Patents

Literature

788 results about "Compressed natural gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compressed natural gas (CNG) (methane stored at high pressure) is a fuel which can be used in place of gasoline, diesel fuel and propane/LPG. CNG combustion produces fewer undesirable gases than the aforementioned fuels. In comparison to other fuels, natural gas poses less of a threat in the event of a spill, because it is lighter than air and disperses quickly when released. Biomethane – cleaned-up biogas from anaerobic digestion or landfills – can be used.

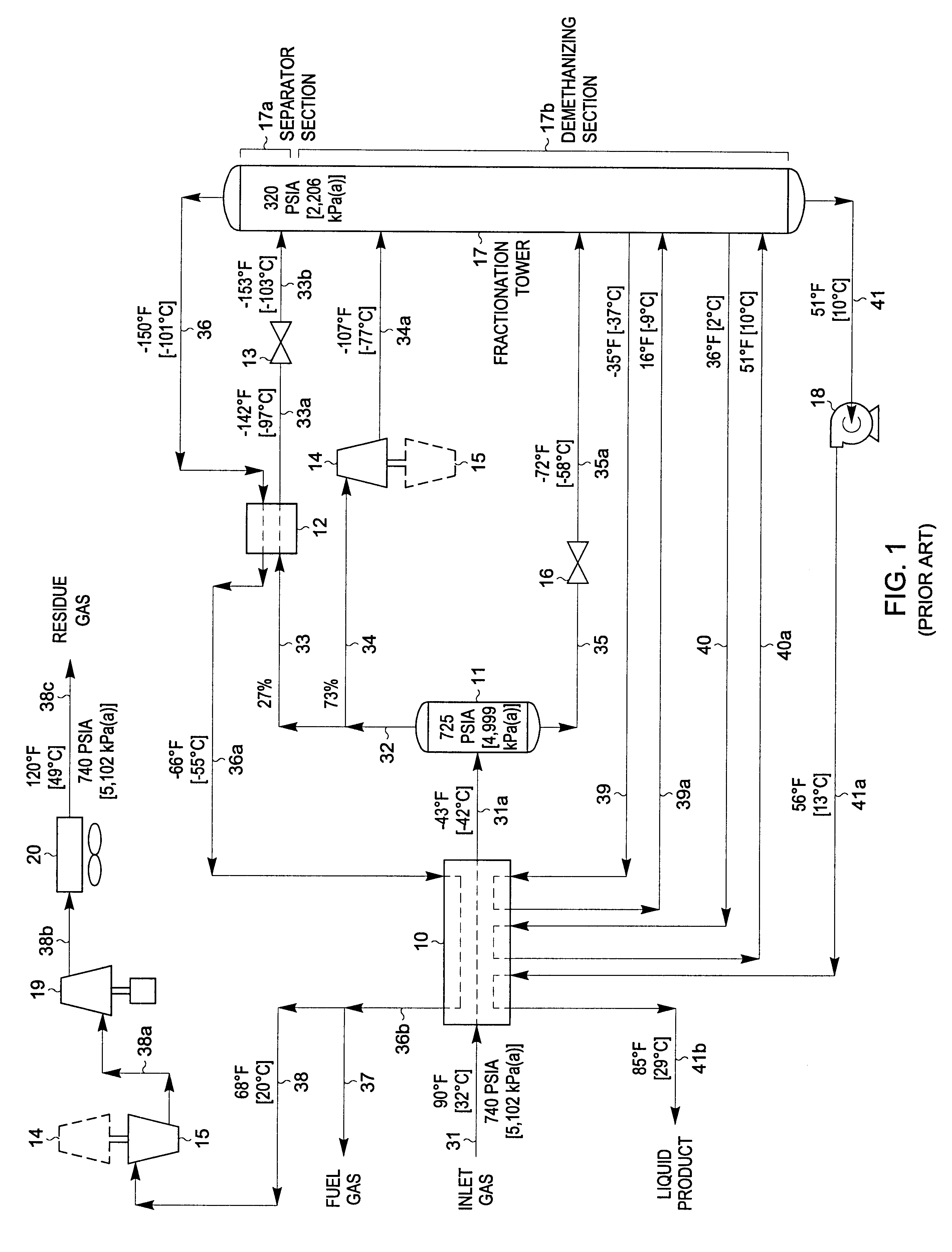

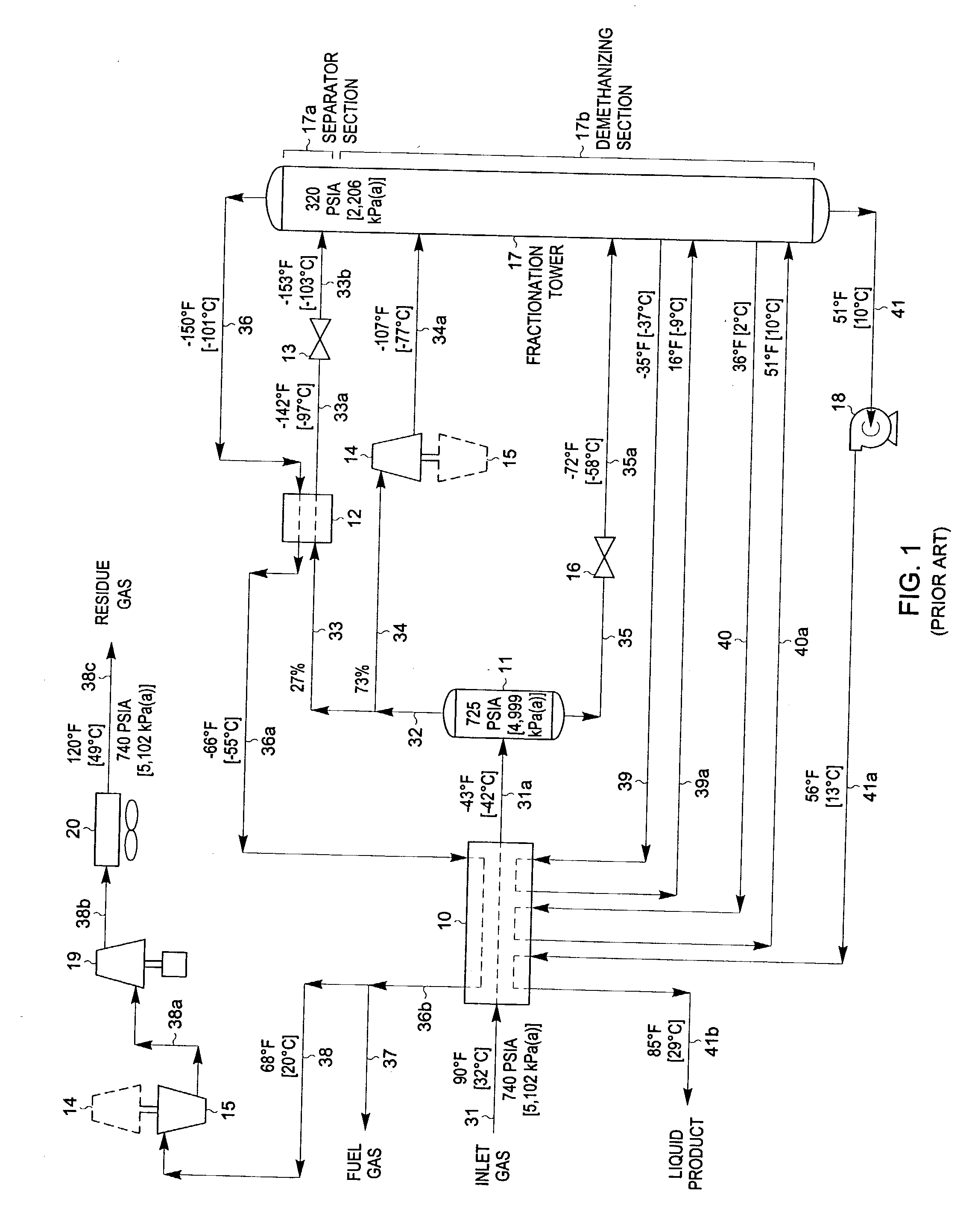

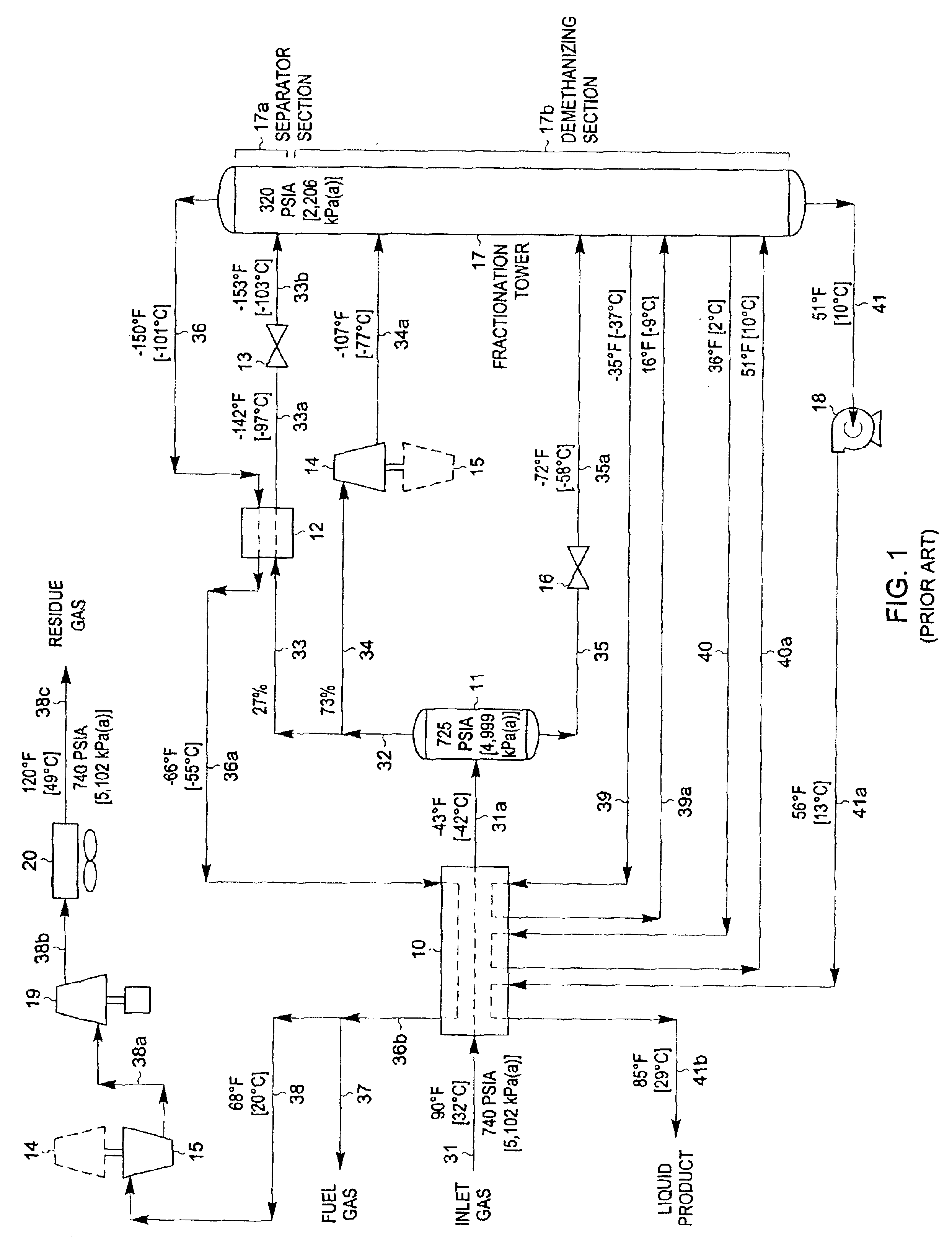

Cryogenic process utilizing high pressure absorber column

Owner:ABB LUMMUS GLOBAL INC

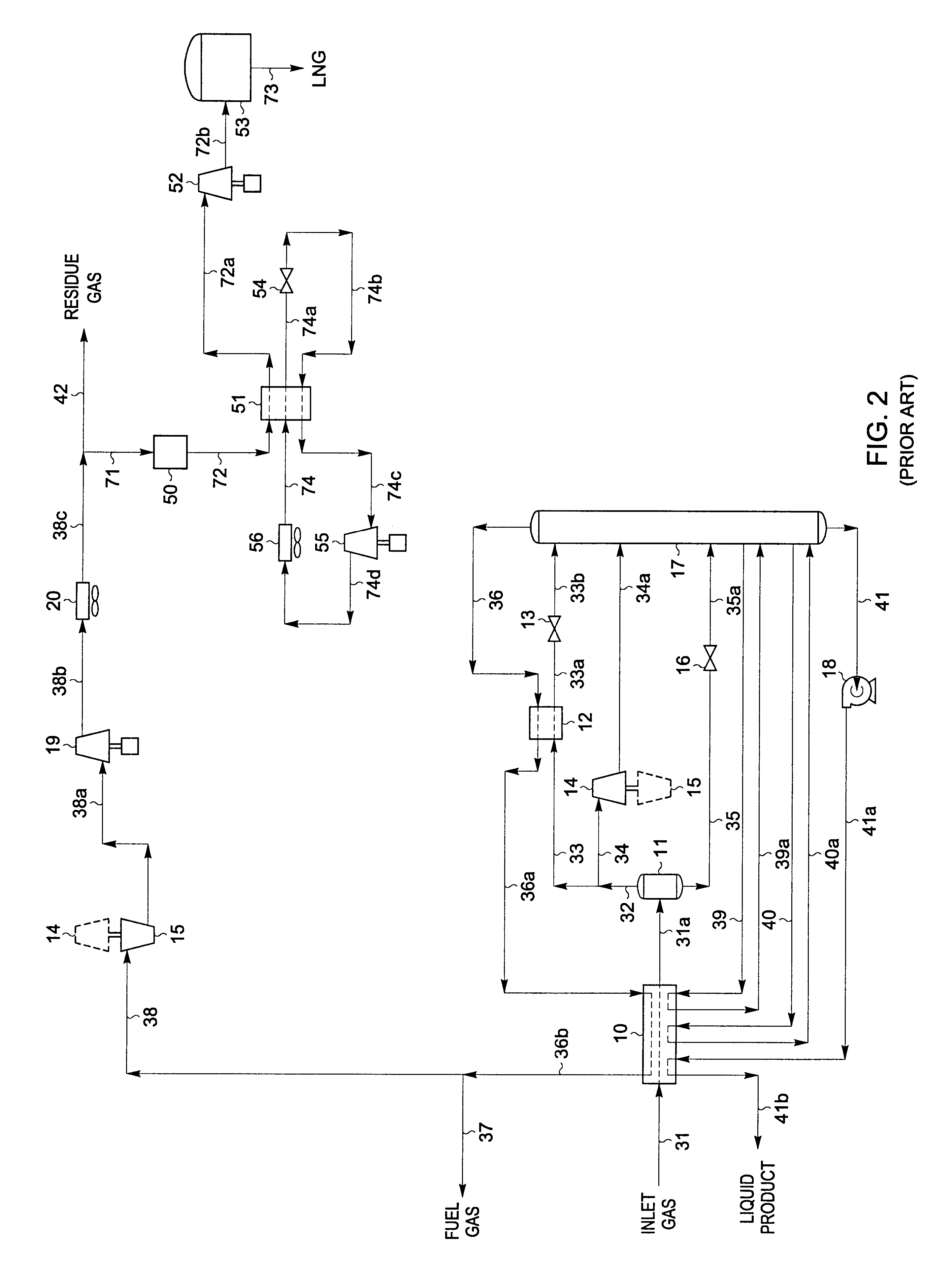

LNG production in cryogenic natural gas processing plants

A process for liquefying natural gas in conjunction with processing natural gas to recover natural gas liquids (NGL) is disclosed. In the process, the natural gas stream to be liquefied is taken from one of the streams in the NGL recovery plant and cooled under pressure to condense it. A distillation stream is withdrawn from the NGL recovery plant to provide some of the cooling required to condense the natural gas stream. The condensed natural gas stream is expanded to an intermediate pressure and supplied to a mid-column feed point on a distillation column. The bottom product from this distillation column preferentially contains the majority of any hydrocarbons heavier than methane that would otherwise reduce the purity of the liquefied natural gas, and is routed to the NGL recovery plant so that these heavier hydrocarbons can be recovered in the NGL product. The overhead vapor from the distillation column is cooled and condensed, and a portion of the condensed stream is supplied to a top feed point on the distillation column to serve as reflux. A second portion of the condensed stream is expanded to low pressure to form the liquefied natural gas stream.

Owner:ORTLOFF ENGINEERS

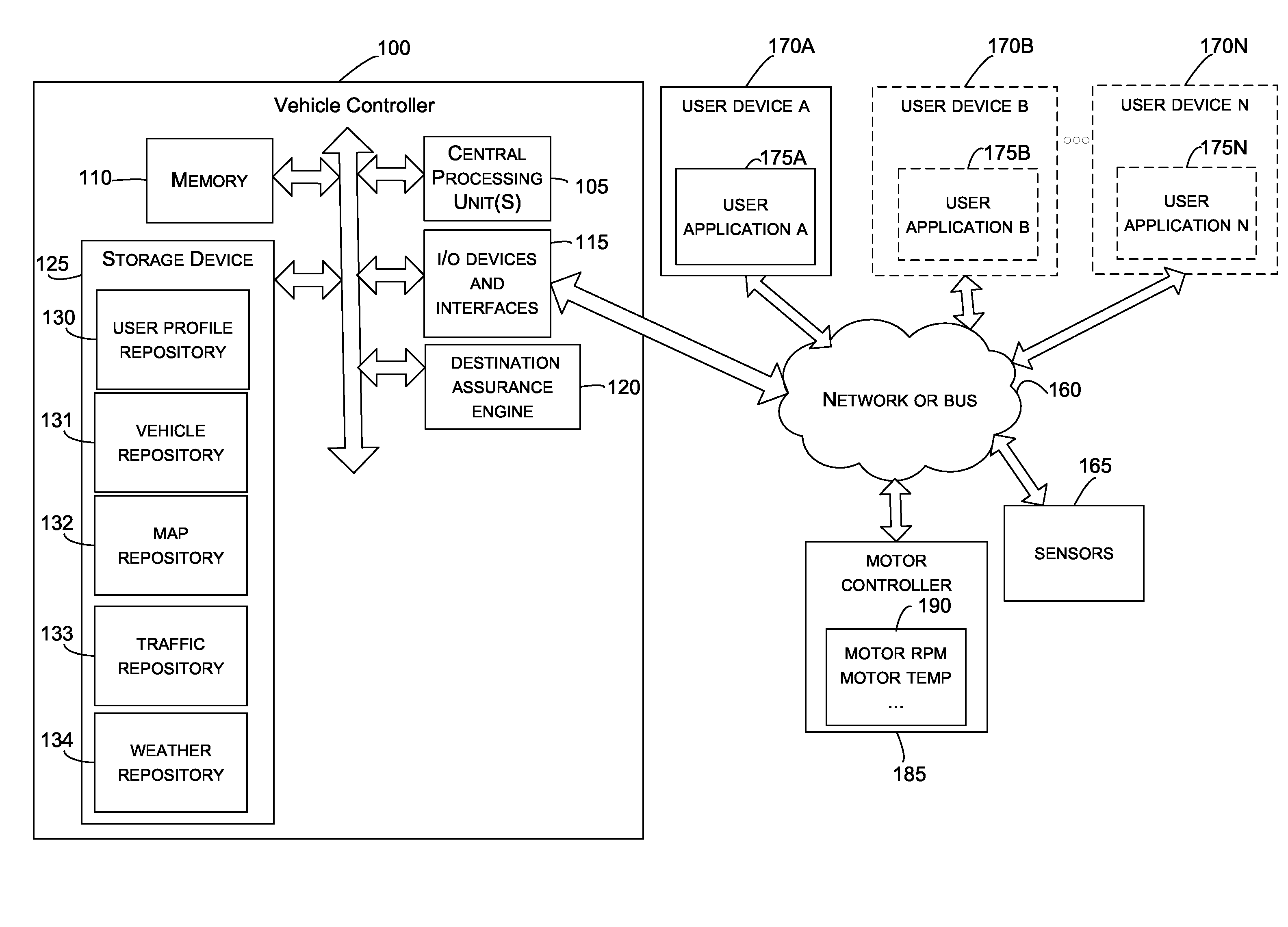

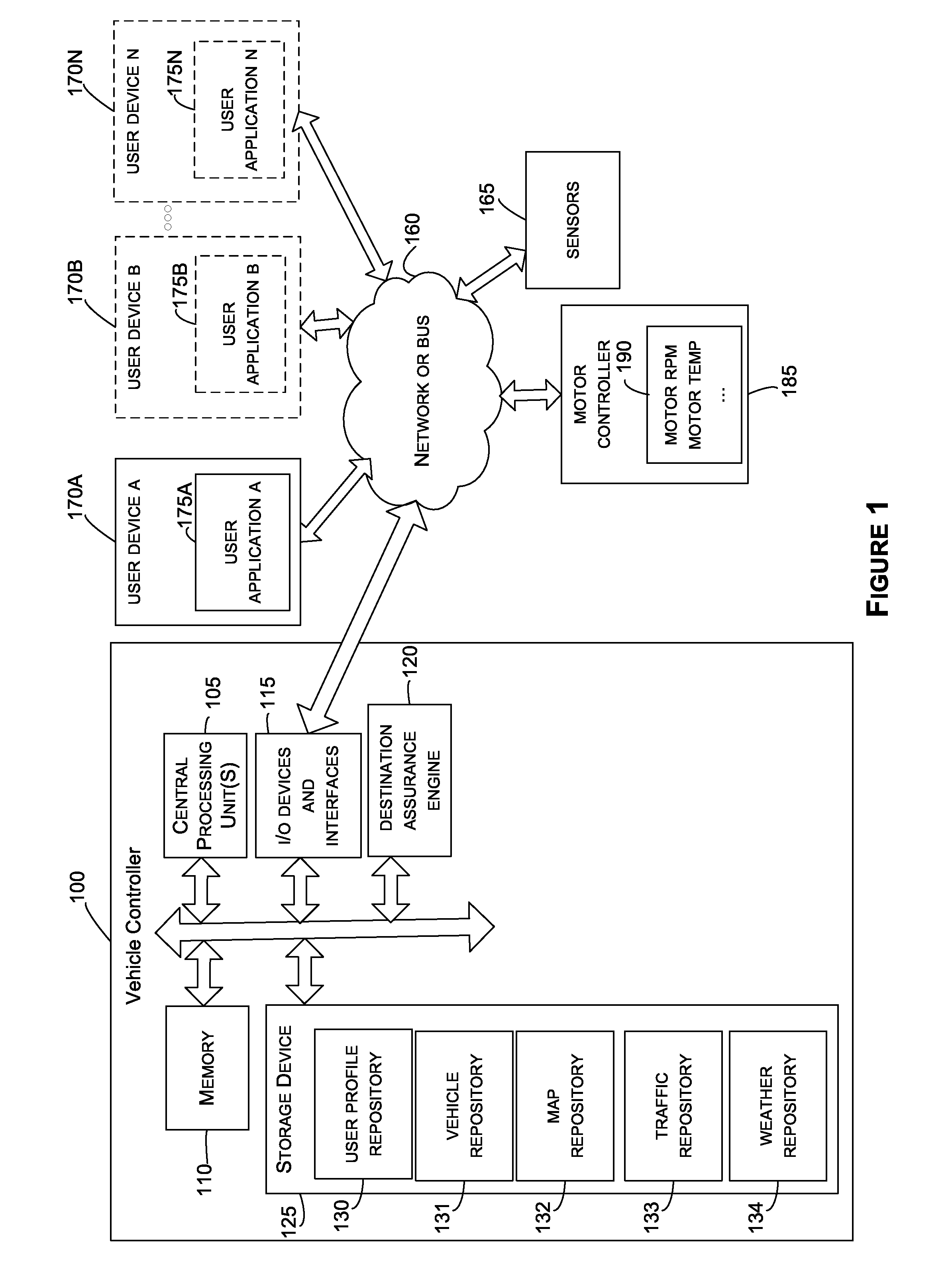

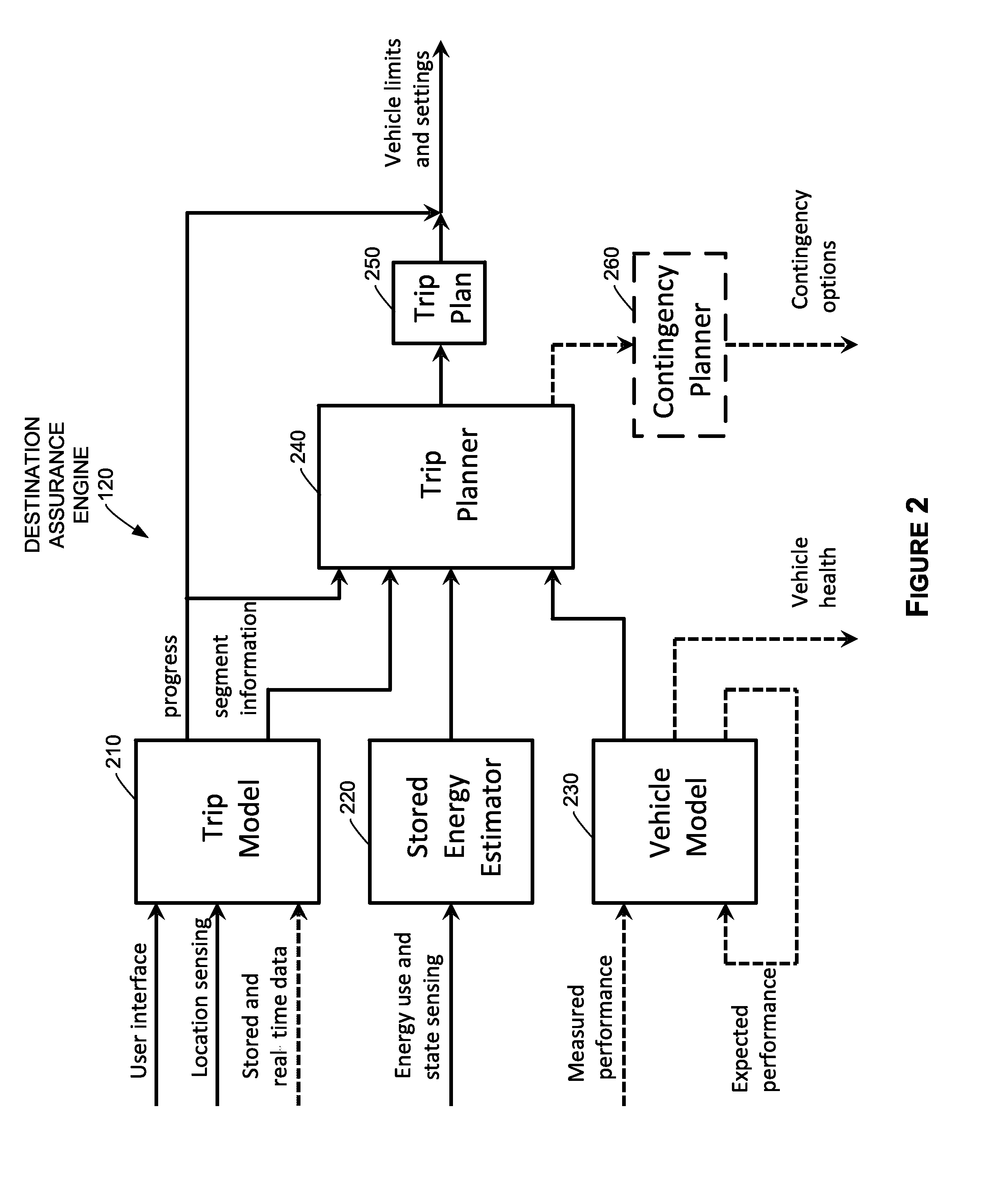

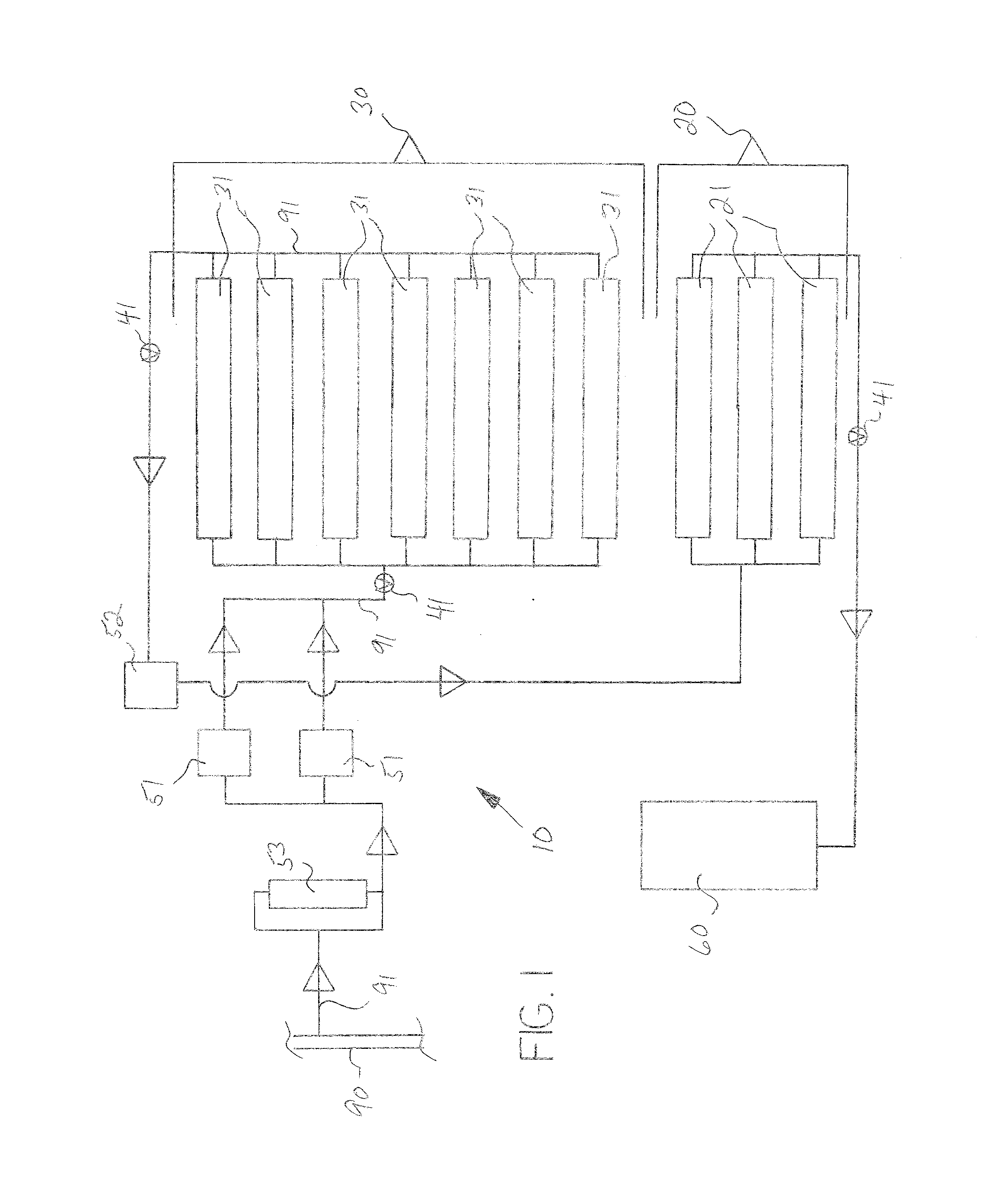

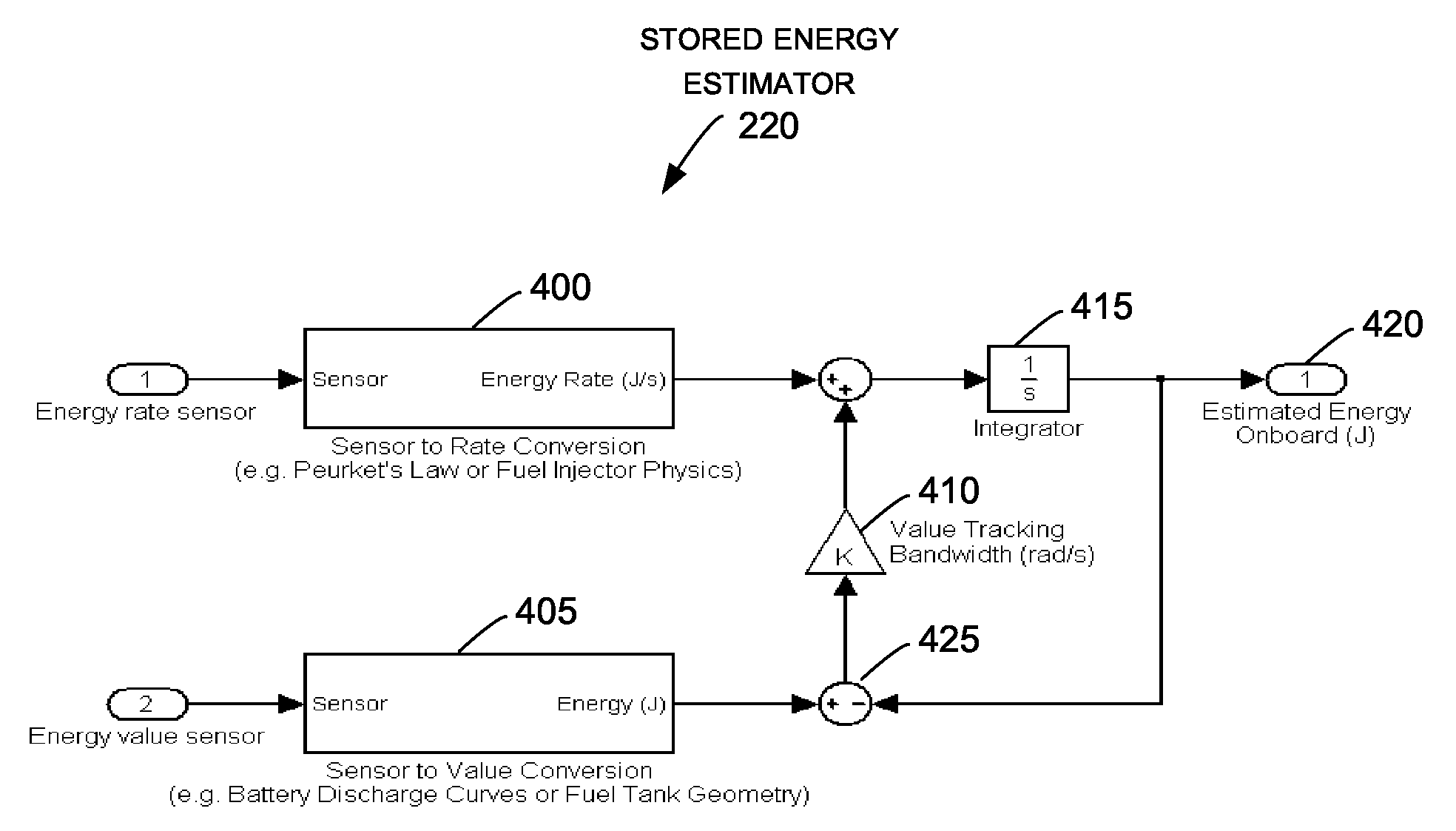

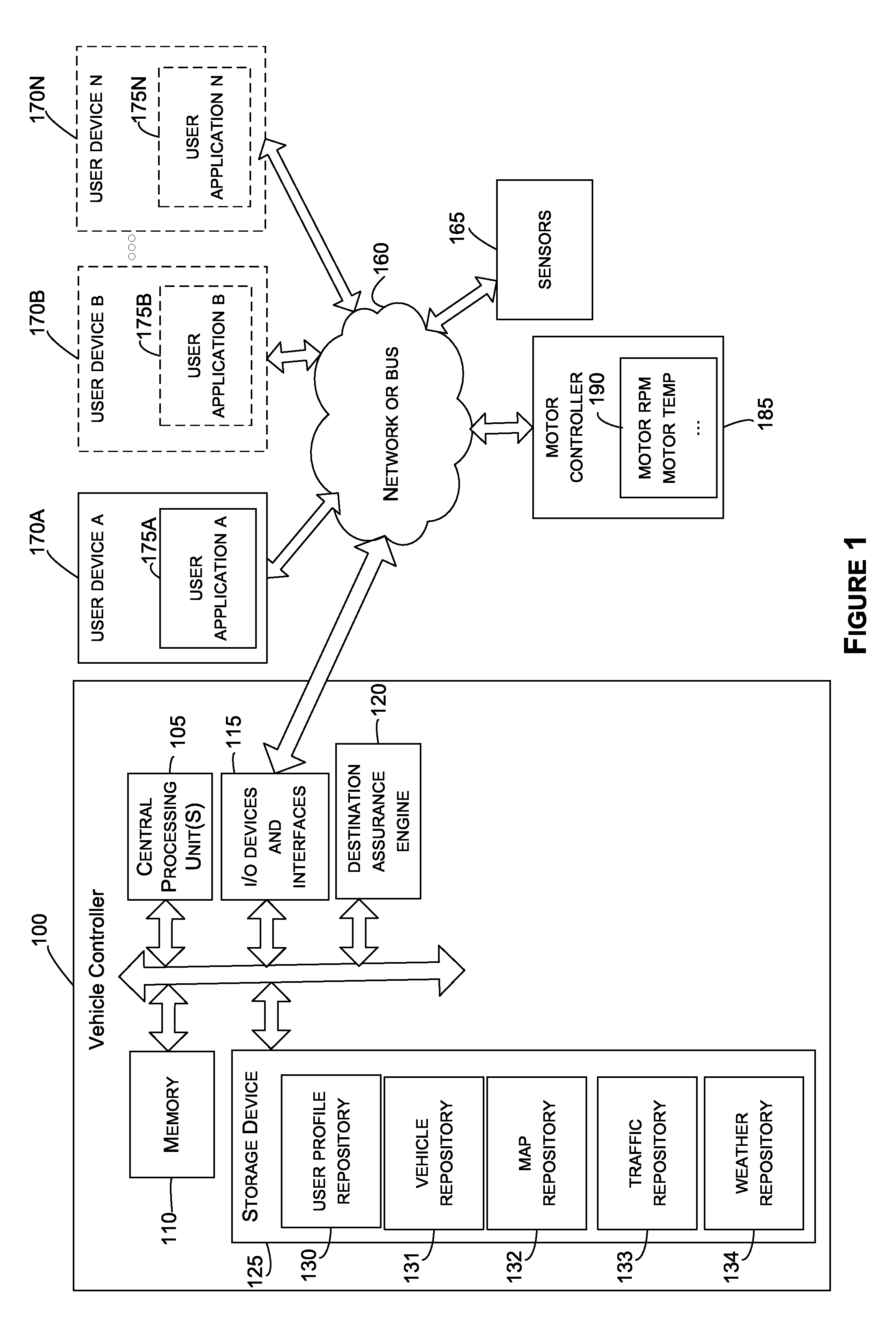

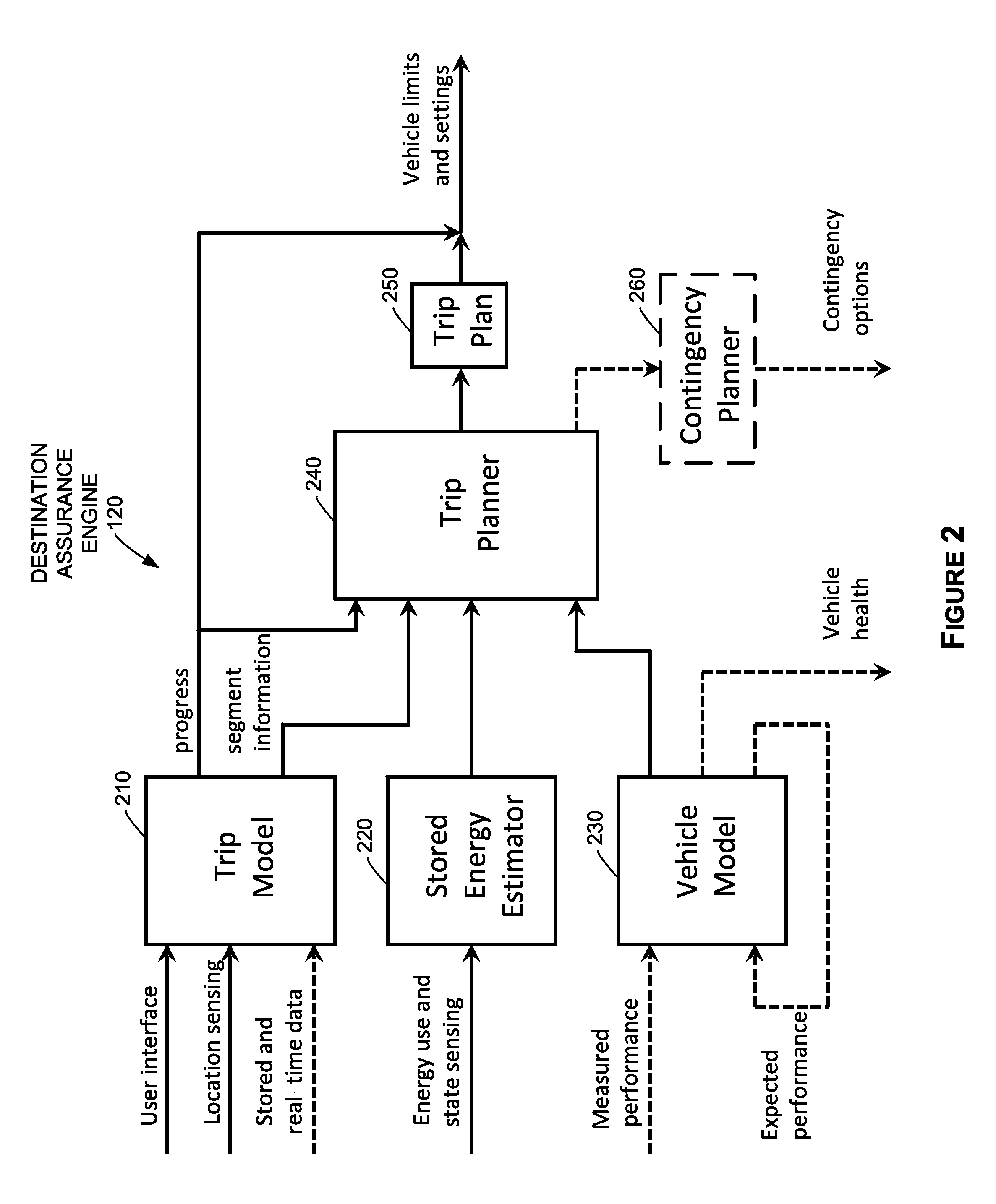

Vehicle control system and methods

InactiveUS20130261914A1Hybrid vehiclesInstruments for road network navigationMaximum torqueElectricity

A control system that makes adjustments, such as limiting the maximum speed or maximum torque in a vehicle, is provided. These adjustments can be based on knowledge about the vehicle and trip, and on the estimated energy remaining. The control system is applicable to a wide range of vehicles, including ground, air, water, and sea vehicles, as well as vehicles powered by battery, electricity, compressed natural gas, or even liquid fuel propulsion systems. The control system may be used to adjust vehicle operation in route to assure the vehicle reaches a destination and to inform or counteract a human vehicle operator. Control system can also be used in racing applications to calculate the fastest-possible race speed and drive torque for a given race length; or alternatively, in endurance racing or delivery applications to optimize the vehicle speed and / or drive torque for a given race length or route.

