Patents

Literature

81 results about "Pressure diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term diffusion pressure deficit (DPD) was coined by B.S Meyer in 1938. Originally DPD was described as suction pressure by Renner (1915). It is a reduction in the diffusion pressure of water in solution or cell over its pure state due to the presence of solutes in it and forces opposing diffusion.

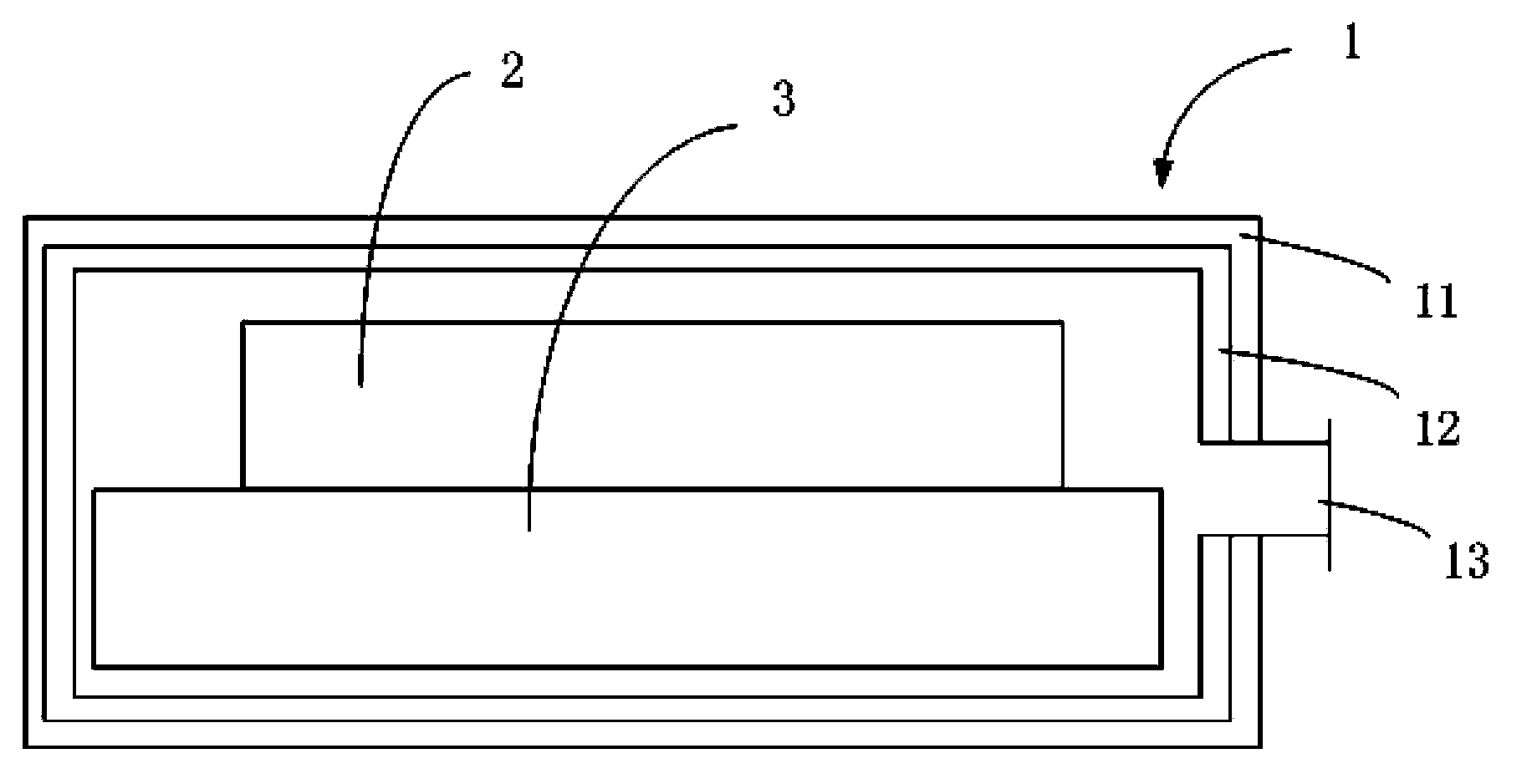

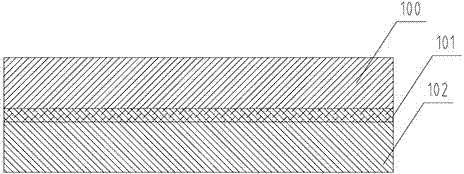

Diaper Structure With Enhanced Tactile Softness Attributes

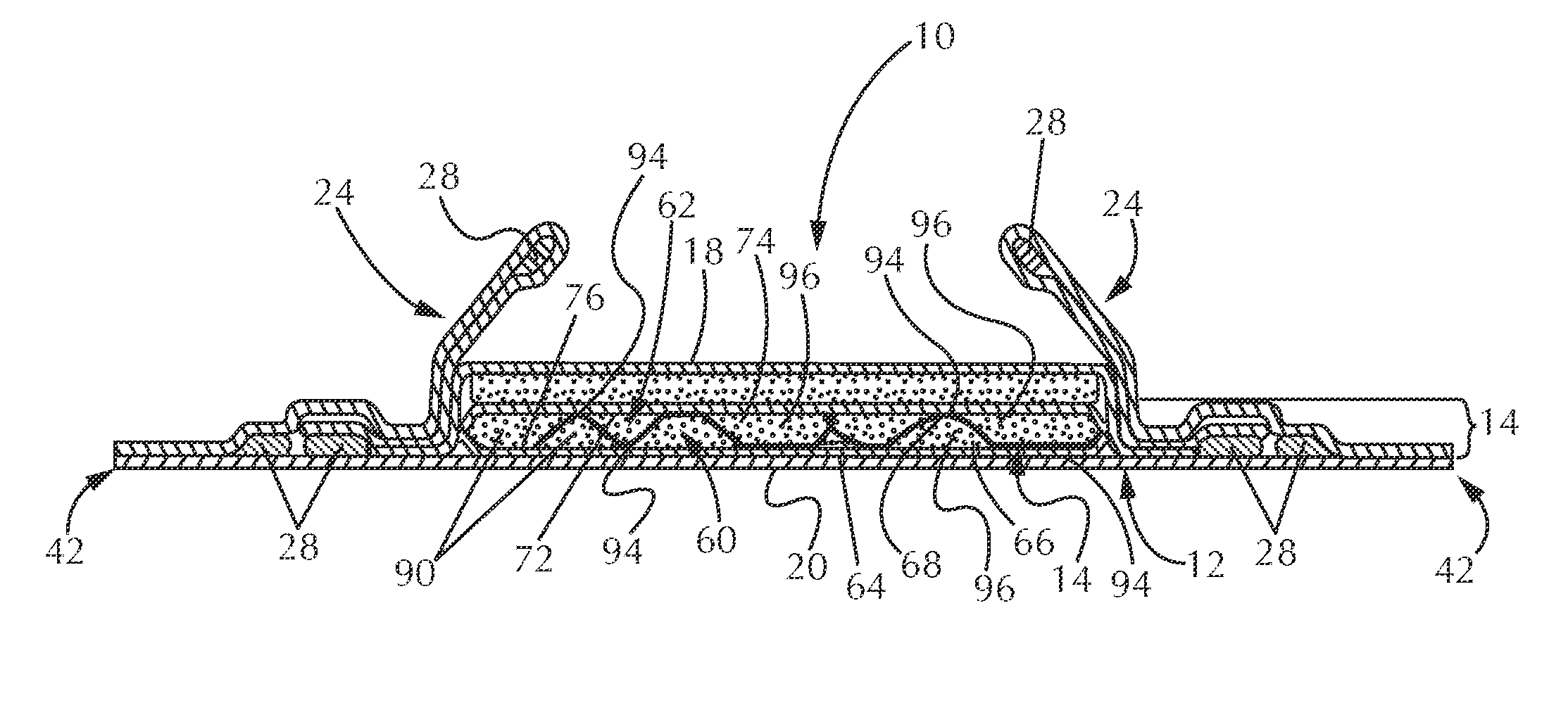

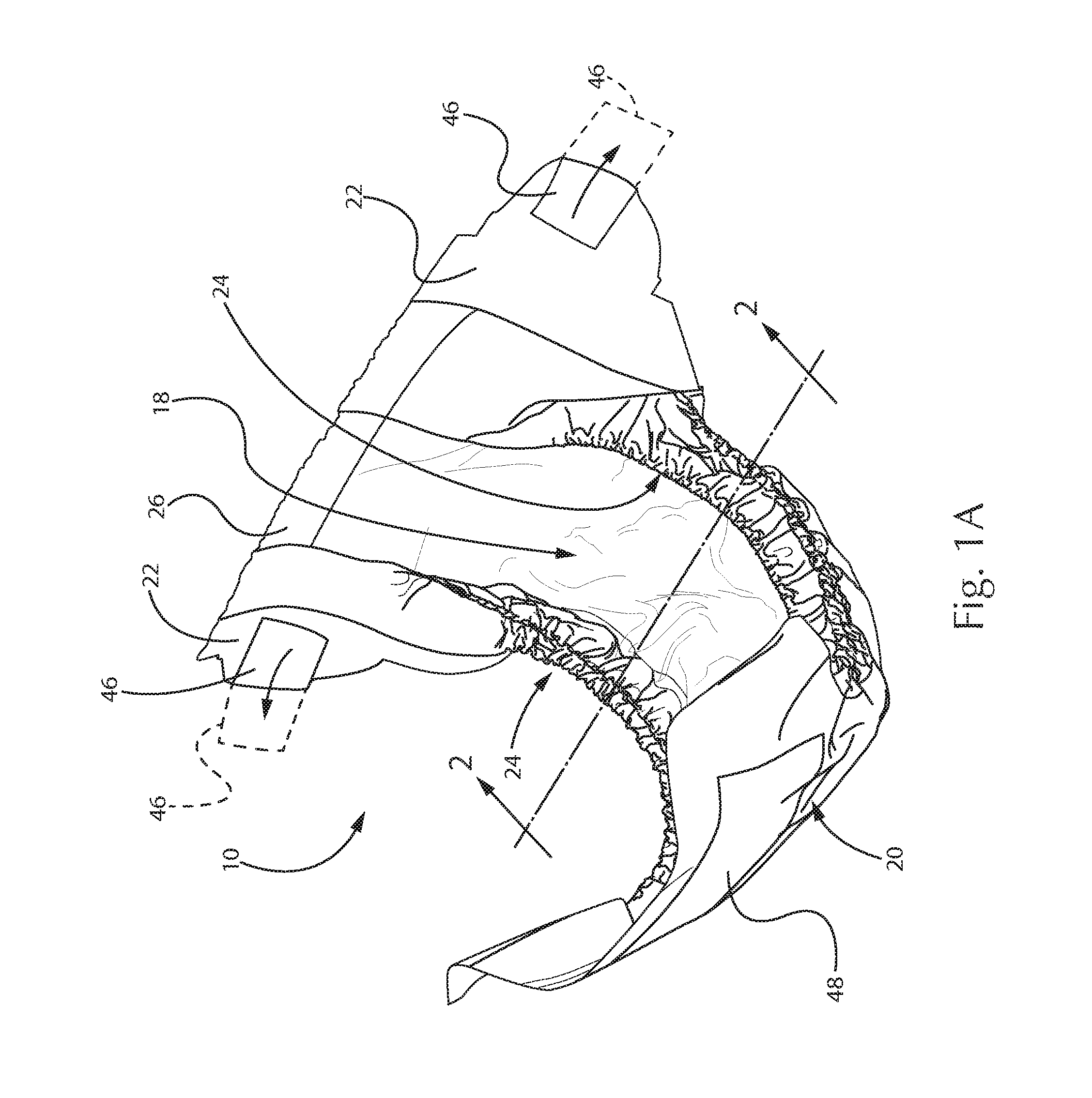

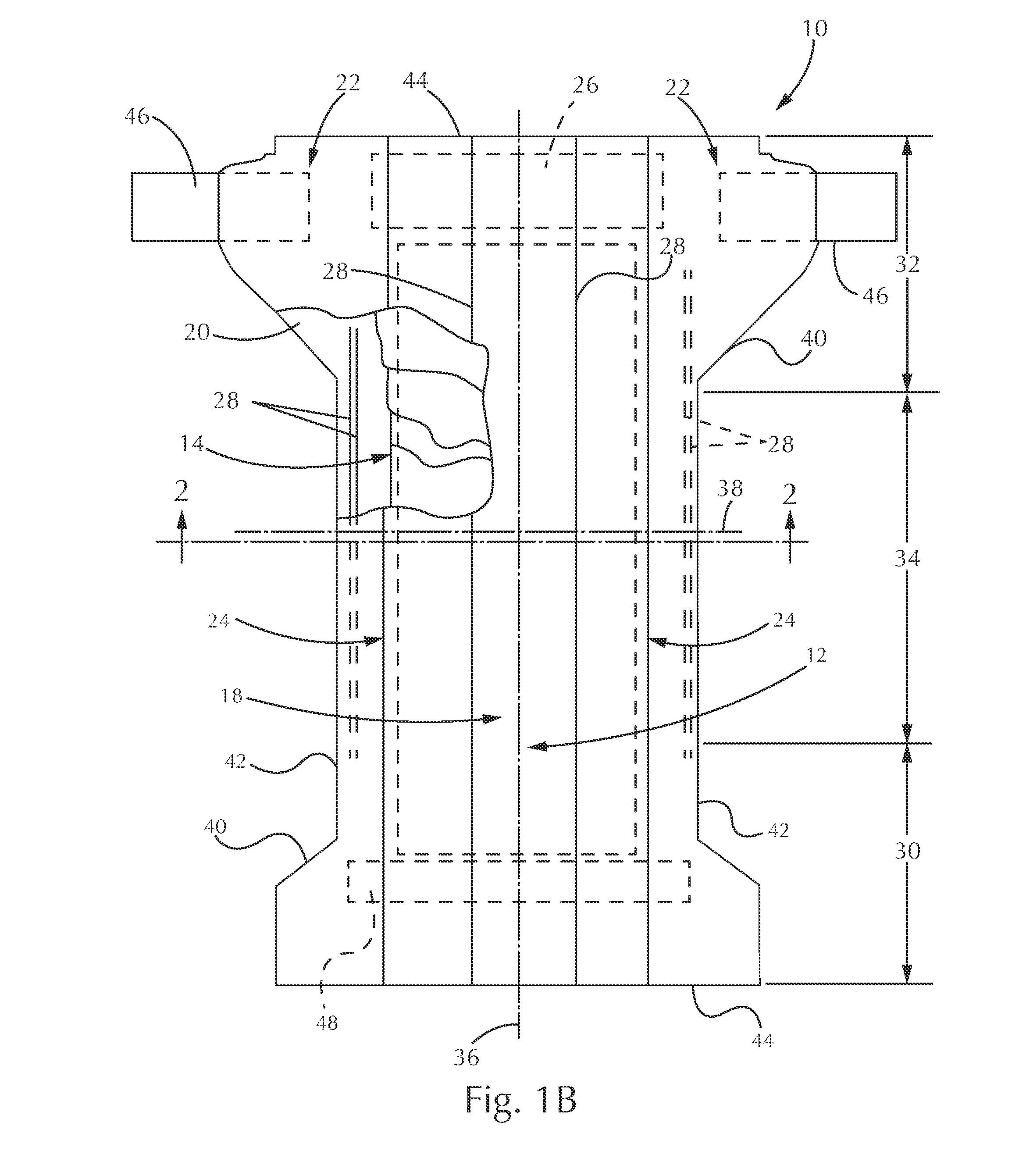

A diaper structure with enhanced softness attributes is disclosed. The diaper structure may include an innermost layer formed of a first nonwoven web, and an outermost layer formed of a second nonwoven web. The first and second nonwoven webs may have a combined basis weight of at least about 30 gsm. The ratio of the first web basis weight to the second web basis weight may range from 30 / 70 to 70 / 30. Each of the webs may have a preconversion density no greater than 65 kg / m3. Each of the webs may have a compression loft of at least 30%. Characteristics affecting pressure diffusion at tactile pressure points may be balanced within ranges between the first and second webs to provide similar tactile pressure diffusion characteristics for the inside and outside of the diaper.

Owner:THE PROCTER & GAMBLE COMPANY

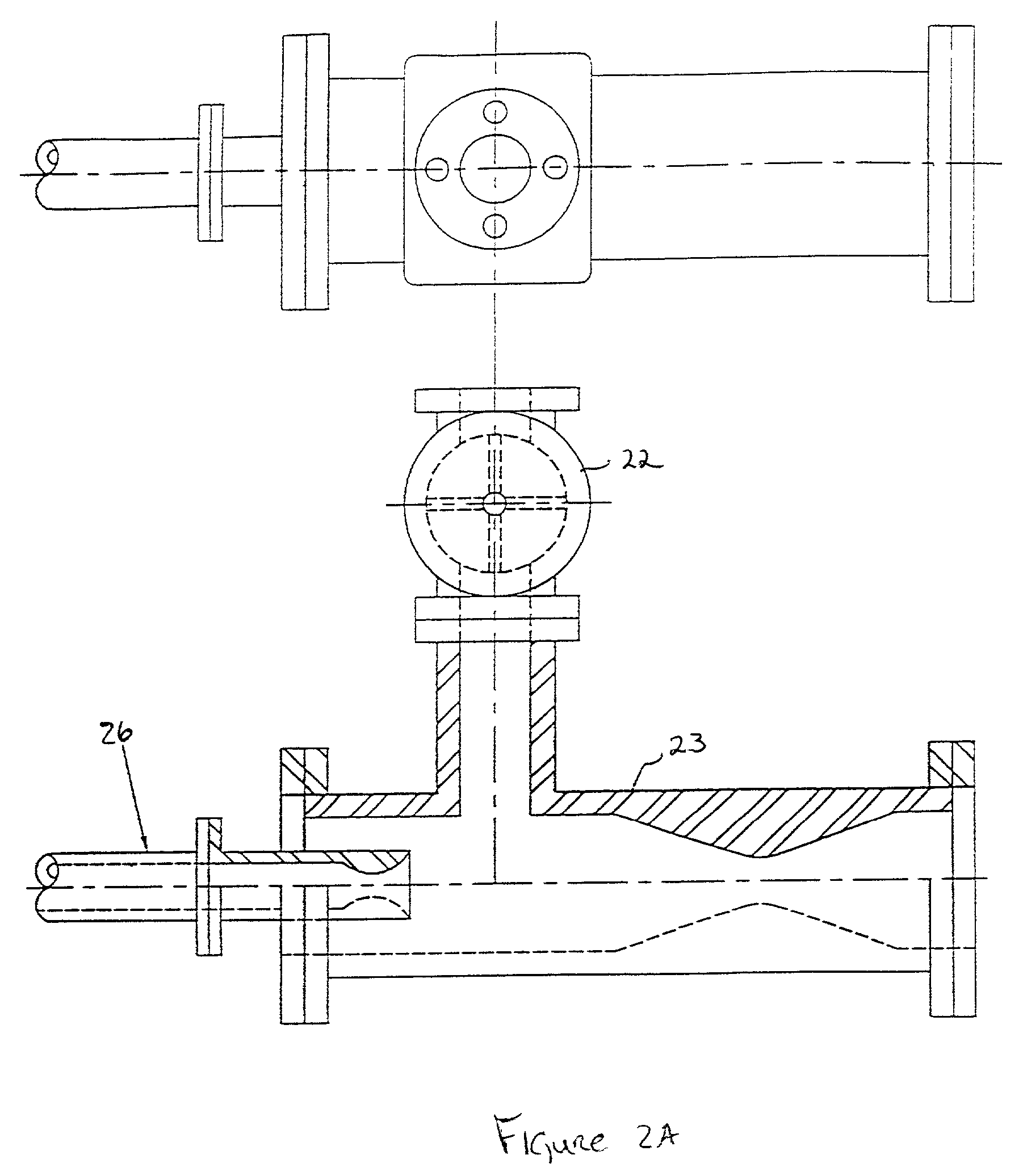

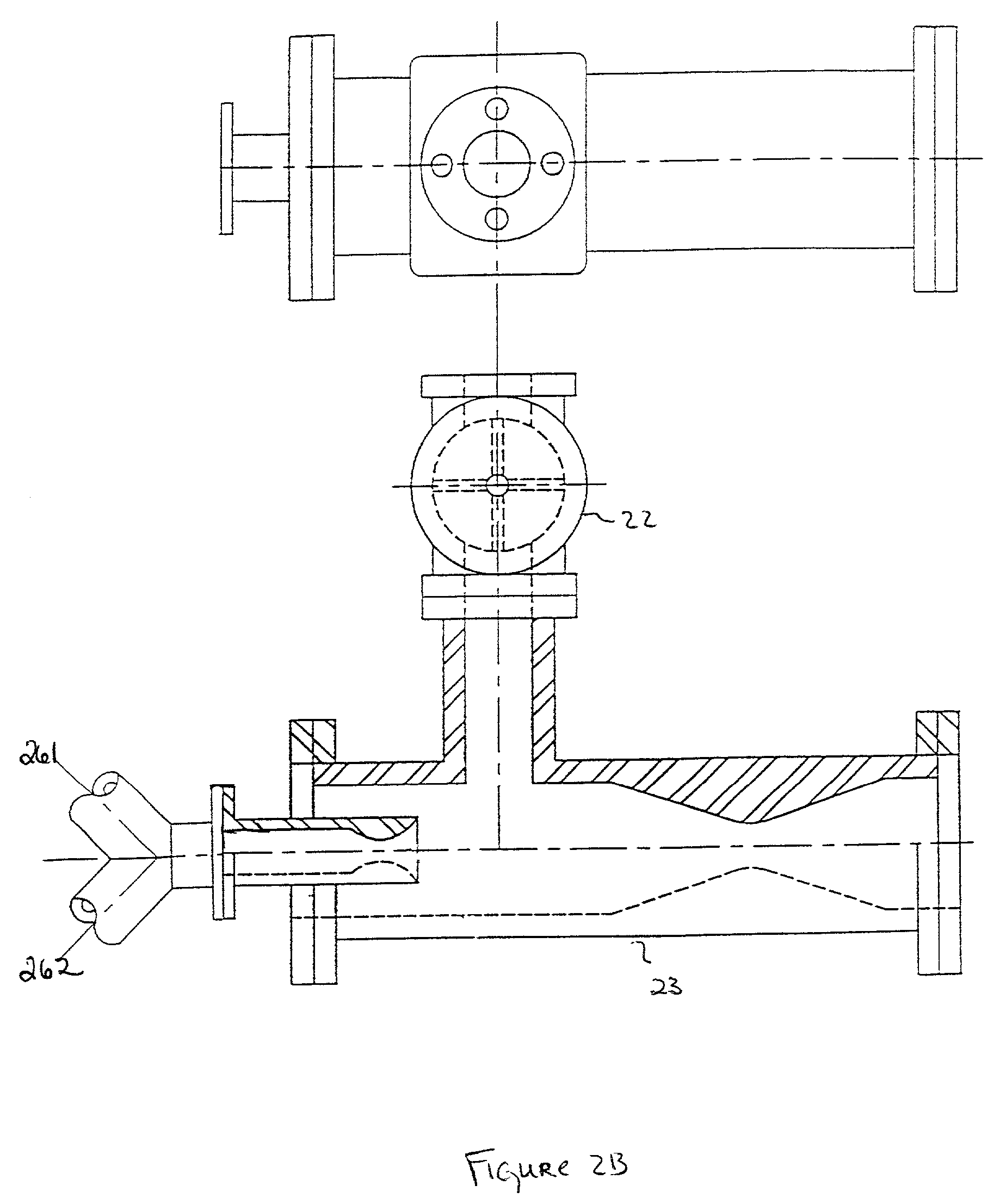

Process and system for continuously extracting oil from solid or liquid oil bearing material

