Patents

Literature

50results about How to "Low mass flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

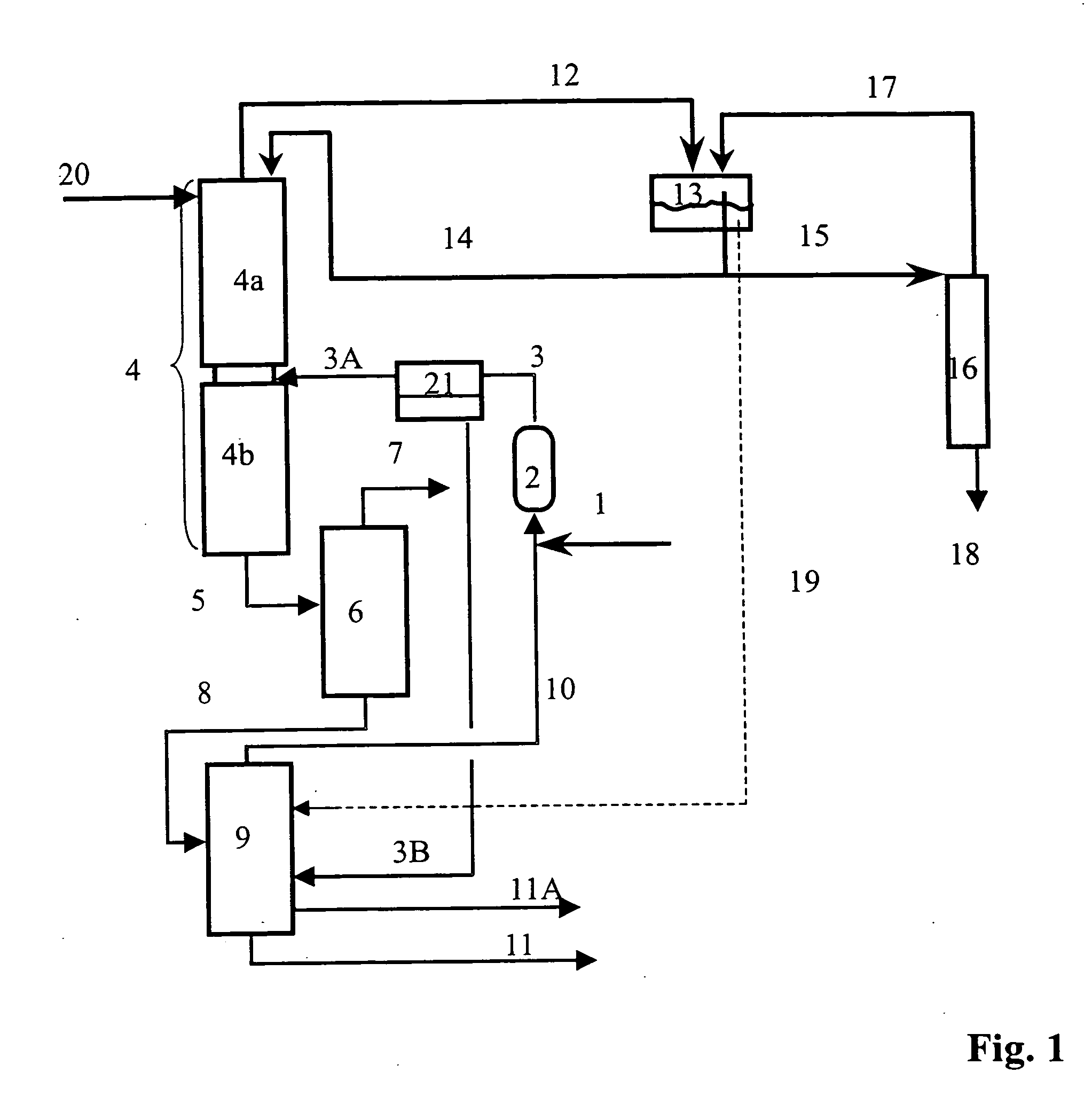

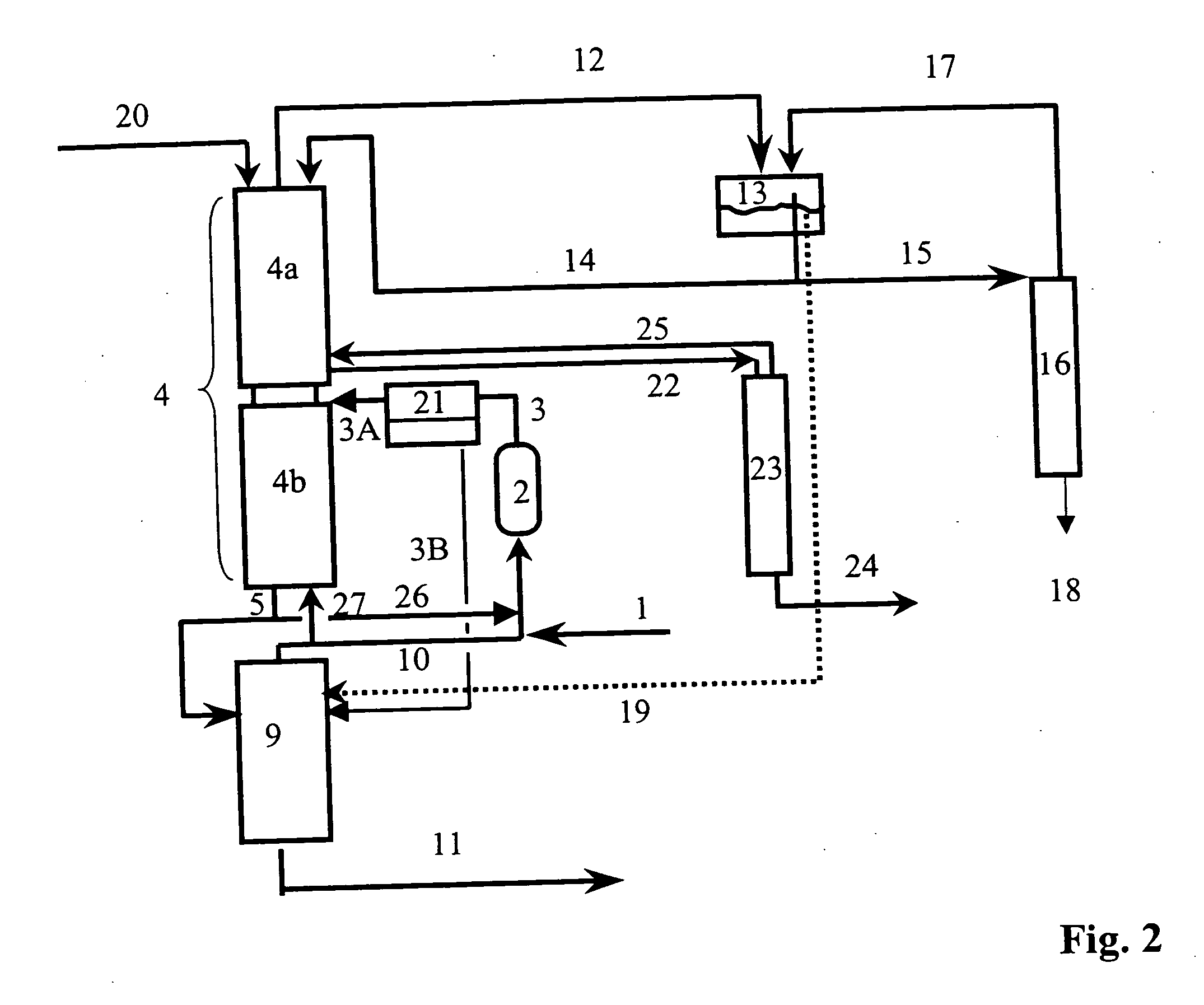

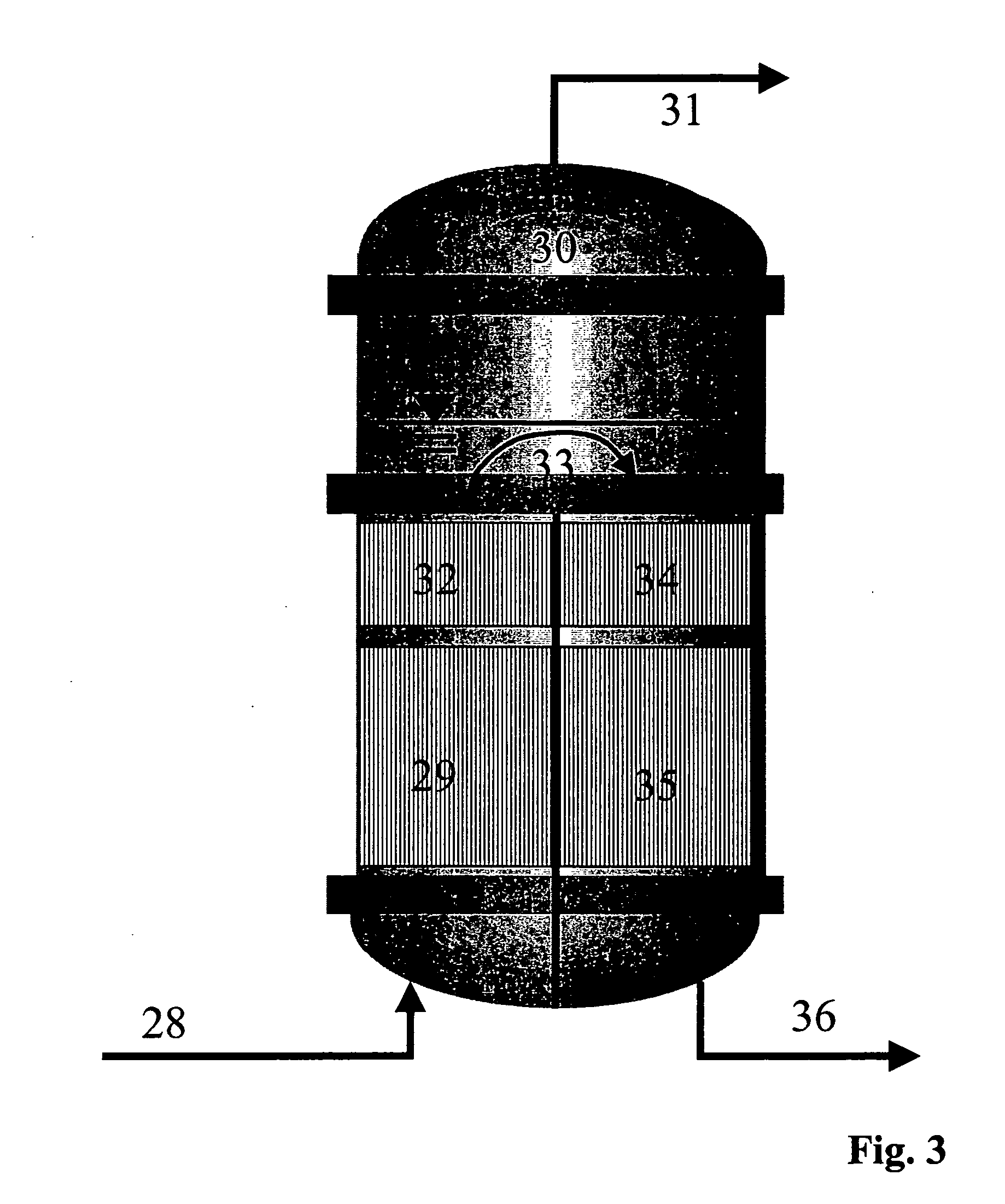

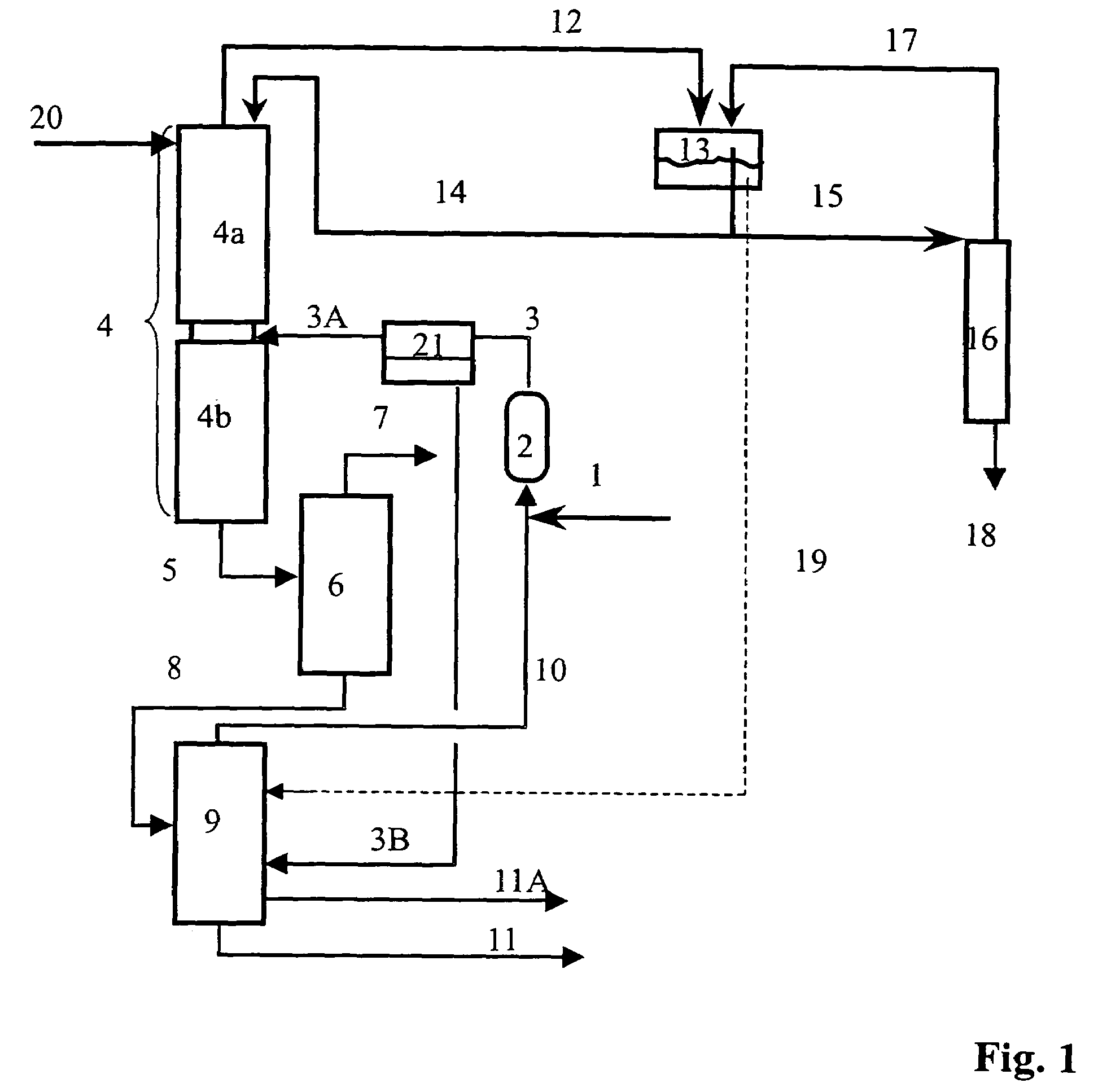

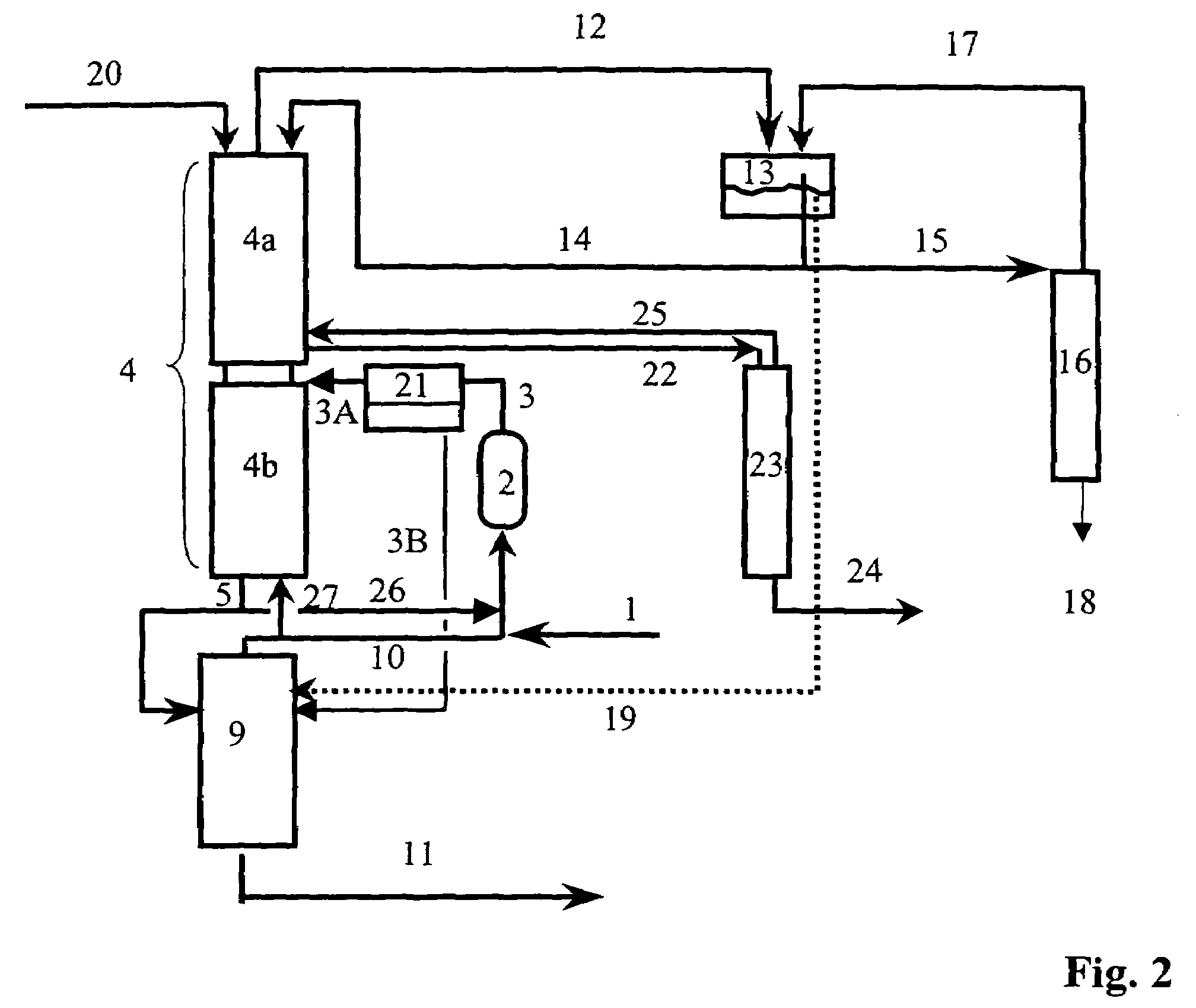

Process for preparing isobutene from tert-butanol

InactiveUS20050014985A1Low mass flowHigh selectivityExhaust apparatusOrganic chemistry methodsFixed bedTemperature difference

Isobutene is prepared by dissociating tert-butanol into isobutene and water over an acid ion-exchange resin arranged as a fixed bed in at least one reactor at a temperature of from 80 to 150° C. and at a pressure of from 5 to 25 bar to obtain a reaction mixture, separating the reaction mixture into isobutene, a by-product, water and at least one mixture of undissociated tert-butanol and water. The reactor is operated pseudo-isothermally, with a temperature difference between inflowing and outflowing streams of less than 15 K.

