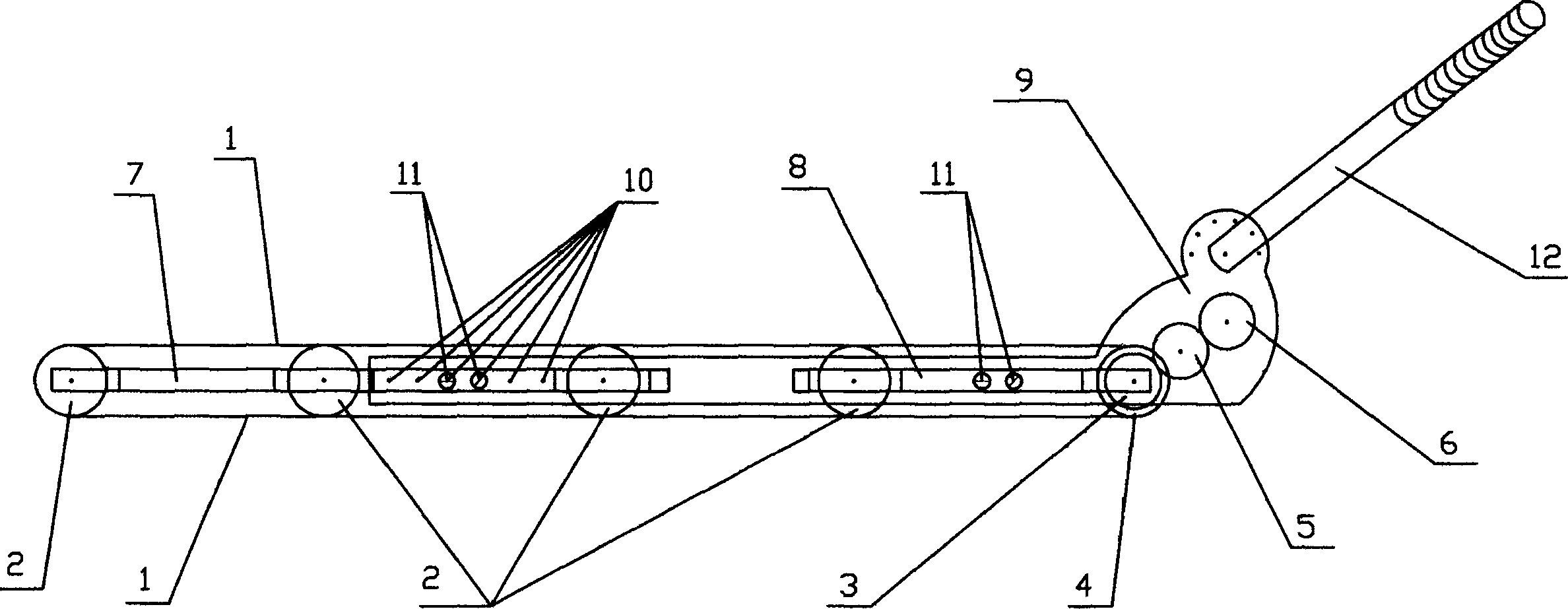

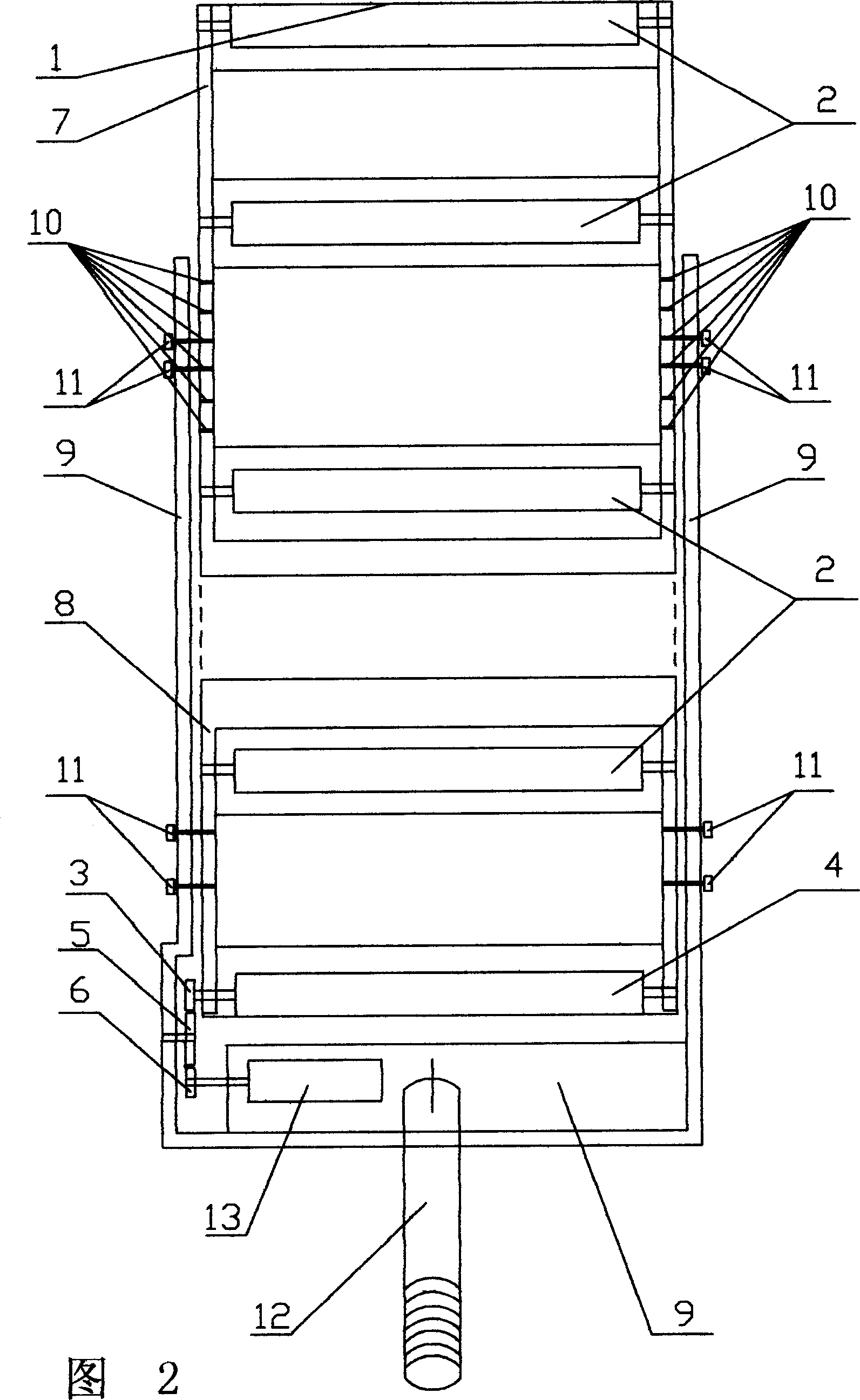

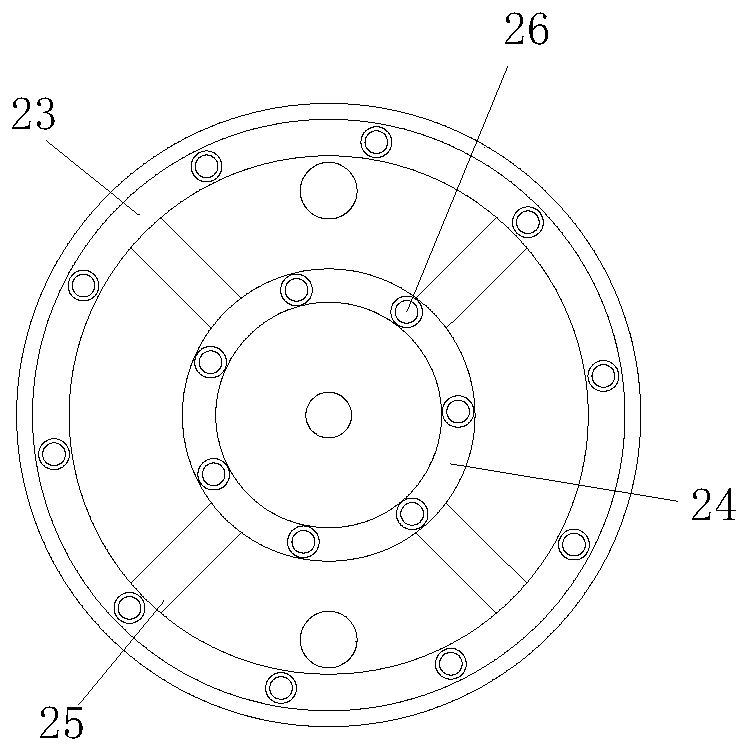

InactiveCN106734004ARealize automatic scrubbingImprove scrubbing efficiencyHollow article cleaningDistribution controlTransmission belt

