Water vapor cycle based on supercritical and subcritical heat regeneration

A supercritical, water-vapor technology, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve the problems of complex equipment and pipeline structure and low income.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

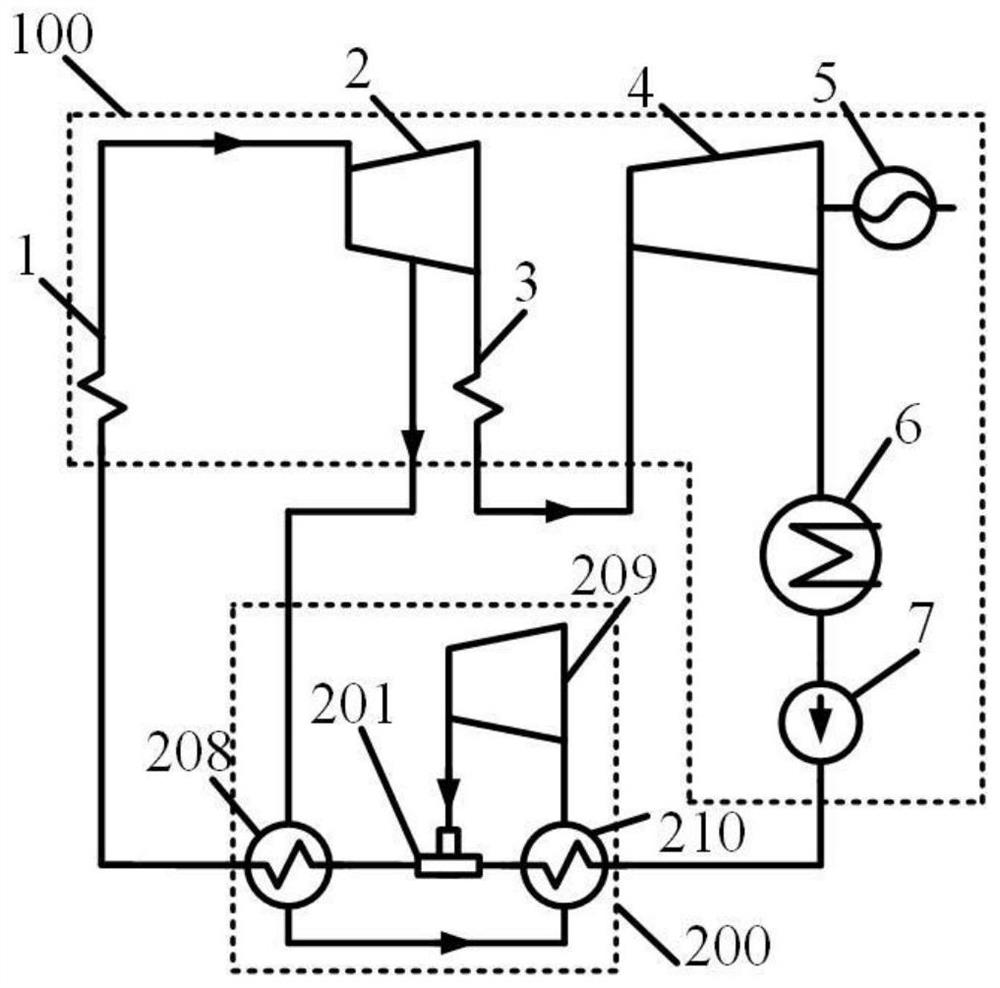

Embodiment 1

[0031] When Example 1 works,

[0032] In the compression supercritical heat recovery system 200, the low temperature working medium (low temperature water) entering from the low temperature water inlet of the compression supercritical heat recovery system 200 (the low temperature water inlet of the second high temperature regenerator 210) passes through the second high temperature heat recovery system. After exchanging heat with the high-temperature steam flowing out of the first high-temperature regenerator 208, the high-temperature steam flowing out of the first compressor 209 joins at the main tee 201, and then enters the first high-temperature regenerator 208 together with the compressor. The high-temperature steam inlet of the supercritical heat recovery system 200 (the high-temperature steam inlet of the first high-temperature regenerator 208) flows into the high-temperature steam with a steam pressure of 22.1-26MPa for heat exchange and is heated to 400°C-490°C; the seco...