Owner:EVONIK DEGUSSA GMBH

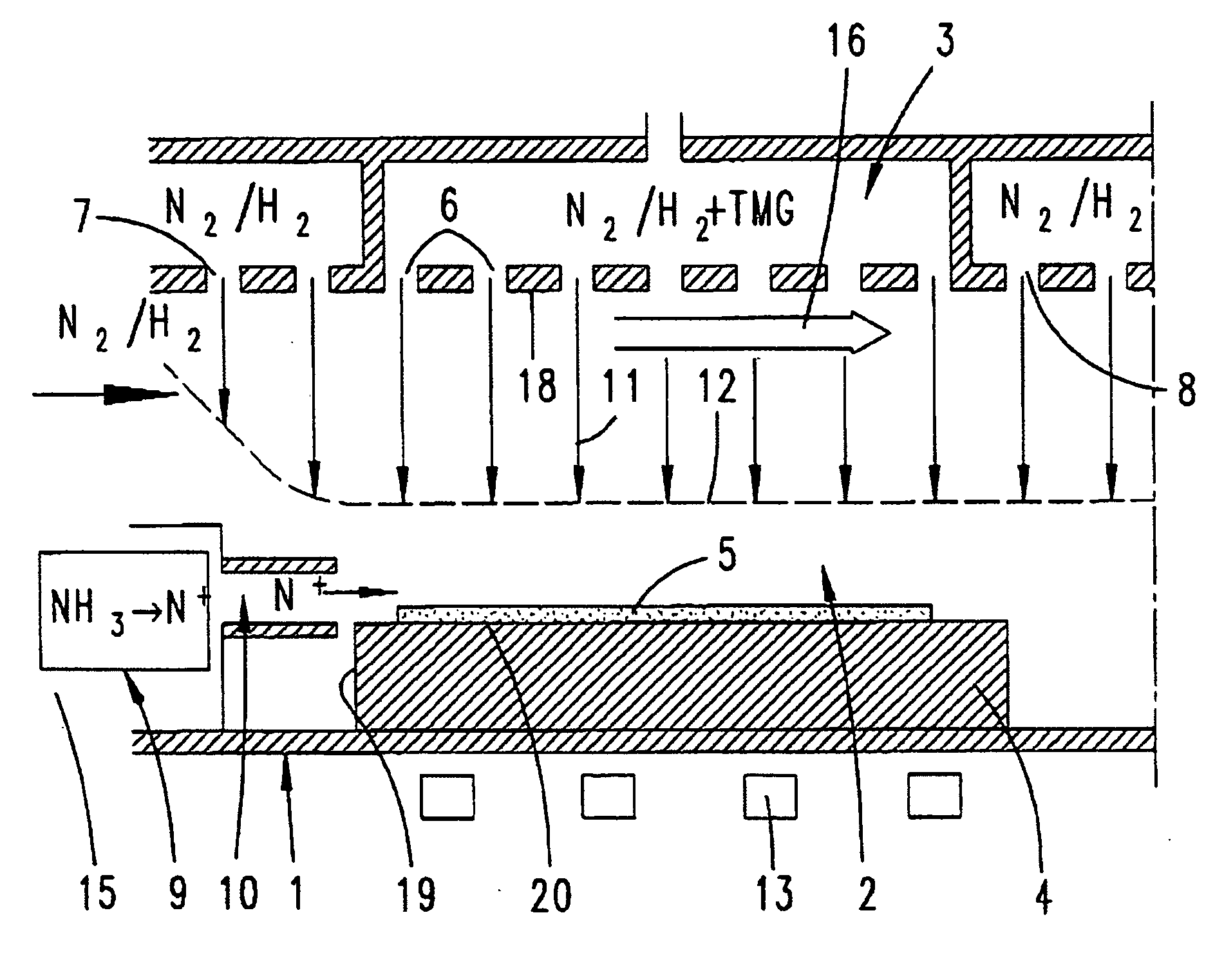

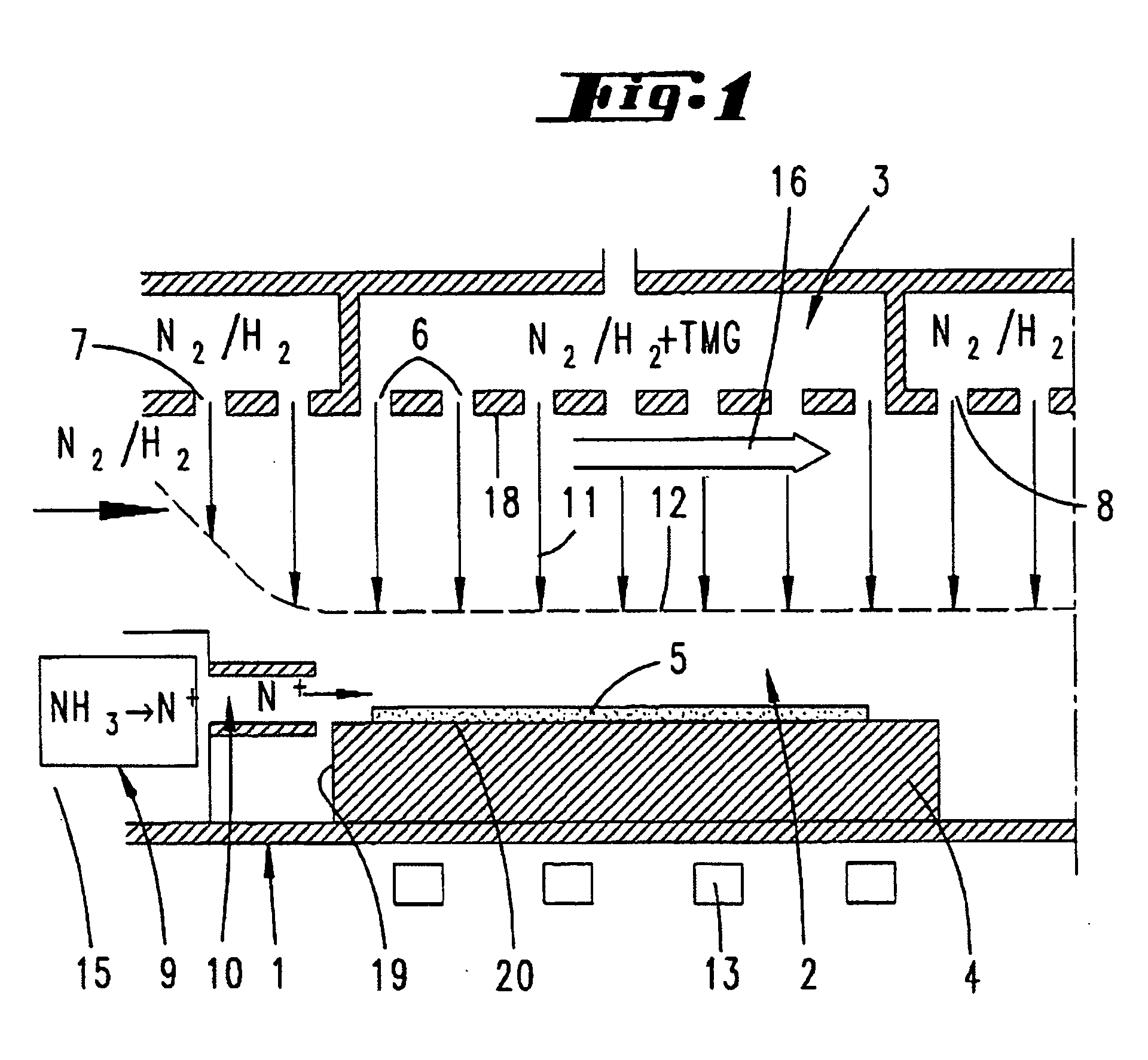

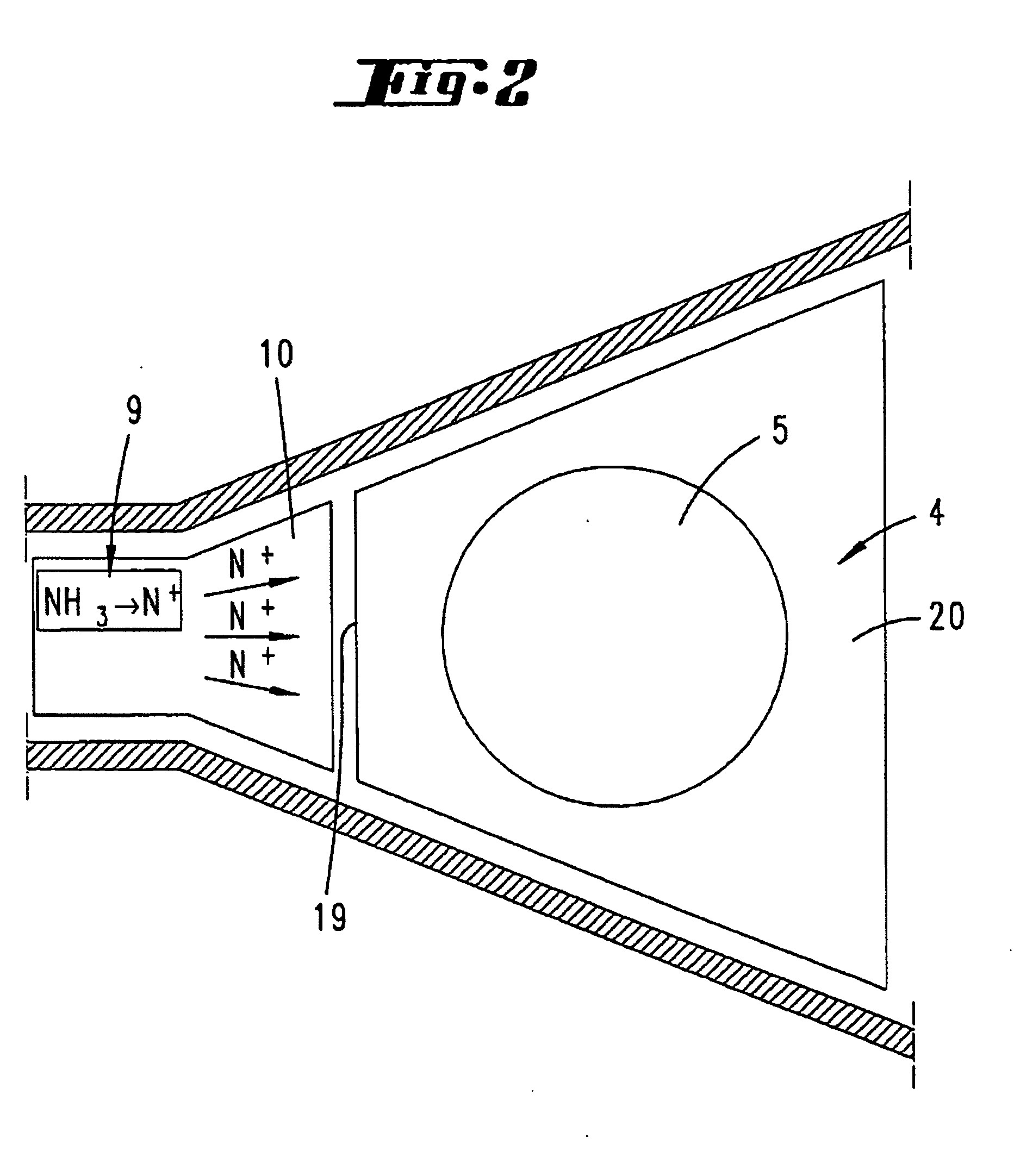

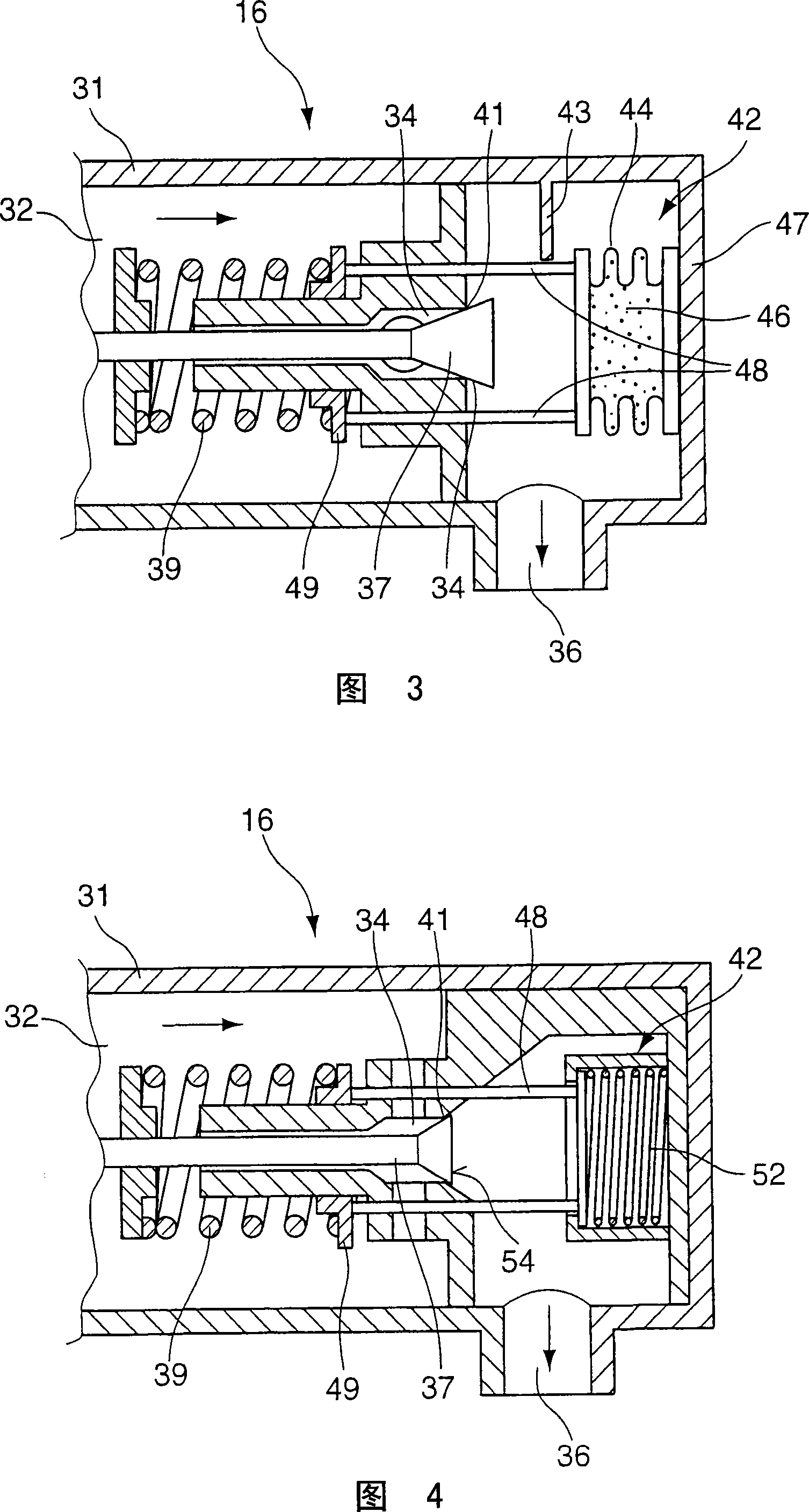

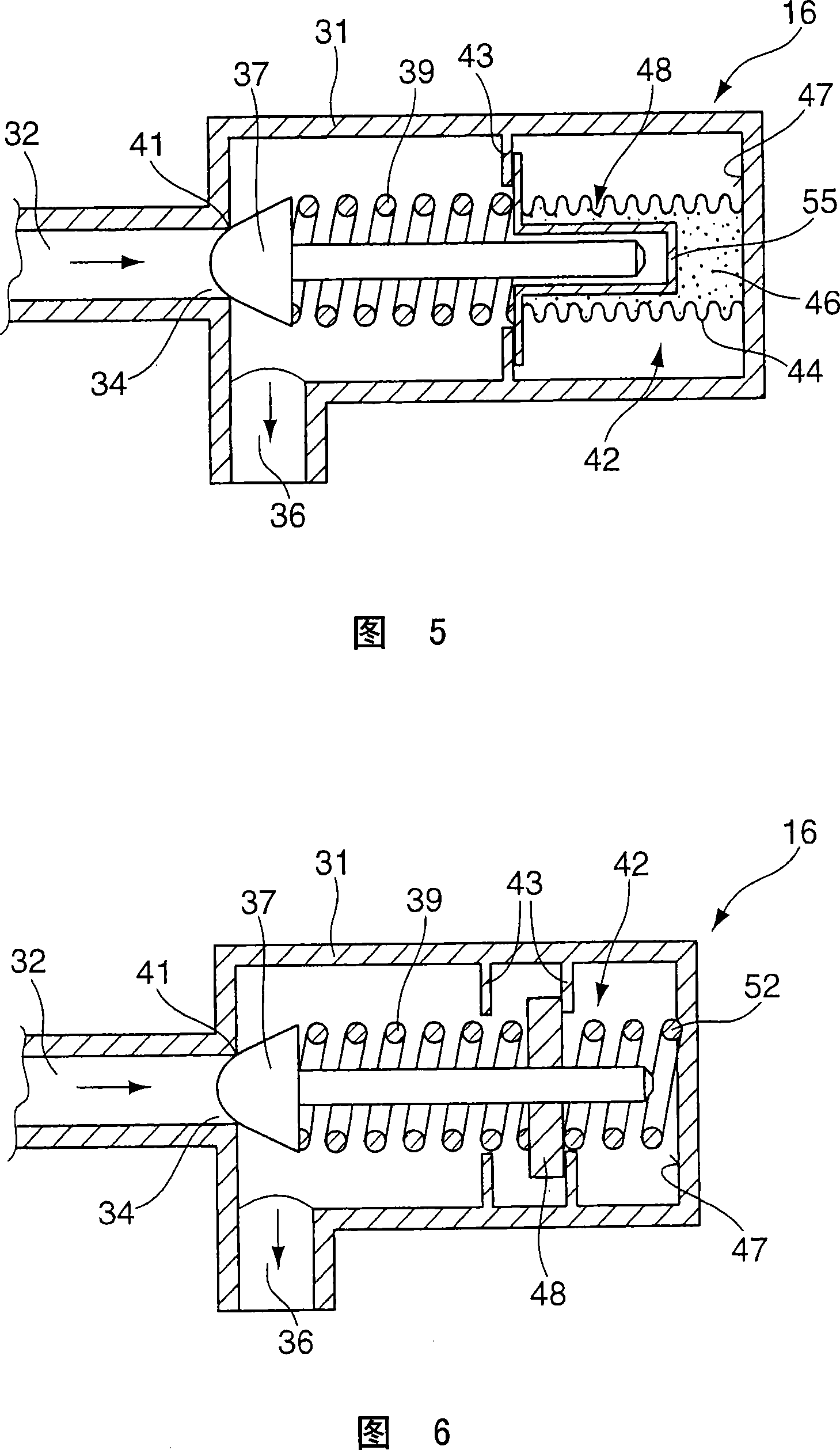

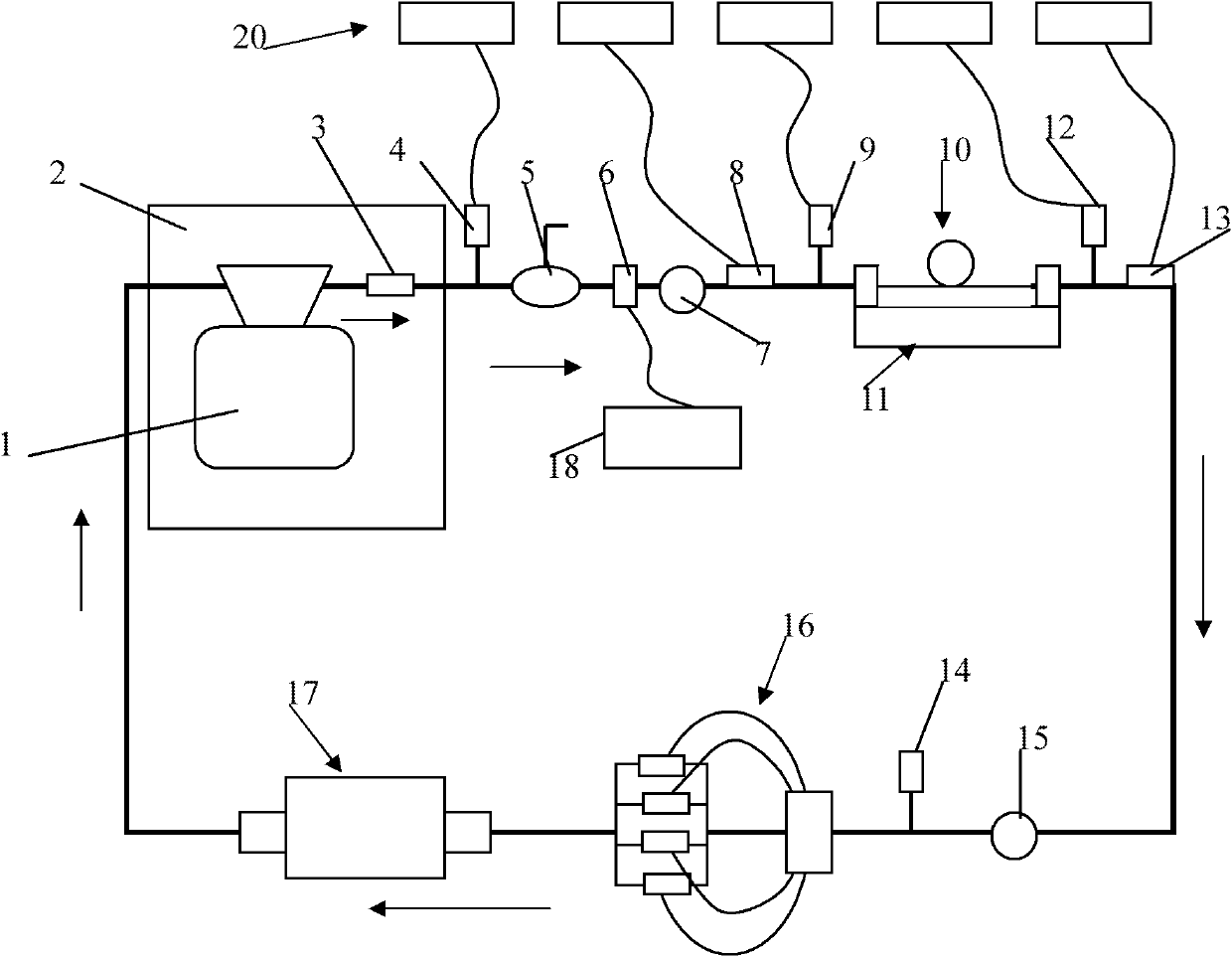

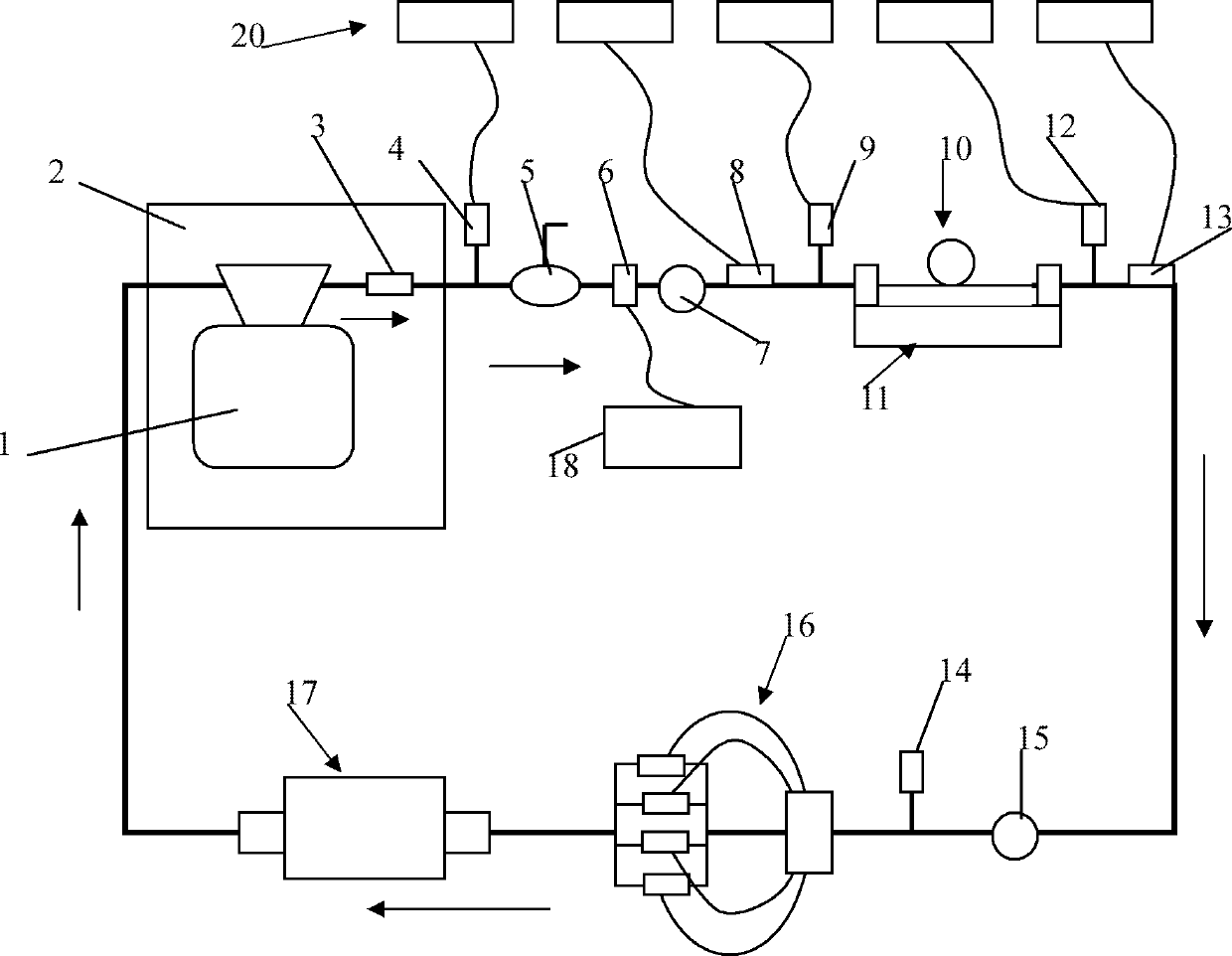

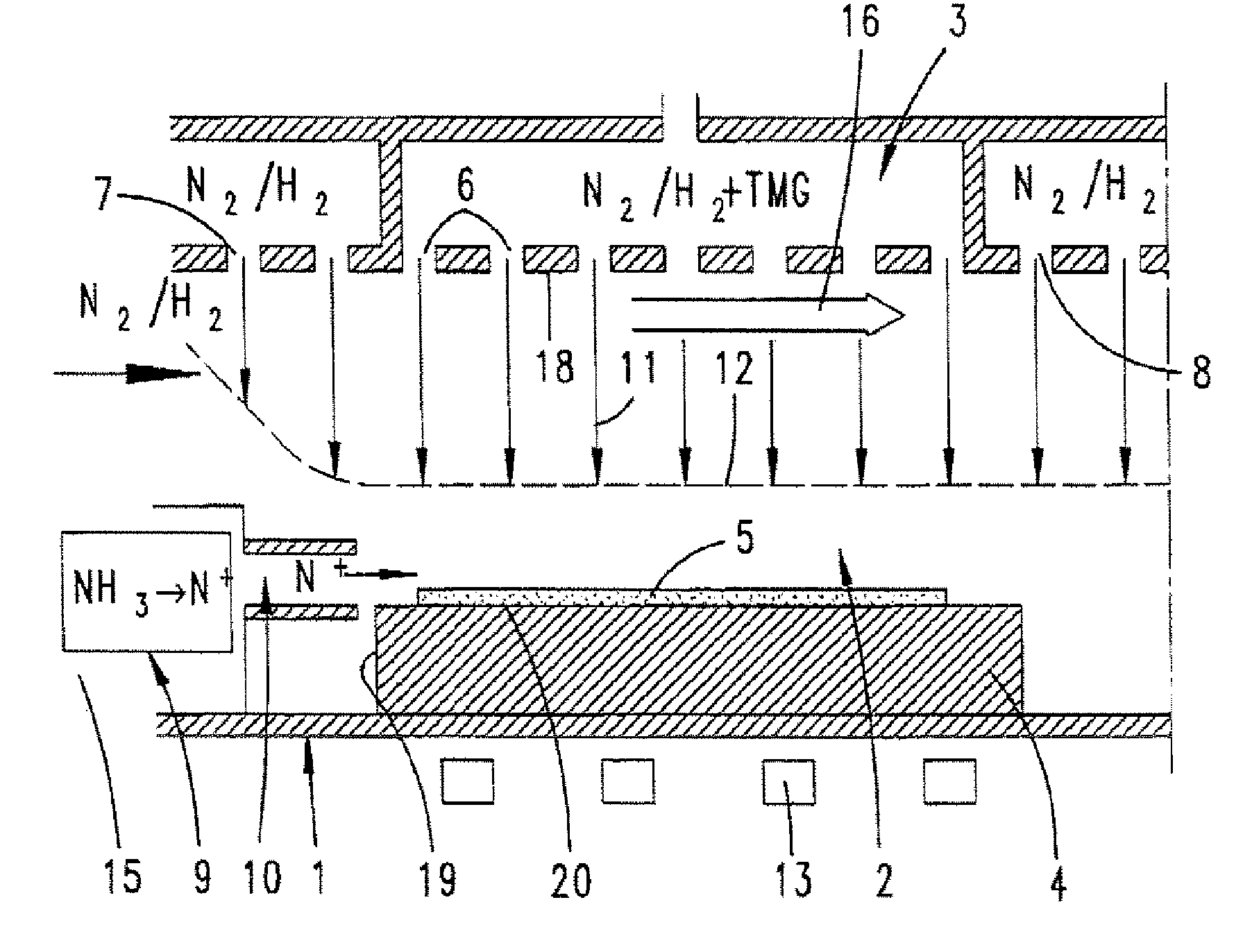

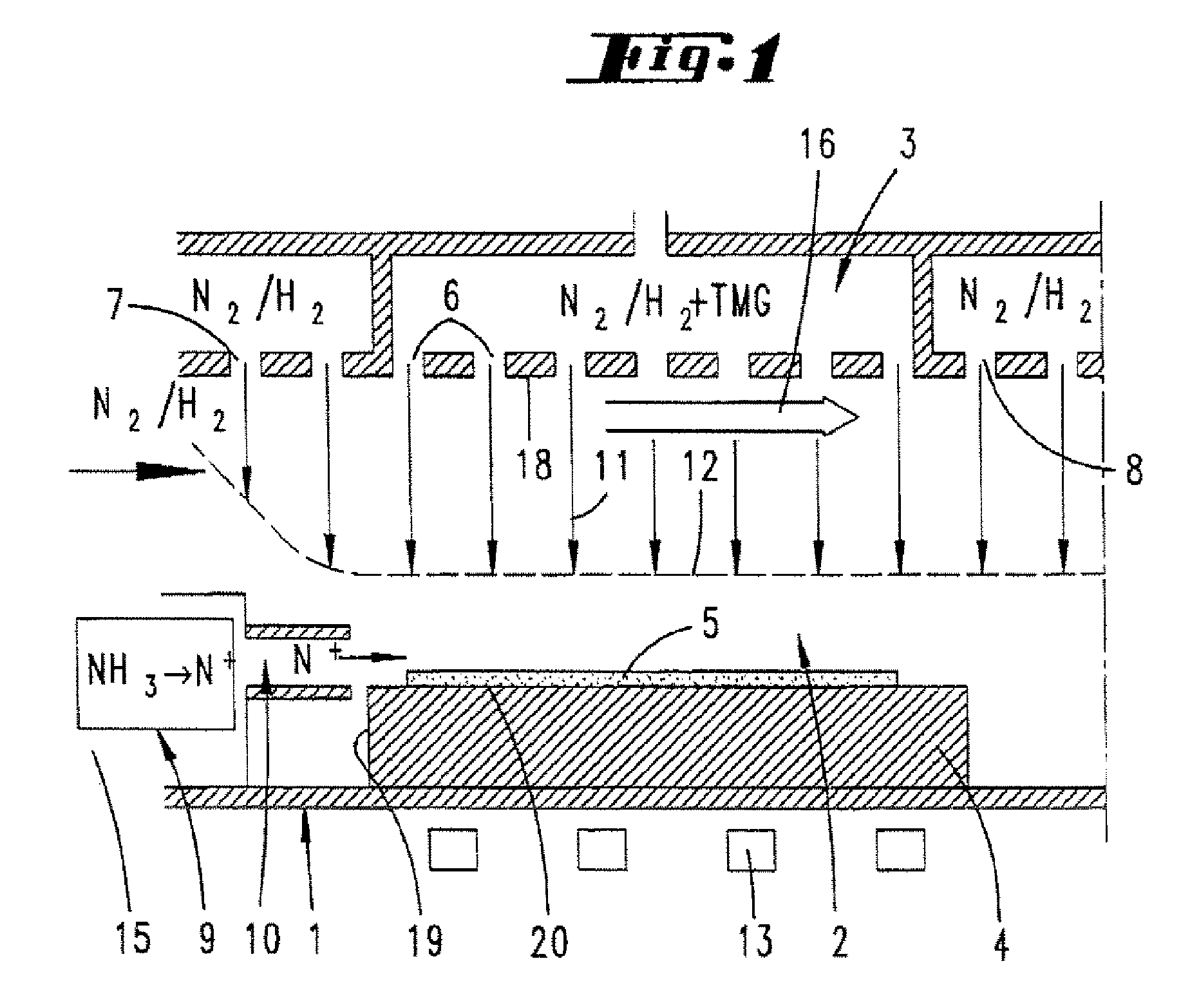

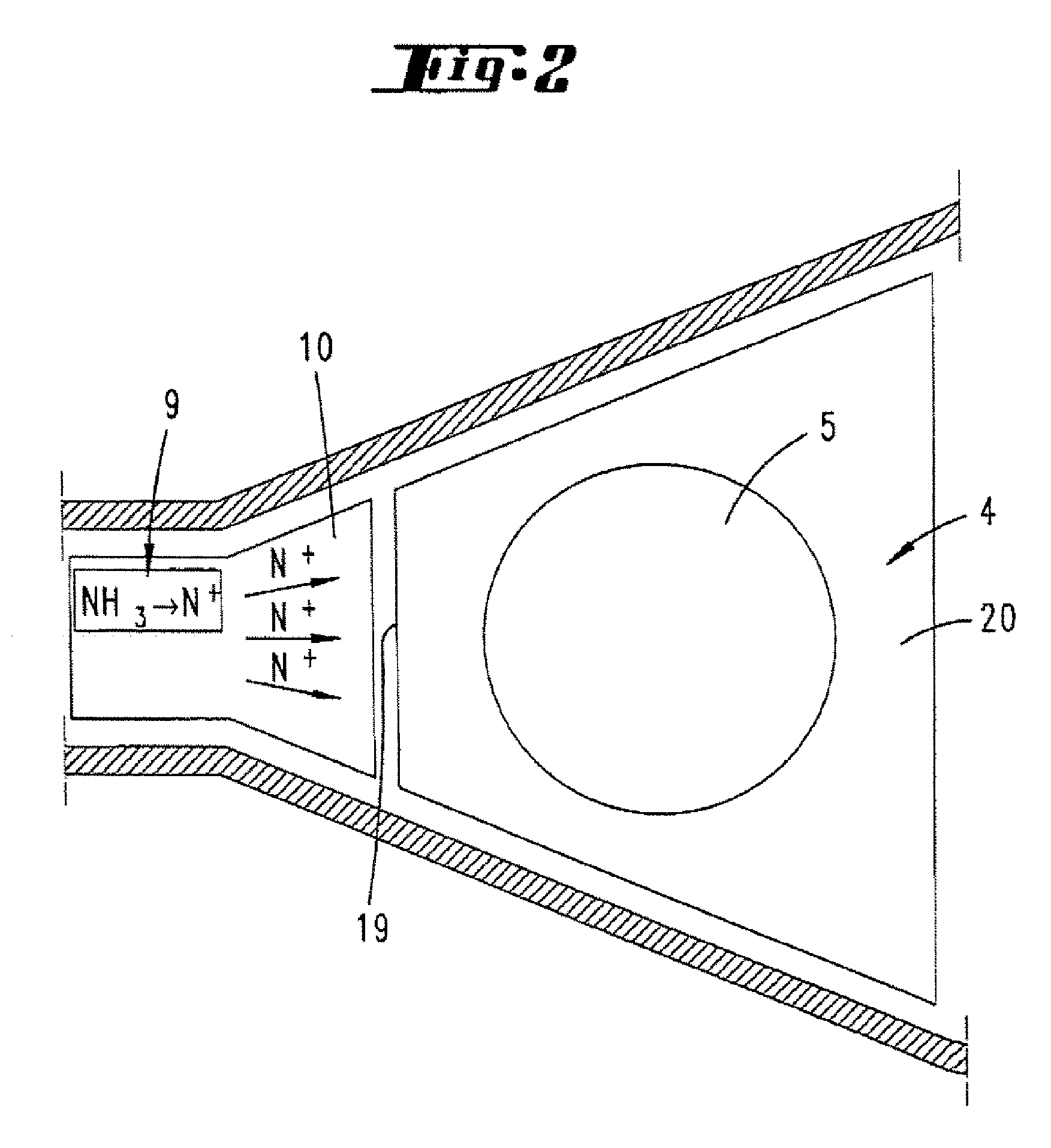

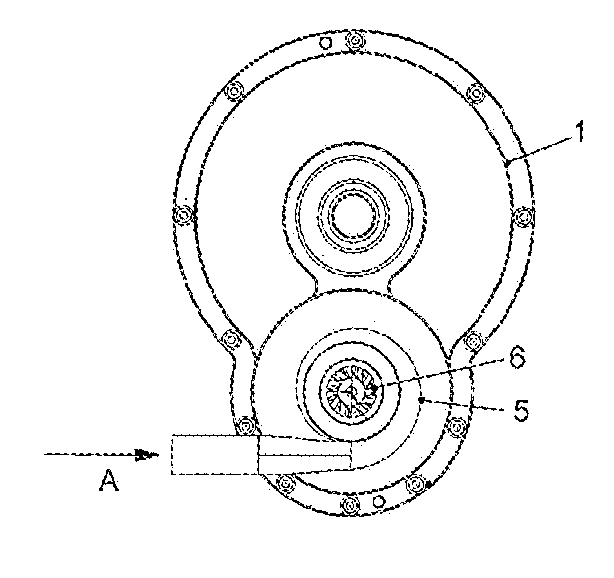

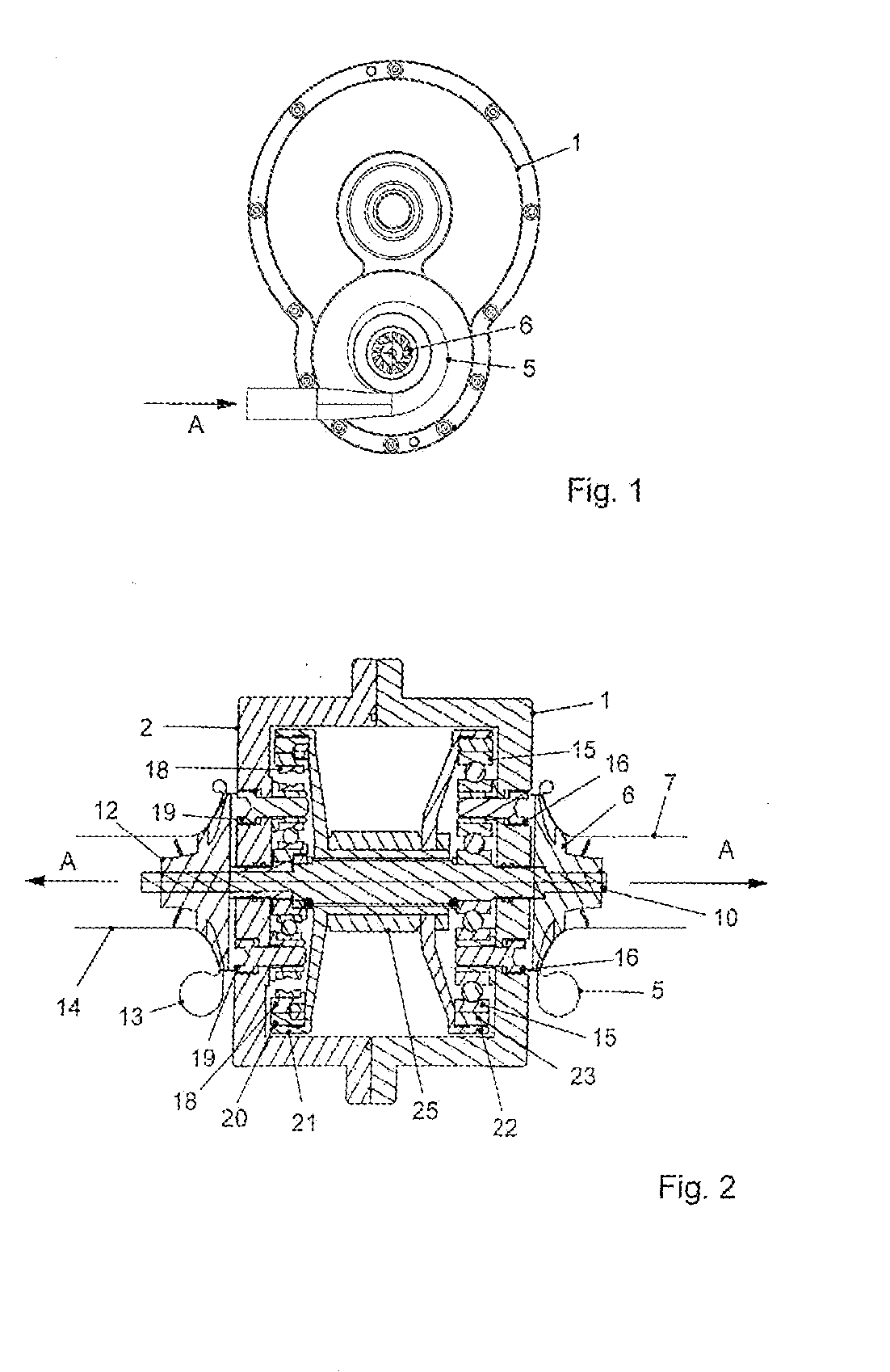

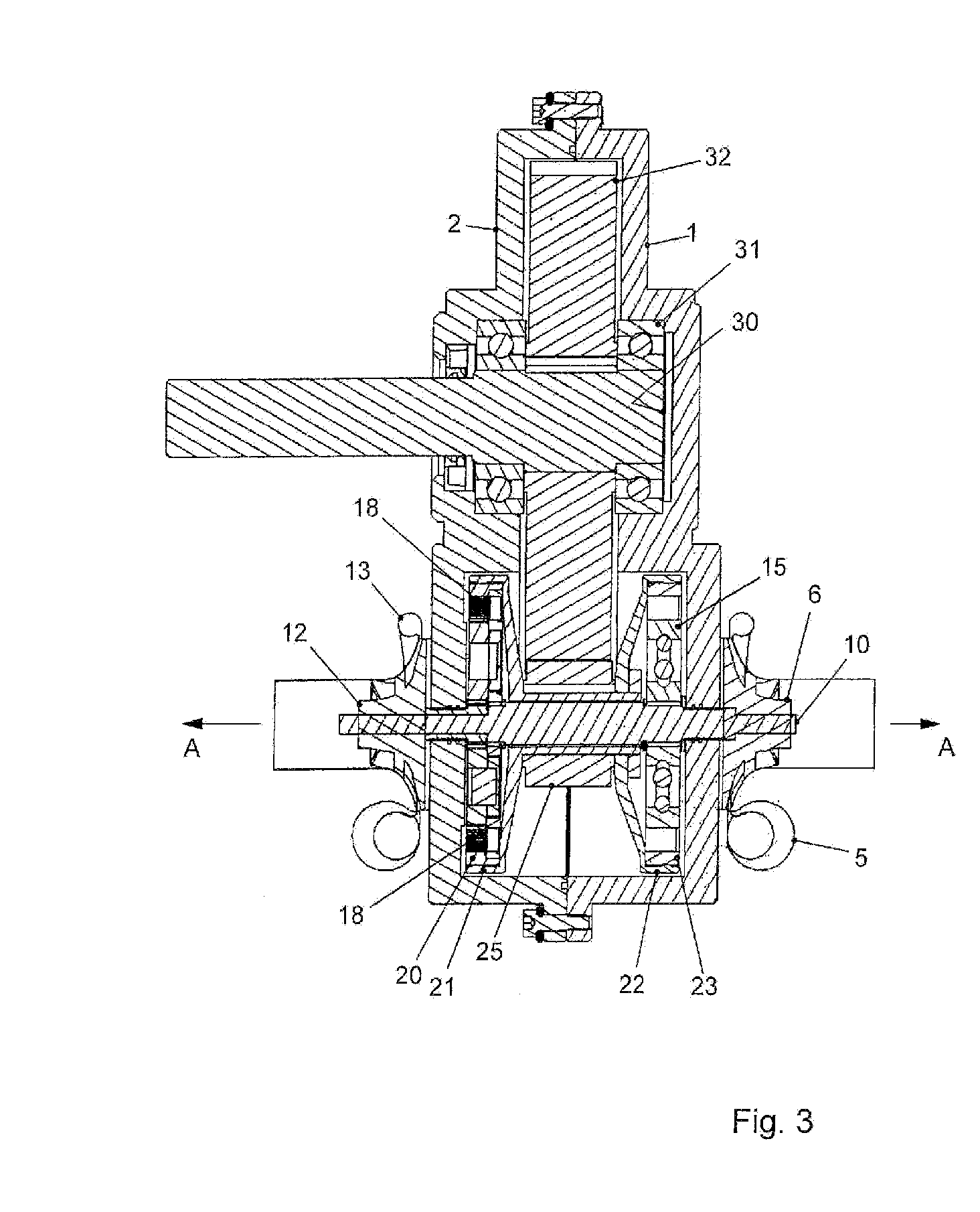

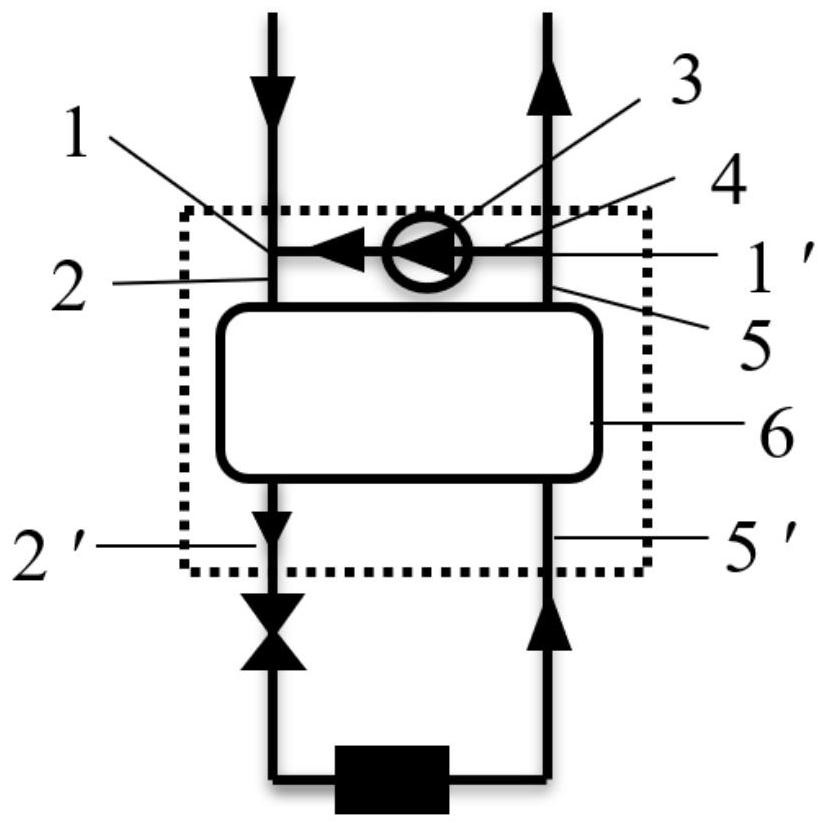

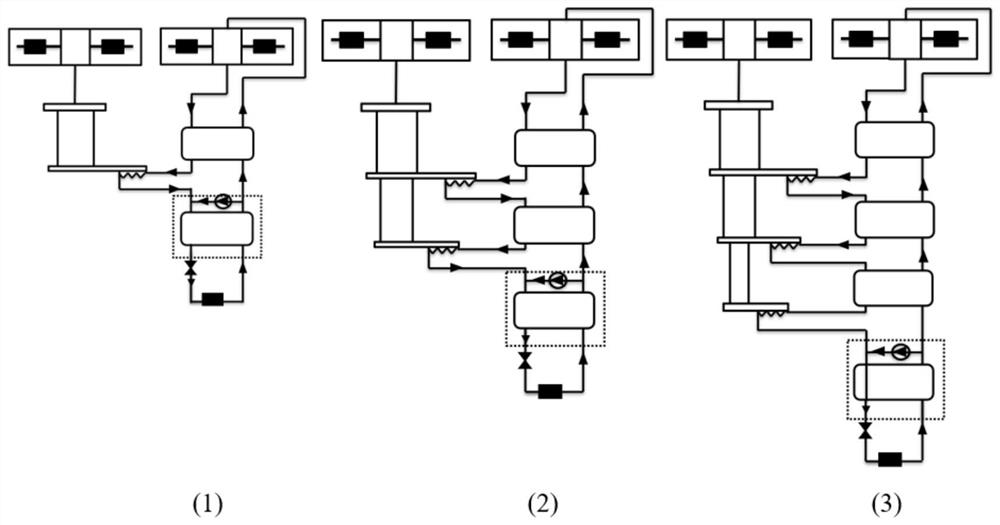

Process and apparatus for depositing semiconductor layers using two process gases, one of which is preconditioned

InactiveUS20060121193A1Raise the ratioImprove light outputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDecompositionThermal activation energy

The invention relates to a method and device for depositing at least one layer, particularly a semiconductor layer, onto at least one substrate (5), which is situated inside a process chamber (2) of a reactor (1) while being supported by a substrate holder (4). The layer is comprised of at least two material components provided in a fixed stoichiometric ratio, which are each introduced into the reactor (1) in the form of a first and a second reaction gas, and a portion of the decomposition products form the layer, whereby the supply of the first reaction gas, which has a low thermal activation energy, determines the growth rate of the layer, and the second reaction gas, which has a high thermal activation energy, is supplied in excess and is preconditioned, in particular, by an independent supply of energy. The first reaction gas flows in a direction (11) toward the substrate holder (4) through a multitude of openings (6), which are distributed over a surface (18) of a gas inlet element (3), said surface being located opposite the substrate holder (4). According to the invention, the second process gas is preconditioned with a plasma before entering the process chamber (1), and it enters the process chamber (2) at the edge (19) of the substrate holder (4) directly thereabove and flows parallel to the substrate holder surface.

Owner:AIXTRON AG

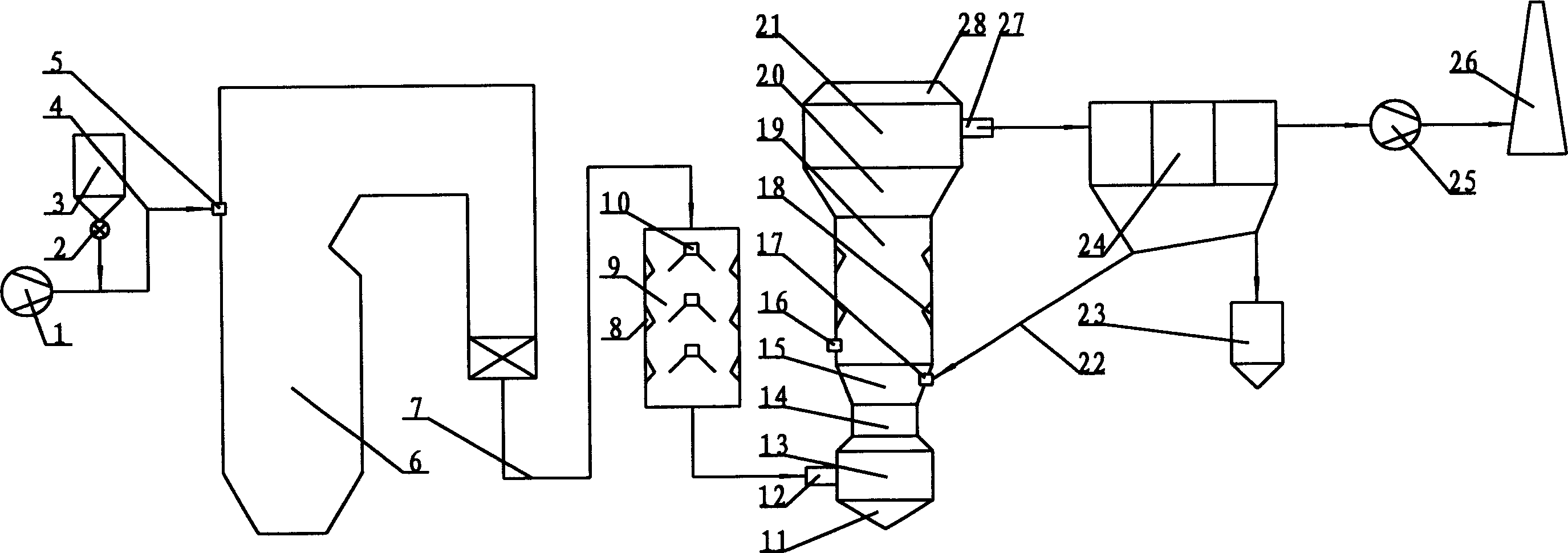

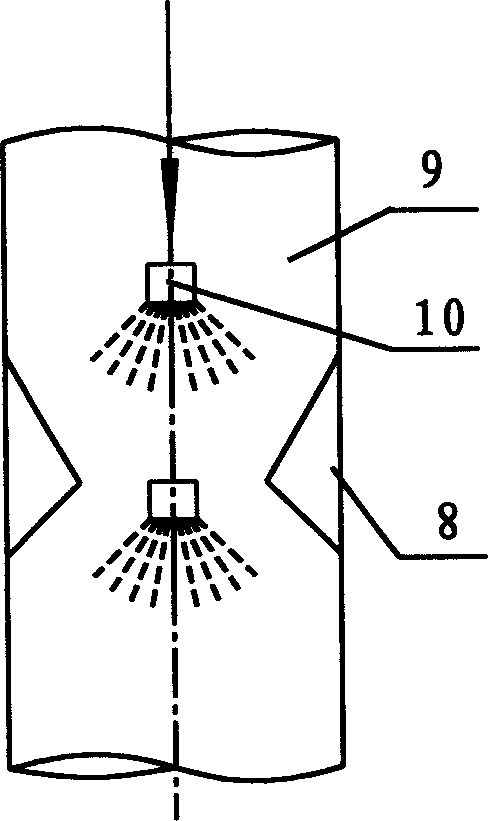

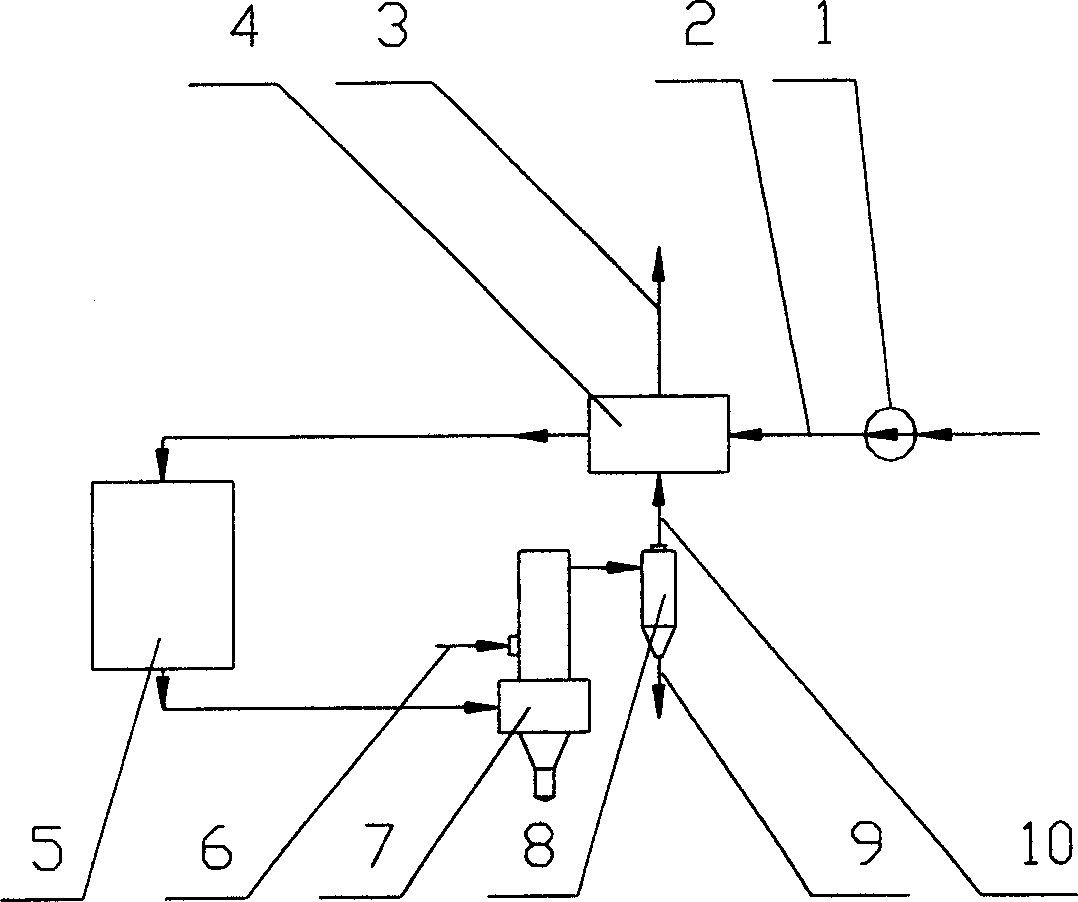

