Patents

Literature

76results about How to "Reduce heat sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

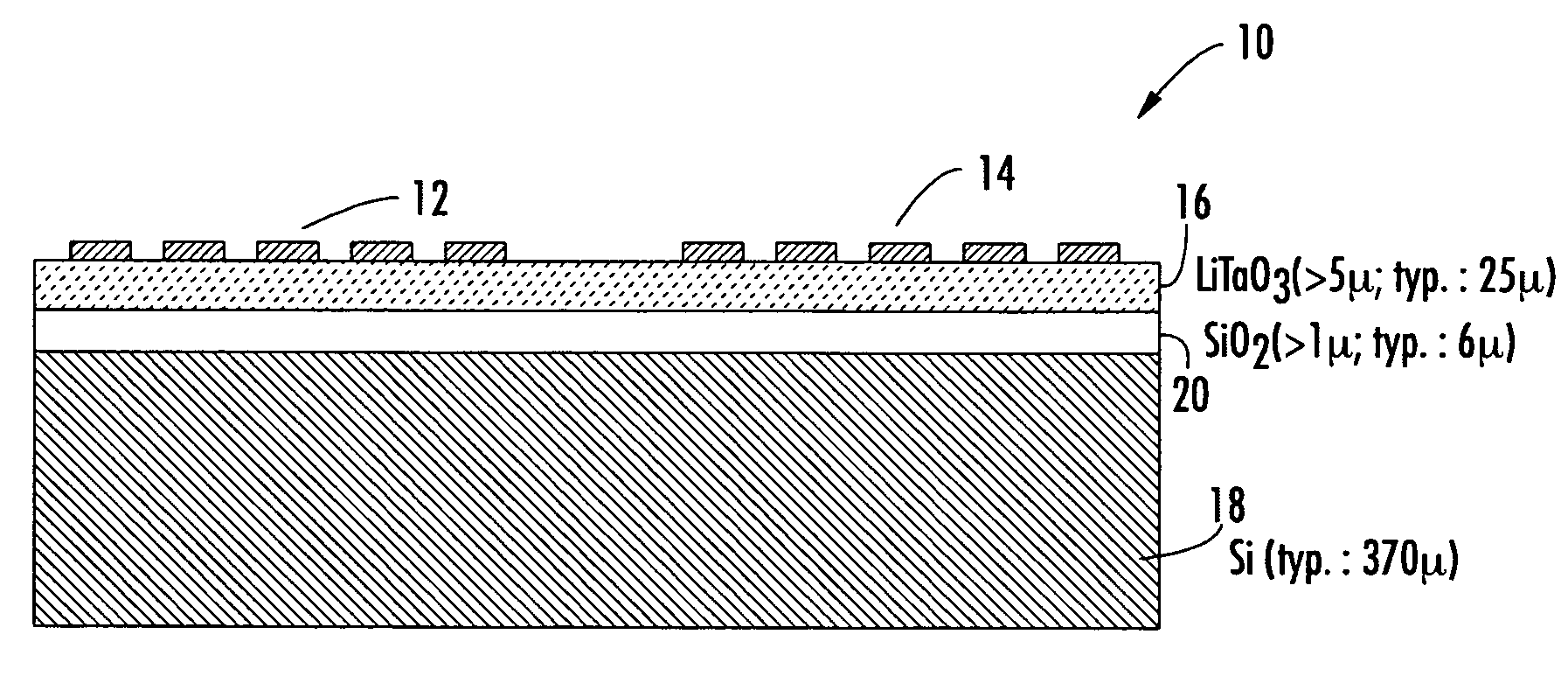

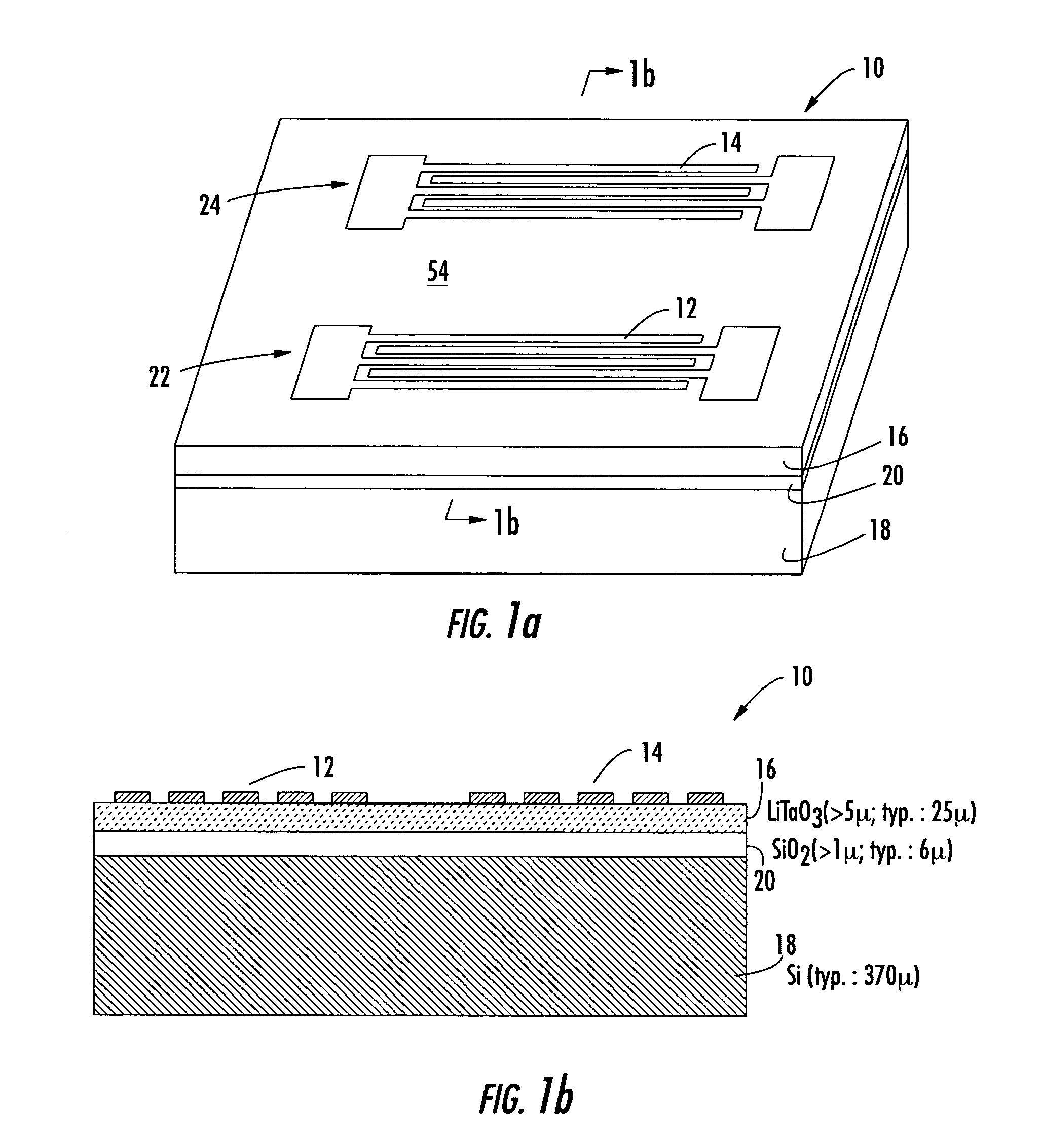

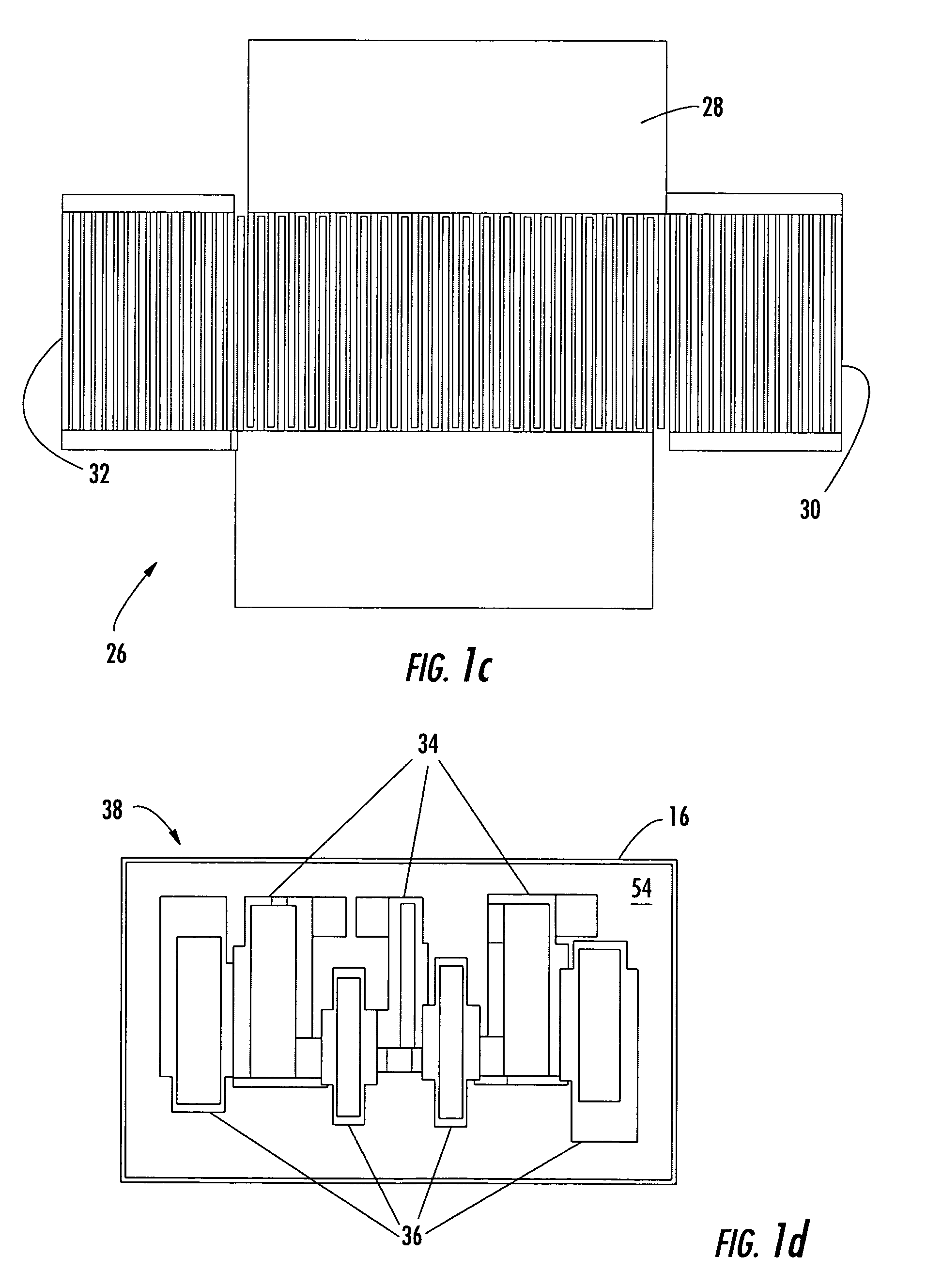

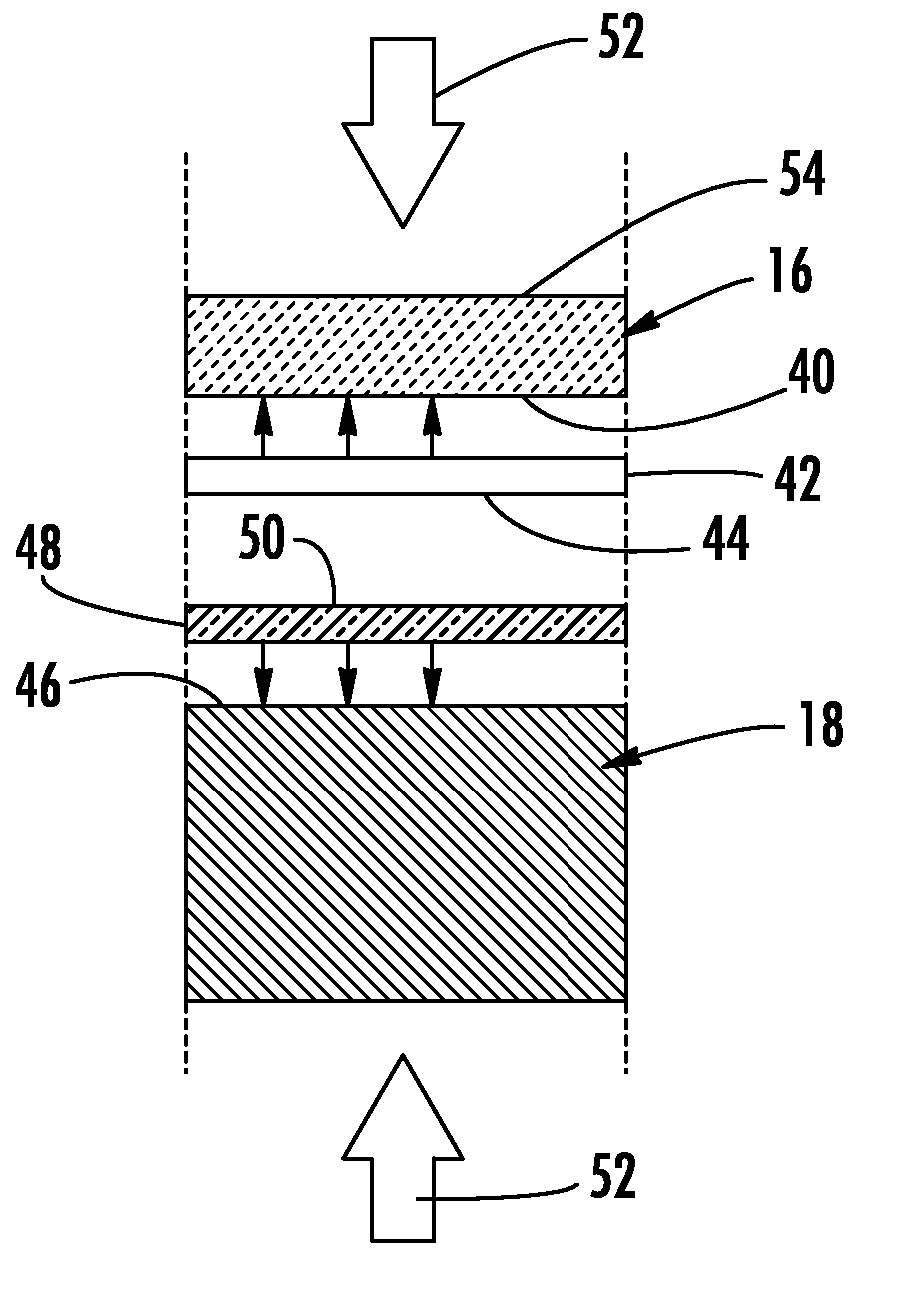

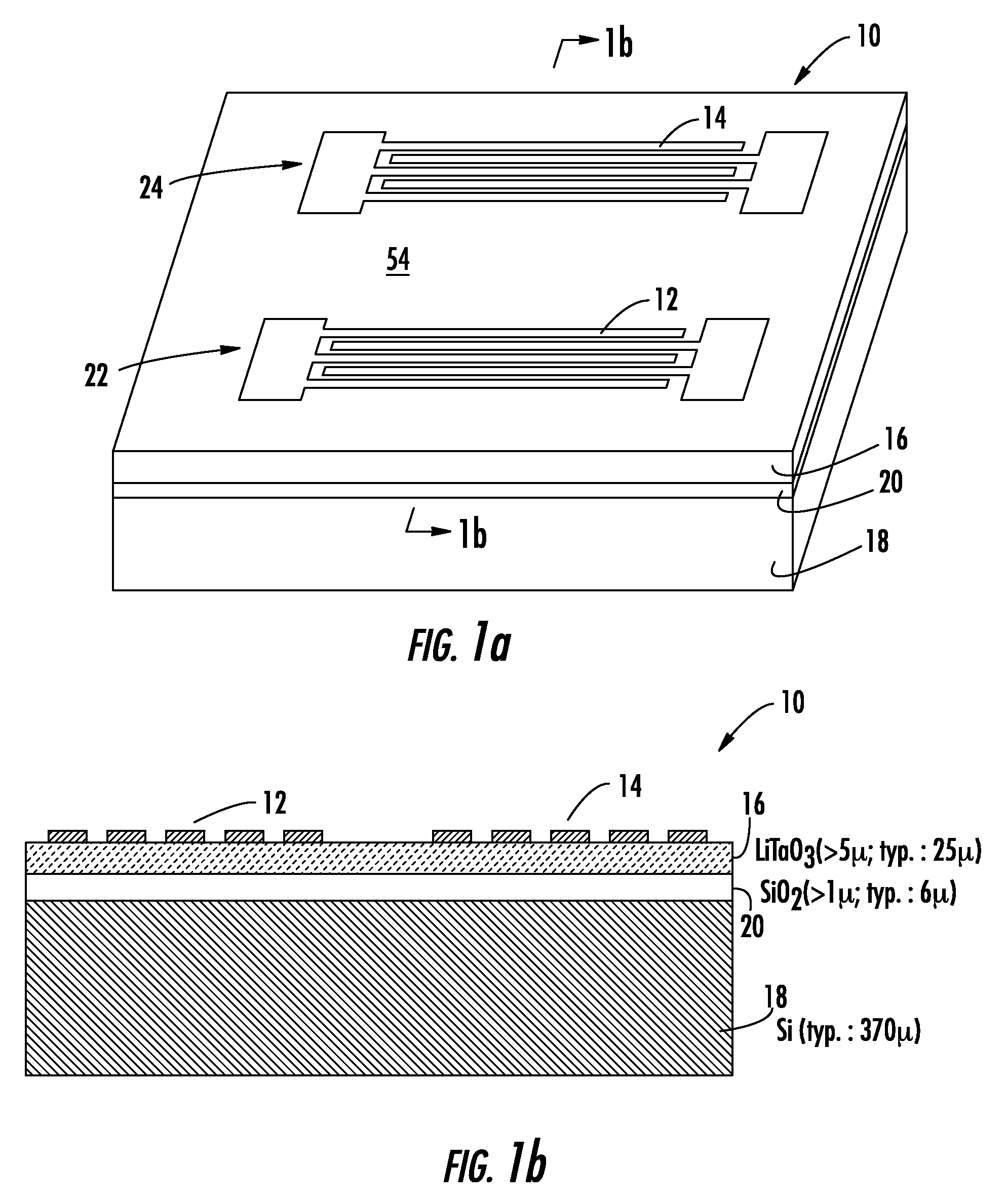

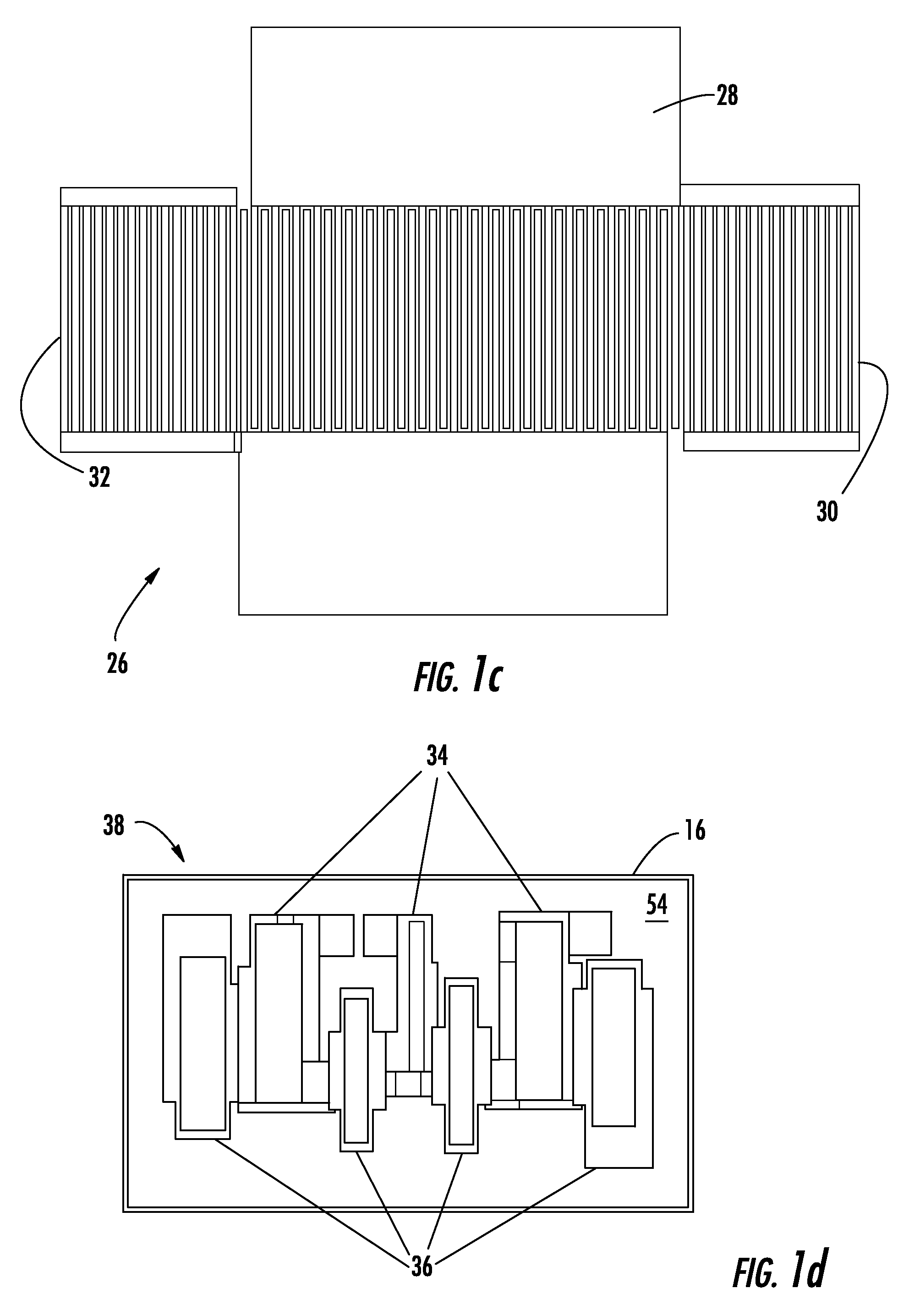

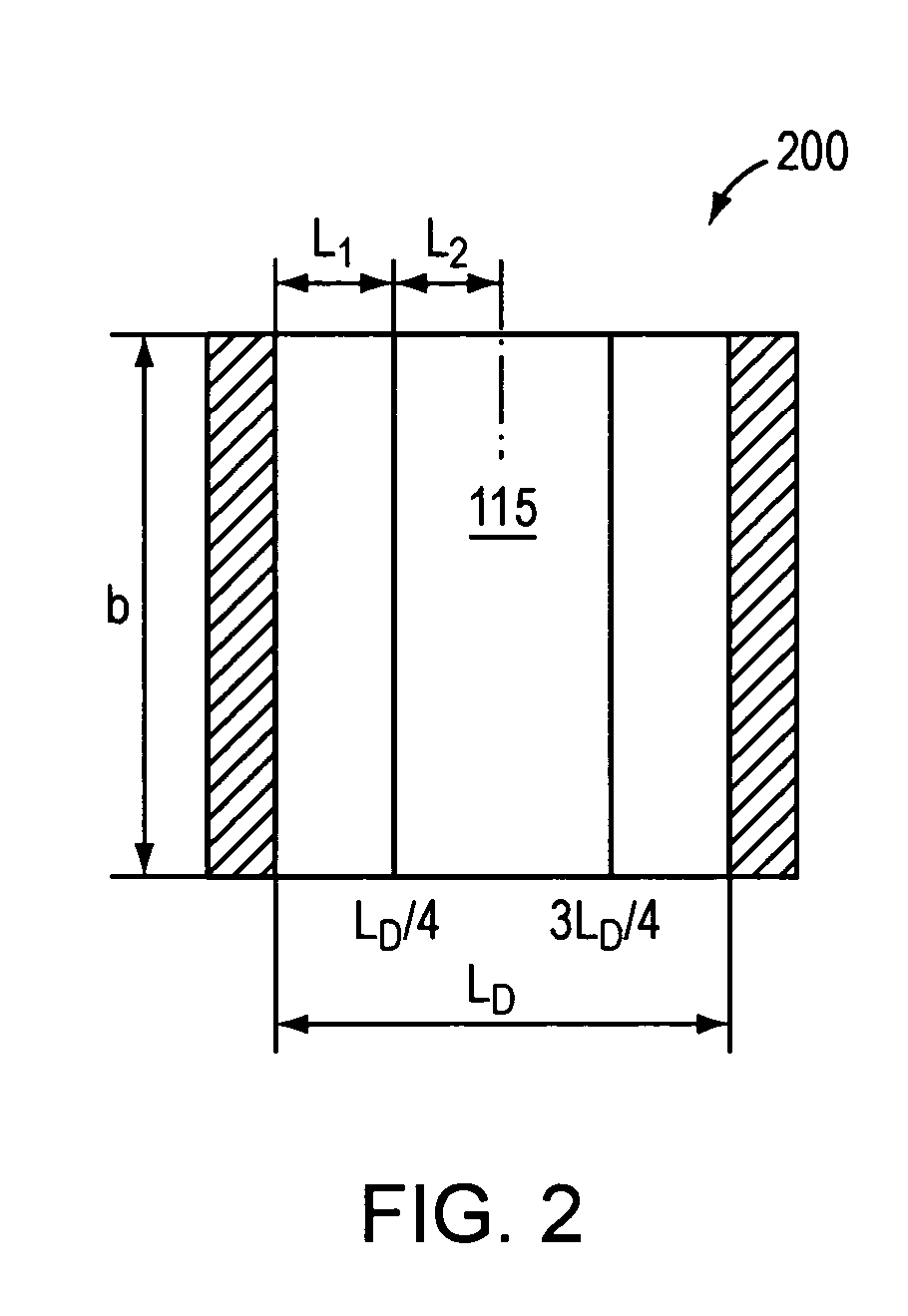

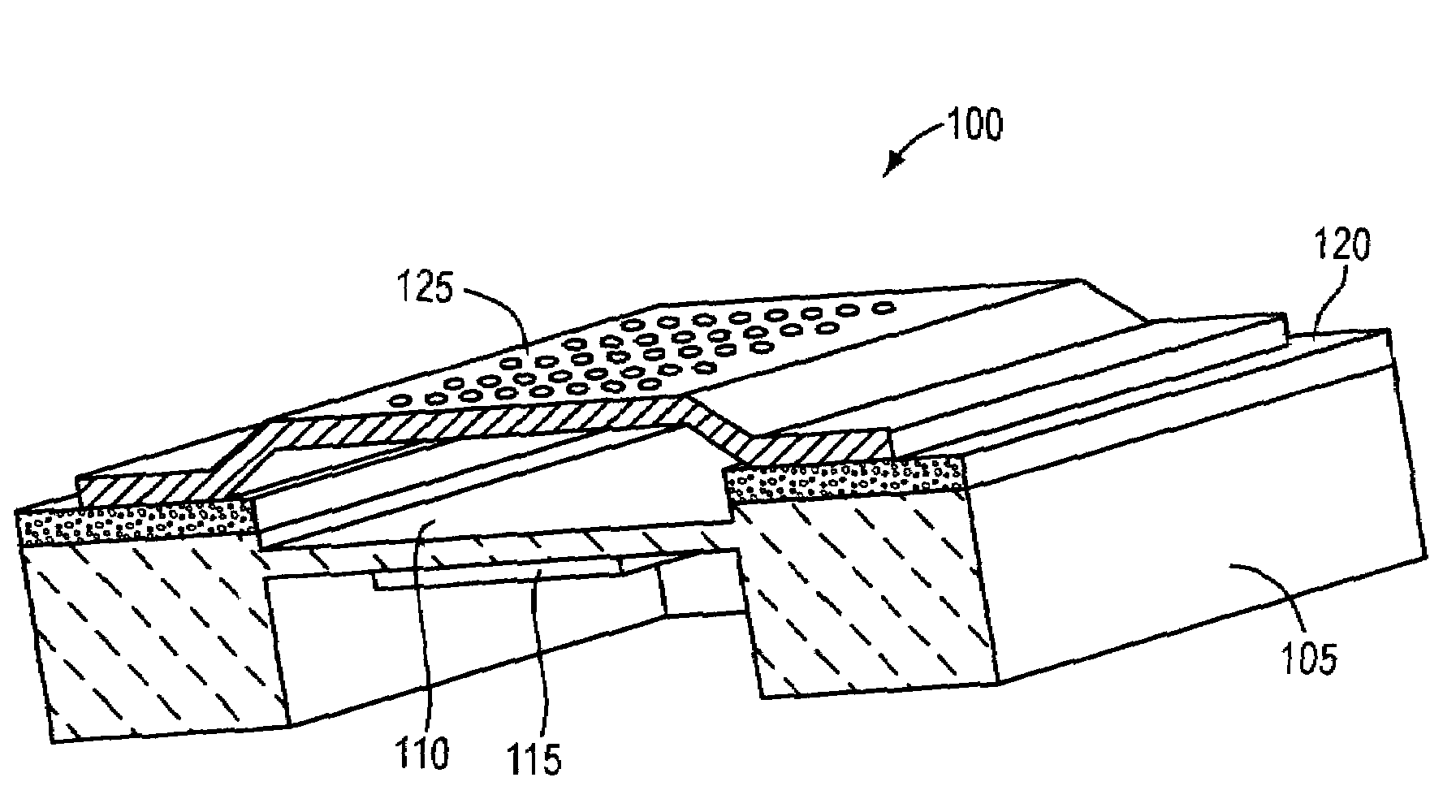

