Patents

Literature

457results about "Membrane purification/separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

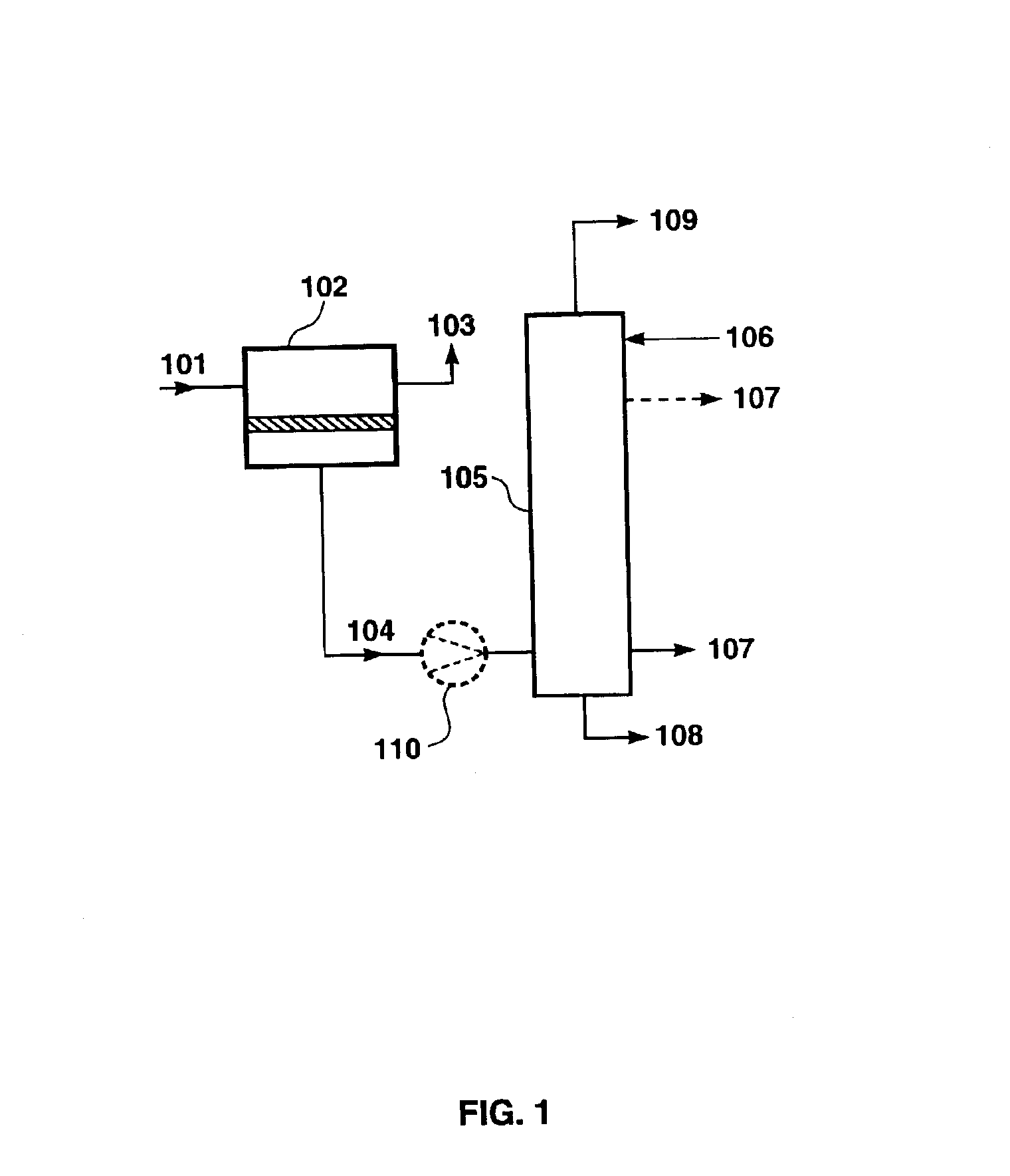

Onboard fuel separation apparatus for an automobile

InactiveUS6972093B2Increase volumeBoost octaneInternal combustion piston enginesUsing liquid separation agentVolatilesEngineering

An onboard fuel separation apparatus separates a material fuel (gasoline) into a high-octane fuel having a higher octane value than the material fuel and a low-octane fuel having a lower octane value than the material fuel using a separation membrane which selectively allows high-octane value components (such as aromatic components) permeate through the membrane. The apparatus increases the ratio of the amount of the high-octane value components permeating through the membrane to the amount of the high-octane value components contained in the material fuel by, (A) Controlling the temperature of the material fuel supplied to the membrane (B) Increasing partial pressure of the low-octane value components on the high-octane fuel side of the membrane and removing volatiles from the permeate, and (C) Bypassing volatiles in the material feed around the membrane.

Owner:EXXON RES & ENG CO +1

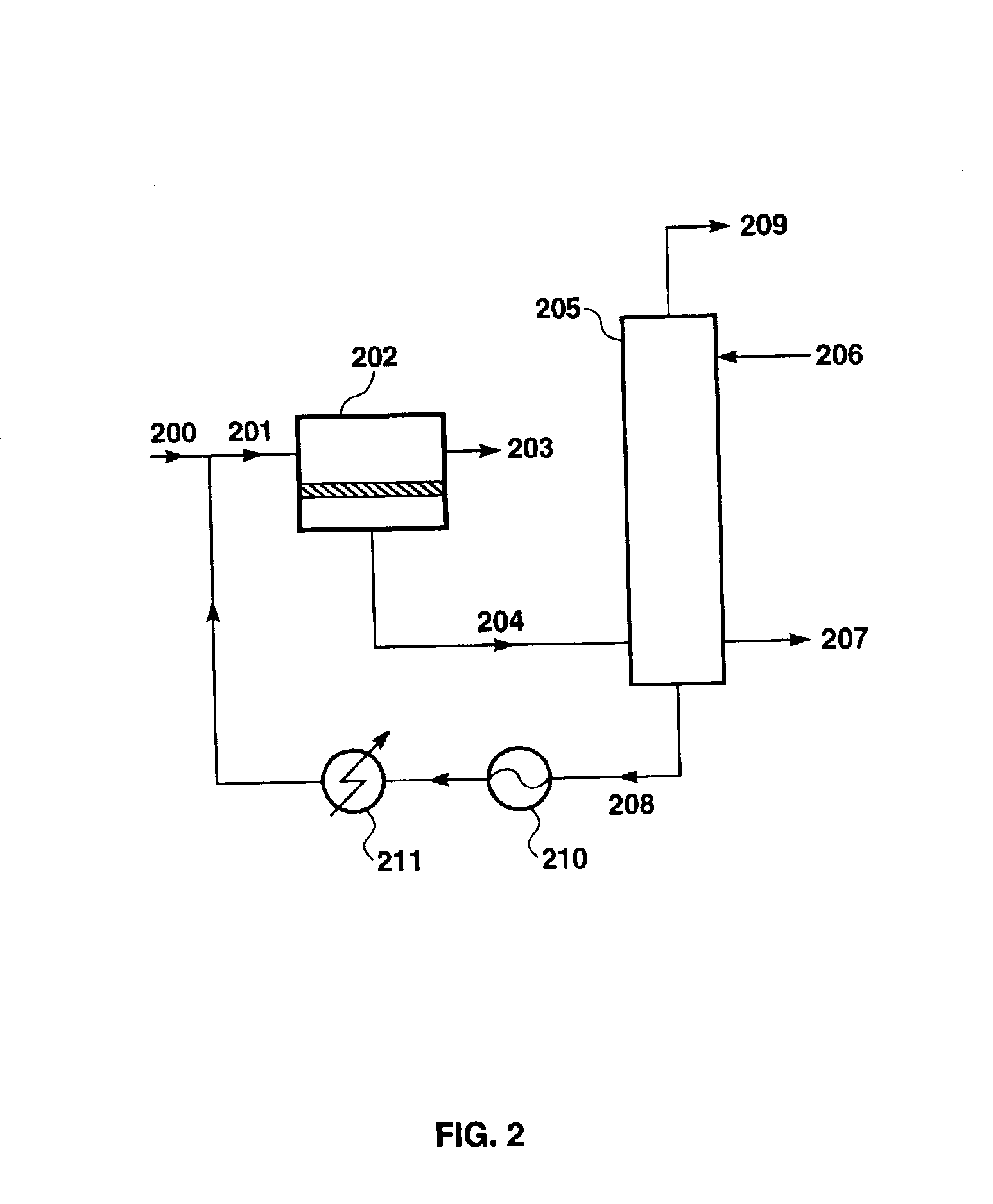

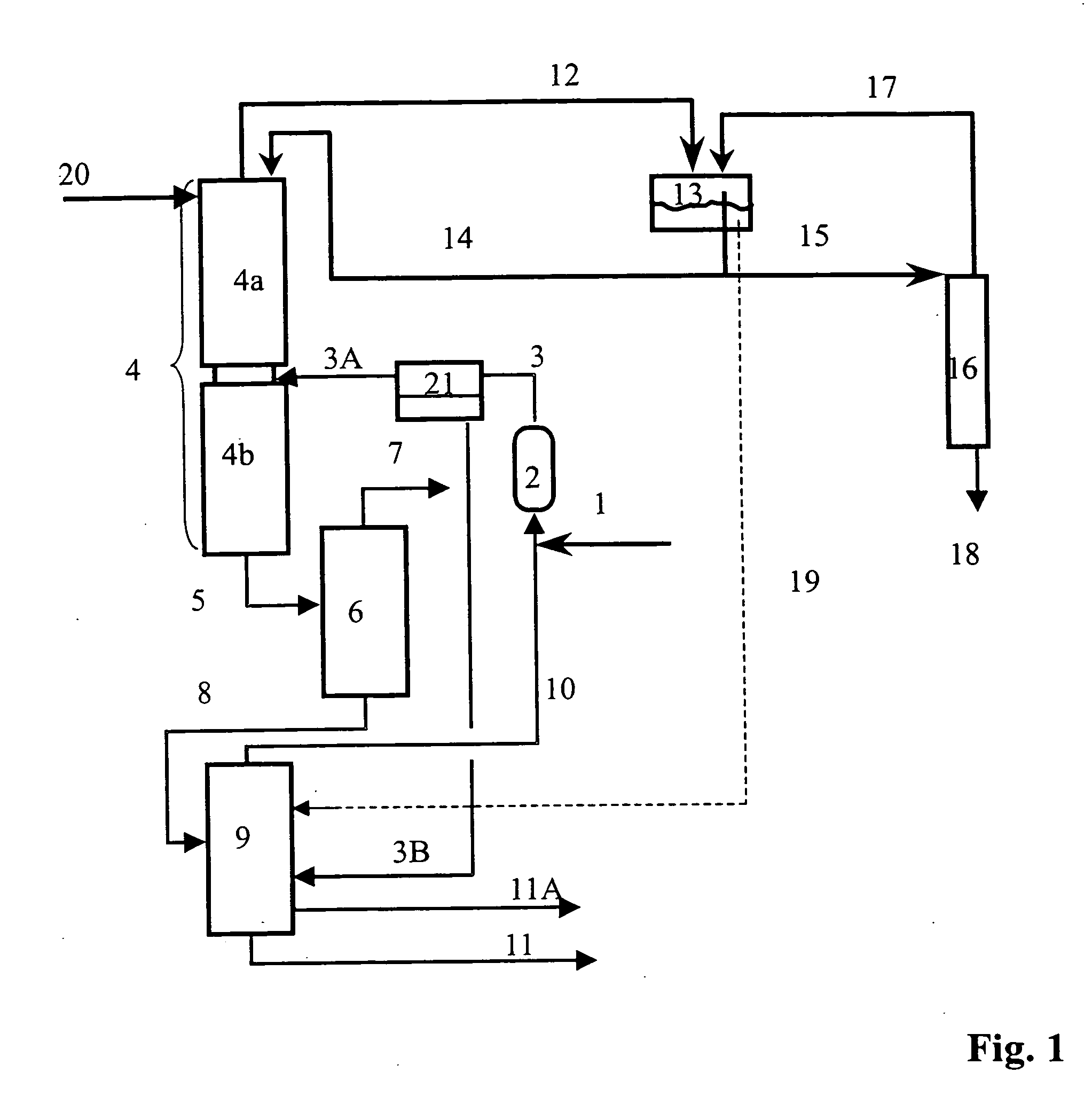

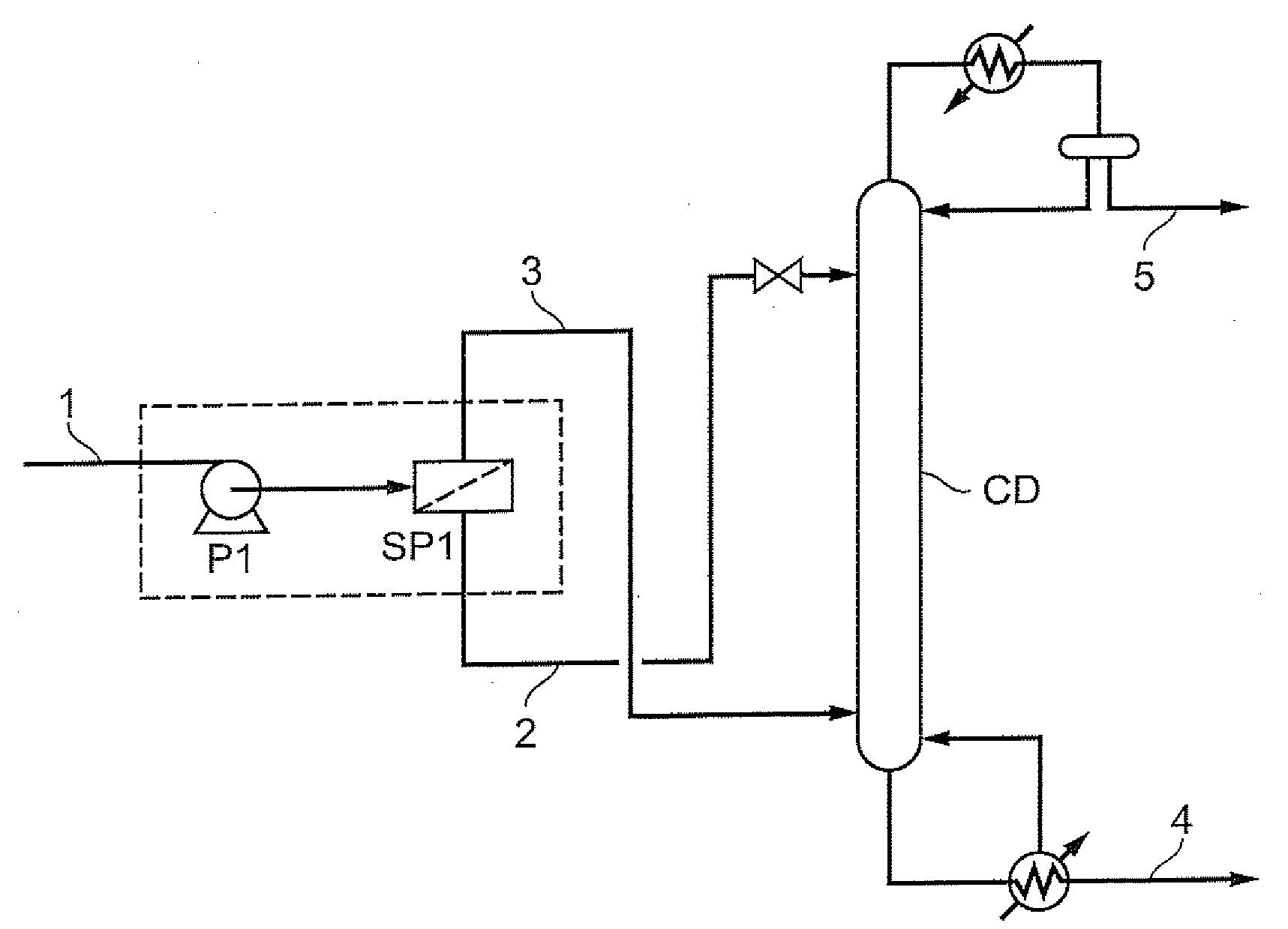

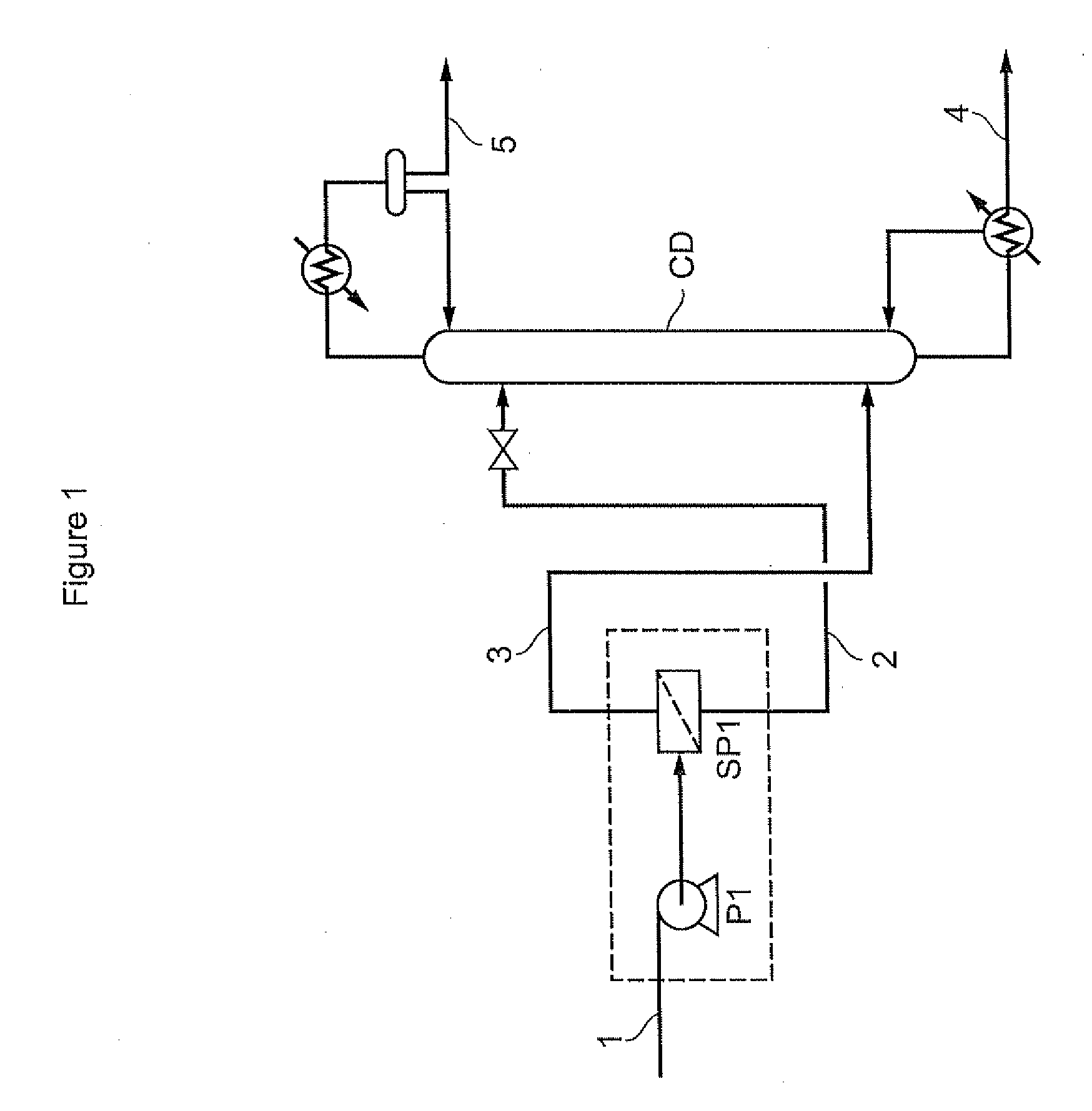

Separation of organic mixtures using gas separation or pervaporation and dephlegmation

InactiveUS6899743B2Easy to separateLow costSemi-permeable membranesSolid sorbent liquid separationZeotropic mixtureGas phase

A process for treating mixtures of organic components, including azeotropic mixtures. The process includes a gas- or liquid-phase membrane separation step in conjunction with a dephlegmation step to treat at least a portion of the permeate vapor from the pervaporation step. The process yields a membrane residue stream, a stream enriched in the more volatile component as the overhead stream from the dephlegmator and a condensate stream enriched in the less volatile component as a bottoms stream from the dephlegmator. Any of these may be the principal product of the process.