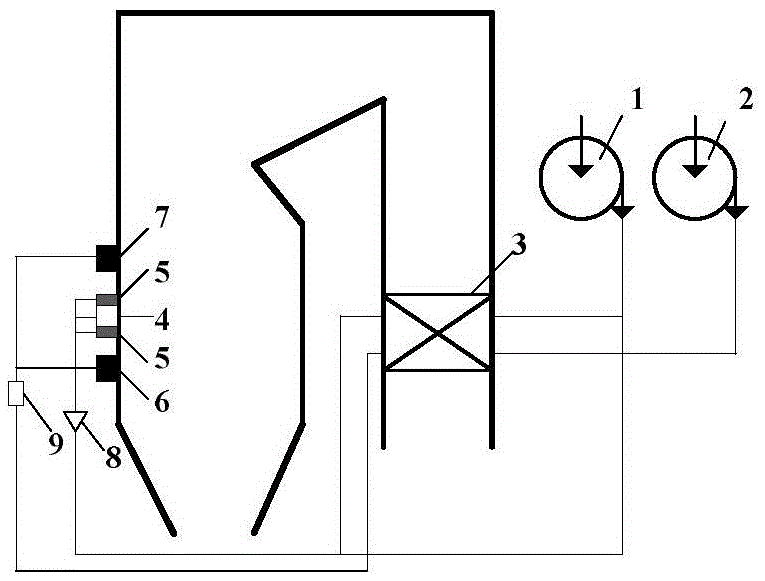

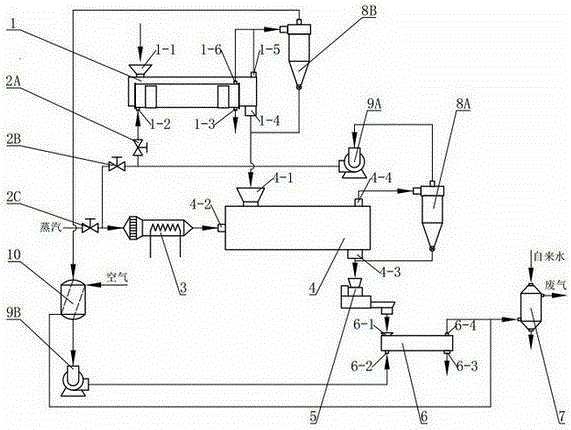

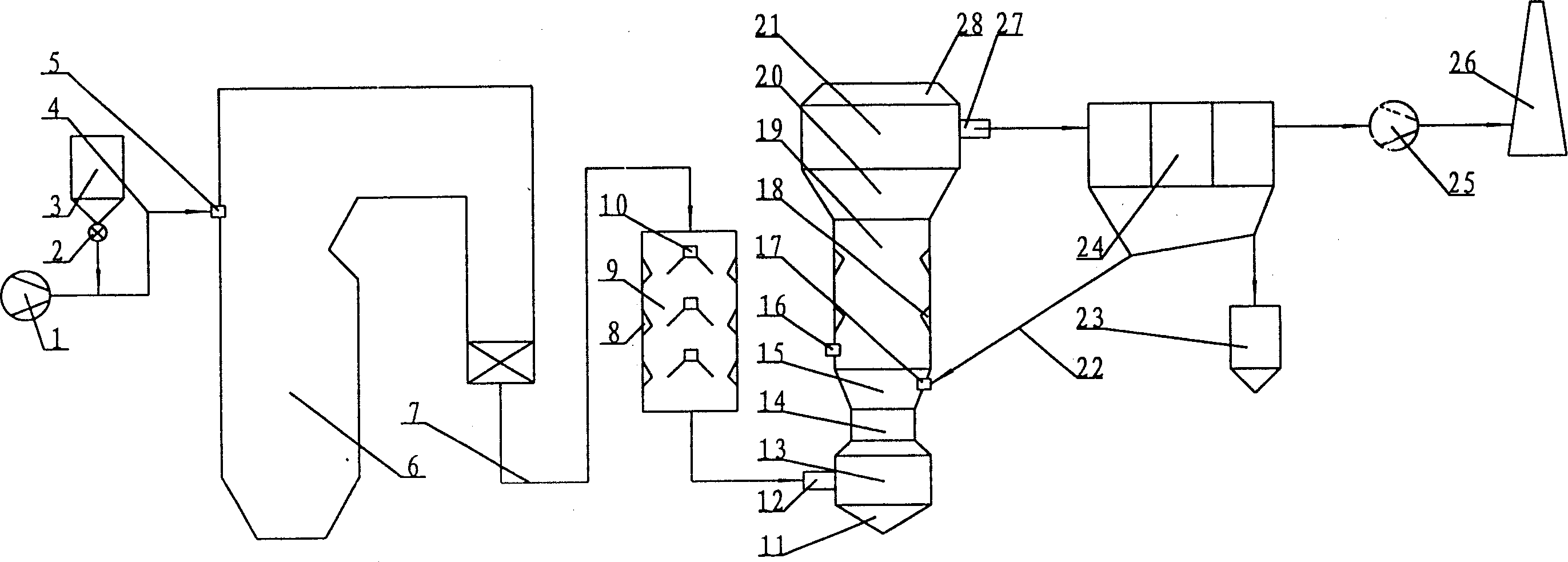

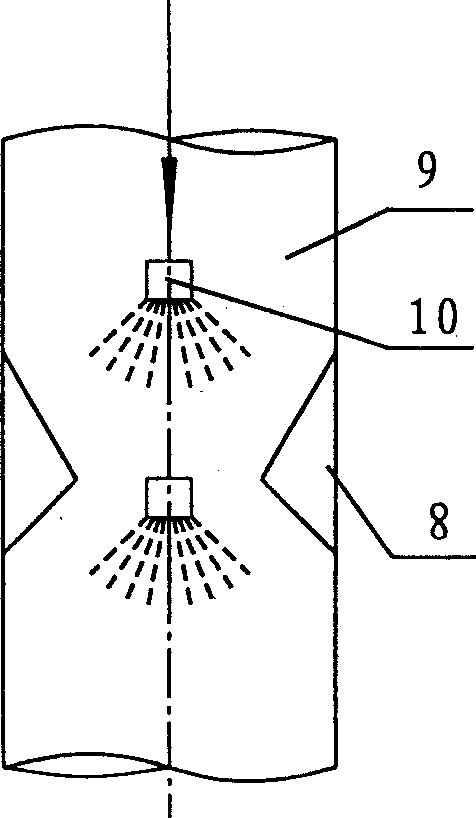

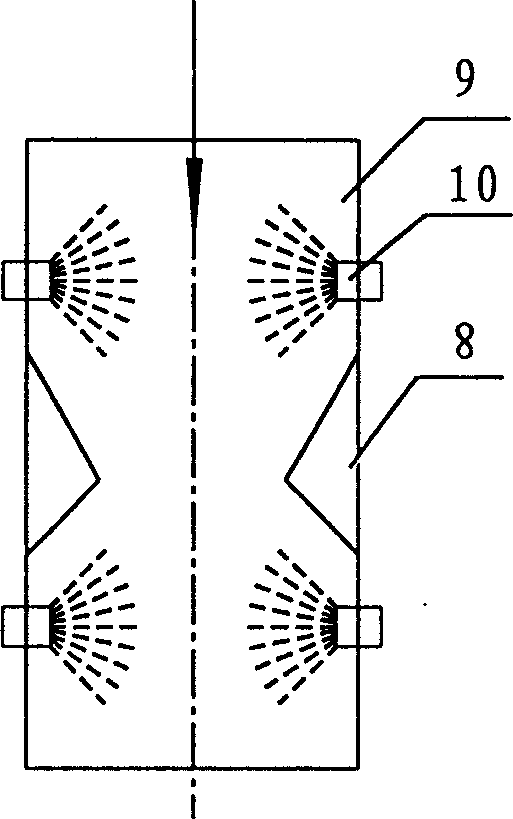

Multiple reaction integrated process for desulfuizing from fume by dry method and its system

ActiveCN1537668AImprove surface activityReduce desulfurization costDispersed particle separationPartial oxidationCalcium sulfite

A multiple reactions integrated process for desulfurizing from the fume by dry method includes such steps as spraying limestone powder in high-temp combustion box from its top to decompose calcium carbonate into calcium oxide and CO2, absorbing SO2 from fume by partial calcium oxide to generate calcium sulfate, spraying water to activate calcium oxide to transform partial calcium oxide to calcium hydroxide and absorb SO2 from fume to generate calcium sulfite, and using the residual calcium hydroxide and calcium oxide to desulfurize the fume in desulfurizing tower. Its system is composed of limestone powder sprayer, moistening flue, desulfurizing tower, external electric duster, draught blower and chimney.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

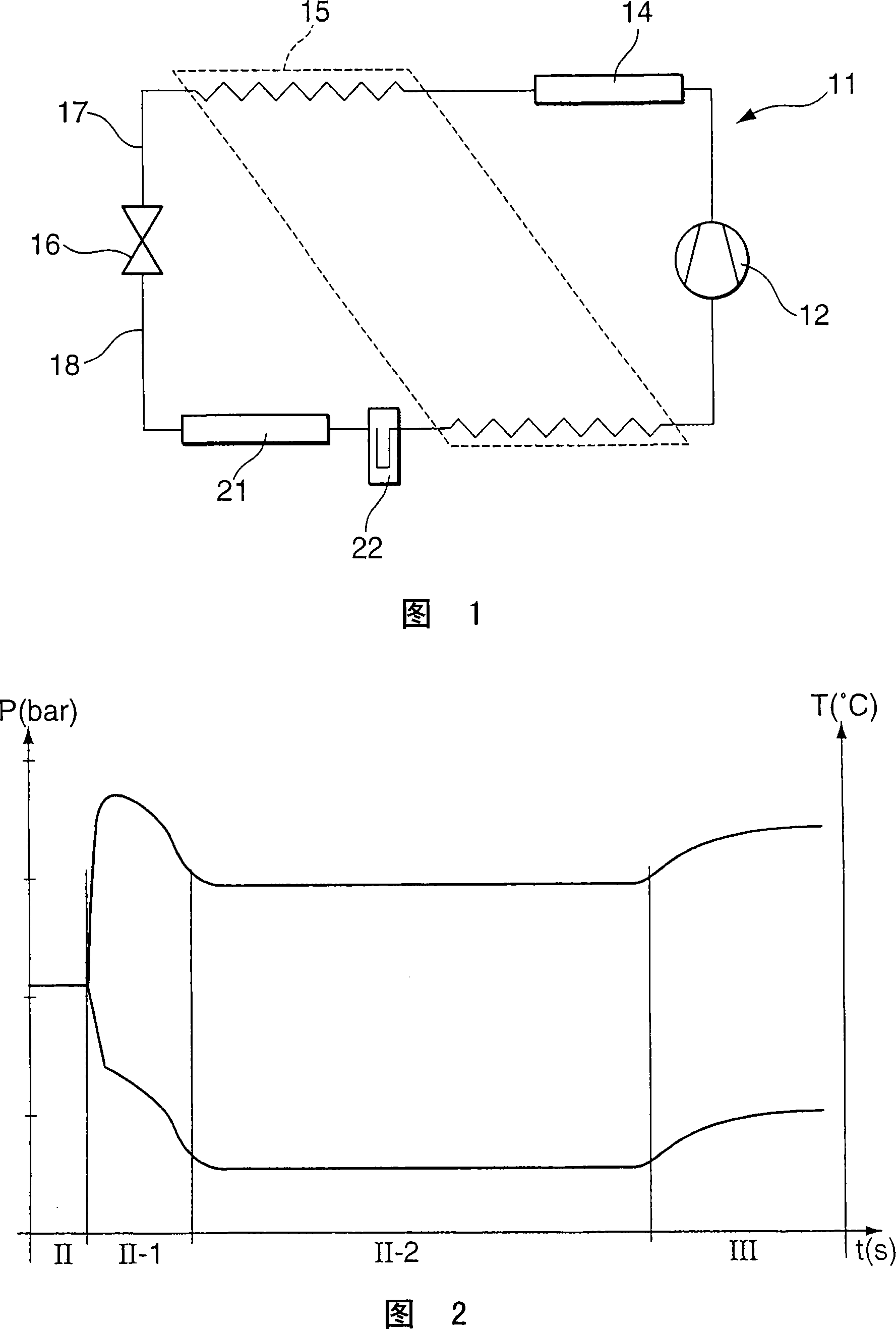

Expansion valve control method, and expansion valve

InactiveCN101135387AImprove responsivenessLow mass flowOperating means/releasing devices for valvesCompression machinesPressure riseEngineering

The invention relates to a method for controlling an expansion valve, in particular for vehicle air-conditioning systems operated with CO2 as the refrigerant, with a valve housing which has a feed opening and a removal opening, with a valve-closing member which closes a valve seat of a passage opening arranged between the feed and removal openings, and with a resetting device which acts in the closing direction of the valve-closing member, an adjusting element, which is assigned to the valve-closing member, on the low-pressure side being activated via a predetermined threshold value as the low pressure rises or as the temperature on the low-pressure side rises and actuates at least one actuating element by means of which a closing force of the resetting device acting on the valve-closing member is reduced such that a passage opening is enlarged or a passage of a bypass valve arranged on the low-pressure side, which passage is arranged parallel to the passage opening, is opened.

