Method for purifying marsh gas by membrane separating technology

A membrane separation and biogas technology, which is applied in separation methods, membrane purification/separation, chemical instruments and methods, etc., can solve the problems of complex equipment, troublesome process, large investment, etc., and achieve the effect of simplified equipment, good effect and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

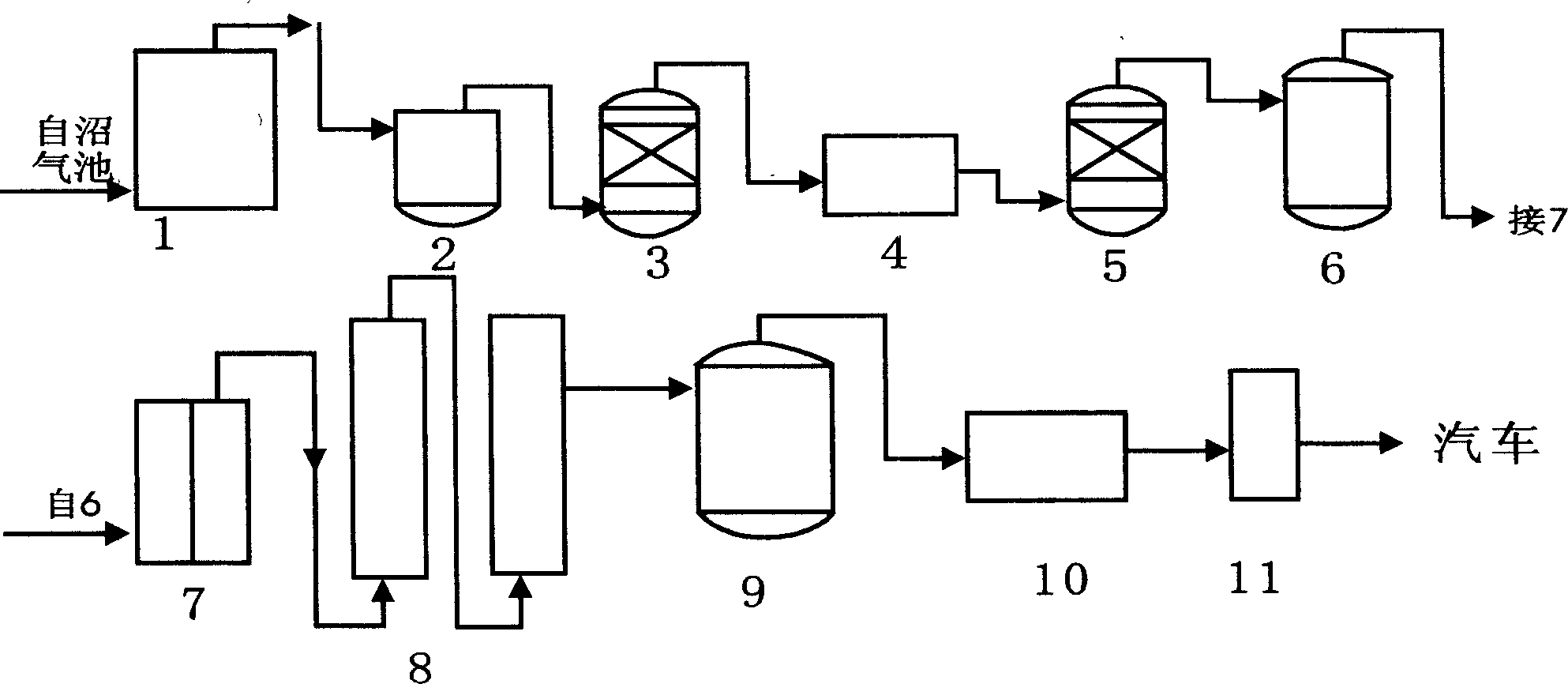

Embodiment 1

[0023] 10,000Nm per day 3 Take biogas for vehicles as an example, the original biogas is 18000Nm 3 . Designed to treat biogas capacity of 760Nm 3 / h, equipment investment 2 million yuan, including the purchase and installation of all equipment, meters and pipelines in "2-9" in the process flow chart, excluding plant, land, and equipment foundation. The membrane separator of the key equipment (8) uses hollow fiber membrane modules made in the United States, and the others are domestic or self-made equipment. Original gas tank (1) The composition of Zhongyuan biogas is stable in CH 4 55-60%, CO 2 30-38%, H 2 O(g)2-3%, H 2 S 500-1500PPm. After purification, the gas scrubber (9) reaches CH 4 ≥97%, CO 2 ≤3%, H 2 S≤15mg / Nm 3 , The dew point of normal pressure is -13℃. The total methane recovery rate of the equipment reaches more than 80%. It can be filled with 600 bottles of biogas for vehicles, with a bottle volume of 70L and a pressure of 200MPa, equivalent to 14Nm 3 Natural gas, equi...

Embodiment 2

[0025] Nissan's civil bottled biogas 2000Nm 3 For example, 3600Nm of original biogas is required 3 , The designed biogas capacity is 160Nm 3 / h, equipment investment is 500,000 yuan, only one-stage membrane separator is used, other equipment and operating conditions are the same as in Example 1, but the size is smaller. Biogas CH after purification 4 Content ≥90%, CO 2 ≤10%, the yield can be increased to more than 90%, and can be filled with 300 bottles of civil biogas. Bottle volume 70L, pressure 10Mpa, 7Nm 3 Natural gas is equivalent to 12L liquefied petroleum gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com