InactiveUS7008528B2Eliminating formationEasy to optimizeRefining with acid-containing liquidsLiquid hydrocarbon mixture productionSufficient timeLiquid state

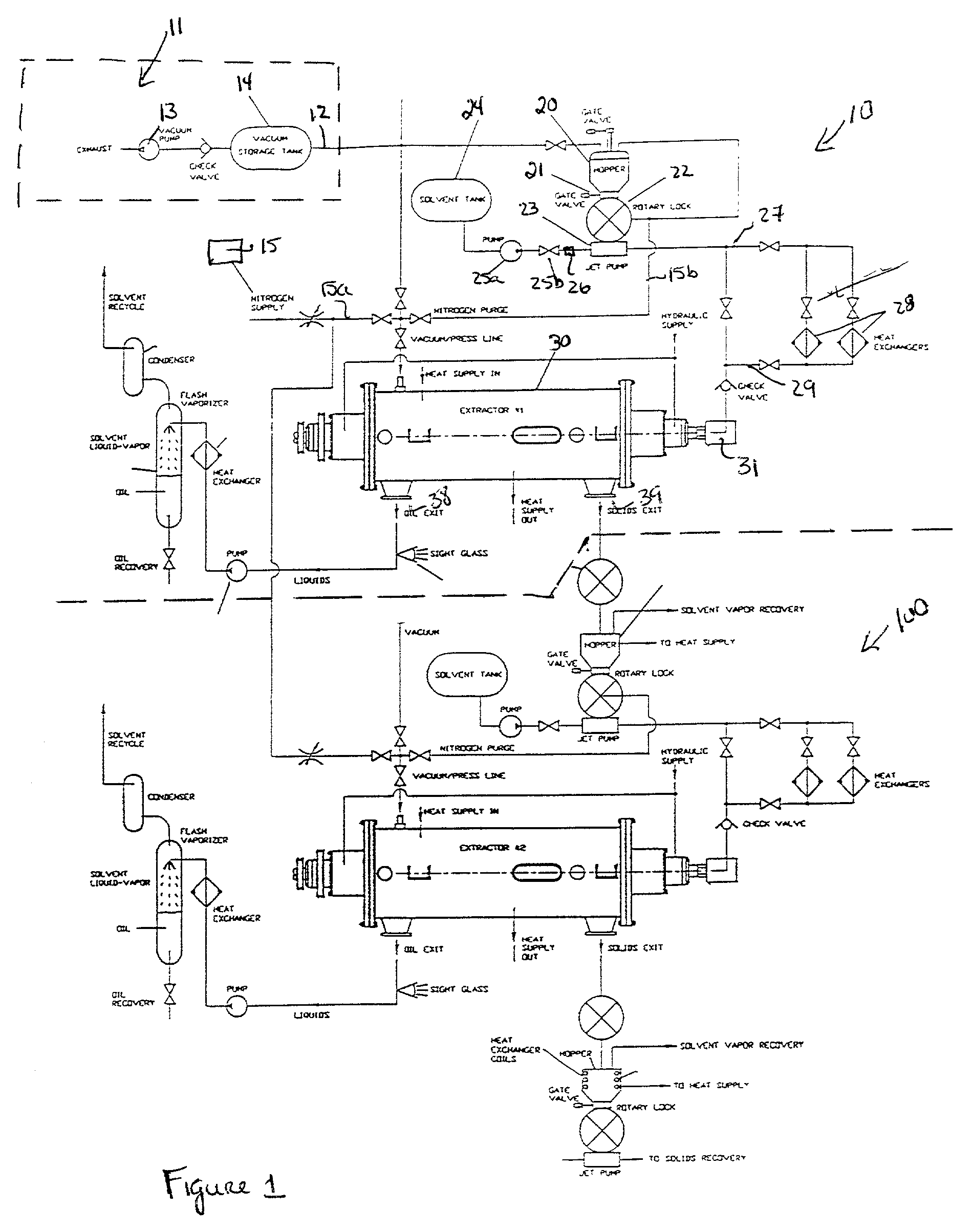

A process for continuously extracting oil from a solid or liquid oil-bearing material comprises (a) removing air from the extraction system, (b) introducing an inert gas into the extraction system at a pressure sufficient to maintain a normally gaseous solvent in liquid state, (c) introducing an oil-bearing material into a silo, (d) passing the oil-bearing material from the to a jet pump mixing device, (e) introducing a liquified normally gaseous solvent into the jet pump mixing device, (f) mixing the oil-bearing material and the solvent in the jet pump mixing device for a time sufficient to permit complete wetting of oil-bearing material by the solvent to form a mixture, (g) heating the mixture to near supercritical conditions; (h) passing the mixture through an extractor having a screw conveyor adapted to rotate at a first rpm range and a centrifugal drum adapted to rotate at a second rpm range, (i) treating the mixture within the extractor in such a manner that supercritical temperature and pressure are attained, wherein treating the mixture includes a combination of increasing the rpms of the centrifugal drum, increasing the temperature inside the extractor and increasing the inert gas pressure inside the extractor, (j) extracting oil from the mixture by pressure diffusion provided by the combination of increased rpms, increased temperatures and increased inert gas pressures at supercritical conditions, (j) removing liquids extracted from the mixture through a liquids exit port, and (k) removing solids extracted from the mixture through a solids exit port.