Owner:OTTO EGELHOF GMBH & CO KG

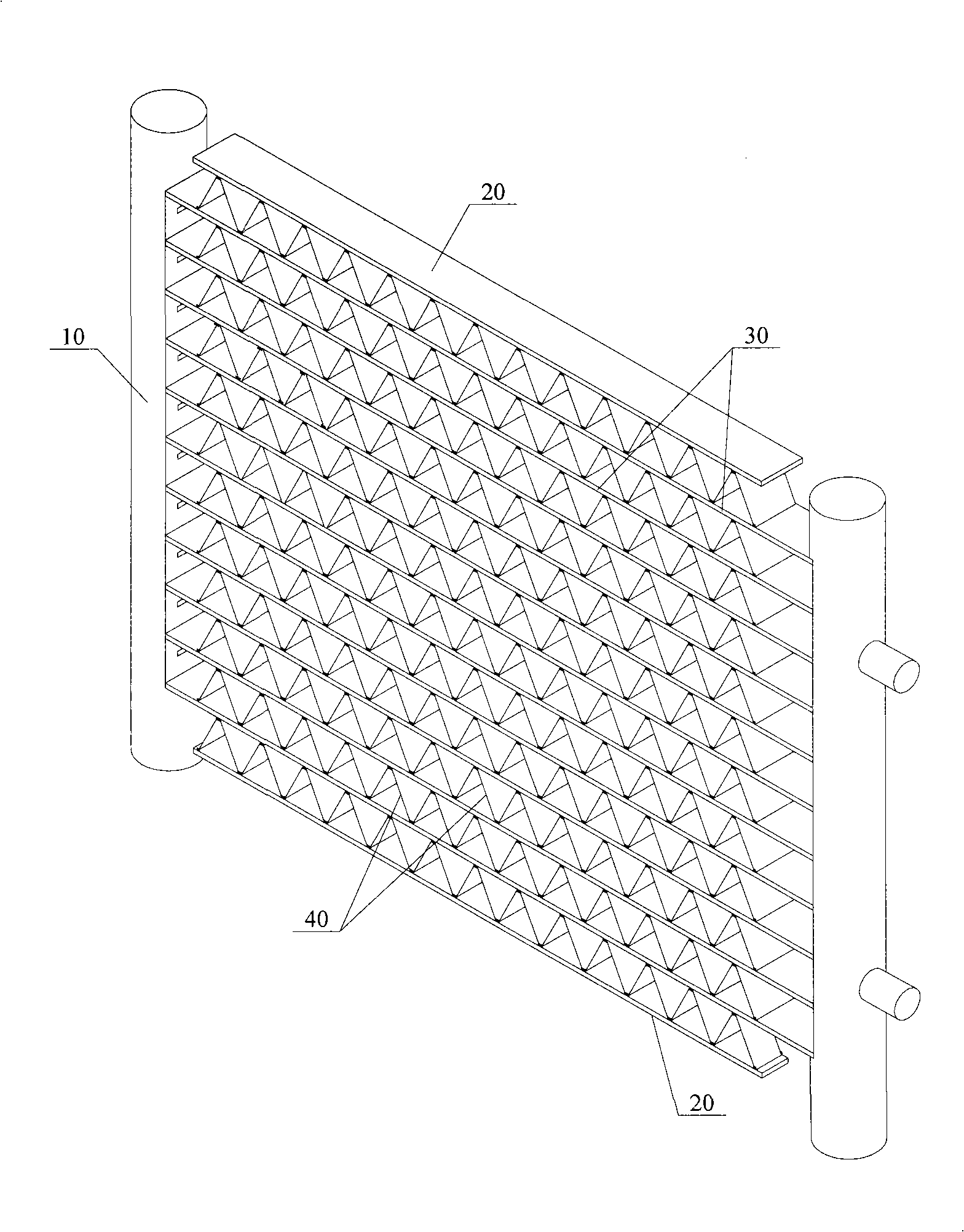

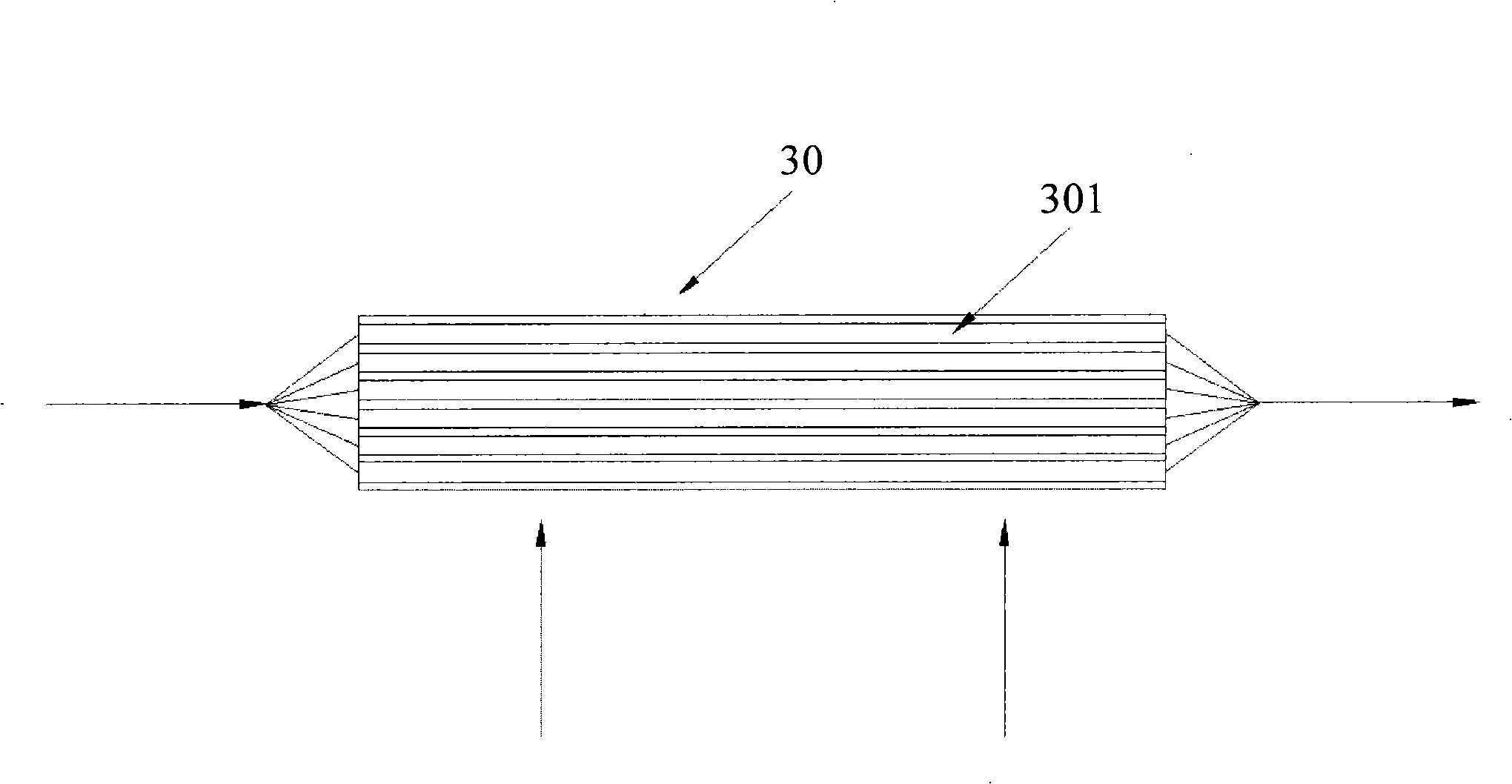

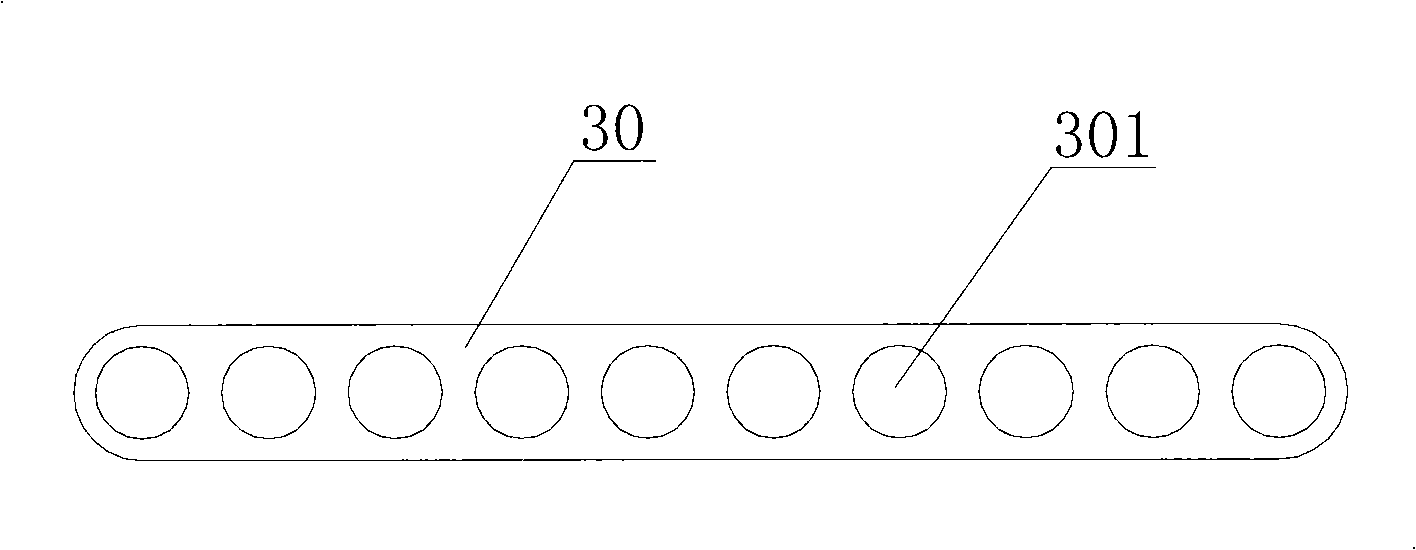

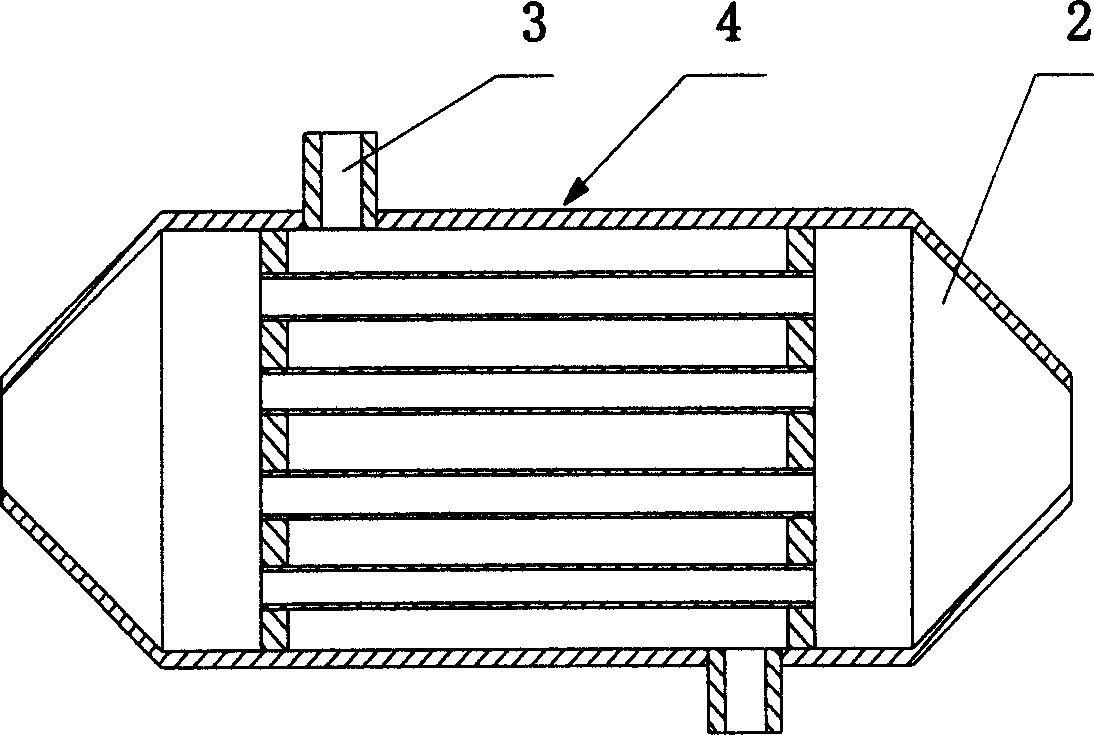

Flat pipe and heat exchanger

InactiveCN101526322AGive full play to the heat transfer performanceUniform stateStationary conduit assembliesTubular elementsPlate heat exchangerHeat transmission

The invention relates to the technical field of heat exchanger, in particular to a flat pipe which comprises not less than two through holes which extend along the lengthwise direction of the flat pipe. The through holes are arranged side by side along the width direction of the flat pipe. Two ends of the flat pipe along the width direction respectively form an external air influx entrance end and an external air outflux end. The section sizes of the through holes are reduced gradually along the direction from the external air influx entrance end of the flat pipe to the external air outflux end of the flat pipe. The through hole near the external air influx entrance end of the flat pipe has larger section size, larger heat transmission temperature difference, large heat exchange volume and larger mass flow. The through hole near the external air outflux end of the flat pipe has smaller section size, lower heat transmission temperature difference, less heat exchange volume and less mass flow. The invention brings the heat exchange performance of the flat pipe into play completely and improves the heat exchange efficiency of the heat exchanger further. The invention also provides a heat exchanger.

Owner:SANHUA(HANGZHOU) MICRO CHANNEL HEAT EXCHANGER CO LTD

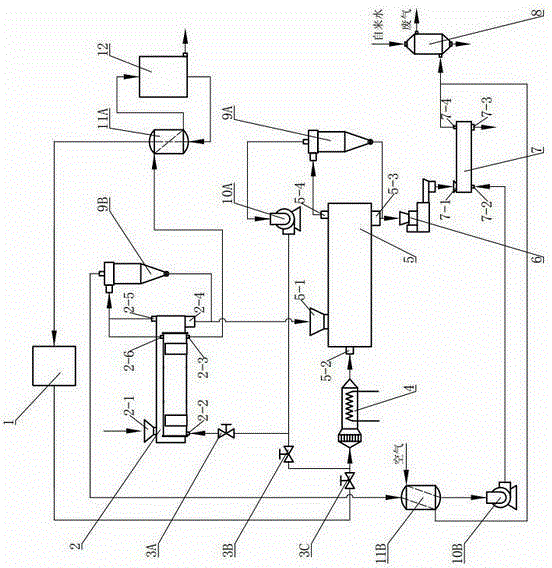

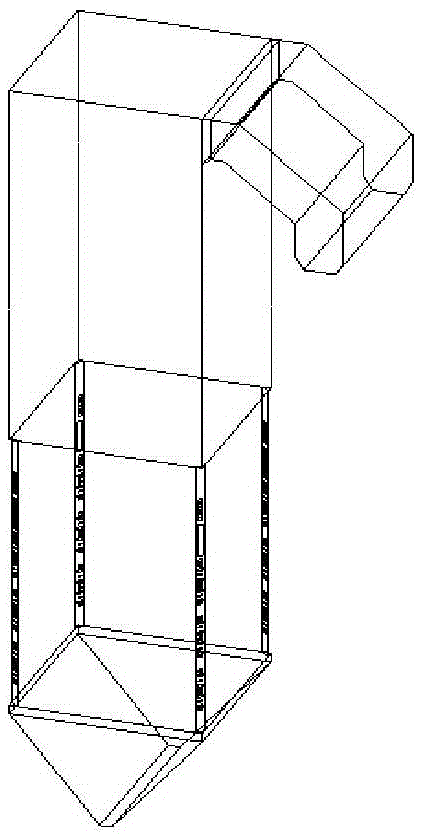

Superheated steam drying method for sludge and drying equipment

InactiveCN1686876AReduces the possibility of dry deflagrationReduce heat transfer areaSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The present invention relates to a sludge drying method, said method utilizes the sensible heat and latent heat of dried tail gas recovered by heat exchanger, and makes it exchange with water and heats it to obtain superheated steam, then makes the superheated steam by fed into a closed direct drying machine to make heat exchange with wet sludge being in said drying machine to obtain the dried sludge. Then said method can make the dried sludge and dried tail gas implement gas-solid separation, so that the dried sludge can be collected. Said drying equipment includes pipe-shell type heat exchanger, heater, closed direct drying machine and gas-solid separator, etc.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD +1

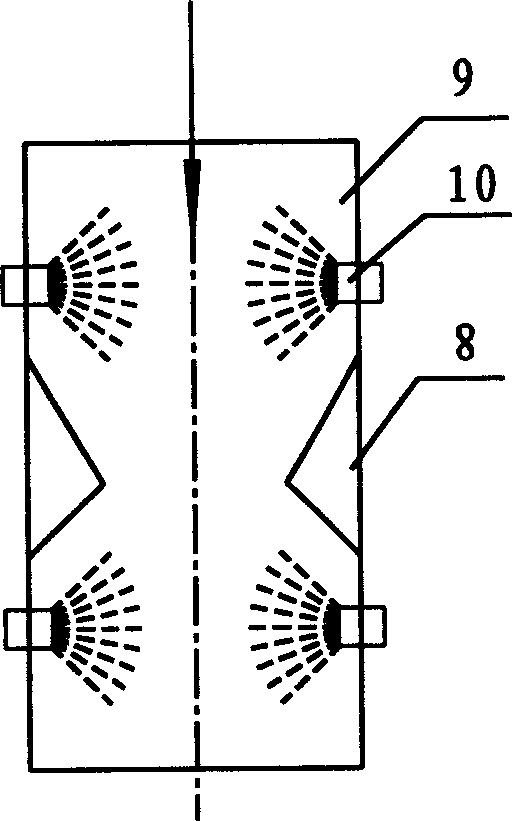

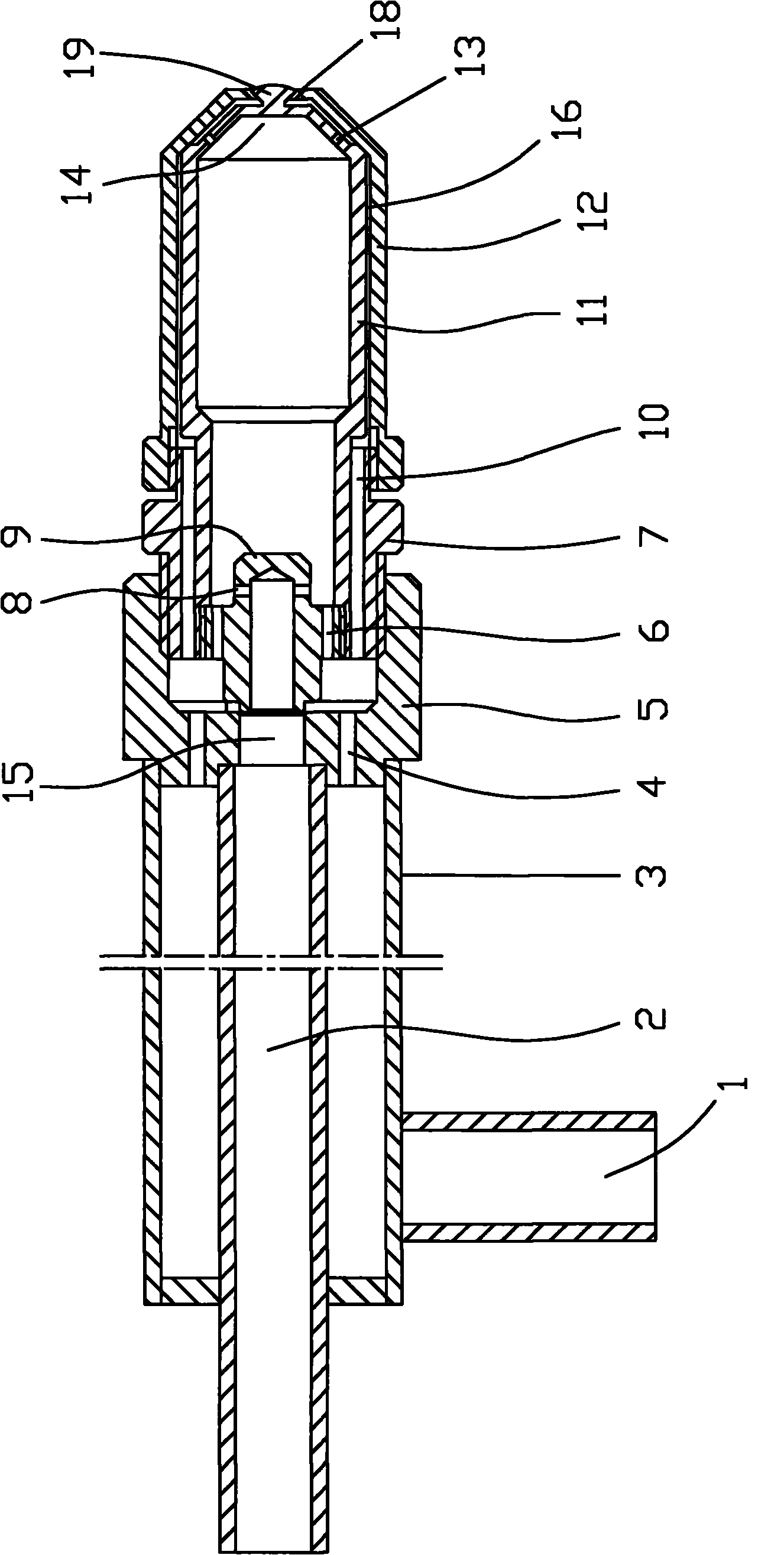

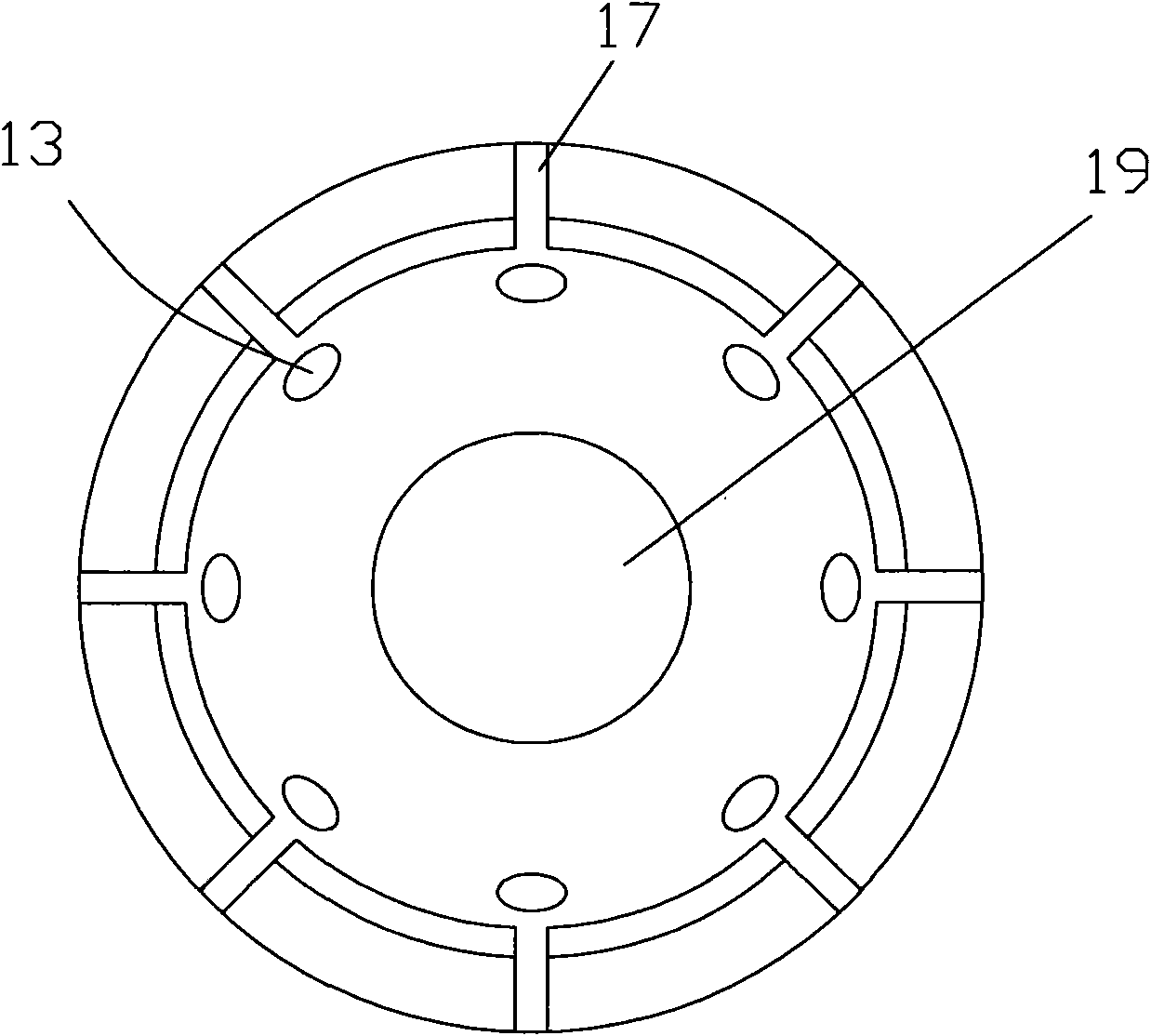

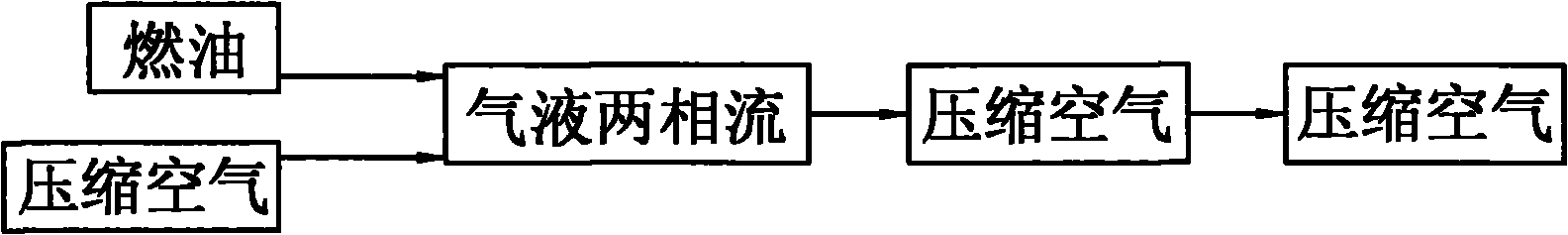

Low-pressure oil film breaking and atomizing technology and device thereof

The invention discloses low-pressure oil film breaking and atomizing technology and device thereof. The low-pressure oil film breaking and atomizing technology is characterized in that fuel oil and an auxiliary gas are formed into gas-liquid two-phase fluids, the gas-liquid two-phase fluids are jetted into a furnace cavity through an oil gun, and the jetted gas-phase fluids enable a formed oil film to be broken by overcoming the surface tension of the jetted gas-phase fluids so as to realize the superfine atomization of the fuel oil; the outlet of a circular jet hole is provided with a secondary transverse ultrasonic air flow, the jet direction of the secondary transverse ultrasonic air flow is perpendicular to that of the circular jet hole, and the secondary transverse ultrasonic air flow further impacts initially-atomized fuel oil jetted from the circular jet hole to carry out secondary breakage and atomization on the fuel oil. The invention has the advantages of smaller average diameter of an oil drop, high penetrating capability of oil mist, good adjustability of an atomized taper angle and very little change of the average dimension of the oil drop when the viscidity of the fuel oil is enhanced or the ejection force of the oil gun is smaller; and in addition, the invention only needs lower fuel oil pressure of 0.4-0.5 MPa, thereby lowering the pressure of a fuel oil system, reducing the electricity consumption of an oil pump and saving the plant electrical consumption.