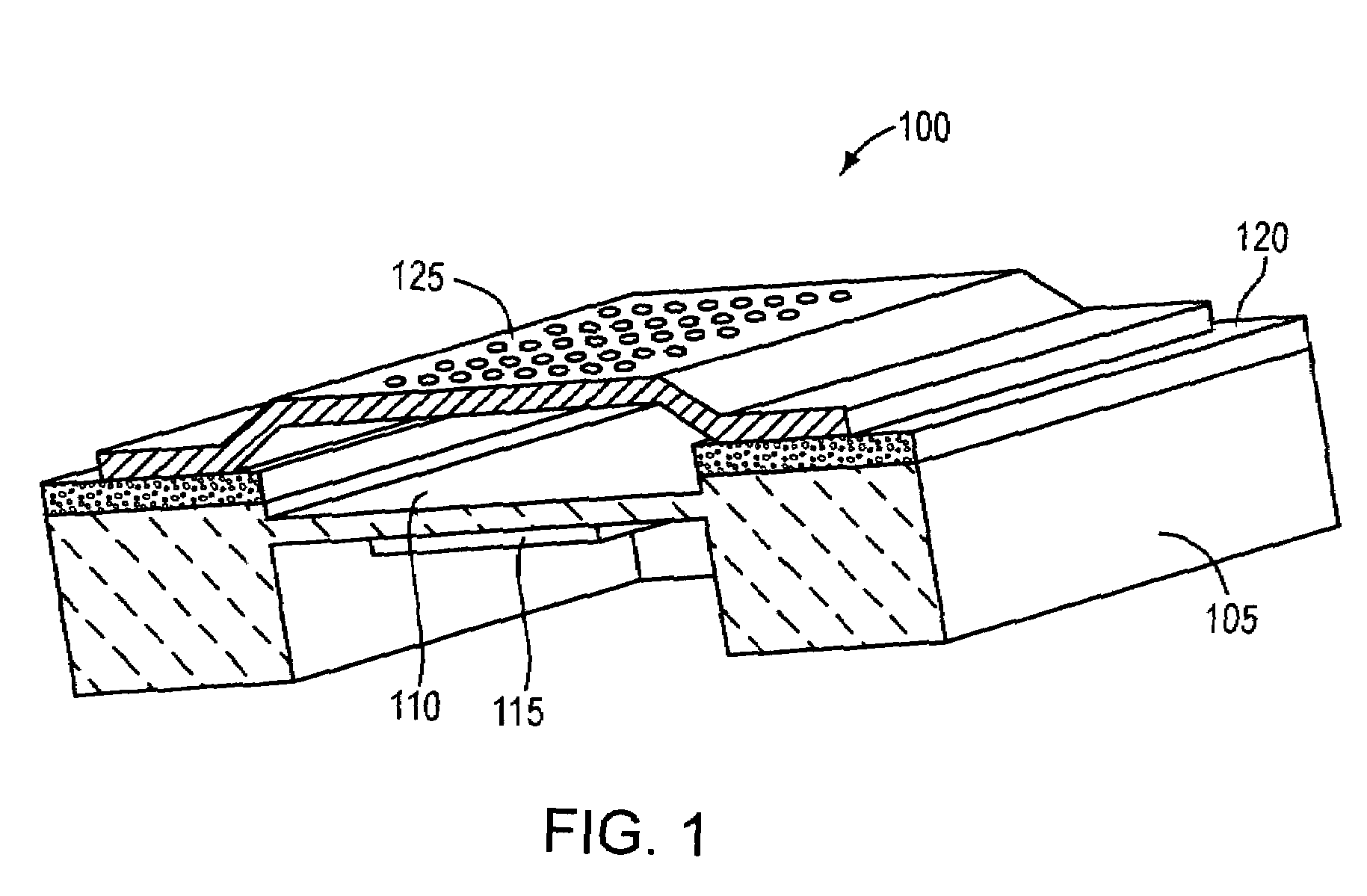

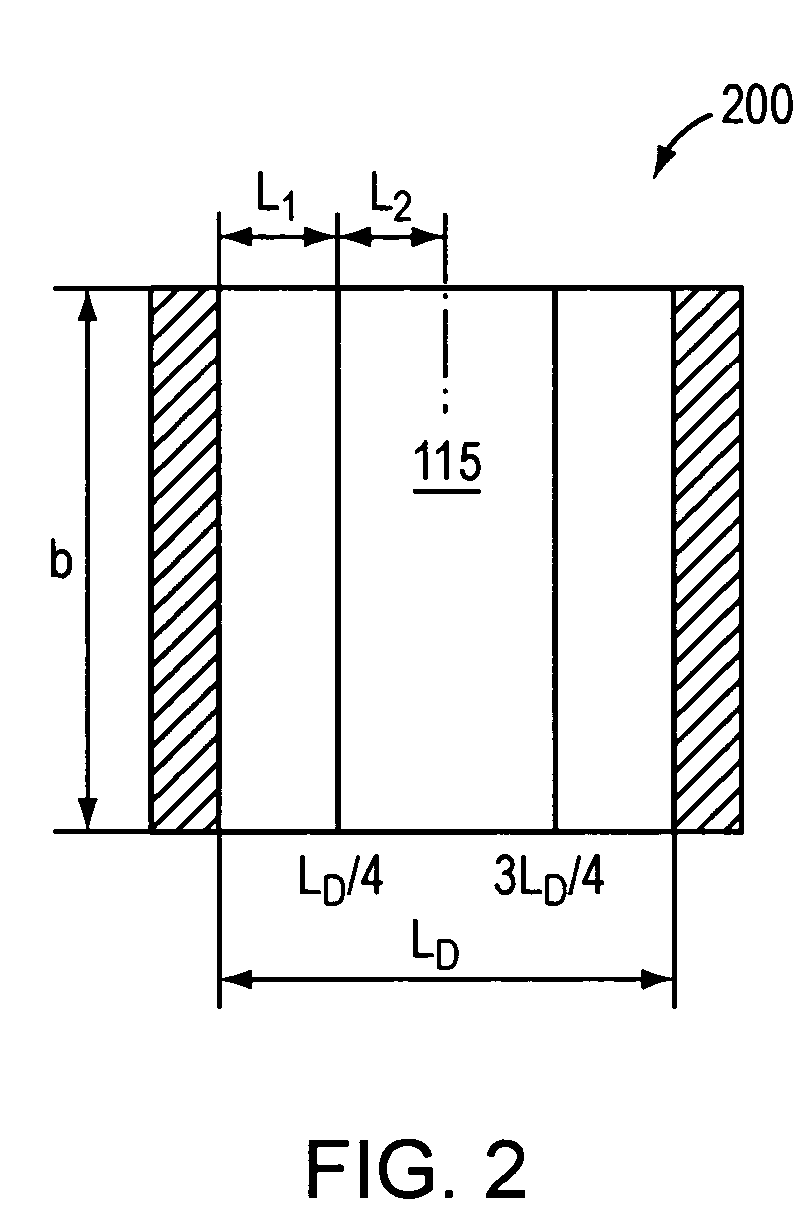

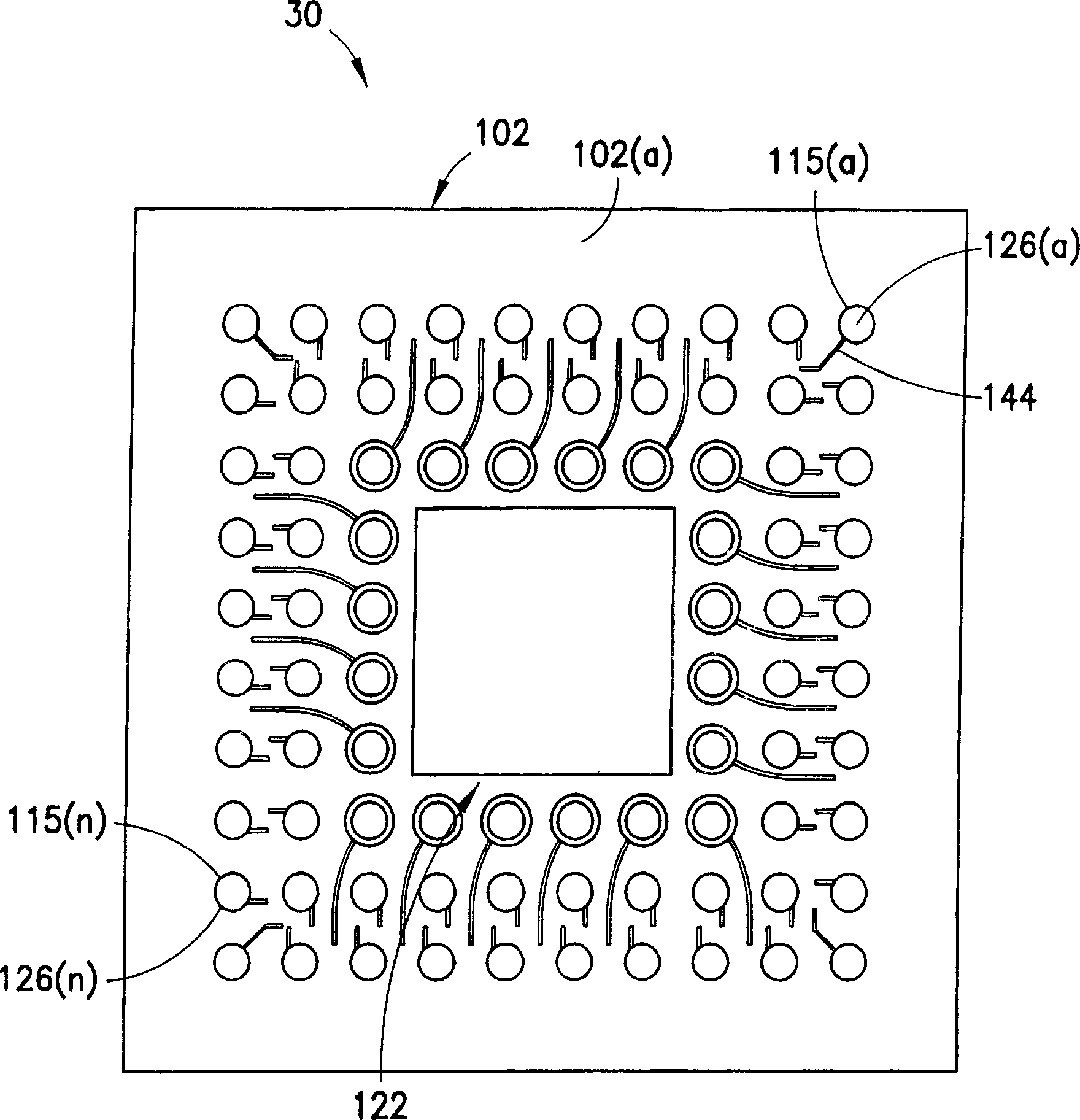

Saw filter device and method employing normal temperature bonding for producing desirable filter production and performance characteristics

ActiveUS7105980B2Improve reliabilityReduce heat sensitivityImpedence networksPiezoelectric/electrostriction/magnetostriction machinesLength waveSilicon

