Patents

Literature

432results about How to "Raise room temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for lathing silicone hydrogel lenses

ActiveUS20060001184A1High oxygen permeabilityImprove machinabilityOptical articlesCeramic shaping apparatusRoom temperaturePolymer chemistry

The present invention provides methods for lathing at room temperature a silicone hydrogel material, in particular silicone hydrogel material having a high oxygen permeability and made of a polymerizable composition containing a relative large amount of oxyperm component, into contact lenses.

Owner:ALCON INC

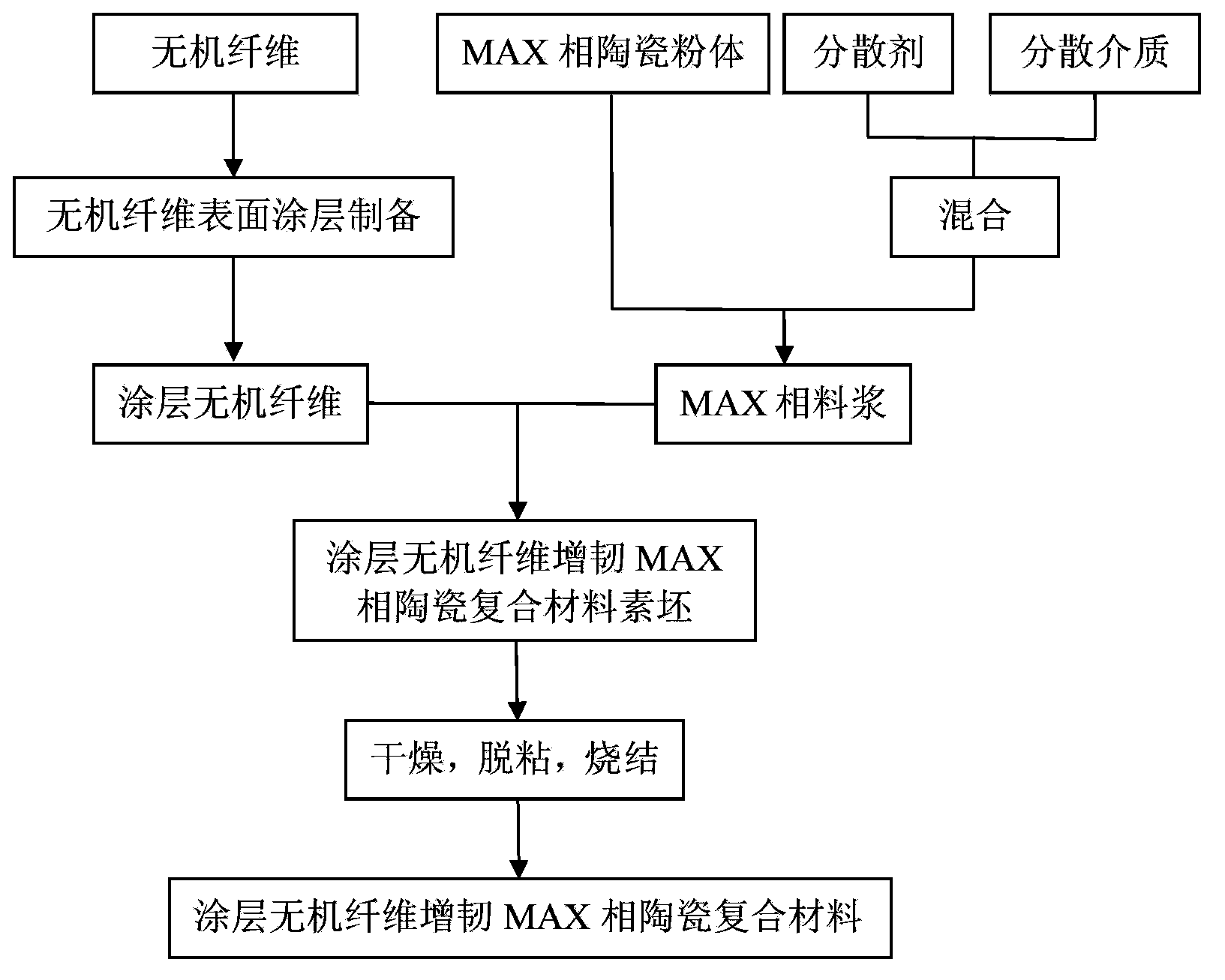

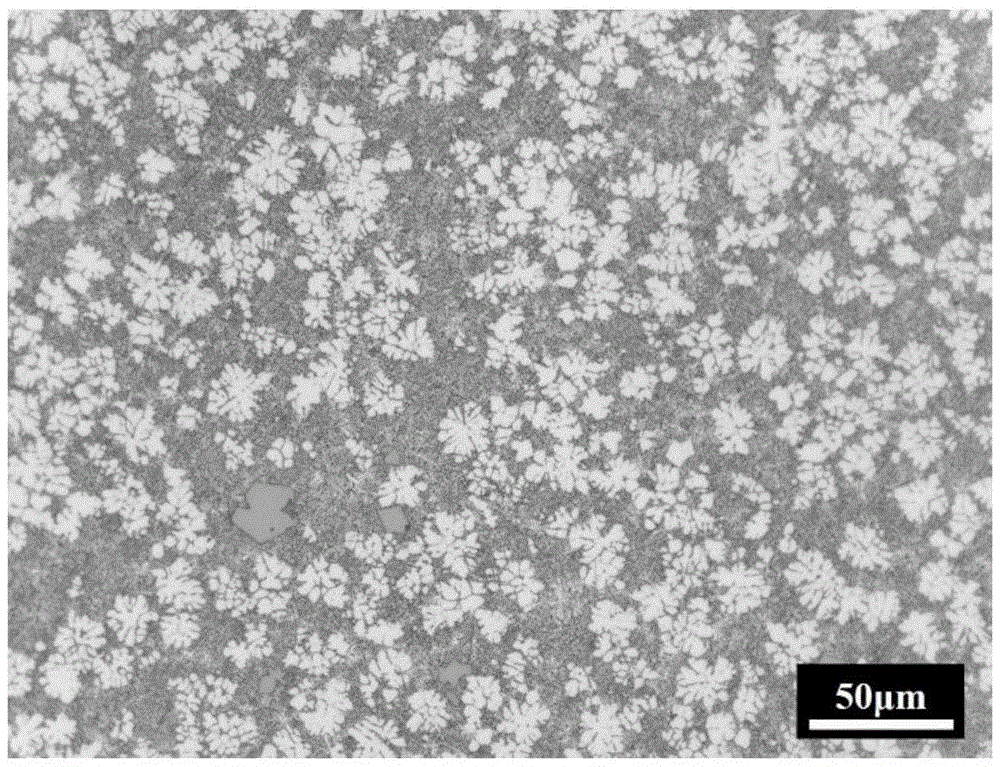

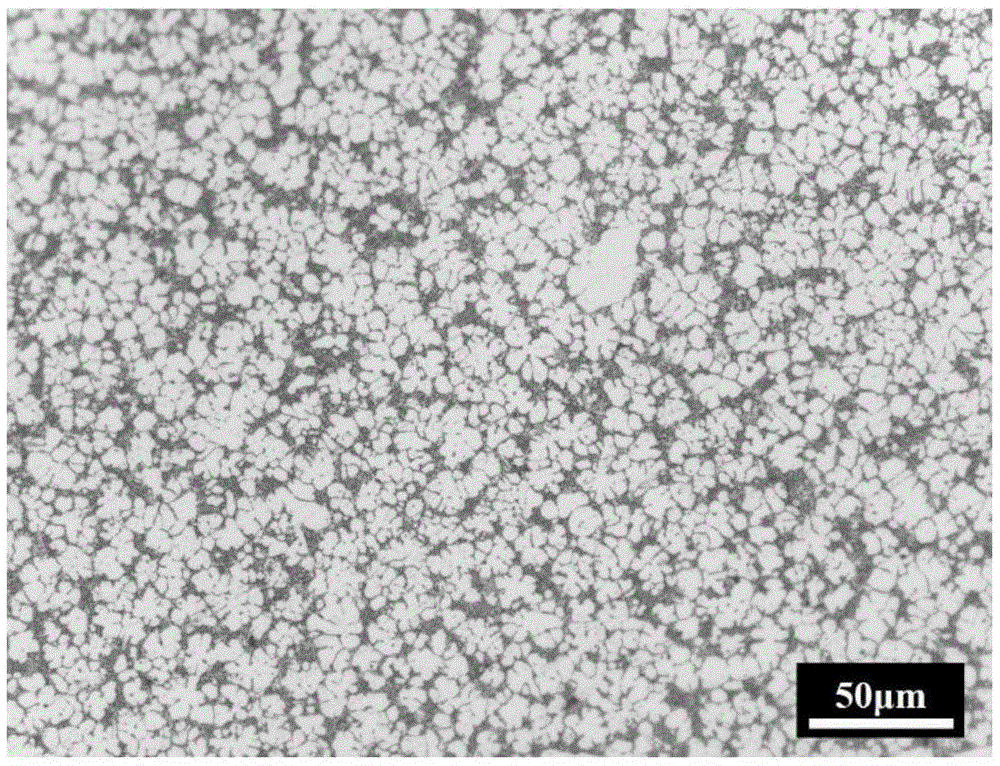

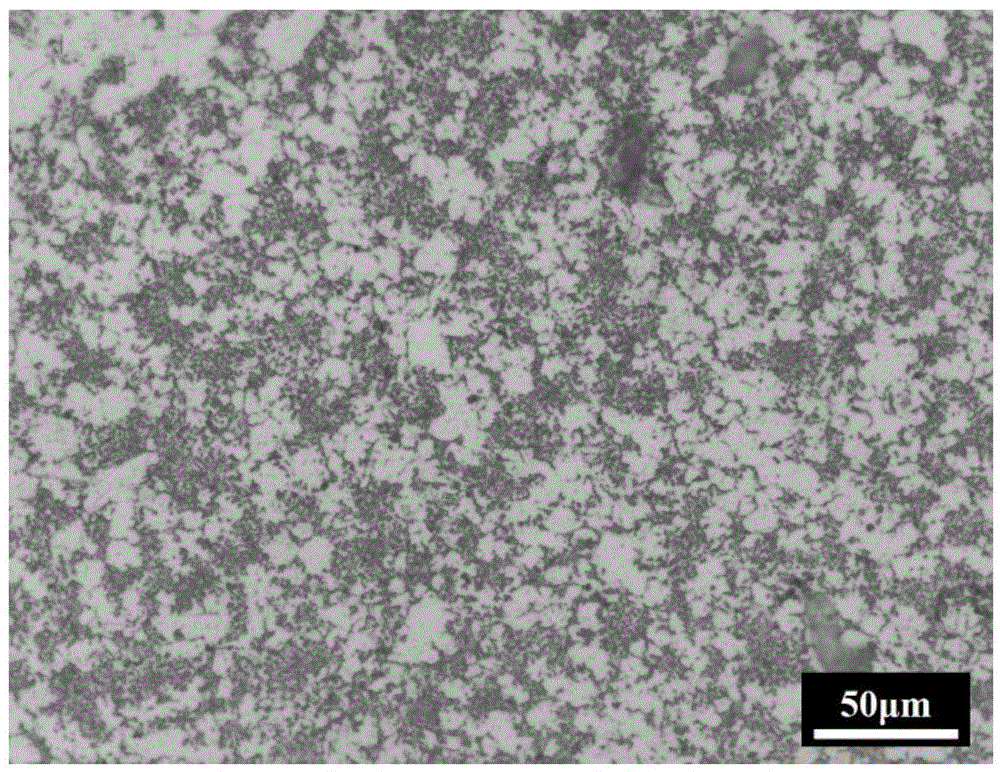

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

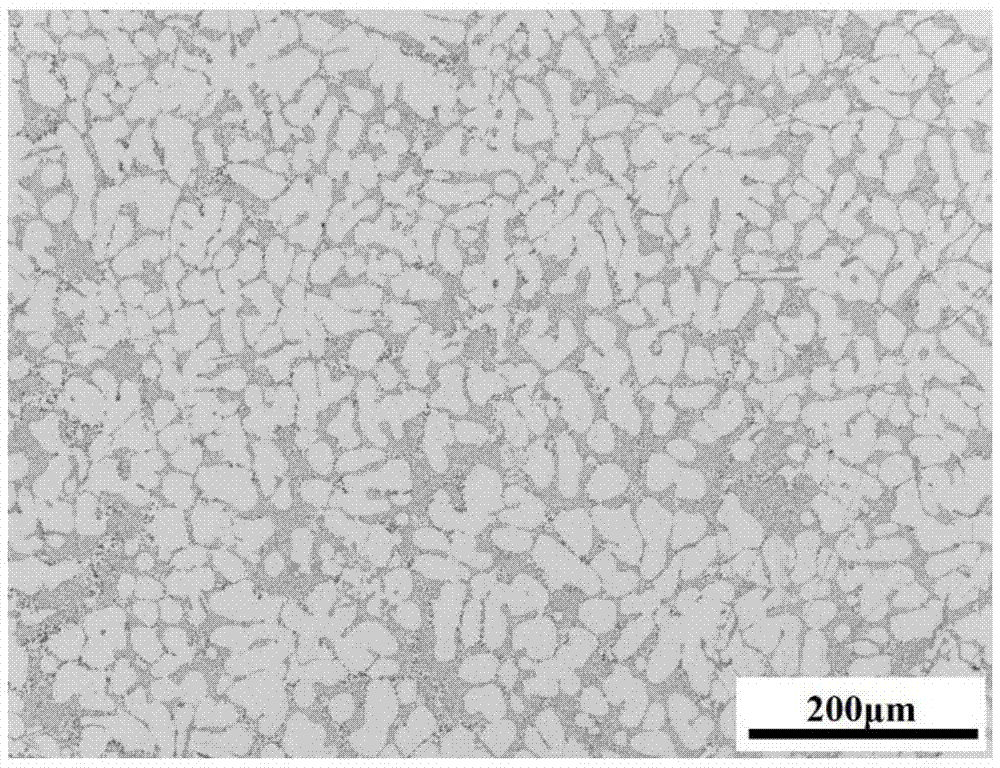

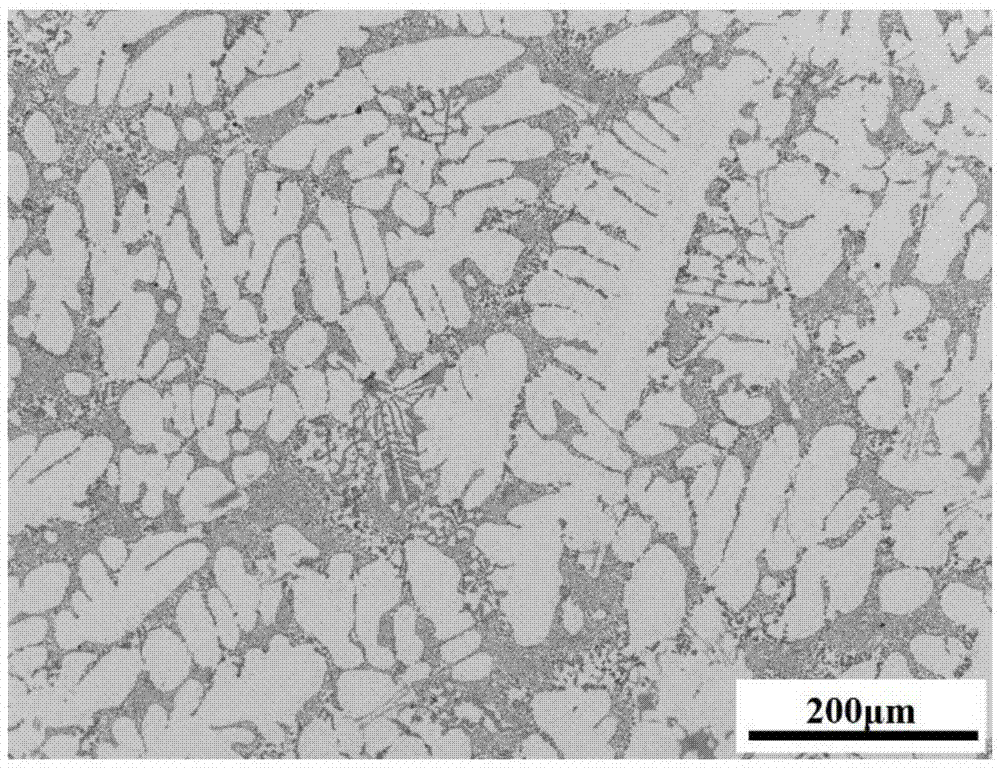

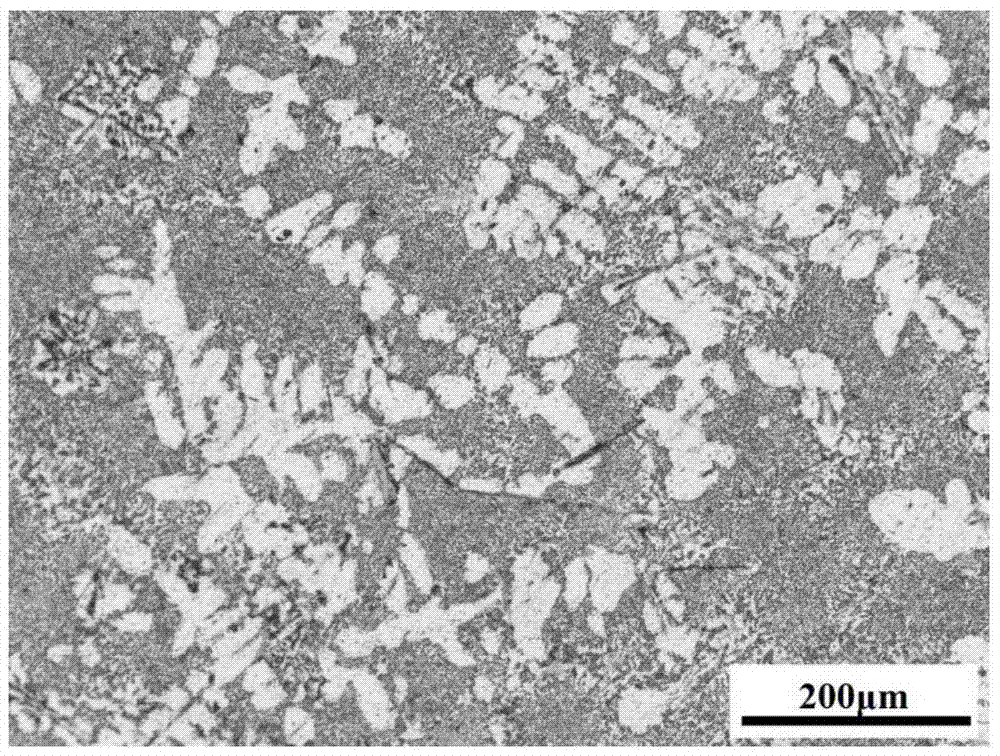

High-strength heat-resisting magnesium alloy and its preparing method

This invention is a high-intensive heat-fast magnesium alloy and its preparation method, and the magnesium alloy has the following components with their weight percentages: 6-15%Gd, 1-6%Y, 0.35-0.8%Zr, 0-1.5%Ca, and impurity elements Si, Fe, Cu and Ni with their gross less than 0.02%, and the rest percentage is Mg. while melting, add Gd, Y, Zr in the Mg melt in Mg-Gd, Mg-Y, Mg-Zr forms, then carry out solution treatment to the magnesium alloy under 450-500deg.C for 6-12 hours, squeeze in in 350-450deg.C, treat in time the squeezing stick for 10-16 hours in 225deg.C to improve its strength.