Owner:MEMBRANE TECH & RES

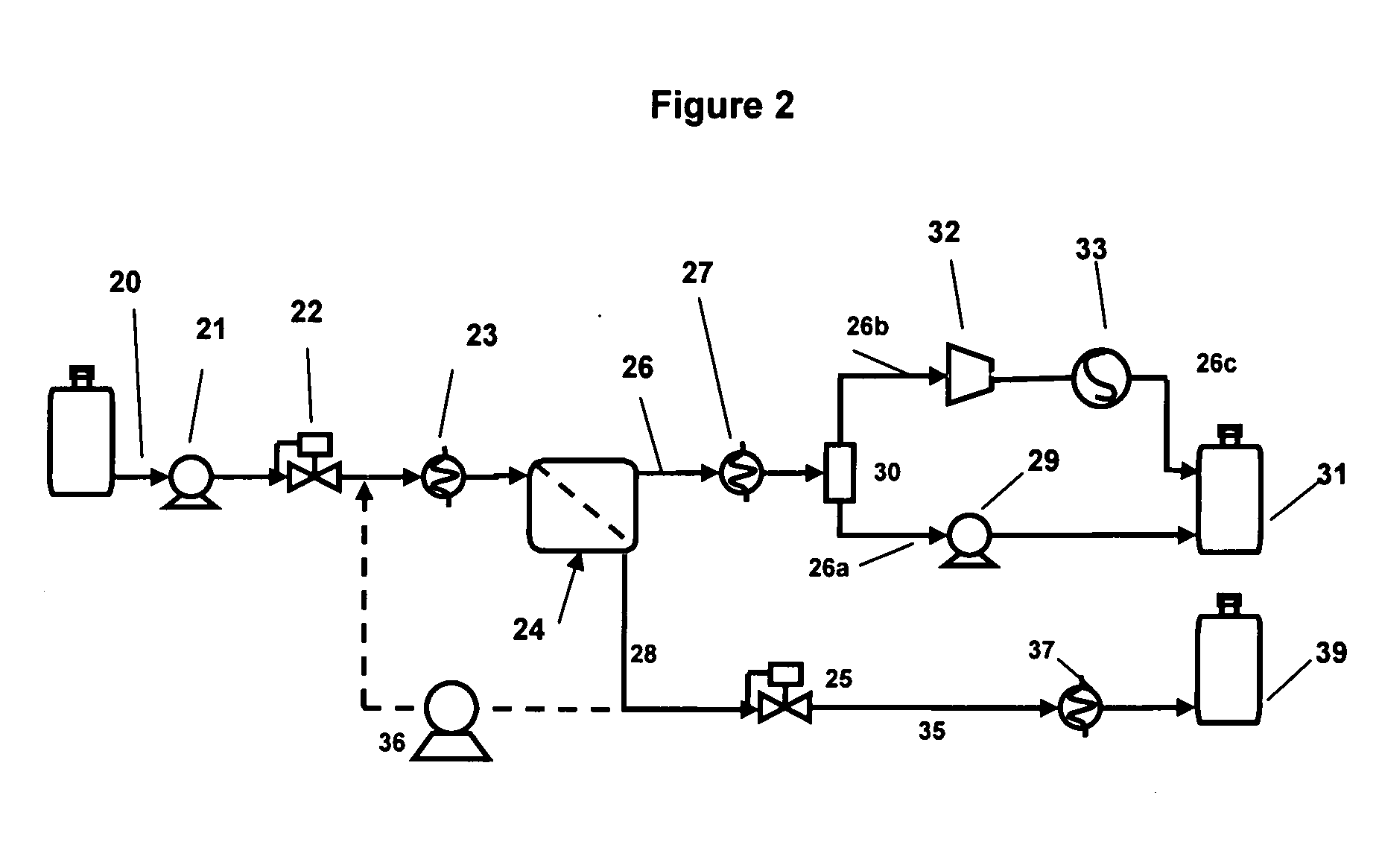

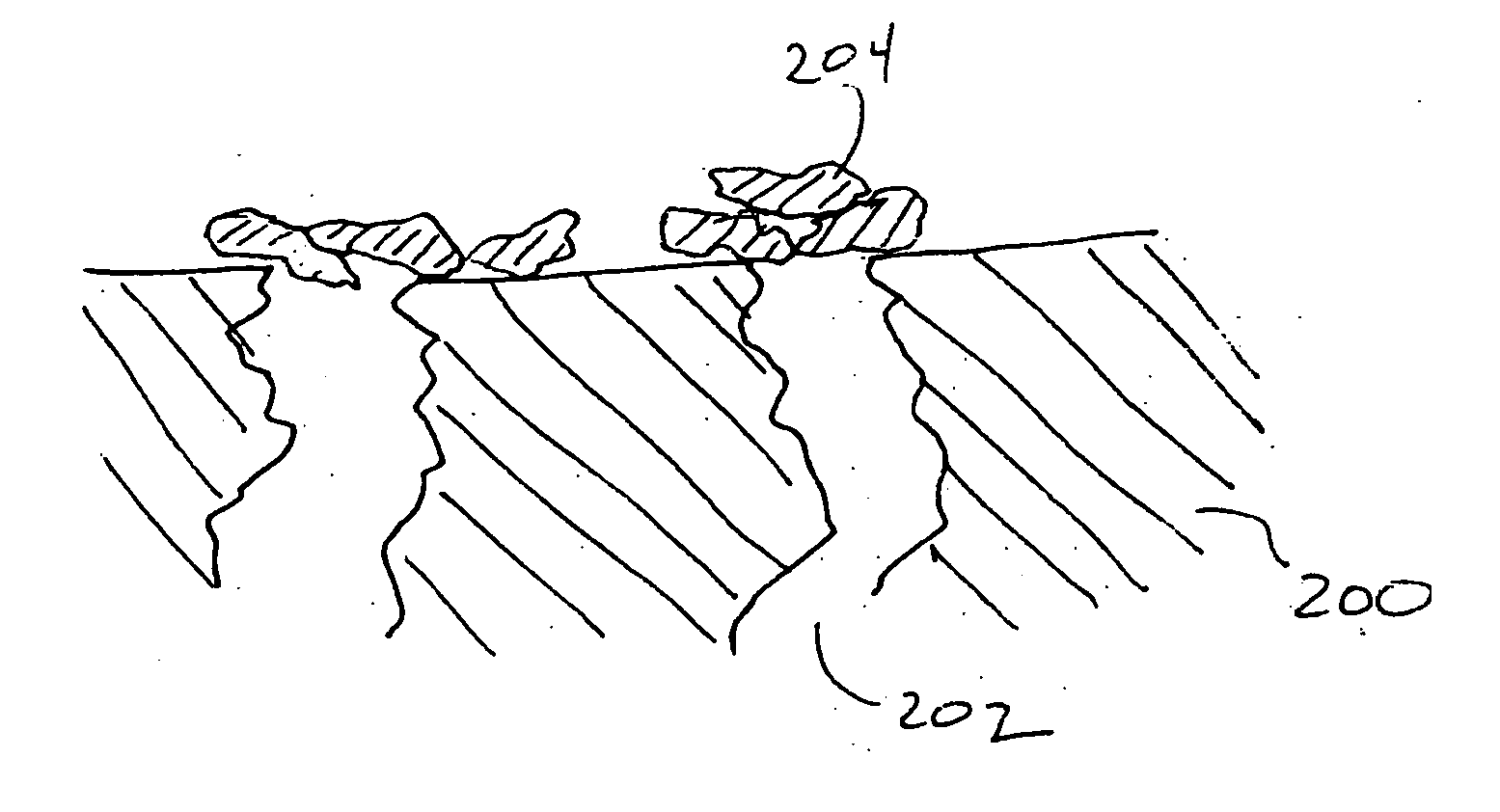

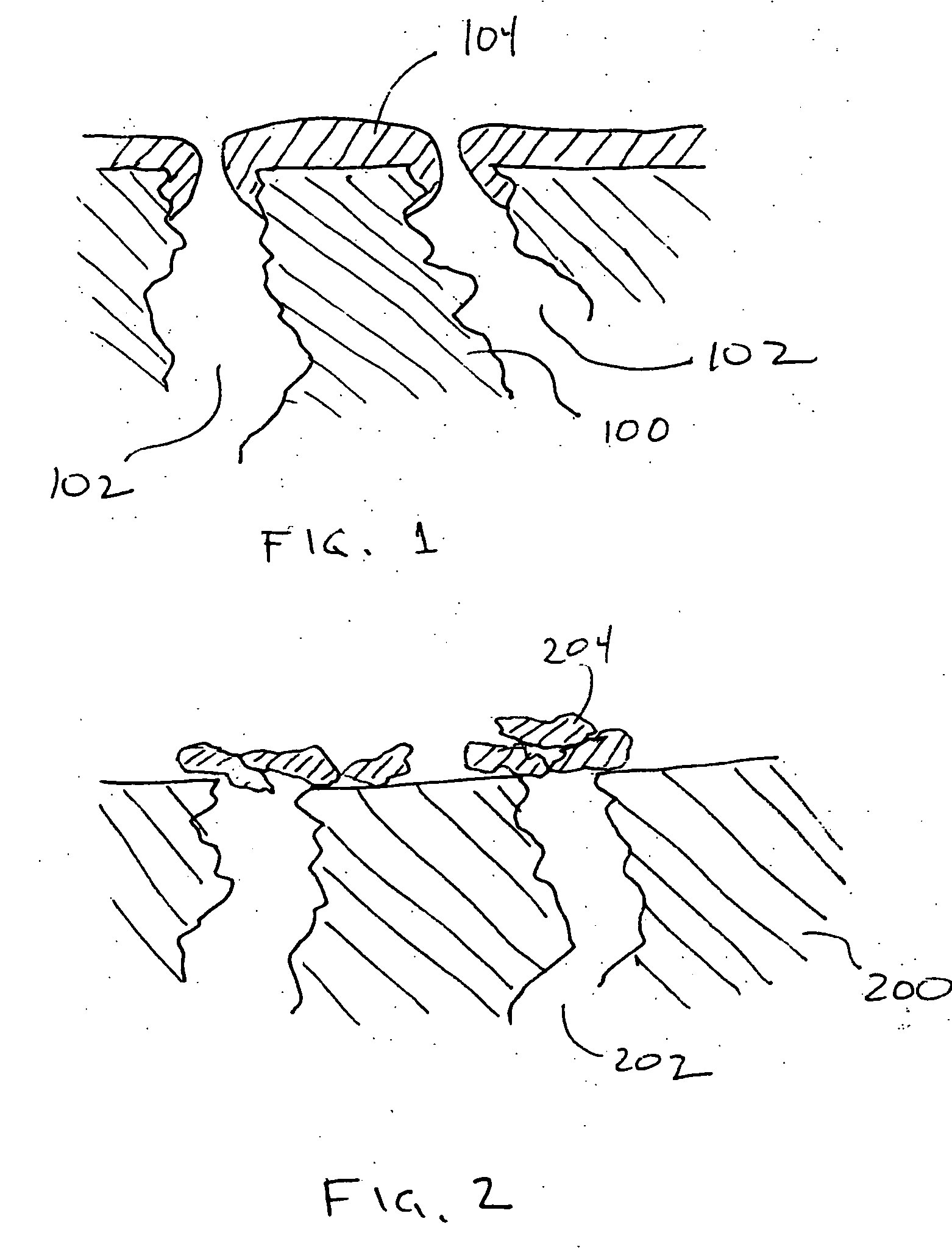

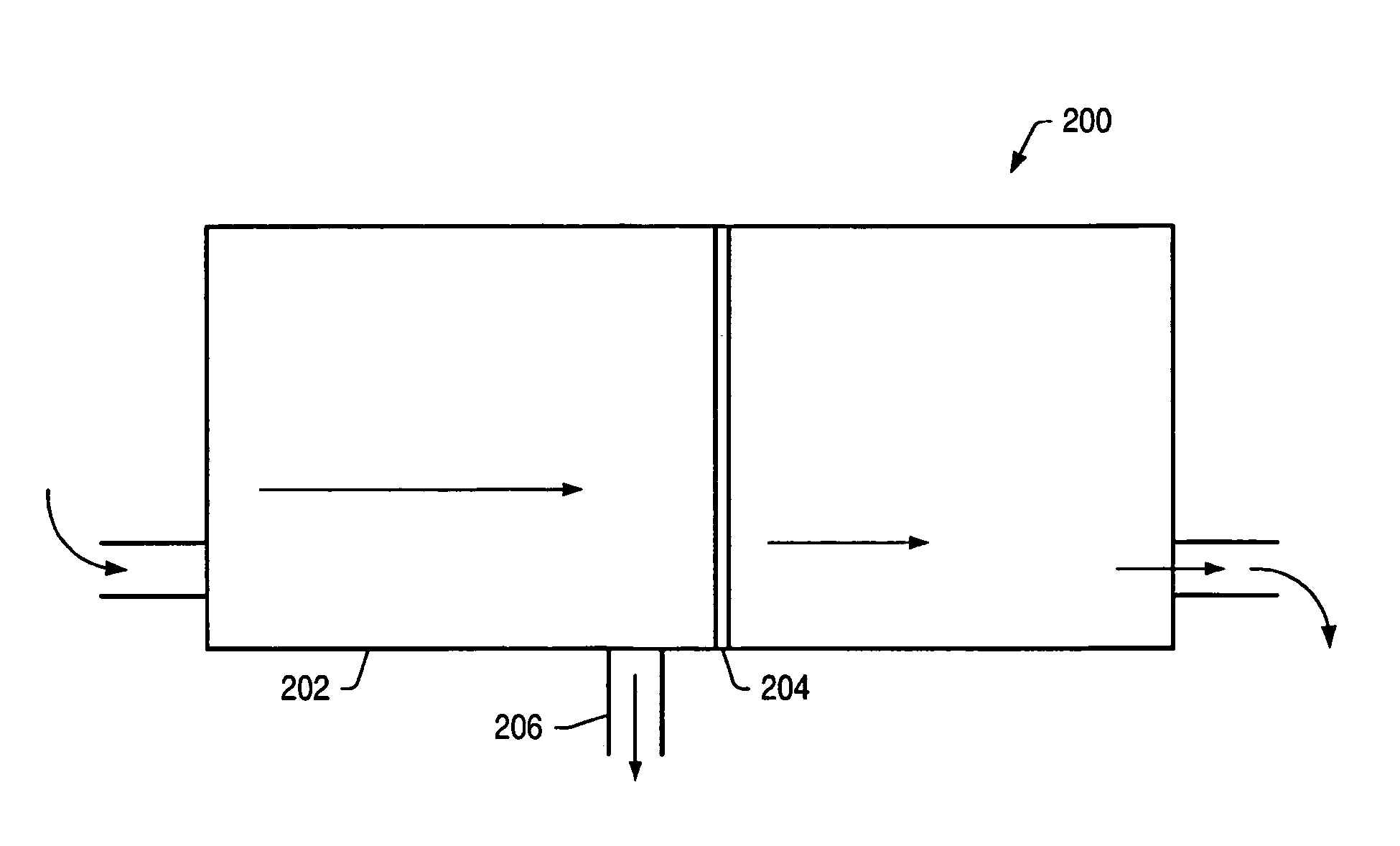

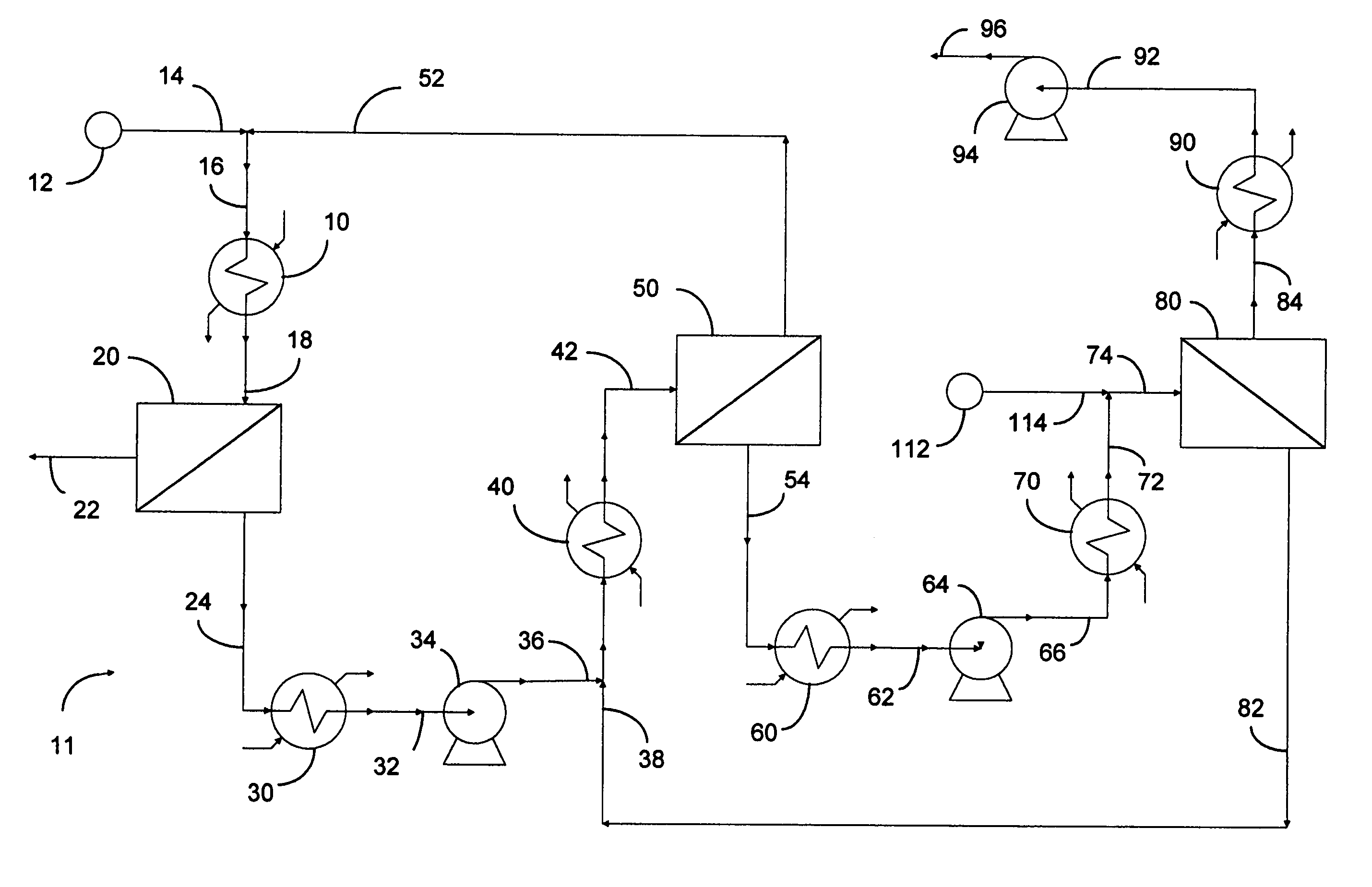

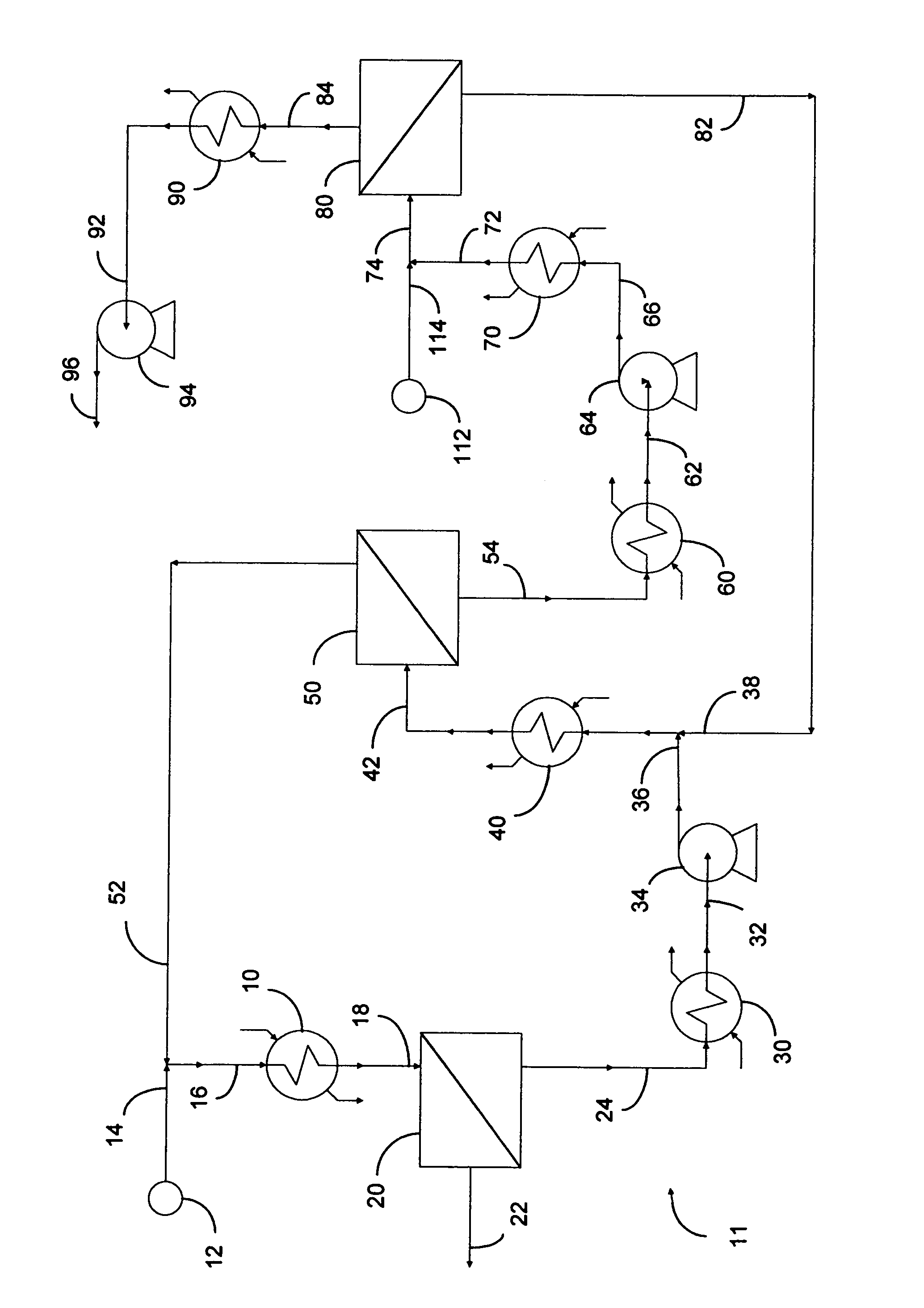

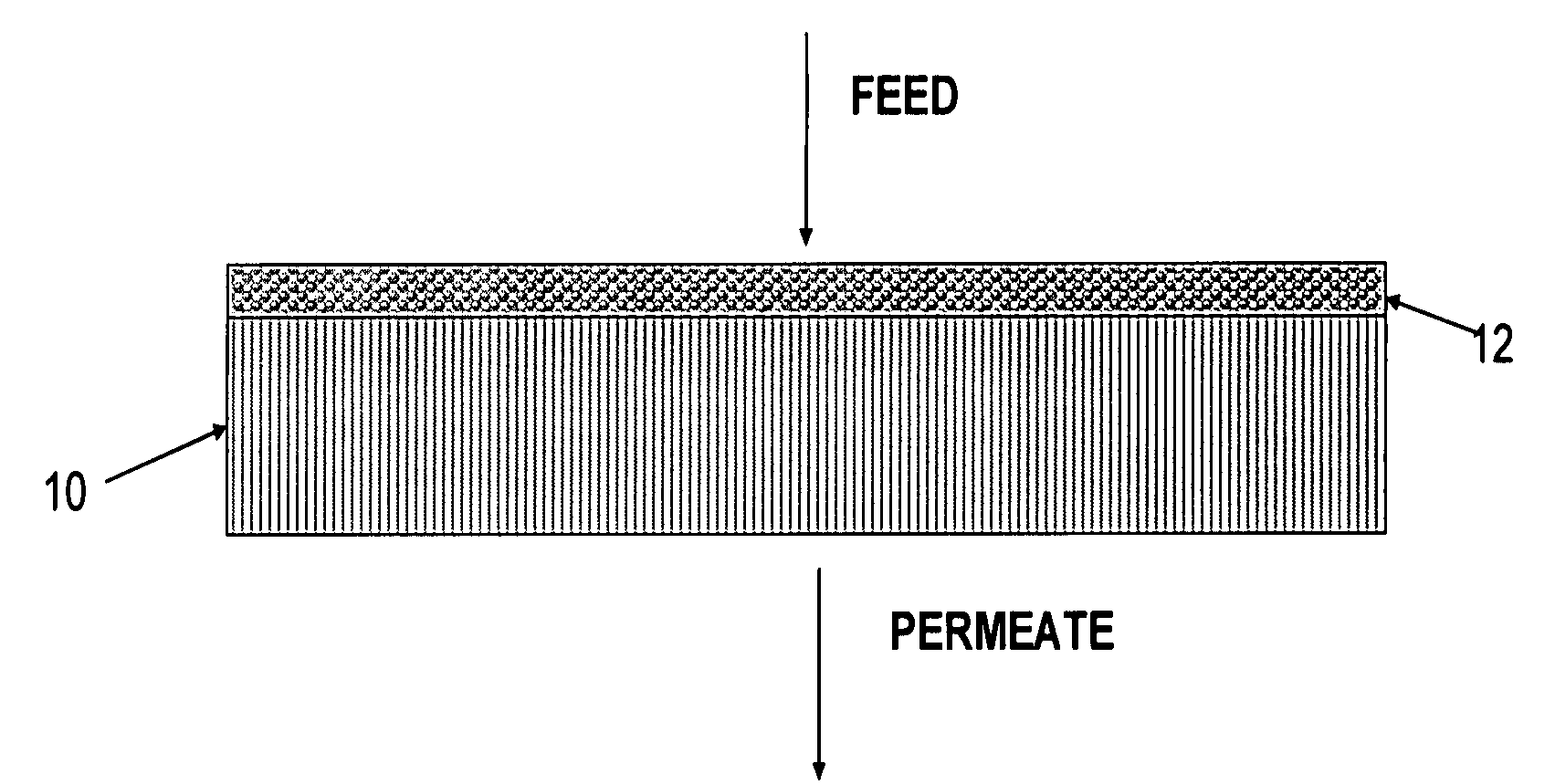

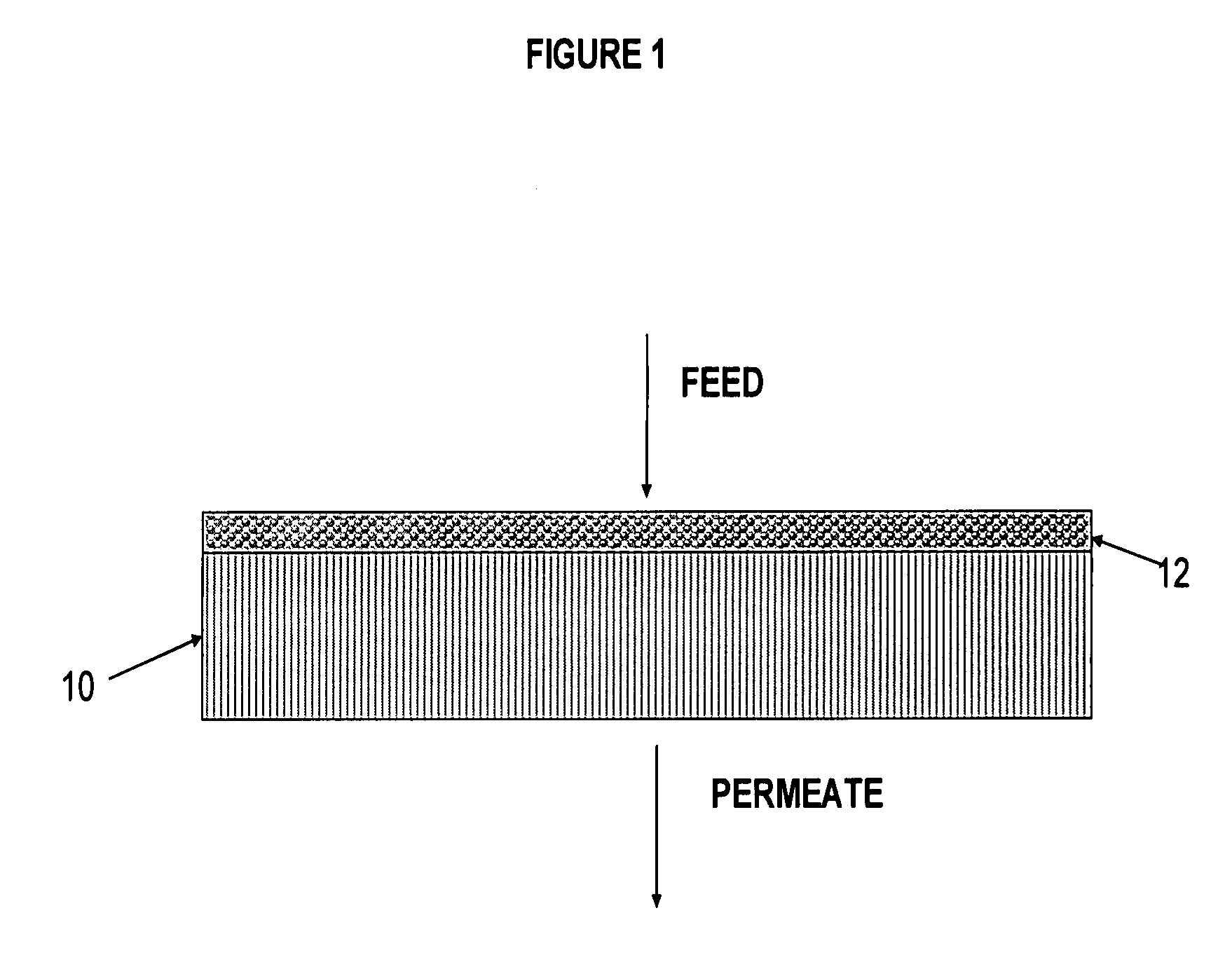

Membrane separation process using mixed vapor-liquid feed

ActiveUS20080011680A1Reduce the impactEfficient executionMembranesSemi-permeable membranesVapor liquidChemical physics

The present invention pertains to a process for the separation of aromatics from a feed stream, including aromatics and non-aromatics by selectively permeating the aromatics through a membrane comprising feeding a mixed phase vapor-liquid feed to a membrane wherein said liquid phase preferentially wets the surface of the membrane.

Owner:EXXON RES & ENG CO

Method for separating hydrocarbon-containing gas mixtures using hydrocarbon-resistant membranes

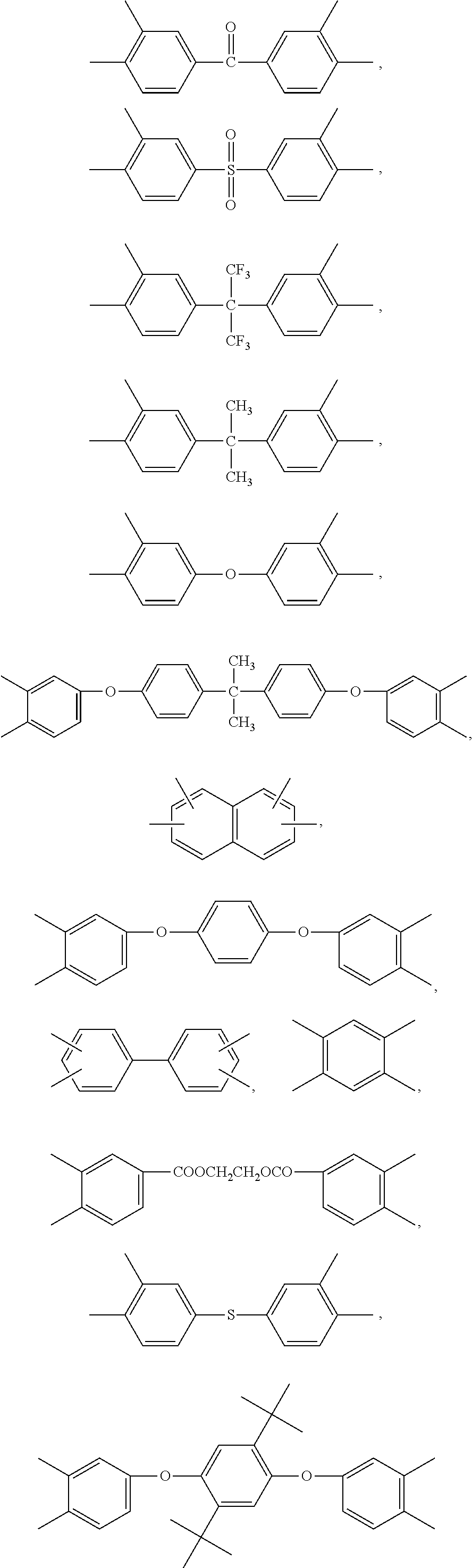

A method of separating or concentrating hydrocarbon-containing gas mixtures such as hydrogen from hydrocarbons, carbon dioxide from hydrocarbons, nitrogen from hydrocarbons, and hydrocarbons from one another using a selectively permeable membrane. The method is well suited to separate hydrocarbon-containing mixtures such as those generated by petroleum refining industries, petrochemical industries, natural gas processing, and the like. The membranes exhibit extremely good resistance to plasticization by hydrocarbon components in the gas mixture under practical industrial process conditions.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

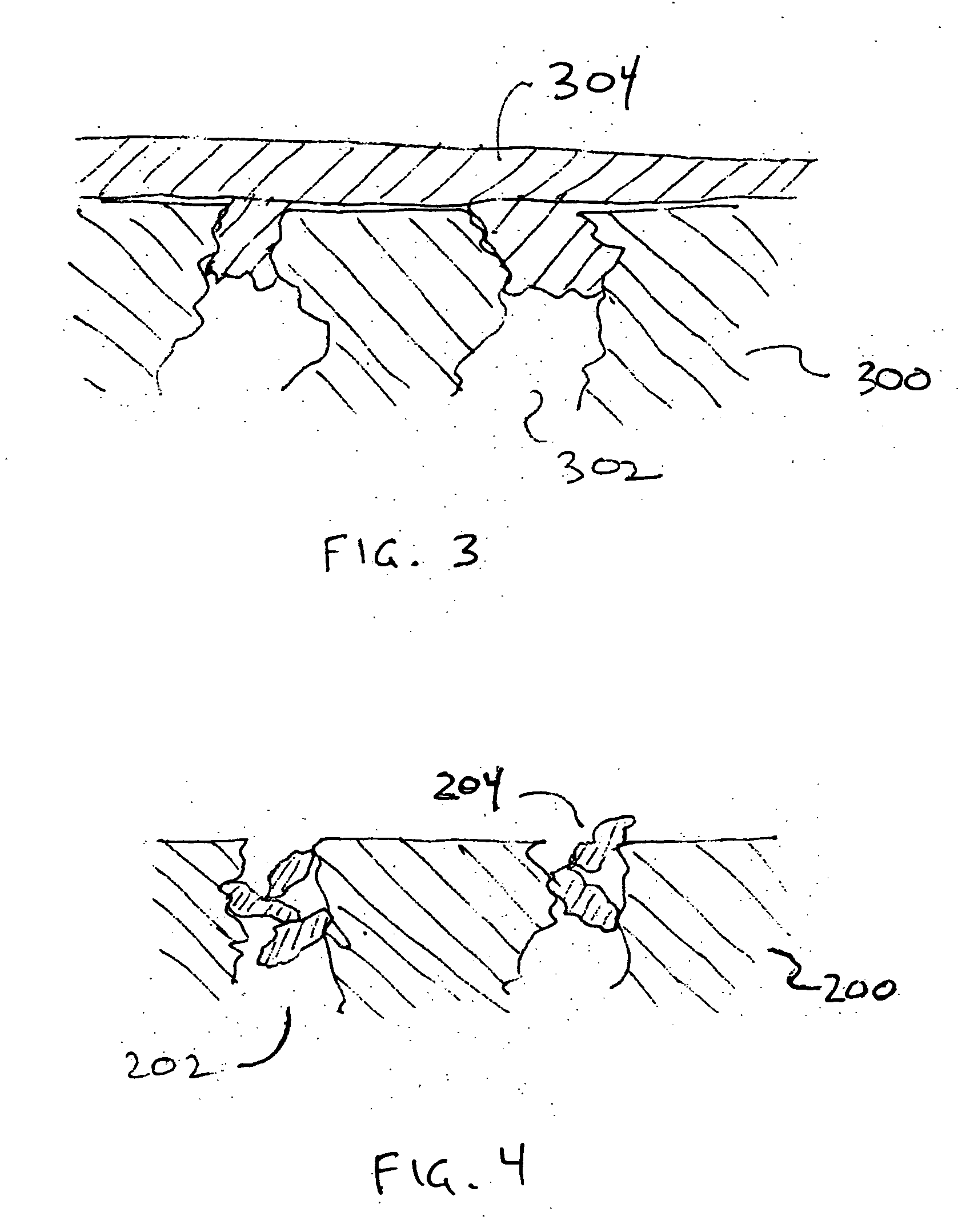

High flux, microporous, sieving membranes and separators containing such membranes and processes using such membranes

InactiveUS20060201884A1Easy to implementReduced membrane surface areaSemi-permeable membranesMembranesHigh fluxChemistry

A sieving membrane comprises a thin, microporous barrier to provide a high flux. The membrane structure can tolerate defects yet still obtain commercially-attractive separations.

Owner:UOP LLC

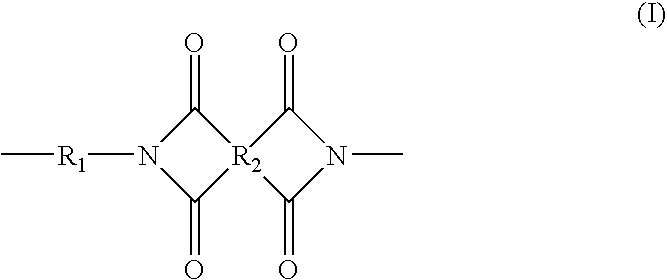

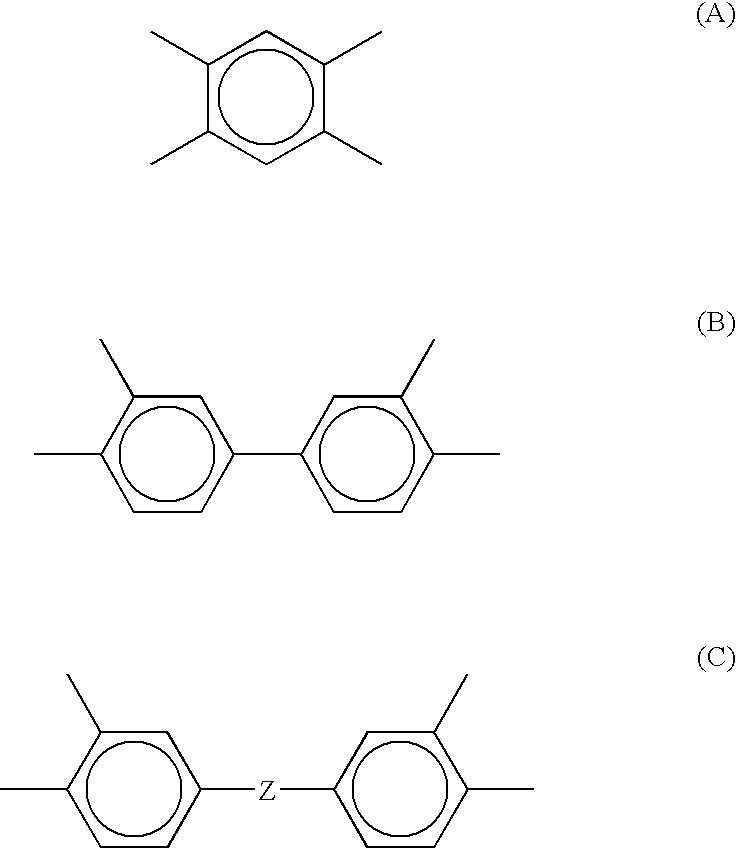

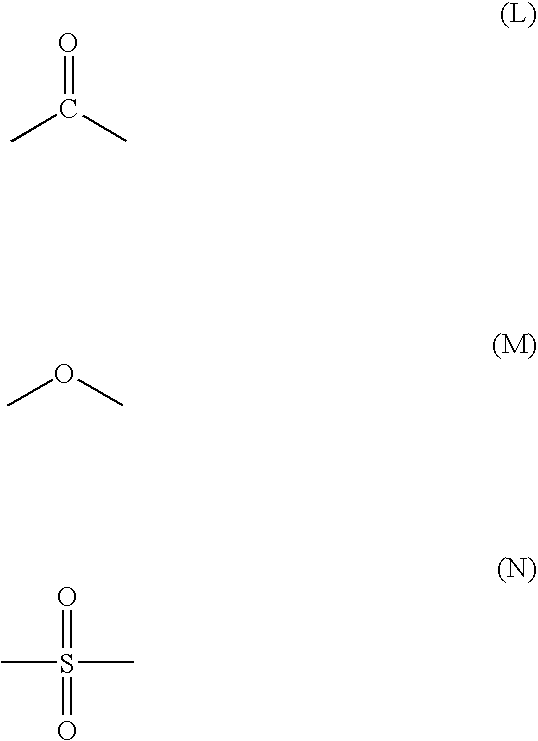

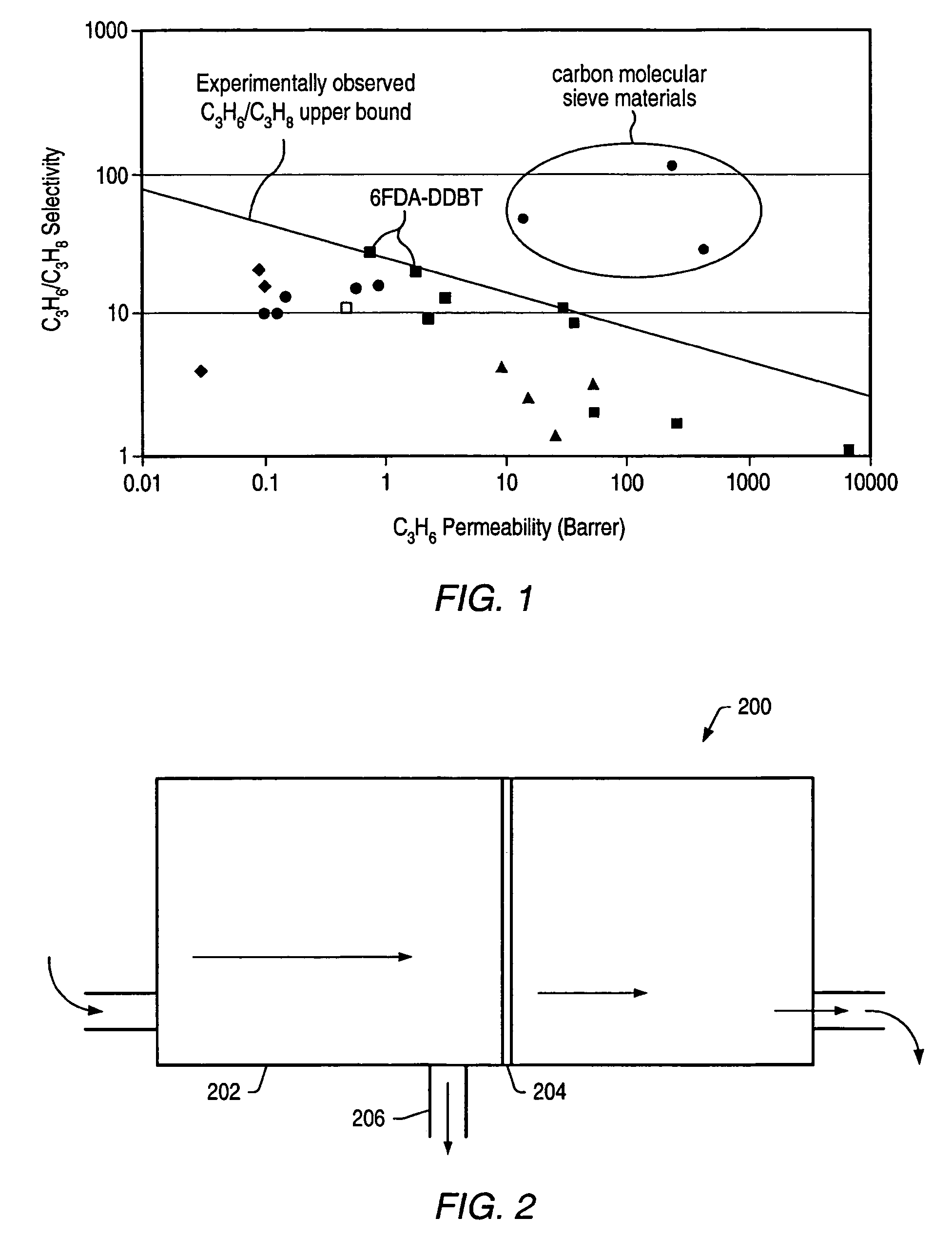

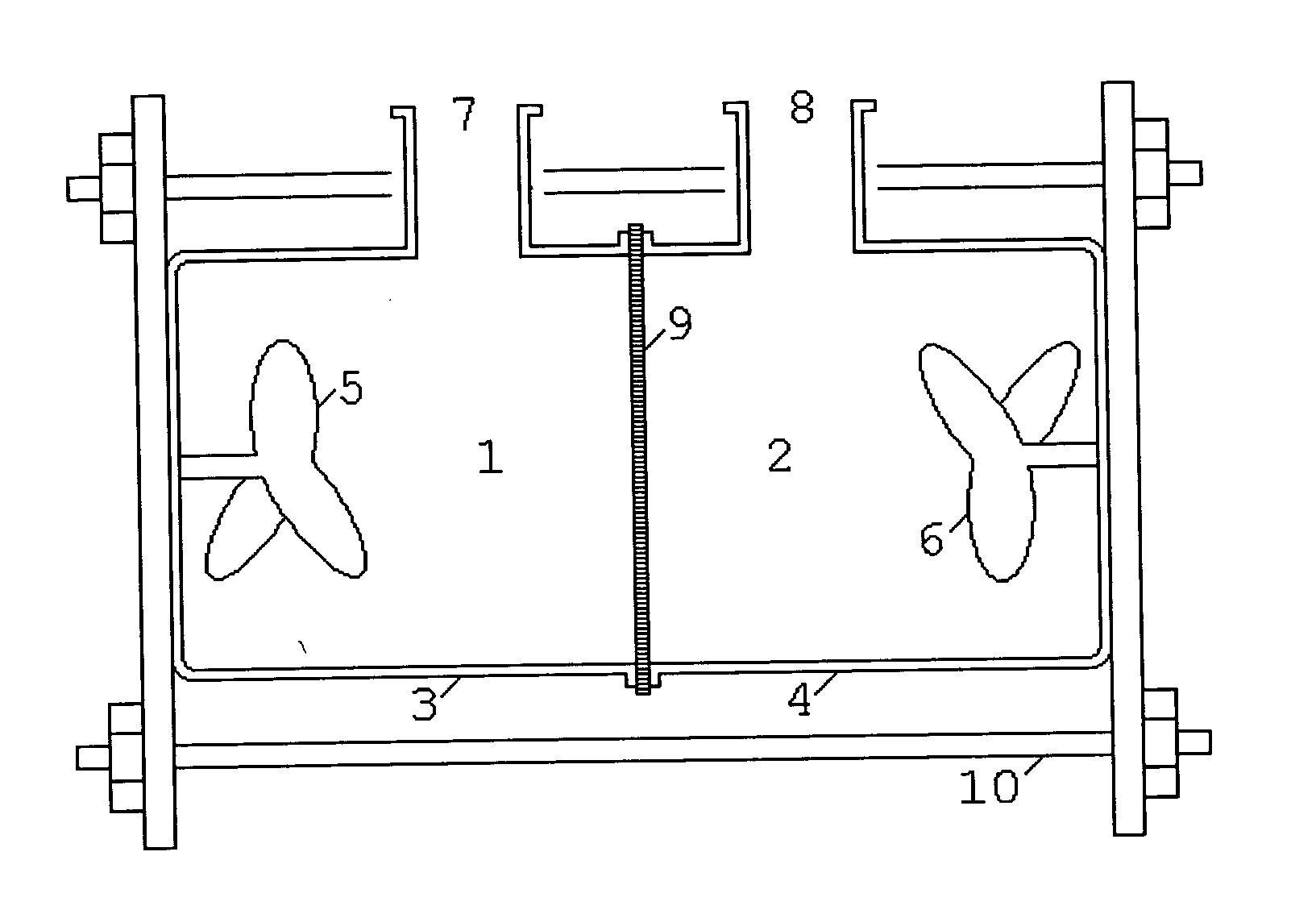

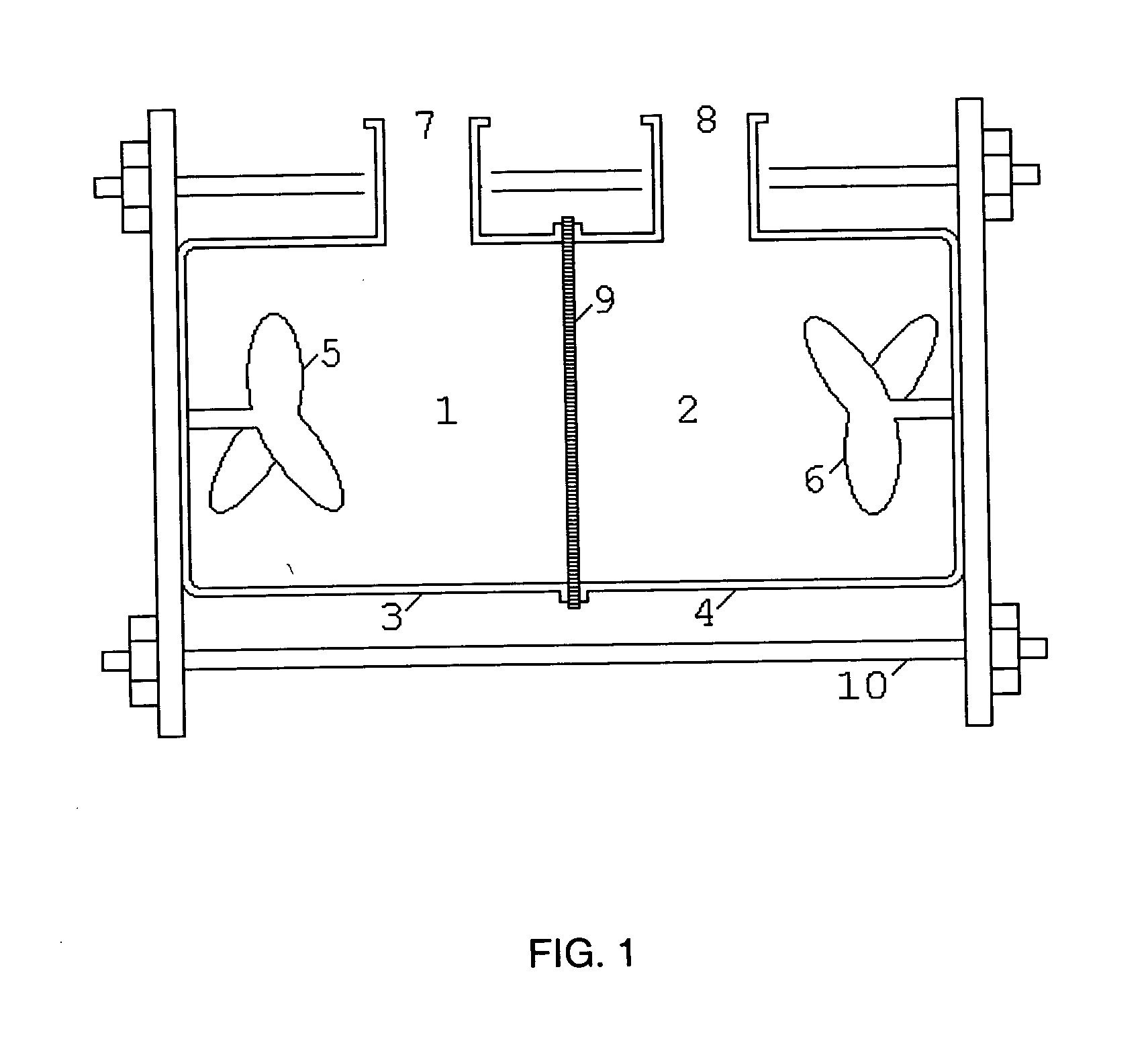

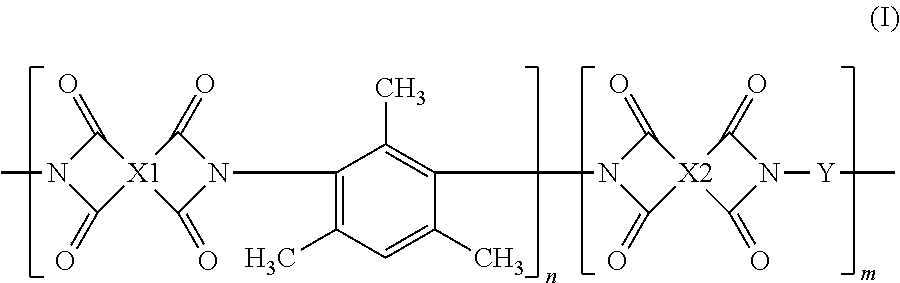

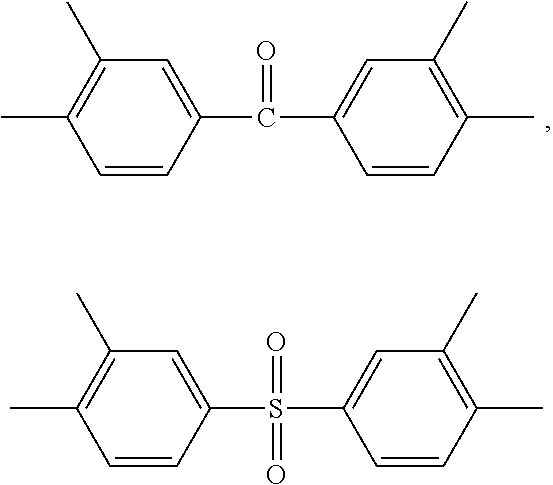

Dithiolene functionalized polymer membrane for olefin/paraffin separation

InactiveUS7160356B2Easy to separateYield maximizationSemi-permeable membranesMembranesImideSolubility

A polymeric composite may be used for forming fluid separation membranes. The membranes may be formed from polyimide, polyamide or poly (pyrrolone-imide) materials. Polyamides may be formed by the condensation of a tetraamine, a tetraacid, and a diamine. Polyimides and poly (pyrrolone-imides) may be formed by the cyclization of a polymer precursor. A polymeric composite may include a dithiolene or a mixture of dithiolenes. A polymer matrix incorporating dithiolenes may exhibit an olefin / paraffin solubility selectivity. A solubility selectivity may be between about 1.1 and about 2.0.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

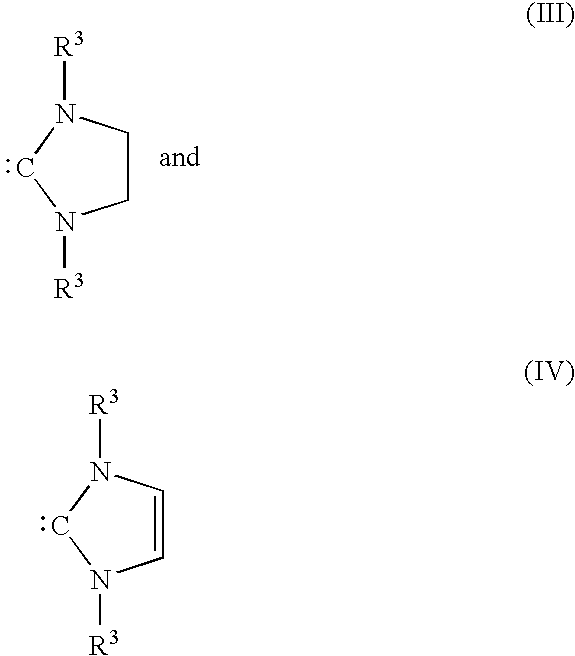

Process for the separation of olefins and paraffins

InactiveUS20050154247A1Carry-outImprove energy efficiencyMembranesSemi-permeable membranesAlkaneParaffin oils

A process for the separation of olefinic hydrocarbons from a liquid feedstock composition comprising at least one olefinic hydrocarbon and at least one paraffinic hydrocarbon, said process comprising contacting the liquid feedstock with a supported ionic liquid membrane wherein the supported ionic liquid membrane comprises a membrane impregnated with an ionic liquid composition.