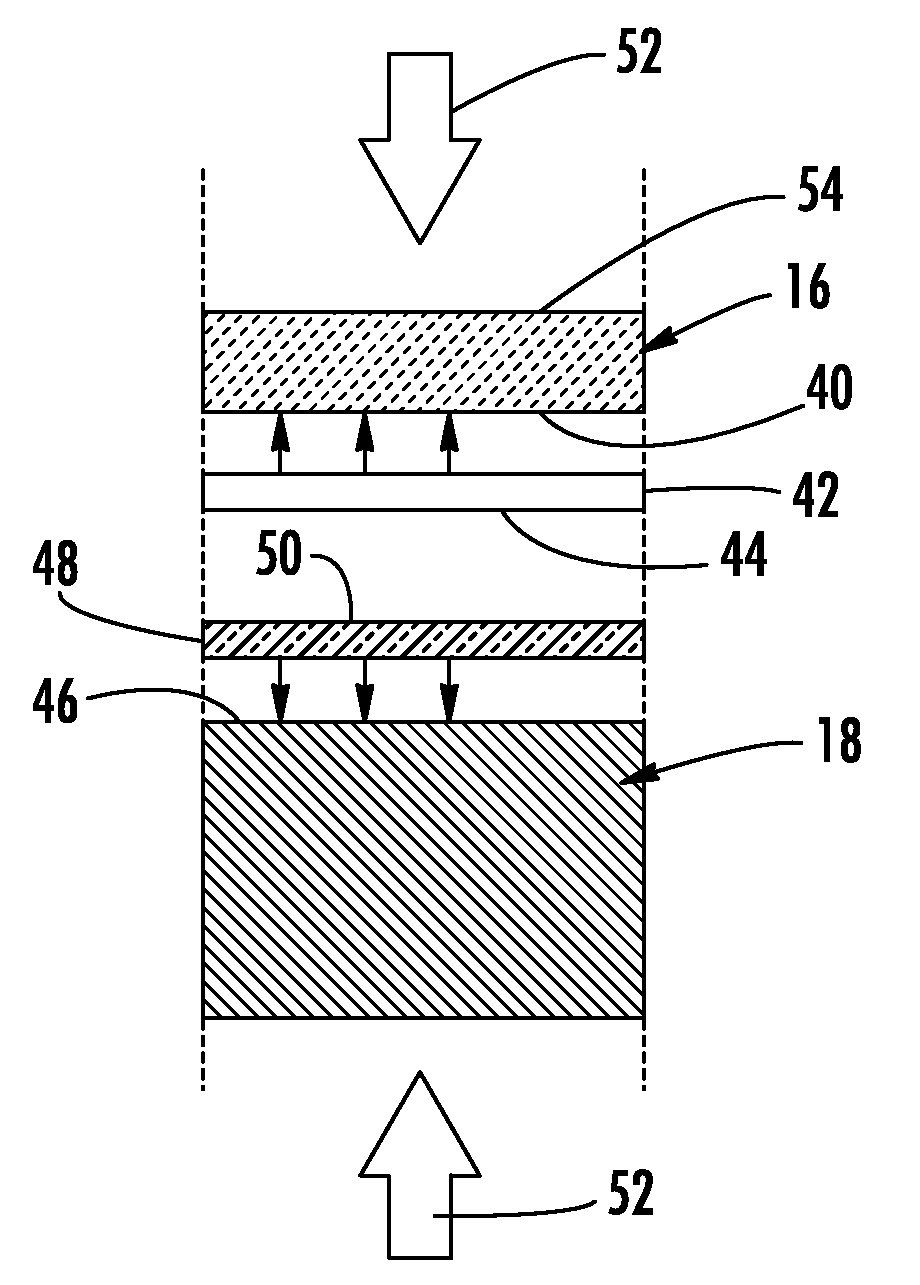

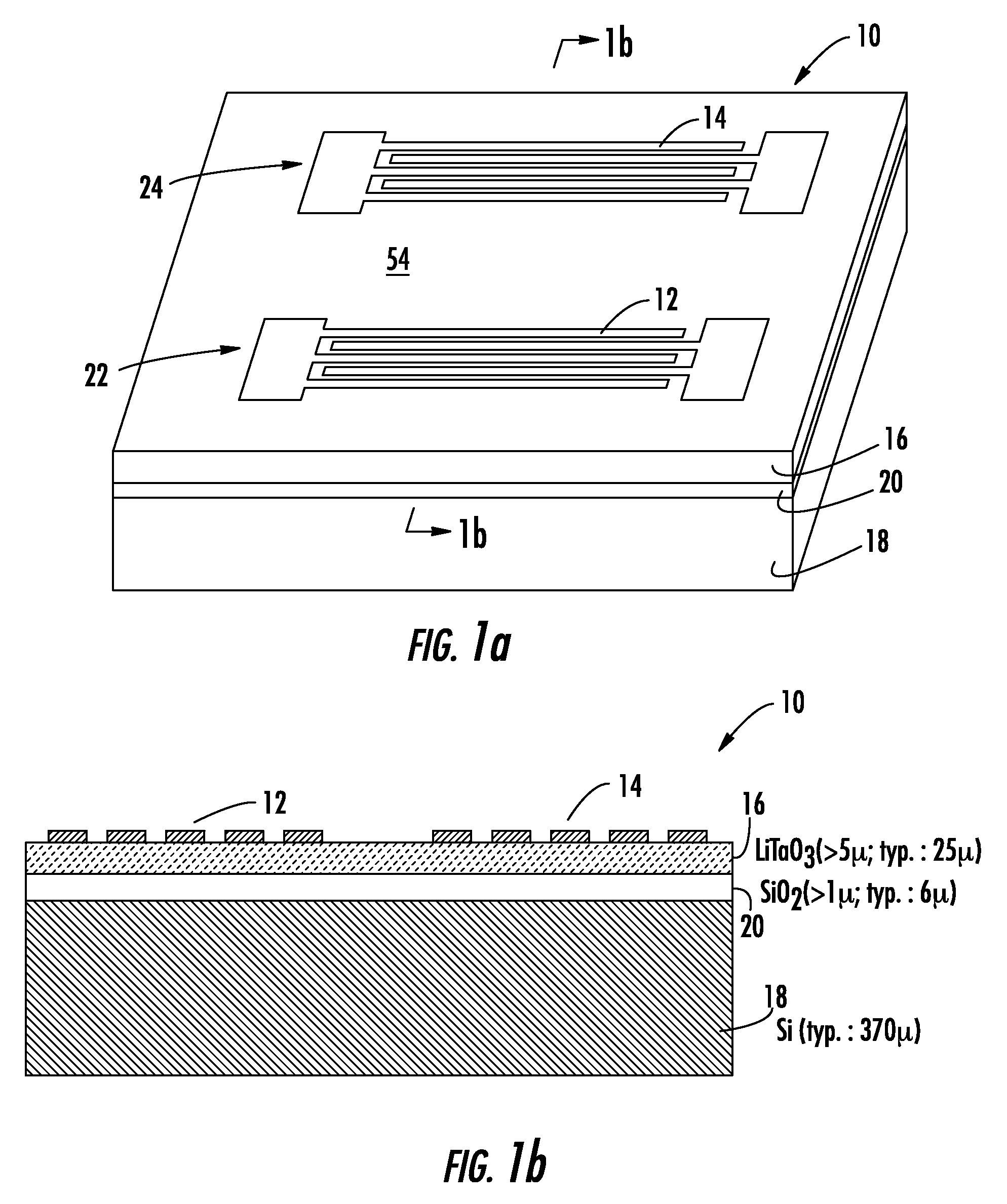

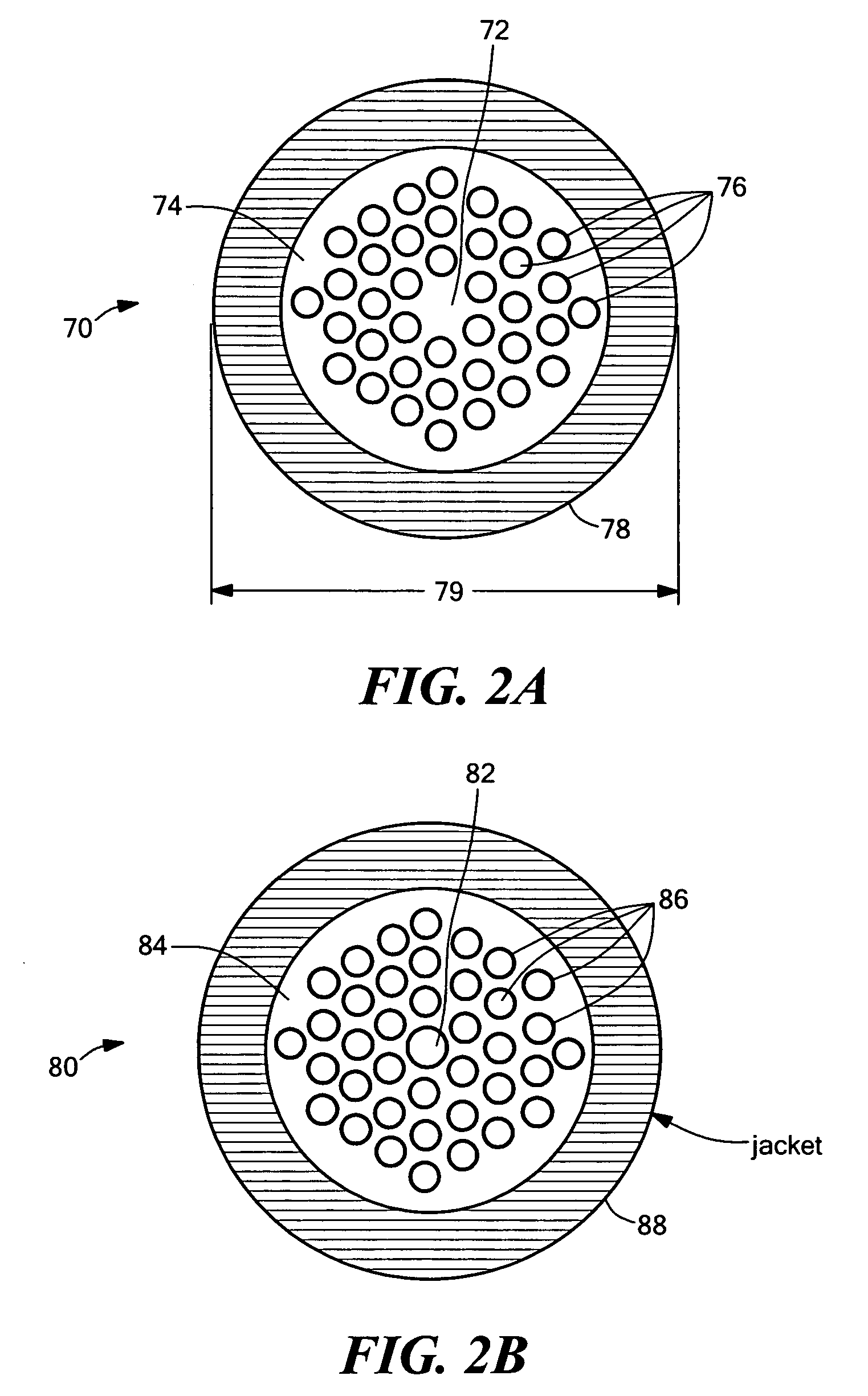

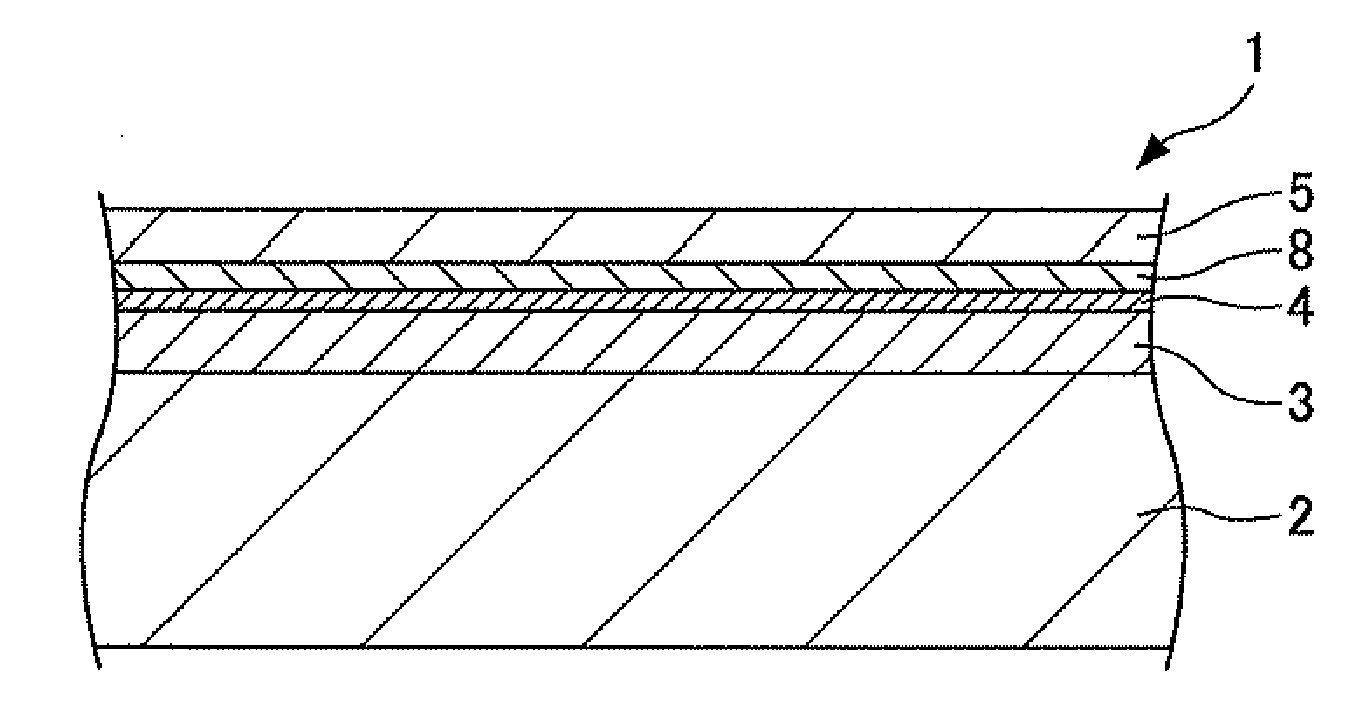

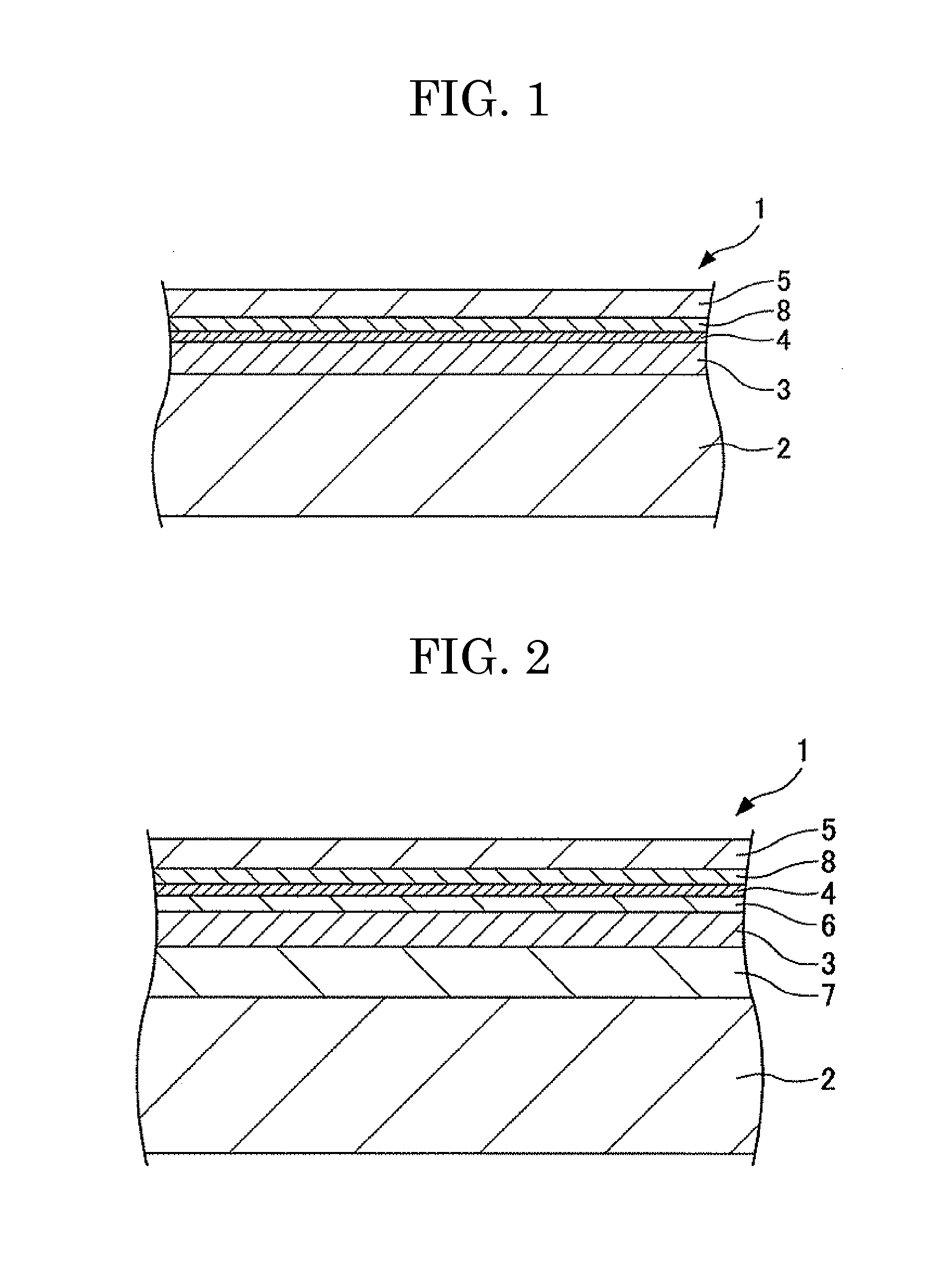

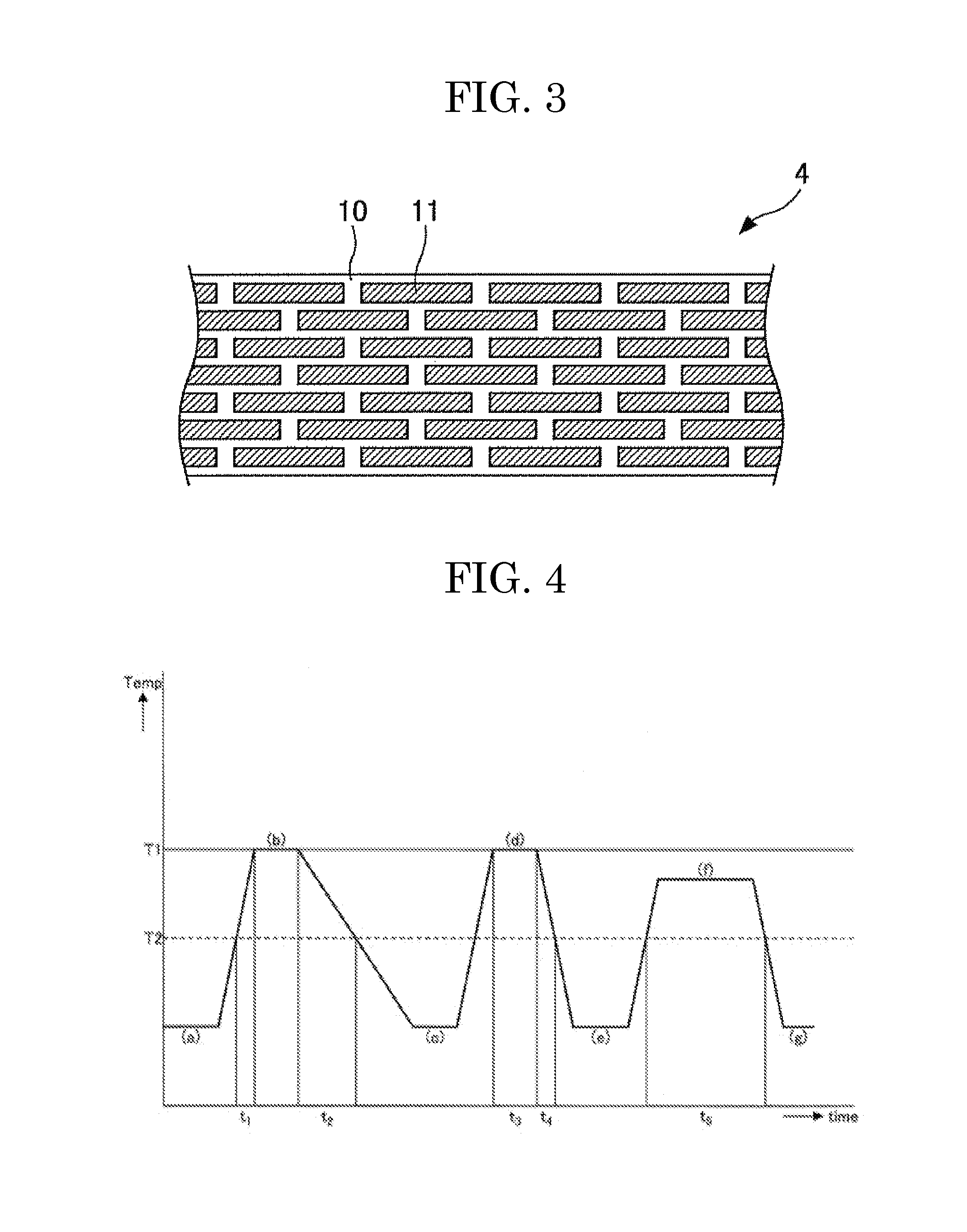

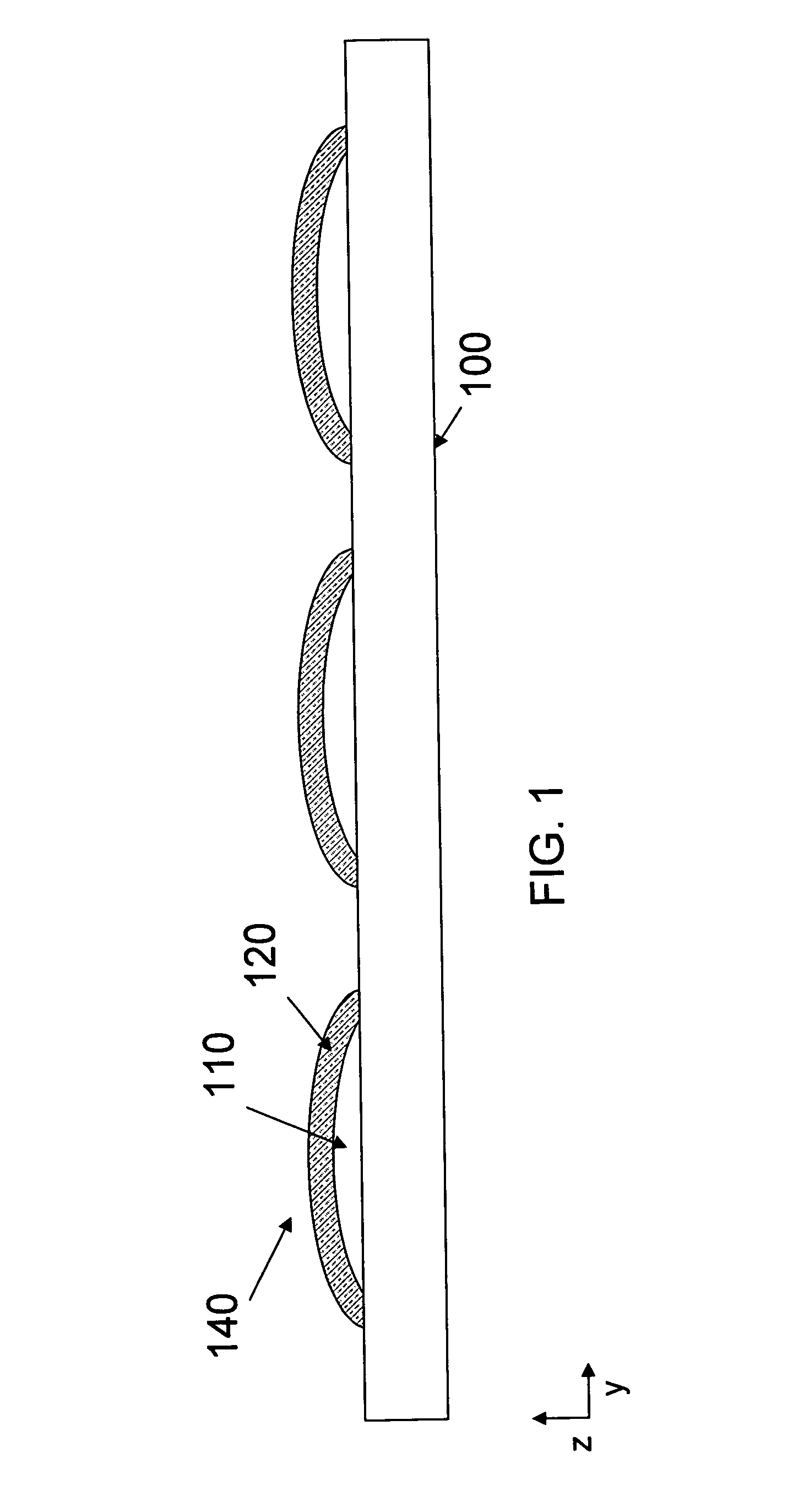

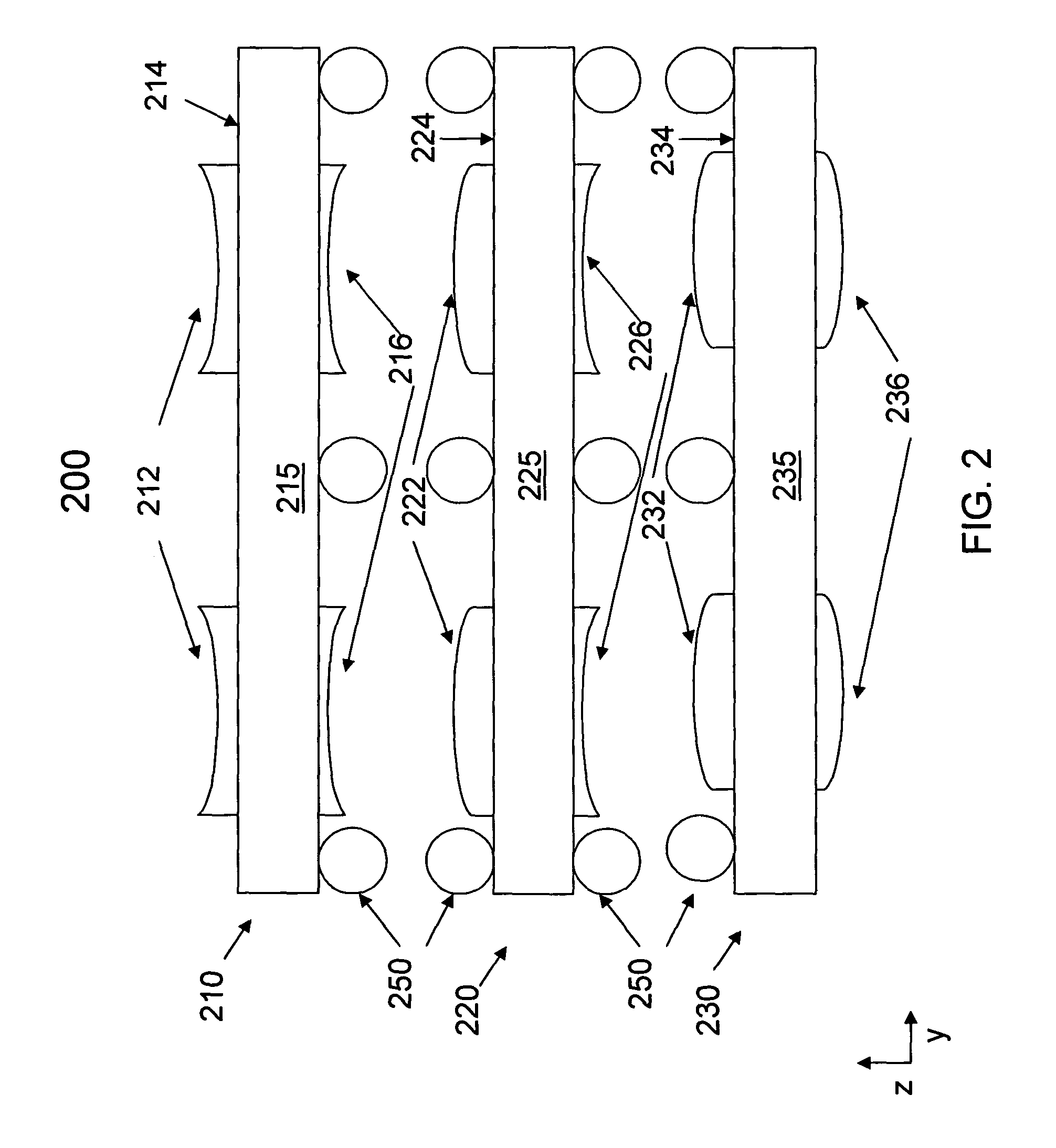

A SAW filter includes a piezoelectric substrate of Lithium Niobate or optionally Lithium Tantalate having a thickness of at least twice an acoustic wavelength. The piezoelectric substrate is bonded to a surrogate substrate of a silicon material. The surrogate substrate is characterized by a resisitivity of at least 100 ohm-cm and an expansion coefficient compatible with the piezoelectric substrate. A catalytic bonding film between the piezoelectric substrate and the surrogate substrate is formed from a first catalytic bonding film deposited onto a surface of the piezoelectric substrate and a second catalytic bonding film deposited onto a surface of the surrogate substrate. The piezoelectric substrate is bonded to the surrogate substrate through a compression force sufficient for providing a bonding at a normal temperature.

Owner:TRIQUINT

Method of forming a surface acoustic wave (SAW) filter device

InactiveUS7213314B2Improve reliabilityReduce heat sensitivityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveLength wave

A SAW filter includes a piezoelectric substrate of Lithium Niobate or optionally Lithium Tantalate having a thickness of at least twice an acoustic wavelength. The piezoelectric substrate is bonded to a surrogate substrate of a silicon material. The surrogate substrate is characterized by a resisitivity of at least 100 ohm-cm and an expansion coefficient compatible with the piezoelectric substrate. A catalytic bonding film between the piezoelectric substrate and the surrogate substrate is formed from a first catalytic bonding film deposited onto a surface of the piezoelectric substrate and a second catalytic bonding film deposited onto a surface of the surrogate substrate. The piezoelectric substrate is bonded to the surrogate substrate through a compression force sufficient for providing a bonding at a normal temperature.

Owner:TRIQUINT

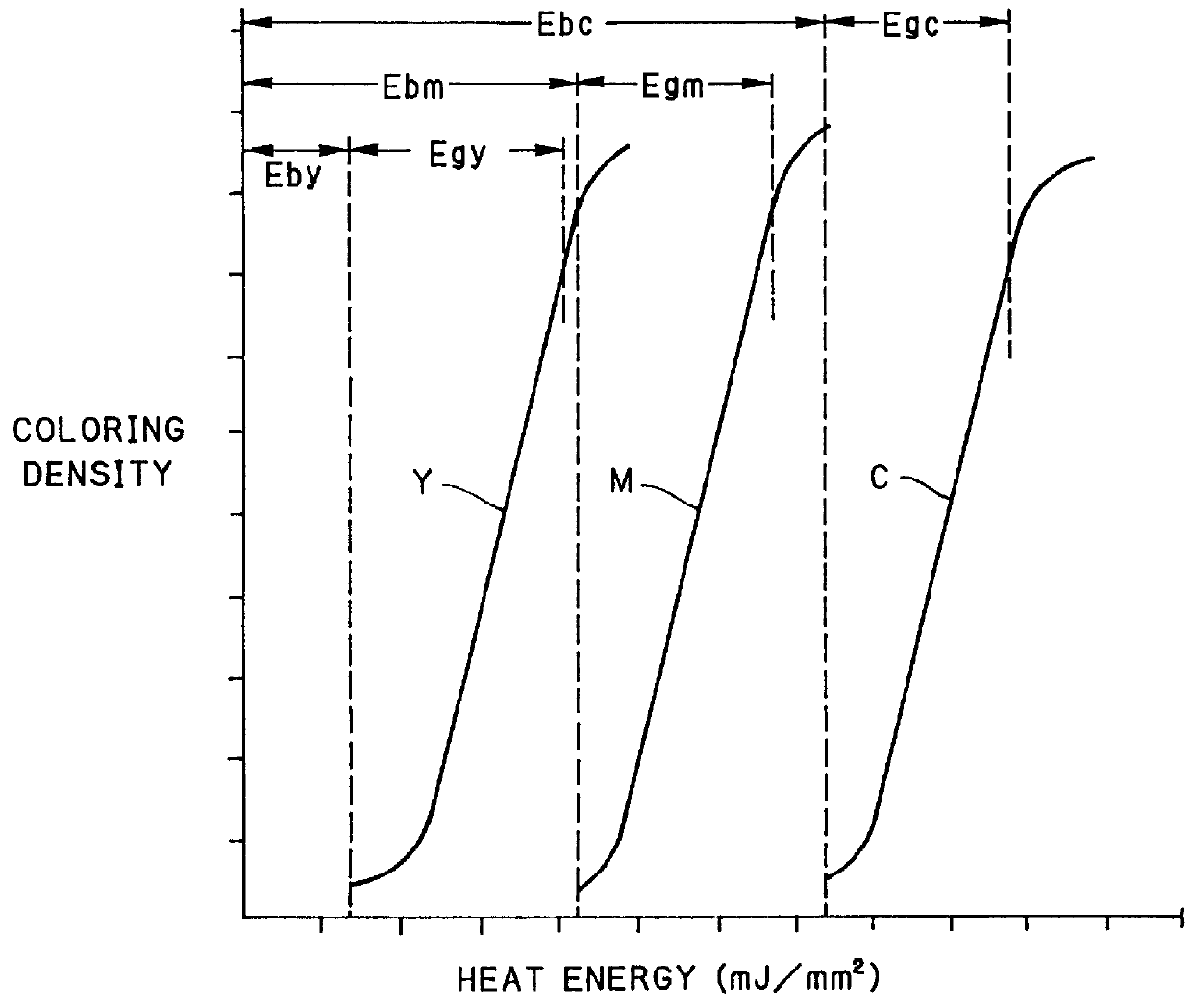

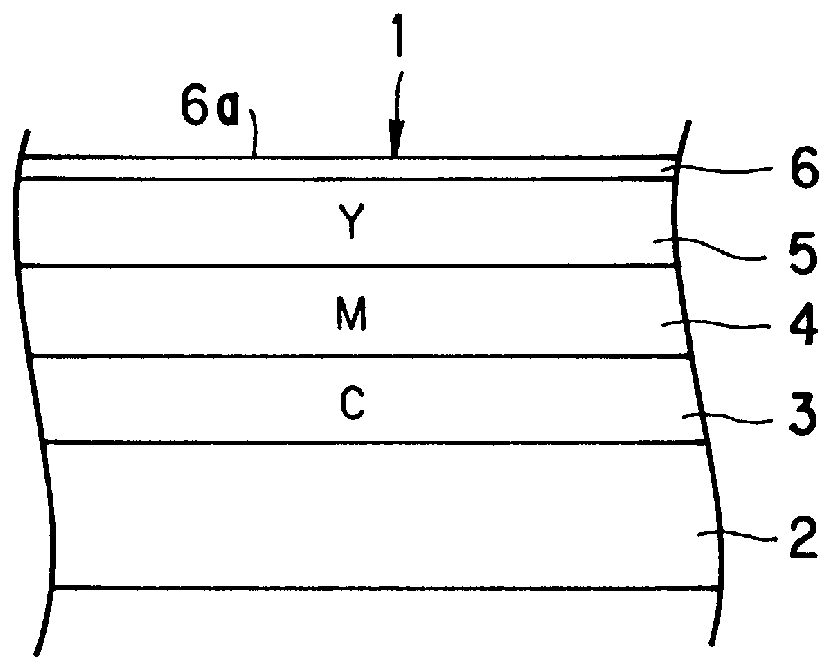

Thermal printing method and thermal printer

InactiveUS6037961AReduce heat sensitivityImprove heat sensitivityThermographyOther printing apparatusPaper sheetThermal energy

A thermosensitive recording sheet is conveyed relative to a thermal head. To effect thermal recording, the thermal head applies heat energy to the recording sheet. The recording sheet is preheated with preheating energy shortly before recording of the recording sheet with the thermal head. The preheating energy is lower than enough to color the recording sheet, but heightens temperature of the recording sheet upon movement of the recording sheet to the thermal head. The heat energy to be applied by the thermal head is reduced according to the preheating energy.

Owner:FUJIFILM CORP

Magnesium alloy surface treatment method

InactiveCN104805345AReduce heat sensitivityImprove solderabilityMolten spray coatingMetallurgyMaterials science

The invention discloses a magnesium alloy surface treatment method which comprises three stages including a pretreatment stage, a spraying stage and an after-spraying treatment stage. By adoption of a compound spraying method, an anti-corrosion and anti-abrasion coating layer which is high in bonding strength, high in compactness and small in environment pollution is formed on the magnesium alloy surface; the surface treatment method is simple and feasible and is low in cost.