Owner:SHANGHAI JIAO TONG UNIV

High-strength and high-corrosion-resistance cast aluminum alloy and pressure casting preparation method thereof

The invention provides high-strength and high-corrosion-resistance cast aluminum alloy and a pressure casting preparation method thereof. The alloy is prepared from, by a certain weight percent, Si, Mg, Fe, Mg, Zn, Sr, Cu, M and the balance Al, wherein M is at least one element of Ti, Zr and V, or the element RE is added in M. After the high-strength and high-corrosion-resistance cast aluminum alloy is subjected to pressure casting, the room temperature tensile strength sigma b of alloy not subjected to heat treatment is larger than or equal to 315 MPa, the room temperature ductility sigma of the alloy not subjected to heat treatment is larger than or equal to 3.0%, and good corrosion resistance is achieved; and the alloy can be applied to automobile parts without ageing or solid solution heat treatment, and the requirement for light automobile development is met.

Owner:SHANGHAI JIAO TONG UNIV

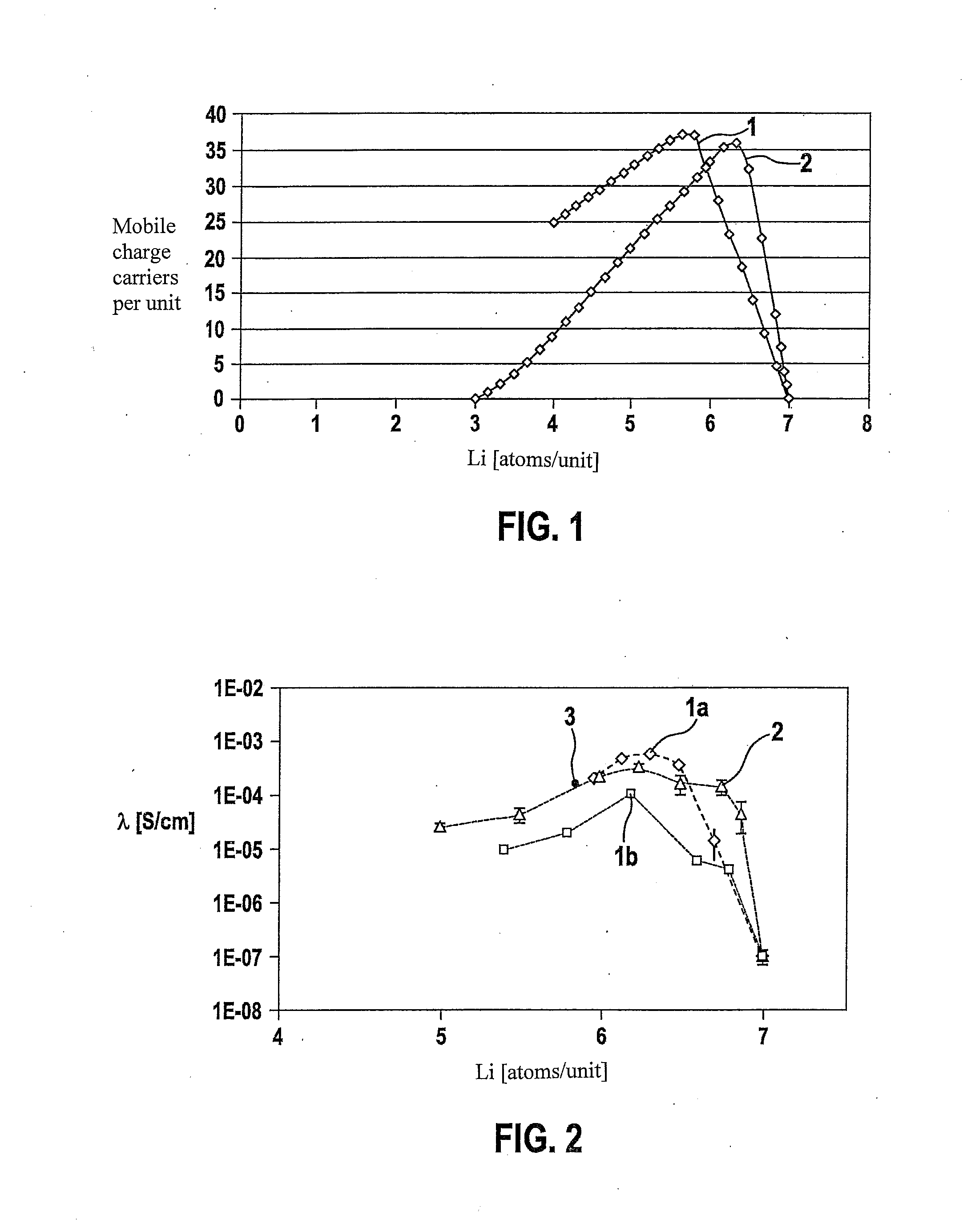

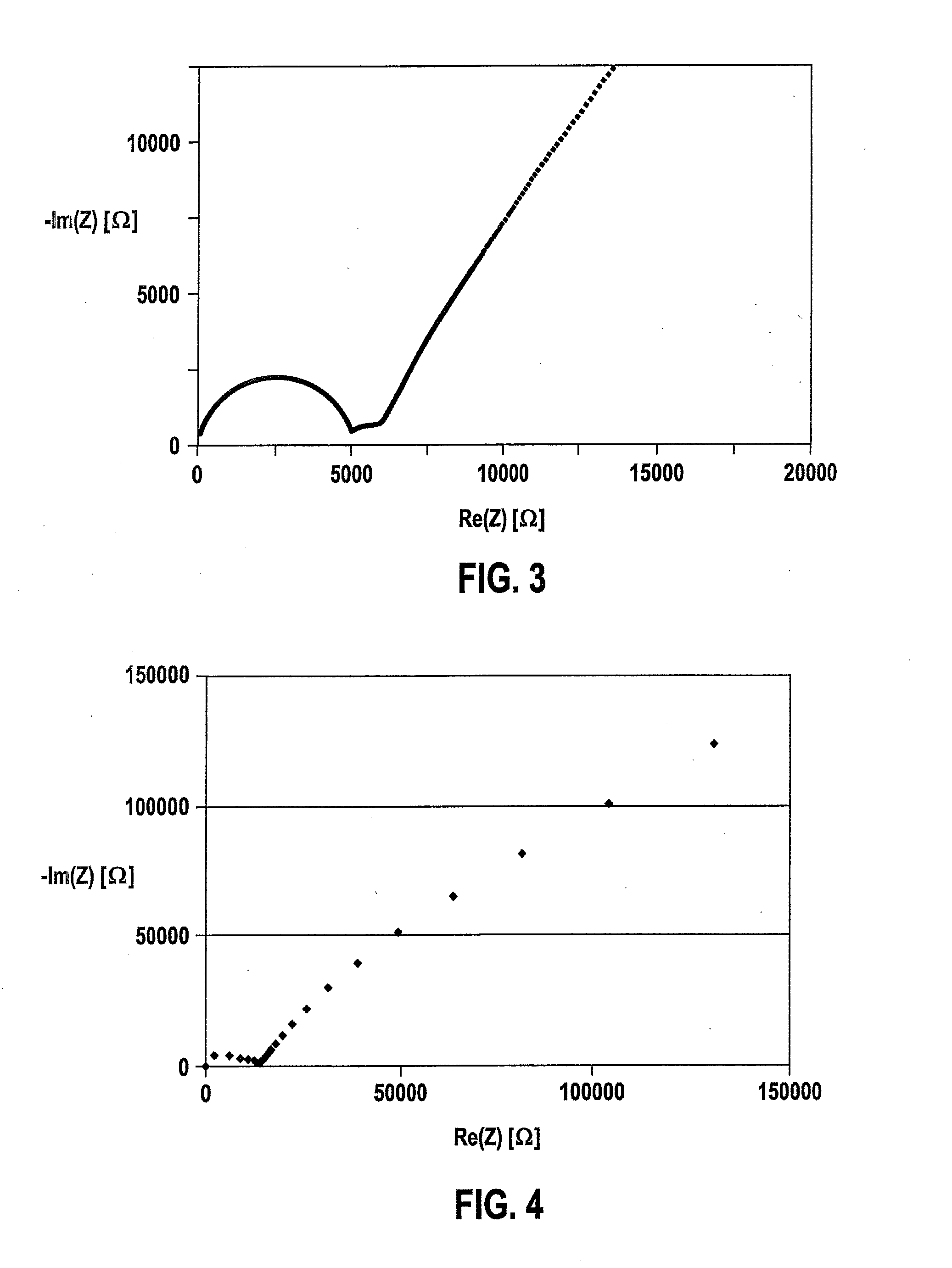

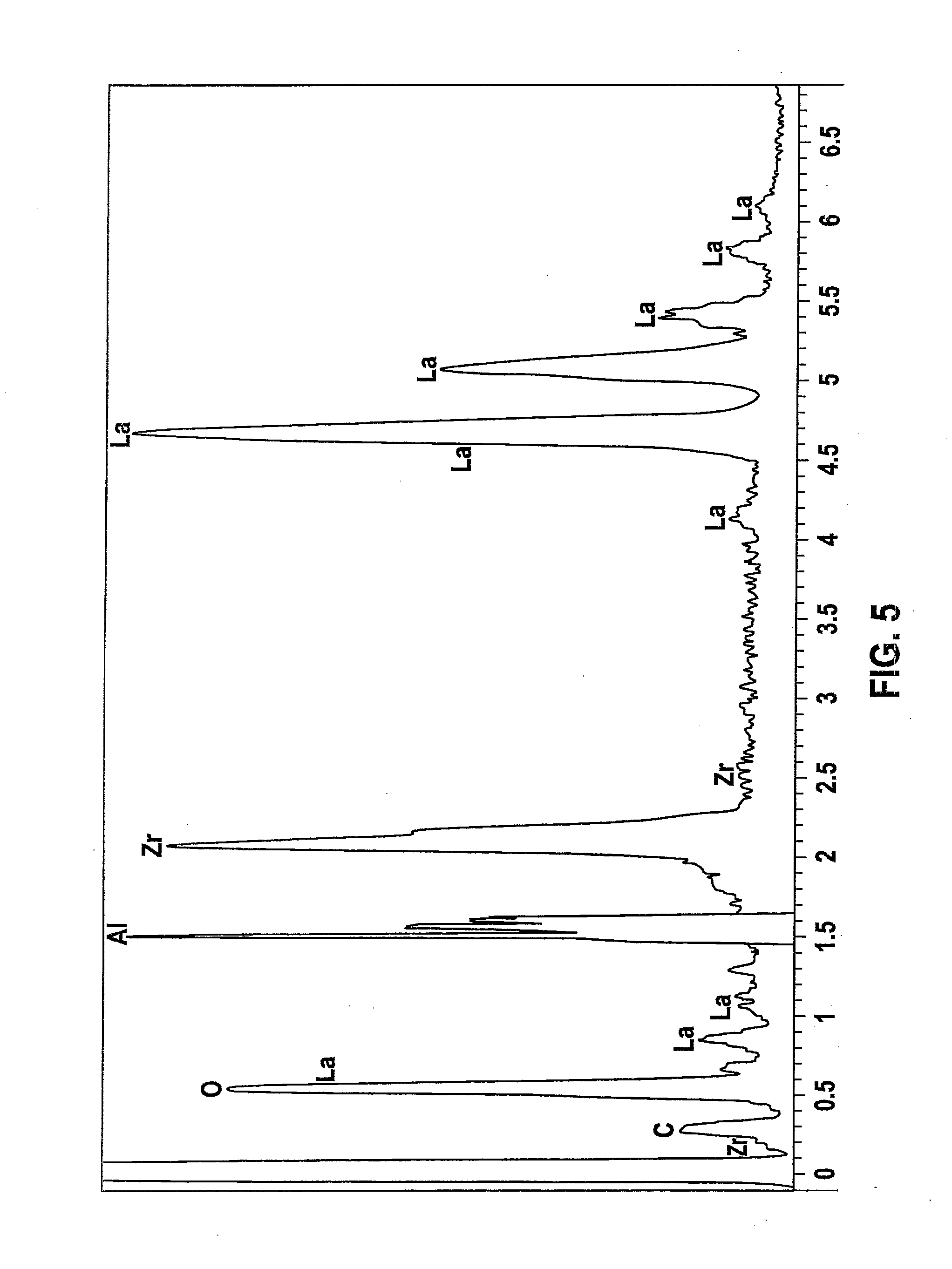

Lithium ion-conducting garnet-like compounds

ActiveUS20140295287A1Loss can be compensatedImprove stabilityTantalum compoundsZirconium compoundsLithiumCompound a

A lithium ion-conducting compound, having a garnet-like crystal structure, and having the general formula: Lin[A(3-a′-a″)A′(a′)A″(a″)][B(2-b′-b″)B′(b′)B″(b″)][C′(c′)C″(c″)]O12, where A, A′, A″ stand for a dodecahedral position of the crystal structure, where A stands for La, Y, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm and / or Yb, A′ stands for Ca, Sr and / or Ba, A″ stands for Na and / or K, 0<a′<2 and 0<a″<1, where B, B′, B″ stand for an octahedral position of the crystal structure, where B stands for Zr, Hf and / or Sn, B′ stands for Ta, Nb, Sb and / or Bi, B″ stands for at least one element selected from the group including Te, W and Mo, 0<b′<2 and 0<b″<2, where C and C″ stand for a tetrahedral position of the crystal structure, where C stands for Al and Ga, C″ stands for Si and / or Ge, 0<c′<0.5 and 0<c″<0.4, and where n=7+a′+2·a″−b′−2·b″−3·c′−4·c″ and 5.5<n<6.875.

Owner:ROBERT BOSCH GMBH

High-toughness heat-resistant Mg-Al-RE-Mn wrought magnesium alloy and preparation method of plate made of same

The invention relates to a high-toughness heat-resistant Mg-Al-RE-Mn wrought magnesium alloy and a preparation method of a plate made of the same. The high-toughness heat-resistant Mg-Al-RE-Mn wrought magnesium alloy comprises aluminum, rare earth, manganese, impurity elements (silicon, iron, nickel and copper) and magnesium. The preparation method comprises the following steps: proportionally preparing pure magnesium, pure aluminum cast ingots, magnesium-manganese (or aluminum-manganese) interalloy and magnesium-rear earth interalloy; smelting and refining by using a smelting furnace, and casting to obtain cast ingots; carrying out homogenizing treatment at 370-410 DEG C, and quenching with water; and before plastic deformation treatment, keeping the temperature at 280-400 DEG C for a period of time, and extruding and rolling, or extruding while rolling, thereby obtaining the high-toughness heat-resistant Mg-Al-RE-Mn wrought magnesium alloy. The high-toughness heat-resistant Mg-Al-RE-Mn wrought magnesium alloy and the plate made of the same provided by the invention have the advantages of high toughness, high heat resistance, high plasticity and favorable hot working properties; and the product can be used as a light-weight high-toughness heat-resistant structural material to satisfy the demands of aviation, spaceflight, civil vehicles and the like for the light-weight high-toughness heat-resistant wrought magnesium alloy material.

Owner:XIAN TECHNOLOGICAL UNIV

High-strength high-corrosion-resistance cast aluminum alloy and gravity casting manufacturing method thereof

The invention provides high-strength high-corrosion-resistance cast aluminum alloy and a gravity casting manufacturing method of the high-strength high-corrosion-resistance cast aluminum alloy. The alloy is composed of Si, Mg, Fe, Mg, Zn, Sr, Cu, M and the balance Al according to certain weight percentages, wherein the M is at least one of Ti, Zr and V or the RE element is added to the M. The cast aluminum alloy has the excellent cast performance and good mechanical property. The tensile strength, the yield strength and elongation are improved, good corrosion resistance is achieved, the aluminum alloy can be applied to automobile parts without solid solution heat treatment, and the requirement of low-weight development of automobiles is met.