Owner:W MORRISON CONSULTING GRP

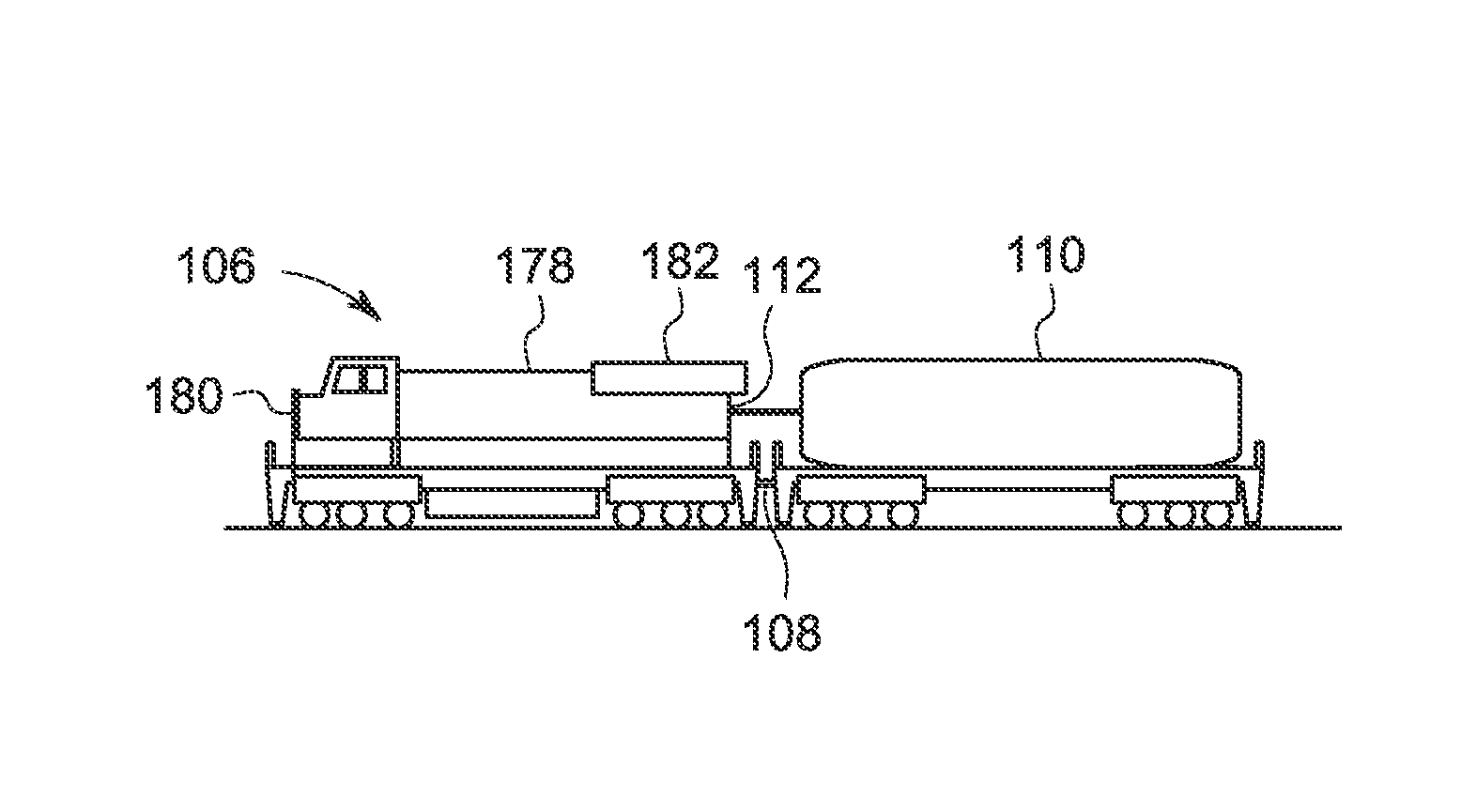

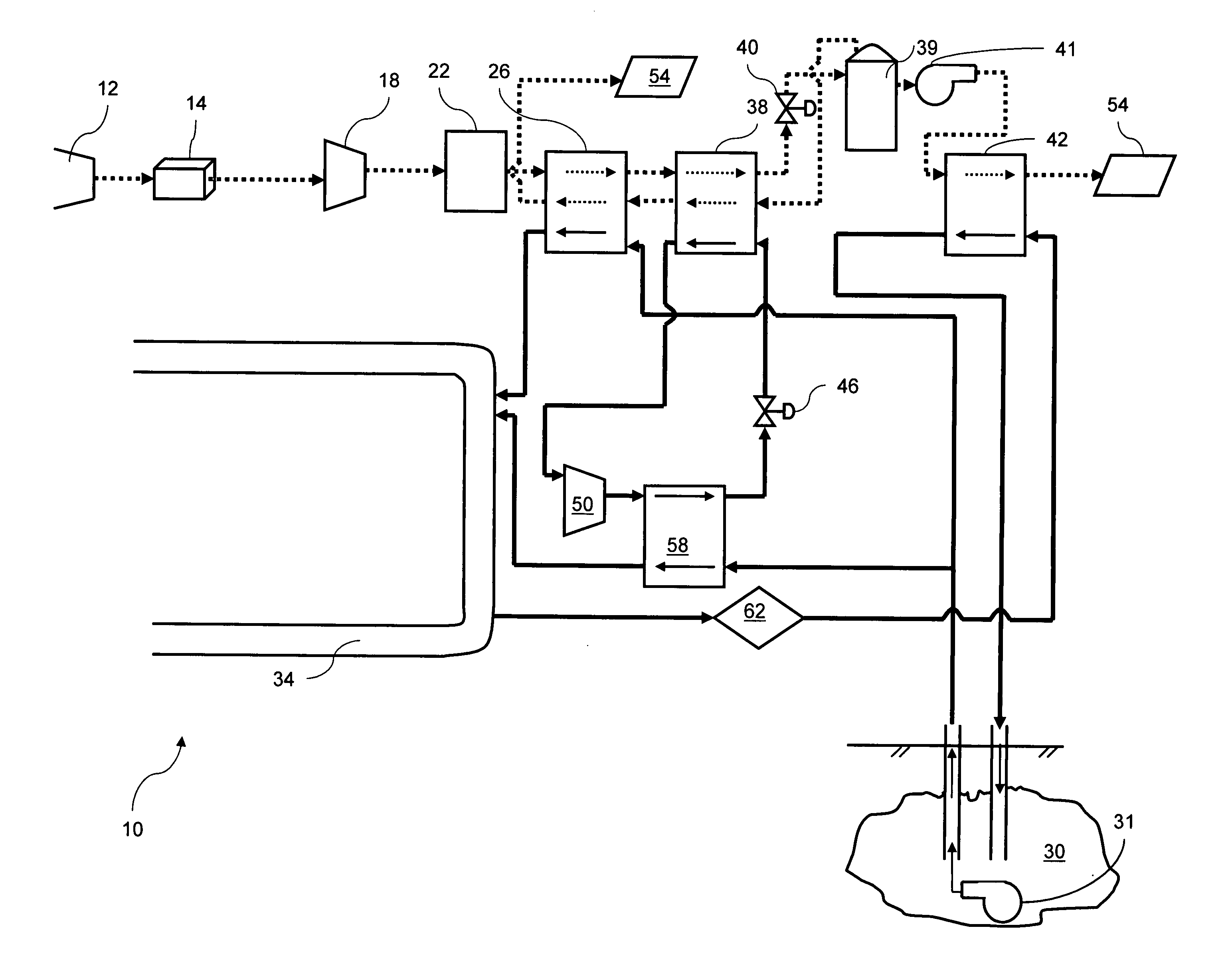

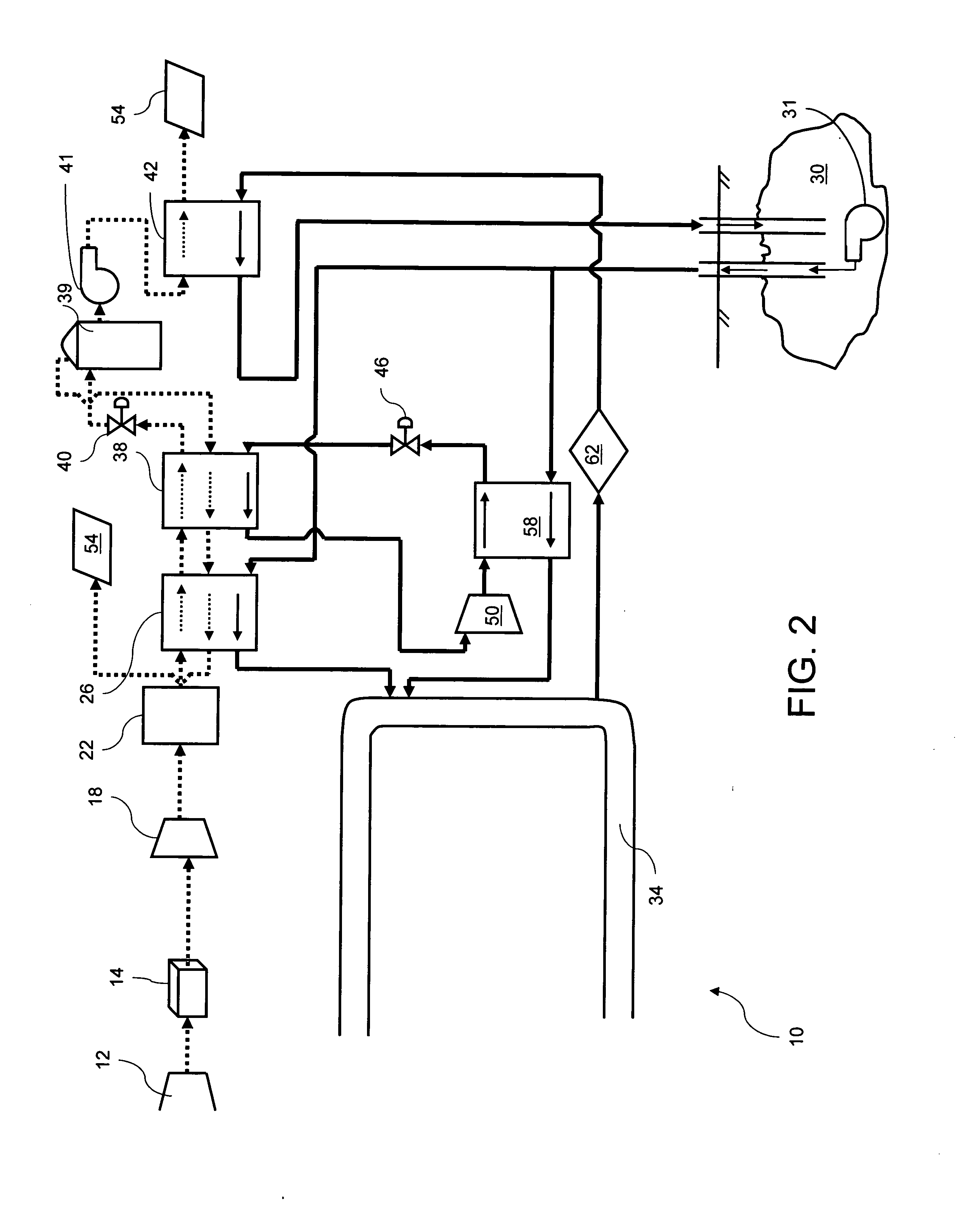

Vehicle system and method

ActiveUS9550501B2Brakes for specific applicationsIC engine locomotivesElectricityCompressed natural gas

Owner:GE GLOBAL SOURCING LLC

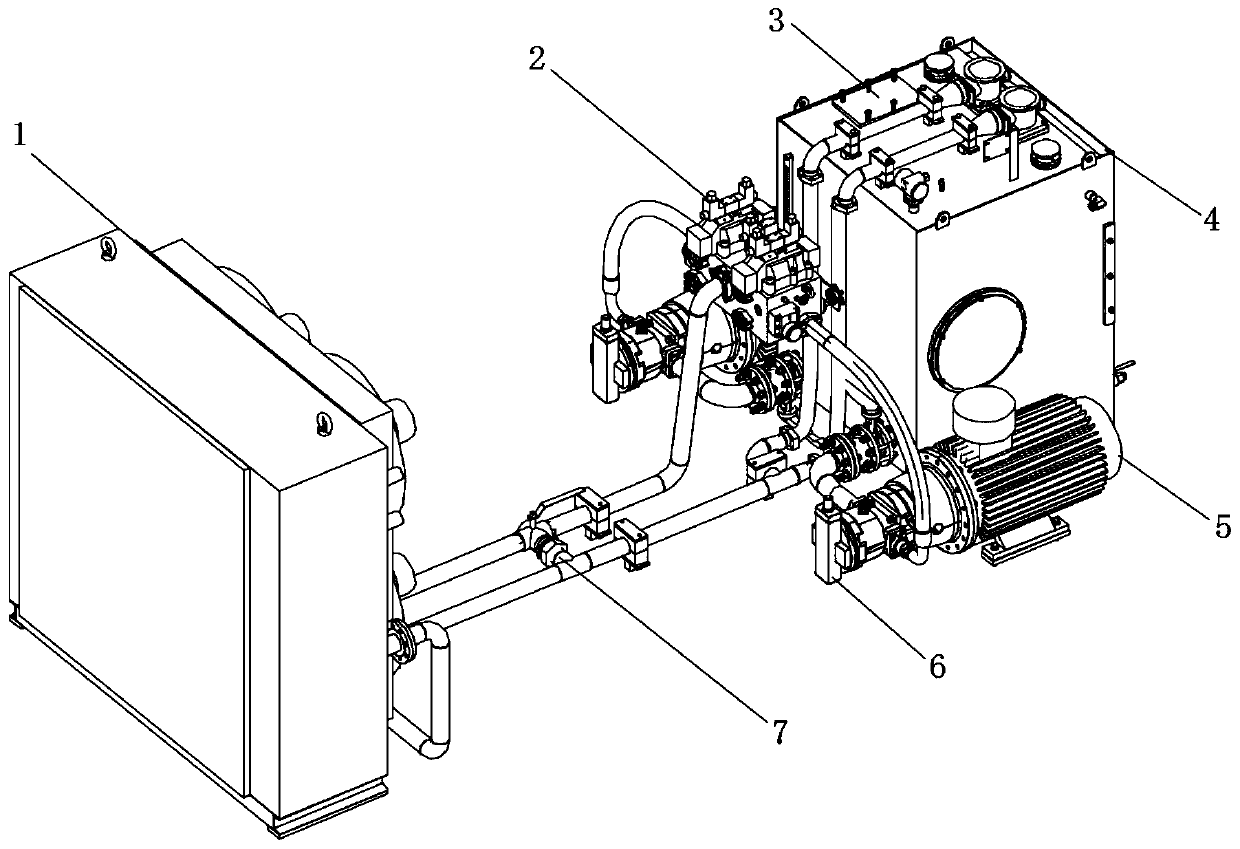

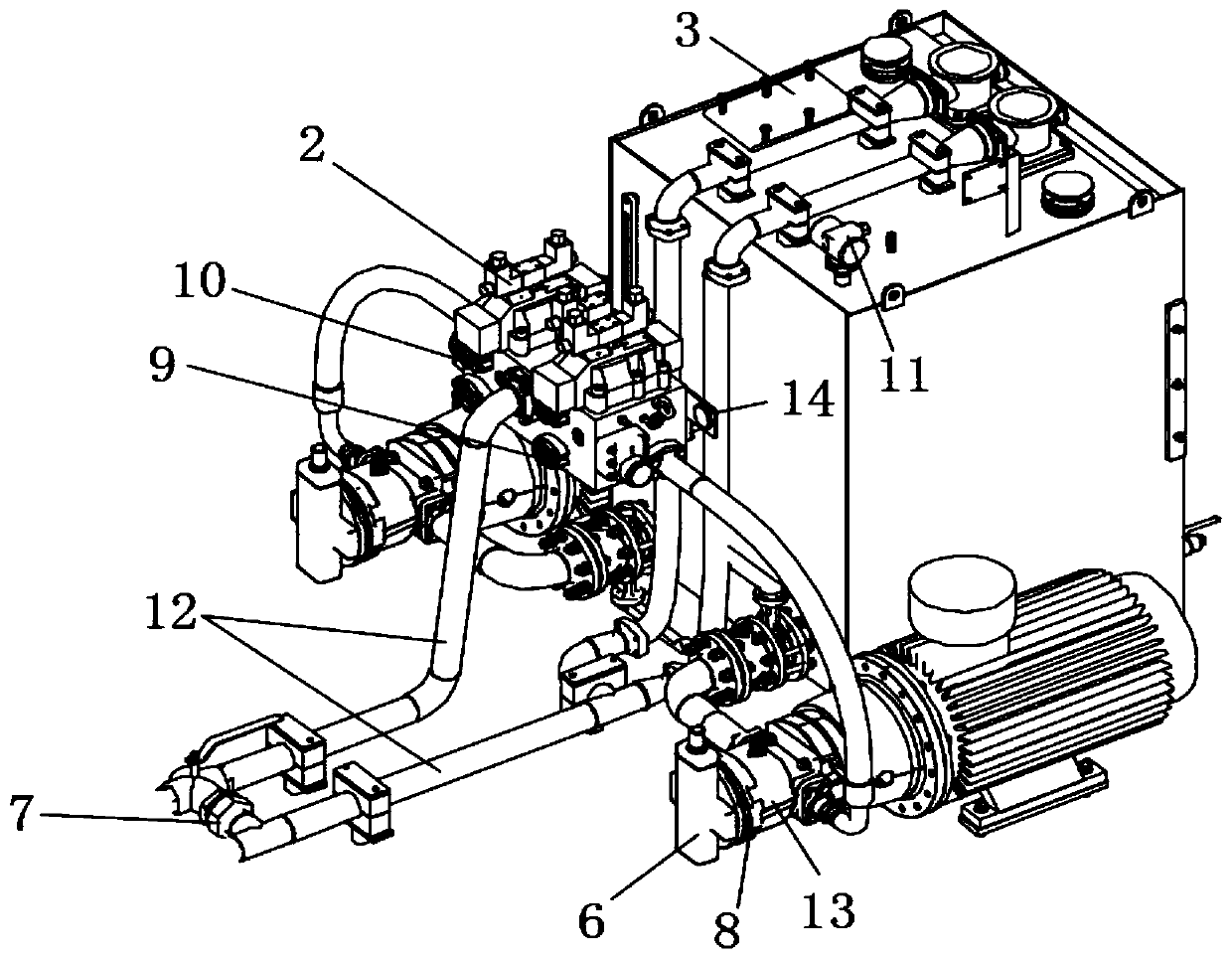

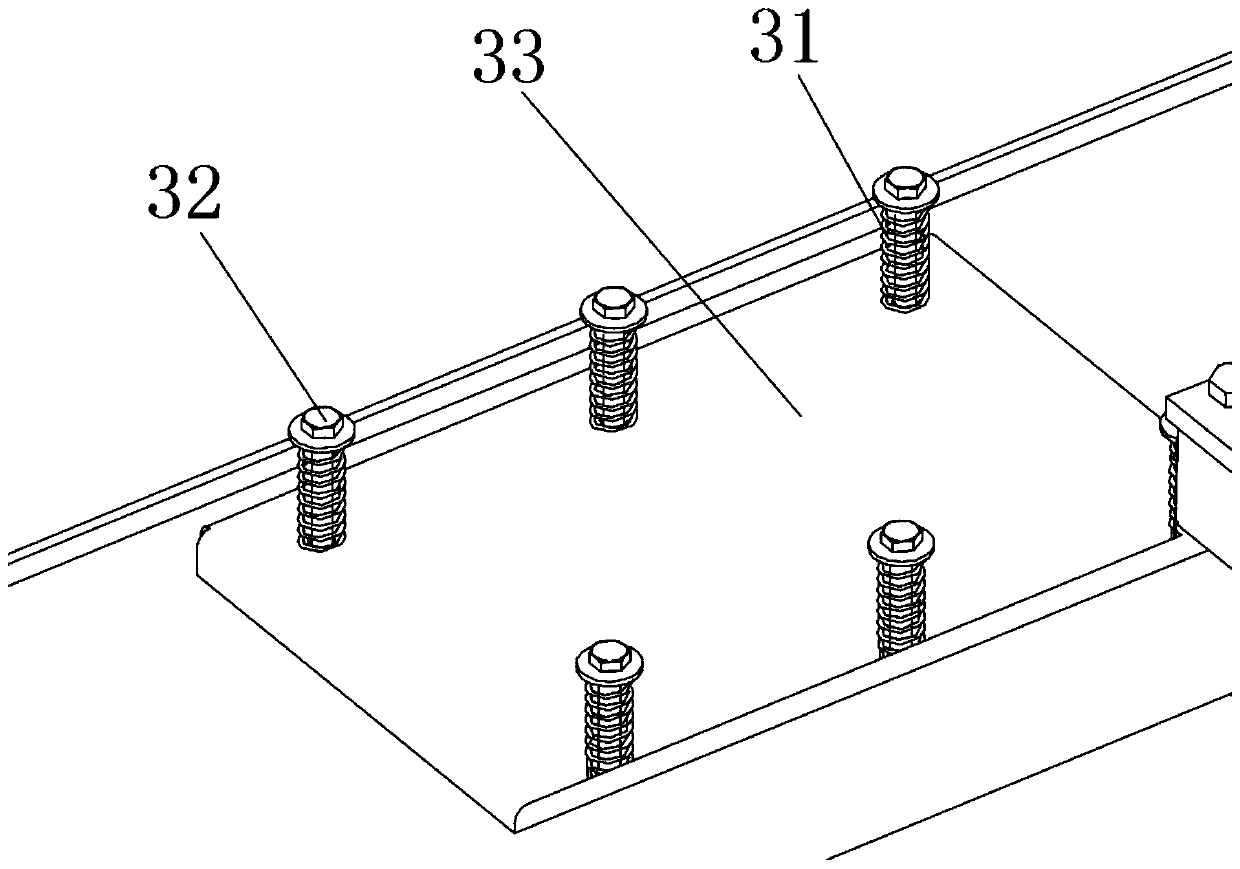

Integrated hydraulic station

InactiveCN110873093AAchieve high integrationRealize automatic control functionFluid-pressure actuator safetyFluid-pressure actuator componentsCompressed natural gasPressure difference

The invention belongs to the technical field of compressed natural gas filling, and particularly relates to an integrated hydraulic station which realizes high integration of an oil tank, plunger pumps, motors, a valve block, a cooler, an instrument and a sensor. The reversing function of hydraulic oil is provided through cooperation of an electro-hydraulic reversing valve and a proximity switch on a hydraulic cylinder, the functions of circulating heating of the low-temperature hydraulic oil, discharging of the high-pressure hydraulic oil and avoiding the hydraulic oil channeling back betweenthe double pumps are realized through cooperation of an unloading valve, a one-way valve and the electro-hydraulic reversing valve in the valve block, the high-pressure difference automatic stop function and the high-pressure gas discharging function are provided, combustible gas leakage and expansion deformation of the oil tank which cannot be recovered caused by high-pressure gas channeling back are avoided, the functions of low oil level monitoring alarm, temperature monitoring alarm and low oil temperature automatic circulating heating before starting of the hydraulic oil tank are provided, a three-way ball valve is adopted to replace an oil return valve block in the aspect of cooling oil return of the hydraulic oil, thus the oil return control function is realize, and the cost and space of the hydraulic station are also reduced.