Owner:SHELL OIL CO

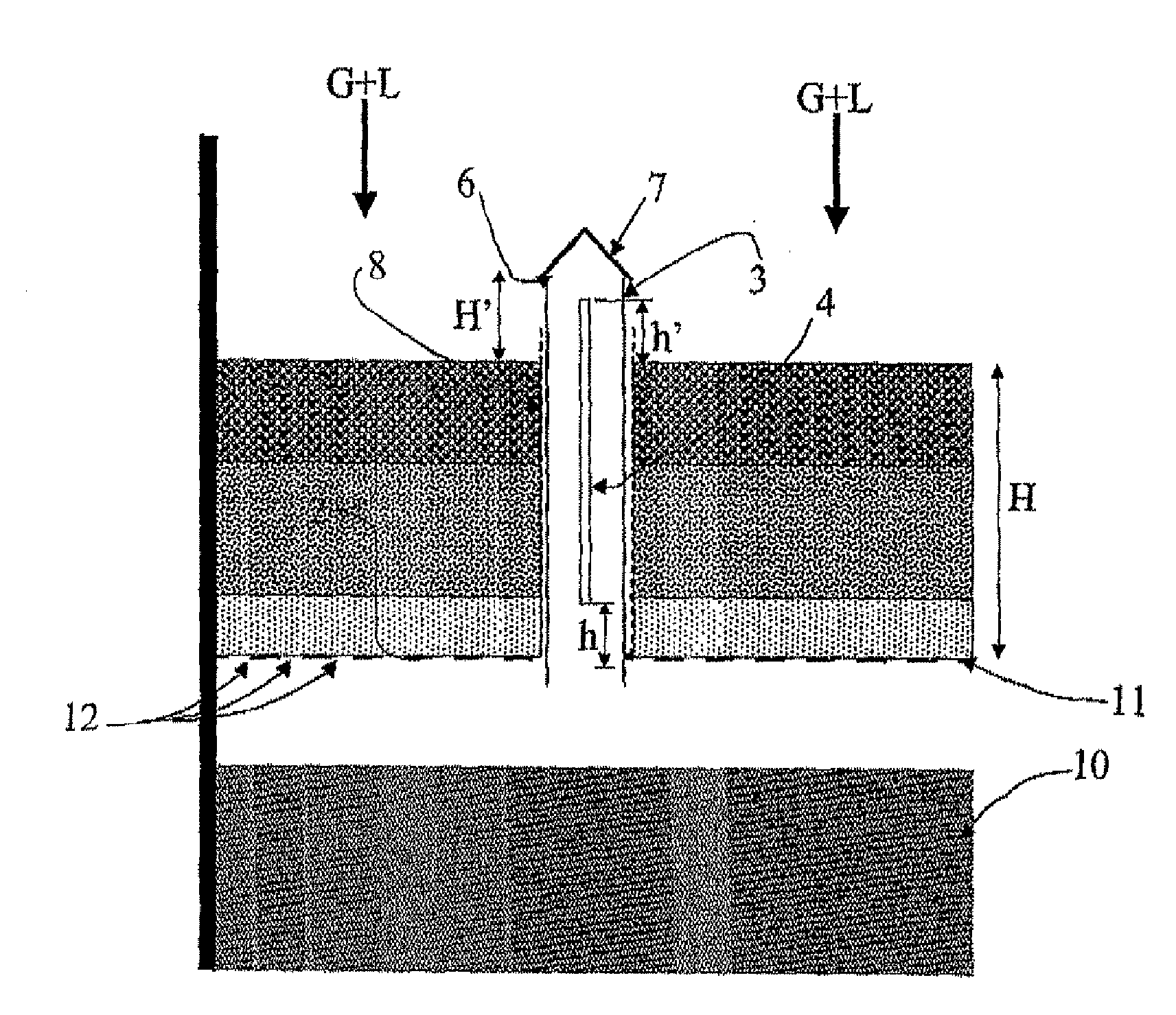

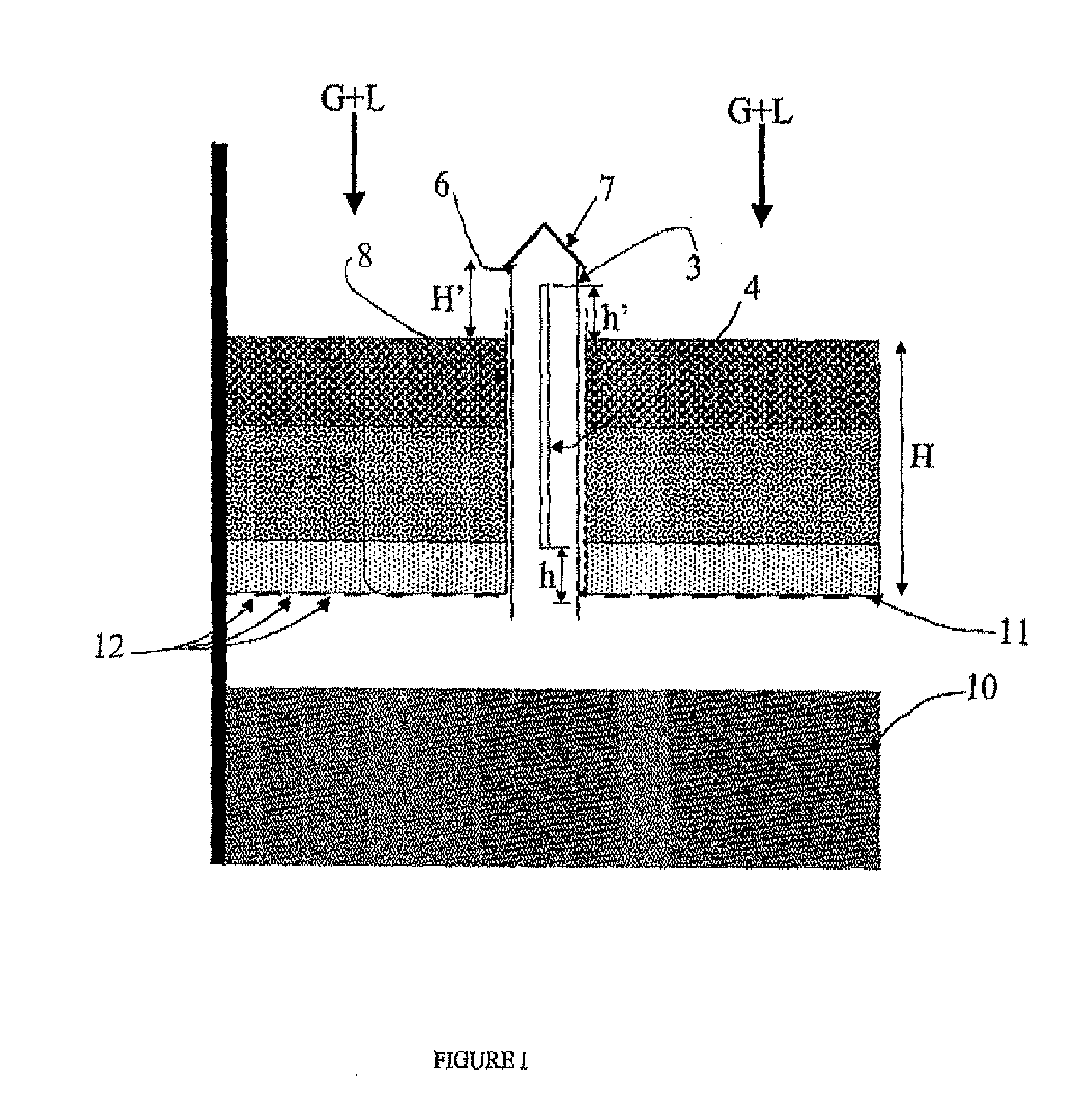

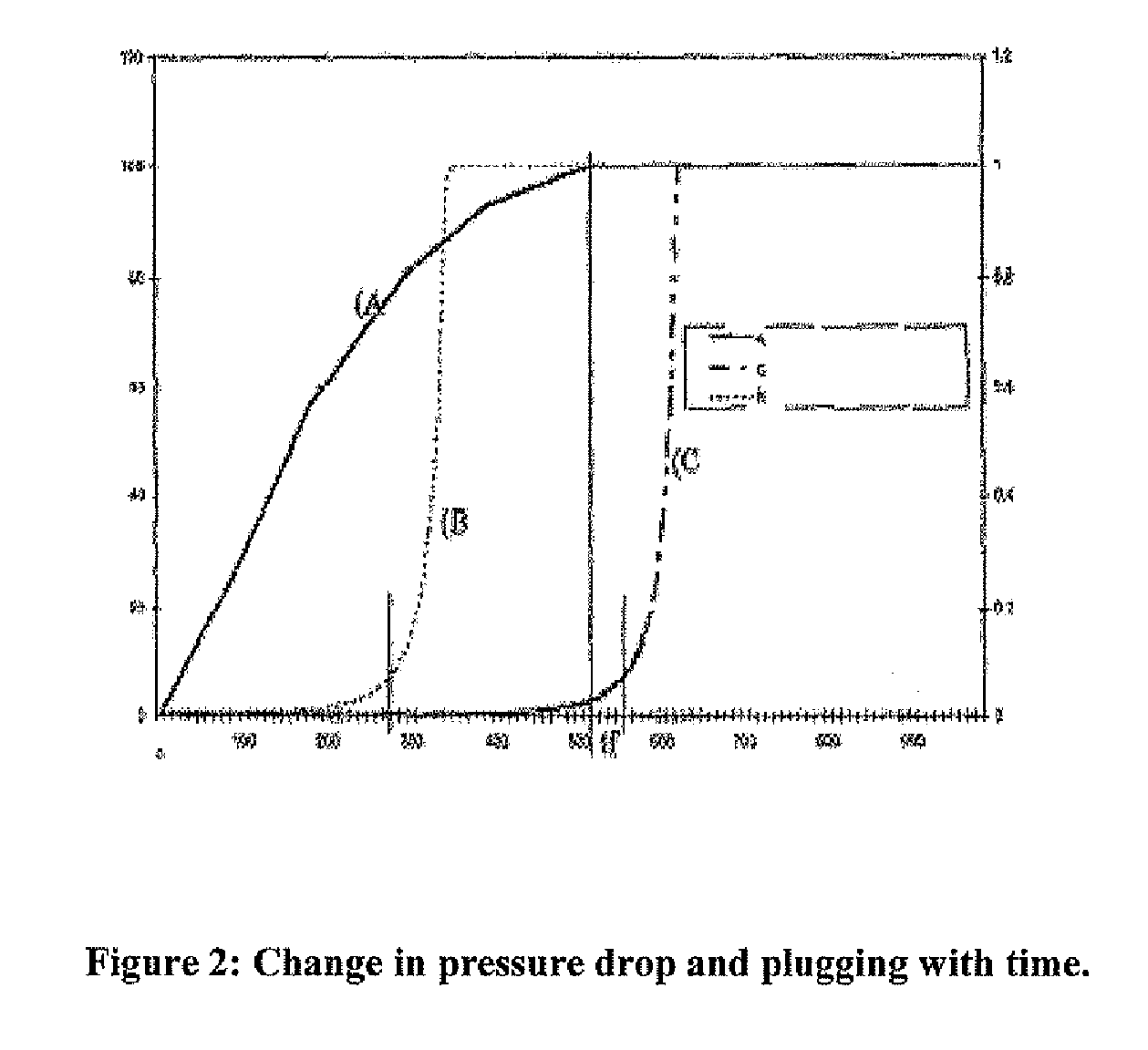

Filtration tray for fixed bed reactor with a co-current down-flow of gas and liquid

The device described in the present invention can trap plugging particles contained in the liquid feed supplying a reactor functioning in gas and liquid co-current down-flow mode using a specific distributor tray comprising a filtration medium.The present device is of particular application to the selective hydrogenation of feeds containing acetylenic and dienic compounds.

Owner:INST FR DU PETROLE

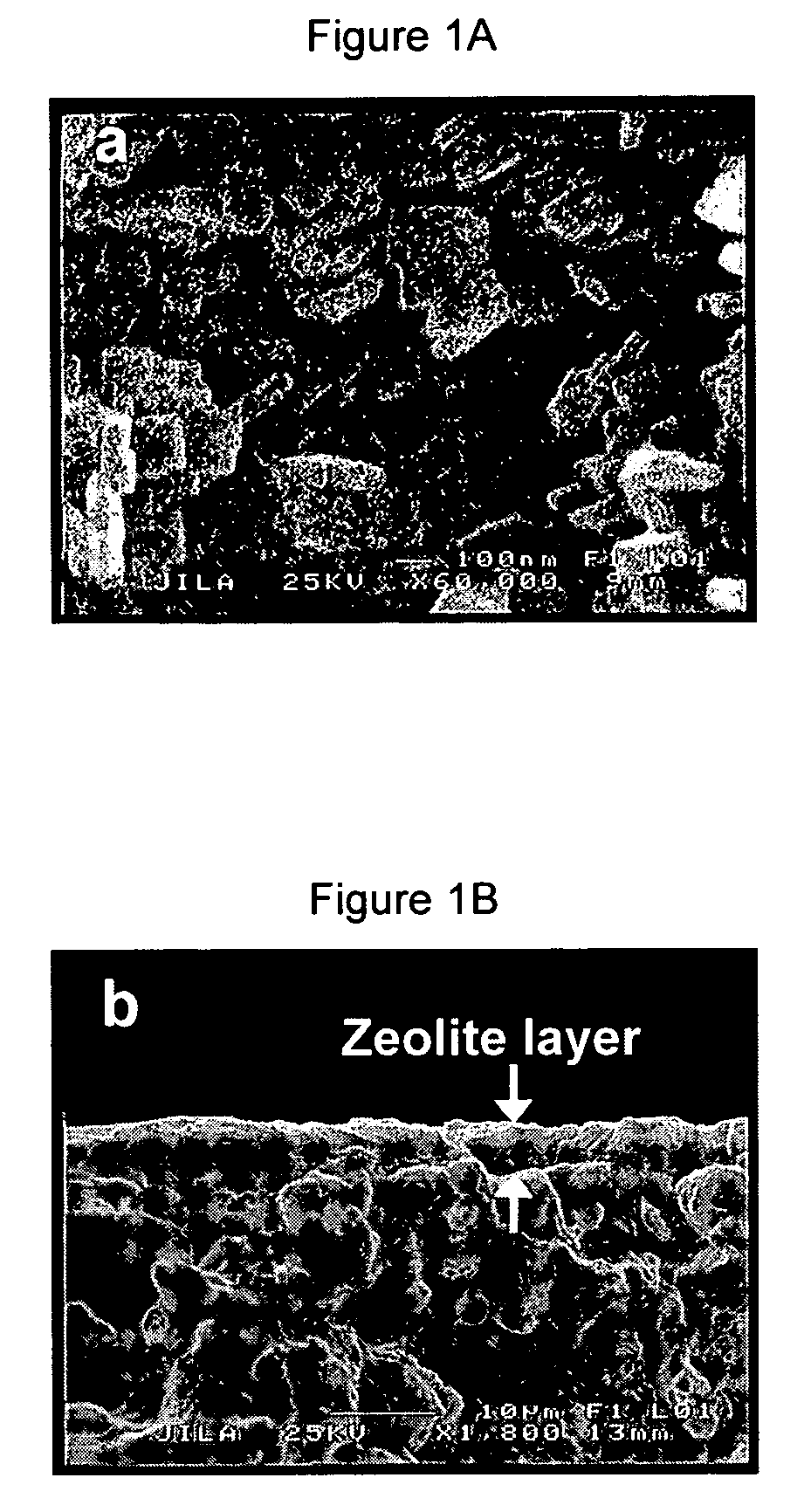

Membranes for highly selective separations

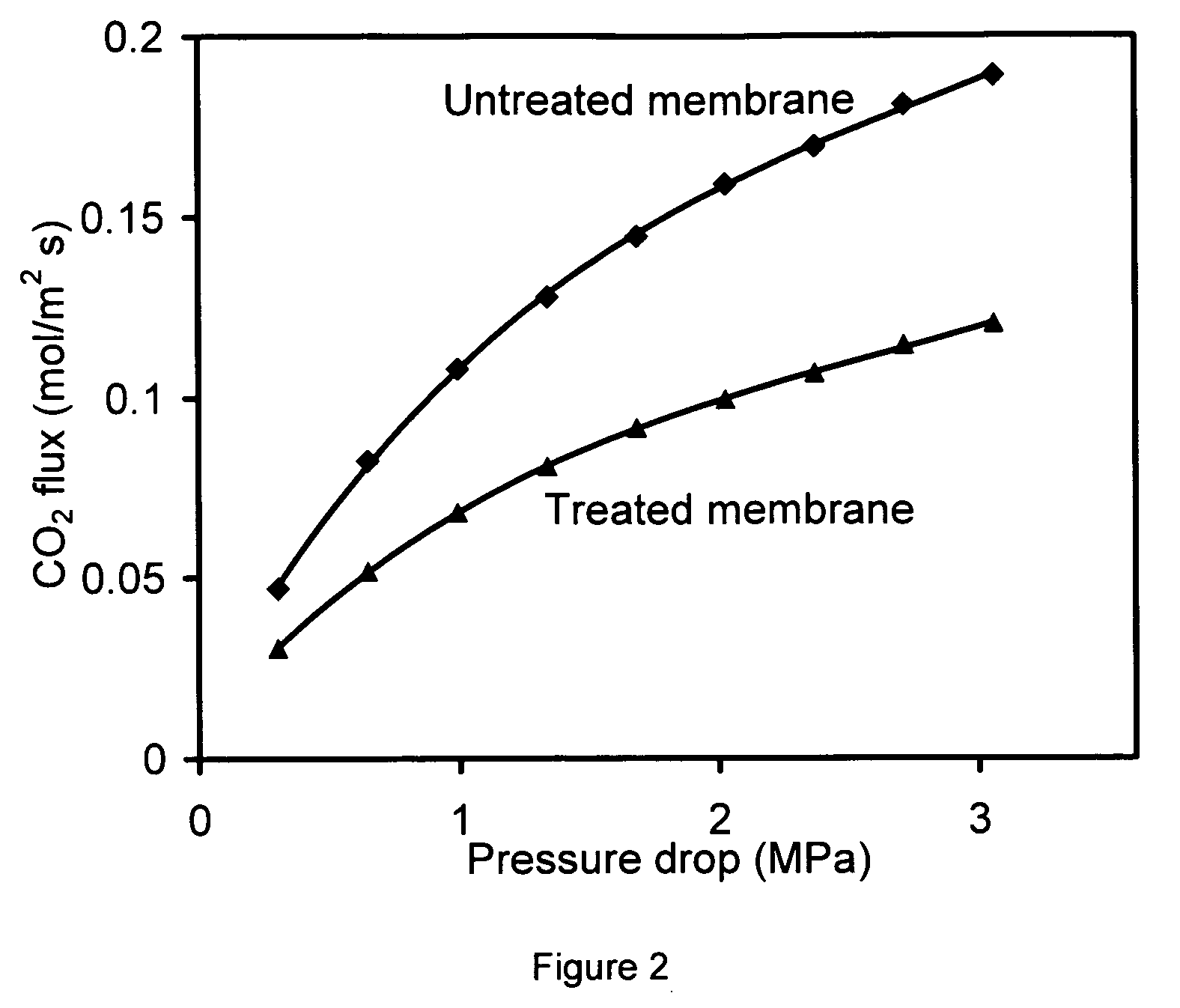

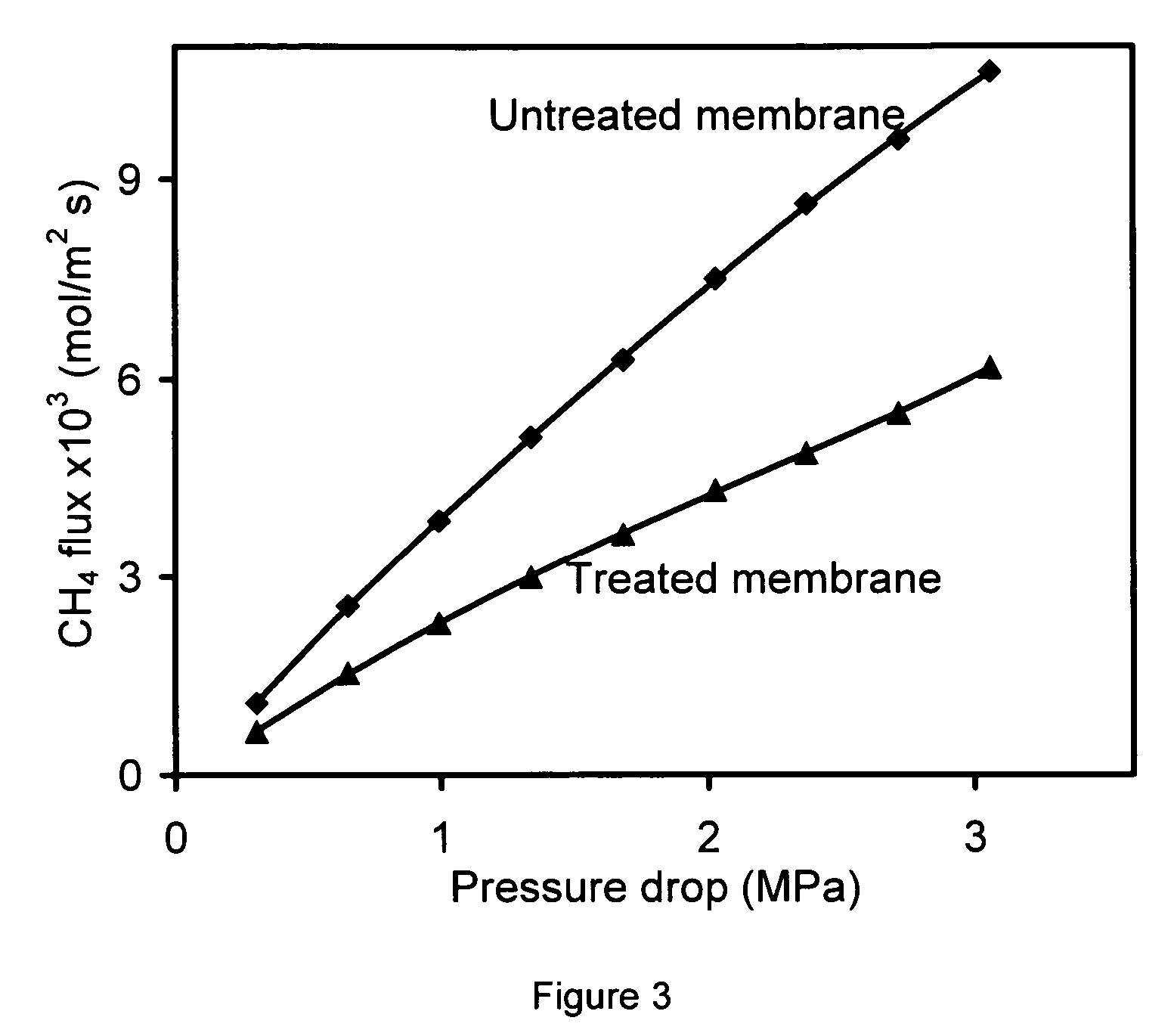

InactiveUS20060079725A1Improves CO2/CH selectivityHigh separation selectivityIsotope separationAlkali metal oxides/hydroxidesMolecular sieveAmmonia

The present invention provides modified molecular sieve membranes with improved CO2 / CH4 separation selectivity and methods for making such membranes. The molecular sieve membranes are modified by adsorption of a modifying agent, such as ammonia, within and / or on the membrane.