Owner:SHANGHAI JIAO TONG UNIV

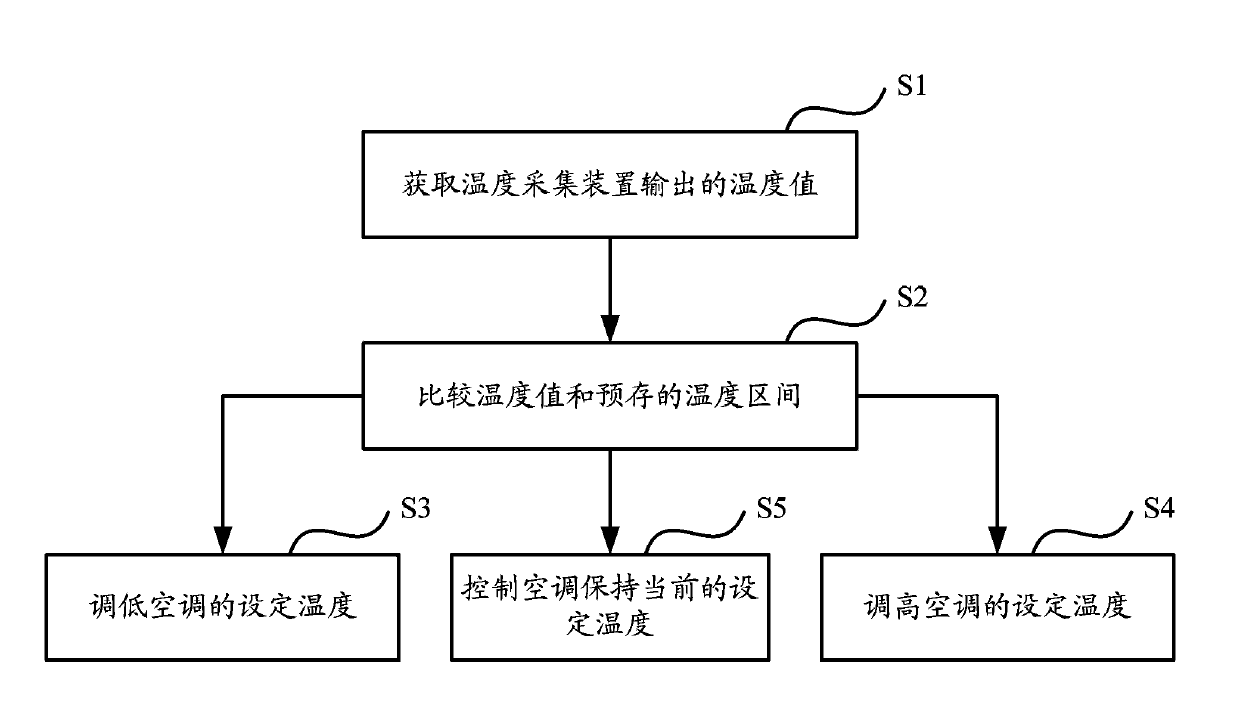

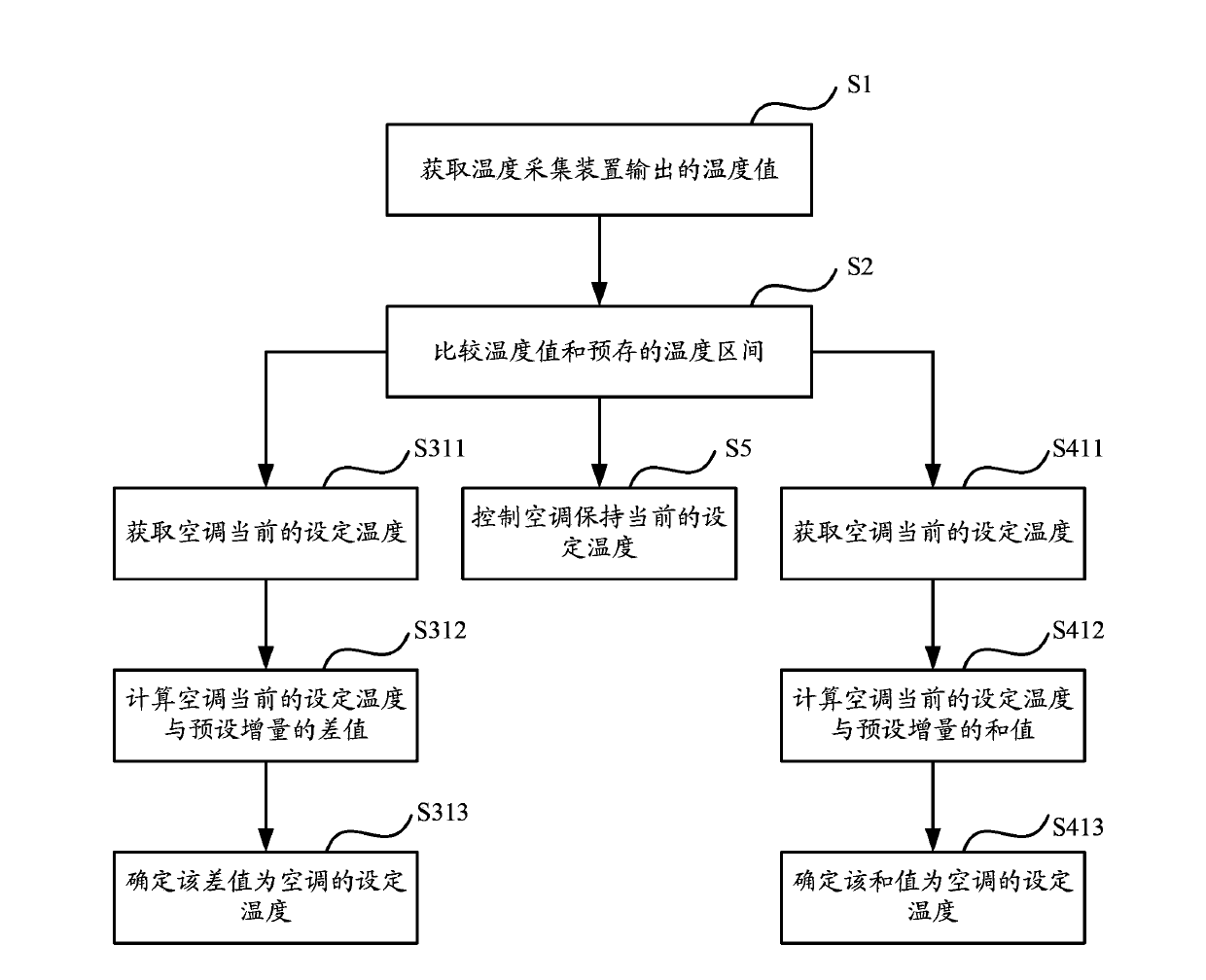

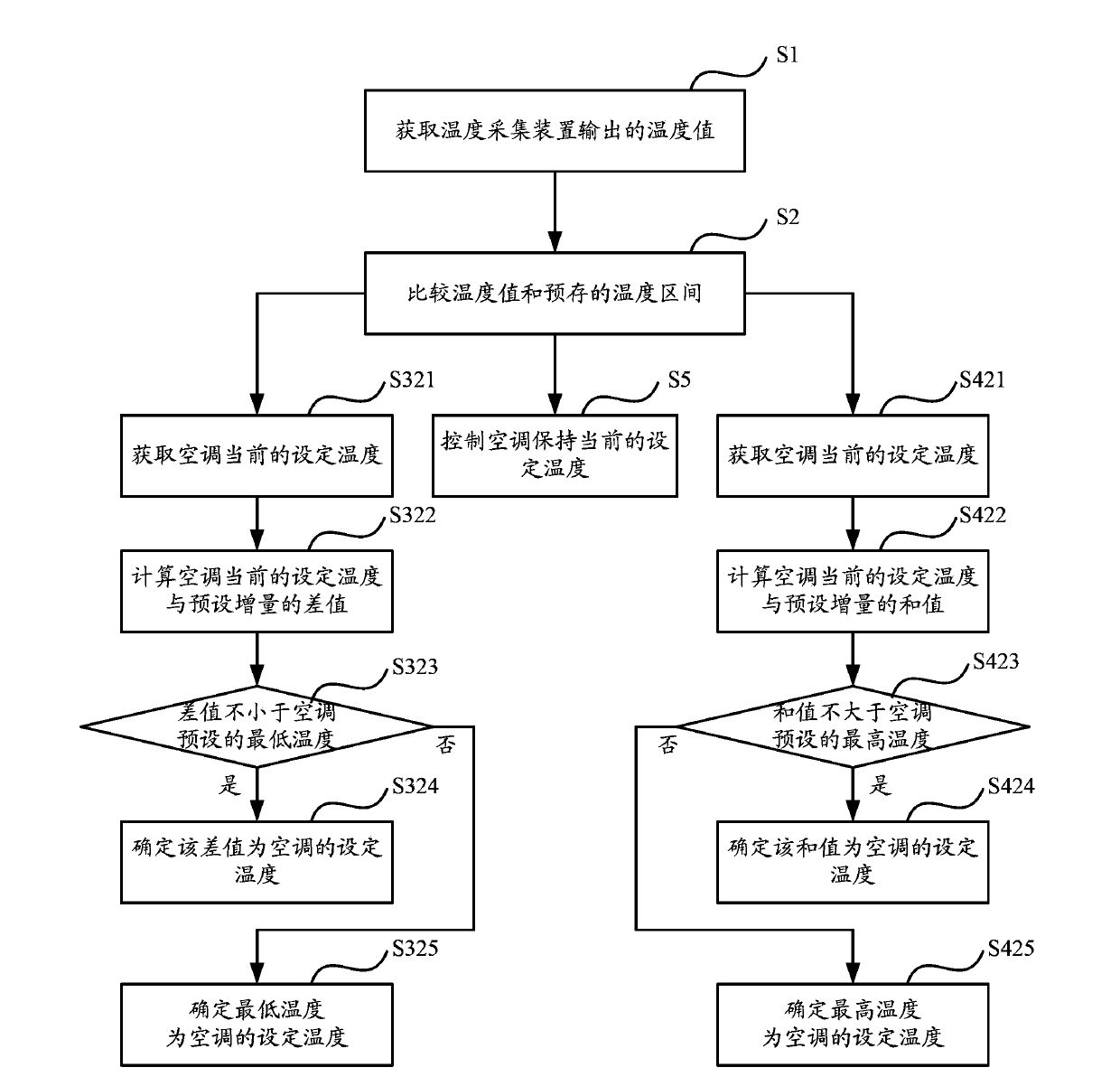

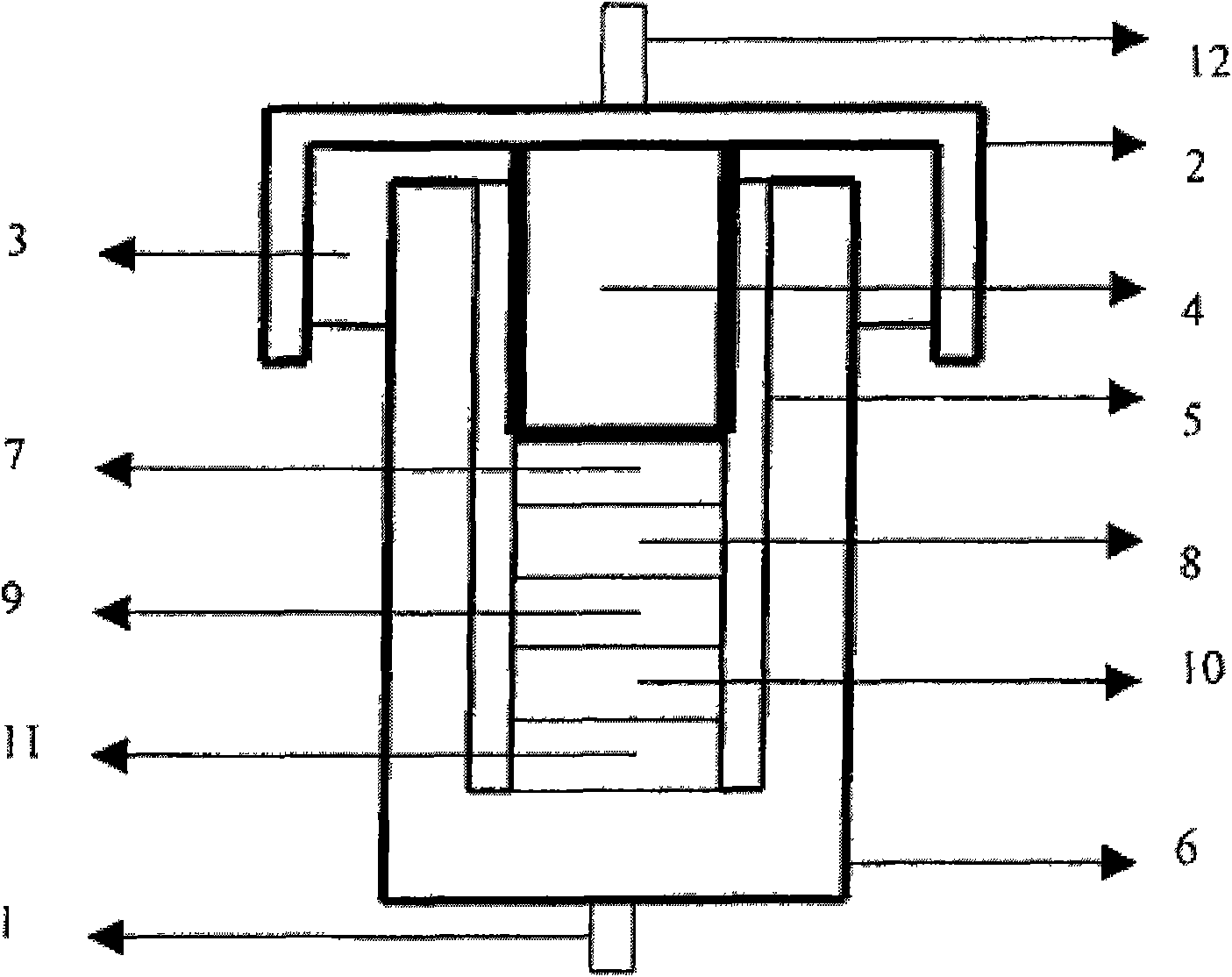

Control method and control device for air conditioner and air conditioner provided with control device

ActiveCN103868196AFlexible Control OperationRaise room temperatureSpace heating and ventilation safety systemsLighting and heating apparatusRoom temperatureEngineering

The invention discloses a control method for an air conditioner. The method comprises the following steps: acquiring a temperature value output by a temperature acquisition device; comparing the temperature value with a prestored temperature interval; when the temperature value is higher than the temperature interval, lowering the set temperature of the air conditioner; when the temperature value is lower than the temperature interval, raising the set temperature of the air conditioner; when the temperature value is in the temperature interval, controlling the air conditioner to keep a current set temperature. By adopting the control method disclosed by the invention, the room temperature is raised when the body temperature value of a user is lower than the temperature interval, and the room temperature is lowered when the body temperature of the user is higher than the temperature interval. Running of the air conditioner can be controlled flexibly according to the body temperature of the user by implementing the control method periodically or non-periodically for multiple times, and the whole control process is more flexible. The specific body condition of the user is taken as a control basis, so that the control method is more user-friendly. The invention further discloses a control device for the air conditioner, and an air conditioner with the control device.

Owner:GREE ELECTRIC APPLIANCES INC

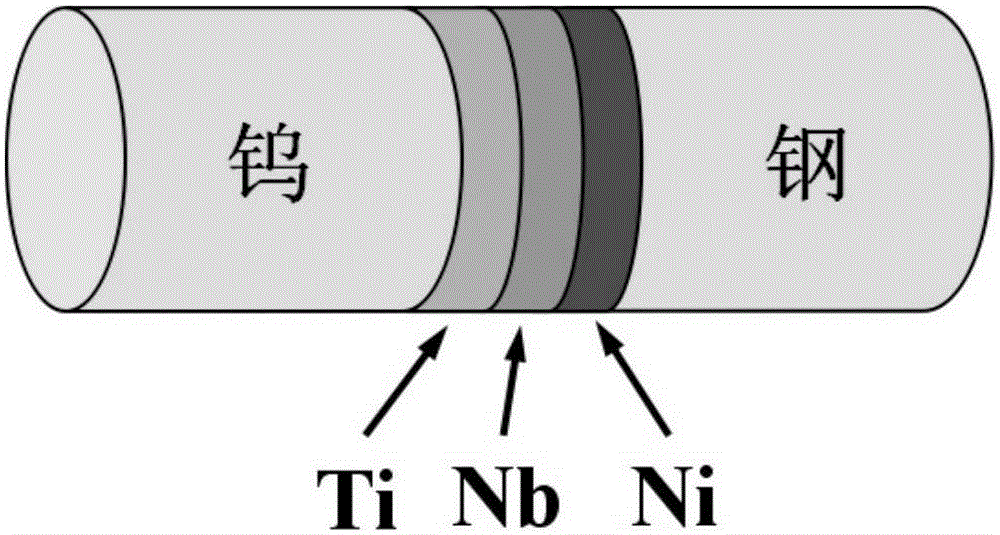

High-performance tungsten/steel composite material based on high-temperature application and preparation method thereof

ActiveCN105216394AHigh tensile strength at room temperatureImprove high temperature mechanical propertiesLaminationLamination apparatusNiobiumJoint stress

The invention relates to a high-performance tungsten / steel composite material based on high-temperature application and a preparation method thereof and belongs to the technical field of preparation of composite materials. By adoption of the high-performance tungsten / steel composite material, the problems of large residual joint stress, low strength, poor heat resistance and high connection temperature in an existing tungsten / steel connector are solved. The high-performance tungsten / steel composite material is prepared from a tungsten-based layer, a titanium layer, a niobium layer, a nickle layer and a steel-based layer which are arranged in sequence and prepared by adopting a welding method. The high-performance tungsten / steel composite material is obtained by superposing the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer in sequence according to the superposition mode of the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer and carrying out vacuum diffusion bonding. The high-performance tungsten / steel composite material has the advantages that the room-temperature tensile strength is larger than or equal to 352MPa, and the tensile strength at the temperature of 650DEG C is larger than or equal to 338MPa; the structure design is reasonable, the process is simple, the large-scale application is convenient, and simultaneously, the high-performance tungsten / steel composite material can be widely applied in diffusion bonding of refractory metal and other dissimilar metal materials.