Owner:JEREH OIL & GAS ENG

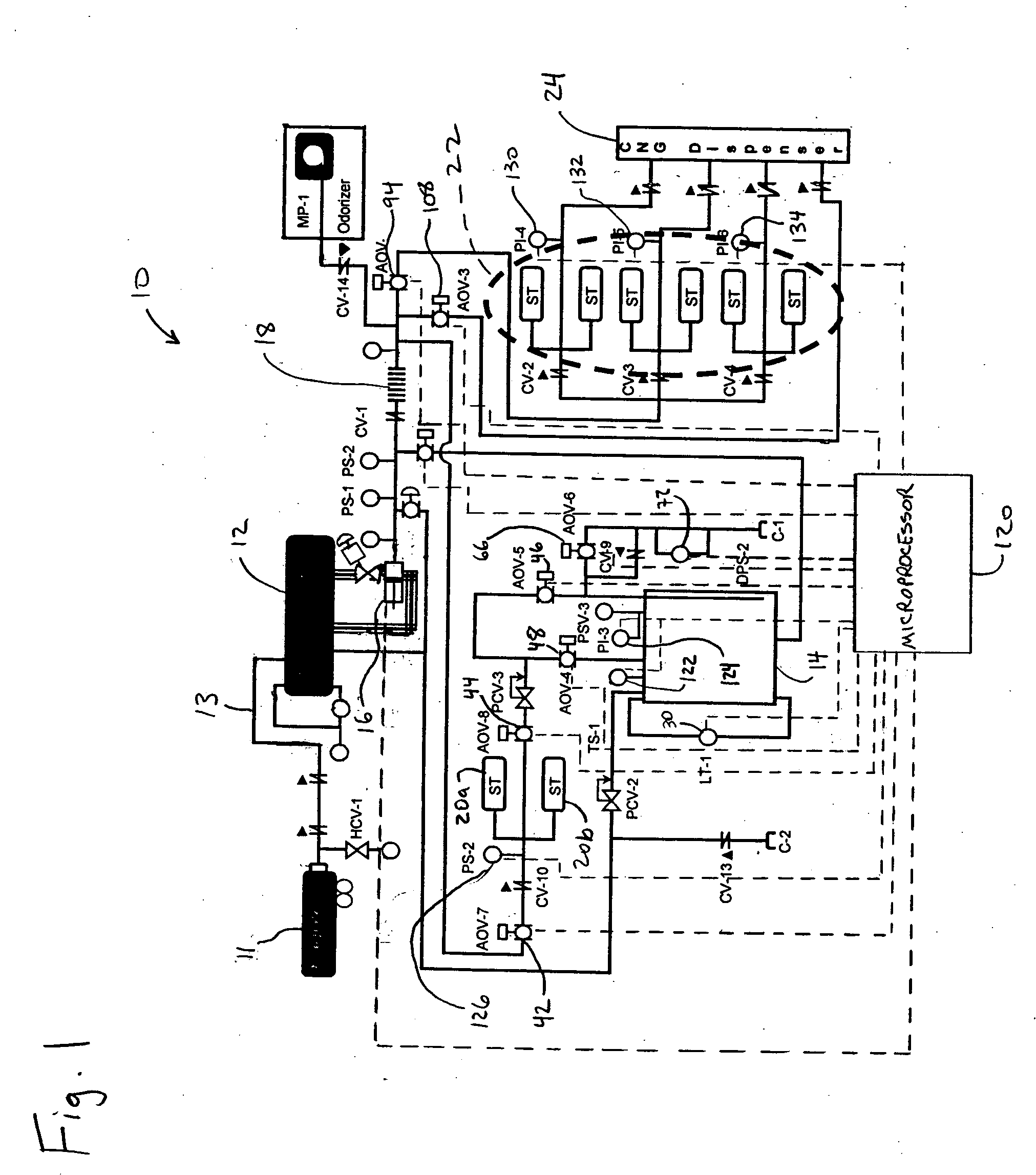

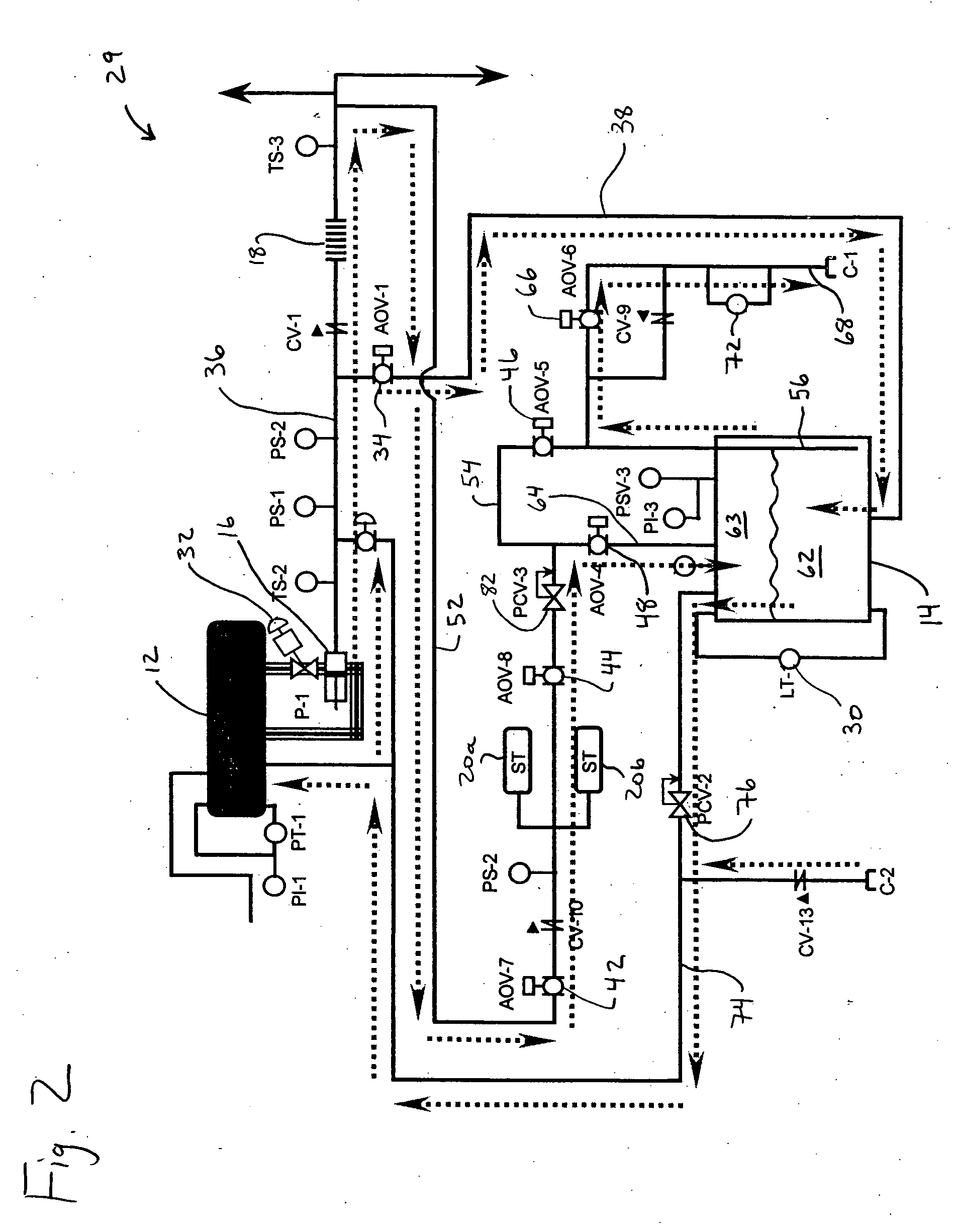

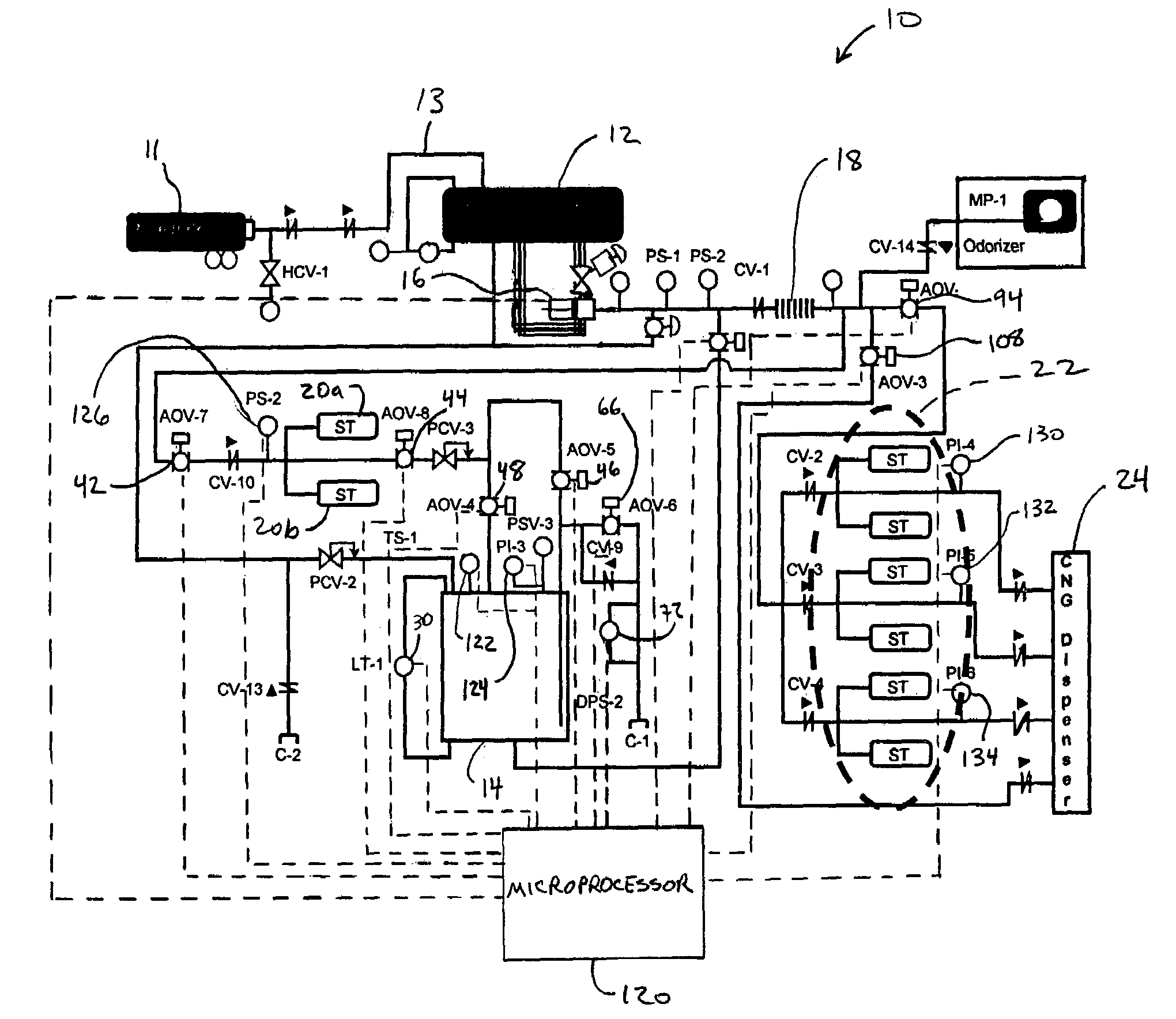

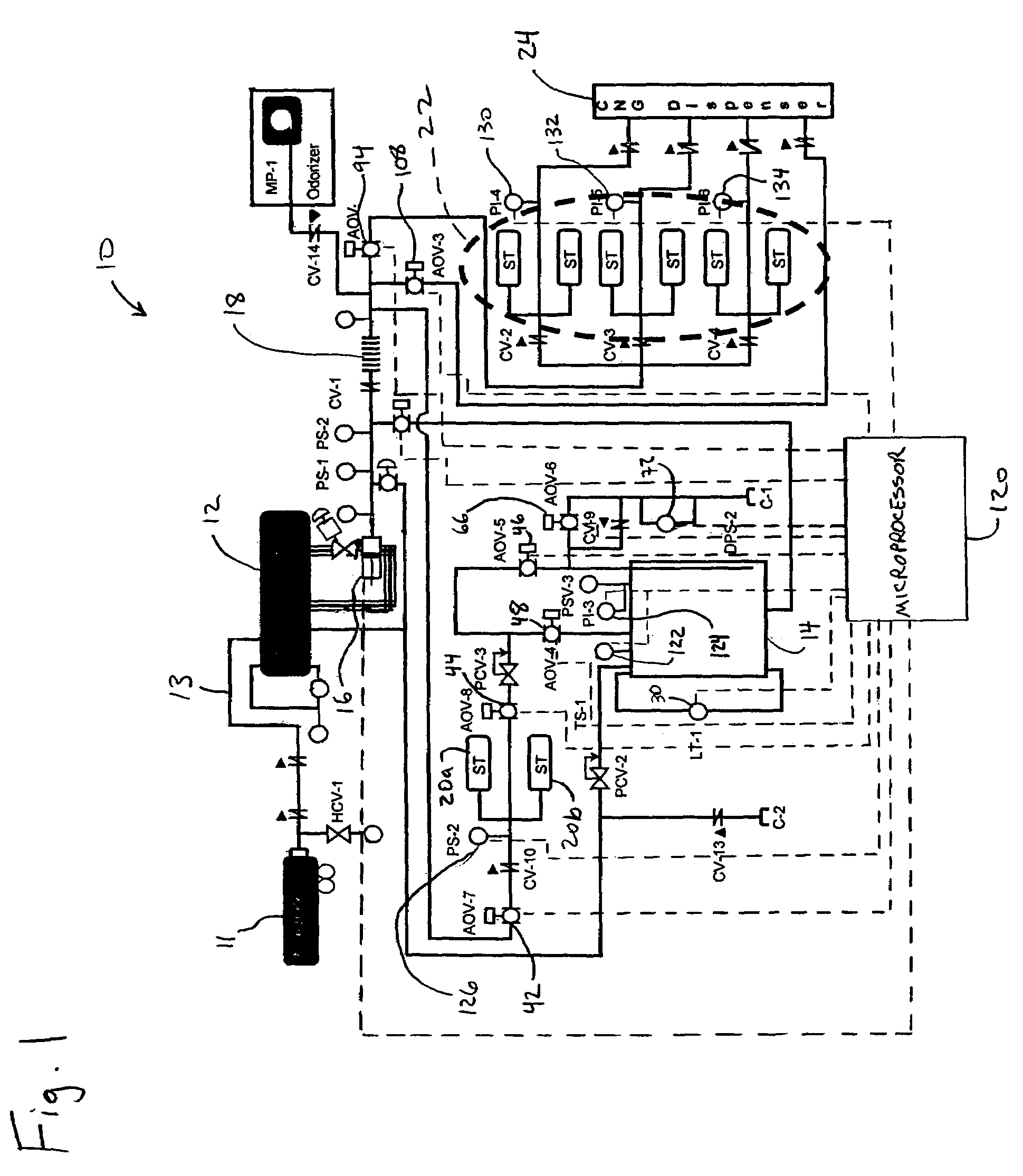

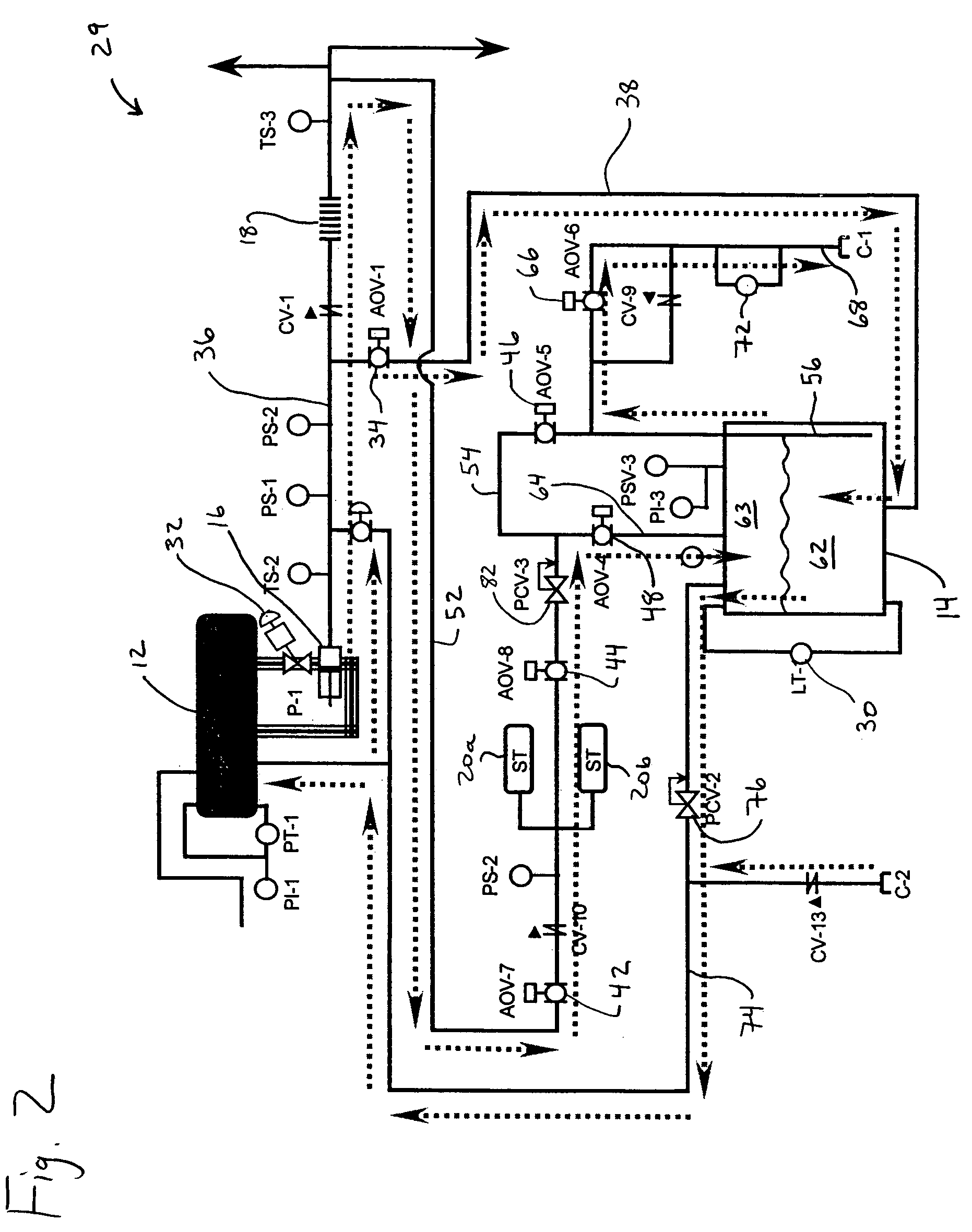

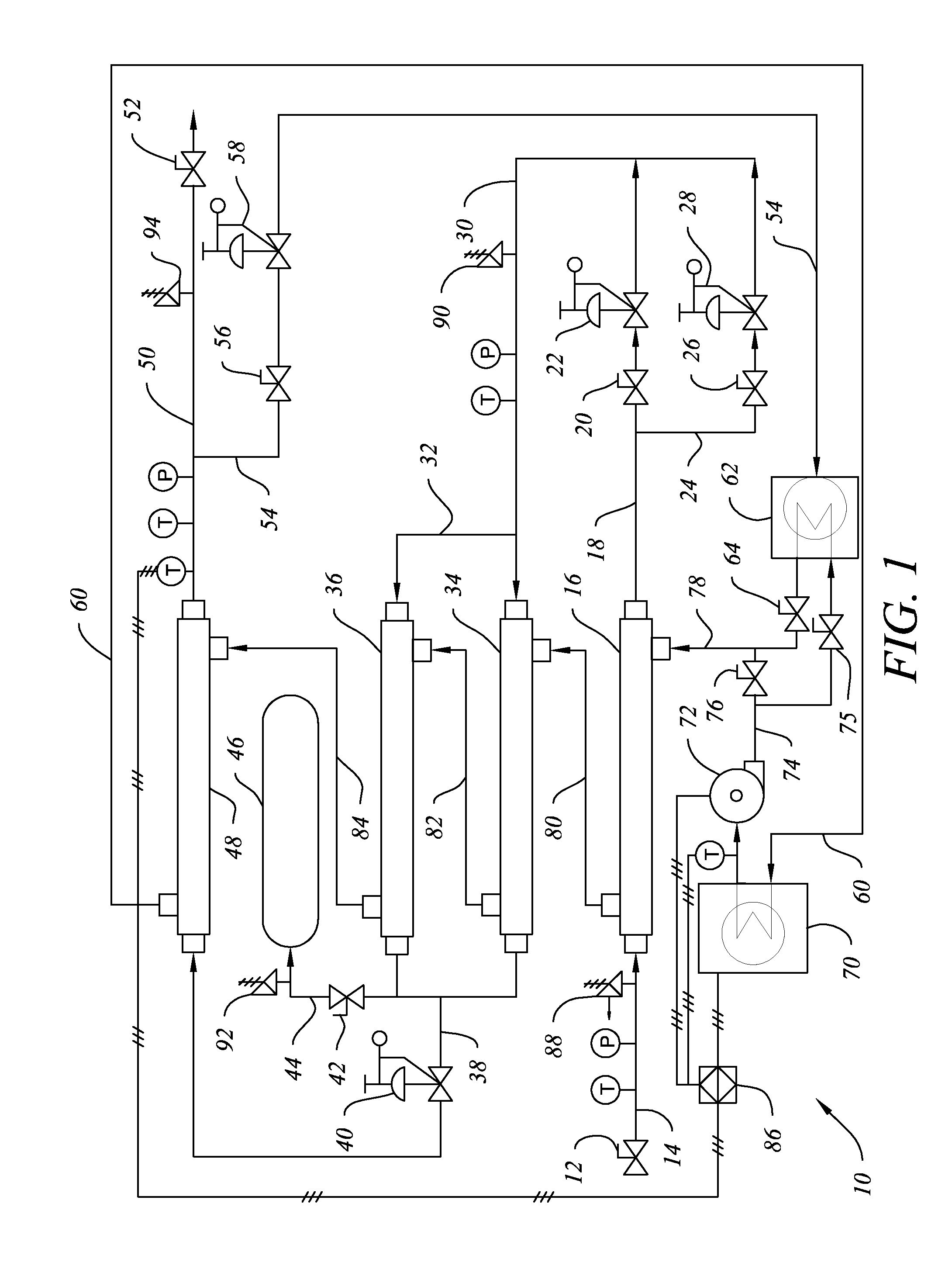

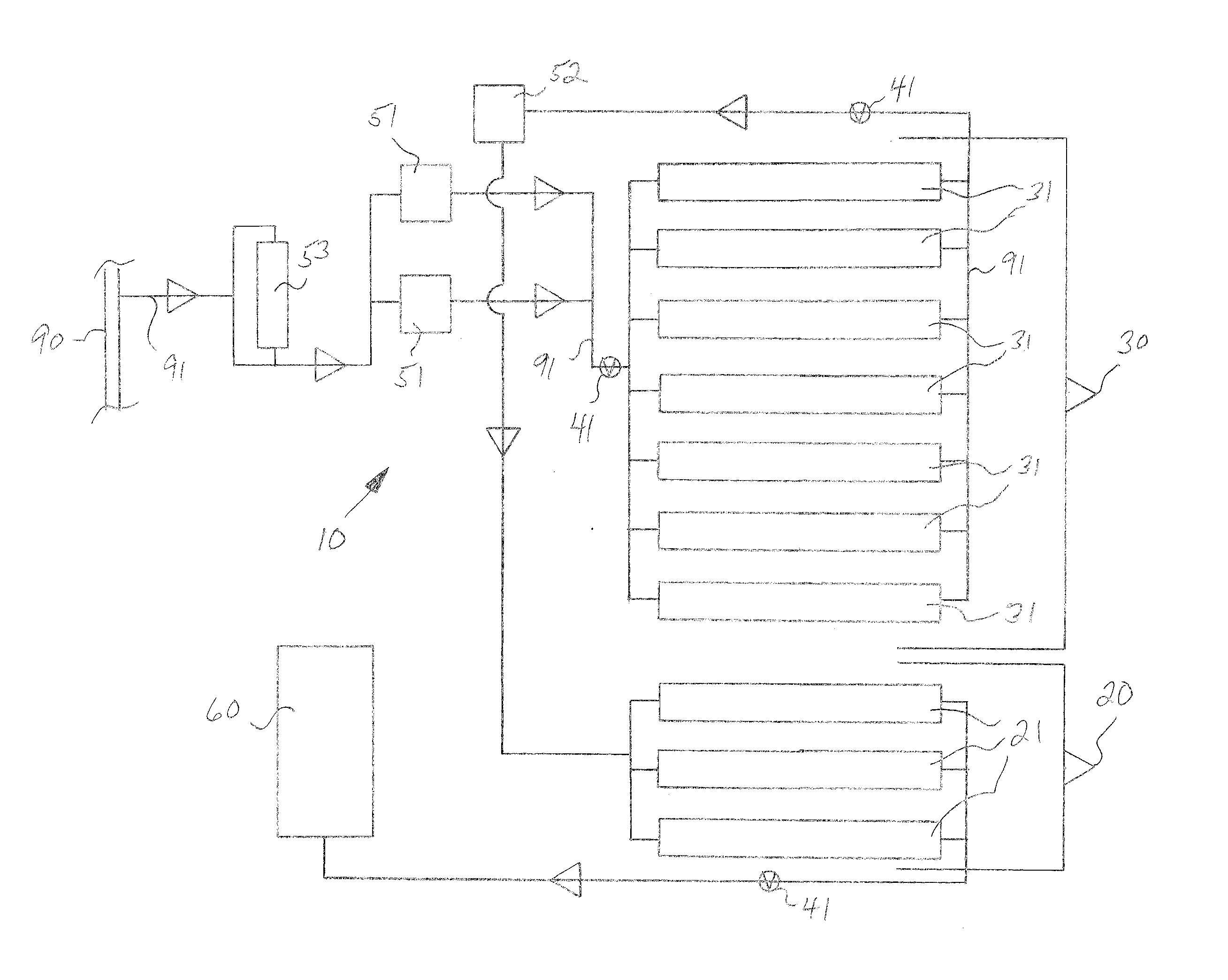

Liquid and compressed natural gas dispensing system

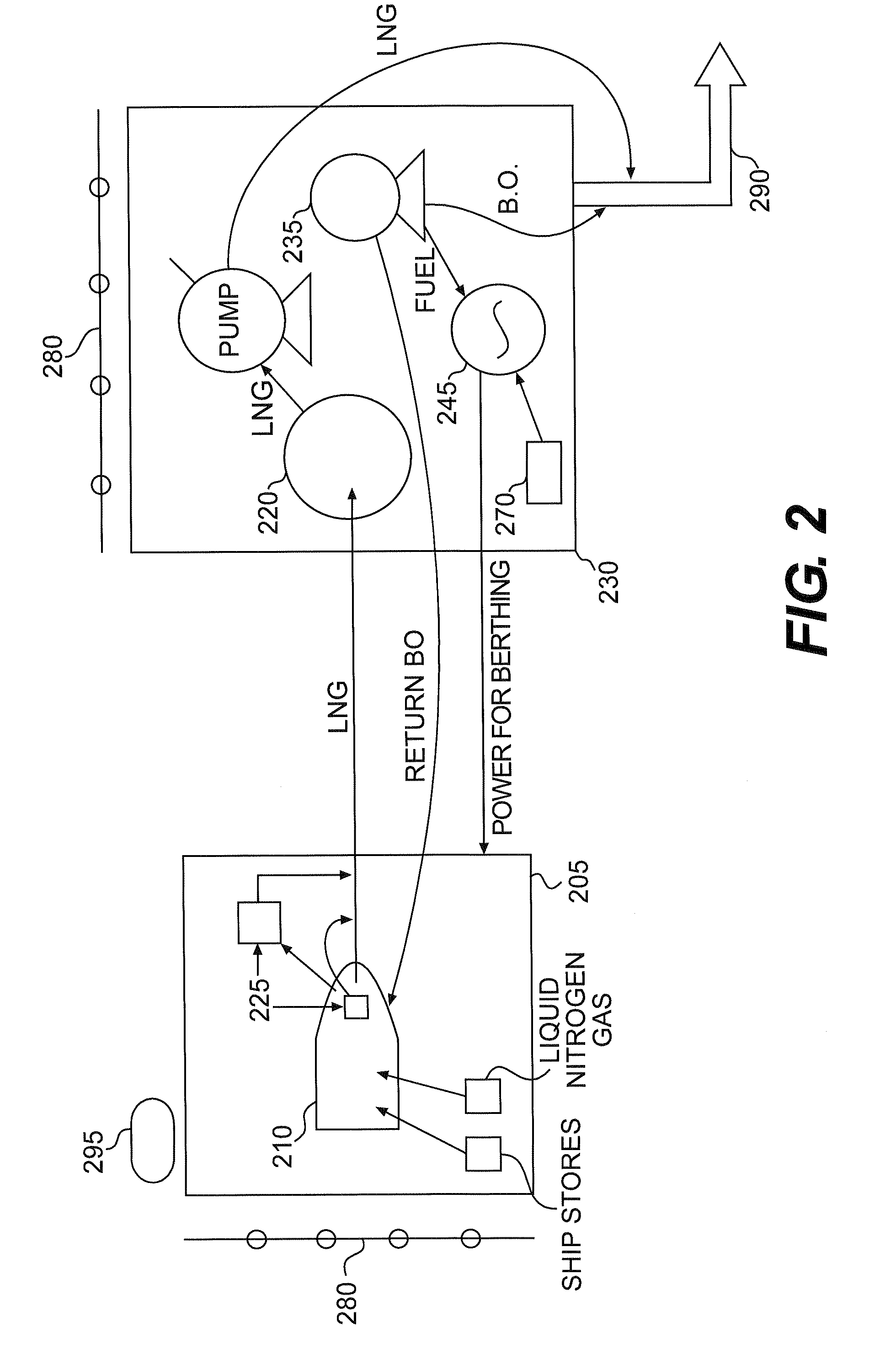

InactiveUS20050016185A1Distribute quicklyEliminate timeGas handling applicationsGas handling/storage effectsCompressed natural gasProcess engineering

A system dispenses both liquid natural gas (LNG) and compressed natural gas (CNG). A bulk tank contains a supply of LNG which is pumped to a smaller storage tank. After the storage tank is refilled, LNG from the bulk tank is pumped to a vaporizer so that CNG is produced. The CNG may be routed to the LNG in the storage tank to condition it. It is also used to recharge a pressurizing cylinder that is placed in communication with the head space of the storage tank when it is desired to rapidly dispense LNG to a vehicle. A bank of cascaded storage cylinders alternatively may receive CNG from the vaporizer for later dispensing through the system CNG dispenser. The CNG from the vaporizer may also be dispensed directly via the system CNG dispenser.