Owner:艾佩克斯科技(北京)有限公司

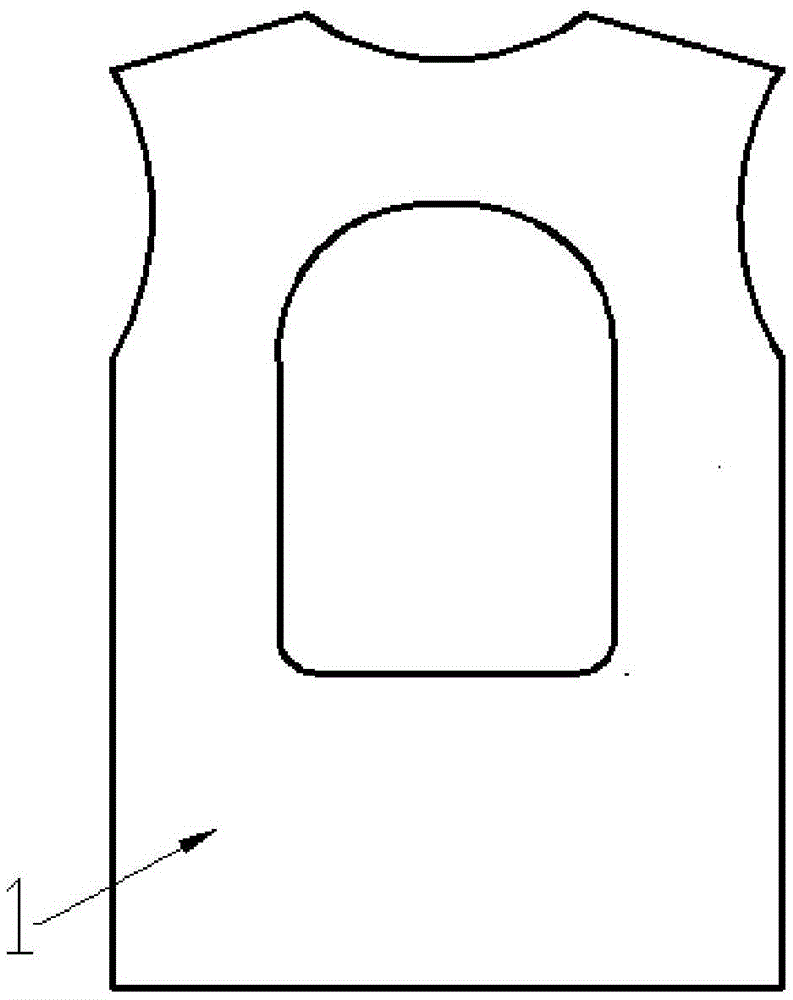

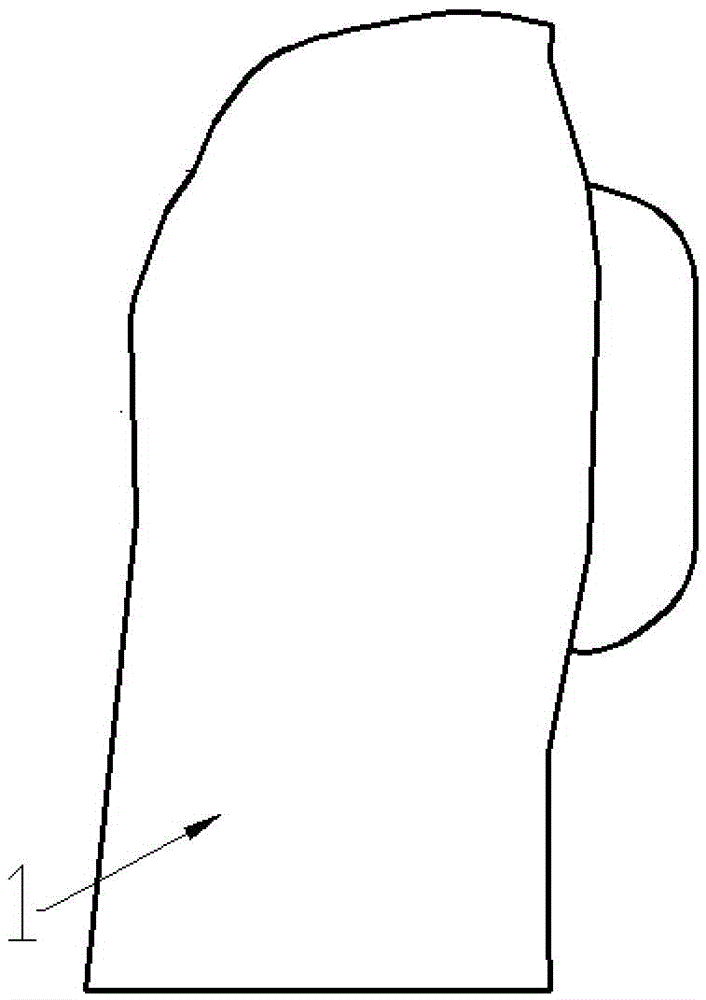

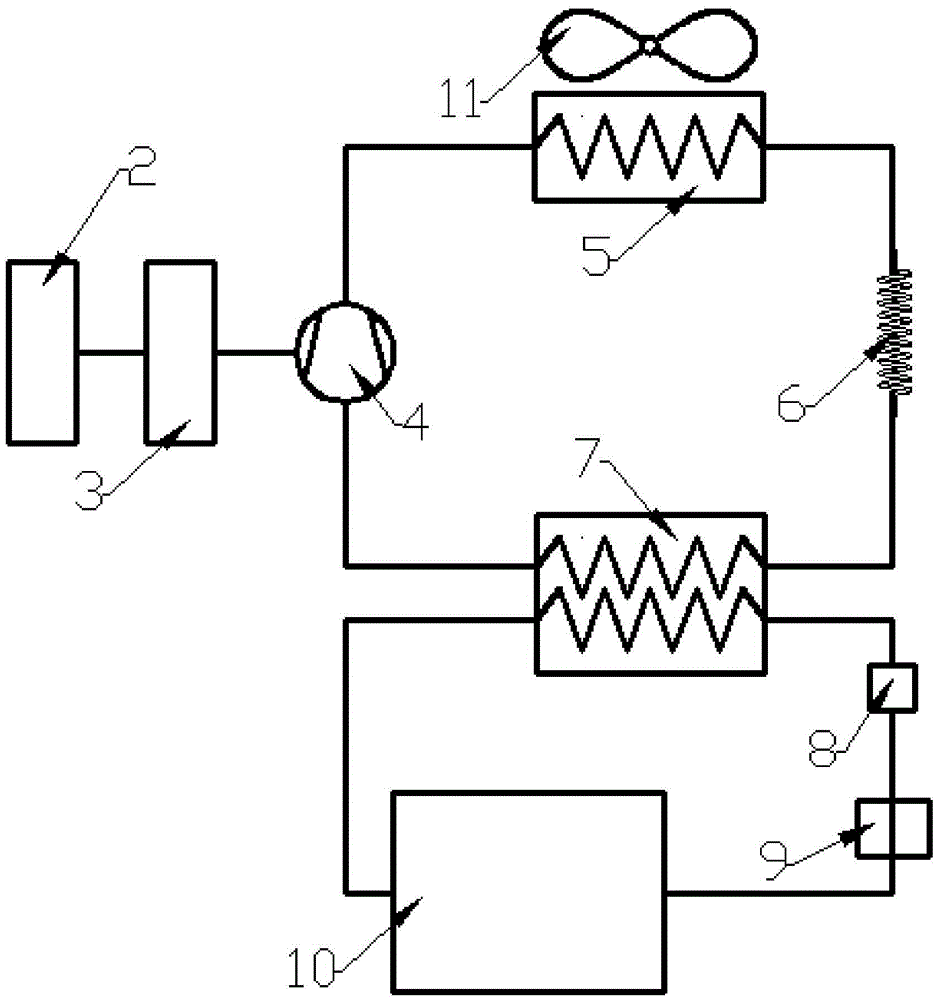

Wearable air conditioning suit based on bionic honeycomb structure

ActiveCN105466057AEasy to deploy in a large areaOptimize layoutCompression machines with non-reversible cycleProtective garmentInsulation layerSurface layer

The invention discloses a wearable air conditioning suit based on a bionic honeycomb structure. A throttling device of the wearable air conditioning suit is respectively connected with a condenser and an evaporator; a miniature compressor is respectively connected with the condenser and the evaporator; the evaporator is also connected with a miniature water pump and a honeycomb structural pipeline, and the miniature water pump is connected with the honeycomb structural pipeline through a small water storage tank; a lithium ion battery pack is connected with a controller; the throttling device adopts a capillary pipe with the diameter of 0.5-0.8mm; a wearing assembly is divided into a plurality of layers; a comfortable layer, a breathable layer, a heat insulation layer and a surface layer are sequentially arranged from inside to outside; the evaporator adopts a plate heat exchanger; a pipe network of a water cooling system is distributed in a net shape by using a honeycomb structure; the condenser adopts a parallel flow heat exchanger; and a small fan is parallel to the parallel flow heat exchanger. By using the wearable air conditioning suit, the temperature of a microenvironment in the suit is maintained within the range of + / -1.5 DEG C based on the temperature set by a user, and therefore, a comfortable microenvironment inside the suit is provided for a human body.

Owner:SOUTH CHINA UNIV OF TECH

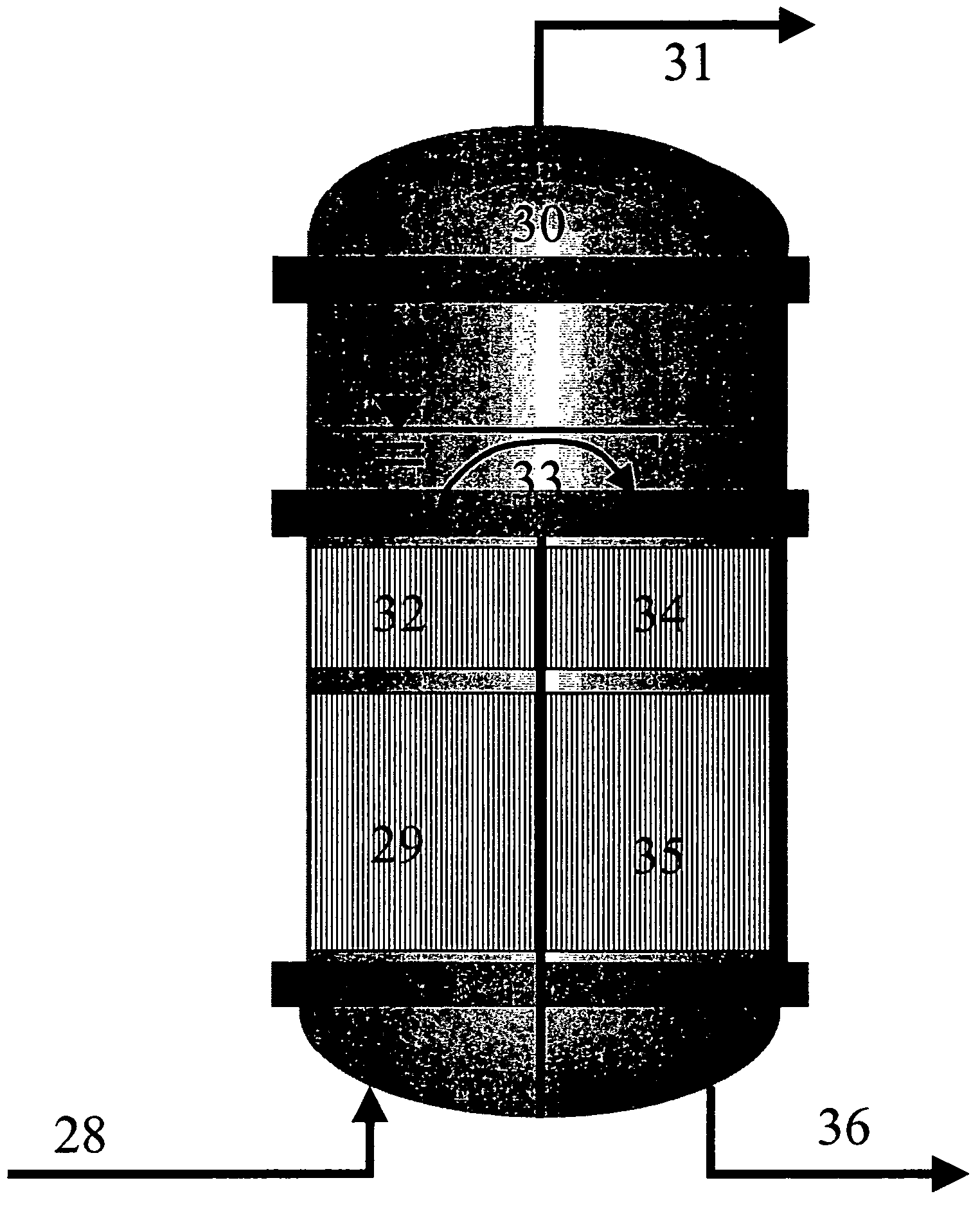

Triple utilization device and method for exhaust steam waste heat produced during superheat steam drying of sludge

ActiveCN105254147AHigh heat and mass transfer coefficientLarge specific heat capacitySludge treatment by de-watering/drying/thickeningSludgeCyclonic separation

Owner:NANCHANG HANGKONG UNIVERSITY

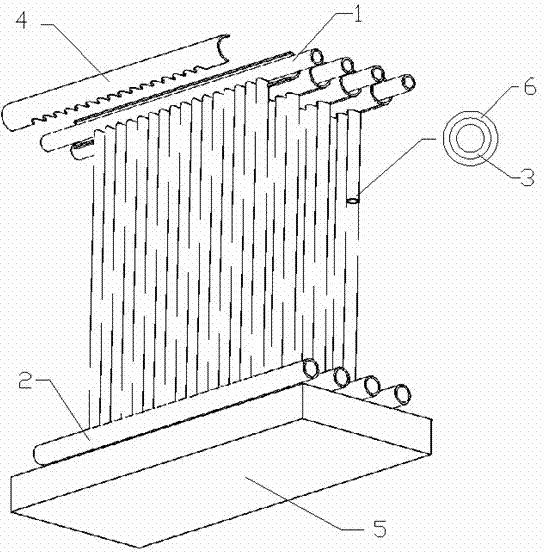

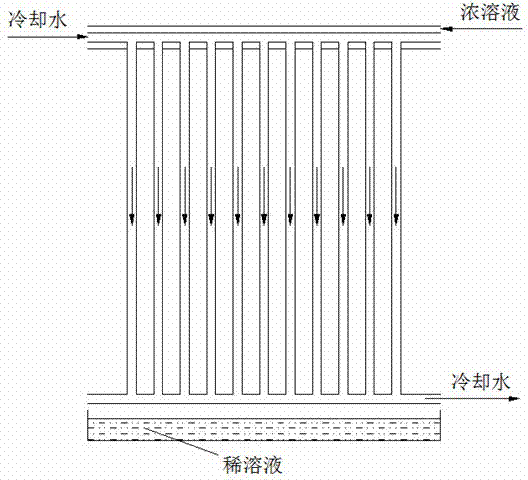

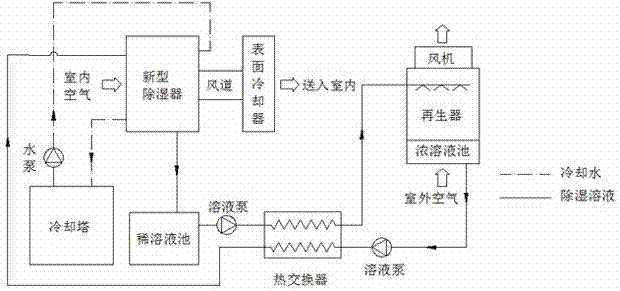

Cross-flow internally-cooled solution dehumidifier and method thereof

InactiveCN103115402AAir side pressure dropGood dehumidification performanceLighting and heating apparatusDispersed particle separationPipingEngineering

The invention discloses a cross-flow internally-cooled solution dehumidifier and a method thereof. The cross-flow internally-cooled solution dehumidifier is composed of a plurality of dehumidifying units which are arranged side by side or connected in series. The dehumidifying units comprise distributive pipes, collecting pipes, capillary pipes, sleeves, liquid collecting grooves and liquid absorbing layers. The distributive pipes are provided with a plurality of capillary pipes in vertical and parallel modes, the collecting pipes are arranged at the ends of the plurality of capillary pipes, the liquid collecting grooves are arranged below the collecting pipes, the sleeves are arranged outside the distributive pipes, and one or more liquid absorbing layers are evenly and tightly wound outside each capillary pipe. Compared with the prior art, the cross-flow internally cooled solution dehumidifier and the method thereof have the advantages that first, the mass flow rate of solutions consumed by the dehumidifier is smaller than that of solutions consumed by a traditional tower type dehumidifier when moisture air with the same mass flow rate is processed; second, the air side pressure drop generated in the process of processing the moisture air is lower, the air which is processed and enters a room does not carry solution liquid drops; and third, compared with a turning wheel solid absorbing dehumidifier and a traditional liquid dehumidifier, the dehumidifier has better dehumidifying performance.

Owner:ZHEJIANG UNIV

Process for preparing isobutene from tert-butanol

InactiveUS7235704B2Low mass flowHigh selectivityExhaust apparatusOrganic chemistry methodsFixed bedTemperature difference

Isobutene is prepared by dissociating tert-butanol into isobutene and water over an acid ion-exchange resin arranged as a fixed bed in at least one reactor at a temperature of from 80 to 150° C. and at a pressure of from 5 to 25 bar to obtain a reaction mixture, separating the reaction mixture into isobutene, a by-product, water and at least one mixture of undissociated tert-butanol and water. The reactor is operated pseudo-isothermally, with a temperature difference between inflowing and outflowing streams of less than 15 K.

Owner:EVONIK DEGUSSA GMBH

Capillary tube flow testing device

InactiveCN102706396AGood throttling effectLow mass flowVolume/mass flow by differential pressureDevice formLiquid storage tank

The invention discloses a capillary tube flow testing device, which comprises a refrigerant liquid storage tank, a one-way valve, a manual switch, a high pressure maintaining valve, a capillary tube clamp, an inlet pressure sensor, an outlet pressure sensor, a back pressure side lower pressure maintaining valve, a self-balancing type pressure control valve, a refrigerant recycling filling machine and a back pressure sensor. The refrigerant liquid storage tank is accommodated in a thermotank; the one-way valve is communicated with an output port end of the liquid storage tank via a pipeline; the manual switch and the high pressure maintaining valve are sequentially serially connected to the rear of the one-way valve; the capillary tube clamp is used for fixing a detected capillary tube; the inlet pressure sensor and the outlet pressure sensor are respectively parallelly connected to refrigerant flowing channels nearby two ends of the detected capillary tube fixed by the capillary tube clamp; the back pressure side low pressure maintaining valve, the self-balancing type pressure control valve and the refrigerant recycling filling machine are sequentially connected to the rear of the capillary tube clamp; and the back pressure sensor is parallelly connected to the rear of the low pressure maintaining valve. The capillary tube flow testing device forms a whole refrigerant loop and truthfully simulates the working state of the capillary tube, and calculates pressure difference of the refrigerant after the refrigerant passes through the capillary tube by controlling and measuring pressure and temperature, so that change of roughness of the capillary tube is detected, and the throttling effect of the capillary tube is improved according to the change.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

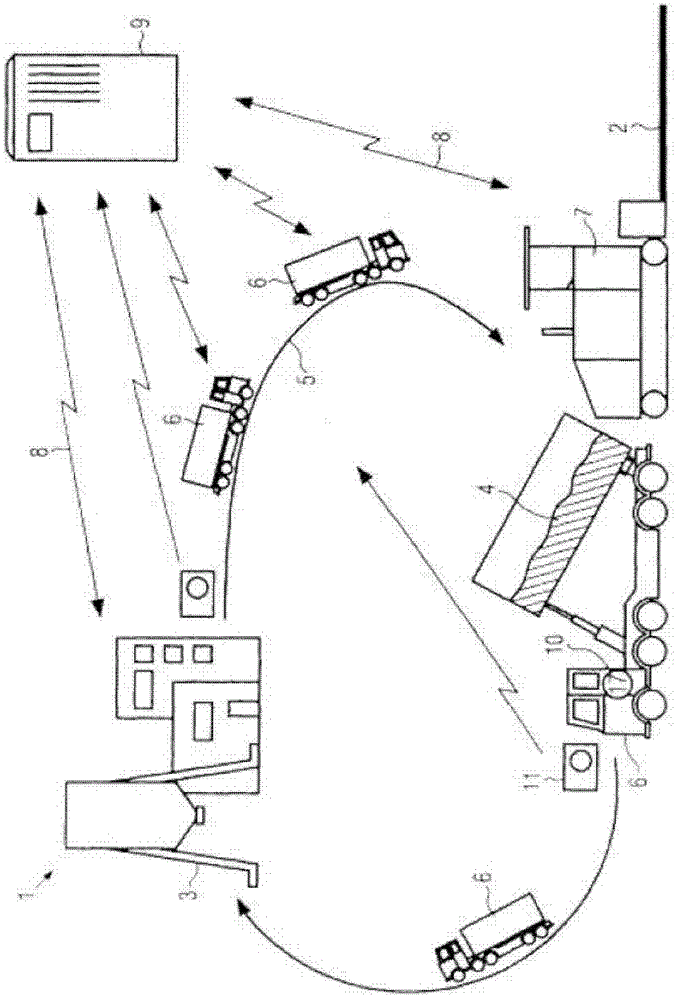

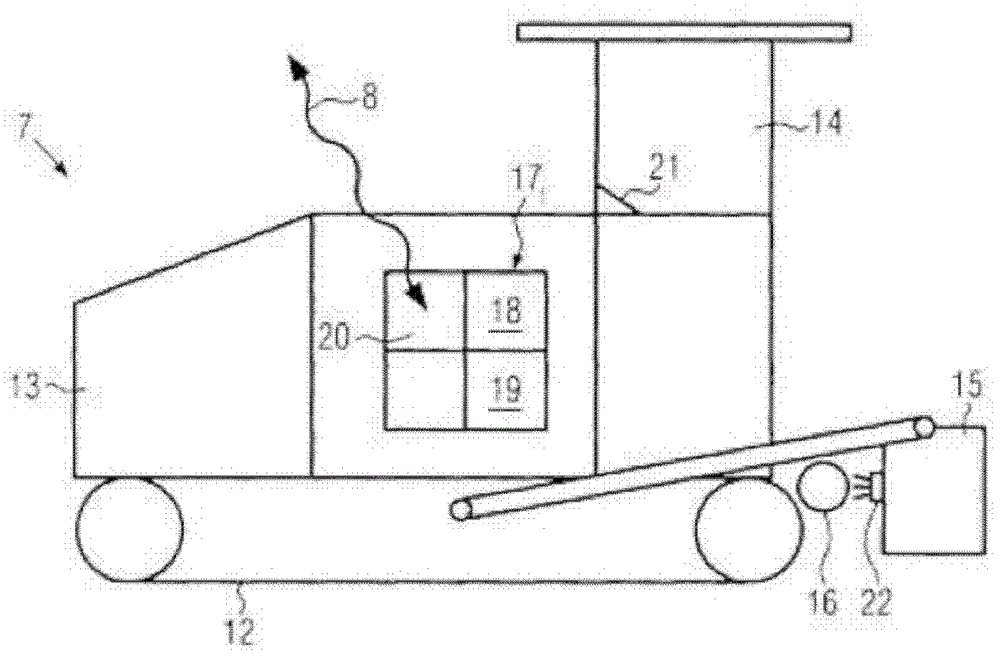

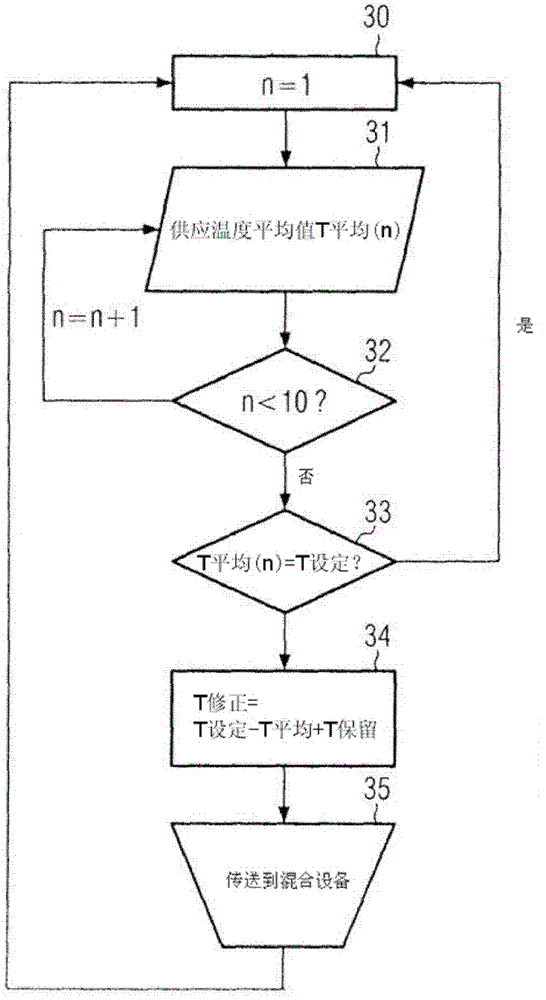

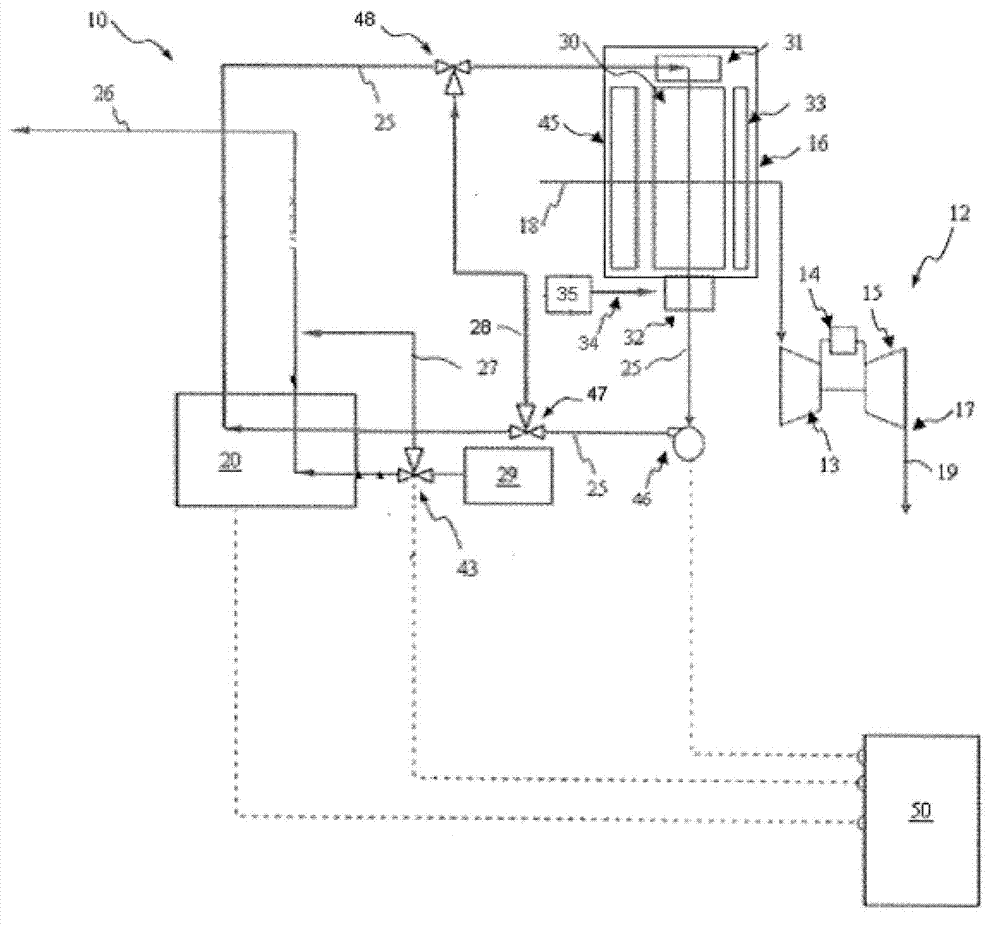

Method and system for applying a road surface

ActiveCN102747671APrevent entry into standstillImprove cooling effectRoads maintainenceProduction rateRoad surface

A method 2 and a system 1 for applying a road surface using a mixing plant for producing laying material 4 a road finishing machine 7 processing the laying material 4 to a road surface2, and a supply chain transporting the laying material from the mixing plant to the road finishing machine. Request commands are transmitted from the road finishing machine to the mixing plant 3 and / or to the supply chain5, and, depending on these request commands, the production rate of the laying material4 in the mixing plant, the temperature of the laying material4 produced in the mixing plant3, and / or the mass flow of laying material4 supplied to the road finishing machine 7 per time unit by means of the supply chain5 are adjusted.

Owner:JOSEPH VOEGELE AG

System and method for gas turbine nox emission improvement

InactiveCN103244275AEmission reductionLow mass flowGas turbine plantsEngine controlNitrogen oxideGas turbines

A gas turbine system for NOx emission reduction and part load efficiency improvement is described. The system includes a gas turbine (12) having a compressor (13) which receives inlet-air (18). A direct-contact heat exchanger (30) heats and humidifies the inlet-air (18) before the inlet-air flows to the compressor (13). Heating the inlet-air (18) reduces an output of the gas turbine (12) and extends the turndown range. Humidifying the inlet-air (18) lowers NOx emissions from the gas turbine unit (12).

Owner:GENERAL ELECTRIC CO

Process And Apparatus For Depositing Semiconductor Layers Using Two Process Gases, One Of Which is Preconditioned

InactiveUS20100012034A1Raise the ratioImprove light outputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDecompositionThermal activation energy

A method and device for depositing at least one layer, particularly a semiconductor layer, onto at least one substrate, which is situated inside a process chamber of a reactor while being supported by a substrate holder, is provided. The layer includes of at least two material components provided in a fixed stoichiometric ratio, which are each introduced into the reactor in the form of a first and a second reaction gas, and a portion of the decomposition products form the layer, whereby the supply of the first reaction gas, which has a low thermal activation energy, determines the growth rate of the layer, and the second reaction gas, which has a high thermal activation energy, is supplied in excess and is preconditioned, in particular, by an independent supply of energy.

