Ultra-fine grain high-entropy metal ceramic composite material and preparing method thereof

A composite material and cermet technology, which is applied in the field of ultrafine-grained high-entropy cermet composite materials and their preparation, can solve the problems of poor comprehensive performance of cermets, health hazards, low wettability, etc., and can improve the room temperature. and high temperature performance, extended application range, good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

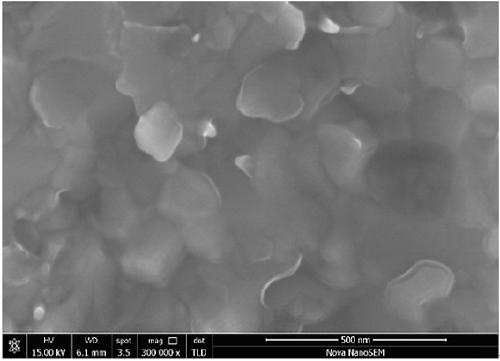

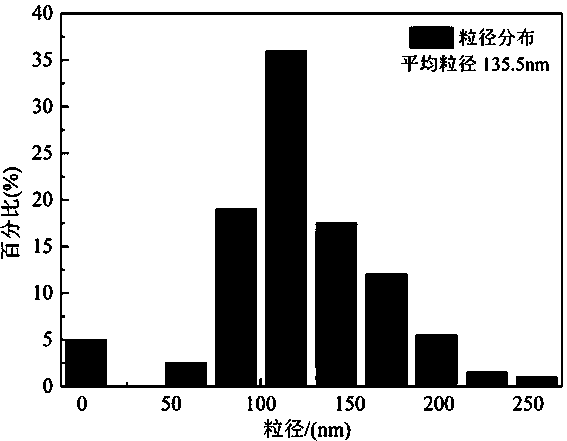

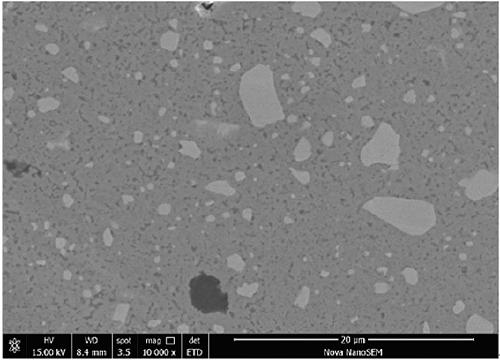

[0027] An ultrafine-grained high-entropy cermet composite material is composed of 94wt.% (MoTiWTaZr)C high-entropy ceramics as the hard phase and 6wt.% FeCoCrNiAl high-entropy alloy as the metal binder phase.

[0028] The specific preparation process is as follows: respectively weighing five kinds of carbide powders of molybdenum carbide, titanium carbide, tungsten carbide, tantalum carbide and zirconium carbide and five kinds of metal elemental powders of iron, cobalt, chromium, nickel and aluminum (purity ≥ 99.5%) , the molar amount of each carbide powder or metal elemental powder is equal; the carbide powder is put into a ball mill jar, and the cemented carbide balls are loaded according to the ball-to-material ratio of 15:1, and high-energy ball milling (ball milling) is carried out in an argon atmosphere The rotating speed is 250rpm; every ball milling is 30min, stop cooling for 5 minutes, the total time of ball milling is 20h), and prepare high-entropy ceramic powder; put...

Embodiment 2

[0030] An ultrafine-grained high-entropy cermet composite material is composed of 92wt.% (MoTiWTaZr)C high-entropy ceramics as the hard phase and 8wt.% FeCoCrNiAl high-entropy alloy as the metal binder phase.

[0031] The specific preparation process is as follows: respectively weighing five kinds of carbide powders of molybdenum carbide, titanium carbide, tungsten carbide, tantalum carbide and zirconium carbide and five kinds of metal elemental powders of iron, cobalt, chromium, nickel and aluminum (purity ≥ 99.5%) , the molar amount of each carbide powder or metal elemental powder is equal; the carbide powder is put into a ball mill jar, and the cemented carbide balls are loaded according to the ball-to-material ratio of 15:1, and high-energy ball milling (ball milling) is carried out in an argon atmosphere The rotating speed is 250rpm; every ball milling is 30min, stop cooling for 5 minutes, the total time of ball milling is 20h), and prepare high-entropy ceramic powder; put...

Embodiment 3

[0033] An ultrafine-grained high-entropy cermet composite material, which is composed of 90wt.%, (MoTiWTaZr)C high-entropy ceramics as the hard phase, and 10wt.% FeCoCrNiAl high-entropy alloy as the metal binder phase.

[0034]The specific preparation process is as follows: Weigh five kinds of carbide powders of molybdenum carbide, titanium carbide, tungsten carbide, tantalum carbide and zirconium carbide and five kinds of metal elemental powders of iron, cobalt, chromium, nickel and aluminum (purity ≥ 99.5%) , the molar amount of each carbide powder or metal elemental powder is equal; the carbide powder is put into a ball mill jar, and the cemented carbide ball is put into the cemented carbide ball according to the ball-to-material ratio of 15:1, and high-energy ball milling (ball milling) is carried out in an argon atmosphere The rotating speed is 250rpm; every ball milling is 30min, stop cooling for 5 minutes, the total time of ball milling is 20h), and prepare high-entropy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com