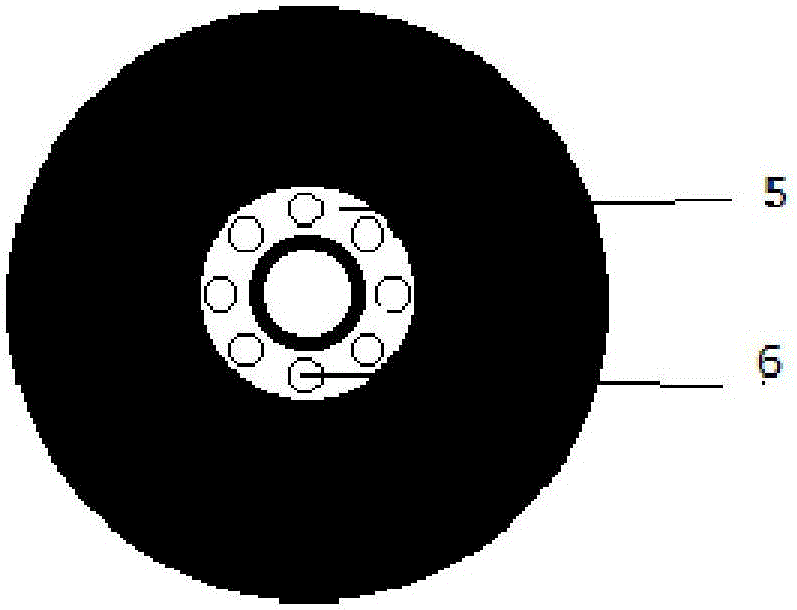

The invention relates to an automatic cleaning machine for bottles. The automatic cleaning machine comprises a rack and a power distribution control cabinet, wherein a conveying device is arranged on the rack; a stop block is arranged at the middle part of the conveying device; a loading device and an unloading device which enable the conveying device to be matched with a scrubbing rotary disc arranged on the rack are arranged at the two sides of the stop block; the rotary shaft of the scrubbing rotary disc is connected to a rotary disc motor, and carriers matched with products are uniformly arranged on the scrubbing rotary disc; each carrier comprises a carrier seat arranged on the scrubbing rotary disc and a carrier rotary disc in which the scrubbing rotary disc penetrates out; the lower end of each carrier rotary disc is connected to a carrier motor through a carrier transmission belt; a bottle pressing mechanism matched with each carrier is arranged on the upper part of the rotary shaft of the scrubbing rotary disc; and an outer scrubbing device matched with the product on each carrier is arranged on the rack at the outer side of the scrubbing rotary disc. The automatic cleaning machine disclosed by the invention guarantees that the carriers can drive the bottles to rotate, and can realize automatic scrubbing for the outer surfaces of the bottles in combination with the scrubbing device arranged at the outer side of the scrubbing rotary disc, thereby greatly increasing the scrubbing efficiency.

Owner:DONGGUAN UNIV OF TECH

Electric endless track type cleaning wiper

The invention relates to a domestic cleaning scrubber, which is characterized in that: it is flat and rectangle and provided with circulating scrubbing track-mounted construction, it comprises generator activation on one side of main frame, crawler wheel mount on another side of main frame, a plurality of crawler wheels installed between mounts and band circular crawler scrubbing cloth supported on round side of crawler wheel. The crawler cloth is made from material with good hydroscopicity and scrubbing effect such as wearable fiber, cotton, yarn, cloth, foam plastic or sponge, or scrubbing cloth is adhered to surface of sub-crawler. The hand-held electric track-mounted scrubber, electric track-mounted mop scrubber or vehicle mounted electric track-mounted floor scrubber can be produced according to requirement. The product is characterized by high working efficiency, strong condition adaptability and flexibility and convenient usage.

Owner:邓通讯

Anti-collision barrel cleaning equipment for bridge construction

ActiveCN108097678AImprove scrubbing efficiencyAvoid shakingHollow article cleaningArchitectural engineeringBuilding construction

The invention relates to anti-collision barrel cleaning equipment, in particular to anti-collision barrel cleaning equipment for a bridge construction. The technical problem that the operation is simple and the use is convenient, the cleaning effect is good, and the anti-collision barrel cleaning equipment for the bridge construction can be cleaned in all directions are solved. The anti-collisionbarrel cleaning equipment for the bridge construction comprises a bottom plate, a left support and the like, wherein the left support is arranged on the left side of the top of the bottom plate; a driving mechanism is arranged on the lower part of the right side of the left support; a first sliding rail is arranged on the upper portion of the right side of the left support; a first sliding block is arranged on the first sliding rail; a cross rod is arranged on the right side of the first sliding block; and a cleaning mechanism is connected to the right end of the cross rod. According to the invention, the operation is simple, the use is convenient, and the cleaning effect is good, the effect of cleaning in all directions can be achieved, the breeding of bacteria can be reduced, so that thediseases are not easy to be spread; and the driving mechanism drives the cleaning mechanism to move up and down, then the anti-collision barrel can be cleaned comprehensively, so the cleaning efficiency is high.

Owner:浙江吉灵机械科技有限公司

Electric industrial brush device convenient to adjust

InactiveCN111701895AEasy to adjustEasy to controlGrinding carriagesGrinding drivesElectric machineryBrush device

The invention discloses an electric industrial brush device convenient to adjust, and relates to the technical field of processing of industrial brushes. The electric industrial brush device comprisesa brushing box, a base, a side edge cleaning mechanism and a top cleaning mechanism; the top cleaning mechanism comprises a second air cylinder, a second telescopic rod, a connecting plate, a secondmotor and an upper-end cleaning brush; the side edge cleaning mechanism comprises a rotating shaft and a rotating track; multiple third motors are arranged inside the rotating track; output shafts ofthe third motors are fixed to side edge brushes; two pairs of reciprocating screws are symmetrically arranged at the upper and lower ends of the brushing box; the side edge cleaning mechanism is fixedthrough a sliding block; and two groups of spraying openings are symmetrically formed in the upper and lower ends of a back plate inside the brushing box. According to the electric industrial brush device, defects in the prior art are overcome, the device is reasonable in design and convenient to use, cleaning and rust removal can be effectively performed on parts in different sizes, meanwhile, the positions of the industrial brushes can be adjusted conveniently, and the cleaning efficiency can be improved.

Owner:潜山卓越机电设备有限公司

Wafer cleaning device

ActiveCN111681978AImprove scrubbing efficiencyImprove scrubbing effectSemiconductor/solid-state device manufacturingCleaning using toolsWaferEngineering

The invention belongs to the technical field of wafer production and processing, and provides a wafer cleaning device, which comprises a cleaning workbench, wherein a cleaning box is installed on thecleaning workbench, a wafer taking and placing opening is formed in one side of the cleaning box, an installation frame driven by a first driving device is installed below the cleaning workbench in asliding mode, a vacuum pipe driven by a second driving device is rotationally installed on the installation frame, a Bernoulli sucking disc is installed at the top end of the vacuum pipe, a lower mounting plate driven by a third driving device is further slidably mounted on the cleaning workbench, an upper mounting plate driven by a fourth driving device is slidably mounted on the lower mounting plate, one end of the upper mounting plate extends into the cleaning box and is rotatably provided with a rotating shaft driven by a fifth driving device, and a sponge brush head is fixedly mounted atthe bottom end of the rotating shaft. According to the invention, automatic scrubbing of the wafer is achieved, the scrubbing efficiency is greatly improved, scrubbing is clean and thorough, secondarypollution and scratching cannot be caused to the wafer, and it is guaranteed that the quality and the percent of pass of the wafer are not affected in the scrubbing process.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

Dual-side safe window scrubber

InactiveCN102631168AIncrease wiping powerImprove wiping effectWindow cleanersEngineeringOperation safety

The invention discloses a dual-side safe window scrubber, which comprises an inner scrubbing box and an outer scrubbing box correspondingly arranged at the two sides of glass of a window and a door, wherein a flexible scrubbing strip is arranged on the scrubbing surface of the inner scrubbing box and the outer scrubbing box; magnetic block grooves are correspondingly arranged on the scrubbing surfaces of the inner scrubbing box and the outer scrubbing box; magnetic blocks for correspondingly adsorbing the inner scrubbing box and the outer scrubbing box on the two sides of the glass are movably arranged inside the magnetic block grooves; a spraying head for spraying water towards the glass is arranged on the outer scrubbing box; a scrubbing groove is further arranged on the scrubbing surface of the inner scrubbing box; an elastic kneading barrel corresponding to the scrubbing groove is arranged on the outer side of the inner scrubbing box; an inner cavity of the kneading barrel is correspondingly communicated with the inner cavity of the scrubbing groove, and the inner cavities of the scrubbing groove and the kneading barrel are filled with flexible scrubbing elements tightly attached on the glass. The dual-side safe window scrubber employing the structure is rational in structure, thorough in scrubbing, convenient in operation, high in scrubbing efficiency and lower in cost, is suitable for cleaning the glass of windows of various buildings, and is conducive to improving the cleaning efficiency and the operation safety.