Owner:CENT SOUTH UNIV

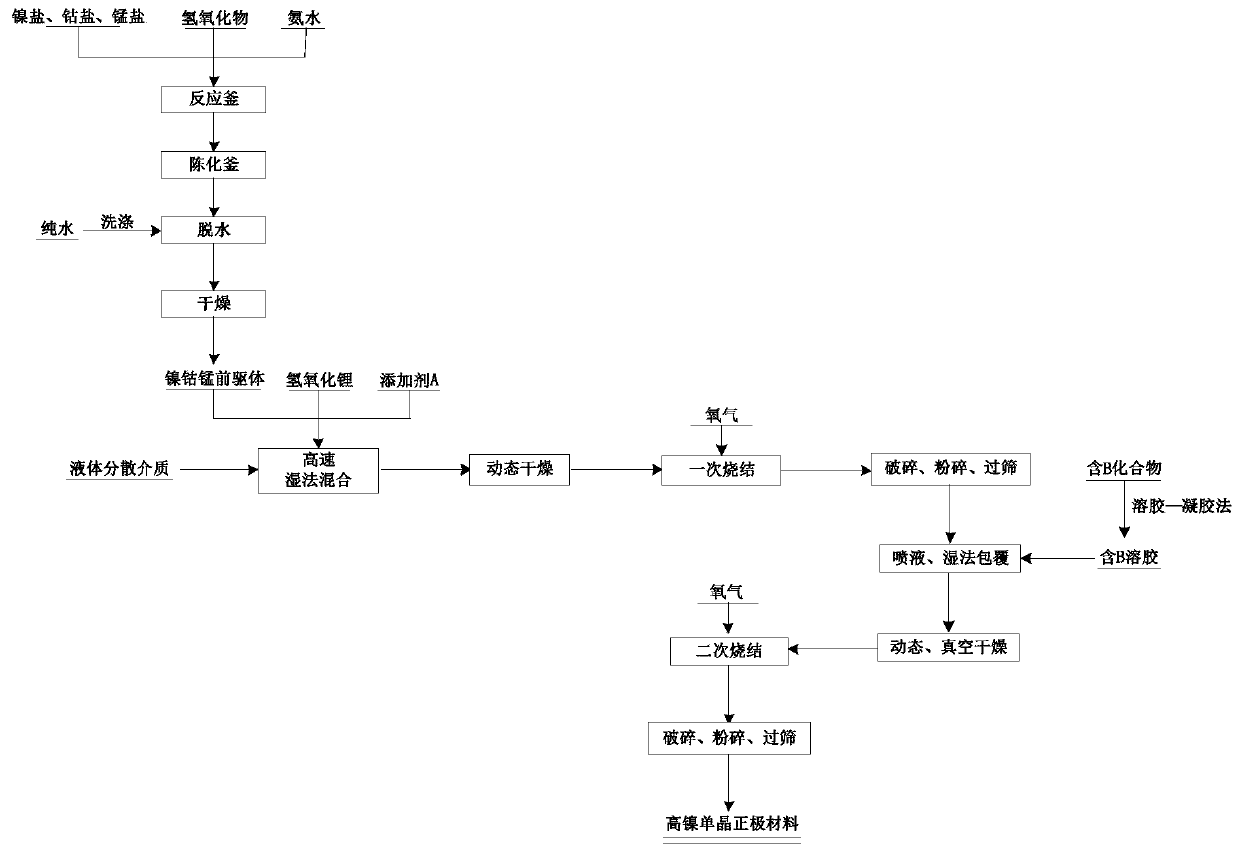

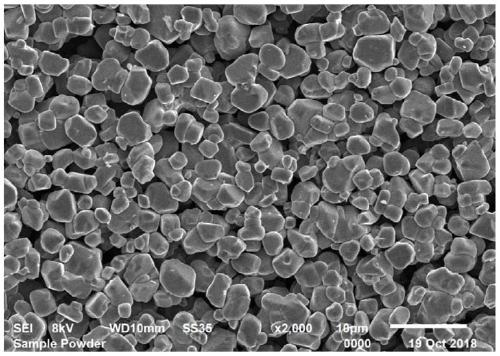

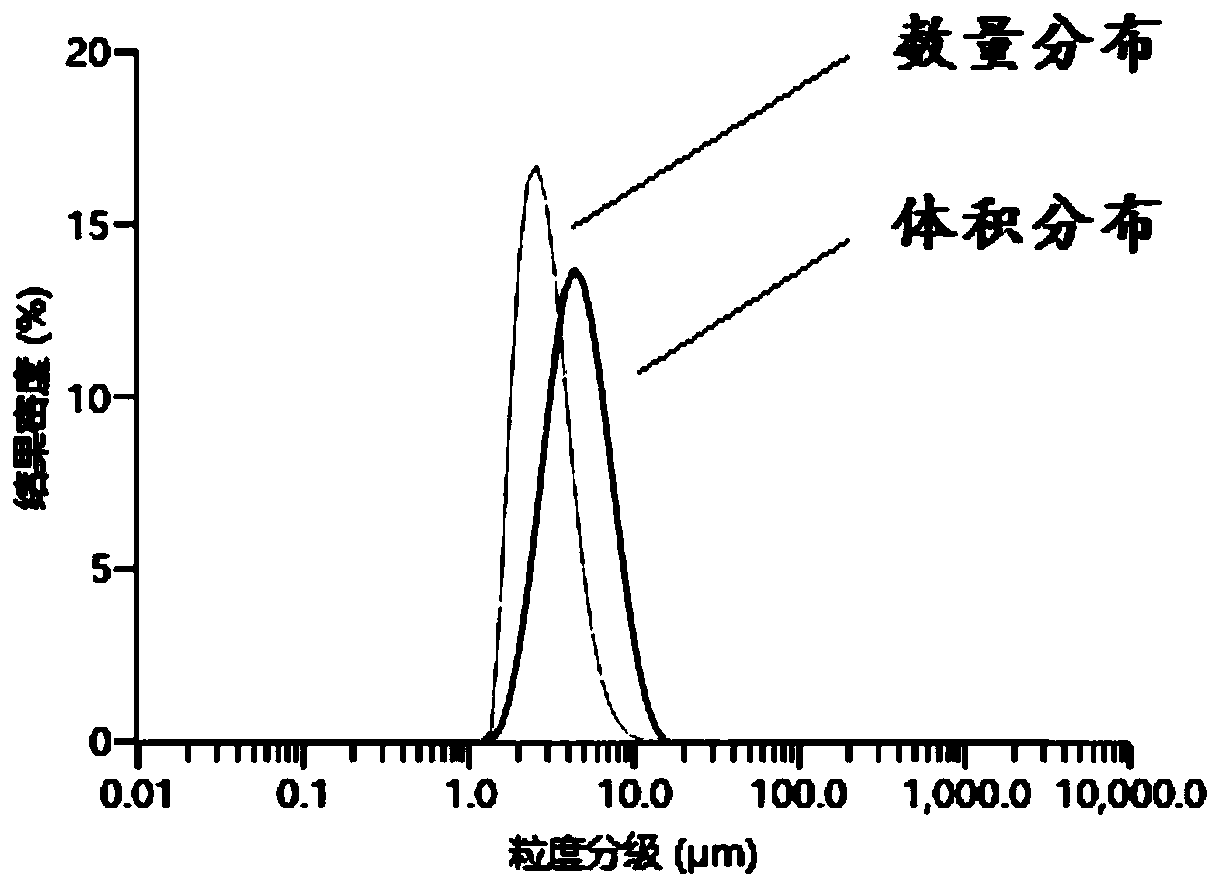

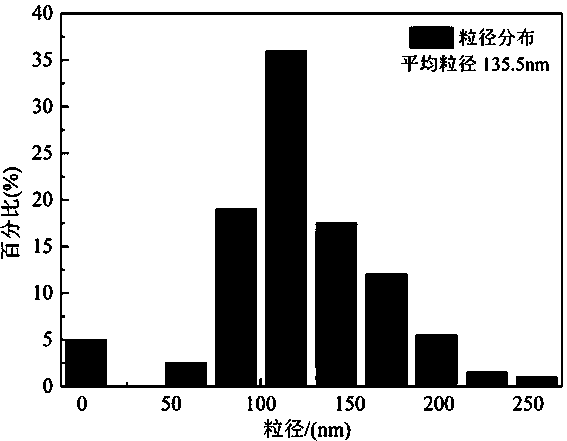

Method for preparing high-nickel long-cycle single-crystal lithium ion battery positive-pole material

InactiveCN110451585AImprove uniformityImprove stabilityCell electrodesSecondary cellsNickel saltLithium hydroxide

The invention relates to a method for preparing a high-nickel long-cycle single-crystal nickel-cobalt-manganese (NCM) lithium ion battery positive-pole material. The preparation method comprises the following steps: (1) mixing a soluble nickel salt, a cobalt salt, a manganese salt, an alkali metal hydroxide and ammonia water, and enabling the mixture to flow into a reaction kettle for constant-temperature coprecipitation to obtain a high-nickel NCM ternary precursor material; (2) uniformly mixing the high-nickel NCM ternary precursor, lithium hydroxide and an additive A in a wet high-speed mixing mode, carrying out drying, then carrying out primary sintering in an oxygen-enriched atmosphere to obtain a spherical high-nickel NCM ternary positive-pole material; (3) carrying out crushing, smashing and sieving to obtain a high-nickel NCM ternary positive-pole material; and (4) carrying out wet mixing and drying on the high-nickel NCM ternary positive-pole material with a coating agent B, carrying out secondary sintering in an oxygen-enriched atmosphere, and carrying out crushing, smashing and sieving to obtain the high-nickel single-crystal NCM lithium ion battery positive-pole material. The positive-pole material prepared by the method has the advantages of high capacity, good cycle performance, high compaction density and the like.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

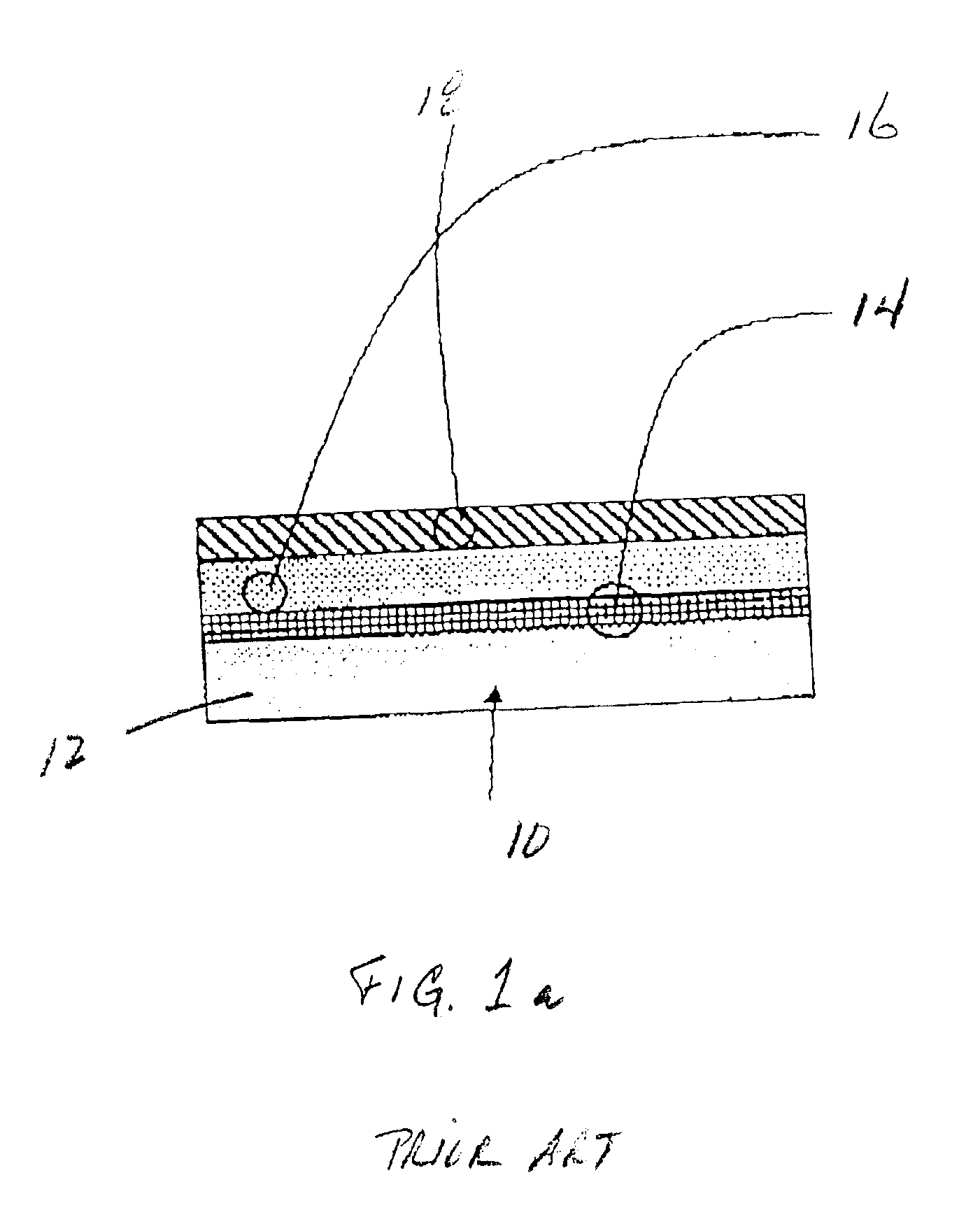

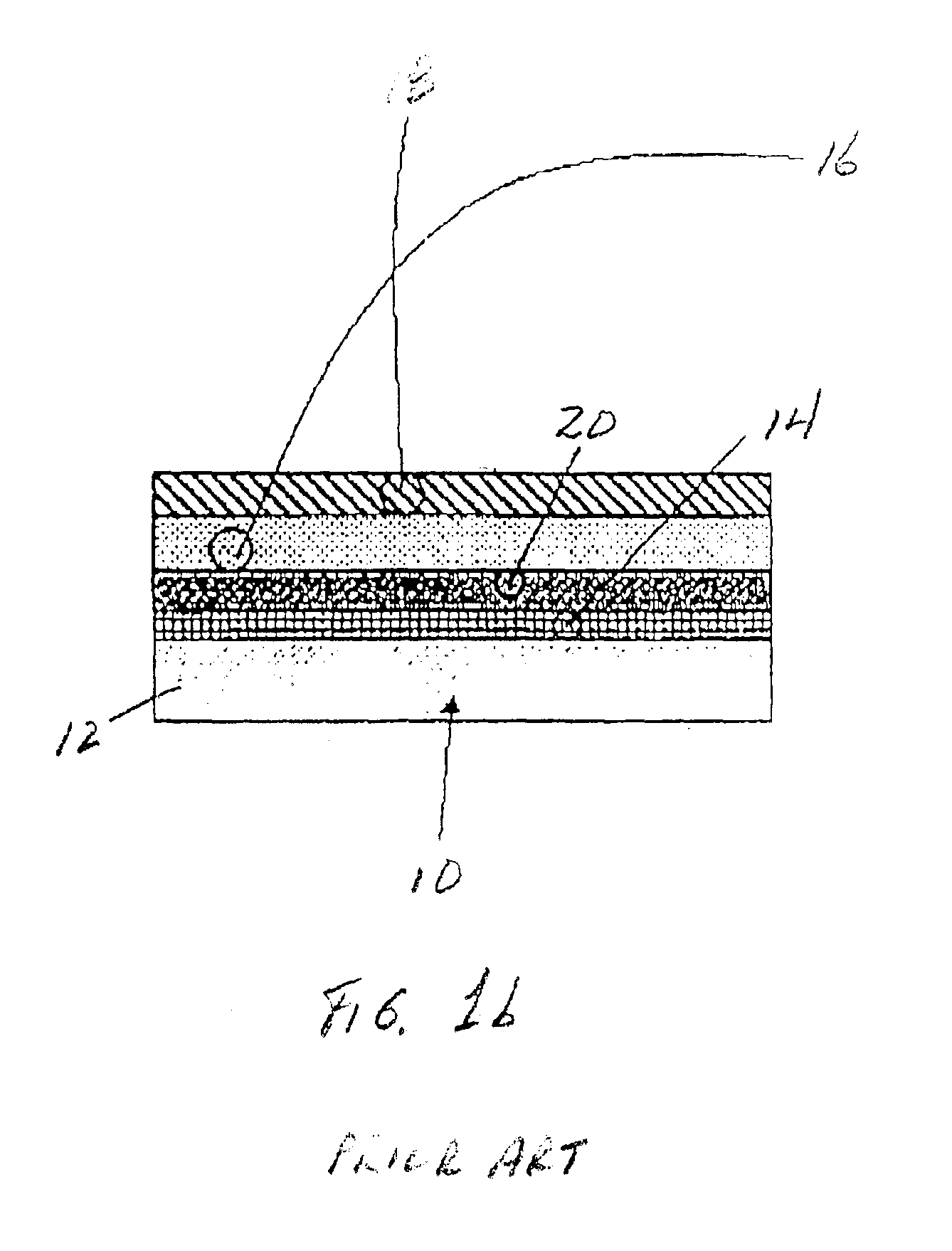

Bond coat for silicon based substrates

ActiveUS7060360B2Improve fracture toughnessMore crack resistantPropellersPump componentsYttriumTungsten

A bond layer for use on a silicon based substrate. The bond layer comprises an alloy comprising a refractory metal disilicide / silicon eutectic. The refractory metal disilicide is selected from the group consisting of disilicides of molybdenum, chromium, hafnium, niobium, tantalum, rhenium, titanium, tungsten, uranium, vanadium, yttrium and mixtures thereof. The refractory metal disilicide / silicon eutectic has a melting point of greater than 1300° C.