Owner:MITCHELL ALLEN R +1

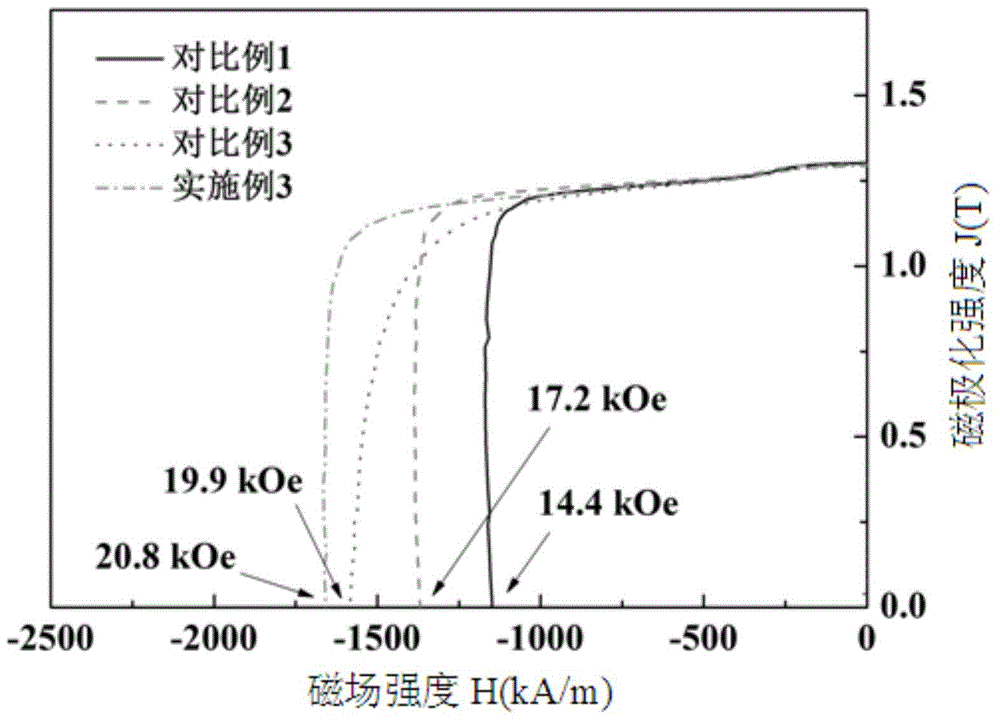

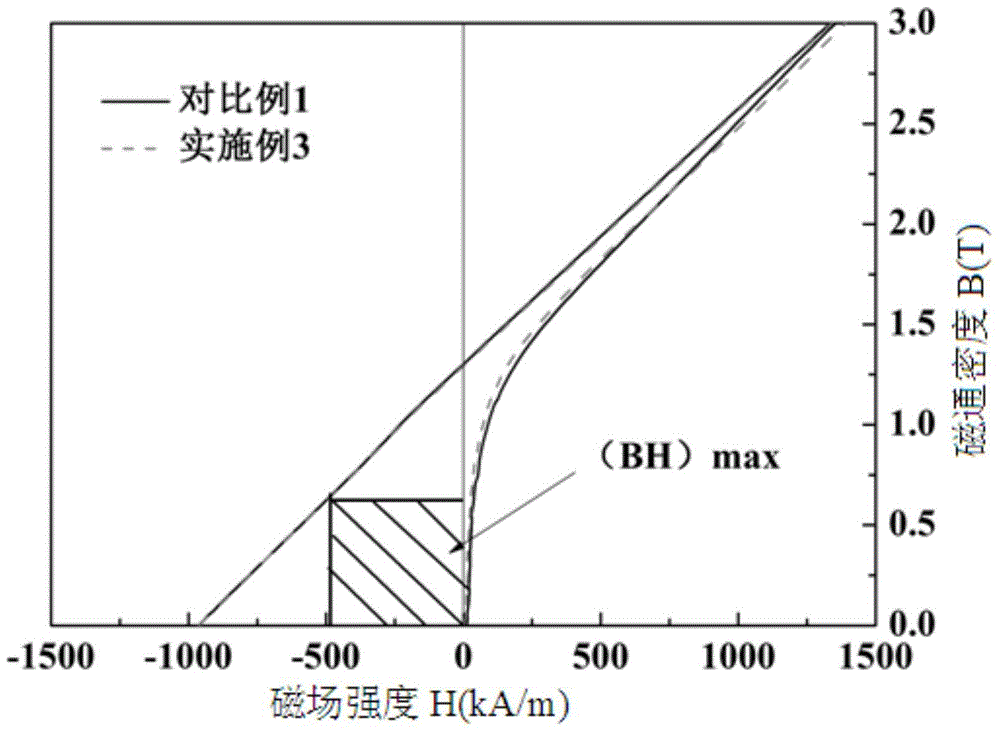

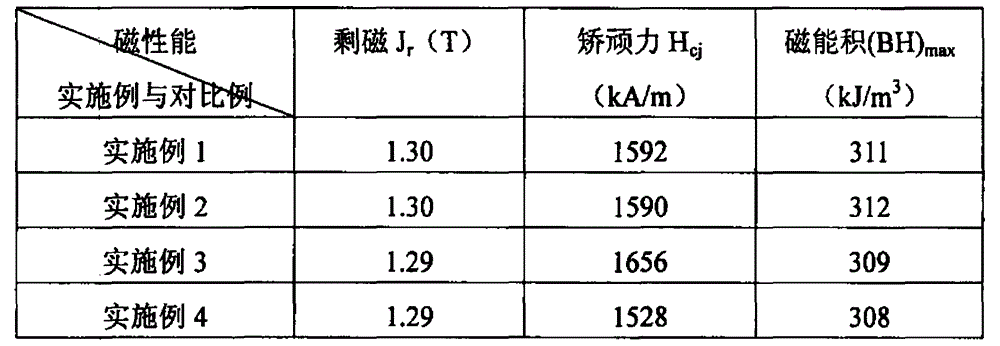

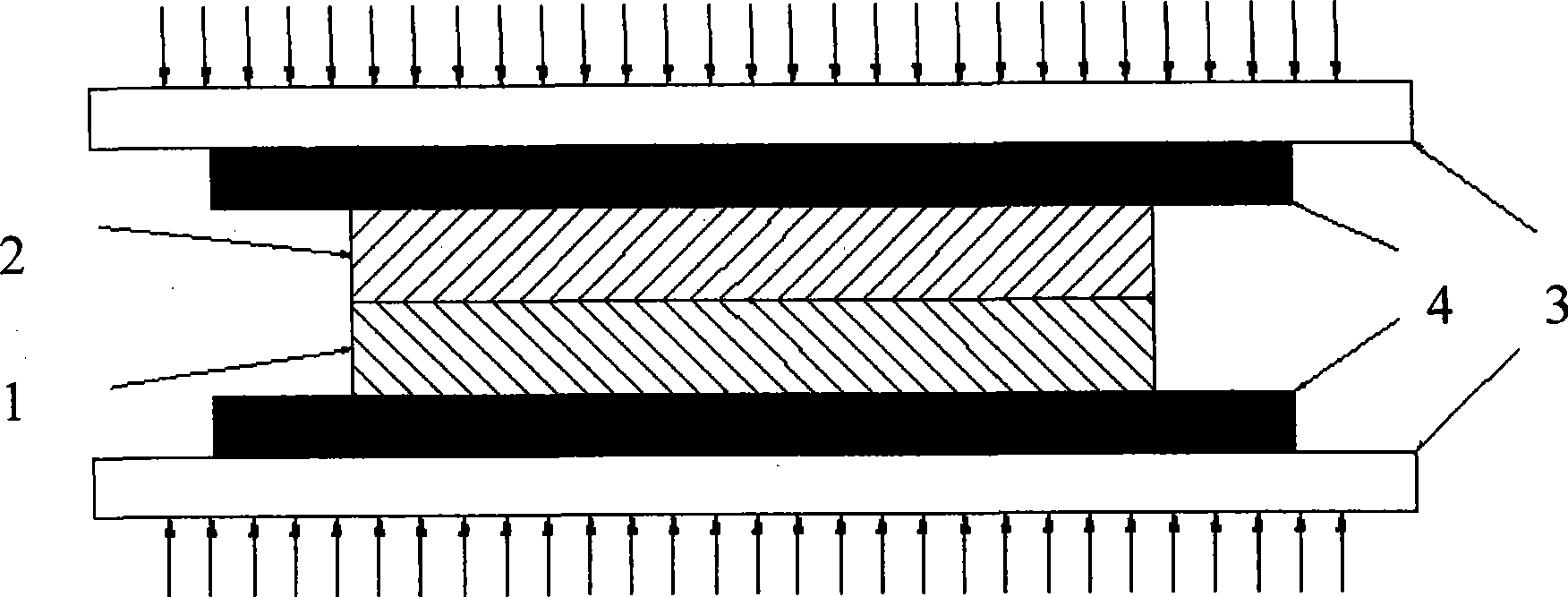

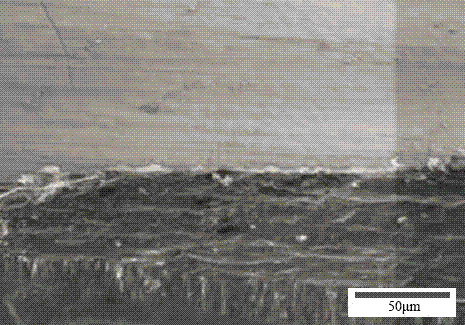

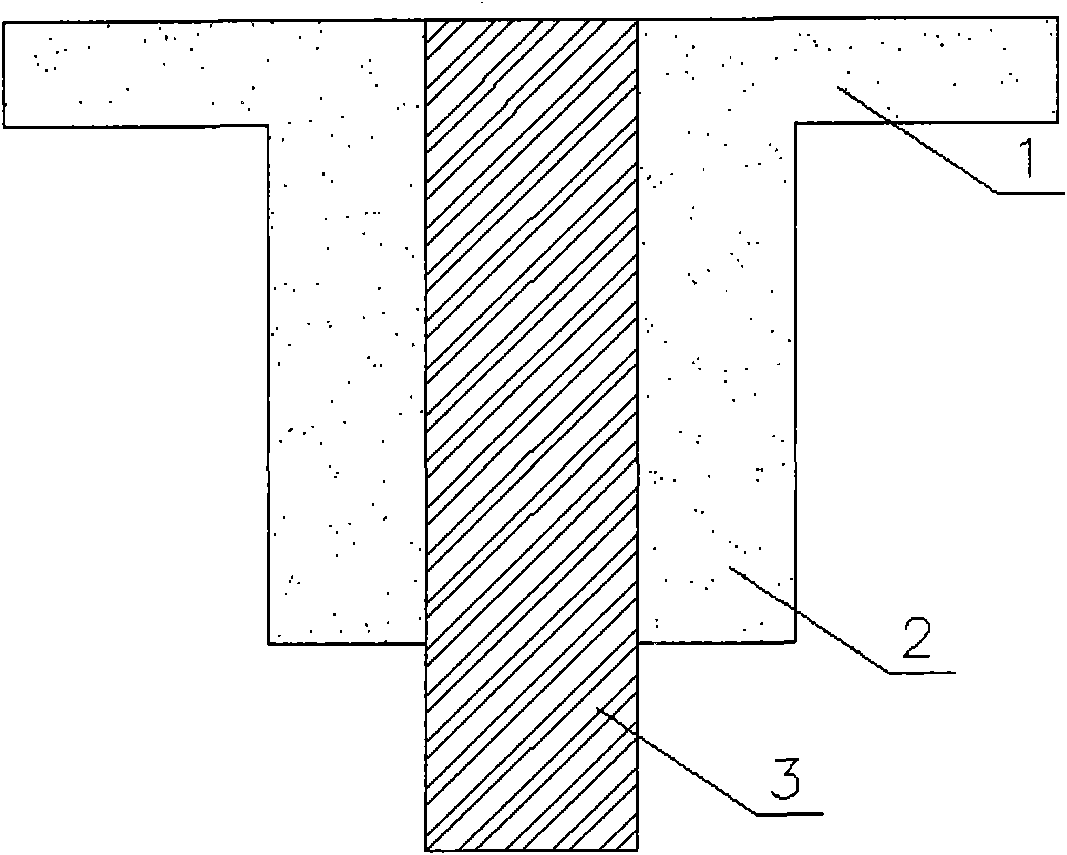

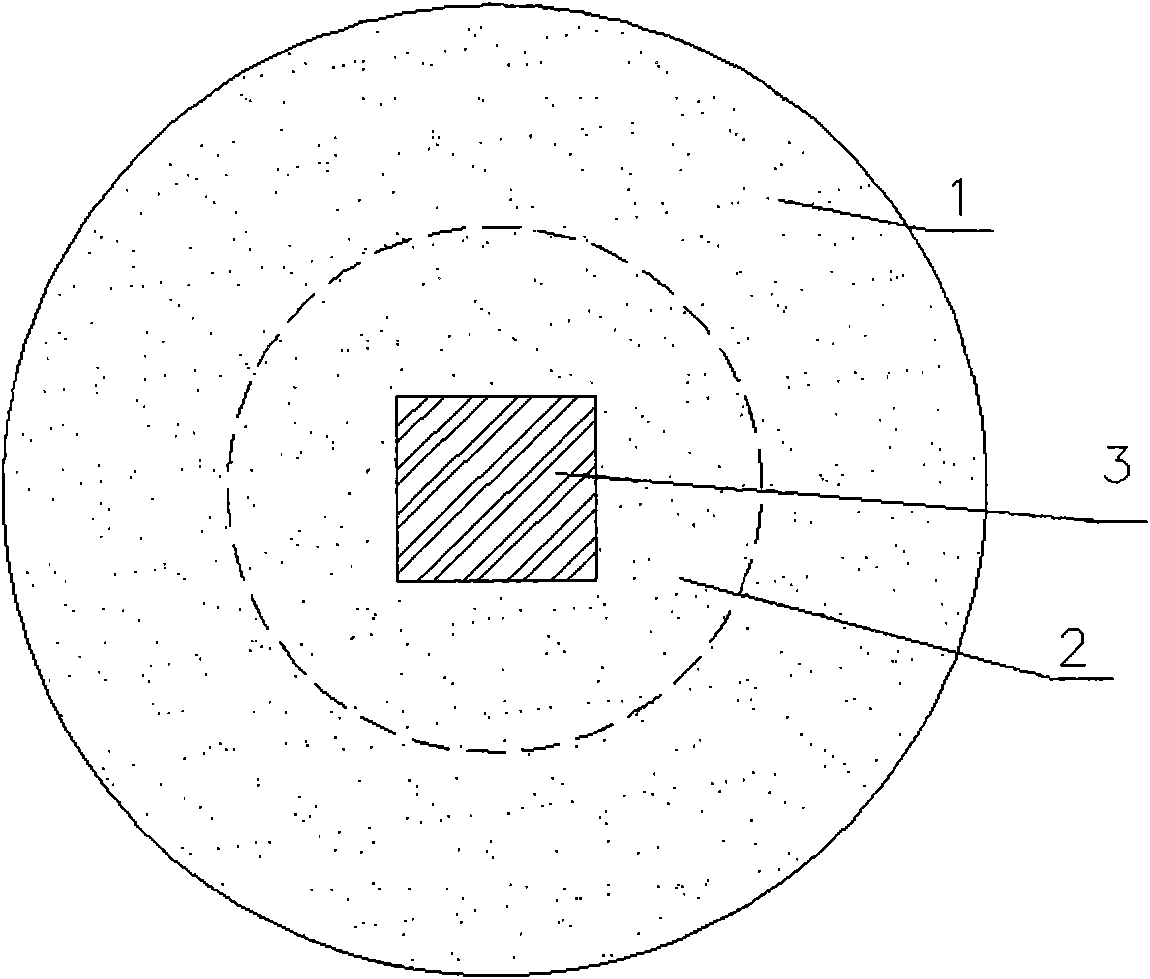

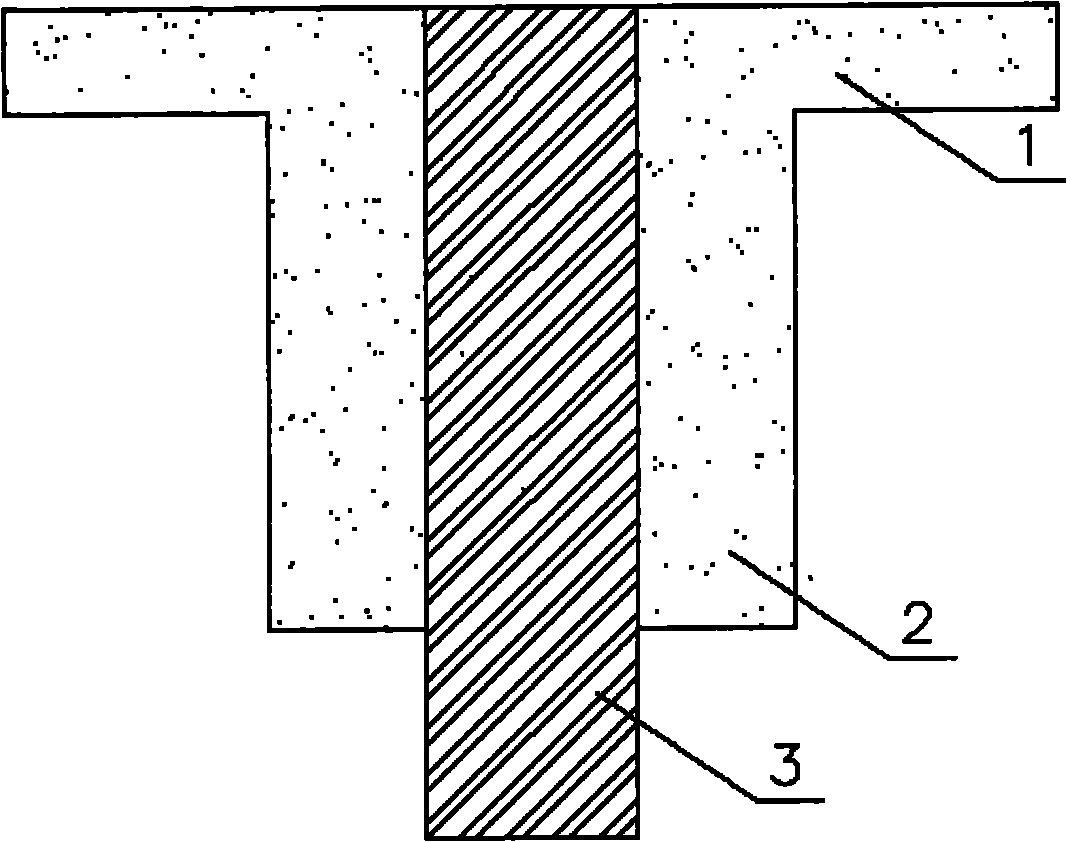

Grain boundary diffusion method for improving properties of sintered NdFeB magnets

ActiveCN104388951AIncreased diffusion kinetic energyLow melting pointInorganic material magnetismRare-earth elementDiffusion methods

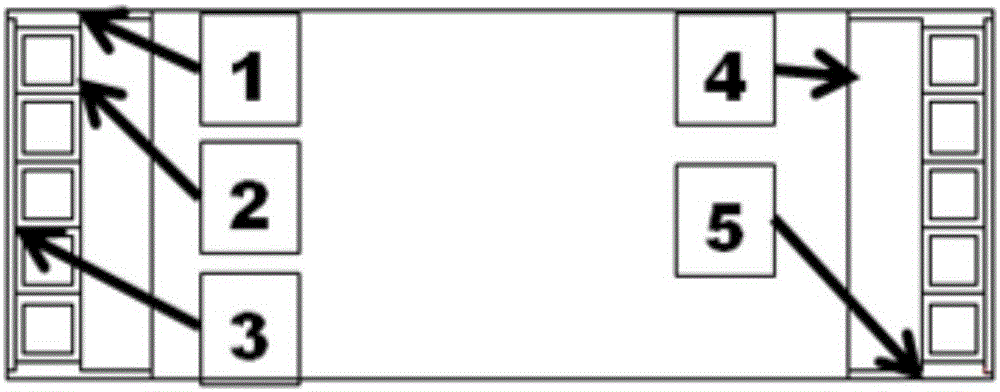

The invention relates to a grain boundary diffusion method for improving properties of sintered NdFeB magnets. The grain boundary diffusion method comprises the following steps of stacking sintered NdFeB magnets and diffusion alloy sheets together and placing in a hot-pressing furnace; vacuumizing the hot-pressing furnace until the vacuum degree reaches a set value, heating the hot-pressing furnace, and when the temperature of the hot-pressing furnace reaches a set value, beginning to exert a pressure and maintaining the pressure and putting the diffused sample into a high-vacuum furnace for annealing, wherein the diffusion alloy sheets are low-melting-point eutectic diffusion alloys and are represented by R-TM, R is one or more of Sc, Y, La, Ce, Pr or Nd and TM is one or more of Ti, V, Cr, Mn, Fe, Co, Ni, Cu and Zn. Compared with the prior art, the sintered NdFeB magnets modified by the pressure diffusion method, which is provided by the invention, have the advantages of large diffusion depth of a diffusion agent, uniform distribution of grain boundary phases, high coercivity and the like, especially, low-melting-point diffusion alloys designed by the invention are free of expensive heavy rare earth element dysprosium and thus the cost of the raw materials is relatively low, the diffusion temperature is low and the energy consumption in the diffusion process is small.

