High-strength high-corrosion-resistance cast aluminum alloy and gravity casting manufacturing method thereof

A technology of casting aluminum alloy and gravity casting, which is applied in the field of high corrosion-resistant cast aluminum alloy and its gravity casting preparation, high strength field, and can solve the problems of high standard electrode potential of Cu-rich phase, poor welding and brazing performance, and high Cu content , to achieve the effect of improving mechanical properties and corrosion resistance, improving performance and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

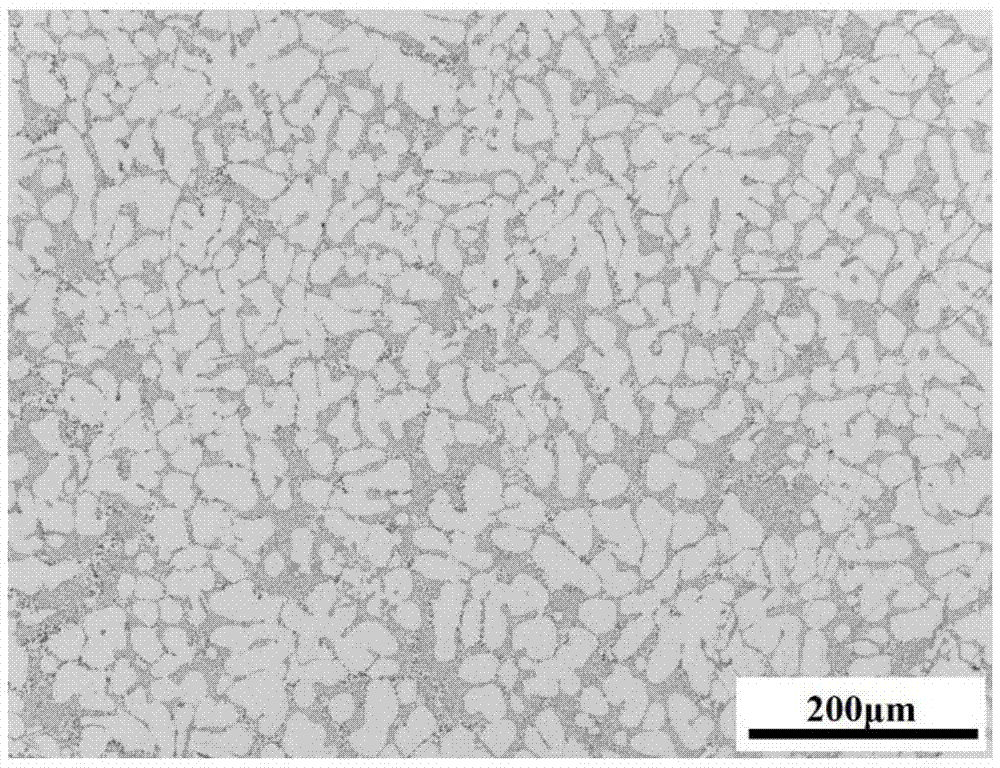

[0033] The weight percent of a high-strength, high-corrosion-resistant cast aluminum alloy is: according to the theoretical ratio, Si8.5%, Mg0.4%, Mn0.5%, Zn0.5%, Sr0.04%, Cu0.25%, Ti0.3%, Zr0.3%, V0.3%, Fe0.4%, the balance is Al and unavoidable impurities.

[0034] Its preparation method is (1) industrial pure aluminum (Al: 99.7wt%), industrial pure magnesium (Mg: 99.95wt%) and industrial pure zinc (Zn: 99.9wt%), and the master alloy AlSi23, AlMn10, AlZr4, AlTi5B1, AlV5, AlFe20, AlCu50, and AlSr10 were polished with 320-grit sandpaper to remove the oxide layer, respectively, and placed in a blast drying oven (200°C) for drying and preheating; (2) stainless steel crucibles were used for alloy casting. , slag removal tools, bell jars and other surfaces are cleaned and rust-removed and coated with paint. The paint is made of 25% talc powder and 5% water glass with an appropriate amount of water, and then baked in an oven at 200°C overnight to remove moisture. Before it can be u...