Owner:SUZHOU TONGMING MACHINERY

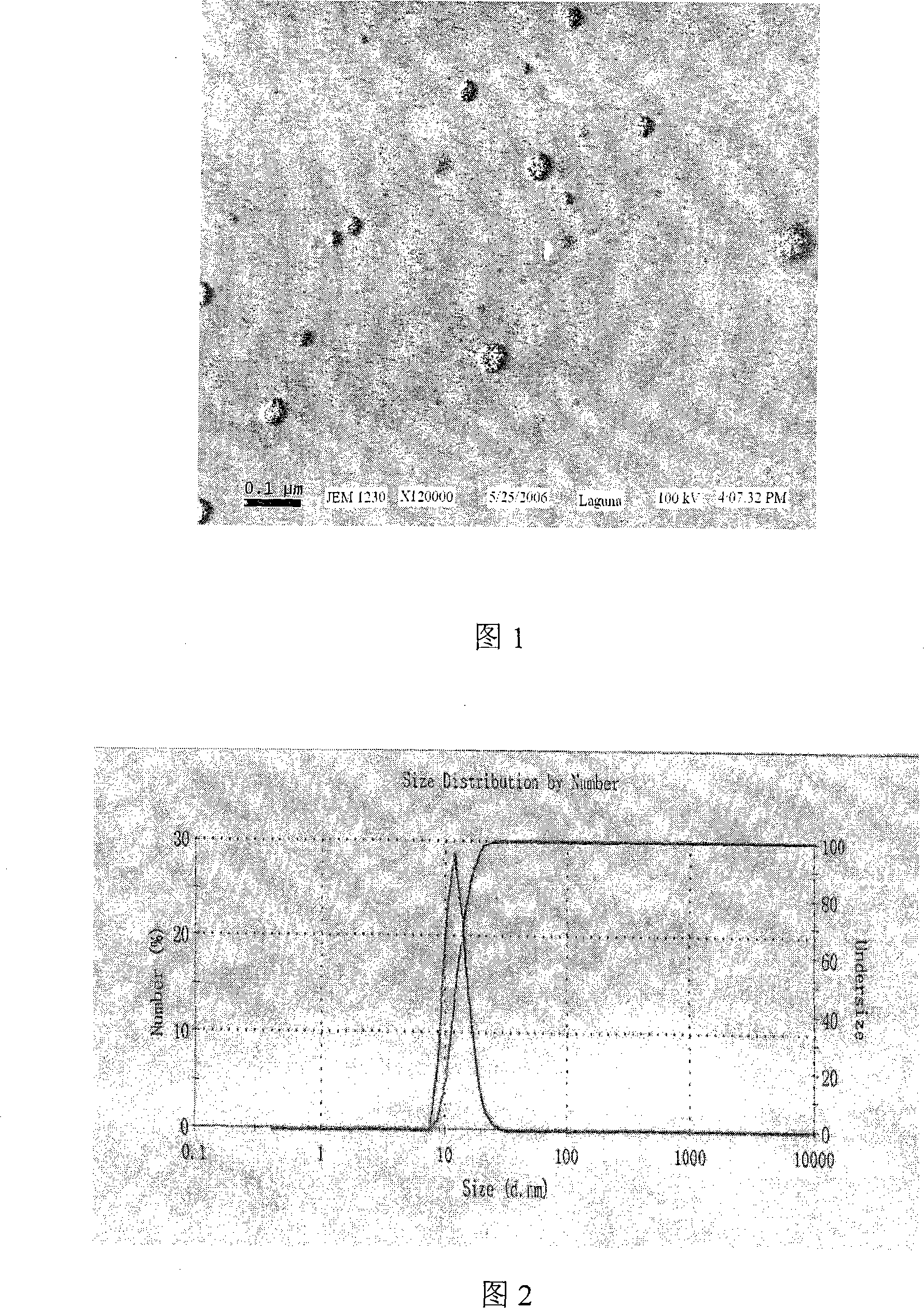

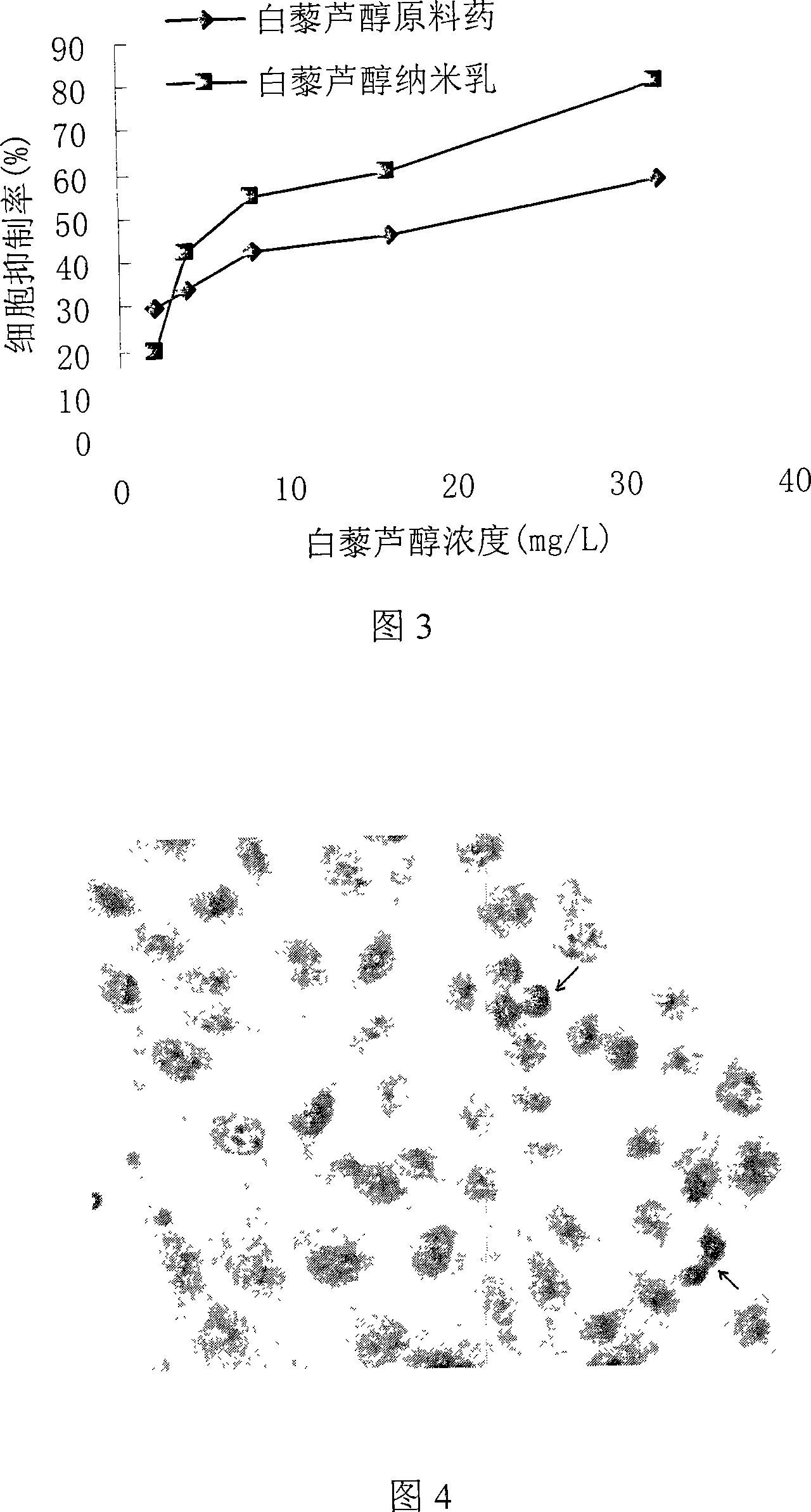

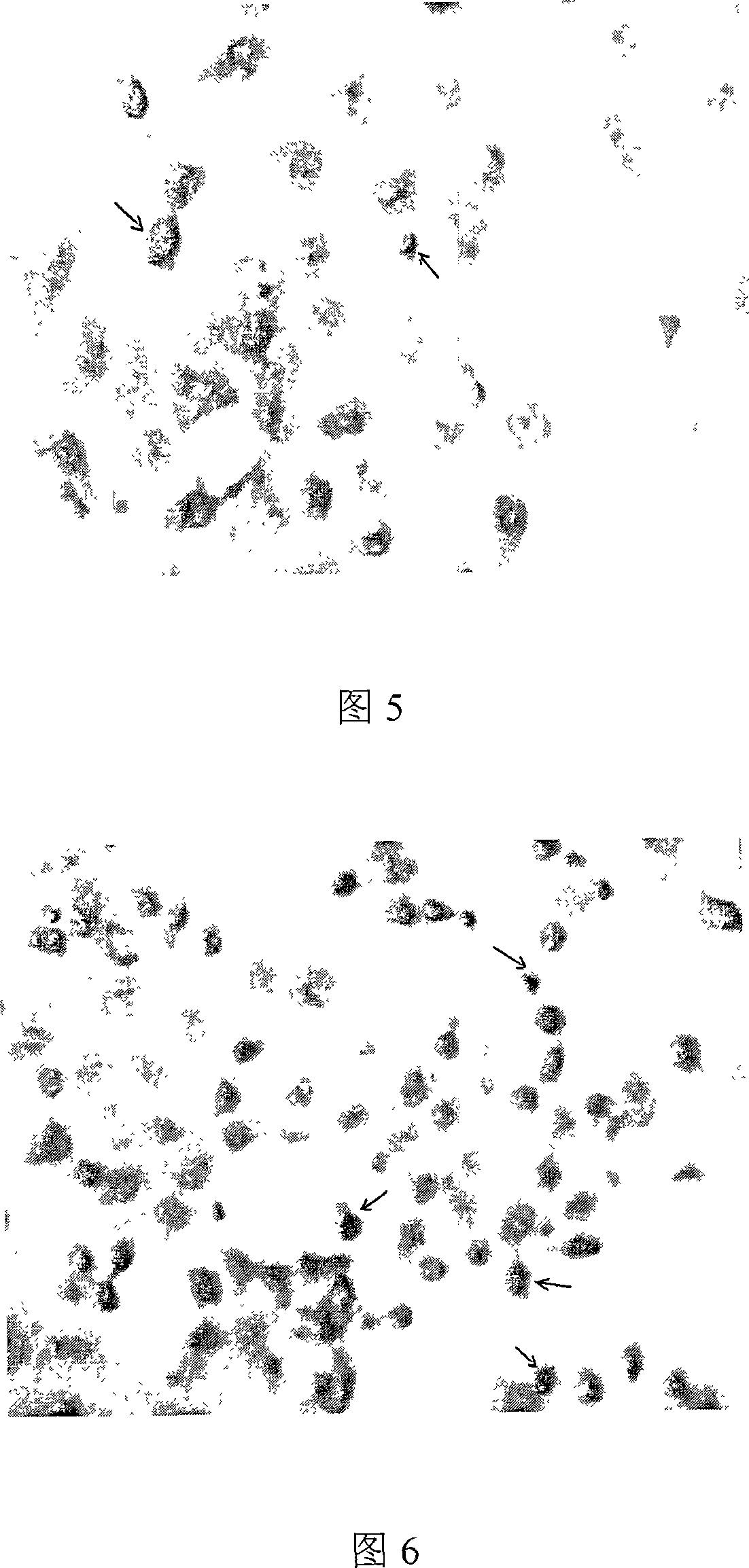

Resveratrol nano emulsion anti-cancer medicine

InactiveCN101214225AIncrease concentrationEvenly distributedHydroxy compound active ingredientsEmulsion deliveryHalf-lifeWilms' tumor

The present invention discloses a resveratrol nano-emulsion anticancer drug which is characterized in that the particle size of the nano-emulsion anticancer drug is between 1nm and 100nm; the raw materials and the weight percentage thereof are: 0.1 percent to 2.0 percent of the resveratrol, 33.3 percent and 42.9 percent of surfactant or cosurfactant, 3.3 percent to 10.0 percent of oil and the distilled water with the rest quantity, and the sum of the percentage of the raw materials is 100 percent. The nano-emulsion has small particles, uniform distribution, little viscidity and good fluidity. After the resveratrol is made into the nano-emulsion, which can increase the anticancer effect thereof obviously, prolong the half-life and reduce medication times; the nano-emulsion can prevent the resveratrol from being oxygenated and increase the stability of the resveratrol, and the preparation method is simple with low energy consumption.

Owner:NORTHWEST A & F UNIV

SAW Filter Device and Method Employing Normal Temperature Bonding for Producing Desirable Filter Production and Performance Characteristics

InactiveUS20070028433A1Improve reliabilityReduce heat sensitivityPiezoelectric/electrostrictive device manufacture/assemblyWave amplification devicesAcoustic waveLength wave

A SAW filter includes a piezoelectric substrate of Lithium Niobate or optionally Lithium Tantalate having a thickness of at least twice an acoustic wavelength. The piezoelectric substrate is bonded to a surrogate substrate of a silicon material. The surrogate substrate is characterized by a resisitivity of at least 100 ohm-cm and an expansion coefficient compatible with the piezoelectric substrate. A catalytic bonding film between the piezoelectric substrate and the surrogate substrate is formed from a first catalytic bonding film deposited onto a surface of the piezoelectric substrate and a second catalytic bonding film deposited onto a surface of the surrogate substrate. The piezoelectric substrate is bonded to the surrogate substrate through a compression force sufficient for providing a bonding at a normal temperature.

Owner:TRIQUINT

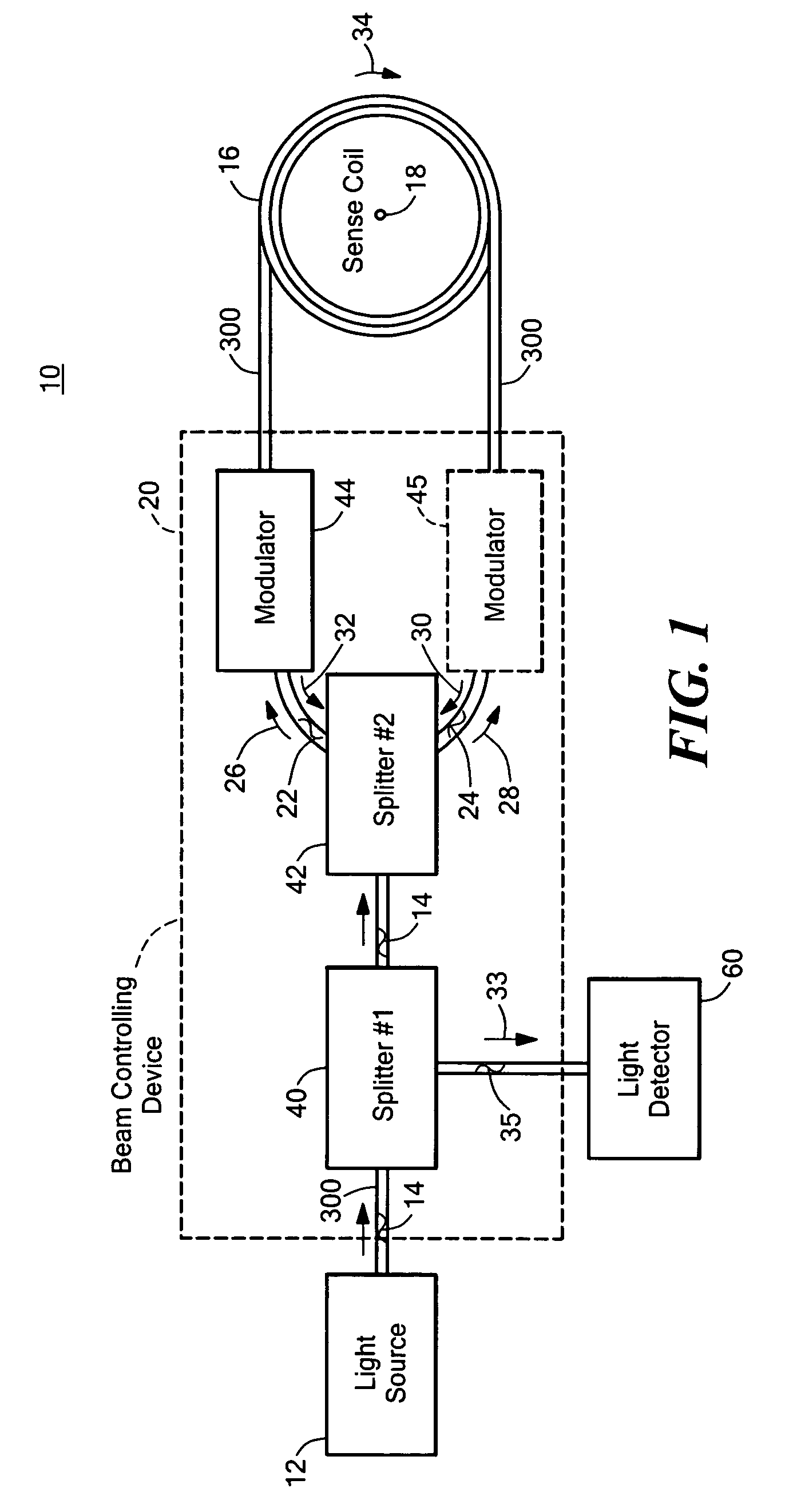

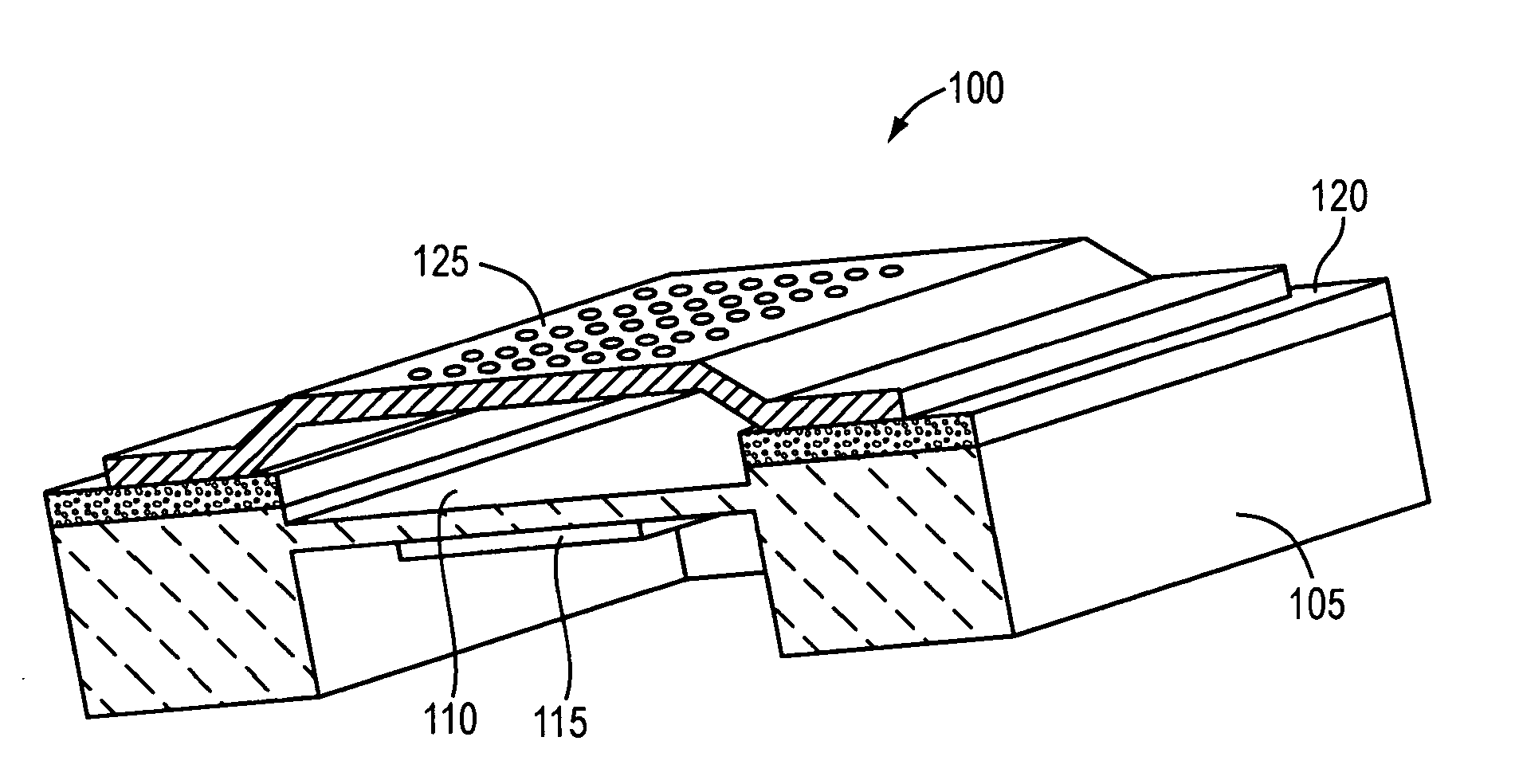

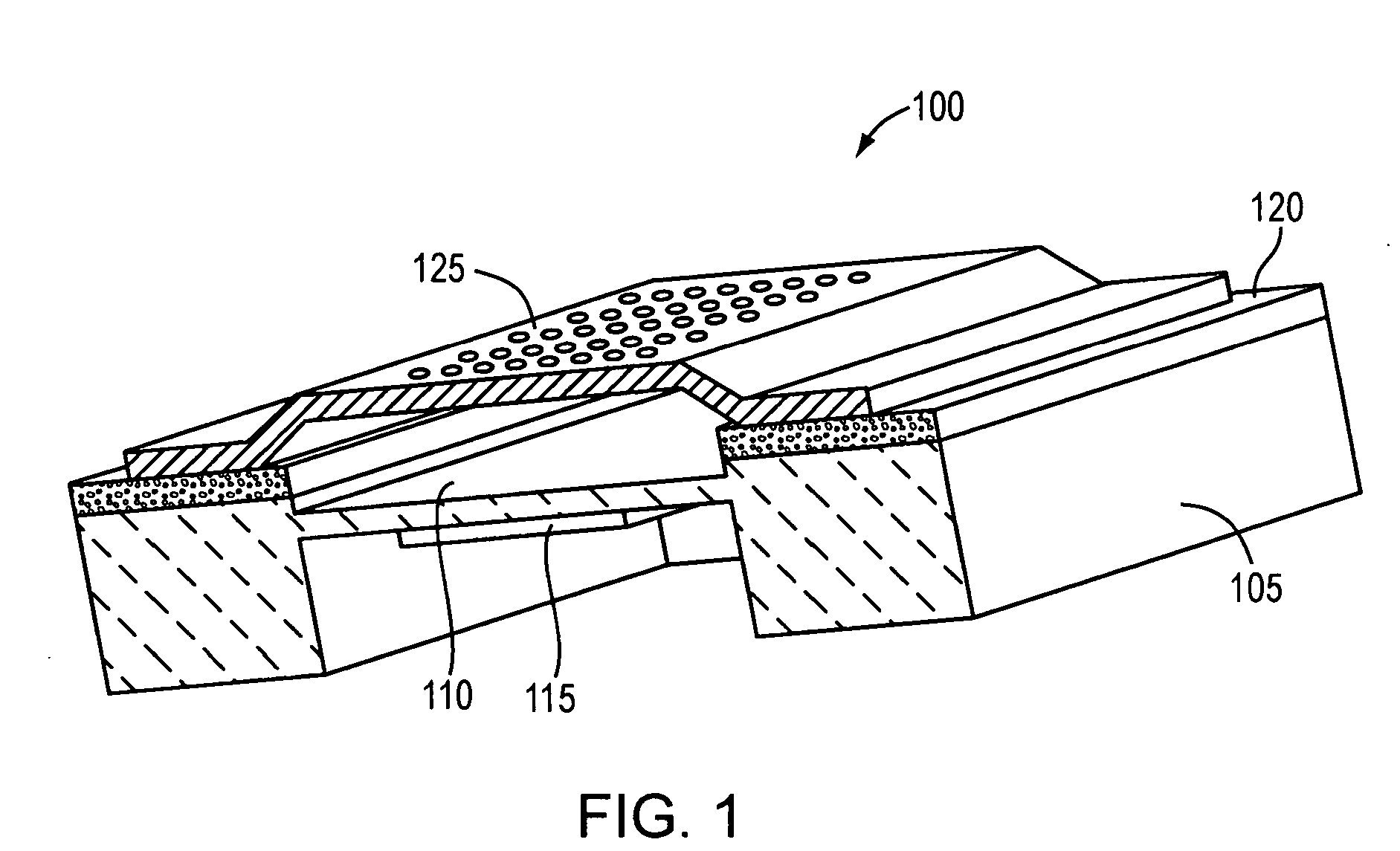

Photonic crystal interferometric fiber optical gyroscope system

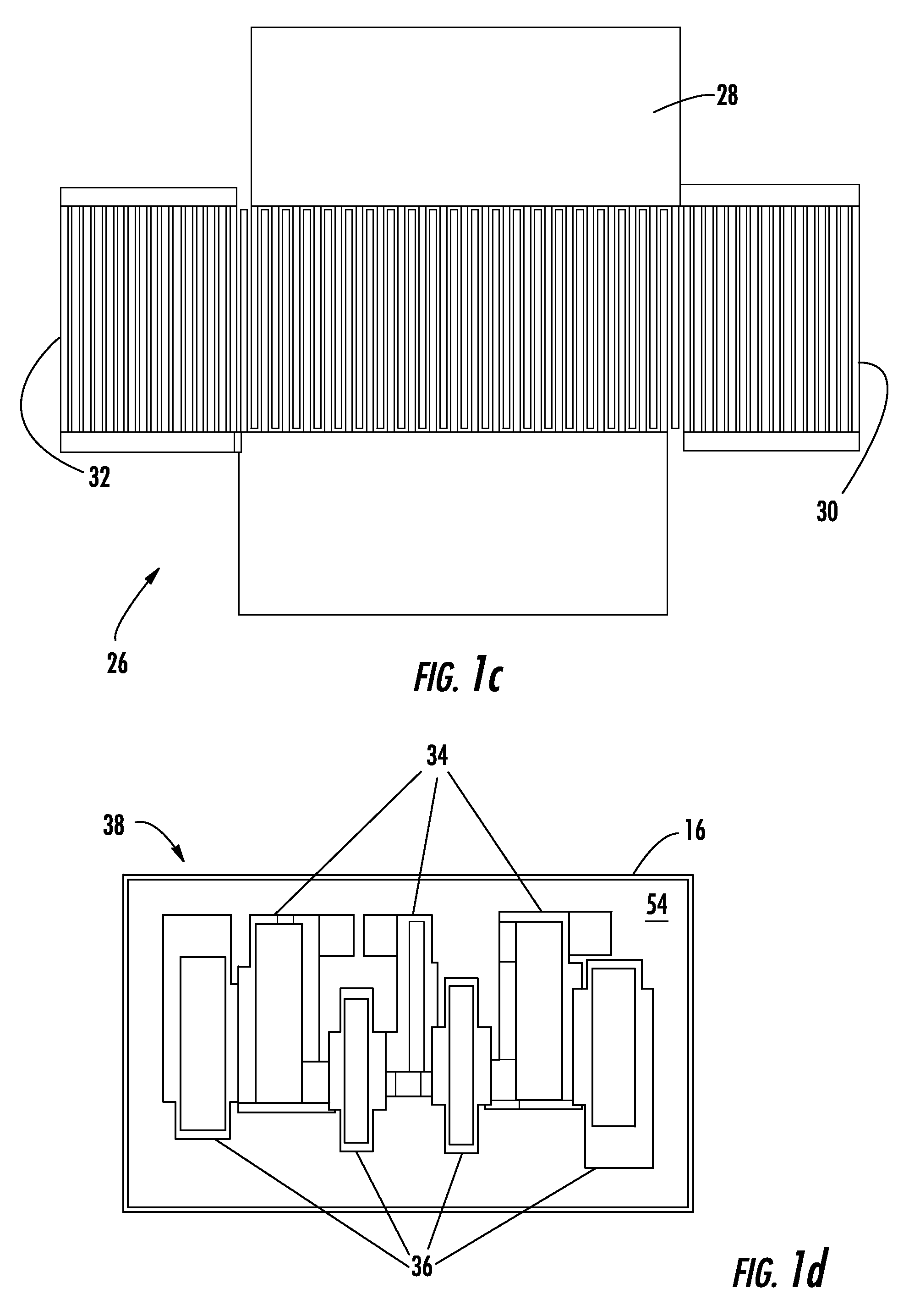

InactiveUS7180598B2Reduce length lossReduce sensitivitySagnac effect gyrometersSpeed measurement using gyroscopic effectsRotational axisPhase shifted

A photonic crystal interferometric optical gyroscope system including a light source for providing a primary beam of light, a photonic crystal sensing coil having a rotational axis, and a beam controlling device configured to split the primary beam into first and second counter-propagating beams in the photonic crystal sensing coil and configured to direct return of the counter-propagating beams wherein the power of the returning counter-propagating beams represents the phase shift between the counter-propagating beams and is indicative of the rate of rotation of the coil about the rotational axis.