Owner:SHANDONG ANDE BIOLOGICAL TECH

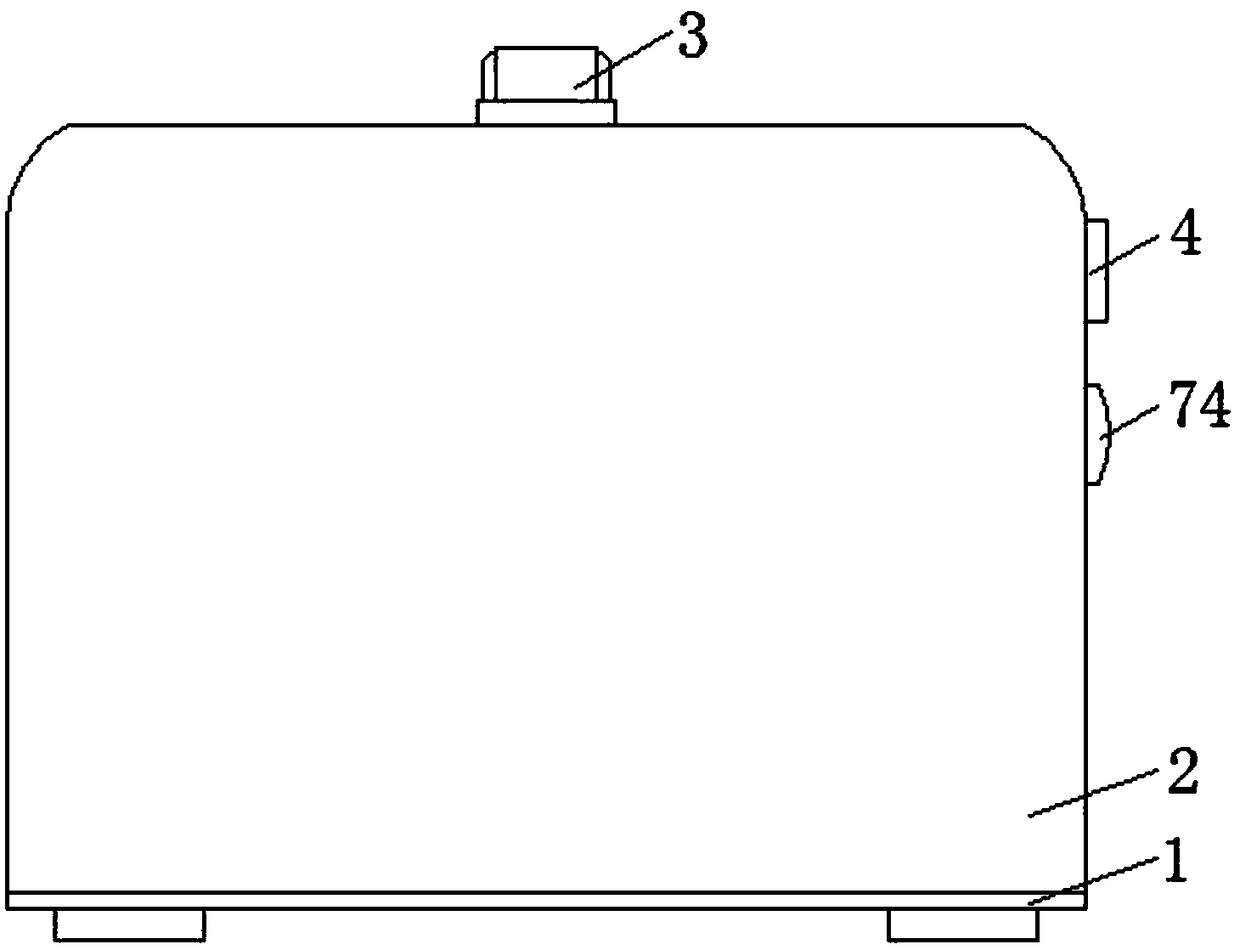

Domestic efficient and energy-saving air purifier

ActiveCN109442625AEasy for initial filtrationInstalled and disassembledMechanical apparatusSpace heating and ventilation safety systemsEngineeringControl switch

The invention relates to the technical field of air purifiers, in particular to a domestic efficient and energy-saving air purifier. The domestic efficient energy-saving air purifier comprises a base.A shell is arranged at the upper end of the base. A PM2.5 sensor is installed at the upper end of the shell through an installation seat. A control switch is arranged on the outer side of the shell.A PLC is installed at the upper end of an inner cavity of the shell. The left side of the inner cavity of the shell is connected with an L-shaped partition plate. A dust sucking draught fan is installed at the upper end of the L-shaped partition plate. Threaded sleeves are connected to the lower end of the L-shaped partition plate at equal intervals, and threaded rods are in screw joint to inner cavities of the threaded sleeves at equal intervals. The left sides of the threaded rods are commonly connected with dustproof covers. First filtering nets are arranged in inner cavities of the dustproof covers. The domestic efficient and energy-saving air purifier is novel in structural design, in addition, the cost is low, the automation degree is high, practicability is high, mounting and demounting are facilitated, maintaining is conducted, the filtering nets and the like can be conveniently cleaned, the air purifying effect is effectively improved, and application and popularization are facilitated.

Owner:淳安农合信息科技有限公司

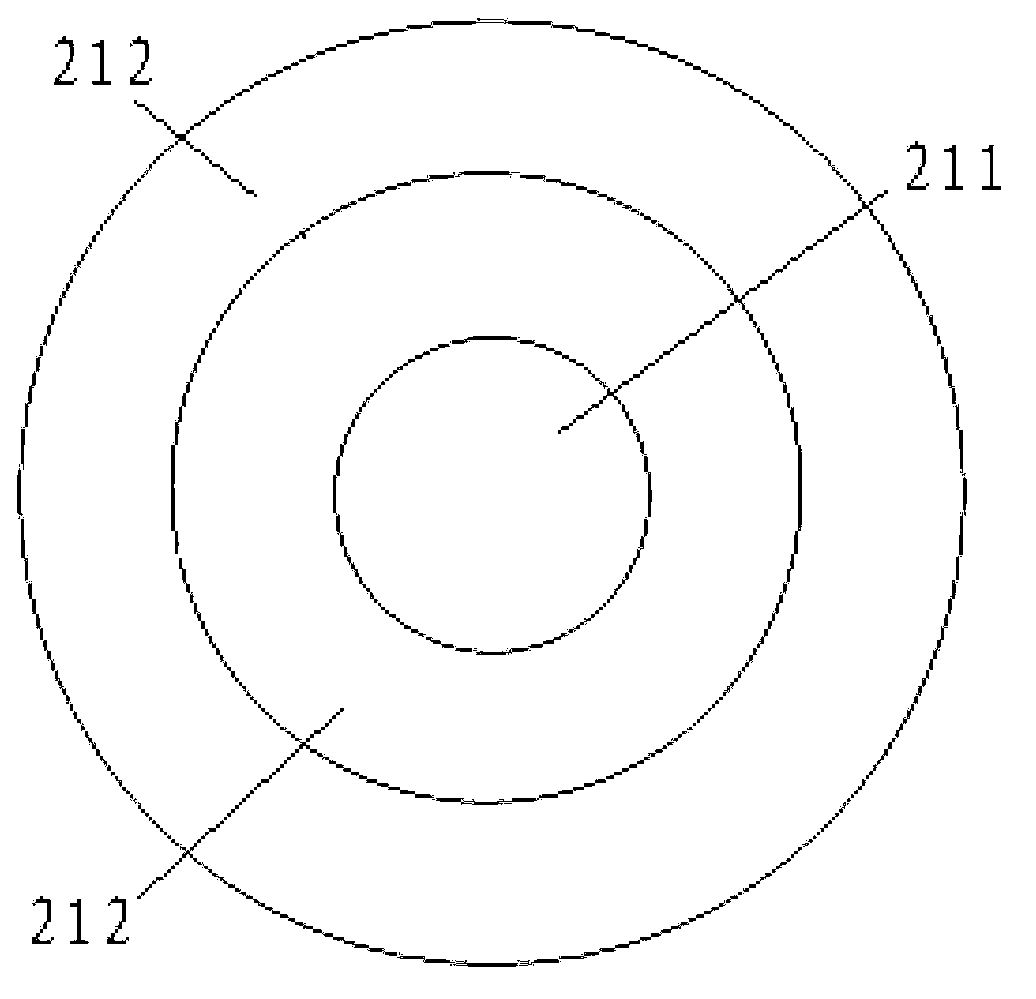

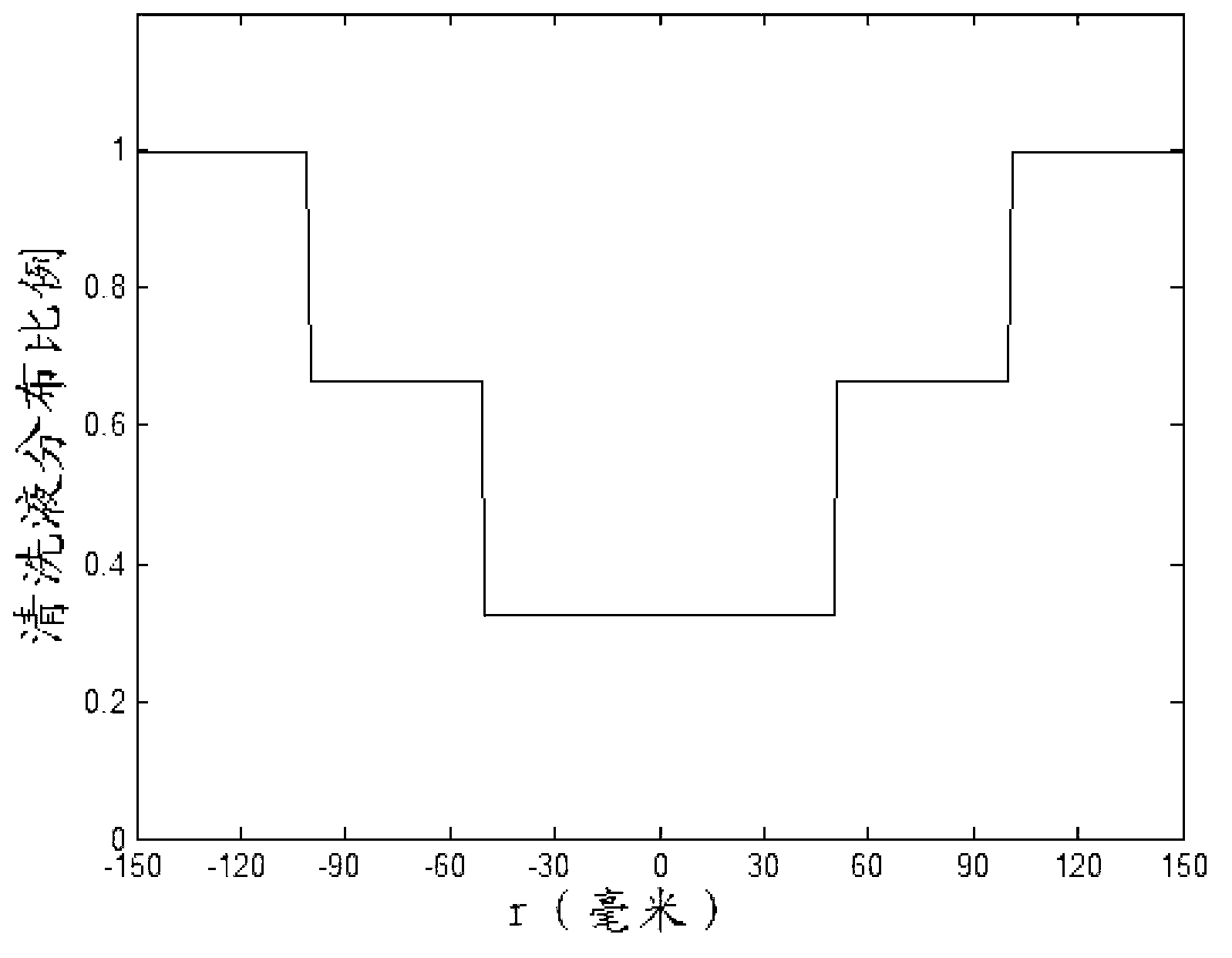

Wafer brushing device and wafer brushing method

ActiveCN103071650AImprove scrubbing efficiencySave scrubbing timeSemiconductor/solid-state device manufacturingCleaning using toolsEngineeringBrush device