Embodiment 2

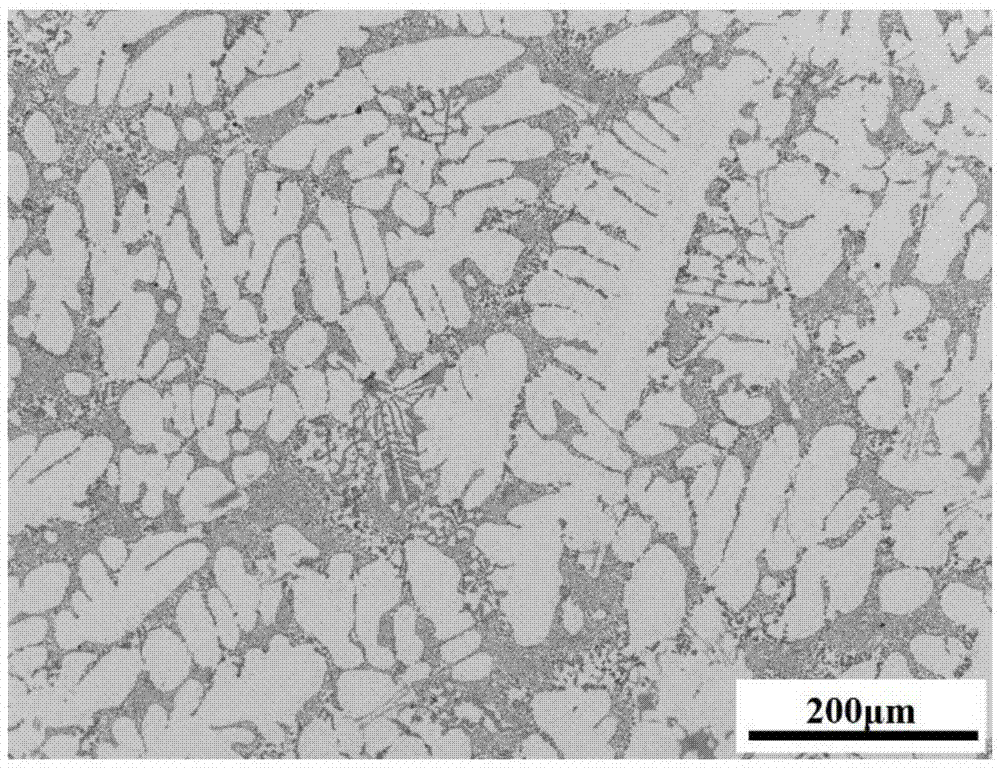

[0039] The weight percent of a high-strength, high-corrosion-resistant cast aluminum alloy is: according to the theoretical ratio, Si7%, Mg0.2%, Mn0.2%, Zn0%, Sr0.02%, Cu0%, Ti0.01%, Fe0 .2%, the balance is Al and unavoidable impurities.

[0040] Its preparation method is (1) with industrial pure aluminum (Al: 99.7wt%) and industrial pure magnesium (Mg: 99.95wt%), and master alloy AlSi23, AlMn10, AlFe20AlTi5B1 and AlSr10 with 320 mesh sandpaper polishing respectively to remove oxide layer, Put them into blast drying oven (200°C) for drying and preheating; (2) use stainless steel crucible for alloy casting, clean and derust the surface of crucible, slag removal tool, bell jar, etc. before use and apply paint. 25% talcum powder and 5% water glass are mixed with an appropriate amount of water, and then baked in an oven at 200°C overnight to remove moisture before use. The temperature gradient of the resistance heating furnace is raised to 710°C, which will account for the mass of...

Embodiment 3

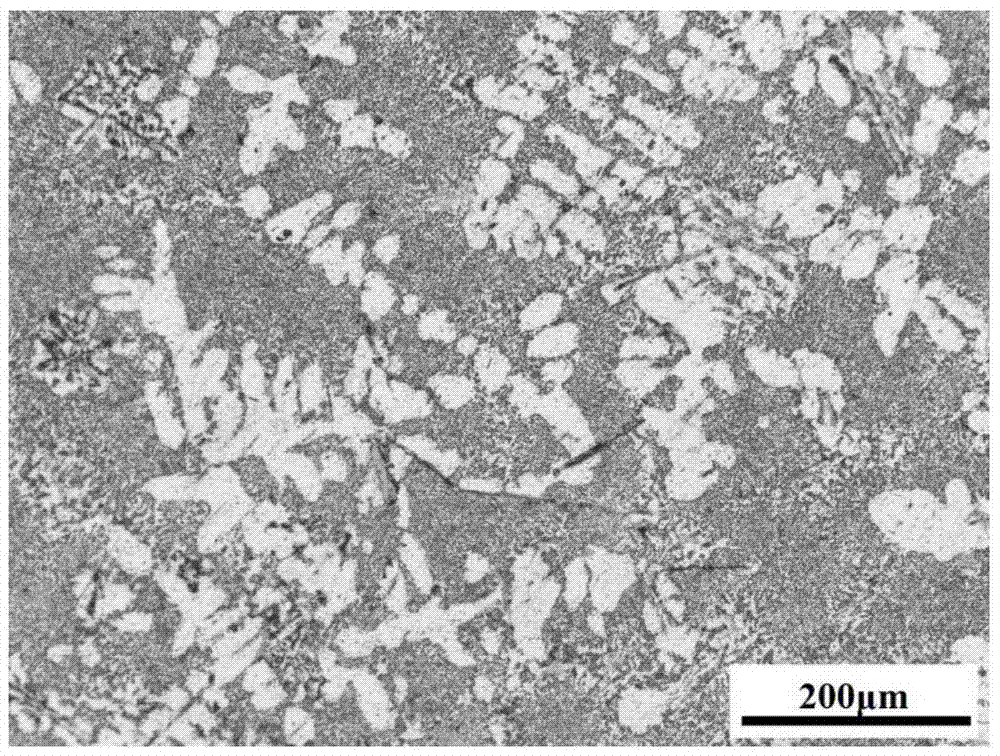

[0045] A high-strength, high-corrosion-resistant cast aluminum alloy and its preparation method are as follows: according to the theoretical ratio, Si15%, Mg0.6%, Mn1%, Zn1%, Sr0.1%, Cu0.5%, Ti0. 5%, Zr0.5%, V0.5%, Fe1%, the balance is Al and unavoidable impurities.

[0046] Its preparation method is (1) industrial pure aluminum (Al: 99.7wt%), industrial pure magnesium (Mg: 99.95wt%) and industrial pure zinc (Zn: 99.9wt%), and the master alloy AlSi23, AlMn10, AlZr4, AlTi5B1, AlV5, AlFe20, AlCu50, and AlSr10 were polished with 320-grit sandpaper to remove the oxide layer, respectively, and placed in a blast drying oven (200°C) for drying and preheating; (2) stainless steel crucibles were used for alloy casting. , slag removal tools, bell jars and other surfaces are cleaned and rust-removed and coated with paint. The paint is made of 25% talc powder and 5% water glass with an appropriate amount of water, and then baked in an oven at 200°C overnight to remove moisture. Before it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com