Owner:CHARLES STARK DRAPER LABORATORY

Composite antisludging agent of reverse osmosis/nanofiltration system

ActiveCN103007768AImprove work efficiencyExtended cleaning cycleSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisColloidal silicaUltrafiltration

The invention provides a composite antisludging agent of a reverse osmosis / nanofiltration system. The composite antisludging agent comprises the following components in percentage by weight: 2%-10% of cyclodextrin solution, namely a component I, 80%-90% of at least one or a mixture of amino trimethylene phosphonic acid (ATMP), a copolymer of maleic anhydride-acrylic acid (MA-AA), 2-phosphonic acid butane-1, 2,4-tricarboxylic acid (PBTCA), and hydroxyl ethylidene diphosphonic acid (HEDP), namely a component II, and 1%-10% of 2,2-dibromo-2-cyano-acetamid (DBNPA), namely a component III. The composite antisludging agent is prepared by mixing the component II and the component III, and then fusing the obtained mixture with the component I. When being applied to the reverse osmosis / nanofiltration / ultrafiltration system, the composite antisludging agent can be used for effectively relieving the pollution to the reverse osmosis / nanofiltration / ultrafiltration system caused by polcard, calcium sulphate salt, barium sulfate, strontium sulfate, calcium fluoride, colloidal iron and colloidal silica, relieving biological contamination simultaneously, improving the working efficiency of the system, prolonging the cleaning period and the service life of the reverse osmosis / nanofiltration / ultrafiltration system, and reducing the cost of reverse osmosis.

Owner:辽宁莱特莱德环境工程有限公司

Stress-based electrostatic monitoring of chemical reactions and binding

InactiveUS20050196877A1Small device sizeIncrease differentiationBioreactor/fermenter combinationsBiological substance pretreatmentsCapacitanceChemical reaction

Electrostatic capacitance measurements are used to detect chemical or biological analytes, or chemical interactions, with great sensitivity. A diaphragm is coated with a material capable of selectively interacting with an analyte of interest, and interaction of the analyte with the coating exerts stresses tangential to the diaphragm's surface. These stresses cause diaphragm displacements that are sensed as varying capacitance.

Owner:CHARLES STARK DRAPER LABORATORY

Asphalt concrete tracking-resisting modifier

The invention relates to a track resistant modifying agent used in asphalt concrete. The asphalt concrete track resistant modifying agent is characterized in that the asphalt concrete track resistant modifying agent consists of raw materials with the weight portion ration of 65 to 80 portions of low density polyethylene, 10 to 30 portions of anchoring agent, and 0 to 5 portions of activated rubber powder. The anchoring agent is petroleum resin or abietic resin. The invention has inexpensive price and excellent performance, and can improve the stability of the asphalt concrete at high temperature, enhance pavement bearing capacity and prolong service life of the pavement.

Owner:WUHAN UNIV OF TECH

Stress-based electrostatic monitoring of chemical reactions and binding

InactiveUS7402425B2High sensitivityReduce or eliminate thermally induced deflectionsBioreactor/fermenter combinationsBiological substance pretreatmentsCapacitanceChemical reaction

Electrostatic capacitance measurements are used to detect chemical or biological analytes, or chemical interactions, with great sensitivity. A diaphragm is coated with a material capable of selectively interacting with an analyte of interest, and interaction of the analyte with the coating exerts stresses tangential to the diaphragm's surface. These stresses cause diaphragm displacements that are sensed as varying capacitance.

Owner:CHARLES STARK DRAPER LABORATORY

Anti-corrosion aluminum alloy door and window and manufacturing process thereof

InactiveCN107267822AReduce heat sensitivityImprove solderabilityRare-earth elementCorrosion resistant

The invention discloses a corrosion-resistant aluminum alloy door and window and a preparation process thereof. The door and window include the following components by weight percentage: Mg: 3-7%, Mn: 2-4%, Zn: 6-10%, Ni : 1‑3%, Si: 2‑6%, Sc: 0.8‑1.2%, P: 0.2‑0.4%, Zr: 0.3‑0.7%, Y: 1‑3%, Ca: 3‑5%, Sr: 1‑5%, B: 0.4‑1.2%, Co: 2‑4%, Sr: 0.6‑1.0%, and rare earth elements: 1‑3%, the rest are Al and unavoidable impurities; the rare earth elements are by weight The percentage meter includes the following compositions: Nd: 15‑25%, Gd: 10‑20%, Pr: 5‑7%, Yb: 10‑20%, La: 6‑10%, Dy: 7‑9%, Sm: 8‑12%, Ce: 10‑20%, the sum of the above rare earth elements is 100%. The preparation process is to firstly melt the raw material components to obtain ingots, and then perform heat treatment on the ingots, and finally pass forging and surface treatment. The aluminum alloy door and window of the invention has strong corrosion resistance, oxidation resistance, high strength, is not easy to break, and has a long service life.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

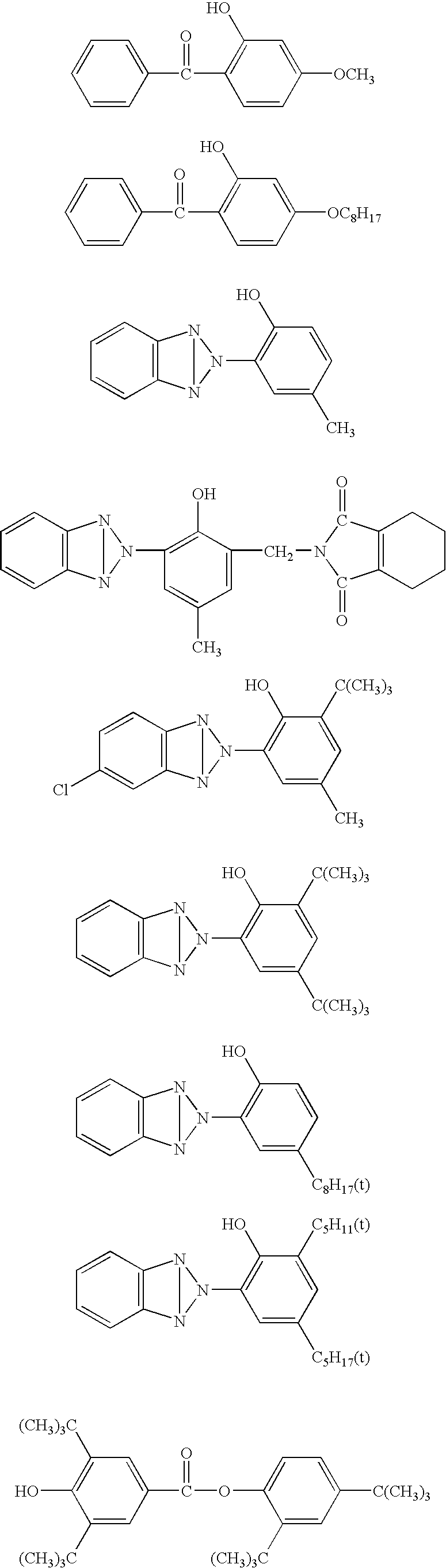

Heat-sensitive recording material

InactiveUS20050088508A1Suppress background foggingReduce heat sensitivityRecording apparatusInk ribbonsHeat sensitiveThermal printing

(A) The invention discloses a thermosensitive recording material comprising: a support; and a thermosensitive recording layer formed on the support, the thermosensitive recording layer containing an electron-donating colorless dye and an electron-accepting compound which develops color upon a reaction with the electron-donating colorless dye, wherein the thermosensitive recording material satisfies at least one of the following conditions (1) to (3). (1) an image density when thermal printing is performed from a side, of the support, having the thermosensitive recording layer with printing energy of 15.2 mJ / mm2 is 1.20 or more, and the thermosensitive recording material is used for a recording device having a printing speed of 10 cm / sec or more; (2) the thermosensitive recording material contains a sensitizer comprising at least one compound selected from the group consisting of 2-benzyloxynaphthalene, dimethylbenzyloxalate, m-terphenyl, ethyleneglycol tolyl ether, p-benzyl biphenyl, 1,2-diphenoxymethyl benzene, diphenyl sulfone and 1,2-diphenoxy ethane, and the image density after the thermosensitive recording material is brought into contact with a heat source of 70° C. for 5 seconds is 0.15 or less; (3) the electron-accepting compound is a compound represented by the following Formula (1) R1-Ph-SO2R2 Formula (1) wherein R1 represents a hydroxyl group or an alkyl group, R2 represents -Ph, —NH-Ph, -Ph-OR3 or —NH—CO—NH-Ph, R3 represents an alkyl group, Ph represents a phenyl group and may be substituted with a substituent containing —SO2R2, and a volume-averaged grain size of the electron-donating colorless dye and electron-accepting compound is in a range of 0.5 to 1.0 μm.

Owner:FUJIFILM HLDG CORP +1

Preparation method for magnesium alloy profile material for automobile oil tank

InactiveCN106591658AReduce heat sensitivityImprove solderabilityUnderstructuresFuel supplyRare-earth elementFuel tank

The invention discloses a magnesium alloy profile material for an automobile oil tank. The magnesium alloy profile material comprises the following components of, by mass, 8%-15% of Al, 2%-4% of Mn, 10%-13% of Zn, 1%-3% of Ni, 7%-9% of Ca, 1%-3% of Cu, 1%-3% of Sc, 0.2%-0.3% of P, 1%-3% of Zr, 2%-4% of B, 0.1%-0.4% of V, 0.002%-0.004% of Nb, 2%-5% of So, 0.01%-0.03% of C, 2%-4% of Co, 0.2%-0.5% of Fe, 0.5%-0.8% of rare earth elements, and the balance Mg. The invention further relates to a preparation method for the magnesium alloy profile material for the automobile oil tank. The preparation method is simple and easy to operate, the prepared oil tank has good corrosion resistance, the service life is long, and the cost is low.

Owner:SUZHOU NIUDONG PRECISION MFG TECH CO LTD

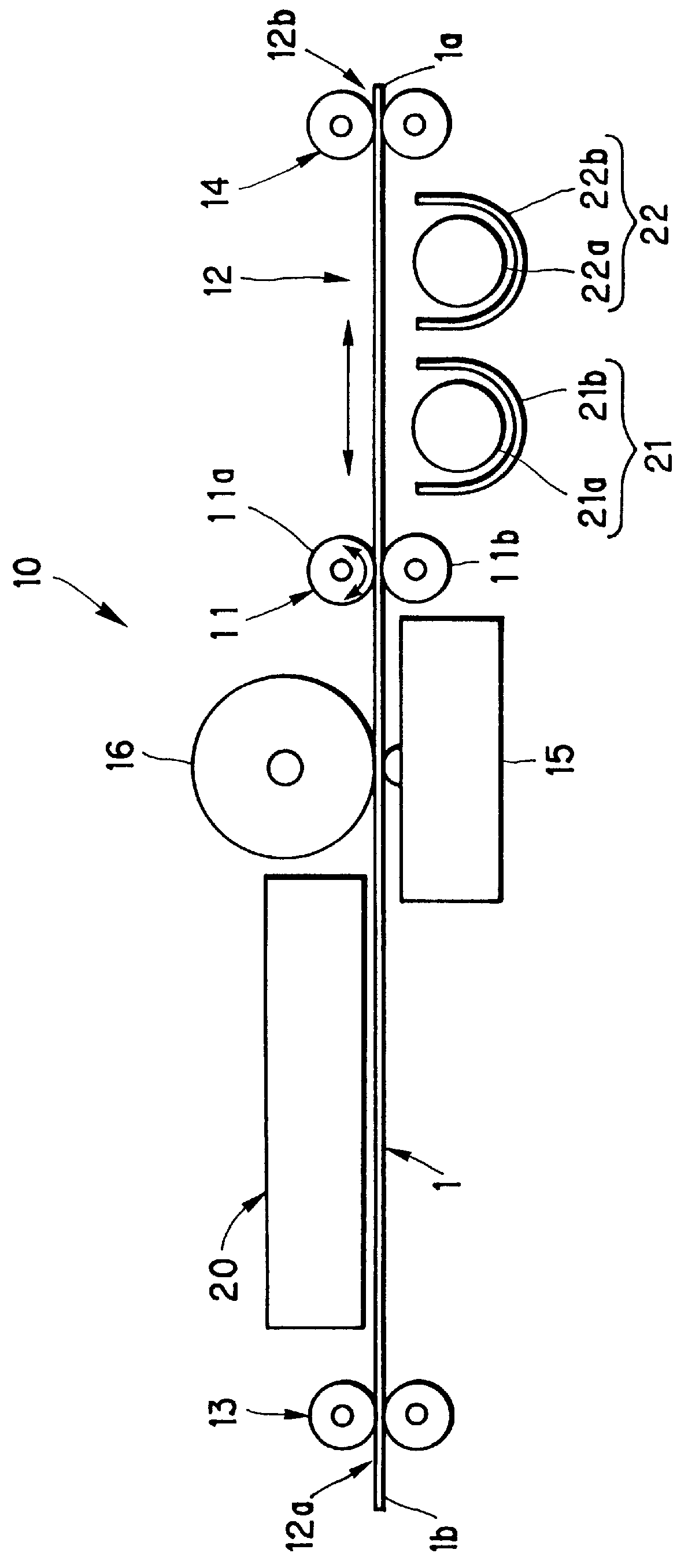

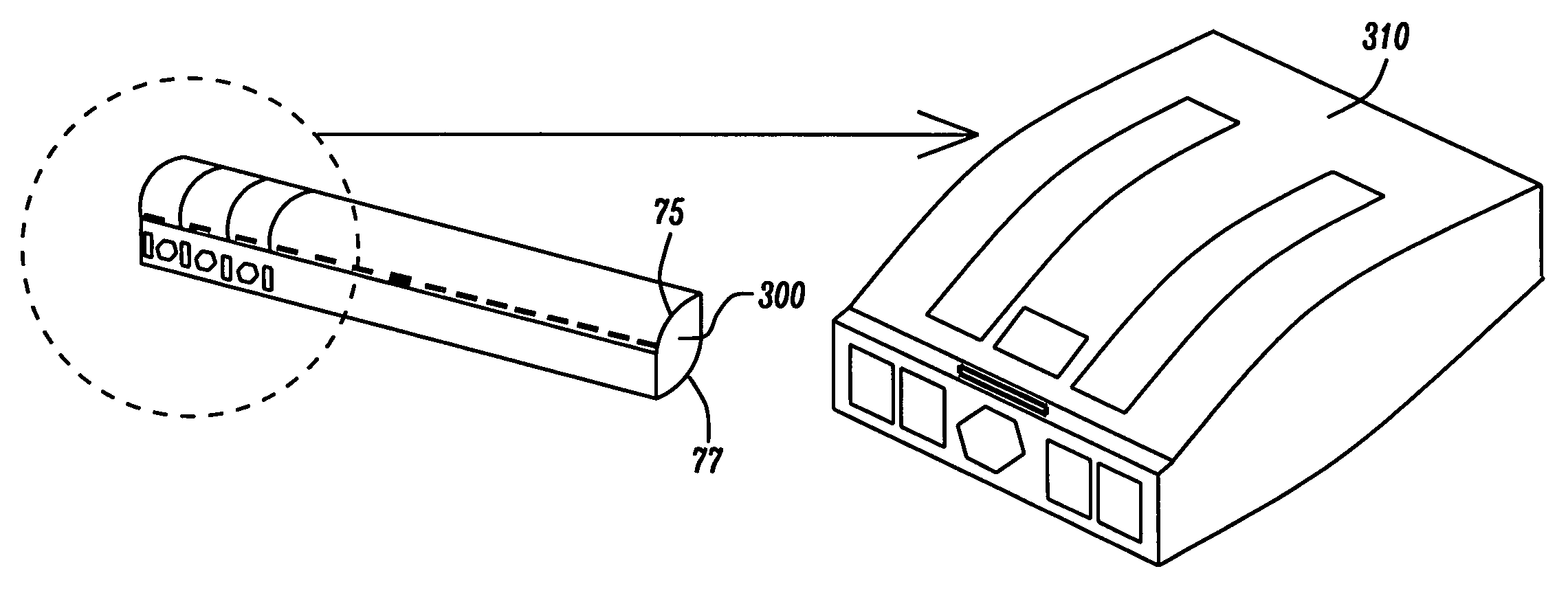

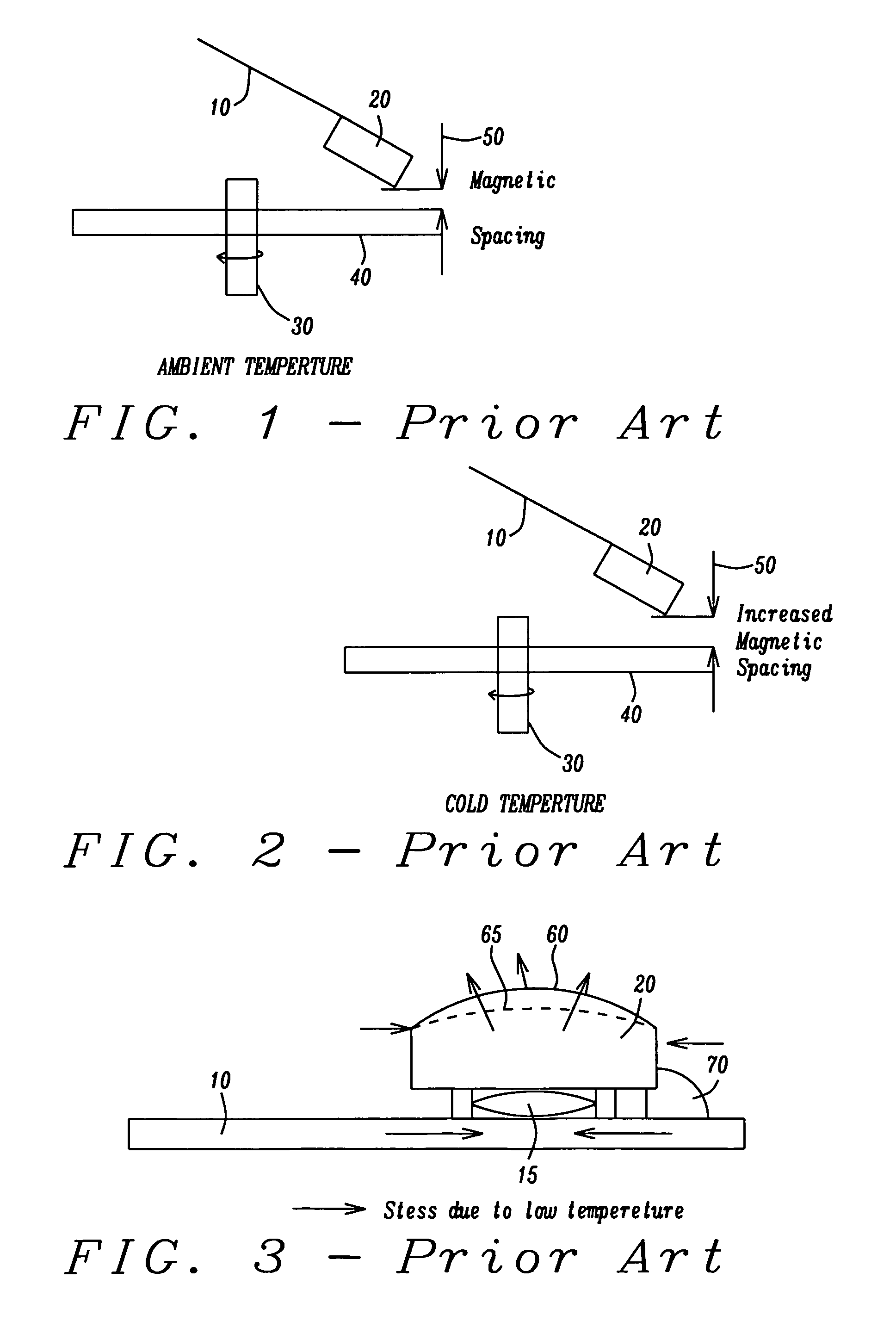

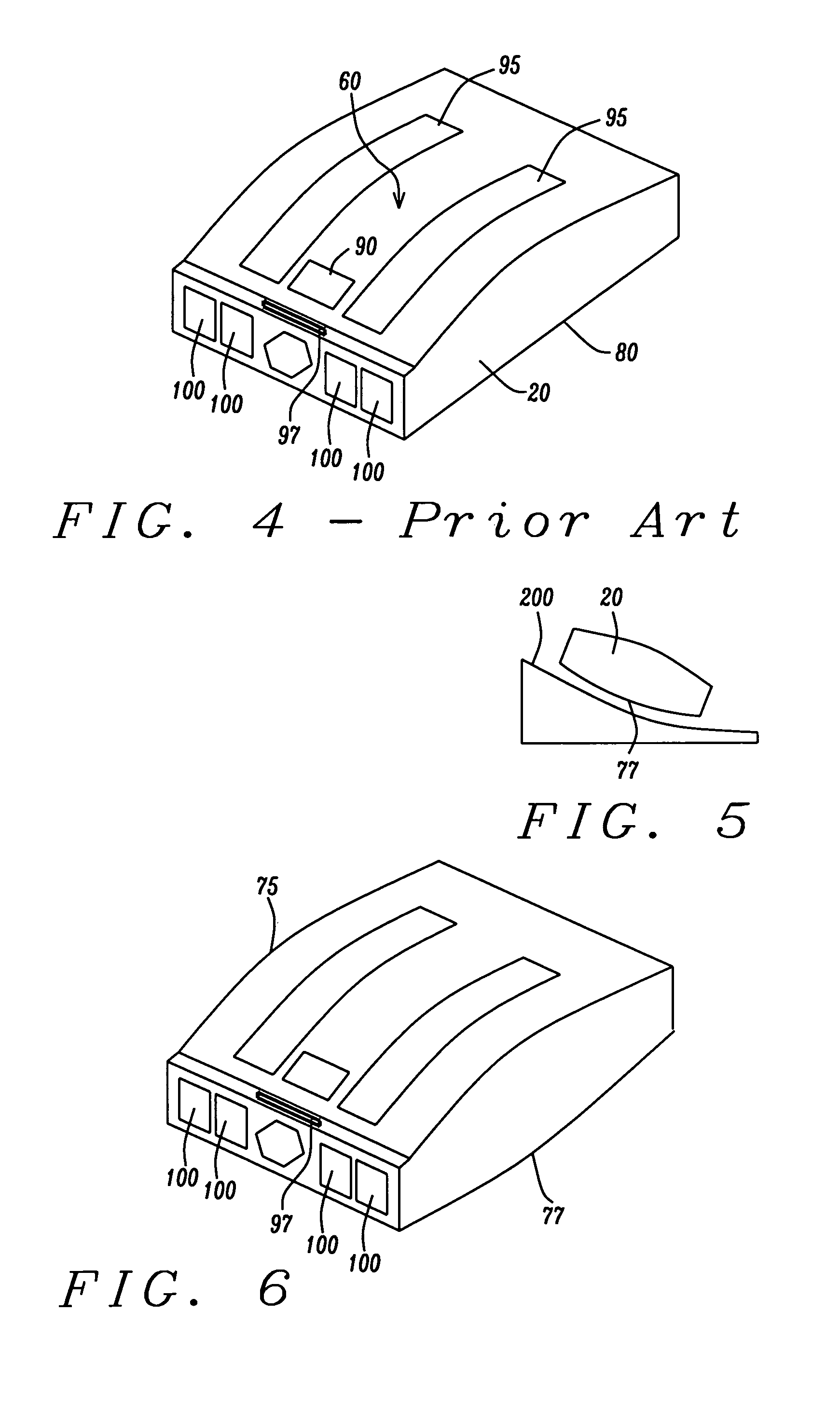

Method to improve crown sigma control of the slider in a hard disk drive

InactiveUS7562435B2Strict controlMinimal modificationElectrical transducersLamination ancillary operationsHard disc driveEngineering

Owner:SAE MAGNETICS (HK) LTD

Material for magnesium alloy doors and windows and production method of material

The invention discloses a material for magnesium alloy doors and windows. The material for the magnesium alloy doors and windows is composed of Mg, Al, Mn, Zn, Cu, Ni, Sc, P, Zr, Y, Ca, Sr, B, Co and a rare earth element, wherein the rare earth element is composed of Ce, Nd, Gd, Pr, Dy, Yb, La and Sm; the invention further discloses a production method of the material for the magnesium alloy doors and windows, and the method comprises the following steps: smelting, heat treatment, forging, quenching and tempering heat treatment, cooling, checking and storing, the production method is simple and easy, the manufacturing cost is low, and the produced material for the magnesium alloy doors and windows is excellent in corrosion resistance, can resist high temperature, is solderable, and has a prolonged service life.

Owner:SUZHOU CITY WUZHONG DISTRICT XUKOU FENGSHOU MACHINERY PARTS FACTORY

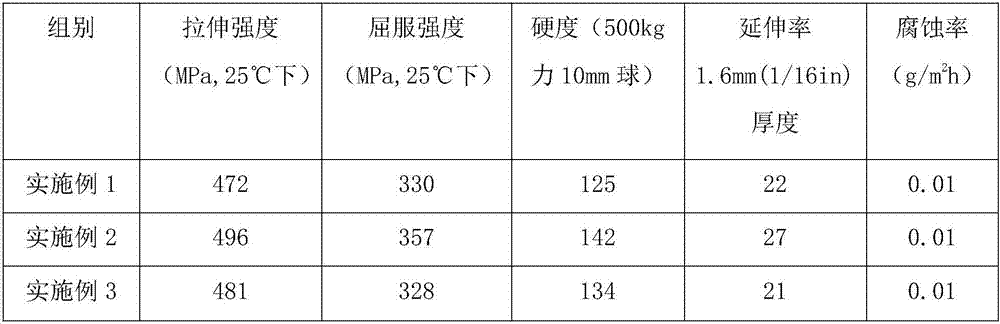

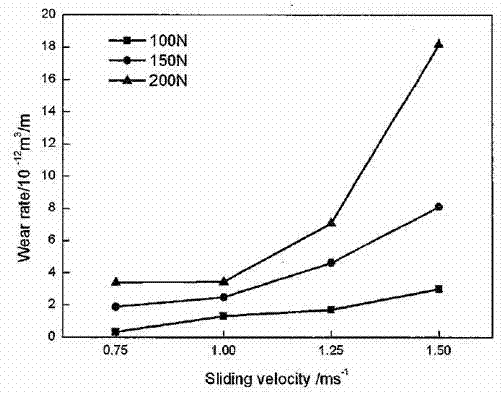

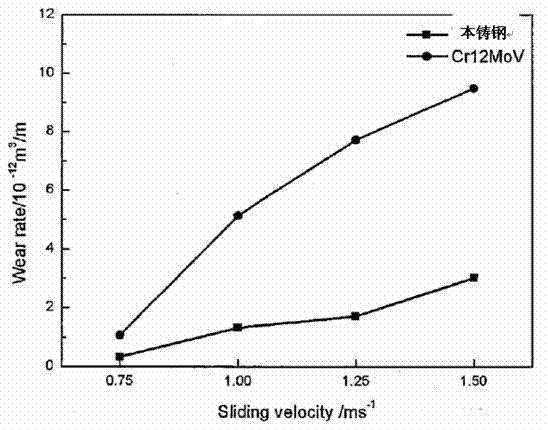

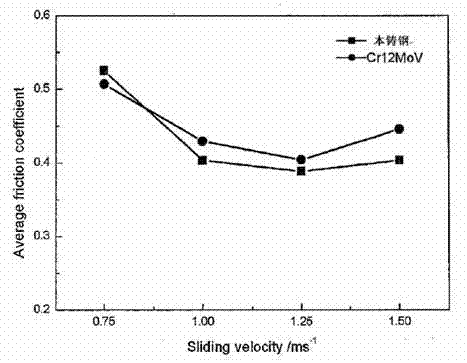

Casting medium alloy steel for cold stamping mould of automobile

The invention relates to casting medium alloy steel for a cold stamping mould of an automobile. The casting medium alloy steel is characterized by comprising the following chemical components in percentage by weight: 0.50-0.65% of C, 0.90-1.20% of Si, 0.60-0.90% of Mn, 4.50-5.50% of Cr, 0.75-0.90% of Mo, 0.70-0.80% of V, less than or equal to 0.02% of S or less than or equal to 0.03% of P. The casting medium alloy steel has high wear resistance and strong toughness, is low in production cost, is easy to process, has the overall quenching hardness of HRC59-62 and can meet the use requirements of the mould.