Owner:CHART INC

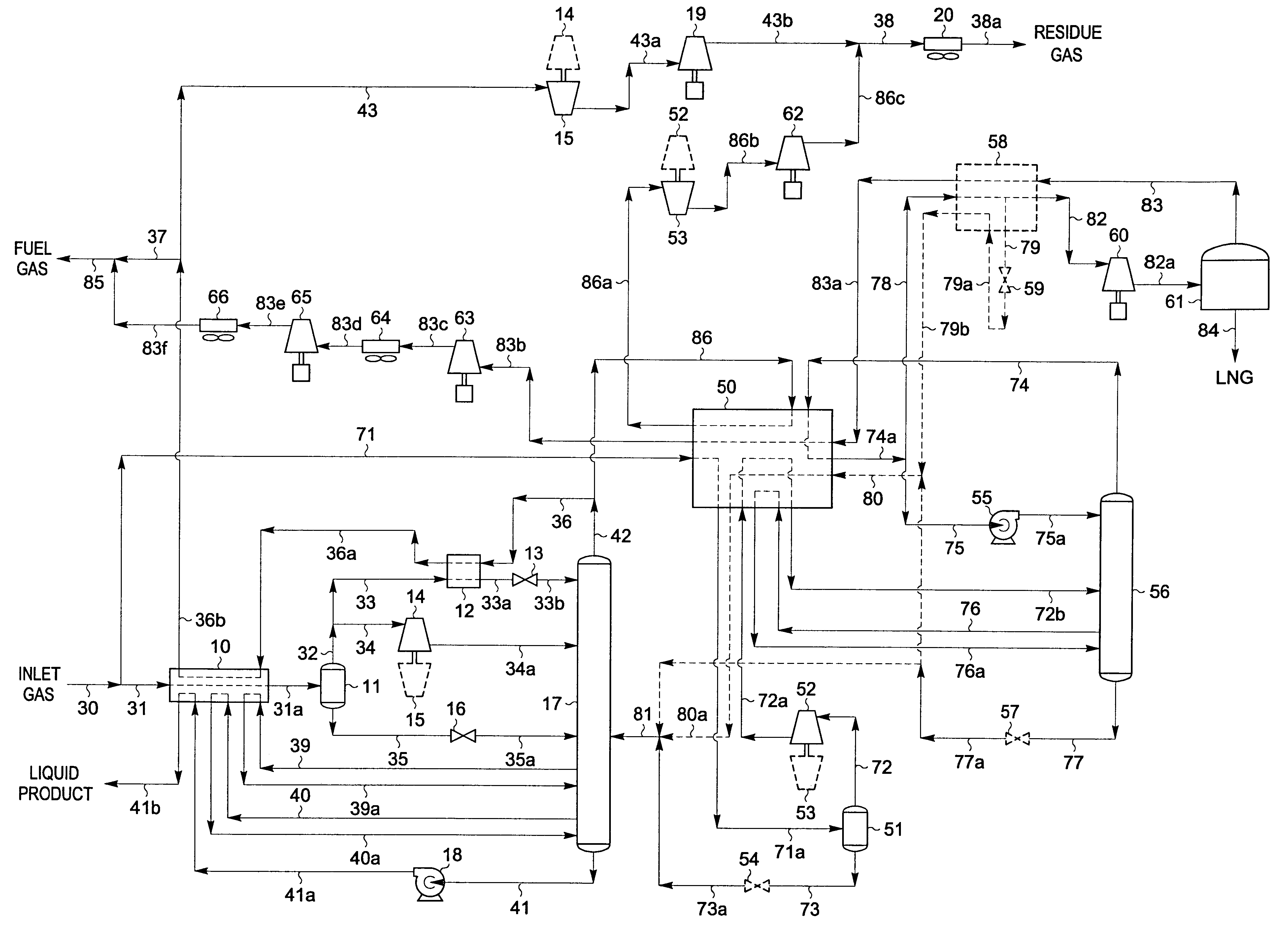

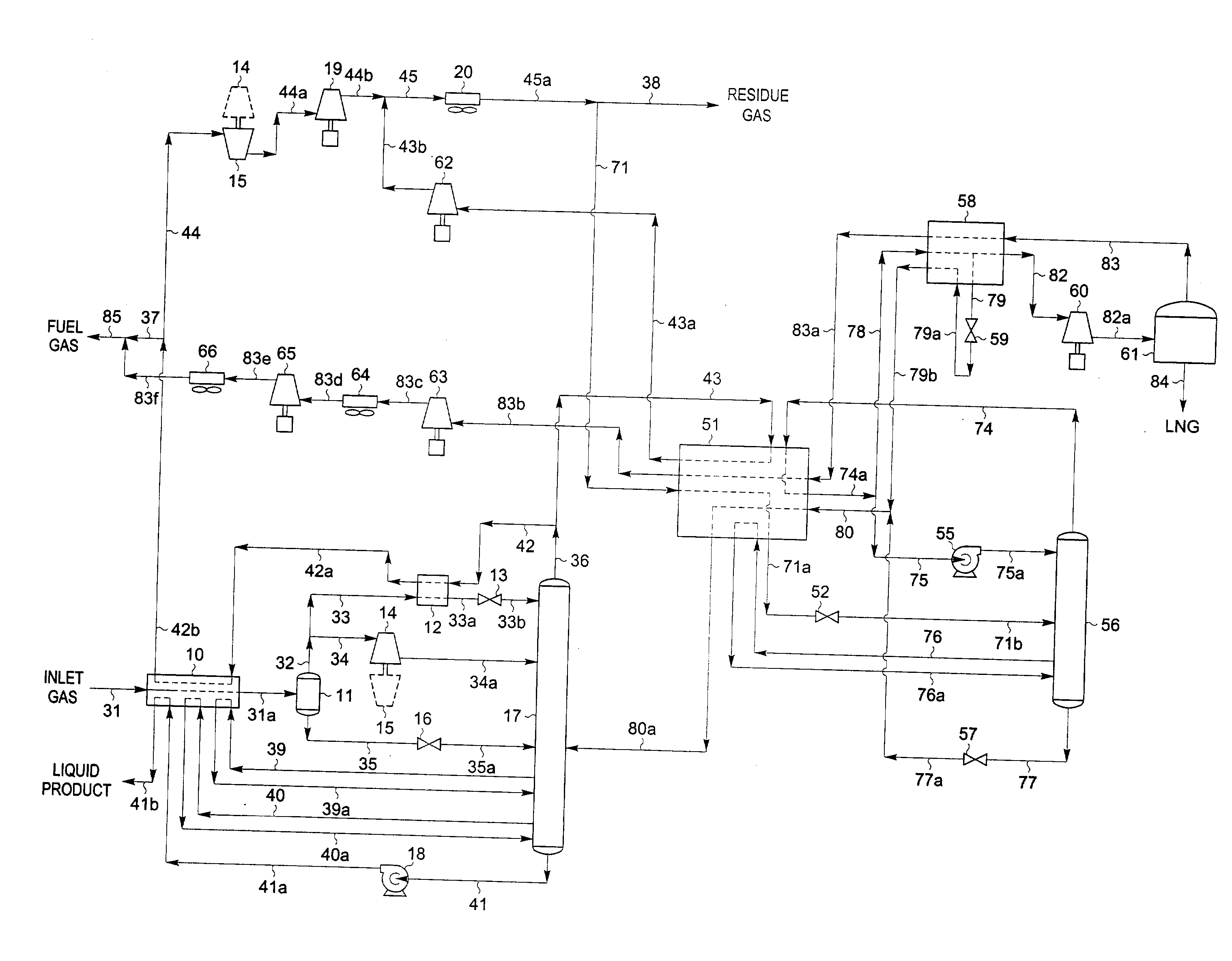

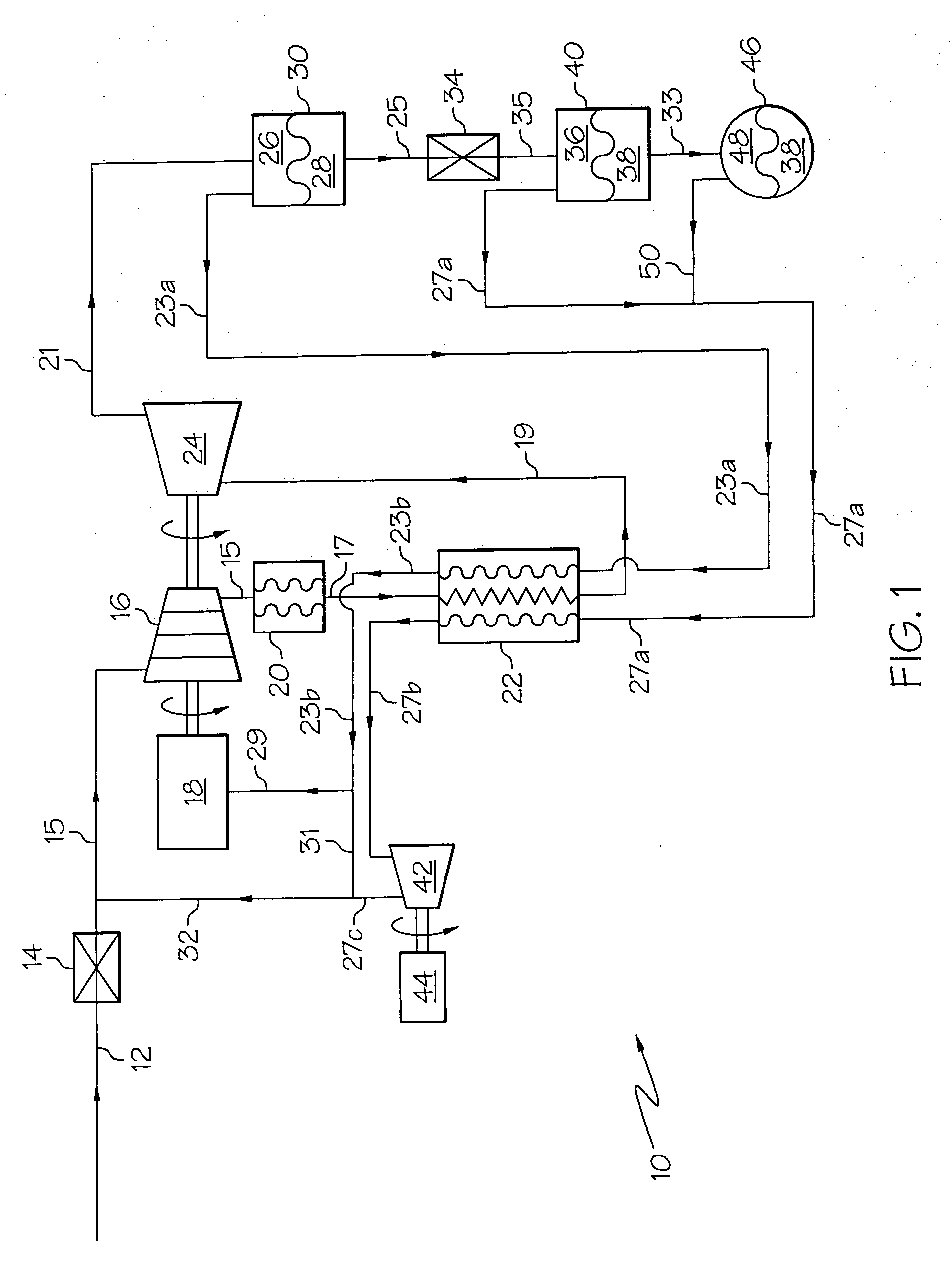

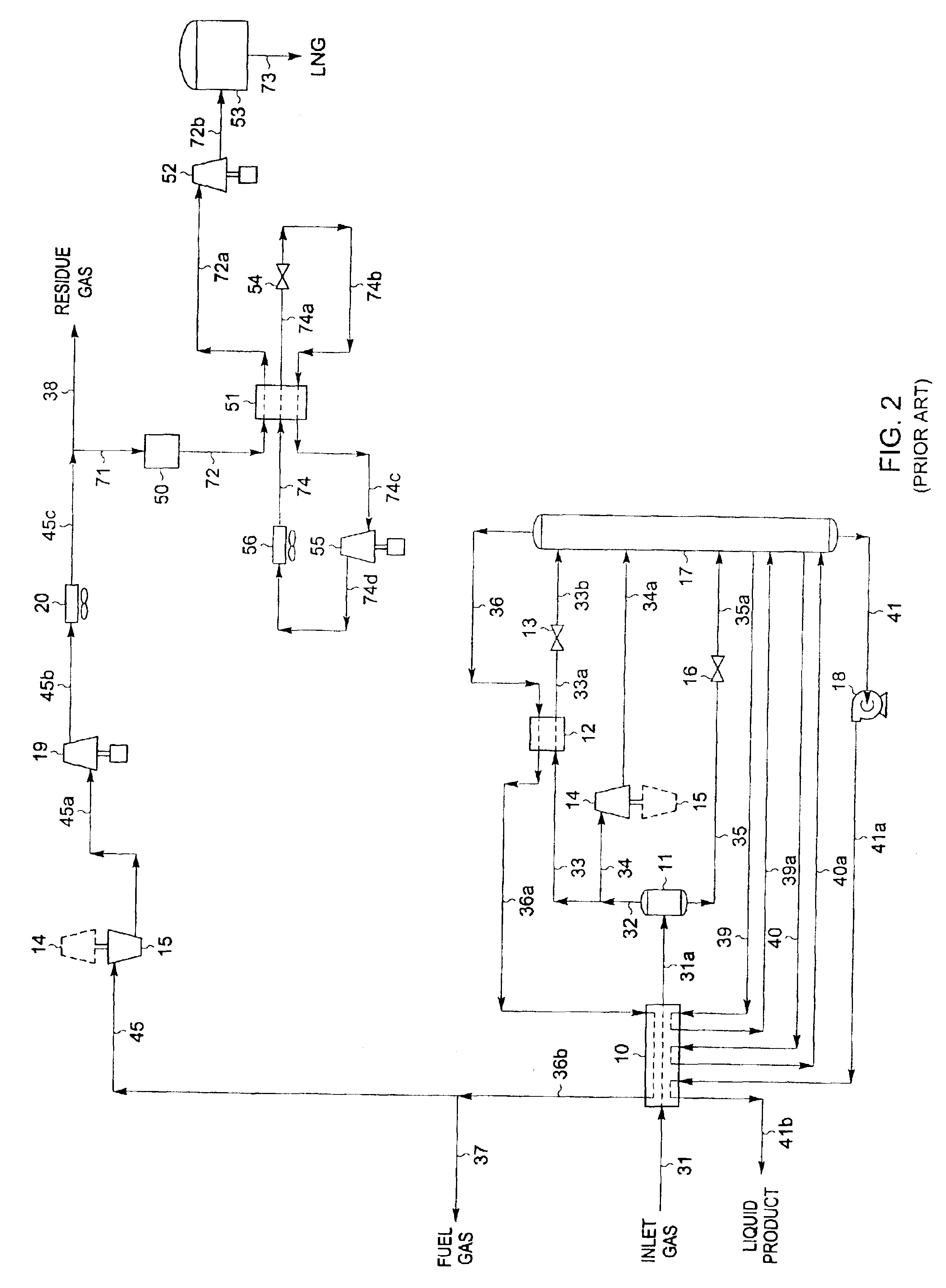

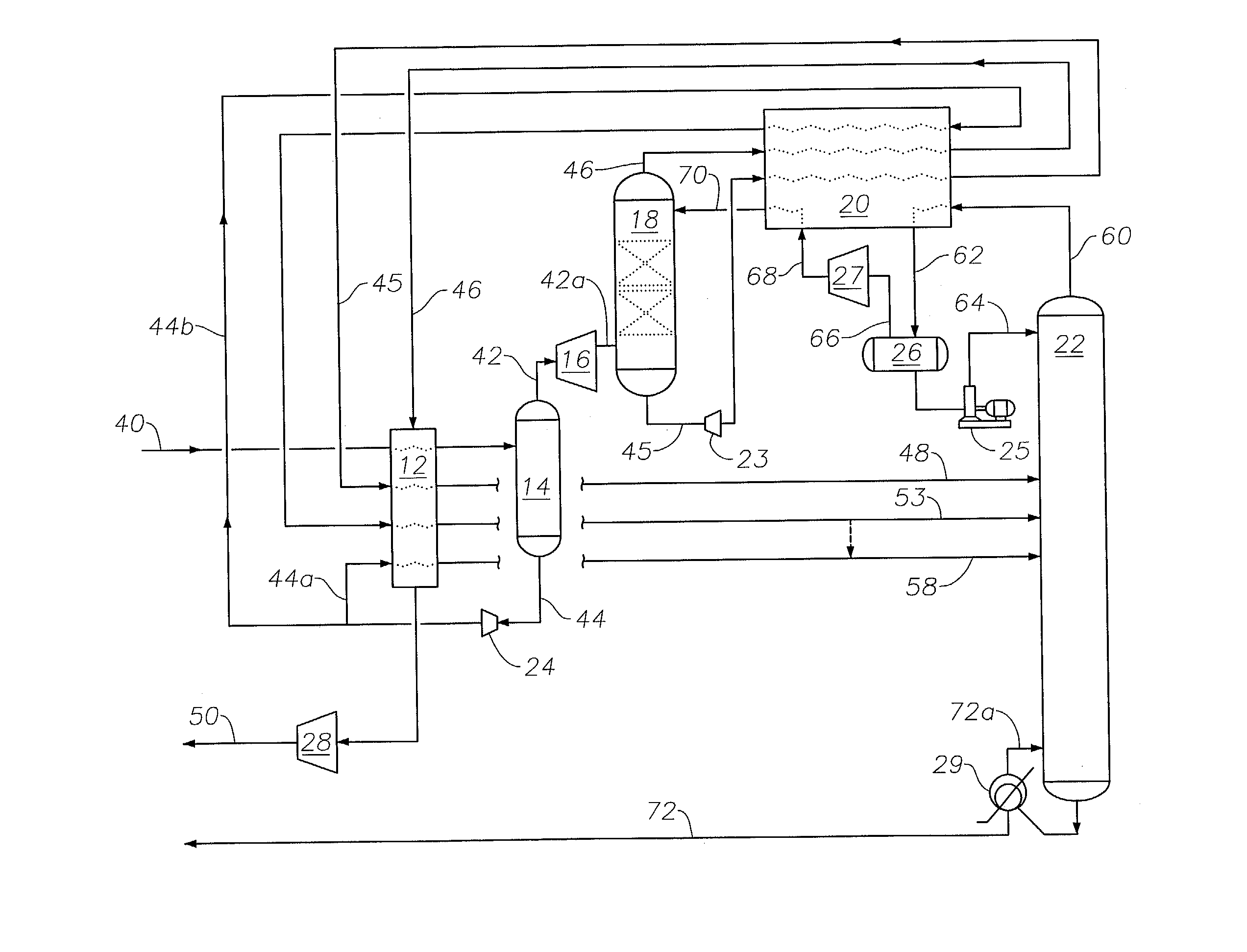

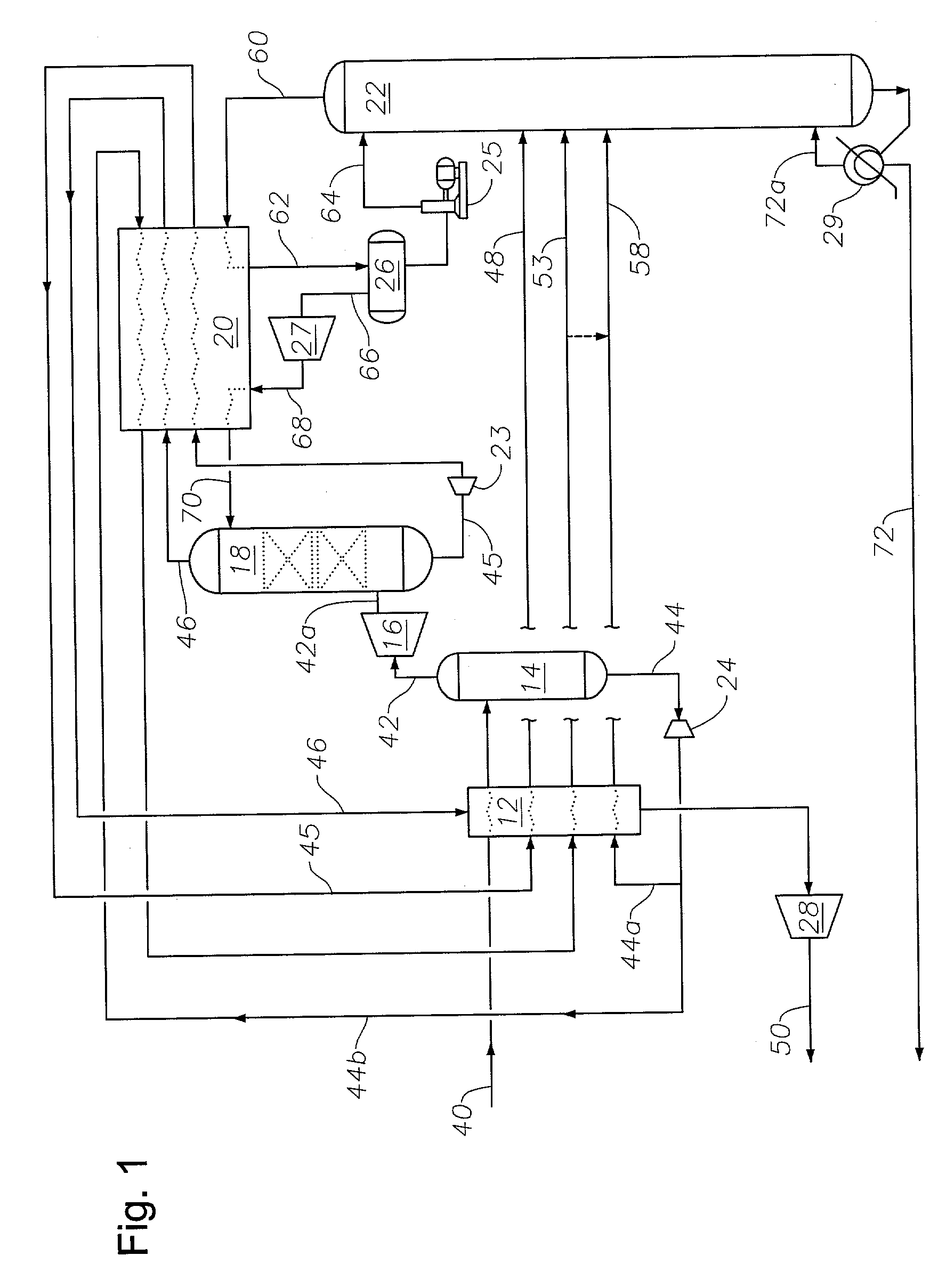

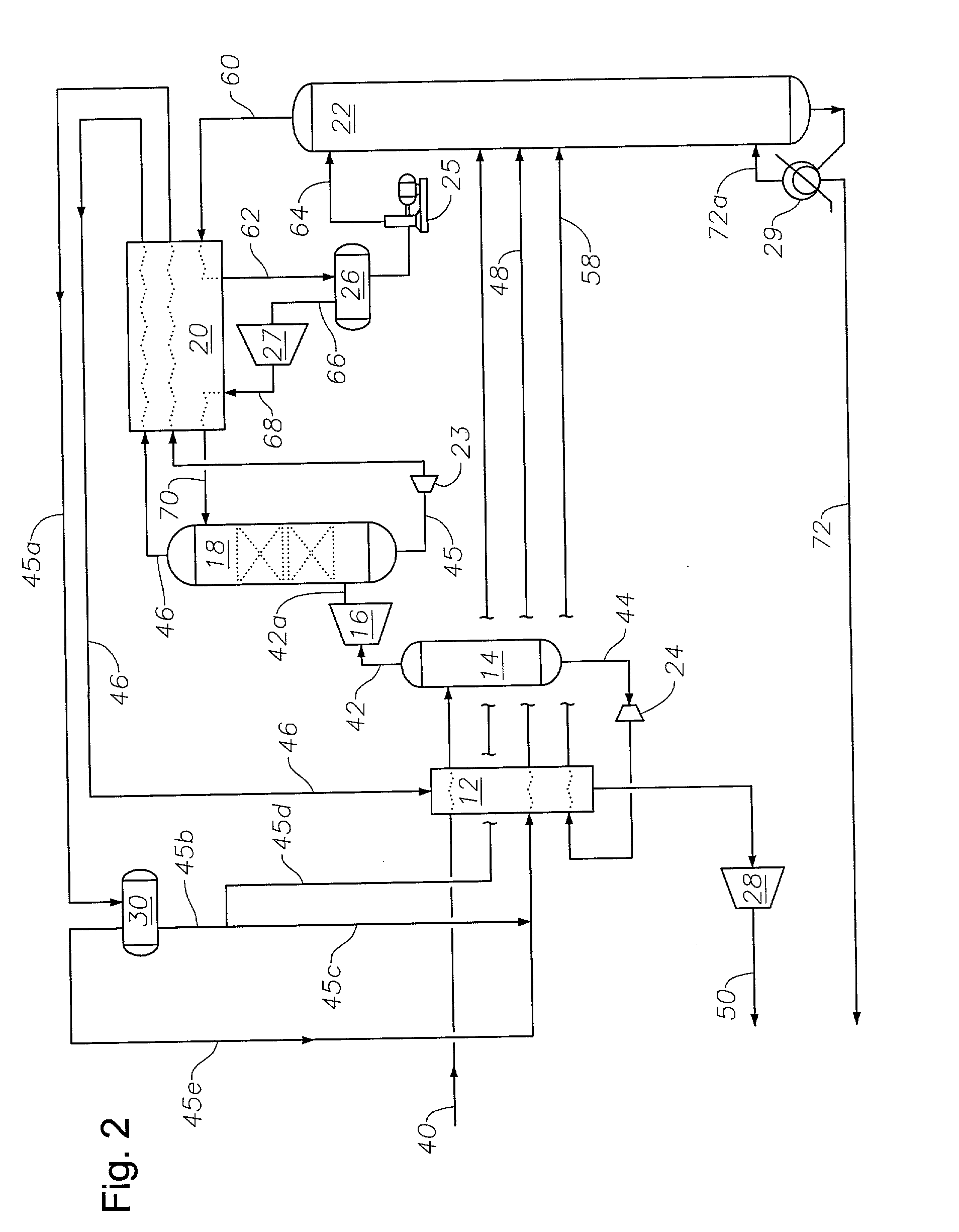

LNG production in cryogenic natural gas processing plants

A process for liquefying natural gas in conjunction with processing natural gas to recover natural gas liquids (NGL) is disclosed. In the process, the natural gas stream to be liquefied is taken from one of the streams in the NGL recovery plant and cooled under pressure to condense it. A distillation stream is withdrawn from the NGL recovery plant to provide some of the cooling required to condense the natural gas stream. A portion of the condensed stream is expanded to an intermediate pressure and then used to provide some of the cooling required to condense the natural gas stream, and thereafter routed to the NGL recovery plant so that any heavier hydrocarbons it contains can be recovered in the NGL product. The remaining portion of the condensed stream is expanded to low pressure to form the liquefied natural gas stream.

Owner:ORTLOFF ENGINEERS

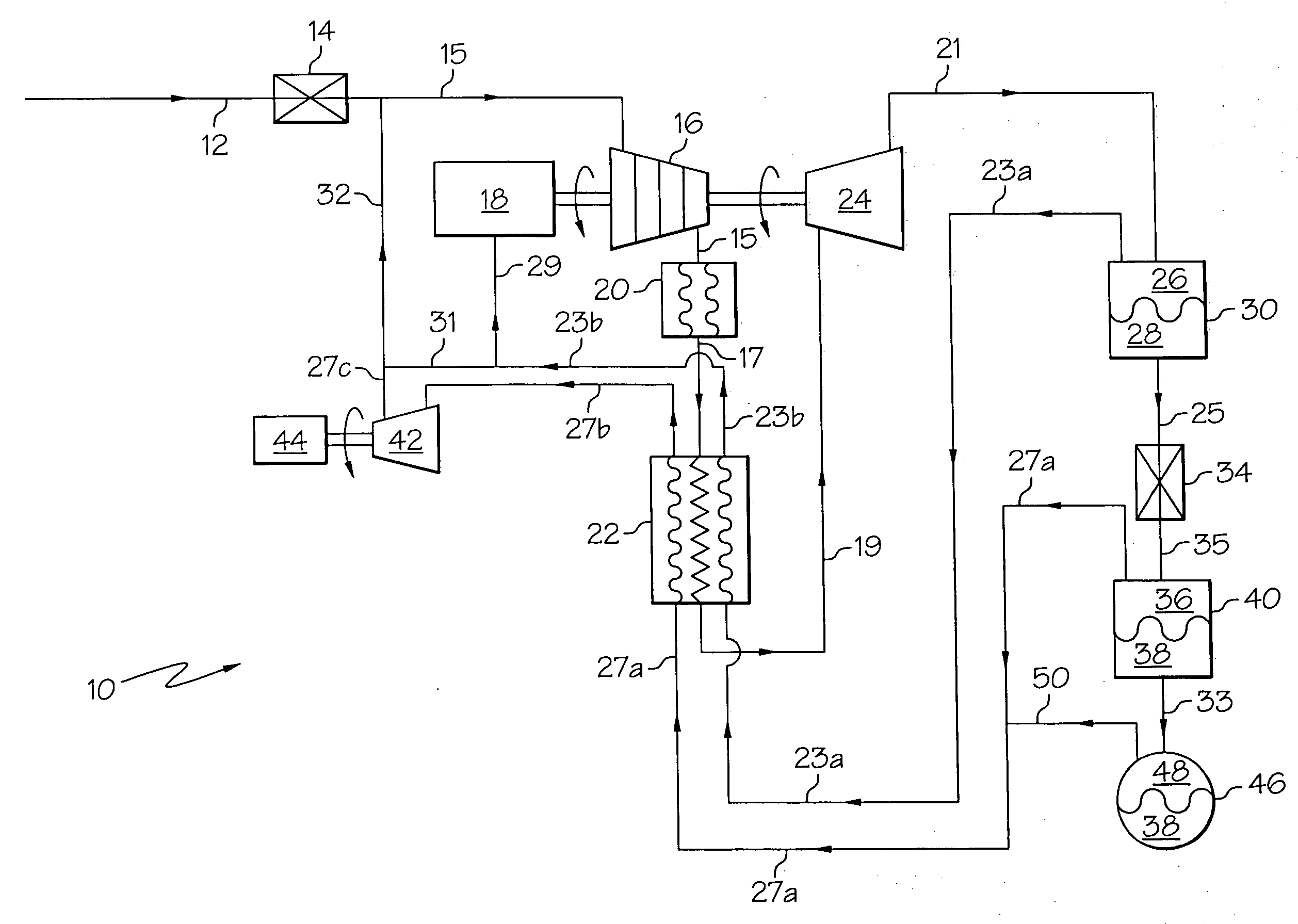

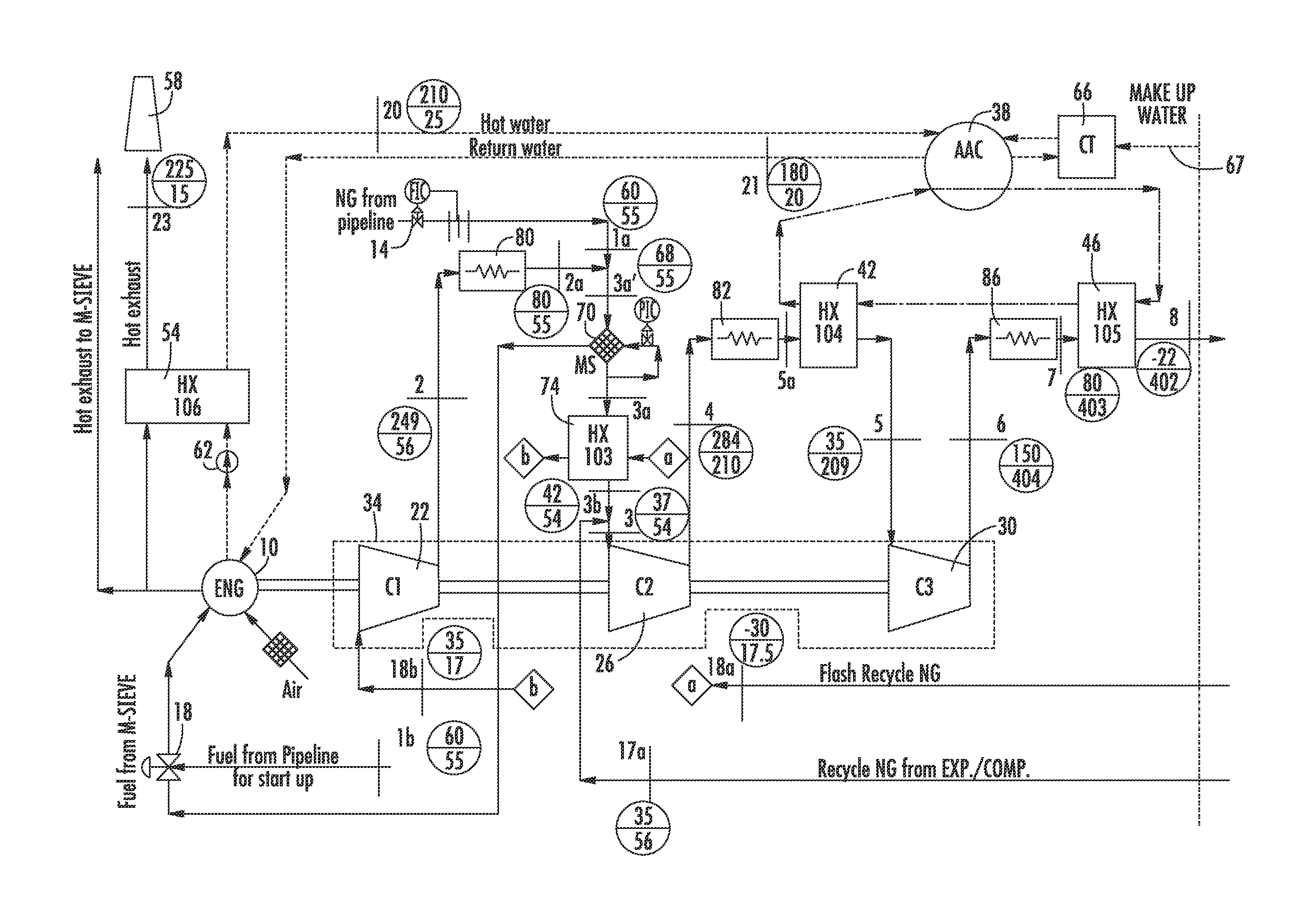

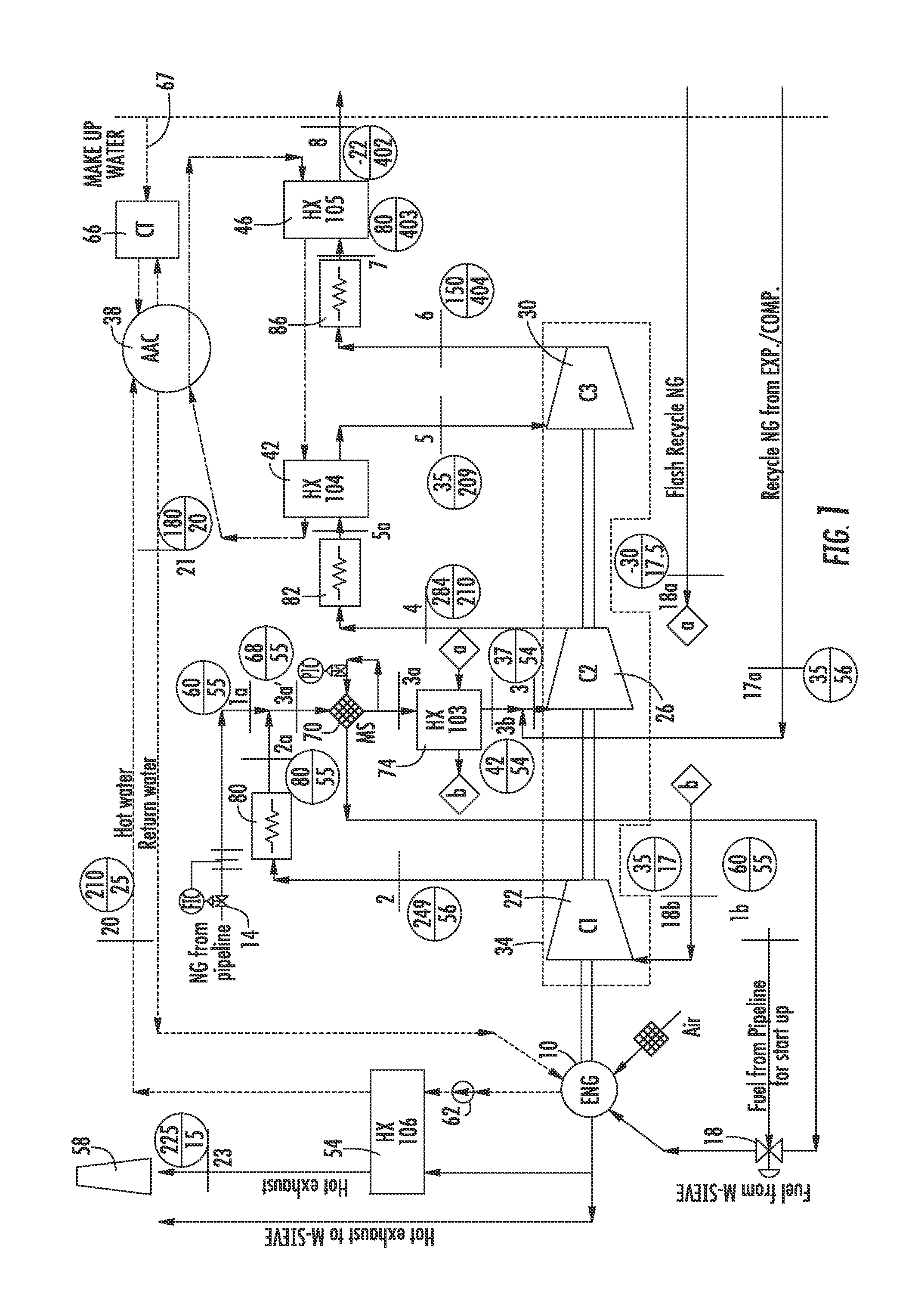

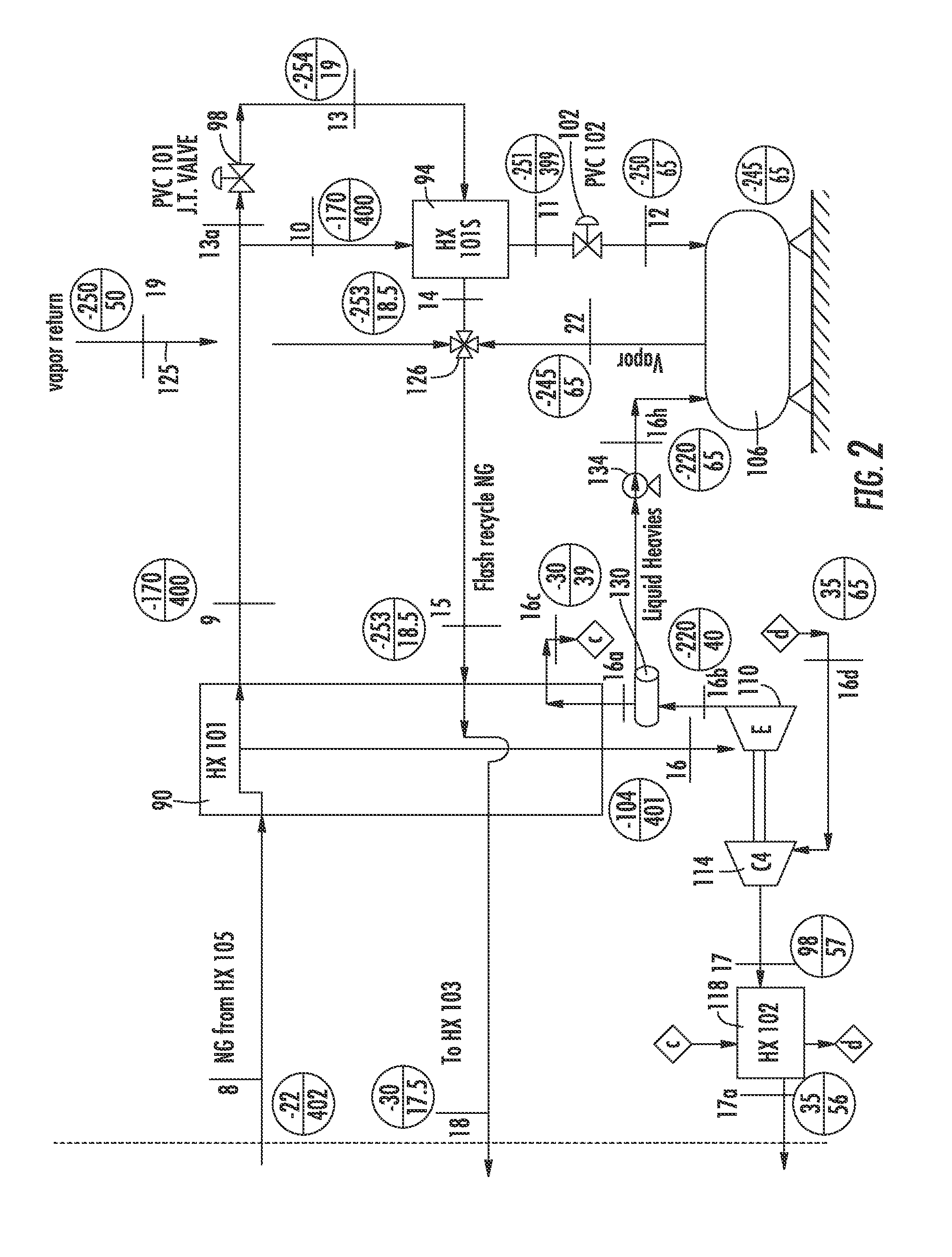

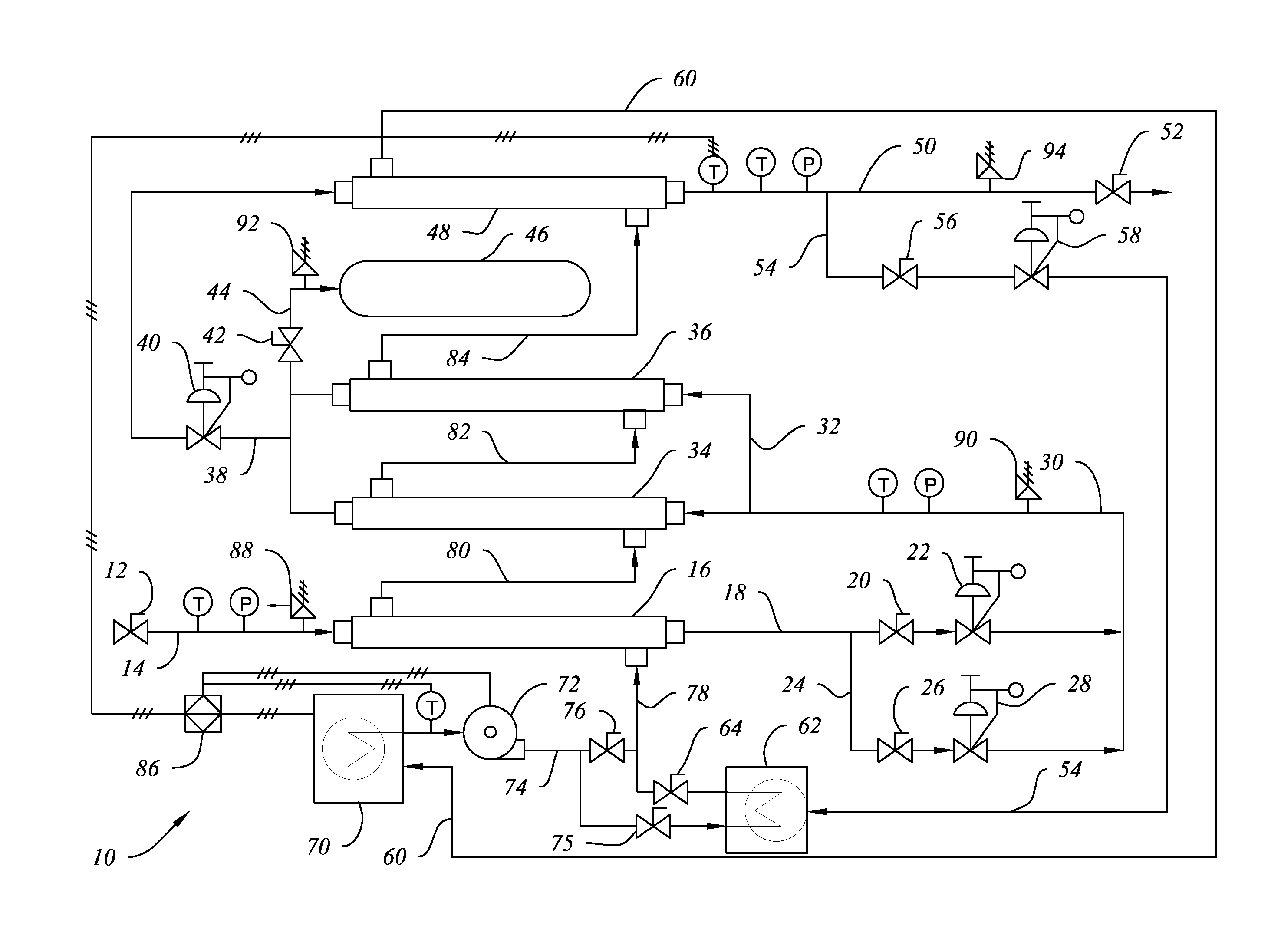

Compact, modular method and apparatus for liquefying natural gas

InactiveUS20060213222A1Cost efficientSolidificationLiquefactionCompressed natural gasProcess engineering

A compact and modular cryogenic method and apparatus for liquefying natural gas. The liquefaction process is highly efficient and requires no external refrigeration system, and the apparatus is small enough to be transportable from one remote site to another. A compressed natural gas feed stream is cooled and then expanded to form a bi-phase stream comprising a first refrigerated vapor component and a first liquid component. The first liquid component is then separated from the bi-phase stream and expanded to form a second bi-phase stream comprising a second refrigerated vapor component and a second liquid component. The second liquid component is then introduced into a means configured for storage and transport. The remaining feed stream can then be recycled, and at least a substantial portion of the original feed stream can be processed into liquefied natural gas (LNG). The first and second vapor components are recycled through the system and comprise at least a portion of the feed stream in the repeated steps.

Owner:CAMBRIDGE CRYOGENICS TECH

LNG production in cryogenic natural gas processing plants

InactiveUS6889523B2Improve efficiencyConsiderable capital and operating costSolidificationLiquefactionCompressed natural gasNatural-gas processing

A process for liquefying natural gas in conjunction with processing natural gas to recover natural gas liquids (NGL) is disclosed. In the process, the natural gas stream to be liquefied is taken from one of the streams in the NGL recovery plant and cooled under pressure to condense it. A distillation stream is withdrawn from the NGL recovery plant to provide some of the cooling required to condense the natural gas stream. A portion of the condensed stream is expanded to an intermediate pressure and then used to provide some of the cooling required to condense the natural gas stream, and thereafter routed to the NGL recovery plant so that any heavier hydrocarbons it contains can be recovered in the NGL product. The remaining portion of the condensed stream is expanded to low pressure to form the liquefied natural gas stream.

Owner:ORTLOFF ENGINEERS

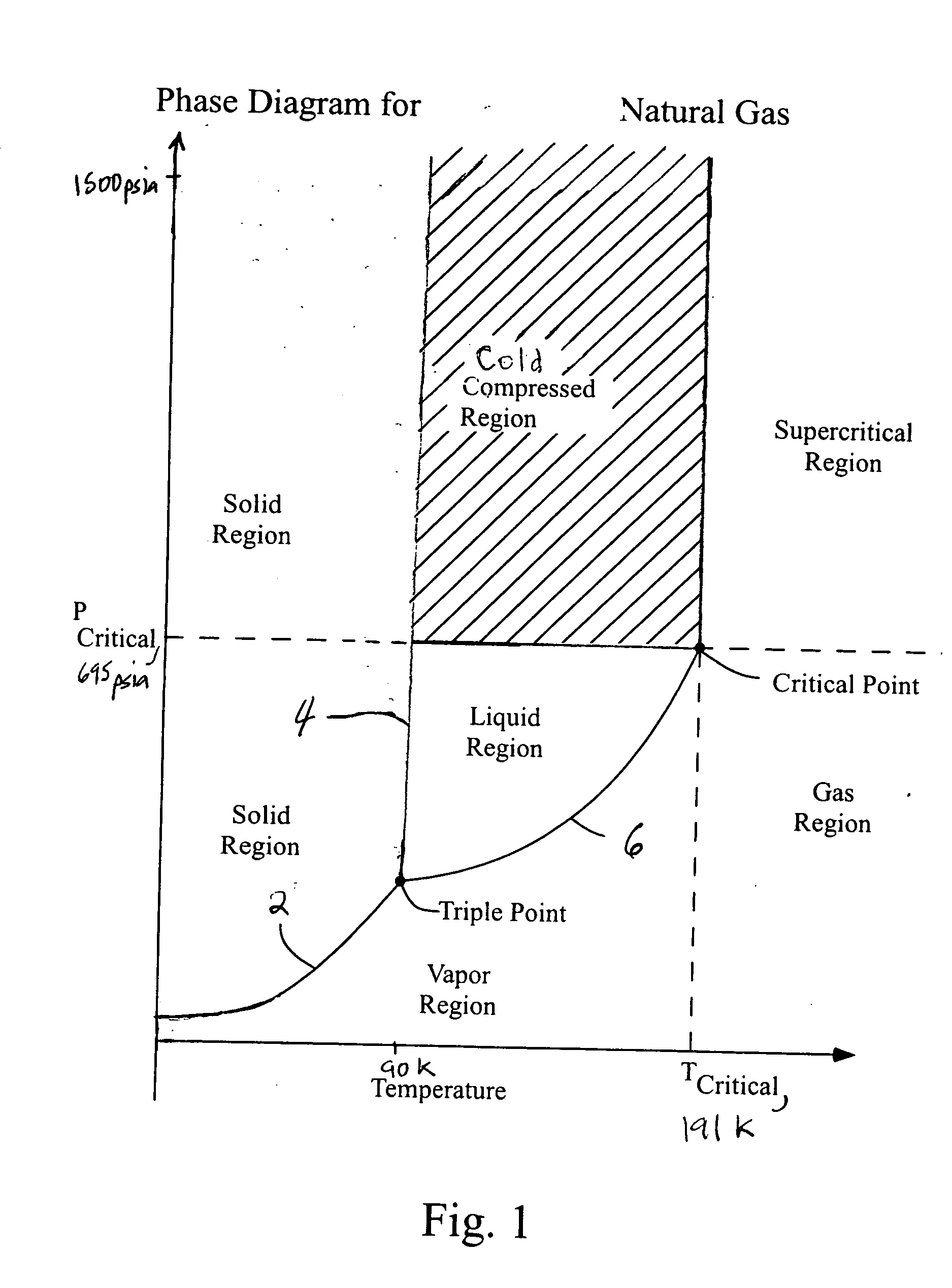

Method and system for the small-scale production of liquified natural gas (LNG) and cold compressed gas (CCNG) from low-pressure natural gas

InactiveUS20120036888A1Decreasing refrigeration “Improve balanceOpening closed containersSolidificationCold compressesCompressed natural gas

A system for the production of LNG from low-pressure feed gas sources, at small production scales and at lower energy input costs. A system for the small-scale production of cold compressed natural gas (CCNG). A method of dispensing natural gas from stored CCNG, comprising: dispensing CCNG from a CCNG storage tank; pumping the CCNG by a cryogenic liquid pump to a pressure suitable for compressed natural gas dispensing and storage in on-vehicle compressed natural gas storage tanks; recovering cold from the CCNG by heat exchange with natural gas feeding the natural gas production plant to replace dispensed product. A system for the storage, transport, and dispensing of natural gas, comprising: means for handling natural gas in a CCNG state where the natural gas is a non-liquid, but is dense-enough to allow for pumping to pressure by a cryogenic liquid pump.

Owner:VANDOR DAVID

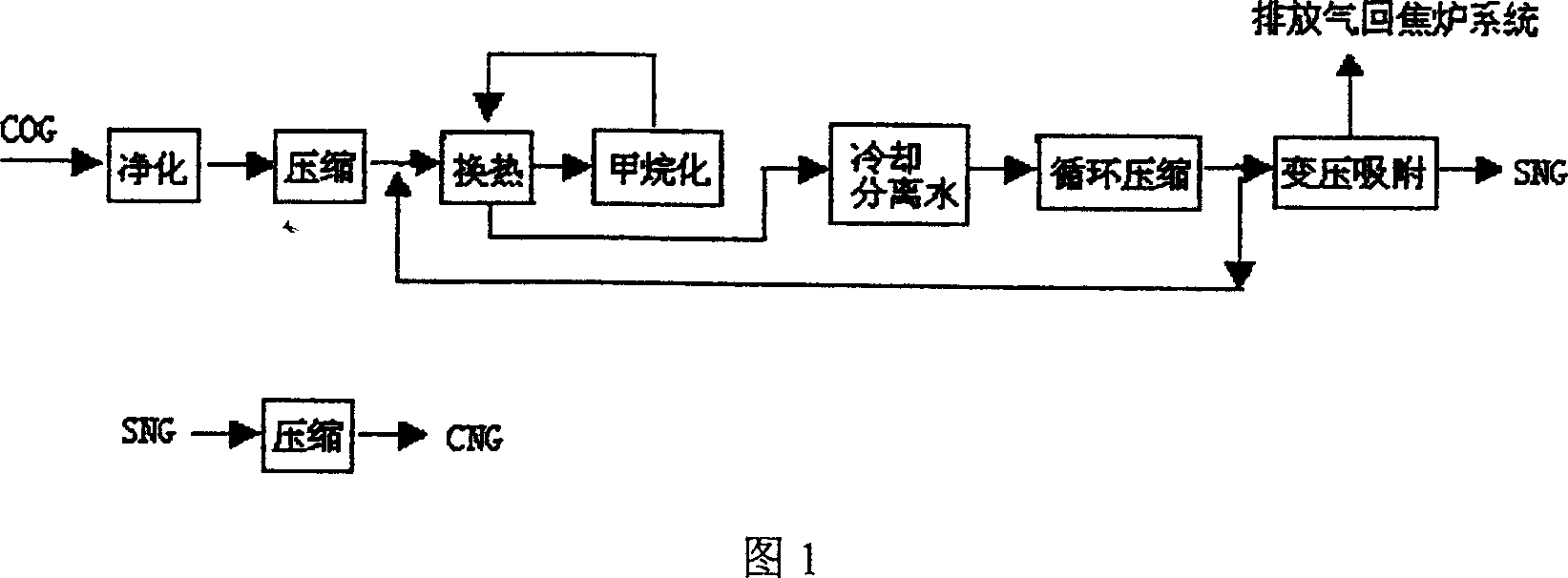

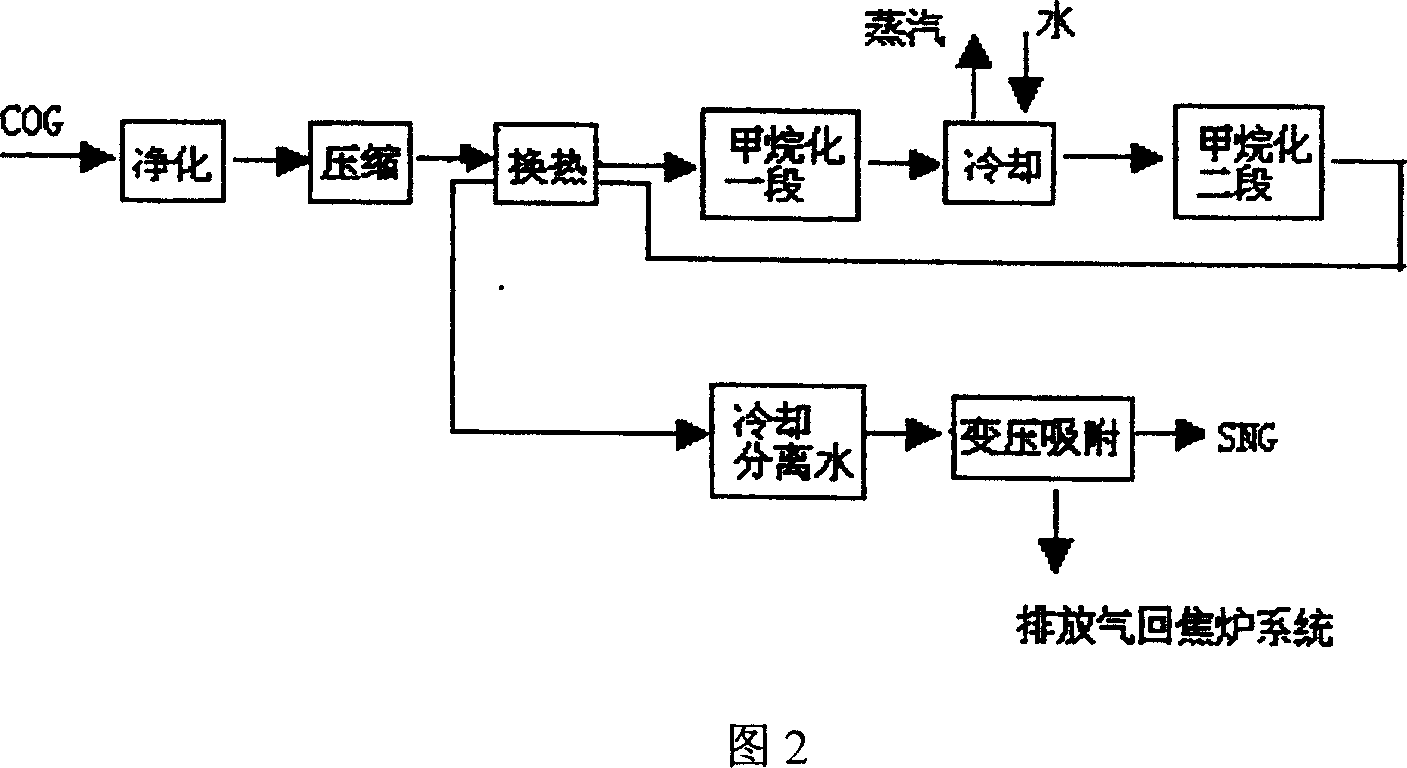

Method of preparing synthetic natural gas by coke oven gas

ActiveCN1919985AHigh calorific valueLow impurity contentGaseous fuelsCompressed natural gasMethanation