The invention discloses a wafer brushing device and a wafer brushing method. The wafer brushing device comprises a rack, a first hair brush, a second hair brush, a first cleaning solution supply unit and a second cleaning solution supply unit, wherein the first hair brush and the second hair brush are oppositely arranged on the rack at intervals and are used for respectively brushing two side surfaces of a wafer; the first cleaning solution supply unit and the second cleaning solution supply unit are oppositely arranged on the rack at intervals and are used for respectively supplying a cleaning solution to the two side surfaces of the wafer; and the quantity of the cleaning solution supplied by each of the first and second cleaning solution supply units is increased from inside to outside along the radial direction of the wafer. According to the wafer brushing device disclosed by the embodiment of the invention can be used for improving the wafer brushing efficiency, reducing the wafer brushing time and reducing the dosage of the cleaning solution for brushing the wafer.

Owner:HWATSING TECH

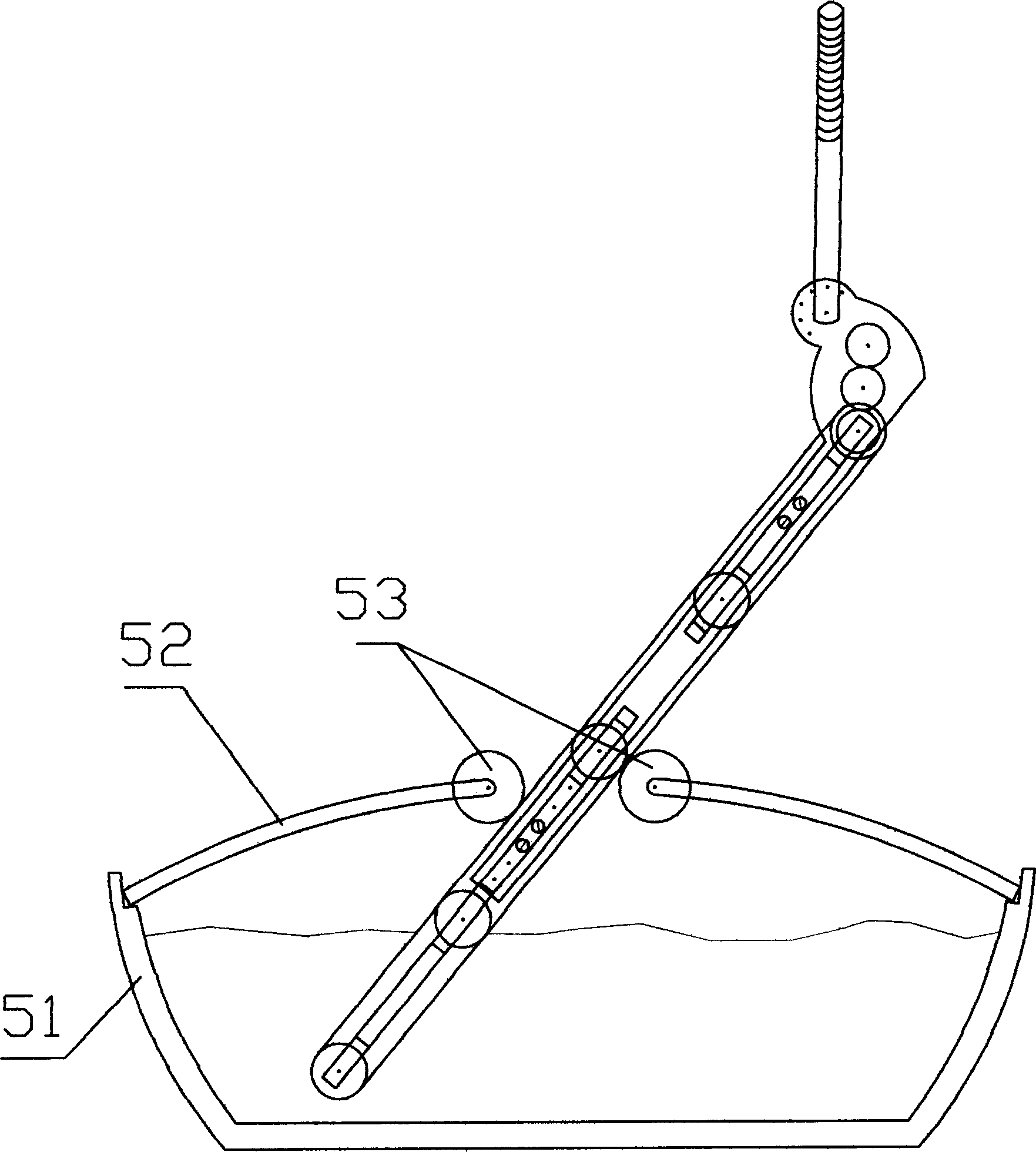

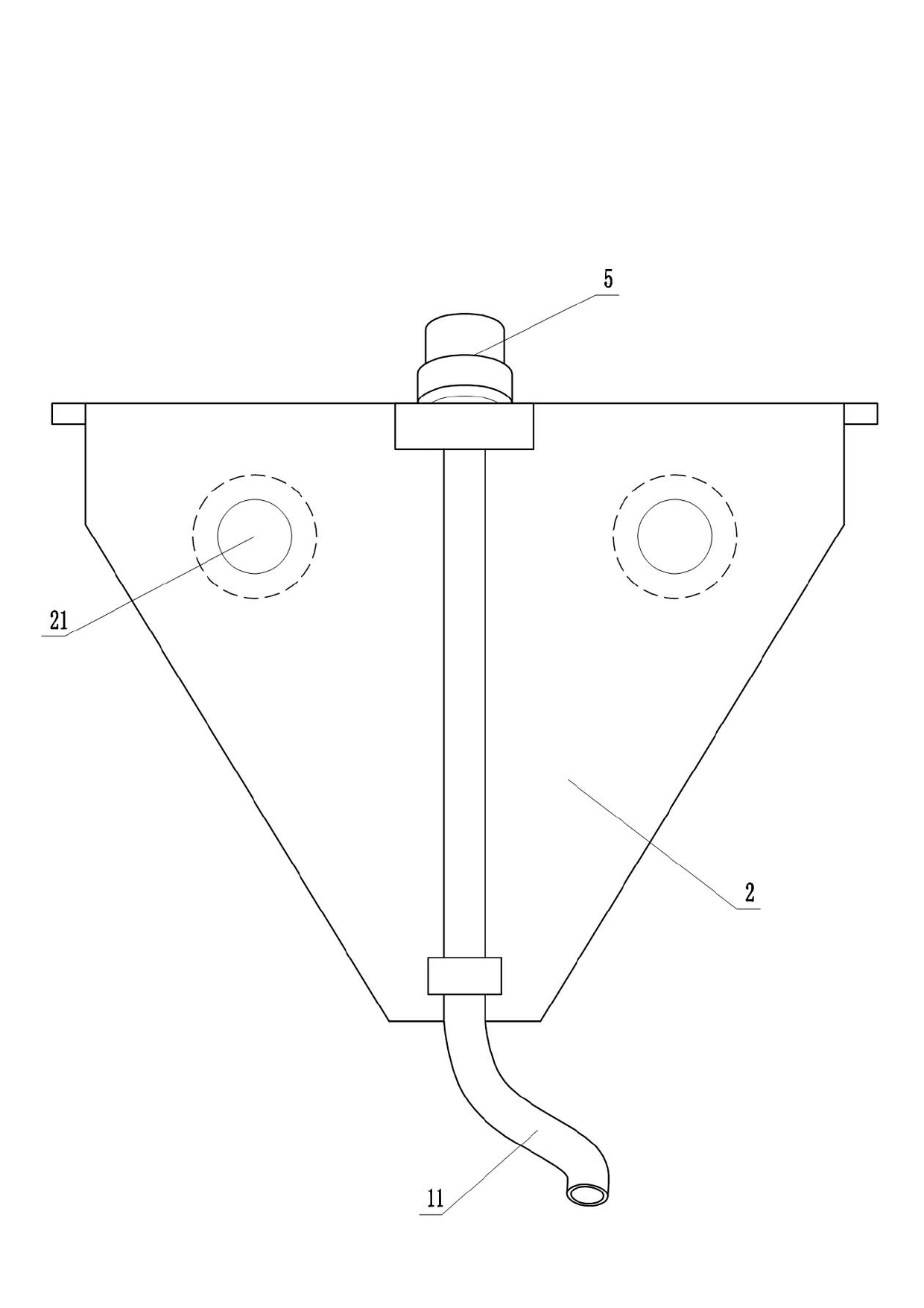

Bathing device adaptive to surface curve of human body

InactiveCN102670115AImprove the effect of scrubbingChange the scrub force at willBathroom accessoriesSelf adaptiveBiomedical engineering

The invention discloses a bathing device adaptive to the surface curve of a human body. The bathing device comprises a support and a bathing head assembly arranged on the support, the bathing head assembly comprises a bathing head rack, a bathing head and a bathing head rack driving mechanism, the bathing head is assembled on the bathing head rack, and the bathing head rack driving mechanism drives the bathing head rack to linearly move back and forth in the plane corresponding to a surface to be scrubbed of the human body. The bathing device is characterized in that the bathing head rack comprises a V-shaped elastic rod, an opening of the V-shaped elastic rod is ahead, two wings of the V-shaped elastic rod elastically swing in an opening and closing manner so that an area, corresponding to the back of the human body, of the V-shaped elastic rod is expanded or reduced, and the two wings, which are close to the bathing head, of the V-shaped elastic rod are connected with the bathing head through a spherical hinge structure or a rotating shaft hinge which can control the bathing head to swing adaptively to concave-convex change of the surface of the human body. The bathing head can be matched with the body curve of a user via the elastic connecting rod at all time in a bathing process, and an existing bathing effect is greatly improved.