Owner:RAYTHEON TECH CORP

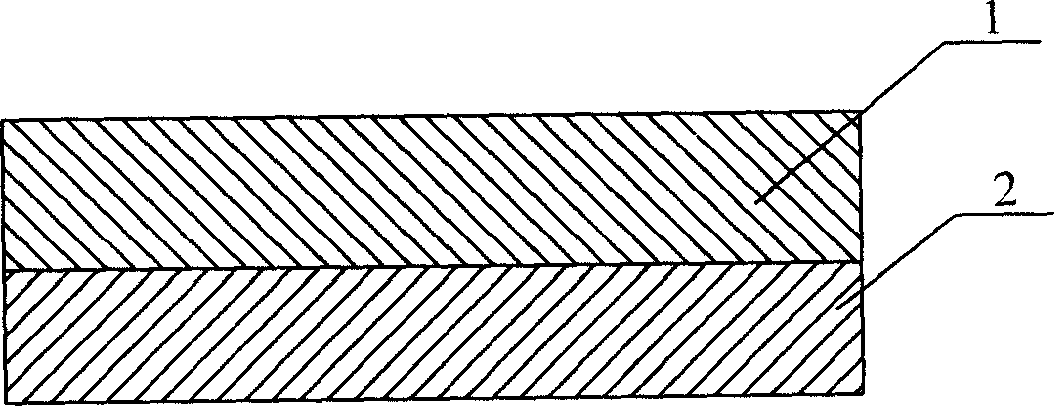

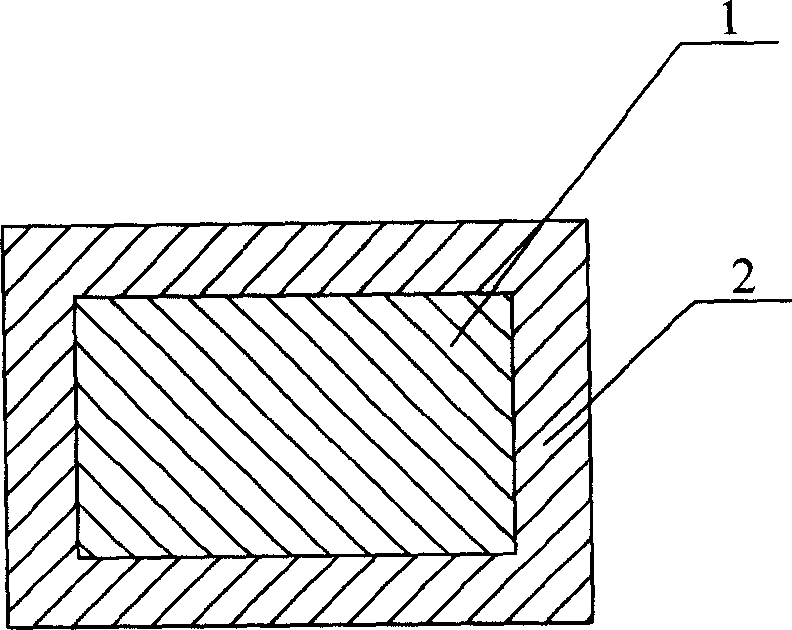

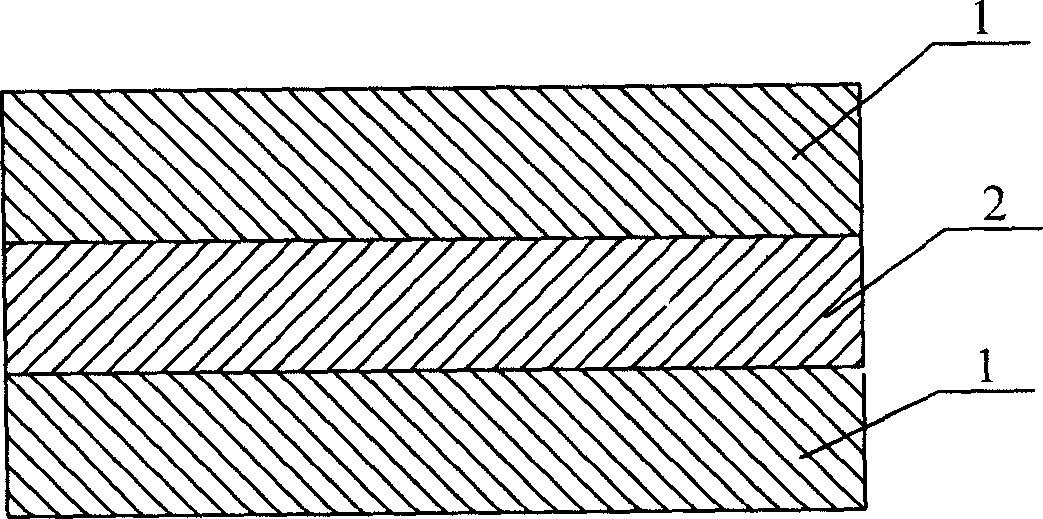

Composite plate of intermetallic TiAl compound and Ti alloy and its production process

InactiveCN1672918AImprove hot workabilityImproved hot workabilityMetal layered productsHeat resistanceComposite plate

The present invention is composite plate of intermetallic TiAl compound and Ti alloy and its production process. The composite plate includes at least one layer of plate of intermetallic TiAl compound and at least one layer of plate of pure Ti or Ti alloy. The production process includes polishing plate or block of intermetallic TiAl compound and plate or block of pure Ti or Ti alloy; and subsequent canning rolling to produce the composite plate at the technological parameters of temperature 600-1400 deg.c, deformation 2-40 % each gate and total deformation of 5-95 %. The composite plate has the advantages of light weight, heat resistance, high strength and high plasticity.

Owner:HARBIN INST OF TECH

High-strength silicon carbide ceramic pipe and manufacturing method thereof

The invention discloses a high-strength silicon carbide ceramic pipe and manufacturing method thereof, and belongs to the technical field of engineering ceramic materials. Silicon carbide ceramic powders with different granularities are used as the main raw materials, graphite powder and carbon black are used as binders, and resin is used as a binder. The materials are uniformly mixed by a spray granulation process; an organic plasticizer of cellulose and a lubrication agent are added into the mixture; and vacuum pugging, decaying and extrusion molding are conducted to obtain a pipe base substrate; and the base substrate is subjected to drying solidification, high temperature sintering reaction, sandblast and heat treatment to obtain the high strength silicon carbide ceramic pipe. The pipe biscuit manufactured by the process has high strength and length of more than 4000mm; after sintering, the pipe has strength of 300MPa or more, and has the advantages of moderate density, high thermal conductivity, high fracture toughness, good thermal shock resistance and low cost, and can be widely applied to chemical and metallurgy fields, such as acid and alkaline corrosion and high temperature erosion.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

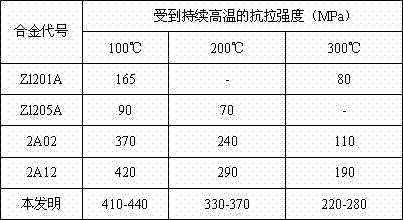

Heat-resistant cast aluminum alloy and extrusion casting method thereof

ActiveCN104561689AGood high temperature performanceHigh hardnessMetallic materialsSolution treatment

The invention relates to a heat-resistant cast aluminum alloy and an extrusion casting method thereof, and belongs to the fields of metallic materials and metallurgy. The alloy consists of the following elements in percentage by weight: Si, Cu, Ni, Mg, Ti, RE, Mn, Fe and Al. The heat-resistant cast aluminum alloy is prepared by virtue of extrusion casting, and after performing solution treatment and artificial aging treatment on the alloy, the room temperature tensile strength sigma b of the alloy is more than or equal to 420MPa, the tensile strength sigma b at 300 DEG C is more than or equal to 220MPa, the tensile strength sigma b at 350 DEG C is more than or equal to 140MPa, the room temperature extensibility delta is more than or equal to 2.5%, the extensibility delta at 300 DEG C is more than or equal to 6.5%, and the extensibility delta at 350 DEG C is more than or equal to 14.5%. According to the alloy and the extrusion casting method thereof provided by the invention, the casting performance is improved, the room-temperature and high-temperature mechanical properties of the alloy are greatly improved, and the application range of Al-Si series cast aluminum alloys is expanded.

Owner:SHANGHAI JIAO TONG UNIV

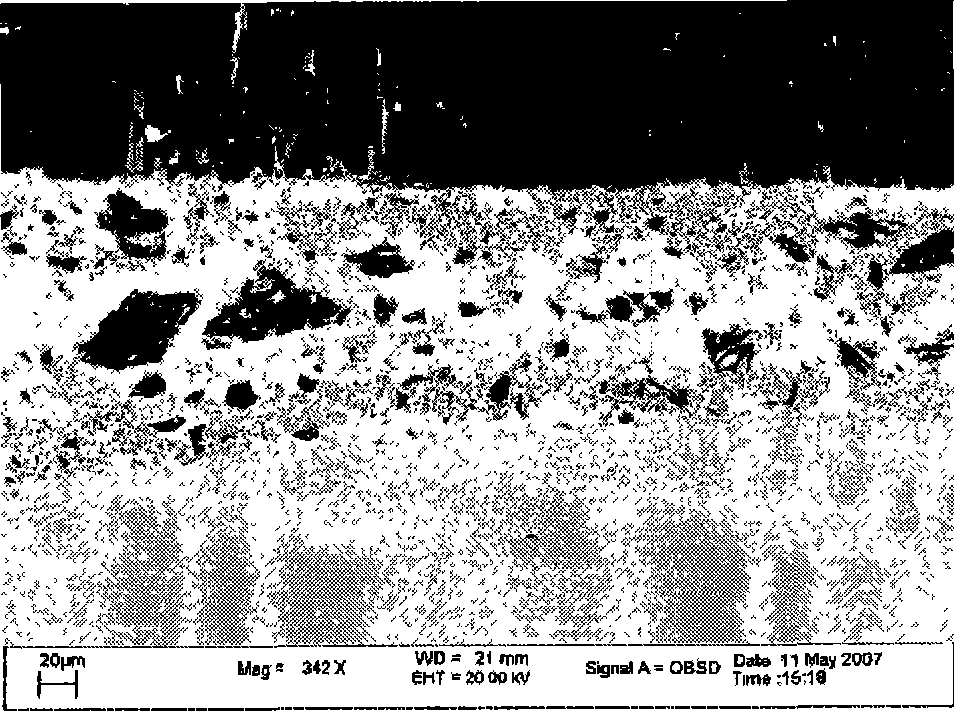

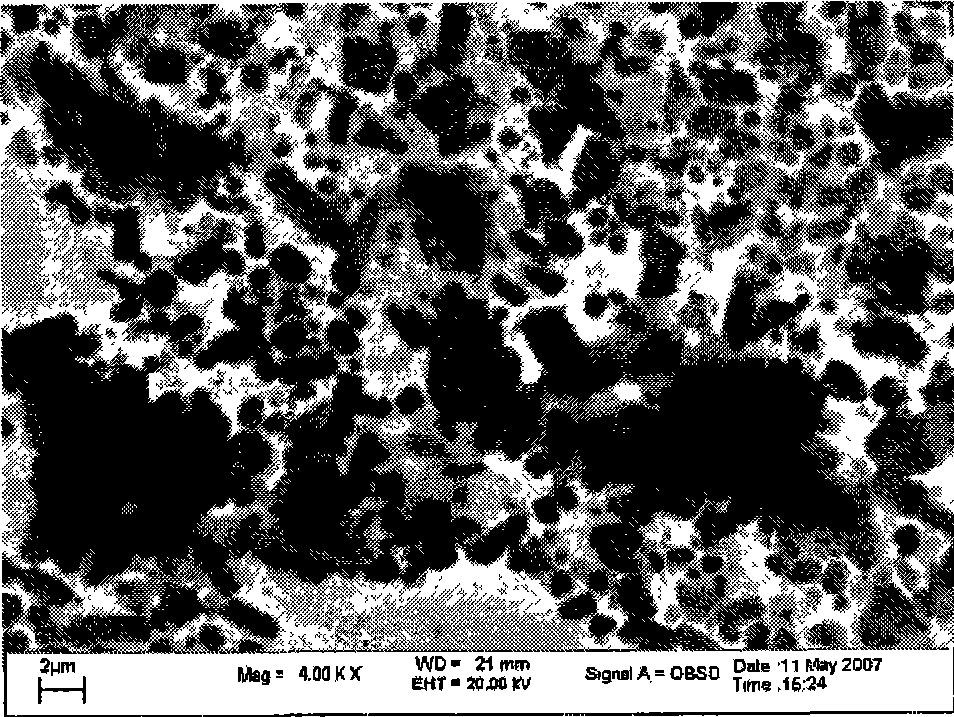

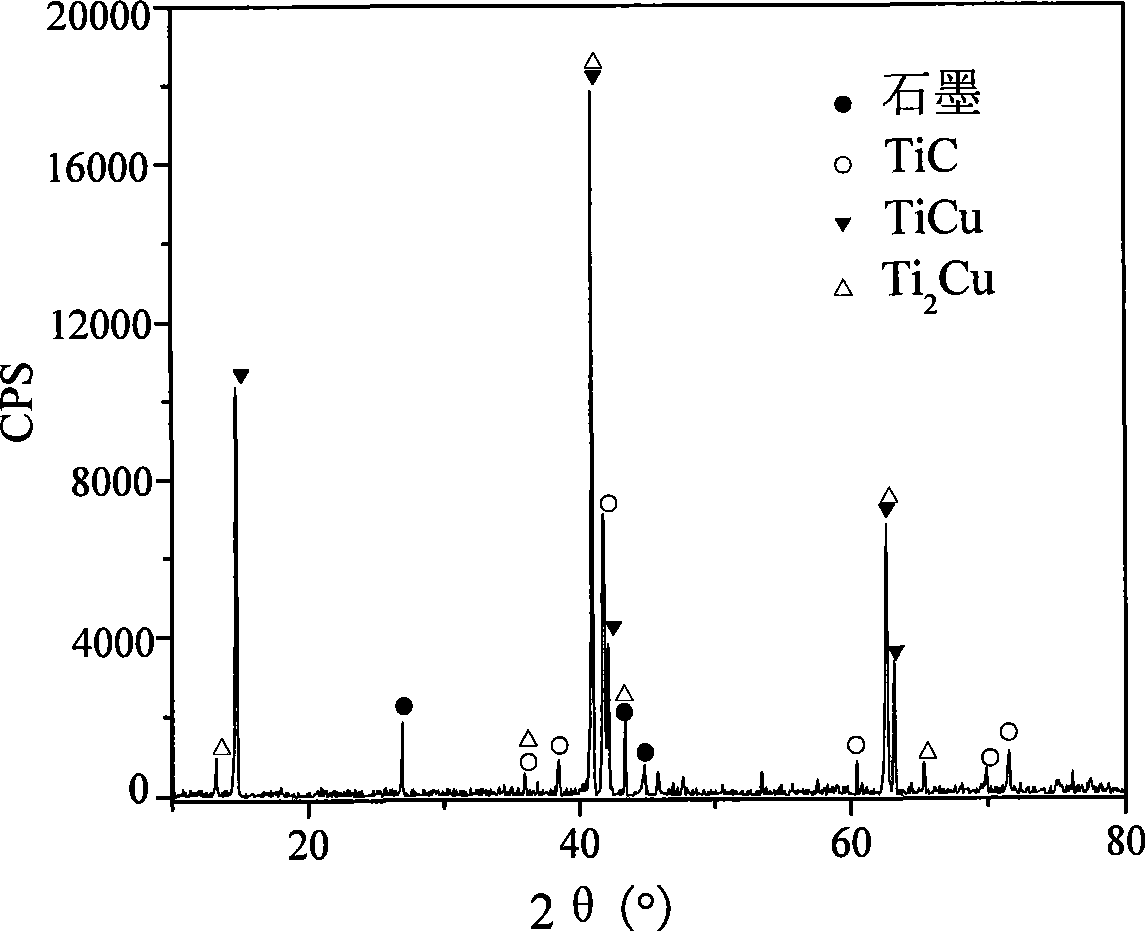

Connecting method for Cf/SiC composite material and titanium alloy

InactiveCN101462890ASmall coefficient of thermal expansionRelief of residual thermal stressRoom temperatureGraphite

A connection method of a Cf / SiC composite material and a titanium alloy belongs to the technical field of dissimilar material connection. The method comprises the following steps: Cu, Ti and graphite powder are evenly mixed at certain proportion and prepared to a pasty solder with alcohol, the prepared pasty solder is spread between the materials to be soldered to solder the Cf / SiC ceramic-based composite material with the titanium alloy in vacuum without applying pressure. A reaction in situ occurs in a connection layer to produce a high-melting-point TiC wild phase in soldering and form a composite connection layer which is similar to a particle reinforced metal-based composite material, thus reducing the thermal expansion coefficient of the whole connection layer, relieving thermal stress of a joint and significantly improving the strength of the joint at room temperature and high temperature. The connection method has the advantages of simple process, easy preparation of connection materials, low cost, low soldering temperature, good joint performance and the like.