Owner:STRAUCH GERHARD KARL +3

Surrounding air method for reducing NOx emission concentration of power station pulverized coal powder plant boiler

InactiveCN105605606AThe total air volume remains unchangedReduce Excess Air CoefficientFuel supply regulationAir supply regulationMomentumAir volume

The invention provides a surrounding air method for reducing the NOx emission concentration of a power station pulverized coal powder plant boiler. The method includes the specific step of replacing existing secondary air with primary air high in wind pressure under the condition that it is ensured that the total air volume of a hearth is not changed, wherein the primary air is used as surrounding air of a cooling pulverized coal spray nozzle. Because the wind pressure of primary air is higher than the wind pressure of secondary air, after the existing surrounding air is replaced with primary air, the flowing speed of surrounding air is increased. It is ensured that the momentum of surrounding air is constant before and after replacement, and therefore the mass flow rate of surrounding air is correspondingly decreased after replacement. Because the momentum of surrounding air is not changed, the cooling effect the same as that of a combustor can be achieved, and rigidity of the pulverized coal jet flow is also ensured. Meanwhile, the mass flow rate of surrounding air is decreased, and therefore the excess air coefficient of the initial combustion period of pulverized coal is decreased, NO generation in the initial period of combustion is restrained, and therefore the NO emission concentration during running of the boiler is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Dual utilization device and method for exhaust steam waste heat produced during superheat steam drying of sludge

ActiveCN105254148AHigh heat and mass transfer coefficientLarge specific heat capacitySludge treatment by de-watering/drying/thickeningCycloneSludge

The invention relates to a dual utilization device and method for exhaust steam waste heat produced during superheat steam drying of sludge The device comprises a shaftless screw feeder, air valves, a heater, a double-shaft stirring dryer, a sludge particle forming machine, a net belt dryer, a tail gas washing tower, cyclone separators (A and B), fans (A and B) and a heat exchanger, wherein the shaftless screw feeder, the double-shaft stirring dryer, the sludge particle forming machine and the net belt dryer are sequentially connected, and a material channel is formed; the heater, the double-shaft stirring dryer, the cycle separator A, the fan A and the air valve B are sequentially connected to form an internal circulation air channel; the shaftless screw feeder, the cyclone separator B, the heat exchanger and the tail gas washing tower are sequentially connected to form an external air channel; the heat exchanger, the fans and the net belt dryer are combined for drying. The device and the method have the advantages that dual utilization of exhaust steam waste heat is realized, the device and the method are efficient and energy-saving, and condensation can be effectively prevented; zero-pollution discharge of waste water and waste gas is realized; formed sludge can be used for preparing fertilizers, and reutilization of the sludge is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

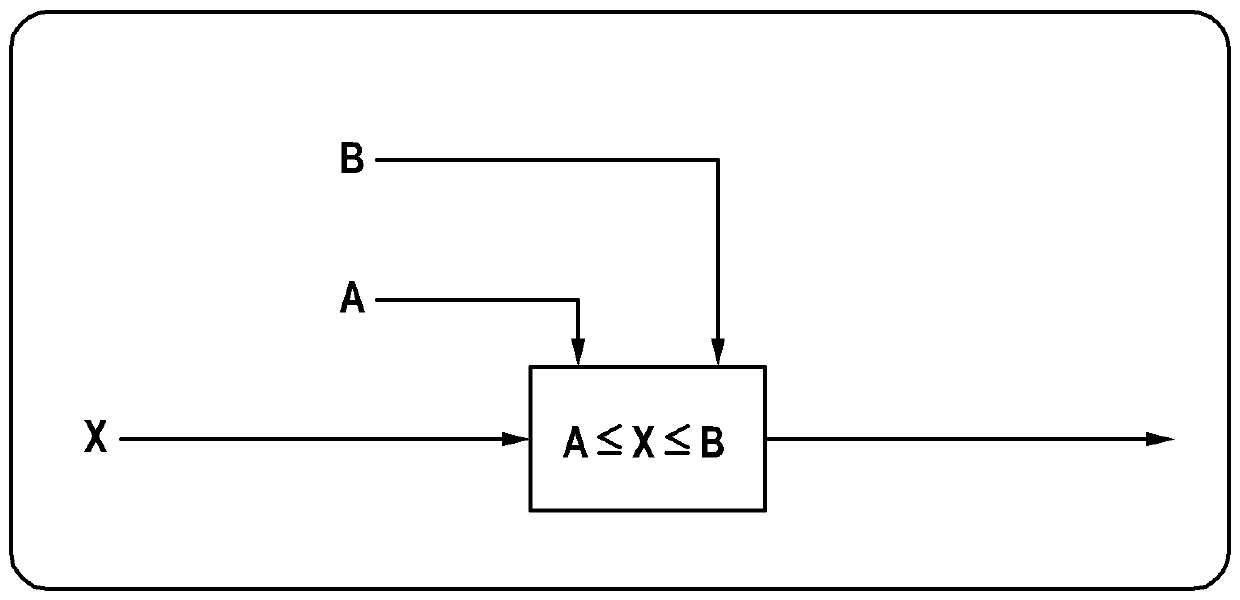

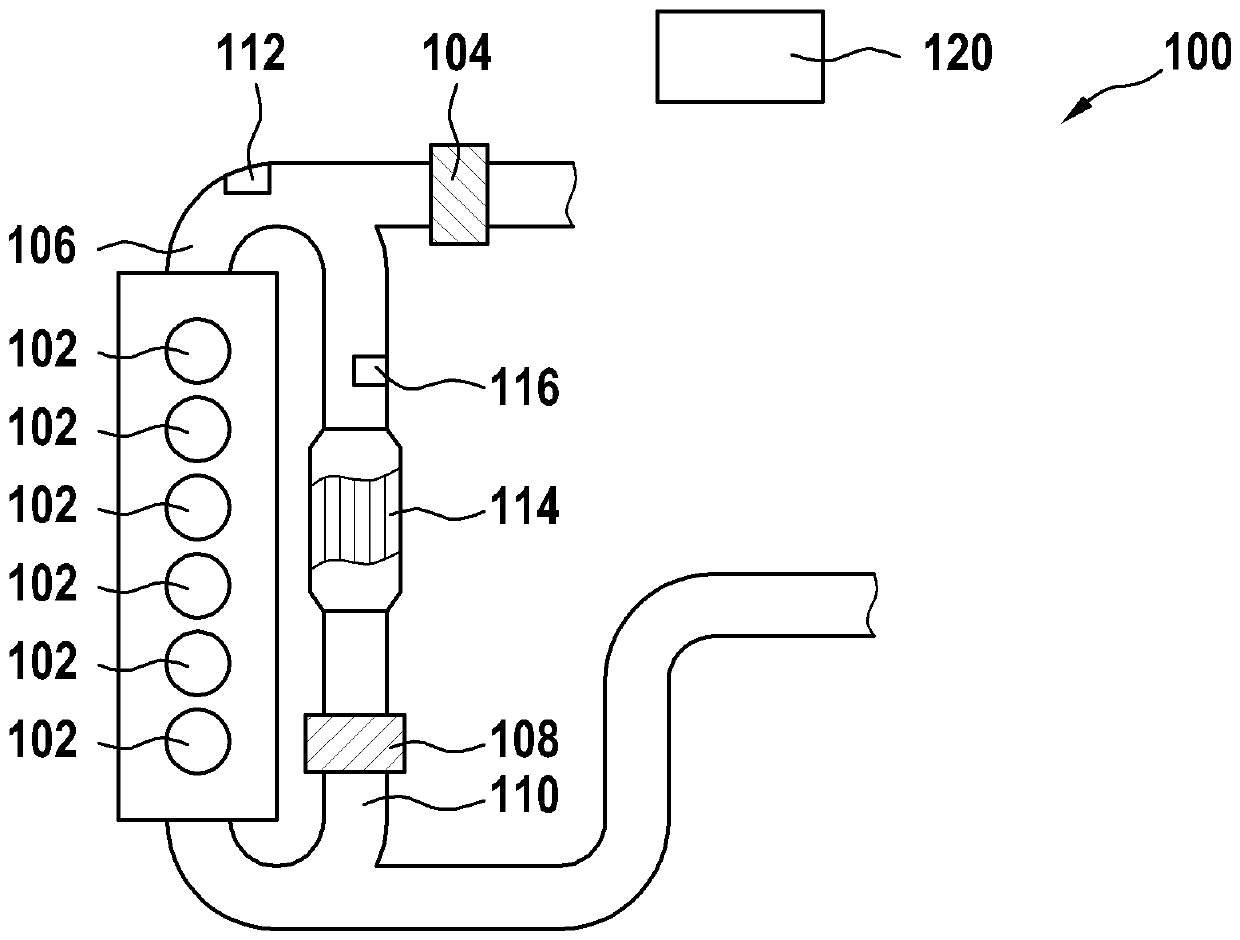

Method and device for operating internal combustion engine having throttle valve and exhaust gas recirculation system for detecting carbon-deposited AGR line

PendingCN110836147AAdjust monitoringDoes not have carbon depositsElectrical controlInternal combustion piston enginesExhaust fumesExhaust gas recirculation

The invention relates to a method and a device for carrying out the method, said method specifying the following steps: opening an exhaust gas recirculation valve (108) of an internal combustion engine (100), closing a throttle valve (104) of the internal combustion engine (100), detecting the value of the intake pipe pressure of the internal combustion engine (100) when the exhaust gas recirculation valve (108) is opened and the throttle valve (104) is closed, comparing the value with a first threshold value and a second threshold value (B) larger than the first threshold value, and determining the running state of the internal combustion engine (100) according to whether the value is within a value range between the first threshold value and the second threshold value (B) or outside thevalue range. Therefore, the method can monitor the formation of carbon deposits in different air system components and in particular in the AGR recirculation path, and can achieve a precise positioning with which defective components can also be positioned.

Owner:ROBERT BOSCH GMBH

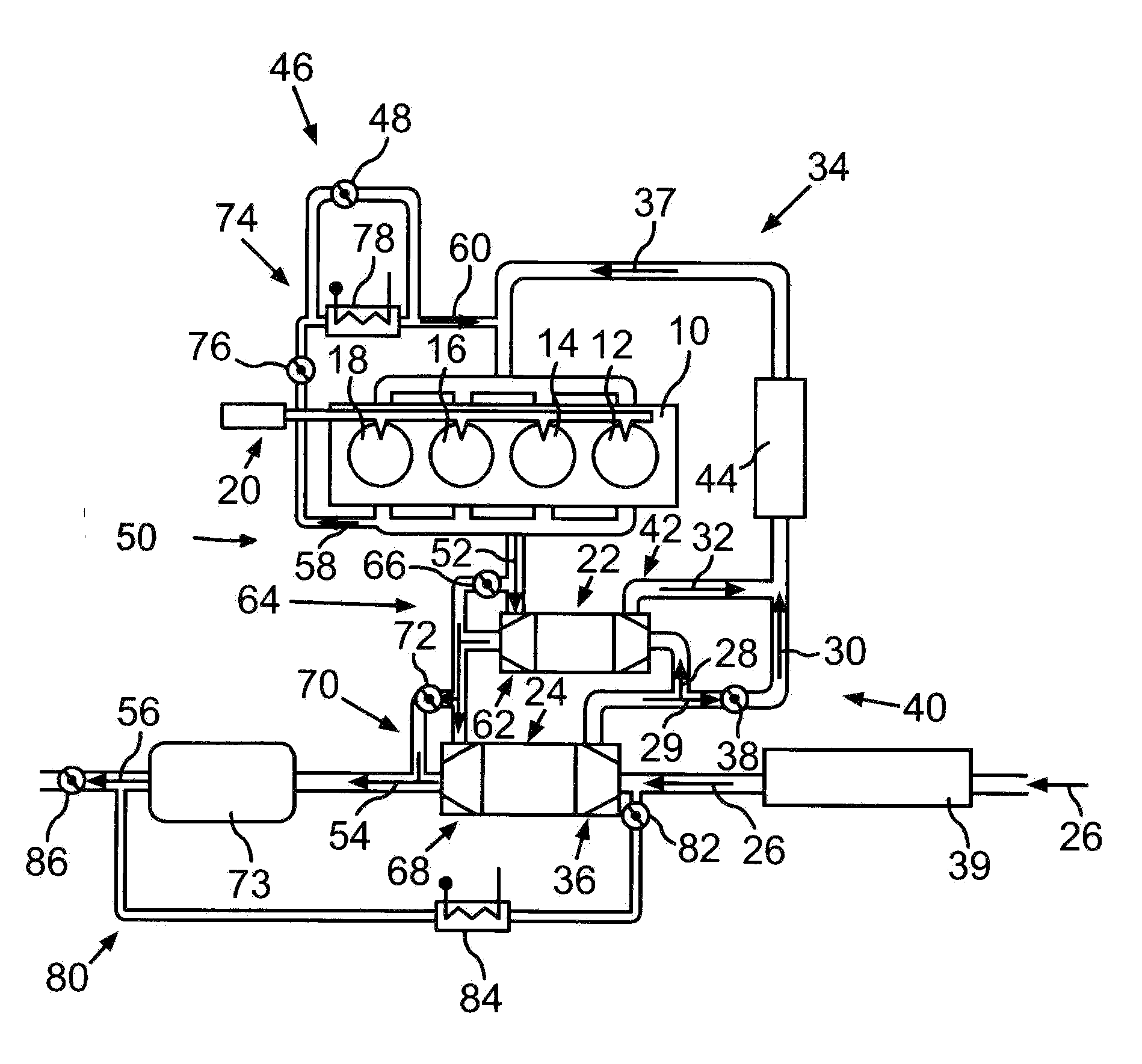

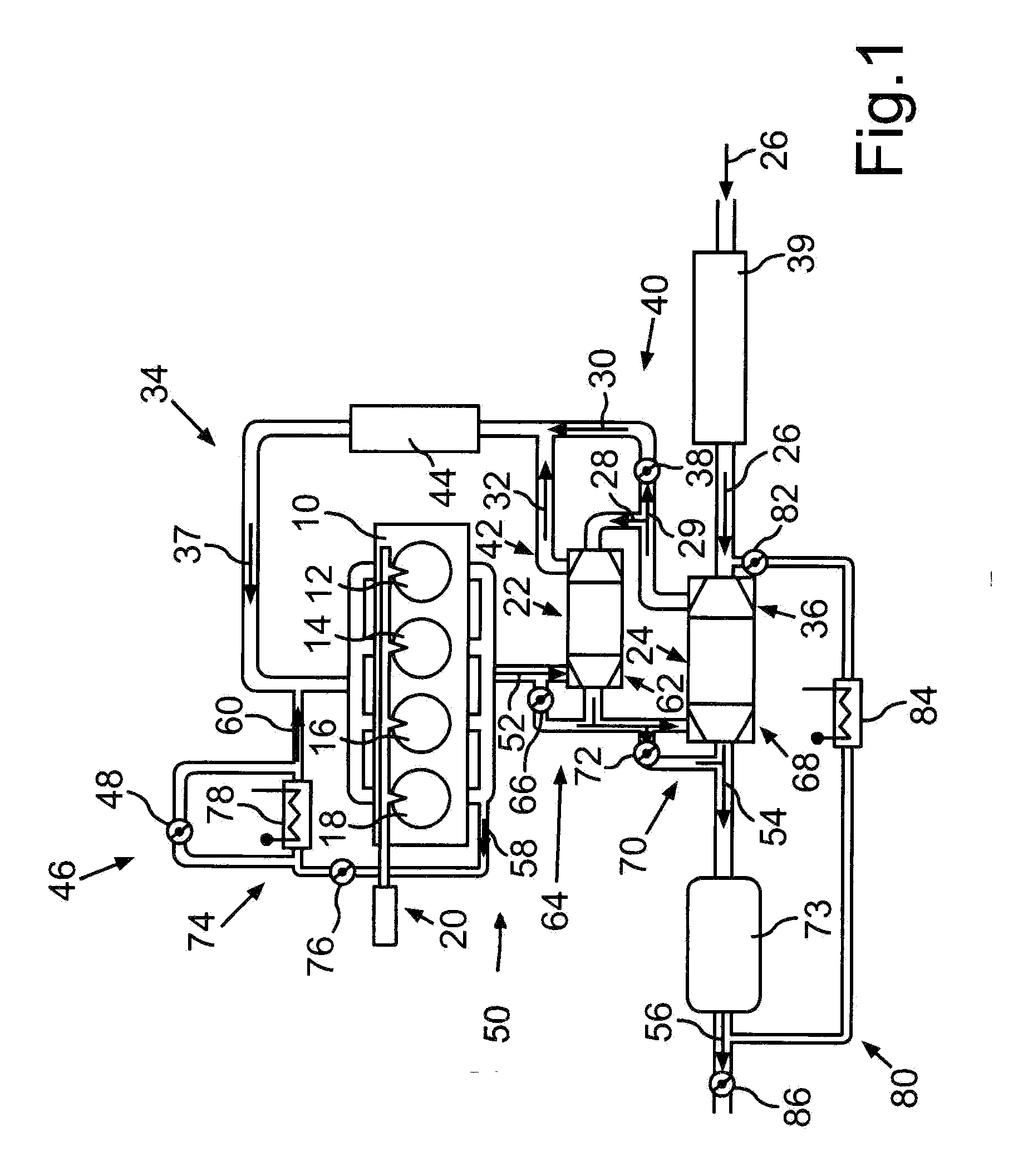

Internal combustion engine

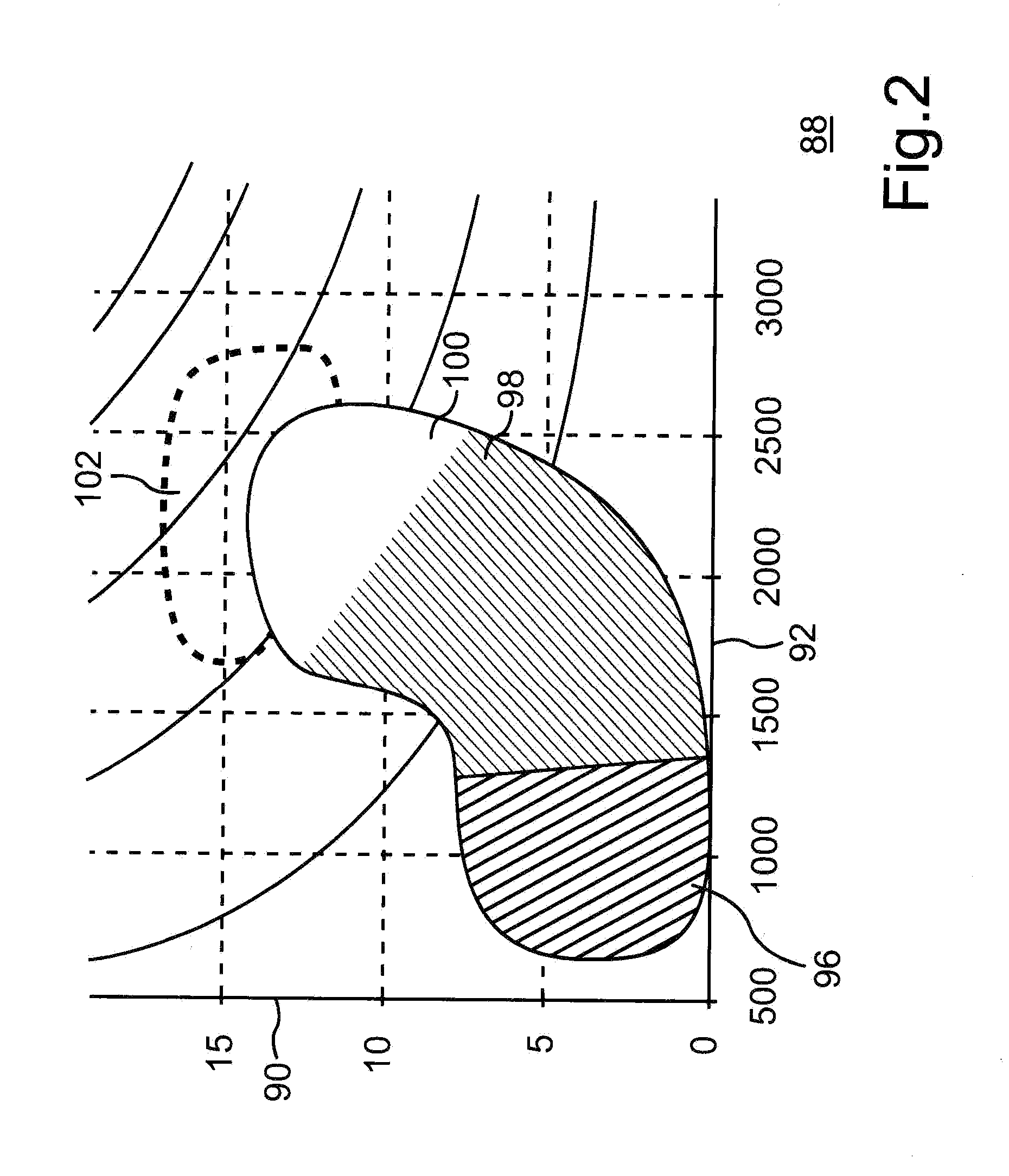

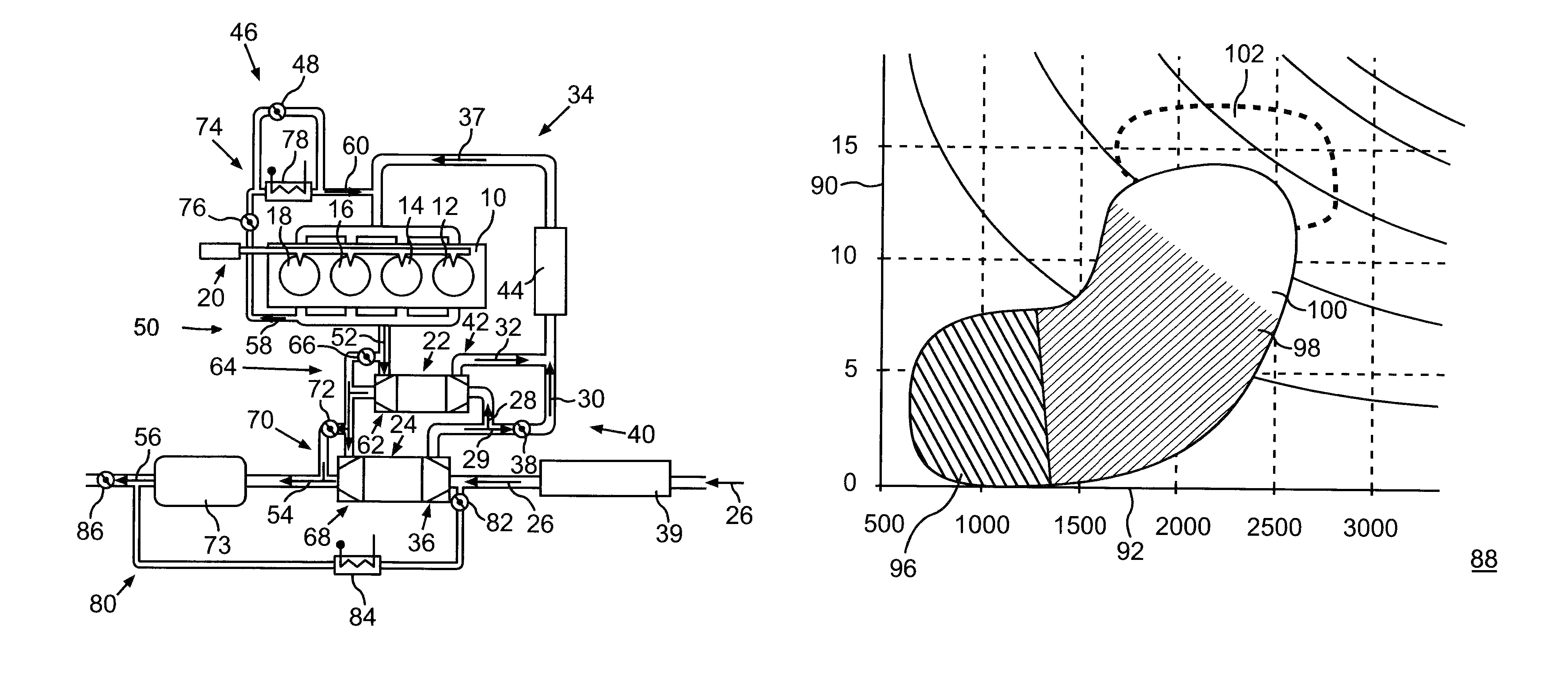

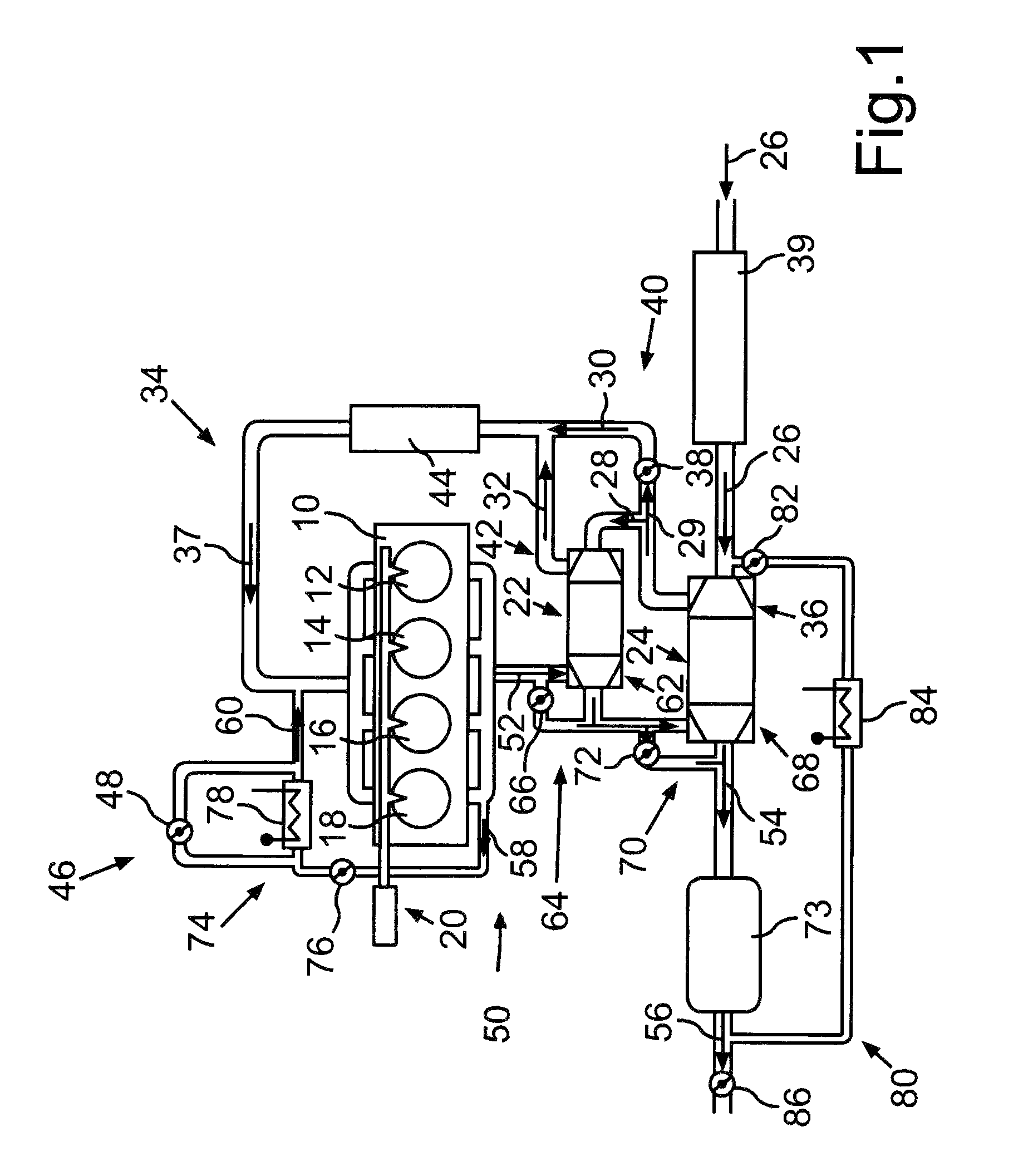

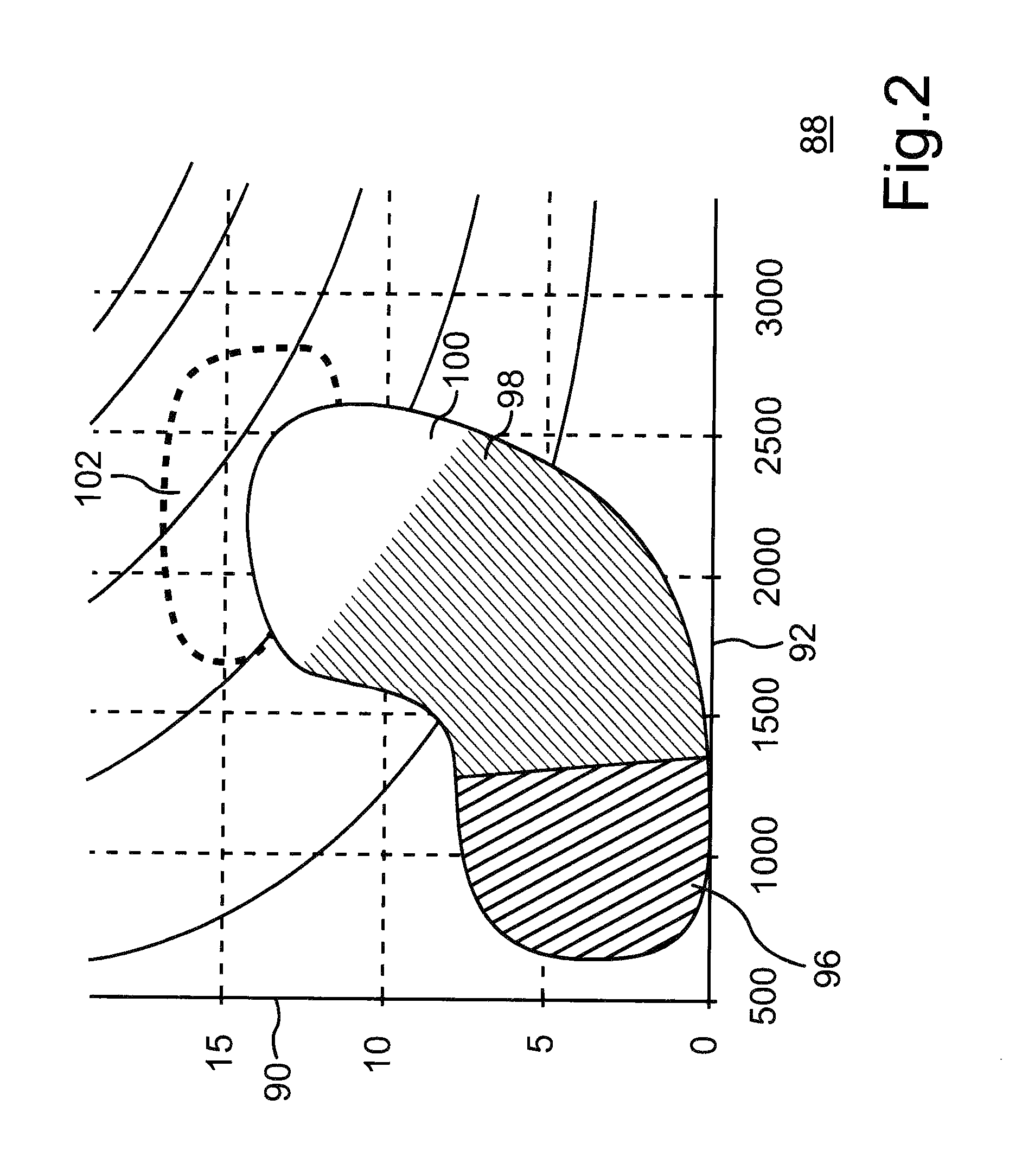

ActiveUS20120180479A1Reduce fuel consumptionEmission reductionInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerExternal combustion engine

In an internal combustion engine and a method of operation the internal combustion engine which includes a high pressure and a low pressure turbocharger having exhaust gas turbines arranged in series in an engine exhaust line provided with a high pressure exhaust gas recirculation line and a low pressure exhaust gas recirculation line via which exhaust gas can be conducted to an inlet line of the engine, the arrangement is switchable depending on the engine speed between an exhaust gas recirculation by way of the high pressure line and an exhaust gas recirculation by way of both, the high pressure and the low pressure line, to achieve low emissions and low fuel consumption.