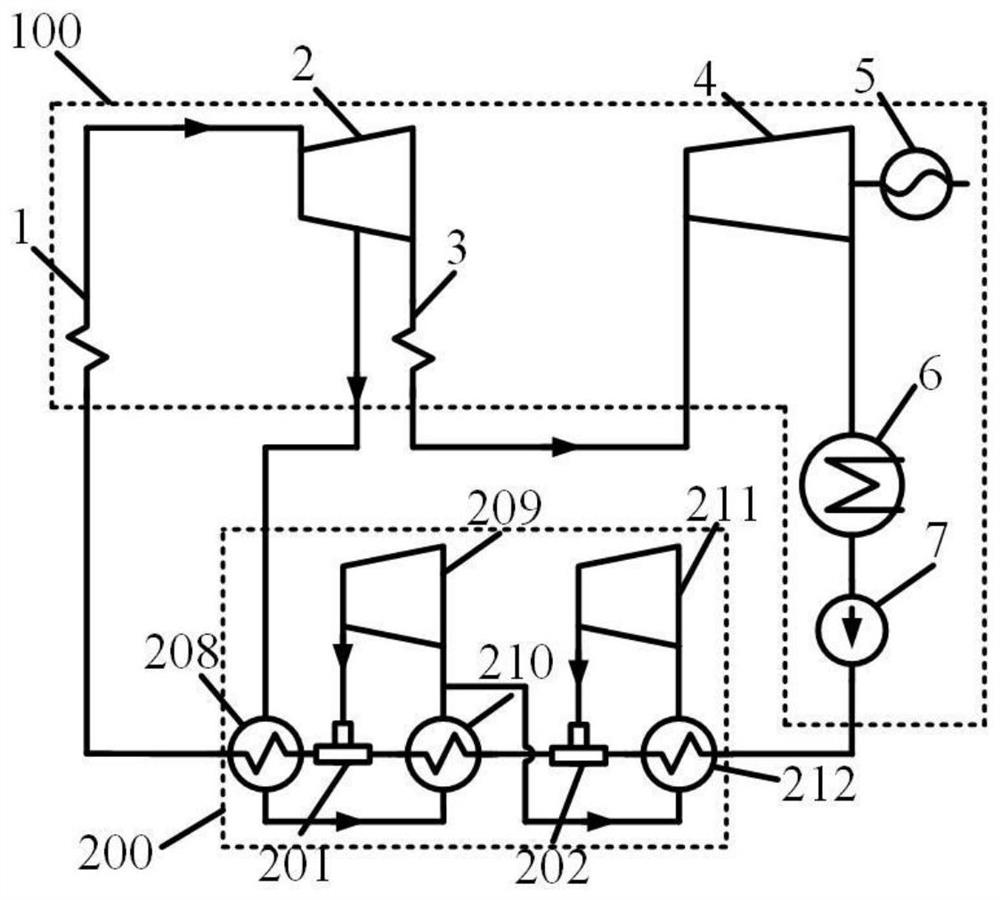

Embodiment 2

[0035] When Example 2 works,

[0036] In the compression supercritical heat recovery system 200, the low temperature water entering from the low temperature water inlet of the compression supercritical heat recovery system 200 (the low temperature water inlet of the third high temperature regenerator 212) passes through the third high temperature regenerator 212 and the second After heat exchange, the high-temperature steam flowing out of the high-temperature regenerator 210 merges with the low-temperature steam flowing out of the second compressor 211 at the auxiliary tee 202, and then enters the second high-temperature regenerator 210 and the first high-temperature regenerator 208 After exchanging heat, the outgoing high-temperature steam merges with the low-temperature steam compressed by the first compressor 209 at the main tee 201, and then enters the high-temperature steam inlet of the first high-temperature regenerator 208 and the compression supercritical heat recovery ...

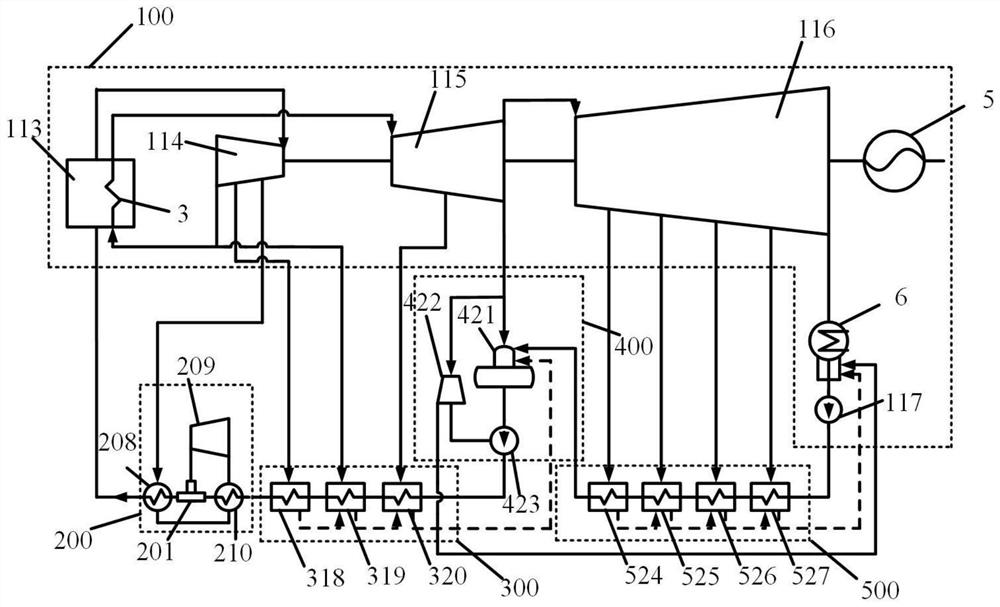

Embodiment 3

[0043] When working in Example 3,

[0044] In the compression supercritical heat recovery system 200, the low-temperature steam with a temperature of 321°C entering from the low-temperature water inlet of the compression supercritical heat recovery system 200 (the low-temperature water inlet of the second high-temperature regenerator 210) passes through the second high-temperature heat recovery system. After exchanging heat with the high-temperature steam flowing out of the first high-temperature regenerator 208, the high-temperature steam flowing out of the first compressor 209 at the main tee 201 merges with the low-temperature steam flowing out of the first compressor 209, and then enters the first high-temperature regenerator 208 together with the compressor The high-temperature steam inlet of the supercritical heat recovery system 200 (the high-temperature steam inlet of the first high-temperature regenerator 208 ) flows into the high-temperature steam for heat exchange, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com