Owner:UNIV OF SCI & TECH BEIJING

Magnesium alloy surface treatment method

InactiveCN104805345AReduce heat sensitivityImprove solderabilityMolten spray coatingMetallurgyMaterials science

The invention discloses a magnesium alloy surface treatment method which comprises three stages including a pretreatment stage, a spraying stage and an after-spraying treatment stage. By adoption of a compound spraying method, an anti-corrosion and anti-abrasion coating layer which is high in bonding strength, high in compactness and small in environment pollution is formed on the magnesium alloy surface; the surface treatment method is simple and feasible and is low in cost.

Owner:SUZHOU TONGMING MACHINERY

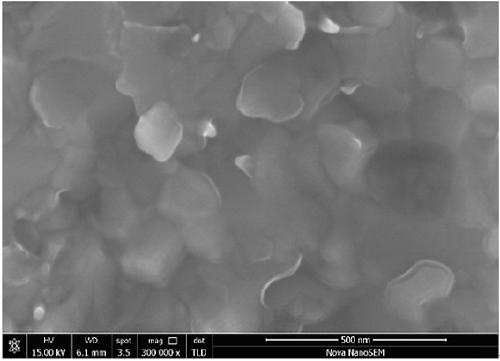

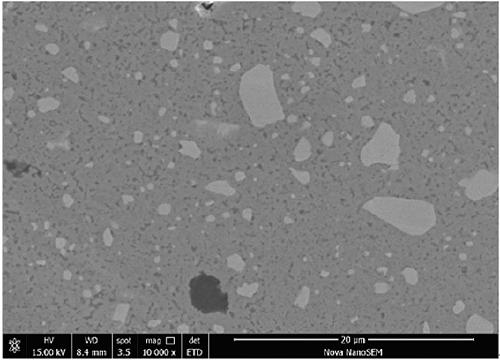

Ultra-fine grain high-entropy metal ceramic composite material and preparing method thereof

InactiveCN110423930AUniform particle sizeImprove mechanical propertiesCeramic compositeHigh entropy alloys

The invention discloses an ultra-fine grain high-entropy metal ceramic composite material and a preparing method thereof. The composite material is made with (MoTiWTaZr)C high-entropy ceramic as a hard phase and FeCoCrNiAl high-entropy alloy as a metal bonding phase. Specifically, five kinds of carbide powder of molybdenum carbide, titanium carbide, tungsten carbide, tantalum carbide and zirconiumcarbide are subjected to high-energy ball milling to form high-entropy ceramic powder, five kinds of metal powder of iron, cobalt, chromium, nickel and aluminum are subjected to high-energy ball milling to form single-phase solid solution high-entropy alloy powder, high-entropy ceramic powder and high-entropy alloy powder are mechanically mixed, through discharge plasma sintering, the ultra-finegrain high-entropy metal ceramic composite material is obtained, and the comprehensive performance of the obtained composite is obviously improved.

Owner:FUJIAN UNIV OF TECH

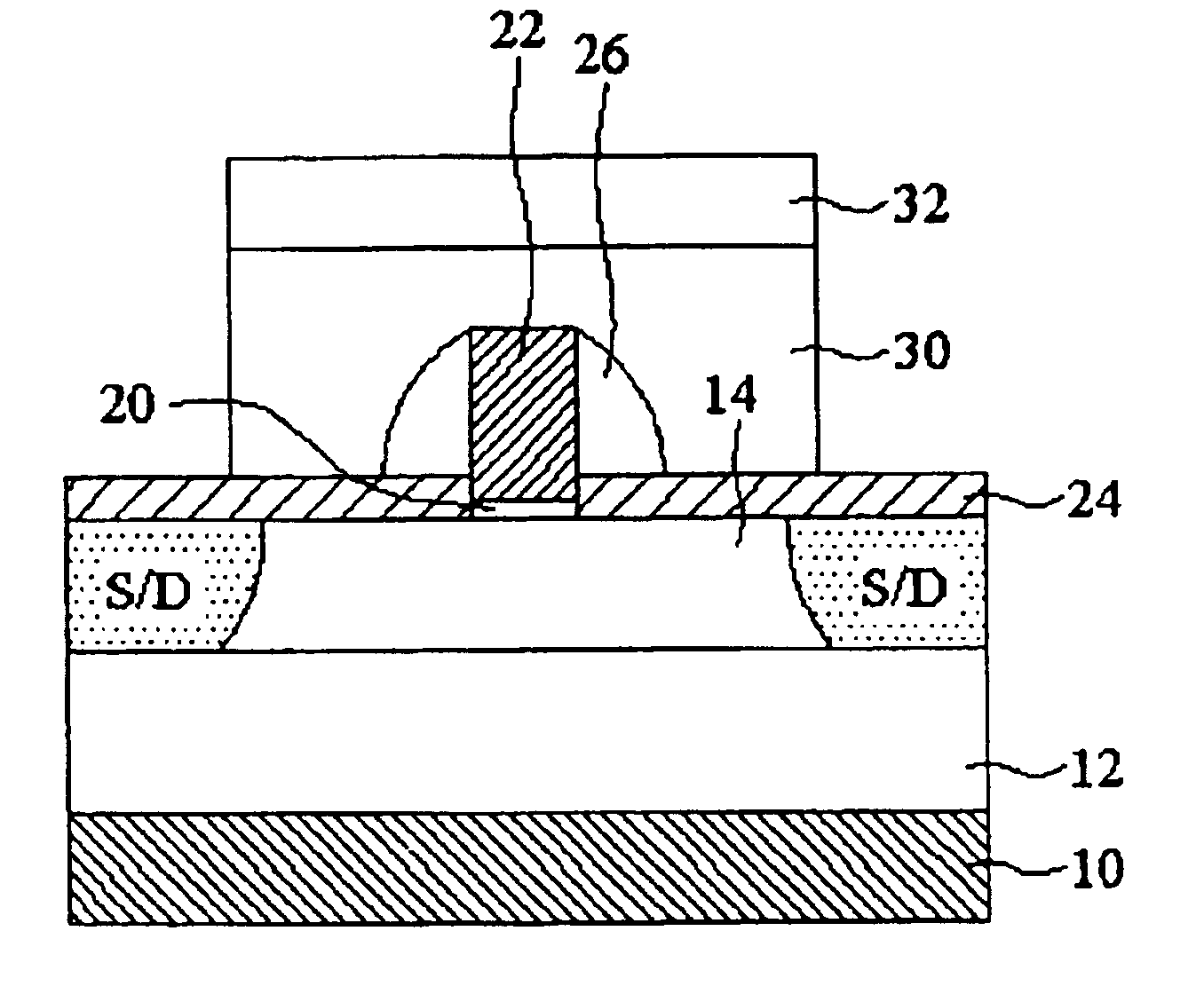

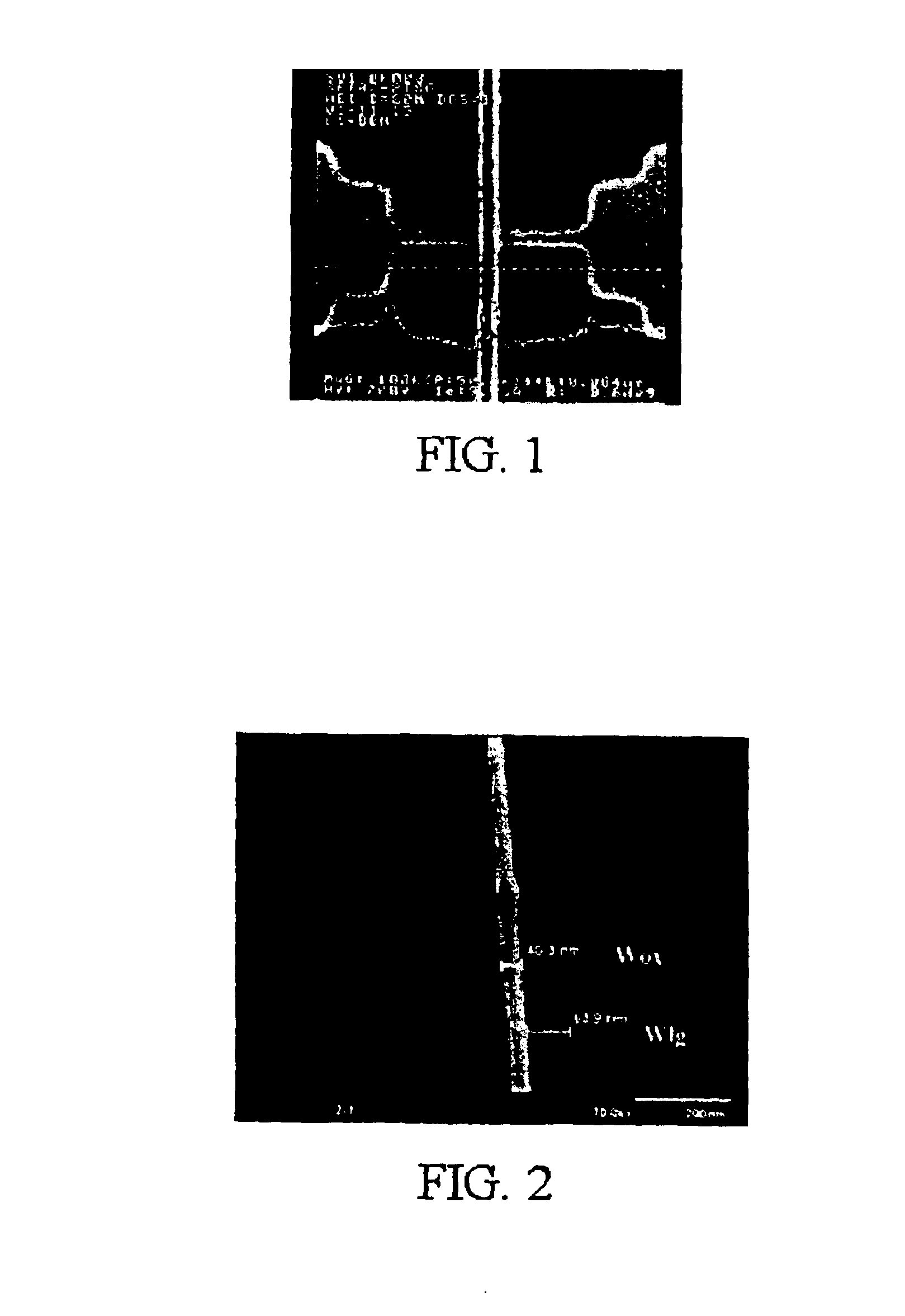

Single-electron transistor and fabrication method thereof

InactiveUS6894352B2Reduce spacingIncrease operating temperature to room temperatureTransistorNanoinformaticsEtchingExternal bias

A method for fabricating a single-electron transistor (SET). A one dimensional channel is formed between source and drain on a silicon-on-insulator substrate, and the separated polysilicon sidewall spacer gates are formed by electron-beam lithographically etching process in a self-aligned manner. Operation of the single-electron transistor with self-aligned polysilicon sidewall spacer gates is achieved by applying external bias to the self-aligned polysilicon sidewall spacer gates to form two potential barriers and a quantum dot capable of storage charges between the two potential barriers. A metal upper gate is finally formed and biased to induce a two-dimensional electron gas (2DEG) and control the energy level of the quantum well. Accordingly, the method of the invention comprises a combination of electron beam (E-beam) lithography with multilayer-aligned direct writing technology, oxidation, and wet etching to form a nanoscale one-dimensional channel between source and drain on a silicon-on-insulator substrate.

Owner:NAT APPLIED RES LAB

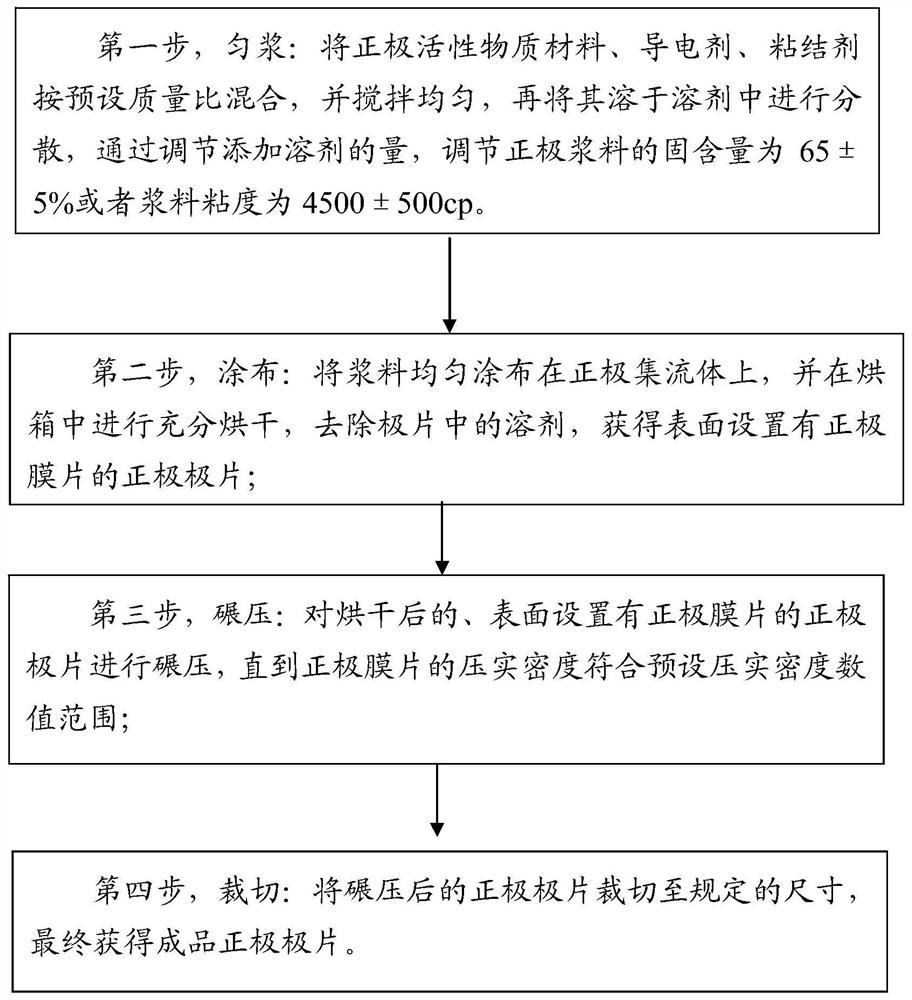

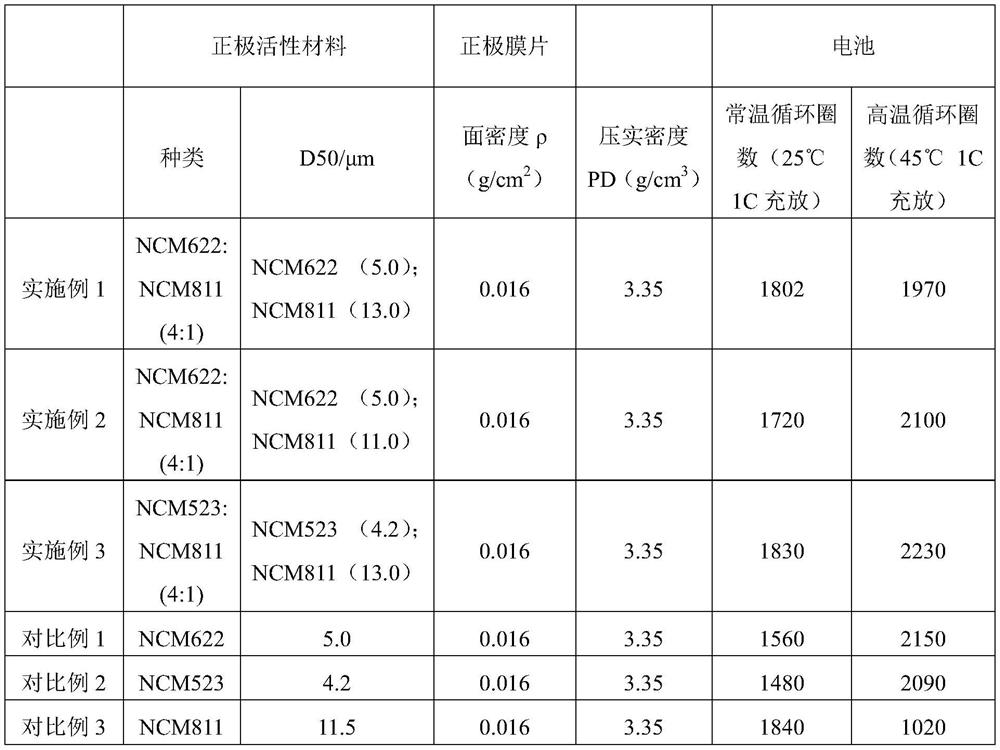

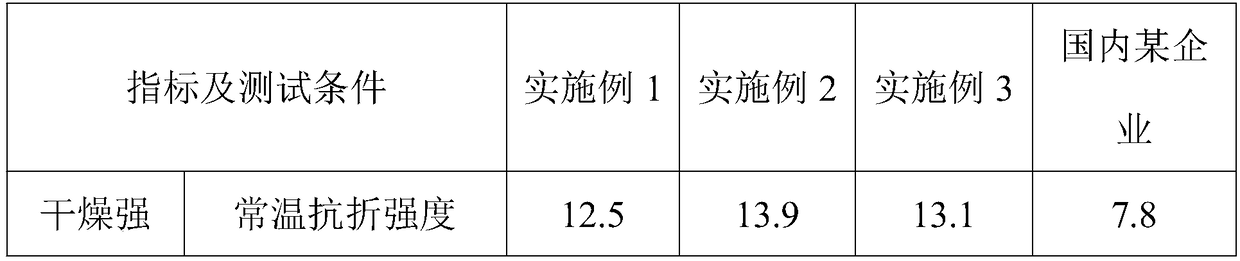

Positive pole piece and preparation method thereof and lithium ion secondary battery

PendingCN111640912AImprove thermal stabilityGood dynamic performanceSecondary cellsPositive electrodesSingle crystalPole piece

The invention discloses a positive pole piece which comprises a positive pole current collector and a positive pole diaphragm arranged on at least one surface of the positive pole current collector, and the positive pole diaphragm comprises a positive pole active substance; the positive electrode active substance comprises at least two lithium nickel cobalt manganese oxides LiNixCoyMn1-x-yO2 withdifferent morphologies and average particle sizes D50, wherein one type is primary particle single crystal LiNixCoyMn1-x-yO2, and the other type is secondary particle polycrystalline LiNixCoyMn1-x-yO2; the weight ratio [omega] of the single crystal to the polycrystalline LiNixCoyMn1-x-yO2 satisfies the relational expression: 0.1<=[omega]<=9. By adjusting the ratio of the primary particle single crystal to the secondary particle polycrystalline material and the nickel content, the positive pole piece can have better thermal stability and excellent dynamic performance, so that the lithium ion secondary battery based on the positive pole piece has the characteristics of long cycle life at normal temperature and high temperature.