Owner:UNIV OF COLORADO THE REGENTS OF

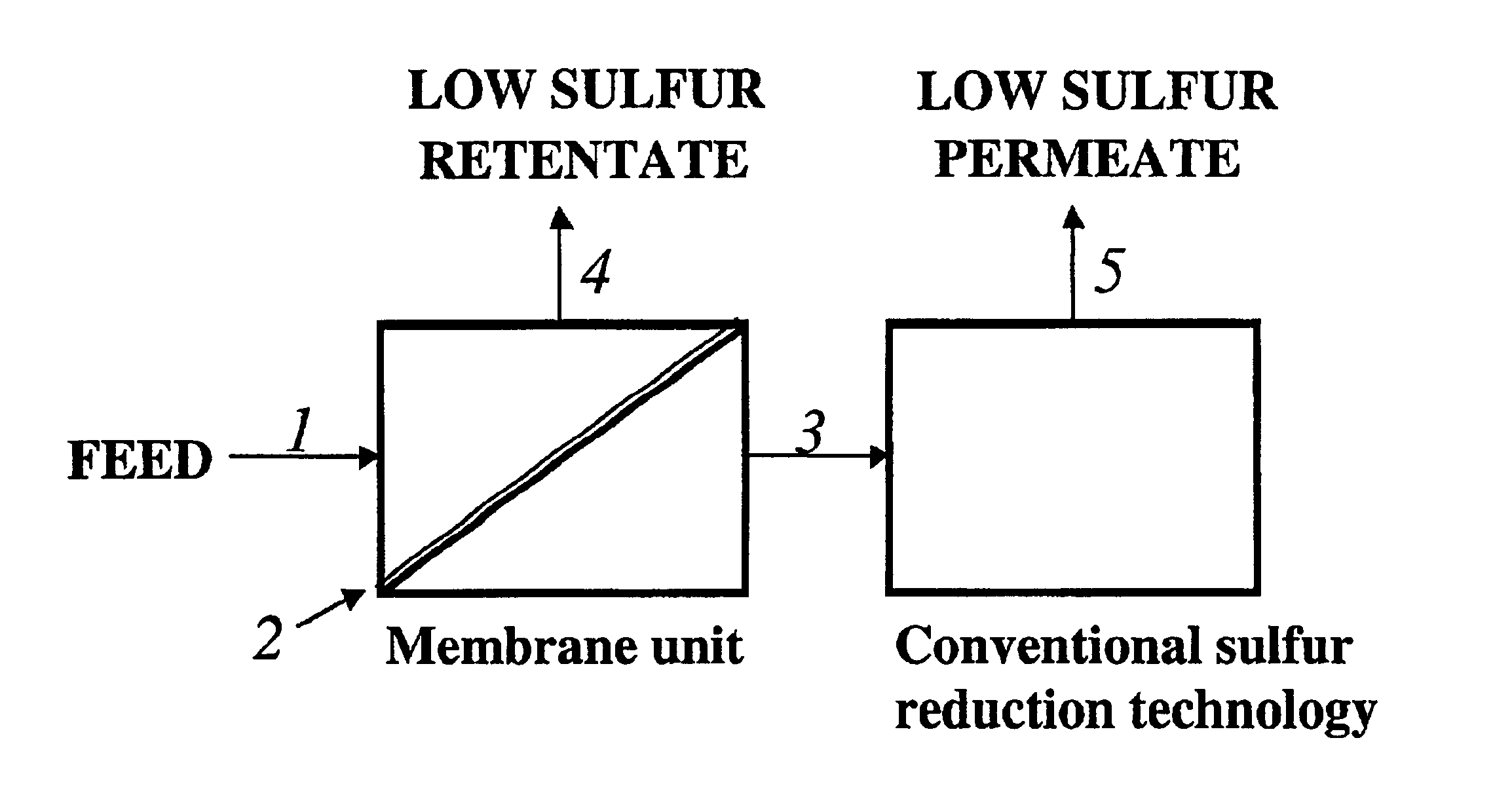

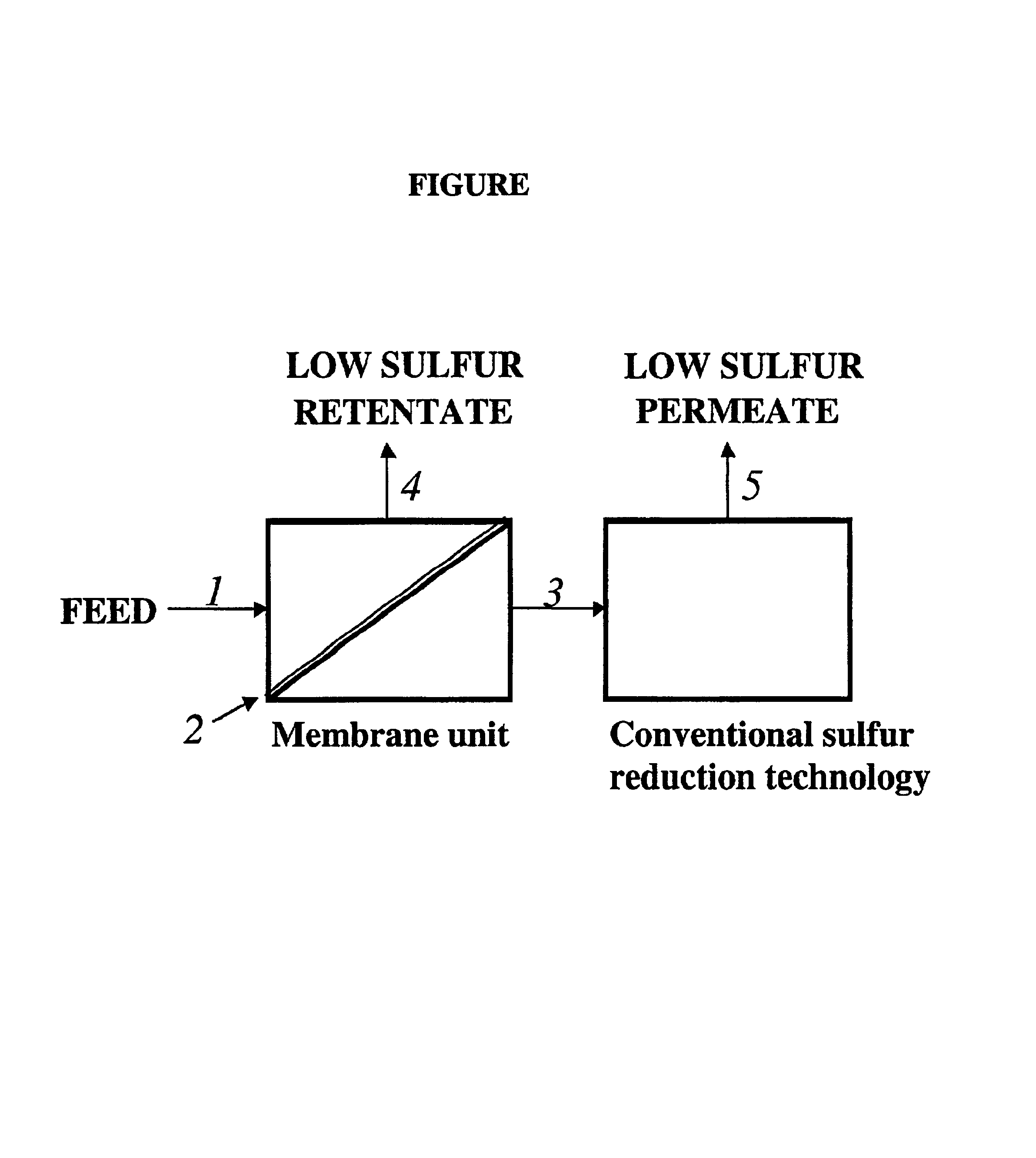

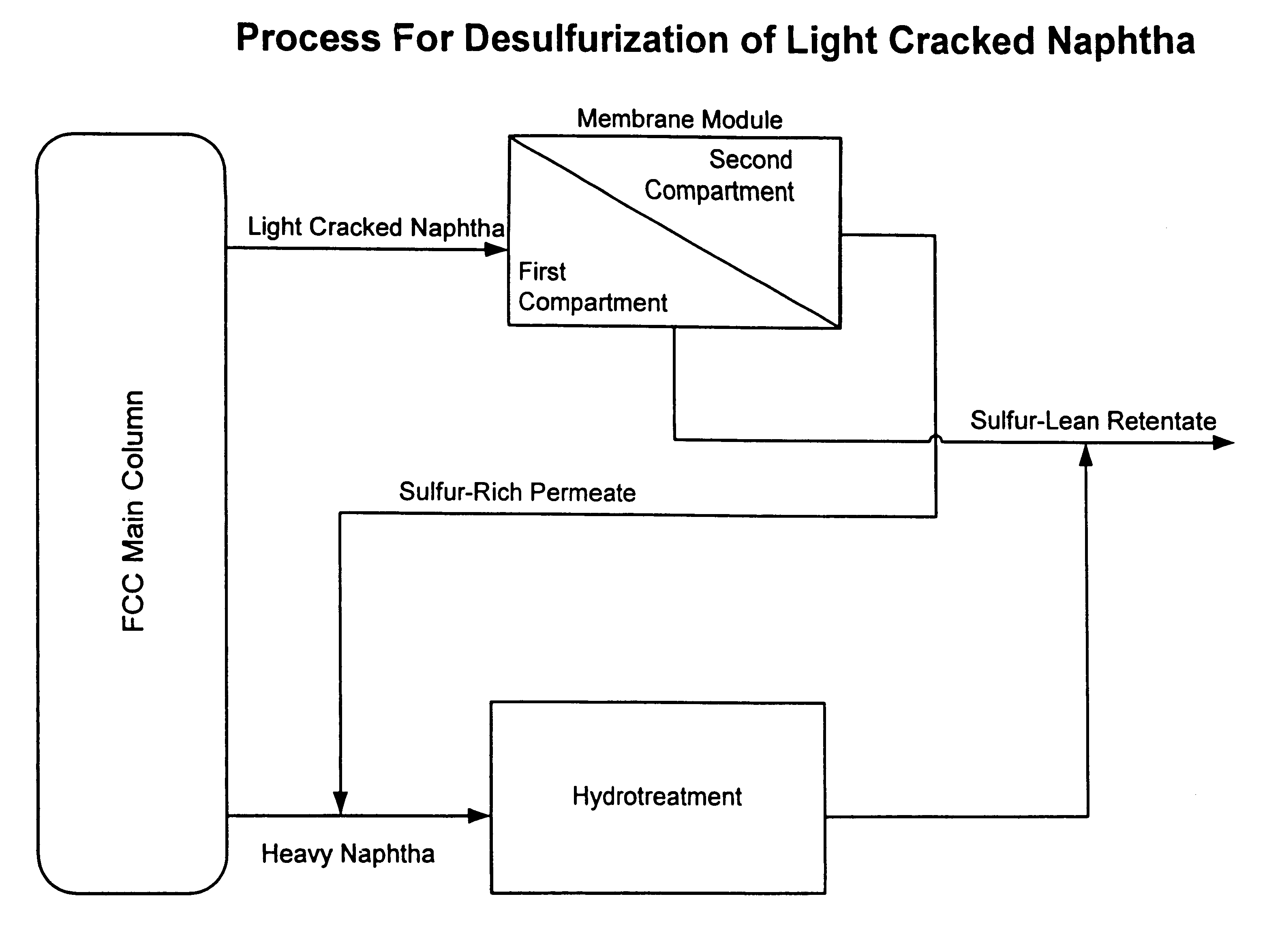

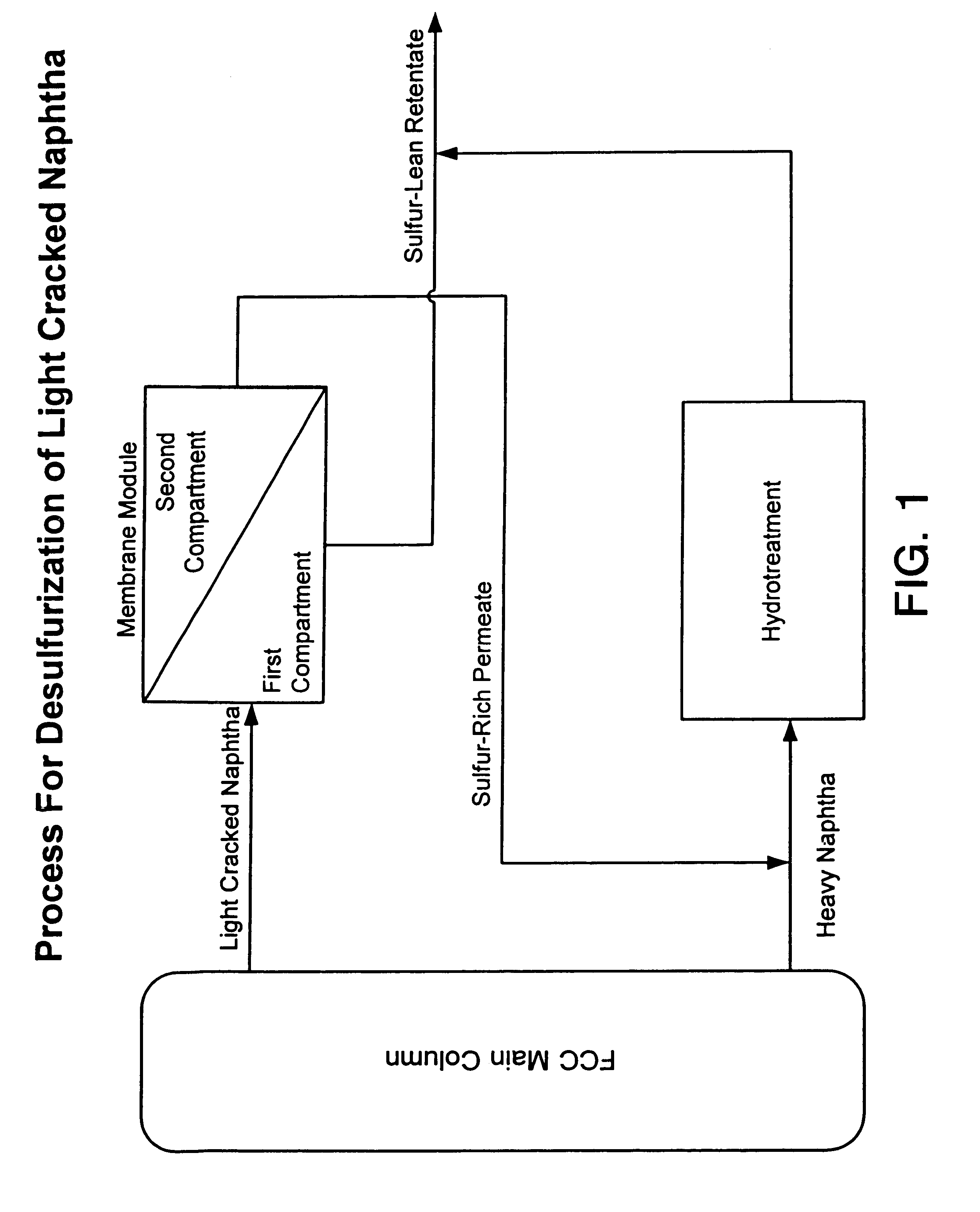

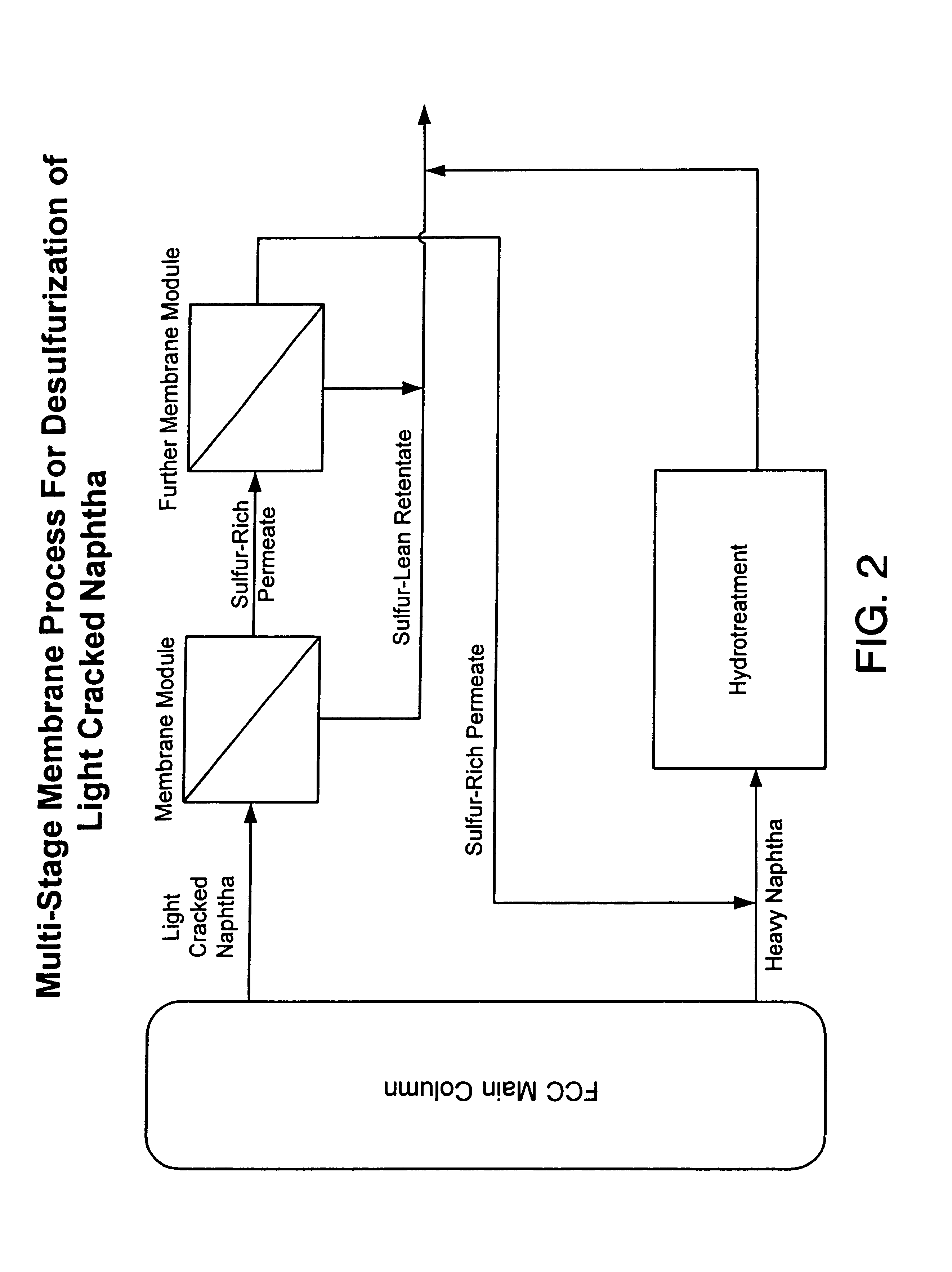

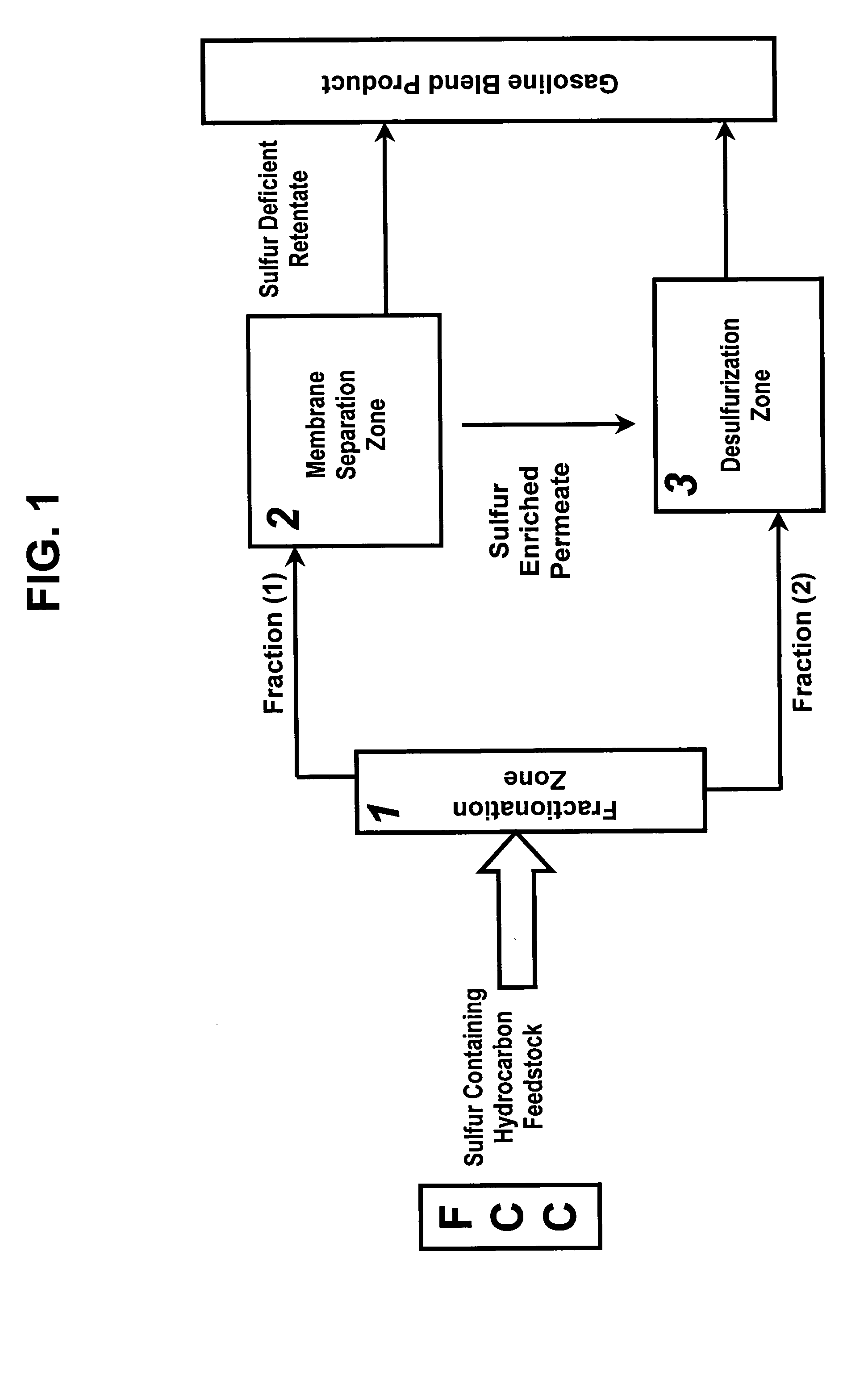

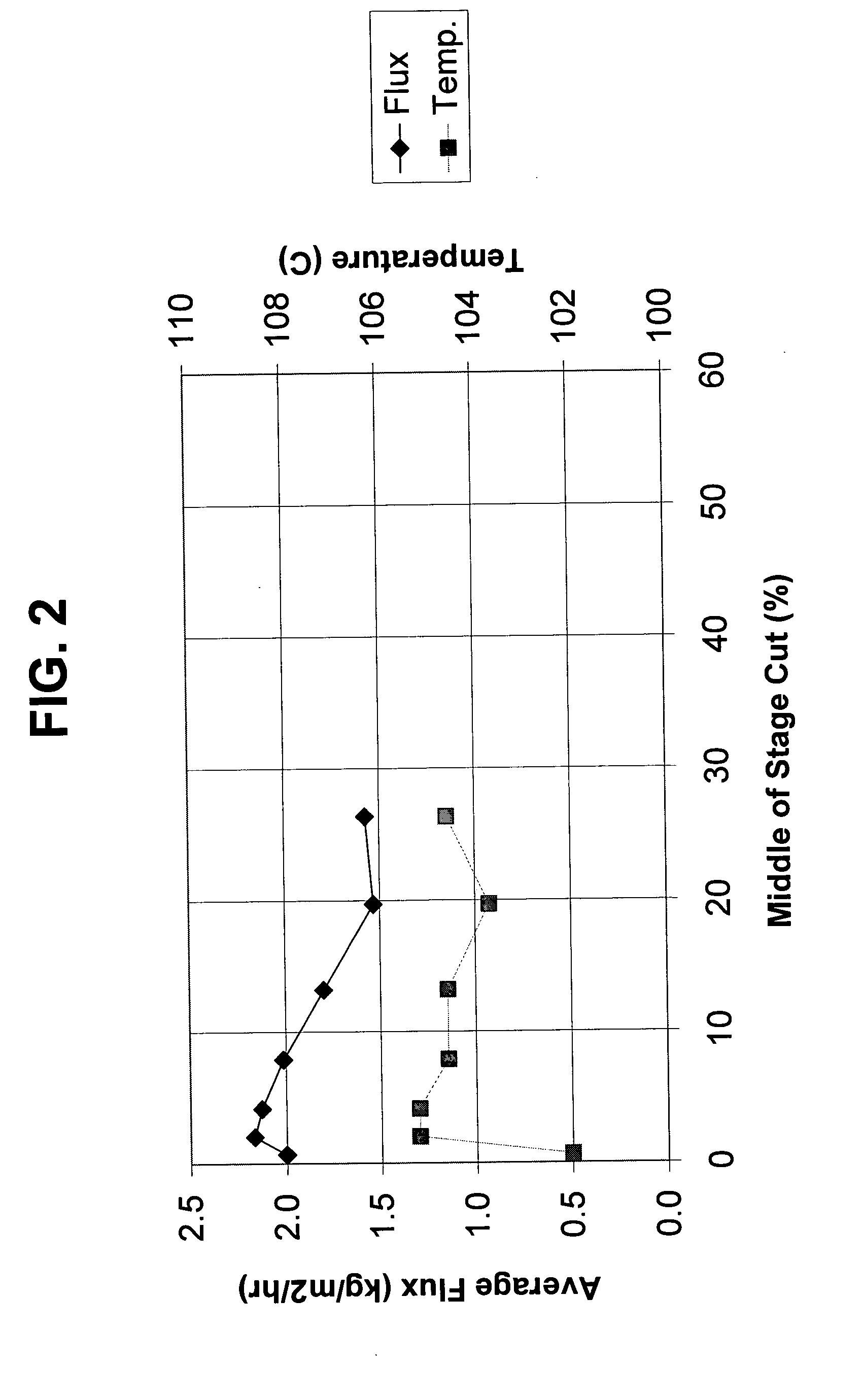

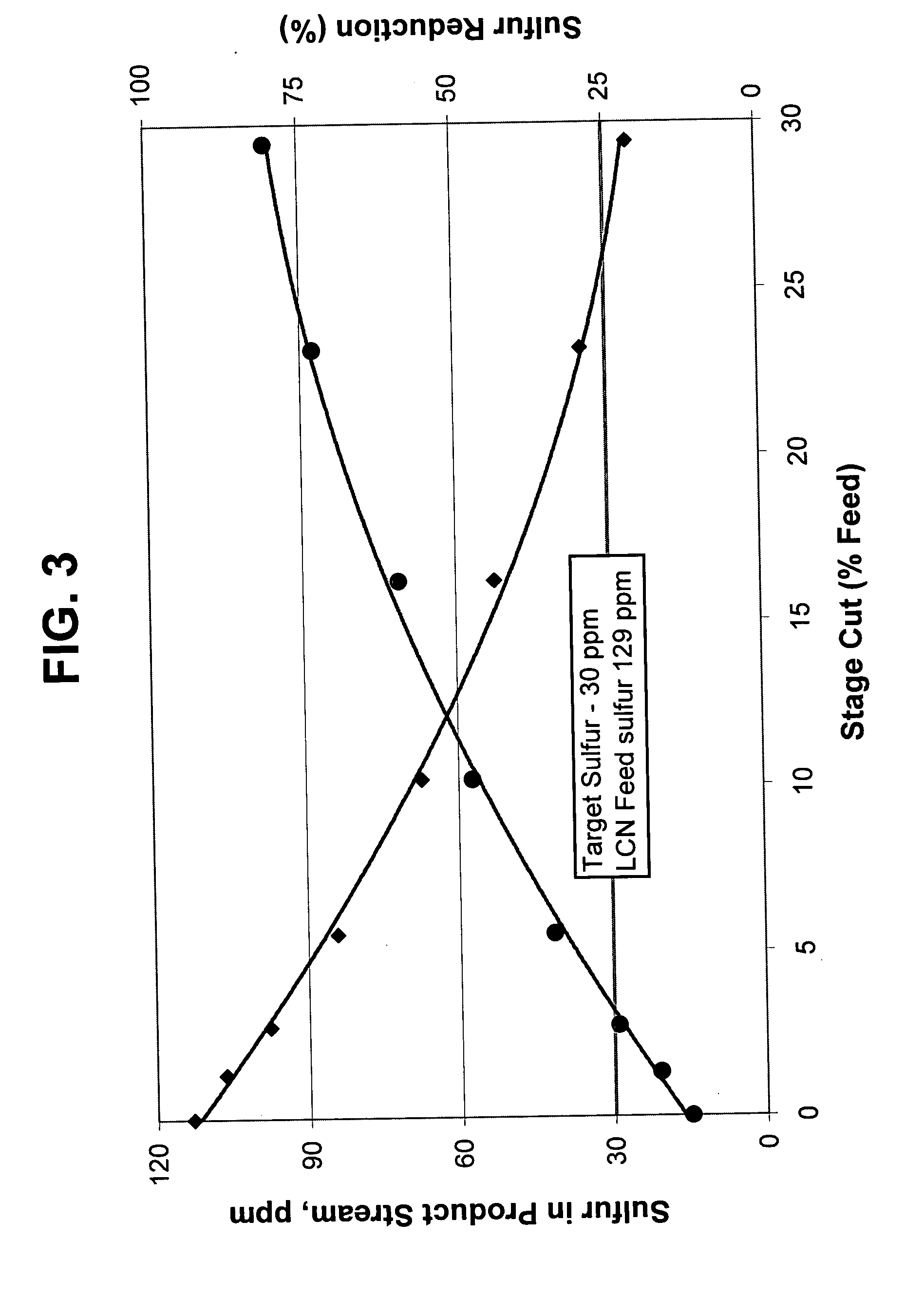

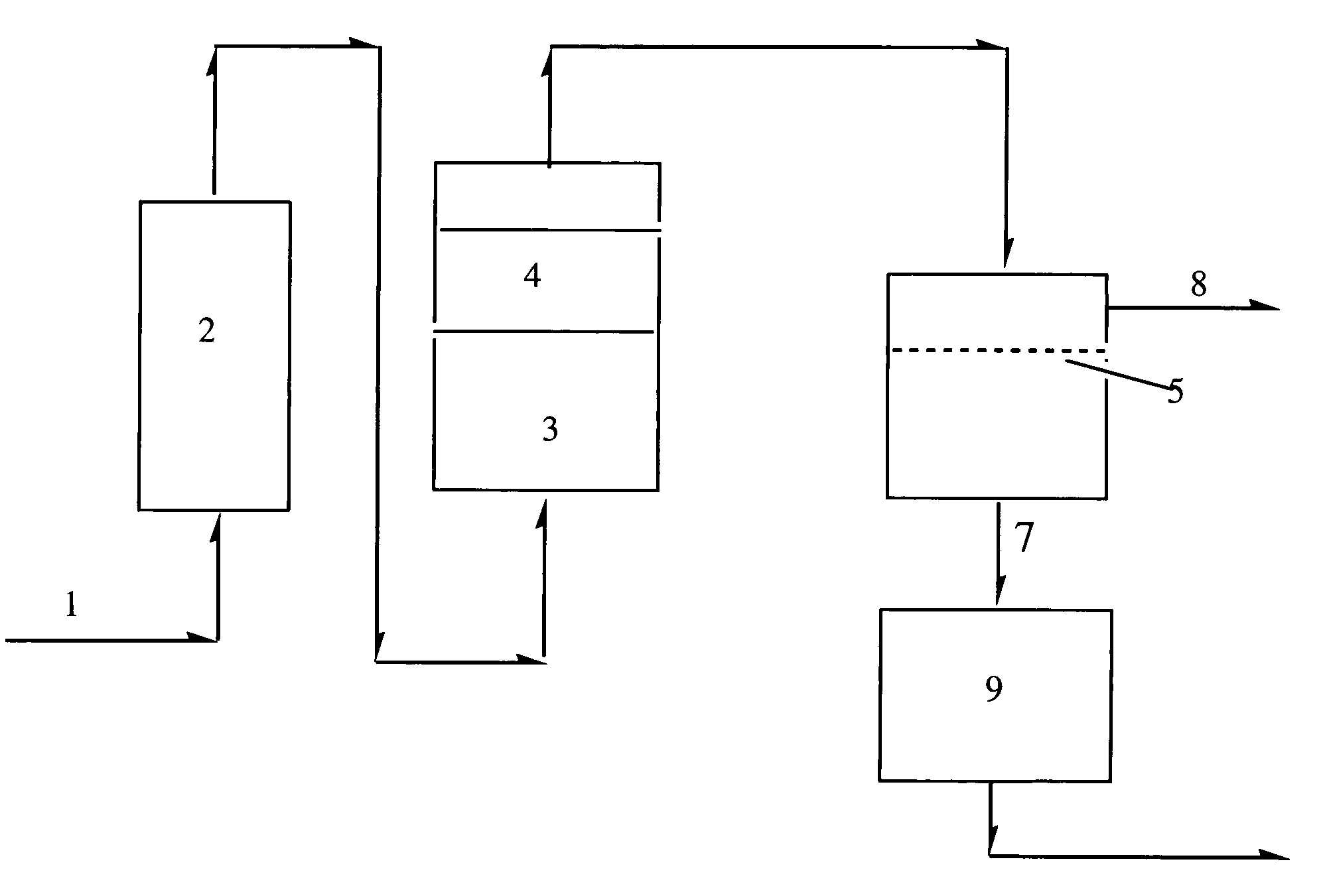

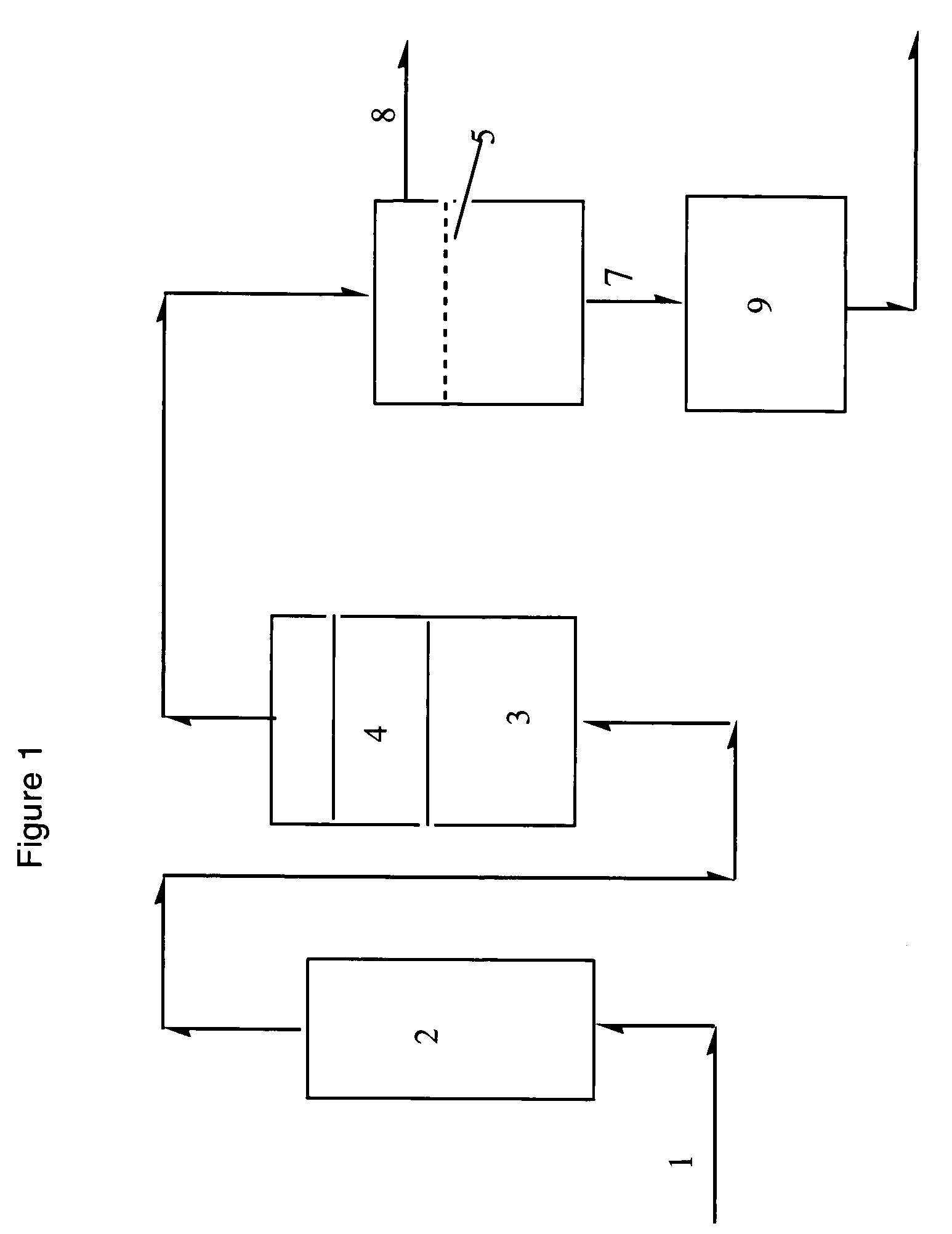

Membrane separation for sulfur reduction

InactiveUS6896796B2Improve economyMinimized volumeDialysisTreatment with plural serial refining stagesNaphthaGasoline

A membrane process for the removal of sulfur species from a naphtha feed, in particular, a FCC light cat naphtha, without a substantial loss of olefin yield is disclosed. The process involves contacting a naphtha feed stream with a membrane having sufficient flux and selectivity to separate a sulfur deficient retentate fraction from a sulfur enriched permeate fraction, preferably, under pervaporation conditions. Sulfur deficient retentate fractions are useful directly into the gasoline pool. Sulfur-enriched permeate fractions are rich in sulfur containing aromatic and nonaromatic hydrocarbons and are further treated with conventional sulfur removal technologies, e.g. hydrotreating, to reduce sulfur content. The process of the invention provides high quality naphtha products having a reduced sulfur content and a high content of olefin compounds.

Owner:WR GRACE & CO CONN

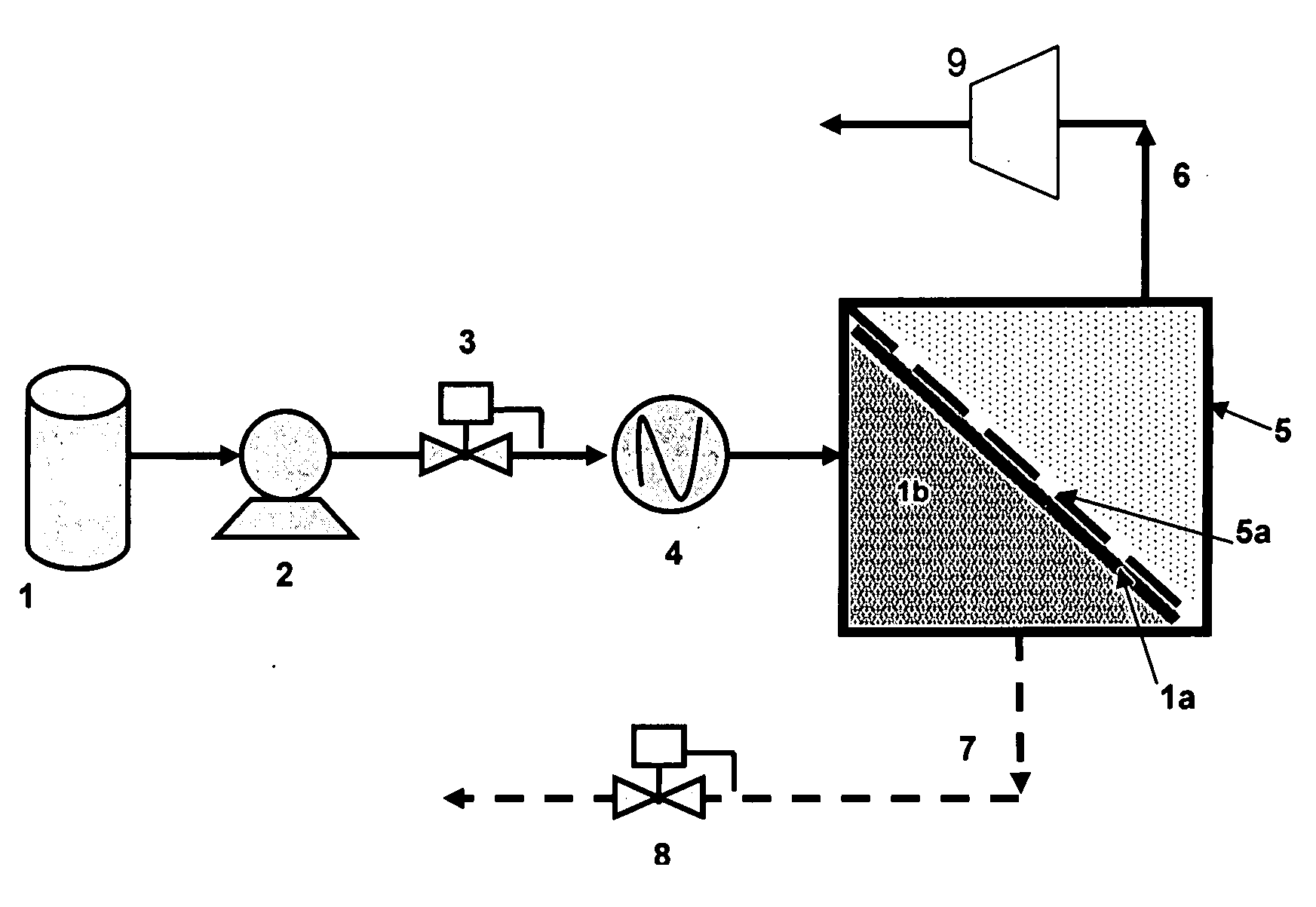

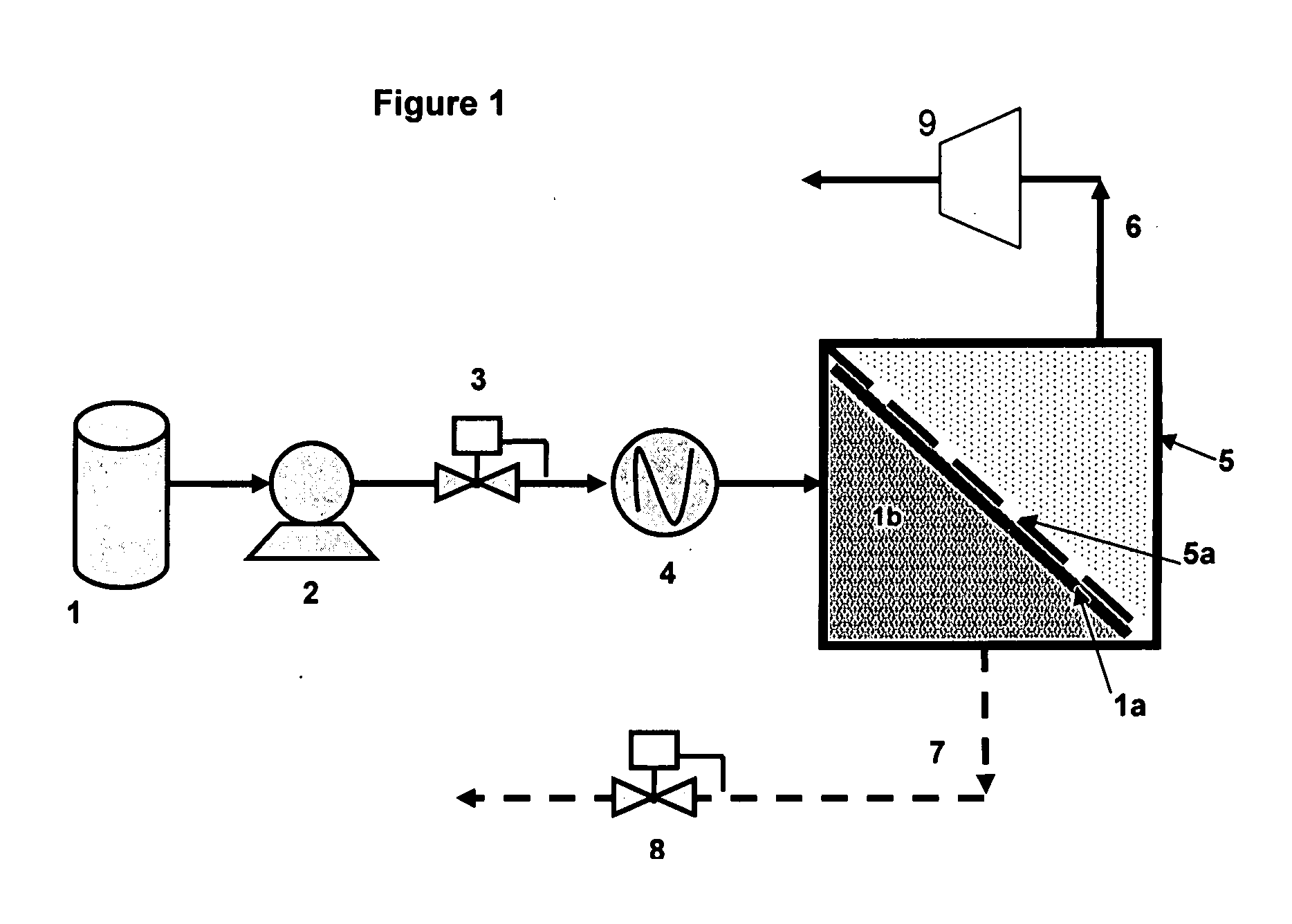

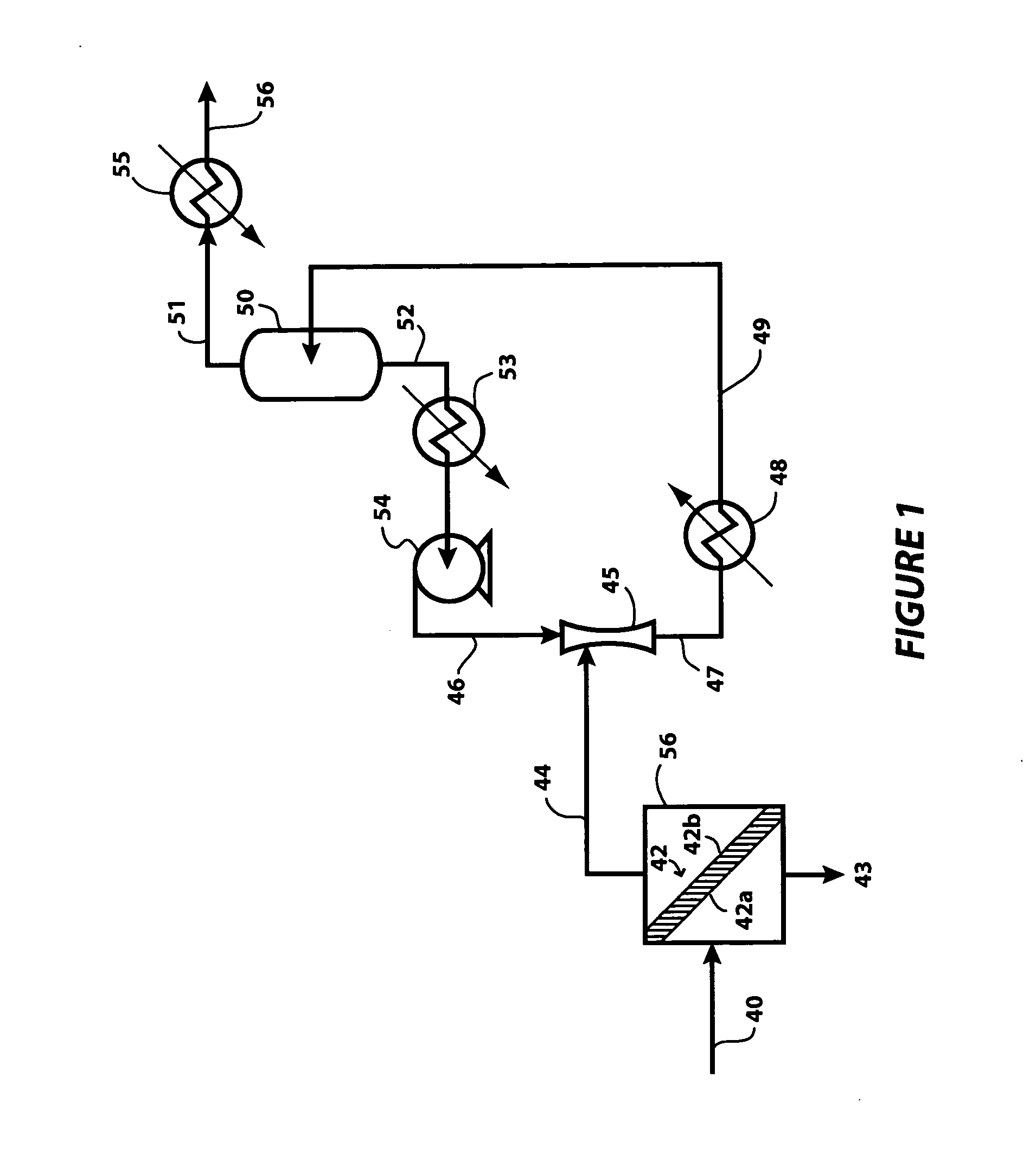

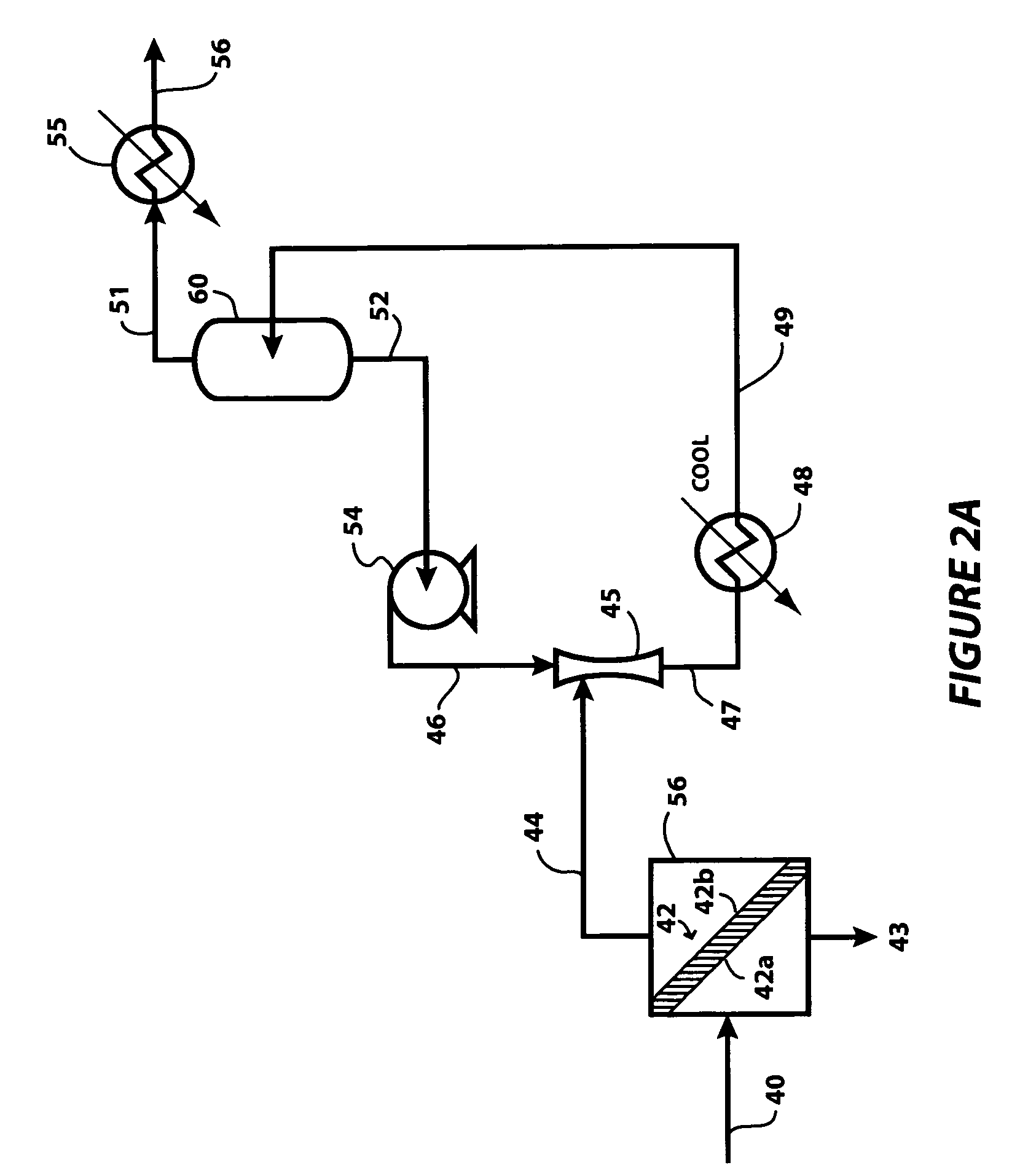

Membrane separation process

ActiveUS20070114177A1Organic compounds purification/separation/stabilisationMembranesSpray nozzlePervaporation

The invention relates to an improved membrane pervaporation and vapor permeation system in which the vacuum is produced by a fluid passing through a Venturi-type nozzle. The fluid is chosen from solvents that have little or no affinity for the permeate molecules. It is applicable over process feed rates, and can be used for the separation of aromatic species from hydrocarbon.