Owner:DAIMLER AG

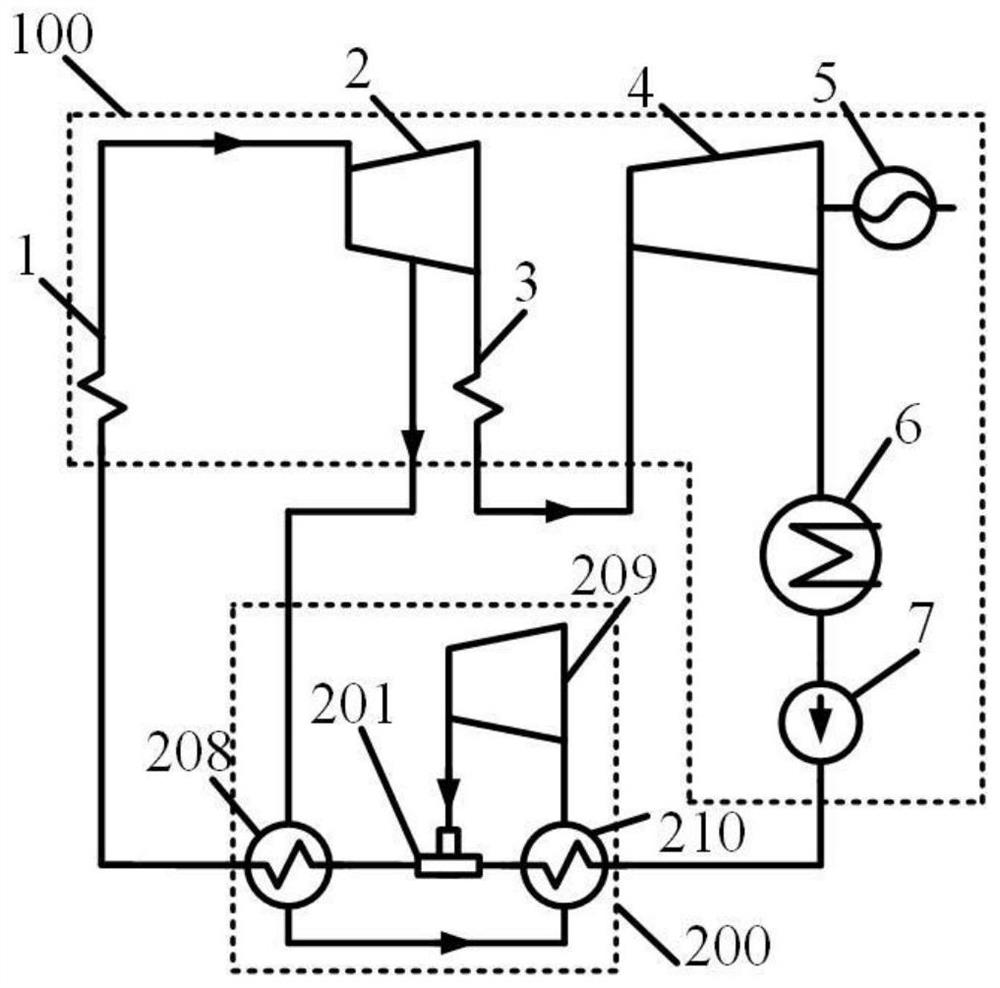

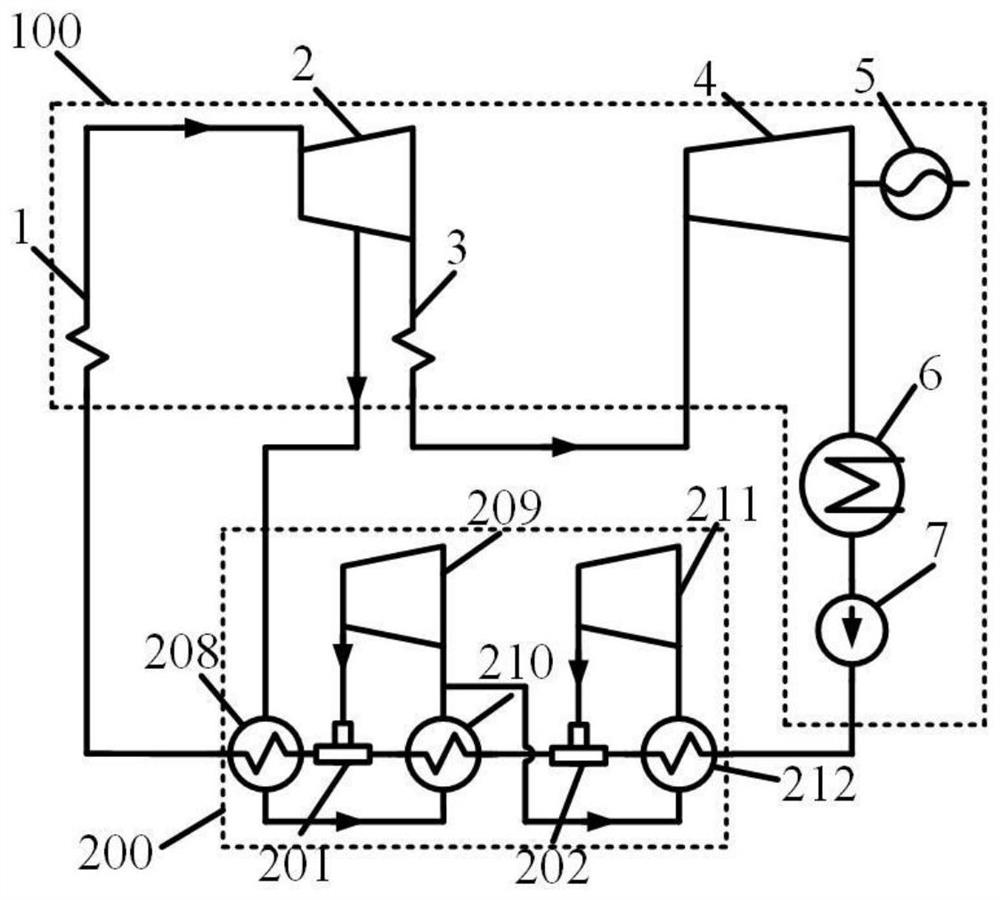

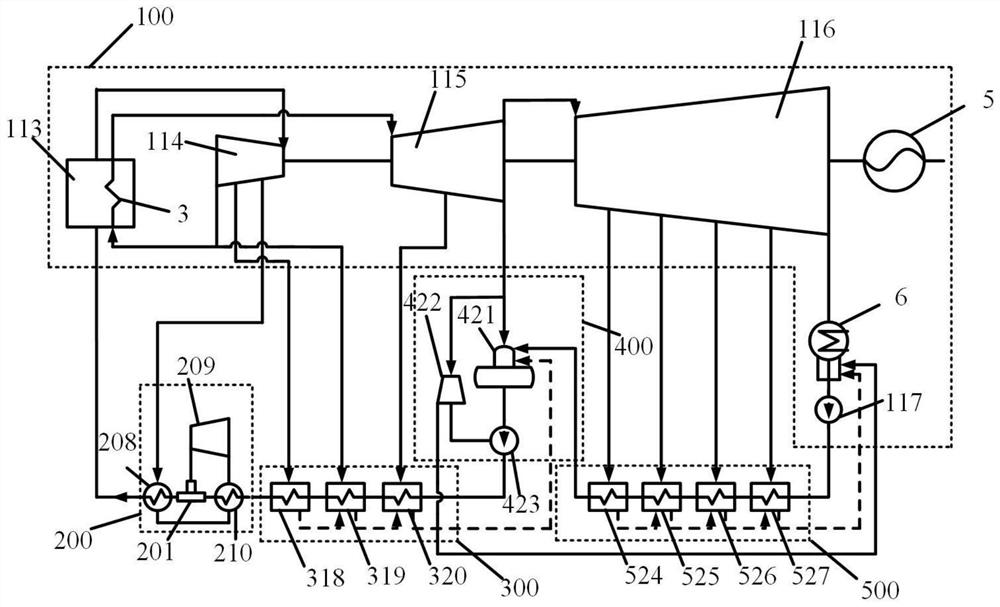

Water vapor cycle based on supercritical and subcritical heat regeneration

ActiveCN112780373AEfficient use ofHigh quality feed water flowSteam engine plantsWater vaporThermal efficiency

The invention discloses a water vapor cycle based on supercritical and subcritical heat regeneration, and belongs to the field of steam engine devices. A low-temperature vapor outlet of a compression supercritical heat regeneration system is connected with a low-temperature vapor inlet of a Rankine cycle system, and a high-temperature vapor inlet of the compression supercritical heat regeneration system is connected with a high-temperature vapor outlet of the Rankine cycle system, a low-temperature water inlet of the compression supercritical heat regeneration system is connected with a low-temperature water outlet of the Rankine cycle system; a low-temperature water inlet of a second high-temperature heat regenerator, a main tee joint and a low-temperature vapor inlet of a first high-temperature heat regenerator are sequentially connected; and low-temperature vapor flowing out of a first compressor and low-temperature vapor flowing out of the second high-temperature heat regenerator are converged into the first high-temperature heat regenerator for heat exchange. A working medium in the cycle is in a supercritical state, the cycle mass flow rate is high, feed water can be generally heated to 400 DEG C or above, due to the characteristics, the average heat absorption temperature is increased, and the cycle heat efficiency is further improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Discharge valve arrangement for a hermetic compressor

InactiveUS20110103937A1Reduce load lossSolve the lack of spaceWind motor controlPositive displacement pump componentsEngineeringRefrigeration

Discharge valve arrangement applied in a hermetic compressor used, for example, in household refrigeration systems including a valve plate closing an end of a compression cylinder and provided with suction and discharge orifices contained within the inner contour of the axial projection of the compression cylinder, said suction orifice occupying an annular sector external to the axial projection of a discharge orifice and being closed by a flexible suction vane having a bending median portion. The valve plate is provided with a plurality of discharge orifices distributed in at least one of the regions defined externally and internally to the contour of the flexible suction vane, each discharge orifice provided internally to the contour of the flexible suction vane being axially aligned with a respective through opening provided in said bending median portion.

Owner:WHIRPOOL SA +1

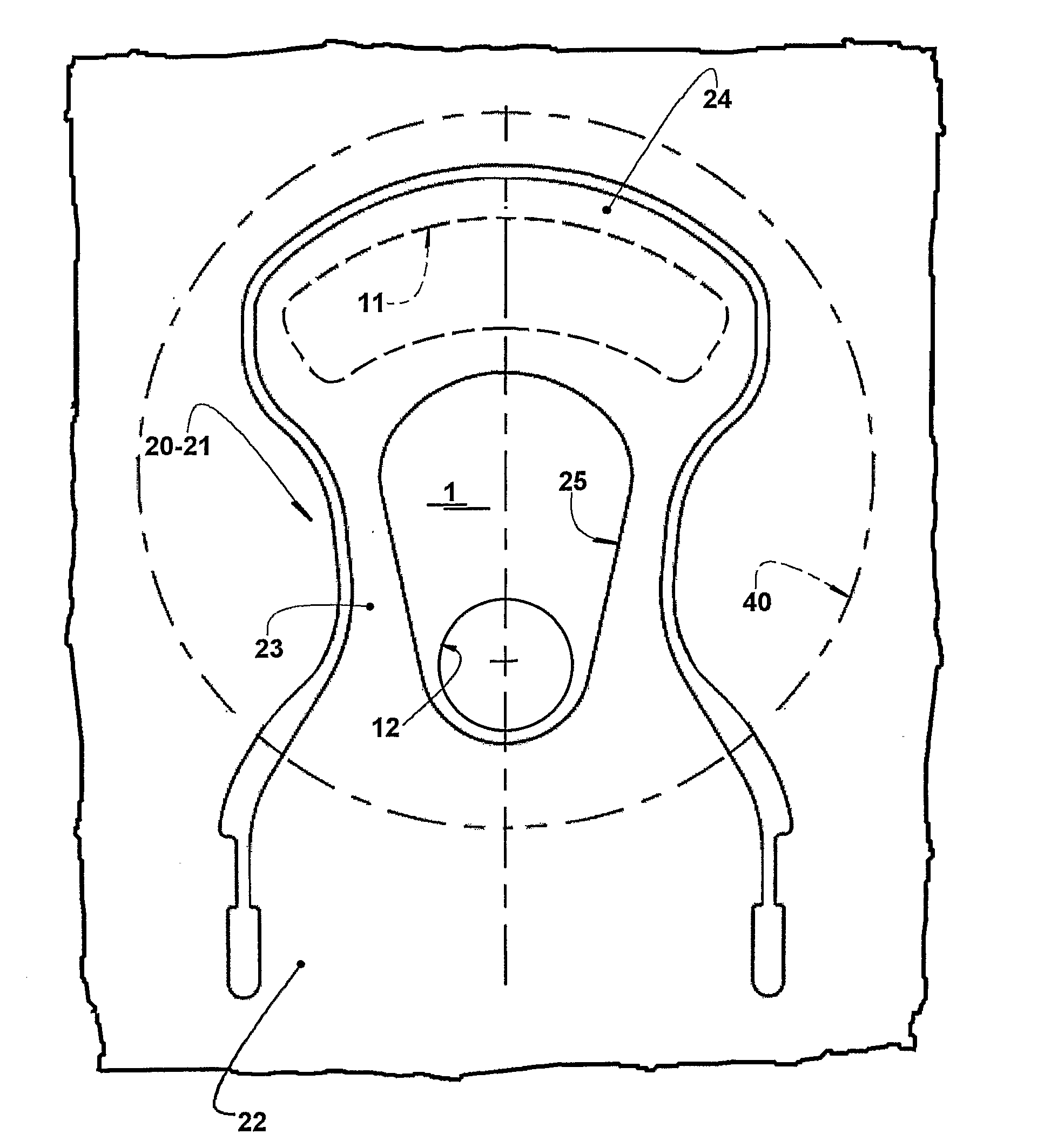

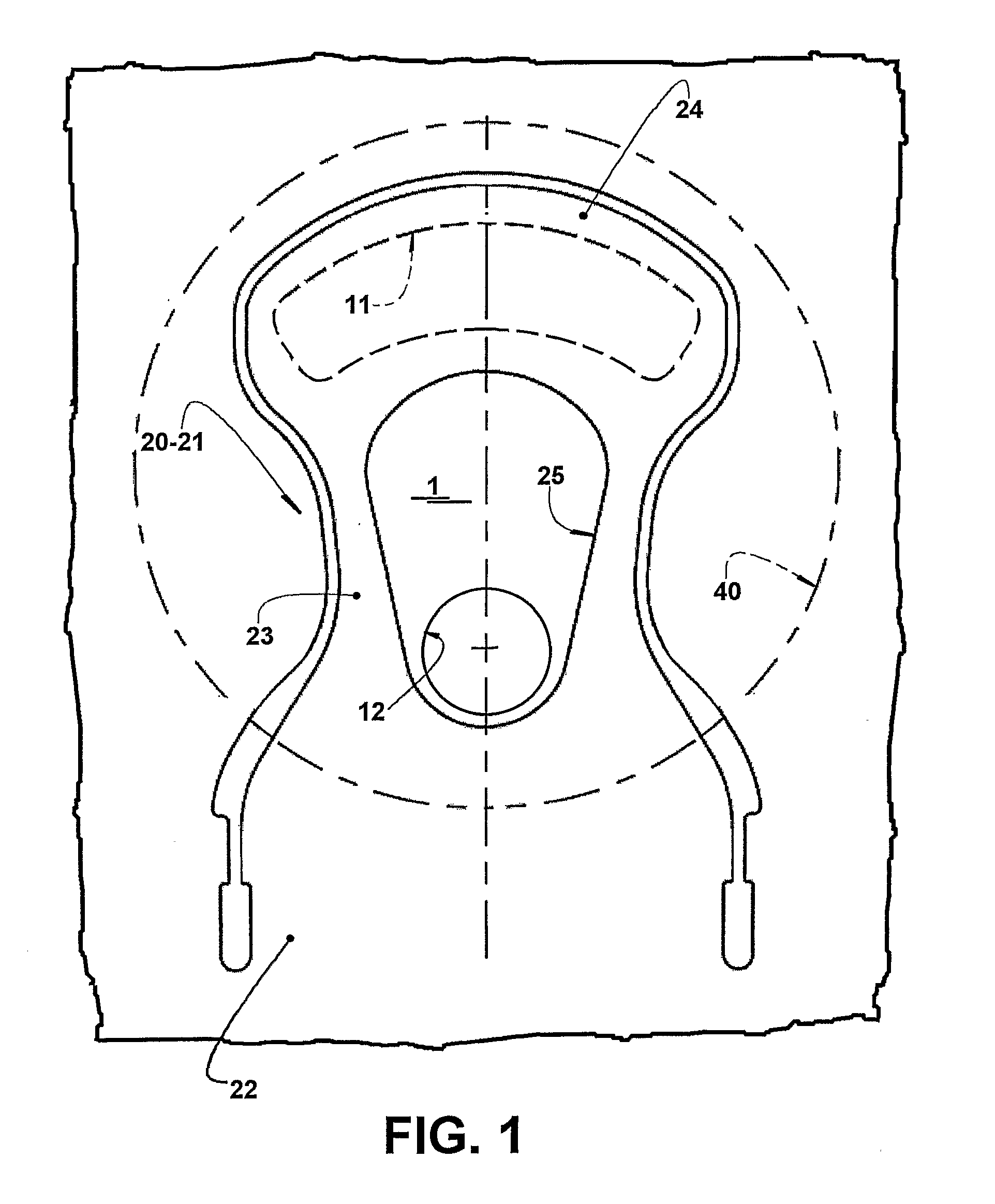

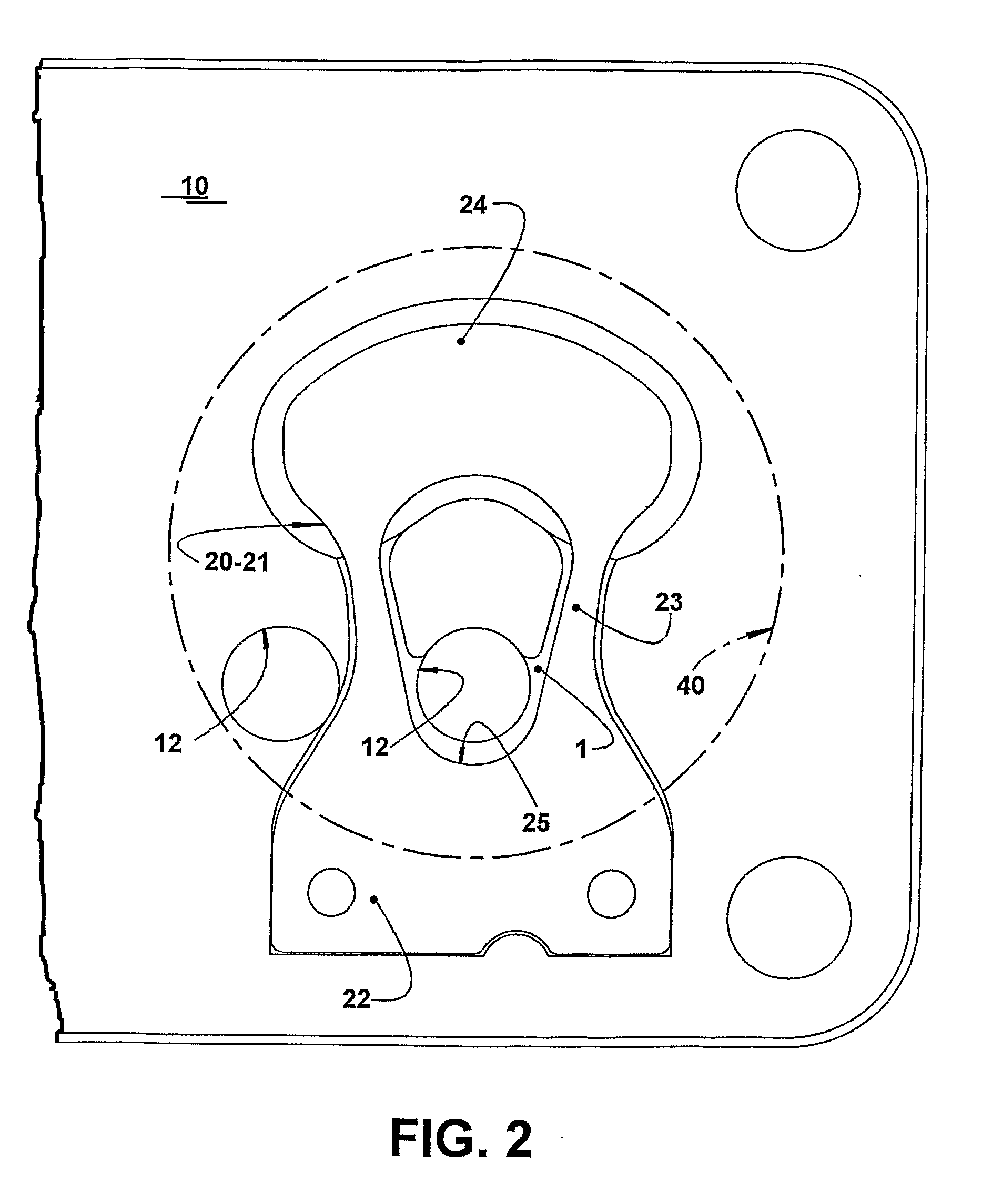

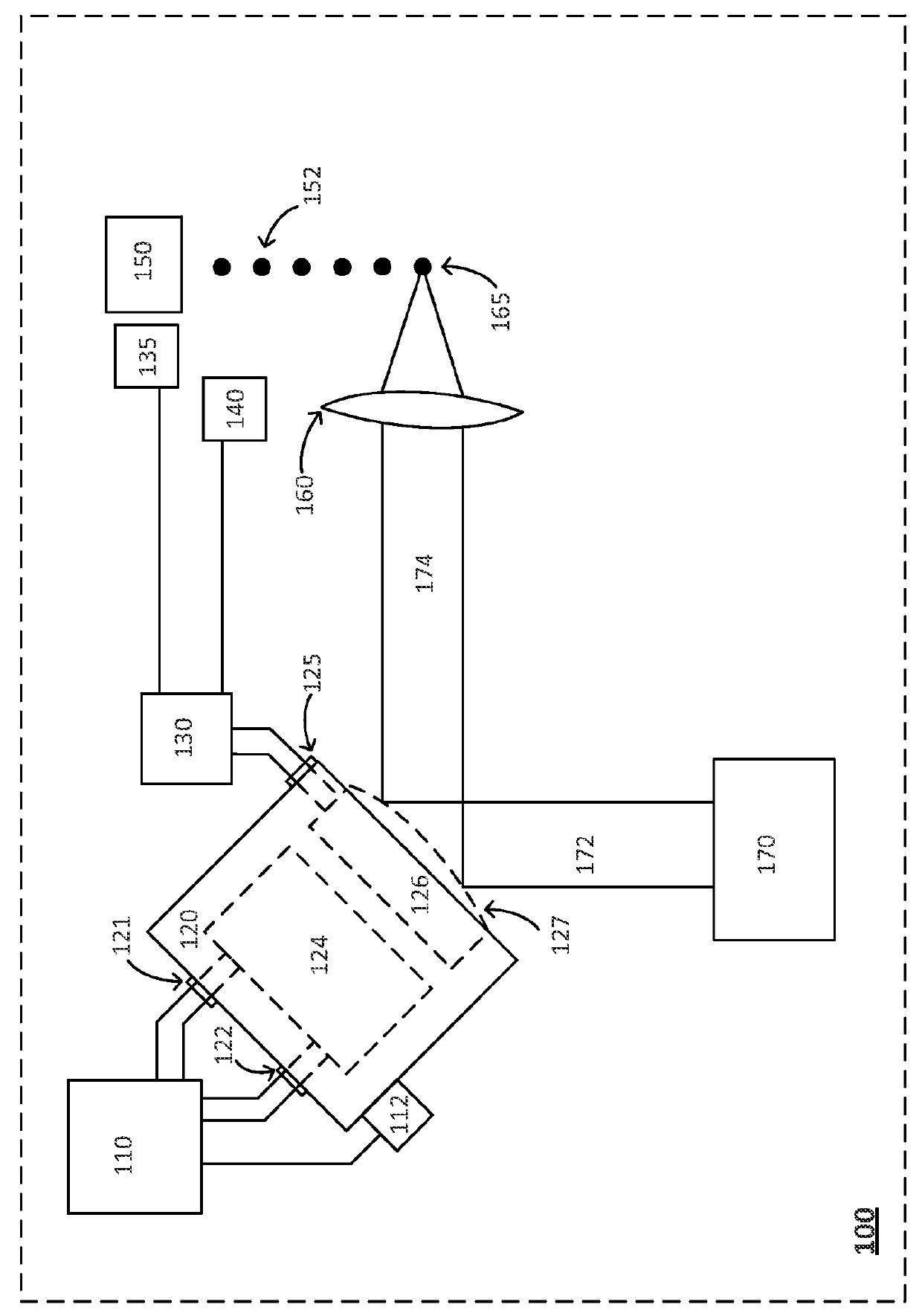

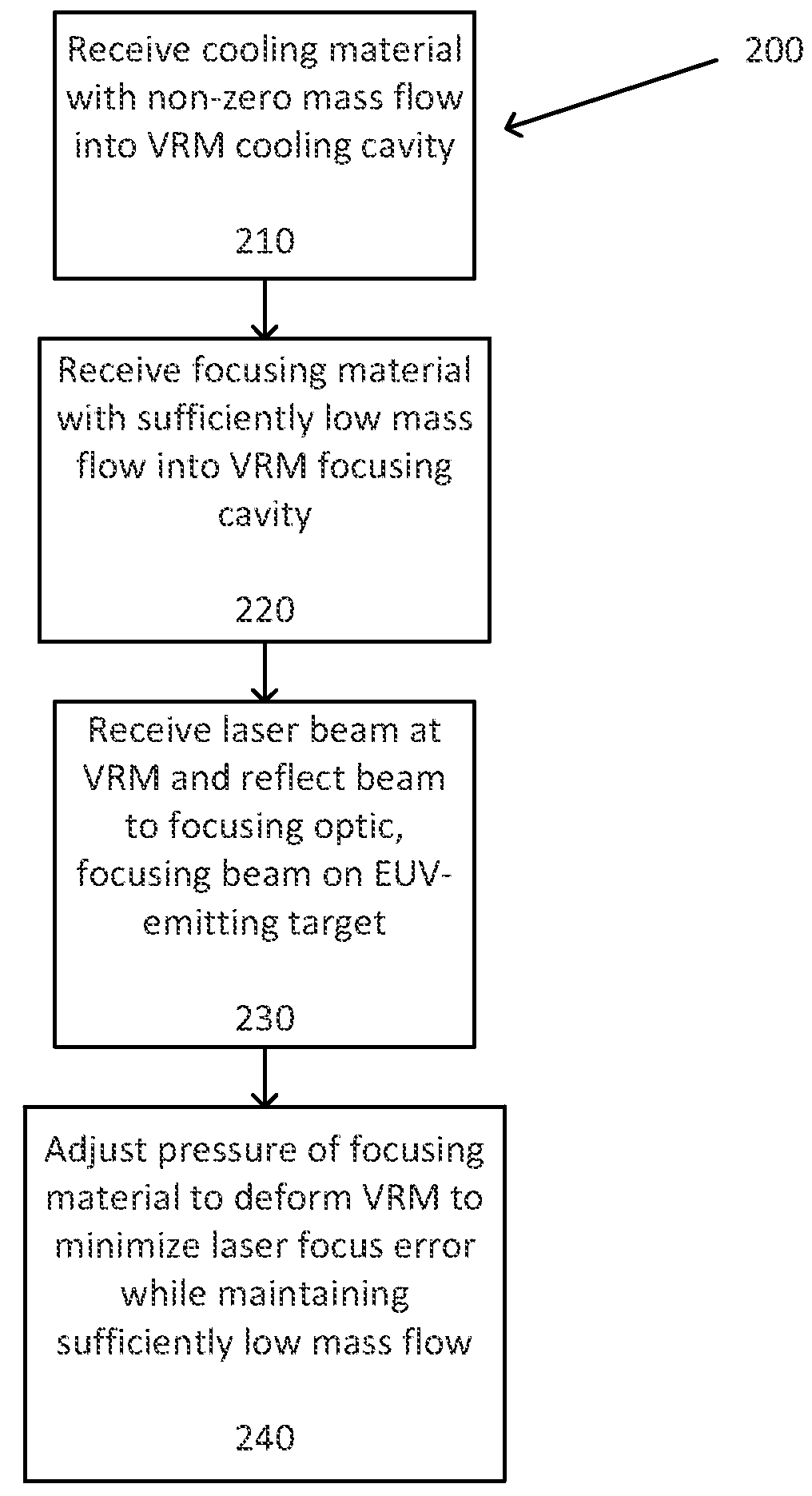

System and method for correcting the focus of a laser beam

ActiveUS9360600B2Minimize focus errorFocus error is minimizedMirrorsX-ray tube with very high currentOptoelectronicsLaser beams

Focus of a laser optical system can be corrected using a variable radius mirror having a focusing cavity and a separate cooling cavity. Pressure of a focusing material at a sufficiently low mass flow in the focusing cavity deforms a reflective surface mounted to the focusing cavity, changing its radius. Cooling material provided to the cooling cavity cools the variable radius mirror. A laser beam is reflected by the deformed reflecting surface to focusing optics, focusing the reflected laser beam on an EUV-emitting target, and minimizing a laser focus error by one or more of: maximizing a measured EUV power or minimizing a measured laser beam divergence. Providing focusing material at a deformation pressure and at a sufficiently low mass flow, and providing a separate cooling cavity, avoids perturbations in the reflective surface which would otherwise affect laser beam focus.