Owner:CHINA FIRST AUTOMOBILE +1

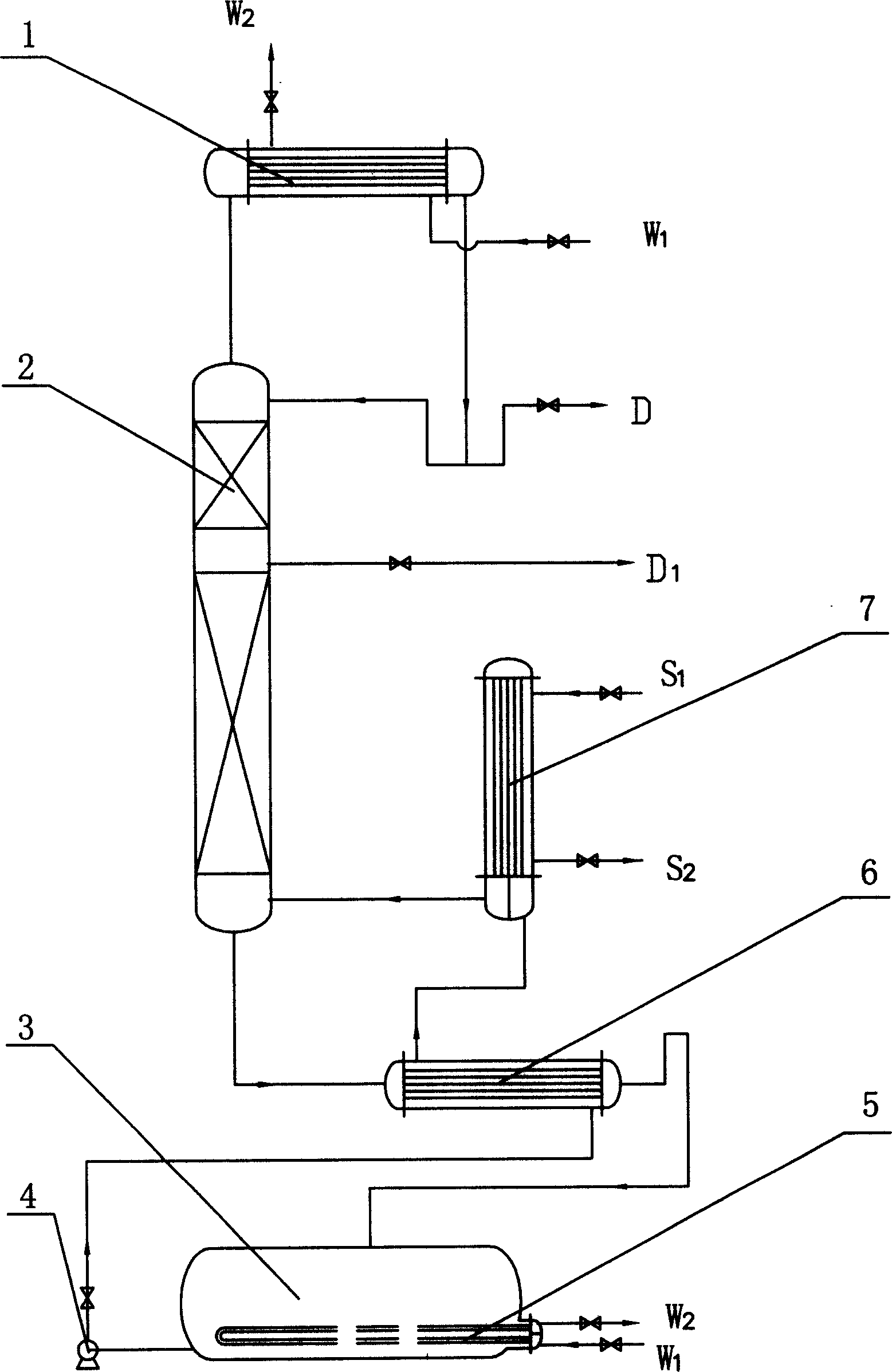

Thermosensitive material intermittent rectifying process having side material output and tower kettle cold material storage

An intermittent rectifying system with side discharge and cold storage of material on top for the thermosensitive material is composed of cold storaging tower still, rectifying tower with side discharging, condenser, cooler, shielding pump and evaporator. The thermosensitive material is stored in cold state. Its advantages are short rectifying time, low thermodecomposing rate of raw material, and high purity and output rate of product.

Owner:TIANJIN UNIV

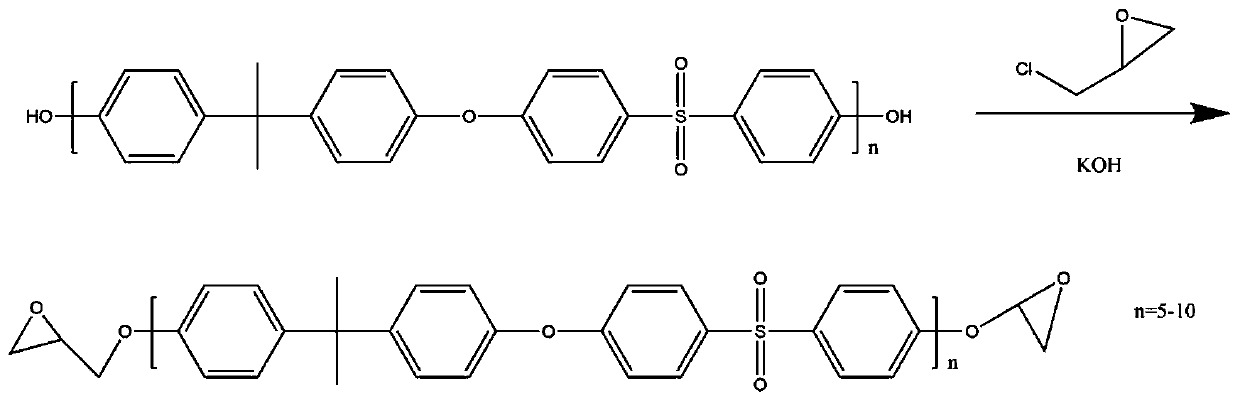

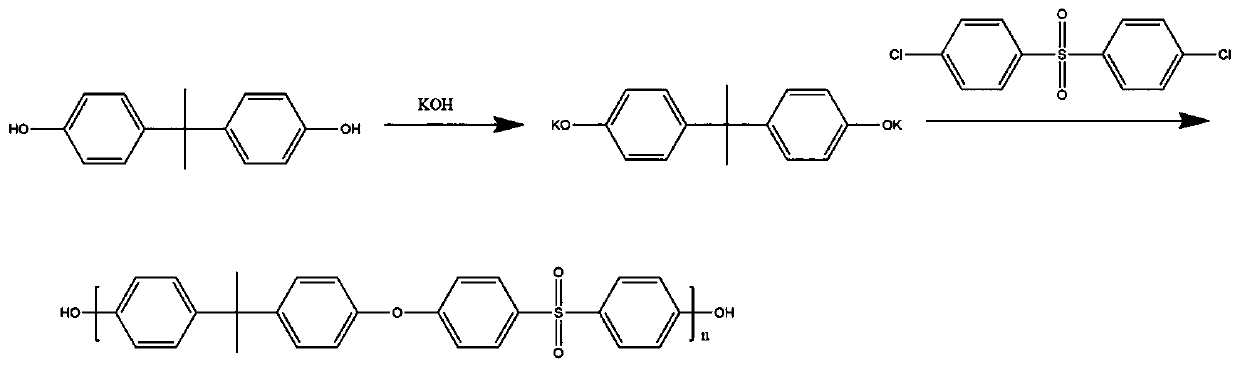

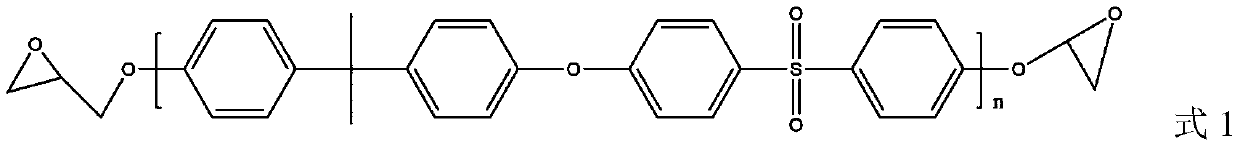

High heat resistant epoxy resin and preparation method thereof

The invention relates to a high heat resistant epoxy resin and a preparation method thereof. The high heat resistant epoxy resin is obtained by curing of epoxy terminated modified oligomeric polyethersulfone and bisphenol A epoxy resin. By introducing the polyether sulfone structure with high heat resistance and good flexibility into the main chain of epoxy resin, the heat resistance and flexibility of the epoxy resin are greatly improved, and the obtained epoxy resin has the characteristics of low viscosity, good heat resistance and high flexibility, and can be widely applied to the field ofcarbon fiber composite materials with high heat resistance and high flexibility requirements.

Owner:张家港楚人新材料科技有限公司

Reversible thermosensitive recording medium and reversible thermosensitive recording member

ActiveUS20120238446A1High degreeImprove surface roughnessAblative recordingThermographyPolyesterHeat sensitive

A reversible thermosensitive recording medium including: a support; a reversible thermosensitive recording layer on the support; and a protective layer on the reversible thermosensitive recording layer, wherein the reversible thermosensitive recording layer contains an electron-donating color-forming compound and an electron-accepting compound, wherein the protective layer contains a polyester acrylate resin, and wherein the protective layer has a glass transition temperature of 230° C. or higher and has an elongation of 10% or higher.

Owner:RICOH KK

Corrosion-resistant high-carbon steel alloy material and preparation method thereof

ActiveCN103882310AReduce temper brittlenessStable and uniform qualityProcess efficiency improvementPorosityNiobium

A corrosion-resistant high-carbon steel alloy material comprises the following chemical elements by mass percent: 0.7-1.0 percent of carbon, 0.7-0.9 percent of silicon, 0.2-0.4 percent of copper, 0.05-0.08 percent of aluminum, 3.3-2.5 percent of manganese, 6.0-6.5 percent of Ni, 0.05-0.09 percent of titanium, 0.3-0.5 percent of boron, 0.1-0.3 percent of Mo, 0.002-0.005 percent of niobium, 0.001-0.003 percent of Ta, 0.03-0.05 percent of Co, less than or equal to 0.030 percent of P, less than or equal to 0.030 of S and the balance of iron. The alloy material, which is prepared from the raw materials including niobium and aluminum by reasonably setting the proportion, production process and dispensing order, has the characteristics of very high strength, hardness and wear resistance, low thermosensitivity, low temper brittleness, atmosphere corrosion resistance, and hydrogen, nitrogen and ammonia corrosion resistance at high temperature; the porosity is decreased by 1-2 degrees by adding a refining agent.

Owner:吉林旭辰机械制造有限公司

Optical device and associated methods

ActiveUS8054564B1Excellent photothermal performanceReduce in quantityPaper-makingBox making operationsEngineering

Owner:FLIR SYSTEMS TRADING BELGIUM BVBA

Automobile semi-axle forging and stamping die

InactiveCN106591685APrevent temper brittlenessReduce heat sensitivityForging/hammering/pressing machinesFerromanganeseFerrosilicon

The invention relates to a forging and stamping die, in particular to an automobile semi-axle forging and stamping die. The automobile semi-axle forging and stamping die is formed by smelting following materials including, by weight, 90-110 parts of 45# steel, 0.8-1.5 parts of silicon iron, 0.6-1.2 parts of ferrovanadium, 5-10 parts of tungsten carbide powder, 0.6-1 part of mid-carbon ferromanganese and 0.05-0.1 part of low-carbon ferrochromium. The automobile semi-axle forging and stamping die provided by the invention is good in material matching and casting density, even in structure, high in strength, resistant to high temperature and long in service life.

Owner:LIUZHOU TONGWEI MACHINERY

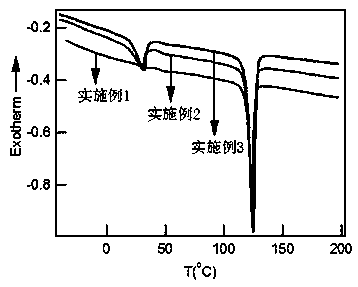

High-temperature anti-rutting modified asphalt and preparation method thereof

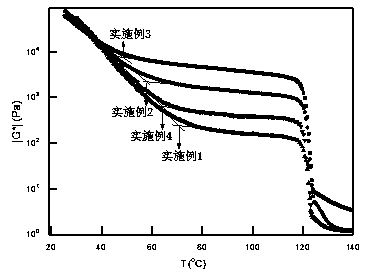

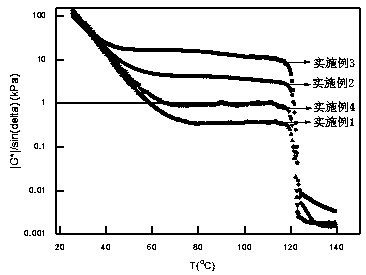

ActiveCN109880389AReduce heat sensitivityPrevent macroscopic deformationBuilding insulationsPolymer sciencePolyethylene glycol

The invention provides high-temperature anti-rutting modified asphalt and a preparation method thereof. Two kinds of crystalline polymers are used for preparing modified asphalt with the phase changeheat absorption effects. The modified asphalt is concretely prepared from the following raw materials in parts by weight: 65 to 100 parts of substrate asphalt, 0 to 10 parts of polyethylene and 0 to 10 parts of polyethylene glycol, wherein the contents of the polyethylene and the polyethylene glycol cannot be zero at the same time; the polyethylene and the polyethylene glycol are jointly phase change materials; the crystal-amorphous phase change heat suction characteristics are given to the modified asphalt; by changing the relative content of the polyethylene and the polyethylene glycol, thecontrollable regulation of the phase change window temperature of the modified asphalt is realized; the high-temperature sensitivity of the asphalt is reduced; the polyethylene is a framework material, the occurrence of macroscopical deformation during the phase change of the material can be prevented; the high-temperature anti-rutting capability and the rheological stability of the modified asphalt are obviously improved; the service life of the asphalt pavement is effectively prolonged. The preparation method is simple; the control is easy; the raw materials are simple and can be easily obtained; the industrialized production is easy; good application prospects are realized.

Owner:CHONGQING UNIV OF TECH

Optical device and associated methods

InactiveUS20120050879A1Excellent photothermal performanceReduce in quantityBox making operationsPaper-makingEngineeringCorrelation method

Owner:FLIR SYSTEMS TRADING BELGIUM BVBA

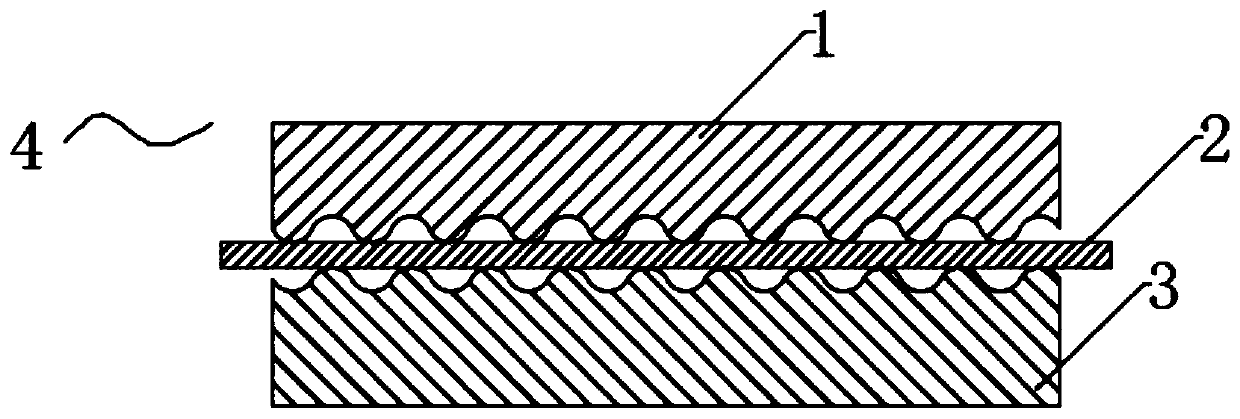

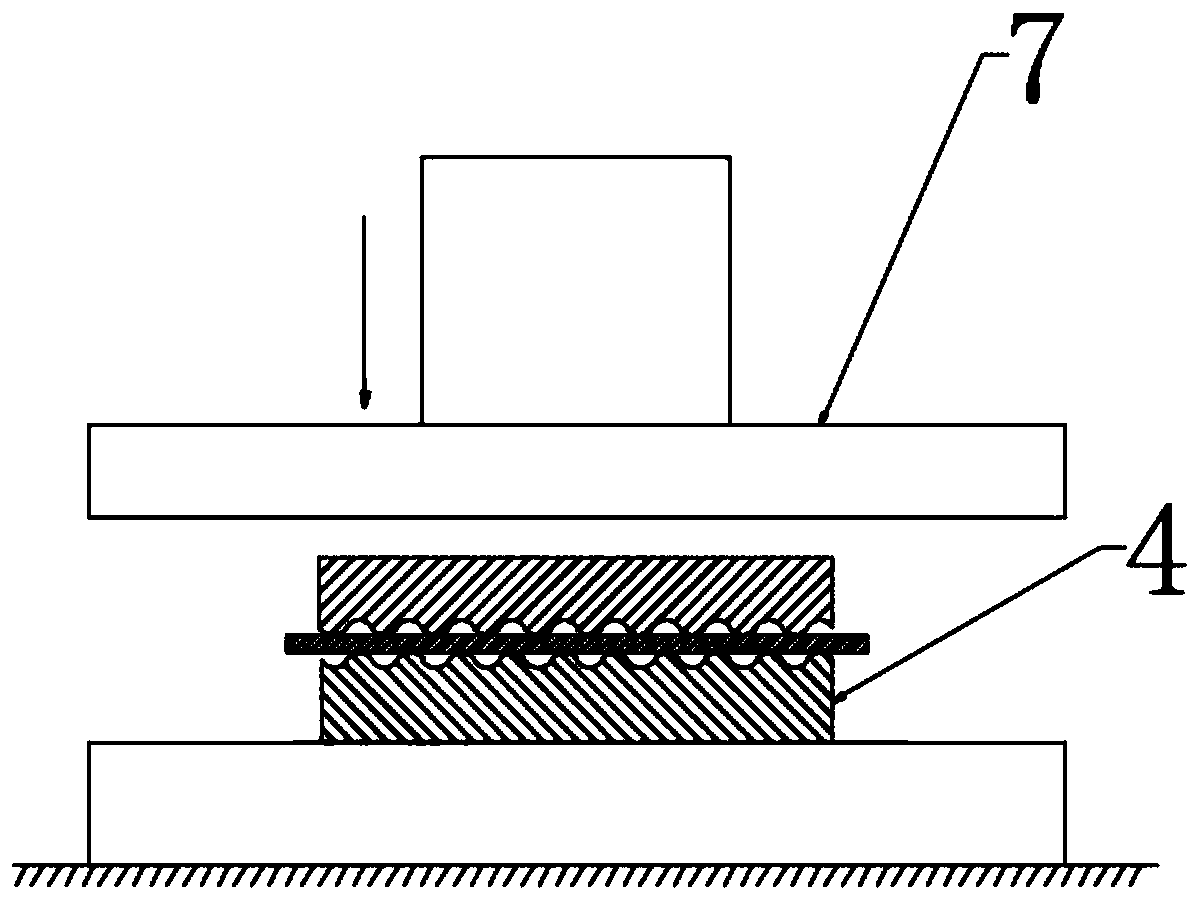

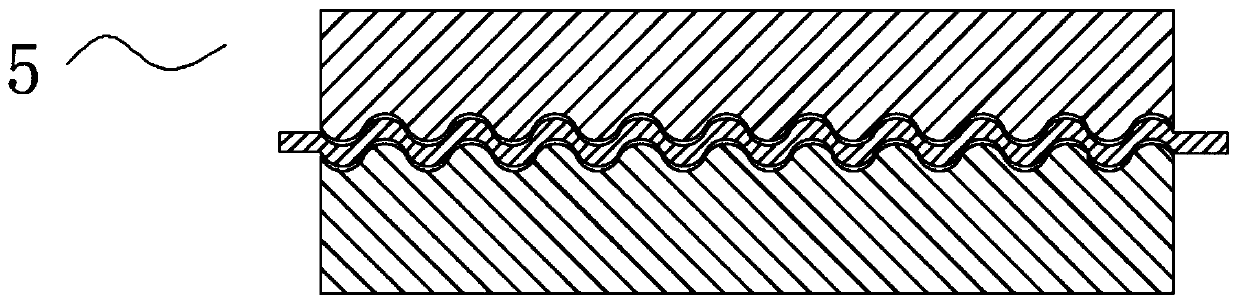

Preparation method for interface space metallurgy bonded aluminum alloy-aluminum-steel transition joint

ActiveCN111230513AReduce difficultyReduce heat sensitivityOther manufacturing equipments/toolsComposite plateUltimate tensile strength

The invention relates to a preparation method for an interface space metallurgy bonded aluminum alloy-aluminum-steel transition joint. The preparation method specifically comprises the following steps: 1) processing a corrugated surface of a to-be-compounded steel plate and a corrugated surface of an aluminum alloy board, and processing the to-be-compounded steel plate, an aluminum board and a to-be-compounded surface of the aluminum alloy board; 2) assembling the to-be-compounded steel plate, the aluminum board and the aluminum alloy board to form assembly blank; 3) compressing and compounding the assembly blank on a press, thereby preparing a primarily bonded aluminum alloy-aluminum-steel composite board; 4) placing the primarily bonded aluminum alloy-aluminum-steel composite board on ahigh-temperature pressure tester, performing micro-pressure thermal diffusion treatment, and finally forming a space metallurgy bonded aluminum alloy-aluminum-steel composite board; and 5) performingedge-cutting treatment on the space metallurgy bonded aluminum alloy-aluminum-steel composite board to obtain the aluminum alloy-aluminum-steel transition joint. The preparation method realizes interface regular-space metallurgical bonding, so that the product is stable in performance, and is reduced in thermal sensitivity of interface strength after being subjected to micro-pressure diffusion annealing.