Owner:EXXON RES & ENG CO

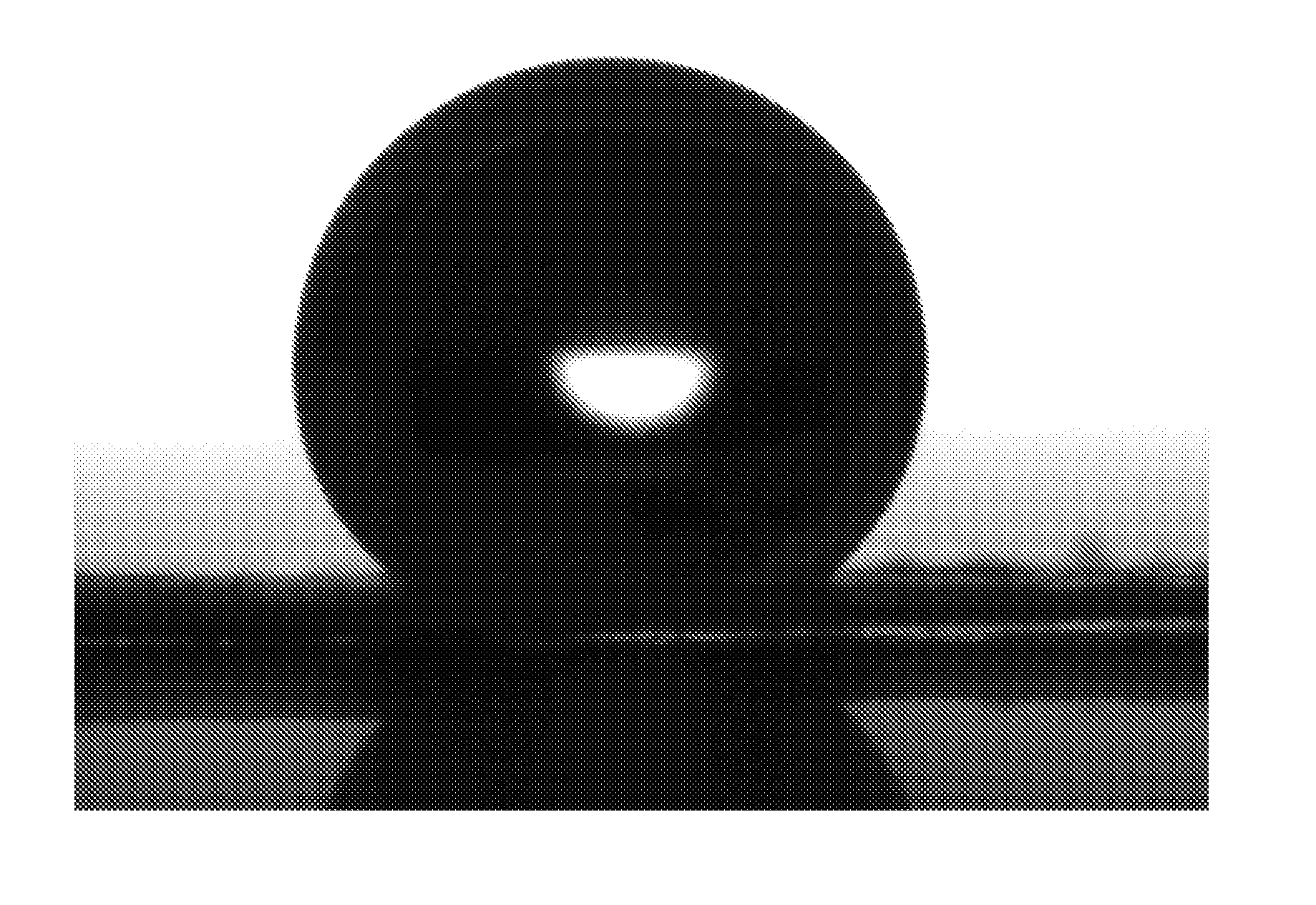

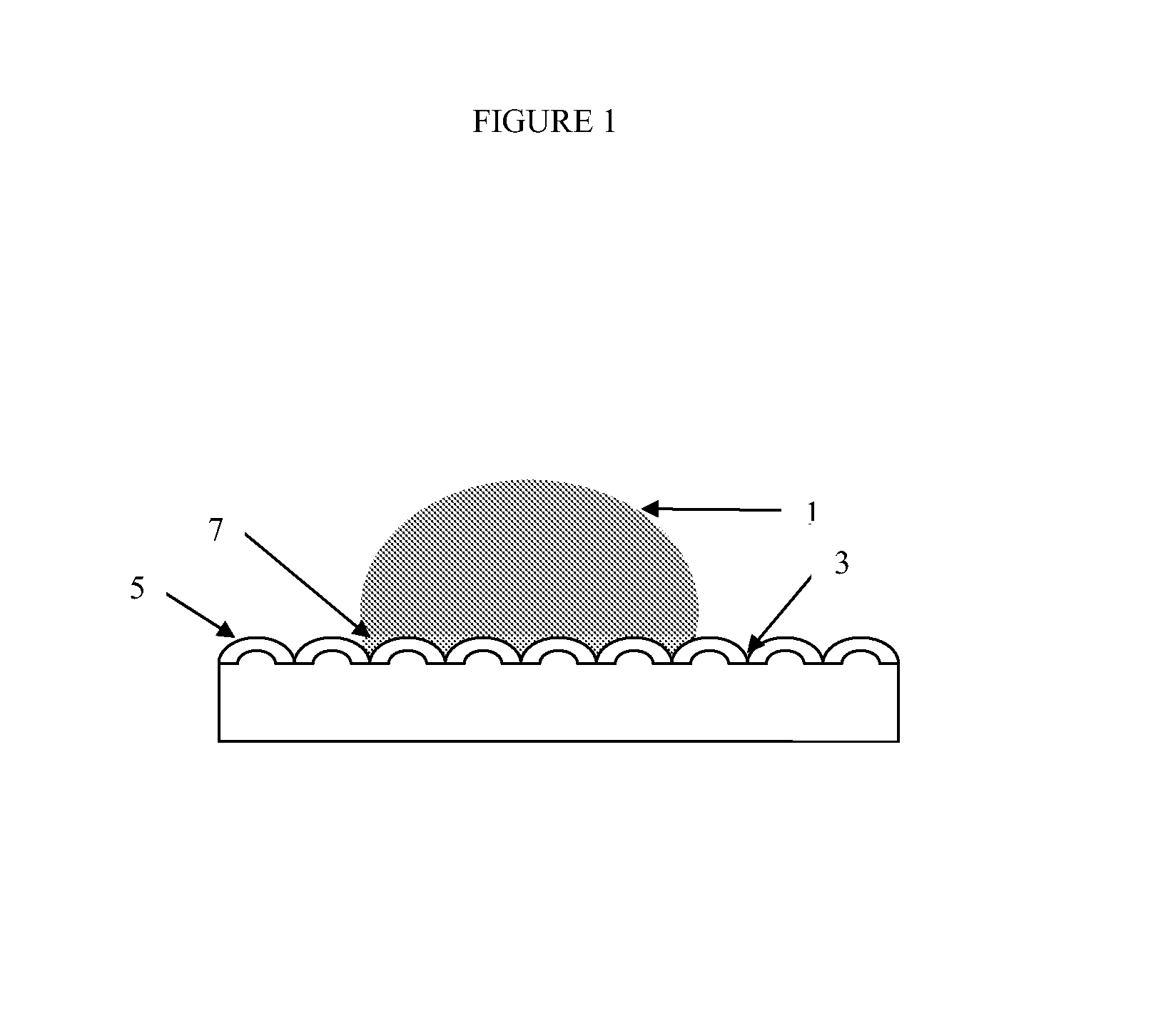

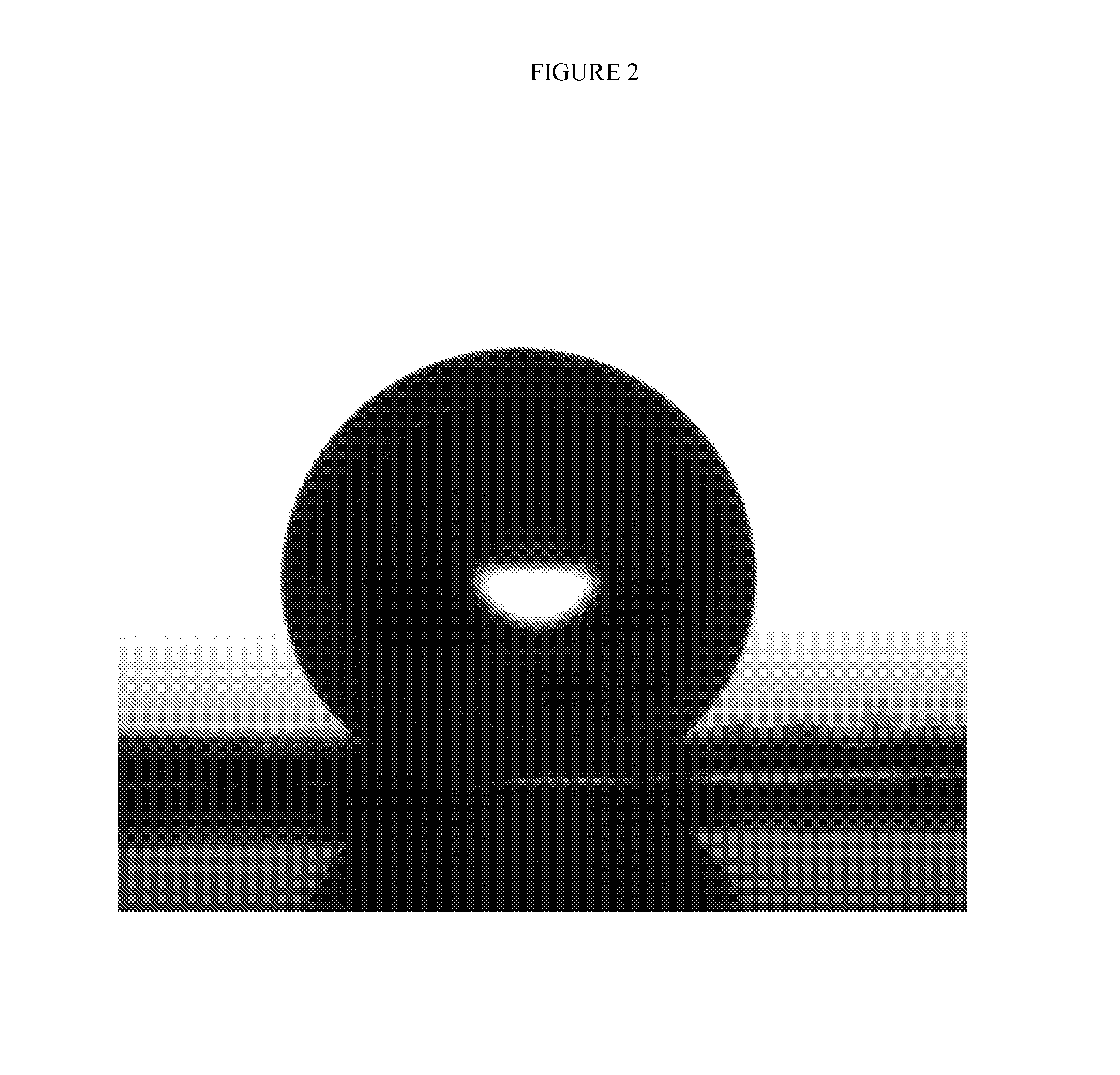

Modified surface energy non-woven filter element

InactiveUS20140275692A1Improve hydrophobicityImprove surface roughnessMembrane filtersHydrocarbonsEngineeringFilter element

A non-woven low surface energy filter element designed to have improved removal of a dispersed liquid phase from a continuous liquid phase is disclosed.

Owner:PARKER HANNIFIN FILTRATION US INC

Selective separation of fluid compounds utilizing a membrane separation process

InactiveUS6986802B2Low costCost prohibitiveGas treatmentLiquid degasificationPermselective membraneControl equipment

Apparatus and processes are disclosed for economical separation of fluid mixtures utilizing perm-selective membranes. Broadly, apparatus of the invention comprises a plurality of membrane modules comprising a solid perm-selective membrane and equipment for controlling enthalpy of selected fluids within the apparatus. Advantageously, the membrane modules are disposed in a first product group, a second product group, and at least one intermediate group. Apparatus of the invention is particularly useful for simultaneous recovery of a very pure permeate product, and / or a desired non-permeate stream, from fluid mixtures of two or more compounds which when subjected to appropriately altered conditions of temperature and / or pressure exhibit a bubble point.

Owner:BP CORP NORTH AMERICA INC

Methane recovery process

ActiveUS7025803B2Safe and economical and environmentally protective recoveryProductsGas treatmentHigh concentrationUnit operation

A system and a process for recovering high concentrations of methane from crude natural gas and solid waste landfill exhaust gas uses a sequential combination of a pressure swing adsorber unit operation to remove volatile organic compounds from the crude feed gas mixture followed by a membrane separation unit operation. The membrane separation uses a membrane which is selectively gas permeable to reject transmission of methane and thus to produce a permeate depleted in methane relative to the feed mixture. The permeate is also free of volatile organic compounds and is recycled to the pressure swing adsorber unit operation to regenerate saturated adsorbers.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

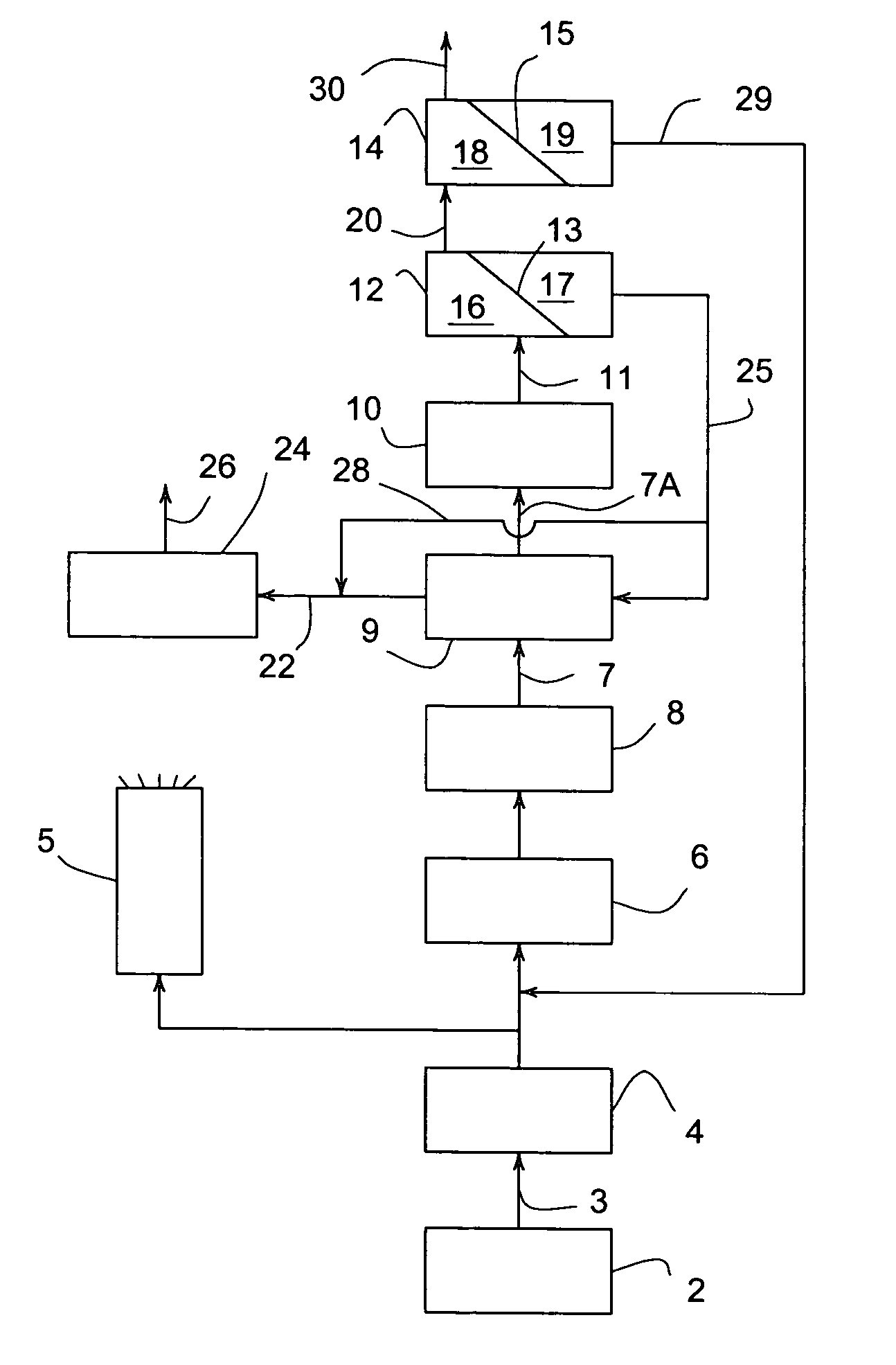

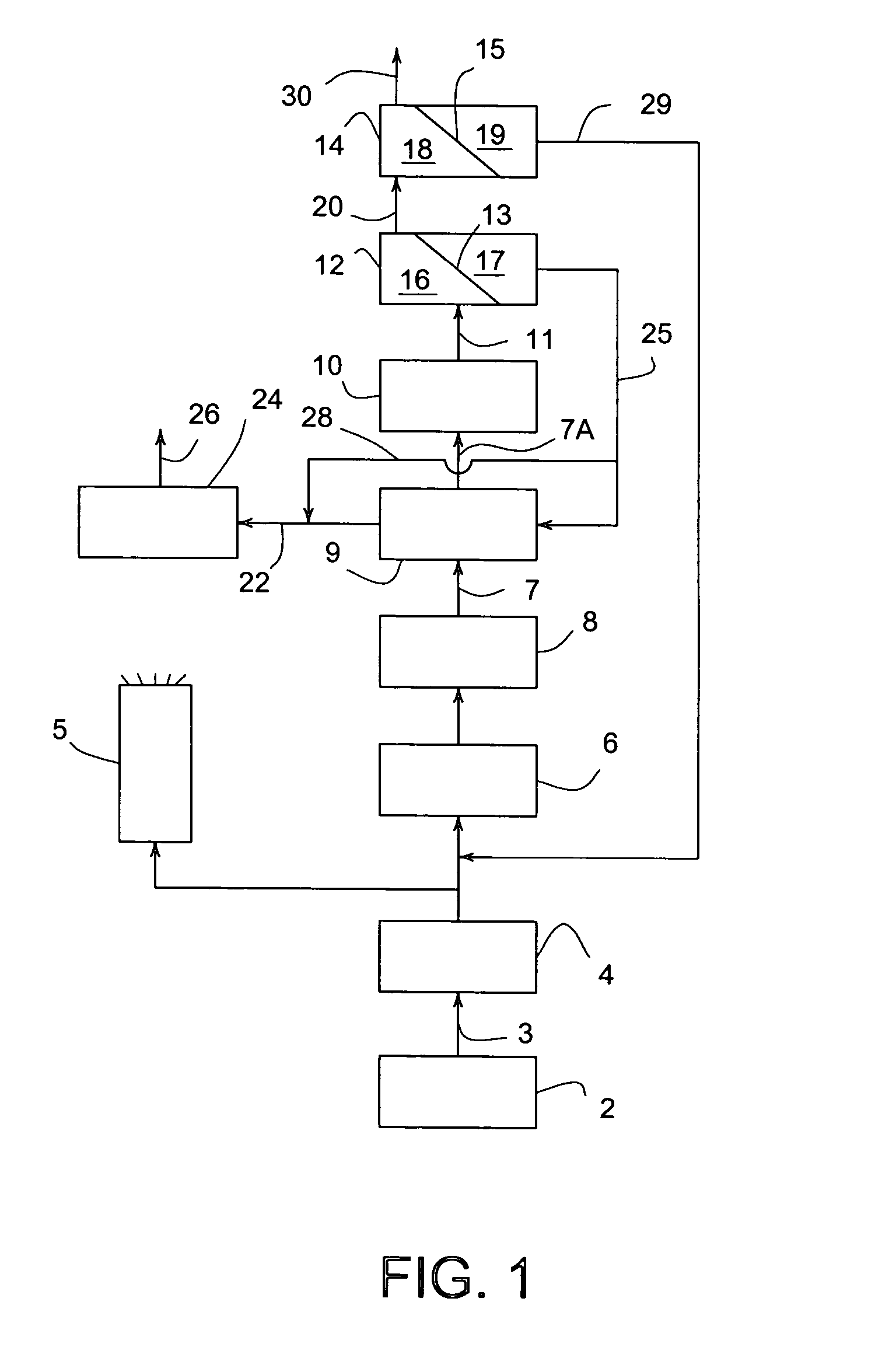

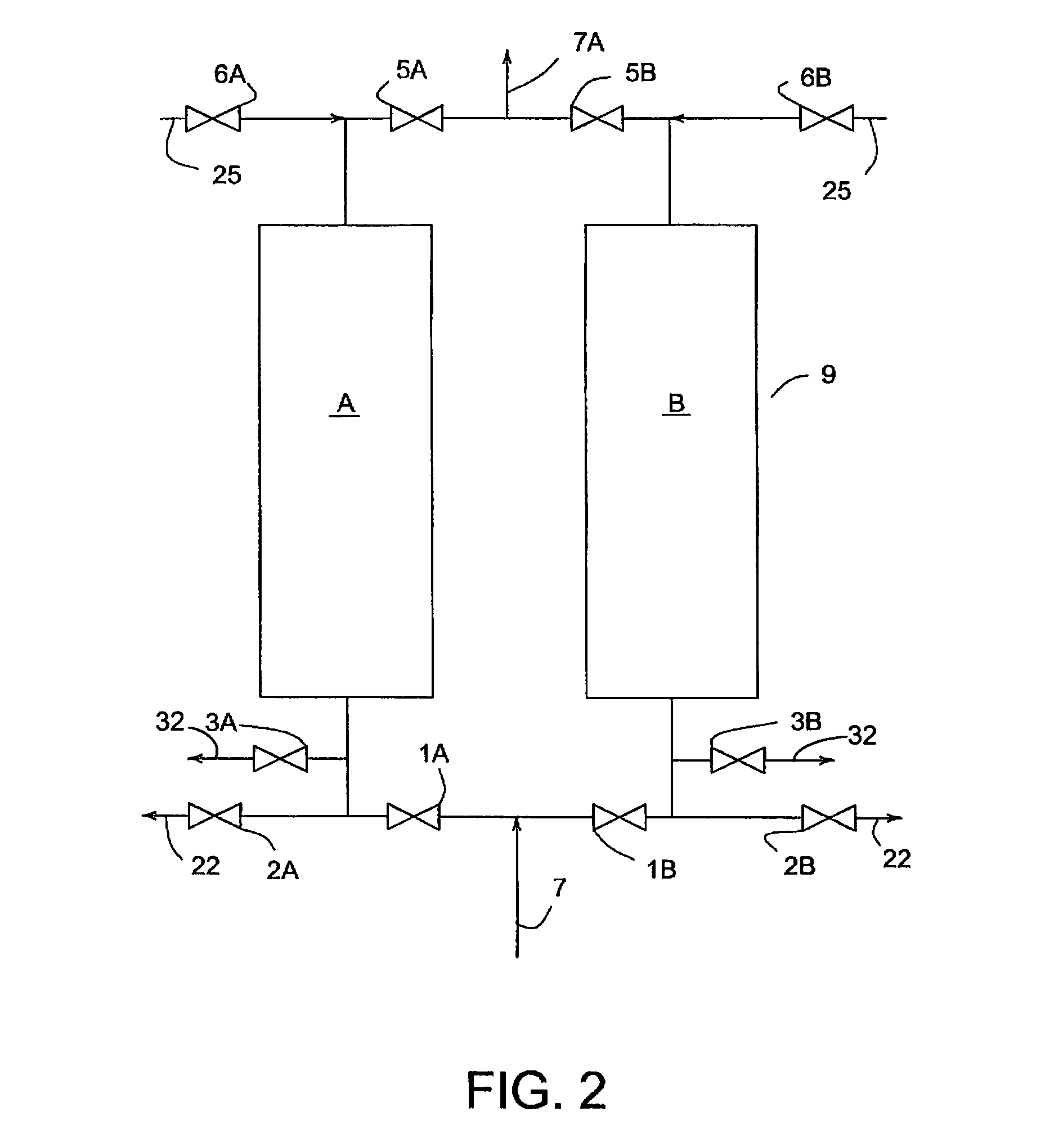

Membrane process for separating sulfur compounds from FCC light naphtha

InactiveUS6649061B2Ion-exchange process apparatusTreatment with plural serial stages onlyNaphthaHydrocarbon mixtures

A process for the separation of sulfur compounds from a hydrocarbon mixture using a membrane is provided. Preferred hydrocarbon mixtures are oil refining fractions such as light cracked naphtha. Membranes are composed of either ionic or non-ionic materials and preferentially permeate sulfur compounds over other hydrocarbons. A single or multi-stage membrane system separates the hydrocarbon mixture into a sulfur-rich fraction and a sulfur-lean fraction. The sulfur-lean fraction may be used in fuel mixtures and the sulfur-rich fraction may be further treated for sulfur reduction.

Owner:EXXON RES & ENG CO

Process of separating gases using polyimide membranes

ActiveUS20120323059A1Improve conductivityHigh selectivityMethane captureIsotope separationCross-linkPolyimide membrane

The present invention discloses a new type of polyimide membrane with high permeances and high selectivities for gas separations and particularly for CO2 / CH4 and H2 / CH4 separations. The polyimide membranes have CO2 permeability of 50 Barrers or higher and single-gas selectivity for CO2 / CH4 of 15 or higher at 50° C. under 791 kPa for CO2 / CH4 separation. The polyimide membranes have UV cross-linkable functional groups and can be used for the preparation of UV cross-linked polyimide membranes having CO2 permeability of 20 Barrers or higher and single-gas selectivity for CO2 / CH4 of 35 or higher at 50° C. under 791 kPa for CO2 / CH4 separation.

Owner:UOP LLC

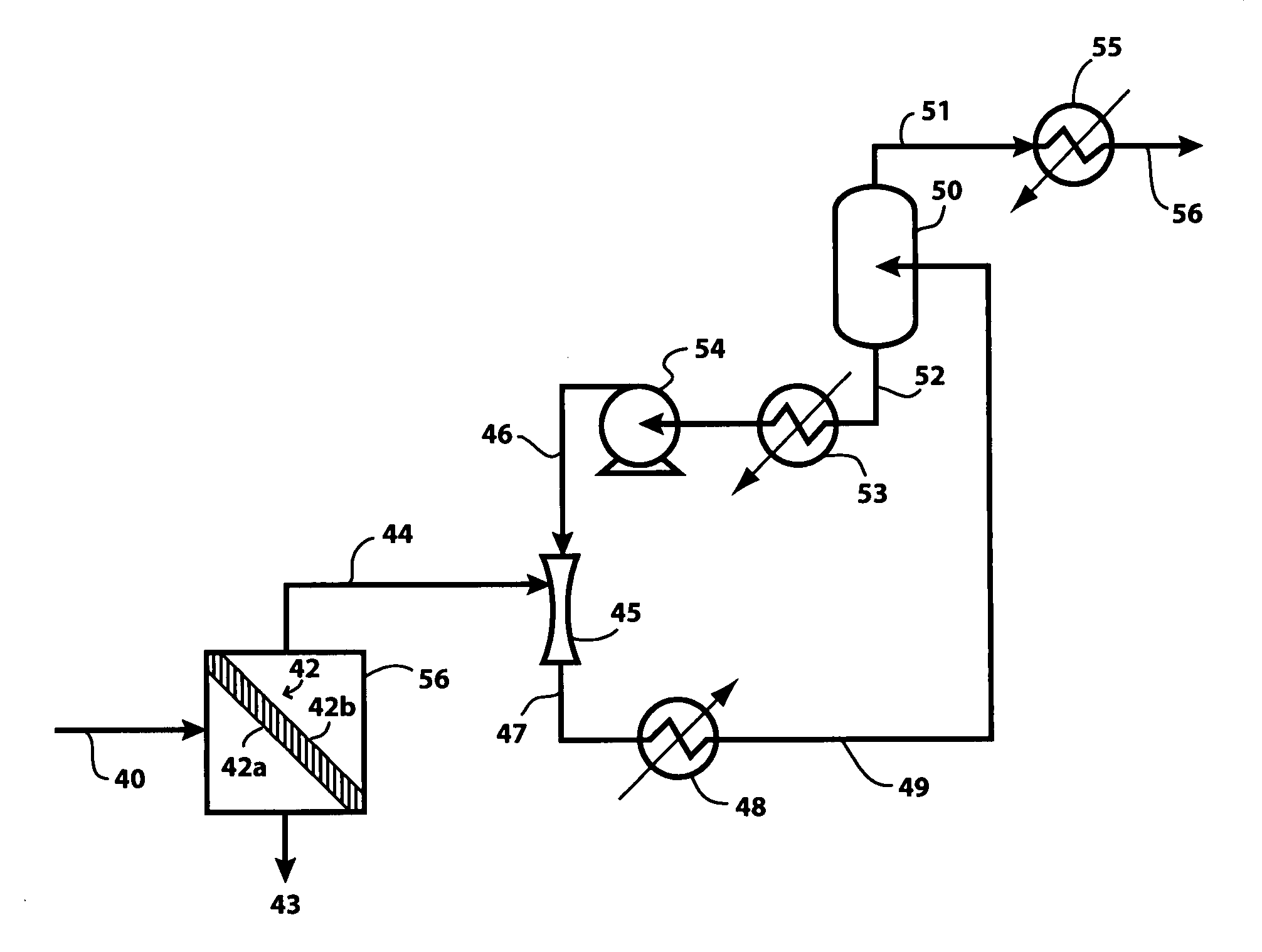

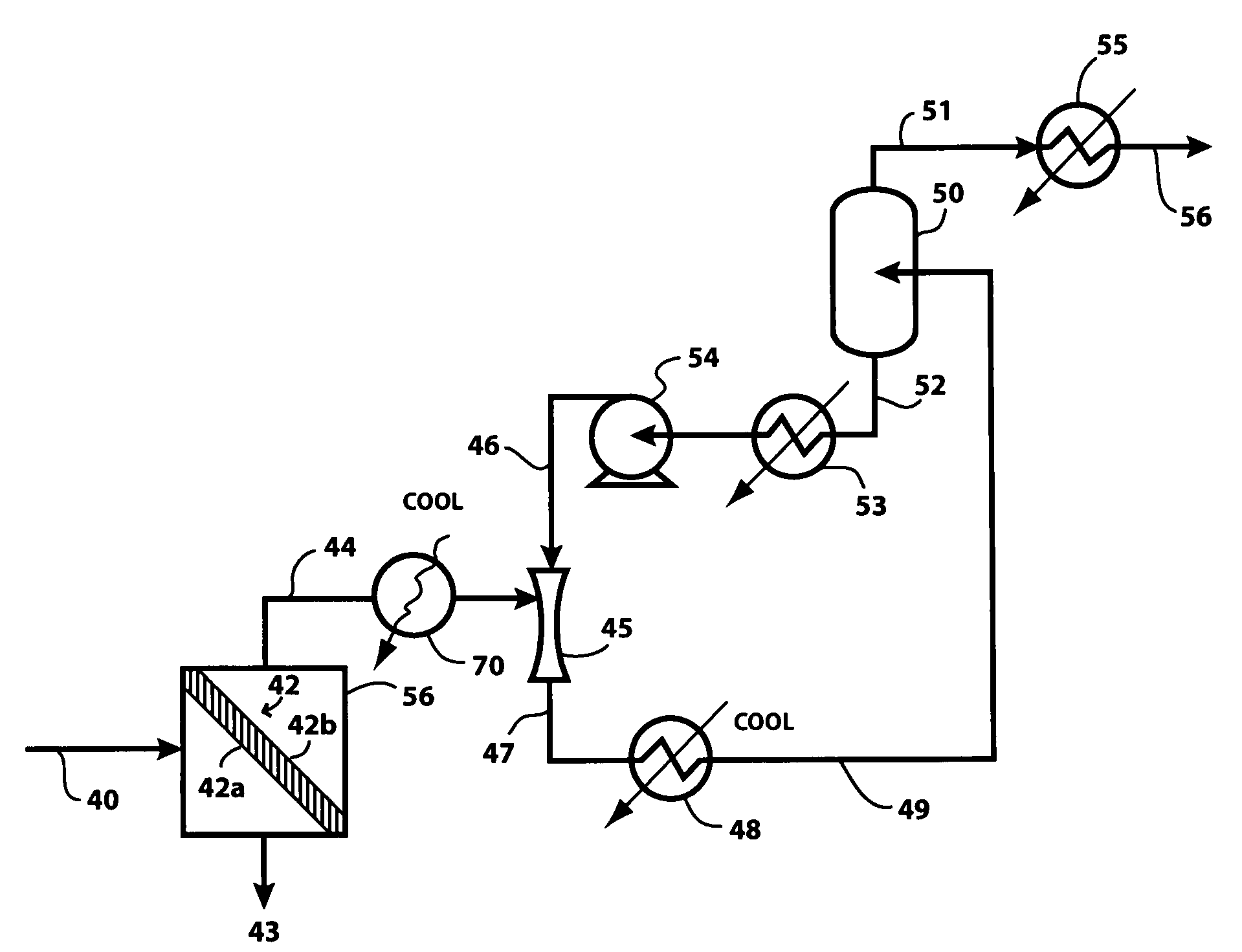

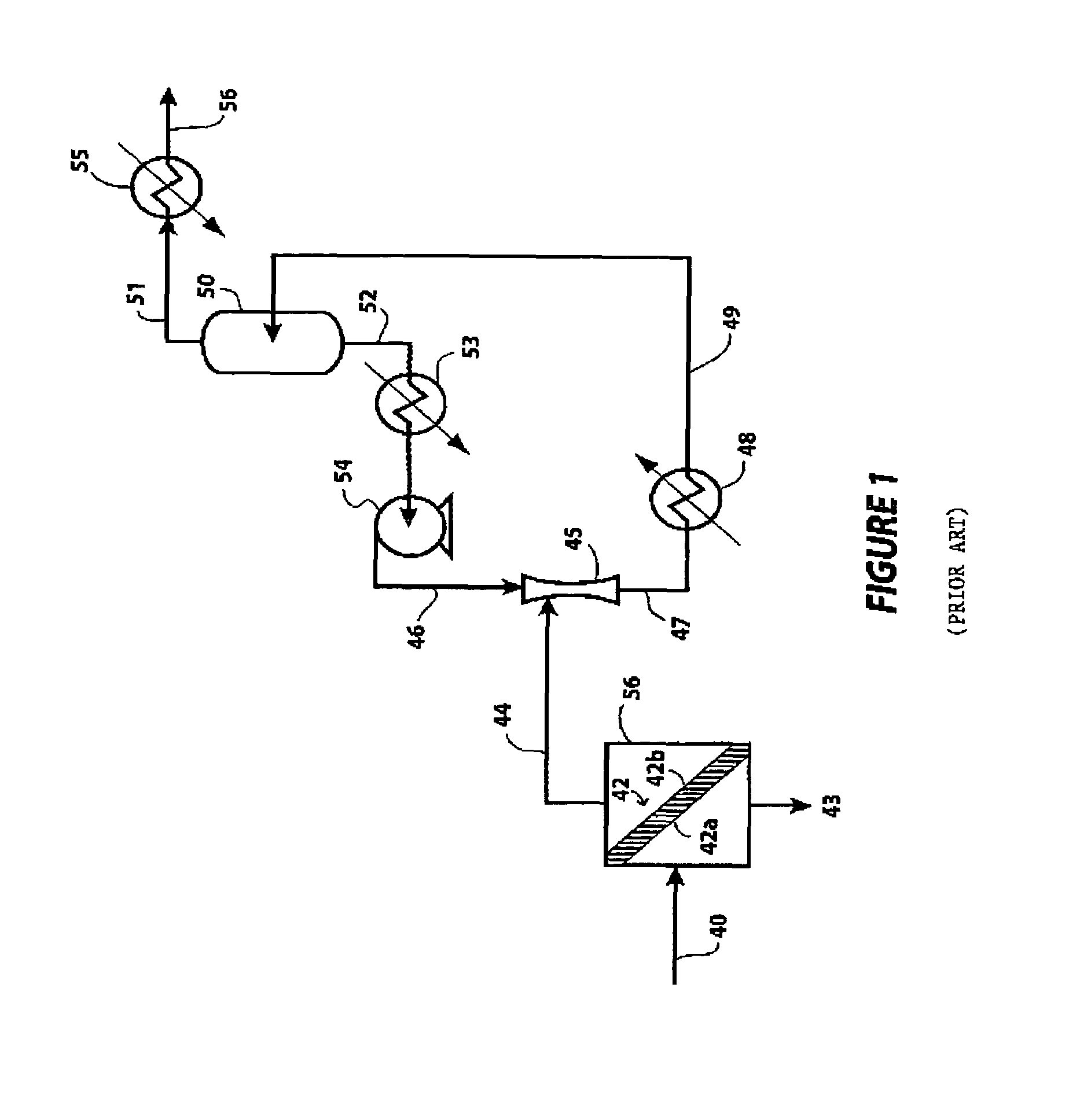

Membrane separation process

ActiveUS7497895B2Organic compounds purification/separation/stabilisationMembranesSpray nozzlePervaporation

The invention relates to an improved membrane pervaporation and vapor permeation system in which the vacuum is produced by a fluid passing through a Venturi-type nozzle. The fluid is chosen from solvents that have little or no affinity for the permeate molecules. It is applicable over process feed rates, and can be used for the separation of aromatic species from hydrocarbon.