Owner:ASML NETHERLANDS BV

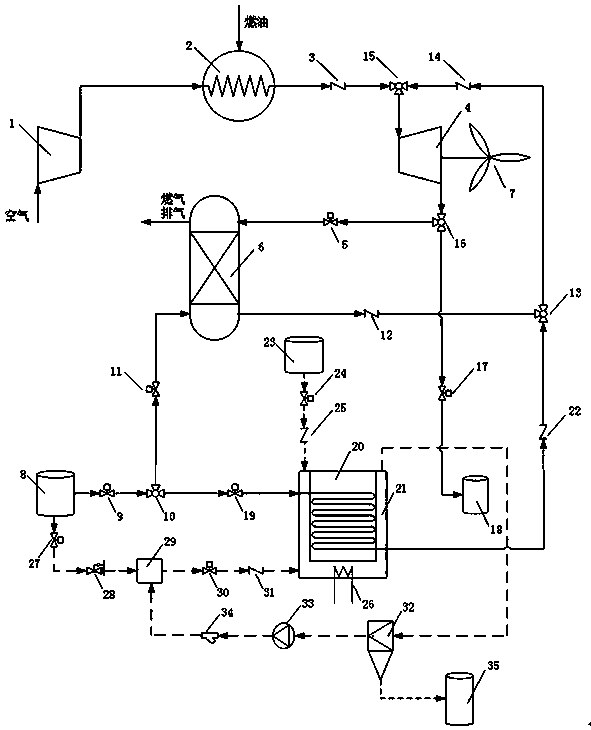

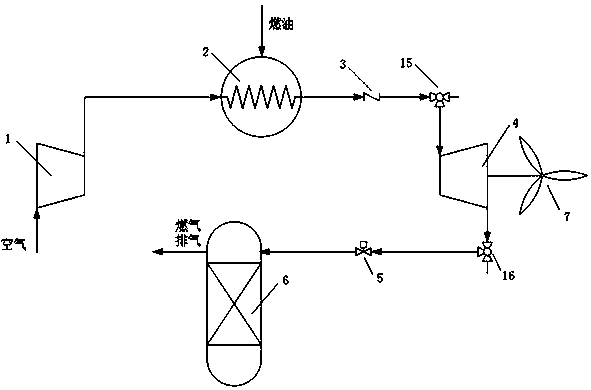

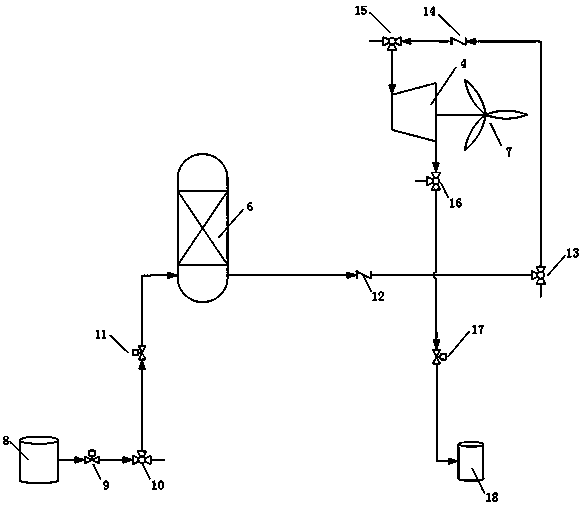

Hybrid turboshaft power system and method based on supercritical carbon dioxide

The invention discloses a hybrid turboshaft power system and method based on supercritical carbon dioxide, and belongs to the field of new energy and high efficiency power. The system mainly includesa compressor, a combustion chamber, a turbine, a heat storage tank, an S-CO2 gas storage tank, a solid fuel storage tank, a chemical reactor, a heat exchanger, a carbon dioxide buffer tank, a carbon dioxide exhaust storage tank, a cyclone separator and a solid powder recovery tank. The hybrid turboshaft power system and method are characterized in that with the help of the supercritical property and high energy storage density of the carbon dioxide, the strong power capability can be generated after heating; the S-CO2 needs to be properly heated before work doing, and one heat source can be selected from heat of tail gas of a conventional gas turbine; and the heat storage tank is used for realizing storage and release of energy, and the temperature of the exhausted tail gas can be reduced;as for preparation of the S-CO2, the S-CO2 can be produced in advance at the grid load low ebb period, and therefore an auxiliary power system can work without the aid of the compressor. The system can reduce infrared radiation, can reduce use of traditional fossil energy, and has high environmental protection.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

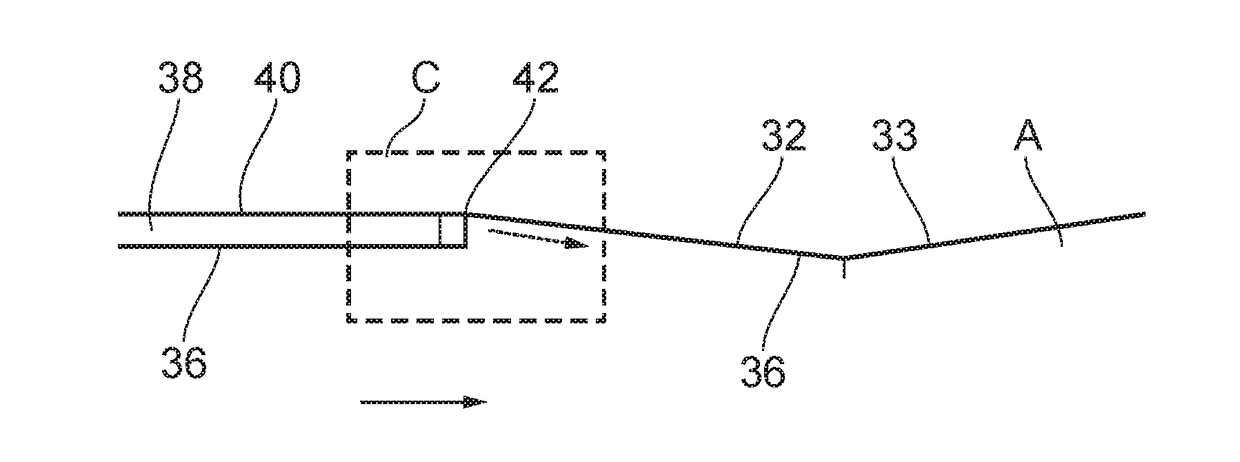

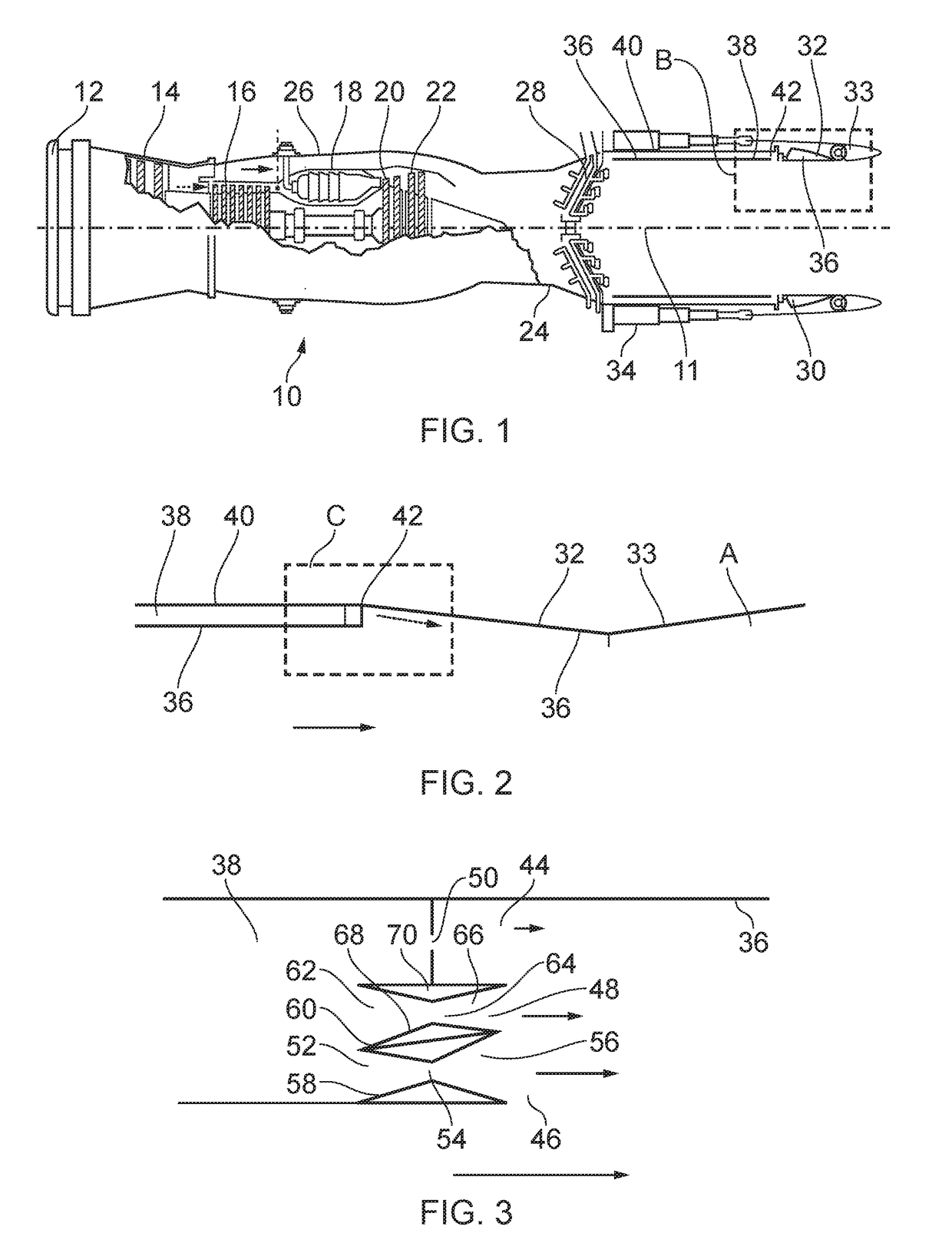

Gas turbine exhaust cooling system

ActiveUS20180119642A1Avoid mixingIncreasing cooling flow effectivenessContinuous combustion chamberTurbine/propulsion engine coolingTurbineGas turbines

A gas turbine engine (10) comprises a main fluid flow exhaust nozzle (30) bounding a main fluid flow path, and a cooling nozzle (38) provided upstream of the main fluid flow exhaust nozzle (30) in the main fluid flow path. The cooling nozzle (38) is arranged to provide cooling air to a surface (36) of the main fluid flow exhaust nozzle (30), the cooling nozzle (38) comprises first and second outlets (44, 46). The first outlet (44) is located adjacent the main fluid flow exhaust nozzle surface (36) and is spaced from the main fluid flow path by the second outlet (46). The second outlet (46) comprises a convergent divergent nozzle configured to accelerate cooling air exhausted from the second outlet (46) to a velocity greater than air exhausted from the first outlet (44).

Owner:ROLLS ROYCE PLC

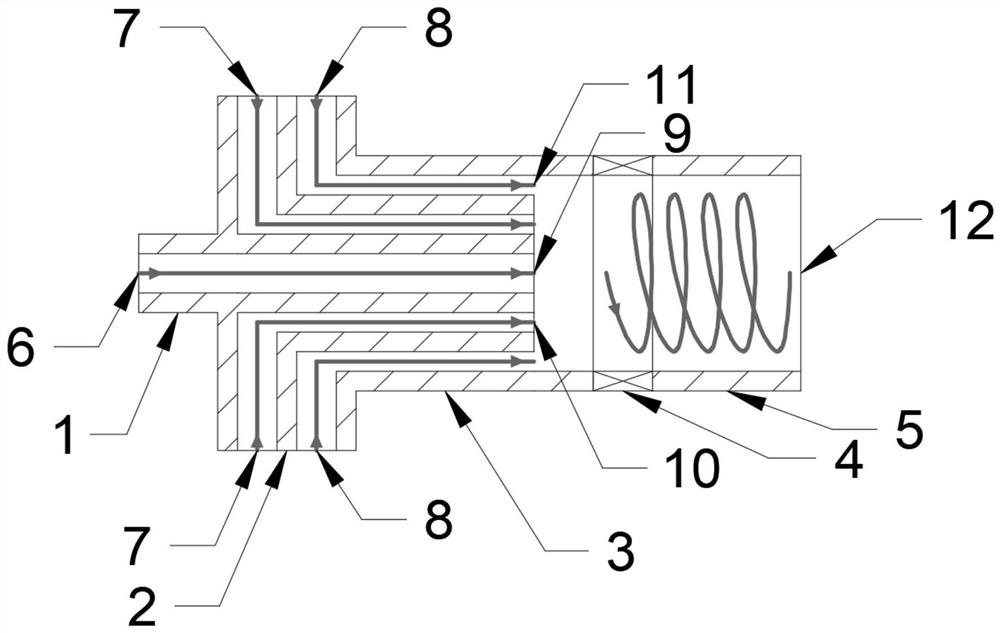

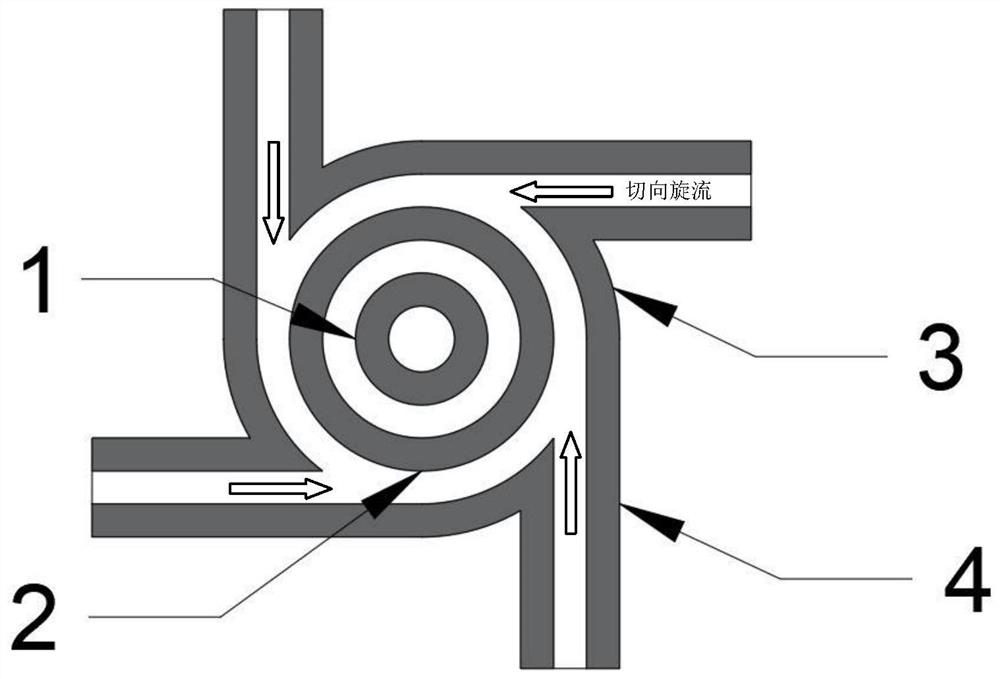

High-temperature and high-speed stable combustion method and device based on multistage jet flow and rotational flow

ActiveCN112594689AGuaranteed stabilityStable high speed flameGaseous fuel burnerThermodynamicsCombustion chamber

The invention discloses a high-temperature and high-speed stable combustion method and device based on multistage jet flow and rotational flow, and belongs to the field of combustion. The device comprises a first-stage axial jet flow generating device, a second-stage axial jet flow generating device, a third-stage axial jet flow generating device, a tangential rotational flow generating device anda combustion chamber structure. An outlet of the first-stage axial jet flow generating device is arranged in an outlet of the second-stage axial jet flow generating device, and an outlet of the second-stage axial jet flow generating device is arranged in an outlet of the third-stage axial jet flow generating device. According to the method and the device, combustion characteristics and flow characteristics of axial jet flow flame and tangential rotational flow flame are fully utilized; the mixed gas of fuel and a diluent and an oxidizing agent which are introduced in a graded mode in the axial direction form high-speed non-premixed jet flames, the premixed gas of the fuel and the oxidizing agent which are introduced in the tangential direction form rotational flow premixed flame, high-speed flowing is guaranteed, meanwhile, the stability of the flame is maintained, and the stable high-speed flame is formed. The method and the device have the advantages of being high in combustion efficiency, stable in flame, resistant to ablation and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Internal combustion engine

ActiveUS8793997B2Emission reductionReduce fuel consumptionInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerExternal combustion engine

In an internal combustion engine and a method of operation the internal combustion engine which includes a high pressure and a low pressure turbocharger having exhaust gas turbines arranged in series in an engine exhaust line provided with a high pressure exhaust gas recirculation line and a low pressure exhaust gas recirculation line via which exhaust gas can be conducted to an inlet line of the engine, the arrangement is switchable depending on the engine speed between an exhaust gas recirculation by way of the high pressure line and an exhaust gas recirculation by way of both, the high pressure and the low pressure line, to achieve low emissions and low fuel consumption.

Owner:DAIMLER AG

Steam turbine

InactiveUS20130064646A1Large gear ratioEasy to operatePropellersPump componentsEngineeringElectric generator

A steam turbine having a mechanical power rating of up to 500 kW for powering a generator having a shaft, a steam inlet, and an open radial flow wheel, which is torque-resistantly connected to the shaft and can be impinged with steam by the steam inlet.

Owner:BIO SYST FUR ANWENDUNGEN BIOLOGISCHER VERFAHREN MBH

Bypass type low-temperature negative-pressure heat exchanger for pre-cooling type JT refrigerator and design method

ActiveCN112212719AIncrease the cooling capacity of the final stageImprove efficiencyCompression machinesStationary tubular conduit assembliesRefrigeration temperatureMechanical engineering

The invention discloses a bypass type low-temperature negative-pressure heat exchanger for a pre-cooling type JT refrigerating machine and a design method. The heat exchanger is composed of a high-pressure side pipeline, a low-pressure side pipeline, a bypass pipeline, a bypass element, a three-way element and a low-temperature negative-pressure dividing wall type heat exchanger. According to theinvention, the temperature and flow distribution of a fluid in the low-temperature negative-pressure heat exchanger are changed through the bypass pipeline, the irreversible loss of the pipeline and the pressure drop loss of the low-pressure pipeline side are reduced, the low-pressure pressure of the pre-cooling type JT refrigerating machine after throttling is reduced, and the final-stage refrigerating temperature of the pre-cooling type JT refrigerating machine is reduced; the flow velocity of a high-low pressure pipeline fluid in the low-temperature negative-pressure dividing wall type heatexchanger is increased, so that the heat exchange efficiency of the low-temperature negative-pressure heat exchanger is improved; the fluid temperature before throttling is reduced, and the refrigerating capacity of the pre-cooling type JT refrigerating machine is increased; and the overall efficiency of the pre-cooling type JT refrigerating machine is improved. The bypass type low-temperature negative-pressure heat exchanger for the pre-cooling type JT refrigerator and the design method have very positive significance for application of the pre-cooling type JT refrigerator in special fieldssuch as extremely low temperature areas, aerospace and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

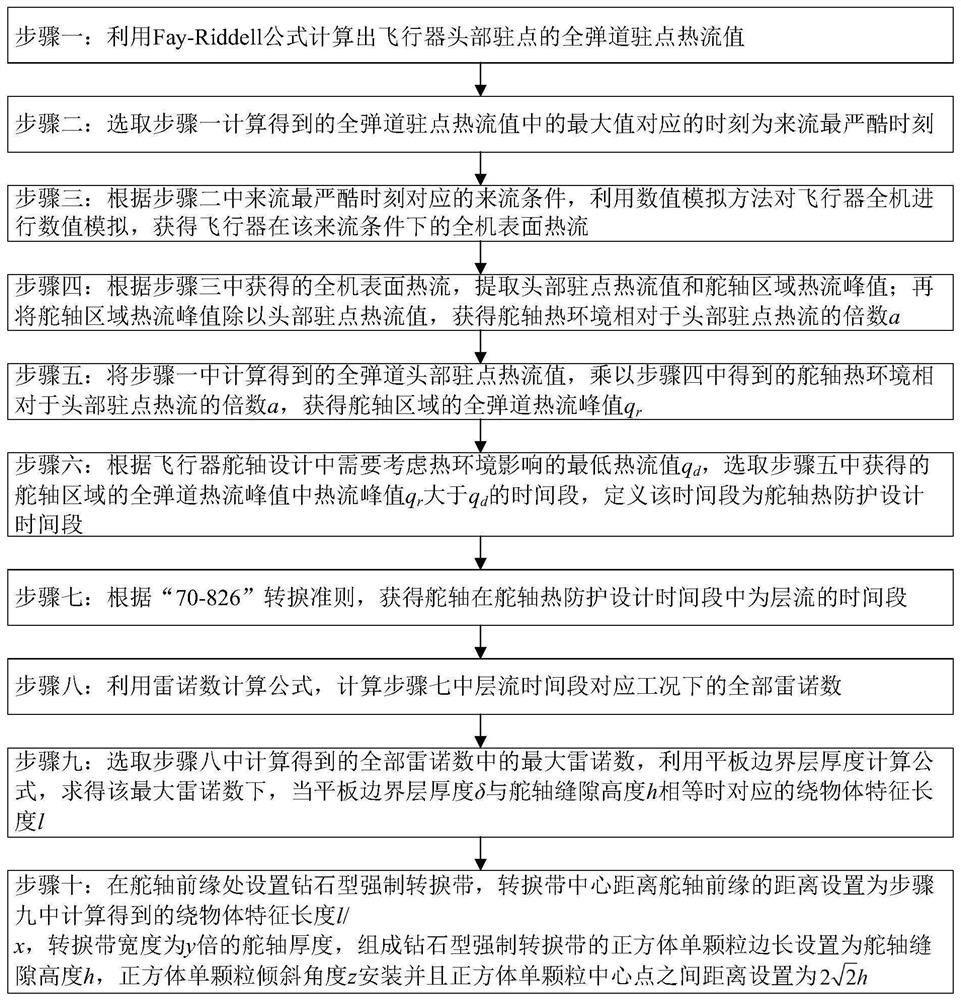

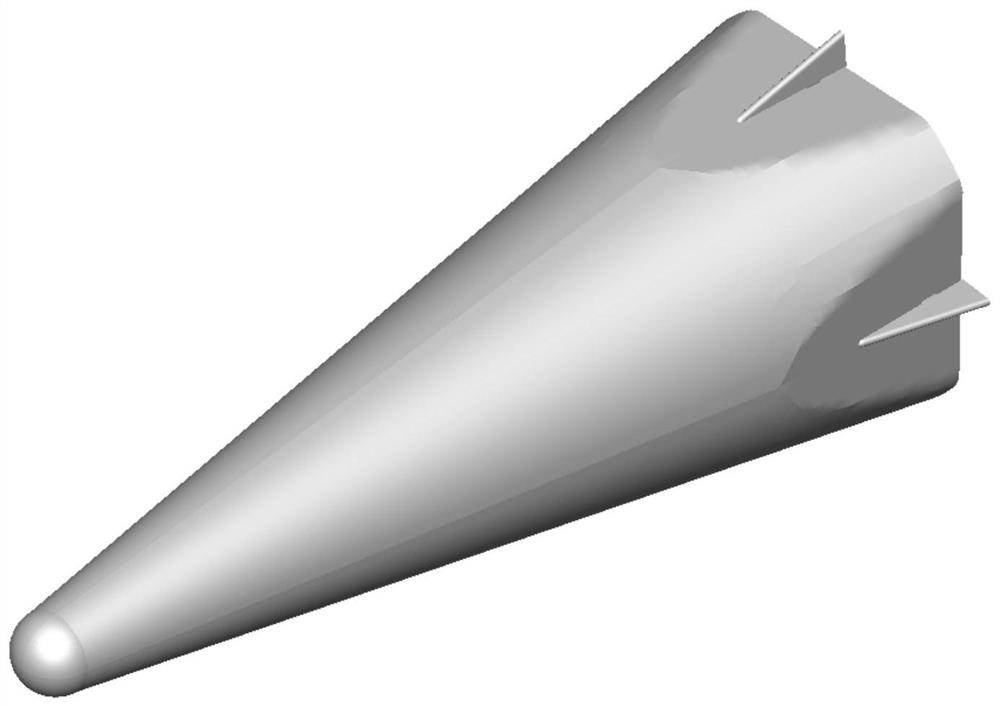

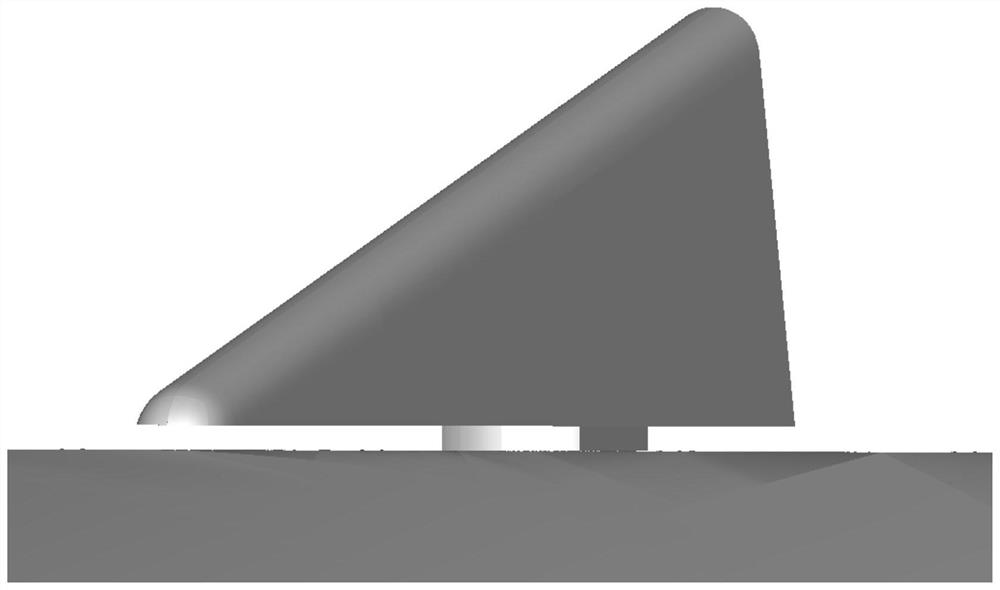

Active heat reduction design method for aircraft rudder shaft gap thermal environment

PendingCN113962017ALow mass flowReduce the impactGeometric CADSustainable transportationLeading edgeThermodynamics

The invention discloses an active heat reduction design method for an aircraft rudder shaft gap thermal environment, which comprises the following steps: calculating a heat flow value of a head stationary point, selecting the most harsh moment of incoming flow to carry out thermal environment numerical simulation on a whole aircraft, and obtaining a multiple relationship between a rudder shaft gap local heat flow peak value and an aircraft head heat flow peak value; acquiring the change condition of a rudder shaft gap local heat flow peak value along a trajectory by the multiple relation, determining a time period in which rudder shaft thermal protection design needs to be carried out according to the change condition, determining a laminar flow time period in the time period by a transition criterion, calculating the maximum Reynolds number in the laminar flow time period, and calculating the maximum Reynolds number under the maximum Reynolds number. When the thickness of the boundary layer is 1 / x of the height of the rudder shaft gap, the corresponding object-surrounding characteristic length is obtained, and finally, the diamond-shaped forced transition tape is arranged at the position away from the front edge of the rudder by the object-surrounding characteristic length, so that the whole rudder shaft gap is in turbulent flow under the working condition that the thermal environment is relatively harsh, and the thermal environment heat flow peak value of the rudder shaft gap is greatly reduced.

Owner:AERODYNAMICS NAT KEY LAB

Multiple reaction integrated process for desulfuizing from fume by dry method and its system

InactiveCN1239232CImprove surface activityReduce desulfurization costDispersed particle separationPartial oxidationCalcium sulfite

A multiple reactions integrated process for desulfurizing from the fume by dry method includes such steps as spraying limestone powder in high-temp combustion box from its top to decompose calcium carbonate into calcium oxide and CO2, absorbing SO2 from fume by partial calcium oxide to generate calcium sulfate, spraying water to activate calcium oxide to transform partial calcium oxide to calcium hydroxide and absorb SO2 from fume to generate calcium sulfite, and using the residual calcium hydroxide and calcium oxide to desulfurize the fume in desulfurizing tower. Its system is composed of limestone powder sprayer, moistening flue, desulfurizing tower, external electric duster, draught blower and chimney.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com