Owner:SHANGHAI JIAO TONG UNIV

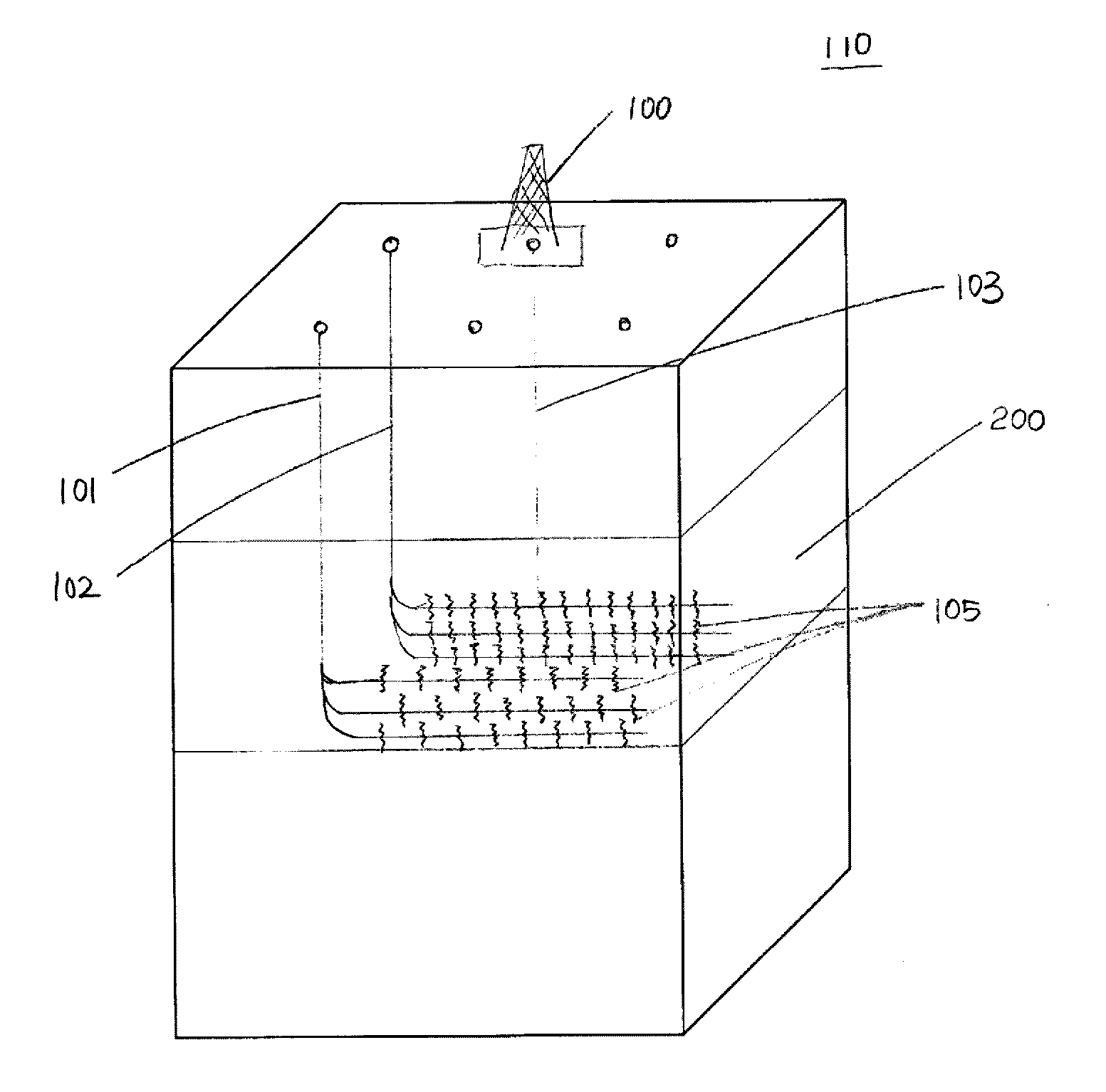

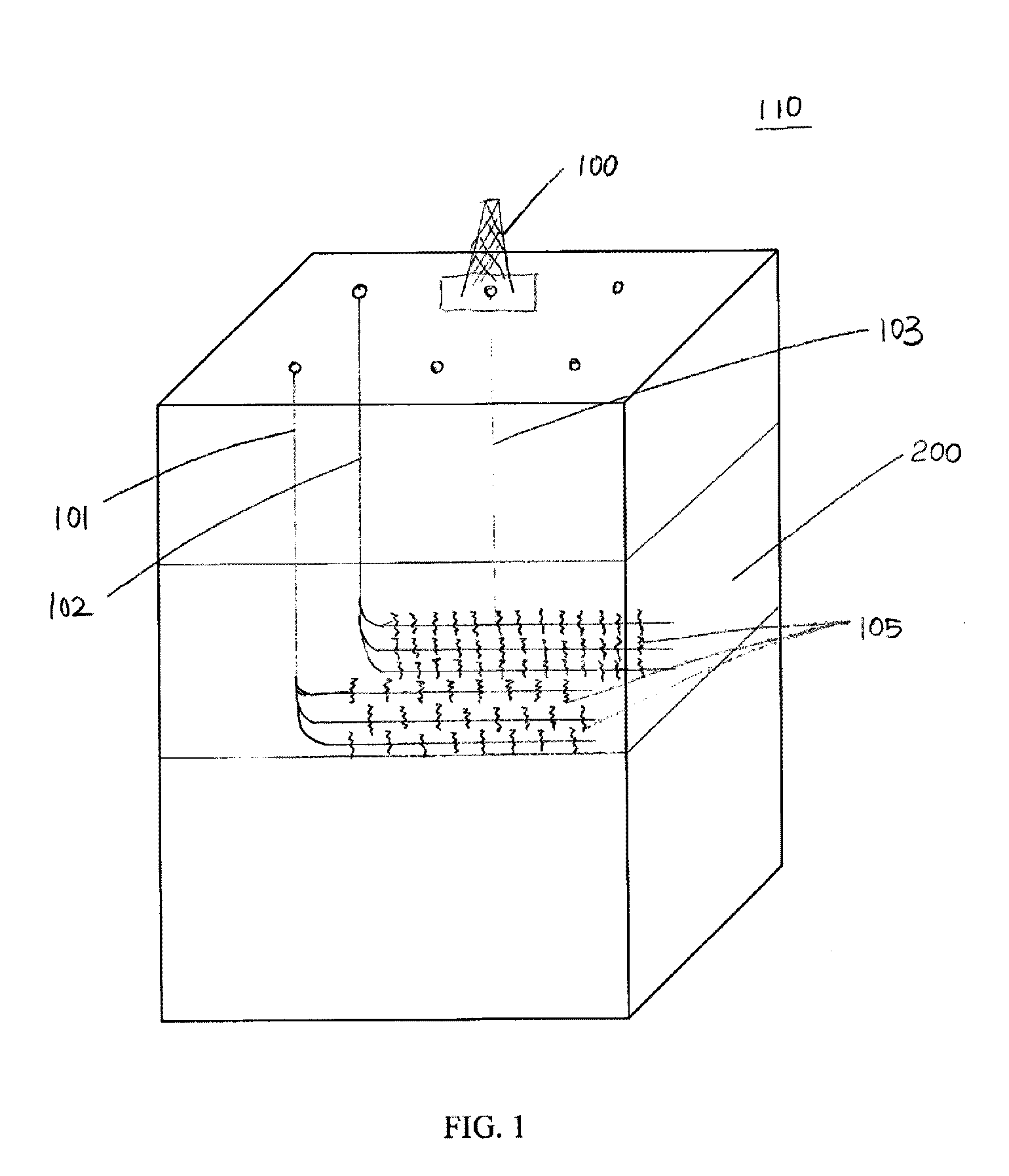

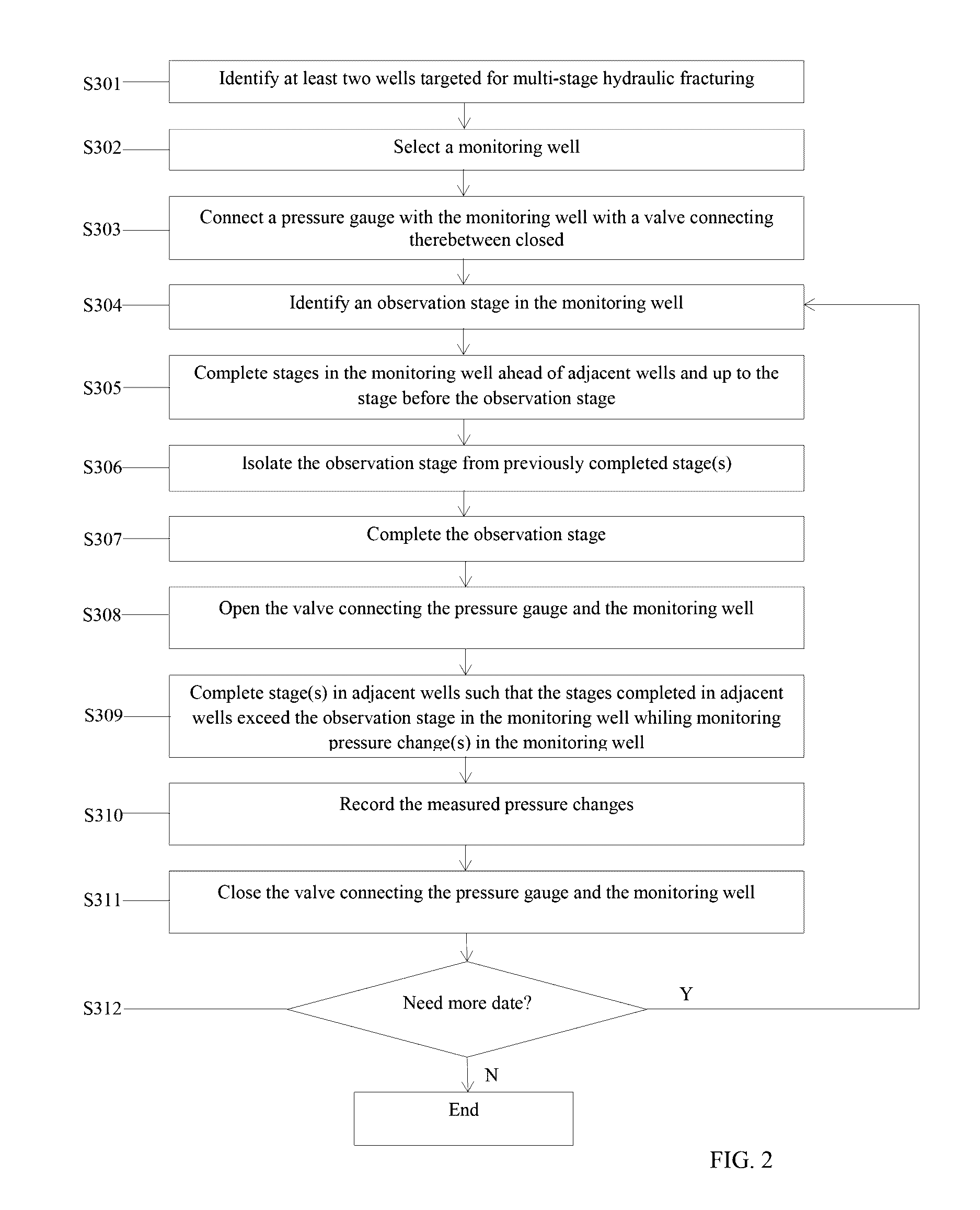

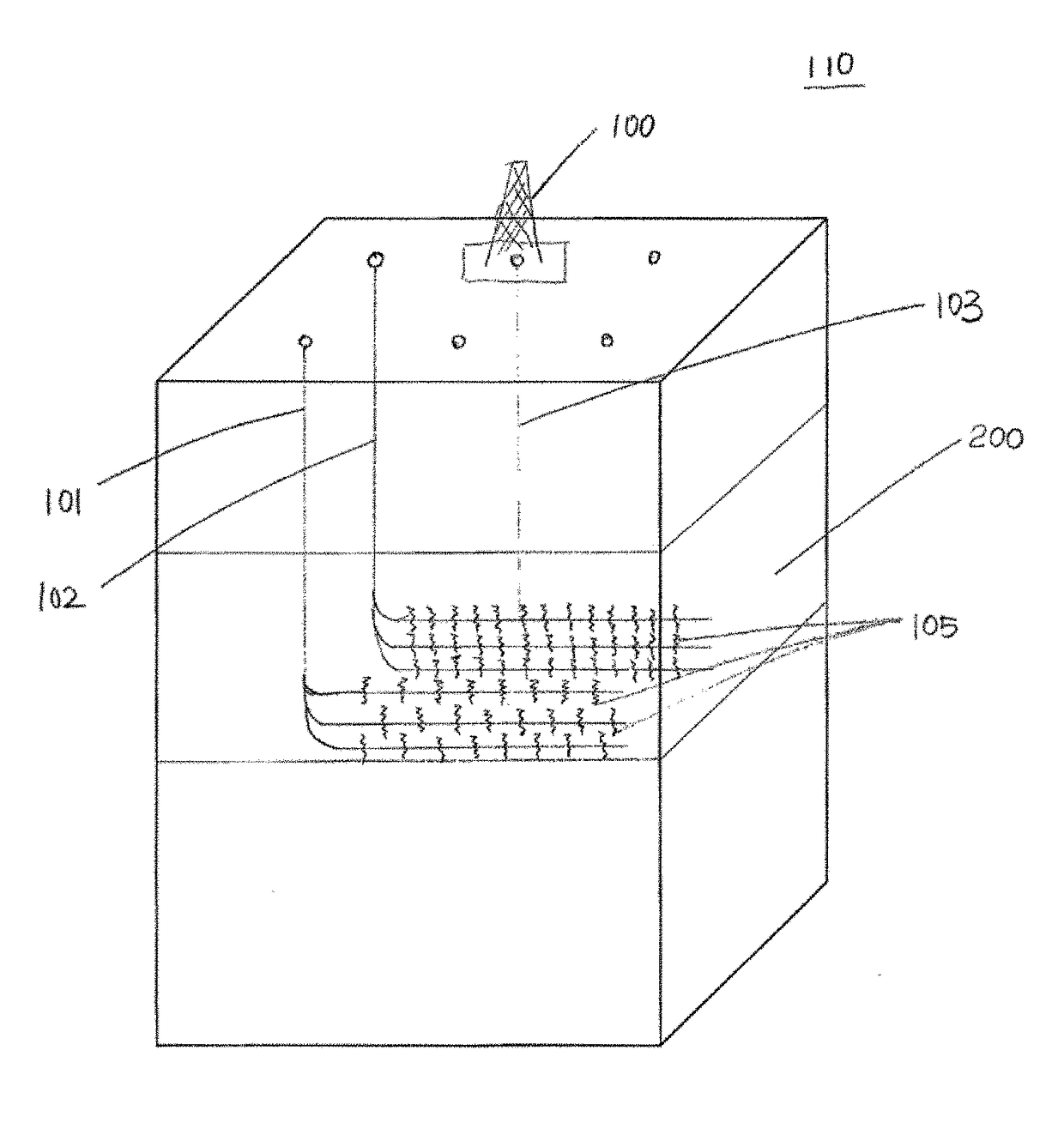

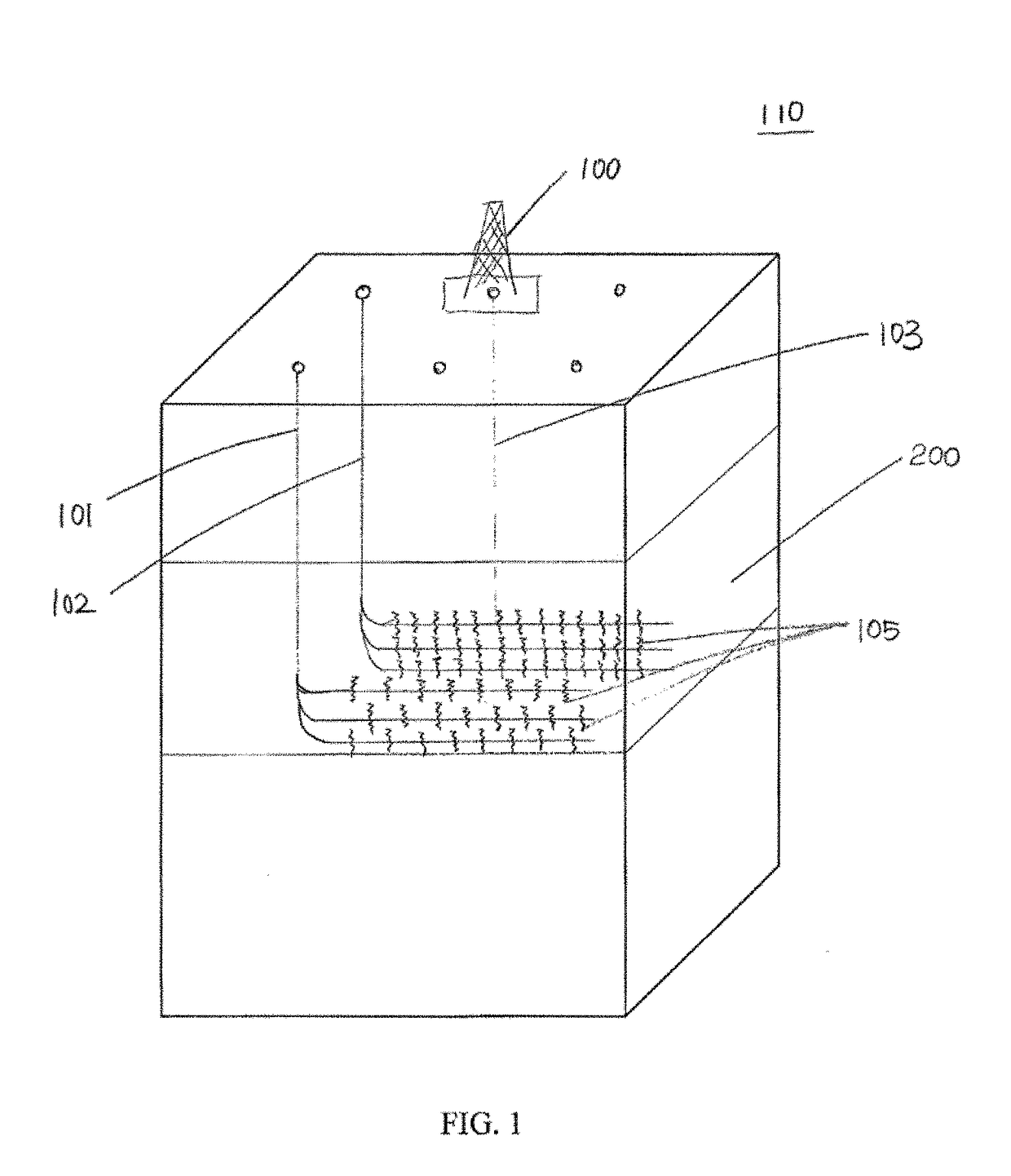

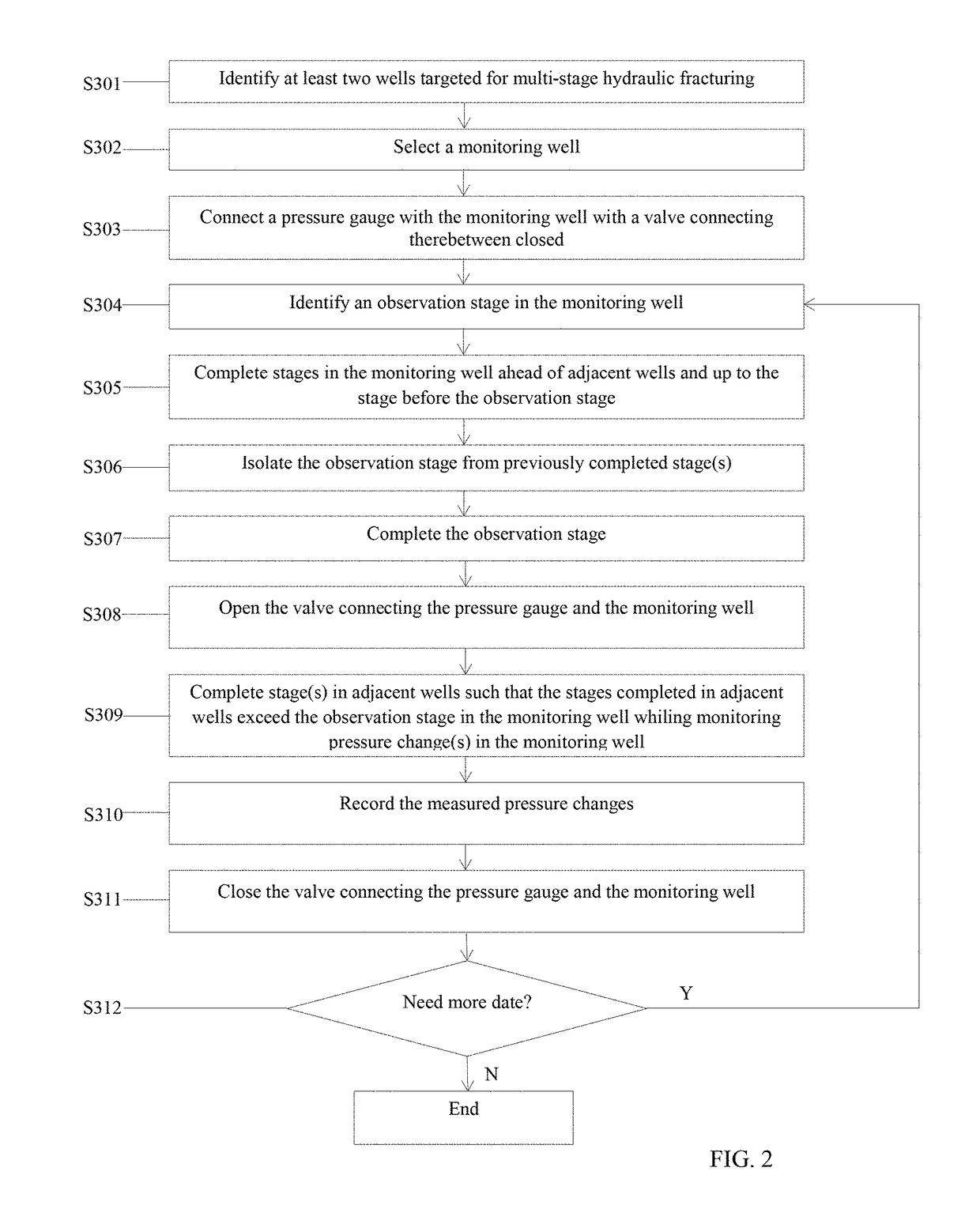

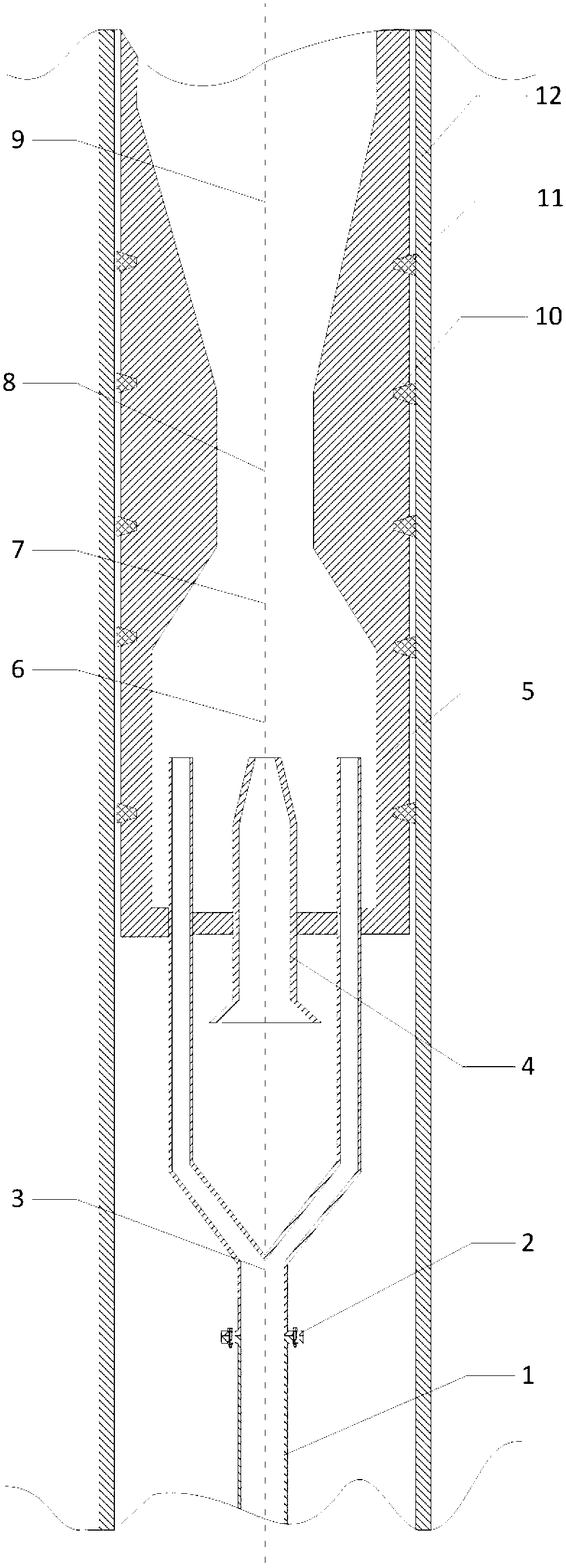

Method of geometric evaluation of hydraulic fractures

A method of evaluating a geometric parameter of a first fracture emanating from a first wellbore penetrating a subterranean formation is provided. The method includes the steps of forming the first fracture in fluid communication with the first wellbore; forming a second fracture in fluid communication with a second wellbore; measuring a first pressure change in the second wellbore in proximity to the first wellbore; and determining the geometric parameter of the first fracture using at least the measured first pressure change in an analysis which couples a solid mechanics equation and a pressure diffusion equation.

Owner:STATOIL GULF SERVICES

Method of geometric evaluation of hydraulic fractures by using pressure changes

ActiveUS9988900B2Improve certaintyLow costSemiconductor/solid-state device manufacturingFluid removalStress changeWellbore

A method of evaluating a geometric parameter of a first fracture emanating from a first wellbore penetrating a subterranean formation is provided. The method includes the steps of forming the first fracture in fluid communication with the first wellbore; forming a second fracture in fluid communication with a second wellbore; measuring a first pressure change in the second wellbore in proximity to the first wellbore; and determining the geometric parameter of the first fracture using at least the measured first pressure change in an analysis which couples a solid mechanics equation and a pressure diffusion equation.

Owner:STATOIL GULF SERVICES

Injection device for discharging accumulated fluids in shaft

InactiveCN103233923AReduce back pressureIncrease productionJet pumpsFluid removalCarrying capacityJet flow

The invention discloses an injection device for discharging accumulated fluids in a shaft. The injection device comprises a main shaft body with a suction chamber. A three-way pipe and a gas inlet nozzle which are inserted in the suction chamber are arranged at the bottom of the main shaft body, a plurality of sealing grooves are arranged on the periphery of the main shaft body, and each of the sealing grooves is provided with a sealing ring. High-speed jet flows are produced by high-pressure gas at an outlet of the air inlet nozzle, so that a certain vacuum degree is produced in the suction chamber, the accumulated fluids at the shaft bottom are drawn to the suction chamber under the action of inside and outside differential pressure and atomized for a certain degree in the suction chamber, flow into the throat and are fully mixed to form stable gas-liquid two-phase flow. In the process, the high-speed jet flows can transmit part of kinetic energy to the accumulated fluids, the fluid production kinetic energy is increased, and the accumulated fluids are lifted to a shaft head through a pressure diffusion section. Accordingly, the return pressure at the shaft bottom is reduced, the production differential pressure is increased, and the yield of a gas well is increased; and the high-pressure gas in the shaft is expanded due to the reduction of pressure, the instantaneous gas volume is increased, the fluid carrying capacity of the gas hole is further improved, and the accumulated fluids in the shaft are discharged.

Owner:XI AN JIAOTONG UNIV

Low temp. and low pressure reaction type diffusion welding for aluminium and copper sheets

InactiveCN1418752AOvercome stressImprove welding rateNon-electric welding apparatusMetallic materialsImpurity

The present invention relates to a low-temp. low-pressure diffusion welding process of aluminium-copper dimetal sheet, and is characterized by that said welding process has no need of adding any intermediate layer, and utilizes Al-Cu-Mg three-component cocrystallization reaction between Al-Mg system alloy and Cu to form liquid phase and connect them together, its temp. is 470 deg.C-520 deg.C, time is 3 min-10 min., pressure is 3MPa-5Mpa and the degree of vacuum is 1X10 to minus second Pa-1X10 to the minus third Pa. Before welding, the surfaces of Al-Mg alloy and Cu have no need of strict surface treatment, only have need of removing greasy dirt, oxide and other impurity from their surface by using mechanical grinding process. Its operation is simple and its welding efficiency is high.

Owner:BEIJING QINGYUN AVIATION INSTR CO LTD

Method for continuous interpretation of monitoring data

InactiveUS20050270903A1Practical and convenientSimple calculationSeismology for water-loggingDiffusionLarge distance

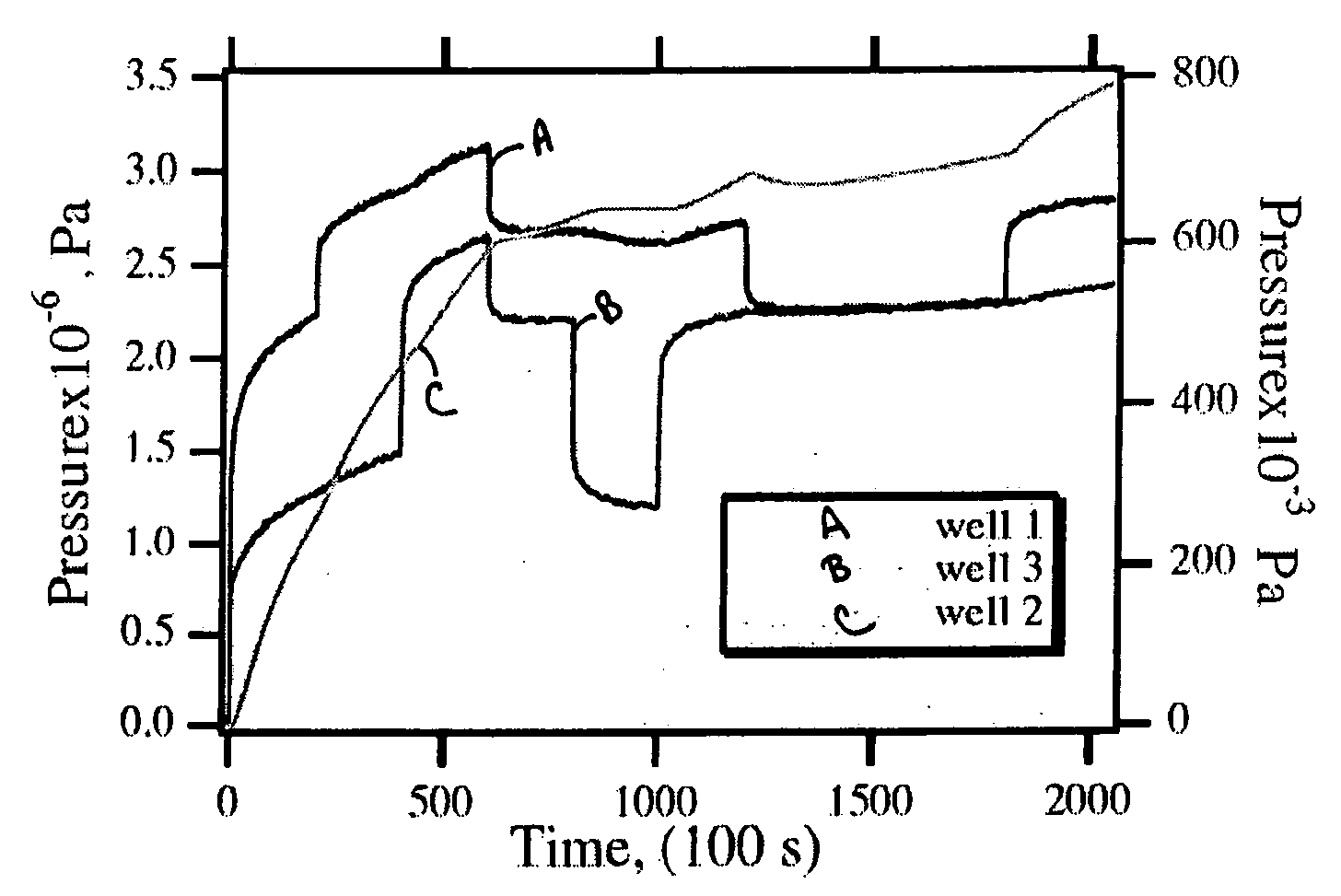

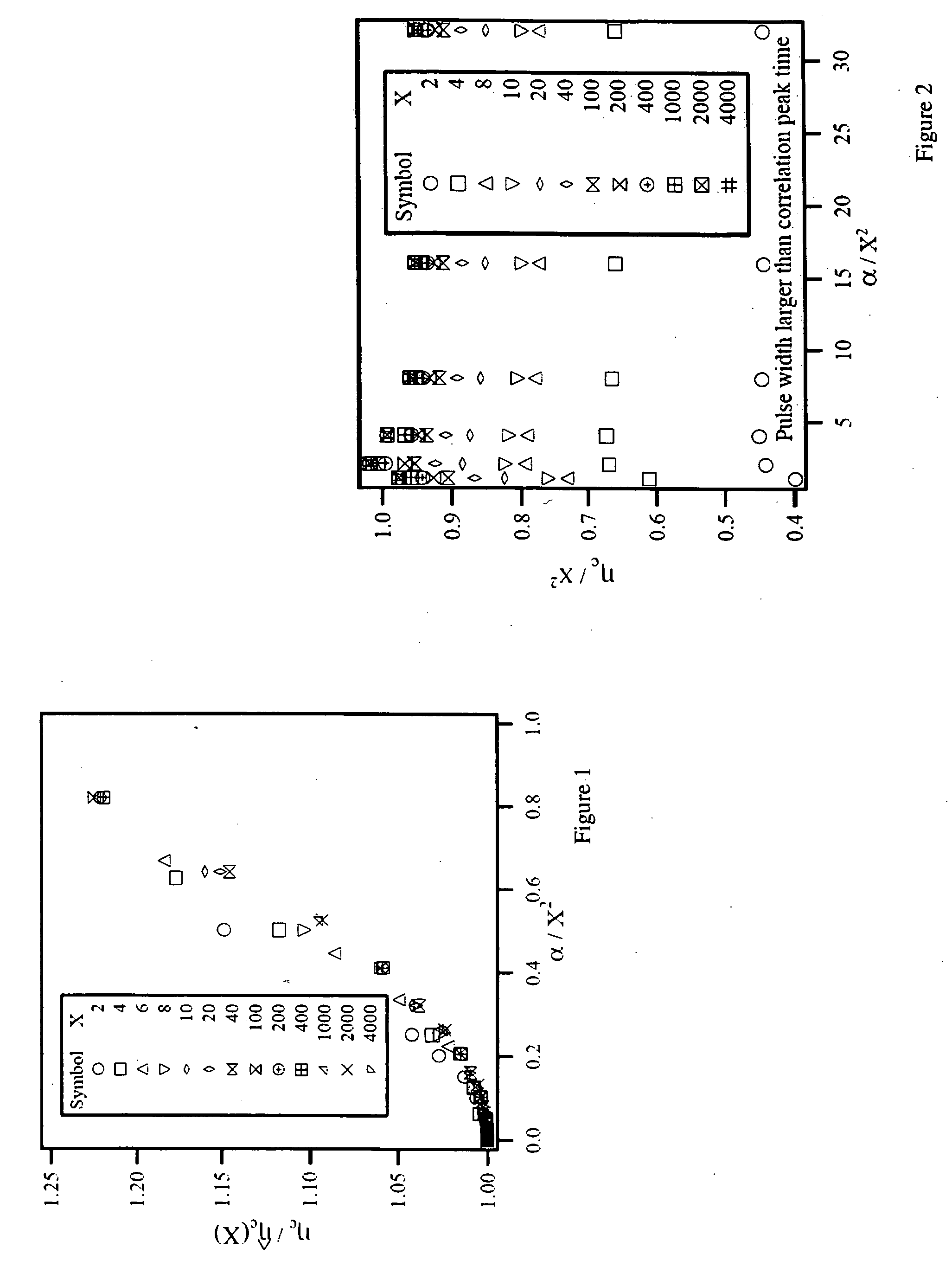

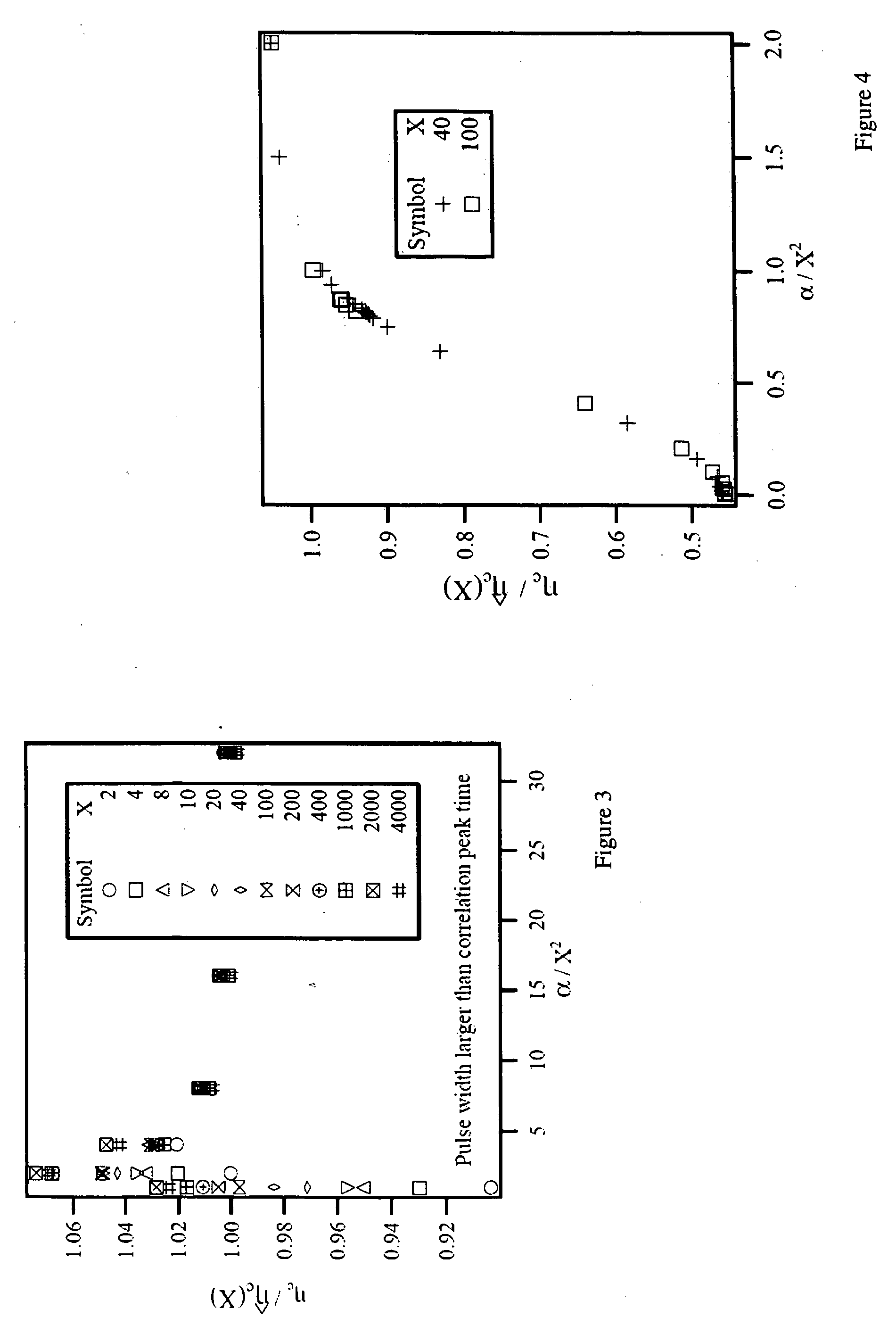

It is shown that a pressure pulse originating in a well is correlated to a pulse observed at a distant well with a characteristic time. The correlation time is directly related to the diffusion time scale arising out of the pressure diffusion equation. The relationship is affected by the source-observer or observer-observer distance but the correction is small for large distances. In practice, further corrections have to be included for finite width pulses. For these pulses, a practical scheme for continuous permeability monitoring is presented.