The invention discloses the method for producing natural gas with coking gas, comprising the following steps: purifying coking gas and removing benzene, naphthalene, hydrocarbon and sulphide, compressing, heat transferring, carrying out methanation reaction with catalyst, hydrogen in COG reacting with carbonic oxide and carbon dioxide to get methane; putting the mixture gas into pressure swing adsorbing device, and getting natural gas whose concentration is 90%. The natural gas has high caloric value, low impurity content.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

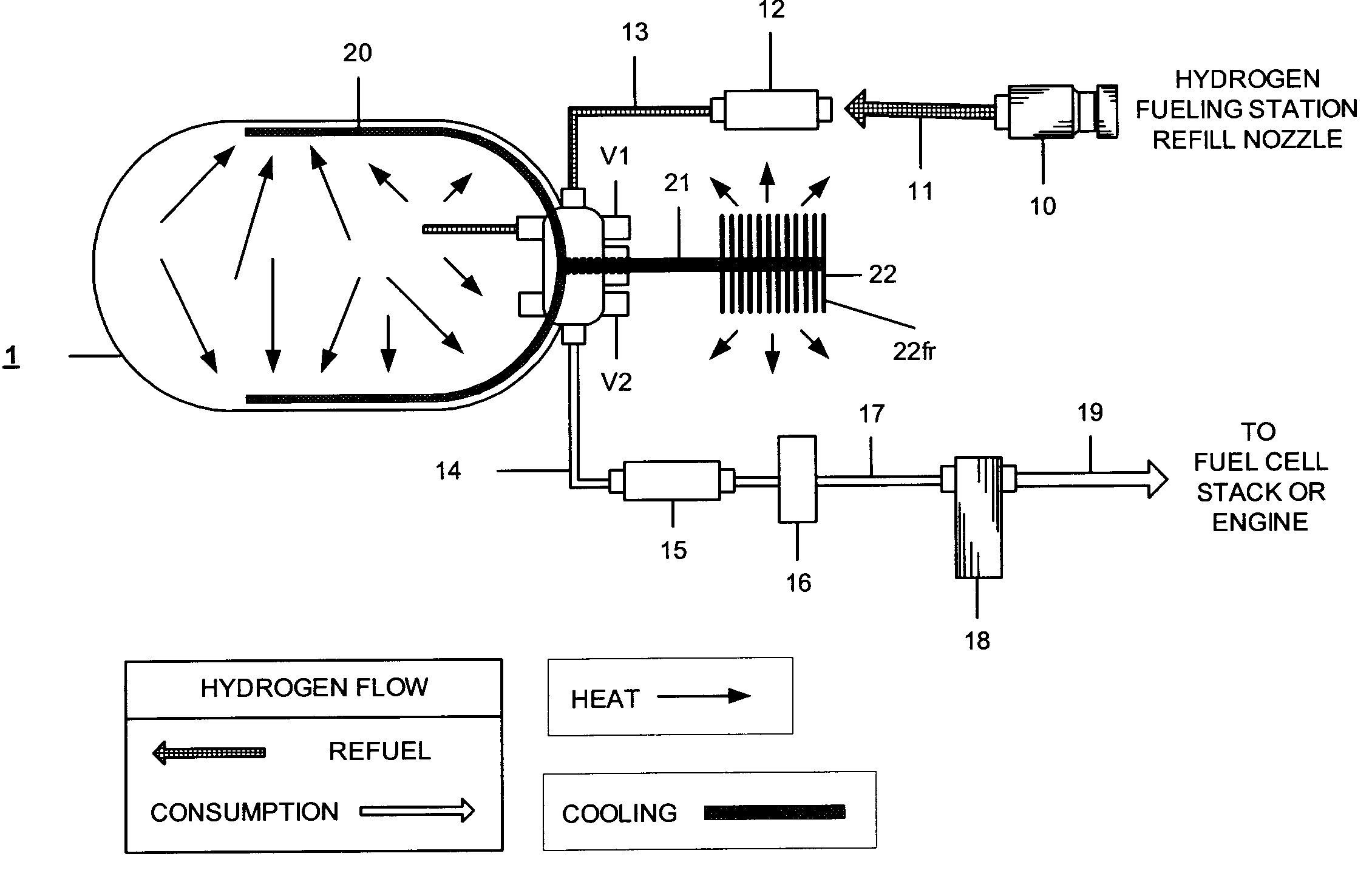

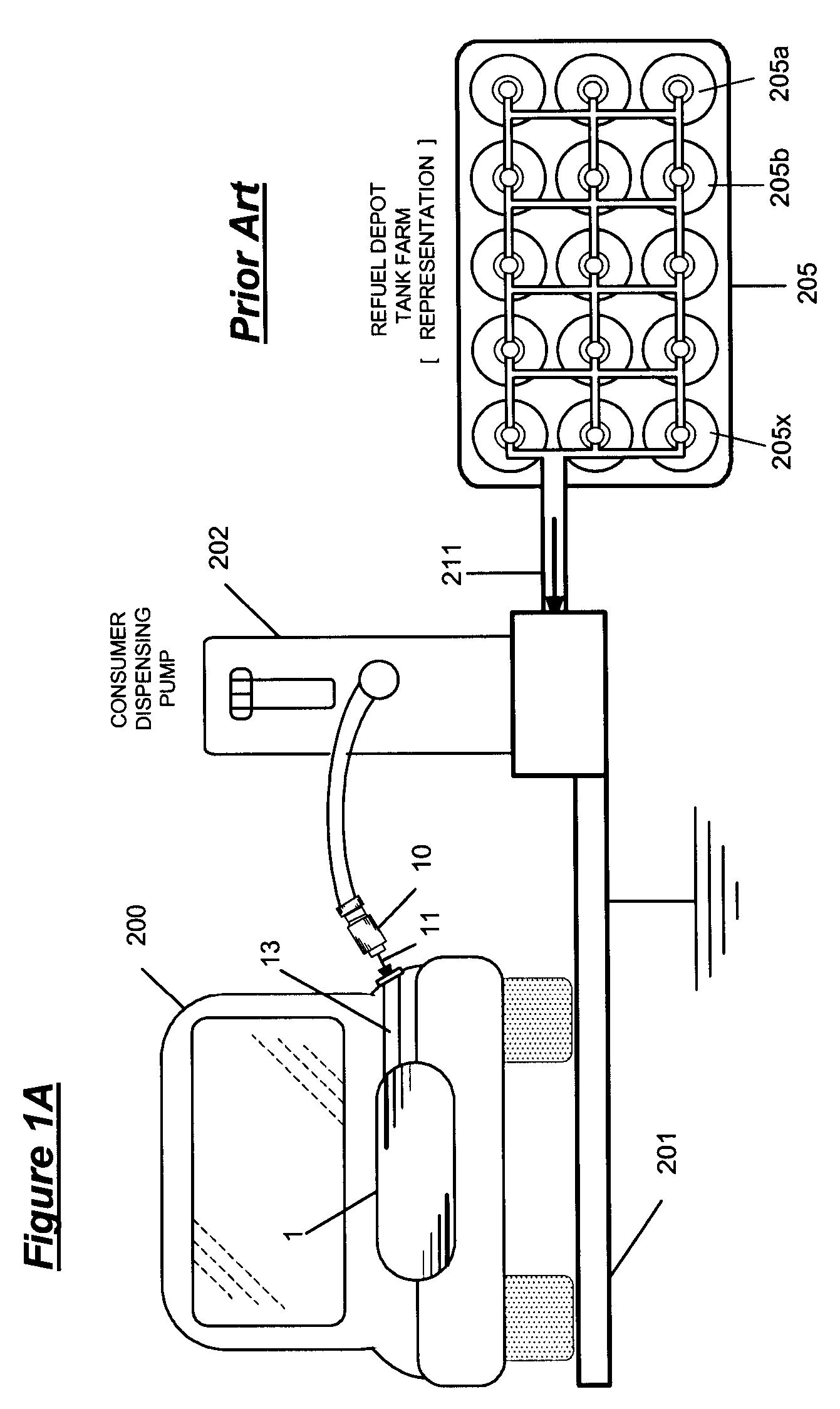

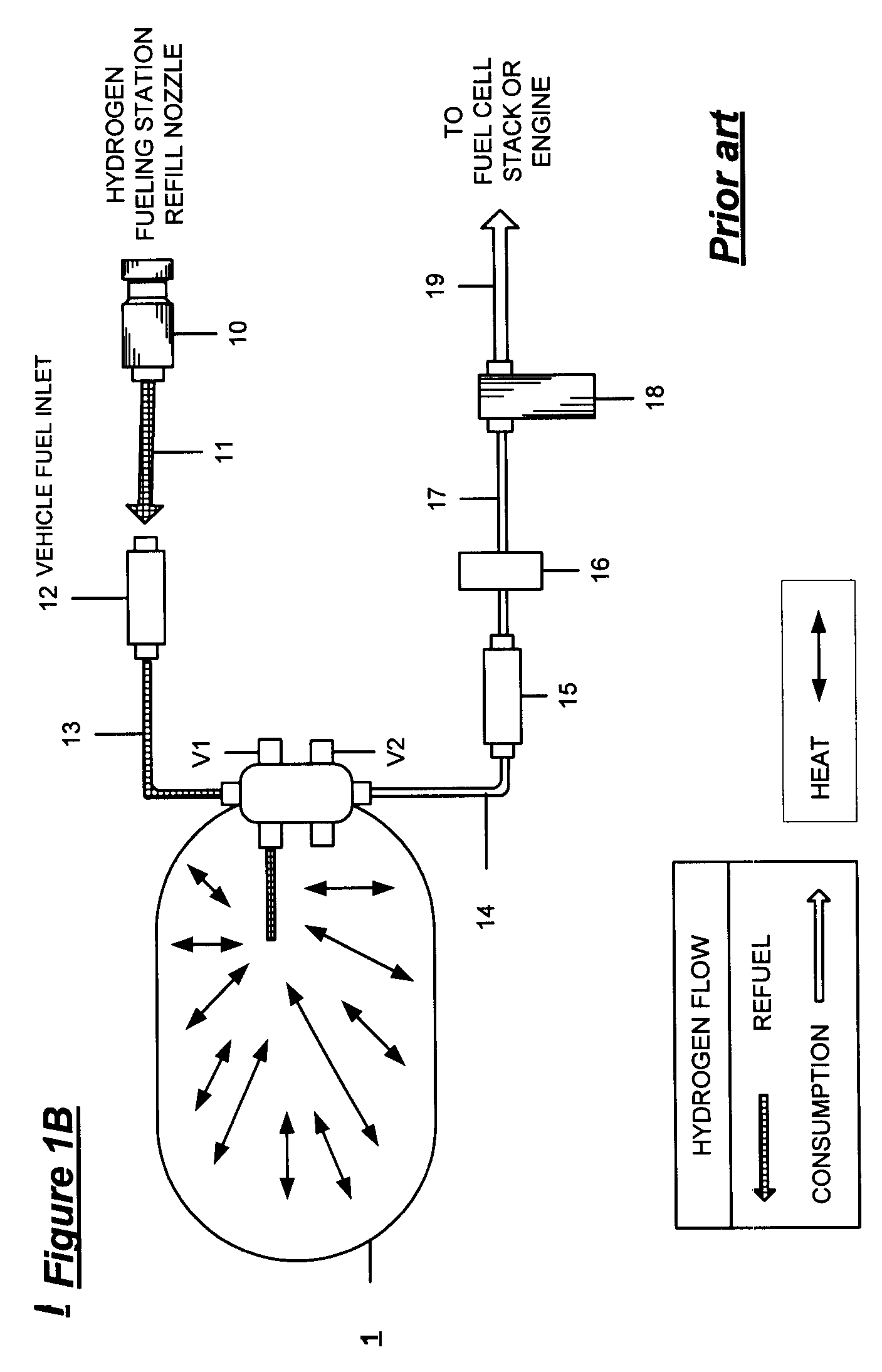

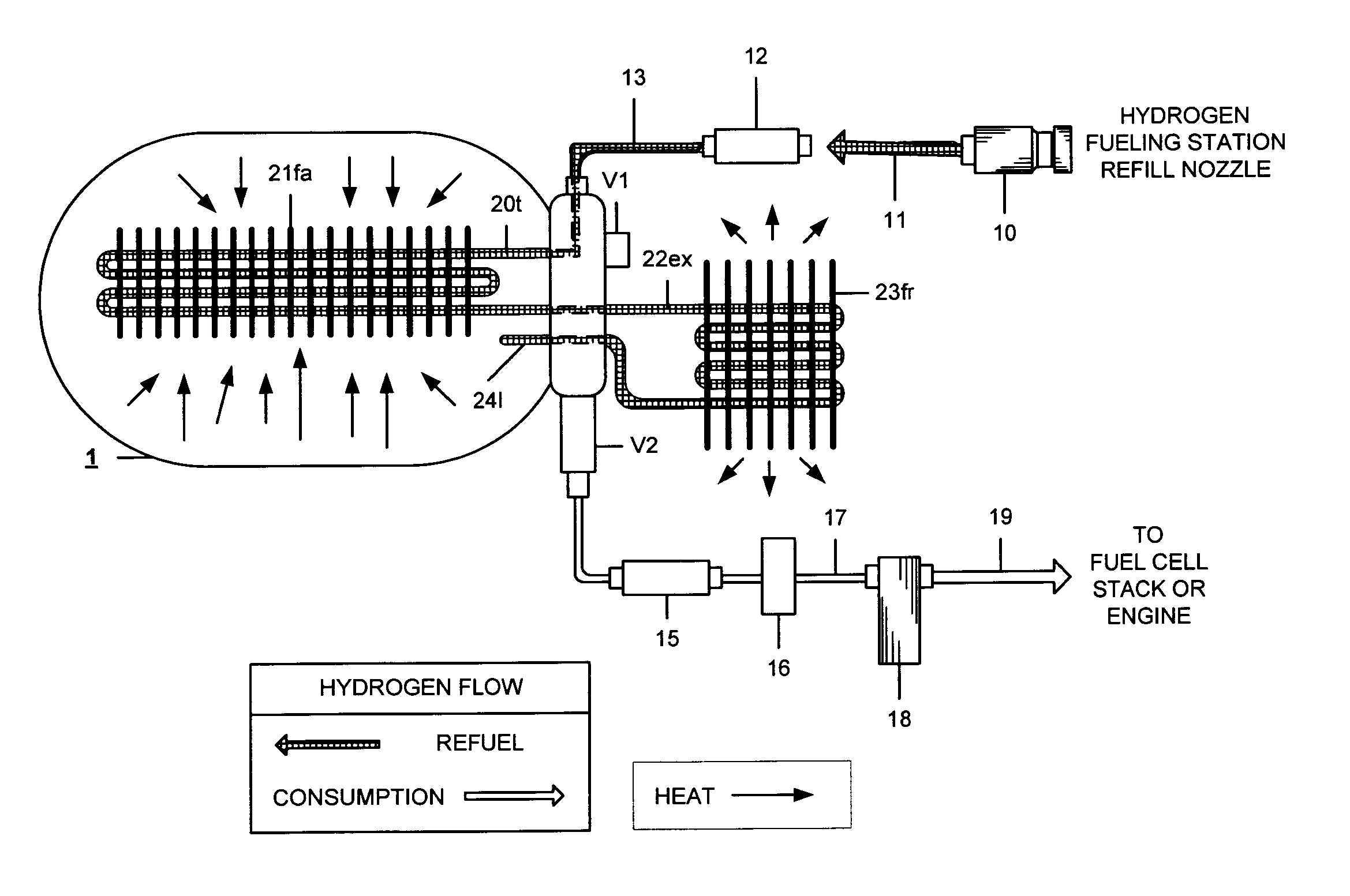

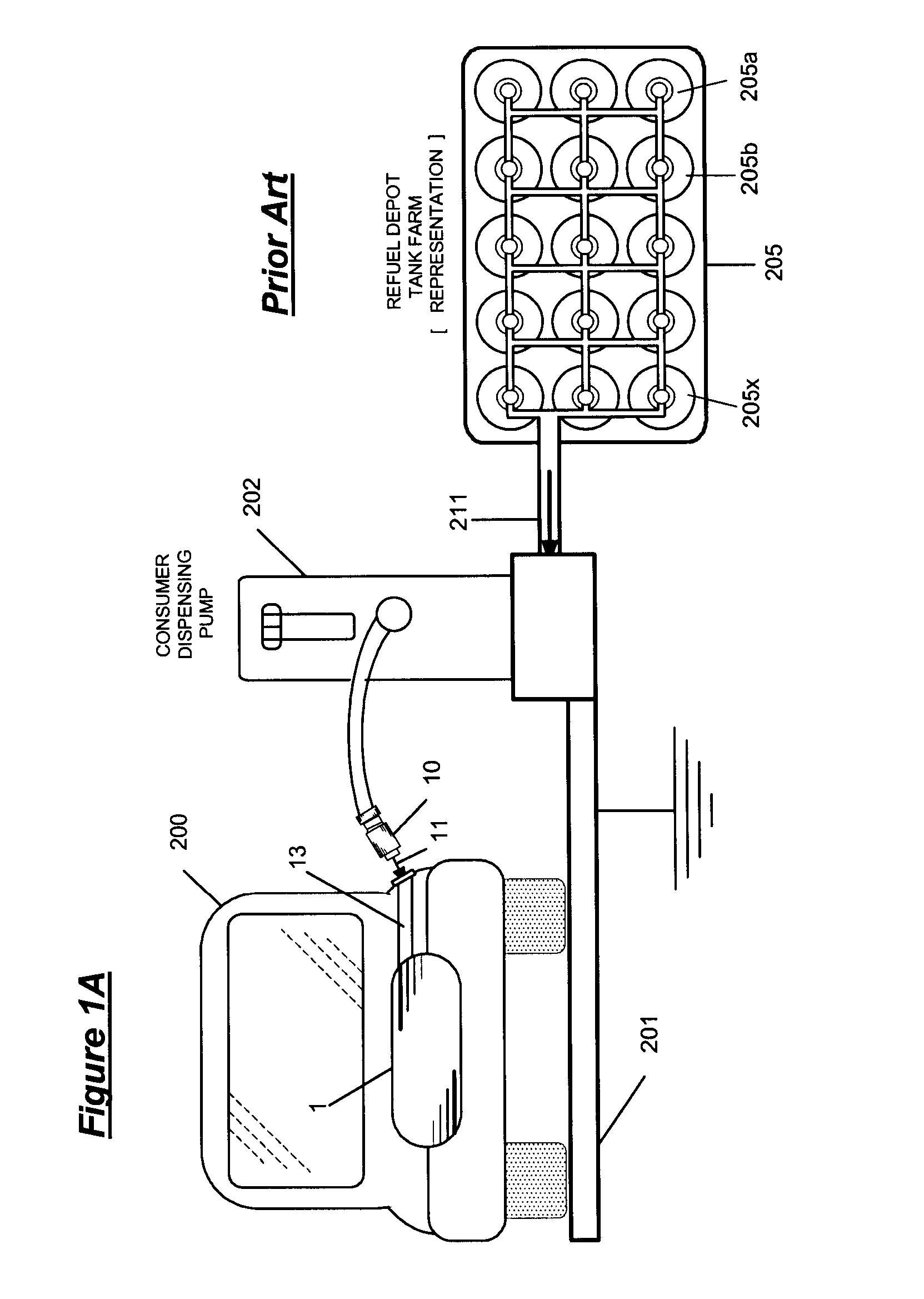

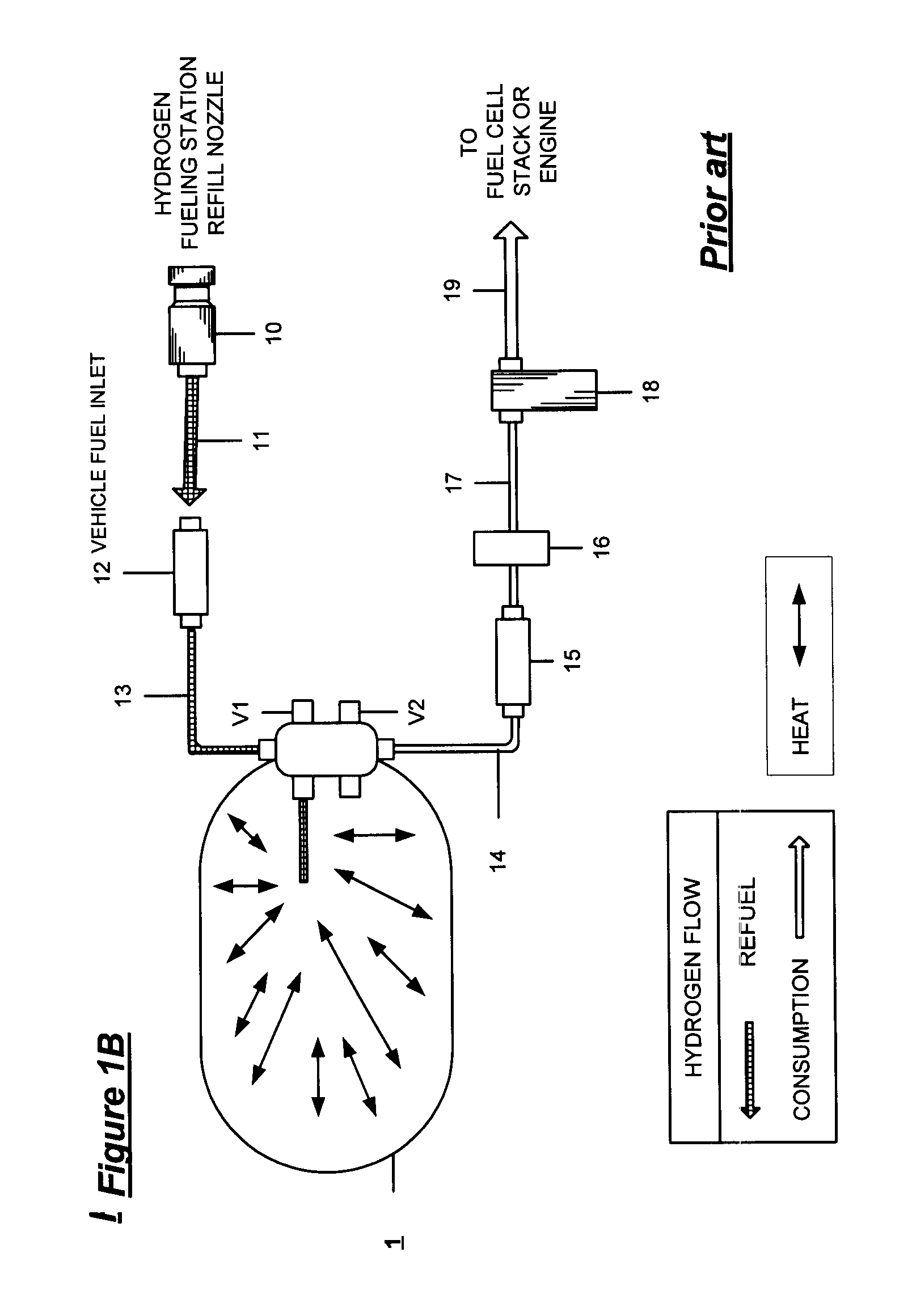

Gas cooling methods for high pressure fuel storage tanks on vehicles powered by compressed natural gas or hydrogen

ActiveUS7377294B2Improve refueling efficiencyIncrease efficiency and refueling capacityGlovesGas handling applicationsThermal energyCompressed natural gas

At a high pressure refuel depot that dispenses high pressure hydrogen or compressed natural gas to vehicles, the thermal energy (heat) generated by the high flow rate of the high pressure refueling gas is evacuated from the on board fuel tank[s] of vehicles eliminating the need for refueling pre treatments such as a slow fill, secondary precooling, and pressure overfill otherwise used to achieve a full vehicle tank refill. In an example, a high pressure fuel depot refilling line is operatively interconnected to an on board vehicle tank having a gas flow circuit wherein the refuel gas itself is circulated within the on board tank to absorb the compression heat of refueling and then to an external radiator before being released into the tank.

Owner:HONDA MOTOR CO LTD

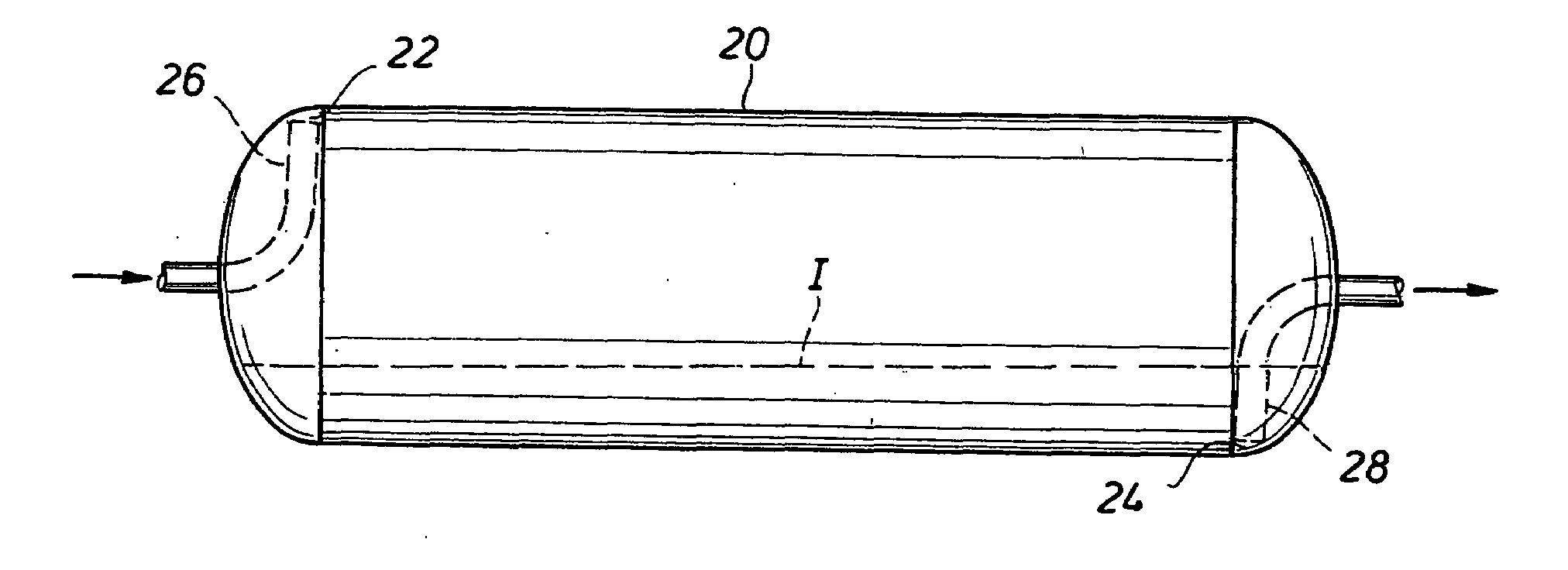

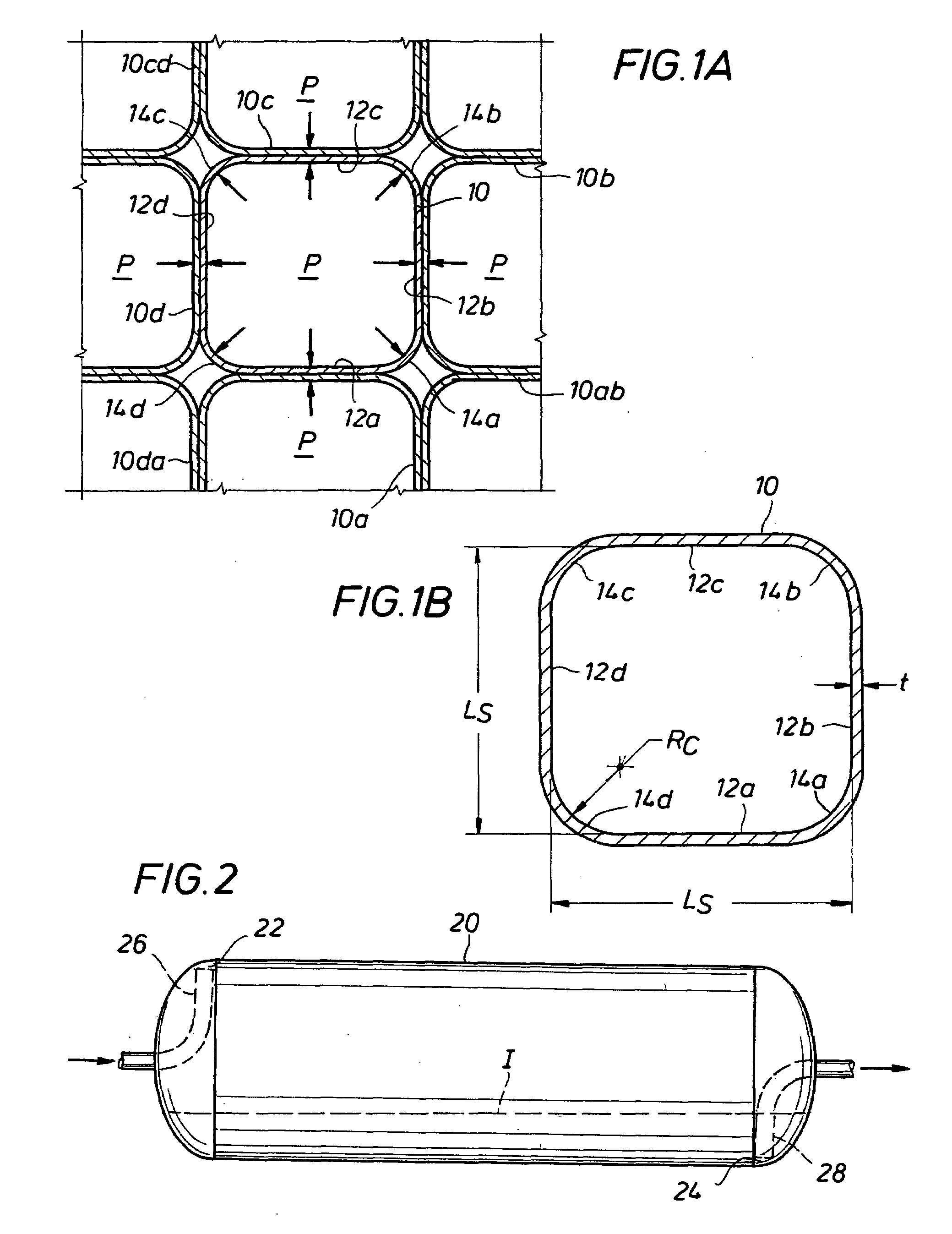

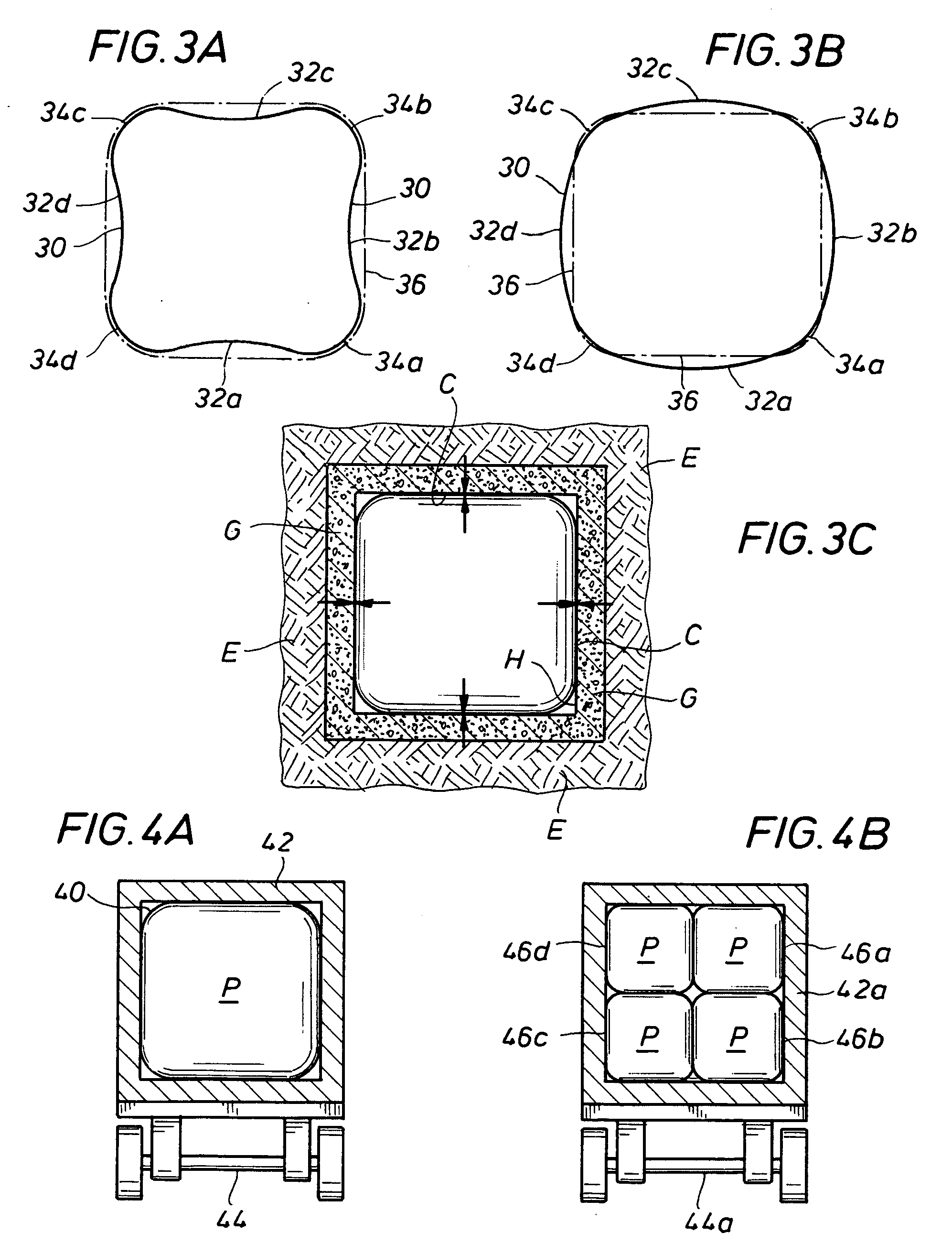

Container for Transport and Storage for Compressed Natural Gas

InactiveUS20080127654A1Reduction tendencySmall surface areaContainer filling methodsGas handling applicationsCompressed natural gasProcess engineering

A method and apparatus for unloading natural gas (NG), including gasifying liquid and / or compressed NG using the latent heat of water and propane, and / or storing liquid or compressed NG gas in a storage cavern system that utilizes a buffer layer to prevent hydrating the NG gas, the storage cavern system being configured such that the NG may be forced out of a first storage chamber by increasing the amount of brine in a second chamber to displace a buffer fluid located therein such that the displace buffer fluid enters the first storage chamber and displaces the NG, as well as the processes for compressing, chilling and / or liquefying quantities of LNG and transporting those volumes to markets for redelivery.

Owner:DARLING CHARLES M +3

Storing, transporting and handling compressed fluids

ActiveUS20080209918A1Reduce the amount requiredDesired rangeGas handling applicationsGas handling/storage effectsSupporting systemSquare cross section

A container and a method for storage and / or transport of a compressed fluid such as compressed natural gas are provided. The container has a pair of opposing heads and a wall section between the heads, the wall section defining a square cross-section comprising substantially planar sides joined together by rounded corners. The container is designed for the side walls to deflect outwardly while under pressure, but to be supported externally by a support system that restricts outward expansion of the side walls. The support system can be provided as the walls of a cargo hold in a marine or land transport vessel, an ISO shipping container or an underground shaft. Multiple containers can be located side by side in the external support system so that the sides of adjacent containers rest against each other for support while under pressure. In one embodiment, a container comprises an outside tank and a flexible membrane tank inside the outside tank, an annular space being defined in between, where a first fluid is charged into the membrane tank and a second fluid is charged into the annular space in order to discharge the first fluid. In another embodiment, a long tube having a square cross-section is coiled in a support structure and made gas-tight for holding a compressed fluid. The walls of the tube would tend to expand while under pressure, but adjacent coils and the support structure limit the expansion.

