Foundry waste sand regeneration and reuse method and device

A technology for foundry waste sand and equipment, which is used in foundry molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of large expansion coefficient of recycled sand, high impurity content of recycled sand, and high regeneration cost, and achieves reduction of impurity content and lightening. Work load, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

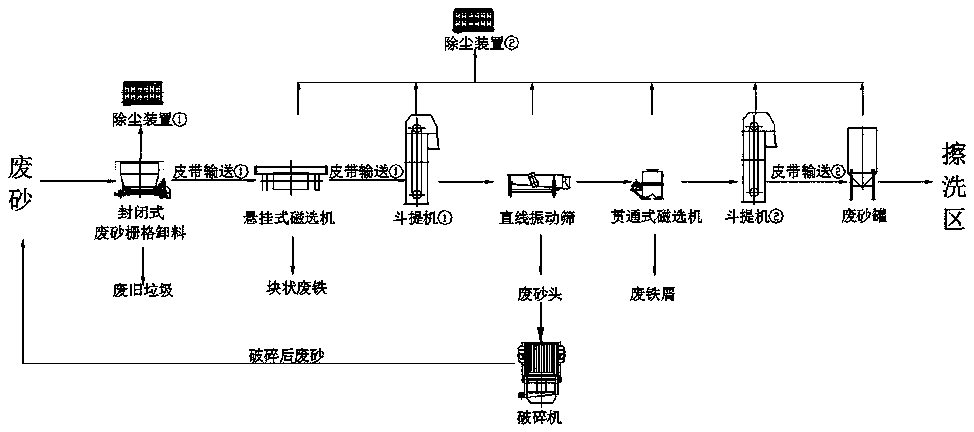

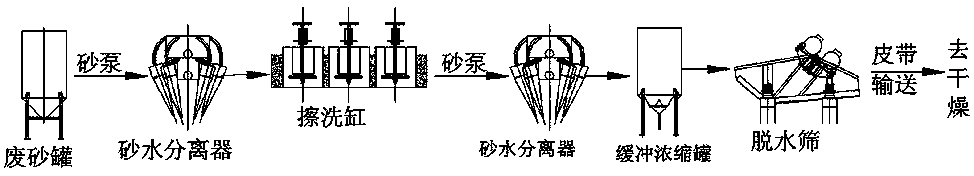

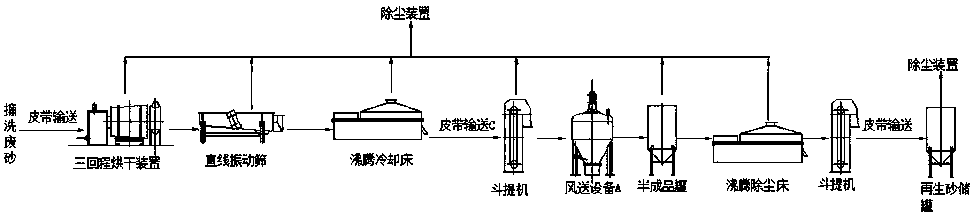

[0039] Such as Figure 1 to Figure 5 As shown, the foundry waste sand recycling process of the present invention is divided into four processes of pretreatment, scrubbing, drying and film covering, and the equipment used is correspondingly divided into pretreatment area, scrubbing area, drying area and film covering area. According to different drying temperatures, it can be divided into two methods: low-temperature drying and high-temperature baking.

[0040] Pretreatment of raw waste sand: the raw waste sand is added to the closed waste sand grid unloader, and under the action of the grid unloader, waste and old garbage such as resin carbides and organic dust are separated and unloaded from the grid. The waste garbage outlet at the bottom of the feeder is collected; the top of the grid unloader adopts a dust removal device with an air curtain type semi-closed dust removal cover to ensure the dust removal effect. The separated sand particles are sent to the suspended magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com