Owner:SCHLUMBERGER TECH CORP

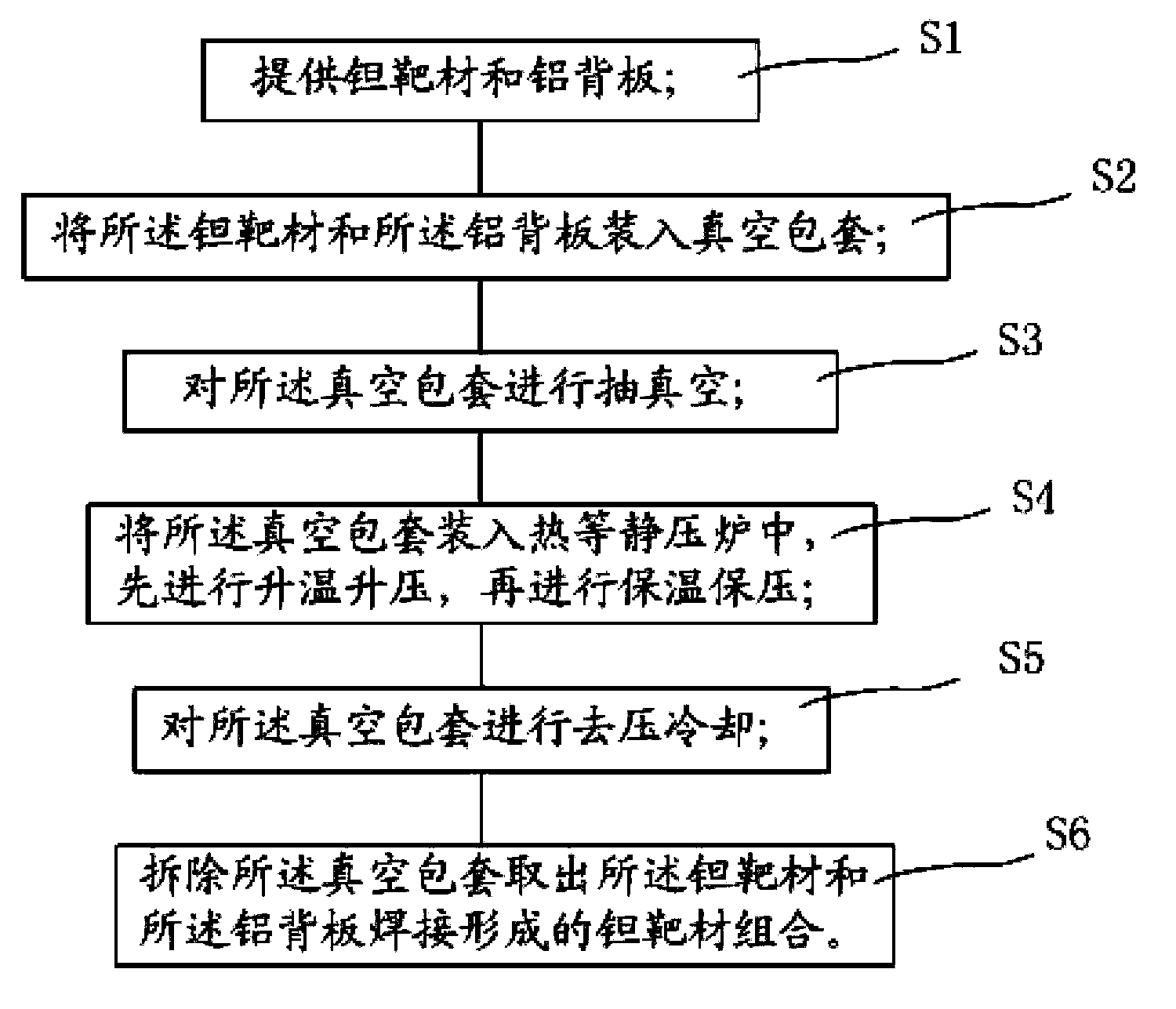

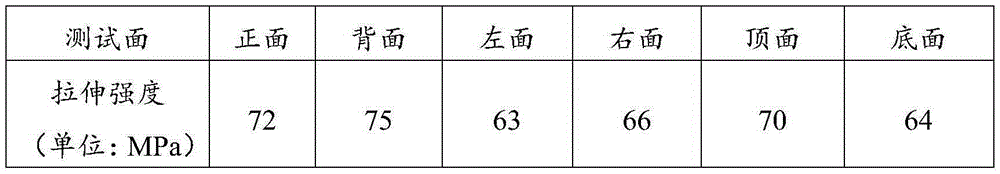

Hot isostatic pressure diffusion welding method for tantalum target and aluminum back plate

InactiveCN103801820APrevent disengagementStrong resistance to heat deformationNon-electric welding apparatusWeld strengthUltimate tensile strength

The invention provides a hot isostatic pressure diffusion welding method for a tantalum target and an aluminum back plate. The hot isostatic pressure diffusion welding method comprises the following steps: placing the tantalum target and the aluminum back plate into a vacuum sheath; vacuumizing the vacuum sheath; placing the vacuum sheath into a hot isostatic pressure furnace, raising the temperature and pressure, and keeping the temperature and pressure; decompressing and cooling the vacuum sheath; removing the vacuum sheath, and taking a target assembly formed by welding the tantalum target and the aluminum back plate out. By adopting the hot isostatic pressure diffusion welding method for the tantalum target and the aluminum back plate provided by the invention, the welding strength of a tantalum target assembly obtained by welding can be up to 150Mpa, and the yield is over 98 percent. The tantalum target assembly formed by using the method has the advantages of high combination firmness, high heating deformation resistance and the like.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

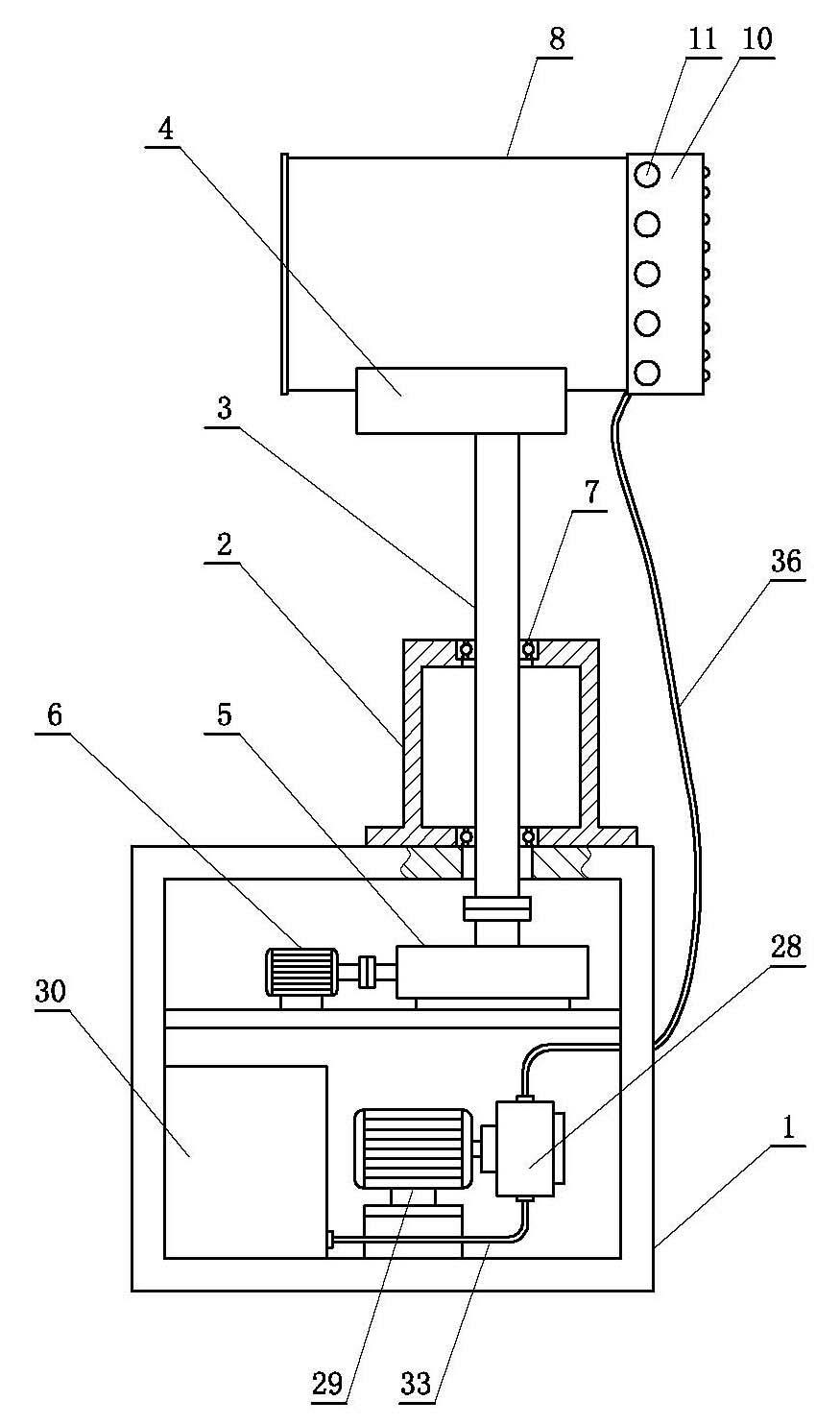

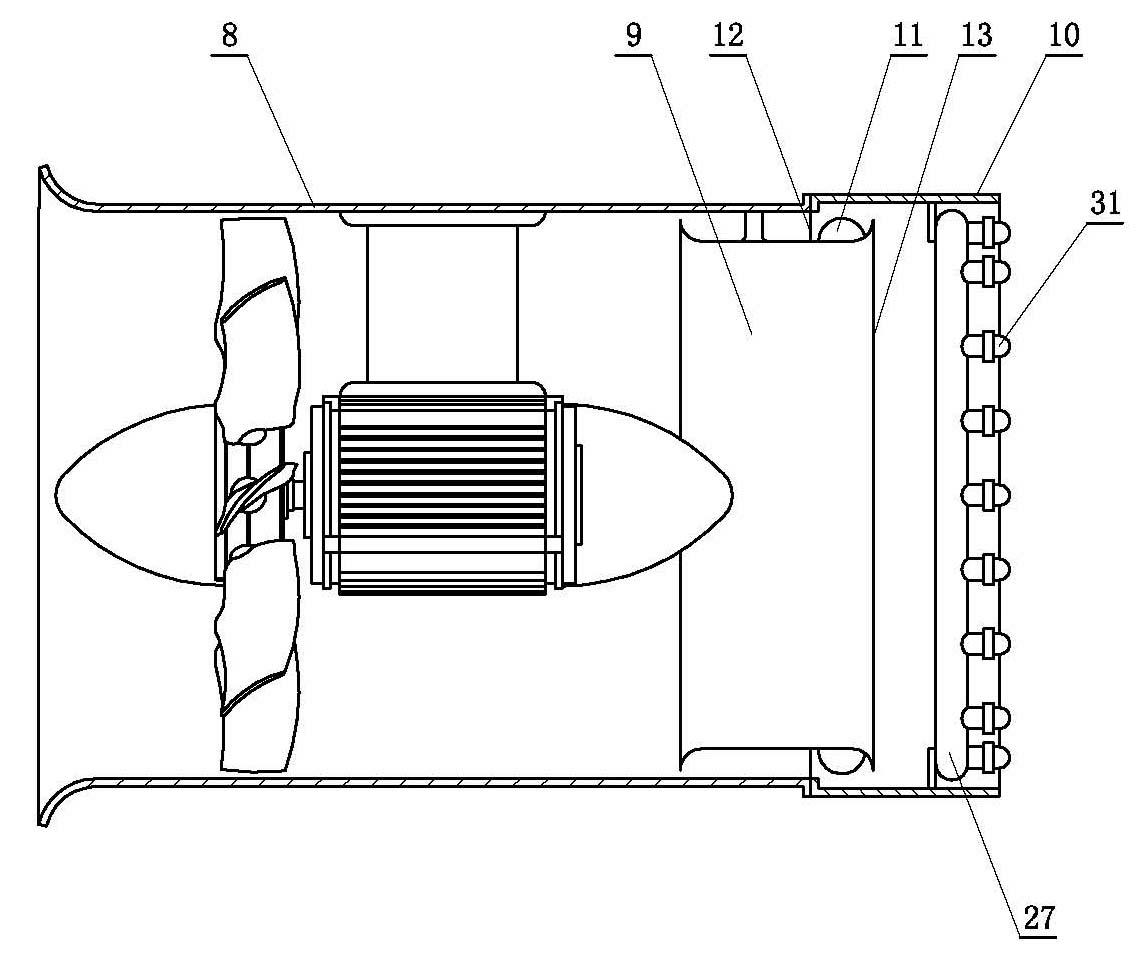

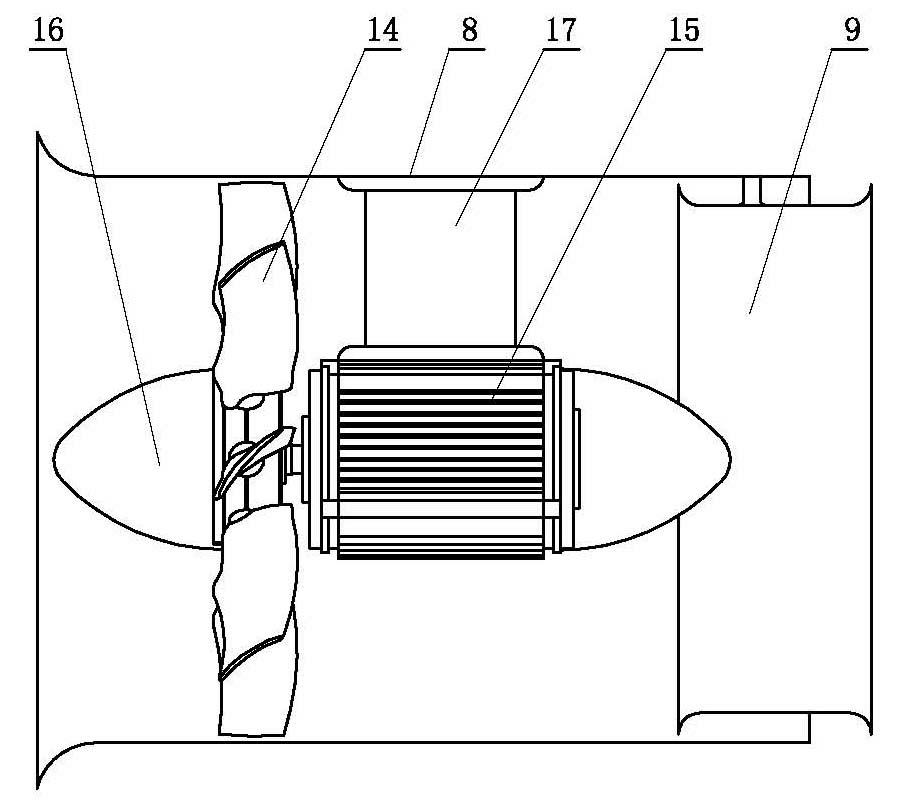

Far range air supply type mist spray purification device

InactiveCN102527548AReduce volumeReduce weightLiquid spraying apparatusRadial piston pumpHigh pressure

The invention relates to a far range air supply type mist spray purification device. The device comprises a machine seat and a main control platform, wherein an air supply device and a mist spray device are arranged on the machine seat; the air supply device is provided with a base; a rotating vertical column is arranged in the center of the base; a supporting plate is fixed at the upper end of the rotating vertical column; the lower end of the rotating vertical column is in power connection with a driving mechanism; an air cylinder is fixed on the supporting plate; a pressure diffusion throat pipe is arranged on the inner side of an air outlet of the air cylinder; the tail end of the air outlet of the air cylinder is connected with a backflow cover; a high-pressure axial flow fan is arranged in the center of the air cylinder; the mist spray device comprises an annular distribution pipe, a radial plunger pump, a motor and a water tank; an atomizing nozzle is arranged on the annular distribution pipe; a liquid absorption opening of the radial plunger pump is communicated with a water supply opening of the water tank through a liquid inflow pipeline; and a liquid outlet of the radial plunger pump is communicated with the annular distribution pipe through a liquid outflow pipeline. The device has a far mist spray range and low energy consumption, particularly can control the sizes of atomized fog drops effectively and has good dust removing and temperature reducing effects.

Owner:陈新

Vacuum diffusion welding process for glass and metal

The invention relates to a glass and metal vacuum diffusion welding technology, which comprises the following steps: 1) glass and metal weldments are subjected to surface treatment; and 2) the treated weldments are arranged in a high vacuum solid-state pressure diffusion welding furnace, and the vacuum is pumped for vacuum diffusion welding, wherein the step 1) comprises: step 1.1) the metal weldment is subjected to cleaning and surface finish treatment, and the surface of the glass weldment is cleaned; and step 1.2) the surface of the metal weldment is subjected to pre-oxidization treatment. The technology has the advantages that the technology improves the tensile strength, service life and vacuum tightness of glass and metal sealing joints, and has low cost and good economic effect.