Owner:WHITE CHARLES N +1

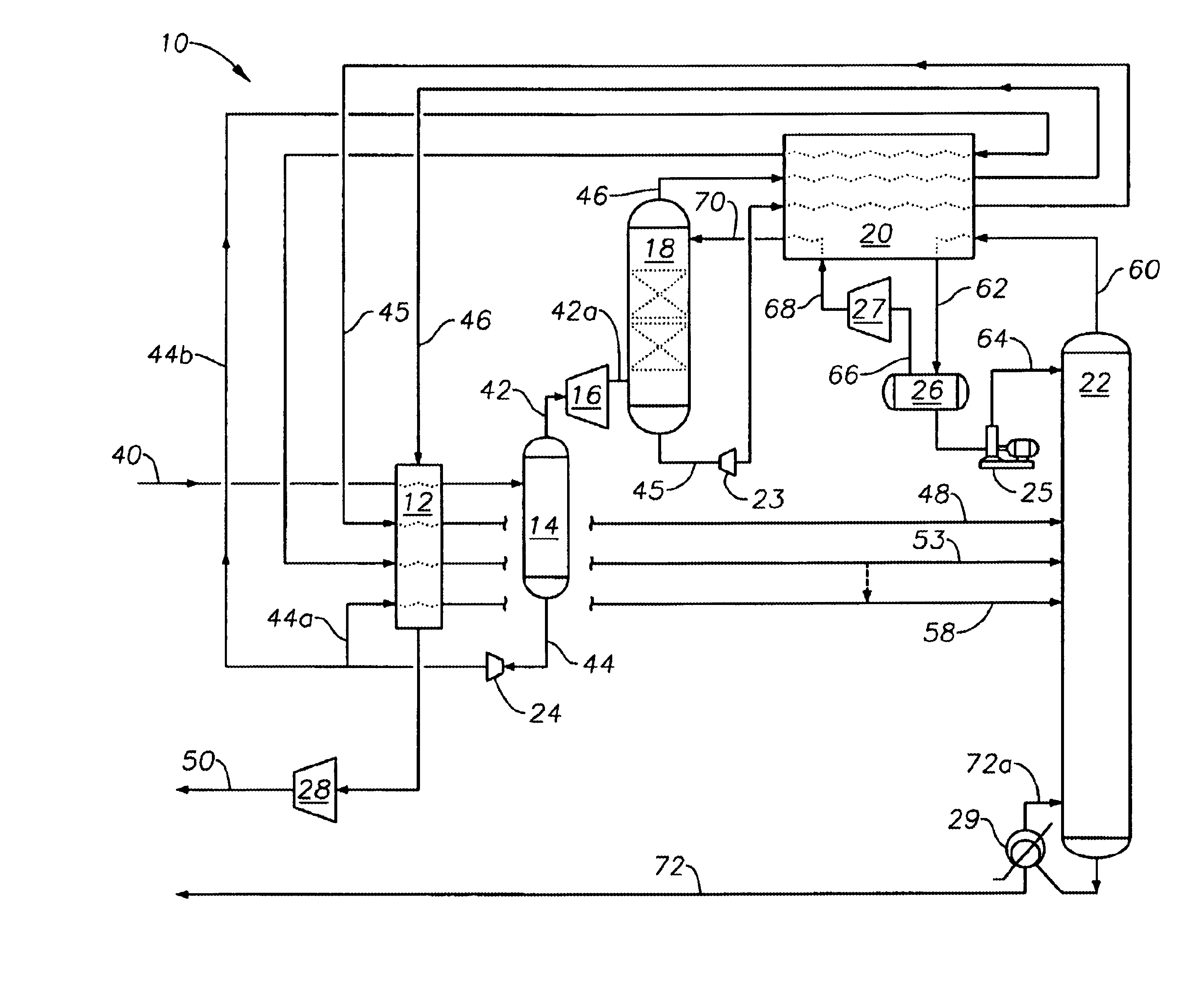

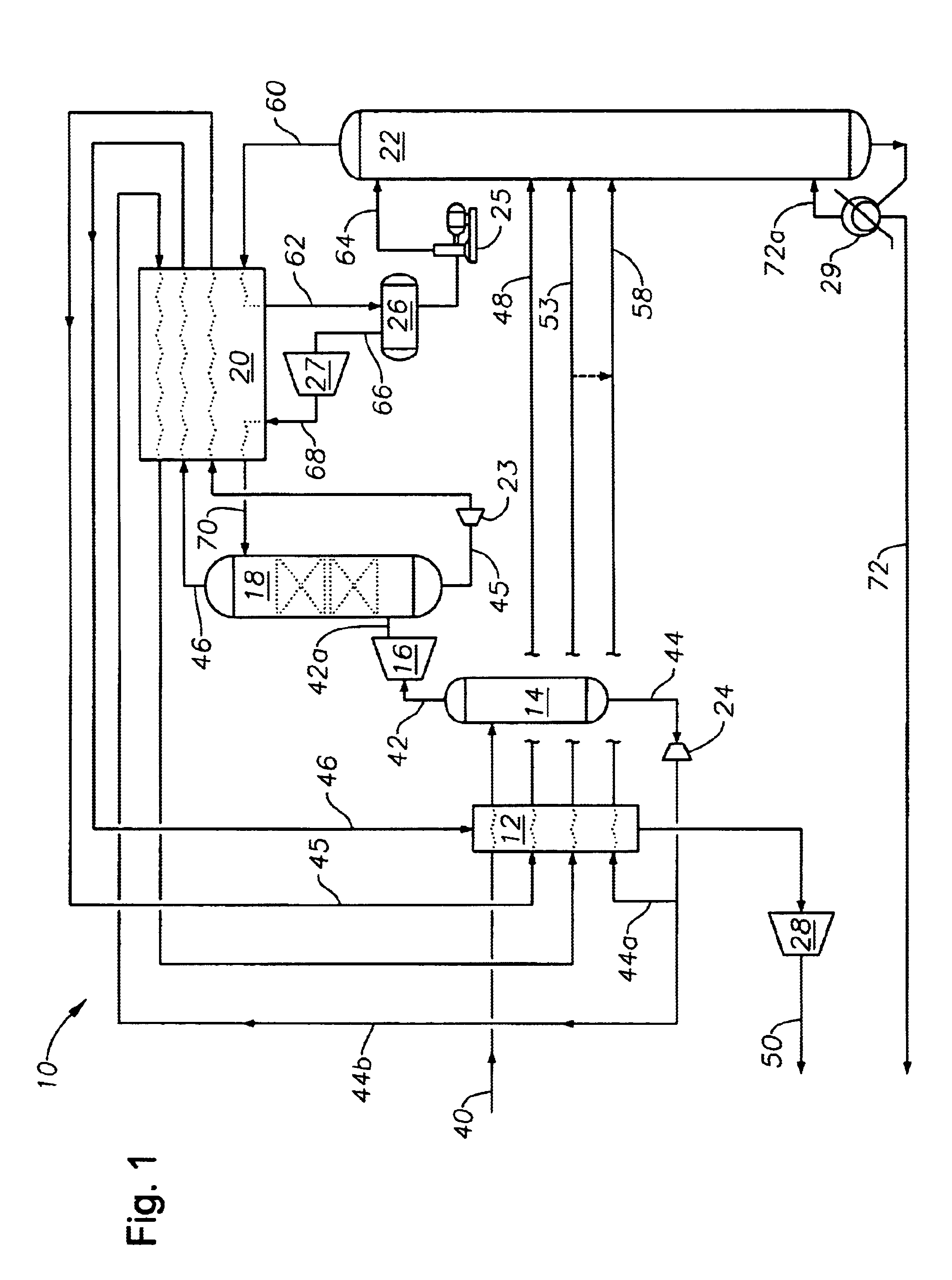

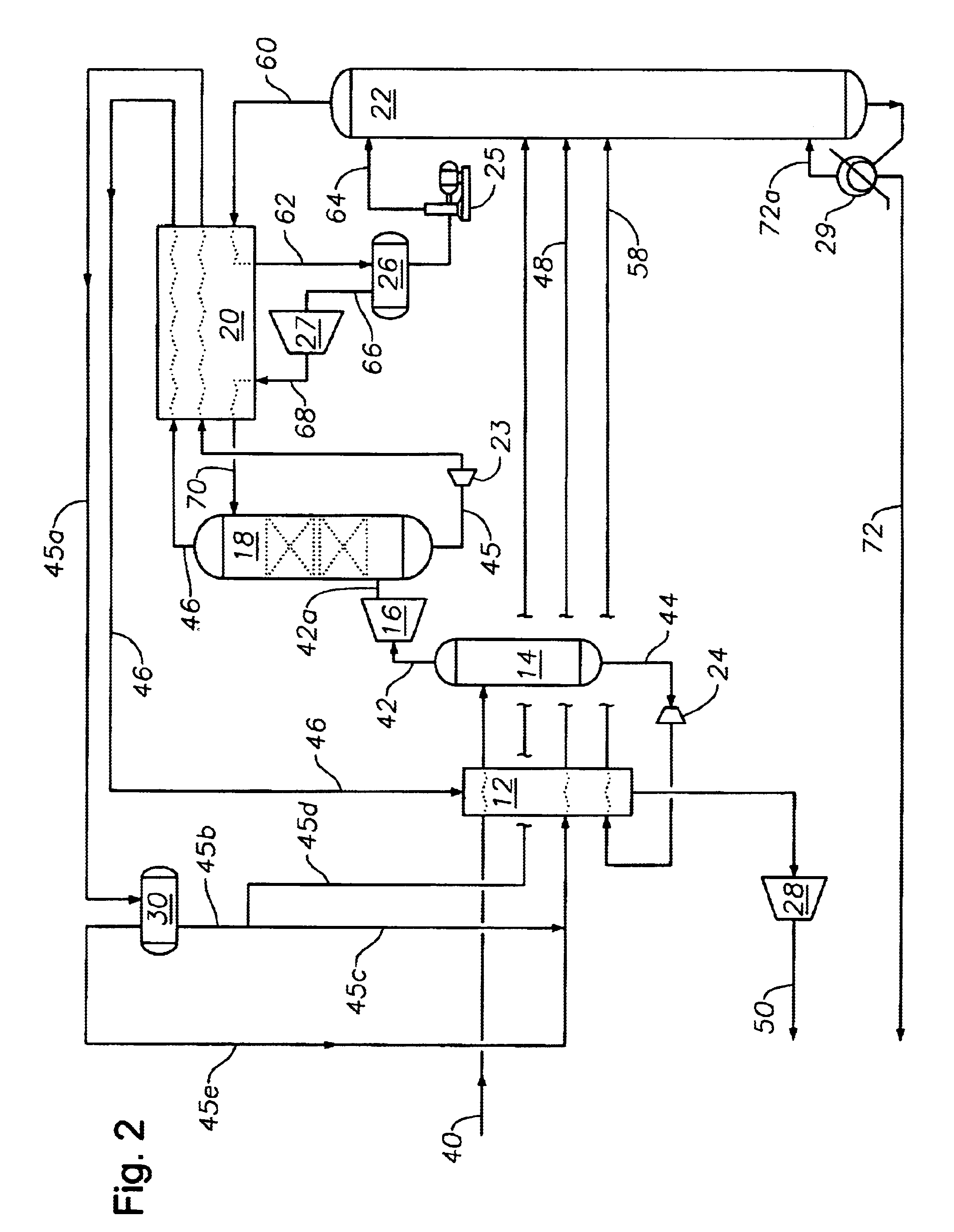

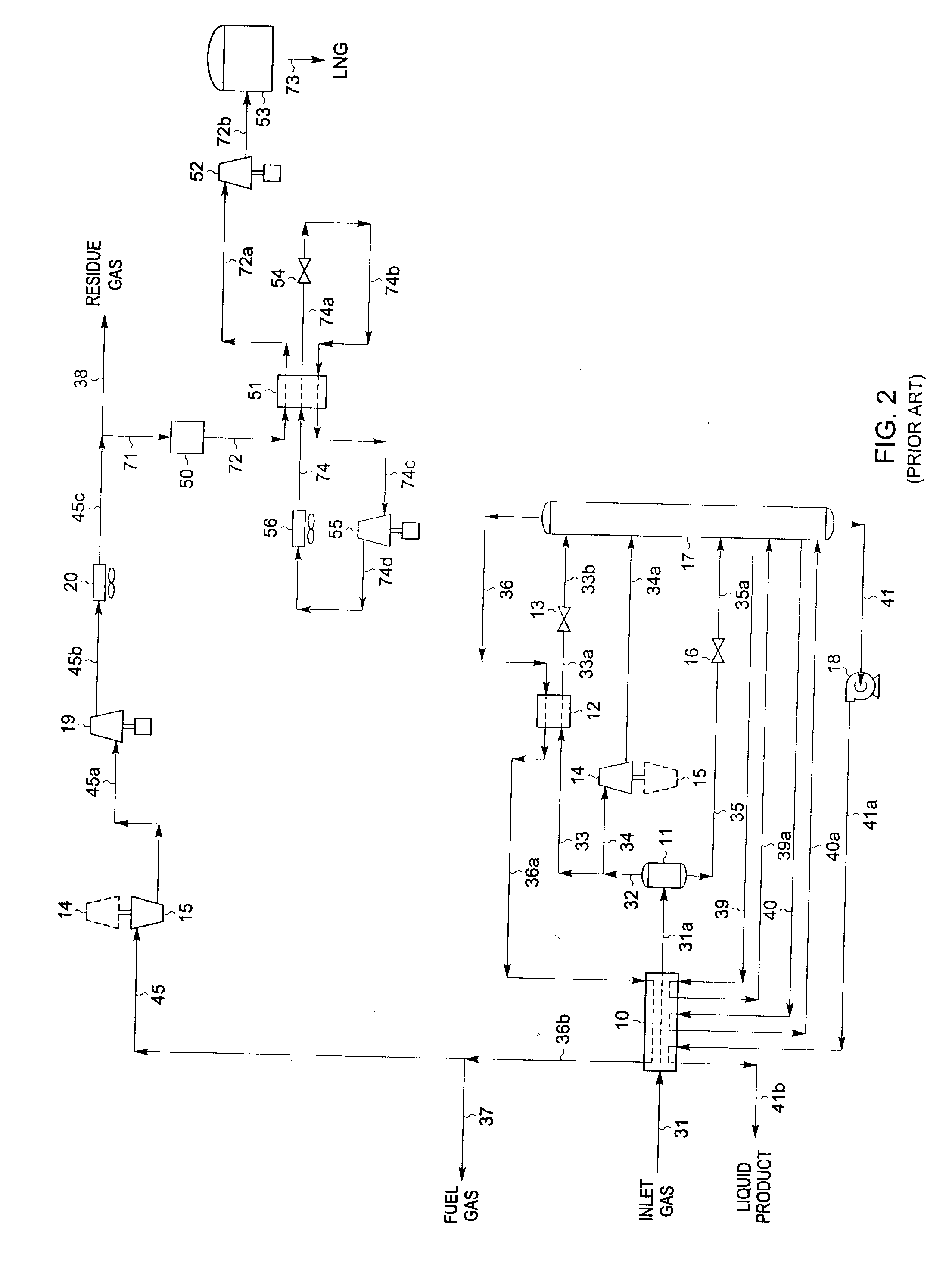

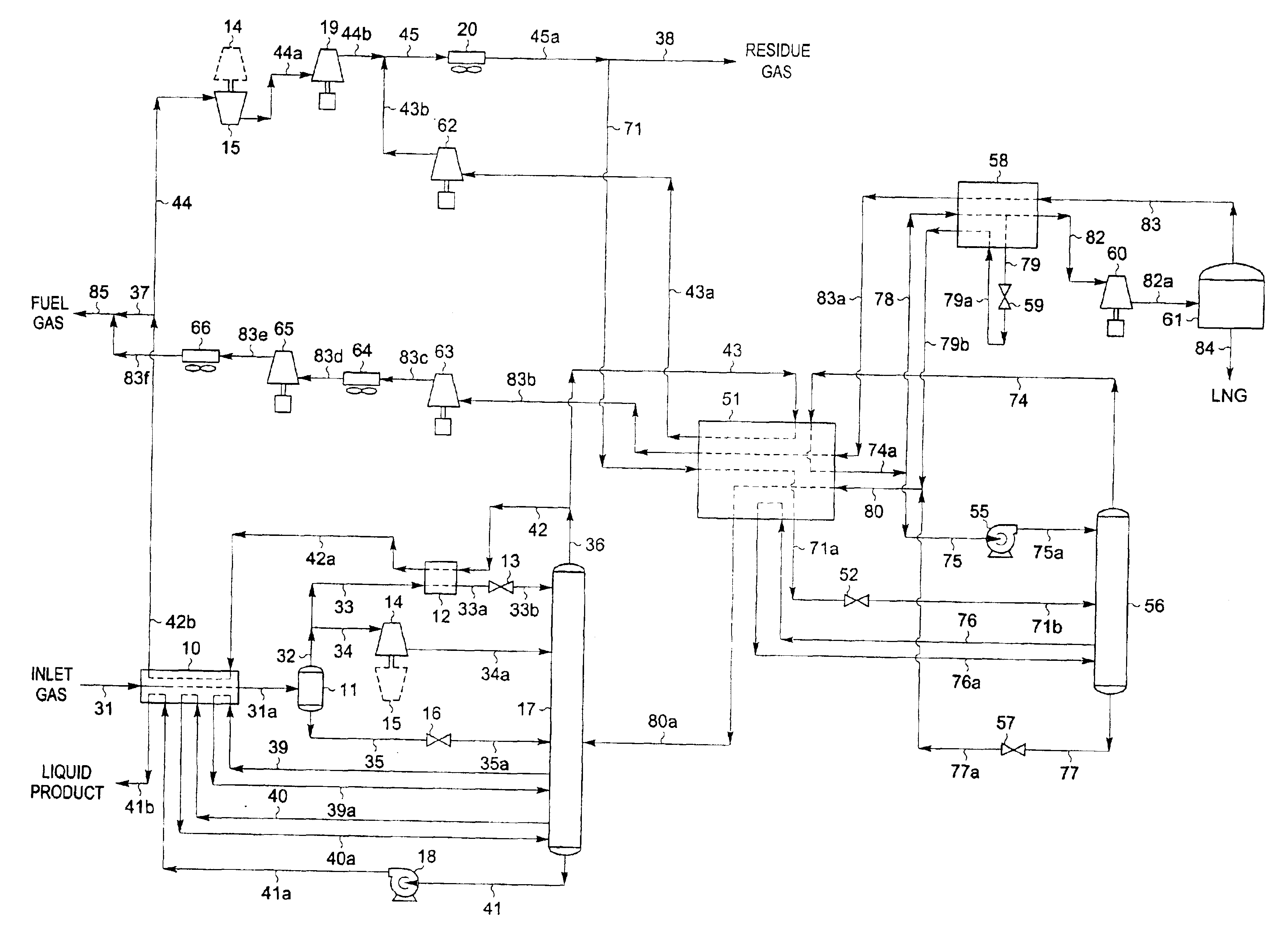

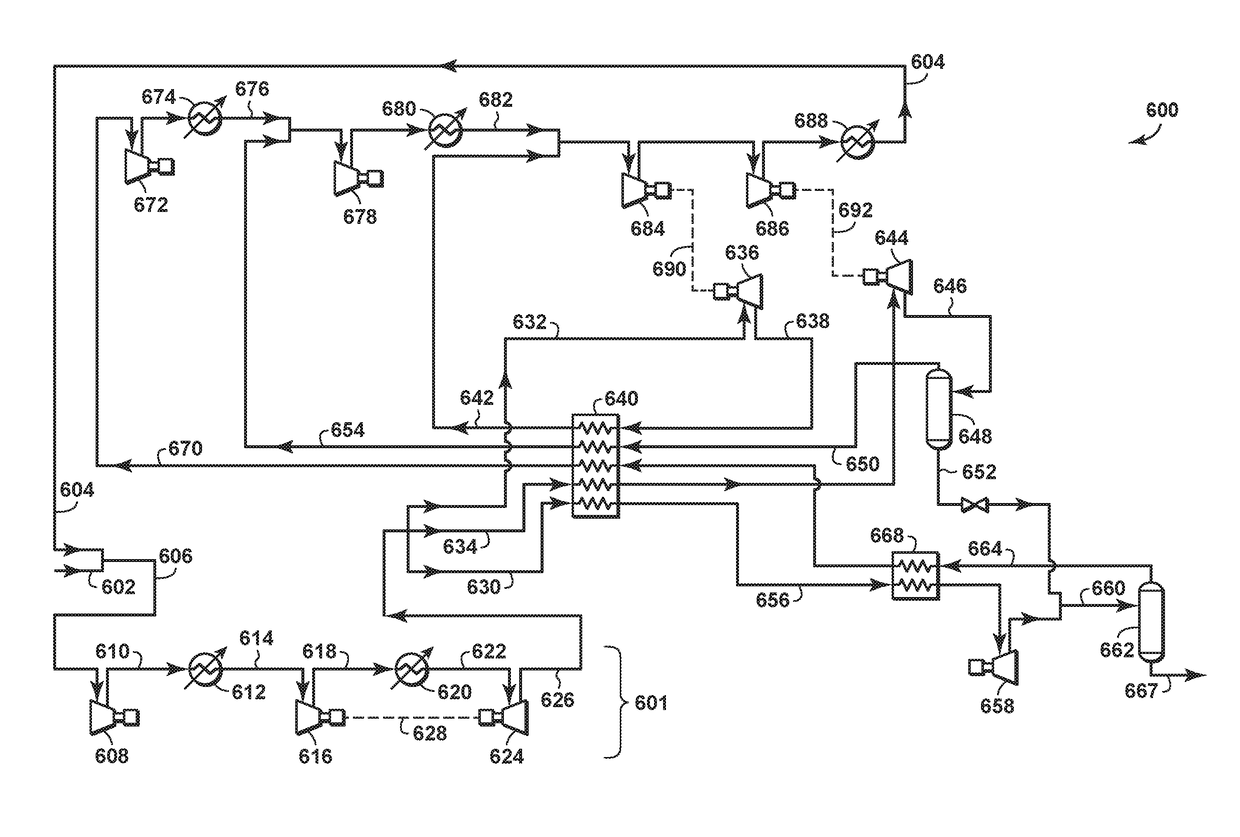

Cryogenic process utilizing high pressure absorber column

A cryogenic process and apparatus for separating multi-component gaseous hydrocarbon streams to recover both gaseous and liquid compounds. More particularly, the cryogenic processes and apparatus of this invention utilize a high pressure absorber to improve the energy efficiency of processing natural gas for pipeline gas sales and recovering natural gas liquids (NGL) gas from gaseous hydrocarbon streams.

Owner:ABB LUMMUS GLOBAL INC

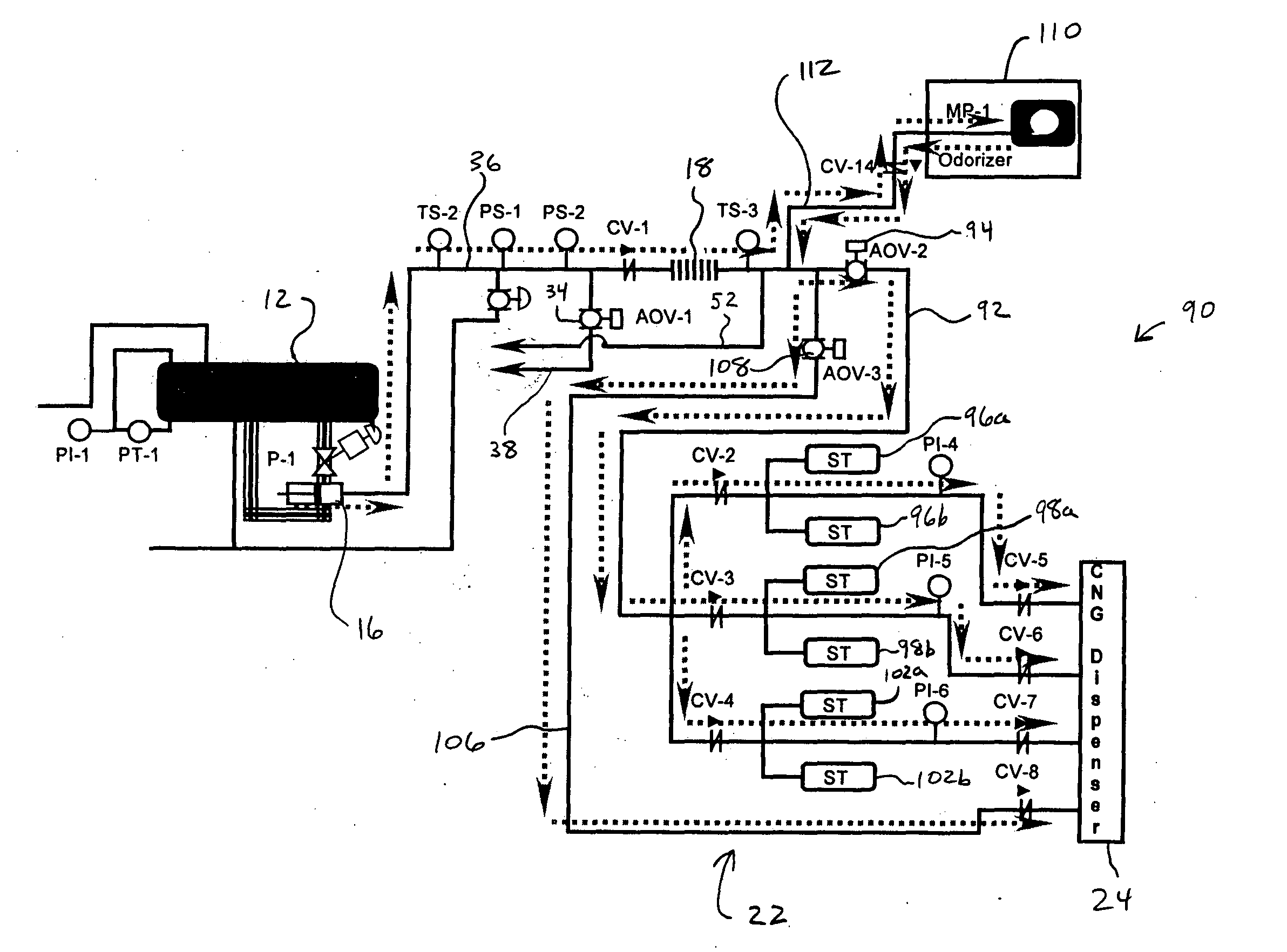

Liquid and compressed natural gas dispensing system

InactiveUS7069730B2Distribute quicklyEliminate timeGas handling applicationsGas handling/storage effectsCompressed natural gasProcess engineering

A system dispenses both liquid natural gas (LNG) and compressed natural gas (CNG). A bulk tank contains a supply of LNG which is pumped to a smaller storage tank. After the storage tank is refilled, LNG from the bulk tank is pumped to a vaporizer so that CNG is produced. The CNG may be routed to the LNG in the storage tank to condition it. It is also used to recharge a pressurizing cylinder that is placed in communication with the head space of the storage tank when it is desired to rapidly dispense LNG to a vehicle. A bank of cascaded storage cylinders alternatively may receive CNG from the vaporizer for later dispensing through the system CNG dispenser. The CNG from the vaporizer may also be dispensed directly via the system CNG dispenser.

Owner:CHART INC

Gas Cooling Methods for High Pressure Fuel Storage Tanks on Vehicles Powered by Compressed Natural Gas or Hydrogen

ActiveUS20070000016A1Reduce energy lossImprove refueling efficiencyGlovesGas handling applicationsThermal energyCompressed natural gas

At a high pressure hydrogen or compressed natural gas vehicle refuel depot, the thermal energy (heat) generated by from the high flow rate of the high pressure refueling gas is evacuated from the on board fuel tank[s] of consumer vehicles eliminating the need for refueling pre treatments such as a slow fill, secondary precooling, and pressure overfill otherwise used to achieve a full vehicle tank refill. In an example, a high pressure fuel depot refilling line is operatively interconnected to an on board vehicle tank having a gas flow circuit wherein the refuel gas itself is circulated within the on board tank to absorb the compression heat of refueling and then to an external radiator before being released into the tank.

Owner:HONDA MOTOR CO LTD

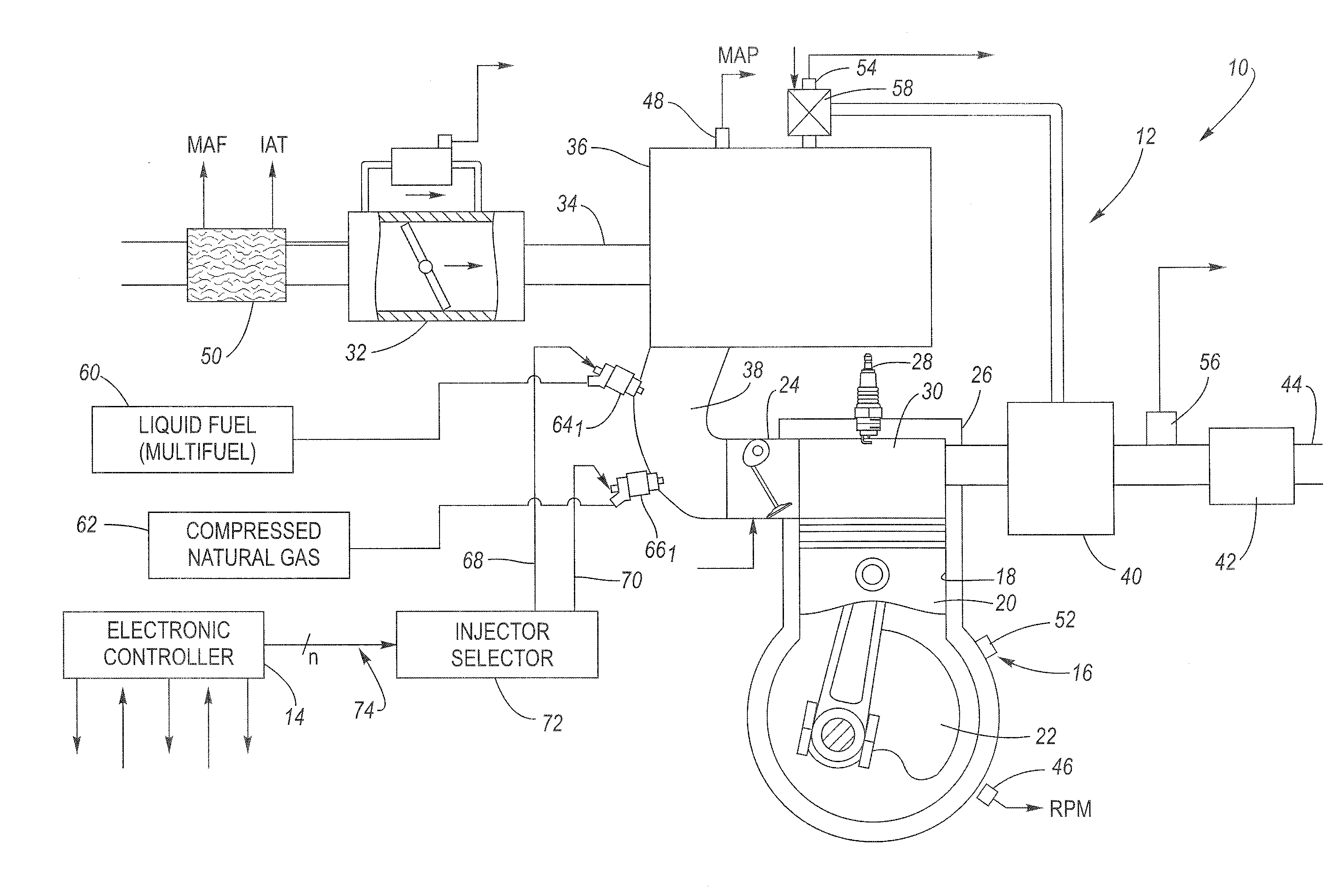

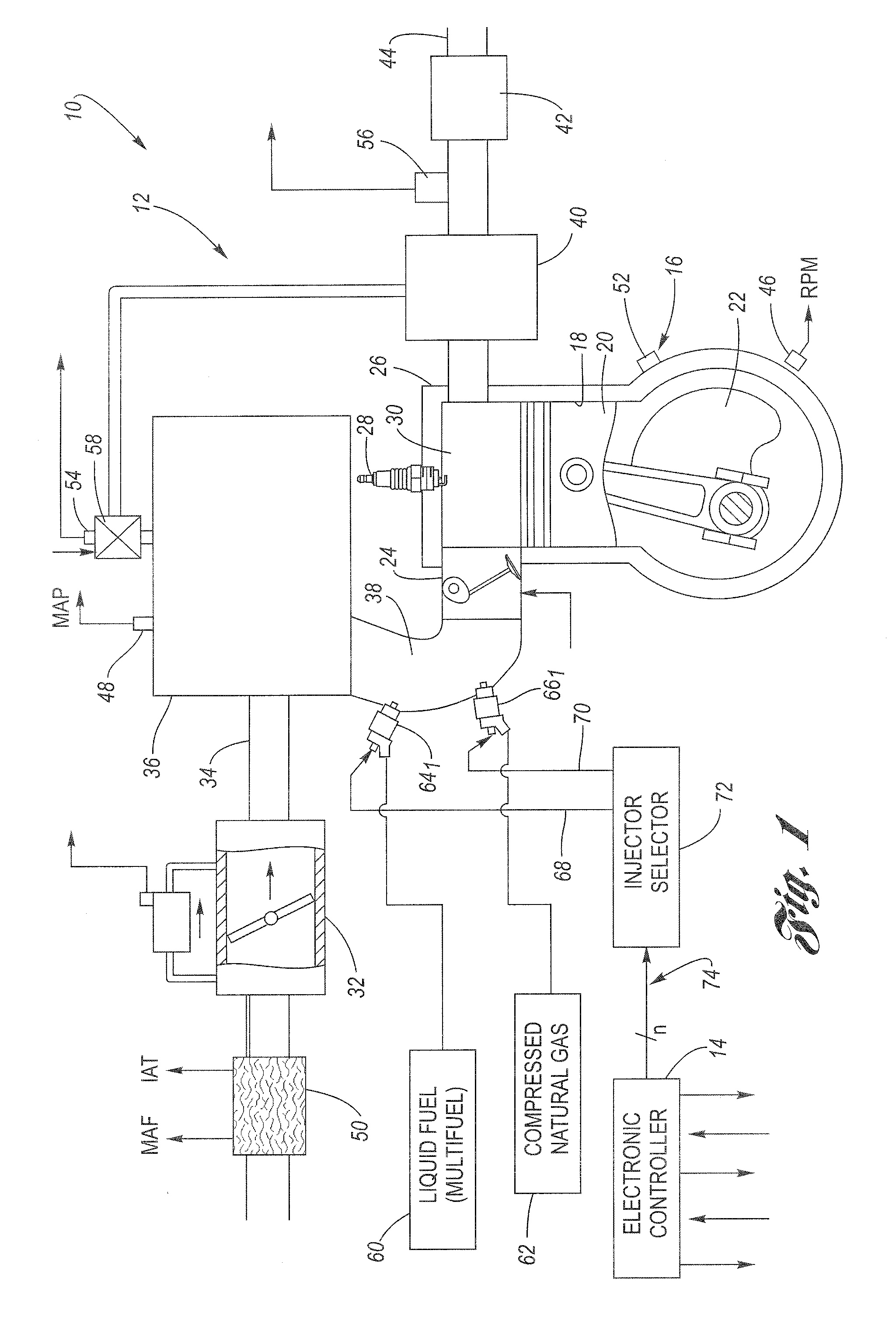

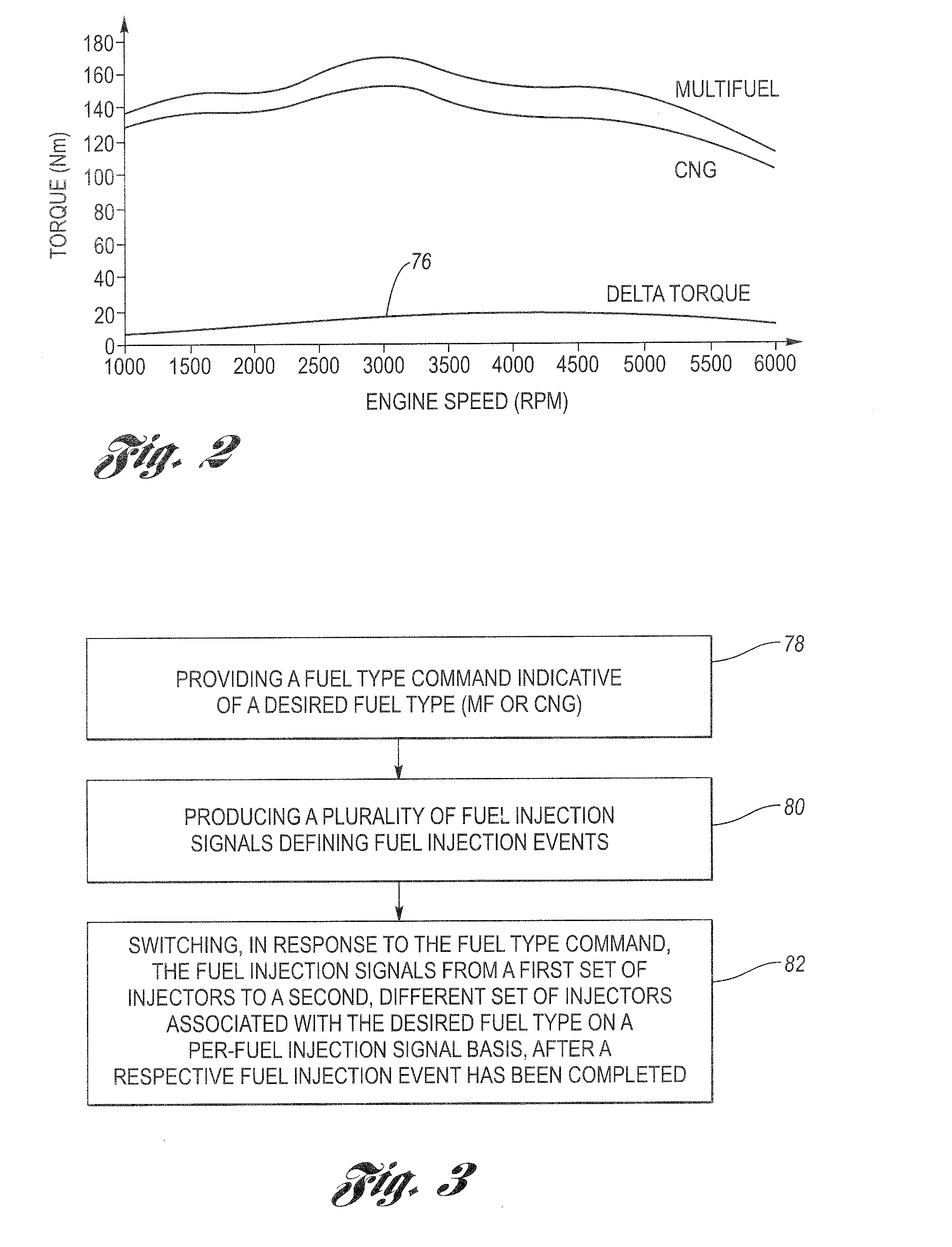

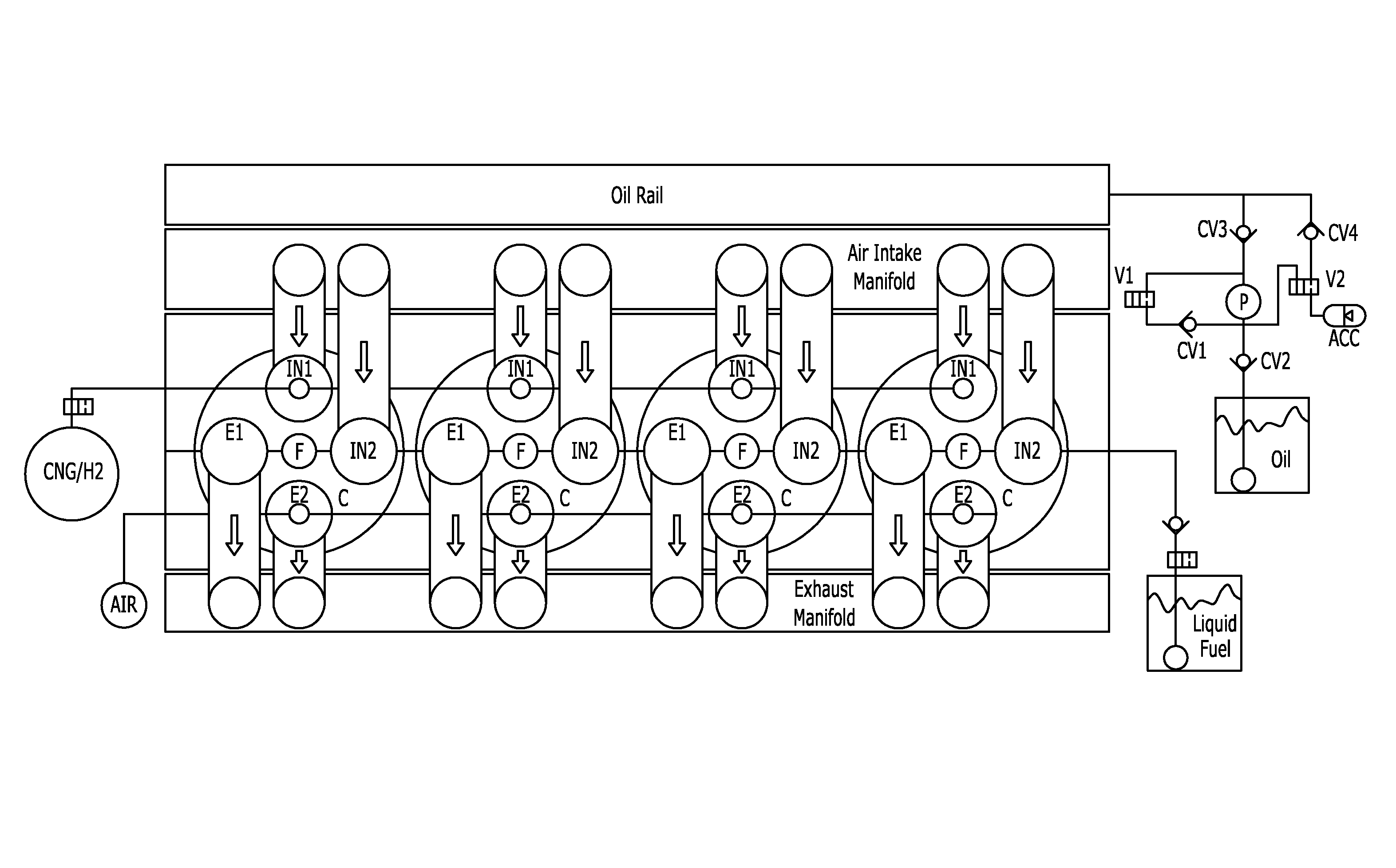

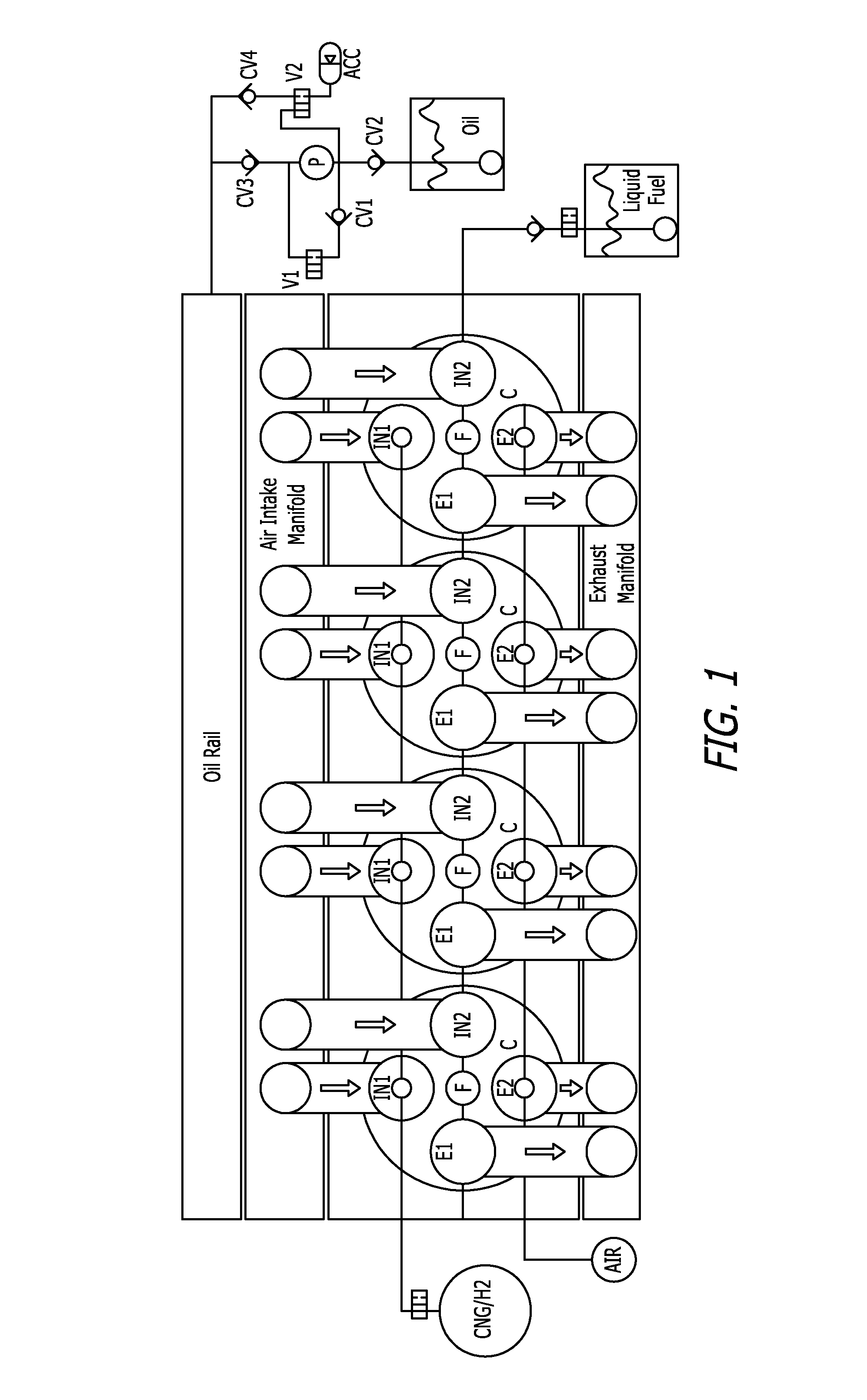

Method and apparatus for synchronous switching of fuel injection control signals

InactiveUS20090024301A1Improve drivabilityHigh torqueElectrical controlNon-fuel substance addition to fuelElectronic controllerCompressed natural gas

An engine management and fuel delivery system allows an internal combustion engine to operate on liquid fuel such as gasoline, ethanol or a blend thereof, or compressed natural gas (CNG). A first set of fuel injectors is configured to deliver liquid fuel to the cylinders. A second set of fuel injectors is configured to deliver natural gas to the cylinders. An electronic controller is configured to generate fuel injection signals for one of the sets of injectors. An injector selector is configured to direct such fuel injection signals to either the first set of fuel injectors or the second set of fuel injectors based on a fuel type command. The fuel type command is indicative of a desired fuel type selected from either liquid fuel or CNG fuel. The fuel type command is synchronized in accordance with an engine crankshaft position signal in order to coordinate the switchover, for each one of the fuel injection signals, one by one, as each fuel injection event is completed.