Owner:HENAN UNIV OF SCI & TECH

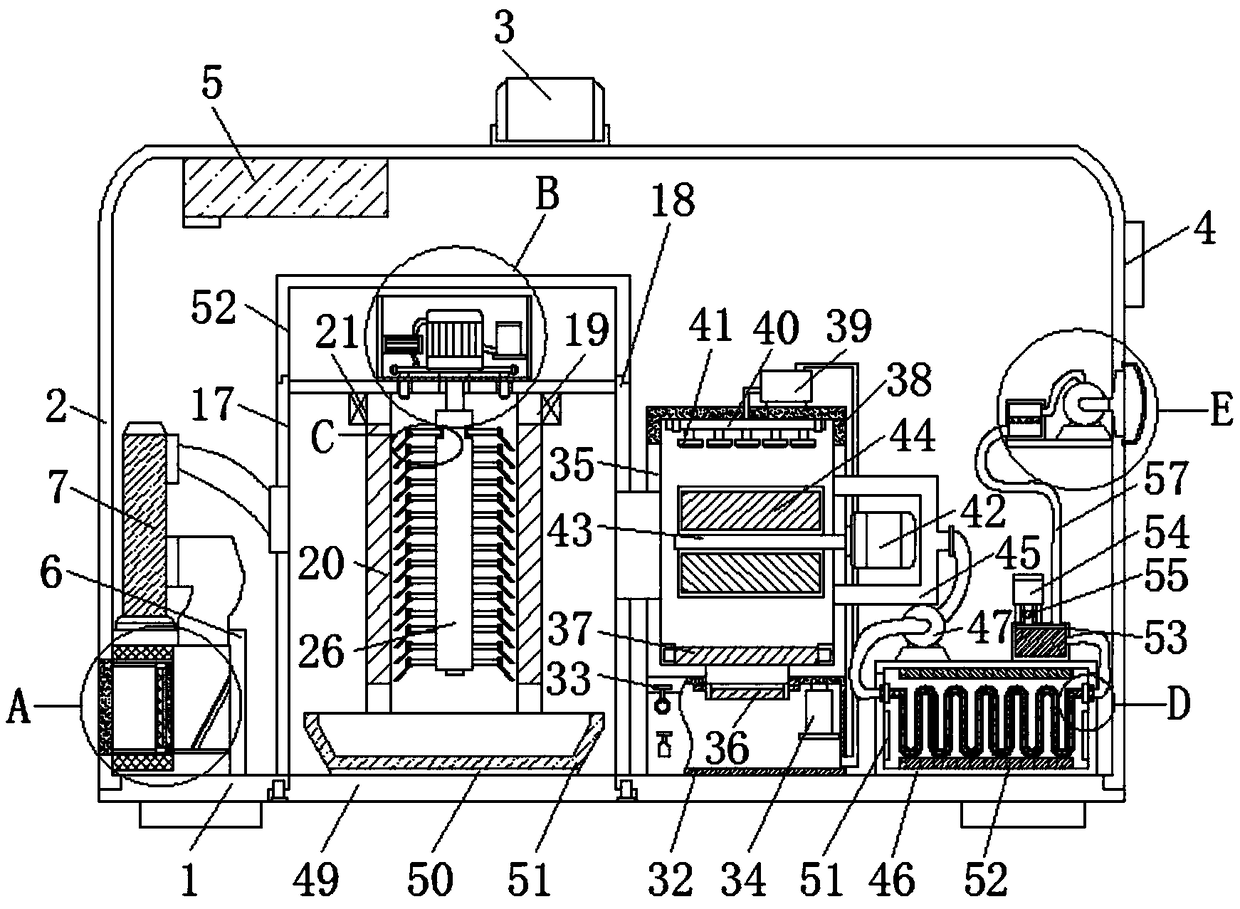

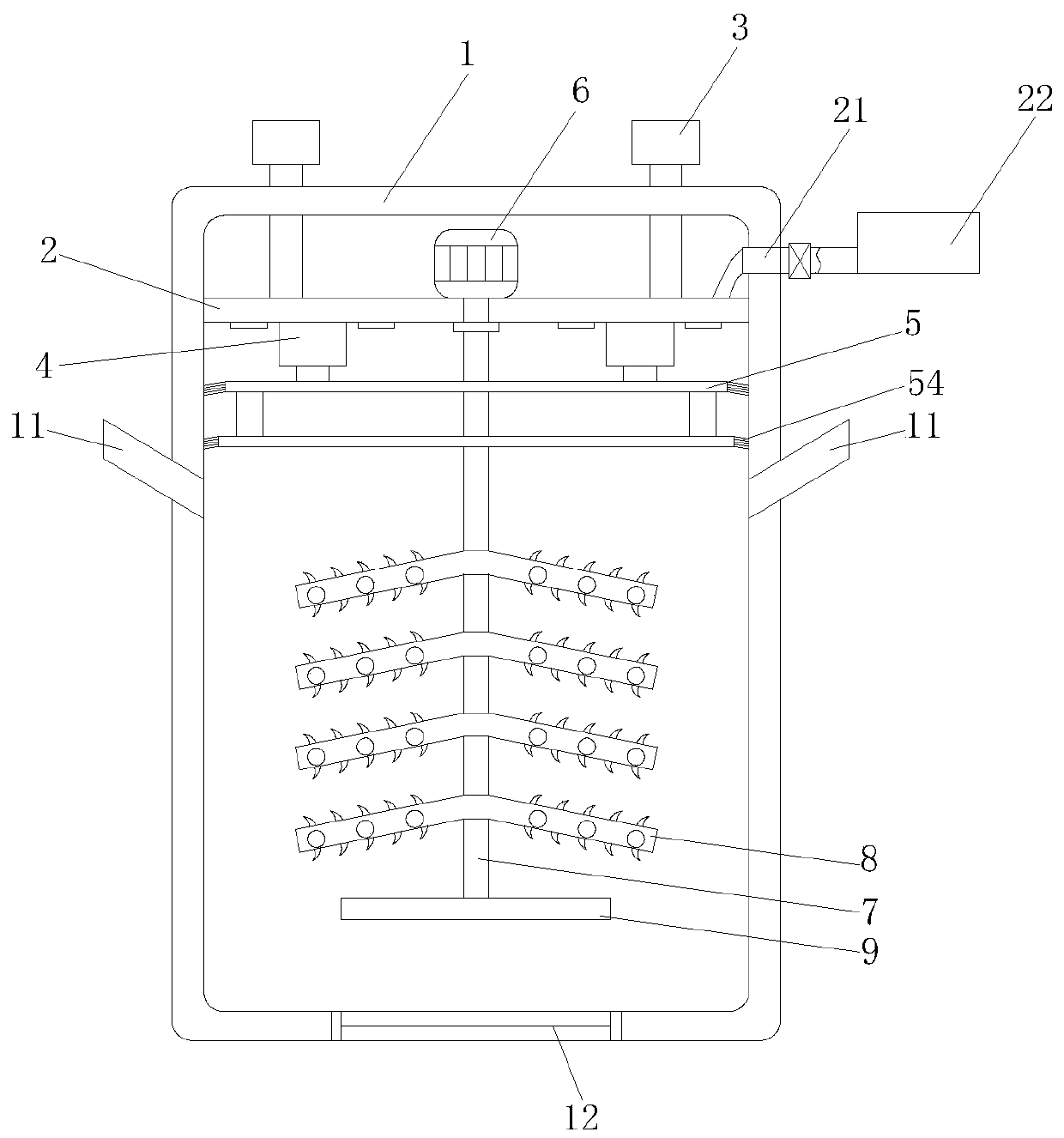

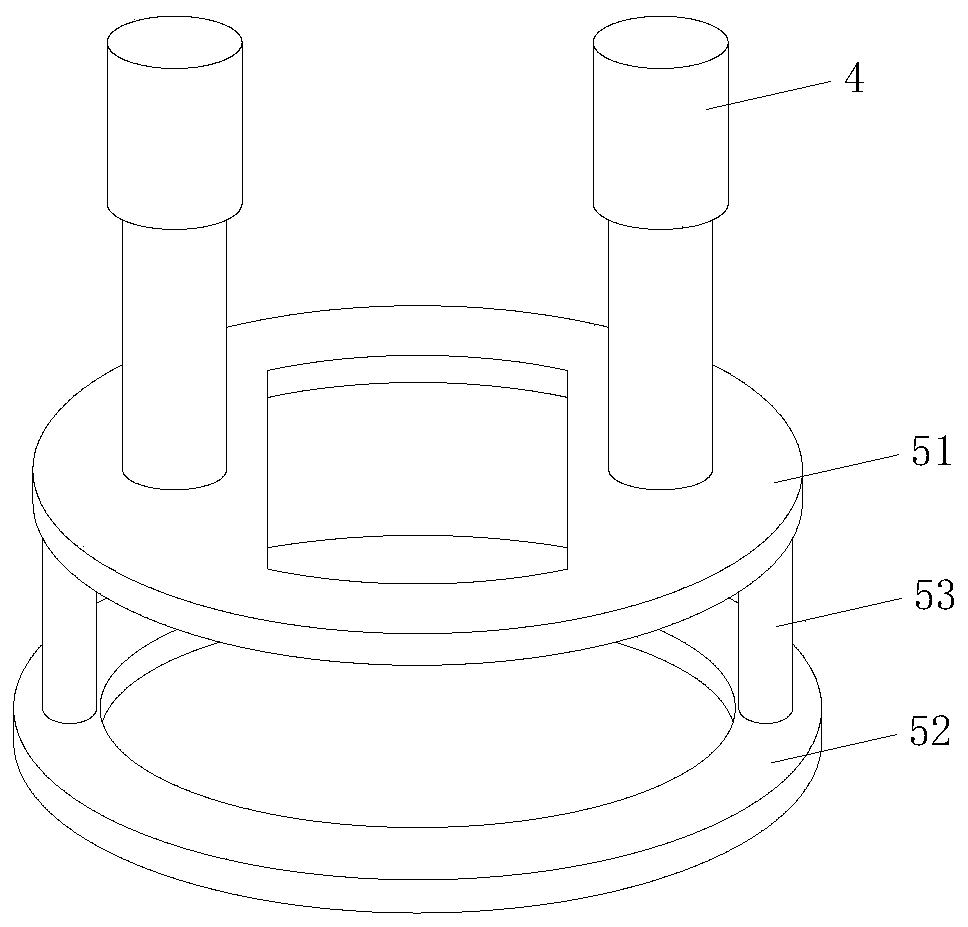

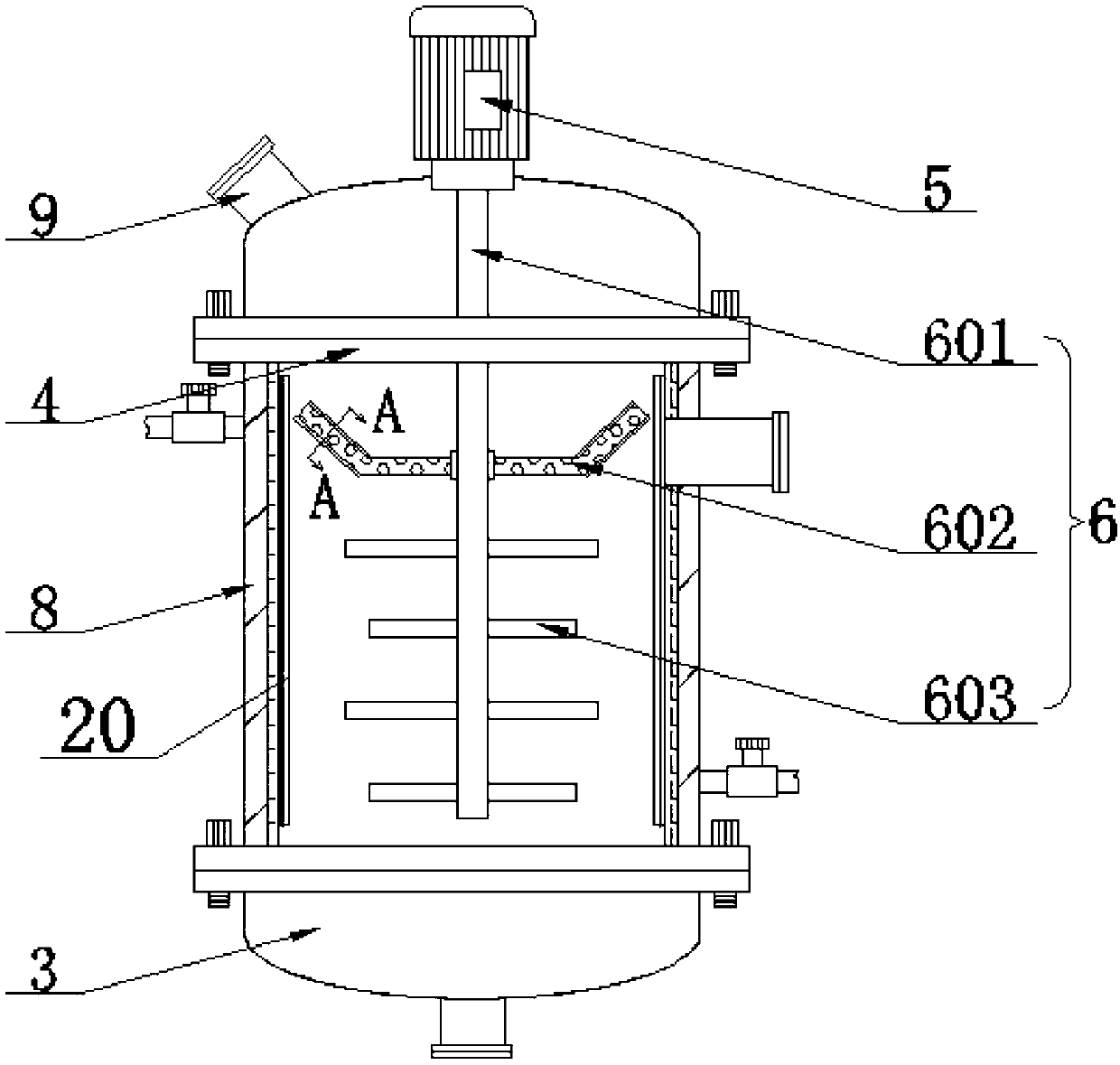

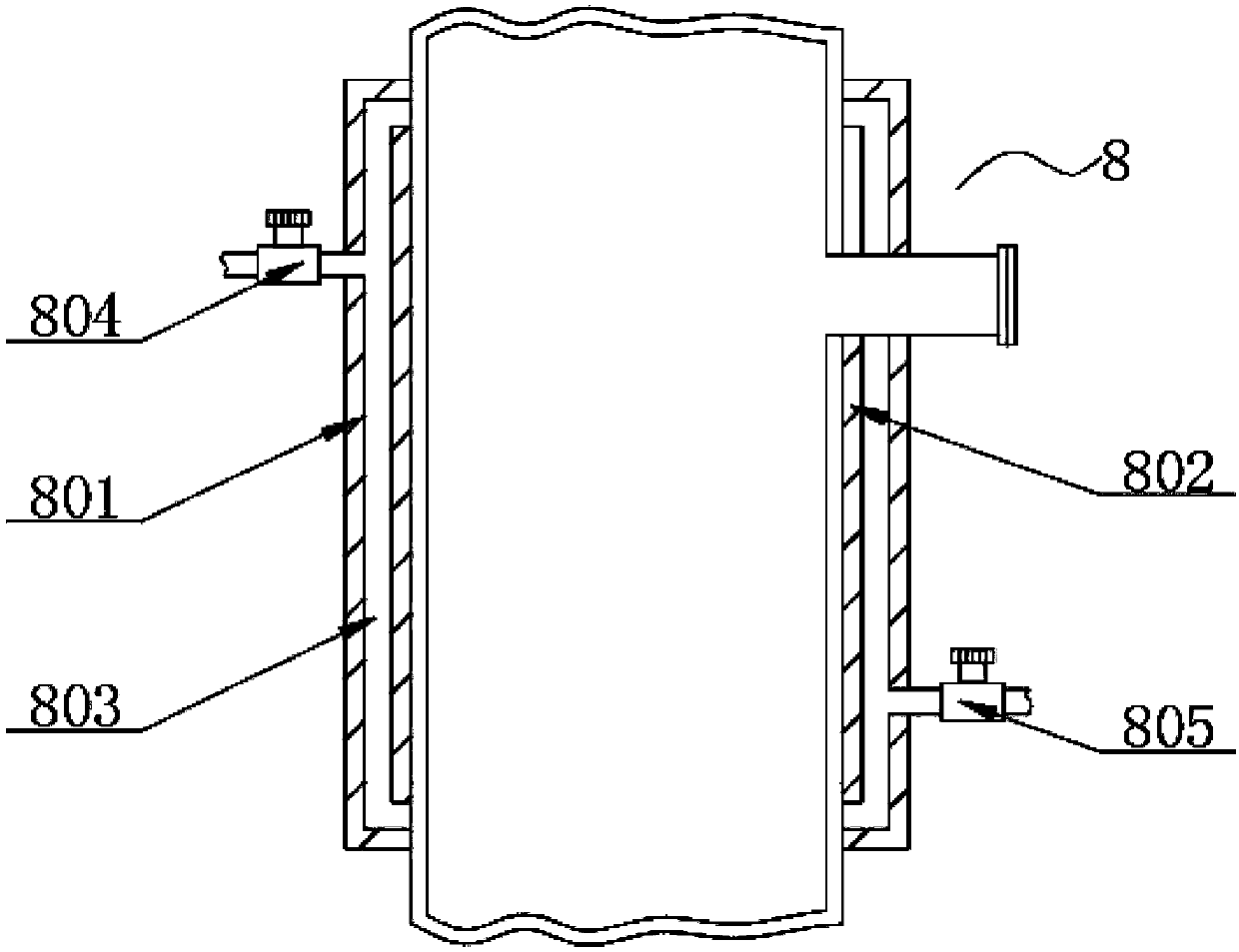

Concrete stirring equipment with internal cleaning function and operation method thereof

PendingCN109968532AAvoid survivalImprove scrubbing efficiencyCement mixing apparatusBristleWater flow

The invention discloses concrete stirring equipment with an internal cleaning function and an operation method thereof, and belongs to the technical field of concrete processing equipment. The concrete stirring equipment comprises a box body, wherein a flow guide plate is horizontally installed inside a box body, a spray water pipe is connected to an upper surface of the flow guide plate, an outerring pipe and an inner ring pipe are embedded at the bottom of the flow guide plate correspondingly, spraying ports are all formed in the bottom of the outer ring pipe and the bottom of the inner ring pipe at equal intervals, and a horizontal material scraping device is arranged at the bottom of the flow guide plate; and the horizontal material scraping device consists of a first horizontal plate, a second horizontal plate, a connecting rod and hard brush bristles. According to the concrete stirring equipment, water inside the water box is pressurized and sprayed out through a booster pump, the hard brush bristles of the outer ring of the first horizontal plate and the hard brush bristles of the outer ring of the second horizontal plate are used for scraping adhered materials inside the box body under the cooperation of a water flow, the double-bristles quicken the clean efficiency, cleaning dead corners are avoided, coagula of concrete on an inner wall is avoided, the cleaning effectis effectively improved, and a guarantee is provided for subsequent stirring operation of the box body.