Owner:NANJING UNIV OF TECH

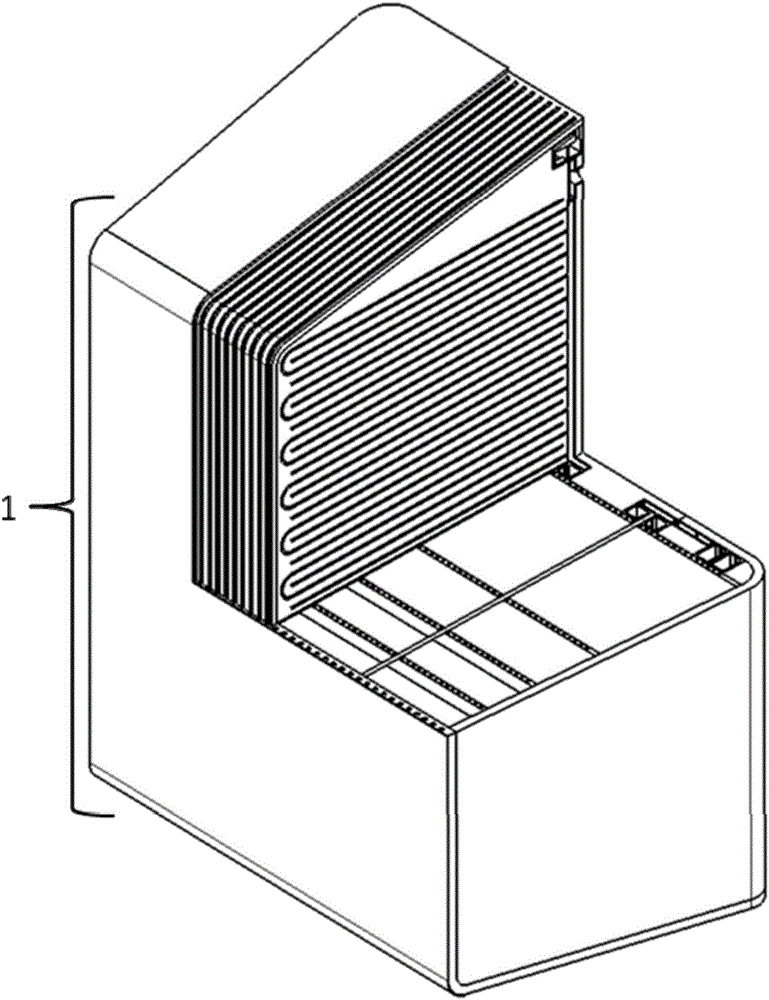

Low-pressure oxidation technology for solar cell

ActiveCN107681018AReduce pressureStable airflowFinal product manufacturePhotovoltaic energy generationPower flowEngineering

The invention discloses a low-pressure oxidation technology for a solar cell, and the technology mainly comprises the steps: preprocessing, reaction preparation, oxidation reaction, cooling and annealing, and boat withdrawing. A silicon dioxide film generated through the technology in a low-pressure environment where the temperature is less than 800 DEG C prolongs the service life of a few of carriers, and finally increases a short-circuit current and an open-circuit voltage of the cell, thereby improving the photoelectric conversion efficiency. A low-pressure diffusion furnace, compared witha normal pressure diffusion furnace, is small in pressure intensity, and is stable in air flow, thereby enabling the structure of the generated silicon dioxide film to be more compact and uniform. Theprepared silicon dioxide film is better in PID resistance.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

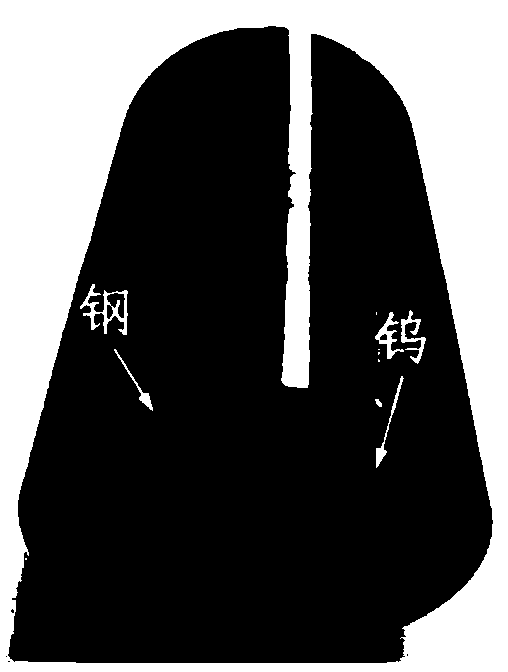

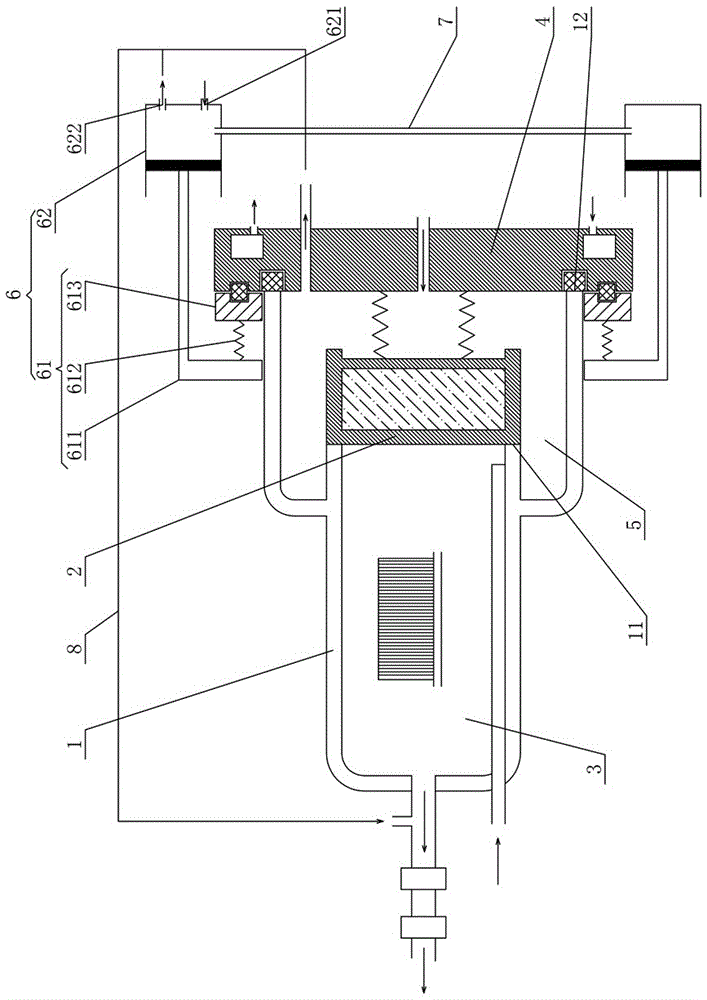

Manufacturing process for tungsten-attached U-shaped flow channel-containing first wall part for fusion reactor cladding

PendingCN106181015AImprove connection strengthSolve processing problemsNon-electric welding apparatusWeld seamTungsten

The invention discloses a manufacturing process method for a tungsten-attached U-shaped flow channel-containing first wall part suitable for a fusion reactor cladding. Functionalization is achieved by compounding tungsten and a U-shaped flow channel-containing steel by adopting a hot isotatic pressure diffusion welding technology. The main points of the process steps are as follows: (1) machining and preparing a U-shaped steel tube material according to a design; (2) machining and preparing a tungsten piece with a coating; (3) machining and preparing an outer sheath tool; (4) performing hot isotatic pressure diffusion welding; (5) removing the sheath, and machining a first wall part with a required size. According to the manufacturing process, hybrid welding of dissimilar materials, a complex structure and a plurality of interfaces is realized by preparing the U-shaped steel tube material and the tungsten piece with the coating and performing a one-time overall hot isotatic pressure process; moreover, the part which is machined by the process does not have a performance weakening area for melting a welding seam, is dense and reliable in overall structure, and is particularly suitable for the preparation of the tungsten-attached first wall part for the fusion reactor cladding.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

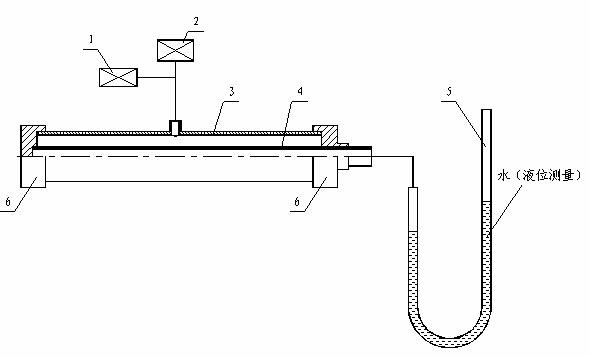

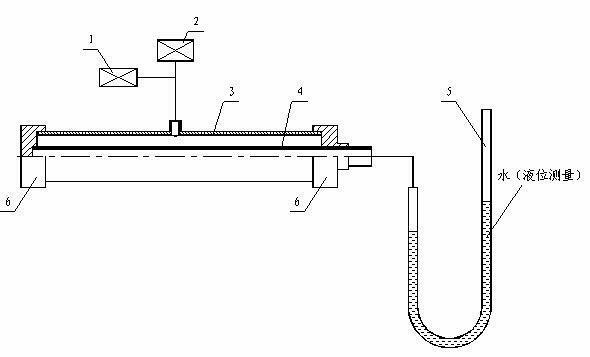

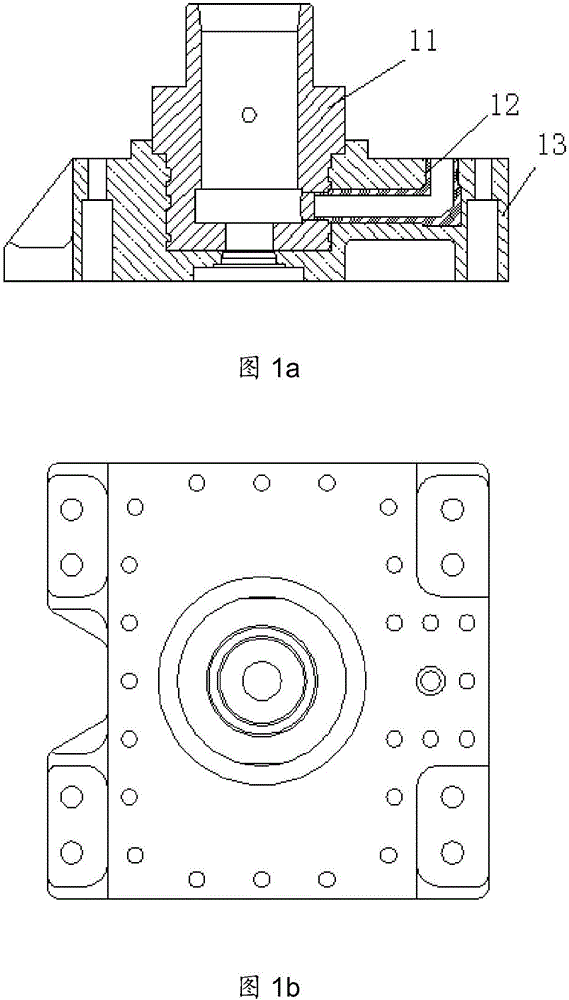

Helium leakage test device and method

InactiveCN102607780AIntuitive Characterization of Pressure Diffusion PerformanceSimple structureMeasurement of fluid loss/gain ratePorosityDiffusion

The invention relates to a helium leakage test device and a method. The device consists of a bearing test piece compressed system, a test medium supply system and a test data acquisition system. The bearing test piece compressed system consists of a pressure vessel and an evacuating device. The pressure vessel is fixed on a test table board, the evacuating device and the test medium supply system are respectively connected with the pressure vessel via pipelines, and a test piece is mounted in the pressure vessel and directly connected with the test data acquisition system. The helium leakage test method can measure and display a numerical value of helium permeating from the outside to the inside of the test piece within unit time. The numerical value can clearly show the pressure diffusion performance of the test piece, and visually shows surface porosity of the test piece, and helium leakage test device and the method play an important role in testing and verifying the quality of a cooling water pipe for a water hydrogen system of a large generator set, and further can be used for detecting other products with certain requirements in the aspect of the gas diffusion performance.

Owner:SHANGHAI PLASTICS RES INST CO LTD

Diffusion welding piece of high-purity zirconium oxide composite ceramic and red copper and production method of diffusion welding piece

InactiveCN107096994AAvoid crackingEven by forceVacuum evaporation coatingSputtering coatingComposite ceramicCopper

The invention provides a diffusion welding piece of high-purity zirconium oxide composite ceramic and red copper and a production method of the diffusion welding piece. By the adoption of a zirconium oxide composite ceramic plate, the ceramic surface is processed through a surface grinding method, then a metal zirconium coating is formed on the surface of the ceramic plate through a vacuum ion plating method, the red copper is in contact with the zirconium oxide composite ceramic plate through the metal zirconium coating, the entirety is put into a hot isostatic pressure sheath, degassing treatment is conducted, finally, the zirconium oxide composite ceramic plate and the red copper are welded through a hot isostatic pressure diffusion welding method, and the diffusion welding piece of the high-purity zirconium oxide composite ceramic and the red copper is obtained. The diffusion welding piece has the advantage that the welding interface strength is high. The technique and equipment are simple, cost is low, energy consumption is low, the production efficiency is high, the production method is suitable for industrial production, and a welding structure, which is stable in quality and high in bonding strength, of the zirconium oxide composite ceramic and the red copper can be obtained.

Owner:南京云启金锐新材料有限公司

Mushroom-shaped mixed composite pile capable of effectively controlling settlement and construction method

InactiveCN101775803AImprove settlement performanceTo overcome the problem that deep stirring can only stop water but not supportBulkheads/pilesUltimate tensile strengthMushroom

The invention relates to a mushroom-shaped mixed composite pile capable of effectively controlling settlement and a construction method. The invention relates to a technique for treating soft geologies in geotechnical engineering, the pile not only solves the defects of the commonly used prior foundation treatment technique, including the low strength of the mixed pile body and the severe compression deformation of the pile body, but also can effectively control post-construction settlement and increase the pressure diffusion angle, and the invention is an economic novel foundation treatment technique. A special-purposed reducing single-shaft mixing pile driver is adopted to shape a mushroom-shaped single-shaft deep-mixed cement-soil pile body, and a precast concrete pile, or a steel pipe or a bamboo-wood material as a core material is inserted in the center of the pile body to form the novel composite pile which consists of a mushroom-shaped cement-soil mixed pile and a high-strength core pile.

Owner:SHANGHAI STRONG FOUND ENG

Hot isostatic pressure diffusion connection preparation method of heterogeneous composite component

ActiveCN106181250AImprove sealingAvoid Interface CrackingPositive displacement pump componentsPositive-displacement liquid enginesMachiningMetal

The invention relates to a hot isostatic pressure diffusion connection preparation method of a heterogeneous composite component. The hot isostatic pressure diffusion connection preparation method of the heterogeneous composite component comprises the steps that (1) a base assembly containing a matrix blank, an insert, a cylinder sleeve blank and a connector blank is designed and machined according to the size of a final product; (2) a pure aluminum sheath assembly comprising a sheath, a sheath cover, a degassing pipe and a cushion block is designed and machined; (3) all the components are subjected to surface treatment; (4) the sheath assembly and the base assembly are assembled, the sheath cover and the sheath are welded, and the degassing pipe and the sheath cover are welded; (5) the interior of the sheath is vacuumized; (6) the sheath is subjected to hot isostatic pressure treatment; and (7) the sheath is removed, and the composite component product is obtained through machining. Mutual connection between at least two kinds of different metal materials is achieved through the heterogeneous metal hot isostatic pressure diffusion connection process, so that the composite component product is obtained, the heterogeneous metal connection interface is good in sealing performance, interface cracking caused by the linear expansion coefficient difference of a casting process is avoided, and the product is stable and reliable in quality.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +2

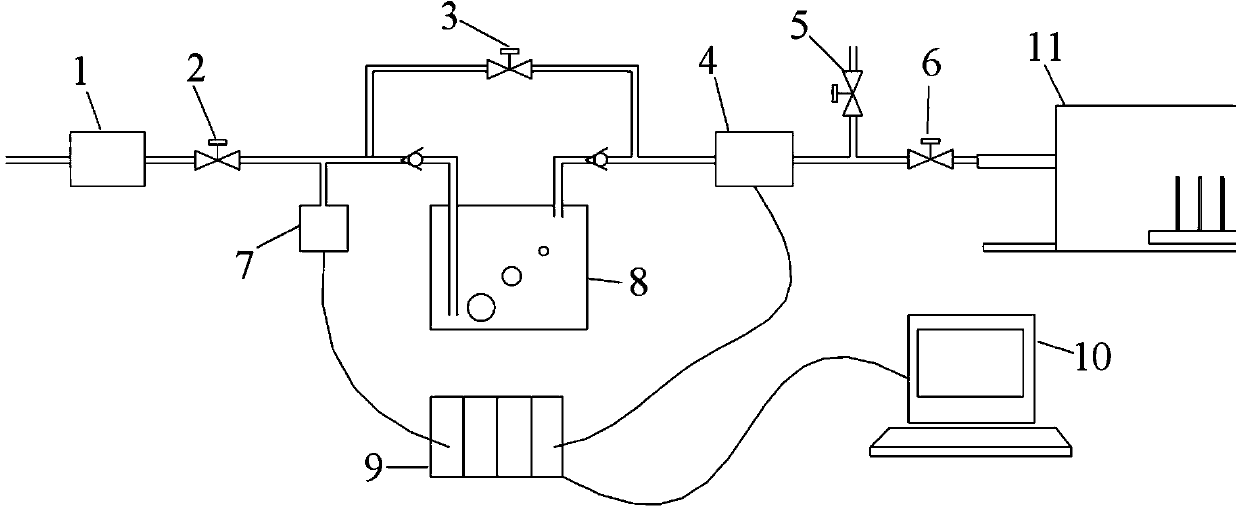

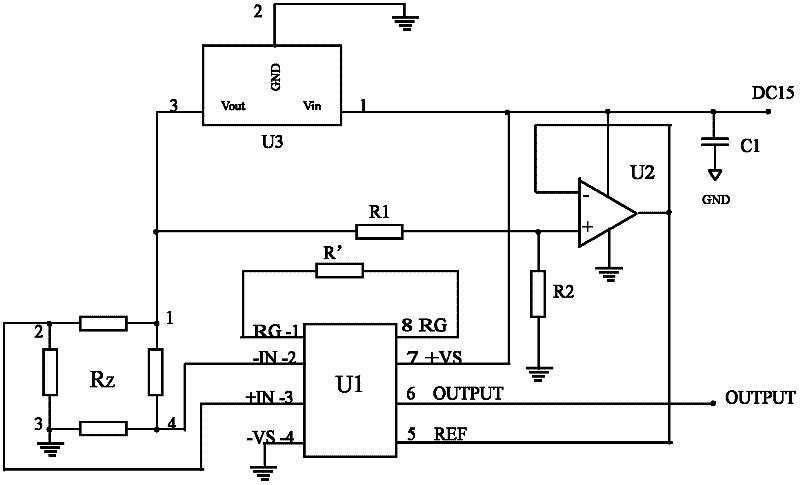

Source flow control system for negative-pressure diffusion furnace

InactiveCN103696020AHigh control precisionExtended service lifeDiffusion/dopingInterference factorStreamflow

The invention relates to a source flow control system for a negative-pressure diffusion furnace. The source flow control system comprises a source flow supply unit, a carrier gas supply unit and a pressure control unit, wherein the carrier gas supply unit is connected with the gas input end of the source flow supply unit through a first control valve; the pressure control unit is connected between the output end of the source flow supply unit and the reaction cavity of the negative-pressure diffusion furnace, can sense the pressure values of the two ends of the source flow supply unit or the pressure value of the output end of the source flow supply unit, and enables the process gas pressure in the inlet of the pressure control unit to achieve the predetermined value through controlling the interval valve, wherein the predetermined value of the process gas pressure is lower than or equal to the atmospheric pressure. Therefore, the source flow control system enables the source flow, introduced in the reaction cavity, to meet the demands of silicon chip sheet resistance and junction depth through precisely controlling the source flow of the diffusion furnace, so that the interference factors of the source flow are largely decreased; in addition, the invention further provides effective and rigorous anti-explosion protective measures.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

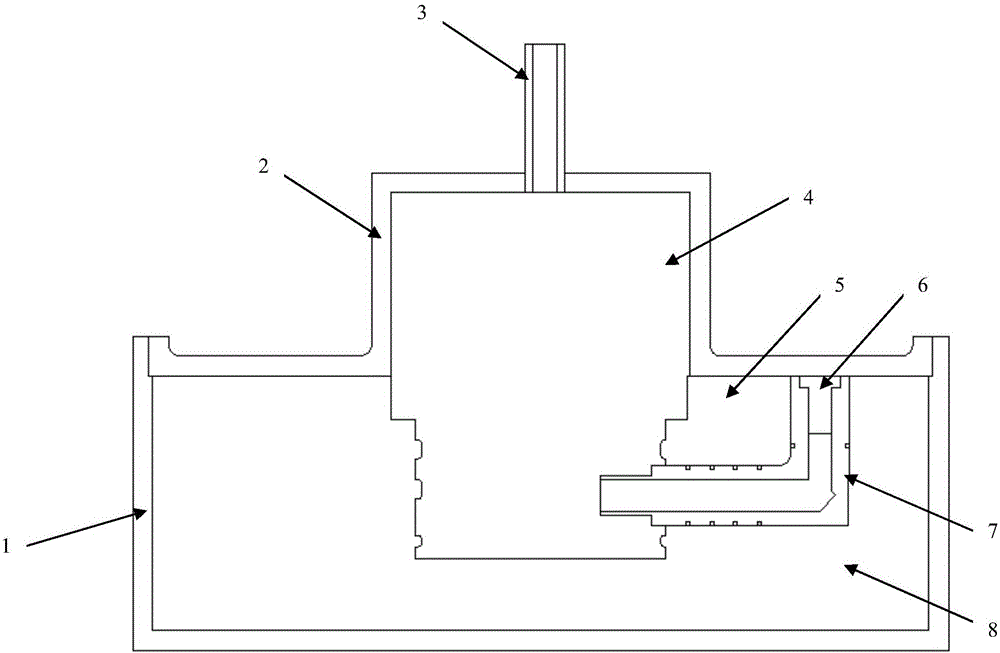

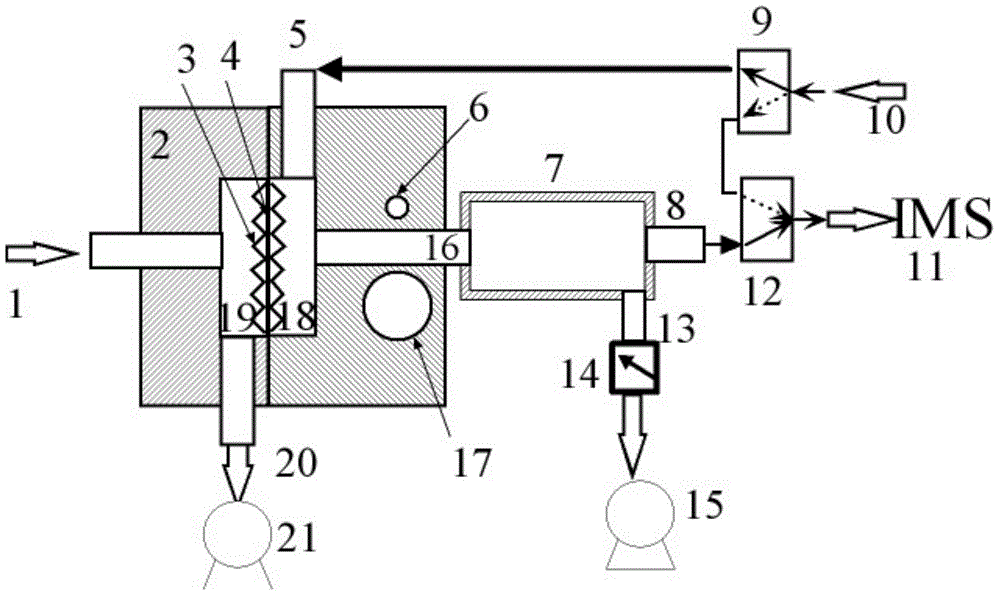

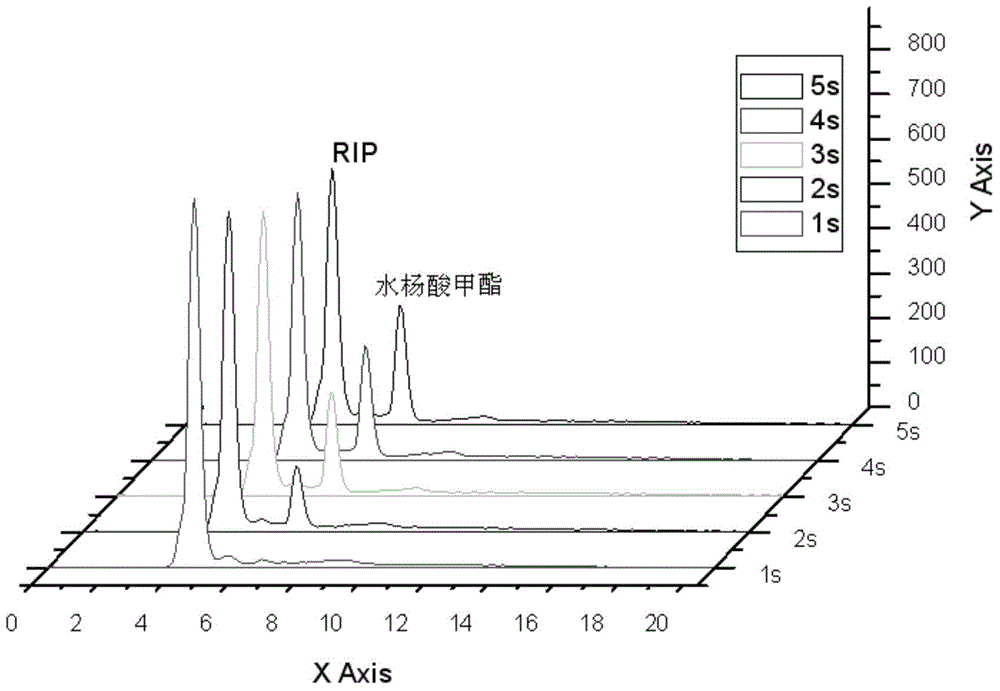

Online membrane sample-entering device for ion mobility spectrometry

InactiveCN105203357AEasy to operateWide applicabilityPreparing sample for investigationMaterial analysis by electric/magnetic meansAir pumpInner membrane