Owner:EXXON RES & ENG CO

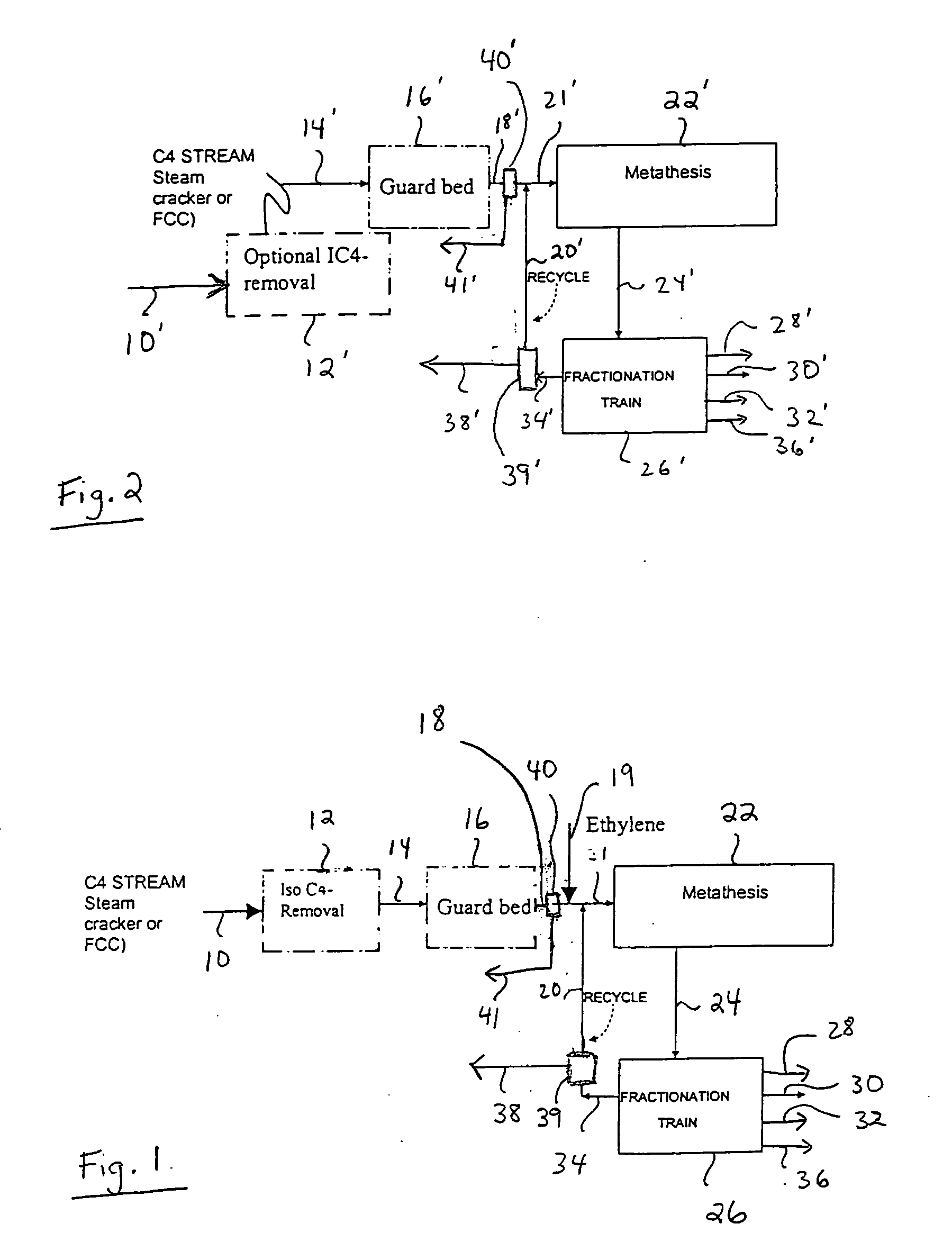

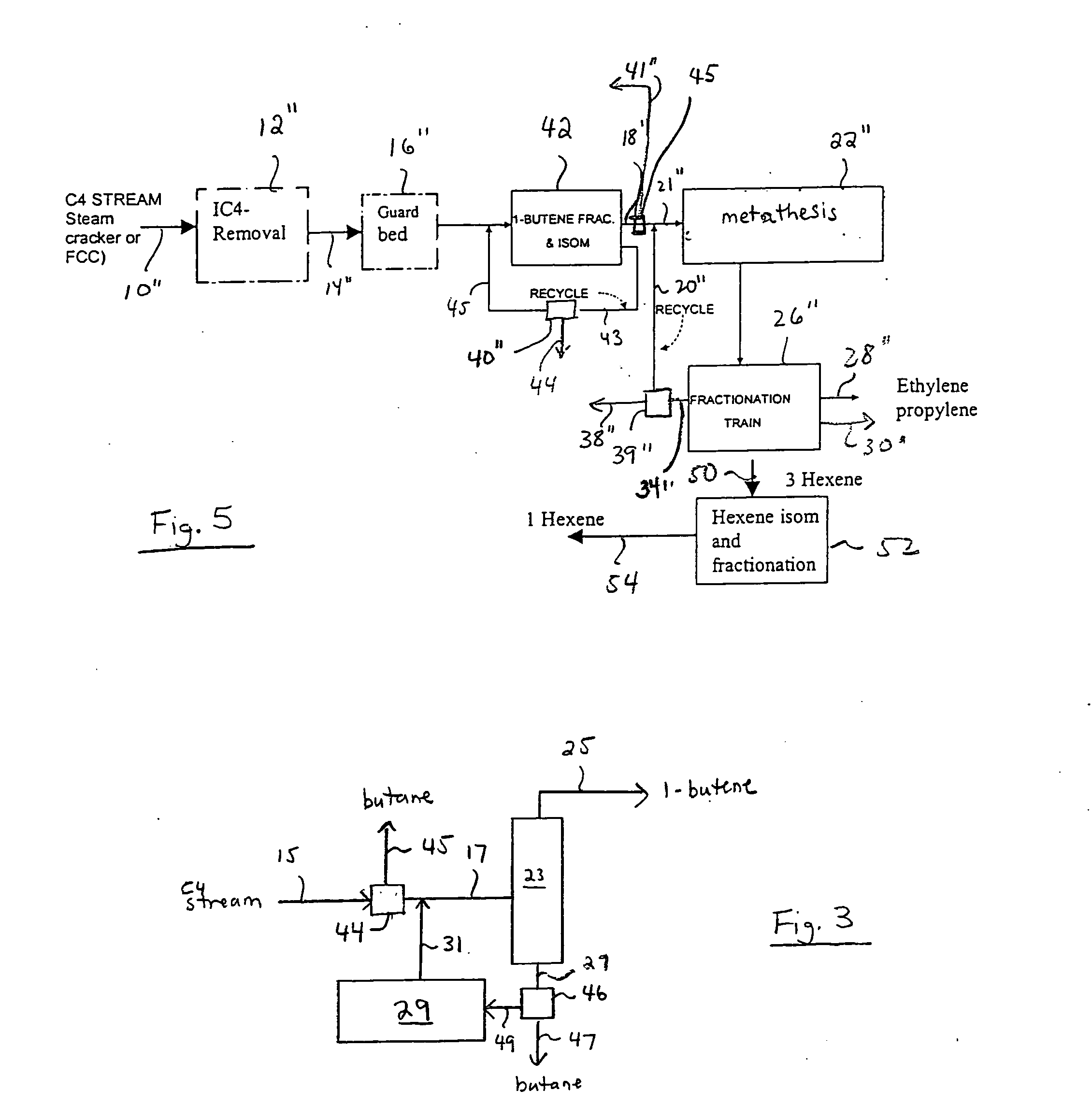

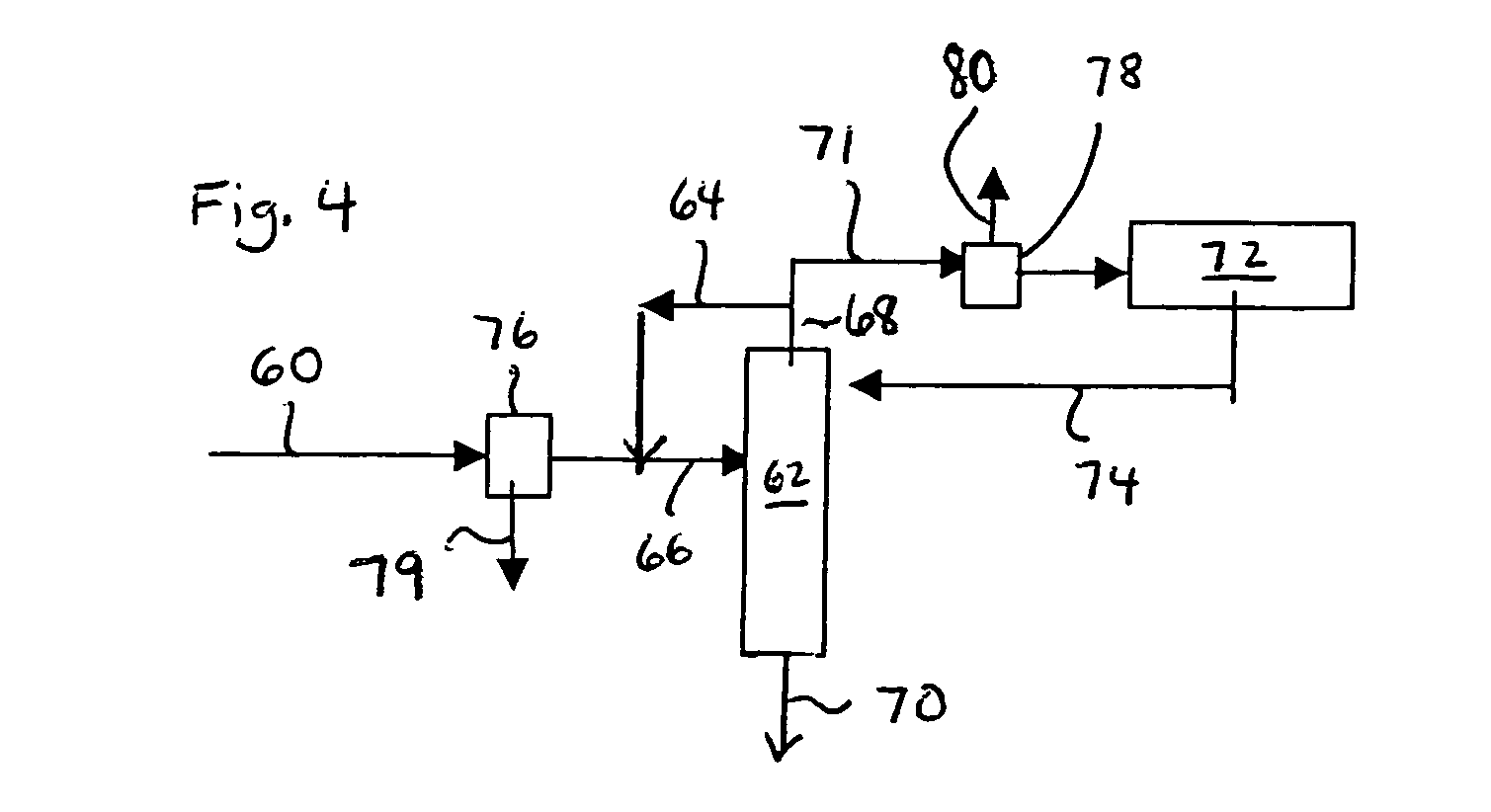

Butane removal in C4 upgrading processes

InactiveUS20060047176A1High efficiency and low costHydrocarbon by isomerisationChemical industryButeneAlkane

Disclosed herein is a process for producing a selected butene, comprising obtaining a C4 feed stream comprising C4 paraffins and C4 olefins, splitting the C4 feed stream to form a first stream comprising a first butene and a second stream comprising a second butene, isomerizing at least a part of the second stream to convert a portion of the second butene to the first butene, and recycling at least some of the isomerized part of the second steam to the splitting step, wherein a portion of at least one of the C4 feed stream and the second stream is passed through a facilitated transport membrane to remove butanes, forming at least one purge stream comprising butanes. A process for the conversion of C4 olefins, comprising obtaining a C4 feed stream comprising C4 paraffins and C4 olefins, including 1-butene and 2-butene, and reacting the C4 feed stream in a metathesis reactor to form a second stream is also disclosed. The second stream is fractionated to form one or more product streams and a recycle stream primarily containing C4 olefins and C4 paraffins. The recycle stream and / or the C4 feed stream is passed through a facilitated transport membrane to remove butanes, forming at least one purge stream.

Owner:ABB LUMMUS GLOBAL INC

Method of reducing sulfur in hydrocarbon feedstock using a membrane separation zone

ActiveUS20050067323A1Reduce sulfur contentEasy to operateTreatment with plural serial refining stagesTreatment with plural parallel refining stagesNaphthaHydrodesulfurization

A membrane is used in combination with fractionation and hydrodesulfurization to reduce the sulfur content of hydrocarbon feeds, preferably sulfur-containing naphtha feeds. A membrane separation zone is employed to treat a fraction of effluent from a fractionation zone containing sulfur-containing non-aromatic hydrocarbons to produce a sulfur rich permeate and sulfur deficient retentate. The sulfur rich permeate and a second fraction of the fractionation zone, which contains sulfur-containing aromatic hydrocarbons, are further treated in a hydrodesulfurization zone. The stream from the hydrodesulfurization zone and the sulfur deficient retentate from the membrane separation zone are then processed as low sulfur hydrocarbon streams, especially those streams being processed in the manufacture of gasoline when the initial hydrocarbon stream is naphtha from a fluidized catalytic cracking unit.

Owner:WR GRACE & CO CONN

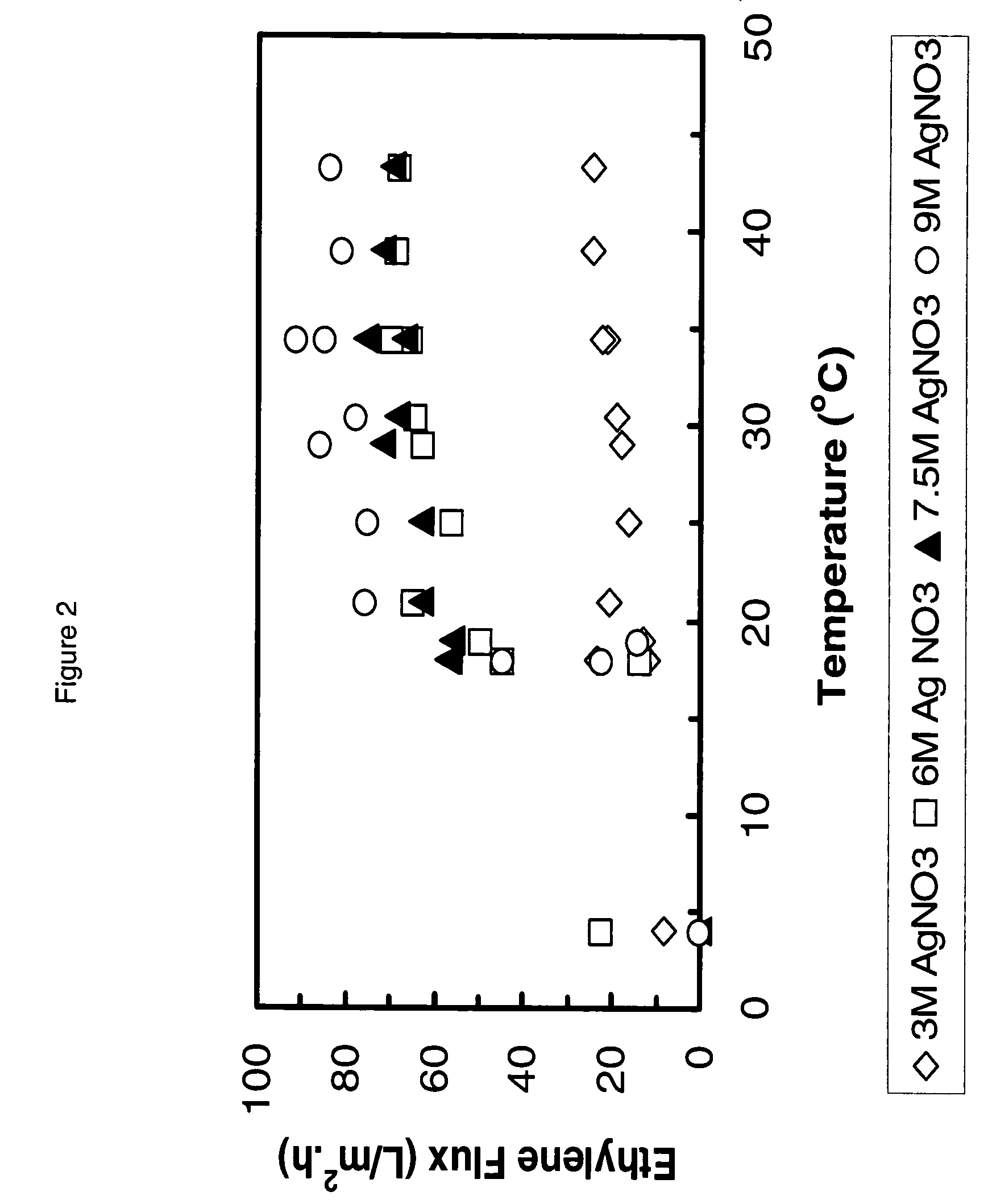

Process for the separation of olefins from paraffins using membranes

Chitosan membranes chelated with silver or cuprous material may be used to separate olefins from a mixture of olefins and paraffins. The feed stream is humidified, demisted, treated to remove sulfur compounds and passed to a cell having a chitosan membrane containing chelated silver or cuprous compounds. The process has a reasonable flux rate and is operable at reasonable temperatures and pressures. The process could be used in an olefin separation train.

Owner:IMTEX MEMBRANES CORP

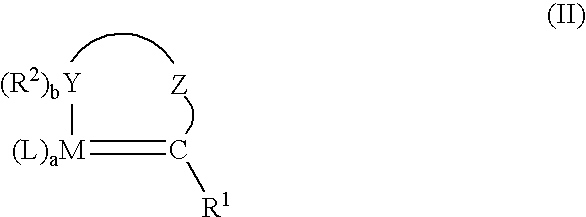

Membrane Separation Of A Metathesis Reaction Mixture

InactiveUS20080103346A1Reduces possibility of undesirableImprove efficiencySemi-permeable membranesCatalystsPolymer scienceCatalyst degradation

A process for separating a homogeneous metathesis catalyst and, optionally, one or more homogeneous metathesis catalyst degradation products from a metathesis reaction mixture containing in addition to said metathesis catalyst and said metathesis catalyst degradation product(s), one or more olefin metathesis products, one or more unconverted reactant olefins, and optionally, a solvent. The process involves contacting the metathesis reaction mixture with a nanofiltration membrane, such as a polyimide nanofiltration membrane, so as to recover a permeate containing a substantial portion of the olefin reaction products, the unconverted reactant olefins, and optional solvent, and a retentate containing the metathesis catalyst, and optionally, metathesis catalyst degradation product(s). In another aspect, this invention pertains to a continuous metathesis reaction-catalyst separation process, preferably, conducted in a nanofiltration membrane reactor.

Owner:DOW GLOBAL TECH LLC

Process for preparing isobutene from tert-butanol

InactiveUS20050014985A1Low mass flowHigh selectivityExhaust apparatusOrganic chemistry methodsFixed bedTemperature difference

Isobutene is prepared by dissociating tert-butanol into isobutene and water over an acid ion-exchange resin arranged as a fixed bed in at least one reactor at a temperature of from 80 to 150° C. and at a pressure of from 5 to 25 bar to obtain a reaction mixture, separating the reaction mixture into isobutene, a by-product, water and at least one mixture of undissociated tert-butanol and water. The reactor is operated pseudo-isothermally, with a temperature difference between inflowing and outflowing streams of less than 15 K.

Owner:EVONIK DEGUSSA GMBH

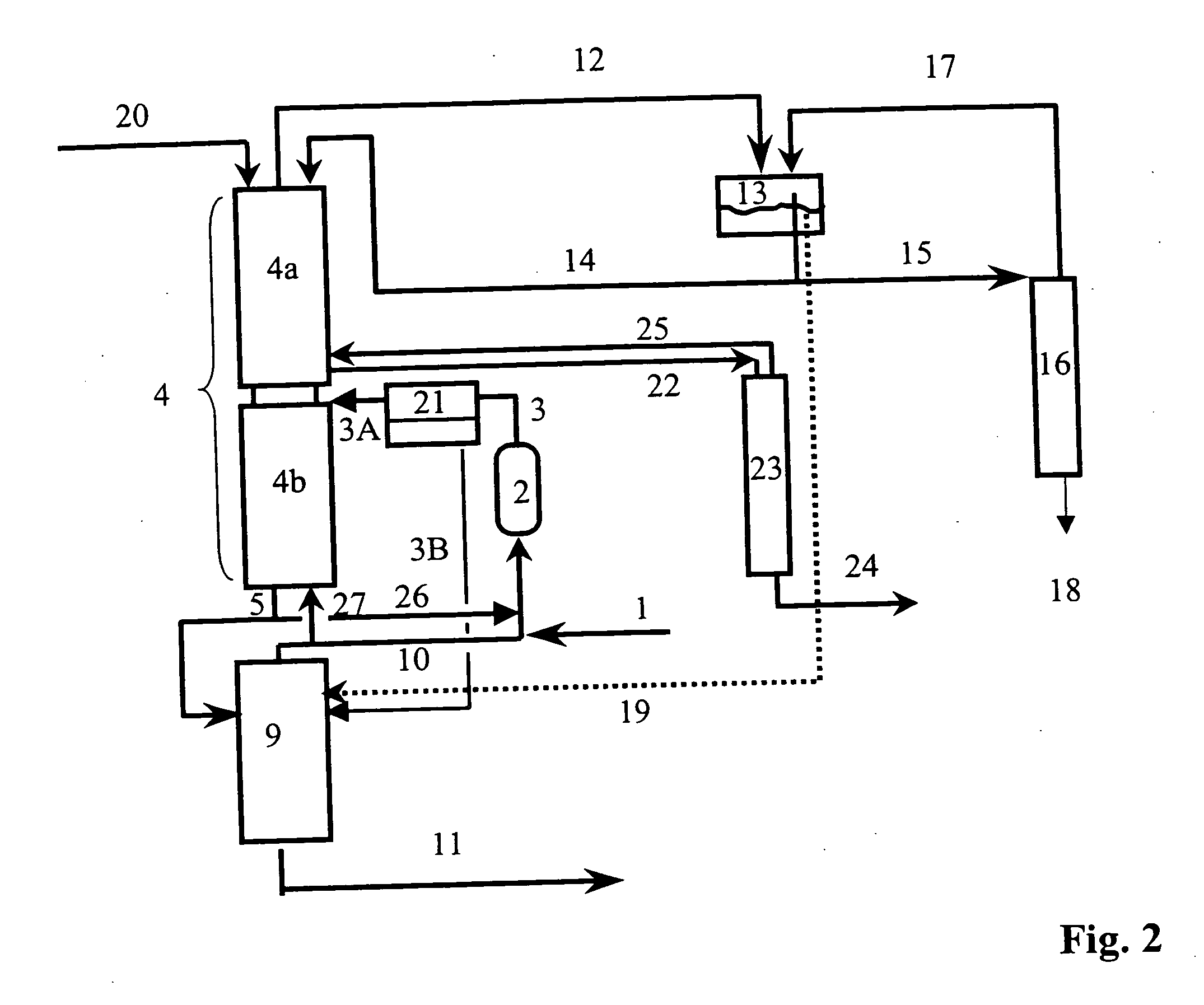

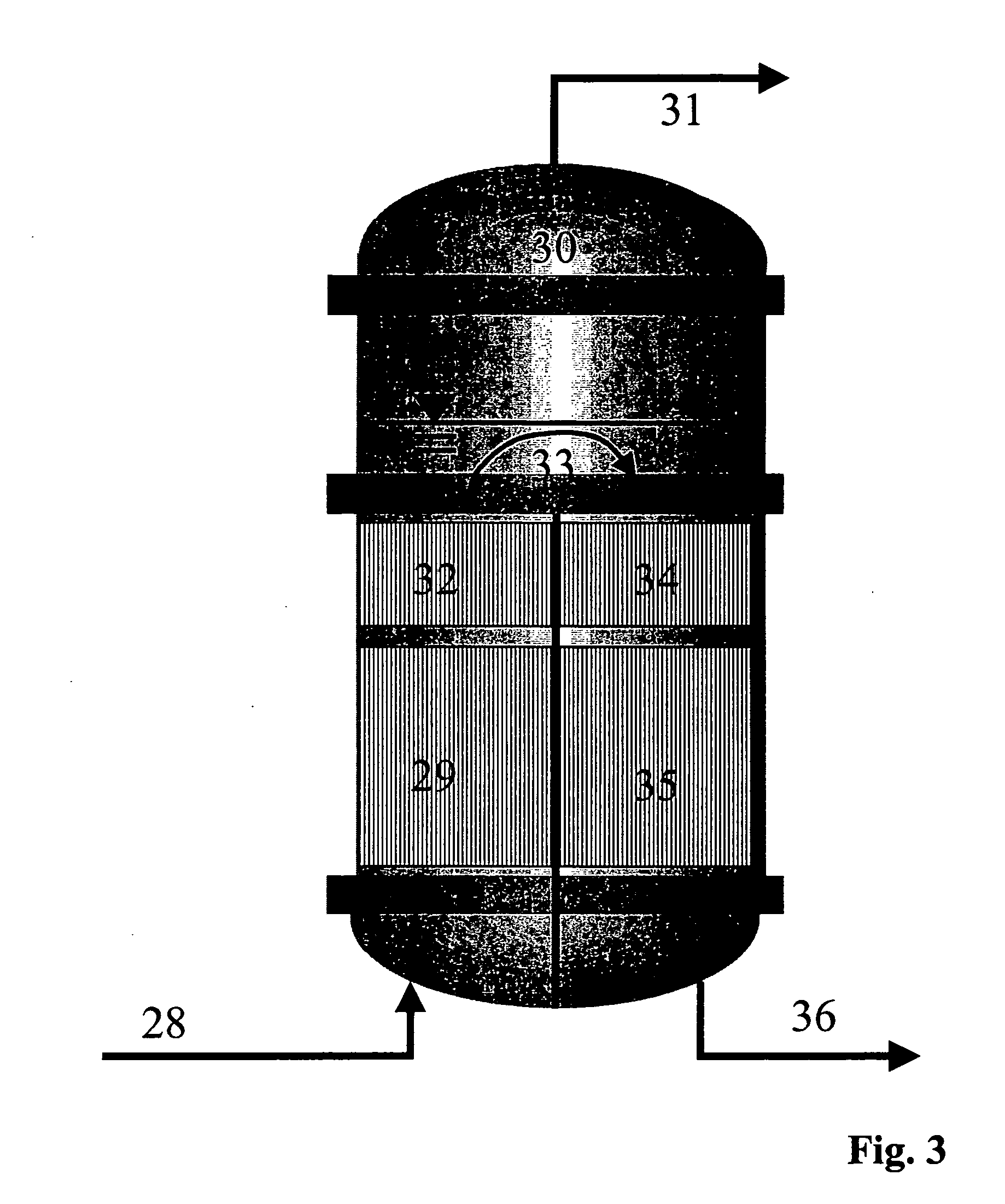

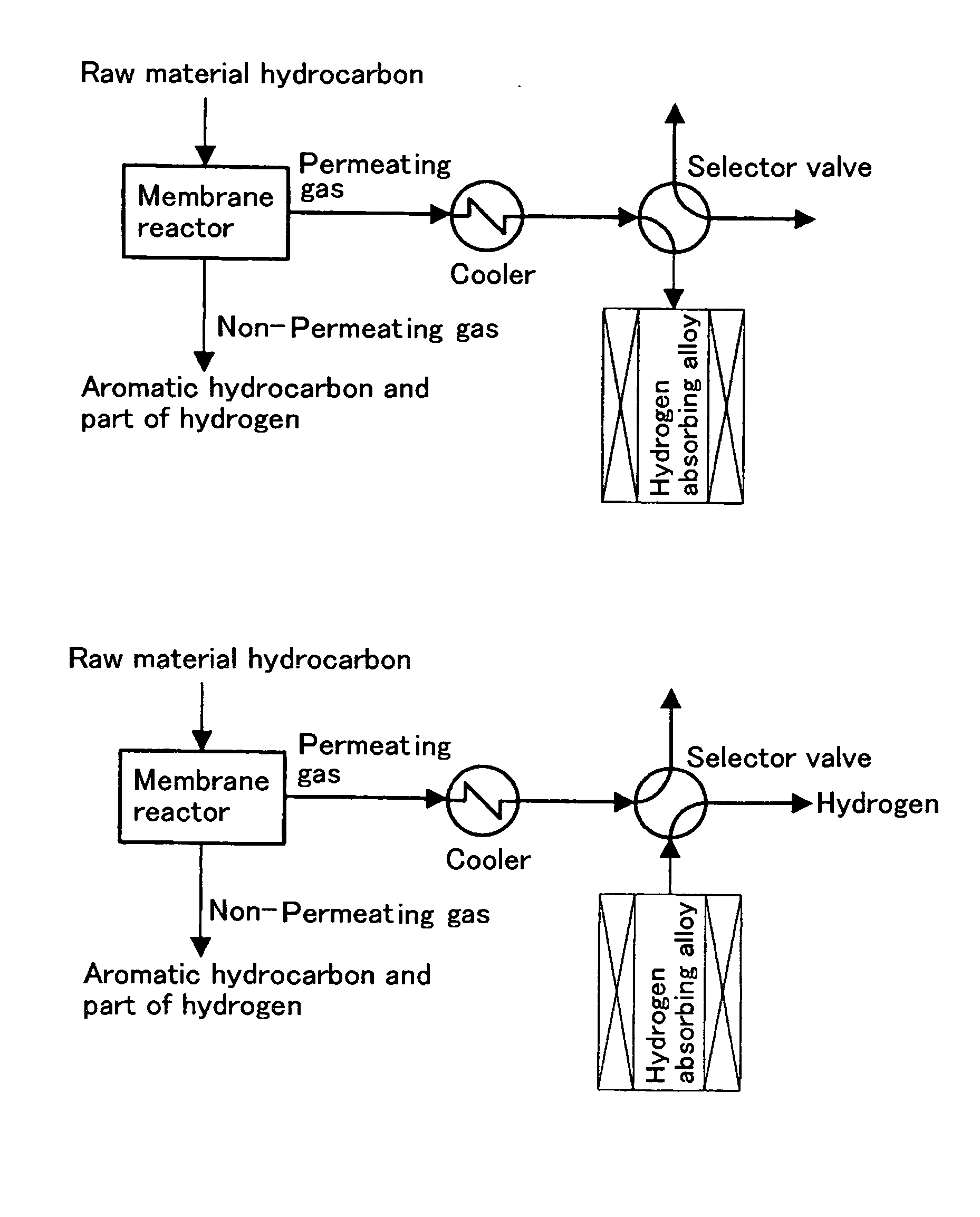

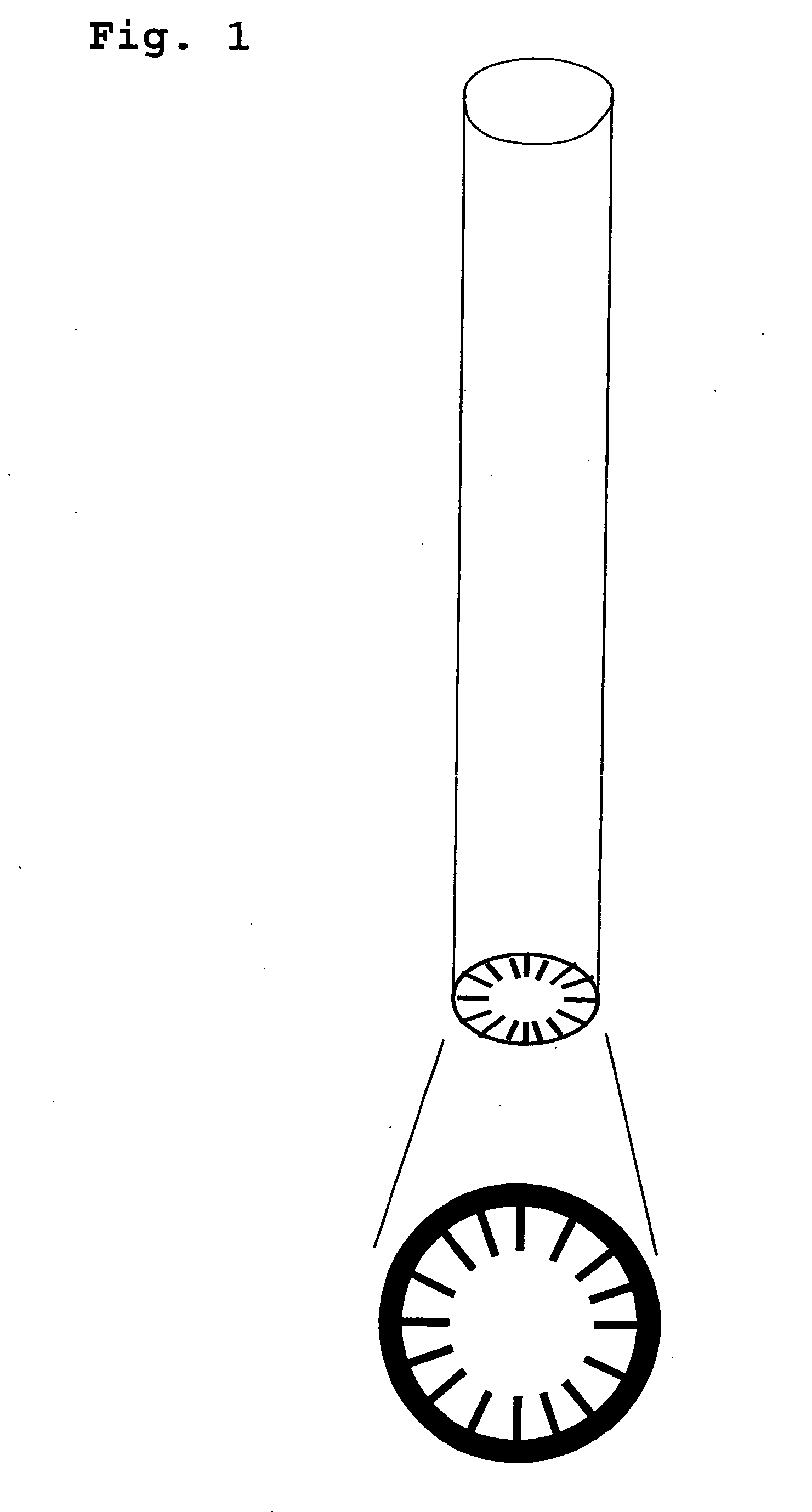

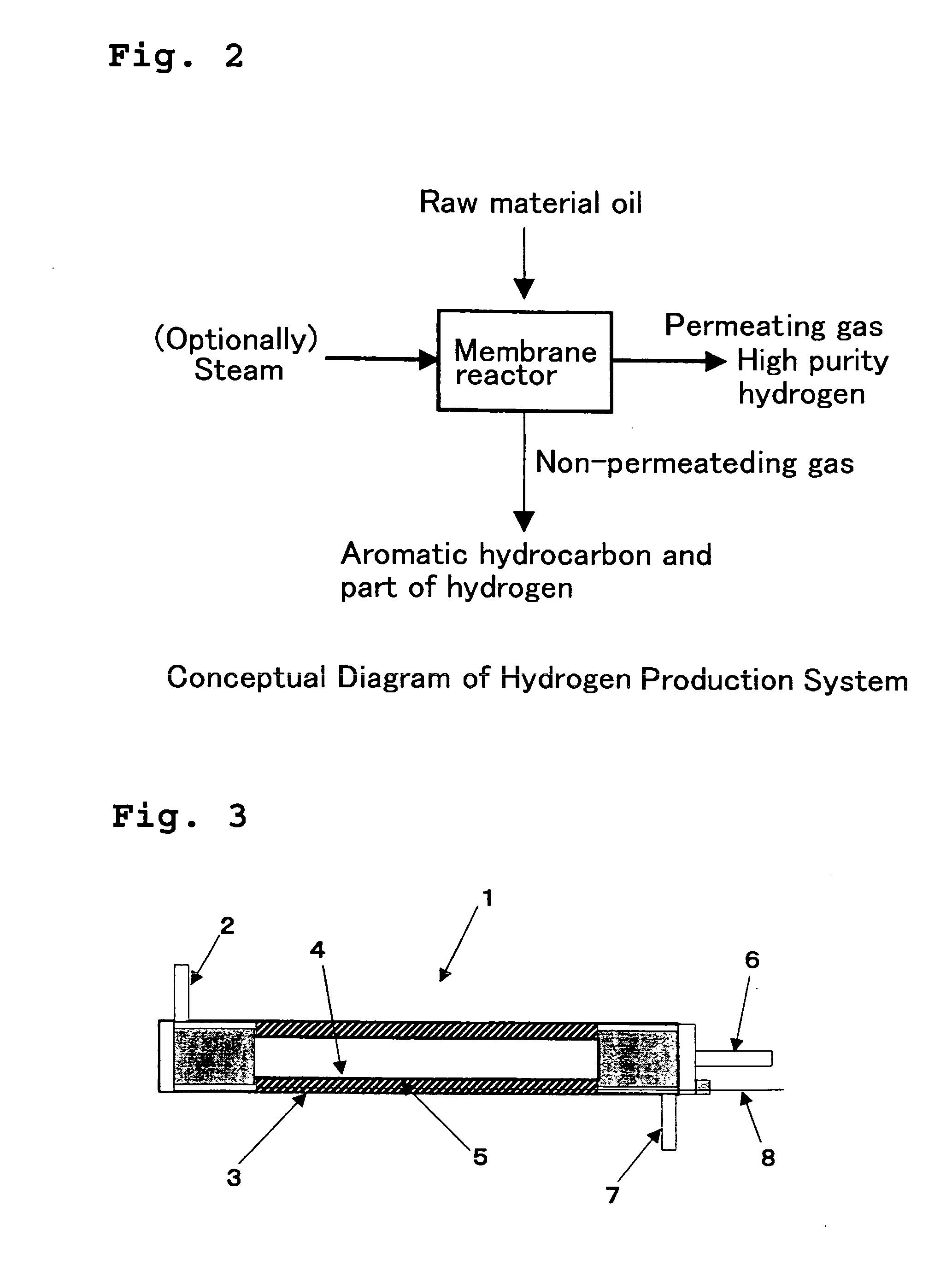

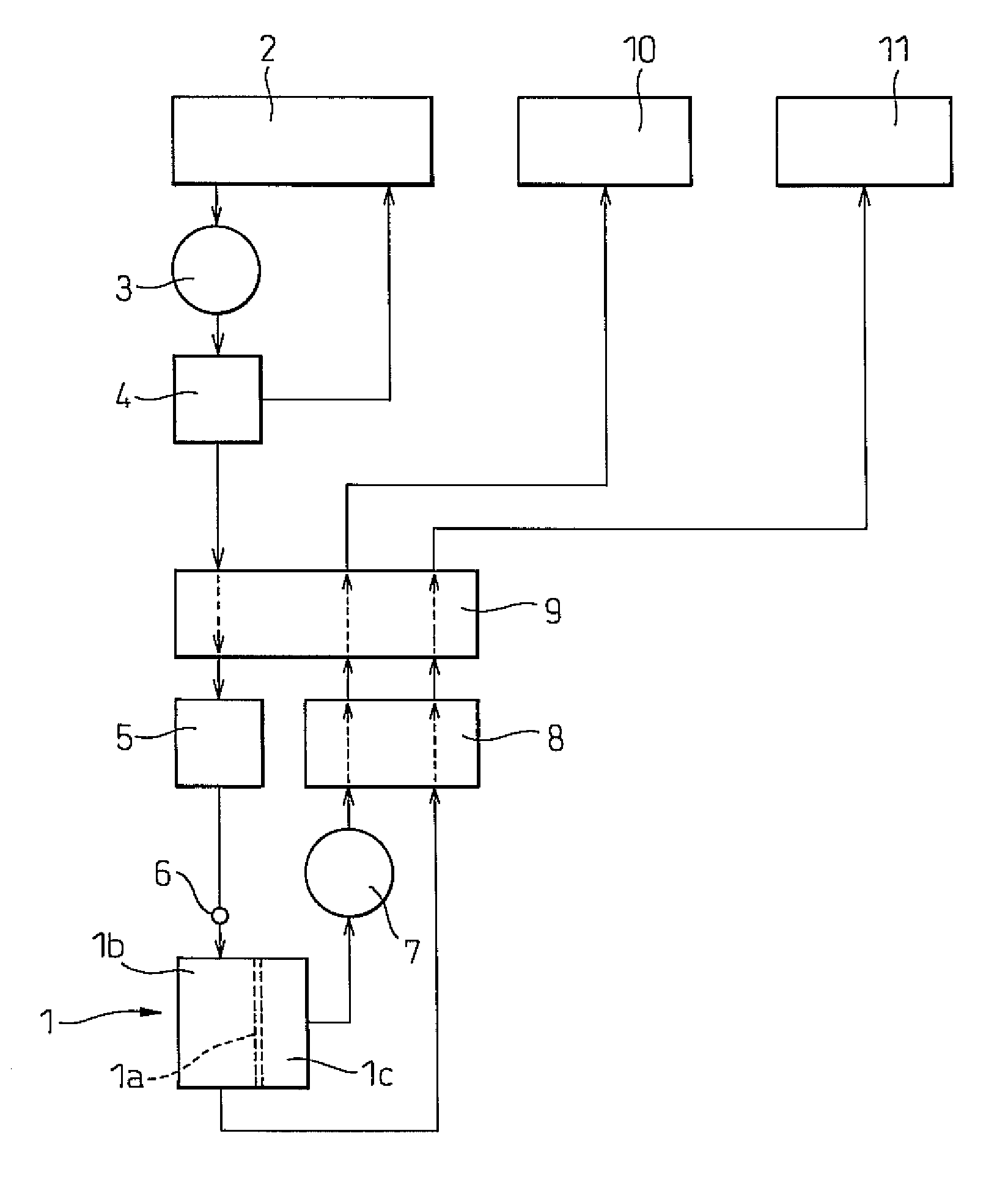

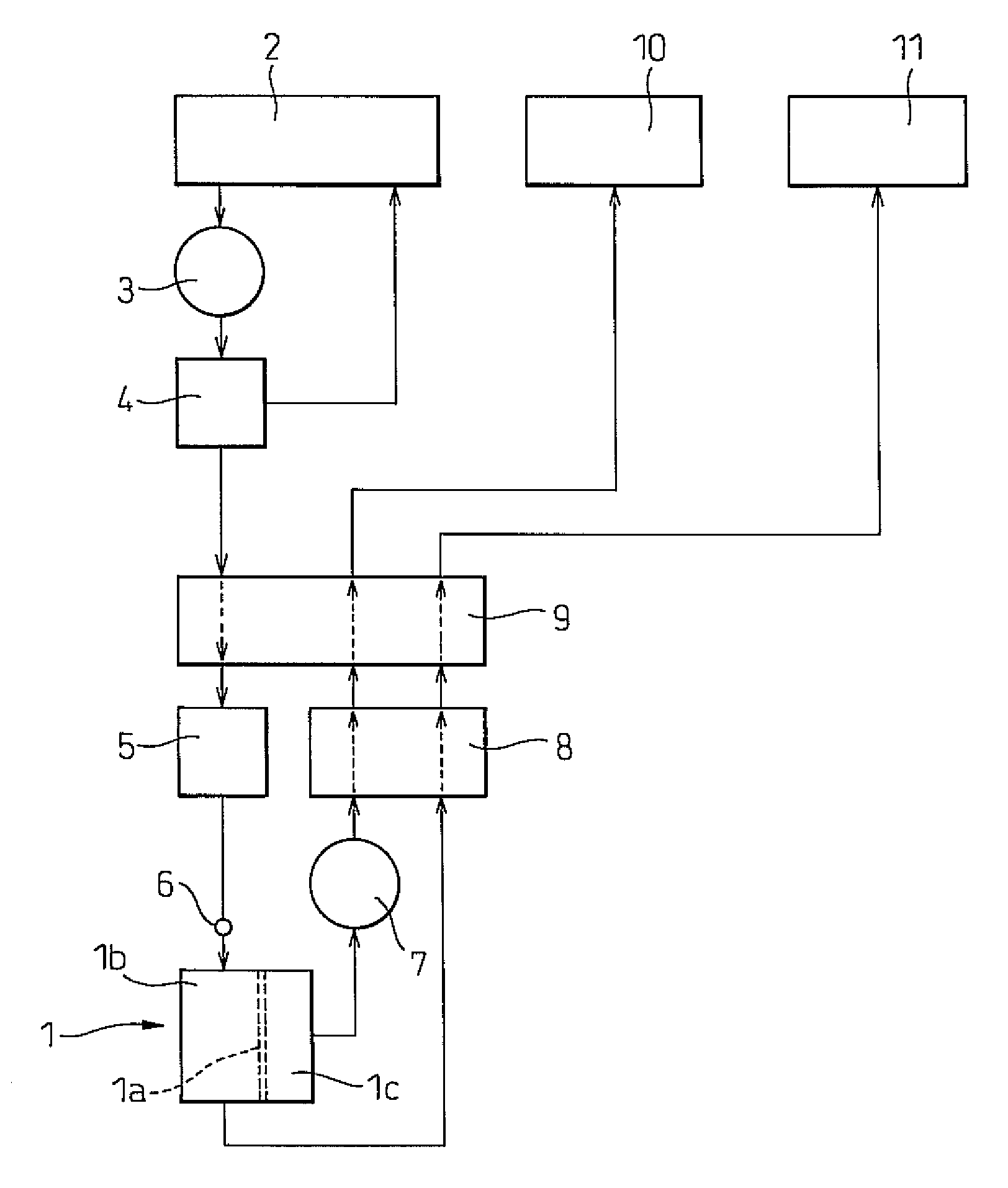

Method for Producing Hydrogen and System Therefor

InactiveUS20080234527A1Efficient productionReduce pressureOrganic chemistry methodsHydrogen/synthetic gas productionDouble tubeDehydrogenation