Owner:山西先进成形智能装备股份有限公司

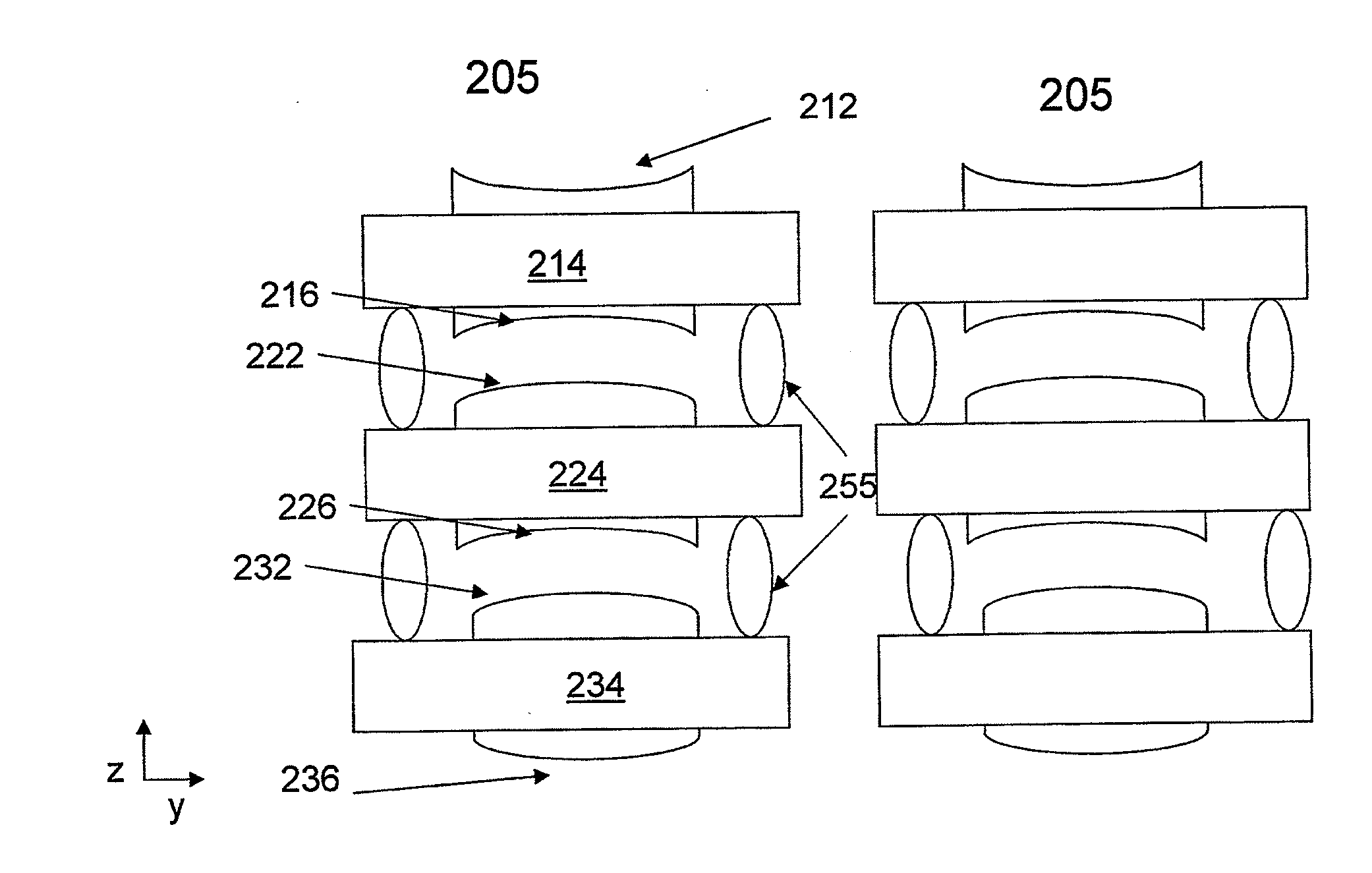

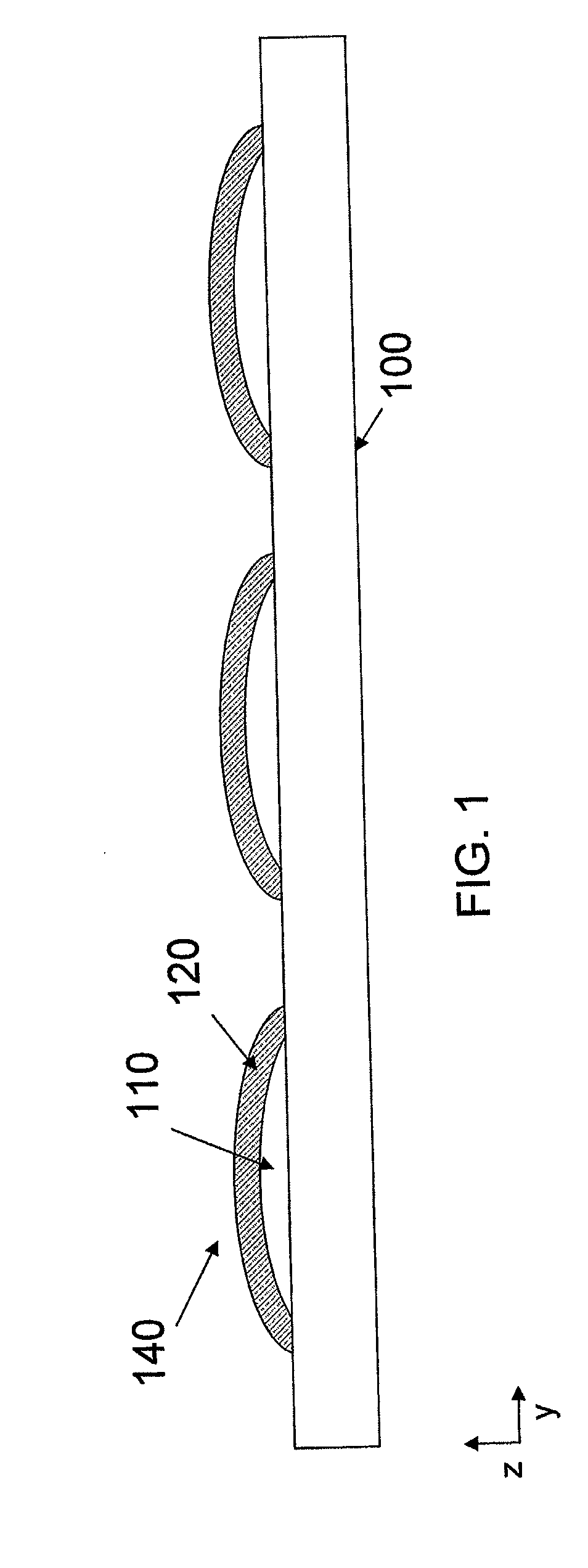

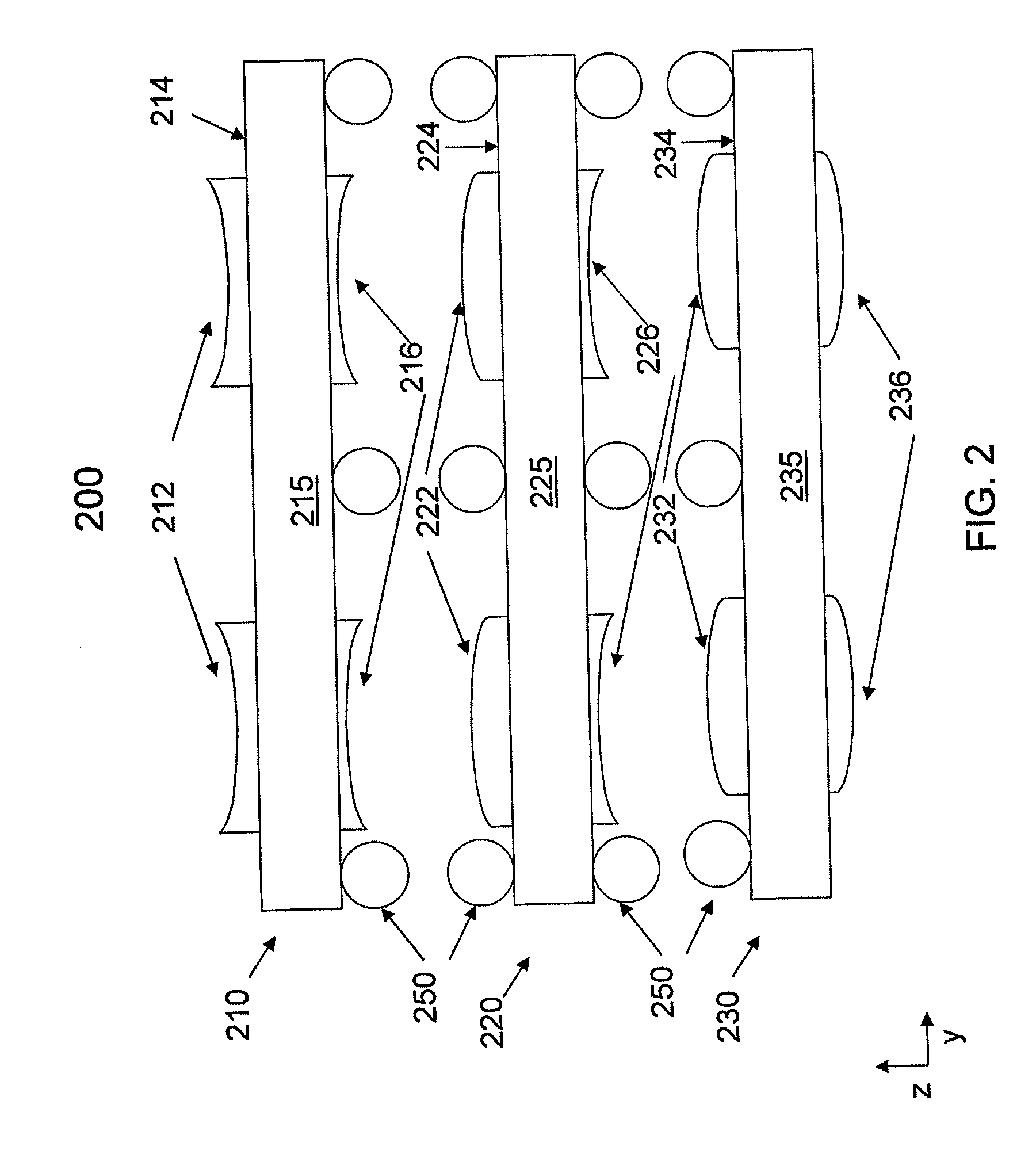

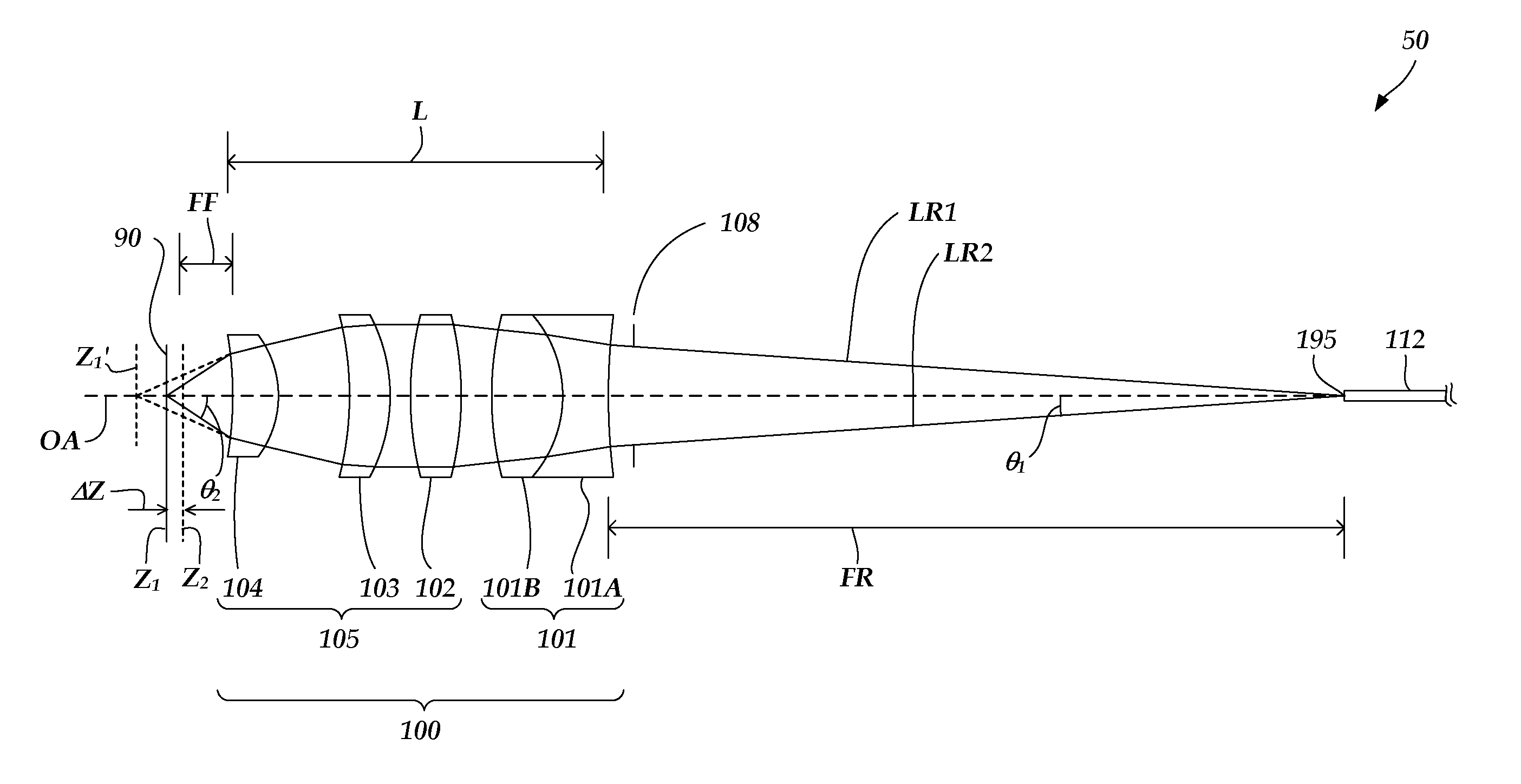

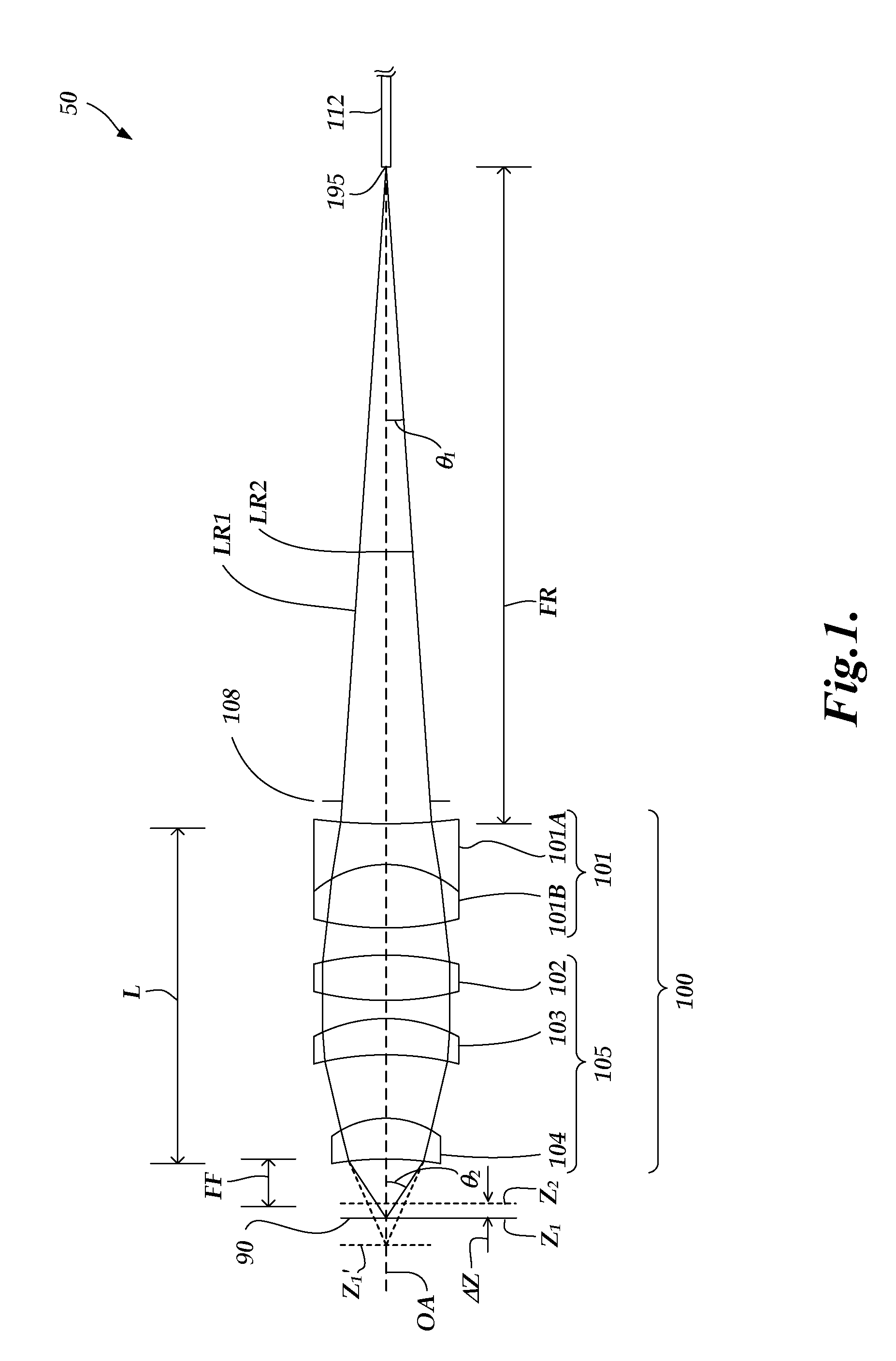

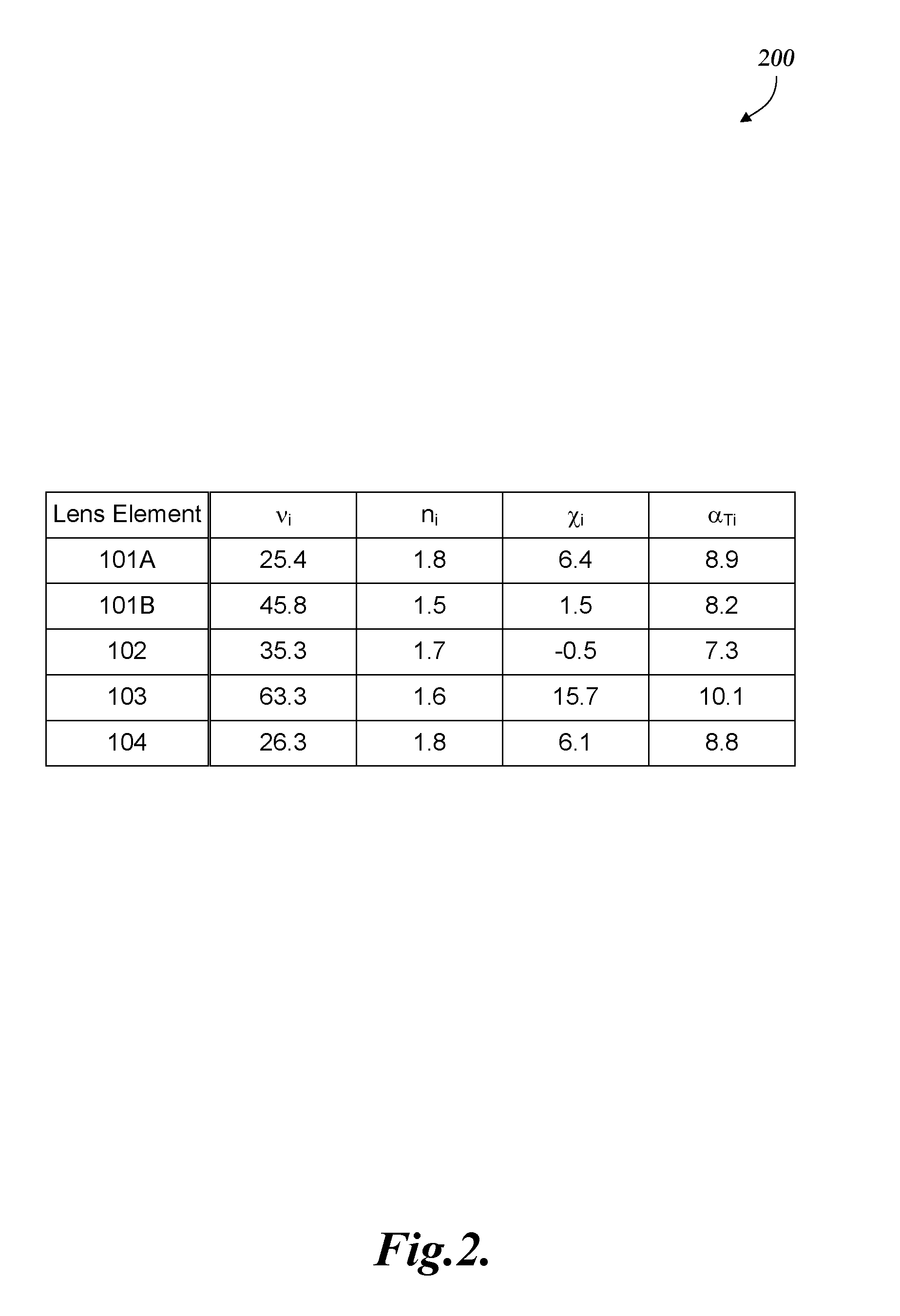

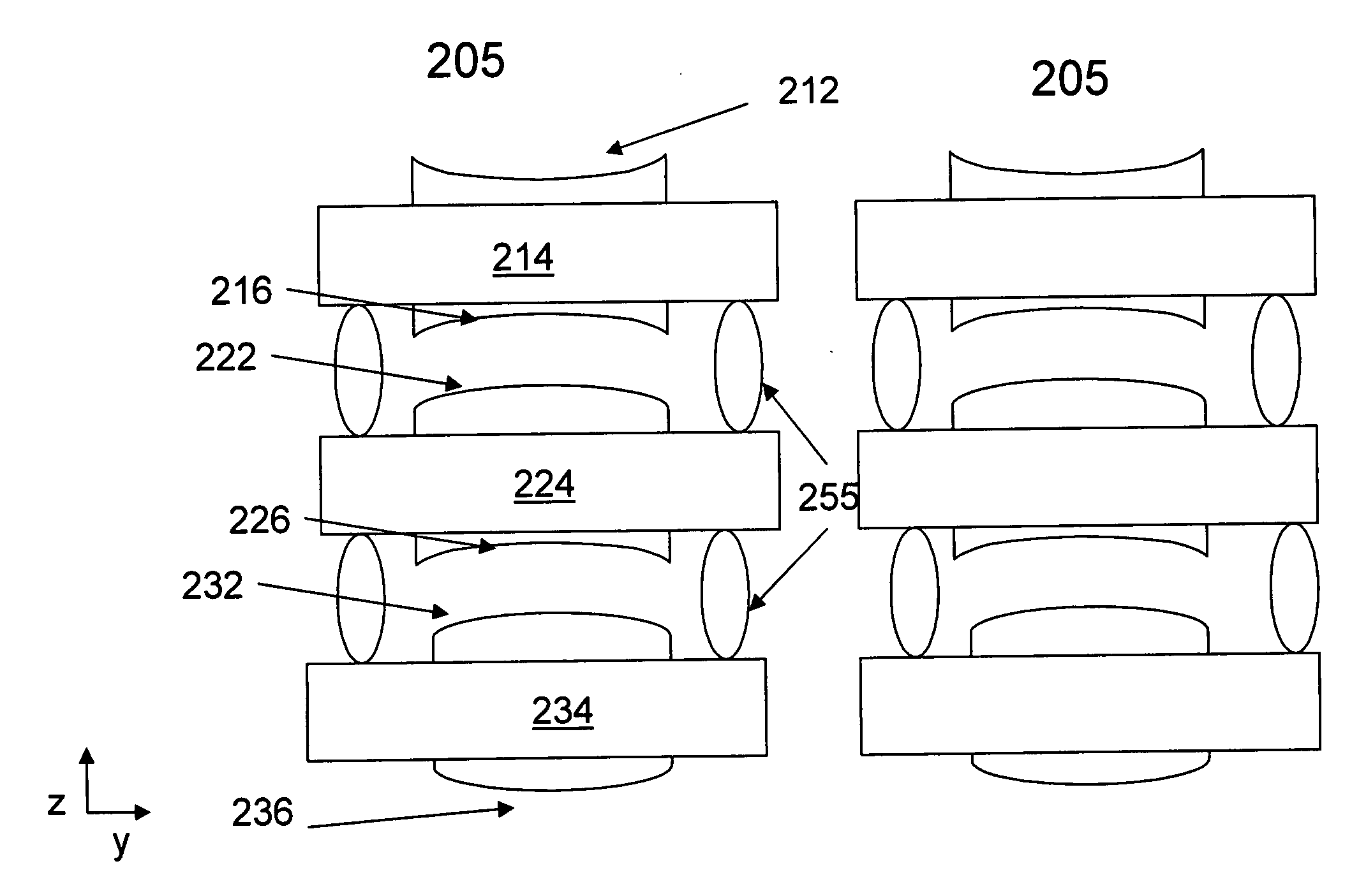

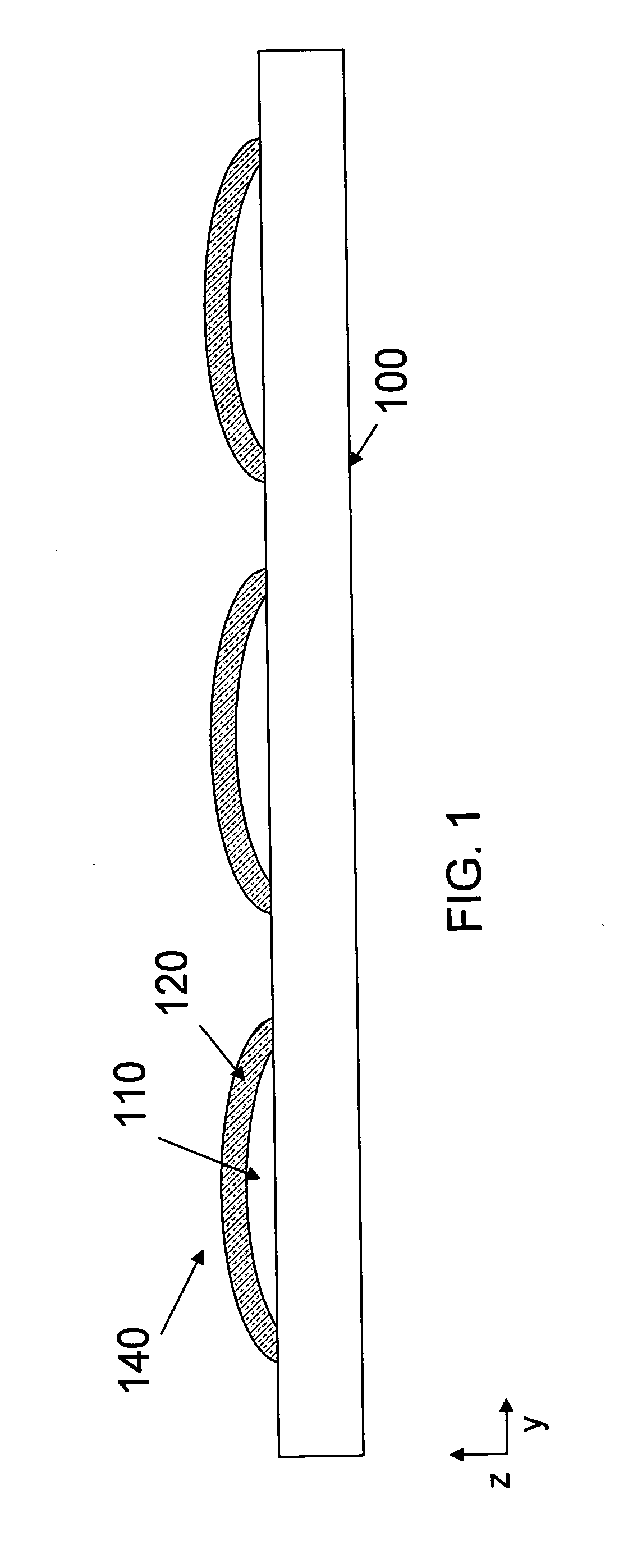

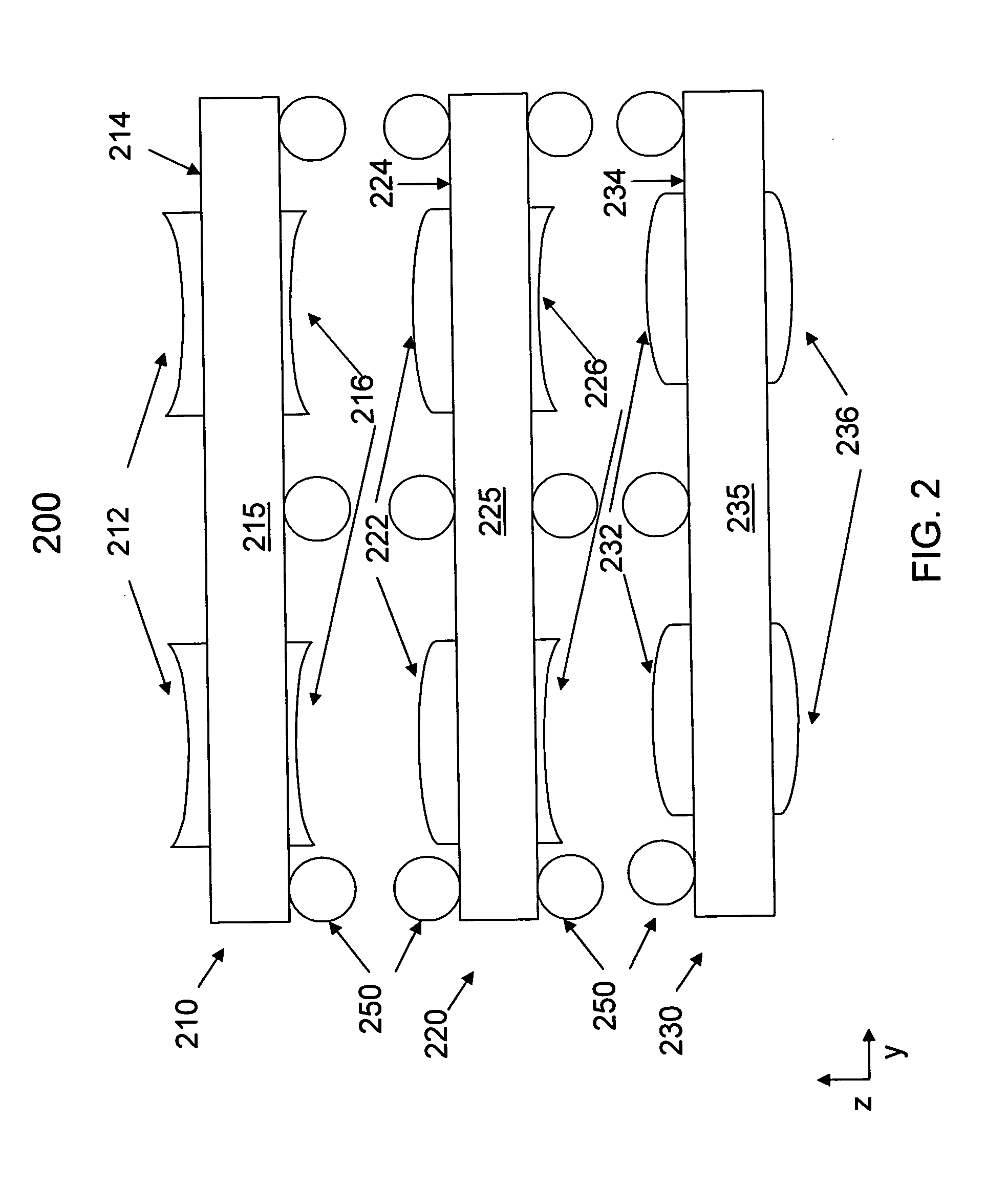

Lens configuration for a thermally compensated chromatic confocal point sensor

ActiveUS20110228250A1Reduce complexityReduce expensesOptical rangefindersHeight/levelling measurementCamera lensNegative power