The invention relates to an ion-mobility-spectrometry membrane sample-entering device. The membrane sample-entering device comprises a membrane device, a sample gathering cavity and two two-position three-way valves. The membrane device is provided with a heating device. A membrane cavity is divided by a membrane into an outer membrane cavity body and an inner membrane cavity body. The outer membrane cavity body is communicated with a sampling pump. The inner membrane cavity body and the sample gathering cavity generate negative pressure under the effect of an air sucking pump. During sample entering, a sample rapidly permeates through the membrane under the three effects of the concentration diffusion effect, the thermal motion diffusion effect and the pressure diffusion effect, so that the membrane permeating speed, the membrane permeating rate and the residual removing rate of the sample are greatly increased. The sample gathering cavity can be further used for gathering a trace quantity of samples. The membrane sample-entering device is mainly used for gas sample entering and can also be used for liquid sample entering. The two modes of discontinuous sample entering and continuous sample entering can be achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

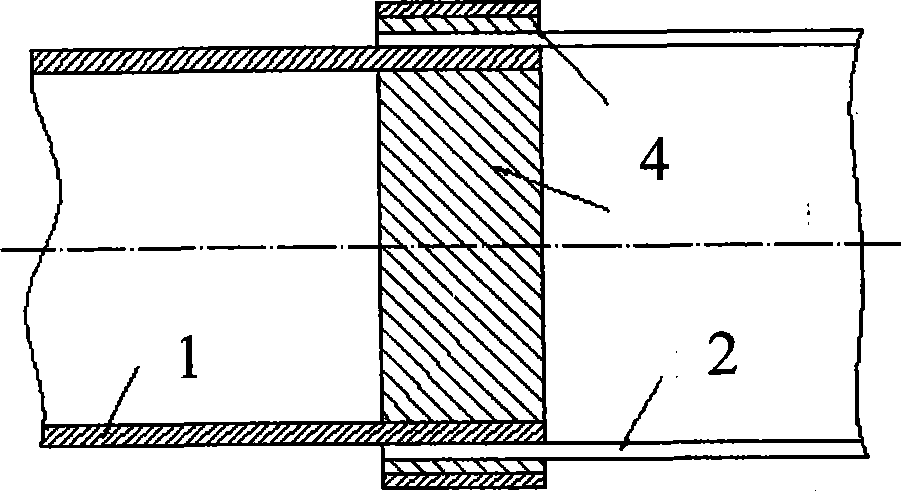

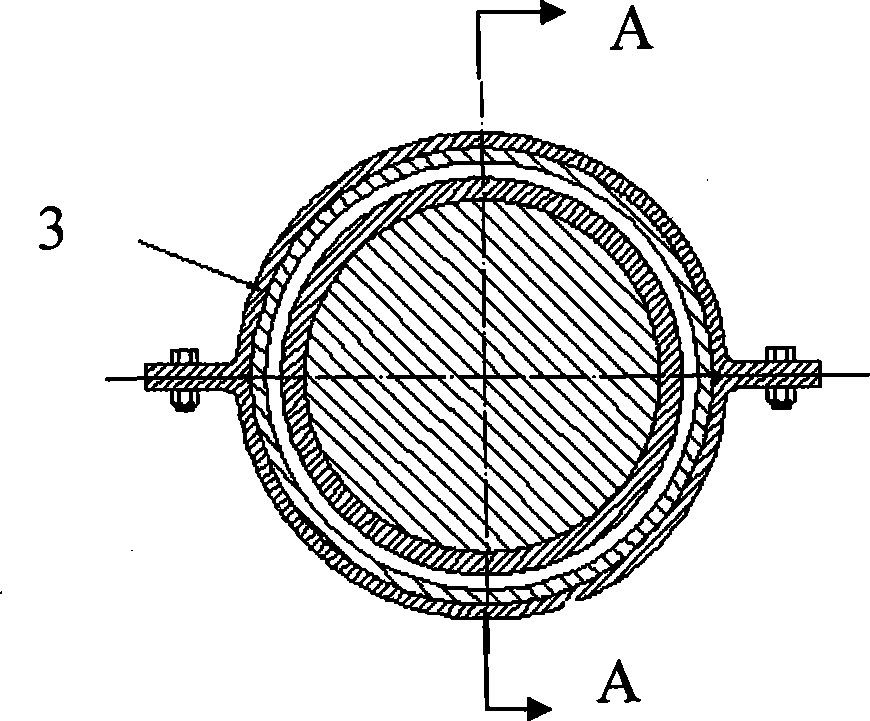

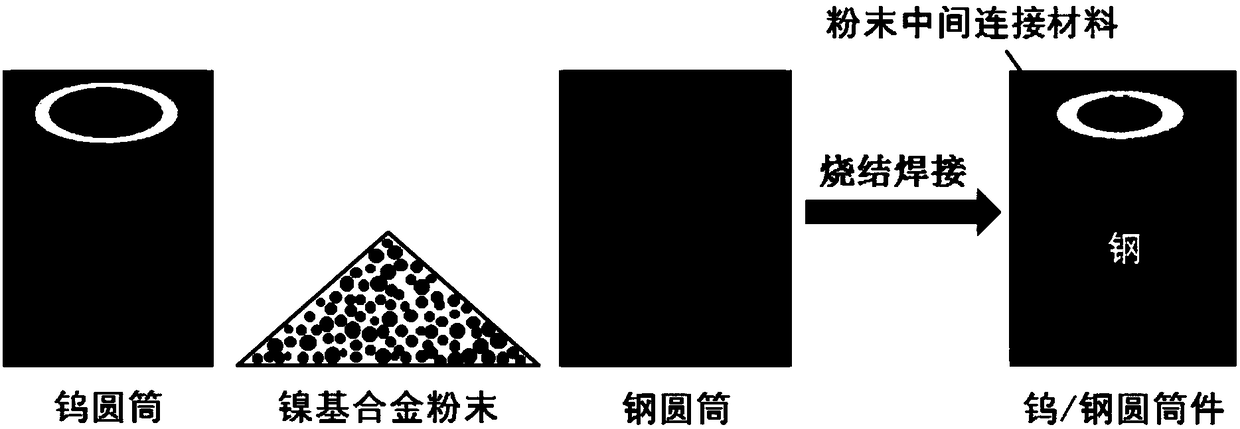

Hot isostatic pressure diffusion bonding method of tungsten/steel cylinder structural part

ActiveCN109454321AGood welding performanceReduce residual stressNon-electric welding apparatusUltimate tensile strengthBond strength

The invention relates to a hot isostatic pressure diffusion bonding method of a tungsten / steel cylinder structural part, and belongs to the technical field of metal welding. According to the hot isostatic pressure diffusion bonding method of the tungsten / steel cylinder structural part, nickel base alloy powder serves as an intermediate bonding material, assembling is conducted according to the laminated structure of a tungsten lining cylinder part / the powdery intermediate bonding material / a steel outer sleeve cylinder part, and then a hot isostatic pressure process is conducted to obtain thetungsten / steel cylinder structural part. By means of the tungsten / steel hot isostatic pressure diffusion bonding method, the problem of bonding of a tungsten / steel two-metal special-shaped part is solved, the preparation process is simple, the production period is short, and the obtained tungsten / steel two-metal cylinder structural part is free of interface defects, high in bonding strength and good in interface stability.

Owner:CENT SOUTH UNIV

Process for performing well completion by utilizing biological completion fluid

InactiveCN101942983AImprove production efficiencySmooth oil flowCleaning apparatusFluid removalEnvironmental resistanceHigh pressure water

The invention discloses a process for performing well completion by utilizing biological completion fluid, which comprises the following steps of: preparing biological enzyme aqueous solution; preparing biological acid aqueous solution; sequentially squeezing or mixing and squeezing the biological enzyme aqueous solution and the biological acid aqueous solution into a well by using a tubing high-pressure water jet device after perforation; and finally closing the well for 24 to 72 hours, washing boreholes after pressure diffusion, and performing a cyclic filling and sand prevention process. As de-plugging and scale formation prevention are combined and physical measures and chemical measures are combined, the process has the advantage of fulfilling the aims of effectively improving the permeability around the well, the production efficiency of an oil well, the yield and the recovery ratio at the premise of protecting oil pools.

Owner:XI'AN PETROLEUM UNIVERSITY

Top gas confluence method and device of atmospheric and vacuum distillation tower

ActiveCN101798518AAvoid the problem of unstable operating pressureStable deliveryHydrocarbon distillationJet pumpsPositive pressureEngineering

The invention discloses a top gas confluence method of an atmospheric and vacuum distillation tower. By the principle that a positive pressure steam generates a vena contracta stream with higher flow speed and lowest pressure after injected at a high speed and entrainment effect on a micro positive pressure gaseous medium around the position of steam vena contracta, the method realizes the confluence of positive-pressure and large-flow gas at the tops of a primary tower and a constant pressure tower of an oil refinery and micro positive pressure and small-flow gas at the top of a vacuum distillation tower. The invention also discloses a top gas confluence device of the atmospheric and vacuum distillation tower, which comprises an injection medium inlet pipe, a spray nozzle, a suction chamber, a medium to be injected inlet pipe, a diffusing section suction opening, a taper gradually diffusing section and a mixing pipe. The invention can realize effective confluence and pressure diffusion of the positive-pressure gas at the tops of the primary tower and the constant pressure tower and the micro positive pressure gas at the top of the vacuum distillation tower, avoid the positive-pressure gas at the tops of the primary tower and the constant pressure tower from returning into gas pipes at the top of the vacuum distillation tower to cause the pressure fluctuation at the top of thevacuum distillation tower, and pressurize and transmit mixed gas to a gas pipeline system of the oil refinery by using a compressor.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

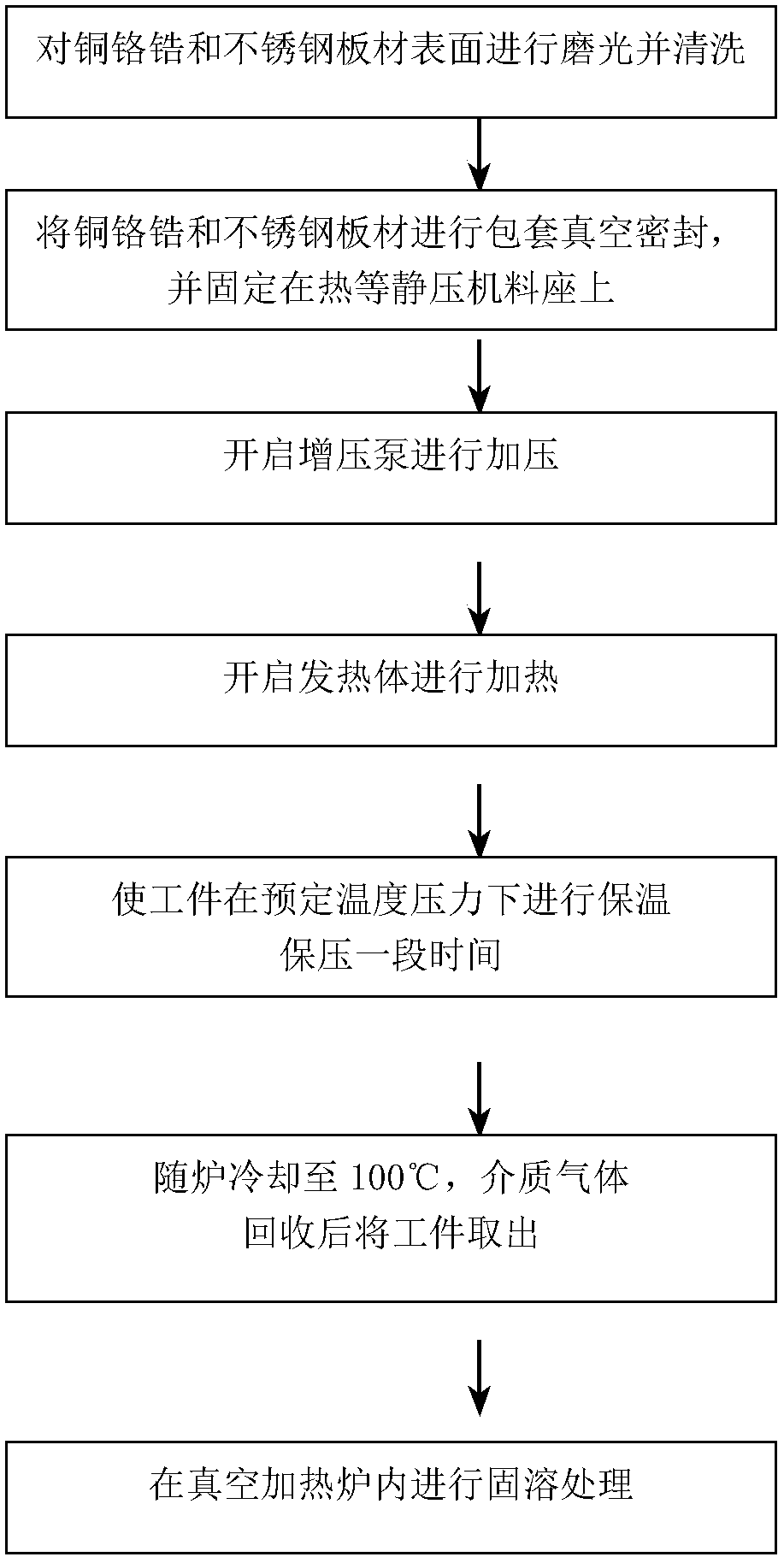

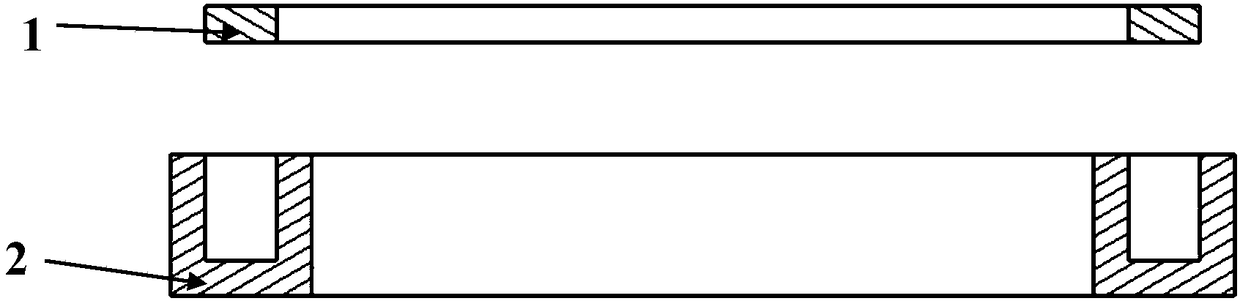

Hot isostatic pressure diffusion bonding method of copper chromium zirconium-stainless steel composite plate

InactiveCN108067724AFirmly connectedReduce defectsNon-electric welding apparatusSolution treatmentComposite plate

The invention belongs to a dissimilar metal diffusion bonding processing technology, and specifically discloses a hot isostatic pressure diffusion bonding method of a copper chromium zirconium-stainless steel composite plate. A plate junction surface is polished and cleaned, and then the plate junction surface is wrapped and sleeved with a vacuum seal and fixed to a hot isostatic press; and the plate junction surface is subjected to pressurization, heating and pressurization, heat and pressure preservation, furnace cooling and solution treatment; and various problems in a traditional connection mode are solved, the connection performance between dissimilar metals are stable, defects of the connection interface are obviously reduced, and the product yield is significantly improved. The mechanical properties and the organization structure of a composite plate connected by hot isostatic pressure diffusion can meet the relevant requirements of fusion test reactor products.

Owner:SOUTHWESTERN INST OF PHYSICS

Diffusion bonding method for high-temperature alloy and oxygen-free copper annular part

InactiveCN108544074AReduce porosityAchieve connectionElectron beam welding apparatusNon-electric welding apparatusPorositySuperalloy

The invention provides a diffusion bonding method for a high-temperature alloy and oxygen-free copper annular part. The diffusion bonding method comprises the steps of preparation of the annular part,preparation of a sleeve, assembly, hot isostatic pressing pretreatment, hot isostatic pressing process control and post-processing. According to the diffusion bonding method for the high-temperaturealloy and oxygen-free copper annular part, the hot isostatic pressure diffusion bonding technology is adopted, the oxygen-free copper and the high-temperature alloy annular part form diffusion bondingunder the condition of high temperature and high pressure, and the high-temperature alloy and oxygen-free copper annular part is formed. According to the diffusion bonding method for the high-temperature alloy and oxygen-free copper annular part, the problems of spalling, block dropping and delamination of a connecting layer and the problem of matrix separation are avoided, the porosity of the connecting layer is reduced, and good metallurgical bonding is achieved.

Owner:BEIHANG UNIV

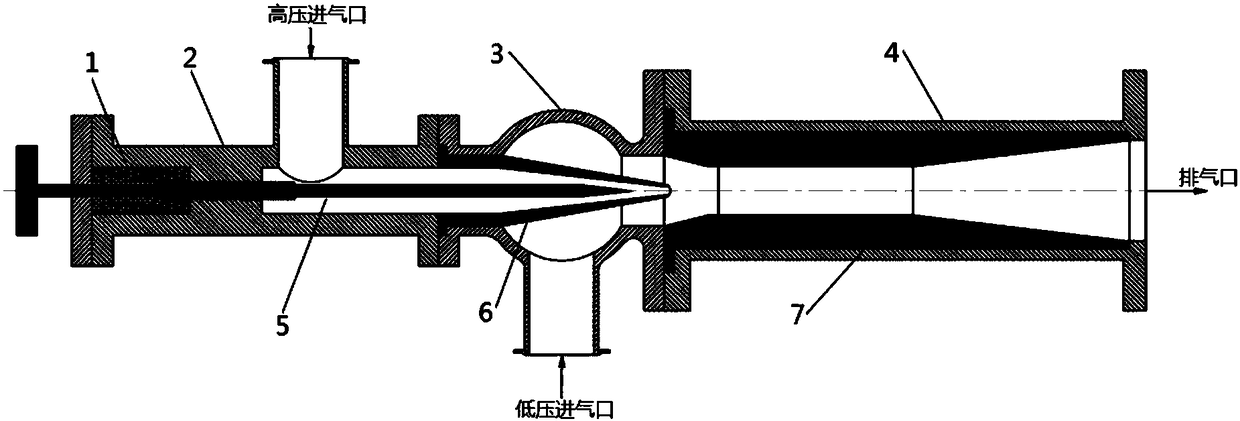

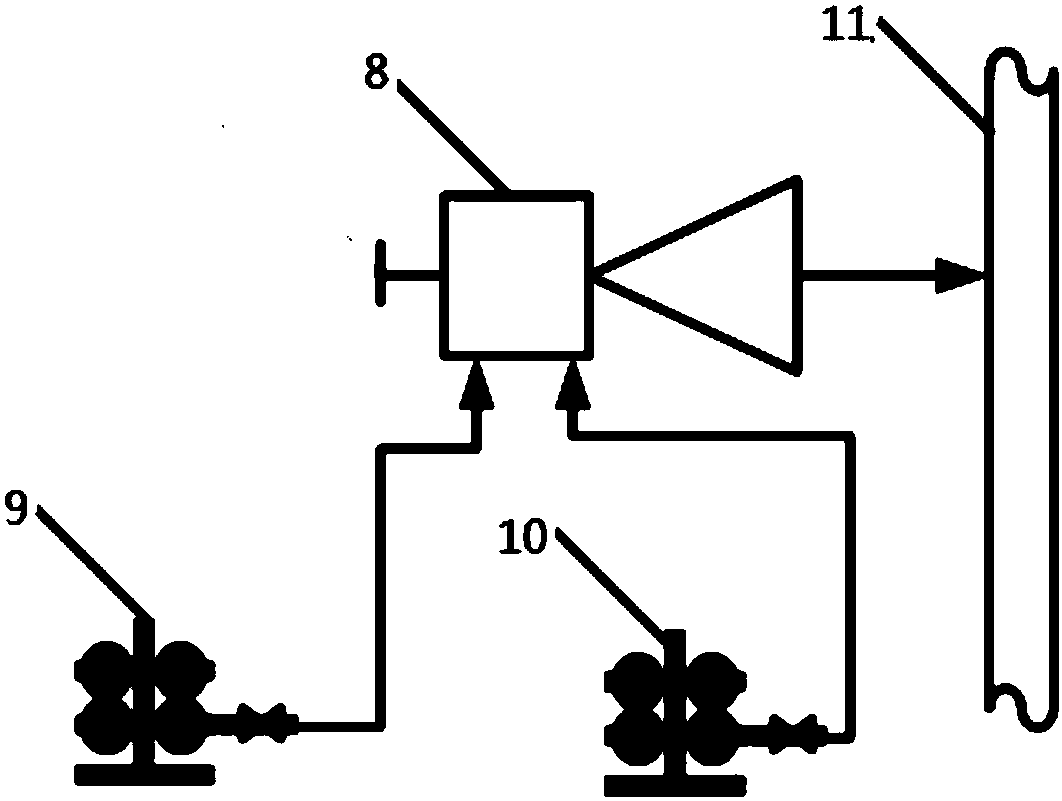

Utilization device for pressure energy of gas well of natural gas

The invention discloses a utilization device for pressure energy of a gas well of natural gas. The device comprises a high-pressure gas inlet pipe, a low-pressure gas inlet pipe, a mixed medium-pressure gas exhaust pipe, a mixing chamber, an ejector, a nozzle and a mixed pressure diffusion pipe; the high-pressure gas inlet pipe is arranged perpendicular to the low-pressure gas inlet pipe, the mixed medium-pressure gas exhaust pipe is arranged parallel and opposite to the high-pressure gas inlet pipe, and the mixed medium-pressure gas exhaust pipe and the high-pressure gas inlet pipe are connected perpendicular to the low-pressure gas inlet pipe; the mixing chamber is a space formed by communicating of the high-pressure gas inlet pipe, the low-pressure gas inlet pipe and the mixed medium-pressure gas exhaust pipe; the ejector comprises an adjustable cone, wherein the adjustable cone is arranged in the high-pressure gas inlet pipe; the nozzle is arranged inside the high-pressure gas inlet pipe and the low-pressure gas inlet pipe, and the nozzle externally sleeves the lower portion of the adjustable cone; and the mixed pressure diffusion pipe is arranged in the mixed medium-pressure gas exhaust pipe. The device has the advantages that through the adjustable natural gas ejector pressurizing structure, during pressure change of the gas well, the ejector structure is adjusted to maximally utilize the pressure energy of the high-pressure natural gas well so as to pressurize the low-pressure natural gas well.