Owner:DELPHI TECH INC

Dual Fuel Compression Ignition Engines and Methods

ActiveUS20100229838A1Non-fuel substance addition to fuelInternal combustion piston enginesHydrogenCompressed natural gas

Dual fuel compression ignition engines and methods that allow compression ignition on gaseous fuels like compressed natural gas, hydrogen and ammonia, yet will run on liquid fuels, including diesel fuels for such purposes as starting or when the gaseous fuel is not available or has been consumed and greater range or operating time is needed. Ignition of fuels having a high self ignition temperature is assured by recirculating high temperature exhaust gas back into the intake charge before compression. Existing engines may be converted to run as a dual fuel engine by replacement of the engine head or heads. Various embodiments are disclosed.

Owner:STURMAN DIGITAL SYST

System and method for cold recovery

A method of cold recovery in a cold compressed natural gas cycle, the method comprising: compressing air; drying air; heat exchanging air with cold compressed natural gas from a storage vessel, in a first heat exchanger, thereby forming cooled air; heat exchanging the cooled air with liquid methane, in a second heat exchanger, such that the cooled air becomes liquid air and the liquid methane becomes methane; heat exchanging the liquid air with natural gas from a pipeline, in a third heat exchanger, such that the natural gas cools to a cold compressed natural gas and the liquid air becomes air in a gaseous state; discharging the air in a gaseous state. A system of cold recovery comprising: an air dryer; an air compressor in fluid communication with the air dryer; a first heat exchanger in fluid communication with the air compressor; a second heat exchanger in fluid communication with the first heat exchanger; a third heat exchanger in fluid communication with the second heat exchanger; a methane expander valve in fluid communication with the second heat exchanger; a fourth heat exchanger in fluid communication with the methane expansion valve; a methane compressor in fluid communication with the second heat exchanger and with the fourth heat exchanger; a natural gas scrubber in fluid communication with a third heat exchanger; a natural gas pipeline in fluid communication with the first heat exchanger; the fourth heat exchanger, and the natural gas scrubber; and a storage vessel in fluid communication with the first heat exchanger, the third heat exchanger, and the fourth heat exchanger.

Owner:EXPANSION ENERGY

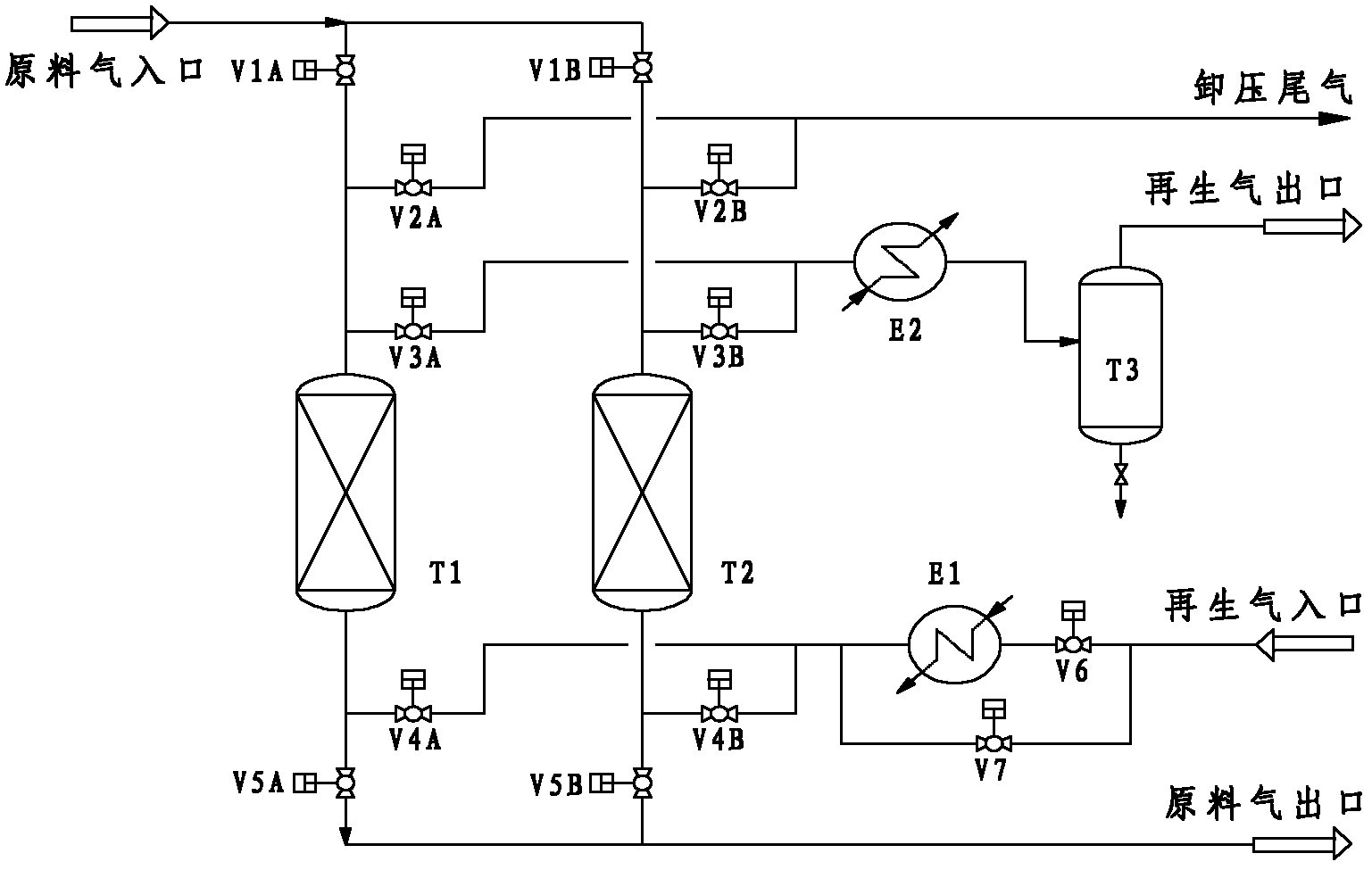

System and Method for Unloading Compressed Natural Gas

InactiveUS20160290563A1Conveniently deliveredImprove efficiencyVessel mounting detailsGas handling applicationsCompressed natural gasEngineering

A system and method for unloading highly pressurized compressed natural gas from transport vessels by depressurizing the gas through flow lines linking a series of automated flow control valves that lower the gas pressure to a predetermined level, the valves being linked in series with and separated by heat exchangers in which the lower pressure gas flowing through the system is also reheated to a predetermined temperature by a heat exchange medium recirculation system in which the heat exchange medium is reheated by a heat source that can be internal to the system. The use of a minor portion of the depressurized and reheated gas as fuel gas to reheat the heat exchange medium is also disclosed. The subject system can be skid-mounted if desired.

Owner:DIGGINS DAVID A

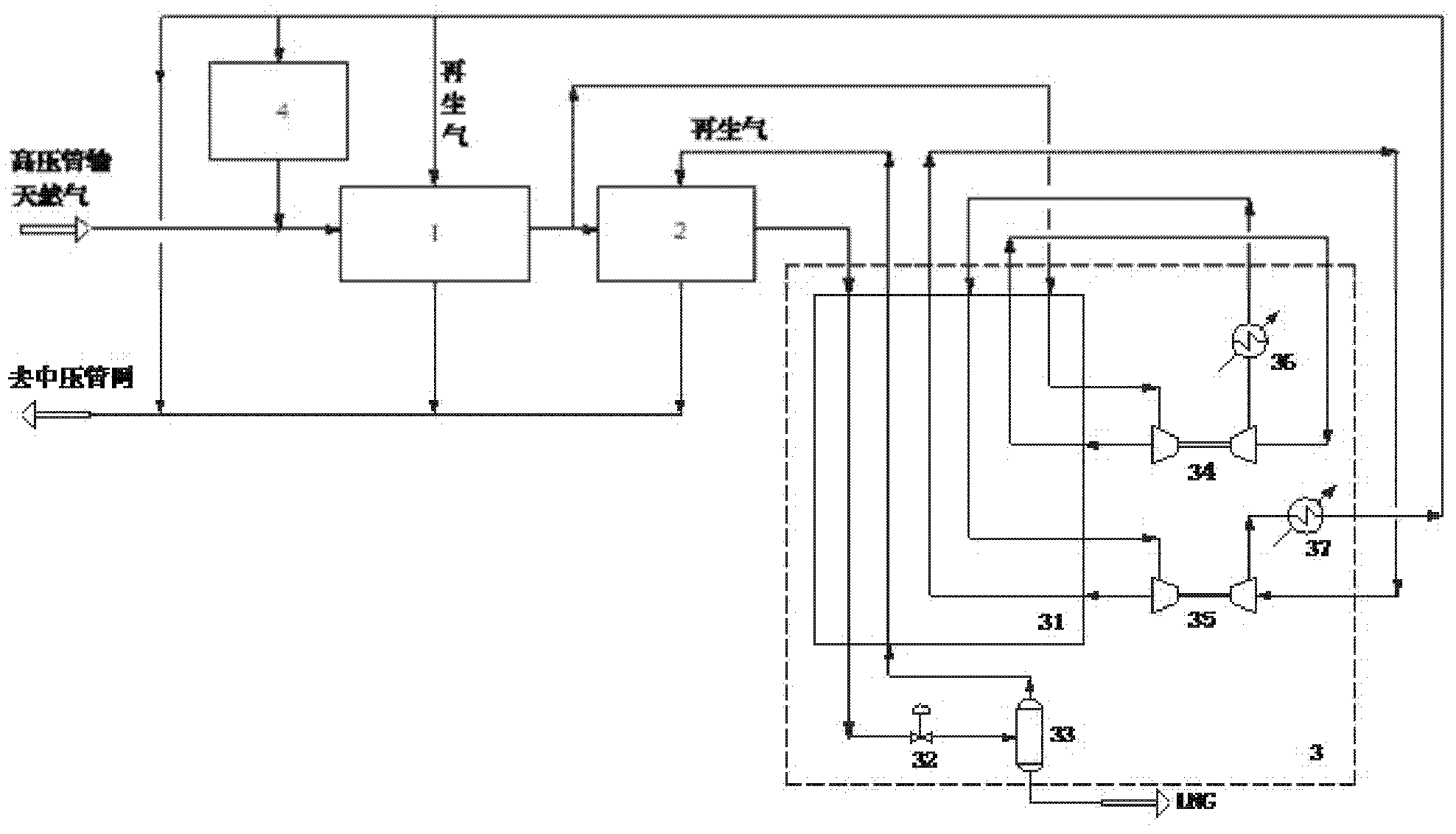

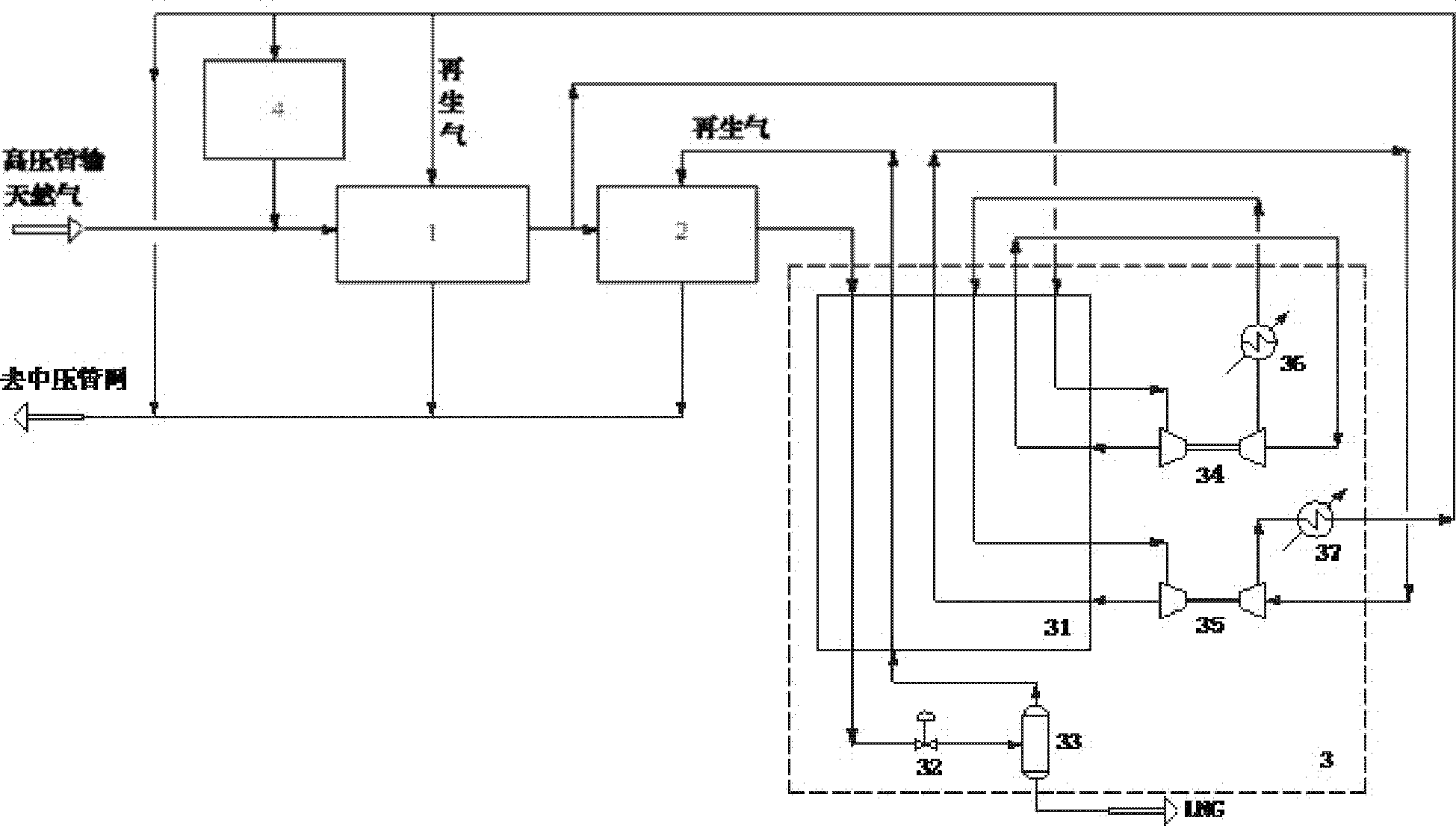

Process and device utilizing pressure of natural gas to partially liquefy natural gas

ActiveCN102660341AEliminate the defect of poor adaptability to changing working conditionsImprove variable load adaptabilitySolidificationLiquefactionNormal loadCompressed natural gas

The invention provides a process and a device utilizing pressure of natural gas to partially liquefy the natural gas. The principle of the process and the device is that pressure energy of high-pressure natural gas generated during pressure regulation of a natural gas pressure regulation station is fully utilized, obtained cold quantity is used for liquefying part of the natural gas in pipe networks through the expansion refrigeration technology, and the value of the natural gas is greatly improved. By arranging a recycle gas circuit, the shortcoming of poor adaptability of variable working conditions of the expansion refrigeration technology is overcome, and variable load adaptability of the device is remarkably improved. In addition, when the device works with normal load, work energy consumption of a unit product approximates zero, and energy required by liquefaction completely comes from the pressure energy between a high-pressure pipe network and a low-pressure pipe network.

Owner:XINDI ENERGY ENG TECH

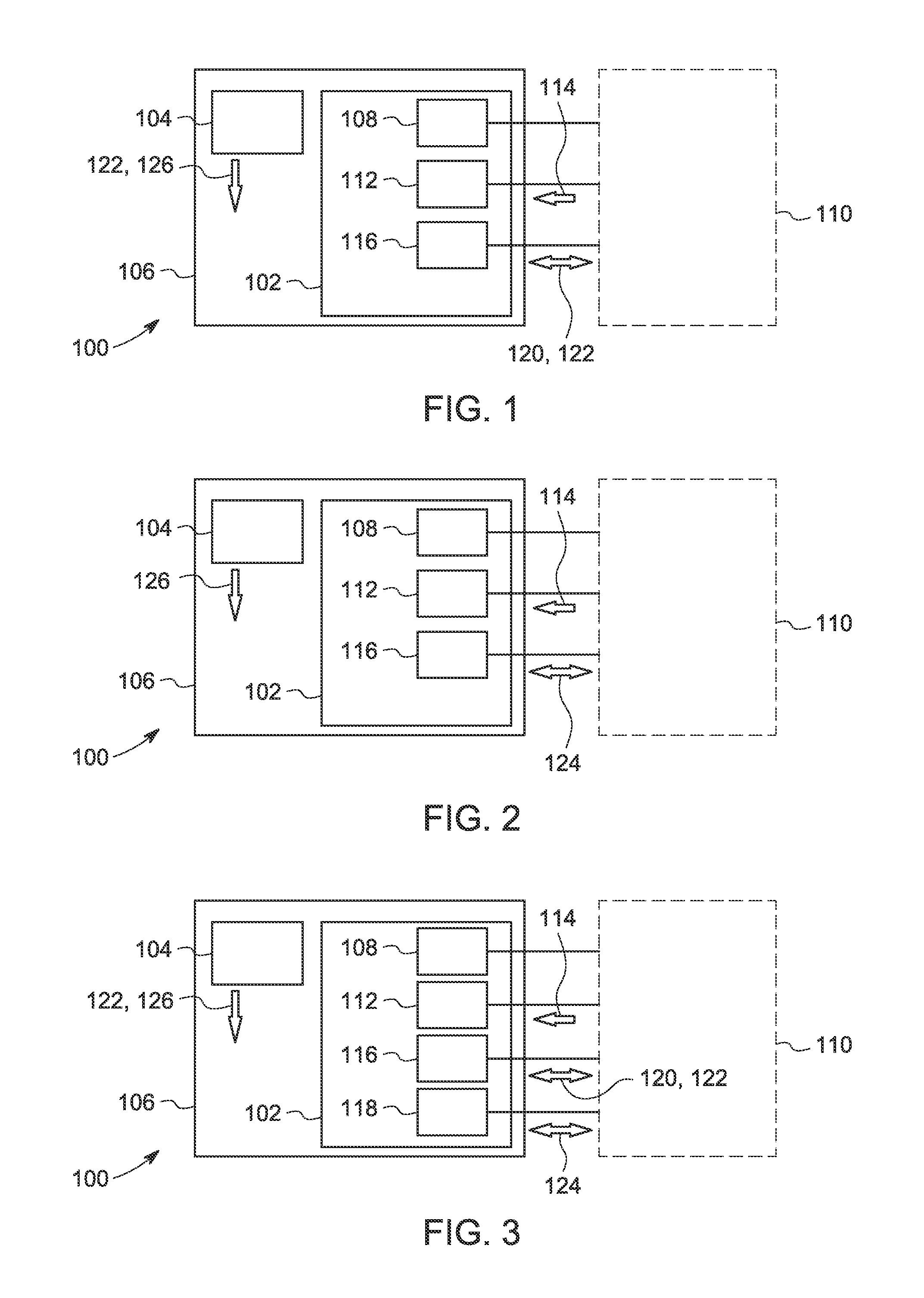

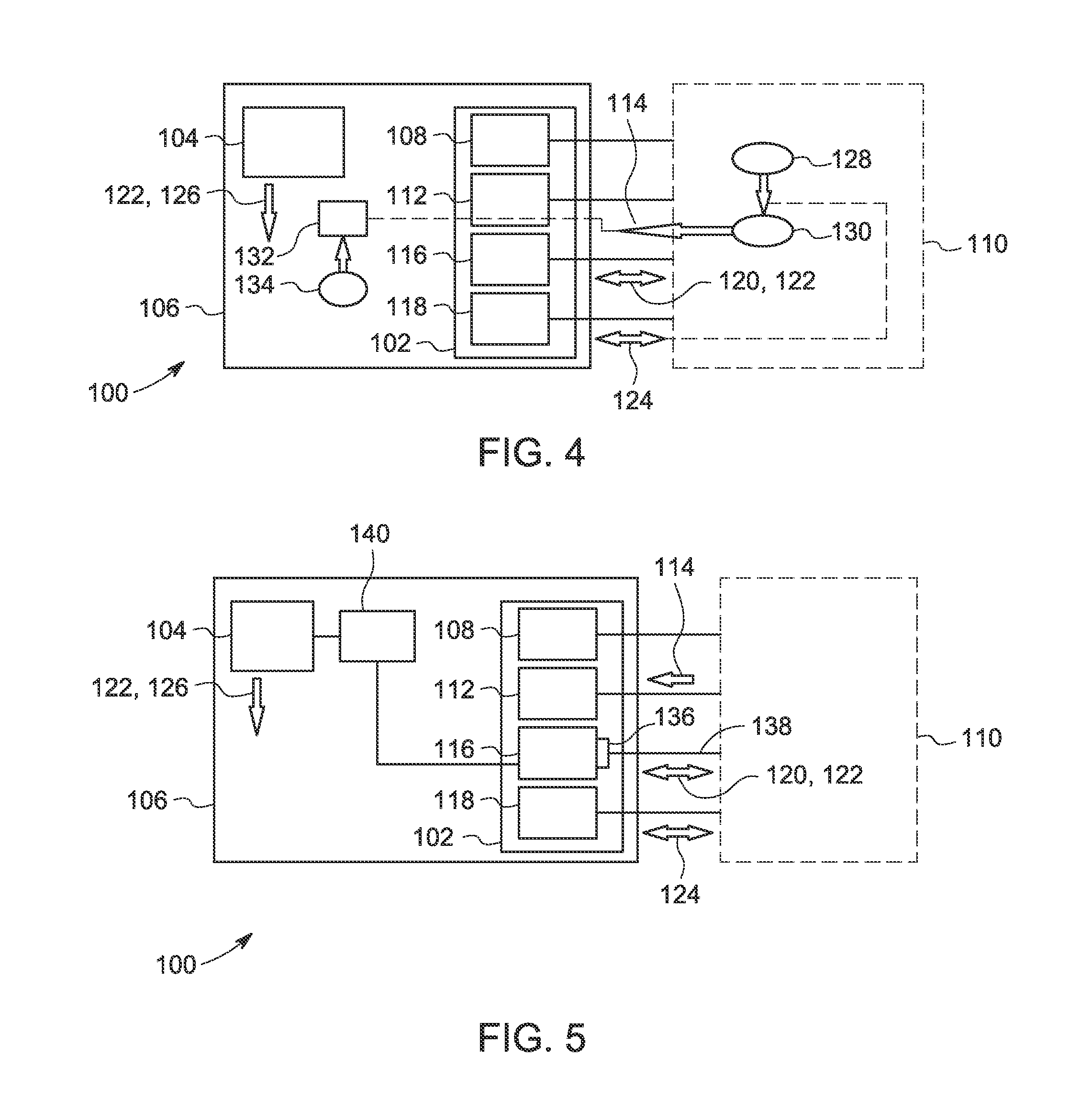

Compressed Natural Gas Storage and Dispensing System

ActiveUS20140202585A1Reduce flow rateLow horse powerGas handling applicationsGas handling/storage effectsMass storageCompressed natural gas

A compressed natural gas storage and dispensing system having bulk storage tanks in fluid communication with a natural gas supply source; a primary compressor delivering the natural gas to the bulk storage tanks; dispensing storage tanks in fluid communication with the bulk storage tanks and in fluid communication with fuel dispensers; a secondary compressor delivering the natural gas to the dispensing storage tanks from the bulk storage tanks; wherein when the pressure within the dispensing storage tanks falls below a predetermined minimum pressure, natural gas is delivered from the bulk storage tanks to the dispensing storage tanks, and wherein when the pressure in the bulk storage tanks falls below a predetermined minimum pressure, natural gas is delivered from the supply source to the bulk storage tanks.

Owner:HOLYSTONE USA INC

Vehicle control system and methods

Owner:W MORRISON CONSULTING GRP

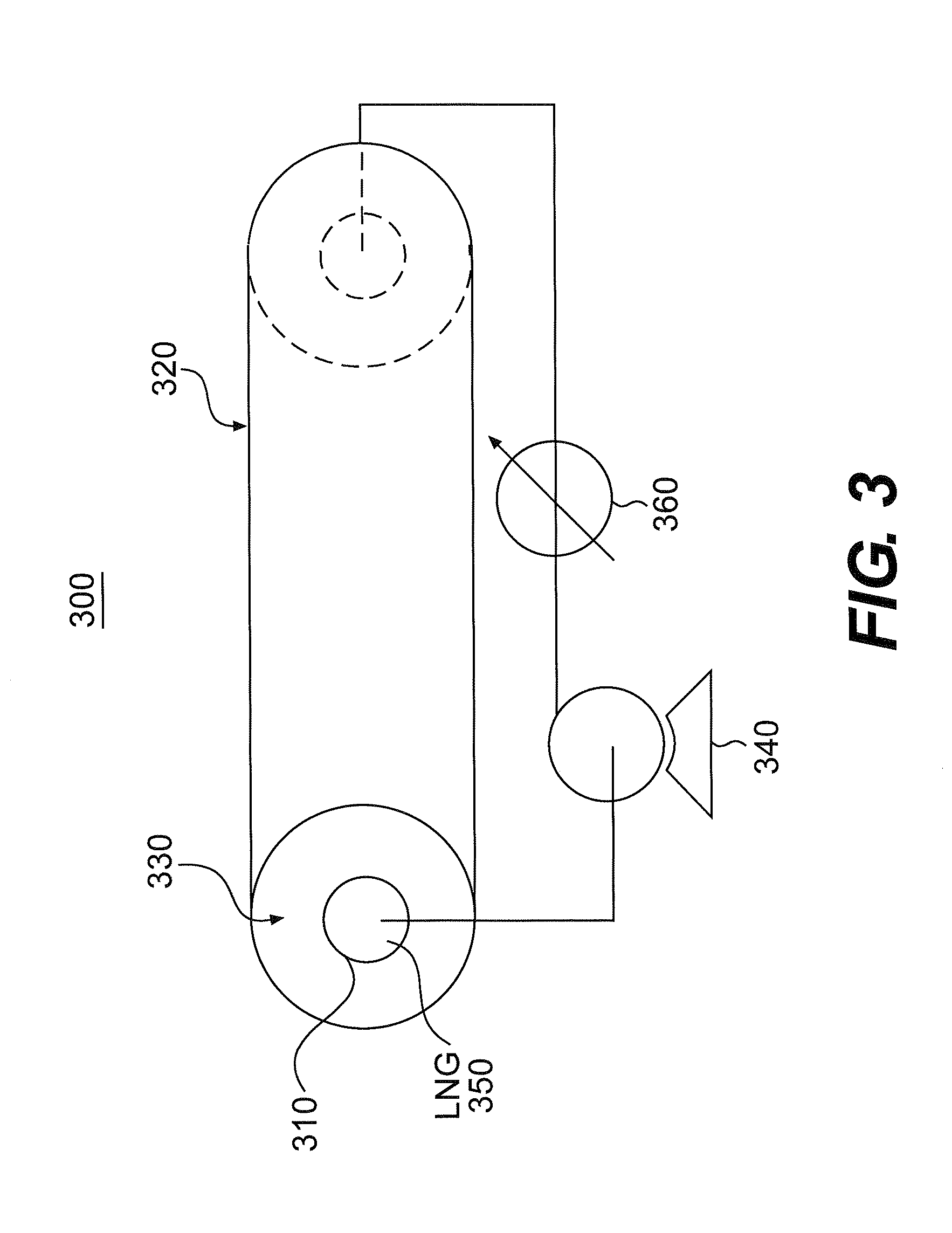

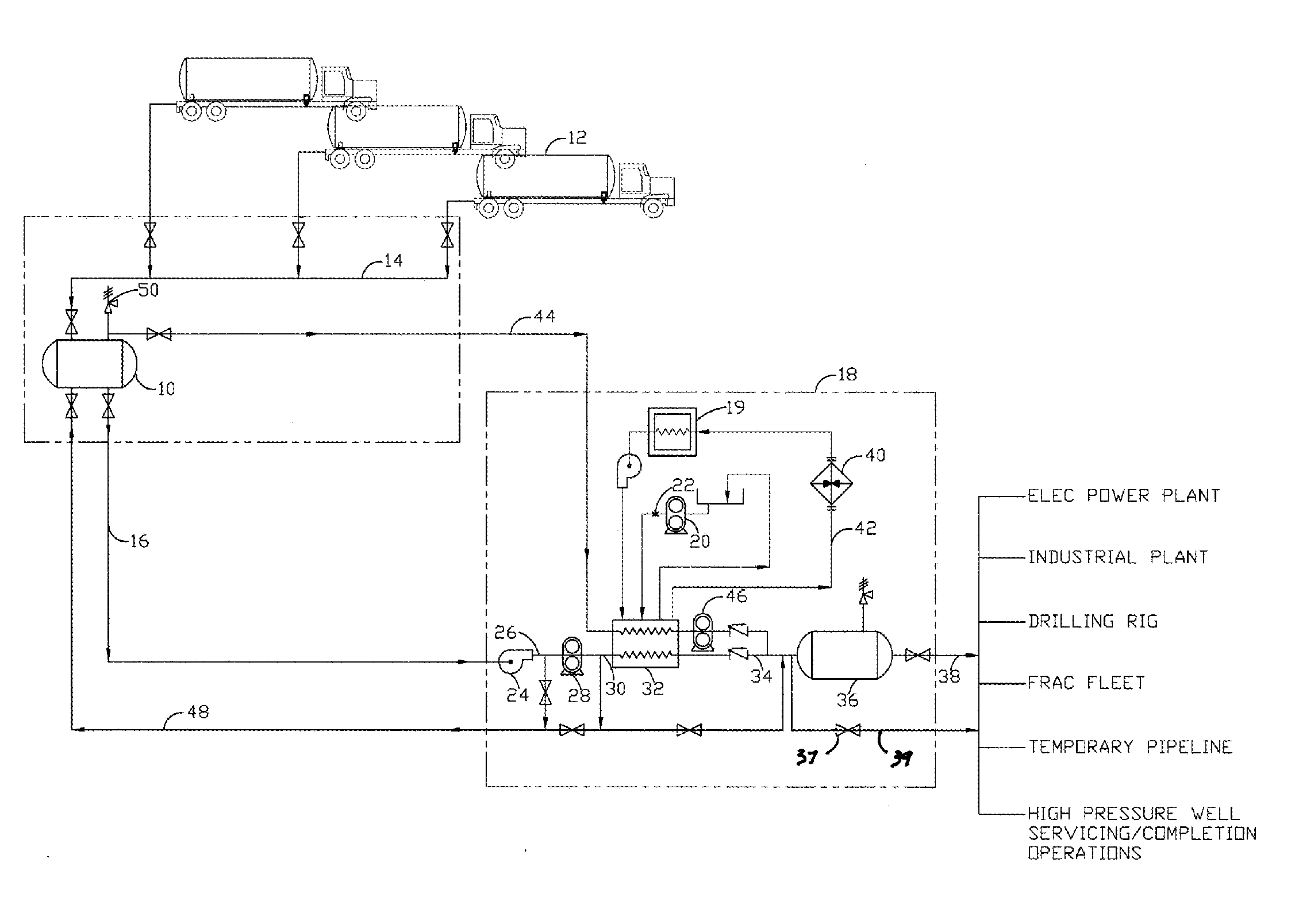

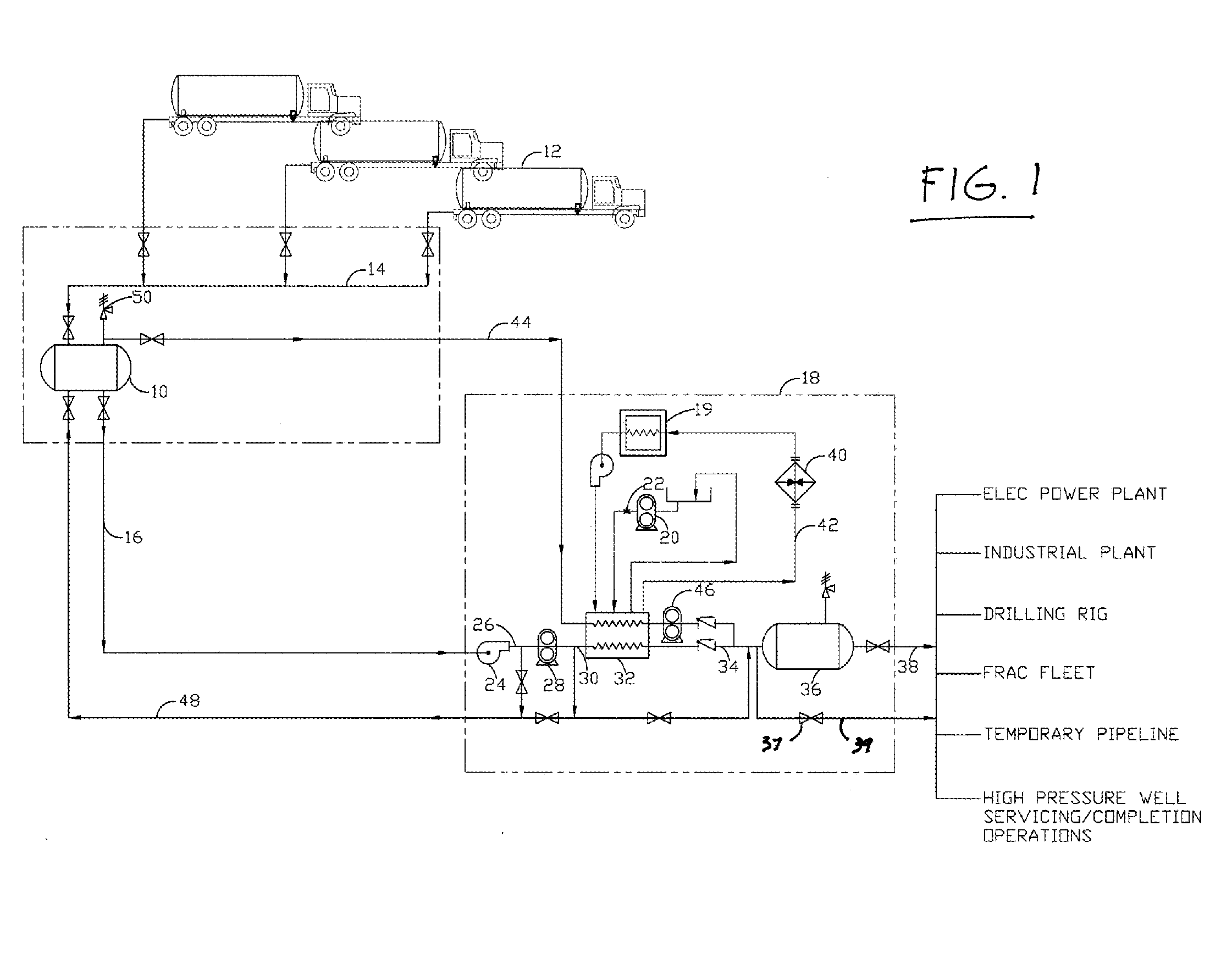

LNG vaporization

InactiveUS20150136043A1Fluid heatersVessel geometry/arrangement/sizeCompressed natural gasExternal combustion engine

Apparatus and methods for vaporizing LNG while producing sufficient volume of compressed natural gas at sufficient pressure to meet the needs of internal combustion engines, gas turbines, or other high consumption devices operating on natural gas or on a mixture of diesel and natural gas. The LNG vaporizer of the present invention incorporates a reciprocating pump to provide vaporized LNG to an output at rates and pressures as required by the particular application. The heat rejected into the engine coolant and the exhaust stream from an artificially loaded internal combustion engine, as well as the hydraulic heat resulting from artificially loading the engine, is transferred to the LNG as the LNG passes through a heat exchanger. Exhaust heat is transferred to the engine coolant after the coolant passes through the heat exchanger.