The present invention provides a hydrogen production method capable of producing hydrogen with good efficiency while solving problems such as separation, lower-temperature reaction and heat supply in production of hydrogen by dehydrogenation reaction of raw material oil. Within a reaction tube of a double-tube structure comprising an inner tube composed of a hydrogen separating membrane, a metallic outer tube having a plurality of internal fins, and a metal oxide layer and further a catalyst supported on the fins, hydrocarbon having cyclohexane ring is dehydrogenated to produce hydrogen and aromatic hydrocarbon, and selective membrane separating operation of hydrogen is performed within the reaction system while conducting the dehydrogenation to remove mainly the hydrogen on a permeating side and obtain mainly the aromatic hydrocarbon on a non-permeating side. The other method comprises absorbing at least part of the resulting hydrogen flow to a hydrogen absorbing (storing) alloy to make the pressure on the hydrogen permeating side of the hydrogen separating membrane lower than that on the non-permeating side.

Owner:NIPPON OIL CORP

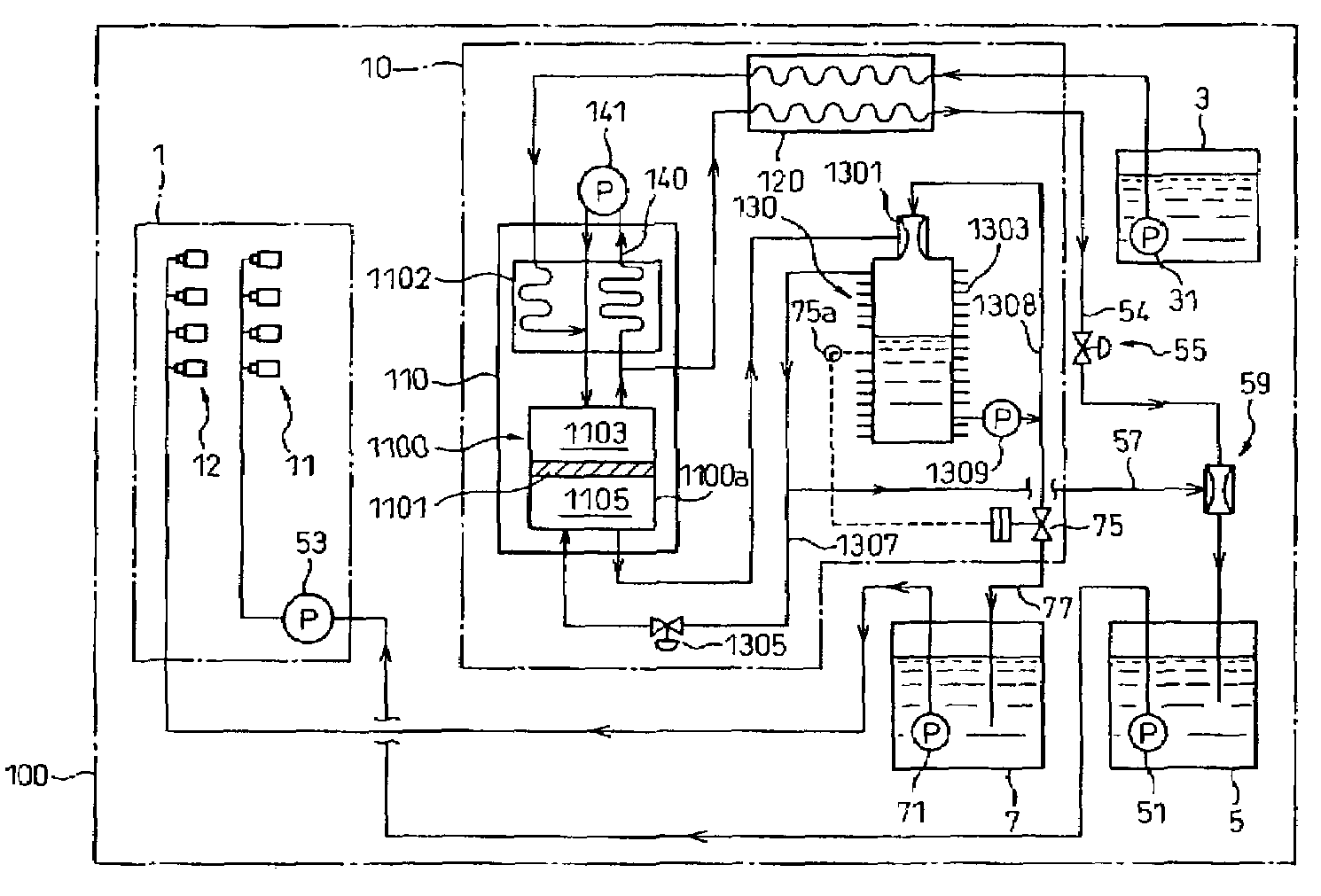

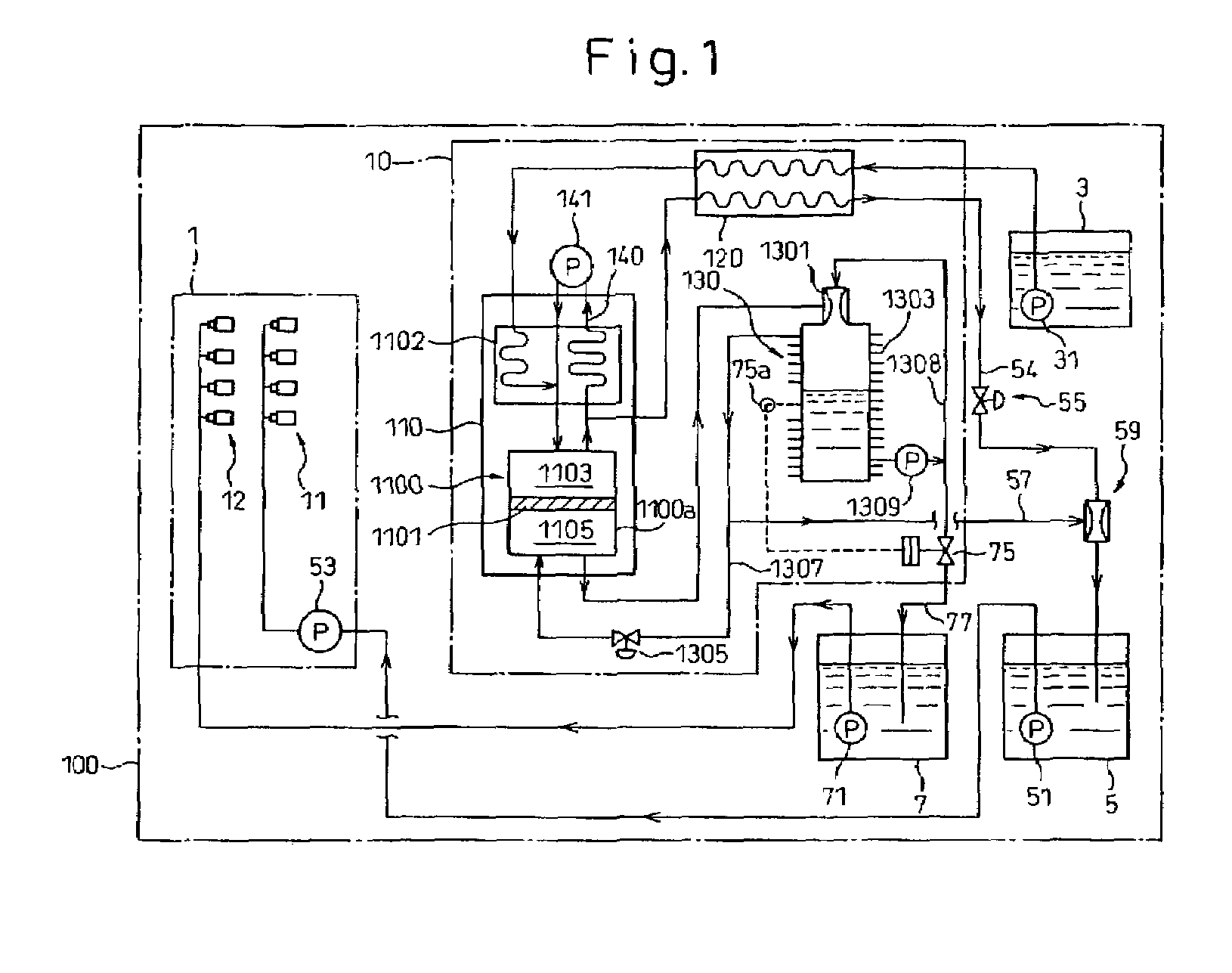

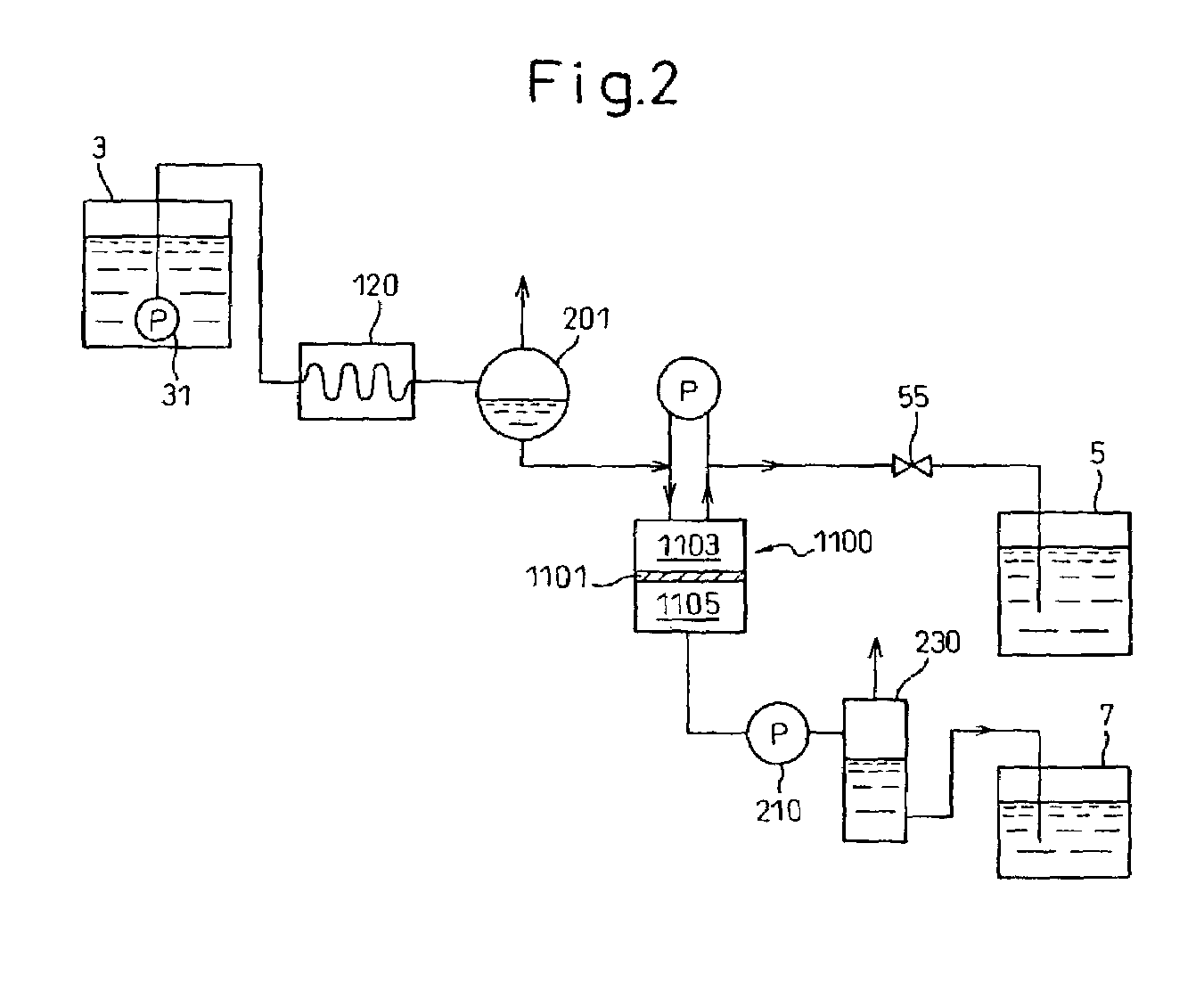

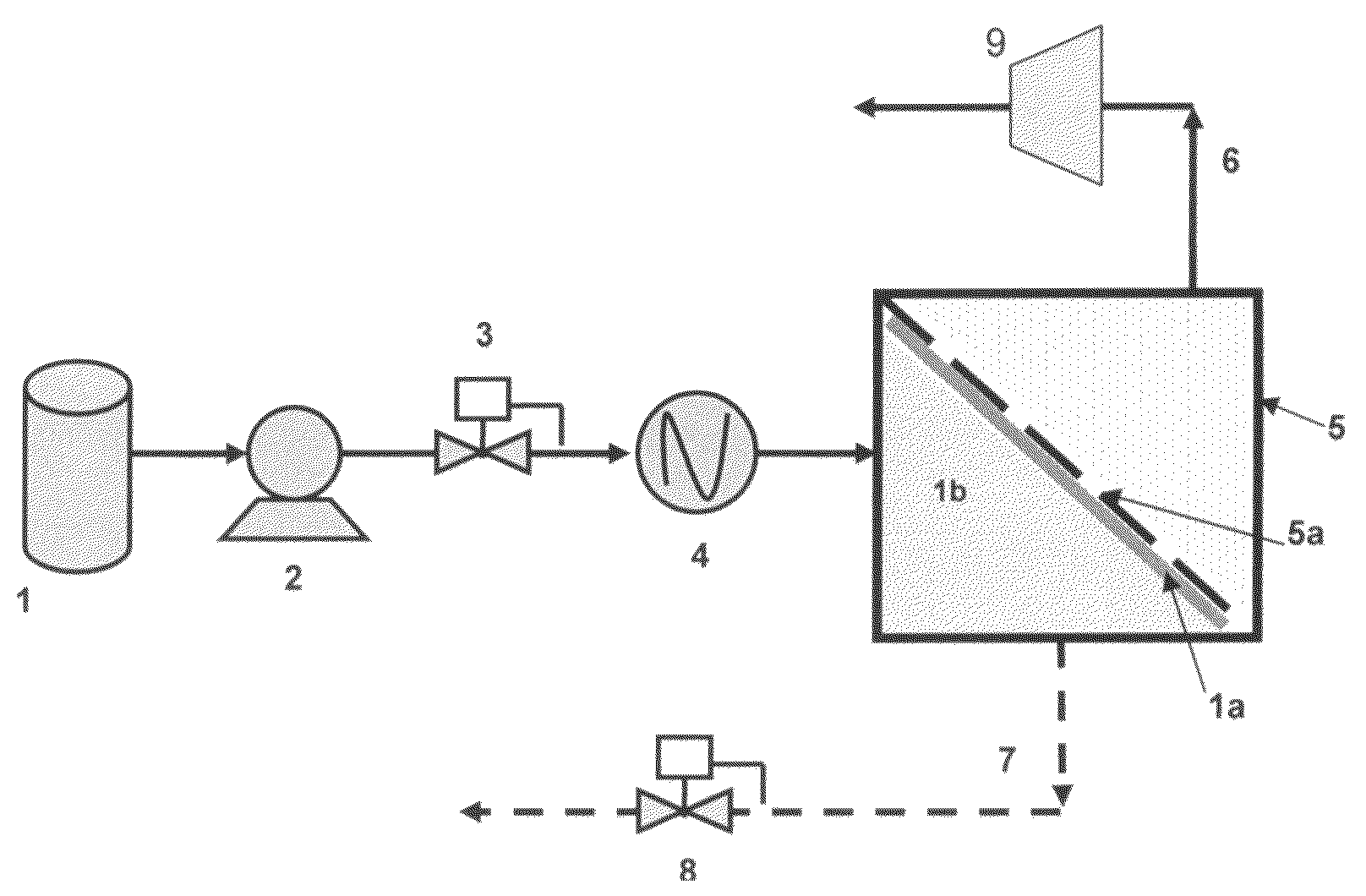

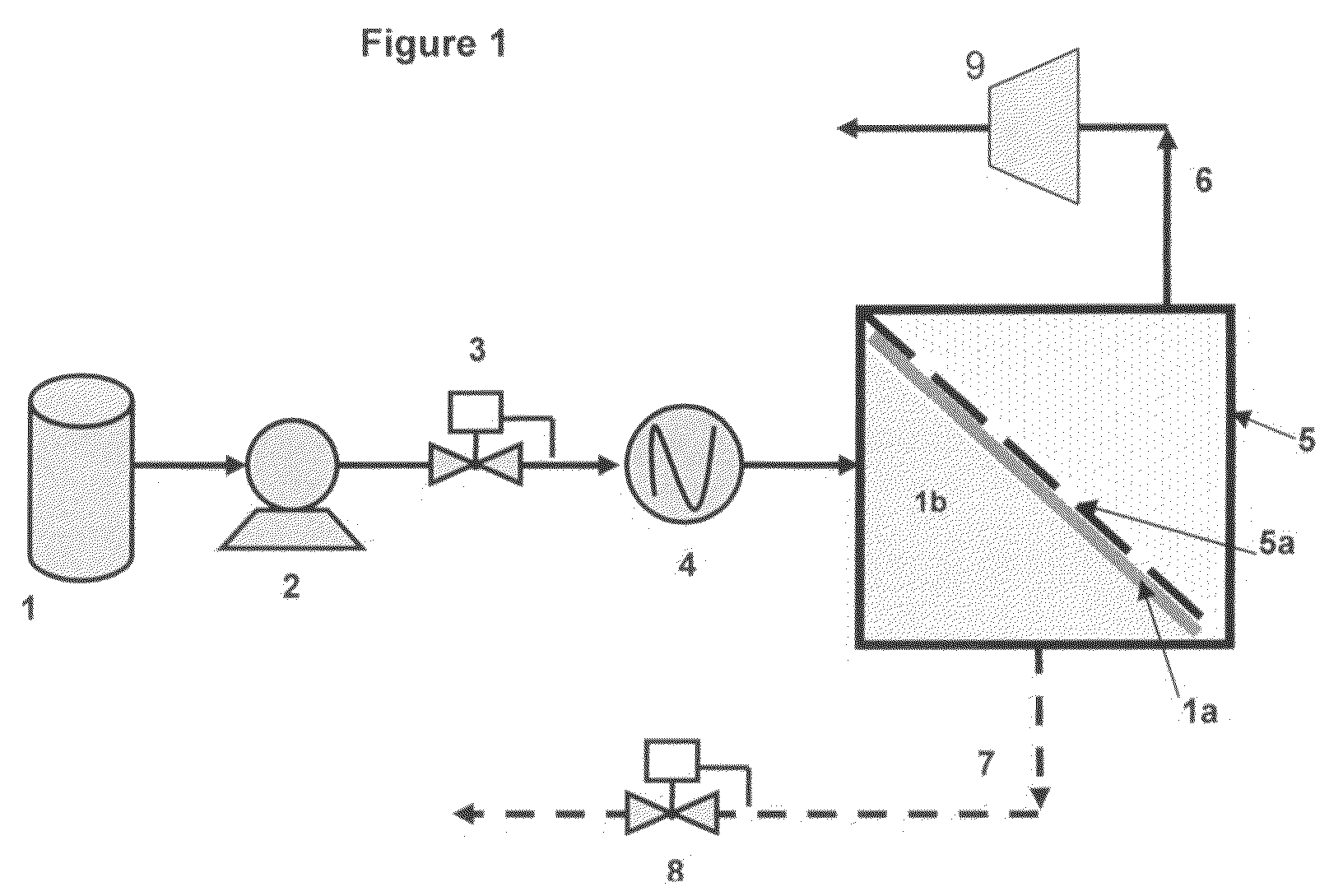

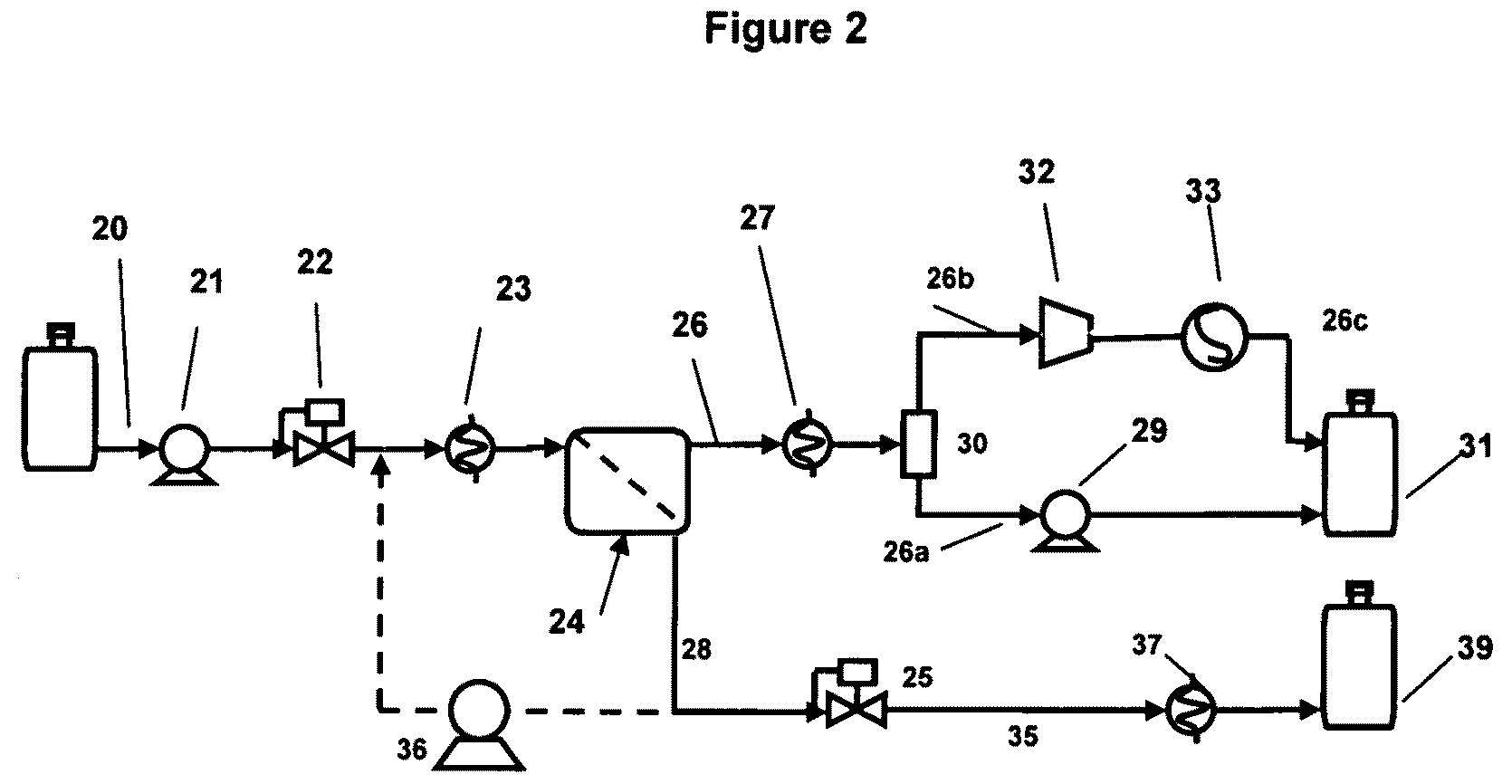

Device for separating fuel components

InactiveUS8580111B2Digital data processing detailsGaseous engine fuelsNuclear engineeringLiquid phase

A device for separating fuel components comprising a separating membrane for separating high-octane fuel components from un-separated fuel and a heat exchanger between first liquid passing through the heat exchanger and second liquid passing through the heat exchanger, is provided. The first liquid is un-separated fuel passing through the heat exchanger before being supplied to the separating membrane. The second liquid is low-octane fuel remaining when the high-octane fuel components are separated from the un-separated fuel, passing through the heat exchanger after changing to an almost liquid phase.

Owner:TOYOTA JIDOSHA KK +1

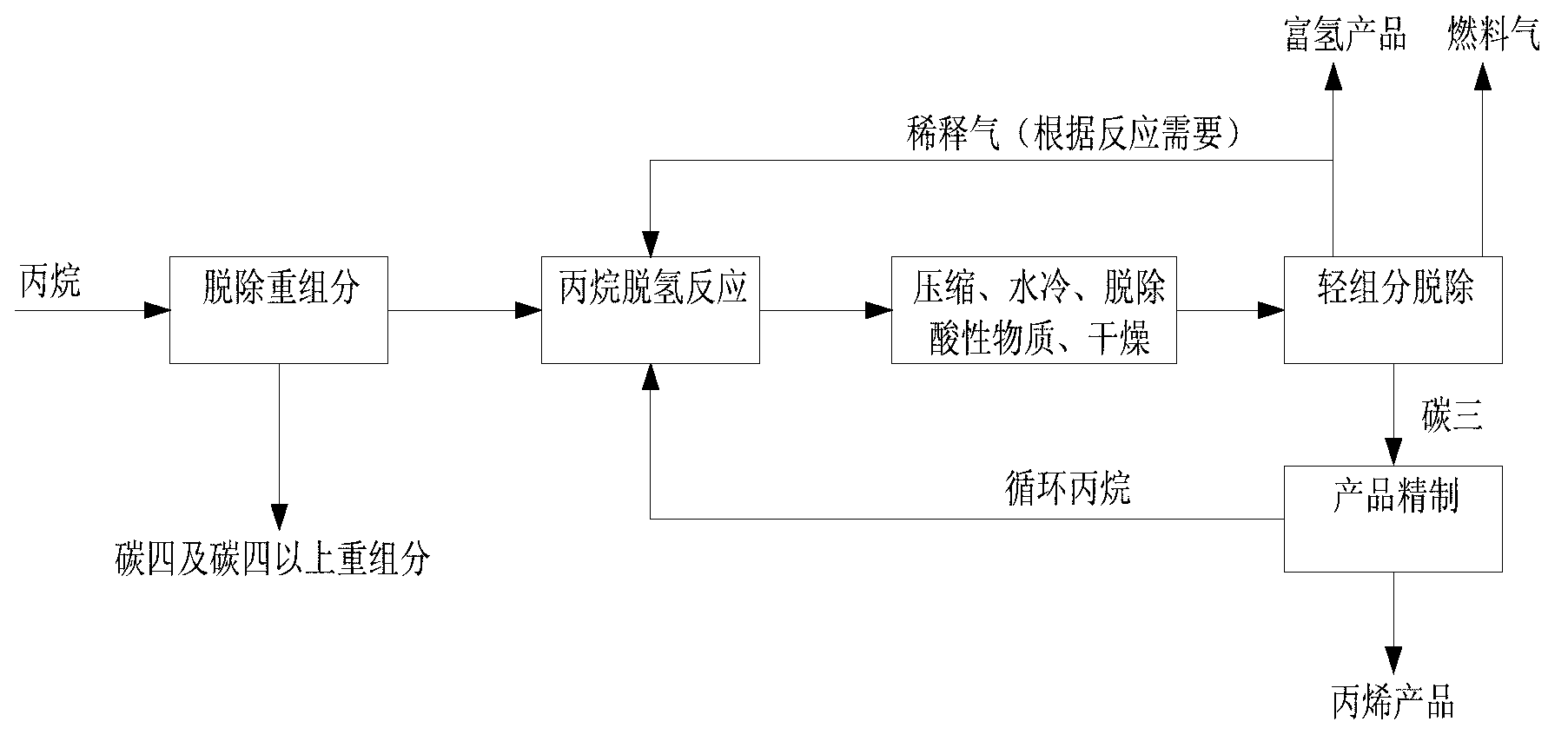

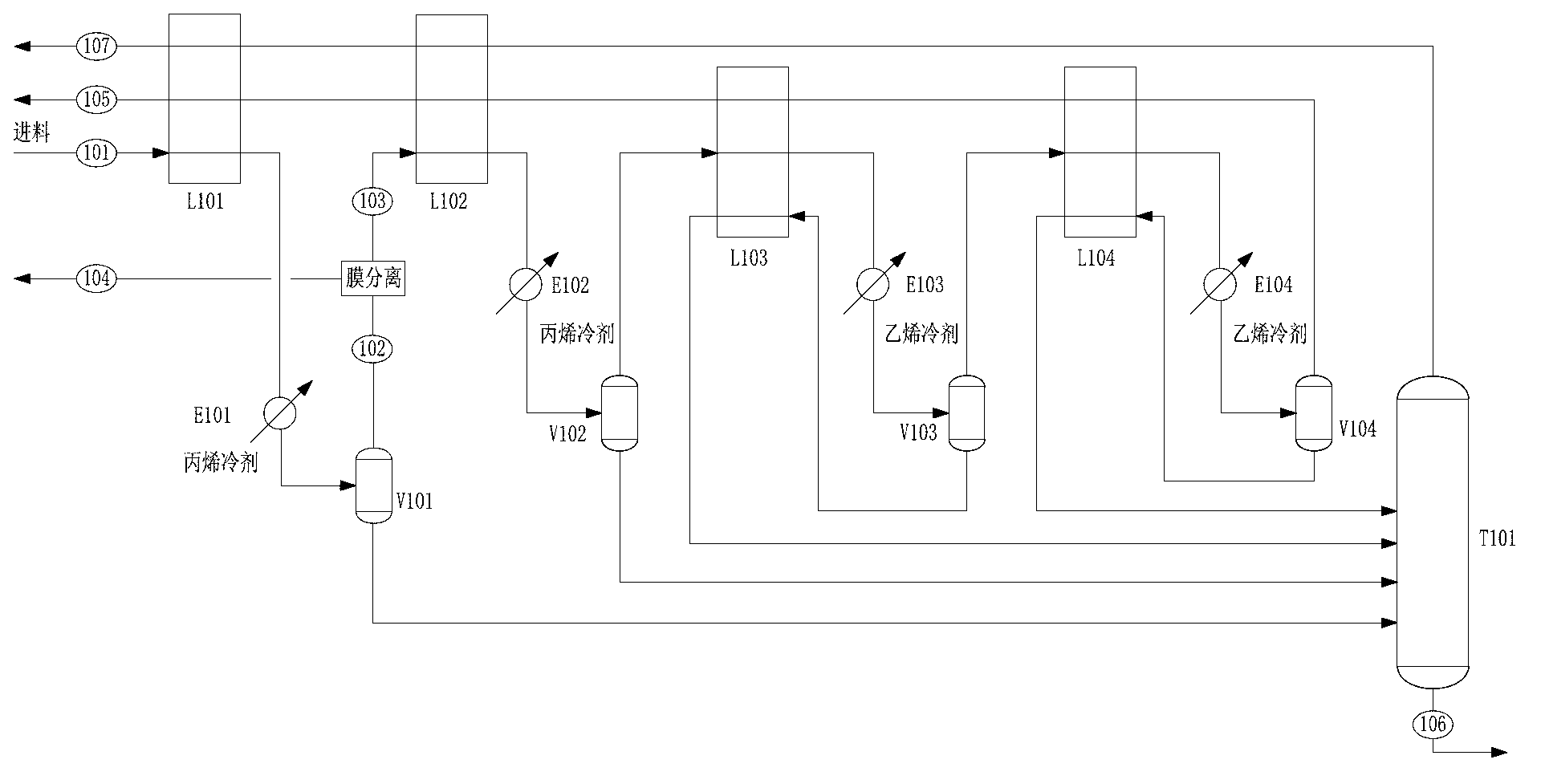

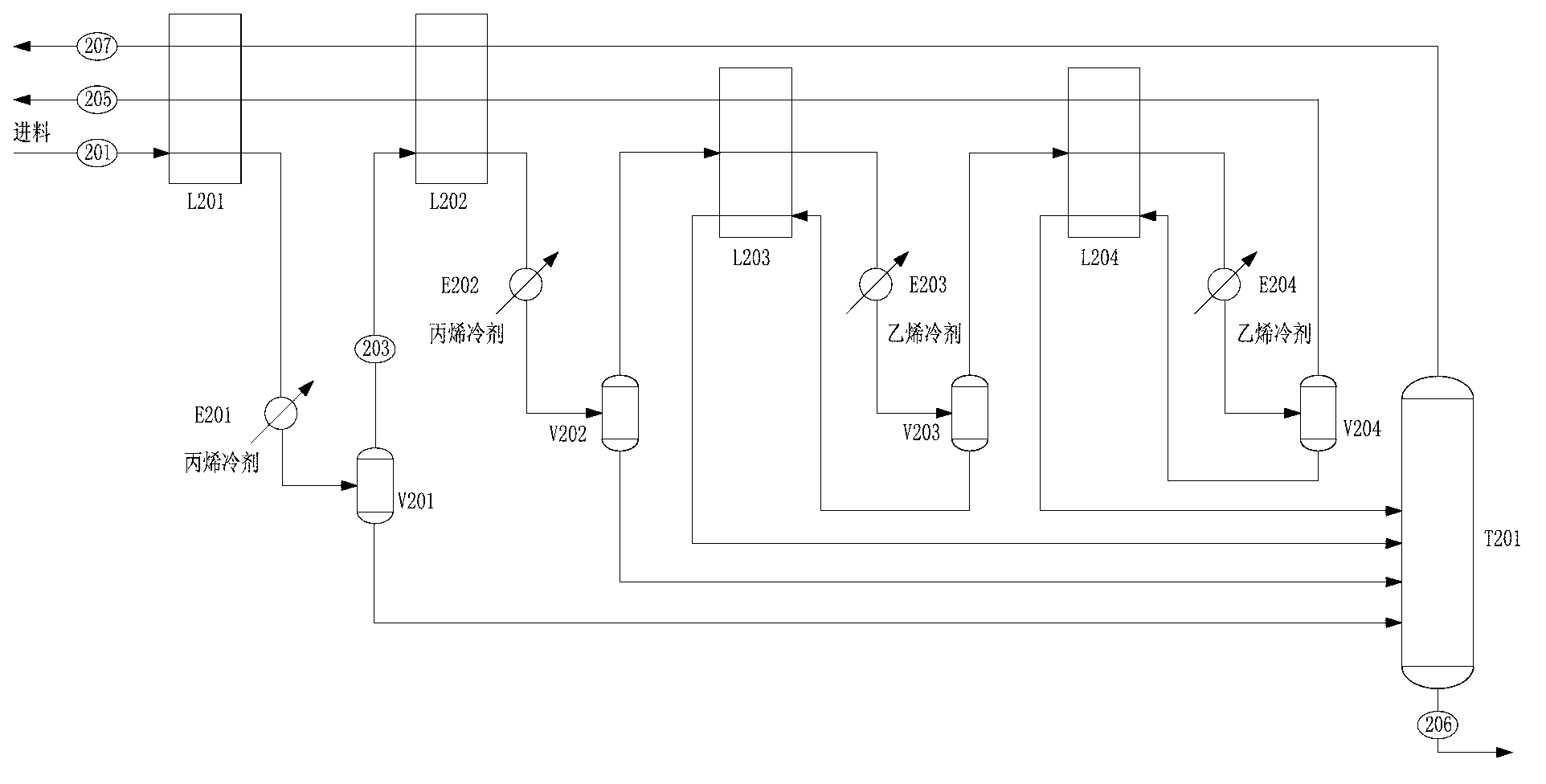

Method for separating reaction products produced during preparation of propylene by dehydrogenating propane

ActiveCN102795956AReduce power consumptionReduce feed throughputChemical industryDistillation purification/separationHydrogenGas phase

The invention relates to a method for separating reaction products produced during preparation of propylene by dehydrogenating propane. In the method, reaction products produced during preparation of propylene by dehydrogenating propane are separated in a way of combining membrane separation with cryogenic separation. The method comprises the following steps of: (1) cooling pretreated reaction products produced during preparation of propylene by dehydrogenating propane, condensing, feeding into a first-stage flash tank, conveying a gas phase serving as a hydrogen-rich product on the top of the first-stage flash tank outwards, or further cooling, condensing and feeding into a next-stage flash tank, gradually cooling and condensing and performing flash evaporation in sequence, conveying a gas phase serving as a hydrogen-rich product on the top of a last-stage flash tank outwards, conveying a liquid phase at the bottom of each stage of flash tank to an ethane removing tower, and discharging C3 out of a tower kettle of the ethane removing tower; and (2) separating into high-purity hydrogen permeable gas and hydrocarbon-rich impermeable material flow through membrane separation by using a membrane separation unit arranged in the step (1), conveying hydrogen permeable gas outwards, cooling and condensing hydrocarbon-rich impermeable material flow, and conveying to a next-stage flash tank. Compared with the prior art, the method has the advantages of high propylene recovery rate, low energy consumption and simple flow.