Owner:马鞍山中鑫工程质量检测咨询有限公司

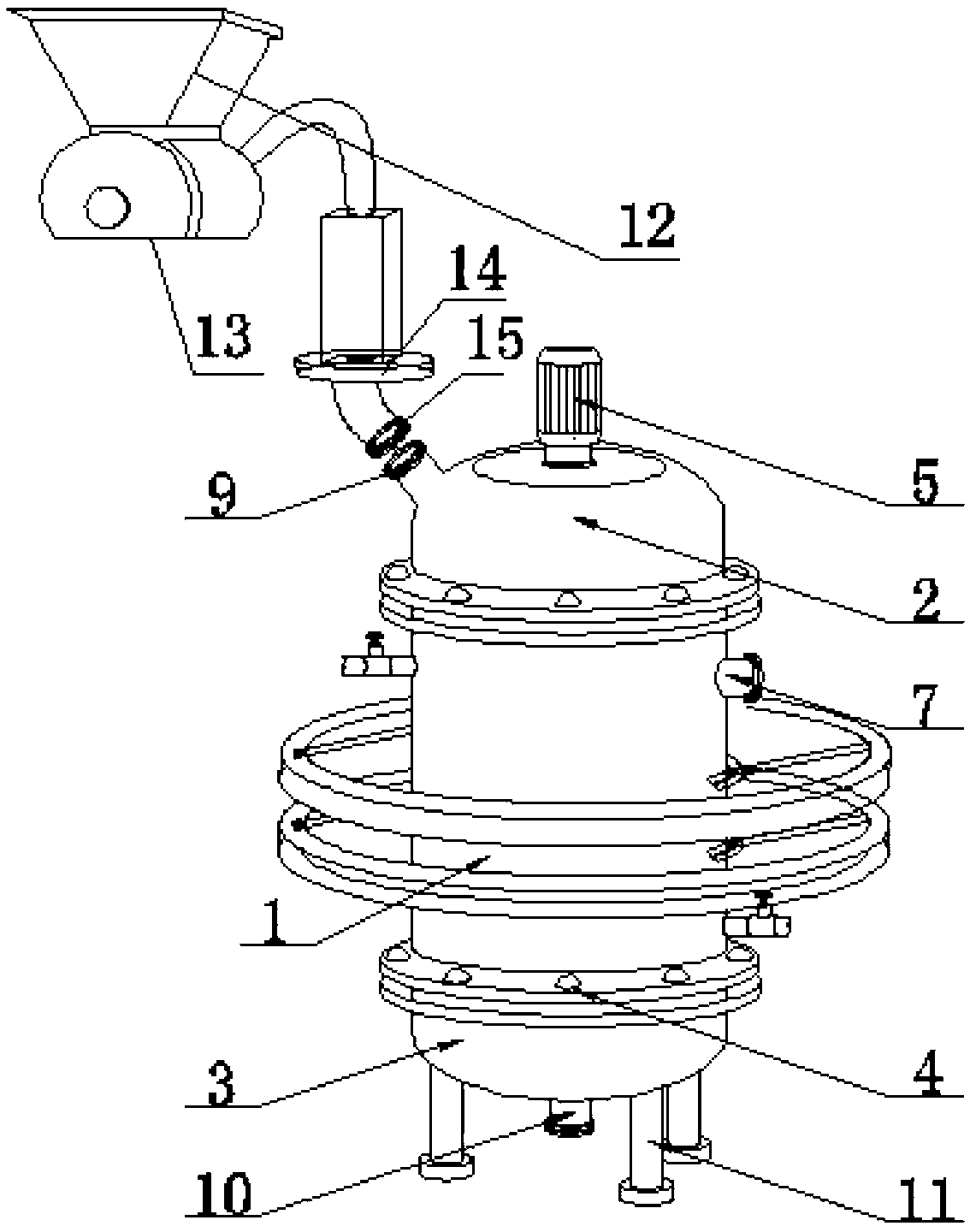

Chemical reaction equipment used for material preparation

InactiveCN109603705AEasy to cleanSimple and reliable driveHollow article cleaningChemical/physical/physico-chemical stationary reactorsMaterials preparationParticulates

The invention discloses chemical reaction equipment used for material preparation. By arranging a cleaning assembly, cleaning is convenient and simple; by the adoption of magnetic driving, driving issimple and reliable, so that the efficiency of brushing is improved greatly; before feeding, a feeding assembly is preheated, so that all raw materials are uniform in temperature during feeding, bad influences of temperature on a reaction are reduced, and material slag caused by non-uniform temperature is prevented. By arranging a stirring plate, large-particle objects of the reaction materials orslag after the reaction can be smashed and filtered, so that the reaction effect is improved, and incompleteness existing in the reaction is prevented; through a stirring assembly, the stirring platecan primarily stir and sieve the raw materials, and it is avoided that the particle size of the raw materials is not uniform, and as a result the chemical reaction is not complete; through two different-size stirring paddles, the raw materials can be stirred at two different degrees, accordingly, eddies of a kettle are formed, the efficiency of stirring is improved, and the preparation time for materials is shortened.