Owner:LISHEN (QINGDAO) NEW ENERGY CO LTD

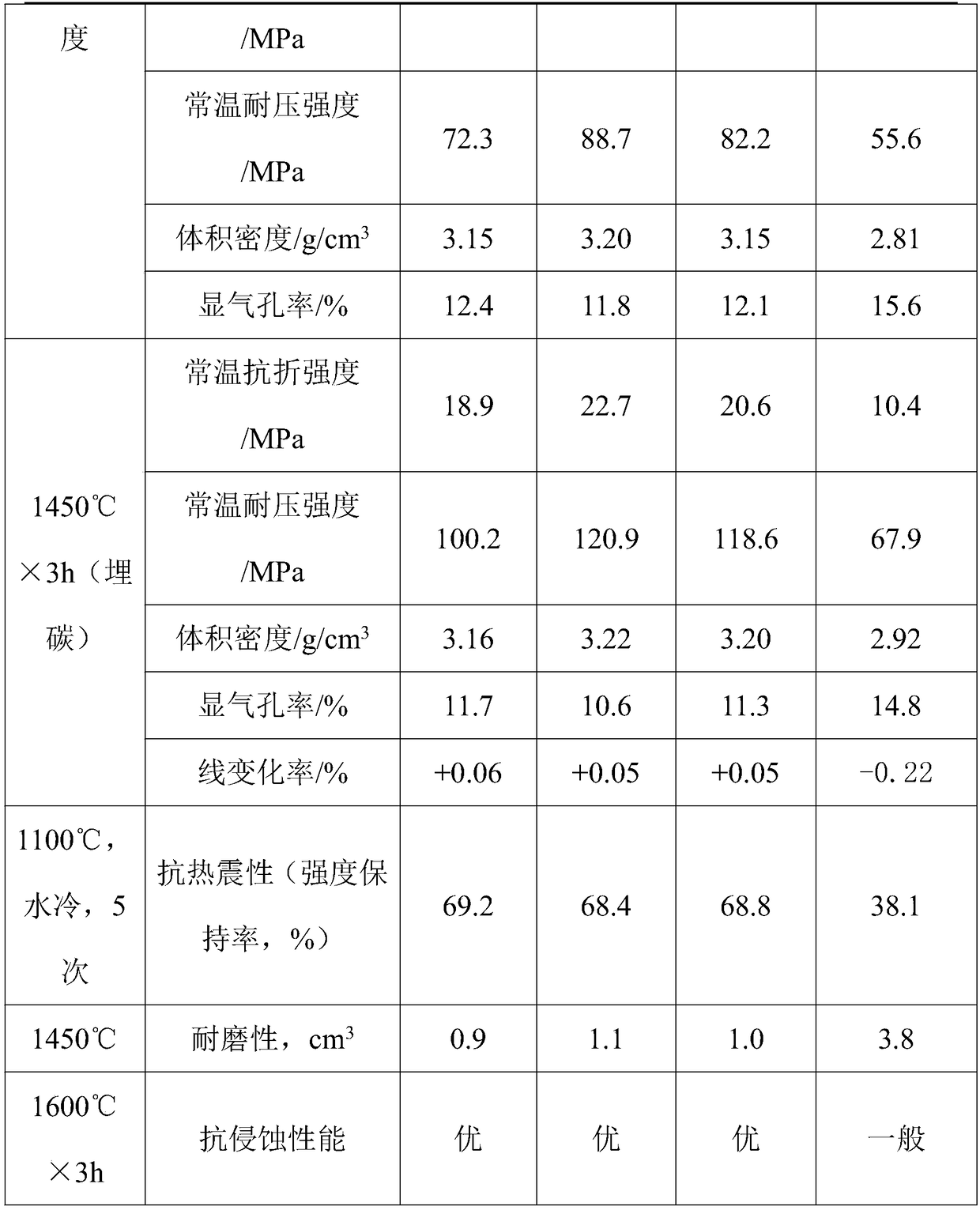

Refractory castable for blast furnace tapping trench and preparation method thereof

InactiveCN109293375AImprove liquidityImprove room and medium temperature strengthAluminiumMicrostructure

The invention discloses method of preparing a refractory castable used for large blast furnace iron runners, and the refractory castable has the advantages of green environmental protection, energy saving and emission reduction, good construction performance, high strength, high temperature volume stability, thermal shock stability and slag corrosion resistance. The method adopts Shanxi high-quality high bauxite (Al2O3 is greater than equal to 88%), fused brown corundum, fused white corundum and 97 silicon carbide as main raw materials, and high bauxite and fused brown corundum are composed ofcertain particles, fused white corundum powder, calcined alumina powder, 95 silicon micropowder, spherical asphalt, metal silicon powder and pure calcium aluminate cement are composition of a matrix,and an appropriate amount of an anti-explosive agent and a high-efficiency dispersant are added for the preparation. The calcined alumina powder used in the long-life environment-friendly tapping trench castable prepared by the method of the invention has uniform microstructure, high fineness, good sinterability and fluidity, and reacts with silicon oxide to form a high-temperature phase of mullite at high temperature, which improves the internal microstructure of the material and improves the thermal shock stability of the material.

Owner:洛阳润昌窑业有限公司

Blended material of ethylene-vinyl alcohol copolymer and high-density polyethylene and method for preparing same

InactiveCN101735537AGood compatibilityExcellent gas barrier performanceLow-density polyethyleneAntioxidant

The invention belongs to the technical field of blending processing of copolymers and discloses a blended material of an ethylene-vinyl alcohol copolymer and high-density polyethylene. The blended material comprises the following components in percentage by weight: 50.0 to 80.1 percent of ethylene-vinyl alcohol copolymers, 10.0 to 30.0 percent of high-density polyethylene, 5.0 to 15.0 percent of flexibilizer, 4.8 to 15 percent of compatilizer, and 0.1 to 1.0 percent of antioxidant. The invention also discloses a method for preparing the blended material. The blended material has high gas resisting property of EVOH as well as high moisture resisting property of HDPE; the product cost is effectively lowered; the EVOH / HDPE blended material is good in toughness, the normal-temperature and the low-temperature impact strengths of the EVOH / HDPE blended material are obviously higher than those of the EVOH, and the application range of EVOH is widened.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Multiphase ceramic hybrid composite reinforced metal matrix composite material and preparation process thereof

The invention relates to a multiphase ceramic hybrid composite reinforced metal matrix composite material and a preparation process thereof, a substrate of the material is aluminum and an alloy thereof and magnesium and the alloy thereof, the hybrid reinforced phase is in-situ TiC and TiB2 and SiC particles added through the vacuum stirring and casting method, the weight percent of the reinforced phase of TiC and TiB2 particles is 4-20% by weight respectively, and the volume percent of SiC particles is 4-25% by volume. The preparation process comprises the following steps: firstly melting a substrate, and carrying out fining, fluxing, refining and degassing on the substrate; introducing argon for protection, then carrying out in-situ reaction and the vacuum stirring and casting composite process, further carrying out vacuum refining and degassing treatment, unloading vacuum, skimming dross and oxide inclusion, standing, and then carrying out casting, thereby preparing the high-performance multiphase ceramic hybrid composite reinforced (TiC+TiB2+SiC) / M(M=Al and the alloy thereof, Mg and the alloy thereof) metal matrix composite material. The preparation process can fully play the complementary role of multiphase hybrid reinforcement and the advantages thereof, thereby significantly improving various performances of the composite material; and the process is simple and easy to realize mass production.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

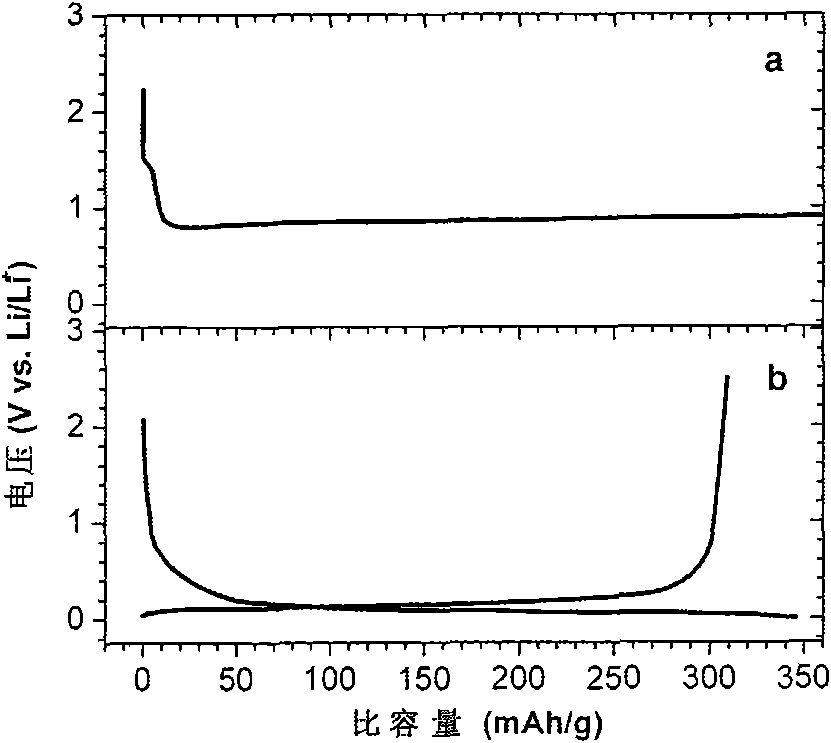

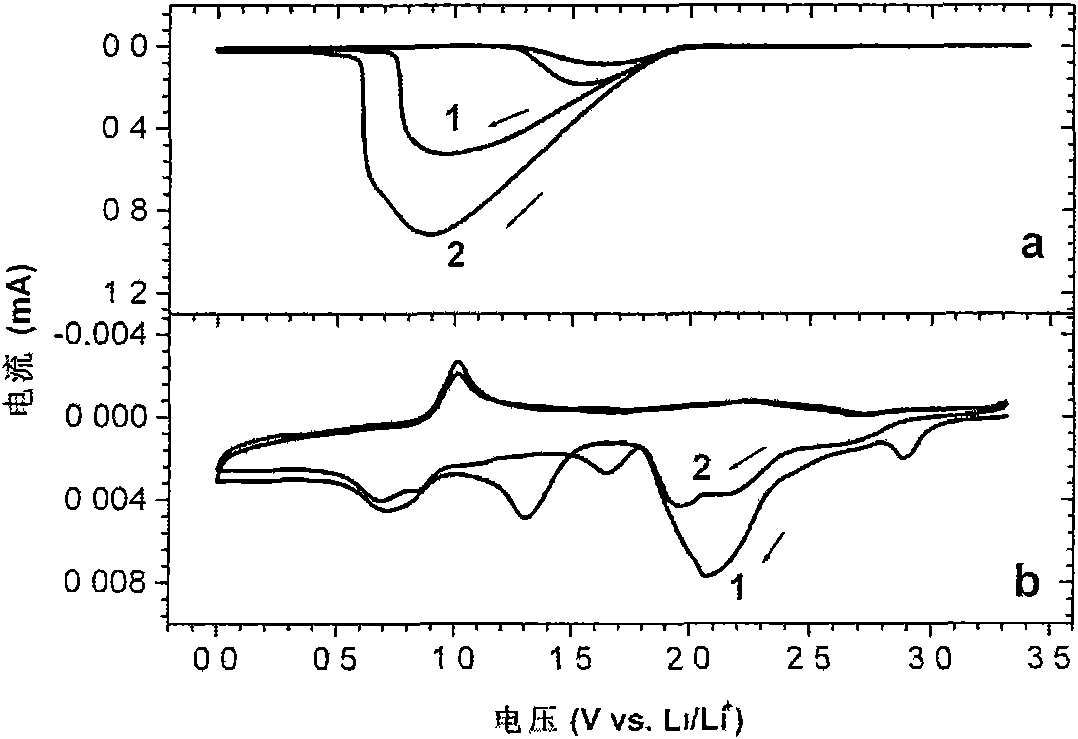

Electrolyte solution, preparation method thereof and use thereof

InactiveCN101662030AHigh lithium ion transfer numberImprove conductivityFuel and primary cellsOrganic electrolyte cellsLithium oxideElectrochemical window

The invention provides electrolyte solution, which contains an organic solvent, a lithium salt or lithium oxide, a compound containing an electron-withdrawing group and an additive, wherein the solvent is a carbonic ester and / or ether solvent; and the additive is a compound having a molecular formula of RBC2O4Li, R in the formula may be -C2O4, -F2, -C6H2O2, alkyl or fluorine-containing substitutedalkyl, and the concentration of the additive in the electrolyte solution is 0.005 to 0.1mol / l. The invention also provides a preparation method of the electrolyte solution. The invention also provides a lithium cell, which comprises a lithium cell diaphragm soaked in the electrolyte solution. The electrolyte solution of the invention has the advantages of high transport number of lithium ions, high conductivity and wide electrochemical window. Meanwhile, the electrolyte solution has high compatibility with a carbon cathode material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

High-energy welded high-toughness steel for resisting corrosion of molten zinc and its preparing process

A high-toughness steel welded with high linear energy (More than 50 KJ / cm) and resisting molten zinc corrosion is prepared through converter smelting at 1250-1320 deg.C, vacuum treating, and rolling at 1000-1180 deg.c or lower than 950 deg.C and cumulative drafts rate is greater than or aqual to 50%. It features that composite Ti oxide is used to resist high linear energy, the Nb, V, etc. and used for raising strength, and the Cu, Ni, B and RE are used to resist molten zinc corrosion. Its advantages are simple technology with high efficiency, low cost, and high performance of finished steel.

Owner:武钢集团有限公司

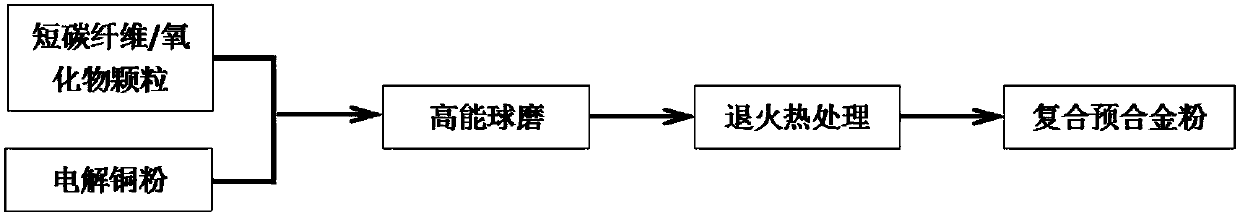

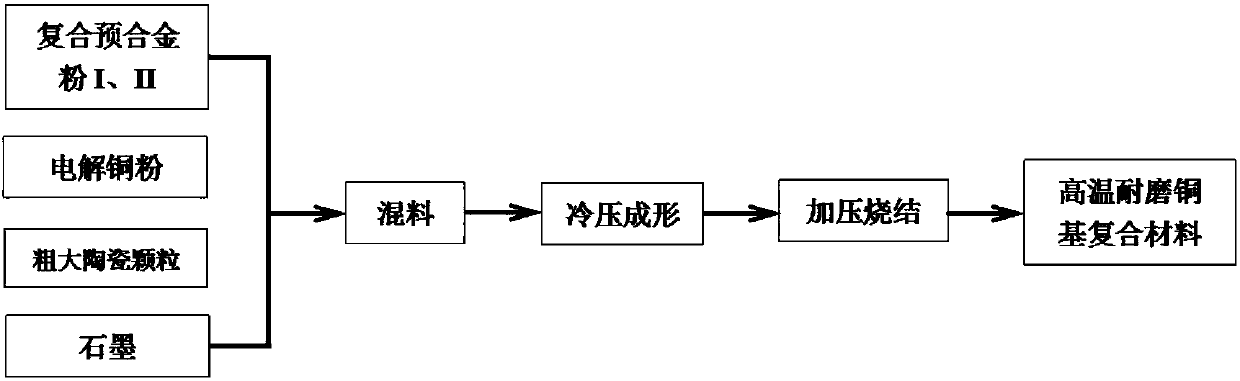

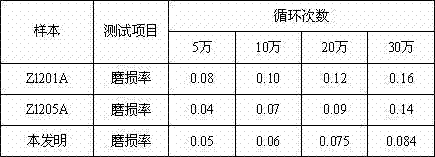

High-temperature abrasion resistant composite material and preparation method thereof

The invention relates to a high-temperature abrasion resistant composite material and a preparation method thereof. The high-temperature abrasion resistant composite material is prepared from raw materials of the following components, by mass, of 1.0%-3.0% of short carbon fibers, 0.5%-1.0% of fine ceramic particles, 1.5%-10.0% of coarse ceramic particles, 6.0%-15.0% of graphite powder and the balance copper powder. The preparation method of the high-temperature abrasion resistant composite material comprises the steps that firstly, composite pre-alloyed powder I and spherical composite pre-alloyed powder II are prepared through the high-energy ball-milling technology with appropriate ball-milling parameters and the annealing technology respectively; then, the coarse ceramic particles, thegraphite powder, the copper powder, the composite pre-alloyed powder I and the spherical composite pre-alloyed powder II are proportioned according to the designed components and mixed uniformly, andthus mixed powder is obtained; and a high-performance finished product can be obtained after pressing and sintering. The designed and prepared copper-based composite material is excellent in mechanical performance, high-temperature resistant performance and abrasion resistant performance and high in conductivity, and the preparation technology is simple.

