Preparation method for interface space metallurgy bonded aluminum alloy-aluminum-steel transition joint

A technology of metallurgical bonding and transition joints, which is applied in the field of preparation of aluminum alloy-aluminum-steel transition joints with metallurgical bonding in the interface space, can solve the problems of poor product quality stability, limited product specifications, noise pollution, etc., and achieves thermal sensitivity. Sensitivity reduction, diversification of sizes, and avoidance of large noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

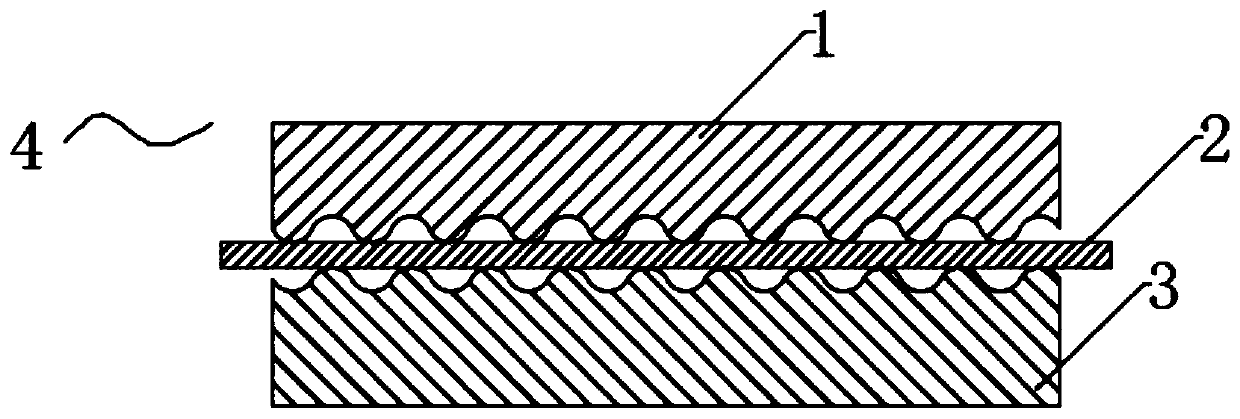

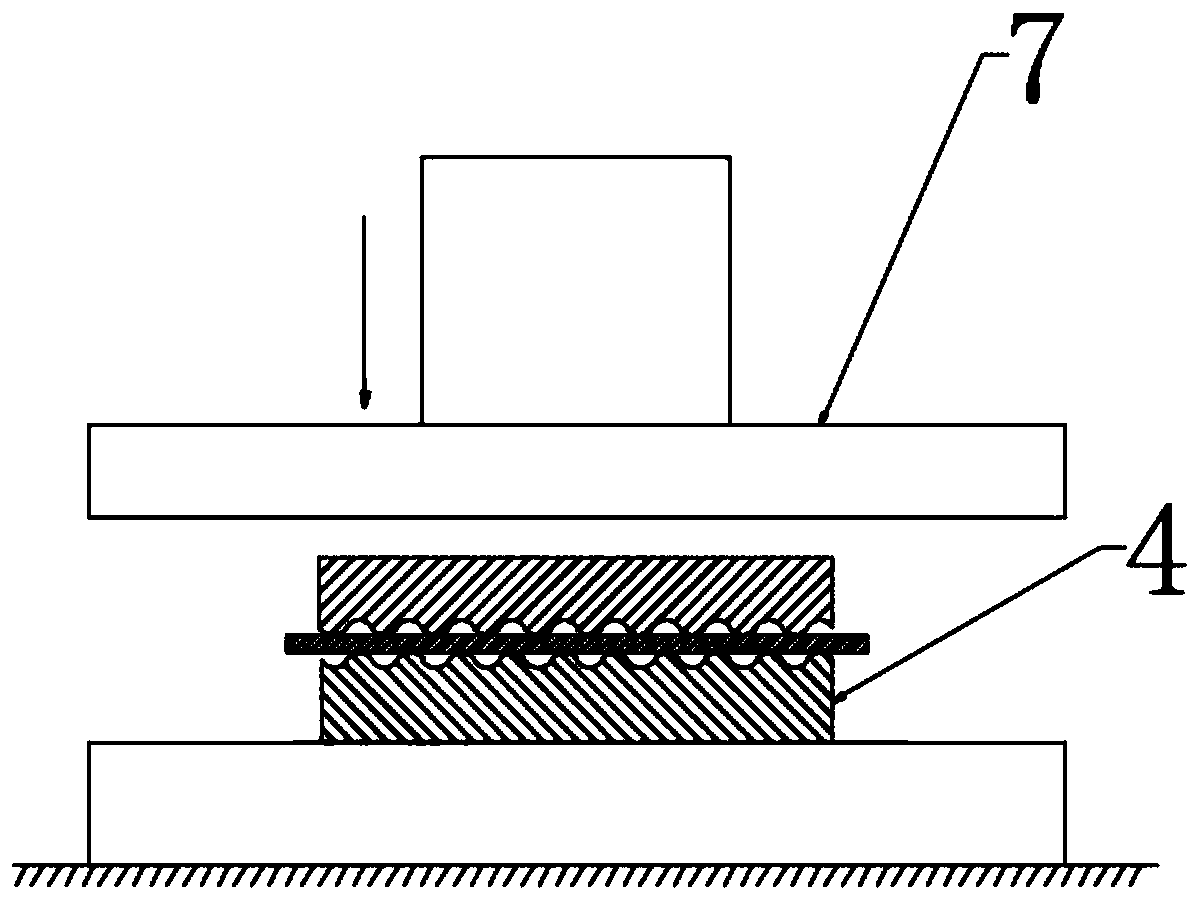

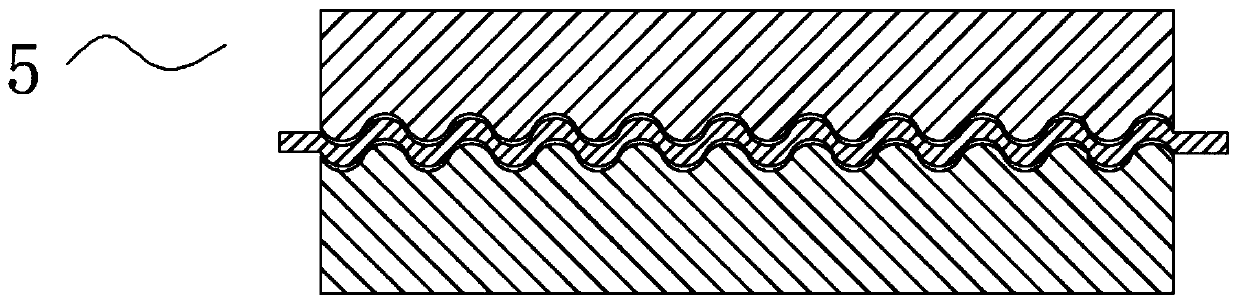

[0031] Such as Figure 1 to Figure 6 As shown, adopt the method of the present invention to prepare 5083-1050-06Cr19Ni10 transition joint, concrete steps are:

[0032] 1) Select the 5083 aluminum alloy plate 1 to be compounded and the 06Cr19Ni10 steel plate 3 to be compounded with a length × width × height of 800 × 100 × 20mm, and use the plastic forming method to form the 5083 aluminum alloy plate 1 to be compounded and the 06Cr19Ni10 steel plate 3 to be compounded Prepare corrugations with a height H of 4 mm and a width L of 4 mm, and the corrugations on the 5083 aluminum alloy plate 1 to be compounded and the 06Cr19Ni10 steel plate 3 to be compounded can engage with each other, and the 5083 aluminum alloy plate 1 to be compounded is subjected to stress annealing at 280 ° C After 2 hours, air-cool to room temperature, remove the oil and oxide film on the corrugated surface, clean the surface to be compounded with acetone and alcohol, then polish the corrugated surface of the...

Embodiment 2

[0038] Such as Figure 1 to Figure 6 As shown, adopt the method of the present invention to prepare 3003-1060-Q235B transition joint, concrete steps are:

[0039] 1) Select the 3003 aluminum alloy plate 1 to be compounded and the Q235B steel plate 3 to be compounded with a length × width × height of 600 × 50 × 10mm, and use a mechanical processing method on the 3003 aluminum alloy plate 1 to be compounded and the Q235B steel plate 3 to be compounded Prepare corrugations with a height H of 1.5 mm and a width L of 2 mm, and the corrugations on the 5083 aluminum alloy plate 1 to be compounded and the 06Cr19Ni10 steel plate 3 to be compounded can engage with each other, and the 3003 aluminum alloy plate 1 to be compounded is destressed at 280 ° C. Anneal for 2 hours, remove the oil and oxide film on the corrugated surface, clean the surface to be compounded with acetone and alcohol, and then use a grinder to polish the corrugated surface of the 3003 aluminum alloy plate 1 to be co...

Embodiment 3

[0045] Such as Figure 1 to Figure 6 As shown, adopt the method of the present invention to prepare 5A05-1070-Q235C transition joint, concrete steps are:

[0046] 1) Select the 5A05 aluminum alloy plate 1 to be compounded and the Q235C steel plate 3 to be compounded with a length × width × height of 800 × 200 × 30mm, and use the plastic forming method to form the 5A05 aluminum alloy plate 1 to be compounded and the Q235C steel plate 3 to be compounded Prepare corrugations with a height H of 2 mm and a width L of 20 mm, and the corrugations on the 5A05 aluminum alloy plate 1 to be compounded and the Q235C steel plate 3 to be compounded can engage with each other, and the 5A05 aluminum alloy plate 1 to be compounded is destressed and annealed at 280 ° C After 2 hours, air-cool to room temperature, remove the oil stain and oxide film on the corrugated surface, clean the surface to be compounded with acetone and alcohol, then polish the corrugated surface of the 5A05 aluminum allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com