Utilization device for pressure energy of gas well of natural gas

A technology of pressure energy and natural gas, applied in gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., can solve the problem of lack of pressurization effect, weakened injection pressurization effect of fixed ejector, and inability to adapt to natural gas. Changes in pressure and flow, etc., to achieve the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

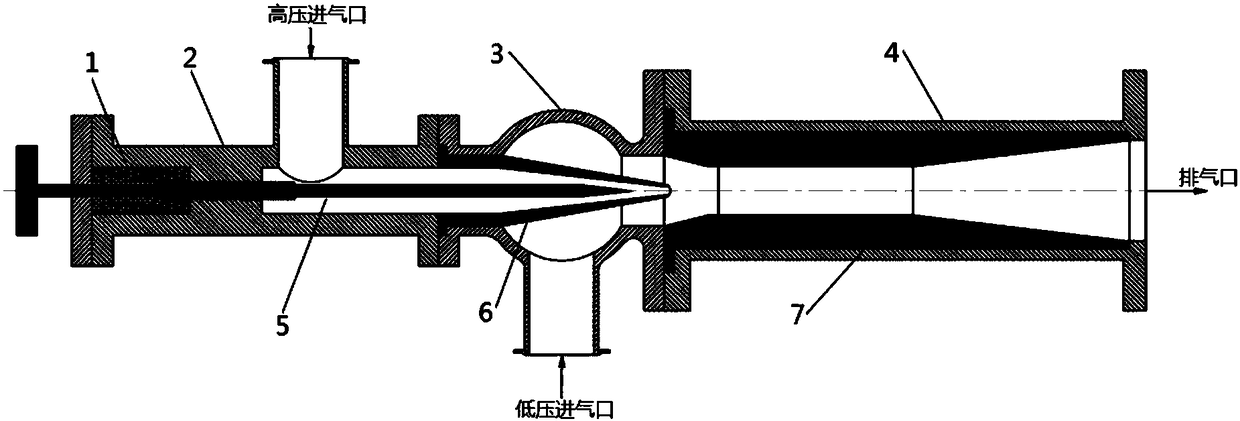

[0052] figure 1 A schematic structural diagram of a natural gas well pressure energy utilization device according to an exemplary embodiment of the present invention is shown.

[0053] The natural gas well pressure energy utilization device according to an exemplary embodiment of the present invention includes:

[0054] a mixing chamber, the mixing chamber communicates with the high-pressure intake pipe 2, the low-pressure intake pipe 3 and the mixed medium-pressure exhaust pipe 4;

[0055] Ejector, ejector includes: adjustable cone 5, adjustable cone 5 is connected with high-pressure inlet pipe 2 through threads, and uses sealing packing 1 to seal high-pressure gas; nozzle 6, nozzle 6 is arranged on high-pressure inlet pipe 2 and Inside the low-pressure intake pipe 3, the nozzle 6 is overlaid on the lower part of the adjustable cone 5, and the nozzle 6 is fixed by the flanges of the high-pressure intake pipe 2 and the low-pressure intake pipe 3;

[0056] The mixing diffuser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube chief | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com