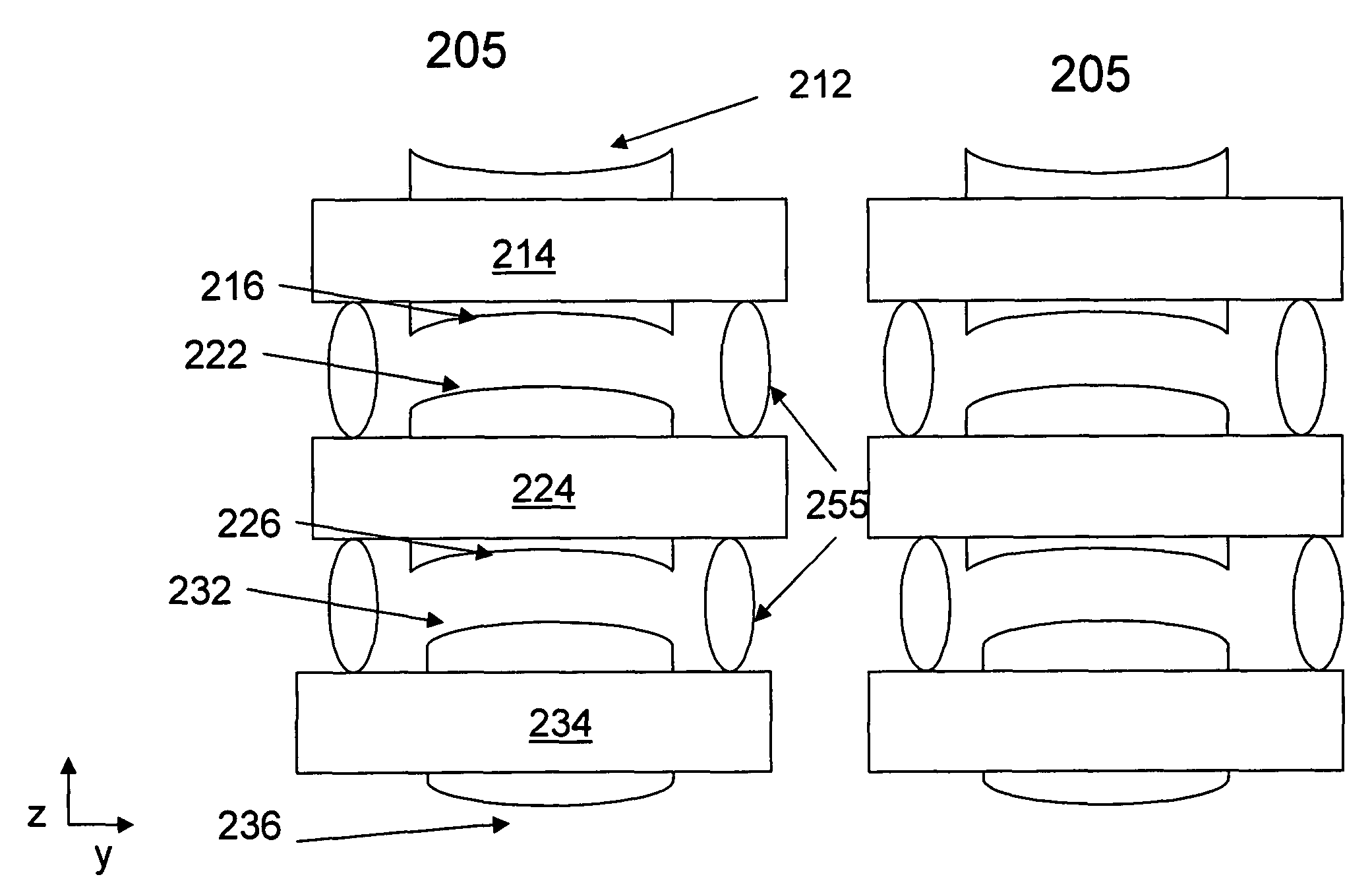

A chromatically dispersive lens configuration including thermal compensation may be utilized in chromatic confocal point sensor optical pens for chromatic range sensing. The lens configuration may include a negative power doublet lens and a positive power lens portion. The positive power lens portion comprises at least two lens elements which compensate for the overall thermal sensitivity of a chromatic confocal point sensor optical pen. The lens elements of the positive power lens portion which compensate for thermal sensitivity have an average coefficient of thermal defocus which is in a range that is at lowest 10 ppm per 10° C. The lens configuration can be implemented with dimensions which fit a standard commercial chromatic confocal point sensor optical pen, while maintaining a level of optical performance sufficient for chromatic range sensing.

Owner:MITUTOYO CORP

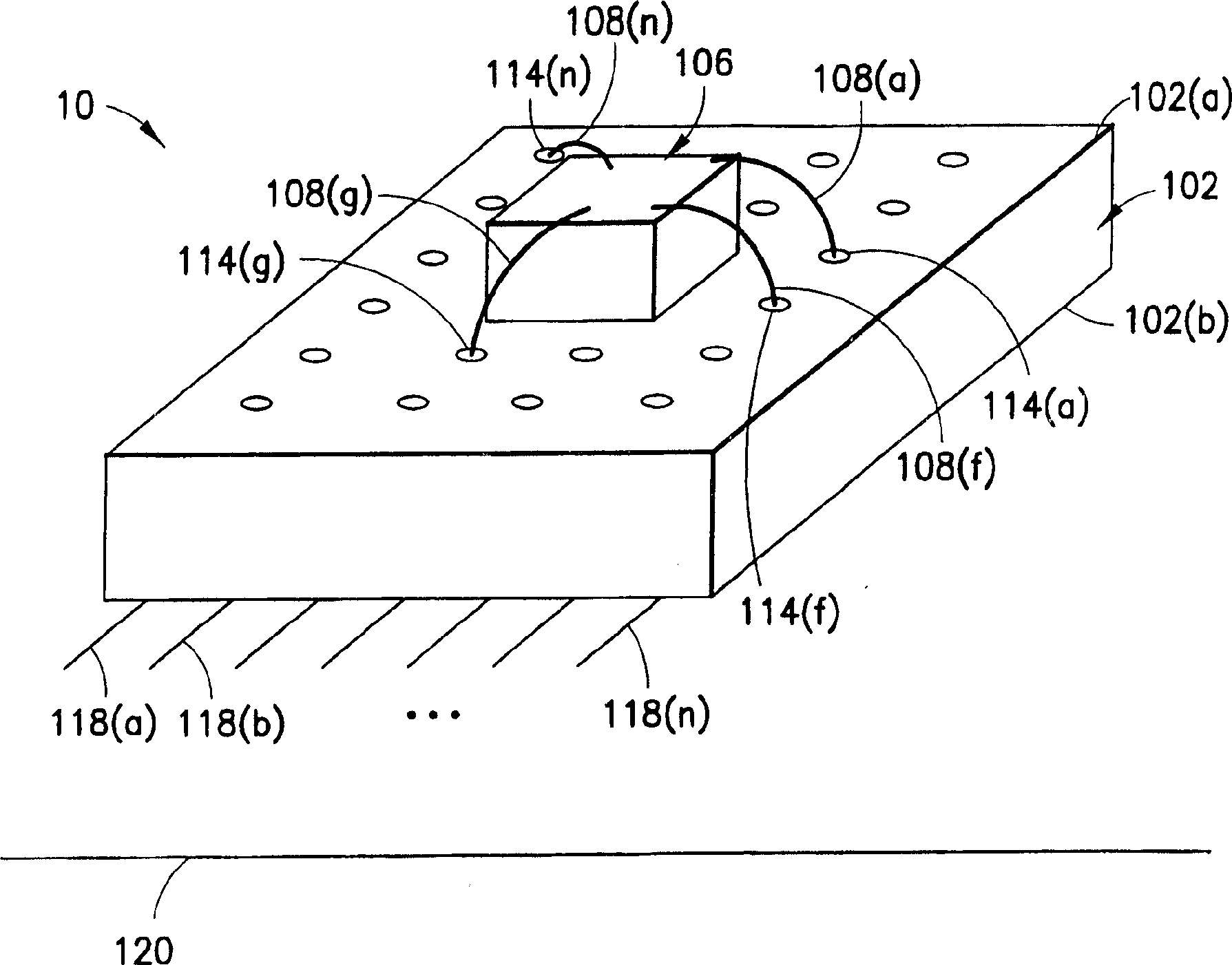

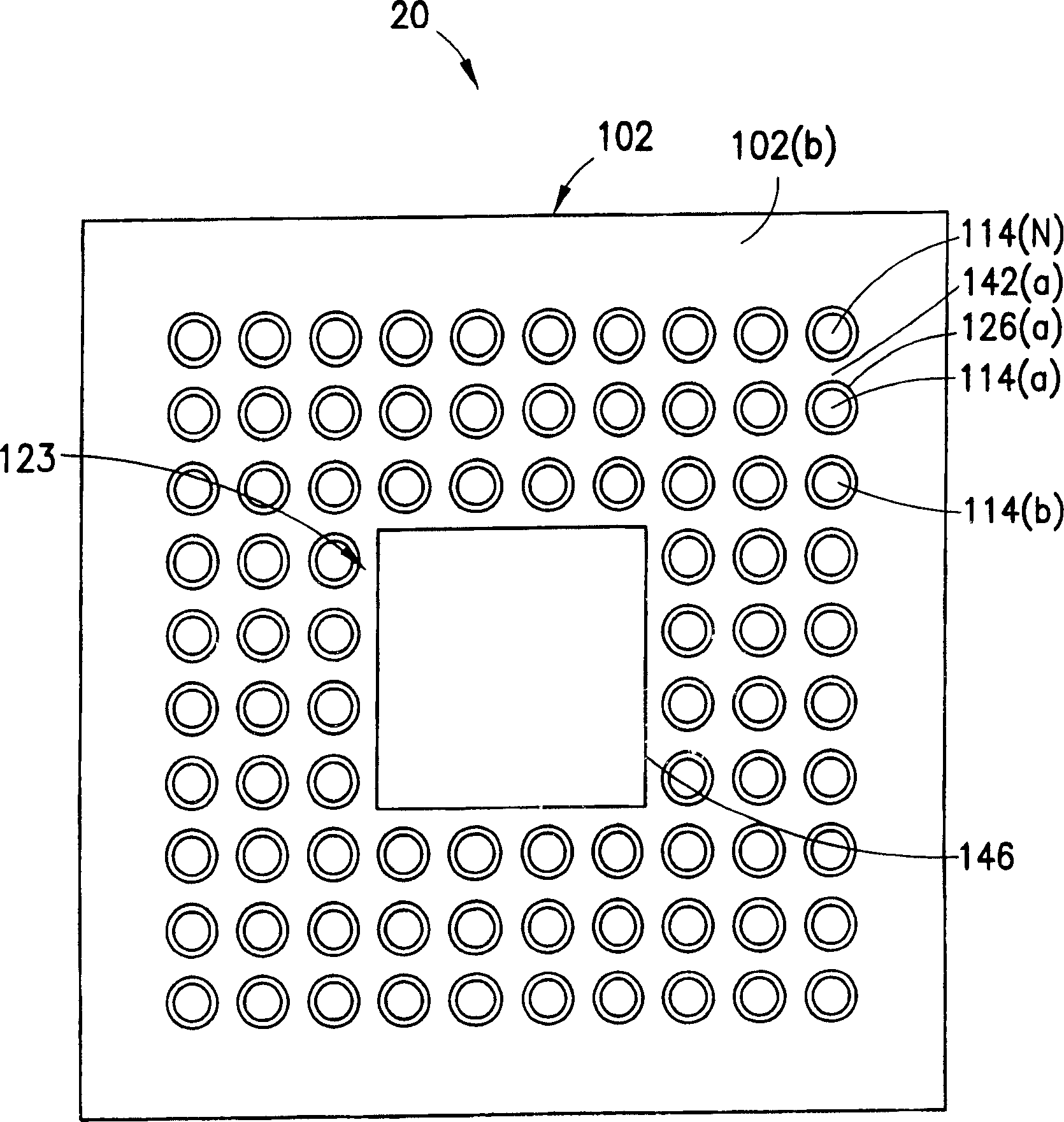

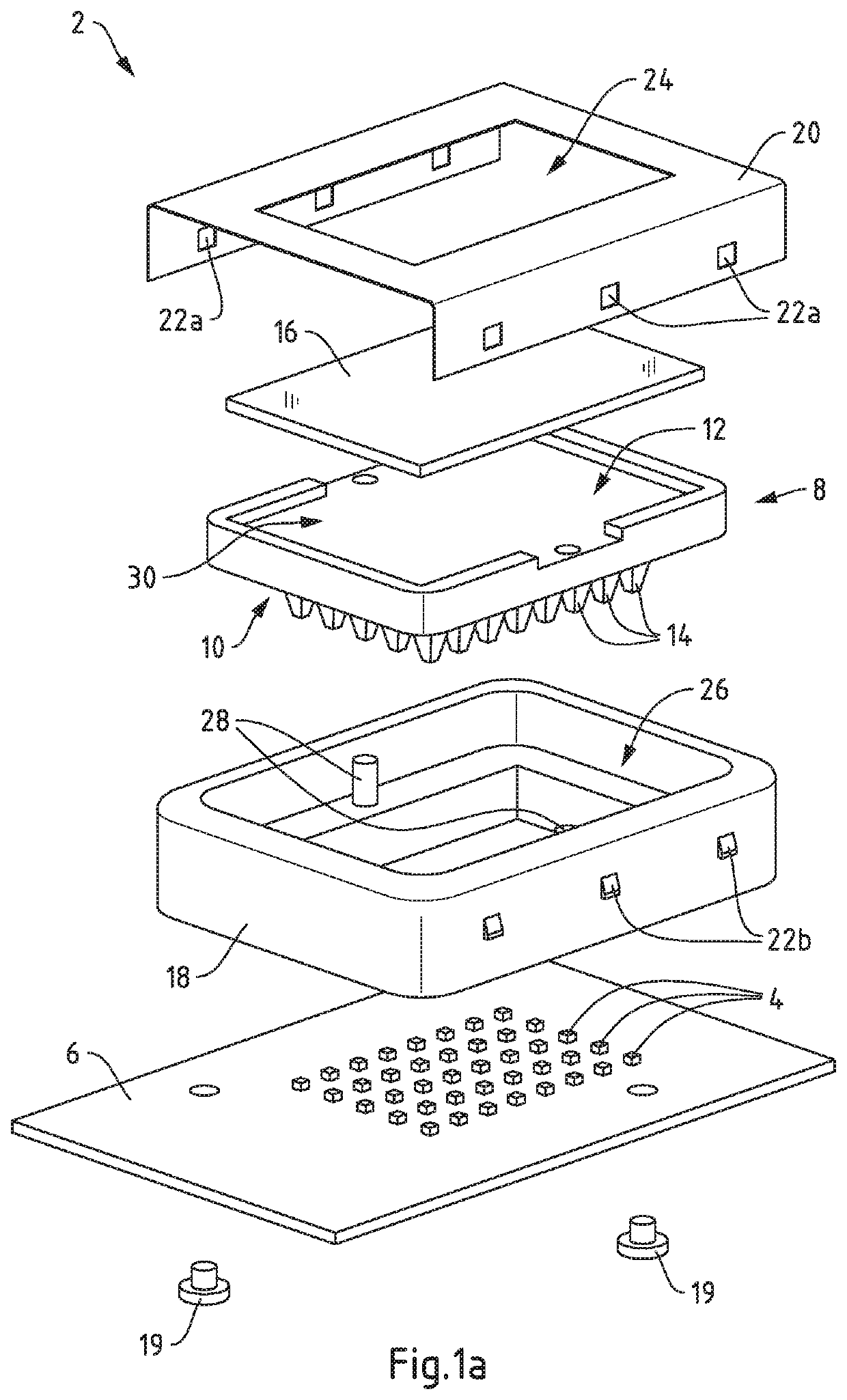

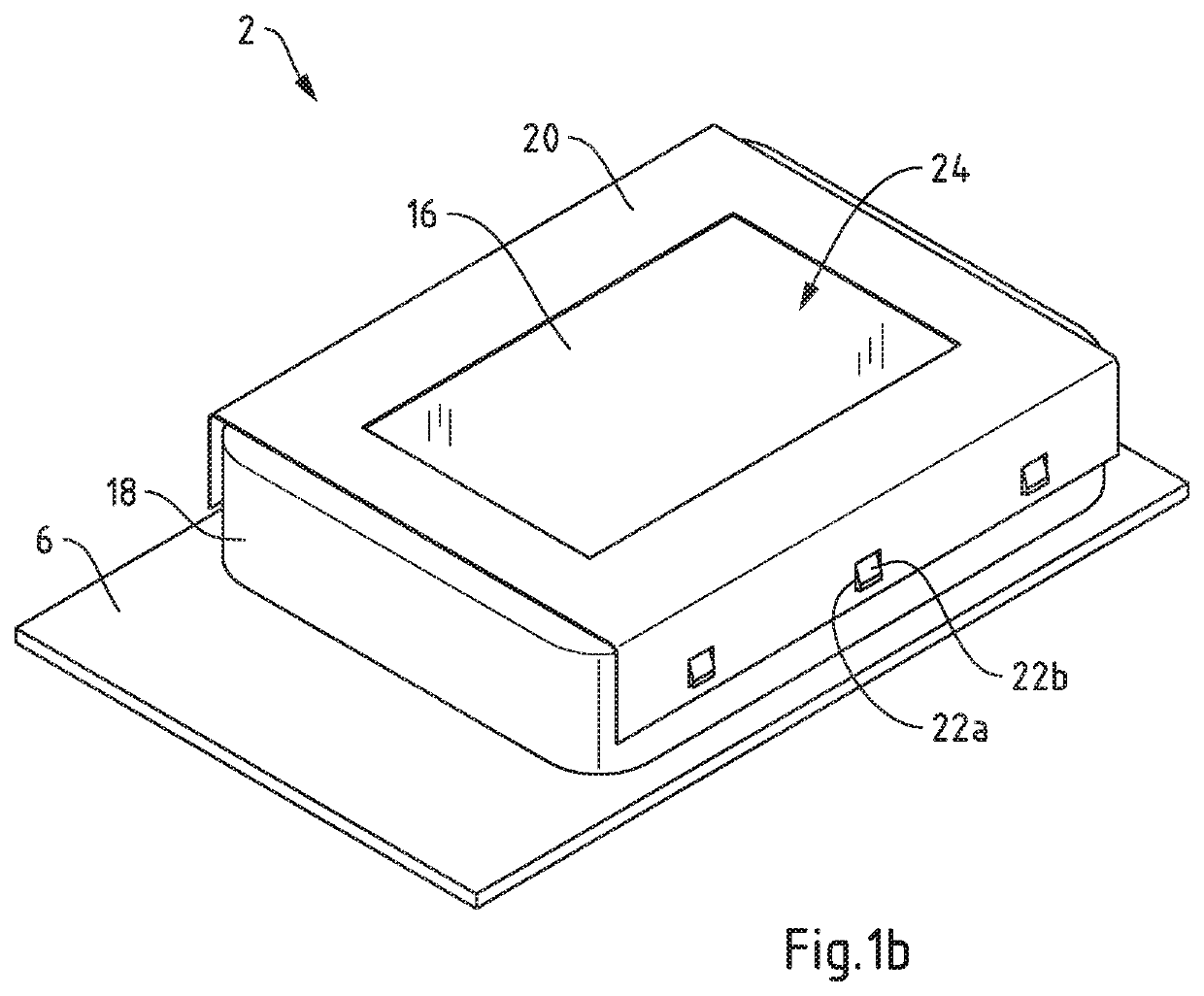

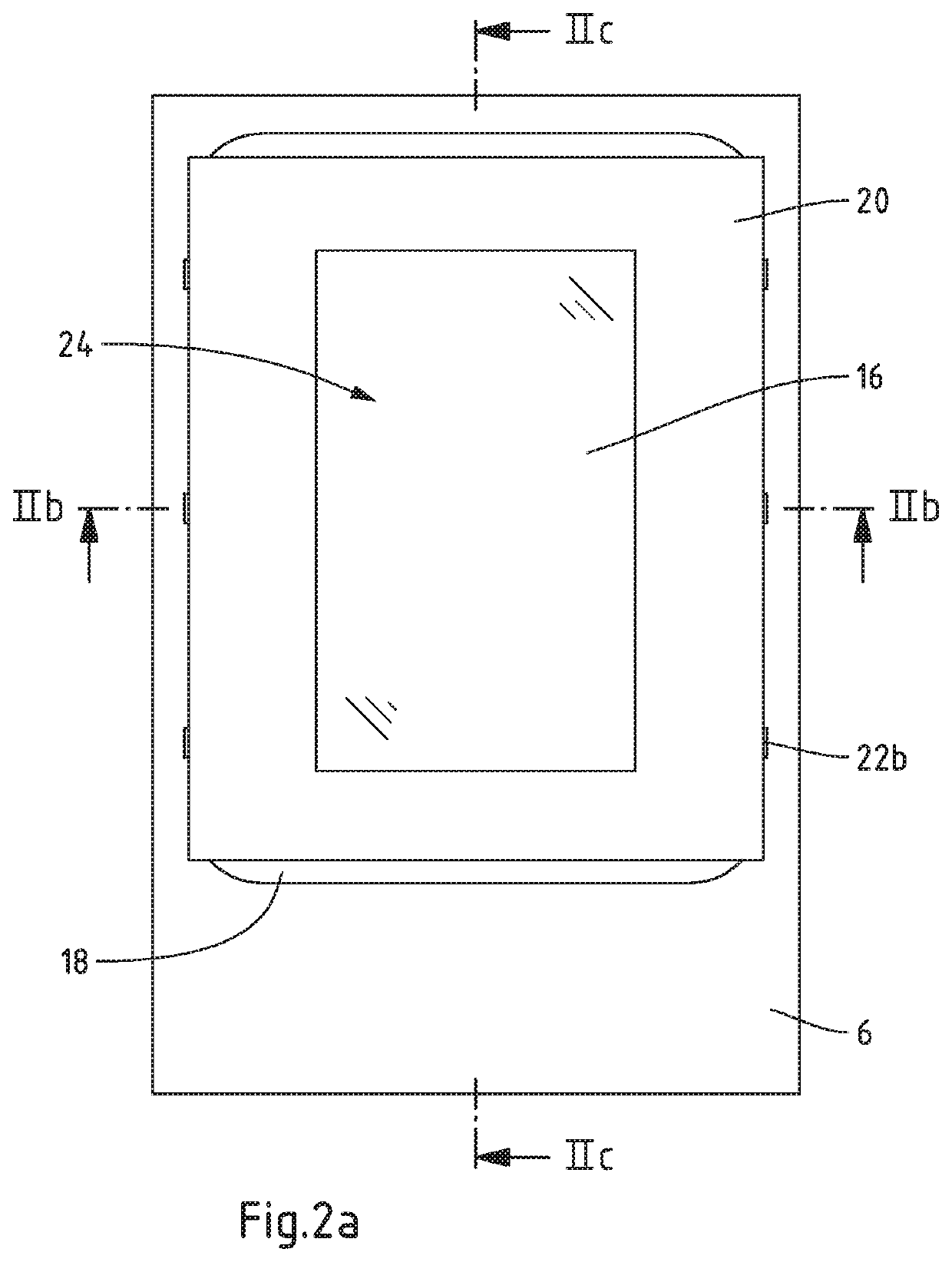

Thermally enhanced component substrate

InactiveCN1574308AImprove thermal performanceSmall thermal performanceSemiconductor/solid-state device detailsSolid-state devicesThermal energySolder ball

An IC package dissipates thermal energy using thermally and electrically conductive projections. The IC package includes a substrate material with a die pad area, which is suitable to support an integrated circuit. A plurality of solder ball pads is disposed on a first surface of the substrate material and a plurality of conductive projections radiate outwardly from the die pad area and extend to cover a corresponding selected solder ball pad to facilitate the dissemination of thermal energy from the die pad area to the substrate and / or printed wiring board.

Owner:NOKIA TECHNOLOGLES OY

Lighting device with transparent stabilizer element

ActiveUS20200309342A1Reduce heat sensitivitySimple wayVehicle headlampsRefractorsLight guideEngineering

The present disclosure relates to a lighting device comprising light-emitting elements such as light-emitting diodes arranged on a substrate. The object to provide a lighting device comprising multiple light-emitting elements and light guides, wherein the thermal sensitivity of the lighting device is reduced in a particularly simple manner, is solved in that the lighting device comprises: a lens with a light entry side and a light exit side; light guides, each light guide being arranged in optical contact to at least one of the light-emitting elements and being configured to guide light emitted by the at least one of the light-emitting elements towards the light entry side of the lens; and a transparent stabilizer element being arranged in mechanical contact to the light exit side of the lens, wherein the transparent stabilizer element is configured to define the shape of the light exit side of the lens at least in regions. The invention further refers to a method for producing a lighting device.

Owner:LUMILEDS

Optical device and associated methods

InactiveUS20110273779A1Excellent photothermal performanceReduce in quantityBox making operationsPaper-makingEngineering

Owner:FLIR SYSTEMS TRADING BELGIUM BVBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com