Owner:CHINA PETROLEUM & CHEM CORP +1

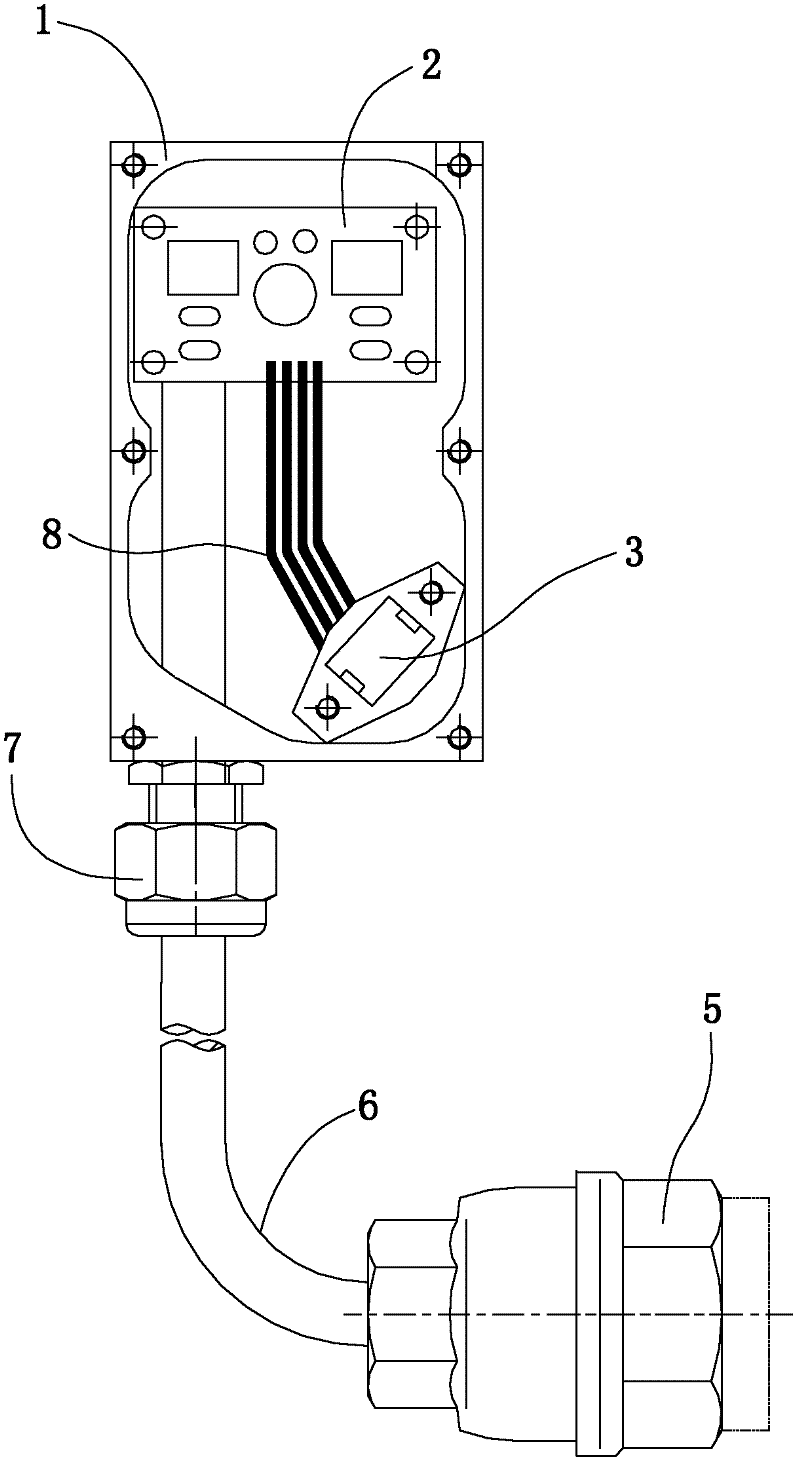

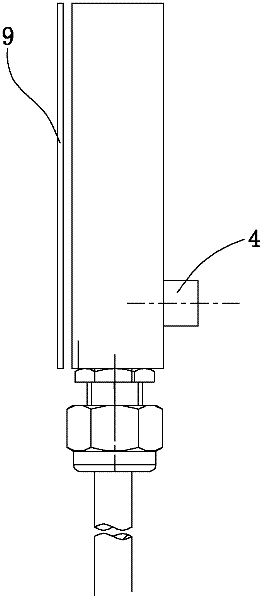

Leak detector

InactiveCN102288371AImprove rigidityReduce deformationMeasurement of fluid loss/gain rateGas detectorEngineering

The invention belongs to the field of pressure detection, and relates to an air leakage detector used for detecting the air leakage of pipe walls of various pipe materials, cigarette paper and the like. The detector consists of a shell, a detection circuit board, a temperature self-compensating diffused silicon pressure sensor, a pressure nozzle, a quick connector, a power supply / output cable, a waterproof connector, a lead wire and a cover plate, and the detection circuit board and a temperature self-compensated diffused silicon pressure sensor. The pressure sensor is installed in the shell and connected by lead wires; one end of the pressure nozzle is connected to the pressure chamber of the temperature self-compensating diffused silicon pressure sensor, and the other end extends out of the shell to connect with the measured pressure source; the waterproof joint is installed on the shell , used to fix the power / output cable; the power / output cable is connected to the detection circuit board and the quick connector. The detector can quickly detect the leakage of gas and liquid in industrial production, and output a linear voltage signal. It has the characteristics of high sensitivity, high detection accuracy, light weight, corrosion resistance, reliable performance, and convenient installation and use.

Owner:王万年

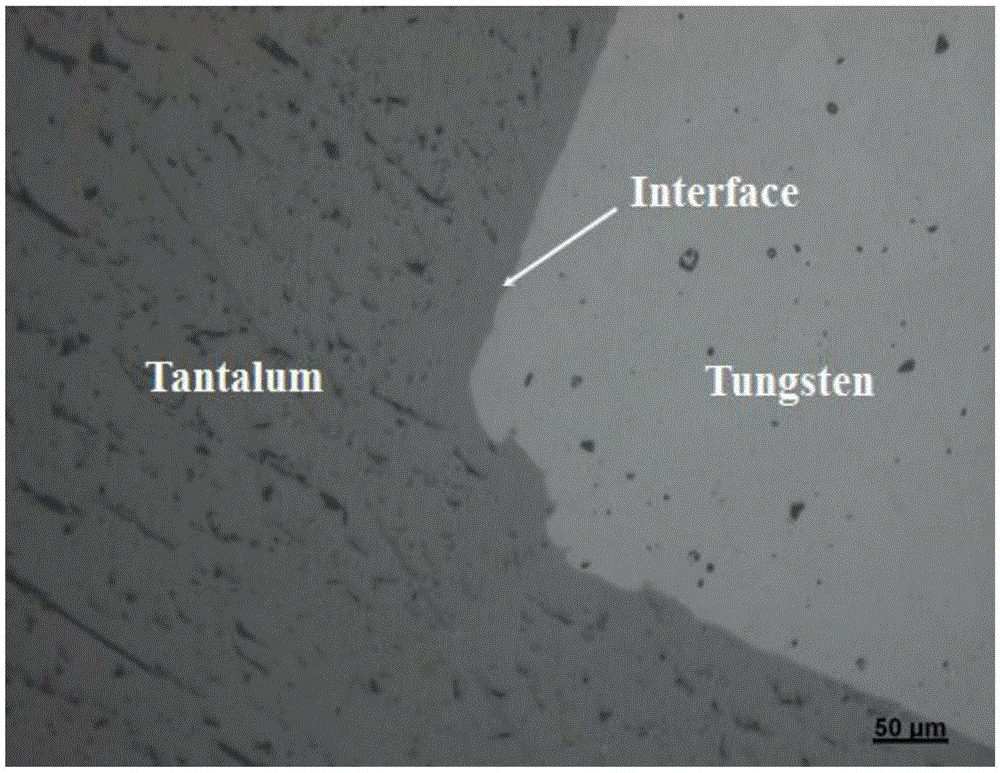

Method for welding tantalum layers to six faces of tungsten block in diffusion manner

ActiveCN105252134AReduce the number of weldsNo air leftElectron beam welding apparatusNon-electric welding apparatusTitaniumMetal sheet

The invention discloses a method for welding tantalum layers to six faces of a tungsten block in a diffusion manner. The method comprises the steps that an outer wrapping sleeve is made of at least one of titanium, iron and molybdenum and is provided with a cavity for containing the tungsten block, spacer sheets and tantalum sheets are sequentially laid on the inner wall of the cavity, and then the tungsten block is placed in the cavity; tantalum sheets and spacer sheets are sequentially laid on the surface of the part, on the end face of the outer wrapping sleeve, of the tungsten block, metal sheets are used for covering, and electron beam welding is carried out on the metal sheets and the outer wrapping sleeve under the vacuum condition; then hot isostatic pressure diffusion welding is carried out; and the outer wrapping sleeve is removed after welding is finished. According to the method, the tantalum sheets and the tungsten block are located through the outer wrapping sleeve, the step of manufacturing a tantalum box through electron beam welding is omitted, no air suction material is needed for wrapping, the technology is simple, and cost is low. Due to the spacer sheets, after diffusion welding is finished, products can be taken out very conveniently, simpleness and easy operation are achieved, the requirement for efficiently producing tantalum-tungsten composite materials in a batch manner can be met, and a basis is laid for research and wide application of spallation neutron sources.

Owner:DONGGUAN NEUTRON SCI CENT +1

Two-grade sealing apparatus used for reduced pressure diffusion systems

ActiveCN105483831AExtended service lifeReduce stressDiffusion/dopingEngineeringMechanical engineering

The invention discloses a two-grade sealing apparatus used for reduced pressure diffusion systems. The apparatus comprises a quartz tube, one orifice of the quartz tube is provided with an inner sealing end surface and an outer sealing end surface which are concentric, the inner sealing end surface is connected with a first-grade sliding door body to form a reaction cavity, the outer sealing end surface is connected with a second-grade sealing door body to form a transition cavity, and the second-stage sealing door body is connected with a push balancing assembly used for preventing pressing damages of the second-stage sealing door body to the outer sealing end surface. The two-grade sealing apparatus has the advantages of simple and reliable structure, and prevention of stress damages of the outer sealing end surface.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

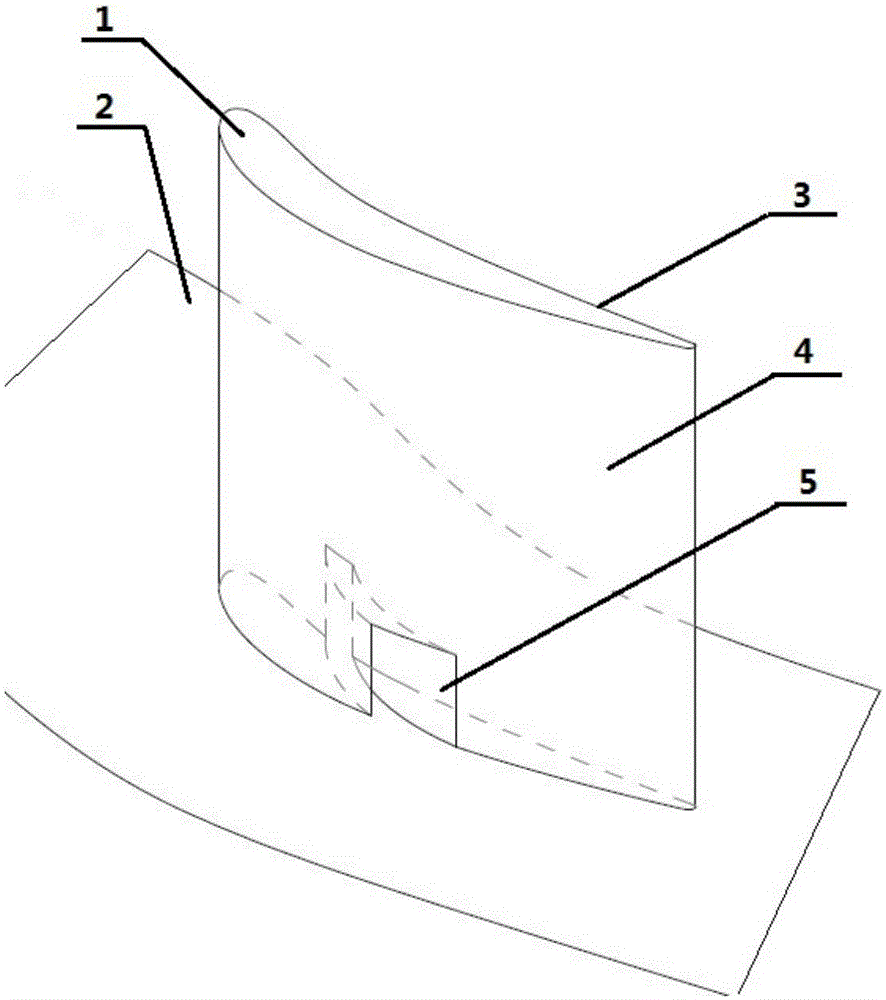

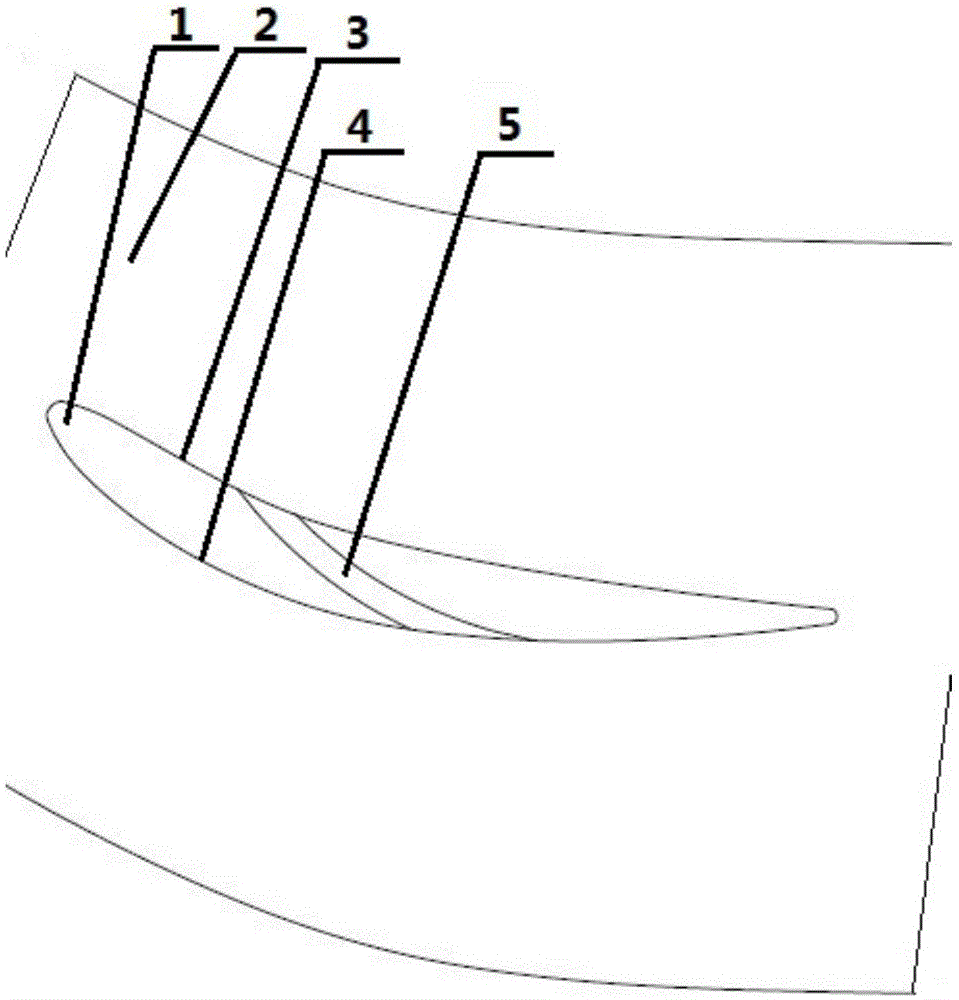

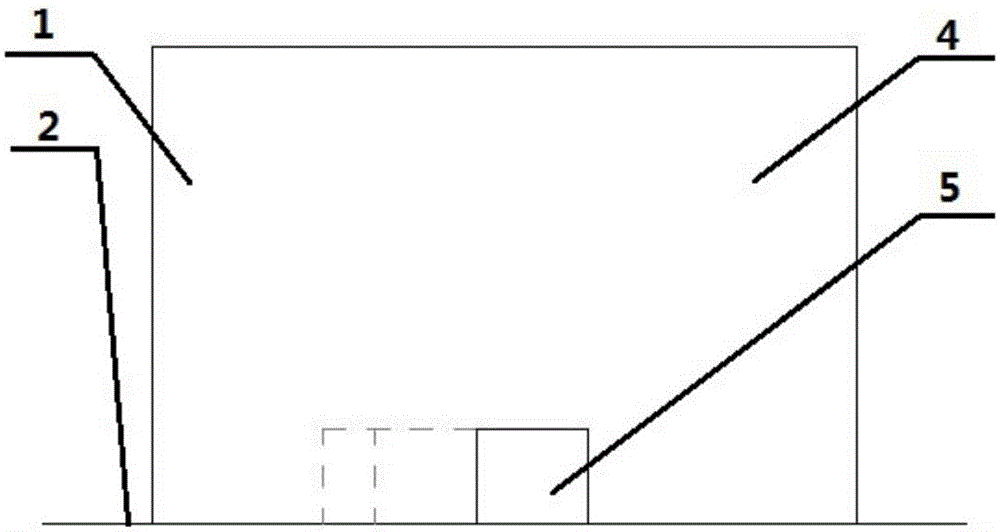

Compressor stator cascade with blade root provided with equal-width circular arc shaped channels

ActiveCN105156361ALarge circulation capacityIncrease kinetic energyPump componentsPumpsImpellerSuction stress

The invention provides a compressor stator cascade with a blade root provided with equal-width circular arc shaped channels, relating to passive flow control technology in the technical field of turbo-machinery. The adverse pressure gradient resistance is stronger, Coanda effects are additionally brought and corner separation is better inhibited by forming the equal-width circular arc shaped channels in an end wall of the blade root of the compressor stator cascade from a pressure surface to a suction surface, forming high-speed jet by utilizing self-differential pressure of blades, increasing the kinetic energy of low energy fluid at a corner and blowing down airflows on boundary layers of the suction surface and the end wall. The compressor stator cascade is characterized in that the channels are formed in the end wall of the blade root of the compressor stator cascade; the spanwise height is a constant value; the number of the channels can be one or multiple; inlets of the channels are formed in the pressure surface of the stator cascade and outlets are formed in the suction surface of the cascade; center lines of the channels are shaped like circular arcs; the two sides of the channels are equally distant from the center lines; and the outlets in the side walls of the channels are tangent to the downstream wall of the suction surface of the cascade. The compressor stator cascade has the beneficial effects of effectively inhibiting corner separation, increasing the cascade flow capacity, reducing the total pressure loss and increasing the pressure diffusion capacity.

Owner:BEIHANG UNIV

Method for preparing metal product based on discrete manufacturing technology

InactiveCN107584117AImprove production efficiencySolve problems with precision metal partsAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyProduct base

The invention discloses a method for preparing a metal product based on a discrete manufacturing technology. The method comprises the following steps of 1, material preparation, 2, sectional forming of parts; 3, preprocessing of the connecting surface of the sectional parts; 4, pre-connection of the sectional parts; 5, hot isostatic pressure diffusion connection; 6, removal of locating and fastening threads. The metal materials comprise nickel alloy, stainless steel, titanium alloy, aluminum alloy, high-temperature alloy, copper alloy and the like, an addition material manufacturing technologyis utilized to discrete and form metal parts, the material, the shape and the size of the metal parts are not restricted, the insufficiencies that an existing addition material manufacturing technology cannot form parts with high precision, large sizes, and complicated shapes are avoided, the manufacturing period is shortened, the manufacturing efficiency of the metal parts is improved, and the application field of the addition material manufacturing technology is expanded.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com