Owner:ANHUI UNIV OF SCI & TECH

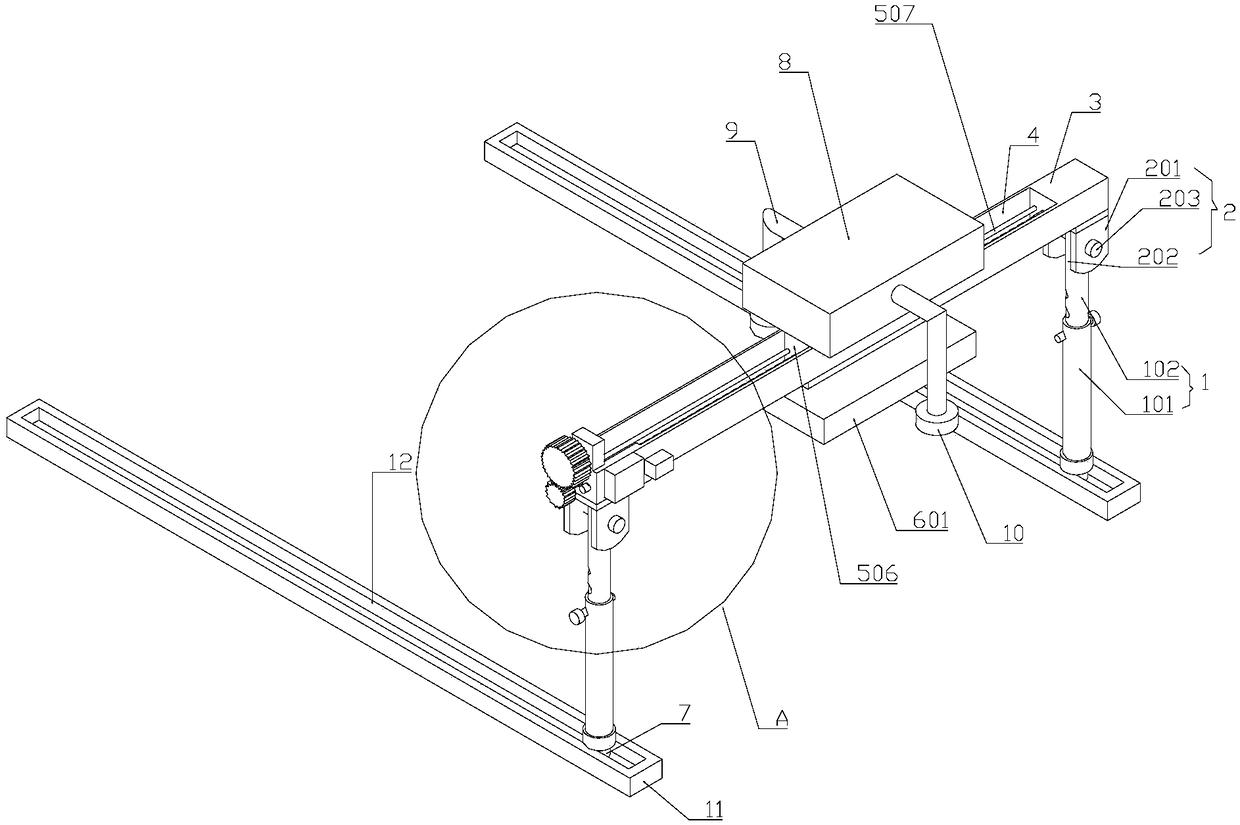

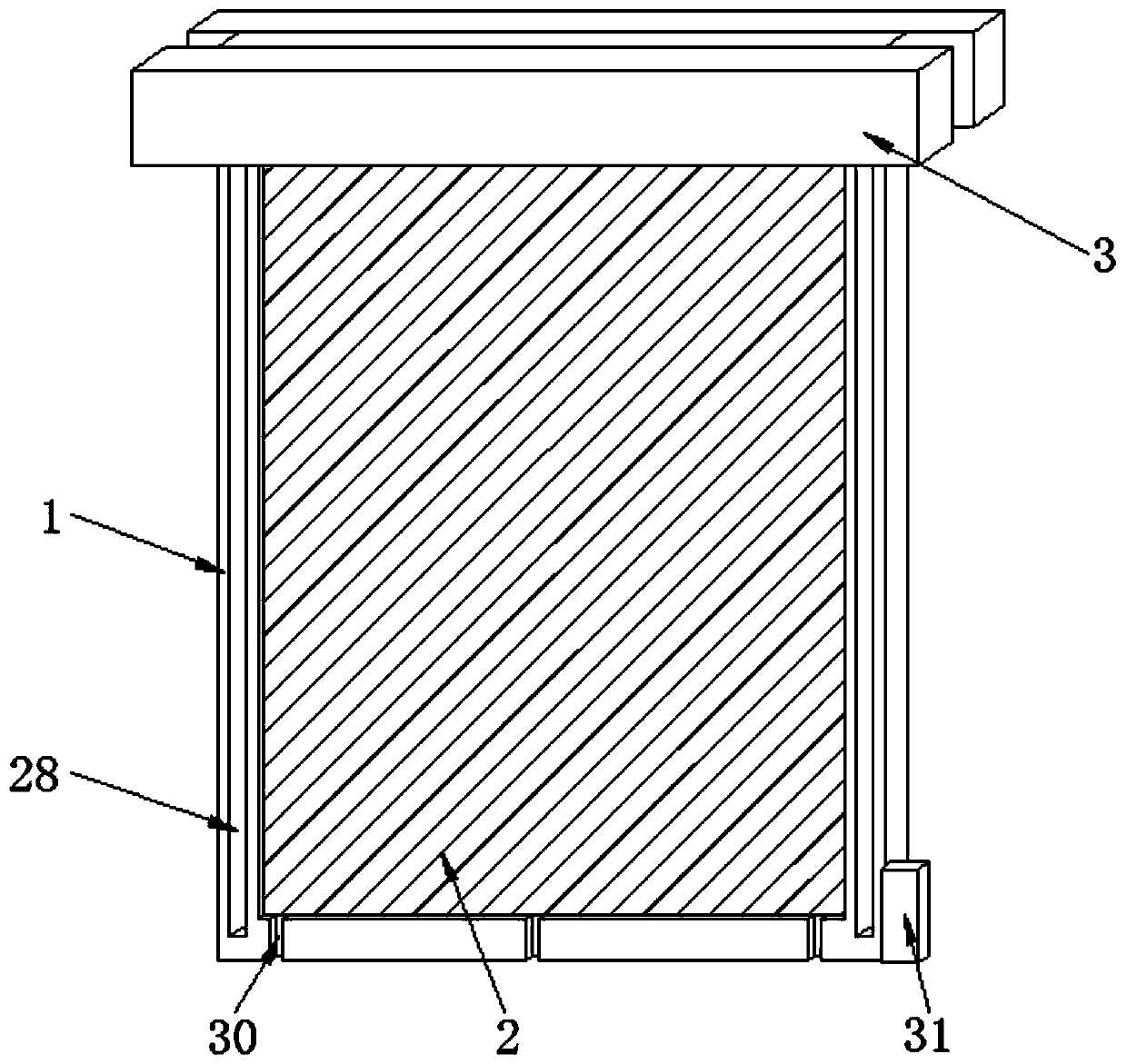

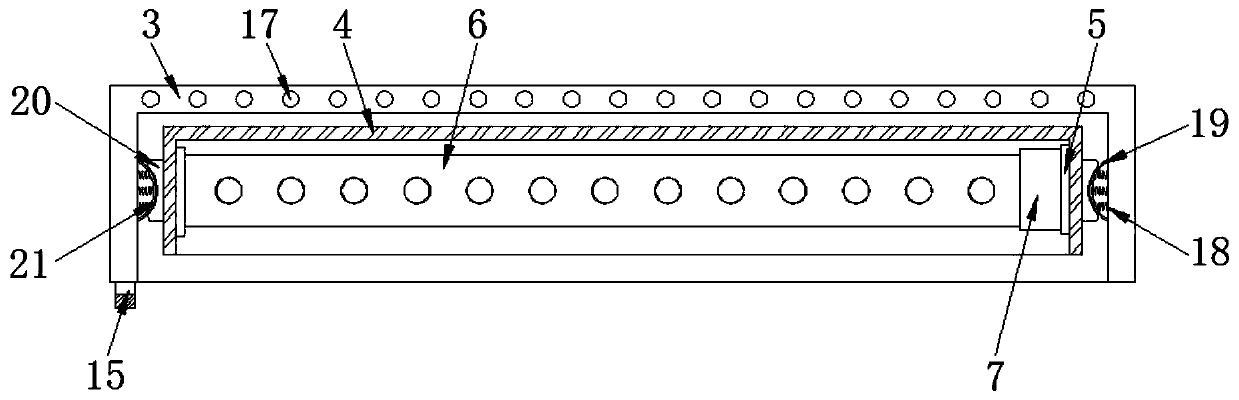

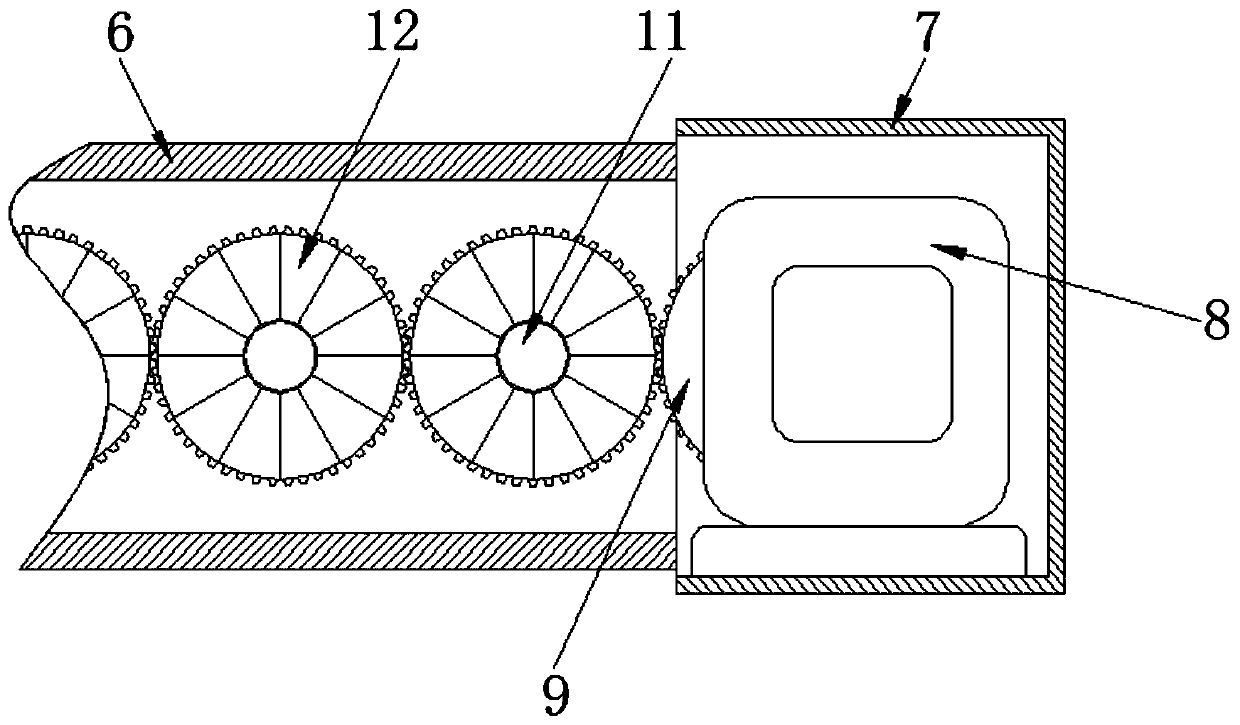

Conveniently-scrubbed door and window and scrubbing structure

InactiveCN110644887AImprove scrubbing effectImprove scrubbing efficiencyWindow/door framesCondensed water drain-offFixed frameGear wheel

The invention discloses a conveniently-scrubbed door and window and a scrubbing structure, and relates to the technical field of door and window cleaning. A window frame, glass, a fixed frame and a movable frame are included, the glass is fixedly connected to the inside of the window frame, and the tops of the front and back surfaces of the window frame are fixedly connected with the fixed frame.By means of the conveniently-scrubbed door and window and the scrubbing structure, a first gear is fixedly connected to the surface of an output shaft of a servo motor, a rotating block is fixedly connected to the back surface of the inner wall of a function box, a rotating rod is rotationally connected to one side of the rotating block, one end of the rotating rod penetrates through the functionbox and extends to the exterior of the function box, a second gear is fixedly connected to the surface of the rotating rod, and the surfaces of the second gear and the first gear are meshed with eachother. By means of device design, the surface of the glass inside the door and window can be scrubbed efficiently, the glass of the door and window does not need to be manually scrubbed, the labor intensity is reduced, time and labor are saved, and the better scrubbing effect on the door and window is achieved.

Owner:合肥四周建筑装饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com