Owner:SHAABAN KHALED +1

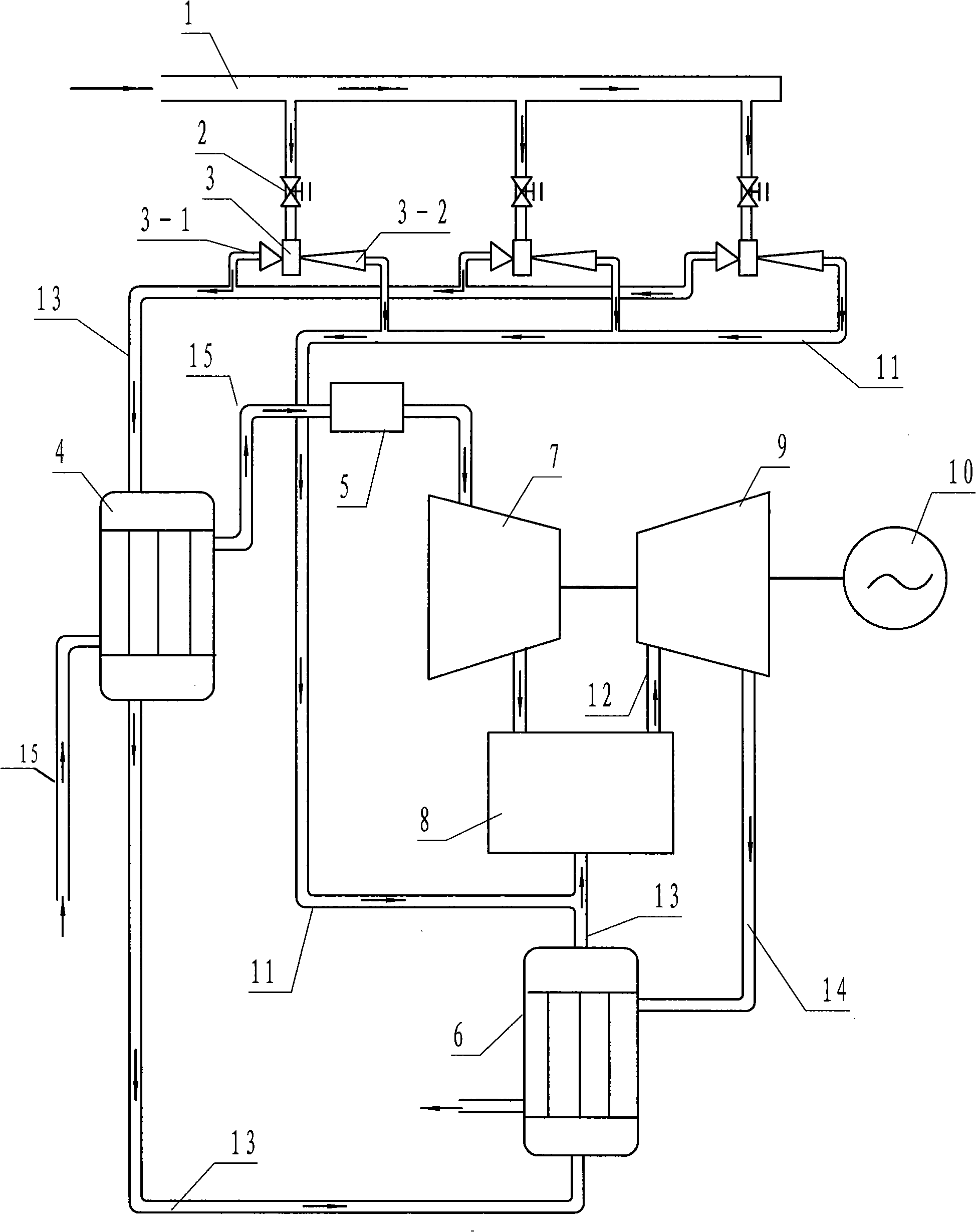

Method and device for reutilization of natural gas pipe network pressure energy in gas turbine working domain

InactiveCN101280723AHigh outputImprove economyTurbine/propulsion fuel heatingGas turbine plantsCold airCombustion chamber

The invention relates to a recycling method for natural gas pipe network pressure energy in the gas turbine working field and a device thereof, aiming at solving the problem of the loss of energy in the depressurization of high-pressure natural gas. The technical proposal is that the cold air flow and the hot air flow generated after the high-pressure natural gas is depressurized through a vortex tube are respectively outputted, the cold air flow after absorbing the inverse air in a heat exchanger and the heat of the exhaust gas of the gas turbine and being heated up joins with the hot air flow and enters a combustion chamber of the gas turbine set; the air cooled by the heat exchanger enters a compressor of the gas turbine set for boosting pressure and then is introduced to the combustion chamber of the gas turbine set; in the combustion chamber, the natural gas is combusted with the air to lead the gas turbine to work and drive energy-consumed equipment. The method of the invention selects the vortex tube to complete the depressurization and pressure adjustment of the natural gas and utilizes the low temperature natural gas flow to cool the intake air of the compressor to increase the mass flow of the intake air, thereby greatly increasing the output of the gas turbine and the economy and effectively utilizing the pressure energy.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

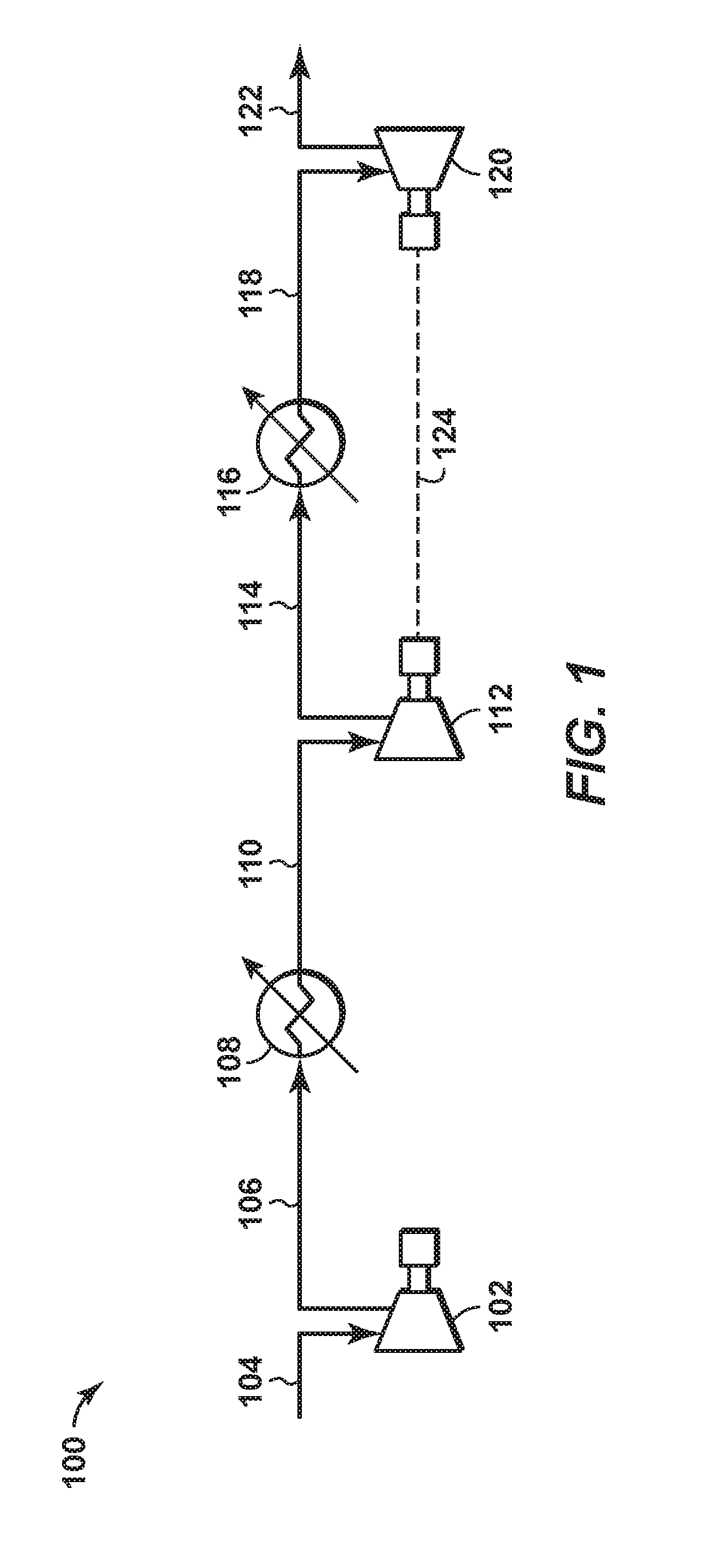

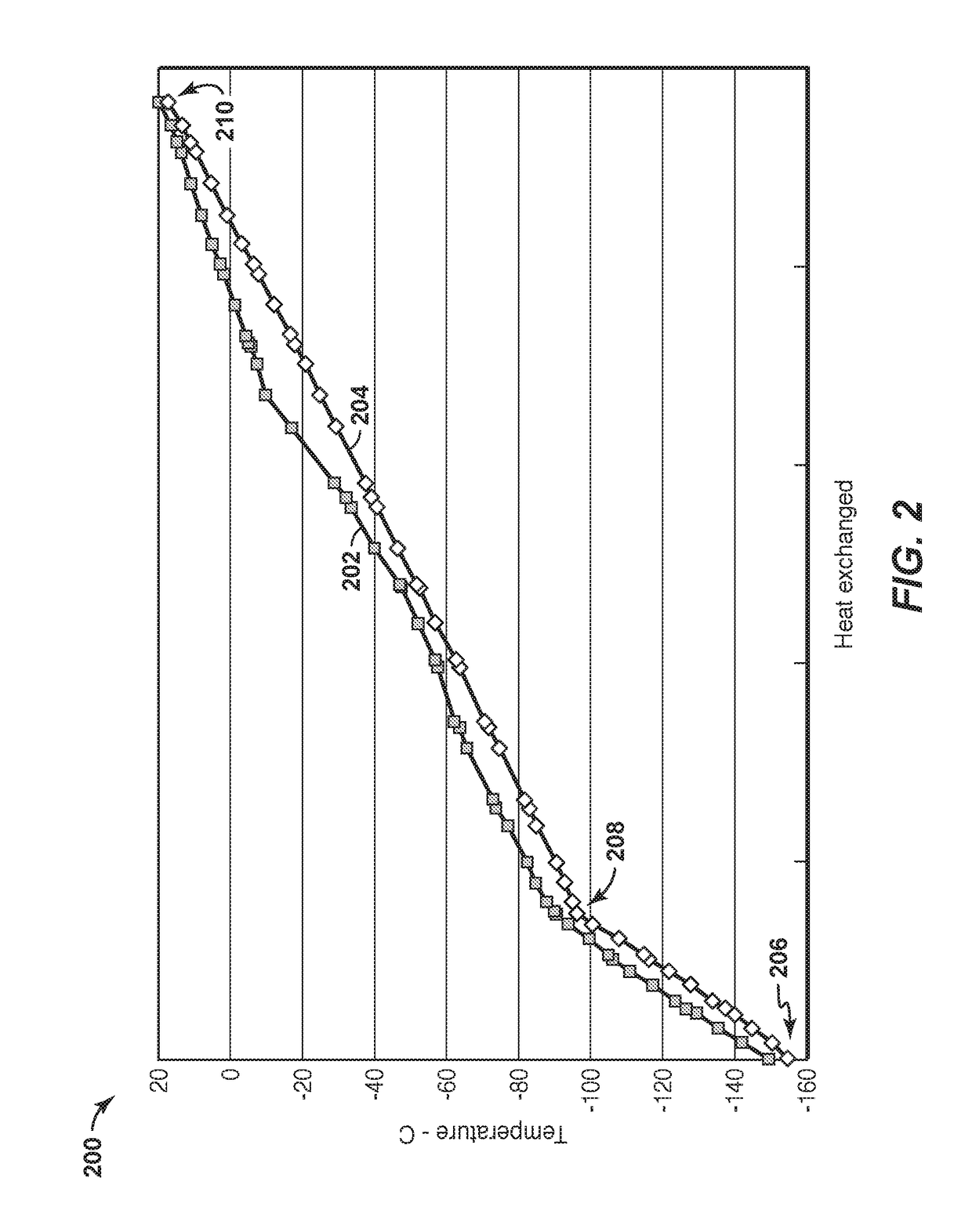

Pre-Cooling of Natural Gas by High Pressure Compression and Expansion

A method of producing liquefied natural gas (LNG) is disclosed. A natural gas stream is provided from a supply of natural gas. The natural gas stream is compressed in at least two serially arranged compressors to a pressure of at least 2,000 psia to form a compressed natural gas stream. The compressed natural gas stream is cooled to form a cooled compressed natural gas stream. The cooled compressed natural gas stream is expanded in at least one work producing natural gas expander to a pressure that is less than 3,000 psia and no greater than the pressure to which the at least two serially arranged compressors compress the natural gas stream, to thereby form a chilled natural gas stream. The chilled natural gas stream is liquefied.

Owner:PIERRE JR FRITZ

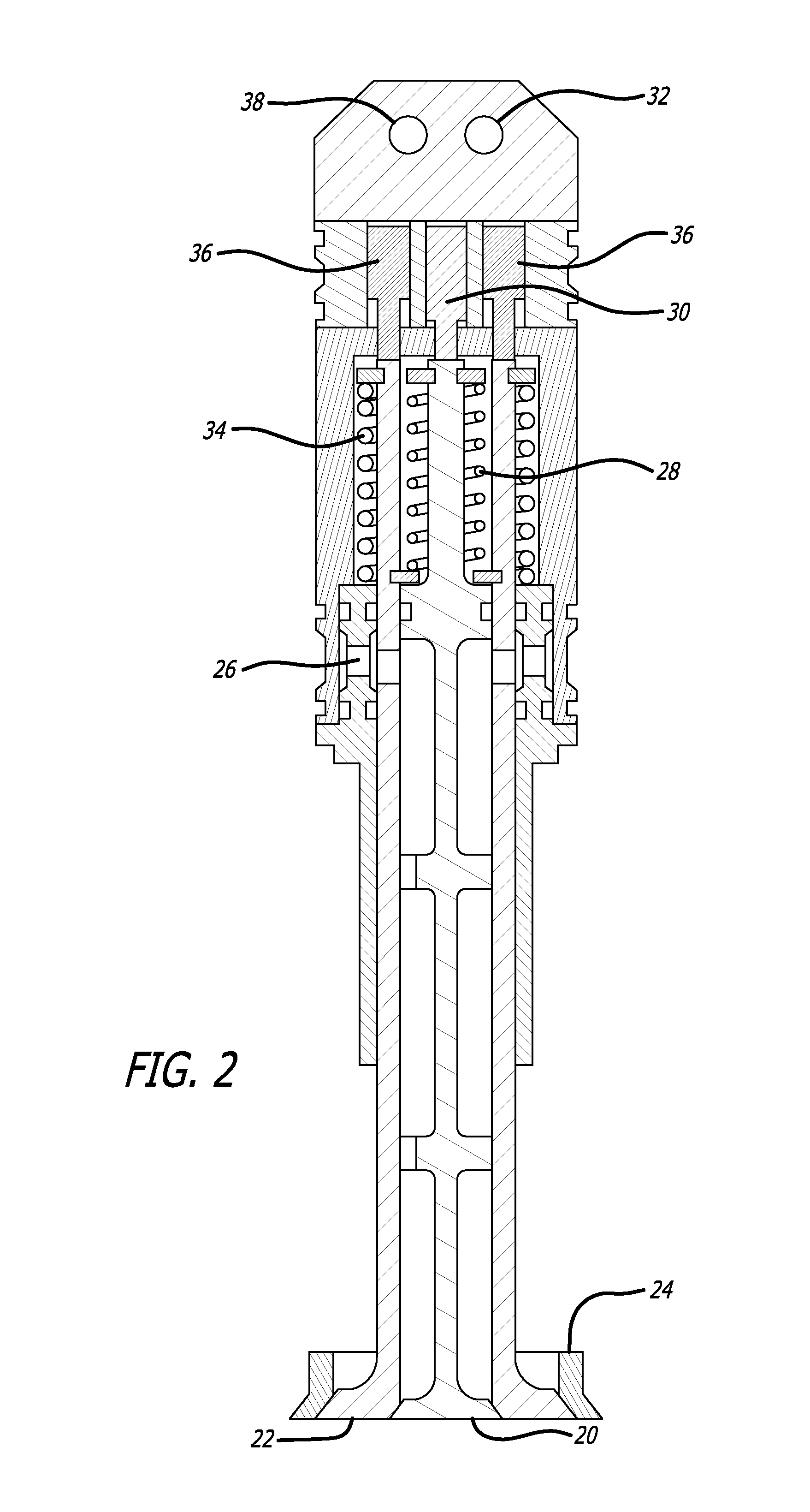

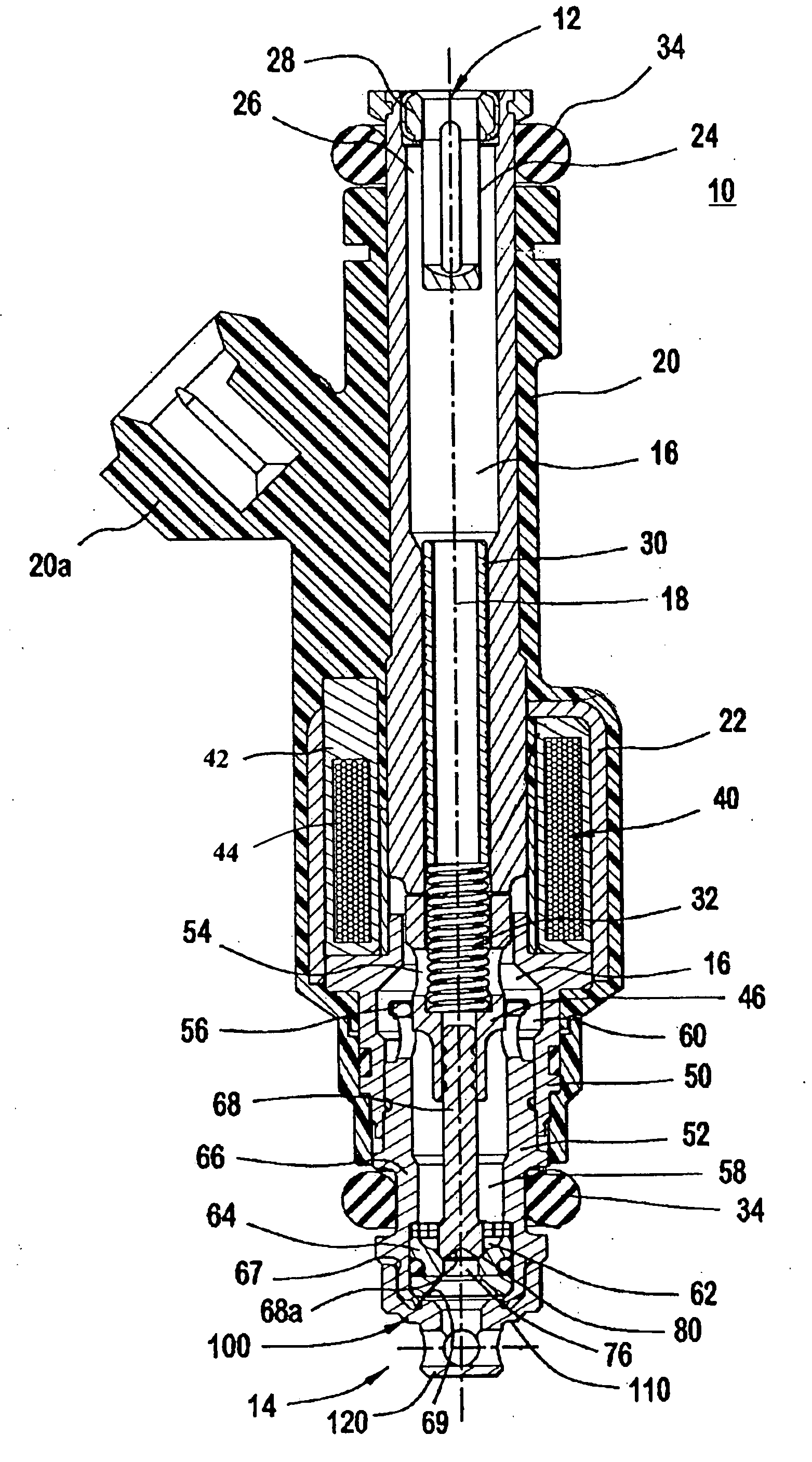

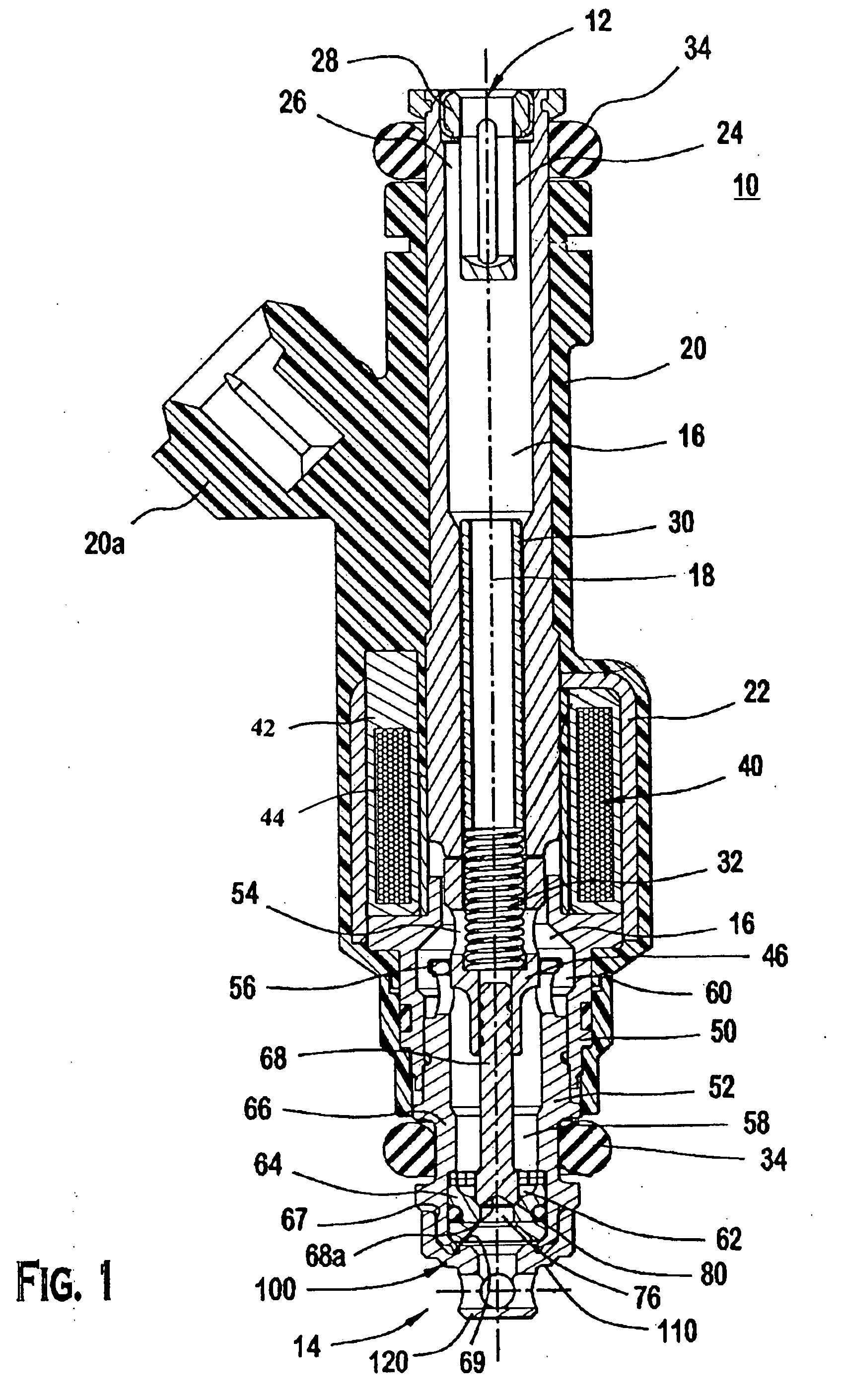

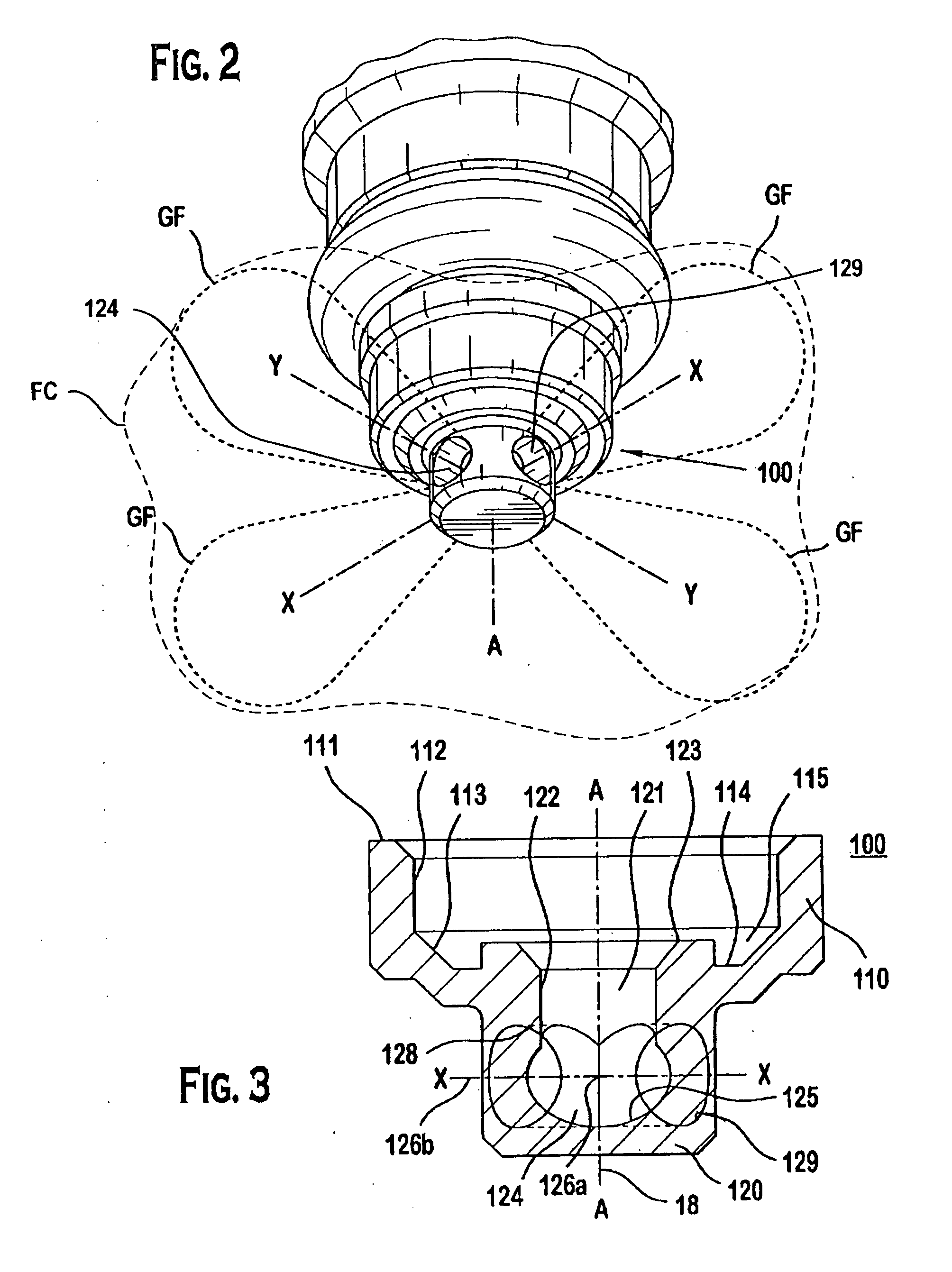

Fuel injector having an external cross-flow nozzle for enhanced compressed natural gas jet spray

InactiveUS20080011887A1Good mixing propertiesImproved gaseous fuel targetingInternal combustion piston enginesFuel supply apparatusCompressed natural gasEngineering

A compressed natural gas fuel injector including a housing, an inlet, an outlet, a seat, a closure member, and an attached nozzle. In a preferred embodiment, the inlet and outlet communicate a flow of gaseous fuel regulated by the closure member. The gaseous fuel passes through the seat, which is coupled to a rim surface of a retainer portion of the attached nozzle, and into a flow passage that further communicates the flow of gaseous fuel into one or more flow channels. The orientation of the flow channels within the attached nozzle greatly affects the discharge pattern and mixing characteristics of the gaseous fuel within an intake manifold. A method of flowing gaseous fuel through the fuel injector is also described.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

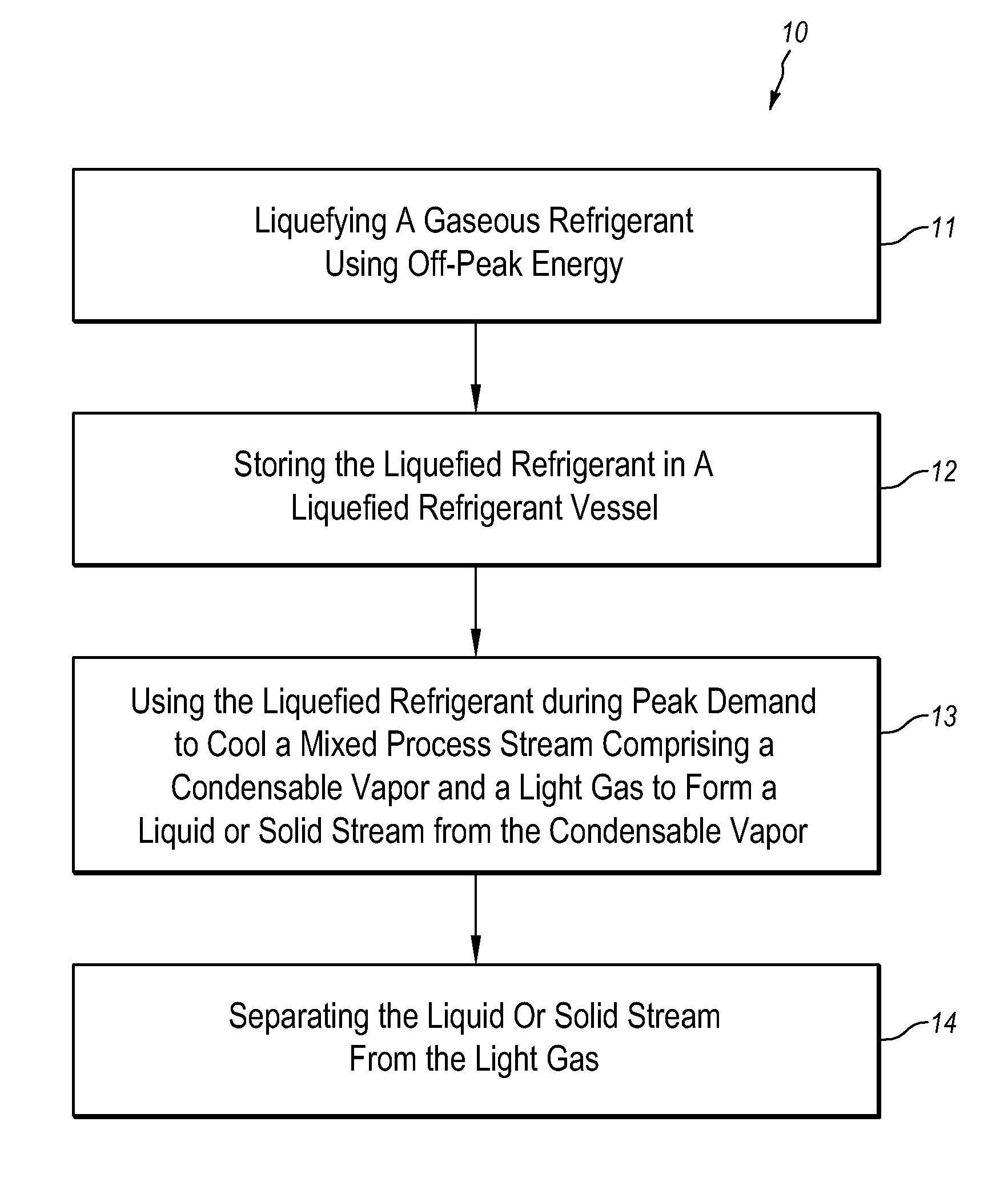

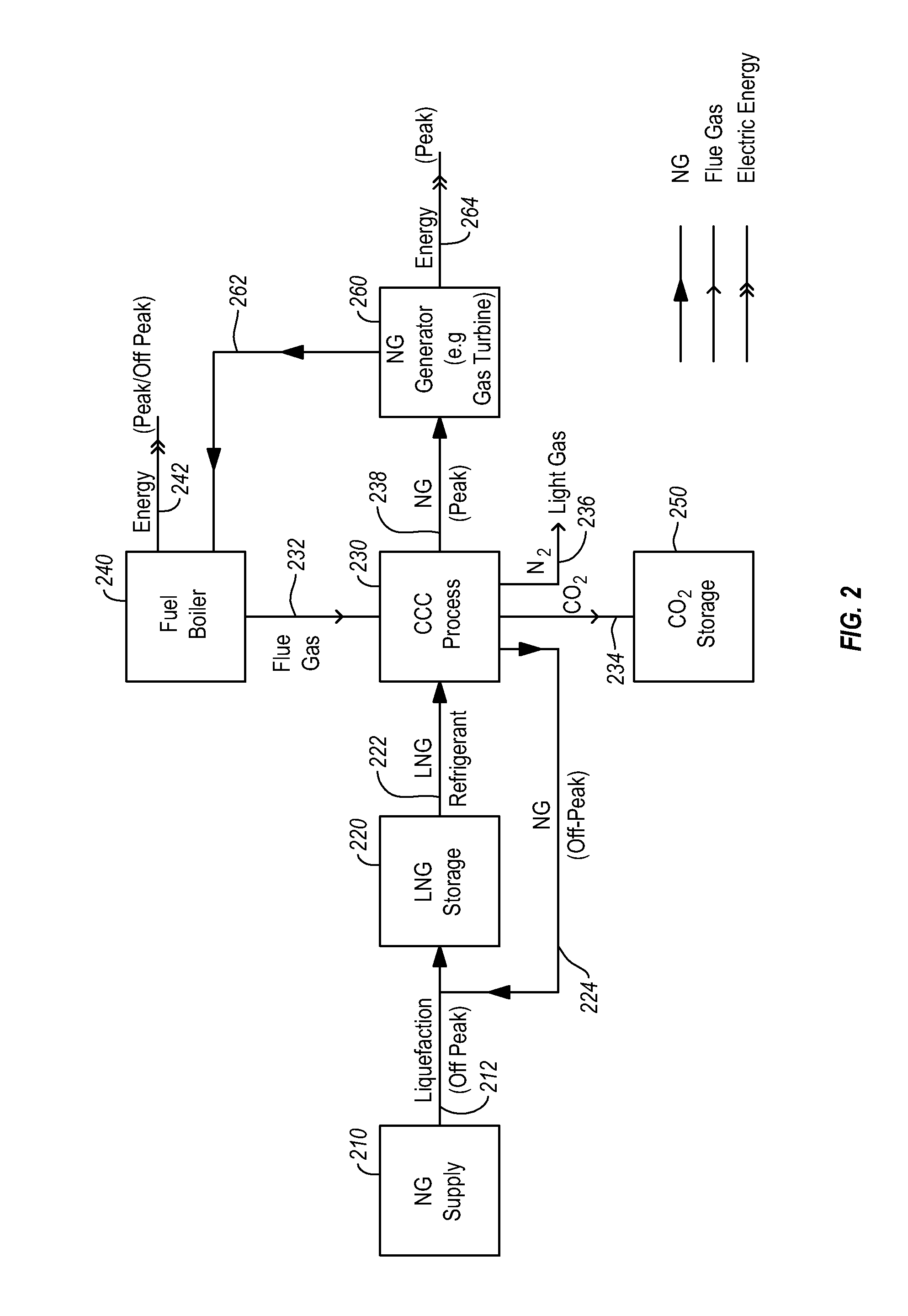

Systems and methods for integrated energy storage and cryogenic carbon capture

ActiveUS20130139543A1Energy-efficient carbon captureIncrease productionSolidificationLiquefactionGrid managementCompressed natural gas

The systems and methods integrate energy storage with cryogenic carbon capture, providing effective grid management and energy-efficient carbon capture capabilities to power plants. The systems store energy during off-peak demand by using off-peak energy to compress natural gas to form liquefied natural gas (LNG) and storing the LNG for use as a refrigerant. The systems use the stored LNG as a refrigerant in a cryogenic carbon capture (CCC) process to isolate carbon dioxide from light gases in a flue gas. The systems supply energy during peak demand by burning the natural gas warmed by the CCC process to generate power.

Owner:U S BANK TRUST CO NAT ASSOC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com