Anti-corrosion aluminum alloy door and window and manufacturing process thereof

A corrosion-resistant aluminum alloy and preparation technology, which is applied in the field of aluminum alloy doors and windows, can solve the problems that affect popularization and use, difficult processing, poor plasticity, etc., and achieve the effects of not being prone to aging and oxidation, reducing heat sensitivity, and enhancing plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

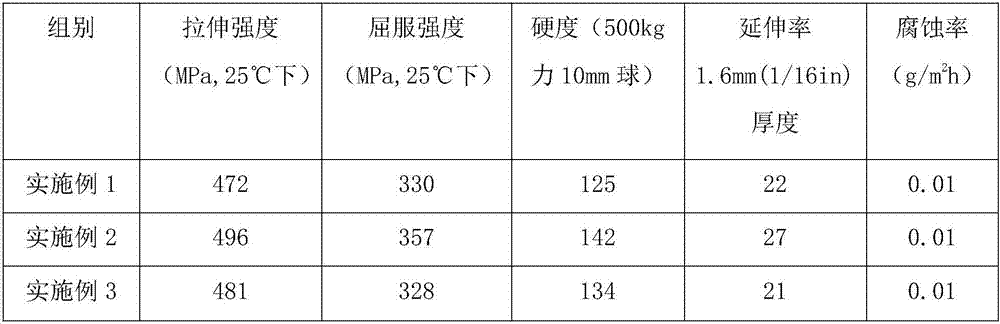

Examples

Embodiment 1

[0028] A corrosion-resistant aluminum alloy door and window, comprising the following components by weight percentage: Mg: 3%, Mn: 2%, Zn: 6%, Ni: 1%, Si: 2%, Sc: 0.8%, P: 0.2 %, Zr: 0.3%, Y: 1%, Ca: 3%, Sr: 1%, B: 0.4%, Co: 2%, Sr: 0.6%, and rare earth elements: 1%, the rest is Al and unavoidable Impurities, and the mass percentage of the impurities is less than or equal to 0.5%;

[0029] The rare earth elements include the following components by weight percentage: Nd: 25%, Gd: 20%, Pr: 5%, Yb: 10%, La: 6%, Dy: 7%, Sm: 8%, Ce: 18%, the sum of the above rare earth elements is 100%.

[0030] The preparation process of the above-mentioned corrosion-resistant aluminum alloy doors and windows is carried out according to the following steps:

[0031] (1) Weigh the required raw materials by weight percentage; preheat the smelting furnace, the preheating temperature is 380°C, and last for 1h;

[0032] (2) first transport the Al and impurities to the smelting furnace, and at the s...

Embodiment 2

[0040] A corrosion-resistant aluminum alloy door and window, comprising the following components by weight percentage: including the following components by mass percentage: Mg: 5%, Mn: 3%, Zn: 8%, Ni: 2%, Si: 4% , Sc: 1.0%, P: 0.3%, Zr: 0.5%, Y: 2%, Ca: 4%, Sr: 3%, B: 0.8%, Co: 3%, Sr: 0.8%, and rare earth elements: 2 %, the rest is Al and unavoidable impurities, and the mass percentage of the impurities is less than or equal to 0.5%;

[0041] The rare earth elements include the following components by weight percentage: Nd: 20%, Gd: 15%, Pr: 6%, Yb: 15%, La: 8%, Dy: 8%, Sm: 11%, Ce: 17%, the sum of the above rare earth elements is 100%.

[0042] The preparation process of the above-mentioned corrosion-resistant aluminum alloy doors and windows is carried out according to the following steps:

[0043](1) Weigh the required raw materials by weight percentage; preheat the smelting furnace, the preheating temperature is 420°C, and last for 1.5h;

[0044] (2) First transport t...

Embodiment 3

[0052] A corrosion-resistant aluminum alloy door and window, comprising the following components by weight percentage: Mg: 7%, Mn: 4%, Zn: 10%, Ni: 3%, Si: 6%, Sc: 1.2%, P: 0.4 %, Zr: 0.7%, Y: 3%, Ca: 5%, Sr: 5%, B: 1.2%, Co: 4%, Sr: 1.0%, and rare earth elements: 3%, the rest is Al and unavoidable Impurities, and the mass percentage of the impurities is less than or equal to 0.5%;

[0053] The rare earth elements include the following components by weight percentage: Nd: 15%, Gd: 10%, Pr: 7%, Yb: 20%, La: 10%, Dy: 9%, Sm: 12%, Ce: 17%, the sum of the above rare earth elements is 100%.

[0054] The preparation process of the above-mentioned corrosion-resistant aluminum alloy doors and windows is carried out according to the following steps:

[0055] (1) Weigh the required raw materials by weight percentage; preheat the smelting furnace, the preheating temperature is 460°C, and last for 2 hours;

[0056] (2) First transport the Al and impurities to the smelting furnace, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com