Owner:WISON ENG

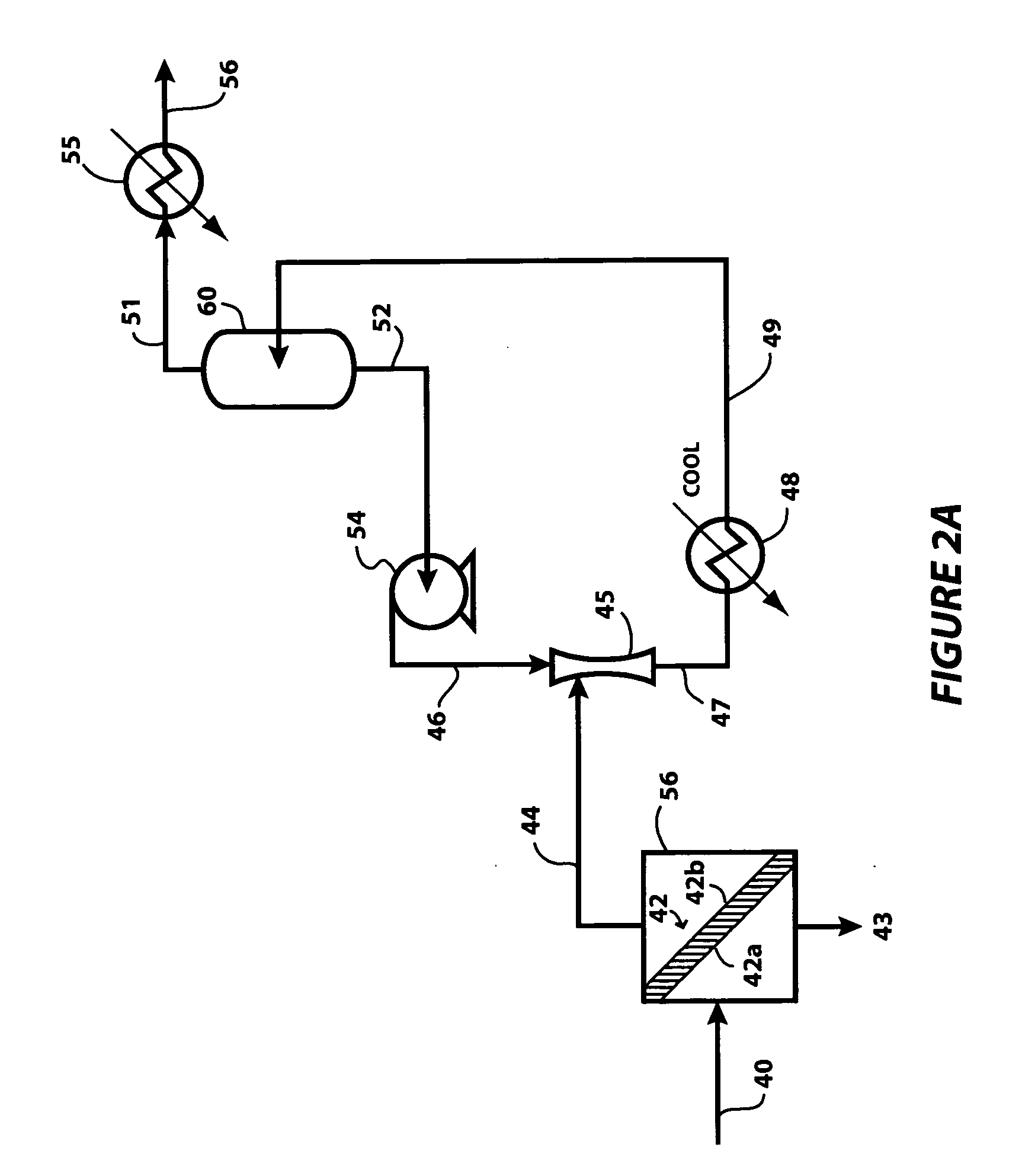

Membrane separation process using mixed vapor-liquid feed

ActiveUS7803275B2Reduce penetrationEfficient executionSemi-permeable membranesMembranesVapor liquidChemical physics

The present invention pertains to a process for the separation of aromatics from a feed stream, including aromatics and non-aromatics by selectively permeating the aromatics through a membrane comprising feeding a mixed phase vapor-liquid feed to a membrane wherein said liquid phase preferentially wets the surface of the membrane.

Owner:EXXON RES & ENG CO

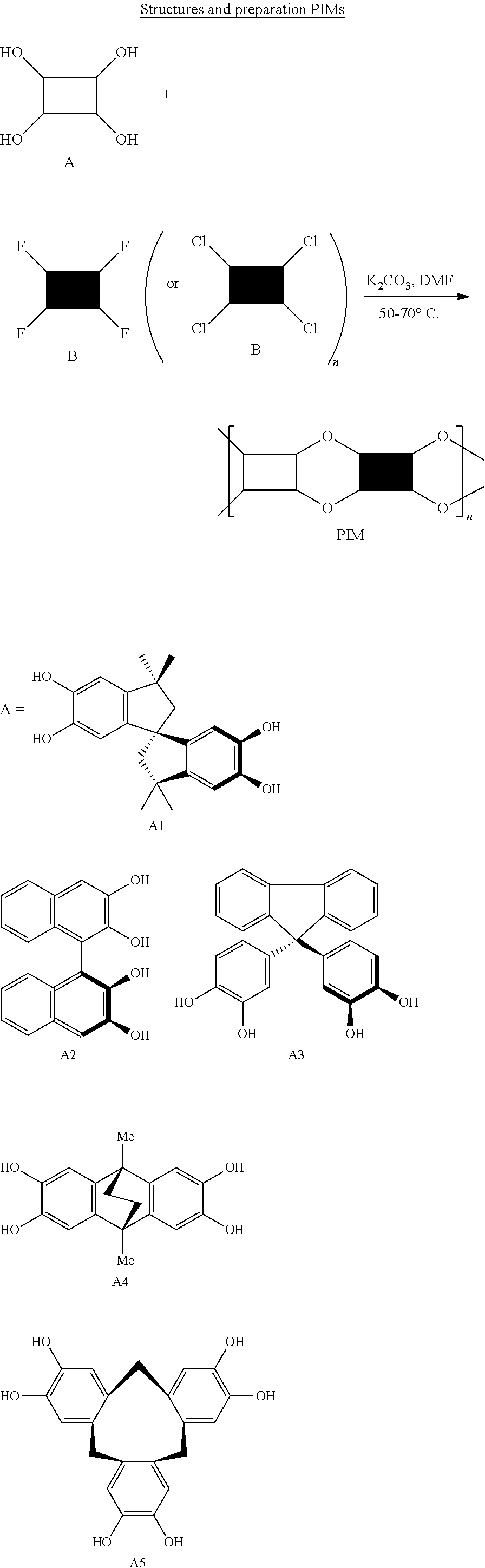

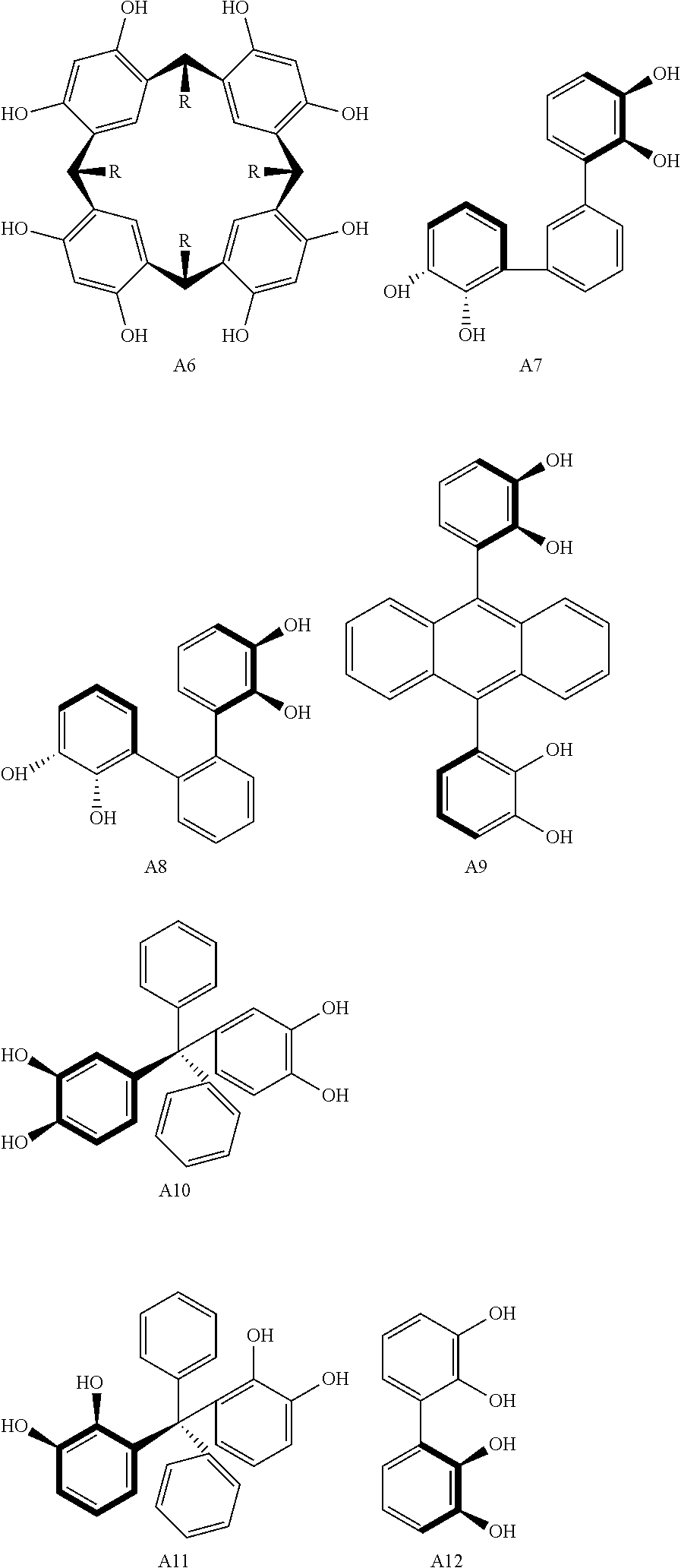

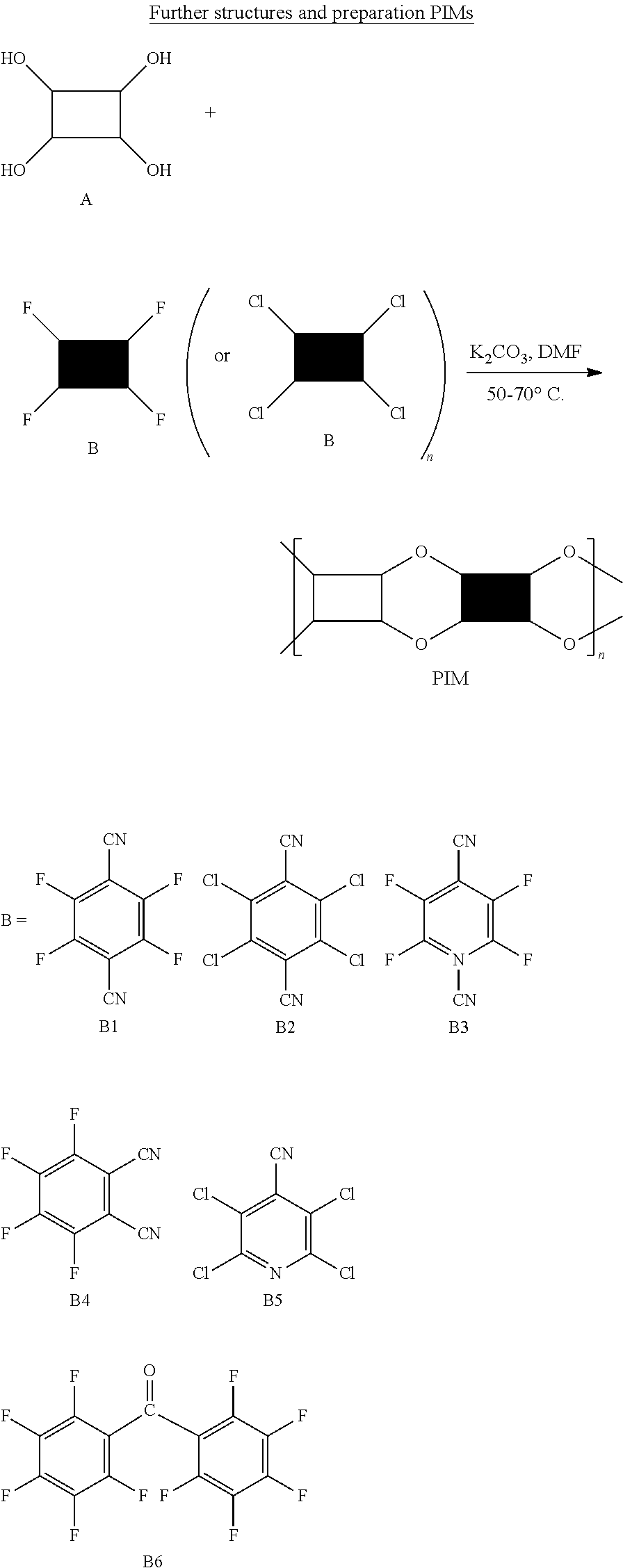

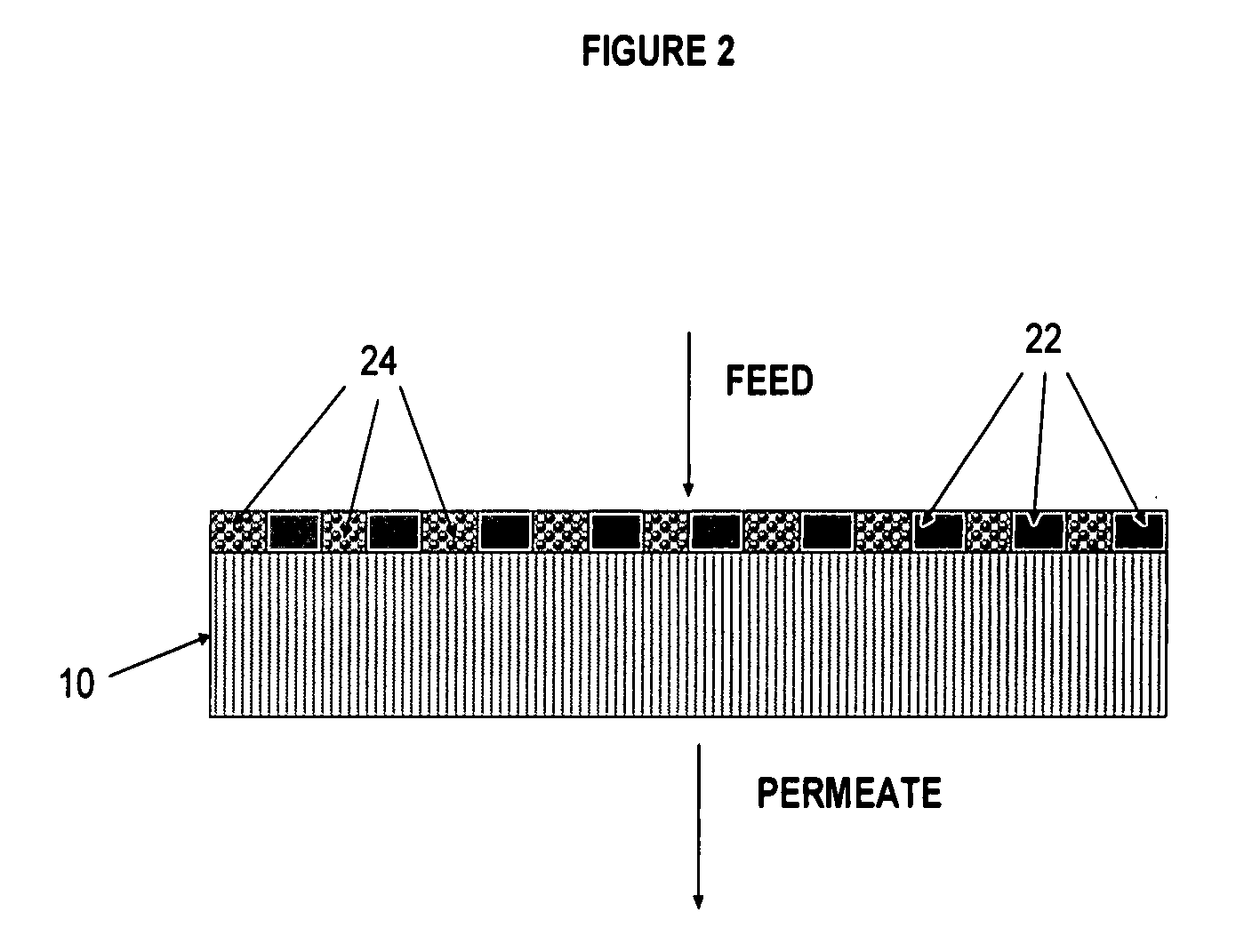

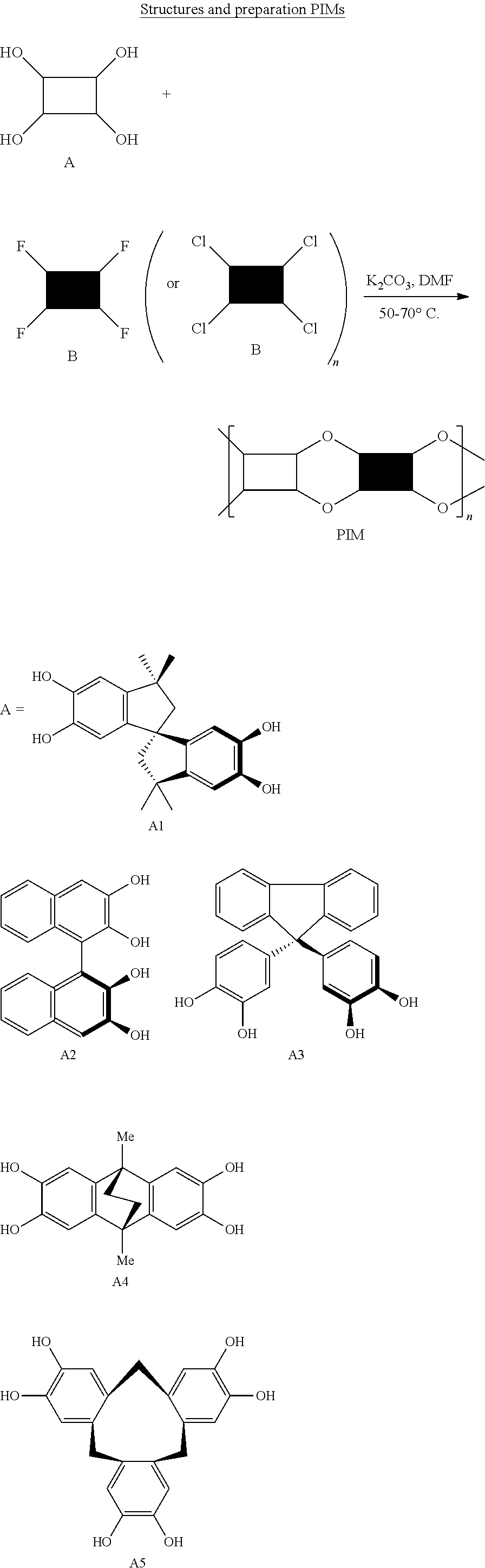

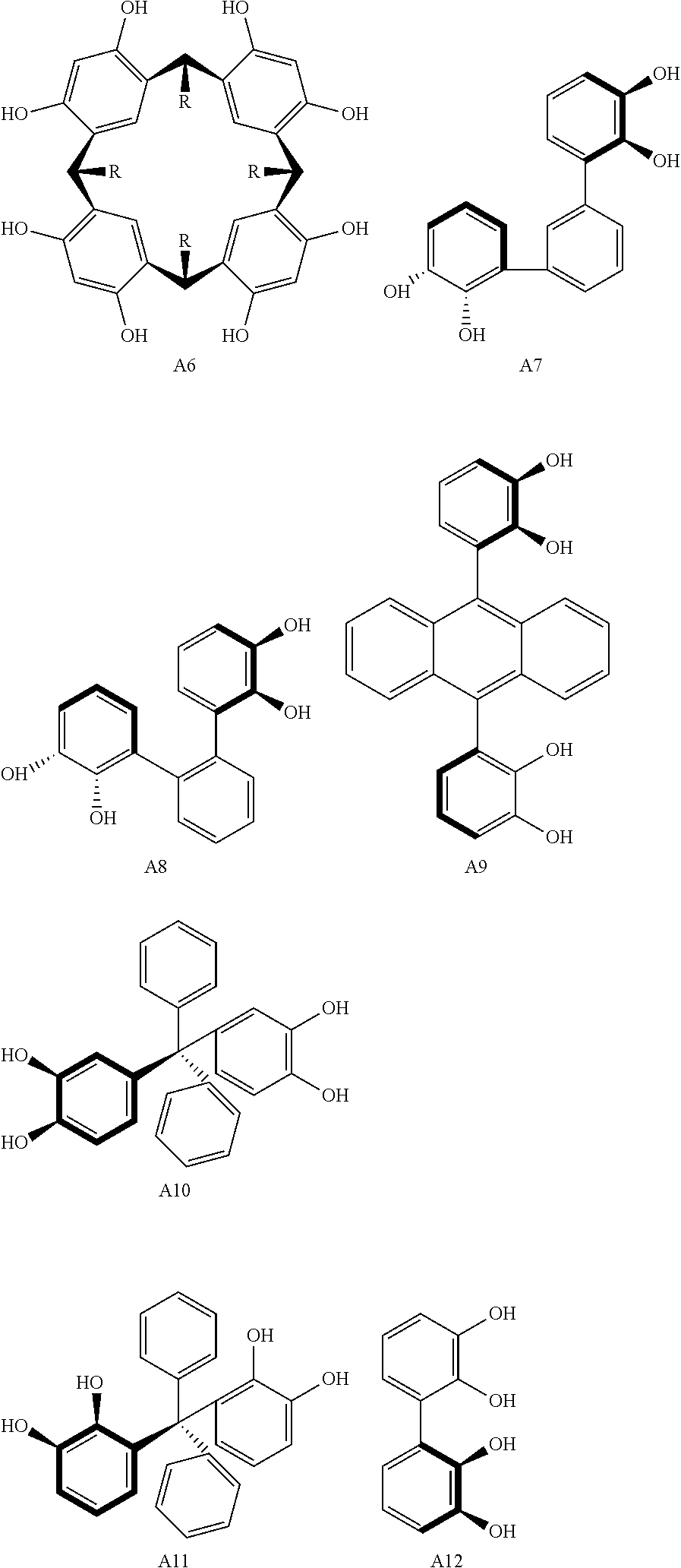

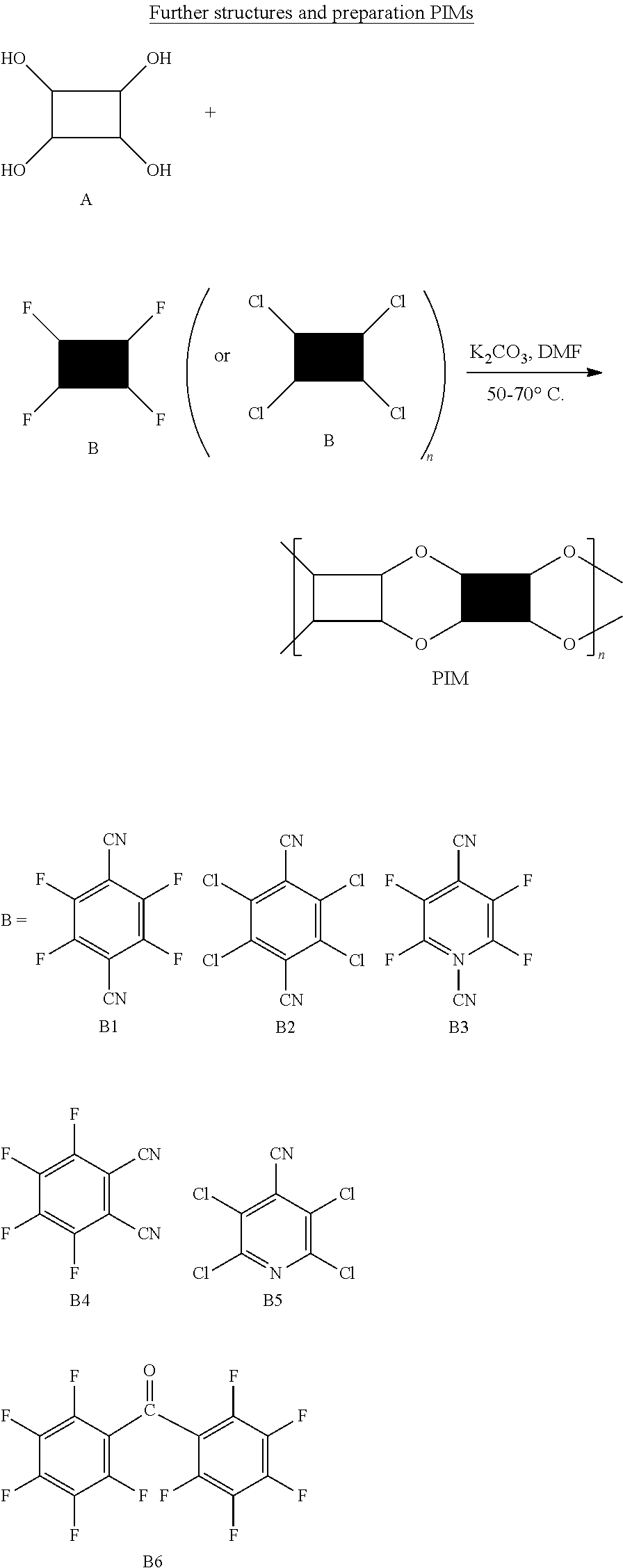

Membrane system for natural gas upgrading

The present invention involves the use of a novel membrane system for natural gas upgrading. This membrane system includes a first-stage membrane such as a membrane prepared from the polymer of intrinsic microporosity (PIM) to selectively remove hydrocarbons from C3 to C35 to control the dew point of natural gas, and a second-stage membrane such as a polybenzoxazole (PBO) or crosslinked PBO membrane to selectively remove CO2 from natural gas. The new membrane system described in the current invention eliminates the use of high cost and high footprint membrane pretreatment. Therefore, the membrane system can significantly reduce the footprint and cost for natural gas upgrading compared to the current commercially available membrane systems that include a non-membrane-related pretreatment system.

Owner:UOP LLC

Polymer-coated inorganic membrane for separating aromatic and aliphatic compounds

InactiveUS20080035557A1Promotes uniform depositionMaximizing permeationMembranesDialysisSilicon dioxideMembrane composition

A membrane composition comprising an inorganic substrate which has a coating of an associating polymer. The membrane composition includes an inorganic substrate selected from the group consisting of a porous silica hollow tube, an alumina hollow tube and a ceramic monolith.

Owner:PARTRIDGE RANDALL D +3

Membrane system for natural gas upgrading

The present invention involves the use of a novel membrane system for natural gas upgrading. This membrane system includes a first-stage membrane such as a membrane prepared from the polymer of intrinsic microporosity (PIM) to selectively remove hydrocarbons from C3 to C35 to control the dew point of natural gas, and a second-stage membrane such as a polybenzoxazole (PBO) or crosslinked PBO membrane to selectively remove CO2 from natural gas. The new membrane system described in the current invention eliminates the use of high cost and high footprint membrane pretreatment. Therefore, the membrane system can significantly reduce the footprint and cost for natural gas upgrading compared to the current commercially available membrane systems that include a non-membrane-related pretreatment system.

Owner:UOP LLC

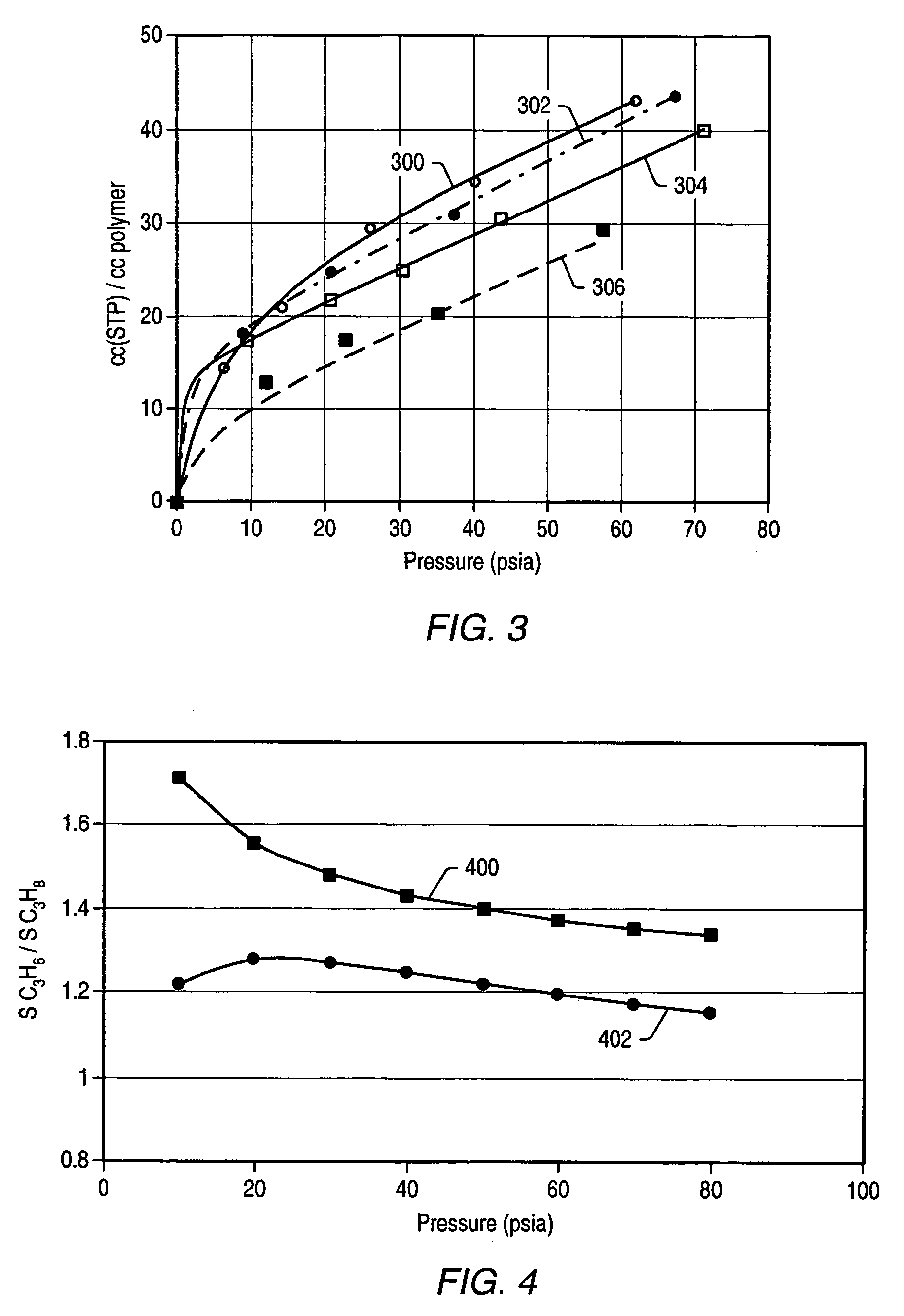

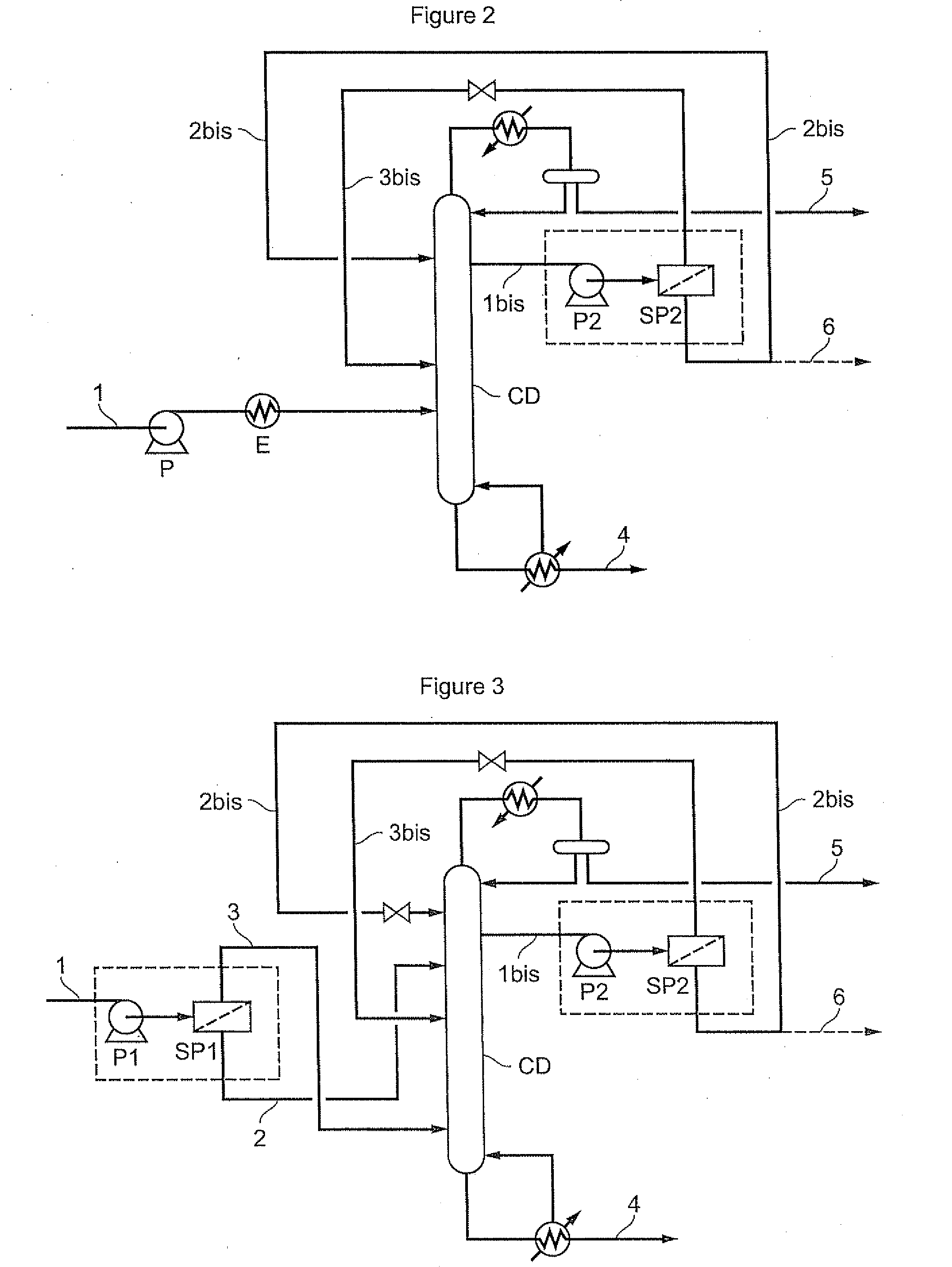

Process for separating propane and propylene using a distillation column and a membrane separation column

InactiveUS20110049051A1Distillation purification/separationSolid sorbent liquid separationDistillationPropane

Process for separating propane and propylene using a distillation column and at least one membrane separation unit constituted by one or more modules operating in series, said membrane separation unit being placed either upstream, or downstream, or upstream and downstream of the distillation column.

Owner:INST FR DU PETROLE

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com