Owner:CENT SOUTH UNIV

Al-Mg-Sc-Zr aluminum alloy plate and manufacturing method thereof

ActiveCN104694801ARaise room temperatureImprove mechanical propertiesHigh concentrationCarrying capacity

The invention provides an Al-Mg-Sc-Zr aluminum alloy plate and a manufacturing method thereof, and relates to the Al-Mg-Sc-Zr aluminum alloy plate and the manufacturing method thereof. Traditional aluminium magnesium alloy is replaced by the novel aluminum alloy plate, so that the purposes of further reducing the dead-weight of aerospace crafts such as spacecrafts, missiles and satellites, improving the carrying capacity, increasing the useful load, and lowering the cost for launching are achieved. The Al-Mg-Sc-Zr aluminum alloy plate contains the following elements: Mg, Mn, Sc, Zr, Ti and Be. The manufacturing method comprises the steps of firstly, burdening; secondly, smelting; thirdly, casting; fourthly, homogenizing annealing; fifthly, hot rolling; sixthly, prestretching; seventhly, finished product saw cutting; and then the Al-Mg-Sc-Zr aluminum alloy plate is obtained. The Al-Mg-Sc-Zr aluminum alloy plate has the advantages that the normal-temperature and low-temperature mechanical property and the damage-resisting tolerance are higher, the welding performance and the corrosion resistance are excellent, and the high concentration hydrogen peroxide compatibility is better. The Al-Mg-Sc-Zr aluminum alloy plate is applicable to the manufacturing field of astronautic and aeronautic aluminum alloy plates.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Heat-resistant cast aluminum alloy and pressure casting method thereof

The invention relates to a heat-resistant cast aluminum alloy and a pressure casting method thereof. The aluminum alloy consists of the following elements according to certain weight percentage: Si, Cu, Ni, Mg, Ti, RE, Mn, Fe and the balance of Al. After pressure casting of the heat-resistant cast aluminum alloy provided by the invention, the tensile strength (sigma)b of the alloy at room temperature is greater than or equal to 400MPa, the tensile strength (sigma)b at 300 DEG C is greater than or equal to 210MPa, and the tensile strength (sigma)b at 350 DEG C is greater than or equal to 130MPa; and the elongation delta at room temperature is greater than or equal to 2.0%, the elongation delta at 300 DEG C is greater than or equal to 6.0%, and the elongation delta at 350 DEG C is greater than or equal to 14.0%. By comparing the alloy and pressure casting preparation method thereof provided by the invention with the existing Al-Si cast aluminum alloy and the pressure casting preparation method thereof, the casting performance is improved, the room-temperature and high-temperature mechanical properties of the alloy are remarkably improved, and the application range of the Al-Si cast aluminum alloy is widened.

Owner:SHANGHAI JIAO TONG UNIV

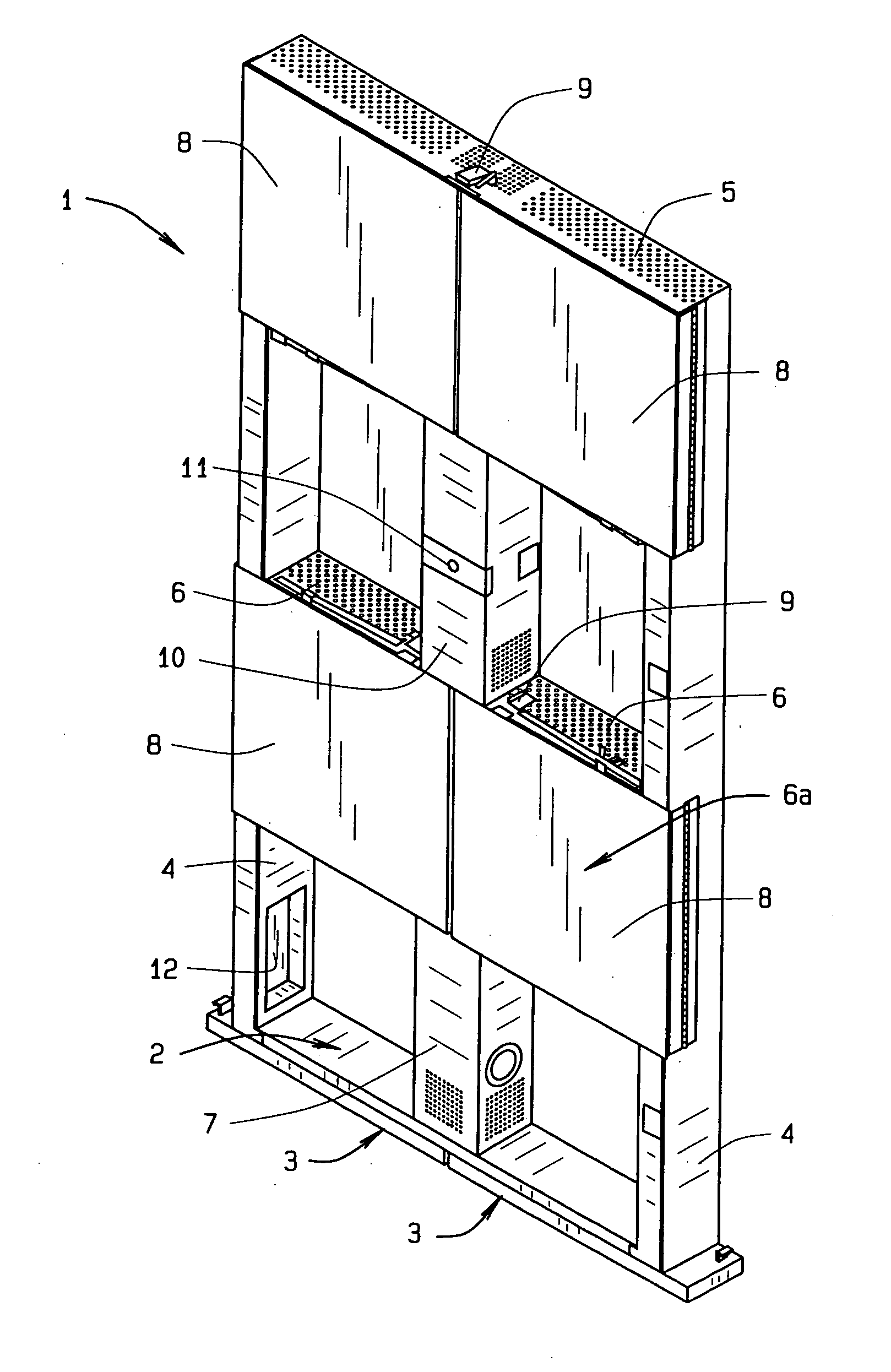

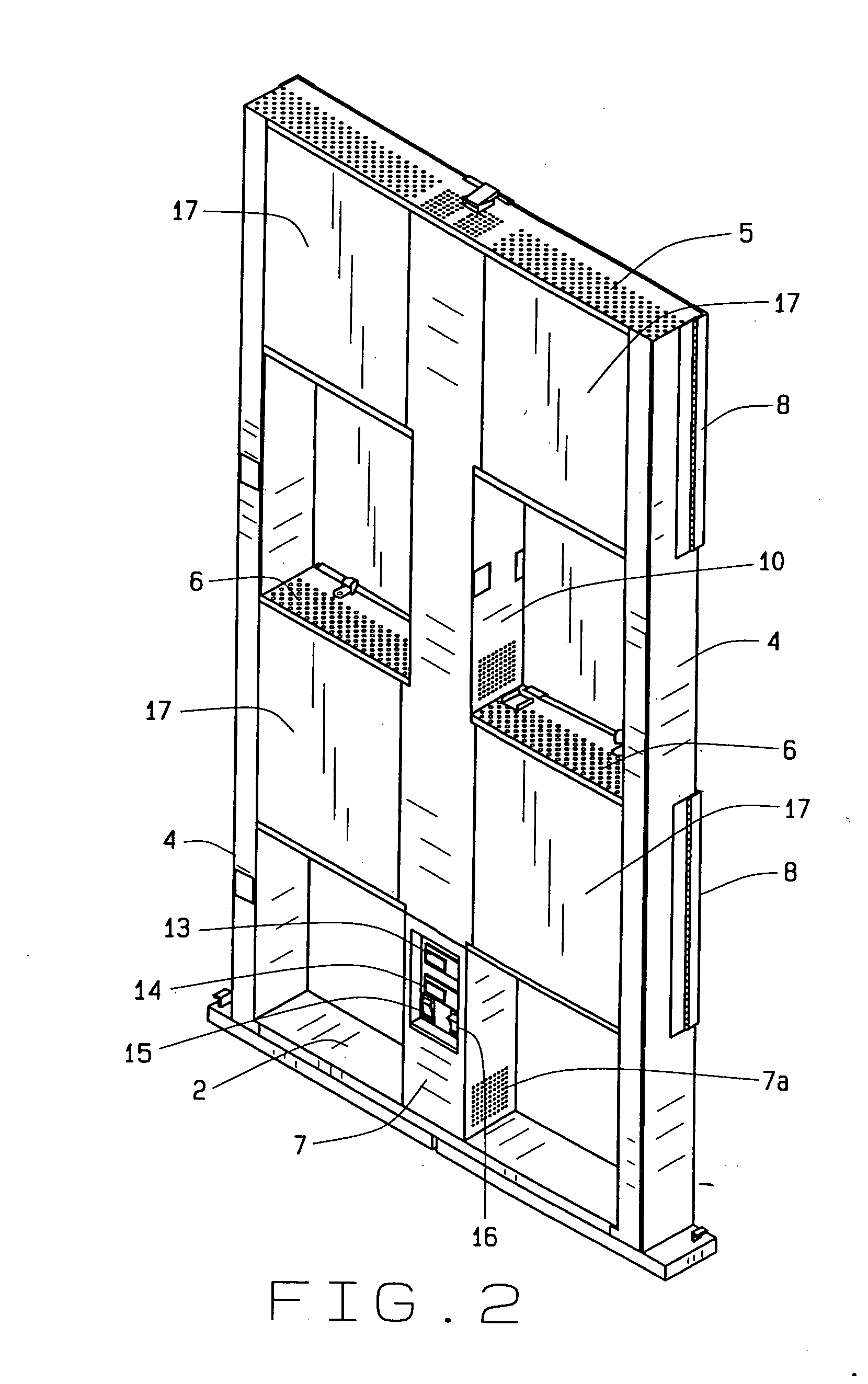

Infra-red heater assembly

InactiveUS20100329649A1Avoid overall overheatingProtection from damageElectric heatingAir heatersEnergy transferInfrared

An infra-red heater assembly takes on the conditions that afflict buildings: bed bugs, termites, other insects, molds, bacteria, and the like, and their resulting odors, and other contaminants. The assembly includes a portable electric infra-red emitting panel system with vertically stacked panels that distribute heat energy to the entire height of a wall. Removable panel covers over the infra-red heating elements protect them from damage during transport and when opened, act as deflectors, to direct, the radiant energy, widthwise, to restrict the line of site energy transferred to a wall. The heating panels are regulated by room air and wall temperature sensors to prevent structural damage and fire during usage of the invention. The infra-red heater may be pivotally mounted within its supporting structure so as to direct heat in various angular directions within the building being treated.

Owner:CAMBRIDGE ENG

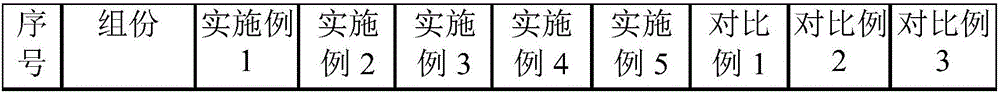

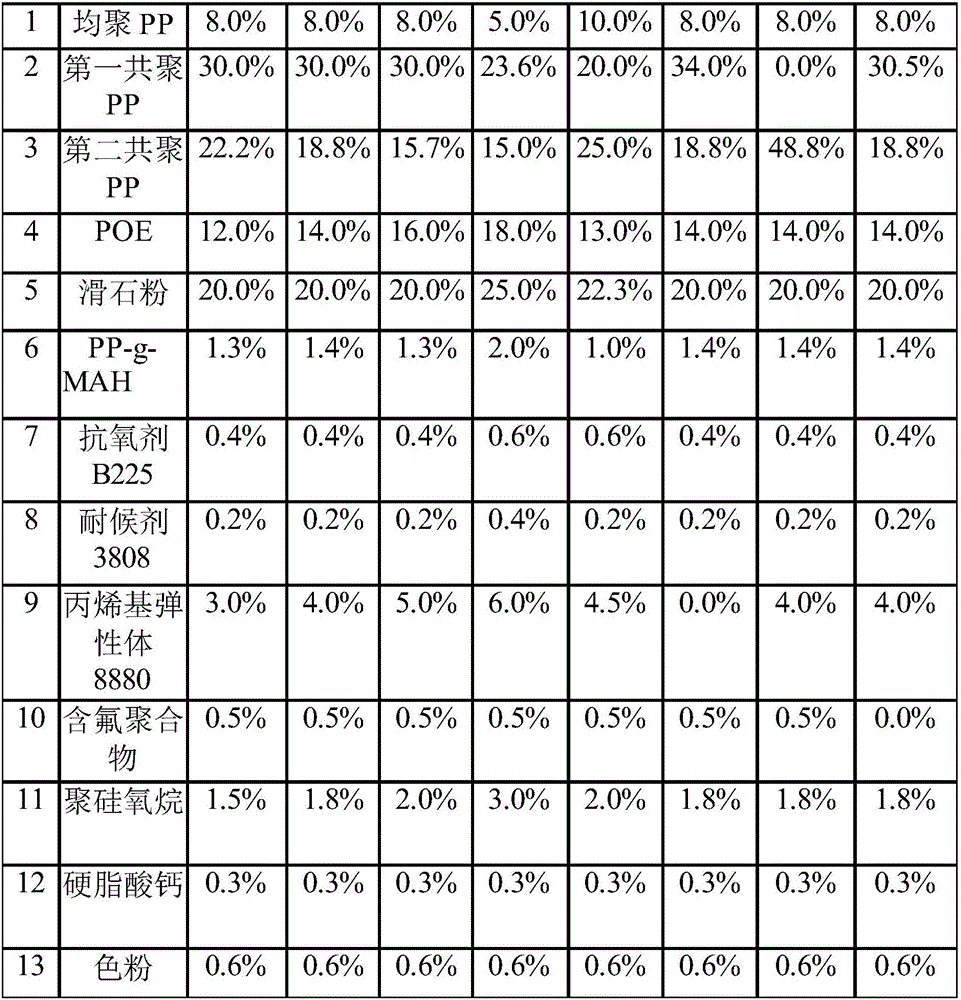

Modified polypropylene material for high-performance thin-wall automobile door panel and preparation method thereof

The invention belongs to the technical field of plastics modification and particularly relates to a modified polypropylene material for a high-performance thin-wall automobile door panel and a preparation method thereof. The material is prepared from, by mass, 5%-10% of homopolymerized PP, 20%-30% of first copolymerized PP, 15%-25% of second copolymerized PP, 12%-18% of toughening agent, 1%-2% of compatilizer, 0.4%-0.6% of antioxidant, 0.2-0.4% of weather resistance agent, 3%-6% of melting index regulator, 20%-25% of mineral enhancer, 1.5-3% of scratch resistant agent and 1-2% of other assistants. The preparation method of the modified polypropylene material comprises the steps of mixing, extrusion and granulation. The material prepared by adopting the preparation method has high liquidity, rigidity and toughness, can well meet the usage requirements of the thin-wall automobile door panel and is low in cost. Compared with the prior art, a high-liquidity allyl elastomer is used as the melting index regulator, the liquidity of the material is remarkably improved, and the thin-wall door panel forming requirements are met. In addition, high-liquidity polypropylene and a low surface energy polymer are used in a mixed mode, and the tiger skin stripe defects on the surface of the thin-wall door panel can be basically eliminated.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

High-strength wear-resisting heat-resisting aluminium alloy material and preparation process thereof

ActiveCN102758109AImprove high temperature deformation resistanceImprove wear resistanceManganeseRare earth

The invention discloses a high-strength wear-resisting heat-resisting aluminium alloy material and a preparation process thereof. The material comprises, by weight, 4.0-6.5% of copper, 0.06-0.4% of titanium, 0.08-0.6% of manganese, 0.03-0.4% of antimony, 0.4-0.6% of nickel, 1.2-1.8% of cobalt, 0.2-0.3% of zirconium, 0.2-1.8% of rare earth and the balance aluminum. During preparation of the material, a special heat treatment process is used. The material has the advantages of being capable of improving the mechanical strength, the abrasive resistance and the high-temperature deformation resistance of an aluminium alloy simultaneously, the material can be used for cast members which are required to bear a certain high temperature and have high mechanical performance requirements, and a new field of application of the aluminium alloy material is developed.

Owner:贵阳华恒机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com